Floating slab rail unit

A floating plate and rail technology, applied in the field of rail transit, can solve the problems of poor vibration damping effect, high maintenance cost, poor driving safety, etc., and achieve the effects of high use flexibility, high driving safety, and improved service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways as defined and covered below.

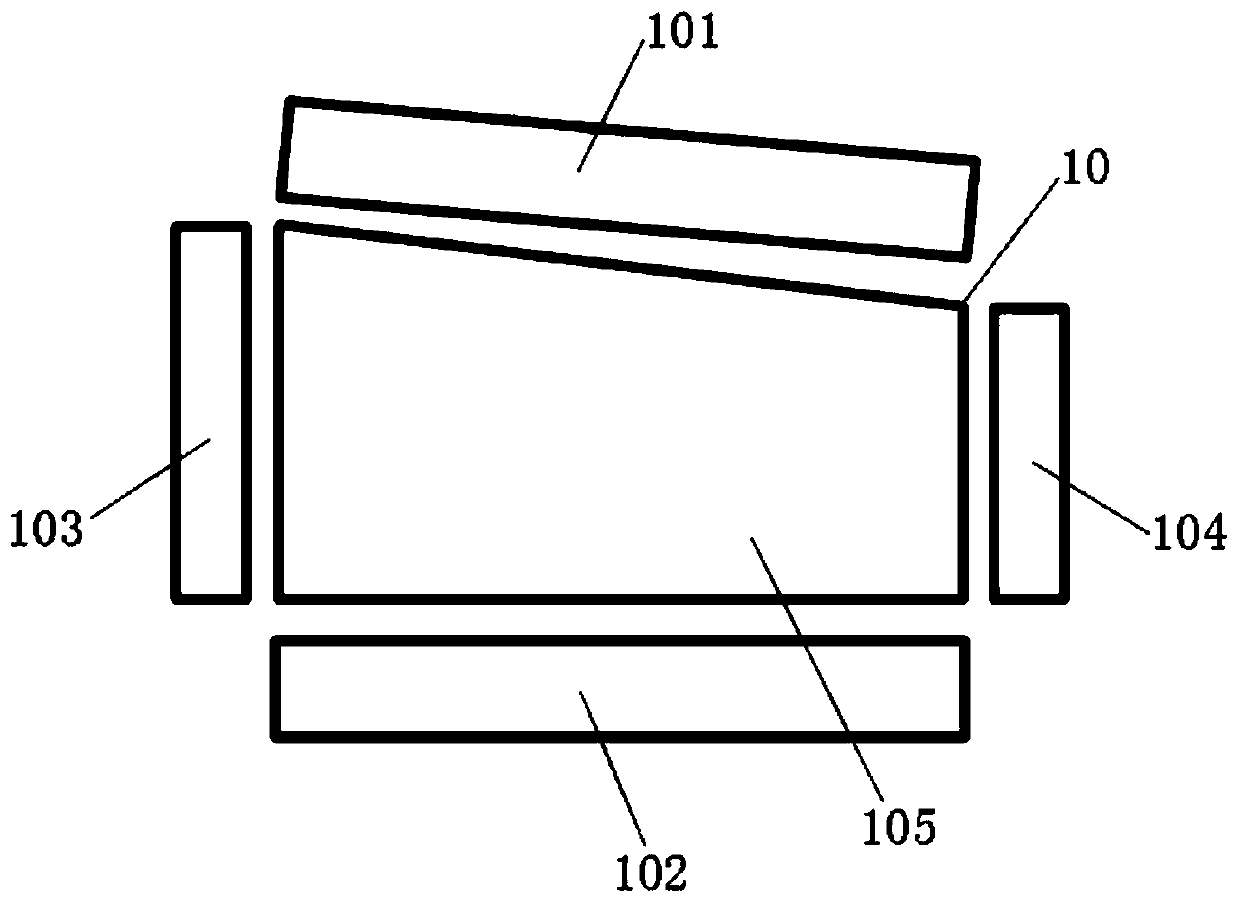

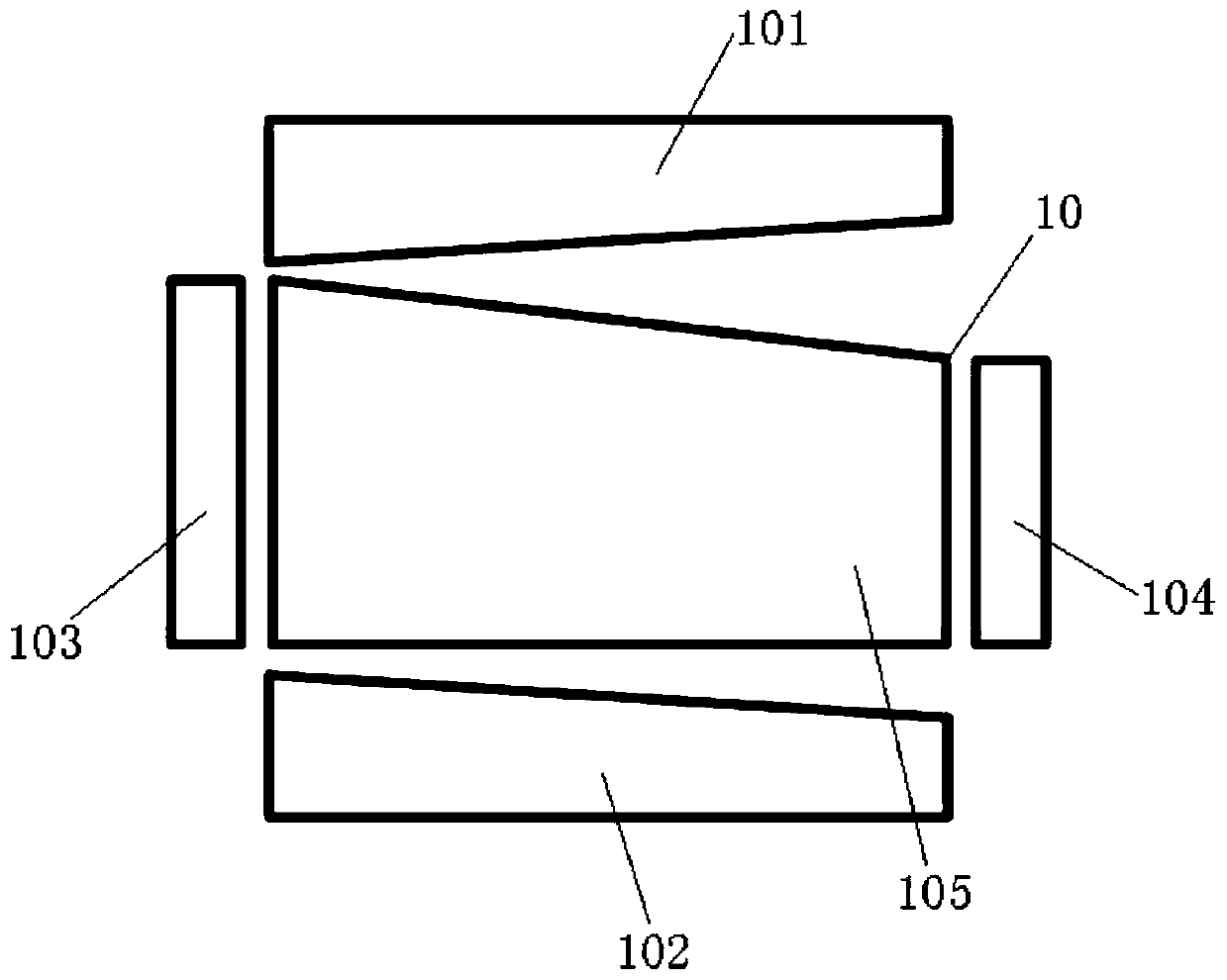

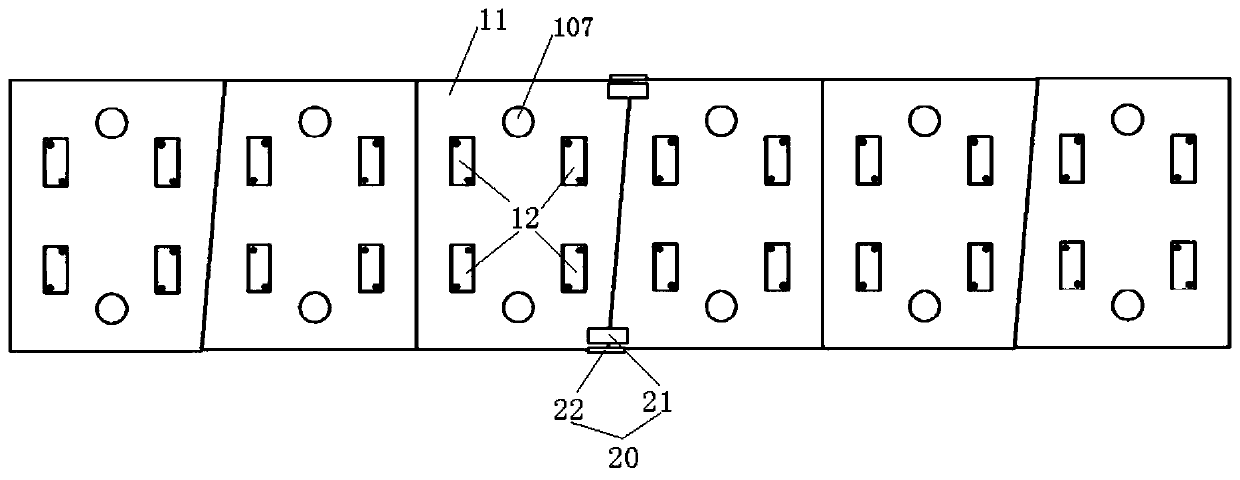

[0041] refer to Figure 1-Figure 13 , a preferred embodiment of the present invention provides a floating board track unit, which is arranged on the track foundation, and the floating board track unit includes a floating cell board arranged along the extending direction of the track line, and a Multiple intelligent vibration isolators for floating support in the vertical direction. The floating unit board includes a plurality of floating board unit blocks 10 and a connecting assembly 20. The plurality of floating board unit blocks 10 are sequentially arranged and spliced together along the extending direction of the track line. Each floating board unit block 10 is provided with a plurality of The connection assembly 20 is used for connecting a plurali...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com