Vibration isolator with magnetic suspension unit

A magnetic levitation and vibration isolator technology, applied in the direction of magnetic spring, spring/shock absorber, mechanical equipment, etc., can solve the problem of low vibration isolation stiffness of vibration isolator, passive vibration damping technology cannot be fully applied, and vibration isolator cannot suppress vibration And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

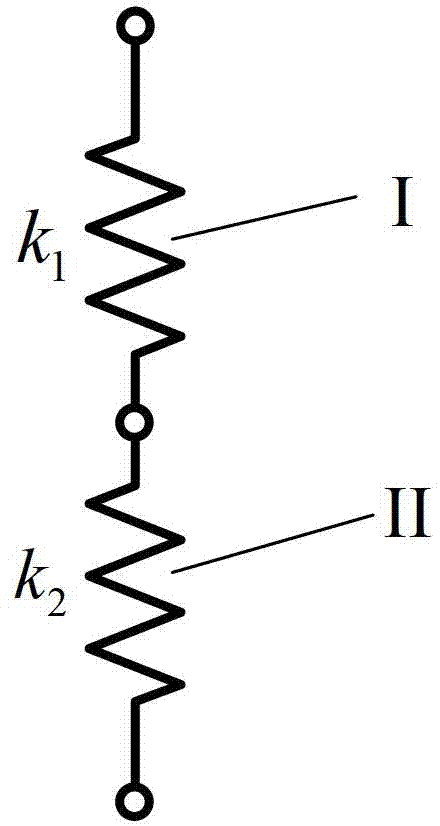

[0015] The design idea of the vibration isolator provided by the present invention is: a magnetic levitation unit with negative stiffness is connected in series with a mechanical spring with positive stiffness to form a large stiffness spring system with extremely high stiffness. Using this large stiffness spring system, a vibration isolation system capable of active vibration suppression of precision instruments and equipment can be designed.

[0016] The present invention will be described in more detail below with the help of examples, but this example is only illustrative, and the protection scope of the present invention is not limited by this example.

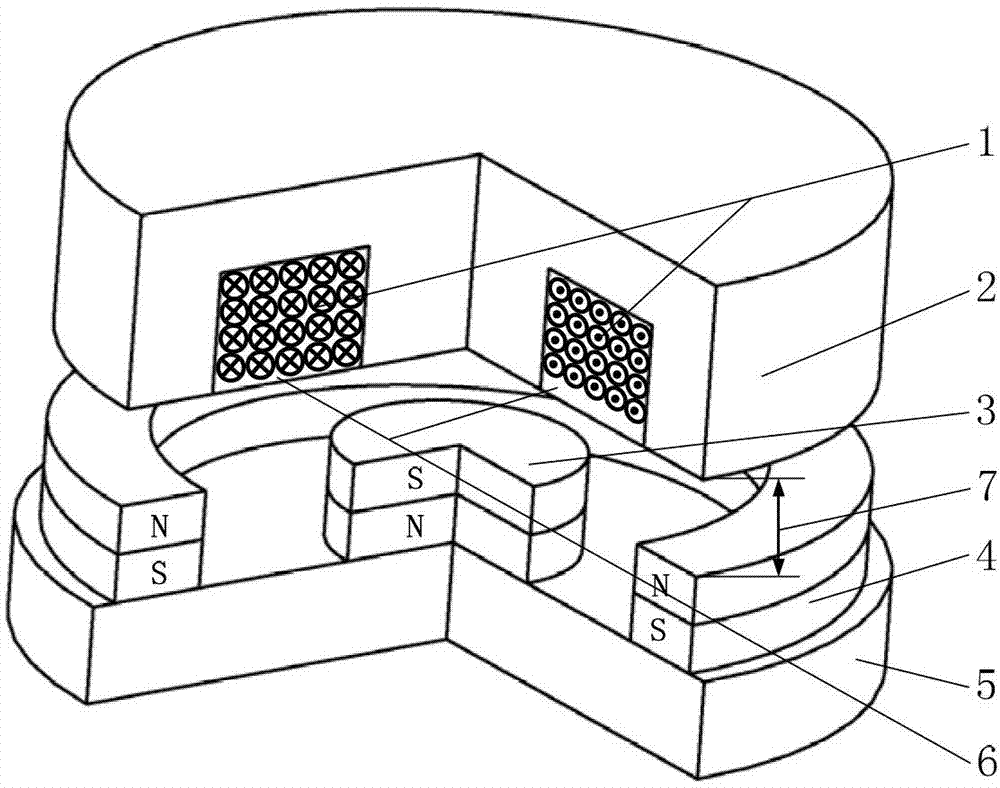

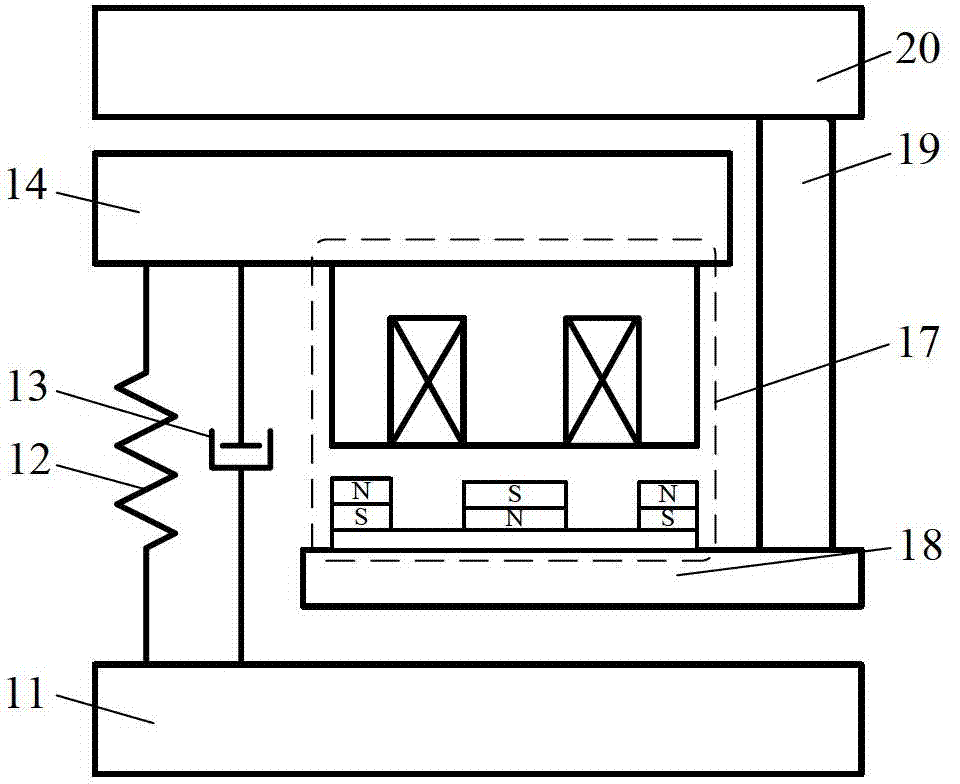

[0017] A system structure and working principle including a magnetic levitation active vibration isolator of the present invention, combined with embodiments and drawings, are described in detail as follows:

[0018] The active vibration isolator provided by the present invention includes a large-rigidity spring system,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com