Patents

Literature

749results about How to "Improve the design level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

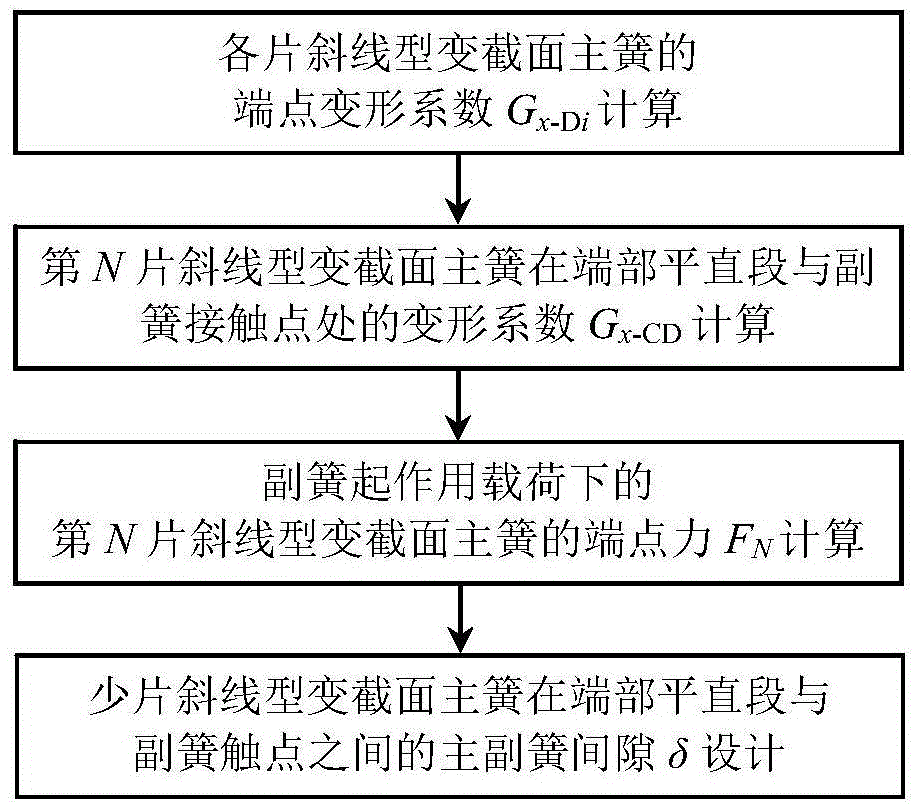

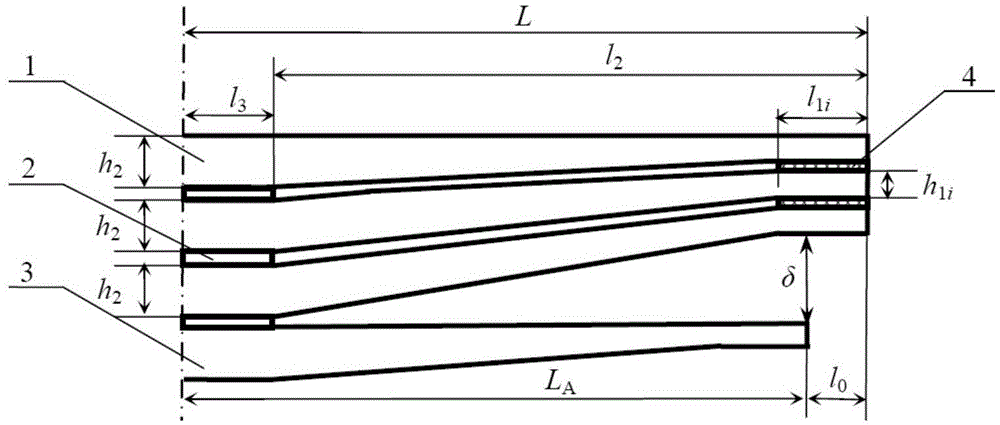

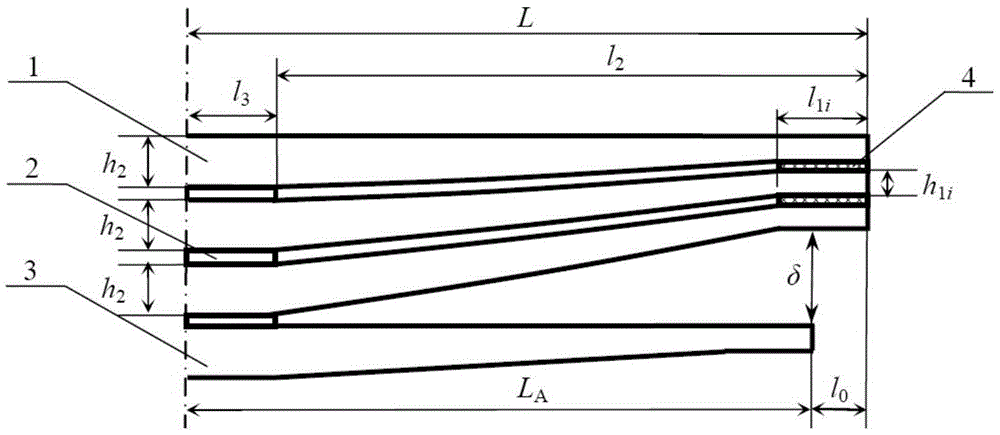

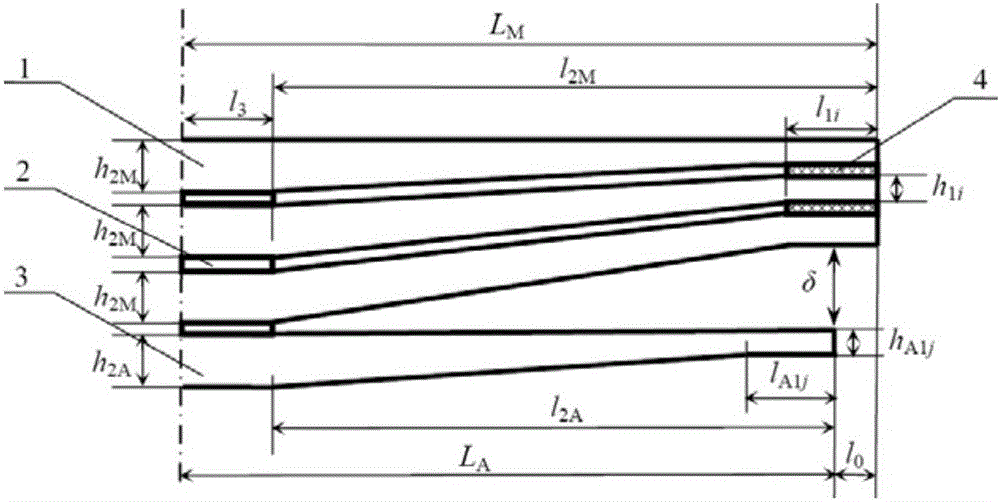

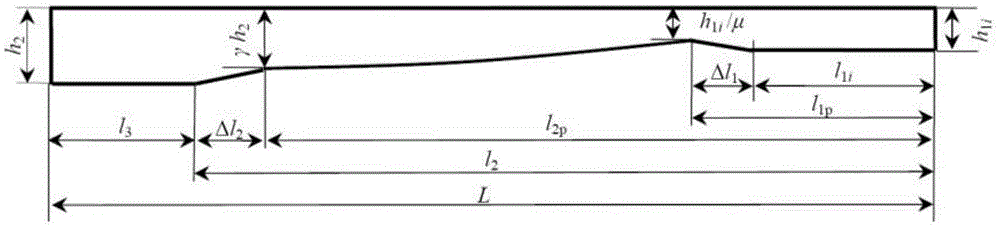

Method for designing gaps of end straight sections of diagonal few-leaf main springs and auxiliary springs

ActiveCN105526290AExact design valueReliable design valueGeometric CADLeaf springsEngineeringDesign values

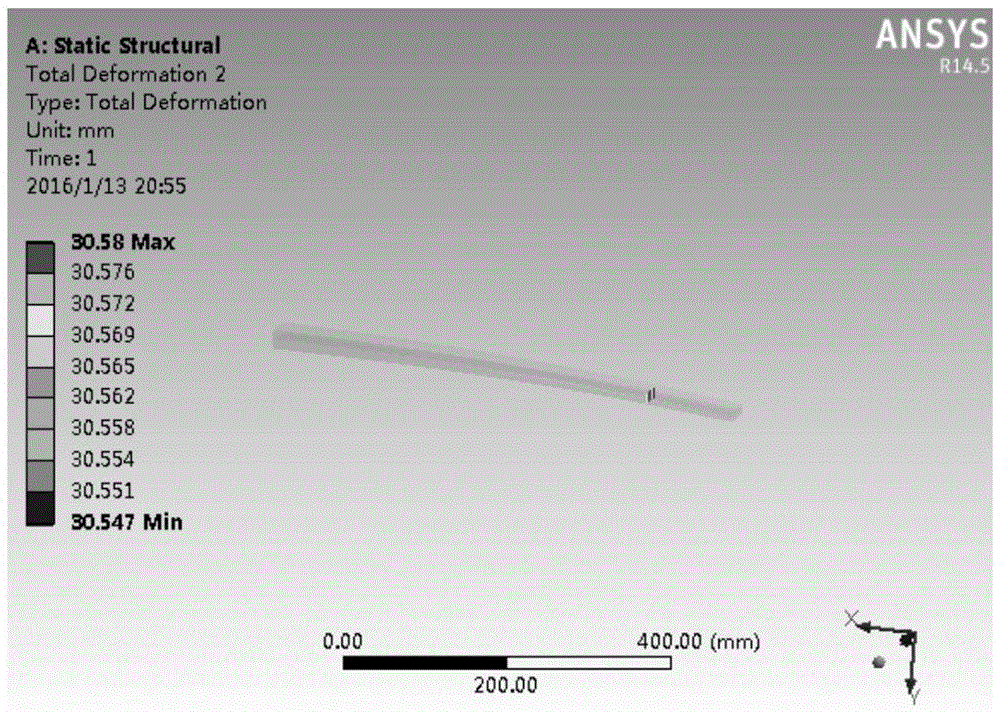

The invention relates to a method for designing gaps of end straight sections of diagonal few-leaf main springs and auxiliary springs, and belongs to the technical field of suspension steel plate springs. The method includes determining endpoint deformation coefficients of the various main springs and deformation coefficients G<x-CD> of contact points of the end straight sections of the N main springs and the auxiliary springs according to structure sizes and elastic modulus of the various diagonal variable-section main springs; acquiring endpoint force F<N> of the N main springs according to acting load of the auxiliary springs and the endpoint deformation coefficients of the various main springs; designing the main and auxiliary spring gaps between contact points of the end straight sections of the main springs and the auxiliary springs according to the thicknesses h<2> of roots of the N main springs, the endpoint force F<N> and the deformation coefficients G<x-CD>. The method has the advantages that as known from simulation verification, design values of the gaps of the end straight sections of the diagonal few-leaf variable-section main springs and the auxiliary springs can be accurately and reliably obtained by the aid of the method, and accordingly the product design level and performance and the vehicle ride comfort can be improved; the design and experiment costs can be reduced, and the product development speeds can be increased.

Owner:山东恒日悬架弹簧股份有限公司

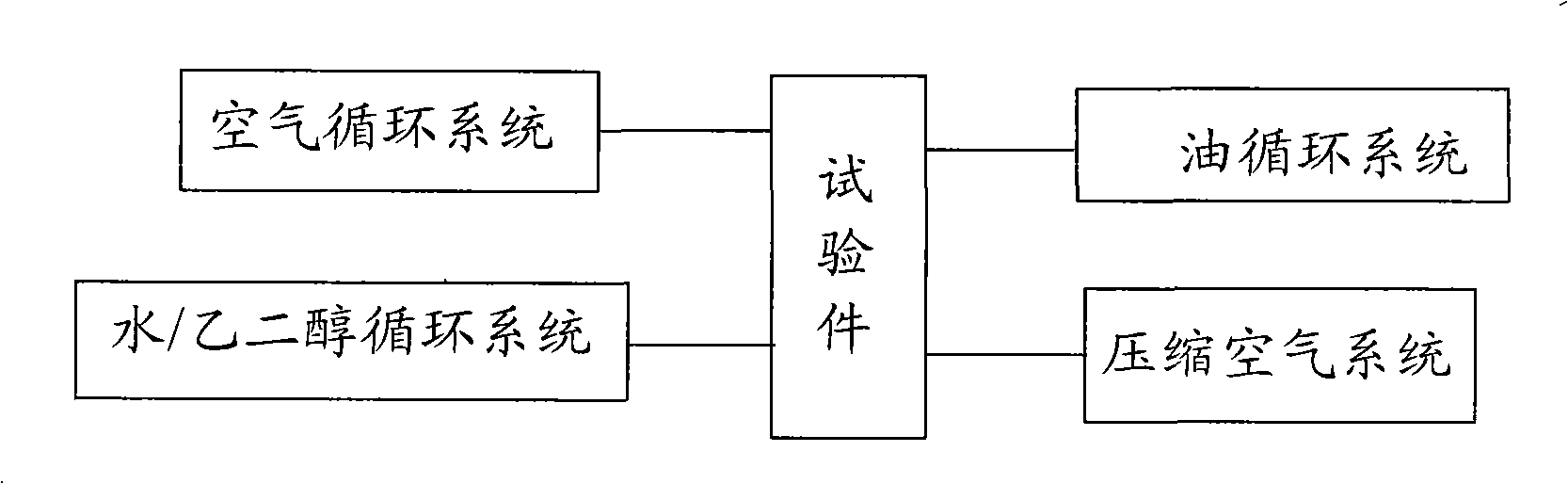

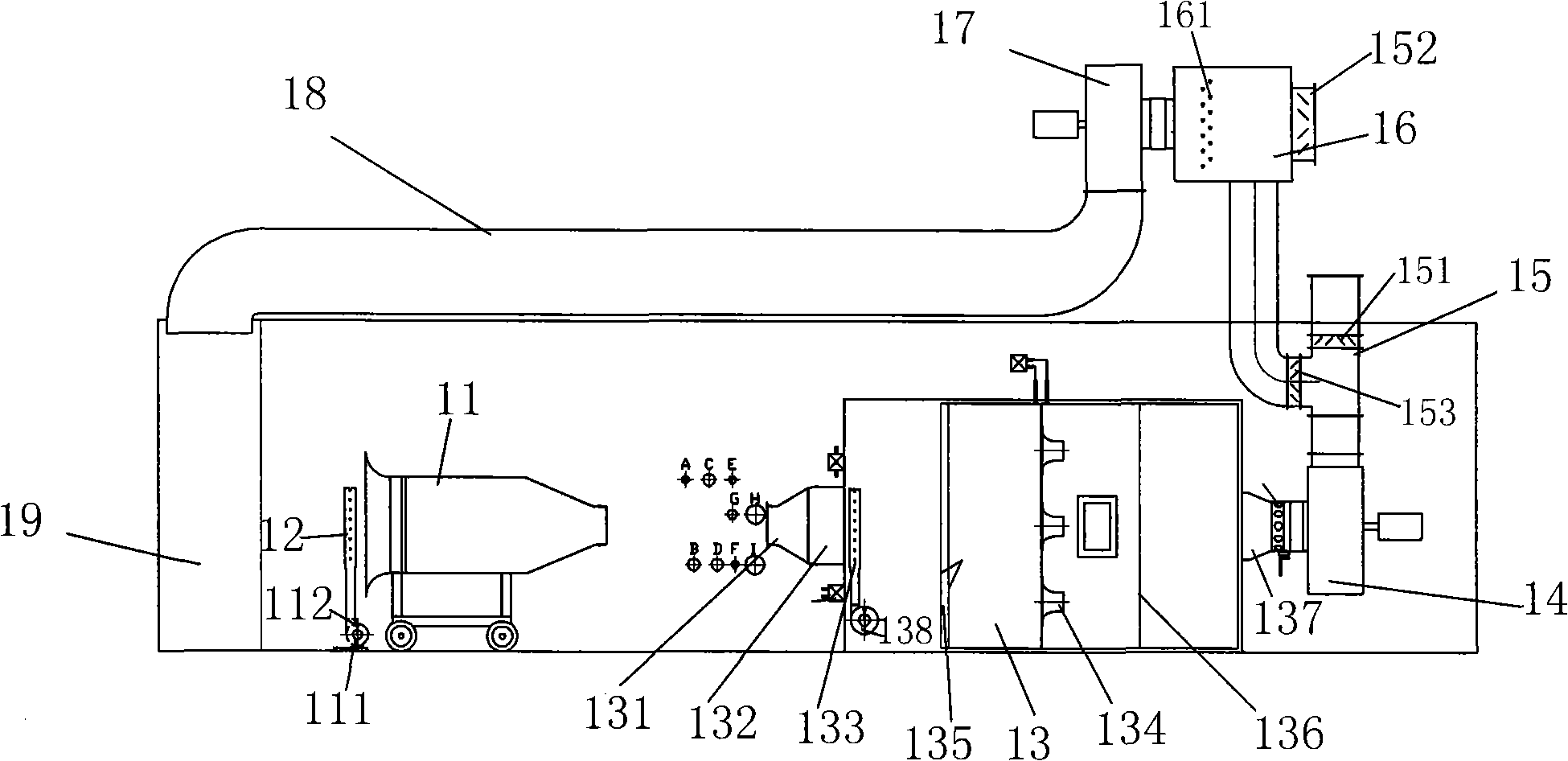

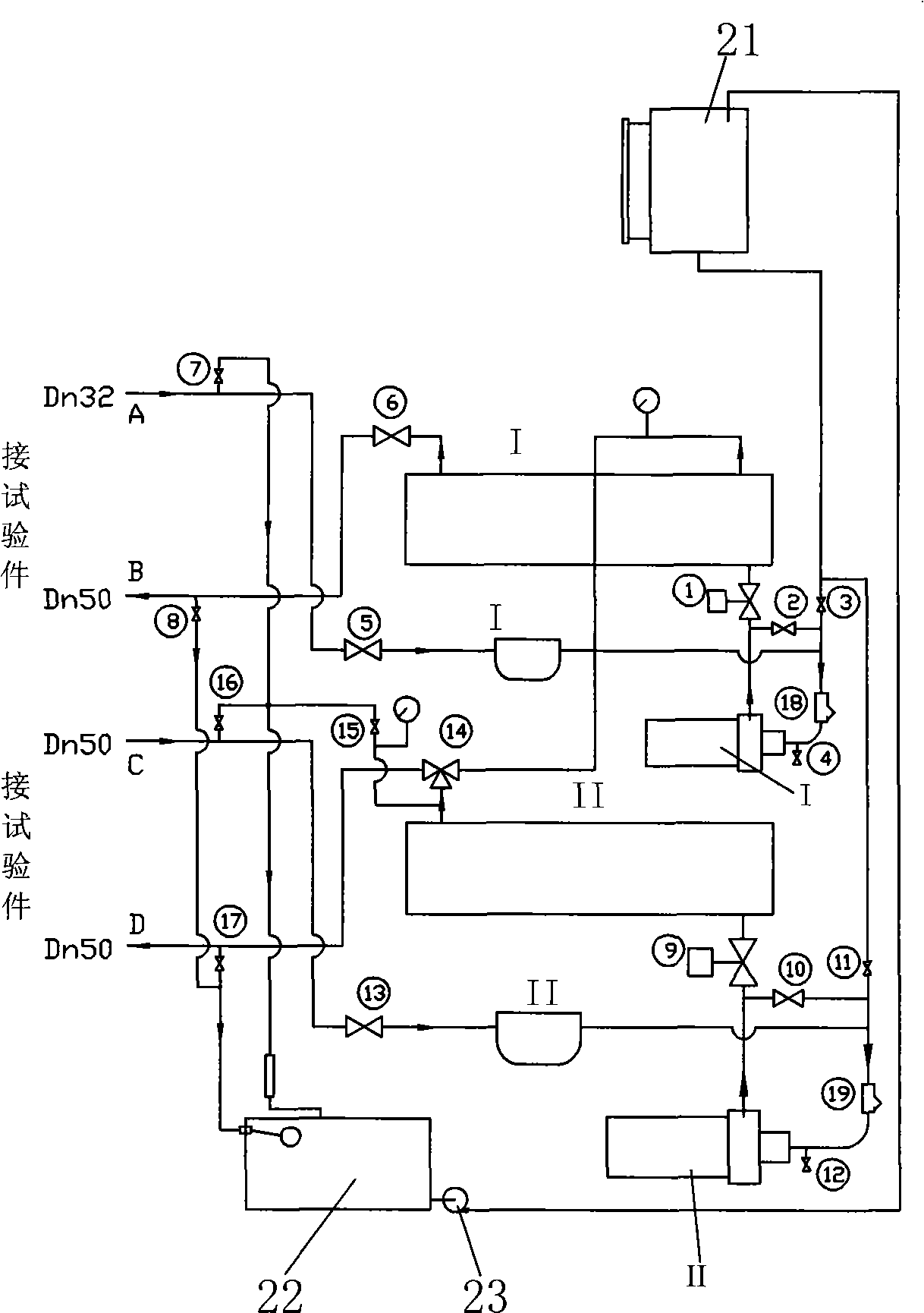

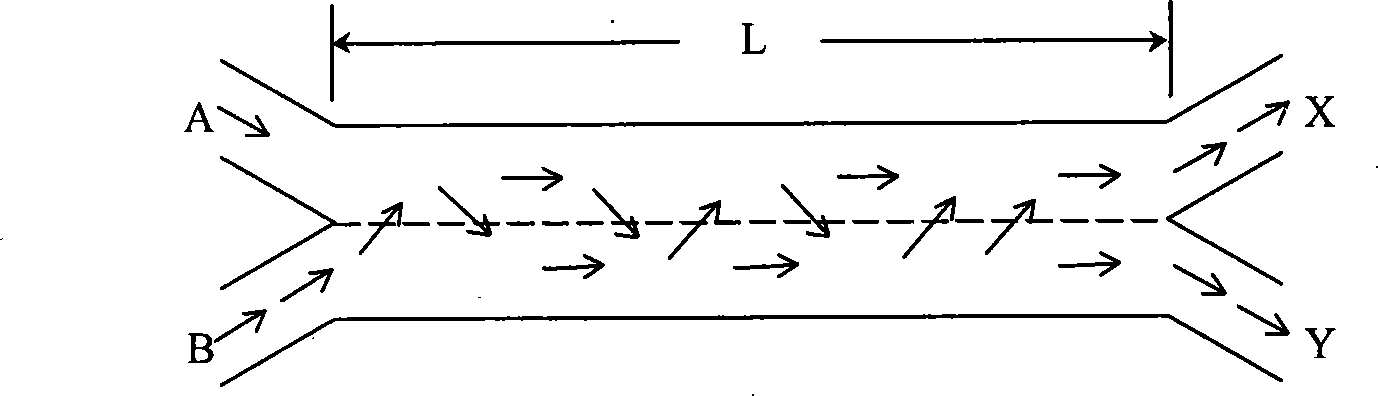

Heat exchanger performance test stand

InactiveCN101261195AImprove the design levelEconomic design levelMaterial heat developmentStructural/machines measurementAir cycleEngineering

The invention discloses a heat exchanger performance test-bed, which comprises an air circulation system, an oil circulation system, a water / ethylene glycol circulation system and a compressed air system that are respectively connected with a test piece. The heat exchanger performance test-bed of the invention, on the one hand, simulates the working condition of the tested heat exchanger test piece so as to test whether the heat transfer capacity and the resistance are qualified for the design regulation requirements, on the other hand, by testing the standard test piece, the performance curve data of fins which have different types and specifications is obtained, and the fin performance database is established and enriched, thereby the design can reach a better, higher and more economical level.

