Patents

Literature

49results about How to "Easy to transport and hoist" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

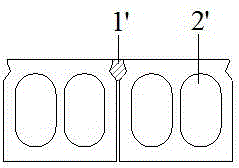

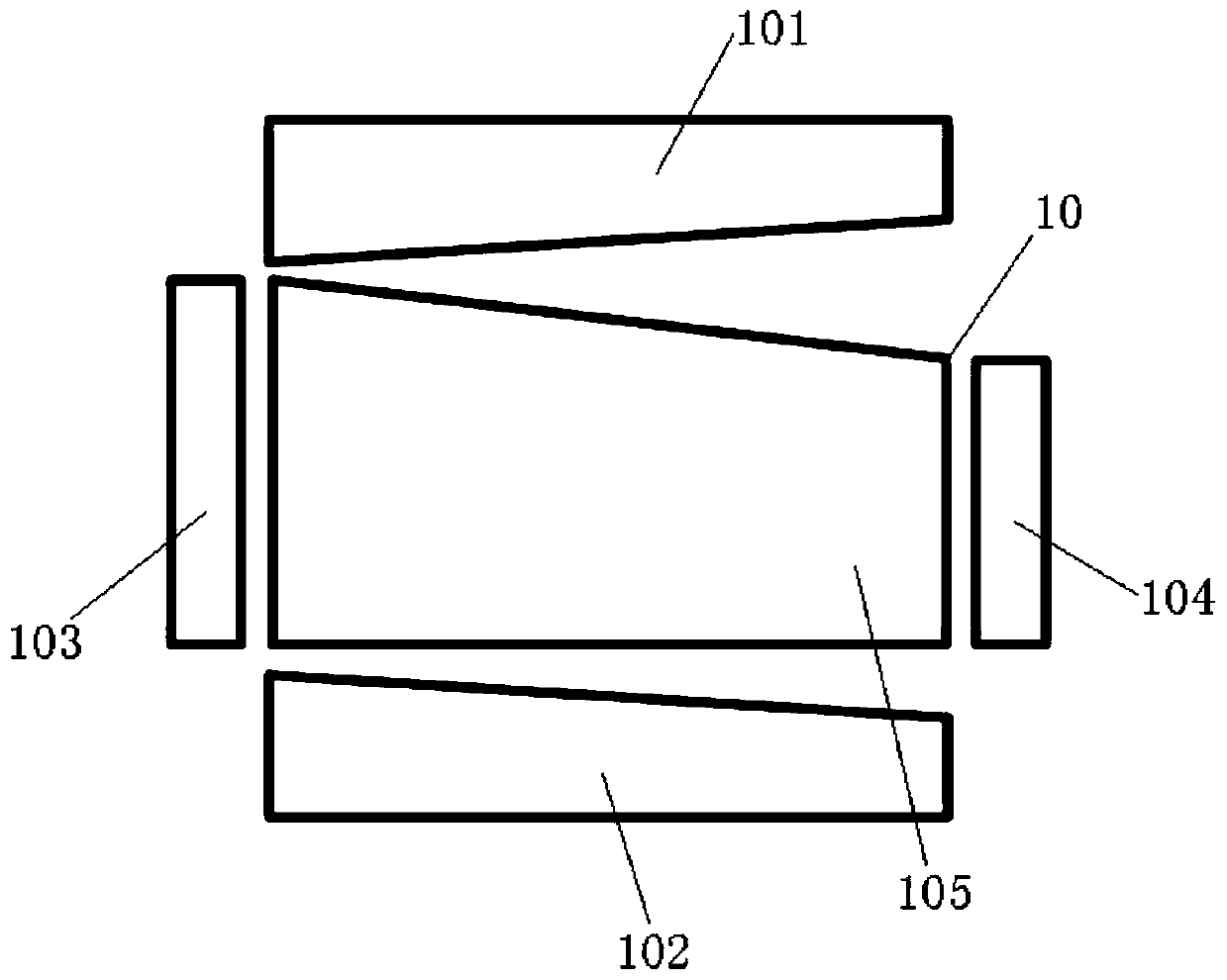

Hollow-wallboard mixed-prefabricated type comprehensive pipe rack and construction method thereof

InactiveCN106088147AEasy to transport and hoistLess patchworkArtificial islandsUnderwater structuresBaseboardArchitectural engineering

The invention discloses a hollow-wallboard mixed-prefabricated type comprehensive pipe rack and a construction method thereof. The hollow-wallboard mixed-prefabricated type comprehensive pipe rack is characterized in that two ends of a cast-in-place baseboard are respectively connected with lower portions of two double-sided prefabricated hollow-wallboard filling-core side walls, the middle portion of the cast-in-place baseboard is connected with the lower portion of a total-prefabricated middle partition, two ends of a overlapped roof are respectively connected with upper portions of the two double-sided prefabricated hollow-wallboard filling-core side walls, and the middle portion of the overlapped roof is connected with the upper portion of the total-prefabricated middle partition. Advantages of prefabrication and cast-in-place technologies are integrated, the hollow-wallboard mixed-prefabricated type comprehensive pipe rack can be disassembled reasonably, dead load of prefabricated components is lowered, the components can be integrally connected through cast-in-place grouting, and the problem about difficulty in prefabrication and assembly construction of multi-cabin pipe rack and pipe rack non-standard pieces can be solved.

Owner:中建五局第三建设有限公司 +1

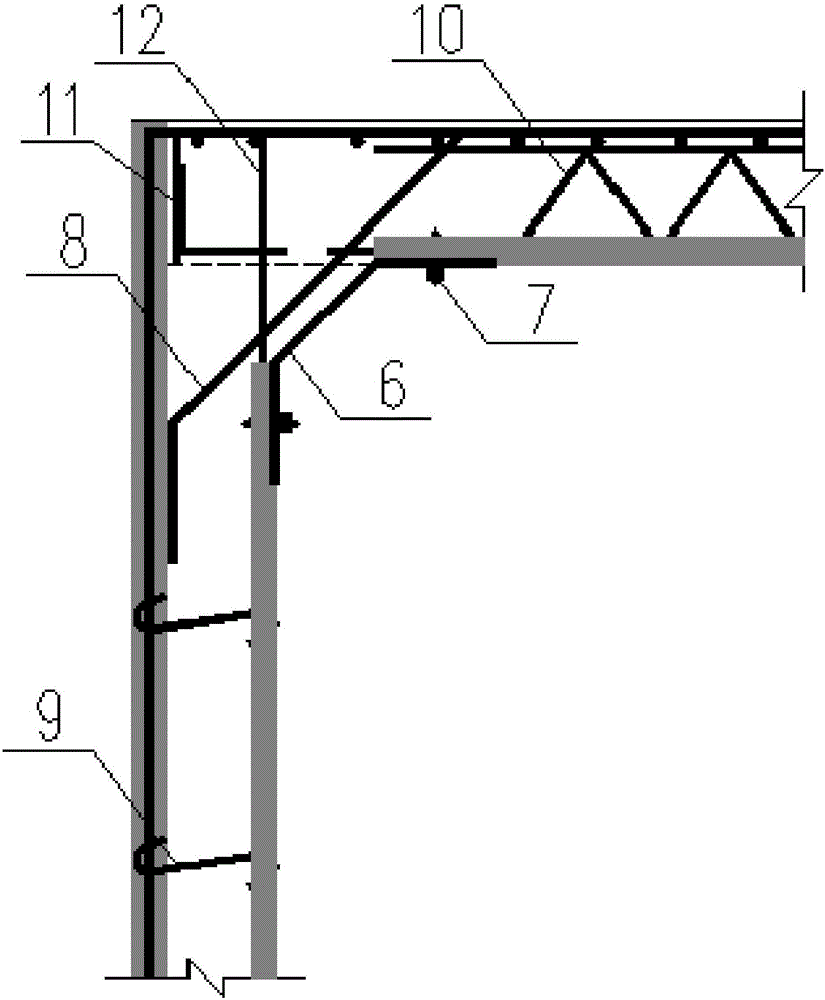

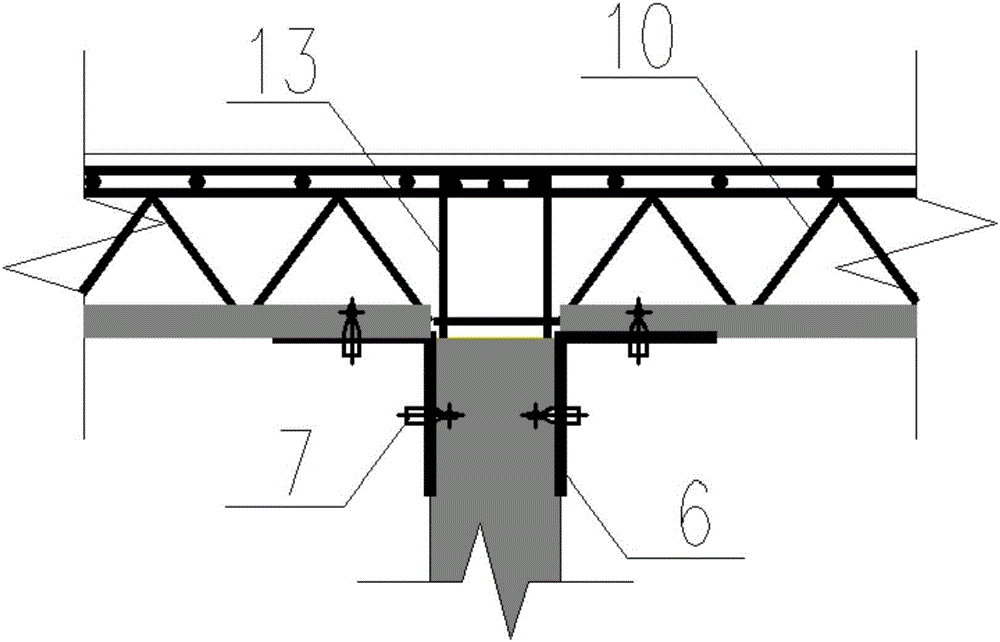

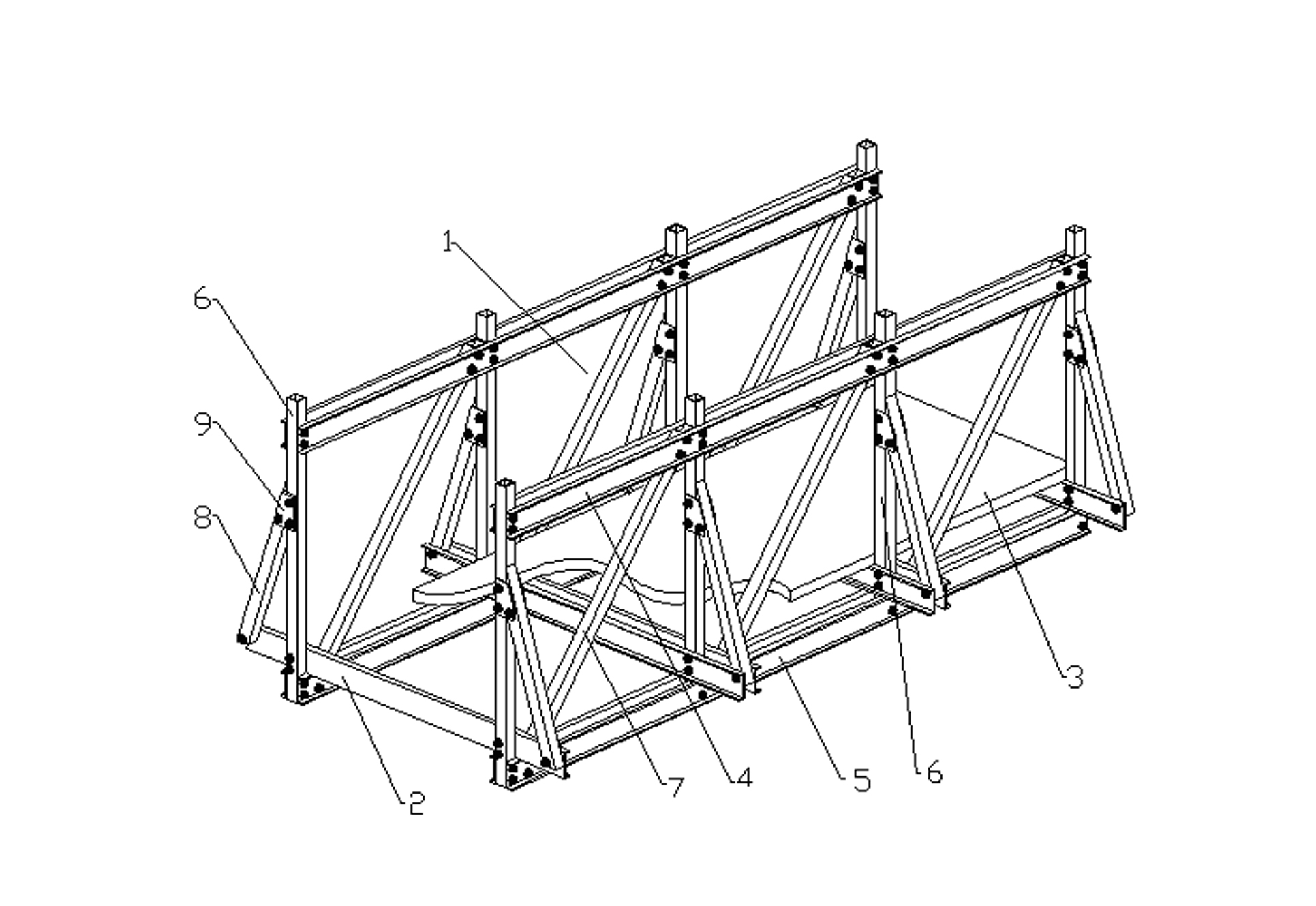

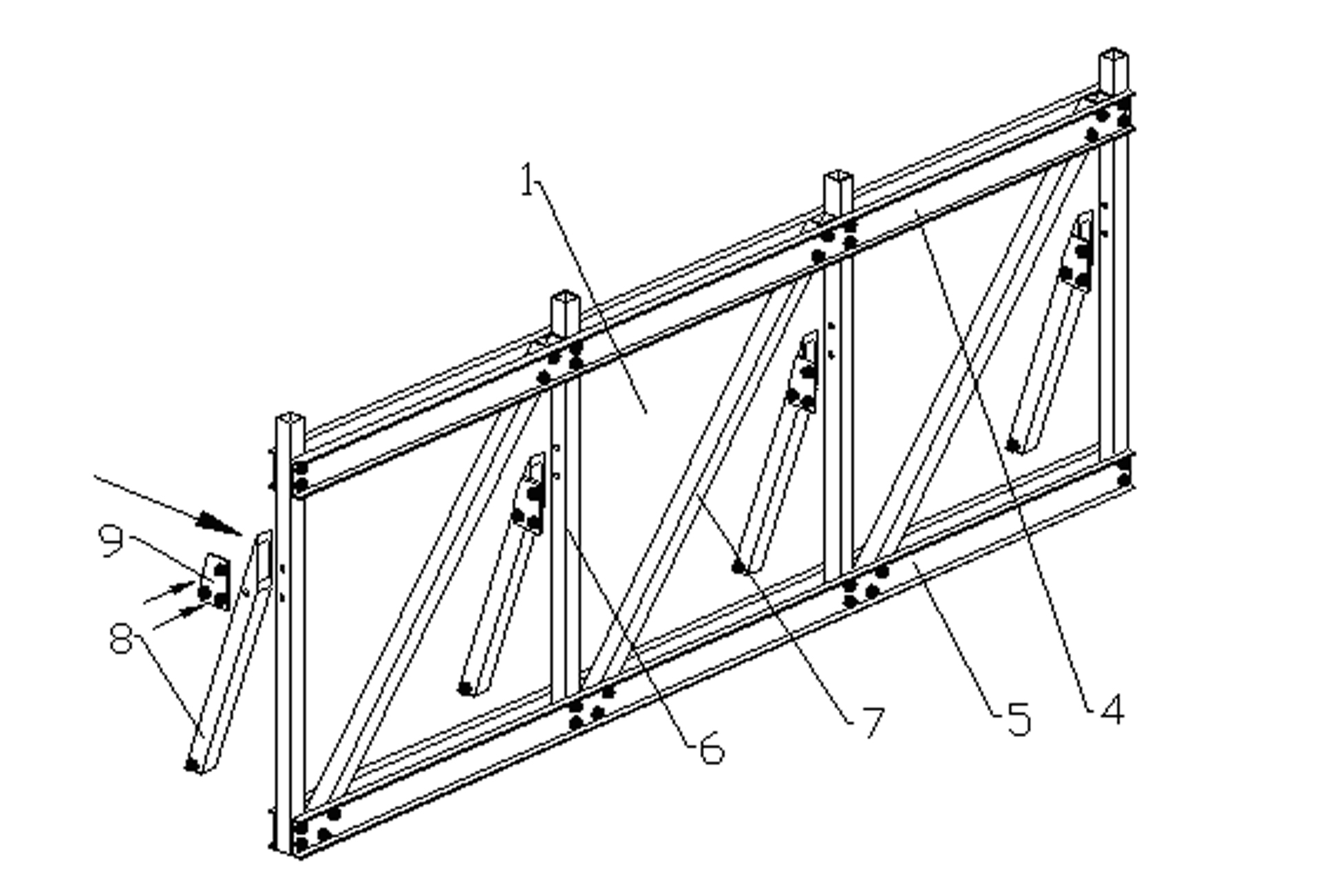

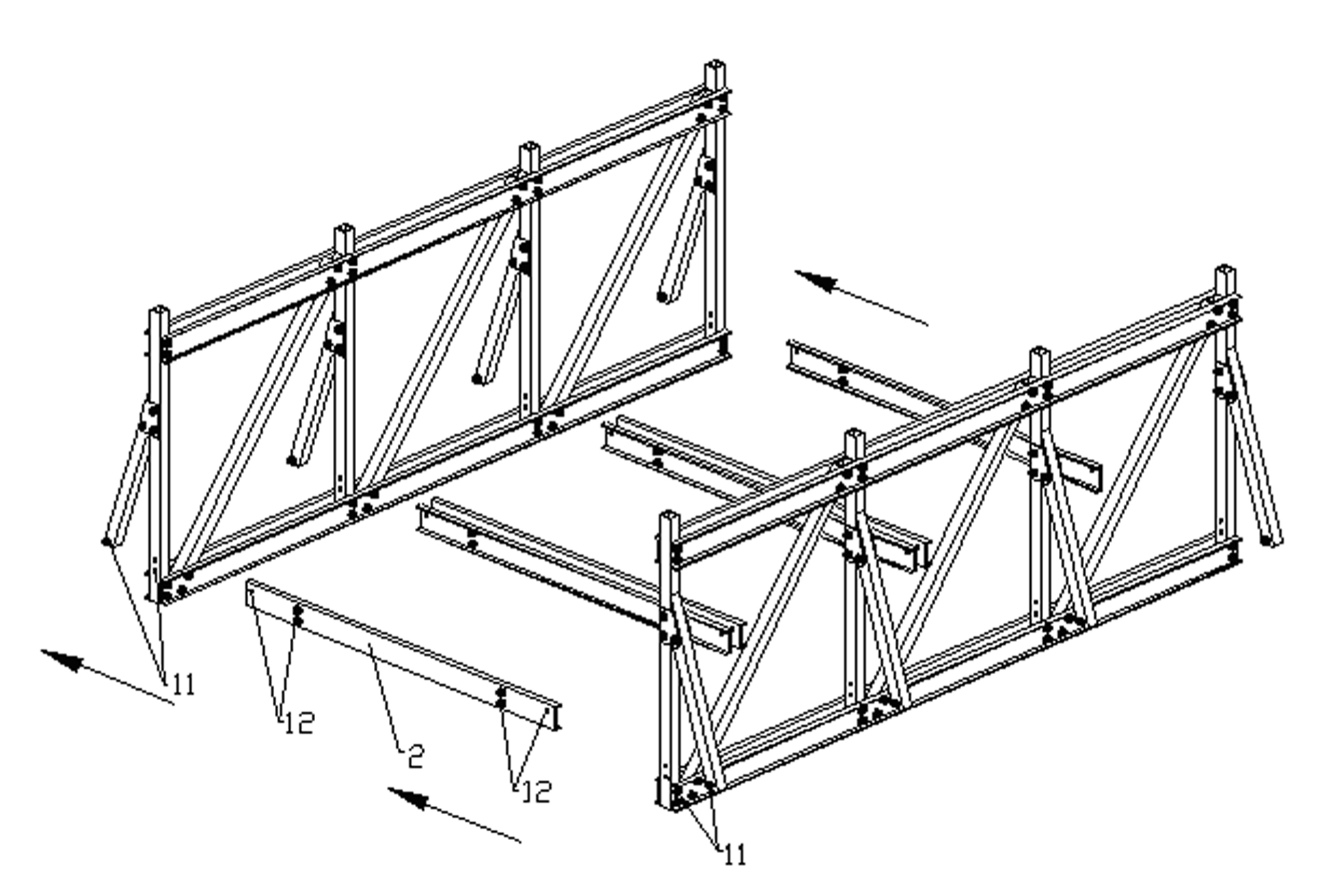

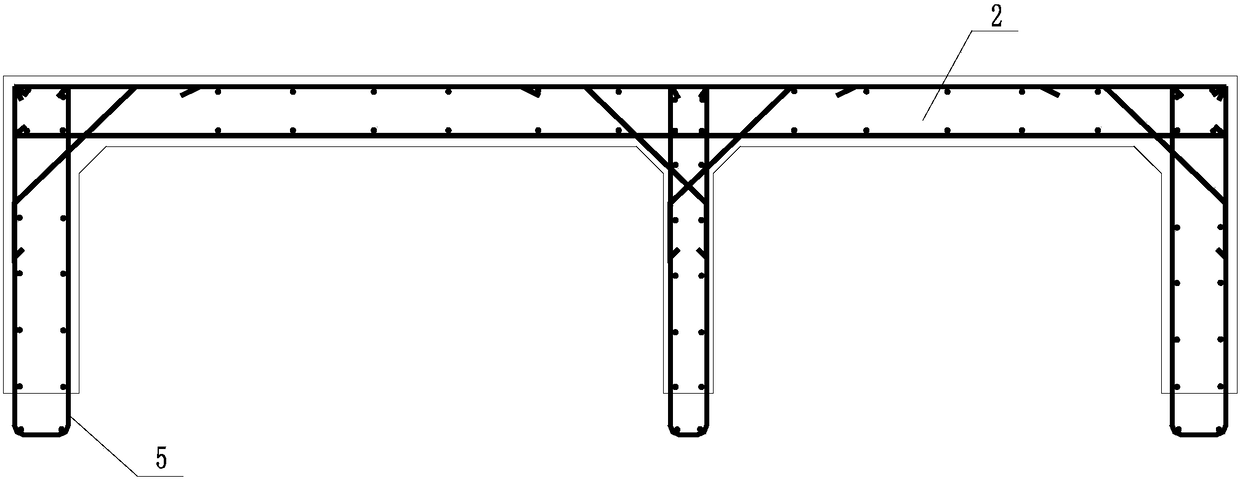

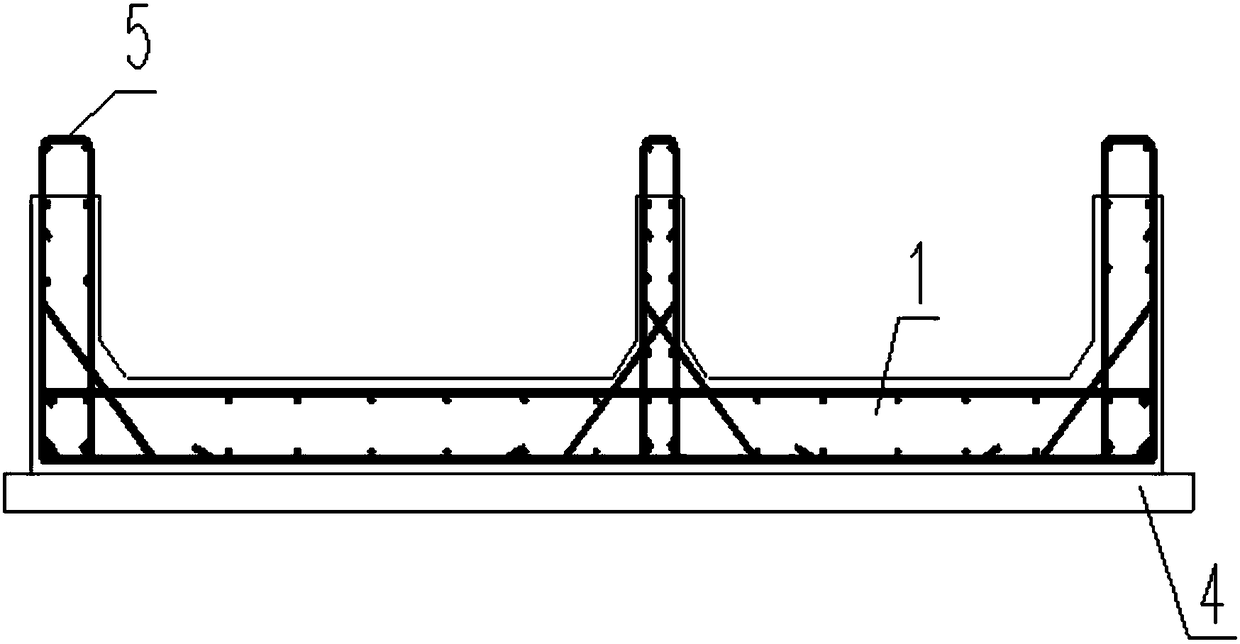

Quick-spliced sectional type composite material truss bridge

InactiveCN101967793AEliminate cracking, steel corrosion and other problemsLight in massTruss-type bridgeEmergency rescueBridge deck

The invention relates to a quick-spliced sectional type composite material truss bridge which comprises facade trusses (1), cross beams (2) and bridge decks (3), wherein each facade truss (1) is composed of an upper chord beam (4), a lower chord beam (5), vertical web girders (6) and inclined web girders (7); the upper chord beam (4) and the lower chord beam are arranged in parallel on the facade and respectively fixed with the upper and lower ends of each vertical web girder (6); each inclined web girder (7) is slantly arranged between every two adjacent vertical web girders (6), and the upper and lower ends of each inclined web girder (7) are respectively fixed with the upper chord beam (4) and the lower chord beam (5); both ends of each cross beam (2) are respectively fixed with two vertical web girders (6) parallel to the facade trusses (1) on the corresponding sides; and each bridge deck (3) is arranged on each cross beam (2) to constitute a truss bridge unit. The invention applies fiberglass reinforced plastics to the entire truss bridge and adopts flexible sectional type design, thus, the invention has the advantages of light weight, shock resistance, corrosion resistance, and convenient and quick transportation and assembly, and has wide application prospects in emergency rescue.

