Patents

Literature

1030 results about "Oxygen-free copper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oxygen-free copper (OFC) or oxygen-free high thermal conductivity (OFHC) copper is a group of wrought high conductivity copper alloys that have been electrolytically refined to reduce the level of oxygen to .001% or below.

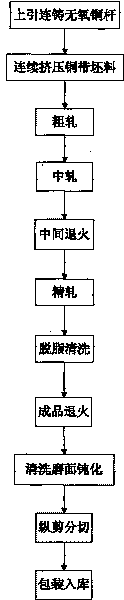

Production technique of copper strips for solar modules

InactiveCN101719527AHigh purityImprove conductivityFinal product manufactureSemiconductor devicesElectrolysisLiquid surfaces

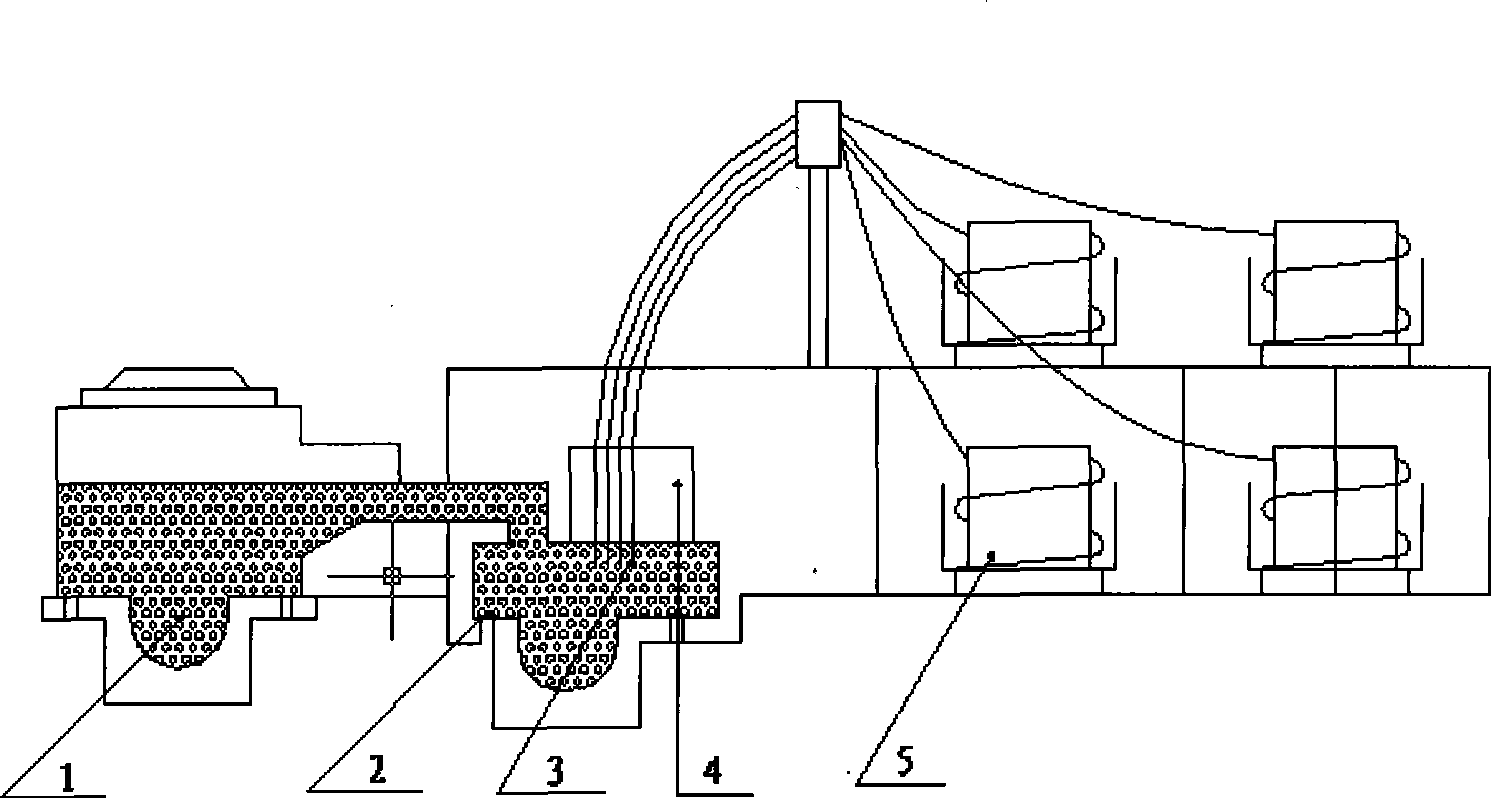

The invention discloses a production technique of copper strips for solar modules, which belongs to the technical field of nonferrous metal processing and comprises the following steps: drawing-up of continuous-casting oxygen-free copper bar: using high-quality electrolytic copper as the raw material, melting at 1150+ / -10 DEG C, keeping the temperature, covering the copper liquid surface with charcoal and graphite scales to ensure the vacuum state during melting, degassing on line, deoxidizing, stirring, and drawing up the copper bar with a tractor set in an on-off vacuum way; continuous extrusion of copper strip blanks: using oxygen-free copper rods as the raw material, producing copper strip blanks by using a continuous extruder set, cooling the extruded copper strip blanks through a vacuum oxidation-resisting pipe and a water tank, drying and coiling; and rough-rolling the copper strip blanks, medium-rolling, interstage annealing, finish rolling, degreasing, washing, annealing the finished product, washing, grinding the surface to passivate, and longitudinally cutting to obtain the finished product. The product of the invention has the advantages of high purity, low oxygen content and high electrical conductivity.

Owner:浙江力博实业股份有限公司

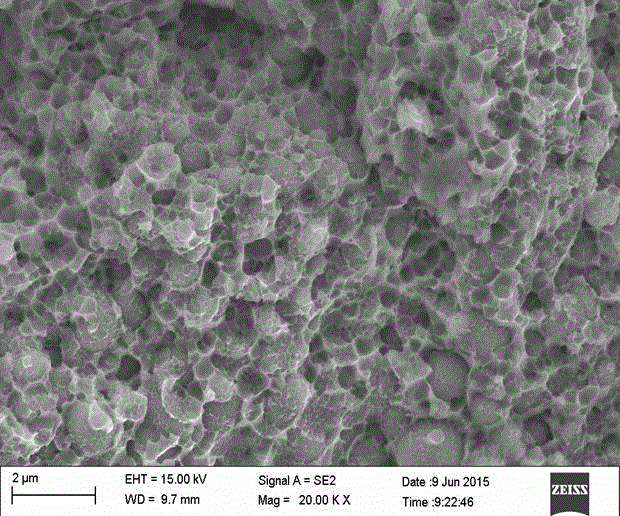

Cu-Al2O3 nano strengthened dispersion alloy and preparation method thereof

The invention relates to a Cu-Al2O3 nanometer dispersion strengthening alloy and preparation thereof. The preparation includes the steps of Cu-Al alloy vacuum smelting, pulverizing, screening, internal oxidizing, hydrogen reducing, vacuum hot pressing, canned hot extruding, etc. Comparing with oxygen-free copper, sigma of the alloy of the invention is 2 to 6 times higher that of the oxygen-free copper, the anti-annealing softening temperature is up to over 900 DEG C, the conductivity is up to 96% IACA and more. The process of the invention is simple, the prepared Cu-Al2O3 nanometer dispersion strengthening alloy has high strength, high conductivity, electrical conductivity higher than 96% IACA, and is anti-annealing and antimagnetic. The alloy can not only used for large-scale integrated circuit lead frame, manufacturing of controlled thermonuclear reaction heat sink components, and is expecially suitable for manufacturing of microwave tube grid mesh, inertial instrument sensor, particle accelerator and other high-precise parts.

Owner:CENT SOUTH UNIV

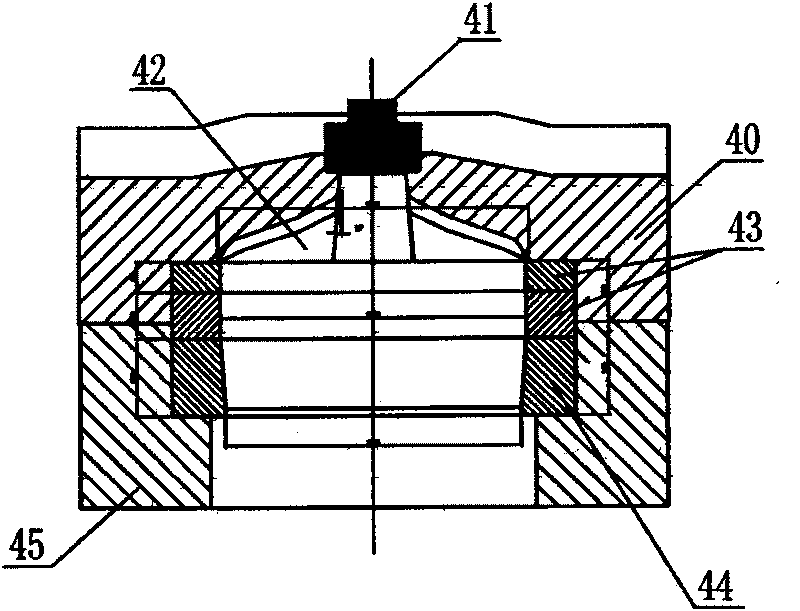

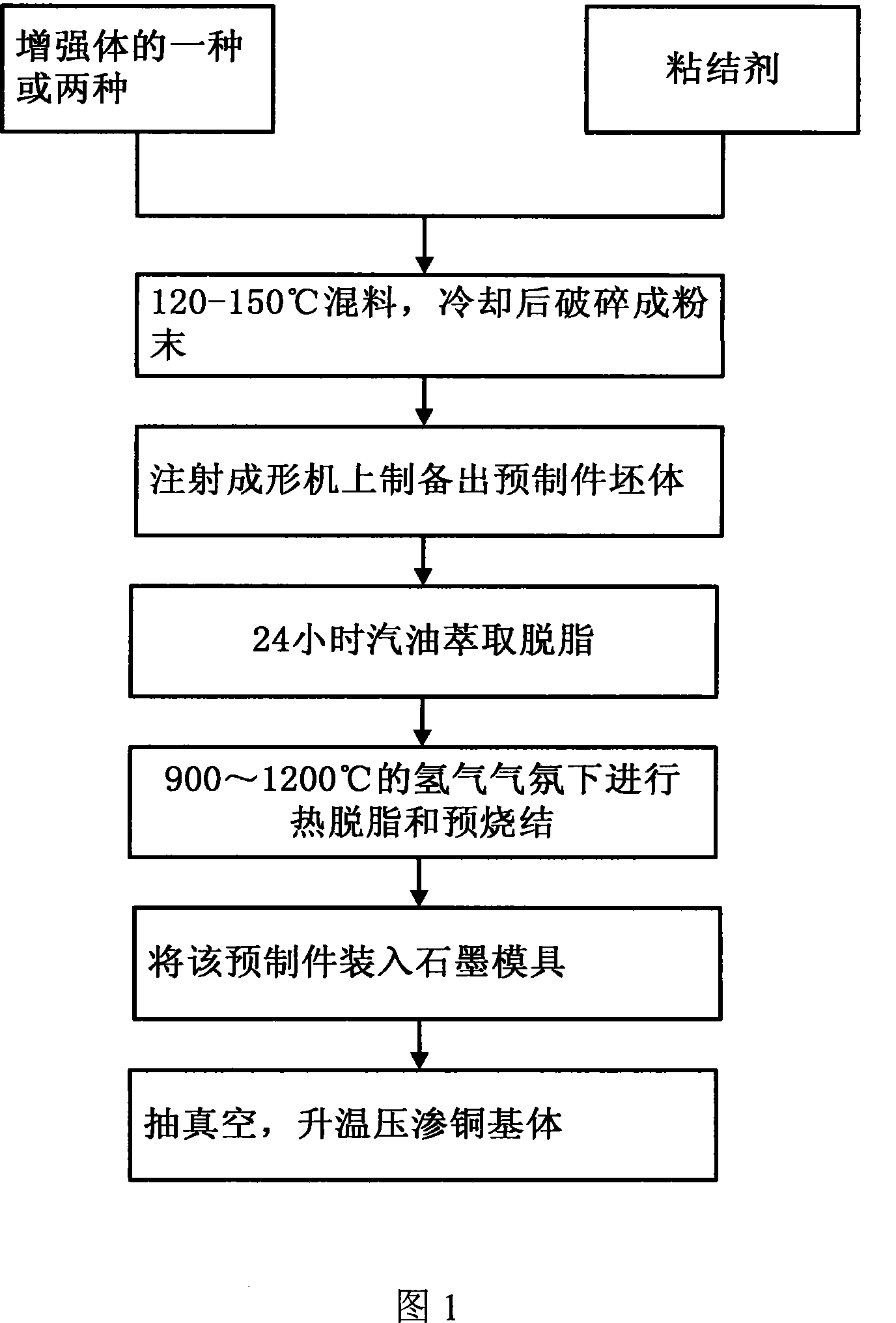

High heat conductivity copper-base composite material and preparation method thereof

The invention belongs to the technical field of preparation of electronic packaging materials, and particularly designs a copper-based composite material with high thermal conductivity and a preparation method thereof. The copper-based composite material is made of a reinforcement and a binder through a prefabricated injection molding process to make a reinforcement prefabricated part, wherein the size of the reinforcement particle is 7-60 μm, and it is composed of silicon carbide particles, diamond particles or aluminum nitride particles. One or two of them; the copper matrix is directly placed on the reinforcement preform, wherein the copper matrix is electrolytic copper or oxygen-free copper, and the volume ratio of the reinforcement to the copper matrix is 50-75%: 25-50 %, made by pressure infiltration process. The preparation method adopts the injection molding process of the prefabricated part and the pressure impregnation process to prepare the high thermal conductivity copper matrix composite material. The thermal conductivity of the copper-based composite material in the present invention is higher than that of the aluminum-based composite material with the same reinforcement system, the material itself has low density and small thermal expansion coefficient, which meets the requirement of light weight of the packaging material.

Owner:GRIMAT ENG INST CO LTD

Production method of high-power precision alloy SMD (surface mount device) resistor

InactiveCN104051099AImprove cooling effectHigh precisionResistors adapted for applying terminalsAlloyThermal transmittance

The invention provides a production method of a high-power precision alloy SMD (surface mount device) resistor. The production method comprises the steps: respectively combining two oxygen-free copper strips with two sides of a resistor alloy strip to form an integrated strip-shaped resistor strip, and wrapping a high-heat-conductivity substrate with the integrated strip-shaped resistor strip; etching a basic resistor structure on a wrapping body; precisely adjusting the resistance value of the basic resistance structure; coating, terminal electroplating and printing a resistor body to form a high-power precision alloy SMD resistor. The material with high heat radiation capability and high heat conductivity such as a metal substrate, a high-heat-conductivity ceramic substrate is used as the substrate, so that the actual load capacity of the resistor is greatly increased; the oxygen-free copper strip is partially arranged on the side surface and below the substrate and used as an electrode lead, so that the contact area is increased, and the heat conductivity of the resistor body is also increased on the other hand.