Owner:WUXI GUANYUN HEAT EXCHANGER

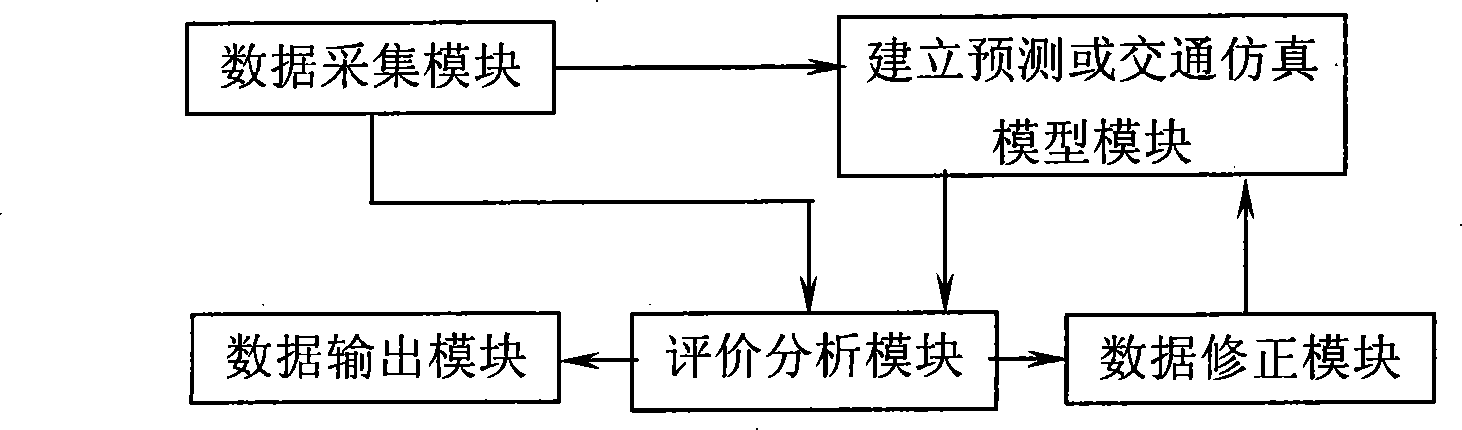

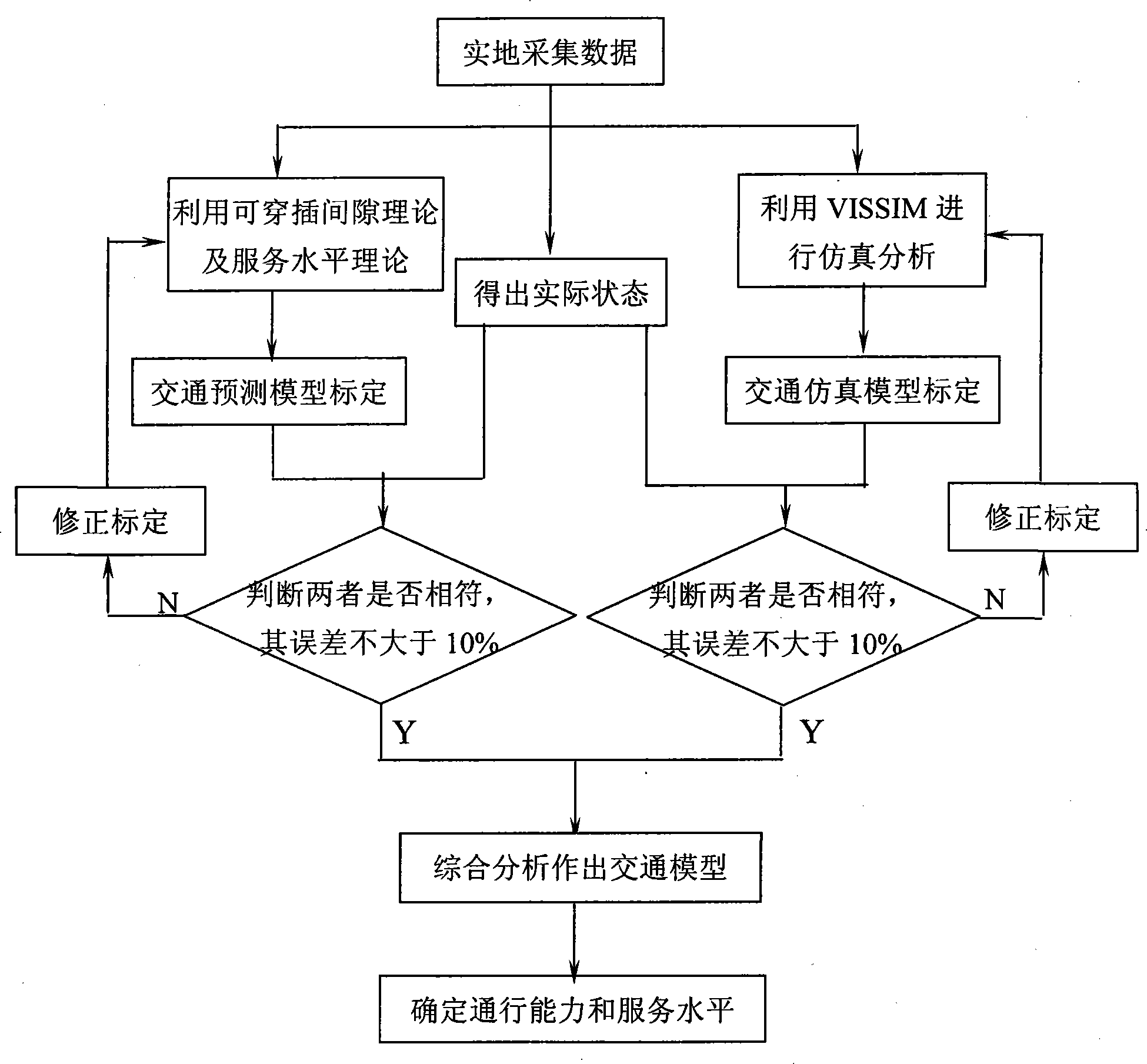

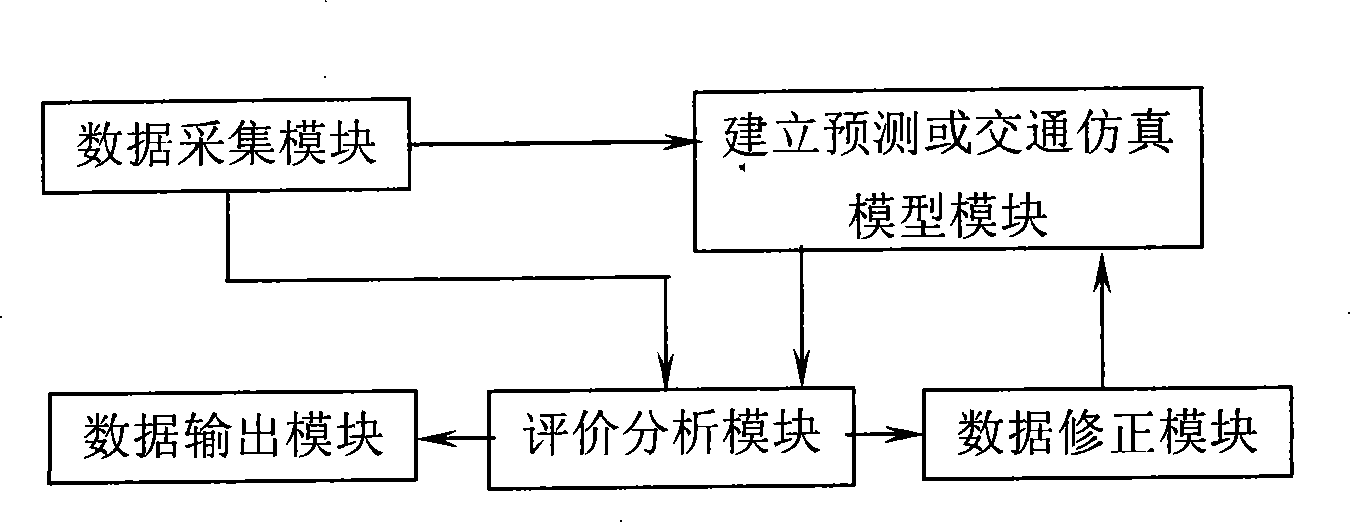

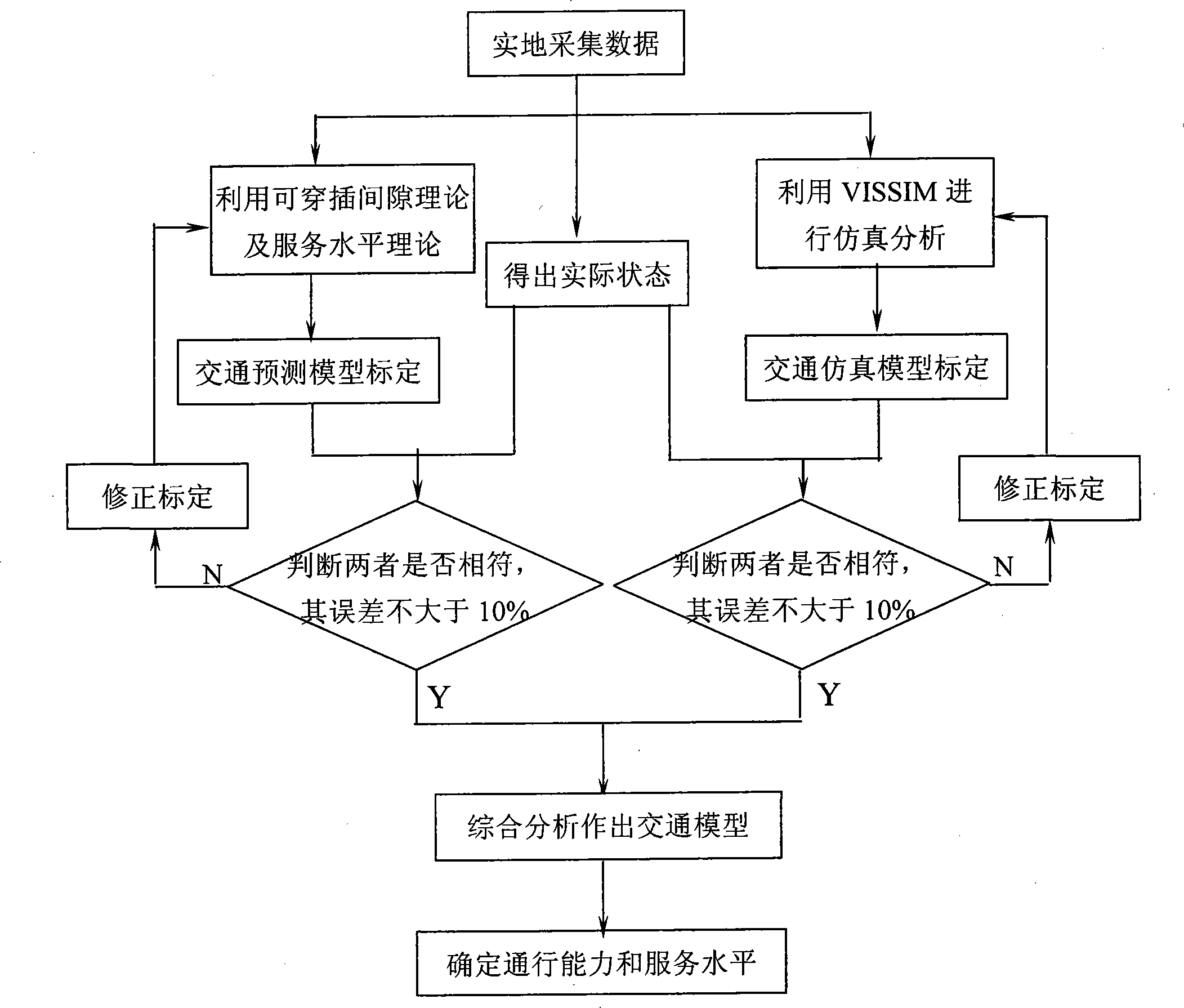

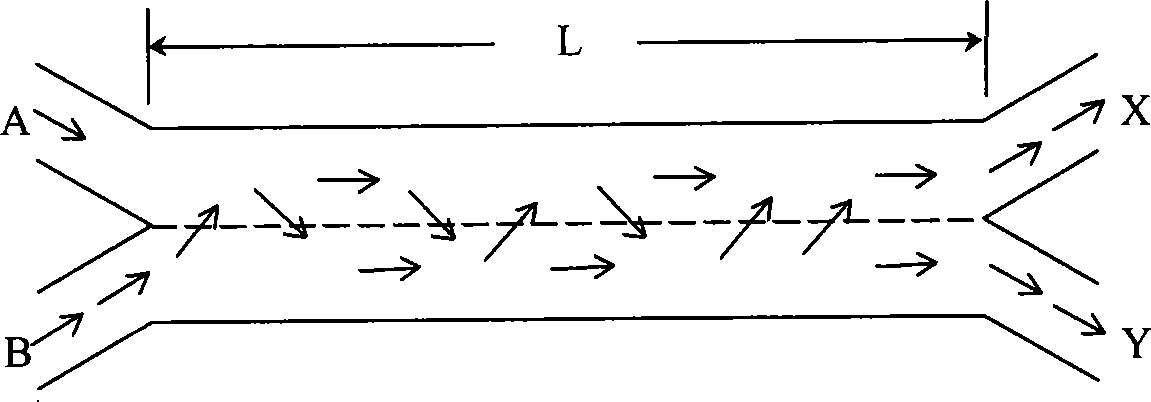

City fast road intercommunicated overpass simulation design system and selection method

InactiveCN101246513AQuantify traffic capacityImprove the design levelDetection of traffic movementSpecial data processing applicationsTriageTraffic capacity

The invention discloses a simulating design system for city expressway interchanges, comprising: data acquisition, model calibration, a data-out module, an evaluation and analysis module connecting with the model calibration module and data-out module respectively, and a data amendment module connecting between the evaluation and analysis module and the model calibration module. Meanwhile a model building and design method using the design system is disclosed too, which comprises: collecting the characteristic parameter of the traffic flow of typical expressway basic sections, interchange triage / confluence area, cutting area and various ramps; building the corresponding database and traffic capacity theoretical analysis model; demarcating and amending speed and density model with determinate service level; building traffic capacity analysis model suiting the traffic flow characteristic of the city expressway interchange. At last, the design of the lectotype of the city expressway interchanges conducted by the design model comprises analyzing and forecasting the traffic, raising a preliminary scheme, calculating the traffic capacity of the interchange, analyzing the suitability, selecting a rational strategy.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

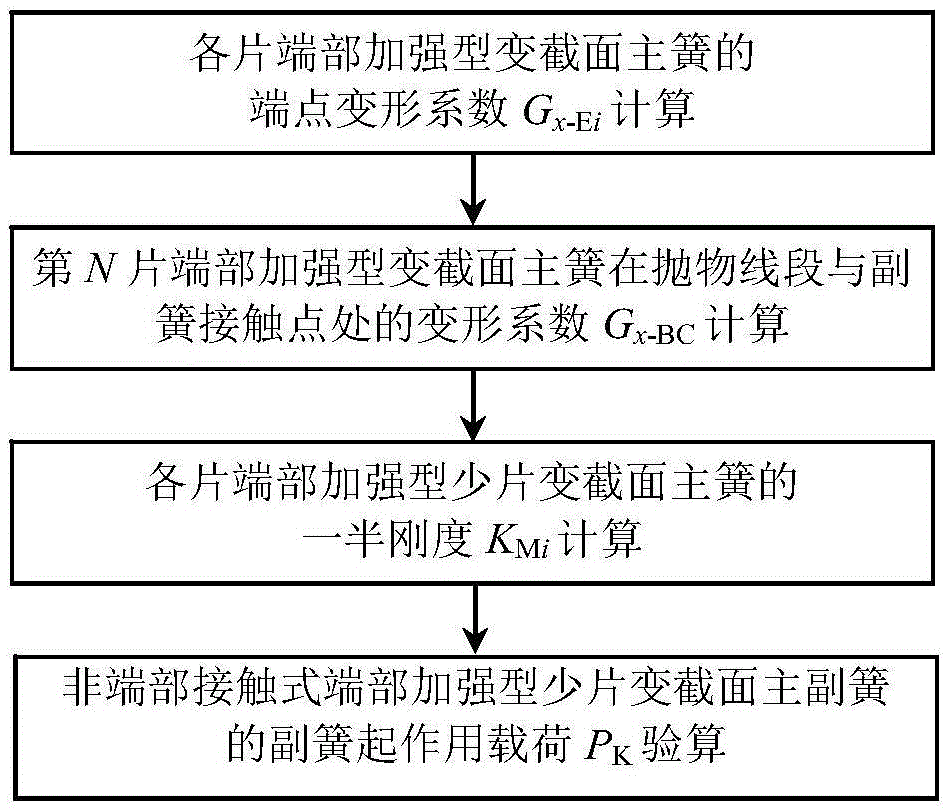

Auxiliary spring work load checking method of non end part contact type end part strengthened few-leaf main and auxiliary springs

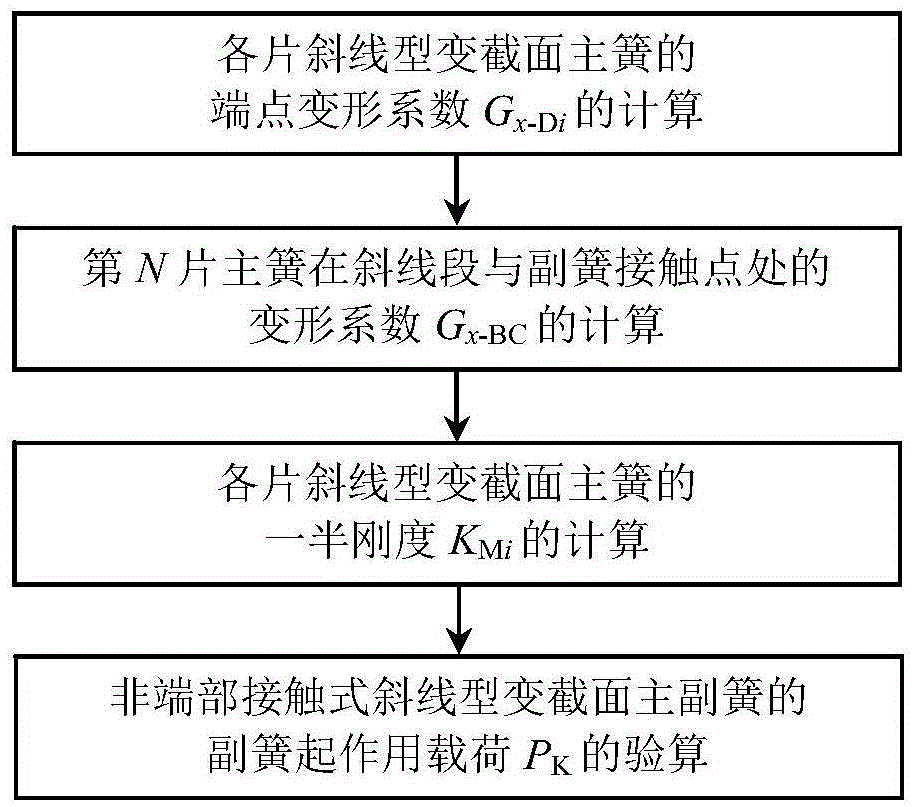

ActiveCN105590009AImprove the design levelThe checking method is reliableDesign optimisation/simulationSpecial data processing applicationsContact typeEngineering

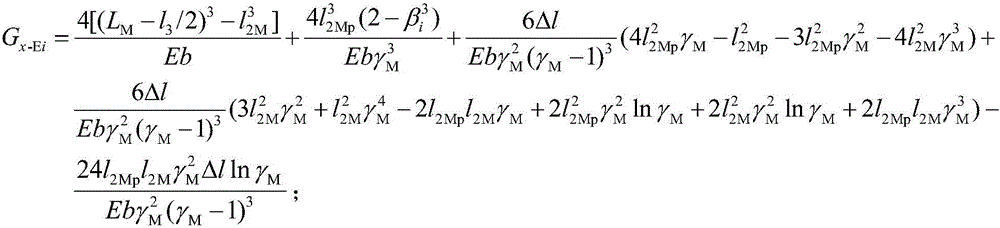

The invention relates to an auxiliary spring work load checking method of a non end part contact type end part strengthened few-leaf main and auxiliary springs belonging to the suspension steel plate spring technical field. According to the method of the invention, firstly, according to the structure size and the elastic modulus of each end part strengthened few-leaf cross-section variable main spring, the end point deformation coefficient Gx-Ei and the half rigidity KMi of each main spring, and the deformation coefficient Gx-BC at the contact point of the Nth main spring and an auxiliary spring on a parabolic segment can be determined; then, according to the half rigidity KMi of each main spring, the thickness h2 of a root straight section, the Gx-BC of the Nth main spring and a main and auxiliary spring interval Delta design value, the auxiliary spring work load of the non end part contact type end part strengthened few-leaf cross-section variable main and auxiliary springs is checked. Through the emulation proof, in adoption of the method of the invention, the accurate and reliable auxiliary spring work load checking value can be obtained; therefore, the design levels and performances of the few-leaf cross-section variable main and auxiliary springs and the smoothness of a vehicle are improved; moreover, the design and test cost is saved; and the product development speed is accelerated.

Owner:SHANDONG AUTOMOBILE SPRING FACTORY ZIBO CO LTD

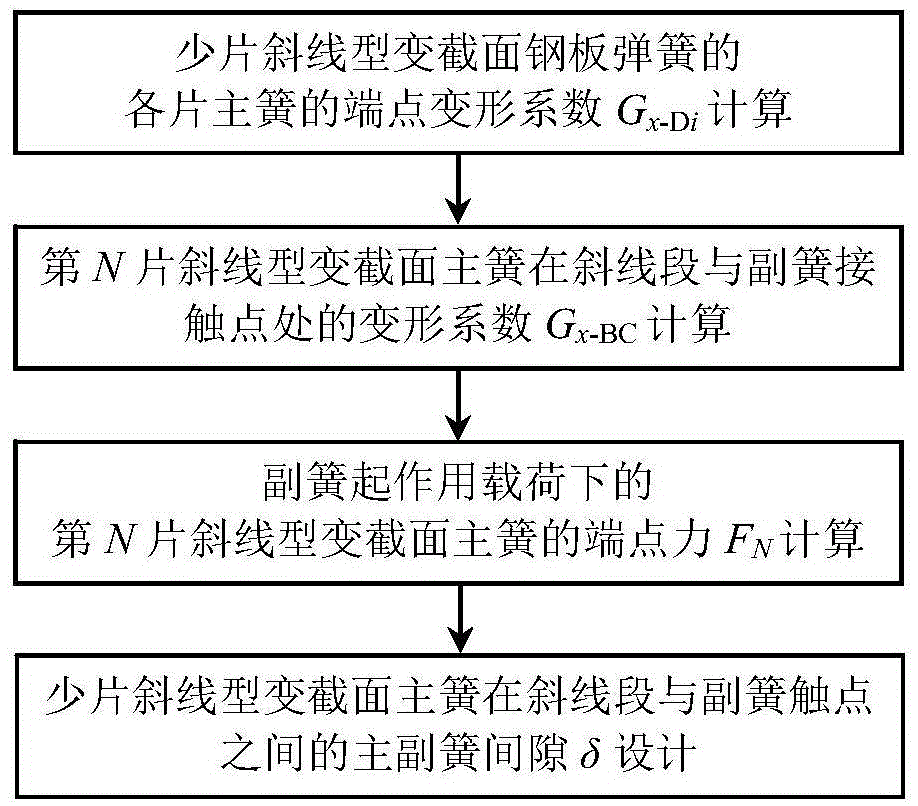

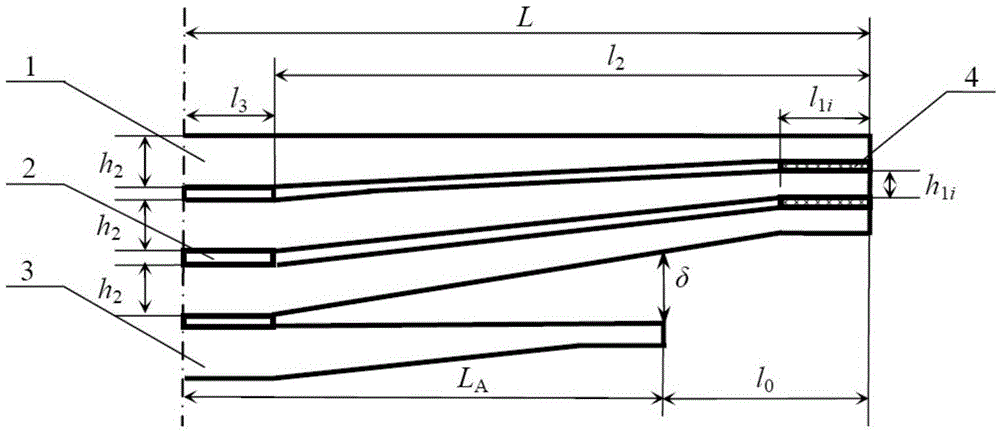

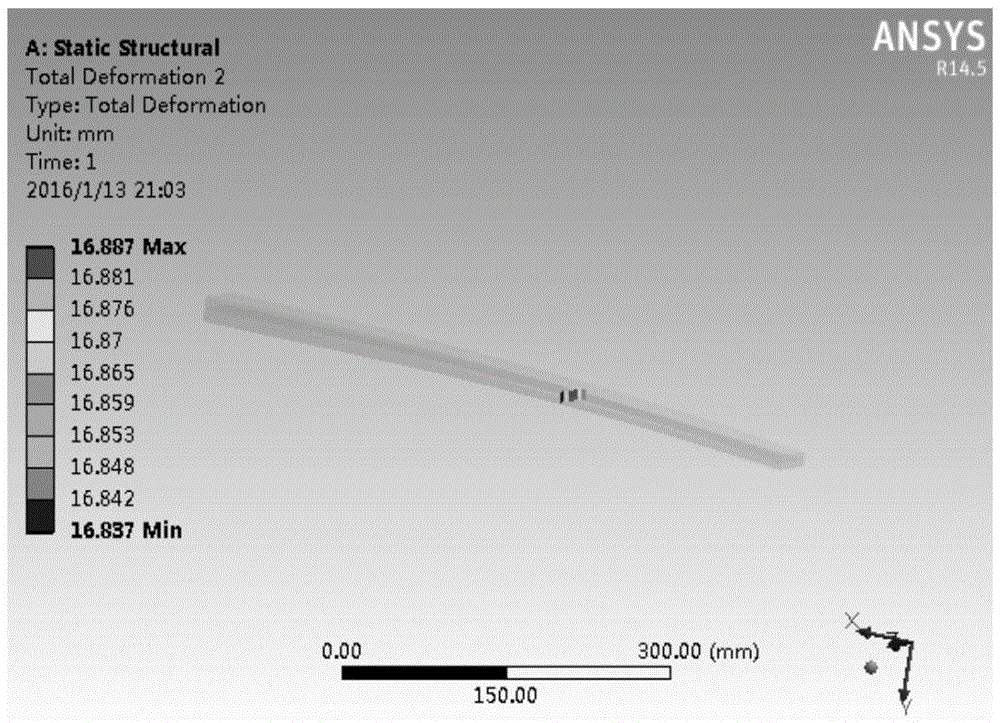

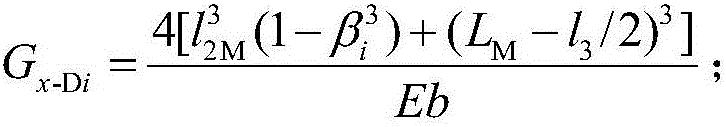

Method for designing few-leaf oblique line type variable-section main springs in gaps between oblique line segments and auxiliary spring

ActiveCN105550487AImprove the design levelQuality improvementGeometric CADDesign optimisation/simulationLine segmentOblique line

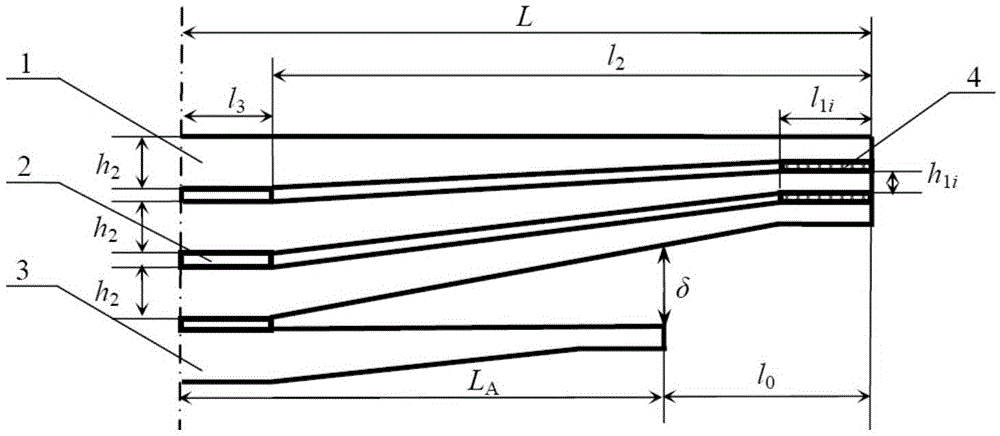

The invention relates to a method for designing few-leaf oblique line type variable-section main springs in the gaps between oblique line segments and an auxiliary spring, and belongs to the technical field of suspension steel plate springs. According to the structural sizes and the elasticity moduli of the oblique line type variable-section main springs, the endpoint deformation coefficient Gx-Di of each main spring and the deformation coefficient Gx-BC of the Nth main spring at the contact point of the corresponding oblique line segment and the auxiliary spring are determined first; then, according to the required auxiliary spring acting load design value and the endpoint deformation coefficient Gx-Di of each main spring, endpoint force FN of the Nth main spring is obtained; then, according to the thickness h of the root straight section of the Nth main spring, the Gx-BC and the FN, main spring and auxiliary spring gaps between the oblique line segment of the main springs and the contact point of the auxiliary spring are designed. Through simulation verification, it can be known that the main and auxiliary spring gap design value meeting the auxiliary spring acting load requirement can be obtained by means of the method, and the product design level, product performance and vehicle smoothness are improved. Meanwhile, design and testing cost is reduced, and product development speed is increased.

