Patents

Literature

76results about How to "Improve interface affinity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

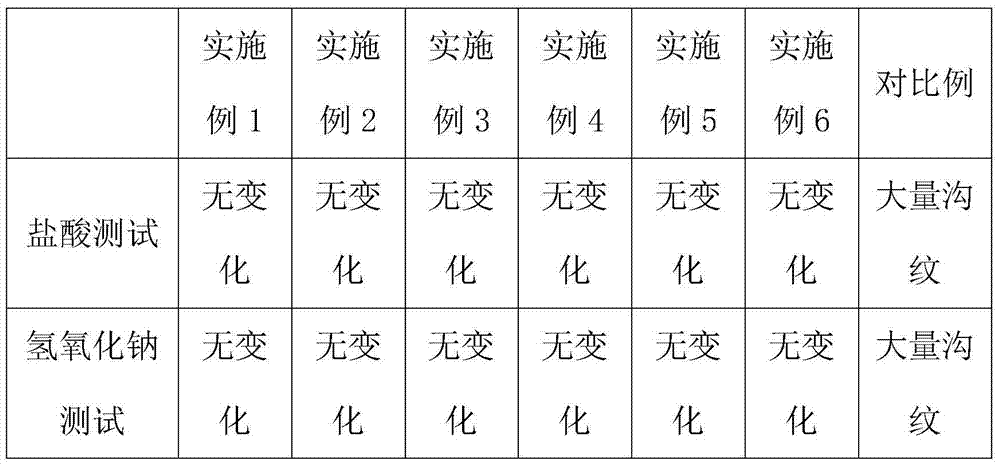

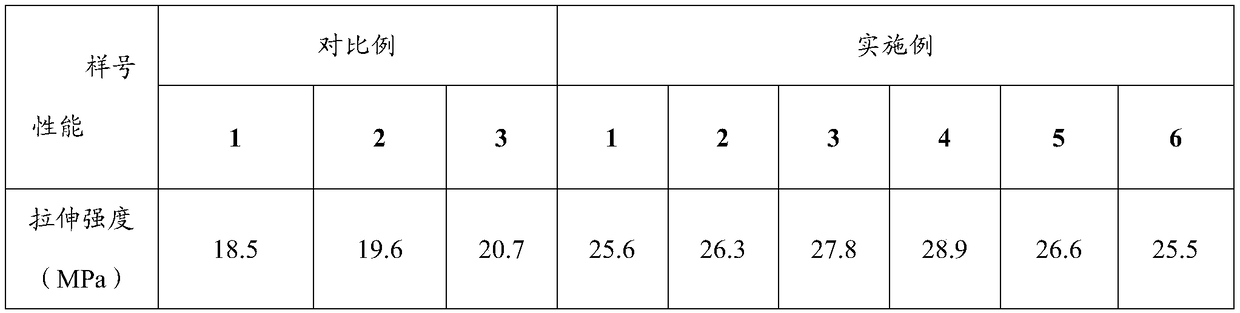

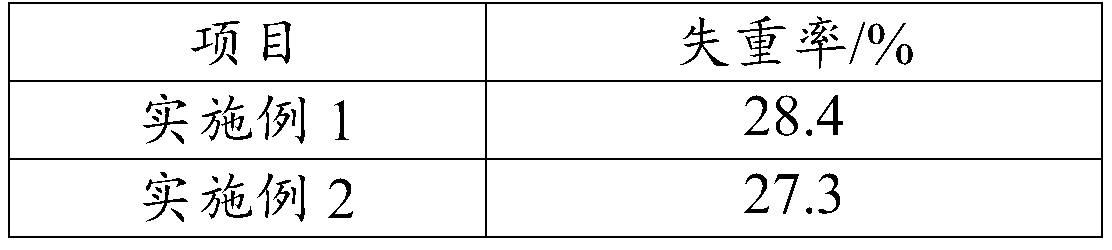

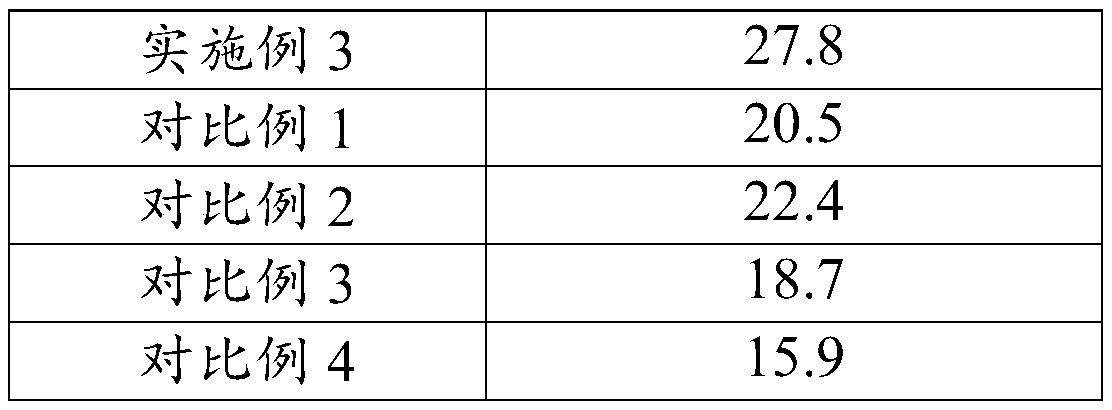

Preparation method of pure p-aramid paper

InactiveCN102517976AImprove interface affinityHigh tensile strengthSynthetic cellulose/non-cellulose material pulp/paperHigh stiffnessHigh density

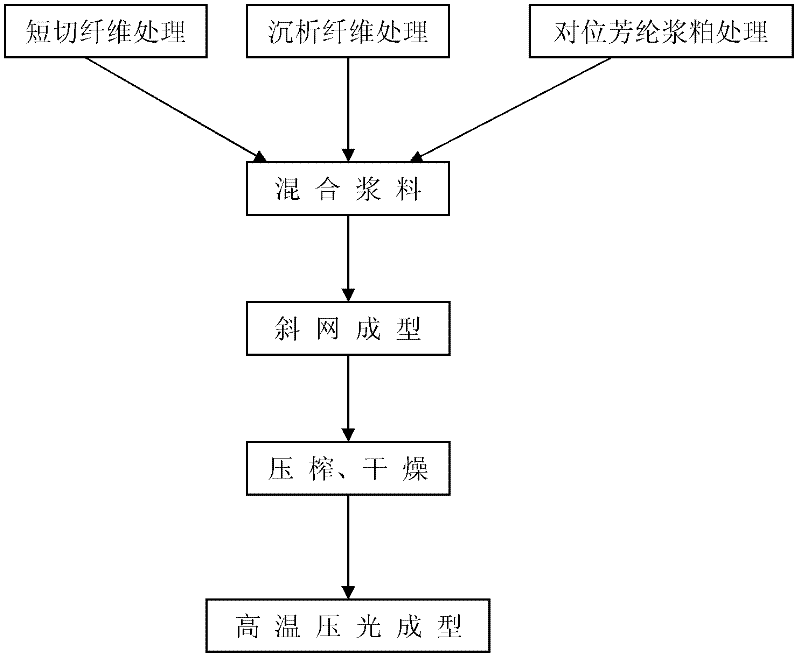

The invention relates to a preparation method of pure p-aramid paper. The preparation method of the pure p-aramid paper comprises the following steps of 1, respectively preparing p-aramid chopped fiber pulp, p-aramid fibrid pulp and p-aramid pulp, and mixing the p-aramid chopped fiber pulp, the p-aramid fibrid pulp and the p-aramid pulp, 2, approaching flows of the mixed pulp onto a net for molding, 3, carrying out squeezing and drying, and 4, carrying out high-temperature press-polish molding. The preparation method of the pure p-aramid paper has the advantages that p-aramid fibrids are utilized as bonding materials of the pure p-aramid paper so that interface affinity of fibers is improved and fiber paper mechanical properties of tensile strength, tearing strength and wear resistance are improved; p-aramid pulp has a high specific surface area so that a hydrogen bond binding capacity of fibers is improved and the pure p-aramid paper having high density, high stiffness and high strength is obtained; and in a preparation process, concentrated sulfuric acid is not needed so that the problems of equipment corrosion and dilute sulphuric acid recovery complexity are solved.

Owner:YANTAI METASTAR SPECIAL PAPER +1

Method for preparing para aramid paper from para aramid fibrid

ActiveCN103572640AImprove interface affinityEnhanced hydrogen bondingPaper/cardboardSynthetic cellulose/non-cellulose material pulp/paperBreaking strengthWear resistance

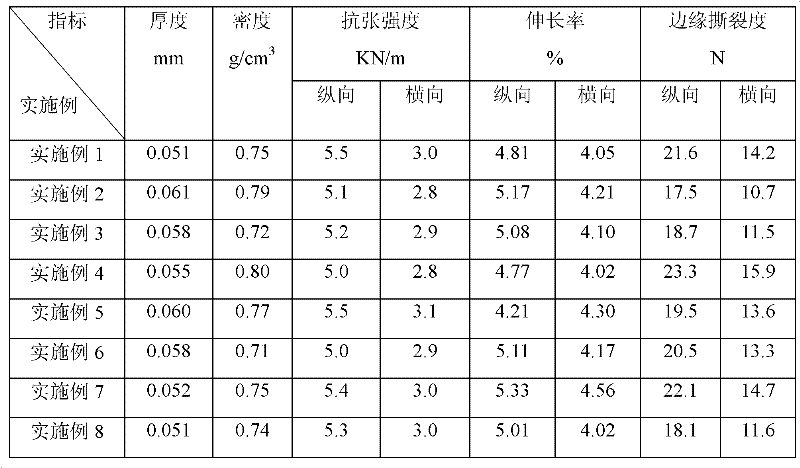

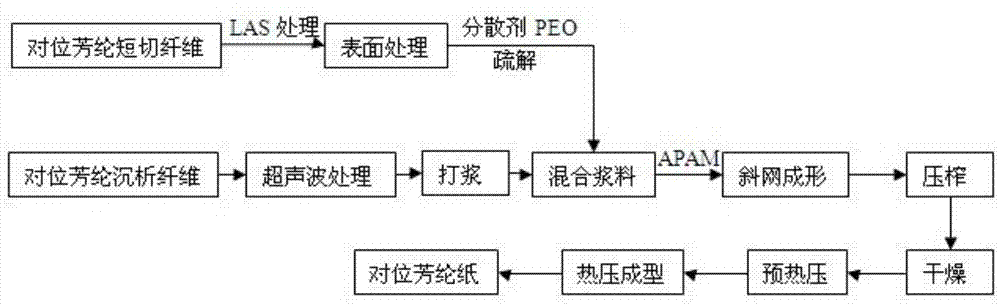

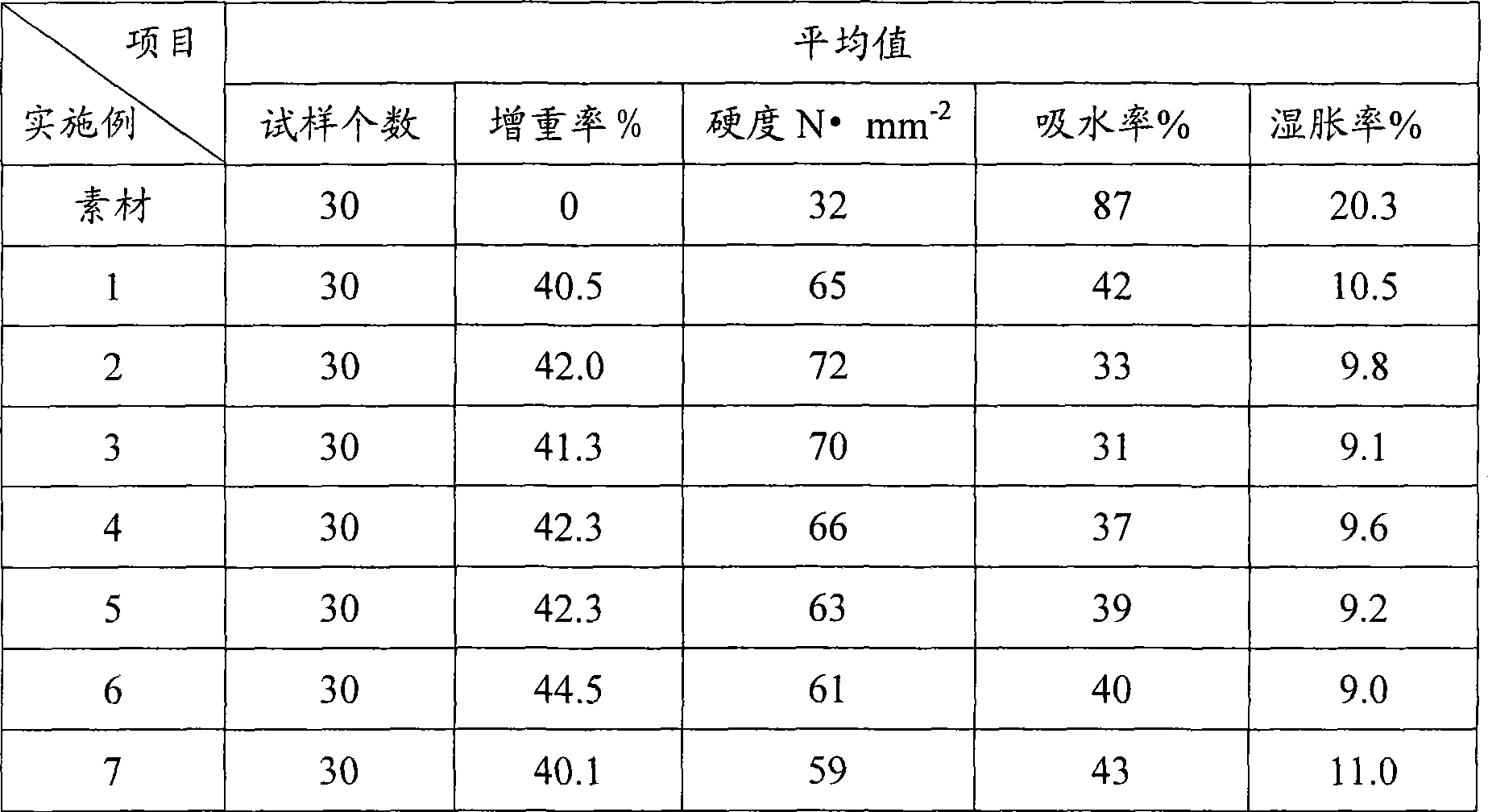

The invention discloses a method for preparing para aramid paper from para aramid fibrid. The method concretely comprises the steps of carrying out surface treatment, defibering and dispersion on para aramid chopped fibers; carrying out ultrasonic treatment and pulping treatment on the para aramid fibrid; mixing the treated para aramid chopped fibers and the treated para aramid fibrid; adding anionic polyacrylamide into the mixed fibers to obtain aramid fiber pulp; shaping the aramid fiber pulp on an inclined wire paper machine; dehydrating, squeezing and drying; carrying out pre-hot-pressing on the dried aramid base paper, and then carrying out hot pressing by a hot press to obtain the para aramid paper. After the method for preparing the para aramid paper from the para aramid fibrid is adopted, the tensile strength, the tearing strength, the breaking strength, the wear resistance and the dielectricity of the para aramid paper are remarkably improved, and the para aramid paper can be taken as a structural material, an insulating material or an electronic material and is relatively widely applied to the fields of transportation, electronics and electric power, aerospace and the like.

Owner:SHAANXI UNIV OF SCI & TECH

Polymer graft modification composite hollow micro-bead and preparation thereof

InactiveCN101434683AHigh compressive strengthSuppression of defective structuresPigment treatment with macromolecular organic compoundsPolymer scienceMicrosphere

The invention relates to a complex hollow microsphere of polymer grafting modification and a preparation method thereof, and pertains to the technical field of surface modification of hollow microsphere. The method provides the complex hollow microsphere of polymer grafting modification and the preparation method thereof aiming at the disadvantages that the surface properties and the compressive strength of the hollow microsphere up to now are hard to be improved simultaneouly. The complex hollow microsphere causes the compressive strength and the compatibility with matrix to be greatly improved by graft polymer on a surface, and can also inhibit defect structure in the surface of the complex hollow microsphere. The method is simple, easy to be operated, and low in cost. The complex hollow microsphere of polymer grafting modification is applied to complex material as light intensified filling.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Polyamide/acrylonitrile-butadiene-styrene copolymer alloy and its prepn

The present invention relates to one kind of polyamide / acrylonitrile-butadiene-styrene copolymer alloy and its preparation process. The polyamide / acrylonitrile-butadiene-styrene copolymer alloy is prepared with polyamide 35-60 wt%, acrylonitrile-butadiene-styrene copolymer 8-50 wt%, compatilizer 2-10 wt%, flexibilizer 2-15 wt%, antioxidant stabilizer 0.2-2 wt%, lubricant 0.3-3 wt%, and nucleator 0.1-2 wt%. The preparation process includes weighing the materials based on the weight proportion, mixing in a high speed mixer for 1-4 min, mixing, melting and extruding in a double screw extruder, and pelletizing. The polyamide / acrylonitrile-butadiene-styrene copolymer alloy has simple processing and molding process and high performance.

