Patents

Literature

70results about How to "Reduce stitching gap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

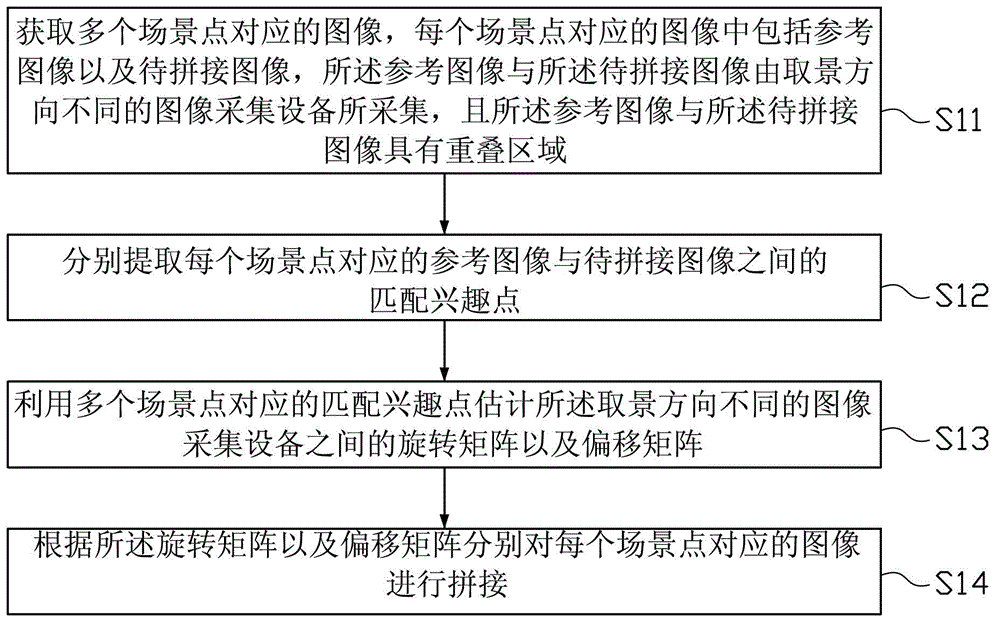

Image stitching processing method and device

ActiveCN103150715AImprove stitching qualityReduce stitching gapImage enhancementGeometric image transformationExternal referenceReference image

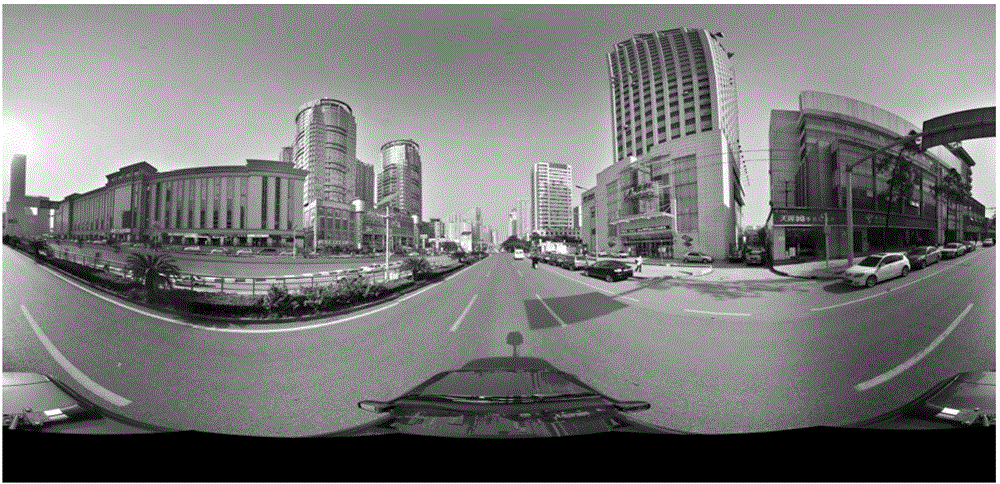

The invention provides an image stitching processing method and device. The method comprises the following steps of: acquiring images which correspond to multiple scene points, wherein an image which corresponds to each scene point comprises a reference image and to-be-stitched images, the reference image and the to-be-stitched images are acquired by different image acquisition devices in the view direction, and the reference image and the to-be-stitched images have overlap areas; respectively extracting matching interest points between the reference image and the to-be-stitched images which correspond to each scene point; estimating rotation matrixes and offset matrixes among the different image acquisition devices in the view direction by utilizing the matching interest points which correspond to the scene points; and respectively stitching the images which correspond to all the scene points according to the rotation matrixes and the offset matrixes. According to the image stitching processing method and device provided by the invention, external references of the image acquisition devices are estimated by utilizing the matching interest points of the images which correspond to the scene points to stitch the images which correspond to all the scene points, and therefore, errors brought by the image acquisition devices can be more equally dispersed, and the stitching quality of the images is improved.

Owner:SHENZHEN TENCENT COMP SYST CO LTD

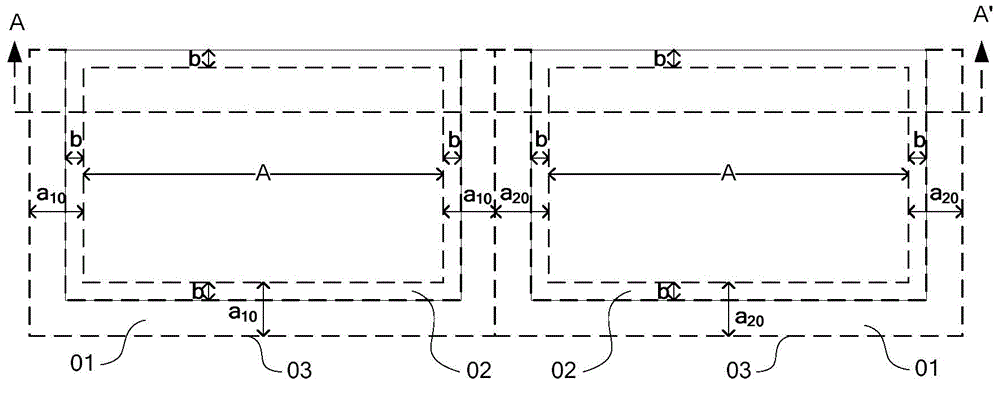

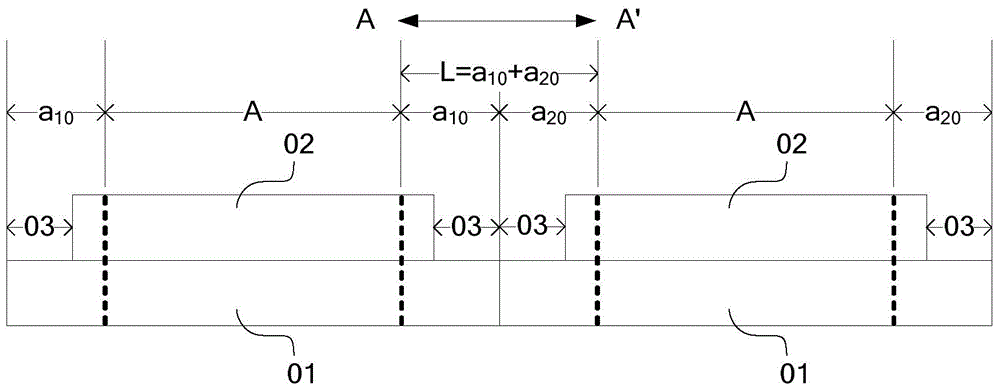

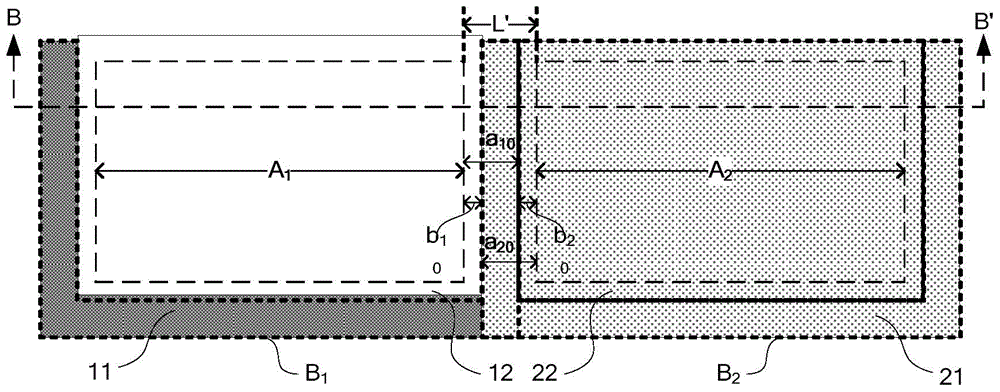

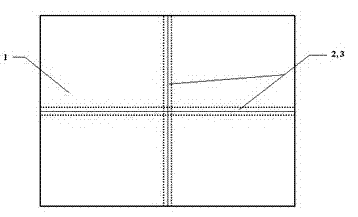

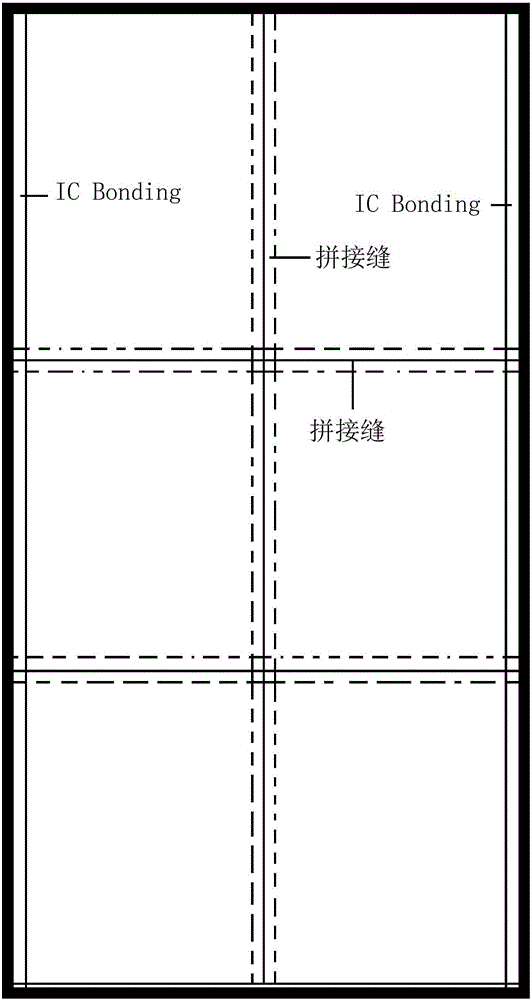

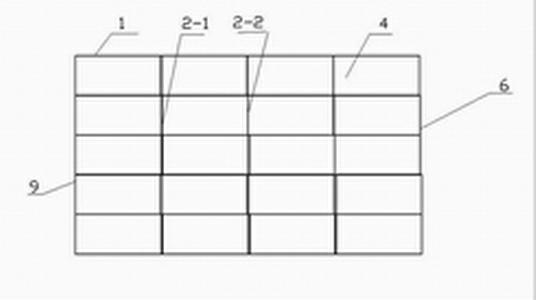

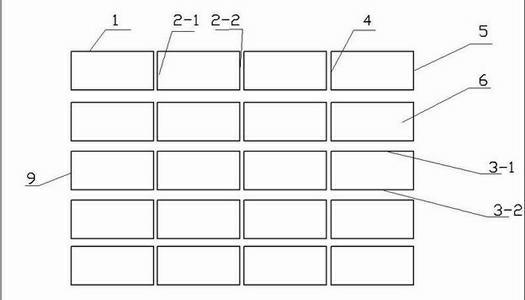

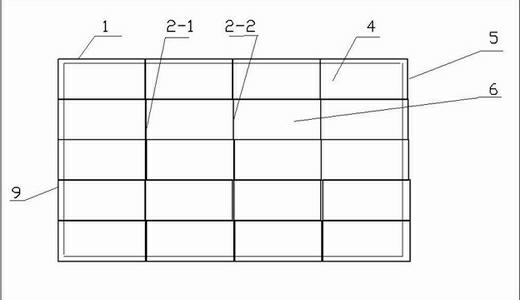

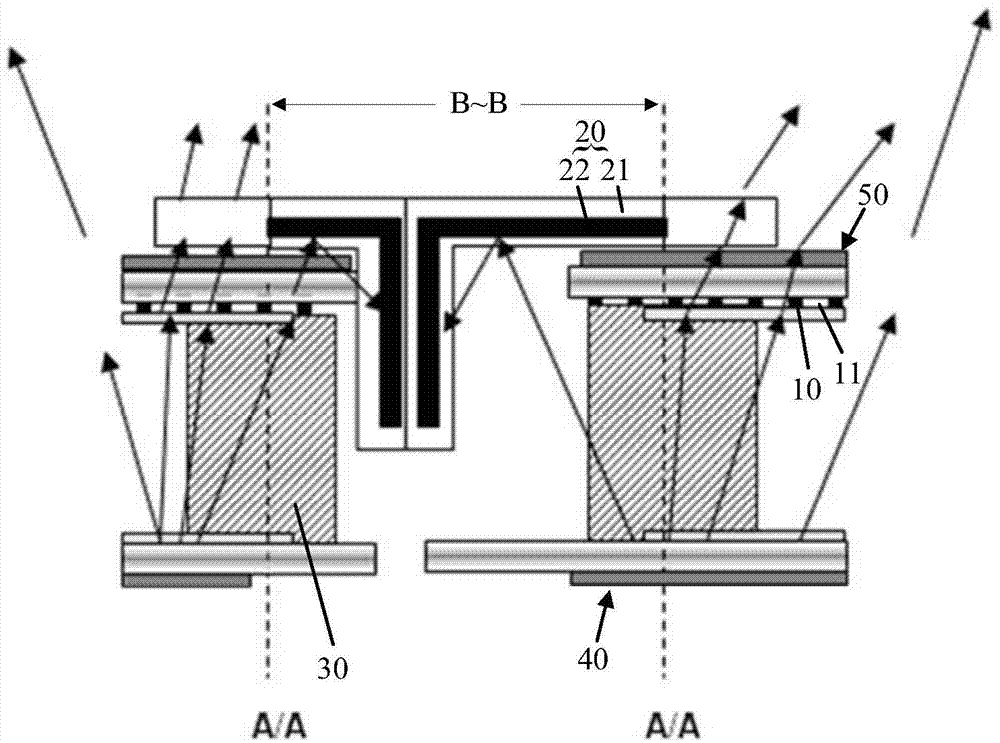

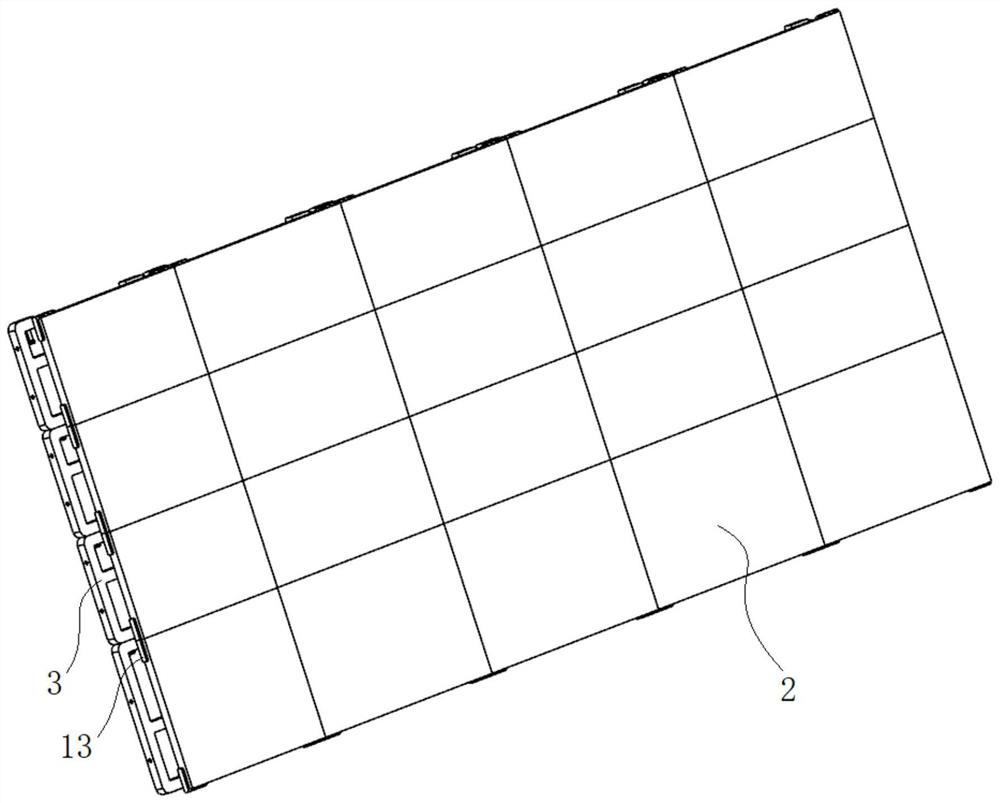

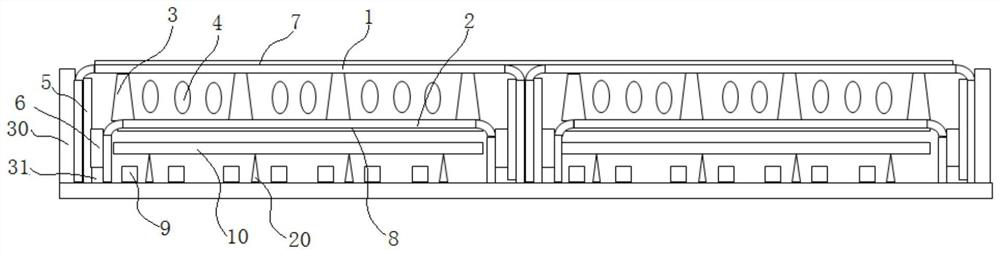

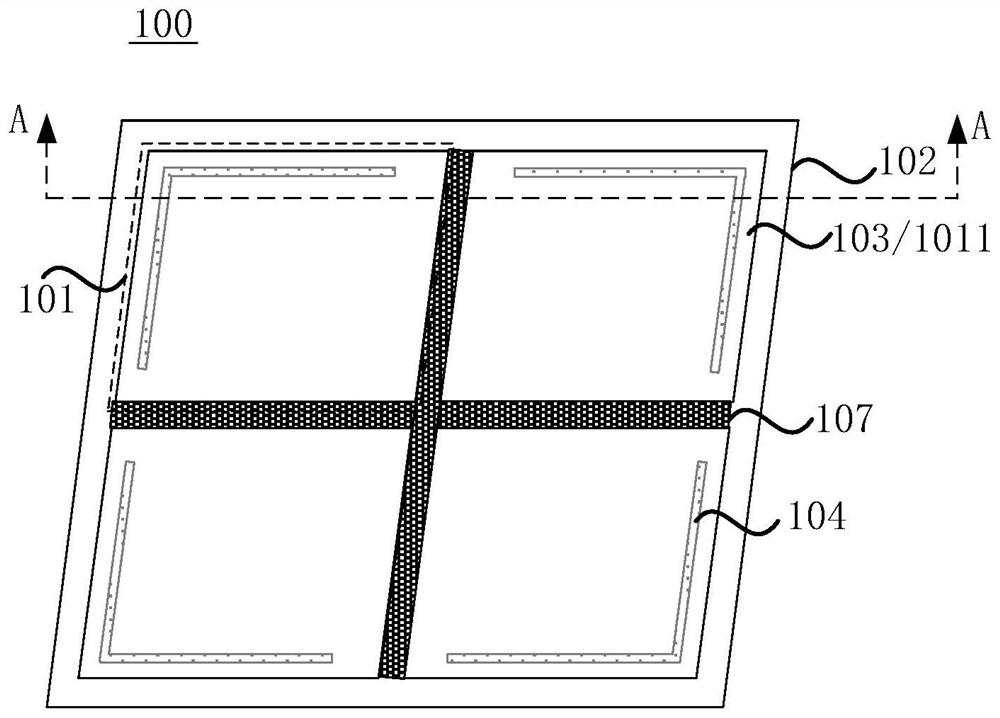

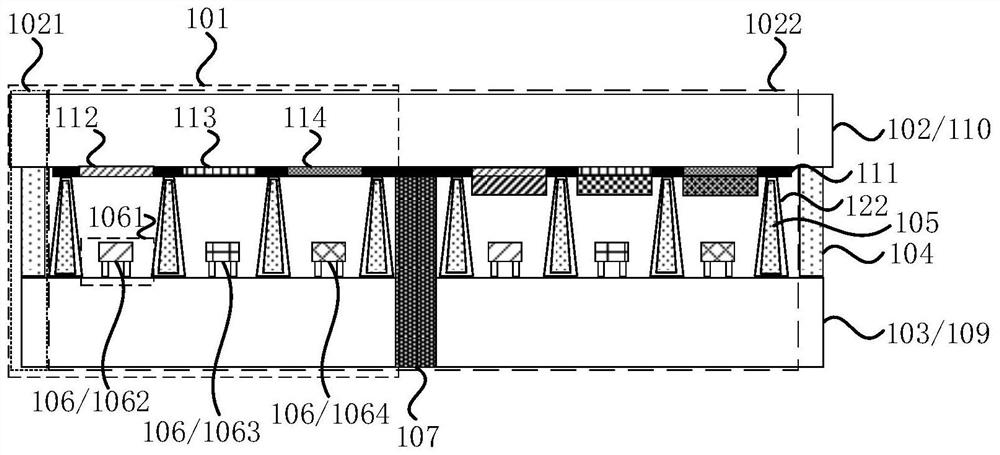

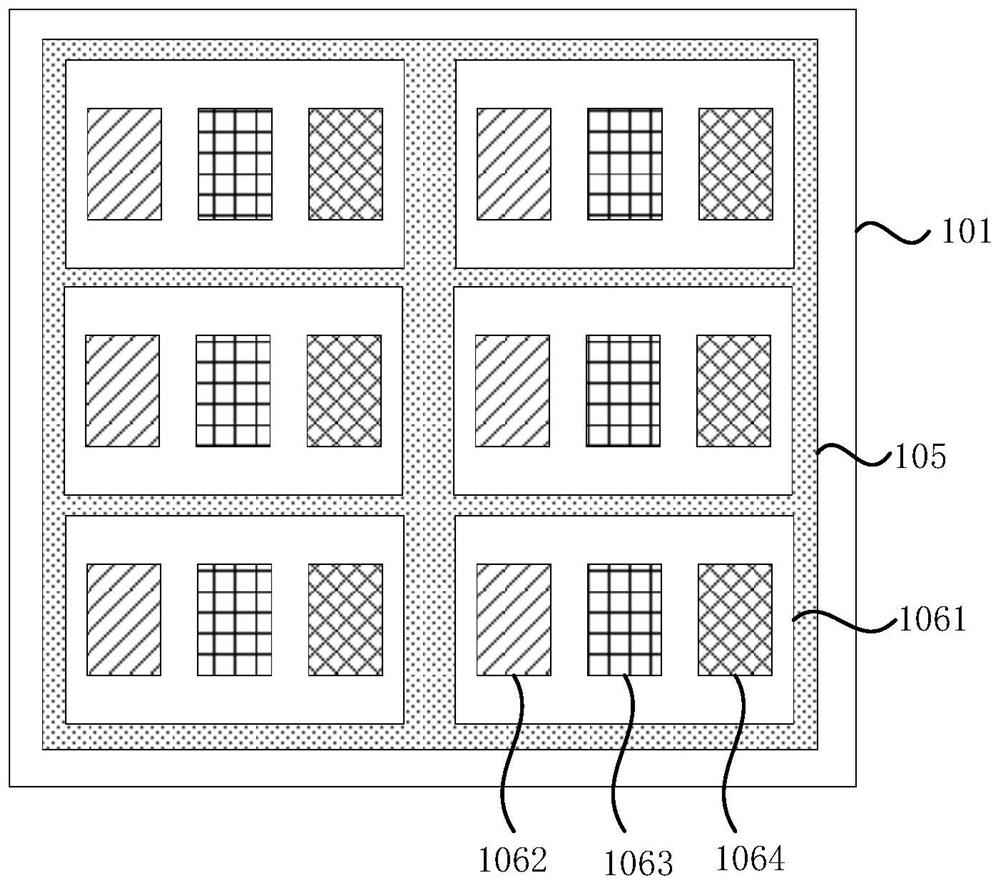

Tiled display panel and display device

ActiveCN104090405AReduce stitching gapReduce distanceNon-linear opticsDisplay deviceComputer science

The embodiment of the invention provides a tiled display panel and a display device and relates to the technical field of display. By the adoption of the tiled display panel and the display device, the edge joint width of the tiled display panel can be reduced, and display effect can be improved. The tiled display panel comprises a first display panel part and a second display panel part. The first display panel part comprises a first substrate and a second substrate, wherein the first substrate comprises a first display area and a first non-display area, the first non-display area comprises first wiring bonding areas, the second substrate is exposed from the first wiring bonding areas, and the first wiring bonding areas are distributed on the two opposite sides of the second substrate at least. The second display panel part comprises a third substrate and a fourth substrate, wherein the third substrate comprises a second display area and a second non-display area, the second non-display area comprises second wiring bonding areas, the fourth substrate is exposed from the second wiring bonding areas, and the second wiring bonding areas are distributed on the two opposite sides of the fourth substrate at least. The first wiring bonding areas of the first substrate correspond to the second wiring bonding areas close to the third substrate.