Owner:JIANGSU HAIHONG MACHINERY MFG

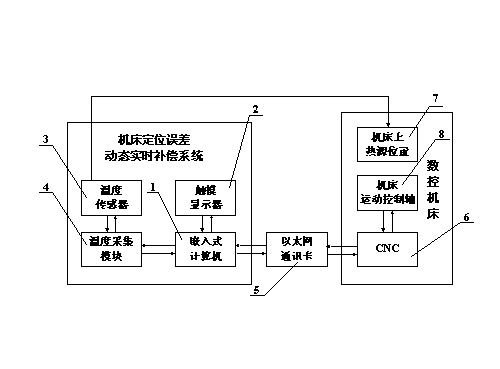

Dynamic real-time compensation system for positioning errors of numerical-control machine tool

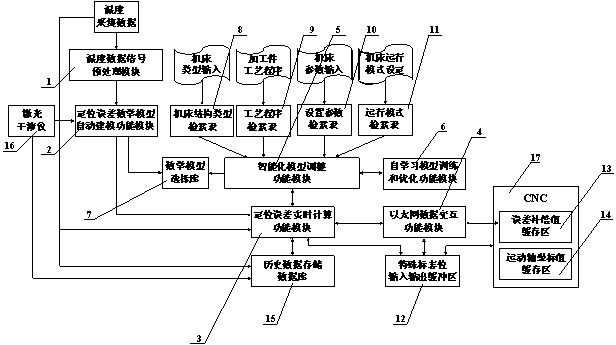

InactiveCN103576604AImprove robustnessImprove adaptabilityProgramme controlComputer controlNumerical controlMathematical model

The invention discloses a dynamic real-time compensation system for positioning errors of a numerical-control machine tool. The system comprises an error compensation hardware system and a compensation software platform based on network data interaction. The hardware system serves as a carrier and an executing part of compensation software and is used for achieving connection, communication, data storage and human-computer interaction between all functional modules. A programming mode oriented to objects is adopted for the software system, the software system has data interaction with CNC through an Ethernet, and therefore temperature signals can be collected and preprocessed, a positioning error mathematical model can be automatically established, and real-time calculation of the positioning errors, the intelligent model adjusting function, and training and optimizing on a self-learning model can be achieved. Due to cooperative work of the software system and the hardware system, the dynamic real-time compensation for the positioning errors of the numerical-control machine tool is achieved. The compensation system for the positioning errors is easy to operate, wide in application range and capable of meeting positioning error compensation requirements of various numerical-control machine tools and has great practical and commercialized application significance in improving machining accuracy of the numerical-control machine tools.

Owner:上海睿涛信息科技有限公司

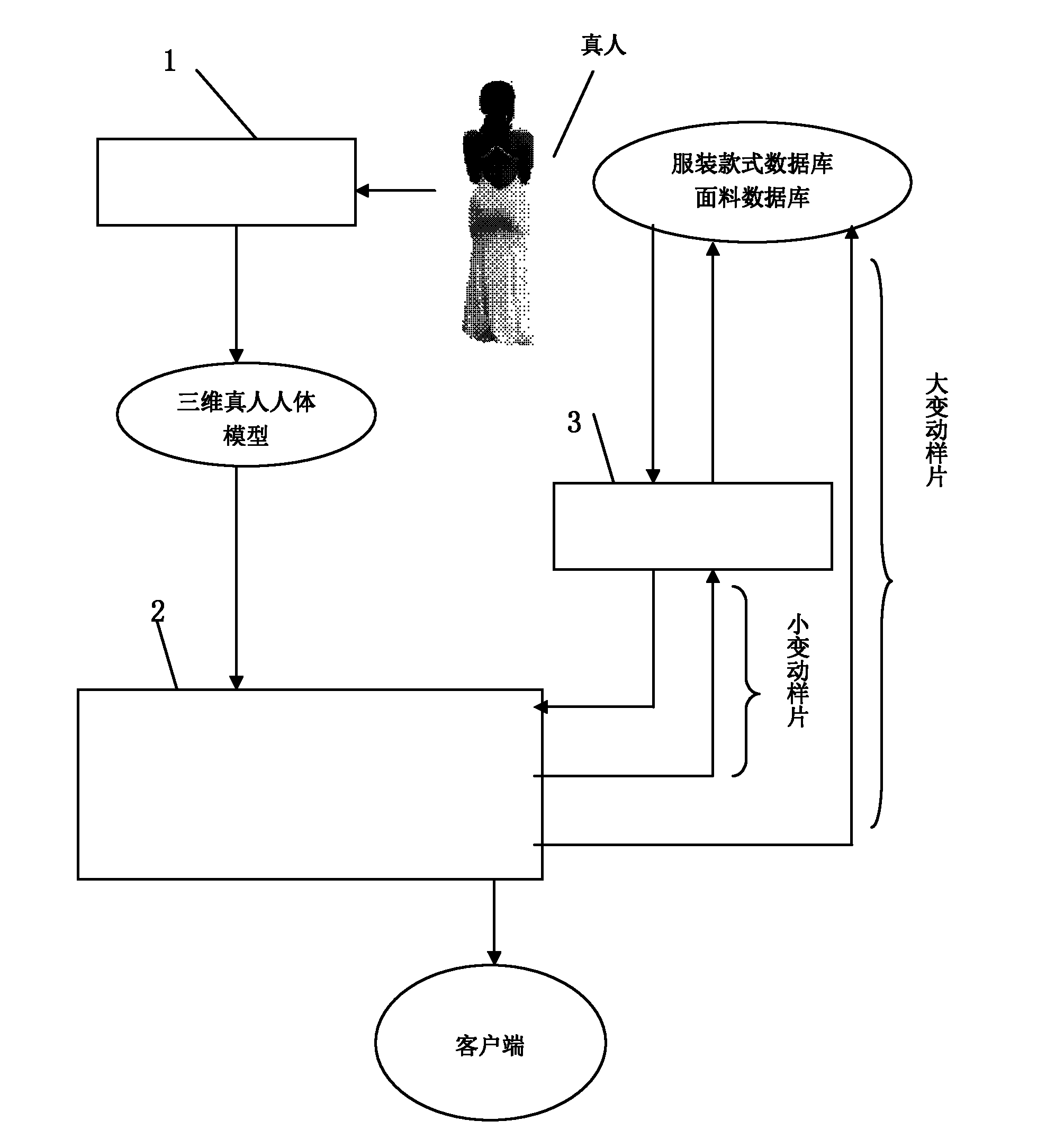

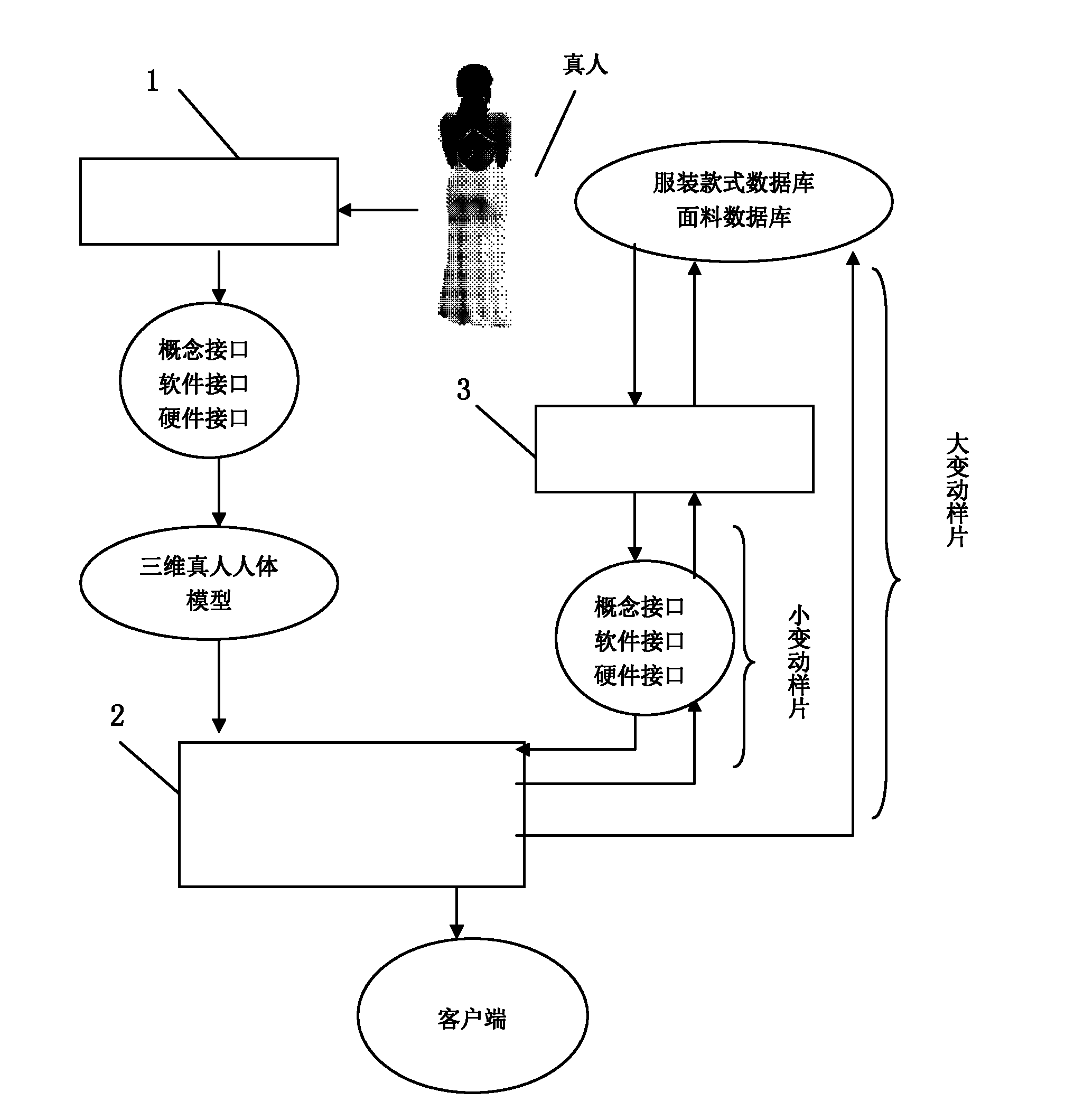

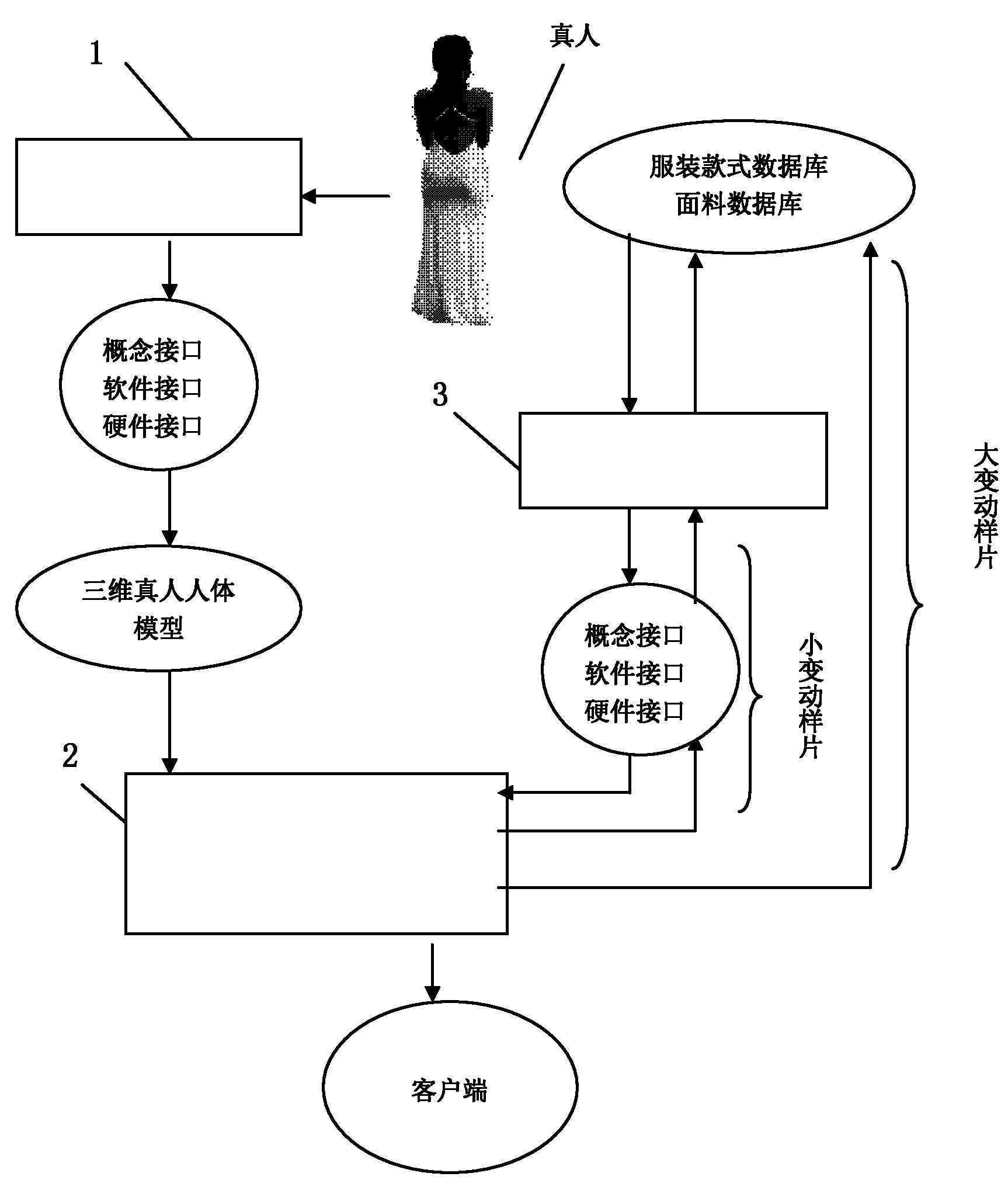

Three-dimensional virtual dressing method of clothes for real person

InactiveCN102044038AImprove the design levelImprove design efficiencyCommercePersonalizationBody measure

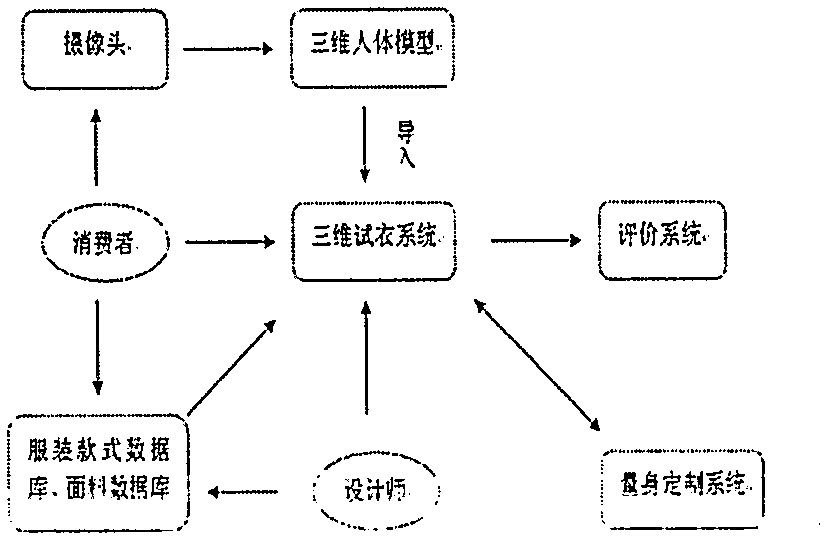

The invention relates to a three-dimensional virtual dressing method of clothes for a real person, relating to the technical fields of digital clothing design. The system is characterized in that an object of the three-dimensional virtual dressing of the clothes is three-dimensional real-person body model structured according to the three-dimensional measuring data of the real person. A three-dimensional body measuring system measures the data of the real-person body of a consumer, the figure curve characteristic and the face characteristic, and guides the data into a three-dimensional dressing system; the original standard body model of the three-dimensional dressing system is corrected according to the data of the real person in the three-dimensional dressing system, and the three-dimensional real-person body model is showed virtually so as to lead the virtual body model to embody the figure characteristic and the face characteristic of the real person; the consumer and a designer decide the style, the fabric and the color design data by two-way selection, guide the data into a tailor-making system, complete the design of clothes and generate individual clothes sample pieces automatically; ready-made clothes are sewn virtually, and when the clothes are worn on the three-dimensional real-person body model, the individual dressing effect is intuitively displayed; and the design level and design efficiency of clothes are greatly improved.

Owner:SHANGHAI UNIV OF ENG SCI

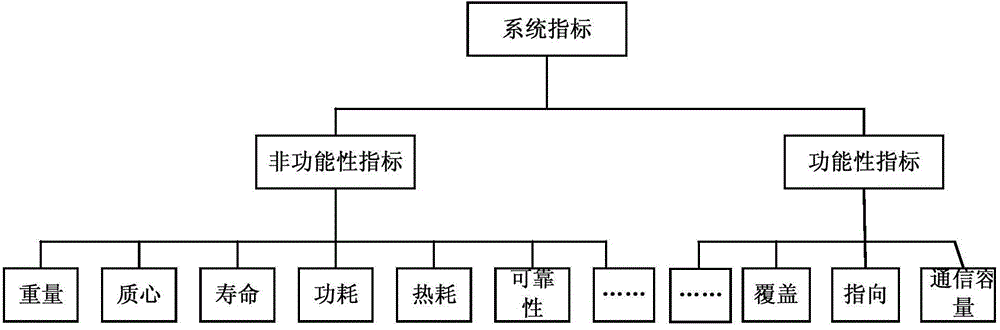

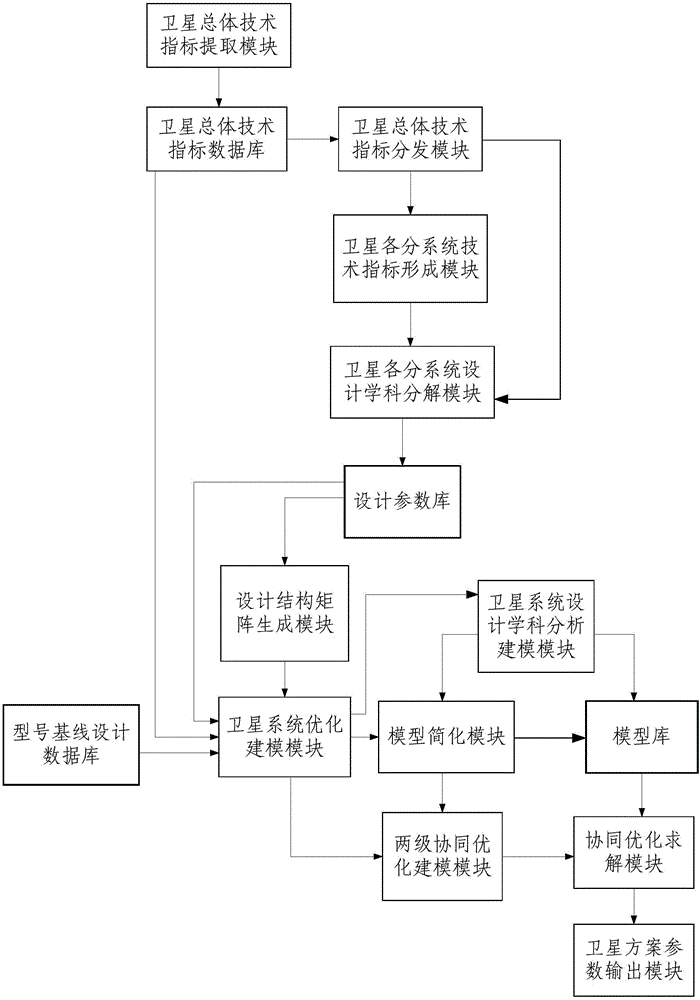

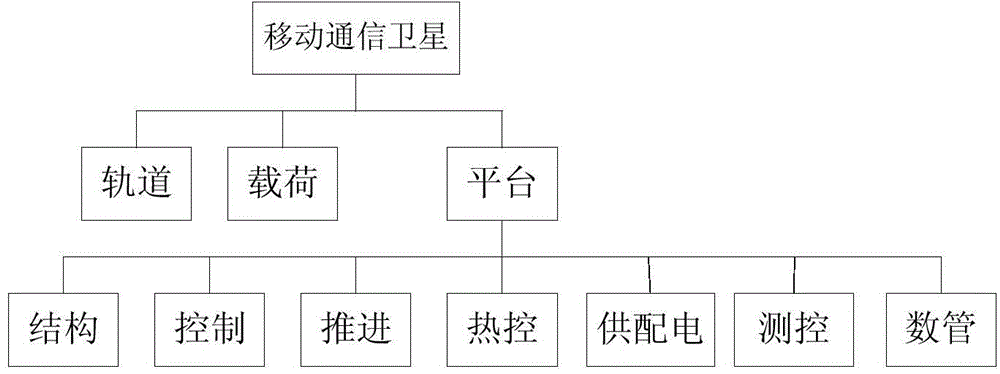

Satellite overall plan confirmation system based on multidisciplinary optimization and realization method

ActiveCN104133932AImprove the design levelImprove performanceDesign optimisation/simulationRadio transmissionSubject analysisDecomposition

The invention discloses a satellite overall plan confirmation system based on a multidisciplinary optimization and a realization method. The satellite overall plan confirmation system comprises a satellite total technical index extraction module, a satellite total technical index distribution module, each subsystem technical requirement formation module of a satellite, a satellite system design subject decomposition module, a design structure matrix generation module, a satellite system design subject analysis modeling module, a satellite system optimal modeling module, a model simplification module, a two-stage collaborative optimization modeling module, a collaborative optimization solving module, a satellite total technical index database, a model number base line design database, a design parameter library, a model library and a satellite overall plan parameter output module. The multidisciplinary design optimization of the satellite overall plan is realized by system index extraction, design task subject decomposition, design subject analysis modeling, design structure matrix construction, satellite overall plan multidisciplinary design optimization description, model simplification and two-stage collaborative optimization modeling and solving.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

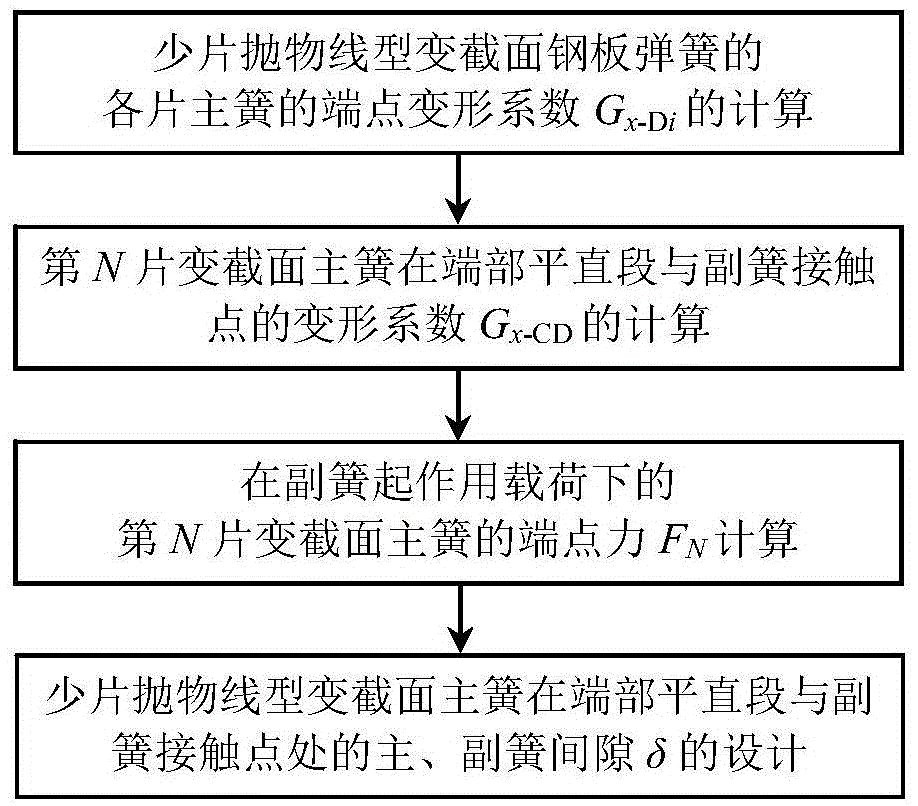

Design method for few parabolic type variable cross-section main spring end and auxiliary spring gaps

ActiveCN105608300AImprove the design levelQuality improvementDesign optimisation/simulationSpecial data processing applicationsSteel platesElastic modulus

The invention relates to a design method for few parabolic type variable cross-section main spring end and auxiliary spring gaps, and belongs to the technical field of suspension steel plate springs. The method comprises the steps that according to the structural size and elastic modulus of each parabolic type variable cross-section main spring, an end point deformation coefficient of each main spring and a deformation coefficient Gx-CD of the Nth main spring on the contact point of an auxiliary spring and the end straight section; then, according to the auxiliary spring acting load design requirement value and the end point deformation coefficient of each main spring, the endpoint force FN of the Nth main spring is obtained; then, according to the thickness h2 of the straight section at the root of the Nth main spring, the FN and the Gx-CD, the main and auxiliary gaps between the contact points of the auxiliary springs and the end straight sections of the main springs are designed. According to simulation verification, the accurate and reliable main and auxiliary spring gap design values can be obtained by means of the method, the auxiliary spring acting load design requirement is met, and the product design level and performance and the vehicle ride comfort are improved; meanwhile, the product development speed is increased, and the design and testing expenses are lowered.

Owner:慕贝尔汽车部件(太仓)有限公司

City fast road intercommunicated overpass simulation design system and method for establishing design model

ActiveCN101246514AQuantify traffic capacityImprove the design levelDetection of traffic movementSpecial data processing applicationsTraffic capacityData acquisition

The invention discloses a simulating design system for city expressway interchanges, comprising: data acquisition, model calibration, a data-out module, an evaluation and analysis module connecting with the model calibration module and data-out module respectively, and a data amendment module connecting between the evaluation and analysis module and the model calibration module. Meanwhile a modelbuilding and design method using the design system is disclosed too, which comprises: collecting the characteristic parameter of the traffic flow of typical expressway basic sections, interchange triage / confluence area, cutting area and various ramps; building the corresponding database and traffic capacity theoretical analysis model; demarcating and amending a speed and density model with determinate service level; building a traffic capacity analysis model suiting the traffic flow characteristic of the city expressway interchanges. Designers can carry out the adaptability analysis of the interchanges for communications using the design model, so as to conduct the design of the lectotype of the city expressway interchanges.

