Patents

Literature

90results about How to "Less patchwork" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

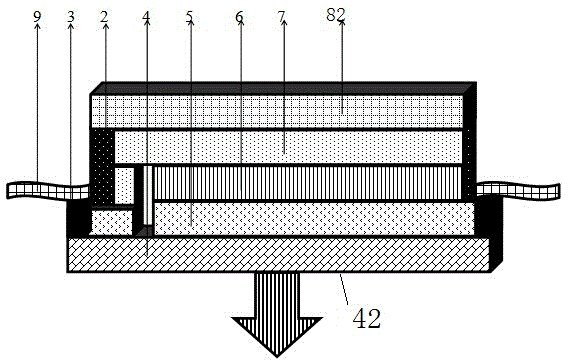

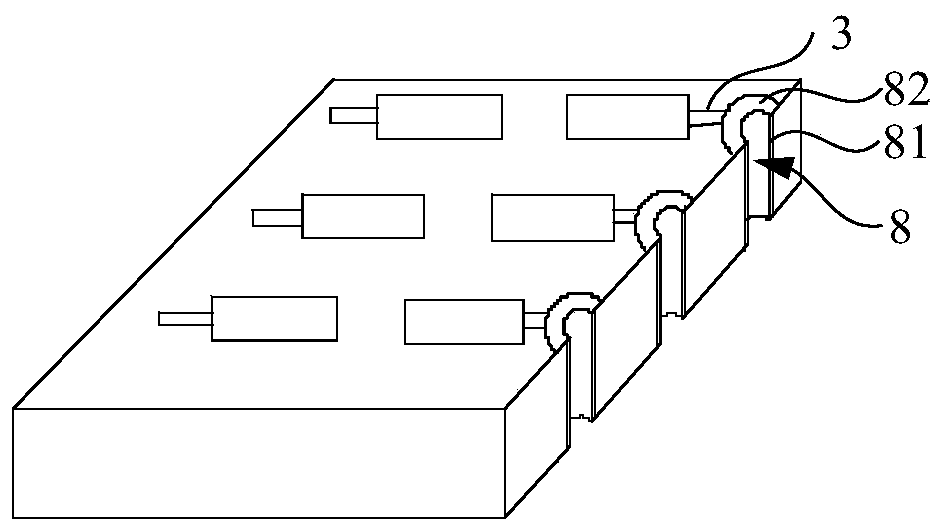

Organic light emitting diode (OLED) display panel and OLED spliced display screen with same

InactiveCN102751308AReduce the non-luminous areaLess patchworkSolid-state devicesIdentification meansMaterial PerforationLight-emitting diode

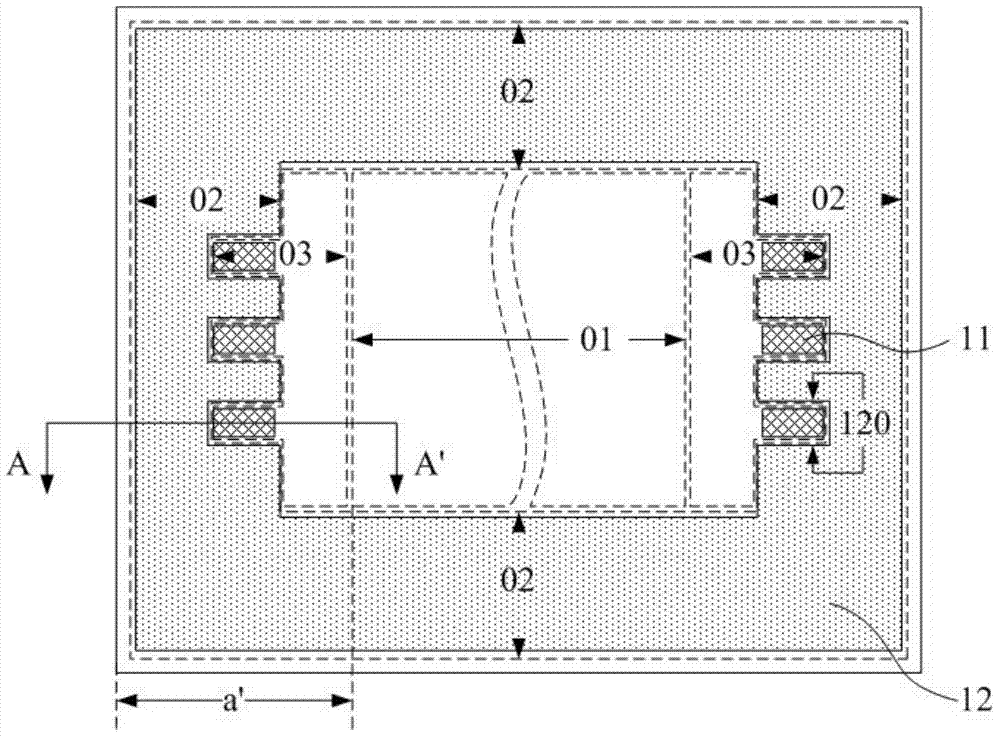

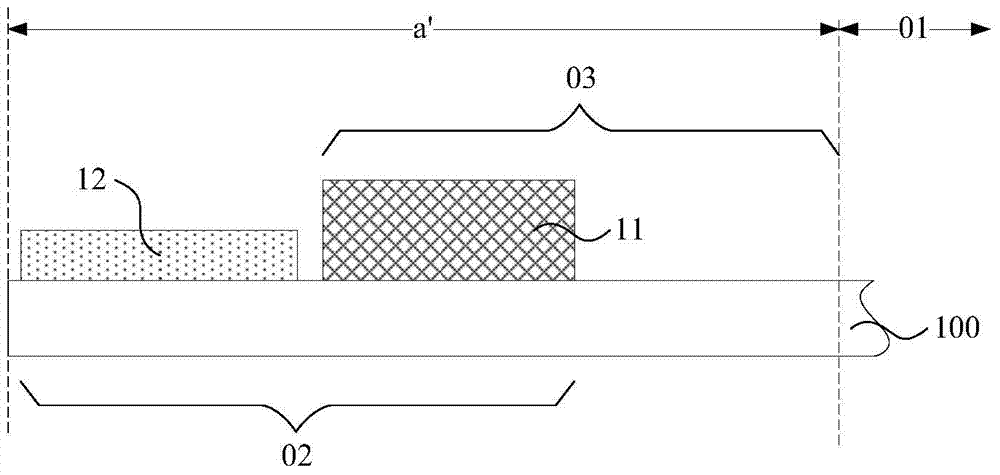

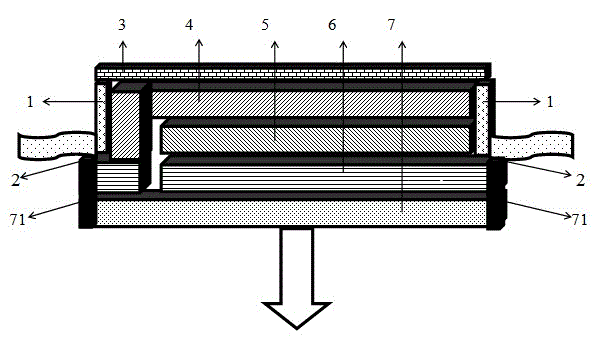

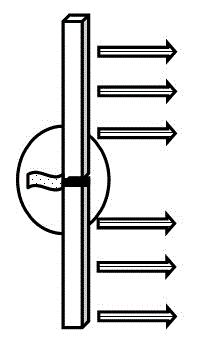

The invention relates to the organic light emitting diode display technology, in particular to an organic light emitting diode (OLED) display panel and an OLED spliced display screen with the same. The OLED display panel comprises a base plate, wherein the base plate is provided with an OLED module; the periphery and the upper part of the OLED module are provided with packaging layers; a structure formed by the OLED module and the back of the luminous surface of the display panel is provided with perforations from which a cathode and an anode are respectively introduced to the back of the luminous direction of the display panel; the positions for introducing the cathode and the anode on the back of the luminous surface of the display panel are respectively provided with conducting film layers which are not mutually connected; and a bonding area of an external-connection circuit is introduced out of the conducting film layers. According to the OLED display panel disclosed by the invention, the bonding area of the external-connection circuit is transferred to the back of the luminous surface of the device from the periphery of the OLED module edge so as to greatly reduce the non-luminous area of the device, and the OLED spliced display screen formed by splicing the OLED display panel is provided with a smaller abutted seam so as to optimize the splicing effect of the OLED spliced display screen.

Owner:GUANGDONG VTRON TECH CO LTD

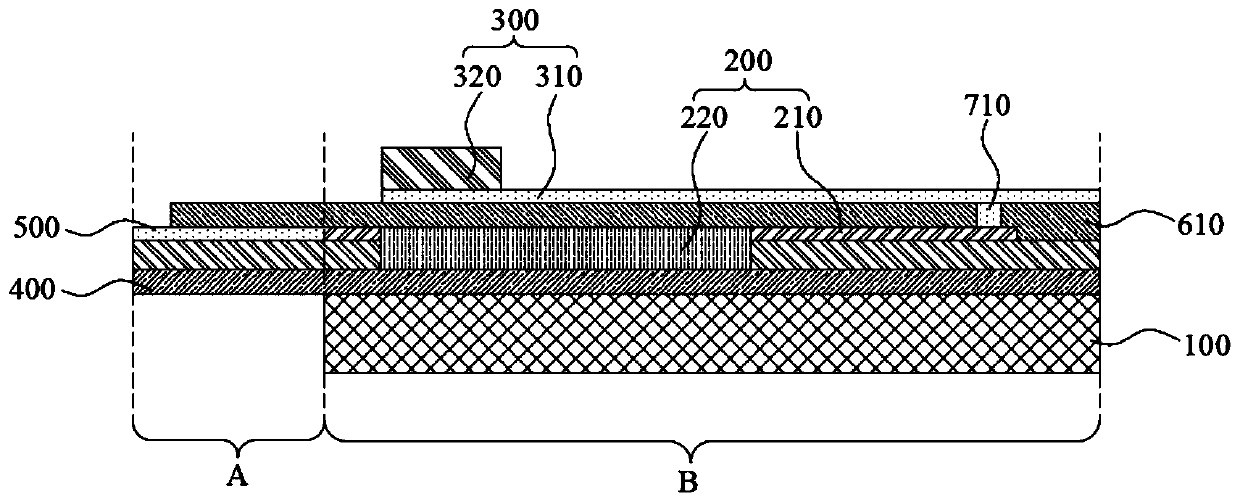

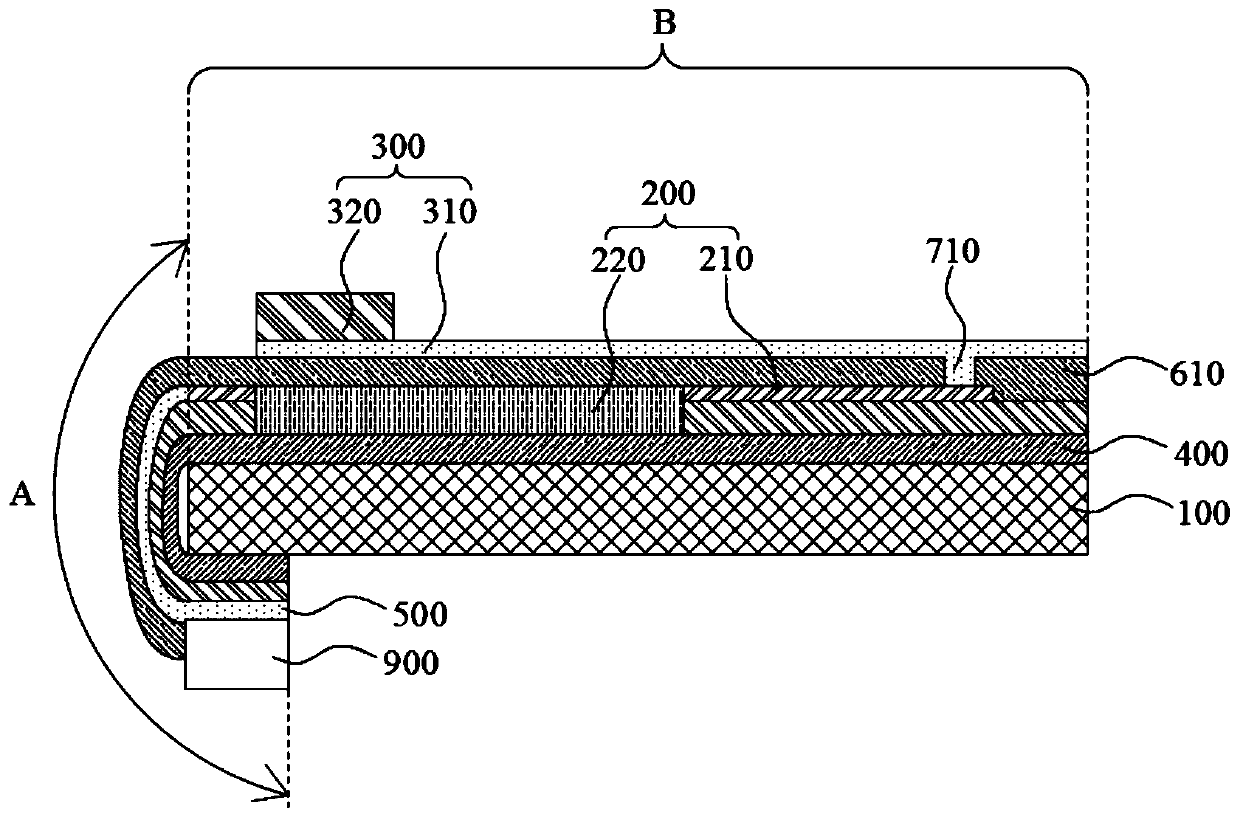

Array substrate, preparation method thereof, display panel and display device

ActiveCN110164901AReduce borderLess patchworkSolid-state devicesSemiconductor devicesDisplay deviceEngineering

The invention provides an array substrate, a preparation method thereof, a display panel and a display device, and belongs to the technical field of display. The array substrate comprises a binding area and a non-binding area. The array substrate further comprises a rigid substrate, a driving circuit layer, a light emitting diode layer, a flexible substrate layer and a binding lead layer, whereinthe rigid substrate is arranged in the non-binding area; the driving circuit layer is arranged at one side of the rigid substrate; the light emitting diode layer is arranged at the side, which is awayfrom the rigid substrate, of the driving circuit layer; the flexible substrate layer is arranged in the binding area and located at the same side of the rigid substrate as the driving circuit layer;the binding lead layer is arranged at the side, which is away from the rigid substrate, of the flexible substrate layer, and the binding lead layer is electrically connected with the driving circuit layer; and the binding lead layer and the flexible substrate layer can be bent to the side, which is away from the driving circuit layer, of the rigid substrate along the edge of the rigid substrate. The array substrate can reduce the frame of the display panel.

Owner:BOE TECH GRP CO LTD

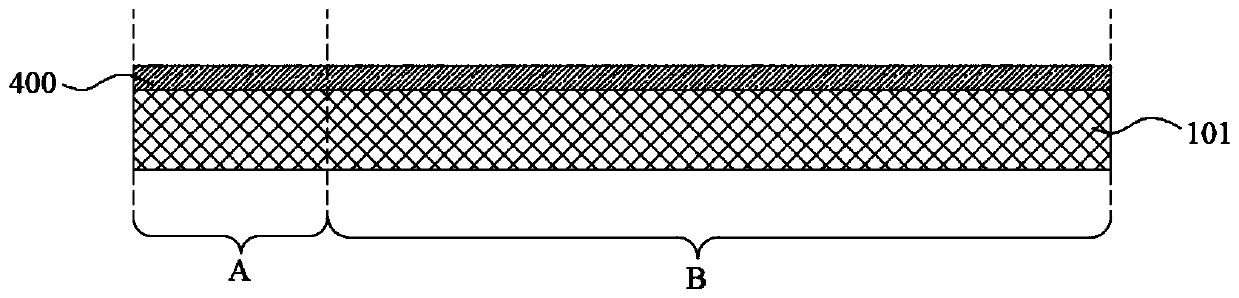

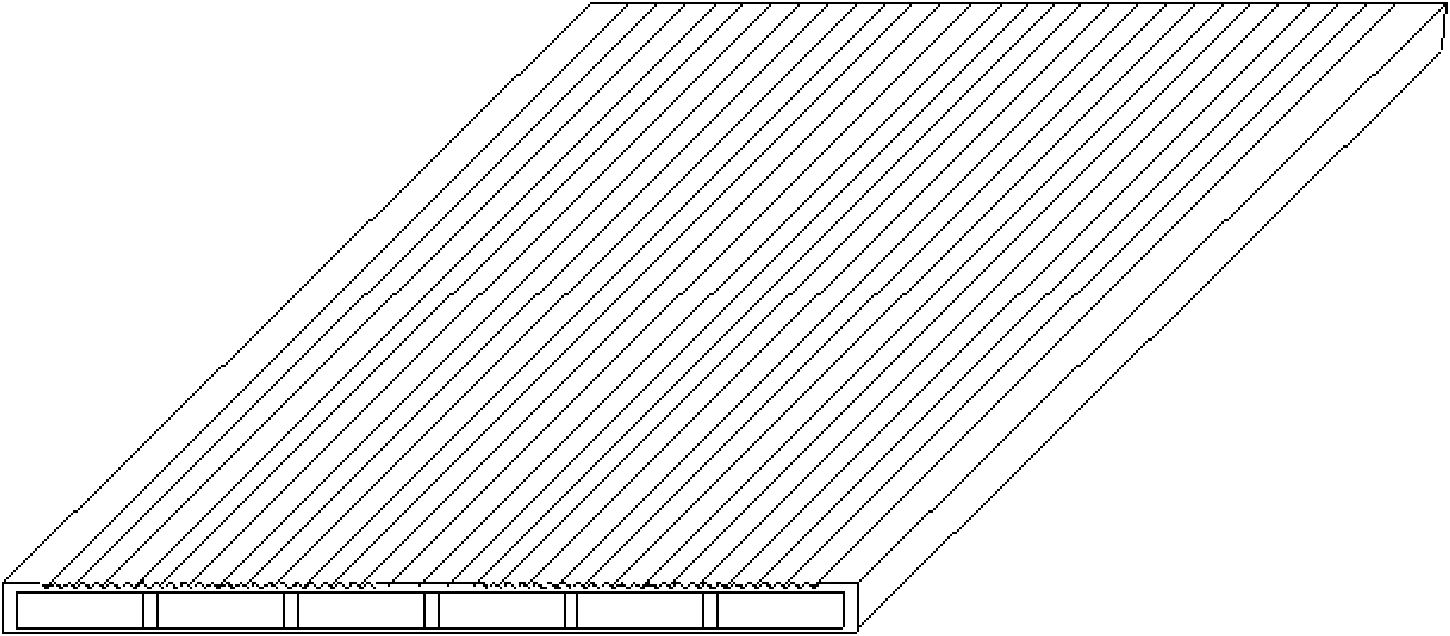

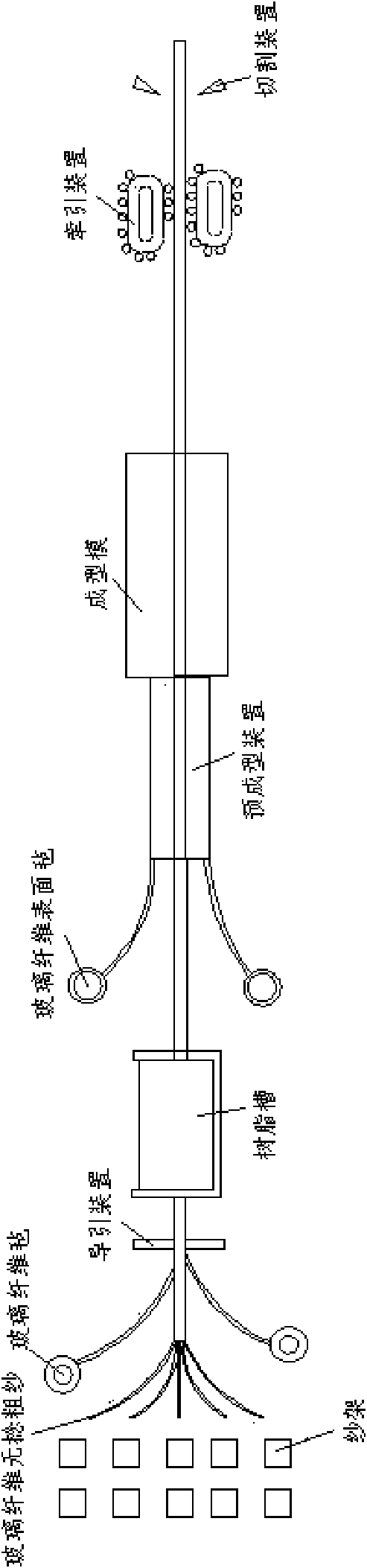

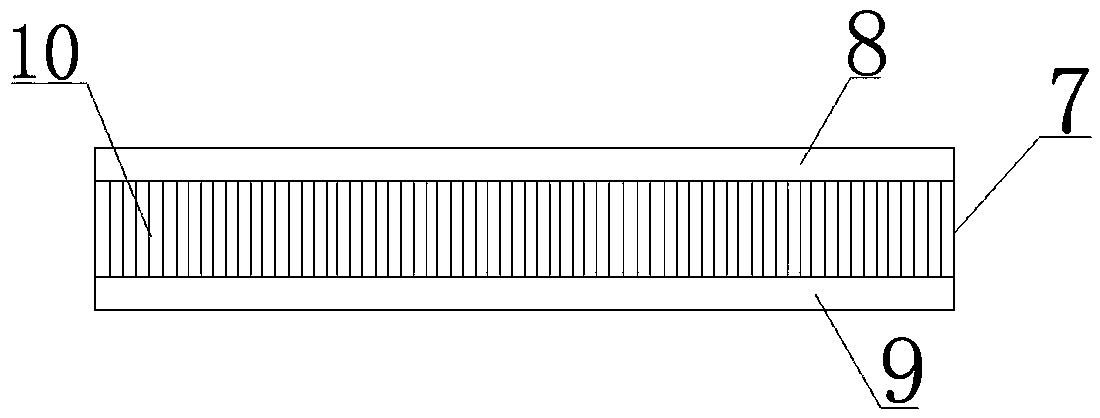

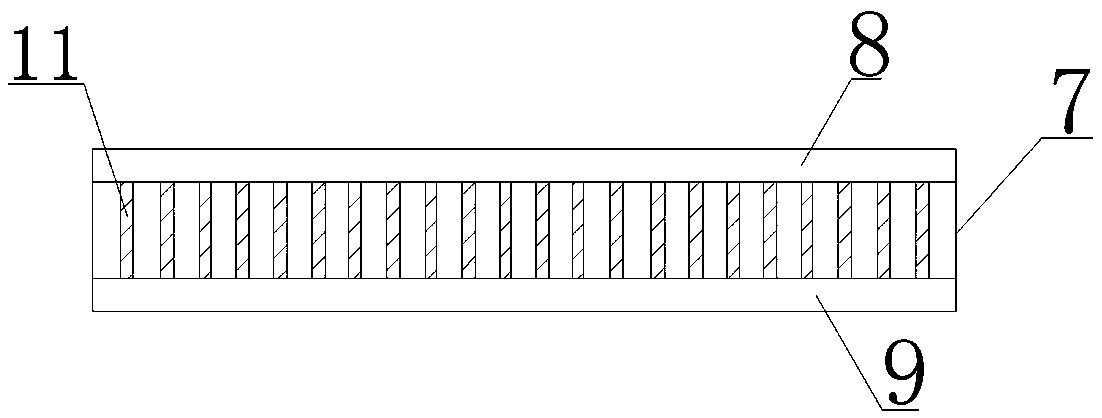

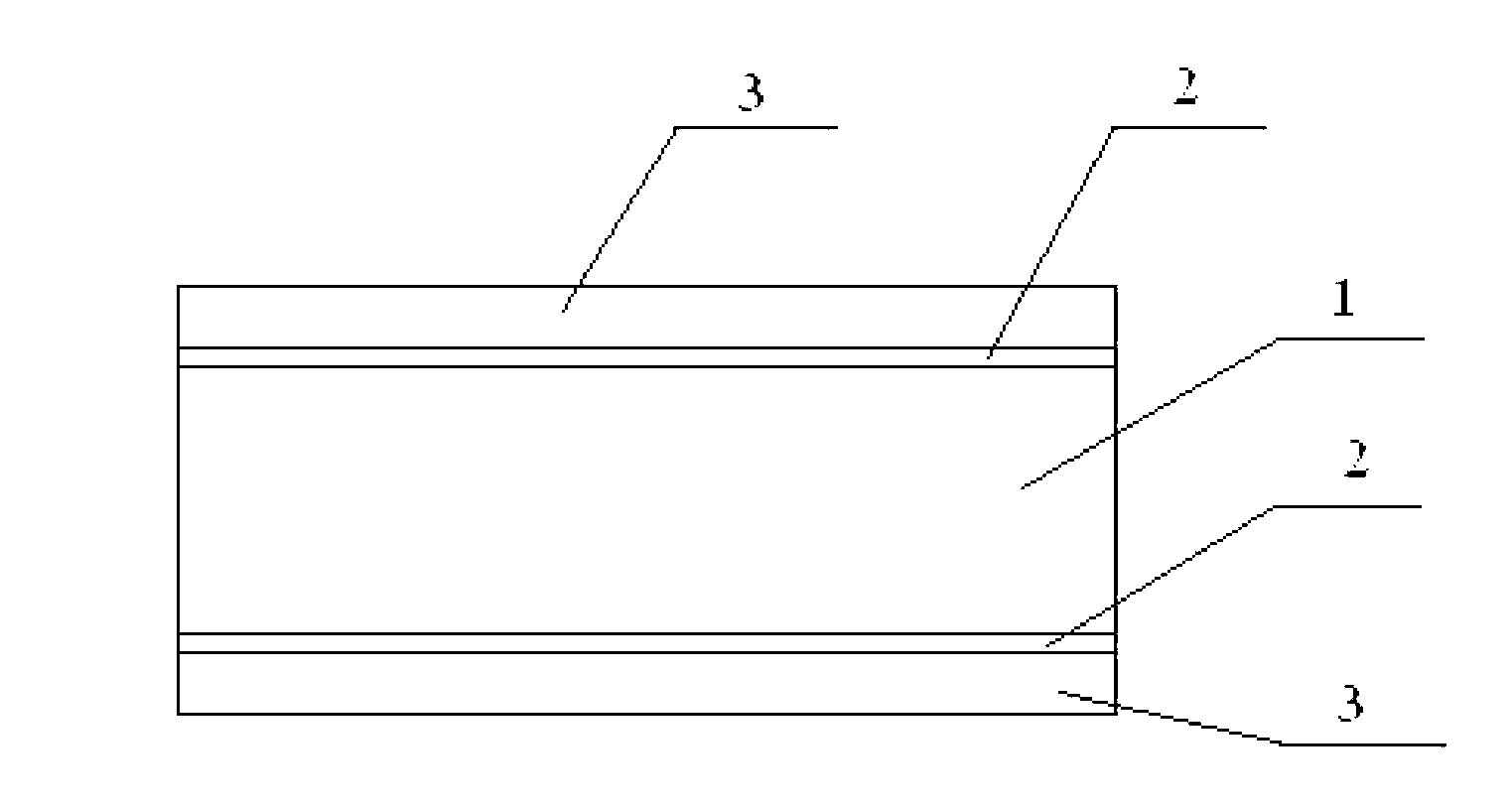

Glass fiber reinforced plastic cable channel cover plate and production method thereof

InactiveCN101672044AImprove corrosion resistanceStrong anti-agingArtificial islandsUnderwater structuresPolyvinyl alcoholEngineering

The invention relates to a glass fiber reinforced plastic cable channel cover plate and a production method thereof. The cover plate is a rectangular hollow belly structure, longitudinal stiffening ribs are arranged in the hollow belly of the cover plate and the upper surface of the cover plate is provided with strip-shaped antiskid grains; the invention comprises the following raw materials: unsaturated polyester resin, curing agent, packing, polyvinyl alcohol solution, pigment, fiberglass roving and fiberglass felt; the invention comprises the following steps: (1) arranging a tooling equipment on an extrusion molding machine; (2) mixing and pouring the raw materials in a resin tank; and (3) inducing the fiberglass roving and the fiberglass felt through immersion, a performing device, a forming device, curing and cutting. The cover plate has high strength, smooth surface, neat and beautiful appearance, corrosion resistance of alkali, acid, petrol and the like, aging resistance, long service life without pulverization, discoloration, crack, deformation and the like. The invention ensures the safe operation of cables and prolongs the service life of the cables.