Owner:SHENZHEN YEZHAN ELECTRONICS

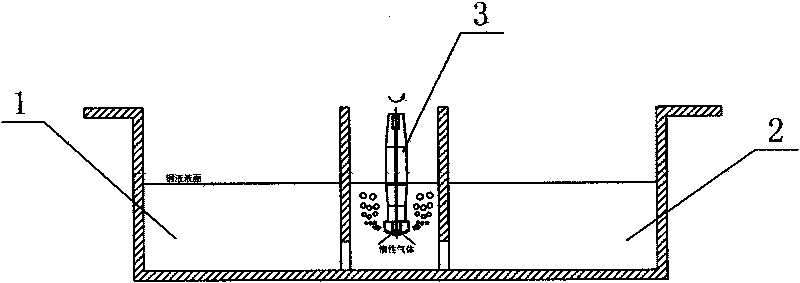

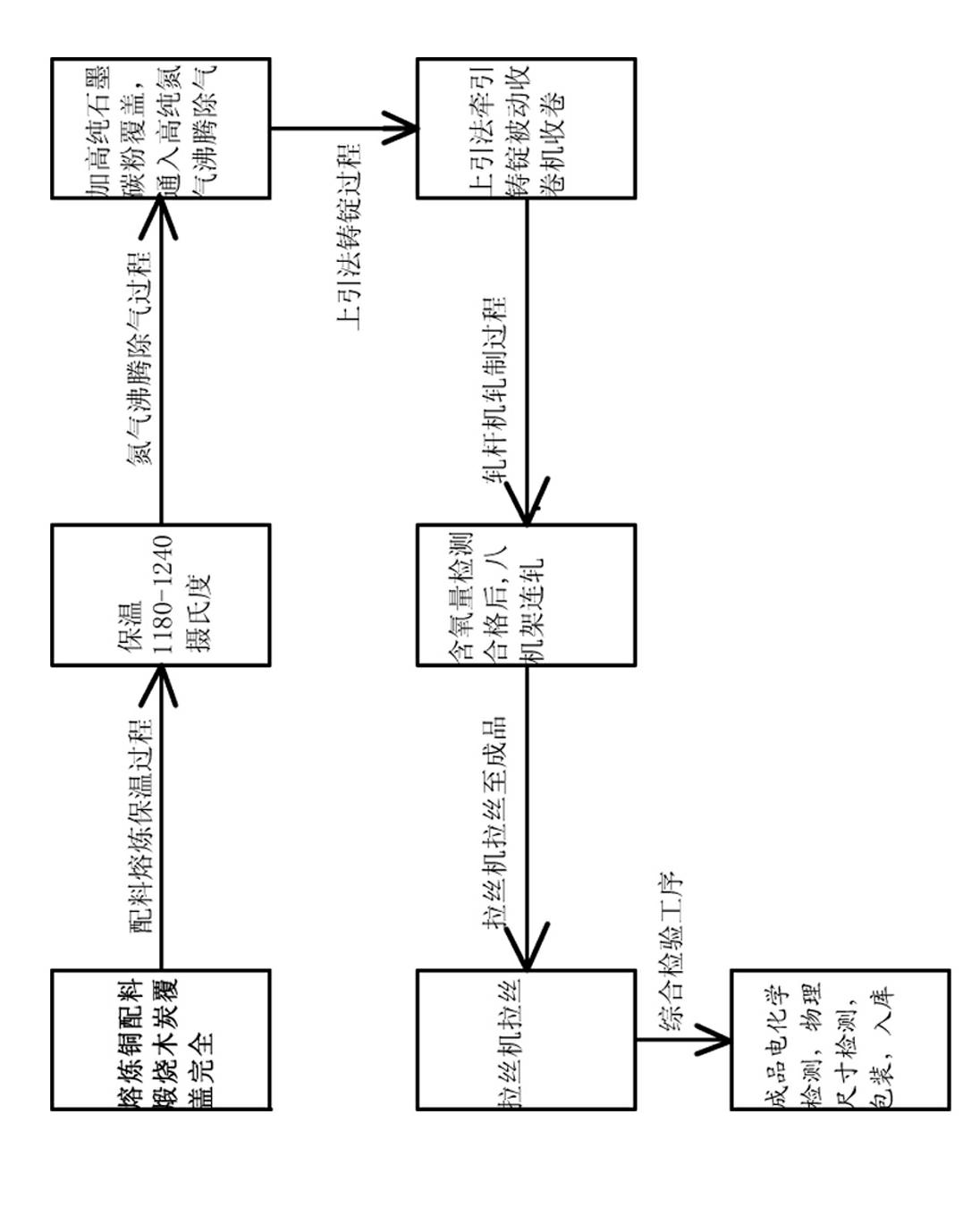

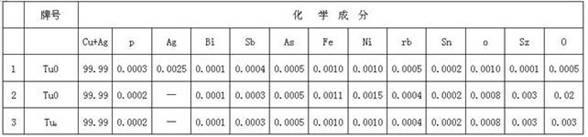

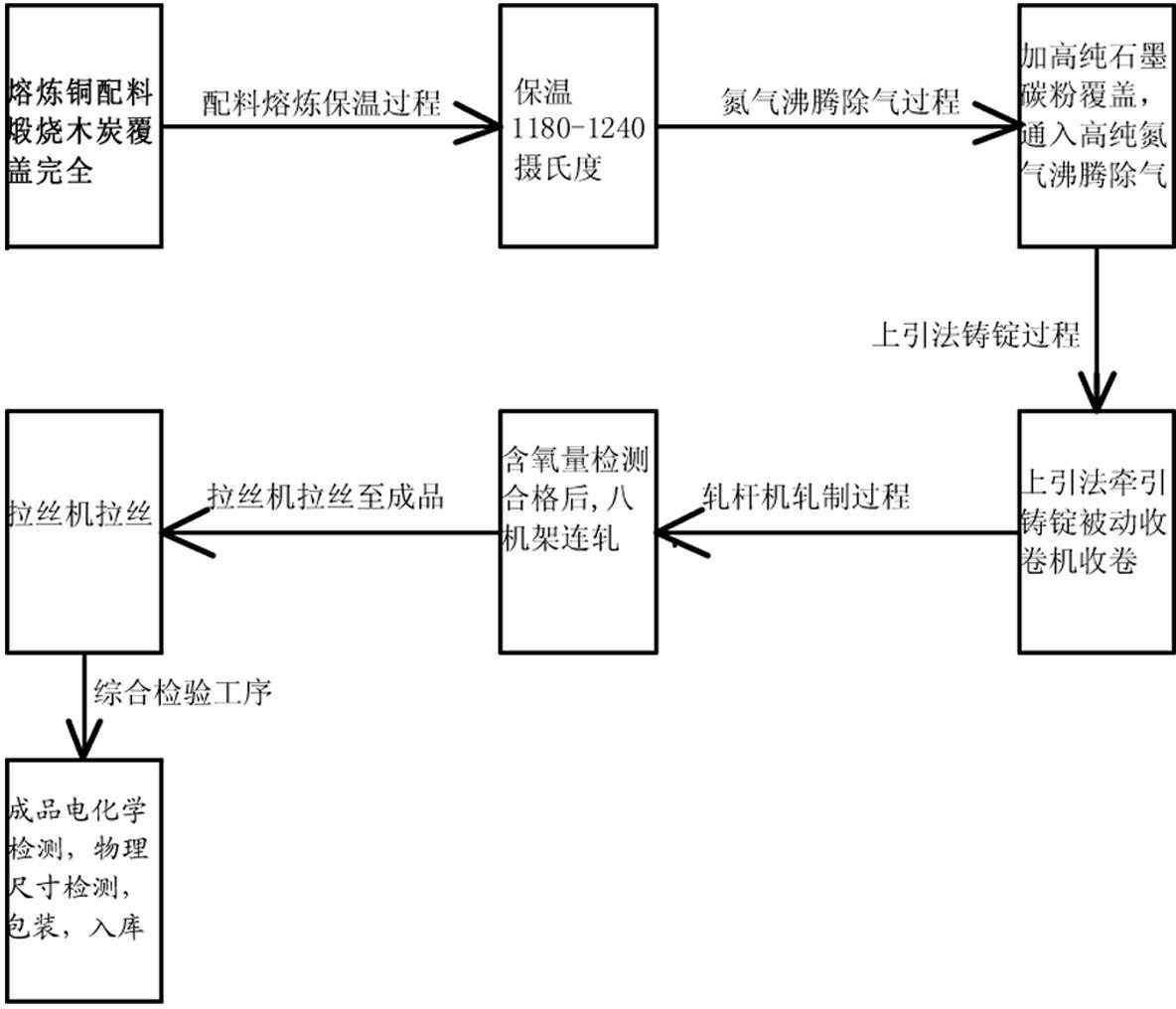

Upcast method for producing high-purity bright copper rod

ActiveCN102168180ALight weightFull reduction reactionProcess efficiency improvementGraphite carbonWinding machine

The invention relates to an upcast method for producing a high-purity bright copper rod. The method comprises the following steps of: drying smelting copper raw materials needed by smelting, mixing, adding the mixture into a smelting furnace, and covering firing charcoal with the thickness of between 100 and 150mm on starting molten copper until red copper is entirely molten, wherein molten copper constantly flows toward a heat preservation furnace under the action of fluid force; boiling the high-temperature molten copper and degassing before ingot guiding, adding prepared high-purity graphite carbon powder onto the liquid level of the molten red copper in the heat preservation furnace, and aerating high-purity nitrogen at the position which is 50 to 100mm lower than the liquid level of the heat preservation furnace; covering the firing charcoal after boiling and degassing, covering a furnace cover, performing draw casting operation, drawing a draw casting machine for draw casting bythe upcast method, cooling in a graphite crystallizer by the upcast method to obtain a qualified high-purity oxygen-free copper rod blank, and winding on a drawn cast ingot passive winding machine; and performing multi-pass rolling and fine-drawing on the high-purity oxygen-free high-brightness copper rod blank by an eight-rack rod cold rolling mill, and drawing the blank until the copper rod is obtained by a wire drawing machine, namely obtaining a finished product after the copper rod passes the inspection.

Owner:ZHONGTIAN ALLOY TECH

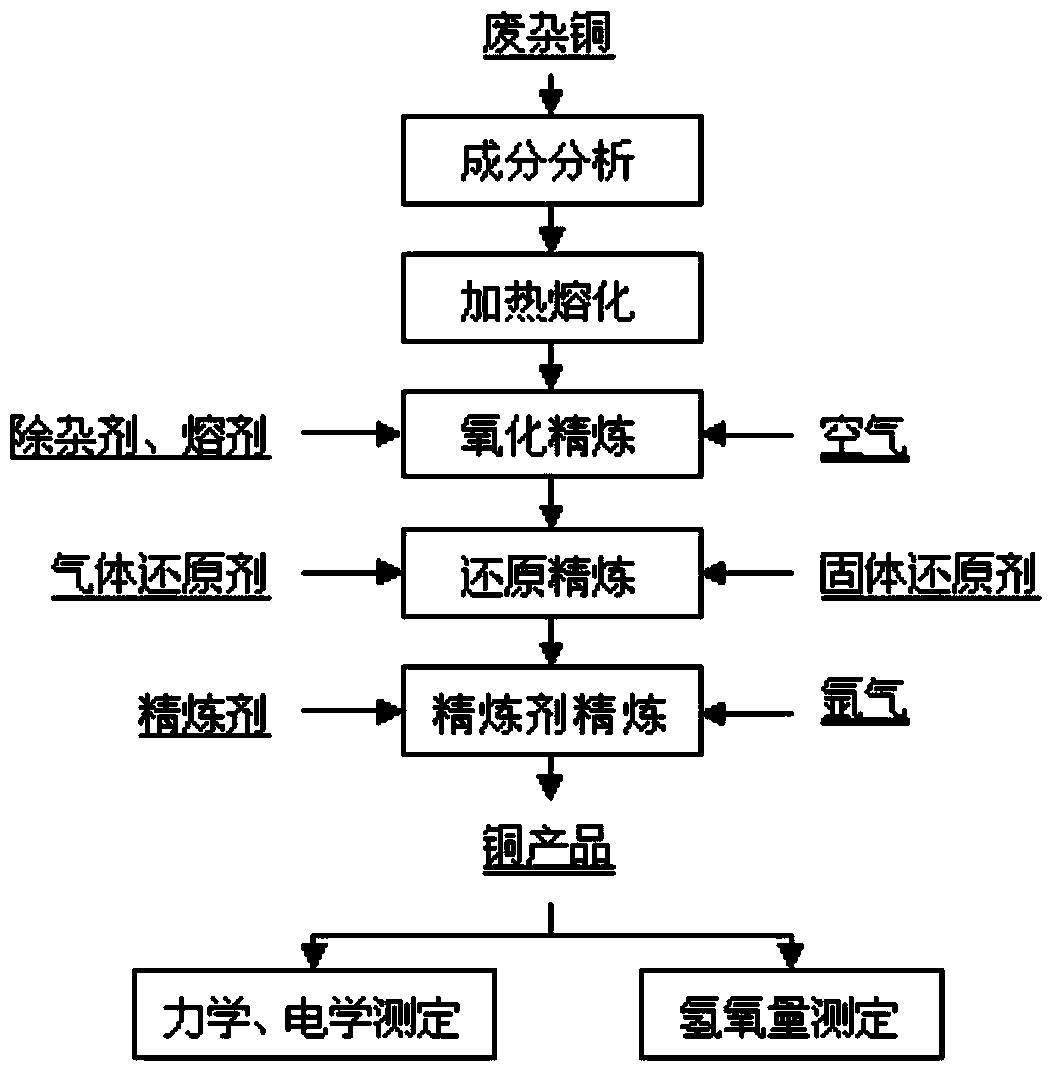

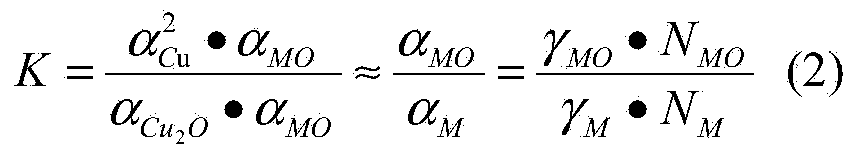

Method for directly producing high-purity oxygen-free copper by pyrogenic process continuous refining of scrap copper

ActiveCN103725897AOptimizing Process ParametersReduce manufacturing costProcess efficiency improvementElectrolysisCopper wire

The invention relates to a method for directly producing high-purity oxygen-free copper by pyrogenic process continuous refining of scrap copper, and belongs to the technical field of non-ferrous metallurgy. The method comprises the following steps: by taking scrap copper as a raw material; analyzing the component characteristics of each batch of raw material, and then preparing into a mixture, wherein the mass percent of a copper element in the mixture is greater than or equal to 93%; adding metaphosphate or phosphorus pentoxide and flux to the mixture; refining by oxidation; stewing and drossing after oxidation is finished, and then orderly carrying out reduction refining and refining agent refining under an agitation state, so as to obtain the high-purity oxygen-free copper of which the copper content is greater than or equal to 99.95% and the oxygen content is smaller than 0.003%, wherein the electrical resistivity of the obtained copper wire after drawing is below 0.017241omega / (mm), and the relative electrical conductivity is over 100% of International annealed copper standard (IACS). The method is strong in flexibility, significant in refining effect, and applicable to different components of scrap copper materials; the scrap copper can be used for directly making a rod after being refined. Compared with the traditional pyrogenic process smelting-electrolytic refining-copper cathode purification process, the method disclosed by the invention has the beneficial effects that the flow is shortened, the cost is reduced, the energy is saved, and continuous operation is achieved.

