UHPC prefabricated assembled comprehensive pipe gallery horizontal curve connecting segment structure and construction method

A comprehensive pipe gallery and prefabricated assembly technology, which is applied in infrastructure engineering, artificial islands, water conservancy projects, etc., can solve problems such as slowing down construction speed, and achieve the effect of improving waterproof performance, good waterproofness, and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

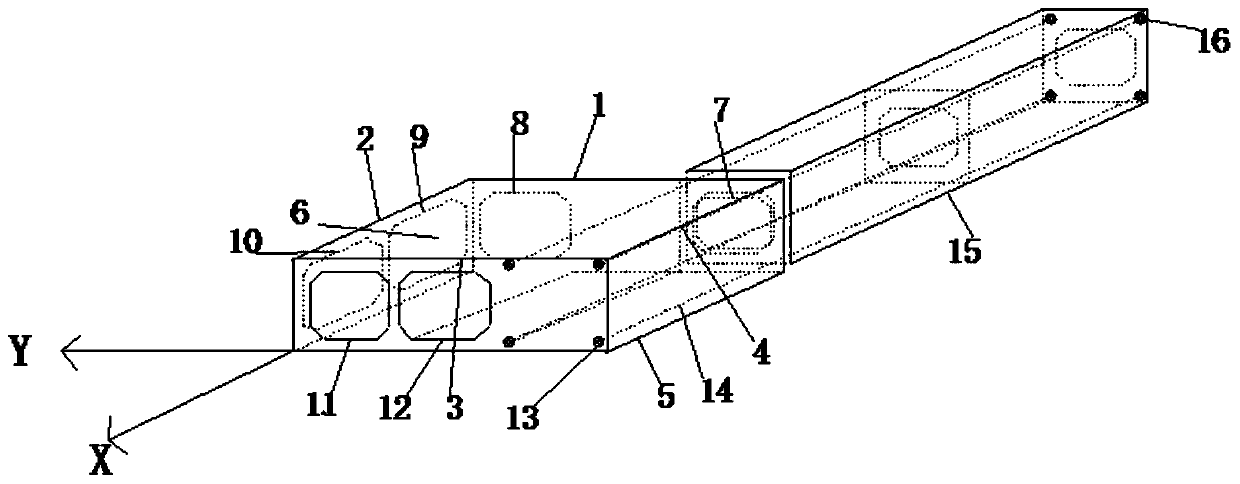

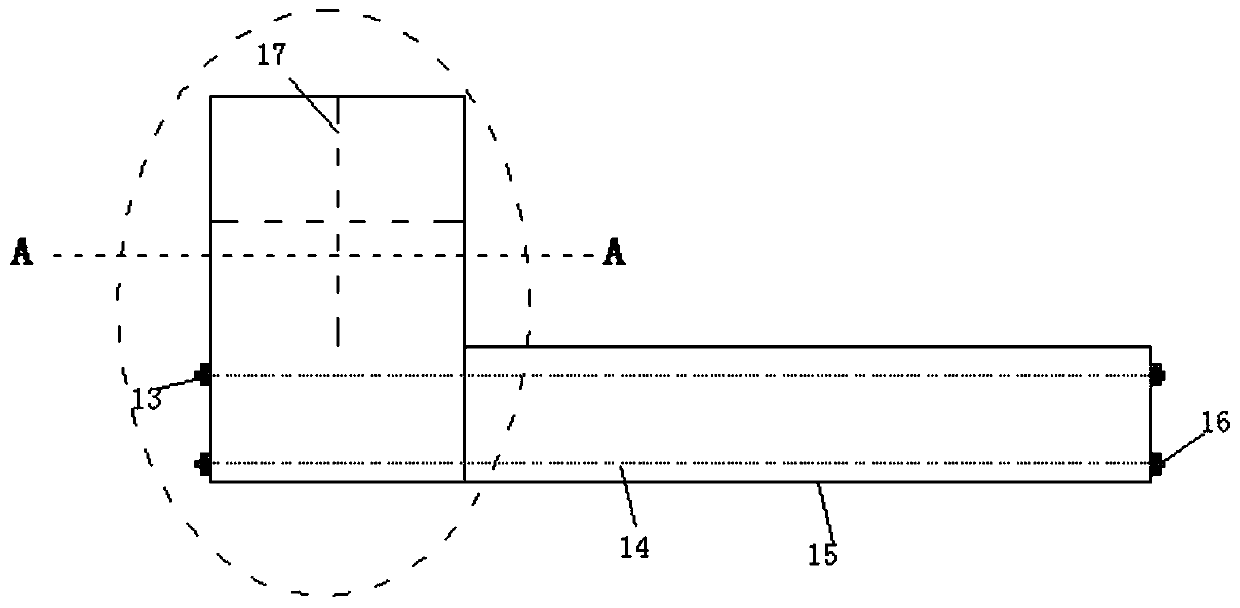

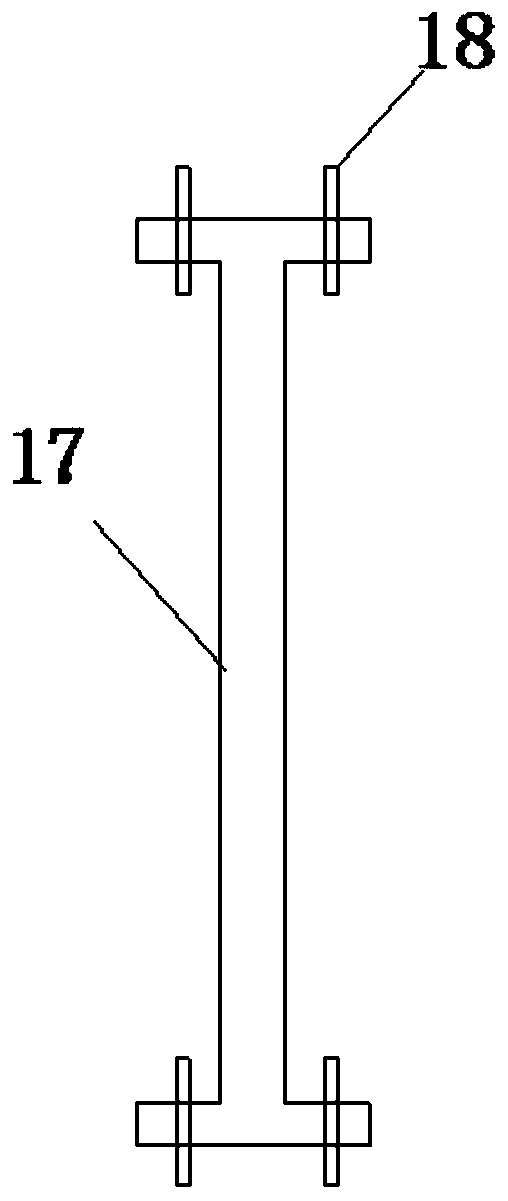

[0039] Such as Figure 1-5 As shown, this embodiment provides a UHPC prefabricated and assembled comprehensive pipe gallery flat curve connection section structure, the UHPC connection section mainly No. 1 side panel 1, No. 2 side panel 2, No. 3 side panel 3, and No. 4 side panel 4 , bottom plate 5, top plate 6, short dividing plate 17, entrance 7 and port 8~12 are formed, and top, base plate and each side plate are prefabricated according to required scheme in the factory, and short dividing plate 17 is on-the-spot setting.

[0040] Further, as figure 1 As shown, in this embodiment, the UHPC connection segment is connected to the prefabricated pipe gallery segment 15 through the inlet 7 and / or the ports 8-12.

[0041] Further, as figure 1 As shown, in this embodiment, the UHPC connection section reserves tension channels, and the prestressed tendons 14 are connected to the prefabricated pipe gallery section 15 through the top and bottom plate tension, which strengthens the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com