Owner:NANJING UNIV OF TECH

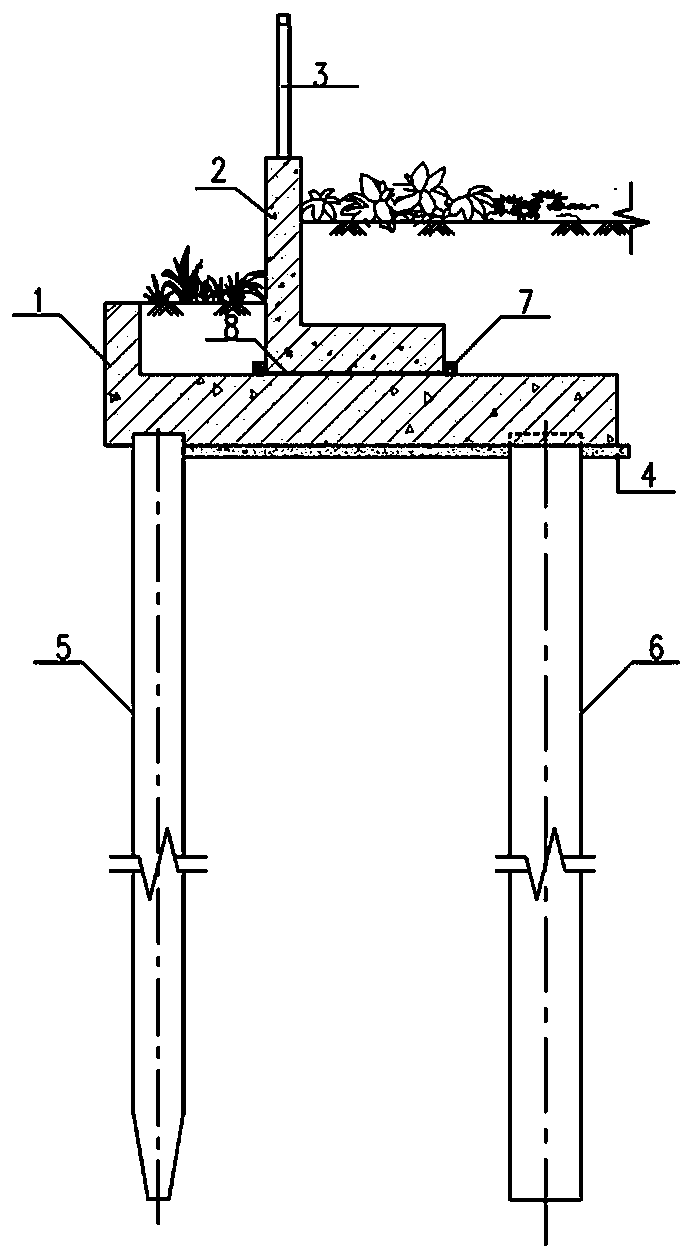

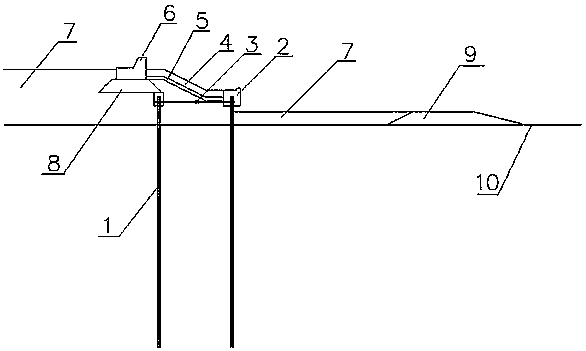

Construction method for mucky soft soil roadbase tubular pile

InactiveCN104894937ASolve widening and transformationComplete specificationsRoadwaysBulkheads/pilesPile capPre stress

The invention discloses a construction method for a mucky soft soil roadbase tubular pile. The construction method comprises the steps of preparatory work, construction for a roadbase soleplate, construction for a prestressed pipe pile, construction for a pile cap, construction for a cushion layer and the like. The construction method for the mucky soft soil roadbase tubular pile provides new thinking for governing differential settlement of a roadbase and solving bump at a bridge-head, freeway widening, etc. The problems of unmanageable construction quality of soft foundation at the bridge head in the soft foundation treatment and uneven settlement after being opening to traffic are solved.