Owner:醴陵市万通新型材料有限公司

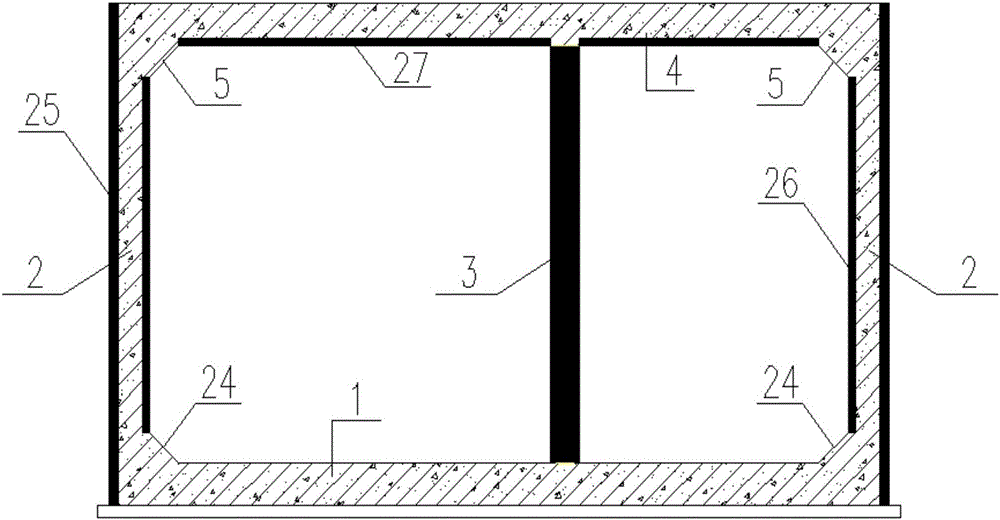

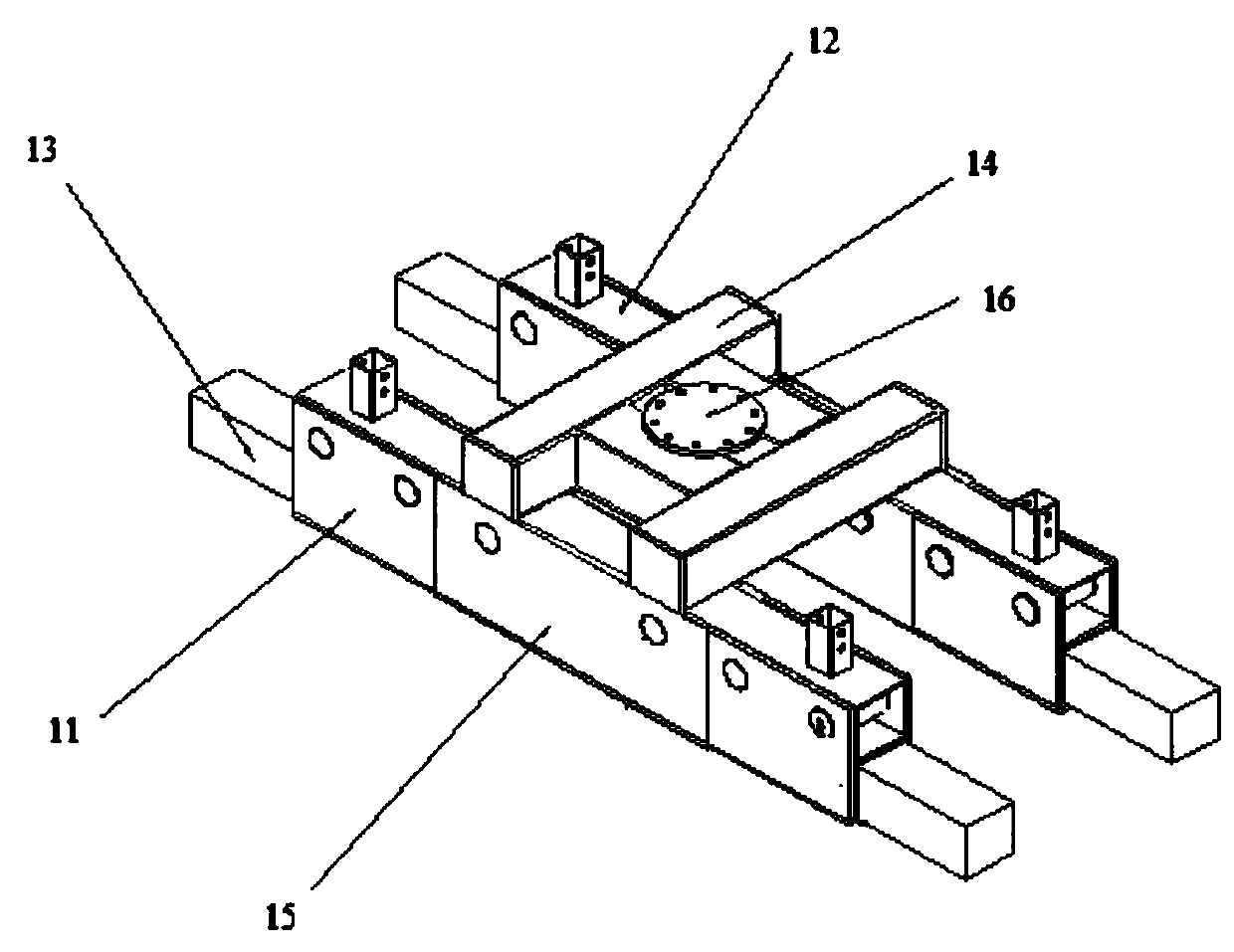

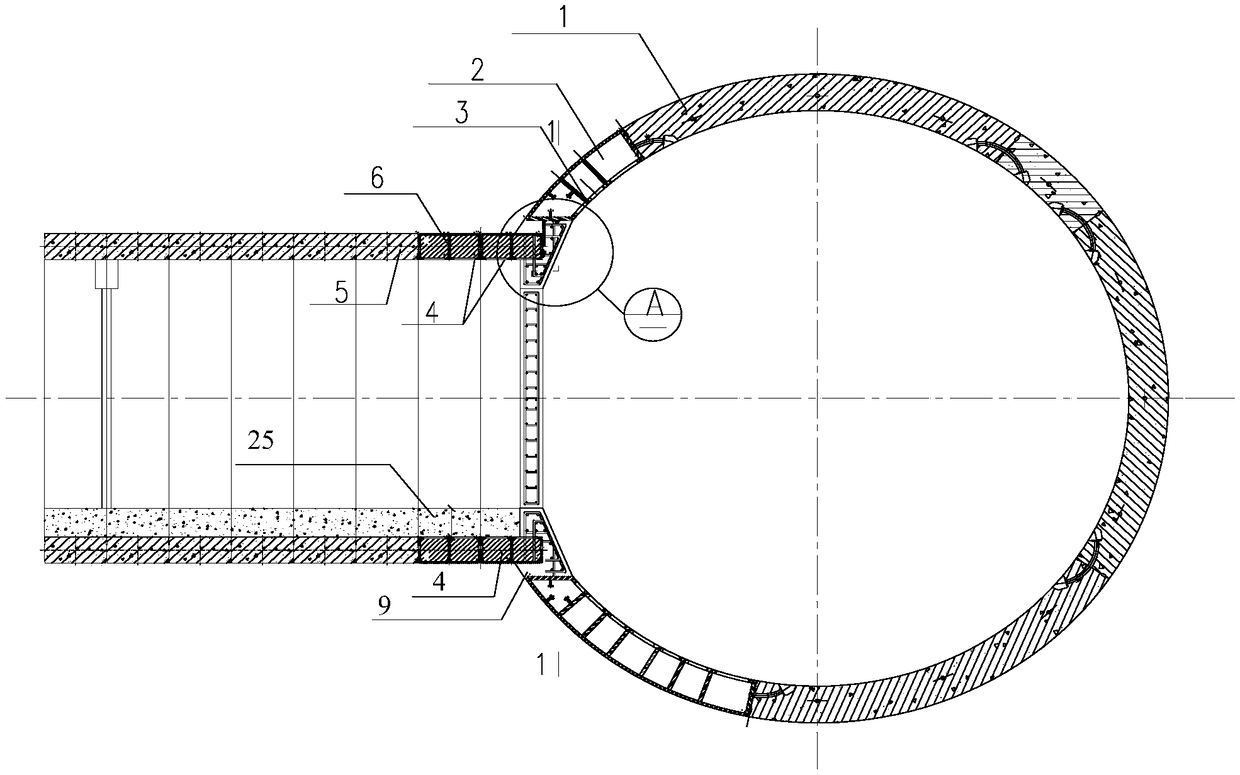

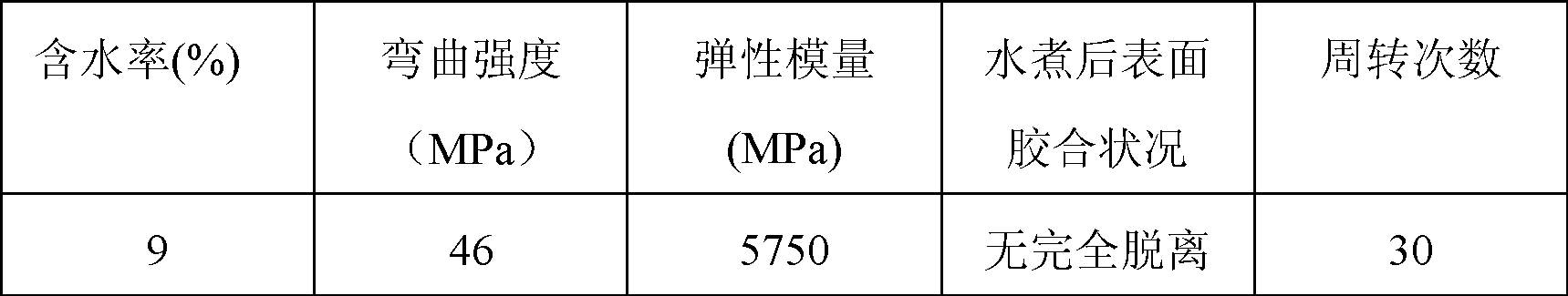

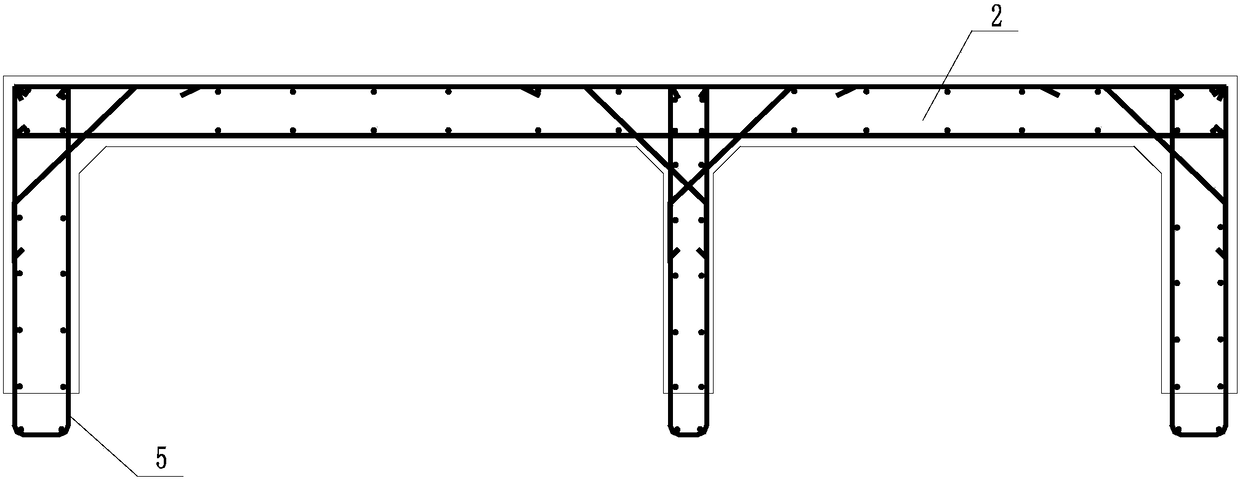

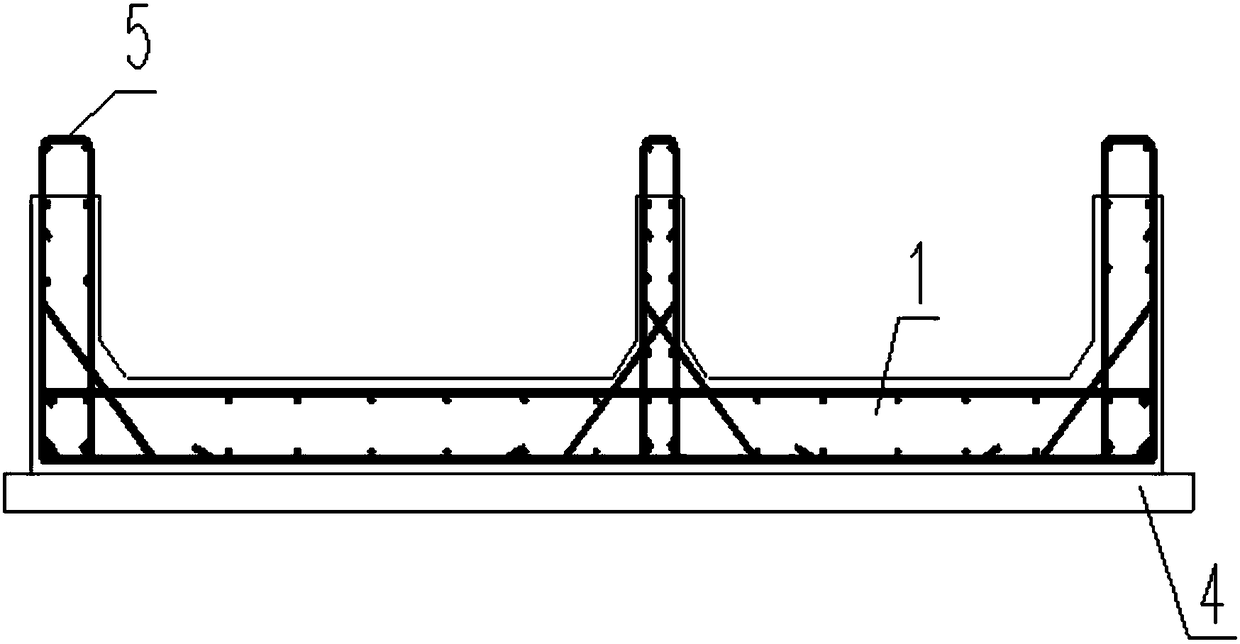

Hollow-wallboard mixed-prefabricated type comprehensive pipe rack and construction method thereof

InactiveCN106088147AEasy to transport and hoistLess patchworkArtificial islandsUnderwater structuresBaseboardArchitectural engineering

The invention discloses a hollow-wallboard mixed-prefabricated type comprehensive pipe rack and a construction method thereof. The hollow-wallboard mixed-prefabricated type comprehensive pipe rack is characterized in that two ends of a cast-in-place baseboard are respectively connected with lower portions of two double-sided prefabricated hollow-wallboard filling-core side walls, the middle portion of the cast-in-place baseboard is connected with the lower portion of a total-prefabricated middle partition, two ends of a overlapped roof are respectively connected with upper portions of the two double-sided prefabricated hollow-wallboard filling-core side walls, and the middle portion of the overlapped roof is connected with the upper portion of the total-prefabricated middle partition. Advantages of prefabrication and cast-in-place technologies are integrated, the hollow-wallboard mixed-prefabricated type comprehensive pipe rack can be disassembled reasonably, dead load of prefabricated components is lowered, the components can be integrally connected through cast-in-place grouting, and the problem about difficulty in prefabrication and assembly construction of multi-cabin pipe rack and pipe rack non-standard pieces can be solved.

Owner:中建五局第三建设有限公司 +1

Array substrate, display panel and display device

ActiveCN104749806AReduce border widthThe effect of the area is smallStatic indicating devicesSolid-state devicesCapacitanceDisplay device

The invention provides an array substrate, a display panel and a display device in an embodiment and relates to the technical field of display. The frame width of the display panel can be reduced without affecting the packaging effect to better conform to the requirements of the present market on the narrow-frame display products. The array substrate is provided with a display region, a packaging region and a drive circuit region; the drive circuit region is located between the display region and the packaging region; the array substrate specifically comprises a packaging metal layer arranged in the packaging region and at least one drive unit arranged in the drive circuit region; at least one groove structure is arranged on one side, close to the drive circuit region, of the packaging metal layer; the drive unit comprises a capacitive structure which is arranged in the groove structure; one groove structure is used for receiving one capacitive structure. The invention relates to the preparation of the array substrate, and the display panel and the display device both comprising the array substrate.

Owner:BOE TECH GRP CO LTD

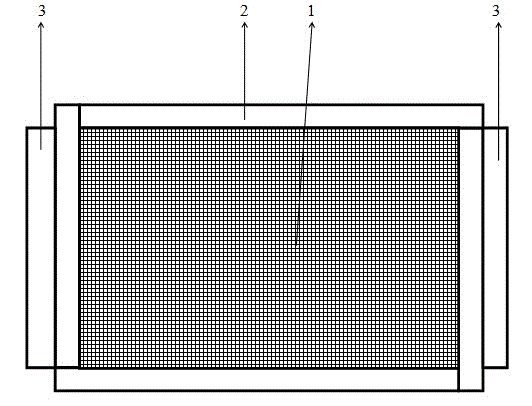

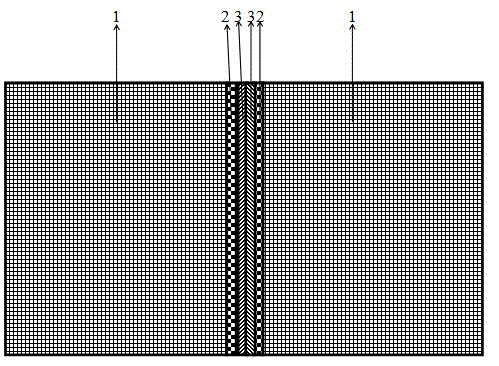

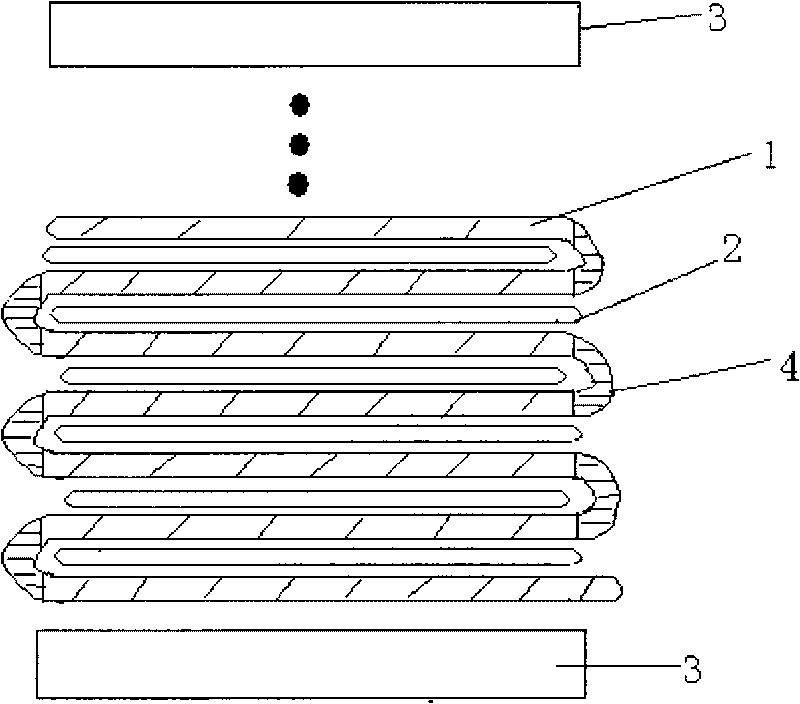

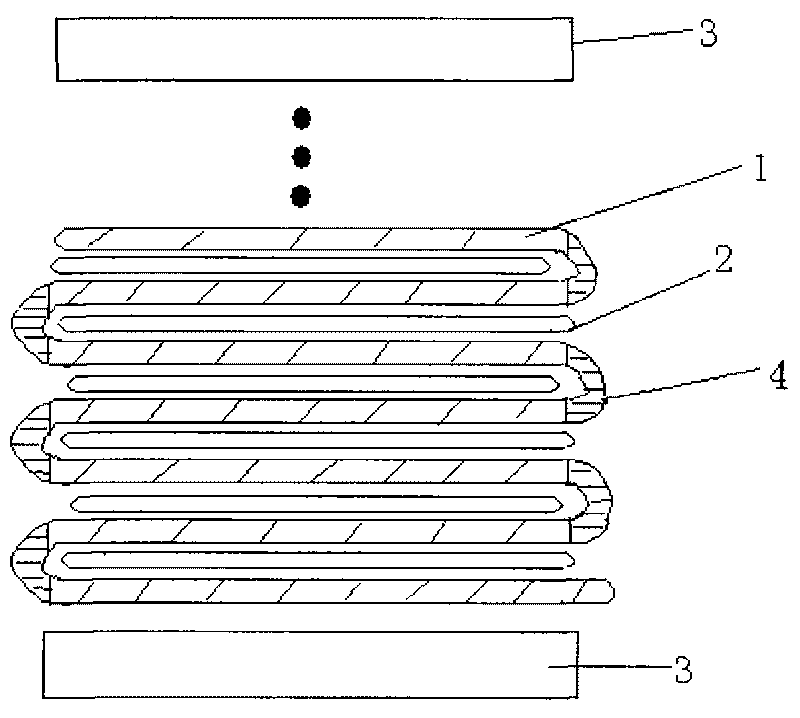

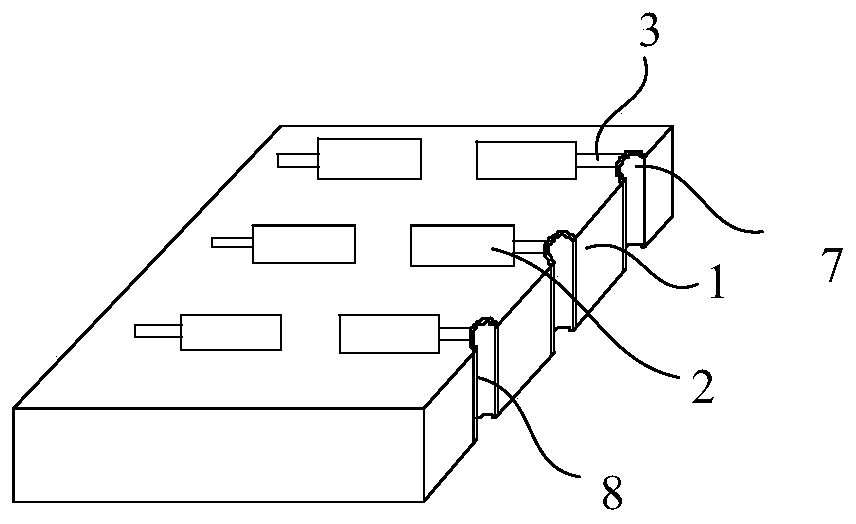

OLED (organic light-emitting diode) display unit and OLED spliced display screen with same

InactiveCN102723445AReduce unlit border areaLess patchworkSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringLight-emitting diode

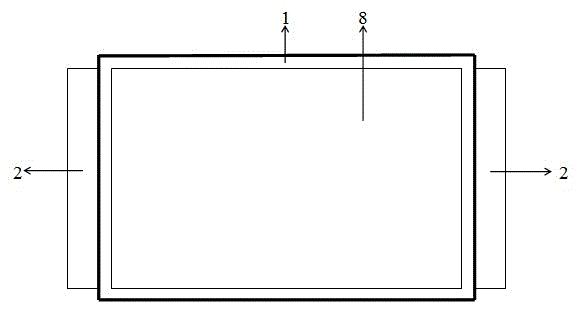

The invention relates to an OLED (organic light-emitting diode) display technology and specifically relates to an OLED display unit and an OLED spliced display screen with the same. The OLED display unit comprises a substrate and an OLED module arranged on the front surface of the substrate, wherein a packaging layer is arranged on the periphery and the front surface of the OLED module, conductive films are plated on the front surface and the peripheral side walls of the substrate, the conductive film on any one side wall of the substrate is connected with an anode in the OLED module, the conductive film on another side wall of the substrate is connected with a cathode of the OLED module, an anode leading wire and a cathode leading wire are respectively led out of the conductive films on another two side walls of the substrate and connected with an external circuit, and the two side walls of the substrate are externally connected with binding regions. According to the OLED display unit disclosed by the invention, the binding regions of an OLED panel are transferred onto the side walls of the substrate through a packaging surface of the OLED module, so that a non-luminous side frame region of a device is reduced, and the splicing effect of the OLED spliced display screen is optimized.

