Novel concrete formwork

A concrete formwork and concrete technology, applied in the direction of molds, mold separation devices, etc., can solve the problems of difficult control of the size of the joints, inconvenient operation, inconvenience, etc., and achieve the effect of increasing the reuse rate, improving the overall effect, and reducing the joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

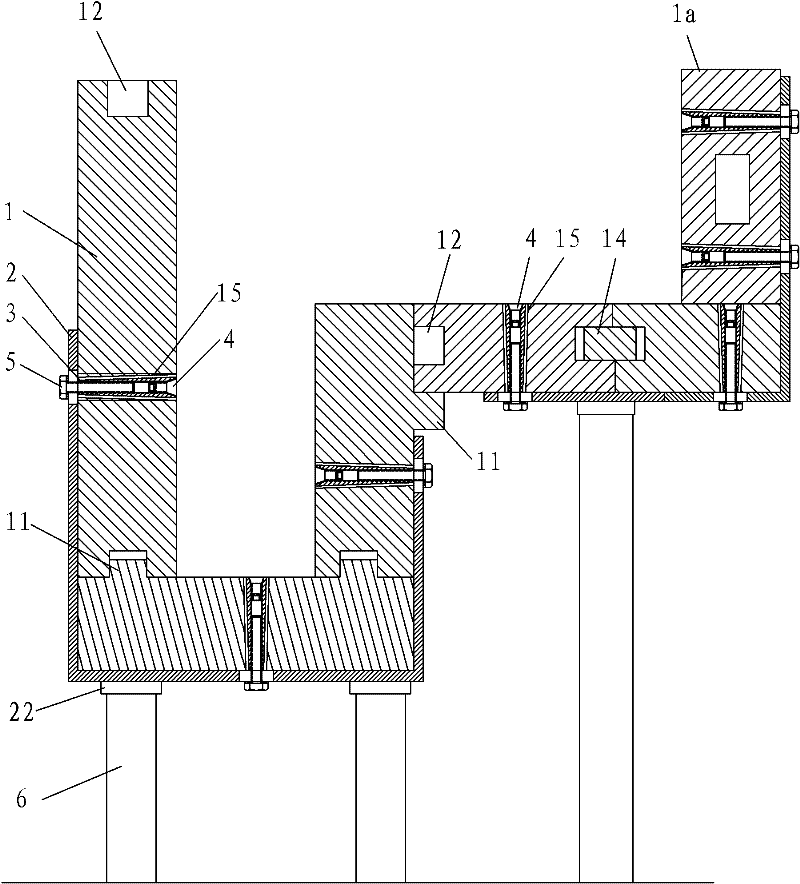

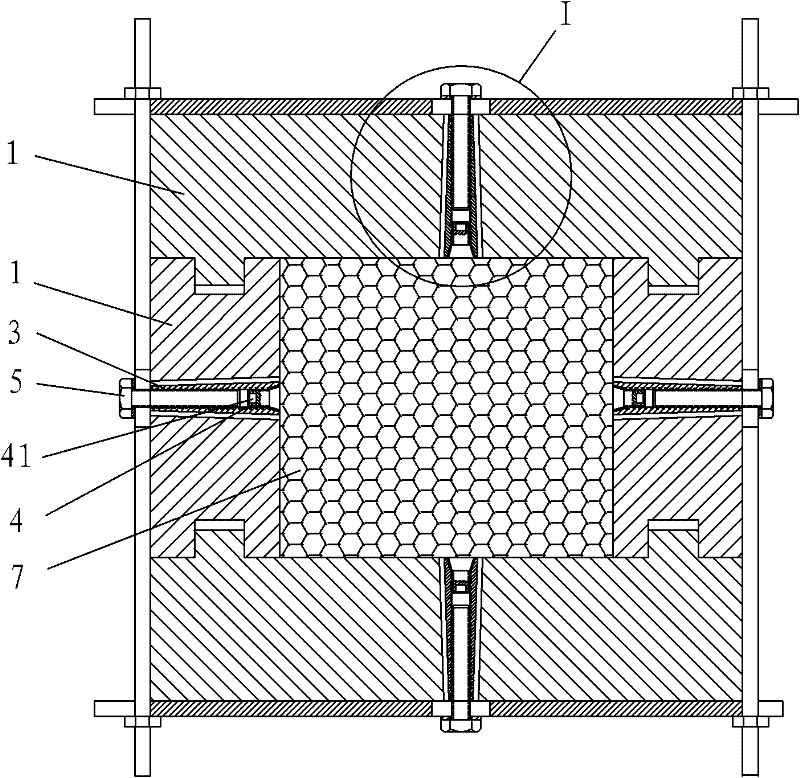

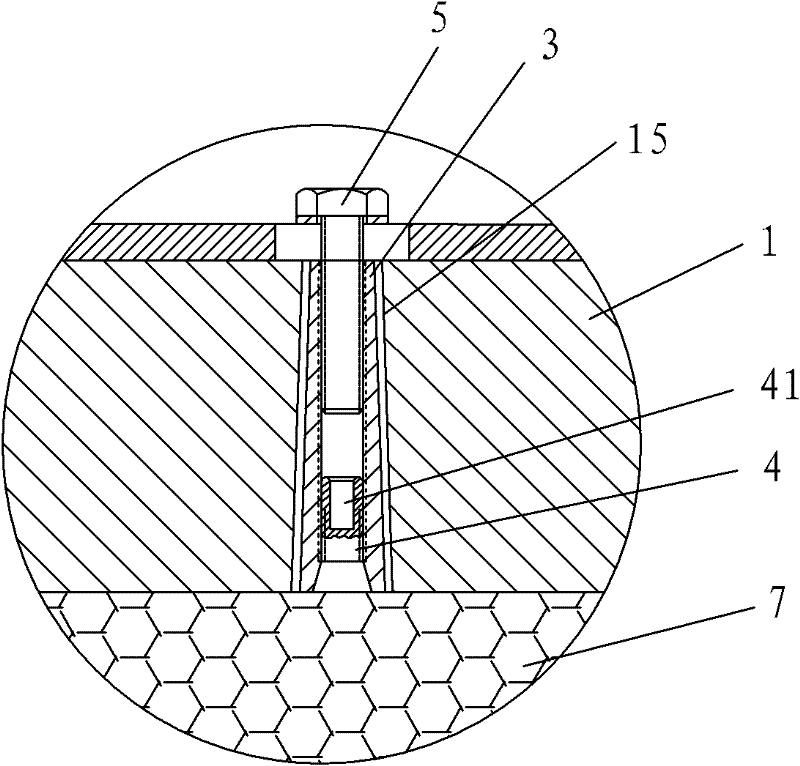

[0044] Such as Figures 1 to 11 As shown, a novel concrete formwork of the present invention includes a formwork unit 1 , formwork fasteners 2 , nuts 3 , demoulding bolts 4 , fixing bolts 5 and support pipes 6 .

[0045] Formwork unit 1 is a rectangular wooden board or plastic board, such as Figures 4 to 7 In the shown embodiments one to four, a tenon 11 and a tenon groove 12 are provided along the periphery of the template unit 1, and the tenon 11 and the tenon groove 12 are respectively arranged on the upper surface, the lower surface or the side surface of the template unit 1, and the tenon 11 and the tenon groove The section of 12 is rectangular, square, dovetail or trapezoidal. The template unit 1 is provided with at least one through hole 13 passing through both surfaces in the length direction, and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com