Method for preparing copper magnesium alloy contact wire

A technology of copper-magnesium alloy and contact wire, which is applied in the manufacture of metal/alloy conductors, overhead wires, cables/conductors, etc., can solve the problems that contact wire defects cannot be eliminated, and achieve excellent mechanical and electrical properties and good performance uniformity , low production and use loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

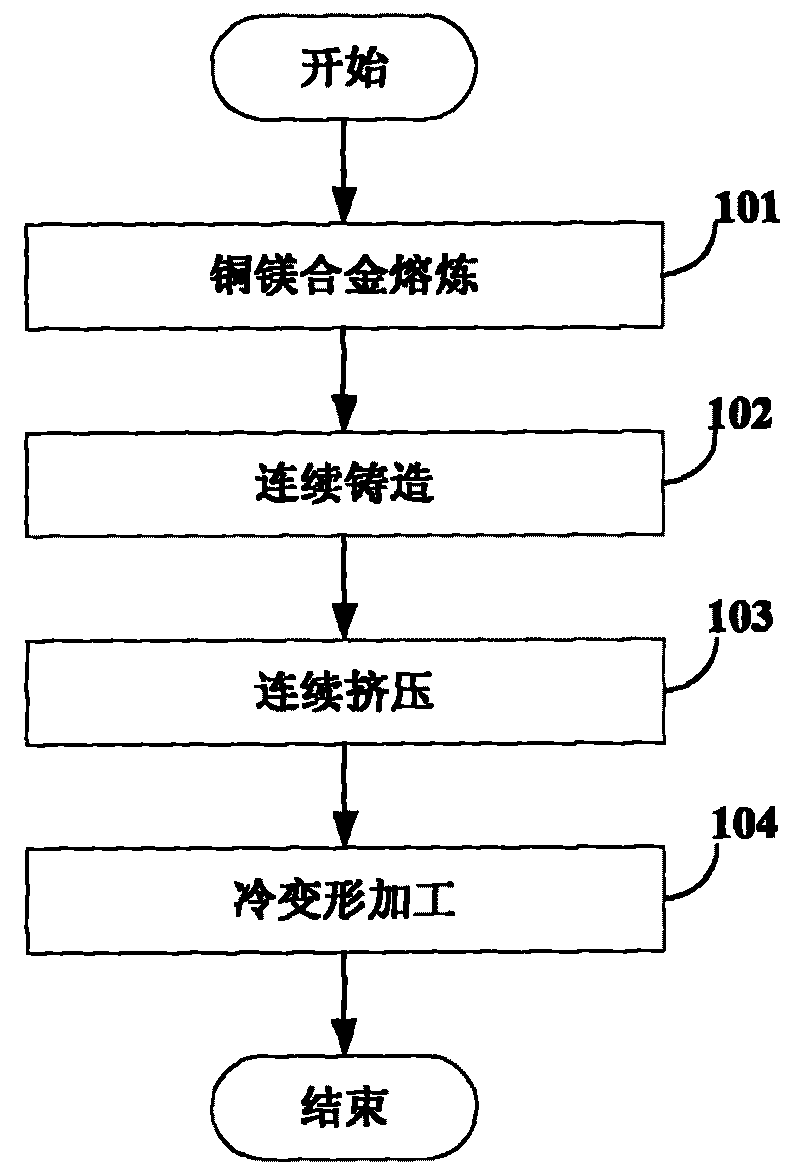

[0020] like figure 1 as shown, figure 1 It is a flowchart of the realization of the preparation method of the copper-magnesium alloy contact wire according to the present invention, which specifically includes the following steps:

[0021] Step 101: Smelting the copper-magnesium alloy; various appropriate smelting methods can be used, and the copper liquid is covered with graphite and charcoal. The way of adding magnesium element can be copper-magnesium master alloy or directly adding pure magnesium to the smelting furnace by weight.

[0022] Step 102: Prepare continuous copper-magnesium alloy oxygen-free casting rods; prepare copper-magnesium alloy oxygen-free casting rods by upward continuous casting or horizontal continuous casting. The diameter of the copper-magnesium alloy anaerobic casting rod is 16-24mm.

[0023] Step 103: Feed the copper-magnesium alloy anaerobic casting rod into the continuous extrusion machine for continuous extrusion, the as-cast structure of the...

Embodiment 1

[0027] The concrete steps of method embodiment one of the present invention are as follows:

[0028] 1) Carry out non-vacuum copper-magnesium alloy melting. The electrolytic copper smelting is carried out in an electromagnetic furnace, the copper liquid is covered with flake graphite, and the copper-magnesium master alloy is added according to the set composition, so that the magnesium element in the furnace accounts for 0.4% to 0.5% of the total weight, and the rest is copper.

[0029] 2) The copper-magnesium alloy oxygen-free casting rod was prepared by upward continuous casting, and the diameter of the produced copper-magnesium alloy oxygen-free casting rod was 20 mm.

[0030] 3) Send the produced copper-magnesium alloy anaerobic casting rod into the Kangfu extrusion machine for continuous extrusion, and the diameter of the extruded copper-magnesium alloy contact wire rod billet is 30mm.

[0031] 4) The extruded copper-magnesium alloy contact wire billet is cold-rolled, an...

Embodiment 2

[0034] The concrete steps of method embodiment two of the present invention are as follows:

[0035] 1) Carry out non-vacuum copper-magnesium alloy melting. The electrolytic copper smelting is carried out in an electromagnetic furnace, the copper liquid is covered with flake graphite, and the copper-magnesium master alloy is added according to the set composition, so that the magnesium element in the furnace accounts for 0.4% to 0.5% of the total weight, and the rest is copper.

[0036] 2) The copper-magnesium alloy oxygen-free casting rod was prepared by upward continuous casting, and the diameter of the produced copper-magnesium alloy oxygen-free casting rod was 20mm.

[0037] 3) Send the produced copper-magnesium alloy anaerobic casting rod into the Kangfu extrusion machine for continuous extrusion, and the diameter of the extruded copper-magnesium alloy contact wire rod billet is 30mm.

[0038] 4) The extruded copper-magnesium alloy contact wire billet is subjected to mul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com