Patents

Literature

117results about How to "Improve stitching quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

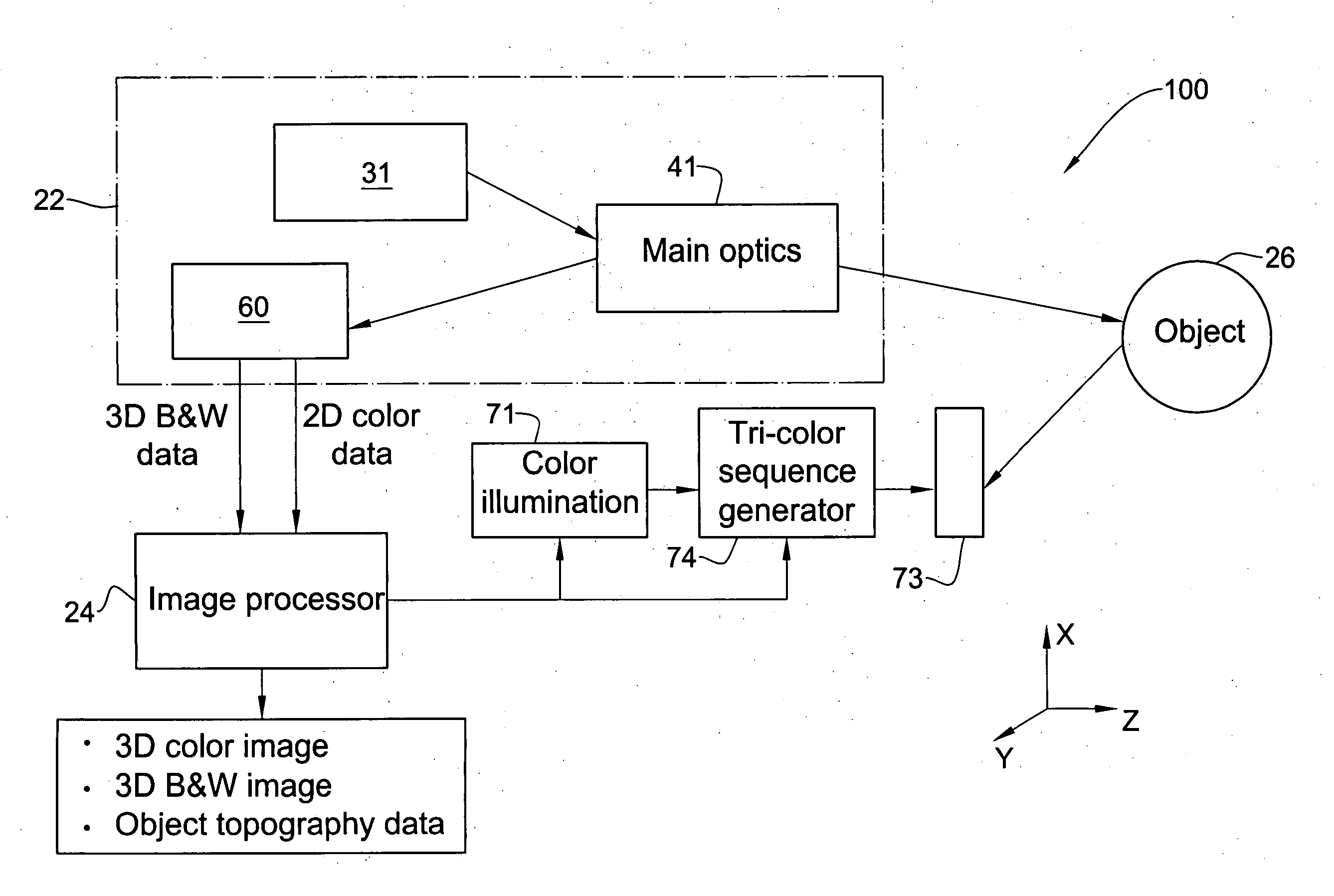

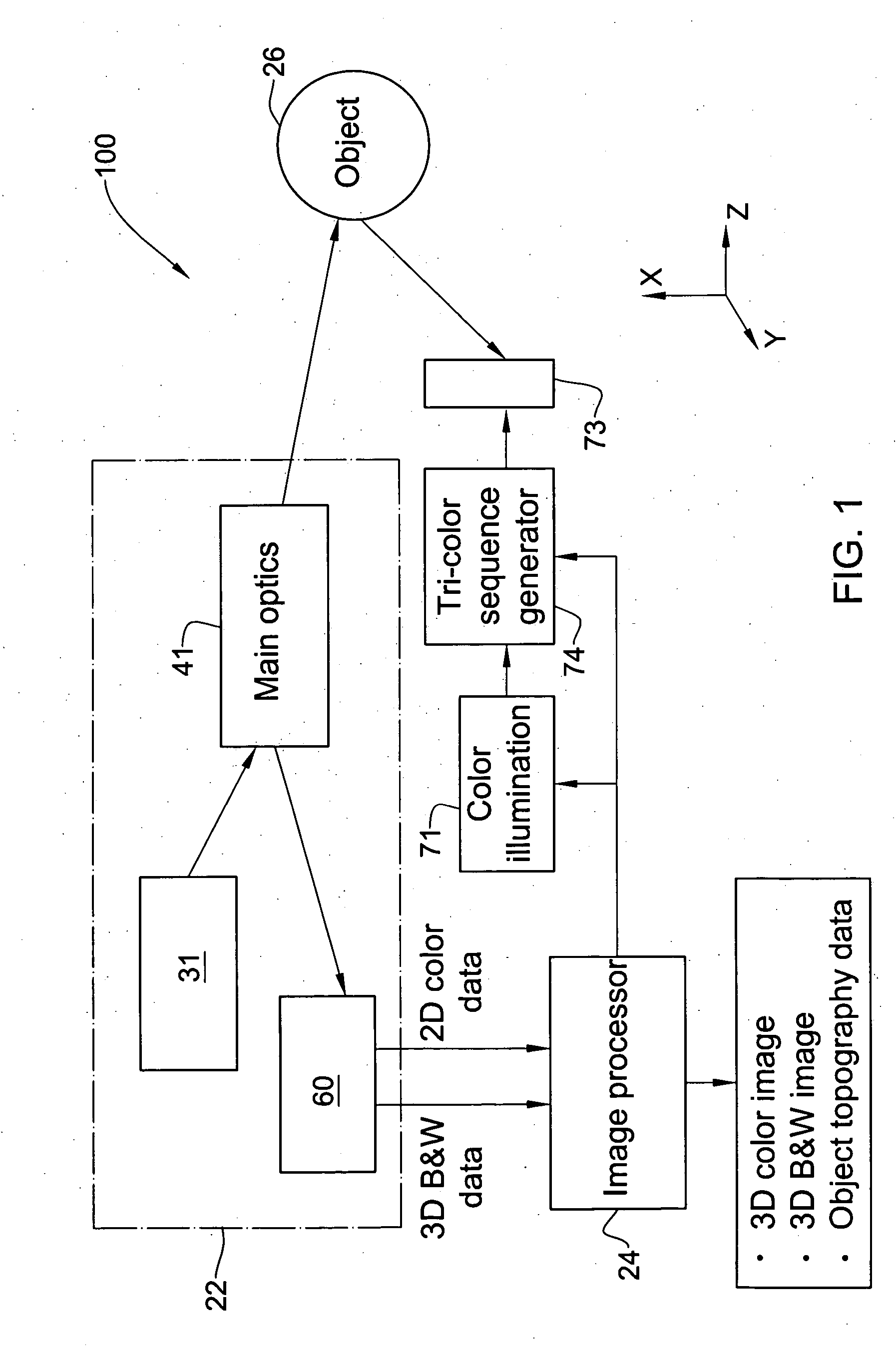

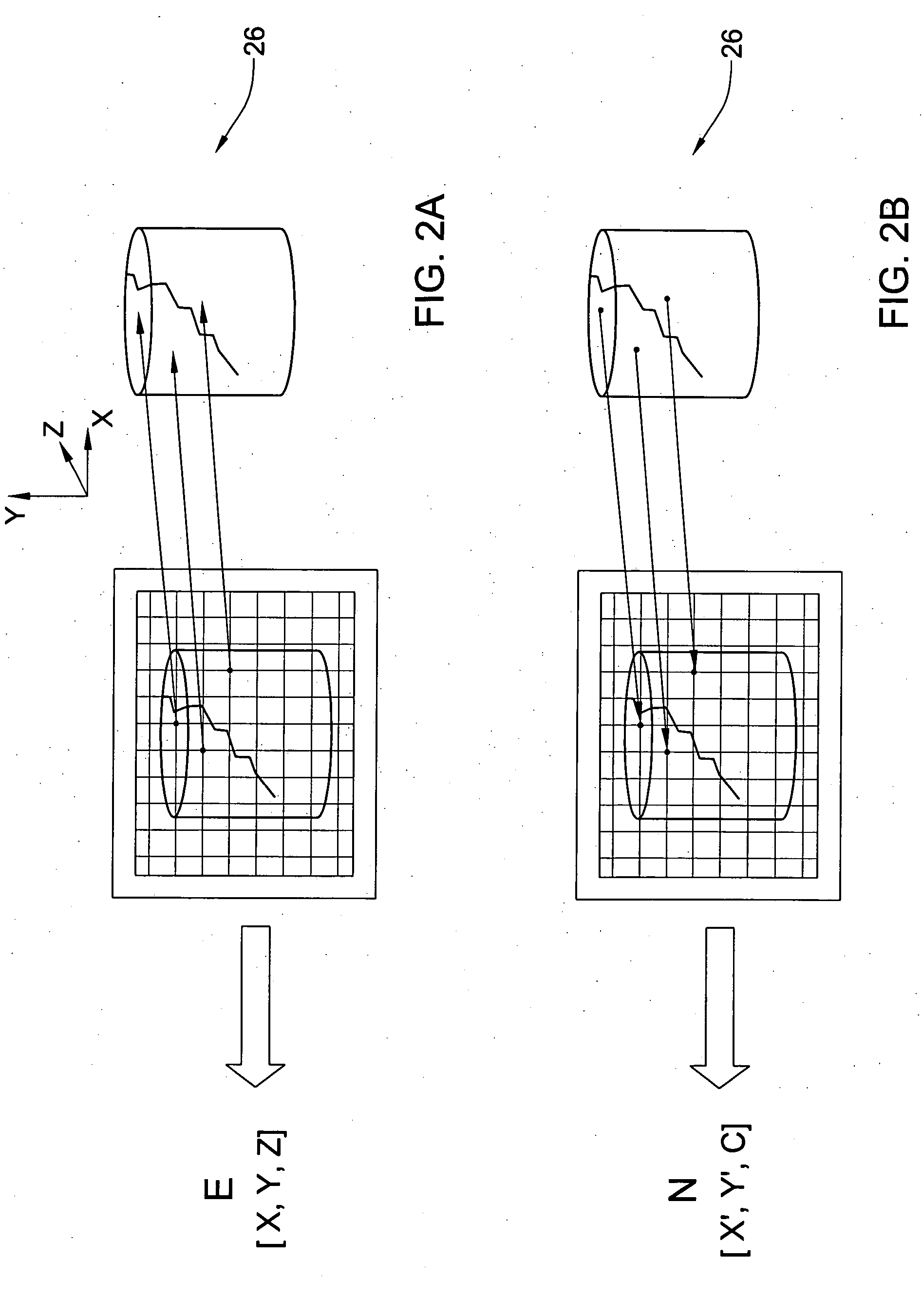

Method for providing data associated with the intraoral cavity

ActiveUS20050283065A1Improve stitching qualityQuality improvementImage enhancementImpression capsComputer scienceThree dimensional surface

A method for providing data useful in procedures associated with the oral cavity, in which at least one numerical entity representative of the three-dimensional surface geometry and color of at least part of the intra-oral cavity is provided and then manipulated to provide desired data therefrom.

Owner:ALIGN TECH

Image splicing method and equipment

InactiveCN101923709AHigh speedEliminate visual inconsistenciesTelevision system detailsImage enhancementVisual perceptionImage splicing

The invention discloses an image splicing method and image splicing equipment which are used for splicing an image rapidly and do not reduce the quality of the spliced image. The method comprises the following steps of: determining a quilt between a first image and a second image; dividing pixels of the first image and the second image into a foreground pixel and a background pixel; splicing the foreground pixel of the first image and the second image based on the quilt; and deforming the background pixel and enabling the background pixel to be fused with the spliced foreground pixel. The method has the characteristics of simple algorithm and high speed. Layered splicing is adopted, and background deformation adapts to the foreground pixel splicing, therefore the inconsistency of vision is eliminated and the quality of image splicing is high.

Owner:NEC (CHINA) CO LTD

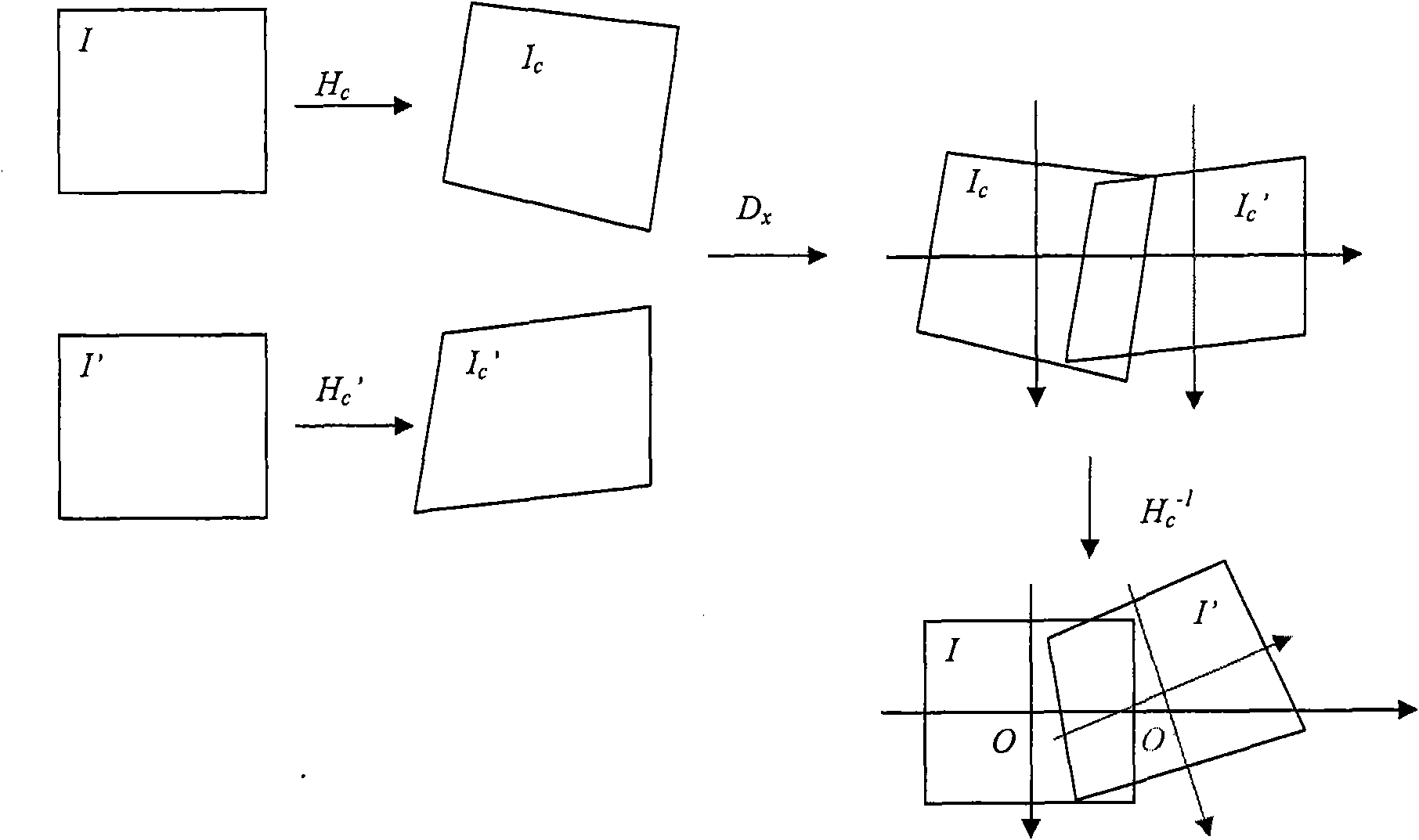

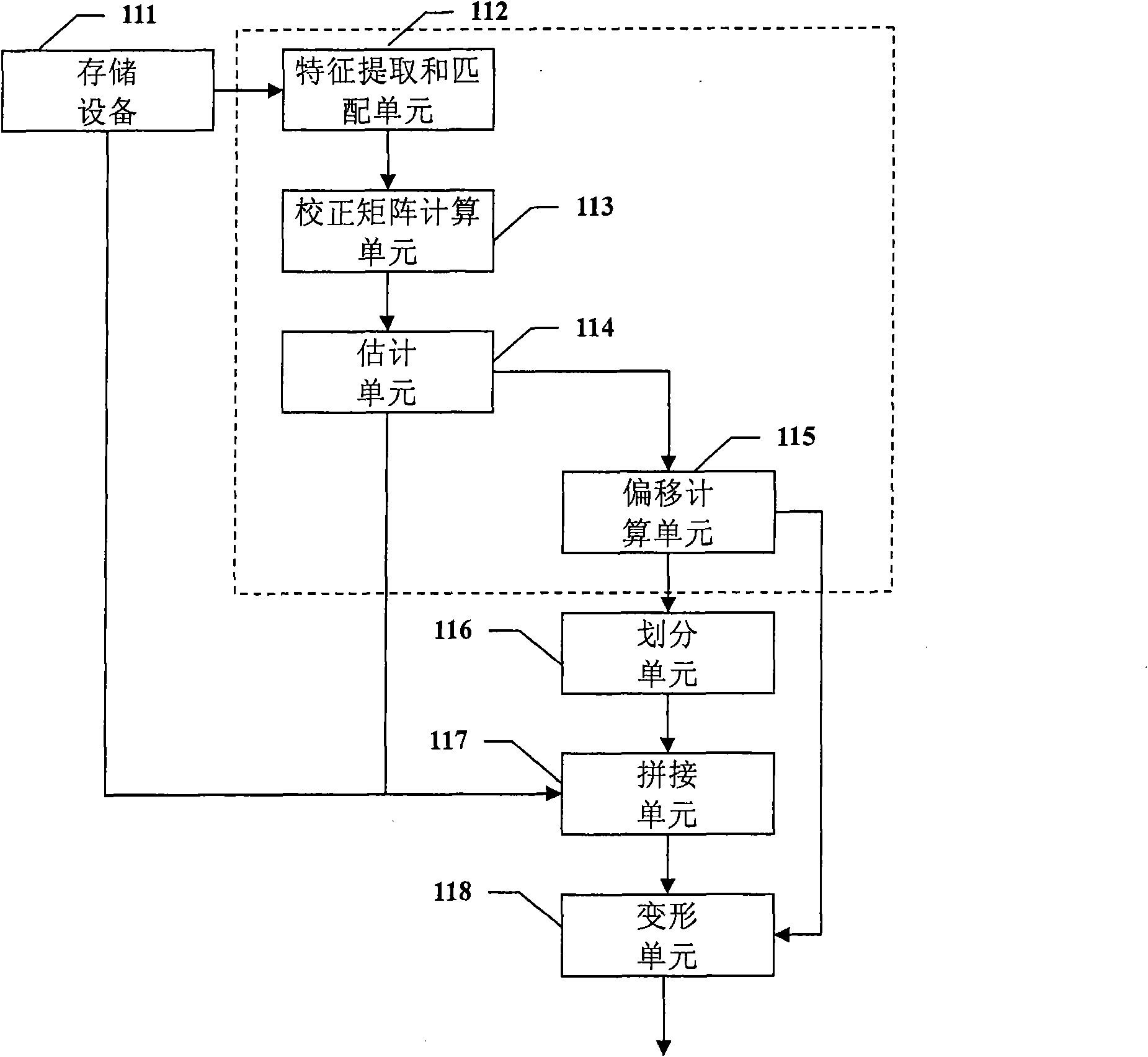

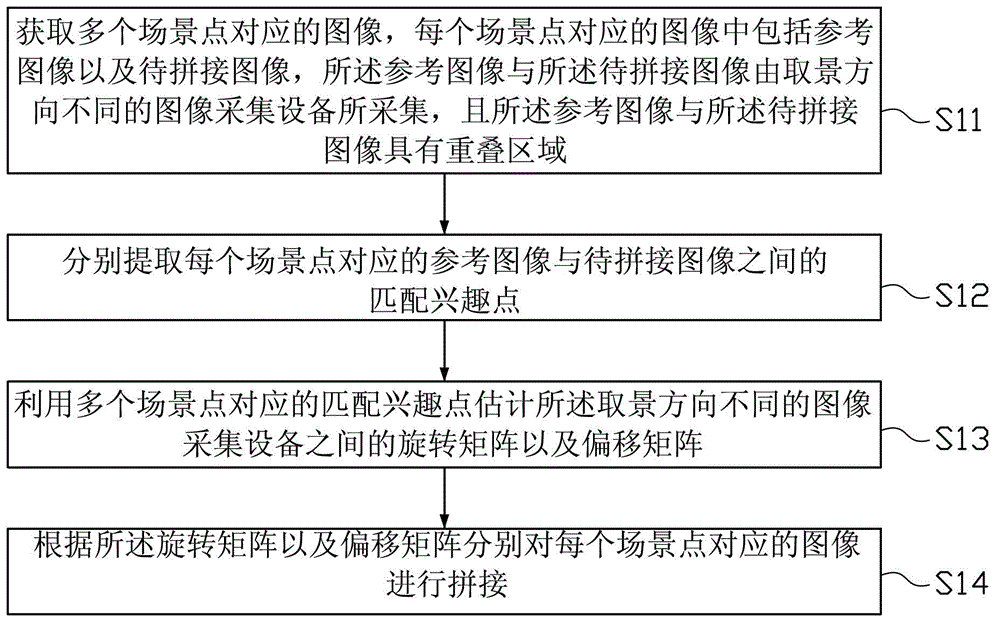

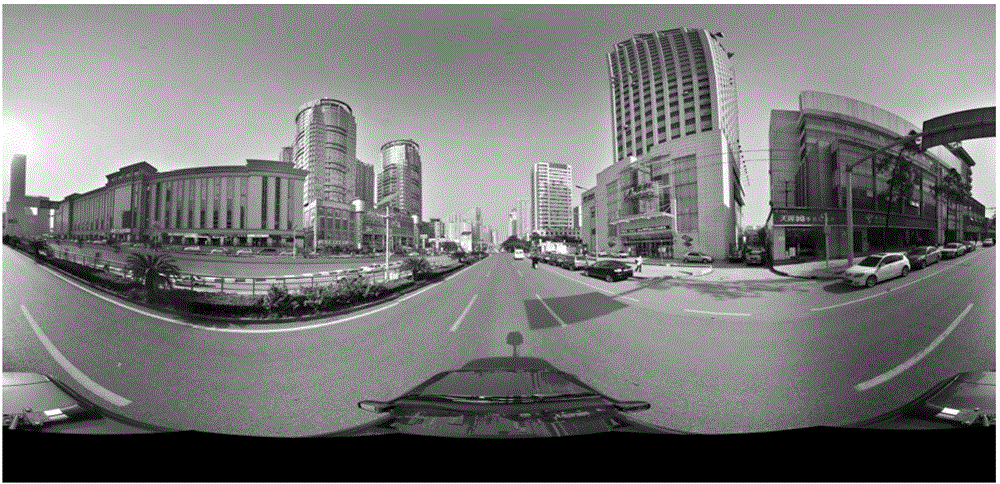

Image stitching processing method and device

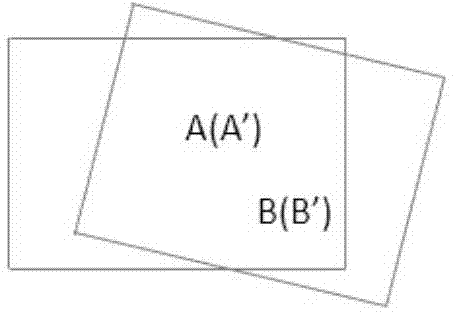

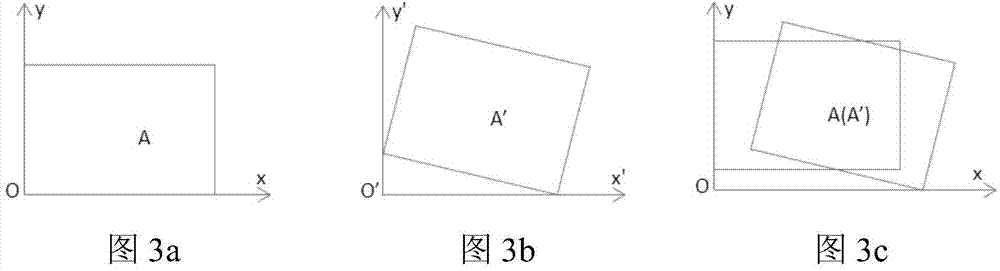

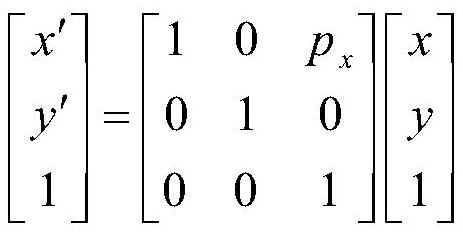

ActiveCN103150715AImprove stitching qualityReduce stitching gapImage enhancementGeometric image transformationExternal referenceReference image

The invention provides an image stitching processing method and device. The method comprises the following steps of: acquiring images which correspond to multiple scene points, wherein an image which corresponds to each scene point comprises a reference image and to-be-stitched images, the reference image and the to-be-stitched images are acquired by different image acquisition devices in the view direction, and the reference image and the to-be-stitched images have overlap areas; respectively extracting matching interest points between the reference image and the to-be-stitched images which correspond to each scene point; estimating rotation matrixes and offset matrixes among the different image acquisition devices in the view direction by utilizing the matching interest points which correspond to the scene points; and respectively stitching the images which correspond to all the scene points according to the rotation matrixes and the offset matrixes. According to the image stitching processing method and device provided by the invention, external references of the image acquisition devices are estimated by utilizing the matching interest points of the images which correspond to the scene points to stitch the images which correspond to all the scene points, and therefore, errors brought by the image acquisition devices can be more equally dispersed, and the stitching quality of the images is improved.