Owner:成军

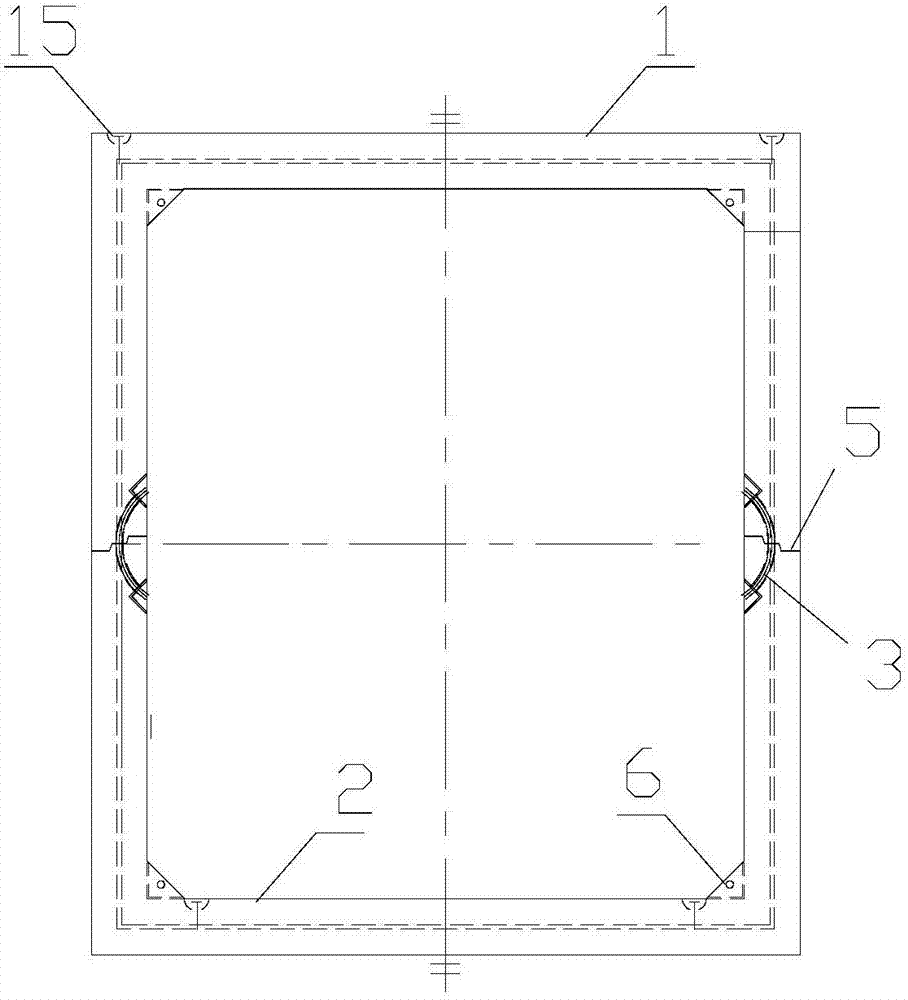

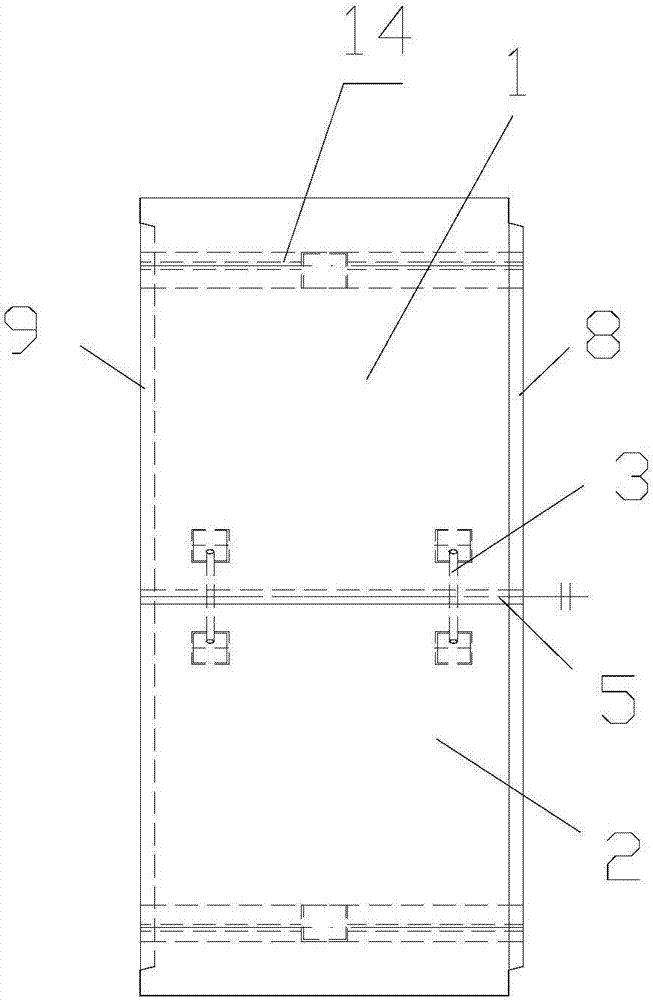

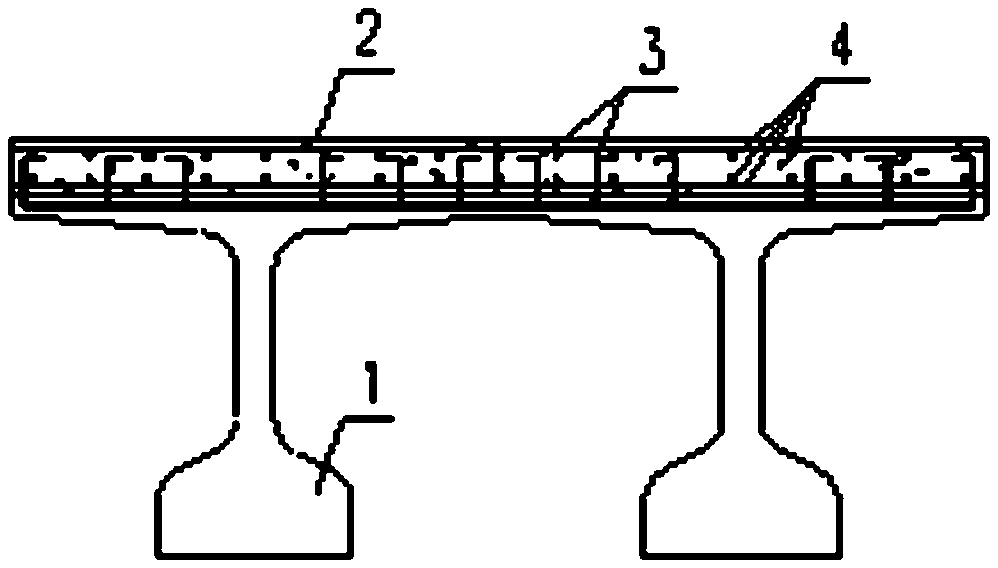

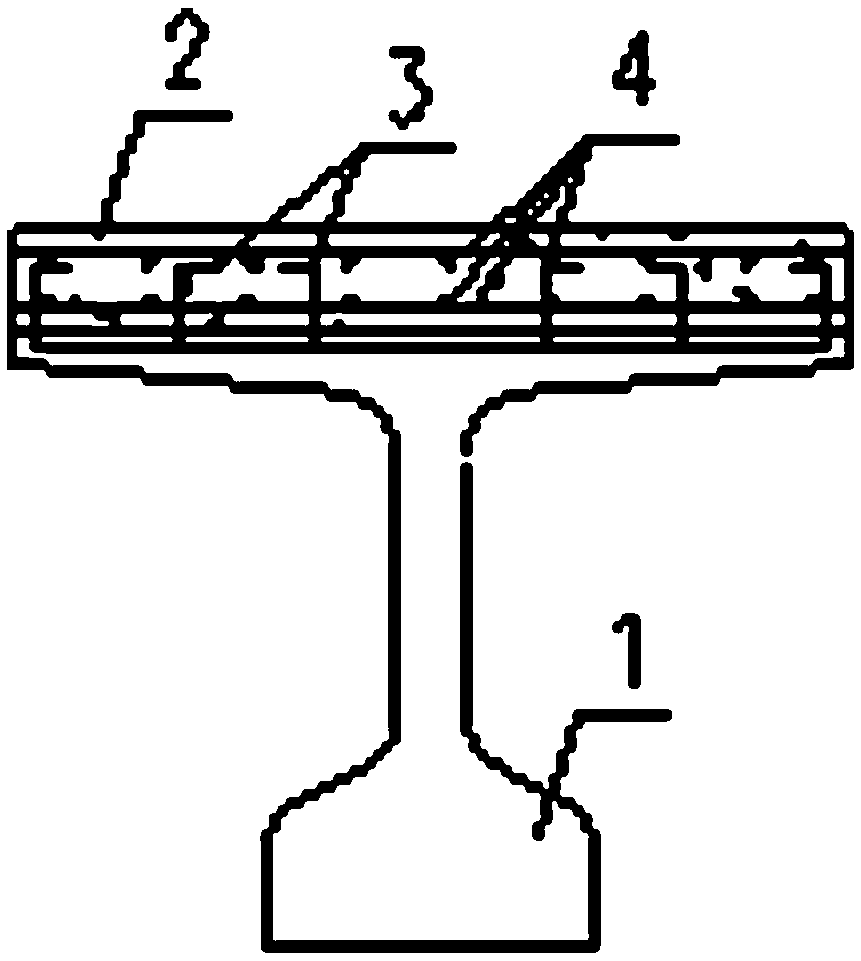

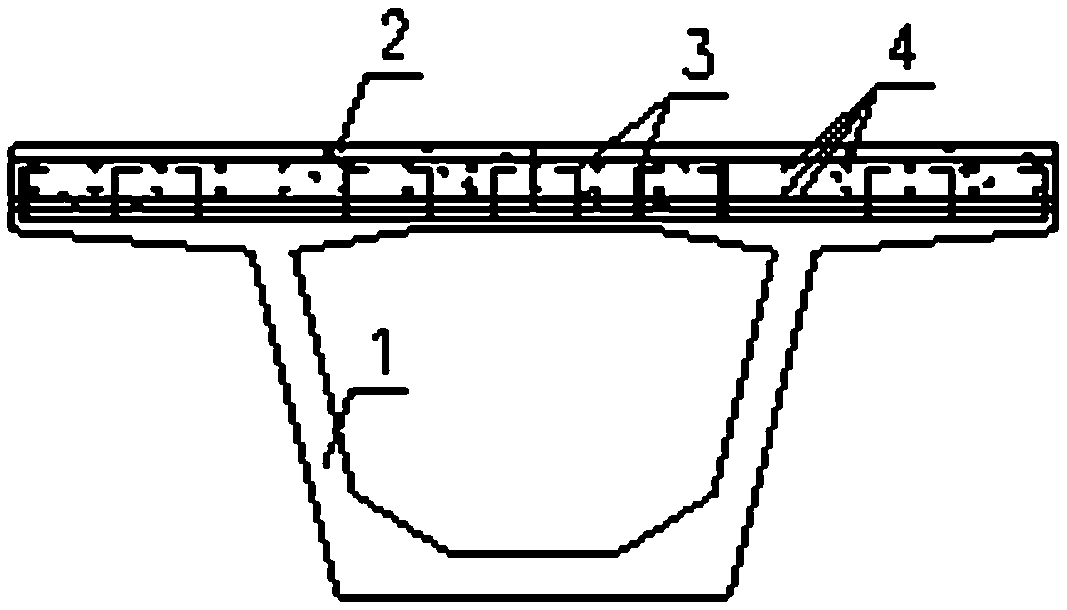

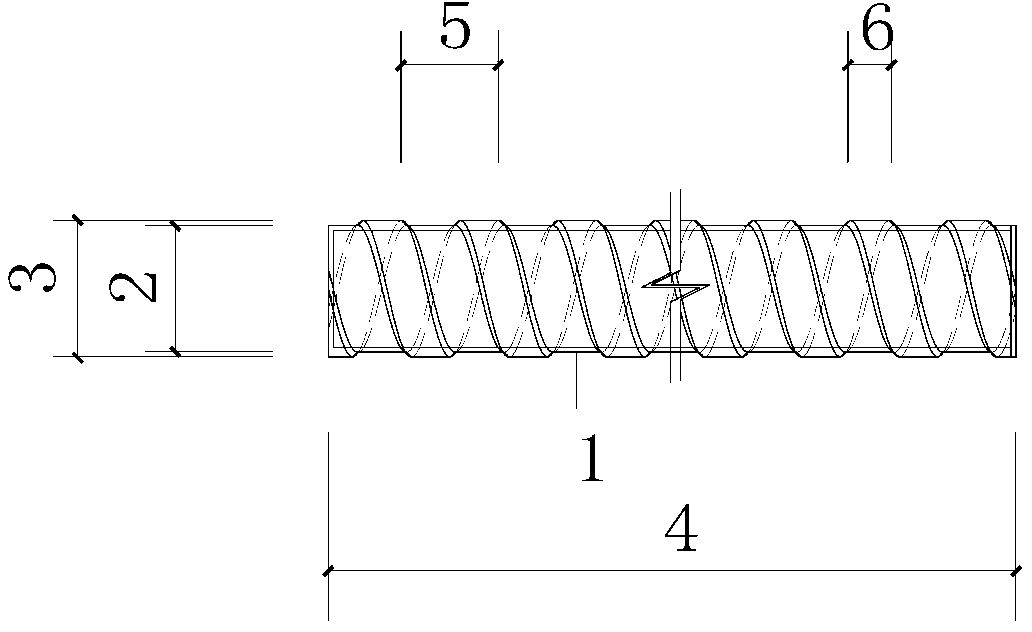

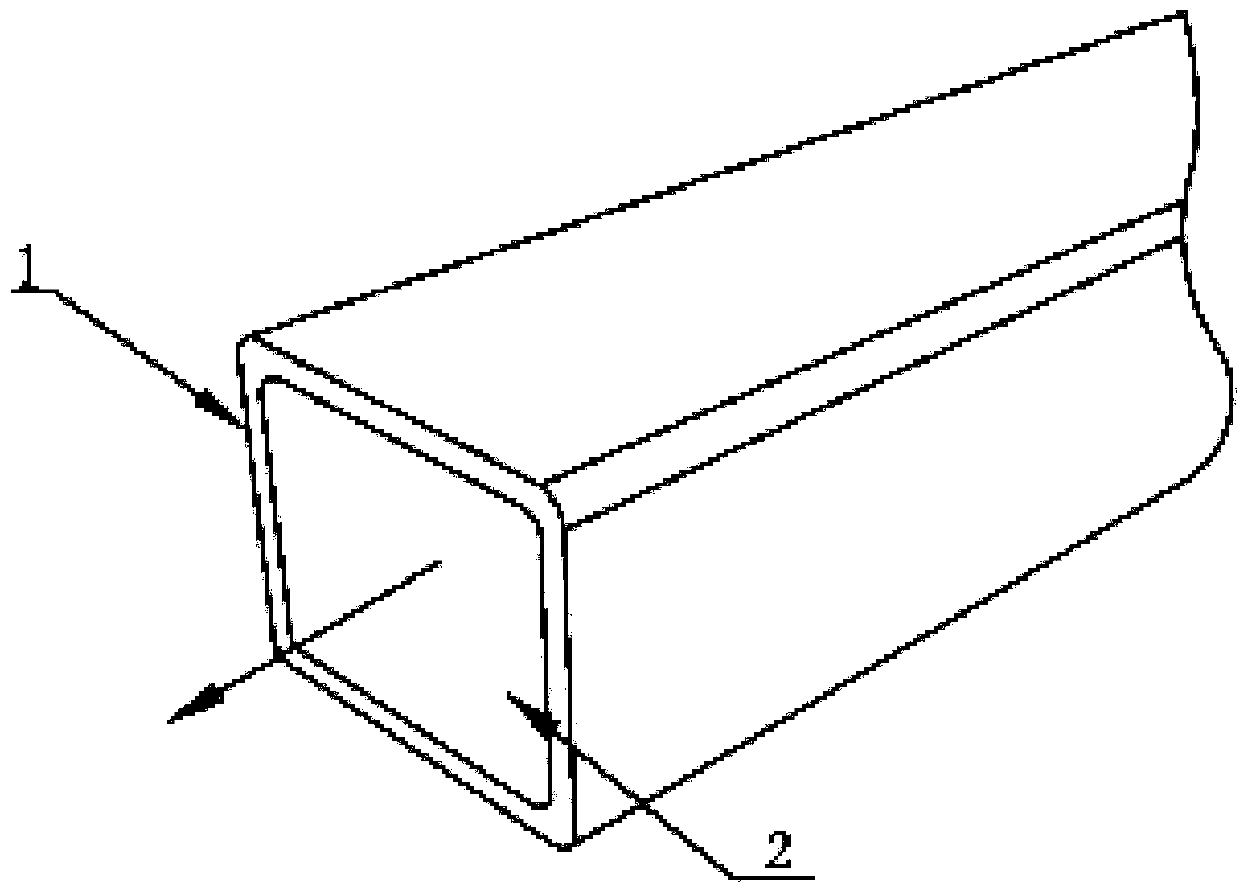

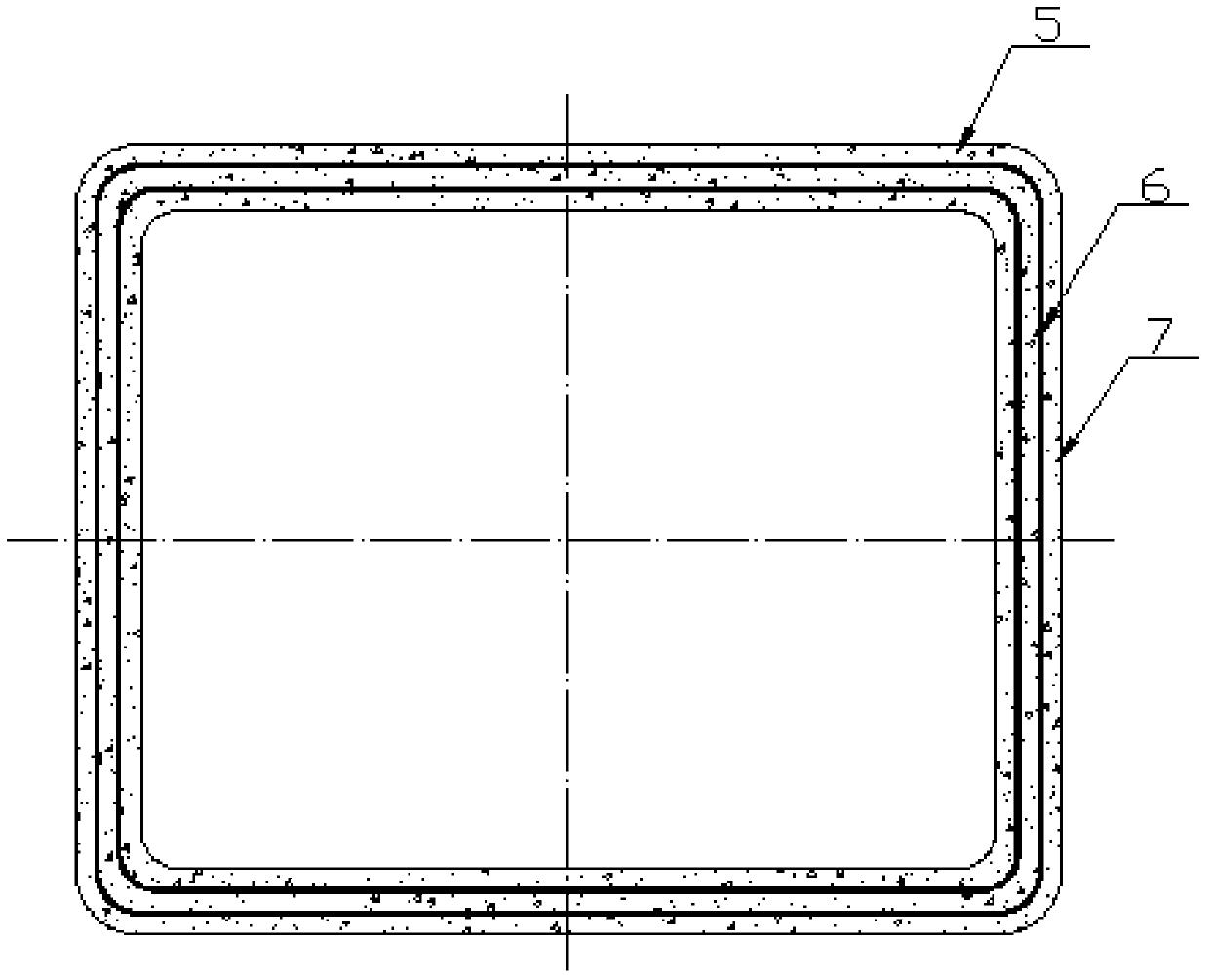

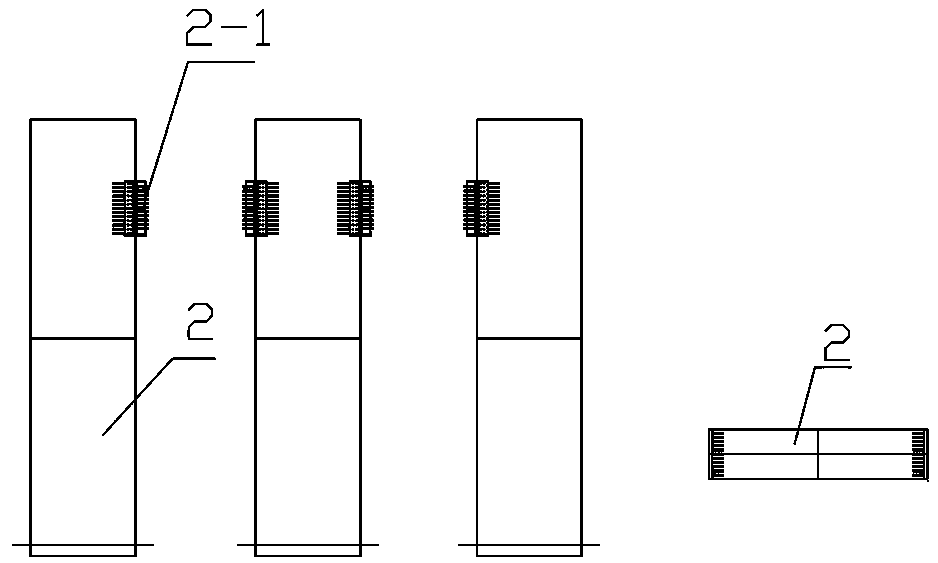

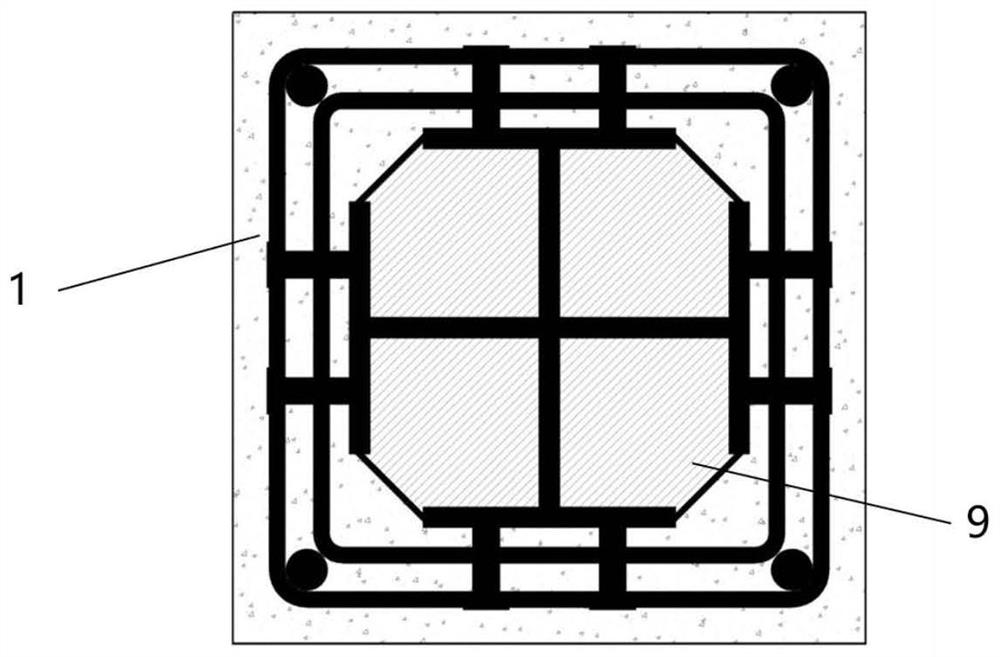

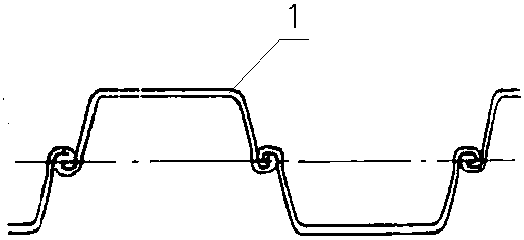

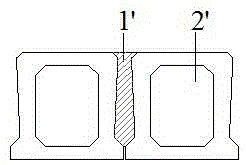

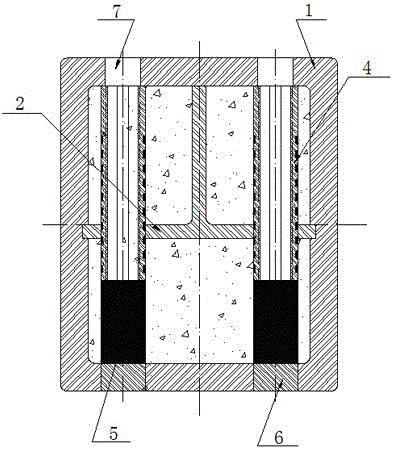

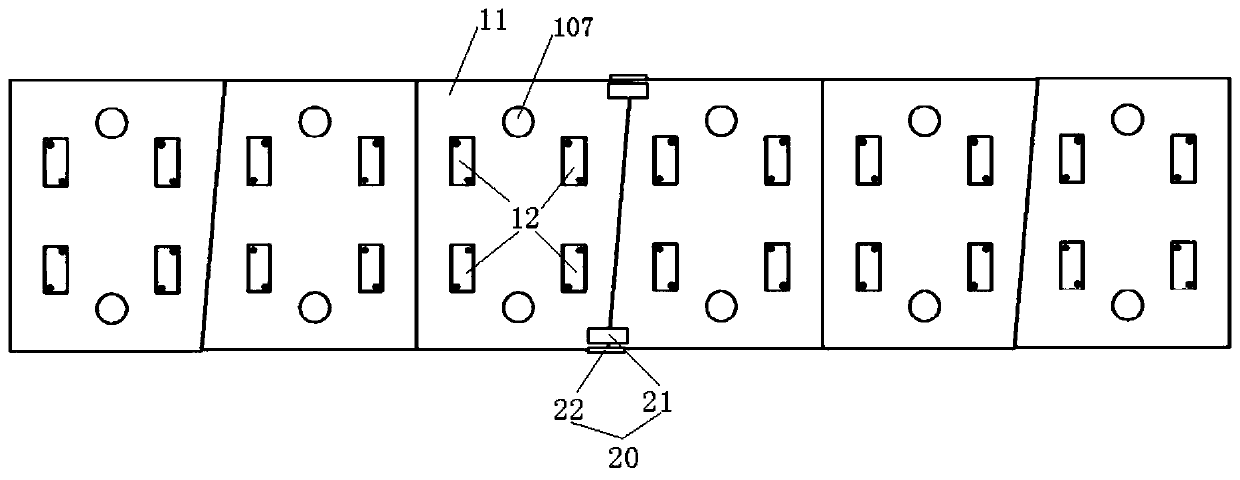

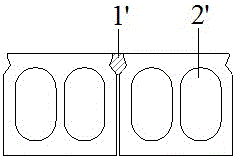

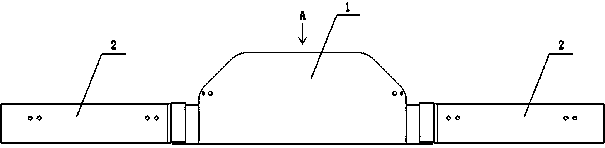

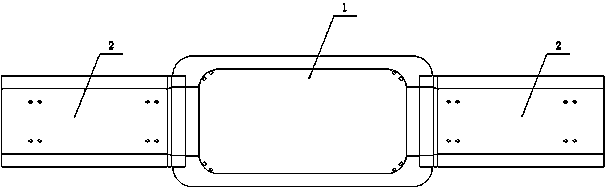

Split component prefabricated type comprehensive pipe gallery and construction method thereof

ActiveCN107059917ALow costEasy to transport and hoistArtificial islandsUnderwater structuresEngineeringPrefabrication

The invention discloses a split component prefabricated type comprehensive pipe gallery and a construction method thereof. The split component prefabricated type comprehensive pipe gallery is formed by connecting a plurality of prefabricated pipe gallery sections; each prefabricated pipe gallery section is split into an upper prefabricated pipe gallery section part (1) and a lower prefabricated pipe gallery section part (2), wherein the upper prefabricated pipe gallery section part (1) is connected with the lower prefabricated pipe gallery section part (2) through a first bell and spigot (5) in a meshed manner, and the upper prefabricated pipe gallery section part (1) and the lower prefabricated pipe gallery section part (2) are jointed with the first bell and spigot (5) through prestress wires (3); and sealing rods are arranged between the first bells and spigots (5) to form waterproof layers. The split component prefabricated type comprehensive pipe gallery integrates advantages of a full prefabricated pipe gallery and a stacked pipe gallery; through reasonable splitting, dead loads of prefabricated components are reduced, the problem that the process of the stacked pipe gallery is complex is solved through prefabrication, and the problems about prefabrication of a multi-cabin pipe gallery and pipe gallery non-standard sections can be solved.

Owner:中建五局第三建设有限公司 +1

Ultra-high performance concrete and ordinary reinforcement concrete combined beam

PendingCN108118610AReduce the height of the structureLight weight structureBridge structural detailsBridge materialsReinforced concreteRebar

The invention relates to the technical field of structure design, and particularly relates to an ultra-high performance concrete and ordinary reinforcement concrete combined beam. The ultra-high performance concrete and ordinary reinforcement concrete combined beam comprises a UHPC prefabricated main beam and a post-cast ordinary reinforced concrete bridge panel; the ultra-high performance concrete and ordinary reinforcement concrete combined beam is characterized in that the UHPC main beam is prefabricated in early period, and the top part of the UHPC main beam is provided with a hear force connector in advance; the UHPC main beam is erected in place and then used as a construction platform; the top edge of the UHPC main beam is provided with a reinforcement mesh piece post-cast ordinaryconcrete; through combination of the shear force connector at the top of the UHPC prefabricated beam, the combined beam is formed. The combined beam is light in member, simple in transportation and hoisting, convenient to construct, good in economic efficiency, and able to fully display the material stress performance.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

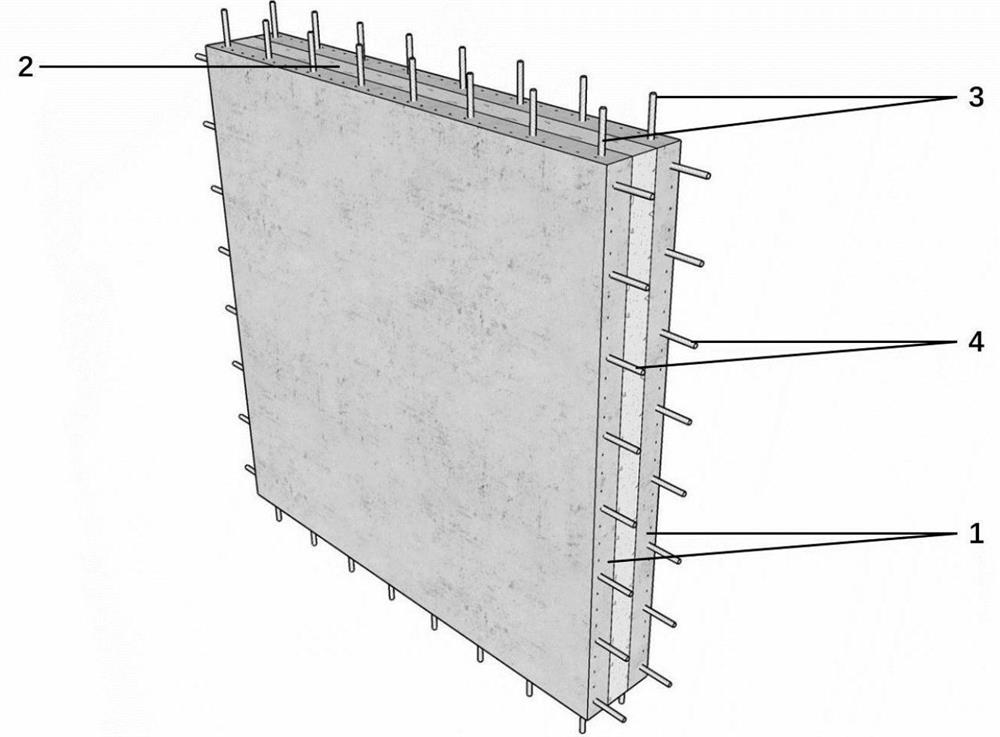

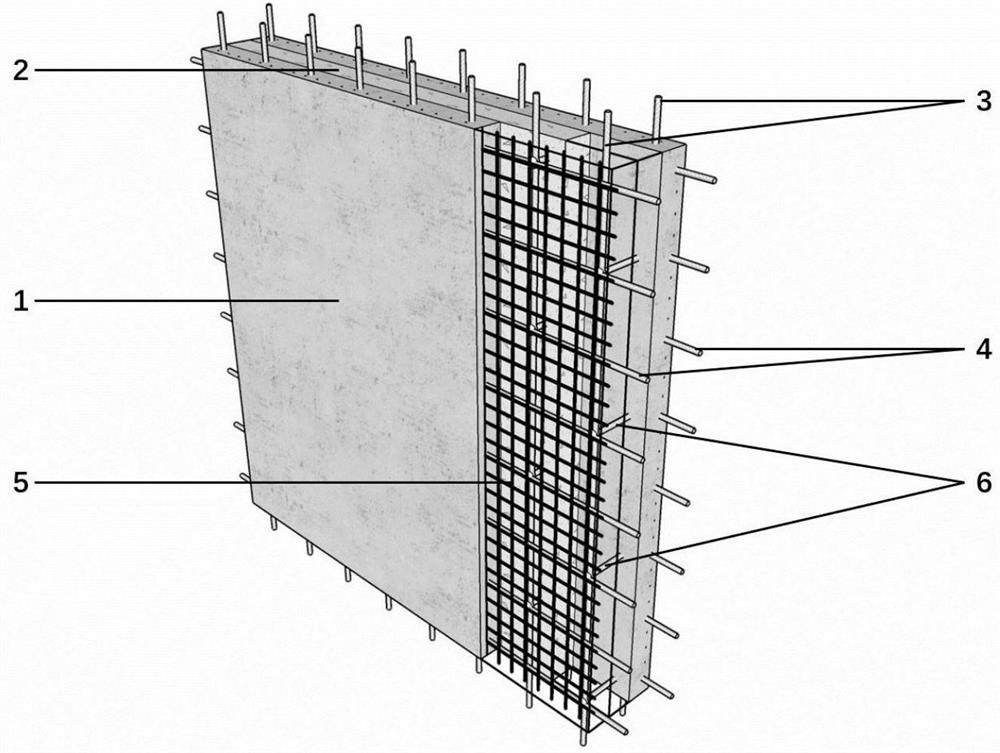

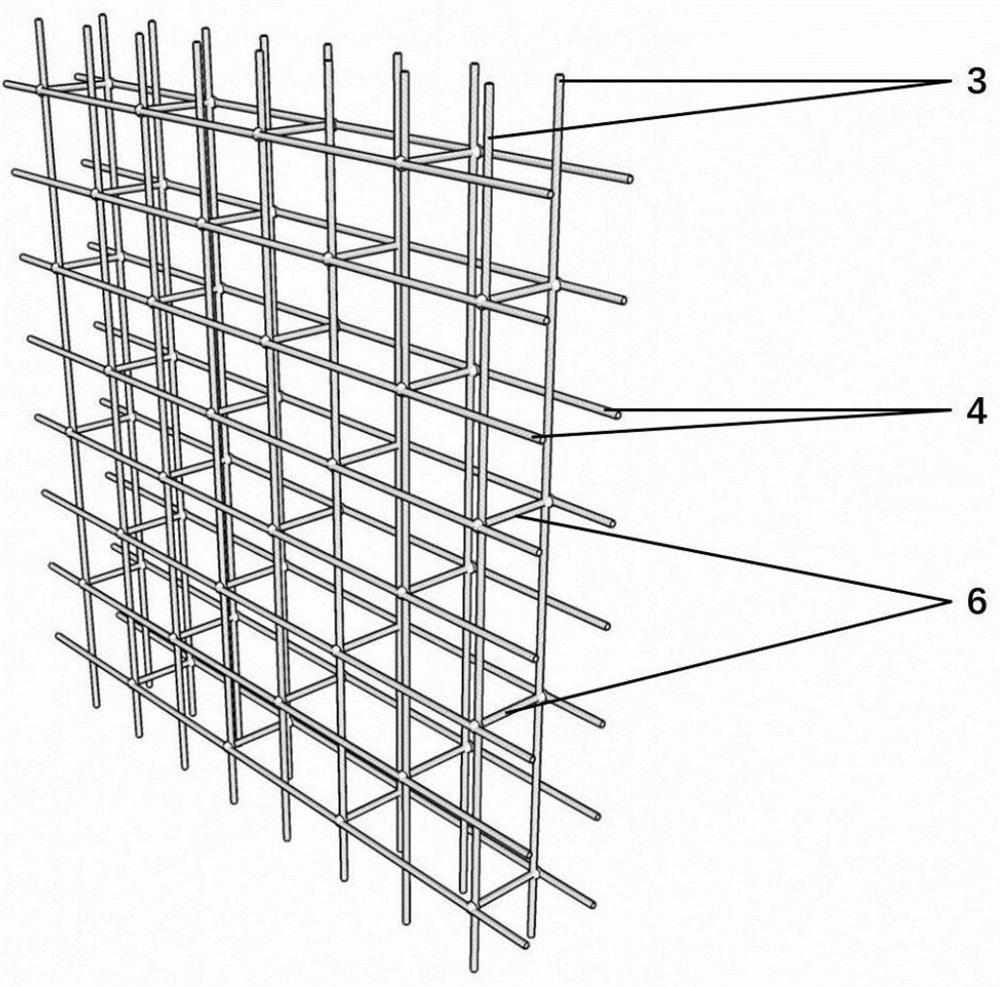

Method and mold for molding precast concrete hollow wall component for concrete-filled laminating

The invention relates to a method and a mold for molding a precast concrete hollow wall component for concrete-filled laminating and belongs to buildings. According to the method, a screw rod mold is placed into a precast concrete hollow wall, and the screw rod mold is screwed out before concretes are subjected to permanent set, so that hollow holes are formed in the precast concrete hollow wall, and shear slip resisting keyslots are formed on the inner walls of the holes, therefore the precast concrete hollow wall component can enable new and old concretes to be combined into a whole after being subjected to concrete cast-in-place laminating during a prefabricated concrete structure engineering; and the mold is used in a process of forming the hollow holes with the shear slip resisting keyslots in the concretes and can be used for manually or mechanically screwing out screw caps conveniently. The mold has the advantages of light weight and convenience in transportation and hoisting, and can be used for obviously improving the construction quality and work efficiency of prefabricated concrete structure buildings and lowering the building construction cost.

Owner:广东新广厦建筑设计院有限公司

Railway sleeper made of composite materials and manufacturing method thereof

The invention discloses a railway sleeper made of composite materials and a manufacturing method of the railway sleeper. The railway sleeper comprises a basic section bar extending in the longitudinal direction. The basic section bar is provided with a cavity passing through the basic section bar in the longitudinal direction. The basic section bar is made of a fiber-reinforced resin matrix composite material. The fiber-reinforced resin matrix composite material comprises resin and a fiber-reinforced material. The fiber-reinforced material comprises fiber felt and a plurality of pieces of fiber yarn. The fiber felt is laid around the cavity in the basic section bar. The fiber yarn pieces are distributed nearby the fiber felt in the longitudinal direction. Moreover, the fiber felt is laid into a unit in the basic section bar or a plurality of units arranged in sequence from the inner layer to the outer layer of the basic section bar. Each unit of the fiber felt comprises a plurality of pieces of fiber felt which are laid around the cavity.

