Patents

Literature

177 results about "Equivalent stiffness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The equivalent stiffness for the beam is the ratio of the applied load to the deflection at the point of application of the load. The equivalent spring constants for beams with various other types of loading and/or boundary conditions can be obtained in a similar manner. Some of the more commonly encountered cases...

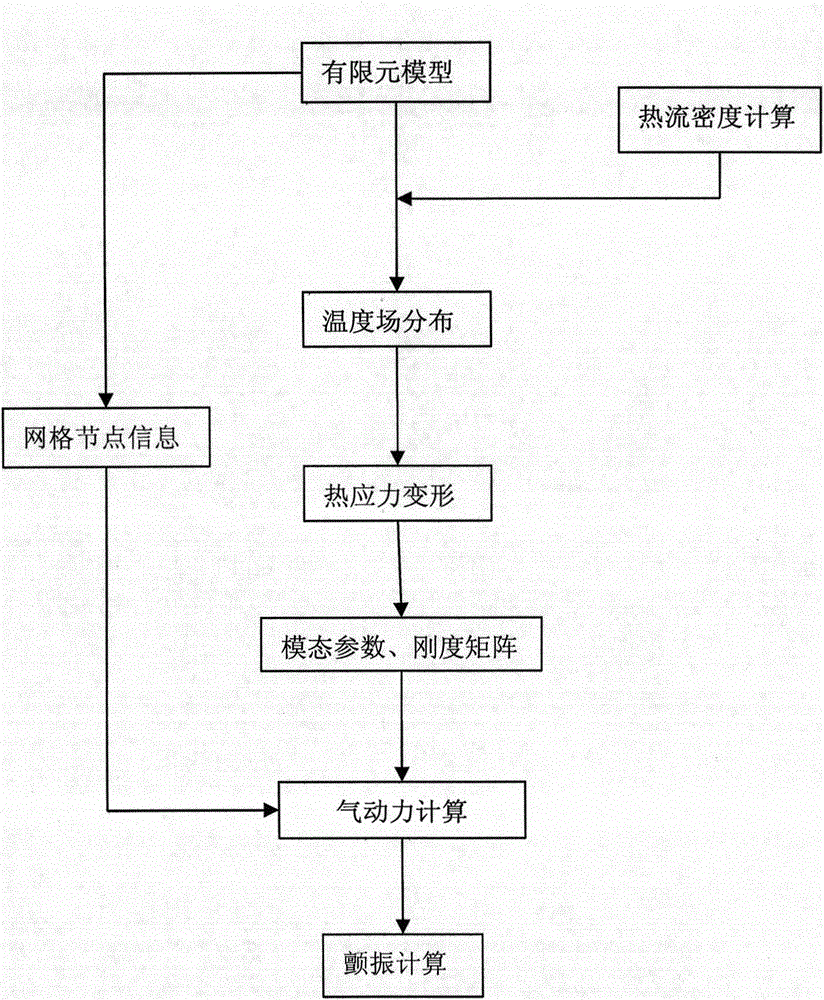

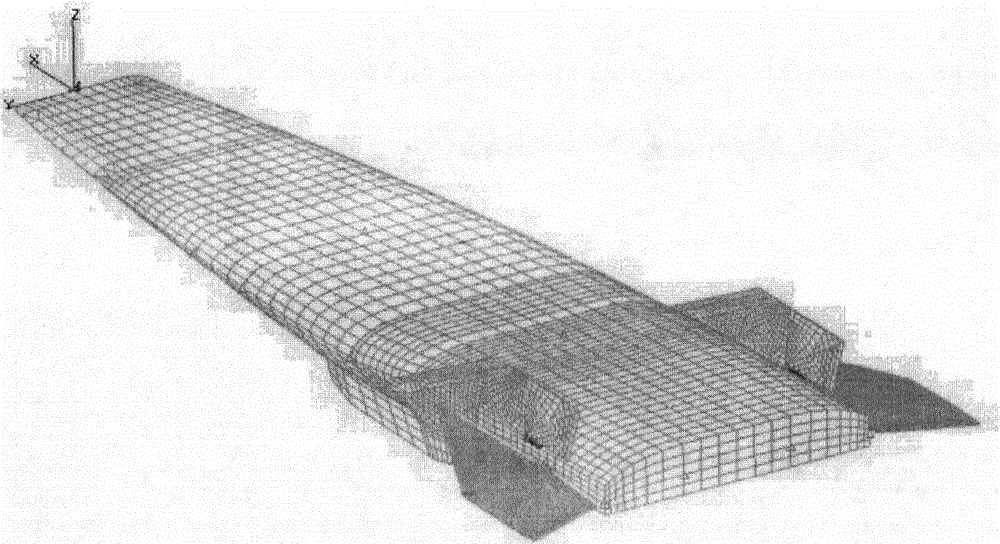

Pneumatic elastic mechanical characteristic analytical method of hypersonic speed aircraft in thermal environment

ActiveCN104133933AGuaranteed continuitySustainable transportationSpecial data processing applicationsElement modelEngineering

The invention relates to a pneumatic elastic analytical method, and provides a pneumatic elastic mechanical characteristic analytical method of a hypersonic speed aircraft in thermal environment. According to the method, the piston theory is used for carrying out frequency domain nonsteady aerodynamic calculation on a full-aircraft finite element model of the hypersonic speed aircraft; on the basis, the pneumatic thermal effect on the model in the hypersonic speed thermal environment is considered; the weak coupling effect of pneumatic thermal input in aerodynamic input and elastic force input is ignored; only the structure temperature steady-state characteristics under the pneumatic thermal load effect are considered; after the steady aerodynamic calculation, the thermal flux density on the surface of the aircraft is obtained by adopting a reference enthalpy method; further, the steady temperature distribution on the surface of the aircraft is calculated; the practical equivalent rigidity matrix of the structure at the moment is obtained; and the critical flutter speed is calculated by an engineering method. The pneumatic elastic mechanical characteristic analytical method has the advantages that the pneumatic elastic analytical problem of the hypersonic speed aircraft in the pneumatic thermal environment is solved, and the pneumatic elastic performance of the hypersonic speed aircraft is improved through flutter speed analysis.

Owner:ANHUI JINSANHUAN METAL SCI & TECH

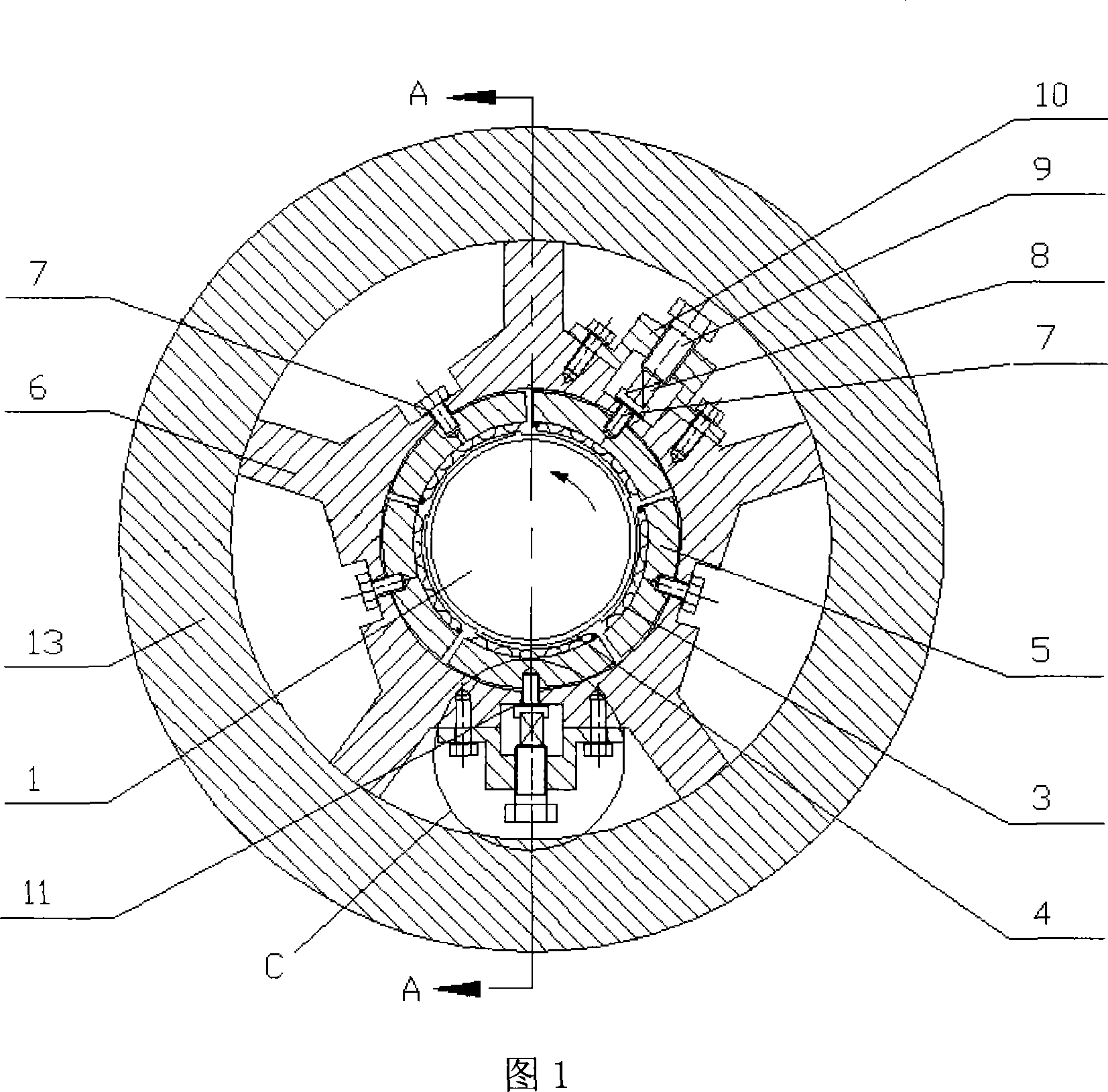

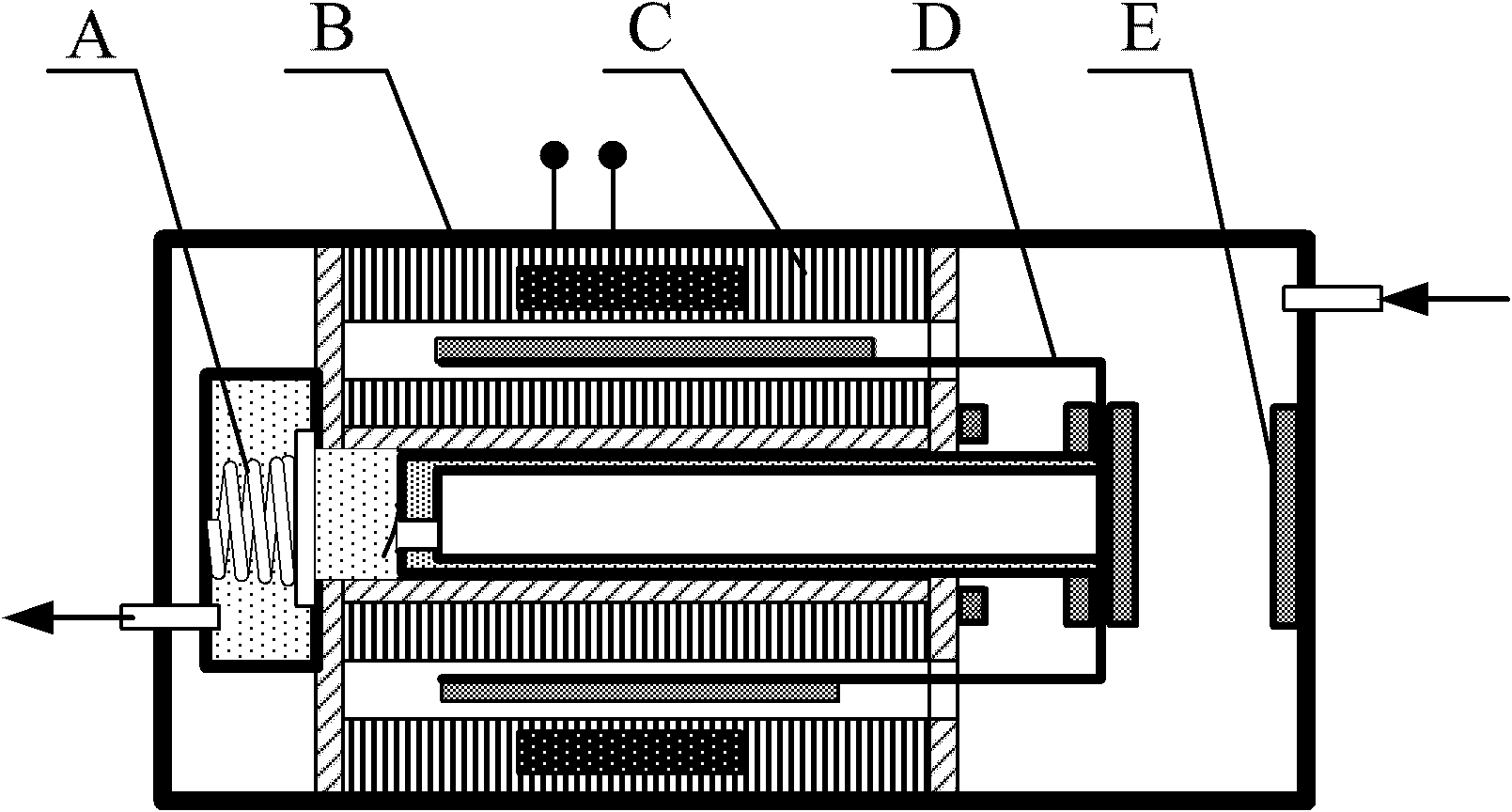

Dynamical pressure gas elasticity foil tablet bearing with stability self-adaptive control function

InactiveCN101225853ARealize micro-displacement control requirementsImprove displacement control accuracyNon-rotating vibration suppressionBearingsDisplacement controlEngineering

The invention relates to a dynamic gas elastic foil bearing with stability and adaptive control functions, comprising a bearing casing, a plurality of bearing pads, an elastic foil, and a piezoelectric ceramics micro displacement actuator. The dynamic gas elastic foil bearing is characterized in that the bearing pads are uniformly distributed along the inner wall of the bearing casing; the bearing pads are welded with a bottom bump foil and one end of a top foil; the other end of the top foil is lapped over an adjacent top foil, wherein the piezoelectric ceramics micro displacement actuator with one end fixed on a set screw and the other end arranged on a jig is connected with two bearing pads; the piezoelectric ceramics micro displacement actuator is connected with a feedback controller PID; an input of the feedback controller PID is connected with an eddy current displacement sensor. The dynamic gas elastic foil bearing with stability and adaptive control functions has the advantages of strengthened equivalent rigidity and equivalent damping of the elastic foil, restrained vibration of rotor system, improved bearing capacity and stability of the bearing, reduced size and structure, increased control precision of displacement, and quickened response speed.

Owner:XI AN JIAOTONG UNIV

Full-section pre-reinforcing construction method for tunnel free-machining anchor bar

InactiveCN101487393AGood deformation propertiesConstruction method safetyUnderground chambersTunnel liningGlass fiberFiber

The invention discloses a tunnel easy-cutting anchor-rod full-section pre-consolidation construction method, comprising the following steps: firstly, survey design before construction is carried out, pre-consolidation is carried out to a face core body to be excavated by adopting an easy-cutting anchor rod according to the sampling analysis and classification of rock-soil, meanwhile, a measuring instrument is installed to monitor the change thereof, and then full-section excavation is carried out. The construction method takes the problem of how to deal with the 'core body to be excavated' in front of the face as the key for controlling the integral stability of the tunnel, an easy-cutting glass fiber anchor rod which is pre-consolidated along tunnel vertical full-section is used for improving the equivalent stiffness of the 'core body to be excavated' and controlling the deformation of the 'core body to be excavated' so as to cause arching effect around the tunnel to function naturally, thus guaranteeing the full-section, safe and quick excavation and drivage of the tunnel. The construction method is safe and reliable, can realize tunnel full-section mechanized and modernized construction, and has good production efficiency, continuous and stable construction progress, and controllable project cost.