Owner:BOE TECH GRP CO LTD

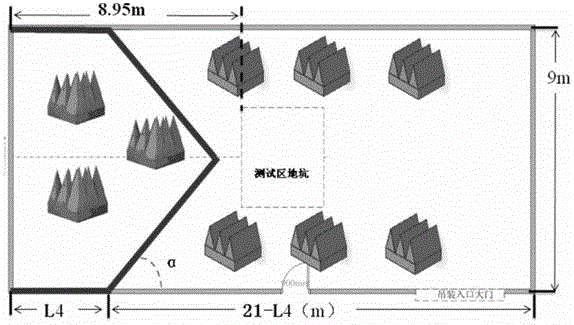

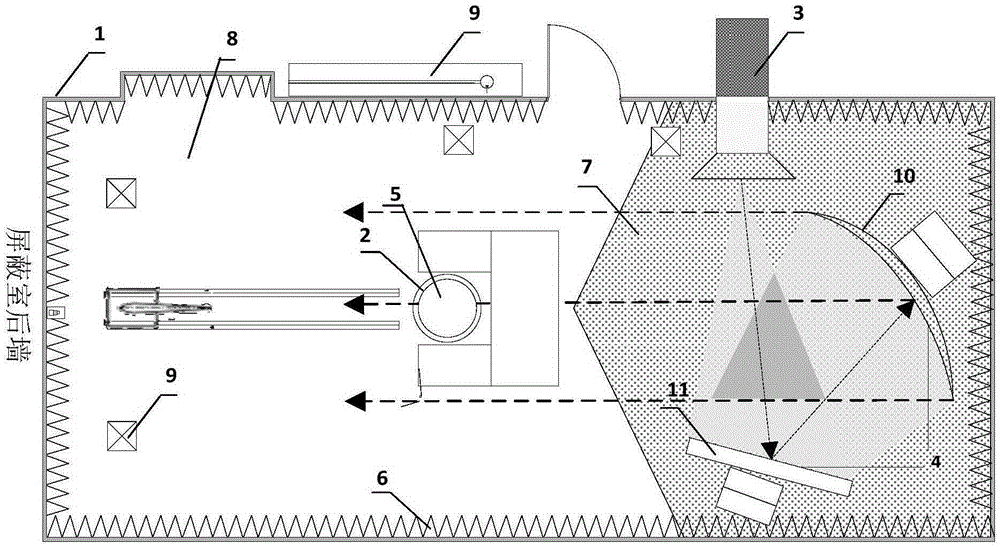

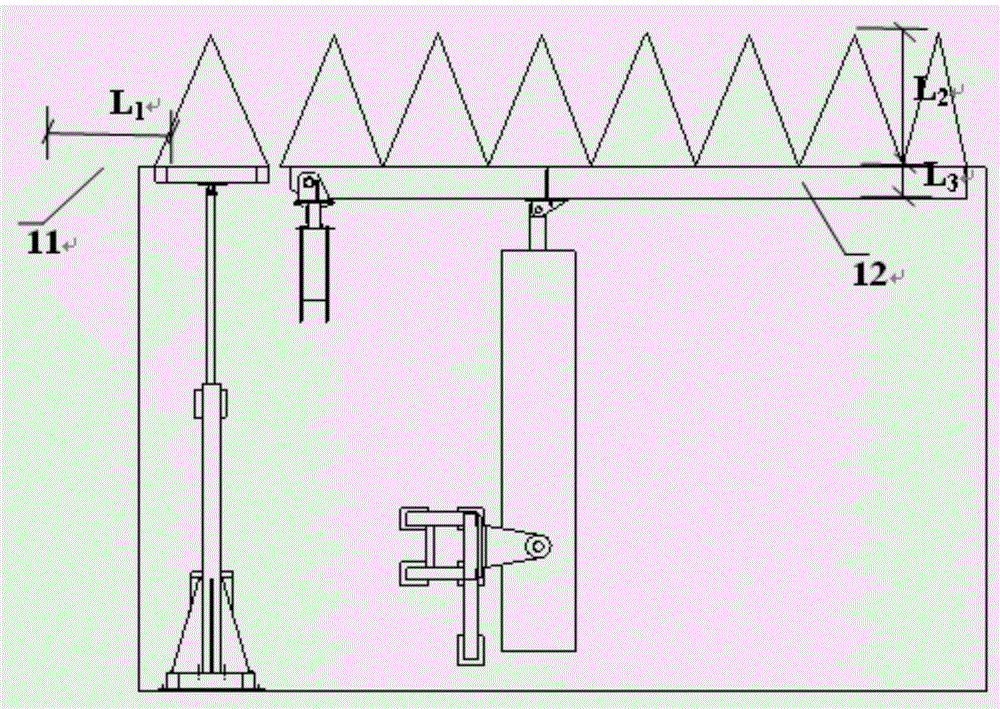

Ultralow ambient level microwave unreflected chamber used for RCS testing

ActiveCN105242249AReduce stitching gapGood background consistencyWave based measurement systemsMicrowaveEngineering

The invention belongs to the scope of low RCS ambient microwave unreflected chamber and particularly relates to an ultralow ambient level microwave unreflected chamber used for RCS testing. The microwave unreflected chamber is composed of shielding walls, a rotary table, a feed source system, metal reflecting surfaces, a support and wave-absorbing materials. The microwave unreflected chamber conducts electromagnetic shielding on a lifting platform and a hoisting mechanism through a metallic shielding cover plate, and the cylindrical support made of foamed materials is fixed to the rotary table, so that the support can just penetrate through a circular hole in the cover plate. The cover plate can be driven to be opened and closed by a motor automatically. According to the ultralow ambient level microwave unreflected chamber, a shielding overturned plate system and an electrically-controlled shielded gate system are adopted, in the opening and closing processes of the shielding overturned plate system and the electrically-controlled shielded gate system, the wave-absorbing materials do not need to be removed, the wave-absorbing materials are small in splicing gap, in the retest process, background consistency is good, it is favorable to improve testing precision, and the chamber can be widely applied to construction of low ambient level microwave unreflected chambers.

Owner:BEIJING RES INST OF MECHANICAL & ELECTRICAL TECH

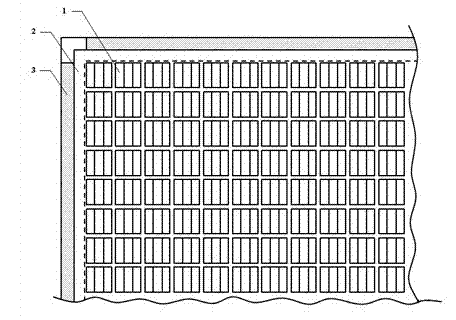

OLED (organic light emitting diode) display module and OLED spliced display screen with OLED display module

InactiveCN102832230AReduce the non-luminous areaReduce stitching gapSolid-state devicesSemiconductor/solid-state device manufacturingPrinted circuit boardLight-emitting diode

The invention relates to the display technology of organic light emitting diodes, specifically to an OLED (organic light emitting diode) display module and an OLED spliced display screen with the OLED display module. The OLED display module comprises a substrate, an OLED structure used for generating OLED luminous pixels and a packaging layer used for packaging the OLED structure; and the substrate is a PCB (printed circuit board) substrate, wherein the OLED structure is arranged on the front side of the substrate, a wiring region connected with an external driving circuit is arranged on the back side of the substrate, contact wires corresponding to the OLED luminous pixels one by one are printed on the PCB substrate, and each of the contact wires is connected with the OLED structure at the position of the corresponding OLED luminous pixel, and is connected with the wiring region through the PCB substrate. According to the invention, a PCB is used as the substrate rather than a glass plate, and the existing non-luminous wiring region on the edge of the device is moved to the back side of the PCB substrate through leads of the contact wires, so that the non-luminous area of the device can be reduced, the splicing gap of the OLED spliced display screen spliced from the OLED display module can be greatly reduced, and the display effect of the screen can be well optimized.

Owner:GUANGDONG VTRON TECH CO LTD

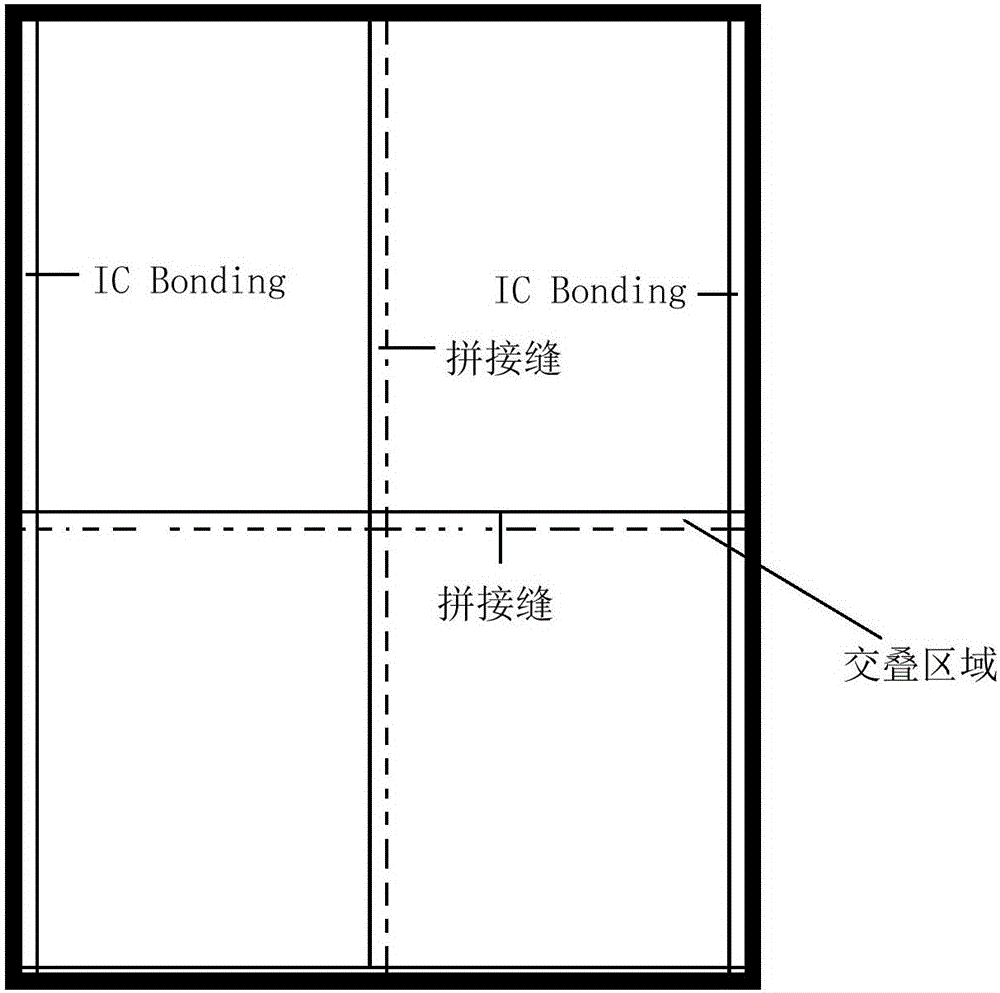

Display device

InactiveCN105788464AImprove stabilityReduce stitching gapIdentification meansDisplay deviceComputer science

The invention discloses a display device.The display device comprises a first display panel and a second display panel.The second display panel and the first display panel are arranged on different layers and are adjacently spliced, and a non-display area of the second display panel and a non-display area of the first display panel intersect and overlap to form an overlapping area.According to the display device, the effects of reducing a splicing seam and improving the stability of a spliced display screen at the same time are achieved.

Owner:BOE TECH GRP CO LTD

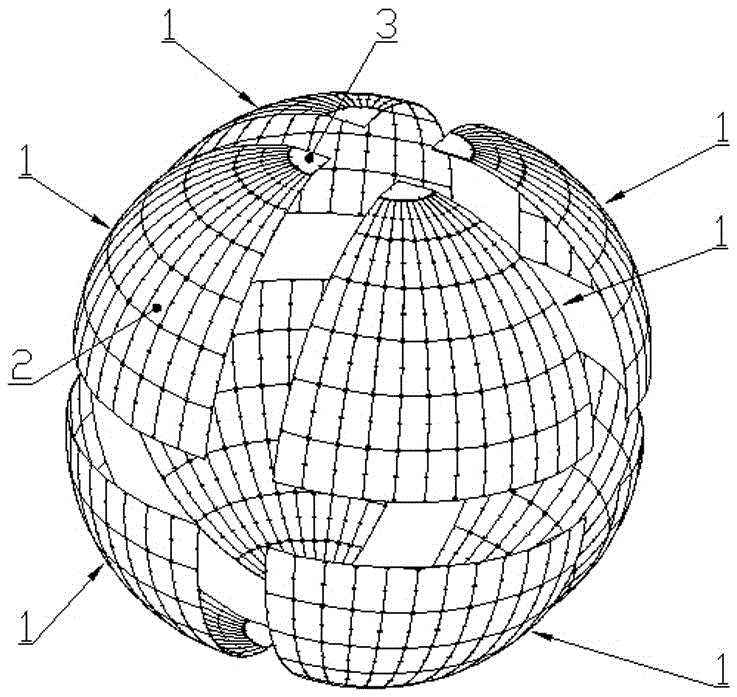

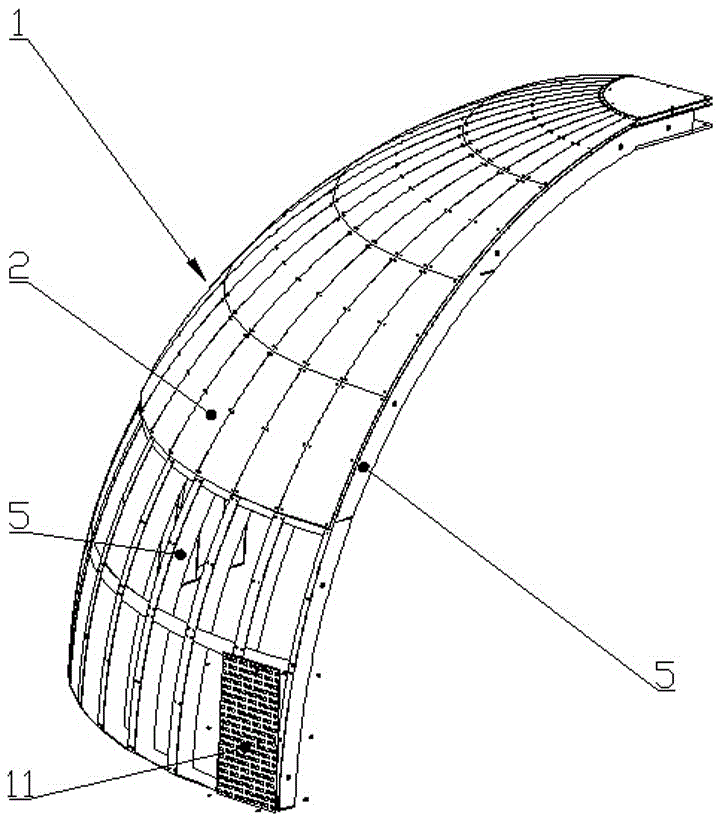

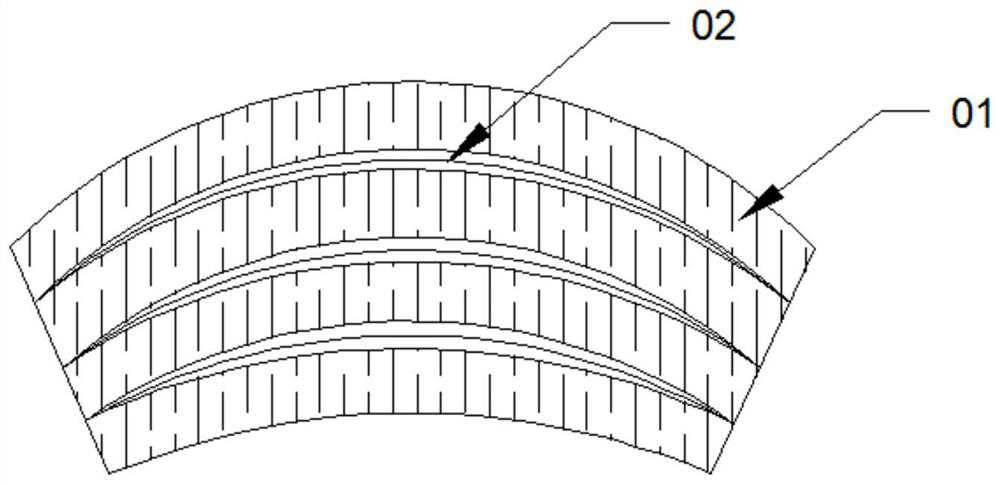

Cylindrical-surface spliced spherical dot-matrix display screen

The invention provides a cylindrical-surface spliced spherical dot-matrix display screen. The display screen comprises display panels which are divided according to longitude lines and latitude lines and adjacently spliced on a spherical surface, the display panels are each shaped like a cylindrical surface which is bent along the spherical surface in the longitudinal direction, and spliced latitudinal edge lines of the display panels on the spherical surface in the bending direction are intersecting lines. Fine-tuning studs are arranged between the display panels and installation beams, and splicing gaps of the display panels can be reduced by properly selecting the length of the fine-tuning studs. The cylindrical-surface spliced spherical dot-matrix display screen has the advantages that the bent planar display panels are mutually spliced on the spherical surface in the shapes of cylindrical surfaces in an intersecting line mode, and splicing of the display panels can be more compact; by means of the fine-tuning studs, the display panel splicing gaps caused by manufacturing errors are reduced; in this way, the precisely manufactured watermelon-peel type spherical dot-matrix display screen is compact in appearance splicing, good in appearance effect, simple in structure and easy to manufacture and maintain.

Owner:潘尚法

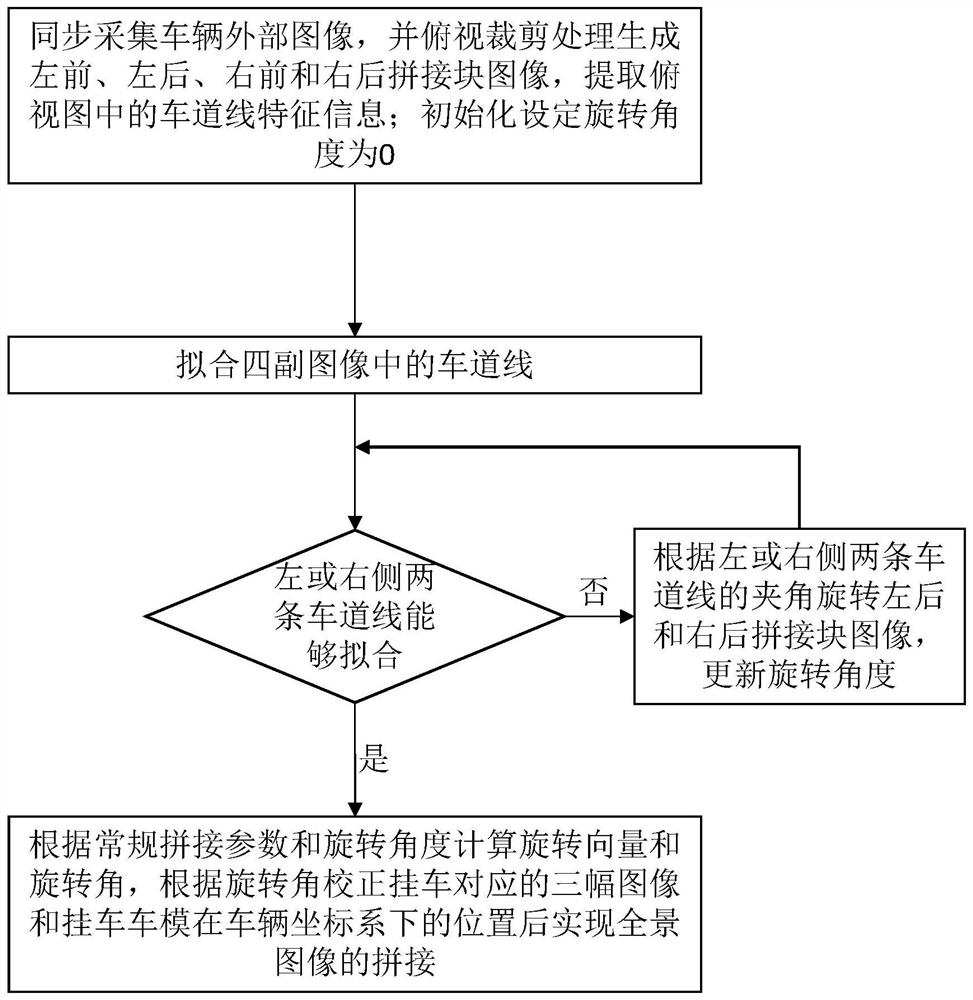

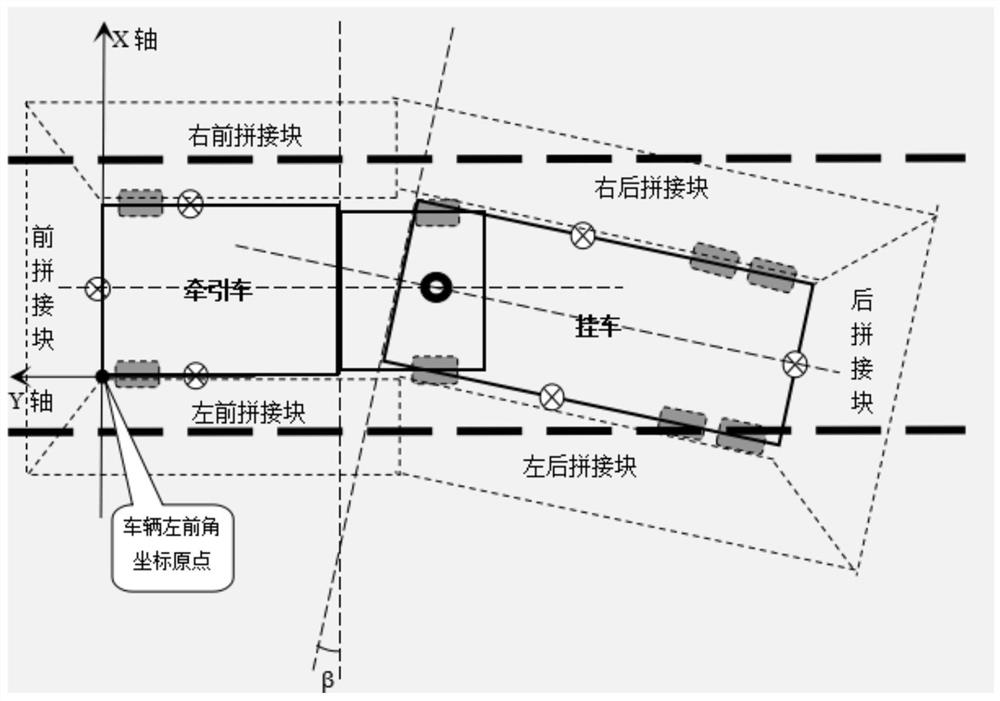

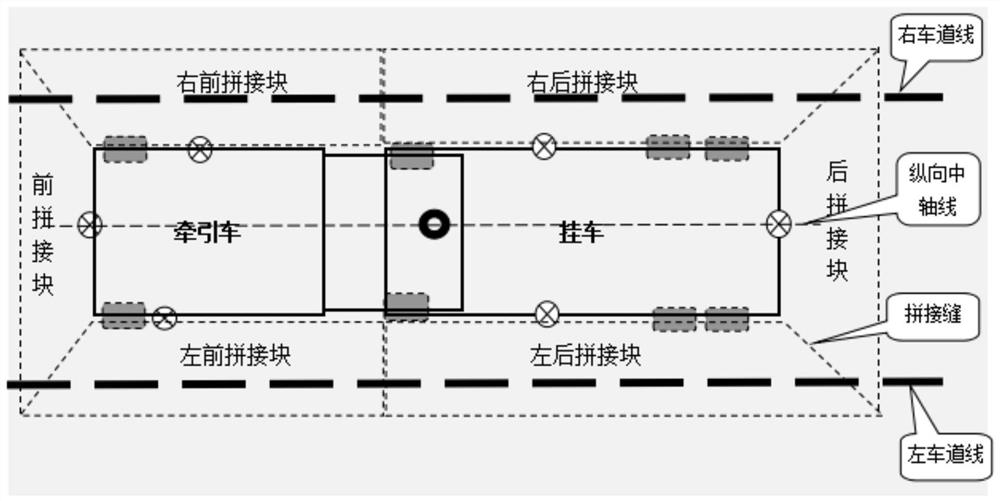

Panoramic image splicing method and device, storage medium and display method and system

PendingCN112348741AHigh precisionForward-lookingImage enhancementImage analysisReal time analysisComputer graphics (images)

The invention relates to a panoramic image splicing method and device, a storage medium and a display method and system, and the method comprises the steps: collecting left and right side pavement scene images in a vehicle driving process through left and right side cameras assembled in a panoramic look-around system, and obtaining a panoramic image through the computer vision and image processingtechnology; analyzing and extracting lane line feature information in the left and right road surface images in real time, fitting lane lines of the left and right spliced block images, rotating thespliced image according to an included angle formed by the lane lines on the same side to enable the spliced image to be fitted into a curve, correcting the spliced block images according to the rotating angle, and splicing the panoramic image. The method has the advantages of being easy to implement, high in image splicing gap accuracy, prospective, high in real-time performance, high in practicability, stable, reliable, free of additional accessories and good in application value and economic benefit.

