Hollow-wallboard mixed-prefabricated type comprehensive pipe rack and construction method thereof

A technology of prefabricated assembly and comprehensive pipe gallery, applied in artificial islands, water conservancy projects, infrastructure projects, etc., can solve the problems of many assembled components, difficult transportation and hoisting, and poor integrity, so as to achieve fewer joints, easy transportation and hoisting, and overall good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

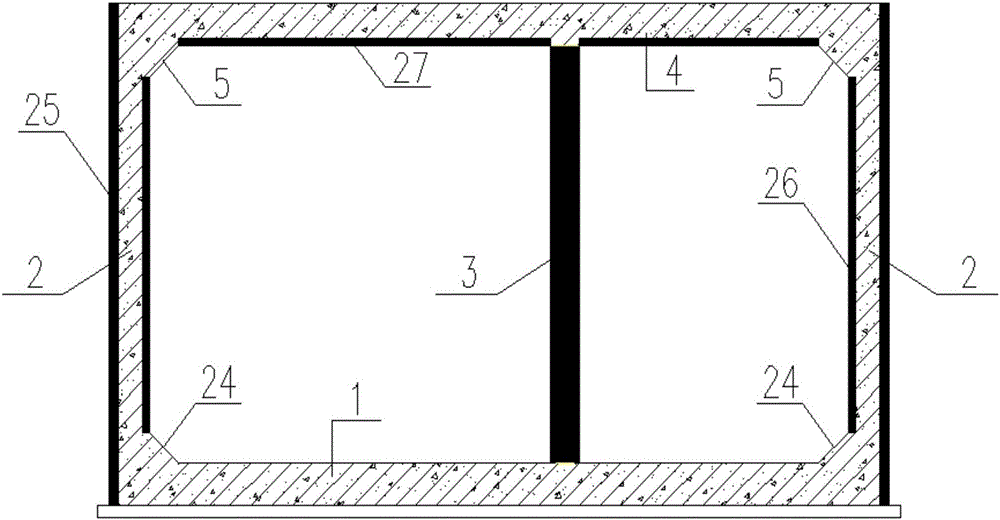

[0066] see figure 1 , prefabricated integrated pipe gallery with hollow wall panels, consisting of cast-in-place bottom plate 1, double-sided prefabricated hollow core-filled side walls 2, fully prefabricated middle partition wall 3 and laminated roof 4. The two ends of the cast-in-place base plate 1 are respectively connected to the lower parts of two double-sided prefabricated hollow core-filled side walls 2, the middle part of the cast-in-place base plate 1 is connected to the lower part of the fully prefabricated middle partition wall 3, and the two ends of the superimposed top plate 4 are respectively connected to the The upper parts of the two double-sided prefabricated hollow core-filled side walls 1 are connected, and the middle part of the superimposed roof 4 is connected with the upper part of the fully prefabricated middle partition wall 3 . The joint between the double-sided prefabricated hollow core-filled side wall 2 and the cast-in-place base plate 1 is provided...

Embodiment 2

[0068] see figure 1 and Figure 5 , according to the prefabricated comprehensive pipe gallery with hollow wall panels described in Embodiment 1, the cast-in-place bottom plate 1 is provided with vertically bent steel bars 14 . The vertically bent steel bar 14 extends into the double-sided prefabricated hollow core-filled side wall 2, and reaches the anchorage length requirement.