Owner:SHENZHEN KEJU NEW MATERIAL

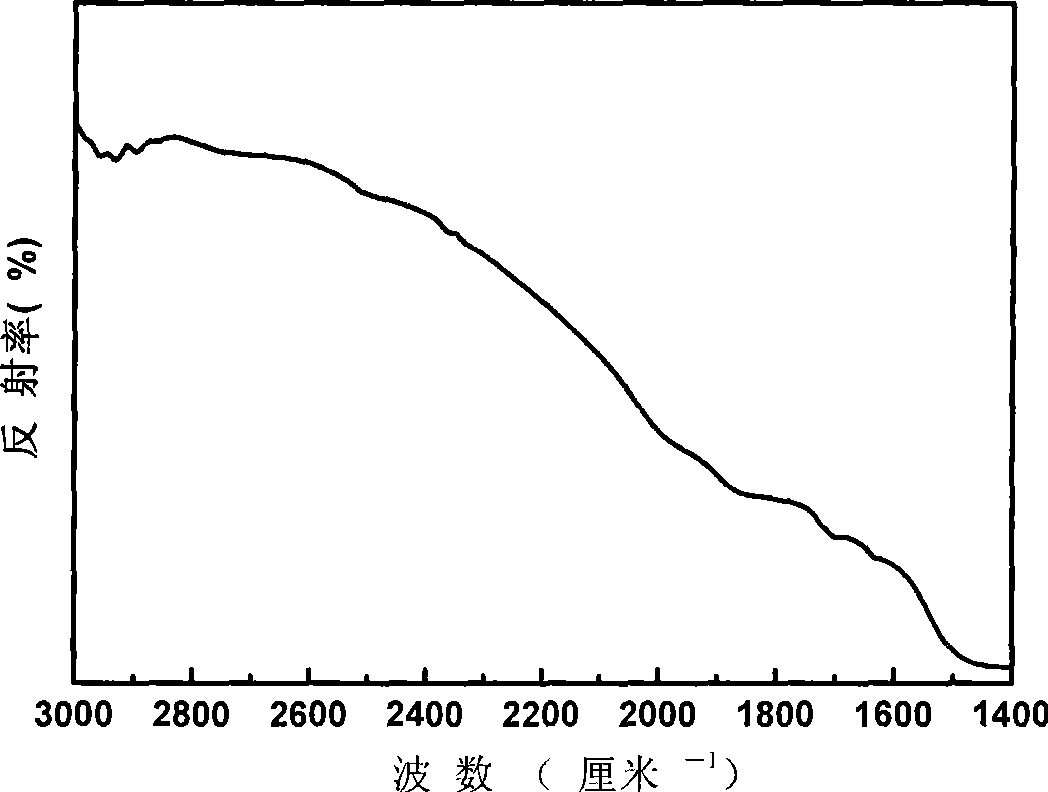

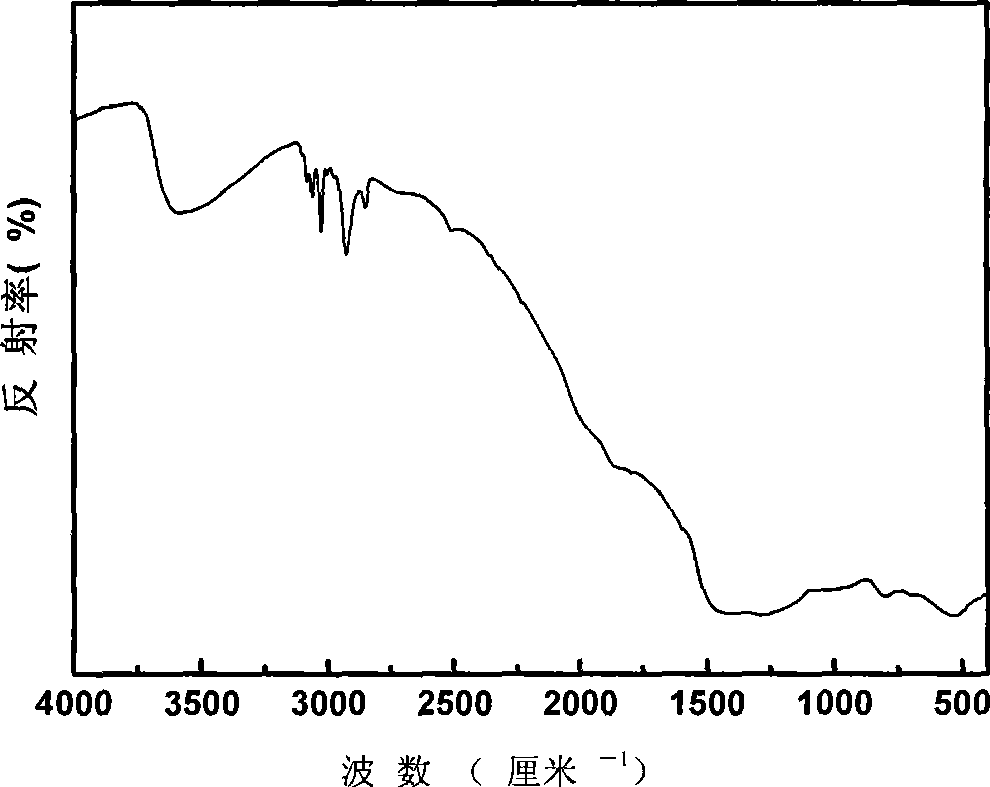

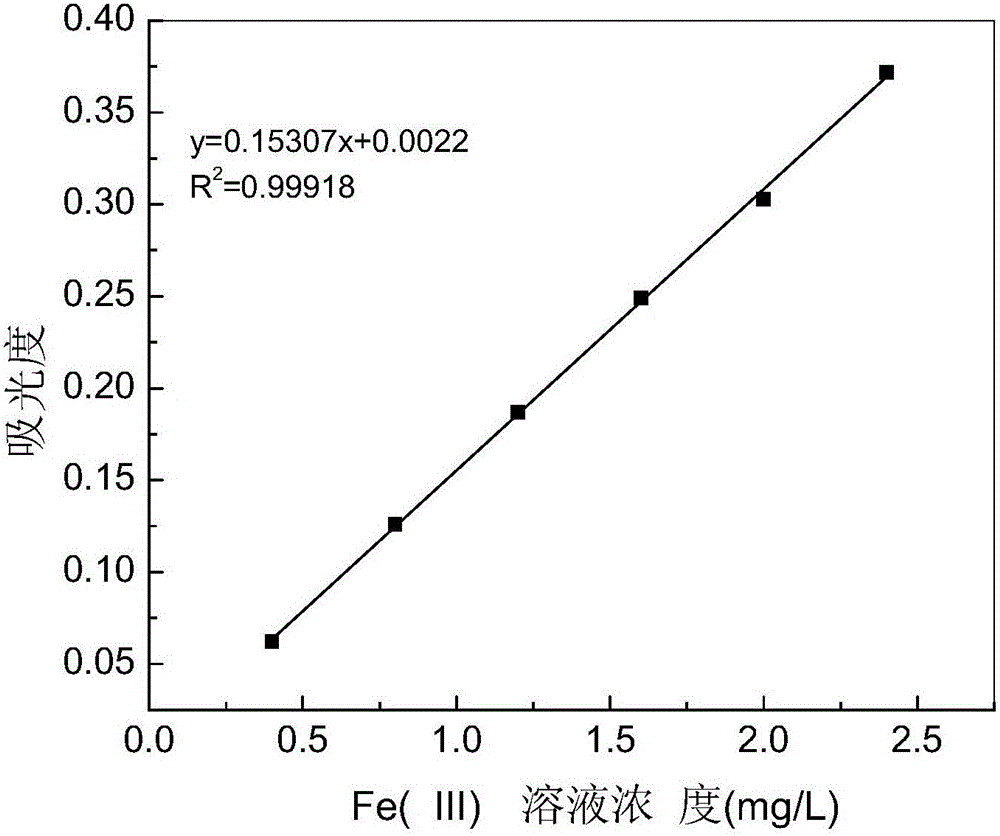

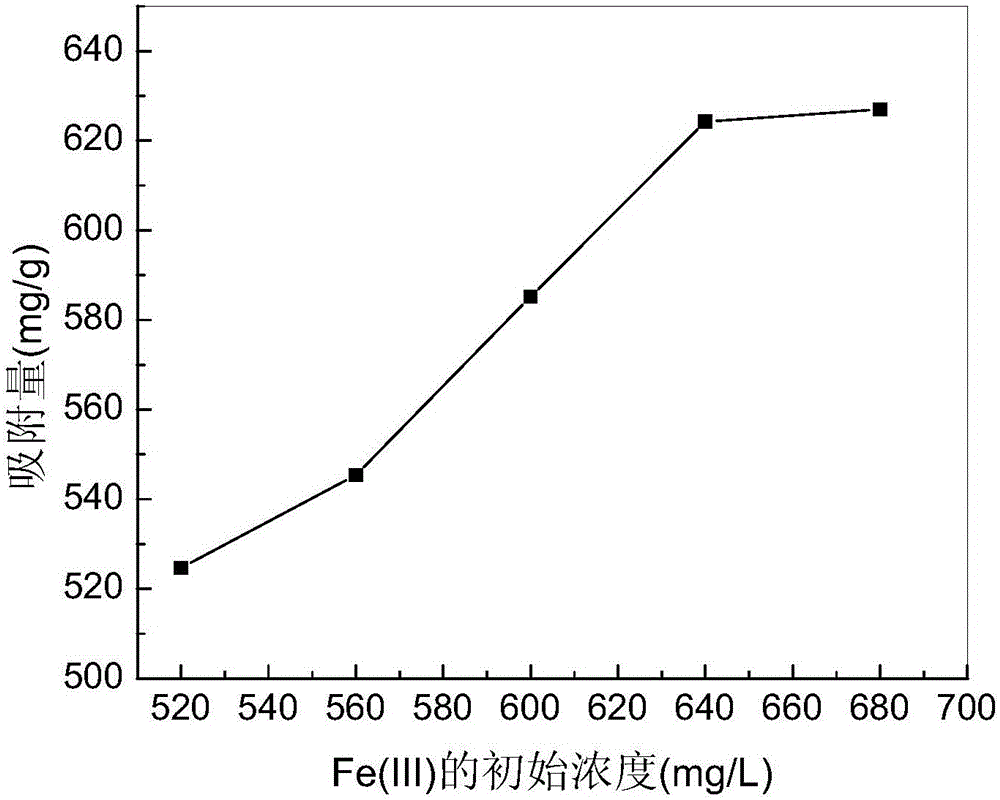

Sulphydryl lignocellulose/montmorillonite composite heavy metal ion adsorbent and preparation and application thereof

ActiveCN105107471AImprove solubilityReduced levitation abilityOther chemical processesWater contaminantsCelluloseSorbent

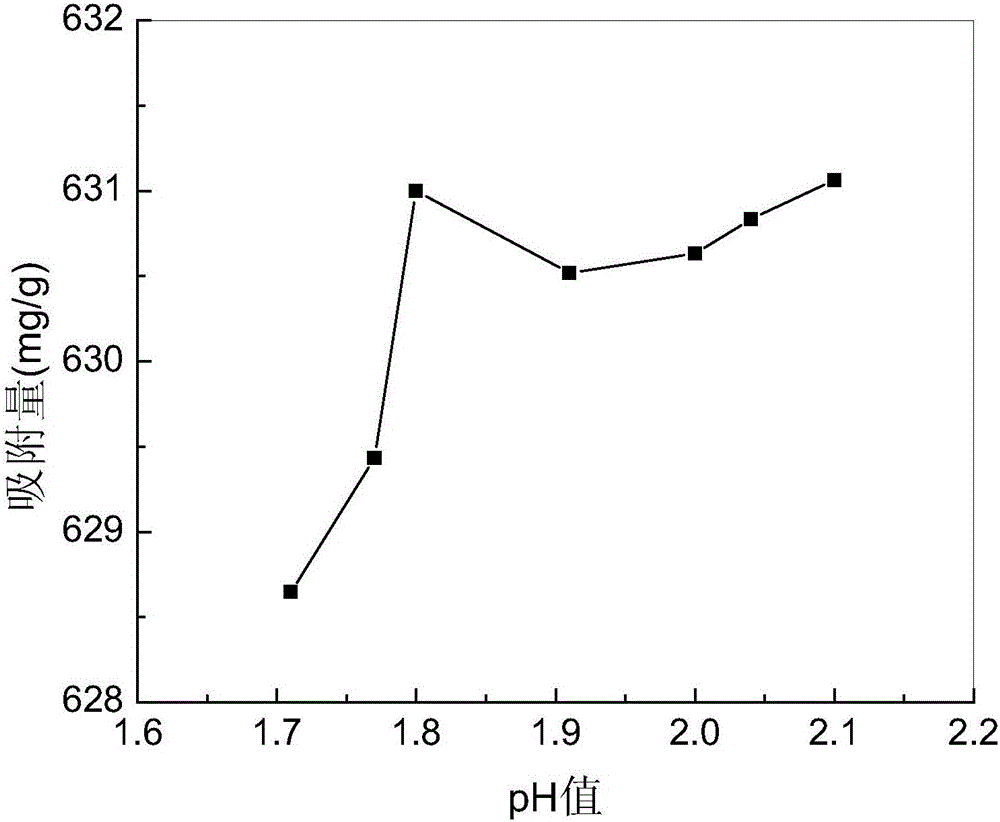

The invention provides sulphydryl lignocellulose / montmorillonite composite heavy metal ion adsorbent and preparation and application thereof. The adsorbent is formed by sulphydryl lignocellulose and montmorillonite in a composite mode, wherein the mass ratio of sulphydryl lignocellulose to montmorillonite is 1:1-1.5:1, and insertion layers of sulphydryl lignocellulose enter between lamination layers of montomorillonite. The sulphydryl lignocellulose / montmorillonite composite heavy metal ion adsorbent is applied to removing heavy metal in waste water. The preparation method of the sulphydryl lignocellulose / montmorillonite composite heavy metal ion adsorbent has the advantages that preparation is easy, raw materials are easy to obtain, environmental friendliness is achieved, and no secondary pollution occurs; the obtained sulphydryl lignocellulose / montmorillonite composite heavy metal ion adsorbent is free of toxin, capable of being biologically degraded and low in cost and achieves simple and convenient adsorbing operation and a high adsorbing quantity when applied to removing heavy metal ions in waste water.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY

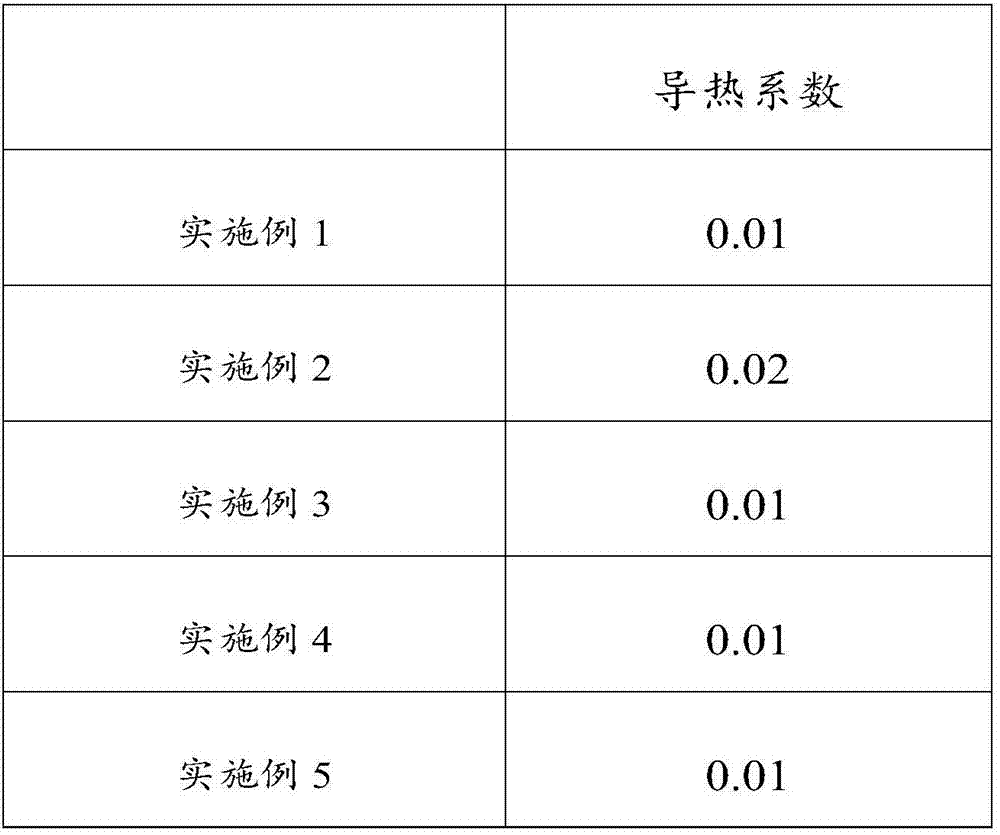

Preparation method of superfine talc powder

InactiveCN103665960AImprove surface activityImprove interface affinityPigment treatment with organosilicon compoundsPigment physical treatmentStearic acidPowder talcum

The invention provides a preparation method of superfine talc powder. The preparation method has the effects of improving the interface affinity of the talc power and polymers and improving the disperse state of the talc powder filler in polymer base materials by carrying out surface modification on the talc powder. The preparation method comprises the following steps: 1) breaking raw materials; 2) milling the raw materials into fine powder with a ball mill; 3) adding water to the milled materials to prepare pulp; 4) after mixing a silane coupling agent, ethanol and stearic acid uniformly to obtain a mixture, adding the mixture to the pulped materials, stirring the materials at 80-105 DEG C for 30-60 minutes and then cooling the materials; 5) grinding the materials for 6-8 hours; and 6) drying the powder and collecting the product. The preparation method has the beneficial effects that the surface activity of the talc powder particles is improved, so that the process is simplified and the cost is reduced; the interface affinity of the talc power and the polymers is improved and the disperse state of the talc powder filler in the polymer base materials is improved, so that talc is well applied and the application field of talc is expanded.

