Patents

Literature

36 results about "Molybdenum hexacarbonyl" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molybdenum hexacarbonyl (also called molybdenum carbonyl) is the chemical compound with the formula Mo(CO)₆. This colorless solid, like its chromium and tungsten analogues, is noteworthy as a volatile, air-stable derivative of a metal in its zero oxidation state.

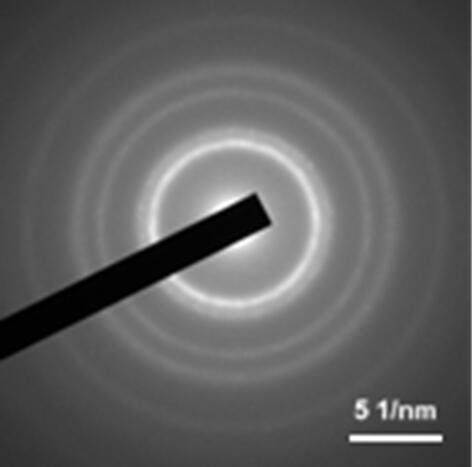

Atomic layer deposition preparation method for large-area molybdenum disulfide film

The invention discloses an atomic layer deposition preparation method for a large-area molybdenum disulfide film. The atomic layer deposition preparation method for the large-area molybdenum disulfidefilm is characterized in that molybdenum hexacarbonyl (Mo(CO)6) and dimethyl disulfide (C2H6S2) are used as precursor sources of molybdenum and sulfur for atomic layer deposition (ALD), a conventional atomic layer deposition device is adopted, and the large-area molybdenum disulfide film is obtained by optimizing reaction parameters. Based on the superiority of the atomic layer deposition technique, the film prepared through the method has the characteristics of large area, good compactness, excellent performance, stable deposition speed, controllable thickness and the like, the quality of the film can be improved, and the application of the molybdenum disulfide film is further enhanced and widened.

Owner:YUNNAN NORMAL UNIV

Synthetic method of 5-bromo-2-chlorobenzoic acid

ActiveCN108250060AReduce pollutionReduce manufacturing costOrganic compound preparationCarboxylic compound preparationBenzoic acid2-Chlorobenzoic acid

The invention discloses a synthetic method of 5-bromo-2-chlorobenzoic acid. The method comprises the following steps of by taking salicylic acid as a starting material, performing bromination reactionto obtain 2-hydroxyl-5-bromo-benzoic acid, and then performing chlorination reaction to obtain the 5-bromo-2-chlorobenzoic acid, wherein a bromination system adopted by the bromination reaction is tetrabutyl ammonium bromide / oxygen / sodium metavanadate, a catalyst is aluminium tribromide, and a solvent is 1,4-dioxane; and a chlorinating agent is carbon tetrachloride, and a catalyst is molybdenum hexacarbonyl. The method provided by the invention adopts the cheap salicylic acid which is wide in source as the starting material and prepares the 5-bromo-2-chlorobenzoic acid through two-step reaction of bromination and chlorination, is novel in synthetic route, relatively low in production cost, relatively small in environmental pollution and very suitable for industrial mass production. According to the method, through the bromination reaction and the chlorination reaction, by selecting proper reagents, relatively high reaction yield and product purity can be obtained.