Owner:NANTONG CIMC ECO NEW MATERIAL DEV CO LTD

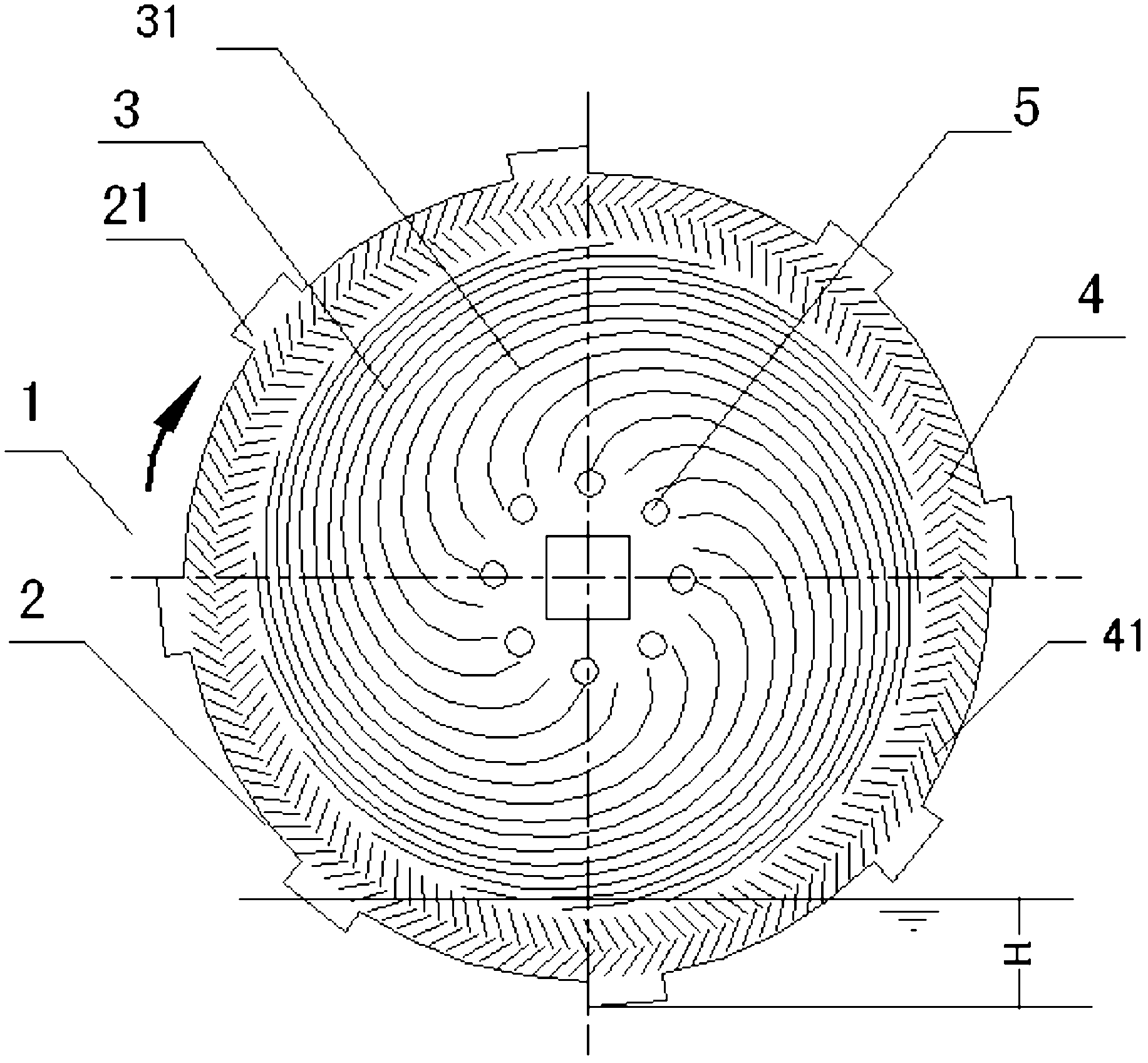

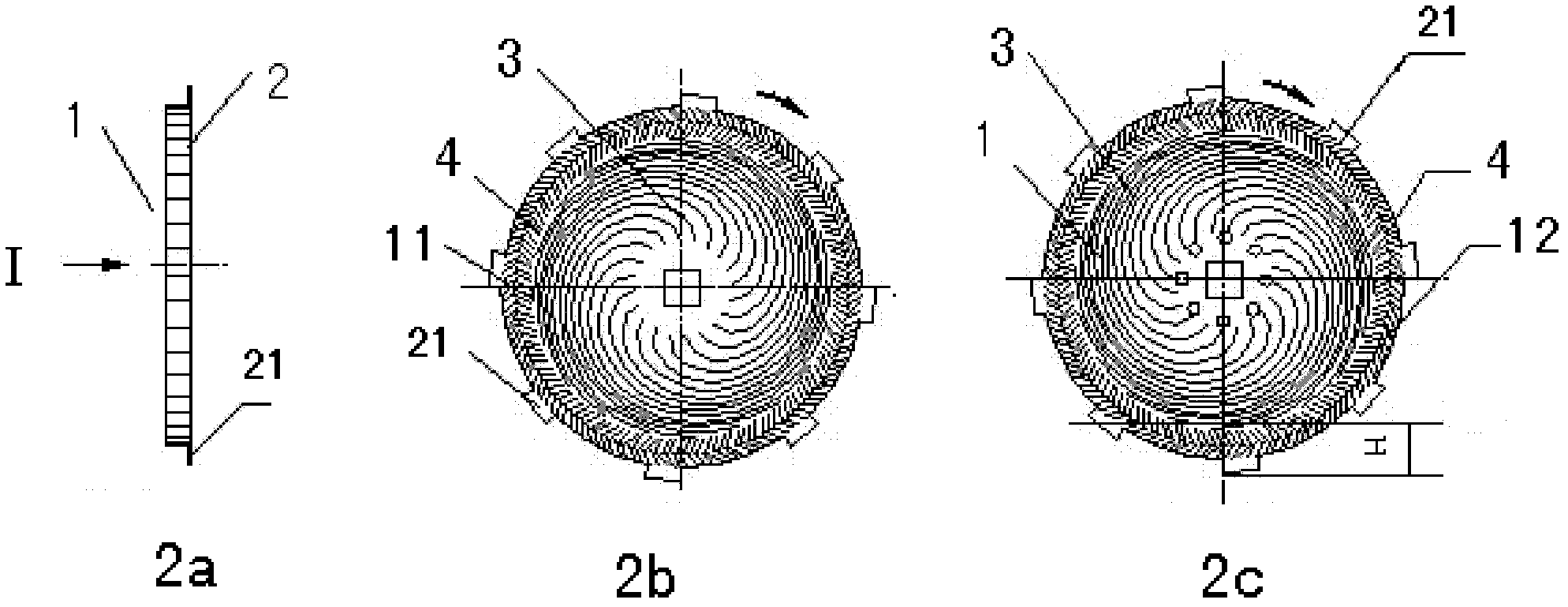

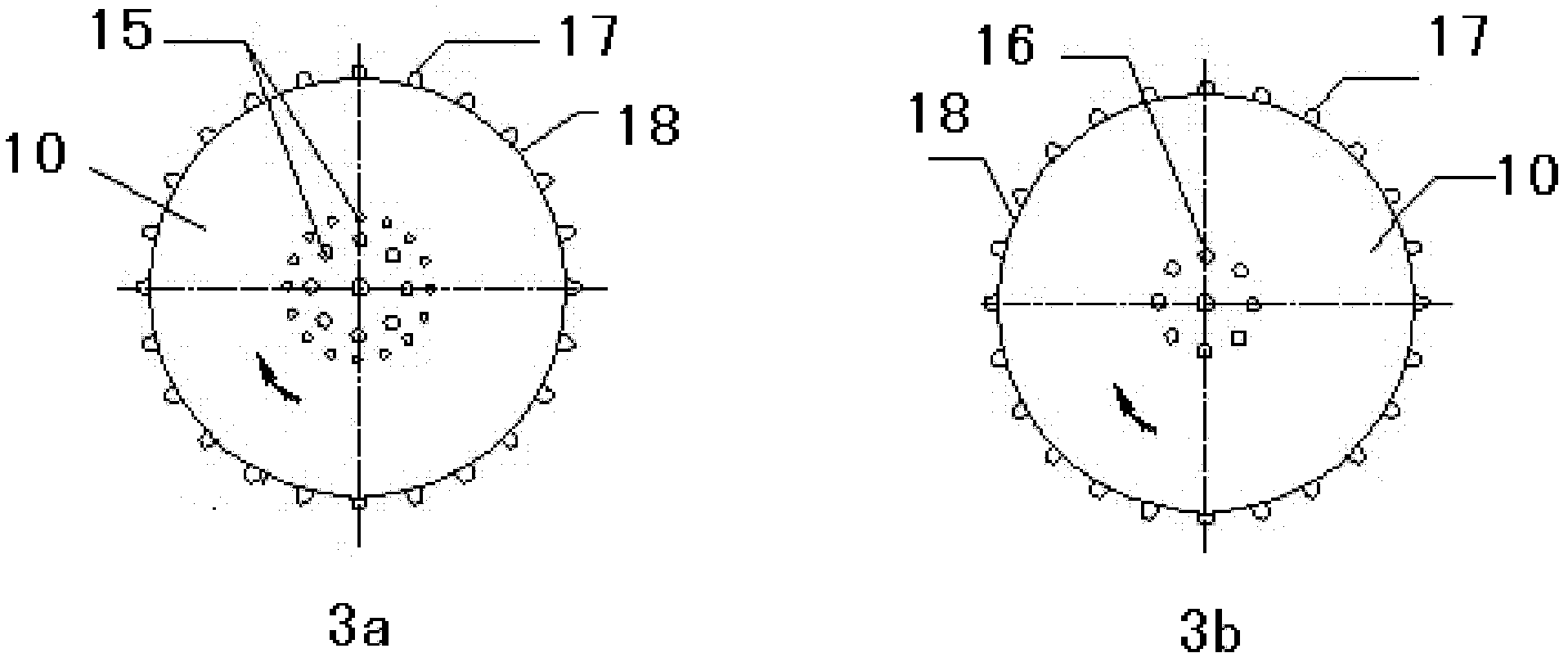

Biological disk, biological revolving drum and integrated revolving drum type domestic sewage treater

ActiveCN102633355AAvoid cloggingLifting special structuresTreatment using aerobic processesMultistage water/sewage treatmentWater flowSewage

The invention provides a biological disk, a biological revolving drum and an integrated revolving drum type domestic sewage treater. The biological disk comprises a circular support disk and blades fixed on the support disk; the blades are vertical to the support disk; an axial hole is formed in the centre of the support disk; the blades comprise lifting blades which are in a plurality of spiral structures in the same direction starting from the axial centre of the support disk; and the distance between every two spiral structures at the position close to a circle centre is more than that at the position far away from the circle centre. According to the invention, because the biological disk is provided with the lifting blades and aeration blades, the area of a turntable is greatly increased; furthermore, in the event of passing through the biological revolving drum disclosed by the invention, the water flow must flow through each disk; therefore, the superficial area contacted with sewage is greatly increased; the sewage treatment capability is greatly increased; the integrated revolving drum type domestic sewage treater is convenient for maintenance and low in intensity; and main body equipment is rustless and corrosion resistant.

Owner:苏州克莱茵环境发展有限公司

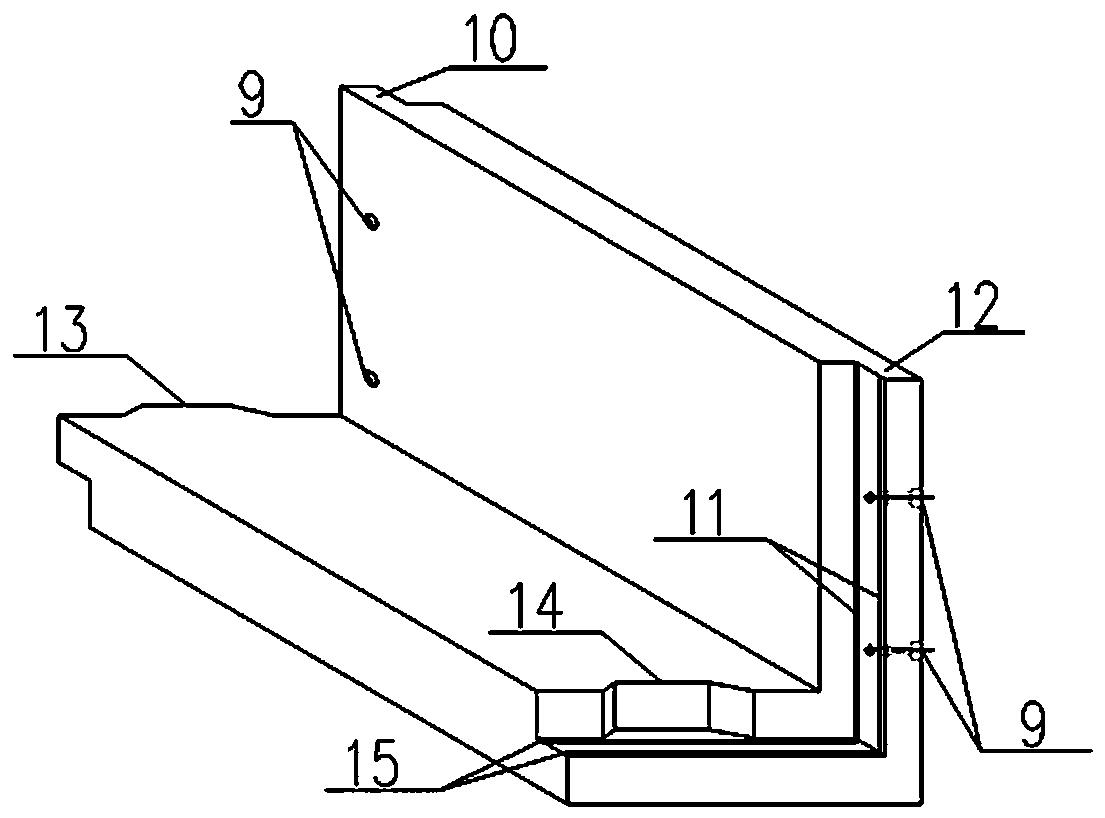

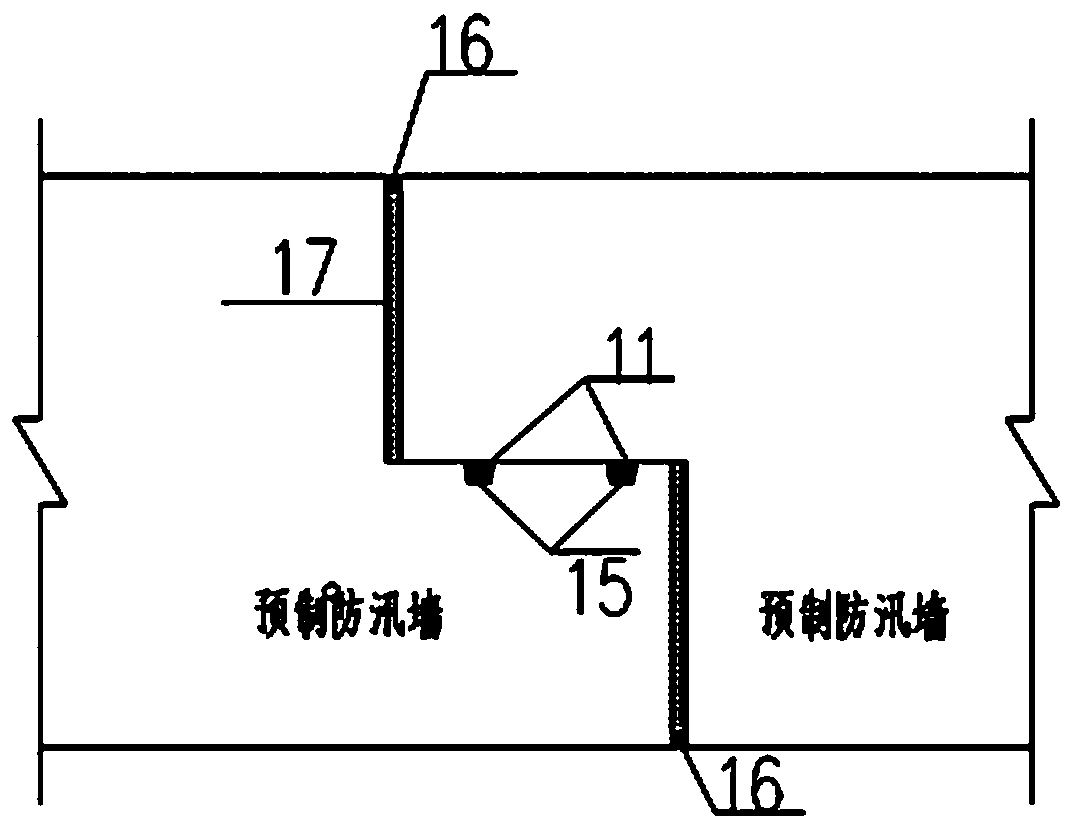

Combined revetment combined with near-term plan and long-term plan

PendingCN109322277ASmall footprintEasy to transport and hoistBreakwatersQuaysSealantSingle component

The invention discloses a combined revetment combined with a near-term plan and a long-term plan. The combined revetment comprises a primary revetment body and a prefabricated secondary L-shaped revetment body, the prefabricated secondary L-shaped revetment body is formed by splicing a plurality of concrete prefabricated revetment sections, the two ends of the concrete prefabricated revetment sections are correspondingly provided with connecting convex teeth and connecting concave teeth which cooperate with each other, every two adjacent concrete prefabricated revetment sections of the prefabricated secondary L-shaped revetment body are connected through the corresponding connecting convex tooth and connecting concave tooth, the connecting convex teeth and the connecting concave teeth areconnected through bolts, rubber water stopping grooves are formed between the connecting convex teeth and the connecting concave teeth, water swelling rubber strips are arranged in groove openings, the joints between the connecting convex teeth and the connecting concave teeth are filled with low-foaming polyethylene plates, and single-component polyurethane sealants are adopted for sealing on theperipheral surfaces of deformation joints. The combined revetment can be implemented according to a planned watercourse blue line in the later period, or when the hydrophilicity requirement for a landscape needs to be improved, the secondary revetment body can be disassembled and reused, so that waste engineering is reduced, the construction difficulty is reduced, and the influence of construction on the surrounding environment is reduced.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