Owner:CENT SOUTH UNIV

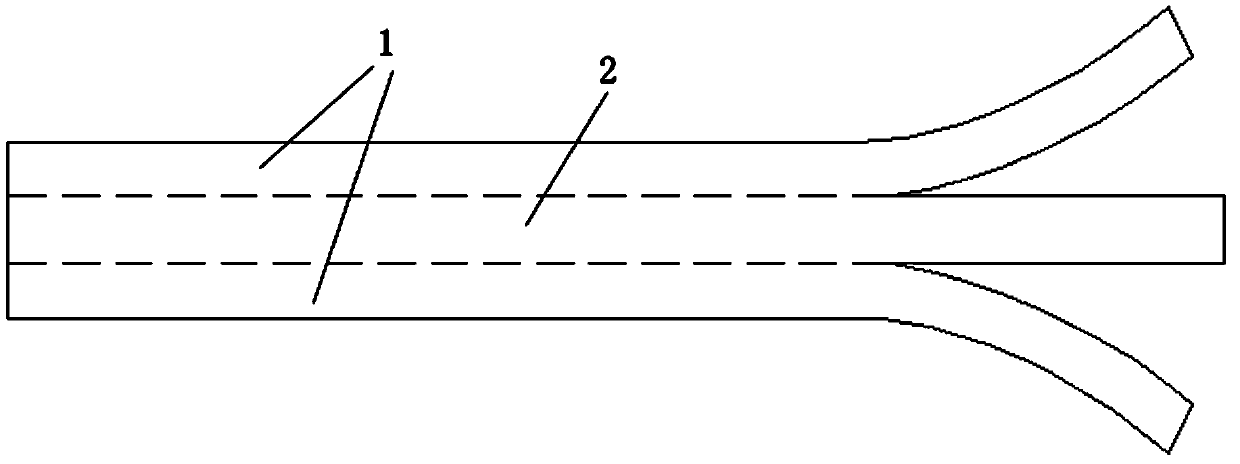

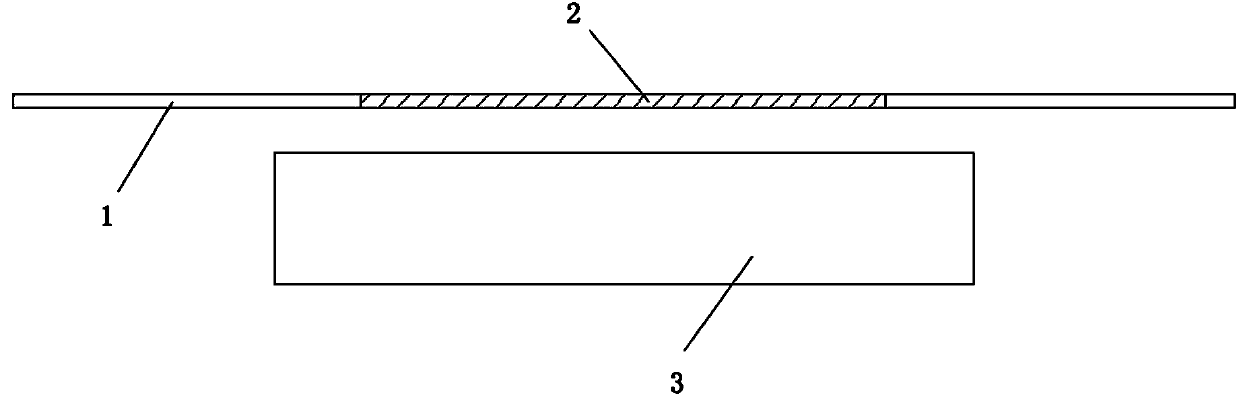

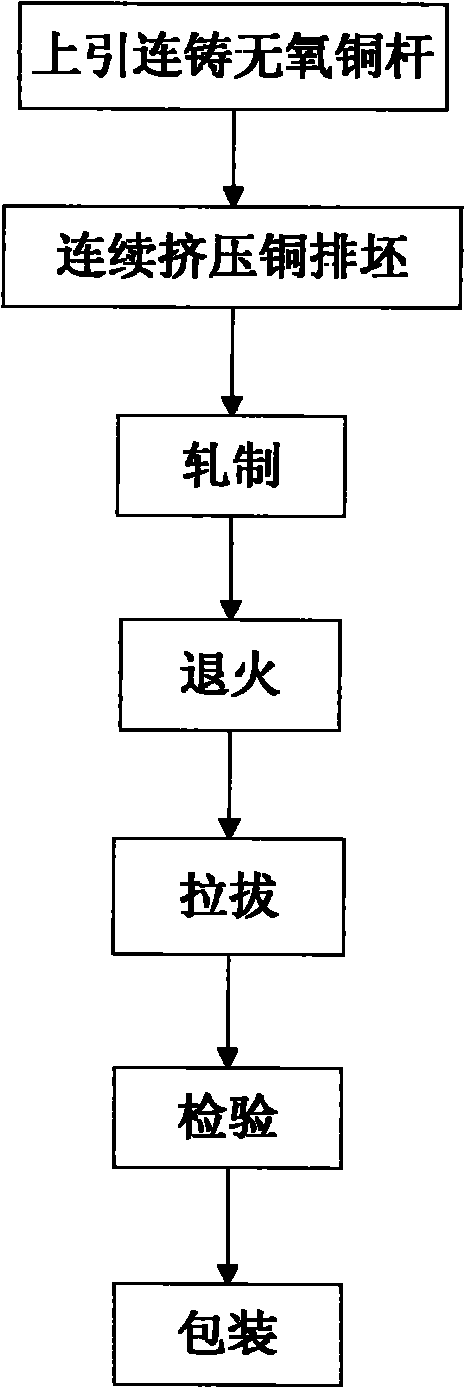

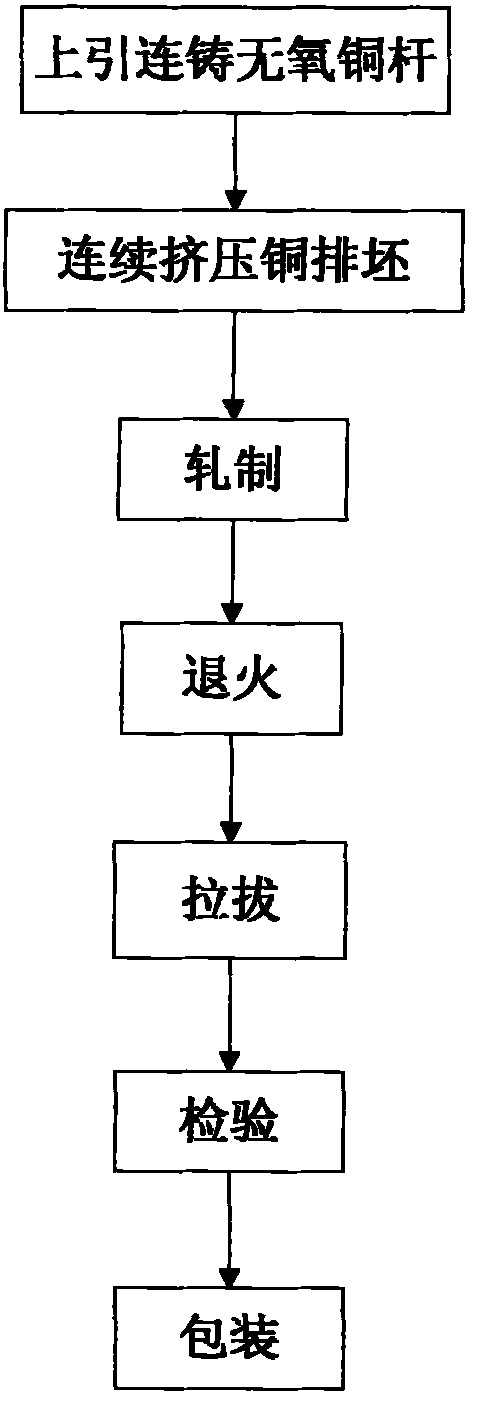

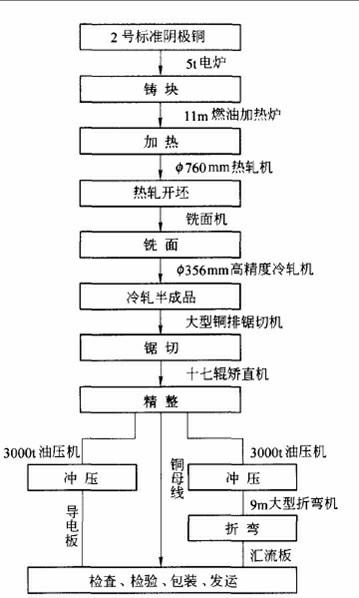

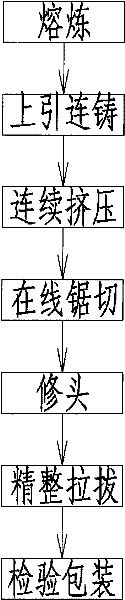

Production method of conducting copper bars for bus duct with large flakiness ratio

InactiveCN101916624AAvoid picklingImprove working environmentOpen bus-bar installationsCable/conductor manufactureLow oxygenHigh conductivity

The invention discloses a production method of conducting copper bars for a bus duct with a large flakiness ratio, belonging to the technical field of processing of non-ferrous metals. The production method is characterized by comprising the following steps of: upward continuously casting oxygen-free copper bars, continuously extruding copper bar billets, rolling, annealing, drawing, checking and packaging. By adopting the continuous extrusion technology to produce the copper bar billets, the continuous production can be realized, and the weight of each roll of copper bar billets can reach more than 3 tons. Moreover, because the copper bar billets are produced in a roll shape, the defect of cutting the head and the tail of each copper bar in the traditional production process is avoided, and the yield of the product reaches more than 90%. Meanwhile, by reasonably setting continuous extrusion process parameters, rolling rate and the like, the invention effectively improves the quality of the product and has the advantages of high purity, low oxygen content, high conductivity, excellent surface quality and the like. The product is detected to show that the content of Cu and Ag is greater than or equal to 99.97%, the content of O is less than or equal to 10ppm, and the conductivity is 98-101% according to the IACS.

Owner:浙江力博实业股份有限公司

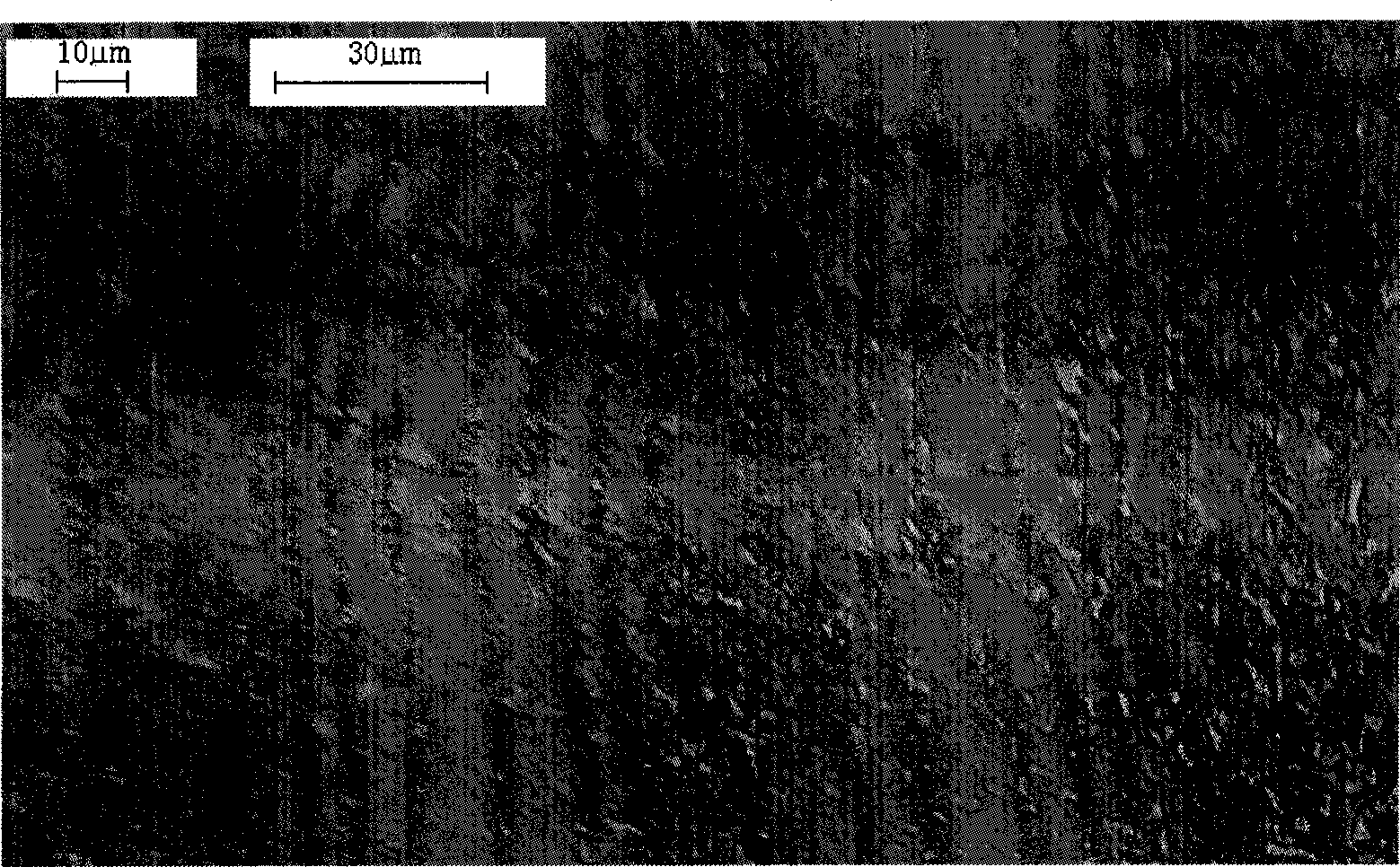

Production technology for bimetal coating copper strip

The invention discloses a production technology for a bimetal coating copper strip, which comprises the following steps: 1, smelting casting: preheating and drying electrolytic copper and placing in a smelting device for melting, adopting wood coal and graphite flakes to cover the surface of copper liquid, and after performing degasification and deoxidation on line by a degasification device, using a traction machine set to guide a copper rod upwards in a vacuum clutch type way to enable the copper rod to enter a wire taking-up device; 2, continuous extruding: enabling the oxygen-free copper rod obtained in step 1 to pass through a continuous extrusion machine set to produce a copper strip plate, and quickly using a cooling medium to cool to 20-30 DEG C to obtain the fine grain structured copper strip plate with the grain size of 0.005 mm to 0.010 mm; 3, rolling; 4, intermediate annealing; 5, fine rolling; 6, annealing; 7, cleaning and inactivating; 8, cutting; and 9, packaging and storing into a warehouse. According to the invention, the production technology has the advantages of excellent welding performance, high plastic processing performance, high electric conductivity, high surface quality and the like, and the technological process is short, and the technology is efficient and energy-saving.