Owner:中铁西南科学研究院有限公司

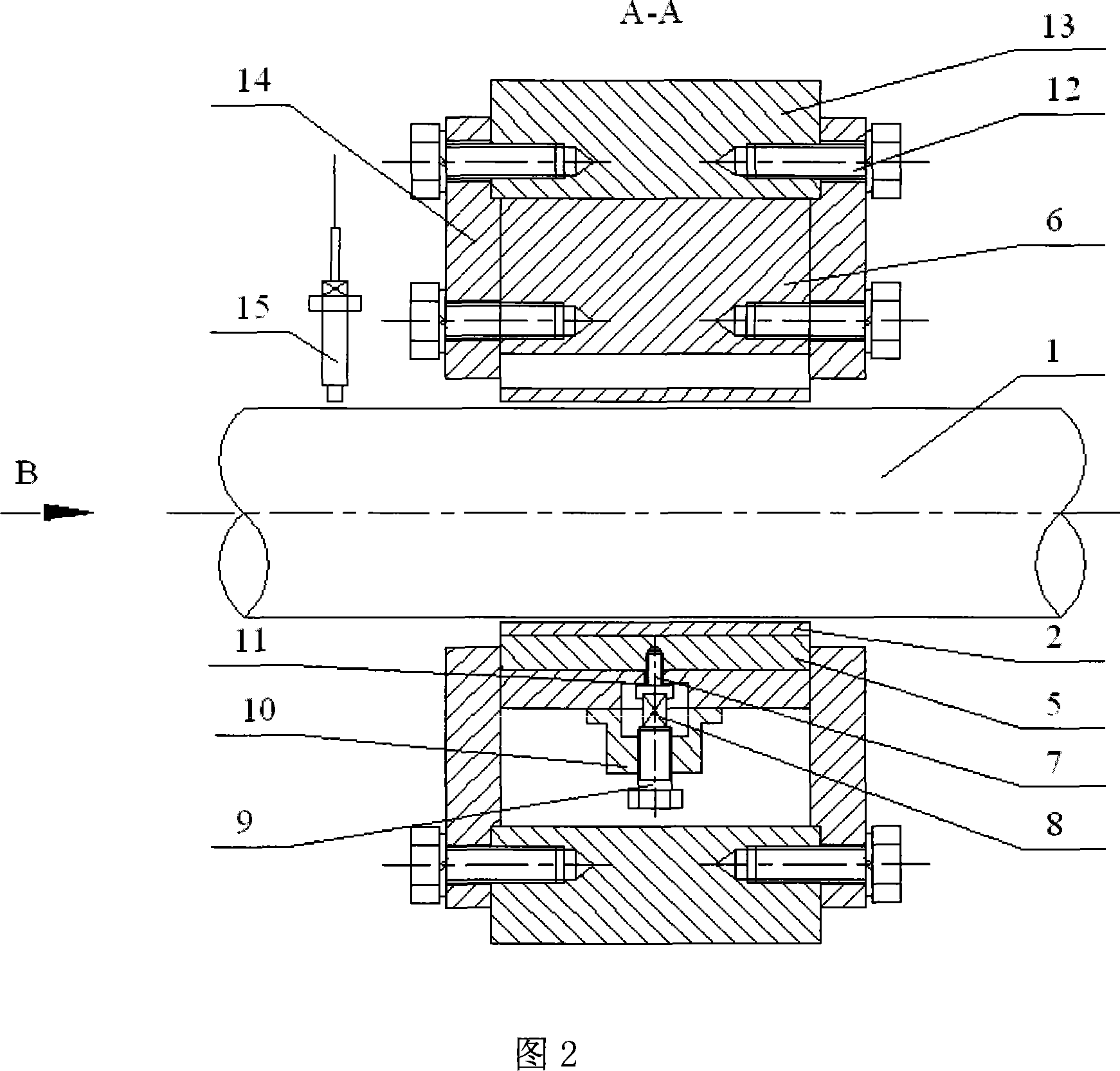

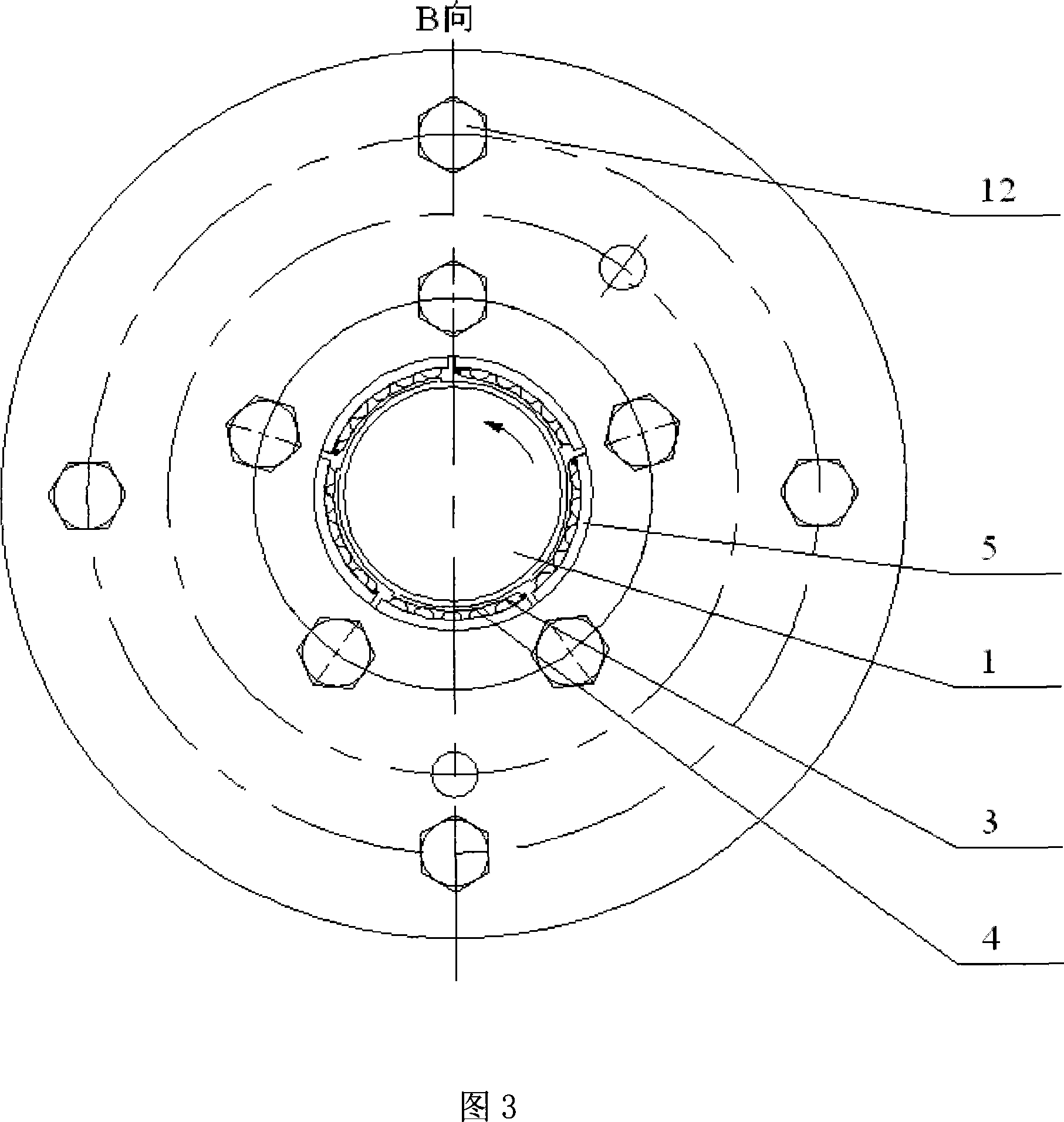

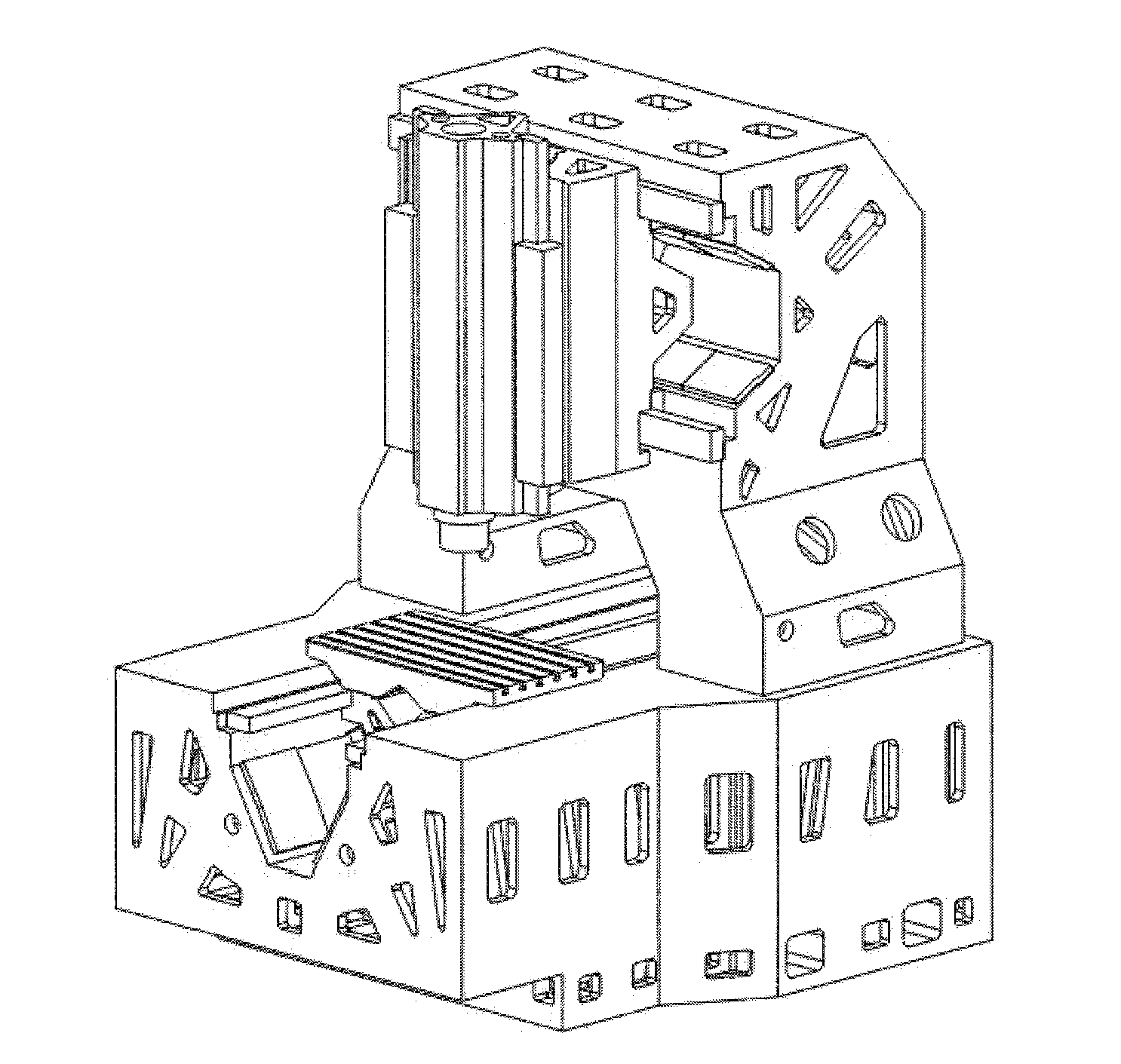

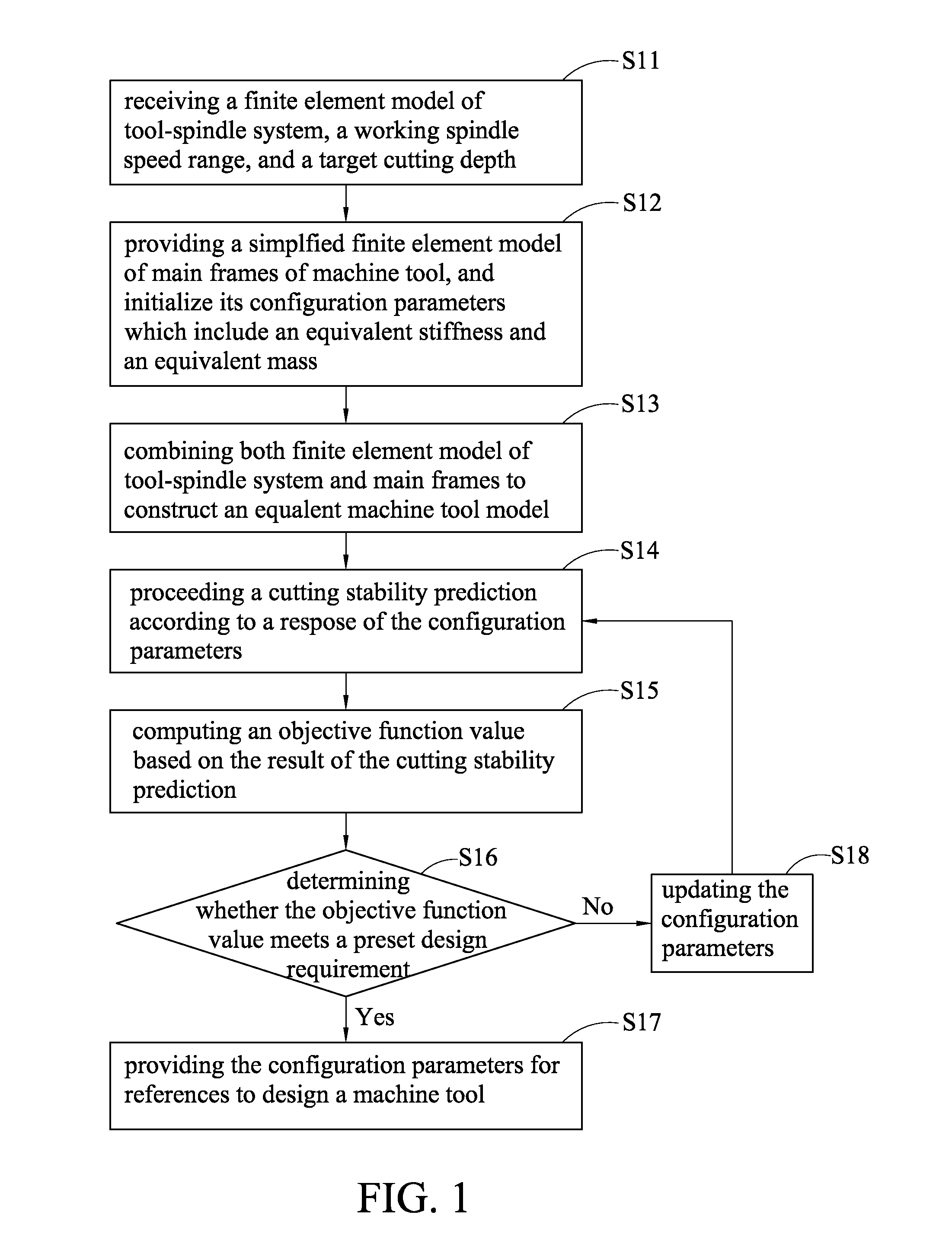

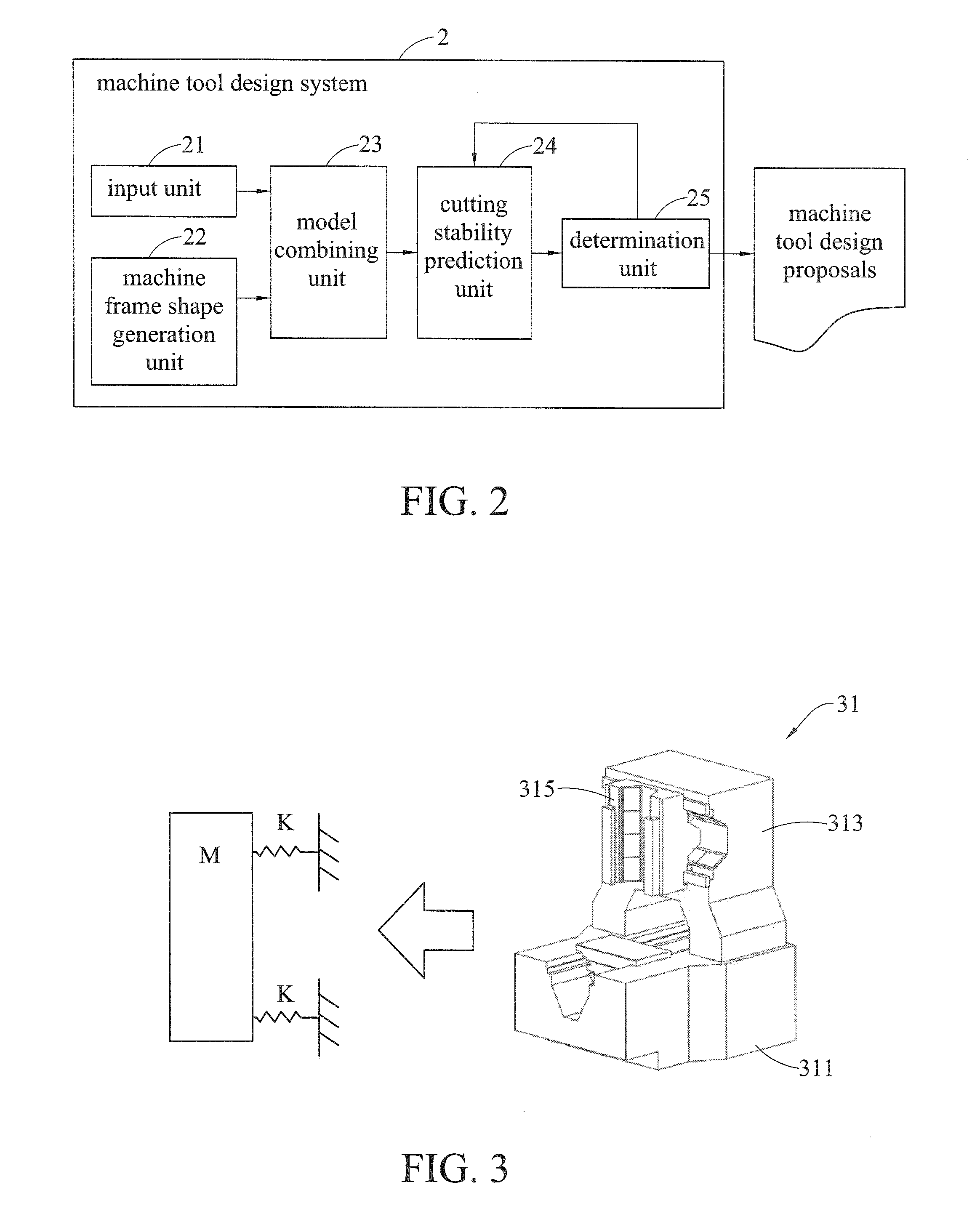

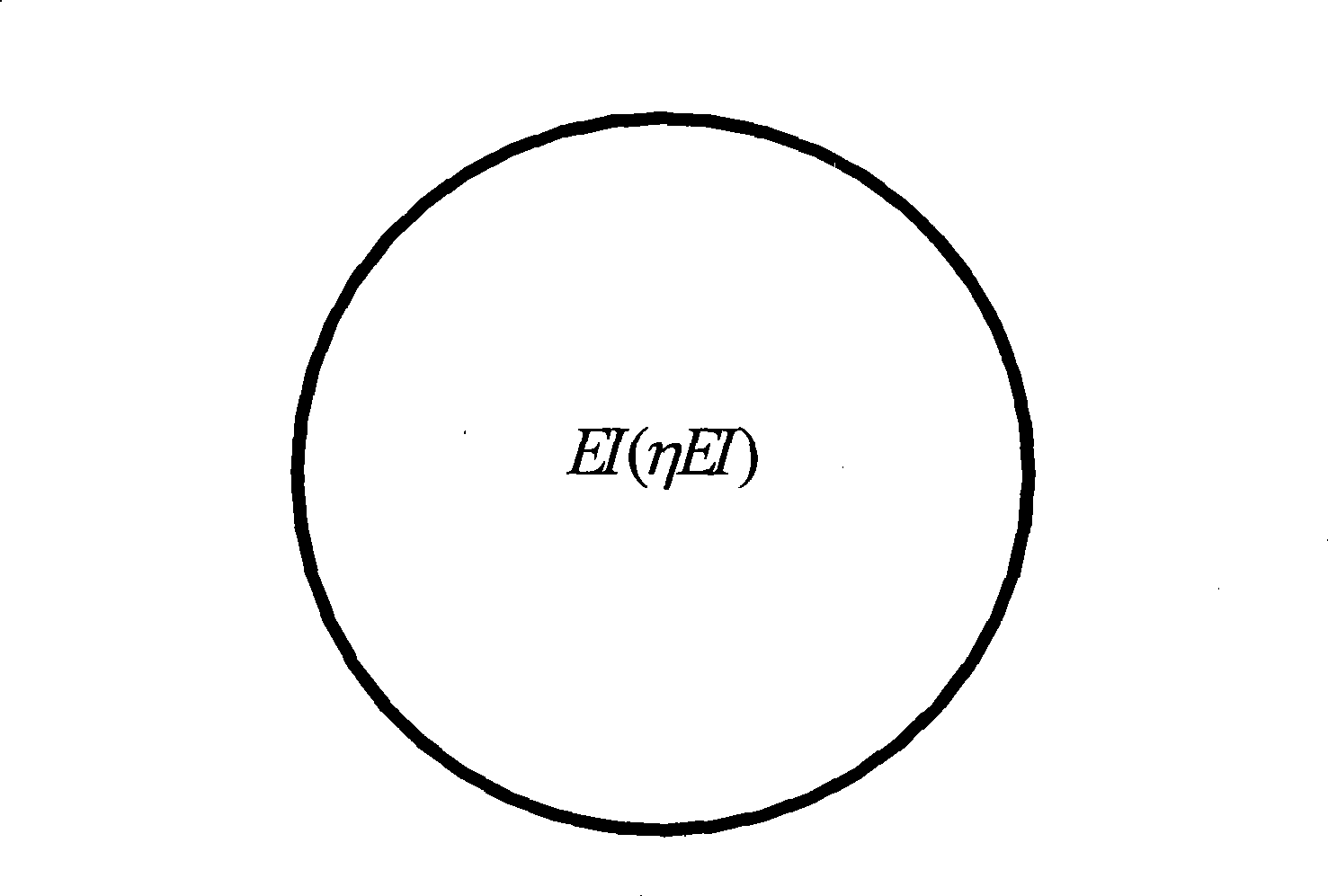

Machine tool design method and machine tool design system

InactiveUS20150294034A1Reduce the burden onRapid designGeometric CADDesign optimisation/simulationElement modelEquivalent stiffness

A machine tool design method includes: receiving a finite element model of tool-spindle system including a cutting tool, a working spindle speed range, and a target cutting depth; providing a simplified finite element model of main frames of machine tool and initializing its configuration parameters including an equivalent stiffness and an equivalent mass; combining the simplified finite element model of main frames of machine tool with the finite element model of tool-spindle system to construct an equivalent machine tool model; according to a response of the configuration parameters, proceeding a cutting stability prediction of the equivalent machine tool model, and computing an objective function value based on a predicted result; and determining whether the objective function value meets a preset design requirement, if yes, employing the configuration parameters to be references to design a machine tool, if not, updating the configuration parameters and proceeding the cutting stability prediction again.

Owner:IND TECH RES INST

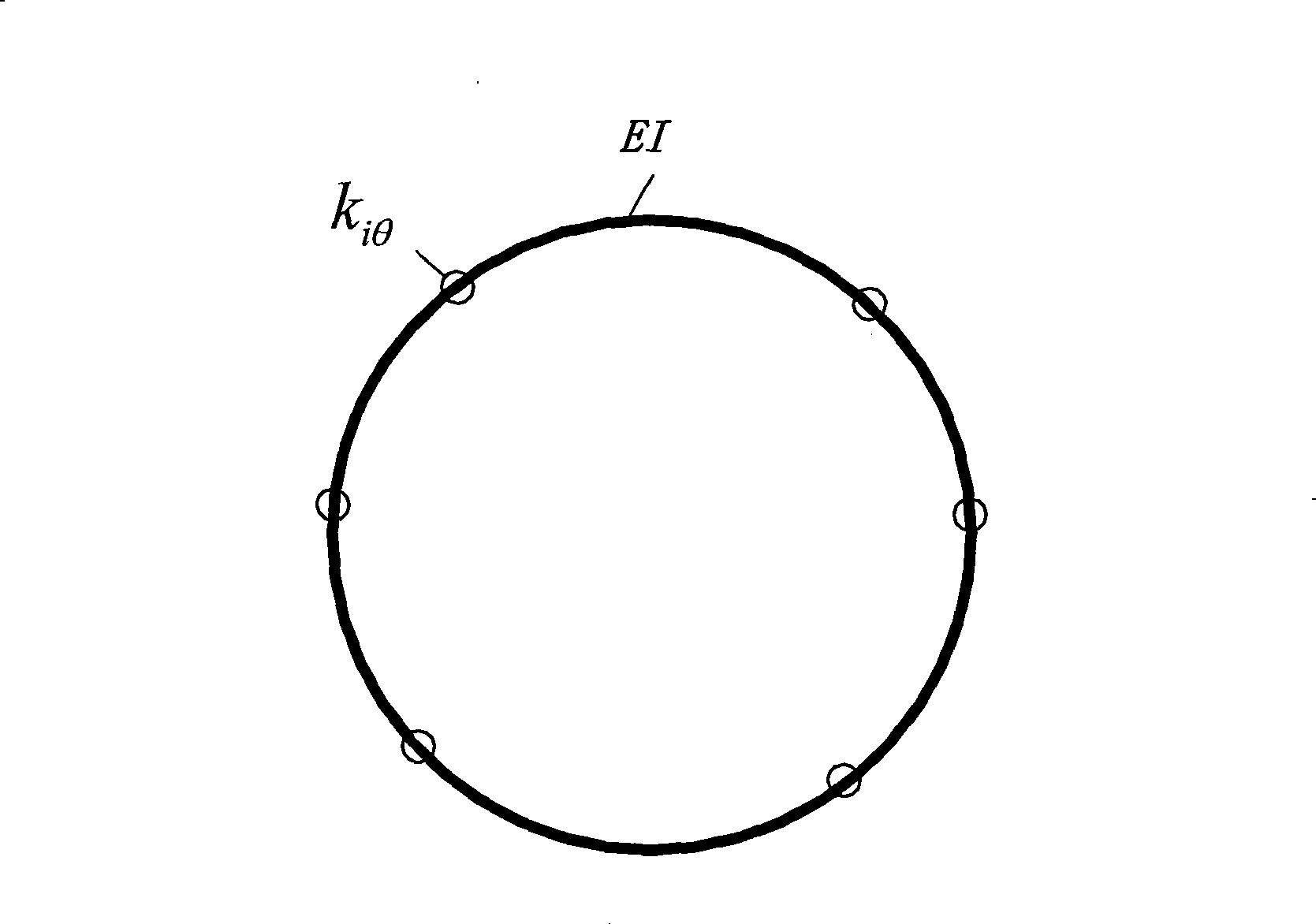

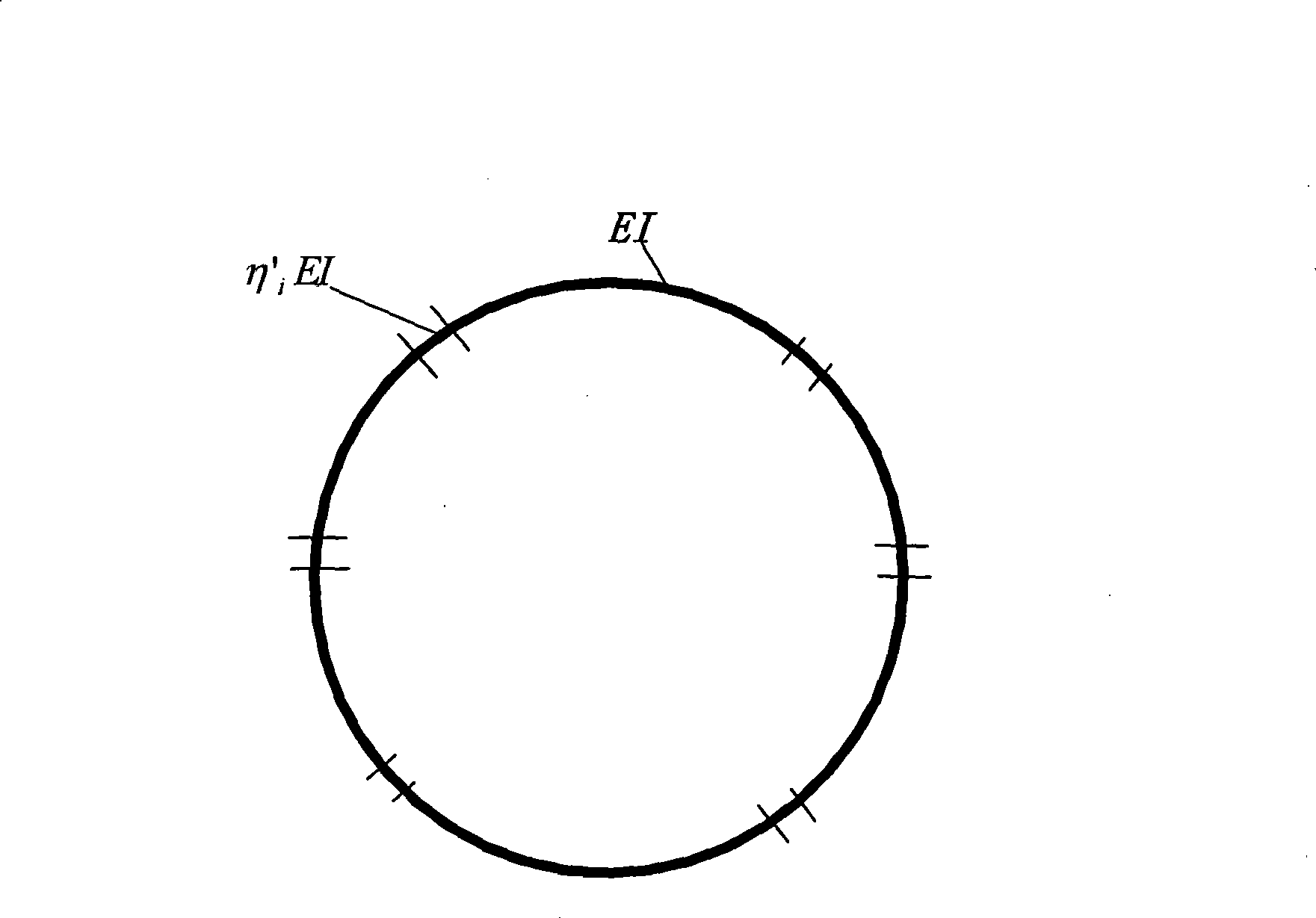

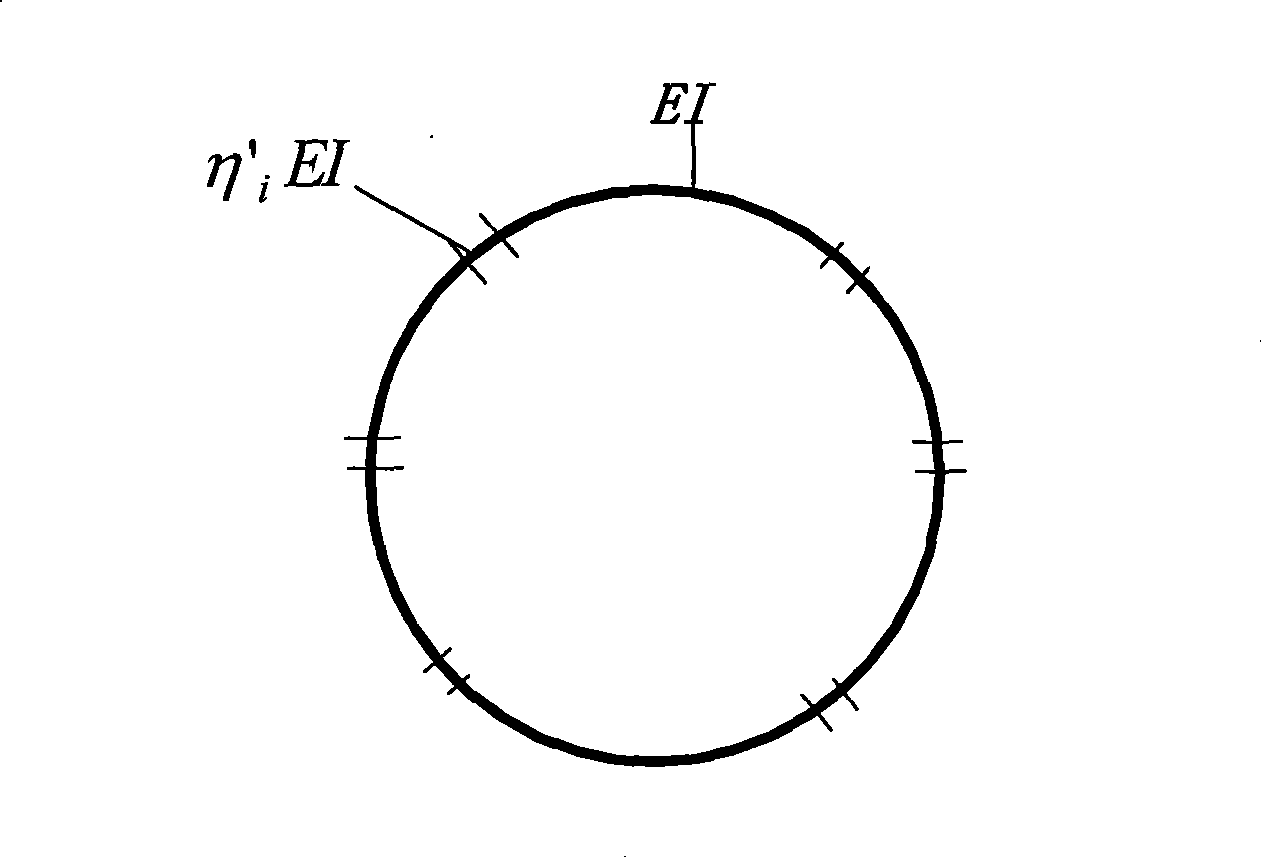

Structural computation method of shield tunnel liner continuous and nonuniform stiffness model

InactiveCN101364241AAvoid uncertaintyWell formedSpecial data processing applicationsEquivalent stiffnessEngineering

The invention discloses a shield tunnel lining continuous / non-uniform stiffness model structural calculation method, which comprises the following steps: at first, calculating a load according to the conventional method and preliminarily calculating a structural internal force, and then working out an equivalent stiffness coefficient in a joint area, finally, determining a structural stratigraphic resistance load; and determining a shield tunnel lining continuous / non-uniform stiffness model, and then applying the stratigraphic resistance load and other loads onto the determined continuous / non-uniform stiffness model, calculating the structural internal force and deformation; then, acquiring the stratigraphic resistance load with interative computation according to the computed deformation, until the last and present results are sufficiently close to each other; acquiring the equivalent stiffness in all the joint areas with interative computation according to the internal force at the joint, until the last and present results are sufficiently close to each other, finally, outputting the internal force and deformation computation results. The model structural calculation method adopts a computation model closer to reality. Therefore, the calculated result is more exact.

Owner:TONGJI UNIV

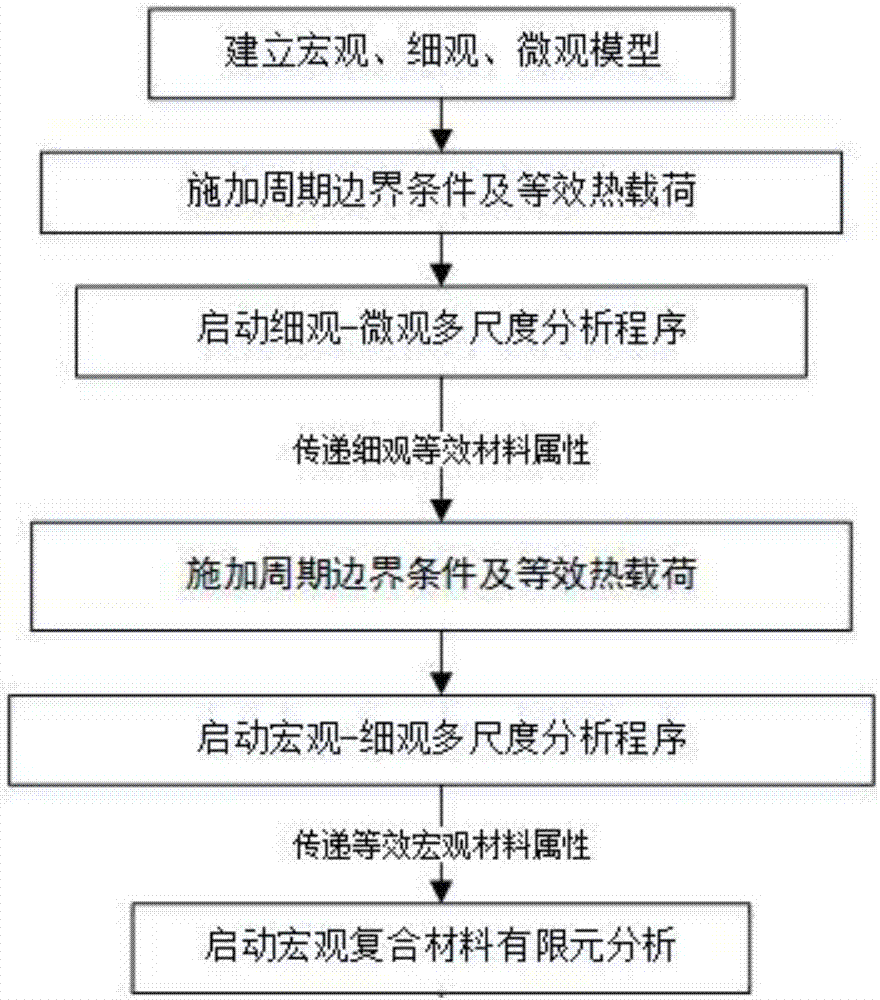

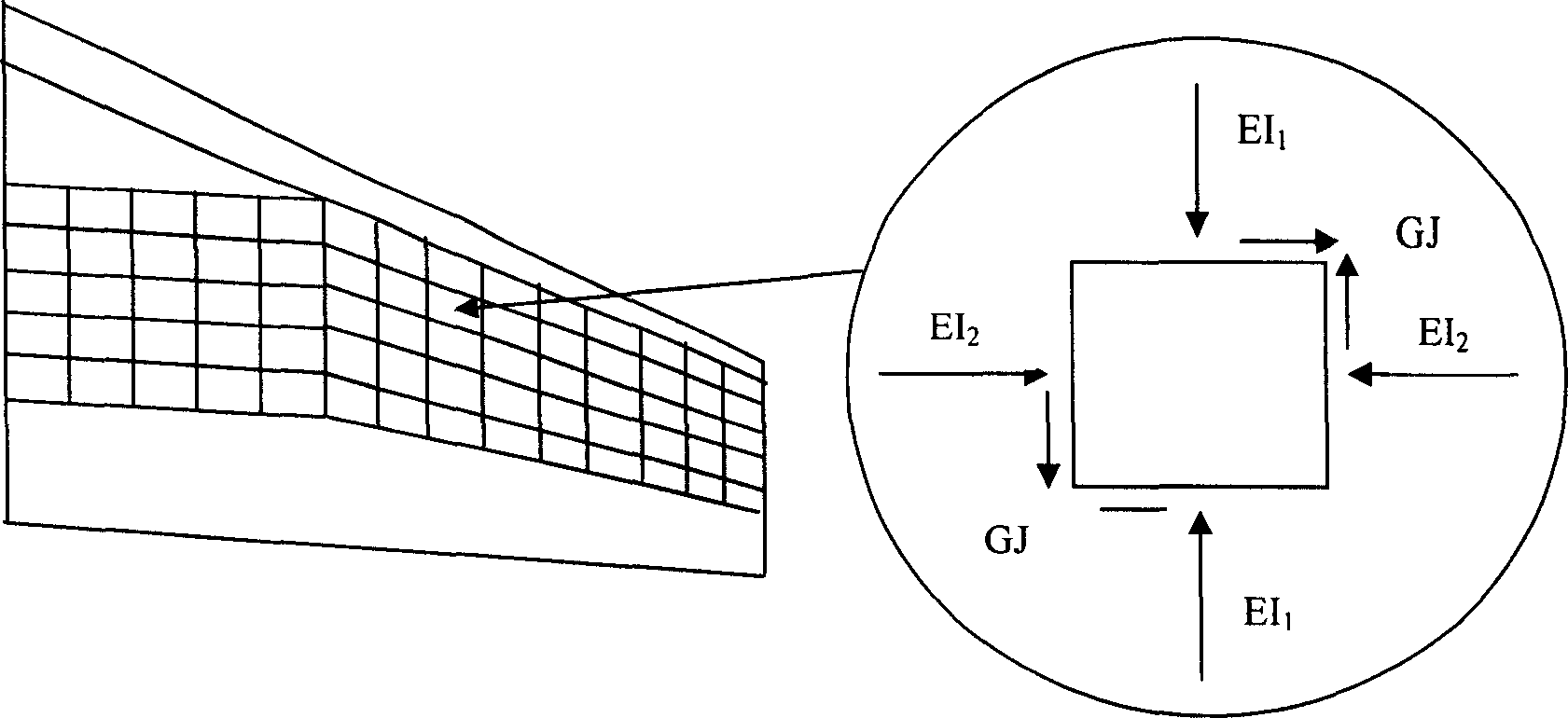

Method for multiscale calculation of equivalent stiffness matrixes of complex composite material structures