Owner:YANGZHOU TIANLI NON METALLIC MATERIAL

Method for preparing novel polyethylene wood-plastic composite material

The invention discloses a method for preparing a novel polyethylene wood-plastic composite material. The method comprises the following steps: (1) smashing a rape stalk, a cotton stalk and a cotton straw, baking to obtain wood powder, immersing the wood powder in a NaOH solution to perform ultrasonic treatment, taking out, rinsing by deionized water, drying and screening to obtain the alkalified wood powder; (2) mixing polyethylene, maleic anhydride, rare earth oxide and DCP to obtain a rare earth compatilizer; (3) adding phenolic resin and rare earth chloride into a reaction kettle, heating and stirring, heating the reaction solution till boiling, performing reflux reaction, continuously heating, keeping the temperature, stopping heating and reacting to obtain the rare earth phenolic resin; (4) mixing polyethylene, the alkalified wood powder, the compatilizer and the rare earth phenolic resin, moving to an oven, and drying to achieve constant weight to obtain the mixed materials; (5) adding the mixed materials into a conical twin-screw extruder, extruding and granulating to obtain the granules, and baking to obtain the polyethylene wood-plastic composite material.

Owner:江西欧居工程有限公司

Rubber material and preparation method thereof

The invention provides a rubber material and a preparation method. The rubber material is prepared by mixing thiol graphene with natural or synthetic rubber latex and demulsifying and agglomerating. The thiol graphene is prepared by two-step reaction from graphene oxide and a thiol-amino compound. Through the process, when the thiol graphene is prepared, the epoxy group and the carboxyl group in the graphene oxide both react with the thiol-amino compound to obtain the graphene oxide with higher grafting efficiency. The preparation method also avoids addition of traditional graphene as a fillerto rubber, and the rubber material is prepared from the thiol graphene and the rubber latex. During the vulcanization of the rubber material, the thiol group can react with rubber double bonds so asto participate in the vulcanization of the rubber, and finally the mechanical properties of the prepared rubber composite material are obviously improved, at the same time, the friction loss due to the poor interface affinity can be reduced, heating of a rubber product during use is reduced, raw materials used in the method are cheap, the preparation process is simple, and the mass production is convenient; and the properties of the rubber product are easy to adjust by changing of the chemical structure.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

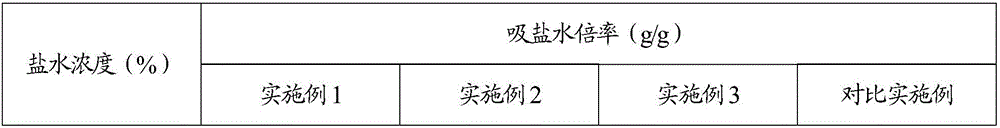

Preparation method of semi-interpenetrating water-absorbent resin particles

The invention discloses a preparation method of semi-interpenetrating water-absorbent resin particles. The preparation method comprises: firstly, neutralizing acrylic acid by using a sodium hydroxide solution, controlling the neutralization degree of the acrylic acid to be 60-90% to obtain an acrylic acid-sodium acrylate solution, then adding dissolved acrylamide, allyl alcohol polyoxyethylene ether and a polyvinyl alcohol solution into the acrylic acid-sodium acrylate solution, and mixing uniformly to obtain a mixed solution; secondly, adding a crosslinking agent into the mixed solution, stirring uniformly, then heating the system to 65 DEG C, adding an initiator, and stirring for 15-20min for reaction to obtain a rubber block; and finally, taking out the rubber block, and washing, drying and crushing the rubber block to obtain semi-interpenetrating water-absorbent resin particles. The preparation method disclosed by the invention is simple to operate, the prepared product has a semi-interpenetrating polymer network structure, the water absorption rate of the product in distilled water reaches 2100g / g or above, the liquid absorption rate of the product in 0.9% brine is also 150g / g or above, and the product is good in water absorbability and high in salt tolerance, and can meet actual needs of oilfield production.

Owner:SOUTHWEST PETROLEUM UNIV +1

Waterglass-polymer homogeneous phase hybrid modified precursor liquid for lumber and preparation method thereof

InactiveCN101434080AWide variety of sourcesLow priceWood impregnation detailsBuilding materialPolymer solution

The invention discloses water glass-polymer homogeneous hybrid timber modification precursor solution and a preparation method thereof, which belongs to the technical field of timber modification in building materials. The prior silicate timber modification solution has poor leachability resistance, large brittleness of modified timber and so on. The modification solution comprises components with the following content: 23 to 50 weight percent of water glass, 0.2 to 4.2 weight percent of hydrophilic polymer, 0.3 to 2.6 weight percent of crosslinking agent, and 45 to 75 weight percent of water. Hydrophilic polymer solution is obtained by adding the hydrophilic polymer into water and stirring the hydrophilic polymer to be dissolved at a temperature of between 30 and 90 DEG C, then the hydrophilic polymer and the water glass are stirred and mixed at a temperature of between 30 and 80 DEG C, and the crosslinking agent is added to continuously stir for 1 to 3 hours to obtain the water glass-polymer homogeneous hybrid timber modification solution. The modification solution has the advantages of low cost, environmental protection, good leachability resistance and so on.

Owner:北京加林生物科技有限公司

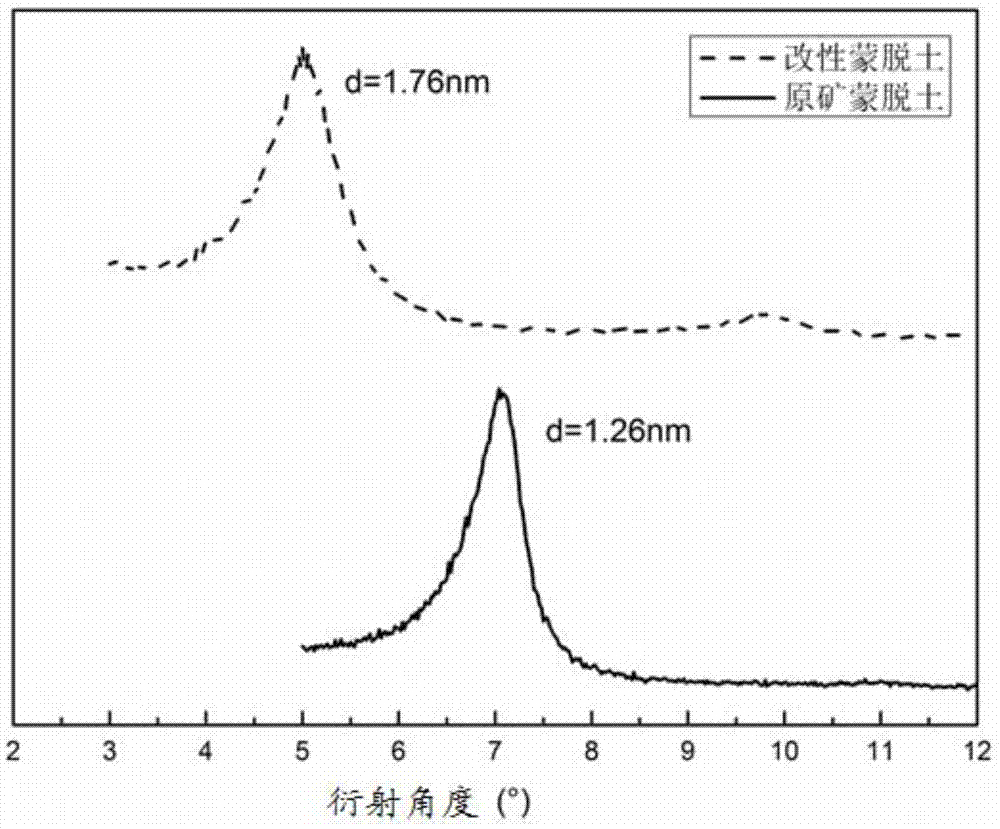

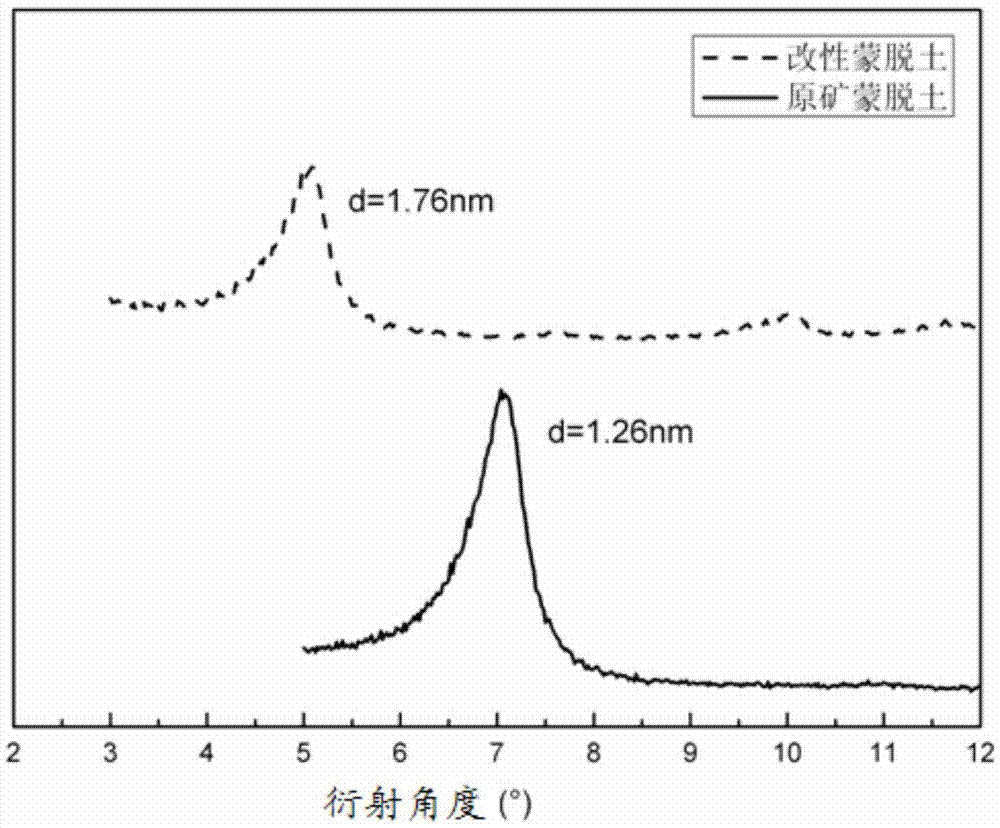

Preparation method of stratified-structure mineral reinforced rubber composite material

The invention relates to a preparation method of a stratified-structure mineral reinforced rubber composite material. The preparation method comprises the following steps: (1) carrying out nano-organic modification on a stratified-structure mineral; (2) preparing an organic modified nano-stratified-structure mineral inserted rubber master batch; (3) preparing the raw materials of an organic modified nano-stratified-structure mineral reinforced rubber composite material; and (4) preparing the organic modified nano-stratified-structure mineral reinforced rubber composite material, wherein the stratified-structure mineral is one or mixture of two of black talc, montmorillonite, kaolin and illite in the same mass ratio. According to the preparation method, the functional rubber composite material with excellent mechanical property, stable weather resistance and good warping strength and humidity resistance is prepared.

Owner:HEBEI UNIV OF TECH

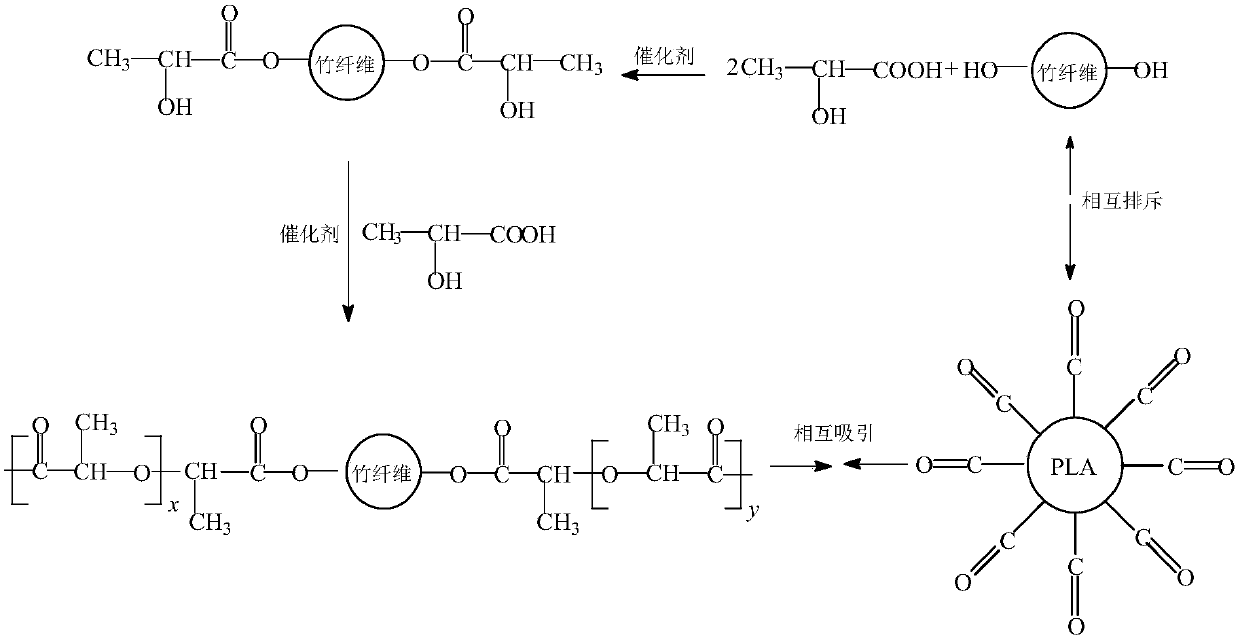

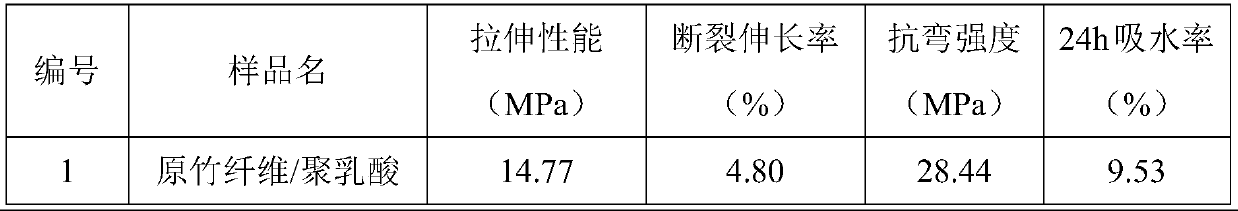

Bamboo fiber/polylactic acid composite material and preparation method thereof

The invention discloses a bamboo fiber / polylactic acid composite material and a preparation method thereof. The preparation method comprises the following steps: dispersing a catalyst in a lactic acidmonomer to obtain dispersion, and mixing the dispersion and bamboo fibers so as to obtain a mixture; adding the mixture into a hydrothermal reactor, and sealing; reacting at the temperature of 60-120DEG C for 1-12 hours so as to obtain lactic acid grafted bamboo fibers; mixing the lactic acid grafted bamboo fibers and polylactic resin, adding a plasticizer, and sealing; mixing at the temperatureof 150-180 DEG C for 10-20 minutes so as to obtain a mixed product; crushing the mixed product, and performing mold pressing, thereby obtaining the bamboo fiber / polylactic acid composite material. The preparation method disclosed by the invention is high in reaction efficiency, has low equipment requirement and is an environmental-friendly green polymerization process. The prepared bamboo fiber / polylactic acid composite material is high in tensile property, high in bending strength and excellent in water resistance.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

High-elasticity durable automobile rubber shock absorbing material

InactiveCN109161042AStrong heat resistanceImprove wear resistanceEpoxy resin coatingsWear resistantAntioxidant

The invention discloses a high-elasticity durable automobile rubber shock absorbing material. The high-elasticity durable automobile rubber shock absorbing material comprises a shock absorbing material body and a wear-resistant coating which coats the outer side of the shock absorbing material body; the shock absorbing material body is prepared from the following raw materials in parts by weight:20 to 30 parts of EPDM, 20 to 25 parts of butyl rubber, 10 to 15 parts of butadiene rubber, 4 to 7 parts of talcum powder, 2 to 5 parts of a toughening agent, 2 to 4 parts of an antioxidant, 1 to 4 parts of an anti-aging agent, 1 to 3 parts of a coupling agent, 3 to 9 parts of epoxidized soybean oil, 3 to 6 parts of a maleic anhydride compatilizer, 3 to 7 parts of paraffin, 5 to 8 parts of nano-barium sulphate, 2 to 5 parts of modified nano silicon nitride, 1 to 3 parts of potassium stearate, 2 to 5 parts of an accelerant, 2 to 4 parts of a coupling agent, 1 to 2 parts of zinc borate and 3 to7 parts of sulphur. According to the high-elasticity durable automobile rubber shock absorbing material, the wear resistance and the durability of a shock absorbing piece are greatly improved by the wear-resistant coating on the outer side of the shock absorbing material body.