Owner:NANTONG JIUWUBA TECH ENTERPRISE INCUBATOR CO LTD

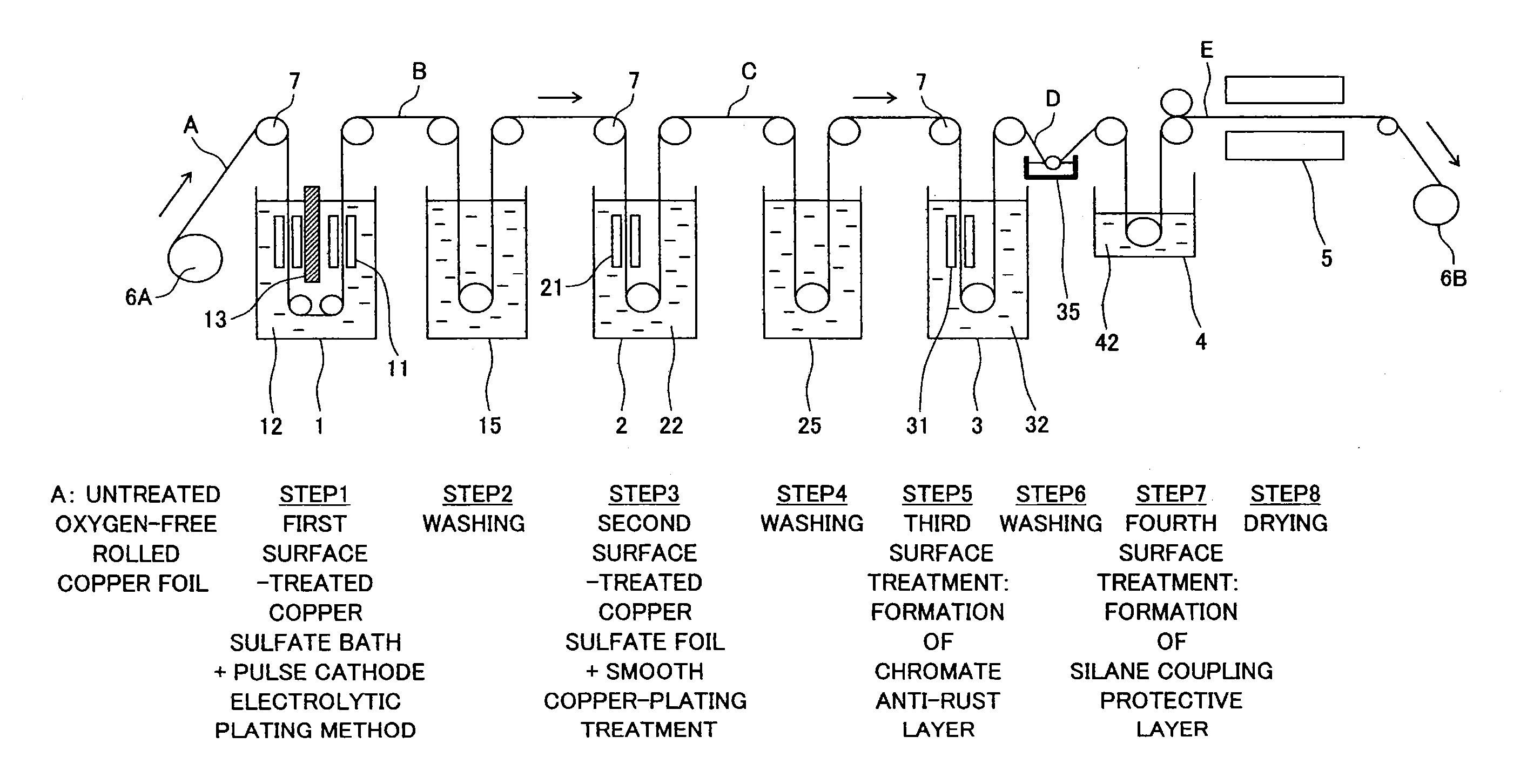

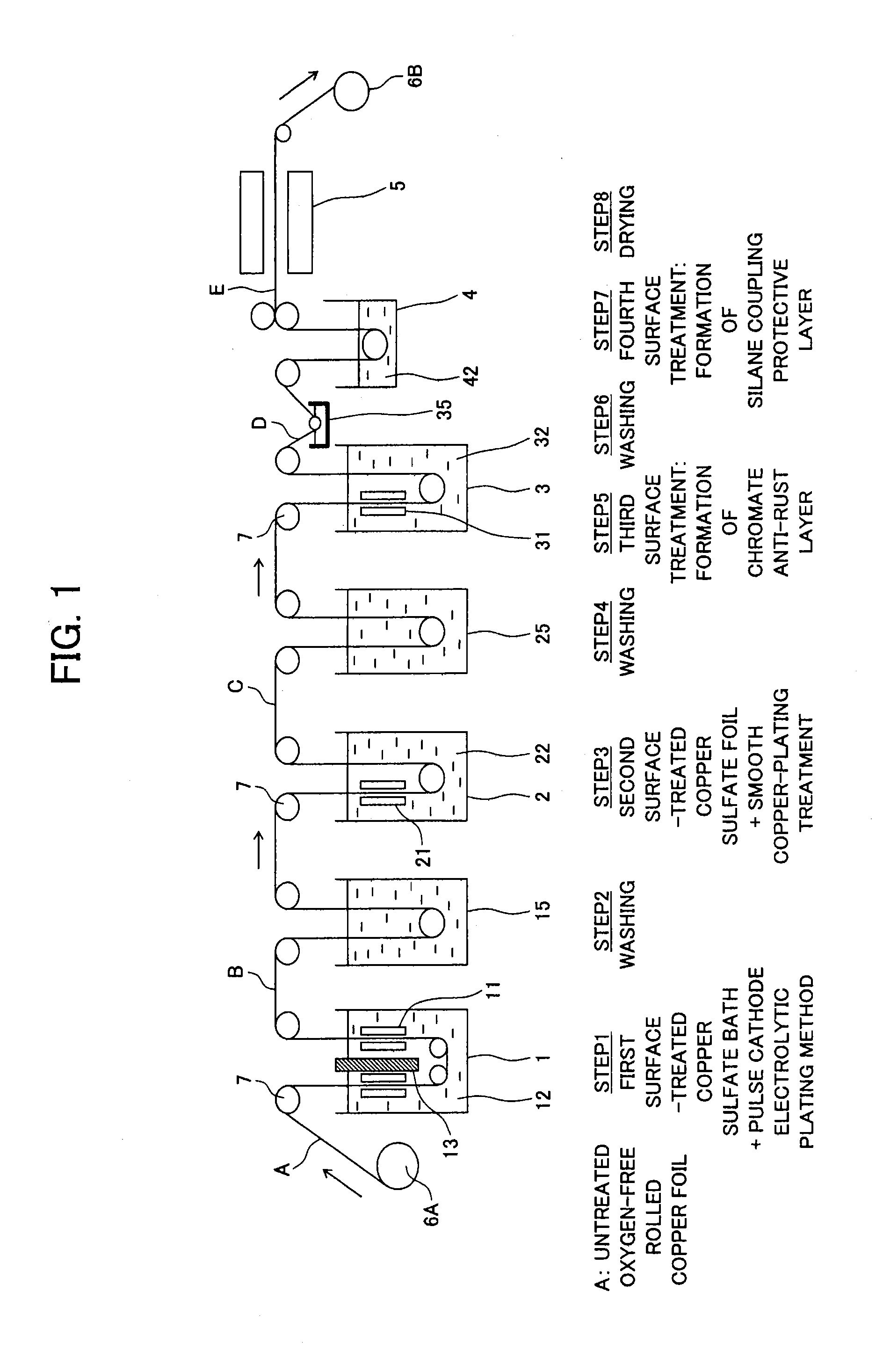

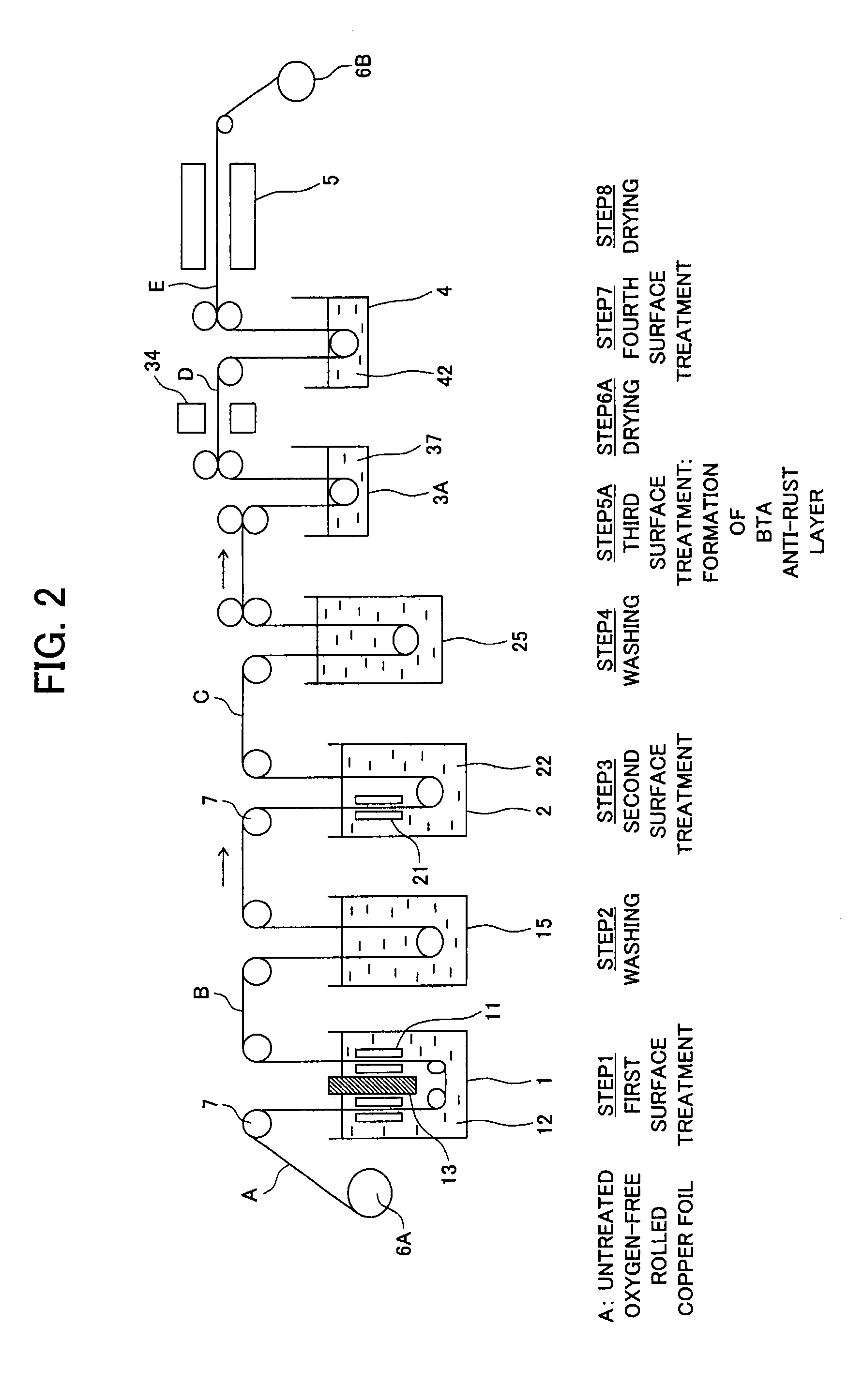

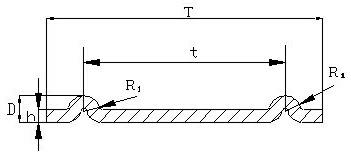

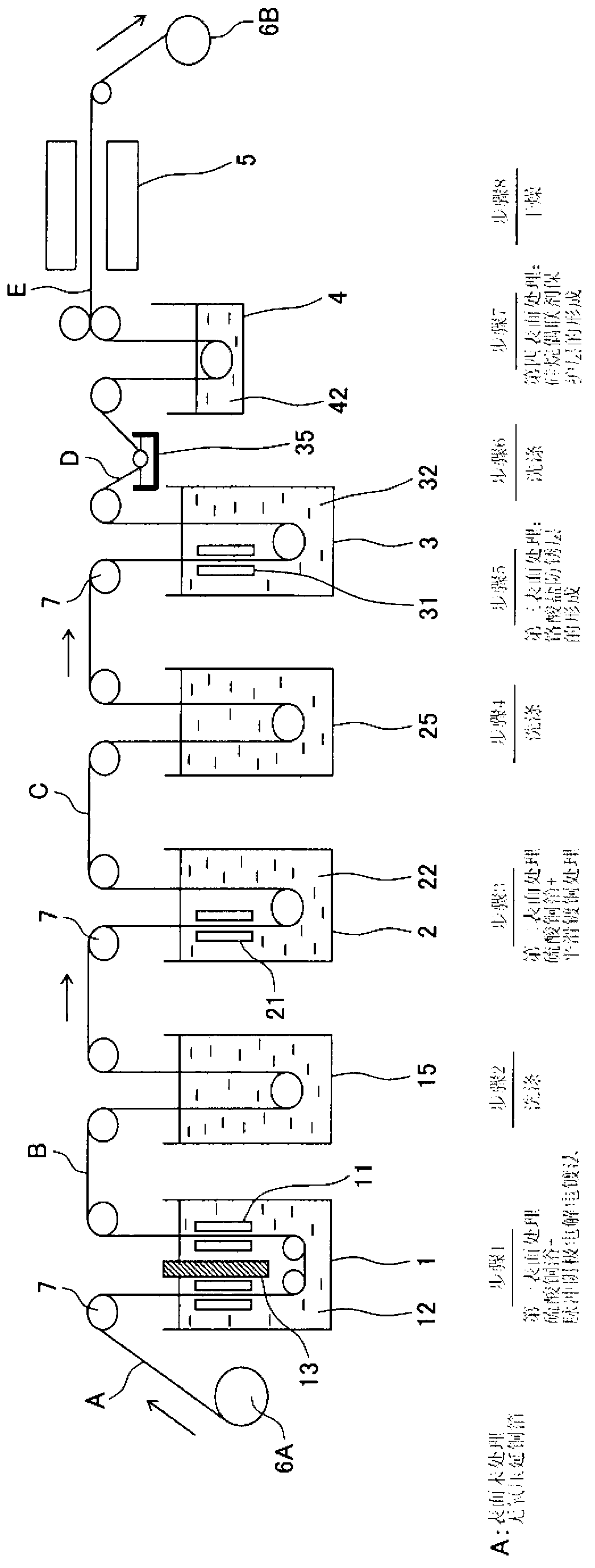

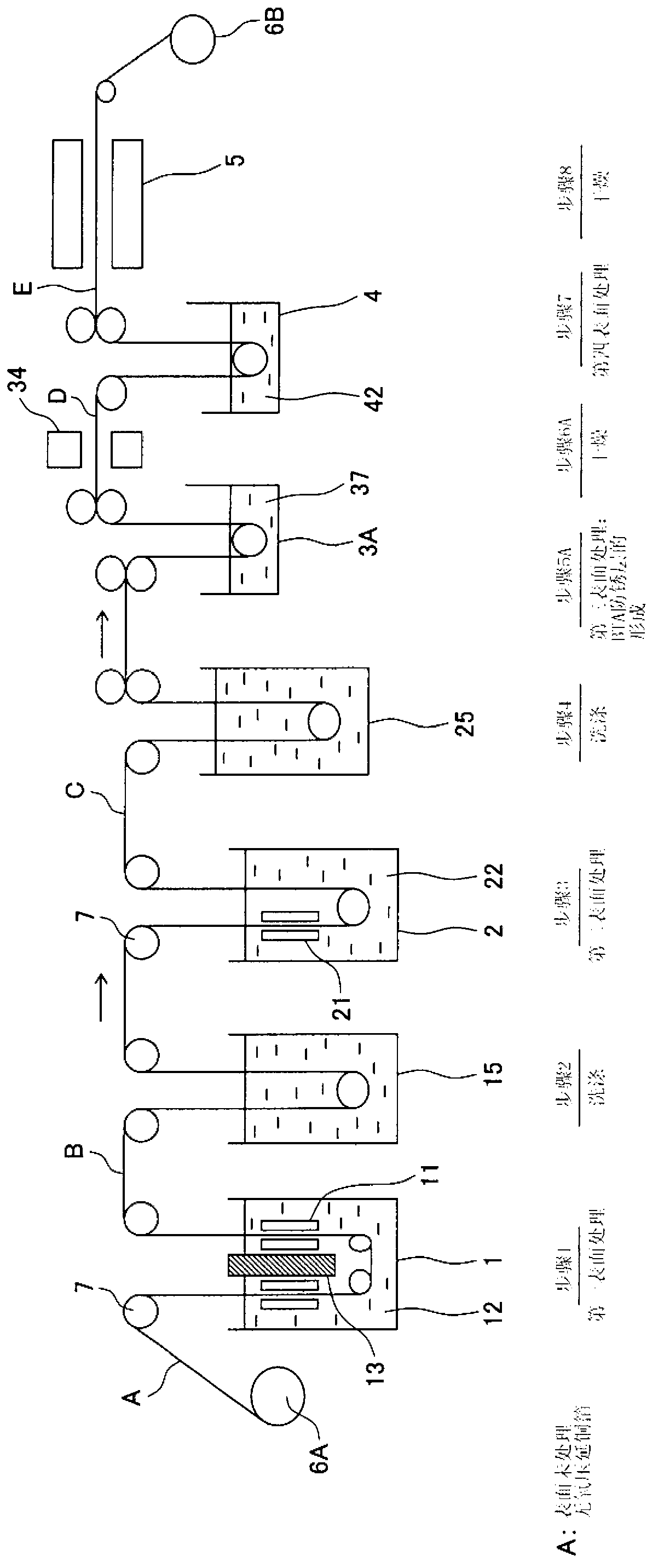

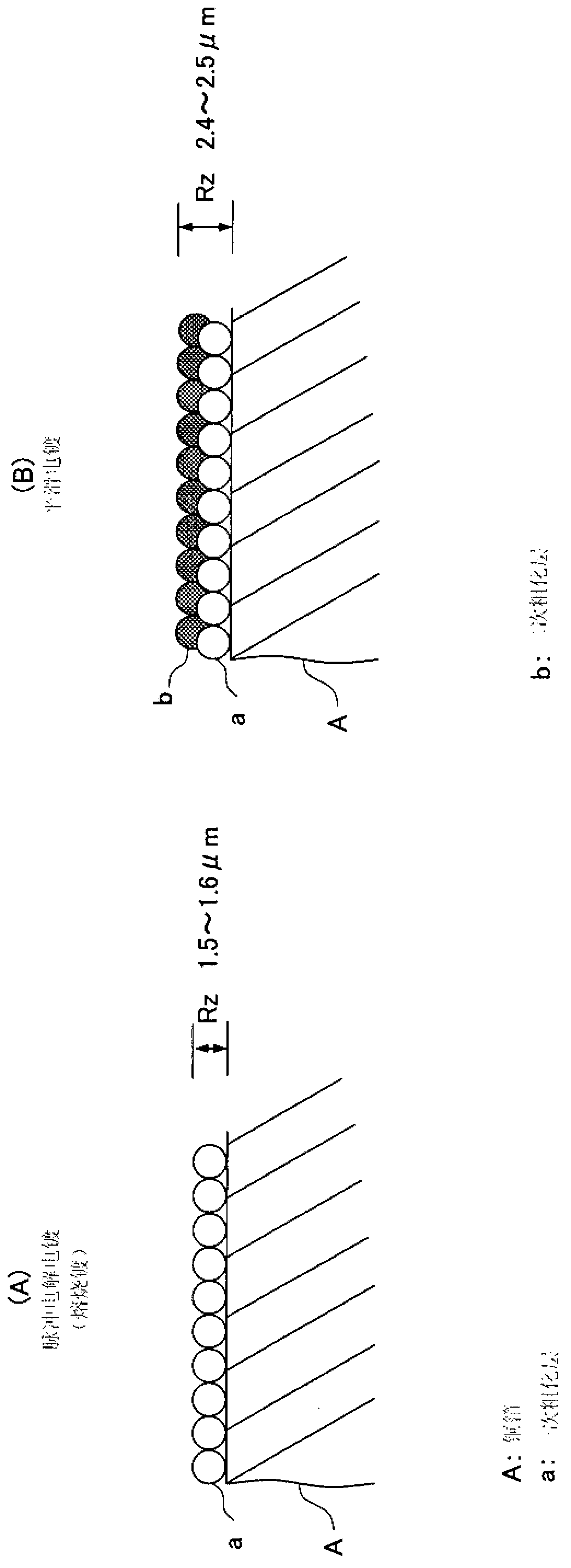

Surface treatment method for copper foil, surface-treated copper foil, and copper foil for negative electrode collector of lithium ion secondary battery

