Patents

Literature

57results about How to "Reliable Simulated Values" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

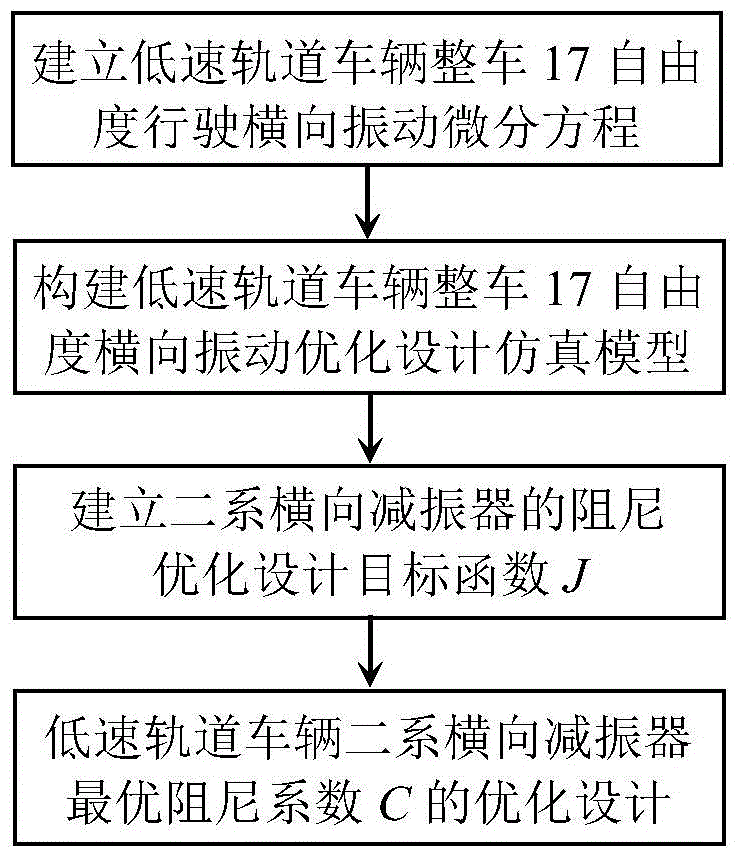

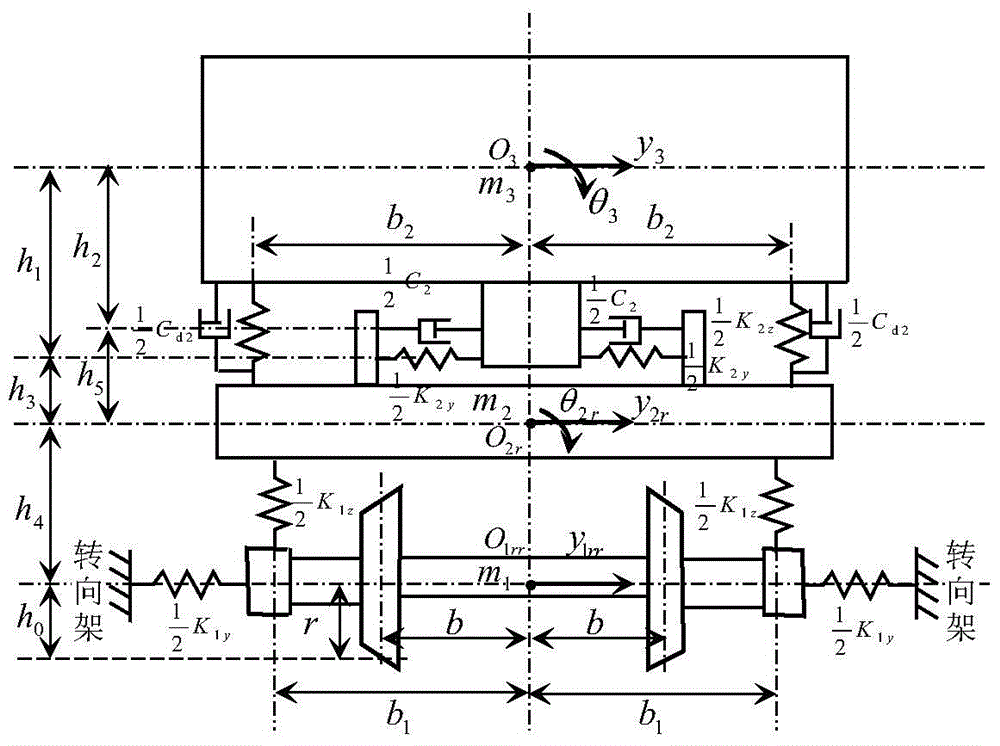

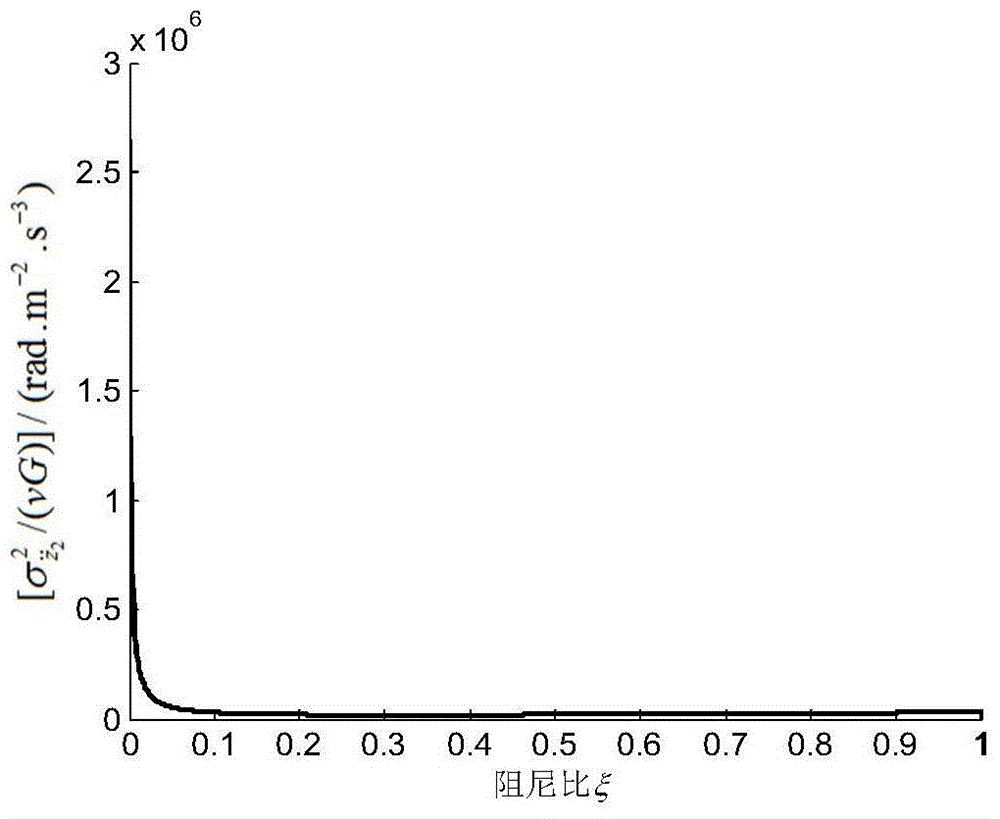

Design method for optimal damping coefficient of secondary transverse shock absorber of low-speed rail vehicle

InactiveCN105069261AImprove powerReliable Simulated ValuesSpecial data processing applicationsDamping factorLow speed

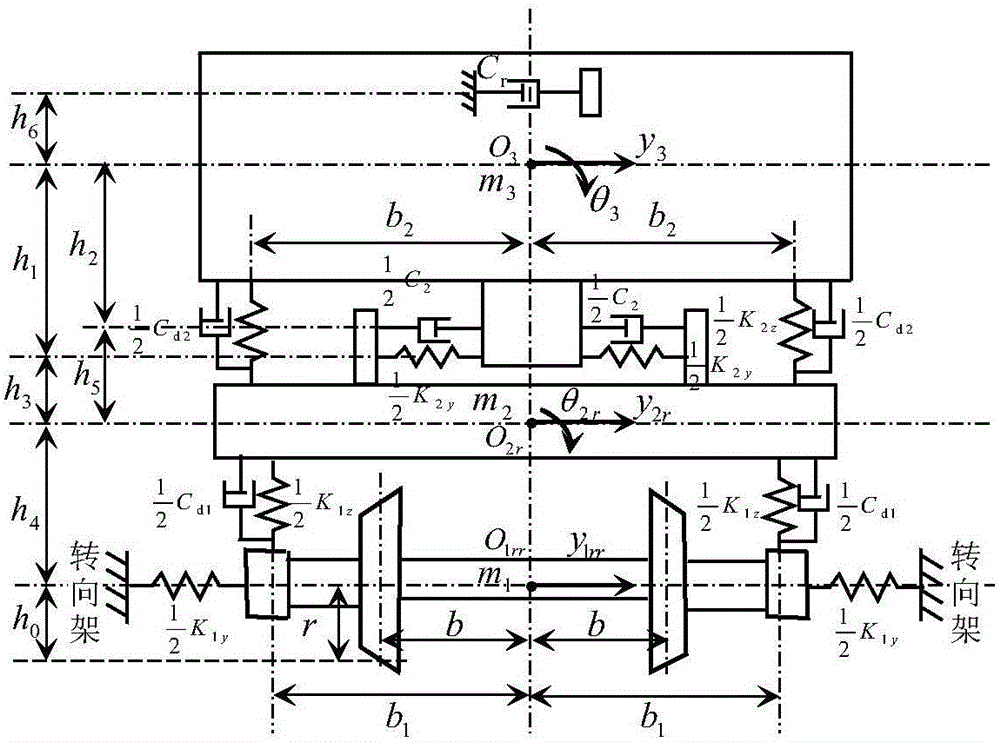

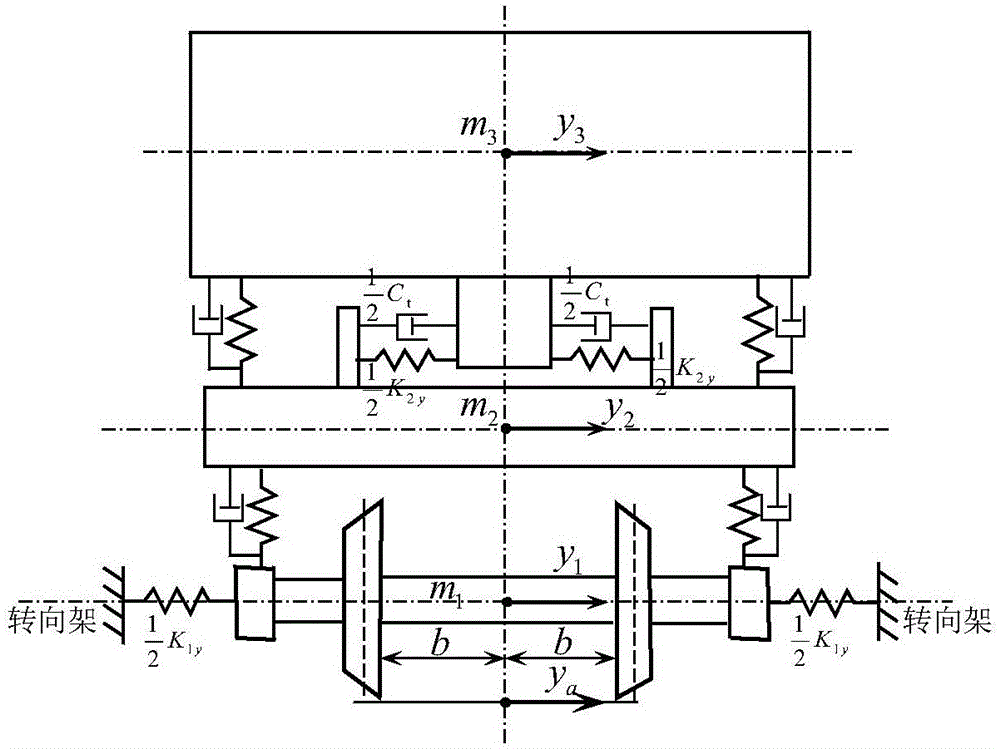

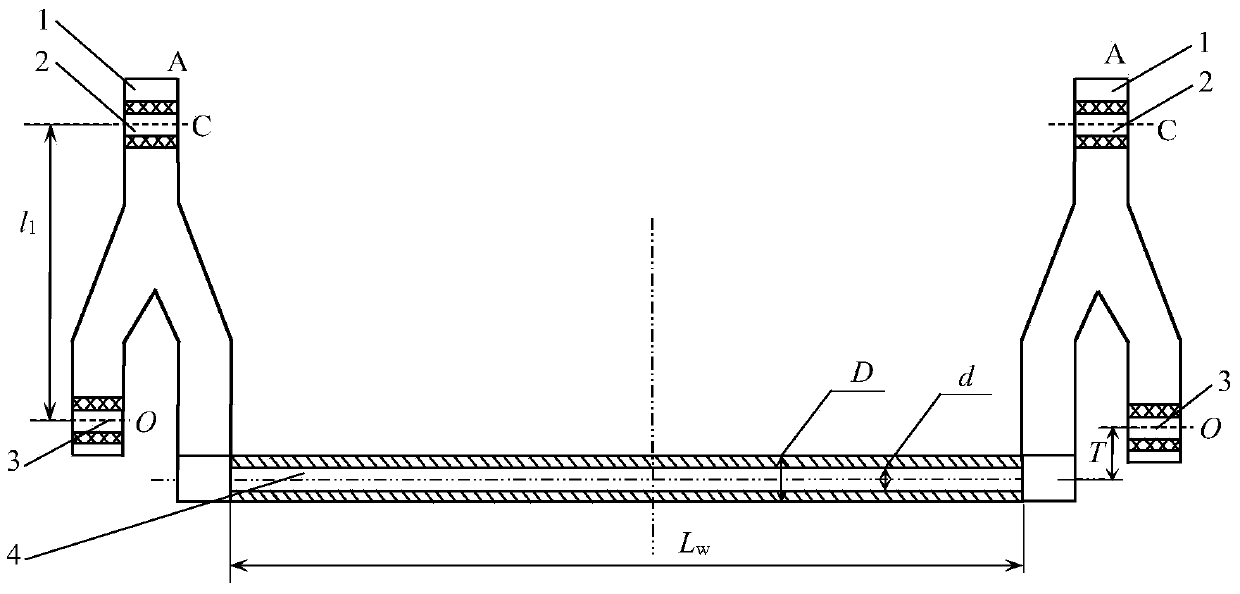

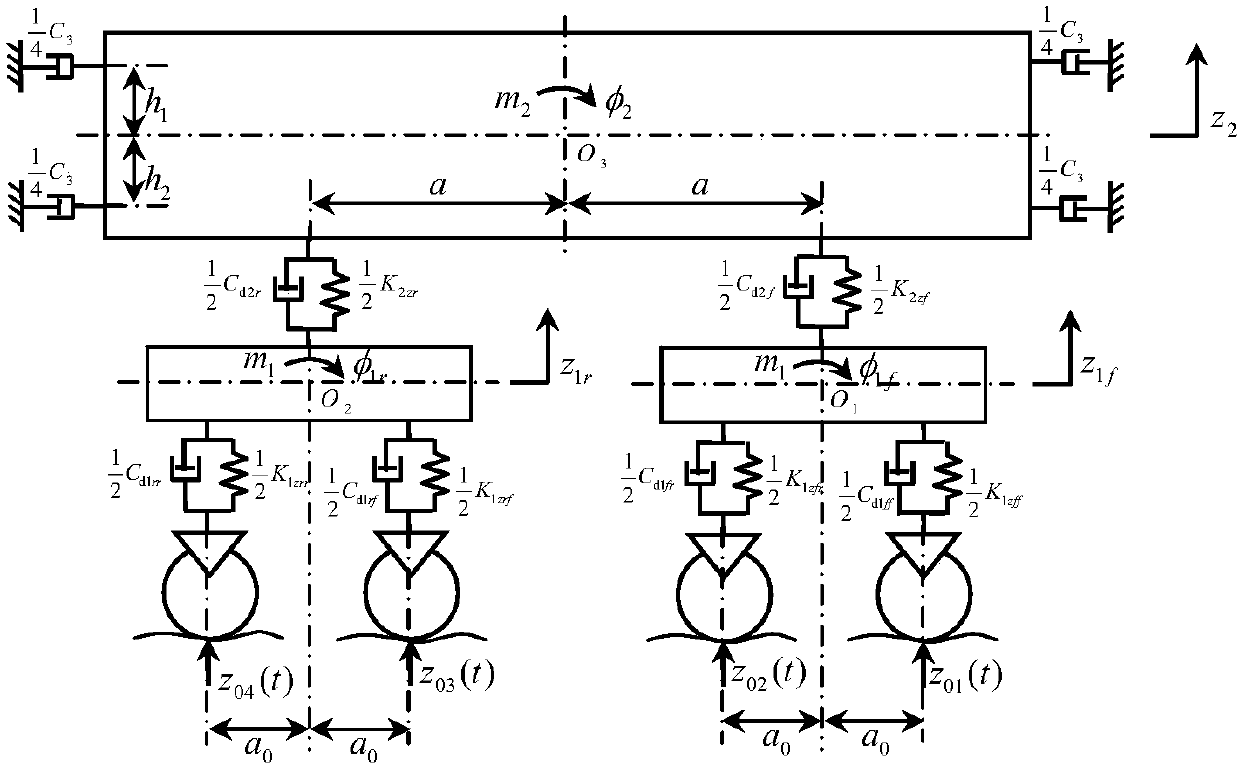

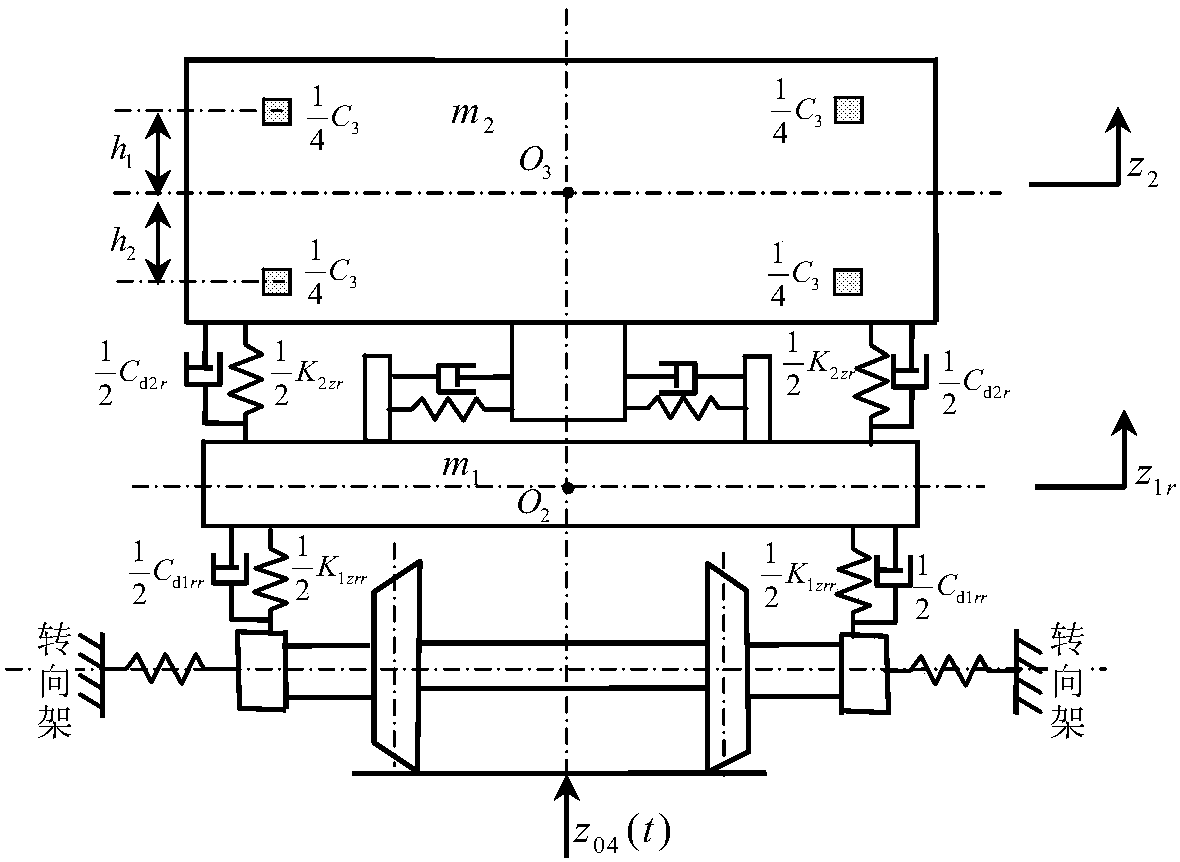

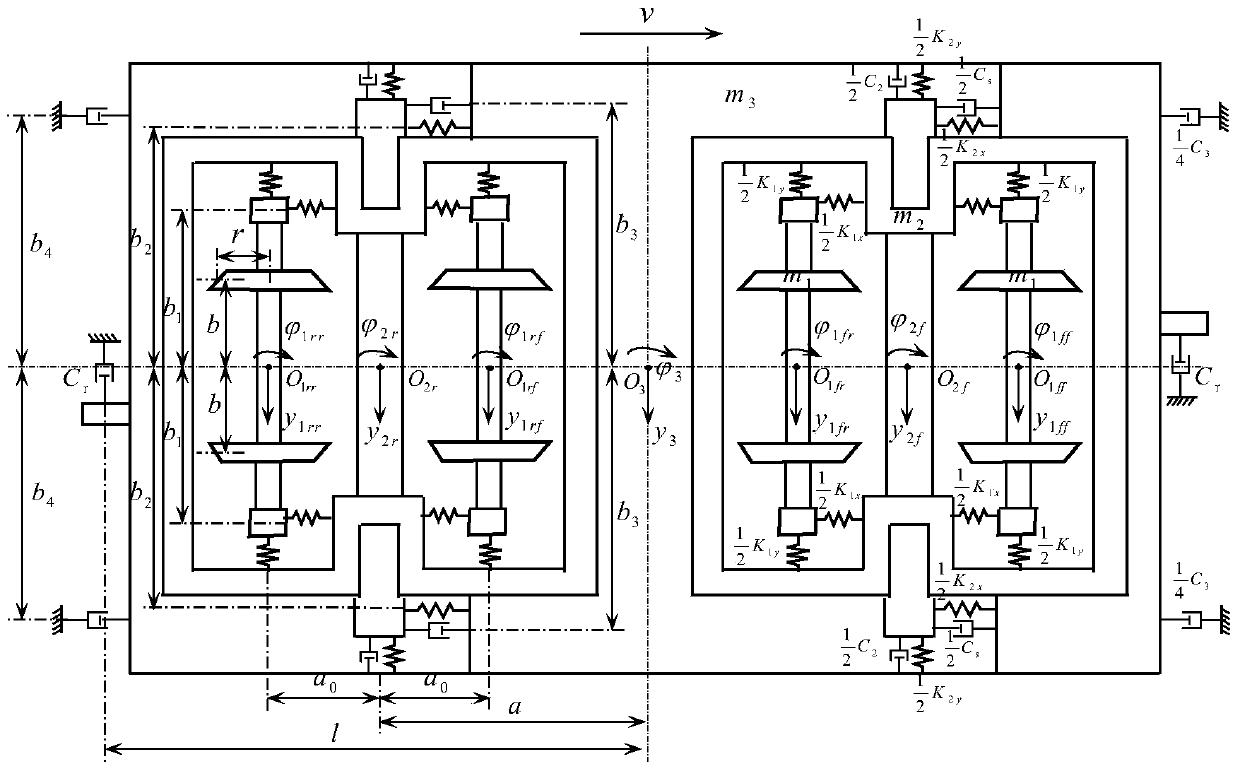

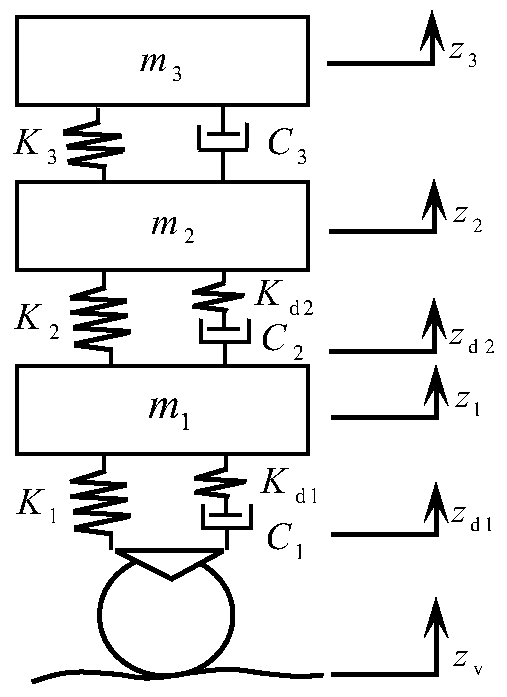

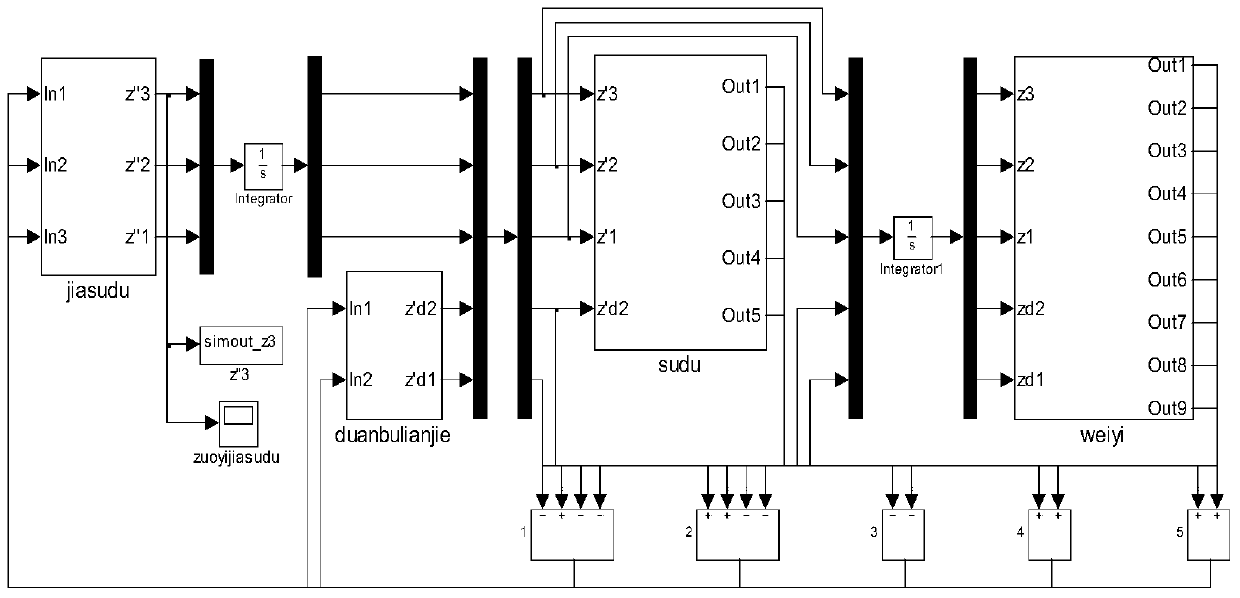

The invention relates to a design method for the optimal damping coefficient of a secondary transverse shock absorber of a low-speed rail vehicle and belongs to the technical field of low-speed rail vehicle suspensions of low-speed rail vehicles. A vehicle 17-degree-of-freedom running transverse oscillatory differential equation of the low-speed rail vehicle is established, MATLAB / Simulink simulation software is used for constructing a 17-degree-of-freedom running transverse oscillatory optimization design simulation model, unevenness in the rail direction and unevenness in the horizontal direction serve as the input stimulus, the minimum oscillatory weighing acceleration root mean square value of transverse movement of a vehicle body serves as the design target, and therefore the optimal damping coefficient of the secondary transverse shock absorber of the low-speed rail vehicle is obtained through optimization design. It can be known through a design example and SIMPACK simulation verification that the accurate and reliable optimal damping coefficient value of the secondary transverse shock absorber can be obtained, and the reliable design method is provided for design of the optimal damping coefficient of the secondary transverse shock absorber of the low-speed rail vehicle. By means of the method, the design level of a suspension system of the low-speed rail vehicle can be obviously improved, and the running safety and stability of the vehicle are improved.

