Patents

Literature

771 results about "Contact wire" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

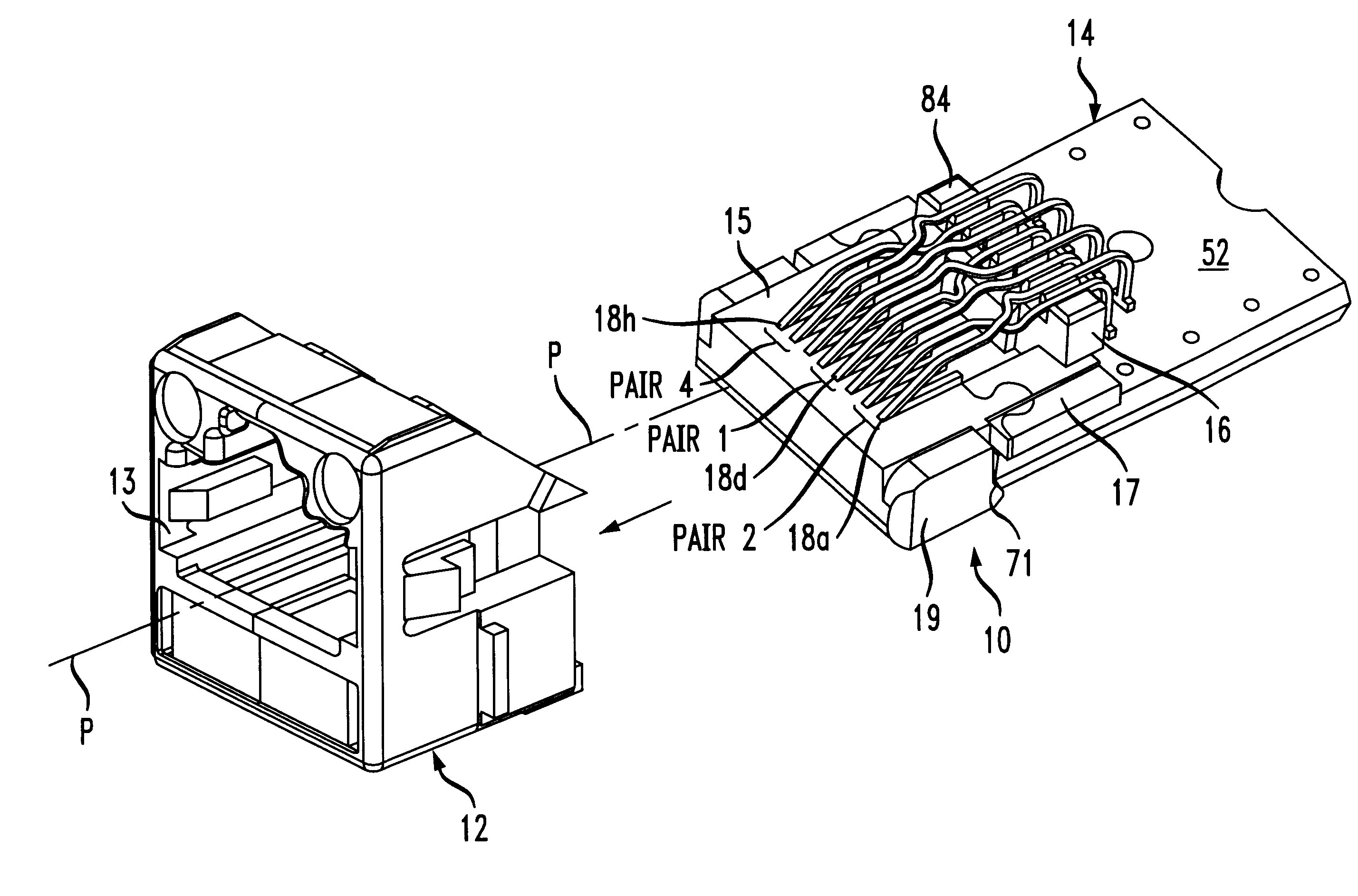

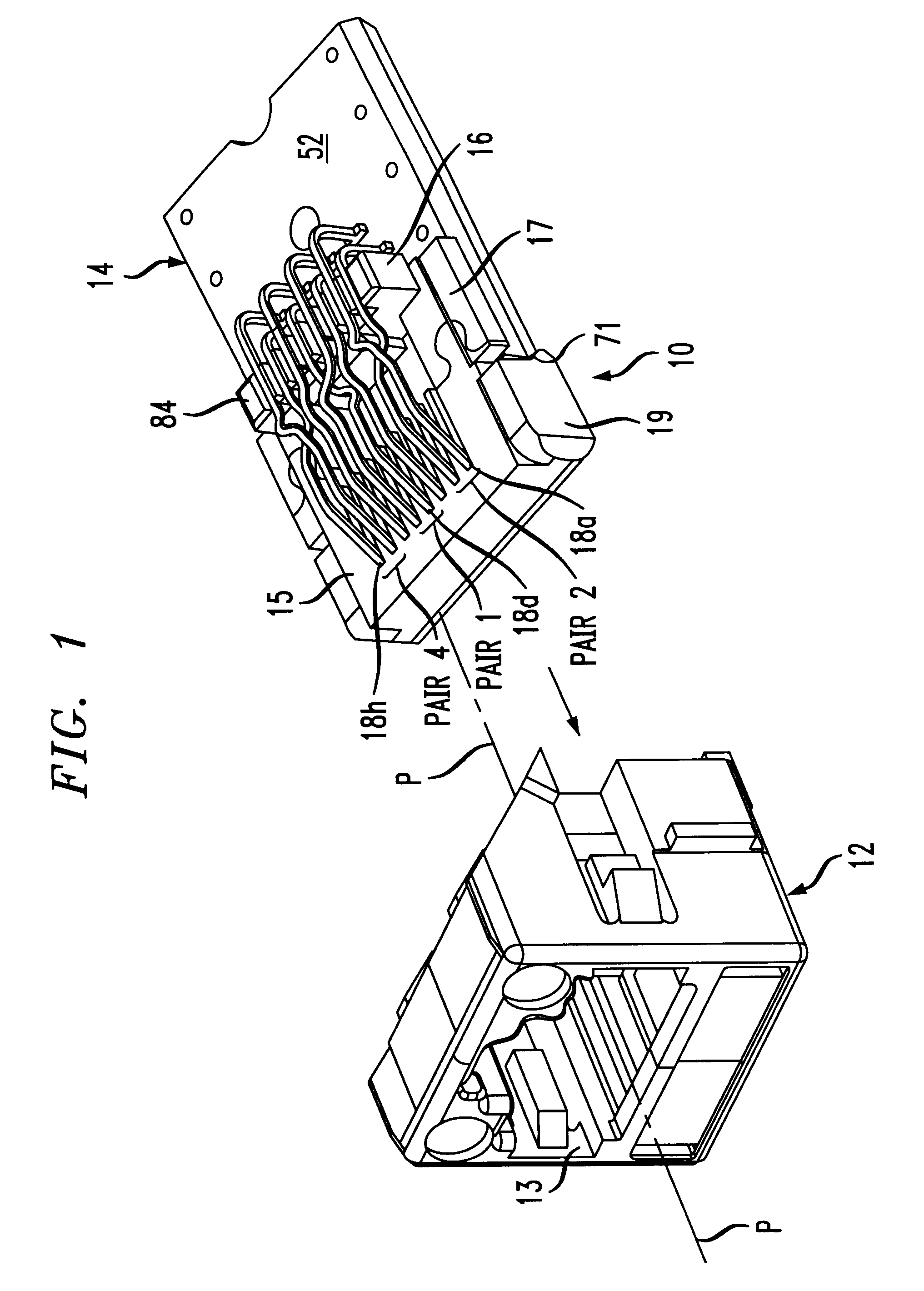

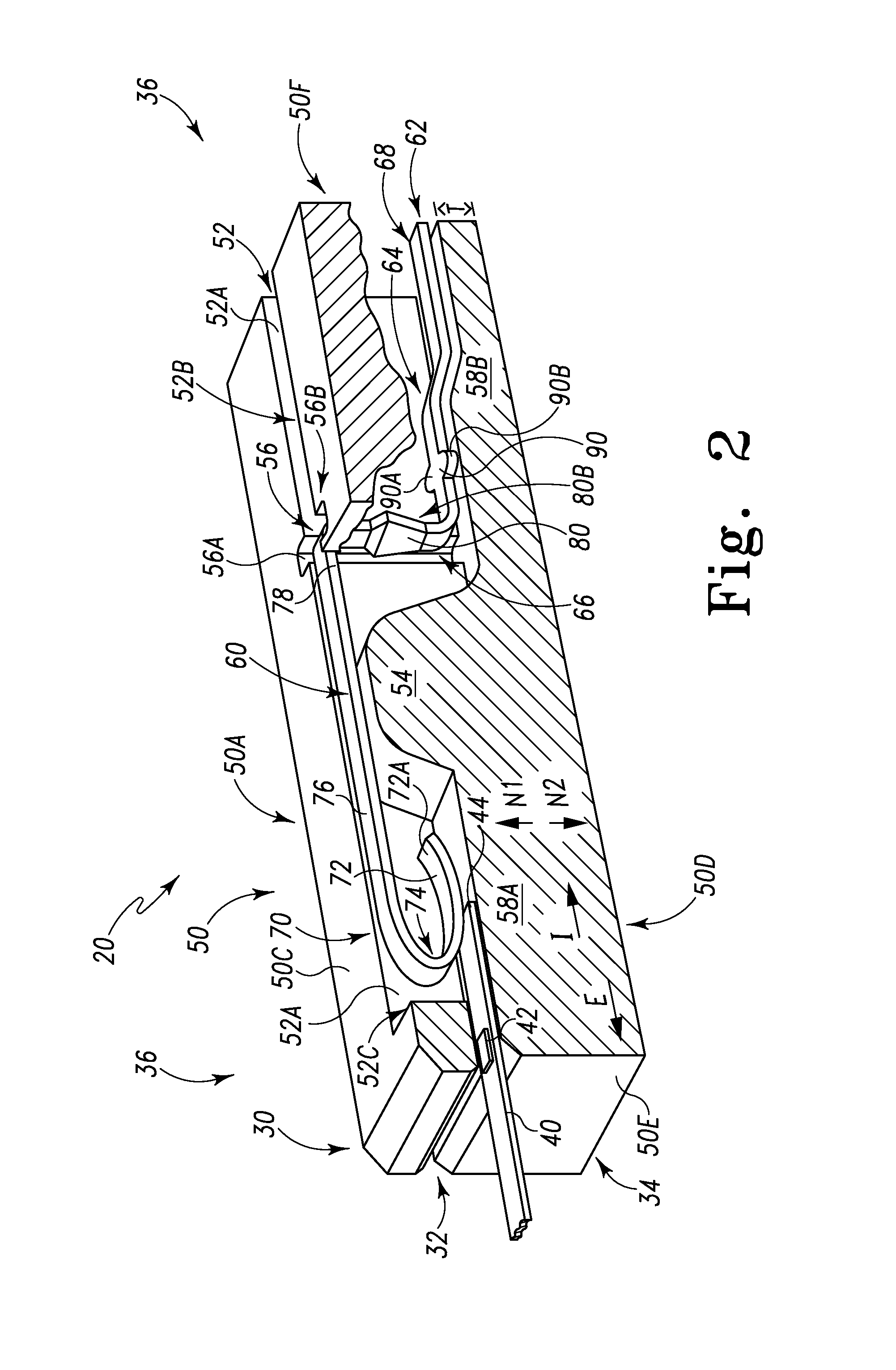

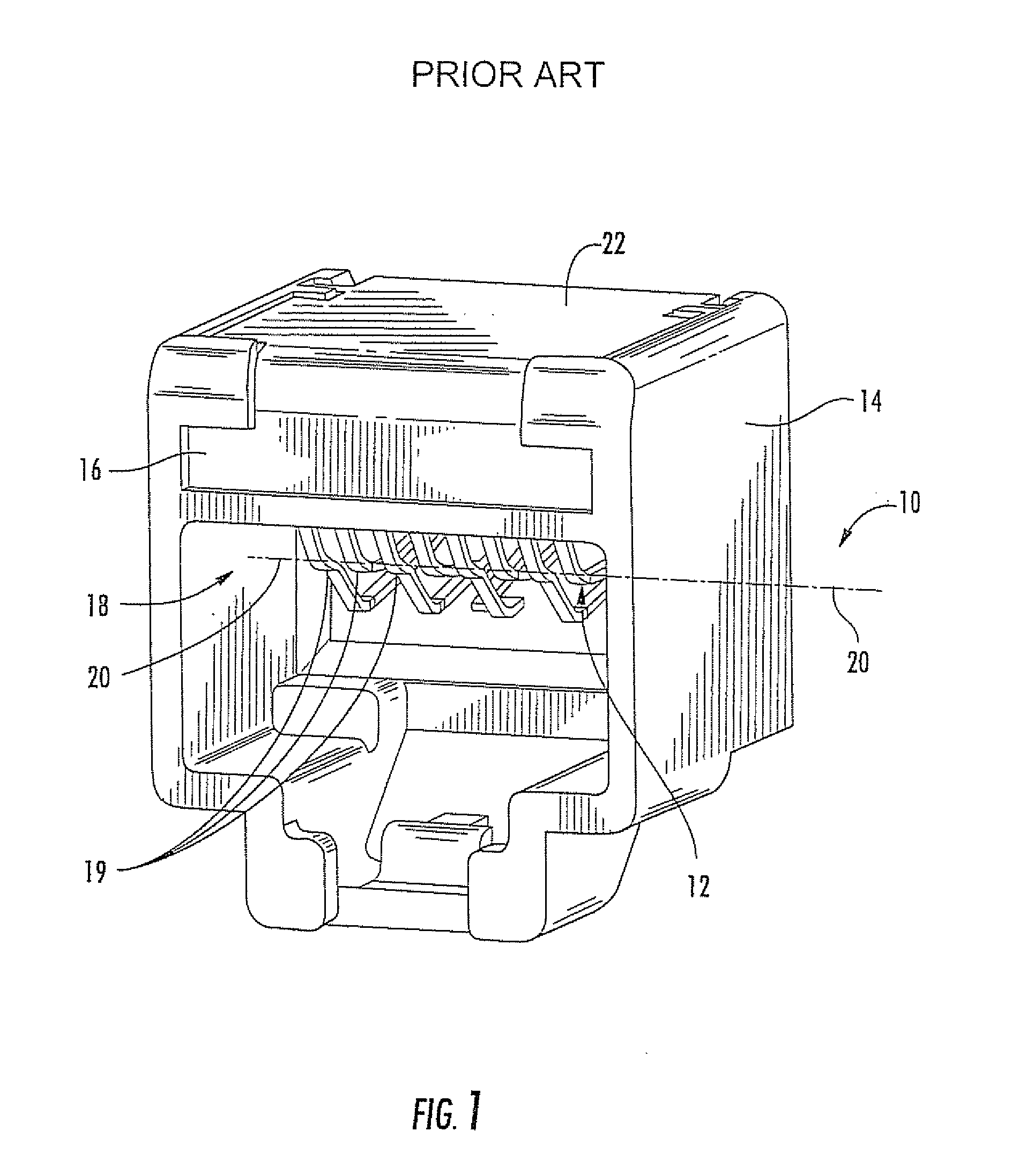

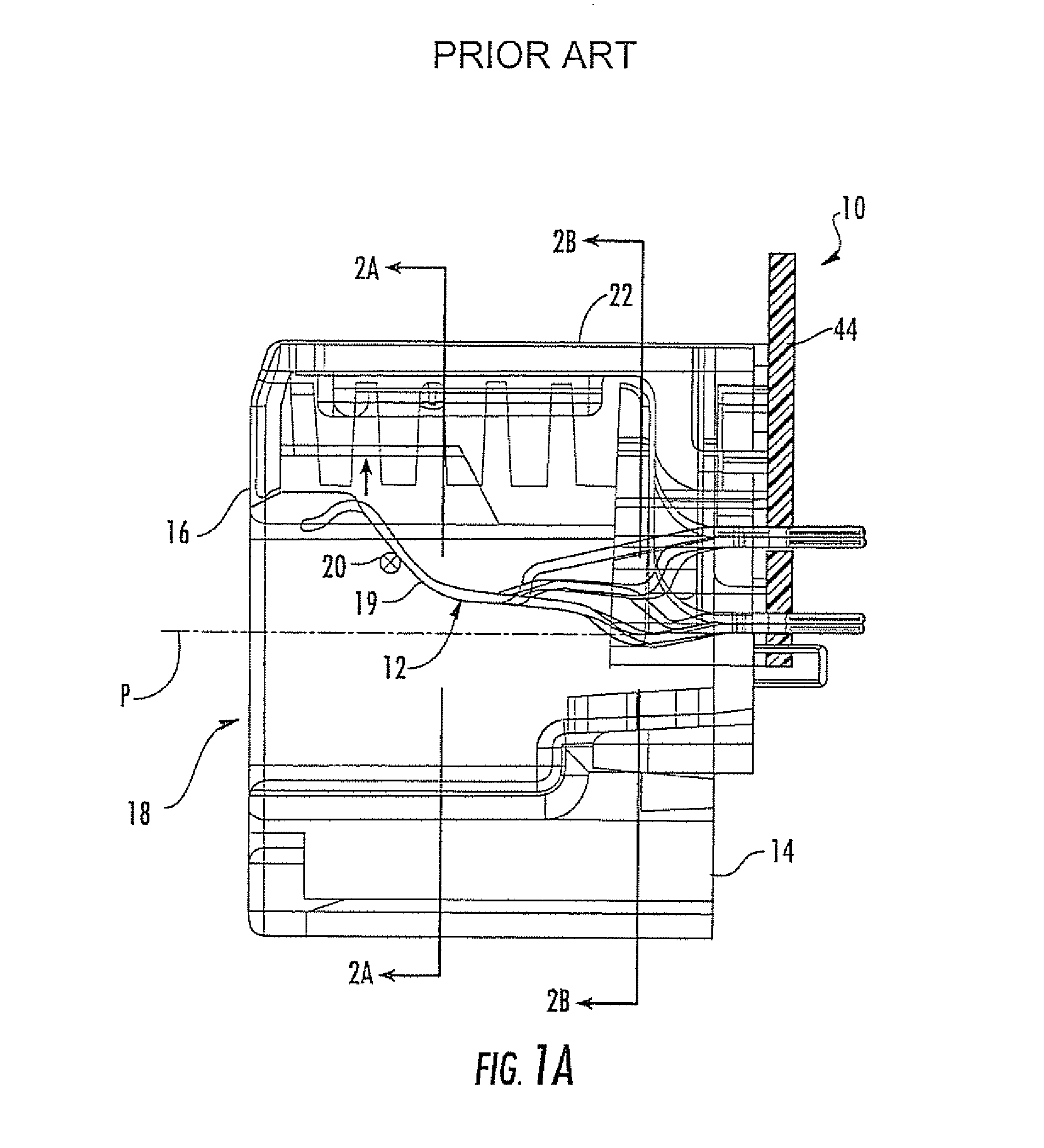

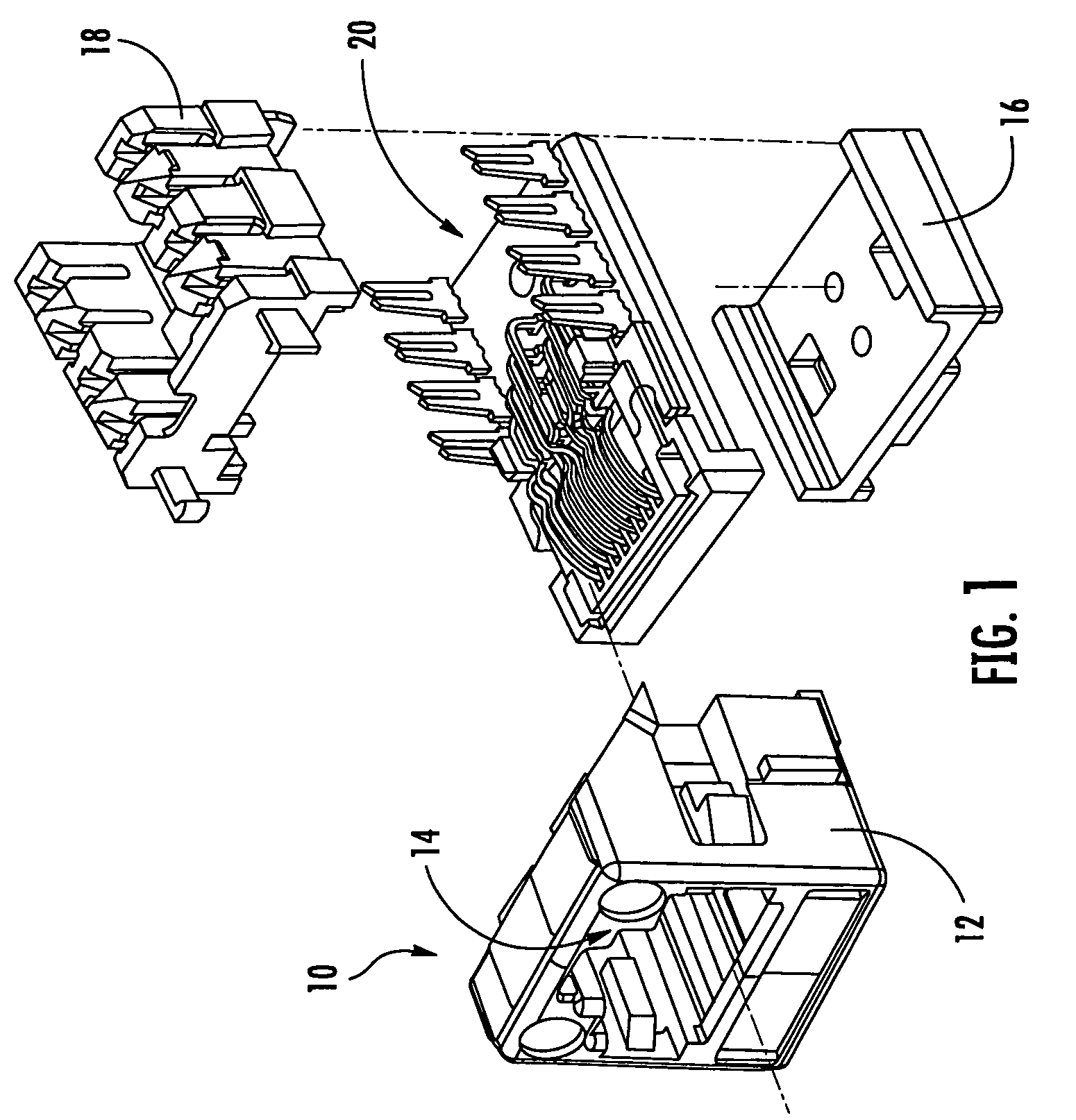

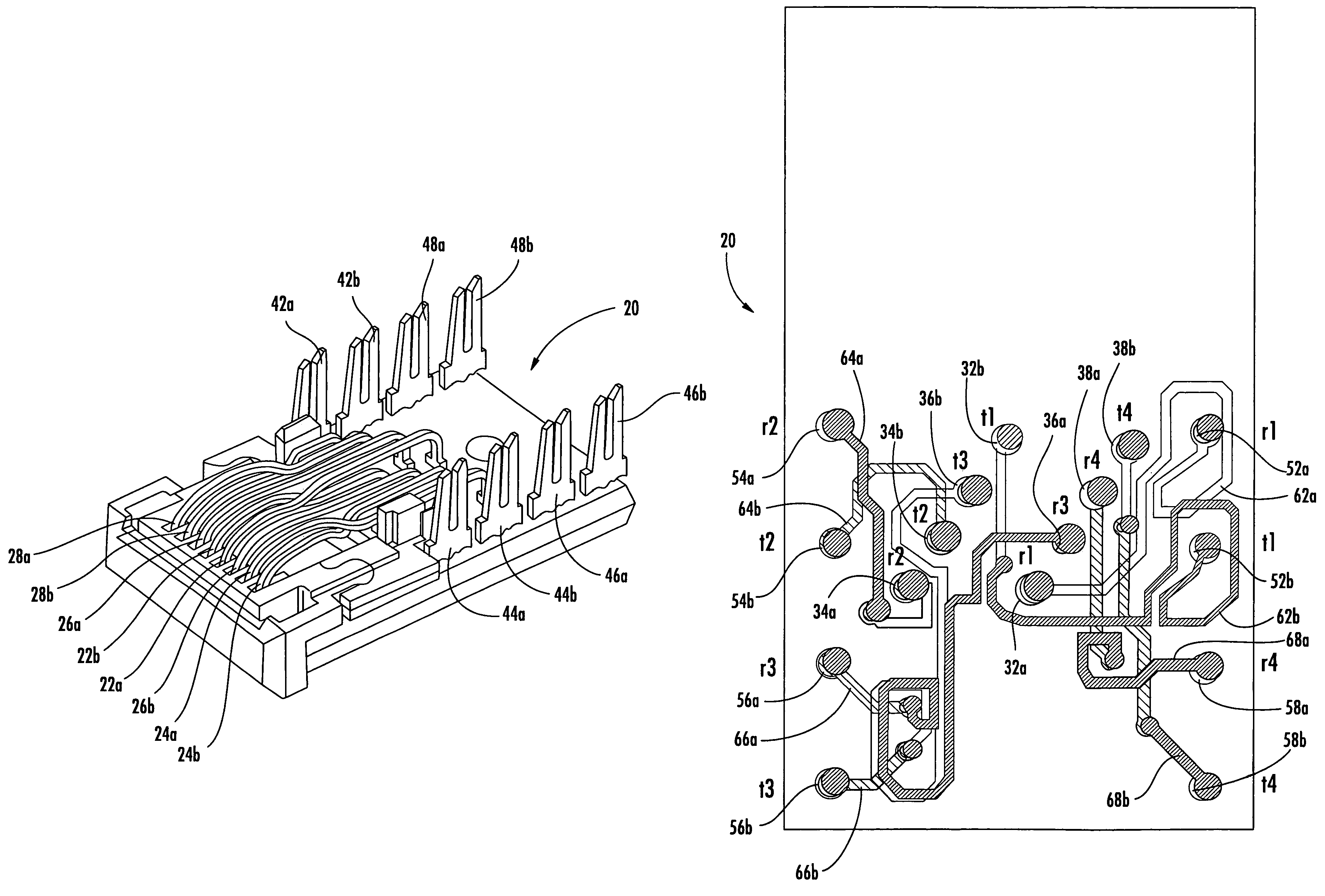

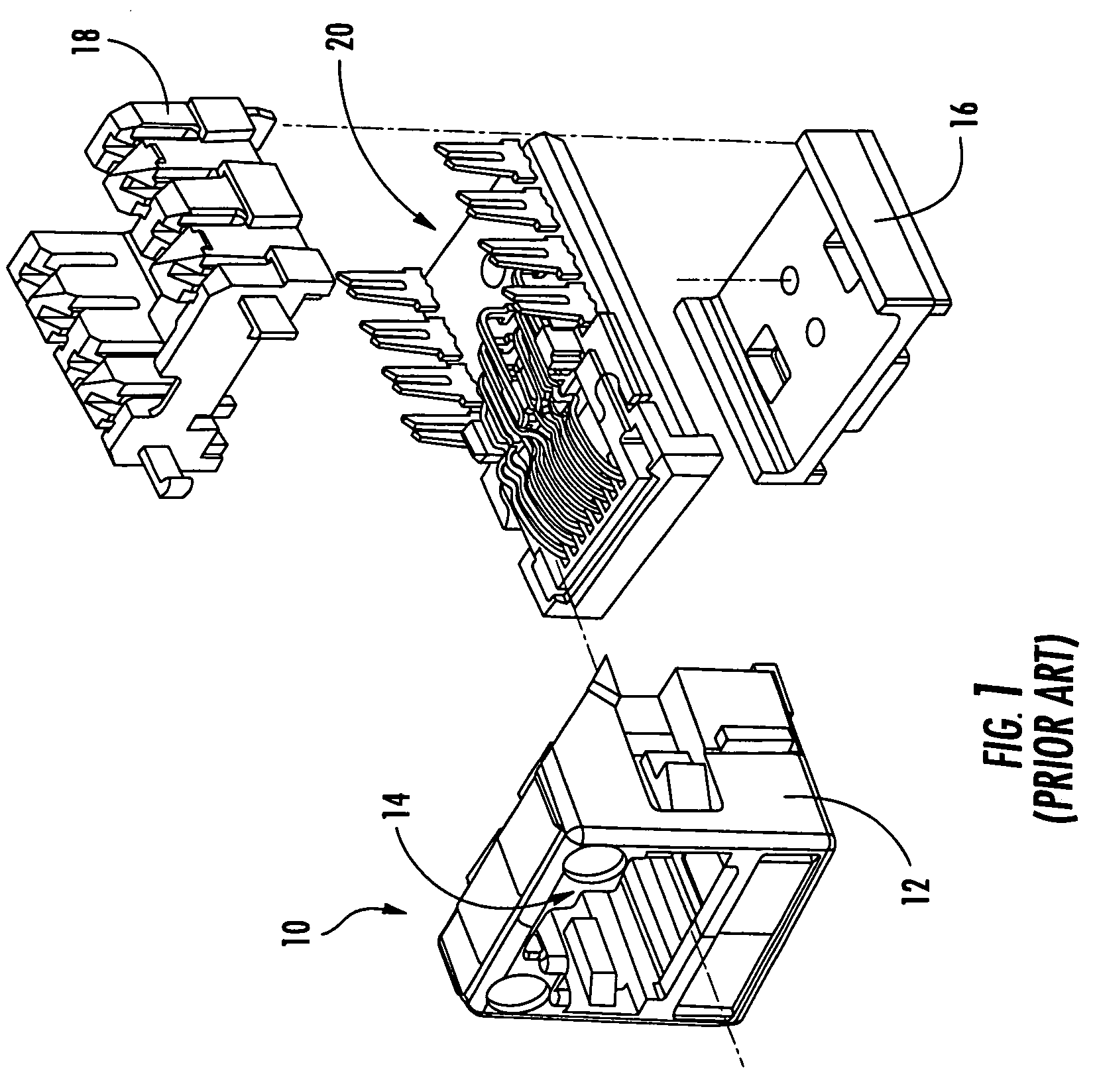

Enhanced communication connector assembly with crosstalk compensation

InactiveUS6186834B1Substations coupling interface circuitsCoupling for high frequencyMating connectionCapacitance

