Analytic calculating method for optimal damping ratio of secondary vertical suspension of low-speed rail vehicle

An optimal damping ratio, secondary vertical technology, applied in calculations, special data processing applications, instruments, etc., can solve problems such as dynamic analysis and calculation difficulties, and no systematic analytical calculation methods are given.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] specific implementation plan

[0037] The present invention will be further described in detail through an embodiment below.

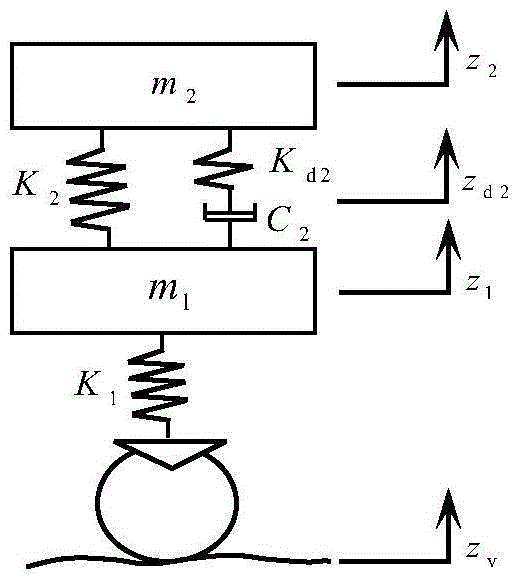

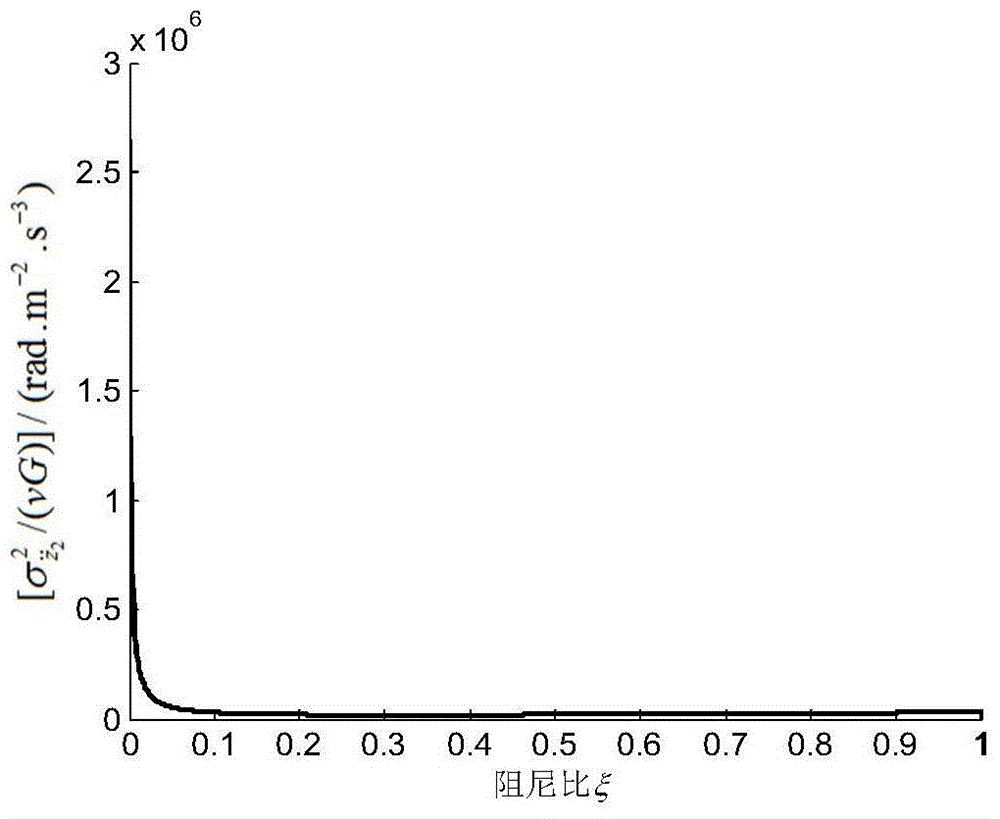

[0038] The full load mass of a 1 / 4 single-section car body of a low-speed rail vehicle m 2 =14228kg, half of the mass of a single bogie frame m 1 =1155kg; The vertical equivalent stiffness K of each axle box positioning device 1 =1.48×10 6 N / m; the stiffness K of the secondary vertical suspension 2 =561.68kN / m; End connection stiffness K of the secondary vertical shock absorber d2 =20×10 6 N / m; the damping ratio of the secondary vertical suspension to be designed is ξ, where the equivalent damping coefficient of the secondary vertical shock absorber The optimal damping ratio of the secondary vertical mount of the low-speed rail vehicle is designed.

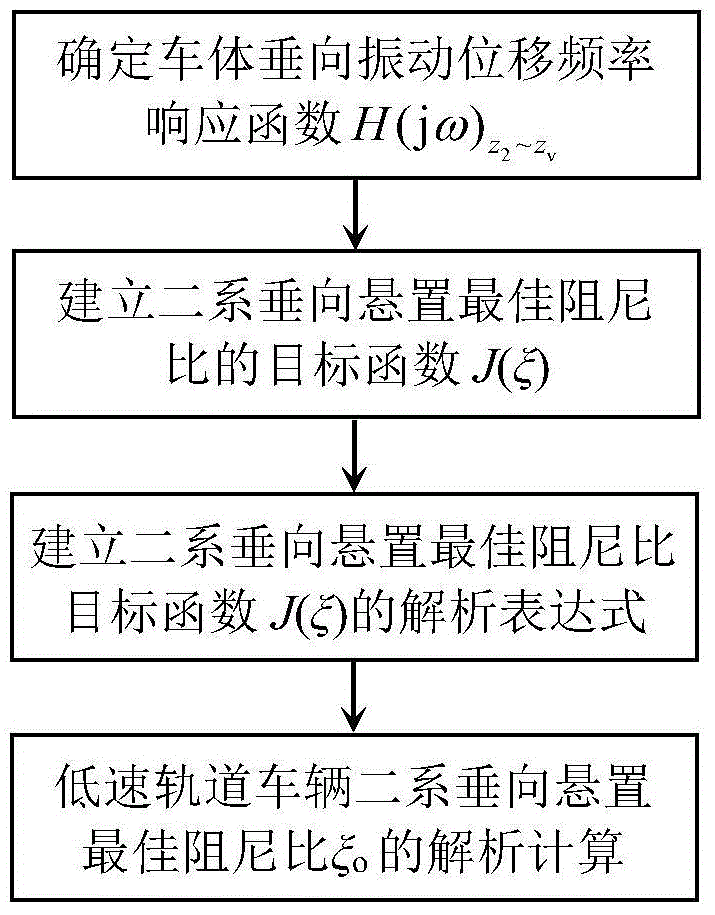

[0039] The analytical calculation method of the optimum damping ratio of the vertical mount of the low-speed rail vehicle secondary system provided by the example of the present invention, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com