Owner:SHANDONG UNIV OF TECH

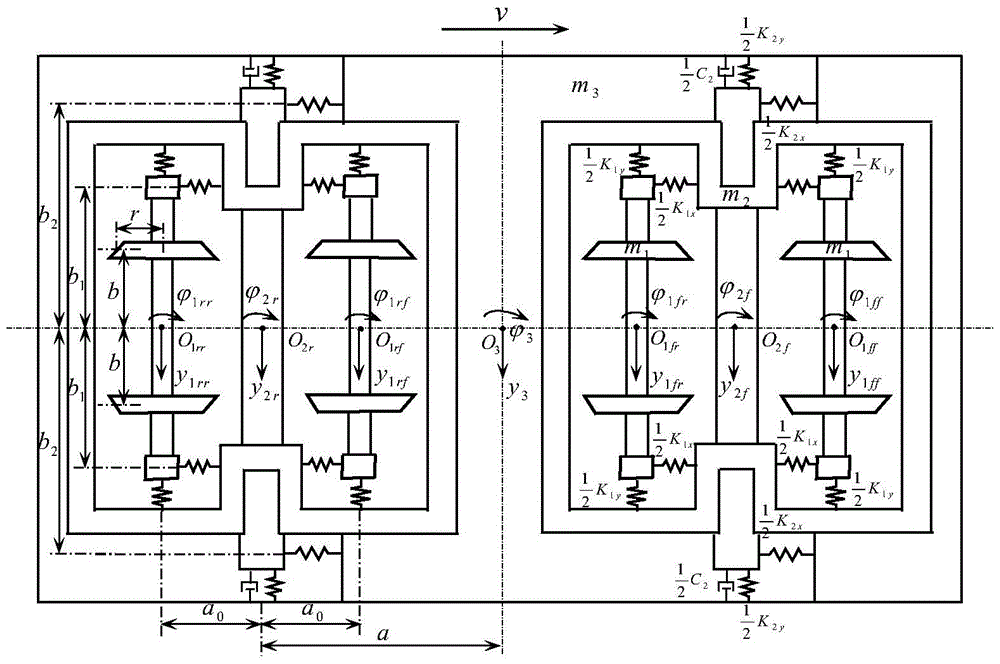

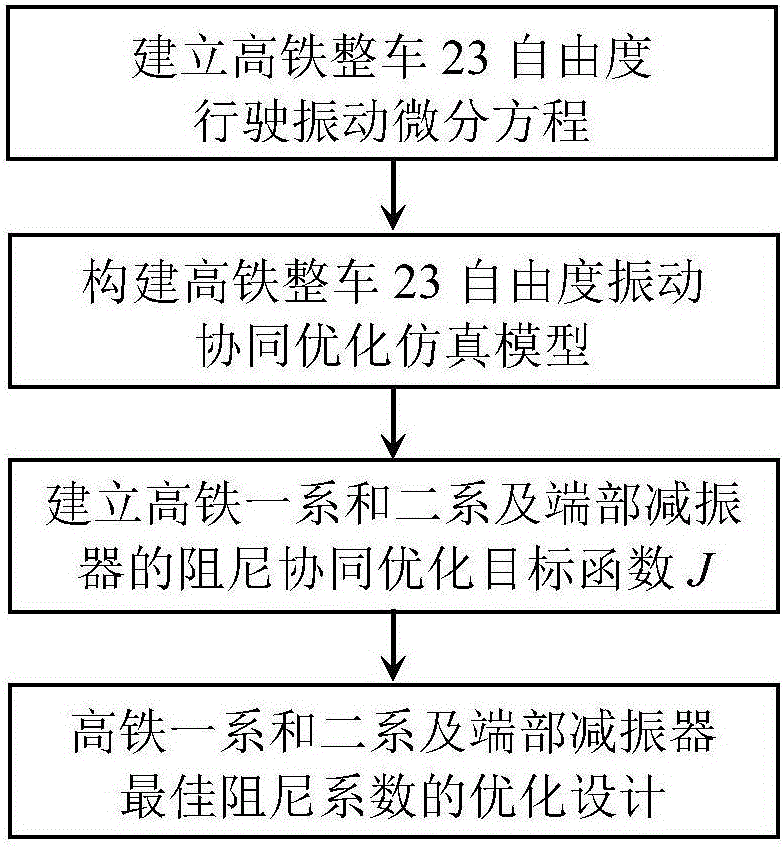

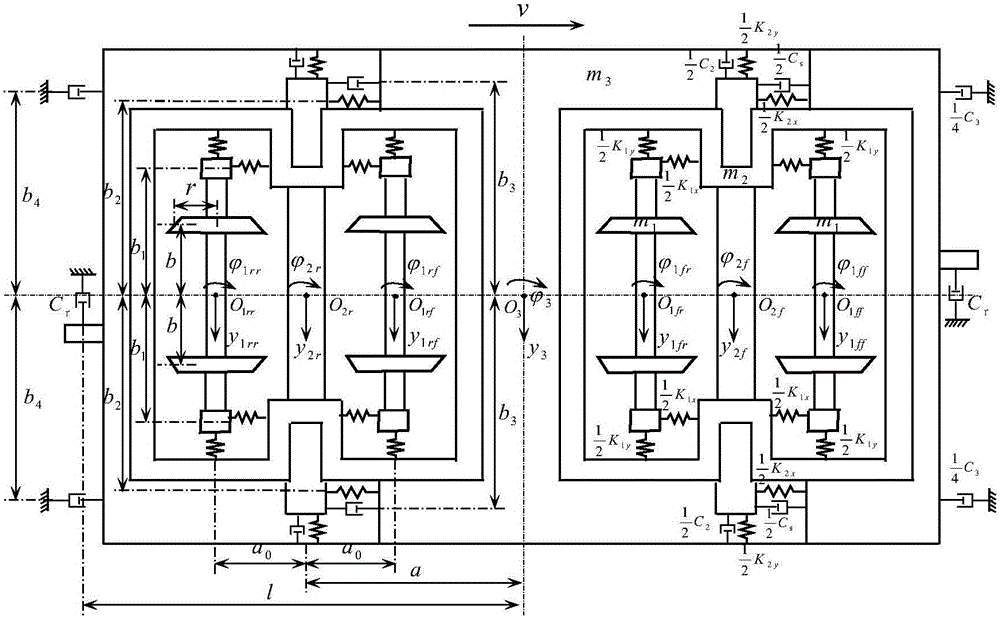

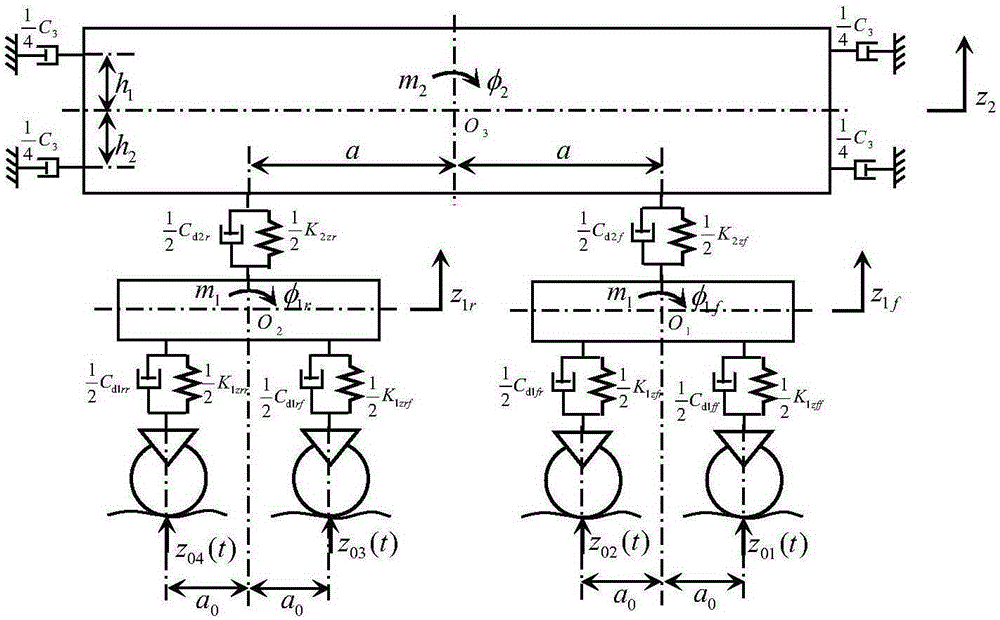

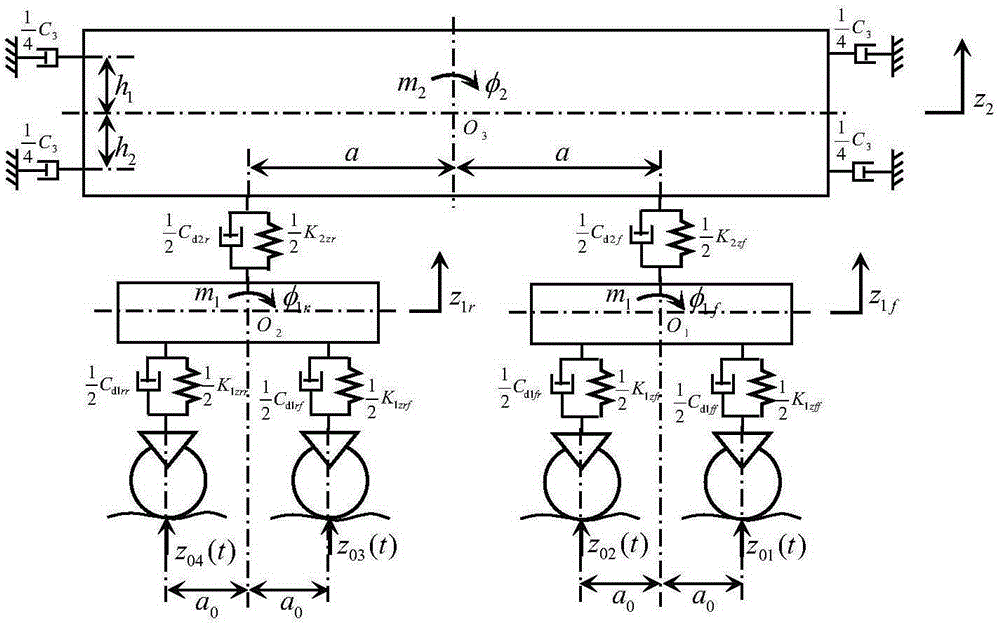

Collaborative optimization method for damping coefficient of high-speed rail primary system and secondary system and end shock absorber

InactiveCN105117556AImprove powerReliable Simulated ValuesSpecial data processing applicationsDamping factorThree degrees of freedom

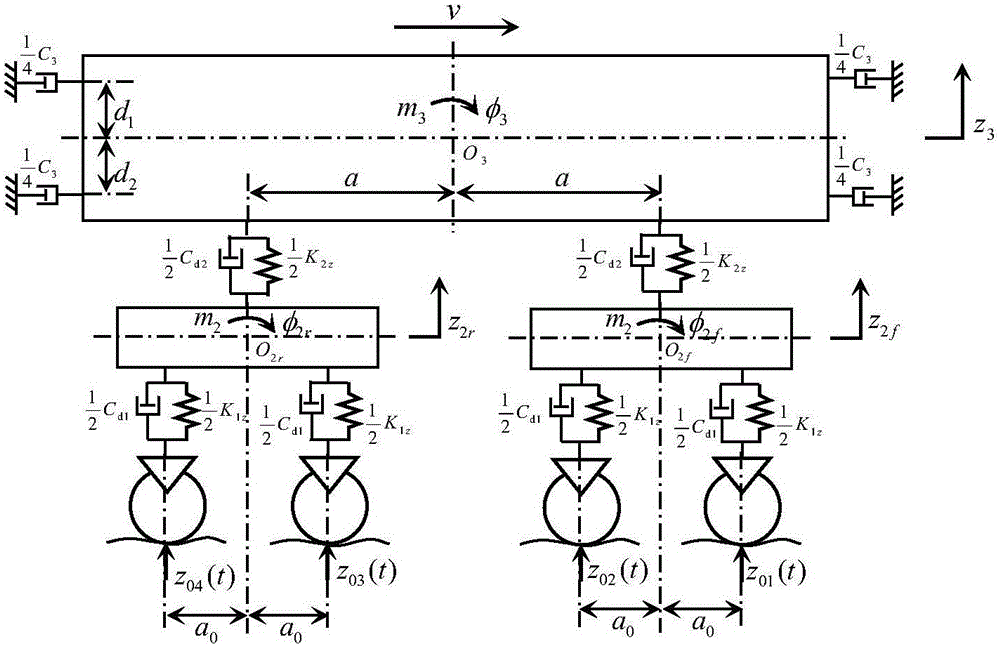

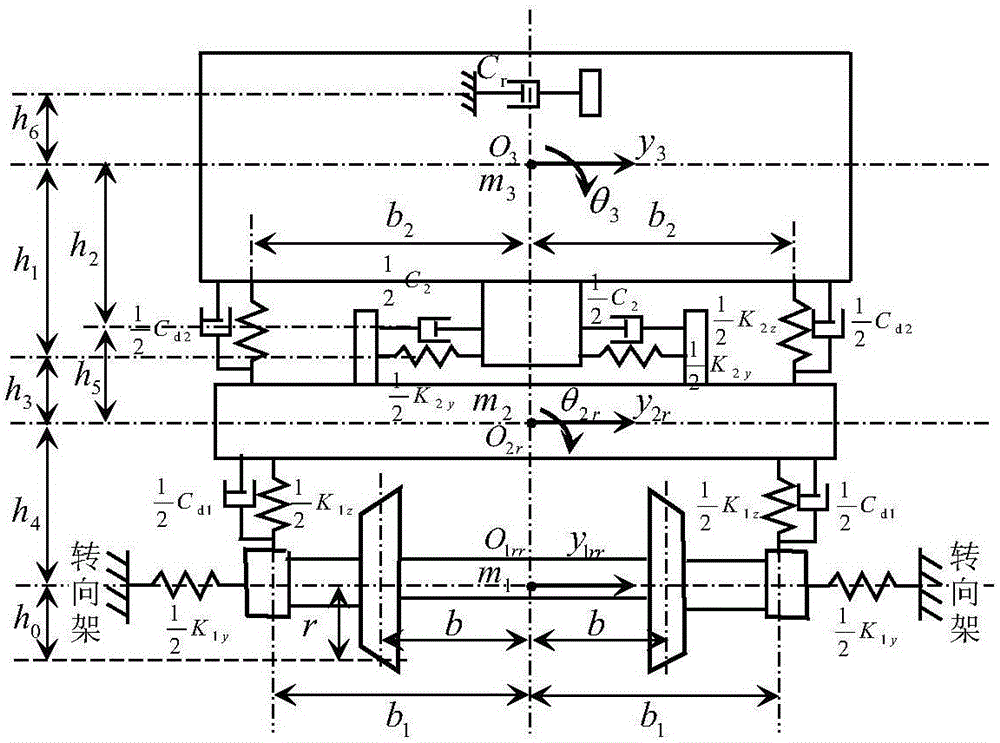

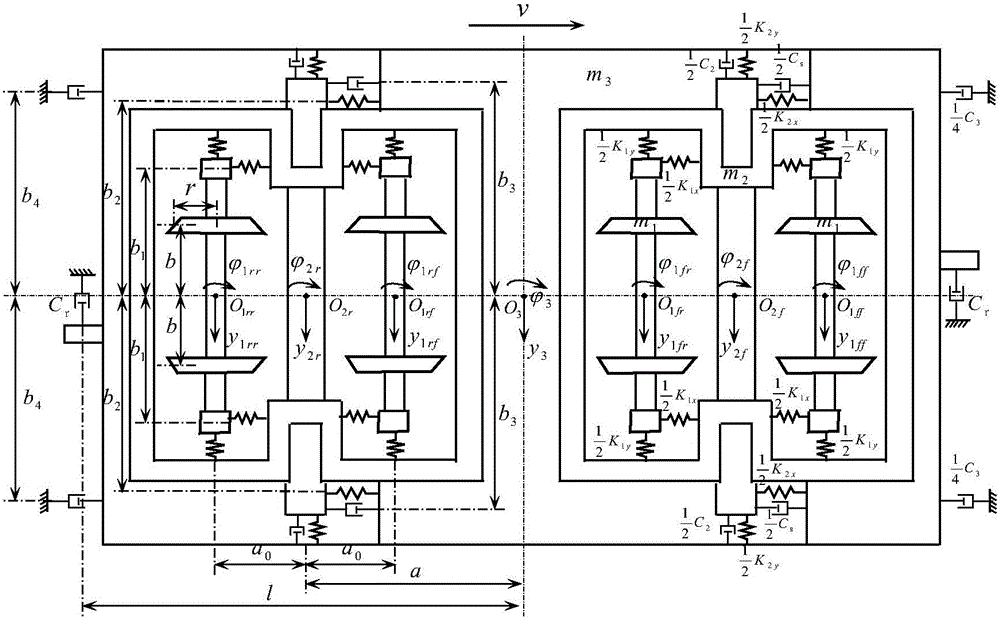

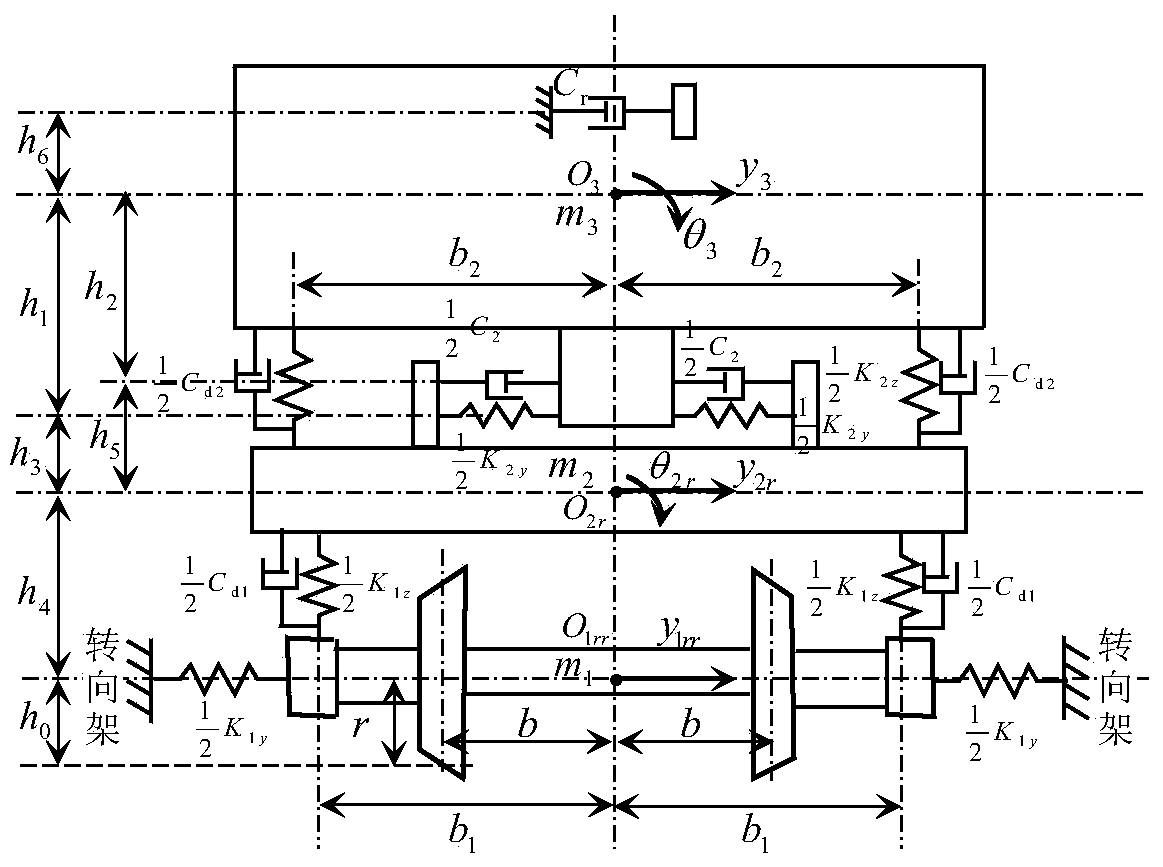

The invention relates to a collaborative optimization method for a damping coefficient of high-speed rail primary system and secondary system and an end shock absorber, belonging to the technical field of suspension of a high-speed rail vehicle. The method comprises the following steps of: building a twenty-three-degree-of-freedom vibration collaborative optimization simulation mode of the whole high-speed vehicle; taking a track vertical profile irregularity random input, an alignment irregularity random input and a cross-level irregularity random input as input excitation; taking minimum root-mean-square value of vehicle vibration weighted acceleration as a design target; and optimizing the design to obtain the optimal damping coefficient of the high-speed rail primary system and secondary system and the end shock absorber. According to a design example and SIMPACK simulation verification, the accurate and reliable damping coefficient value of the primary system, the secondary system and the end absorber can be acquired through the method, and a reliable design method is provided for the design of the damping coefficient of the primary system, the secondary system and the end absorber. By the method, the design level of a high-speed suspension system and the safety and the stationarity of vehicle running can be improved, the product design and test cost also can be reduced, and the international market competitiveness of the rail vehicle of our country is enhanced.