Owner:SHENZHEN TENCENT COMP SYST CO LTD

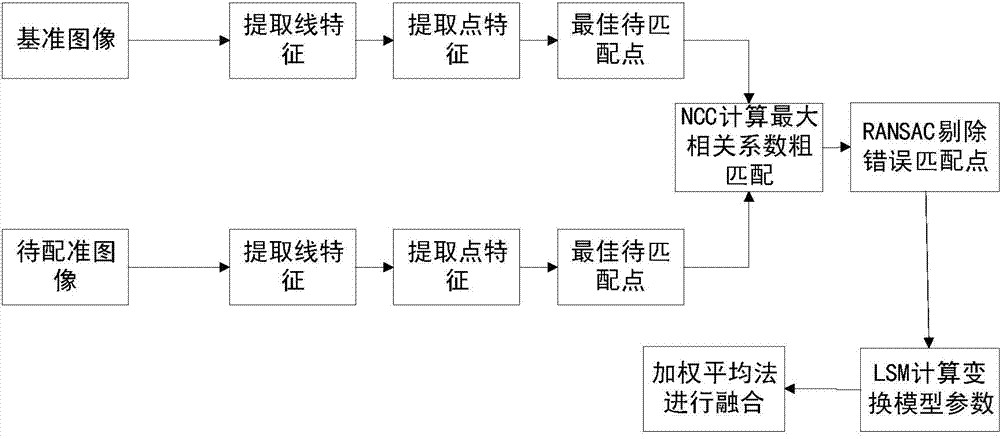

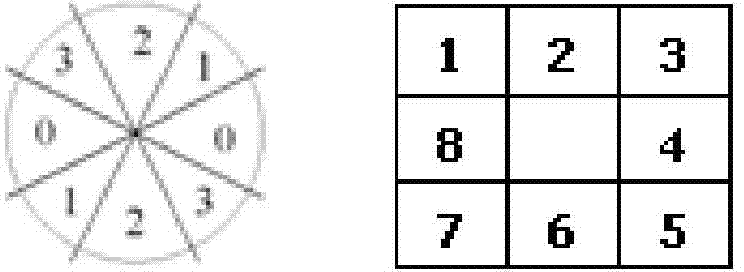

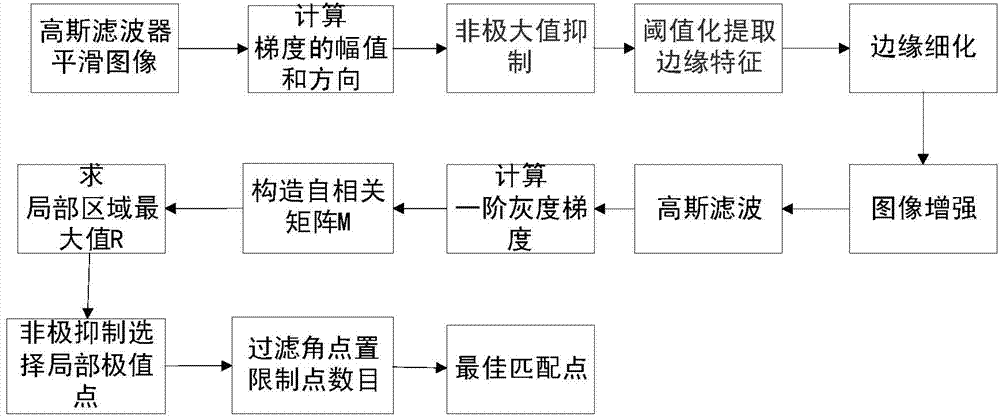

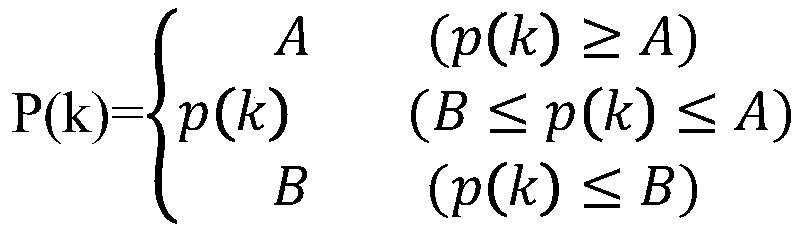

Rapid image splicing method based on point and line features

ActiveCN103679636AImprove stitching qualityAvoid lossImage enhancementGeometric image transformationWeighted average methodModel parameters

The invention provides a rapid image splicing method based on feature matching. The method includes the steps: respectively extracting line features and point features of images by the aid of a Canny edge detection algorithm and a Harris corner point detection algorithm and combining the line features and the point features to obtain the best feature points; roughly matching the feature points by the aid of similarity metric NCC (normalized cross correlation), removing mismatched points by the aid of an RANSAC (random sample consensus) algorithm to improve image matching accuracy, and calculating transformation model parameters by an LSM (least square method); finally, fusing the spliced images by a weighted average method and eliminating splicing gaps. The points to the matched are determined according to the point and line image features, image details can be enhanced, image matching errors caused by underexposure, overexposure, camera shake and the like are avoided, and image splicing quality is improved to a certain degree.

Owner:JIANGSU R & D CENTER FOR INTERNET OF THINGS

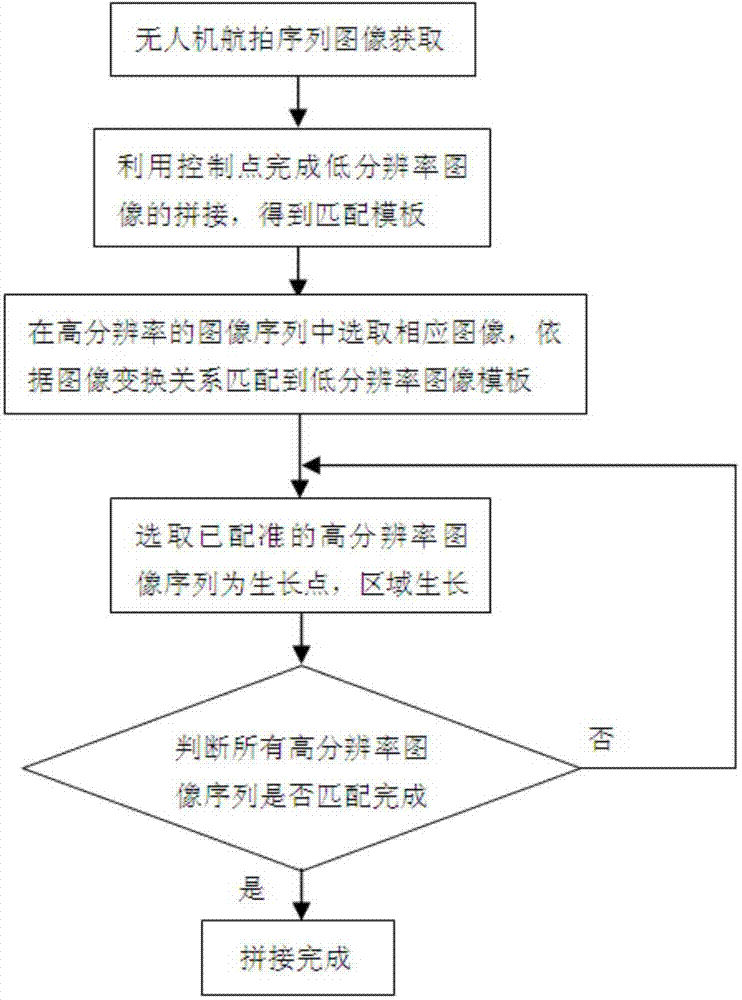

Multi-resolution image stitching method based on control points

InactiveCN104732482ARealize real-time stitchingAvoid accumulationImage enhancementGeometric image transformationImage resolutionHigh resolution image

The invention discloses a multi-resolution image stitching method based on control points. The multi-resolution image stitching method includes the steps that 1, unmanned-aerial-vehicle aerial photography sequence images are obtained, wherein rotation and transverse-movement transformation relations of the images are obtained through two sets of ground control point pairs in overlapped areas of the adjacent frames of low-resolution images, and finally the low-resolution sequence images are stitched and fused; 2, the stitching result of the low-resolution sequence images serves as a high-accuracy matching template, and final integral image matching is completed from coarse to fine; 3, the high-resolution sequence images matched to the template serve as growing points, the high-resolution sequence images of four adjacent regions of the growing points are stitched and fused through region growing, and the corresponding low-resolution images are replaced; then the high-resolution images of four adjacent regions serve as new region growing points for continuous growing till all the sequence images are matched to the template. By means of the multi-resolution image stitching method, the technical problems that in the existing image stitching technology, the image matching efficiency is low, and the aerial photography sequence images can not be stitched in real time are solved.

Owner:NO 63655 TROOPS OF THE CHINESE PEOPLES LIBERATION ARMY

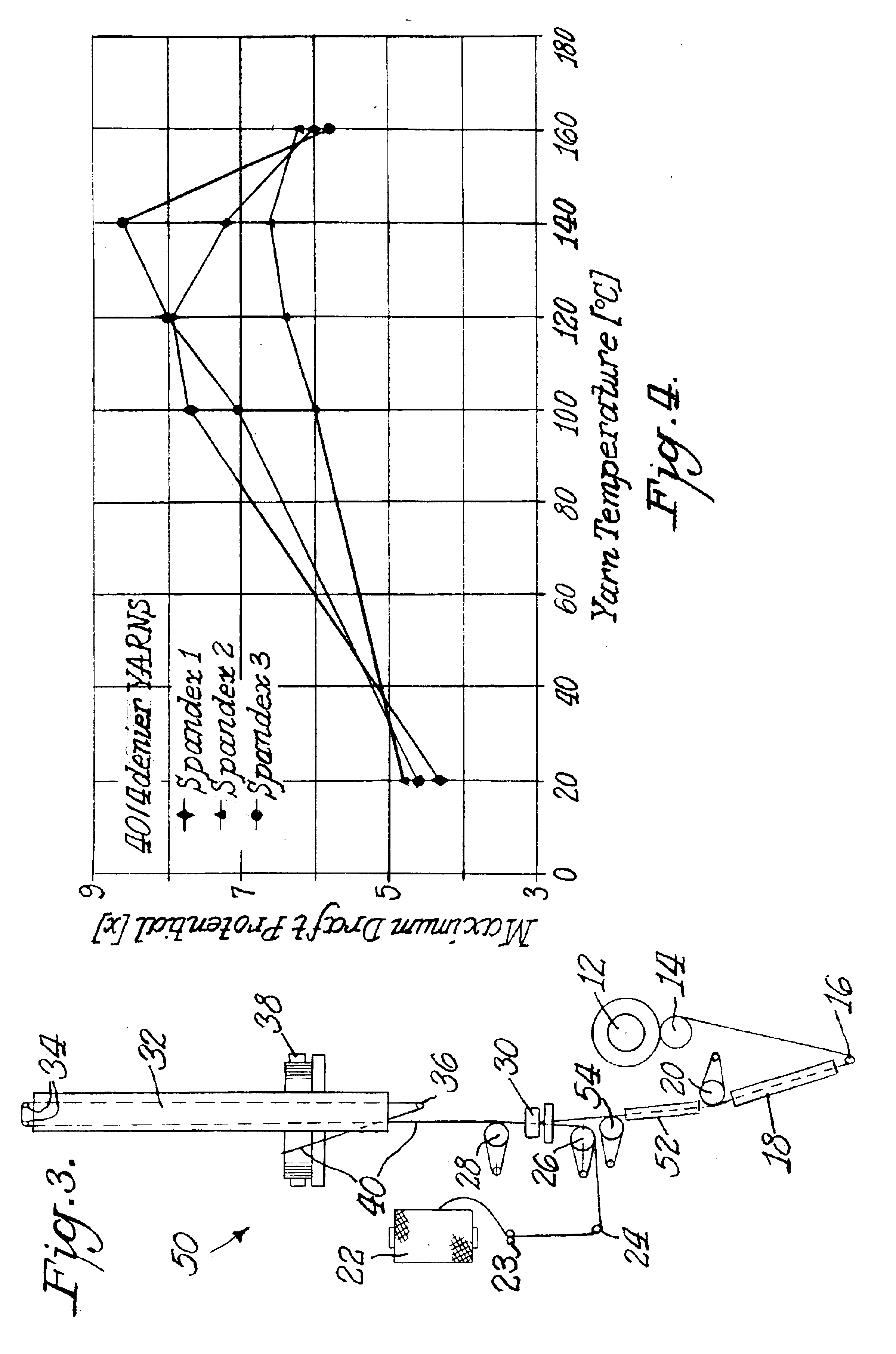

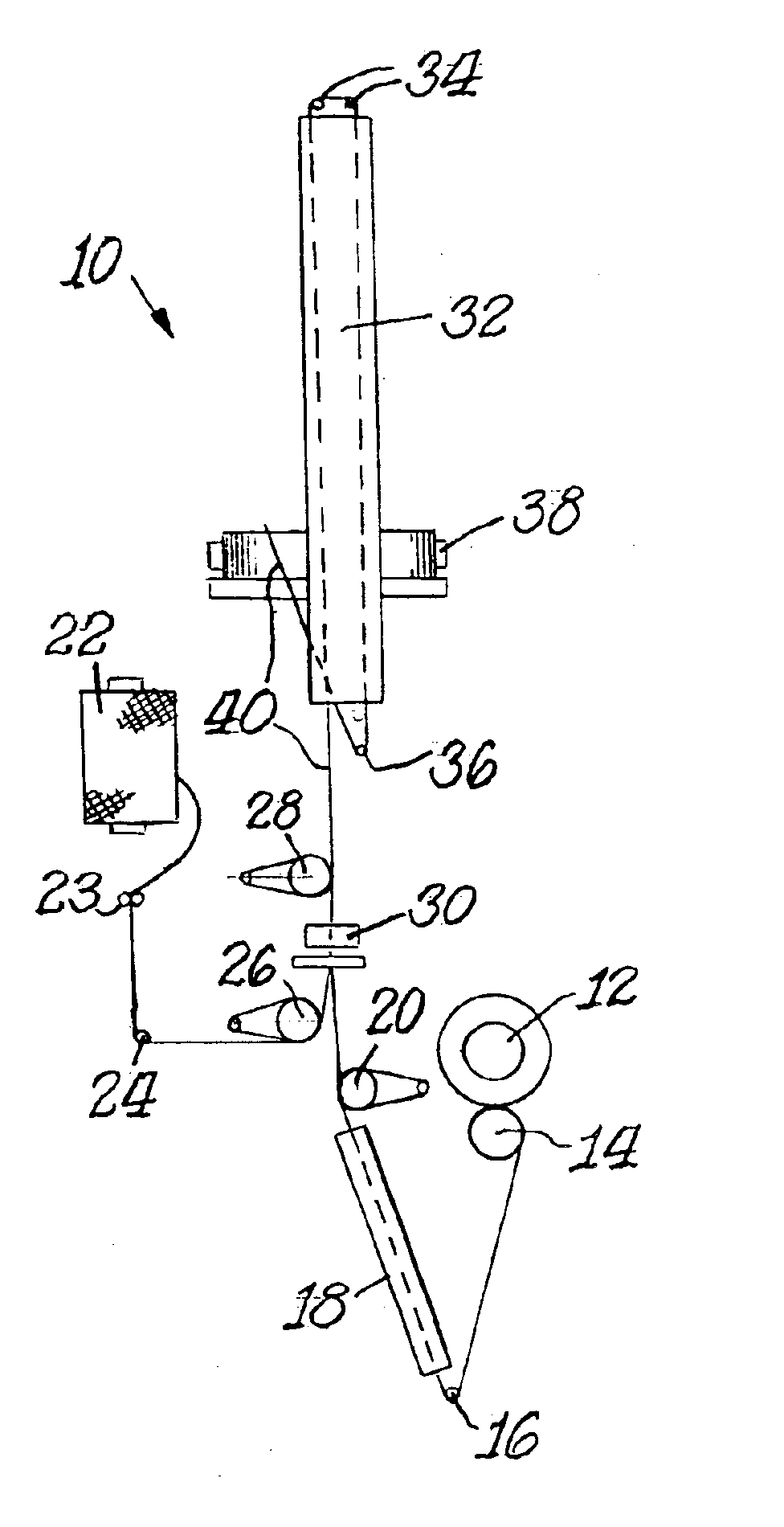

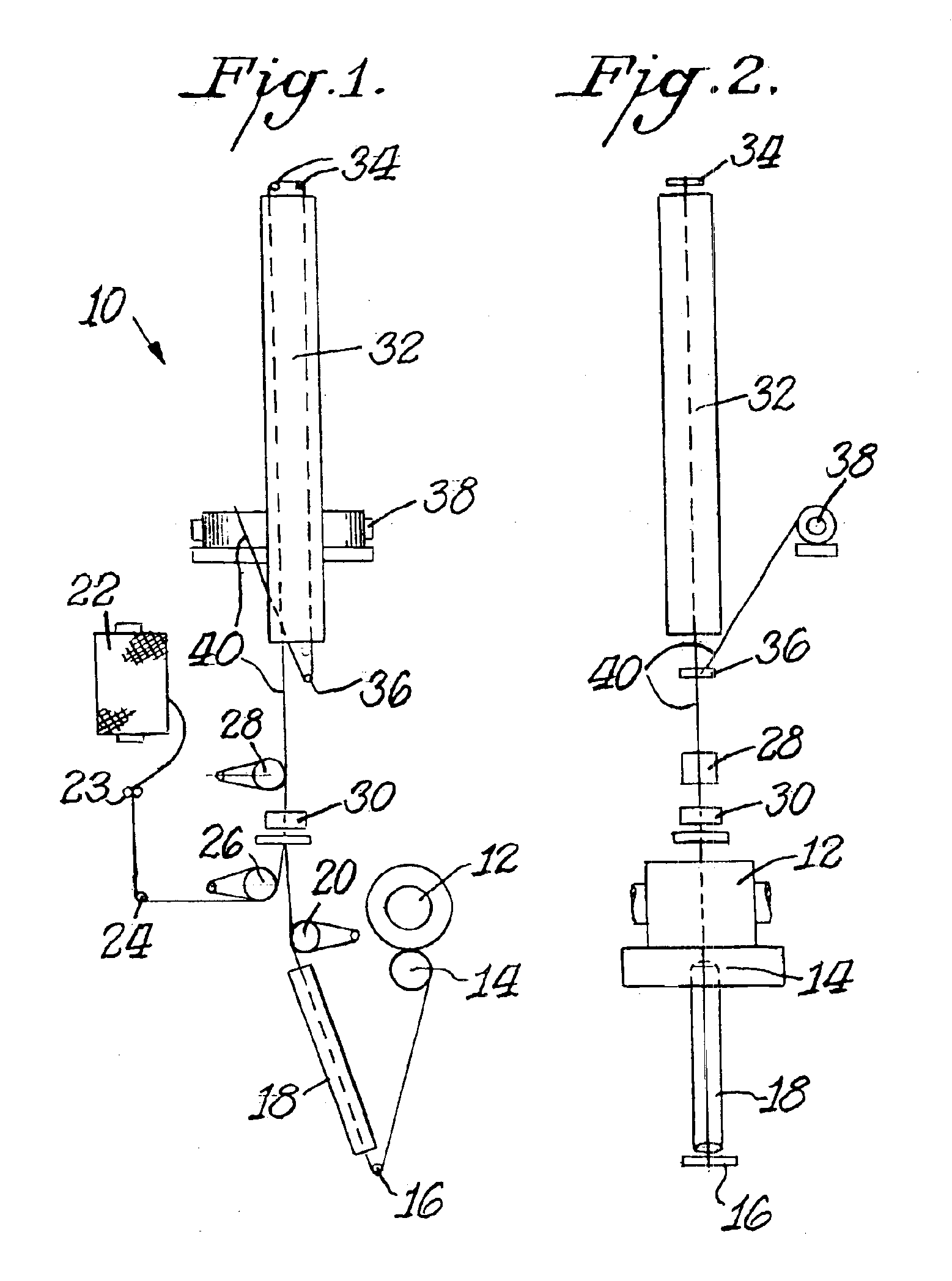

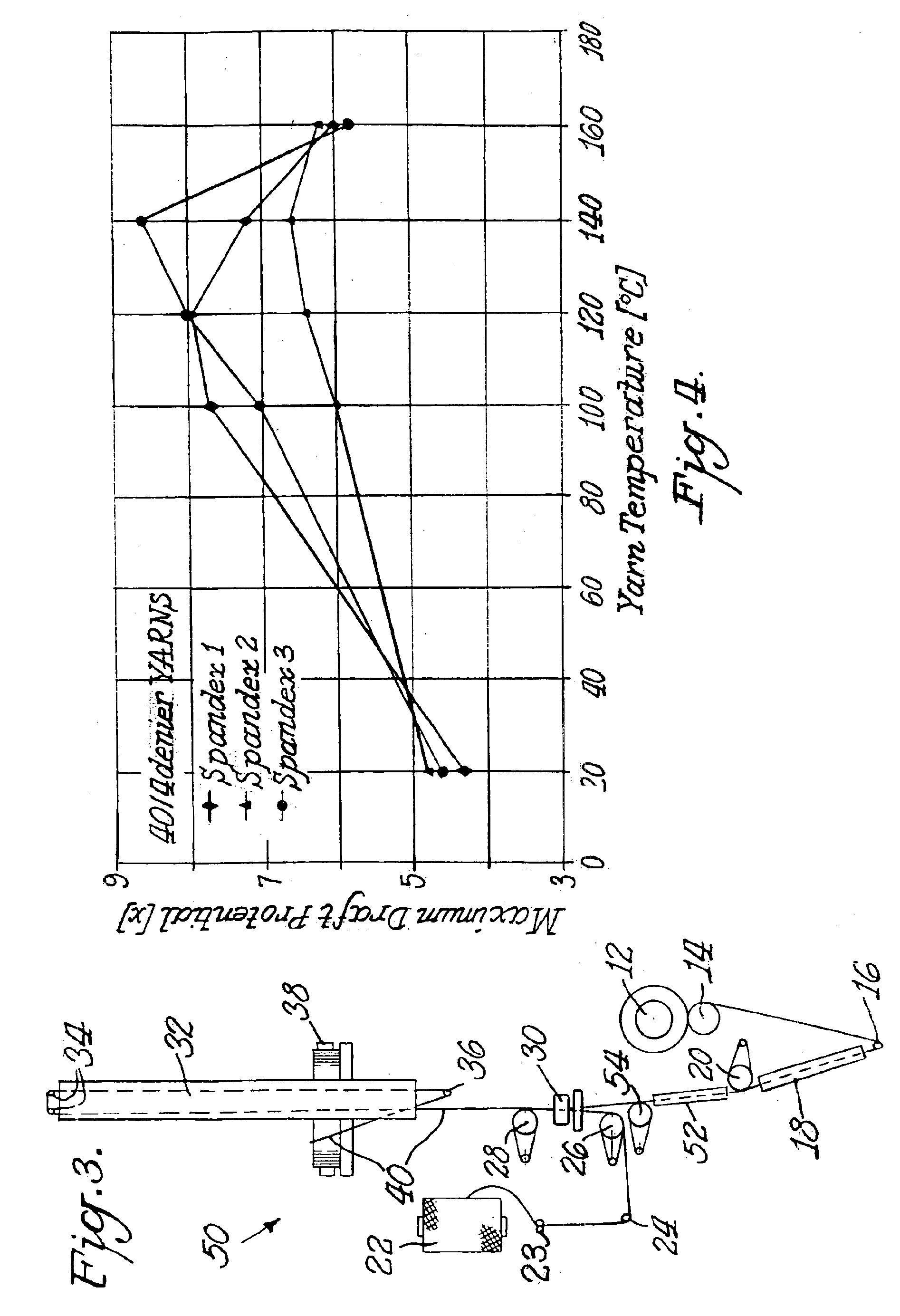

Air-jet method for producing composite elastic yarns

A continuous method for producing composite elastic yarns at speeds up to 700 m / min by (a) stretching (drafting) an elastomeric yarn (e.g., spandex) by 2.0×(100%) to 10.5×(950%) while heating (max. heating temperature 220° C.) in a single or double stage draft, (b) air-jet entangling with a relatively inelastic yarn component to create a composite elastic yarn, and then (c) in-line heat-treating (max. heating temperature 240° C.) the composite elastic yarn. The initial draft stage(s) may also be carried out at ambient temperature. The resulting composite elastic yarn has improved stitch clarity, particularly suited for hosiery, and its properties can be tailored to provide fabric properties for knit and woven fabrics hitherto not possible with standard spandex yarns.