Owner:江苏尚莱特医药化工材料有限公司

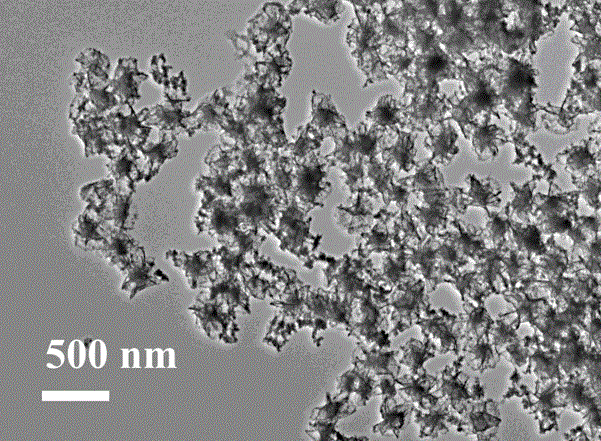

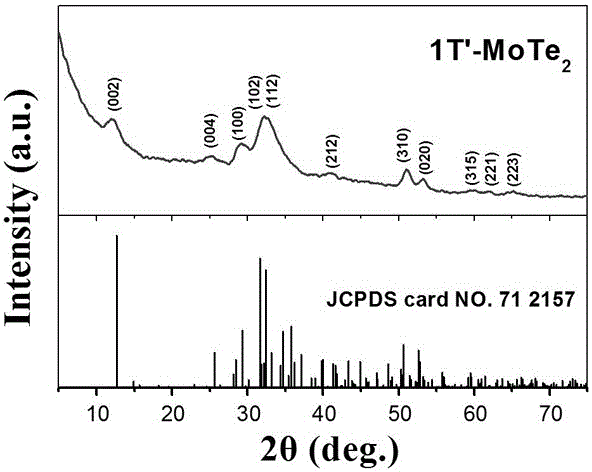

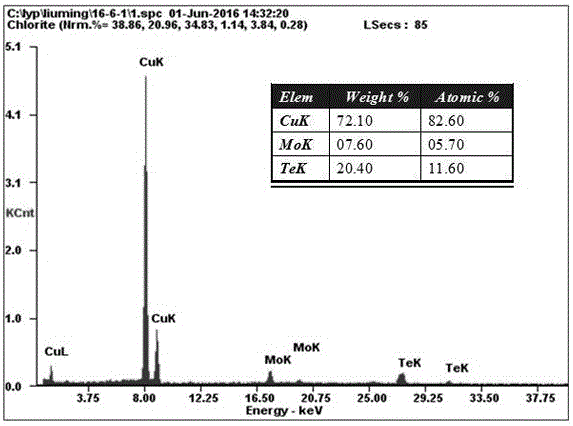

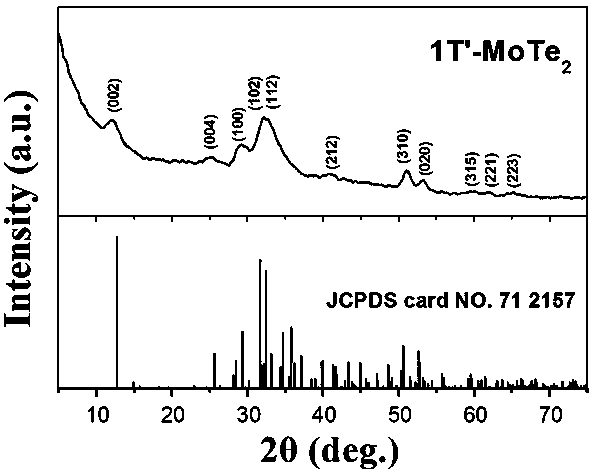

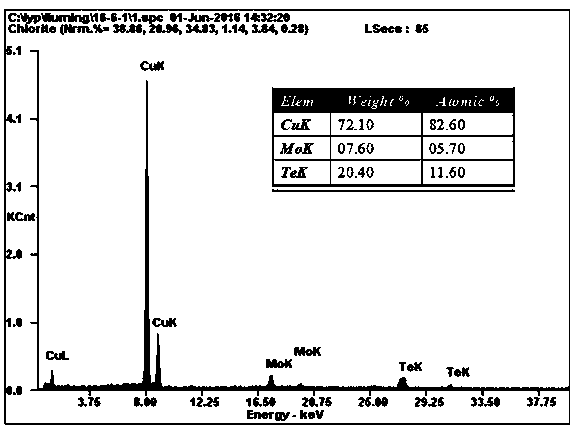

Molybdenum ditelluride electrochemical energy storage material, preparation method and application thereof

InactiveCN106395765AImprove electrochemical energy storage performanceImprove electrochemical stabilityMetal selenides/telluridesBinary selenium/tellurium compoundsMolybdenum tellurideNew energy

The invention provides a molybdenum ditelluride electrochemical energy storage material which is molybdenum ditelluride (MoTe2) in a metastable state, a expression formula is 1T' MoTe2, and the morphology is a nano flower structure or nanosphere structure assembled by ultrathin nanosheets. The invention also provides a preparation method and application of the molybdenum ditelluride electrochemical energy storage material. The metastable-state hexagonal-phase molybdenum ditelluride nano flower structure or nanosphere structure with a uniform size and a regular shape is prepared by using oleylamine as a reducing agent and molybdenum hexacarbonyl or molybdenum pentachloride as a precursor matter, injecting a Te-trioctylphosphin precursor at certain temperature and controlling reaction temperature and reaction time. The material shows excellent super capacitor energy storage performance and is suitable for the new energy development field.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Manufacturing method for pure tungsten or molybdenum thin-wall device