Owner:GUANGDONG VTRON TECH CO LTD

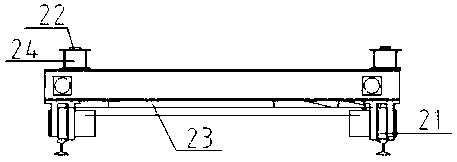

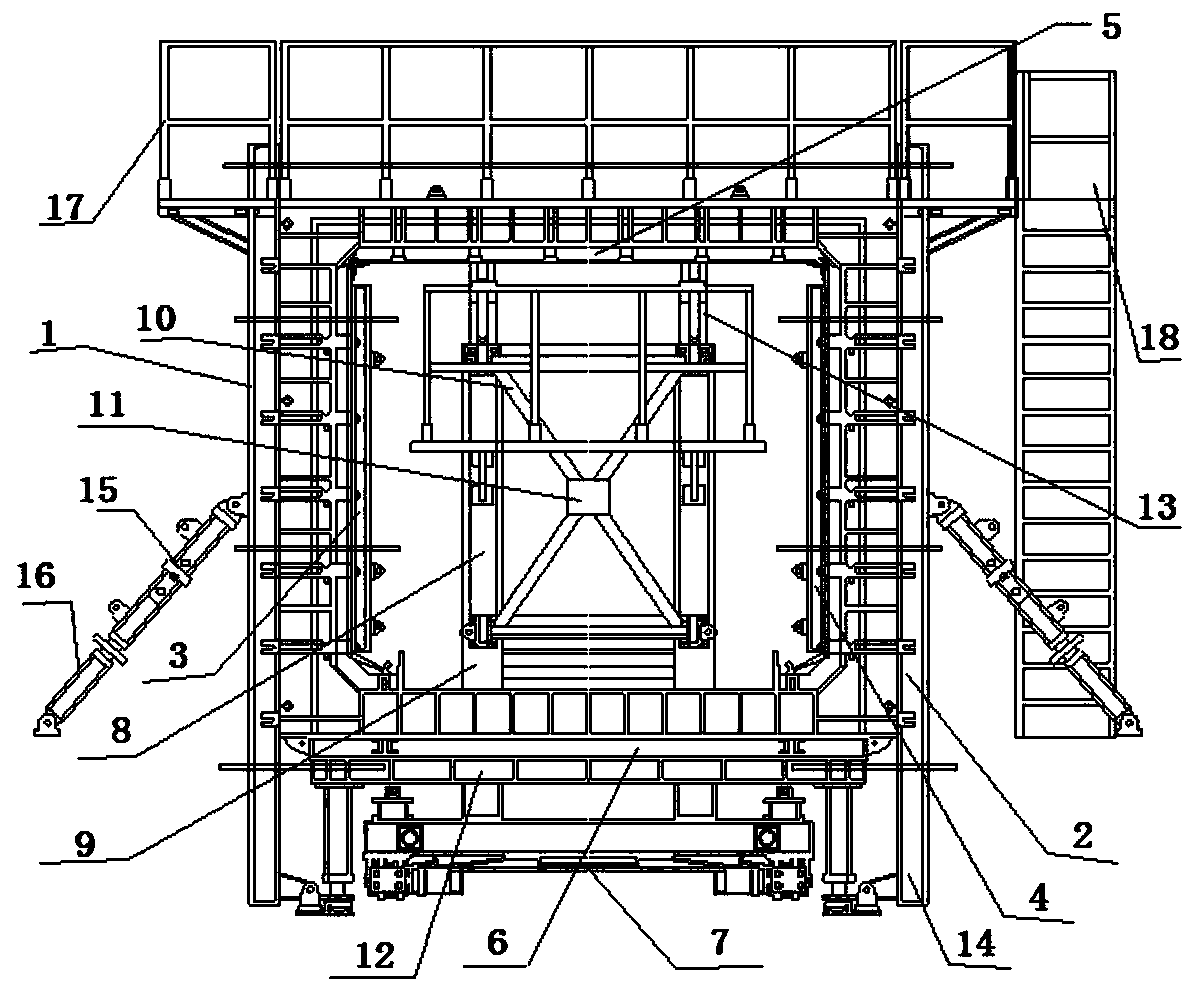

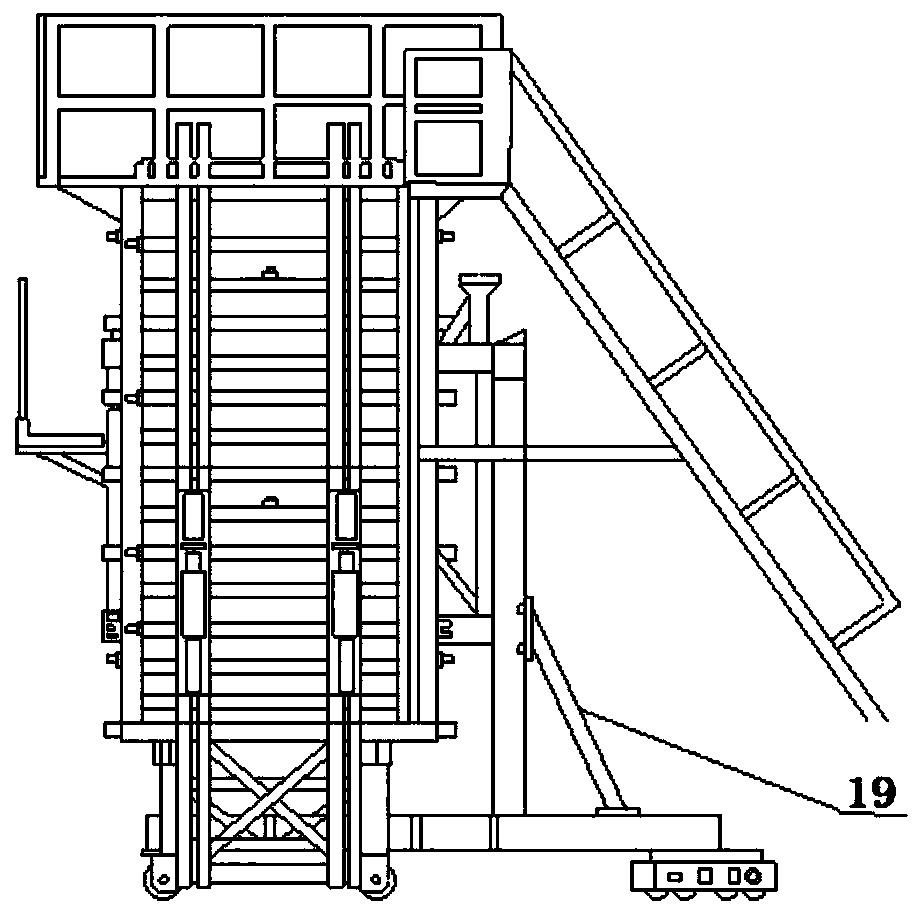

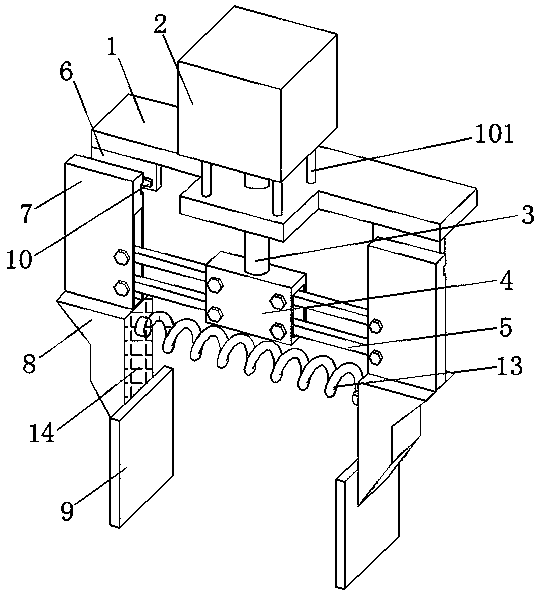

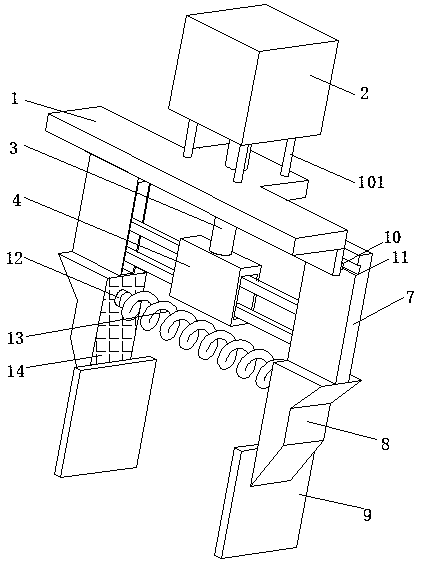

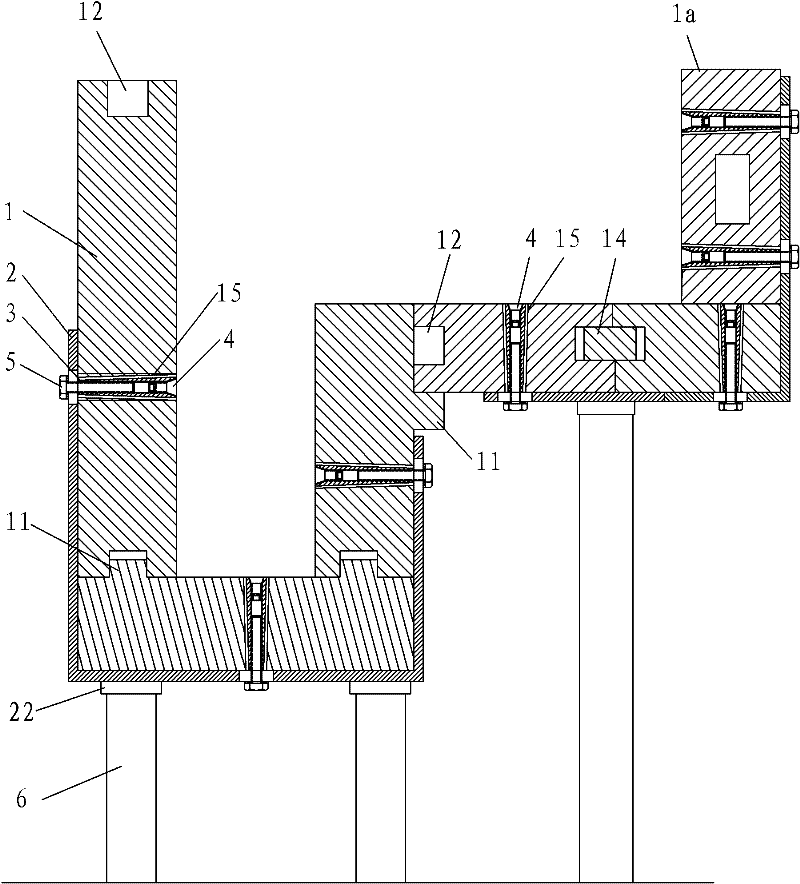

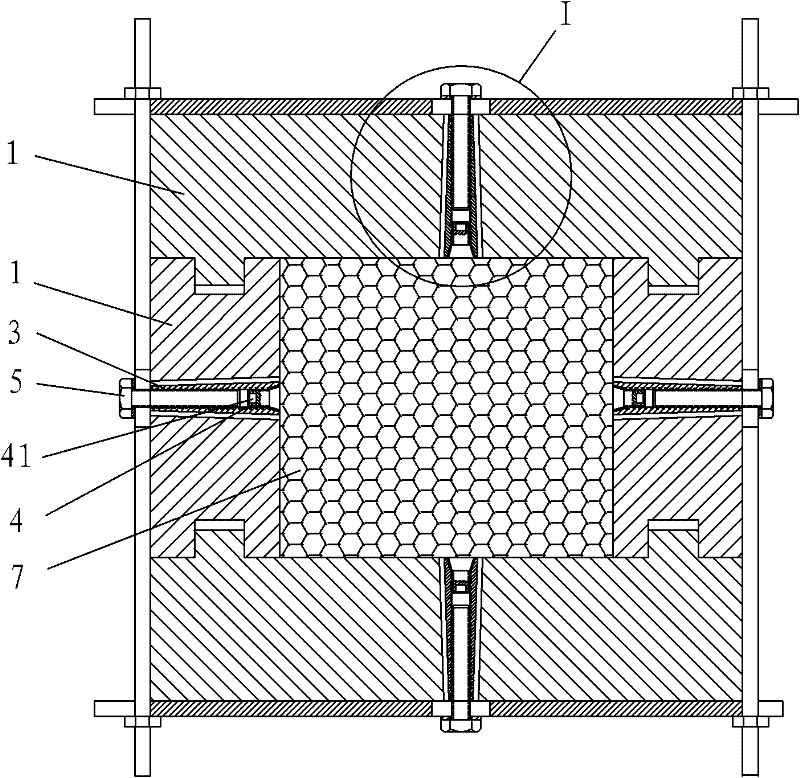

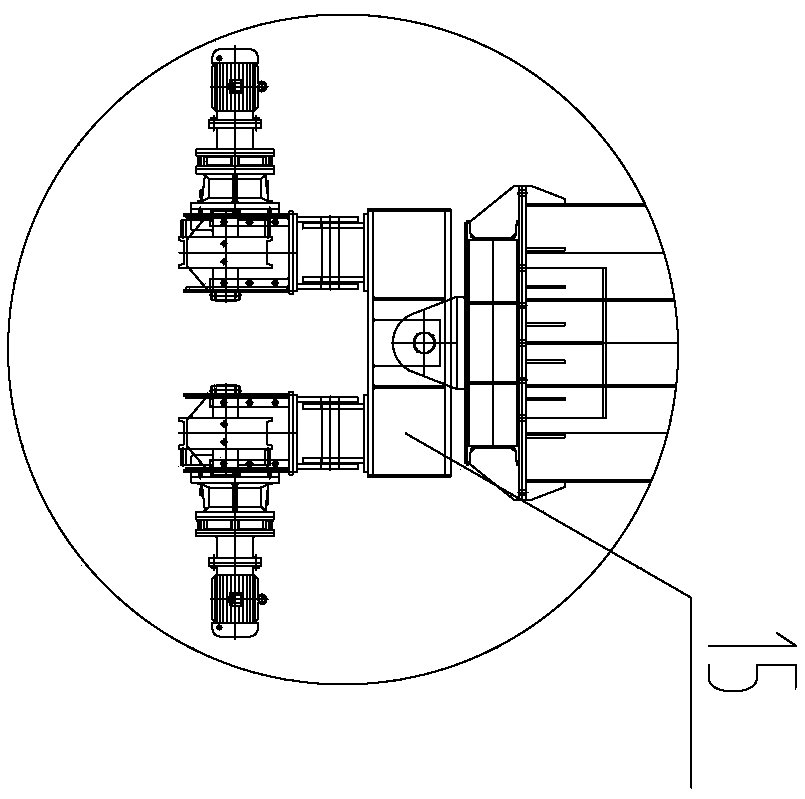

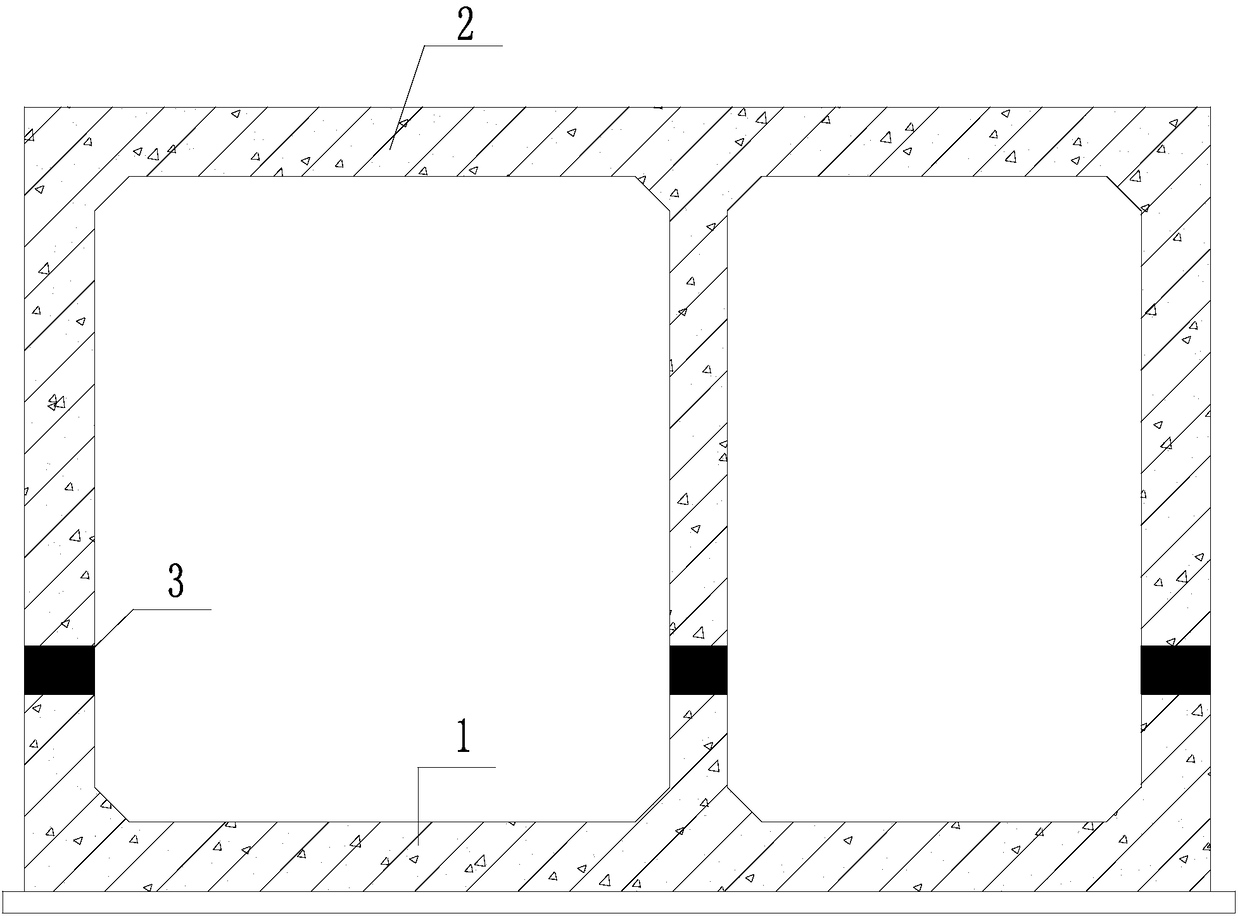

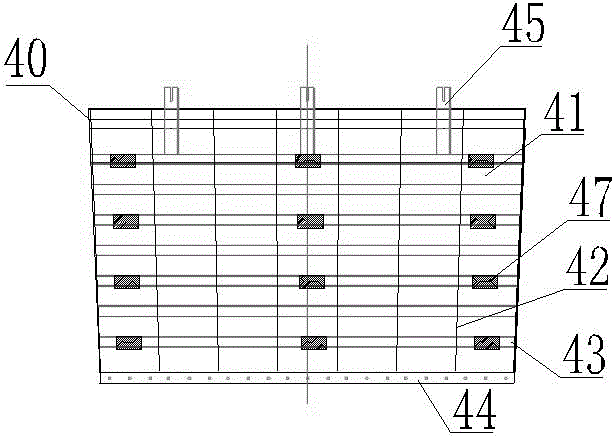

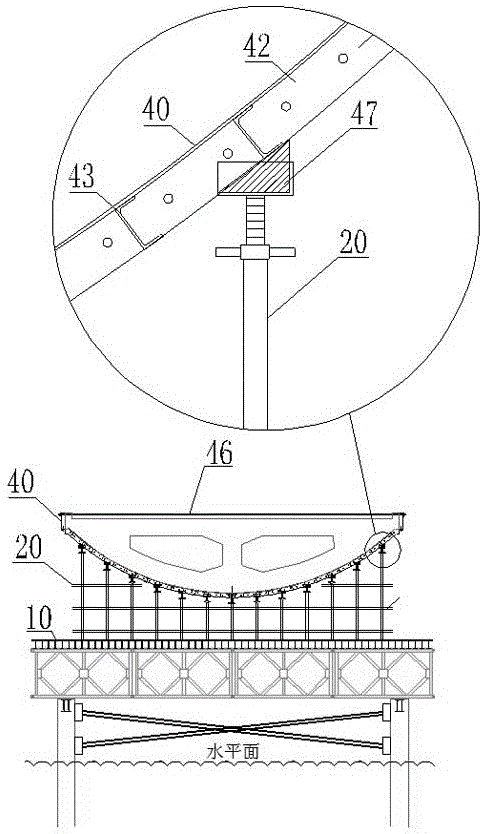

Integral hydraulic formwork applied to box culvert prefabrication

ActiveCN110394885AGuaranteed installation qualityQuick demolitionMouldsAuxillary shaping apparatusHigh surfacePrefabrication

The invention belongs to the field of box culvert pouring, and provides an integral hydraulic formwork applied to box culvert prefabrication. The integral hydraulic formwork comprises an internal formwork component, a bottom formwork component, an external formwork component, an end formwork component and a retaining formwork component; the internal formwork component includes internal formworks and an internal top formwork; the internal formworks include the first internal formwork and the second internal formwork; the bottom formwork component includes a bottom formwork; the external formwork component includes external formworks; the external formworks include the first external formwork and the second external formwork; the retaining formwork component includes a first retaining formwork and a second retaining formwork; the end formwork component includes a convex end formwork and a concave end formwork; and the space enclosed by the first external formwork, the second external formwork, the first internal formwork, the second internal formwork, the internal top formwork, the bottom formwork, the first retaining formwork, the second retaining formwork, the convex end formwork and the concave end formwork is used for pouring concrete. By mean of the integral hydraulic formwork applied to box culvert prefabrication, the prefabrication quality is high and stable, the adopted set shaped steel formwork has high surface rigidity, is not prone to deforming, and has good flatness.