Owner:THE LYCRA CO LLC

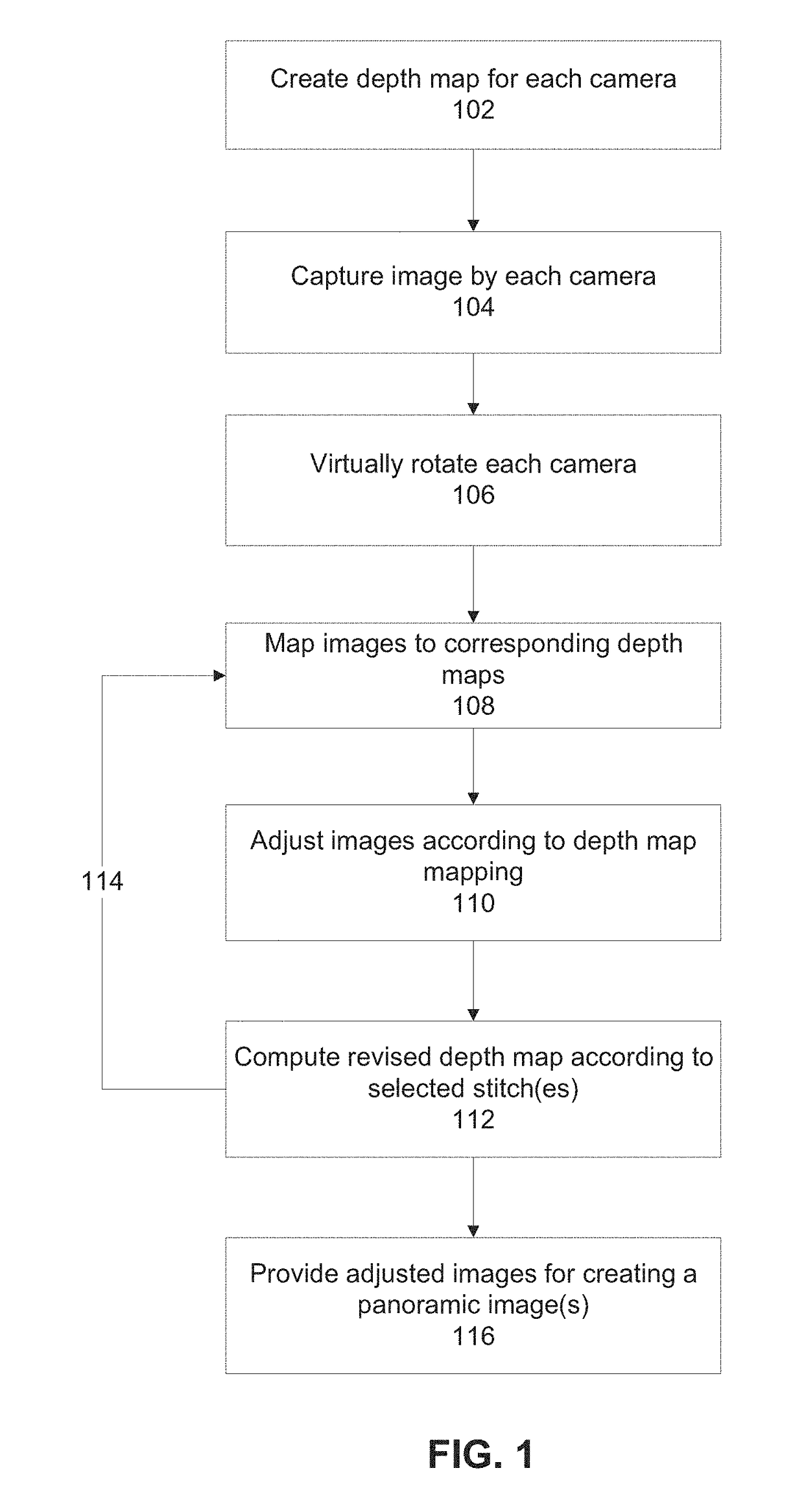

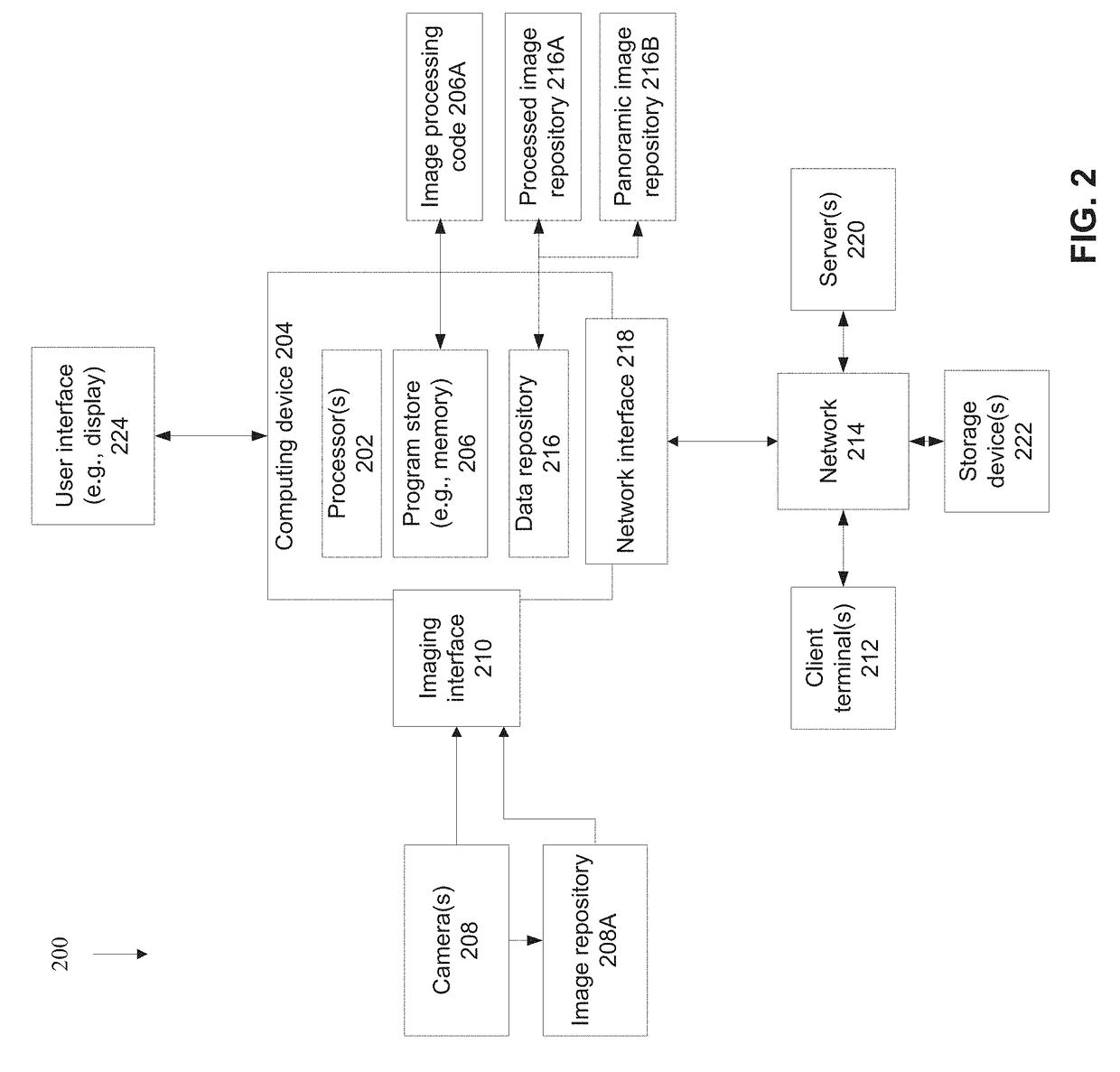

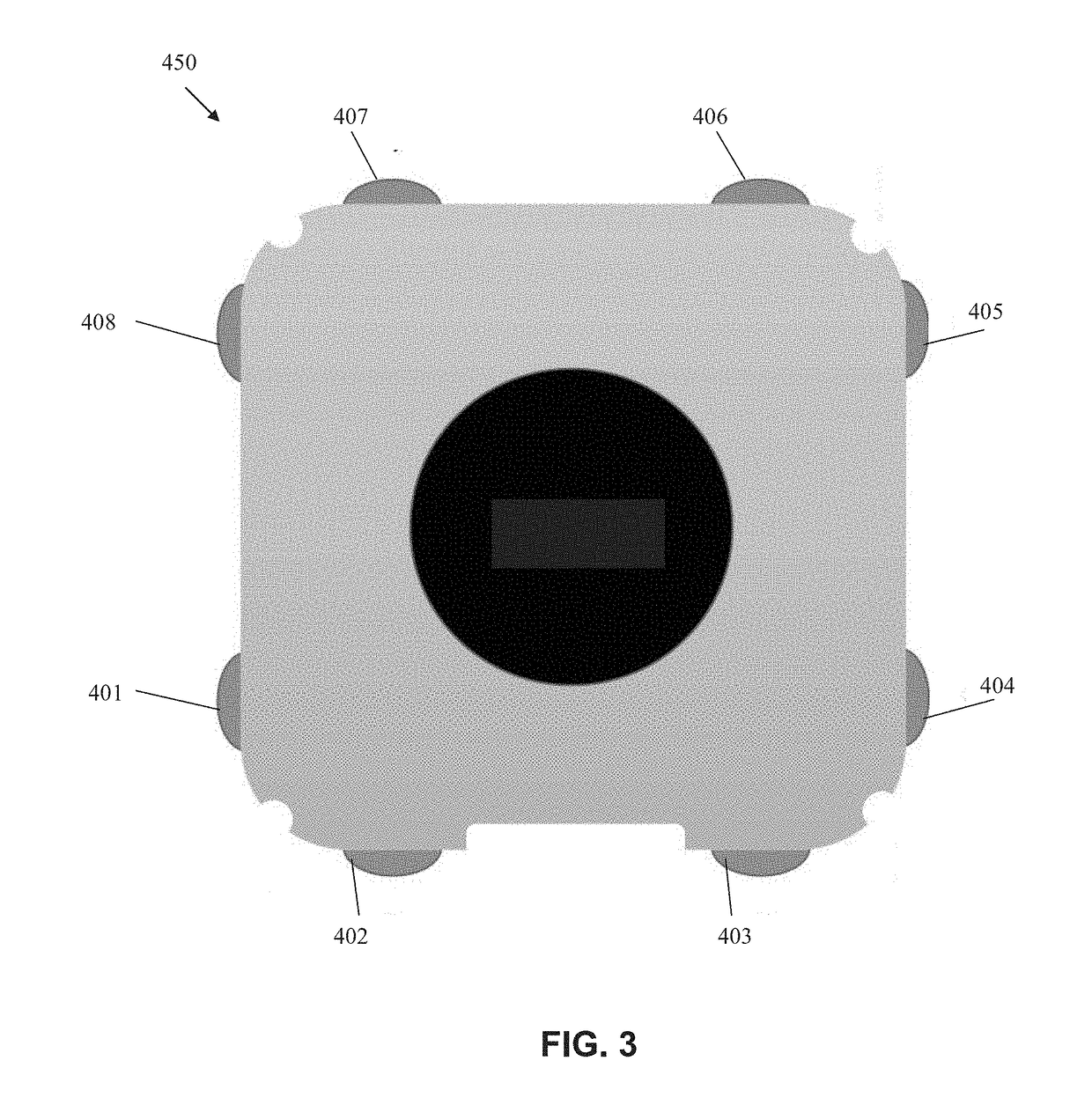

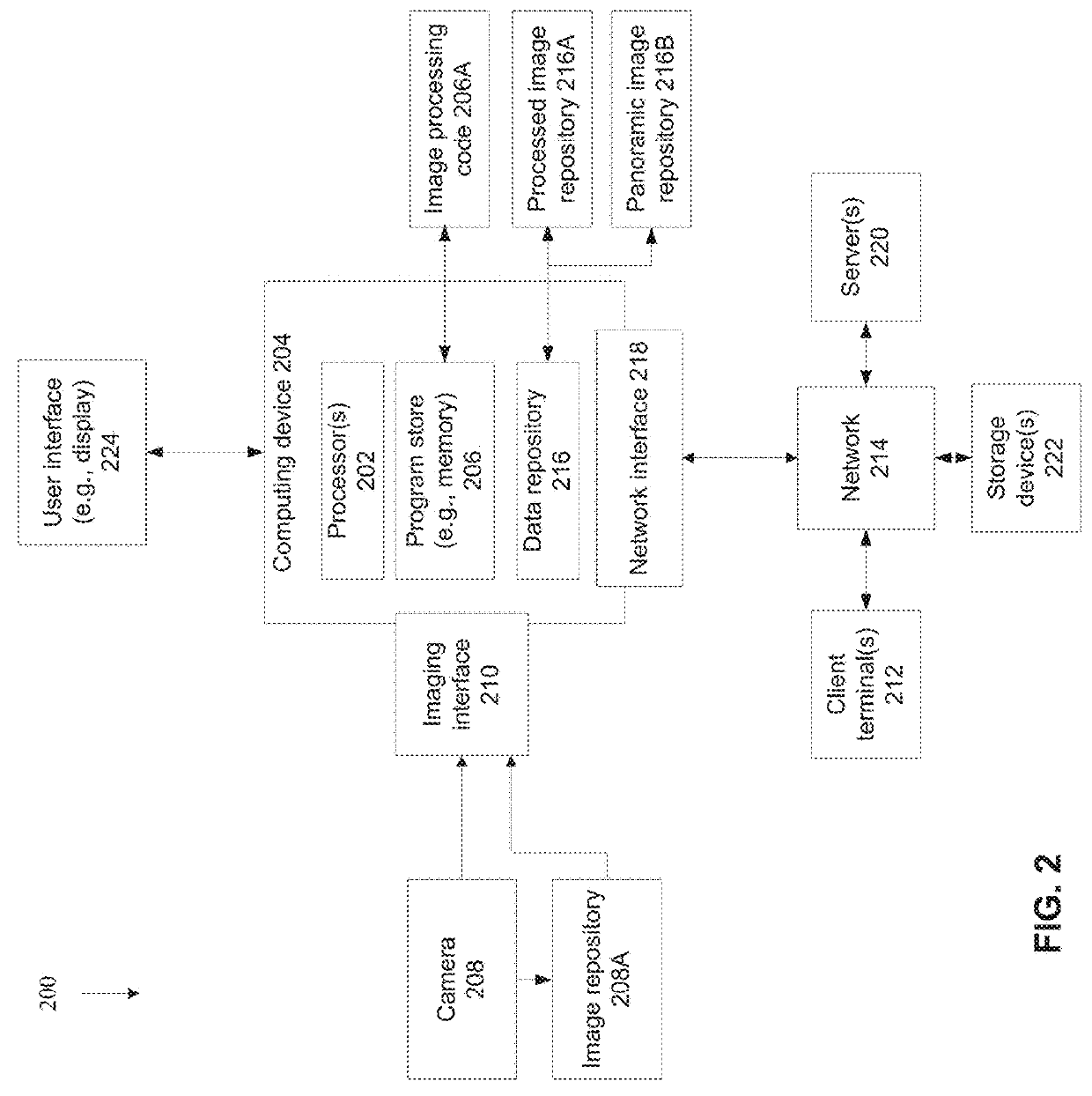

Systems and methods for adaptive stitching of digital images

ActiveUS20190012818A1Suppress mutationImprove computing powerImage enhancementTelevision system detailsParallaxDigital image

There is provided a method of processing digital images associated with a parallax shift for creation of a digital panoramic image, comprising: computing a respective depth map storing values denoting distances to regions of a scene, for each camera located at a respective first position, capturing a respective image by each camera, virtually rotating each camera to second positions at respective angles computed according to a certain region of the image relative to the center point of the camera, mapping between each respective region of the image associated with each respective second position and a corresponding region of the respective depth map computed for the respective camera, and adjusting intensity values of pixels of the regions of each image according to corresponding distance values of the mapped regions of the depth map of the respective camera, to create a plurality of adjusted images for creation of the panoramic image.

Owner:HUMANEYES TECH

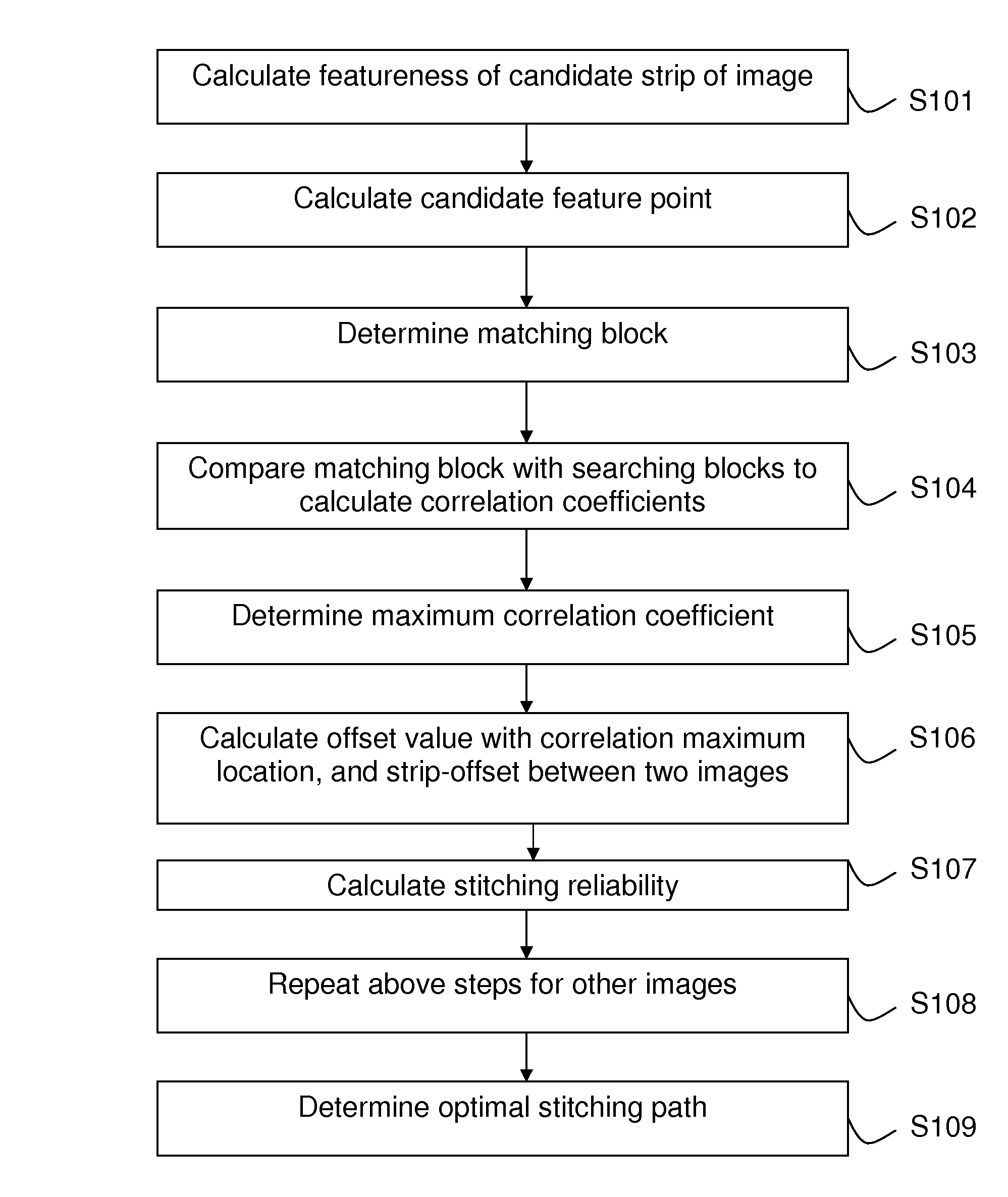

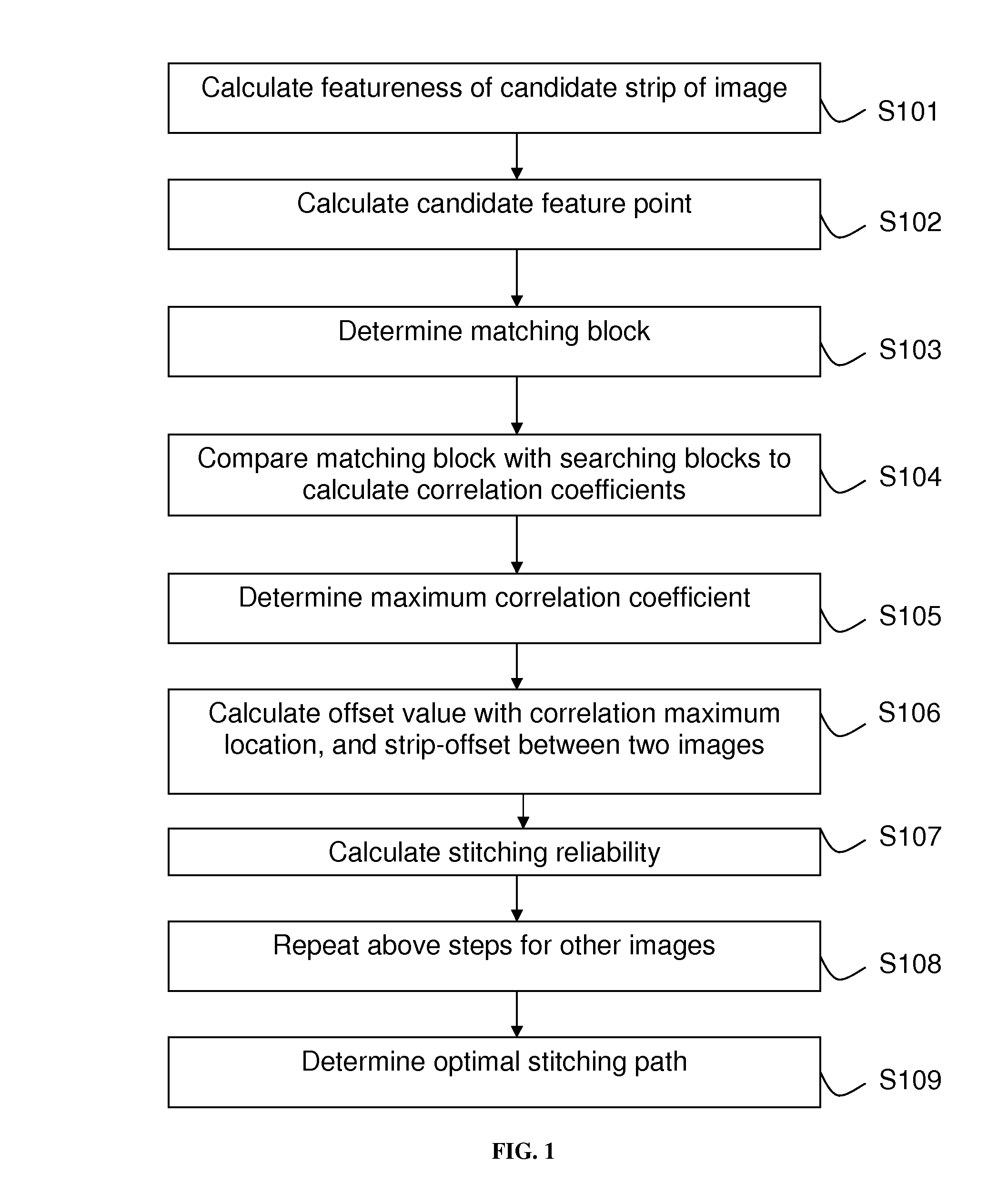

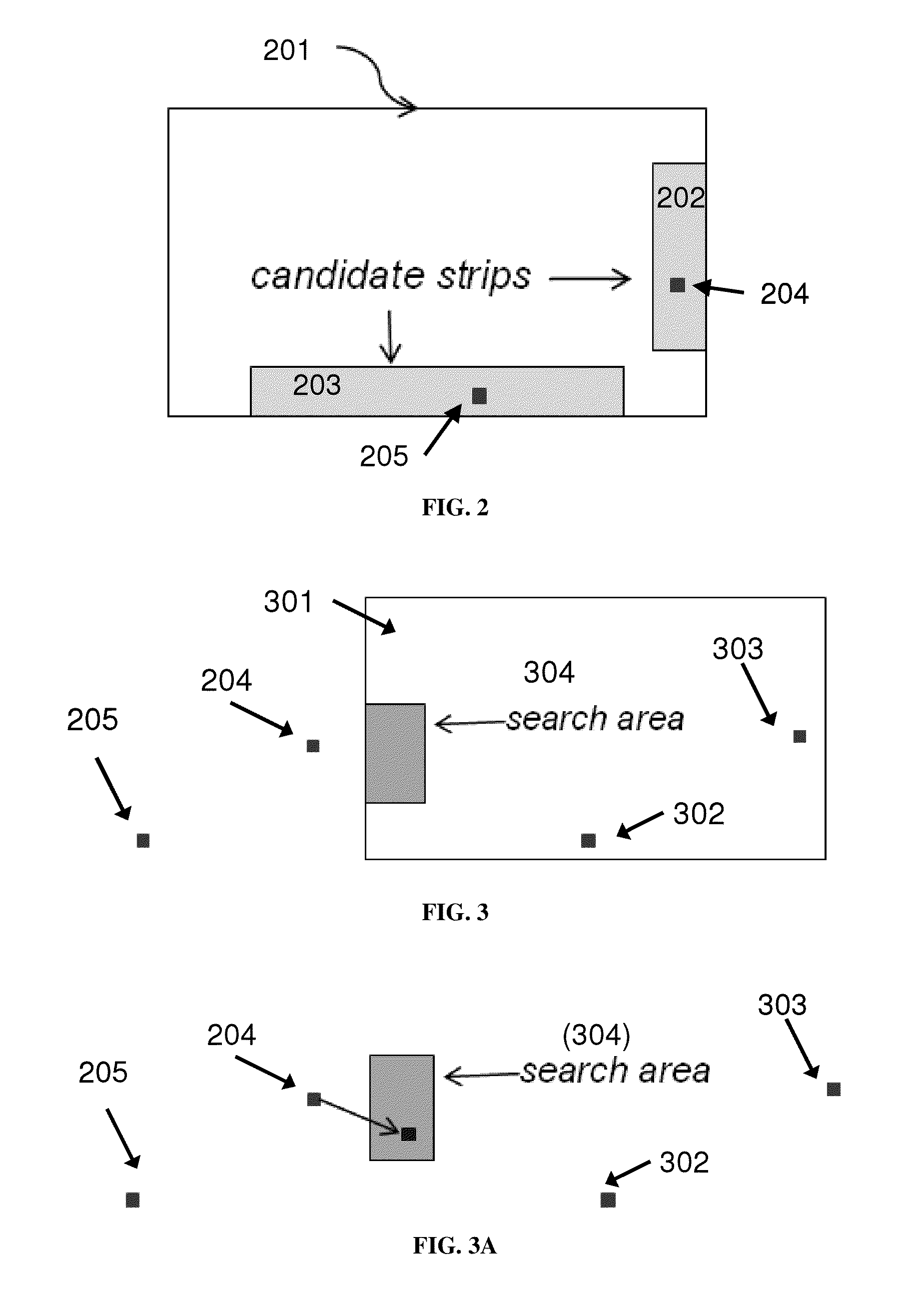

Method of on-the-fly image stitching

ActiveUS8917951B1Fast computational speedAvoid post-scan delayImage enhancementImage analysisImage stitchingFunction computation

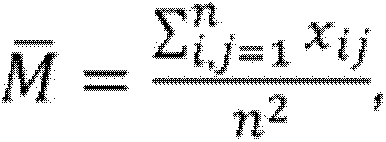

The presently claimed invention provides a method for stitching a plurality of images together in a way with least memory and CPU usage, and minimum file input and output, while still possessing fast computation speed to avoid post-scan delay for whole slide viewing and good stitching quality. The method of the present invention comprises the steps of calculating featureness of each candidate strip of a image by applying a mathematical transformation, calculating offset of the strip with correlation maximum location, calculating stitching reliability of the candidate strip from the pre-defined weighted function of its featureness and the correlation coefficients of each matching block, and determining optimal stitching path with stitching reliability.

Owner:HONG KONG APPLIED SCI & TECH RES INST

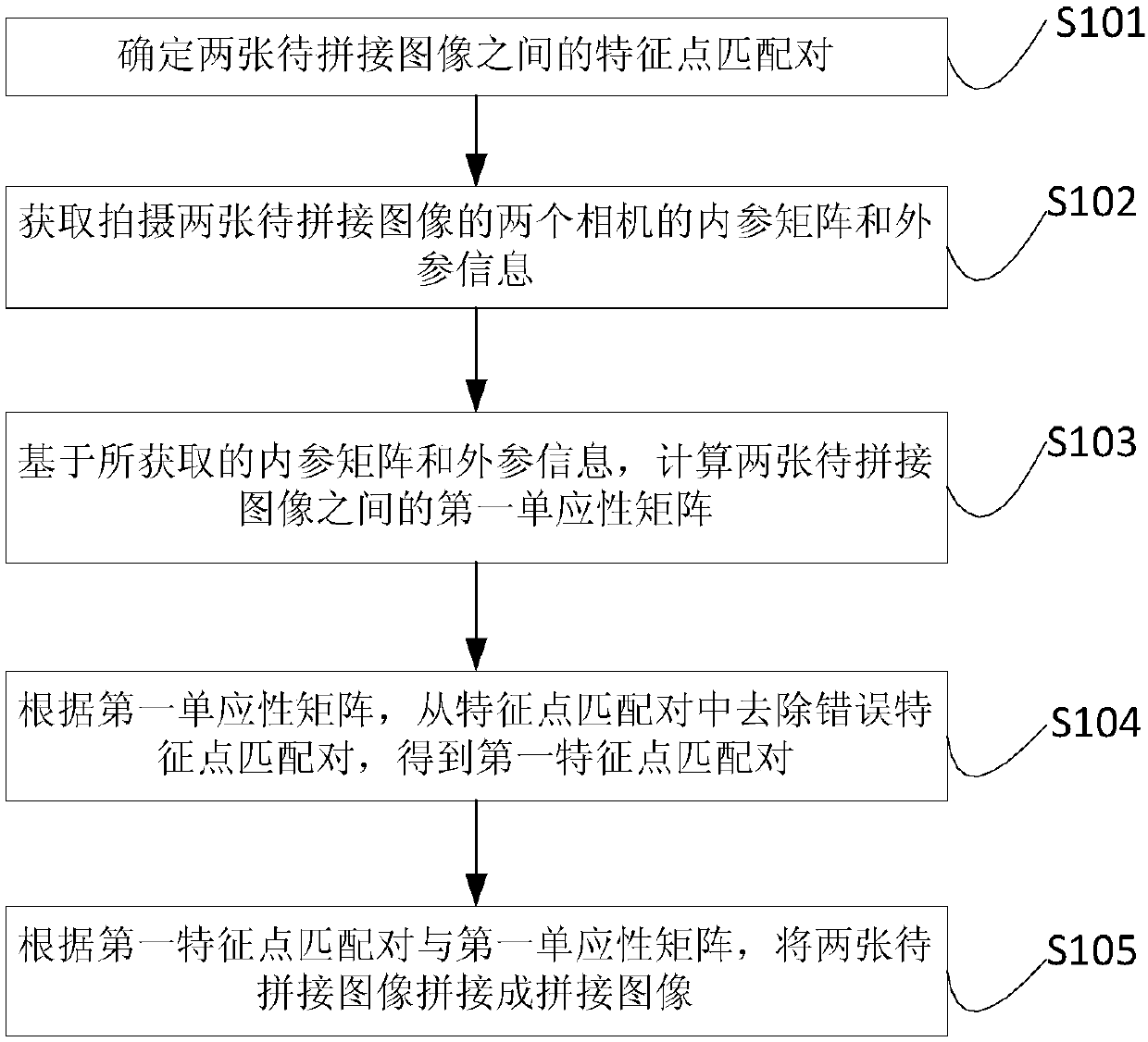

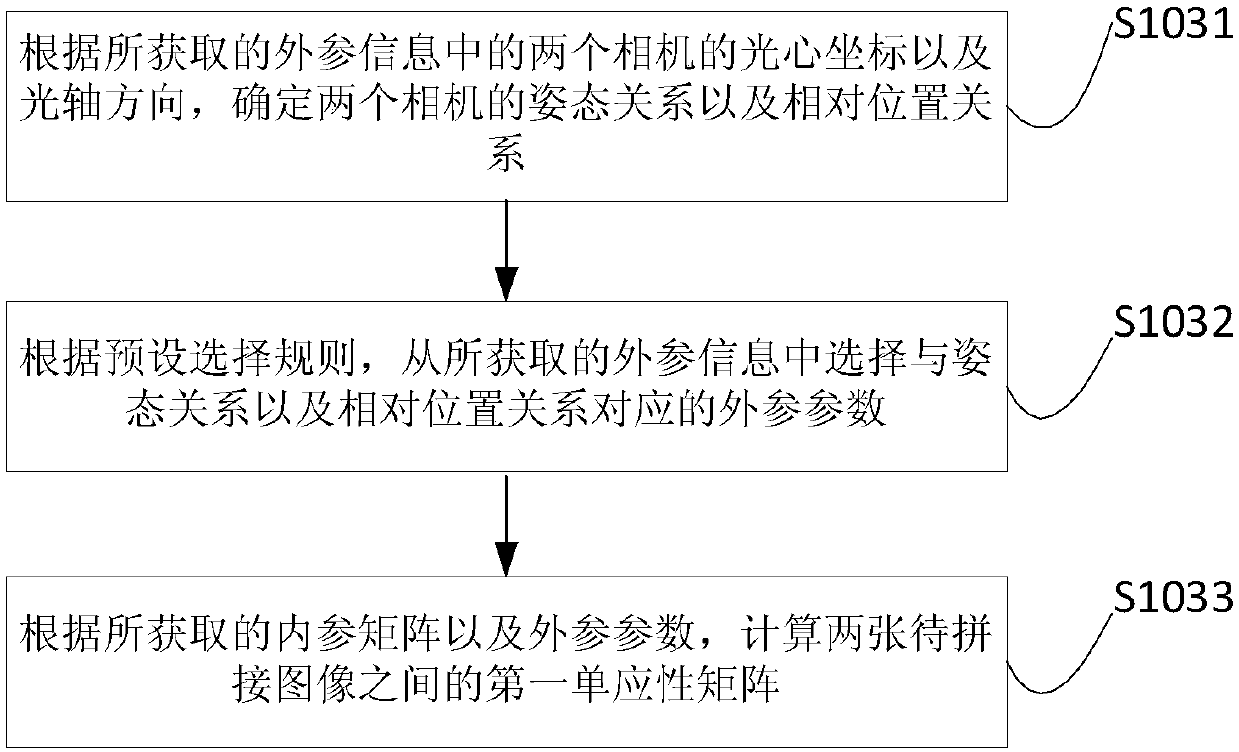

Image splicing method and device and electronic equipment

PendingCN109840884AImprove stitching qualityGeometric image transformationInternal combustion piston enginesFeature point matchingPoint pair

The embodiment of the invention provides an image splicing method and device and electronic equipment, and the method comprises the steps: determining a feature point matching pair between two to-be-spliced images; acquiring internal parameter matrixes and external parameter information of two cameras which shoot the two to-be-spliced images; calculating a first homography matrix between the two to-be-spliced images based on the acquired internal parameter matrixes and external parameter information; according to the first homography matrix, removing wrong feature point matching pairs from thefeature point matching pairs, and obtaining first feature point matching pairs; and splicing the two images to be spliced into a spliced image according to the first feature point matching pair and the first homography matrix. According to the invention, the first homography matrix is determined according to the property of the cameras, so that the wrong matching point pairs can be removed no matter the quantity is large or small, and the purpose of improving the splicing quality of the spliced image is achieved.