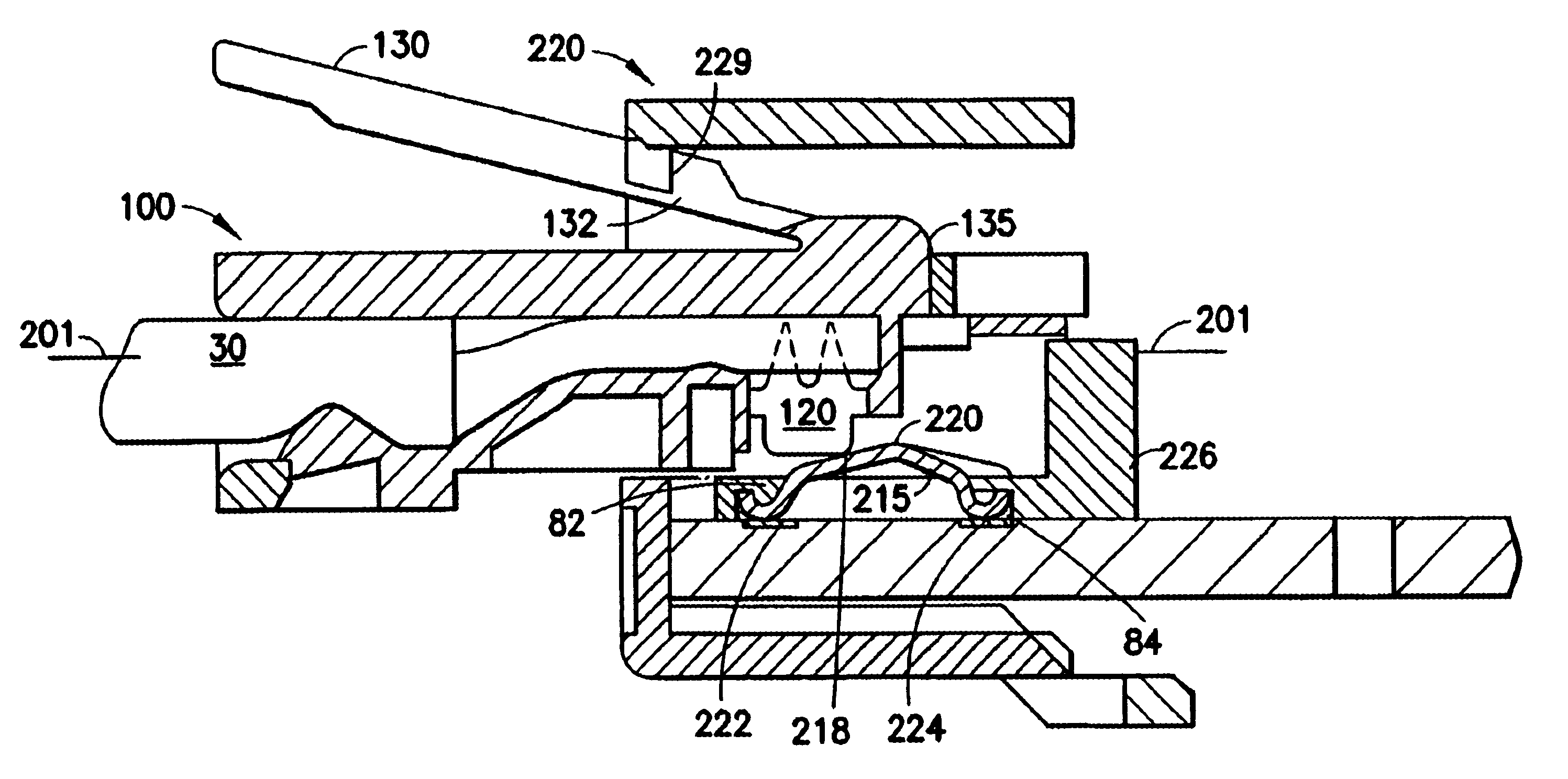

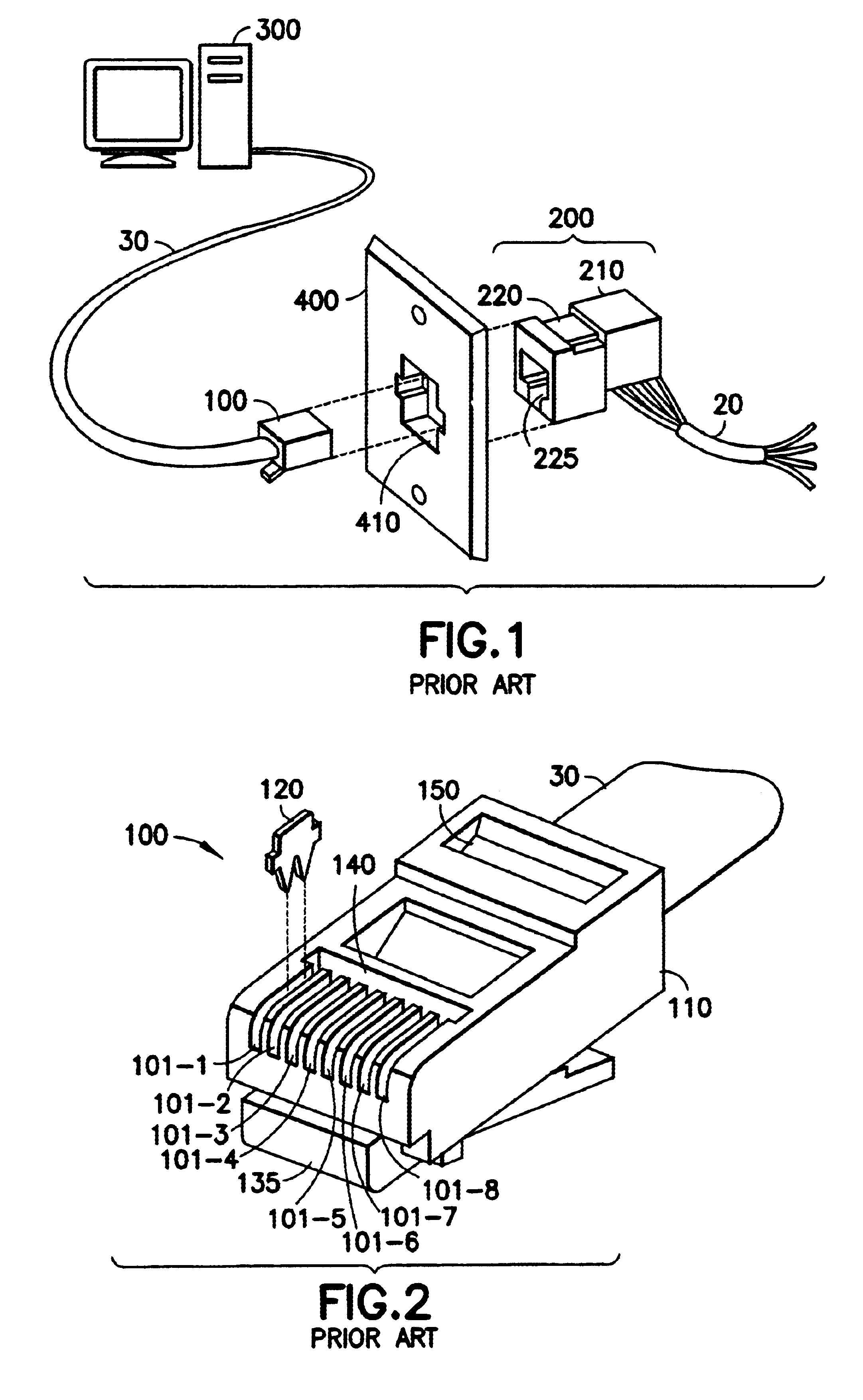

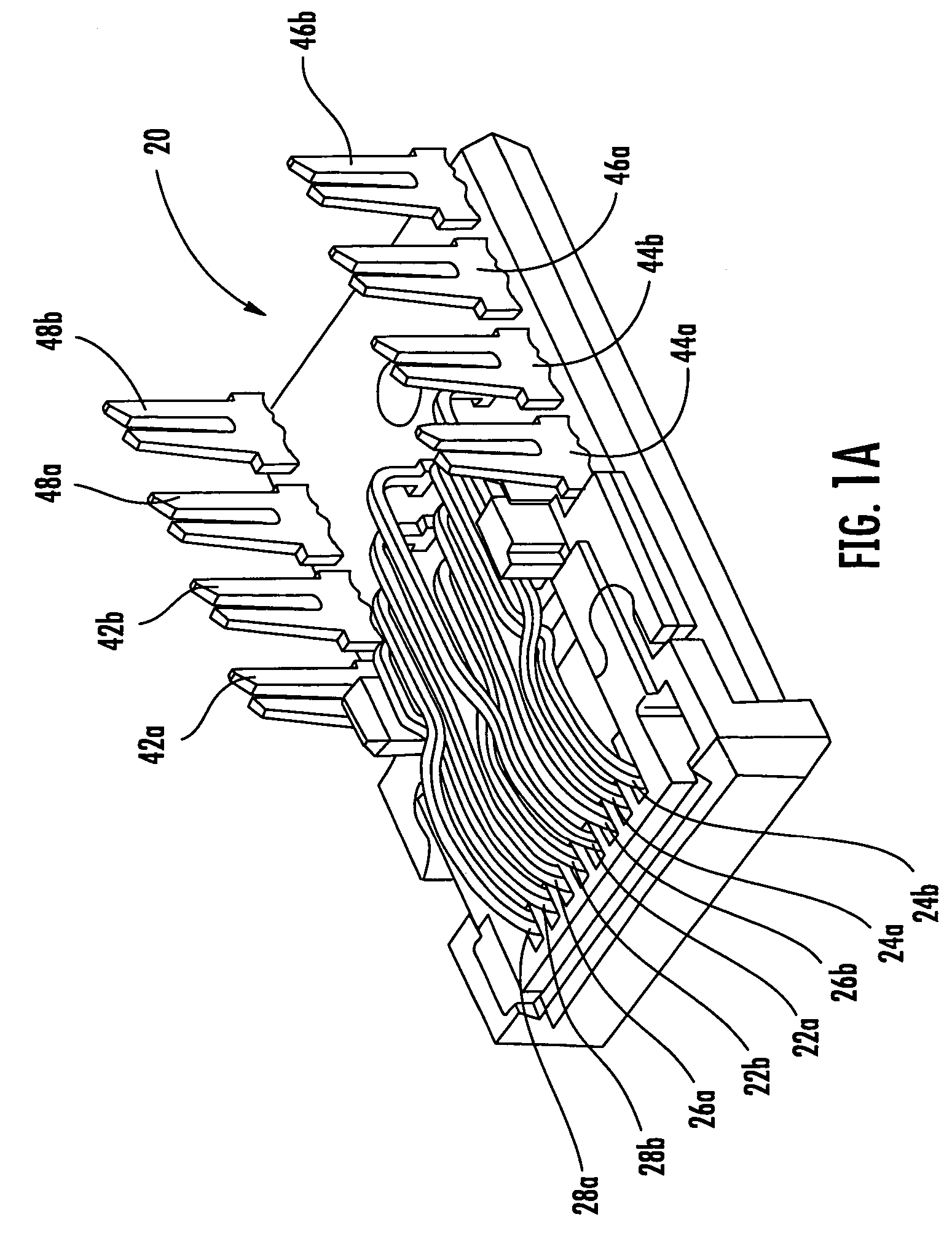

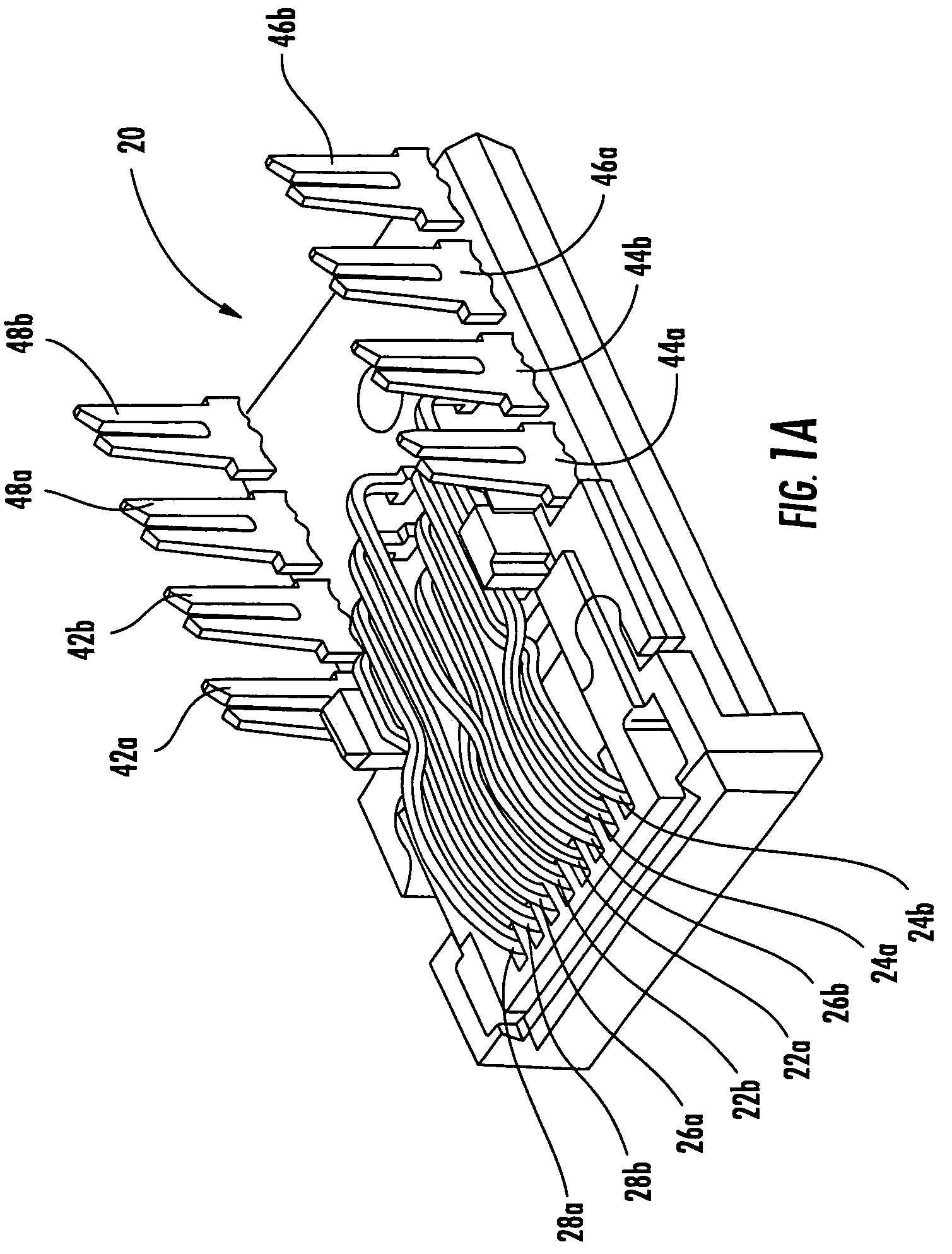

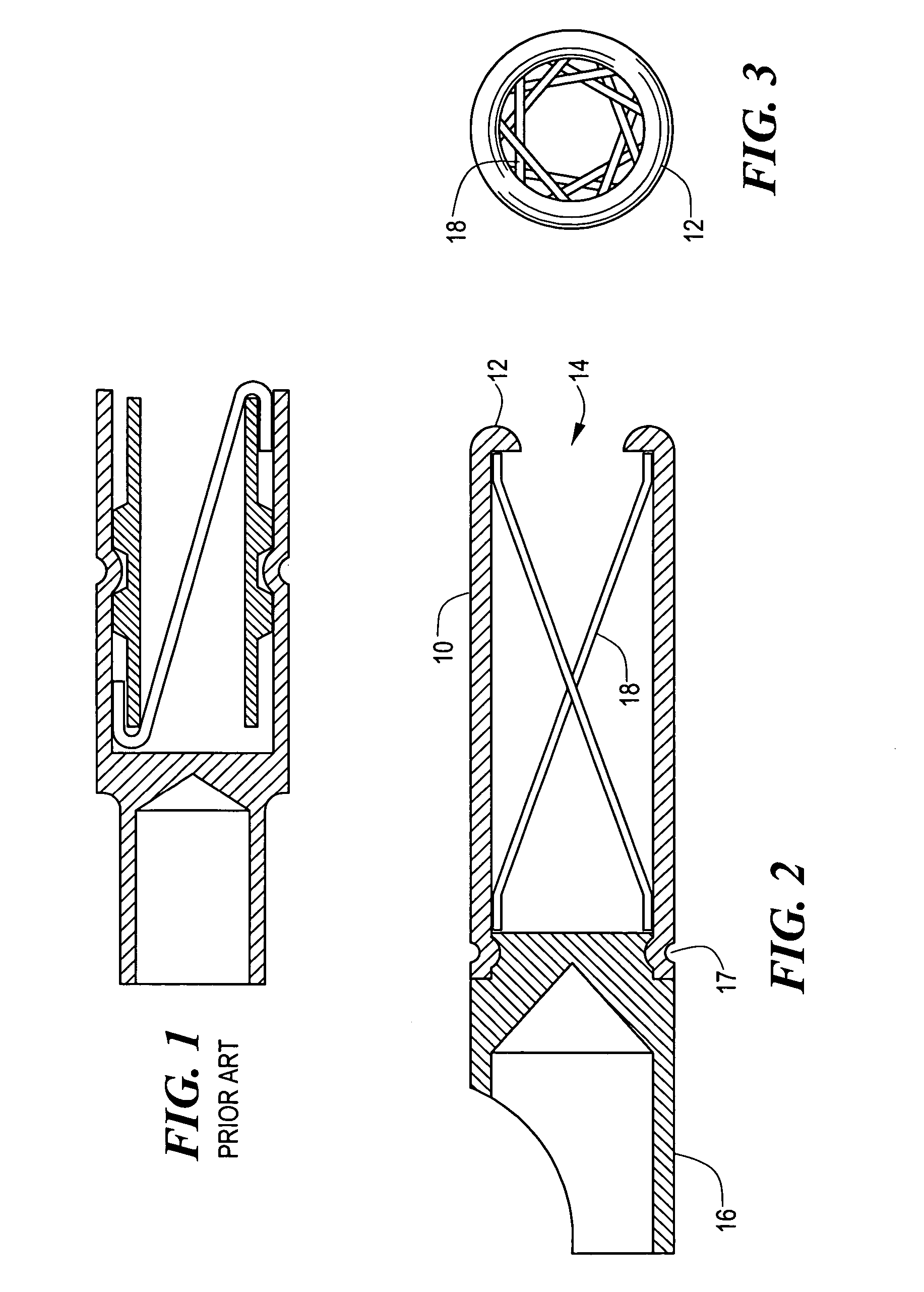

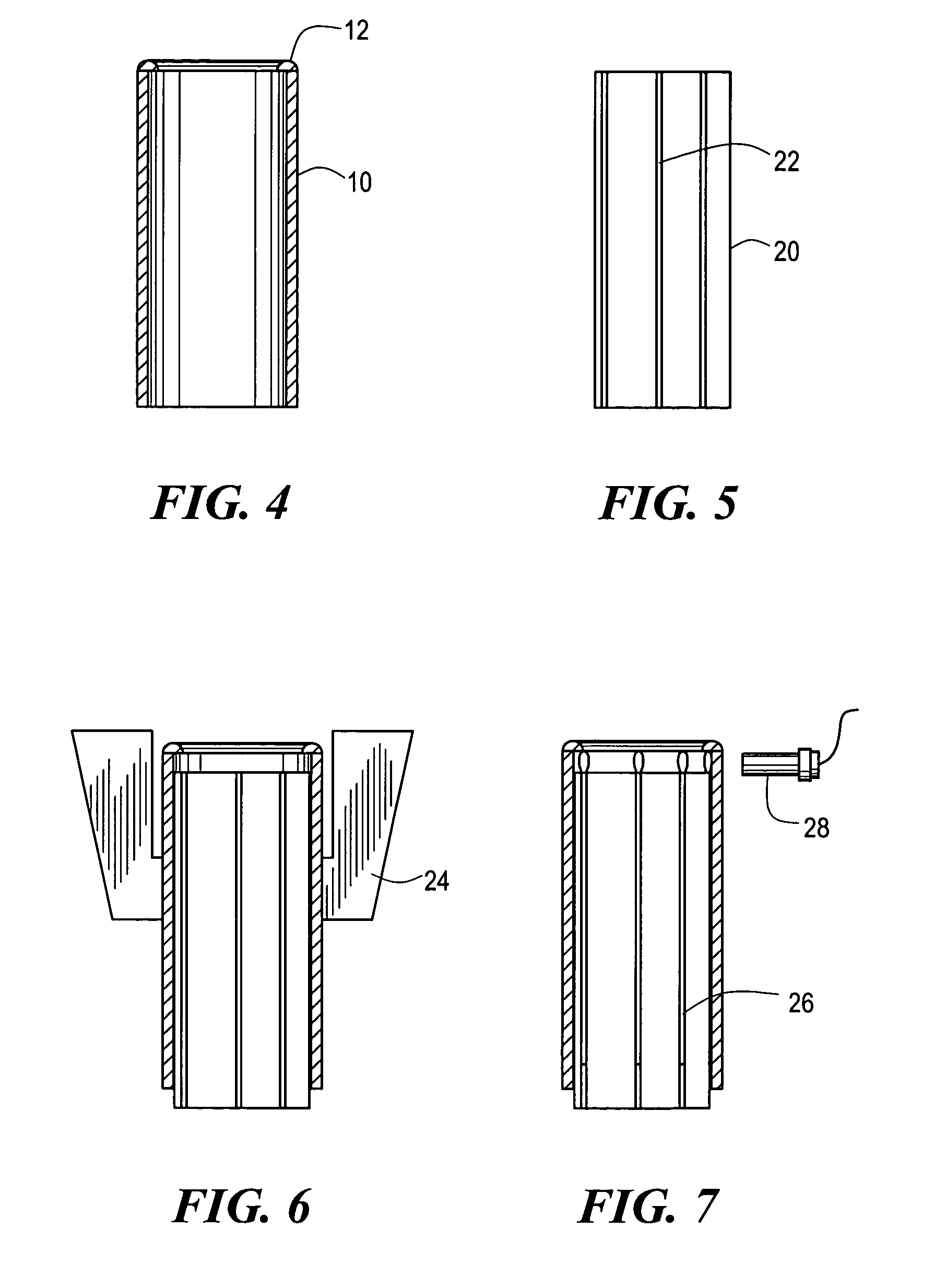

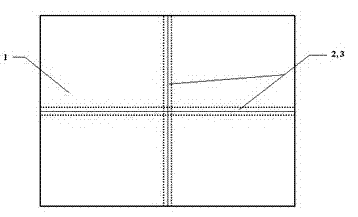

An enhanced communication connector assembly capable of meeting Category 6 performance levels with respect to near end crosstalk (NEXT), when the assembly is connected to a mating connector. The assembly includes a wire board, and a number of elongated terminal contact wires with base portions that are supported on the board. The contact wires have free end portions opposite the base portions for making electrical contact with a mating connector. A crosstalk compensating device on the wire board is constructed and arranged to cooperate with sections of selected terminal contact wires to provide capacitive compensation coupling between the selected terminal contact wires, when the contact wires are engaged by the mating connector.