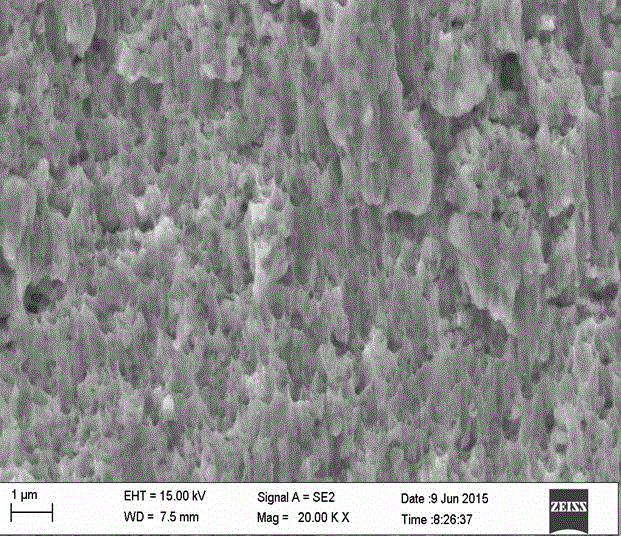

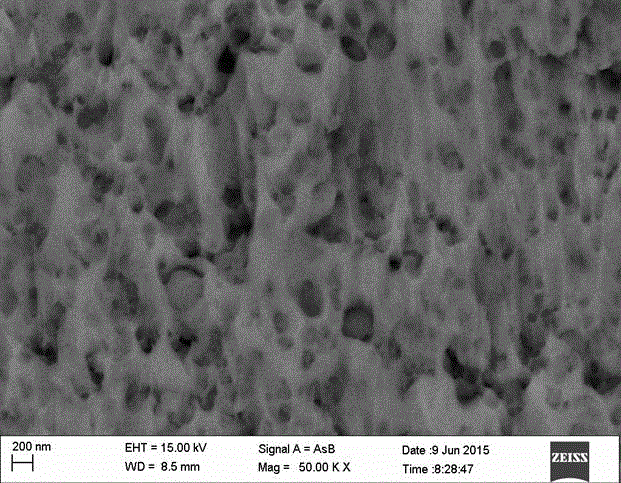

InactiveUS20130071755A1Improve conductivityEasy surface processingElectrode carriers/collectorsMetallic material coating processesLithiumCopper plating

Disclosed is a copper foil for a negative electrode collector capable of simultaneously achieving high capacity and long life charge / discharge cycles in a secondary battery, wherein the front and back surfaces are of a uniform shape and, for example, the properties of a silicon active material of a lithium ion secondary battery are sufficiently realized; and a negative electrode using the copper foil. In one embodiment, a first roughened layer of metallic copper is formed by pulse cathode electrolysis roughening treatment on the surface of an untreated rolled copper foil base material of oxygen-free copper in a first roughening treatment tank (1) filled with a copper-sulphuric acid electrolyte (12), and a second copper-plate layer is formed on the surface of the first roughened layer by smooth copper plating treatment in a second copper plating treatment tank (2) filled with a copper-sulphuric acid electrolyte (22).

Owner:FURUKAWA ELECTRIC CO LTD

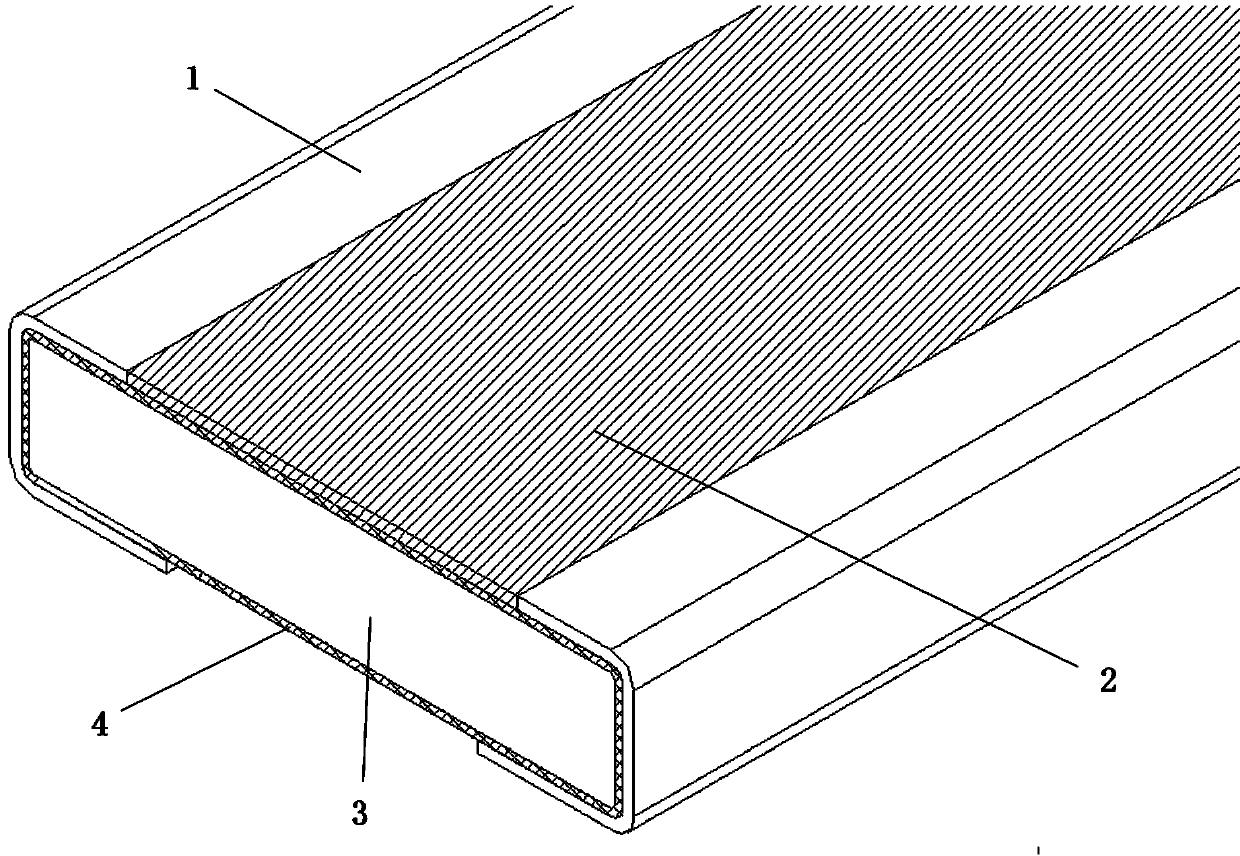

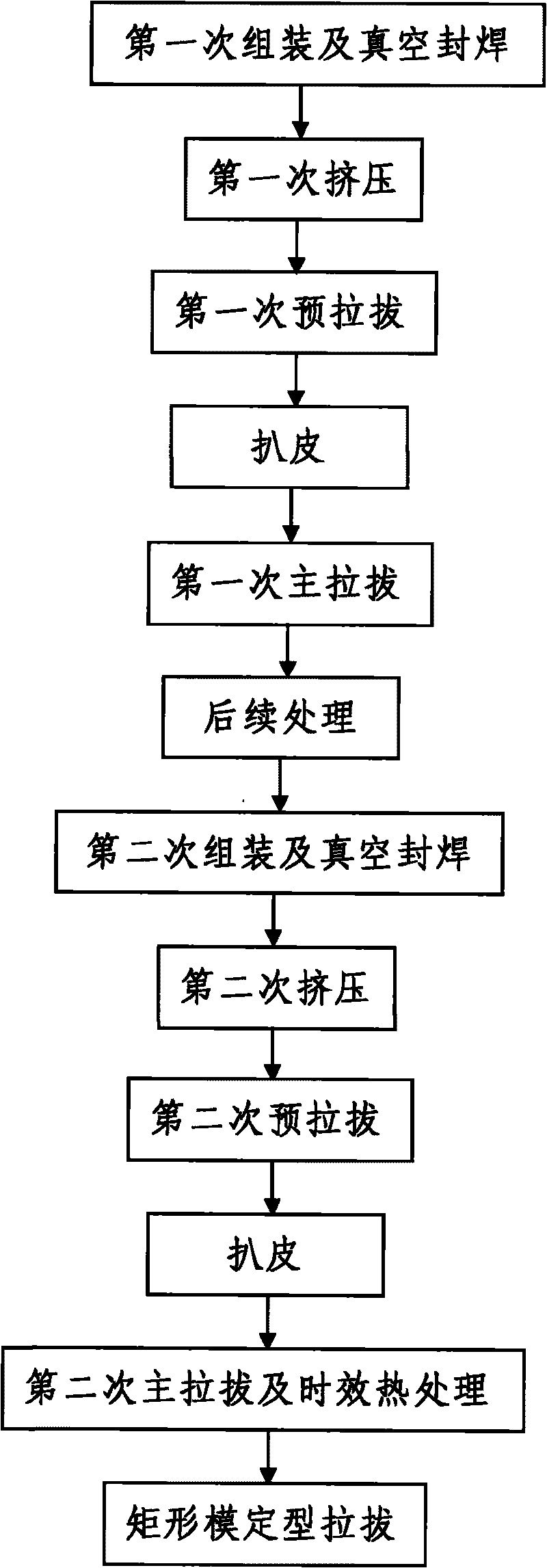

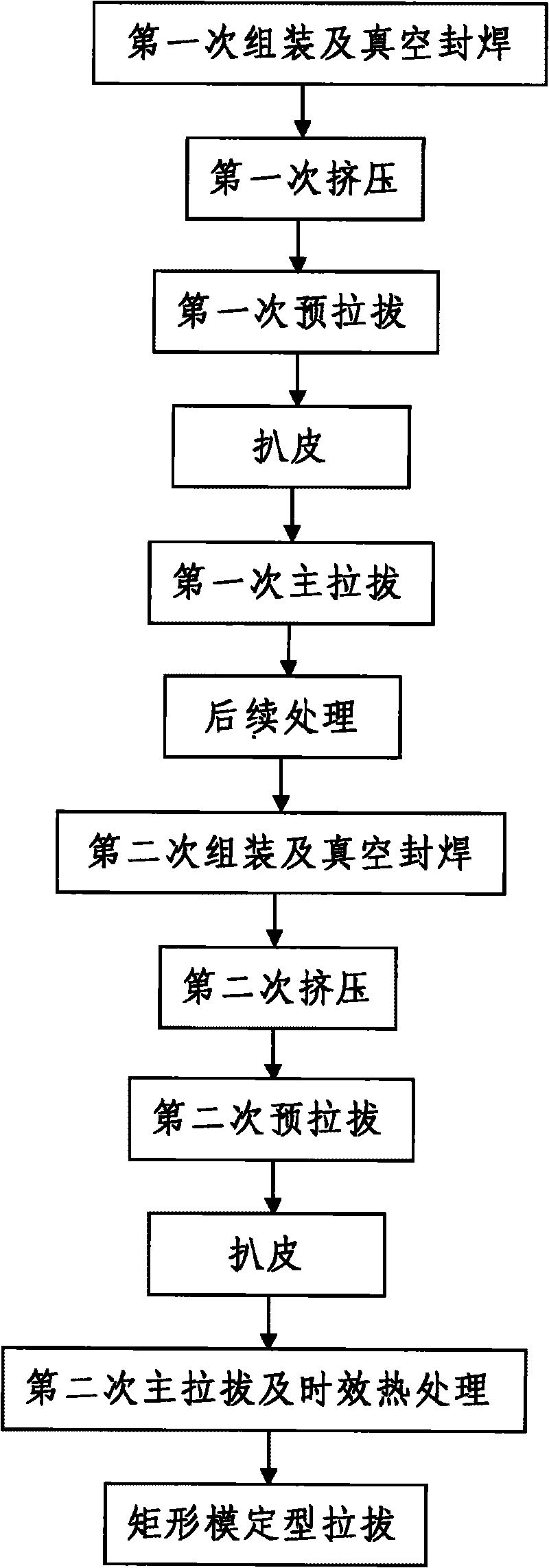

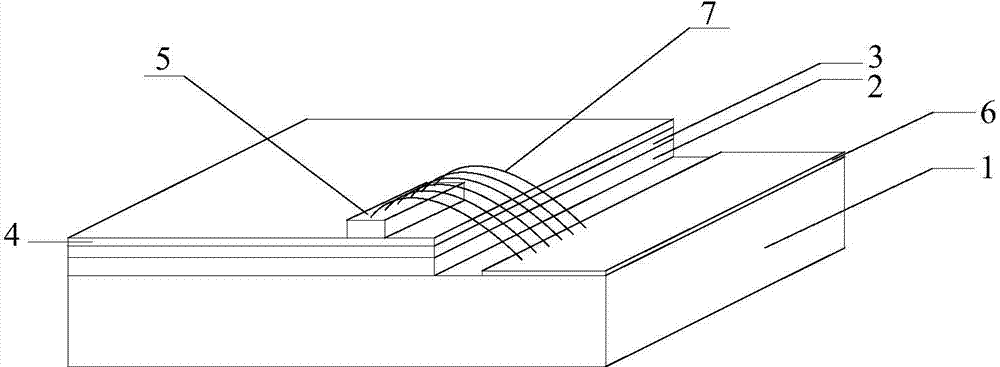

Preparation method for NbTi/Cu multi-core composite superconducting wire with rectangular section

InactiveCN101728029AThe process steps are simpleShort processSuperconductors/hyperconductorsSuperconductor devicesConductor CoilMaterials science

The invention discloses a preparation method for an NbTi / Cu multi-core composite superconducting wire with a rectangular section, which comprises the following steps of: firstly, assembling an NbTi bar, a pure Nb inner pipe and an oxygen-free copper sheath in turn to form an NbTi / Cu composite sheath, sealing an upper end cap and a lower end cap of the NbTi / Cu composite sheath through vacuum welding, and then performing primary extrusion to obtain an NbTi / Cu composite bar; secondly, drawing and scaling the composite bar, and keeping on drawing the composite bar to obtain a hexagonal core rod, and performing assembling for the second time; and thirdly, performing vacuum solder sealing, hot isostatic pressing, secondary extrusion, bar drawing and scaling on the sheath which is assembled in the second time to finally obtain the NbTi / Cu multi-core composite superconducting wire with the rectangular section. The preparation method has the advantages of simple process flow, low preparation cost and good preparation effect, improves the fill factor among windings in the process of coiling a superconducting magnet but simultaneously keeps high critical current density for the wire, and overcomes the defects that the conventional four-high mill or forming roll mill is unevenly stressed, is difficult to process and the like in the rolling process.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Shortened method for producing oxygen-free copper belt

InactiveCN101502872AUniform performanceEliminates effects on product surface qualityElectrolysisProduct gas

The invention provides a short process oxygen-free copper strip production method which is characterized in that the method comprises the following steps: an electrolytic copperplate is cleaned and dried, melted and insulated; after an upward continuous casting step, a copper rod is obtained; a continuous squeezing step is carried out on the copper rod to obtain a strip stock; after cold rolling, annealing and post treatment, the strip stock is made into a copper strip finished product. An upward casting rod is used by the invention to be continuously squeezed into the strip stock. The upward casting rod is directly made into the thickness of the finished product by cold rolling without surface milling and middle annealing. The continuous bright non-oxidation annealing is realized under the protection of air. Hot water degreasing is adopted for substituting the natron degreasing. The advantages of the up-draw process and the continuous squeezing method are combined. The product has the advantages of low oxygen content, pure tissue, small grain and perfect comprehensive performance. The short process oxygen-free copper strip production method has the advantages of brief process, energy saving, environment protection, pollution-free and the like.