Owner:ANHUI WEIWEI RUBBER PARTS GRP

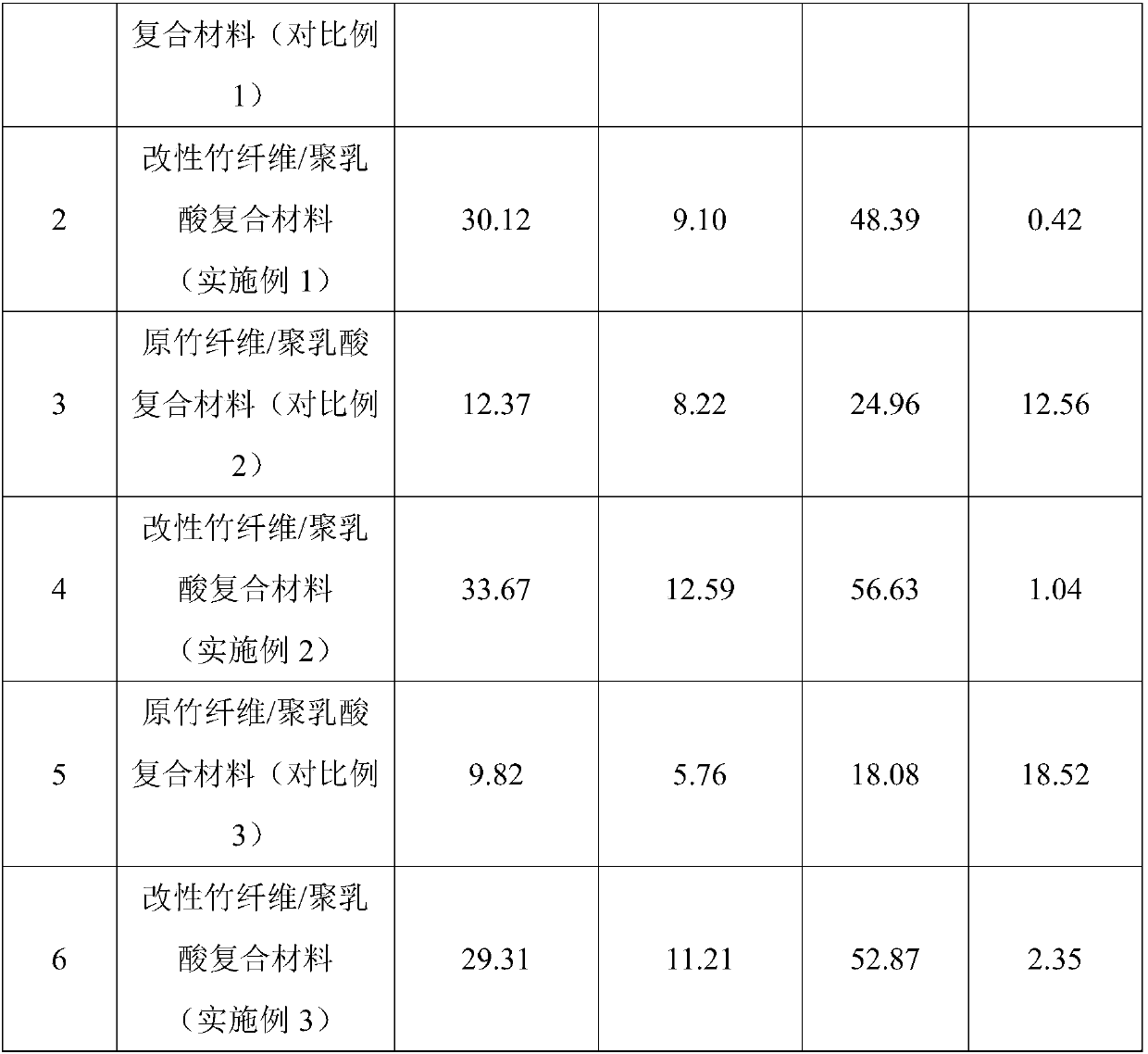

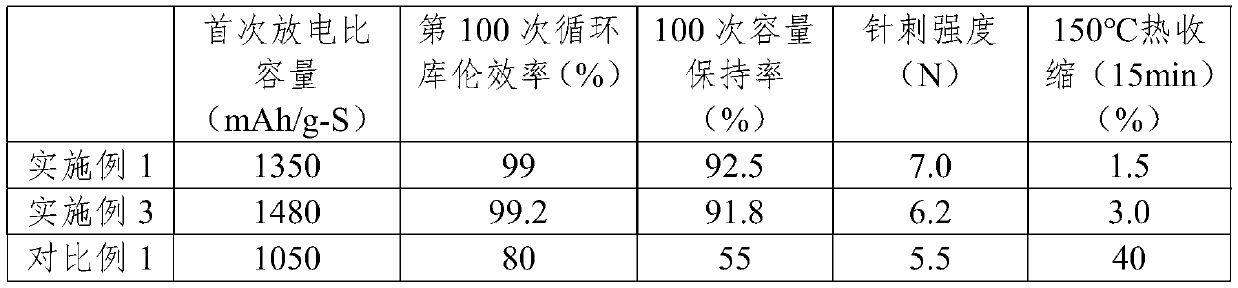

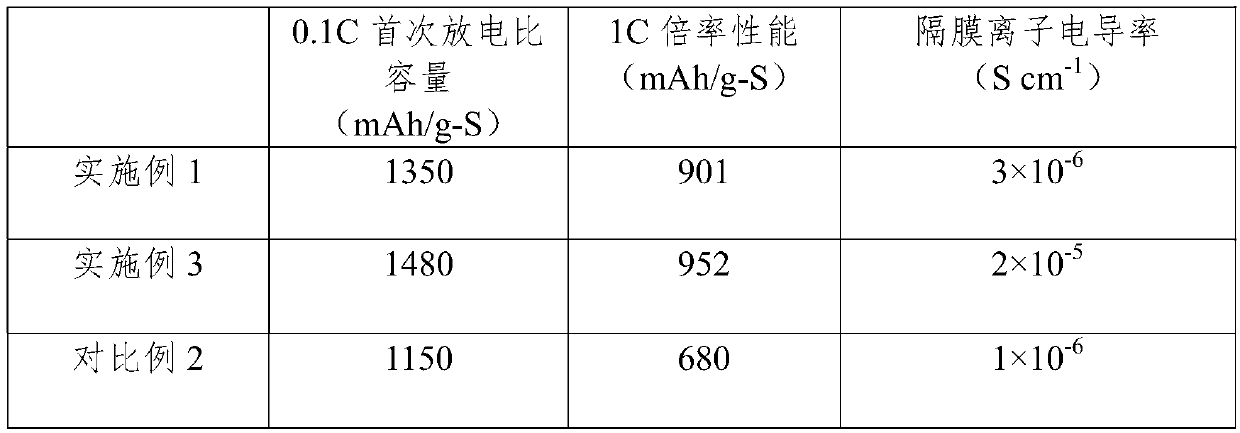

Composite diaphragm for alkali metal battery and preparation and application thereof

ActiveCN110707267AHigh ion conductivityHigh mechanical strengthSecondary cellsCell component detailsCeramic coatingPhysical chemistry

The invention relates to a composite diaphragm for an alkali metal battery and a preparation method of the composite diaphragm. The composite diaphragm comprises an organic diaphragm matrix layer coated with a ceramic coating and an amorphous alkali metal ion conductor inorganic solid layer, and the preparation method is a vacuum physical deposition method and comprises the following steps of passing an organic diaphragm substrate through a vacuum deposition cavity in a roll-to-roll mode, wherein the vacuum degree of a vacuum box body is 0.5-5 Pa, the reaction gas is nitrogen, the deposition power supply power is 30-180 W, the deposition time is 5-30 min; and depositing to prepare the composite diaphragm. The deposited inorganic solid layer is compact and non-porous, so that the diaphragmhas very strong mechanical property and high-temperature resistance, and the internal short circuit caused by the battery impurities and the metal dendrites and the thermal deformation of the batterydiaphragm can be effectively prevented. Meanwhile, the inorganic solid layer has the alkali metal cation high-speed conduction performance, stability in air and a hetero-ion blocking function, so thatthe safety performance and the cycle life of the battery can be remarkably improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

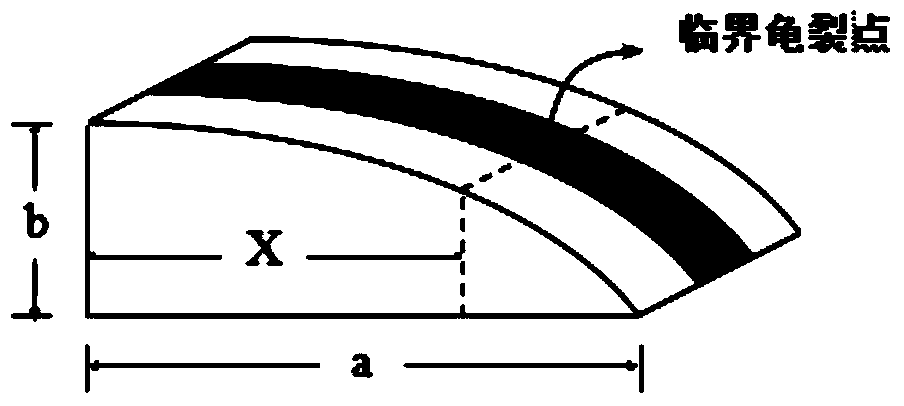

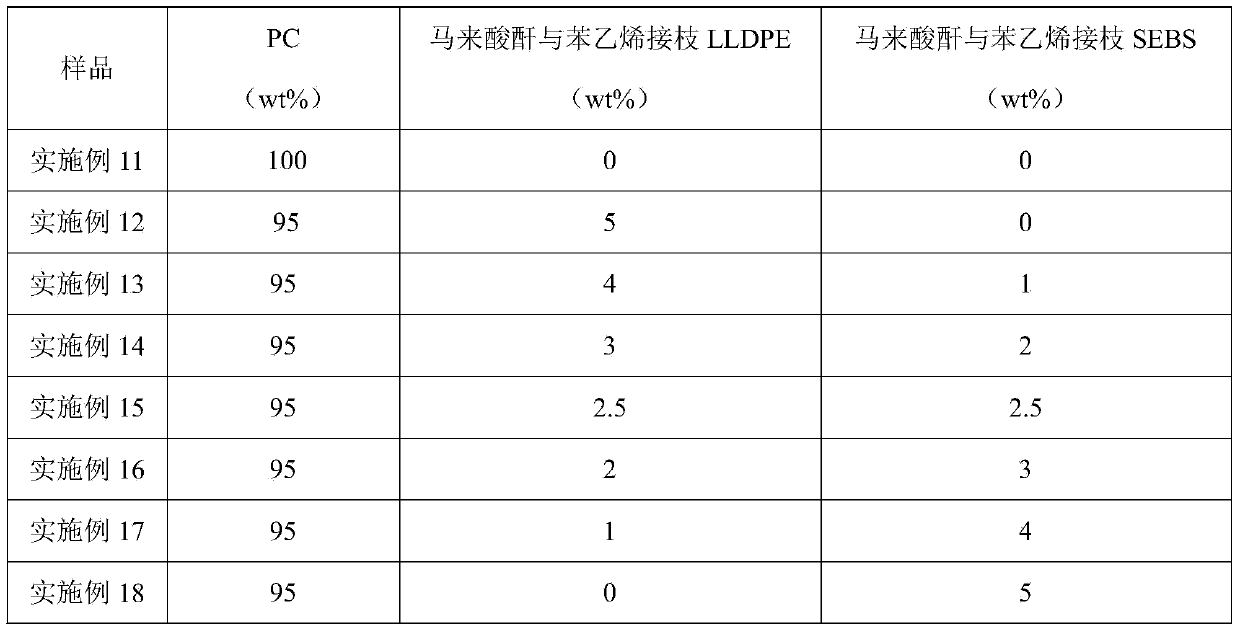

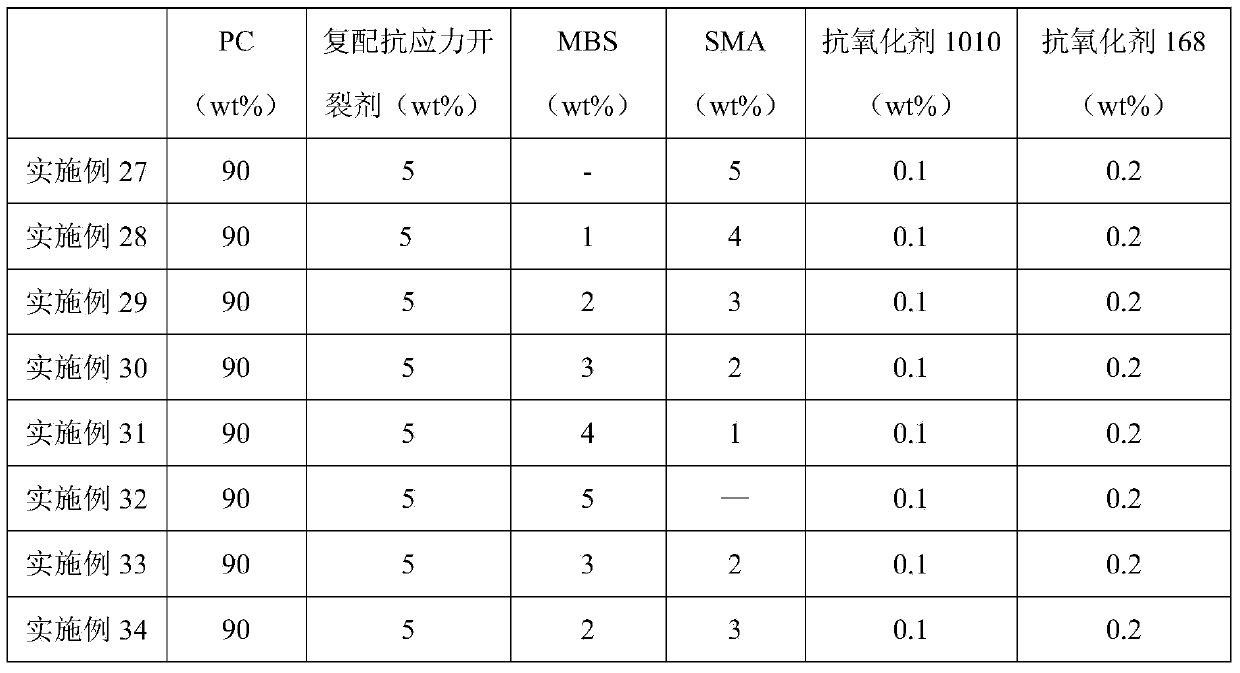

Anti-stress cracking agent, preparation method and application thereof as well as anti-stress PC (Poly Carbonate) polyester

ActiveCN103435753AGood compatibilityImprove interface affinityLinear low-density polyethyleneLow-density polyethylene

The invention relates to an anti-stress cracking agent as well as anti-stress PC (Poly Carbonate). The anti-stress cracking agent is linear low-density polyethylene grafted by maleic anhydride and styrene or hydrogenated SBS (Styrene Butadiene Styrene) grafted by the maleic anhydride and styrene. The mass ratio of the maleic anhydride to the styrene to the linear low-density polyethylene in the linear low-density polyethylene grafted by the maleic anhydride and styrene is (1-5):(1-5):(50-100); the mass ratio of the maleic anhydride to the styrene to the hydrogenated SBS in the hydrogenated SBS grafted by the maleic anhydride and the styrene is (1-5):(1-5):(50-100). The anti-stress cracking agent disclosed by the invention is a composition of the linear low-density polyethylene grafted by the maleic anhydride and the styrene and the hydrogenated SBS) grafted by the maleic anhydride and the styrene in a weight ratio of (1-3):(1-2). Being detected by an anti-stress test, the anti-stress PC disclosed by the invention has good anti-stress cracking performance.