Owner:明见(厦门)技术有限公司

Electrotype splicing method

The invention relates to an electrotyping technology in holographic anti-counterfeiting printing, in particular to an electrotype splicing method, in which a large-area holographic nickel plate with high positioning precision and an optional area is formed by unit nickel plates through splicing. The unit nickel plates are obtained through replication, and medium viscosity protective film is adhered to the front surface of each unit nickel plate; any two opposite edges of each unit nickel plate are evenly cut by a plate cutter according to identical specifications; the cut edges are spliced linearly by hand, and the joints are connected through adhesive tape, so as to form a unit group; the other pair of opposite edges of each unit group is cut by the plate cutter according to the identical specifications, so that the upper and the lower edges of each unit group are evenly cut, and a large plate can be formed by the unit groups through splicing; and the plate joints on the back of the large plate are pasted through special electrotyping tape, the medium viscosity protective film is torn off, and the large plate is connected through electrotyping. The electrotype thickness is required to be above 100 microns, the connection strength is guaranteed, the splicing quality and efficiency are improved, effects from human factors are reduced, the edge cutting is controlled, fixed reserved edges are kept, and the cutting precision is ensured.

Owner:HUBEI LHTC ANTI COUNTERFEITING TECH CO LTD

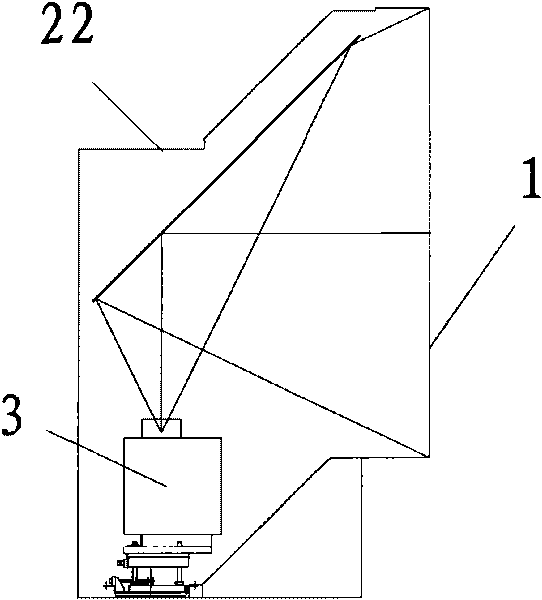

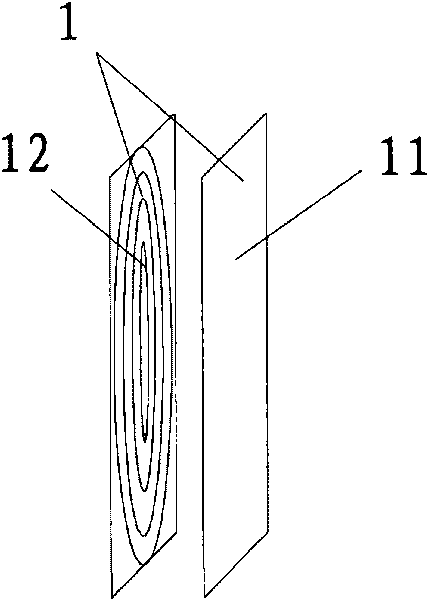

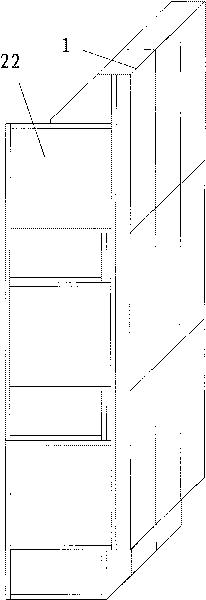

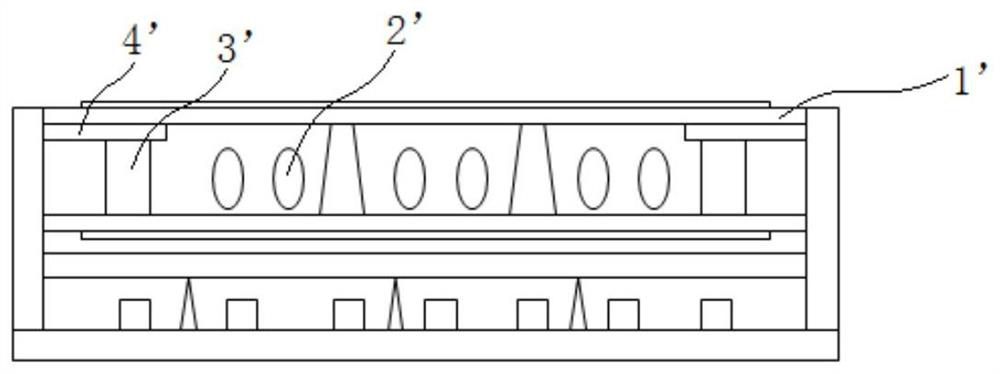

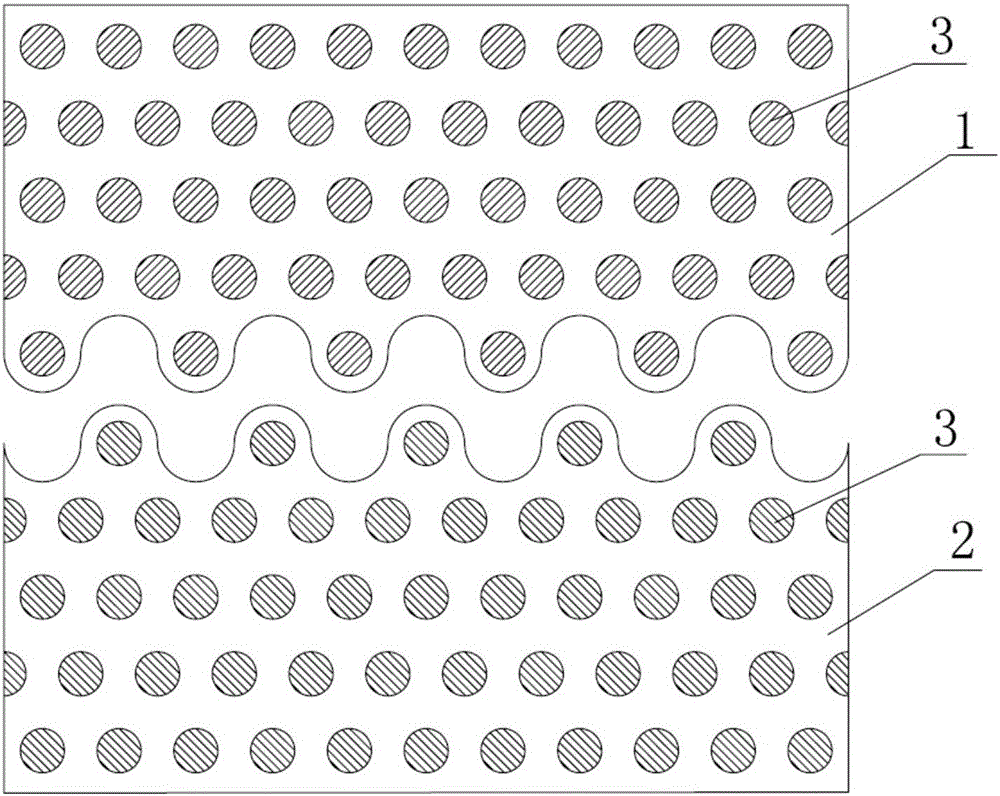

Back projection splicing display screen

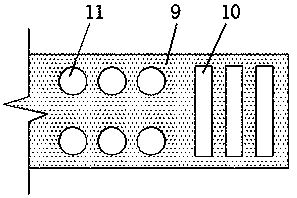

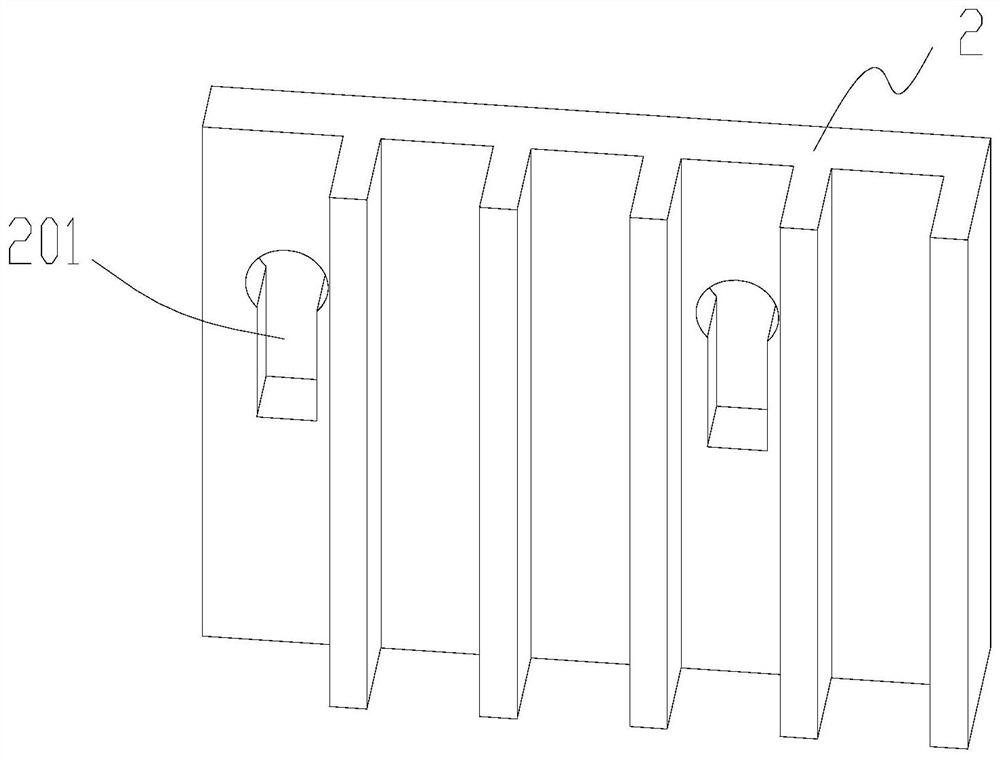

InactiveCN101762965AReduce stitching gapTelevision system detailsProjectorsBack projectionComputer engineering

The invention provides a back projection splicing display screen which has no or less screens (1) and is arranged for displaying back projection. The back projection splicing display screen comprises a plurality of spliced back projection cabinets (2) and one or more screen panel (11), wherein the back projection cabinet (2) comprises a box (22) arranged for placing a back projector and a lens (12) fixedly arranged on the front side of the box (22) and each screen panel (11) is arranged on the front side of the lens (12) of the spliced back projection cabinets (2).