Embodiment 3

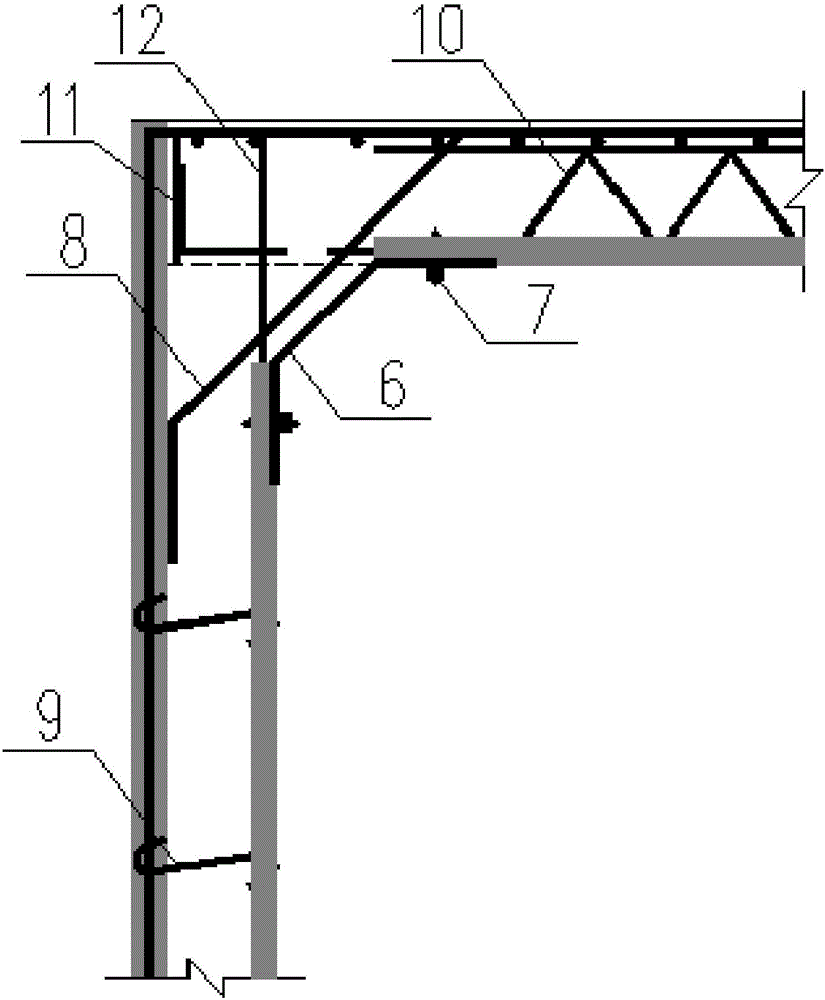

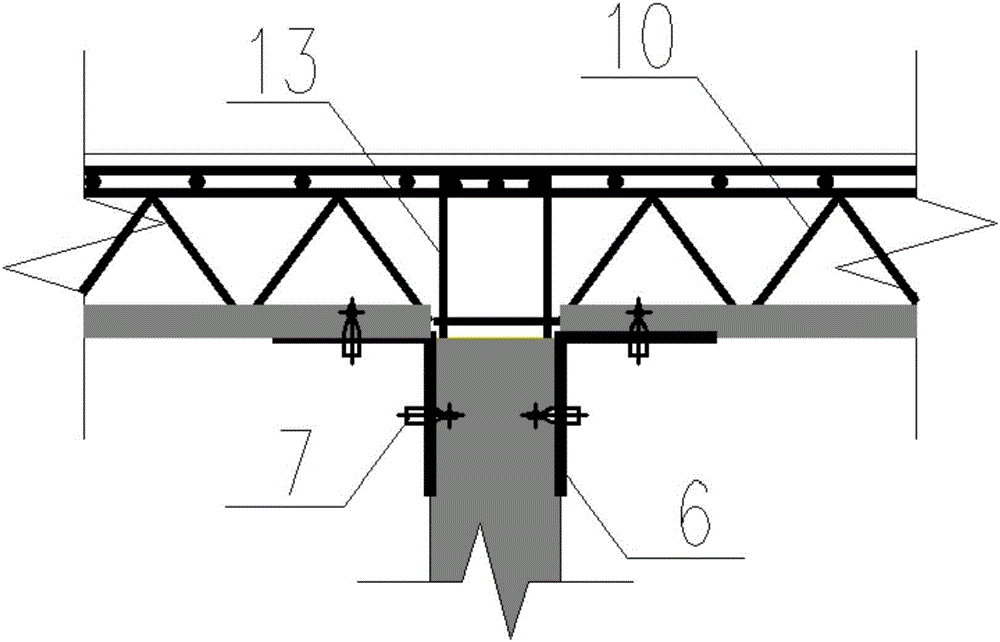

[0070] see figure 1 , image 3 , Figure 6 , Figure 8 and Figure 9 , according to the hollow wall panel mixed prefabricated integrated pipe gallery described in embodiment 2, the structure of the double-sided prefabricated hollow core-filled side wall 2 is: the precast concrete layer 25 on the filling side and the precast concrete layer 26 on the non-filling side are set There are steel bars and the precast concrete layer 25 on the filling side and the steel bars provided in the precast concrete layer 26 on the non-filling side are connected by tie bars 9; the prefabricated height of the precast concrete layer 25 on the filling side is from the bottom of the bottom plate to the top of the roof; The prefabricated height of the prefabricated concrete layer 26 on the non-filling side is from the top of the axil corner of the bottom slab to the bottom of the axillary corner of the top slab; The prefabricated concrete layer 26 on the filling side is poured together, and the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com