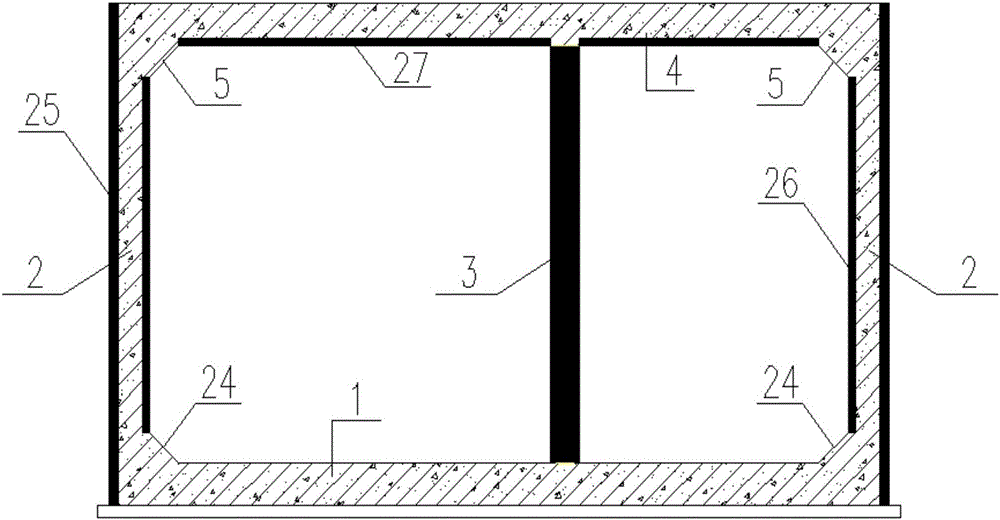

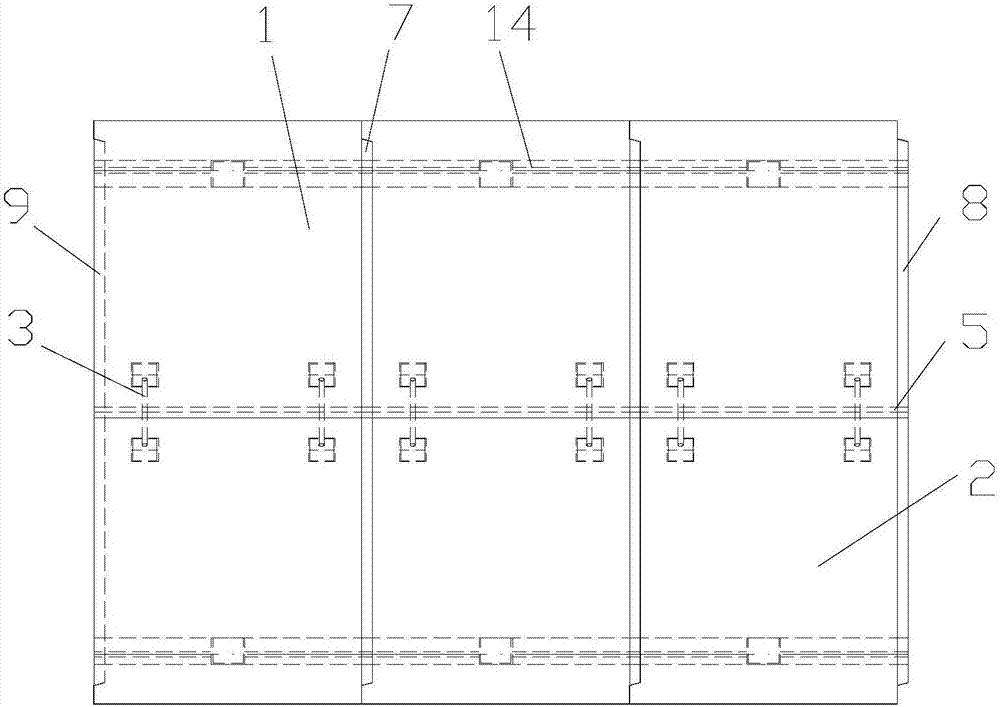

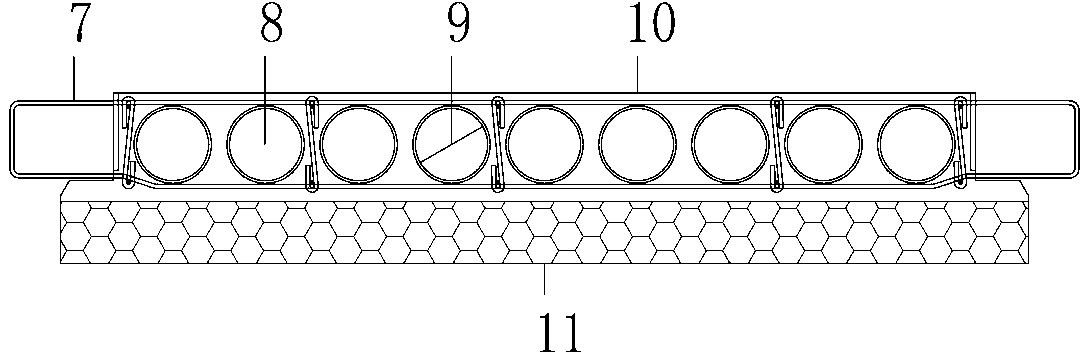

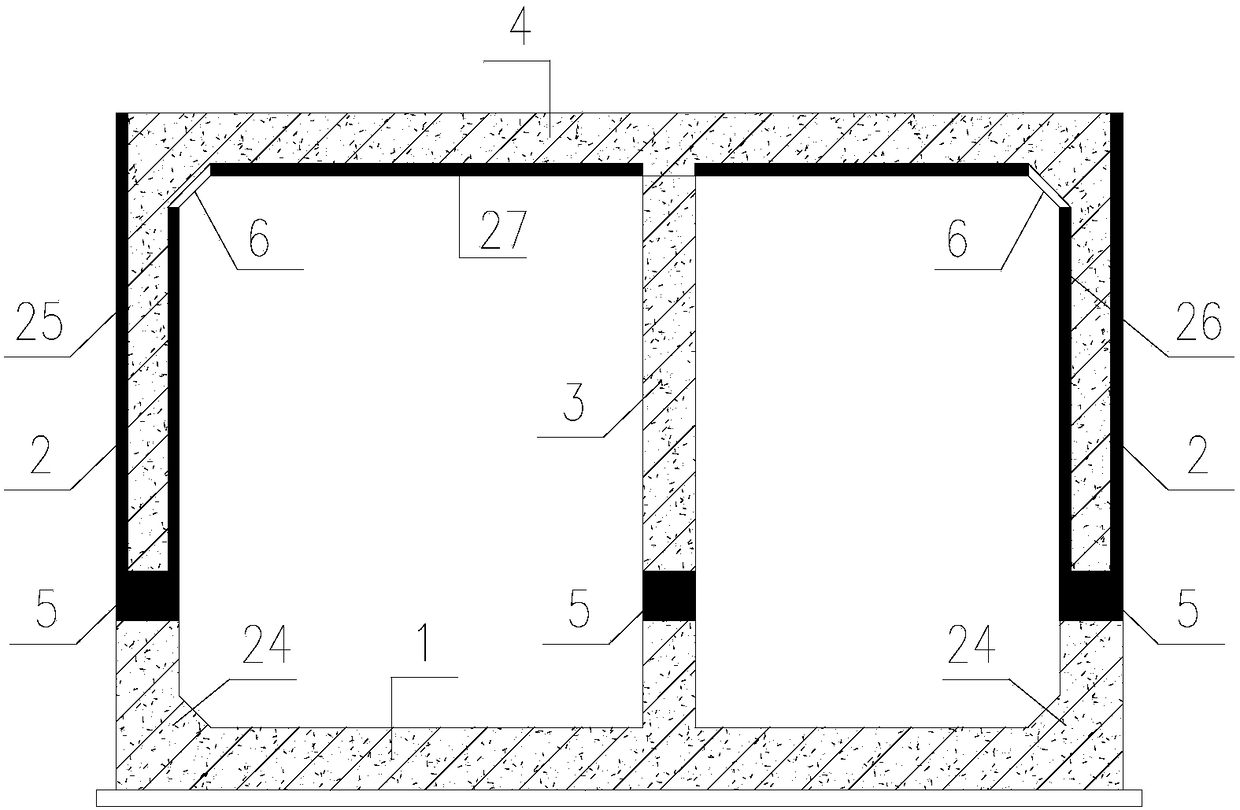

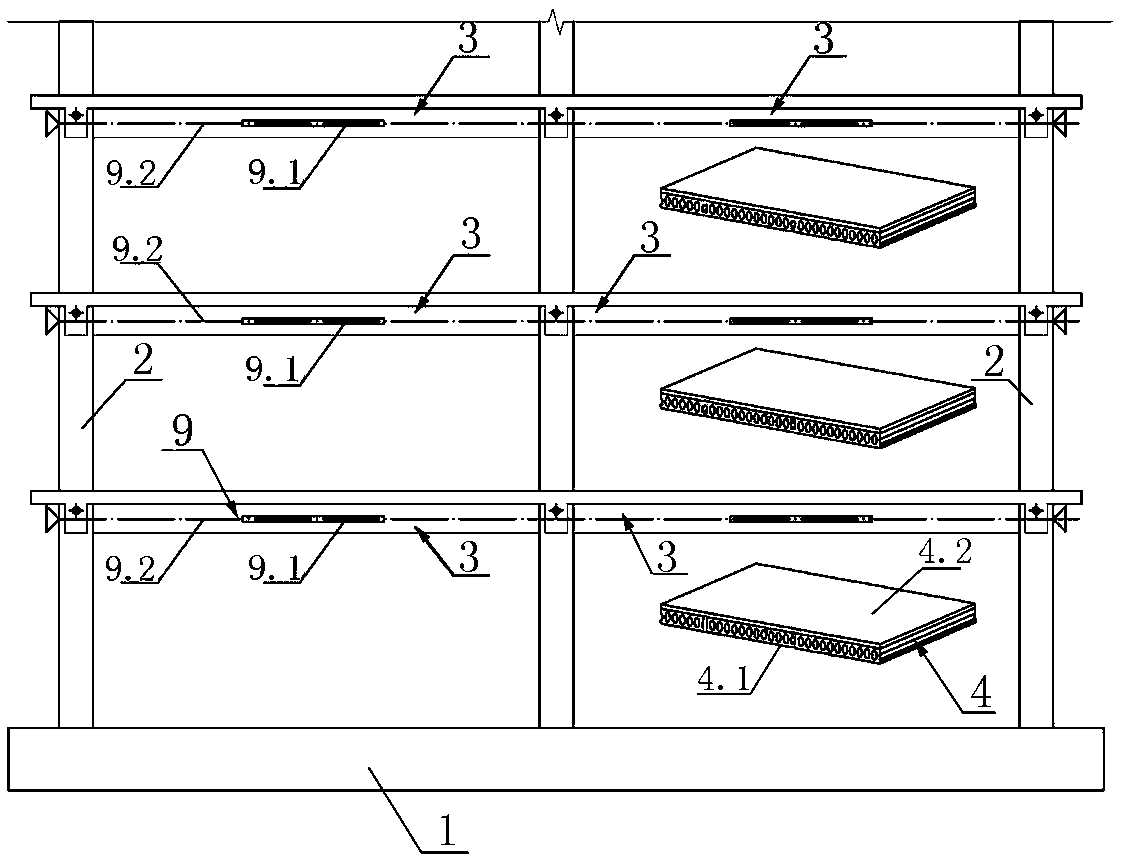

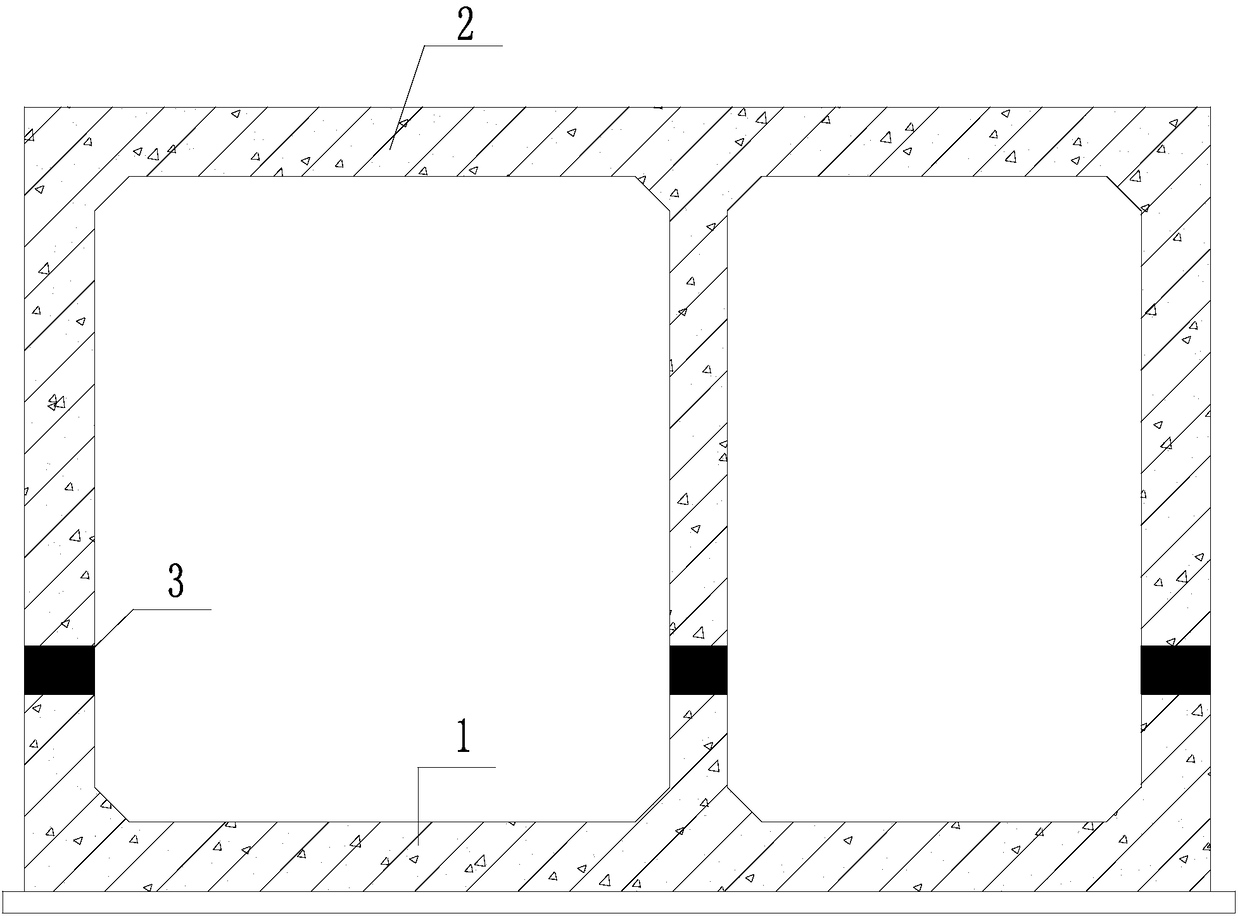

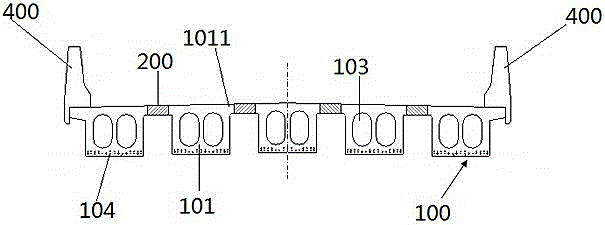

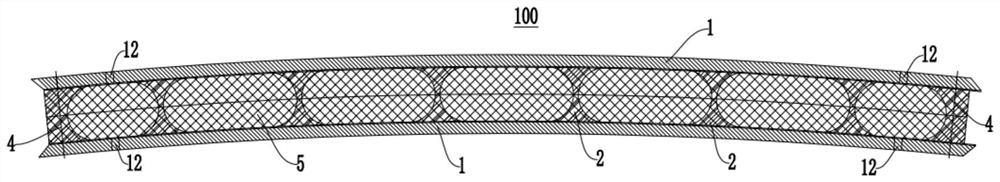

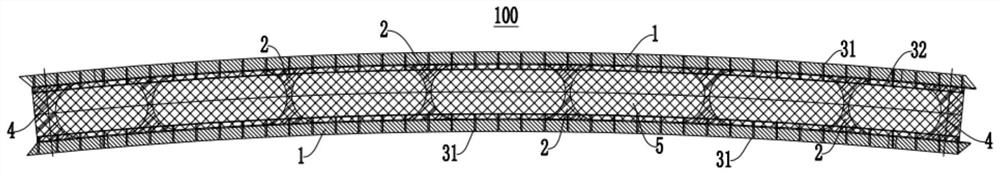

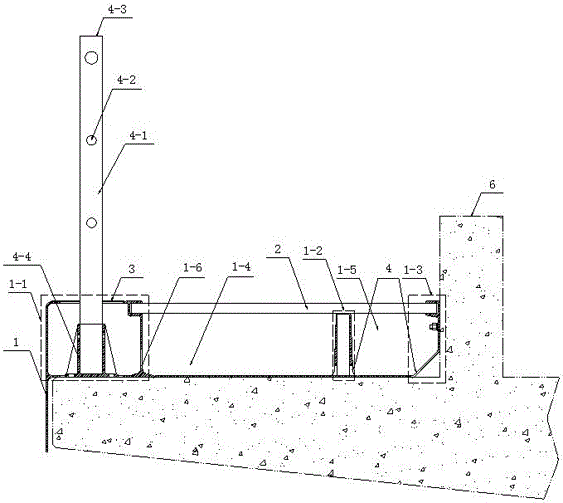

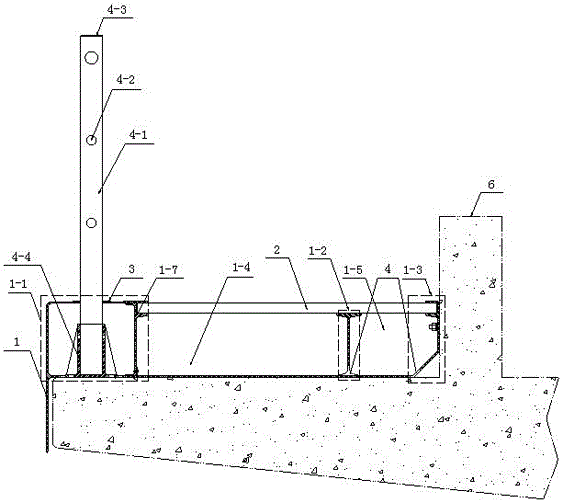

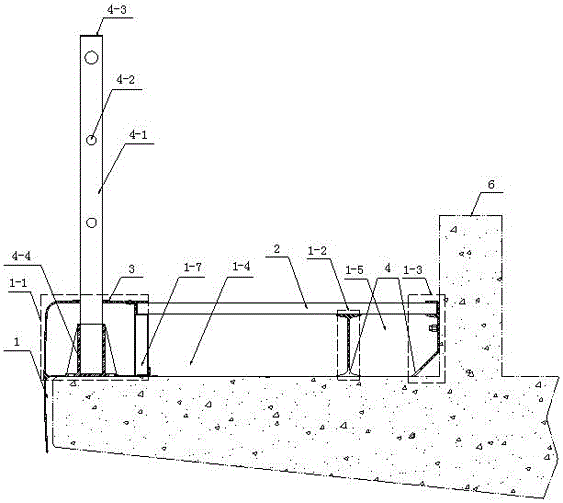

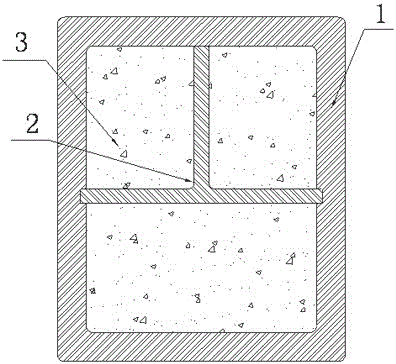

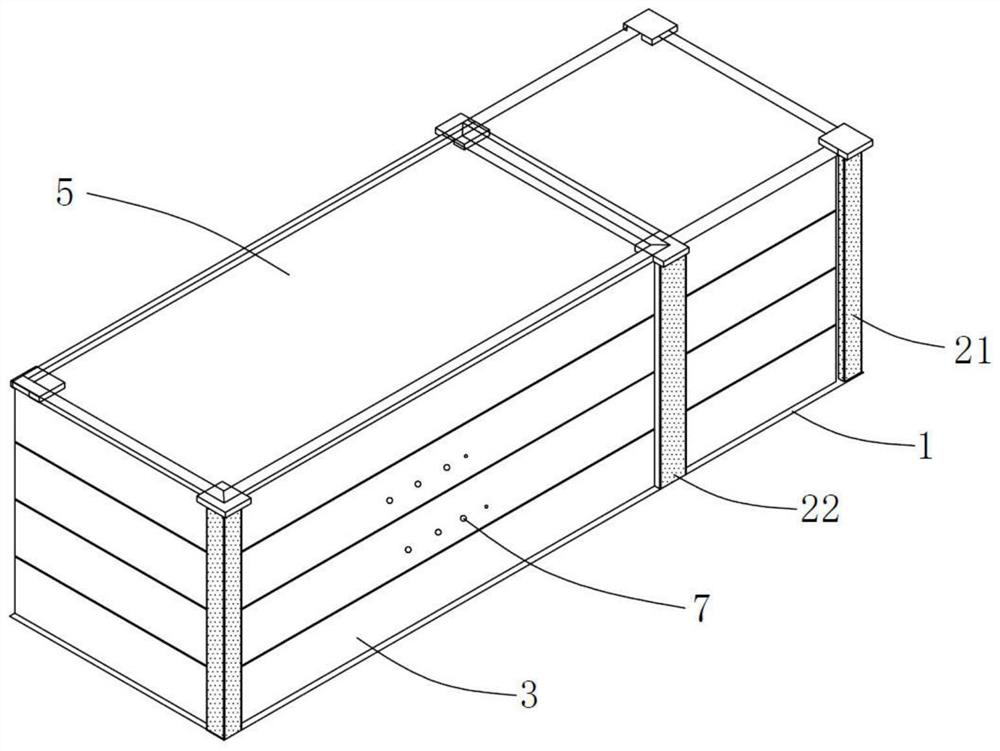

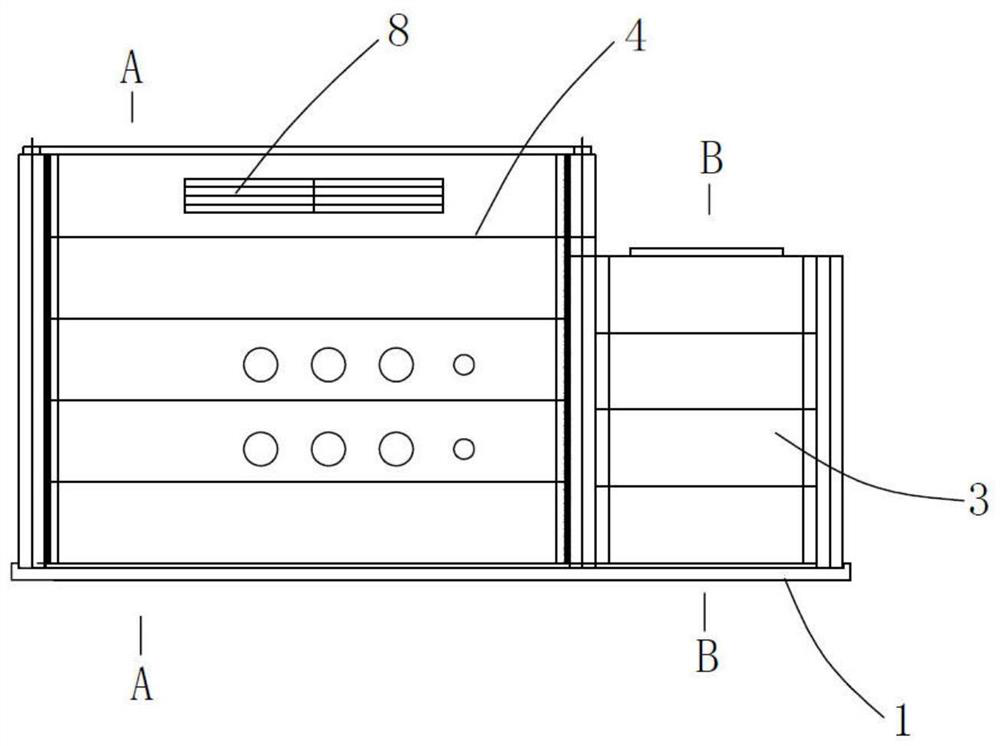

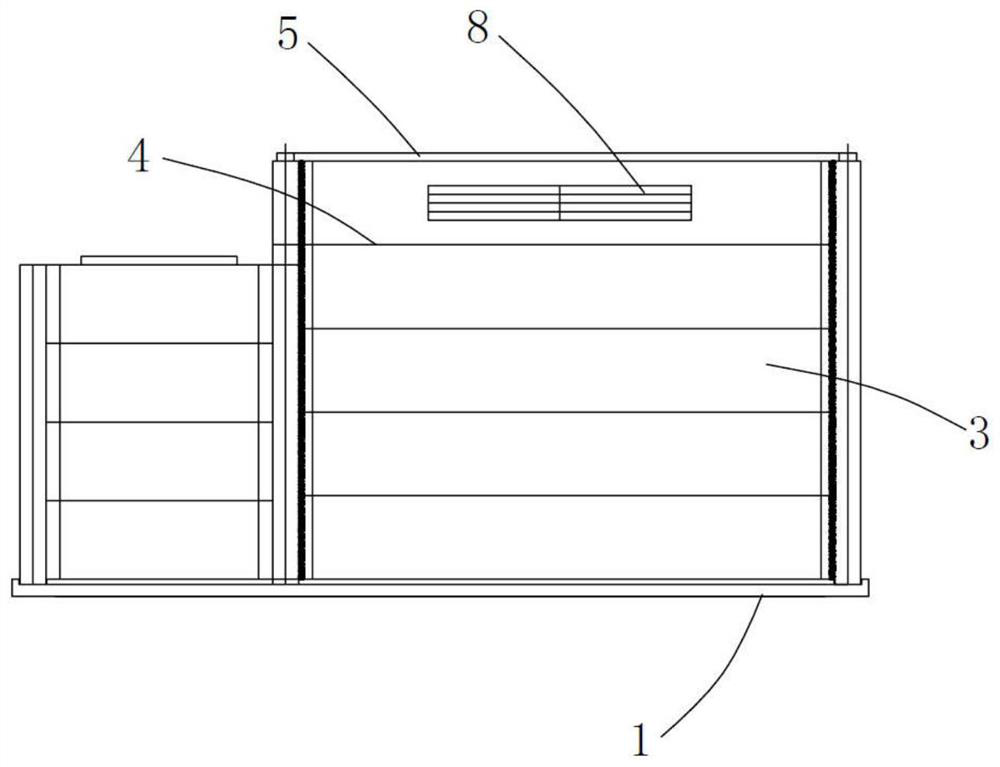

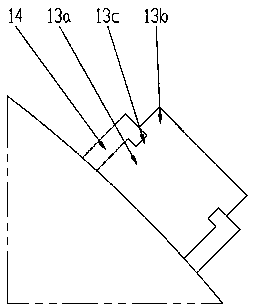

Prefabricated utility tunnel spliced by virtue of cast-in-place hidden beams and mixed with hollow-core wall boards, and construction method thereof

ActiveCN108086353ALight weightSolving prefab assembly challengesArtificial islandsUnderwater structuresUtility tunnelHollow core

The invention discloses a prefabricated utility tunnel spliced by virtue of cast-in-place hidden beams and mixed with hollow-core wall boards, and a construction method thereof. The two ends of a cast-in-place bottom plate are connected with the lower part of a double-sided prefabricated hollow core-filled side wall through a splicing hidden beam separately; the middle part of the cast-in-place bottom plate is connected with the lower part of a fully-prefabricated middle partition wall through a splicing hidden beam; the two ends of a laminated top plate are connected with the upper part of the double-sided prefabricated hollow core-filled side wall separately; and the middle part of the laminated top plate is connected with the upper part of the fully-prefabricated middle partition wall.The prefabricated utility tunnel integrates the advantages of a prefabrication process and a cast-in-place process; and the dead weights of prefabricated parts can be reduced through reasonable detachment, and the parts can be connected into one piece through cast-in-place core filling and the splicing hidden beams, so that the purpose of prefabrication for a multi-cabin tunnel and a non-standardsection of the tunnel can be achieved.