Owner:HANGZHOU HIKVISION DIGITAL TECH

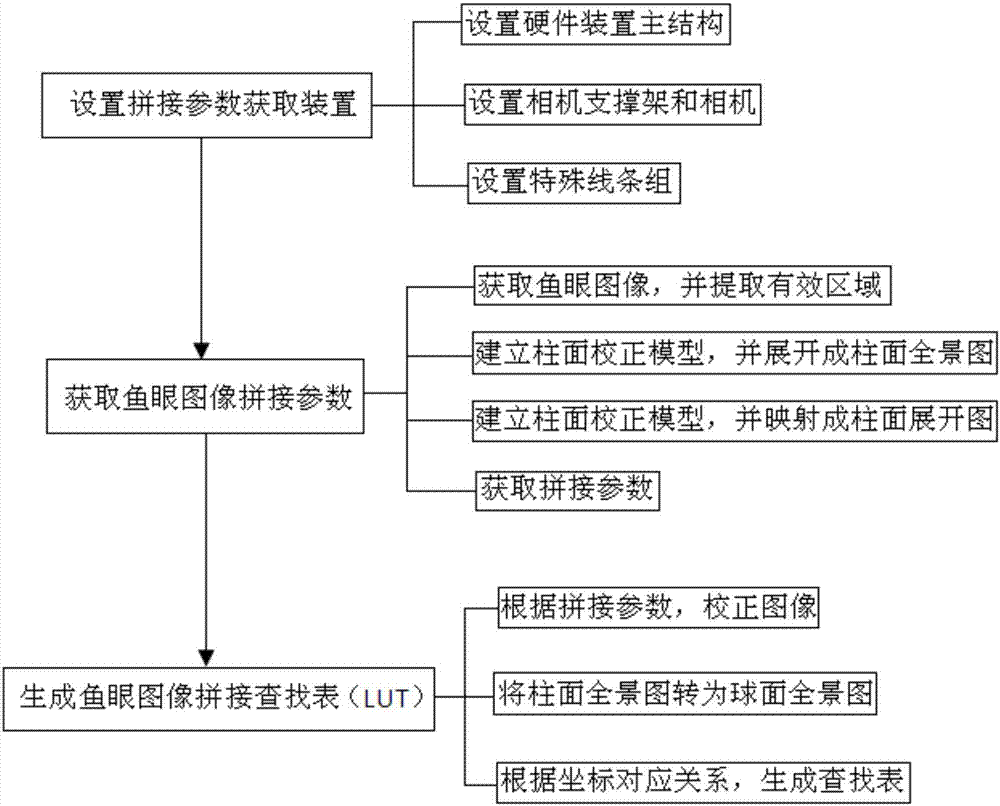

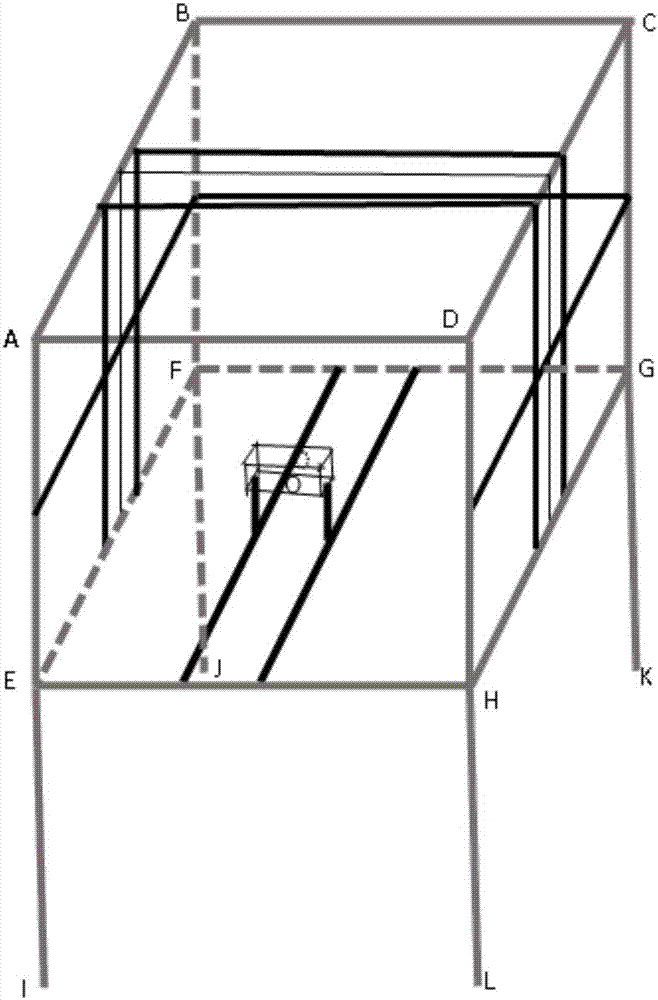

Quick binocular fisheye panoramic picture stitching method based on fixed stitching parameter

InactiveCN107274341AHomemade easyEasy to implementGeometric image transformationOverlap ratioLookup table

The invention discloses a quick binocular fisheye panoramic picture stitching method based on a fixed stitching parameter. The method comprises the following steps that: (1) arranging a fisheye panoramic picture stitching parameter acquisition device; (2) obtaining stitching parameters, i.e. a rotation offset parameter and a zone overlapping parameter; and (3) through the rotation offset parameter and the zone overlapping parameter, generating a fisheye panoramic picture stitching LUT (Lookup Table), and utilizing the LUT to realize the position mapping of the two fisheye pictures to the stitched picture so as to realize the quick stitching of the two fisheye pictures. Through a simple hardware device, the rotation offset parameter and an overlap ratio are obtained to obtain the LUT of the stitched fisheye picture, and the position mapping of the fisheye pictures to the stitched picture can be realized so as to realize the quick binocular fisheye panoramic picture stitching. The method has the advantages of being simple in operation, good in stitching effect, easy in hardware implementation and high in speed.

Owner:HEFEI UNIV OF TECH

Air-jet method for producing composite elastic yarns

A continuous method for producing composite elastic yarns at speeds up to 700 m / min by (a) stretching (drafting) an elastomeric yarn (e.g., spandex) by 2.0× (100%) to 10.5× (950%) while heating (max. heating temperature 220° C.) in a single or double stage draft, (b) air-jet entangling with a relatively inelastic yarn component to create a composite elastic yarn, and then (c) in-line heat-treating (max. heating temperature 240° C.) the composite elastic yarn. The initial draft stage(s) may also be carried out at ambient temperature. The resulting composite elastic yarn has improved stitch clarity, particularly suited for hosiery, and its properties can be tailored to provide fabric properties for knit and woven fabrics hitherto not possible with standard spandex yarns.

Owner:THE LYCRA CO LLC

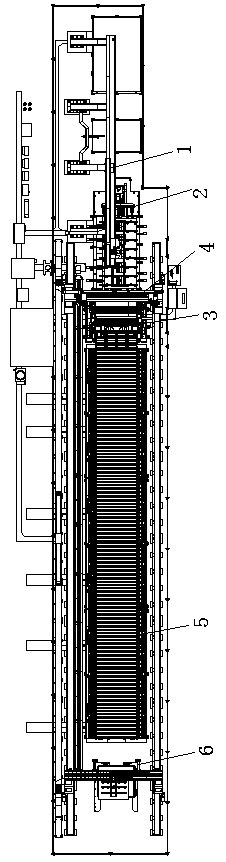

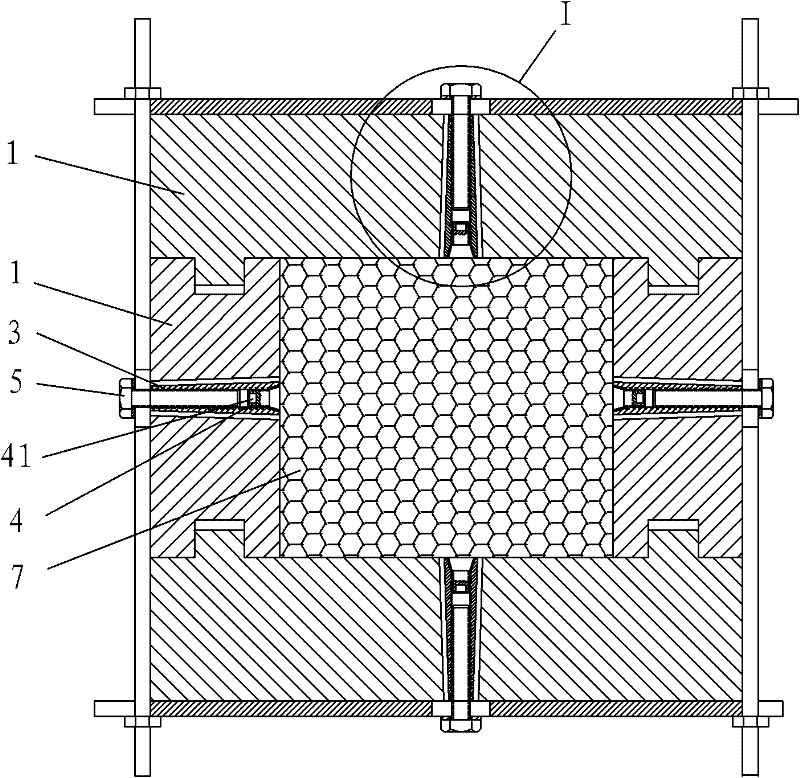

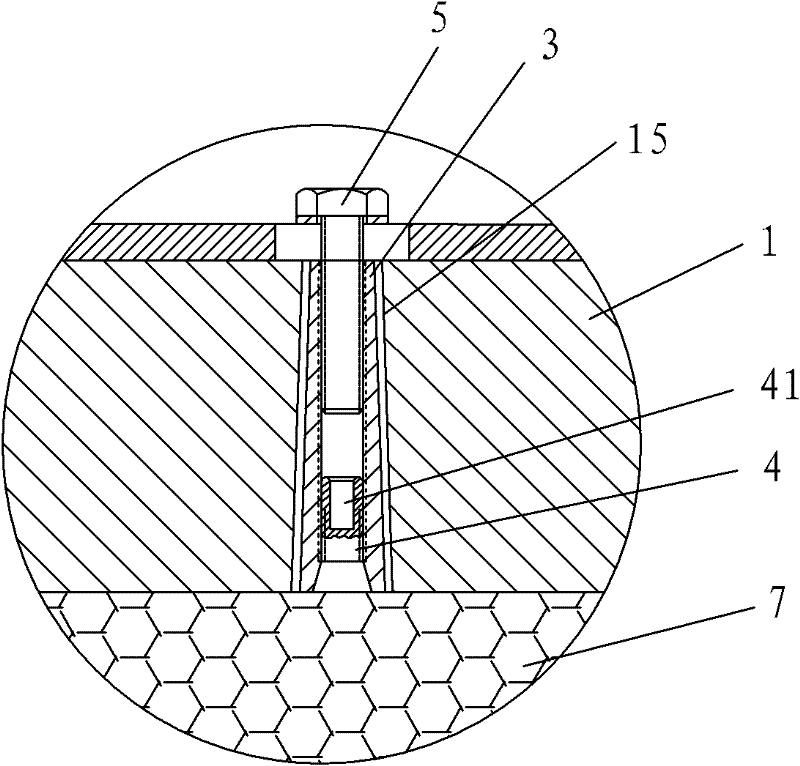

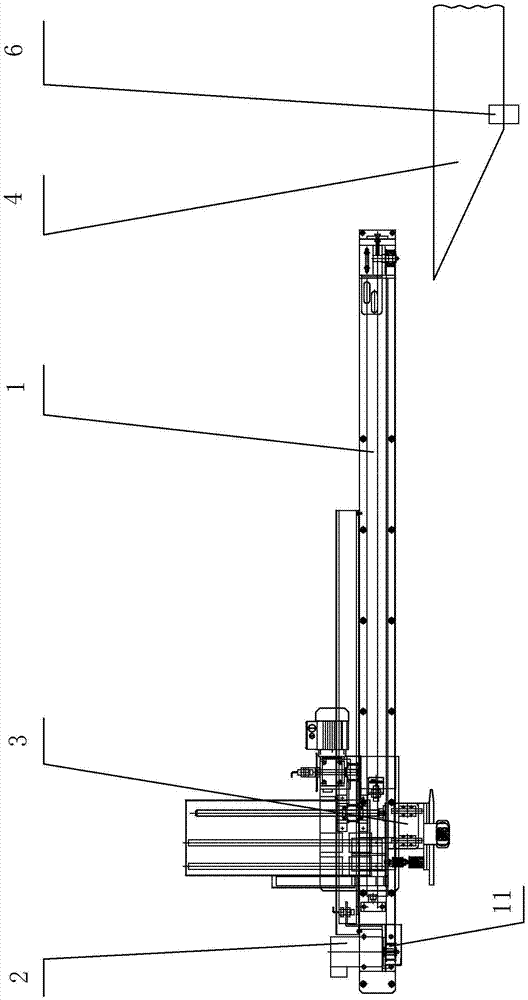

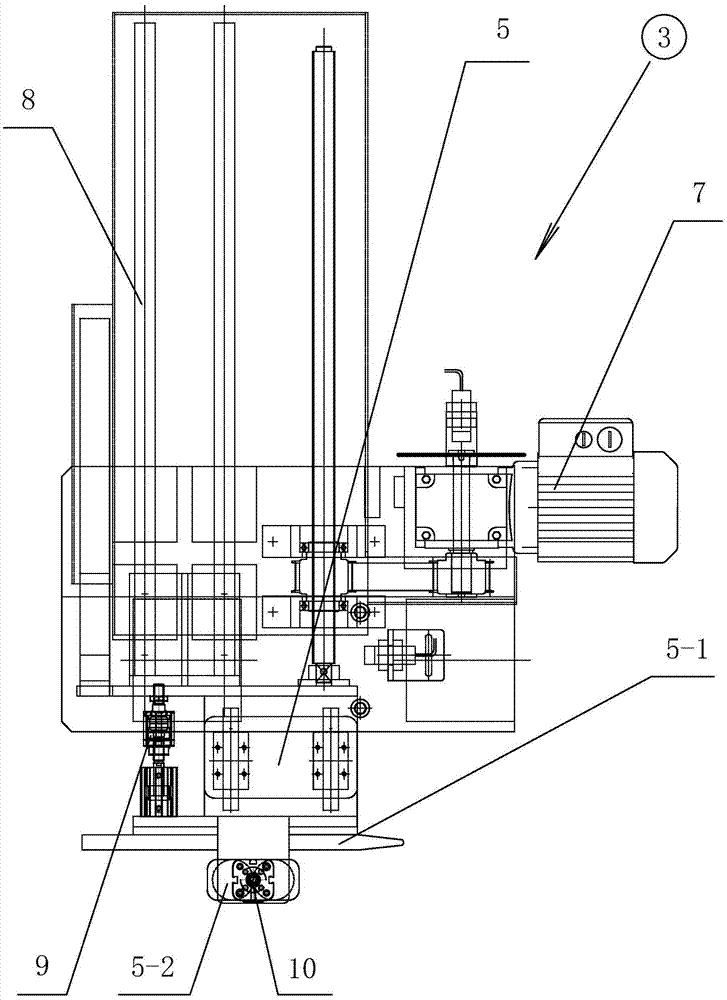

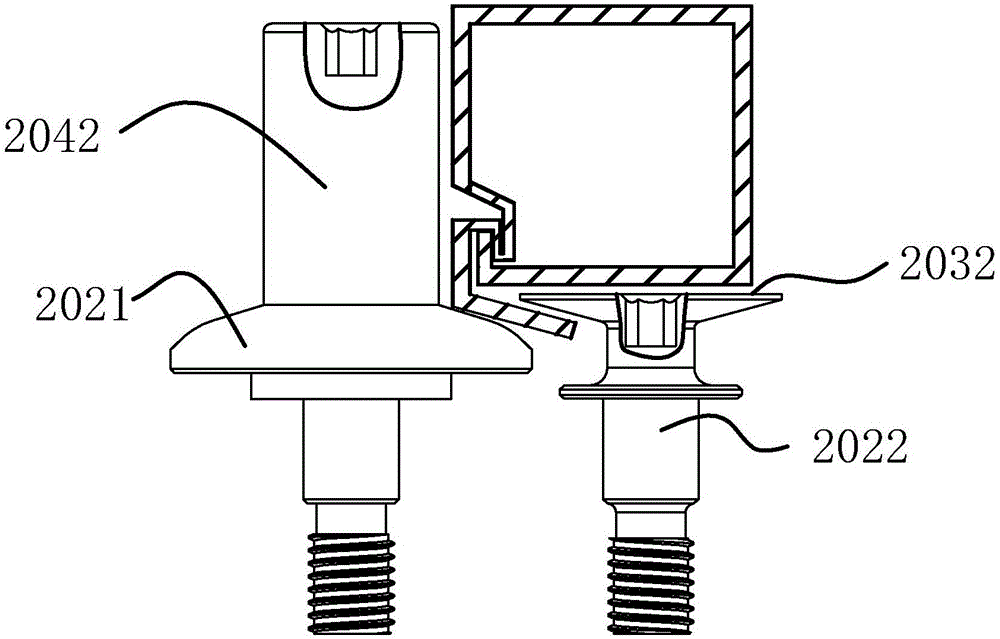

Integrated plate automatic cutting and welding device

PendingCN110340671AReduce consumptionImprove stitching qualityOther manufacturing equipments/toolsMetal working apparatusEnergy consumptionIntegrated devices

The invention belongs to the technical field of plate assembly welding and particularly relates to an integrated plate automatic cutting and welding device. The integrated plate automatic cutting andwelding device comprises a feeding device, an input locating device, a cutting and welding auxiliary device, a roller bed conveying device with a liftable hammering machine, a cutting and welding integrated device used for cutting and assembling plates and a pulling device used of driving the plates to move. The feeding device, the input locating device, the cutting and welding auxiliary device and the roller bed conveying device are arranged in the moving direction of the plates in sequence. The cutting and welding integrated device comprises a working end and a driving unit used for drivingthe working end to move the location above the cutting and welding auxiliary device and the roller bed conveying device. The integrated plate automatic cutting and welding device provided by the invention can improve the assembling and welding quality, reduce the process difficulty, improve the machining efficiency and reduce energy consumption.

Owner:WUHAN FARLEYLASERLAB CUTTING SYST ENG

Dynamic image splicing method

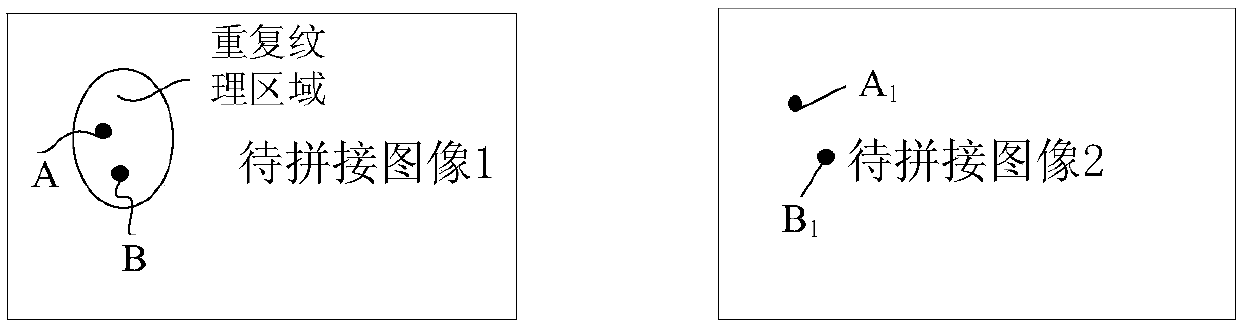

ActiveCN103390275AAvoid double loadingReduce occupancyImage enhancementImage analysisPattern recognitionCorrelation coefficient

The invention provided a method for splicing a plurality of images together. The method occupies the smallest memory and the lowest CPU utilization rate, has the smallest file input and output, and still has a higher calculation speed and provides good splicing quality at the same time. The method comprises the steps as follows: a characteristic of each candidate strip of an image is calculated by using mathematical manipulation; matching blocks used for calculating deviation amount between adjacent images are selected at the same time; positions of search blocks which have the maximum correlation coefficients with the matching blocks in the adjacent images are calculated, so that the deviation of the candidate strips is determined; and the splicing reliability of the candidate strips is calculated according to the maximum correlation coefficient of each predefined matching block and the weighting function of the characteristic of the matching blocks, and an optimum splicing path is determined according to the splicing reliability.