InactiveCN107451307AGood precisionIdentify the damage mechanismGeometric CADDesign optimisation/simulationScale modelStructure analysis

The invention discloses a method for multiscale calculation of equivalent stiffness matrixes of complex composite material structures. The method comprises the following steps of: separating a macro-meso-micro three-scale structure by adoption of a scale separation method, and respectively establishing each scale analysis model according to geometric features of different scale models; and converting a three-scale problem into two multiscale problems: a macro-meso multiscale problem and a meso-micro multiscale problem, analyzing the two multiscale problems in sequence, and finally returning an equivalent modulus obtained by a micro multiscale problem to a macro multiscale problem. According to the method, the disadvantages such as low calculation efficiency and bad precision of the traditional structure analysis are overcome and the efficiency and precision of predicting performance of composite material structures are effectively enhanced; and the method can be used for instructing the work such as production, research and development of composite materials. The method can be applied to design and analysis of complex composite material structures in the field of aerospace, and can be applied to thermal and mechanical analysis problems of structure design in the engineering field of other composite materials.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

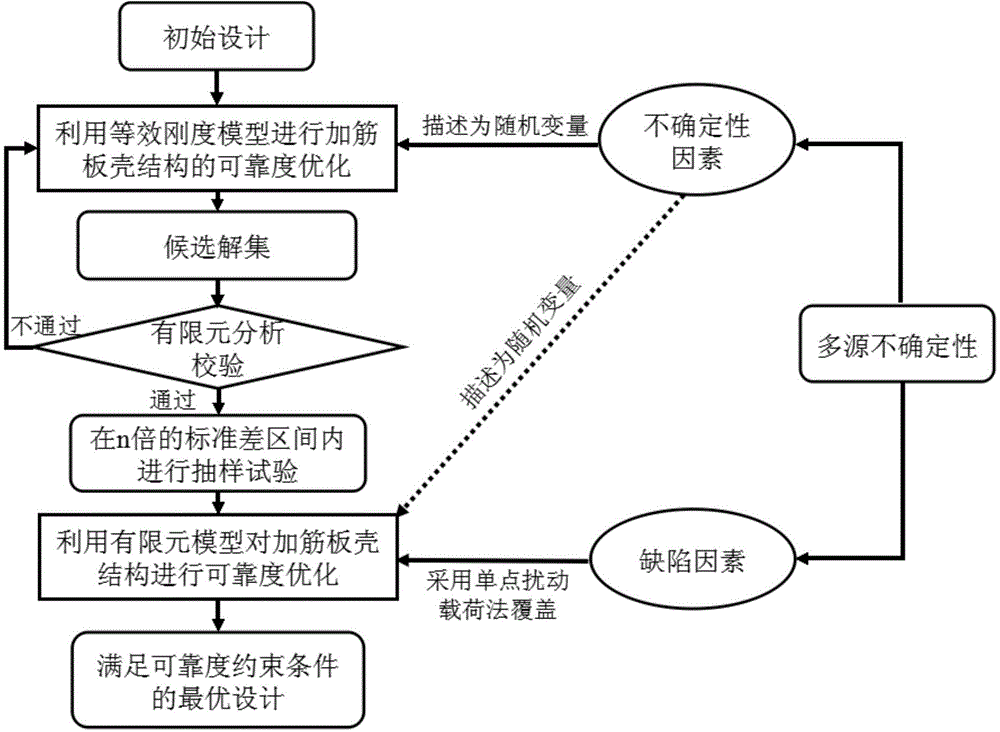

Stiffened plate shell structure reliability optimization method with multisource uncertainty being considered

ActiveCN104484531AImprove reliabilityMake up for the disadvantages of not being able to consider the impact of defectsSpecial data processing applicationsElement modelElement analysis

The invention relates to the technical field of optimization design and provides a stiffened plate shell structure reliability optimization method with the multisource uncertainty being considered. The stiffened plate shell structure reliability optimization method with the multisource uncertainty being considered comprises the following steps of performing reliability optimization on a stiffened plate shell structure by utilizing an equivalent stiffness model; performing finite element analysis validation on every elite individual in a candidate solution set, wherein the finite element analysis validation comprises performing nonlinear post-buckling analysis on the stiffened plate shell structure comprising defects by utilizing a single-point disturbing load method with defect factors being considered to screen out the elite individuals satisfying a reliability constraint condition; performing the reliability optimization on the stiffened plate shell structure by utilizing a finite element model. The stiffened plate shell structure reliability optimization method with the multisource uncertainty being considered can improve the reliability optimization efficiency of the stiffened plate shell structure and reduce calculation costs.

Owner:DALIAN UNIV OF TECH

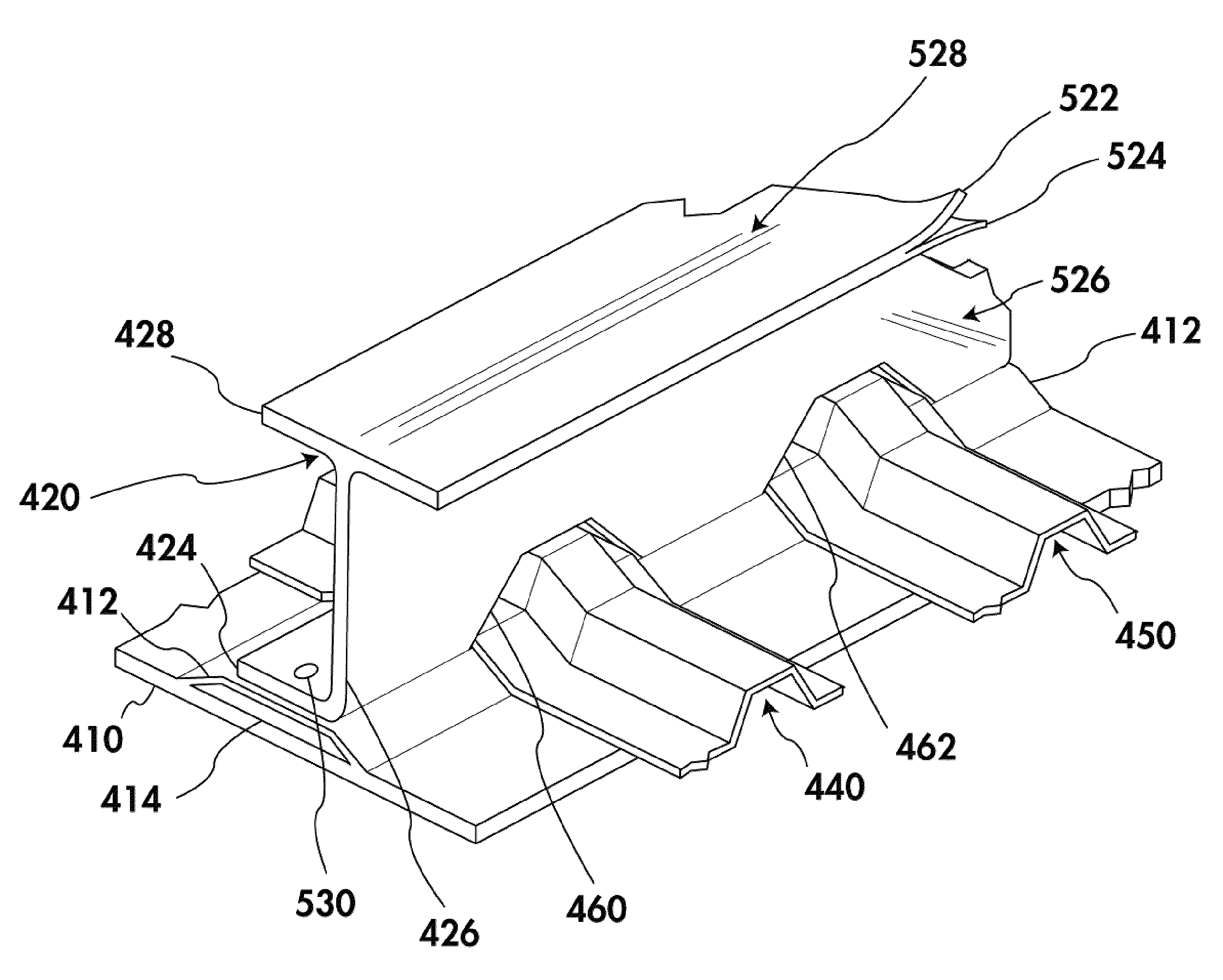

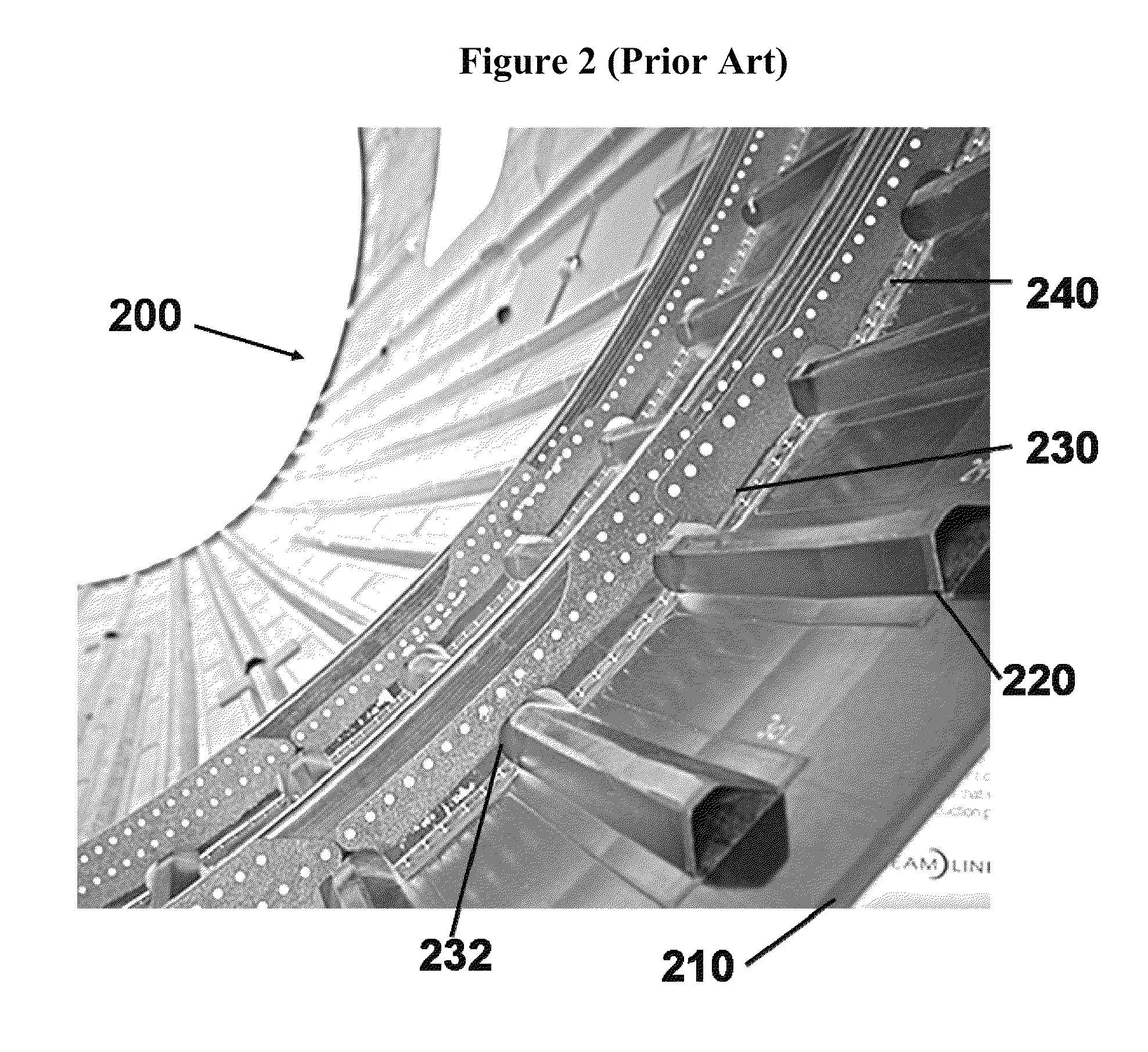

Composite bulkhead and skin construction

ActiveUS8490920B2Thickened area of the skinIncrease stiffnessFuselage framesEfficient propulsion technologiesEquivalent stiffnessEngineering

Owner:KAREM ABE

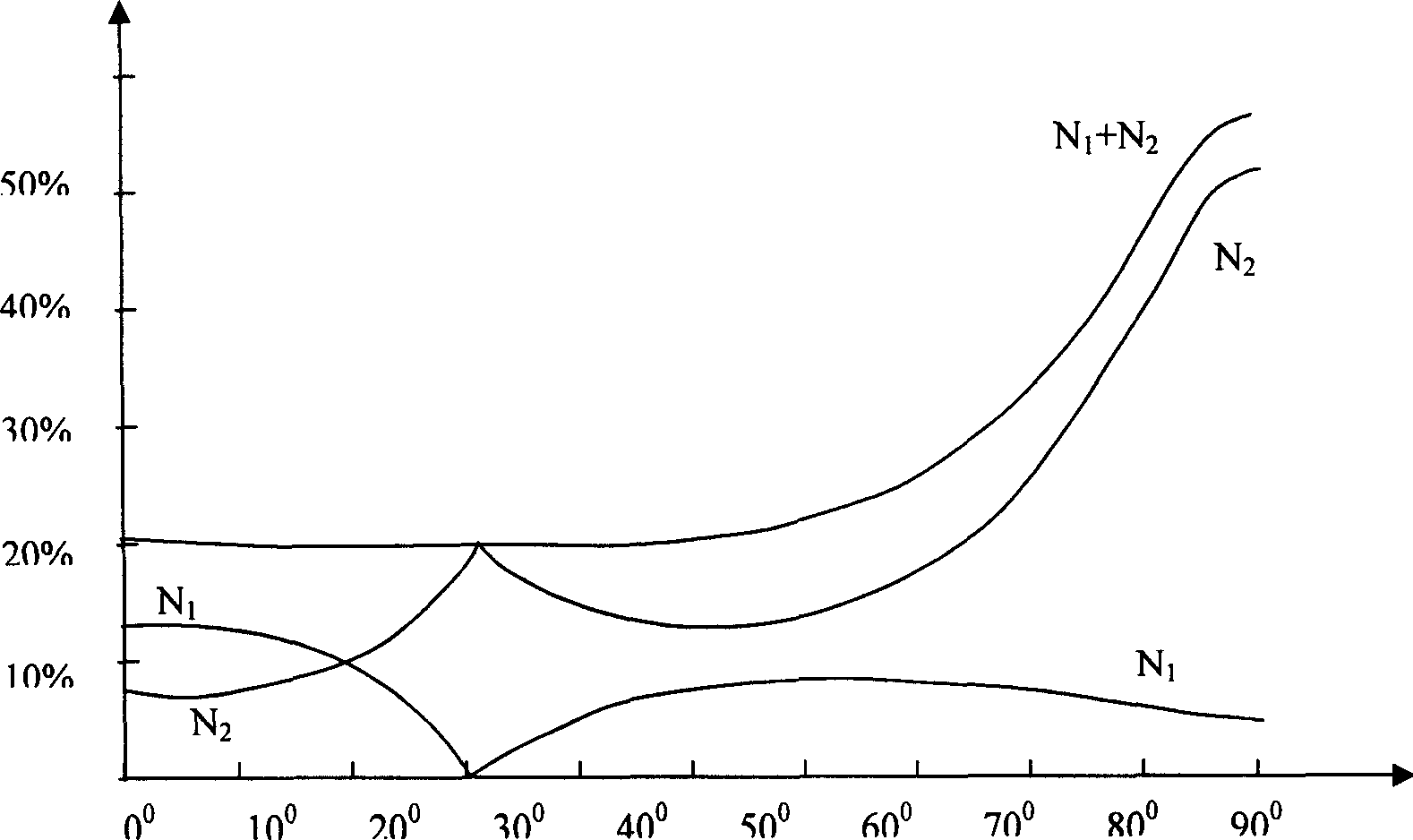

Layer spreading design calculating method of composite material according to rigidity requirement

A design calculation method based on the rigidity requirement for laminated composite material, such as the vertical tail fin of airplane features that when the relative angle between layers of a laminated plate with equal rigidity in three directions is changed, its thickness or weight characteristic is not changed, and the relation between the rigidity in three directions and the relative weight is used in the aerodynamic elasticity calculation to replace complex calculation model.

Owner:BEIHANG UNIV

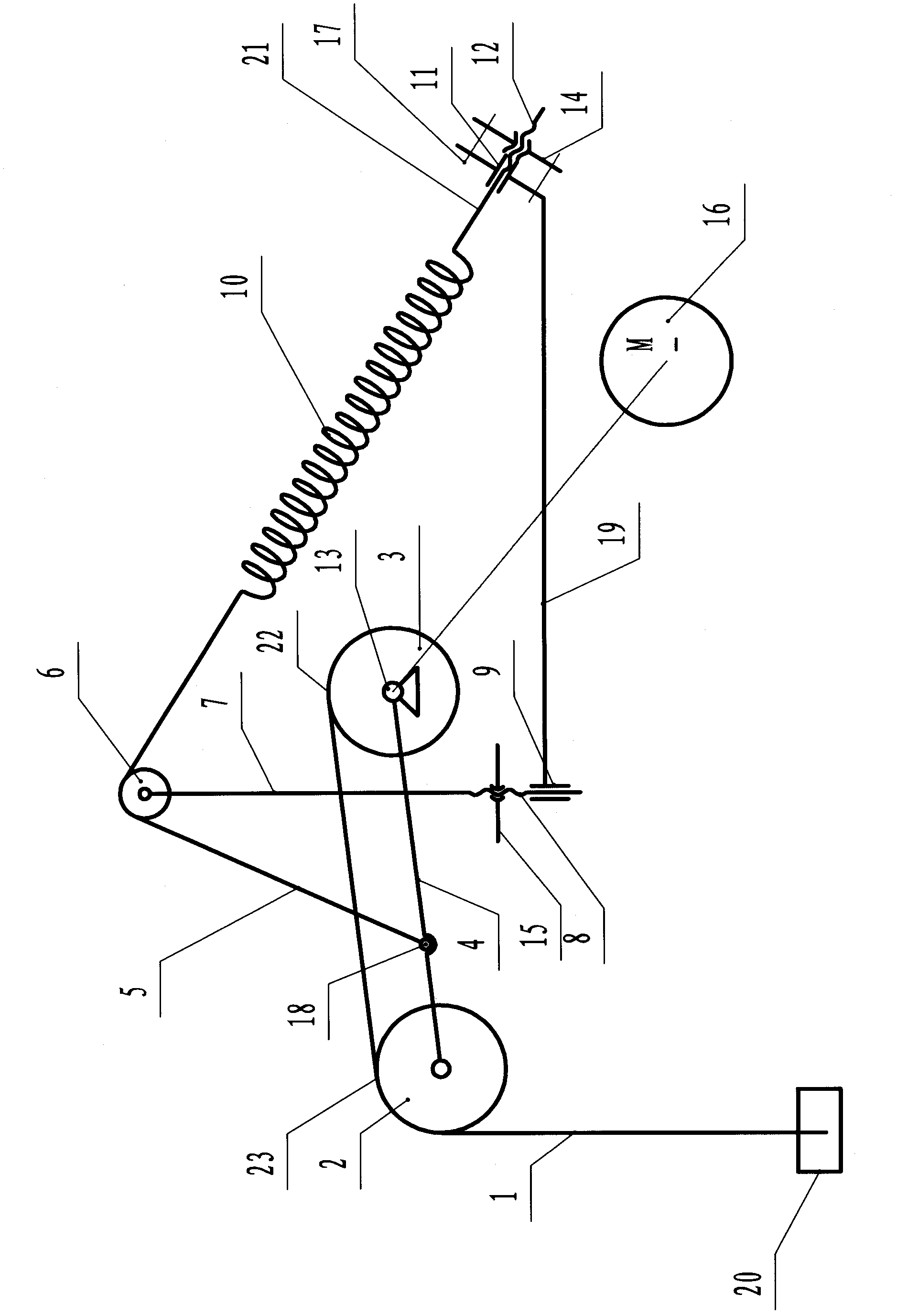

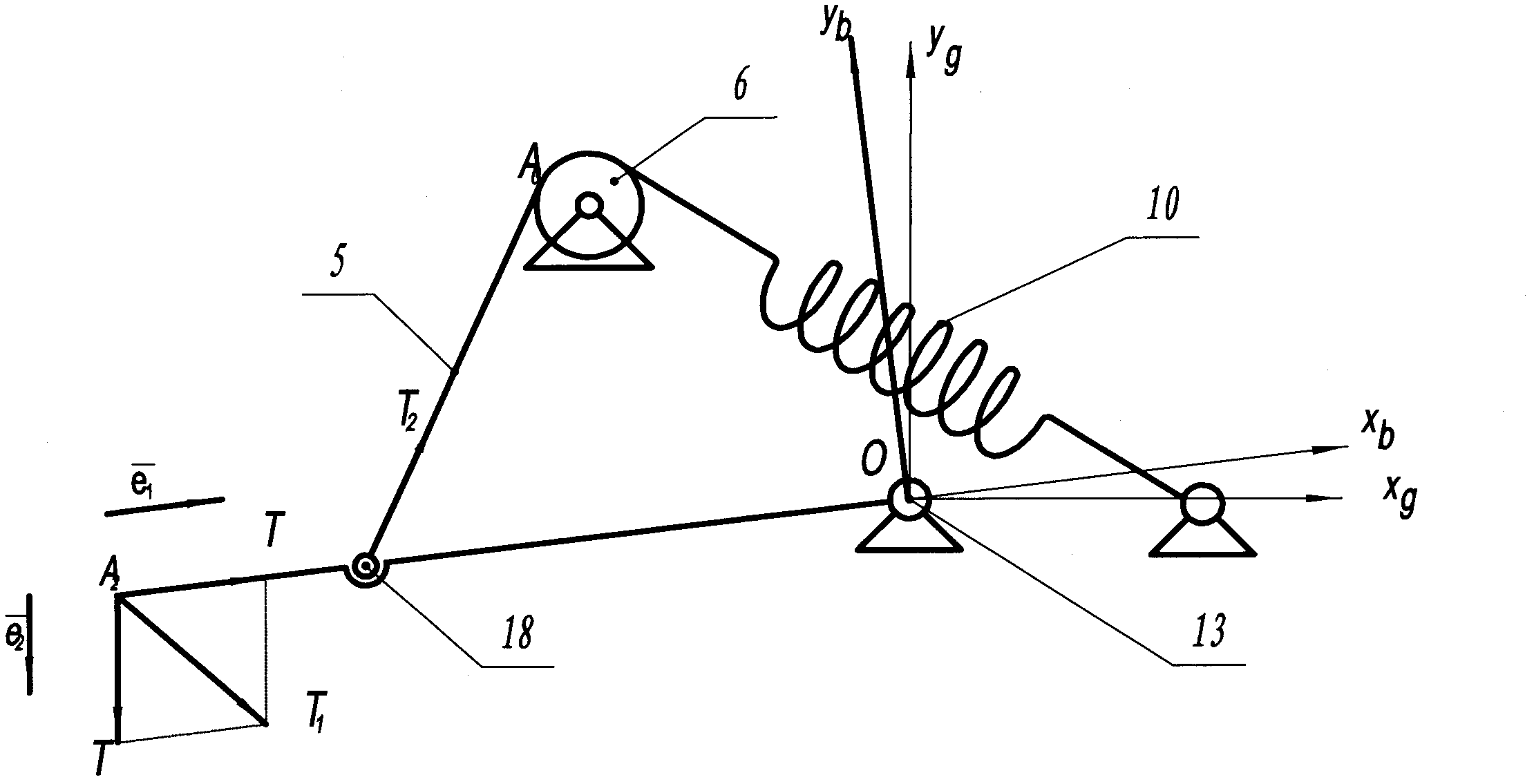

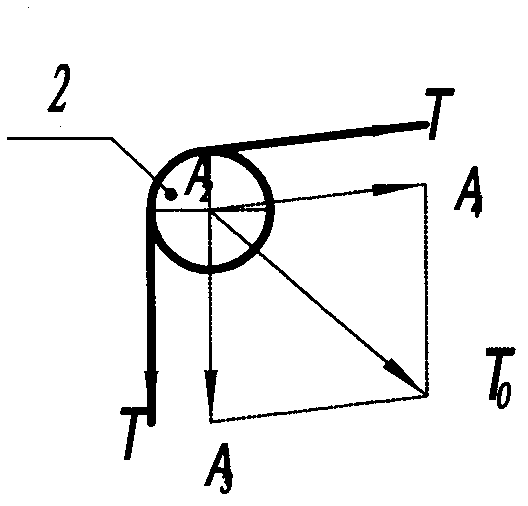

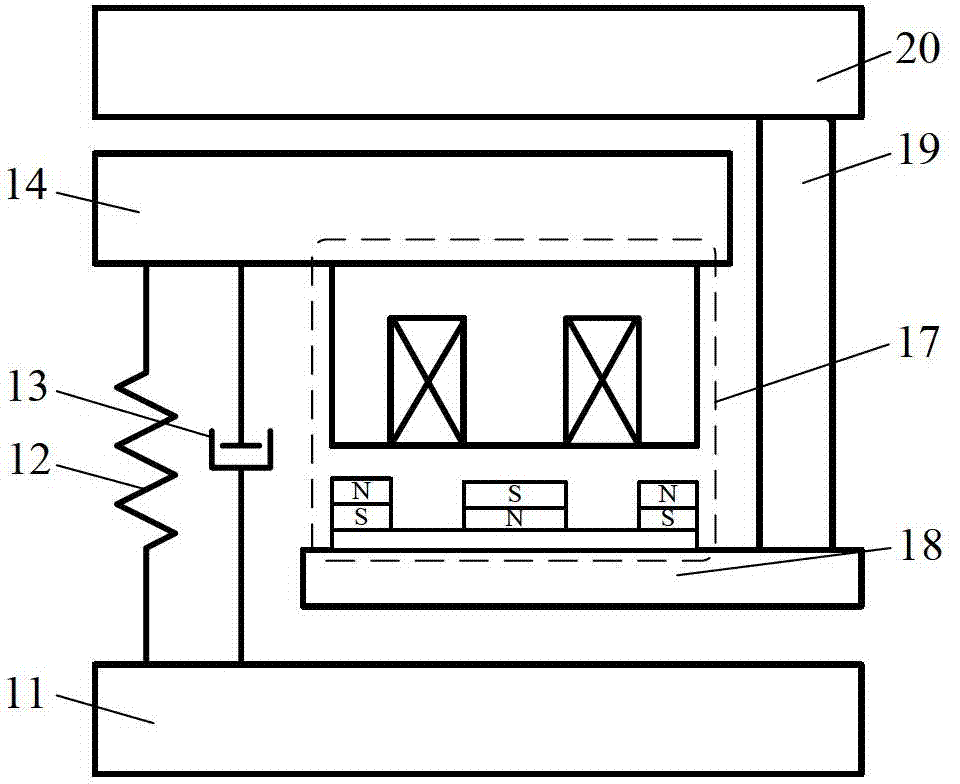

Sling-type low-gravity simulation tension control buffer mechanism and adjustment method

InactiveCN102862688ARobustEffect of equivalent elastic coefficientCosmonautic condition simulationsStructural/machines measurementPull forceEquivalent stiffness

The invention relates to a sling-type low-gravity simulation tension control buffer mechanism and an adjustment method, wherein one end of a swing rod is connected with an axle center of a balance wheel and the other end of the swing rod is connected with an axle center of a winding drum; one end of a sling is wound on the winding drum and the other end of the sling passes through a wheel groove of the balance wheel to be connected with a work piece, of which the tension needs to be controlled; the winding drum and a motor shaft of a torque motor are coaxially installed and the balance wheel can swing around the motor shaft; the radius of the balance wheel is the same with that of the winding drum; a section, between a line outlet point on the winding drum and a line inlet point on the balance wheel, of the sling is parallel to the axis of the balance wheel; a hinge point on the swing rod is connected with one end of a steel wire rope and the other end of the steel wire rope passes through a rope sheave located above the swing rod to be connected with one end of a tension spring; the other end of the tension spring and the lower end of a rope sheave upper seat are separately connected with a support seat; and the rope sheave is installed on the upper end of the rope sheave upper seat. The suspension-type low-gravity simulation tension control buffer mechanism and the adjustment method of the invention are an important part of a constant tension control subsystem and can be used to obtain low equivalent stiffness near a large tension working point in a large range of buffering movement.