Owner:TIANJIN MUNICIPAL ENG DESIGN & RES INST

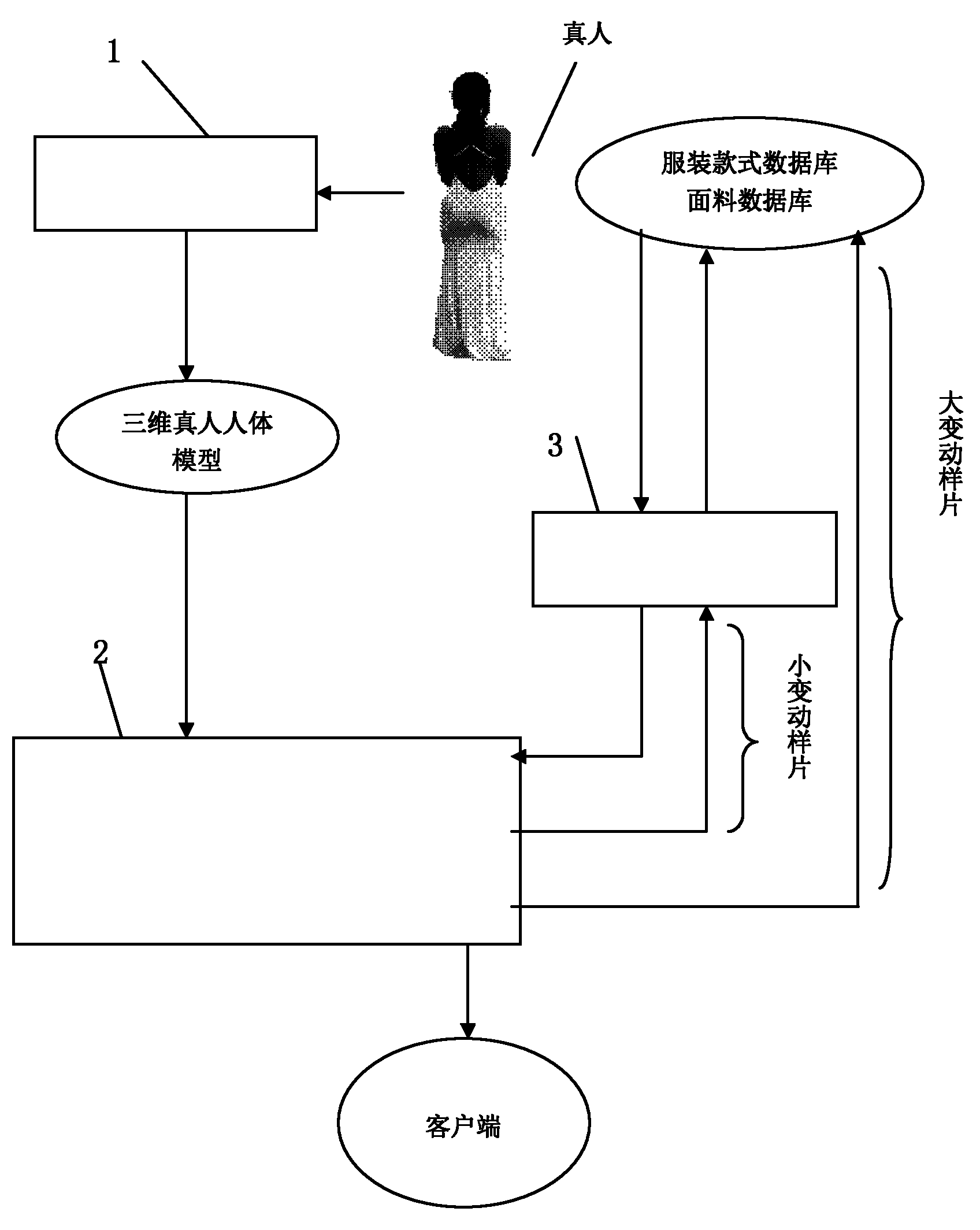

Three-dimensional virtual fitting system

InactiveCN103106586AImprove the design levelImprove efficiencyCommerceImage data processingHuman bodyPersonalization

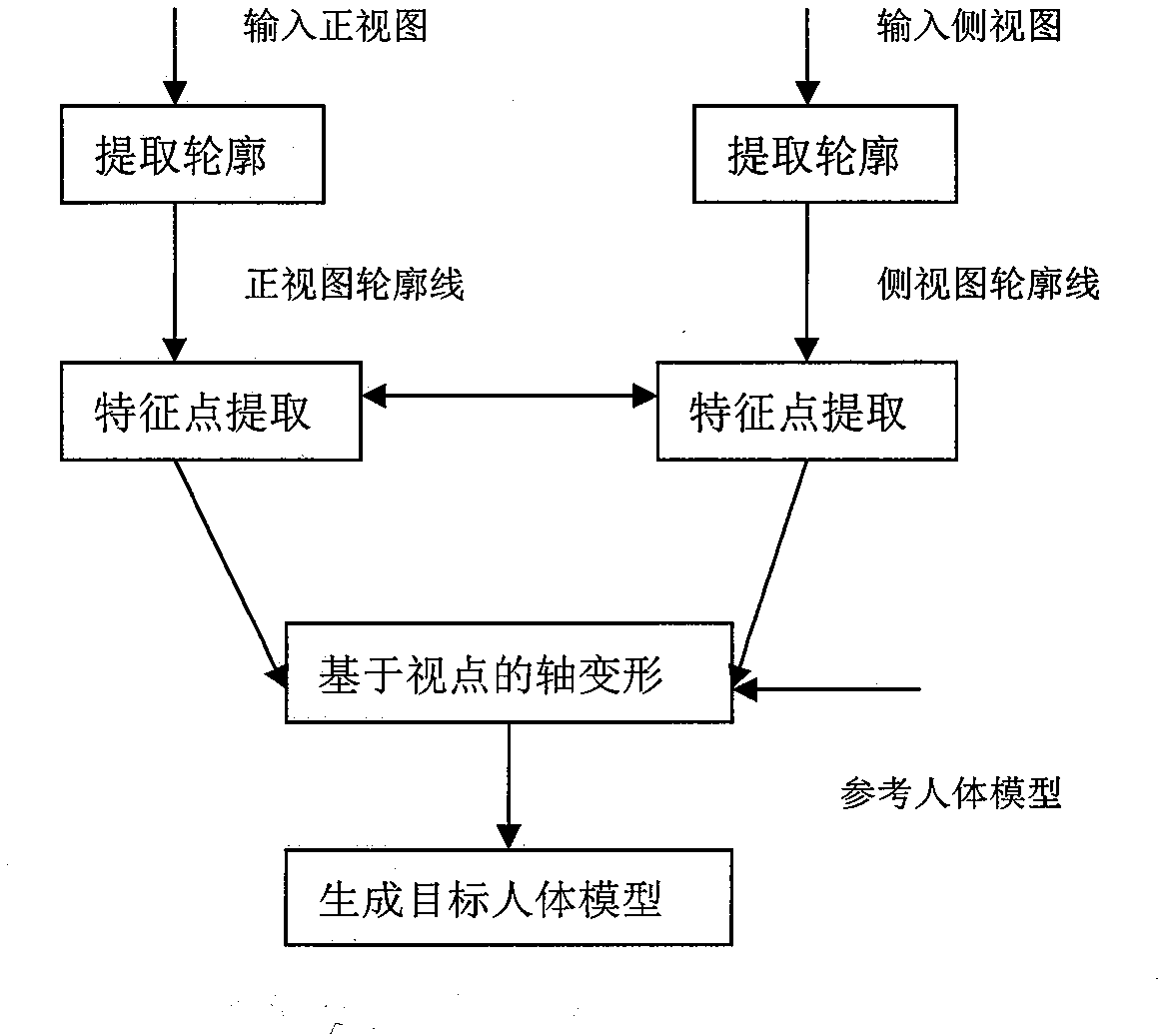

The invention discloses a three-dimensional virtual fitting system and relates to the technical field of robot vision and digitized costume design. The three-dimensional virtual fitting system is characterized in that the object of costume three-dimensional virtual fitting is a three-dimensional human body model which is built through shooting and processing of a real human body. A customer is shot by a camera to obtain multiple groups of images; contour extraction and feature extraction are carried out on the images in a computer, based on axial deformation of viewpoints, with the human body model as reference, further factors including human body types and the like are considered, and the real-person human body model of the customer is finally obtained; the obtained model is input into the three-dimensional fitting system; through two-way selection, a style, cloth, design and color and the like of clothes are determined by the customer and a designer; the data are input into a 'custom-made system' to complete a costume design, an individual fashion sample is generated automatically and input back into the three-dimensional fitting system, and then a custom ready-to-wear is sewed in a virtual mode and worn on the real-person human body model to display an individual fitting effect intuitively; relative marking is carried out by an evaluation system, and scores can be a reference index for the customer and the designer; and the design level and design efficiency of the costume are greatly improved.

Owner:JIANGNAN UNIV

Method for checking useful load of auxiliary springs of non-end contact diagonal main and auxiliary spring

ActiveCN105653883AImprove transportation efficiencyImprove securityInformaticsSpecial data processing applicationsEngineeringOblique line

The invention relates to a method for checking a useful load of auxiliary springs of a non-end contact diagonal primary and auxiliary spring, and belongs to the technical field of suspension steel plate springs. The method comprises the following steps: firstly, determining an endpoint deformation coefficient and the half rigidity of each main spring, as well as a deformation coefficient Gx-CB of the contact point between an Nth main spring and the auxiliary spring at an oblique line segment according to a structural dimension and an elastic modulus of the diagonal variable cross-section main spring with non-isostructural end parts; then, checking the useful load of the auxiliary springs of the non-end contact few-leaf diagonal variable cross-section main and auxiliary spring according to the thicknesses of root straight sections of the main springs, Gx-CB of the Nth main spring, the half rigidity of each main spring and a design value of the clearance Delta between the main springs and the auxiliary springs. The simulated verification shows that an accurate checking value of the useful load of the auxiliary springs of the non-end contact diagonal main and auxiliary spring can be obtained by using the method, the design level and performance of products are improved, the vehicle running smoothness is improved, meanwhile, the design, manufacturing and test costs are reduced, and the product development speed is increased.

Owner:平邑经济开发区投资发展有限公司

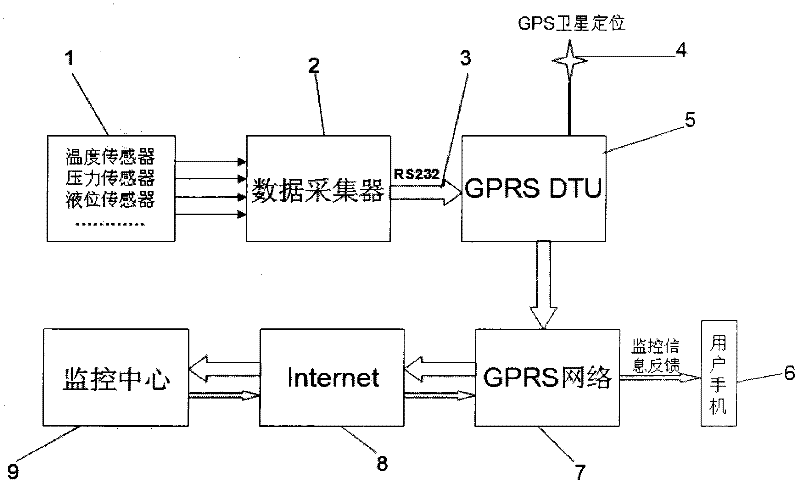

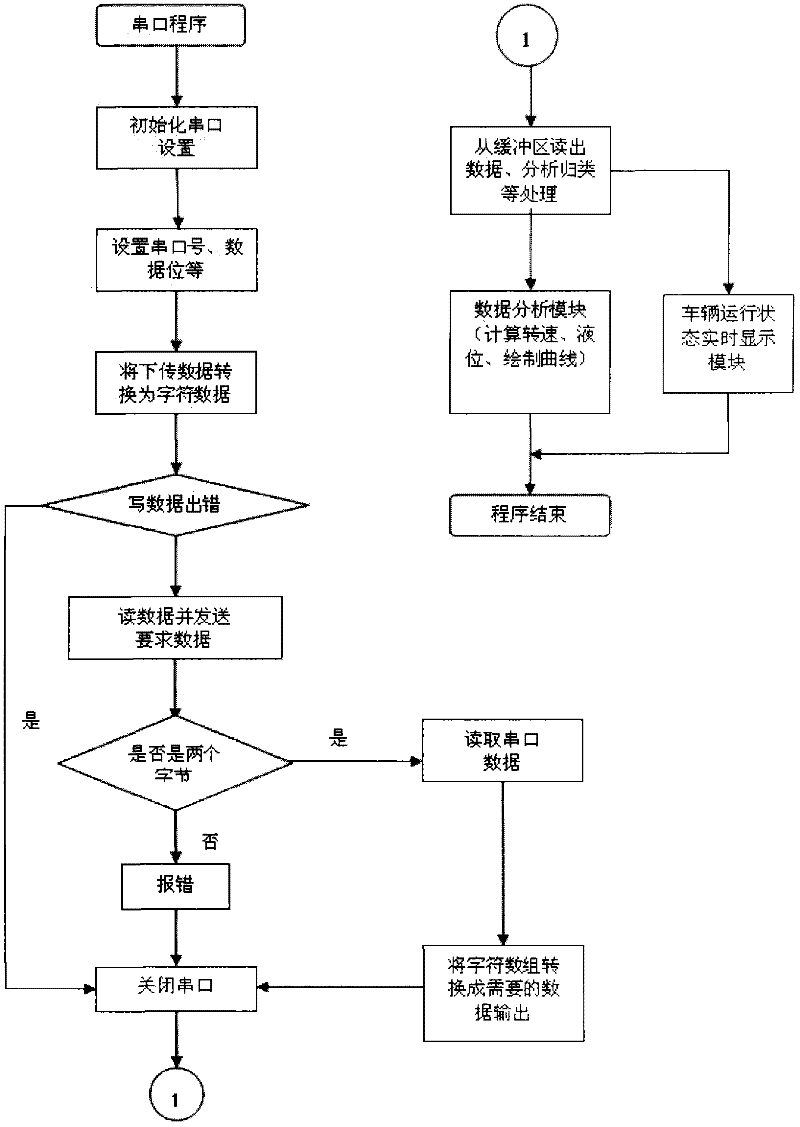

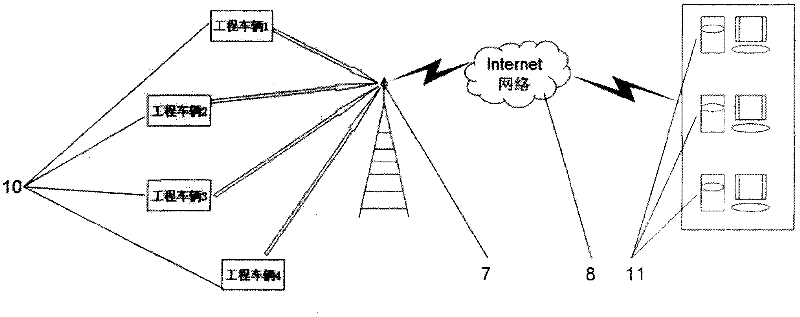

System for remotely monitoring operation state of engineering vehicle

InactiveCN102360211AImprove the level of after-sales serviceFully reflect the running statusElectric testing/monitoringGeneral Packet Radio ServiceInternet network

The invention discloses a system for remotely monitoring the operation state of an engineering vehicle. The monitoring system consists of a vehicle-mounted terminal part, a data transmission part and a monitoring center part, wherein the vehicle-mounted terminal part comprises a monitoring parameter sensor, a data acquirer and a wireless data transmission terminal; the data transmission part comprises a general packet radio service (GPRS) wireless communication network and an Internet network; and the monitoring center part comprises Internet access equipment, a monitoring center computer and monitoring computer software.

Owner:SHANDONG UNIV OF TECH

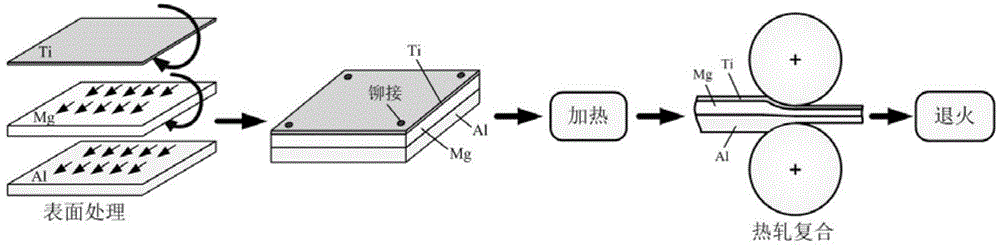

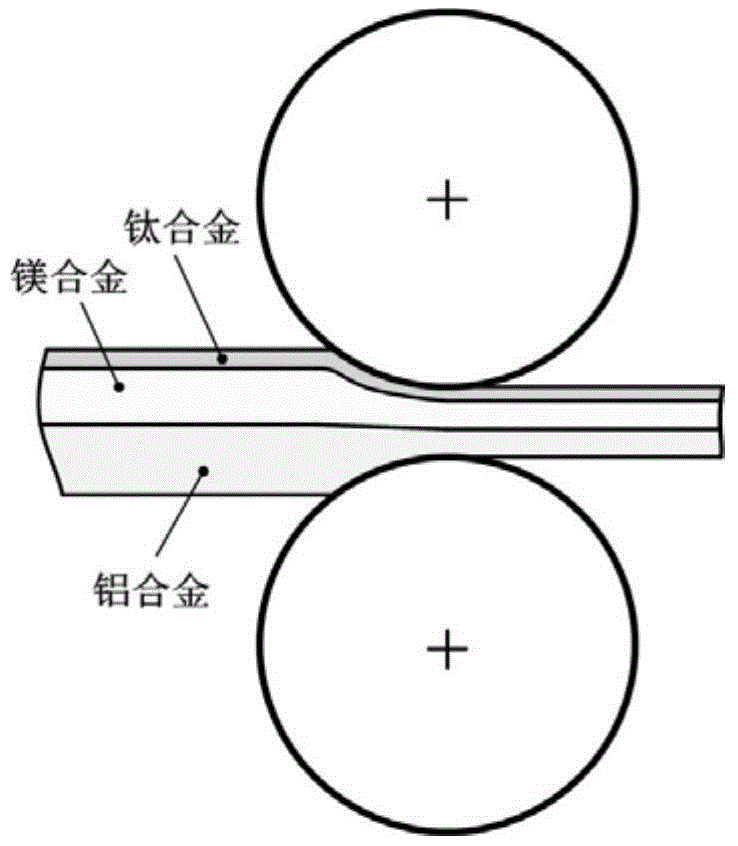

Rolling compounding method for aluminum/magnesium/titanium three-layer composite plate

ActiveCN104056859ALow densityHigh specific strengthAuxillary arrangementsMetal rolling arrangementsComposite plateTitanium alloy

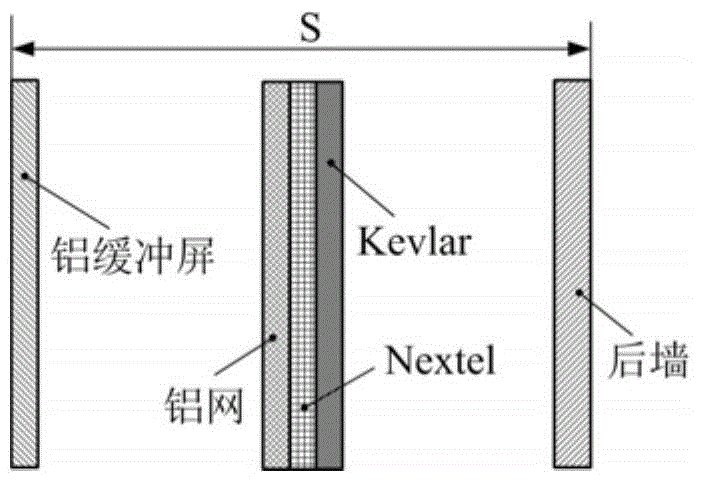

The invention discloses a rolling compounding method for an aluminum / magnesium / titanium three-layer composite plate. The characteristics of high strength of titanium alloy, low melting point and good vibration reducing performance of magnesium alloy, good plasticity and space adaptation of the aluminum alloy, and the like, are utilized and the excellent characteristics of respective component metals are combined by the aluminum / magnesium / titanium three-layer composite plate provided by the invention, so that the high-speed impact damage resisting property which the component metals do not own is acquired. Through the control on the ratio and interface of the aluminum alloy, the magnesium alloy and titanium alloy, the degree of fragmentation, melting and atomizing of shred cloud after the buffer composite plate is subjected to high-speed impact is changed and adjusted, so that the form of the shred cloud is changed, the degree of impact damage to a backplate is reduced, and the high-speed impact damage resisting property is increased. The aluminum / magnesium / titanium three-layer composite plate is applied to an outer layer buffer plate in an outer layer protecting structure of an aerospace vehicle and can be used for replacing a traditional single aluminum alloy material. The space environmental effect and protecting level of the space vehicle are increased; the design level of the space vehicle are greatly promoted, and the service life of the space vehicle are greatly prolonged.

Owner:CHONGQING UNIV

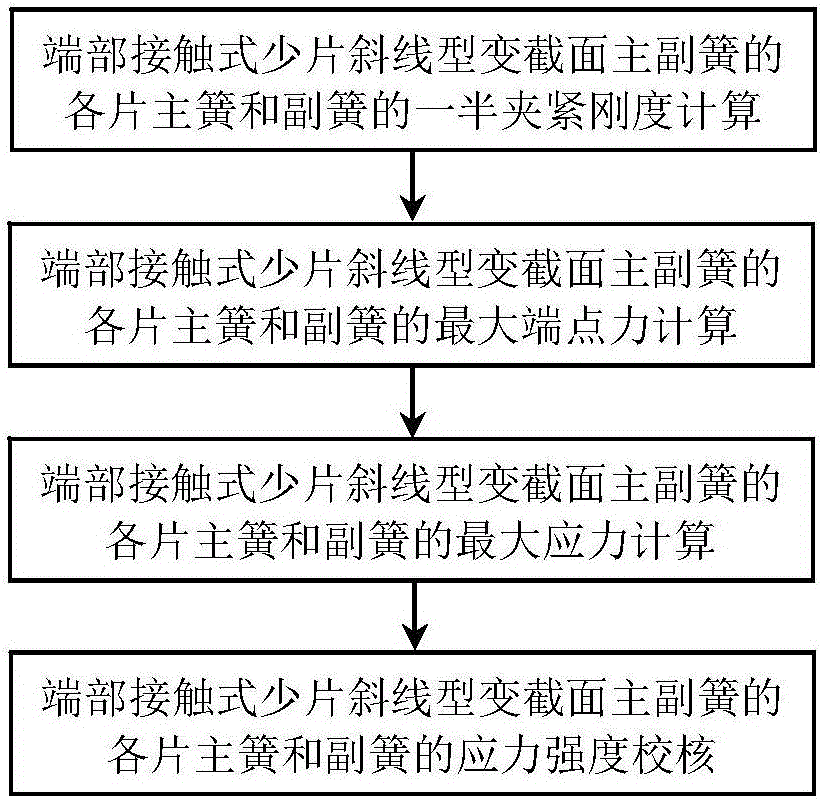

Method for verifying strength of each leaf of end contact type few-leaf oblique main and auxiliary springs

InactiveCN105740591AThe calculation value of the maximum stress check is accurate and reliableImprove the design levelDesign optimisation/simulationSpecial data processing applicationsEngineeringStress strength

The invention relates to a method for verifying strength of each leaf of end contact type few-leaf oblique main and auxiliary springs and belongs to the technical field of suspension leaf springs. It is possible to verify and calculate stress strength of each of main and auxiliary leaves according to structural parameters, elastic model and allowable stress of all main and auxiliary leaves of the end contact type few-leaf oblique variable-section main and auxiliary springs, acting load of each auxiliary spring and maximum load bearable by a main spring. Experiments and simulation tests show that this method is correct, maximum stress verification calculations of all main and auxiliary leaves are accurate and reliable, the design level, product quality and life of the end contact type few-leaf oblique variable-section main and auxiliary leaf springs as well as vehicle driving smoothness may be improved; meanwhile, it is also possible to reduce designing and testing cost and increase product development speed.

Owner:王炳超

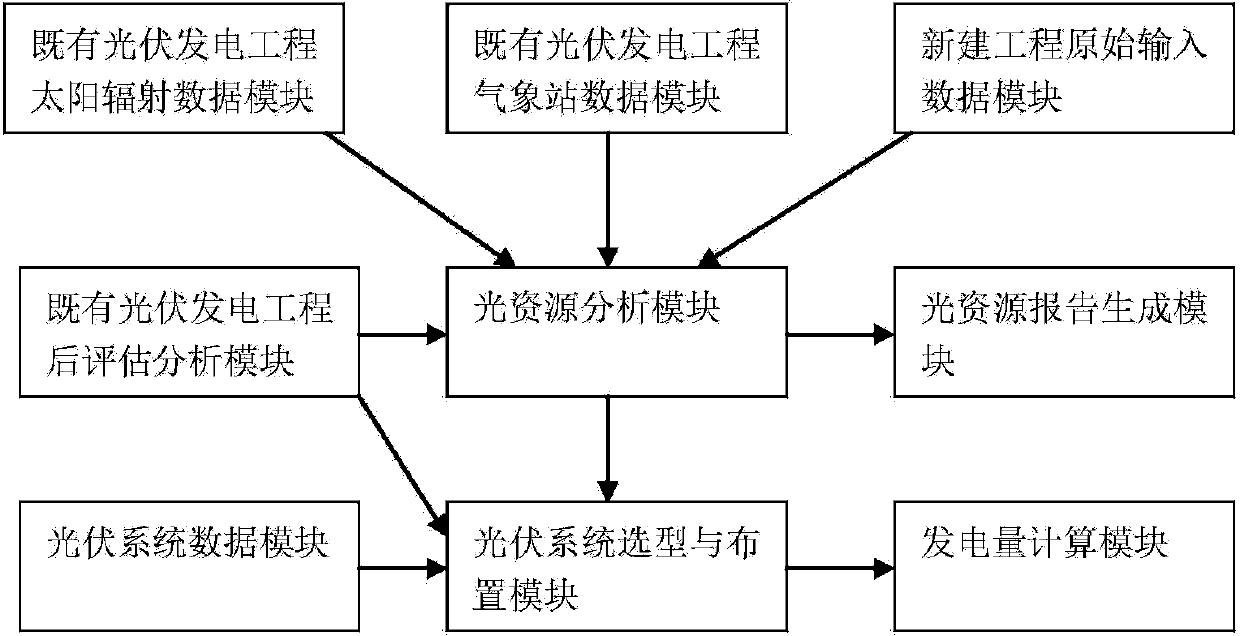

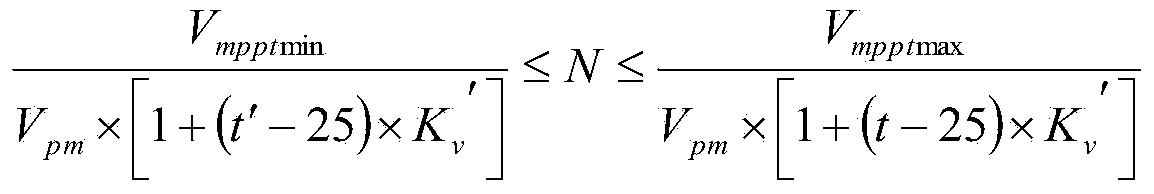

Expert system designed for photovoltaic power station

ActiveCN104182564AShorten the timeImprove the design levelData processing applicationsSystems intergating technologiesComputer modulePhotovoltaic power station

The invention provides an expert system designed for a photovoltaic power station and belongs to the technical field of design of the expert system. The expert system comprises a solar radiation data module of the existing photovoltaic power generation engineering, a meteorological-station data module of the existing photovoltaic power generation engineering, a primary input data module, a light-resource analysis module, a photovoltaic system data module and a photovoltaic system type-selection and arrangement module, wherein the solar radiation data module is used for establishing one or more on-site solar radiation observation station data table of the existing photovoltaic power generation engineering; the meteorological-station data module is used for establishing one or more reference meteorological-station data table of the existing photovoltaic power generation engineering; the primary input data module is used for inputting primary data of a newly-built photovoltaic power generation engineering; the light-resource analysis module is used for generating a solar-energy resource analysis chart; the photovoltaic system data module is used for establishing a photovoltaic-system data table; and the photovoltaic system type-selection and arrangement module is used for type selection of equipment and arrangement of photovoltaic components. The expert system provided by the invention has the advantage that the technical problem that the photovoltaic power station can not be reasonably and accurately designed is solved.