Owner:GUANGDONG VTRON TECH CO LTD

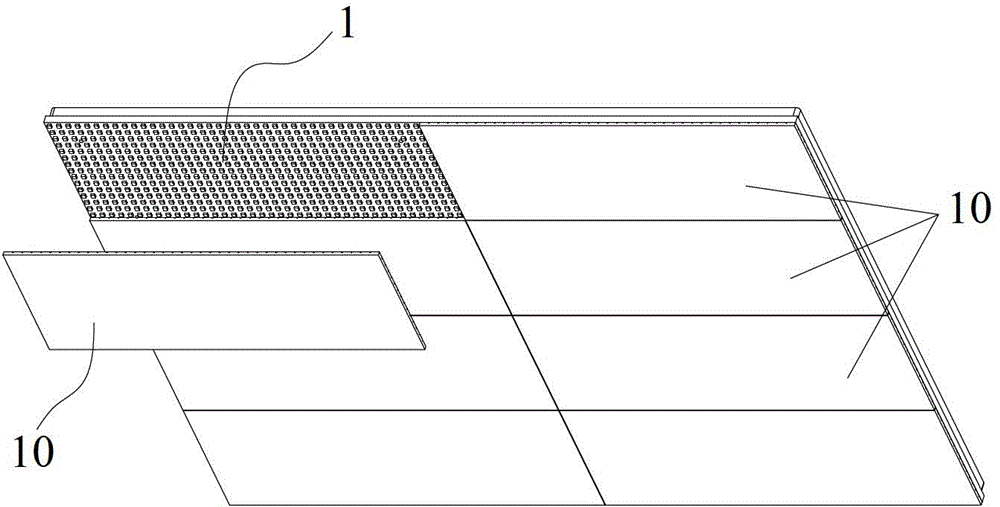

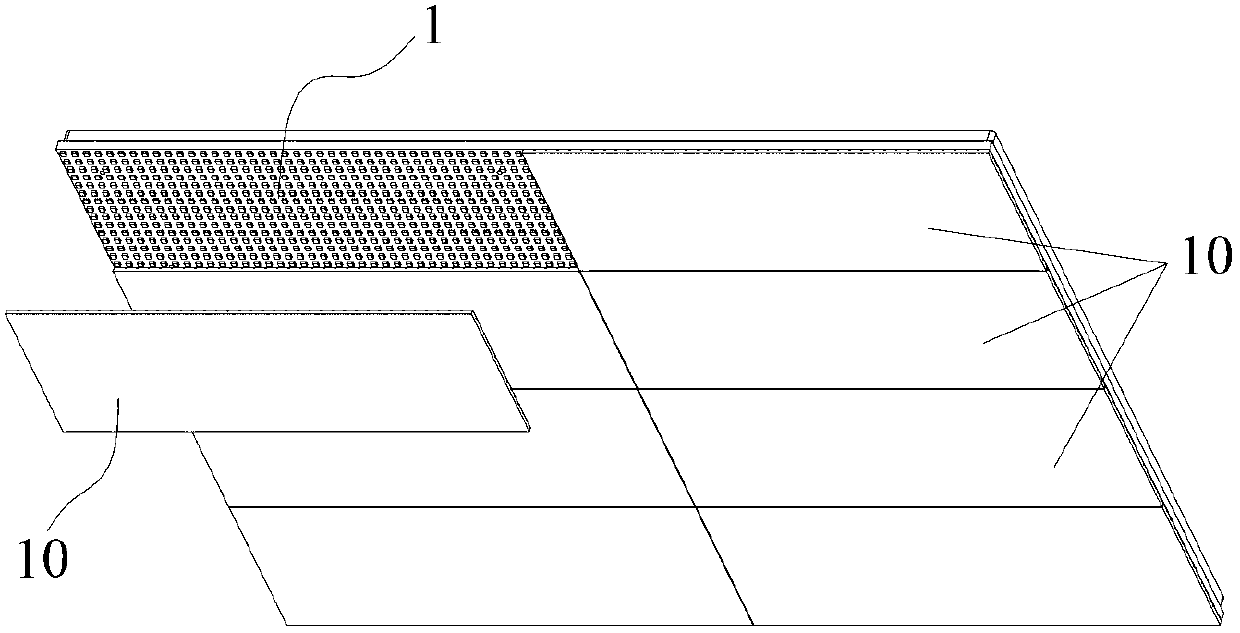

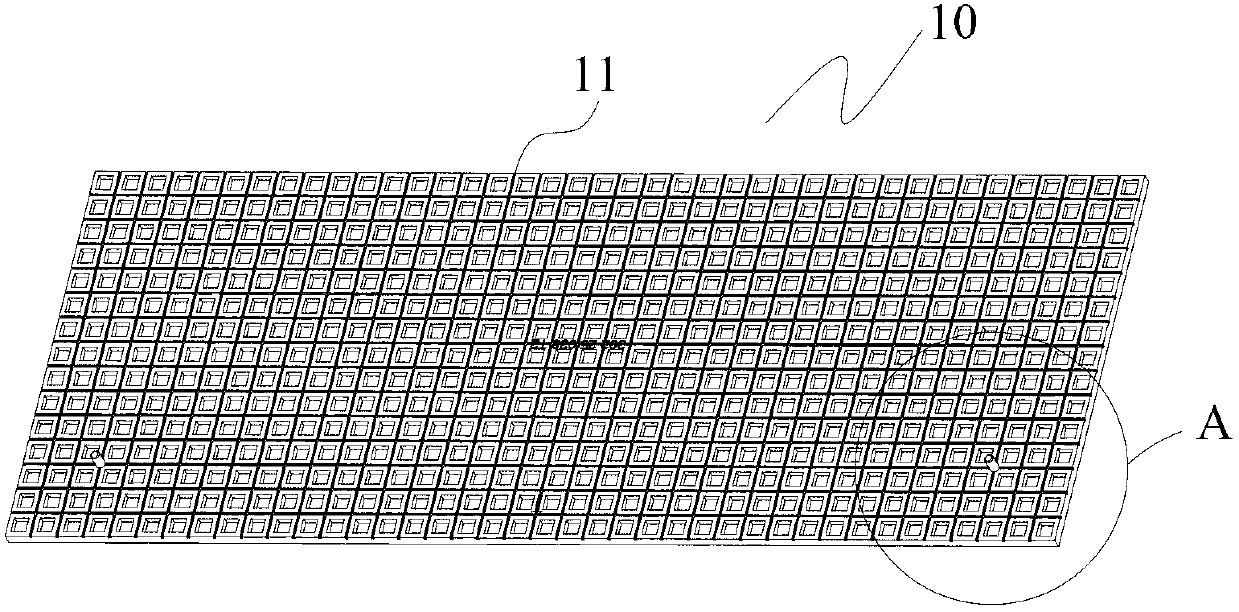

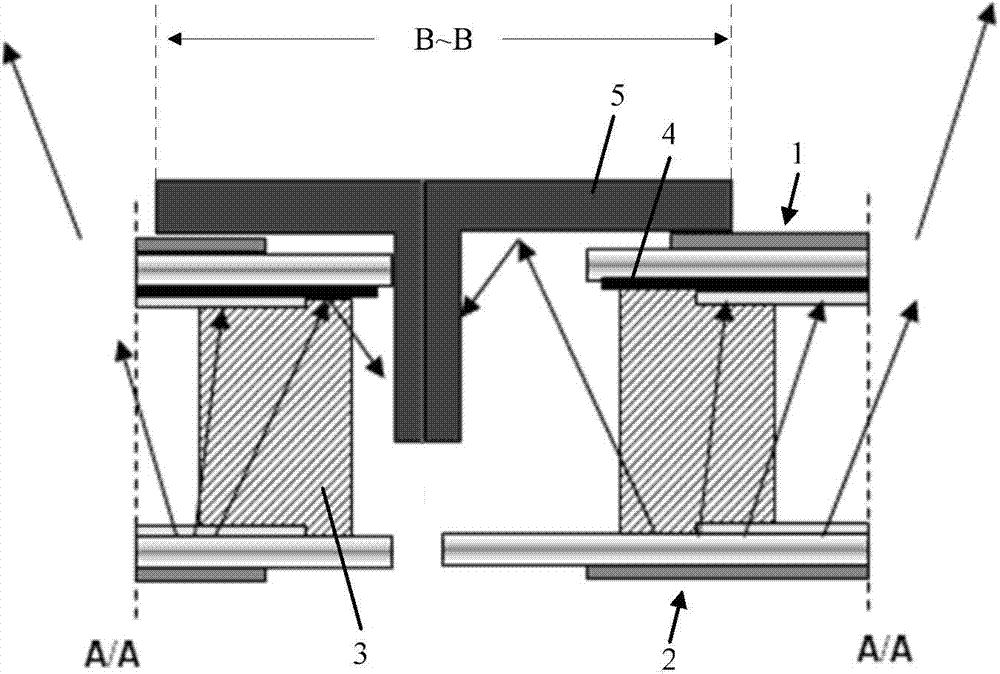

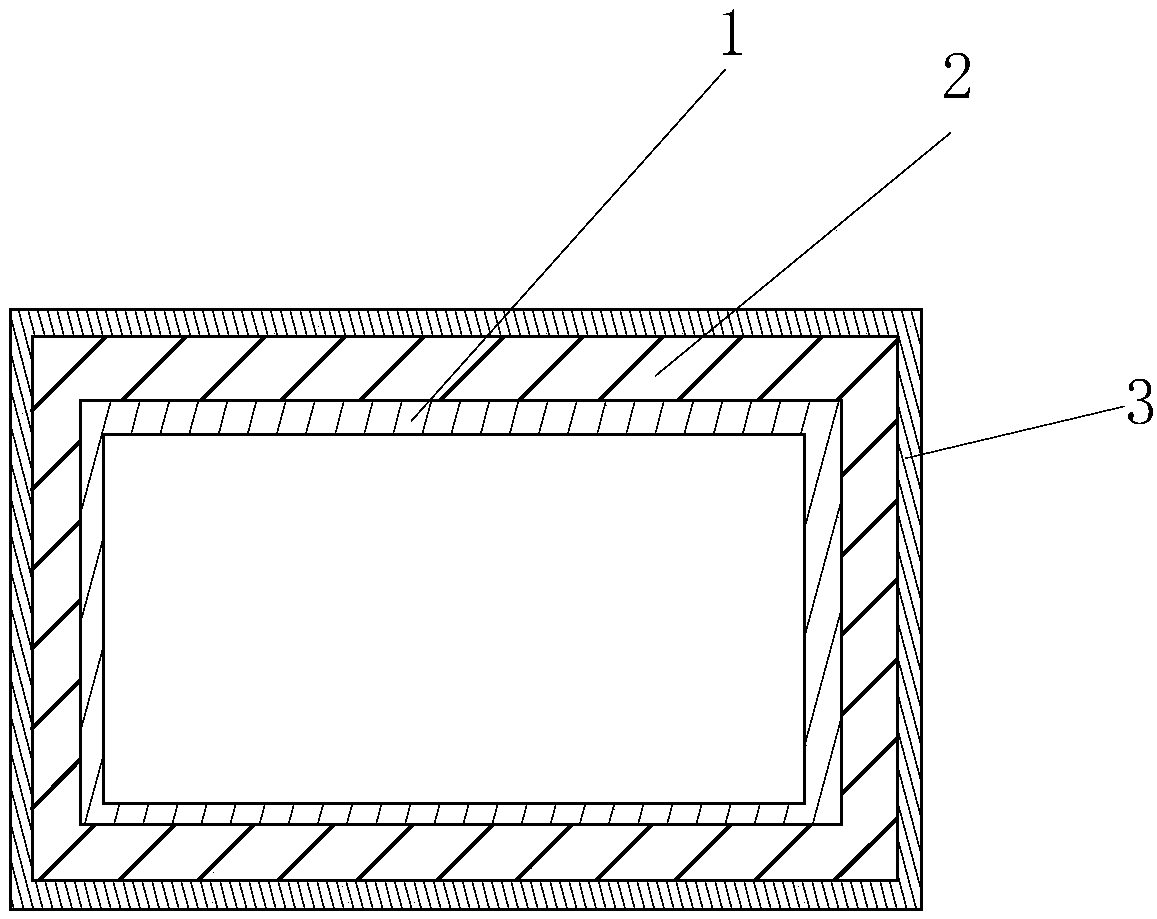

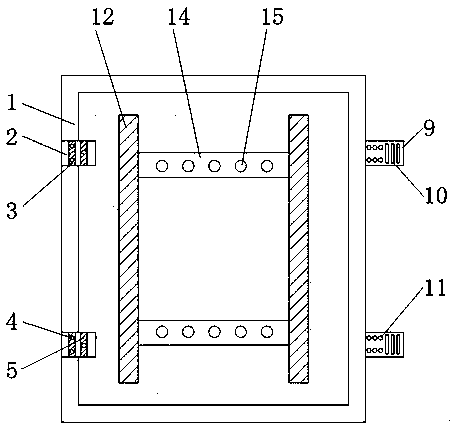

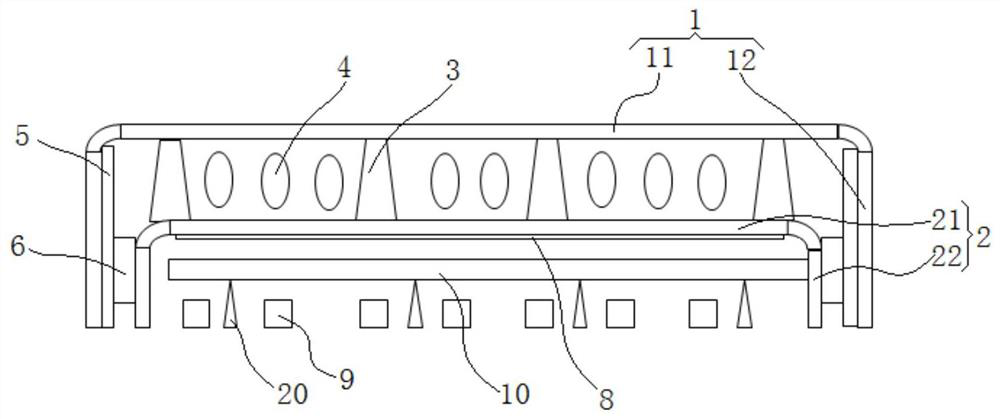

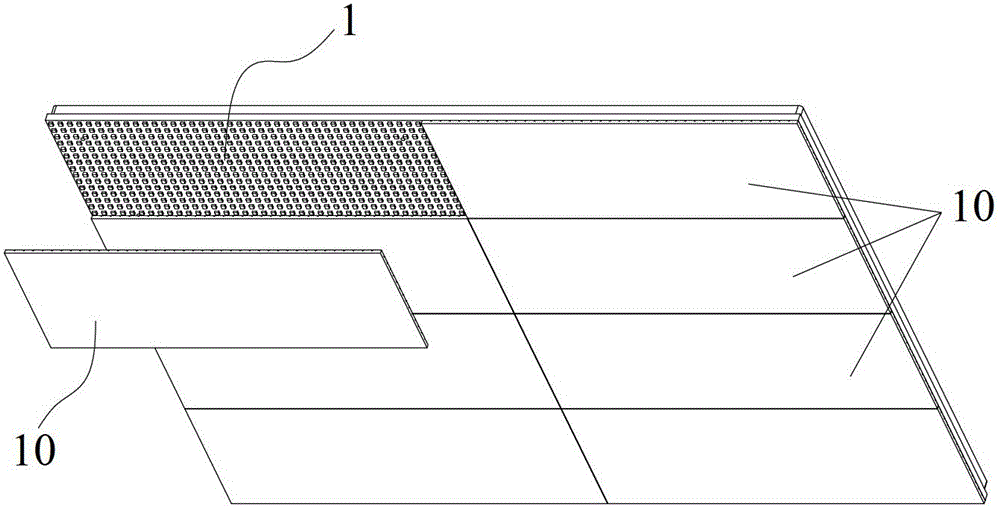

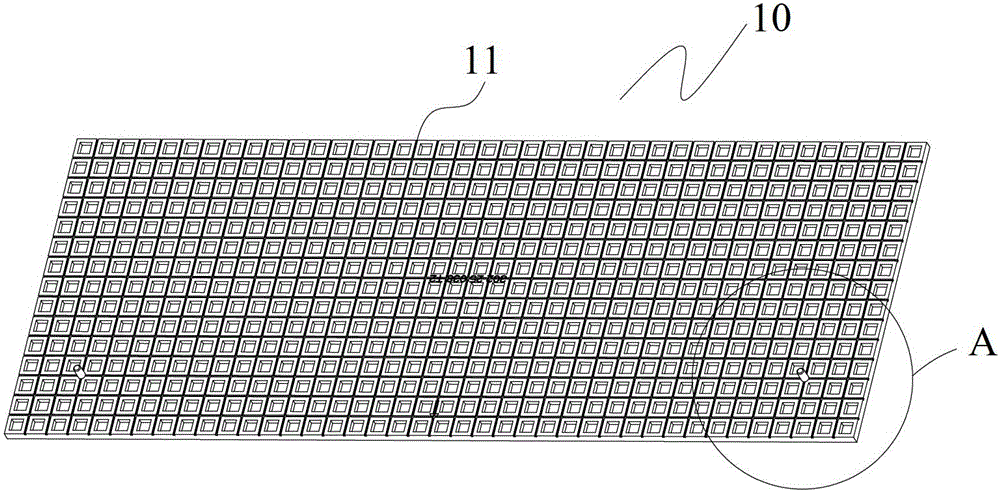

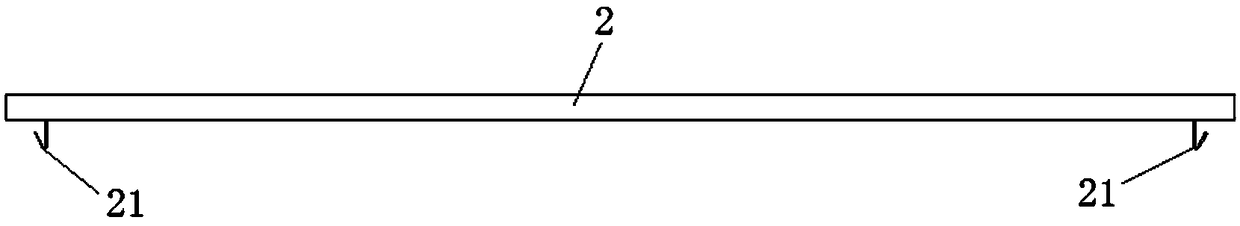

LED display device

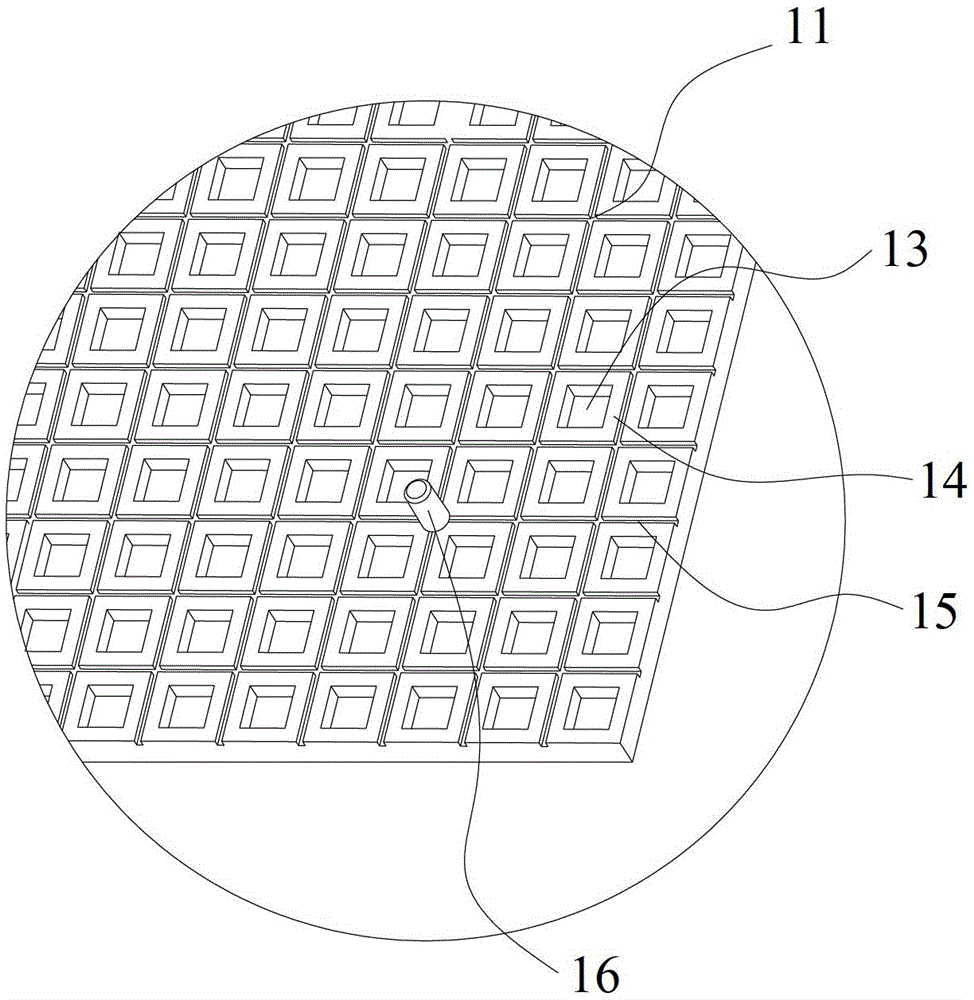

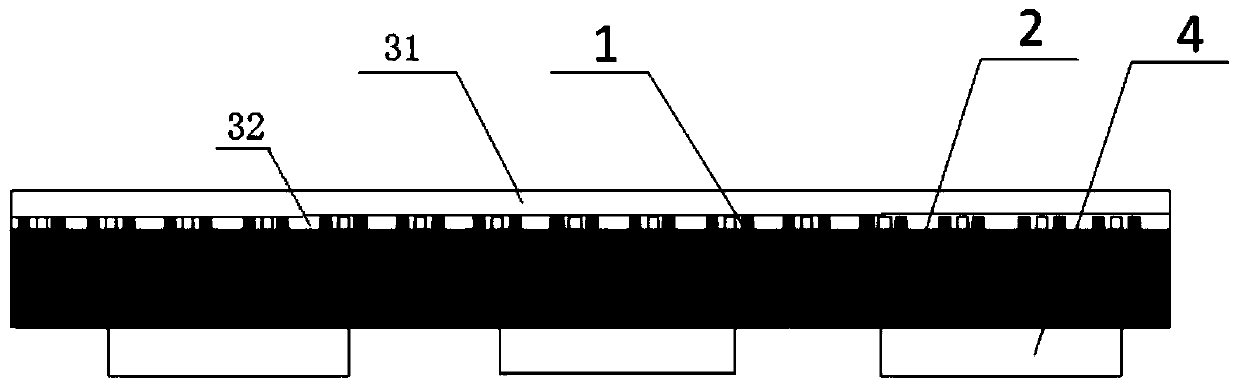

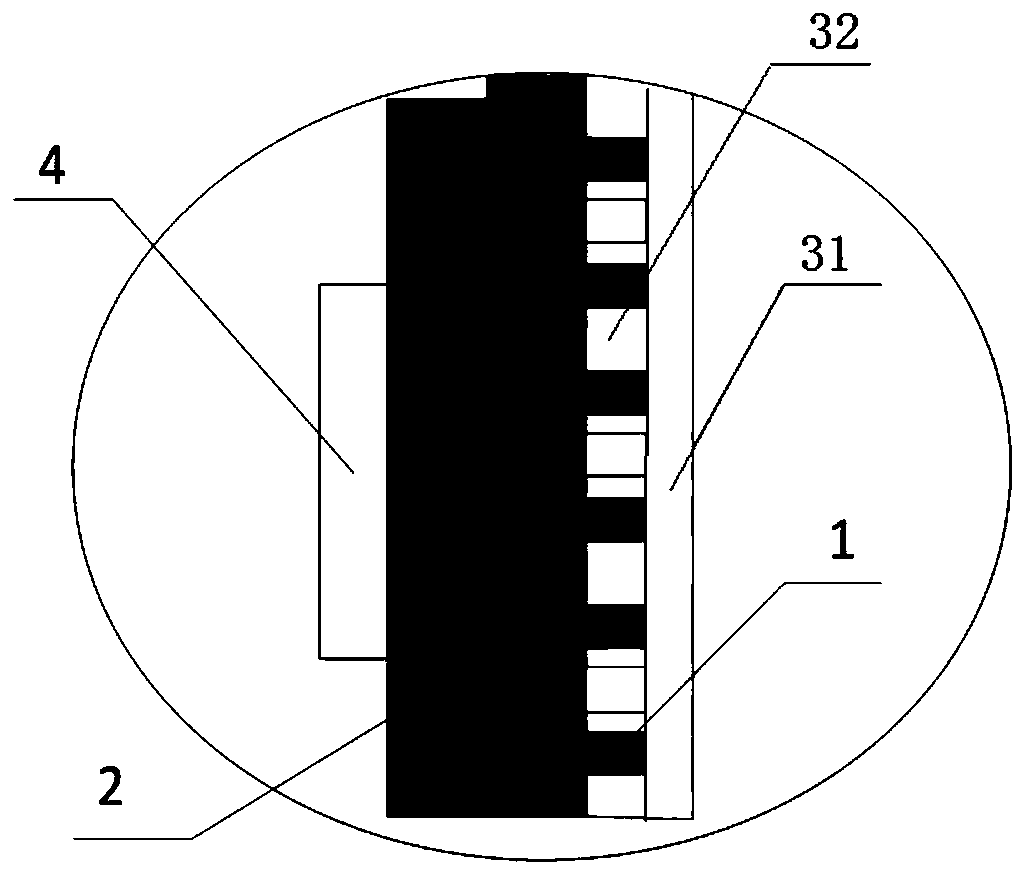

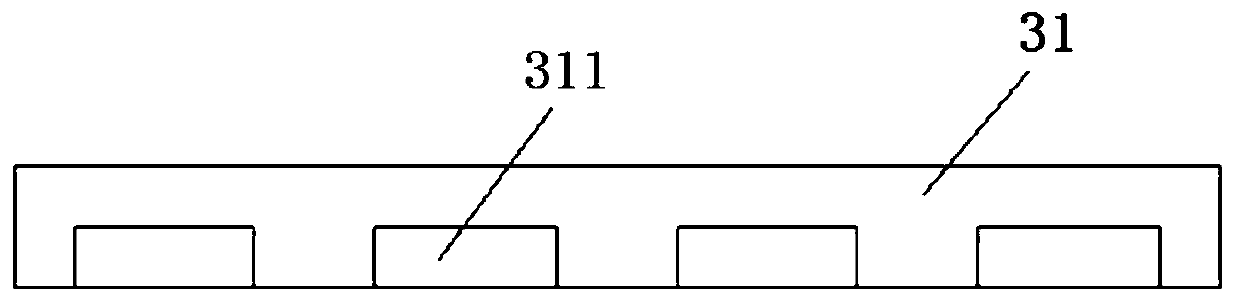

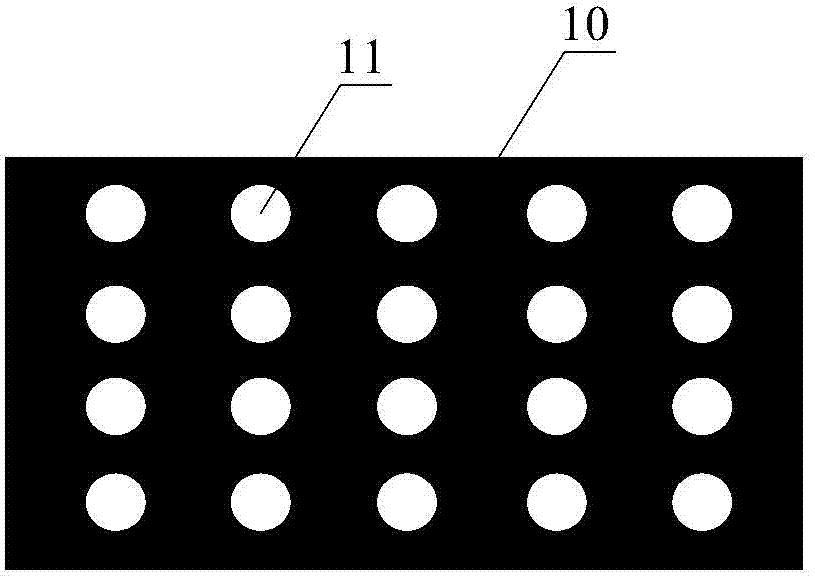

ActiveCN103150970AReduce stitching gapAccurate locationIdentification meansLED displayDisplay device

The invention provides an LED (Light-emitting Diode) display device which comprises an LED display board (1), and a mask arranged on one side of the LED display board (1), wherein the mask comprises a plurality of light-transmission cover units (10); the light-transmission cover units (10) are bonded with the LED display board (1); and a locating structure is arranged among the light-transmission cover units (10) and the LED display board (1) and used for limiting pasting positions of the light-transmission cover units (10) on the LED display board (1). The LED display device is small in splicing gap, and better in display effect.

Owner:LEYARD

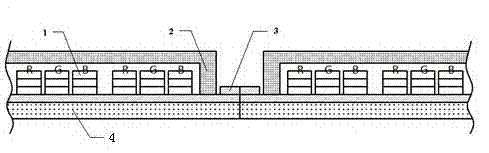

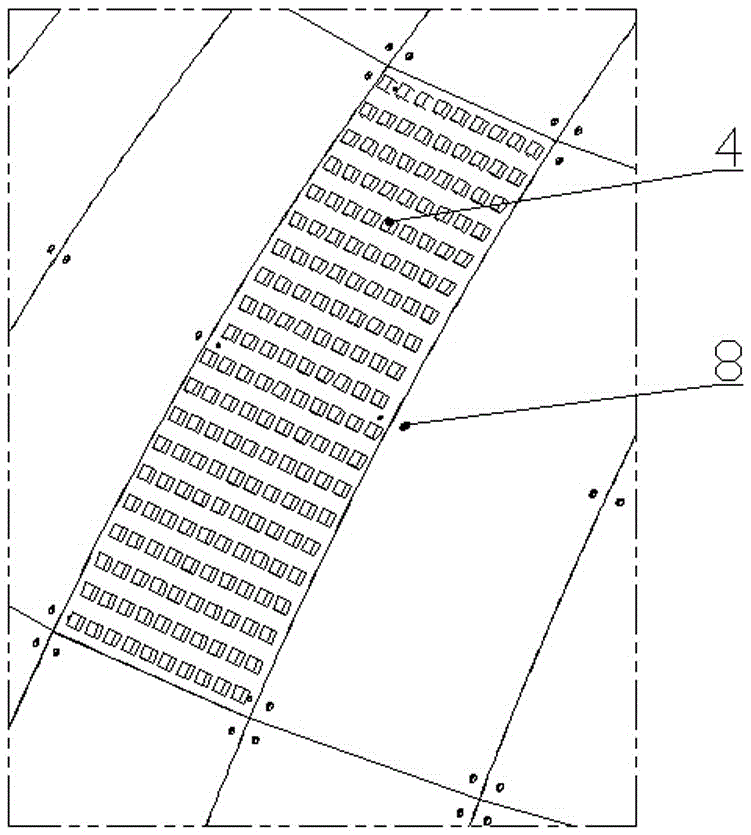

Thin film packaged LED display array module

The invention relates to a thin film packaged LED display array module. The module is formed by splicing a plurality of LED display modules, wherein the LED display module comprises a driving IC, a display substrate and an LED wafer; the driving IC is welded to the rear surface of the display substrate; the LED wafer is fixed on the front surface of the display substrate; at least one layer of thin film is further packaged on the front surface of the display substrate; and the total thickness of the thin film is 0.1-0.8 mm. The LED display array module has the advantages of large visual angleand high color consistency, meanwhile, a traditional glue filling or die pressing packaging process is omitted, a production process is simplified, the cost is reduced, and meanwhile, a splicing gap is favorably further reduced.

Owner:CHANGCHUN CEDAR ELECTRONICS TECH CO LTD

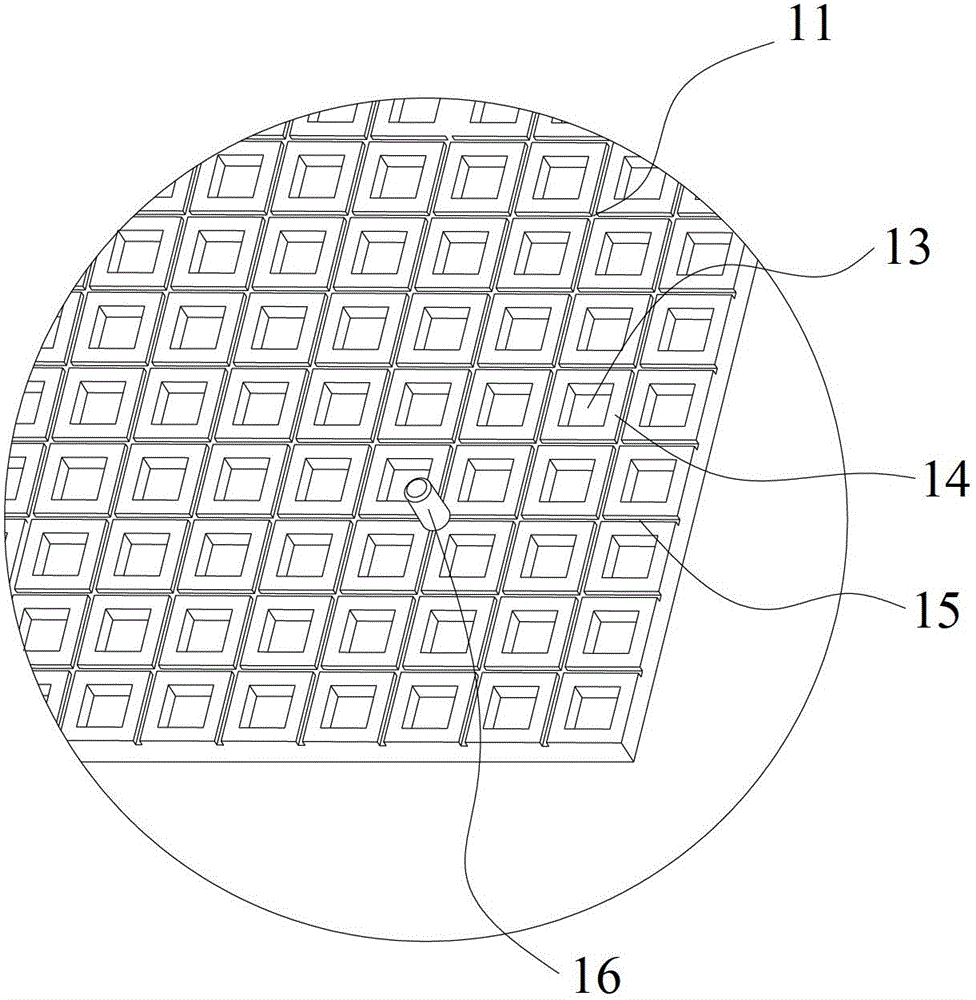

Light-emitting diode (LED) display device

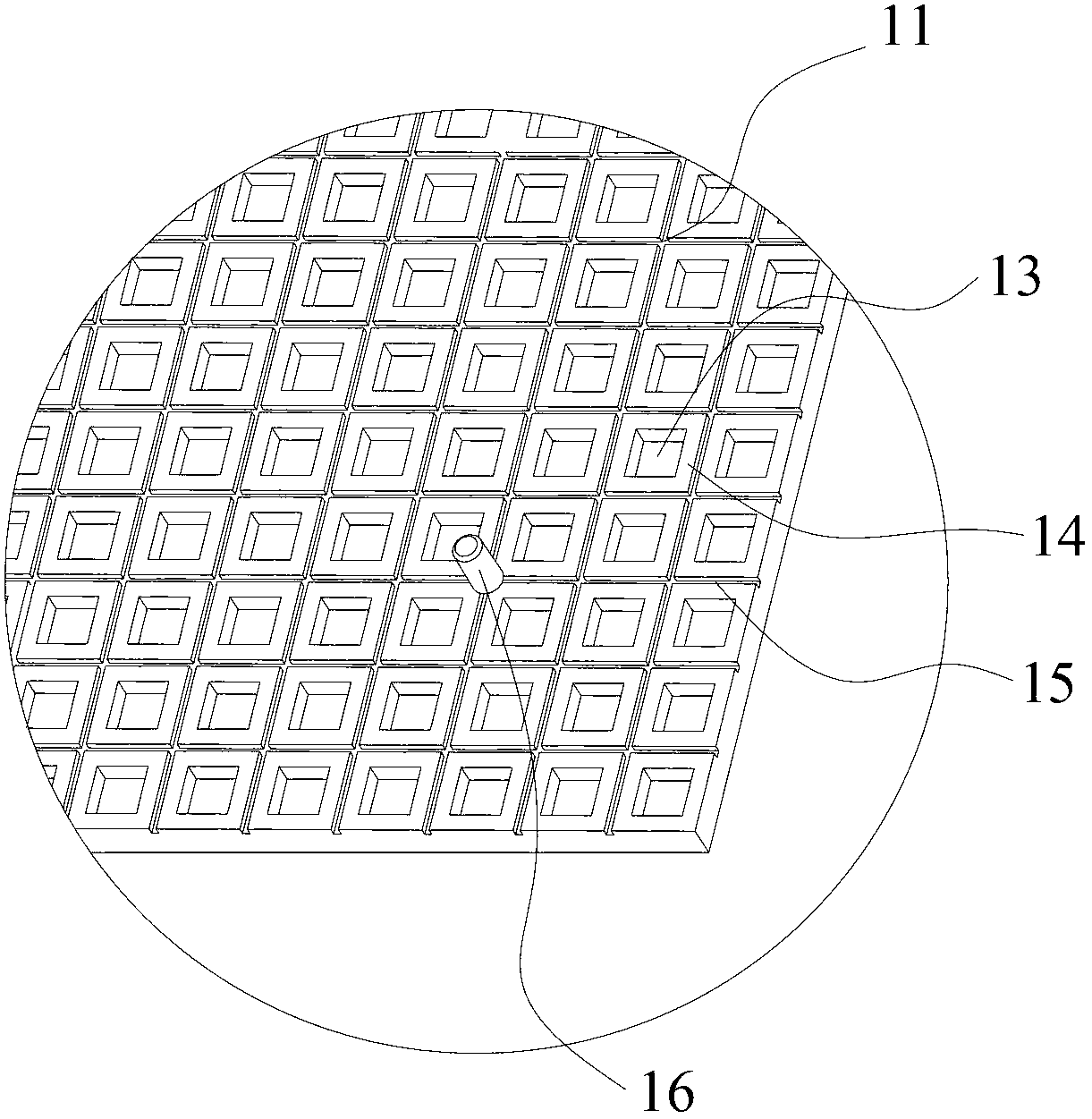

ActiveCN103137029AReduce stitching gapAccurate locationIdentification meansOptical elementsEngineeringLED display

The invention provides a light-emitting diode (LED) display device which comprises an LED display panel (1) and a face guard. The face guard is placed on one side of the LED display panel (1) and comprises a plurality of light transmission cover units (10) which are pasted with the LED display panel. Positioning structures are placed between the light transmission cover units (10) and the LED display panel (1) to limit the pasting positions of the light transmission cover units (10) on the LED display panel (1). Each light transmission cover unit (10) is provided with a first side (11) and a second side (12), wherein the fist side (11) faces the LED display panel (1), the second side deviates from the LED display panel (1), and a grating structure is placed on the second side (12). The LED display device is small in splicing gap, good in evenness and display effects.