Owner:HARBIN INST OF TECH

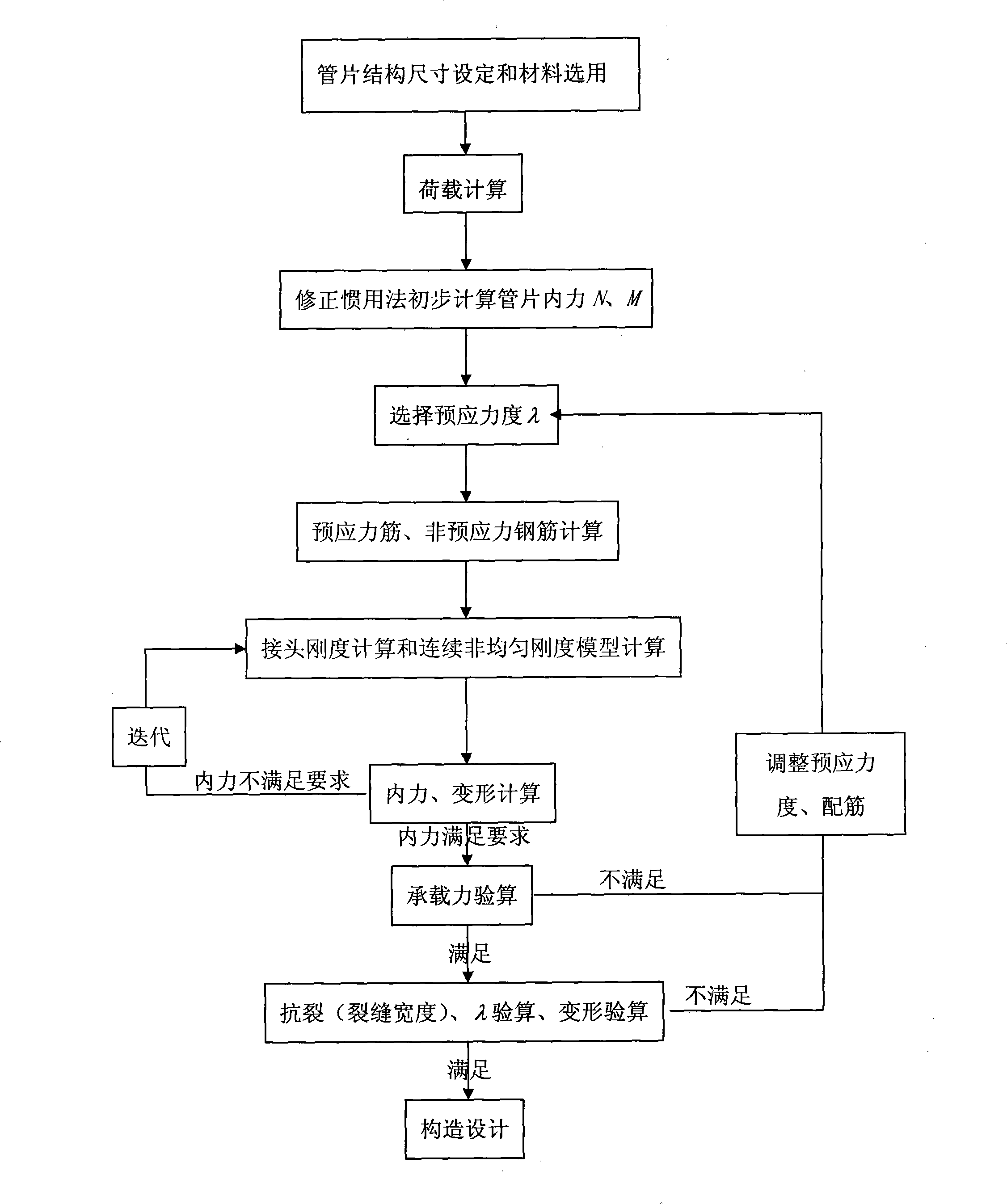

Pre-stress lining design method for shield tunnel

InactiveCN101363323ASimple design methodIn line with design habitsUnderground chambersTunnel liningCarrying capacityCrack resistance

The present invention discloses a method for designing a shield tunnel prestressed liner. Firstly, the steps of setting duct piece structure and size, selecting material, calculating load and calculating the structure internal force primarily are taken. According to the requirement of a liner structure, the prestressed liner type and prestressing strength are confirmed. A stressed reinforcement and a non-prestressed reinforcement are confirmed. Joints are calculated, and continuous uneven rigidity calculation model is confirmed. Prestressing force equivalent load is calculated and is applied to the calculation model together with the load calculated primarily to get the inner force and the distortion of the structure. The equivalent rigidity of a joint area is calculated and compared with the prior result, if the difference is not large, the subsequent calculation is processed; otherwise iterative computation is required to be processed. The calculation of the carrying capacity of the structure is checked, if the requirement is not met, the prestressing strength and reinforcement assembly are required to be adjusted, and the prestressing strength is selected again and calculated. If the carrying capacity meets the requirement, the calculation of crack resistance and crack width and the calculation of deformation are checked, and the relative component design is carried out finally.

Owner:TONGJI UNIV

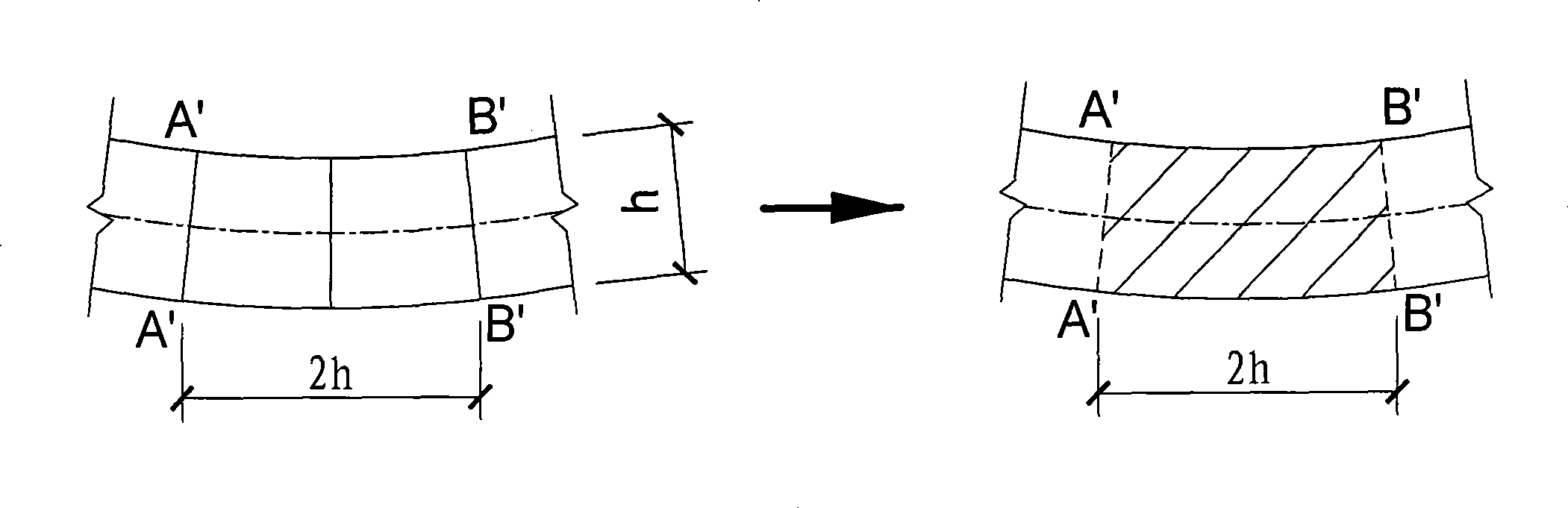

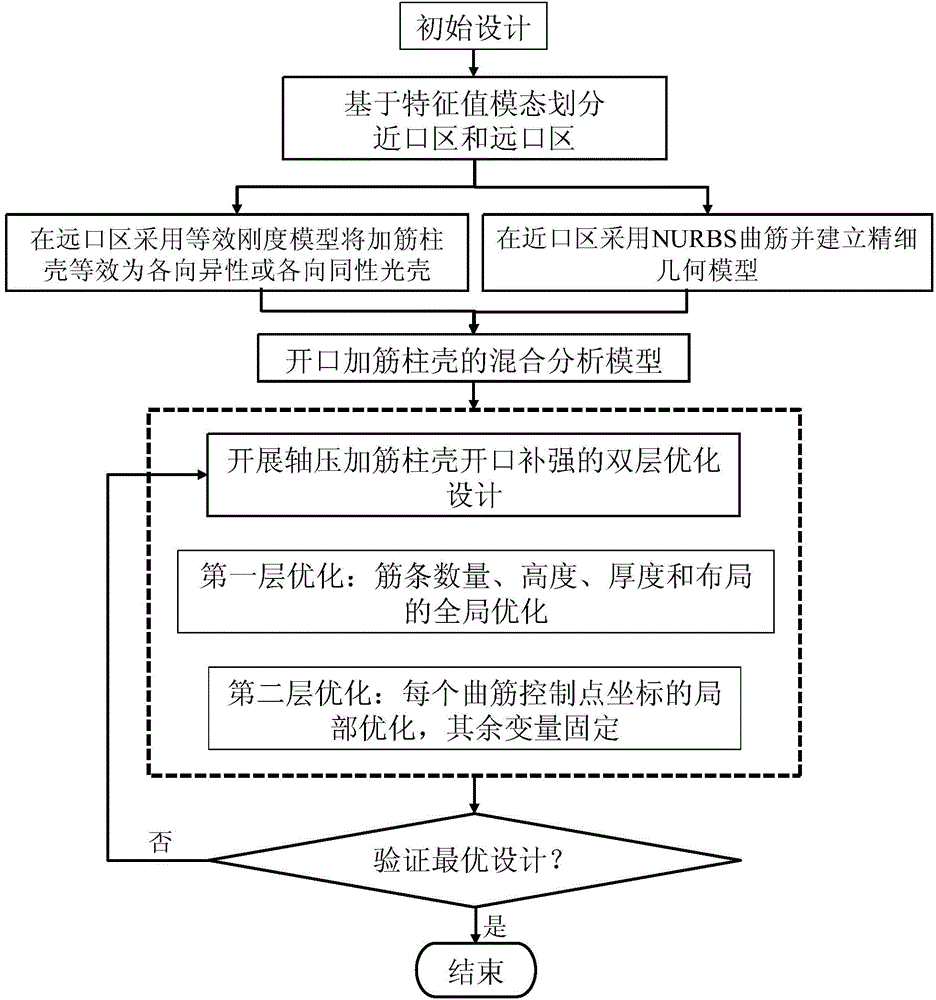

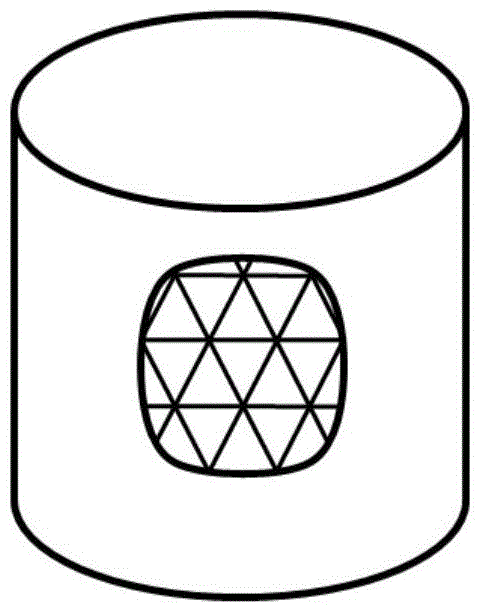

Opening reinforcement method of shaft pressing reinforced cylindrical shell

ActiveCN104866673AHigh structural efficiencyRational determinationSpecial data processing applicationsEquivalent stiffnessMechanical engineering

The invention relates to the field of aerospace structure main load-bearing member design, and provides an opening reinforcement method of a shaft pressing reinforced cylindrical shell. The opening reinforcement method of the shaft pressing reinforced cylindrical shell comprises the following steps: step 100, dividing the shaft pressing reinforced cylindrical shell with an opening into a distal opening area and a proximal opening area; step 200, establishing an equivalent stiffness model in the distal opening area, establishing a fine geometric model in the proximal opening area, and obtaining a hybrid analysis model of the shaft pressing reinforced cylindrical shell; step 300, peforming opening reinforcement and optimization on the shaft pressing rinforced cylindrical shell, and verifying an optimal result. According to the opening reinforcement method of the shaft pressing rinforced cylindrical shell, the opening reinforcing efficiency of the shaft pressing rinforced cylindrical shell can be improved, and the computing cost is reduced.

Owner:DALIAN UNIV OF TECH

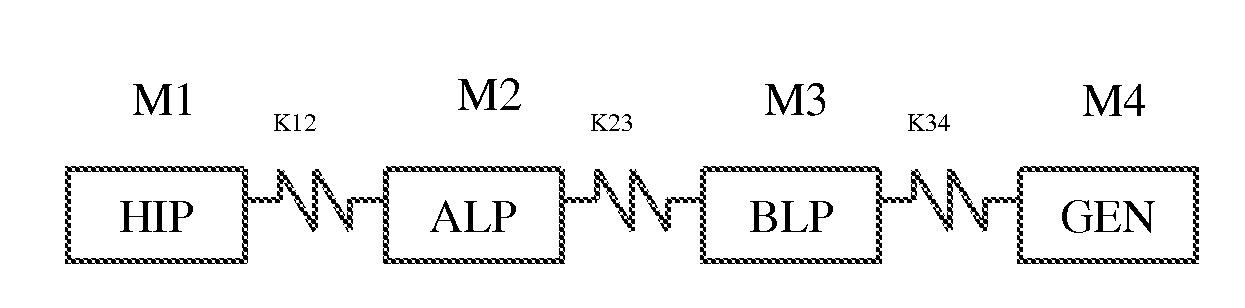

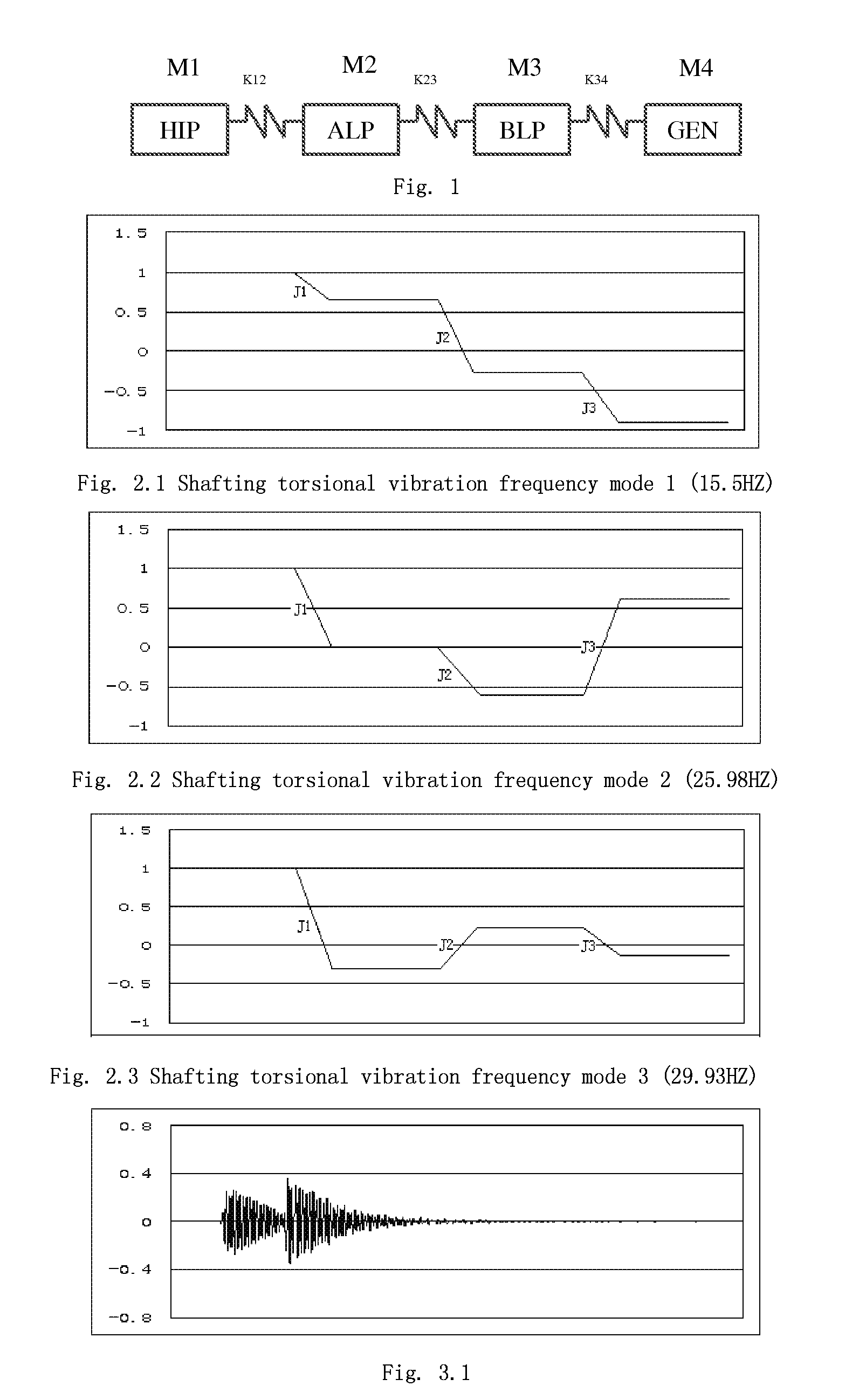

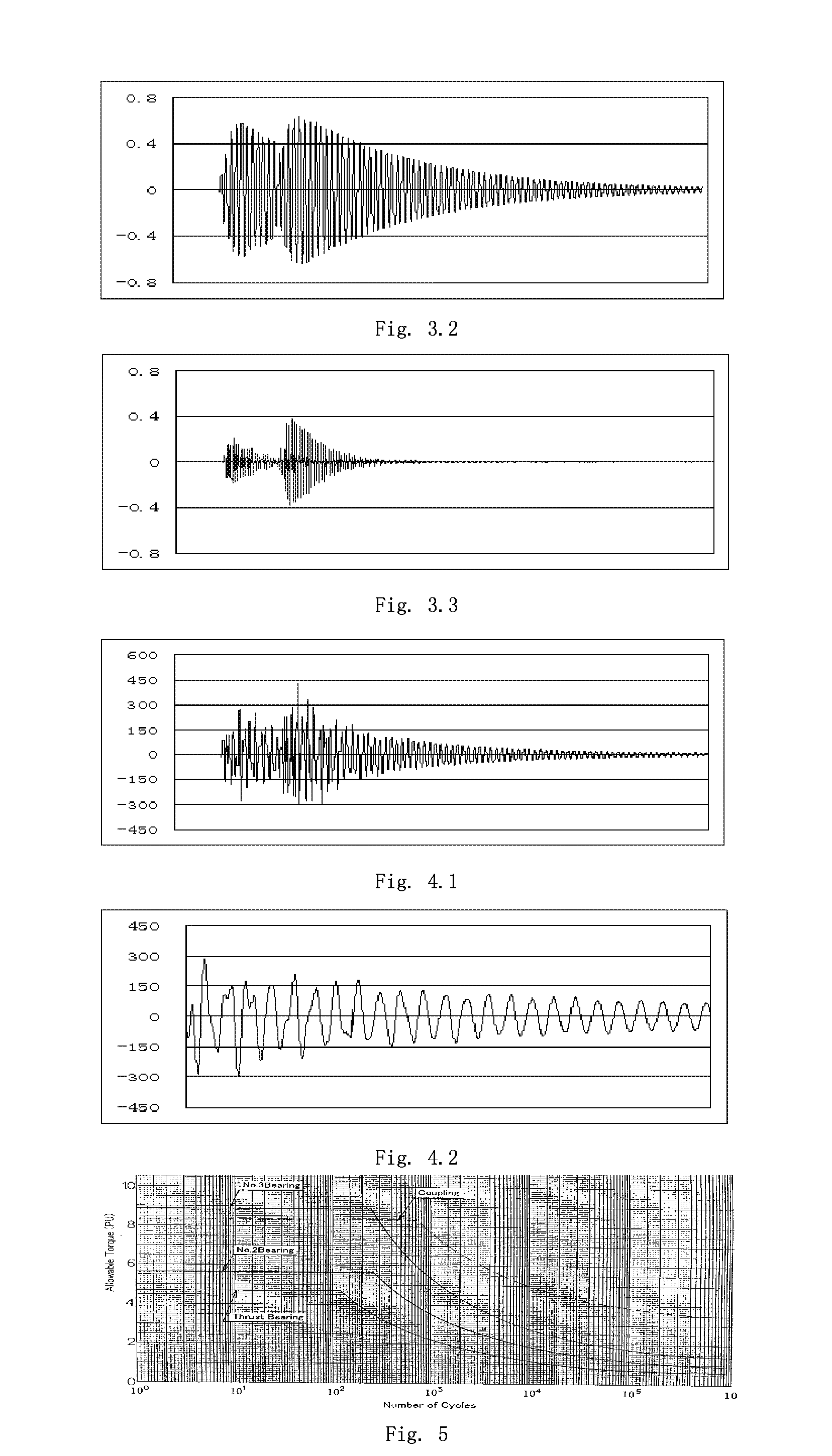

Method for measuring shafting mechanical fatigue of turbine generator set

ActiveUS20100250150A1Accurate measurementOscillation suppressionVibration measurement in solidsPlug gaugesFatigue damageAngular velocity

A method for measuring mechanical fatigue in shafts forming part of a turbine generator set, which involves determining a lumped mass model of a turbine generator set and its parameters; calculating a model frequency and a mode shape of the turbine generator set; acquiring an angular velocity change at a machine end; calculating a torque at a calculating section of shafting based on the model frequency, a mode shape curve and an equivalent rigidity of the lumped mass model, so as to obtain a torque-time history curve at the calculating section of the shafting; calculating a fatigue damage accumulative value for a dangerous section of a set shafting under a certain malfunction or disturbance, that is, the shafting mechanical fatigue of the turbine generator set.

Owner:BEIJING SIFANG JIBAO AUTOMATION

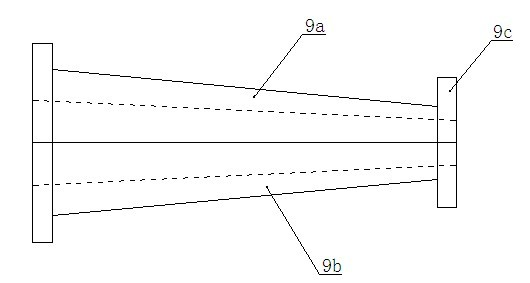

Fan tower inherent frequency analyzing method based on conservation of mechanical energy

Provided is a fan tower inherent frequency analyzing method based on conservation of mechanical energy. According to the method, a tower is regarded as a beam of a variable cross-section with one end fixed and the other end having concentrated mass and inertia moment, the fan tower is divided into a few sections, each section is signified by a constant-section beam, the rigidity of the beam is determined by adopting an equivalent rigidity method, a certain offset distance exists between a top mass center and the center of the beam, the mentioned parameters are regarded as the analyzing basis of the fan tower, and influences of relative parameters on the inherent frequency of the tower are determined by determining a first stage bending inherent frequency analyzing model and a first stage torsional inherent frequency analyzing model respectively.

Owner:CSR ZHUZHOU ELECTRIC LOCOMOTIVE RES INST

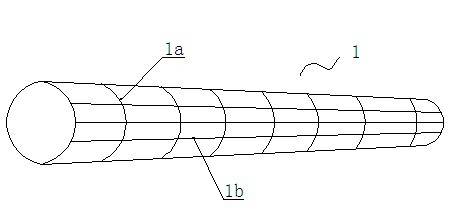

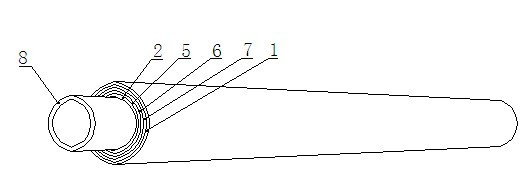

Method for manufacturing conical composite rod

The invention discloses a method for manufacturing a conical composite rod. The method comprises the following steps of: (a) manufacturing conical rod fiber fabrics; (b) making a vacuum bag film, a diversion net, an isolating film and demolding cloth all into conical bodies which imitate a fiber conical rod in shape, wherein the diversion net is combined with a resin diversion pipe and a vacuuming pipe; (c) sequentially sleeving the conical vacuum bag film, the conical diversion net combined with the resin diversion pipe and the vacuuming pipe, the conical isolating film and the conical demolding cloth on a conical core mold firstly, and then, sleeving the fiber fabrics layer by layer; and (d) feeding the whole body in the step (c) into a conical external mold which is formed by oppositely combining an upper mold with a lower mold, removing the core mold, and demolding under certain conditions to obtain a finished product. According to the method for manufacturing the conical composite rod, resin is imported by adopting a vacuum method, so that the void ratio of the product is extremely low, and the fiber content reaches up to 70%; and meanwhile, as the conical composite rod is formed by once intramode molding, the efficiency is high, the appearance is smooth, the complicated polishing treatment is not needed, no powder dust is generated, and the energy consumption is extremely low during production. Thus, the material consumption can be reduced under the equivalent stiffness requirements, and the resources are saved.

Owner:JIANGSU JIUDING NEW MATERIAL CO LTD

Method for designing fuel cell stack integral packaging by using equivalent stiffness mechanical model

The invention discloses a method for whole packaging fuel cell stack designed by applying a mechanical model with equivalent stiffness. The method is characterized in that the fuel cell stack is simplified into the mechanical model with equivalent stiffness under the action of packaging force by utilizing the mechanical theory, the corresponding relation between deflection of packaging components and packaging load inside the structure is derived, then the deformational condition caused by temperature of various components after packaging is supplemented and corrected, and finally the optimal packaging parameters of the cell stack are confirmed according to the concrete design requirements. The invention also supplements the conditions that triad membrane electrodes and sealing components of the fuel cell stack with the proton exchange membrane before packaging have different thickness. The invention radically overcomes the defects of great computation load in the finite element method, low flexibility and long design period, simple measurement and computation are only performed, so that the distribution of equivalent stiffness and packaging load inside the structure of the fuel cell stack in the packaging load direction can be obtained, under the condition of ensuring the packaging accuracy, the computation consumption can be enormously reduced, and the design period of packaging the fuel cell stack is shortened.