Owner:SHANGHAI KANGCHENG COPPER GROUP +1

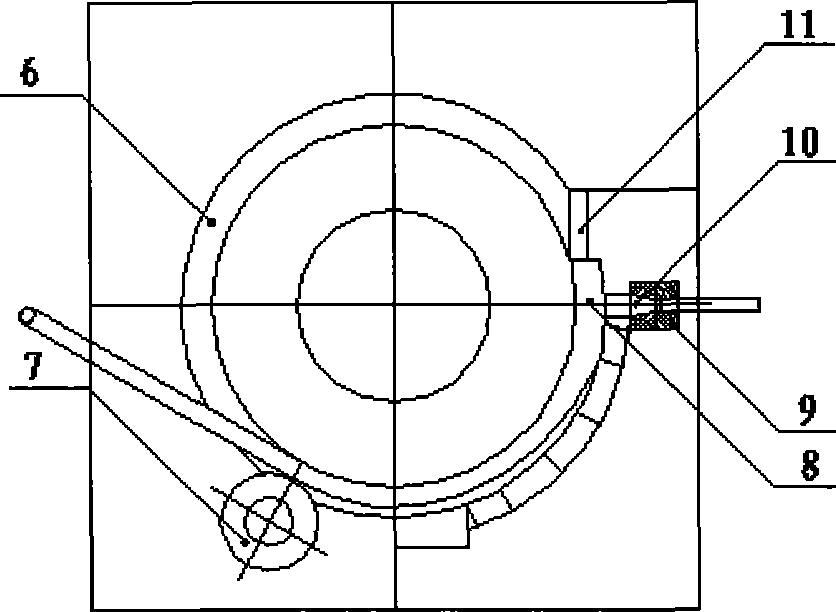

Preparation method of fine-grained CuCr alloy

The invention provides a preparation method of a fine-grained CuCr alloy, which comprises the processing steps that (1) an oxygen-free copper block and a chromium block are subjected to induction heating to be molten and dissolved mutually, molten liquid is ejected by argon gas pressure and subjected to centrifugal atomization by a copper roller rotation quenching melt spinning or a water-cooling rotating disk; (2) a fine-grained CuCr alloy material is subjected to ball milling by a high-energy ball mill under argon shield; (3) fine-grained composite CuCr alloy powder is loaded into a mould briquette to be made into a green blank; and (4) the green blank is loaded into a graphite drying pot, and placed in a vacuum sintering furnace to be sintered to form the fine-grained CuCr alloy. In the fine-grained CuCr alloy prepared by the method, the particle sizes of chromium particles are 0.5-10 micrometers, the surface hardness is 65-162HV, and the conductivity is 26.0-80.8% IACS (International Annealed Copper Standard); compared with the existing CuCr alloy with the equivalent chromium content, the particle sizes are reduced obviously, and the alloy performance is improved significantly; and the fine-grained CuCr alloy has more excellent effect in an application of an electrical contact material.

Owner:NORTHEASTERN UNIV

Forming copper powder suitable for 3D printing, and manufacturing method and purposes of forming copper powder

The invention belongs to the field of materials for 3D printing, and discloses forming copper powder suitable for 3D printing and a manufacturing method of the forming copper powder. The method comprises the steps that TU0 oxygen-free copper is smelted to 1250 DEG C-1400 DEG C by adopting an argon shield furnace, impurities mixed in fused copper liquid are removed by blowing argon at the bottom of the furnace, the copper liquid is completely fused, and temperature evenness is achieved. The fused copper liquid is injected into a tundish crucible by being protected by the argon, the copper liquid flows through a gas atomization nozzle through the tundish crucible and a guide nozzle under stable micropressure, preheated sound-speed argon flow ejected by the gas atomization nozzle washes the surface of the copper liquid to produce shear force and extrusion force, so that the copper liquid deforms, the diameter of the liquid flow becomes smaller and smaller, small liquid drops are formed finally, and then spherical metal powder is manufactured in an atomization chamber in a cooled mode. The 3D printing copper powder manufactured in the method is high in powder obtaining rate, the degree of sphericity is high, the oxygen content is less than 500 ppm, the grain size is less than 10 microns, and distribution is narrow.

Owner:KUN SHAN DOTOP METAL TECH CO LTD

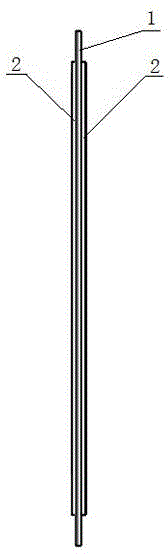

Process for specially-shaped electrolytic conductive material

InactiveCN102543310AReduce consumptionShort production processCable/conductor manufactureElectrolysisConductive materials

The invention discloses a process for a specially-shaped electrolytic conductive material. The process comprises the following steps of: 1) by taking highly-pure cathode copper as a raw material, performing centrifugal vacuum up-drawing continuous-casting on an oxygen-free copper rod by using a traction unit; 2) processing the oxygen-free copper rod in the step 1) by using a continuous extrusion unit to form a blank of the specially-shaped electrolytic conductive material; 3) drawing and finishing the blank of the specially-shaped electrolytic conductive material by using a fully-automatic hydraulic drawing machine to form the specially-shaped electrolytic conductive material, wherein the blank is formed in the step 2); and 4) checking and packaging the specially-shaped electrolytic conductive material which is formed in the step 3). The invention provides the specially-shaped electrolytic conductive material which is high in production efficiency, high in yield, high in product quality and free from environmental pollution and can overcome the defects of the conventional production process.

Owner:徐高磊

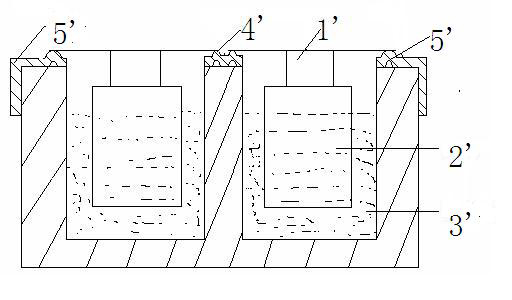

Surface treatment method for copper foil, surface treated copper foil and copper foil for negative electrode collector of lithium ion secondary battery

InactiveCN102884660AExcellent adhesionGood adhesionElectrode carriers/collectorsMetallic material coating processesLithiumCopper plating

Disclosed is a copper foil for a negative electrode collector capable of simultaneously achieving high capacity and long life charge / discharge cycles in a secondary battery, wherein the front and rear surfaces are of a uniform shape and, for example, the properties of a silicon active material of a lithium ion secondary battery are sufficiently manifested; and a negative electrode using the copper foil. In one embodiment, a first roughened layer of metallic copper is formed by pulse cathode electrolysis roughening treatment on the surface of an untreated rolled copper foil substrate of oxygen-free copper in a first roughening treatment vessel (1) filled with a copper-sulphuric acid electrolyte (12), and a second copper-plate layer is formed on the surface of the first roughened layer by smooth copper plating treatment in a second copper plating treatment vessel (2) filled with a copper-sulphuric acid electrolyte (22).

Owner:FURUKAWA ELECTRIC CO LTD

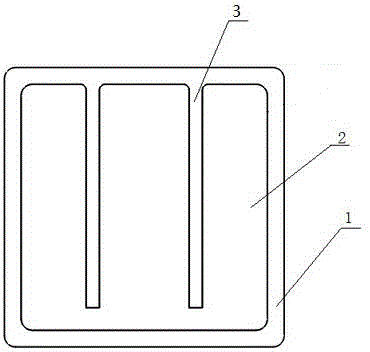

Preparation method for oxygen-free copper tube for magnetron

ActiveCN102605192AReduce oxygen contentOxygen isolationMagnetronsTransit-tube cathodesGranularityLanthanum

The invention relates to a preparation method for an oxygen-free copper tube for a magnetron. The preparation method is characterized in that the contents of copper and silver in a material of the oxygen-free copper tube is larger than or equal to 99.97%, and oxygen content is smaller than or equal to 0.001%. The preparation method includes following process steps: 1, smelting: placing number 1 high-purity cathode copper in a power frequency induction furnace with a core, raising the temperature of the furnace to smelt the cathode copper into copper liquid, adding lanthanum with the mass fraction ranging from 0.01% to 0.016% into the copper liquid, keeping the copper liquid at the temperature of 1170 + / -10 DEG , and covering a charcoal layer with the thickness ranging from 100mm to 120mm and the charcoal granularity ranging from 40mm to 60mm on the surface of the copper liquid; 2, upward continuous casting; 3, precise cold rolling; 4, recrystallization; 5, cold drawing forming; and 6,finishing. The oxygen content is low, electric conduction is excellent, yield is high, and metal loss is low.

Owner:江阴和宏特种材料有限公司

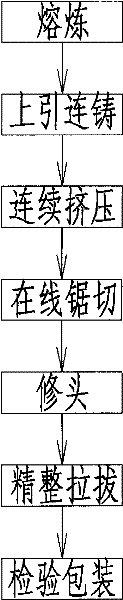

Large-section oxygen-free copper busbar and preparation method thereof

InactiveCN102262924AHigh purityImprove conductivitySingle bars/rods/wires/strips conductorsMetal/alloy conductorsBusbarOxygen content

The invention relates to an oxygen-free copper busbar and a preparation method thereof, in particular to a large-section oxygen-free copper busbar and a preparation method thereof, belonging to the technical field of nonferrous metal processing. The technological process of the present invention is: smelting→upward continuous casting→continuous extrusion→online sawing→head trimming→drawing→inspection and packaging. The invention solves the shortcomings of the traditional process of large-section copper bus bars, provides a production technology with short process flow, high degree of automation, low oxygen content, excellent product quality, environmental protection and pollution-free, and effectively improves the quality and performance of products , has the advantages of high purity, low oxygen content, high electrical conductivity, and excellent surface quality.

Owner:SHANDONG ZHONGJIA NEW MATERIALS

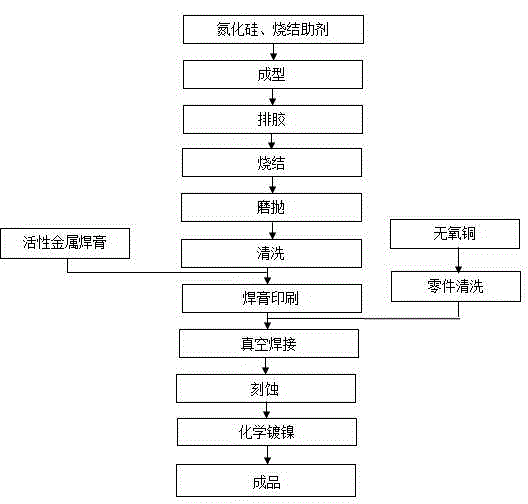

High-thermal-conductivity silicon nitride ceramic copper-clad plate and manufacturing method thereof

ActiveCN104409425AHigh strengthImprove impact resistanceSemiconductor/solid-state device detailsSolid-state devicesManufacturing technologyFlexural strength

The invention discloses a high-thermal-conductivity silicon nitride ceramic copper-clad plate and a manufacturing method thereof and relates to the field of the copper-clad plate manufacturing technology. The high-thermal-conductivity silicon nitride ceramic copper-clad plate comprises a high-thermal-conductivity silicon nitride ceramic substrate and oxygen-free copper layers; the upper and lower surfaces of the high-thermal-conductivity silicon nitride ceramic substrate are respectively welded with the oxygen-free copper layers; and the welding is a high-temperature welding in a vacuum brazing furnace by using an active metal welding paste. The bending strength of the high-strength and high-thermal-conductivity silicon nitride ceramic substrate is 2-3 times that of an aluminum nitride ceramic substrate, and the cladding of the high-thermal-conductivity silicon nitride ceramic substrate and a thick copper substrate can be realized; the thermal conductivity is 3-4 times that of the aluminum nitride ceramic substrate, so that the heat dissipation performance of the substrate can be improved greatly; compared with a direct copper-cladding process, the active copper-welding process has higher interface bonding strength, less cavities and higher reliability. Therefore, the high-thermal-conductivity silicon nitride ceramic copper-clad plate has the features of high strength, high conductivity and high reliability.

Owner:HEBEI SINOPACK ELECTRONICS TECH

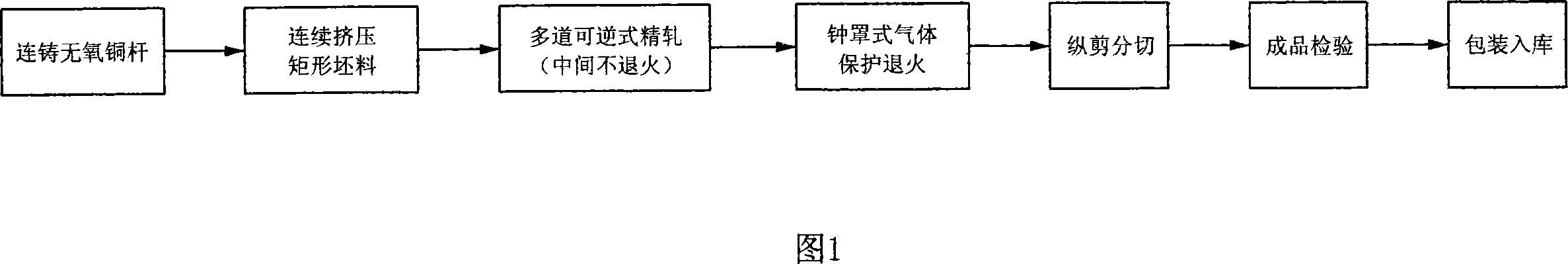

Production technology of big-length oxygen-free copper stripe

InactiveCN101134276AHigh purityHigh anaerobicRoll mill control devicesExtrusion control devicesOxidation resistantImpurity

The present invention discloses great length oxygen-free copper belt producing process, which includes continuously casting oxygen-free copper rod, continuously extruding rectangular blank, several gates of reversible finish rolling, annealing, longitudinally shearing, inspection, packing and other steps. By means of using oxygen-free copper rod as initial blank, continuous extrusion, continuous finish rolling, anti-oxidizing treatment, light gas protection and complete annealing, the present invention obtain great length oxygen-free copper belt product with high performance and good color.

Owner:浙江力博实业股份有限公司

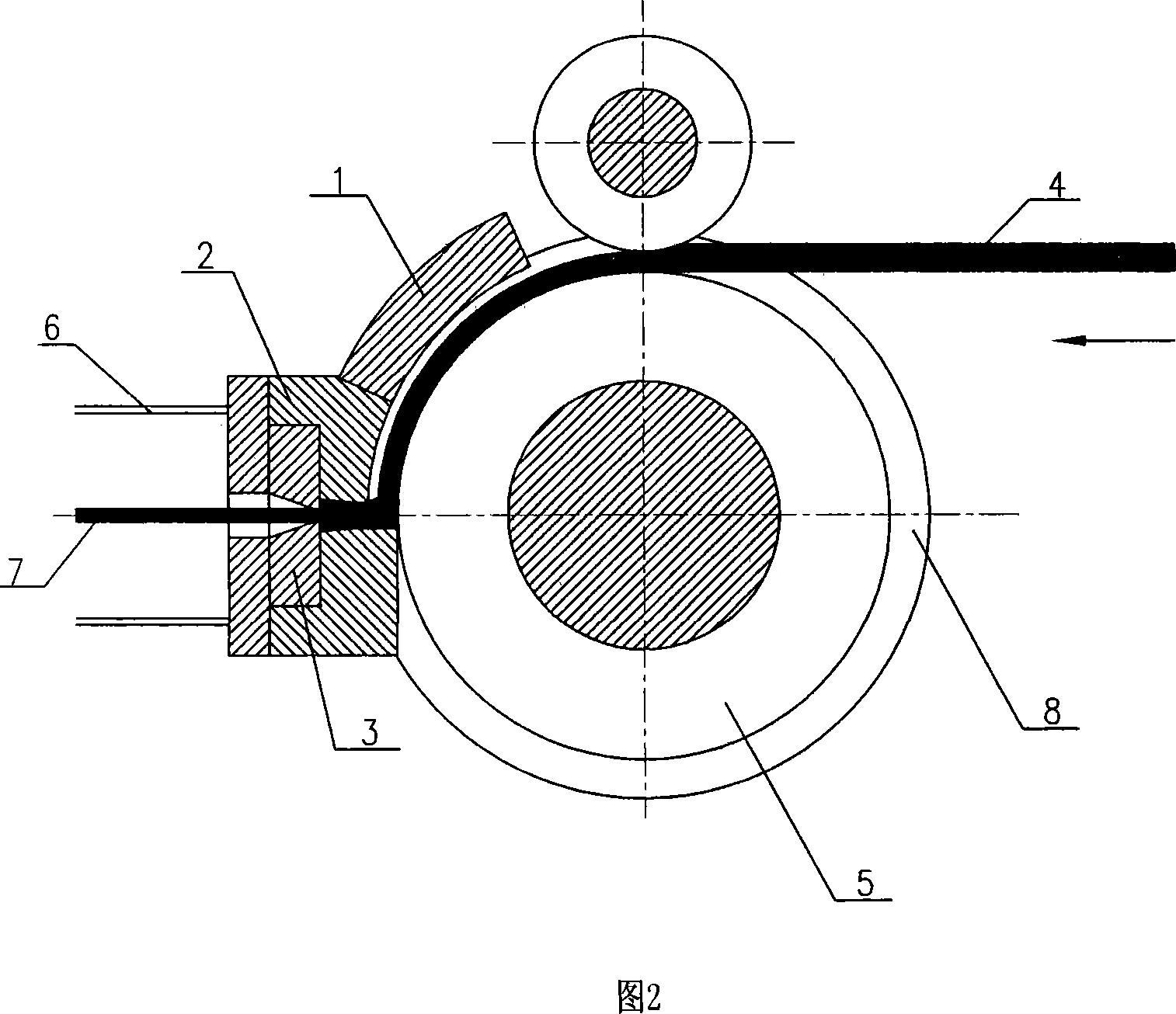

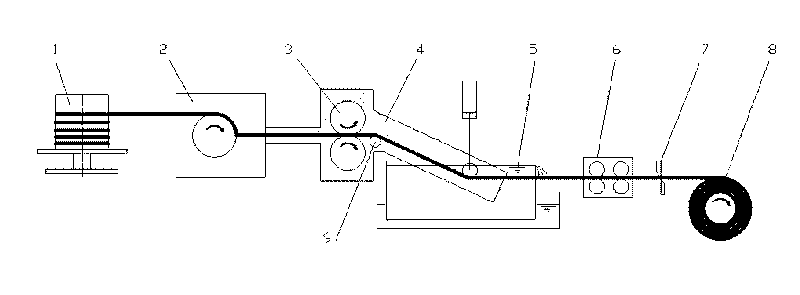

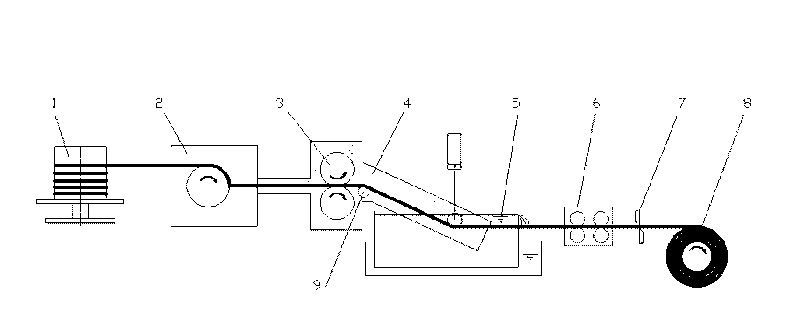

Continuous extrusion and continuous rolling process method and production line used for producing oxygen-free copper strip billet