Owner:INNER MONGOLIA ROAD & BRIDGE

Quick construction method of tunnels traversing unfavorable geology

InactiveCN104100272ALess patchworkEasy to installUnderground chambersTunnel liningKarstGeological survey

The invention discloses a quick construction method of tunnels traversing unfavorable geology. The method includes the following steps: performing pre-construction karst survey and geological survey, and selecting an appropriate layered and partitioned excavation scheme for the sake of stability of excavation surrounding rock; adopting an advanced pipe roof or advanced grouting method and the like to perform advanced natural ground reinforcement; adopting a controlled blasting or presplitting blasting form and the like to perform tunnel blasting, excavating a main tunnel inwards along a tunnel portal, subjecting the main tunnel to supporting treatment, enhancing supporting intensity of a key part, and constructing an inverted arch so as to close an excavation face; and reinforcing a tunnel foundation. The construction scheme for tunnel portal engineering, the main tunnel, a first side tunnel and a second side tunnel needs to be optimized and determined according to geological conditions of the tunnels before construction, construction period is shortened to a certain extent, industrial modular processing and production of waterproof steel plates is adopted, mounting is facilitated, few joints exist, waterproof effect is good, and construction progress can be guaranteed.

Owner:CHINA ROAD & BRIDGE

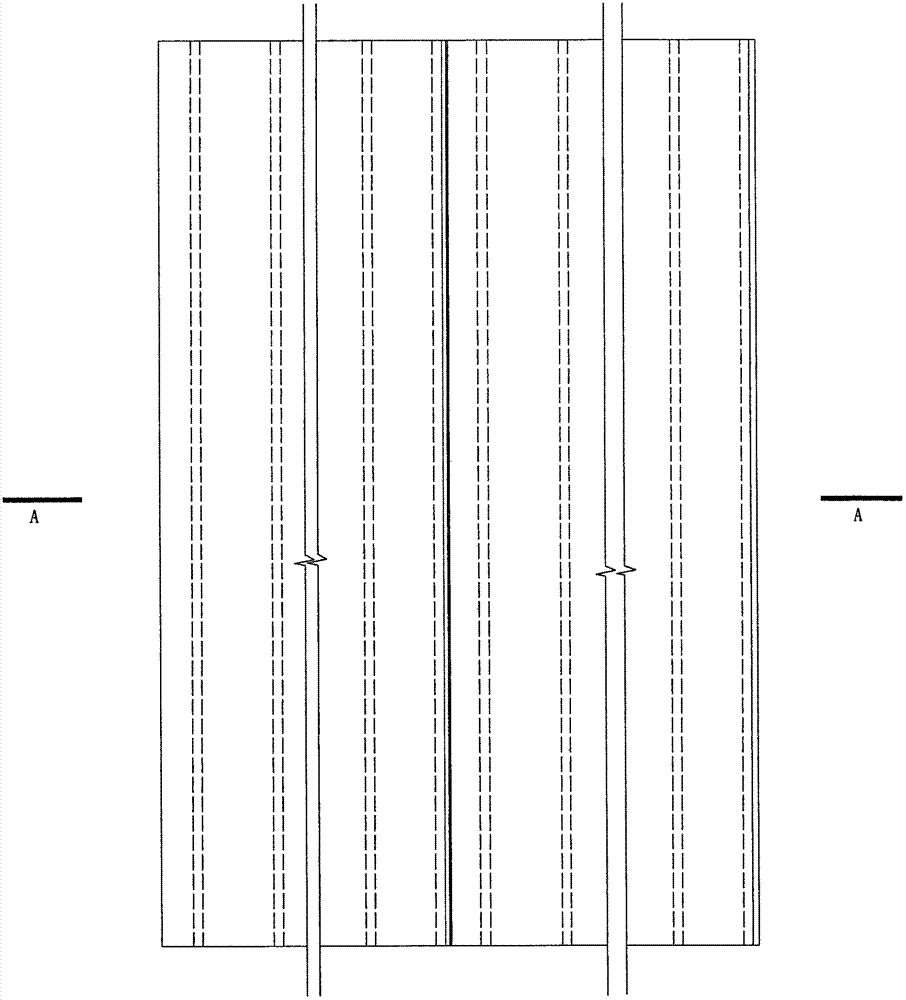

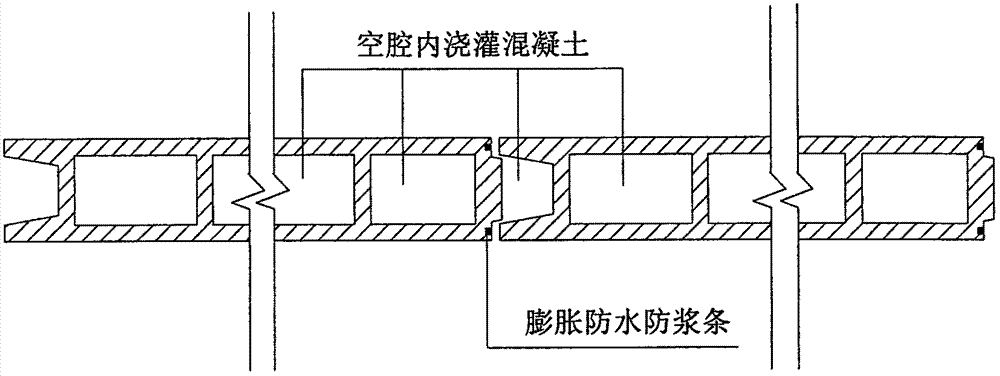

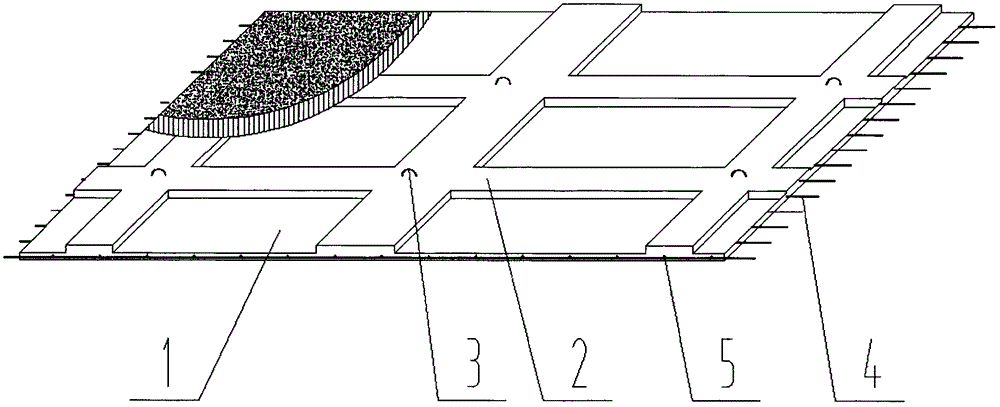

Thin wall prefabricated superposed concrete underground continuous wall

InactiveCN103046578AEasy to liftSpeed upArtificial islandsUnderwater structuresEngineeringHigh intensity

A thin wall prefabricated superposed concrete underground continuous wall is made of splicing multiple prefabricated wall plates. Each prefabricated wall block is provided with multiple rectangular holes in the middle to reduce weight and be easy to hoist, and rib plates are arranged among the rectangular holes. Two ends of the wall are provided with prefabricated notches, and expansion water stopping strips are embedded in the notches. After soil is digged to form a groove, the wall plates are hoisted in place for splicing, and concrete is poured in cavities to jointly form a whole together with a prefabricated concrete wall. The thin wall prefabricated superposed concrete underground continuous wall has the advantages of high intensity and good penetration resistance.