Owner:DALIAN UNIV OF TECH

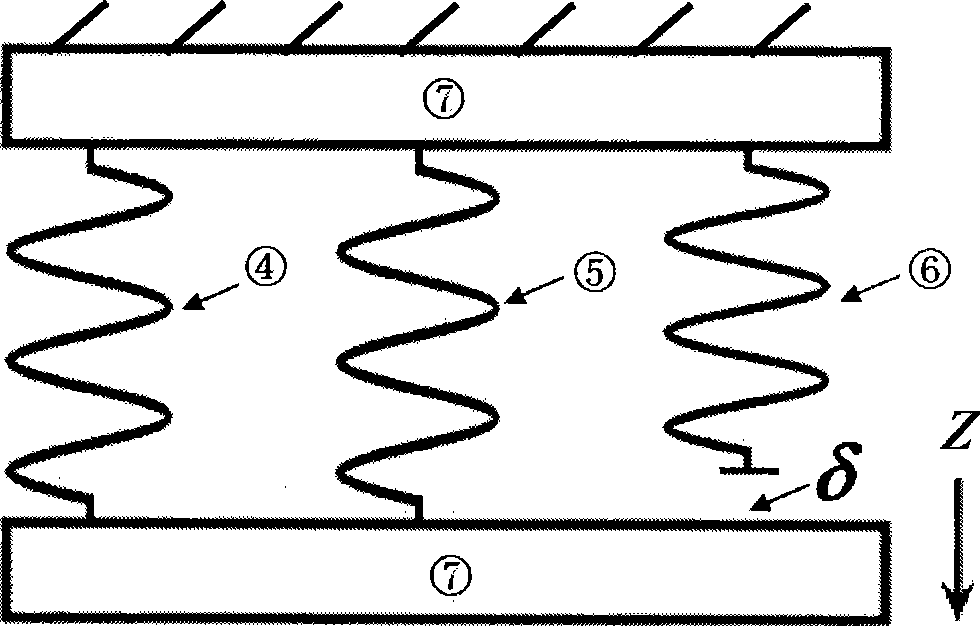

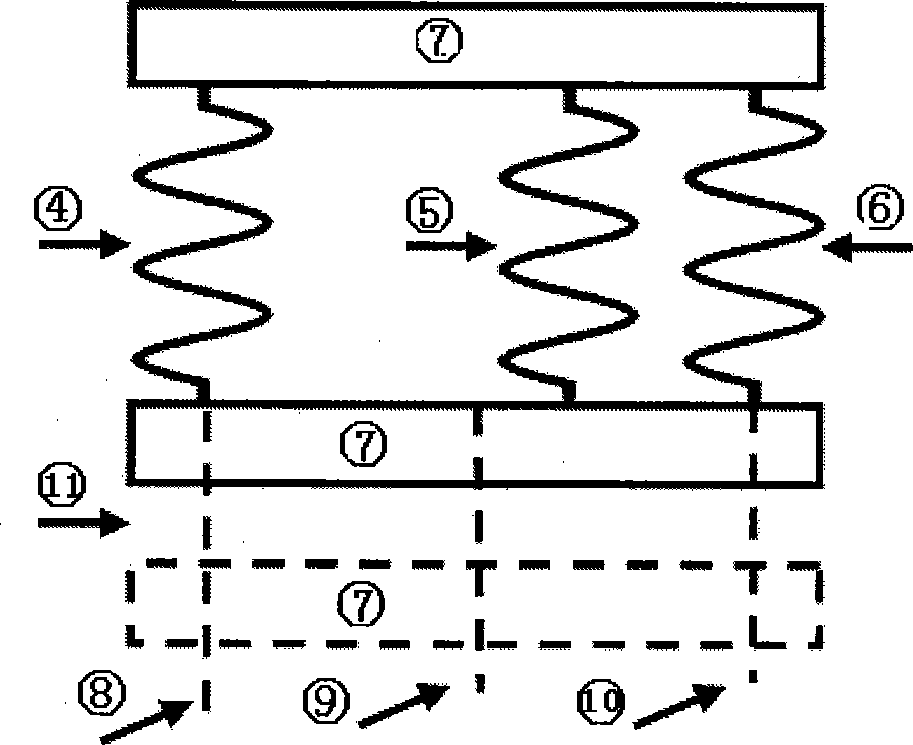

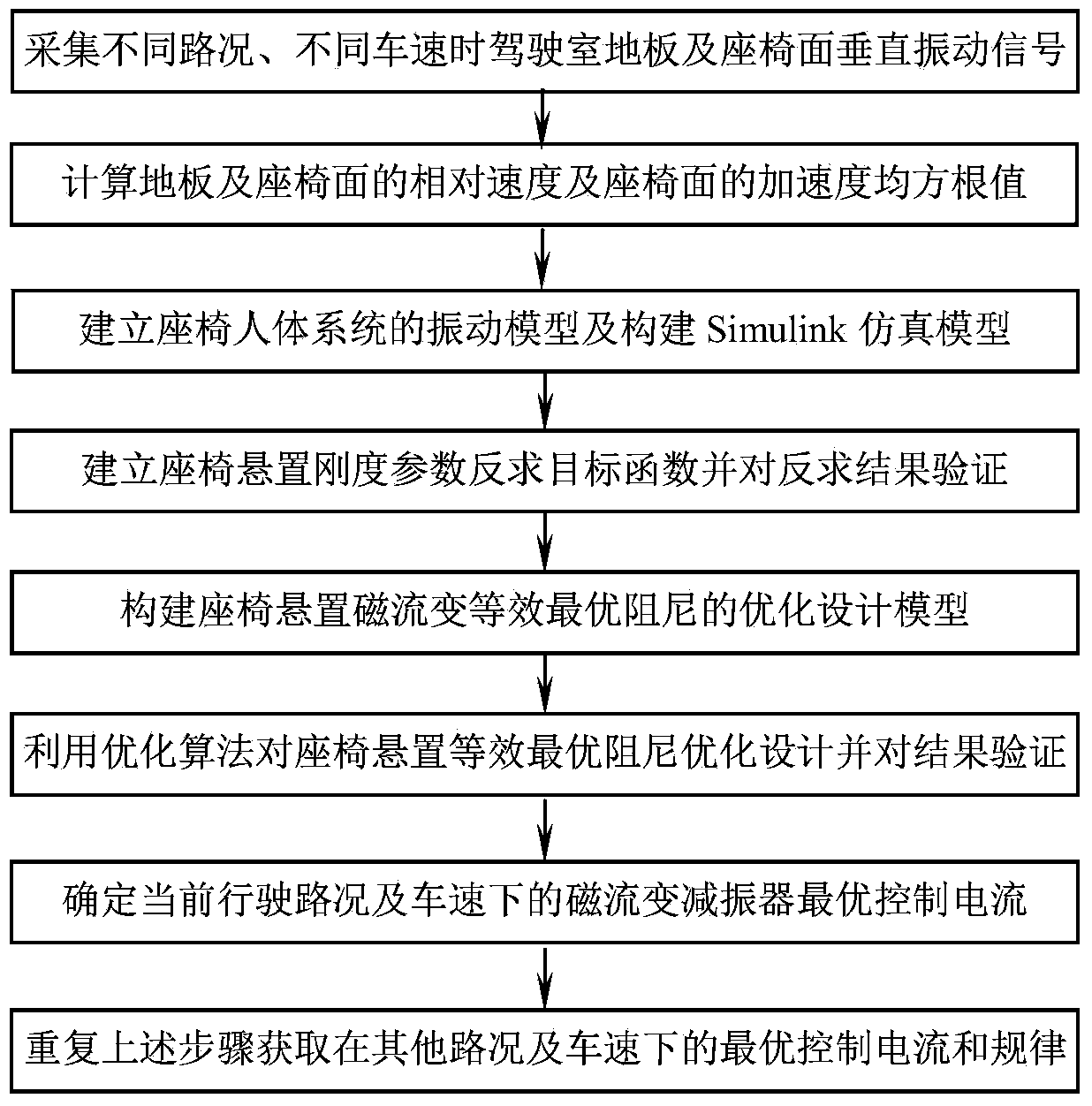

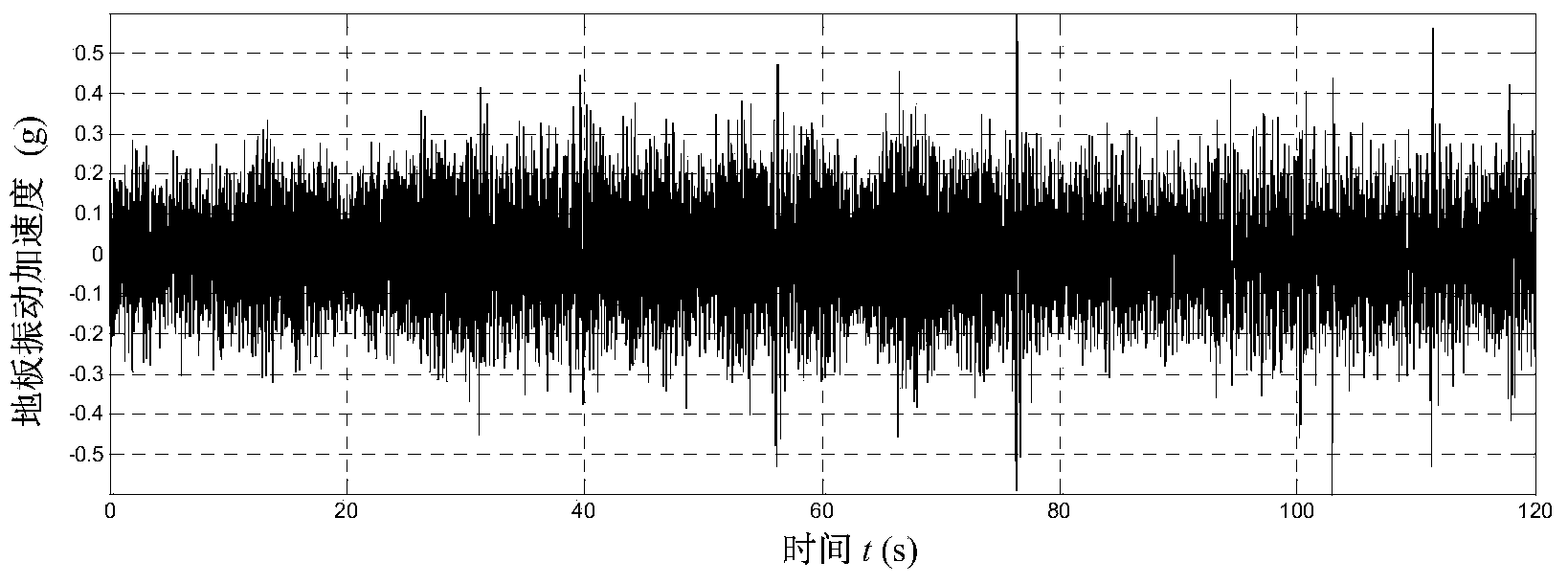

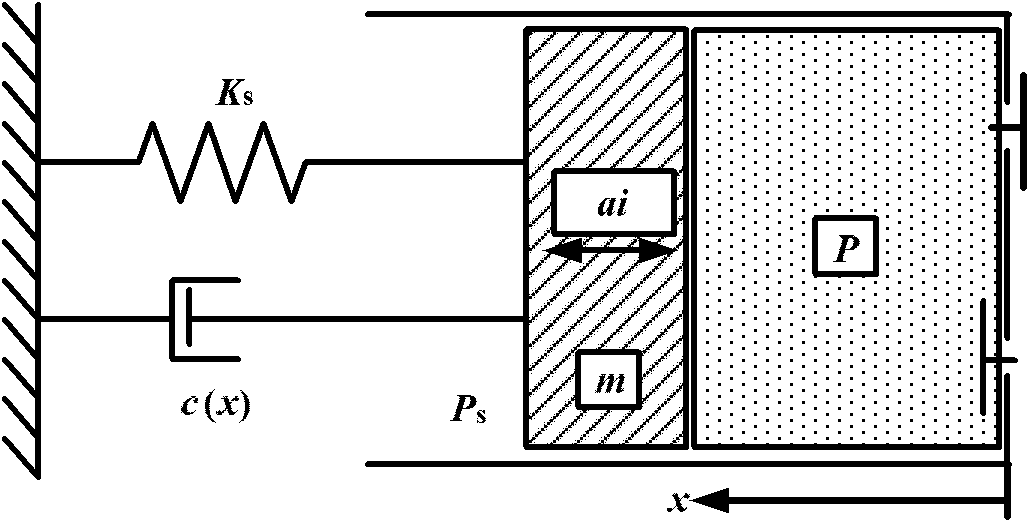

Design method for optimal control current of vehicle seat suspension magnetorheological damper

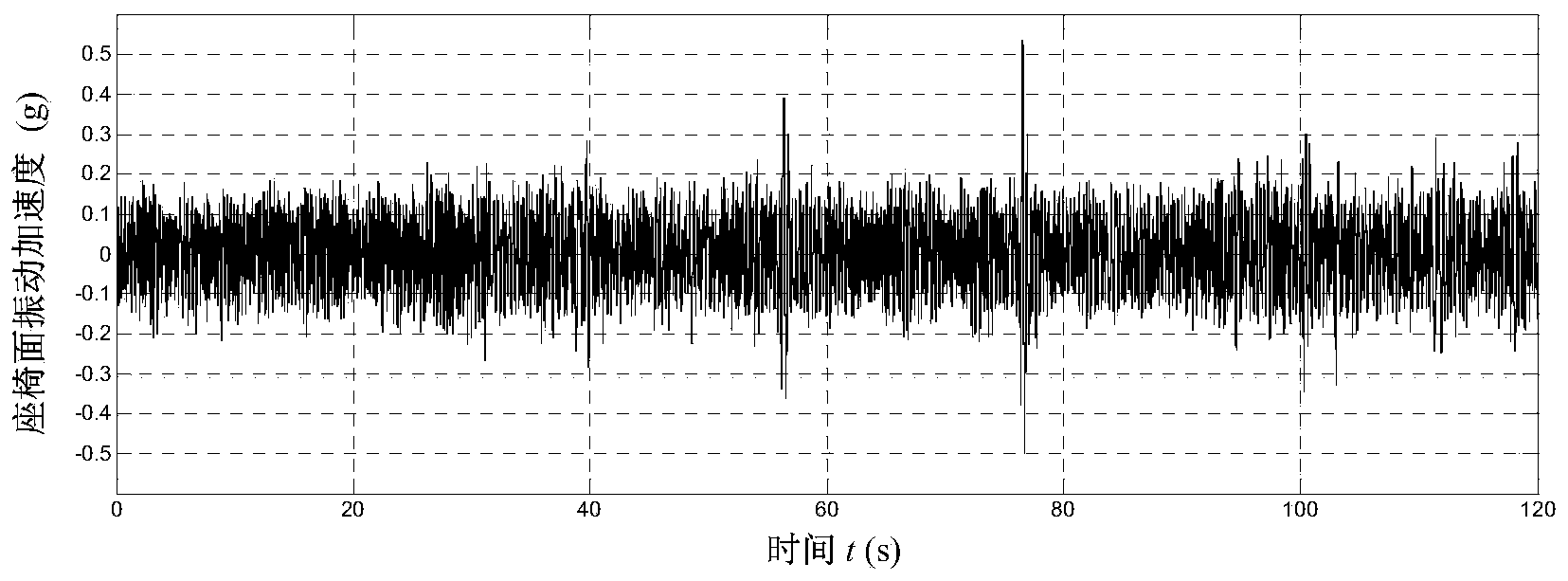

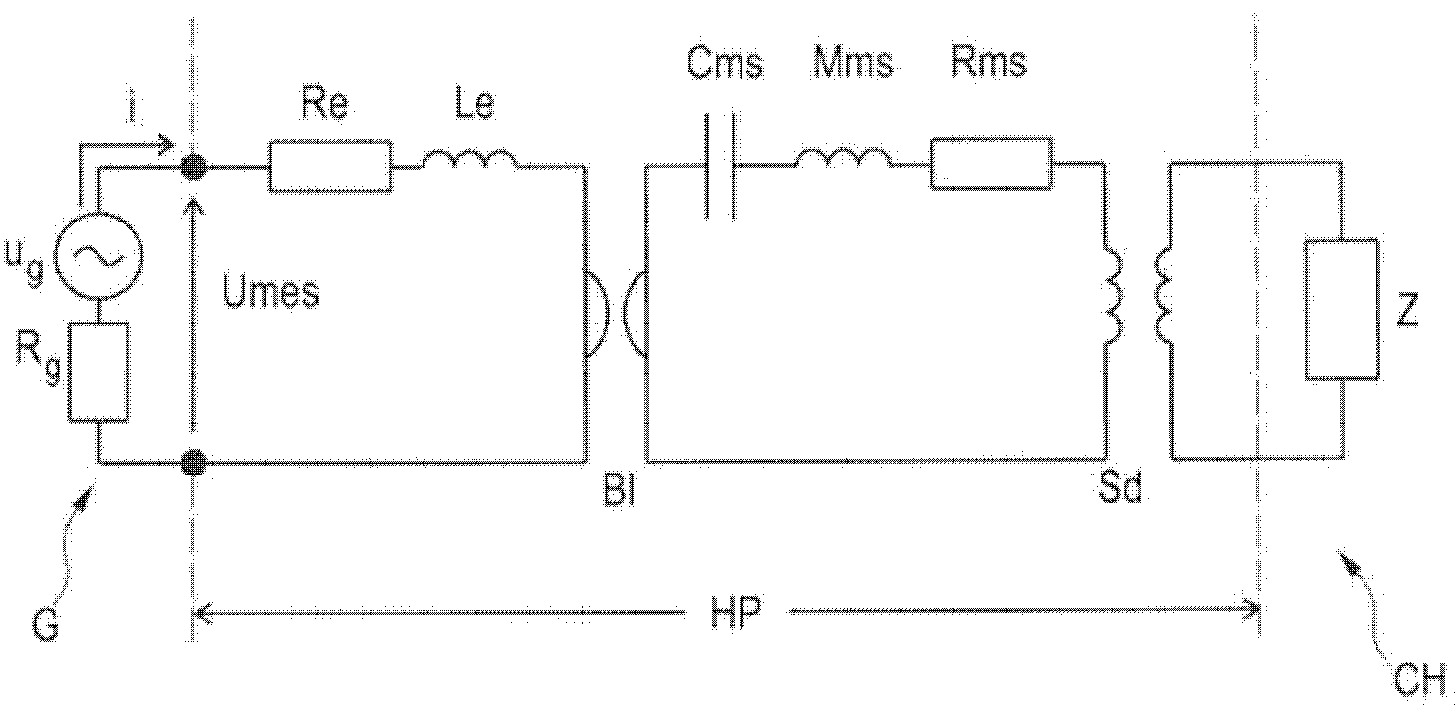

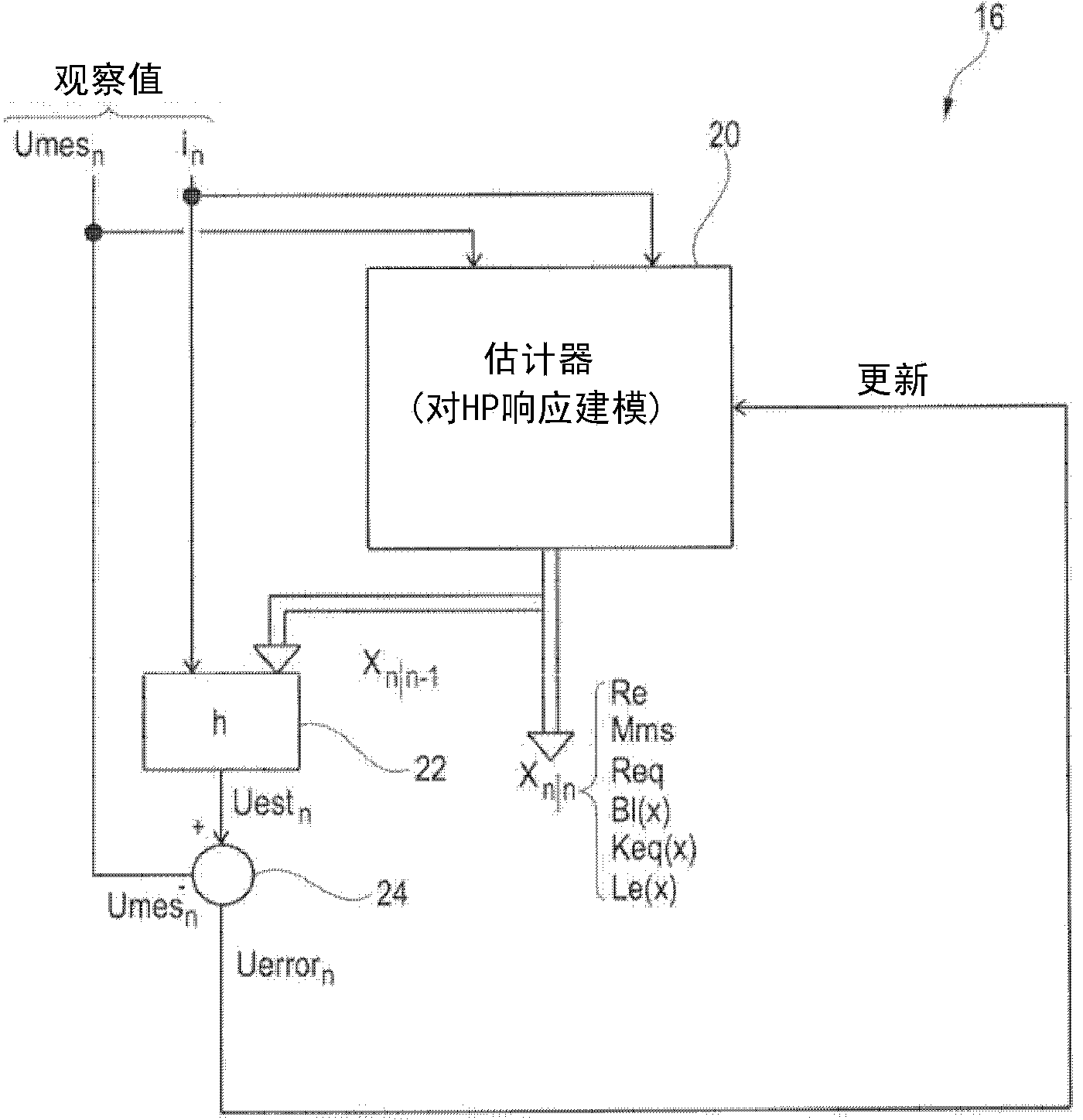

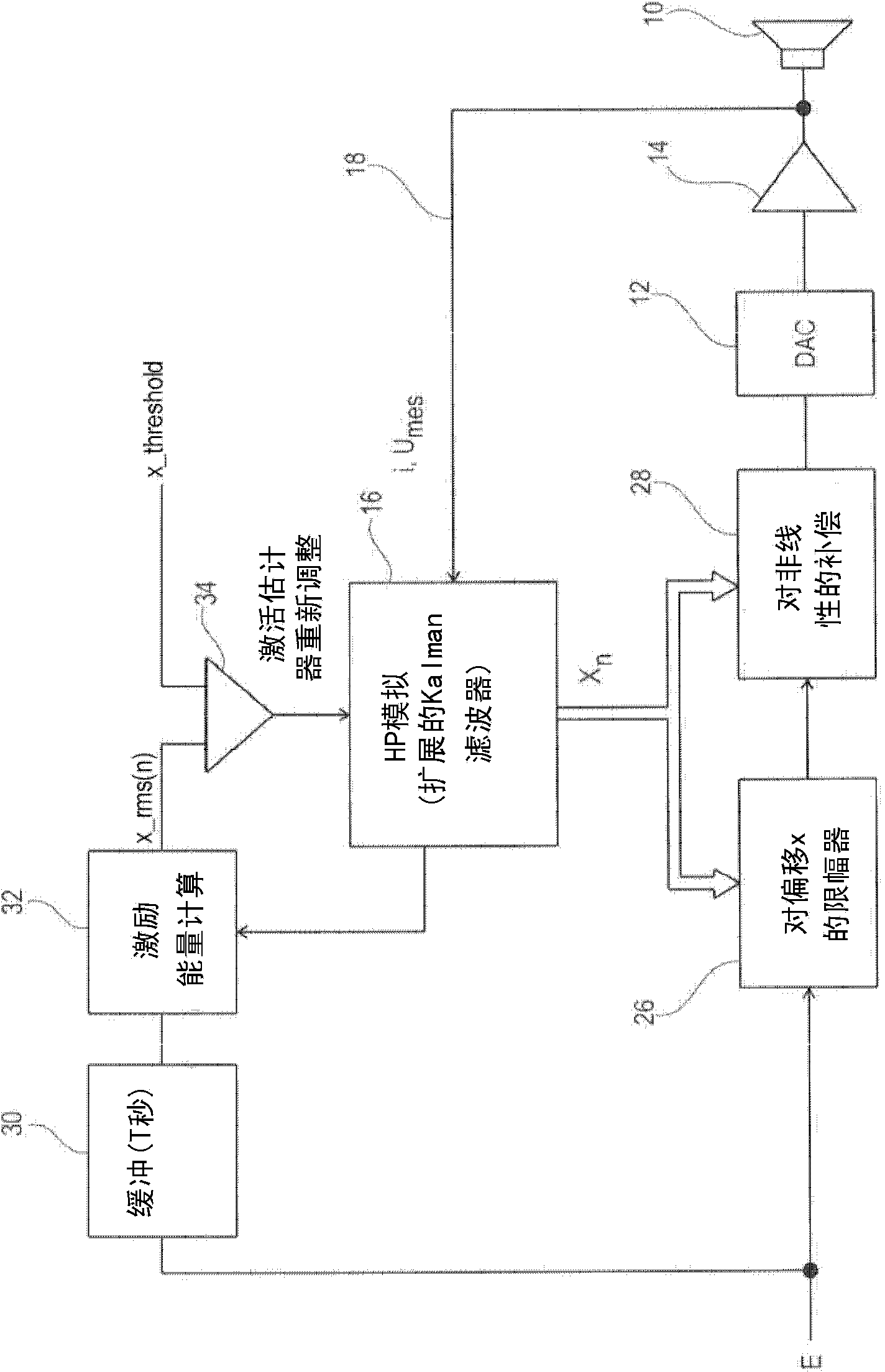

InactiveCN104175920AImprove comfortLow costSeat suspension devicesVibration accelerationEquivalent stiffness

The invention relates to a design method for optimal control current of a vehicle seat suspension magnetorheological damper, and belongs to the technical field of vehicle seats. The design method is characterized in that seat suspension equivalent stiffness Ks is obtained by the aid of a parameter retrieving target function according to measured vibration acceleration signals and relative speeds of a seat mounting floor and a seat surface of an actual running vehicle, a seat human system simulink model and a seat suspension damping Cs design target function are re-built by the aid of the retrieved seat suspension equivalent stiffness, equivalent optimal damping Cs-o is designed by the aid of optimization algorithm, and the optimal control current of the magnetorheological damper is designed by the aid of the relationship between damping force and control current. The control current is obtained according to the actual vehicle running condition, so that the control current is more reliable, and comfort of the seats is remarkably improved. Besides, an expensive hardware device is not needed by the aid of an optimal current control rule table, so that cost is reduced.