Owner:北京航天凯恩新材料有限公司 +1

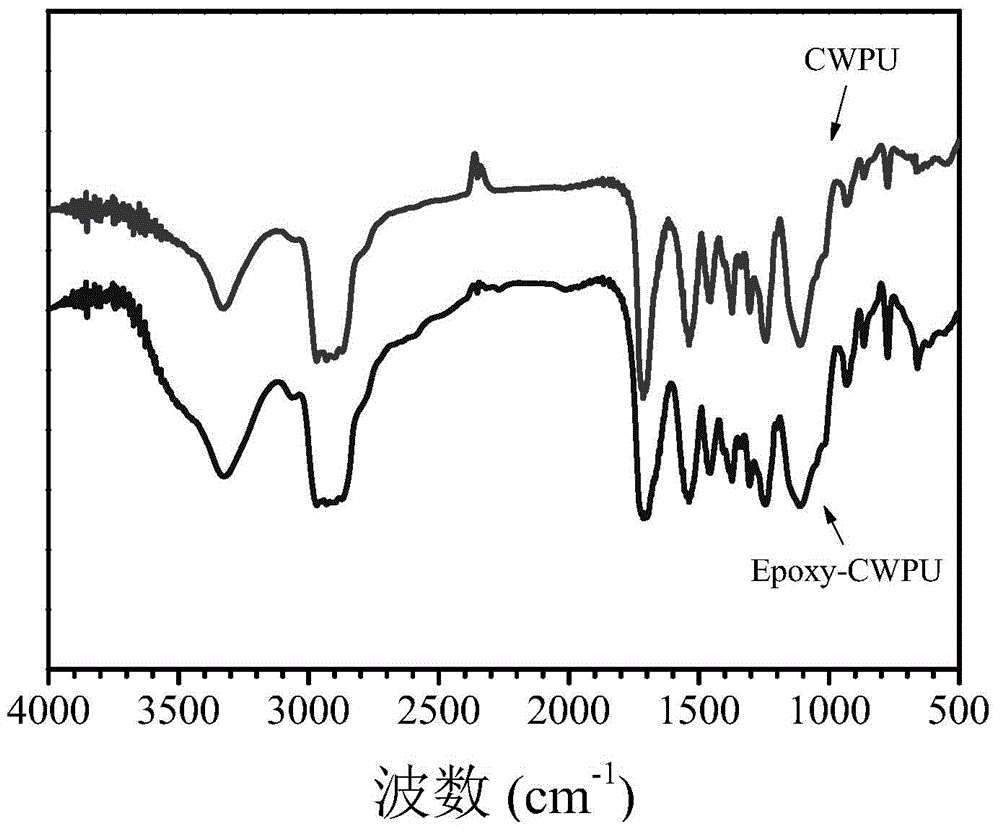

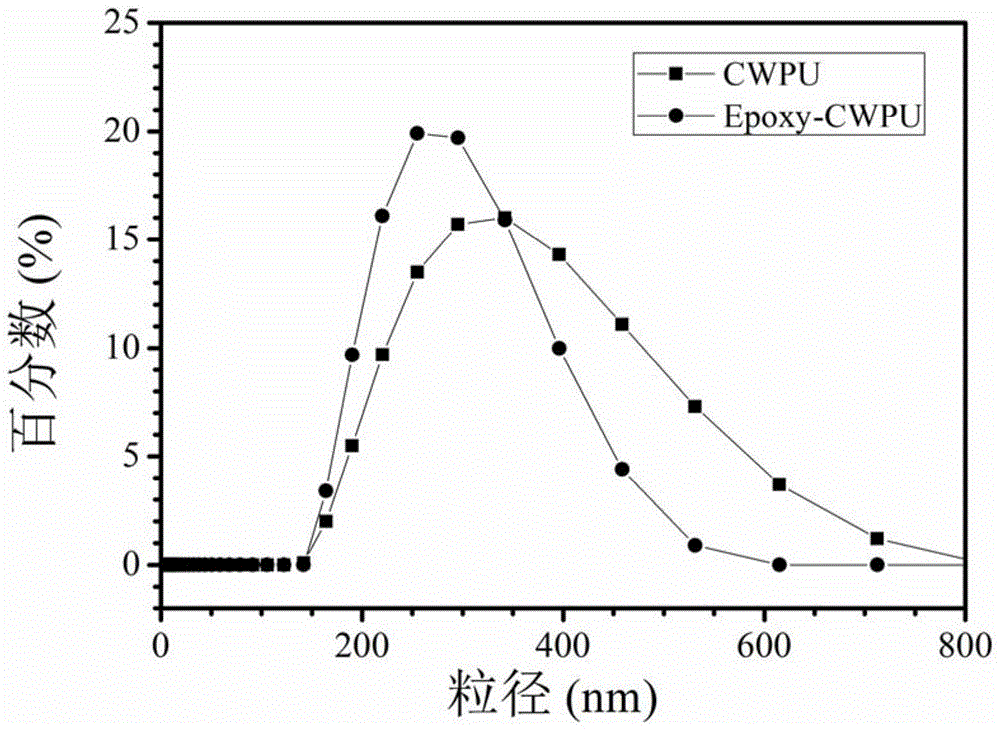

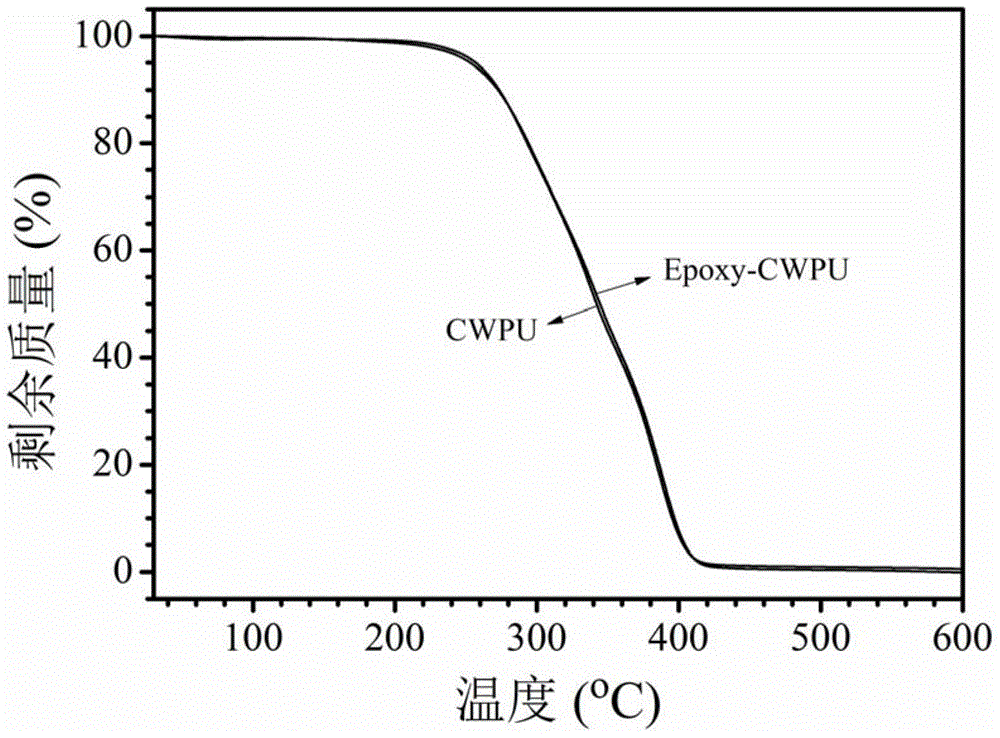

Preparation method of waterborne polyurethane based on glycidyl methacrylate

The invention discloses a preparation method of waterborne polyurethane based on glycidyl methacrylate. The preparation method comprises the following steps: firstly carrying out a reaction between diisocyanate and macromolecular dihydric alcohol, micromolecular dihydric alcohol and a hydrophilic chain extender; adding an end-capping reagent to obtain a double bond-terminated polyurethane prepolymer; and carrying out copolymerization by adding glycidyl methacrylate so as to obtain epoxy group-controllable block cationic waterborne polyurethane. According to the method, the epoxy group is bonded to polyurethane through a chemical bond to form a single component system which is convenient to use, can be used along with amines, polyatomic acid or polyisocyanate compounds for cure-crosslinking, modification and the like and has stronger machinable property. The synthesized block cationic waterborne polyurethane has smaller particle size, narrower particle size distribution and higher emulsion storage stability.

Owner:UNIV OF SCI & TECH OF CHINA

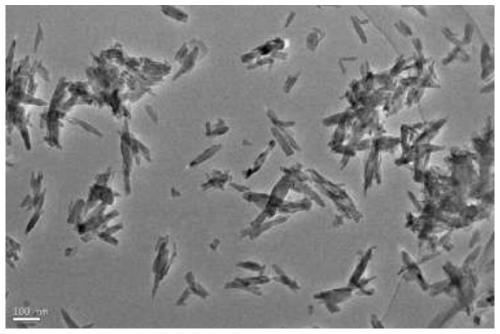

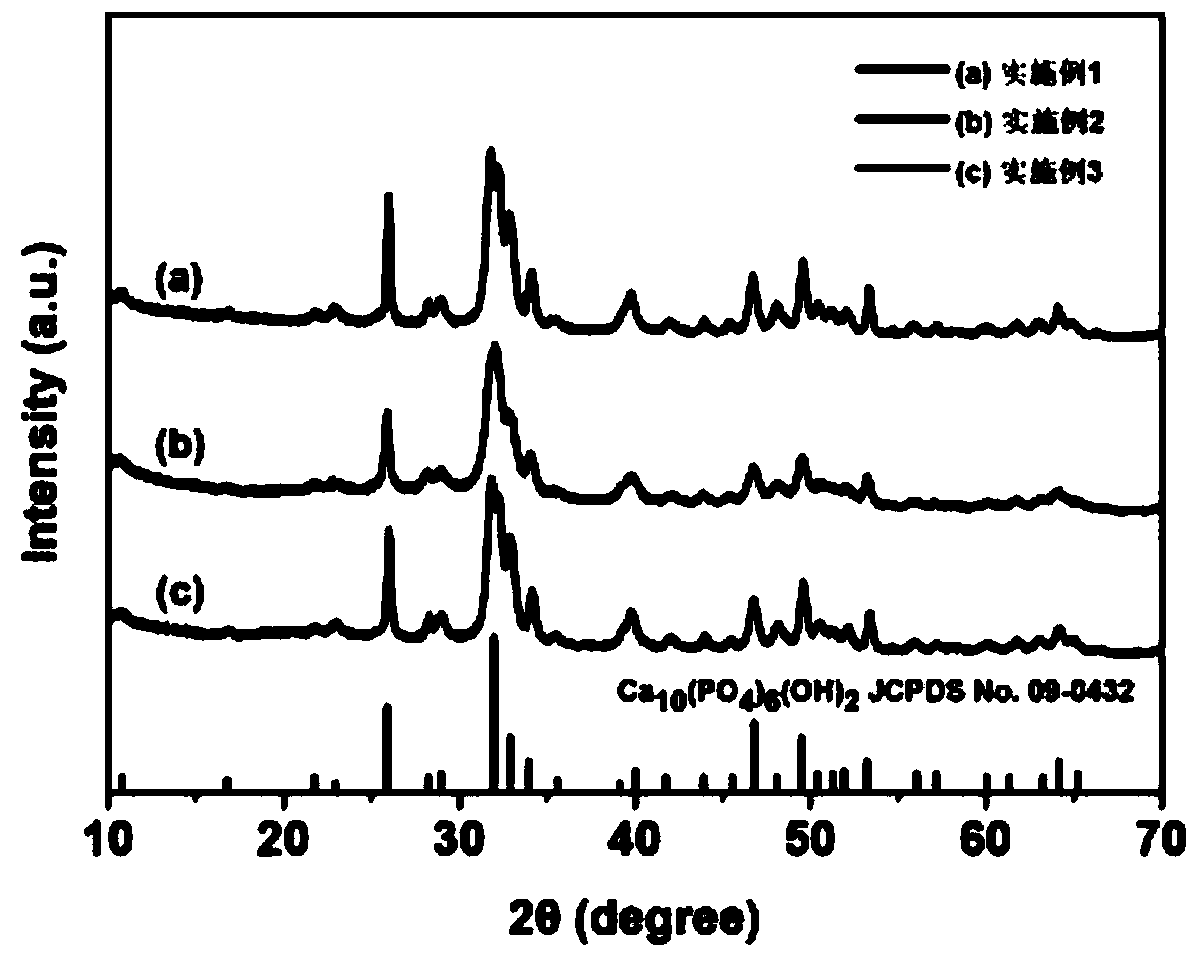

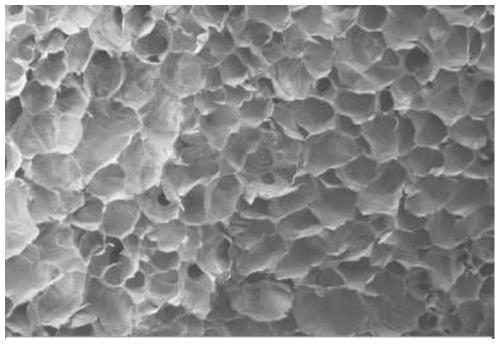

Aminoized hydroxyapatite/chitosan composite aerogel as well as preparation method and application thereof

The invention provides aminoized hydroxyapatite / chitosan composite aerogel as well as a preparation method and application thereof. The preparation method comprises the following steps: preparing hydroxyapatite by a liquid phase coprecipitation method, taking the hydroxyapatite as a high-thermal-stability and high-toughness inorganic reinforced phase, modifying the hydroxyapatite by a silane coupling agent, improving the affinity of a nano-crystal structure interface, uniformly mixing a chitosan solution, and preparing the aminoized hydroxyapatite / chitosan composite aerogel by a Schiff base chemical crosslinking and directional prefreezing-freeze drying technology. The composite aerogel has excellent properties of low volume density, high porosity, high mechanical strength and low heat-conducting coefficiency, and is a green, low-cost, novel and heat-insulating composite aerogel material.