Owner:内蒙古电力勘测设计院有限责任公司

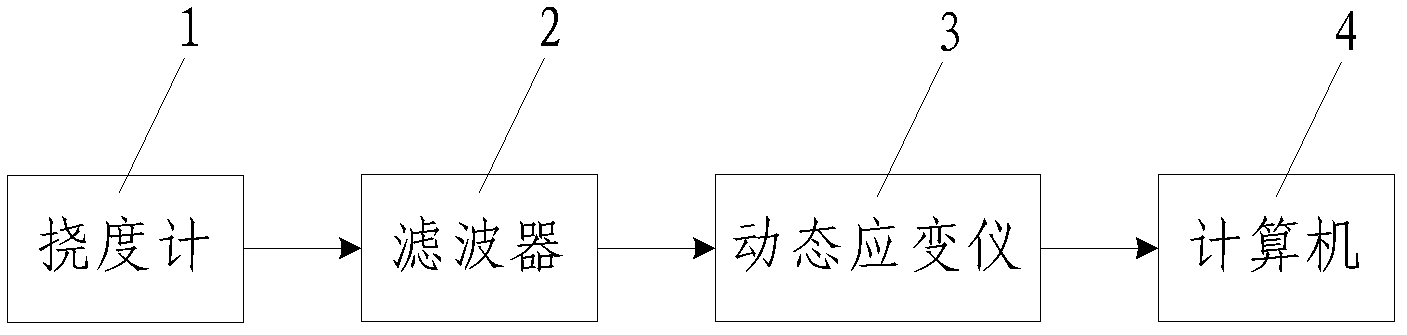

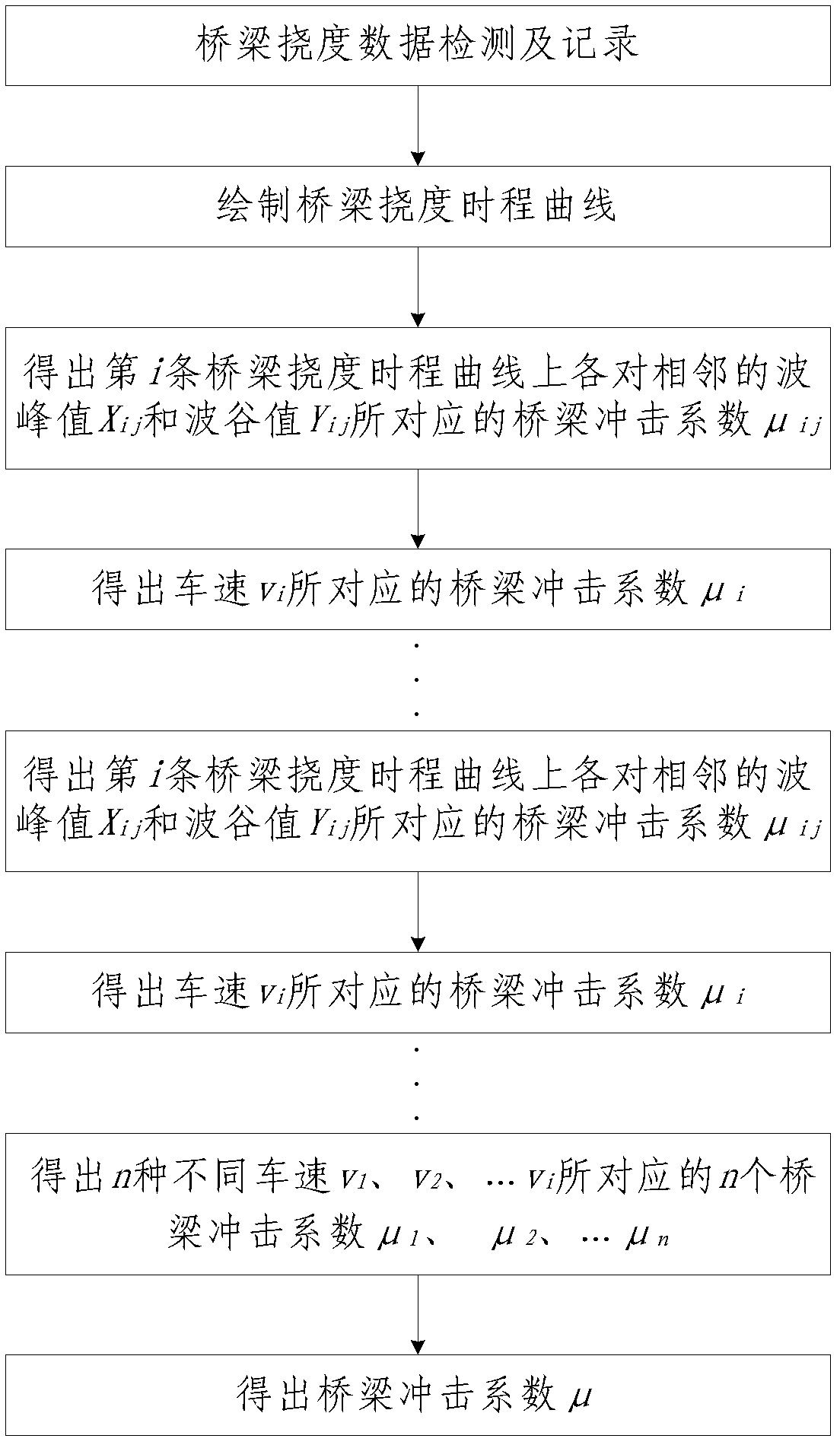

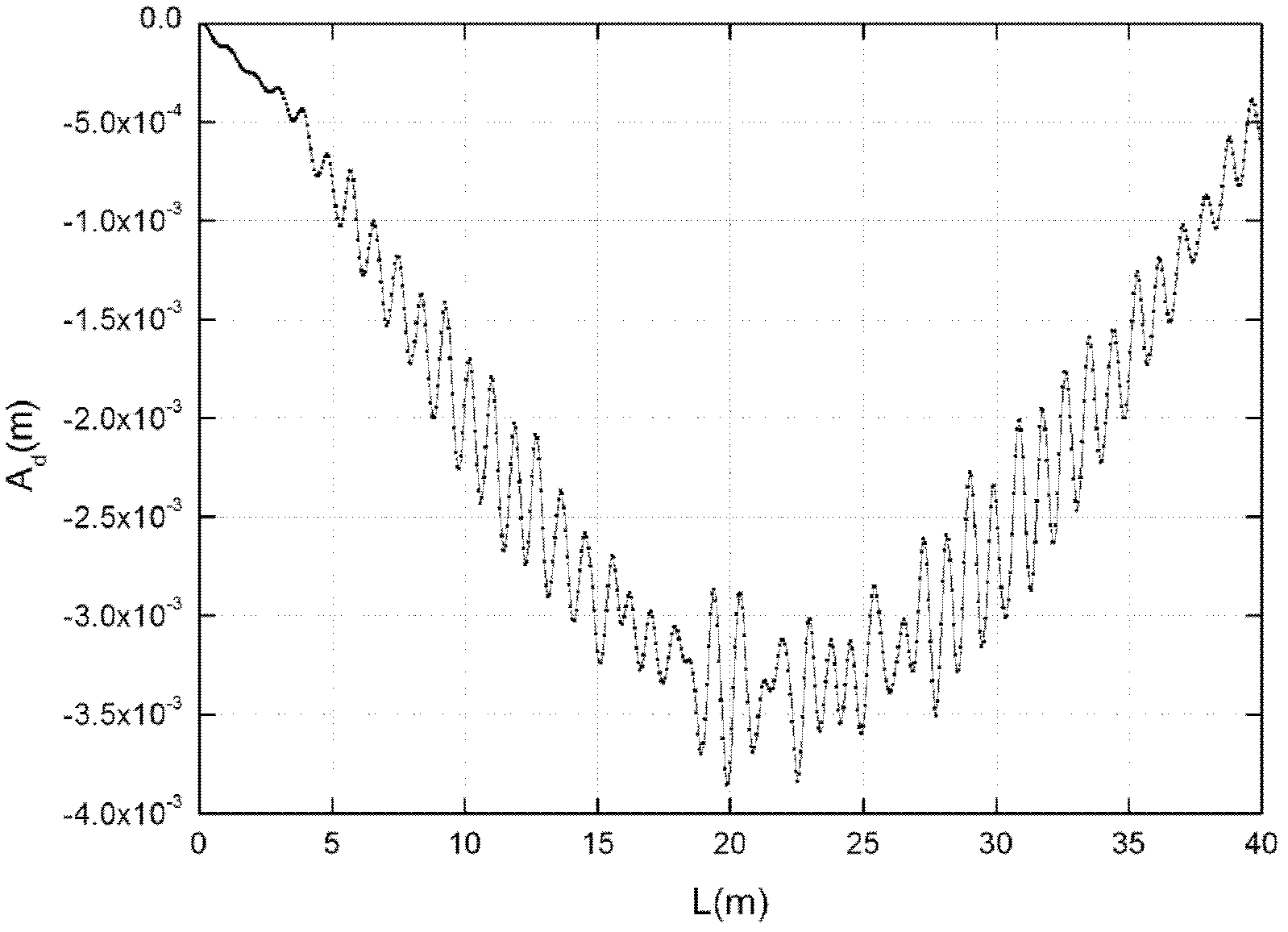

Method for detecting bridge impact coefficient based on dynamic load test

The invention discloses a method for detecting a bridge impact coefficient based on a dynamic load test. The method comprises the steps of: (1) detecting and recording deflection data of a bridge; (2) drawing a deflection schedule curve of the bridge; (3) obtaining a bridge impact coefficient muij corresponding to each pair of adjacent wave peak value Xij and wave trough value Yij on the i-th deflection schedule curve of the bridge; (4) obtaining a bridge impact coefficient mui corresponding to a vehicle speed vi; (5) repeating the step (3) and the step (4) until n bridge impact coefficients mu1, mu2, ...mun corresponding to n different vehicle speeds v1, v2, ...vn are obtained; and (6) obtaining a bridge impact coefficient mu. The method for detecting the bridge impact coefficient based on the dynamic load test, disclosed by the invention, has the advantages of rational design and convenience in realization; the bridge impact coefficient obtained by detection is safer, so that dynamic effect of the bridge structure can be reflected more exactly and more rationally under the function of the load of movable vehicles; the practical problem that the conventional impact coefficient cannot reflect exactly that the movable load acts on the bridge structure in form of multiple load points is solved efficiently; and the method for detecting the bridge impact coefficient based on the dynamic load test, has strong practicability and high popularization and application values.

Owner:CHANGAN UNIV +1

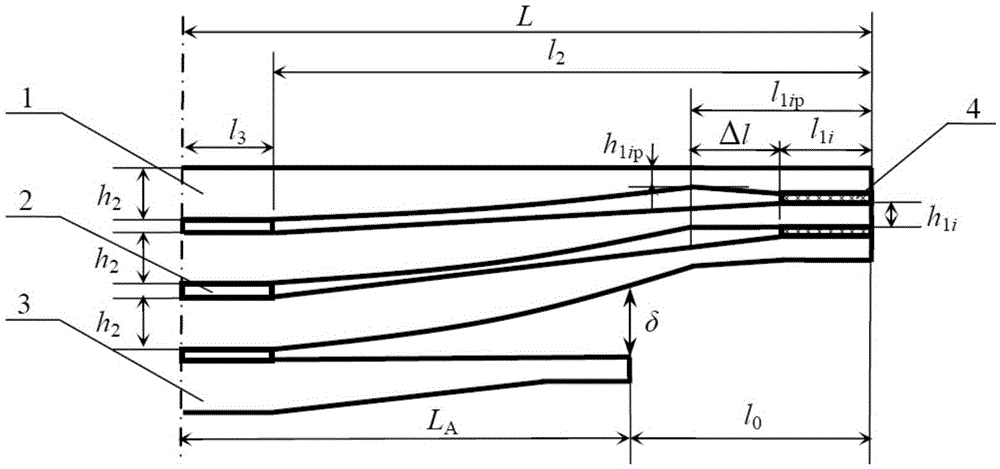

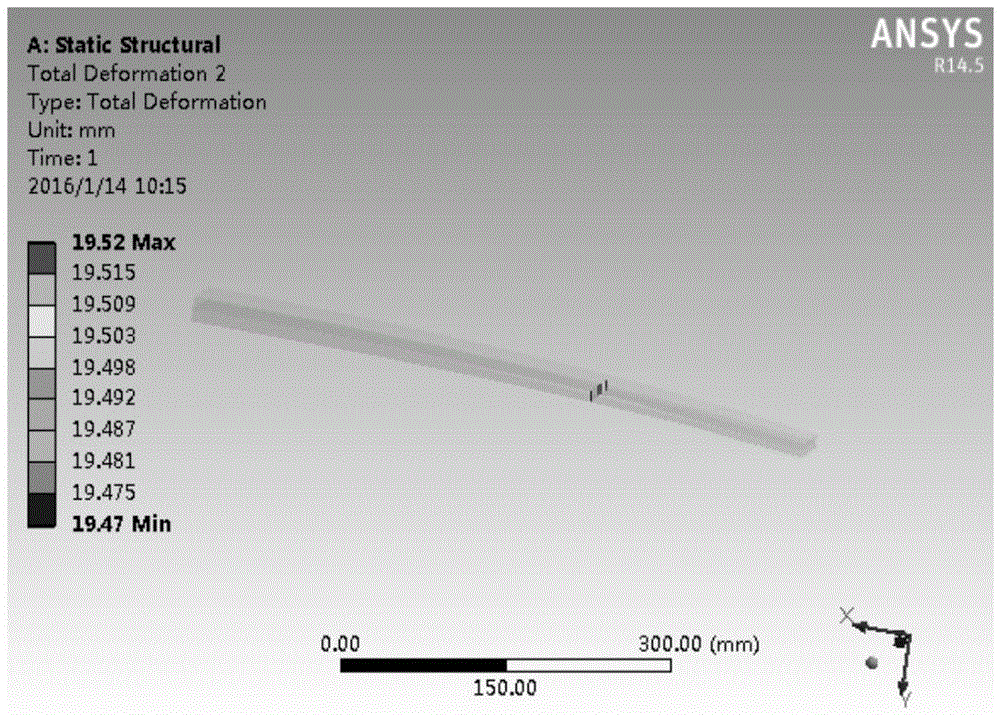

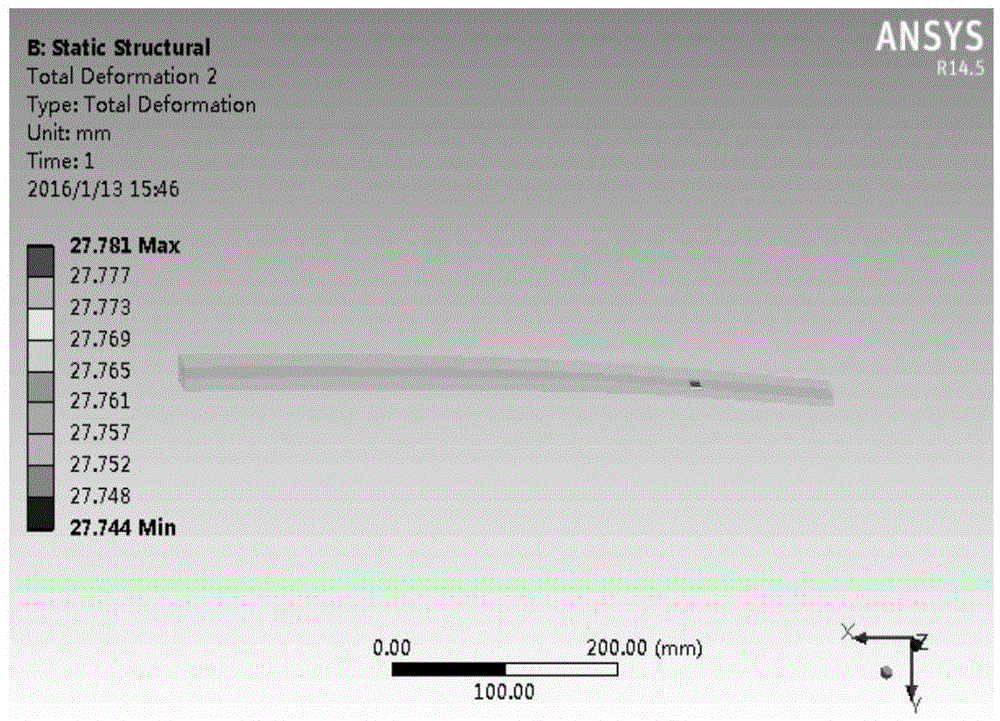

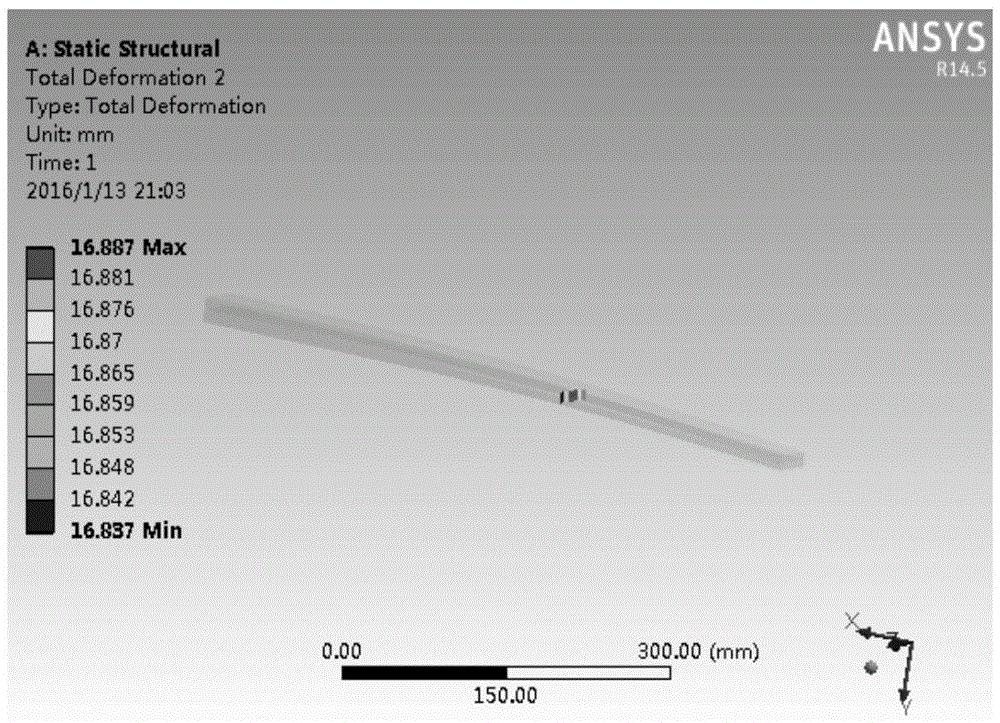

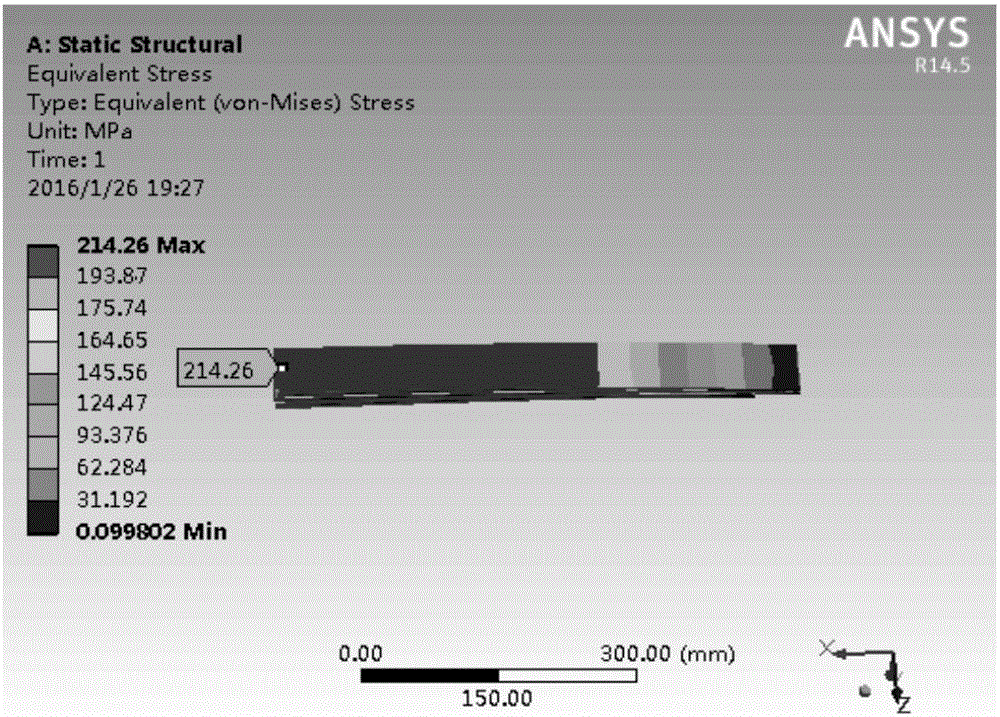

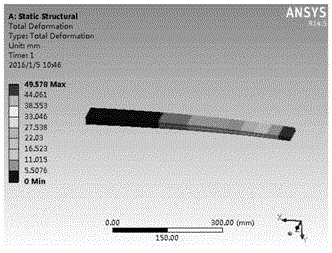

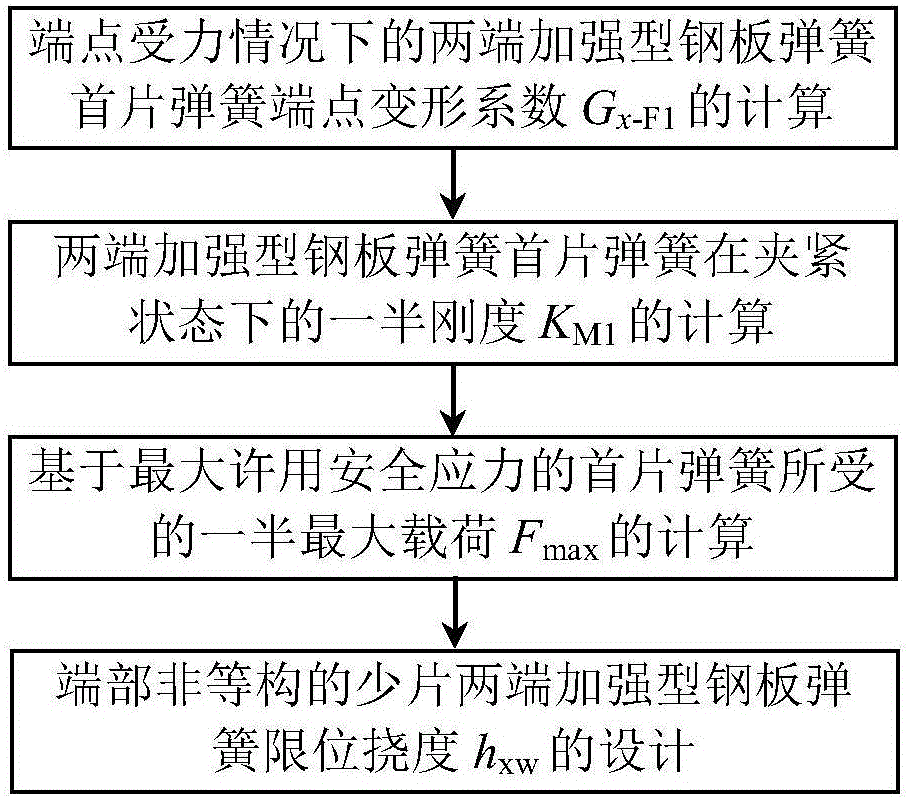

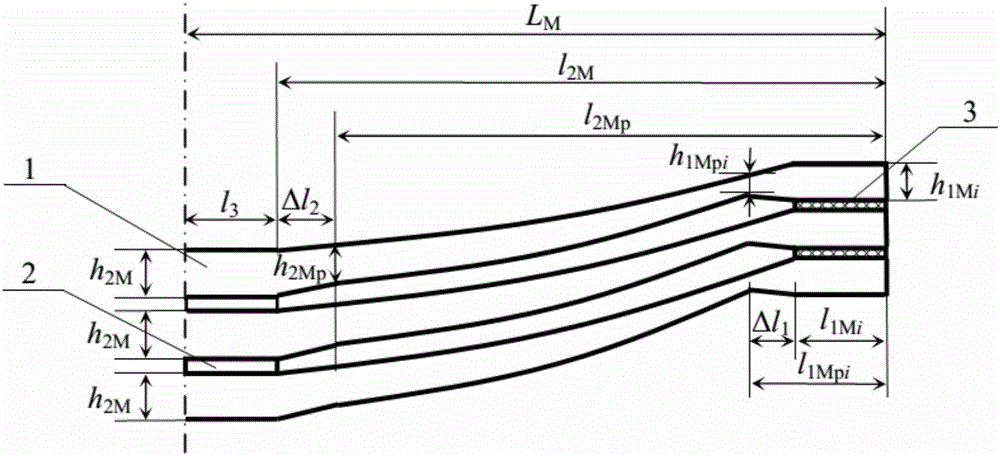

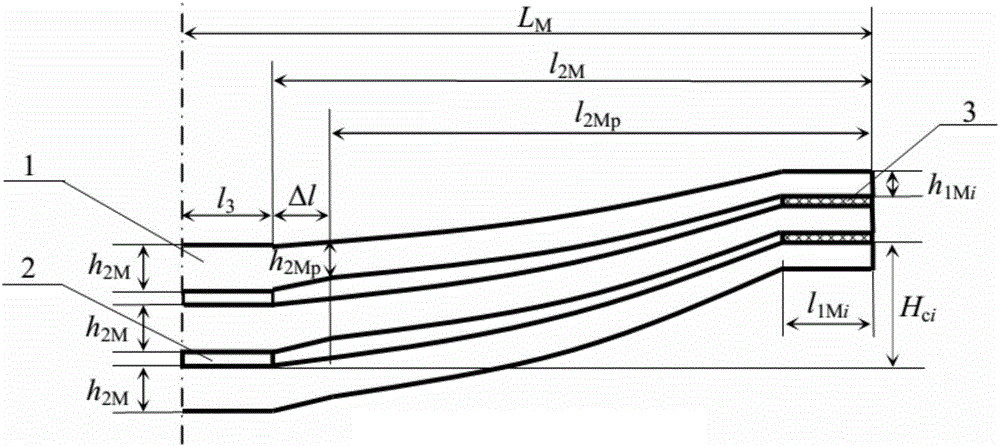

Design method for end part- and root-reinforced few-leaf variable-section steel plate springs

ActiveCN105673753AImprove transportation efficiencyImprove driving safetyLeaf springsDesign optimisation/simulationReal variableEngineering

The invention relates to a design method for end part- and root-reinforced few-leaf variable-section steel plate springs, and belongs to the technical field of suspension steel plate springs. The design method disclosed by the invention comprises the following steps: determining the toot thickness he of an equivalent single leaf according to the structure of each steel plate spring, a design rigidity, the thickness ratio of oblique line segments on the root and the end parts, and the thickness ratio of primarily-selected parabolic segments, and determining the maximum allowable thickness [h2] of the root according to an allowable pressure at first; then designing the number N and the root thickness h2 of the few-leaf variable-section steel plate springs according to he and [h2]; and then designing the thicknesses and the lengths of straight segments on the end parts of each leaf separately according to the end part thickness beta he of the equivalent single leaf. Through ANSYS simulation and verification, the accurate parameter design values of the end part- and root-reinforced few-leaf variable-section steel plate springs can be obtained by virtue of the method, the design level and the performance of products are improved, the weights of the springs are reduced, and the running smoothness of vehicles are improved; and meanwhile, the design and test expenses are reduced, and the development speed of the products is increased.