Owner:COMMSCOPE INC

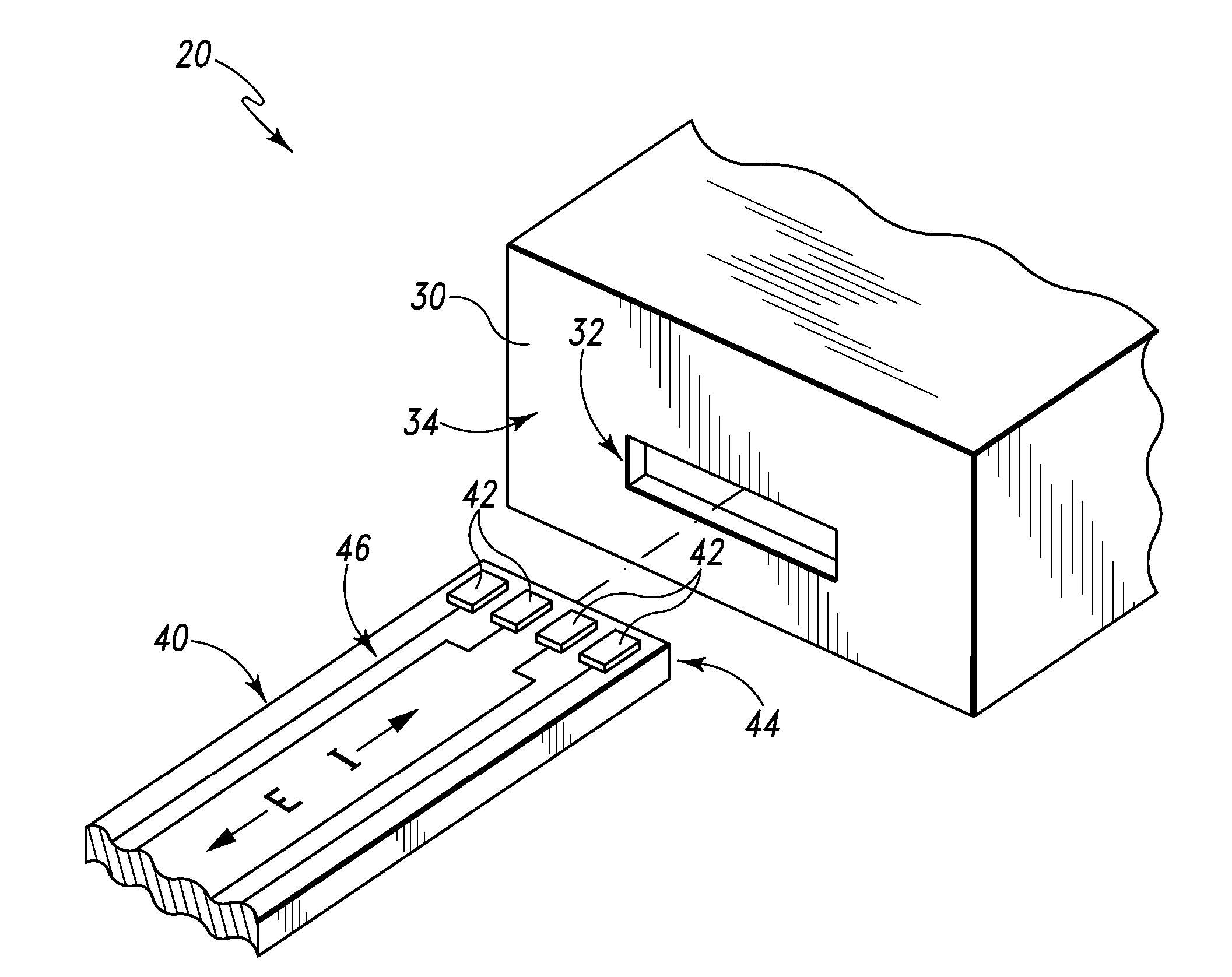

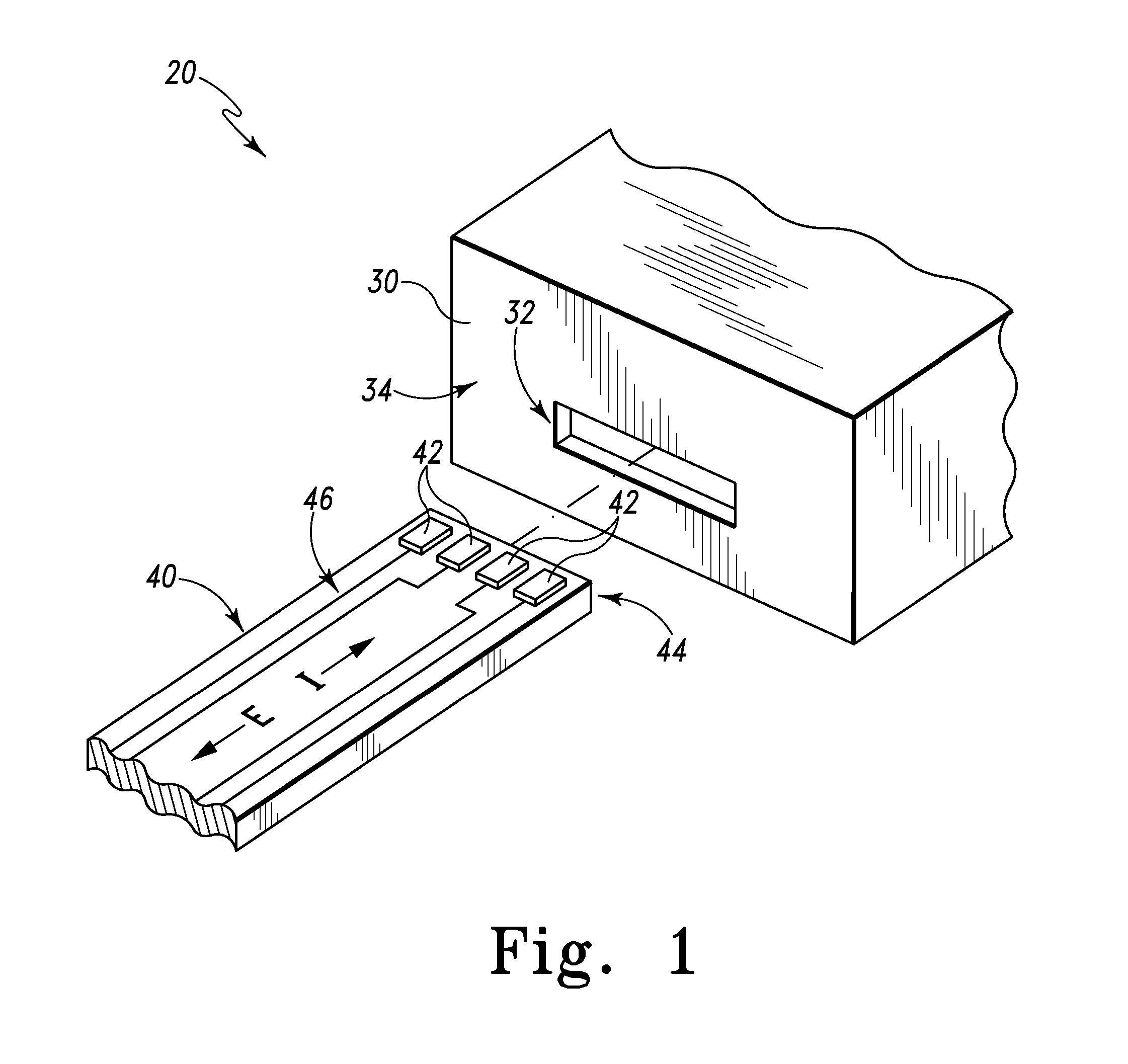

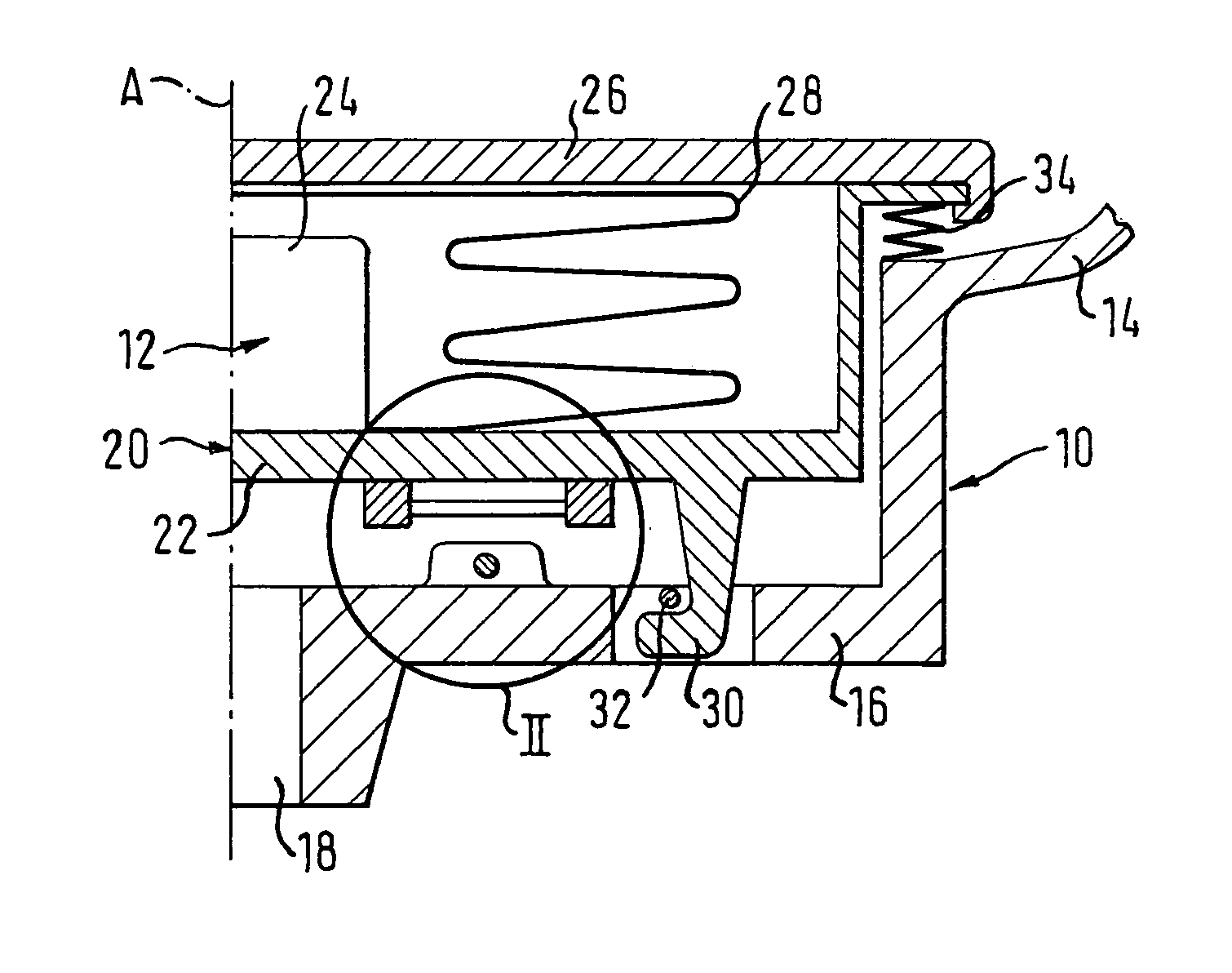

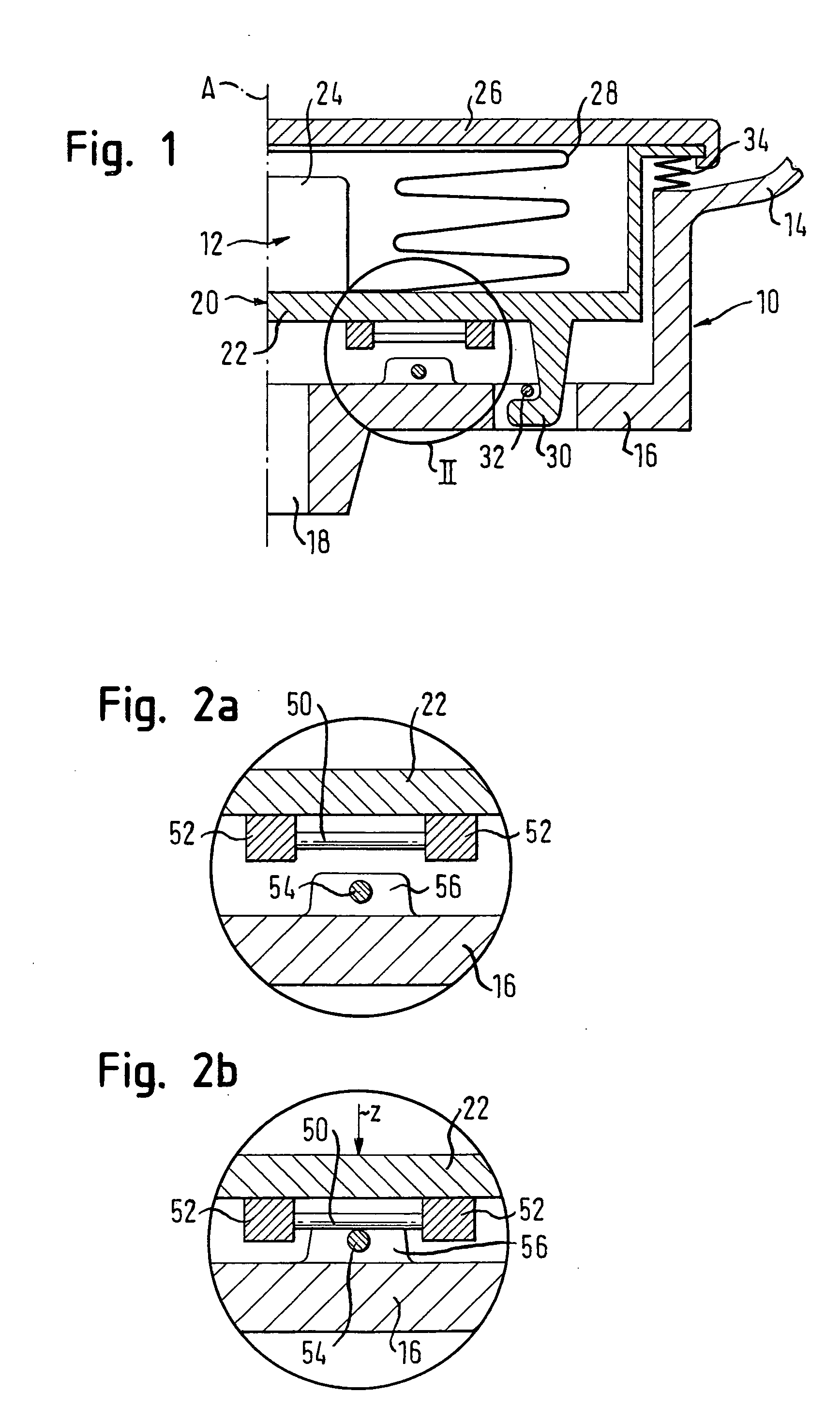

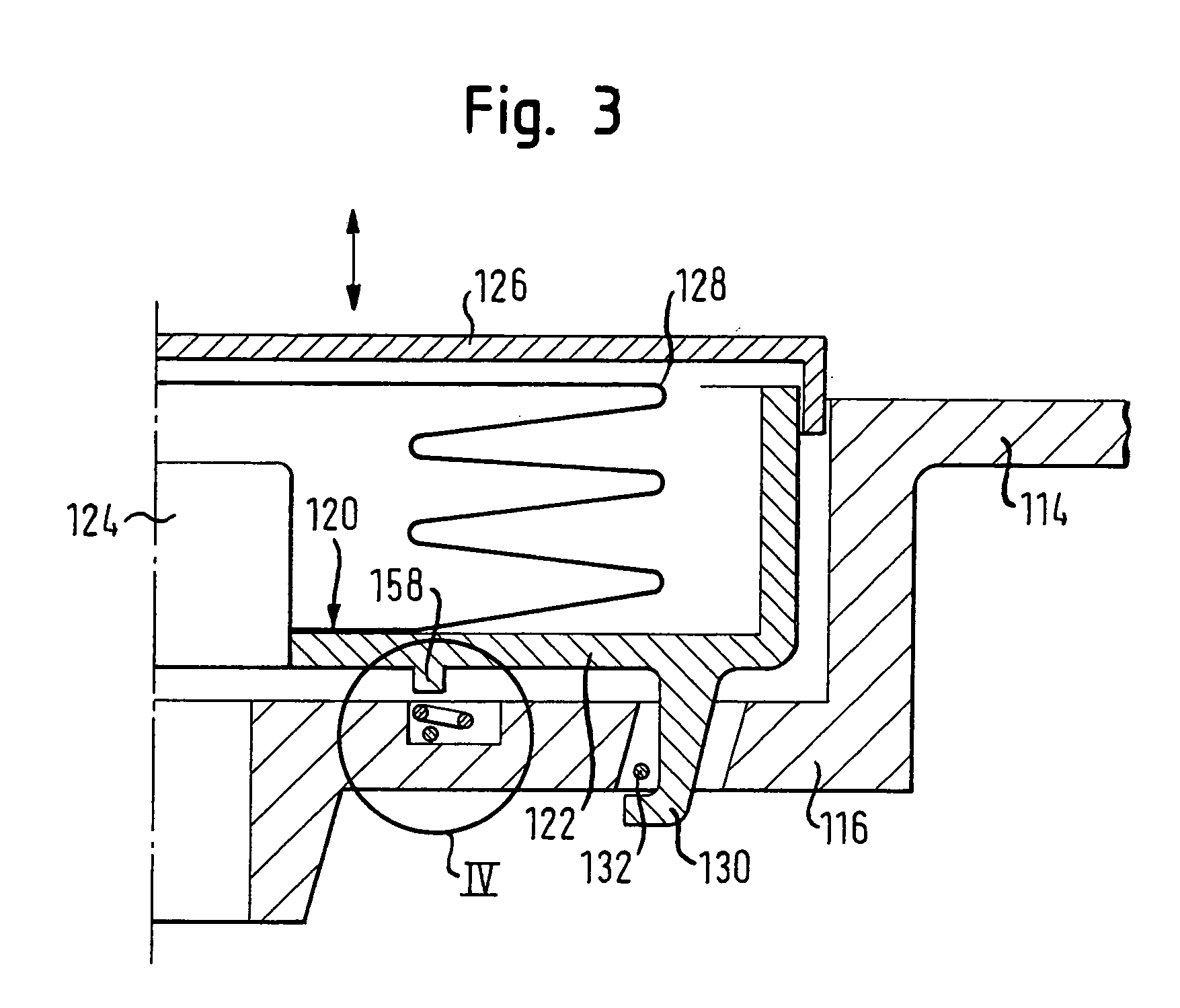

Biological testing system

ActiveUS20070249921A1Improve user experienceIncrease probabilityMaterial analysis by electric/magnetic meansDiagnostic recording/measuringElectrical resistance and conductanceContact pad

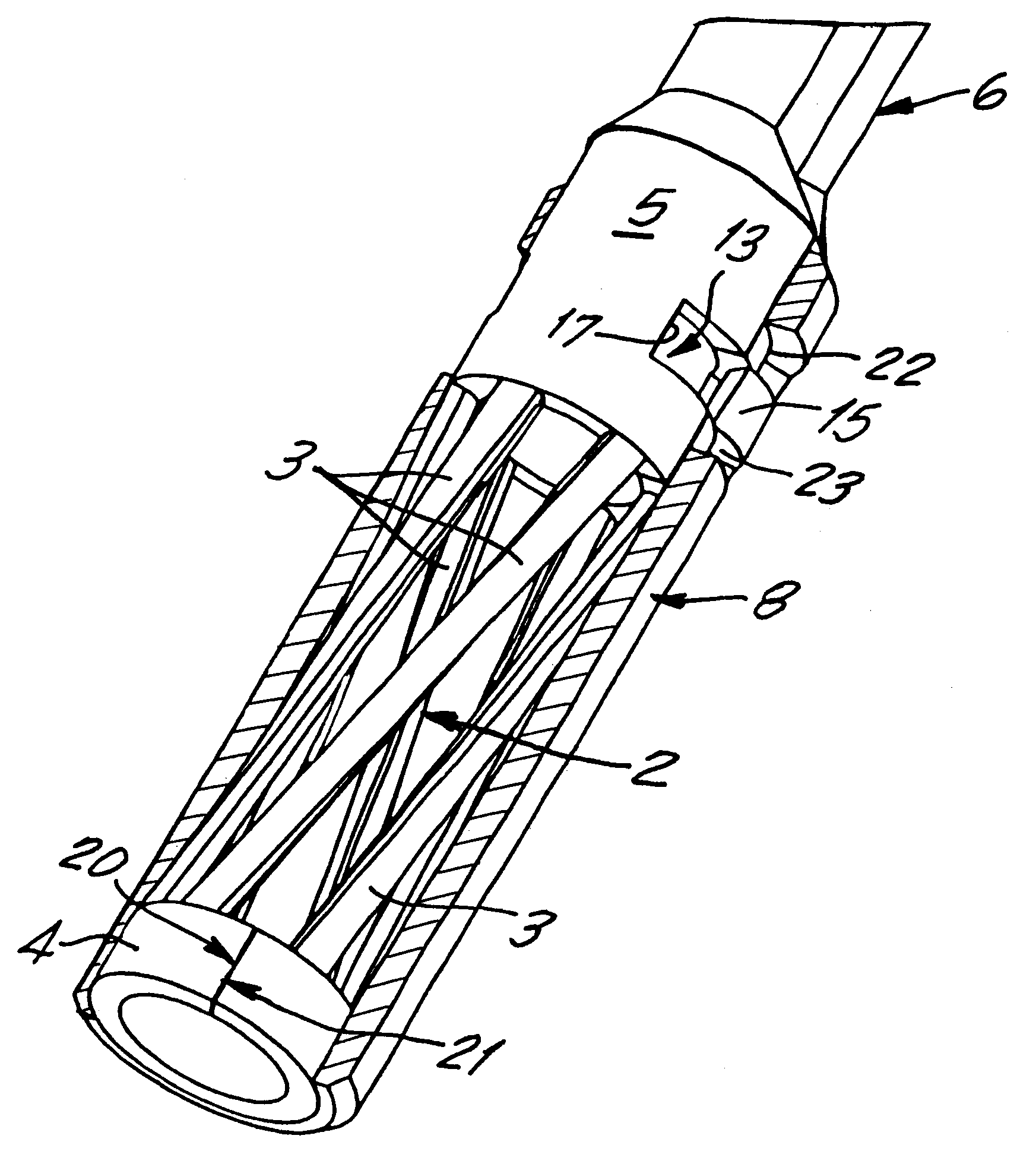

A connector for establishing electrical connection between a testing device and a test strip with a biological fluid thereon includes a contact pad on the test strip, and one or more contact wires in the testing device. When the strip is inserted into the testing device, part of the strip's end engages a contact portion of a contact wire and deflects it in a direction normal to the direction of insertion. In certain embodiments the radius of curvature (in the direction of insertion) of the contact portion is controlled to reduce abrasion of the strip by the wire. In other embodiments the radius of curvature (perpendicular to the direction of insertion) is controlled to reduce the abrasion of the strip by the wire. Sometimes the contact portion and / or contact pad is plated with a sacrificial material to reduce the coefficient of friction. In other embodiments various numbers of contacts receive the end of the strip substantially simultaneously, or are staggered in rows to distribute the resistance presented.

Owner:ROCHE DIABETES CARE INC

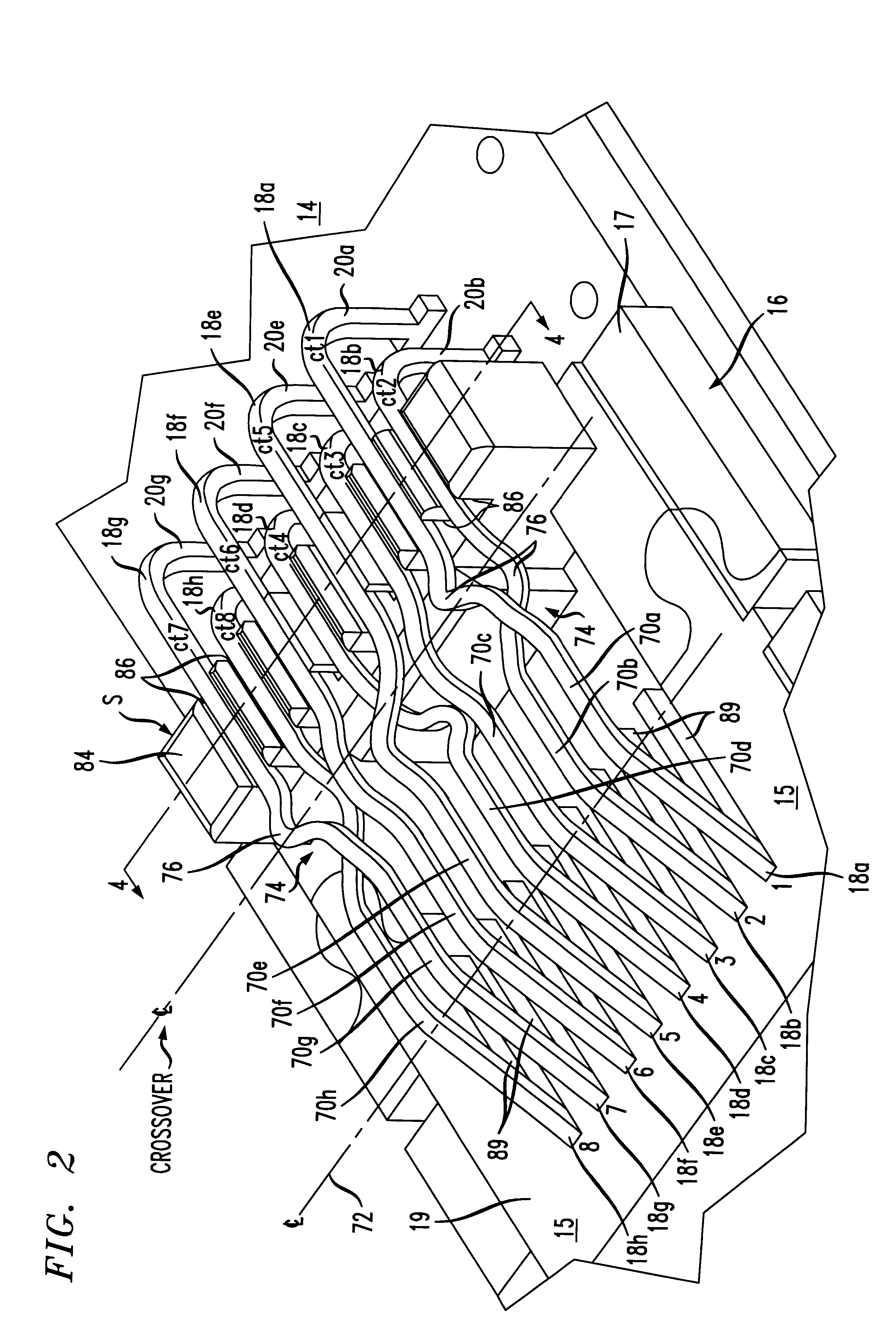

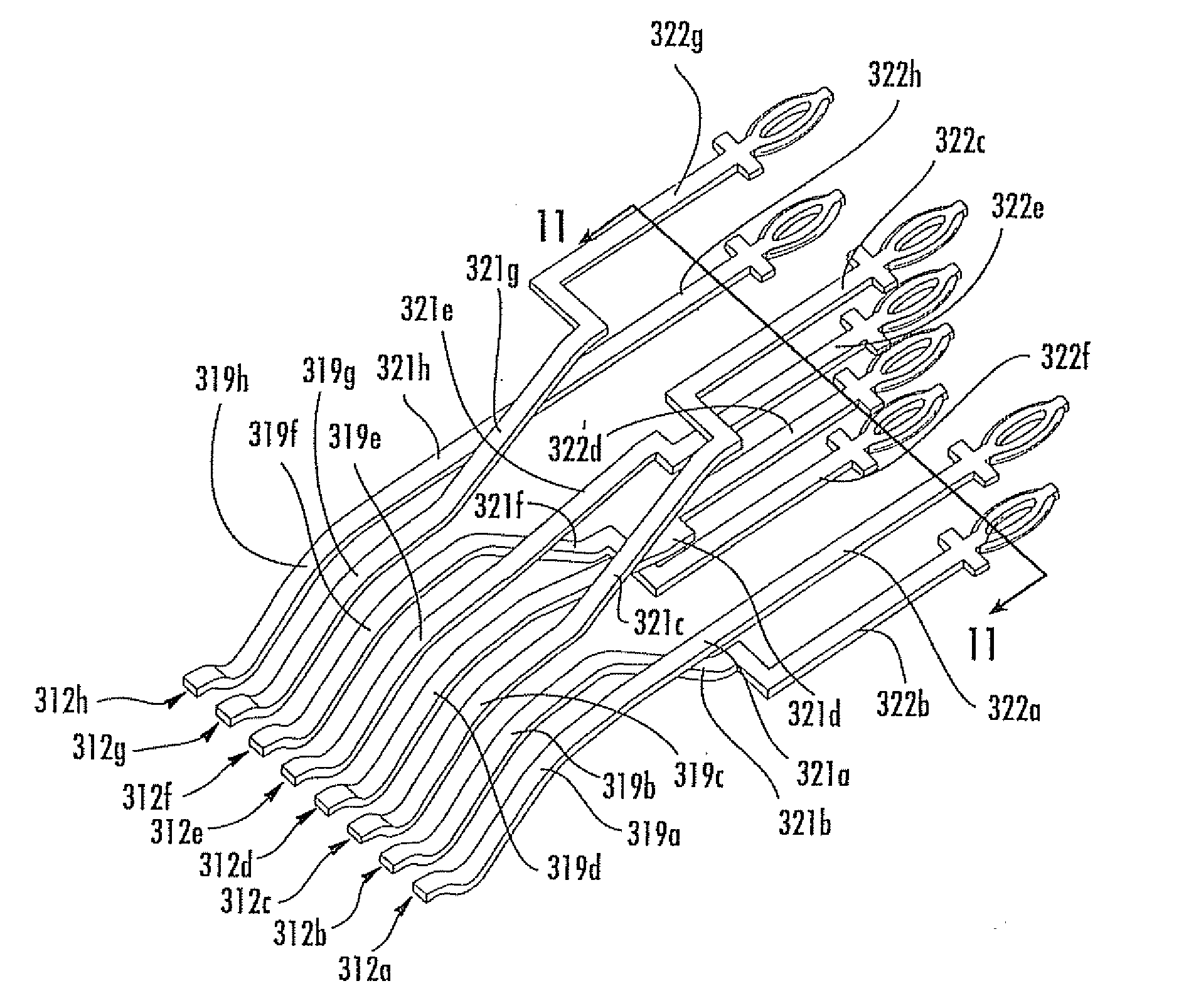

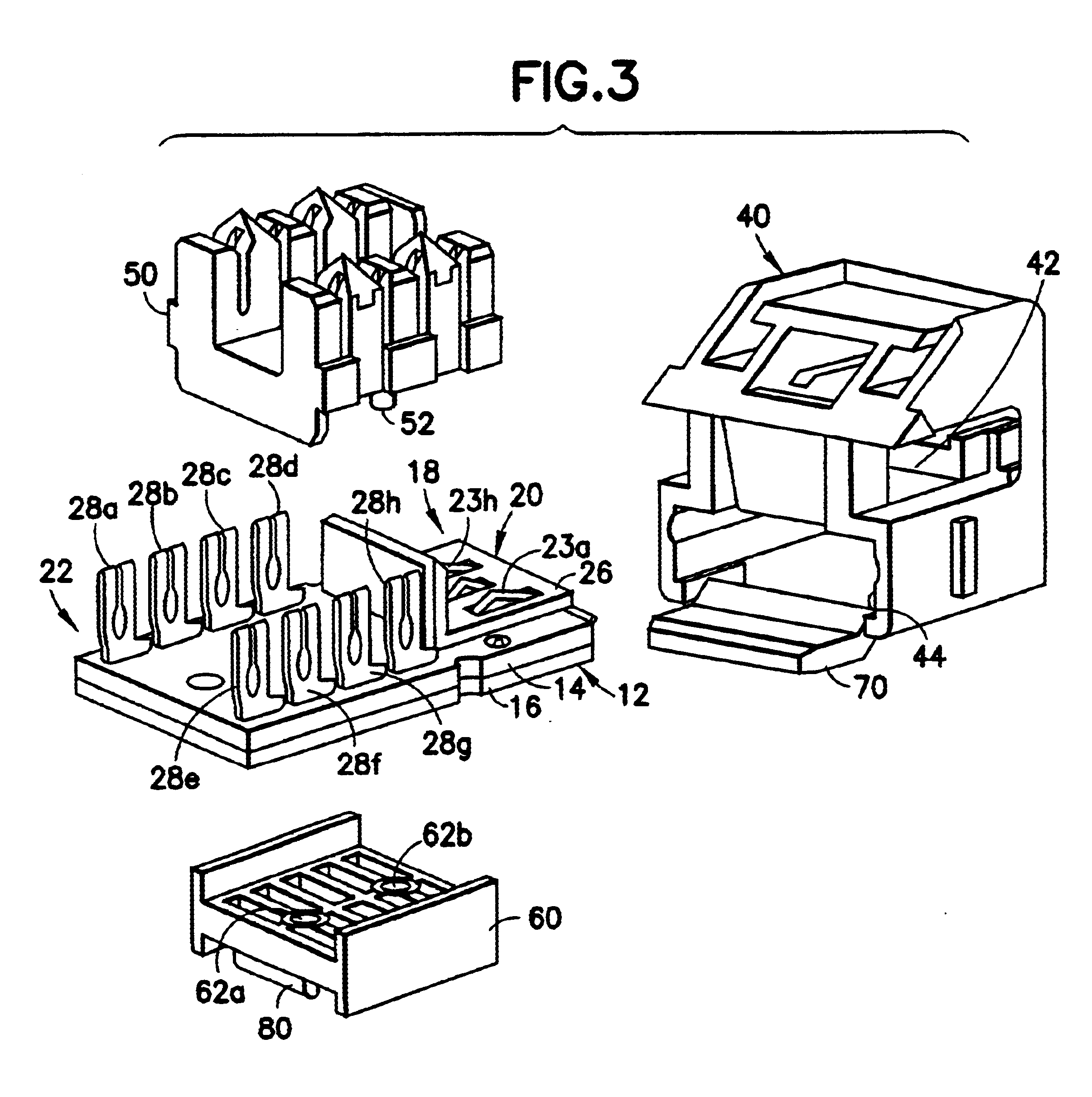

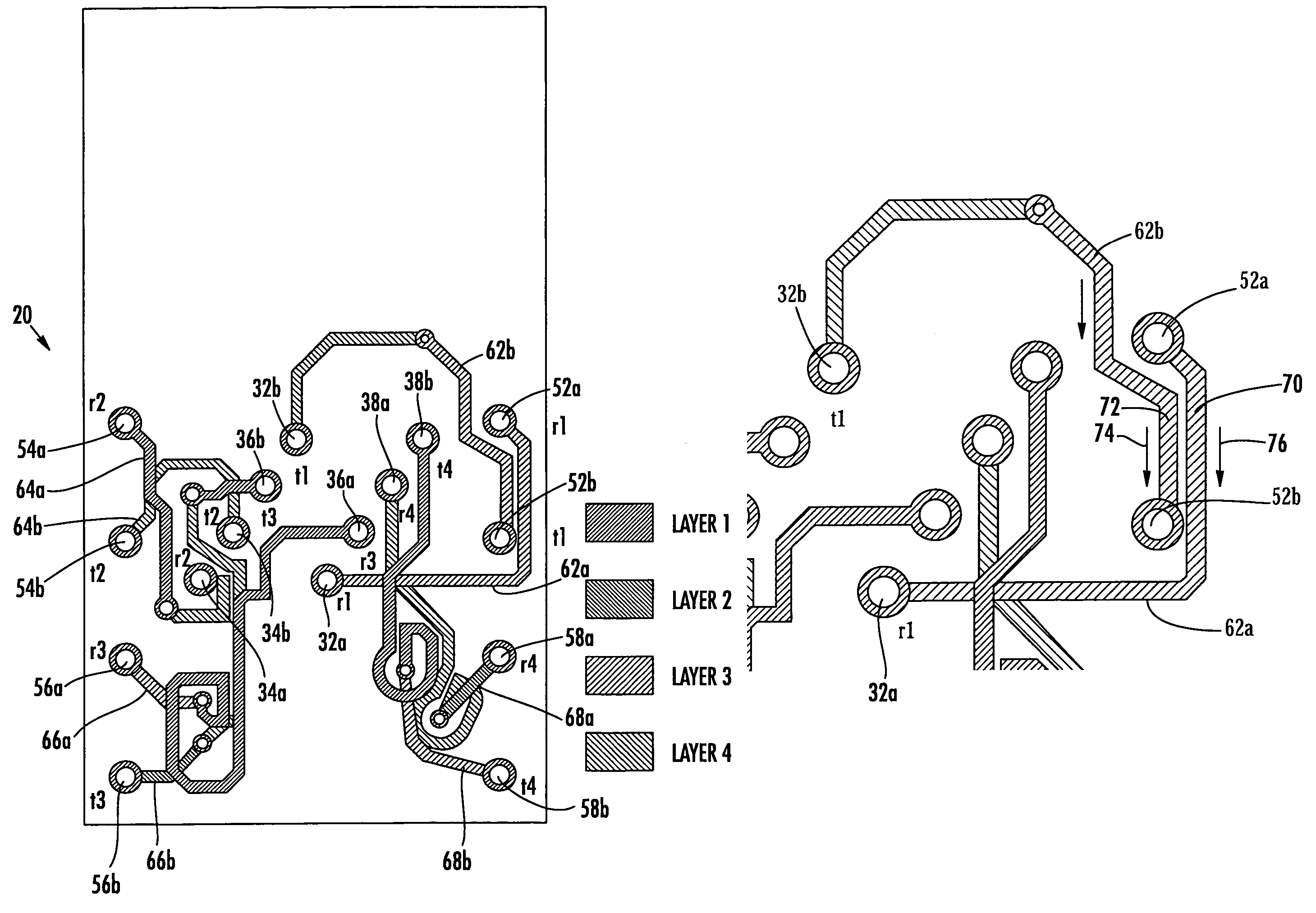

Communications connector with leadframe contact wires that compensate differential to common mode crosstalk

InactiveUS7166000B2Good compensationCoupling device detailsTwo-part coupling devicesElectrical polarityElectrical connection

A communications jack includes: a dielectric mounting substrate; and a plurality of contact wires, each of the contact wires having a contact segment, a compensating segment in electrical connection with the contact segment, and a base in electrical connection with the compensating segment and mounted in the mounting substrate. The contact segments are generally transversely aligned and parallel with each other. The contact segments are arranged in pairs, with a first pair of contact segments being immediately adjacent each other, a second pair of contact segments being immediately adjacent each other and positioned one side of the first pair, a fourth pair of contact segments being immediately adjacent each other and positioned on an opposite side of the first pair, and a third pair of contact segments sandwiching the first pair, with one of the contact segments of the third pair being disposed between the first and second pairs, and the other of the contact segments being disposed between the first and fourth pairs. The compensating segments are configured and arranged such that differential to common mode crosstalk generated between the contact segments of the second and third pairs is opposite in polarity to the differential to common mode crosstalk generated between the compensating segments of the second and third pairs.