Owner:朱立新

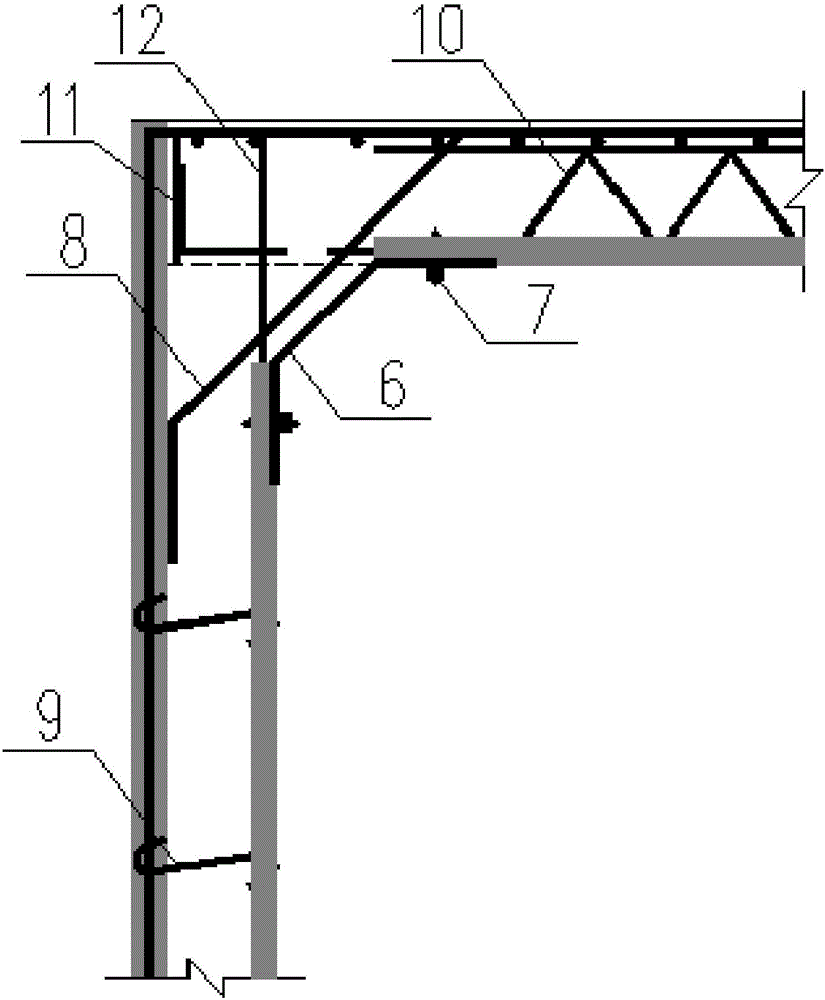

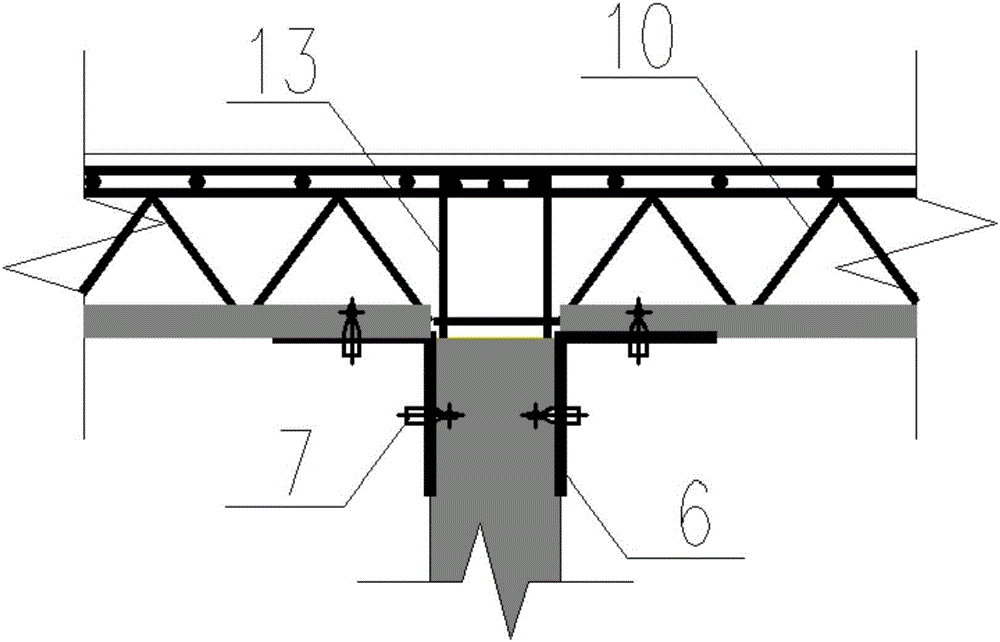

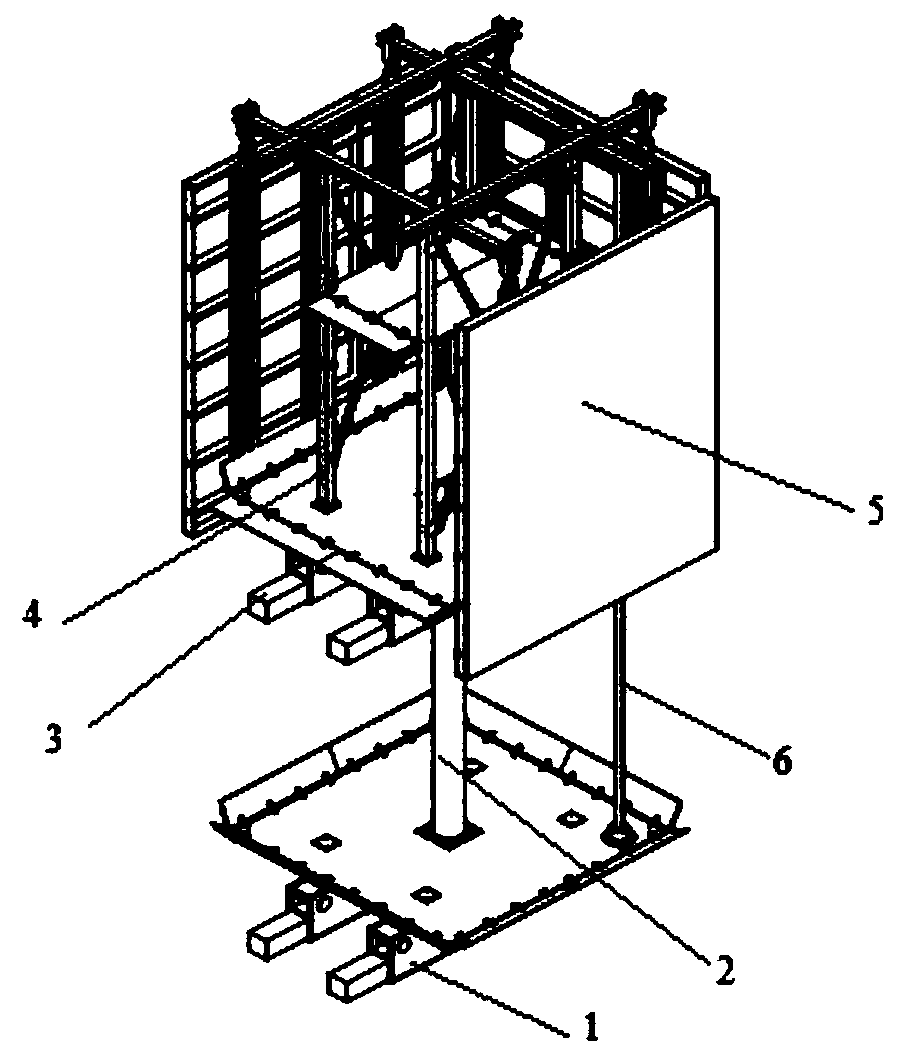

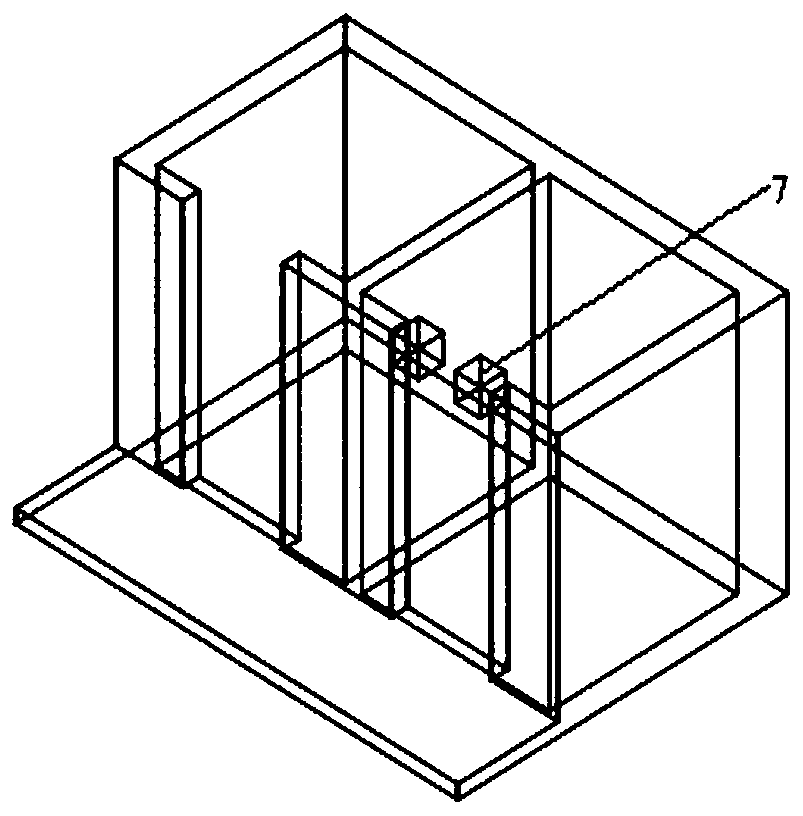

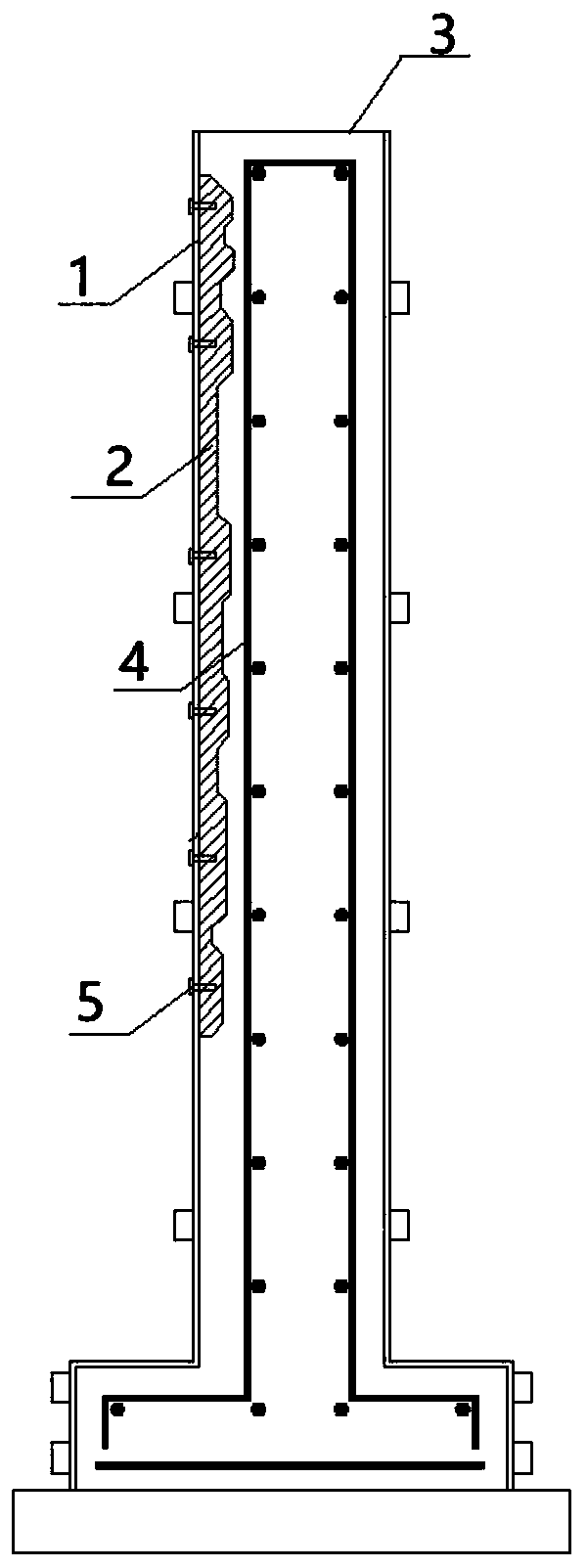

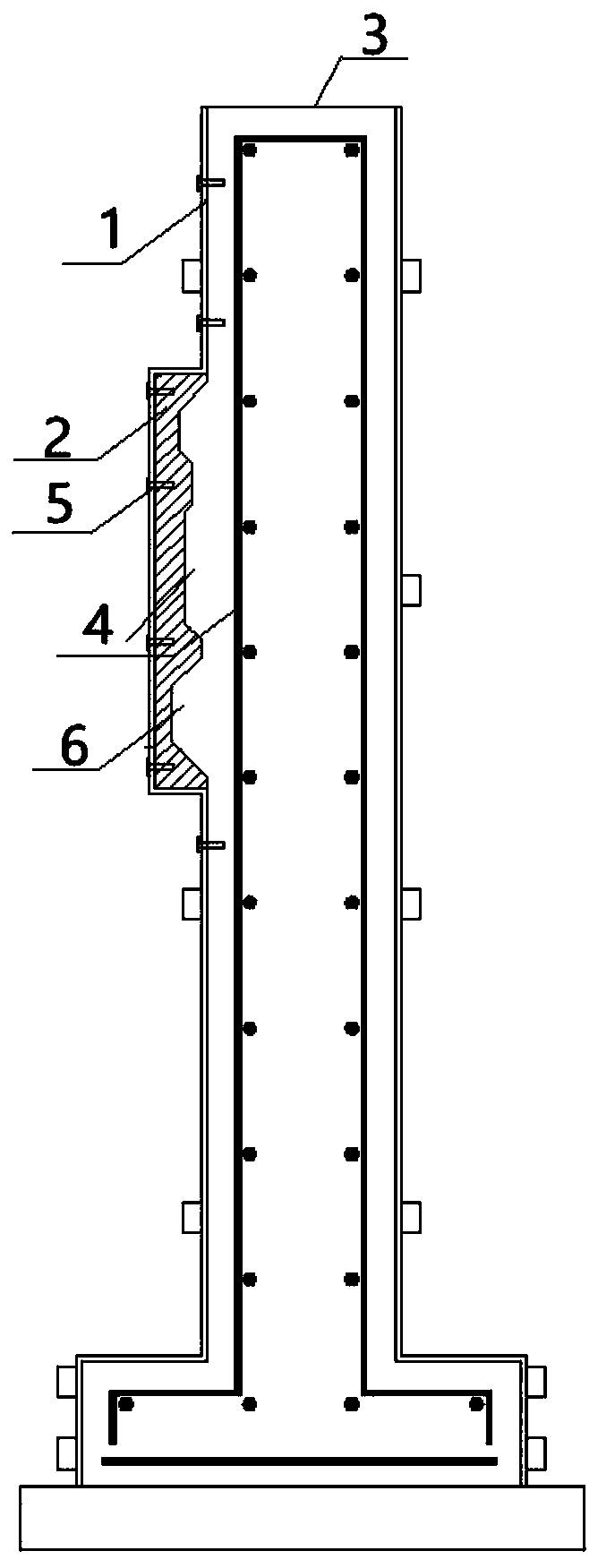

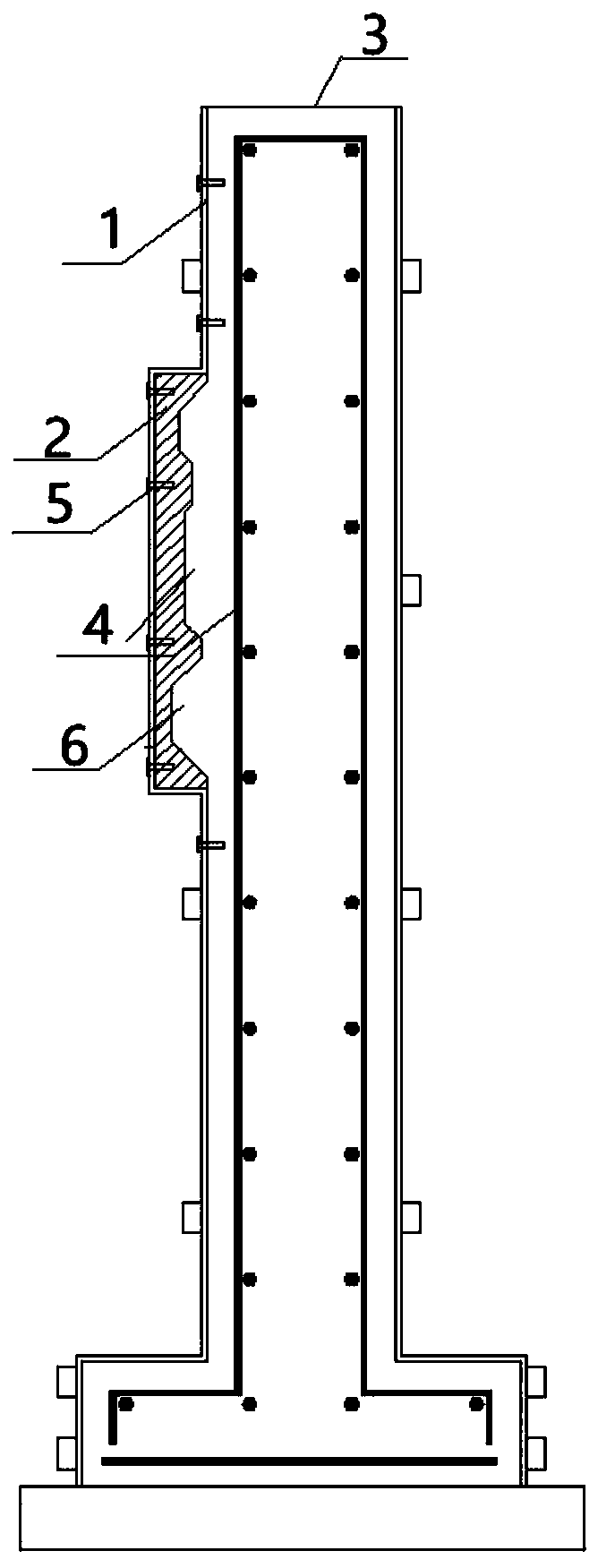

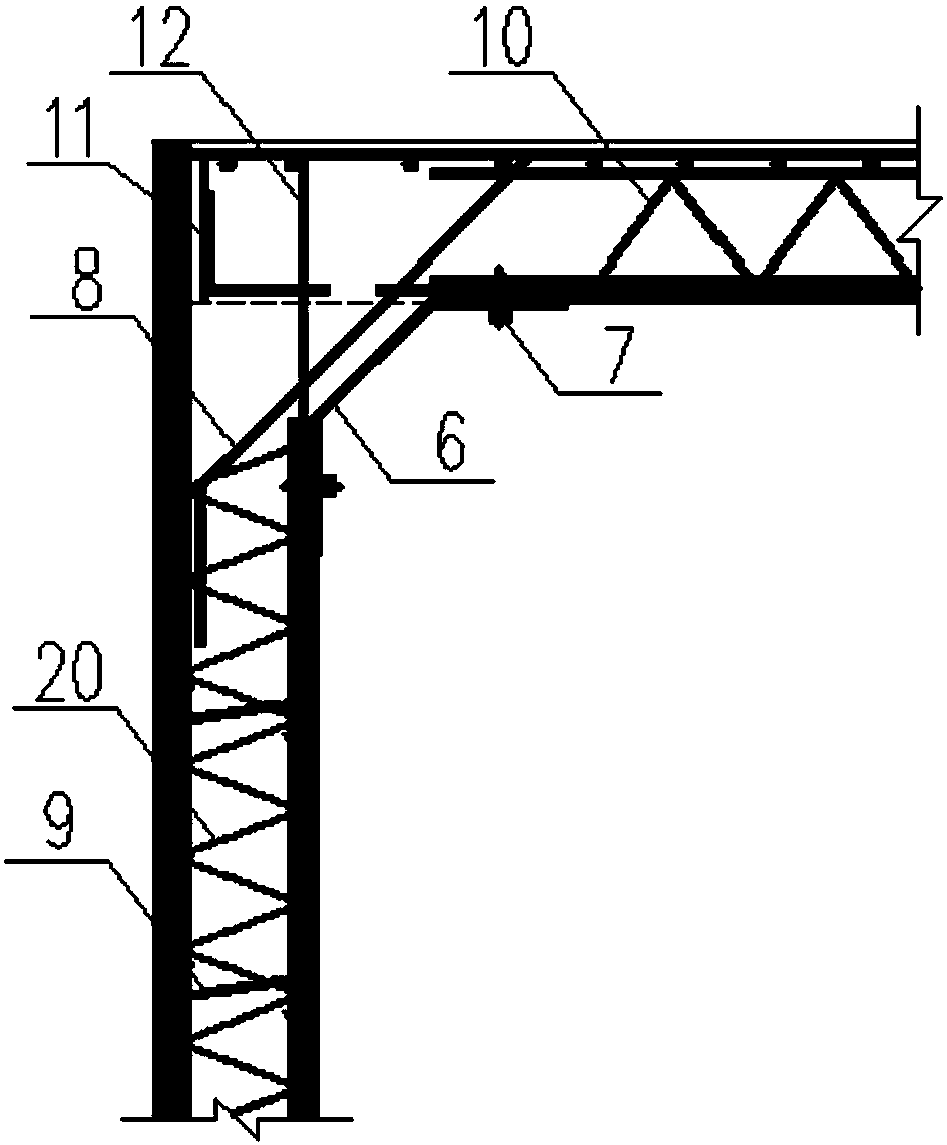

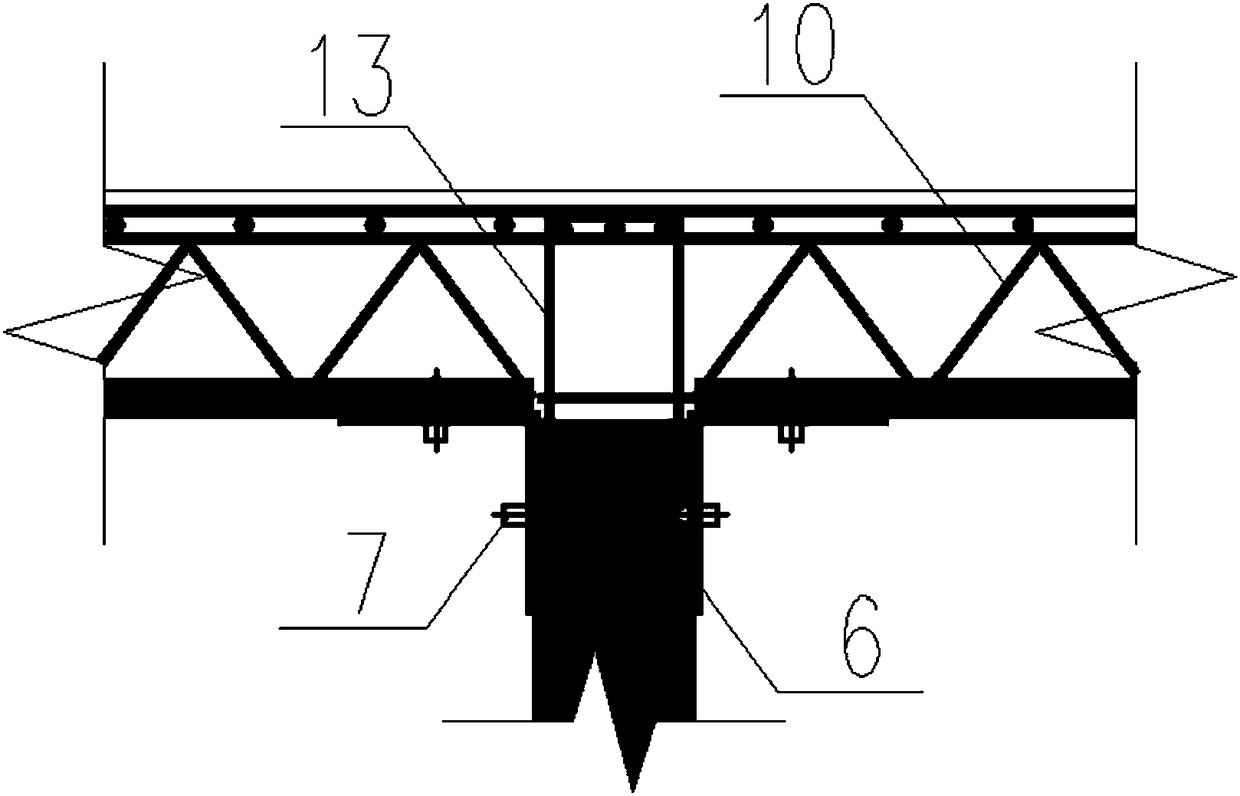

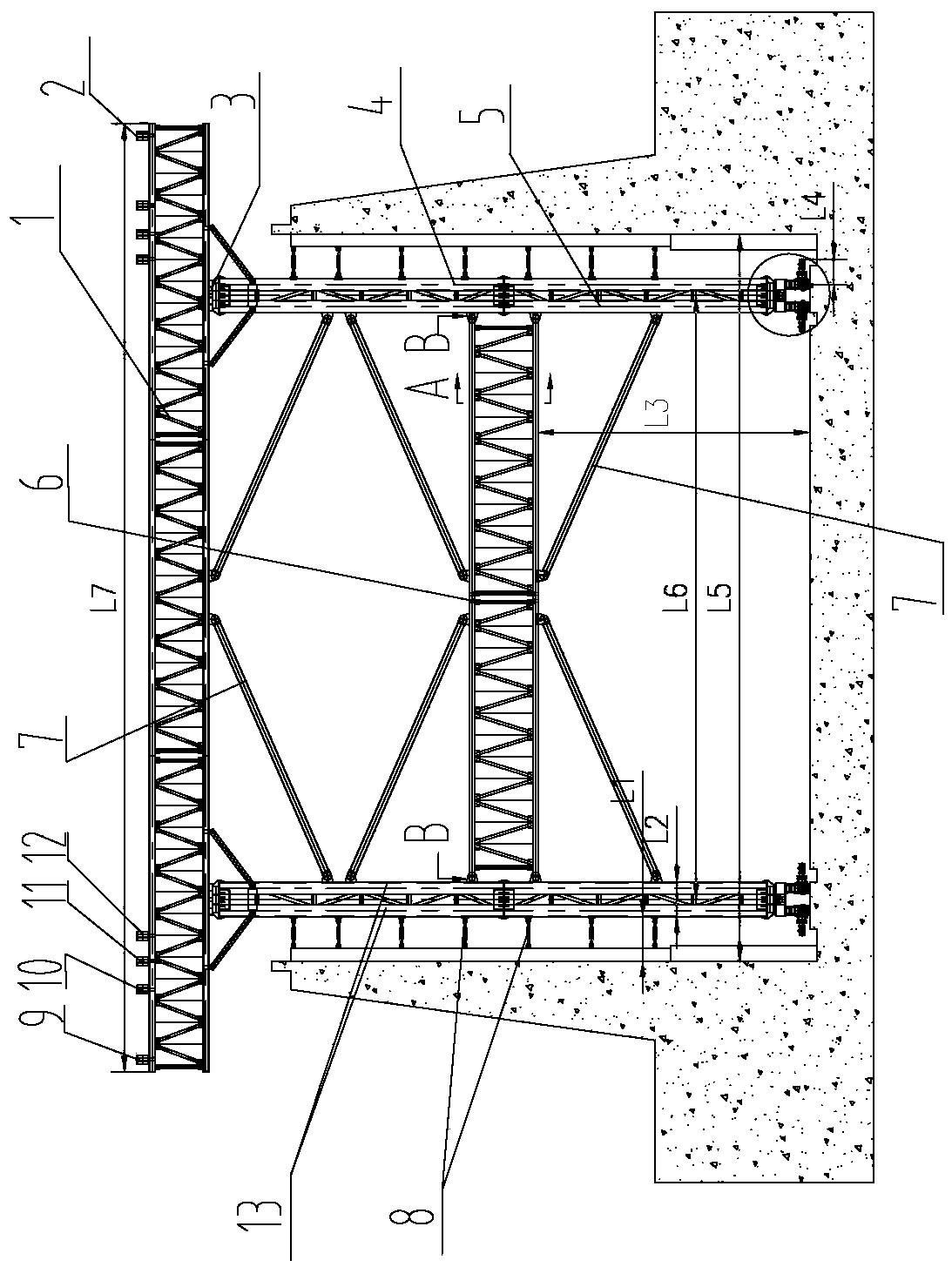

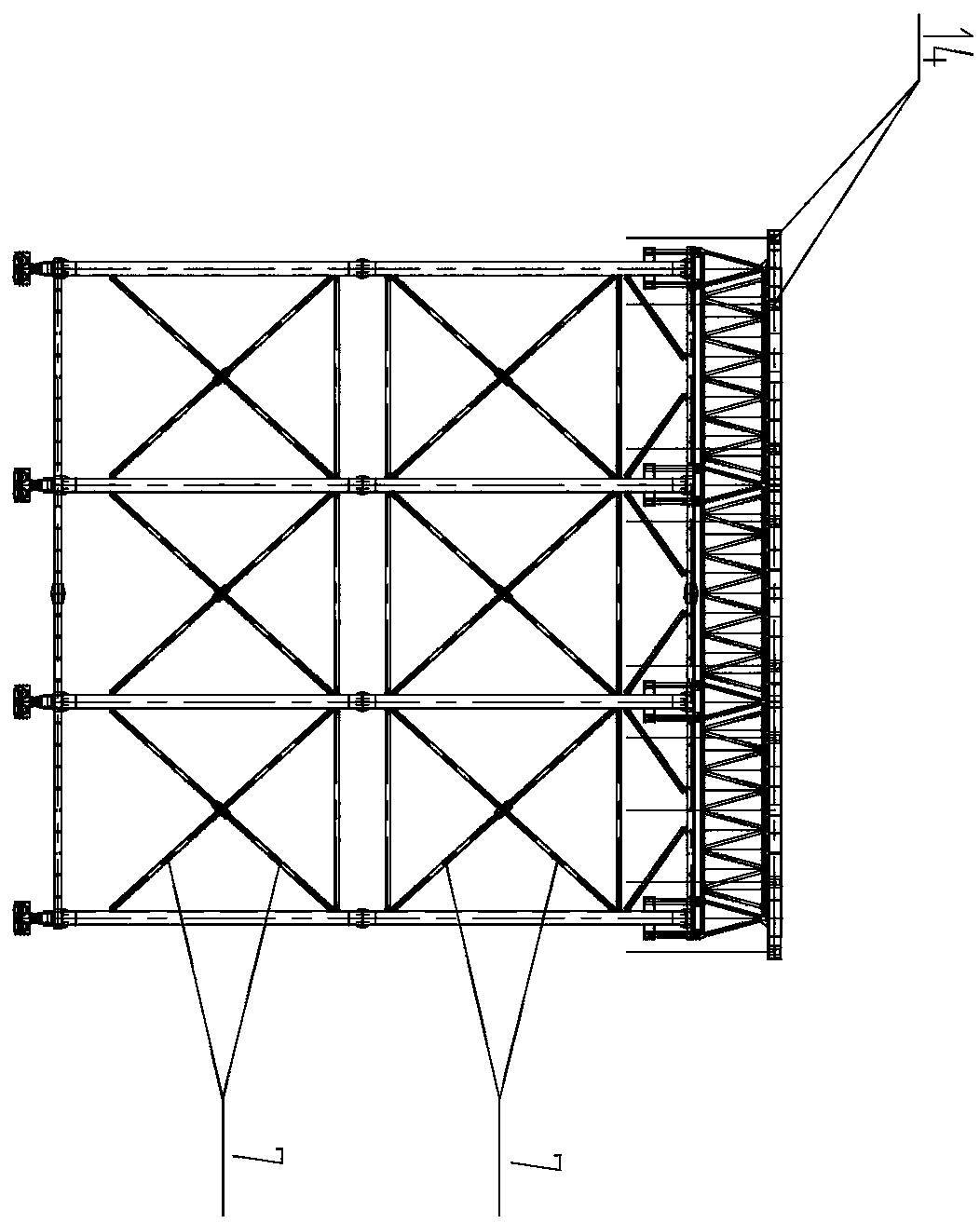

High-rise elevator shaft jacking formwork system and construction method thereof

PendingCN110469106AStructure miniaturizationLess template seamsForms/shuttering/falseworksBuilding support scaffoldsShear wallControl system

The invention discloses a high-rise elevator shaft jacking formwork system and a construction method thereof. The system comprises a bottom supporting mechanism, a vertical jacking hydraulic device, an upper supporting mechanism, a formwork supporting device and a control system. The bottom supporting mechanism and the upper supporting mechanism are connected through the vertical jacking hydraulicdevice. The vertical jacking hydraulic device is used for jacking the upper supporting mechanism and lifting the bottom supporting mechanism. The formwork supporting device is arranged at the top ofthe upper supporting mechanism, and a formwork is detachably arranged on the periphery of the formwork supporting device. The vertical jacking hydraulic device, the upper supporting mechanism and thebottom supporting mechanism are electrically connected with the control system. According to the high-rise elevator shaft jacking formwork system and the construction method thereof, independent detachment is not needed when the formwork is installed and dismounted, the formwork can be lifted as a whole along with a hydraulic lifting system, mechanical and intelligent construction of a shear wallin an elevator shaft of a high-rise building is achieved, and the safety and reliability of the system are improved.

Owner:甘肃第七建设集团股份有限公司

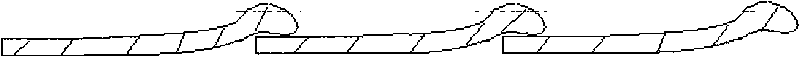

Dam bag of rubber dam and processing technology thereof

ActiveCN101691743ASingle width increaseImprove appearance qualityBarrages/weirsRheidSafety coefficient

The invention relates to a dam bag of a rubber dam and a processing technology thereof, belonging to the technical fields of dam bags of the rubber dam and a production method thereof. The dam bag of the rubber dam comprises successively-connected dam bodies, a unvulcanized rheid section is used for connecting adjacent dam bodies, the dam bodies and the rheid sections are in an integral structure, the number of the dam bodies 1 is more than or equal to 2, ranging from 2 to 10, and the rheid section 4 is a rubber rheid. The processing technology comprises the following steps: 1) folding; 2) separating; 3) vulcanizing and shaping at one time; and 4) flattening. As for the dam bag of the rubber dam and the production method thereof provided by the invention, the dam is long in service life, convenient in processing and high in safety coefficient, and the breadth of the dam bag is as much as 10m.