Owner:HONG KONG APPLIED SCI & TECH RES INST

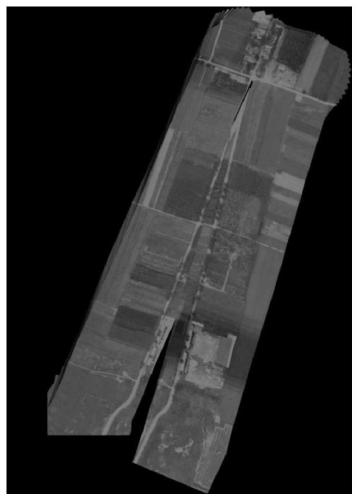

Aerial image splicing and positioning method based on aerial strip GPS and scale invariant constraints

ActiveCN111507901AImprove stitching qualityEliminate splicing distortion problemsImage enhancementImage analysisPattern recognitionEngineering

The invention discloses an aerial image splicing and positioning method based on an aerial strip GPS and scale invariant constraints, and belongs to the technical field of graphic image conversion andimage calibration. The method comprises the steps: preprocessing a to-be-spliced image; according to traditional feature point extraction and description, obtaining an accurate matching result through a BF matching method and an RANSAC method, calculating an affine transformation matrix for the feature matching result through scale invariant constraints, constructing second flight strip splicingthrough existing flight path information, and fusing a GPS into a panorama. According to the invention, the splicing quality of images between air strips is improved by using air strip GPS informationand scale invariant constraints, the problem of single air strip splicing deformation caused by the pitch angle is eliminated, the pixel center point coordinates of a subsequent splicing frame are restrained through the mapping relation obtained through the first air strip, the splicing effect of multiple air strips is improved, and the high GPS positioning precision is further achieved.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

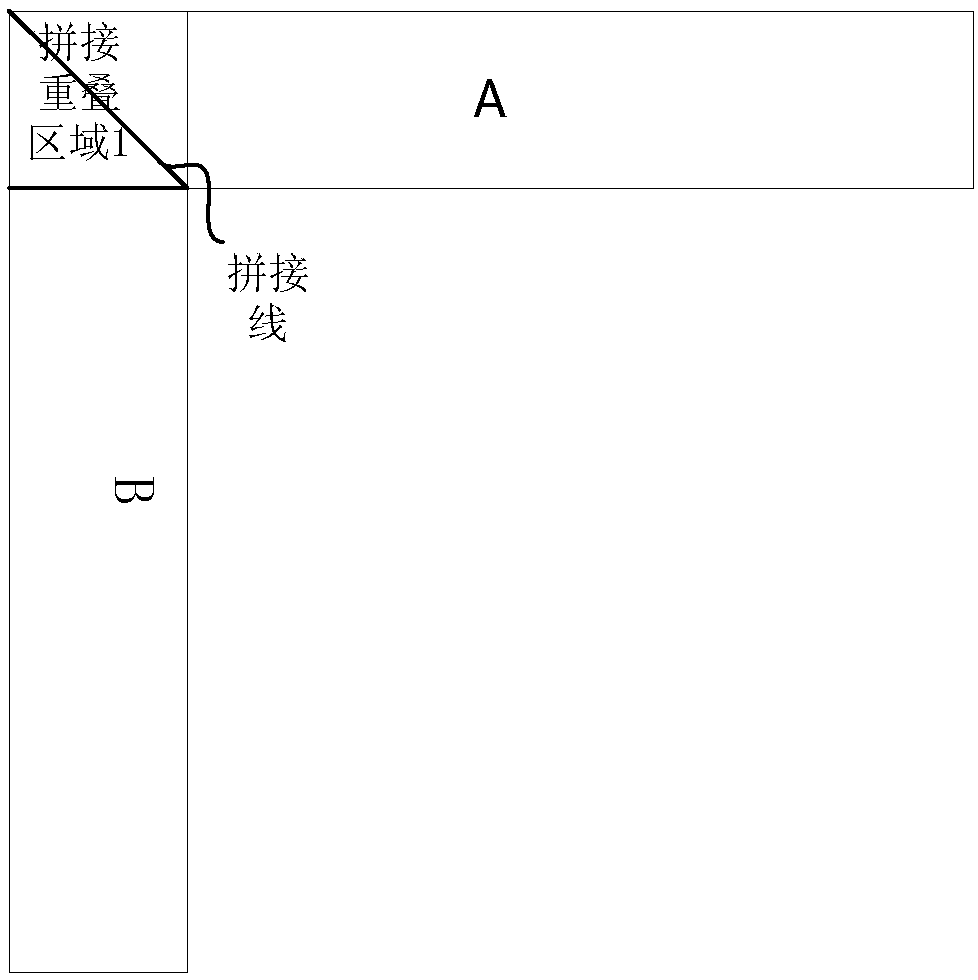

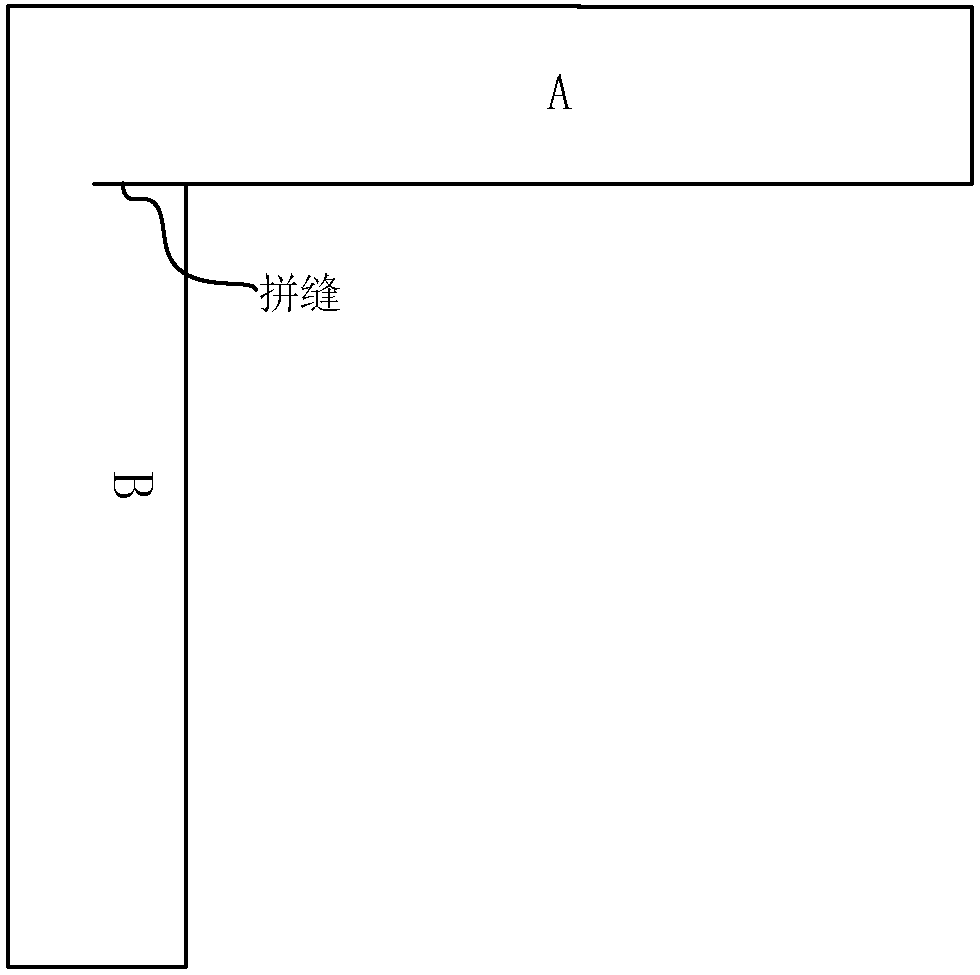

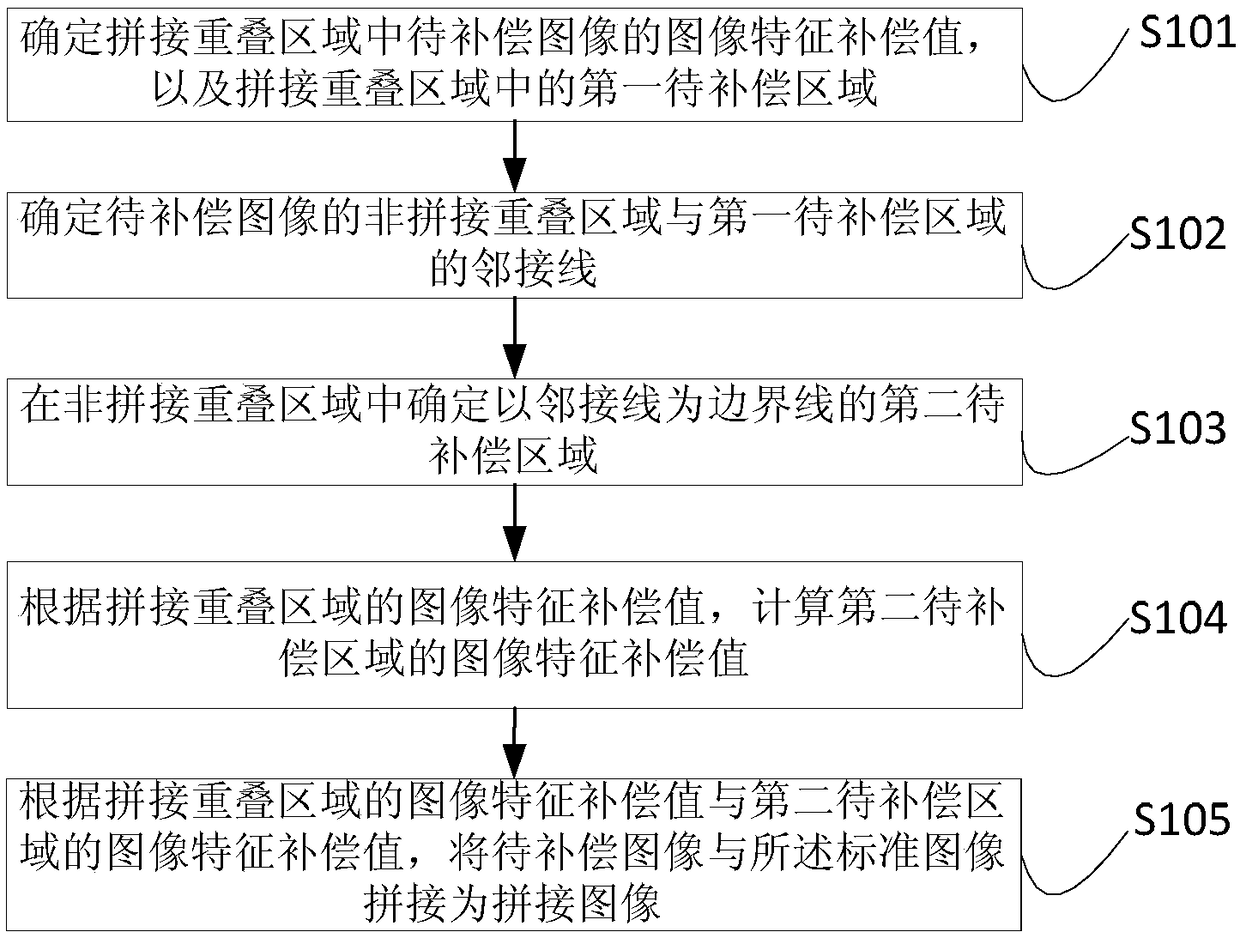

Image mosaic method, device, electronic device and storage medium

ActiveCN109300084AImprove stitching qualityGeometric image transformationComputer graphics (images)Imaging Feature

An embodiment of the present invention provides an image mosaic method, device, electronic apparatus and storage medium. The method includes determining an image feature compensation value of an imageto be compensated in a mosaic overlap area and a first region to be compensated in the mosaic overlap area, determining an abutment line between a non-mosaic overlap area of an image to be compensated and a first area to be compensated, determining a second region to be compensated with an adjacent line as a boundary line in the non-spliced overlap region. The image feature compensation value ofthe second region to be compensated is calculated according to the image feature compensation value of the mosaic overlap region, and the image to be compensated and the standard image are mosaic intoa mosaic image according to the image feature compensation value of the mosaic overlap region and the image feature compensation value of the second region to be compensated. Thus, when stitching images, the second area to be compensated that may exist in the stitching is compensated, thereby avoiding the generation of stitching and improving the stitching quality.

Owner:HANGZHOU AUTOMOTIVE TECH CO LTD

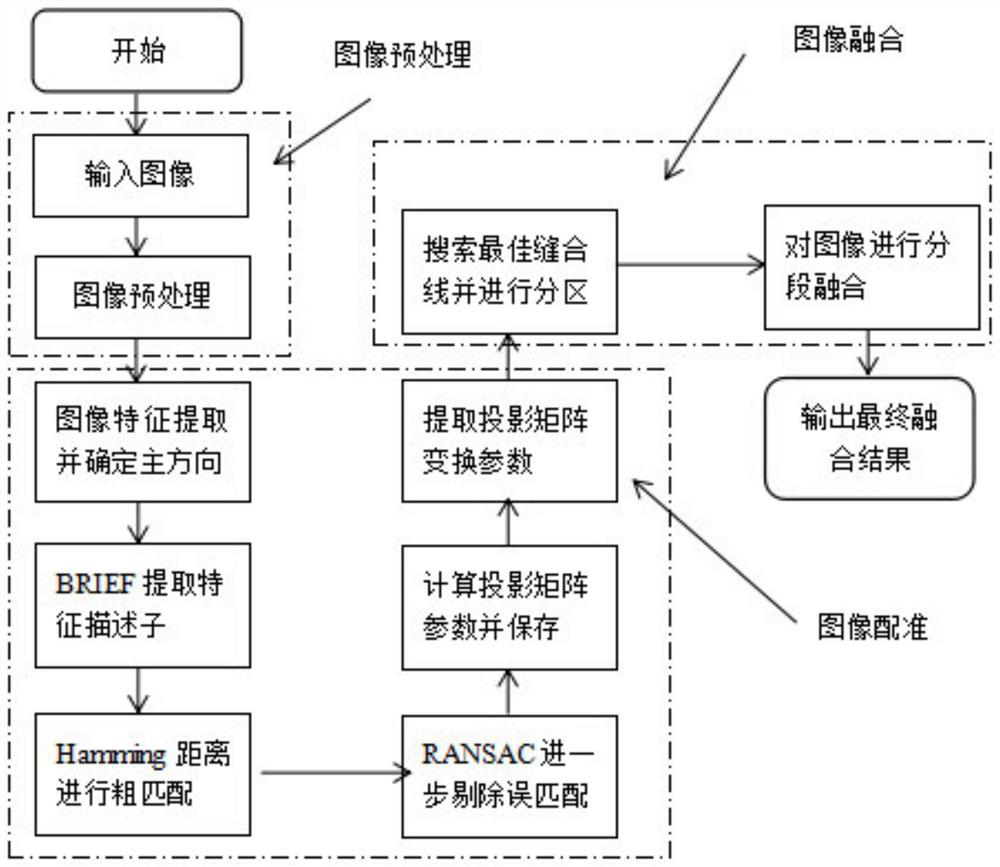

Image splicing method based on improved ORB feature algorithm

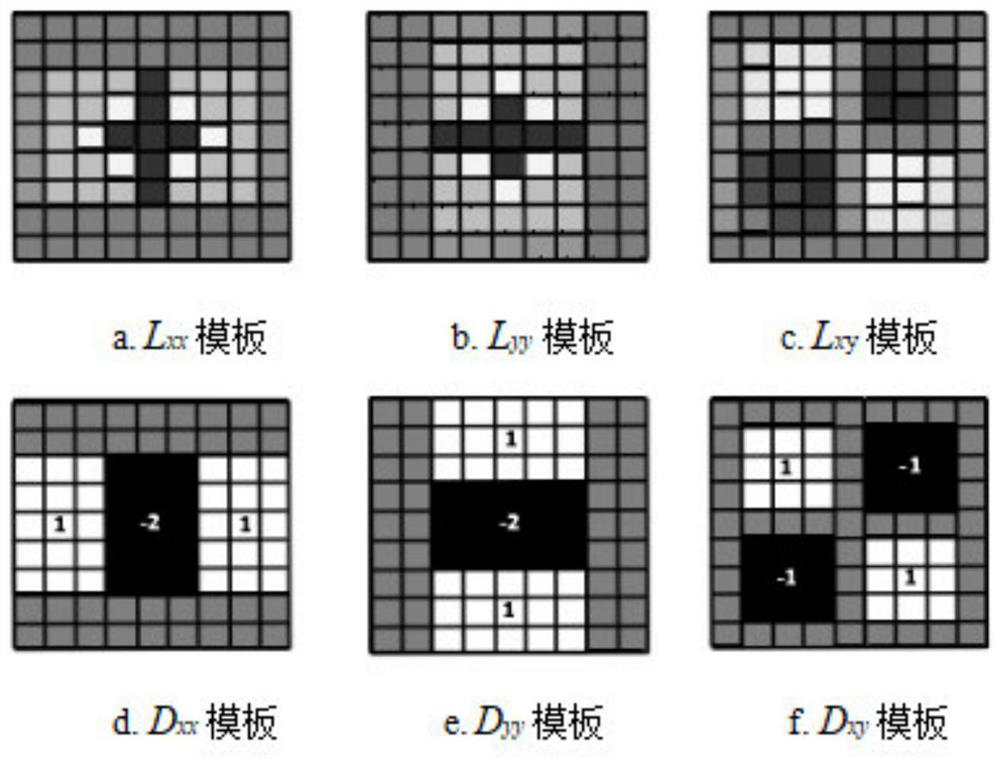

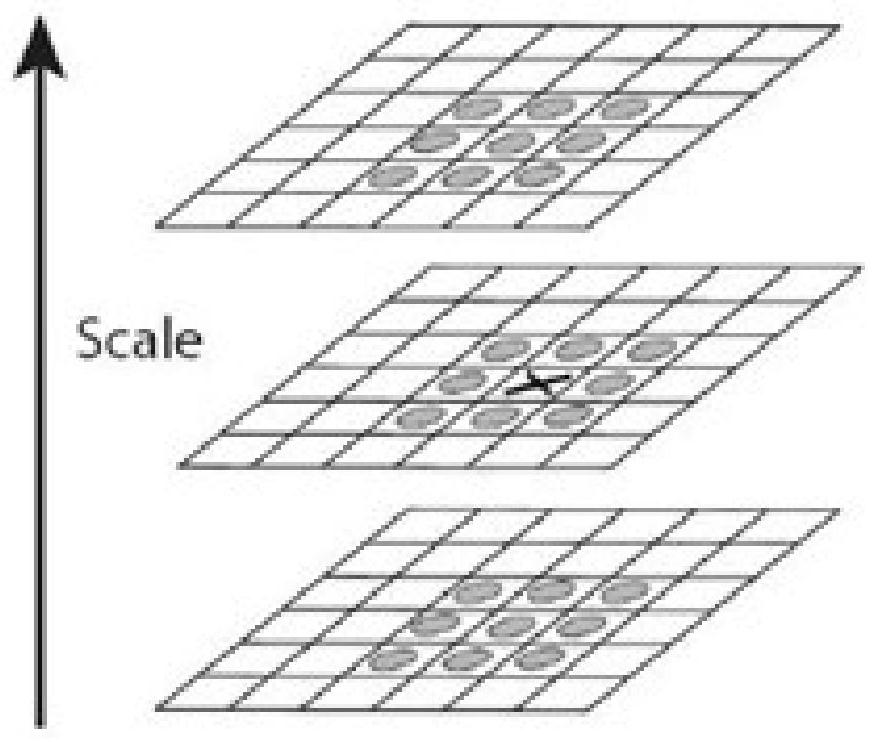

PendingCN111784576ATo achieve the purpose of scale invarianceAvoid ghostingImage enhancementImage analysisPattern recognitionScale space

The invention discloses an image splicing method based on an improved ORB feature algorithm. The method comprises the following steps: constructing a Hessian matrix, and determining feature points ofeach to-be-spliced image; extracting a feature descriptor of each image to be spliced by using a BRIEF binary feature descriptor; performing rough matching by using a Hamming distance, and distinguishing correct matching point pairs from wrong matching point pairs by using a grid motion feature algorithm; removing error matching feature point pairs by using an improved random sampling consistencyalgorithm; searching an optimal suture line; dividing an overlapping region; and performing segmented fusion to complete image splicing. Through the multi-scale space theory, the Hessian matrix and the Gaussian pyramid are used for improving the registration method, the purpose of scale invariance is achieved, and meanwhile the matching precision of the matching point pairs is improved.

Owner:CHANGAN UNIV

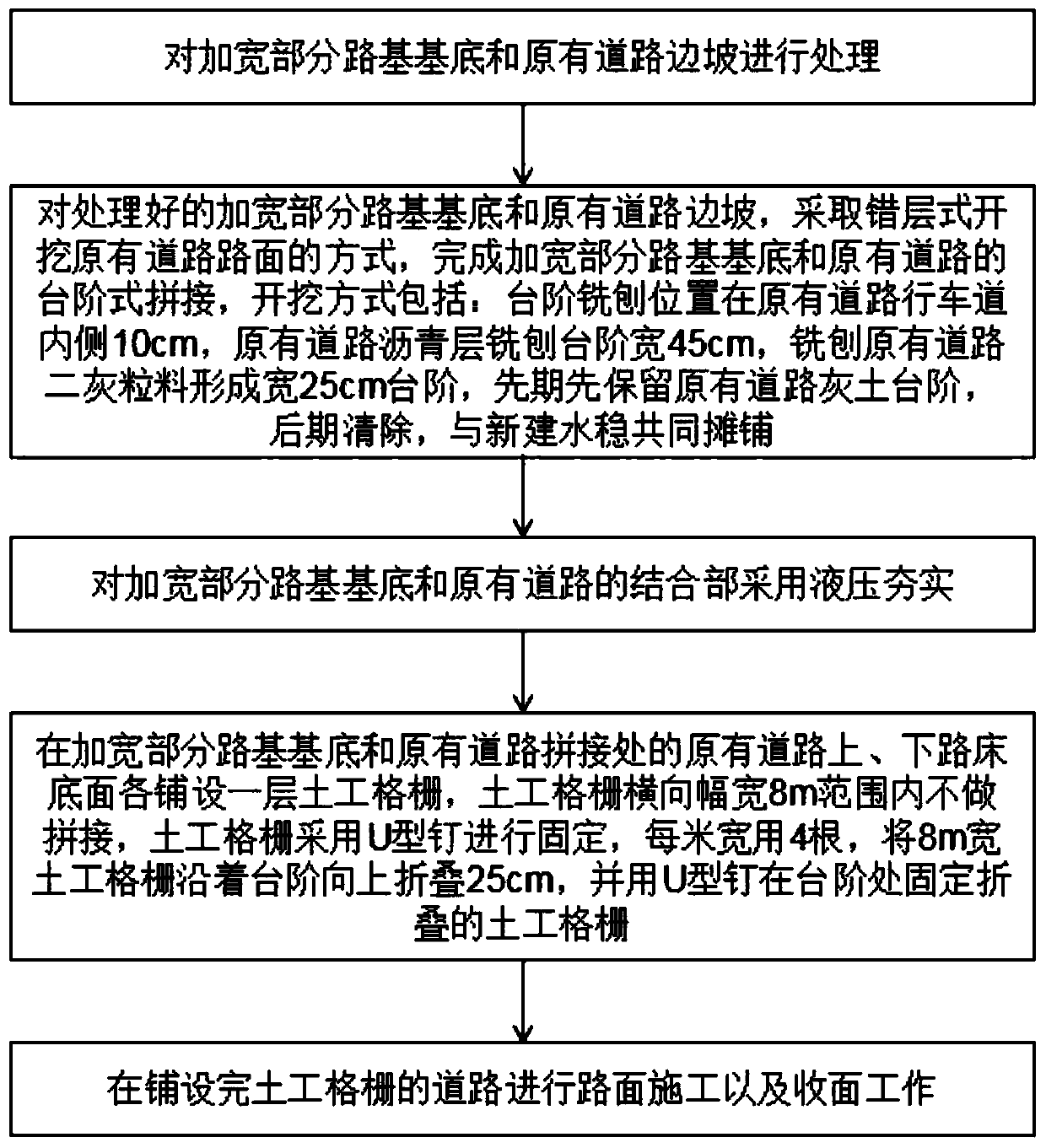

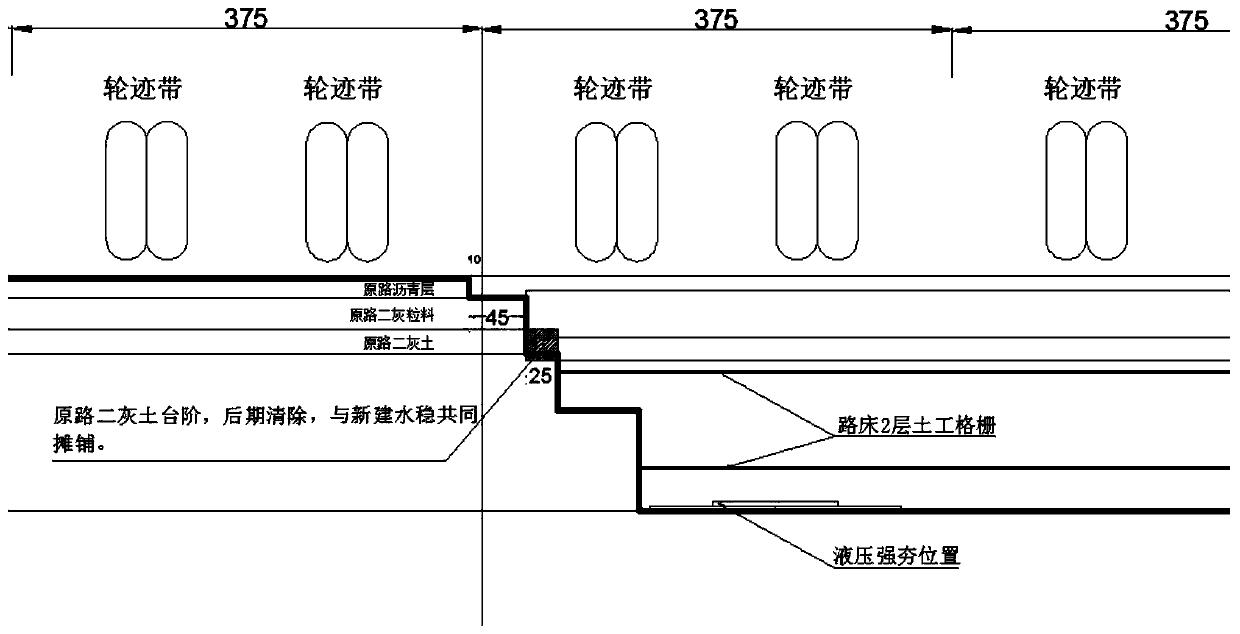

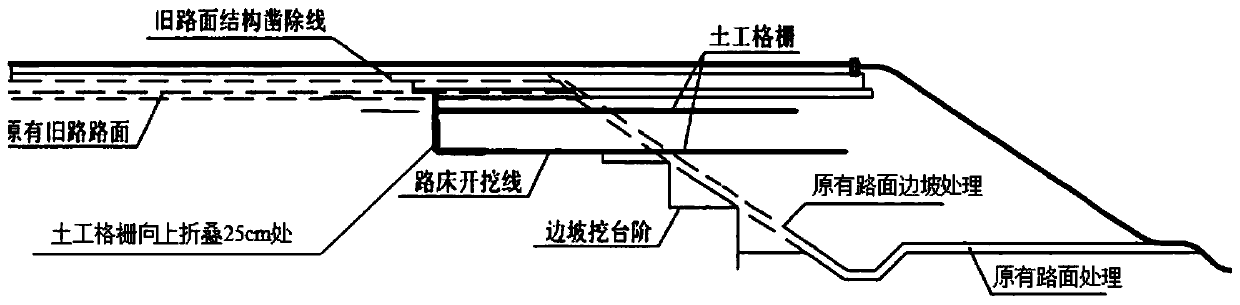

Splicing construction method for rebuilt and expanded new and old roads

InactiveCN110644324AImprove stitching qualityIntegrity guaranteedPaving detailsArchitectural engineeringCarriageway

The technical scheme of the invention provides a splicing construction method for rebuilt and expanded new and old roads. A step milling position is arranged on a position which is 10cm far away fromthe inner side of an original road traffic lane to avoid a wheel track tape; under a vehicle load function, longitudinal cracks can be effectively reduced; the width of an original road asphalt layermilling step is 45cm; the lime-ash soil aggregates of the original road are milled to form a step of which the width is 25cm; in an early period, the lime earth step of the original road is kept, andis cleared in a later period; the lime earth step and a new water stability base course are jointly paved, so that step integrity and lime earth strength can be guaranteed; and a geogrid of which thewidth is 8m is upwards folded by 25cm along the step, the folded geogrid is fixed by a U-shaped nail on the step, and the skid resistance capability and the bearing capacity of a spliced width roadbedcan be integrally improved. By use of the splicing construction method for rebuilt and expanded new and old roads, complex technologies are reduced, key links are paid attention, construction difficulties are lowered, new and old road splicing quality is improved, and a purpose of efficient construction and stable quality control is realized, and the splicing construction method is good.

Owner:CHINA COMM NORTH ROAD & BRIDGE +1

Electrotype splicing method

The invention relates to an electrotyping technology in holographic anti-counterfeiting printing, in particular to an electrotype splicing method, in which a large-area holographic nickel plate with high positioning precision and an optional area is formed by unit nickel plates through splicing. The unit nickel plates are obtained through replication, and medium viscosity protective film is adhered to the front surface of each unit nickel plate; any two opposite edges of each unit nickel plate are evenly cut by a plate cutter according to identical specifications; the cut edges are spliced linearly by hand, and the joints are connected through adhesive tape, so as to form a unit group; the other pair of opposite edges of each unit group is cut by the plate cutter according to the identical specifications, so that the upper and the lower edges of each unit group are evenly cut, and a large plate can be formed by the unit groups through splicing; and the plate joints on the back of the large plate are pasted through special electrotyping tape, the medium viscosity protective film is torn off, and the large plate is connected through electrotyping. The electrotype thickness is required to be above 100 microns, the connection strength is guaranteed, the splicing quality and efficiency are improved, effects from human factors are reduced, the edge cutting is controlled, fixed reserved edges are kept, and the cutting precision is ensured.

