Railway sleeper made of composite materials and manufacturing method thereof

A composite material and sleeper technology, applied in the field of composite material sleepers, can solve the problems of environmental protection, low carbon, environmental pollution, etc., and achieve the effects of saving maintenance and protection costs, reducing construction costs, and low thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

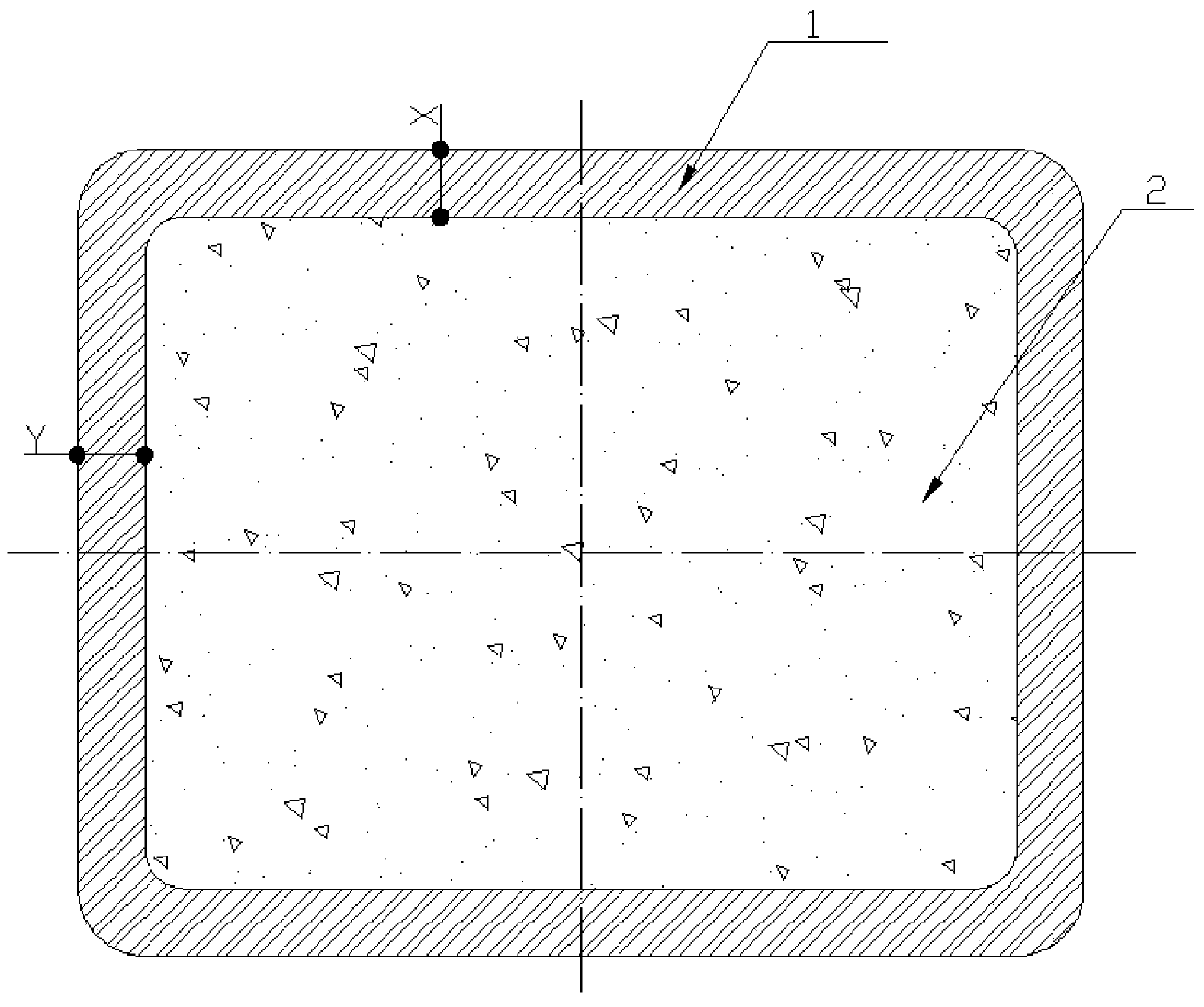

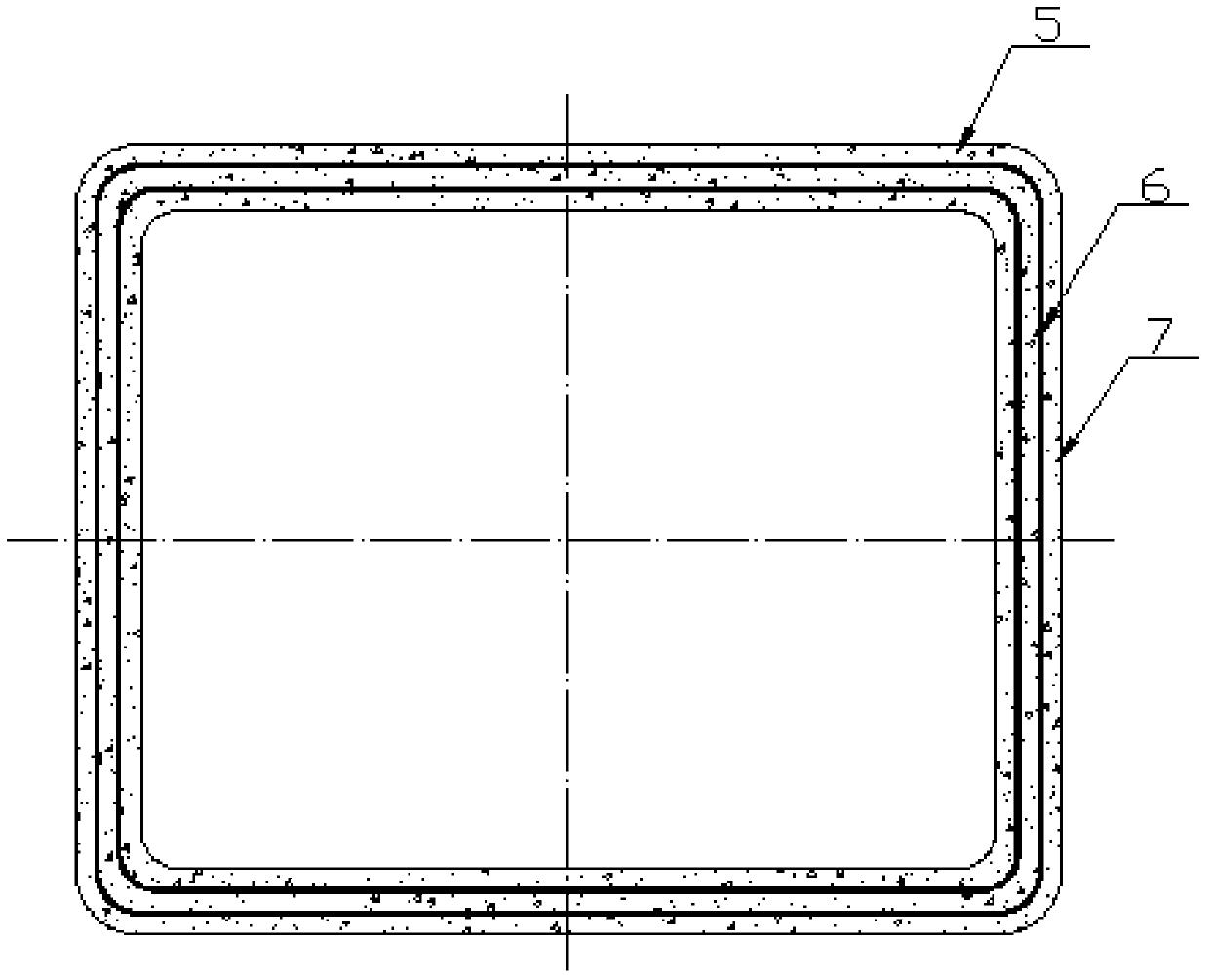

[0025] The same reference numbers used in the figures denote identical or technically equivalent elements.

[0026] The terms "longitudinal" and "transverse" respectively denote that an element extends along a given direction and in a plane perpendicular to this direction. "Cross-section" refers to a section perpendicular to the "longitudinal" direction.