Owner:SHANDONG UNIV OF TECH

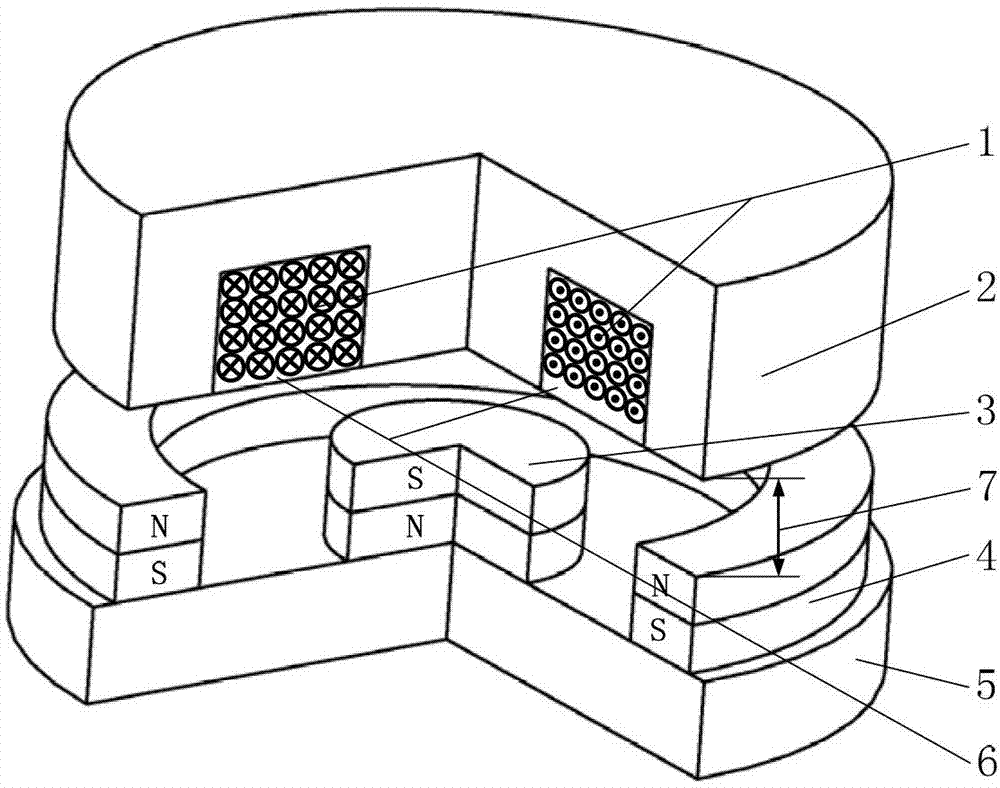

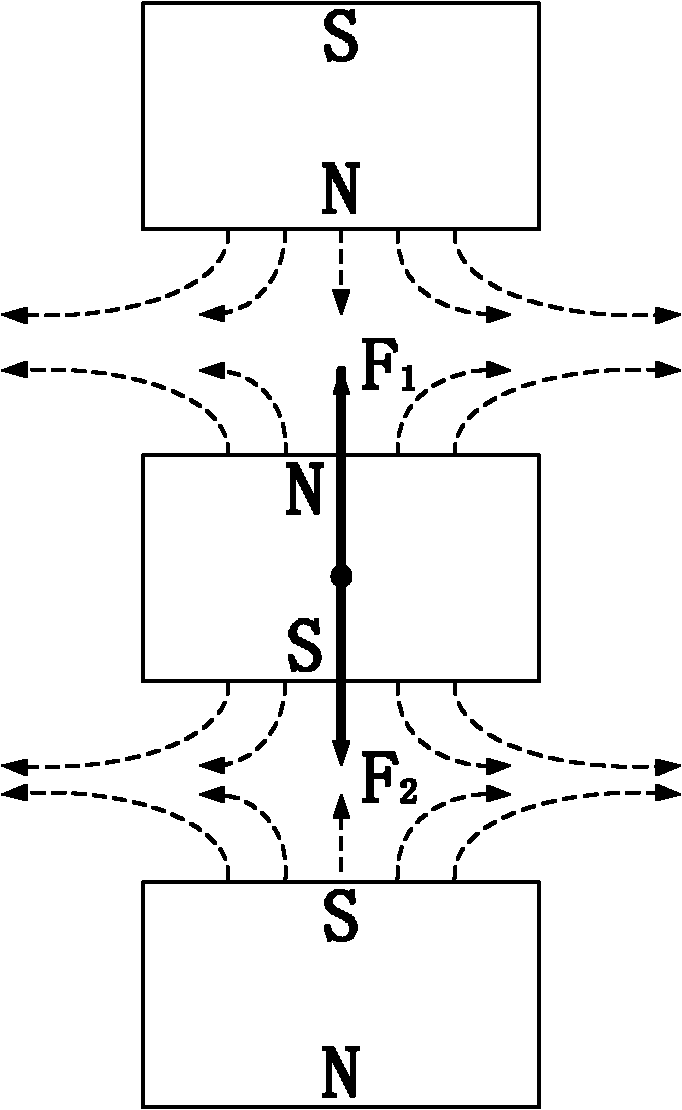

Vibration isolator with magnetic suspension unit

The invention belongs to the field of vibration isolation, and provides a vibration isolator with a magnetic suspension unit. The vibration isolator comprises the magnetic suspension unit for generating negative stiffness, and a mechanical spring damping unit for generating positive stiffness, wherein the two units are connected with each other in series to form a high-stiffness spring system with infinite stiffness in theory. After being connected in series with the conventional mechanical spring, the vibration isolator provided by the invention can achieve high equivalent stiffness of a vibration isolating system, so that the vibration directly acting on precise equipment can be suppressed; and meanwhile, the elastic coefficient of the conventional mechanical spring can be ensured to be small, therefore, the vibration transmitted from the ground to the precise equipment can be isolated, and furthermore, the purposes of isolating the vibration transmitted from the ground to the precise equipment and suppressing the vibration directly acting on the precise equipment can be achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

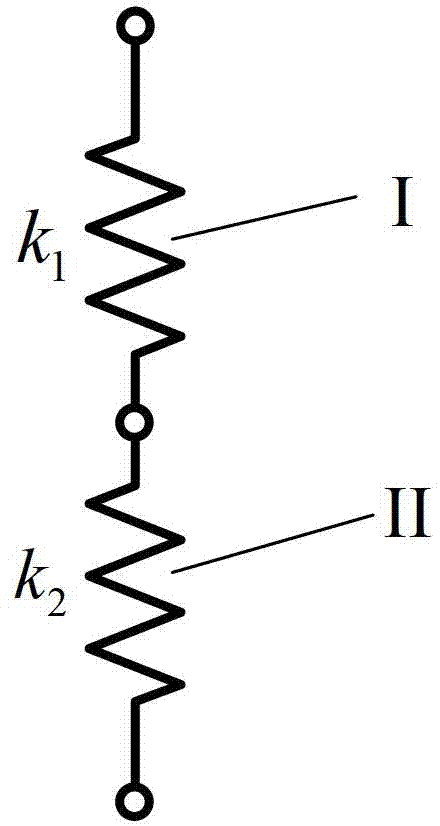

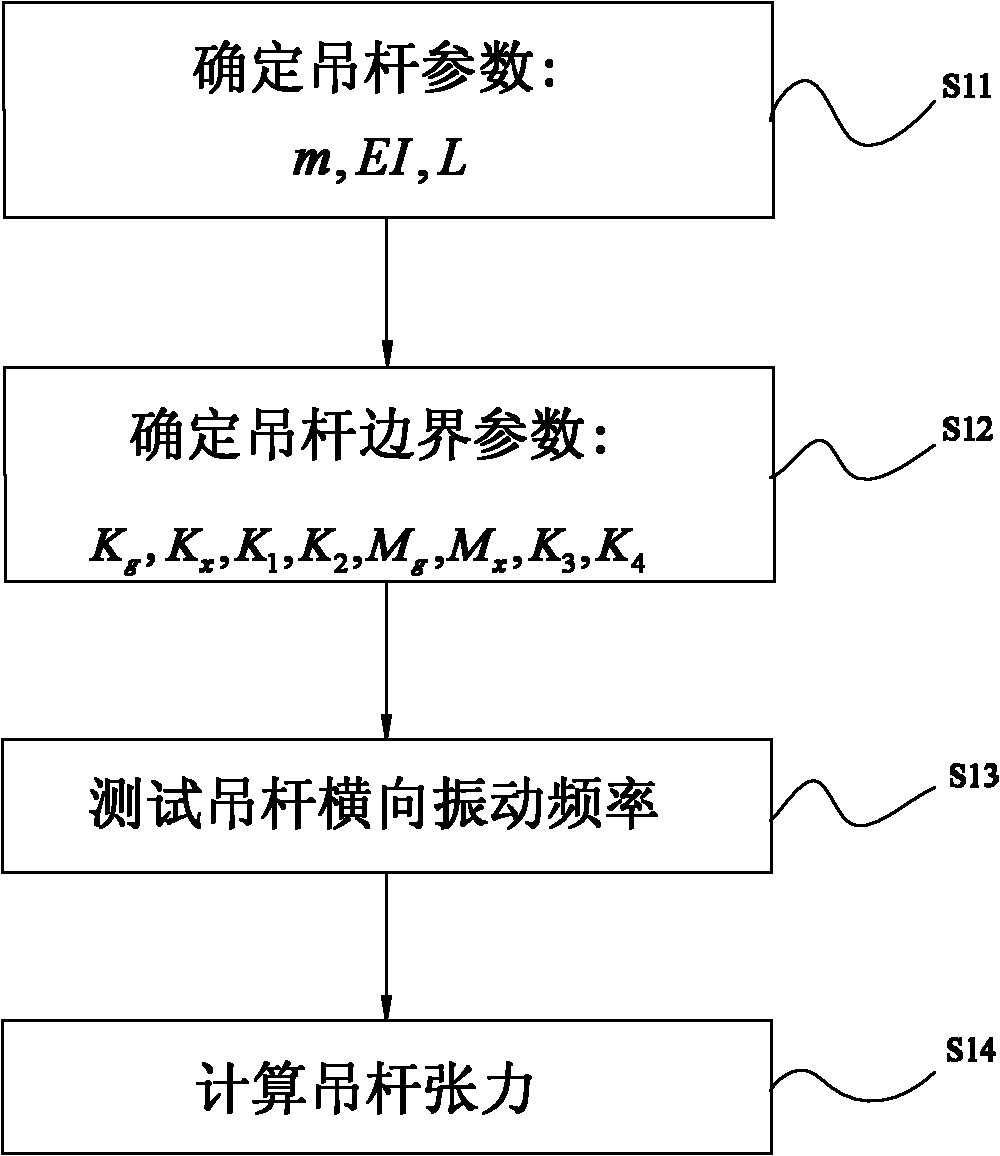

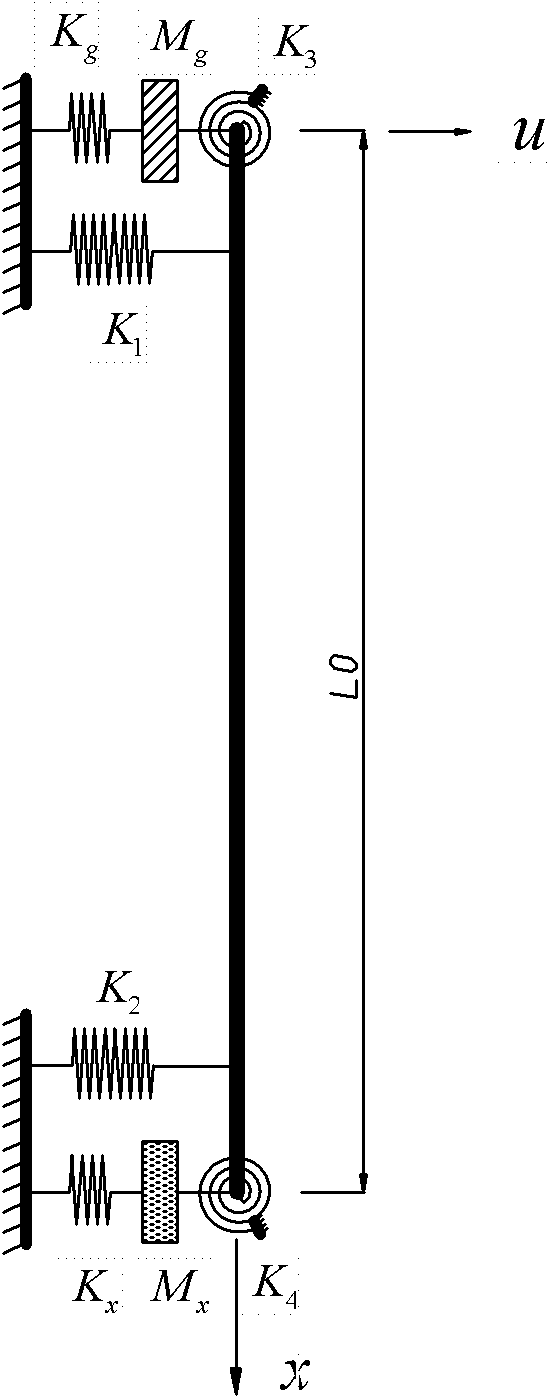

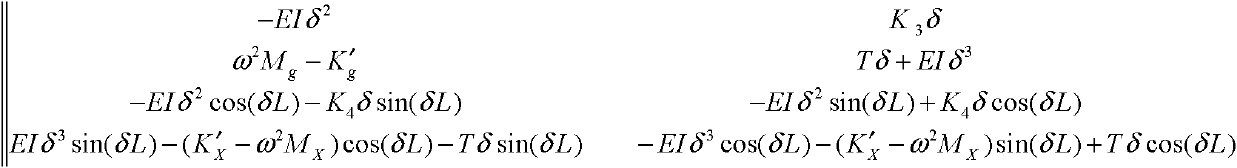

Frequency method-based suspender tension determining method

InactiveCN102230833AThe calculation result is accurateForce measurement by measuring frquency variationsEquivalent stiffnessAnalytical expressions

The invention discloses a frequency method-based suspender tension determining method. The method comprises the following steps of: measuring the transverse vibration frequency omega of a suspender; and acquiring suspender tension according to an analytical expression between the suspender tension T and the transverse vibration frequency omega under the condition of complex boundaries, wherein inthe analytical expression, K'g=Kg+K1, K'X=KX+K2, Mg is equivalent mass of an arch rib, Mx is equivalent mass of a tie beam, the Kg is axial equivalent rigidity of the arc rib to the suspender, the Kxis axial equivalent rigidity of the tie beam to the suspender, the K1 is axial equivalent rigidity of an anti-vibration pad in the arc rib to the suspender, the K2 is axial equivalent rigidity of an anti-vibration pad in the tie beam to the suspender, K3 is rotary equivalent rigidity of the arc rib to the suspender, K4 is rotary equivalent rigidity of the tie beam to the suspender, m is mass of the suspender in unit length, EI is flexural rigidity of the suspender, and L is calculated length of the suspender. By the method, boundary constraints such as additional mass, elastic supporting and the like of the suspender are relatively fully considered, and calculation results are relatively accurate for both short suspenders and long suspenders in spite of complicated forms.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

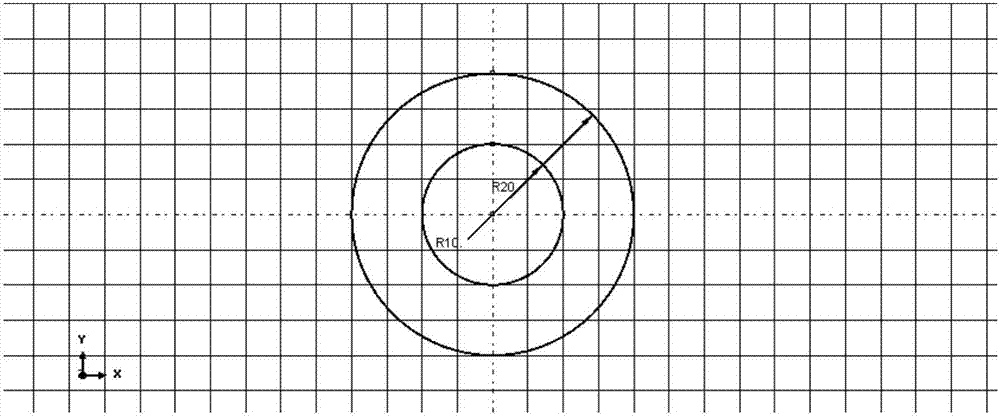

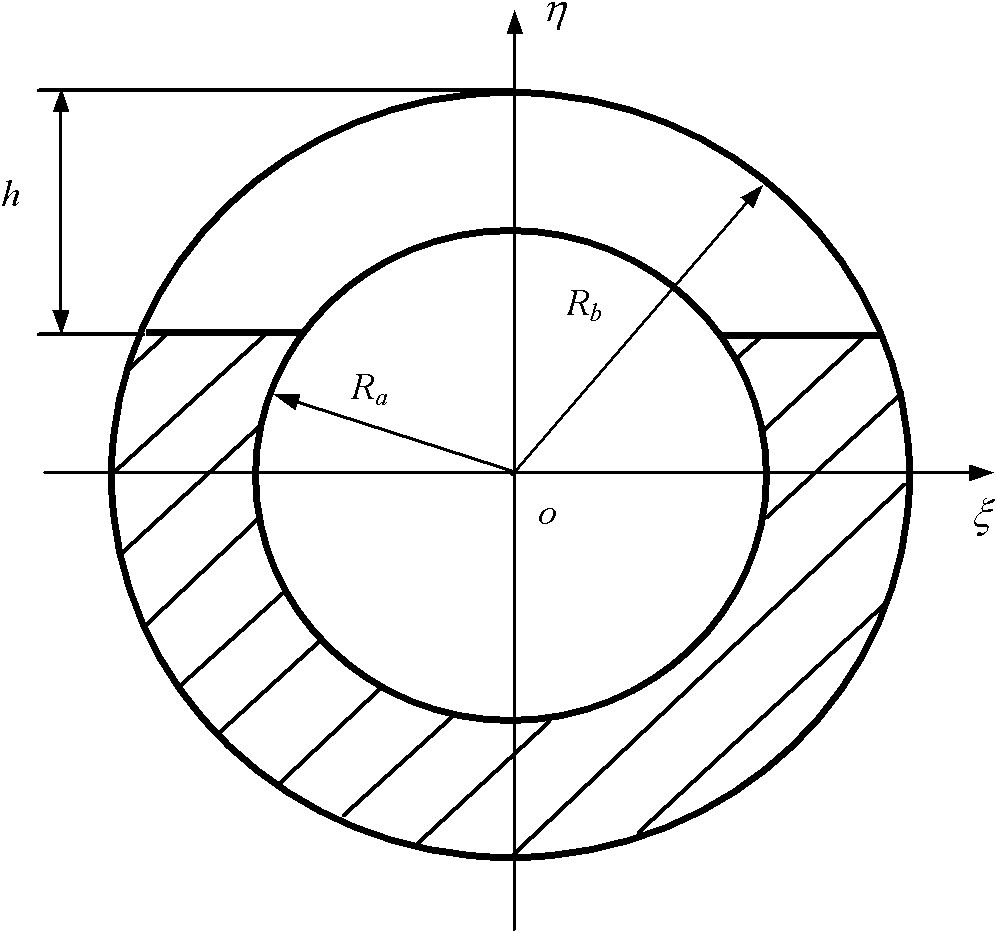

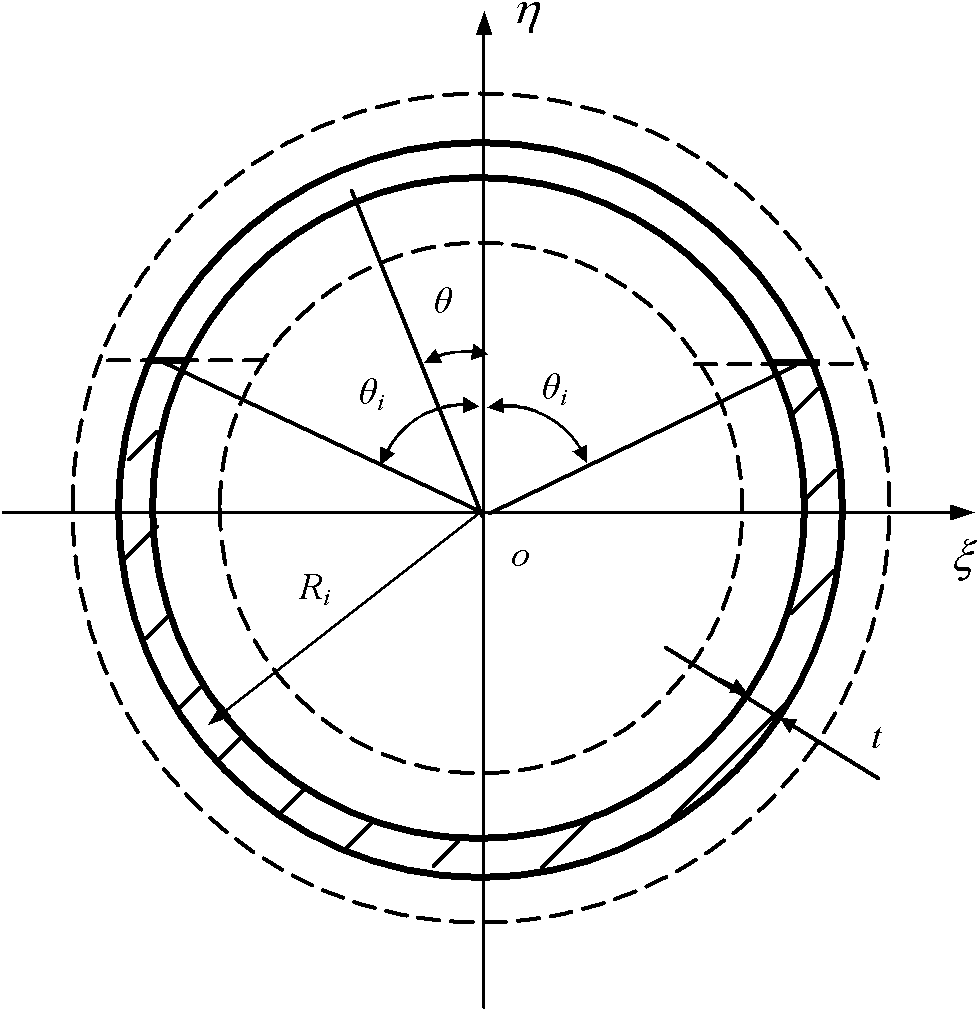

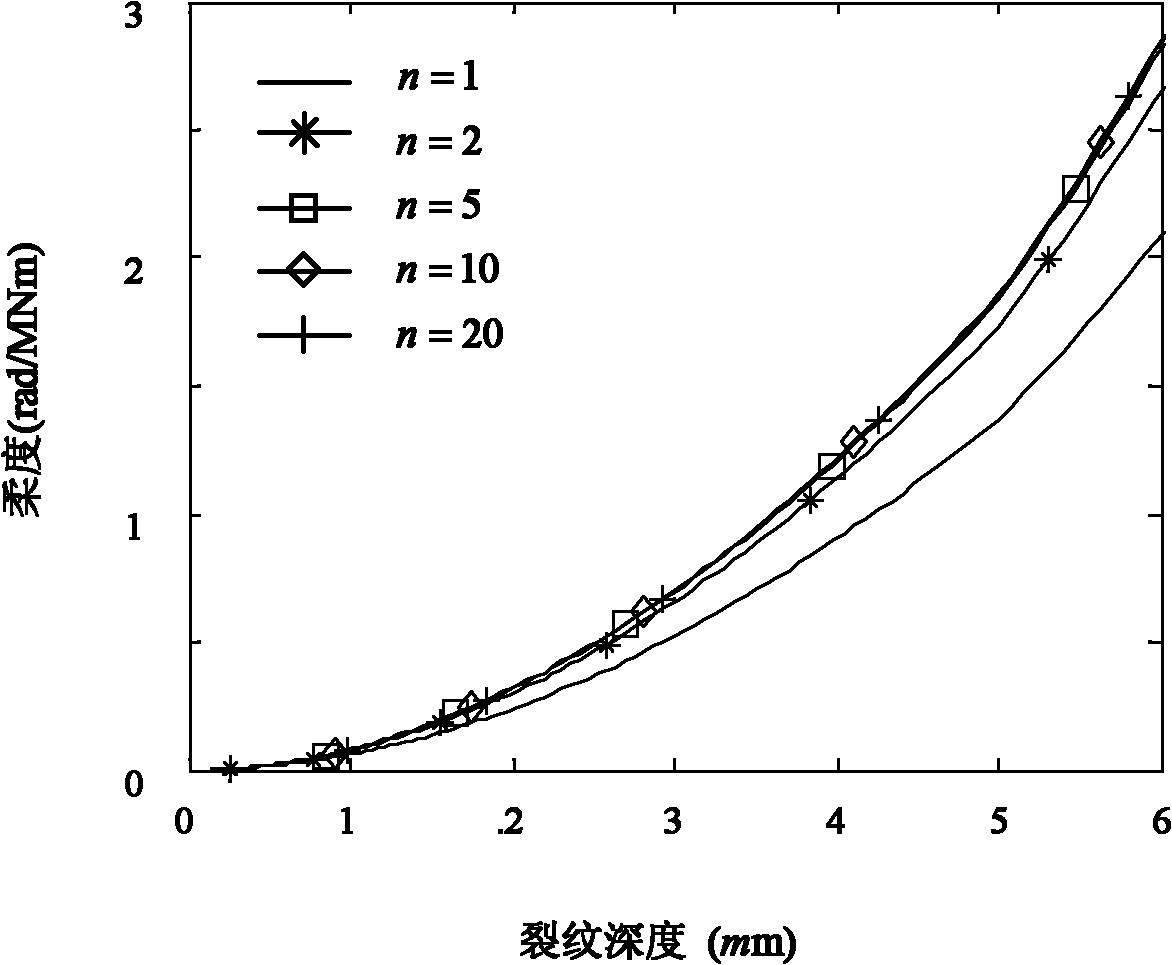

Pipeline crack equivalent stiffness calculation method based on stress intensity factor

The invention discloses a pipeline crack equivalent stiffness calculation method based on a stress intensity factor. In the method, pipeline structures are scattered into a series of sequentially nested thin-wall rings along the radial direction so that the stress intensity factors of the pipeline structures are solved, and then the equivalent stiffness of cracks is calculated. In the research ofa vibration-based crack diagnosis method, the structural local stiffness change caused by the cracks can be described by adopting a torsion line spring model. Therefore, the acquired equivalent stiffness of the cracks can be used for identifying the position and the size of the cracks of a pipeline. By the method, the equivalent stiffness of the crack at any position in the pipeline can be acquired, a large amount of fussy experiment work is avoided, the result is reliable, the operation is simple and feasible, and a foundation is provided for further diagnosing the cracks of the pipeline.

Owner:盐城韩资工业园产业发展有限公司

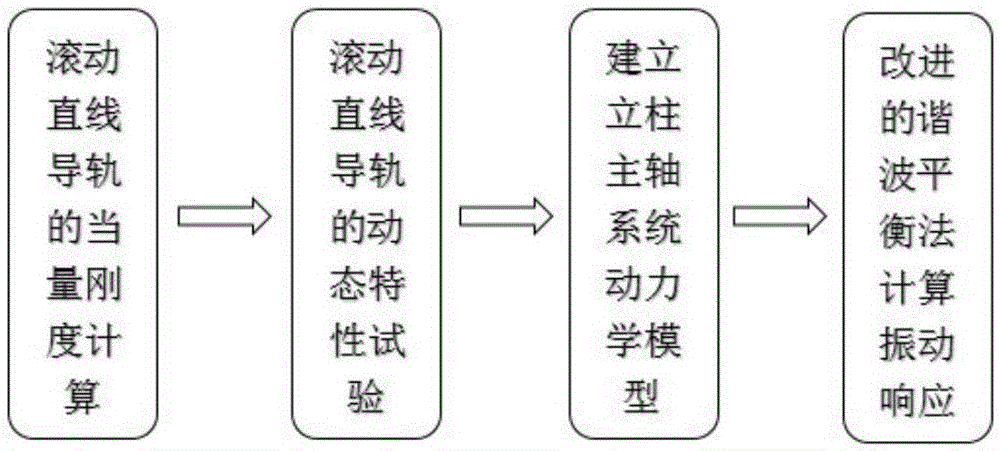

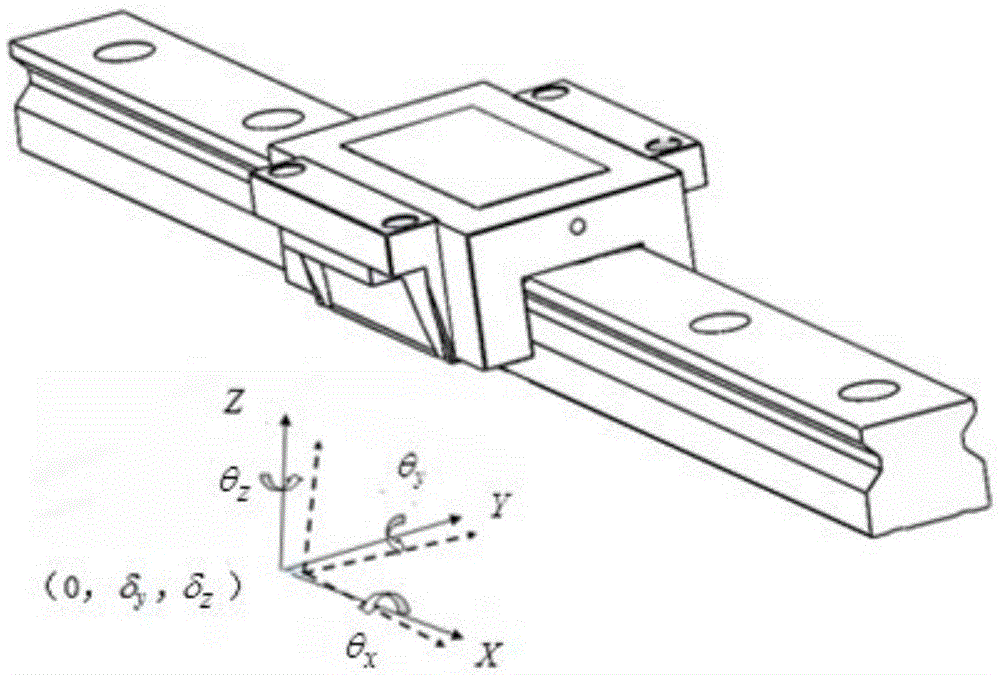

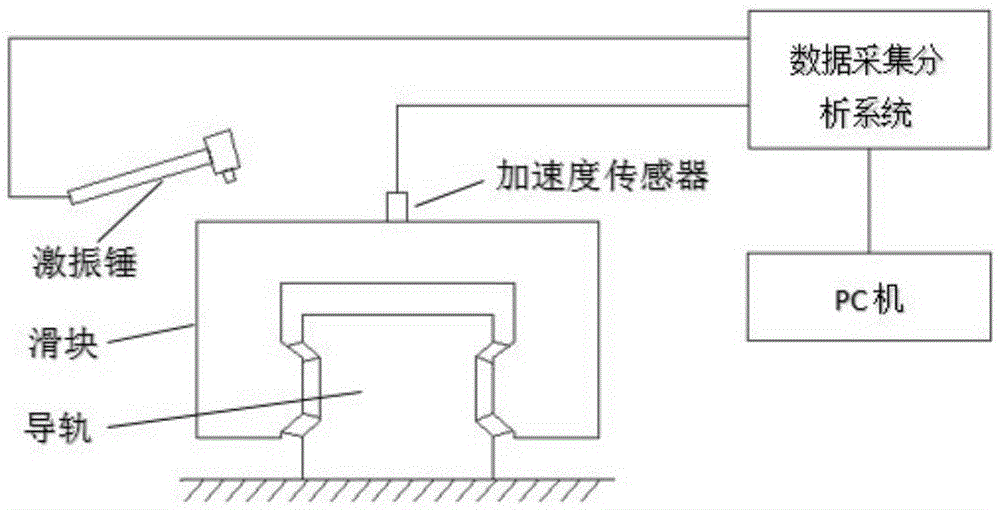

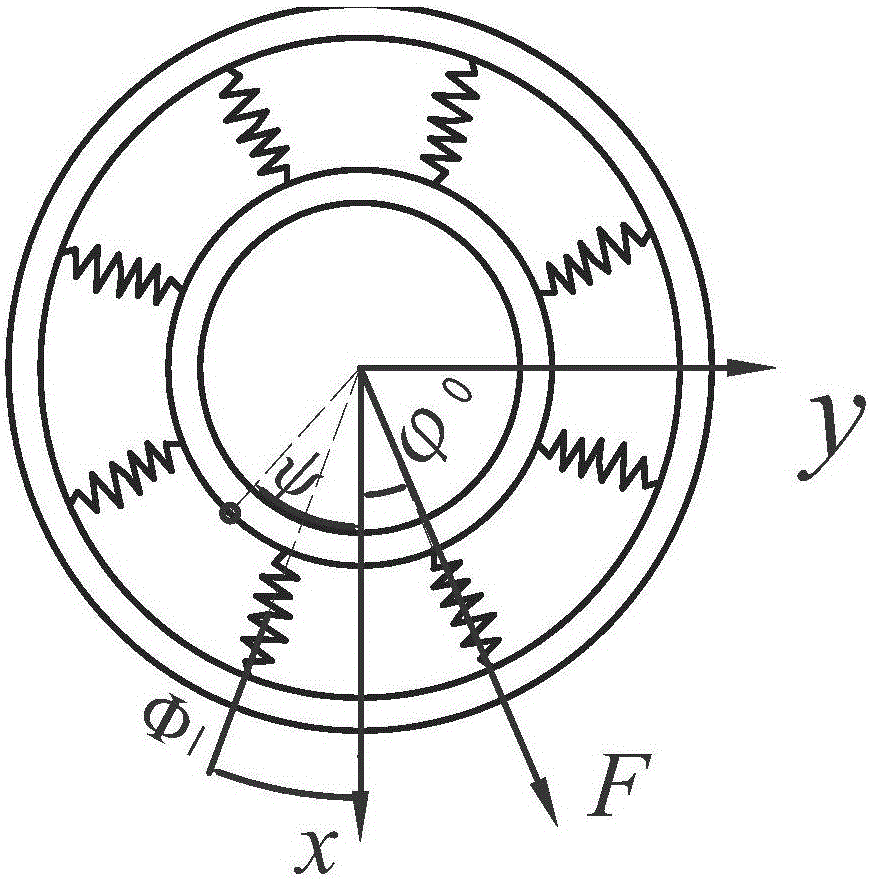

Guideway joint feature-considered vibration response analysis method for upright post-spindle system

InactiveCN105571847ATrue expressivenessSolving for Response CurvesMachine part testingSystem dynamics modelHarmonic balance

The invention provides a guideway joint feature-considered vibration response analysis method for an upright post-spindle system. Firstly, the relationship between a single roller and the bearing capacity is represented based on the Hertz contact theory, and a relational expression between the load and the deformation is established. After that, in the multiple-support excitation and multiple-support response manner, the inherent frequency and the inherent damping of a guideway joint at each order are identified. Then, a kinetic model for the upright post-spindle system is established. Finally, according to the improved harmonic balance method, the vibration response of the upright post-spindle system under the effect of sinusoidal excitation is calculated. According to the technical scheme of the invention, on one hand, the equivalent stiffness of a roller linear guide rail under an arbitrary load is calculated, and the guideway joint is simplified as a system capable of providing the non-linear restoring force. On the other hand, the nonlinear vibration theory-based calculation method is adopted to provide a vibration model for the upright post-spindle system, and the harmonic balance method is improved. Moreover, a response curve is obtained more quickly based on the principle of least square method. The above method provides a solving means for conducting the accuracy research and the optimized design of linear guide rails.