Owner:LEYARD

Display screen and spliced display screen

ActiveCN103901643AImprove continuityReduce stitching gapNon-linear opticsIdentification meansImage displayComputer science

Owner:BOE TECH GRP CO LTD +1

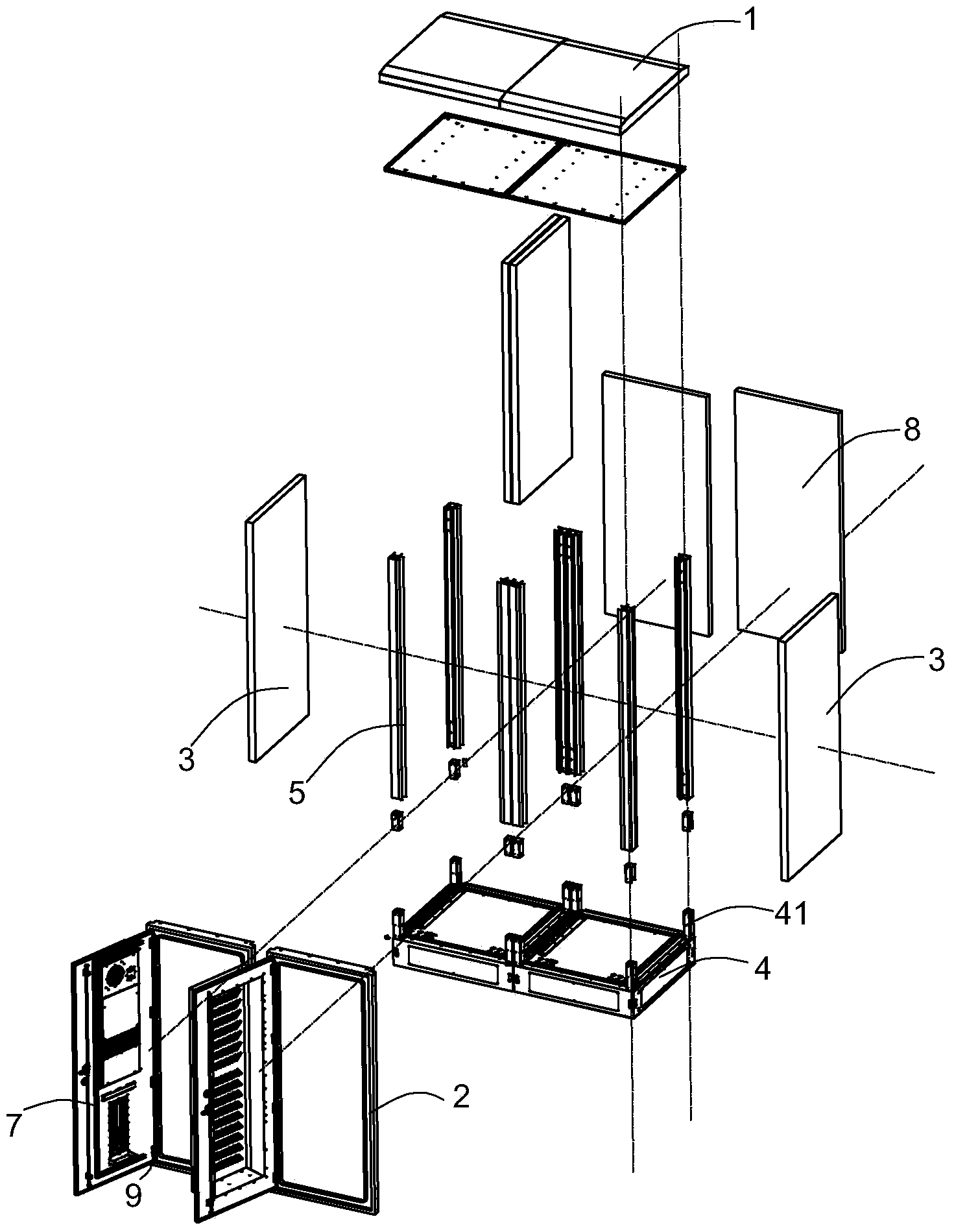

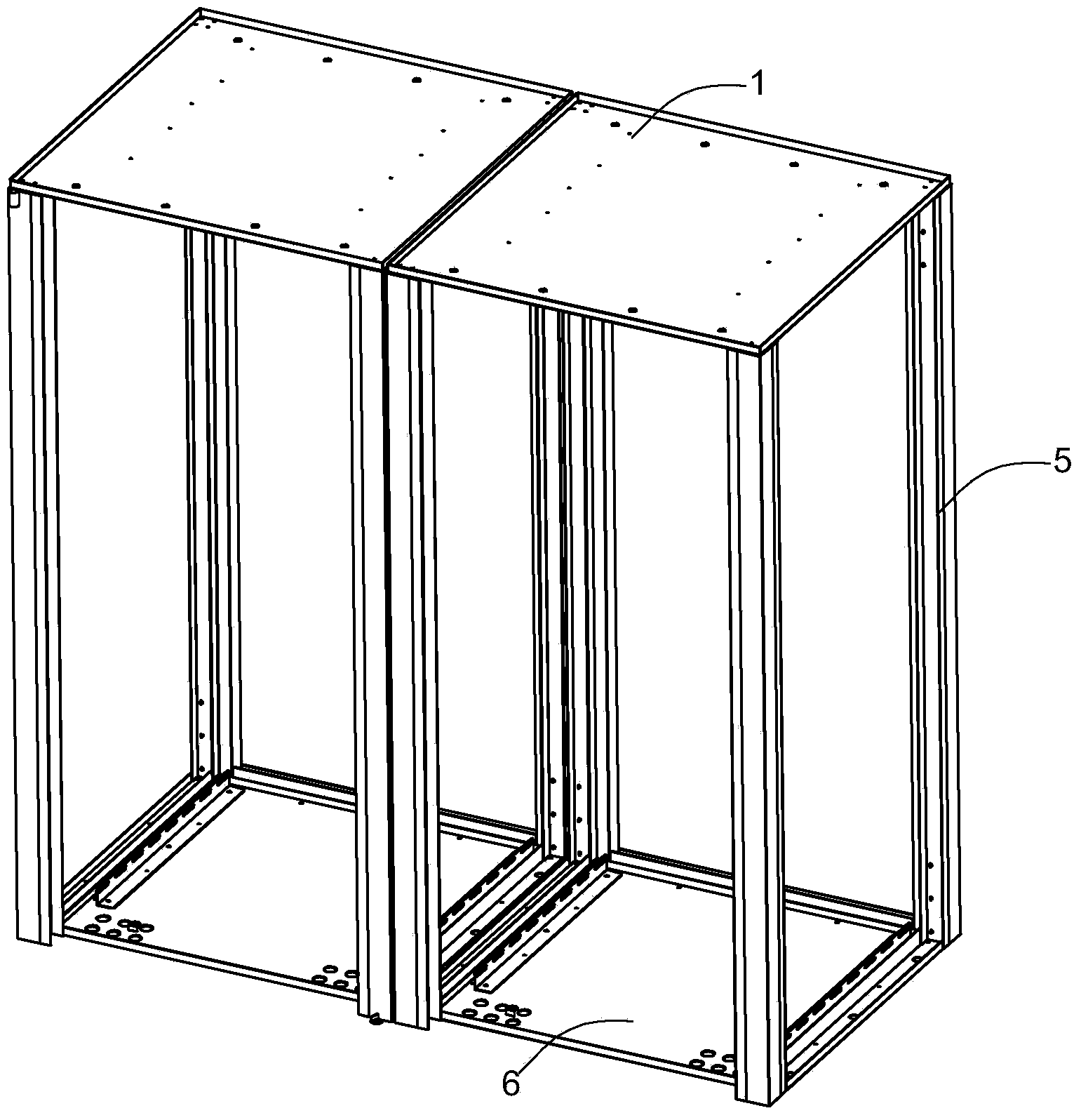

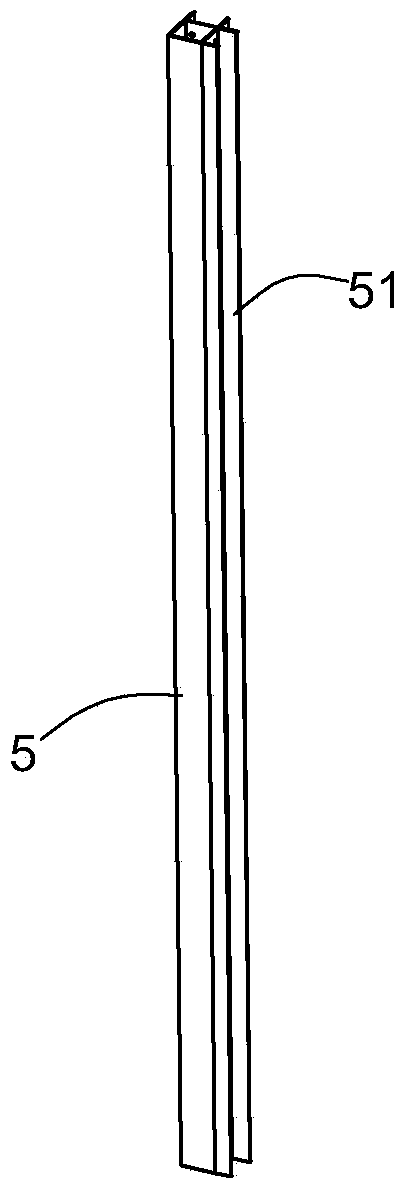

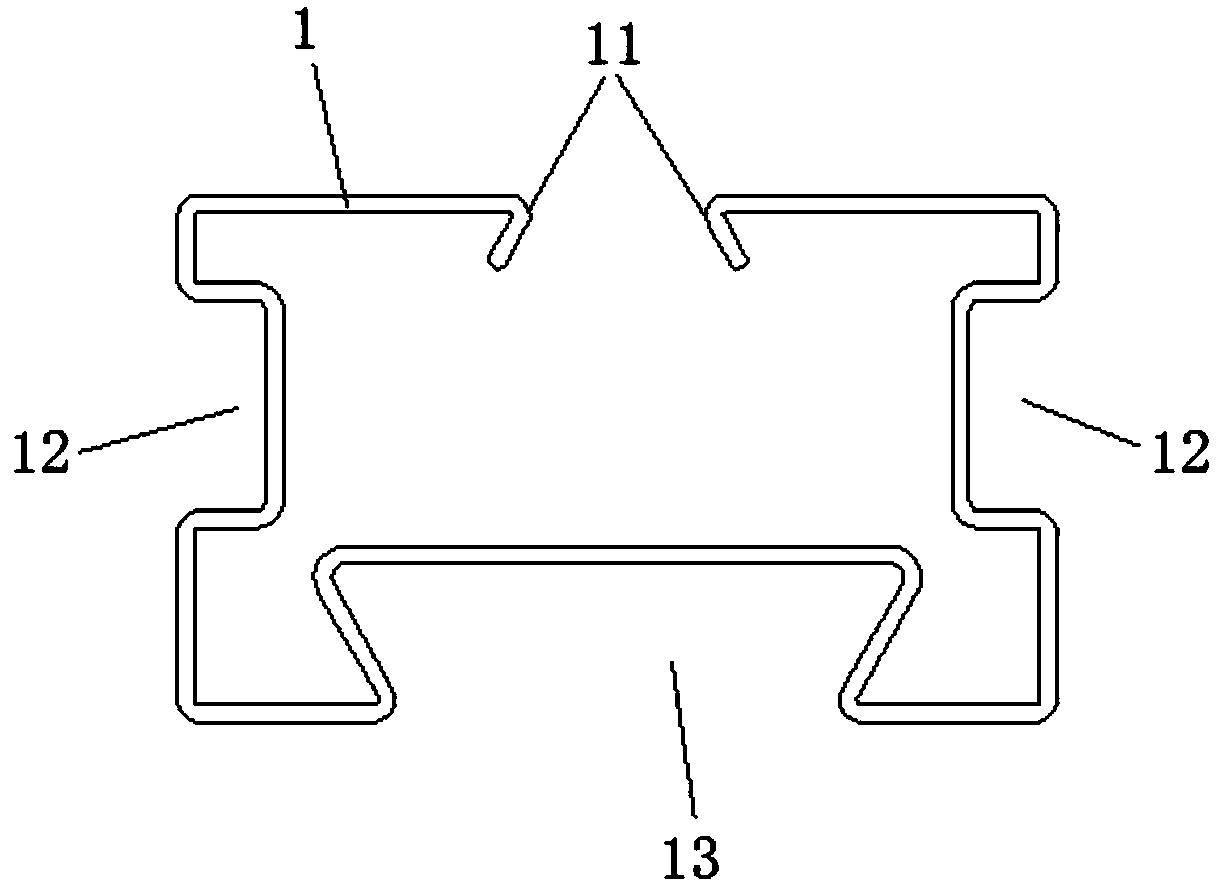

Assembled cabinet

InactiveCN103889177AImprove sealingImprove tamper resistanceCasings/cabinets/drawers detailsRack/frame constructionBack door

The invention relates to an assembled cabinet comprising a frame and a cabinet assembly which covers the outer surface of the frame. The frame is mainly formed by a base and upright columns. The cabinet assembly comprises a top cover, a door frame and side plates. The top cover is detachably arranged at the top of the frame. The side plates can cover the side faces of the frame. The assembled cabinet is characterized in that the upright columns are at least four hollow square columns which are provided with jacks at least at end parts, correspondingly the four corners of the base are provided with convex blocks which can be inserted into the upright column jacks, the four corners of the top cover are also provided with convex blocks which can be inserted into the upright column jacks, thus the frame is formed together, at least two adjacent side walls of the upright columns are provided with slots which extend outwards along mutually vertical directions and hold the door frame and the side plates, and the door frame is also rotatingly connected with a front door or a back door. Compared with the prior art, the assembled cabinet has the advantages that an assembled structure is employed overall, the modular disassembly, assembly and repair of the cabinet can be carried out after the cabinet is damaged accidentally, the modification is easy, and the field engineering installation is convenient.

Owner:宁波隆兴电信设备制造有限公司

Air conditioning duct for rail vehicle and preparation method of air conditioning duct

ActiveCN108501399AReduce stitching gapReduce connectivityRailway heating/coolingFiberThermal insulation

The invention discloses an air conditioning duct for a rail vehicle. The duct is a composite pipe, and sequentially comprises an inner side layer, a fiber-reinforced aerogel felt layer and an outer side layer from inside to outside, wherein the inner side layer and the outer side layer are solidified prepreg or metal sheets. The air conditioning duct for the rail vehicle is a pipe which can be directly spliced and installed; the middle fiber-reinforced aerogel layer is light in weight, has a prominent thermal insulation effect, and is an incombustible material, so that the air conditioning duct for the rail vehicle has good fire resistance and thermal insulation effect; since the fiber-reinforced aerogel material is encapsulated between the solidified prepreg layers, after the duct is installed on a bullet train, the problem that the fiber-reinforced aerogel material drops powder is not caused regardless of how the train drives the duct to vibrate, and the thermal insulation effect isaccordingly stable and lasting.

Owner:CHANGZHOU INST OF LIGHT IND TECH

Combined type LED (light emitting diode) display screen with effects of reducing splicing joints and facilitating installation

InactiveCN107806552AReduce stitching gapEasy to installStands/trestlesIdentification meansLED displayLight emitting device

The invention discloses a combined LED display screen which can reduce the splicing gap and is easy to install. groove, and the inside of the connection groove is fixed with a first support frame, the first support frame is provided with a first fixing hole, the fixing rod is fixed on the upper surface of the first fixing plate, and the first fixing plate passes through Through the second support frame, the fixed frame is fixed on the back of the display screen body, and the inside of the fixed frame is provided with a sliding groove, and the inside of the sliding groove is provided with a second fixing plate, and the second fixing plate is installed There is a third fixing hole. The combined LED display that can be seamlessly spliced and is easy to install, when the telescopic spring is in a normal state, the first fixing plate is in contact with the bottom surface of the connecting groove, so that when the connecting plate is installed in the connecting groove, the first fixing plate The plate can fix the connecting plate in the connecting groove.

Owner:NANJING LENIAS PHOTOELECTRIC EQUIP

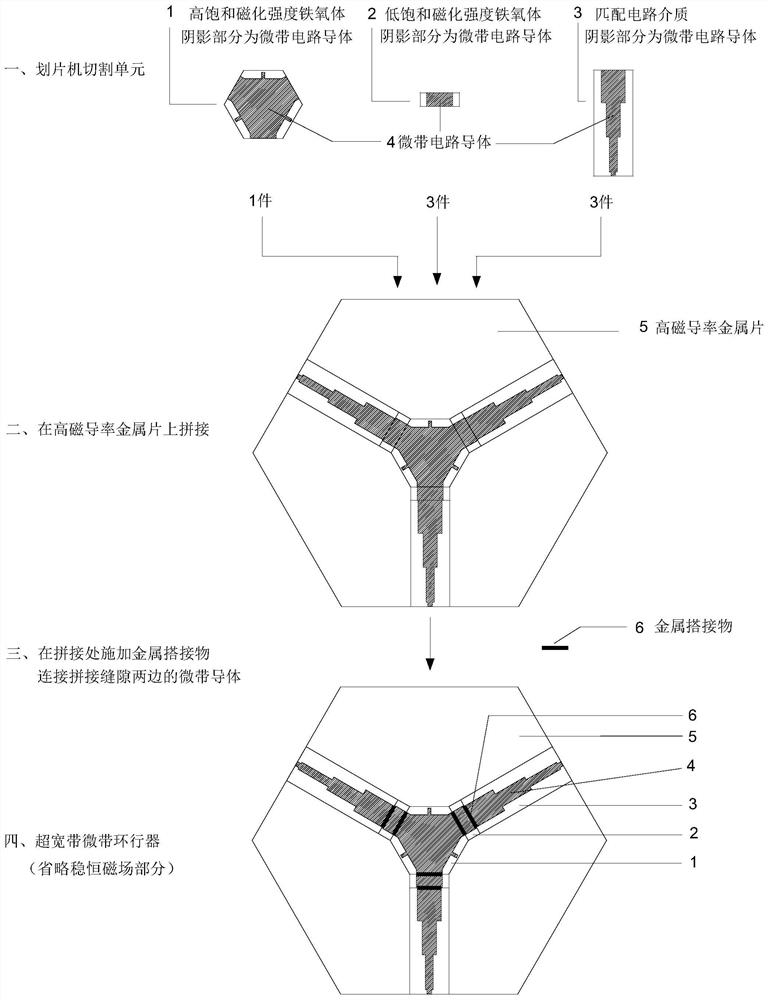

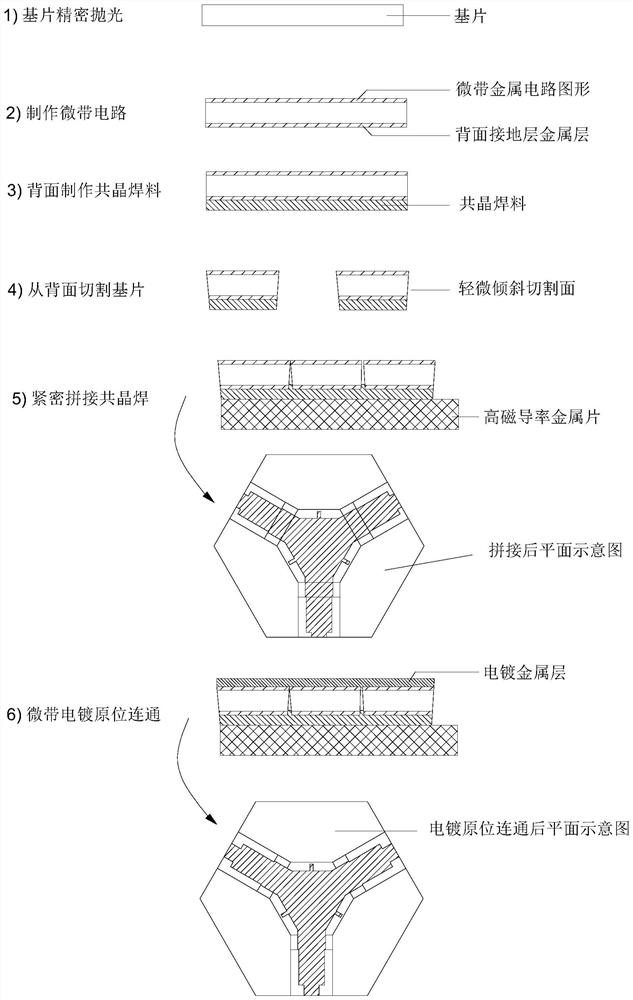

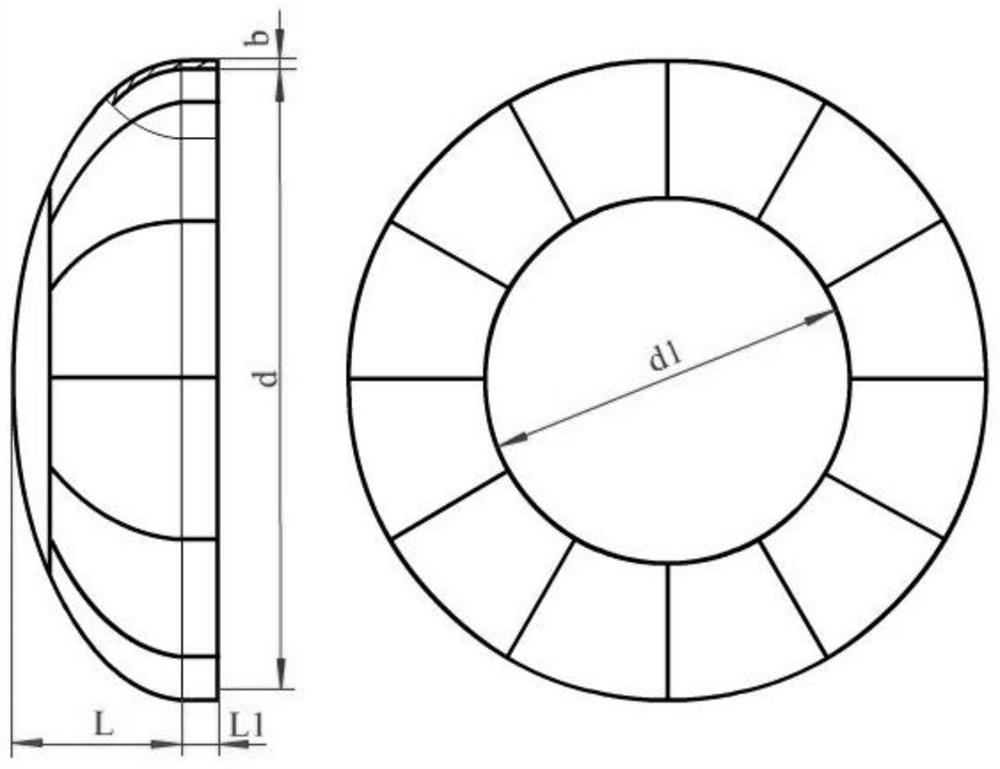

Manufacturing method of ultra-wideband composite ferrite circulator

ActiveCN111786063AAvoid discontinuitiesImprove tightnessWaveguide type devicesUltra-widebandHemt circuits

The invention discloses a method for manufacturing a spliced ultra-wideband composite ferrite microstrip circulator with high yield, and the method comprises the following steps: 1, precisely polishing substrates: precisely polishing each substrate required by the spliced ultra-wideband composite ferrite microstrip circulator before use so as to control the thickness tolerance of the substrates within + / -5 [mu]m; 2, manufacturing a microstrip circuit: manufacturing a microstrip metal circuit pattern on each precisely polished substrate through a conventional thin film circuit process, and manufacturing a back grounding metal layer on the back surface of each substrate through a conventional thin film circuit process; 3, manufacturing eutectic solder on the back face; 4, cutting the substrate from the back surface; 5, carrying out the tight splicing eutectic welding; 6, performing microstrip electroplating in-situ communication: electroplating a metal layer on the microstrip metal circuit pattern, wherein the thickness of the metal layer is 4-6 [mu]m.