Owner:SHANDONG UNIV OF TECH

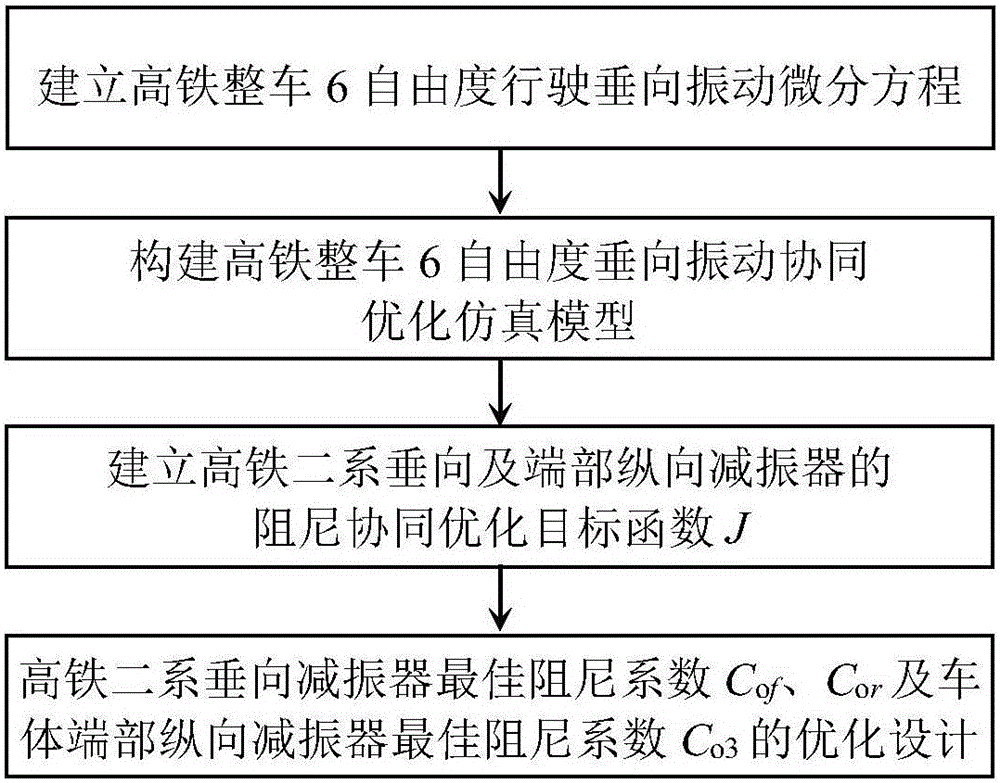

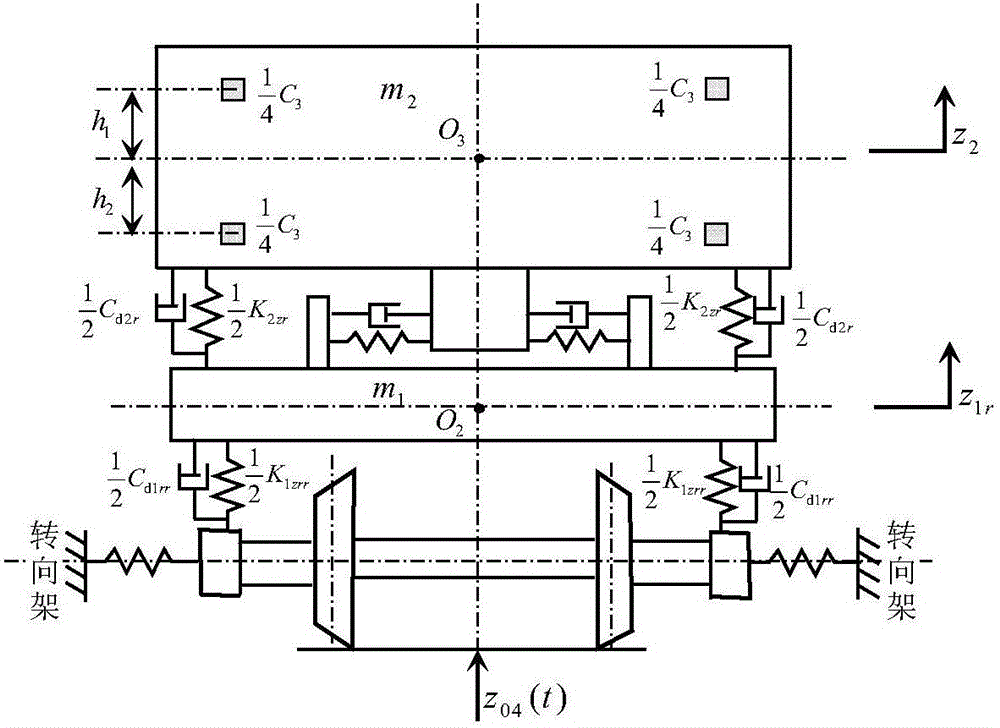

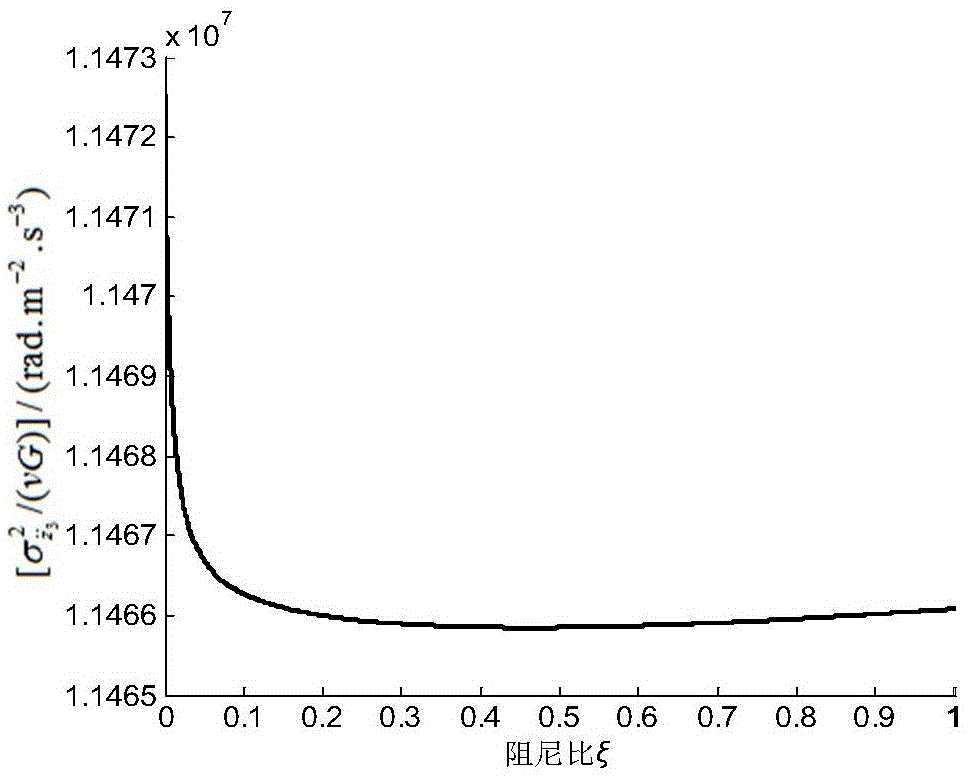

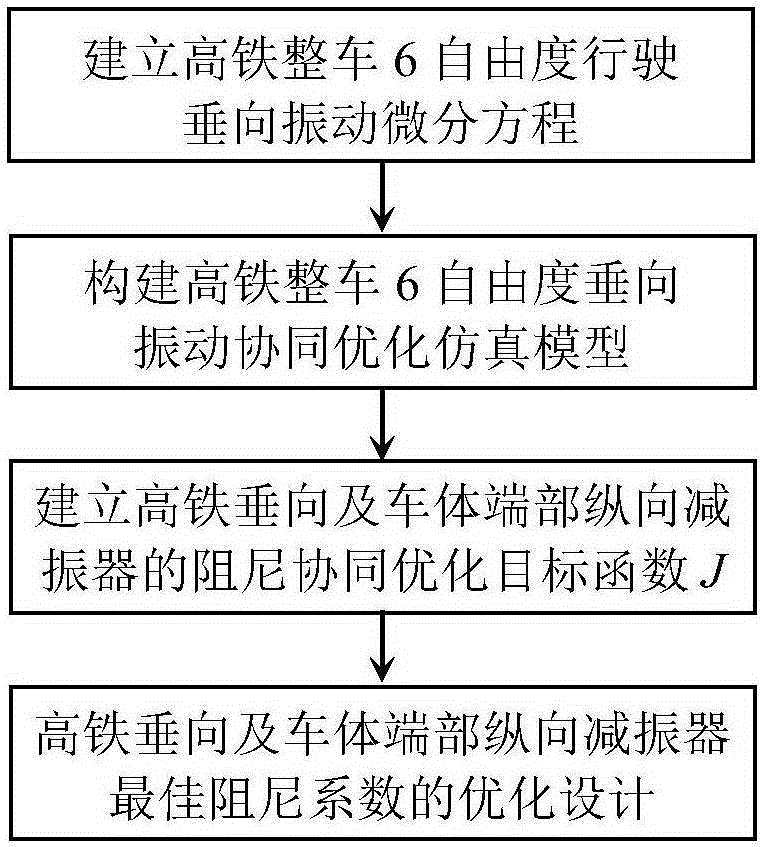

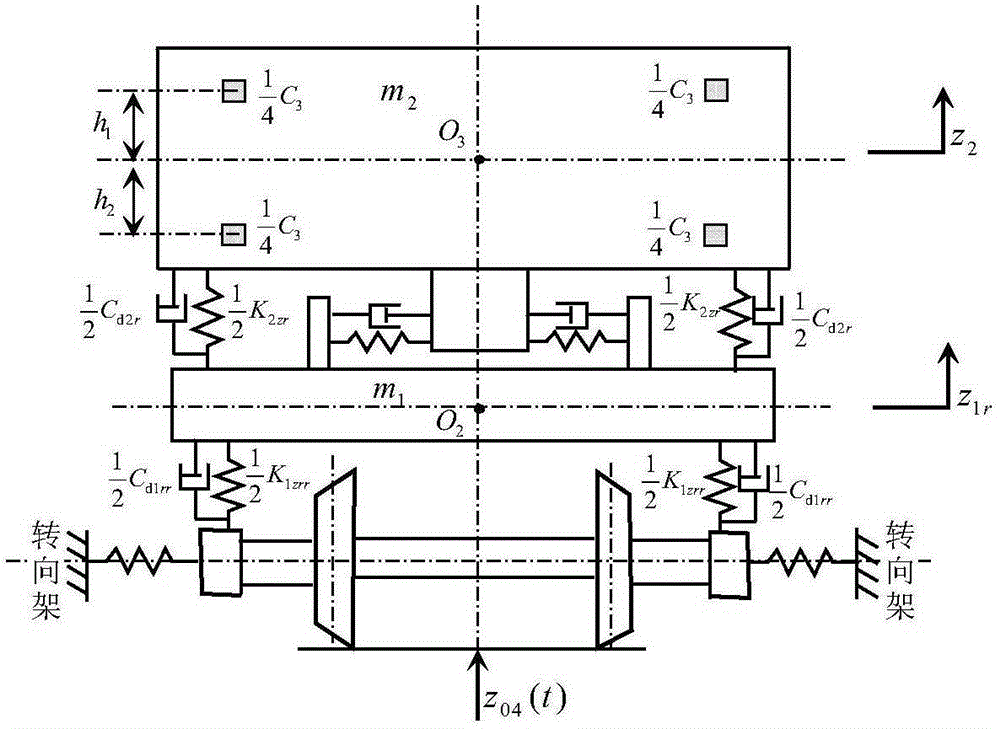

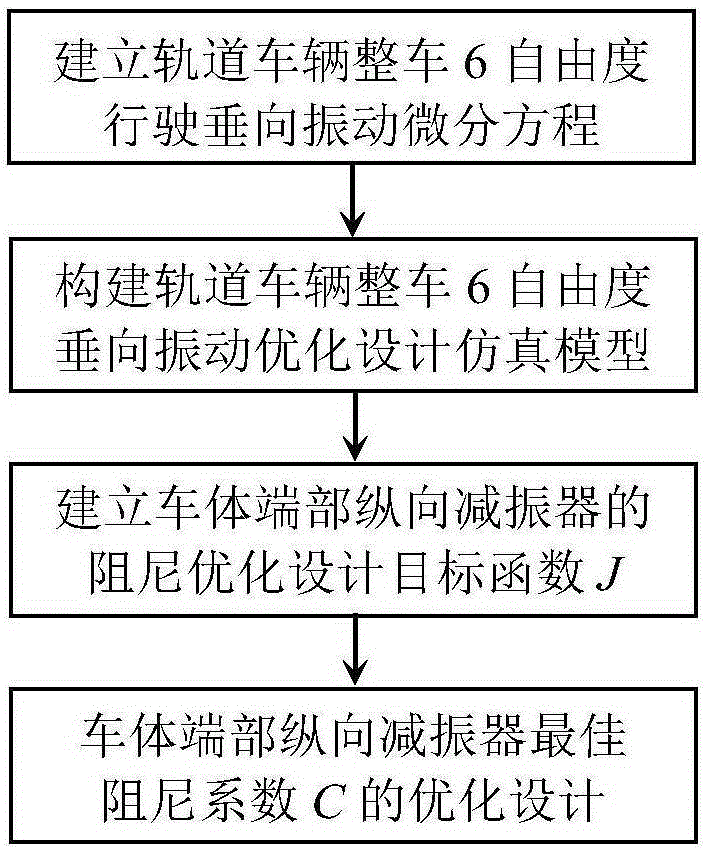

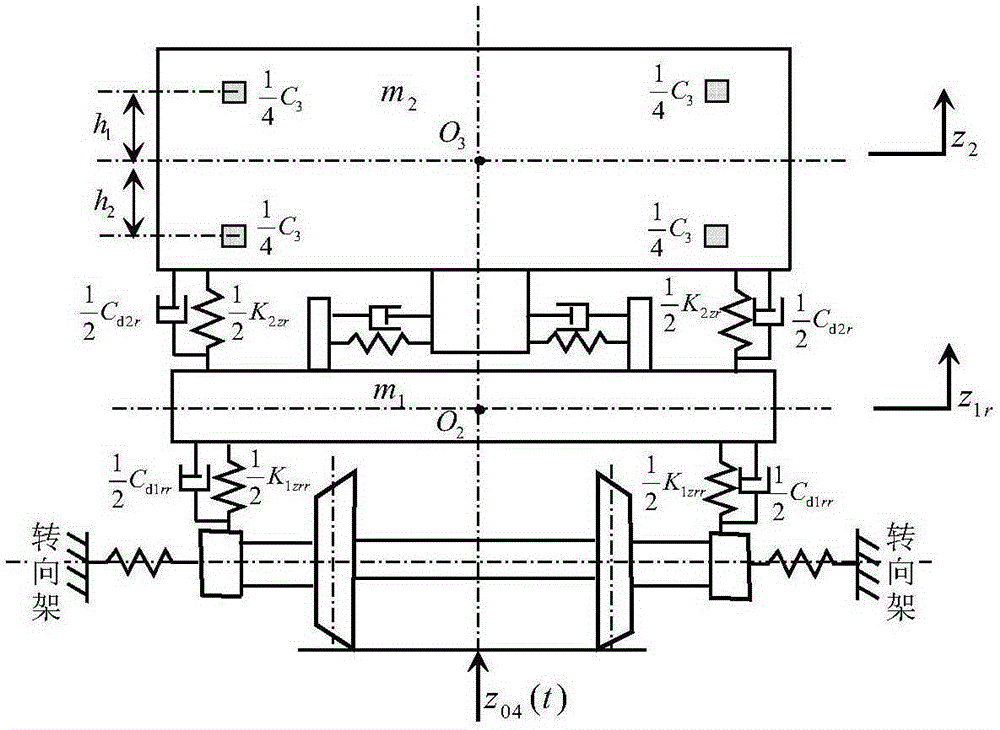

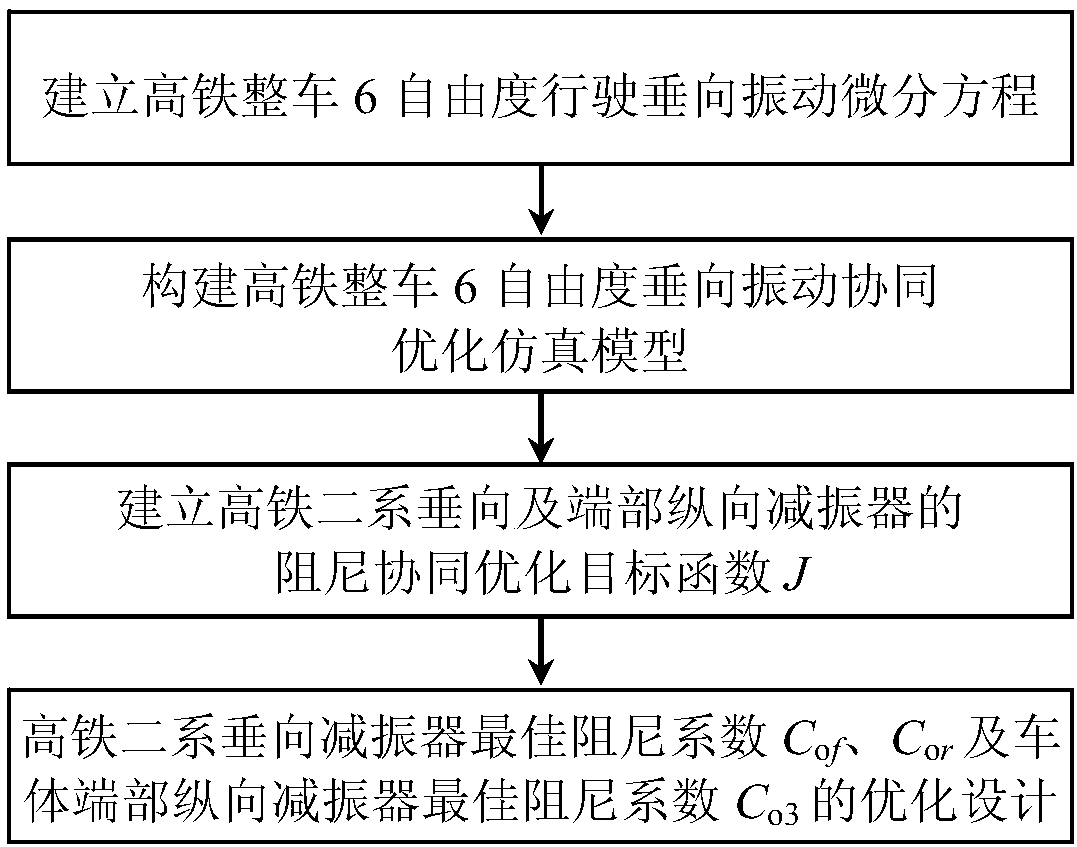

Collaborative optimization method of two-line vertical and end part longitudinal damper damping coefficient of high-speed railway

InactiveCN105160105AImprove powerReliable Simulated ValuesSpecial data processing applicationsDamping factorVertical vibration

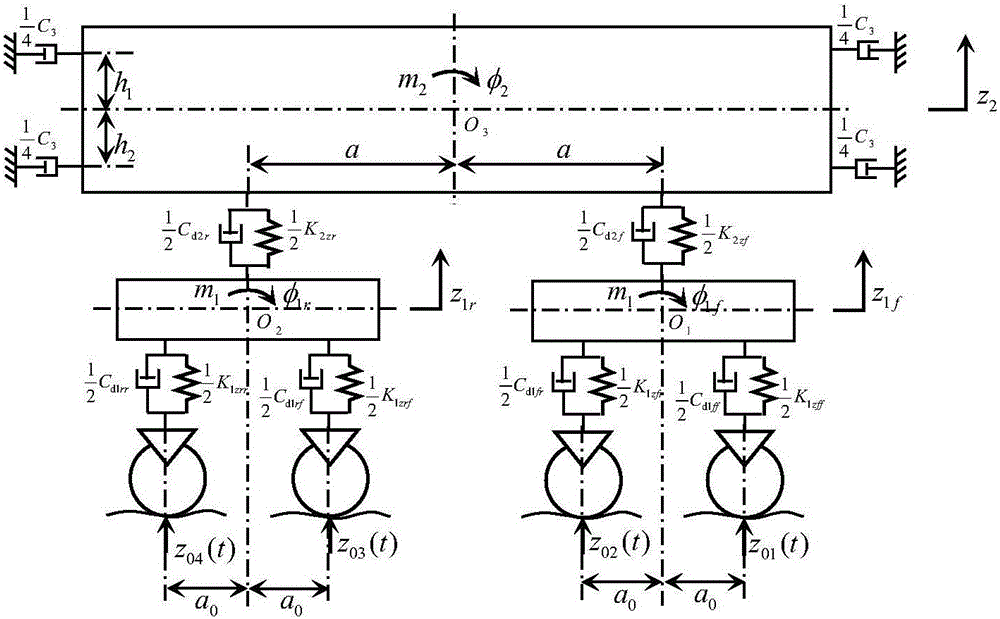

The invention relates to a collaborative optimization method of a two-line vertical and end part longitudinal damper damping coefficient of a high-speed railway, and belongs to the technical field of high-speed railway suspension. A complete railway six-degree-of-freedom vertical vibration collaborative optimization simulation model of the high-speed railway is established, the uneven random input of the railway is used as input stimulation, the minimum of the vibration acceleration root-mean-square value of vehicle body vertical movement is taken as a design target, and optimal design is carried out to obtain an optimal damping coefficient of the two-line vertical and vehicle body end part longitudinal damper damping coefficient of the high-speed railway. Through a design example and SIMPACK simulation verification, the method can obtain the accurate and reliable two-line vertical and vehicle body end part longitudinal damper damping coefficient value, and provides a reliable design method for the design of the two-line vertical and vehicle body end part longitudinal damper damping coefficient of the high-speed railway. The method can improve the design level of the suspension system of the high-speed railway, improves vehicle driving safety and stability, can lower product design and experiment cost and enhances the international market competitiveness of the railway vehicle in China.

Owner:SHANDONG UNIV OF TECH

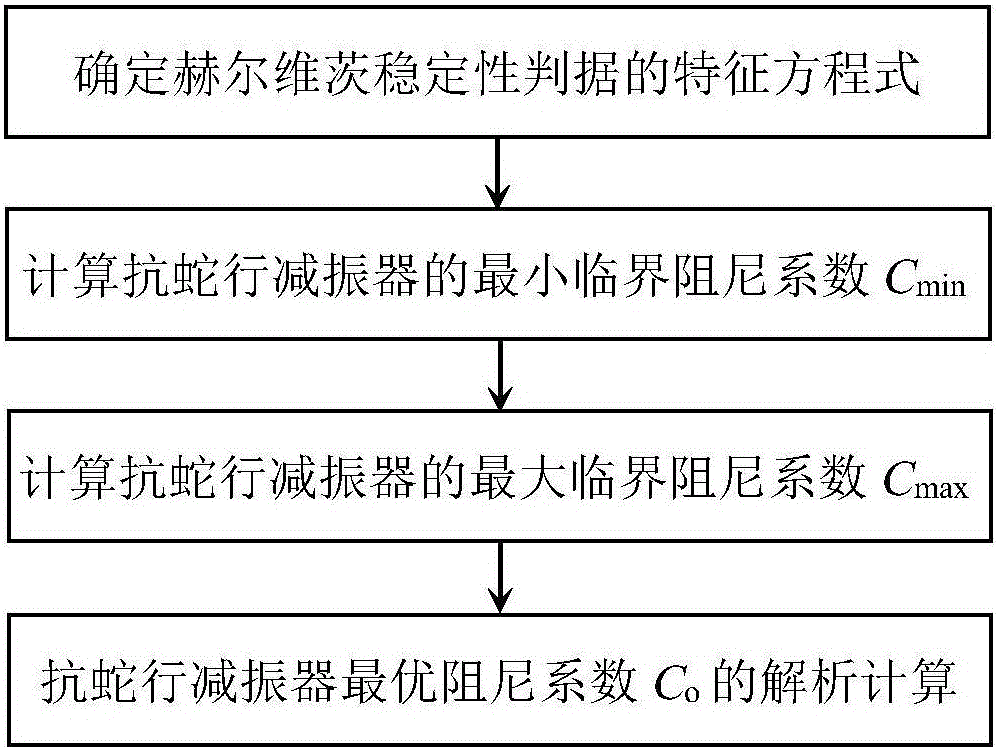

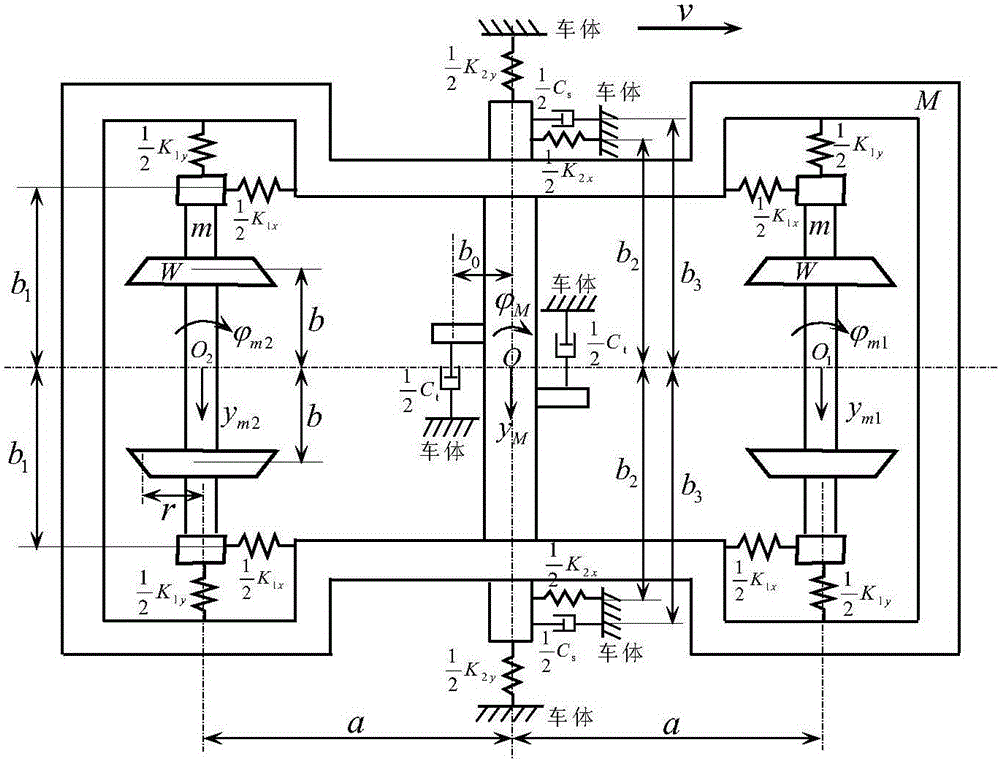

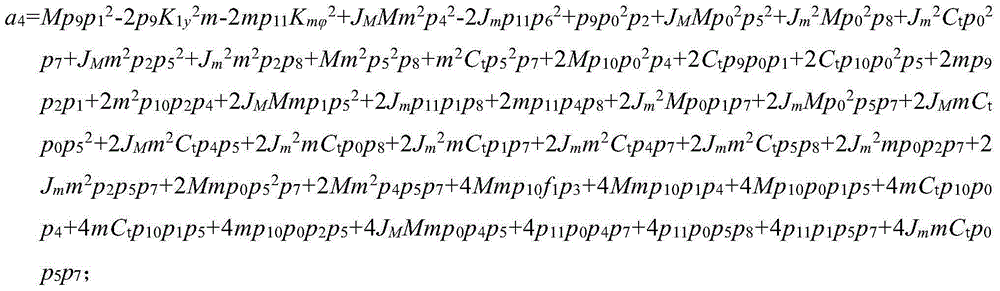

Analytic calculation method of optimal damping coefficient of anti-snake movement damper of high-speed railway vehicle

InactiveCN105160104AImprove powerReliable Simulated ValuesSpecial data processing applicationsStability criterionAutomotive engineering

The invention relates to an analytic calculation method of an optimal damping coefficient of an anti-snake movement damper of a high-speed railway vehicle, and belongs to the technical field of the high-speed railway vehicle suspension. A Hurwitz stability criterion is used for calculating to obtain a minimum critical damping coefficient of the anti-snake movement damper, a maximum critical damping coefficient of the anti-snake movement damper is calculated by requirements on the steering resistance coefficient of a bogie when a vehicle carries out curve driving, and an optimal damping coefficient of the anti-snake movement damper is calculated by a golden section principle. Through a design example and SIMPACK simulation verification, the method can obtain the accurate and reliable damping coefficient value of the anti-snake movement damper, and provides a reliable design method for the design of the damping coefficient of the anti-snake movement damper of the high-speed railway vehicle. The method can improve the design level of the suspension system of the high-speed railway vehicle, and vehicle riding comfort and safety, simultaneously can lower product design and experiment cost and enhances the international market competitiveness of the railway vehicle in China.

Owner:SHANDONG UNIV OF TECH

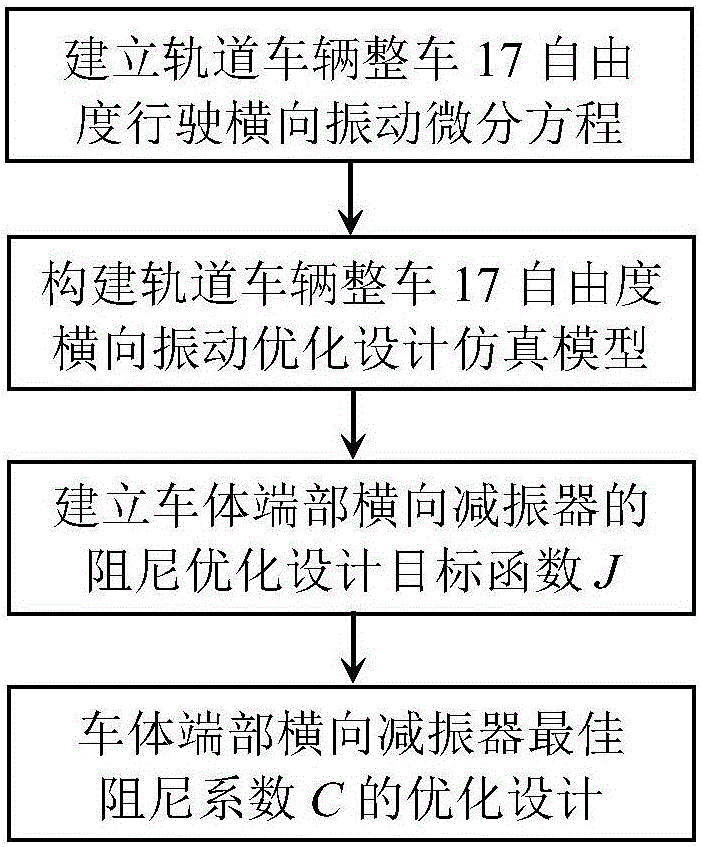

Design method for damping coefficient of vehicle body end transverse damper of high-speed rail vehicle

InactiveCN105138783AImprove powerReliable Simulated ValuesSpecial data processing applicationsDamping factorVibration acceleration

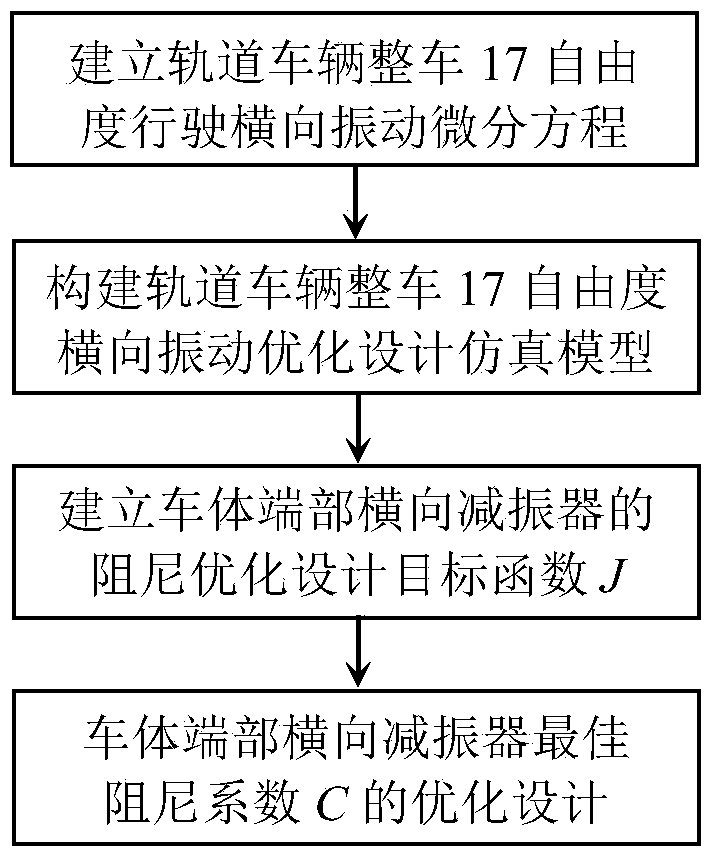

The invention relates to a design method for the damping coefficient of a vehicle body end transverse damper of a high-speed rail vehicle, and belongs to the technical field of suspension of high-speed rail vehicles. As a seventeen-freedom-degree transverse vibration optimization design simulation model of the whole rail vehicle is set up, and irregularity in the railway direction and horizontal irregularity serve as input excitation, with the minimum root-mean-square value of vibration acceleration of vehicle body side roll motion as the design target, the optimal damping coefficient of the vehicle body end transverse damper is obtained through optimization design. It can be known through design examples and SIMPACK simulation verification that the damping coefficient value of the vehicle body end transverse damper can be obtained accurately and reliably through the method, and a reliable design method is provided for designing the damping coefficient of the vehicle body end transverse damper of the high-speed rail vehicle. By means of the method, the design level of a high-speed rail vehicle suspension system can be improved, traveling safety and stability of the vehicle are improved, product design and test cost can be reduced, and the international market competitiveness of the rail vehicles in China is enhanced.

Owner:SHANDONG UNIV OF TECH

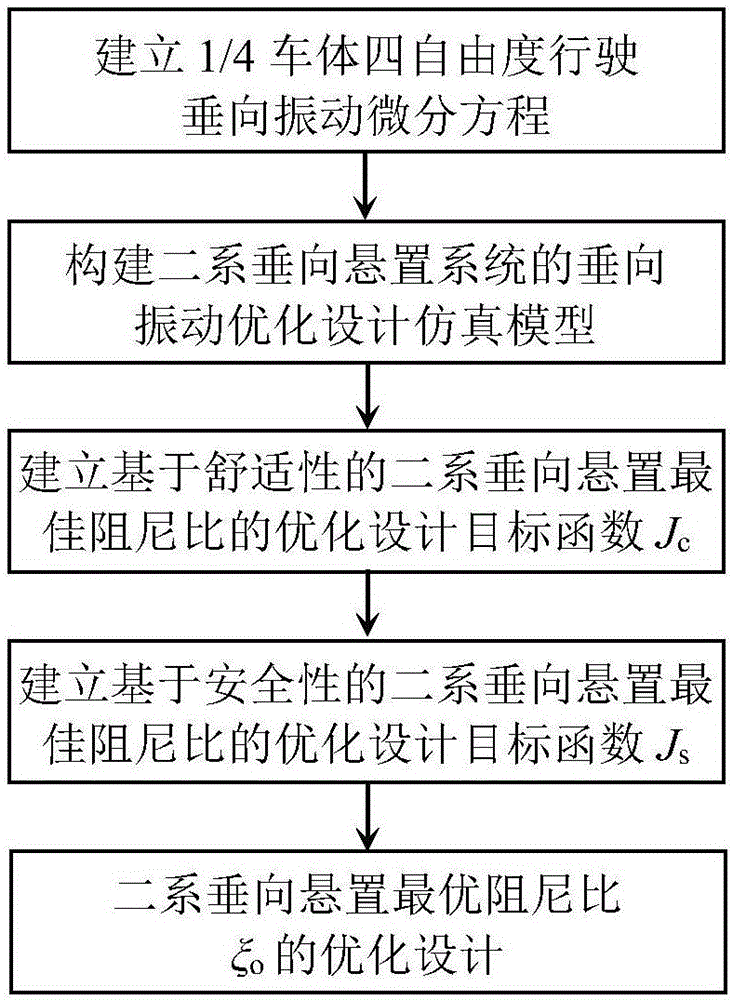

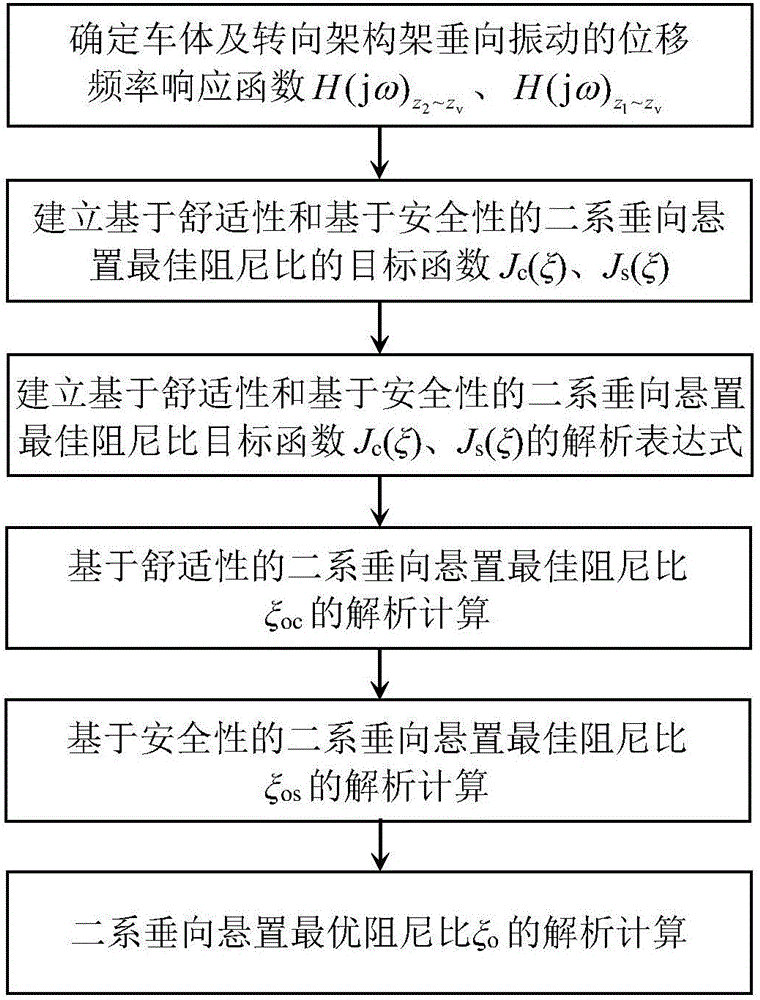

Optimization design method for secondary vertical suspension optimal damping ratio of high-speed railway vehicle