[0027] The following will be described in sequence: (1) the embodiment of the composite material sleeper; and (2) the embodiment of the method for manufacturing the composite material sleeper.

[0028]

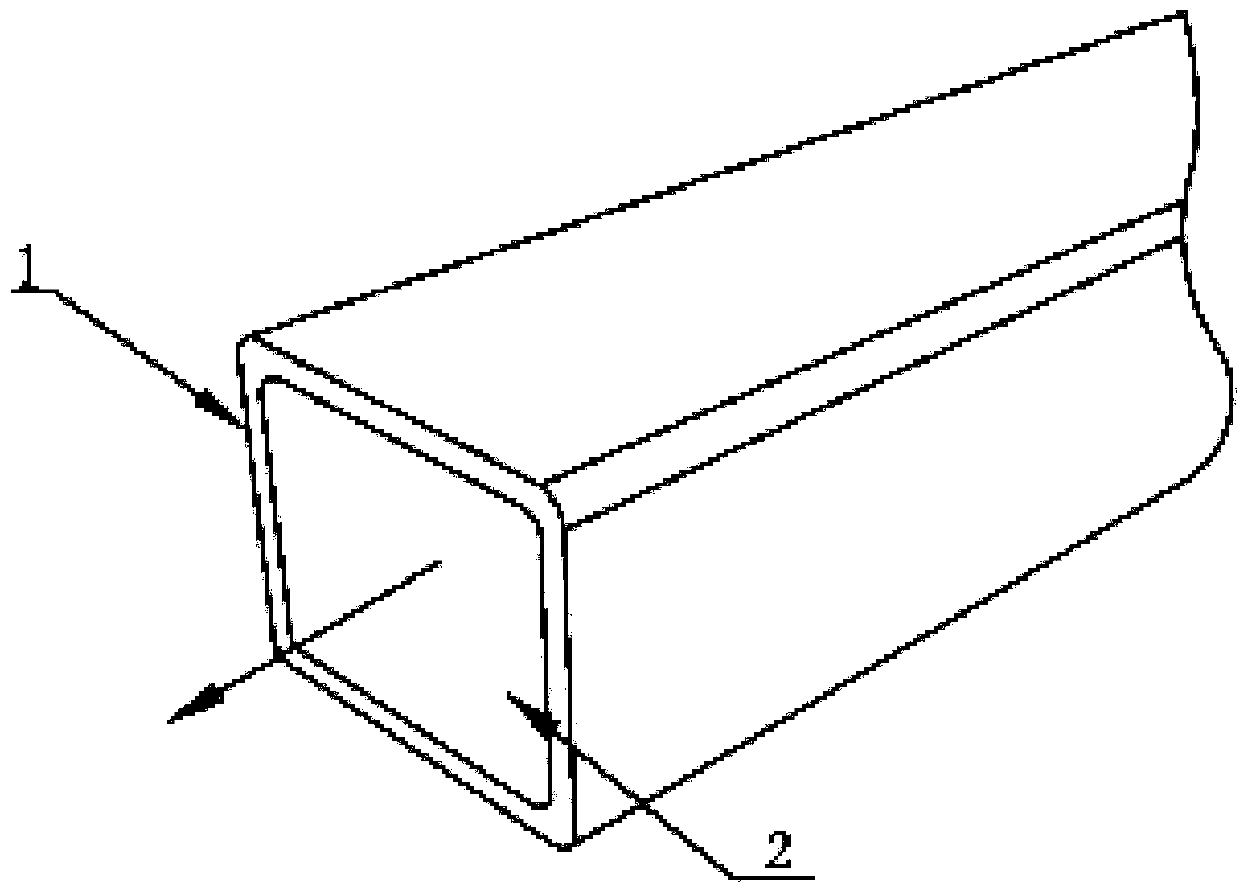

[0029] see figure 1 . figure 1 A schematic perspective view of a composite sleeper according to an embodiment of the invention is shown. Sleepers include along the longitudinal direction (such as figure 1 The basic profile 1 extending in the direction indicated by the middle arrow). The base profile 1 has a cavity extending through it in the longitudinal direction. The cavity may be empty or filled with a core 2 to p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com