Owner:苏州华博电子科技有限公司

Spliced screen

ActiveCN112133191AReduce stitching gapReduce manufacturing costIdentification meansEngineeringMechanical engineering

Owner:爱奇视智慧技术(深圳)有限公司

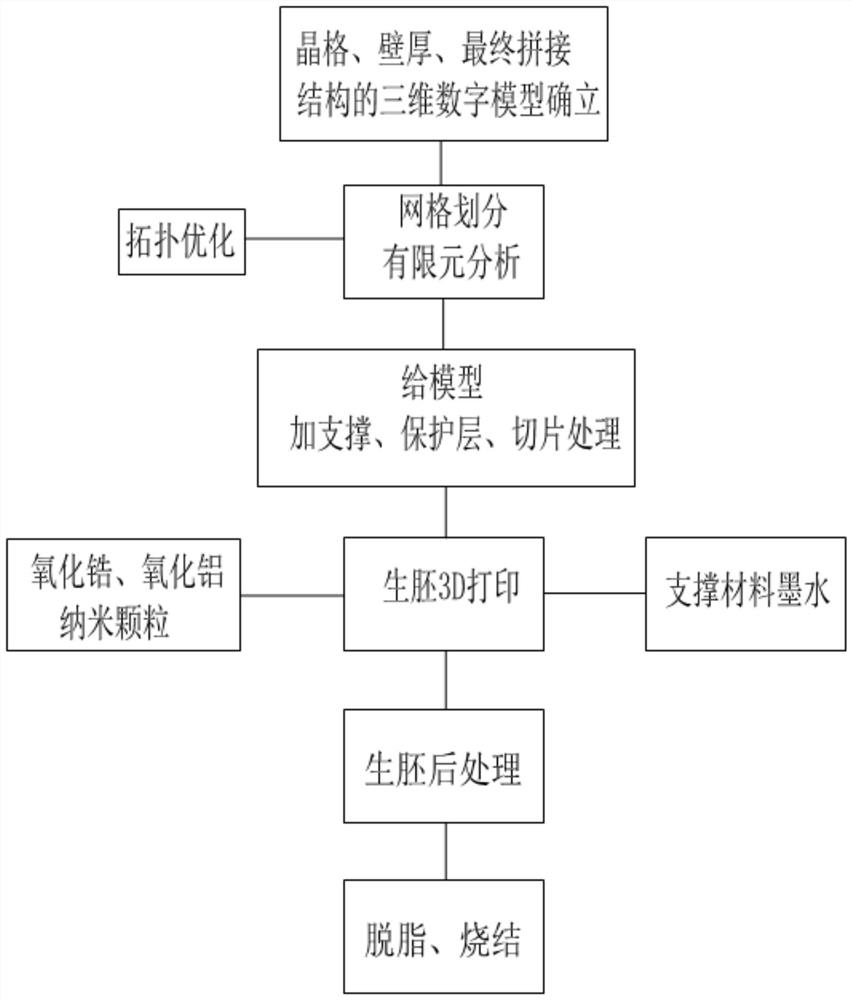

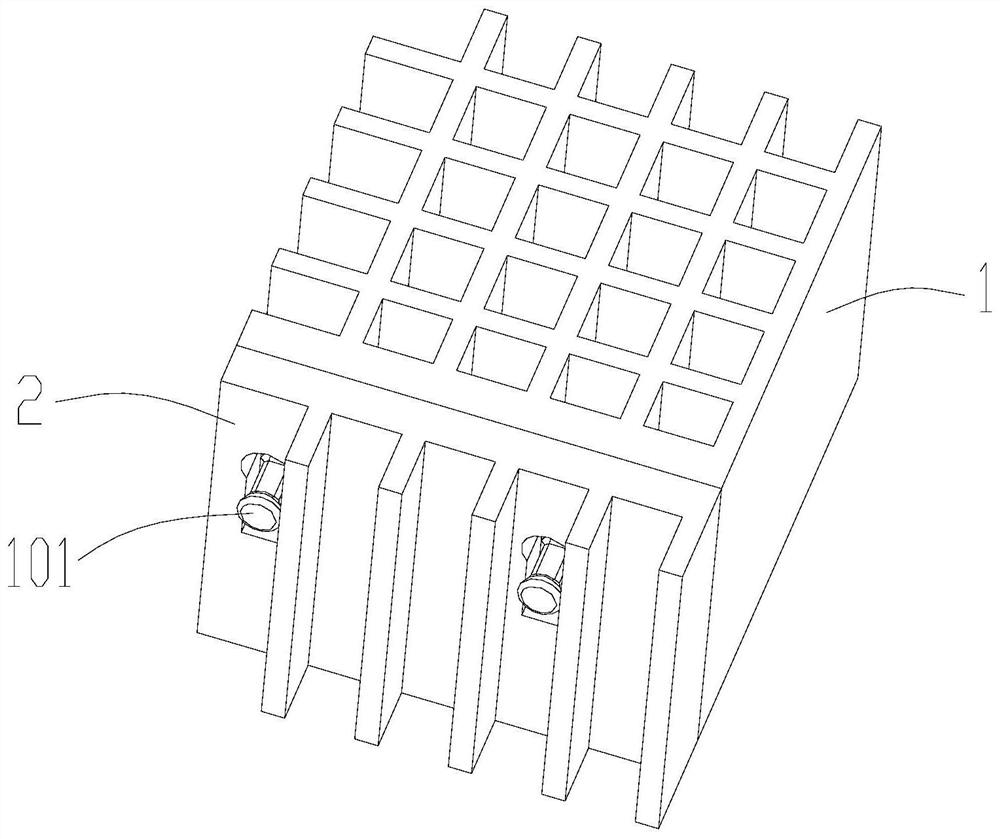

Preparation method of porous ceramic plate produced by utilizing nano ink-jet 3D printing technology

InactiveCN112679208ATo achieve the purpose of splicingReduce stitching gapAdditive manufacturing apparatusCeramicwareDigital mockupPorous ceramics

The invention discloses a preparation method of a porous ceramic plate produced by using a nano ink-jet 3D printing technology, and the method is characterized in that the method the following steps: establishing a three-dimensional digital model of the porous ceramic plate, meshing the three-dimensional digital model of the porous ceramic plate, topologically optimizing the three-dimensional digital model according to an analog result, and importing the model into a processing STL format 3d modeling editing repair tool to carry out support adding, protection layer adding, slicing processing, green body 3D printing, green body post-processing, degreasing and sintering on the model. According to the invention, splicing of a plurality of ceramic plates is realized, different wall thicknesses or different crystal lattice types exist on the same plate, the geometric structure shrinkage ratio is more controllable, degreasing and sintering of a formed green body are combined into one, the sintering efficiency is improved, large-batch post-treatment operation without intensive labor force is realized, and the production efficiency is improved.

Owner:杭州普太科技有限公司

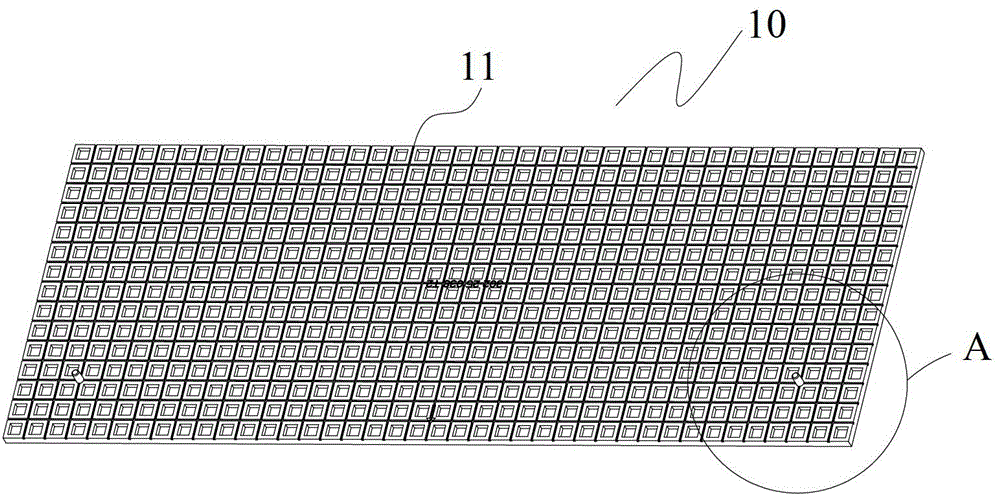

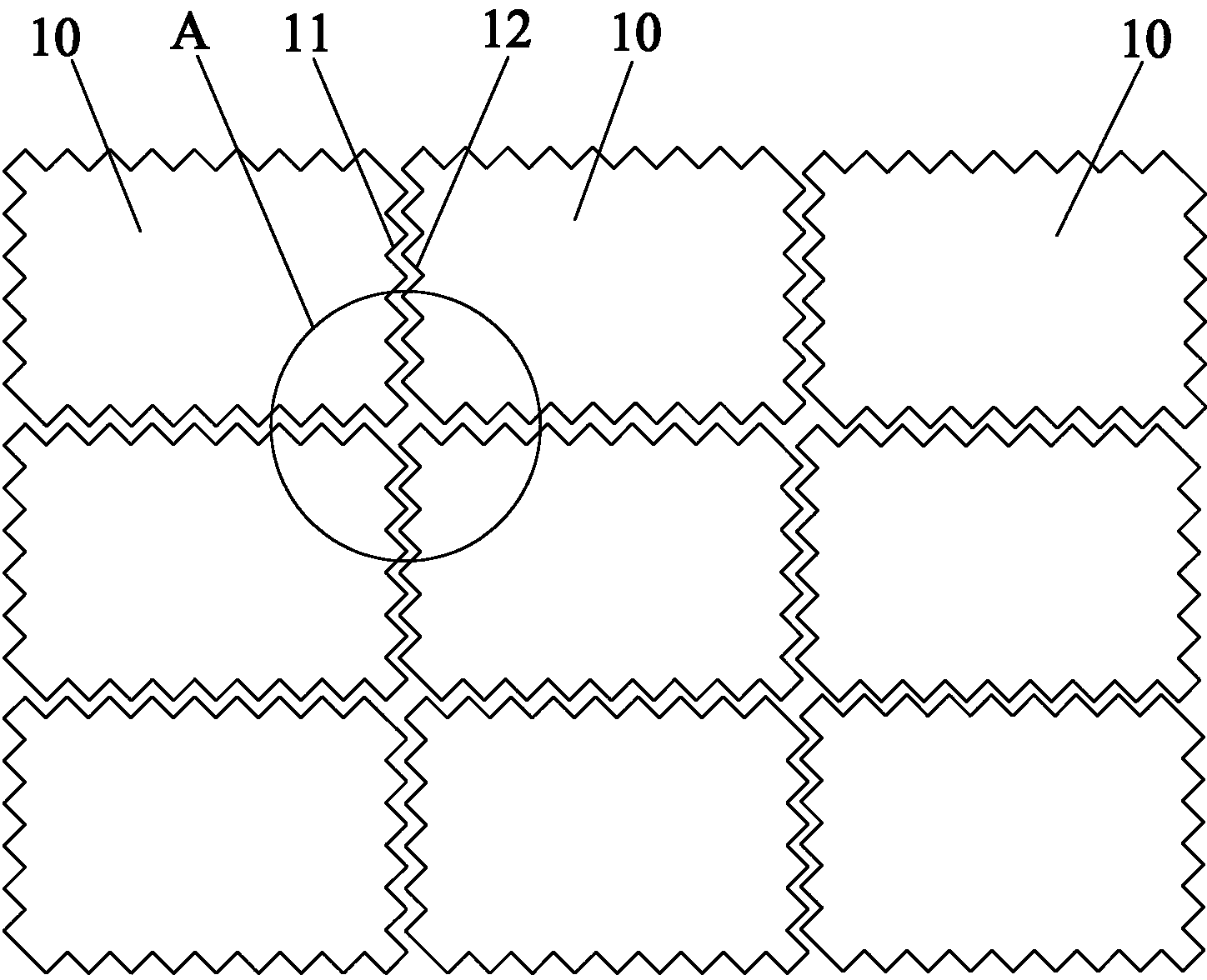

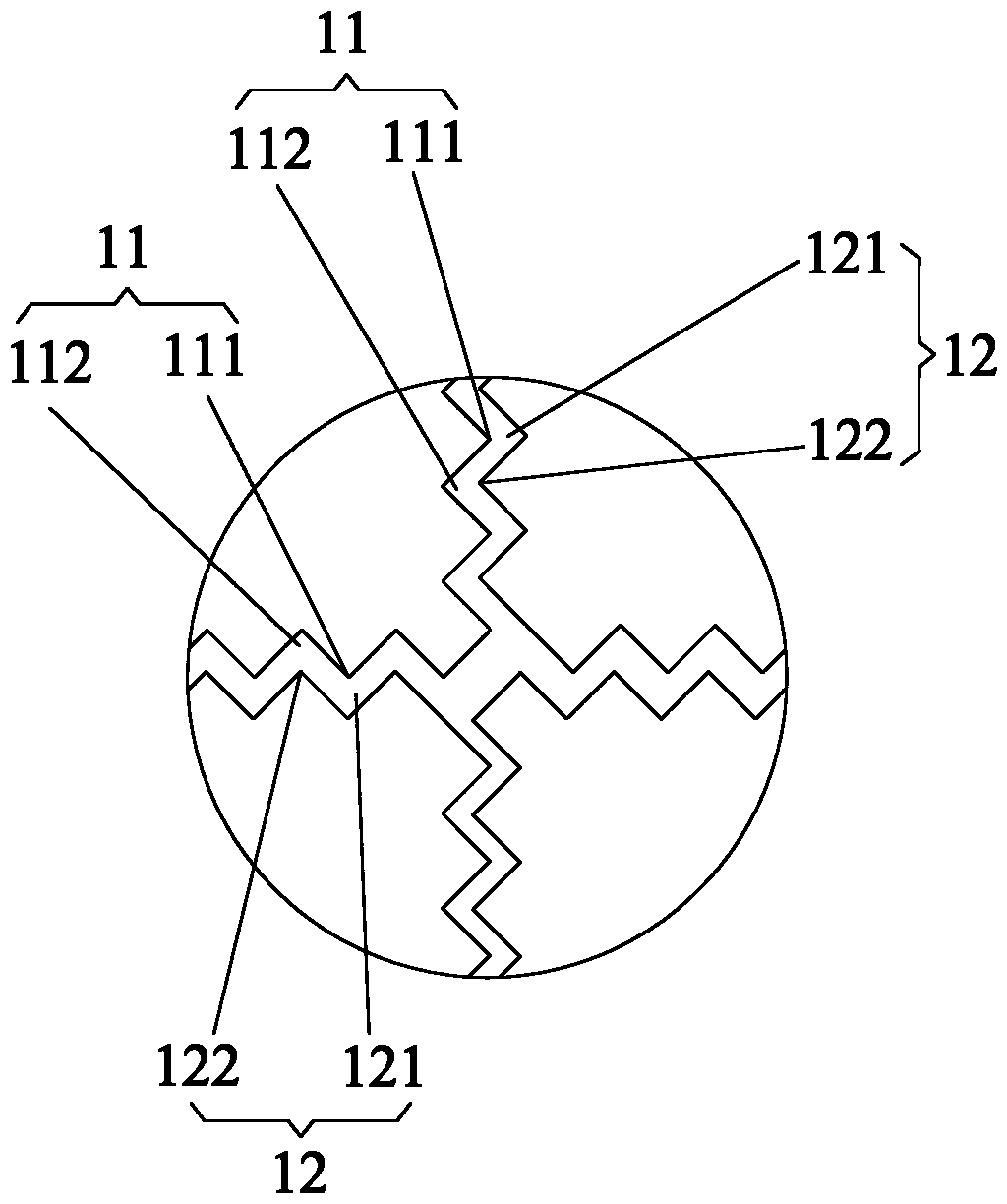

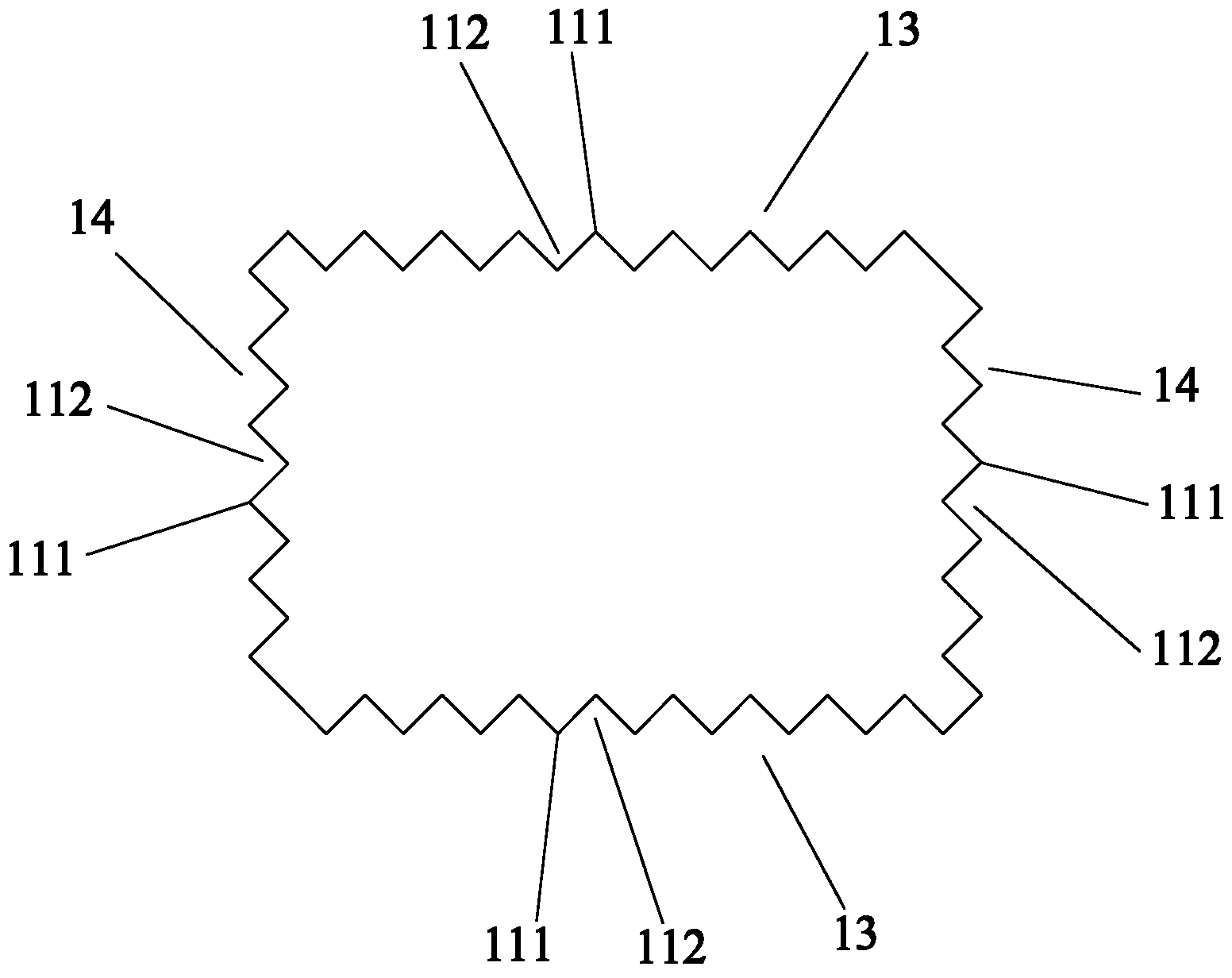

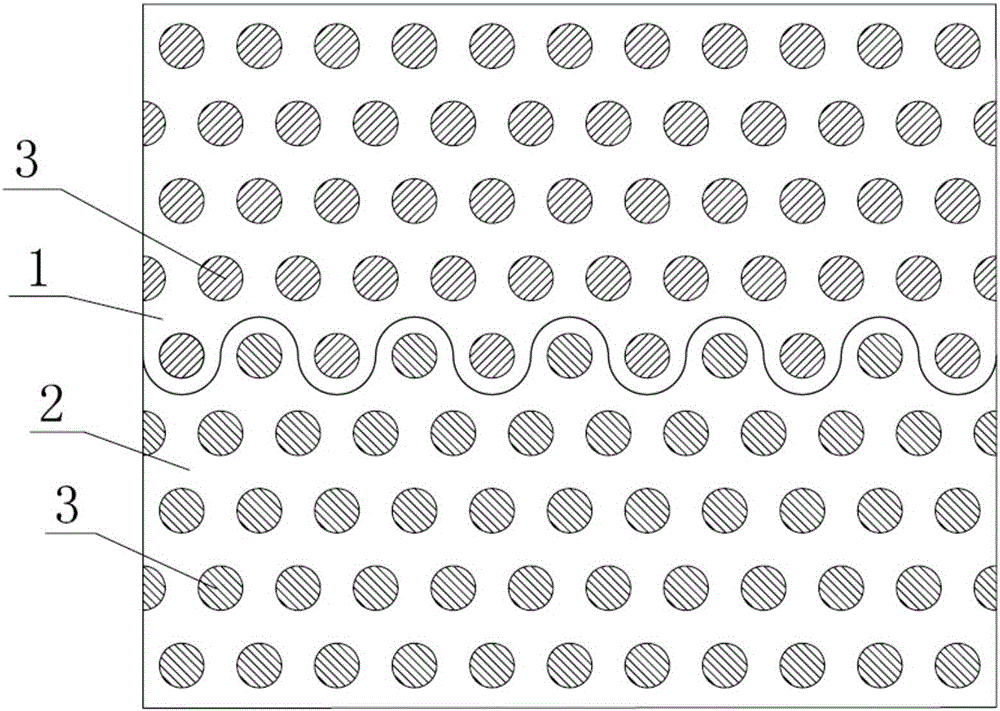

Light-emitting diode (LED) lamp board assembly

InactiveCN103258481AMachining accuracy is easy to guaranteeReduce stitching gapPlanar light sourcesLighting support devicesEngineeringLED lamp

The invention provides a light-emitting diode (LED) lamp board assembly which comprises a plurality of LED lamp boards (10) which are spliced mutually. Splicing portions are arranged between adjacent LED lamp boards (10). Each splicing portion comprises a first splicing edge (11) and a second splicing edge (12) adaptive to the first splicing edge (11) in terms of structure. A plurality of first connection protruded portions (111) and a plurality of first connection concave portions (121) are arranged on each first splicing edge (11) at intervals, a plurality of second connection concave portions (121) adaptive to the first connection protruded portions (111) in terms of shape and a plurality of second connection protruded portions (122) adaptive to the first connection concave portions (112) in terms of shape are arranged in each second splicing edge (12). The LED lamp board assembly can effectively reduce splicing gaps.