InactiveCN102560412AHigh purityImprove the finishChemical vapor deposition coatingGas phaseNitrogen gas

The invention discloses a manufacturing method for a pure tungsten or molybdenum thin-wall device, belonging to the technical field of powder metallurgy. The manufacturing method comprises the following process steps of: manufacturing a template of the required device by using a red copper material and keeping the surface clean and dry, wherein the surface roughness Ra of the template is lower than 6.3; placing the template into a vapor deposition chamber; with tungsten hexacarbonyl or molybdenum hexacarbonyl as an reactive organic source and with high-purity hydrogen gas or nitrogen gas as diluent gas, carrying out thermal decomposition vapor deposition on the template under the conditions that the pressure of the vapor deposition chamber is 500-10000Pa and the deposition temperature is 280-420DEG C and carrying out annealing once every 2-4 hours in the deposition process according to the requirement of the deposited wall thickness; after the deposition is finished, closing an organic source valve and continuously introducing the dilute gas and keeping the device cooled to the room temperature; and removing a red copper template matrix from the device of which the template surface is deposited with tungsten or molybdenum by adopting a nitric acid corrosion method to obtain the pure tungsten or molybdenum thin-wall device with the wall thickness being 0.1-3mm. The manufacturing method has the advantages of low deposition temperature, high deposition speed, high purity of deposition film, dense film layer, favorable smoothness of film surface, short process flow and no pollution or corrosion.