Owner:COMMSCOPE INC

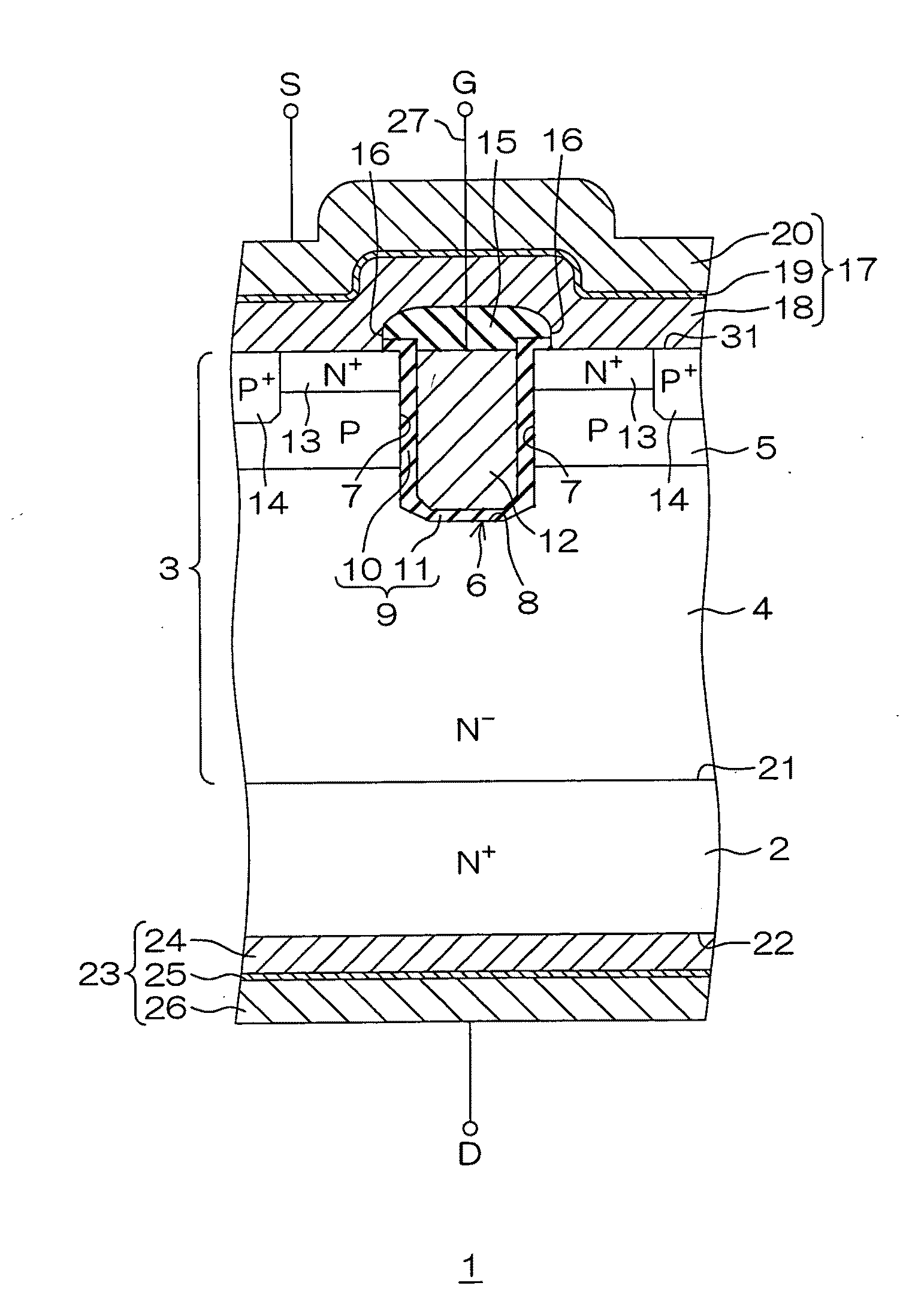

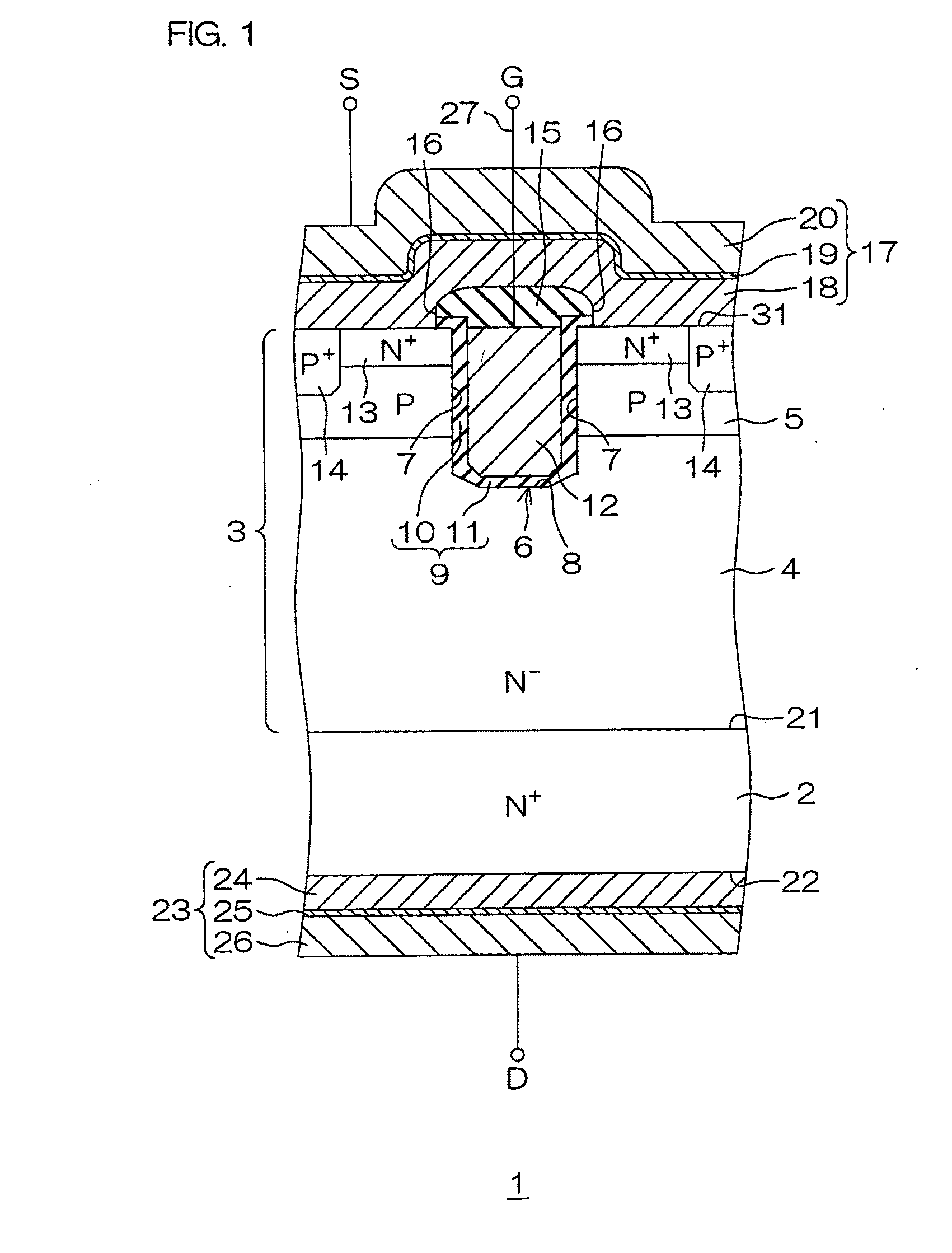

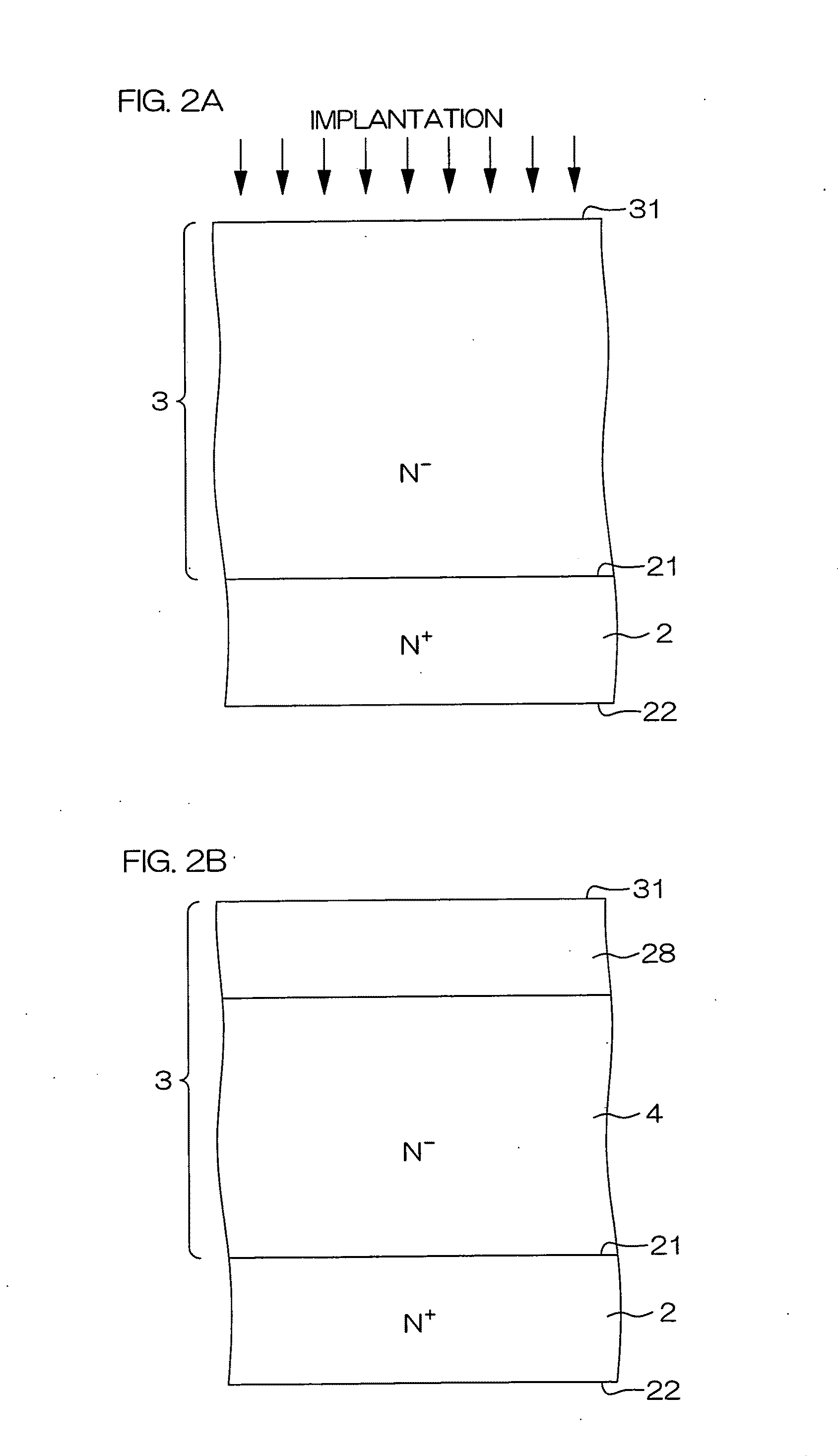

Semiconductor device

The semiconductor device according to the present invention includes: a semiconductor layer made of SiC; an impurity region formed by doping the semiconductor layer with an impurity; and a contact wire formed on the semiconductor layer in contact with the impurity region, while the contact wire has a polysilicon layer in the portion in contact with the impurity region, and has a metal layer on the polysilicon layer.

Owner:ROHM CO LTD

High frequency telecommunication connector

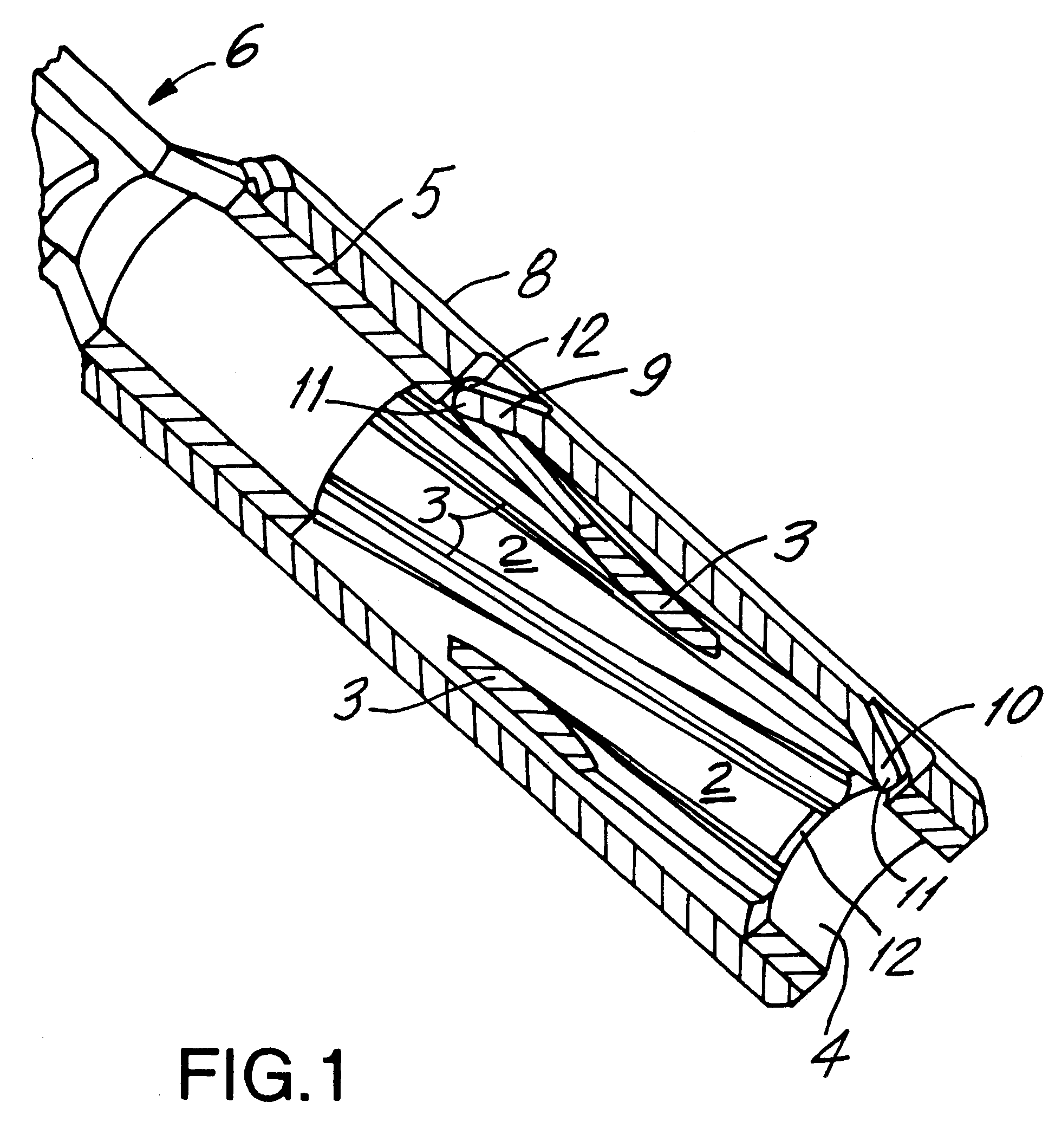

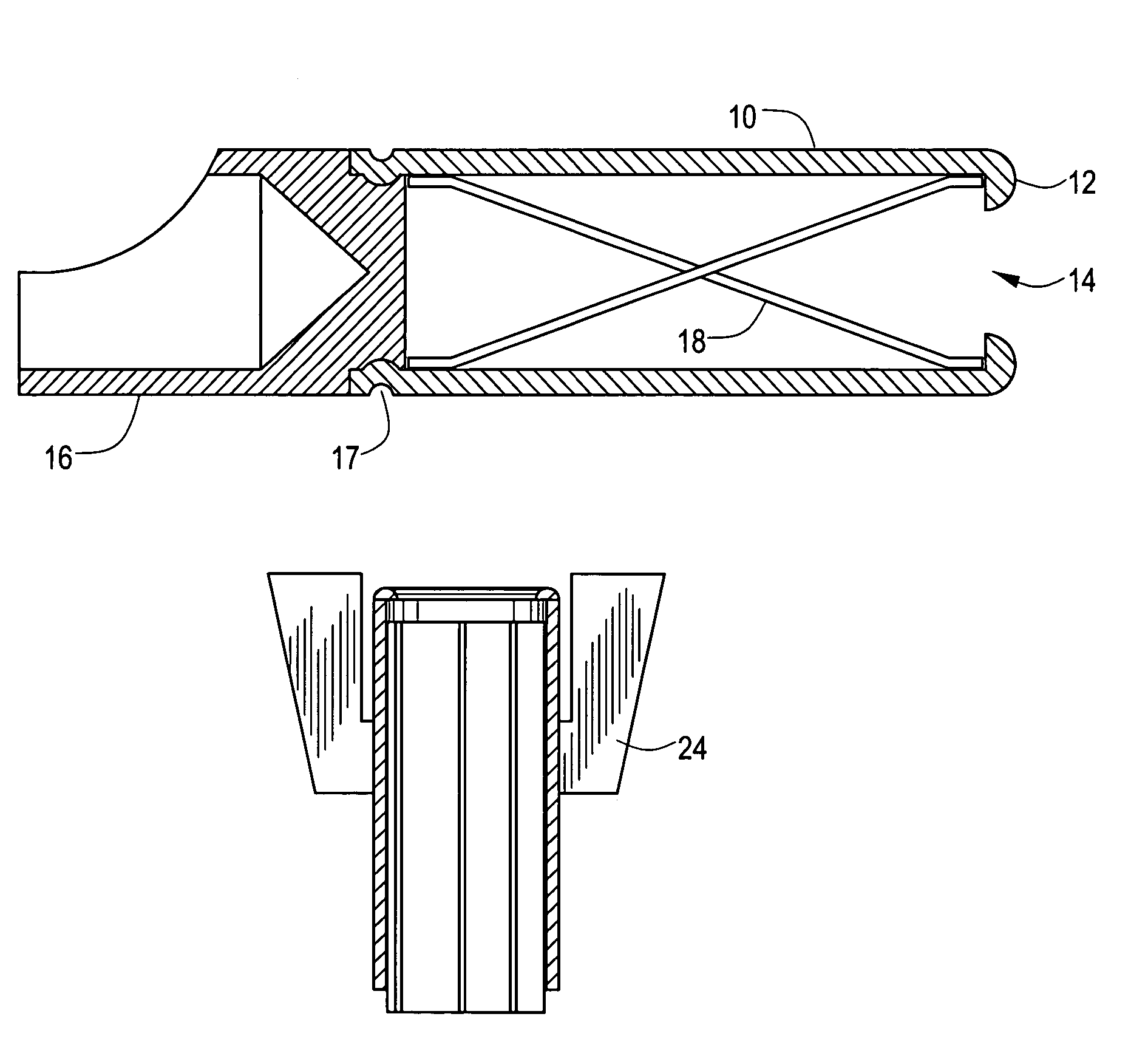

In accordance with the invention, there is provided a telecommunication jack that is free of cross-over sections, has cross-talk characteristics that approach Category 6 levels, and avoids the use of spring contact wires supported in a cantilevered fashion. This is achieved in a preferred implementation by spring terminal contact wires that are arch shaped. Each spring wire has a first leg having an end, a second leg having an end and an apex portion located between the first and second legs where the ends of the legs are supported on a wire board and each end makes electrical contact with separate conductive pads. When utilized in an operating circuit, one end and leg of a spring terminal contact wire is coupled to a conductive pad on the wire board that is in a current carrying signal path, and the other end and leg of that spring terminal contact wire is coupled to a different conductive pad on the wire board adapted for connection to a cross-talk compensating component. In accordance with the invention, both pads of the wire board are connected to a common spring terminal contact wire, although only one pad and one leg of the arch shaped spring wire may be in the current carrying signal path. The legs of the arch shaped spring terminal contact wires can be of equal or unequal length, the arch can be semi-circular, triangular or the like, and the conductive pads on the wire board of adjacent spring wire terminals can be either aligned or staggered in distance from the edge of the wire board.

Owner:COMMSCOPE INC

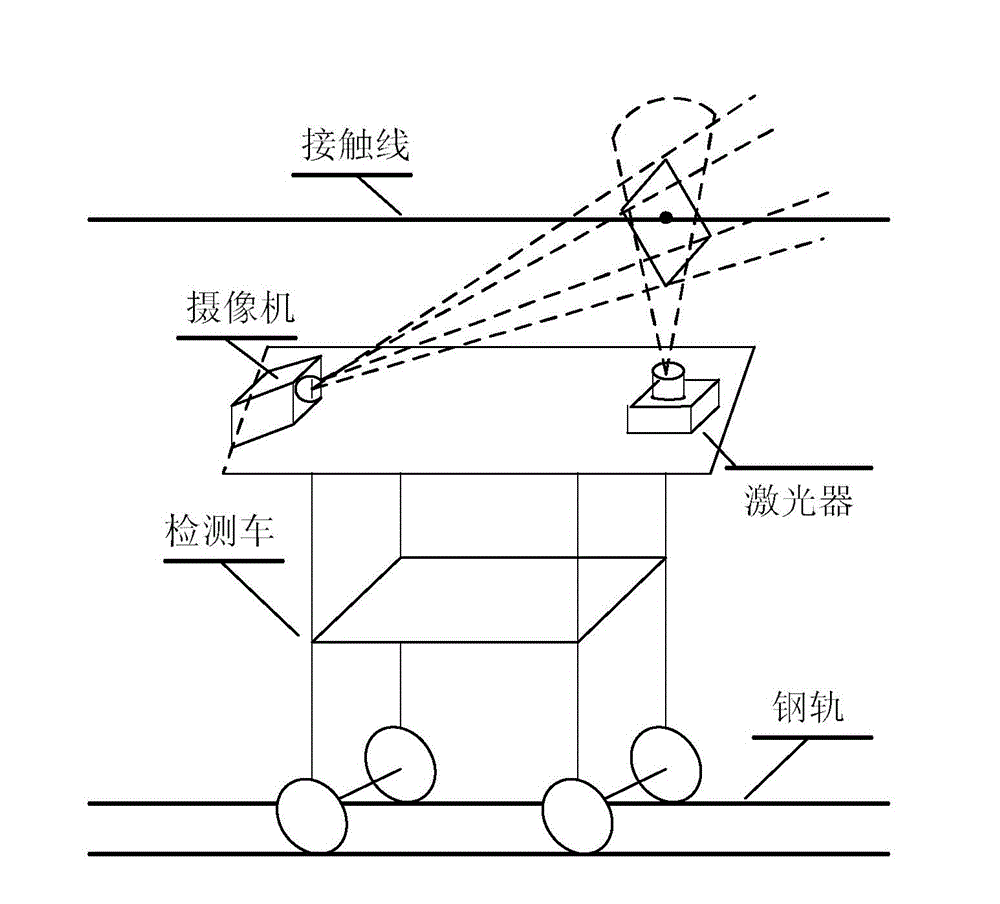

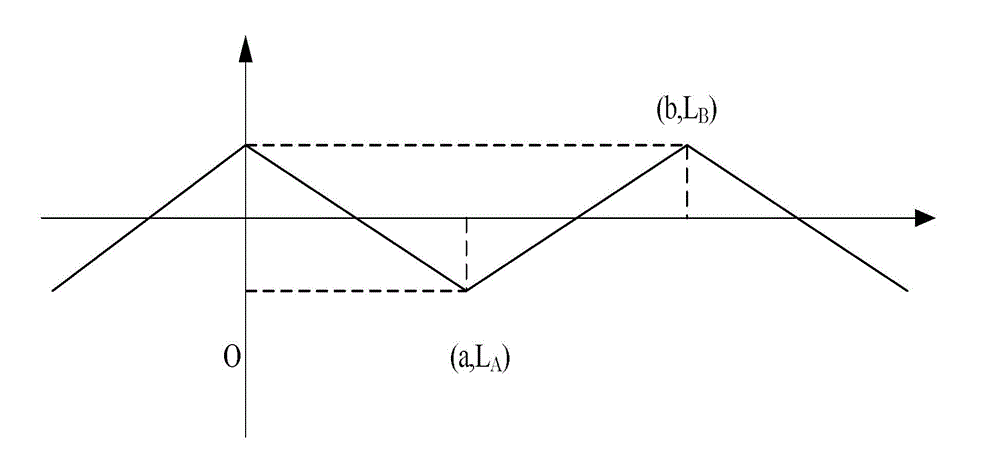

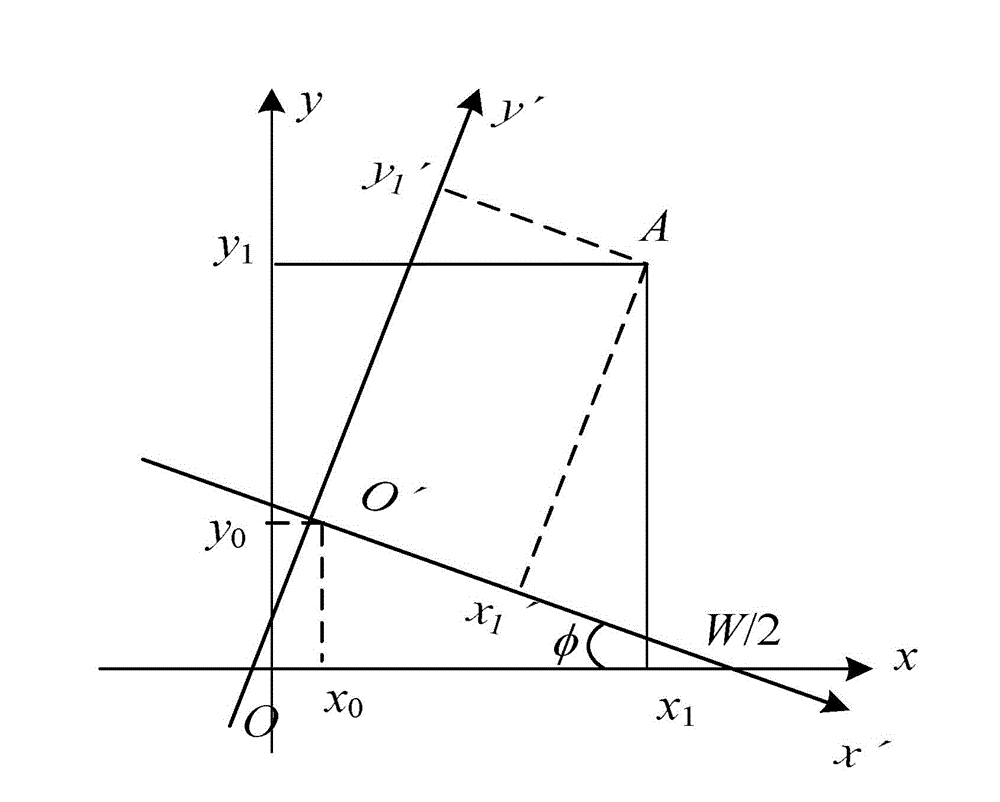

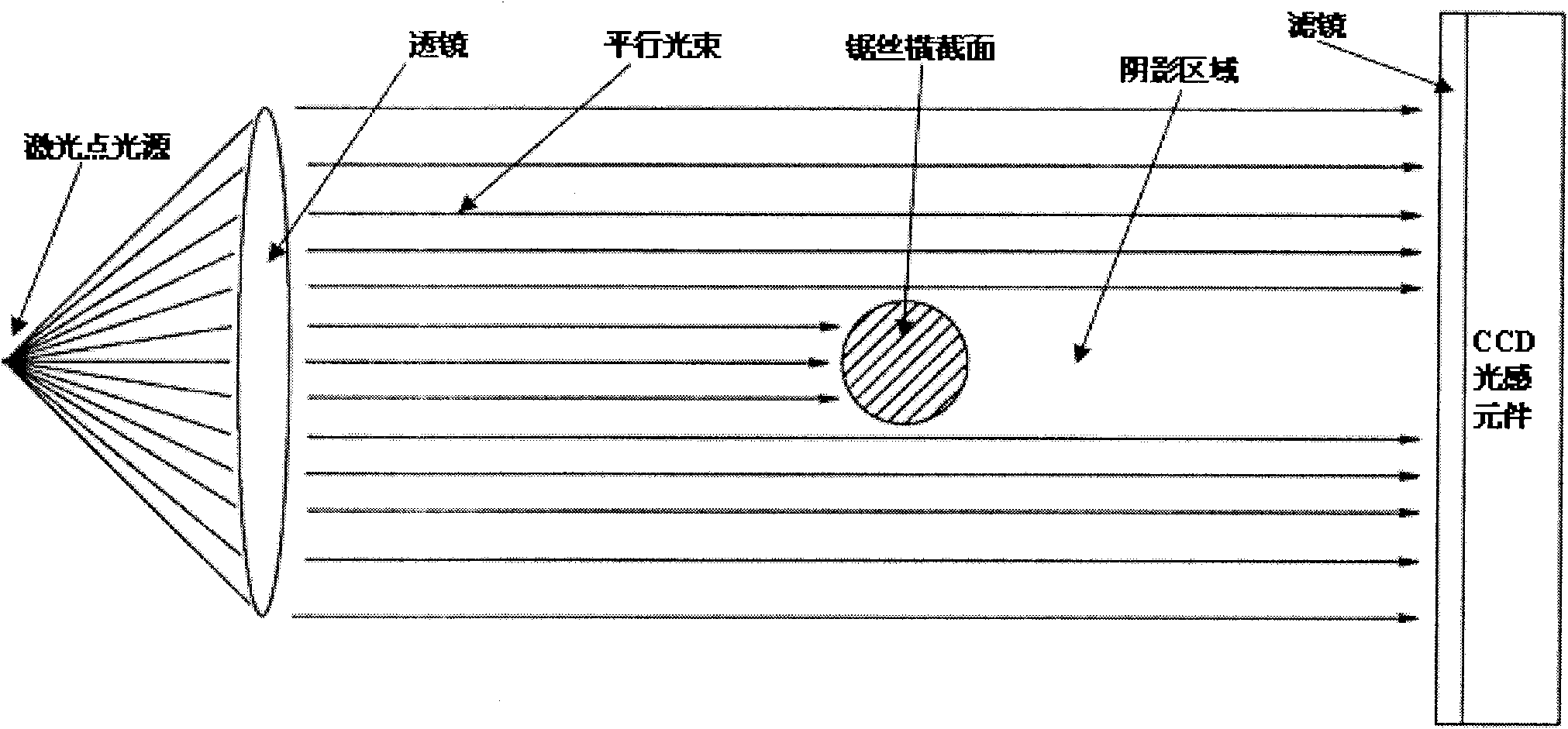

High-speed rail catenary geometric parameter detection non-contact compensation and Kalman filtering correction method

InactiveCN103557788AGuaranteed real-timeImprove processing efficiencyUsing optical meansPull-offVideo image

Owner:SOUTHWEST JIAOTONG UNIV

Communications jack with printed wiring board having paired coupling conductors

ActiveUS7264516B2Increasing return lossPrinted circuit aspectsCoupling device detailsElectrical conductorCoupling

A communications jack includes: a jack frame having a plug aperture; a plurality of contact wires, the contact wires having free ends that extend into the plug aperture, the free ends of the contact wires being arranged serially in side-by-side relationship; a plurality of electrical terminals, the terminals being arranged in pairs, each pair defining a communication channel; a dielectric mounting substrate, the mounting substrate including a plurality of mounting locations for contact wires and a plurality of mounting locations for the electrical terminals; and a plurality of conductors mounted on the substrate, each of the conductors extending, defining a path, and establishing electrical connection between a contact wire mounting location and an electrical terminal mounting location. First and second of the conductors that are connected to one of the pairs of terminals each include a coupling section, the coupling sections being immediately adjacent to each other and having identical instantaneous current direction such that the sections couple and cause a localized increase in inductance.

Owner:COMMSCOPE INC

Contact socket for electrical pin-and-socket connector

InactiveUS6425786B1Easy to produceReasonable priceCoupling contact membersElectric connection basesEngineeringContact wire

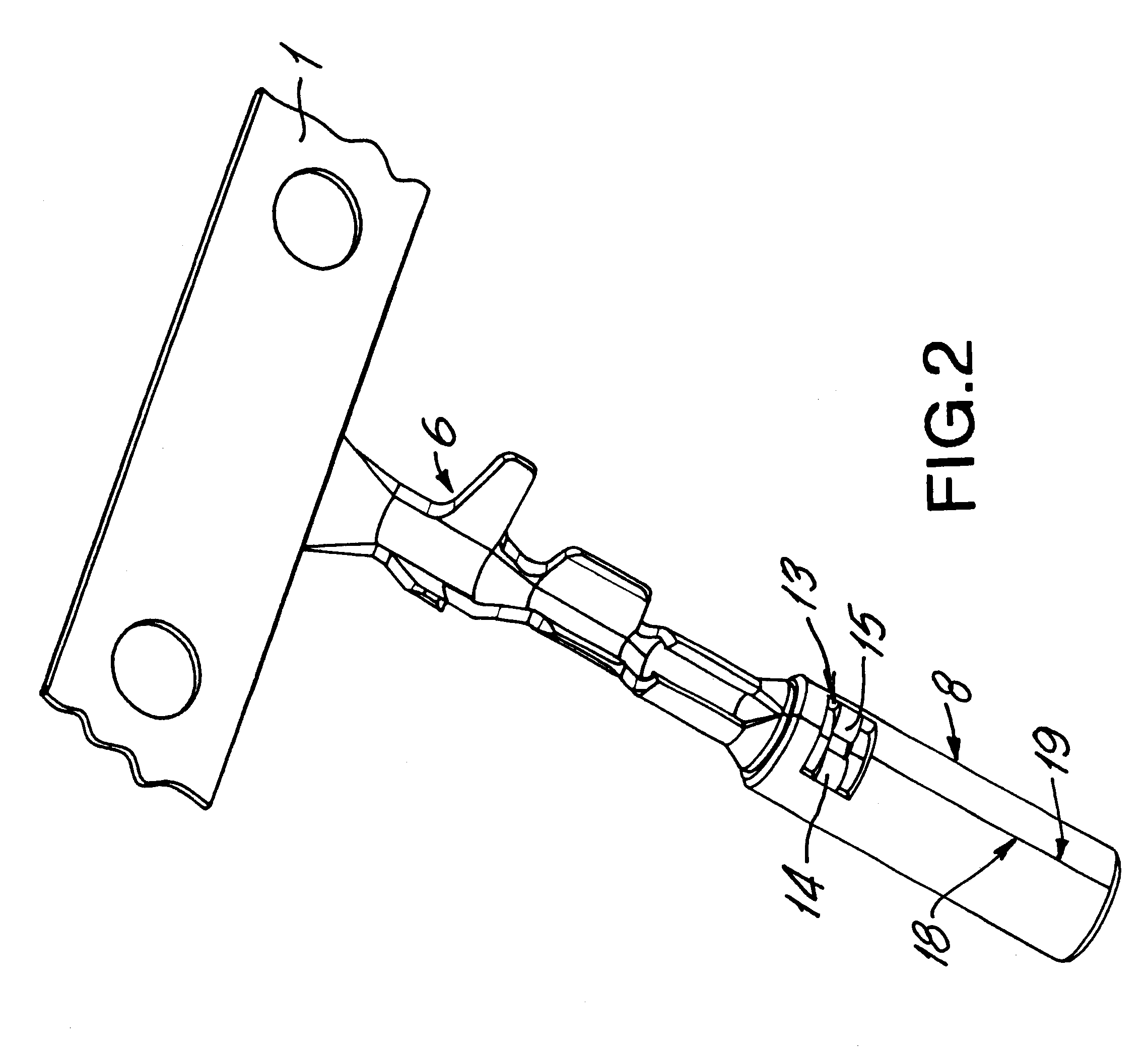

For a readily manufactured configuration of contact plugs for electrical plug connectors, which consists of a stable sleeve body, formed from a sheet material, and a contact spring plug, lying in this sleeve body and having a plurality of contacting means, such as contacting wires or contacting strips in linear or strip-shaped contact with a contact pin, which is to be introduced into the plug, it is proposed that the sleeve body be provided with at least one projection, which is directed transversely to the longitudinal axis of the contact plug and formed by at least one stamping and is in positive engagement with one of the two edge strips of sheet material, connecting the contact wires or contact strips of the contact spring plug with one another.