Owner:山东恒日悬架弹簧股份有限公司

Three-dimensional virtual dressing system of clothes for real person

InactiveCN102043882AImprove design level and design efficiencyImprove the design levelSpecial data processing applicationsDigitizationSoftware

The invention relates to a three-dimensional virtual dressing system of clothes for a real person, relating to the technical fields of clothing design and digital equipment thereof. The system comprises a three-dimensional anthropological measuring system, a three-dimensional dressing system, a tailor-making system, a clothing style database and a fabric database. By a concept interface, a software interface and a hardware interface, smooth transfer and conversion of data among different systems are achieved, and three-dimensional virtual dressing for the real person is realized. The three-dimensional virtual dressing system for the real person has the characteristics that a virtual three-dimensional body model similar to the practical body can be generated in a fast, convenient and vivid manner by connection and integration among all isocitric software and hardware, three-dimensional virtual dressing is carried out on the real-person model. The design level and design efficiency of clothes are greatly improved.

Owner:SHANGHAI UNIV OF ENG SCI

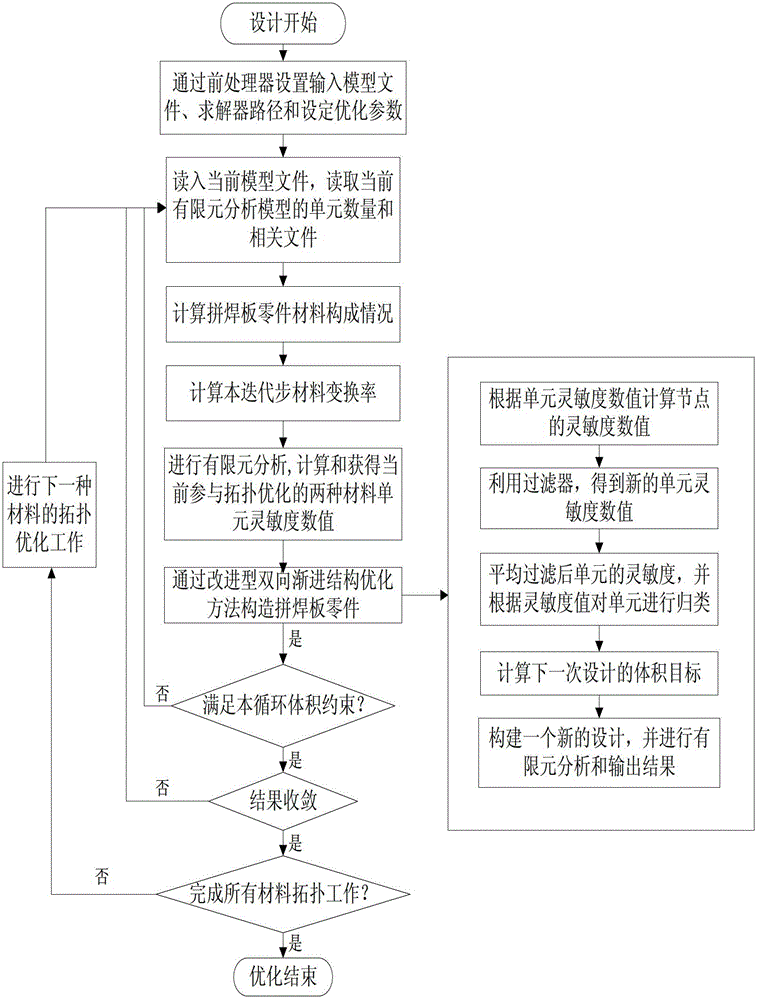

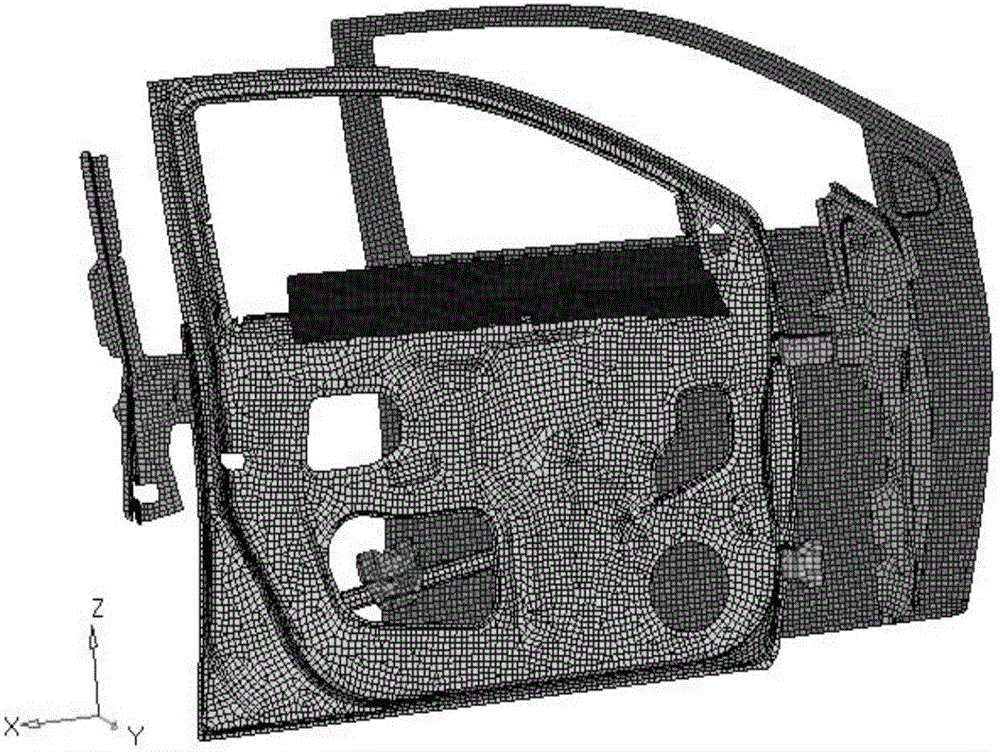

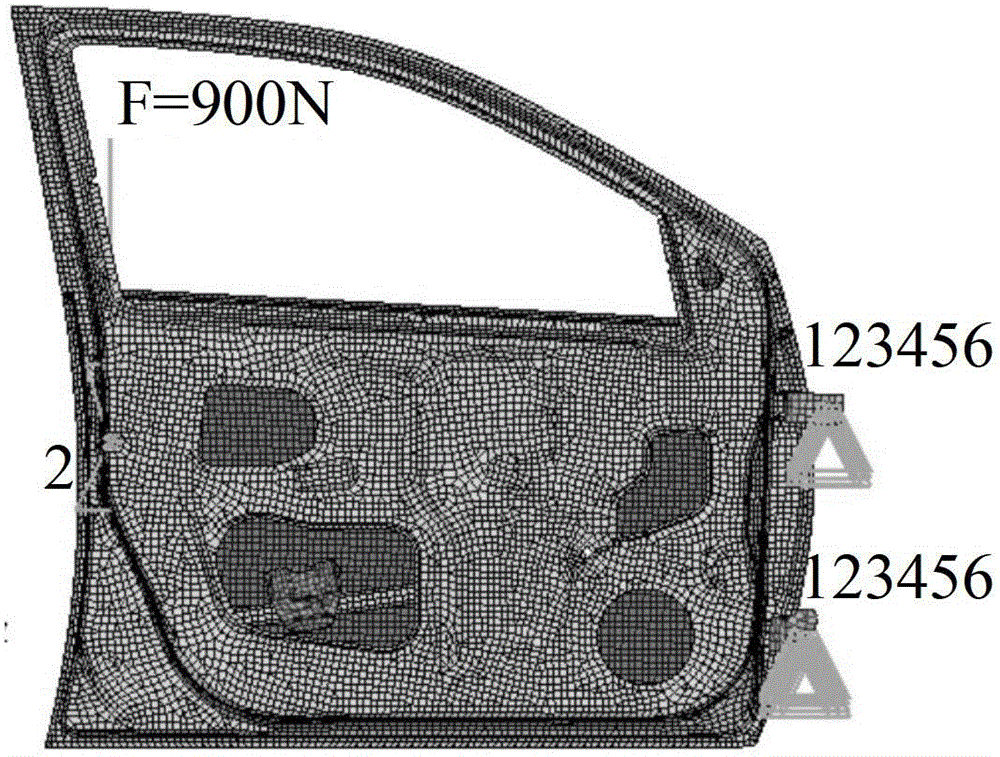

Optimal design method for spliced and welded plate automobile door

InactiveCN102799704AConvenient guidanceWith guidanceSpecial data processing applicationsTopology optimizationEngineering

The invention relates to an optimal design method for a spliced and welded plate automobile door, and aims to rationally design the spliced and welded plate automobile door, reduce the number of parts, reduce the weight of the automobile door, improve the rigidity of the automobile door and improve the collision safety of an automobile. The optimal design method comprises the following steps of: determining arrangement of weld lines of the spliced and welded plate automobile door by a bidirectional progressive topological optimization method, namely the design of a splicing and welding scheme; after specific positions of the weld lines are determined, namely the splicing and welding scheme is determined, dividing an inner plate of the automobile door into several regions by the weld lines, wherein the regions represent spliced and welded plates of different thicknesses; and constructing an automobile door system light-weight optimal model based on different working condition responses by a sensitivity analysis method and a size optimization method, performing optimal calculation, and determining the specific thickness of each spliced and welded plate of the inner plate of the automobile door.

Owner:HUNAN UNIV

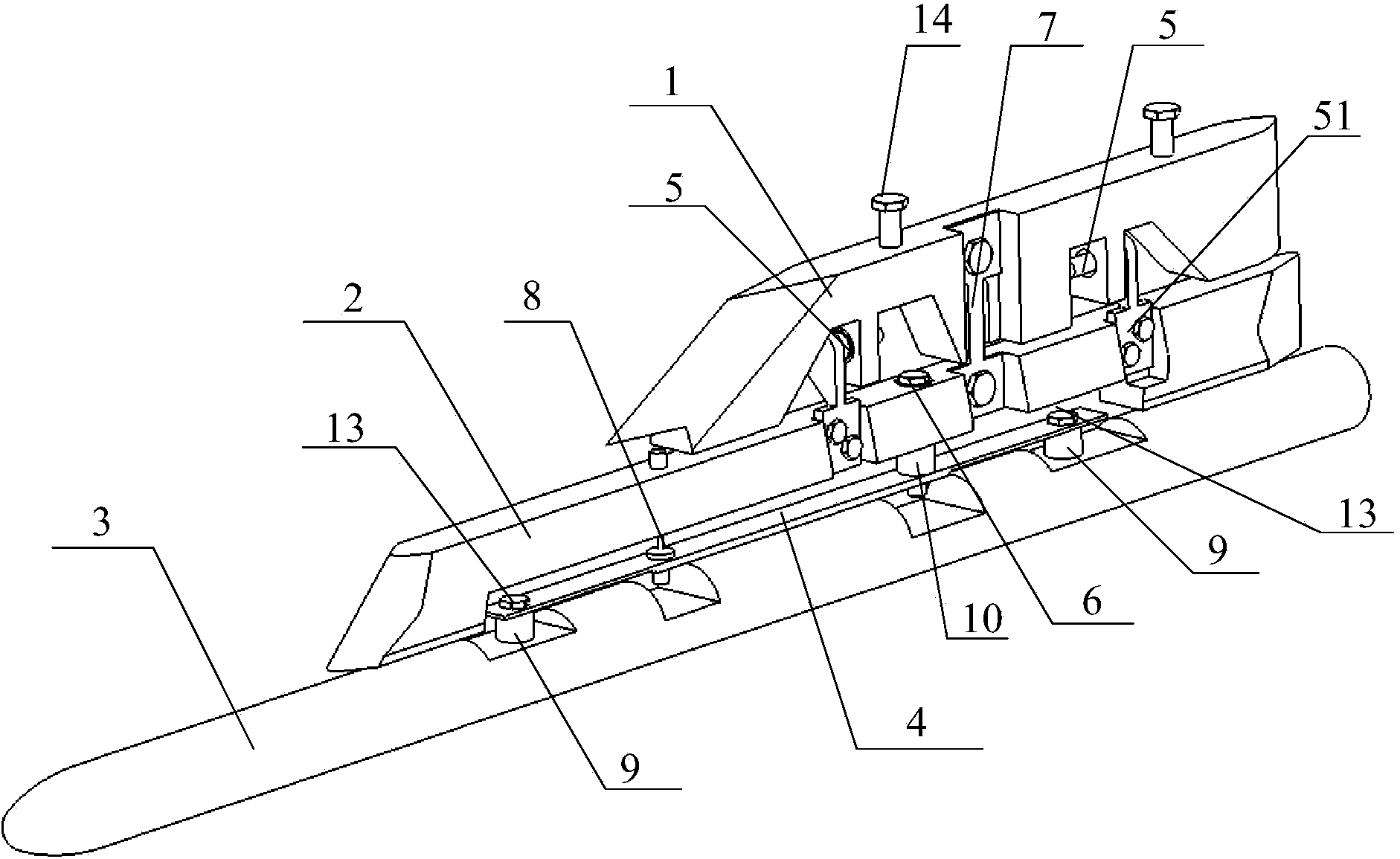

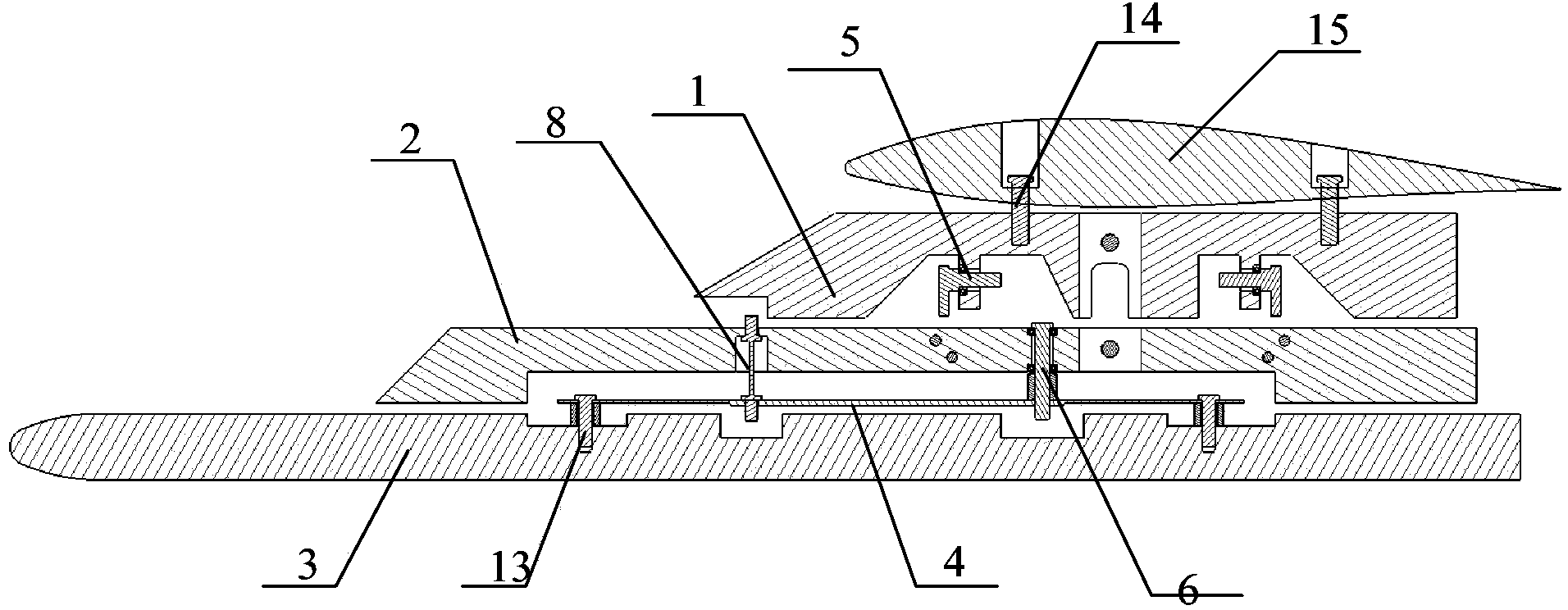

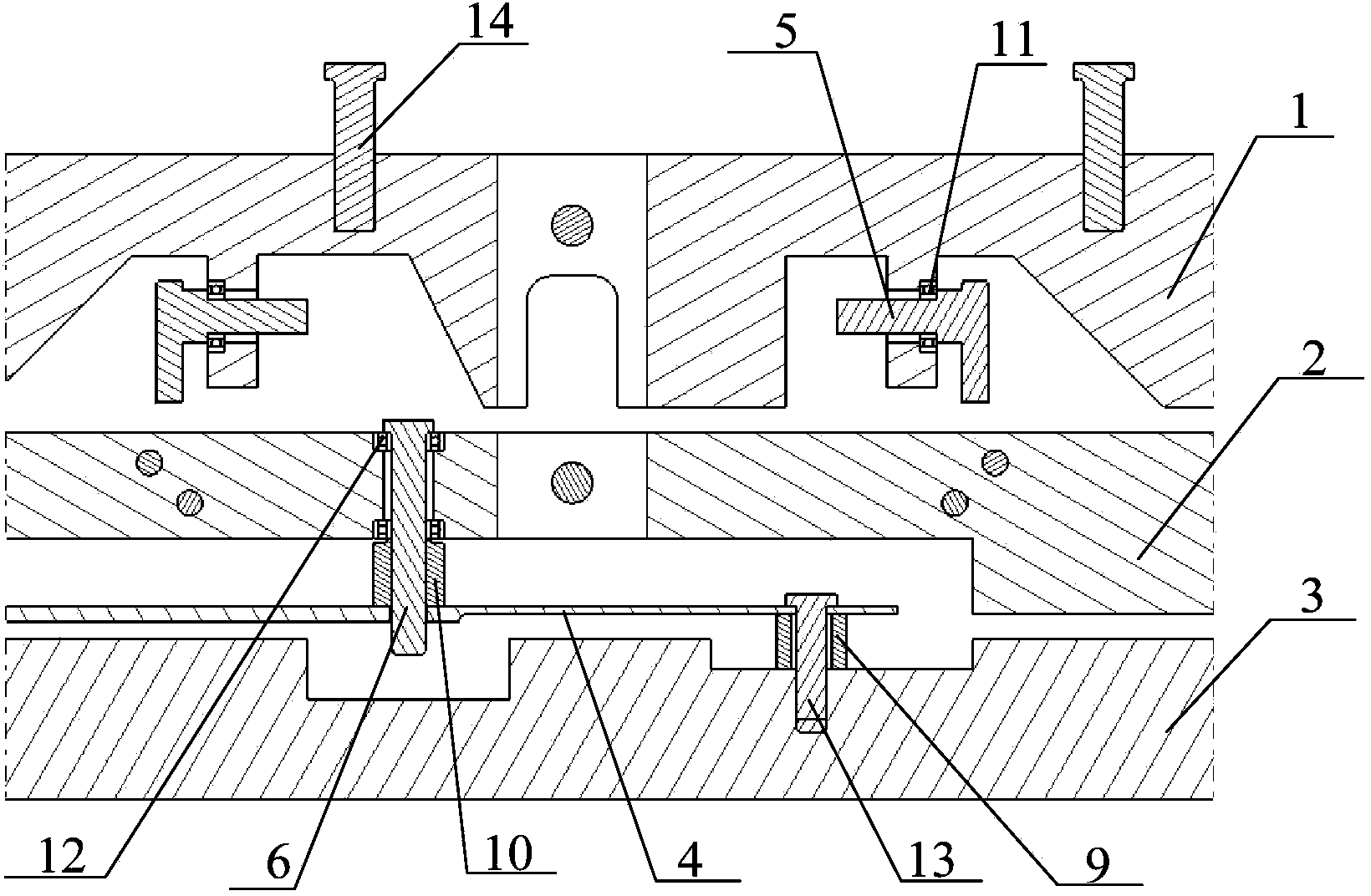

Three-freedom-degree simulation external store flutter model for wind tunnel test

The invention provides a three-freedom-degree simulation external store flutter model for a wind tunnel test. The three-freedom-degree simulation external store flutter model comprises an external store, a rolling beam and a suspended beam suspended on an aircraft airfoil model. The rolling beam is arranged below the suspended beam and hinged to the suspended beam through a first hinged shaft, the first hinged shaft is horizontally arranged, the axial direction of the first hinged shaft is consistent with the length direction of the rolling beam, an elastic device is arranged below the rolling beam and hinged to the rolling beam through a second hinged shaft, the second hinged shaft is perpendicular to the first hinged shaft, and the external store is connected to the elastic device and can perform pitching motion relative to the rolling beam in the vertical direction through the elastic device. The three-freedom-degree simulation external store flutter model for the wind tunnel test can achieve decoupling and simulation in a three-freedom-degree vibration mode, and the design level of the external store flutter model and precision of flutter wind tunnel test results are greatly improved.

Owner:INST OF HIGH SPEED AERODYNAMICS OF CHINA AERODYNAMICS RES & DEV CENT +1

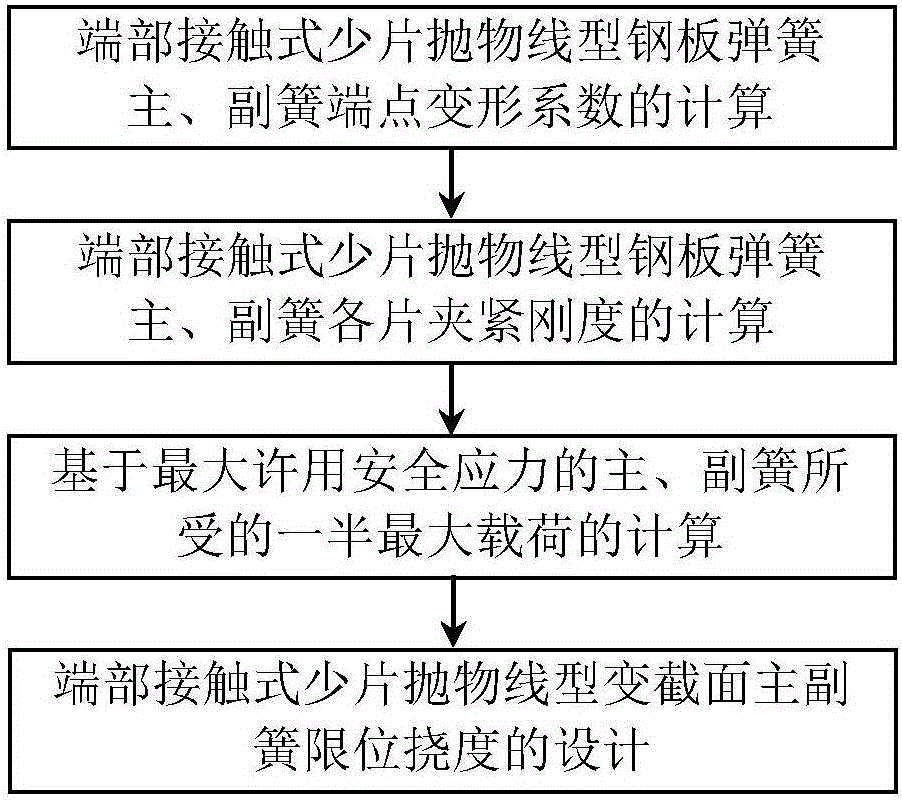

Design method for limit deflections of end part contact type less-leaf parabola type main and auxiliary springs

InactiveCN106295086AImprove ride comfortAccurate and reliable limit deflection design valueGeometric CADLeaf springsContact typeDesign methods

The invention relates to a design method for the limit deflections of end part contact type less-leaf parabola type main and auxiliary springs, and belongs to the technical field of suspension steel plate springs. According to the method, the limit deflections of the end part contact type less-leaf parabola type main and auxiliary springs can be designed according to the structural parameters, the elastic modulus, the maximum allowable safe stress and the free length of a limiting block of all leaf springs. A prototype loading transformation test shows that the design method for the limit deflections of the end part contact type less-leaf parabola type main and auxiliary springs is correct, an accurate and reliable limit deflection design value can be obtained, and a reliable technological basis is laid for the design of the end part contact type less-leaf parabola type main and auxiliary springs and the development of CAD software. By the use of the method, the design level, the quality and the performance of a product can be improved, and the vehicle running smoothness can be improved; meanwhile, the cost for product design and test is reduced, and the product development speed is increased.

Owner:SHANDONG UNIV OF TECH

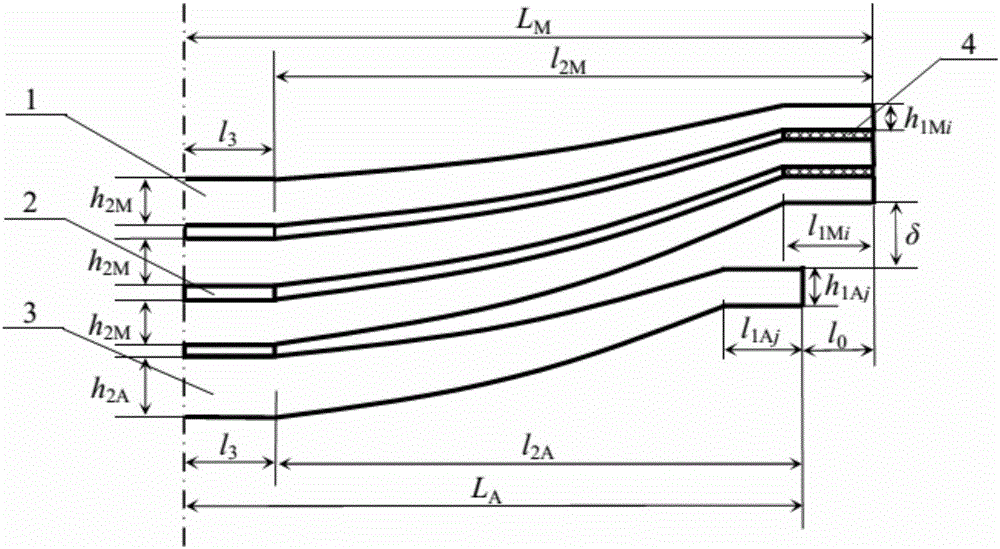

Method for designing limiting deflection of few-leaf two-end-reinforced plate springs with ends of non-equal structures

InactiveCN106246778AImprove ride comfortAccurate and reliable limit deflection design valueLeaf springsInformaticsComputer Aided DesignEngineering

The invention relates to a method for designing limiting deflection of few-leaf two-end-reinforced plate springs with ends of non-equal structures, and belongs to the technical field of suspension steel plate springs. The limiting deflection of the few-leaf two-end-reinforced plate springs with the ends of the non-equal structures can be designed by the aid of the method according to structural parameters, elastic modulus and the maximum allowable safety stress of various leaf springs and the free lengths of limiting stoppers. The method has the advantages that as known from sample machine loading deformation experiments and tests, the method for designing the limiting deflection of the few-leaf two-end-reinforced plate springs with the ends of the non-equal structures is correct, accurate and reliable limiting deflection design values can be obtained by the aid of the method, and a reliable technical foundation can be laid for designing the few-leaf two-end-reinforced plate springs with the ends of the non-equal structures and developing CAD (computer-aided design) software; the design level of products can be upgraded by the aid of the method, the quality and the performance of the products and the riding comfort of vehicles can be improved, the design, experiment and test costs of the products can be reduced, and the product development speeds can be increased.