Owner:中建五局第三建设有限公司

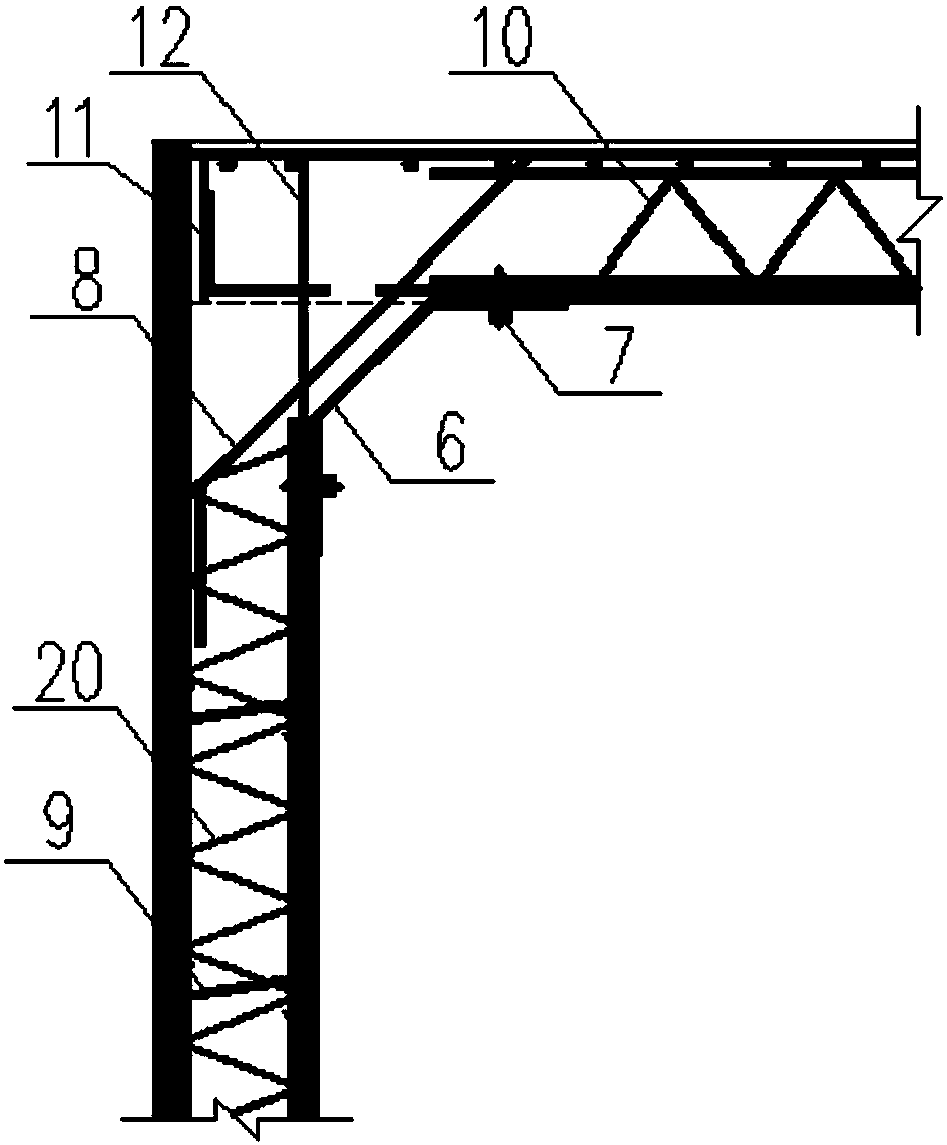

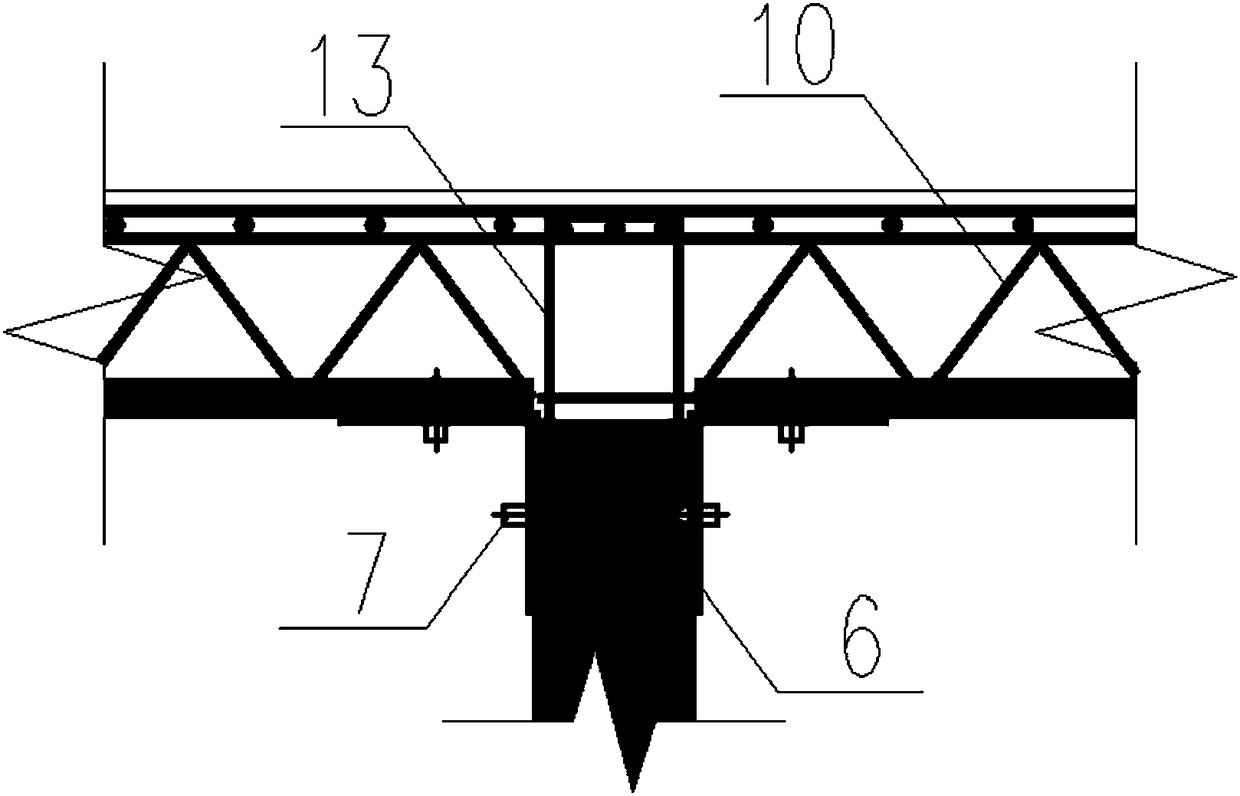

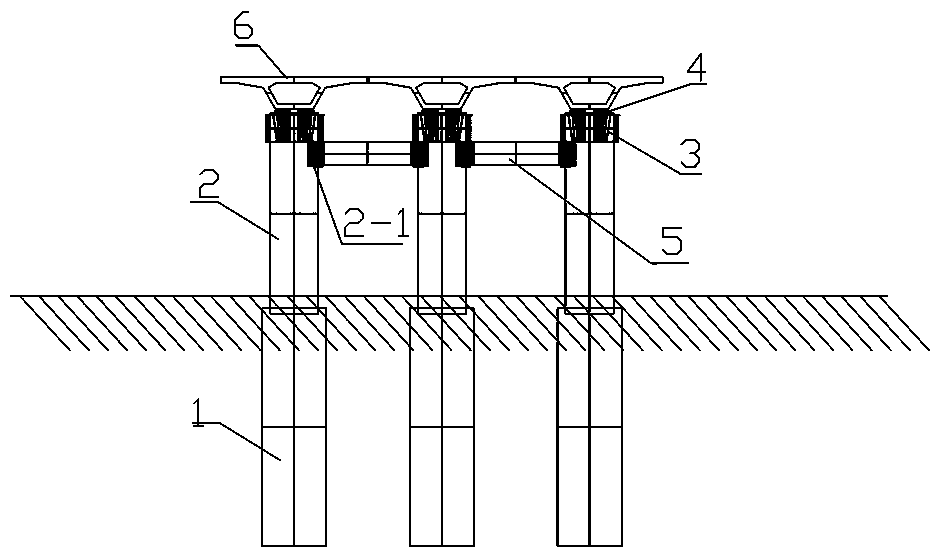

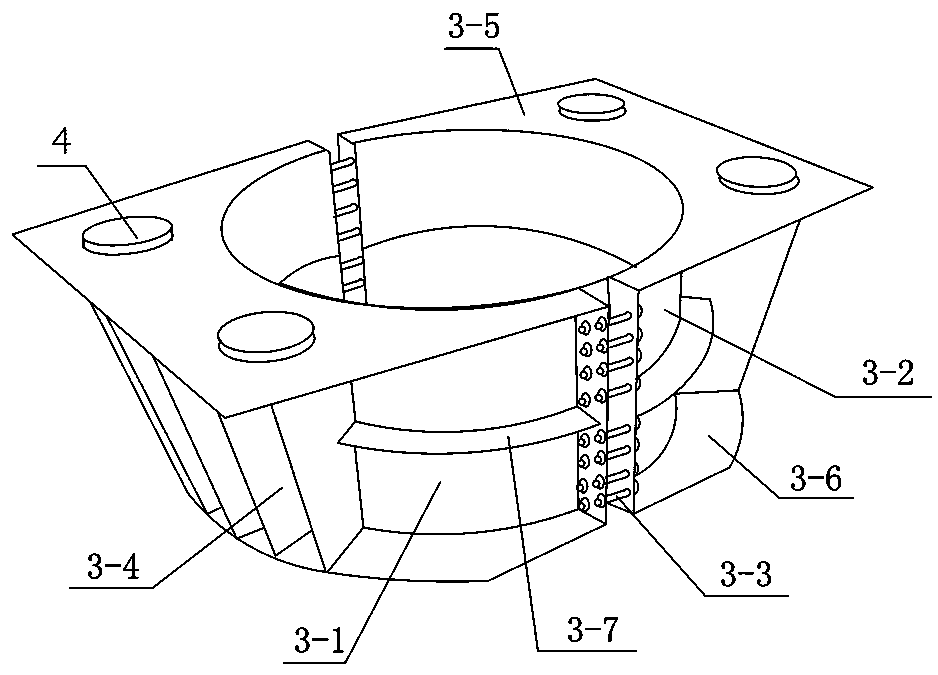

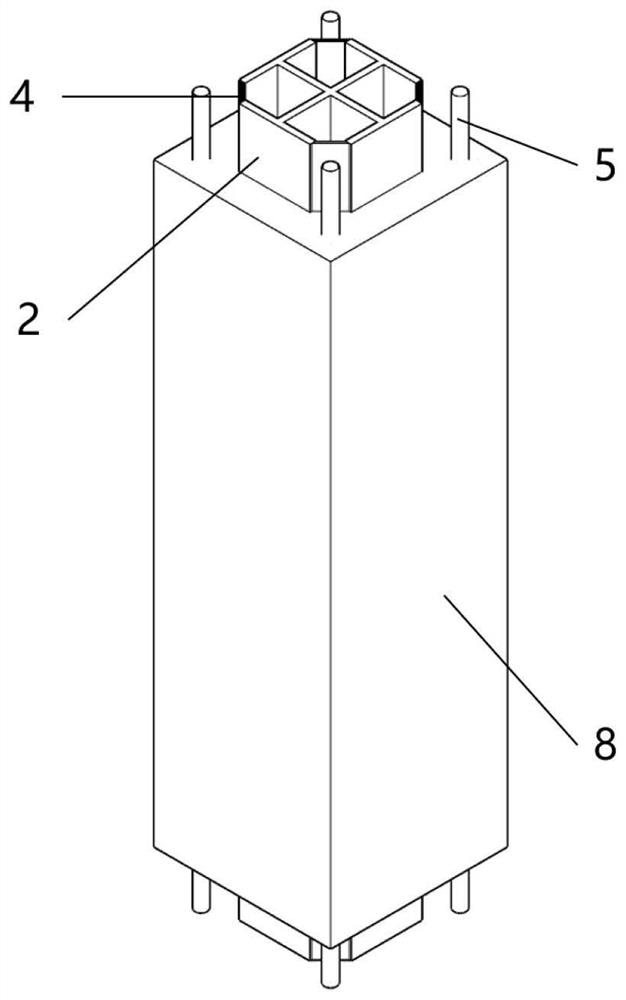

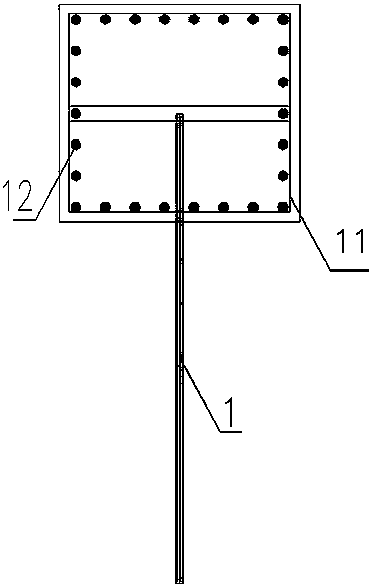

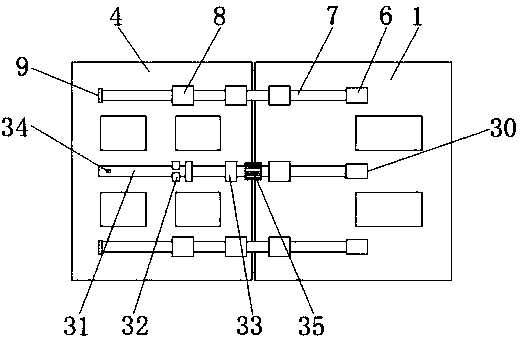

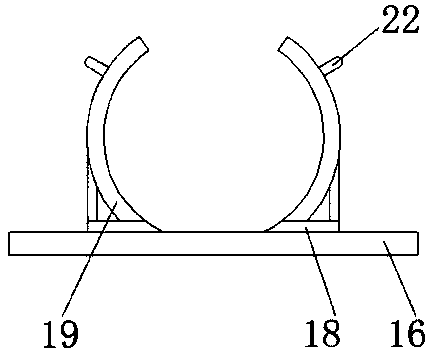

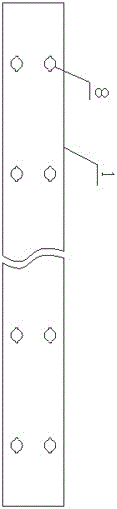

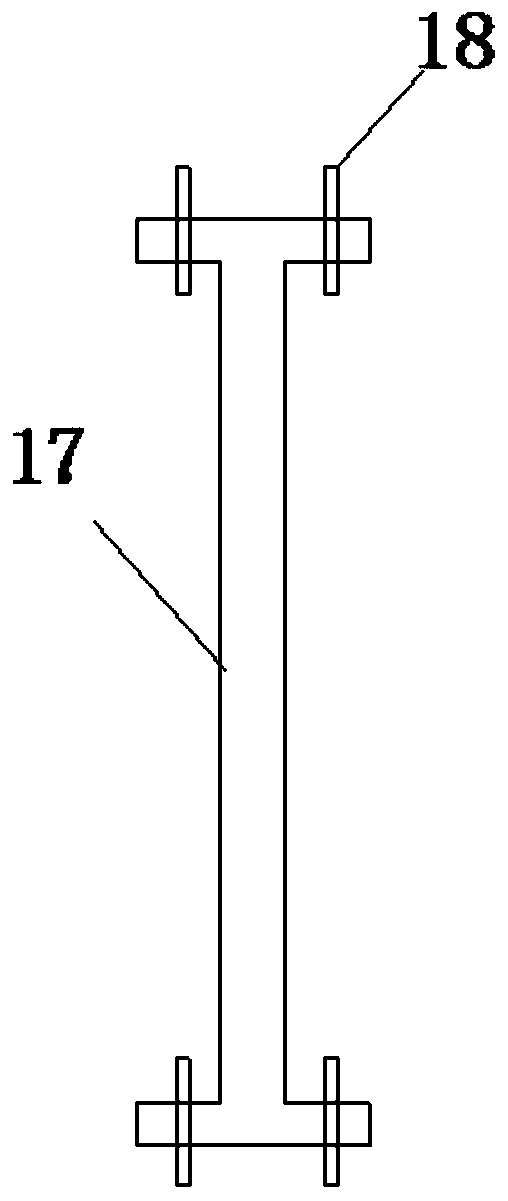

Prefabricated columnar pier and construction method thereof

PendingCN109868726AReduce distractionsSimple processBridge structural detailsBridge erection/assemblyEngineeringBolt connection

The invention discloses a prefabricated columnar pier. The prefabricated columnar pier comprises pile foundations and prefabricated pier studs mounted on the pile foundations. A hoop platform is mounted at the top of each prefabricated pier stud, and temporary supports are arranged on the hoop platforms in a balanced manner. Each hoop platform is formed by a sleeve form by connecting two arc plates through pretightening force bolts arranged on the connecting sides in a penetrating manner, and vertical stiffening ribs are longitudinally arranged in the middles of the outer side walls of the twoarc plates of each hoop platform. The upper opening edges and the lower opening edges of the two arc plates of each hoop platform horizontally extend to form an upper top plate and a lower bottom plate, and the temporary supports are arranged on the surfaces of the upper top plates. Connectors are pre-buried in the prefabricated pier studs corresponding to the positions of prefabricated system beams, and the two ends of the prefabricated system beams and the connectors on the prefabricated pier studs are welded or in bolt connection into a whole. The invention further discloses a constructionmethod of the prefabricated columnar pier. The bridge pier is ingenious in structure and convenient to transport and hoist, the construction procedures are simple, energy saving and environment protection are achieved, and wide application prospects are achieved in urban bridge building.

Owner:HENAN PROVINCIAL COMM PLANNING & DESIGN INST CO LTD +2

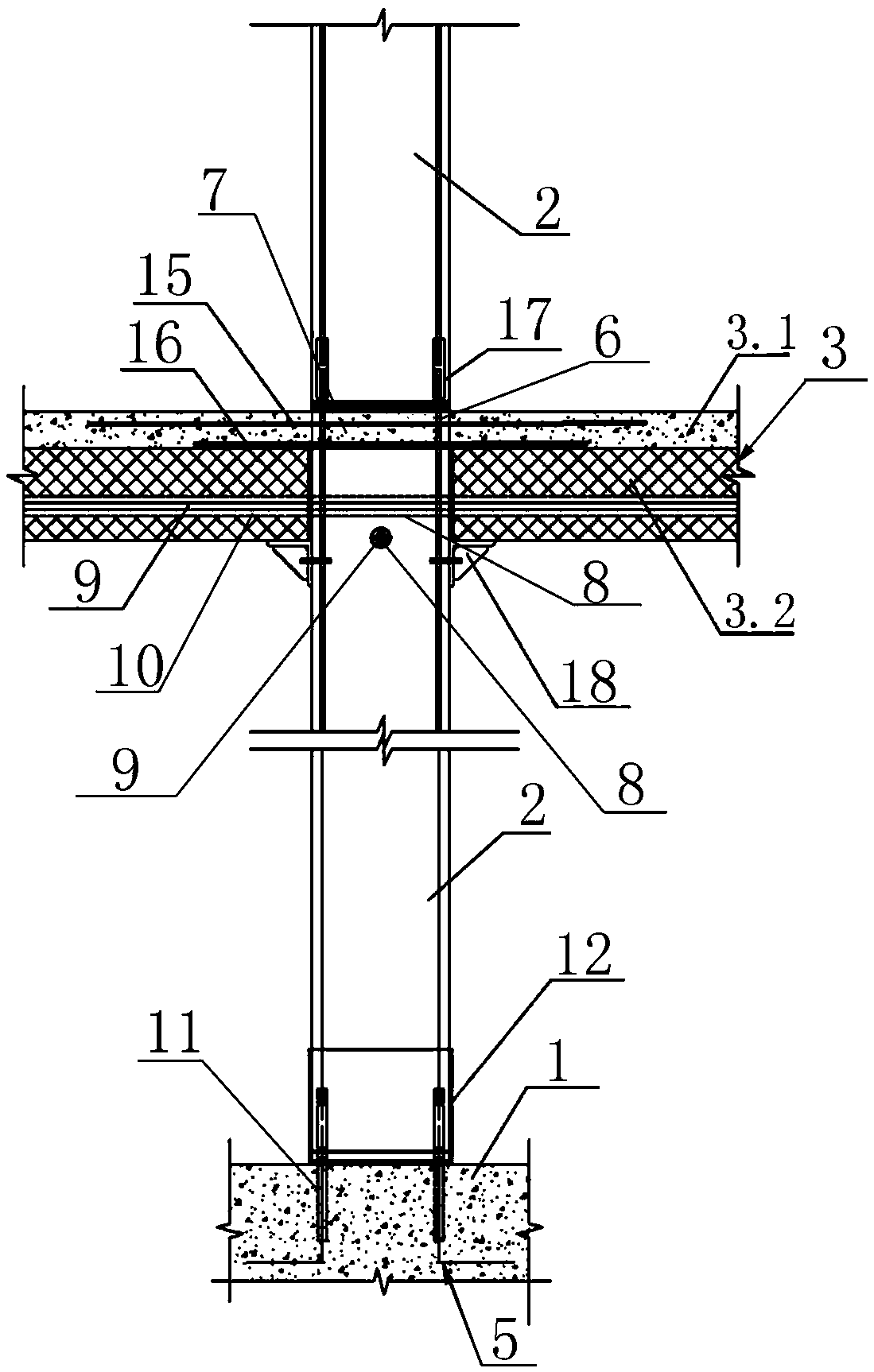

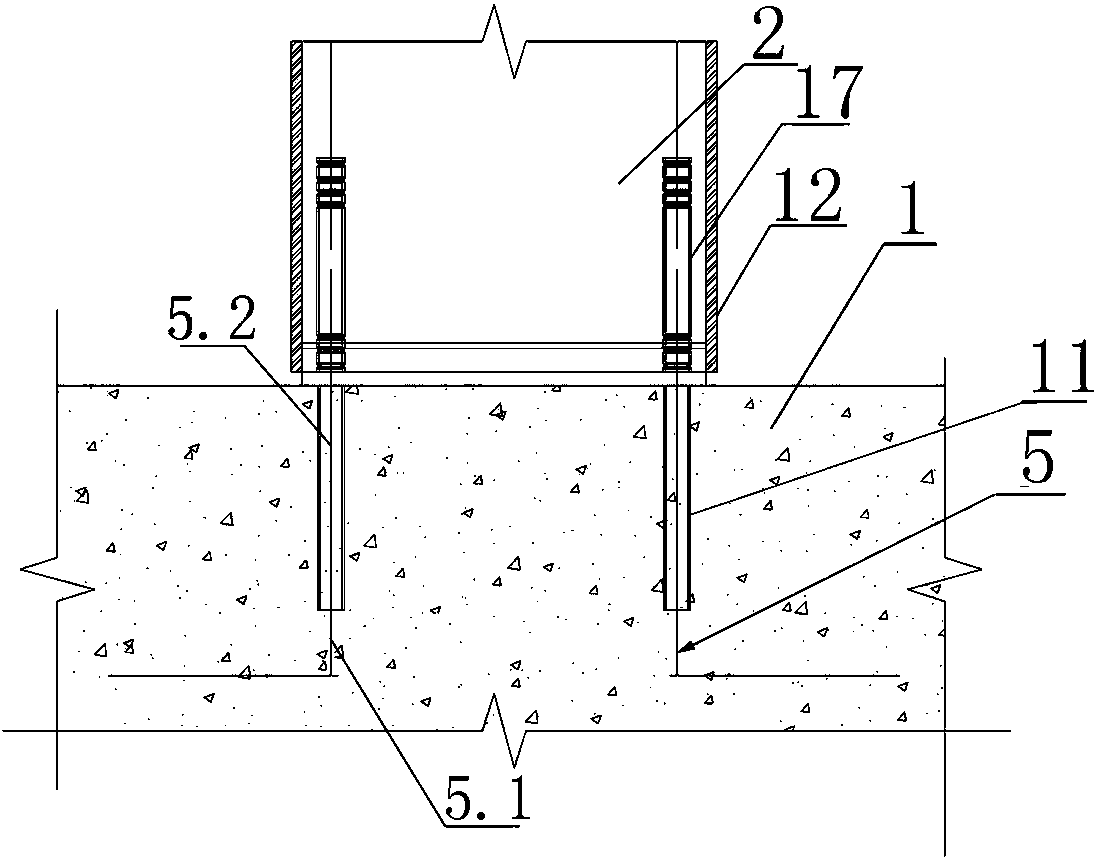

Mixed-connection post-tensioned prestressing assembly concrete frame system and construction method thereof

ActiveCN107700653AHigh speedImprove the level of green constructionProtective buildings/sheltersBuilding material handlingVertical edgePre stress

The invention discloses a mixed-connection post-tensioned prestressing assembly concrete frame system and a construction method thereof. The mixed-connection post-tensioned prestressing assembly concrete frame system comprises a foundation, a frame column, a frame beam and a floor; a connecting reinforcement is buried in the deigned position, inside the foundation, corresponding to the frame column, and the connecting reinforcement is in an L shape and comprises vertical edges and transverse edges connected to one sides of the bottom ends of the vertical edges; the lower portions of the vertical edges of the connecting reinforcement and the transverse edges are buried in the foundation, and the portion, buried in the foundation, of the connecting reinforcement comprises connecting reinforcement bonding sections and connecting reinforcement non-bonding sections; the connecting reinforcement non-bonding sections are located on the positions, located on the lower side of the top surface of the foundation and close to one end of the foundation, of the vertical edges, and the lengths of the connecting reinforcement non-bonding sections are 3-20 times the diameter of the connecting reinforcement; and the connecting reinforcement bonding sections are located on the positions, located on the lower side of the top surface of the foundation and close to one ends of the transverse edges,of the vertical edges and the transverse edges of the connecting reinforcement. According to the mixed-connection post-tensioned prestressing assembly concrete frame system and the construction methodthereof, the technical problems that in an existing structural system, the transporting hoisting difficulty is large, the structural robust property is low, the wet working quantity is large, and therepairing cost of column feet after earthquakes is high are solved.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