Owner:HUBEI LHTC ANTI COUNTERFEITING TECH CO LTD

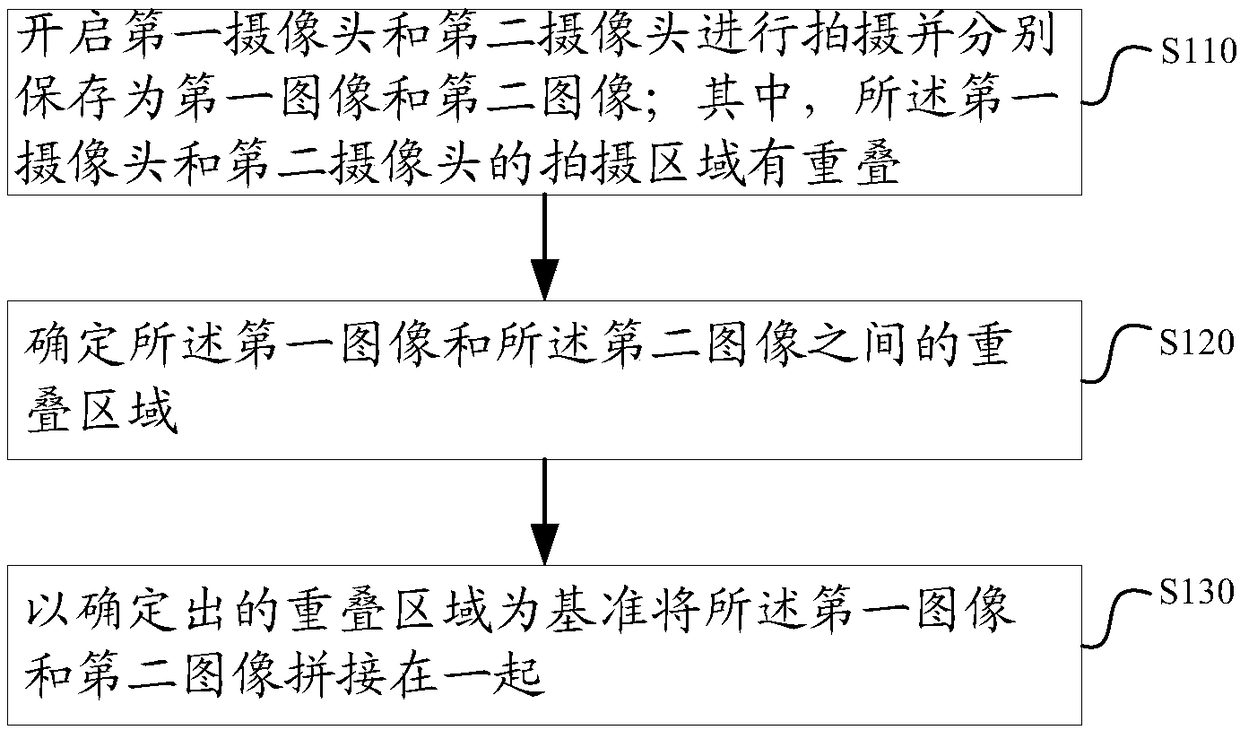

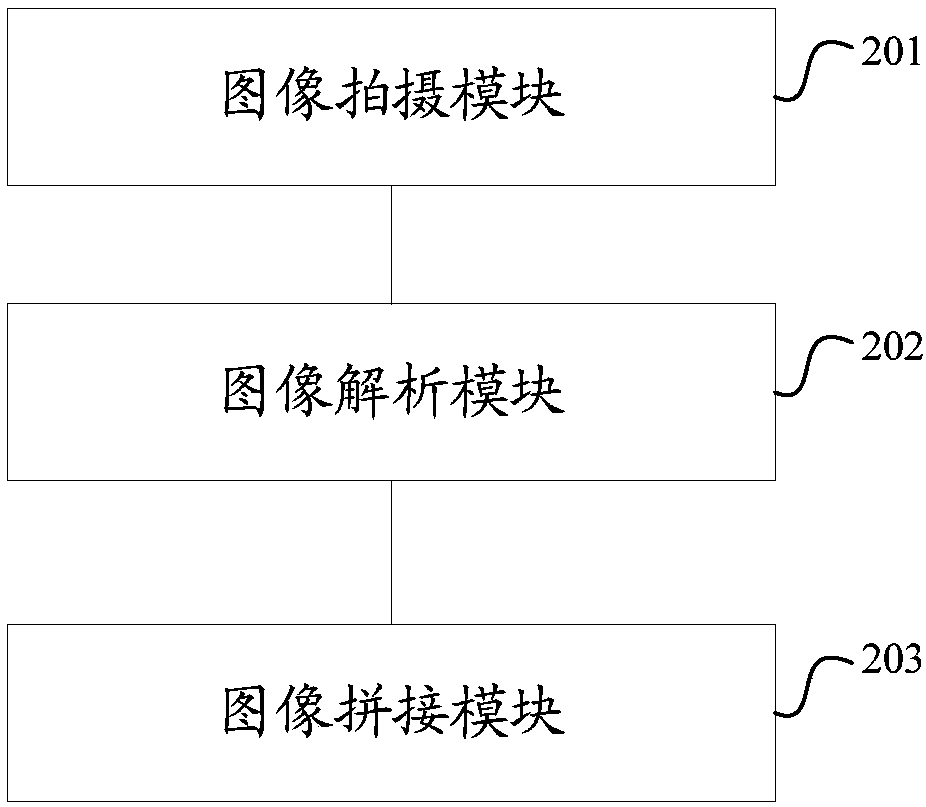

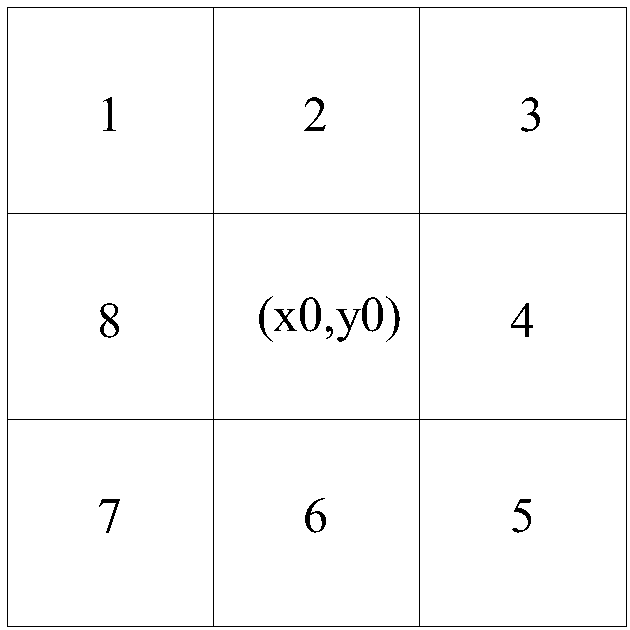

Image stitching support method and terminal

PendingCN108205801AImprove stitching qualitySimplify the shooting processImage enhancementImage analysisComputer terminalImage stitching

The invention discloses an image stitching support method and a terminal. The image stitching support method comprises the steps that a first camera and a second camera are started for shooting, and shot images are saved as a first image and a second image respectively, wherein a shooting area of the first camera and a shooting area of the second camera overlap; an overlapping area of the first image and the second image is determined; and the first image and the second image are stitched together with the determined overlapping area being a benchmark. Through the technical scheme, image stitching can be realized by use of the two cameras on the terminal, the shooting process is simple, and image stitching quality is high.

Owner:ZTE CORP

System and methods for correcting overlapping digital images of a panorama

ActiveUS20180278854A1Smooth changeImprove computing powerImage enhancementTelevision system detailsComputer visionDigital image

Owner:HUMANEYES TECH

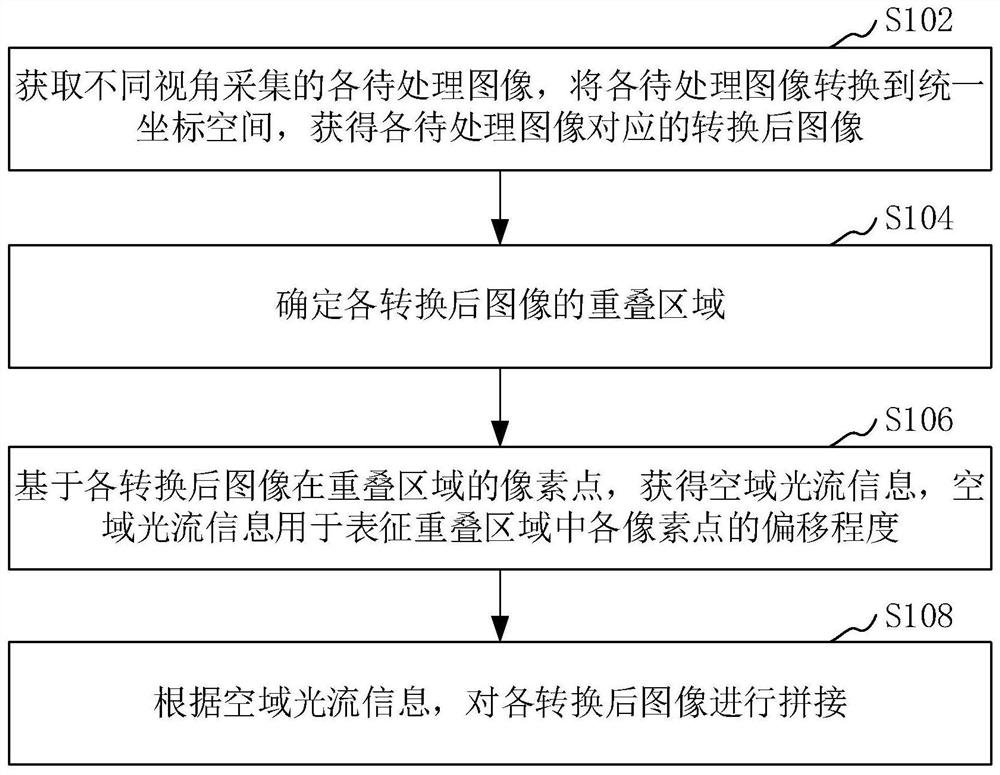

Image splicing method and device, computer equipment and storage medium

PendingCN111915483AAvoid seams or ghostingImprove image stitching qualityGeometric image transformationPhysicsOptical flow

The invention relates to an image splicing method and device, computer equipment and a storage medium. The method comprises the steps of obtaining to-be-processed images collected from different visual angles, converting the to-be-processed images into a unified coordinate space, and obtaining converted images corresponding to the to-be-processed images; determining an overlapping region of each converted image; based on the pixel points of each converted image in the overlapping area, obtaining spatial domain optical flow information, wherein the spatial domain optical flow information is used for representing the deviation degree of each pixel point in the overlapping area; and splicing the converted images according to the airspace optical flow information. By adopting the method, the image splicing quality can be improved.

Owner:MEGVII BEIJINGTECH CO LTD

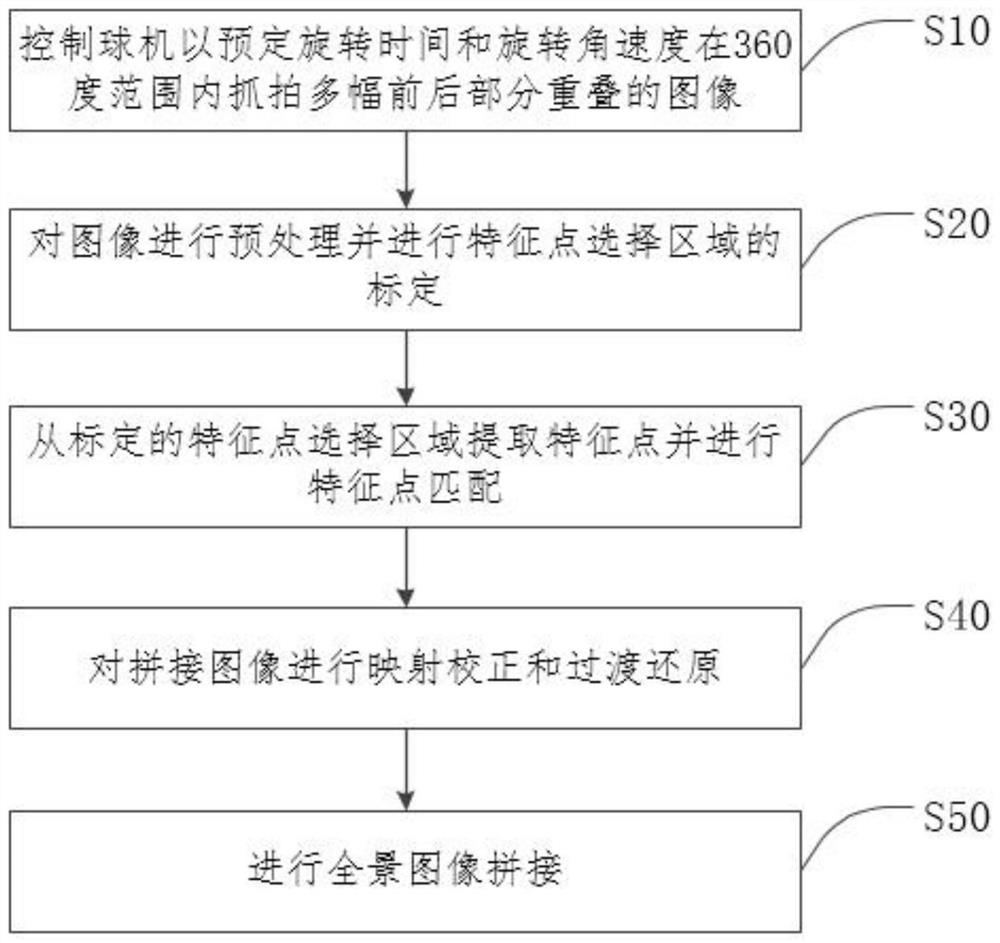

Self-adaptive panoramic stitching method based on snapshot pictures of dome camera

ActiveCN111815517AImprove match qualityImprove detection efficiencyImage enhancementImage analysisComputer graphics (images)Panorama

The invention discloses a self-adaptive panoramic stitching method based on pictures captured by a dome camera. The method comprises the following steps: S10, controlling the dome camera to capture aplurality of images of which the front parts and the rear parts are partially overlapped in a 360-degree range at preset rotation time and rotation angular speed; s20, preprocessing the image and calibrating a feature point selection region; s30, feature points are extracted from the calibrated feature point selection area, and feature point matching is carried out; s40, performing mapping correction and transition reduction on the spliced image; and S50, panoramic image splicing is carried out. According to the self-adaptive panoramic stitching method based on the dome camera snapshot pictures, the images snapshot by the dome camera can be spliced in a self-adaptive manner; by calibrating the feature point selection area, the feature point detection area is reduced to the image overlapping area from the whole image, the matching quality of the feature points is optimized while the detection efficiency is improved, the splicing efficiency and the splicing quality are greatly improved,and 360-degree dead-corner-free monitoring of a scene is realized.

Owner:SUZHOU WANDIANZHANG NETWORK TECH CO LTD

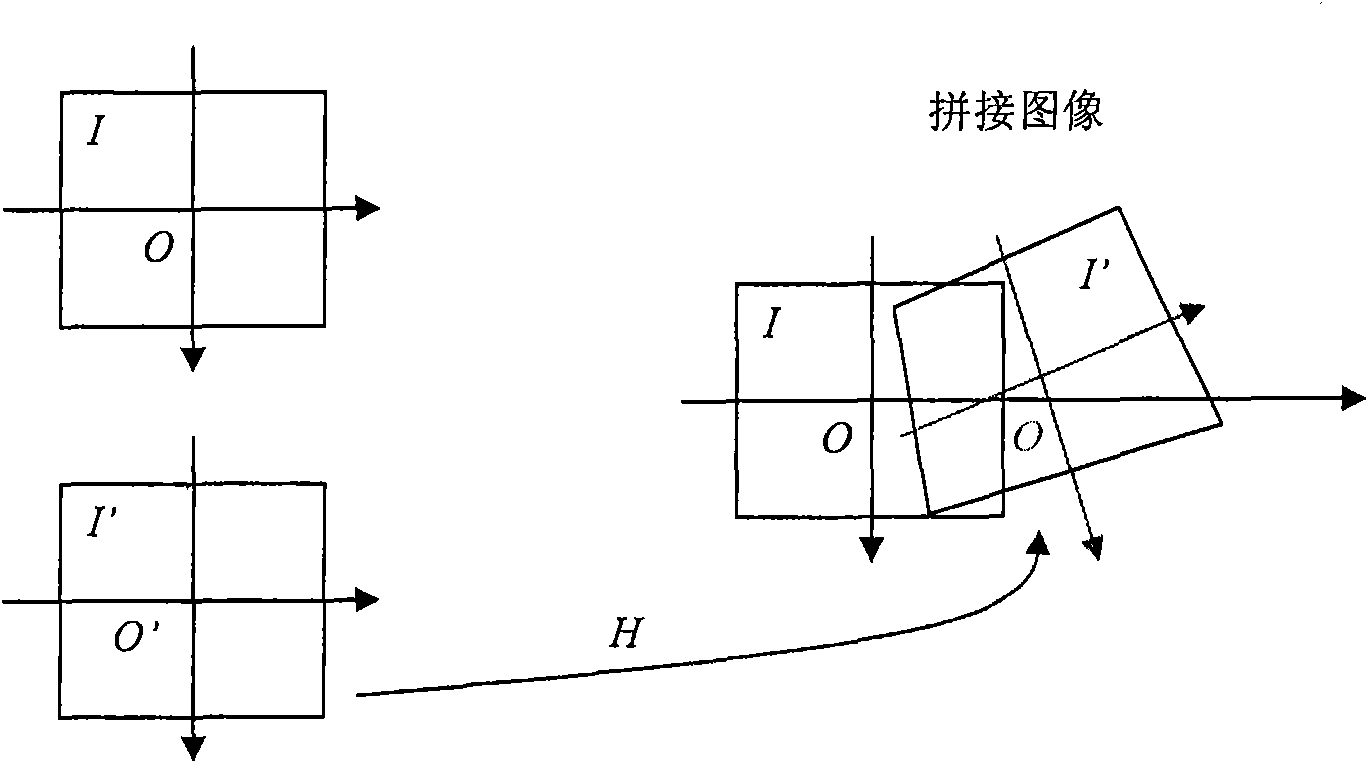

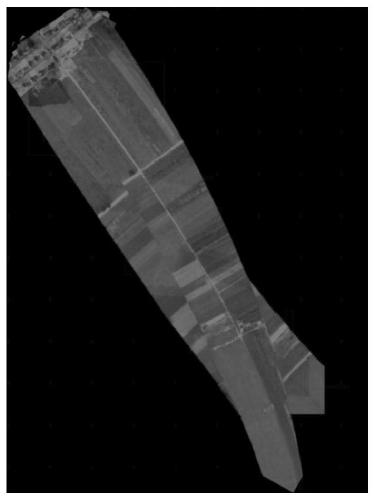

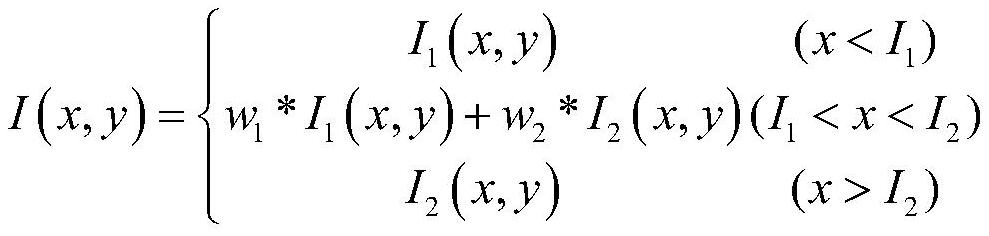

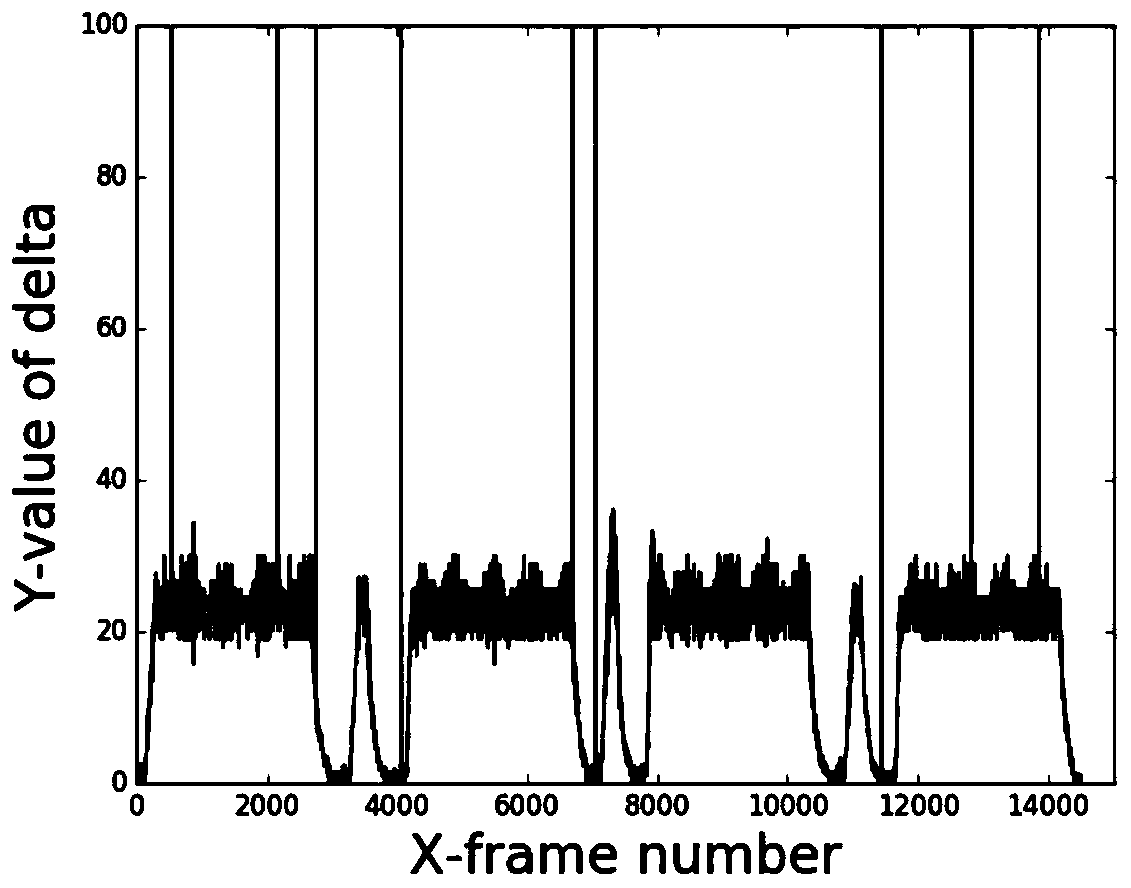

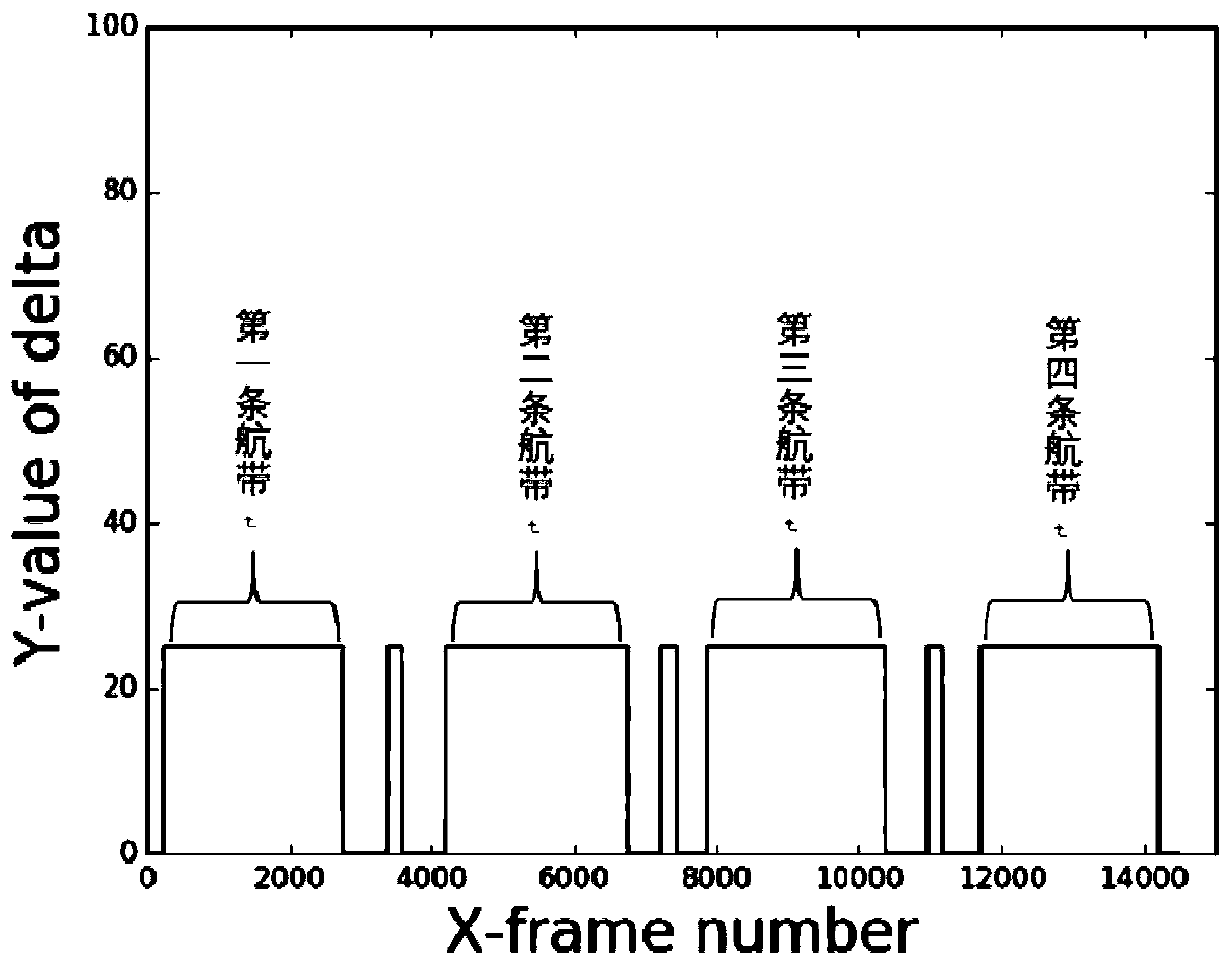

Multi-air strip image splicing and positioning method based on unmanned aerial vehicle flight path constraint

ActiveCN110097498AImprove stitching qualityHigh positioning accuracyInternal combustion piston enginesGeometric image transformationSurveyorAerial video

The invention relates to the field of computer image processing and map surveying and mapping, in particular to a multi-air strip video image splicing and positioning method based on multi-rotor unmanned aerial vehicle flight path constraint, which is mainly used for improving the splicing quality of the images between the air strips and the positioning precision of a panorama. The method comprises the following steps of firstly, processing the GPS information of all images in an aerial video, obtaining the flight path information, then performing a series of image processing operations on theto-be-spliced image to obtain a homography matrix, mapping the to-be-spliced image into the spliced image by utilizing the matrix, and finally realizing a GPS positioning function by utilizing a one-to-one correspondence relationship between the image and the GPS information. According to the invention, the image splicing effect under the condition that the plurality of air strips are parallel can be effectively improved, all scene information shot during the flight process of the unmanned aerial vehicle can be truly reflected by the obtained splicing result, in addition, the GPS coordinatesof each pixel point in the splicing result can be positioned by combining the GPS information acquired in the flight process, and the positioning error is not more than 10m.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