Owner:HYPERTAC

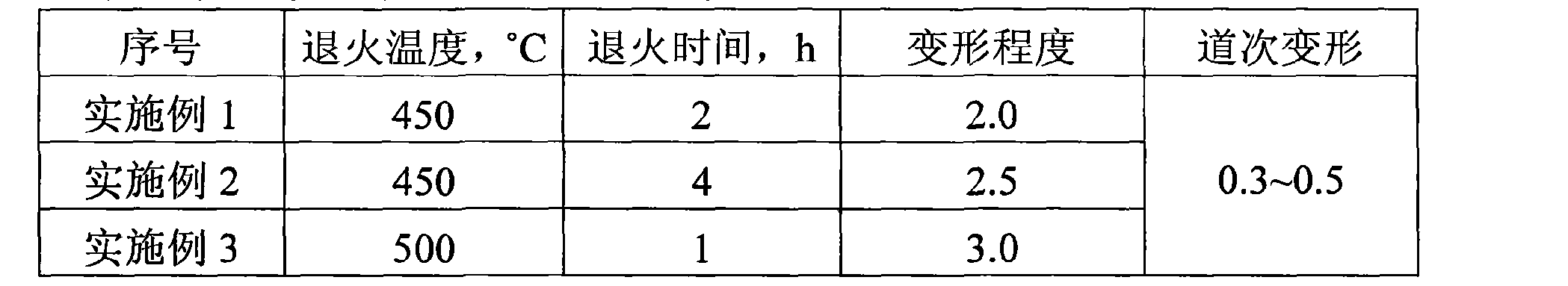

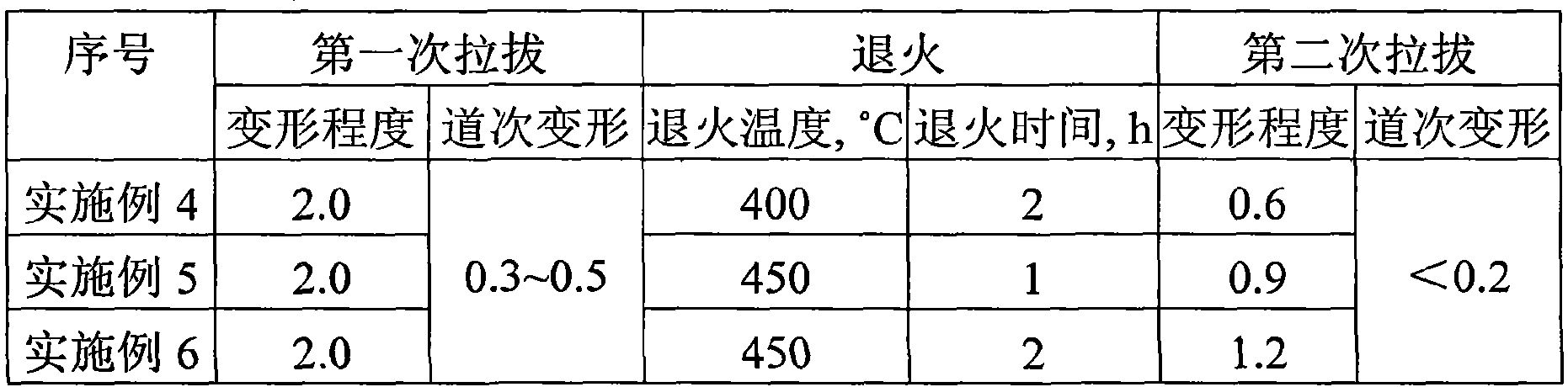

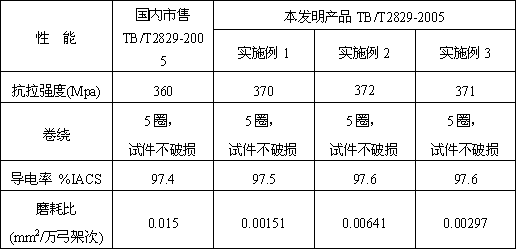

Cu-Cr-Zr alloy preparation technology for contact wire

The invention discloses a process for preparing Cu-Cr-Zr alloys applicable to contact lines. The process comprises the following steps that alloys comprising 0.30 to 0.50 percent of Cu, 0.10 to 0.15 percent of Cr, 0.01 to 0.02 percent of Zr and Si are melt in a vacuum induction furnace, wherein alloy elements, namely Cr, Zr and Si, are added by master alloys; fine casting-state crystal grains and oversaturated matrix tissues having secondary dendritic crystal spaces are obtained by controlling solidification velocity and cooling velocity; rolling in fit, drawing deformation and annealing thermal treatment to the fine casting-state crystal grains and oversaturated matrix tissues are carried out so as to control deformation degrees and parameters for the thermal treatment; and the strain-hardening effect and the precipitation strengthening effect are organically combined. Therefore, the alloys have the advantages of excellent tensile strength, electrical conductivity and high-temperature resistant softening capacity and lower cost under the conditions of simplified process and the simpler apparatus and components, and are applicable to industrial production.

Owner:邢台鑫晖铜业特种线材有限公司 +3

Communications jack with printed wiring board having self-coupling conductors

ActiveUS7326089B2Increasing return lossCoupling device detailsTwo-part coupling devicesCouplingElectrical connection

A communications jack includes: a jack frame having a plug aperture; a plurality of contact wires, the contact wires having free ends that extend into the plug aperture, the free ends of the contact wires being arranged serially in side-by-side relationship; a plurality of insulation displacement connectors; a dielectric mounting substrate, the mounting substrate including a plurality of mounting locations for contact wires and a plurality of mounting locations for insulation displacement connectors; and a plurality of conductors mounted on the substrate, each of the conductors extending, defining a path, and establishing electrical connection between a contact wire mounting location and an insulation displacement connector mounting location. At least one of the conductors includes two self-coupling sections that are immediately adjacent to each other and that have identical instantaneous current direction such that the sections self-couple and cause a localized increase in inductance.

Owner:COMMSCOPE INC

Copper-chromium-zirconium alloy contact wire and production technique thereof

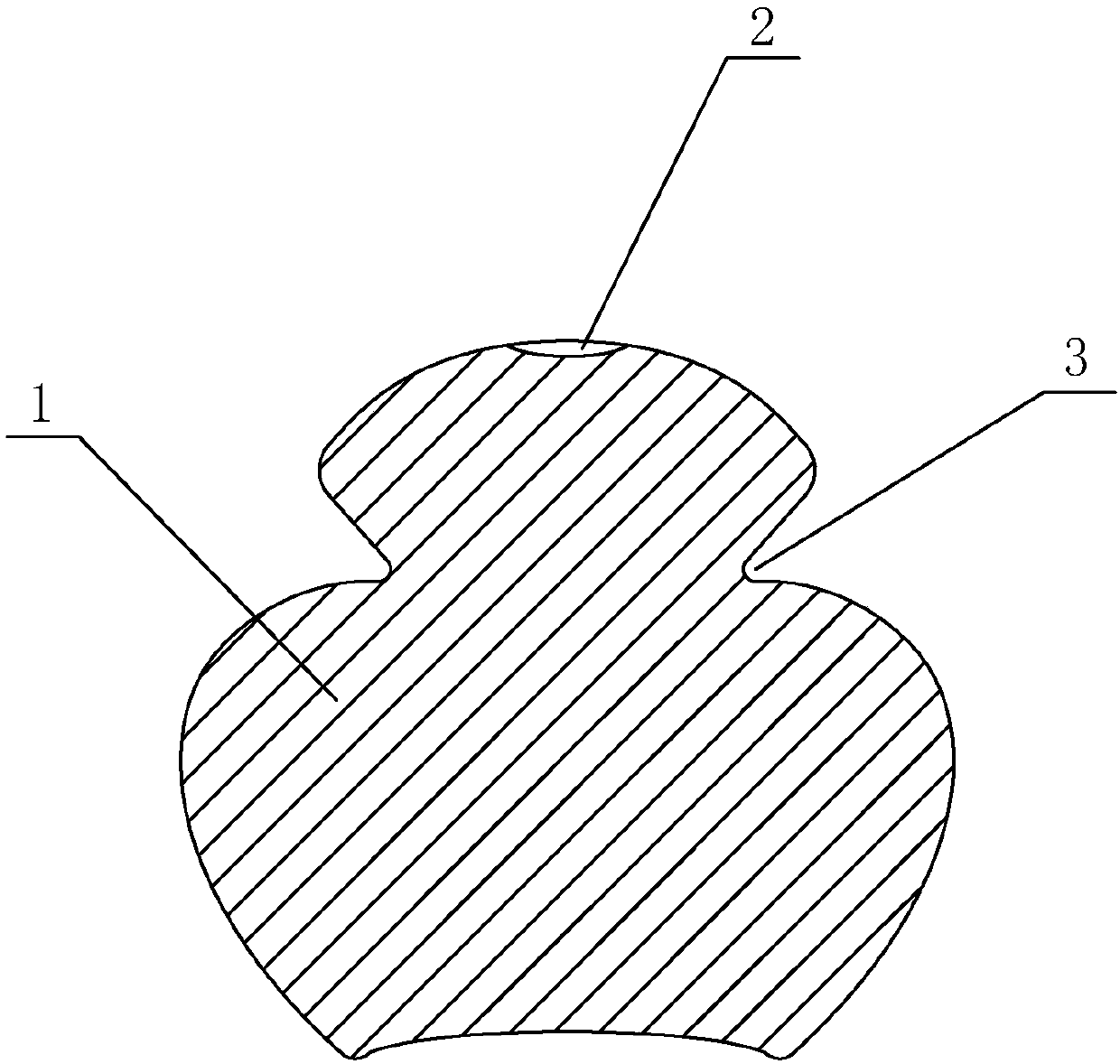

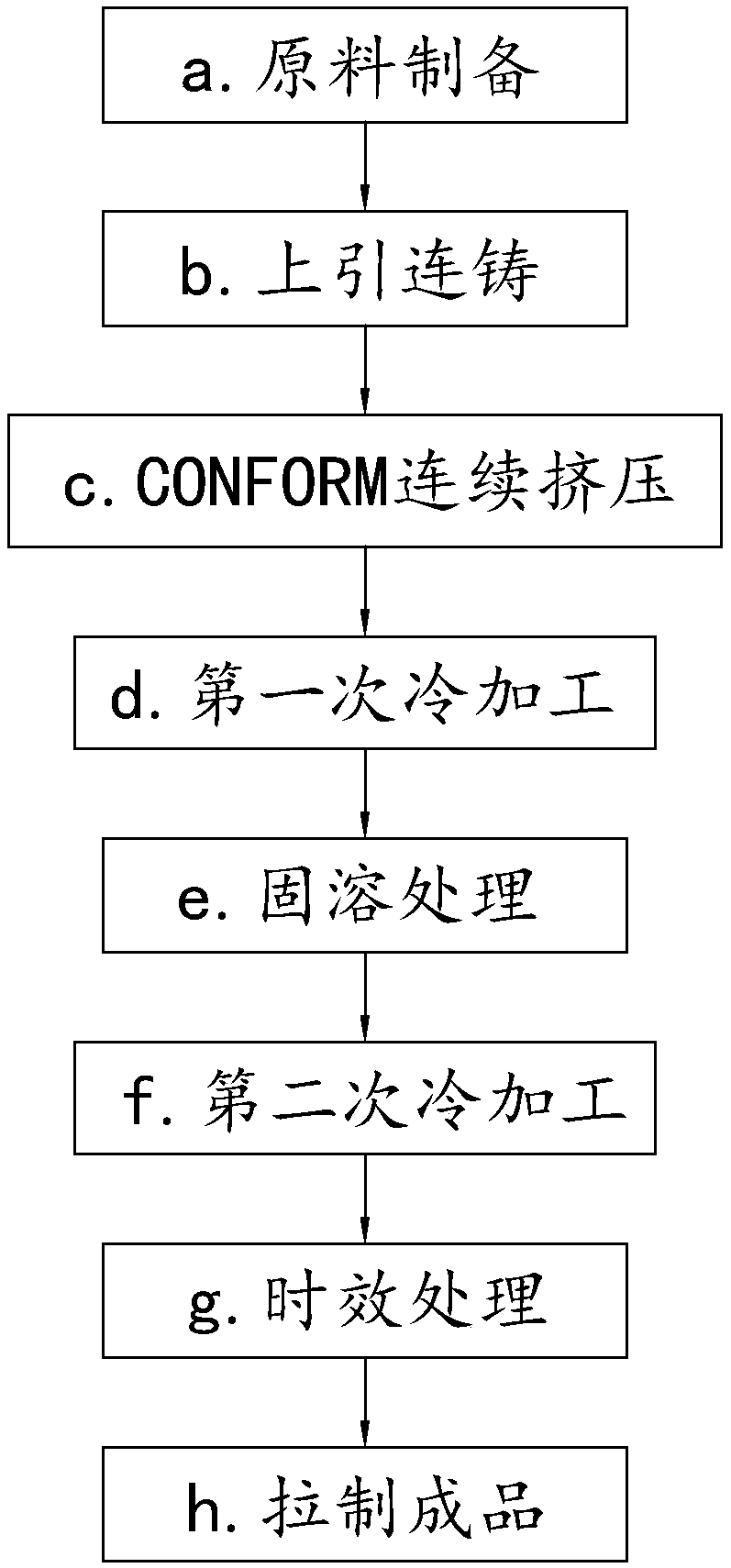

ActiveCN107739872AMeet the needs of rapid developmentConductive materialMetal/alloy conductorsZirconium alloyImpurity

The invention discloses a copper-chromium-zirconium alloy contact wire and a production technique thereof. The copper-chromium-zirconium alloy contact wire is composed of copper, chromium, zirconium and inevitable impurity elements according to the set mass percentages. In preparation, the main technique comprises the steps of raw material preparation, up-drawing continuous casting, CONFORM continuous squeezing, primary cold machining, solution treatment, secondary cold machining, aging treatment and finished product drawing. According to the copper-chromium-zirconium alloy contact wire manufactured by the technique and materials, the matching of the contact wire raw materials is reasonably adjusted, the ratio of all element components in the contact wire is adjusted, and the special production technique is combined so that a high-strength high-conductivity contact wire product can be produced, wherein the weight of one single contact wire product is larger than two tons, the IACS electrical conductivity of the contact wire product is 75-90%, and the tensile strength of the contact wire product is 550-700 MPa; and the requirement of current electric railway high-speed development can be better met.

Owner:CENTURAY TECH CO LTD

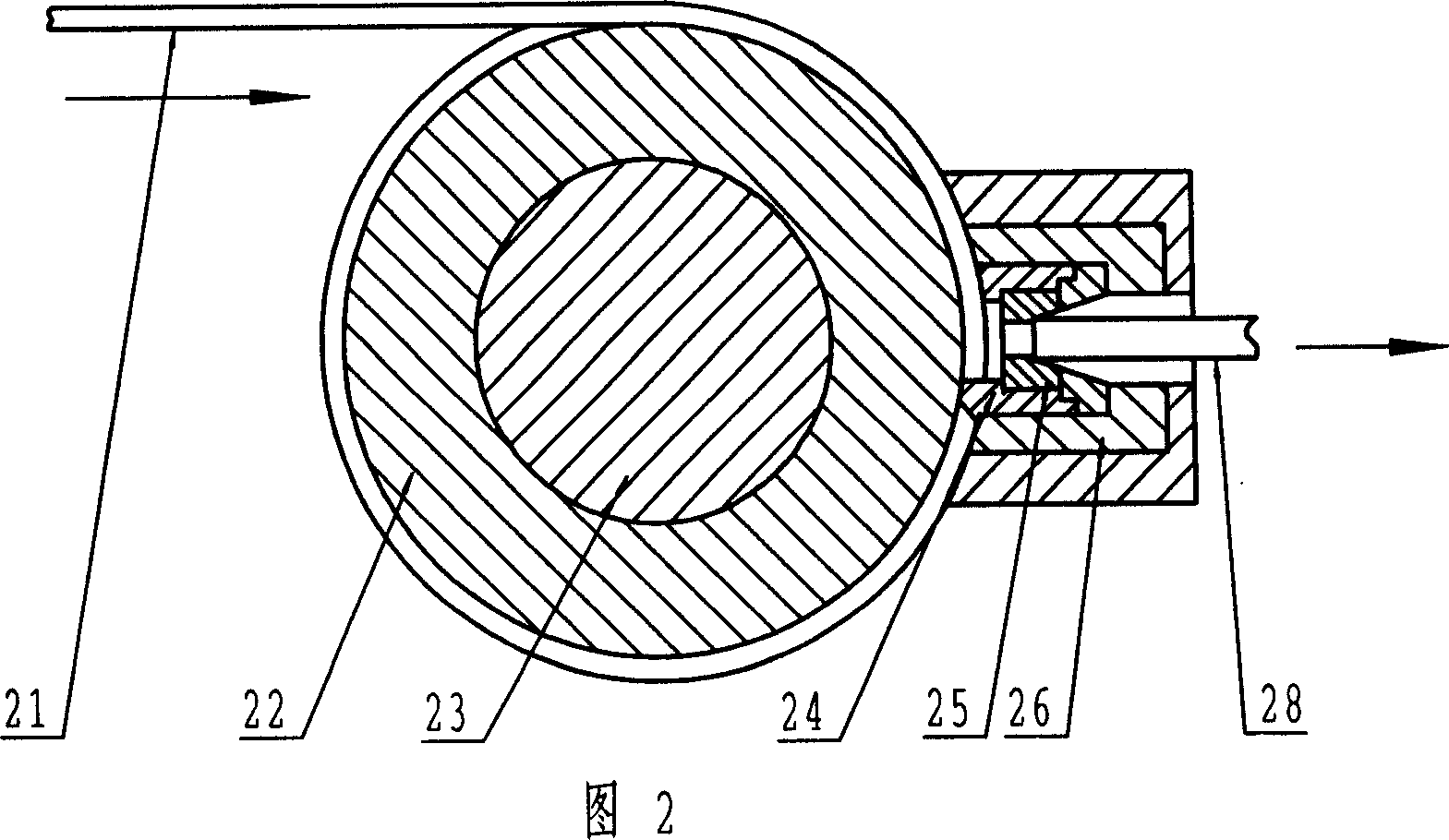

Method of making a hyperboloid electrical contact

InactiveUS7191518B2Reduce the overall diameterCost efficient to manufacturePrinted circuit assemblingContact member manufacturingHyperboloidConductive materials

A hyperboloid contact socket is provided which comprises a tubular body of conductive material and preferably having at one end a lip defining an entrance aperture for receiving a mating pin terminal and having on the opposite end a termination of an intended configuration for attachment to a circuit board or other device or item. The tubular body contains a plurality of conductive wires conductively and permanently affixed at their respective ends torespective inner surfaces at or near the outer and inner ends of the body and disposed in an angular disposition to the longitudinal axis to form the shape of a single sheet hyperboloid. In one aspect of the invention a mandrel employed to orient the wires within the tubular body during fabrication of the contact socket remains attached to the tubular body after assembly of the contact wires and serves as a connecting pin to which various terminations can be attached.

Owner:QA TECHNOLOGIES

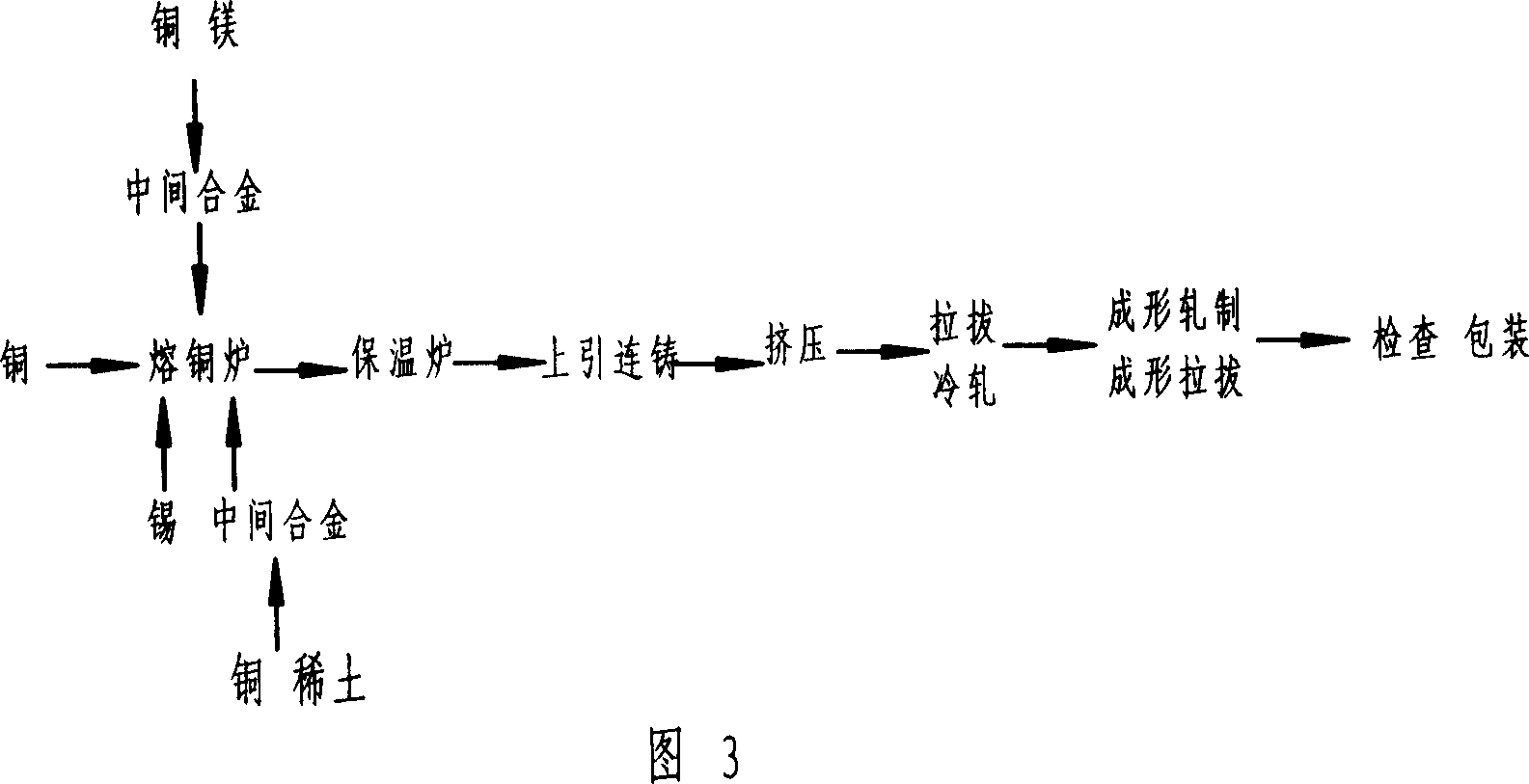

Method for producing copper alloy contact wire with excellent comprehensive performance

ActiveCN1933037ASolve brittleSolve the two major problems of poor flow effectCable/conductor manufactureImpurityTin

The invention is concerned with the copper alloy touching line and the preparation method with choiceness integrative performance that uses to improve the using performance of the touching line of the cable technology field. It is: the copper alloy is as the material that the material melts with the following percentage weight, magnesium 0.05~ 0.35%, stannum 0.35~0.05%, total quantity of impurity is smaller than 0.10%, remainder is copper; the above material makes to be the touching line by the steps of smelting, heat preservation, casting pole, pressing, cold rolling, molding rolling. The index of the touching line achieves and overruns the international similar product level, such as the intensity, the conductivity, the elongation ratio, the reverse, repeating bending, convolution.

Owner:邢台鑫晖铜业特种线材有限公司

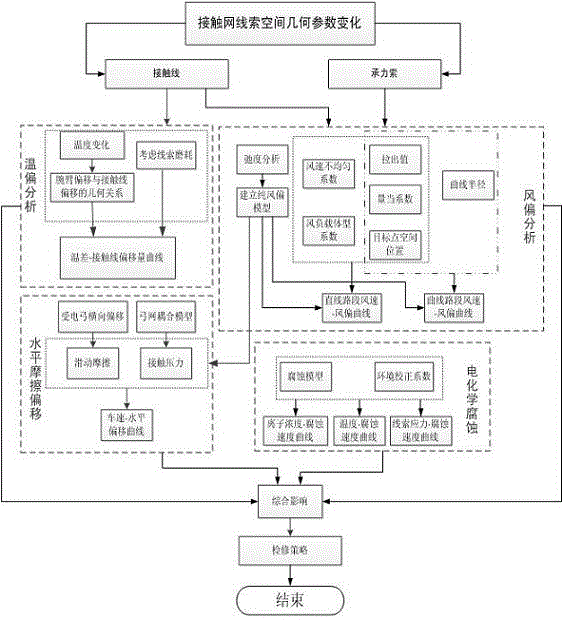

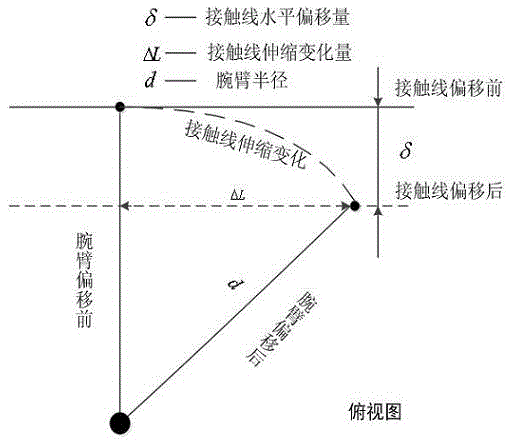

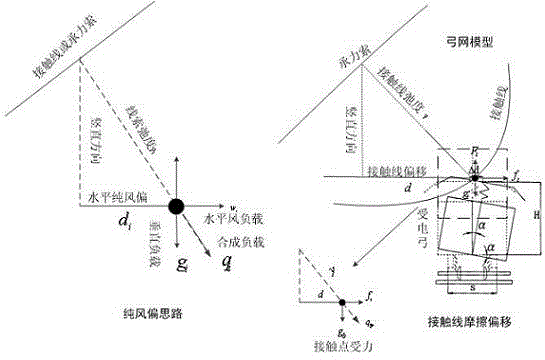

Line space geometric state parameter detecting method for high-speed rail overhead line system

InactiveCN104534989AAvoid maintenance costsSave human effortUsing optical meansControl theoryOverhead line

The invention relates to a line space geometric state parameter detecting method for a high-speed rail overhead line system and belongs to the field of fault detection of the electrification rail overhead line system. The invention aims to provide a line space geometric state parameter comprehensive evaluation method for the high-speed rail overhead line system. The method comprises the steps that a laser distance meter is used for measuring geometric parameter values of a line of the overhead line system and important equipment machines; the geometric parameter change law of the overhead line system under various external conditions is mastered in the aspects of line variation caused by temperature changes, change conditions of deviation of the overhead line along with wind speed, and friction deviation of the overhead line when trains with different time speeds pass; a theoretical model of the corrosion rate of the overhead line system in the air under the electrochemical polarization control condition is set up for studying the durability of the overhead line system to form a comprehensive evaluation system. Operation in a maintenance work area can be guided according to the change trend of the line space geometric parameters of the overhead line system, and the work efficiency of maintaining the overhead line system is improved.

Owner:TONGJI UNIV

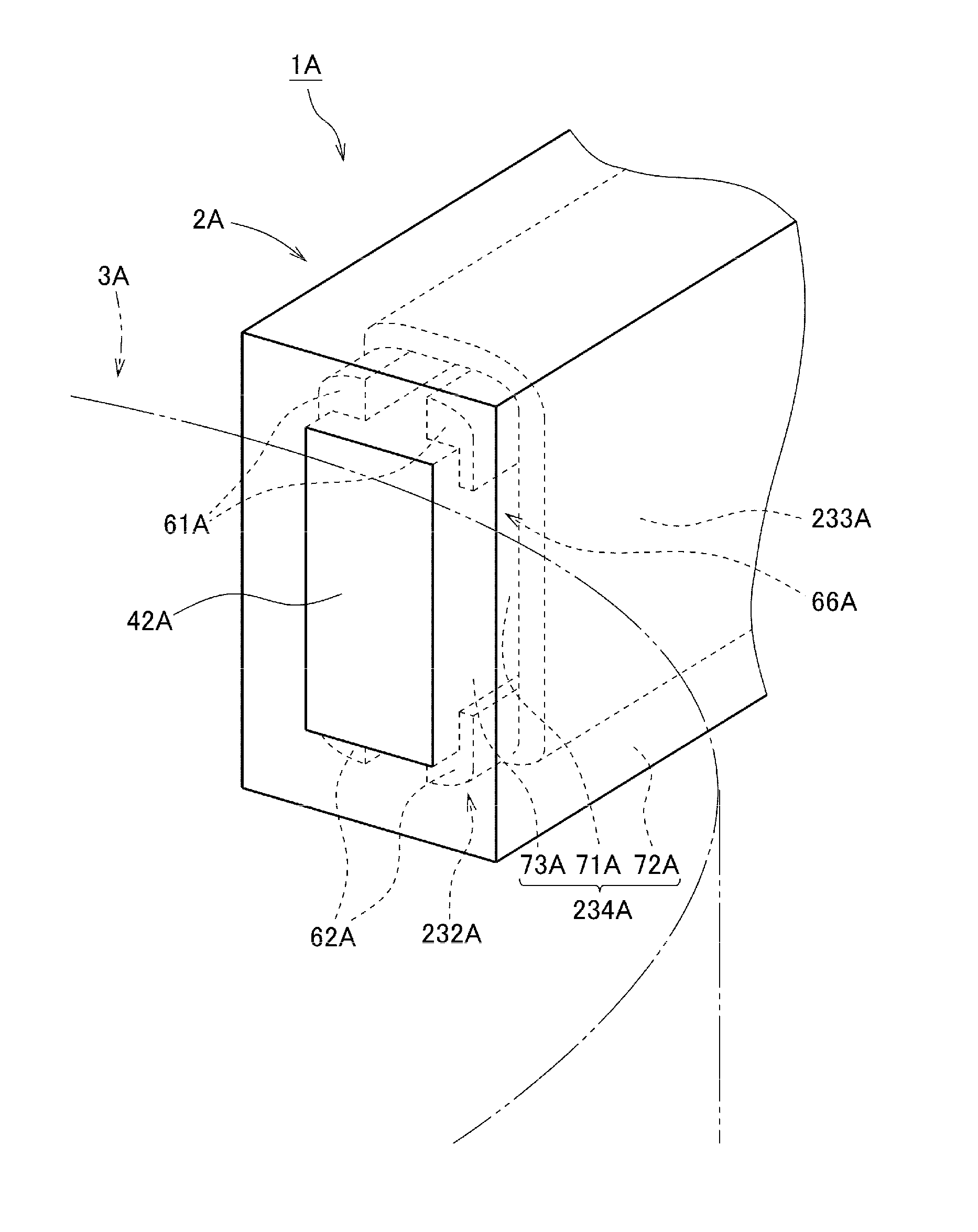

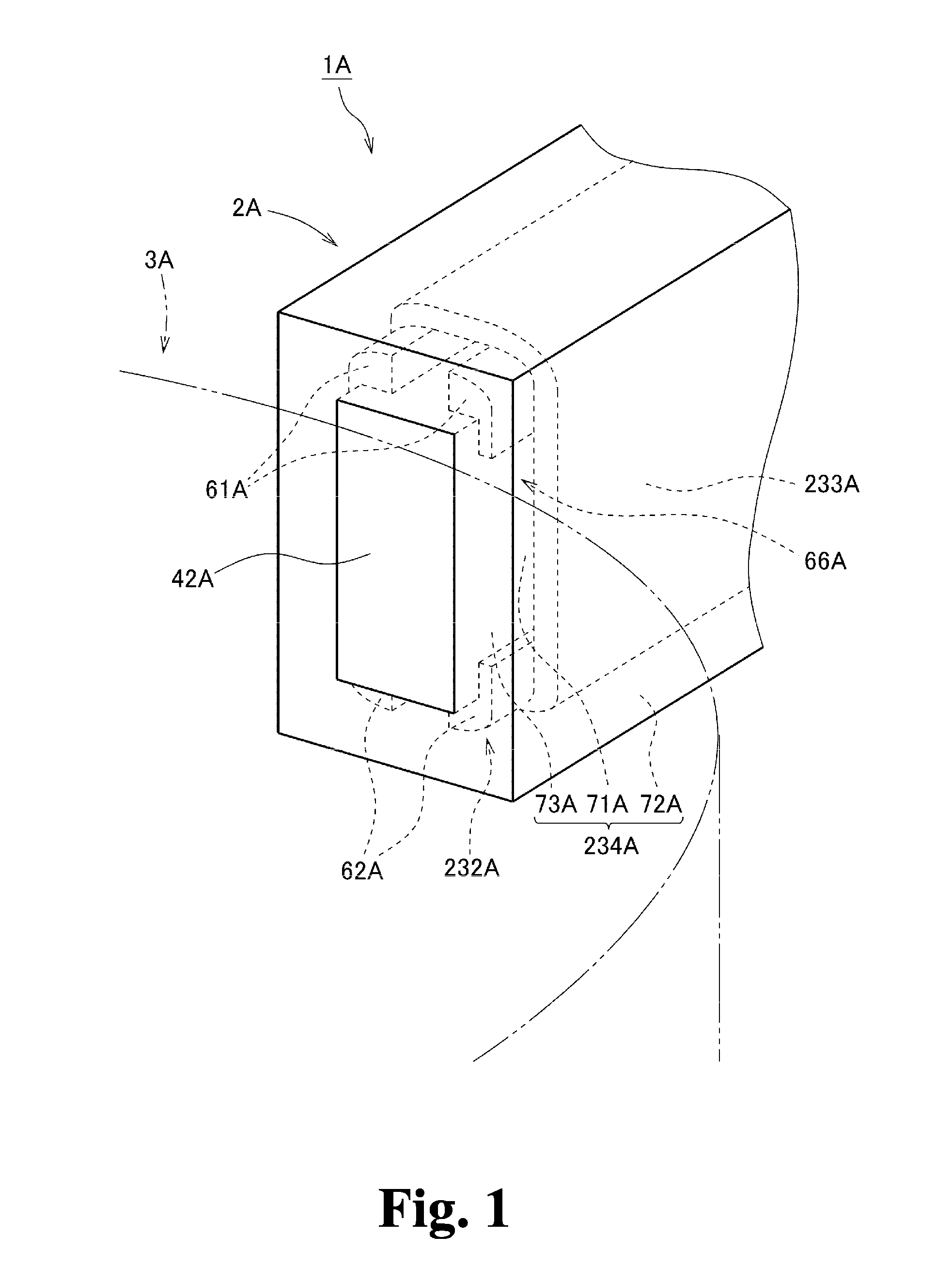

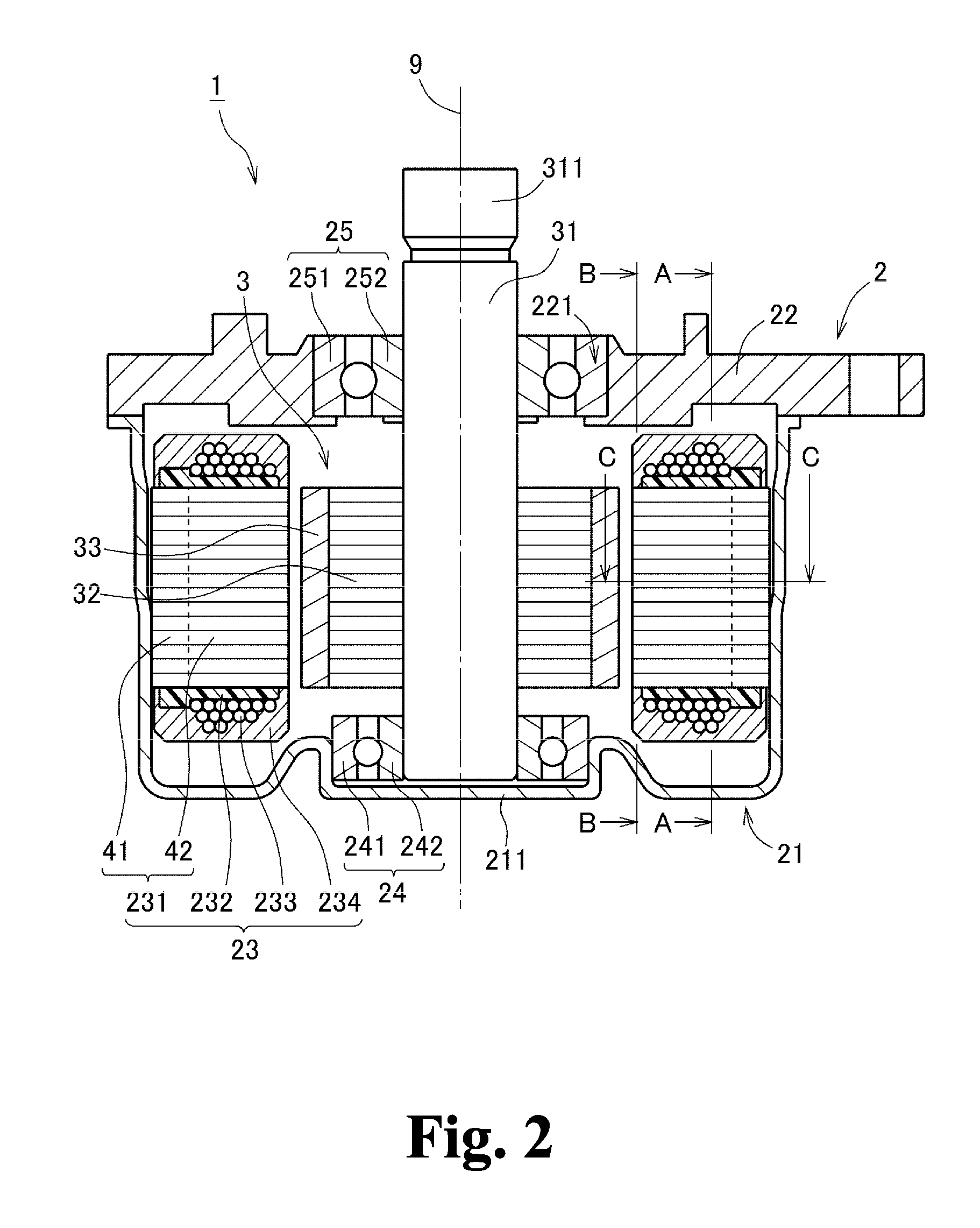

Motor and method of manufacturing motor

ActiveUS20150008769A1Improve cooling effectIncrease the areaWindings insulation materialWindings insulation shape/form/constructionEngineeringMechanical engineering