Owner:CENT SOUTH UNIV

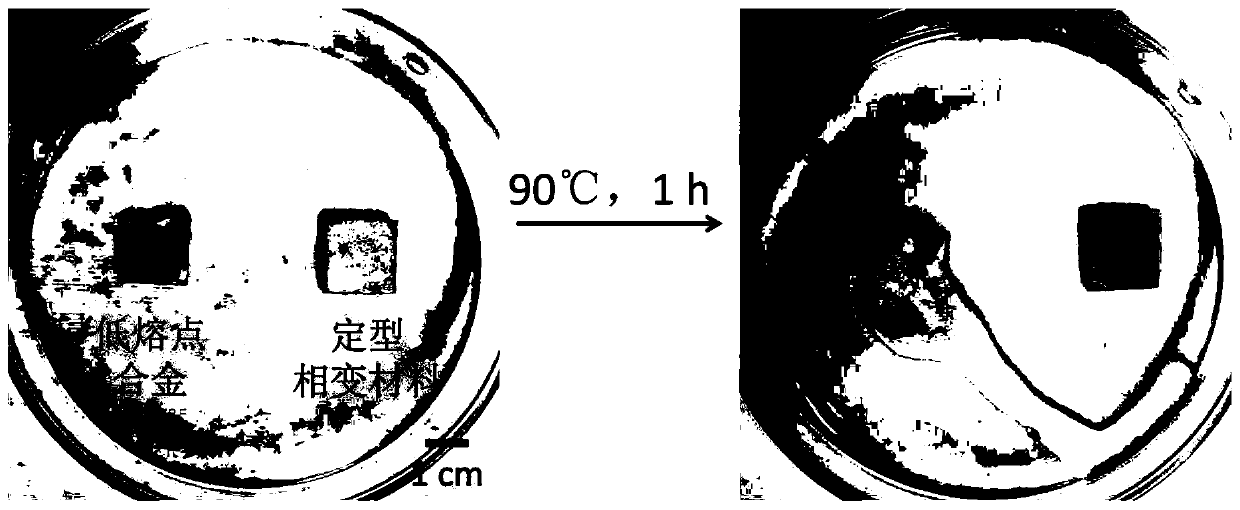

Low-melting-point metal shaped phase-change material and preparation method thereof

ActiveCN111040736AImprove heat storage performanceEasy to processHeat-exchange elementsPhase-change materialMacromolecule

The embodiment of the invention relates to a low-melting-point metal shaped phase-change material and a preparation method thereof. The preparation method comprises the following steps: dispersing a heat-conducting material in a solvent to form a dispersion, soaking polymer foam in the dispersion, and taking out and drying the soamed polymer foam to obtain composite foam; and soaking the compositefoam into molten low-melting-point metal, and taking out and cooling the soaked composite foam to obtain the low-melting-point metal shaped phase-change material. The low-melting-point metal shaped phase-change material obtained by the preparation method is easy to process, good in heat storage performance and good in interface affinity.

Owner:TIANJIN POLYTECHNIC UNIV

Polyimide composite film as well as preparation method and application thereof

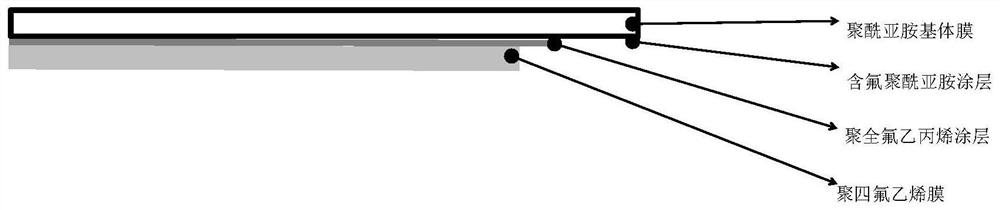

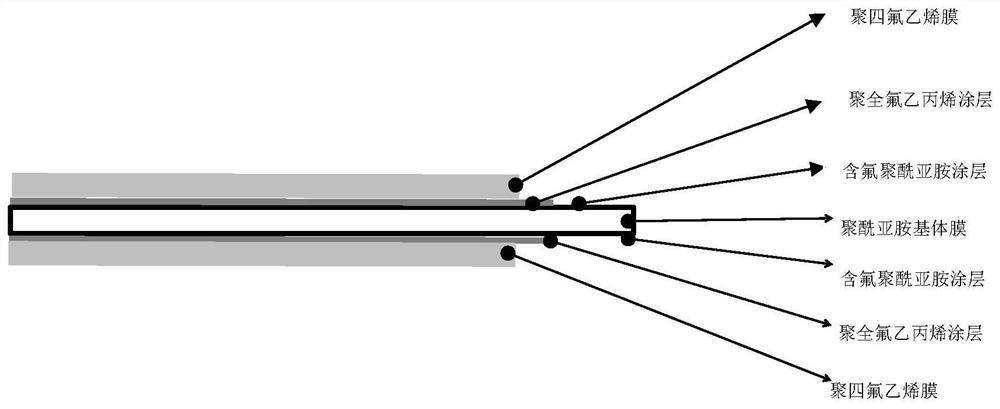

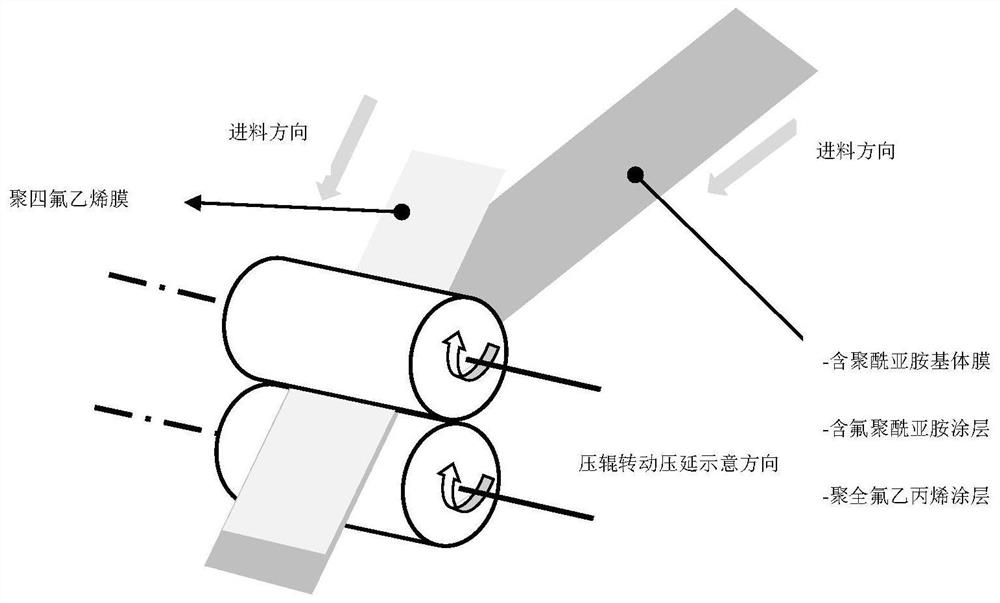

The invention provides a polyimide composite film as well as a preparation method and application thereof, belonging to the technical field of insulating materials for aerospace cables. According to the invention, a fluorine-containing polyimide coating and a polyimide matrix film are connected through covalent bonds, so the fluorine-containing polyimide coating and the polyimide matrix film form a whole; and meanwhile, the fluorine-containing polyimide coating contains fluorine atoms and has good affinity with a fluorinated ethylene propylene coating, and due to the existence of the fluorine-containing polyimide coating, the interface affinity between polyimide and the fluorinated ethylene propylene coating is greatly improved, and interface effect is remarkably reduced; and a tetrafluoroethylene-hexafluoropropylene copolymer coating can be effectively adhered to a polytetrafluoroethylene film in a hot pressing process, so interfaces among different films in the composite film are greatly improved, and the problem that the composite film is easy to crack in a use process is solved.

Owner:DONGHUA UNIV

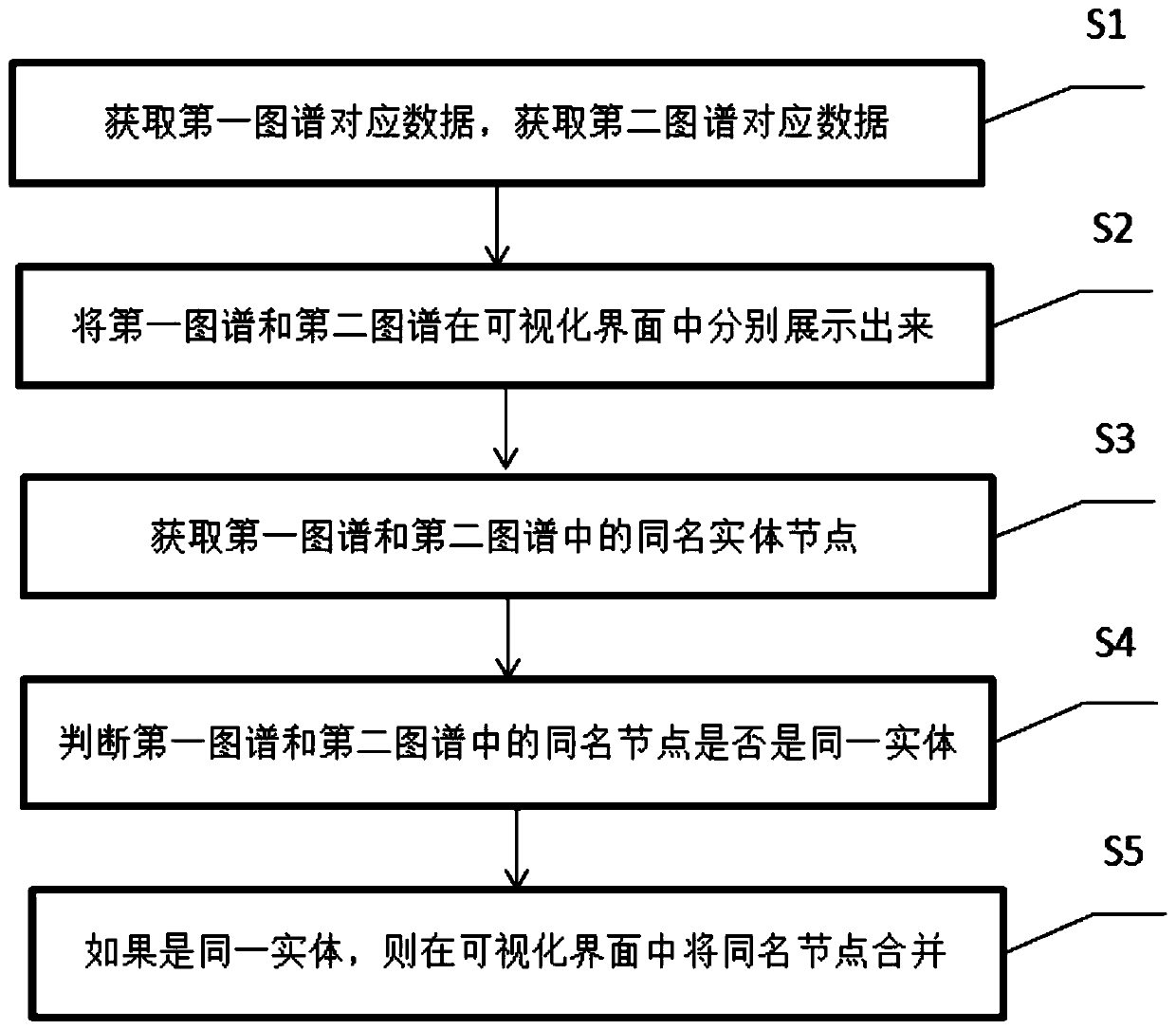

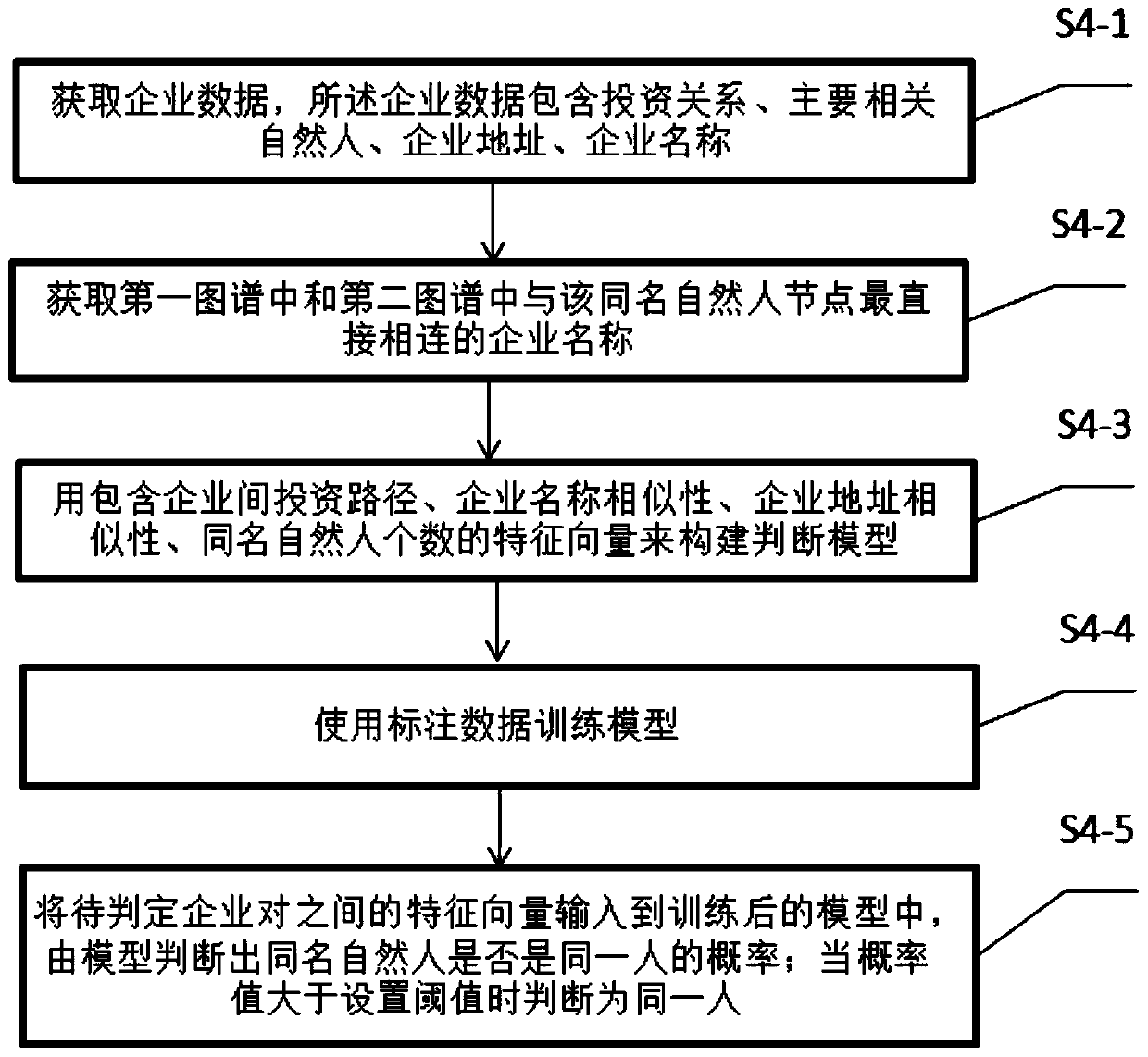

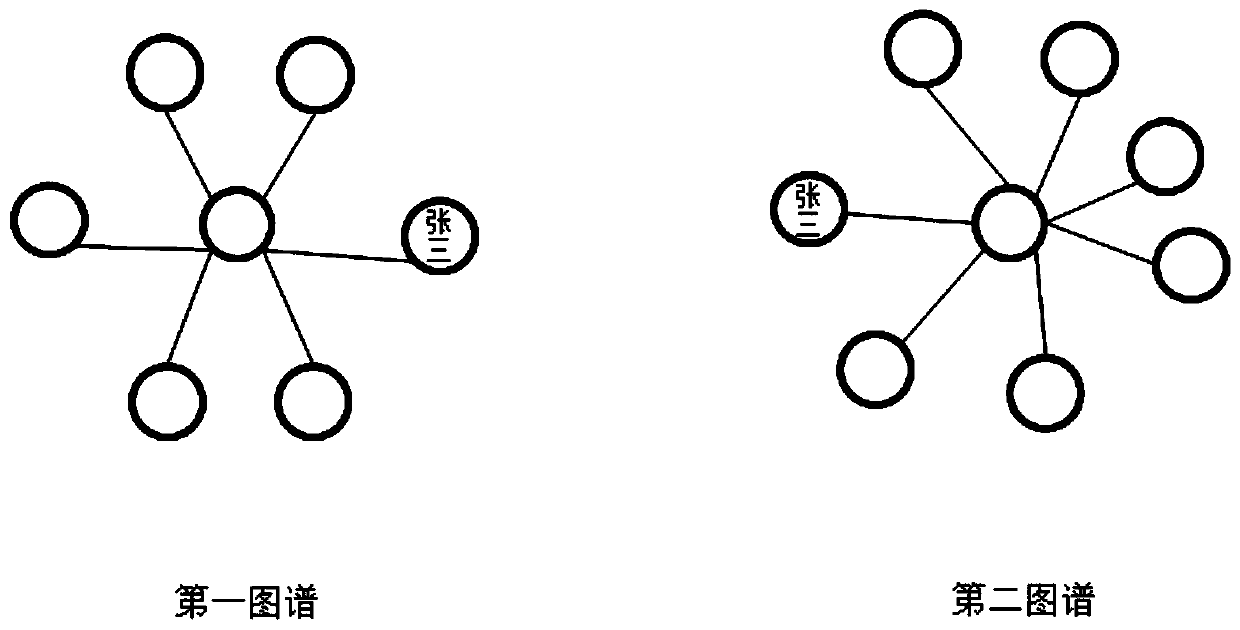

Visual atlas fusion method and system based on entity alignment

PendingCN111428093AClear contrastDefine the conjoint analysis processOther databases indexingOther databases browsing/visualisationData sourceNuclear medicine

The invention relates to a visual atlas fusion method and system based on entity alignment. According to the method and the system, data corresponding to a first atlas is acquired, and data corresponding to a second atlas is acquired; respectively displaying the first atlas and the second atlas in a visual interface; acquiring same-name entity nodes in the first graph and the second graph; judgingwhether the homonymous nodes in the first graph and the second graph are the same entity or not; and if the first atlas and the second atlas are the same entity, merging the homonymous nodes in a visual interface, thereby realizing visual fusion of the first atlas and the second atlas. The fusion process of the atlas is visually displayed in a visual interface, the logic is very clear, and the data source comparison and joint analysis process is clearer; and the interface affinity is excellent. And the method has an excellent application effect in a multi-party data joint investigation process. And multi-feature comprehensive judgment is adopted in the same-name natural person entity recognition process, so that the judgment and recognition accuracy is high.