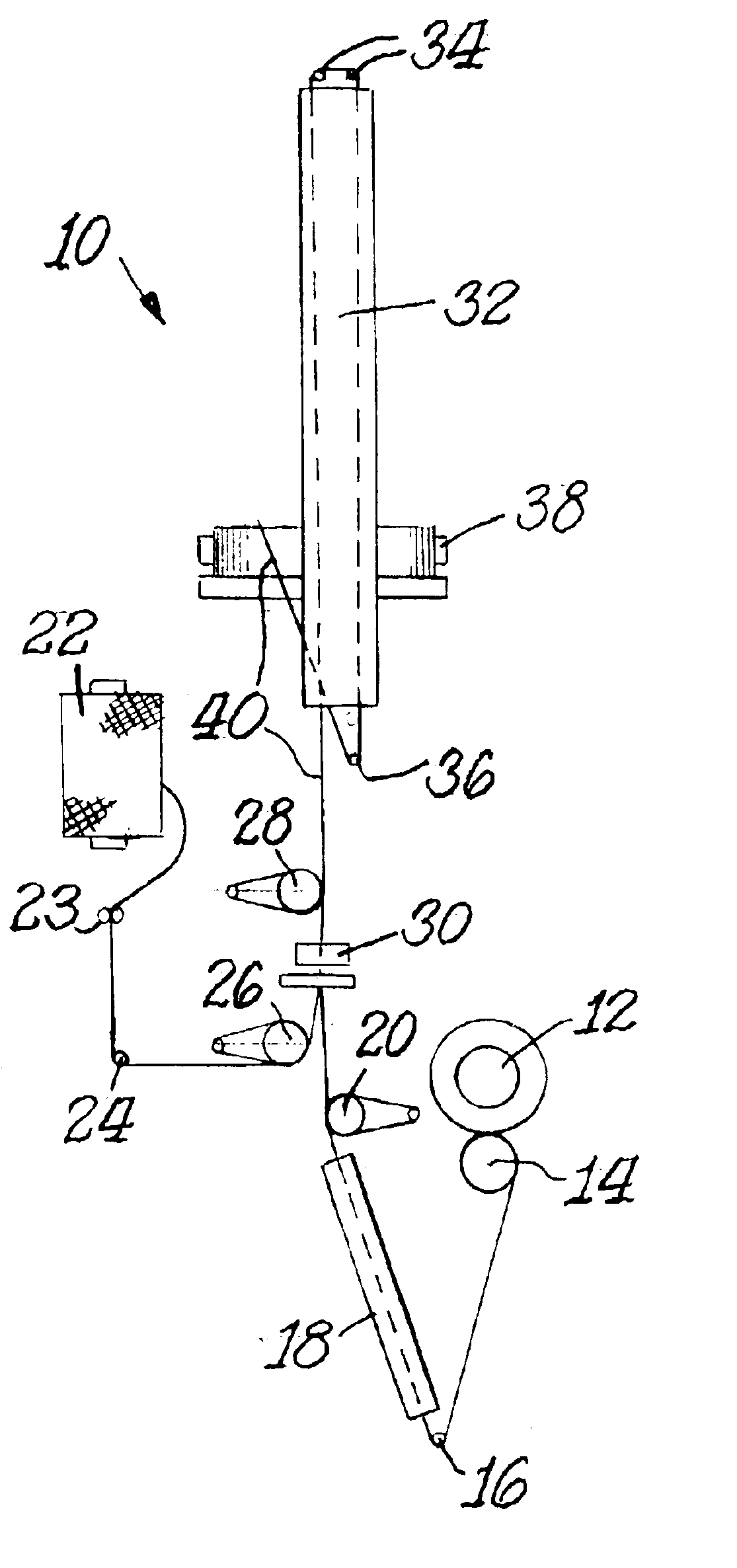

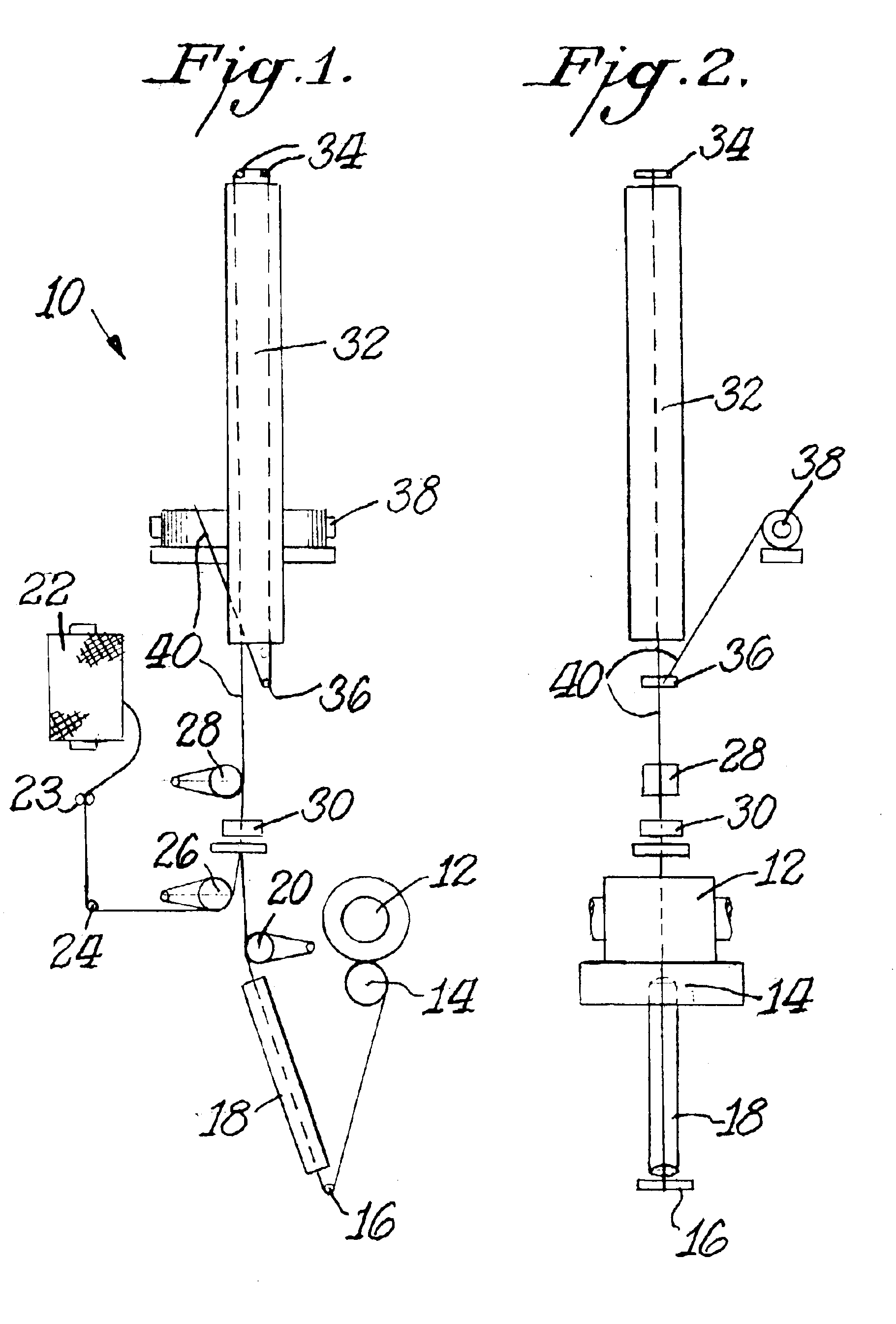

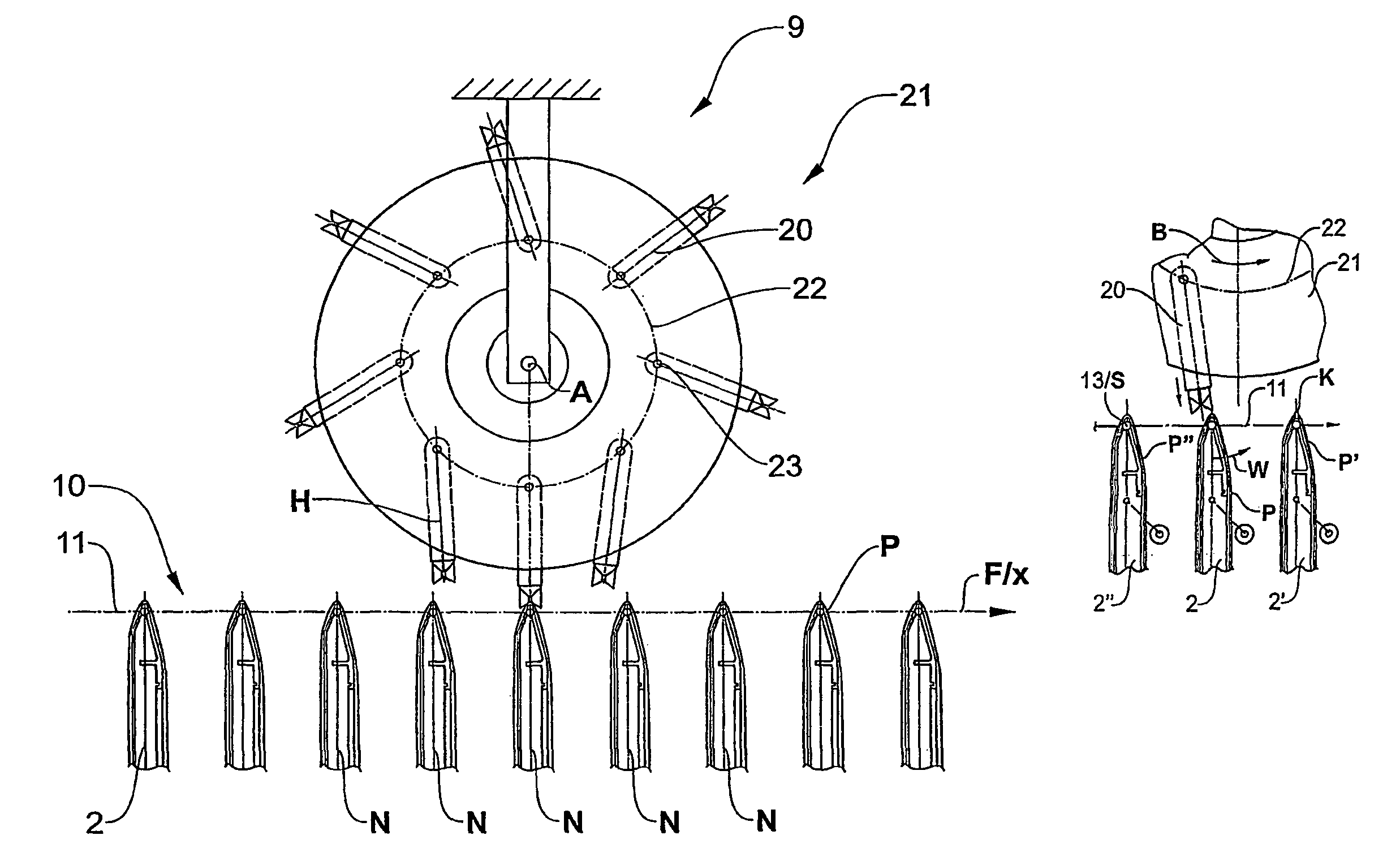

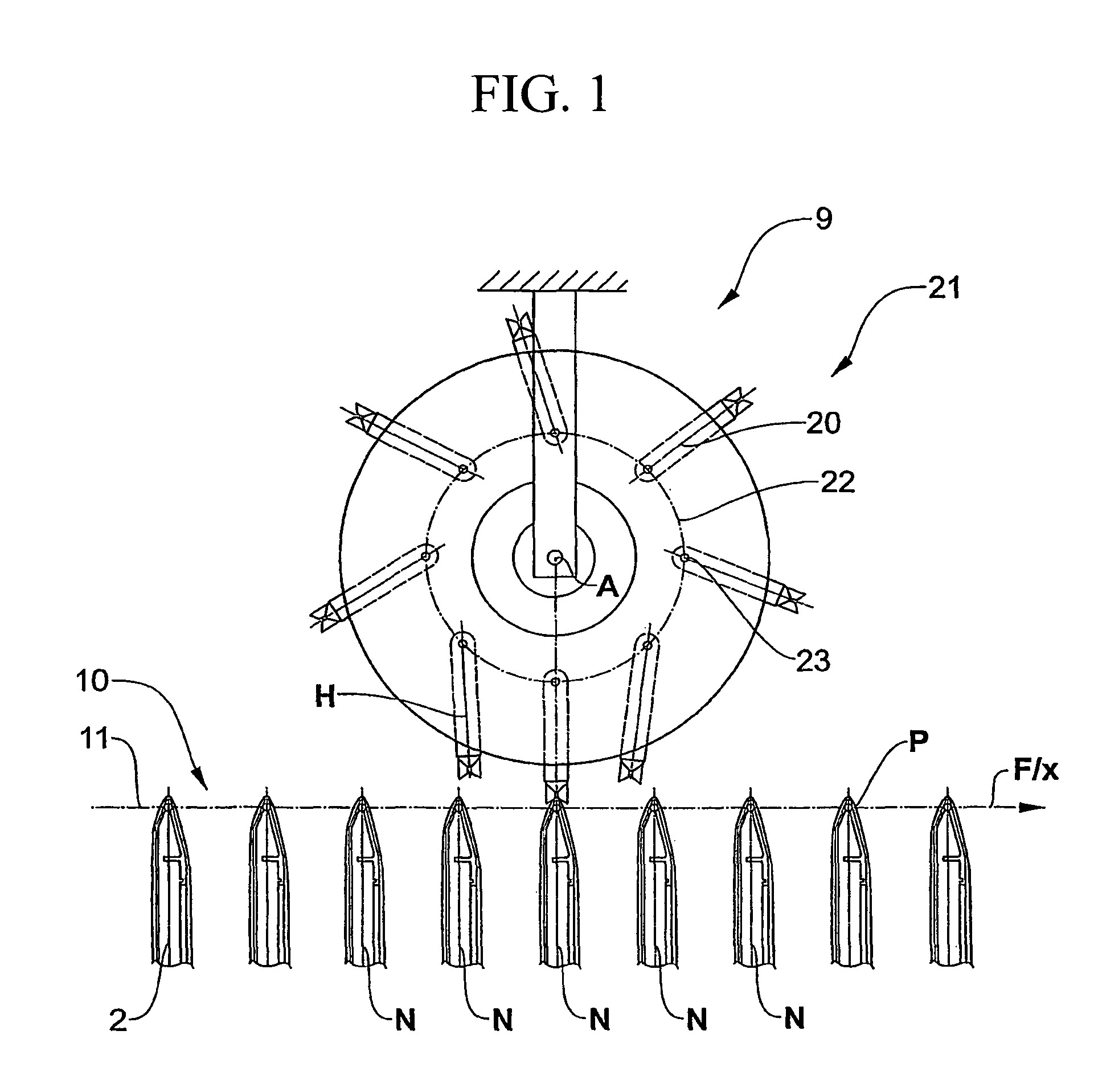

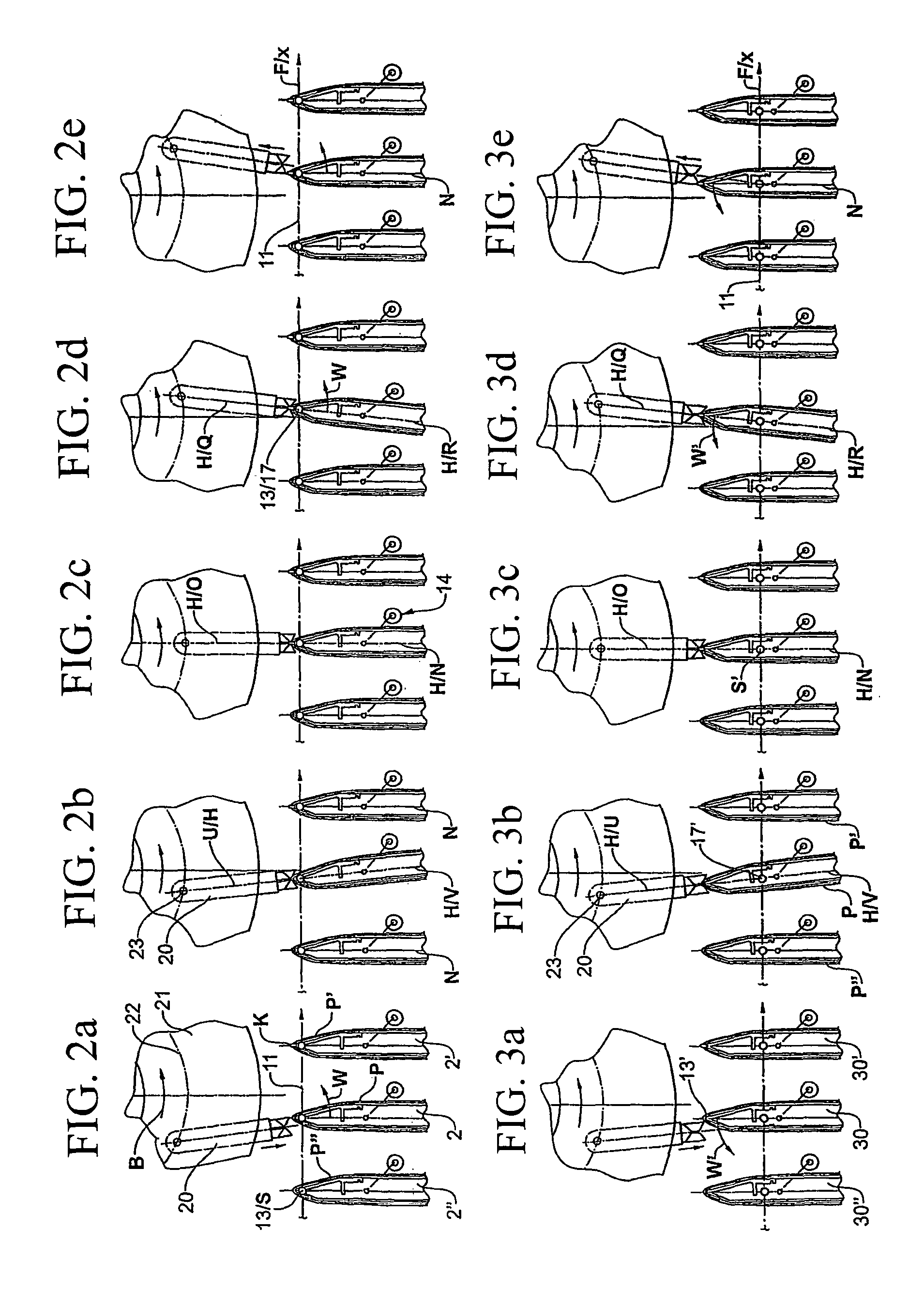

Gathering and stitching machine

InactiveUS7900902B2Conducive to loadImprove stitching qualityArticle feedersSheet bindingEngineeringSaddle shape

A new gathering and stitching machine (10) and a new method for operating a gathering and stitching machine (1) are proposed, which make it possible to drive in the staples (K) in a positionally correct manner and to close them satisfactorily even in the case of relatively short staple setting times. This is achieved by the novel control of the position of the staple heads (20) and the saddle-shaped supports (2, 30, 40, 50) in the region of the interaction during stapling. It is an essential feature of the present invention that the staple head (20) and the support (2, 30, 40, 50) are pivoted towards one another in such a way that they come to lie within a common stapling plane (H). This means that the saddle plane which is defined by the pivoting axis (S) of the saddle-shaped support (2, 30, 40, 50) and the support edge (13) and the staple-head plane which is defined by the pivoting axis of the staple head (20) and the ram tip are superimposed on one another in the region of the interaction and for the duration of the interaction and define what is known as the stapling plane (H). Here, the stapling plane (H) is pivoted continuously, with the result that it stands orthogonally on the main conveying plane (X) only in a central position.

Owner:FERAG AG

Novel concrete formwork

InactiveCN102514088ALess patchworkImprove the overall effectMould separation apparatusMouldsFastener