Owner:NIDEC CORP

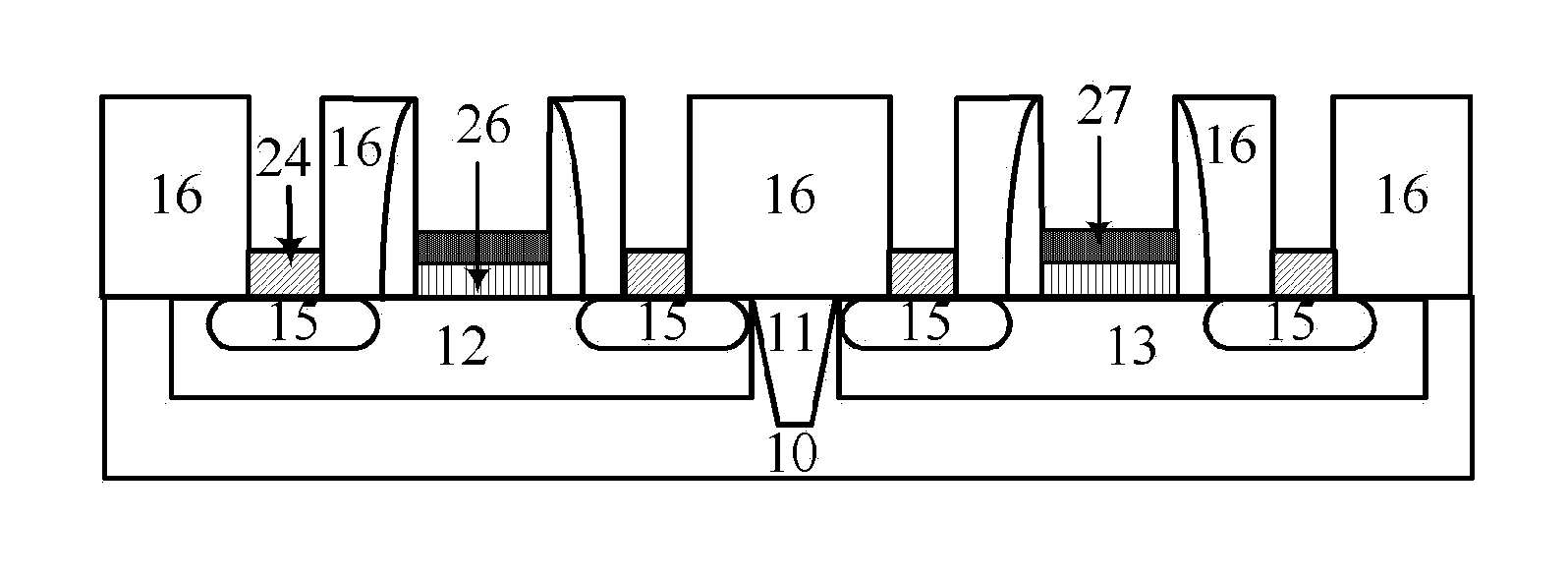

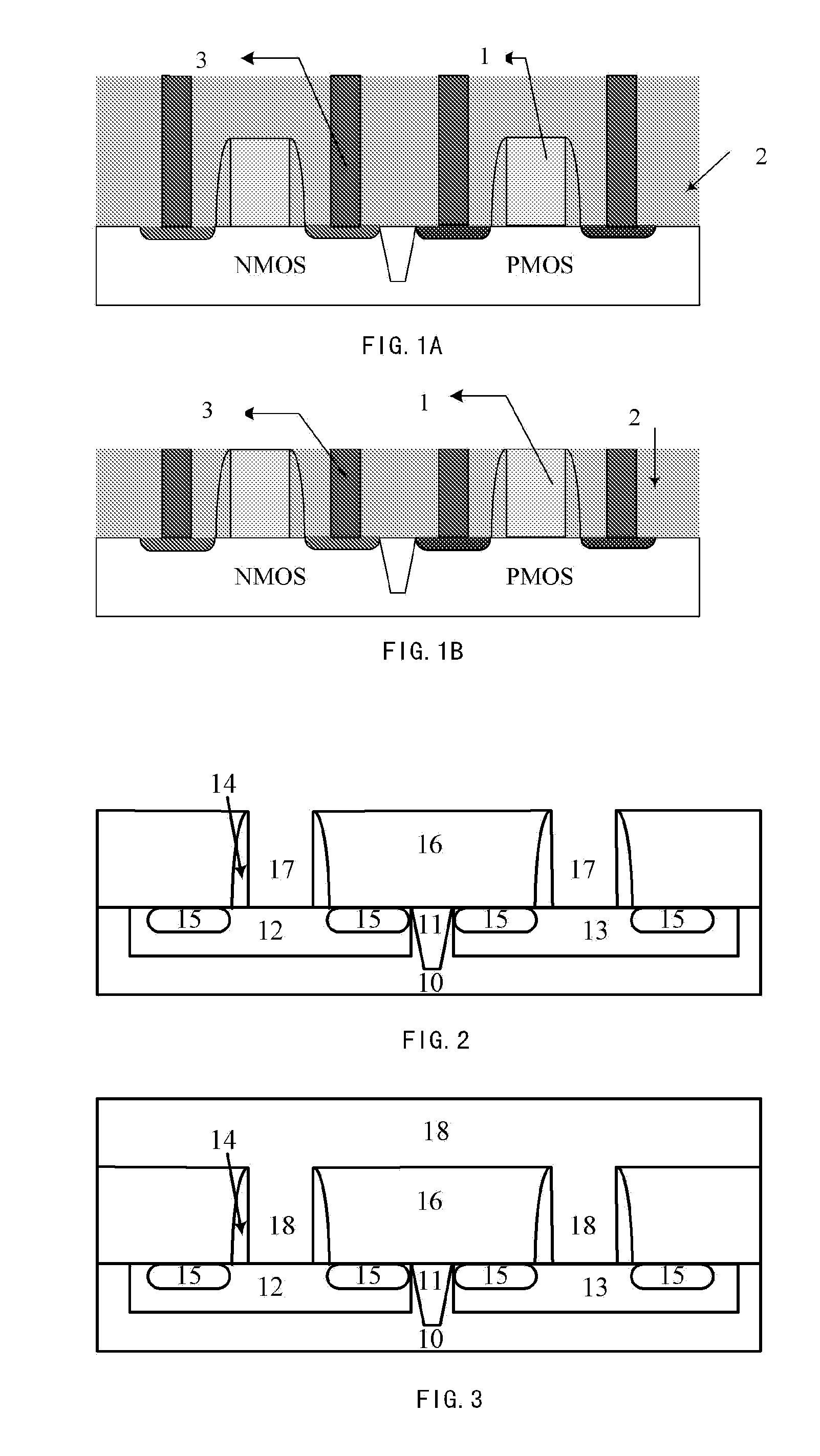

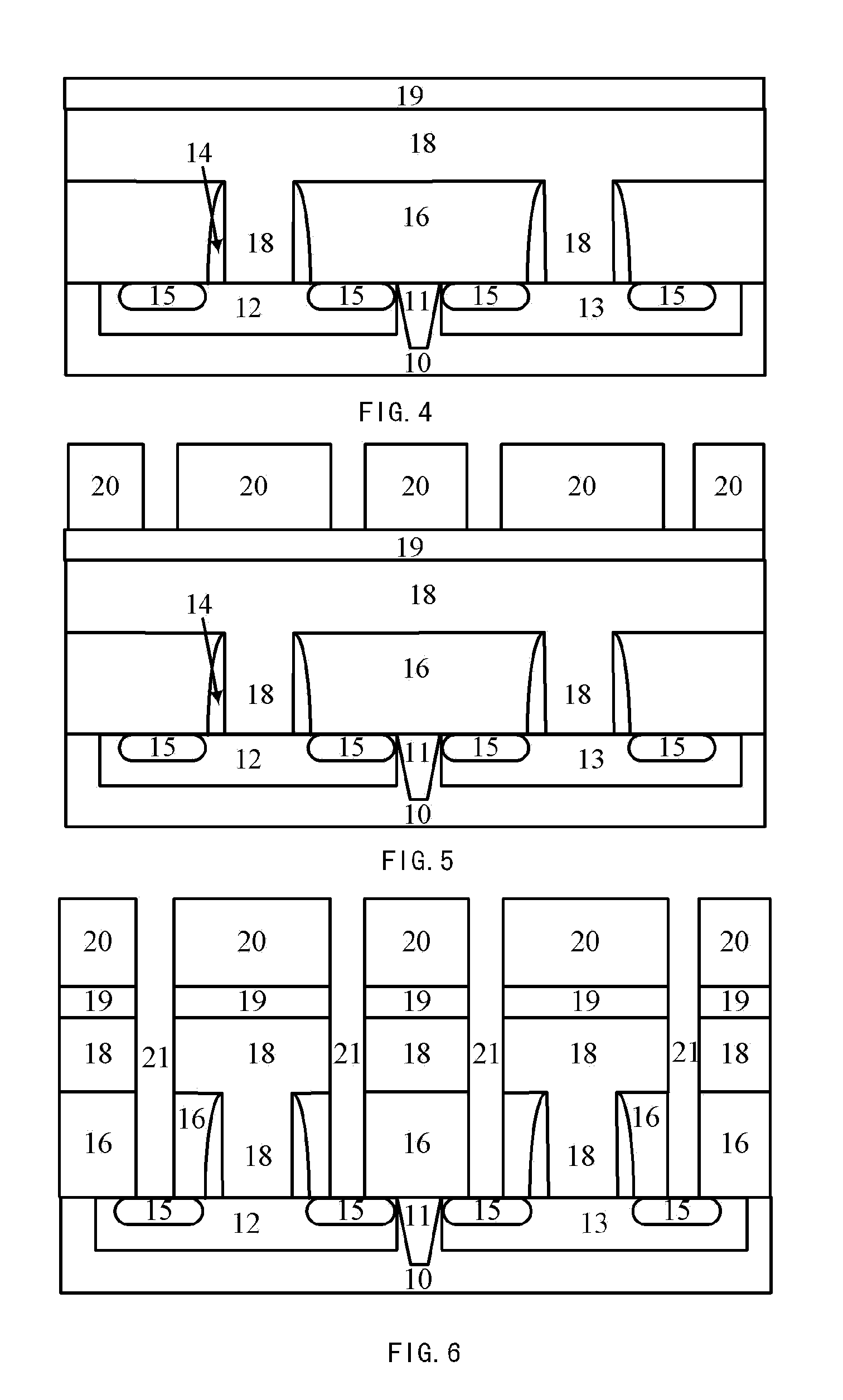

Method for manufacturing electrodes and wires in gate last process

InactiveUS20130059434A1Simplify complexityEasy to controlSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricMetal silicide

The present invention provides a method for manufacturing a gate electrode and a contact wire simultaneously in a gate last process, comprising the steps of: forming a gate trench in an inter layer dielectric layer on a substrate; forming a filling layer in the gate trench and on the inter layer dielectric layer; etching the filling layer and the inter layer dielectric layer to expose the substrate, to thereby form a source / drain contact hole; removing the filling layer to expose the gate trench and the source / drain contact hole; forming metal silicide in the source / drain contact hole; depositing a gate dielectric layer and a metal gate in the gate trench; filling metal in the gate trench and the source / drain contact hole; and planarizing the filled metal. In accordance with the manufacturing method of the present invention, the gate electrode wire will be made of the same metal material as the contact hole such that the two can be manufactured by one CMP process. Such a design has the advantages of simplifying complexity of process integration on one hand and greatly strengthening control of defects by CMP process on the other hand, thereby avoiding the defects like erosion and dishing that may be produced between different metal materials.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Copper alloy material for lead frame and preparation method thereof

The invention relates to a copper alloy material used for lead frame and the preparation method, belonging to the copper alloy material field; wherein nickel accounts for 0.9 to 3.5% (weight percentage), silicon accounts for 0.18 to 0.8%, phosphorus accounts for 0.02 to 0.1% and the rest is copper. The preparation method is that all the components according to the weight ratio are mixed and melted, after casting, hot forging, solid solution, multiple cold rolling, deformation and aging, the product is got. The copper alloy material used for lead frame has the advantages of tensile strength of 600 to 850MPa, conductivity of 45 to 65%IACS, elongation of 5 to 8% and softening temperature of 500 to 550 centigrade; thereby the requirements on the copper alloy material performance of the lead frame in electronic industrial field is well achieved; the copper alloy material can also be used in the copper alloy material field needing high strength and high conductive, such as contact lines in trolleys and electric locomotives, rotor bars of the high-speed turbine generator and inner liners of the large thrust rocket engines.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

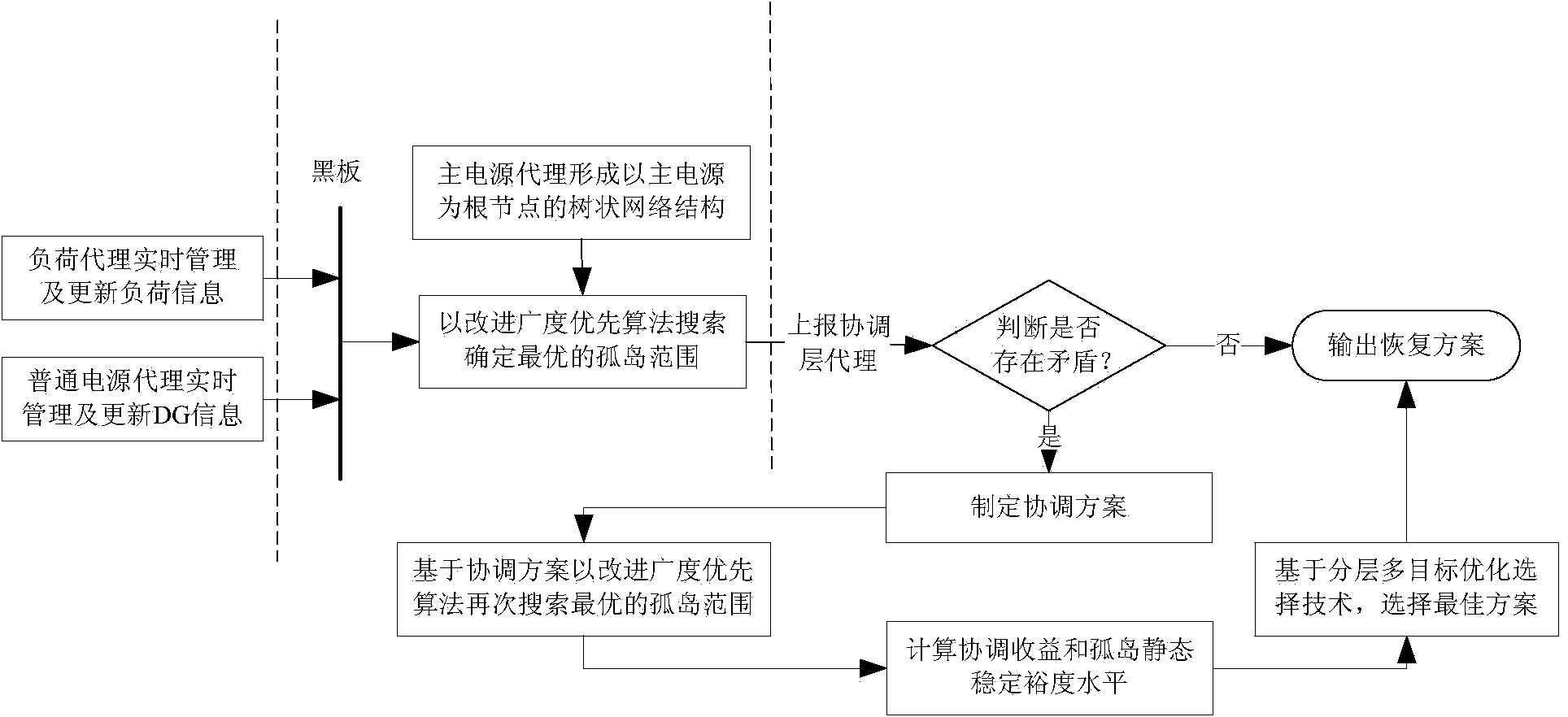

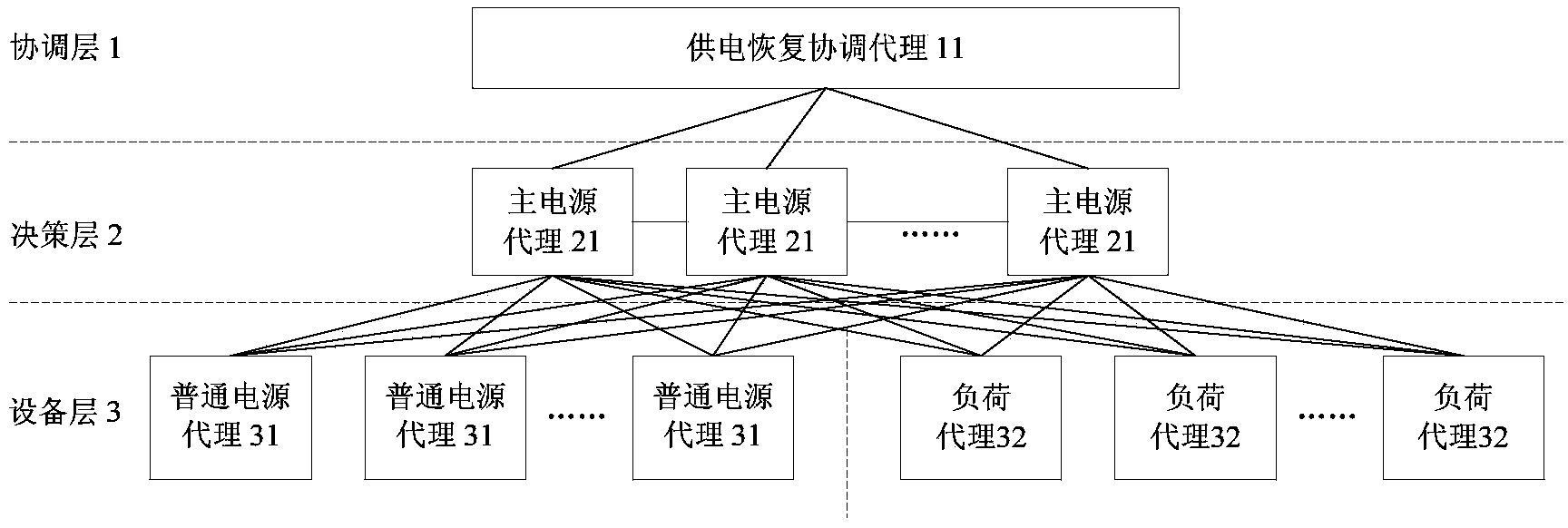

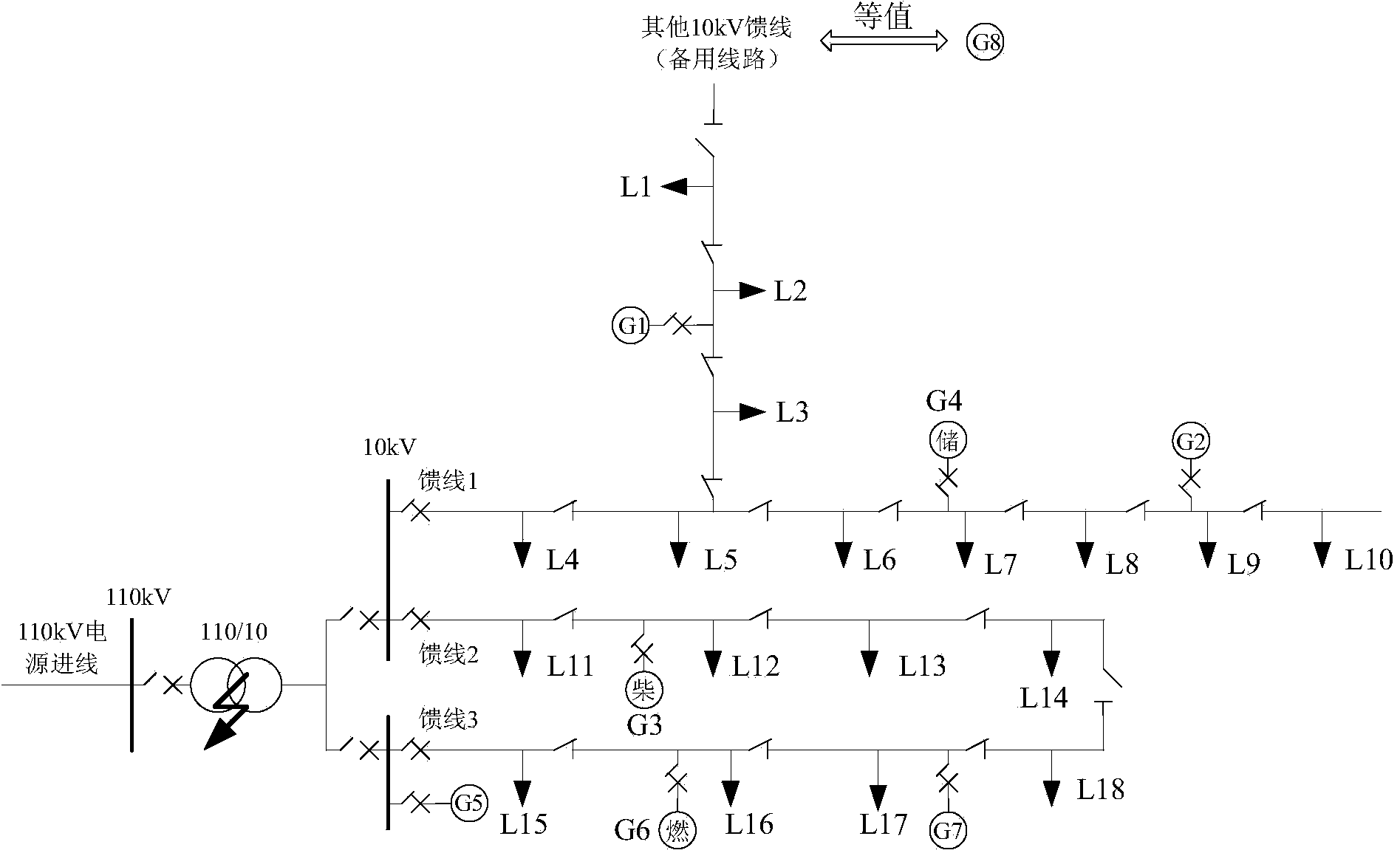

Method and system for restoring power after fault of power distribution network containing DGs (distributed generation)

InactiveCN103532140AImprove power recovery capabilityInformation technology support systemAc network circuit arrangementsElectricityIslanding

The invention relates to a method and a system for restoring power after fault of a power distribution network containing DGs. According to the method, the DGs integrated in the power distribution network are processed in a classified manner according to the control method of the DGs and are divided into main power supplies and ordinary power supplies, wherein the main power supplies are controllable DGs, and the ordinary power supplies are random and uncontrollable DGs; and meanwhile, a standby contact wire is used as a main power supply, then, a multi-agent system for power restoration after fault of the power distribution network containing the DGs is established, and the optimum power supply scheme of a power-losing area is planned in a master-slave control mode. Compared with the prior art, the standby contact wire and the DGs integrated in the power distribution network are fully utilized in the restoration process, the power outage load is restored to the maximum, and the isolated island operation capacity of the DGs and randomness and volatility of output power are given full consideration, so that a restoration scheme can continuously and stably operate.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