Owner:SHANDONG UNIV OF TECH

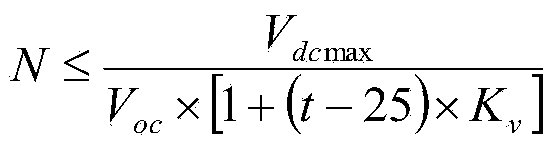

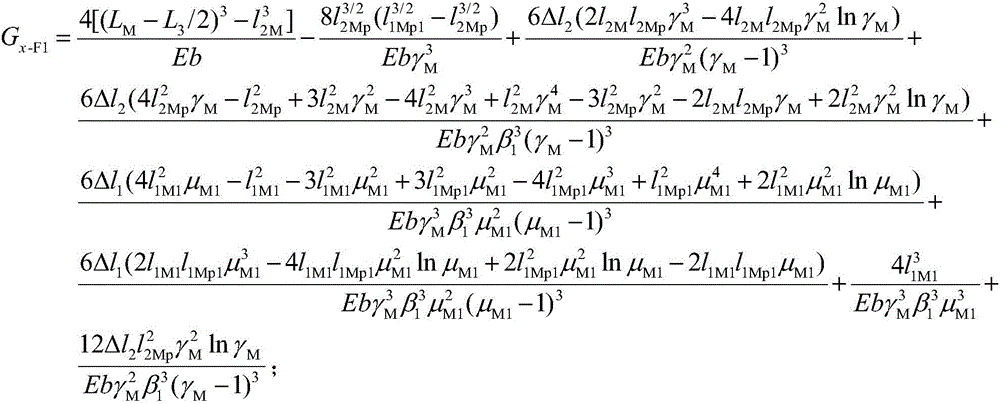

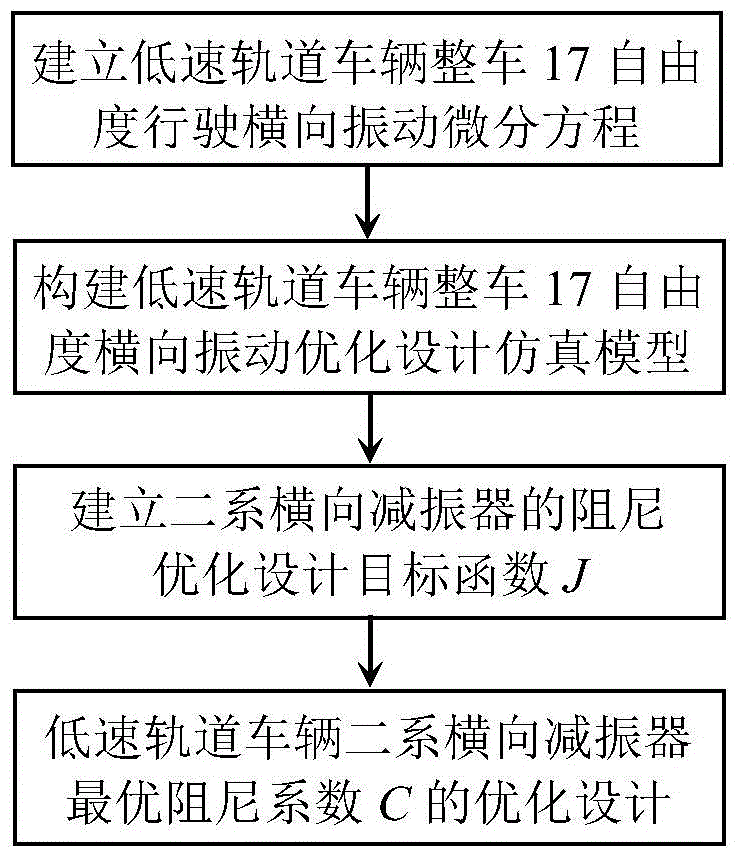

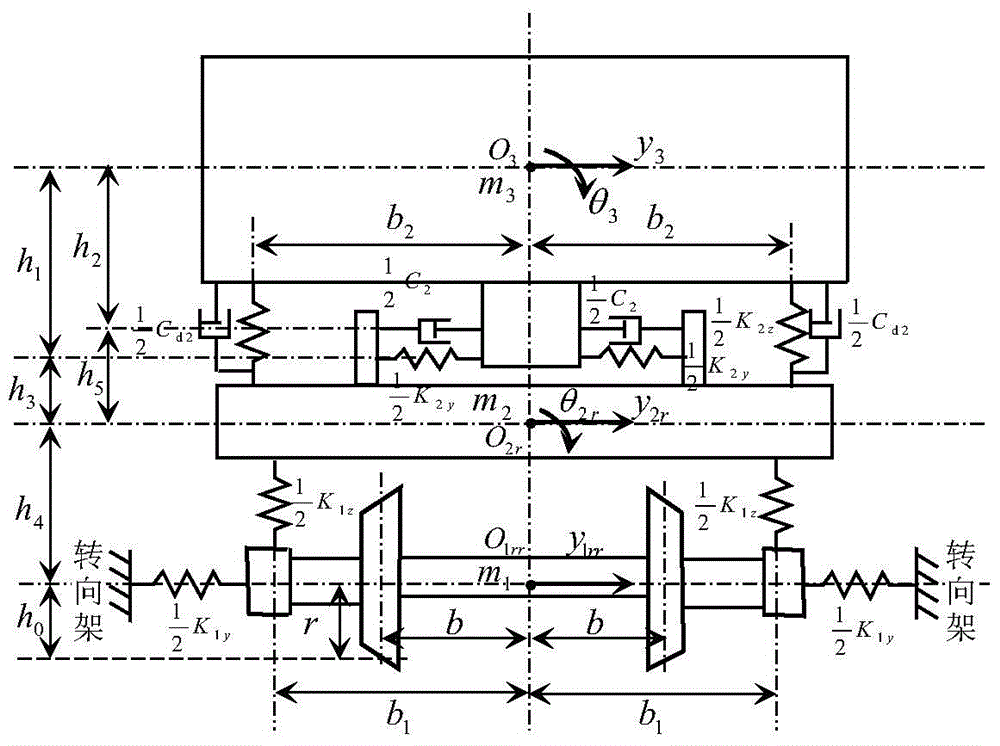

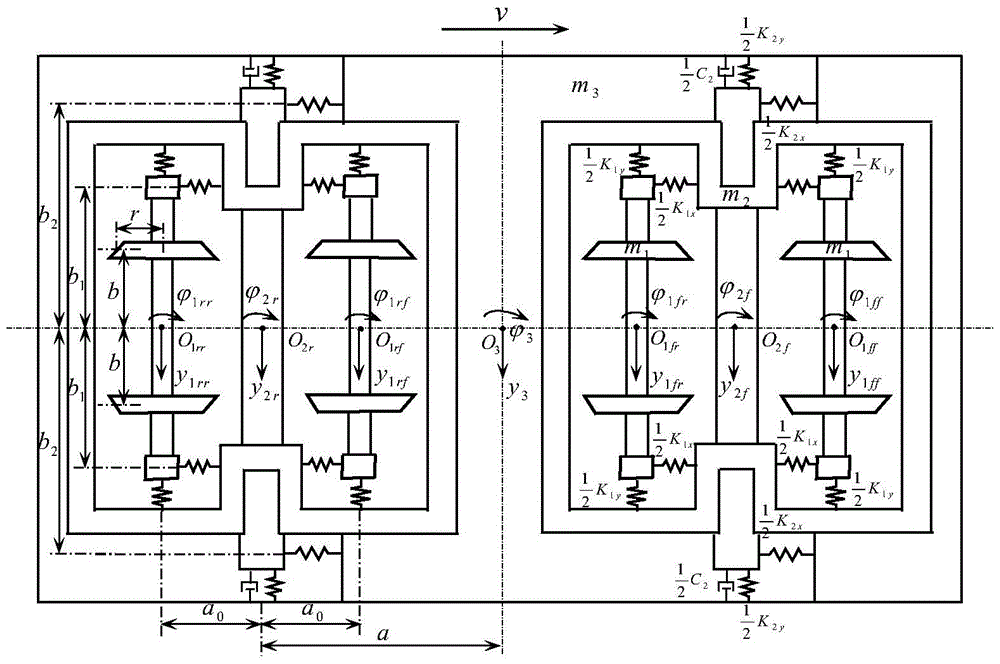

Design method for optimal damping coefficient of secondary transverse shock absorber of low-speed rail vehicle

InactiveCN105069261AImprove powerReliable Simulated ValuesSpecial data processing applicationsDamping factorLow speed

The invention relates to a design method for the optimal damping coefficient of a secondary transverse shock absorber of a low-speed rail vehicle and belongs to the technical field of low-speed rail vehicle suspensions of low-speed rail vehicles. A vehicle 17-degree-of-freedom running transverse oscillatory differential equation of the low-speed rail vehicle is established, MATLAB / Simulink simulation software is used for constructing a 17-degree-of-freedom running transverse oscillatory optimization design simulation model, unevenness in the rail direction and unevenness in the horizontal direction serve as the input stimulus, the minimum oscillatory weighing acceleration root mean square value of transverse movement of a vehicle body serves as the design target, and therefore the optimal damping coefficient of the secondary transverse shock absorber of the low-speed rail vehicle is obtained through optimization design. It can be known through a design example and SIMPACK simulation verification that the accurate and reliable optimal damping coefficient value of the secondary transverse shock absorber can be obtained, and the reliable design method is provided for design of the optimal damping coefficient of the secondary transverse shock absorber of the low-speed rail vehicle. By means of the method, the design level of a suspension system of the low-speed rail vehicle can be obviously improved, and the running safety and stability of the vehicle are improved.

Owner:SHANDONG UNIV OF TECH

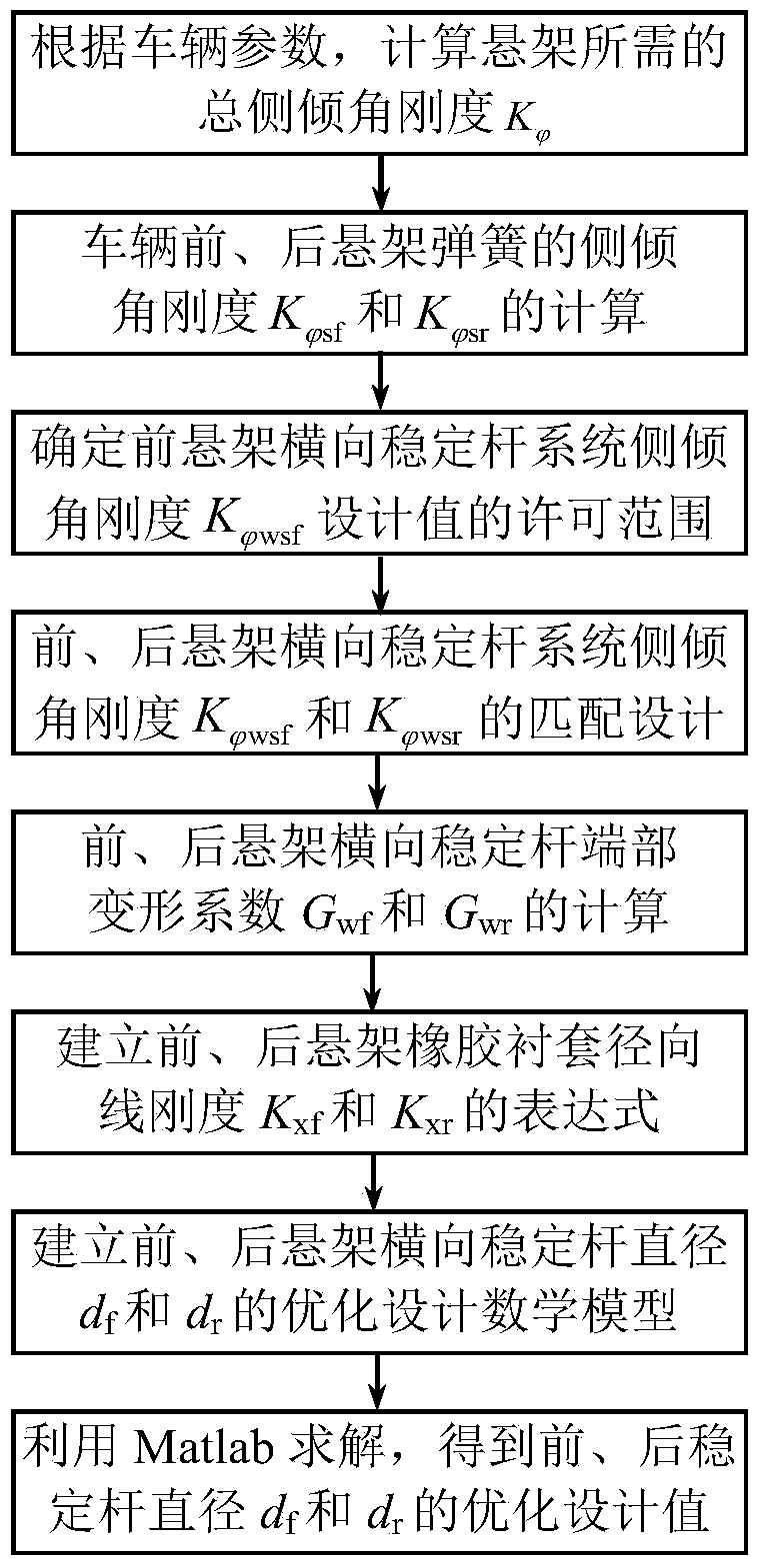

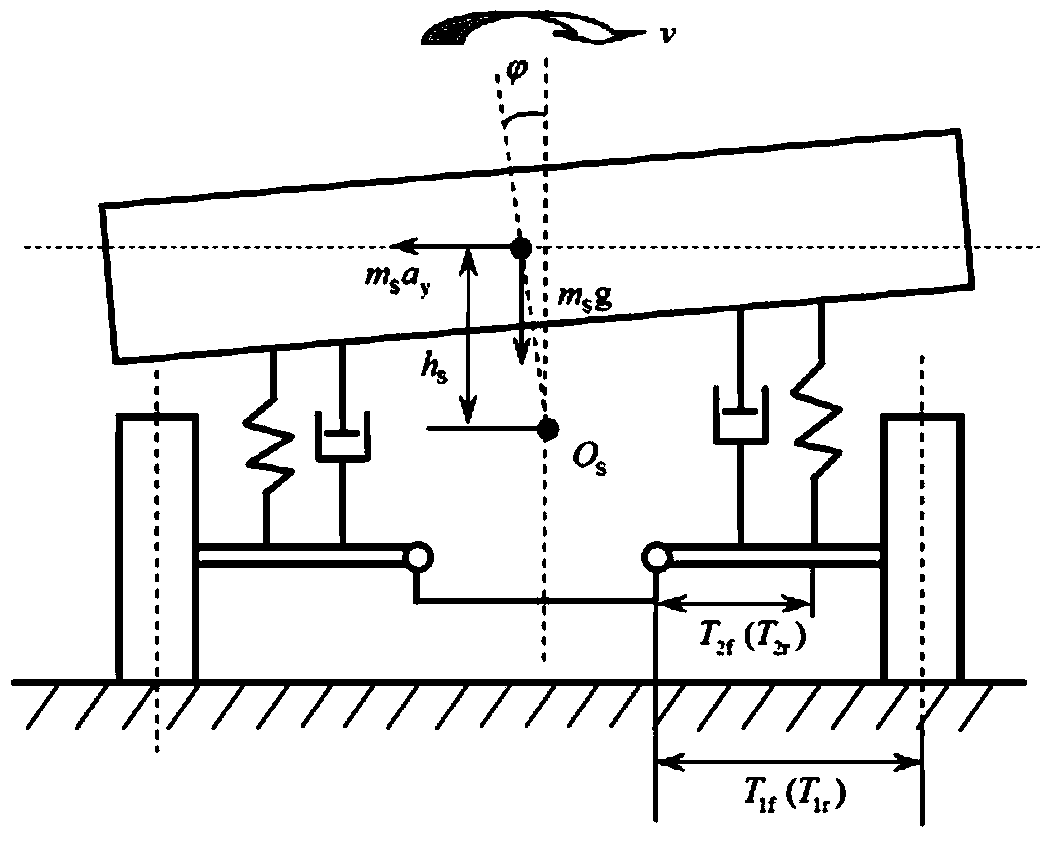

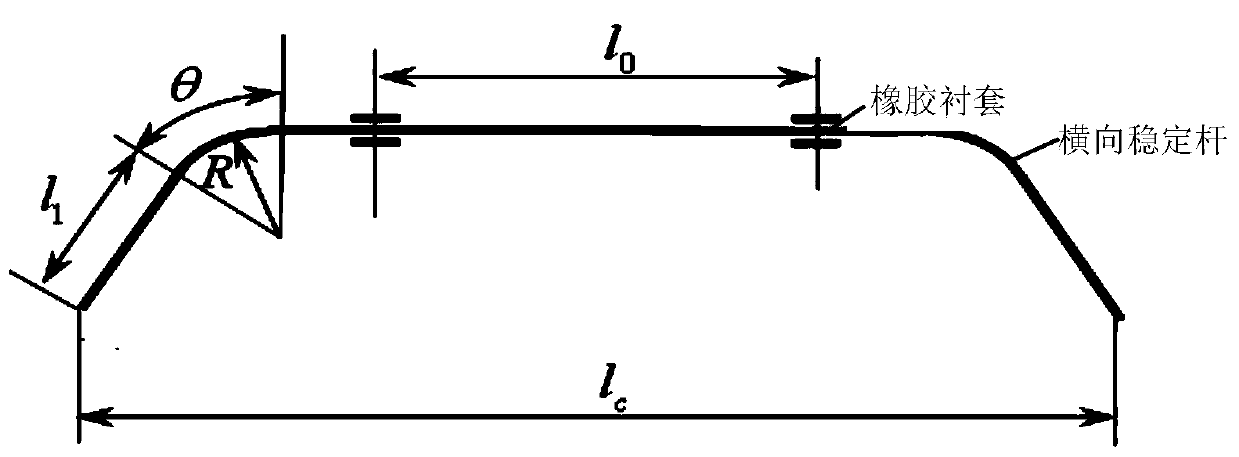

Design method for stiffness matching and diameter of vehicle suspension stabilizer bars

InactiveCN104200040AAccurate design methodRobust Design MethodInterconnection systemsSpecial data processing applicationsStiffness coefficientOptimal design

The invention relates to a design method for stiffness matching and diameter of vehicle suspension stabilizer bars and belongs to the technical field of vehicle suspensions, aiming to fill a gap of the reliable optimal design method for diameter of the stabilizer bars due to limitation of radial deformation analytic analysis and inter-coupling of the stabilizer bars and rubber bushings. The design method is characterized by including the steps of firstly, performing matching design on stiffness of angle of roll of a front suspension stabilizer bar system and a rear suspension stabilizer bar system according to vehicle parameters and roll models; secondly, building an optimal design mathematical model of the stabilizer bar diameter d according to the matching design value of stiffness of the angle of roll, the radial stiffness coefficient Kx of the rubber bushings and the deformation coefficient expression Gw of ends of the stabilizer bars so as to obtain the accurate and reliable optimal design value of the stabilizer bar diameter d by means of a Matlab program. By the design method, design level and performance of the suspensions and the stabilizer bars can be improved, riding comfort and safety of vehicles can be improved, and meanwhile, design speed for product development can be increased and cost for design and test can be reduced.