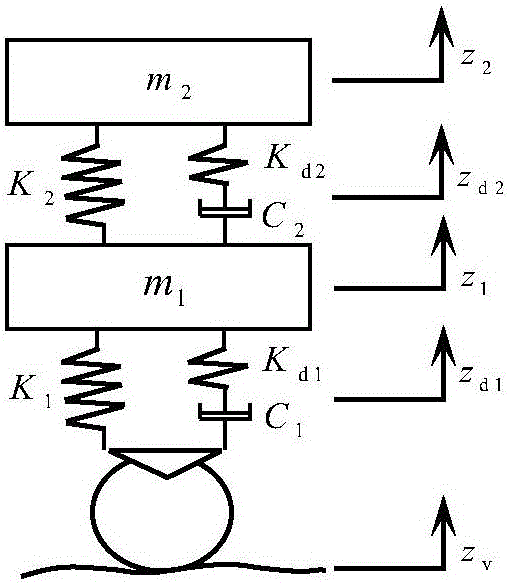

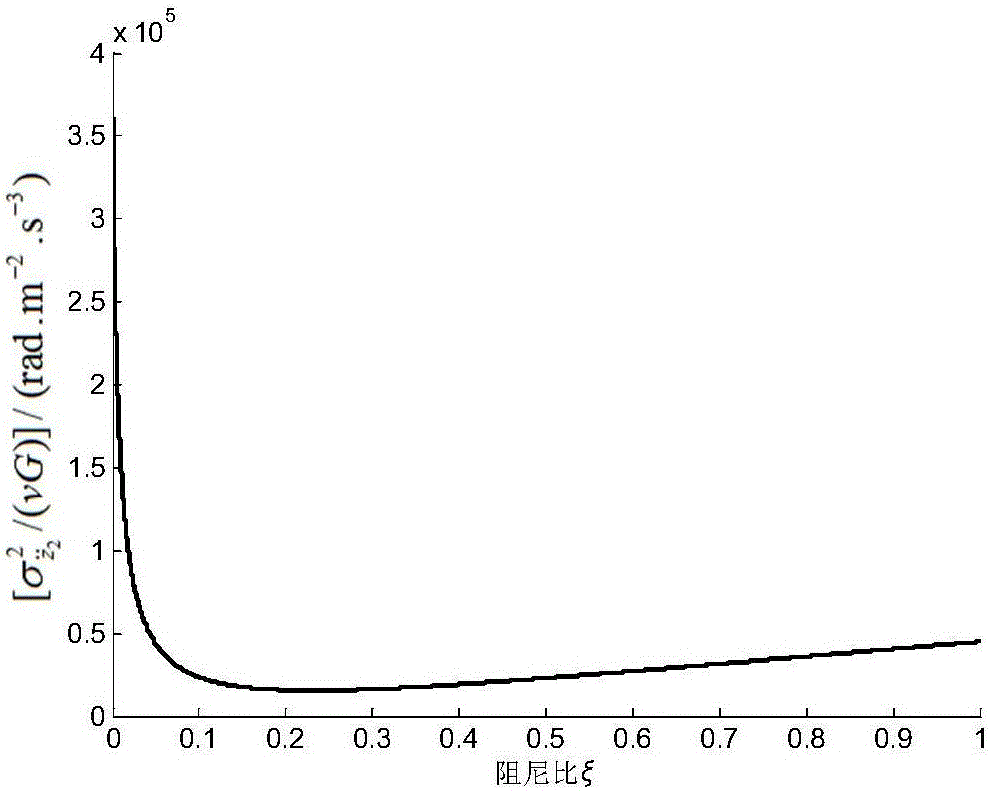

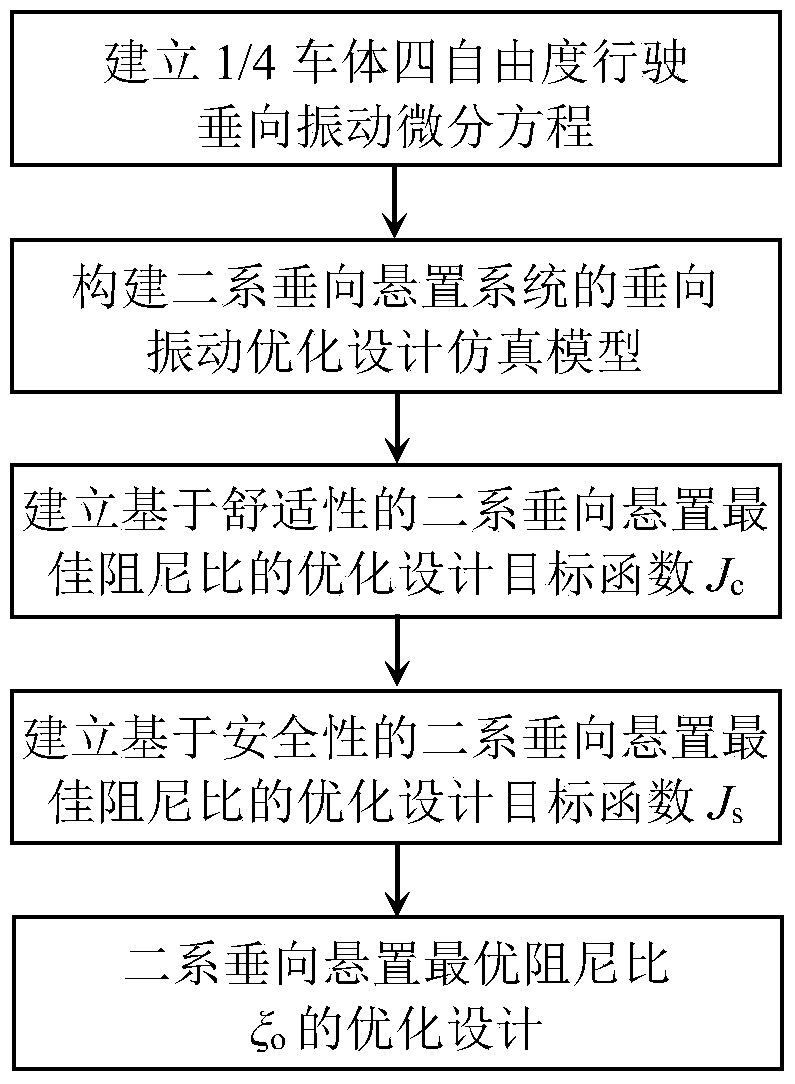

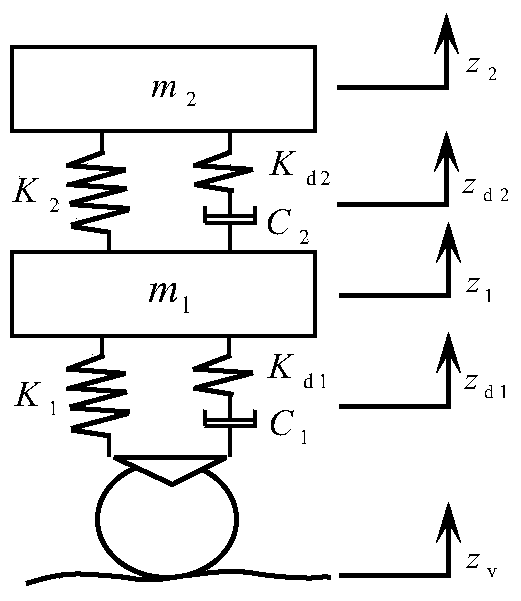

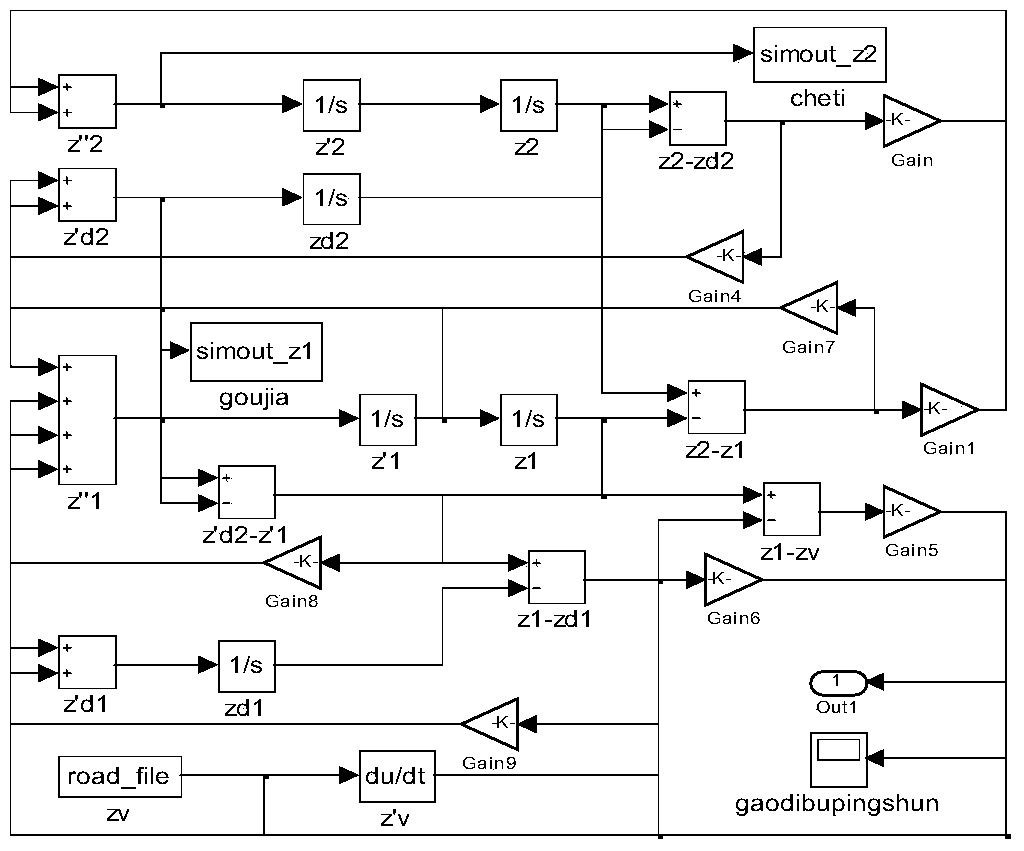

InactiveCN105069260AImprove powerReliable Simulated ValuesInternal combustion piston enginesSpecial data processing applicationsVertical vibrationBogie

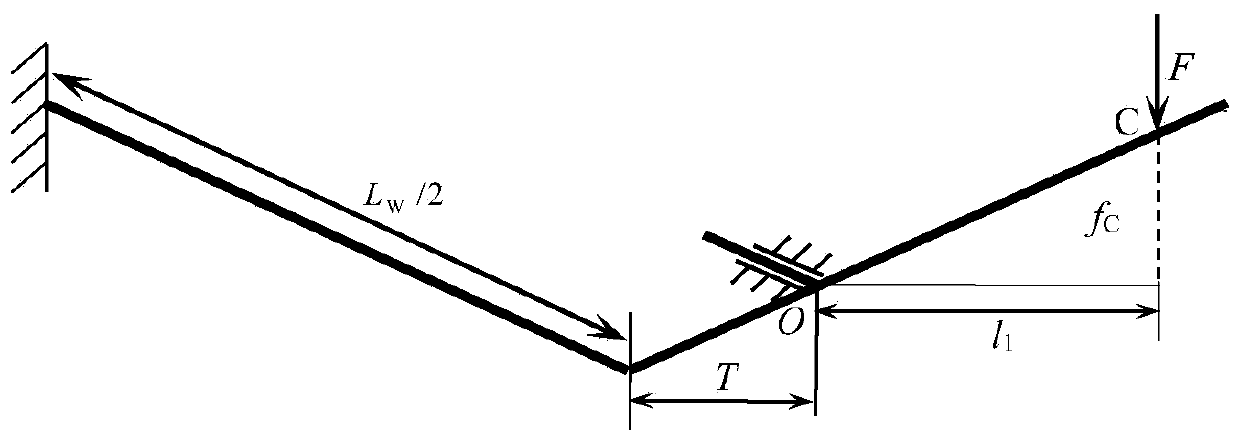

The invention relates to an optimization design method for the secondary vertical suspension optimal damping ratio of a high-speed railway vehicle, and belongs to the technical field of high-speed railway vehicle suspension. The method comprises the steps that a vertical vibration optimization design simulation model of a secondary vertical suspension system is constructed, track vertical profile irregularity random input is taken as the input excitation, the vibration acceleration root-mean-square value minimum of vertical motion of a vehicle body and a truck frame is taken as the design objective, the best damping ratio, based on the comfortability and safety, of the secondary vertical suspension system is obtained through the optimization design, and then the secondary vertical suspension optimal damping ratio is obtained through calculation. According to the method, through the design example and SIMPACK simulation verification, it can be known that the accurate and reliable optimal damping ratio value of the secondary vertical suspension system can be obtained, and the reliable design method is supplied to the design of the secondary vertical suspension damping ratio of the railway vehicle; by utilizing the method, not only can the suspension system design level and the vehicle riding comfortability and safety of the high-speed railway vehicle be improved, but also the product design and test cost can be lowered.

Owner:SHANDONG UNIV OF TECH

Design method for optimal damping ratio of primary vertical suspension of high-speed rail vehicle

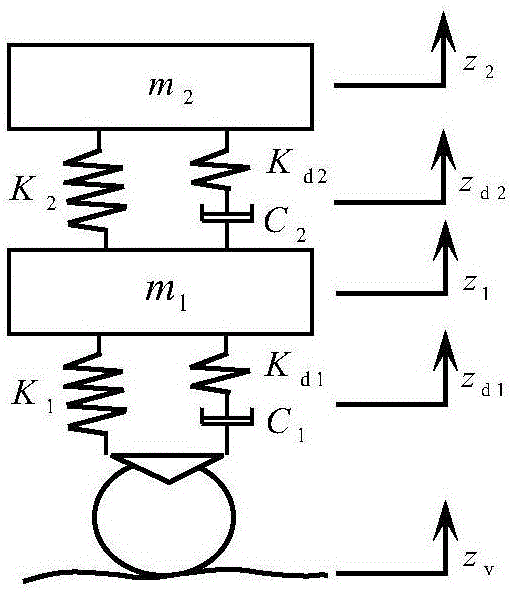

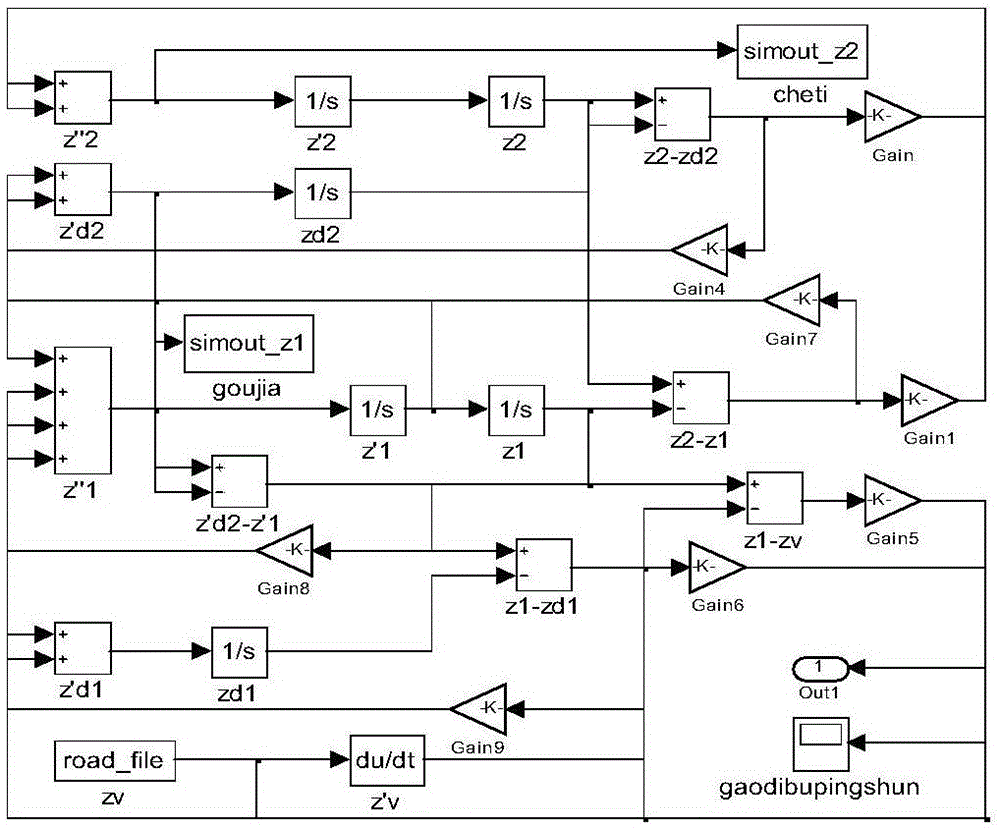

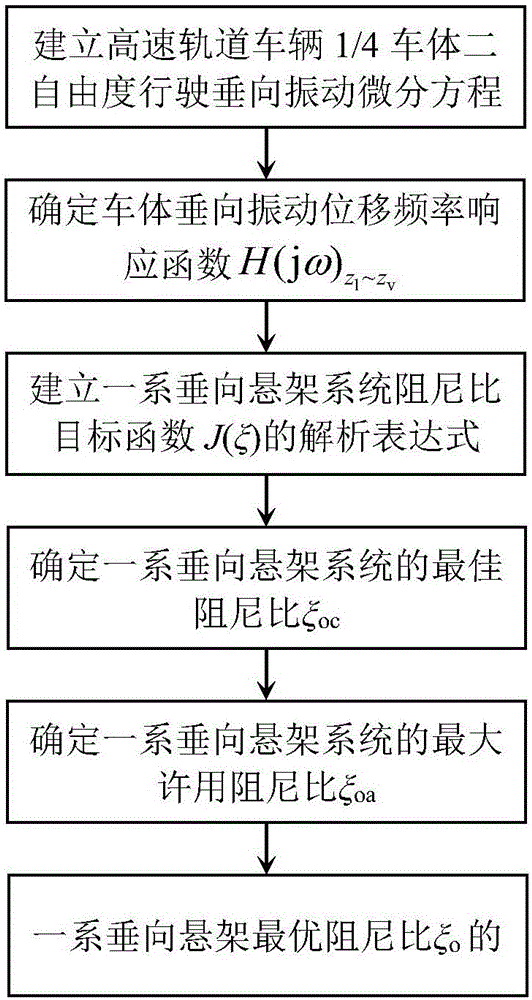

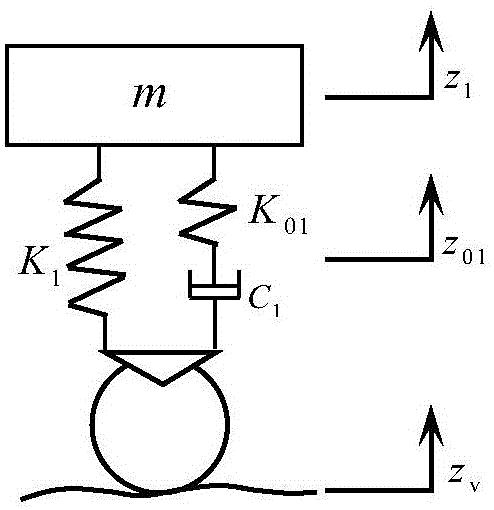

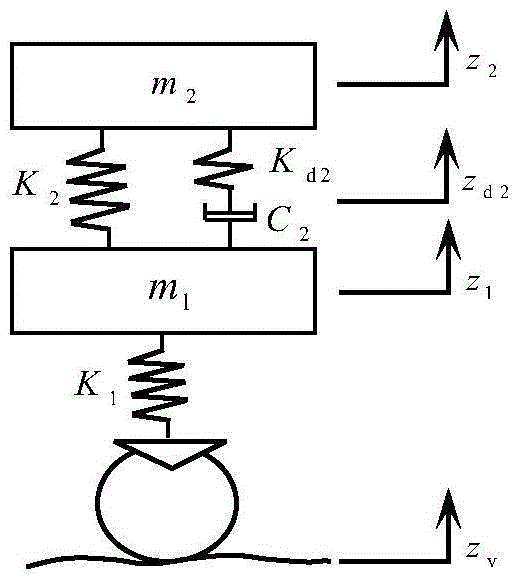

InactiveCN105117554AImprove powerReliable Simulated ValuesSpecial data processing applicationsVertical vibrationInternational market

The invention relates to a design method for an optimal damping ratio of a primary vertical suspension of a high-speed rail vehicle, and belongs to the technical field of suspension of high-speed rail vehicles. According to the design method, a target function of a damping ratio of a primary vertical suspension system is established by establishing a two-degree-of-freedom driving vertical vibration model of a 1 / 4 vehicle body of the high-speed rail vehicle, the optimal damping ratio and a maximum allowable damping ratio of the primary vertical suspension system are calculated, and the optimal damping ratio of the primary vertical suspension system is calculated by utilizing a golden section principle. Through design instances and SIMPACK simulation verification, the method can obtain accurate and reliable optimal damping ratio of the primary vertical suspension system, and the reliable design method is provided for the design of the damping ratio of the primary vertical suspension of the high-speed rail vehicle. With the method, the design level and the product quality of the suspension system of the high-speed rail vehicle can be improved, the riding comfort and safety of the vehicle can be improved, the product design and test expenses can be reduced, and the international market competitiveness of rail vehicles in China can be enhanced.

Owner:SHANDONG UNIV OF TECH

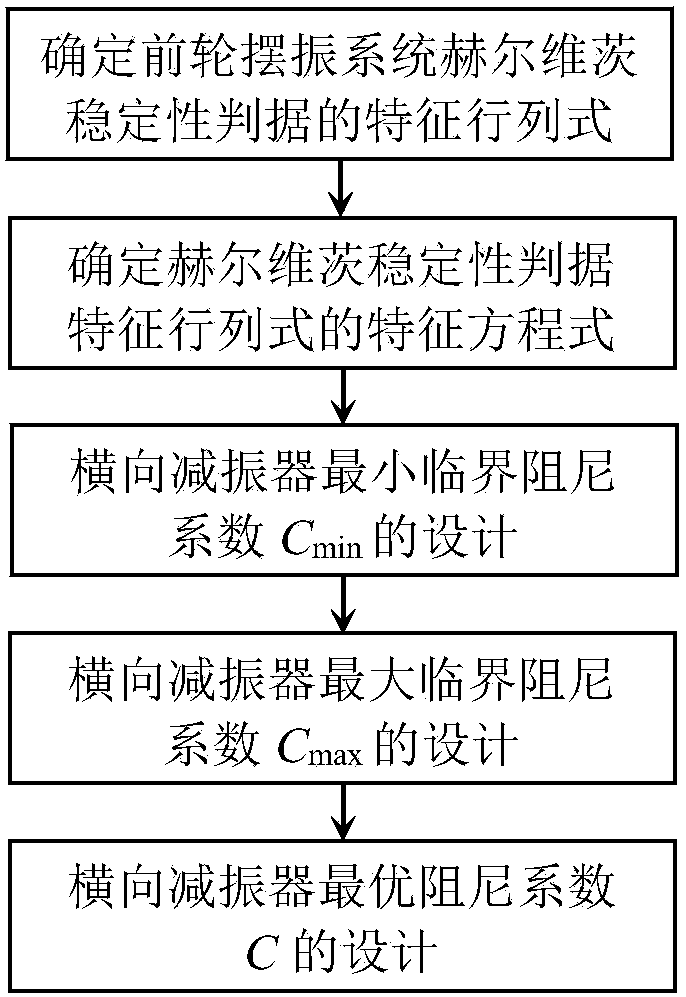

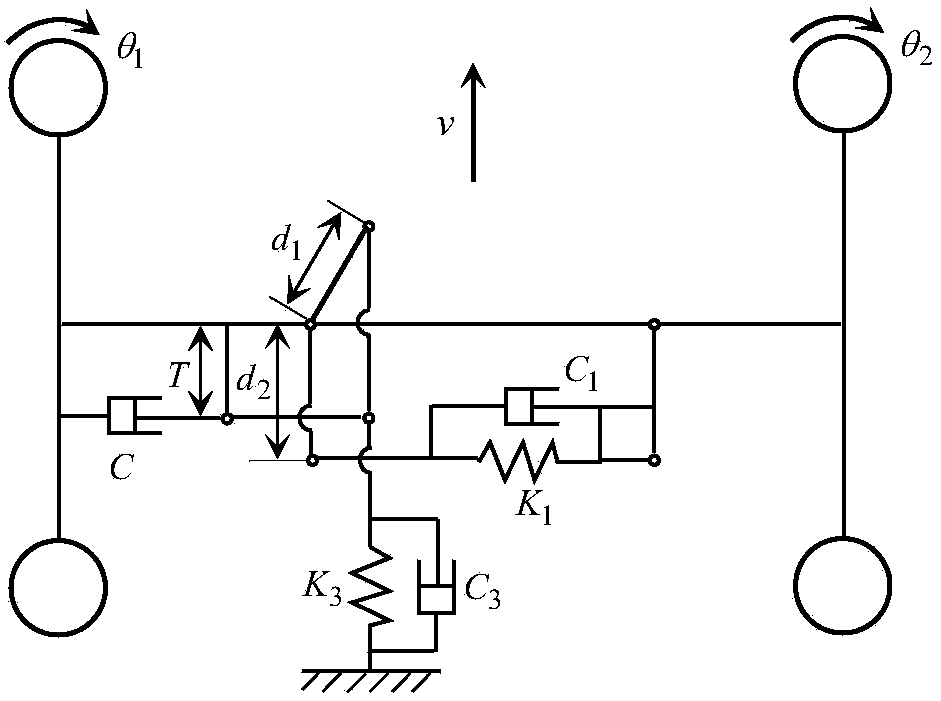

Method for designing optimal damping coefficient of transverse damper of truck front-wheel shimmying system

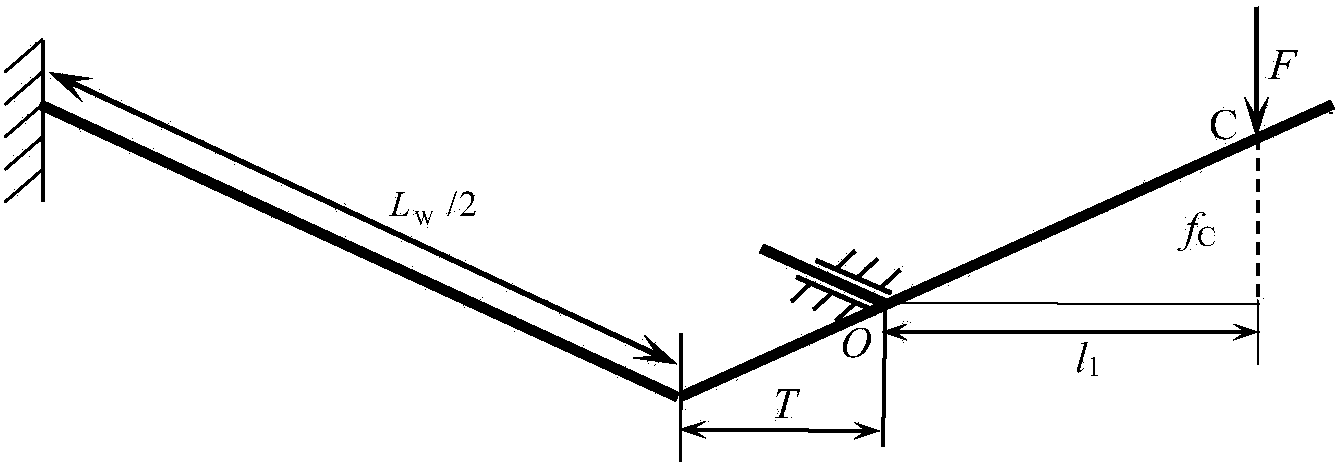

InactiveCN105183985AImprove powerReliable Simulated ValuesSpecial data processing applicationsDamping factorEngineering

The invention relates to a method for designing the optimal damping coefficient of a transverse damper of a truck front-wheel shimmying system, and belongs to the technical field of truck front-wheel shimmying systems. The method includes the steps that the minimum critical damping coefficient of the transverse damper is calculated through the Hurwitz stability criterion; the maximum critical damping coefficient of the transverse damper is calculated according to the relationship among tire in-situ steering resistance, damping force of the transverse damper and force of a hydraulic power steering gear; then the optimal damping coefficient of the transverse damper is designed through the golden section principle. Through a design example and Matlab / Simulink simulation verification, it can be known that an accurate and reliable optimal damping coefficient design value of a transverse damper can be obtained, and a reliable design method is provided for designing the optimal damping coefficient of the transverse damper of the truck front-wheel shimmying system. By means of the method, the design level of the truck transverse damper and truck driving safety can be improved, design cost and experiment cost can be further reduced, and the product development period can be shortened.