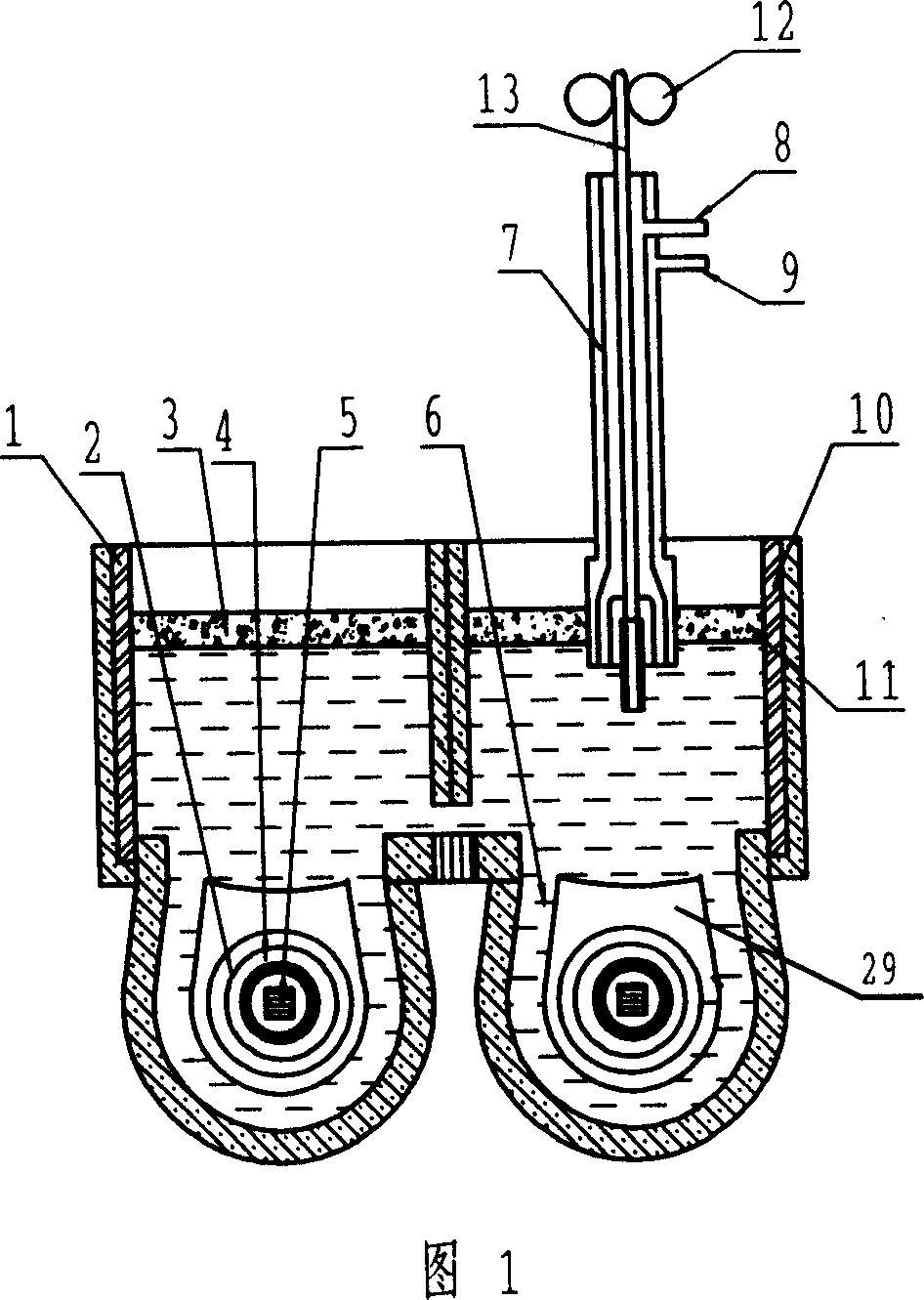

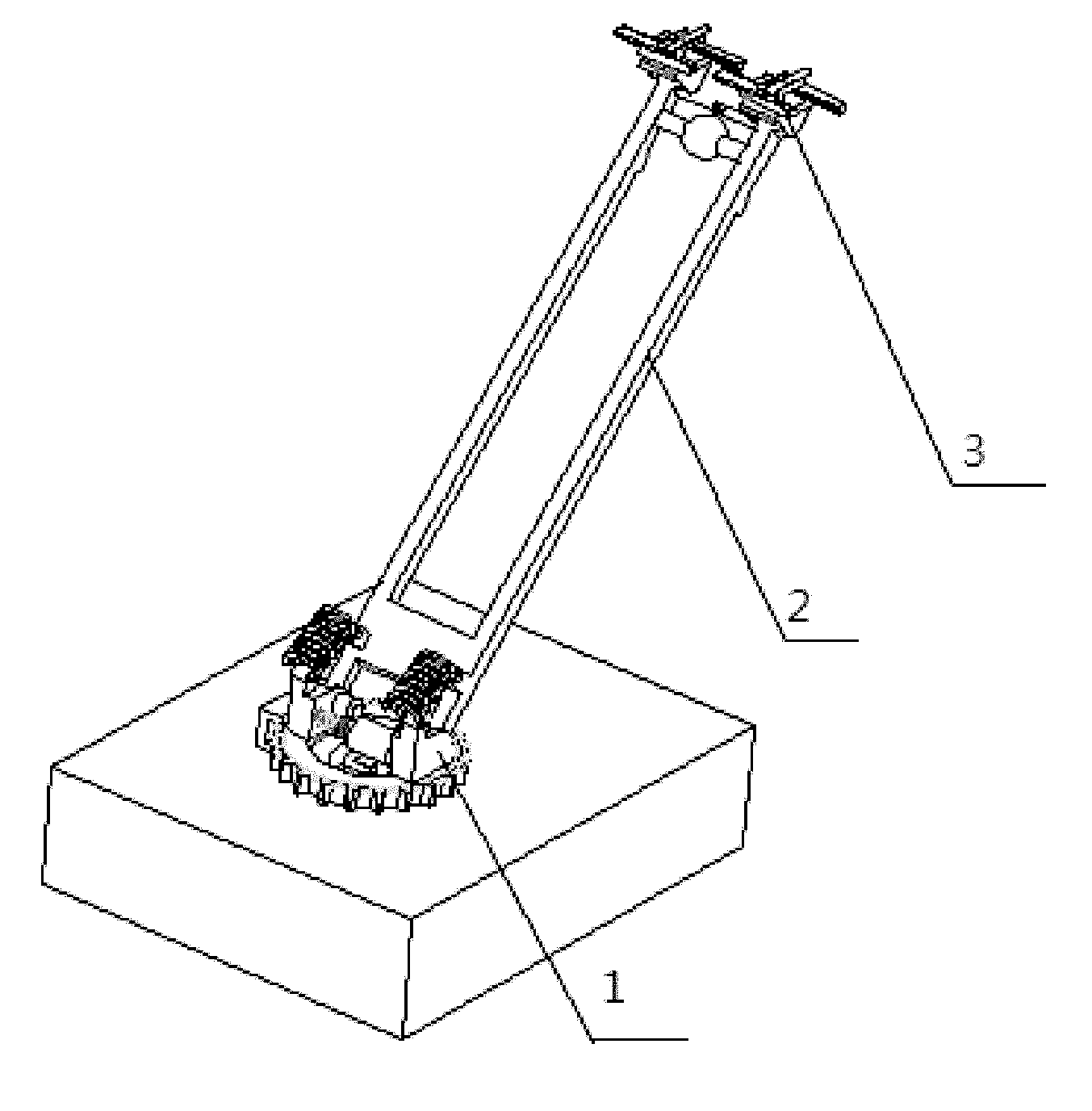

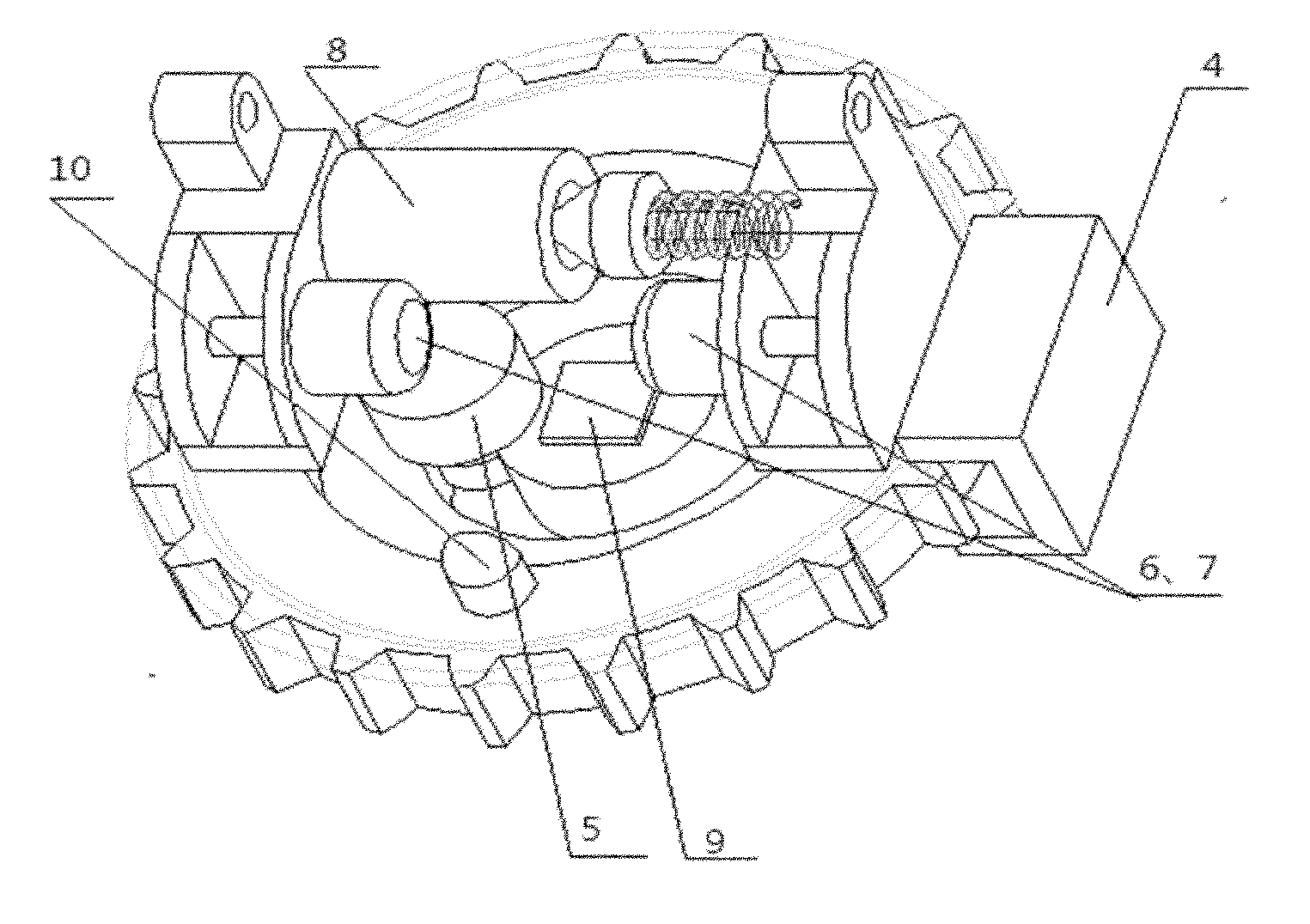

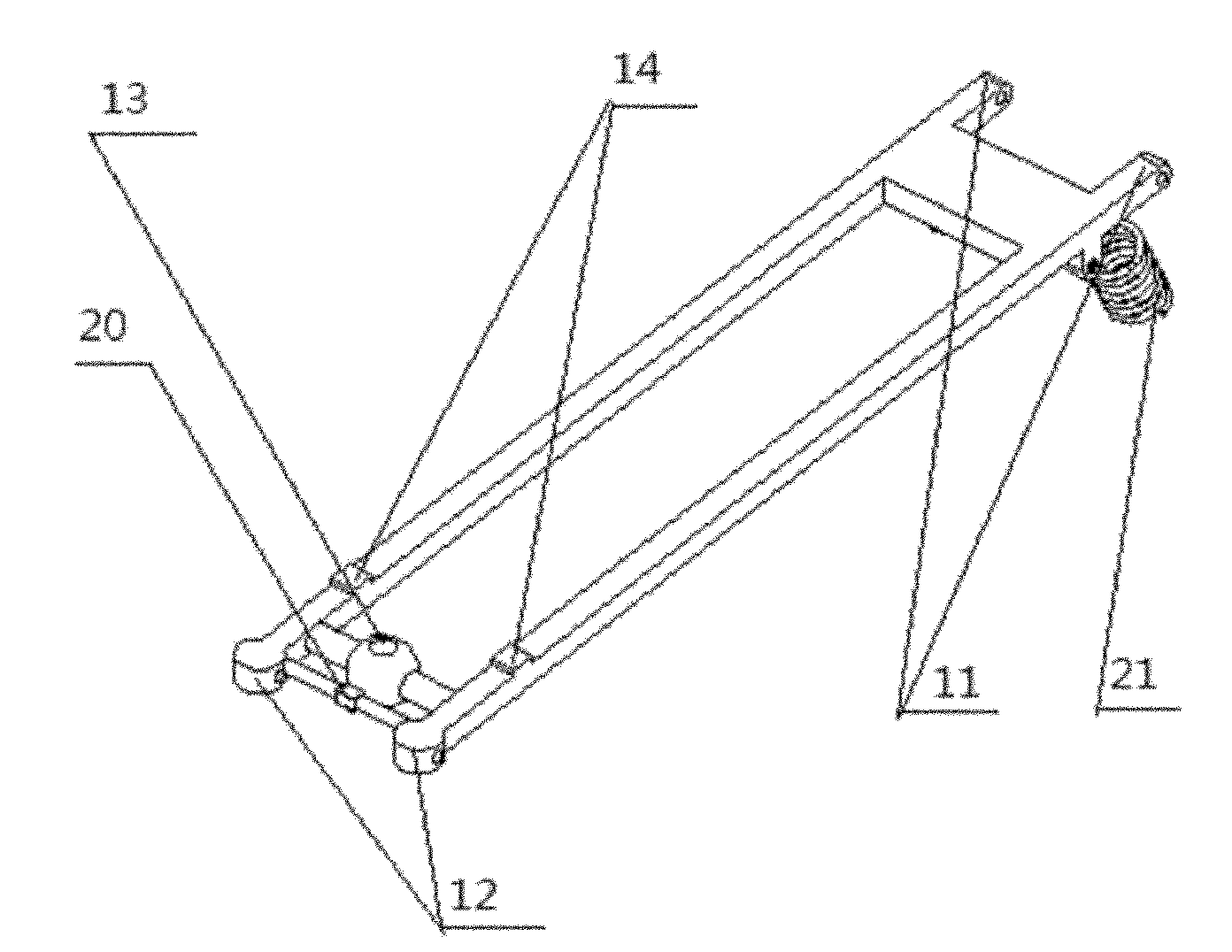

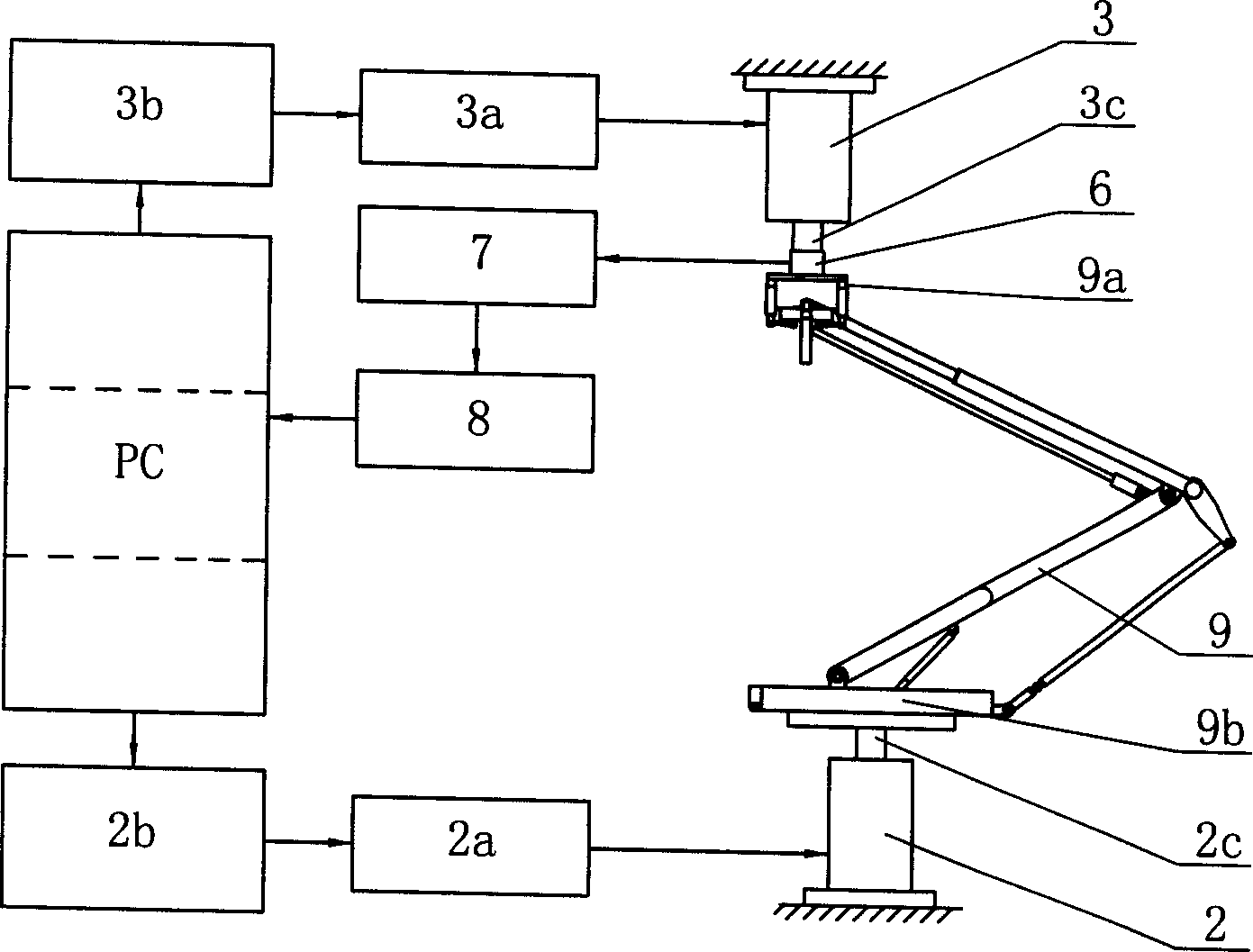

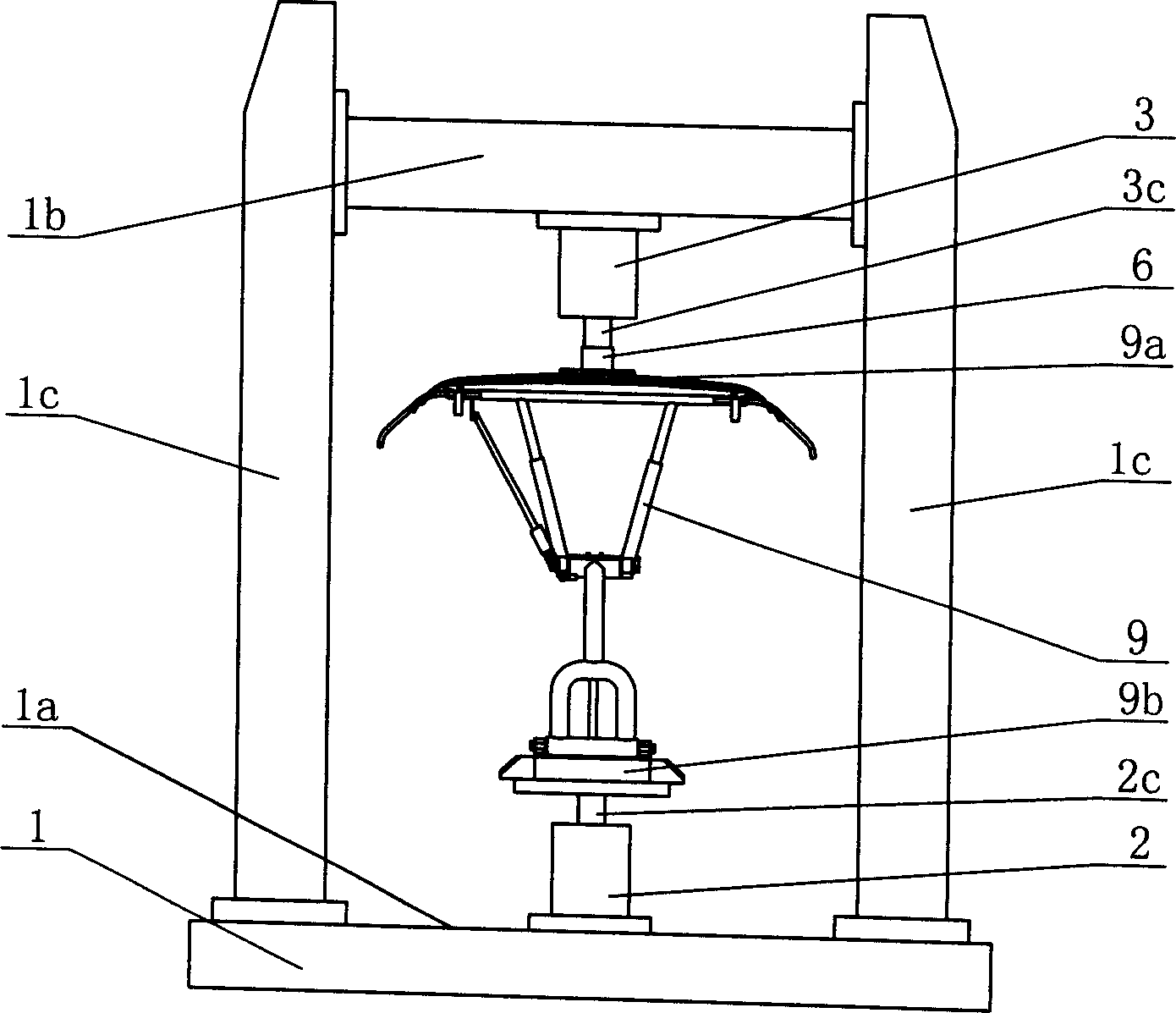

Intelligent pantograph device for trolley bus and using method thereof

InactiveCN102092296AFor automatic positioningRapid positioningElectric vehicle charging technologyPower current collectorsInfraredElectricity

The invention relates to an intelligent pantograph device for trolley bus and a using method thereof, which relate to the field of intelligent control of pantograph of a trolley bus and solve the problem that the conventional trolley bus can only realize overtaking on a single side and the problem that the automatic connection cannot be realized between the pantograph and a contact wire in an overtaking process. In the invention, when the pantograph is lifted, a contact wire tracing program based on the processing of image captured by an infrared camera on a pantograph assembly is adopted to regulate the angle of the pantograph, a movable cable clamp is used to compensate for an error, and thus, the pantograph is connected to the contact wire automatically; during overtaking, a rear vehicle informs a front vehicle of lowering the pantograph through a communication unit and determines if to allow the pantograph of the front vehicle to return, the contact wire tracking program is used to lower the pantograph of the front vehicle if the pantograph of the front vehicle does not return, and the head of the pantograph is allowed to return to the edge above the vehicle body; and when the pantograph is lowered, the pantograph can fall and return automatically. The device can realize the automation of the power connection and disconnection of the trolley bus and the automation of overtaking, and greatly improve the operation efficiency and flexibility of the trolley bus. Thus, the device has certain practical value.

Owner:JILIN UNIV

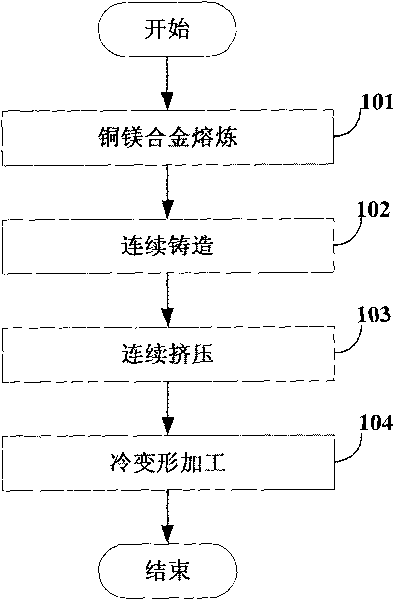

Method for preparing copper magnesium alloy contact wire

ActiveCN101710505ALow oxygenUltra-fine grain strengthening effect is lowSingle bars/rods/wires/strips conductorsTrolley linesThermal deformationHigh intensity

The invention discloses a method for preparing a copper magnesium alloy contact wire. In the method, an as-cast copper magnesium alloy structure is broken by continuous extrusion and is re-crystallized to obtain a tiny and even grain structure so as to make the copper magnesium alloy contact wire have the super fine-grain strengthening effect. The method comprises production process flows of continuous casting, continuous extrusion and cold machining molding. Compared with the conventional production process for the copper magnesium alloy contact wire, the method ensures that as-cast grains of an oxygen-free copper magnesium alloy casting pole molded by continuous casting are broken by the continuous casting and continuous extrusion processes, and are re-crystallized under the action of thermal deformation to form a copper magnesium alloy contact wire pole blank having a fine-grain structure, and the pole blank is subjected to cold machining to prepare the high-strength copper magnesium alloy contact wire having the super fine-grain strengthening effect. The production process is simple and reliable, and yield and quality completely meet the requirements of the conventional high-speed electrified railways.

Owner:CHINA RAILWAY CONSTR ELECTRIFICATION BUREAUGRP +1

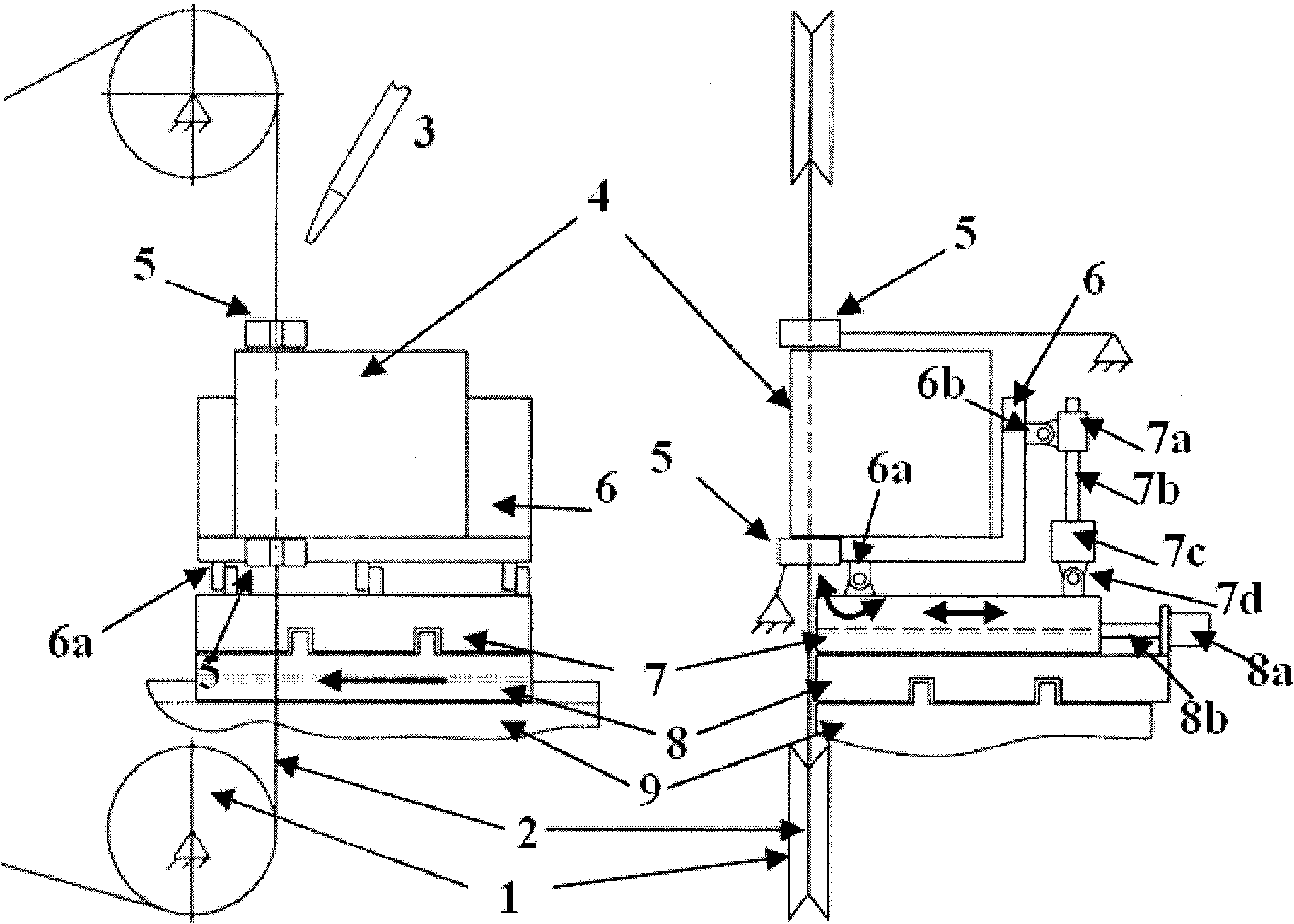

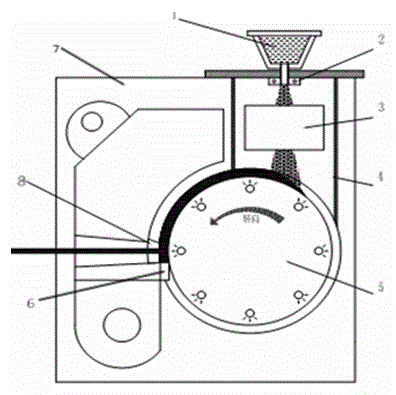

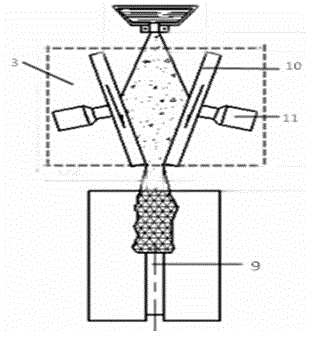

Bow net analogue test method and its special device

InactiveCN1776393ACorrectly reflect the flow qualityRailway vehicle testingContact pressureEngineering

Under condition for simulating vibration of vehicle body and dynamic action of contact line, the method carries out testing contact pressure between pantograph and bow net as well as dynamic change regulation between pantograph and contact wire. At different speed, and different operating condition of contact line, under dynamic coupling state between pantograph and contact line, the method obtains dynamic change regulation between contact pressure of bow net and vertical displacement of contact point so as to be able to estimate quality of pantograph for receiving current.

Owner:SOUTHWEST JIAOTONG UNIV

Real-time deviation correcting method for precise cutting process of diamond wire saw

InactiveCN101817209AQuick correctionAvoid wear and tearFine working devicesStone-like material working toolsTime deviationComputer control system

The invention discloses a real-time deviation correcting method for a precise cutting process of a diamond wire saw, which belongs to the technical field of precise cutting and machining of large-size artificial crystal. The method is characterized by comprising the following steps of: detecting the position offset of the diamond wire saw in real time by using a photoelectric position detecting element, and feeding back the position offset to a computer control system to control a workbench to perform corresponding position and angle adjustment so that the wire saw moves towards the direction of reducing the cutting deviation and the cutting deviation correction is realized. The method has the advantages that abrasion brought to contact detection and deviation correction of the wire saw can be avoided by adopting non-contact wire saw position detection and wire saw deviation correcting motion; and in addition, compared with a method for reducing cutting deviation by improving the precision of a machine tool, a deviation feedback-based deviation correcting strategy adopted by the invention has the advantage that: good deviation correcting effect can be achieved for wire saw precision cutting of a large-scale workpiece on the premise of not remarkably improving the manufacturing cost of a wire saw cutting system. Theoretically, the method can obtain highest deviation correcting precision of 17 microns.

Owner:DALIAN UNIV OF TECH

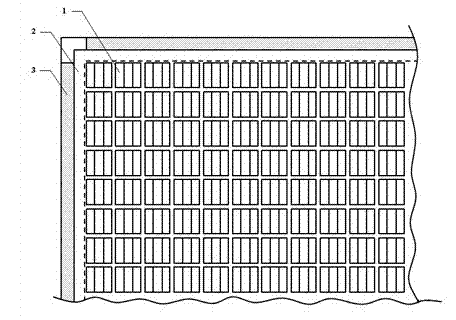

OLED (organic light emitting diode) display module and OLED spliced display screen with OLED display module

InactiveCN102832230AReduce the non-luminous areaReduce stitching gapSolid-state devicesSemiconductor/solid-state device manufacturingPrinted circuit boardLight-emitting diode

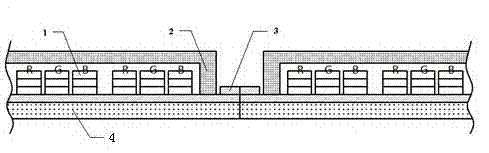

The invention relates to the display technology of organic light emitting diodes, specifically to an OLED (organic light emitting diode) display module and an OLED spliced display screen with the OLED display module. The OLED display module comprises a substrate, an OLED structure used for generating OLED luminous pixels and a packaging layer used for packaging the OLED structure; and the substrate is a PCB (printed circuit board) substrate, wherein the OLED structure is arranged on the front side of the substrate, a wiring region connected with an external driving circuit is arranged on the back side of the substrate, contact wires corresponding to the OLED luminous pixels one by one are printed on the PCB substrate, and each of the contact wires is connected with the OLED structure at the position of the corresponding OLED luminous pixel, and is connected with the wiring region through the PCB substrate. According to the invention, a PCB is used as the substrate rather than a glass plate, and the existing non-luminous wiring region on the edge of the device is moved to the back side of the PCB substrate through leads of the contact wires, so that the non-luminous area of the device can be reduced, the splicing gap of the OLED spliced display screen spliced from the OLED display module can be greatly reduced, and the display effect of the screen can be well optimized.

Owner:GUANGDONG VTRON TECH CO LTD

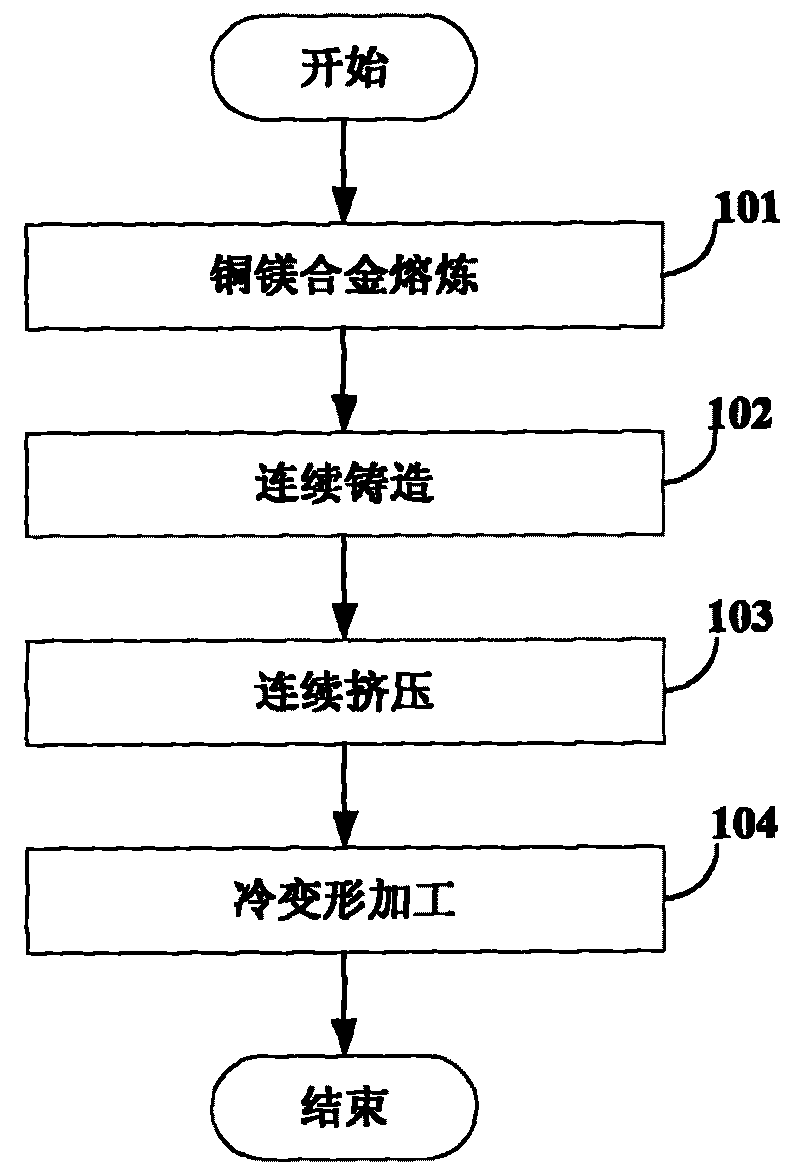

Preparation method of copper and magnesium alloy contact wire for railway electrification

ActiveCN103276237AIncrease production capacityReduce the temperatureSingle bars/rods/wires/strips conductorsMetal/alloy conductorsMisch metalNiobium

A copper and magnesium alloy contact wire for railway electrification comprises a copper base and alloy metal, wherein the alloy metal comprises components in percentage by weight as follows: 0.5-0.6% of magnesium, 0.012-0.014% of zirconium, 0.012-0.014% of niobium, 0.005-0.008% of titanium and 0.02-0.04% of misch metal. A preparation technology adopts an upward continuous casting extrusion-cold rolling-stretching technology. The oxygen content of the prepared contact wire reaches an oxygen-free copper level, the grain is fine, the mechanical property is remarkably improved, the contact wire is uniform in a length direction, the flatness is good, the locomotive picking-up performance is good, the tensile strength, the elongation percentage, the grain size and the toughness are greatly improved when the copper and magnesium alloy contact wire is compared with a conventional wire, and the copper and magnesium alloy contact wire has wide popularization and application values in the high-speed railway electrification field.