Owner:LEYARD

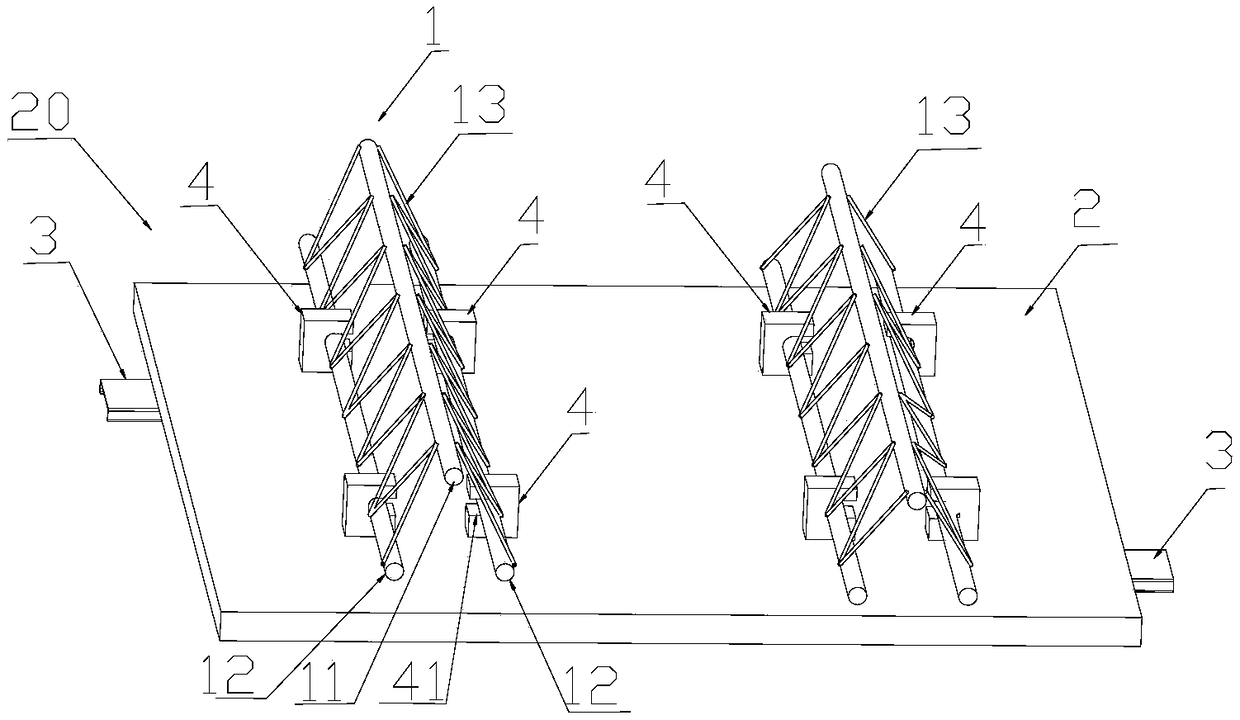

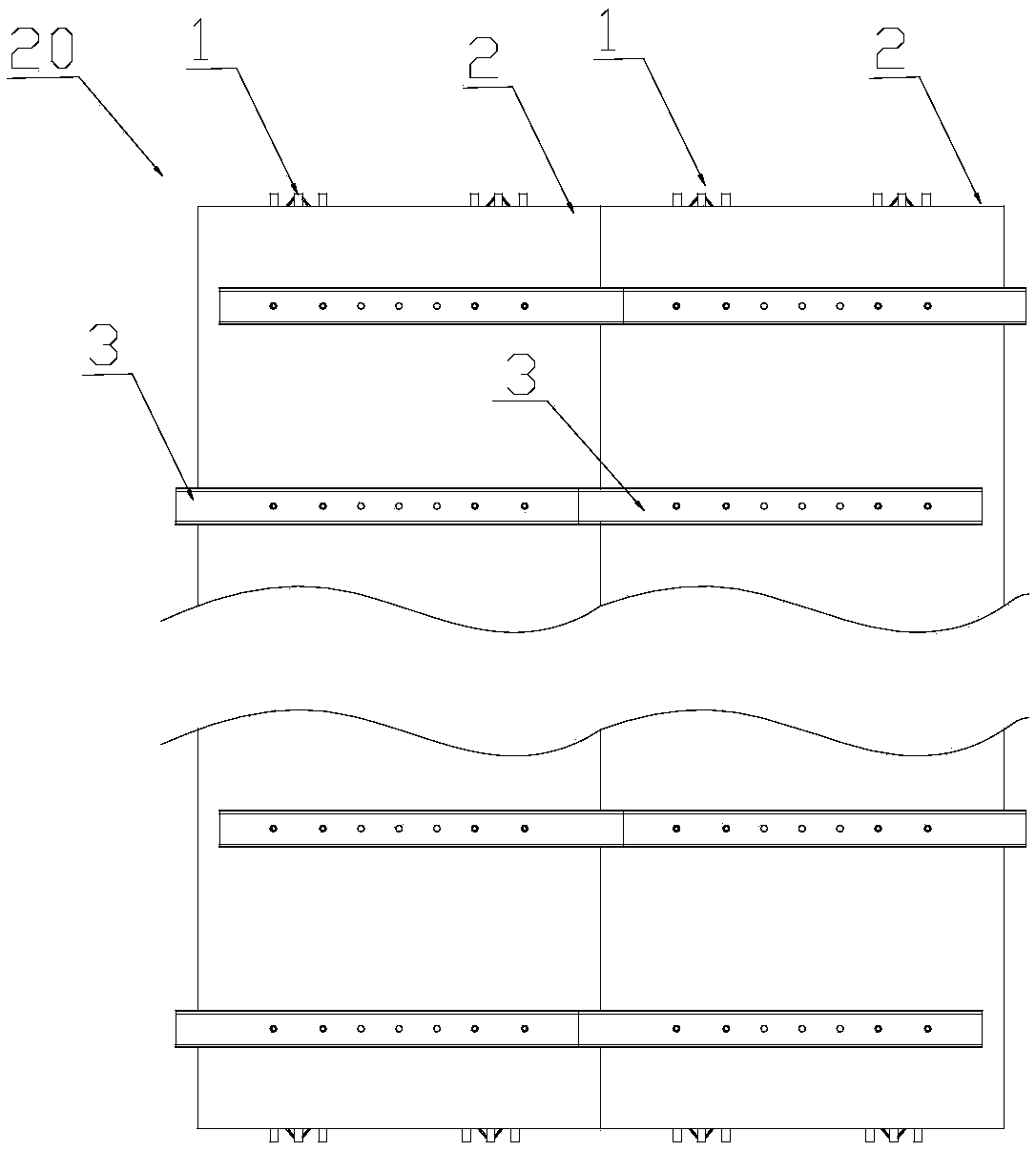

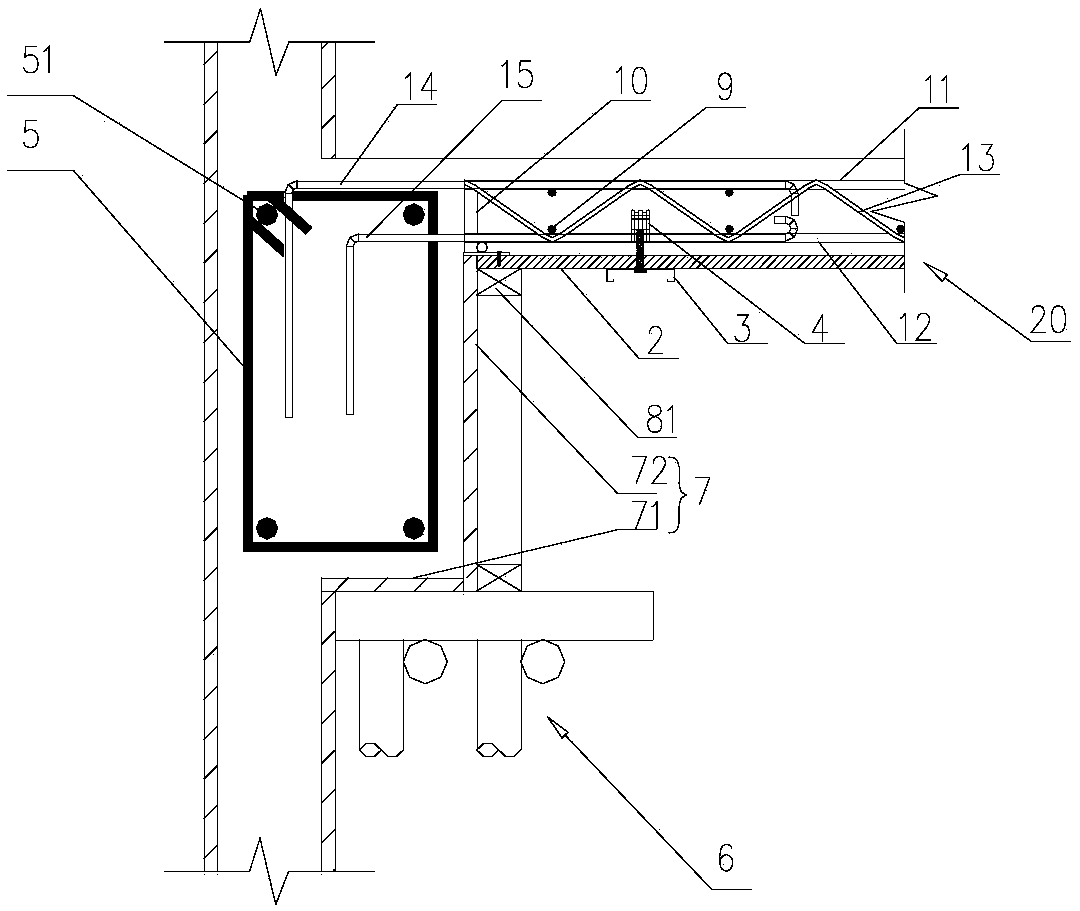

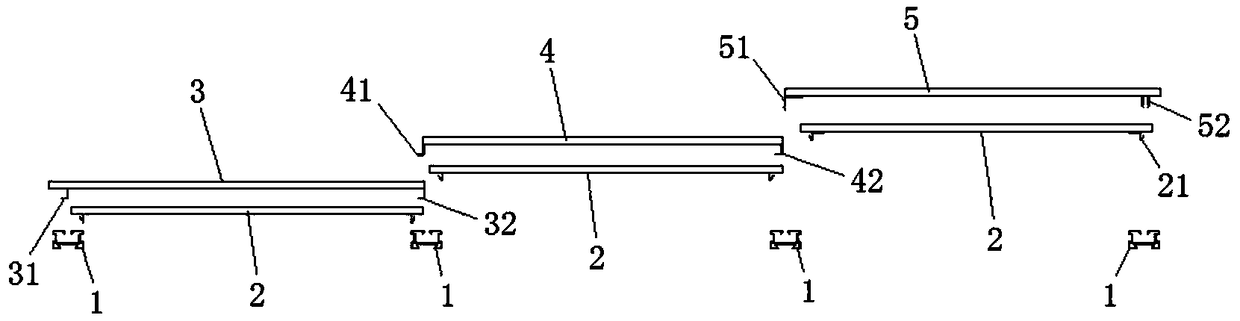

End supporting joint structure and construction method of detachable steel bar truss plate

PendingCN108625488ASimple stitchingEasy to dismantleFloorsForms/shuttering/falseworksSlurrySurface level

The invention relates to the field of concrete structure building construction, in particular to an end supporting joint structure of a detachable steel bar truss plate. The end supporting joint structure comprises the steel bar truss plate, a frame structure and a first supporting piece. The steel bar truss plate comprises a floor bearing plate and a steel bar truss detachably connected to one side of the floor bearing plate. A frame formwork is arranged on the outer side of the frame structure and comprises a side formwork, the floor bearing plate is arranged on one side of the side formwork, and the upper end of the side formwork and the upper surface of the floor bearing plate are equivalent in height. The first supporting piece is provided with the end for supporting the steel bar truss plate. The ends of the side formwork and the floor bearing plate mutually abut or are arranged in a clearance mode, thus splicing and dismantling of the side formwork and the floor bearing plate are easy and easy to operate, slurry is not prone to leaking, the formed floor face and the beam face or a wall face are good in transition, the pour-formed floor face is good in integrity, shock and impact resistance and waterproofness, and the floor face is level and can be directly whitewashed, assembled and disassembled.

Owner:ZHE JIANG ZHONGYI BUILDING MATERIALS TECH CO LTD

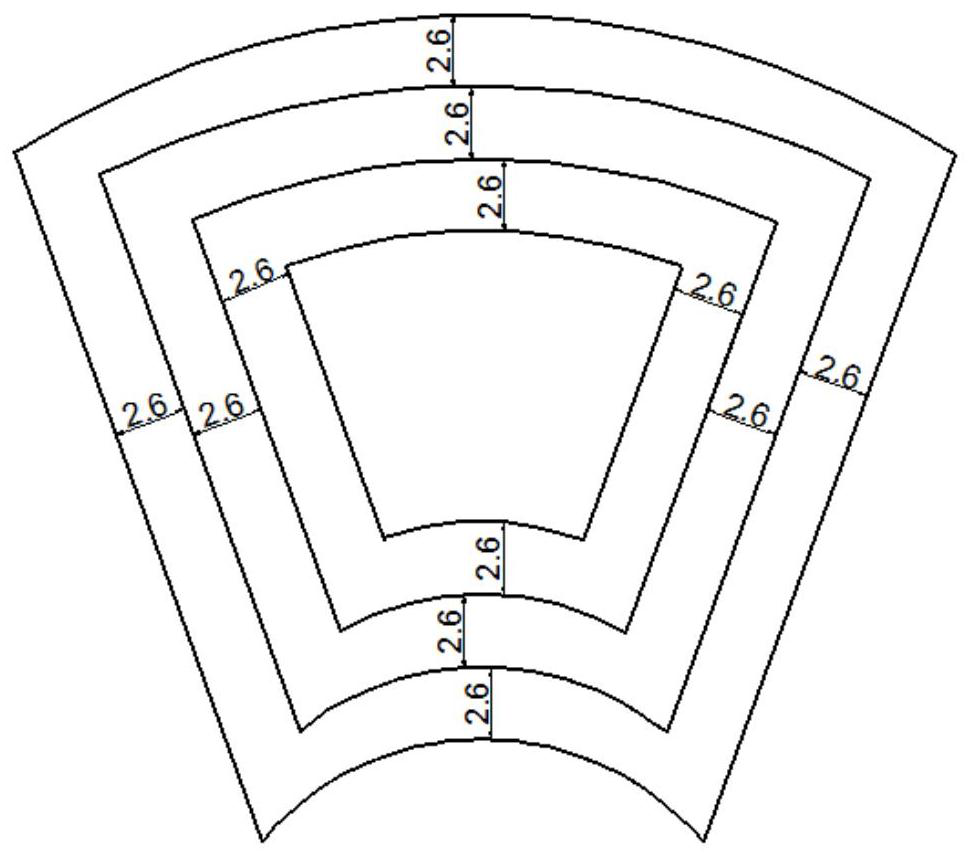

Large complex special-shaped curved surface composite thermal insulation layer and preparation method thereof

ActiveCN111923556AImprove thermal insulation performancePrevent collapse and accumulationLamination ancillary operationsSynthetic resin layered productsInsulation layerThermal insulation

The invention discloses a large complex special-shaped curved surface composite thermal insulation layer, which consists of a plurality of curved surface modules. Each curved surface module sequentially comprises an inner thermal insulation layer, a bonding layer, a solid thermal insulation layer and a protection layer. The inner thermal insulation layer of each curved surface module is made of acotton like material; the solid thermal insulation layer is formed by overlapping a plurality of paper like or felt like material thermal insulation layers and a plurality of reflecting layers in a crossed manner; the contour sizes of the thermal insulation layers and the reflection layers, which are mutually crossed and overlapped in the solid thermal insulation layer are sequentially increased by 1-5 mm from inside to outside, and the contour edges of the same sides of the thermal insulation layers and the reflection layers are aligned and attached to the same plane. The curved surfaces areused for splicing and fitting the curved surfaces to form the same outline as the curved surfaces, splicing gaps are reduced, the manufactured curved surfaces are smooth, the splicing gaps between thecurved surfaces are reduced, heat leakage is reduced, and the thermal insulation performance is improved. The service life is prolonged.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

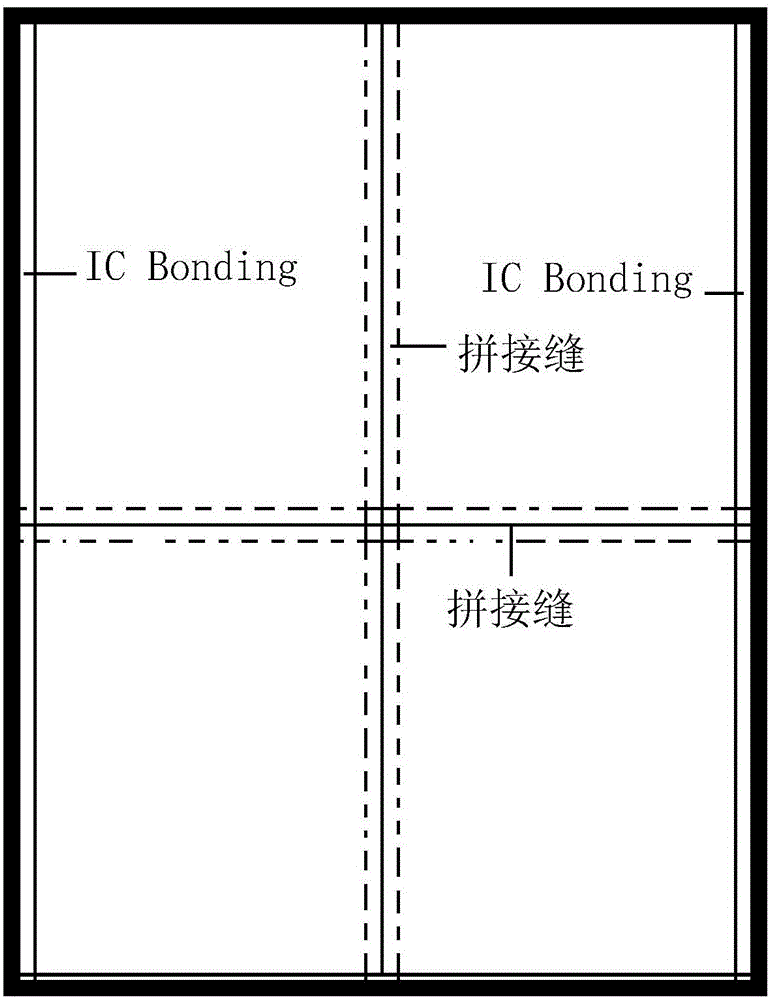

TFT-LCD display panel, manufacturing method thereof and display device

InactiveCN113031338AReduce black border sizeReduce stitching gapNon-linear opticsDisplay deviceEngineering

The invention discloses a TFT-LCD display panel and a manufacturing method thereof and a display device. The TFT-LCD display panel comprises a first substrate, a second substrate, a spacer, a shading part and a rubber frame. The first substrate comprises a display part and non-display parts connected to the two ends of the display part, and the second substrate is located on the inner side of the first substrate. The second substrate comprises a first supporting part and second supporting parts connected to the two ends of the first supporting part, the first supporting part corresponds to the display part, the second supporting parts correspond to the non-display part, the shock insulator is located between the display part and the first supporting part, and the liquid crystal element is located between the display part and the first supporting part. The shading part is located between the two non-display parts and the second supporting part, the shading part is bonded to the non-display parts and / or the second supporting part through the rubber frame, and the upper polaroid is attached to the outer side wall of the display part. According to the display panel, the size of the splicing seam can be well reduced, so that the visual effect is improved.

Owner:HUIZHOU VISION NEW TECH CO LTD

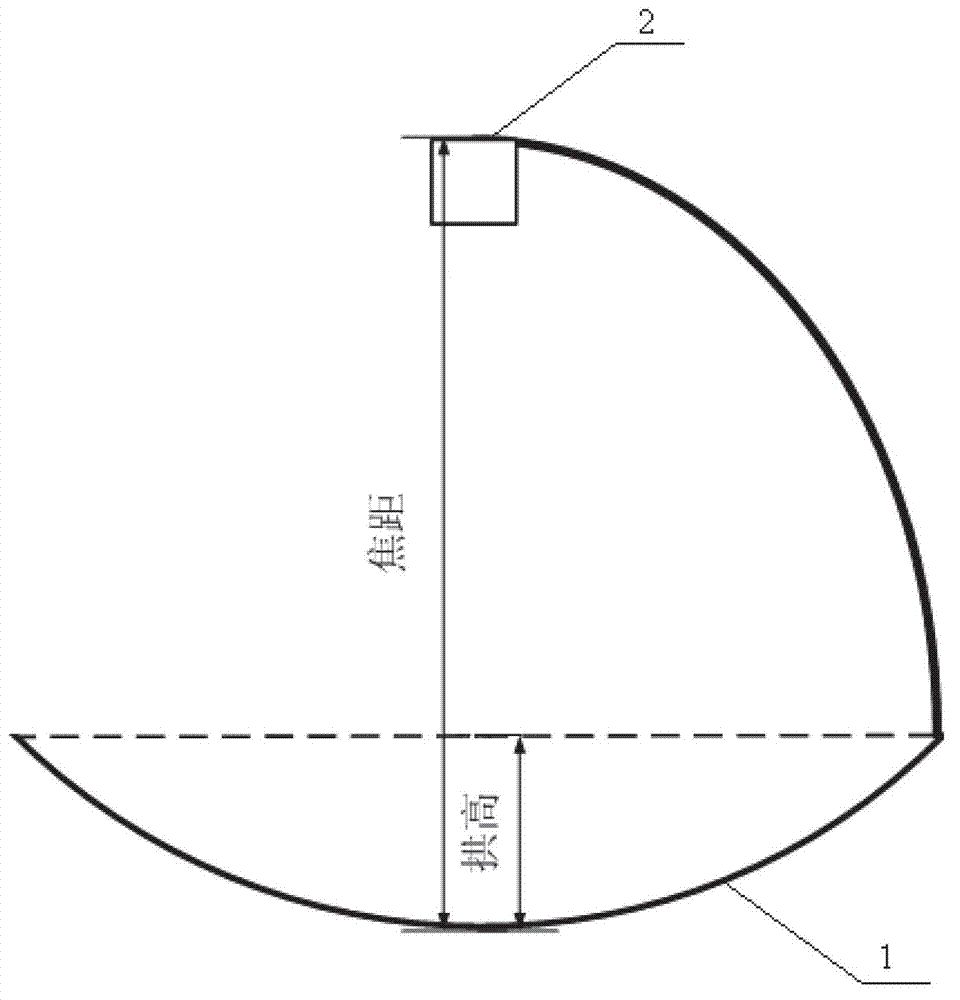

Solar power generation device

ActiveCN102790555AExtended service lifeReduce stitching gapPhotovoltaicsPhotovoltaic energy generationLight spotSolar power

The invention discloses a solar power generation device, which comprises a light reflector and a solar cell; the light reflector is shaped like a paraboloid of revolution, the paraboloid of revolution abides by a formula (y equal to x2 / 4f), wherein f is the focus of the paraboloid of revolution, and the light reflector consists of one to six reflecting surfaces; and the solar cell is arranged at the position of the focus of the light reflector. Since the light reflector is shaped like the paraboloid of revolution and consists of one to six reflecting surfaces, the connecting gaps between the small reflecting surfaces are reduced, the diameter of the condensed light spot at the focus is less than 5mm, the sunlight utilization efficiency of the solar power generation device is greatly increased, and meanwhile, the service life of the light reflector is greatly prolonged. Since the solar cell is arranged at the position of the focus of the light reflector, light is reflected only once; meanwhile, since the weather fastness of the light reflector is greatly enhanced and the service life of the light reflector is greatly prolonged, the light reflector can be exposed in the outside environment, and thereby the energy utilization efficiency of the solar power generation device is increased.