Owner:SHANDONG UNIV OF TECH

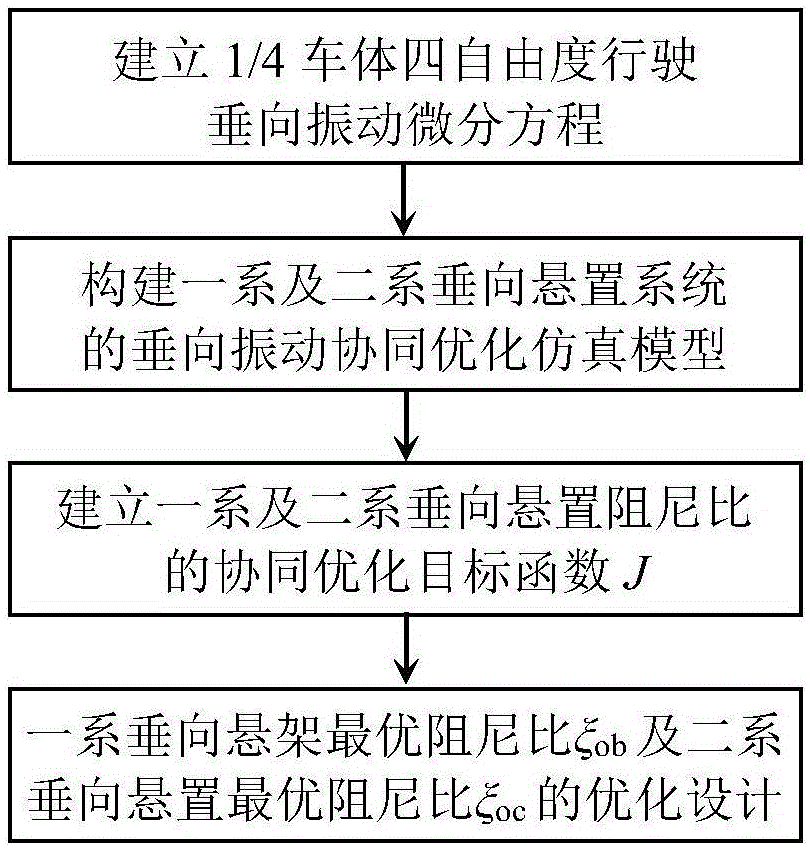

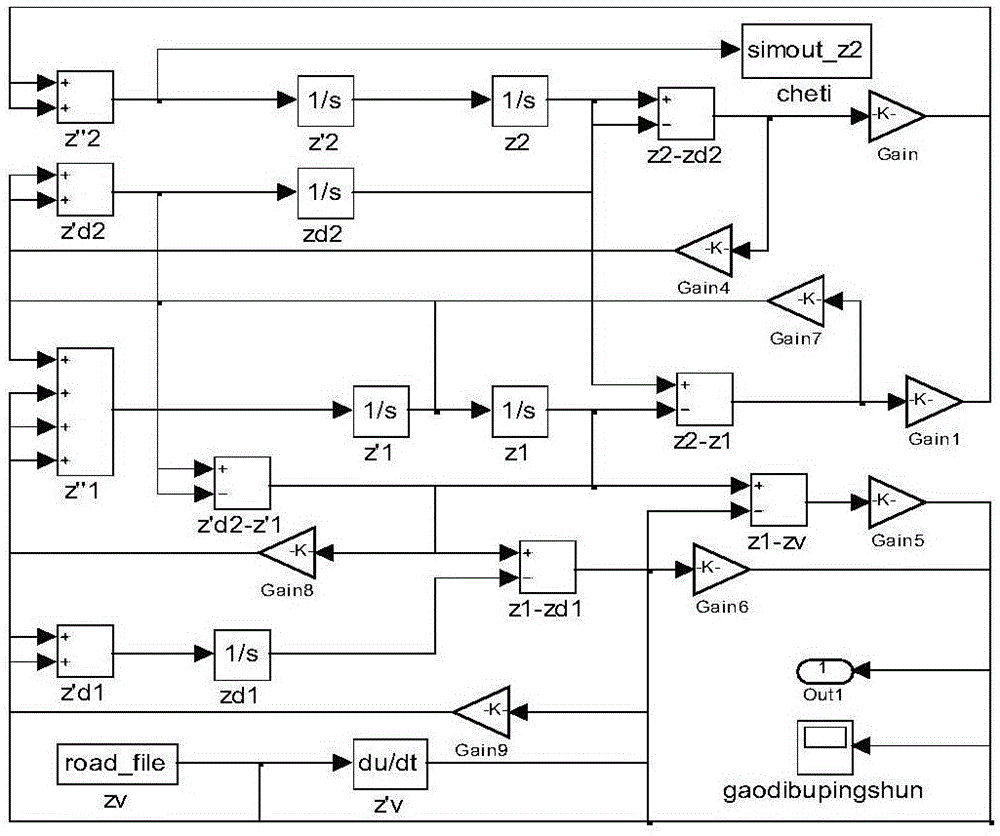

Collaborative optimization method of one-line and two-line vertical suspension damping ratio of high-speed railway vehicle

InactiveCN105160103AImprove powerReliable Simulated ValuesInternal combustion piston enginesSustainable transportationVertical vibrationVibration acceleration

The invention relates to a collaborative optimization method of a one-line and two-line vertical suspension damping ratio of a high-speed railway vehicle, and belongs to the technical field of high-speed railway vehicle suspension. A vertical vibration collaborative optimization simulation model of a one-line and two-line vertical suspension system is constructed, the uneven random input of a railway is used as input stimulation, the minimum of the vibration acceleration root-mean-square value of vehicle body vertical movement is taken as a design target, and optimal design is carried out to obtain an optimal damping ratio of an optimal one-line and two-line vertical suspension damping ratio. Through a design example and SIMPACK simulation verification, the method can obtain the accurate and reliable optimal damping ratio of the one-line vertical suspension and the two-line vertical suspension system, and provides a reliable design method for the design of the one-line and two-line vertical suspension damping ratio of the high-speed railway vehicle. The method can improve the design level and the vehicle riding comfort of the suspension system of the high-speed railway vehicle, can lower product design and experiment cost and enhances the international market competitiveness of the railway vehicle in China.

Owner:SHANDONG UNIV OF TECH

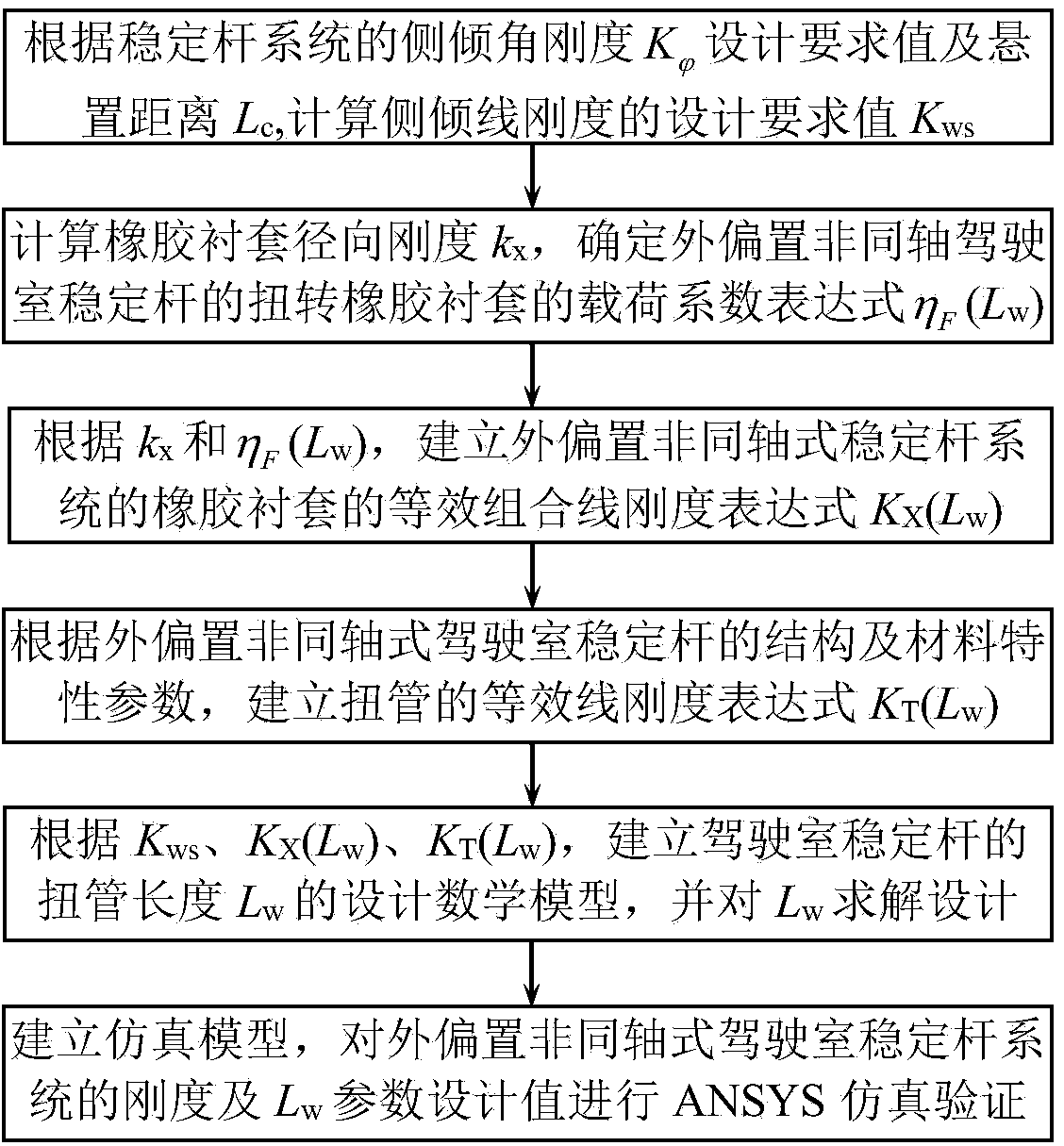

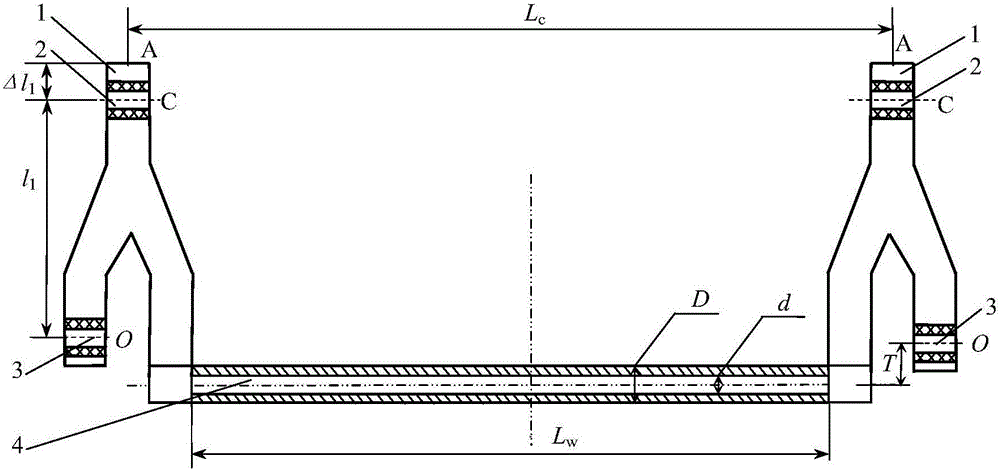

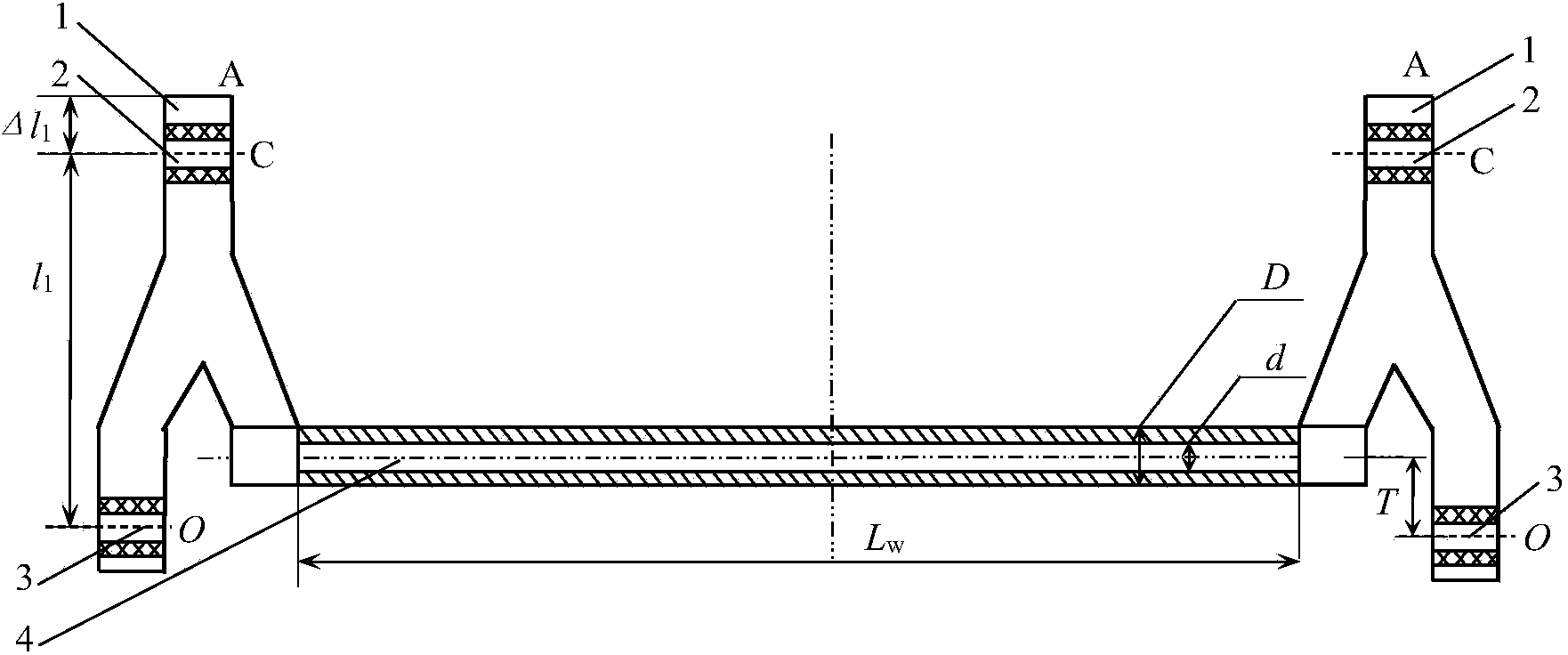

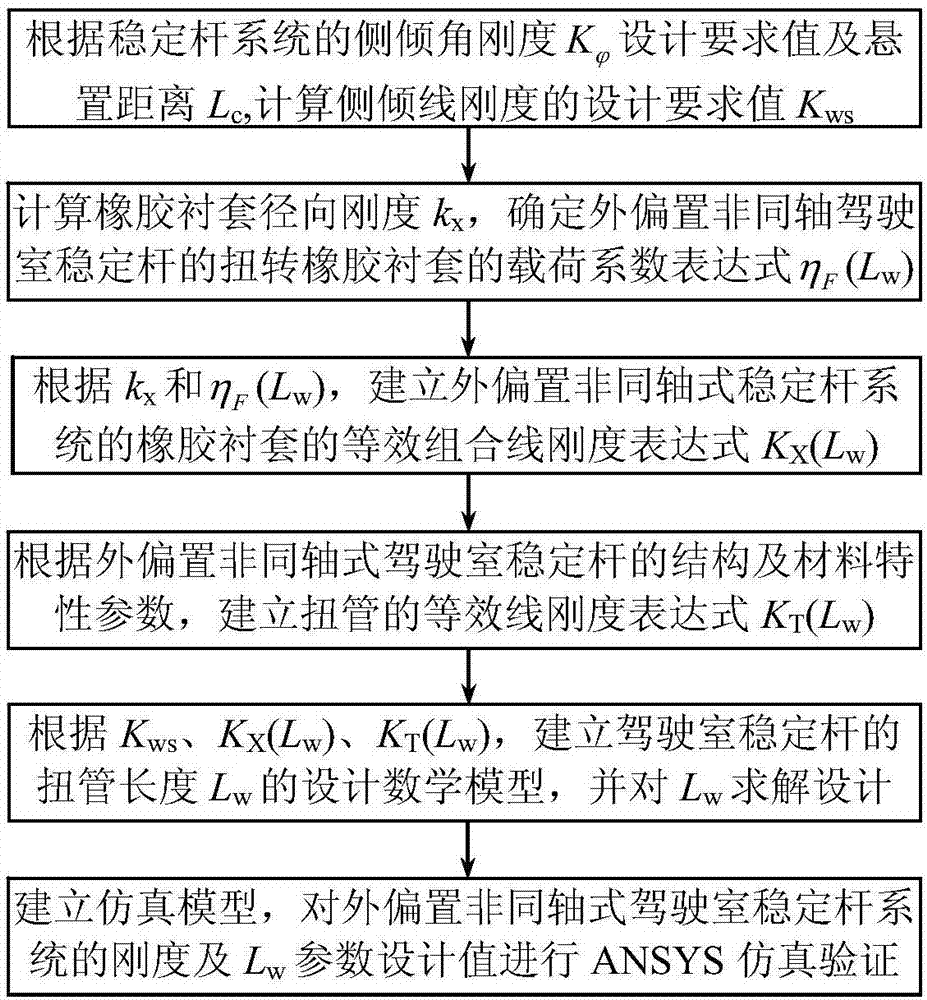

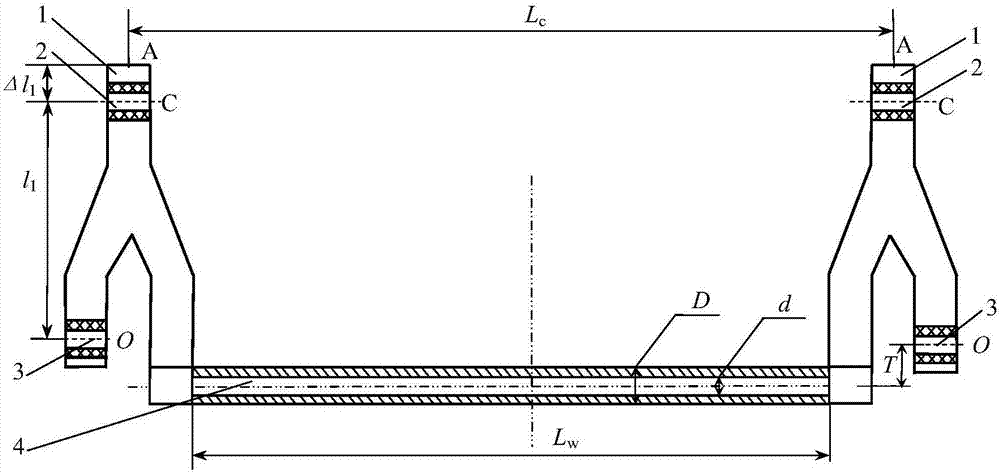

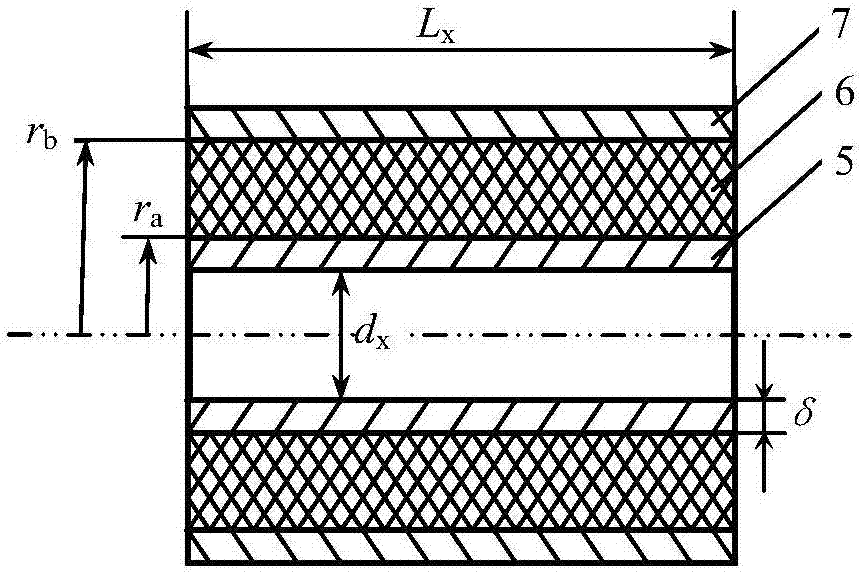

Method for designing length of torsion pipe of external biasing non-coaxial cab stabilizer bar

InactiveCN104331576ARobust Analytical Design MethodReliable Simulated ValuesSpecial data processing applicationsSystems designEngineering

The invention relates to a method for designing the length of a torsion pipe of an external biasing non-coaxial cab stabilizer, which belongs to the technical field of the cab suspension. The length of the torsion pipe is adopted as a parameter, a torsion pipe length design mathematic model of the stabilizer bar is established by utilizing a load coefficient expression of a torsion rubber bushing, an equivalent combined linear rigidness expression of the rubber bushing and an equivalent linear rigidness expression of the torsion pipe, and the torsion pipe length design mathematic model is solved by utilizing a Matlab program. By adopting the method, an accurate and reliable torsion pipe length design value can be acquired by virtue of a design example and the ANSYS simulation verification, and a reliable technical foundation can be provided for the design of the stabilizer bar system and the development of the CAD software. By utilizing the method, on the premise of not increasing the product cost, not only can the design level and design quality of the stabilizer bar system be improved by virtue of adjustable design of the torsion pipe length, but also the design requirement of the roll angle rigidness of the stabilizer bar system can be met, and the driving smoothness and safety of a vehicle can be improved; meanwhile, the design and experiment expense also can be reduced.