Owner:山东维点技术有限公司

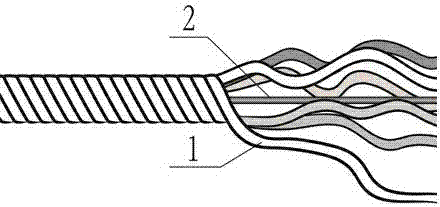

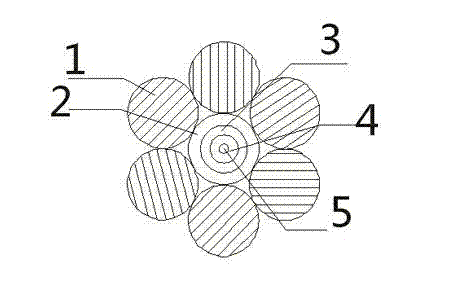

Metal-based cable-like distributed optical fiber sensor

InactiveCN102288125AImprove the coupling effectImprove the delivery effectThermometers using physical/chemical changesUsing optical meansWire rodAnalyte

Metal-based cable-shaped distributed optical fiber sensor, the central sensing fiber with a sheath is twisted and wrapped around the core by six surrounding metal wires to form a metal-based cable distributed optical fiber sensor. In particular, the sensing optical fiber with the sheath has the same diameter as the metal wire, and is in tight contact with the surrounding 6 metal wires. The outer steel wire bundle is wrapped around the central sensing optical fiber in a helical form, and the central sensing optical fiber is kept straight and not entangled. The optical fiber (cable) located in the center of the cable is tightly wound helically by six steel wires with matching diameters to form a metal cable body that can directly sense strain and temperature. The sensing optical cable of this structure not only senses the close contact between the optical fiber and the peripheral reinforced steel wire and the object to be measured, but also realizes the distributed monitoring of the stress and strain of the steel wire and the surrounding object to be monitored, and uses high-strength steel wire to protect the delicate The fragile sensing optical fiber has significantly improved its tensile strength, impact resistance and bending resistance.

Owner:SUZHOU NANZEE SENSING TECH

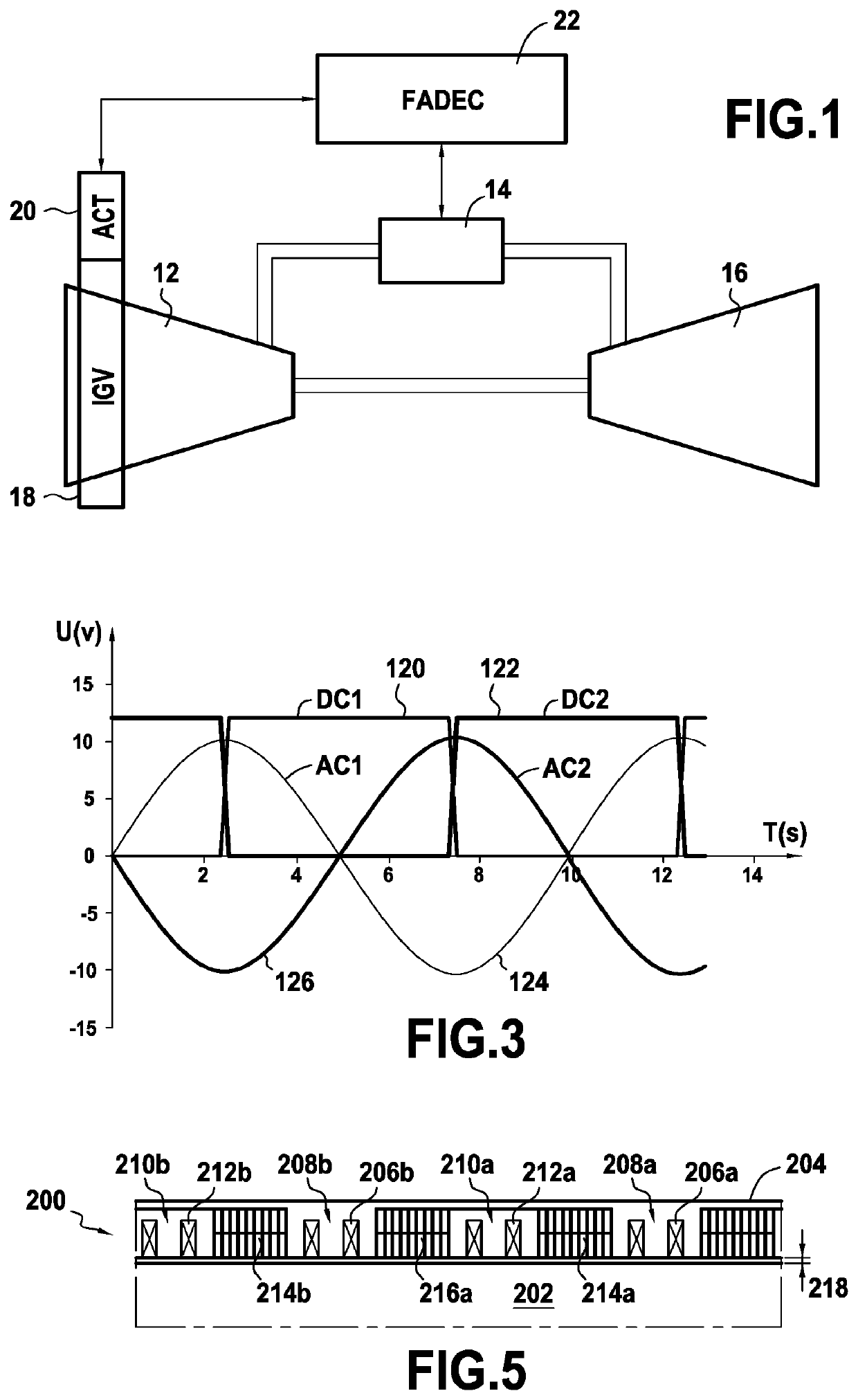

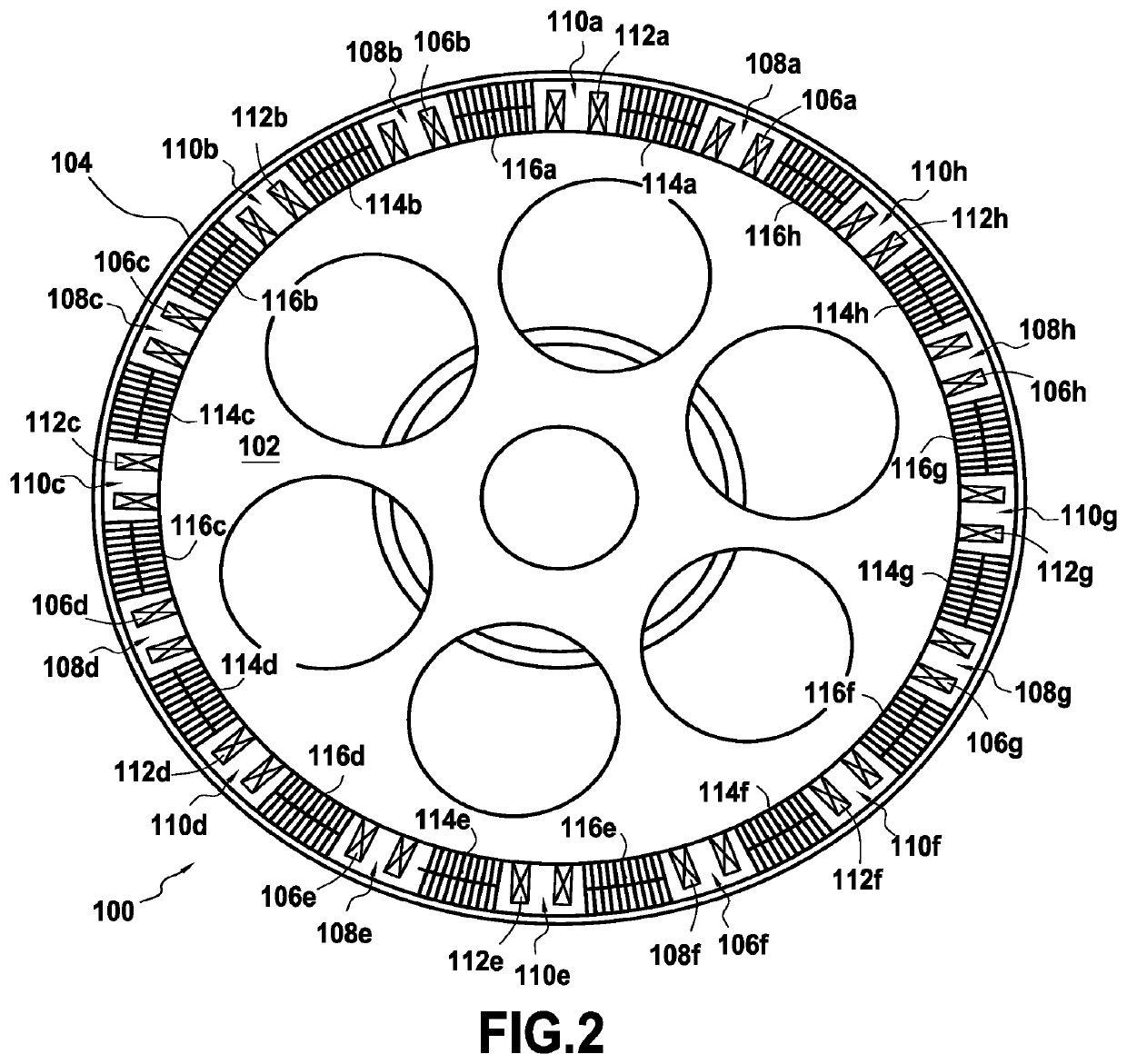

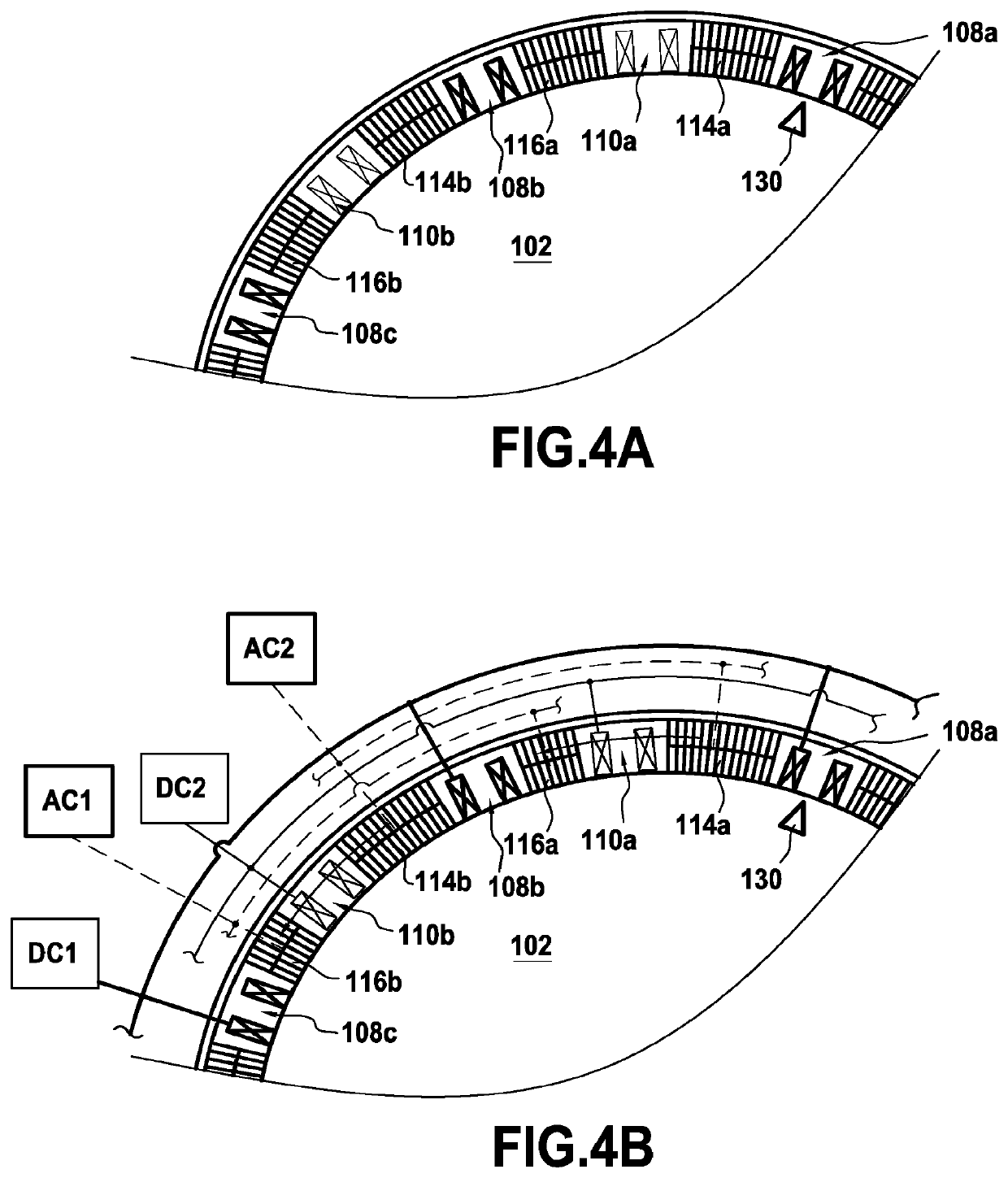

Device for controlling inlet guide vanes by means of a multilayer piezoelectric actuator

ActiveUS10731504B2Safe behaviorGas turbine plantsEfficient propulsion technologiesPiezoelectric actuatorsCommon line

An electric actuator for inlet guide vanes of a gas turbine engine, the electric actuator including a fixed portion secured to a stationary portion of the engine and a movable portion that is mechanically connected to the inlet guide vanes, stationary electromagnets distributed at regular intervals around the periphery of the movable portion and fastened to the fixed portion, and movable electromagnets arranged between the stationary electromagnets, each movable electromagnet being secured on either side to first and second piezoelectric elements, the movable electromagnets and the first and second piezoelectric elements having a degree of freedom of movement relative to the movable portion and having inside faces forming a common line of contact that is tangential to the movable portion.

Owner:SAFRAN HELICOPTER ENGINES

Highly wear resistant copper silver alloy contact wire and production method thereof

ActiveCN102867595ASolve the brittleness problemImprove wear resistanceMetal/alloy conductorsCable/conductor manufactureIndiumWear resistant

The invention relates to a highly wear resistant copper silver alloy contact wire which is characterized in that in the highly wear resistant copper silver alloy contact wire, copper content is higher than or equal to 99.75% (percentage by weight), silver content is 0.08-0.10% (percentage by weight), indium content is 0.005-0.006% (percentage by weight), and tellurium content is 0.0008-0.010% (percentage by weight). The production method comprises the following processing steps: smelting in a vacuum melting furnace for the first time; smelting in a main frequency furnace for the second time; and then performing upward continuous casting, continuous extrusion, multi-roll rolling, and cold drawn molding to form the contact wire. According to the invention, the highly wear resistant copper silver alloy contact wire prepared by the method can meet the strength requirement and conductive performance of a high speed electric railway, and the service life can be prolonged.

Owner:JIANGYIN ELECTRICAL ALLOY

Vehicle steering wheel

InactiveUS20050161308A1Compact and simple to installReduce the overall heightAcoustic signal devicesPedestrian/occupant safety arrangementSteering wheelEngineering

A vehicle steering wheel comprises a steering wheel skeleton, a longitudinal axis, at least two components movable relative to each other, and a horn contact switch, which has two electrical contact elements which are brought in contact with each other by means of a relative movement of the two components to each other for a horn actuation. The electrical contact elements are contact wires.

Owner:TRW AUTOMOTIVE SAFETY SYST

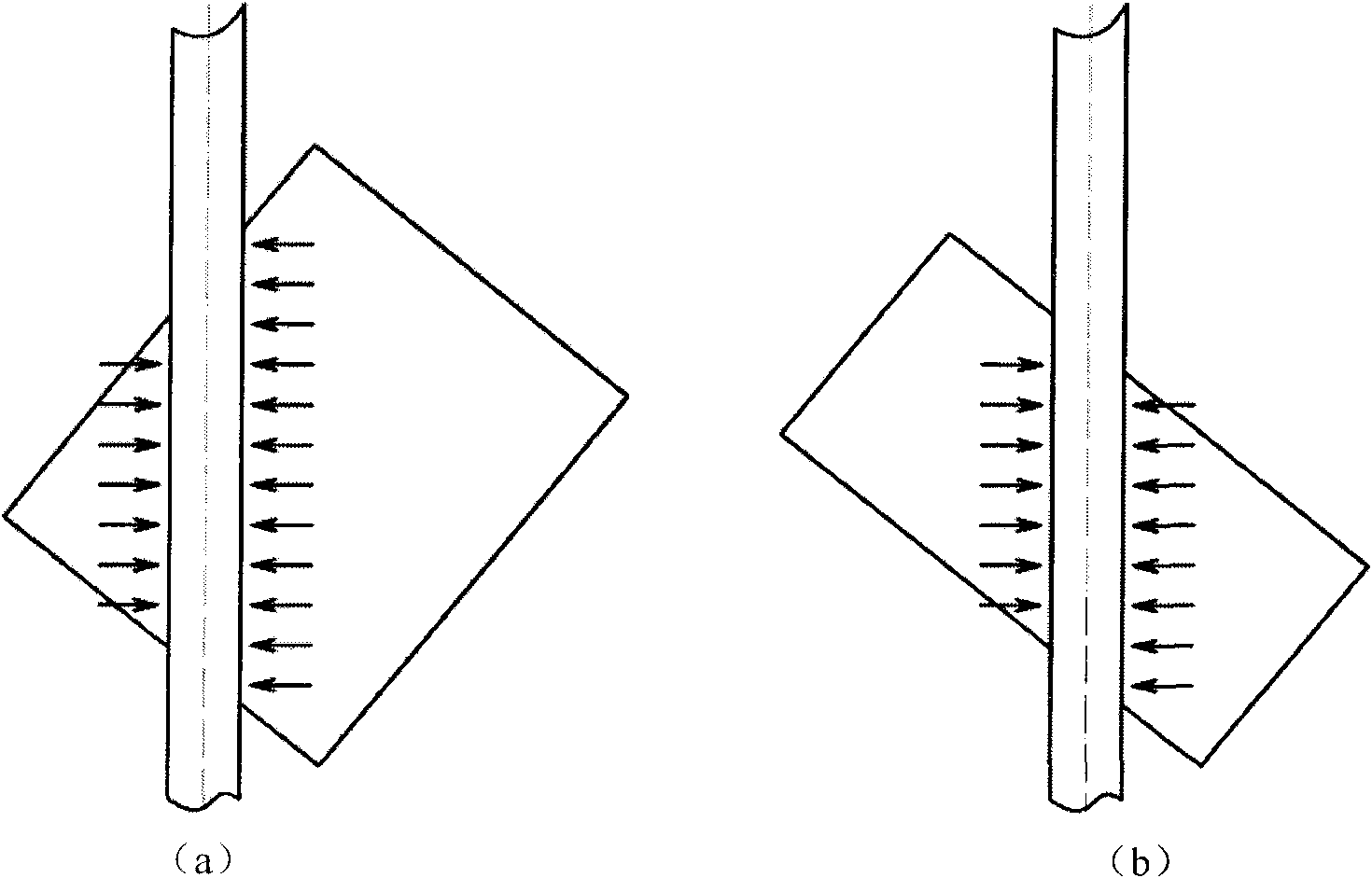

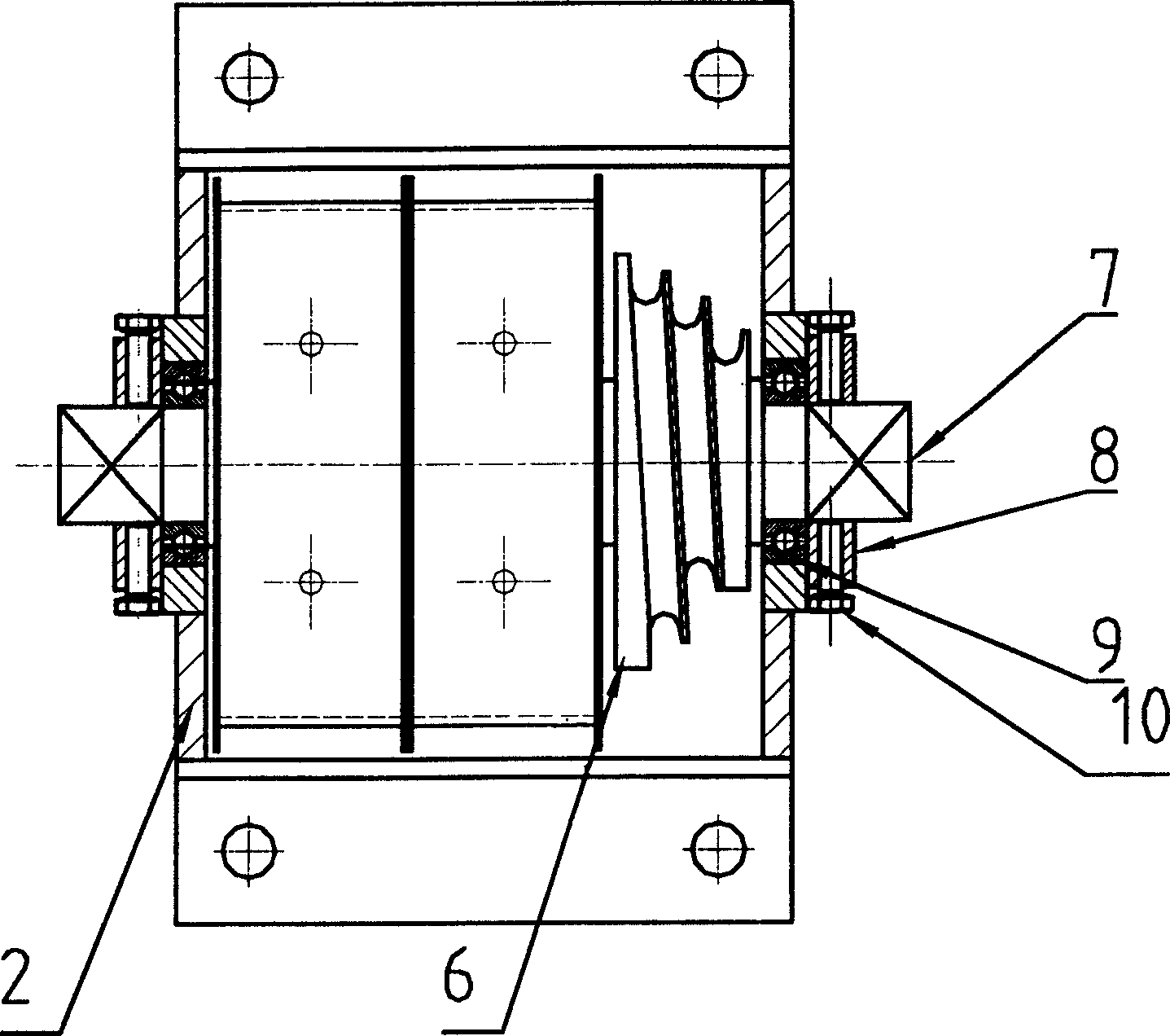

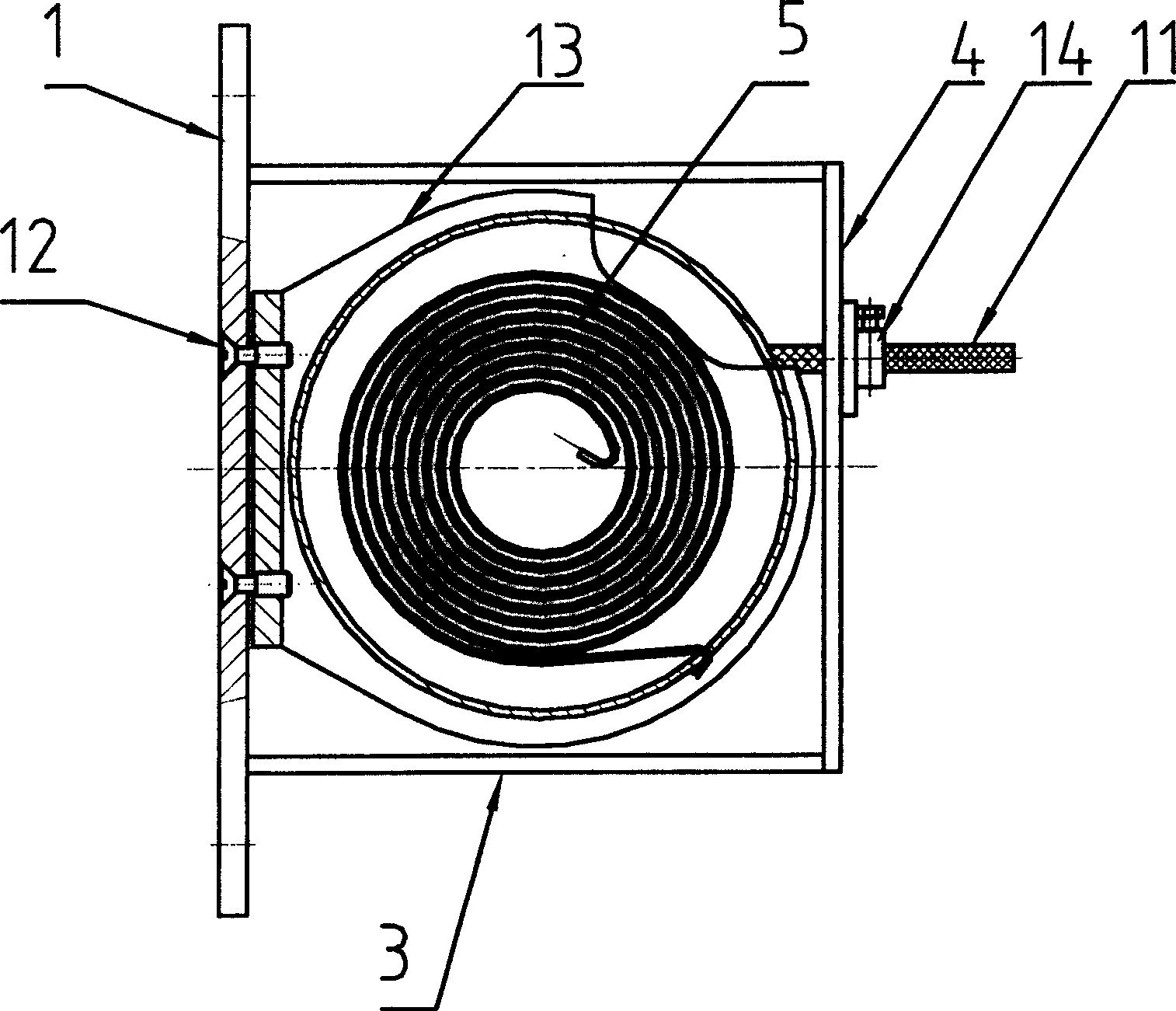

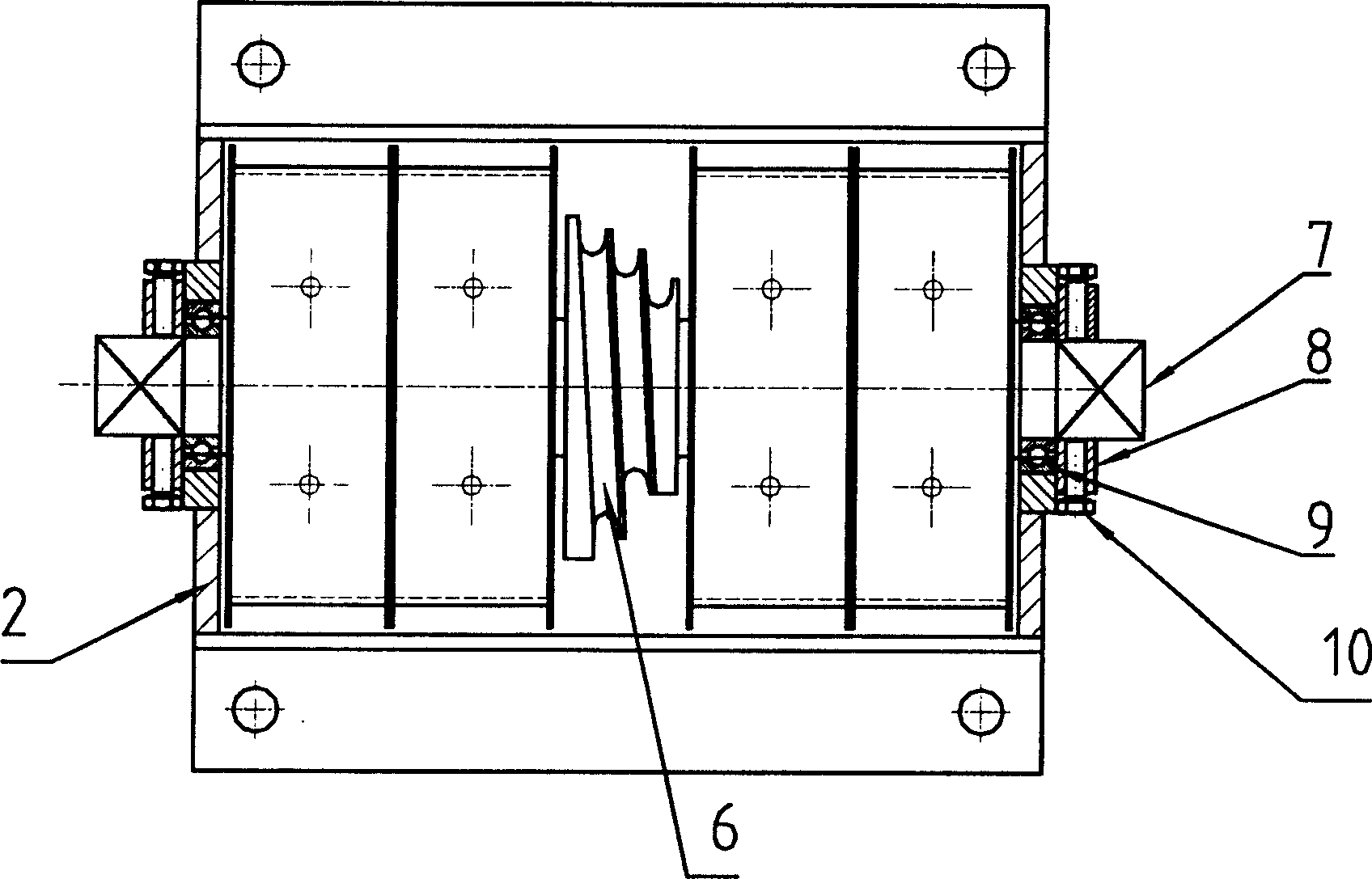

Tension constant compensation device

InactiveCN1663839ACompact structureReduce volumeTrolley linesRailway electrification systemContact wire

The invention relates the constant tension compensation equipment, and belongs to the electrolyzed railway power supply technology field. The equipment comprises the spring on the substrate, and the said spring is the constant turning rule or linear changeable turning rule plane turbination spring with one end fixed opposite to the substrate and the other to the main shaft; the said main shaft is supported on the substrate and the shaft is rigidly set with the crown chute, the screw chute, the linear chute that are enwound by the steel wire lines. When the stress cable and the contacting wire lead the length change as the environmental temperature changing, the matching group of the springs and the chutes can be compensatively adjusted through the tension of the springs and maintain the constant tension on the stress cable and the contacting wires so as to meet the demand of the electrolyzed railway engineering. The invention has the strong points of tight structure, small volume, light weight and convenient equipment.

Owner:YANGZHOU DONGFANG HANGER FRAME CO LTD

Preparation method of Cu-Cr-Zr alloy contact wire

ActiveCN105039883AImprove performanceReduce segregationCable/conductor manufactureStructure propertyUltimate tensile strength

The invention discloses a preparation method of a Cu-Cr-Zr alloy contact wire, and belongs to the technical field of copper alloy processing and preparation. The contact wire with a cross section area of 110 to 150 mm2 is prepared through steps of melting, spray deposition and continuous extrusion, planetary rolling, aging, and drawing. In the provided method, the product structure property and overall dimension can be controlled in one technology. The Cu-Cr-Zr alloy contact wire prepared by the spray deposition and continuous extrusion method has the advantages of high strength, good conductivity, and excellent high temperature softening resistant property. The preparation method has the advantages that the process flow is short, the material utilization rate is high, the product performance can be guaranteed, at the same time, the production cost is reduced, the contact wire can be made into any length in theory, and the contact wire is suitable for industrial application.

Owner:北京兴荣源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com