Owner:CHINA IRON & STEEL RES INST GRP

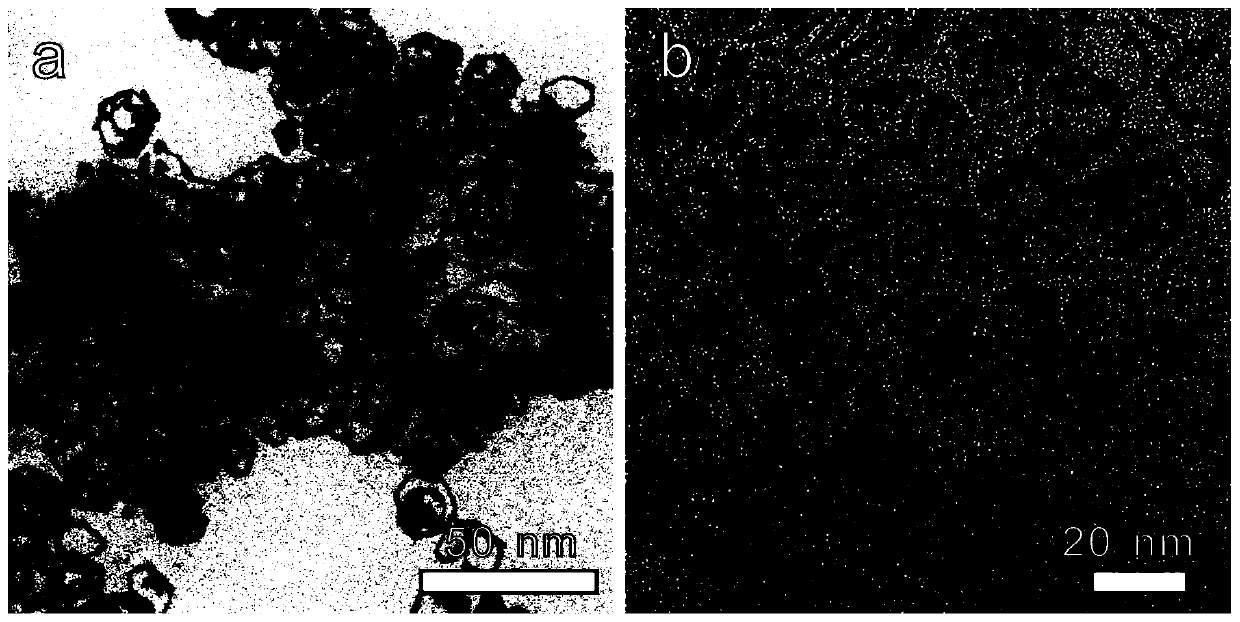

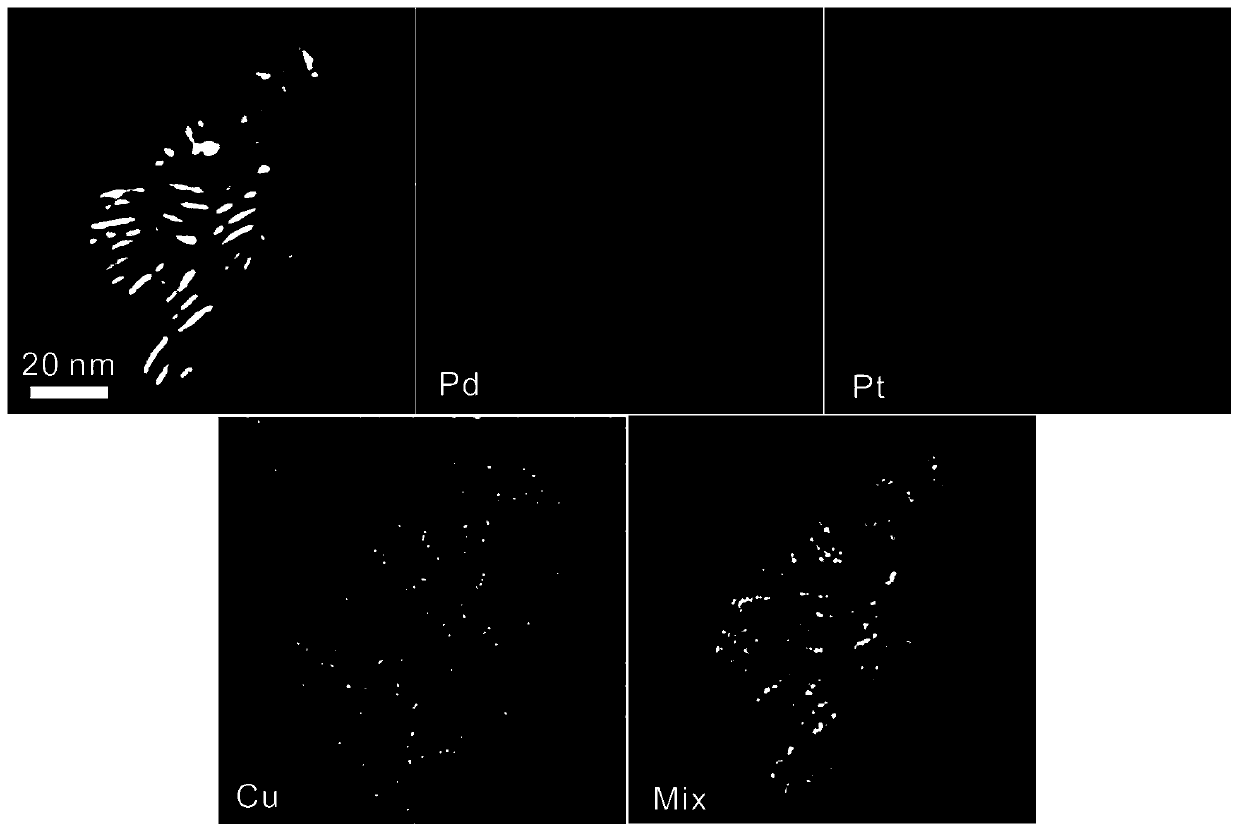