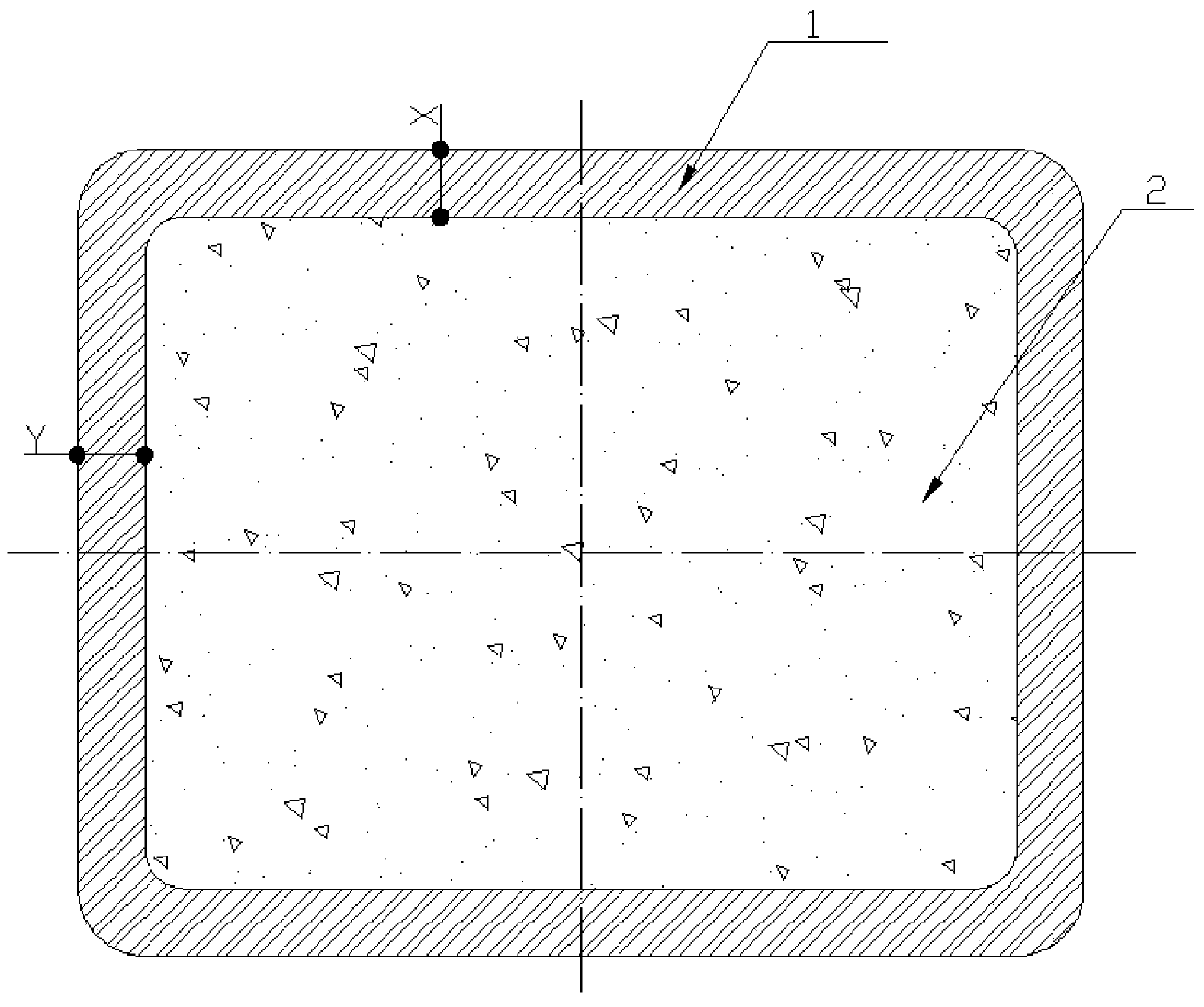

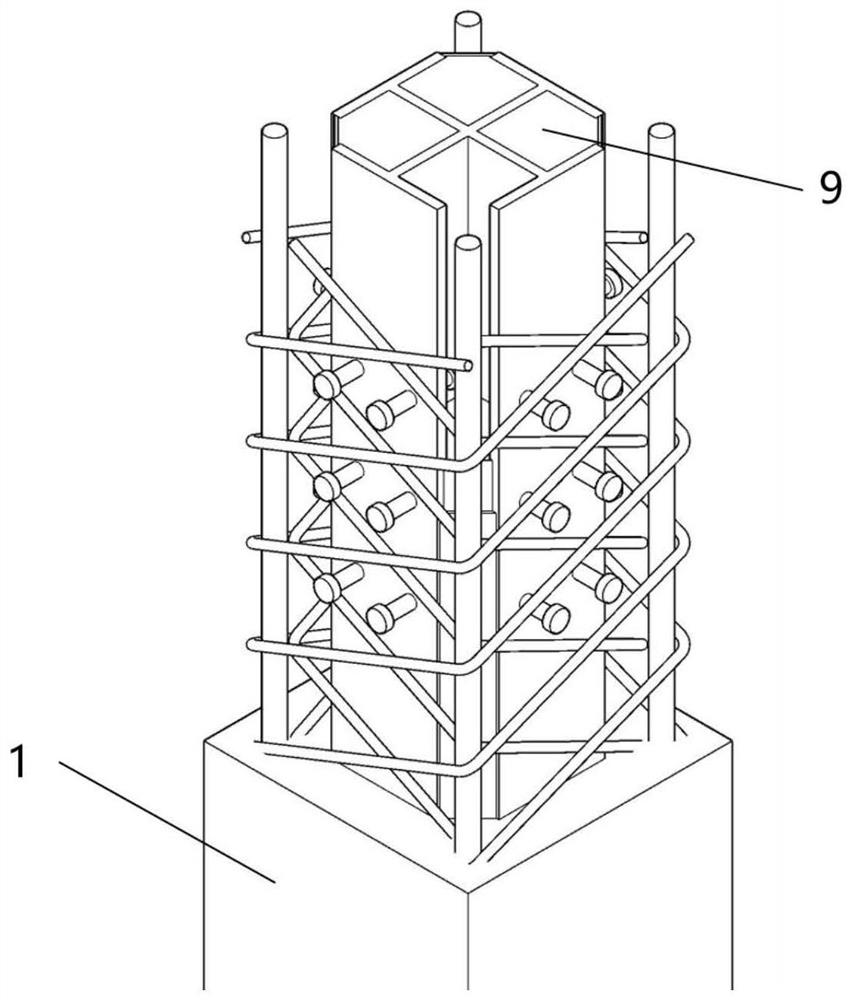

Composite column with ultra-short studs and double-layer high-strength spiral stirrups and construction method

PendingCN113216516AEasy constructionEasy to transport and hoistStrutsBuilding reinforcementsArchitectural engineeringStirrup

The invention discloses a composite column with ultra-short studs and double-layer high-strength spiral stirrups. The composite column with the ultra-short studs and the double-layer high-strength spiral stirrups is composed of a prefabricated ultra-high-performance concrete shell and cast-in-place concrete, the prefabricated ultra-high-performance concrete shell is of a long and straight hollow structure formed by pouring ultra-high-performance concrete, high-strength section steel is arranged in the interior of the prefabricated ultra-high-performance concrete shell in the length direction, the plurality of ultra-short studs are distributed on the outer sides of flanges of the high-strength section steel in the length direction, the adjacent flanges of the high-strength section steel are connected through riffled steel plates in the length direction, the ultra-short studs are located in the ultra-high-performance concrete, a plurality of longitudinal bars which are arranged in the length direction, inner layer high-strength spiral stirrups which wind around the inner sides of the longitudinal bars and outer layer high-strength spiral stirrups which wind around the outer sides of the longitudinal bars are further arranged in the ultra-high-performance concrete, and the cast-in-place concrete is poured into a hollow part of the prefabricated ultra-high-performance concrete shell. The invention further provides a construction method of the composite column. According to the composite column, the anti-seismic performance and fire-resistant performance are excellent, the prefabricated part is convenient to transport and hoist, the construction quality is good, the design is flexible, the concrete can be used in a differentiated mode, and the cost is low.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Sea wall structure with double-row steel sheet piles

PendingCN109487747AQuality improvementEnsure stabilityBreakwatersQuaysEnvironmental resistanceSheet steel

The invention relates to a sea wall structure with double-row steel sheet piles in complex foundation sea reclamation engineering. The sea wall structure with the double-row steel sheet piles comprises the two steel sheet piles, concrete cap beams, a pull rod, two stone template layers, a wave blocking wall and medium coarse sand, wherein the front and rear two steel sheet piles are connected through the pull rod, the front and rear two steel sheet piles are tensioned by the pull rod, the tops of the two steel sheet piles are cast in situ with the concrete cap beams, the two stone template layers are arranged between the concrete cap beams, the wave blocking wall is arranged on the outer side of the rear steel sheet pile, the outer side of the front steel sheet pile is backfilled with themedium coarse sand, and back pressure is carried out by backfilling with the medium coarse sand. The sea wall structure with the double-row steel sheet piles can safely and reliably prevent a bank slope from losing stability and sliding, and a cofferdam body has a small occupied area; and high retaining strength, good erosion resistance and seepage resistance, high construction speed, less raw material consumption, environmental protection principle, simple structure and convenient construction are achieved.

Owner:GUANGDONG PROVINCE PLANNING & DESIGN INST FOR WATER TRANSPORTATION

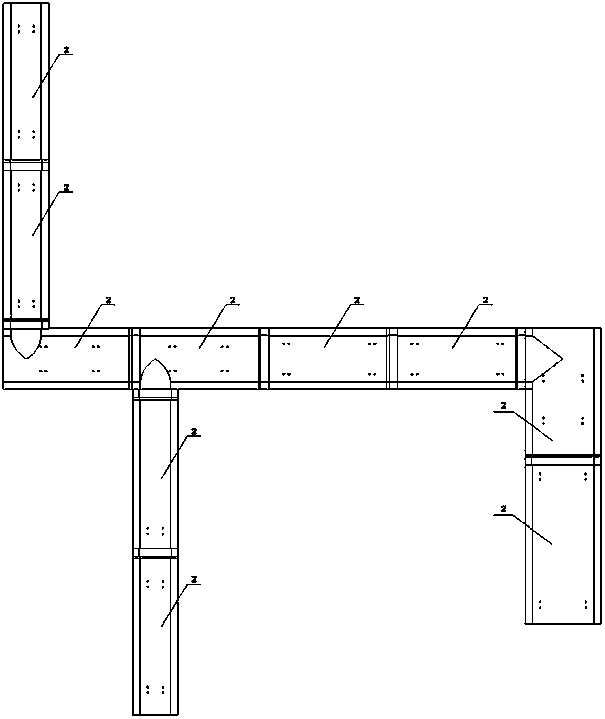

Half-prefabricated assembled comprehensive pipe gallery formed by splicing cast-in-situ hidden beams and construction method of half-prefabricated assembled comprehensive pipe gallery

InactiveCN108166525ALight weightSolving prefab assembly challengesArtificial islandsCeramic shaping apparatusLap jointEngineering

The invention provides a half-prefabricated assembled comprehensive pipe gallery formed by splicing cast-in-situ hidden beams and a construction method of the half-prefabricated assembled comprehensive pipe gallery. The half-prefabricated assembled comprehensive pipe gallery comprises a plurality of comprehensive pipe gallery bodies, wherein each comprehensive pipe gallery body is formed by splicing a cast-in-situ baseplate and an upper prefabricated pipe gallery; U-shaped dowel bars I are reserved on the sides, facing the corresponding upper prefabricated pipe gallery, of the two ends and themiddle of each cast-in-situ baseplate; U-shaped dowel bars II which are matched with the U-shaped dowel bars I in position are arranged on each upper prefabricated pipe gallery; and all the cast-in-situ baseplates and upper prefabricated pipe galleries are connected in a staggered lap-joint manner through the U-shaped dowel bars I and the U-shaped dowel bars II. The construction method comprisesthe following steps: after the manufacturing of prefabricated components as well as the positioning and setting-out operation, binding steel bars of the cast-in-situ baseplates, casting the cast-in-situ baseplate, and carrying out curing and demolding; and then, assembling the prefabricated components, mounting steel bars and mold plates at the splicing positions, and carrying out concrete pouringat the cast-in-situ parts, so as to form the half-prefabricated assembled comprehensive pipe gallery. The half-prefabricated assembled comprehensive pipe gallery provided by the invention integratesthe advantages of both the prefabrication and cast-in-situ processes; not only can the own weights of the prefabricated components be reduced through reasonable splitting and the hoisting constructionbe facilitated, but also all the prefabricated components can be connected as a whole through the cast-in-situ hidden beams; and under the premise that the overall bearing capacity and the deformability of the comprehensive pipe gallery bodies are not reduced, the problem about how to prefabricate and assemble a multi-cabin gallery and a non-standard gallery segment can be solved.

Owner:中建五局第三建设有限公司

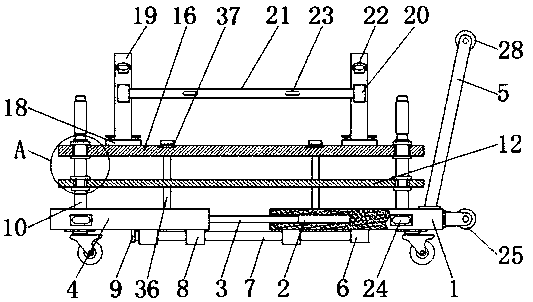

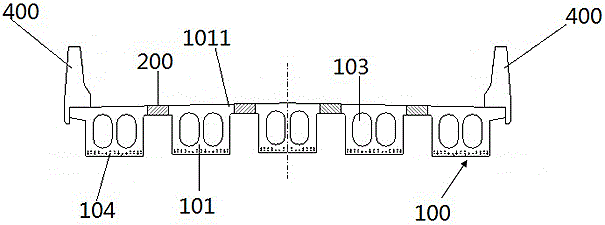

Solar water heater transporting vehicle convenient to detach and hoist

InactiveCN108639117AEasy to transport and hoistEasy to disassembleLoad-engaging elementsHand carts with multiple axesSolar waterAerospace engineering

The invention discloses a solar water heater transporting vehicle convenient to detach and hoist. The solar water heater transporting vehicle convenient to detach and hoist comprises a first bottom plate; a slide groove is formed in the left side of the first bottom plate; a supporting plate is connected to the interior of the slide groove in a sliding manner; and a second bottom plate is fixedlyconnected to the right side of the supporting plate. The invention relates to the technical field of solar energy. According to the solar water heater transporting vehicle convenient to detach and hoist, through coordination of supporting columns, limiting rings, limiting cylinders, first limiting blocks, second limiting blocks and rotating limiting blocks, a first partition plate and a second partition plate can be fixed so that an upper space and a lower space can be partitioned; a heat collection tube and a fixing frame of a solar water heater can be separately fixed and stored to prevent the heat collection tube from being damaged; by using an annular fixing frame, a water tank of the solar water heater can be fixed so that the solar water heater can be integrally fixed to be convenient for transportation and hoisting; and the first partition plate, the second partition plate and the annular fixing frame are convenient to detach; and the solar water heater transporting vehicle convenient to detach and hoist can be used as a normal trailer after being detached, and therefore, the operation is simple and convenient, and the practicability is high.

Owner:陈昌

Hollow plate girder bridge structure and construction process thereof

ActiveCN104631317ALow costSolve the force problem after emptyingBridge structural detailsBridge erection/assemblyBridge deckEngineering

The invention discloses a hollow plate girder bridge structure. The hollow plate girder bridge structure comprises a plurality of hollow plate girders which are spliced together, wherein each hollow plate girder comprises a rectangular body; the top of each rectangular body extends towards the two side edges to form small cantilever arm steel bars respectively; the ends of the rectangular bodies are provided with cross beam steel bars; after the small cantilever arm steel bars of the adjacent hollow plate girders are connected, concrete is filled up, bridge deck cast-in-place joints are formed, and the adjacent hollow plate girders are connected together; after the cross beam steel bars of the adjacent hollow plate girders are connected, concrete is filled up, cast-in-place cross beam joints are formed, and the adjacent hollow plate girders are connected together. The invention further discloses a construction process of the hollow plate girder bridge structure. The hollow plate girder bridge structure is good in overall stress performance, reliably guarantees the durability of a bridge, and can be applied to a new project and used for replacing an existing hinged hollow plate girder bridge on the basis of reserving original capping beams, stand columns and other substructures.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

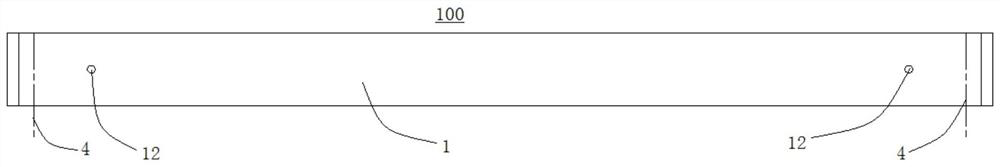

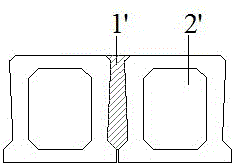

Track beam and construction method of track beam

ActiveCN113463494AReduce weightEasy to transport and hoistRailway tracksBridge structural detailsTrackwayEngineering

Owner:BYD CO LTD

Railway line subsidiary facilities and mounting method thereof

InactiveCN106592456AIncrease productivityReduce waste of raw materialsNoise reduction constructionBridge structural detailsPultrusionEngineering

The invention discloses railway line subsidiary facilities. The railway line subsidiary facilities are mounted on a beam body, the subsidiary facility on one side of the beam body is the guardrail section subsidiary facility, and the subsidiary facility on the other side of the beam body is the sound barrier section subsidiary facility. The guardrail section subsidiary facility is composed of an integral type curtain plate structure or an assembling type curtain plate structure, a guardrail, a trail plate and a decorating plate. The sound barrier section subsidiary facility is composed of an integral type curtain plate structure or an assembling type curtain plate structure, a sound barrier upright column, a sound barrier base, a trail plate and a decorating plate. The railway line subsidiary facility products are produced by a pultrusion process, and the products have the characteristics of lightweight, high strength, high bearing capacity, no transformation, no moisture absorption, stable size, chemical corrosion resistance, ageing resistance, good shock absorption property, no electric conduction, simple structure, convenient on-site installation and the like.

Owner:CHINAGRATE COMPOSITES STRUCTURE NANTONG

Sleeper and method for installing nut sleeves thereof

ActiveCN104652182BReduce wasteUnlimited lengthBallastwayRail fastenersEngineeringMoisture absorption

The invention relates to a sleeper and a method for installing a nut sleeve thereof. The sleeper includes a sleeper body, the material of the sleeper body is a fiber-reinforced resin-based composite material, and the pillow core of the sleeper body is made of a fiber-reinforced resin-based composite material profile and a fiber-reinforced resin-based composite material. The fiber-reinforced resin-based composite material profile of the pillow core is first produced by a pultrusion process alone. The invention has the advantages of light weight, high strength, high bearing capacity, no deformation, no moisture absorption, stable volume, chemical corrosion resistance, aging resistance, good shock absorption, non-conductivity, simple structure and convenient on-site installation.

Owner:CHINAGRATE COMPOSITES STRUCTURE NANTONG

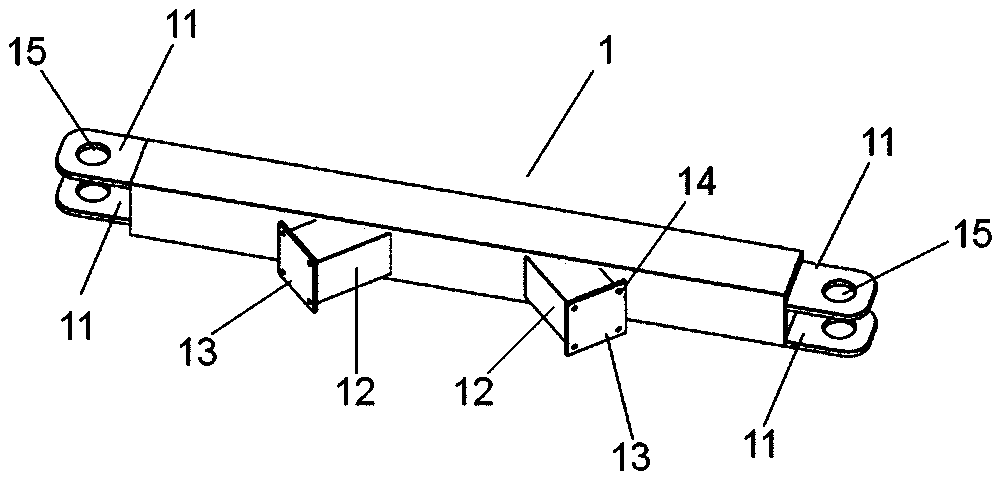

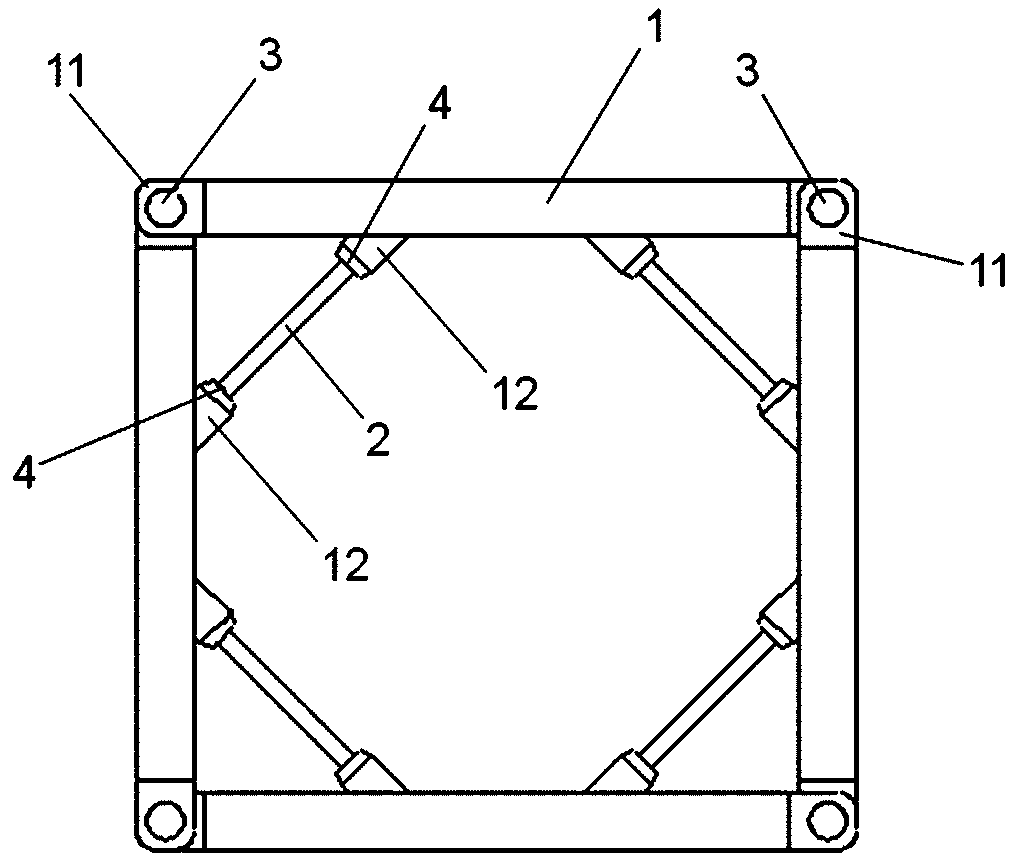

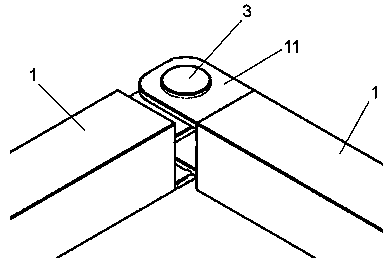

Prefabricated assembled integrated foundation pit horizontal supporting system and construction method thereof

The invention relates to a prefabricated assembled integrated foundation pit horizontal supporting system and a construction method thereof. The horizontal supporting system comprises a plurality of ring beam components which are connected end to end to form a whole; hinge pieces is welded to the two ends of the ring beam components respectively, the hinge pieces of the adjacent ring beam components need to be stacked up and down and then are fixed; and the middle section of the ring beam components is welded with two brackets with different directions and obliquely arranged; bracket connecting plates are welded to the plane end of the brackets back-to-ring beam components; the two adjacent ring beam components are connected through the inclined struts, and then the adjacent ring beam components are fixed. A plurality of ring beam components are hoisted into a foundation pit on site and are hinged through a hinge joint in sequence, and finally the integrated foundation pit horizontal supporting system is formed together with the inclined struts, so that the quality and stability of the horizontal supporting system can be guaranteed.