Owner:JIANGSU ENEUTRAL NEW ENERGY TECH CO LTD

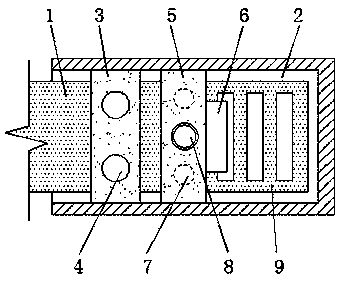

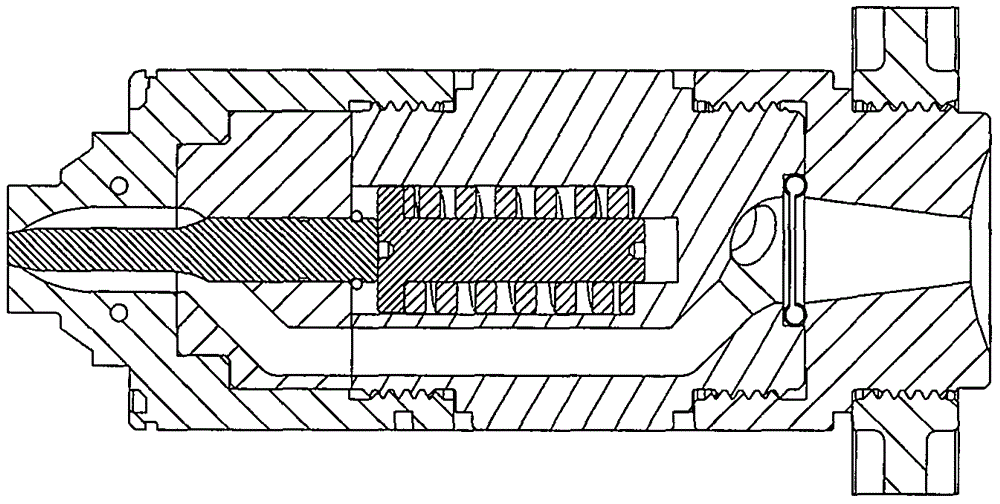

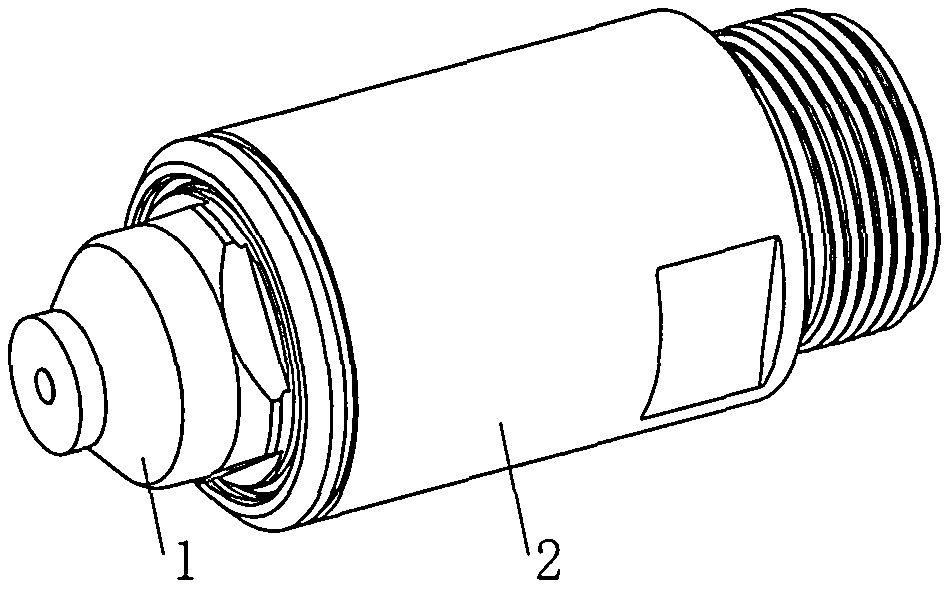

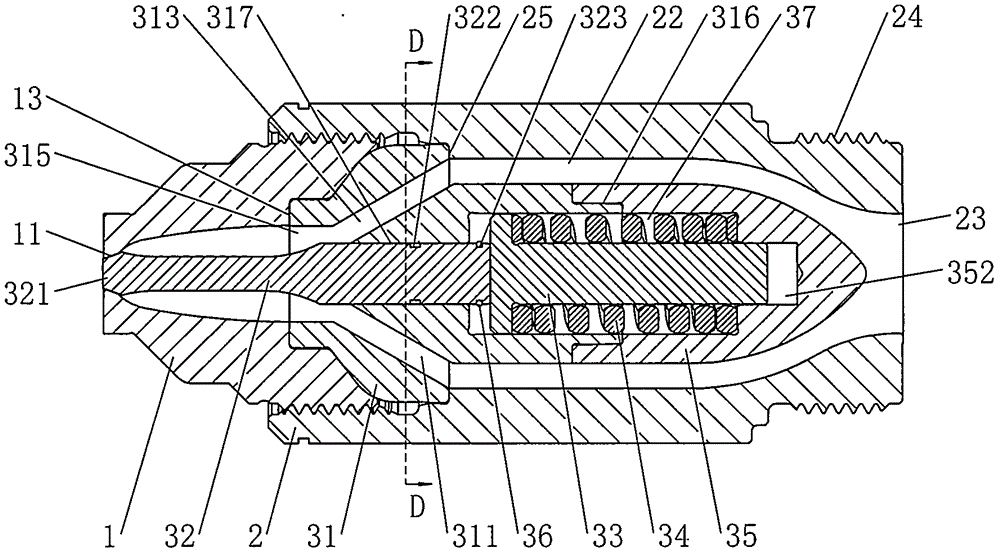

Direct-injection sprue type passive needle valve

InactiveCN105937631AImprove color changeReduce stitching gapLift valveValve housingsColor changesBiomedical engineering

A direct-injection sprue type passive needle valve comprises a valve mouth, a valve body and a valve core. The valve core is majorly composed of a valve core body, a valve needle, a push rod, a spring and a valve core lid. At least two sub-runners are evenly distributed on the valve core in the circumferential direction. A stepped through hole is formed in the center of the valve core body. A stepped hole is formed in the center of the valve core lid. The stepped hole of the valve core lid and the stepped through hole of the valve core body are jointed in a butt joint mode to form a cavity. The push rod and the spring are arranged inside the cavity. The valve needle is arranged in the stepped through hole of the valve core body. The valve mouth is arranged at one end, close to the valve needle, of the valve core in a sleeving mode. The other end of the valve core is sleeved with the valve body. A passageway is formed from a small hole end of the valve body to a center ejection opening of the valve mouth. According to the direct-ejection sprue type passive needle valve, the flow resistance inside the sub-runners in the needle valve is reduced, the color changing property of the passive needle valve is improved, the difficulty of assembling and maintenance is reduced, the maintenance time period is shortened, and the cost of after-sales service is reduced.

Owner:高建鸣

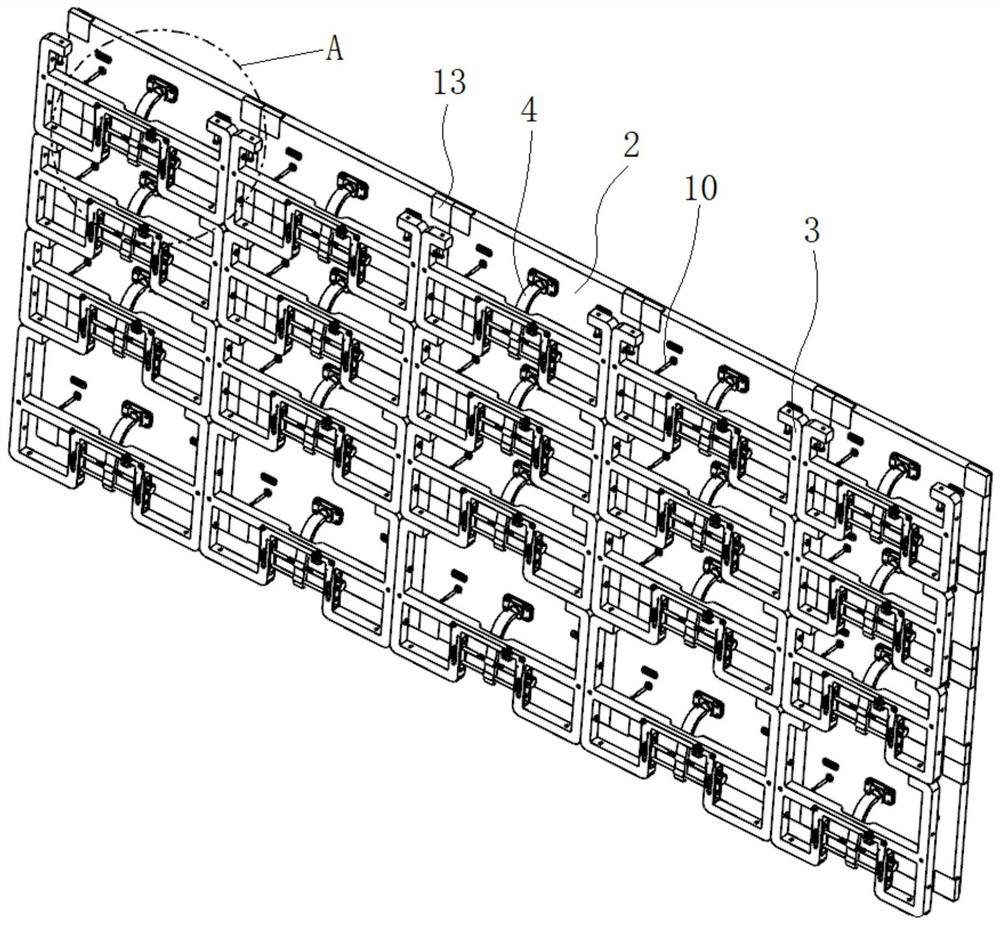

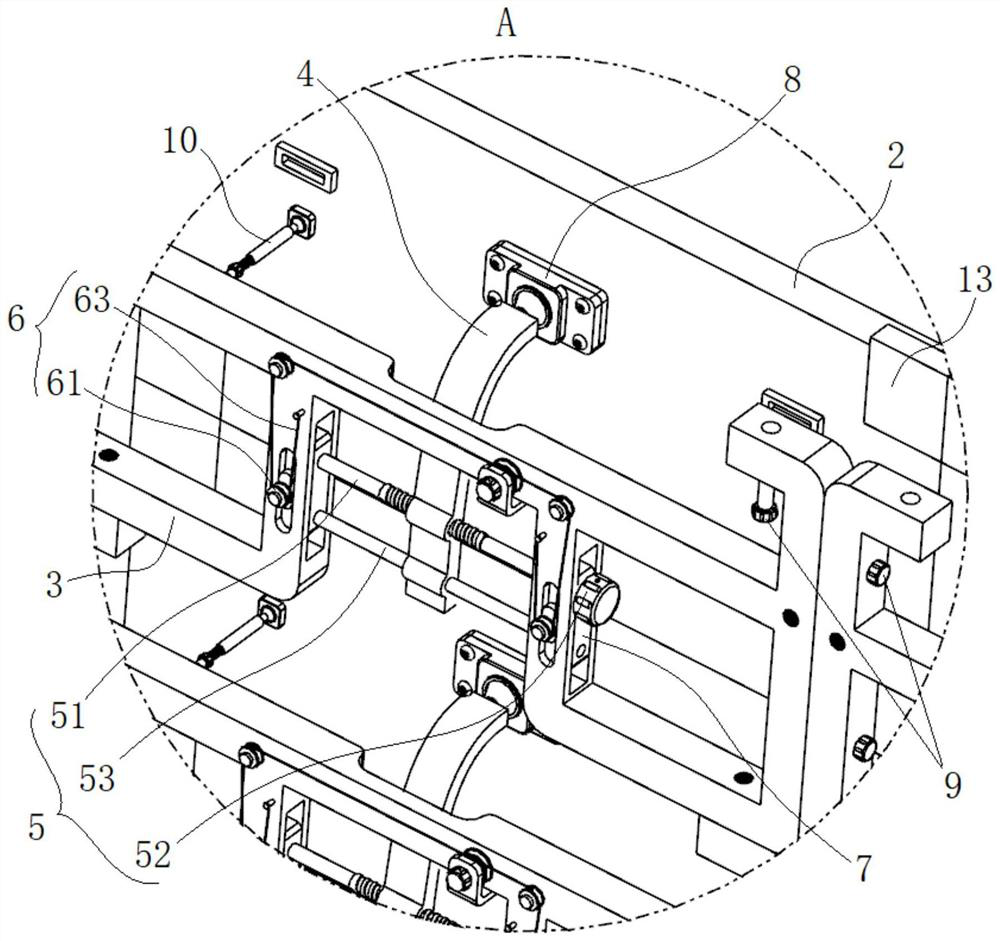

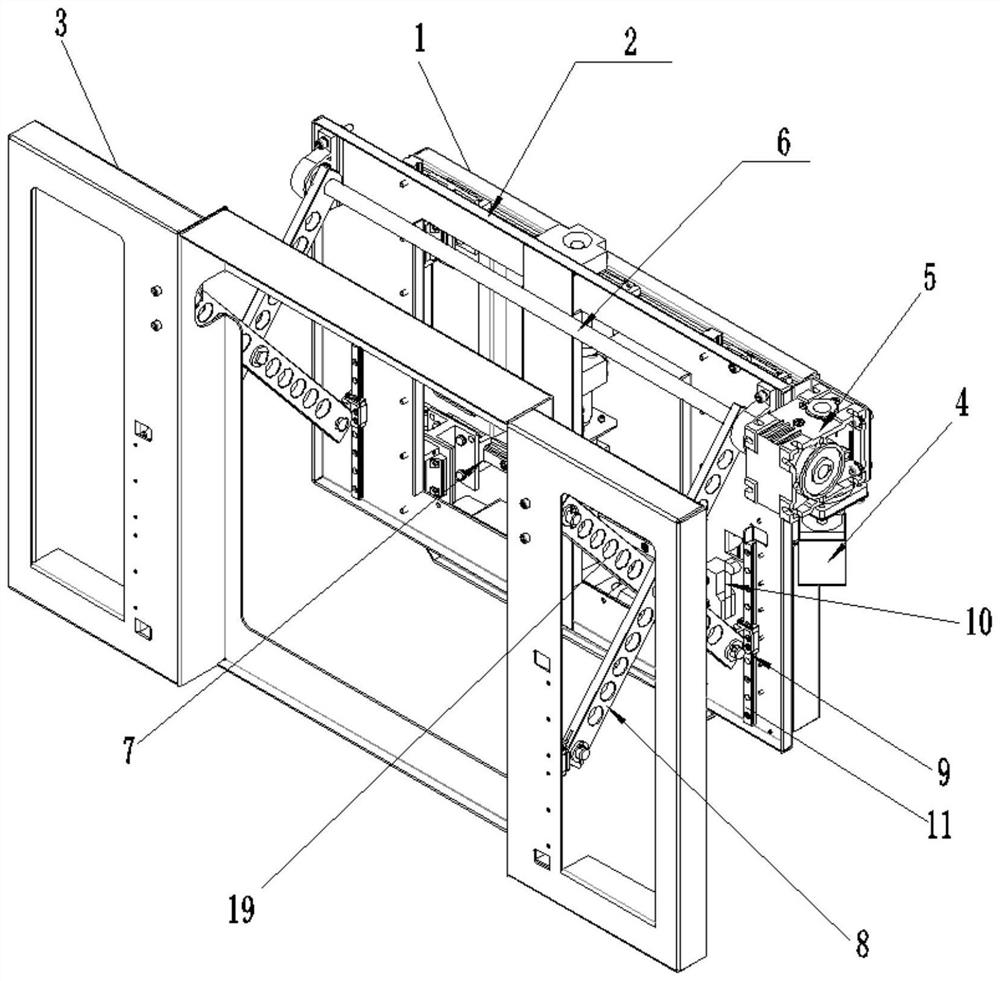

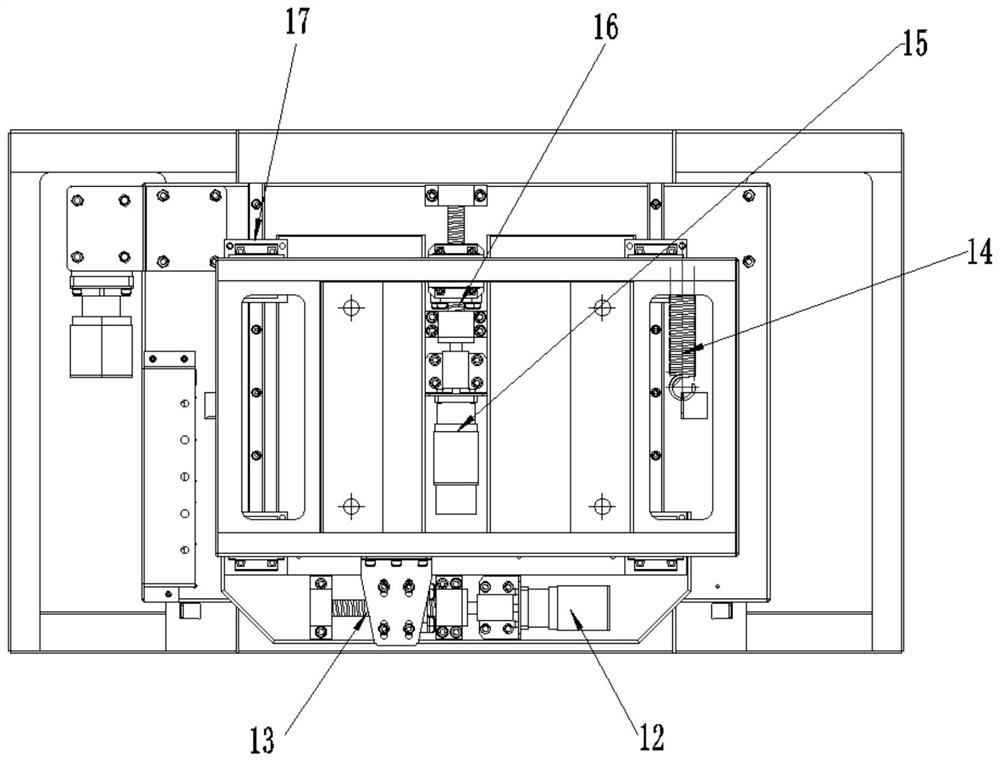

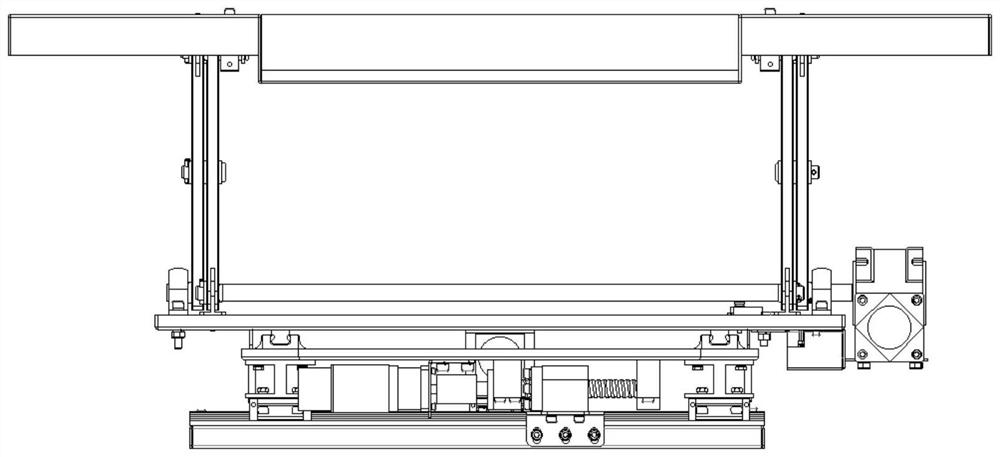

Display screen splicing, supporting and regulating device for screen

InactiveCN111649195AMeet the needs of splicing installationGood lookingStands/trestlesIdentification meansElectric machineryEngineering

The invention relates to a display screen splicing, supporting and regulating device for a screen. The display screen splicing, supporting and regulating device comprises a fixed plate, a transition plate, a display screen mounting plate, a transverse regulating mechanism, a vertical regulating mechanism and a horizontal regulating mechanism, wherein the transition plate is mounted on the front part of the fixed plate; the transverse regulating mechanism is mounted between the fixed plate and the transition plate; under drive of the transverse regulating mechanism, the transition plate slidesin the horizontal direction of the fixed plate; the front part of the transition plate is equipped with a slide plate; the vertical regulating mechanism is mounted between the transition plate and theslide plate; under drive of the vertical regulating mechanism, the slide plate slides in the vertical direction of the fixed plate. The display screen splicing, supporting and regulating device has the advantages that: market display screen splicing mounting needs can be met; an instruction is send by an upper computer for the regulating process of the display screen, and a step motor performs drive, so that the operation process is simple and easily controlled precisely, and filed layout is simple.

Owner:沈阳易诚智讯科技发展有限公司

LED display device

The invention provides an LED (Light-emitting Diode) display device which comprises an LED display board (1), and a mask arranged on one side of the LED display board (1), wherein the mask comprises a plurality of light-transmission cover units (10); the light-transmission cover units (10) are bonded with the LED display board (1); a locating structure is arranged among the light-transmission cover units (10) and the LED display board (1) and used for limiting pasting positions of the light-transmission cover units (10) on the LED display board (1); each light-transmission cover unit (10) is provided with a first side (11) facing towards the LED display board (1) and a second side (12) departing from the LED display board (1); and the second sides (12) are in plane shapes and provided with mirror face semi-permeable membranes. The LED display device is small in splicing gap, better in smoothness, and better in display effect.

Owner:LEYARD

Ultra-wide silk screen dot print film splicing method

The invention relates to an ultra-wide silk screen dot print film splicing method. The method includes the following steps that two or more laser film pieces with same dot patterns are manufactured, the film pieces are overlapped and spliced, so that the overlapped width is just the needed width of a silk screen, and the dot patterns on the upper and lower film pieces at spliced joints are completely coincident; dots of overlapped parts of the film pieces are removed through a hole punching tool, therefore the dot patterns are arranged at intervals, and the edges of the sides of the upper and lower film pieces form concave-convex structures which can be mutually embedded and matched in a concave-convex mode; and after cutting, the two film pieces are flatly spread on a pre-sunned screen printing plate, horizontal embedding-matching approaching of the concave and convex edges is performed, the spliced positions are fixed through transparent adhesive tape, then air pumping, flattening and exposure are started, and ultra-wide film is obtained. According to the ultra-wide silk screen dot print film splicing method, a semi-circle concave-convex embedding-matching mode is adopted, so that the two film pieces are spliced to form a large film piece, the spliced joints are small, and one-time printing is only needed; and the printed patterns do not have spliced lines which exist during two-time printing and splicing, and the dot patterns in the spliced positions are complete and attractive.

Owner:TIANJIN NORTH GLASS IND TECHN

Assembly type wall body and mounting method thereof

The invention discloses an assembly type wall body and a mounting method thereof. The assembly type wall body comprises a special-shaped keel, an inner wall board, a starting outer wall board, a middle outer wall board and an ending outer wall board; a first buckling position is formed at the front side of the special-shaped keel; second buckling positions are formed at the left side and right side of the special-shaped keel respectively; two sides of the back surface of the inner wall board are respectively provided with inner wall buckles buckled to the second buckling positions; two sides othe back surface of the starting outer wall board are respectively provided with first outer wall buckling edges which are buckled to the first buckling position; two sides of the back surface of themiddle outer wall board are respectively provided with second outer wall buckling edges which are buckled to the outer sides of the first outer wall buckling edges, the outer sides of second outer wall buckling edges or the first buckling position; and two sides of the back surface of the ending outer wall board are respectively provided with outer clamping buckles which are buckled to the outersides of the first outer wall buckling edges, the outer sides of the second outer wall buckling edges or the first buckling position. The invention also discloses a mounting method applied to the assembly type wall body. With the mounting method adopted, the mounting mode of the wall body is more convenient and quicker; the wall body is easy to remove; and the structure of the wall body can be flatter and more compact.

Owner:广东爱特仕建材有限公司

Display panel and preparation method and device

PendingCN113178139AReduce areaReduce stitching gapSolid-state devicesIdentification meansStructural engineeringMechanical engineering

The embodiment of the invention discloses a display panel and a preparation method and device. The display panel comprises a plurality of sub-panels, wherein each sub-panel comprises a first substrate, a second substrate, frame glue located between the first substrate and the second substrate, a plurality of retaining wall structures and a plurality of light-emitting elements, at least one light-emitting element forms a pixel unit and the retaining wall structures are located between the adjacent pixel units; and joint glue positioned between the adjacent sub-panels, wherein the first substrates of the plurality of sub-panels are the same first substrate, the joint glue is arranged on the first substrate, the first substrate comprises a display area and a non-display area surrounding the display area; the light-emitting elements and the retaining wall structure are located in the display area, and the frame glue is located in the non-display area. According to the display panel provided by the embodiment of the invention, the splicing gaps between the adjacent sub-panels can be effectively reduced, so that the display effect of the display panel is improved.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com