Owner:YANTAI SUNNY RUBBER

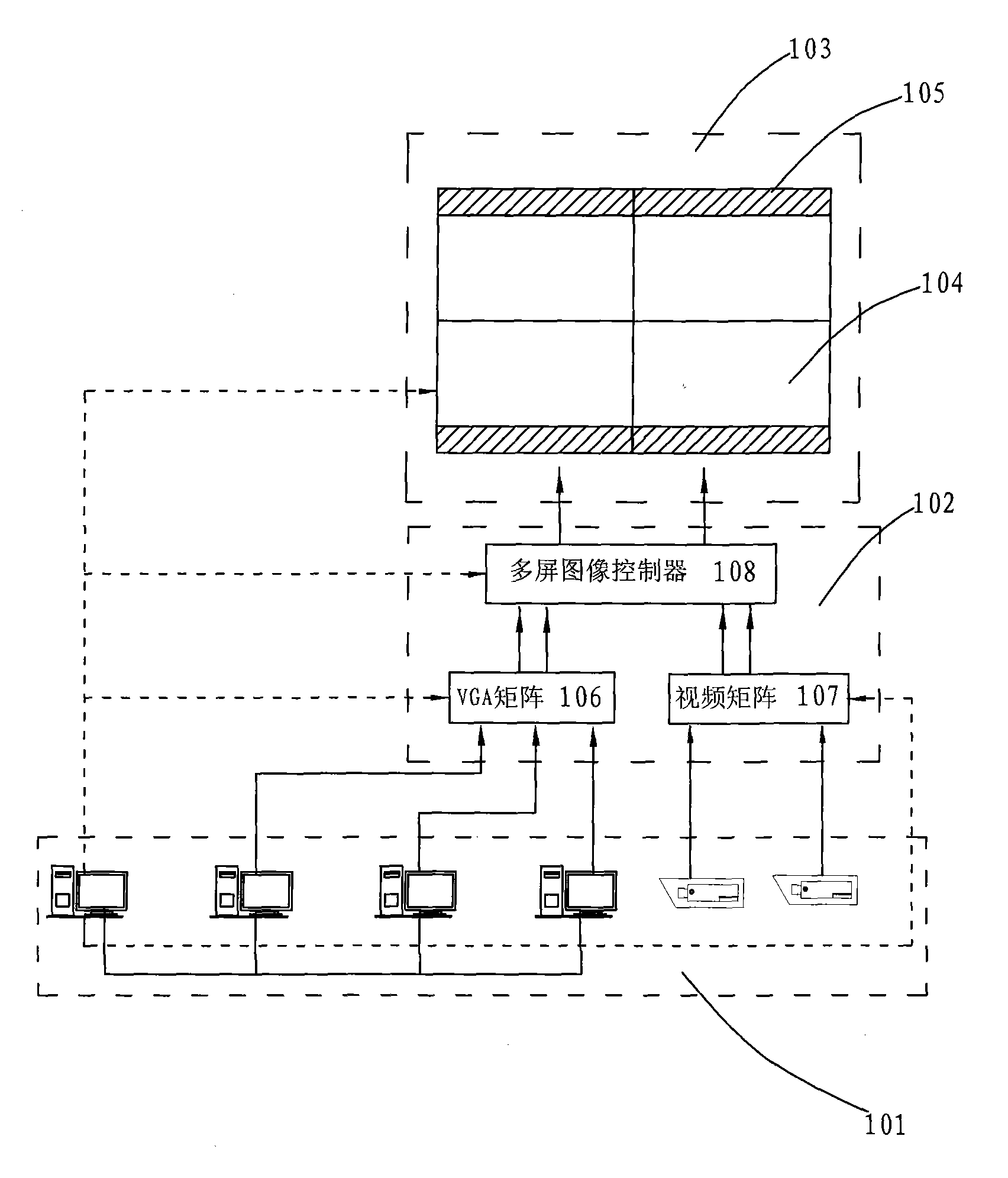

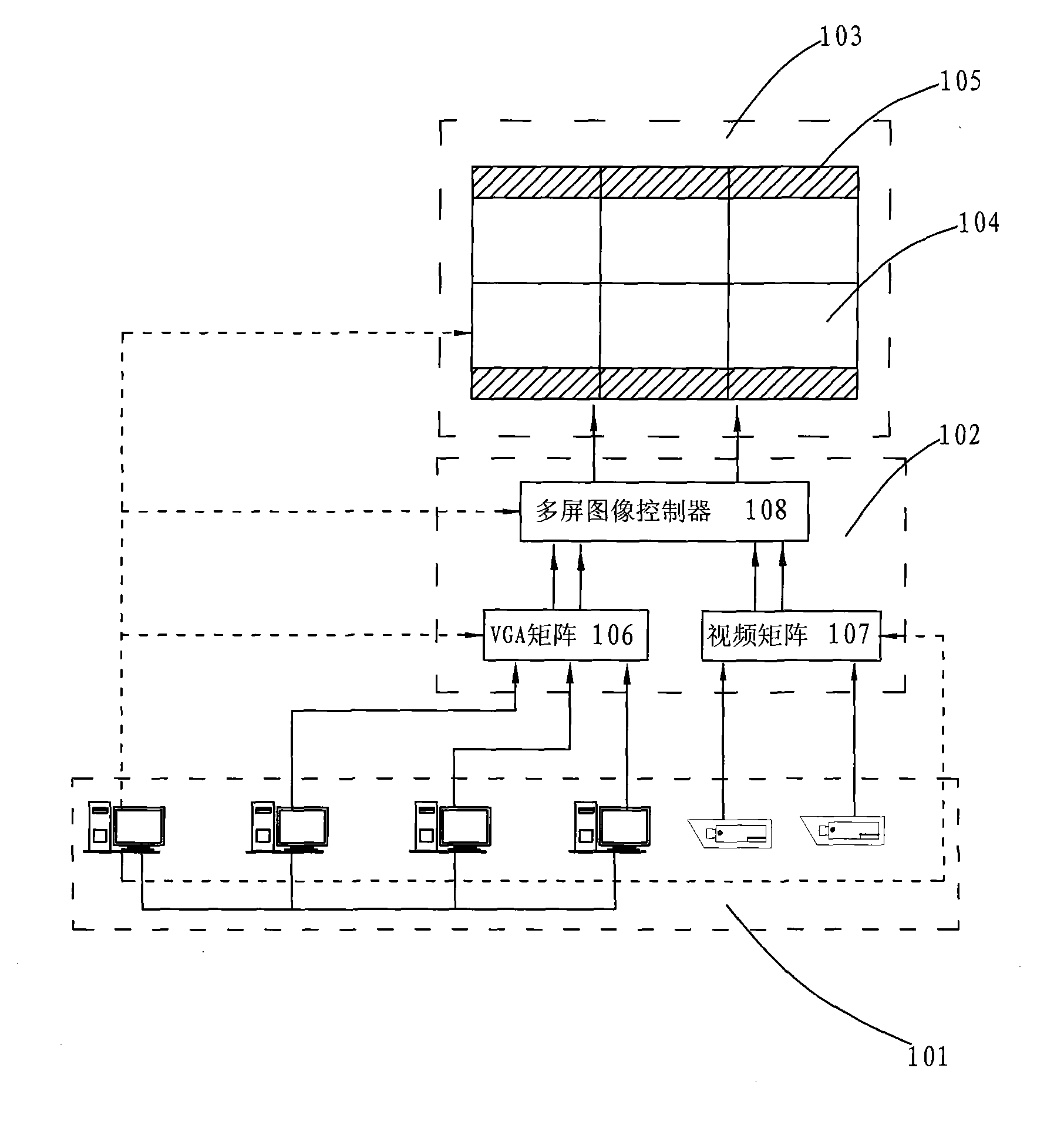

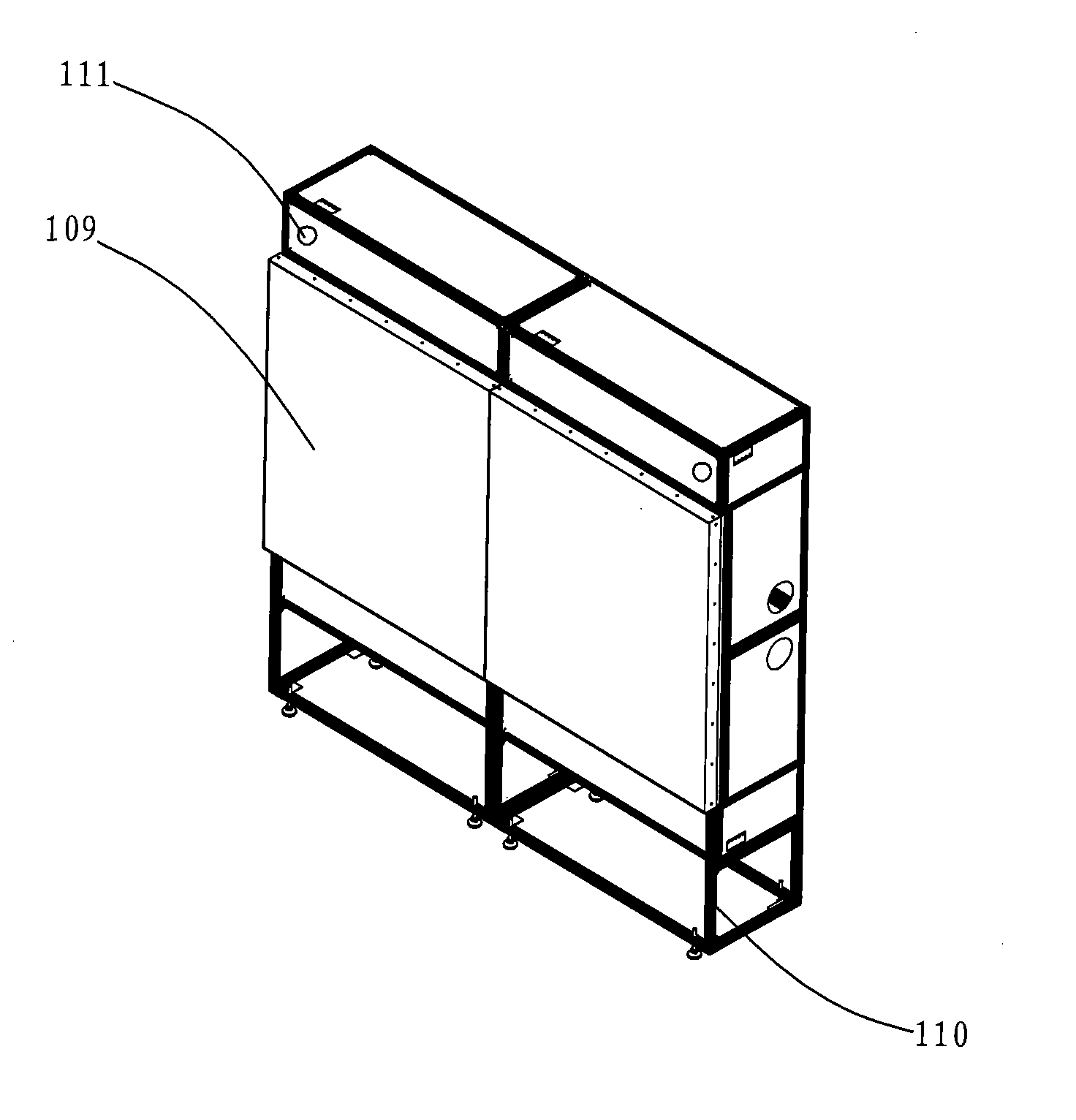

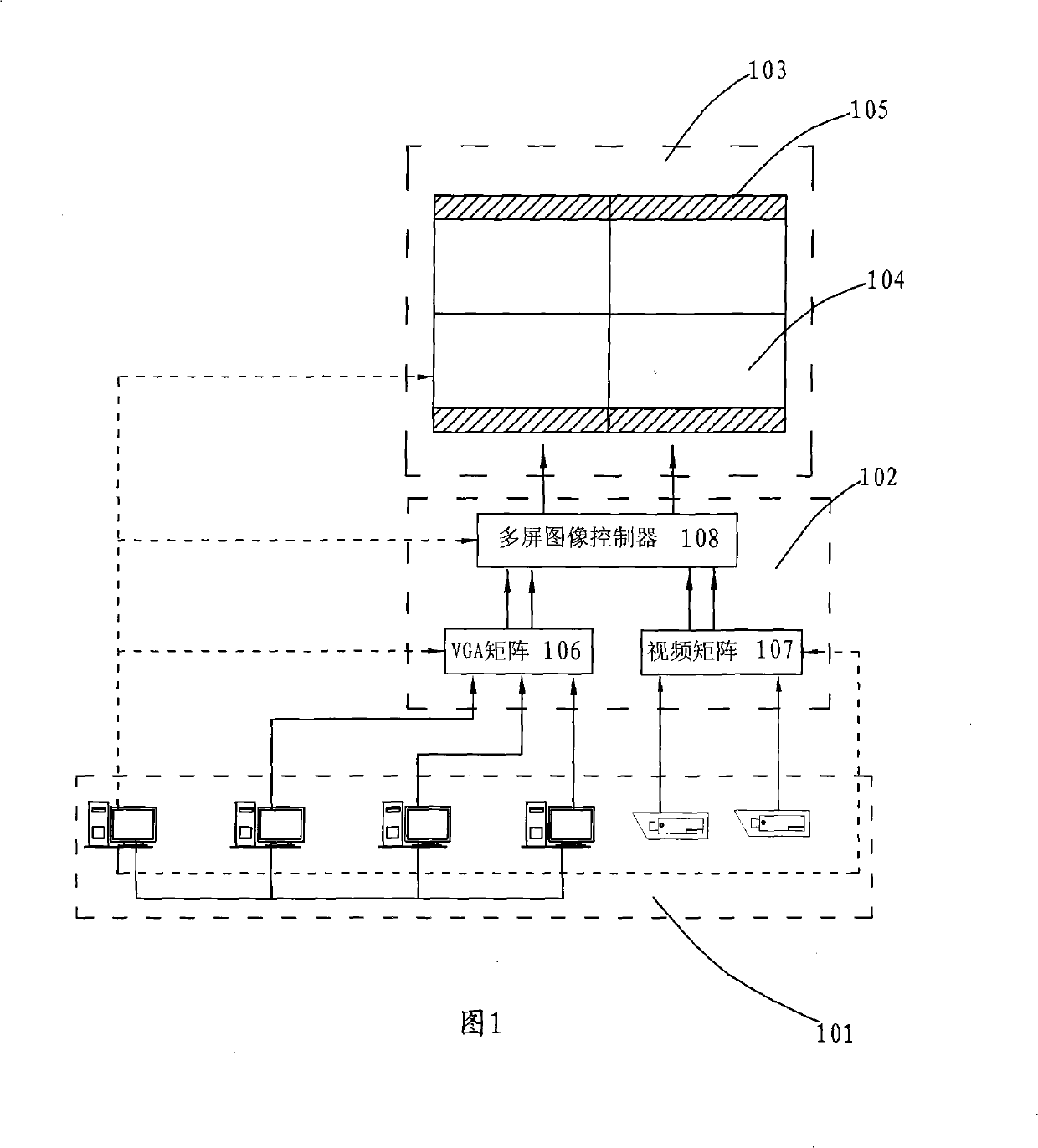

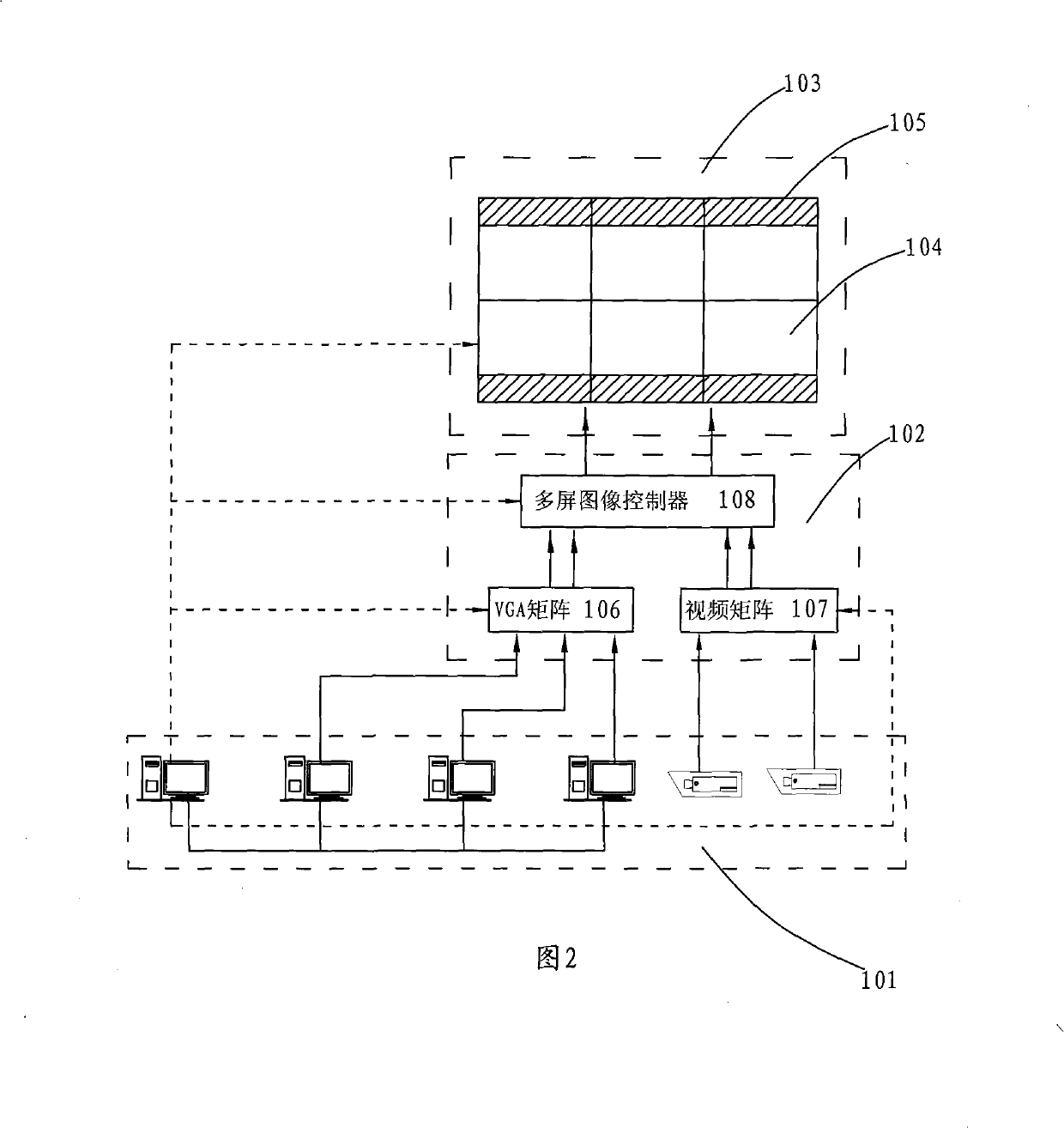

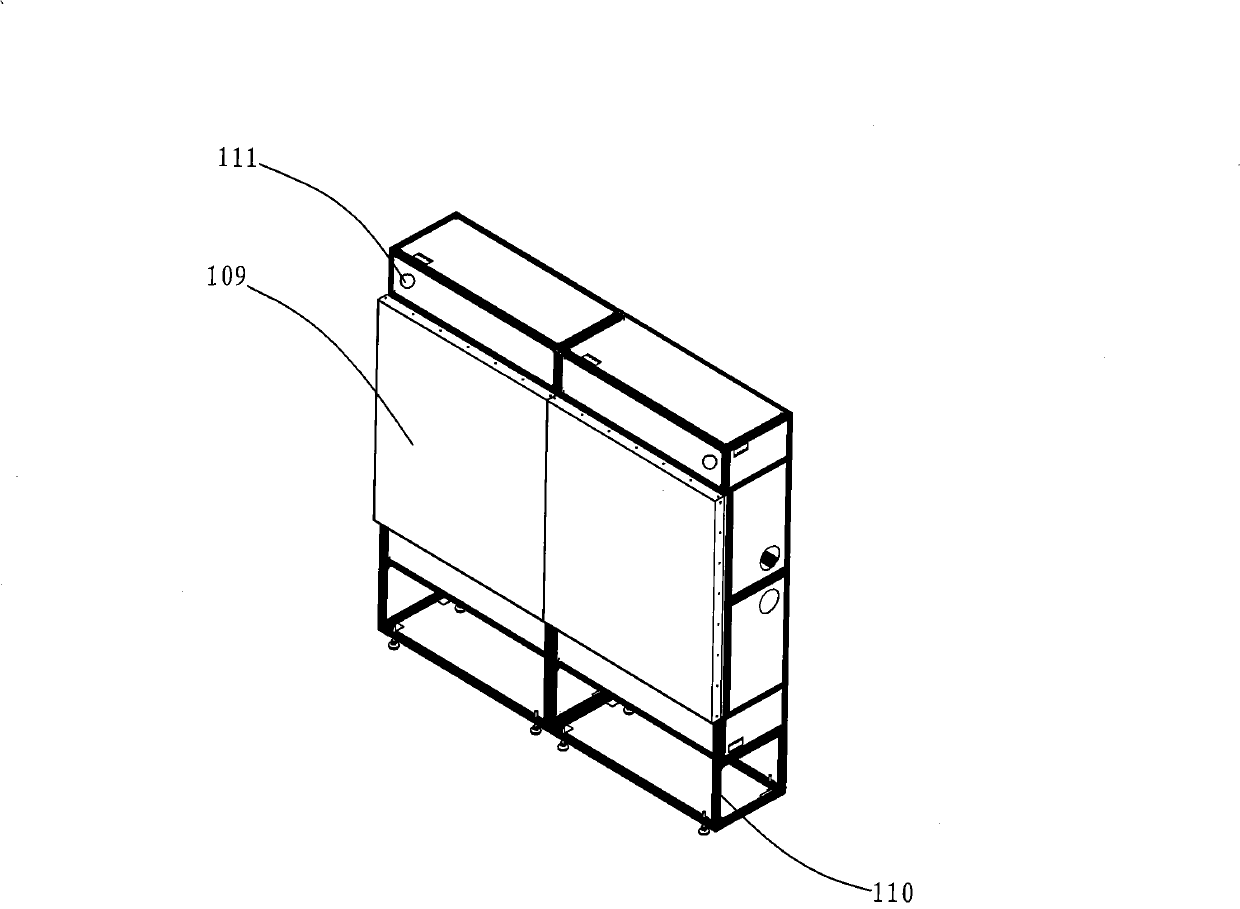

DLP display screen system and splicing method thereof

InactiveCN101778232ANo display color falloffNo afterimage phenomenonTelevision system detailsPicture reproducers using projection devicesInformation transmissionComputer science

The invention relates to a DLP display screen system and a splicing method thereof. The DLP display screen system comprises: a signal input end, an information transmission unit and a 16:9 DLP wide-screen display terminal, wherein the signal input end is connected with the information transmission unit which is connected with the 16:9 DLP wide-screen display terminal. The DLP display screen splicing method comprises the steps: installing 16:9 DLP single-screens in a frame one by one based on a 2 x N mode and installing 16:9 light-emitting machines above and / or below the 16:9 DLP display screen. The 16:9 DLP display screen system has good display effect, low use cost, low power consumption and small amount of heat dissipation, and is suitable for most long-time indoor display. By adopting the DLP display screen splicing method according to the invention, small splicing seam between screens is achieved, and the 16:9 light-emitting machines are arranged at the upper and lower ends of thespliced screen, so no space for maintenance is required in advance, which reduces the thickness of the screen.

Owner:SCT OPTRONICS +1

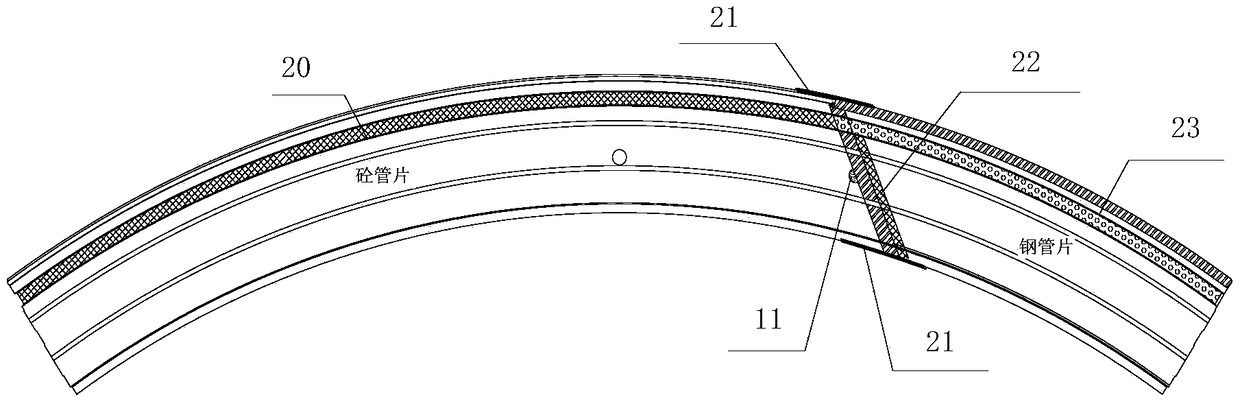

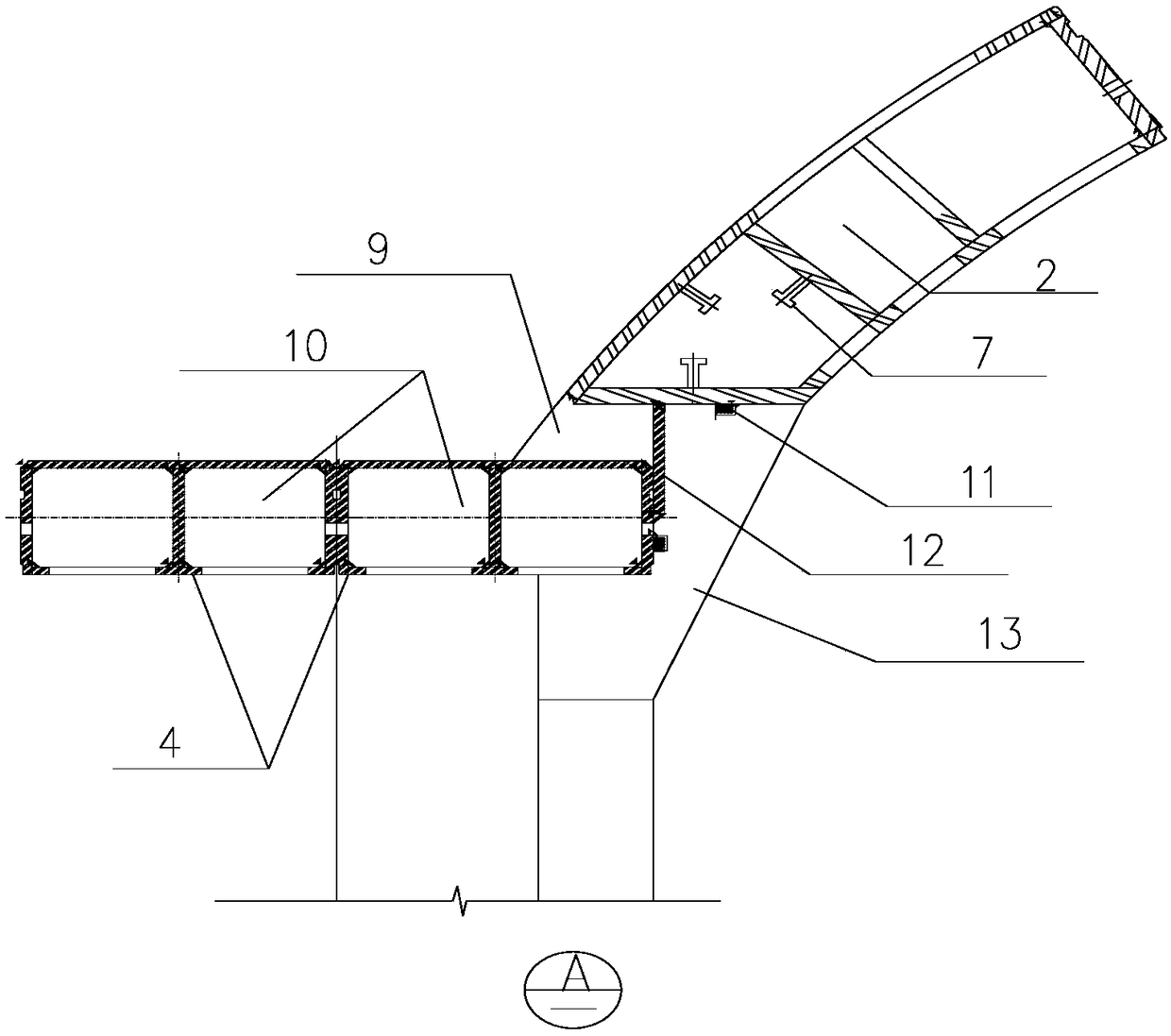

Adaptive waterproofing structure for T-joint part of mechanical method contact passage

ActiveCN108825269AImprove waterproof performanceEasy to installUnderground chambersTunnel liningRubber sheetSelf adaptive

The invention relates to an adaptive waterproofing structure for a T-joint part of a mechanical method contact passage. The adaptive waterproofing structure comprises an external-wrapping waterproofing system, a shield tunnel composite segment waterproofing structure, a backfill water-stopping grouting body of a shield tunnel, a contact passage segment waterproofing structure and a backfill water-stopping grouting body of the contact passage. The external-wrapping waterproofing system comprises blocking steel plates arranged at a bottom plate and a top plate of a tunnel body structure, and side wall blocking steel plates arranged on the two sides of the tunnel body structure. Blocking steel plate subunits are modularly welded to contact passage steel segments. The shield tunnel composite segment waterproofing structure comprises shield tunnel composite segments, shield tunnel concrete segments, water swelling rubber strips for longitudinal seams, water swelling rubber sheets, cement-based permeated crystal type coating and water swelling sealing pads for circumferential seams. The adaptive waterproofing structure for the T-joint part of the mechanical method contact passage has thebeneficial effects that the blocking steel plates adopted in the adaptive waterproofing structure are machined and produced industrially and modularly, mounting is convenient, the number of abutted seams is small, the waterproofing effect is good, and the construction progress can be ensured.

Owner:宁波用信建设有限公司

Construction method with supports and templates in single side of arc shear wall

ActiveCN109208790ASide pressure ensuresGuarantee molding qualityWallsForms/shuttering/falseworksArchitectural engineeringSlurry

The invention discloses a construction method with supports and templates in the single side of an arc shear wall, and belongs to the technical field of architectural engineering. The method comprisesthe steps of measurement and line layering, steel bar installation, manufacturing the templates of the arc shear wall, assembling and fixing the templates, fixing the bottoms of the templates in theouter sides, erecting supports, concrete pouring and dismounting the templates and supports. The large templates are used to reduce splicing seams of the templates, reduce template assembling time andaccelerate construction; the customized arc templates of a steel and plastic combined template system are used to reduce the deviation of arc degree and verticality, and the engineering quality is improved; the bottom is fixed by split bolts and compressed by square strips in the lower, the template stability is improved, template displacement is reduced, and conditions including slurry leakage,surface unevenness, template expansion and staggering of the bottom of the exterior wall are avoided; a triangular steel pipe truss system of the wall uses steel pipes, fasteners and template steel bar back ribs for fixation, inclination of the templates is controlled and the safety is improved; and the large steel-plastic templates and the triangular steel pipe truss system are used repeatedly sothat energy is saved, the environment is protected and the cost is reduced.

Owner:WENZHOU CONSTR GROUP

Reinforced concrete shear wall and construction method thereof

ActiveCN109989506AAvoid harmEasy to adjustWallsBuilding material handlingReinforced concreteSlide plate

The invention discloses a reinforced concrete shear wall and a construction method thereof, and belongs to the technical field of civil engineering construction. The reinforced concrete shear wall comprises a first fixing plate, wherein the top of the first fixing plate is connected with a supporting rod, the top of the supporting rod is connected with a cylinder, the output end of the cylinder isconnected with a pull rod, a through hole matched with the pull rod is formed in the top of the first fixing plate, the end, away from the cylinder, of the pull rod penetrates through the through hole and is connected with a connecting box, connecting rods are rotationally connected to the inner walls of the two sides of the connecting box, second fixing plates are fixedly connected to the two ends of the first fixing plate, sliding plates are slidably connected to the outer walls of the two second fixing plates, the ends, away from the connecting box, of the connecting rods are connected with the sliding plates, clamping plates are connected to the bottoms of the sliding plates, and wood formworks are connected to the outer walls of the clamping plates. According to the invention, the cylinder is used for controlling the clamping plates to clamp the wood formworks, the clamping distance between the wood formworks can be adjusted, the use requirement is met, nails are not needed for fixing, and dismounting and mounting are convenient.