Owner:SHANDONG UNIV OF TECH

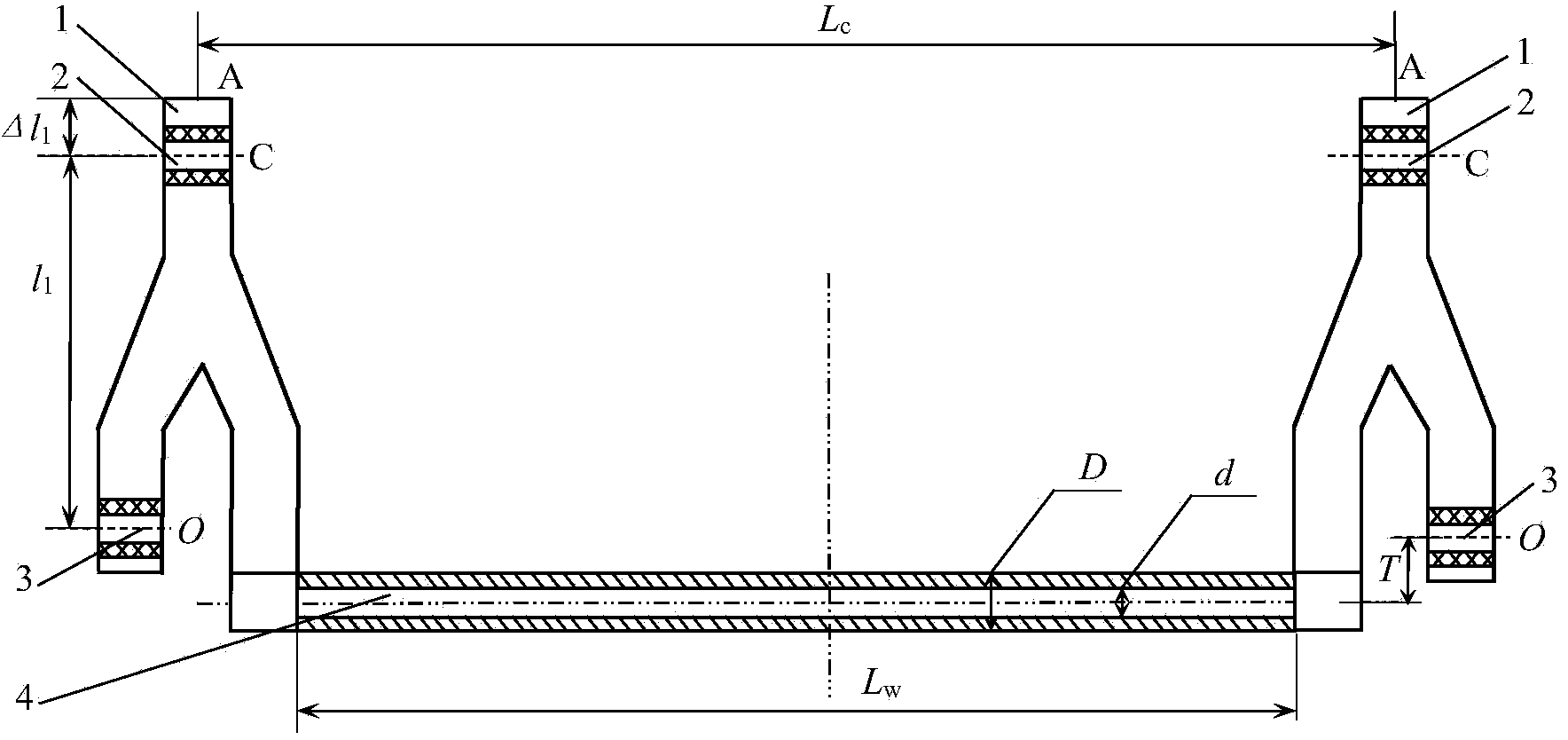

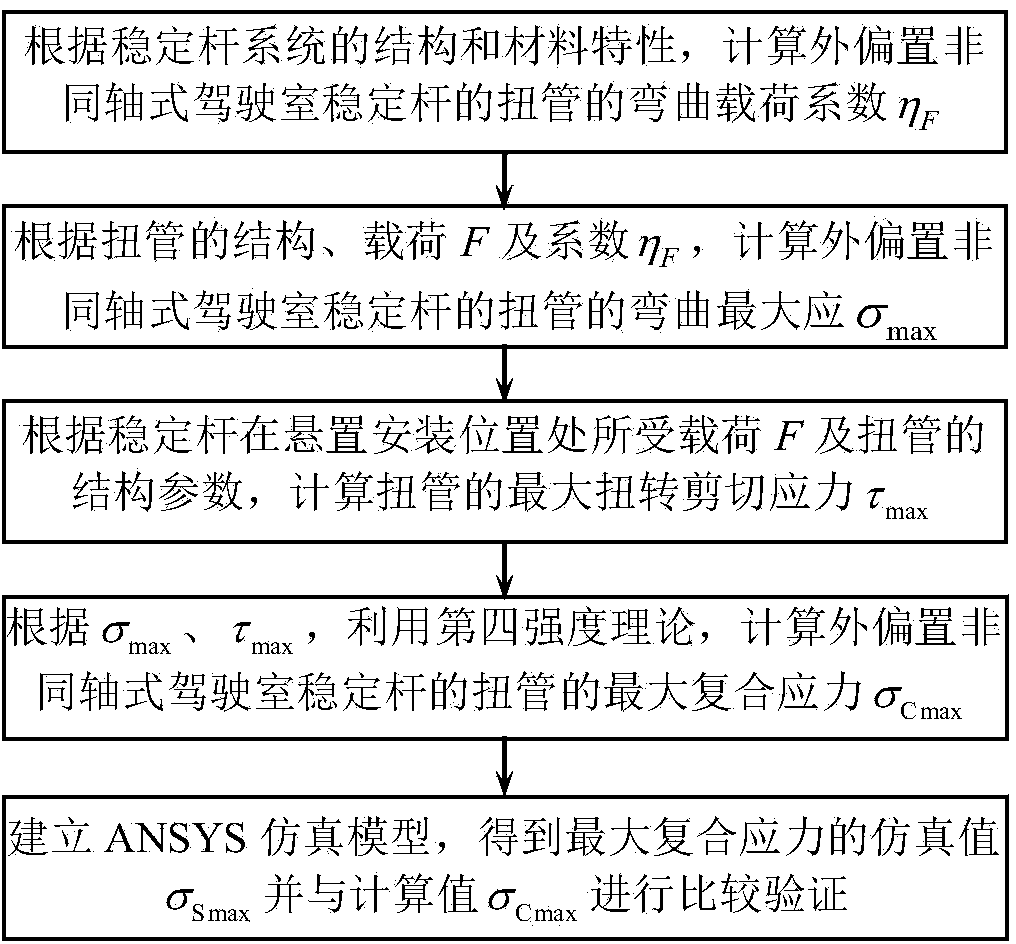

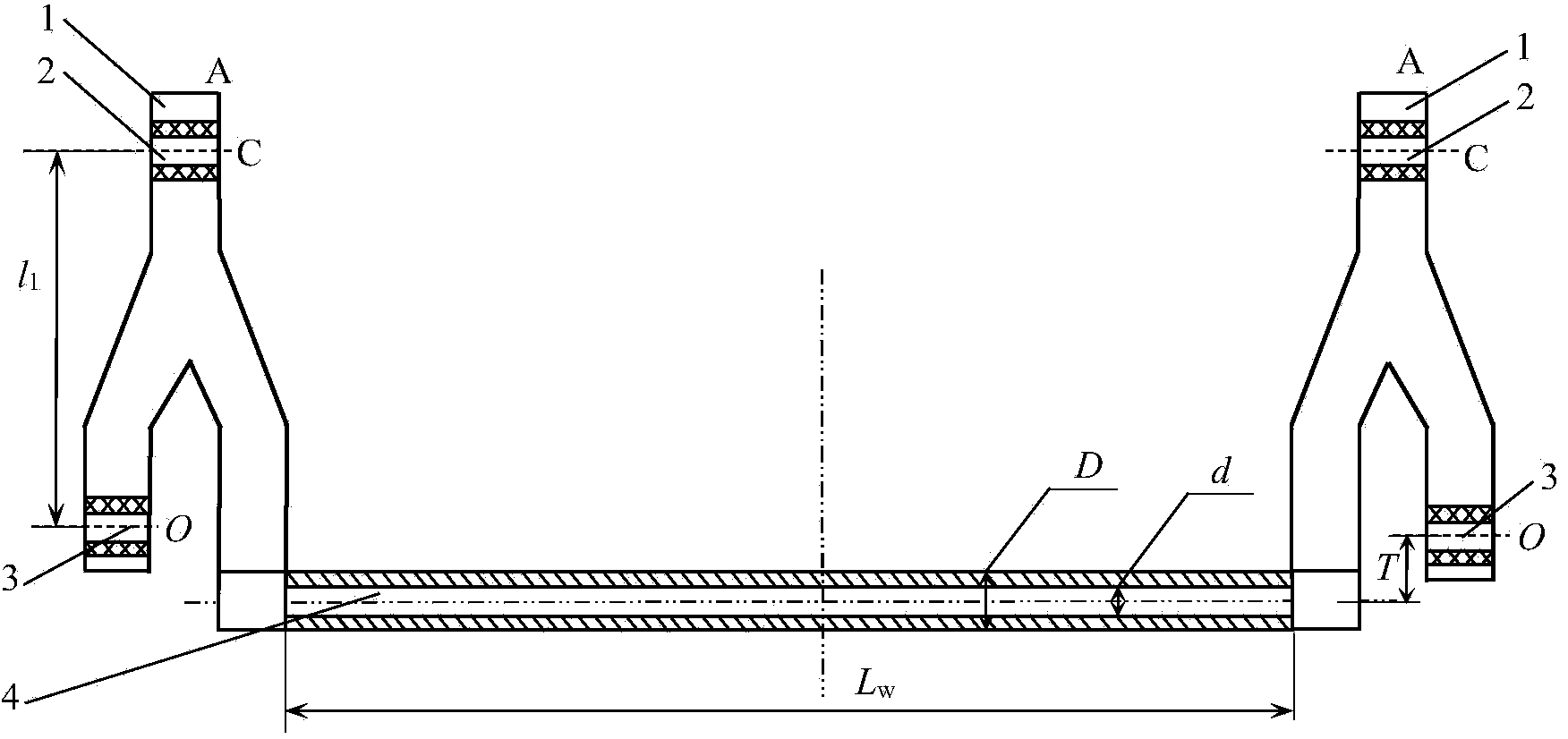

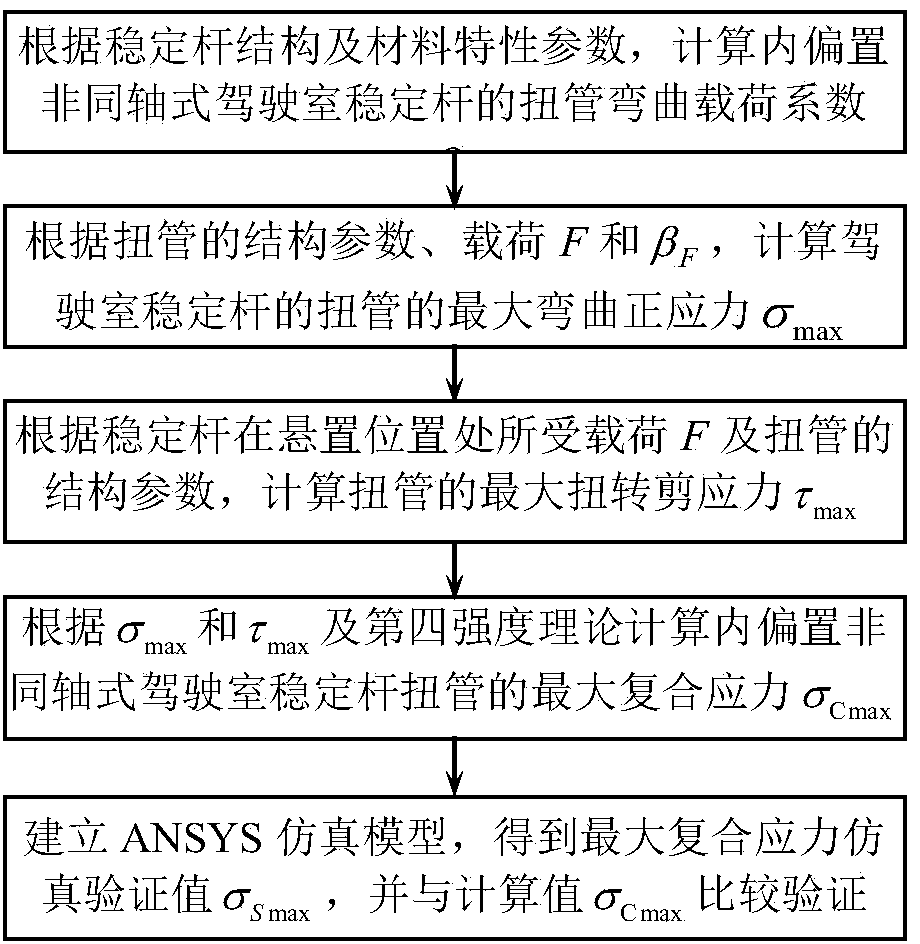

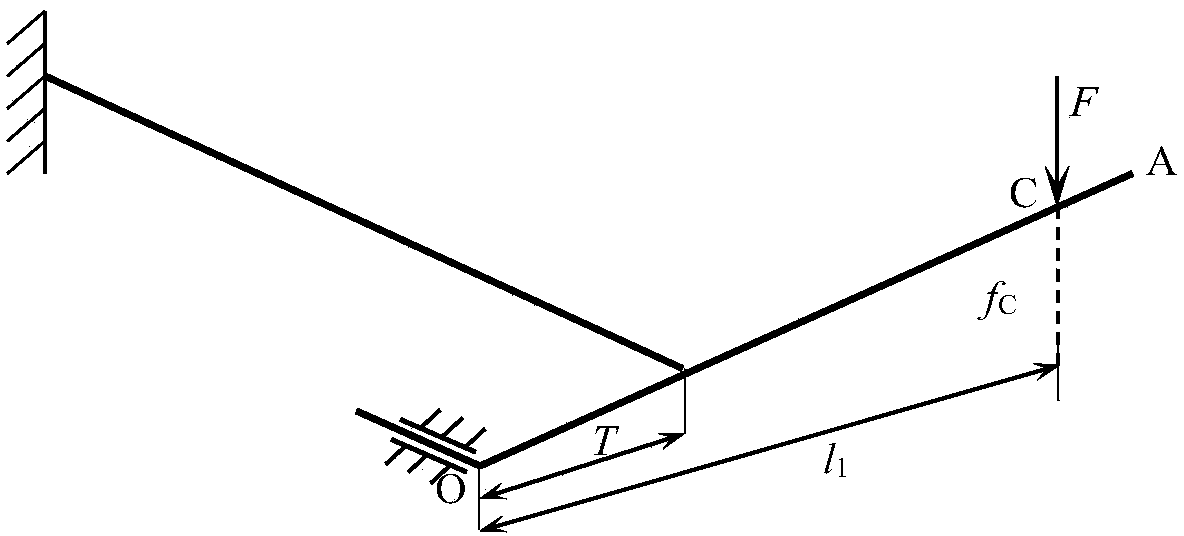

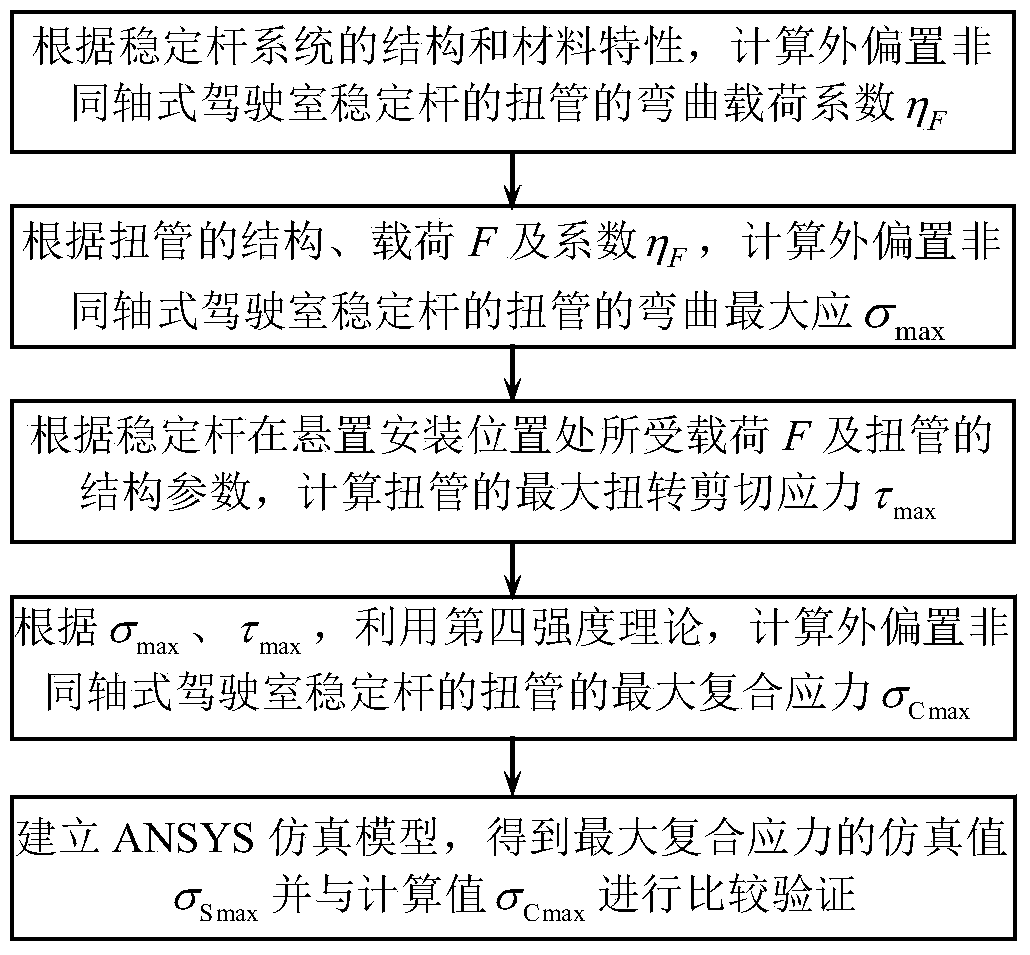

Torque tube stress intensity checking method for externally biased non-coaxial type cab stabilizer bar

InactiveCN104318041AAccurate and reliable stress intensity calculationsImprove the design levelSpecial data processing applicationsShear stressTorsional deformation

The invention relates to a torque tube stress intensity checking method for an externally biased non-coaxial type cab stabilizer bar, and belongs to the technical field of vehicle cab suspension. A bending load coefficient of a torque tube is built according to the structure parameters, material characteristic parameters and loads of an externally biased non-coaxial type cab stabilizer bar system and the torque tube by utilization of the relation between bending and torsional deformation and loads of the torque tube; the torque tube stress intensity checking method for the externally biased non-coaxial type cab stabilizer bar is built according to the bending normal stress and torsional shearing stress of the torque tube. Through living example calculation and ANSYS emulation proofs, it can be known that an accurate and reliable torque tube stress intensity calculation value can be obtained according to the method, and the stress intensity checking method is reliable for design of the cab stabilizer bar system. By utilization of the method, the design level, quality and performance of the cab stabilizer bar system can be improved, and running smoothness and safety of vehicles are improved. Meanwhile, the design and testing expenses can be reduced, and the product development speed is increased.

Owner:SHANDONG UNIV OF TECH

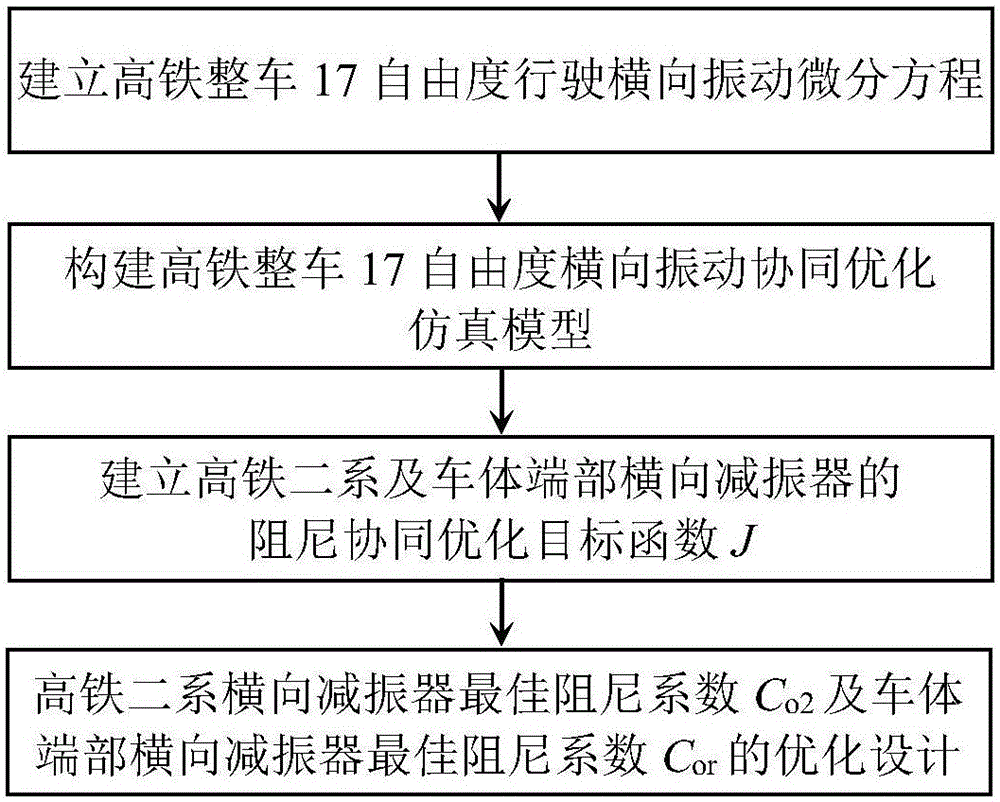

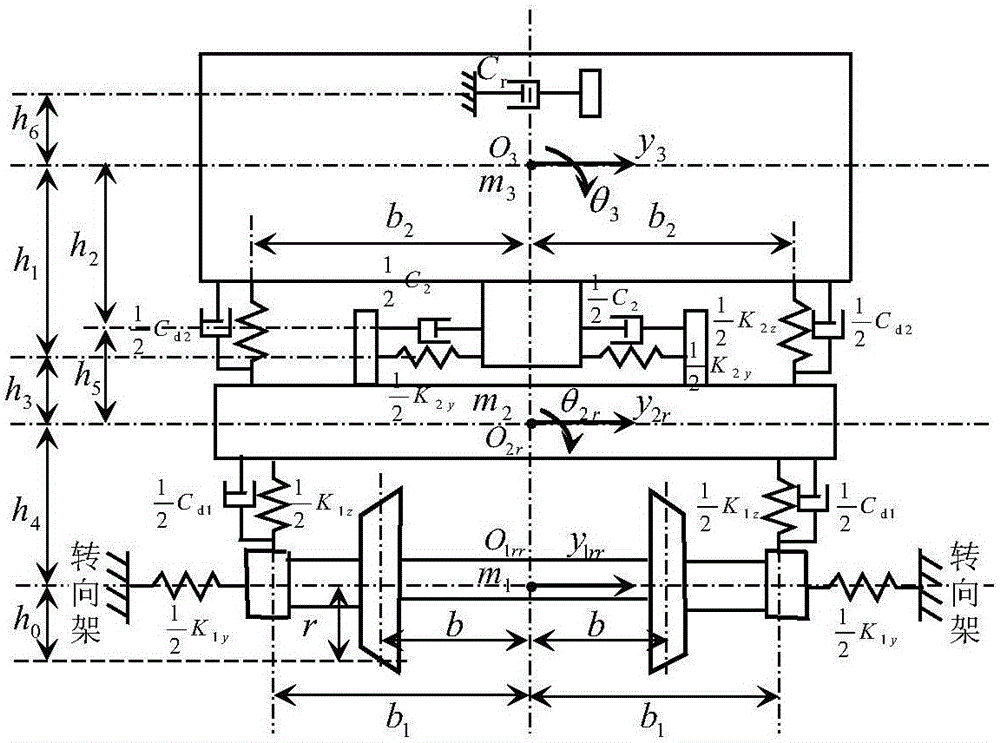

Collaborative optimization method for damping coefficients of high-speed rail secondary transverse damper and vehicle body end transverse damper

InactiveCN105138786AImprove powerReliable Simulated ValuesSpecial data processing applicationsDamping factorInternational market

The invention relates to a collaborative optimization method for damping coefficients of a high-speed rail secondary transverse damper and a vehicle body end transverse damper, and belongs to the technical field of suspension of high-speed rail vehicles. As a seventeen-freedom-degree transverse vibration collaborative optimization simulation model of a whole high-speed rail vehicle is set up, and irregularity in the railway direction and horizontal irregularity serve as input excitation, with the minimum root-mean-square value of vibration weighted acceleration of vehicle body transverse motion as the design target, the optimal damping coefficients of the high-speed rail secondary transverse damper and the vehicle body end transverse damper are obtained through optimization design. It can be known through design examples and SIMPACK simulation verification that the damping coefficient values of the high-speed rail secondary transverse damper and the vehicle body end transverse damper can be obtained accurately and reliably through the method, and a reliable design method is provided for designing the damping coefficients of the high-speed rail secondary transverse damper and the vehicle body end transverse damper. By means of the method, the design level of a high-speed rail vehicle suspension system can be improved, traveling safety and stability of the vehicle are improved, product design and test cost can be reduced, and the international market competitiveness of the rail vehicles in China is enhanced.

Owner:SHANDONG UNIV OF TECH

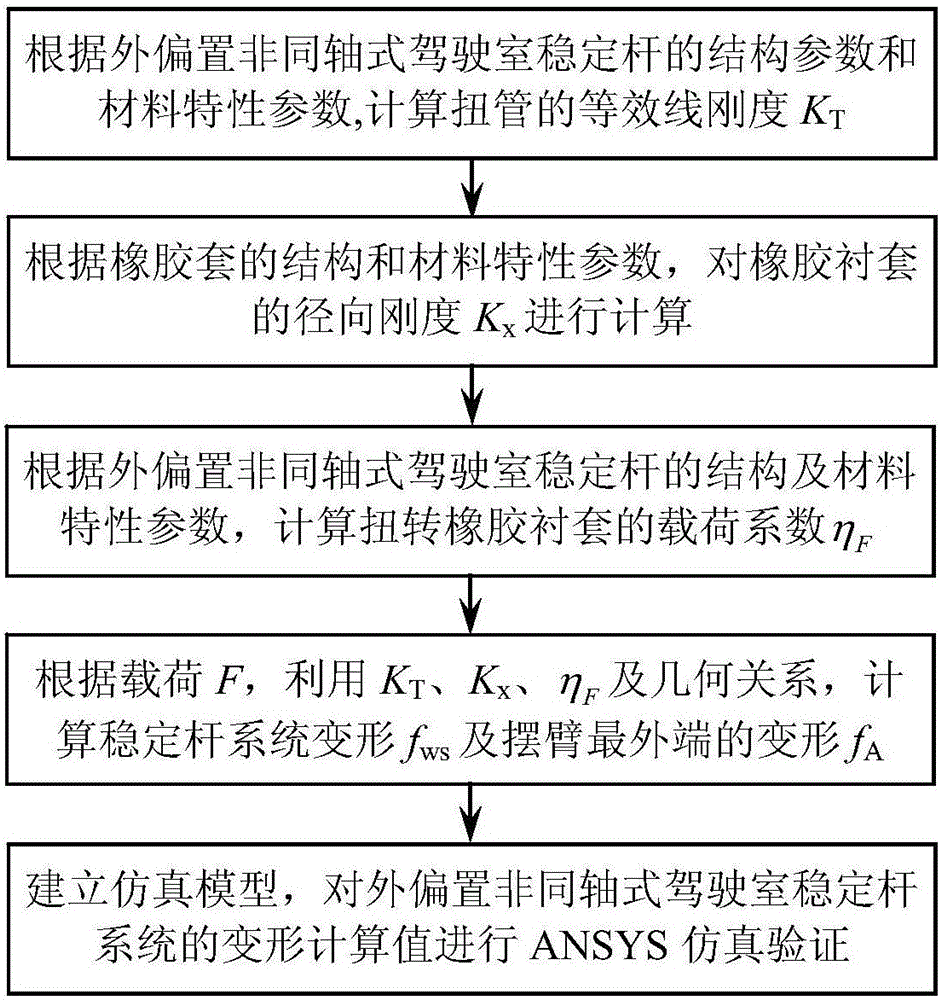

Method for calculating deformation of external bias non-coaxial cab stabilizer bar system

InactiveCN106096131AReliable Simulated ValuesAccurate Simulation ValuesGeometric CADDesign optimisation/simulationExternal biasDesign software

The invention discloses a method for calculating the deformation of an external bias non-coaxial cab stabilizer bar system and belongs to the technical field of vehicle cab suspension. The deformation of the external bias non-coaxial cab stabilizer bar system can be analyzed and calculated based on the structural parameters, material property parameters and borne loads of an external bias non-coaxial cab stabilizer bar and a rubber bushing according to the equivalent line rigidity of a torsion tube, the load parameters of a torsion rubber bushing, and the radial rigidity and combined equivalent line rigidity of the rubber bushing. Through practical calculation and ANSYS simulation verification, an accurate and reliable calculation value of the external bias non-coaxial cab stabilizer bar system can be obtained with the method, a reliable technical foundation is laid for analytical design of the external bias non-coaxial cab stabilizer bar system and development of CAD design software, and then the design level and product performance of the stabilizer bar and vehicle traveling smoothness are improved, design and test expenses are reduced, and product development speed is increased.

Owner:SHANDONG UNIV OF TECH

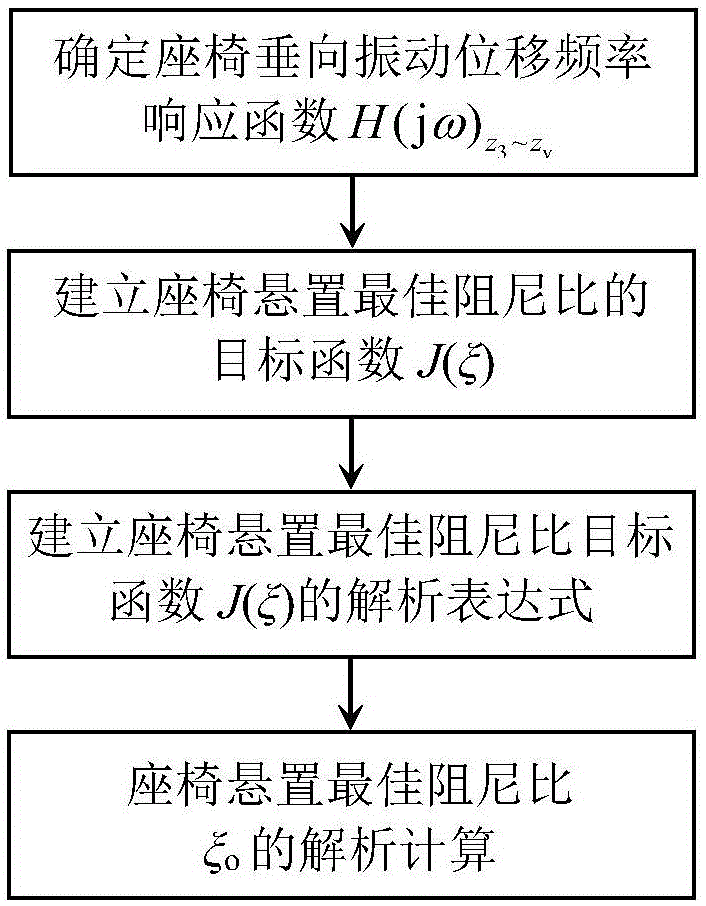

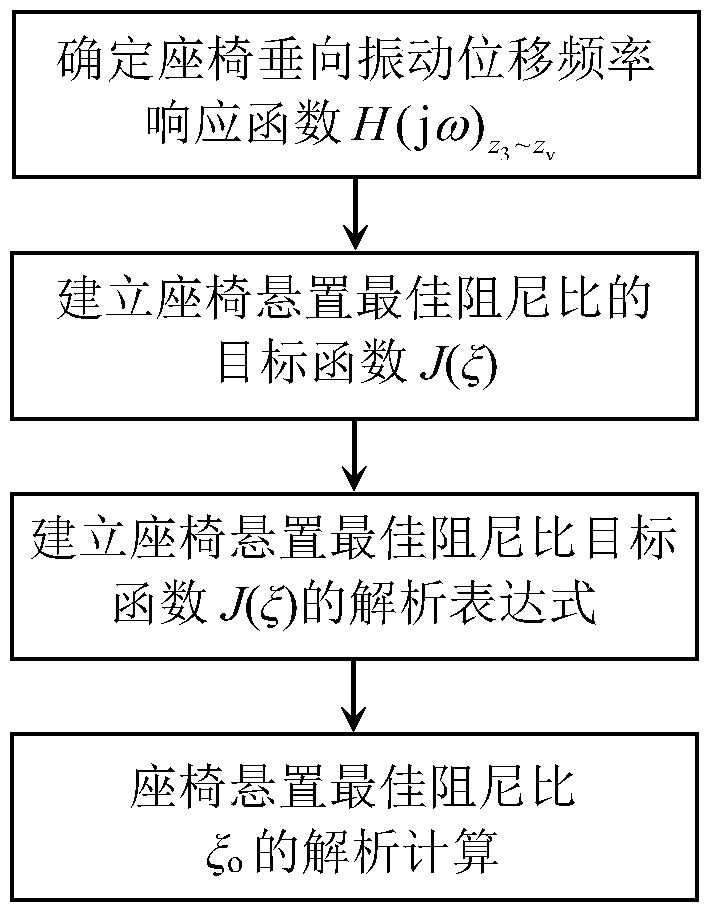

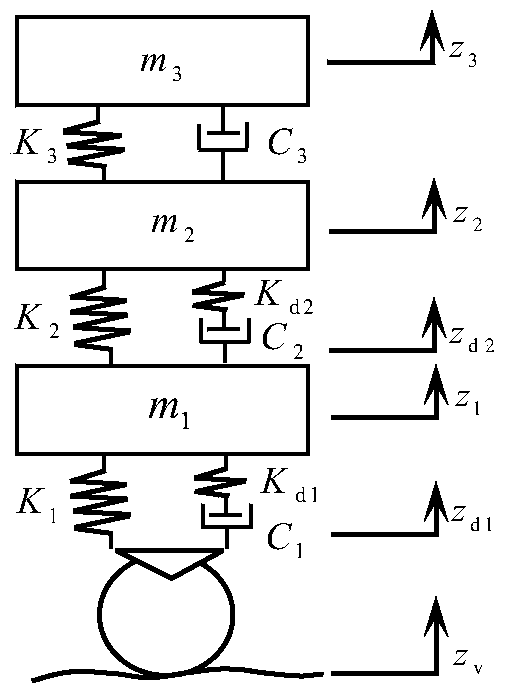

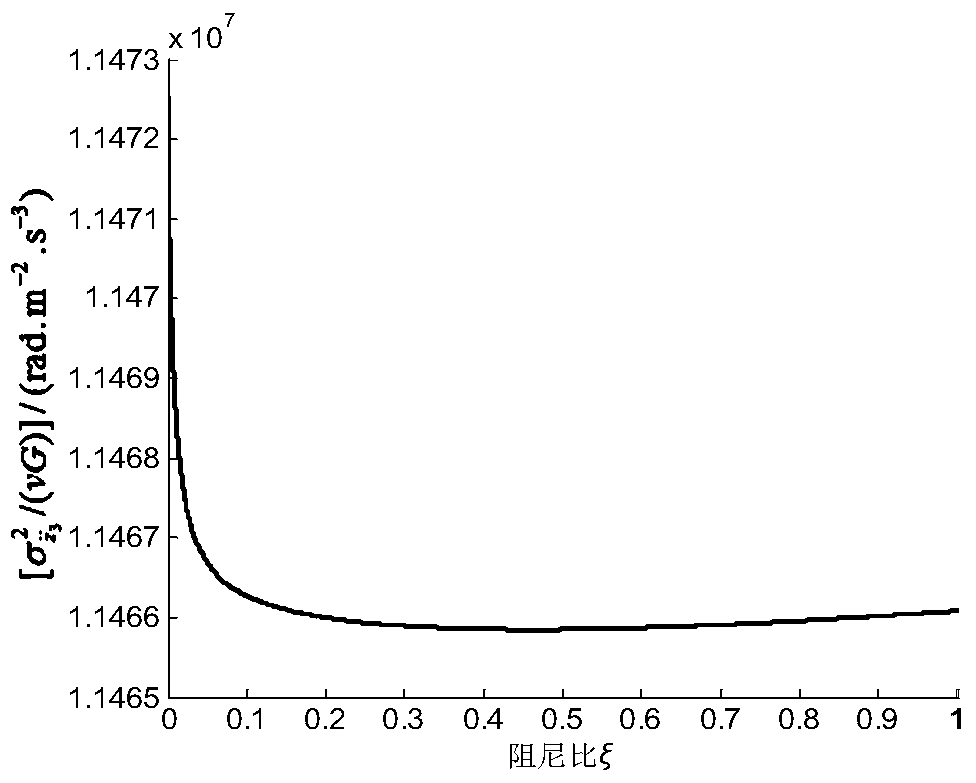

Analytic calculation method for optimal damping ratio of seat suspension of high-speed rail vehicle

InactiveCN105138784AImprove powerReliable Simulated ValuesSpecial data processing applicationsVertical vibrationInternational market

Owner:SHANDONG UNIV OF TECH

High-speed rail vertical damper and vehicle body end part longitudinal damper damping coefficient collaborative optimization method

InactiveCN105183979AImprove powerReliable Simulated ValuesSpecial data processing applicationsDamping factorVertical vibration

The present invention relates to a high-speed rail vertical damper and vehicle body end part longitudinal damper damping coefficient collaborative optimization method, and belongs to the technical field of high-speed railway vehicle suspension technology. A high-speed rail complete vehicle six degree-of-freedom vertical vibration collaborative optimization simulation model is established, track longitudinal irregularity is used as an input stimulus, minimization of a root mean square value of weighed vibration acceleration is the design object, and optimal damping coefficients of primary vertical, secondary vertical and vehicle body end part longitudinal dampers of a high-speed rail are obtained through design optimization. Through design examples and SIMPACK simulation verification, damping coefficients of the primary vertical, secondary vertical and vehicle body end part longitudinal dampers can be accurately and reliably obtained through the method, and a reliable design method is provided for the design of the damping coefficients of the primary vertical, secondary vertical and vehicle body end part longitudinal dampers. By using the method, the design level of a high-speed railway suspension system is raised, vehicle travelling safety and stability are raised, and design and testing expenses are also reduced.