Owner:SHANDONG UNIV OF TECH

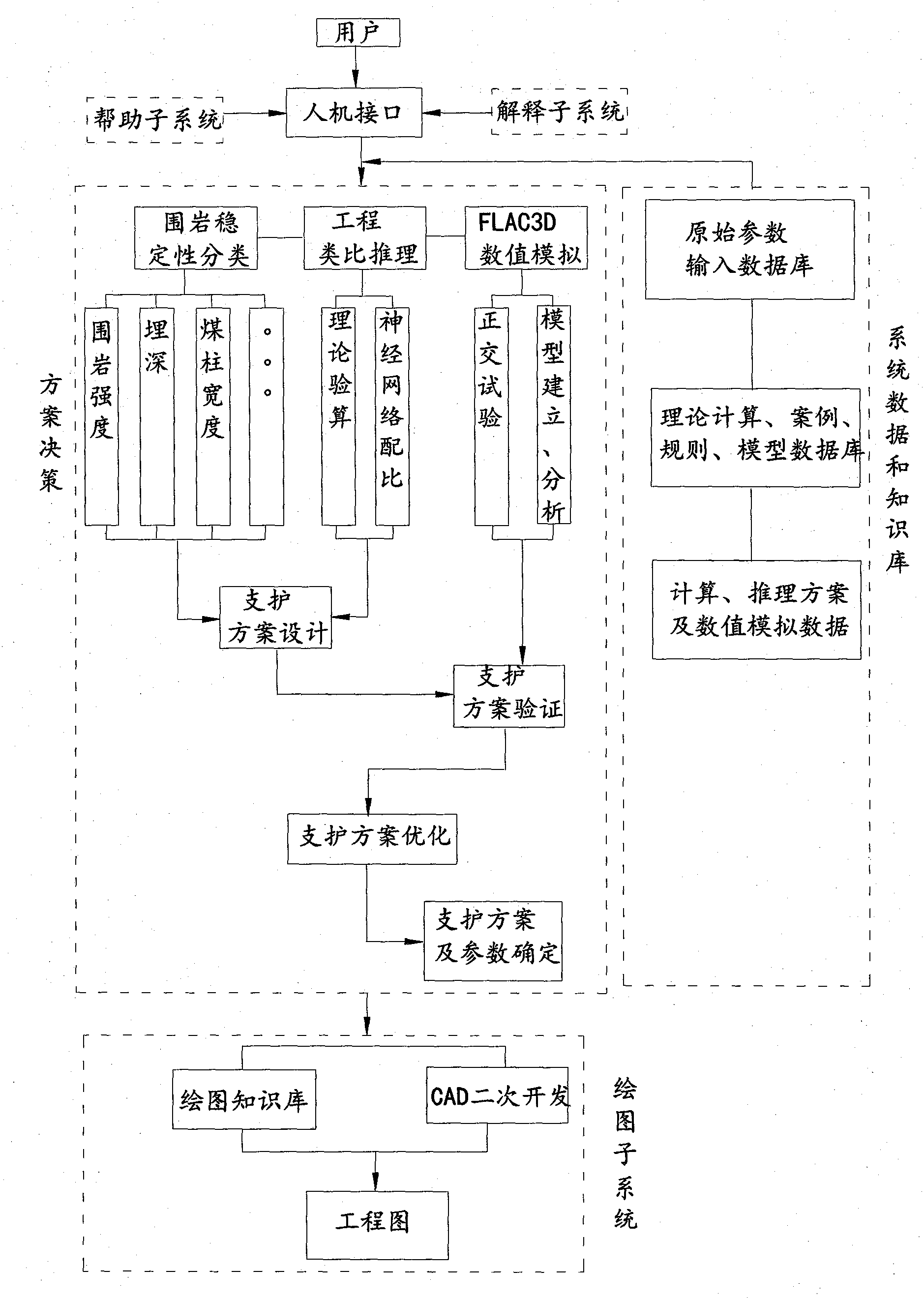

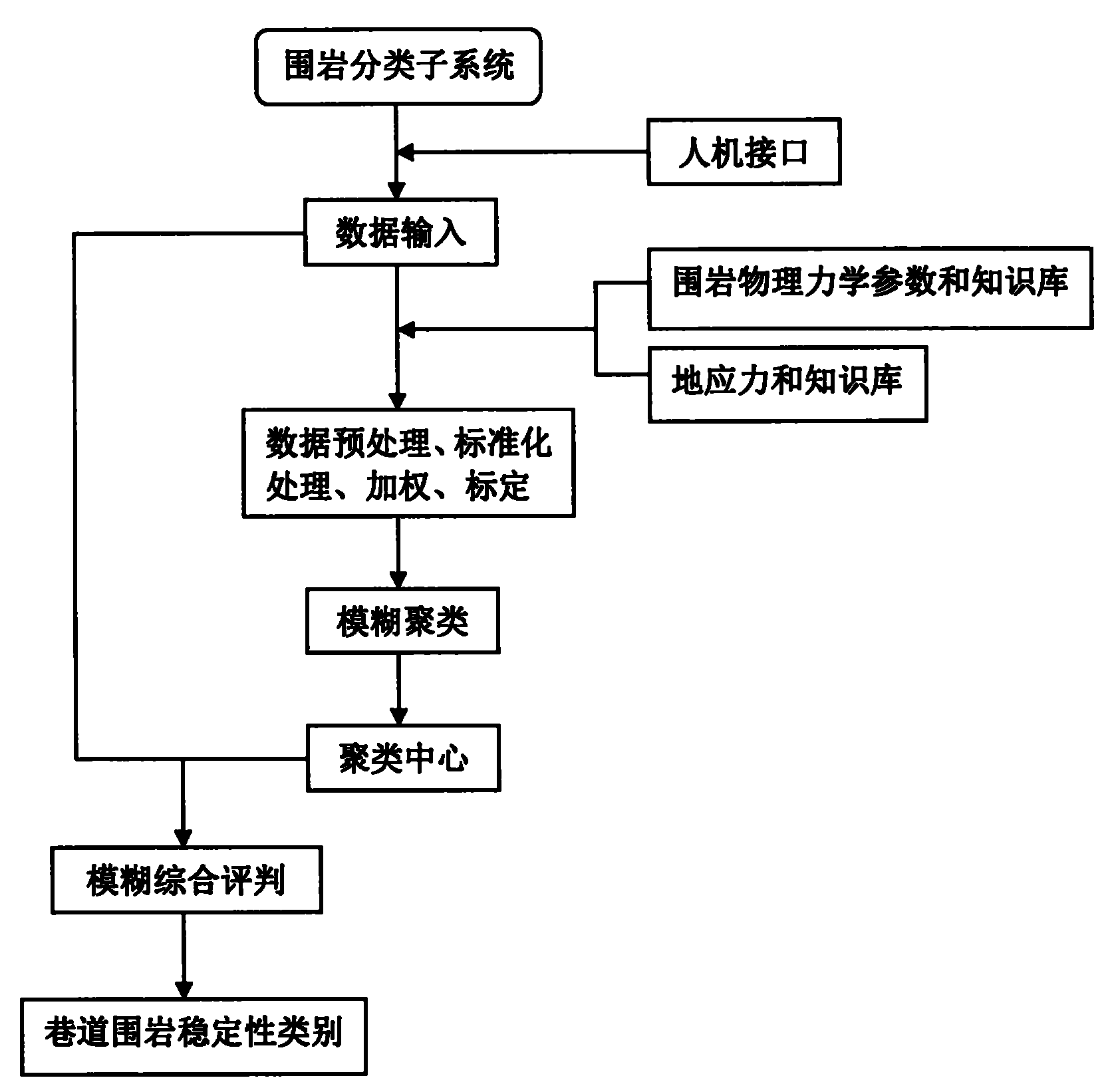

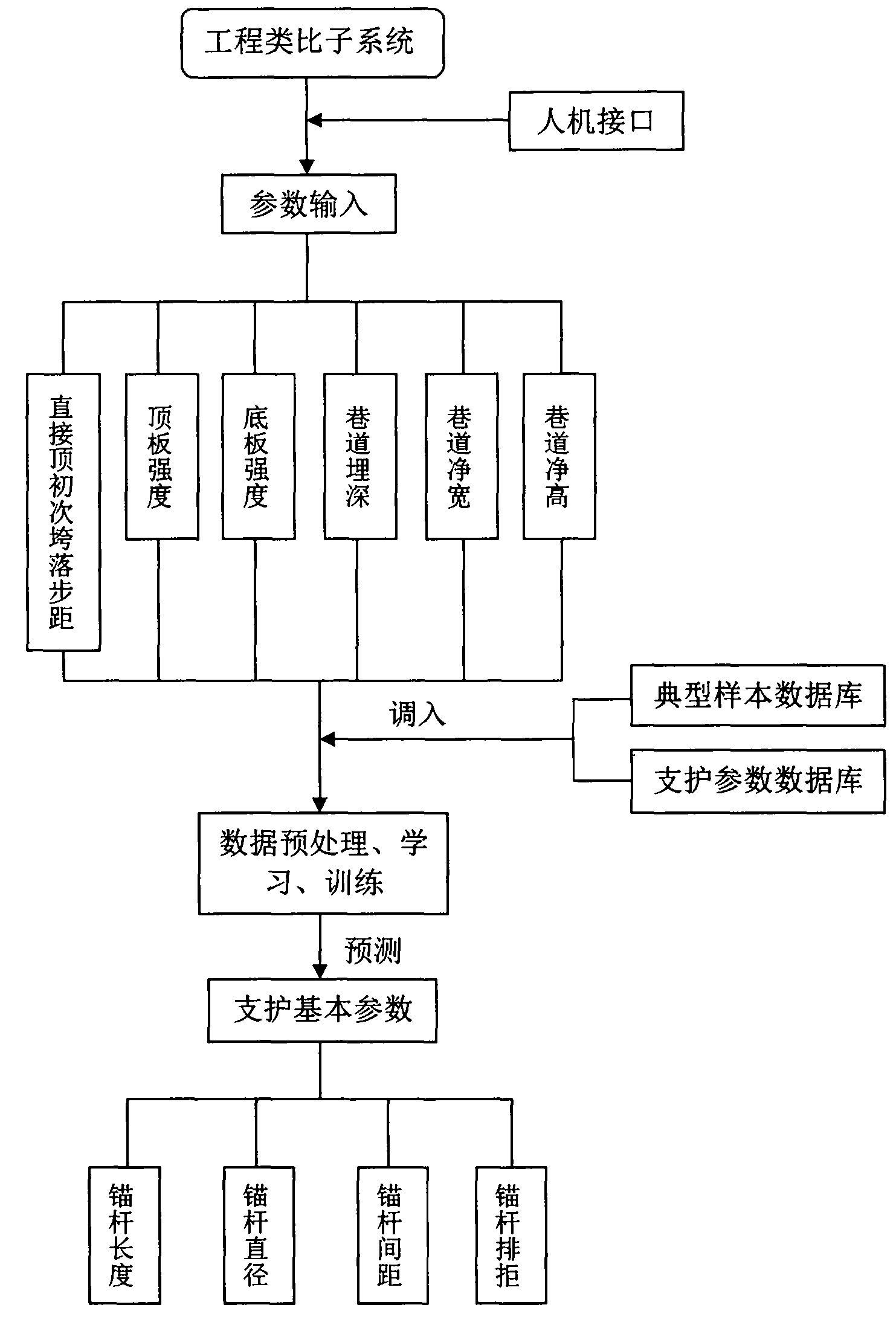

Automatic intelligent design and optimization system for anchor bolt support of coal tunnel

ActiveCN103984788AChange limitationsChange data requirementsSpecial data processing applicationsSupporting systemIntelligent design

The invention relates to an automatic intelligent design and optimization system for an anchor bolt support of a coal tunnel. The system comprises a tunnel surrounding-rock index obtainment and stability classification subsystem, an anchor bolt support parameter intelligent-matching subsystem and a support design verification and optimization subsystem, wherein the tunnel surrounding-rock index obtainment and stability classification subsystem realizes the classification and evaluation of tunnel surrounding-rock stability by processing data input by a user or calling parameters in relevant knowledge bases; the anchor bolt support parameter intelligent-matching subsystem establishes a training model based on a sample tunnel training BP (Back Propagation) neural network in an internal knowledge base of the system to realize the intelligent matching of anchor bolt support parameters of the coal tunnel; the support design verification and optimization subsystem implements theoretic checking calculation based on a suspension theory, a combined beam theory, a combined arch theory and an energy theory according to the anchor bolt support parameters obtained by the anchor bolt support parameter intelligent-matching subsystem, and automatically analyzes various support schemes to select the support scheme which meets the deformation requirements of tunnel surrounding-rocks, wherein the selected support scheme being the optimal support scheme is recommended to the user. By applying the system, the scientificity and the reasonability of the anchor bolt support structure and parameters are effectively guaranteed; the reliability of an anchor bolt support system is improved; the healthy development of an anchor bolt support technique for the coal tunnel in our country is promoted.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

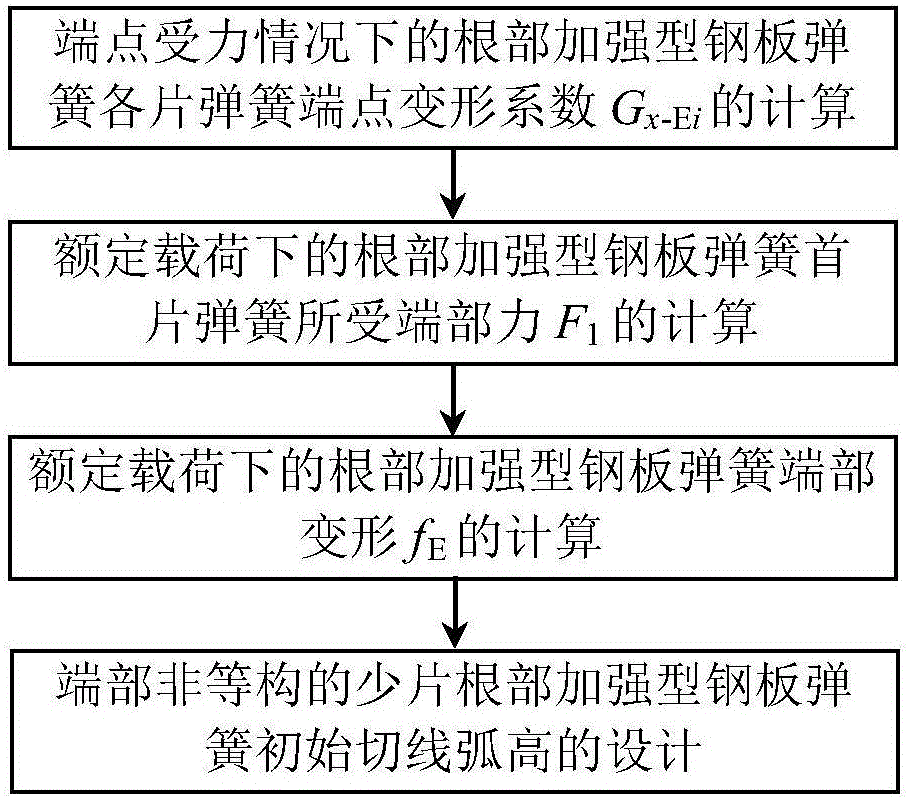

Design method for arc height of end-non-isomorphic few-leaf root-strengthening-type steel plate spring

InactiveCN106286660AImprove ride comfortRobust Design MethodGeometric CADLeaf springsSoftware developmentEngineering

The invention relates to a design method for the arc height of an end-non-isomorphic few-leaf root-strengthening-type steel plate spring, belonging to the technical field of suspension steel plate springs. According to the design method, the initial tangent arc height of the end-non-isomorphic few-leaf root-strengthening-type steel plate spring can be designed according to the structure parameters, the elastic modulus, the rated load and a residue tangent arc height design required value under the rated load of each leaf of spring. According to a model machine loading deformation test, the design method for the arc height of the end-non-isomorphic few-leaf root-strengthening-type steel plate spring is correct; an accurate and reliable initial tangent arc height design value can be obtained; and a reliable technical basis is provided for design and CAD software development of the end-non-isomorphic few-leaf root-strengthening-type steel plate spring. By utilizing the method, the product design level, quality and performance and automobile driving smoothness can be improved; meanwhile, product design and testing cost is lowered; and product development is accelerated.

Owner:SHANDONG UNIV OF TECH

Ship whole elastic-plastic movement response predication method and system under action of underwater explosion

InactiveCN104657611AImprove the design levelGood attack performanceSpecial data processing applicationsUnderwater explosionMarine engineering

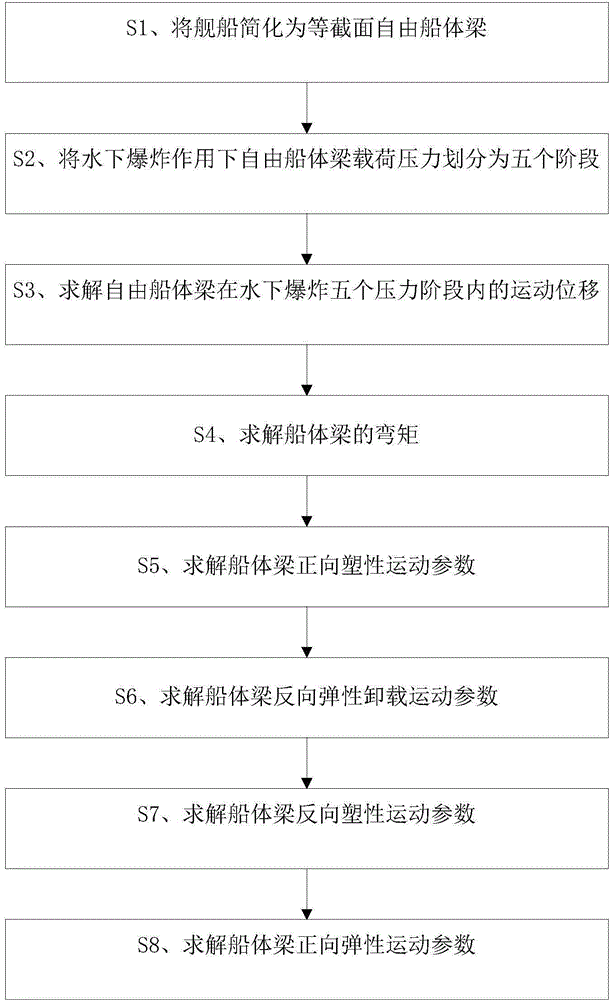

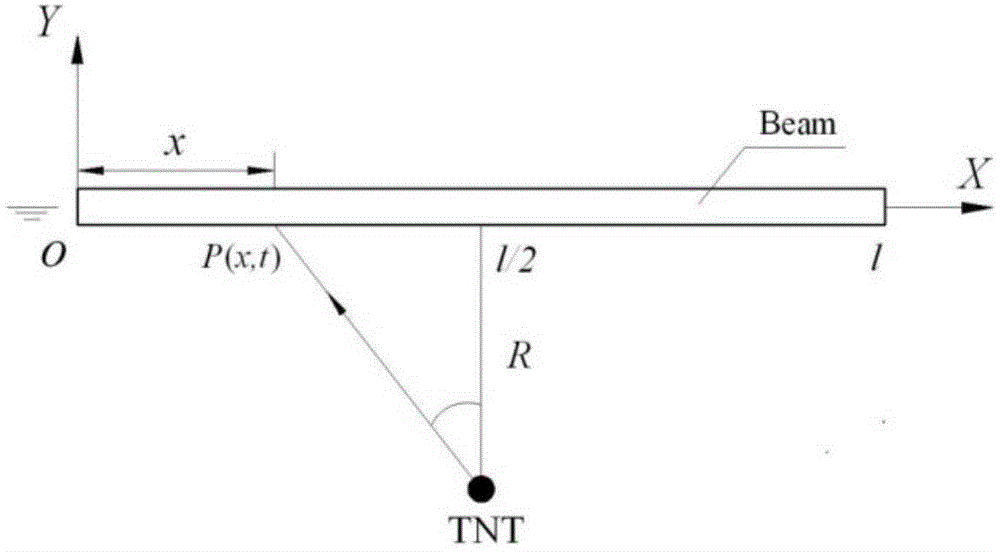

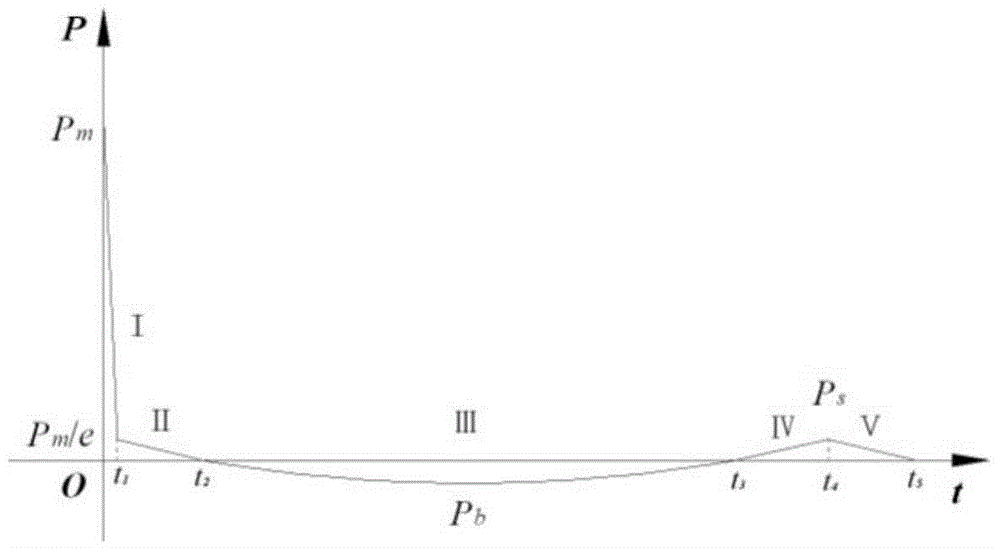

The invention discloses a ship whole elastic-plastic movement response predication method and system under the action of underwater explosion. The method comprises the following steps: S1, simplifying a ship into a free ship body beam with an equal section; S2, dividing load pressure of the free ship body beam into five time phases under the action of the underwater explosion; S3, solving movement displacement of the free ship body beam in the five time phases under the action of the underwater explosion; S4, solving a bending moment of the ship body beam; S5, solving forward plastic movement parameters of the ship body beam; S6, solving backward elastic unloading movement parameters of the ship body beam; S7, solving backward plastic movement parameters of the ship body beam; S8, solving forward plastic movement parameters of the ship body beam. The invention further provides a system for realizing the method. According to the method and the system disclosed by the invention, the ship plastic movement process is analyzed on the basis of comprehensively considering the impact effect on the whole ship body by impact waves and air bubble loads, and engineering predication of ship whole elastic-plastic movement deformation under the action of the underwater explosion can be accurately and conveniently realized.

Owner:NAVAL UNIV OF ENG PLA

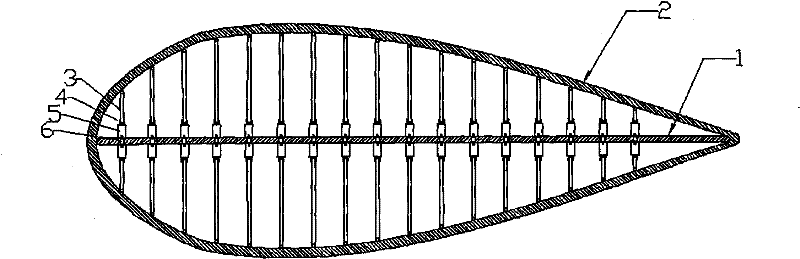

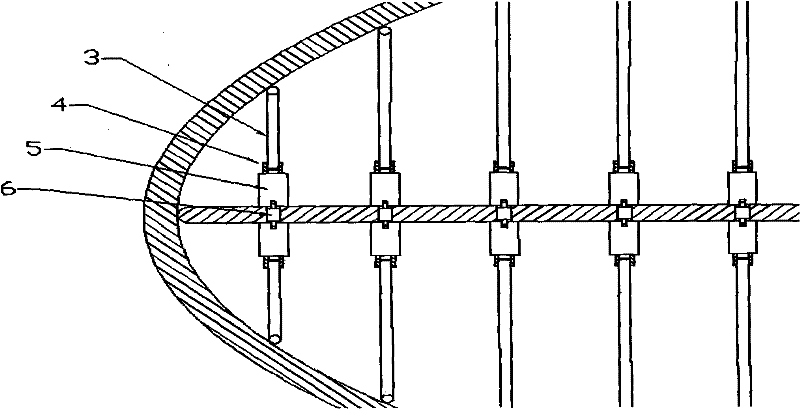

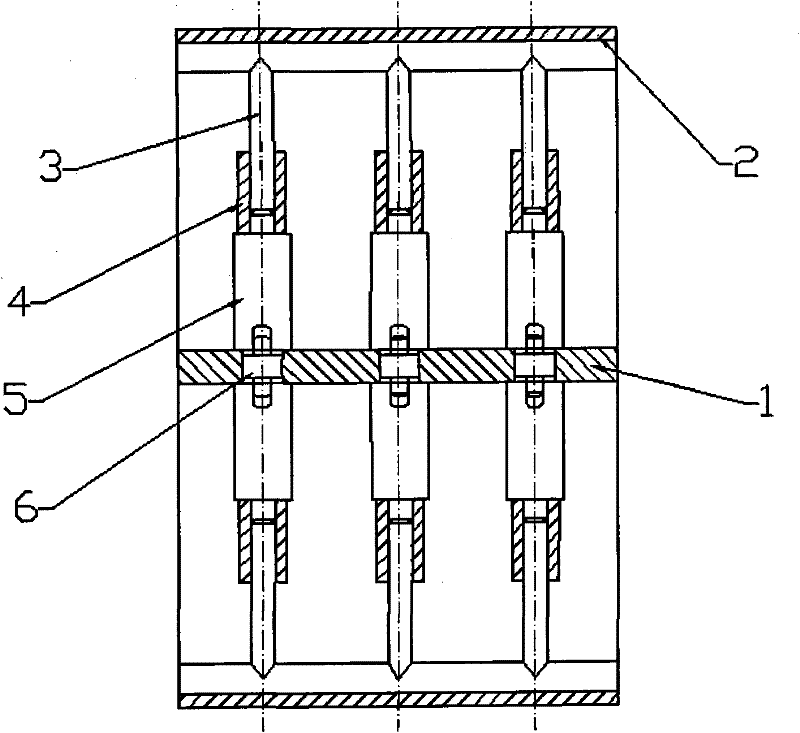

Device for adjusting wing surface of wing wind tunnel blowing model and adjustment method

InactiveCN102221444AEliminate theoretical flawsElimination methodAerodynamic testingControl signalActuator

The invention relates to a device for adjusting the wing surface of a wing wind tunnel blowing model and an adjustment method. In the device provided by the invention, the width of a support base is equal to the chordwise length of the wing wind tunnel blowing model; the length of the support base is equal to the spanwise length of the wing wind tunnel blowing model; multiple rows of actuators are distributed along the length direction of the support base; each row of actuators comprises multiple actuators; each actuator is respectively positioned on each design point of the wing and corresponds to the horizontal ordinates of each design point of the wing; the actuators are installed on the upper surface and lower surface of the support base in pairs; and the actuators in the same column on the same surface are connected through a data line and used for receiving the same control signals and carrying out the equal amplitude displacement. The invention provides a convenient and practical wing surface deformation adjusting mechanism for the wing surface deformation based on the wing shape design of a wind tunnel experiment, establishes a high-efficiency wing shape optimization design system by means of the environment and conditions of the wind tunnel experiment and provides different wing shape results for the engineering actually, thereby improving the design level and design efficiency of the existing wing shape.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

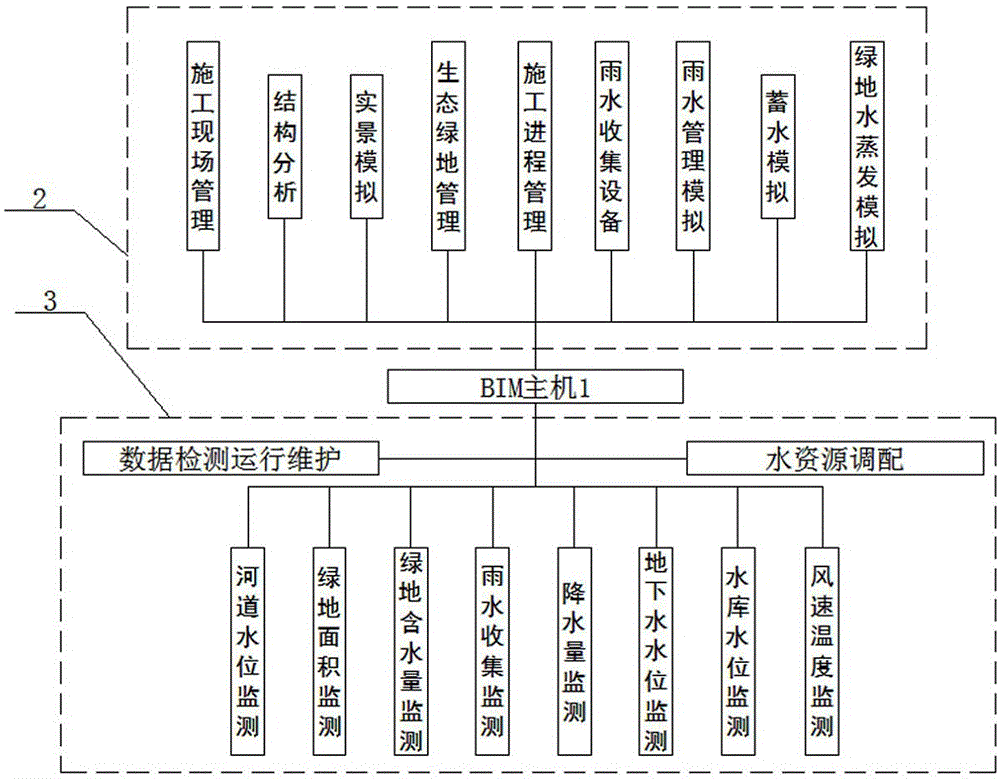

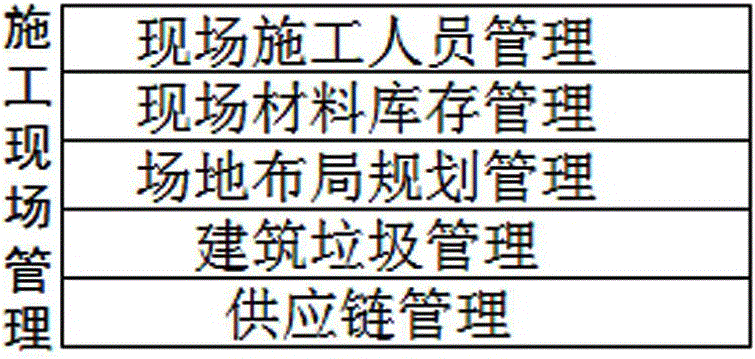

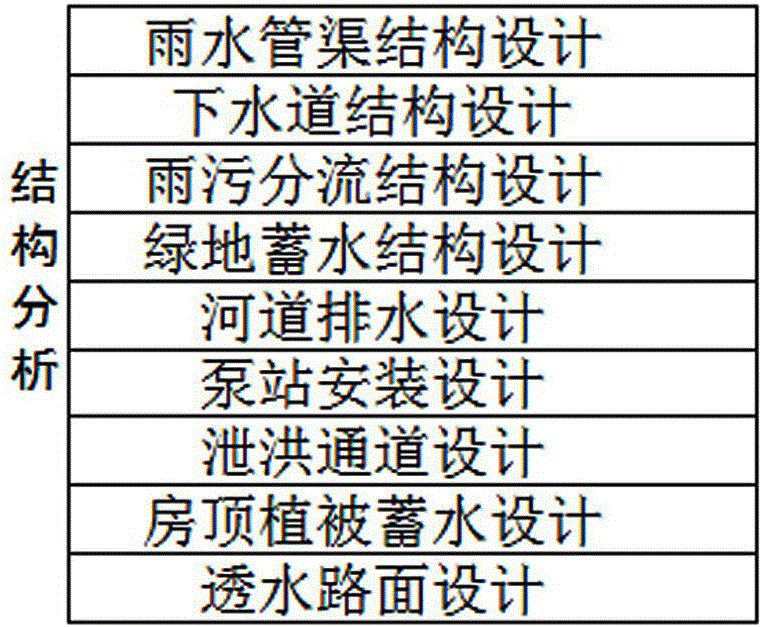

Application management of BIM technology to sponge city construction

ActiveCN106812145APrevent floodingImprove air qualityFoundation engineeringSewage drainingWater sourceEvaporation

The invention relates to sponge city construction, in particular to application management of a BIM technology to sponge city construction. All modules of a sponge city BIM site construction management module are in communication connection with a BIM host. A sponge city monitor, maintenance and deploy management module comprises a data detection operating maintenance module, a riverway water level monitor module, a green land area monitor module, a green land tax-inclusive monitor module, a rainwater collection monitor module, a precipitation amount monitor module, an underground water level monitor module, a reservoir water level monitor module, a wind speed and temperature monitor module, a water source deploy module and the like. All the modules of the sponge city monitor, maintenance and deploy management module are in communication connection with the BIM host. A construction progress management module manages all construction progresses and construction management through the BIM host. A green land water evaporation simulation module simulates different vegetation green lands through the BIM host. According to the application management, design, simulation, construction and management of all sponge city construction are carried out through the BIM, and drainage, irrigation and other management are carried out by monitoring data of all positions.

Owner:HUNAN COMM POLYTECHNIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com