Sea wall structure with double-row steel sheet piles

A technology of steel sheet piles and seawalls, which is applied in the direction of foundation structure engineering, jetties, embankments, etc., can solve the problems of difficulty in guaranteeing construction quality, slow construction speed, and high project cost, and achieve increased shear resistance and anti-sliding capacity, fast construction speed, The effect of reliable pile body quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

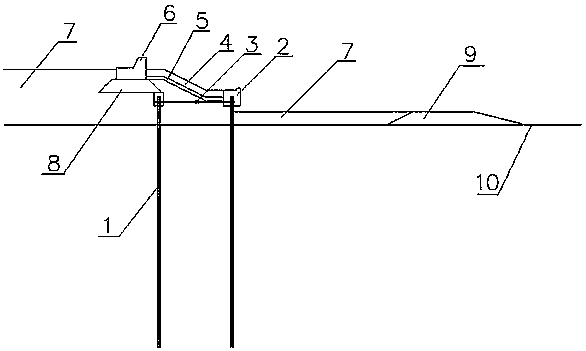

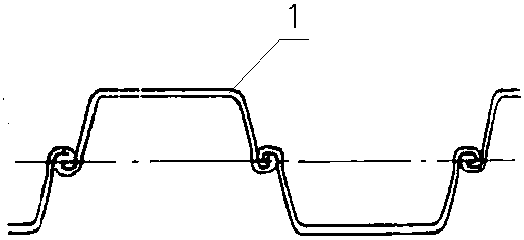

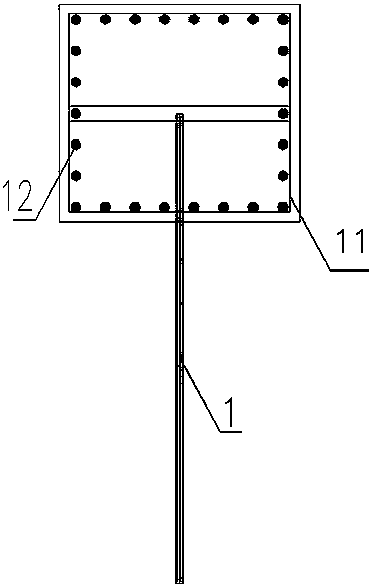

[0010] figure 1 It is a cross-sectional schematic diagram of a seawall structure with double rows of steel sheet piles of the present invention, including two steel sheet piles 1, a concrete cap beam 2, a tie rod 3, two stone cushions 5, a wave wall 6, and medium coarse sand 7, wherein the front and rear The two steel sheet piles 1 are connected by tie rods 3, and the front and rear two steel sheet piles 1 are tensioned by tie rods 3. The top of the two steel sheet piles 1 has cast-in-place concrete cap beams 2, and two stone pads are set between the concrete cap beams 2. In layer 5, a wave wall 6 is set on the outer side of the rear steel sheet pile 1, and the outer side of the front steel sheet pile 1 is backfilled with medium-coarse sand 7, and the medium-coarse sand 7 is backfilled for back pressure.

[0011] In this embodiment, the outer toe of the medium-coarse sand 7 backfilled on the outer side of the front steel sheet pile 1 is filled with the presser foot of a large ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com