Owner:BEIJING UNIV OF TECH

Linear compressor with magnetic spring structure

InactiveCN102052420ACompact structureAffect performancePositive displacement pump componentsMagnetic springsLinear motionLinear compressor

The invention relates to a magnetic spring structure and a linear compressor structure thereof, in particular relating to a linear compressor with a magnetic spring structure. The linear compressor is characterized in that a magnetic spring assembly is composed of a permanent moving magnet and a permanent stationary magnet, the permanent stationary magnet is fixed on a compressor body, and the permanent moving magnet, a piston and a motor rotor constitutes a piston motion assembly; under the action of alternating thrust of a motor, the piston motion assembly makes a reciprocating linear motion along the axial direction of the motor so as to complete a process comprising the steps of expansion, air suction, compression and air exhaust of the compressor; and meanwhile, under the action of mutual magnetic forces, the permanent moving magnet and the permanent stationary magnet are acted as energy-storage components. The linear compressor with a magnetic spring structure has the advantages that the equivalent stiffness coefficients of the permanent magnets can be changed through changing the diameters, coercive forces and remanence strengths of the permanent magnets; when the compressor is in a large piston stroke, the compressor still has high performances and reliability; and because the magnetic spring is simple in structure, the permanent moving magnet part of the magnetic spring can be inlaid on the piston, so that the structure of the linear compressor is more compact and the volume thereof is smaller.

Owner:XI AN JIAOTONG UNIV

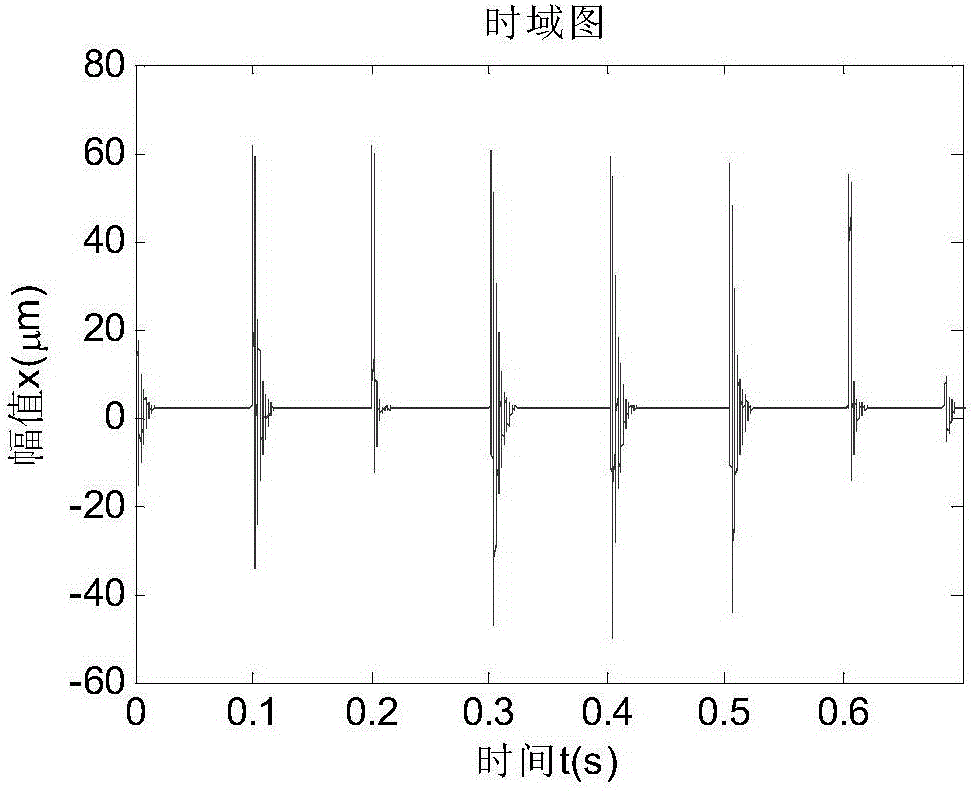

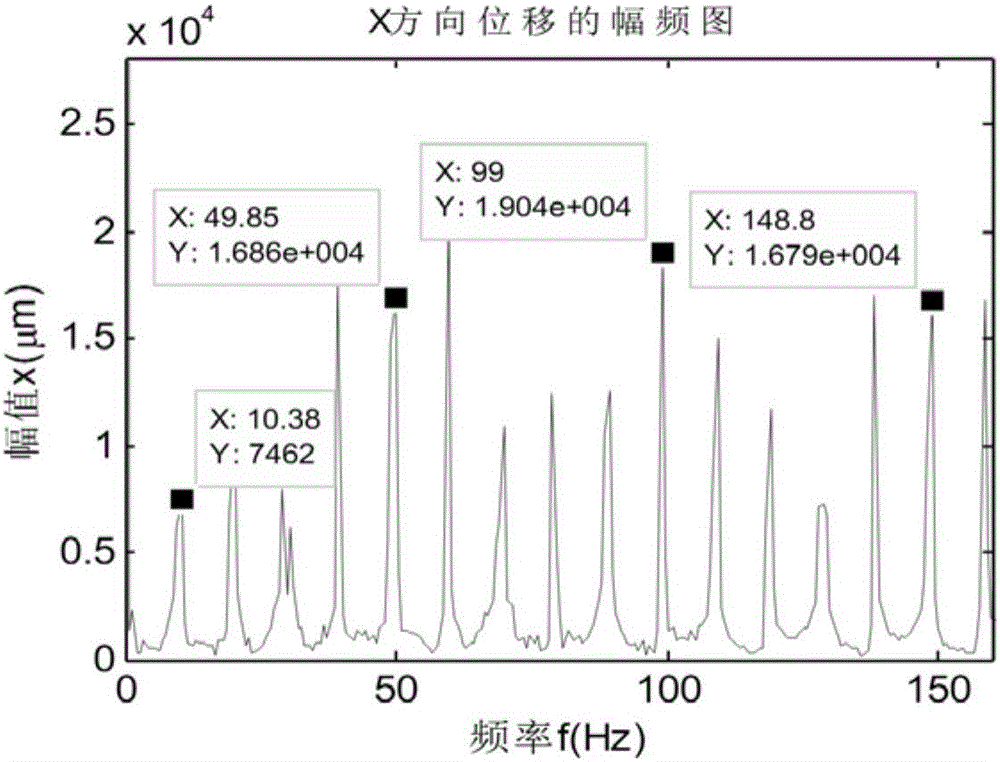

Antifriction bearing surface damage fault dynamics modeling method

InactiveCN106126850AIn line with the actual situationThe calculated result is accurateGeometric CADMachine bearings testingRolling-element bearingSimulation

The invention discloses an antifriction bearing surface damage fault dynamics modeling method, comprising the following steps: 1) on the basis of obtaining antifriction bearing contact equivalent stiffness and equivalent damping, considering antifriction bearing clearance and variation of a supporting region, establishing an antifriction bearing spring damping vibration model; 2) respectively loading impulse functions of surface damage fault points on an outer ring, an inner ring, and a rolling element, respectively establishing an antifriction bearing outer ring fault model, an antifriction bearing inner ring fault model, and an antifriction bearing rolling element fault model. The impulse functions of the surface damage fault points are respectively loaded on the outer ring, the inner ring, and the rolling element, and the antifriction bearing outer ring fault model, the antifriction bearing inner ring fault model, and the antifriction bearing rolling element fault model are established, the models meet actual conditions better, and calculated results are more accurate.

Owner:HUNAN UNIV OF SCI & TECH

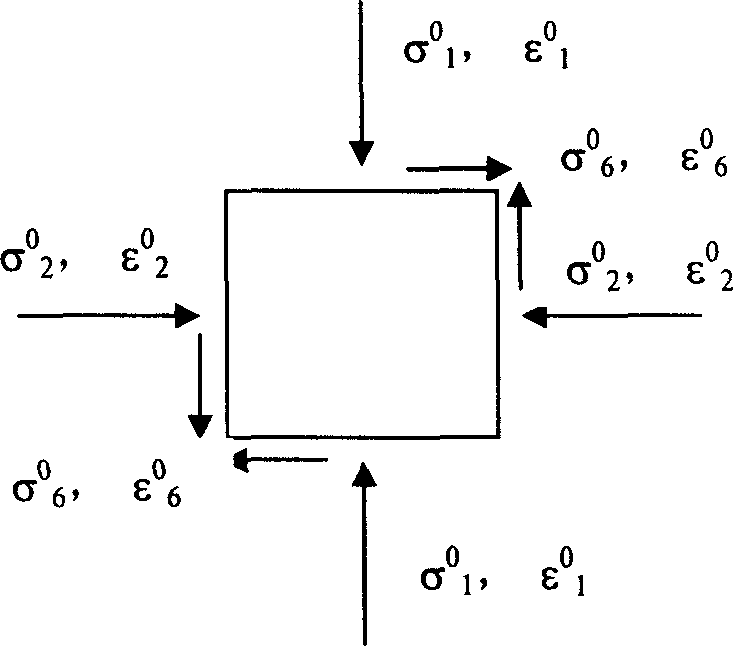

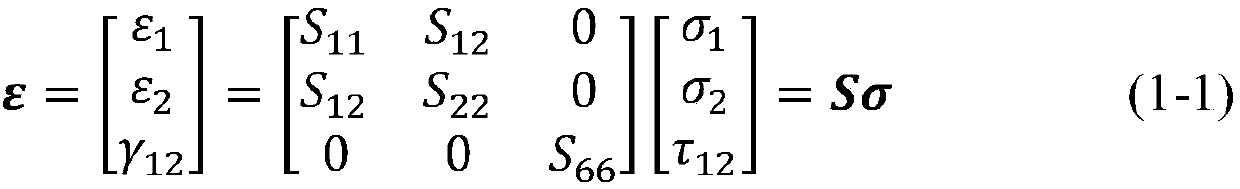

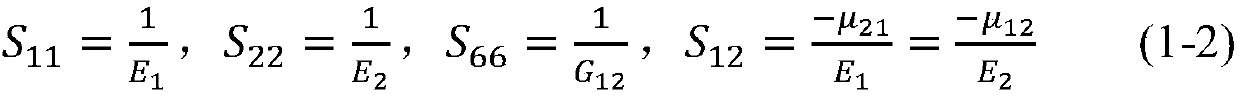

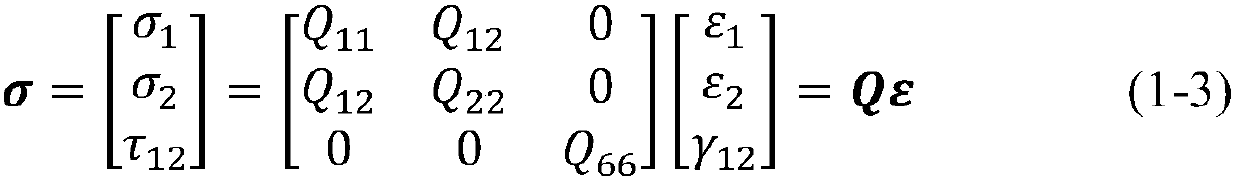

Calculation of equivalent modulus of composite laminates and strength verification under given load

ActiveCN108984841AFast resultsHigh precisionSustainable transportationDesign optimisation/simulationIn planeMaterial Design

The invention relates to the field of composite material design, in particular to calculation of equivalent modulus of composite laminates and strength verification under a given load. The invention comprises an information input module, an operation module and an information output module. Material property information, laminating information and load data information are input into the information input module. Three stiffness matrices A, D, B of composite laminates are calculated according to the input data by a computing program, and the equivalent modulus and stiffness matrices of composite laminates under pure in-plane load and pure bending-torsion load are calculated according to the matrix A and matrix D. At the same time, according to the stiffness matrix and load information, theoverall strain and deflection rate of the laminate can be calculated, and the stress and strain information of each single layer can be obtained. Through adoption of three composite failure criteria,whether the laminate meets the strength requirements under the specified load can be checked. The invention greatly improves the calculation speed, and the accurate numerical solution of stress and strain can be directly and quickly obtained for the analysis of the laminated plate under the simple stress condition, and the design efficiency is improved.

Owner:WEIHAI GUANGWEI COMPOSITES

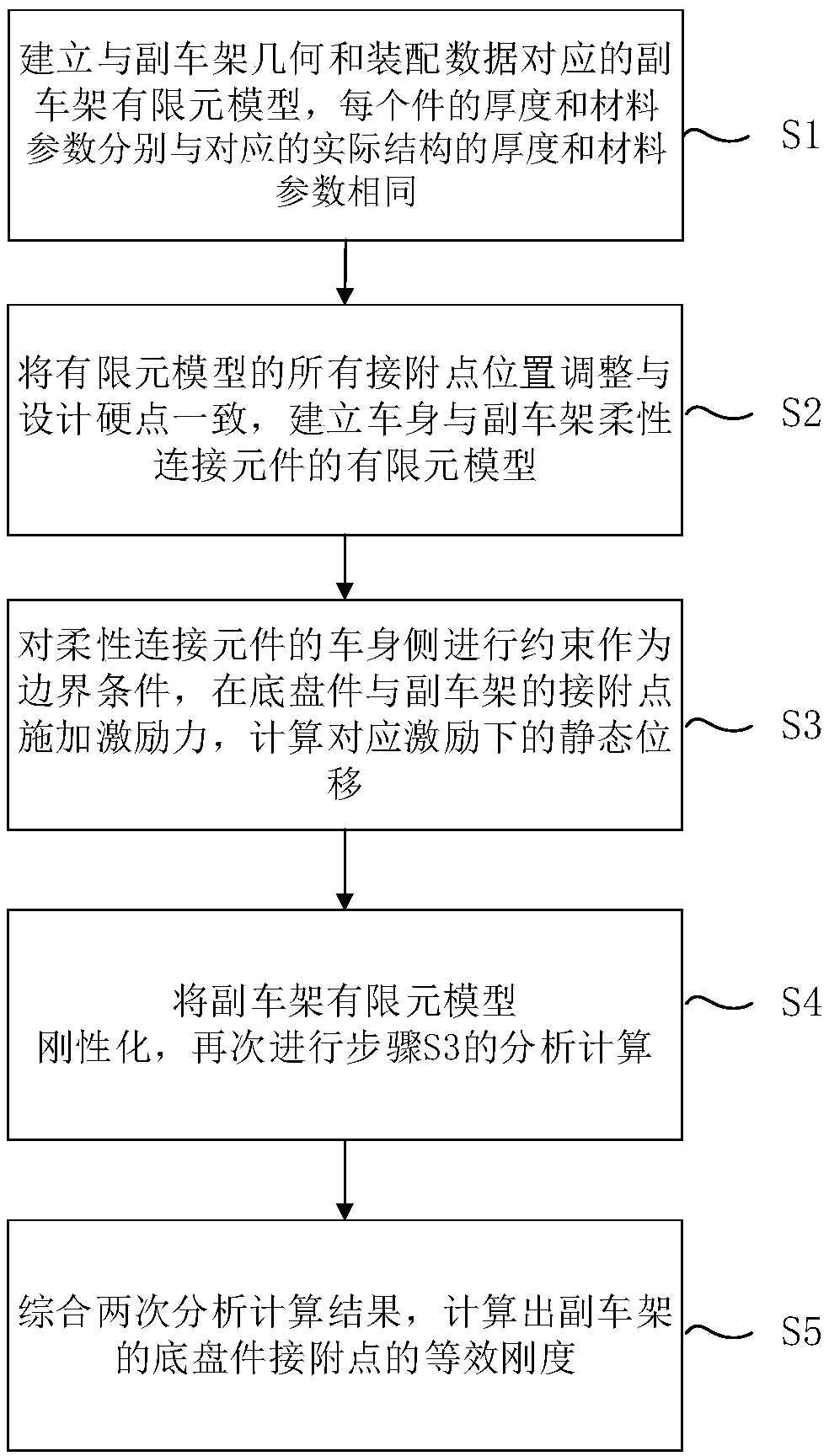

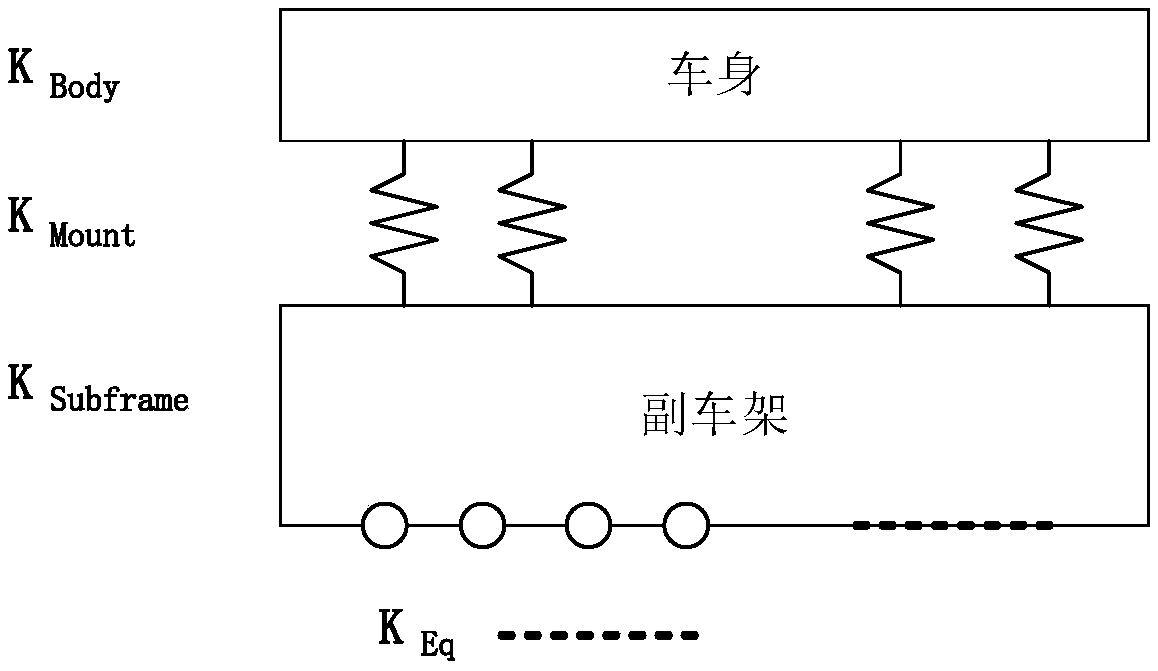

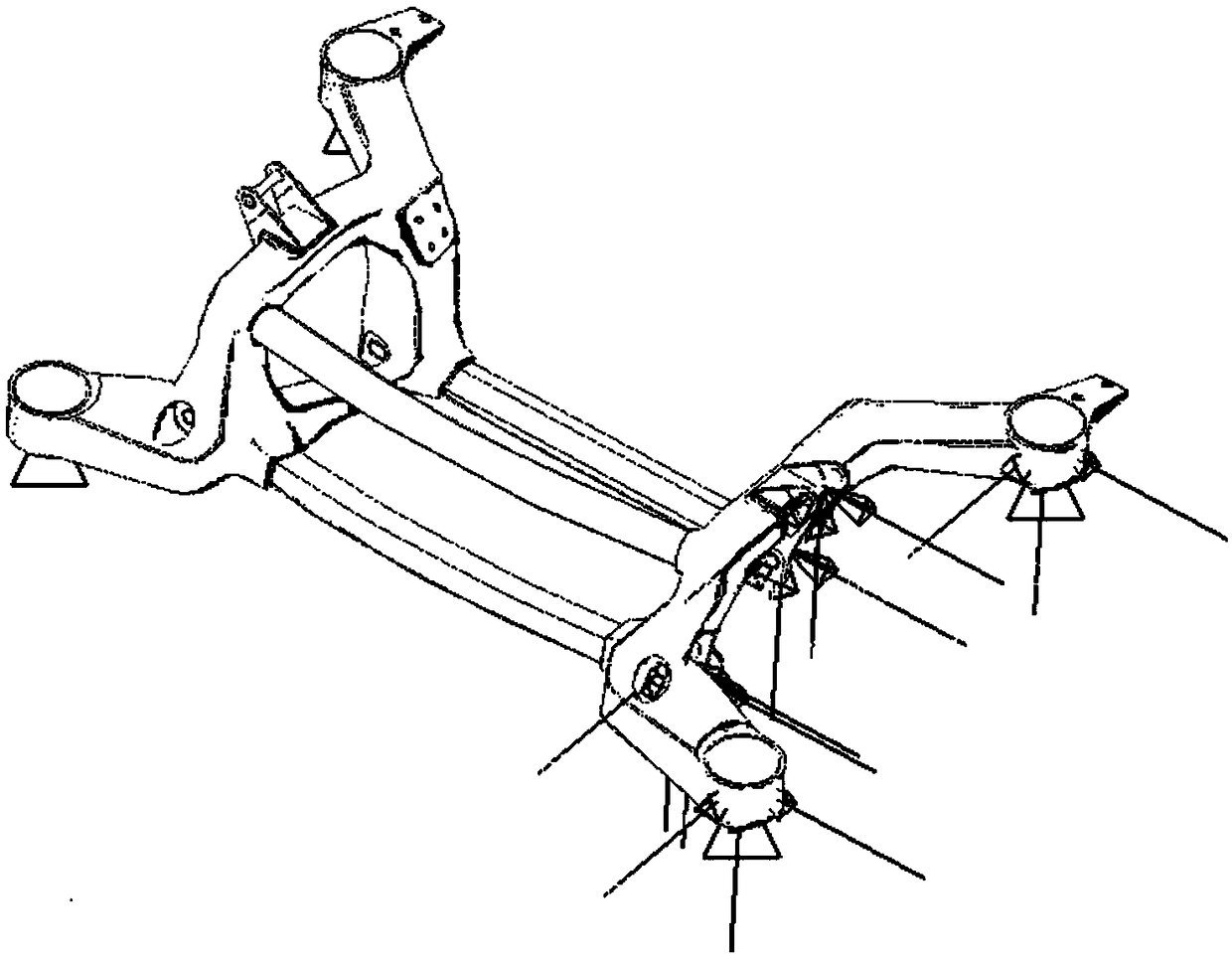

Stiffness analysis method for attachment point of flexible connection between subframe and vehicle body

PendingCN108959748AExact equivalent stiffnessEasy to analyze and evaluateGeometric CADSustainable transportationVehicle frameEquivalent stiffness

The invention relates to a stiffness analysis method for - attachment points of a flexible connection between a subframe and a vehicle body. The method comprises the following steps: 1, establishing afinite element model of the subframe corresponding to the geometry and assembly data of the subframe; 2, adjusting the positions of all attachment points of the finite element model of the subframe to be consistent with the design hard points, and establishing the finite element model of the flexible connecting element of the vehicle body and the subframe; 3, taking the constraint on the body side of the flexible connecting element as a boundary condition, applying an exciting force at the attachment point of the chassis member and the subframe, and calculating a first static displacement value under the correspond excitation; 4, after the finite element model of the subframe is rigidified, calculating the second static displacement value by the method of the step 3; 5, calculating the equivalent stiffness of the chassis attachment point of the subframe by two static displacement values. Compared with the prior art, the method can obtain more accurate equivalent stiffness of the attachment point, and is favorable for analyzing and evaluating the stiffness of the attachment points of the subframe chassis with vibration isolation.