ActiveCN101712050ARealize continuous productionReduce heatingMetal rolling arrangementsProduction lineShielding gas

The invention belongs to the field of copper processing, relating to the process method of the production of copper strip material, and in addition, relating to a copper strip material continuous extrusion and continuous rolling device. The invention provides a continuous extrusion and continuous rolling method used for producing oxygen-free copper strip billet, comprising the following steps: taking the oxygen-free copper rod as a raw material to carry out continuous extrusion to obtain the copper slabs; utilizing the heat generated in extrusion to carry out continuous hot rolling on the copper slabs; and cooling the copper bandlets after hot rolling, discharging to obtain the copper strips, wherein protective gas is adopted to protect the space between the extrusion outlet and the cooling inlet. The invention combines the advantages of low content of oxygen of the upper-draw process, great deformation of the continuous extrusion method and good performance of hot rolling method; the product has the advantages of low content of oxygen, compact organization, fine grains and excellent comprehensive performance; and the process method has the advantages of short flow, less heating and annealing processes, energy saving and environmental protection and the like.

Owner:大连康丰科技有限公司

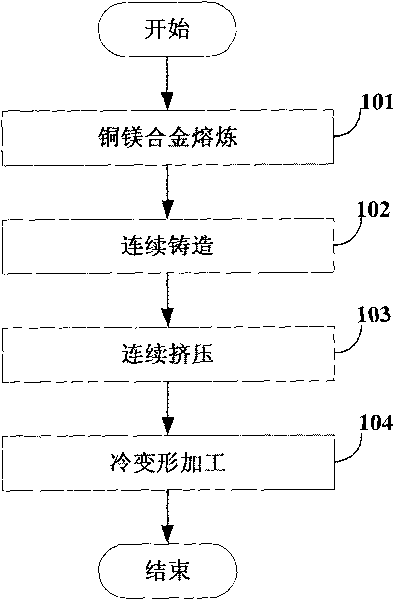

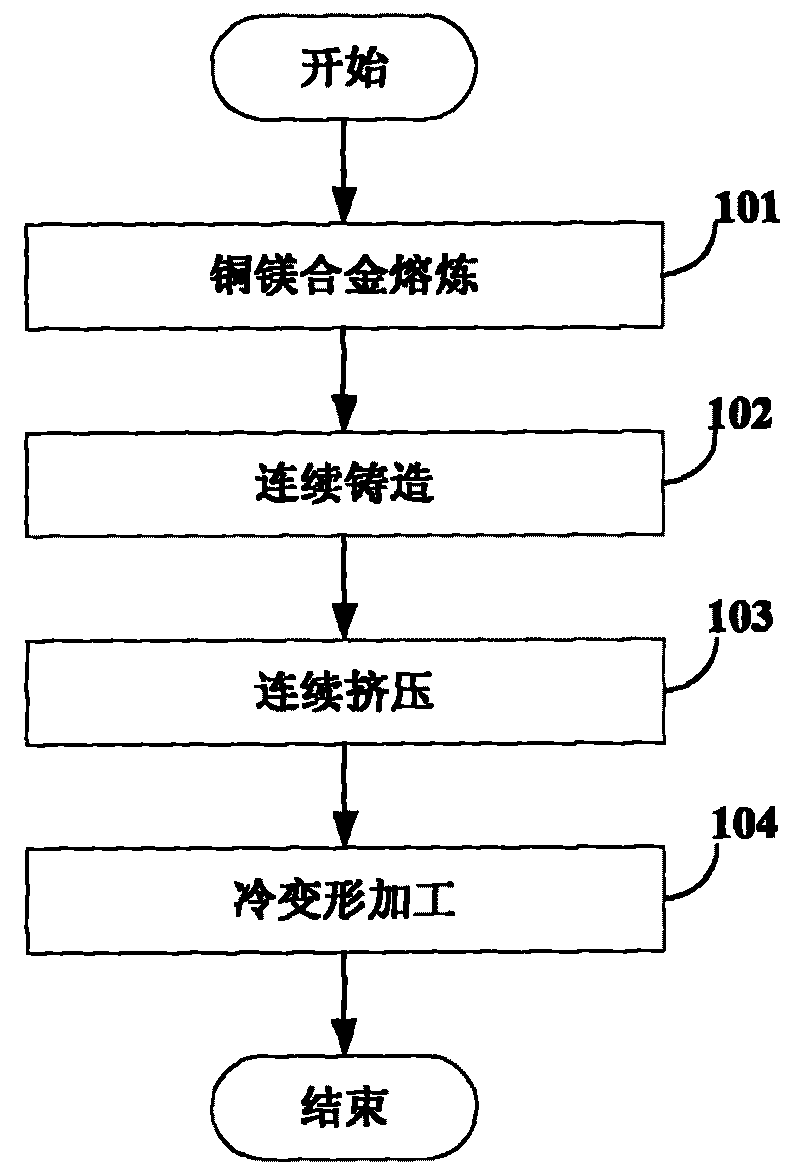

Method for preparing copper magnesium alloy contact wire

ActiveCN101710505ALow oxygenUltra-fine grain strengthening effect is lowSingle bars/rods/wires/strips conductorsTrolley linesThermal deformationHigh intensity

The invention discloses a method for preparing a copper magnesium alloy contact wire. In the method, an as-cast copper magnesium alloy structure is broken by continuous extrusion and is re-crystallized to obtain a tiny and even grain structure so as to make the copper magnesium alloy contact wire have the super fine-grain strengthening effect. The method comprises production process flows of continuous casting, continuous extrusion and cold machining molding. Compared with the conventional production process for the copper magnesium alloy contact wire, the method ensures that as-cast grains of an oxygen-free copper magnesium alloy casting pole molded by continuous casting are broken by the continuous casting and continuous extrusion processes, and are re-crystallized under the action of thermal deformation to form a copper magnesium alloy contact wire pole blank having a fine-grain structure, and the pole blank is subjected to cold machining to prepare the high-strength copper magnesium alloy contact wire having the super fine-grain strengthening effect. The production process is simple and reliable, and yield and quality completely meet the requirements of the conventional high-speed electrified railways.

Owner:CHINA RAILWAY CONSTR ELECTRIFICATION BUREAUGRP +1

Process for producing ultra-fine copper wire

Owner:浙江力博实业股份有限公司

Semiconductor laser heat sink with graphene layer and manufacturing method thereof

ActiveCN103887703AImprove conductivityReduce weightLaser detailsSemiconductor laser structural detailsBoron nitrideZirconia ceramic

The invention relates to a semiconductor laser heat sink with a graphene layer. The semiconductor laser heat sink with the graphene layer comprises a base material layer, an oxygen-free copper layer and the graphene layer which sequentially deposit from bottom to top, wherein the base material layer is made of any one of aluminum nitride ceramics, aluminum oxide ceramics, zirconia ceramics, silicon nitride ceramics, silicon carbide and boron nitride. The invention further relates to a method for manufacturing the semiconductor laser heat sink. The graphene layer is adopted as heat dissipation materials of the heat sink, the physical property of high heat conductivity of graphene is fully used, the heat generated when a semiconductor laser works is conducted out and dissipated, under the condition of not increasing the weight and the size of the semiconductor laser, the heat dissipation capacity of the semiconductor laser is largely improved, the temperature of the semiconductor laser in the working process is lowered, the photoelectric property and reliability of the semiconductor laser are guaranteed, and the service life of the semiconductor laser is prolonged.

Owner:BEIJING PEONY ELECTRONICS GROUP CORP

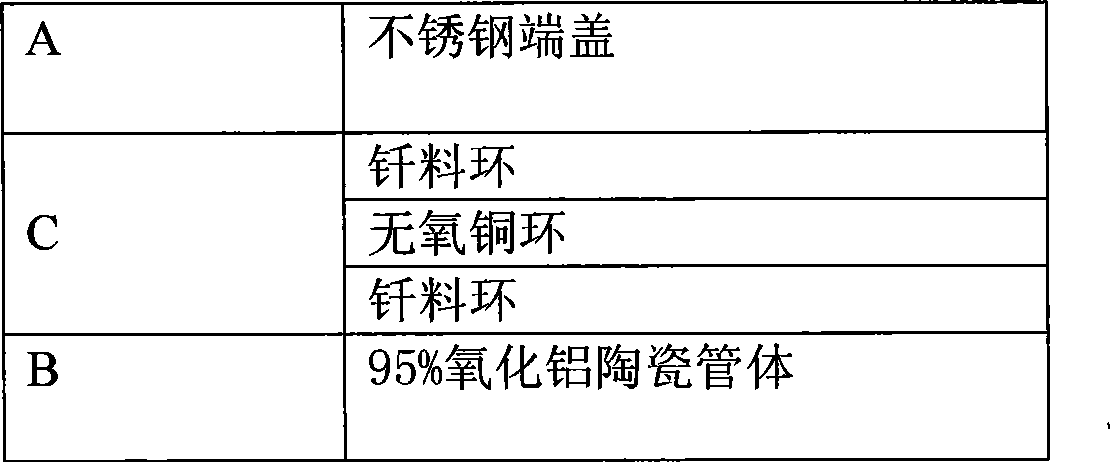

Stainless steel / alumina ceramic low stress hermetic seal solder

InactiveCN101475395AStrong stress absorption effectWelding/cutting media/materialsSoldering mediaAlloy compositeComposite solder

The invention relates to a silver alloy composite solder strip for a vacuum switch tube stainless steel and 95 percent alumina ceramic low-stress hermetic seal joint. The cross section of the composite solder strip has a three-layer overlapping structure of a solder alloy layer, a copper core layer and a solder alloy layer, wherein solder in the composite solder comprises the following compositions in percentage by mass: 55 to 72 percent of silver, 19.0 to 43.0 percent of copper and 0.50 to 4.50 percent of nickel; the melting temperature of the solder is between 780 and 835 DEG C, and the hermetic seal temperature is between 820 and 850 DEG C; the unilateral thickness of the solder alloy layer in the composite solder is between 0.08 and 0.20 millimeter; the copper core layer in the composite solder is copper with the purity of more than or equal to 99.95 percent or oxygen free copper; the interlayer composite proportion of the composite solder, namely the thickness of the solder layer to the thickness of the copper core layer to the thickness of the solder layer, is 1:X:1 (wherein, X is between 1.8 and 3.5); and firm metallurgical combination is formed between various layers. The intensity of the vacuum switch tube stainless steel and 95 percent alumina ceramic joint is more than or equal to 90 MPa, and the leakage rate of the joint is less than or equal to 1*10Pa.m / s.

Owner:SINO PLATINUM METALS CO LTD

Method for cladding copper on surface of infiltration sintered tungsten-copper composite material

The invention discloses a method for cladding copper on a surface of an infiltration sintered tungsten-copper composite material. The method comprises the following steps: a mixture of tungsten powder and copper powder is prepared, wherein the content of the tungsten powder is 65-85 weight%, and the content of the copper powder is 15-35 weight%; after the prepared mixture is added to forming agent, and is dried for pelletizing through spraying, the prepared mixture is compressed for forming in a mold to obtain a tungsten skeleton pressing blank, wherein the pressing pressure is 150-400 MPa; oxygen-free copper is pressed into a copper bar serving as sintering infiltration agent; the sintering infiltration agent is stacked on the tungsten skeleton pressing blank, then the sintering infiltration agent and the tungsten skeleton pressing blank are put in a graphite mold, and are sintered in a vacuum furnace to obtain the tungsten-copper composite material; the tungsten-copper composite material consists of a tungsten-copper alloy layer and a copper layer; and the copper layer covers the surface of the tungsten-copper alloy. The infiltration density of the tungsten-copper composite material is raised to more than 99% to totally satisfy the requirements of some special equipment parts, so that the service life of the special equipment is greatly prolonged.

Owner:ZHEJIANG LIGHT TOUGH COMPOSITE MATERIALS

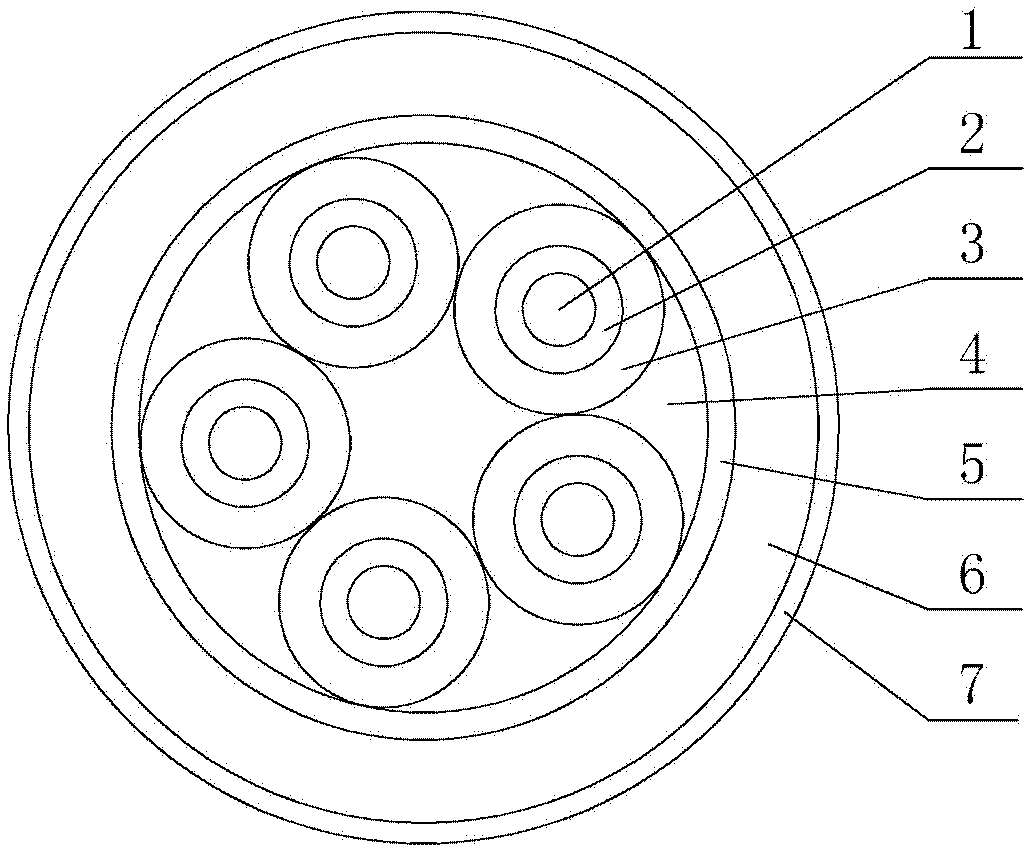

Special tensile dragging control cable and method for manufacturing same

ActiveCN102360603AHigh tensile strengthImprove electrical performanceFlexible cablesMetal/alloy conductorsCopper conductorEnvironmental resistance

The invention discloses a special tensile dragging control cable. An insulating wire core consists of a plurality of multi-stranded zinc-coated soft steel wires, a tin-coated oxygen-free copper wire and an insulating extruded layer; a plurality of insulating wire cores are stranded into a cable core; a filling layer which consists of hemp ropes is filled in a clearance of the cable core; the cable core is wound with a tear-resistant polypropylene belt in an overlapping mode and extruded with a tensile wear-resistant polyurethane elastic outer sheath; the outermost layer of the cable is a braided zinc-coated steel wire outer sheath layer; each insulating wire core consists of the plurality of multi-stranded zinc-coated soft steel wires which serve as reinforcing cores and the tin-coated oxygen-free copper wire which serves as a copper conductor; and the insulating extruded layer is made of ethylene-propylene-diene monomer compound rubber. The special tensile dragging control cable has the characteristics of high tensile strength, high flexibility, high tear resistance, oil resistance, aging resistance, external environment weather resistance and the like, has excellent functions ofhigh bending winding capacity, dragging resistance, environment friendliness and the like, and is applicable to equipment such as a winding drum, a port machine and an excavator; and the service lifeof the dragging cable is greatly prolonged.