Owner:CITIC GUOAN CONSTR GRP CO LTD

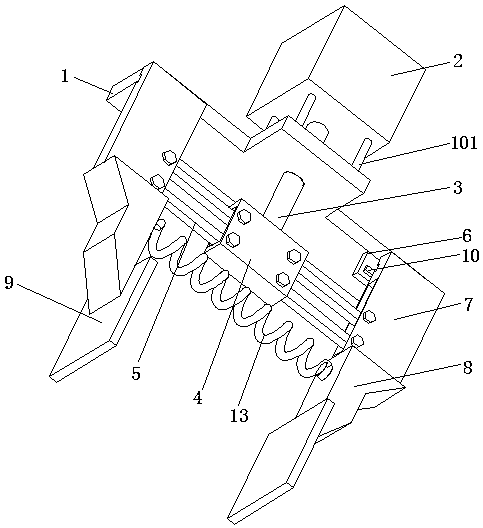

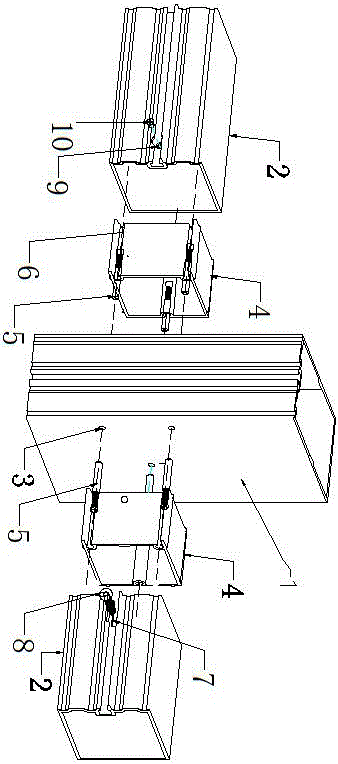

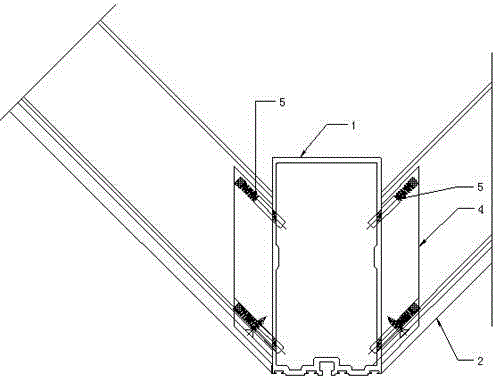

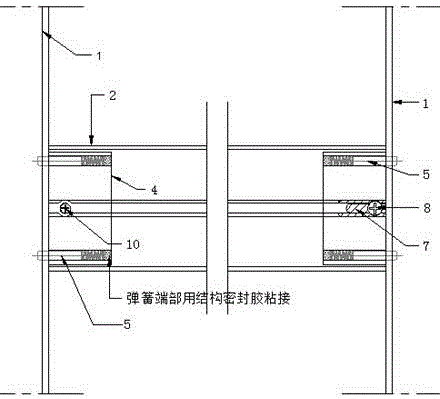

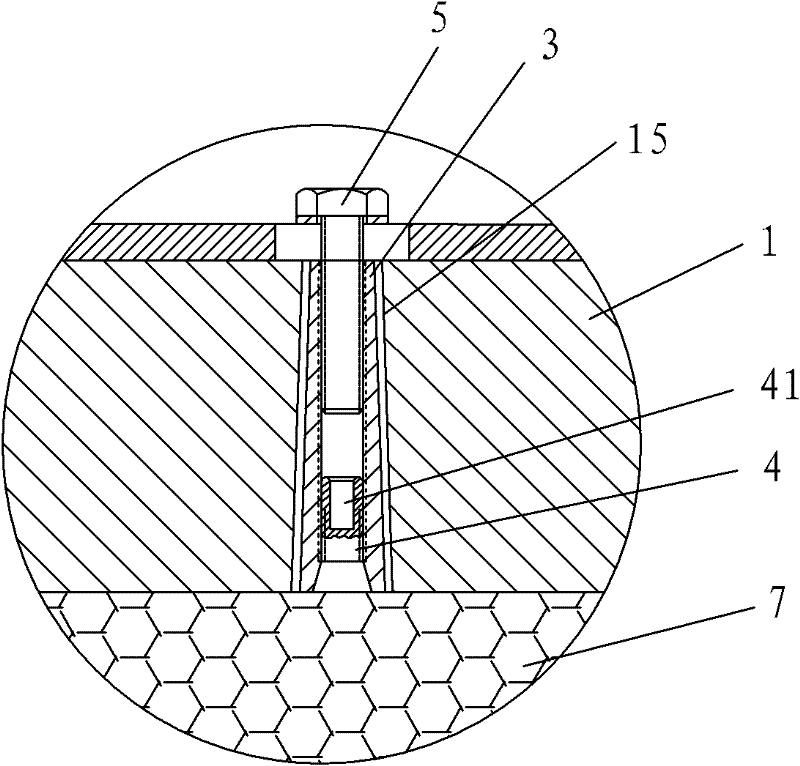

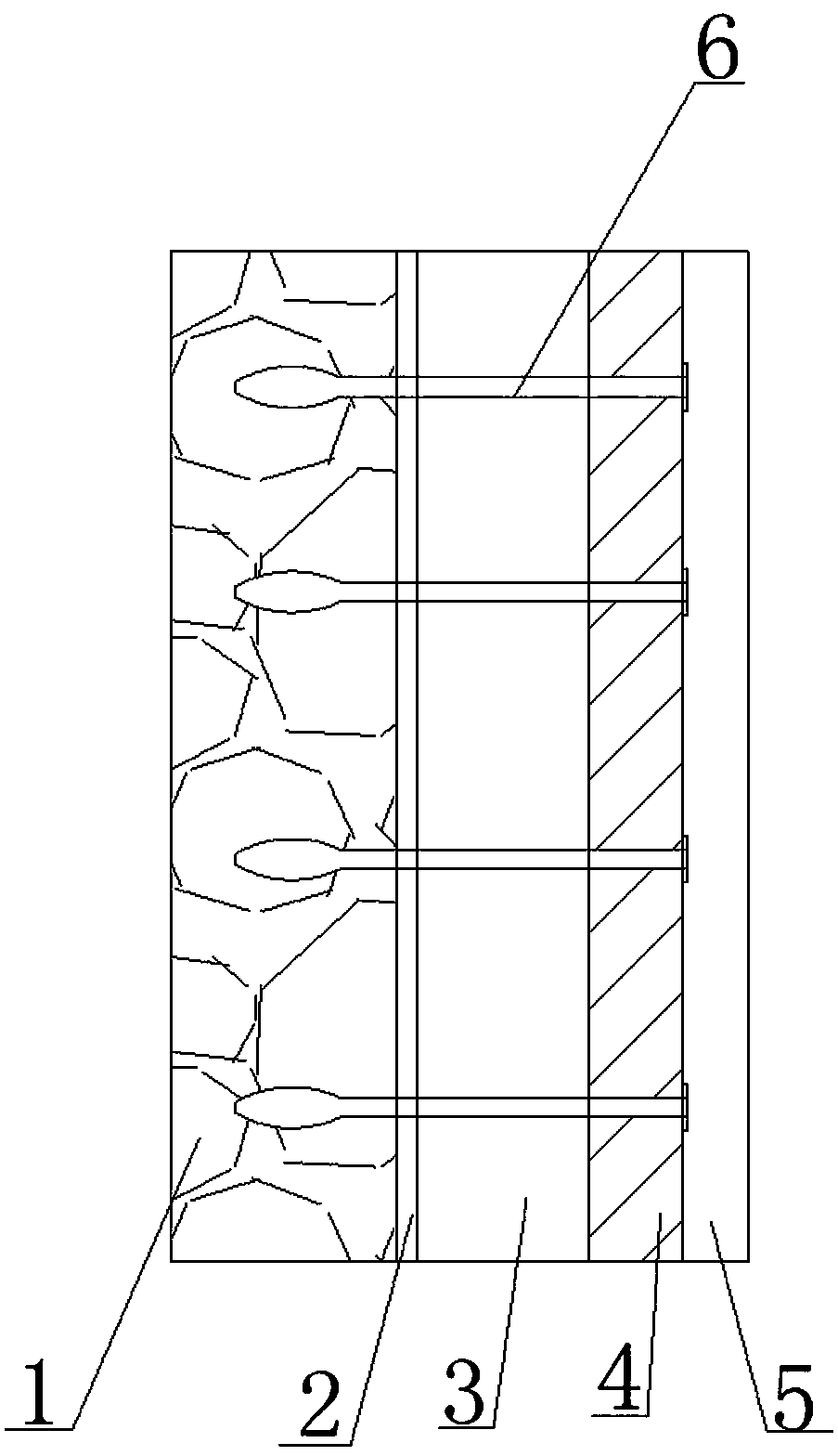

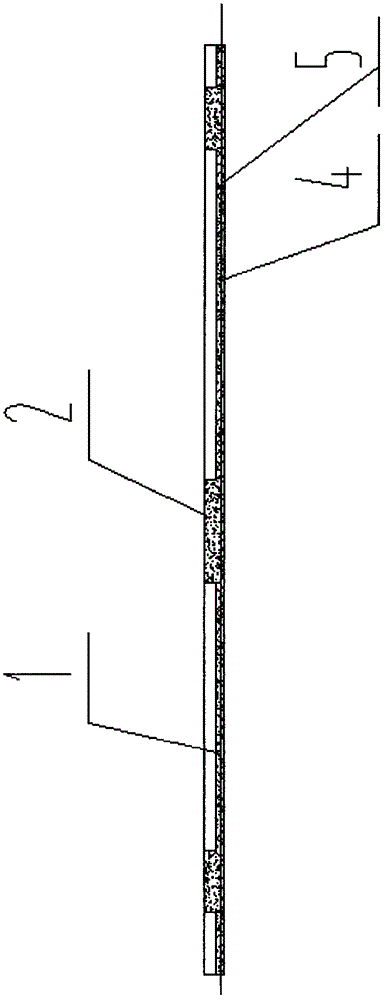

Aluminum alloy cross beam and upright post connecting structure for fixing glass curtain wall

The invention discloses a connection structure of an aluminum alloy beam and a column for fixing a glass curtain wall, which comprises an aluminum alloy column (1), and a beam (2) is arranged between the two aluminum alloy columns (1). A mounting hole (3) is opened at the position where the beam (2) is installed on the alloy column (1), and a ferrule (4) is socketed and fixed at both ends of the beam (2), and a ferrule (4) is installed on the ferrule (4). The spring steel pin (5), the end of the spring steel pin (5) is plugged in the mounting hole (3). The present invention adopts a closed profile, which enhances the performance of the profile, has less seams and is more beautiful; there are three holes on the ferrule, which are distributed in a triangle on the edge of the ferrule, which greatly improves the stability of the beam.

Owner:GUIZHOU ZHENGFANG IND

Manufacturing method of concrete relief wall

InactiveCN111119383ANo need for secondary decorationFast constructionWallsForms/shuttering/falseworksBrickArchitectural engineering

The invention discloses a manufacturing method of a concrete relief wall. The manufacturing method comprises the following steps: S1, manufacturing a waxy female die according to a relief pattern; S2,manufacturing a relief die plate, coating a release agent on the inner side wall, excepting the position on which the waxy female die is mounted, of an outer side die plate, and according to the relief position, fixing the waxy female die on the inner side of a poured die plate to form the relief die plate; S3, mounting the relief die plate and other die plates in place to form a complete pouringdie; S4, pouring concrete in the pouring cavity of the pouring die; S5, separating the outer side die plate from the waxy female die, dismantling the outer side die plate, and taking out a combination of a concrete wall body and the waxy female die; and S6, adopting the heating manner to melt the waxy female die in the concrete wall body to completely melt and lose the waxy female die to obtain the concrete relief wall. According to the manufacturing method, a complicated relief and fretwork effect similar to the brick carving can be imitated on the surface of a fair-faced concrete wall, secondary decoration is not needed for the wall body, the construction speed is high, and the final effect can be shown after form removal.

Owner:金蓉

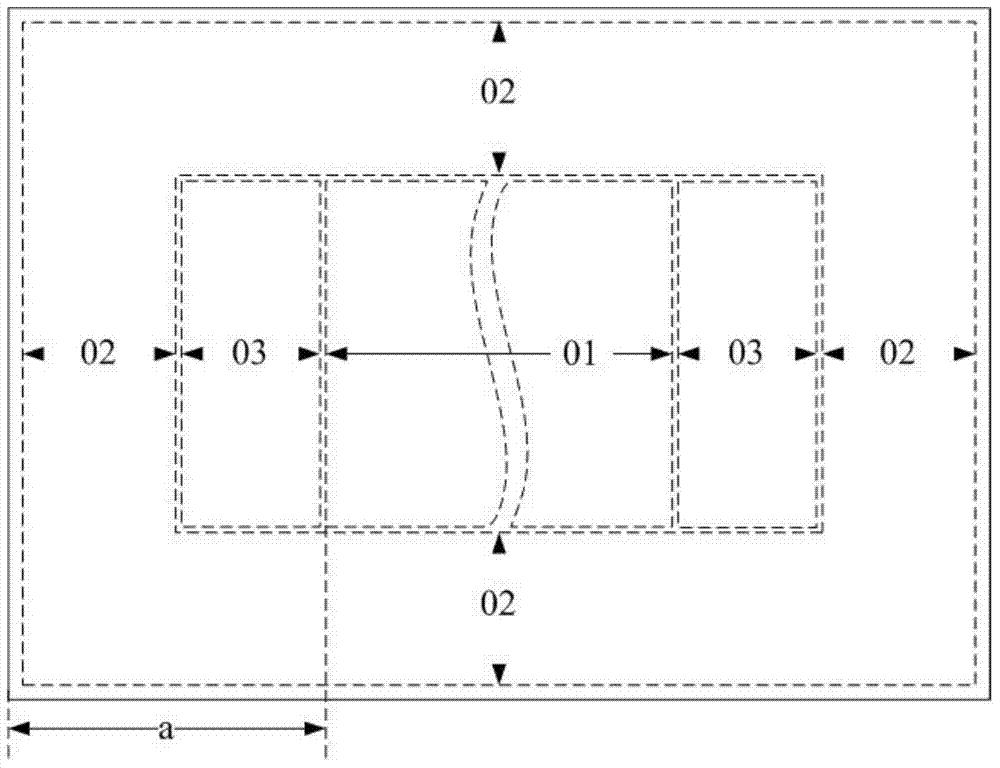

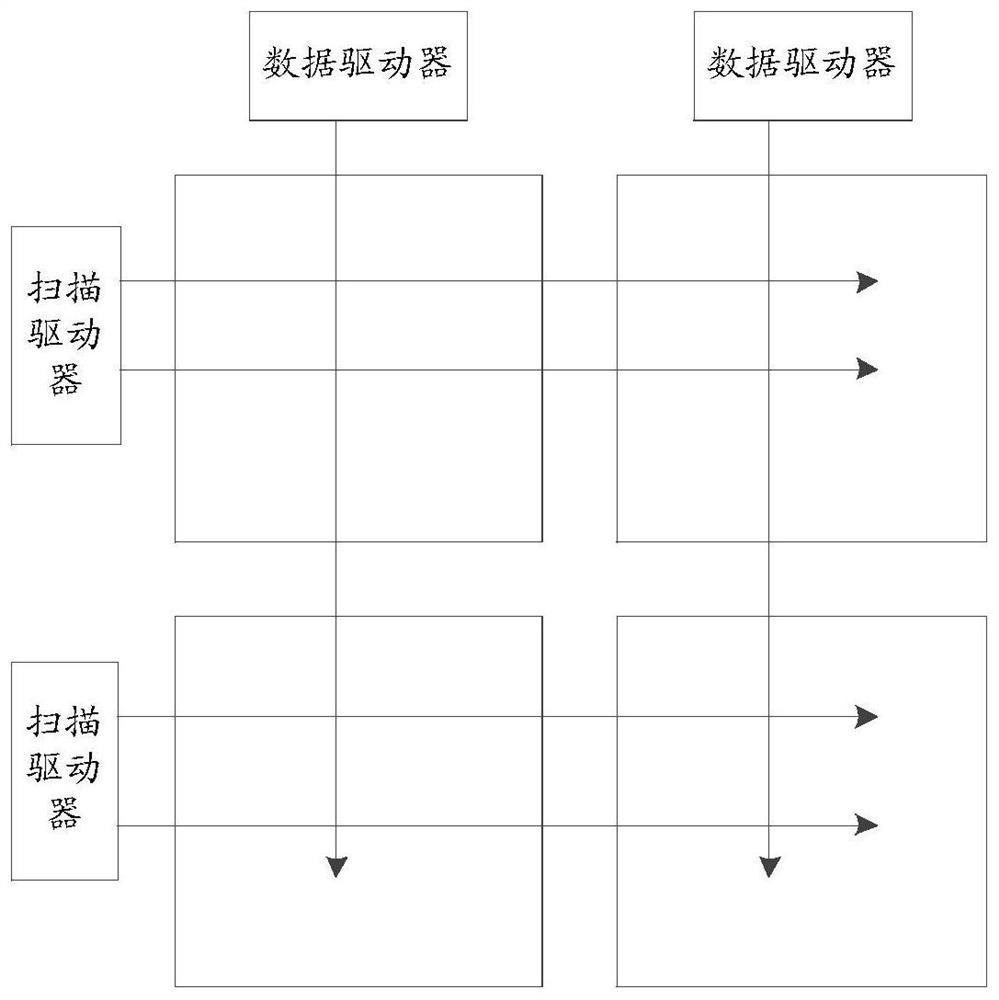

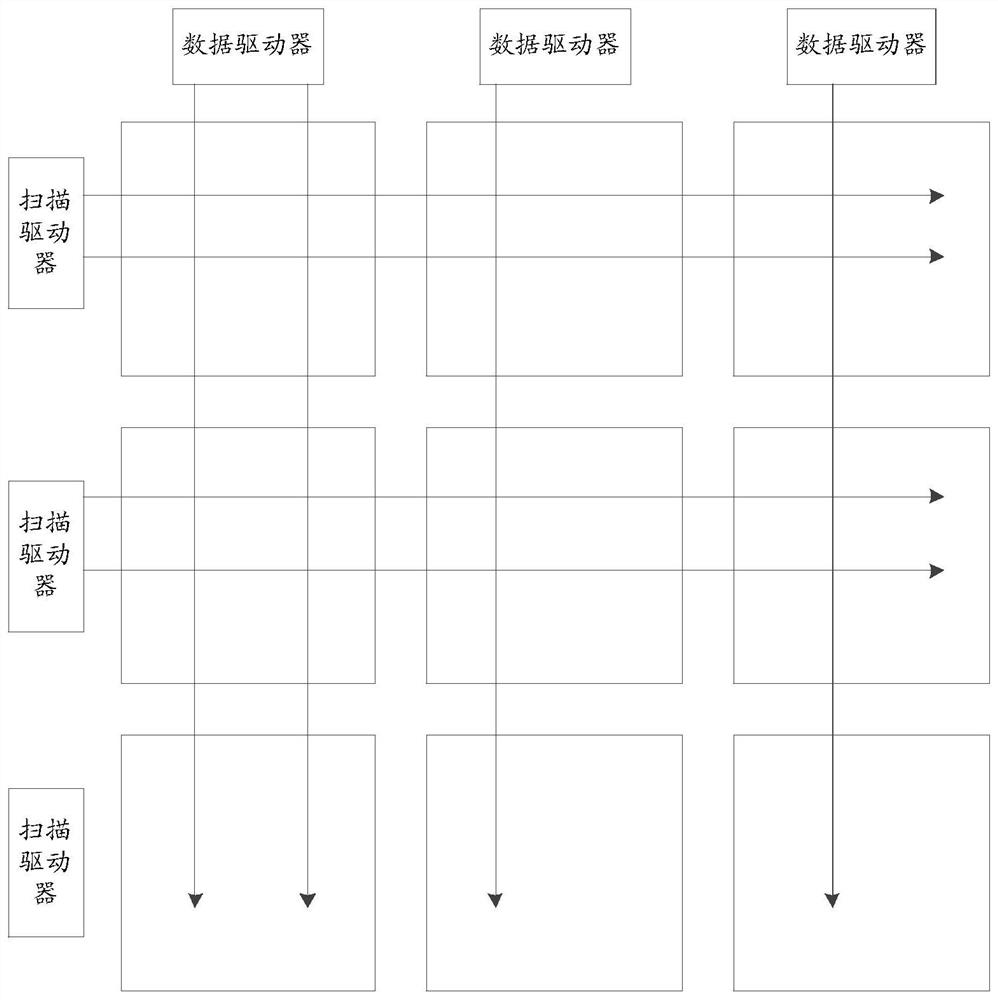

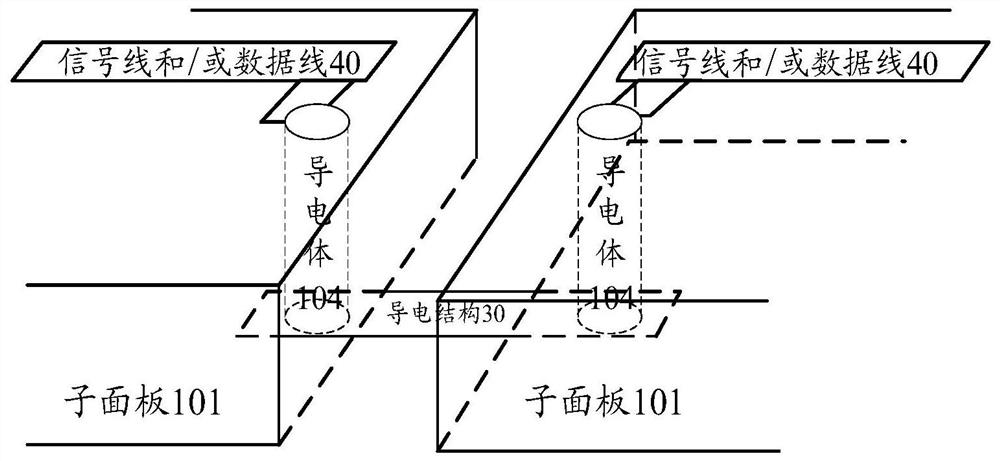

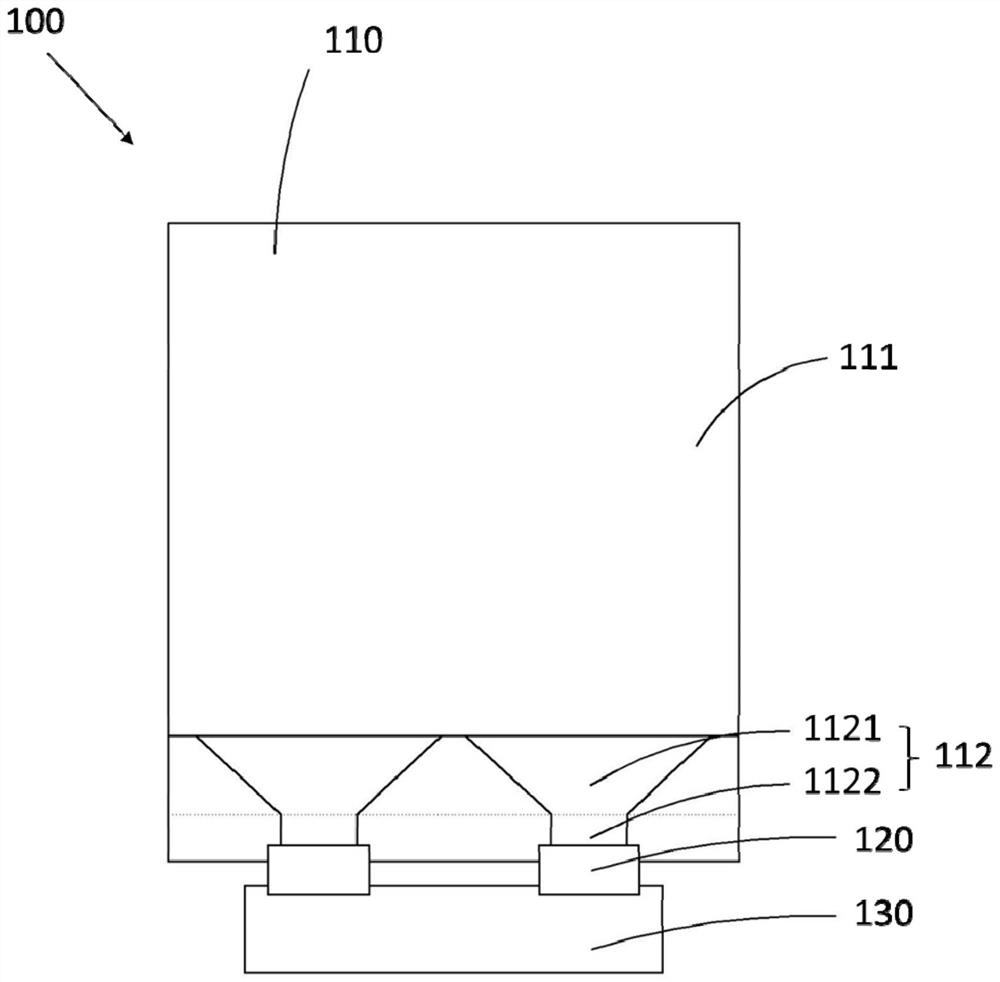

Display device and display device preparation method

PendingCN112309268AImprove picture qualityLess patchworkIdentification meansImaging qualityDisplay device

The invention provides a display device and a preparation method of the display device which are used for solving the problems of large splicing seams and poor image quality of a display panel due tothe fact that an micro LED is electrically connected through an external driver. The device comprises a display panel and a flexible substrate located on the side, deviating from a light emitting surface, of the display panel. The surface, facing the display panel, of the flexible substrate is provided with a conductive structure. A signal line and / or a data line are / is arranged on one side, deviating from the flexible substrate, of the display panel; the display panel comprises a plurality of sub-panels distributed in an array mode, in every two adjacent sub-panels in the row direction and / orthe column direction, the edge, adjacent to the other sub-panel, of one sub-panel is provided with a plurality of conductive channels, the conductive channels are filled with electric conductors, oneend of each electric conductor is connected with a conductive structure, and the other end of each electric conductor is connected with the signal line and / or the data line. the sub-panels are not electrically connected through the external driver, and a plurality of scanning and data circuits are arranged, so that the image quality of the display panel is improved.