Owner:SHANDONG UNIV OF TECH

Design method for damping coefficient of end longitudinal shock absorbers of high-speed railway vehicle body

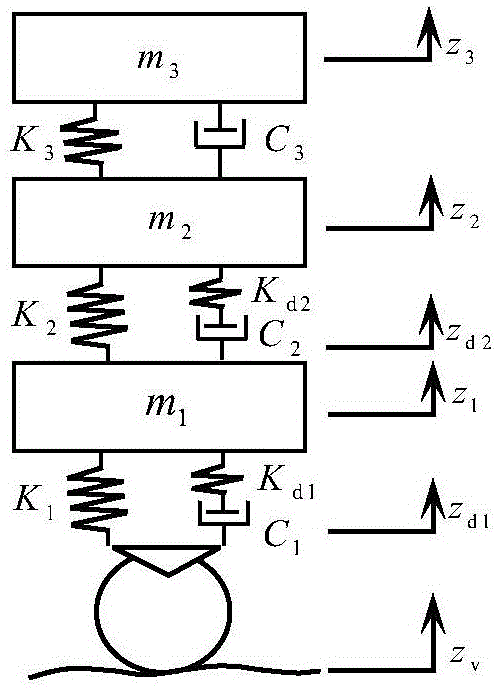

InactiveCN105183982AImprove powerReliable Simulated ValuesInternal combustion piston enginesSpecial data processing applicationsVertical vibrationDamping factor

The invention relates to a design method for the damping coefficient of end longitudinal shock absorbers of a high-speed railway vehicle body, and belongs to the technical field of high-speed railway vehicle suspension. Through establishing a six-freedom-degree vertical vibration optimal design simulation model of a whole railway vehicle, with railway vertical irregularity being input excitation and the minimum root-mean-square value of vibration acceleration of vehicle body bounce movement being a design target, the optimal damping coefficient of the end longitudinal shock absorbers of the vehicle body is obtained through optimal design. Through a design example and SIMPACK simulation verification, the accurate and reliable damping coefficient value of the end longitudinal shock absorbers of the vehicle body can be obtained through the method, and the reliable design method is provided for the design of the damping coefficient of the end longitudinal shock absorbers of the high-speed railway vehicle body. By the utilization of the method, the design level of a high-speed railway vehicle suspension system can be increased, and the driving safety and stability of the vehicle are improved; meanwhile, the product design and test costs can be lowered, so that the international market competitiveness of the railway vehicle in China is enhanced.

Owner:SHANDONG UNIV OF TECH

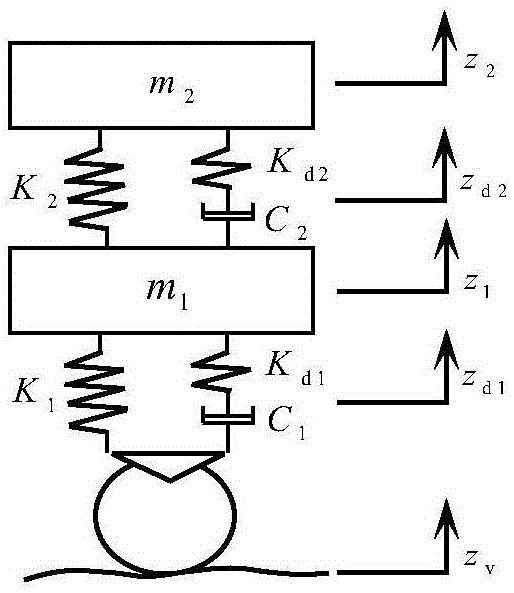

Analytic calculation method of optimal damping ratio of two-line vertical suspension of high-speed railway vehicle

InactiveCN105160180AImprove powerReliable Simulated ValuesComplex mathematical operationsVertical vibrationInternational market

The invention relates to an analytic calculation method of an optimal damping ratio of the two-line vertical suspension of a high-speed railway vehicle, and belongs to the technical field of the high-speed railway vehicle suspension. A 1 / 4 vehicle body four-degree-of-freedom driving vertical vibration model is established, the optimal human body riding comfort and minimum vertical force borne on a wheel set and an axle are independently taken as a design target, calculation is carried out to obtain the optimal damping ratio of a two-line vertical suspension system on the basis of comfort and safety, and the calculation is carried out to obtain the optimal damping ratio of the two-line vertical suspension system by a golden section principle. Through a design example and SIMPACK simulation verification, the method can obtain the accurate and reliable optimal damping ratio of the two-line vertical suspension system, and provides a reliable design method for the design of the damping ratio of the two-line vertical suspension of the high-speed railway vehicle. The method can improve the design level of the suspension system of the high-speed railway vehicle, and vehicle riding comfort and safety, can lower design and experiment cost and enhances the international market competitiveness of the railway vehicle in China.

Owner:SHANDONG UNIV OF TECH

Analytic calculation method of optimal damping ratio of two-line horizontal suspension of high-speed railway vehicle

InactiveCN105160179AImprove powerReliable Simulated ValuesSpecial data processing applicationsHorizontal forceHuman body

Owner:SHANDONG UNIV OF TECH

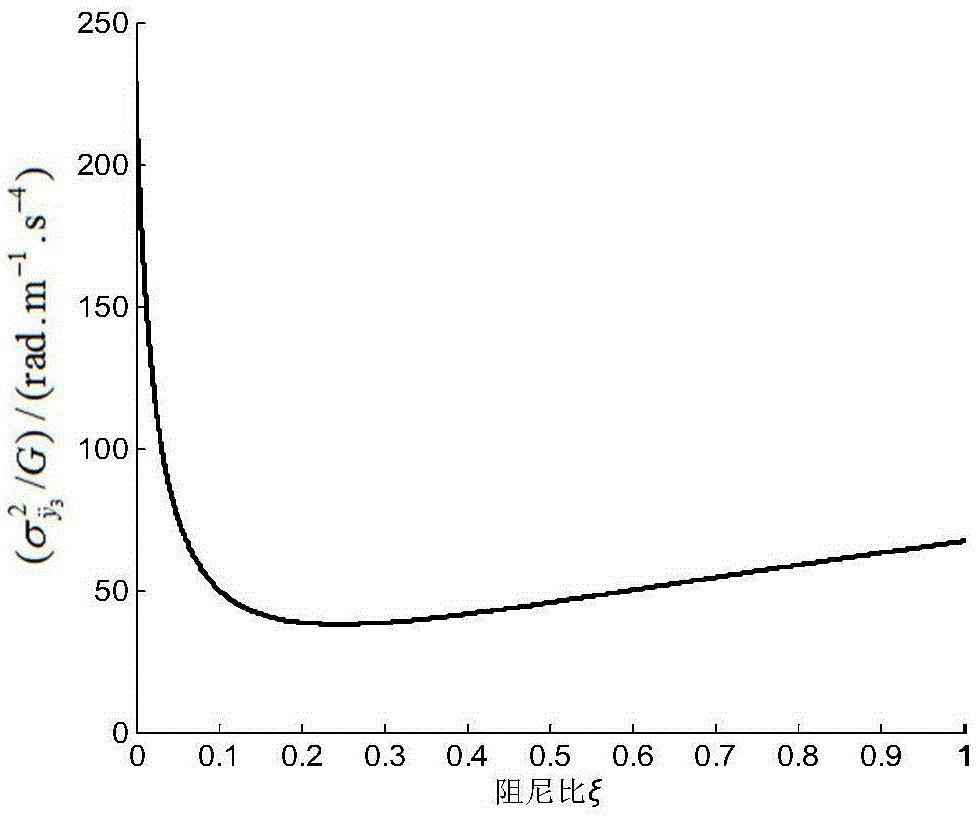

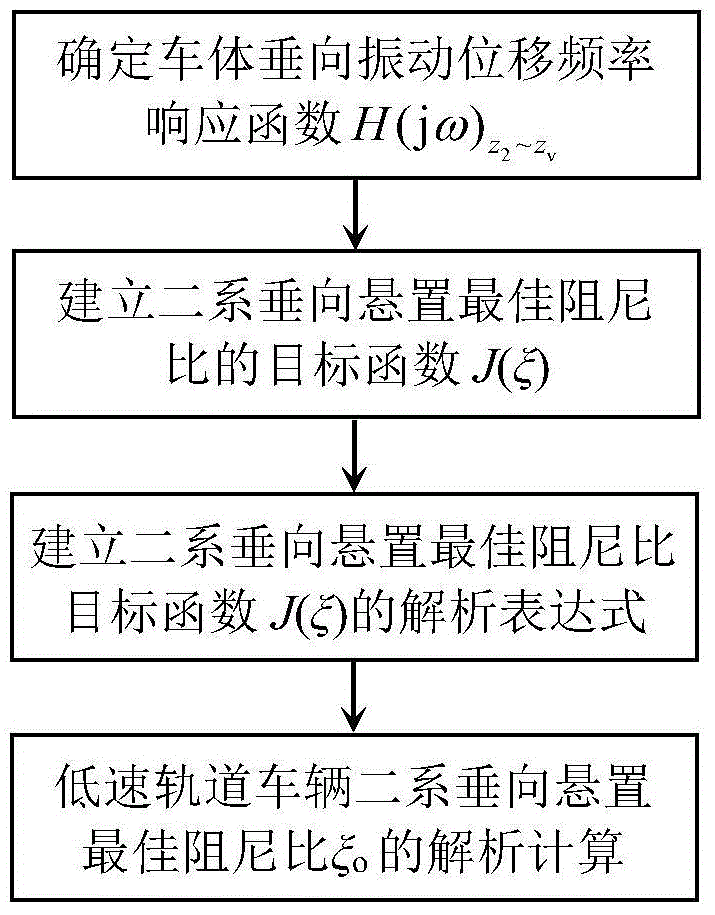

Analytic calculating method for optimal damping ratio of secondary vertical suspension of low-speed rail vehicle

InactiveCN105069259AImprove powerReliable Simulated ValuesSpecial data processing applicationsVertical vibrationLow speed

The invention relates to an analytic calculating method for the optimal damping ratio of a secondary vertical suspension of a low-speed rail vehicle and belongs to the technical field of vehicle suspensions of low-speed rail vehicles. A 1 / 4 vehicle body four-degree-of-freedom running vertical vibration model of the low-speed rail vehicle is established, a target function of the optimal damping ratio of the secondary vertical suspension is established based on a random vibration theory, analytic calculating is conducted, and therefore the optimal damping ratio of a secondary vertical suspension system of the low-speed rail vehicle is obtained. It can be known through a design example and SIMPACK simulation verification that the accurate and reliable optimal damping ratio of the secondary vertical suspension system can be obtained, and the reliable design method is provided for design of the damping ratio of the secondary vertical suspension of the low-speed rail vehicle. By means of the method, the design level and the product quality of the suspension system of the low-speed rail vehicle can be improved, and the riding comfort of the vehicle is improved; meanwhile, the product designing and testing cost can also be reduced, the product design period is shortened, and the international market competition ability of the track vehicle of China is improved.

Owner:SHANDONG UNIV OF TECH

Method for checking twisted pipe stress intensity of inner biased non-coaxial type cab stabilizer bar

ActiveCN104318033AAccurate and reliable stress intensity calculationsImprove the design levelSpecial data processing applicationsShear stressEngineering

The invention relates to a method for checking twisted pipe stress intensity of an inner biased non-coaxial type cab stabilizer bar and belongs to the technical field of vehicle cab suspension. According to an inner biased non-coaxial type cab stabilizer bar system and structure parameters and material characteristic parameters of a twisted pipe, the bending load coefficient of the twisted pipe is established by utilizing the relations of twisted pipe bending, torsional deflection and load, and the method for checking twisted pipe stress intensity of the inner biased non-coaxial type cab stabilizer bar is established through bending normal stress and torsional shear stress. As can be known through example calculation and ANSYS simulation verification, the accurate and reliable twisted pipe stress intensity calculation value of the inner biased non-coaxial type cab stabilizer bar can be obtained through the method, and a reliable stress verifying calculation method is provided for the design of the cab stabilizer bar system. The method can improve the design level, quality and performance of the cab stabilizer bar system and improve vehicle running smoothness and safety; and the design and testing expense can be reduced.