Owner:ANHUI SIAIT CABLE GROUP

High-purity high-conductivity oxygen-free copper rod and processing method thereof

InactiveCN106180616AImprove craftsmanshipSolve the problem of the utilization of renewable resourcesLithium oxideInsulation layer

The invention discloses a processing method of a high-purity high-conductivity oxygen-free copper rod. The processing method comprises the following steps of S1 melting a copper material so as to form copper liquid, refining so as to remove impurities, and then adding deoxidant in batches, wherein the deoxidant is prepared from the following components in parts by weight: 40 to 45 parts of lanthanum, 20 to 25 parts of cerium, 5 to 10 parts of praseodymium, 15 to 30 parts of calcium hexaboride and 15 to 30 parts of lithium oxide; S2 leading the copper liquid in a smelting furnace to a holding furnace, controlling the temperature of the holding furnace to 1150 to 1160 DEG C, and covering an oxygen insulation layer on the surface of the copper liquid in the holding furnace; and S3 leading high-purity nitrogen below the liquid level of the copper liquid in the holding furnace for boiling degassing, and then adopting up-drawn continuous casting so as to obtain the high-purity high-conductivity oxygen-free copper rod. According to the processing method of the high-purity high-conductivity oxygen-free copper rod, the oxygen content of the high-purity high-conductivity oxygen-free copper rod is less than or equal to 20 PPM, the conductivity of the high-purity high-conductivity oxygen-free copper rod is greater than or equal to 0.064, and the whole process has the advantages of simple conditions, wide application range and less pollution.

Owner:安徽晋源铜业有限公司

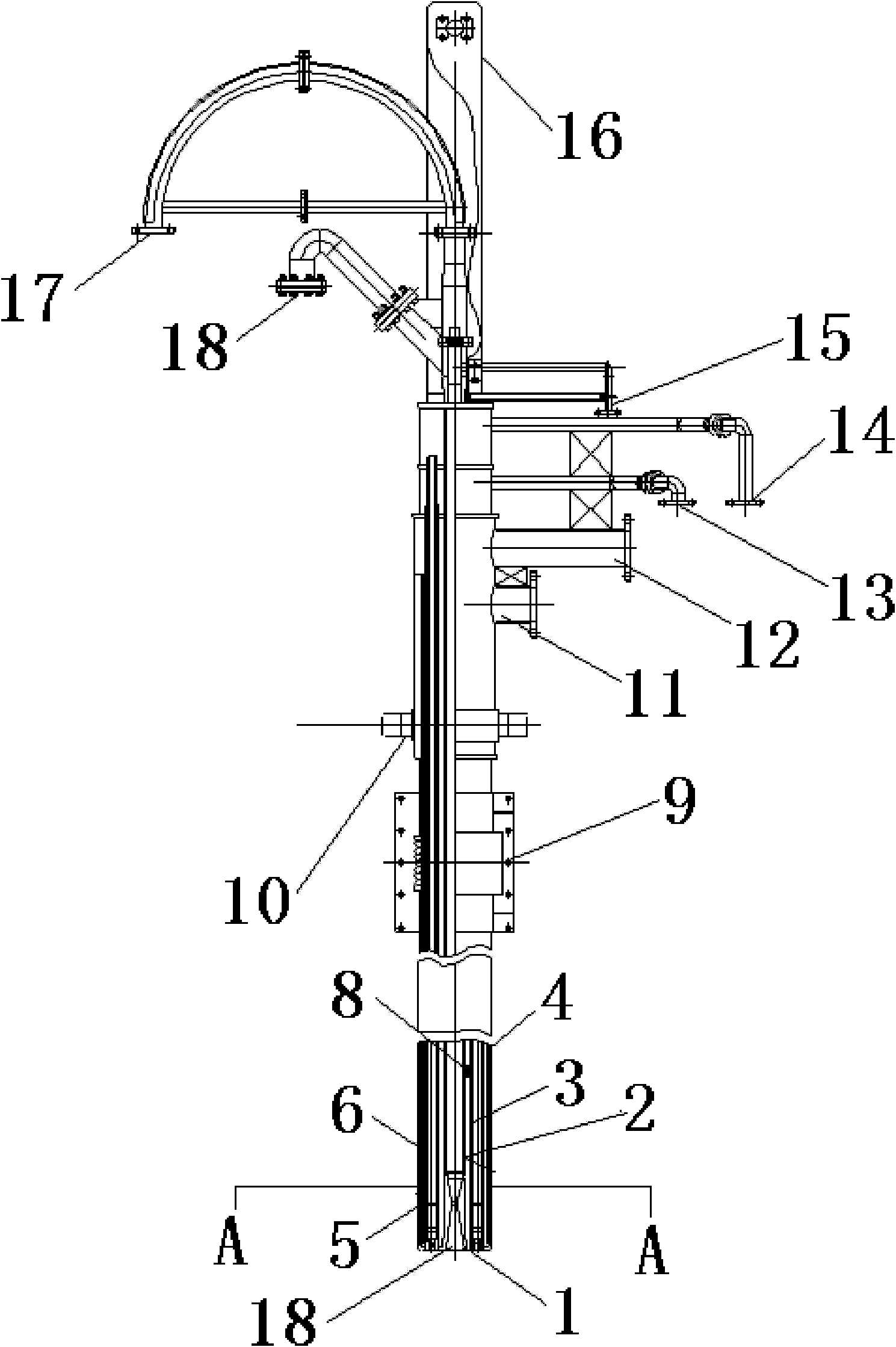

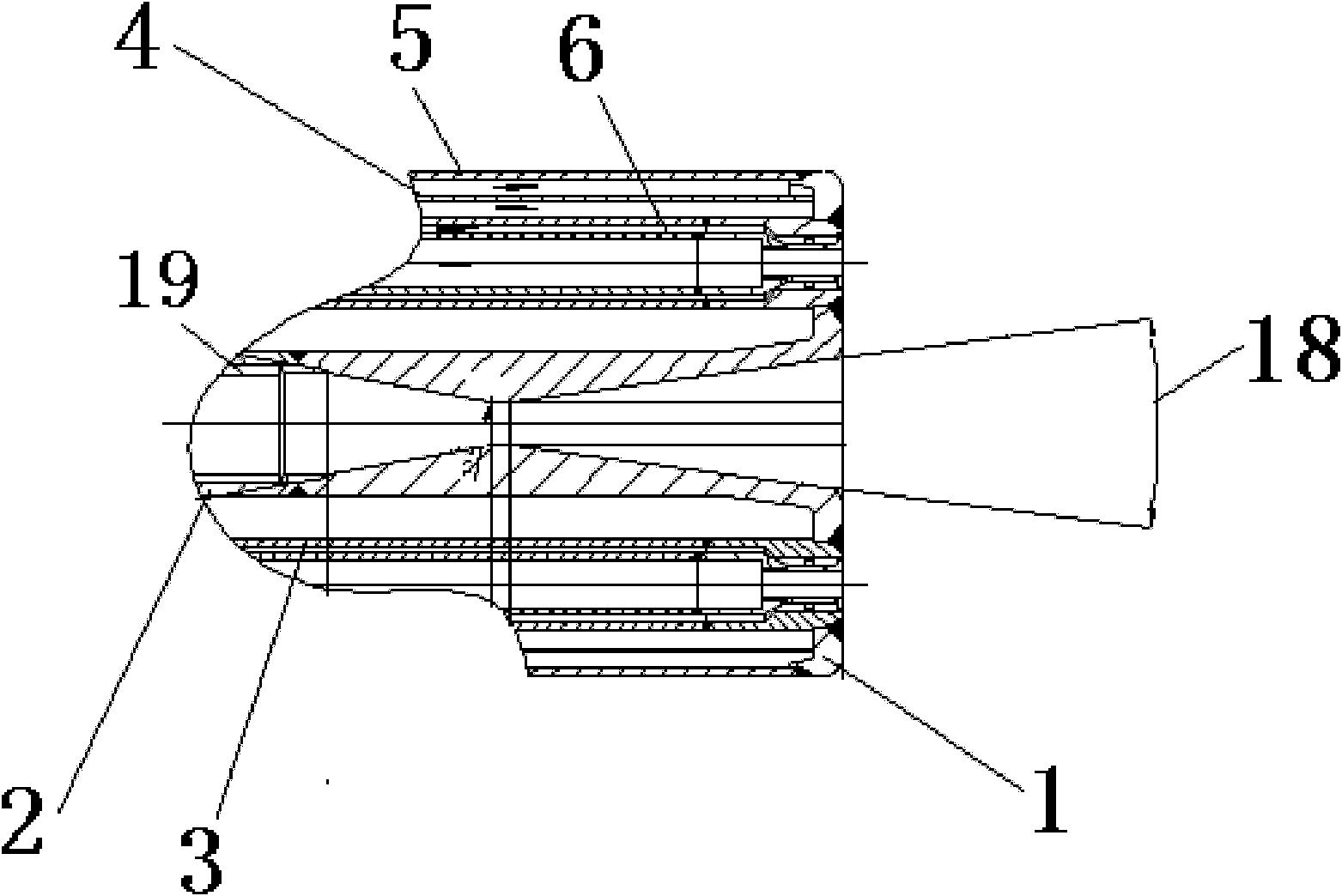

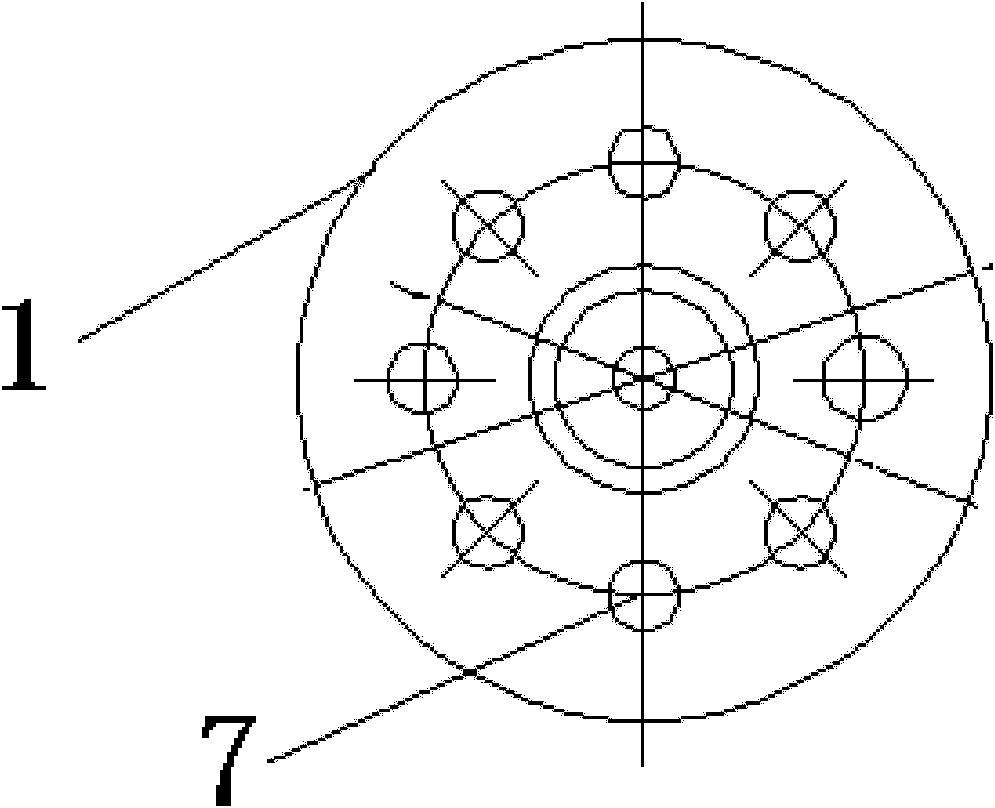

Top gun applied to steel production

InactiveCN102022917AExtended service lifeDusting shorteningCharge manipulationManufacturing convertersNitrogenEngineering

The invention provides a top gun applied to steel production in the technical field of steel production. The top gun comprises a Laval gun head (1), a gun head center pipe (2), a fuel pipe (3), a marine riser (4), an outer pipe (5), an oxygen pipe (6), a flame detector installing hole (7), an isolation device (8), a gun body flexibility regulating device (9), a hanging device I (10), a cooling water outlet pipe (11), a cooling water inlet pipe (12), a combusting oxygen inlet pipe (13), a fuel inlet pipe (14), a nitrogen inlet pipe (15), a hanging device II (16) and a center oxygen inlet pipe(17), wherein the Laval gun head (1) of the top gun is made of TU2 oxygen-free copper materials, and a chromium electroplating hard layer is additionally arranged on the inner surface of the gun head center pipe (2). The top gun can prolong the service life of the gun head, can increase the powder injecting and oxygen blowing quantity in unit time, shorten the power injecting and oxygen blowing time, and lower the manufacture cost of the top gun.

Owner:MAANSHAN IRON & STEEL CO LTD

Preparation method of copper and magnesium alloy contact wire for railway electrification

ActiveCN103276237AIncrease production capacityReduce the temperatureSingle bars/rods/wires/strips conductorsMetal/alloy conductorsMisch metalNiobium

A copper and magnesium alloy contact wire for railway electrification comprises a copper base and alloy metal, wherein the alloy metal comprises components in percentage by weight as follows: 0.5-0.6% of magnesium, 0.012-0.014% of zirconium, 0.012-0.014% of niobium, 0.005-0.008% of titanium and 0.02-0.04% of misch metal. A preparation technology adopts an upward continuous casting extrusion-cold rolling-stretching technology. The oxygen content of the prepared contact wire reaches an oxygen-free copper level, the grain is fine, the mechanical property is remarkably improved, the contact wire is uniform in a length direction, the flatness is good, the locomotive picking-up performance is good, the tensile strength, the elongation percentage, the grain size and the toughness are greatly improved when the copper and magnesium alloy contact wire is compared with a conventional wire, and the copper and magnesium alloy contact wire has wide popularization and application values in the high-speed railway electrification field.

Owner:山东维点技术有限公司

High-purify upper oxygen-free copper rod production method

The invention discloses a method for producing high-purity upward oxygen-free copper rods, which comprises the following steps: uniformly adding copper plates into a melting furnace in batches during melting of copper materials; adopting a Cu-RE intermediate alloy rod to continuously add single rare earth element or mischmetal element, realizing electromagnetic stirring in the melting furnace through induction heating coils, and making the rare earth element uniformly distributed in molten copper; and arranging a ceramic filtration baffle plate on the front of a sluice between the melting furnace and a heat-insulating furnace, making the ceramic filtration baffle plate completely cover the sluice, preventing rare earth oxide from being rolled into upward oxygen-free copper rods, and obtaining the high-purity upward oxygen-free copper rods. The method has the advantages of simple production technique, stable production process, less residual oxide inclusion formed by the rare earth element, good purification effect of the copper materials, and good product quality.

Owner:JIANGSU UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com