Owner:SHANGHAI COTECH AUTOMOTIVE ENG CORP LTD

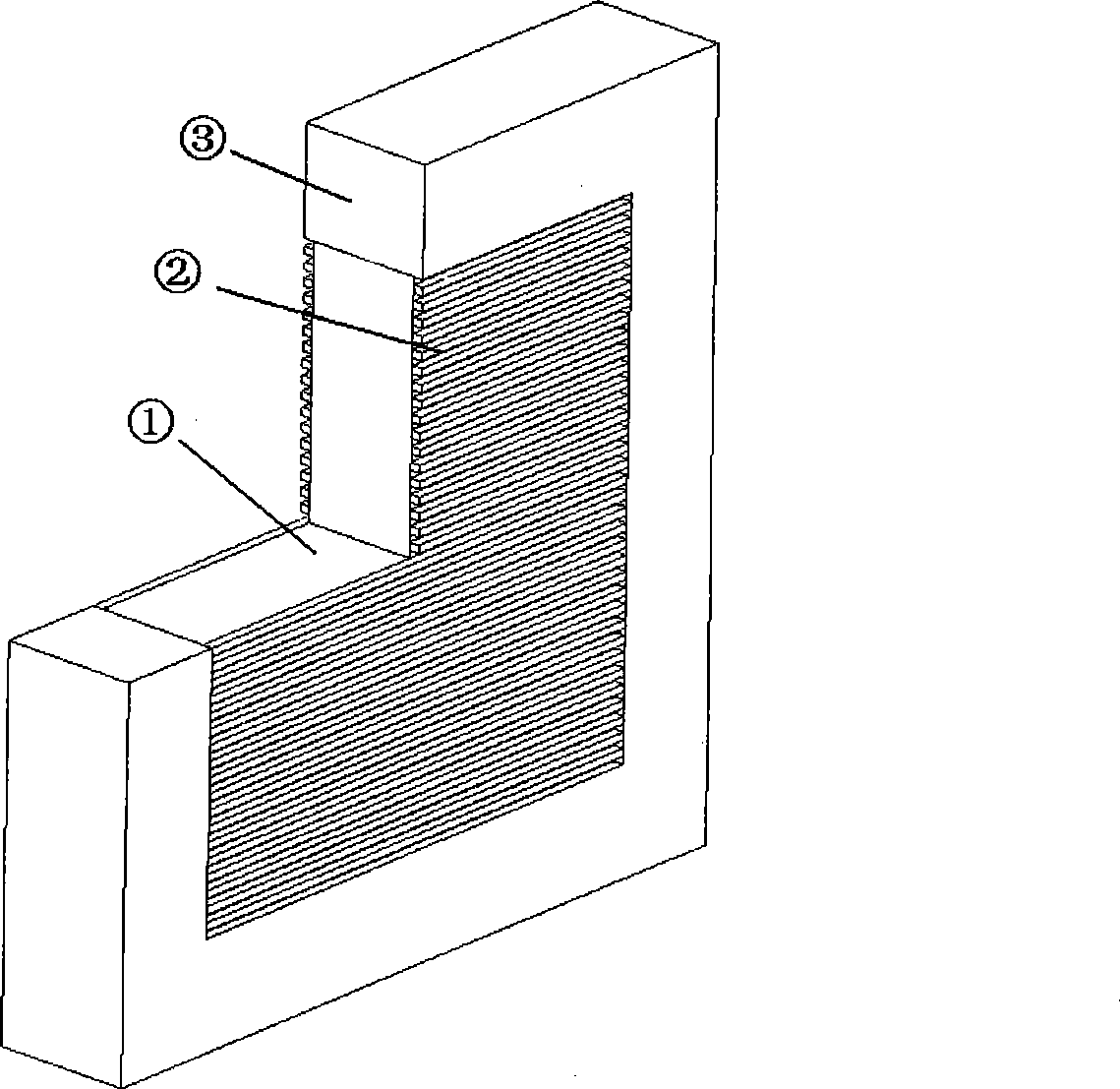

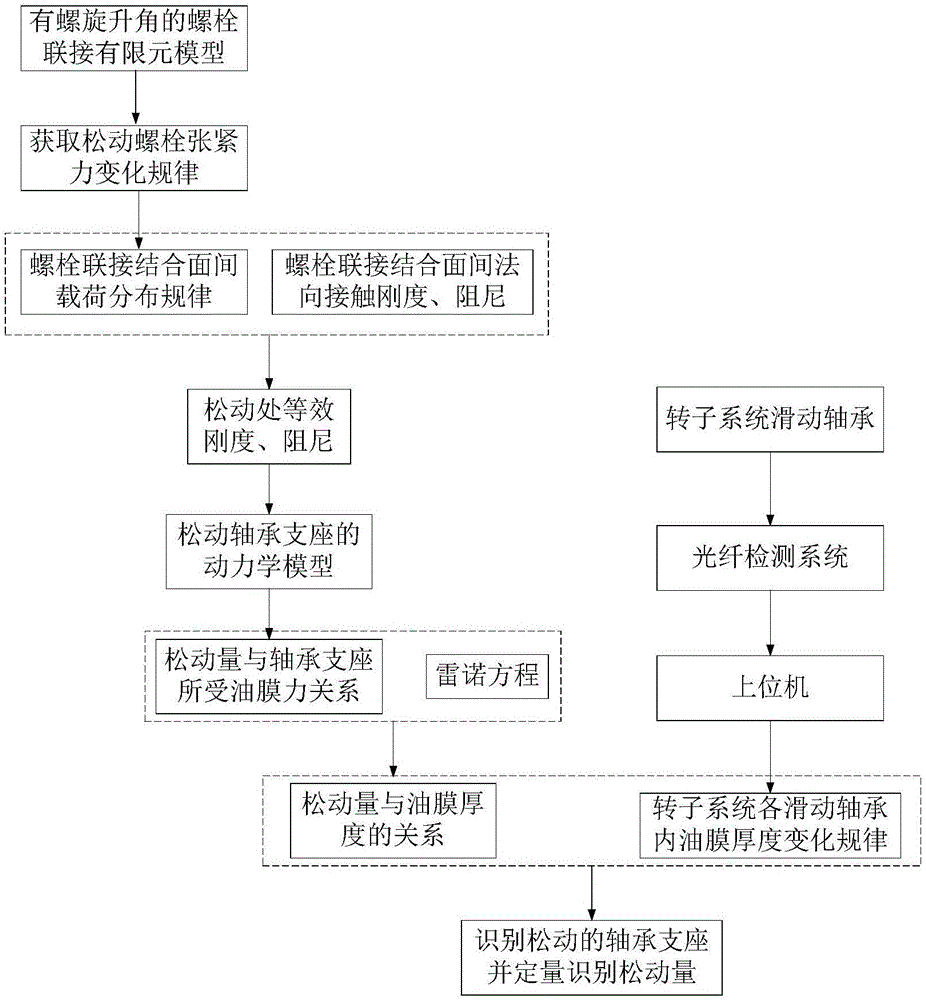

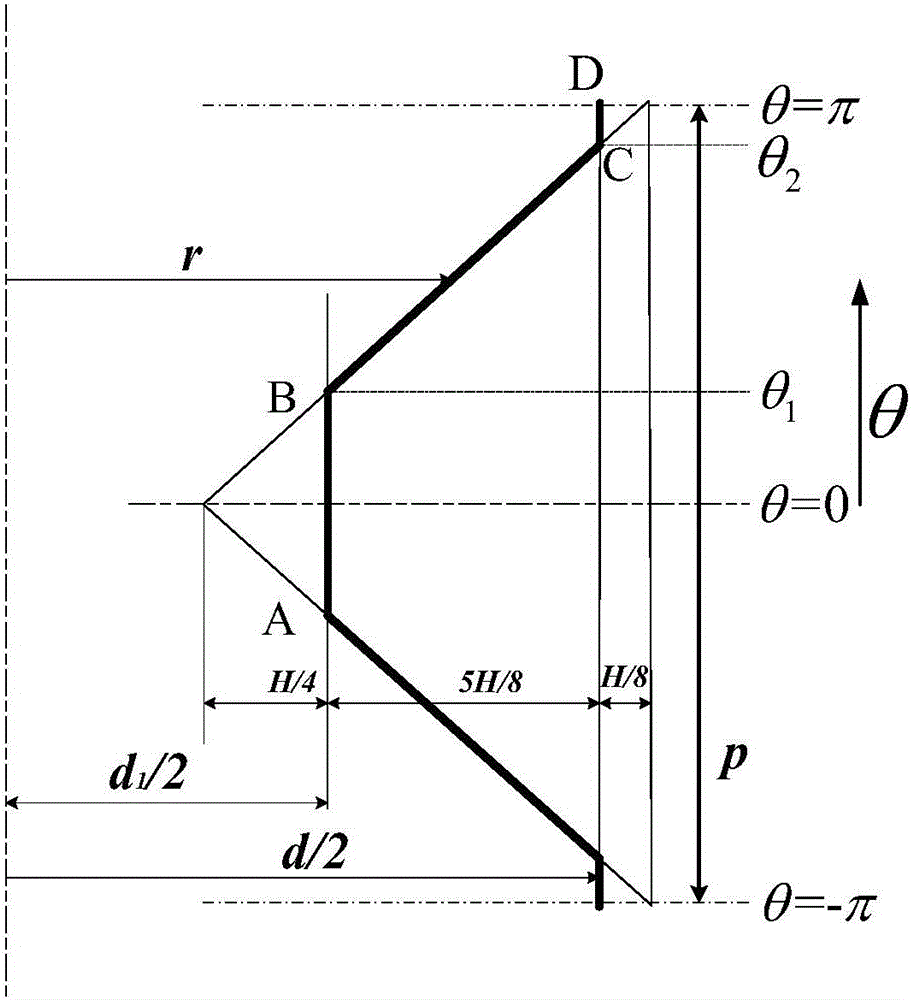

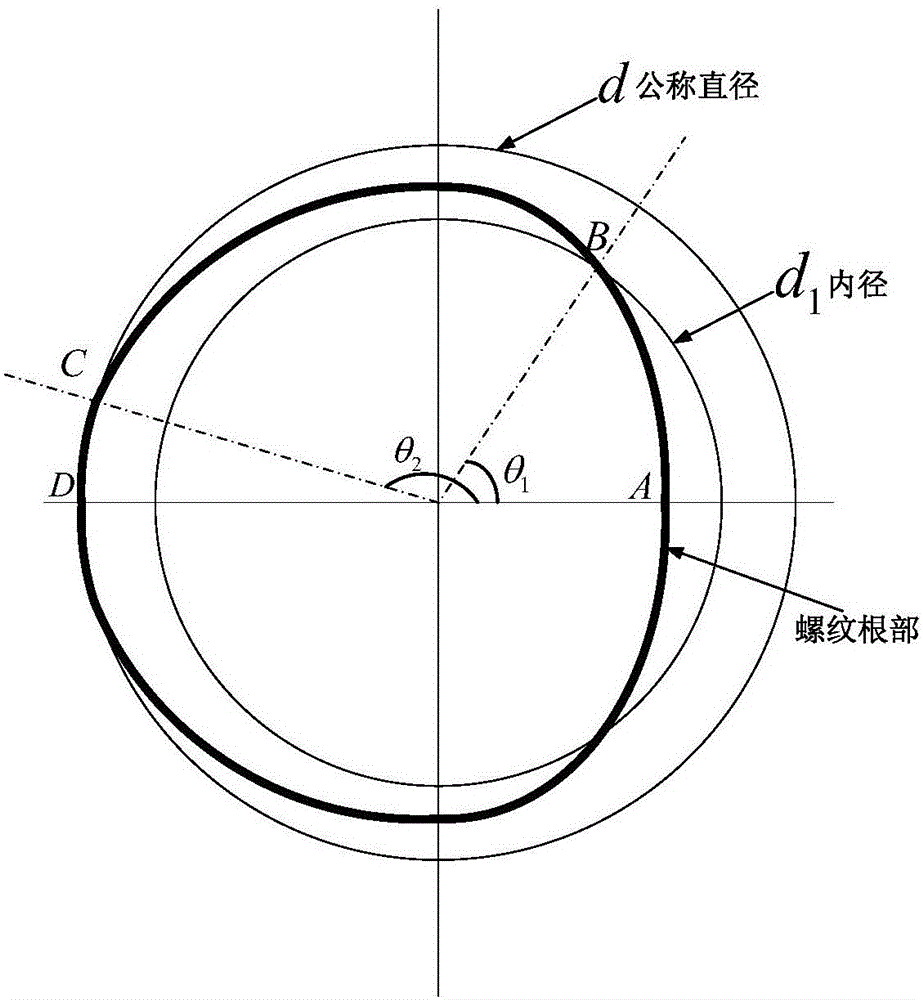

Online quantitative recognition analysis method for loose fault of bearing support of rotor system

ActiveCN106650146ARealize quantitative analysisShorten the pathGeometric CADDesign optimisation/simulationMomentumEquivalent stiffness

The invention provides an online quantitative recognition analysis method for a loose fault of a bearing support of a rotor system. The method comprises the following steps: 1) establishing a bolt model with spiral threads; 2) acquiring a change rule of load distribution between junction surfaces of screw connection following the loose amount; 3) acquiring the change rule of normal contact stiffness and damp of the junction surfaces of screw connection following the loose amount; 4) acquiring the change rule of equivalent stiffness and damp at the loose position following the loose amount; 5) establishing a dynamical model taking the loose bearing support as an object, thereby acquiring a relation between the loose amount of the bearing support and the oil film pressure endured by the bearing support; 6) acquiring the relation between the thickness distribution of a lubricating film and the loose amount; 7) monitoring the change rule of the thickness distribution of the lubricating film in a sliding bearing online in real time; 8) quantitatively recognizing and analyzing a loose fault signal of the bearing support online. According to the method provided by the invention, a dynamical model establishing method and a fault carrier signal with a shorter route and few influence factors are supplied for the loose fault of the bearing support.

Owner:XI AN JIAOTONG UNIV

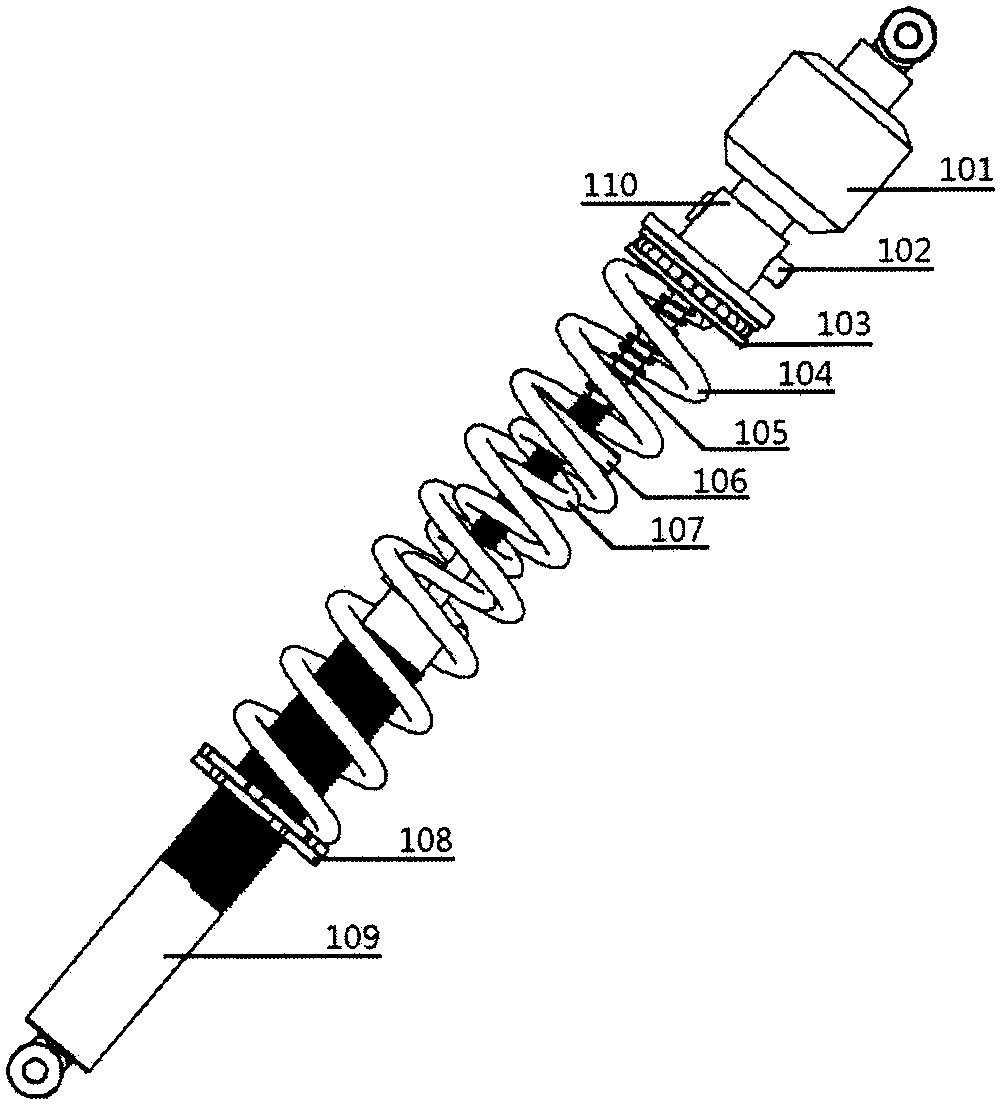

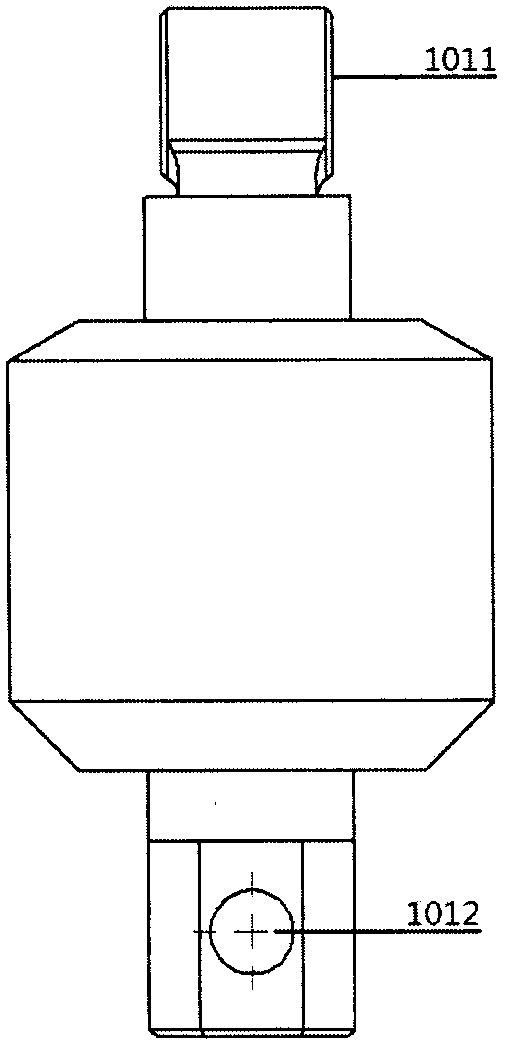

Automatic suspension system, and control system and method of automobile suspension system

InactiveCN108081894AEnsure handling stabilityAdjustable stiffnessResilient suspensionsVehicle springsControl systemEquivalent stiffness

The invention relates to an automobile suspension system, and a control system and method of the automobile suspension system and belongs to the technical field of automobile suspension. The automobile suspension system comprises a lower swing arm, a shock absorber assembling component, an upper swing arm and a wheel assembling component. According to the automobile suspension system, the equivalent stiffness of suspension springs is adjusted according to signals collected by a sensor, and the manipulation stability and traveling comfort of an automobile are fully combined; the height of an automobile chassis is adjusted appropriately, and the traveling passing ability of the automobile is improved; a rotary type stepping motor of the suspension system further has the effect similar to a force generator in an active suspension system and can provide reacting force counteracting impact of wheels for the suspension system through forward rotation or reverse rotation; and a limiting nut and a piston rod thread constitute a lead screw nut structure, so that the self-locking function is achieved, thus, electric energy is consumed only when the rotary type stepping motor rotate forwardsor reversely, and the energy saving effect of the automobile suspension system is better than that of the active suspension system.

Owner:李天逸

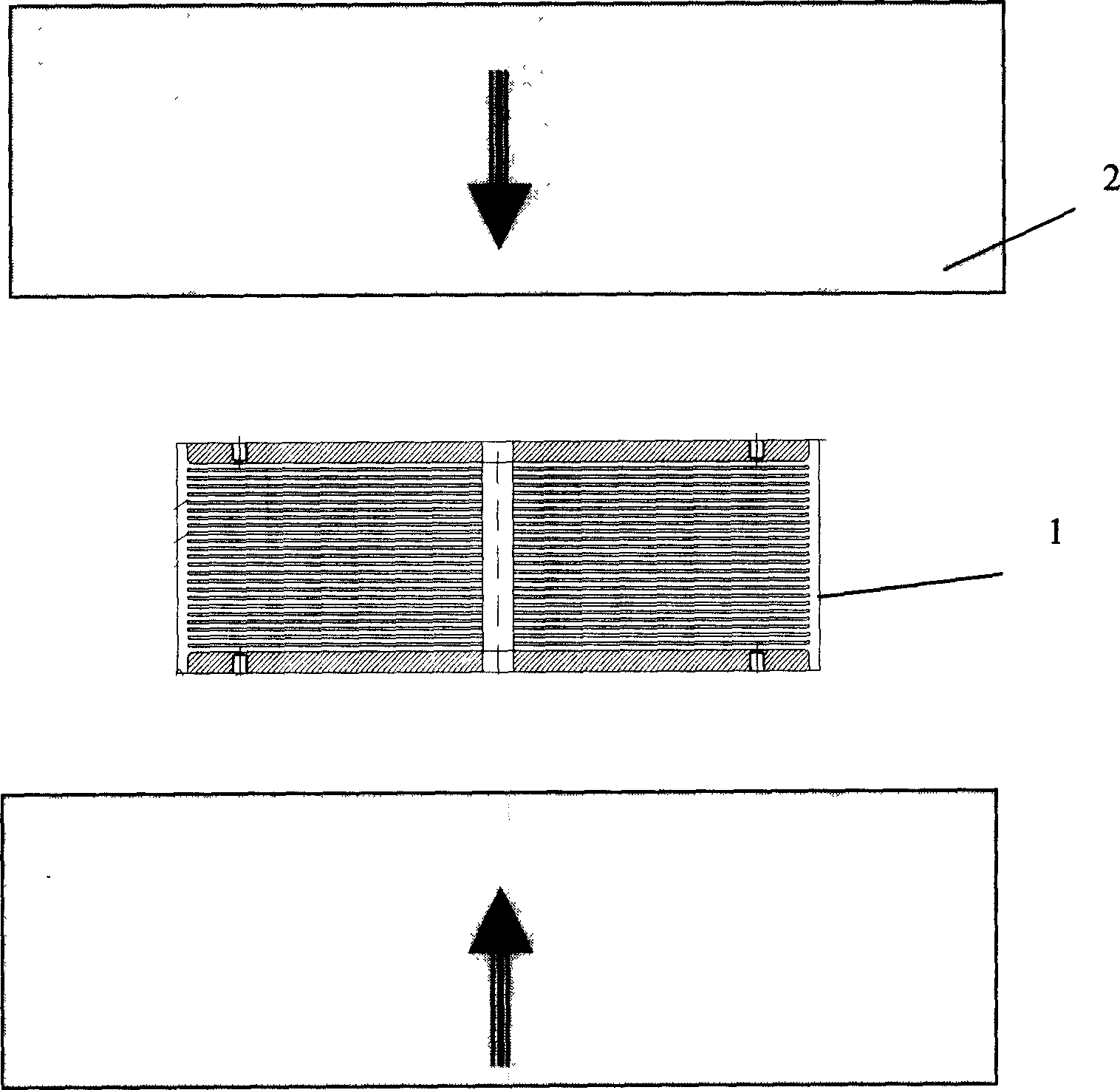

Method for detecting horizontal equivalent stiffness of rubber shock insulation support

InactiveCN1595099ASimple test methodMaterial strength using repeated/pulsating forcesInvestigating material hardnessEquivalent stiffnessEngineering

This invention relates to a method to measure the horizontal equivalent stiffness of the rubber shock insulation holder, which is to locate the rubber shock insulation holder in the load device and exert vertical pressure on the rubber insulation holder. When the pressure amounts to certain designed value, it repeats the load and unload experiences based on the designed value and get the stress difference value Sigma1-Sigma2 between maximum load and minimum load and get the relevant deformation differential value Delta1-Delta2 of maximum load and minimum load and get the horizontal equivalent stiffness of the rubber insulation holder according toe the formula Kh=(Sigma1-Sigma2)A / (Delta1-Delta2) / Phi / S1.

Owner:GUANGZHOU UNIVERSITY

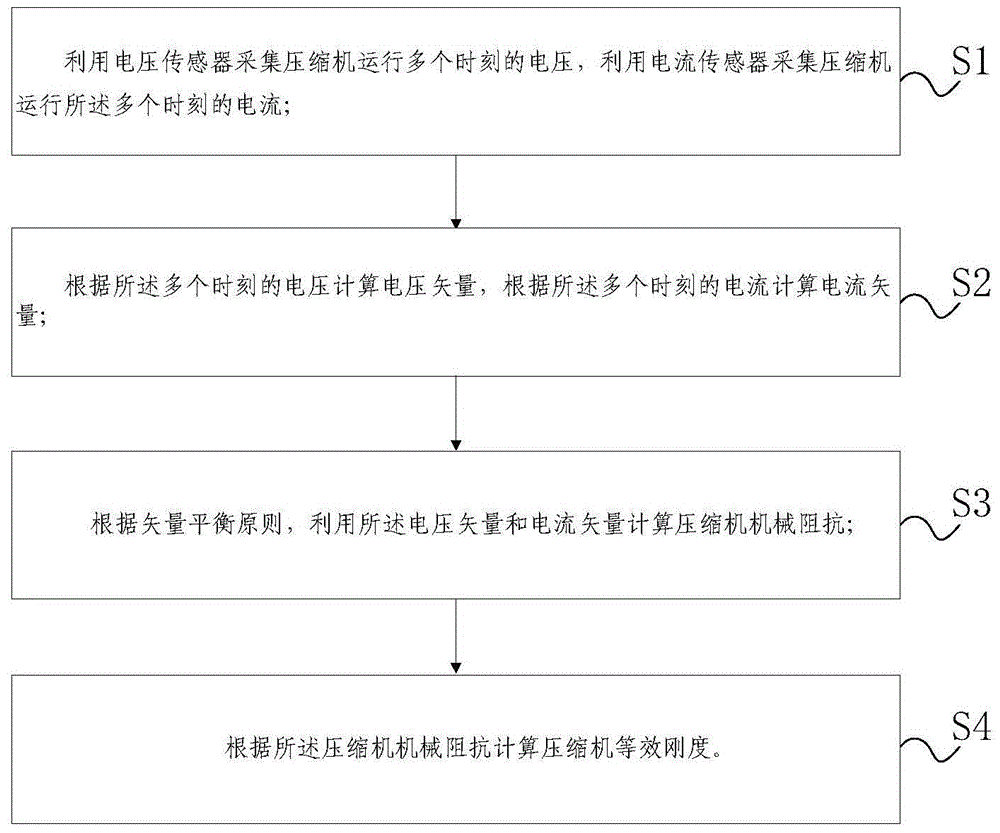

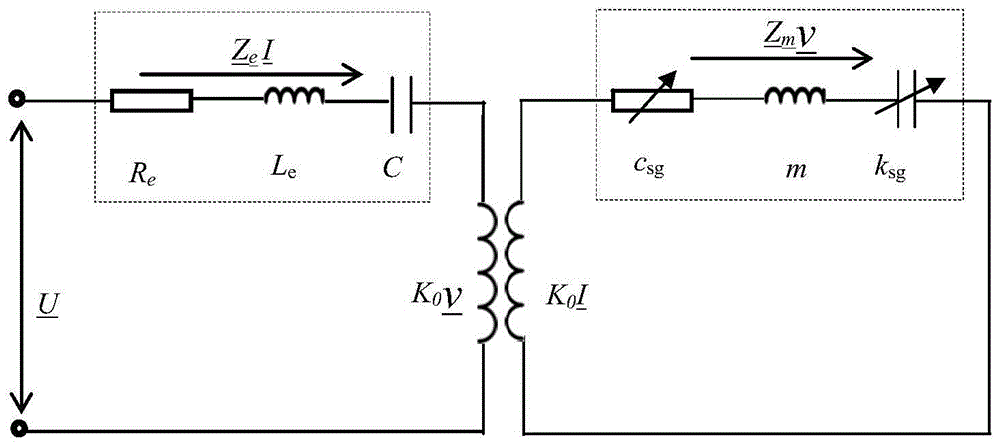

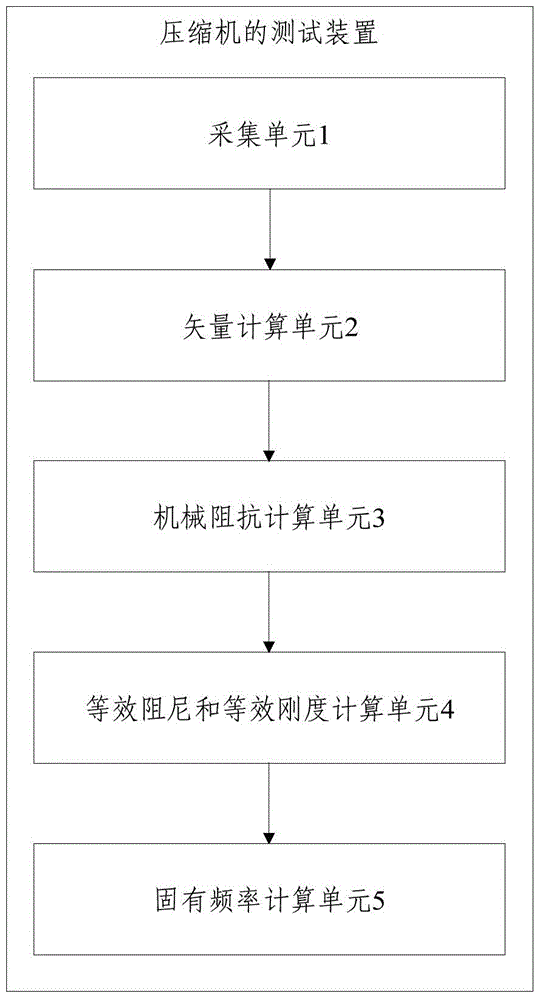

Testing method and device of compressor

ActiveCN104963849AReal-time detection of equivalent stiffnessPump testingPositive-displacement liquid enginesVoltage vectorPower flow

The invention discloses a testing method and device of a compressor. Equivalent stiffness of a linear compressor and a linear oscillation motor can be detected accurately in real time. The method comprises the steps that a voltage sensor is utilized for collecting voltages of the compressor running at multiple moments, and a current sensor is utilized for collecting currents of the compressor running at the multiple moments; according to the voltages at the multiple moments, the voltage vector is calculated, and according to the currents at the multiple moments, a current vector is calculated; on the basis of a vector balance principle, the voltage vector and the current vector are utilized for calculating mechanical impedance of the compressor; and according to the mechanical impedance of the compressor, the equivalent stiffness of the compressor is calculated.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com