Owner:成都数联铭品科技有限公司

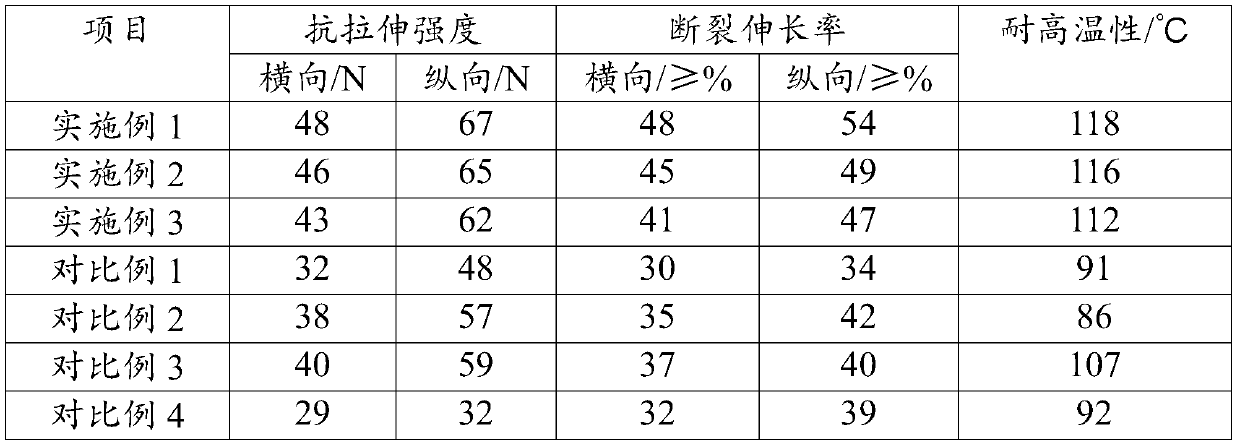

Environment-friendly degradable packaging composite film and preparation method thereof

ActiveCN109988400AStable hydrated dispersionWell hydrated dispersionComposite filmMechanical property

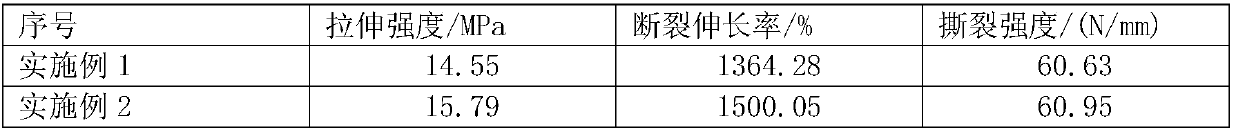

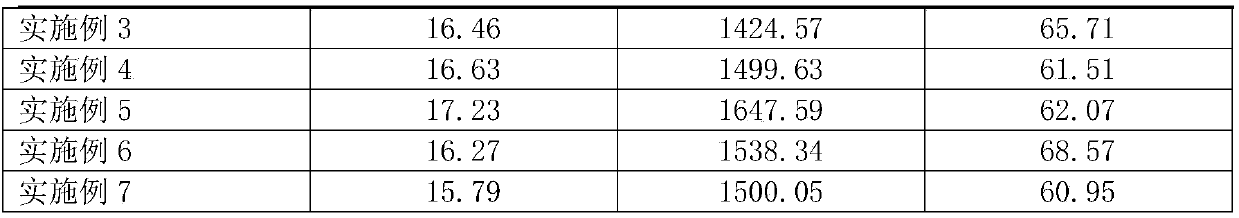

The invention discloses an environment-friendly degradable packaging composite film and a preparation method thereof. The composite film comprises the following raw materials: in parts by weight, 120-150 parts of modified PBS resin, 45-60 parts of heat-resistant modified starch, 15-22 parts of a degradation accelerator, 12-16 parts of nano-pozzolan, 5-11 parts of calcium stearate and 3-9 parts ofnano-calcium carbonate powder, and pulverization mixing and multi-layer co-extrusion casting are performed so as to prepare the composite film. The PBS resin is modified through selection of the sagostarch, an environment-friendly plasticizer and functional filler so that the mechanical properties and heat resistance of the PBS resin are improved; the modified PBS resin and the heat-resistant modified starch, the degradation accelerator, the lubricant calcium stearate and the nano-filler are pulverized and mixed, and multi-layer co-extrusion cast stretching is performed so as to obtain the composite film; and it is shown through tests with standard methods that the composite film has good tensile strength, elongation at break, heat-resistant flame retardancy and light-biological double-degradation performance.

Owner:瑞力恒生态科技(深圳)有限公司

Flame-retardant molybdenum disulfide modified polystyrene composite material and preparation method thereof

The invention relates to the technical field of polystyrene, and discloses a flame-retardant molybdenum disulfide modified polystyrene composite material. Nano molybdenum disulfide forms a LixMoS2 interlayer compound under hydrothermal stripping of n-butyllithium, single-layer nano molybdenum disulfide is obtained, surface sulfur atom defects are formed, the single-layer nano molybdenum disulfide can react with 3-mercapto-1-propylamine to obtain aminated molybdenum disulfide, the aminated molybdenum disulfide reacts with trichloroacetyl isocyanate to obtain trichloroacetyl molybdenum disulfide, carbon free radicals are formed at alpha carbon positions of halogen groups under the action of molybdenum hexacarbonyl, and the alpha carbon free radicals are used as active initiation sites to initiate styrene polymerization. Through a chemical bond connection mode, the interface affinity of molybdenum disulfide and polystyrene is improved, molybdenum disulfide has chemical barrier and catalytic char formation effects in a matrix, propagation of flammable volatile matters in a thermal decomposition process can be reduced, degradation and combustion in the polystyrene matrix are delayed, and the thermal stability and the flame retardant property of the polystyrene are improved.

Owner:宁波朗涌工贸有限公司

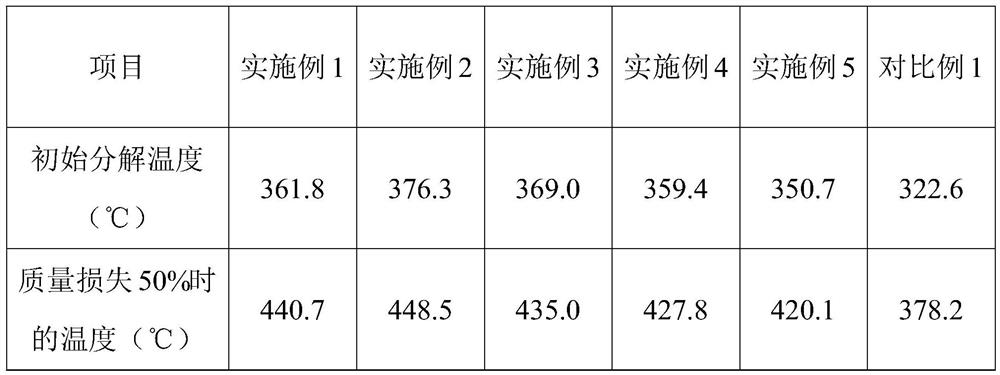

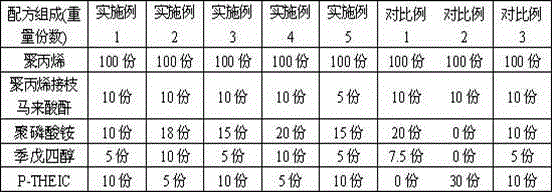

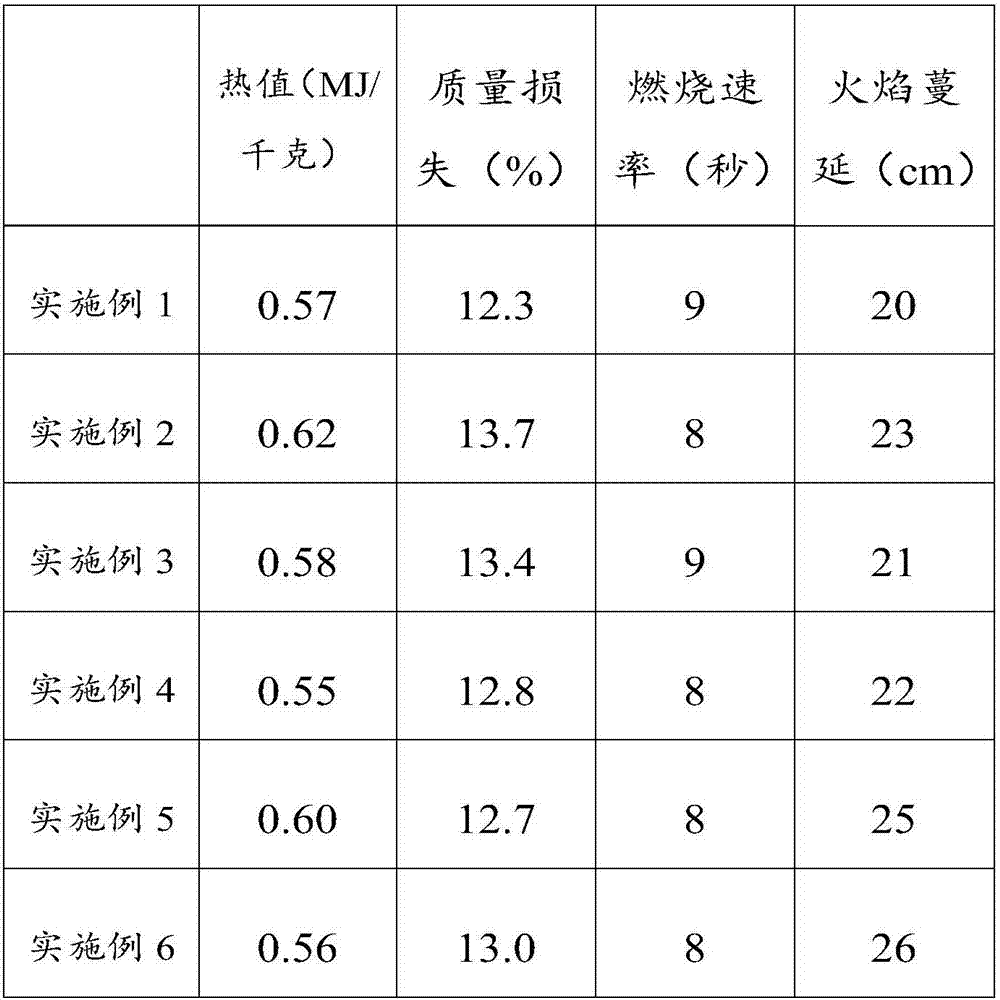

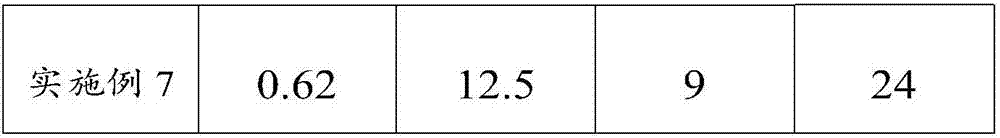

Flame-retardant polypropylene material containing char-forming agent and preparation method thereof

The invention relates to a flame-retardant polypropylene material containing a char-forming agent and a preparation method thereof and relates to the technical field of propylene flame-retardant polymers. The flame-retardant polypropylene material comprises the following components: polypropylene, a char-forming phosphorus-nitrogen flame-retardant P-THEIC (Phosphorus-Trihydroxyethyl Isocyanurate), ammonium polyphosphate, pentaerythritol and a compatilizer. In an ammonium polyphosphate and pentaerythritol flame retardant polypropylene composite material system, the material can reach no drop during combustion and the grade UL-94 level-0 through the addition of a small quantity of P-THEIC phosphorus-nitrogen flame retardant under the situation that the addition amount of the flame retardant is not increased; as the P-THEIC is liquid under normal temperature, through the addition of the P-THEIC, the dispersity of a solid flame retardant in polypropylene can be improved, and the flowing property of the flame-retardant polypropylene material during processing can also be improved, so that molding is facilitated; as the polarity of the P-THEIC flame retardant is very small, the interface affinity is favorably improved, so that the impact strength is obviously improved.

Owner:CHANGZHOU UNIV

AB composite insulation board and insulation board assembly

InactiveCN107399955AImprove insulation effectImprove fire performanceHeat proofingCeramicwareThermal insulationAdhesive

The invention relates to the field of fire prevention and thermal insulation and in particular relates to an AB composite insulation board and an insulation board assembly. The AB composite insulation board is mainly prepared by adhering a grade-A fireproof insulation board and a grade-B graphite polystyrene board through an adhesive. The AB composite insulation board is capable of well insulating heat and has excellent fireproof performance.