Owner:许金锔 +1

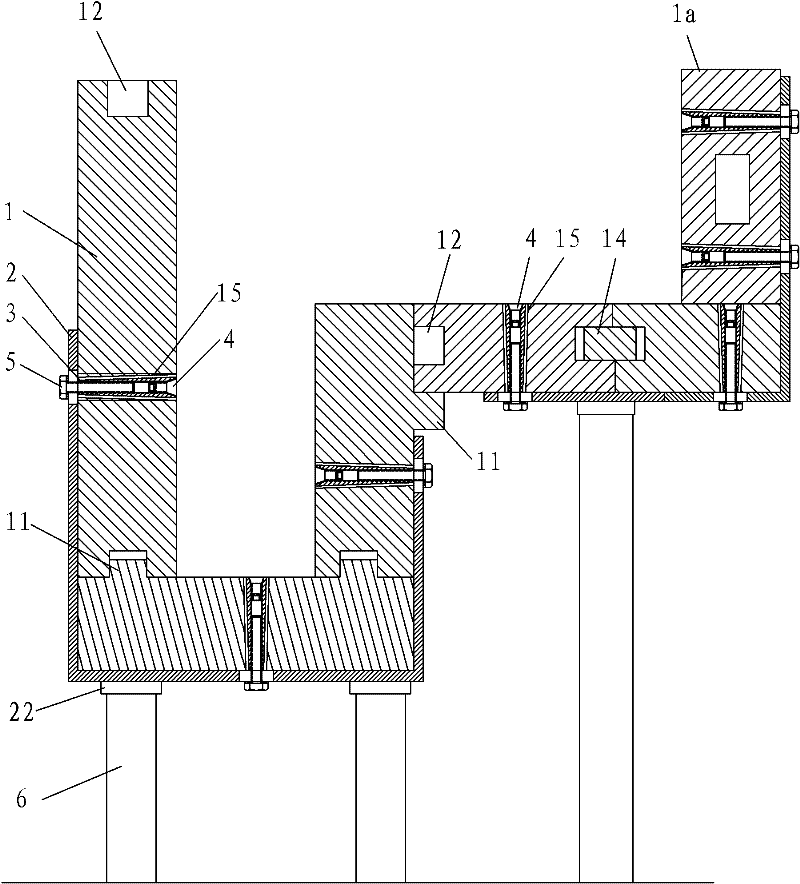

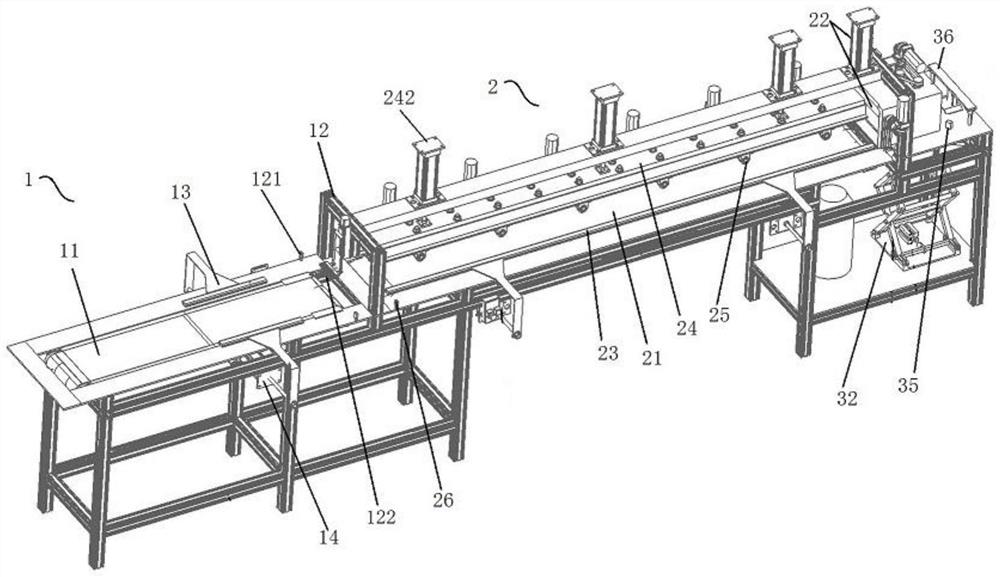

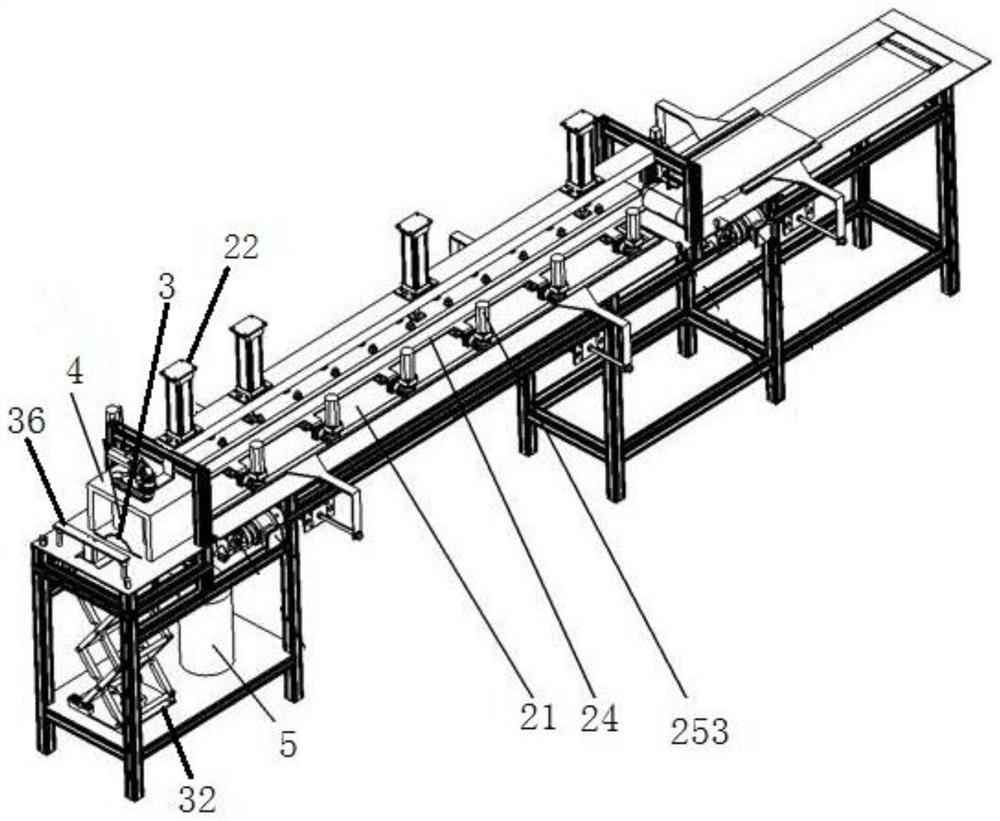

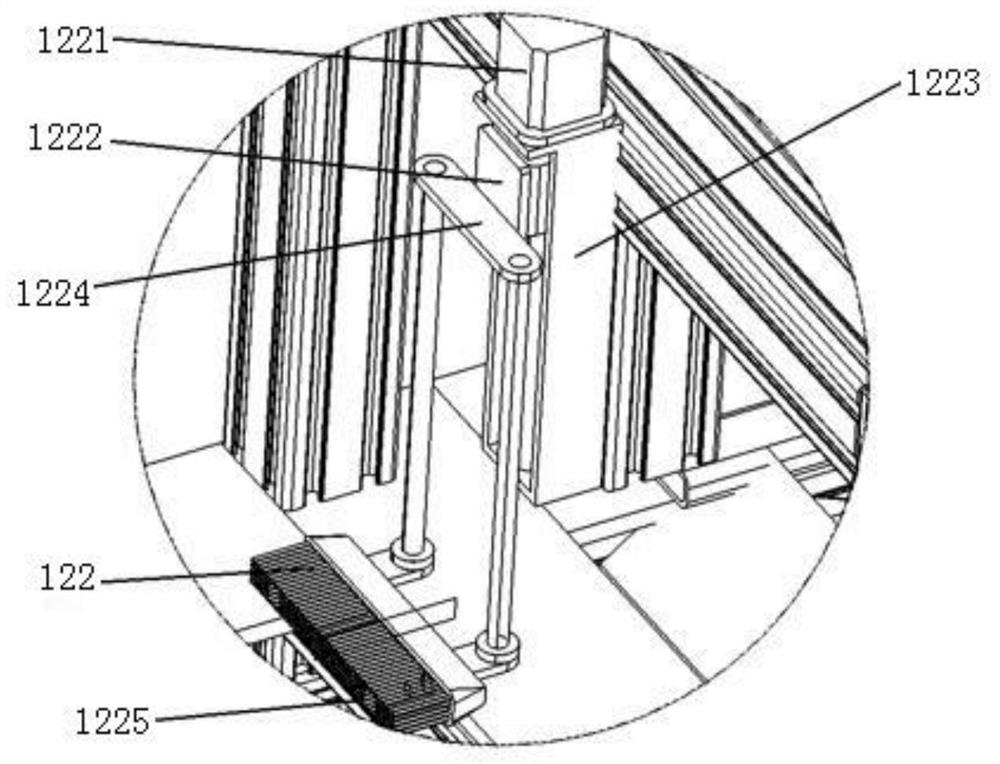

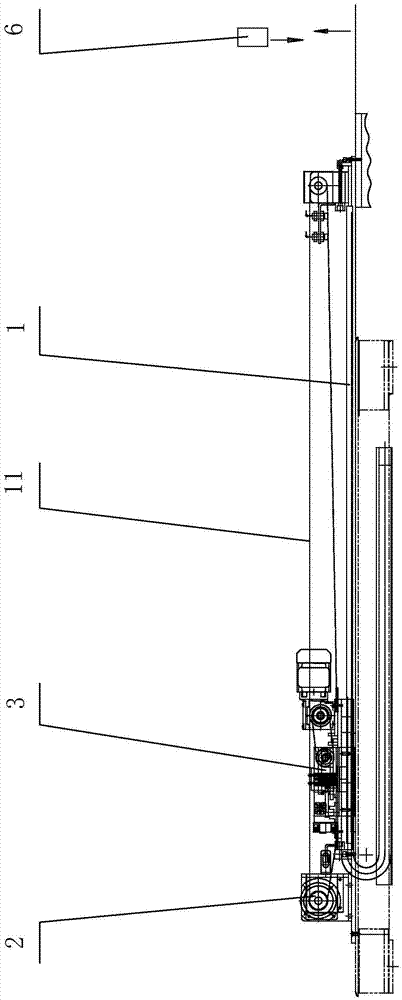

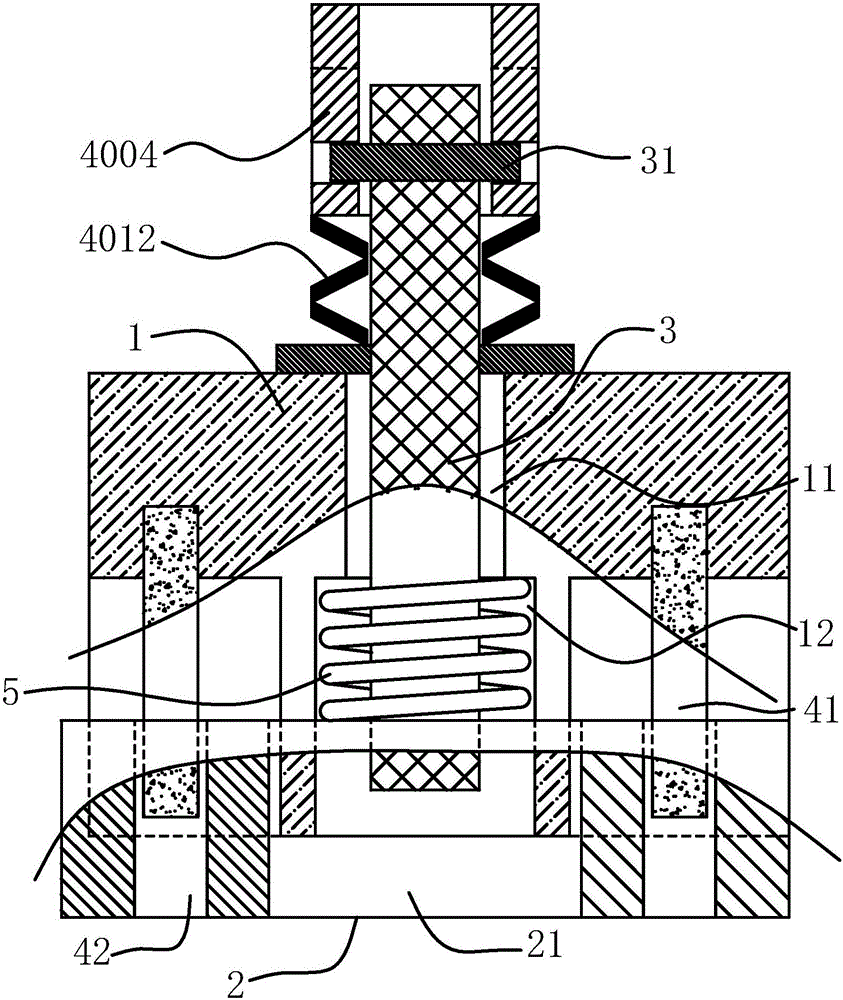

Multi-dimensional automatic sizing and forming wood finger jointing machine

ActiveCN111805645AAdhesivelyQuality improvementGuide fencesGrinding drivesAgricultural engineeringStructural engineering

The invention discloses a multi-dimensional automatic sizing and forming wood finger jointing machine. The multi-dimensional automatic sizing and forming wood finger jointing machine comprises a feeding and gluing device (1). The tail end of the feeding and gluing device (1) is connected with a pressing device (2). The feeding and gluing device (1) comprises a conveying belt I (11). The tail end of the conveying belt I (11) is provided with a gluing mechanism (12). Two sides of the conveying belt I (11) are provided with a pair of positioning and clamping side plates I (13) capable of moving towards each other. The pressing device (2) comprises a conveying belt II (21). The head end of the conveying belt II (21) is connected with the gluing mechanism (12). The tail end is provided with a material blocking mechanism (22). Two sides are provided with a pair of positioning and clamping side plates II (13) capable of moving towards each other. A pressing mechanism (24) capable of moving vertically is arranged above. The bottom of the pressing mechanism (24) is provided with a rolling wheel (25) capable of rotating. The multi-dimensional automatic sizing and forming wood finger jointingmachine has the characteristics of good splicing quality, using flexibility, high production efficiency, low production cost and environmental protection.

Owner:GUIZHOU INST OF TECH

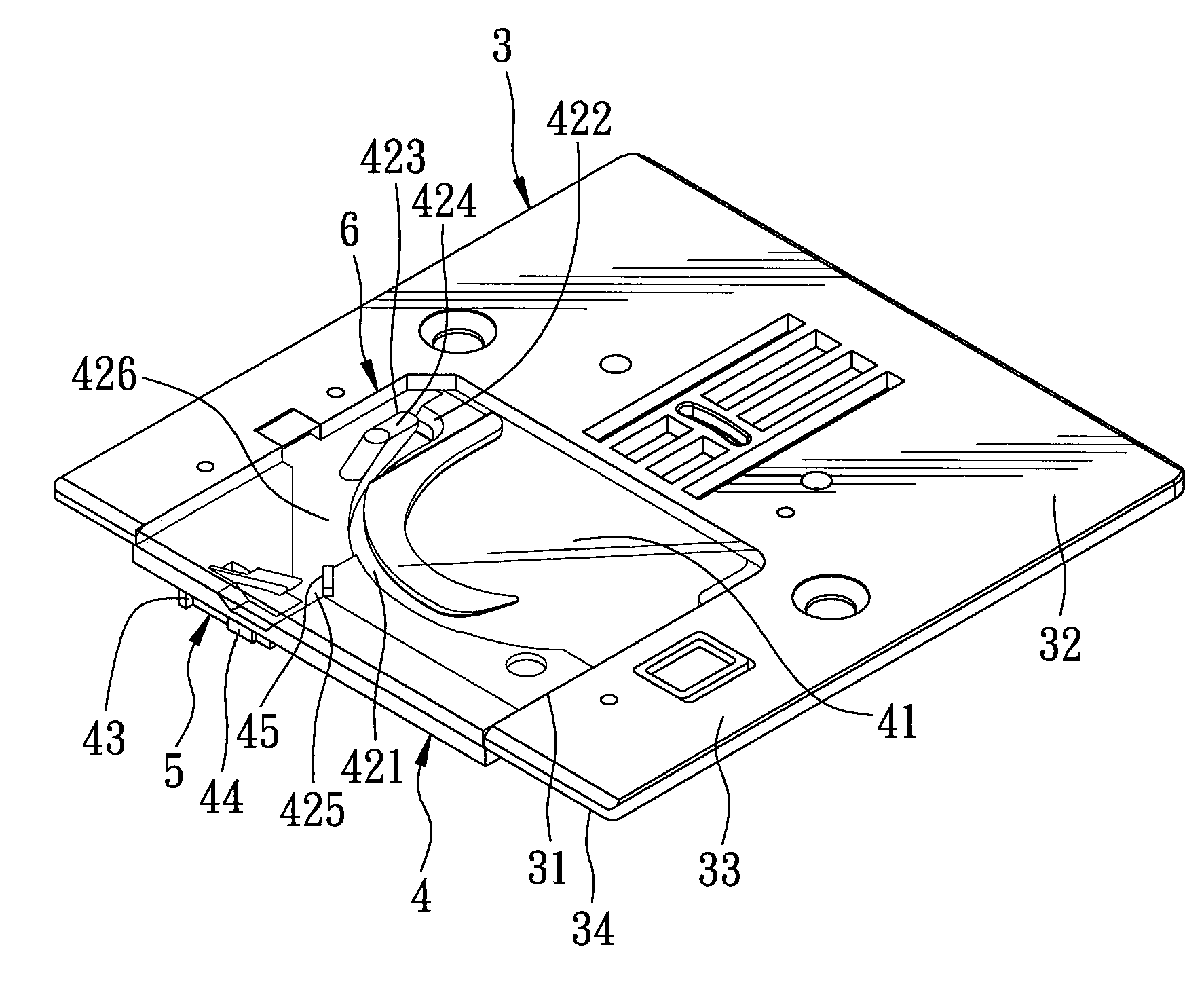

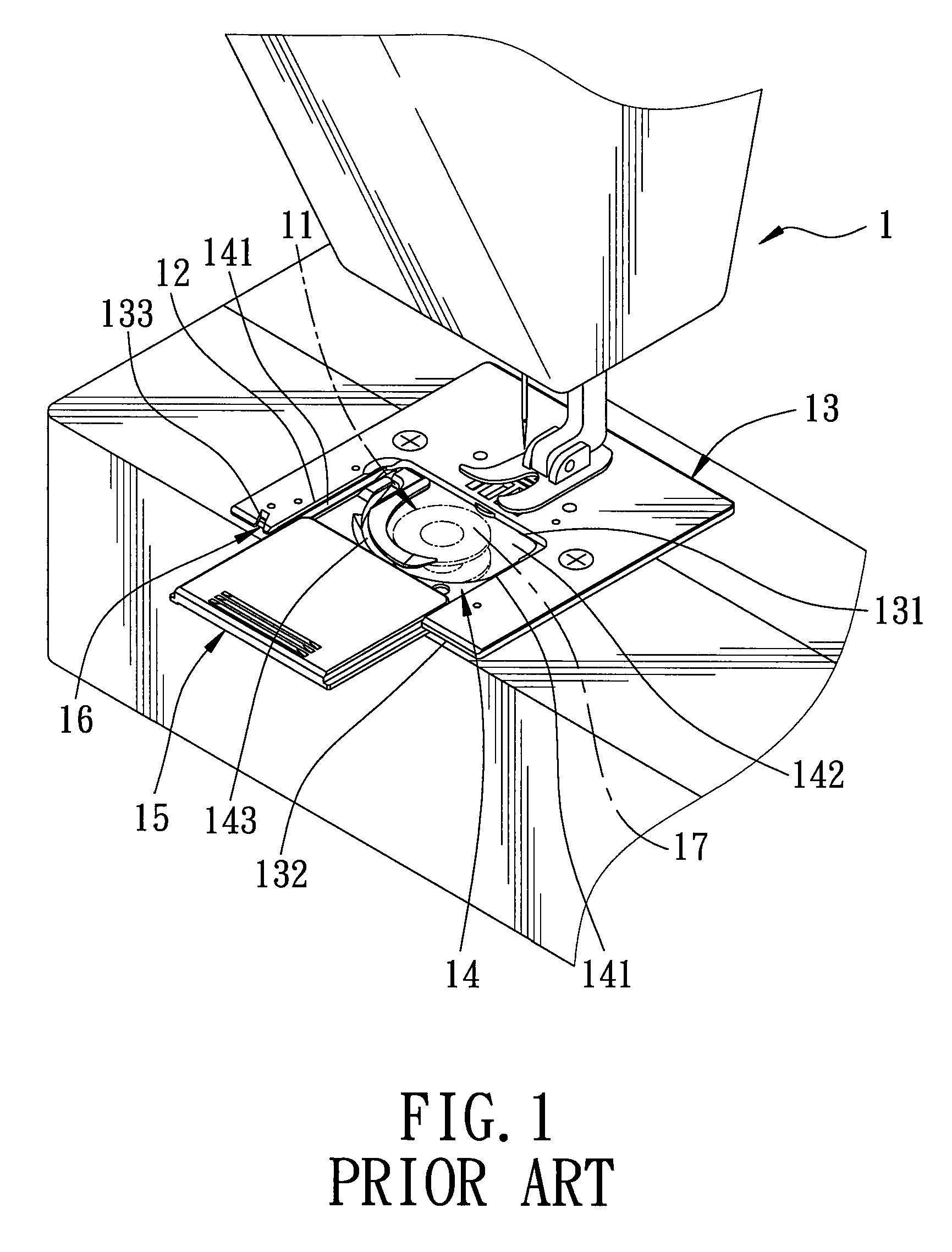

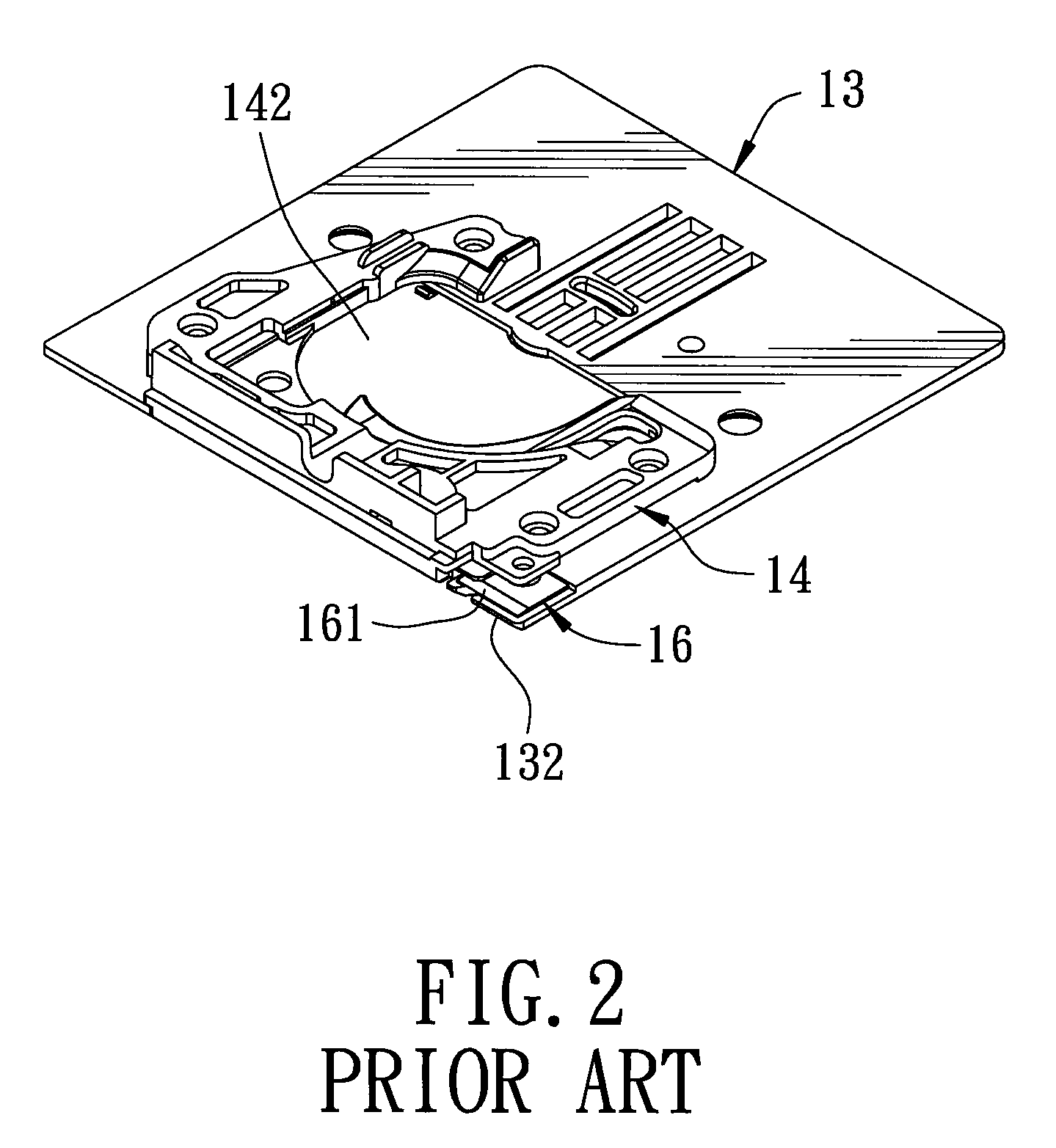

Stationary thread-cutting device for a sewing machine

InactiveUS8082865B2Improve stitching qualitySewing-machine casingsNeedle severing devicesBobbinEngineering

Owner:ZENG HSING INDUSTRIAL CO LTD

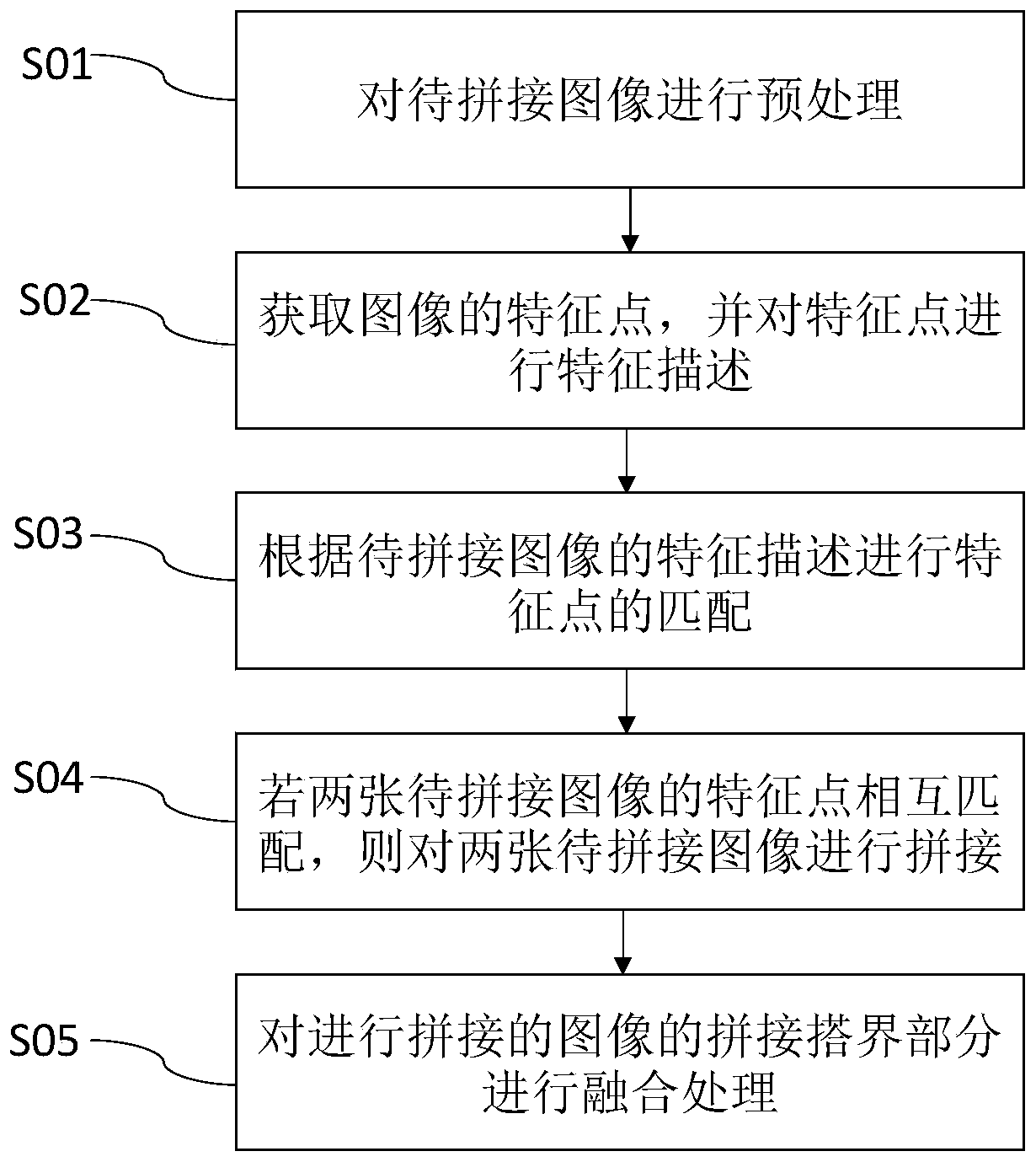

Image splicing method

PendingCN110969594AImprove splicing efficiencyImprove stitching qualityImage enhancementImaging qualityRadiology

The invention provides an image splicing method. The method comprises the following steps: preprocessing a to-be-spliced image; acquiring feature points of the image, and performing feature description on the feature points; matching the feature points according to the feature description of the to-be-spliced image; if the feature points of the two to-be-spliced images are matched with each other,splicing the two to-be-spliced images; and carrying out fusion processing on the splicing boundary parts of the spliced images. By adopting the image stitching method and device, the image splicing efficiency and quality are improved, and a good splicing effect is achieved for the to-be-spliced images with poor imaging quality.

Owner:广东优世联合控股集团股份有限公司

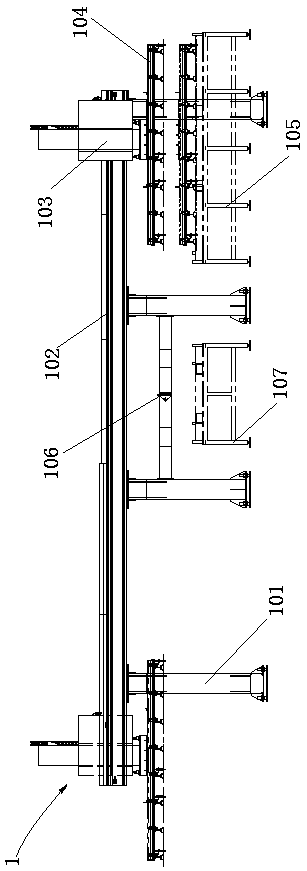

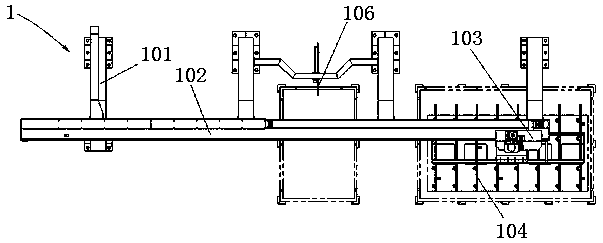

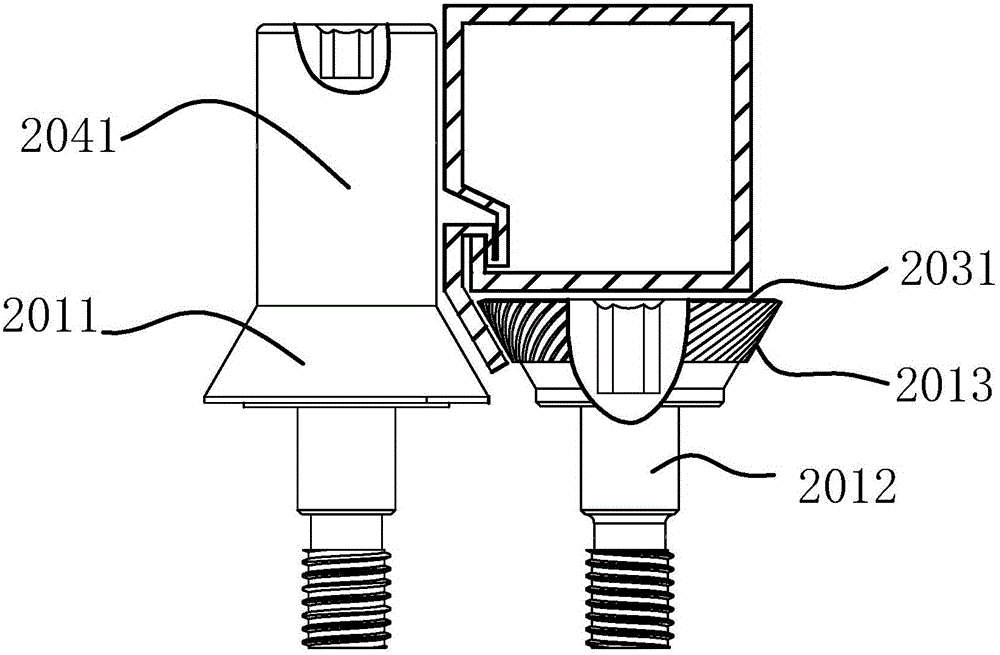

Automatic splicing conveying auxiliary device of wire cord fabric cutting machine and conveying method thereof

The invention discloses an automatic splicing conveying auxiliary device of a wire cord fabric cutting machine. The automatic splicing conveying auxiliary device comprises a linear guide rail mechanism arranged in a conveying direction and a magnetic adsorption mechanism driven by a servo control system to reciprocate on the linear guide rail mechanism; the magnetic adsorption mechanism comprises a magnetic adsorption head arranged on an acute-angle straight side edge of a wire cord fabric to adsorb the head of the wire cord fabric, and a servo motor driving mechanism for automatically adjusting a position of the magnetic adsorption head on a linear guide rail mechanism perpendicular to the conveying direction of the wire cord fabric according to a sensor feedback signal of detecting a position of the other straight side edge of the wire cord fabric; a conveying method of the automatic splicing conveying auxiliary device comprises the following steps that: the magnetic adsorption head adsorbs a wire cord fabric to a seaming position at a constant conveying speed; after releasing the wire cord fabric, the magnetic adsorption head returns to an initial position to wait for delivery of next wire cord fabric, and the process is circulated continuously until conveying and splicing of the wire cord fabrics are completed automatically. The automatic splicing conveying auxiliary device of the wire cord fabric cutting machine has the advantages of improving the accuracy of butting of heads and tails of wire cord fabrics, improving the quality of splicing, improving the reliability of equipment and reducing artificial auxiliary time.

Owner:桂林中昊力创机电科技有限公司

Portable plate sewing machine and usage method thereof

The invention discloses a portable plate sewing machine and a usage method thereof. The portable plate sewing machine comprises a guide mechanism, a work wheel set, a guide-in plate and a locking mechanism. An installation seat and the guide mechanism are connected through a sliding block, thereby being stable in transmission and reliable in work. Through matching of the work wheel set, sewing can be conducted stably with high quality when the portable plate sewing machine works. Through the locking mechanism, the portable plate sewing machine can be self-adaptive to plates with different thicknesses while the portable plate sewing machine clamps a turned edge tightly very well. The connection structure, the locking structure and the guide structure of the portable plate sewing machine are very compact and reliable, so that the portable plate sewing machine is small in size, low in weight and good in sewing quality. The portable plate sewing machine is used for sewing of the plates.

Owner:袁则怀

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com