Owner:SHANDONG UNIV OF TECH

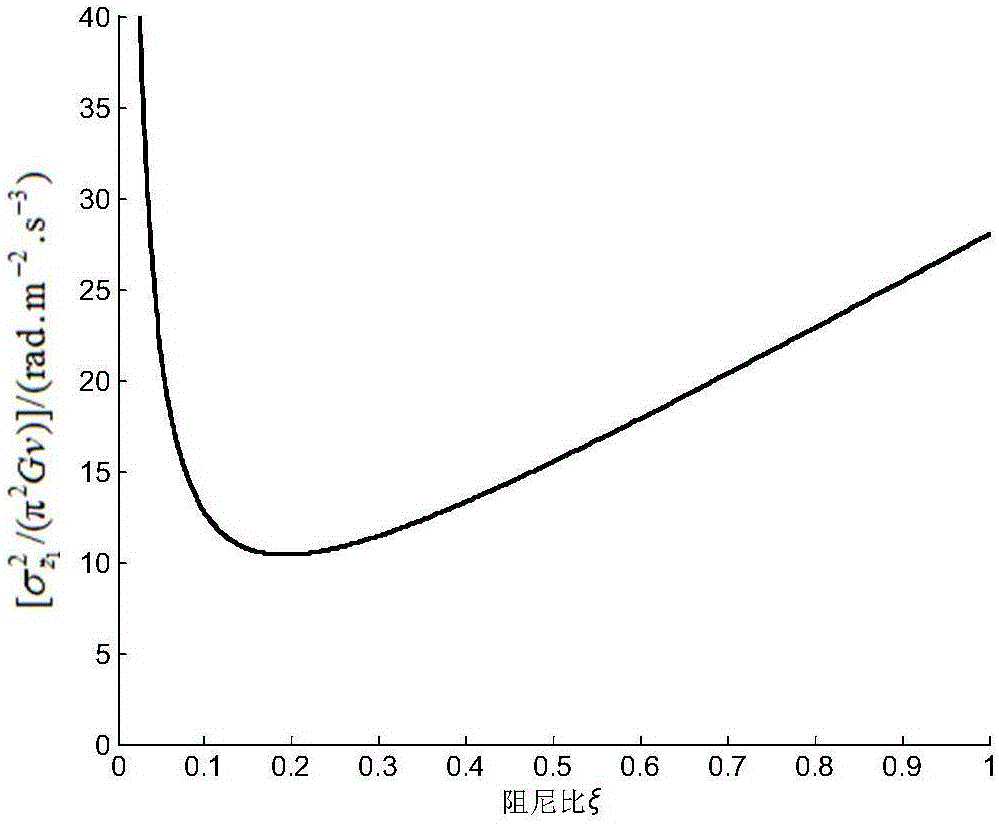

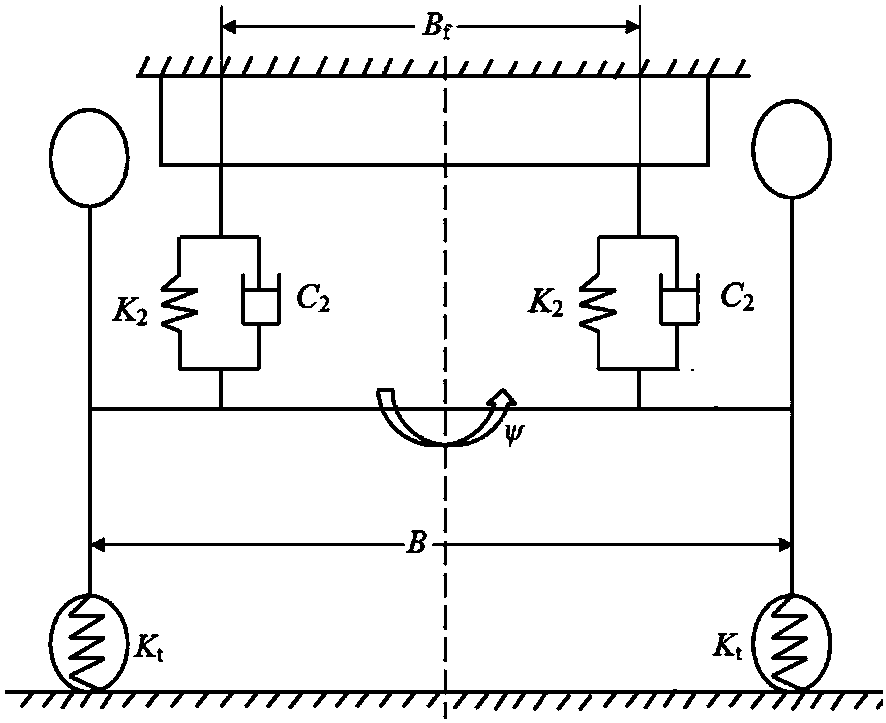

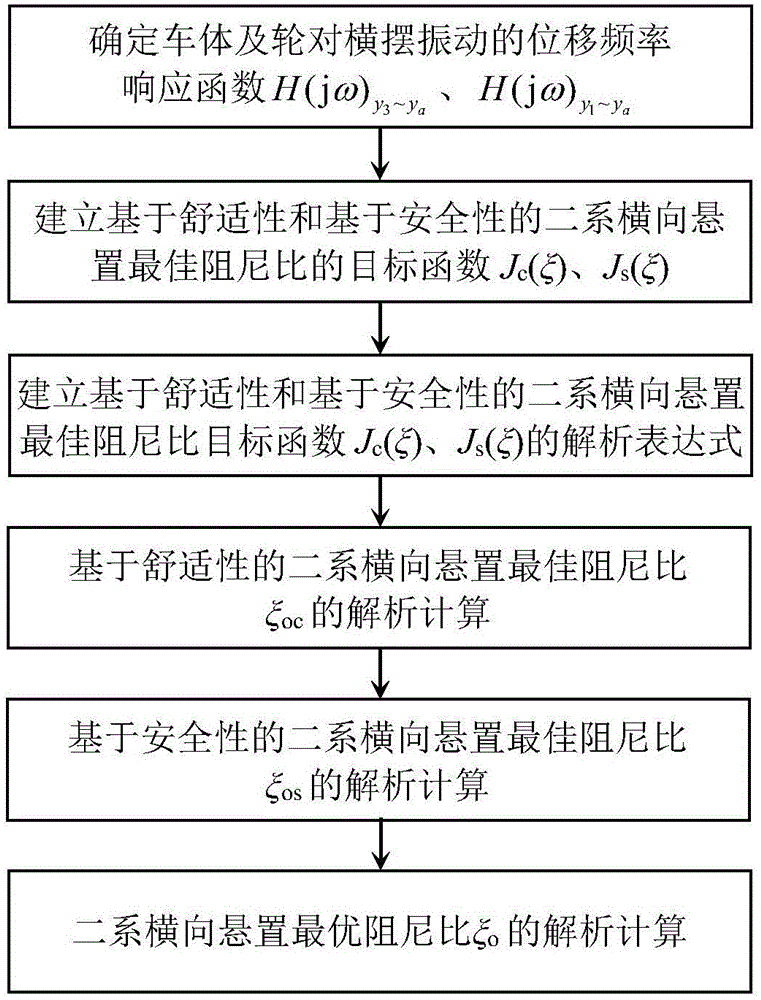

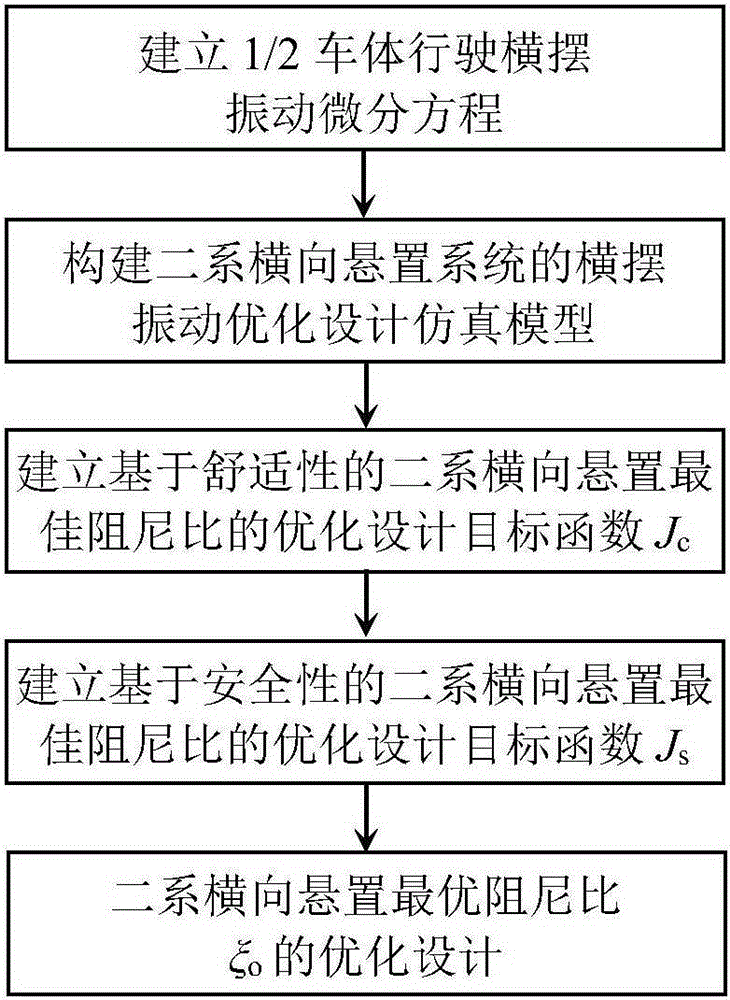

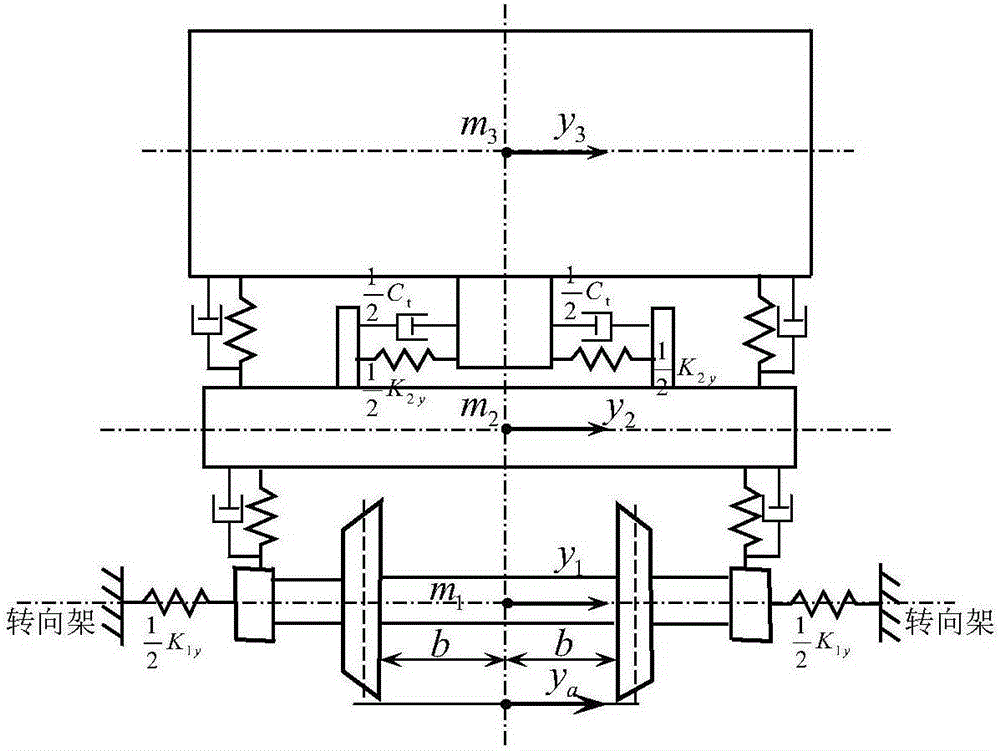

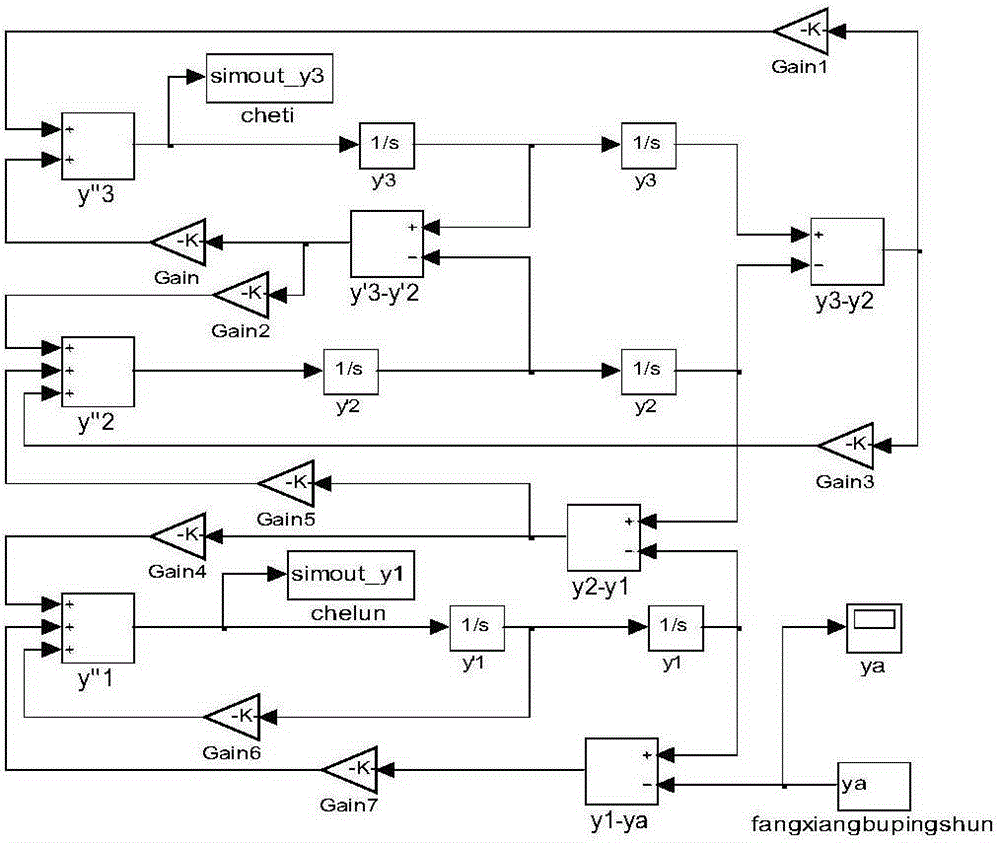

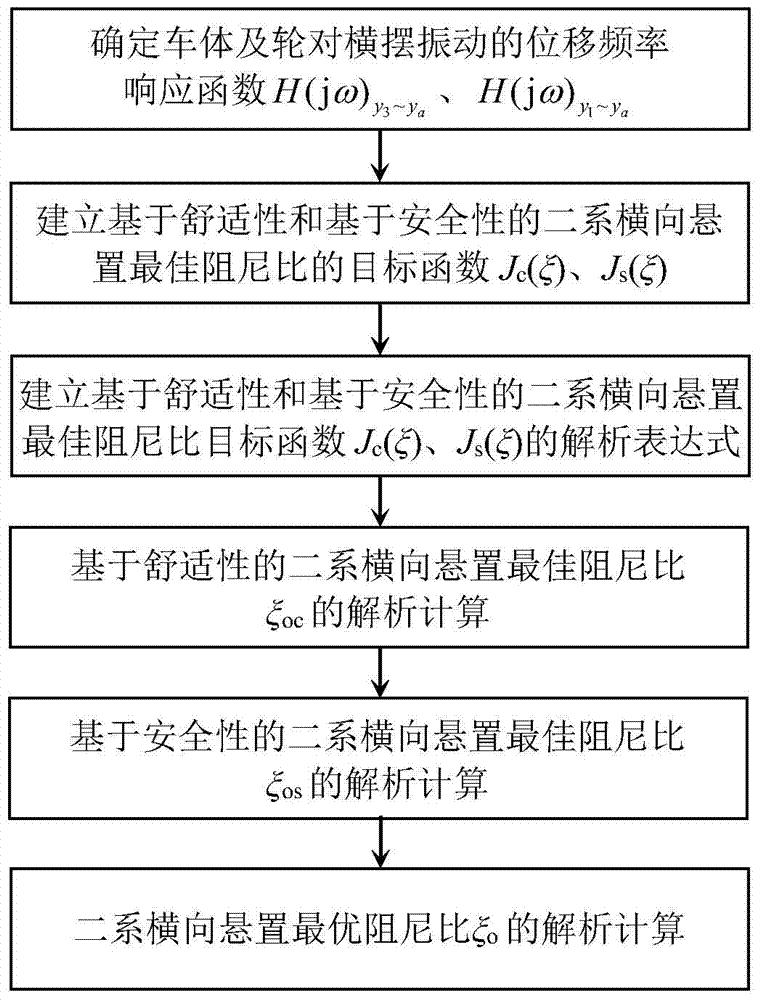

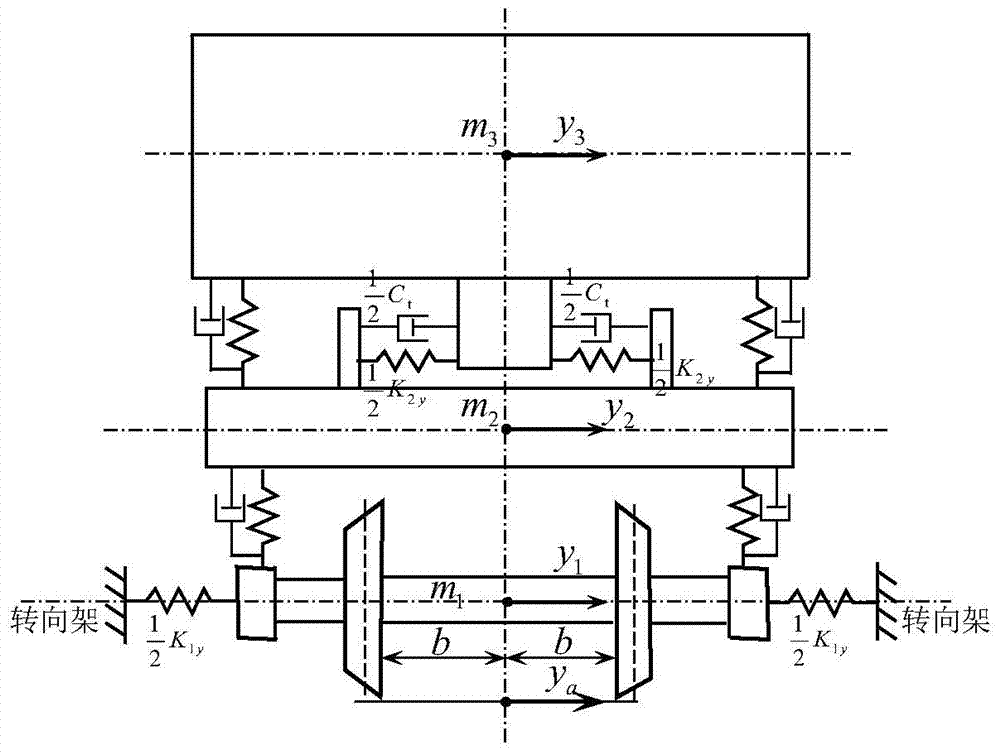

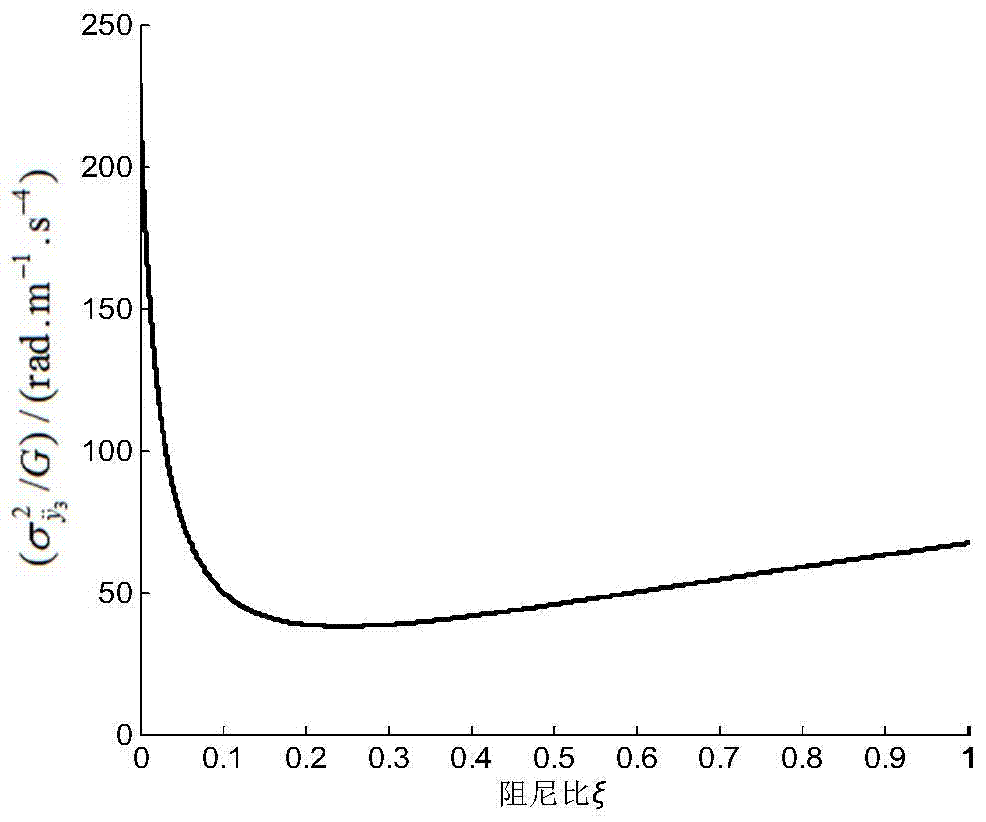

Optimization design method for optimum damping ratio of secondary transverse suspension of high-speed rail vehicle

InactiveCN105224718AImprove powerReliable Simulated ValuesInternal combustion piston enginesSpecial data processing applicationsVibration accelerationDamping ratio

The present invention relates to an optimization design method for an optimum damping ratio of a secondary transverse suspension of a high-speed rail vehicle, and belongs to the technical field of high-speed rail vehicle suspensions. The method comprises: constructing a yawing vibration optimization design simulation model of a secondary transverse suspension system by establishing a 1 / 2 vehicle body driving yawing vibration differential equation and using MATLAB / Simulink simulation software; obtaining an optimum damping ratio, based on comfort and based on safety, of the secondary transverse suspension system by taking a non-smooth random input in an orbit direction as input excitation and taking a smallest vibration acceleration root mean square of the vehicle body and wheel yaw motion as a design target; and further carrying out calculation to obtain the optimum damping ratio of the secondary transverse suspension system. As known from design examples and SIMPACK simulation verification, an accurate and reliable optimum damping ratio of the secondary transverse suspension system can be obtained by the method provided by the present invention, thereby providing a reliable design method for the damping ratio of the secondary transverse suspension of the high-speed rail vehicle. By use of the optimization design method for the optimum damping ratio of the secondary transverse suspension of the high-speed rail vehicle, the design level of the suspension system of the rail vehicle and comfort and safety of vehicle riding can be improved.

Owner:SHANDONG UNIV OF TECH

Checking Method of Torsion Tube Stress Intensity of Outer Offset Non-coaxial Cab Stabilizer Bar

InactiveCN104318041BReliable Simulated ValuesAccurate and reliable stress intensity calculationsSpecial data processing applicationsSystems designShear stress

The invention relates to a method for checking the stress strength of a torsion tube of an external offset non-coaxial cab stabilizer bar, and belongs to the technical field of vehicle cab suspension. The present invention establishes the bending load coefficient of the torsion tube by using the relationship between the bending and torsional deformation of the torsion tube and the relationship between the external offset non-coaxial cab stabilizer bar system and the torsion tube's structural parameters, material characteristic parameters and load , and through the bending normal stress and torsional shear stress of the torsion tube, a method for checking the torsion tube stress strength of the external offset non-coaxial cab stabilizer bar is established. Through example calculation and ANSYS simulation verification, it can be seen that this method can obtain accurate and reliable calculation value of torsion tube stress intensity, which provides a reliable stress intensity check method for the design of cab stabilizer bar system. Using the method can improve the design level, quality and performance of the stabilizer bar system in the cab, and improve the driving comfort and safety of the vehicle; at the same time, it can also reduce design and test costs and speed up product development.

Owner:SHANDONG UNIV OF TECH

Optimal design method for optimal damping ratio of secondary vertical mounts of high-speed rail vehicles

InactiveCN105069260BImprove powerReliable Simulated ValuesInternal combustion piston enginesSpecial data processing applicationsBogieVertical vibration

The invention relates to an optimal design method for the optimal damping ratio of a secondary vertical mount of a high-speed rail vehicle, and belongs to the technical field of high-speed rail vehicle mounts. The present invention constructs the vertical vibration optimization design simulation model of the secondary vertical suspension system, takes the random input of track height irregularity as the input excitation, and takes the minimum root mean square value of the vibration acceleration of the vertical motion of the car body and bogie frame as The design goal is to optimize the design to obtain the optimal damping ratio of the secondary vertical mount system based on comfort and safety, and then calculate the optimal damping ratio of the secondary vertical mount. Through the design example and SIMPACK simulation verification, it can be seen that the method can obtain the accurate and reliable optimal damping ratio of the secondary vertical mount system, and provides a reliable design method for the design of the damping ratio of the secondary vertical mount of rail vehicles. Using this method can not only improve the design level of the suspension system of the high-speed rail vehicle and the ride comfort and safety of the vehicle, but also reduce the product design and test costs.

Owner:SHANDONG UNIV OF TECH

Analytical Calculation Method for Optimum Damping Ratio of Seat Mounts in High Speed Rail Vehicles

InactiveCN105138784BImprove powerReliable Simulated ValuesSpecial data processing applicationsVertical vibrationInternational market

The invention relates to an analytic calculation method for the optimal damping ratio of seat suspension of a high-speed rail vehicle, and belongs to the technical field of suspension of high-speed rail vehicles. As a 1 / 4 vehicle body-seat traveling vertical vibration model of the rail vehicle is set up, an objective function of the optimal damping ratio of seat suspension is set up by means of the random vibration theory and analytically calculated to obtain the optimal damping ratio of seat suspension. It can be known through design examples and SIMPACK simulation verification that the optimal damping ratio of seat suspension can be obtained accurately and reliably through the method, and a reliable design method is provided for designing the optimal damping ratio of seat suspension of the high-speed rail vehicle. By means of the method, the design level and product quality of a high-speed rail vehicle suspension system can be improved, riding comfort of the vehicle is improved, product design and test cost can be reduced, the product design cycle is shortened, and the international market competitiveness of the rail vehicles in China is enhanced.

Owner:SHANDONG UNIV OF TECH

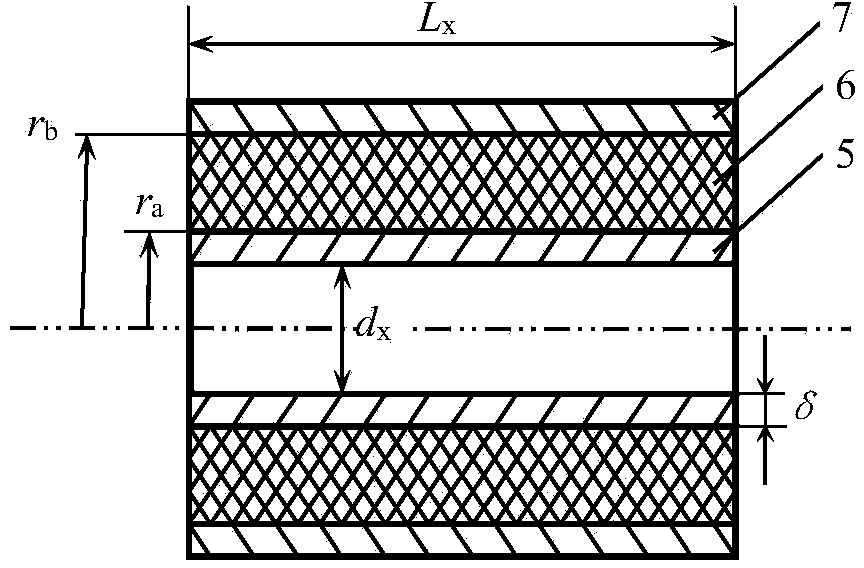

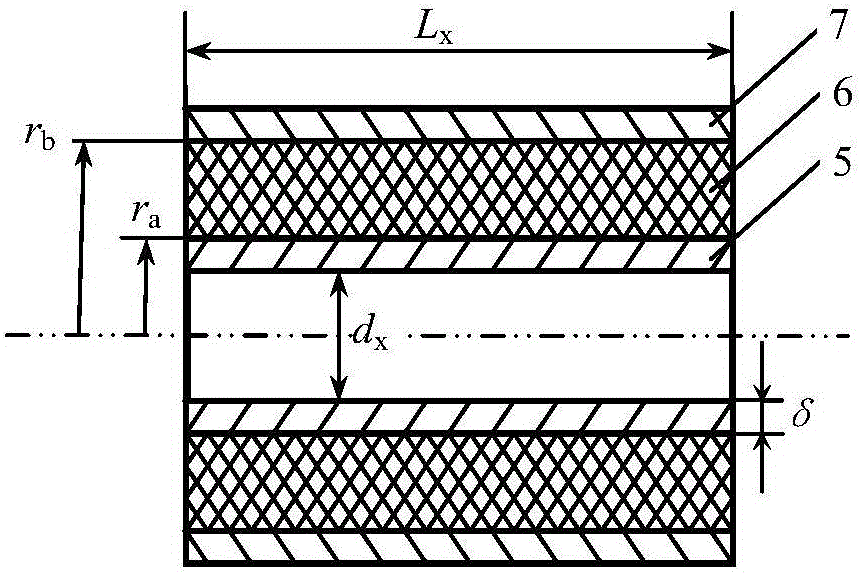

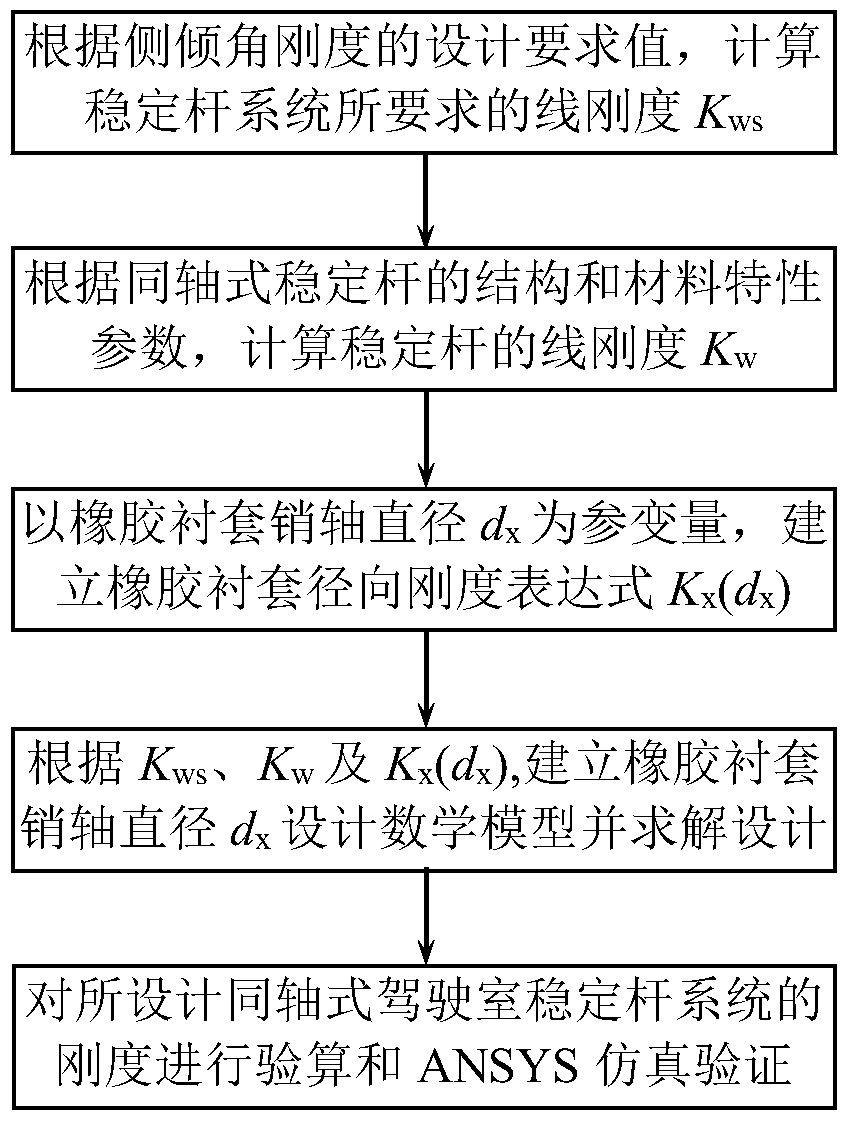

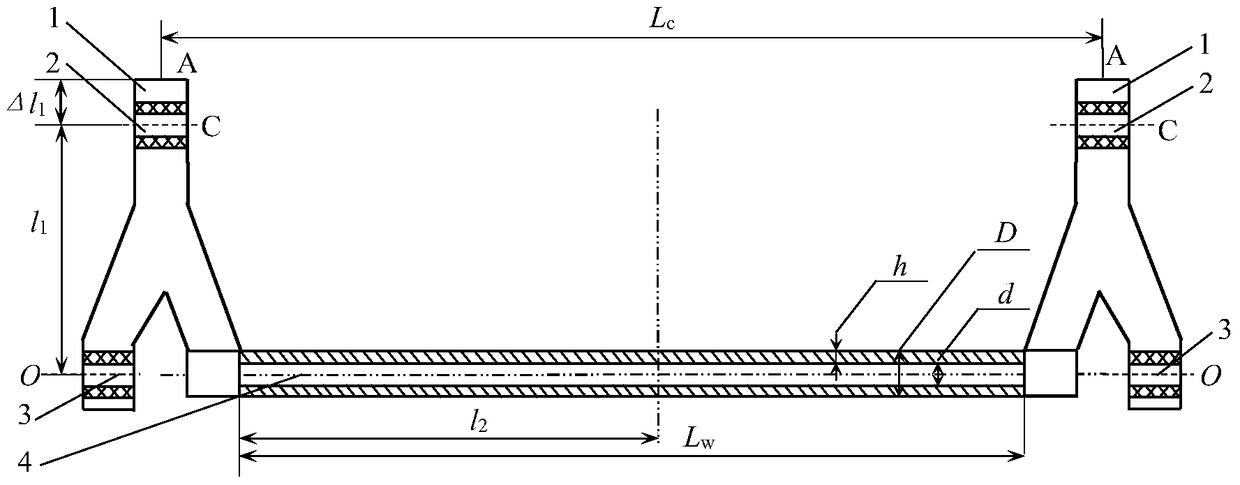

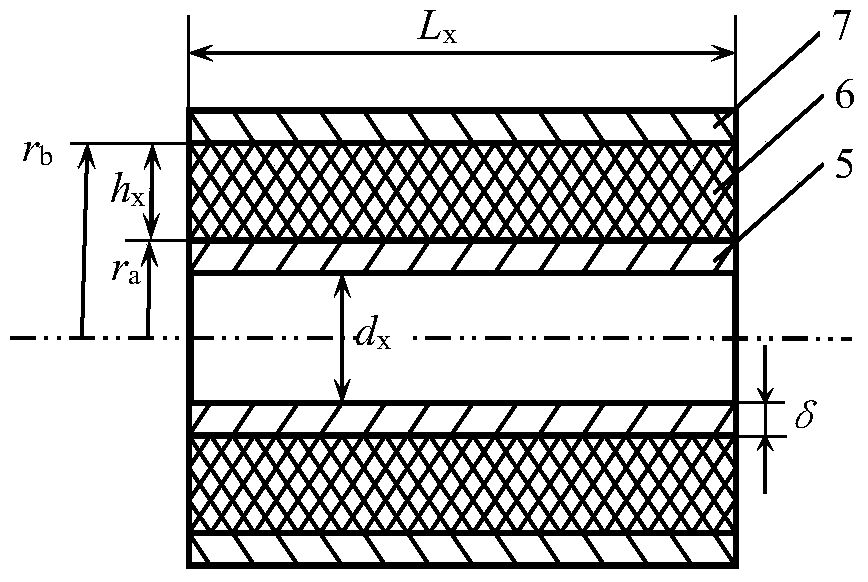

Design method of rubber bushing pin diameter of coaxial cab stabilizer bar

InactiveCN104318018BReliable Simulated ValuesImprove the design levelSpecial data processing applicationsComputer Aided DesignSystems design

The invention relates to a design method for the diameter of a pin shaft of a rubber bushing of a coaxial cab stabilizer bar, and belongs to the technical field of cab suspension. According to the design requirement value of the roll angle stiffness, the structure of the stabilizer bar, the length Lx of the rubber sleeve and the material characteristic parameters, the present invention can analyze and design the pin shaft diameter dx of the rubber bushing of the coaxial cab stabilizer bar. Through the example calculation and simulation verification, it can be seen that the accurate and reliable design value dx of the rubber bushing pin diameter of the coaxial cab stabilizer bar can be obtained by using this method, which lays a reliable technical foundation for the design of the cab stabilizer bar system and the development of CAD software . Using this method can not only improve the design level of the coaxial cab stabilizer bar system, but also achieve the design of the roll angle stiffness of the stabilizer bar system only through the adjustment design of the rubber bush pin diameter dx Requirements, improve the ride comfort and ride comfort of the vehicle; at the same time, it can also reduce the design and test costs.

Owner:SHANDONG UNIV OF TECH

Collaborative optimization method for the damping coefficient of the vertical and end longitudinal shock absorbers of the second series of high-speed railway

InactiveCN105160105BImprove powerReliable Simulated ValuesSpecial data processing applicationsDamping factorVertical vibration

The invention relates to a collaborative optimization method for the damping coefficient of the vertical and end longitudinal shock absorbers of the secondary series of high-speed railways, and belongs to the technical field of high-speed rail vehicle suspension. The present invention establishes a 6-degree-of-freedom vertical vibration collaborative optimization simulation model of a high-speed rail vehicle, takes track height irregularity as an input excitation, and takes the minimum root-mean-square value of the vibration-weighted acceleration of the vertical motion of the vehicle body as the design goal, and optimizes the design to obtain a high-speed rail Optimum damping coefficients for secondary vertical and body end longitudinal shock absorbers. Through the design example and SIMPACK simulation verification, it can be seen that the method can obtain accurate and reliable damping coefficient values of the secondary vertical shock absorber and the longitudinal shock absorber at the end of the car body, which is the value for the vertical damping of the secondary vertical and longitudinal shock absorbers at the end of the high-speed rail. The design of the damping coefficient of the vibrator provides a reliable design method. Using this method can not only improve the design level of the high-speed rail suspension system, improve the safety and stability of the vehicle, but also reduce the cost of product design and testing, and enhance the international market competitiveness of my country's rail vehicles.

Owner:SHANDONG UNIV OF TECH

Design method for damping coefficient of transverse shock absorber at the end of high-speed rail vehicle body

InactiveCN105138783BImprove powerReliable Simulated ValuesSpecial data processing applicationsBody rollDamping factor

Owner:SHANDONG UNIV OF TECH

Analytical Calculation Method for Optimum Damping Ratio of Secondary Lateral Mounts of High Speed Rail Vehicles

InactiveCN105160179BImprove powerReliable Simulated ValuesSpecial data processing applicationsDamping ratioDesign objective

The invention relates to an analytical calculation method for an optimal damping ratio of a secondary lateral mount of a high-speed rail vehicle, and belongs to the technical field of high-speed rail vehicle mounts. The present invention establishes a 1 / 2 car body running yaw vibration model, and takes the best riding comfort of the human body and the minimum lateral force on the wheel set and wheel axle as the design goals, and calculates the secondary lateral suspension based on comfort and safety. The optimal damping ratio of the system is calculated, and the optimal damping ratio of the secondary lateral suspension system is calculated by using the golden section principle. Through the design example and SIMPACK simulation verification, it can be seen that the method can obtain the accurate and reliable optimal damping ratio of the secondary lateral mount system, and provides a reliable design method for the design of the damping ratio of the secondary lateral mount of high-speed rail vehicles. Using this method can not only improve the design level of the suspension system of high-speed rail vehicles, but also improve the ride comfort and safety of the vehicles; at the same time, it can also reduce the design and test costs and enhance the international market competitiveness of my country's rail vehicles.

Owner:SHANDONG UNIV OF TECH

Design method of torsion tube length for external offset non-coaxial cab stabilizer bar

InactiveCN104331576BRobust Analytical Design MethodReliable Simulated ValuesSpecial data processing applicationsSystems designEngineering

The invention relates to a design method for the length of a torsion tube of an external offset non-coaxial cab stabilizer bar, and belongs to the technical field of cab suspension. The present invention takes the length of the torsion tube as a parameter, uses the load coefficient expression of the torsion rubber bushing, the equivalent combination line stiffness expression of the rubber bushing, and the equivalent line stiffness expression of the torsion tube to establish the torsion tube of the stabilizer bar Design the mathematical model of the length, and solve the design through the Matlab program. Through the design example and ANSYS simulation verification, it can be seen that the method can obtain accurate and reliable design value of the torsion tube length, which provides a reliable technical basis for the design of the stabilizer bar system and the development of CAD software. Using this method, the design level and quality of the stabilizer bar system can be improved only by adjusting the length of the torsion tube without increasing the product cost, and the design requirements of the roll angle stiffness of the stabilizer bar system can be met, and the ride comfort and performance of the vehicle can be improved. Safety; at the same time, design and test costs can also be reduced.

Owner:SHANDONG UNIV OF TECH

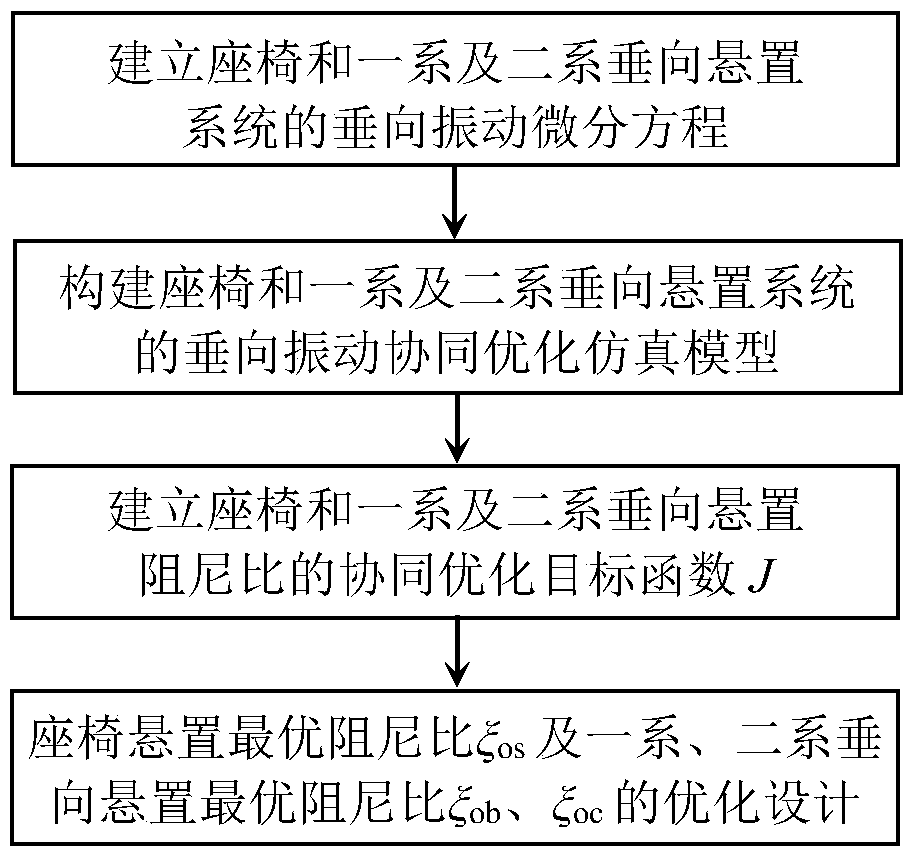

Collaborative optimization method for damping ratio of high-speed rail seat and primary and secondary vertical suspensions

InactiveCN105138785BImprove powerReliable Simulated ValuesSpecial data processing applicationsVertical vibrationVibration acceleration

The invention relates to a method for synergistically optimizing the damping ratio of a high-speed rail seat and a vertical suspension of the first series and the second series, and belongs to the technical field of high-speed rail vehicle suspension. The present invention constructs the vertical vibration collaborative optimization simulation model of the seat and the primary and secondary vertical suspension systems, takes the random input of track height irregularity as the input excitation, and takes the minimum root mean square value of the vertical vibration acceleration of the seat as The design goal is to optimize the design to obtain the optimal damping ratio of the high-speed rail seat mount and the primary and secondary vertical mounts. Through the design example and SIMPACK simulation verification, it can be known that this method can obtain the optimal damping ratio of the high-speed rail seat suspension and the primary and secondary vertical suspension systems accurately and reliably. The design of the suspension damping ratio provides a reliable design method. Using this method can not only improve the design level of the high-speed rail suspension system and the ride comfort of the vehicle, but also shorten the product design cycle and enhance the international market competitiveness of my country's rail vehicles.

Owner:SHANDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com