Owner:河北泰晟利华节能材料有限公司

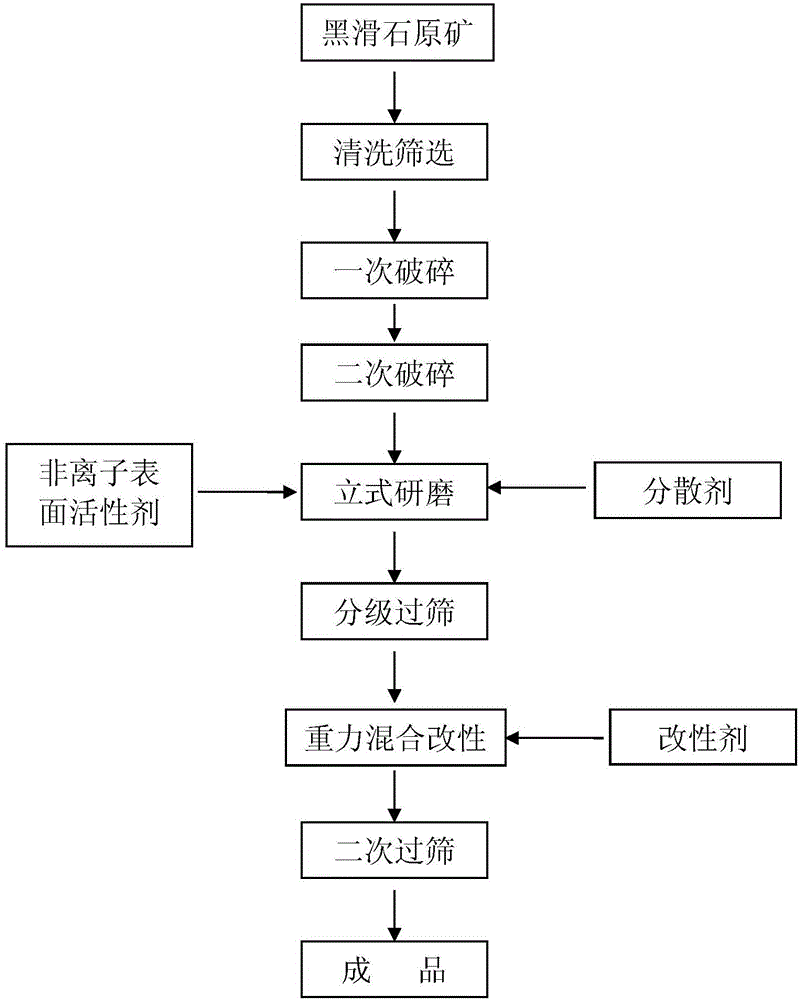

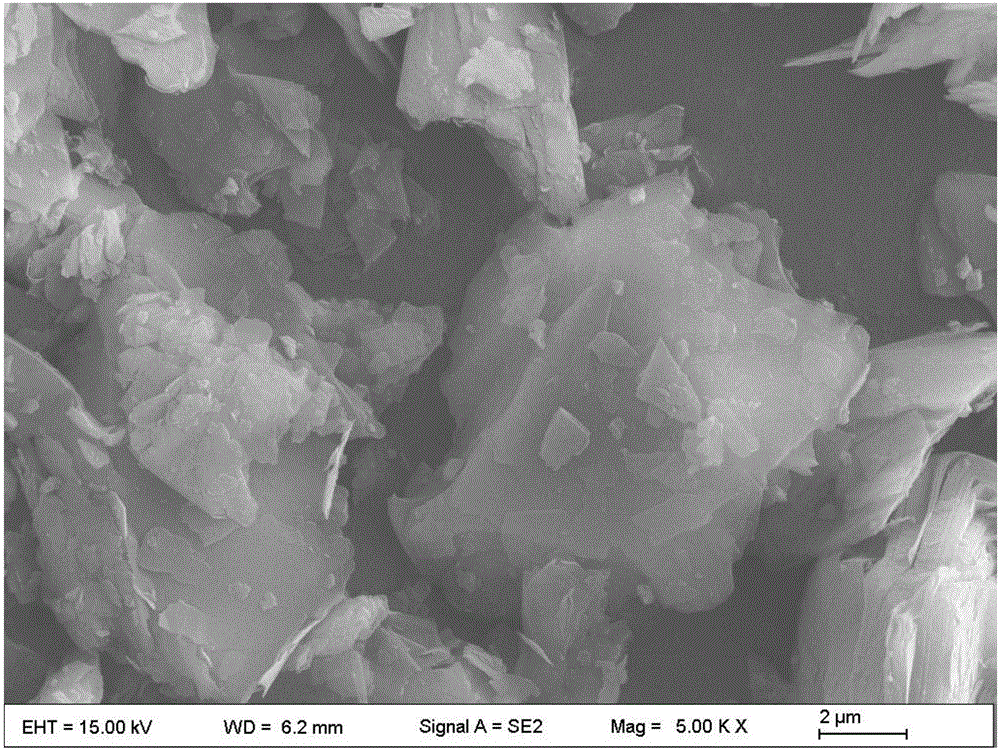

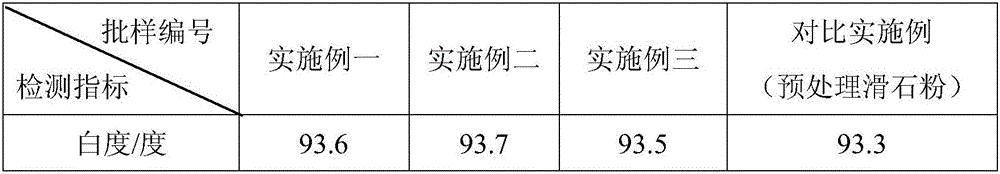

Preparation method of talcum powder used for ship anticorrosion coatings

InactiveCN106366705AImprove compactnessPrevent infiltrationAnti-corrosive paintsPigment treatment with macromolecular organic compoundsPolyethylene oxideSodium stearate

The invention provides a preparation method of talcum powder used for ship anticorrosion coatings. The method comprises the following steps: 1, crushing raw ores to form 0.5-1 cm broken stones; 2, adding a nonionic surfactant and a polyacrylamide dispersant to the broken stones, adding the obtained mixture to a vertical grinding device, and grinding the mixture to obtain preprocessed talcum powder; 3, adding the powder to a multi-stage grading system, collecting powder with the fineness of 2500-3500 meshes through a cyclone collecting system, and sieving the powder with the fineness of 2500-3500 meshes by a 300-500 mesh sieve; 4, adding the obtained powder into a gravity mixing modifier, and adding a modifier to modify the powder, wherein eh modifier includes sodium stearate, a silane coupling agent, a zirconate aluminate coupling agent, a phosphate salt coupling agent and a polyethylene oxide surfactant; and 5, carrying out secondary sieving. The talcum powder used for ship anticorrosion coatings, with the advantages of fine and unfirom granularity and complete sheet structure, is prepared through the method.

Owner:JIANGXI GUANGYUAN CHEM

Hot melt adhesive for polyolefin and application thereof

ActiveCN106893527AStable chemical propertiesNo smellNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer sciencePolyolefin

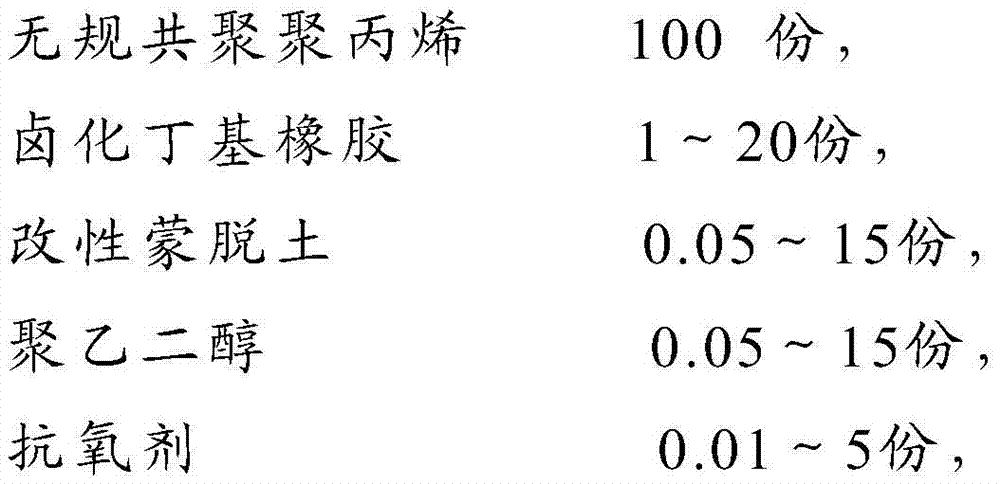

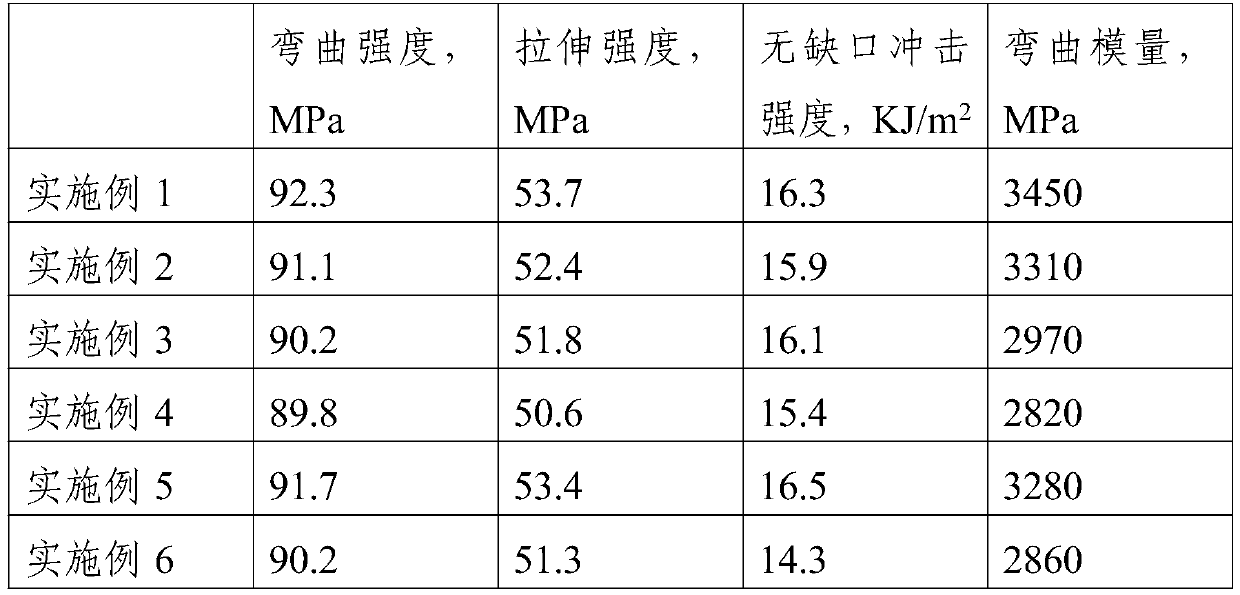

The invention discloses a hot melt adhesive for polyolefin, which is prepared from, by weight, 100 parts of polypropylene random copolymer, 1-20 parts of halogenated butyl rubber, 0.05-15 parts of modified montmorillonite, 0.05-15 parts of polyethylene glycol, and 0.01-5 parts of an antioxidant. The softening point of the hot melt adhesive is 125-140 DEG C. The softening point of the polypropylene random copolymer is 125-140 DEG C. The halogenated butyl rubber is one or two of chlorinated butyl rubber or brominated butyl rubber. The modified montmorillonite is prepared through intercalation modification to montmorillonite raw ore with polyethylene glycol. The preparation method of the hot melt adhesive includes the steps of 1) melt-blending the modified montmorillonite with the polypropylene random copolymer, halogenated butyl rubber, polyethylene glycol and antioxidant; and 2) discharging the material and shearing the material into granules to obtain a product of the hot melt adhesive. The hot melt adhesive is used for adhesion of a polyolefin thin film and a polyolefin catheter, especially, for adhesion of medical polypropylene materials.

Owner:BEIJING UNIV OF CHEM TECH

Light high-strength ABS wood-plastic foamed board and preparation method thereof

InactiveCN111073327AImprove reaction binding abilityImprove mechanical propertiesFoaming agentAcid anhydride

The invention provides a light high-strength ABS wood-plastic foamed board and a preparation method thereof. The wood-plastic foamed board is prepared from the following components in parts by weight:20-30 parts of ABS resin particles, 10-20 parts of maleic anhydride grafted ABS resin particles, 40-60 parts of wood flour, 5-10 parts of coated flame-retardant polypropylene fibers, 5-7 parts of modifier and 2-5 parts of foaming agent and 0-6 parts of a filler. Reasonable raw material selection and self-made pretreatment of part of raw materials are carried out, the reaction combination effect between the materials is effectively improved and the performance effect is higher; and the ABS is adopted as a board substrate, the comprehensive quality is good, the applicability is high, the prepared board is light, high in strength and excellent in corrosion resistance, mildew resistance, acid and alkali resistance, water resistance, heat preservation, flame retardance and the like, the mechanical property is remarkably improved, and the popularization and application value is high.

Owner:安徽智晟通讯科技有限公司

Production method of foaming type wood plastic recombination wood

InactiveCN1475333AIncreased plastic surface areaImproved interface affinityWood working apparatusDomestic articlesHot pressingMaterials science

A foamed composite wood is prepared through treating the sheets made of plant stems by coupling agent, modifying plastic powder by compatibilizer, adding foamer, coating it on the surfaces of said sheets, laminating, and hot pressing at 90-260 deg.C under 0.3-15 MPa while foaming.

Owner:张黔

Amorphous high-conductivity quaternary metal nitride and preparation method thereof

ActiveCN111807418AImprove conductivityHigh electrocatalytic oxygen evolution capacityPhysical/chemical process catalystsNitrogen compoundsMicrostructureHigh conductivity

The invention relates to the field of new materials, and aims to provide an amorphous high-conductivity quaternary metal nitride and a preparation method thereof. The product comprises four metal elements of Co, Cu, Ce and Mo, wherein the molar ratio of Co to Cu to Ce to Mo is 1: 1: (0.2-0.4): (0.8-1.2); the product is powdery, and the microstructure of the product is an amorphous sheet-shaped structure or an olive-shaped structure. The method has the advantages that by strictly controlling the preparation process of parameters, non-crystallization and microstructure controllability can be achieved according to the requirements of application in different fields; and the prepared amorphous high-conductivity quaternary metal nitride has high conductivity, high electrocatalytic oxygen evolution capacity and good interface affinity with metal silver. More high-valence active sites can be formed on the surface of the catalyst, so that the electro-catalytic performance is improved. Good interface bonding with a metal substrate is facilitated, the conductivity of the metal composite material is improved due to the high conductivity characteristic of the metal composite material, and excessive reduction of the conductivity due to addition of a reinforcing phase is avoided.

Owner:ZHEJIANG UNIV

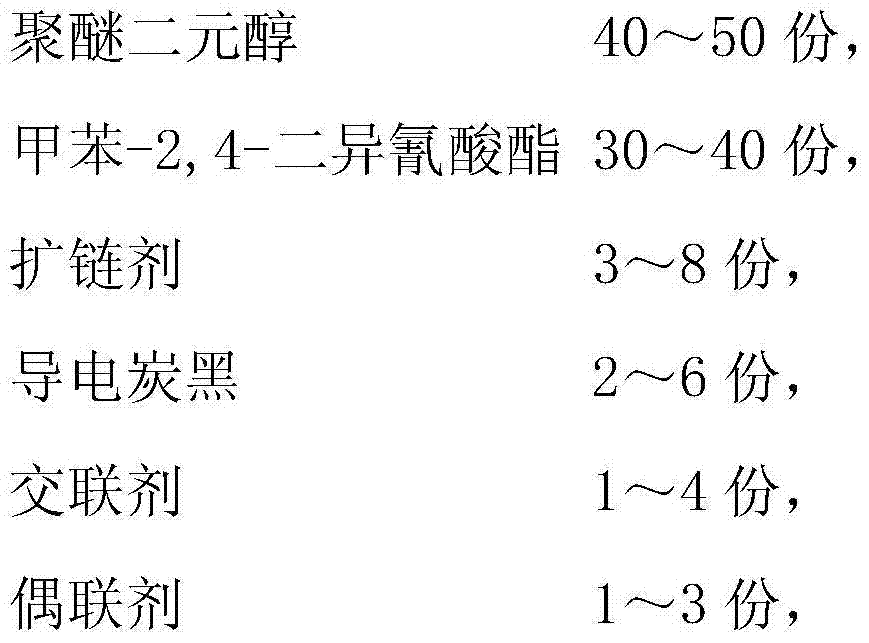

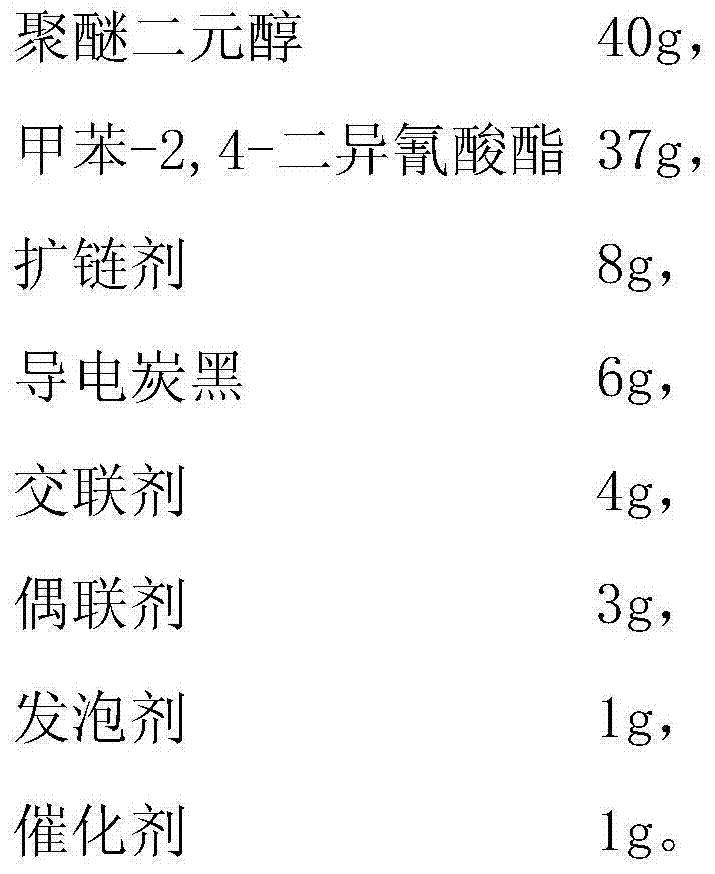

Antistatic polyurethane shoe material and manufacturing method thereof

The invention provides an antistatic polyurethane shoe material which is prepared from the following components in parts by weight: 40-50 parts of polyether dibasic alcohol, 30-40 parts of tolyl-2,4-diisocyanate, 3-8 parts of chain extender, 2-6 parts of graphitized carbon black, 1-4 parts of crosslinking agent, 1-3 parts of coupling agent, 0.1-1 part of foaming agent and 0.2-1 part of catalyst. The invention also provides a manufacturing method of the antistatic polyurethane shoe material. The polyurethane shoe material provided by the invention has favorable antistatic property.

Owner:SUZHOU JINGRO TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com