Owner:福建建中建设科技有限责任公司

Floating slab rail unit

PendingCN111155362AImprove driving safetyGood vibration reduction effectBallastwayRailway fasteningStructural engineeringMechanical engineering

The invention discloses a floating slab rail unit. The floating slab rail unit comprises a floating unit slab and a plurality of intelligent vibration isolators used for carrying out floating supporting on the floating unit slab in the vertical direction. Each floating unit plate comprises a plurality of floating plate unit blocks and a connecting assembly, the floating plate unit blocks are sequentially arranged in the extending direction of the rail line and connected in a spliced mode, each floating plate unit block is provided with a plurality of mounting preformed holes used for installing the intelligent vibration isolators, and the connecting assemblies are used for connecting the floating plate unit blocks to form the floating unit plates. The intelligent vibration isolator comprises an inner cylinder assembly and an outer cylinder assembly which are arranged in an inner-outer sleeving mode in the vertical direction. The upper end of the outer cylinder assembly is arranged in acorrespondingly arranged mounting preformed hole; the inner cylinder assembly is sleeved with the outer cylinder assembly, the lower end of the inner cylinder assembly extends out of the lower end ofthe outer cylinder assembly and then is connected with the rail foundation, and the inner cylinder assembly is used for providing elastic supporting force for telescopic arrangement of the outer cylinder assembly in the vertical direction so that the outer cylinder assembly can conduct floating supporting on the floating unit plate in the vertical direction.

Owner:CENT SOUTH UNIV

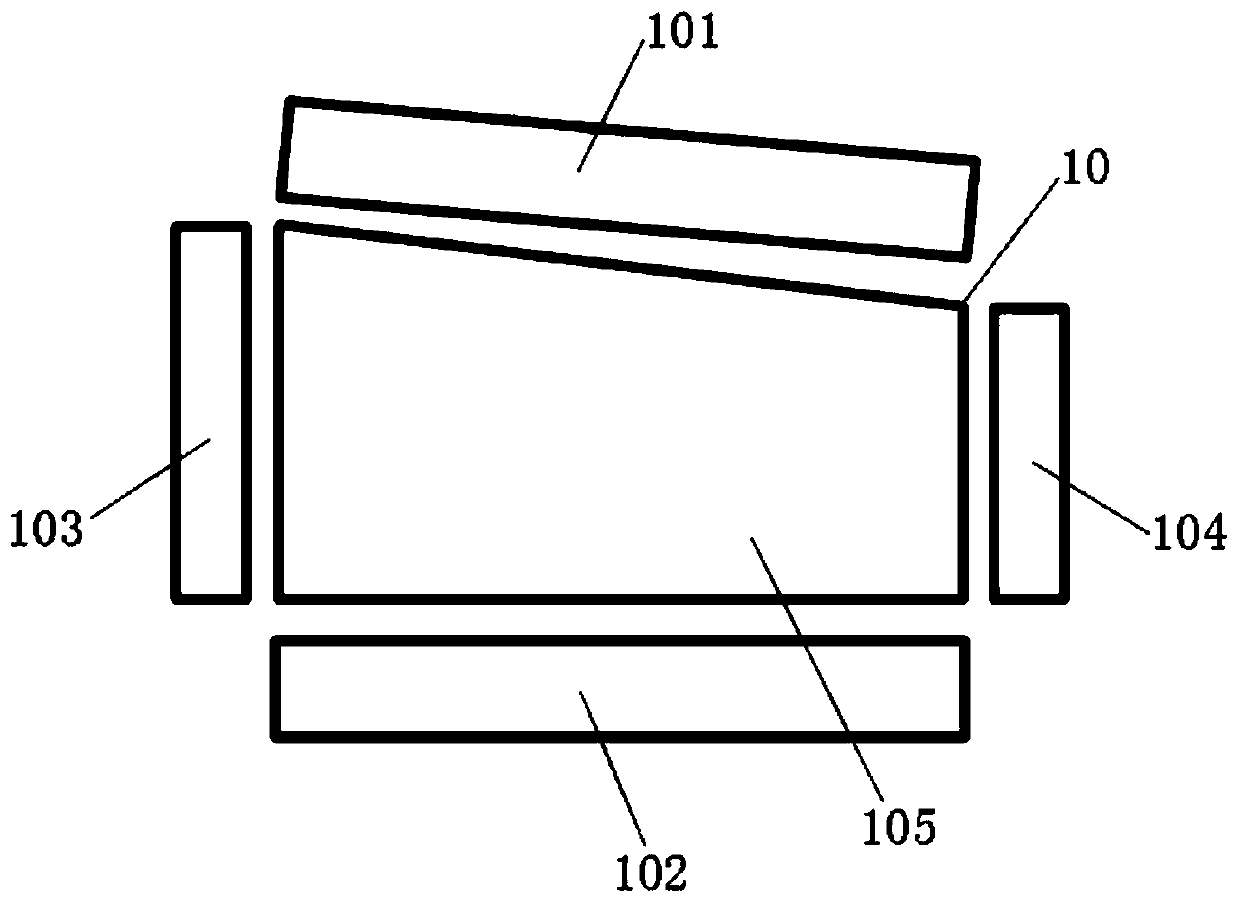

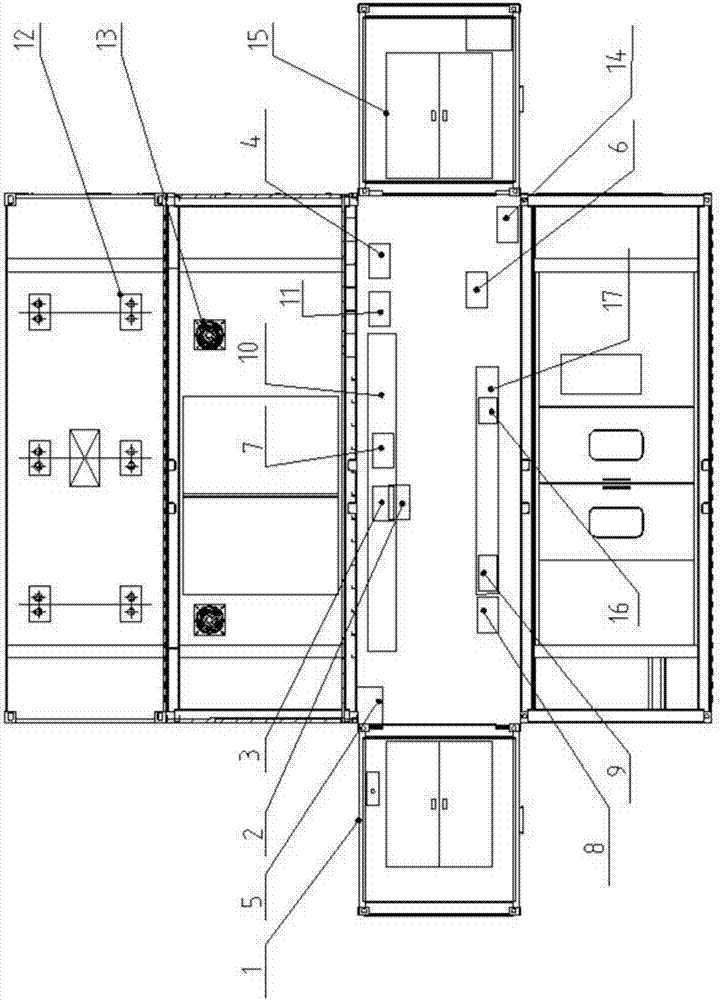

Prefabricated steel concrete combined ring main unit foundation

PendingCN112814019AReduce pollutionQuality improvementFoundation engineeringWall plateDistribution networks

Owner:CHUZHOU POWER SUPPLY CO OF STATE GRID ANHUI ELECTRIC POWER CORP +1

A Hollow Slab Girder Bridge Structure and Its Construction Technology

ActiveCN104631317BLow costSolve the force problem after emptyingBridge structural detailsBridge erection/assemblyBridge deckEngineering

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

Fabricated FRP-gradient sea sand concrete composite wallboard

PendingCN113047511AIncrease the bearing capacity of the wallImprove ductilityConstruction materialBuilding material handlingCorrosion resistantWall plate

The invention discloses a fabricated FRP-gradient sea sand concrete combined wallboard. The combined wallboard comprises FRP grids, FRP ribs, a high-ductility fiber reinforced sea sand cement-based composite material, sea sand concrete and connecting pieces; a wallboard main body is composed of a high-ductility fiber reinforced sea sand cement-based composite material layer and an internal sea sand concrete layer, wherein the FRP grids, and the vertical and horizontal FRP bars are planted in the two sides of the high-ductility fiber reinforced sea sand cement-based composite material layer; and the vertical FRP bars and the horizontal FRP bars on the two sides are connected through the connecting pieces at part of crossed joints. According to the fabricated combined wallboard, the characteristics of light weight, high strength, corrosion resistance and the like of a FRP material and the advantage that the sea sand concrete can be obtained from local materials are fully utilized, so that the fabricated combined wallboard has the characteristics of easiness in standardization of the structural form, convenience in transportation, construction and installation, corrosion resistance, high bearing capacity, high lateral stiffness, high flexural rigidity and the like, has good adaptability in severe environments such as coastal ocean, and is suitable for popularization and application.

Owner:WUHAN UNIV

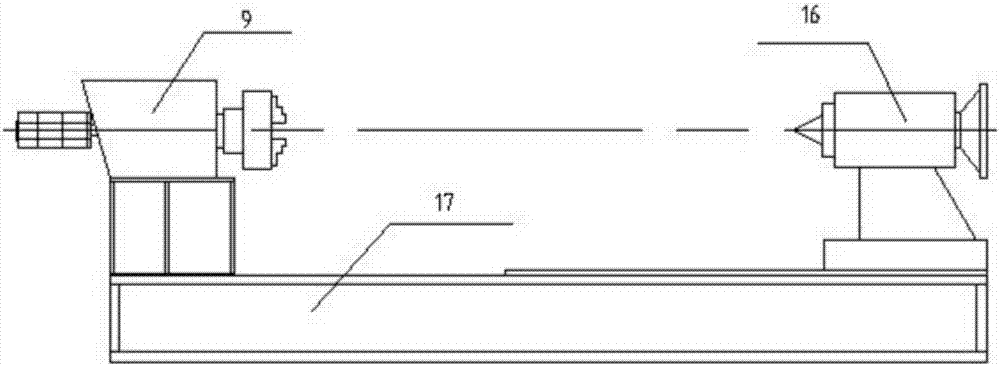

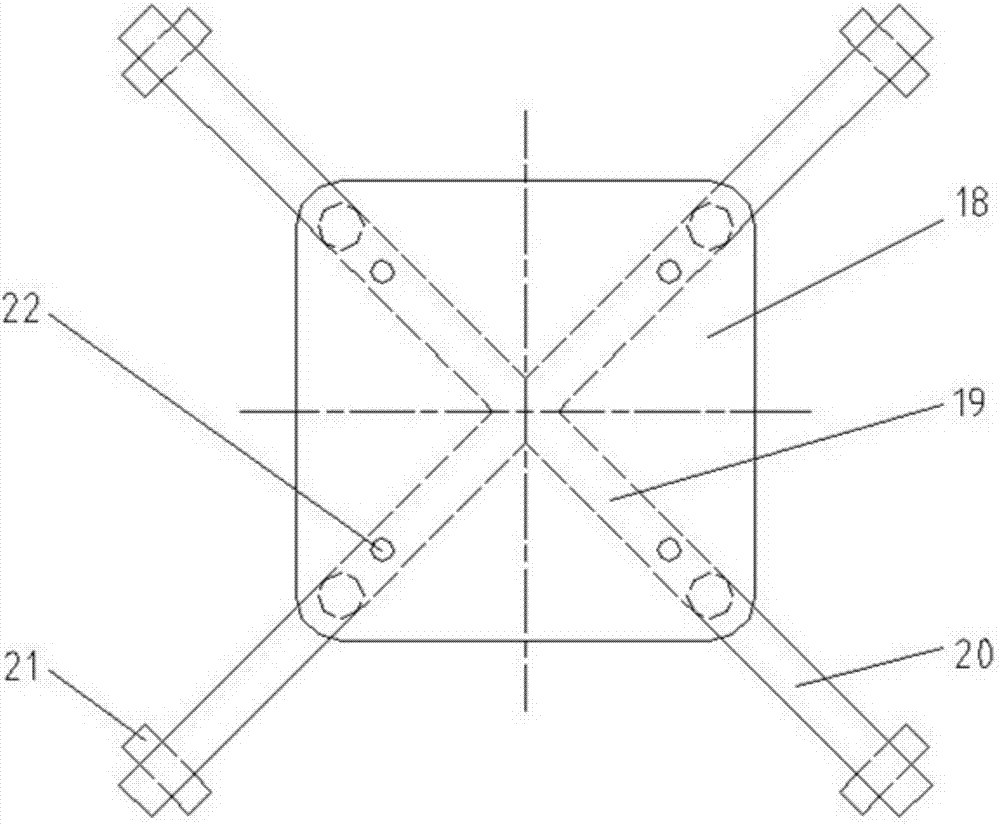

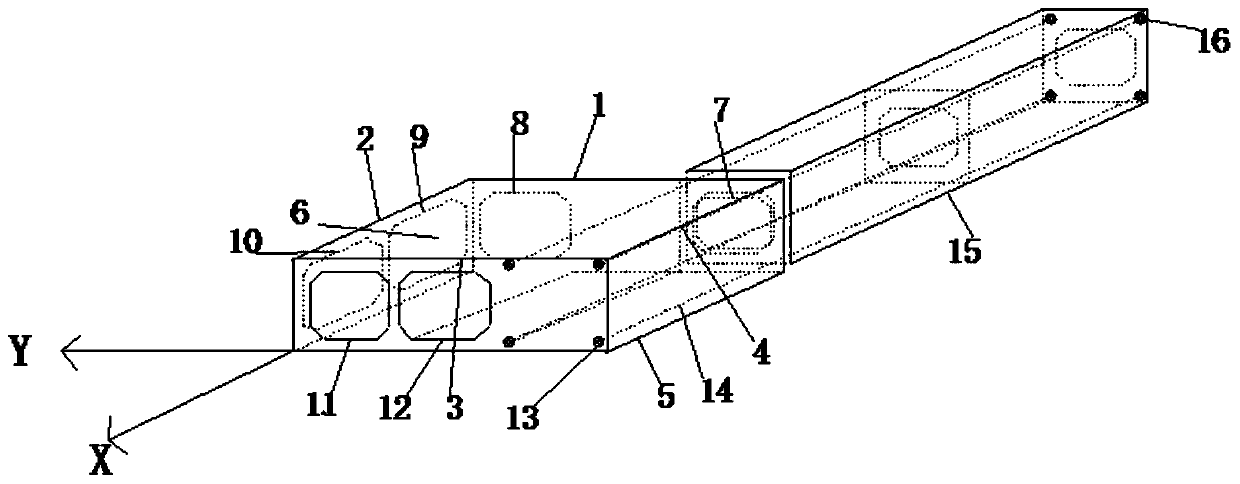

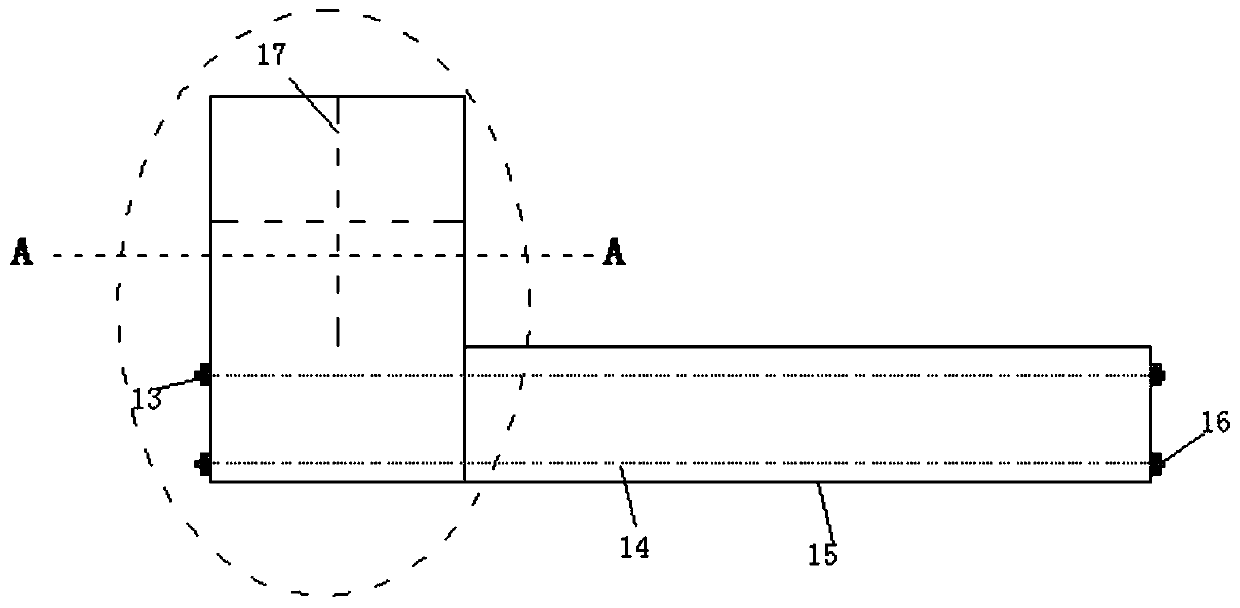

Movable type laser cladding complete equipment integrated cabin system

ActiveCN107059002AEasy to transport and hoistHigh cladding powerMetallic material coating processesHigh power lasersLighting system

The invention discloses a movable type laser cladding complete equipment integrated cabin system which comprises a cabin shell, a laser, a robot, a pressure stabilizing machine, a cooling-water machine, an air compressor, a powder feeding system, a dryer, a position changing machine, a robot sliding table, an off-machine operation platform, lighting systems, a temperature regulation system, a total power supply control cabinet, a tailstock center and a tailstock sliding table. According to the movable type laser cladding complete equipment integrated cabin system, high power laser cladding complete equipment is integrated into the movable type cabin, instantaneous power supply work is conducted through an integrated control system, site timely repairing of parts is met, the cabin system is suitable for conducting mobile operation on a customer site for a long term, and meanwhile hoisting and transportation are convenient; and cabin system is large in cladding power, high in speed, high in production efficiency, reliable, flexible and safe, and is widely used in the fields of engineering manufacturing, steel metallurgy and the like such as on-site operation repairing of a steel production line.

Owner:大连华锐重工特种备件制造有限公司

UHPC prefabricated assembled comprehensive pipe gallery horizontal curve connecting segment structure and construction method

PendingCN111305267AReasonable structureThe connection method is firm and reliableArtificial islandsProtective foundationArchitectural engineeringStructural engineering

The invention discloses a UHPC prefabricated assembled comprehensive pipe gallery horizontal curve connecting segment structure and a construction method. The structure is composed of side plates, a bottom plate, a top plate, short partition plates, an inlet and through openings; a connecting segment is connected with a prefabricated pipe gallery segment through the inlet or the through openings;tensioning hole channels are reserved in the connecting segment, and the connecting segment is connected with the prefabricated pipe gallery segment through prestressed tendons; and the UHPC connecting segment has a reasonable structure and a firm and reliable connecting mode so that the angle adjustment and curve transformation of a prefabricated pipe gallery segment laying route can be achieved,the UHPC connecting segment is suitable for zones where the geological condition of foundations is poor, a joint is good in waterproof performance and high in durability, and the flexibility of the prefabricated assembled pipe gallery laying route is improved. According to the UHPC prefabricated assembled comprehensive pipe gallery horizontal curve connecting segment structure and the construction method, the development of the full-prefabricated assembled comprehensive pipe gallery technology is promoted, the durability, rigidity and waterproof performance of a pipe gallery are greatly improved, and the good engineering significance is achieved.

Owner:SHENZHEN MUNICIPAL DESIGN & RES INST

Underwater facility protection cover

PendingCN109898559AReduce wasteIncrease productivityArtificial islandsUnderwater structuresConnection typeEngineering

The invention discloses an underwater facility protection cover. The underwater facility protection cover comprises a first protective cover, or comprises a second protective cover, or is composes ofa plurality of second protective covers, or is composed of a plurality of first protective covers and the multiple second protective covers in a splicing mode. The first protective cover is a rectangular shell protective cover, the specification and size of the connecting ends of the first protective covers are smaller than the specification and size of the connecting ports of the second protective covers, the shapes of the second protective covers are in an omega shape, and the second protective covers are of a straight-through type or a right-angle connection type. The underwater facility protection cover has the advantages of light weight, high strength, high bearing capacity, chemical corrosion resistance, aging resistance, non-conduction and the like.

Owner:CHINAGRATE COMPOSITES STRUCTURE NANTONG

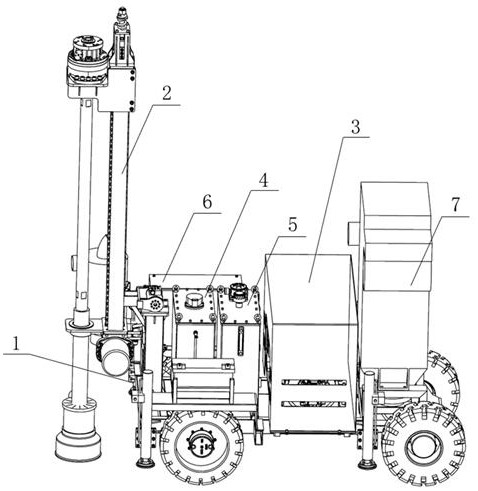

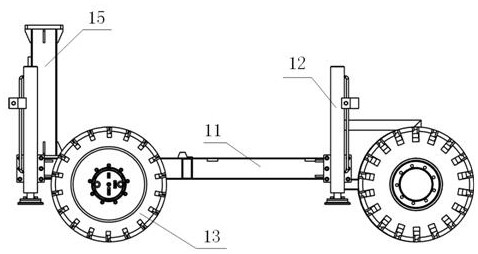

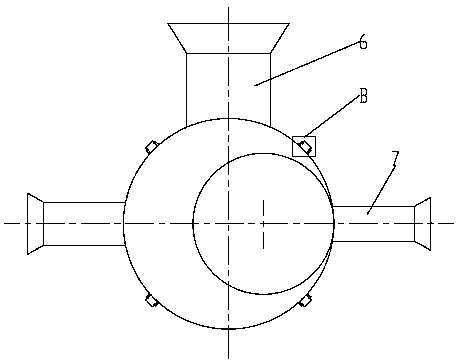

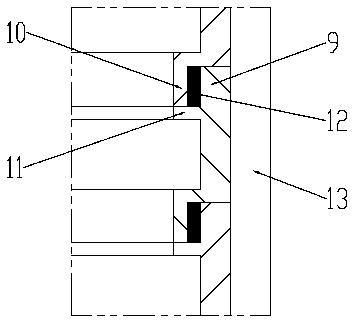

Modularized ultra-light movable drilling machine

PendingCN114856419AEasy to transport and hoistInstalled and disassembledConstructionsDerricks/mastsHydraulic motorVehicle frame

Owner:STATE GRID ECONOMIC TECH RES INST CO +1

Nodular cast iron prefabricated assembly type drainage inspection well

The invention discloses a nodular cast iron prefabricated assembly type drainage inspection well which comprises an inspection well body, and the inspection well body comprises a well body section located on the lower portion and a well shaft section located on the upper portion. At least one water inlet section is arranged between the well body section and the well shaft section, and an adjustingsection used for adjusting the elevation is arranged between every two adjacent water inlet sections and / or between the well body section and the water inlet section located at a lowest position and / or between the well shaft section and the water inlet section located at an uppermost position; the well body section is provided with a water outlet used for being connected with a water outlet pipe,and the water inlet section is provided with a water inlet used for being connected with a water inlet pipe. A bell and spigot assembly structure is adopted between every two adjacent sections of theinspection well body. A limiting and stabilizing mechanism used for preventing the water inlet section and the adjusting section from moving in the radial direction and enabling the water inlet section and the adjusting section to rotate in the circumferential direction is arranged between the well body section and the well shaft section at intervals. The nodular cast iron prefabricated assemblytype drainage inspection well has the advantages that the elevation of the water inlet pipe can be adjusted, and the stability of an assembly structure is good.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com