Owner:HISENSE VISUAL TECH CO LTD

Novel concrete formwork

InactiveCN102514088ALess patchworkImprove the overall effectMould separation apparatusMouldsFastener

Owner:许金锔 +1

Lightweight dismantle-free heat insulation template integrated composite heat insulation system and manufacturing technology thereof

PendingCN110258867AReduce manual labor intensityEnhanced deformation stressWallsClimate change adaptationInsulation layerManufacturing technology

The invention belongs to a lightweight dismantle-free heat insulation template integrated composite heat insulation system and manufacturing technology thereof. The lightweight dismantle-free heat insulation template integrated composite heat insulation system comprises a cast-in-place concrete base wall body, a heat insulation template inner protective layer, an organic heat insulation material layer, seamed reinforced glass wool or a rock wool board inorganic material insulation layer, and a polymer mortar layer are sequentially arranged on the outer side of the cast-in-place concrete base wall body, and are fixedly mounted and connected with the cast-in-place concrete base wall body through pre-embedded anchoring connecting parts, and the outer surface of the seamed reinforced glass wool or the rock wool board inorganic material insulation layer is coated with the polymer mortar layer. The lightweight dismantle-free heat insulation template integrated composite heat insulation system has the advantages that structure design is reasonable, the lightweight, high intensity and low heat conductivity performance are achieved, the comprehensive cost can be lowered, the load of buildings is relieved, the whole thickness of the mortar layer on the outer surface of the wall body is advantageously controlled, and the safety of anti-cracking, anti-falling-off and anti-fire is improved.

Owner:河南省澳科保温节能材料技术开发有限公司

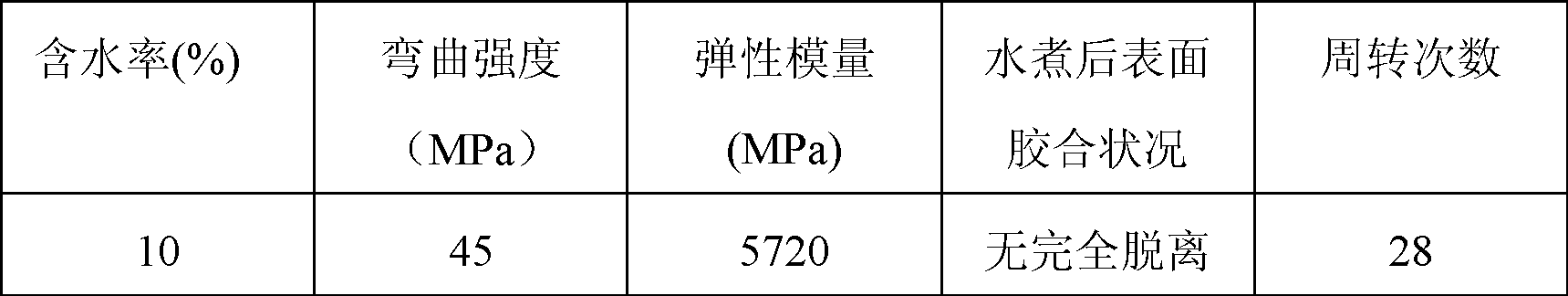

Building template with high cost performance and preparation method thereof

InactiveCN102936952AGood value for moneyCost-effectiveSynthetic resin layered productsLaminationTurnover timePolyolefin

The invention provides a building template with a high cost performance and a preparation method thereof, relates to the building template and the preparation method thereof and mainly solves the problems that the existing waste template cannot be regenerated and reused, a wood template is not easy to de-mould in a use process and the turnover time is low. The product is formed by respectively sticking one layer of a sticking layer on each one of upper and lower surfaces of a core plate. The method comprises the following steps of: taking nails and sorting the waste templates; vertically cutting; leveling; transversely combing, and vertically connecting and combing; transversely splicing; filling holes; drying; sanding double faces with a fixed thickness to prepare the core plate; preparing a non-woven fabric polyolefin sticking face; coating an adhesive on a non-woven fabric of the non-woven fabric polyolefin sticking face; and coating on the upper and lower surfaces of the core plate, and pressing to finish. The building template with the high cost performance disclosed by the invention adopts the core plate made of the waste template, solves the regeneration and reutilization problems of the waste templates, and greatly improves the cost performance of the building template; and the property that the surface activity of the polyolefin sticking face is low is utilized, the template is easy to de-mould, and the turnover time is high.

Owner:安徽省崃山建材有限公司

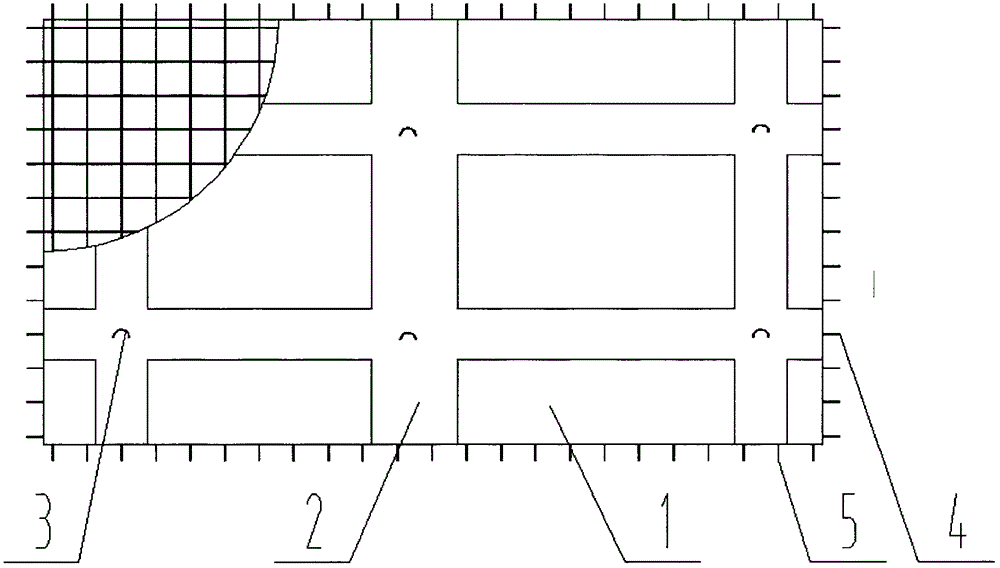

Prefabricated utility tunnel spliced by virtue of cast-in-place hidden beams and mixed with hollow-core wall boards, and construction method thereof

ActiveCN108086353ALight weightSolving prefab assembly challengesArtificial islandsUnderwater structuresUtility tunnelHollow core

The invention discloses a prefabricated utility tunnel spliced by virtue of cast-in-place hidden beams and mixed with hollow-core wall boards, and a construction method thereof. The two ends of a cast-in-place bottom plate are connected with the lower part of a double-sided prefabricated hollow core-filled side wall through a splicing hidden beam separately; the middle part of the cast-in-place bottom plate is connected with the lower part of a fully-prefabricated middle partition wall through a splicing hidden beam; the two ends of a laminated top plate are connected with the upper part of the double-sided prefabricated hollow core-filled side wall separately; and the middle part of the laminated top plate is connected with the upper part of the fully-prefabricated middle partition wall.The prefabricated utility tunnel integrates the advantages of a prefabrication process and a cast-in-place process; and the dead weights of prefabricated parts can be reduced through reasonable detachment, and the parts can be connected into one piece through cast-in-place core filling and the splicing hidden beams, so that the purpose of prefabrication for a multi-cabin tunnel and a non-standardsection of the tunnel can be achieved.

Owner:中建五局第三建设有限公司

Construction method for movable mold frame for lock chamber wall of ship lock

InactiveCN107386246AReduce equipmentReduce labor intensityDry-docksClimate change adaptationSingle sectionBuilding construction

Owner:周学顺

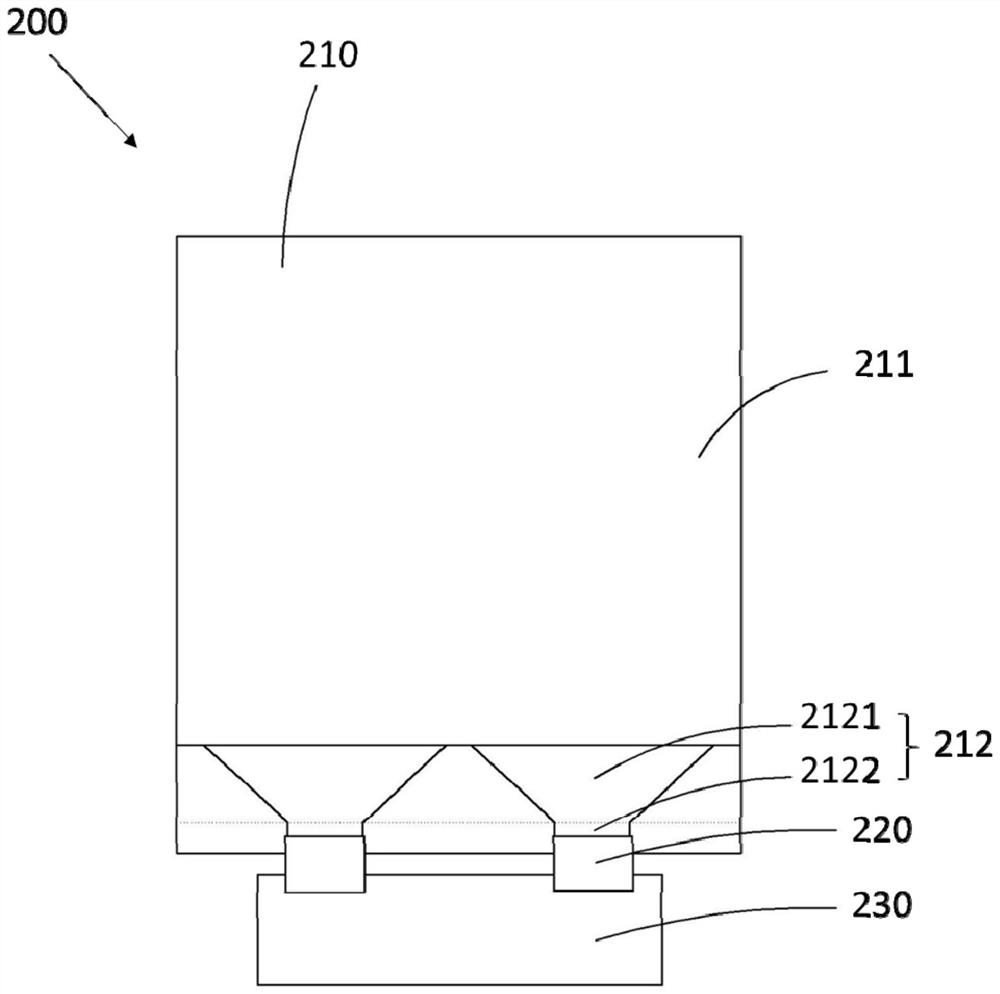

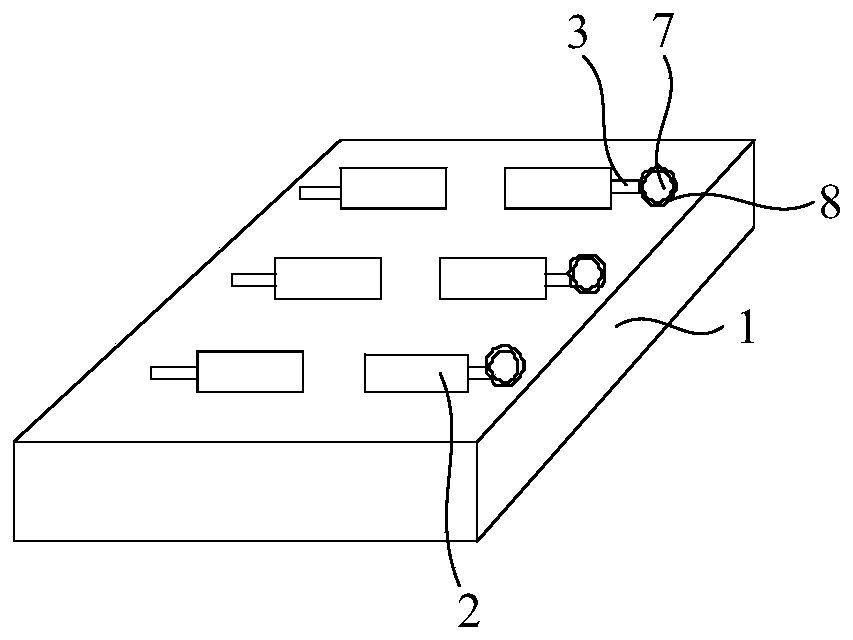

Display module

PendingCN111796463AGood lookingImprove bendabilitySolid-state devicesNon-linear opticsEngineeringMechanical engineering

The invention discloses a display module. The display module comprises a display panel which comprises a display region and a frame region disposed at the outer side of the display region, and a plurality of bonding pads are disposed in the frame region; the display module further comprises a printed circuit board and a plurality of binding wires, one ends of the plurality of binding wires are bound on the plurality of bonding pads one by one, and the other ends of the plurality of binding wires are electrically connected with the printed circuit board. According to the display module, the printed circuit board is directly connected with the binding bonding pads on the display panel through the binding wires, so that the width of the frame of the display module is effectively reduced, theappearance effect of the display module is improved, and when the display module is applied to splicing display equipment, smaller splicing seams can be formed.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

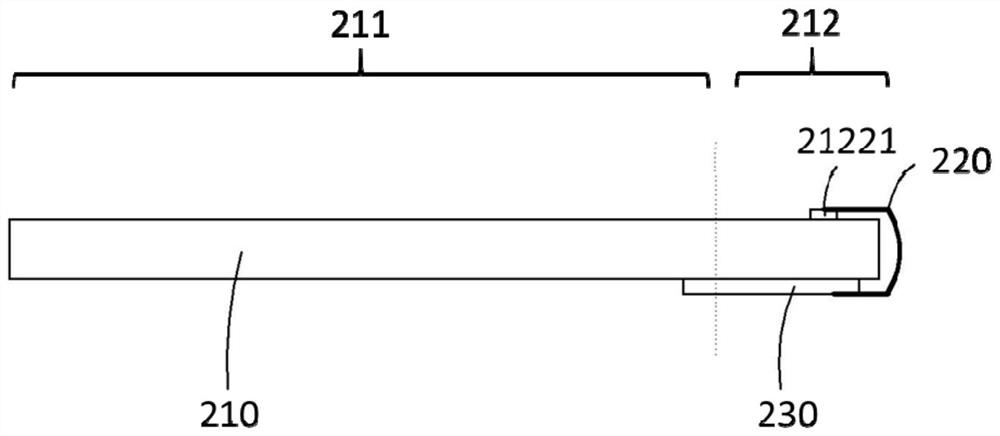

Miniature light-emitting diode display panel and manufacturing method thereof

ActiveCN110911392AHigh precisionAvoid disconnectionStatic indicating devicesSolid-state devicesPhysicsThin membrane

The invention discloses a miniature light-emitting diode display panel and a manufacturing method thereof, and the display panel comprises a substrate which comprises a first surface and a second surface which are opposite to each other; a micro light-emitting diode and a driving circuit are arranged on the substrate, the driving circuit comprises a plurality of signal lines located on the first surface of the substrate and signal leads which are located on the second surface of the substrate and correspond to the signal lines one to one, and the ends of the signal lines and the ends of the signal leads extend to a preset edge area of the substrate; holes which are arranged in the preset edge area and correspond to the signal lines one to one, and a metal film connecting part, the holes penetrate through the substrate, each metal film connecting part at least comprises a first metal film connecting part plated on the side wall of the corresponding hole, and the two ends of each metal film connecting part are connected with the corresponding signal line and the corresponding signal lead respectively. According to the display panel, the signal line and the signal lead can be accurately aligned and connected, and the metal film connecting part is prevented from being broken.

Owner:BOE TECH GRP CO LTD +1

Concrete laminated slab prefabricated part with two-way ribs

A concrete laminated slab prefabricated component with two-way ribs relates to the field of concrete prefabricated parts technology and prefabricated structures in the construction industry. The thin plate (1) is made of a group of horizontally stressed steel bars (4) and a group of vertically stressed steel bars (5) bound together and then poured concrete, and the two sets of reinforcing ribs (2) are respectively arranged on the thin plate (1) in two directions perpendicular to each other, and the set of suspension rings (3) are respectively fixedly installed on the two sets of reinforcing ribs (2). Two-way ribs increase the stiffness of the component, reduce the deformation of the prefabricated component and the stress of the steel bar during construction; it is convenient to ensure the thickness of the protective layer for laying the steel bar on the slab; the thin concrete slab reduces the weight of the prefabricated component, which is conducive to the transportation and hoisting of the component; Tensile steel bars can be prestressed steel bars, which can save a lot of steel.

Owner:赵洪波

Half-prefabricated assembled comprehensive pipe gallery formed by splicing cast-in-situ hidden beams and construction method of half-prefabricated assembled comprehensive pipe gallery

InactiveCN108166525ALight weightSolving prefab assembly challengesArtificial islandsCeramic shaping apparatusLap jointEngineering

The invention provides a half-prefabricated assembled comprehensive pipe gallery formed by splicing cast-in-situ hidden beams and a construction method of the half-prefabricated assembled comprehensive pipe gallery. The half-prefabricated assembled comprehensive pipe gallery comprises a plurality of comprehensive pipe gallery bodies, wherein each comprehensive pipe gallery body is formed by splicing a cast-in-situ baseplate and an upper prefabricated pipe gallery; U-shaped dowel bars I are reserved on the sides, facing the corresponding upper prefabricated pipe gallery, of the two ends and themiddle of each cast-in-situ baseplate; U-shaped dowel bars II which are matched with the U-shaped dowel bars I in position are arranged on each upper prefabricated pipe gallery; and all the cast-in-situ baseplates and upper prefabricated pipe galleries are connected in a staggered lap-joint manner through the U-shaped dowel bars I and the U-shaped dowel bars II. The construction method comprisesthe following steps: after the manufacturing of prefabricated components as well as the positioning and setting-out operation, binding steel bars of the cast-in-situ baseplates, casting the cast-in-situ baseplate, and carrying out curing and demolding; and then, assembling the prefabricated components, mounting steel bars and mold plates at the splicing positions, and carrying out concrete pouringat the cast-in-situ parts, so as to form the half-prefabricated assembled comprehensive pipe gallery. The half-prefabricated assembled comprehensive pipe gallery provided by the invention integratesthe advantages of both the prefabrication and cast-in-situ processes; not only can the own weights of the prefabricated components be reduced through reasonable splitting and the hoisting constructionbe facilitated, but also all the prefabricated components can be connected as a whole through the cast-in-situ hidden beams; and under the premise that the overall bearing capacity and the deformability of the comprehensive pipe gallery bodies are not reduced, the problem about how to prefabricate and assemble a multi-cabin gallery and a non-standard gallery segment can be solved.

Owner:中建五局第三建设有限公司

DLP display screen system and splicing method thereof

InactiveCN101778232BReduce location requirementsLess patchworkTelevision system detailsPicture reproducers using projection devicesInformation transmissionComputer science

The invention relates to a DLP display screen system and a splicing method thereof. The DLP display screen system comprises: a signal input end, an information transmission unit and a 16:9 DLP wide-screen display terminal, wherein the signal input end is connected with the information transmission unit which is connected with the 16:9 DLP wide-screen display terminal. The DLP display screen splicing method comprises the steps: installing 16:9 DLP single-screens in a frame one by one based on a 2 x N mode and installing 16:9 light-emitting machines above and / or below the 16:9 DLP display screen. The 16:9 DLP display screen system has good display effect, low use cost, low power consumption and small amount of heat dissipation, and is suitable for most long-time indoor display. By adopting the DLP display screen splicing method according to the invention, small splicing seam between screens is achieved, and the 16:9 light-emitting machines are arranged at the upper and lower ends of thespliced screen, so no space for maintenance is required in advance, which reduces the thickness of the screen.

Owner:SCT OPTRONICS +1

Wood formwork fixture for building concrete construction and operation method of wood formwork fixture

InactiveCN110094053ASave resourcesLow costForms/shuttering/falseworksArchitectural engineeringScrew thread

Owner:CITIC GUOAN CONSTR GRP CO LTD

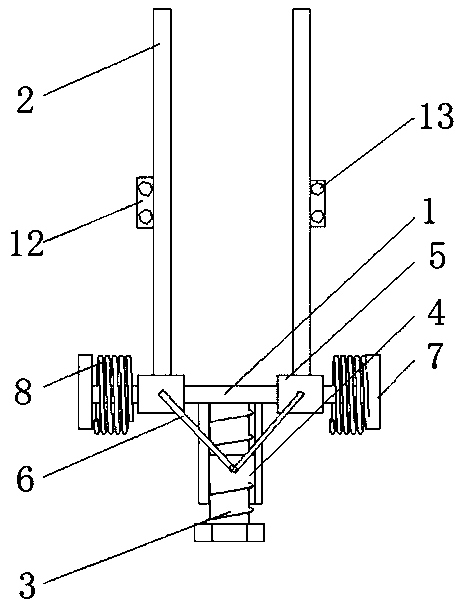

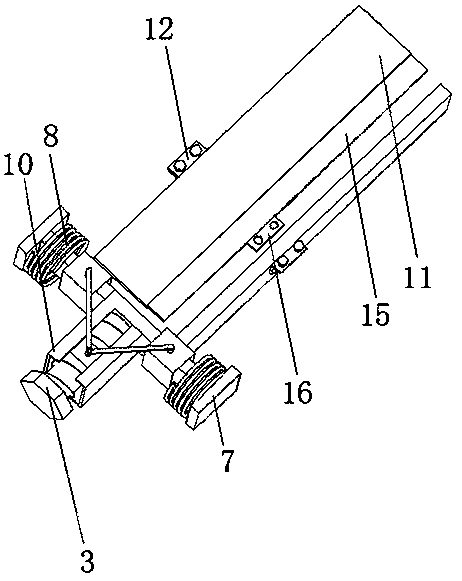

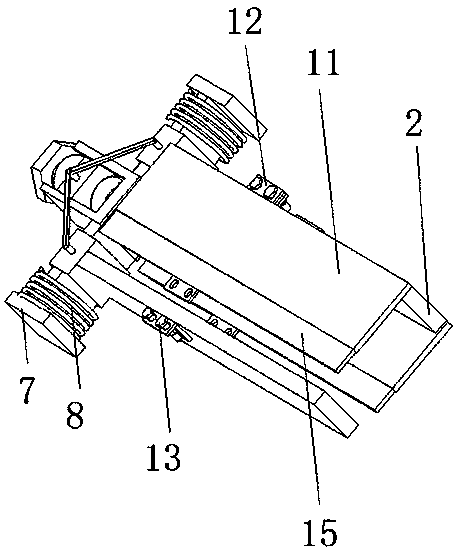

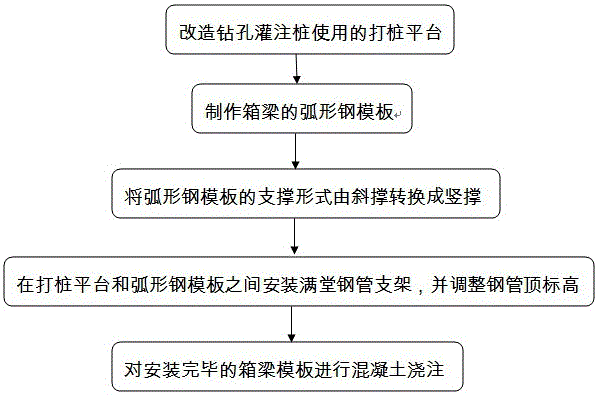

Construction method of curved fish-bellied cast-in-place reinforced concrete box girder above water

ActiveCN105568854BSimple structureImprove economyBridge erection/assemblyBridge materialsReinforced concreteEngineering

A construction method of an overwater curved fish-bellied cast-in-place reinforced concrete box girder comprises steps as follows: a piling platform for a cast-in-place bored pile is modified and taken as a bearing foundation for full-hall steel tube supports; arc-shaped steel formworks of the box girder are manufactured; the bracing form of the arc-shaped steel formworks is changed into vertical bracing from diagonal bracing; the full-hall steel tube supports are mounted between the piling platform and the arc-shaped steel formworks; a mounted box girder formwork is subjected to concrete casting. According to the construction method of the overwater curved fish-bellied cast-in-place reinforced concrete box girder, the piling platform is used as the bearing foundation, the full-hall steel tube supports are erected on the foundation, the structure of the formwork support is optimized by improving the girder formwork, the safety, economy and adaptability of the formwork support are remarkably improved, the construction difficulty is substantially reduced, the construction period is greatly shortened, construction of a fish-bellied special-shaped bridge with a unique model is successfully completed, and a safe, convenient and economical construction technology is provided for construction of similar bridges.

Owner:GUANGZHOU HENGSHENG CONSTR ENG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com