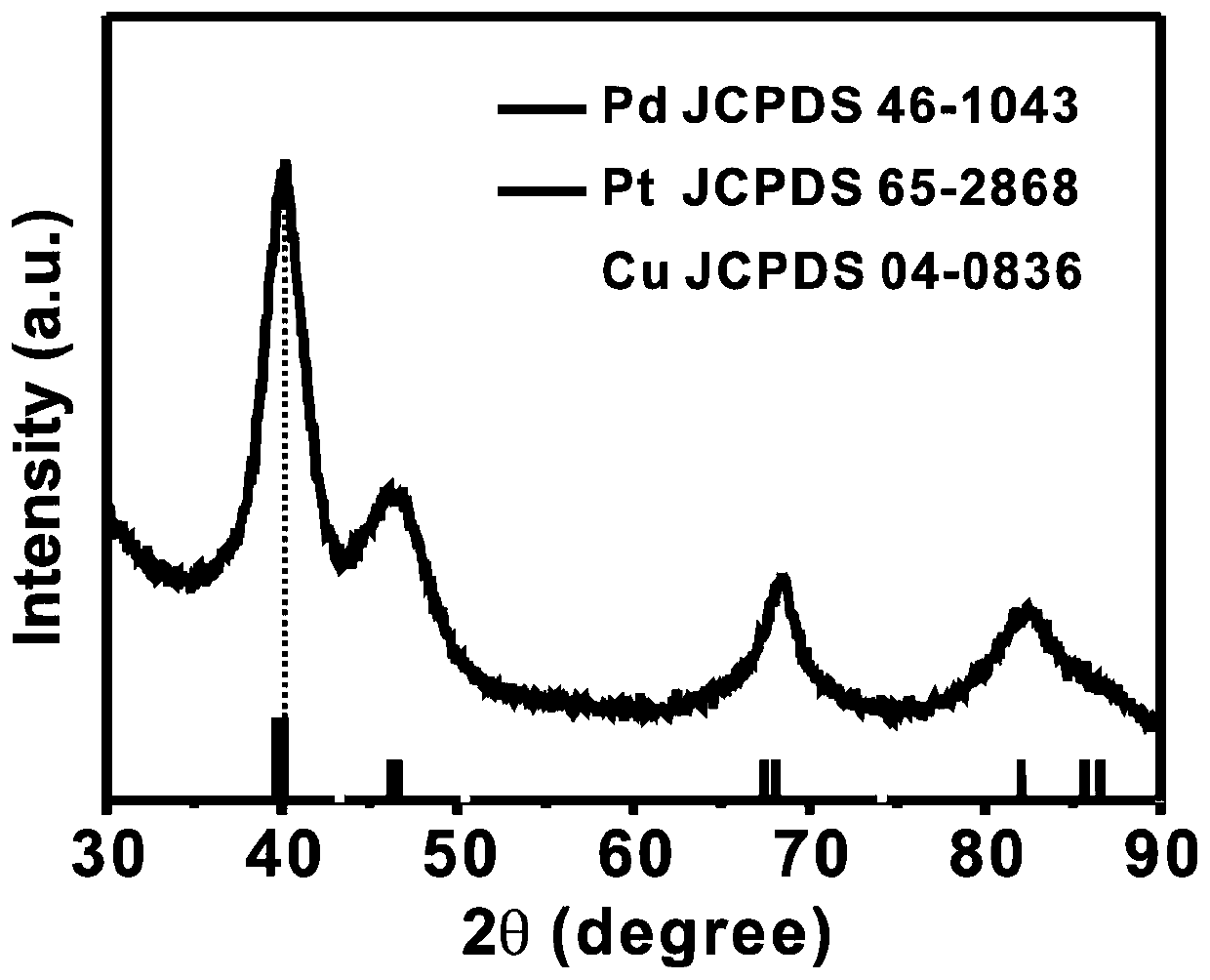

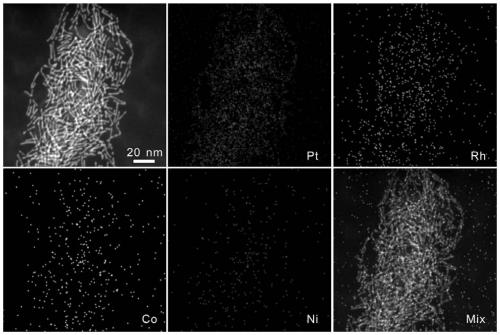

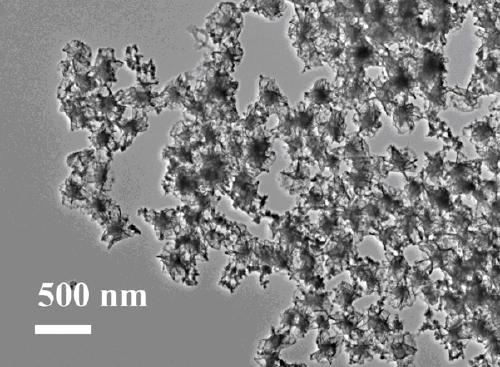

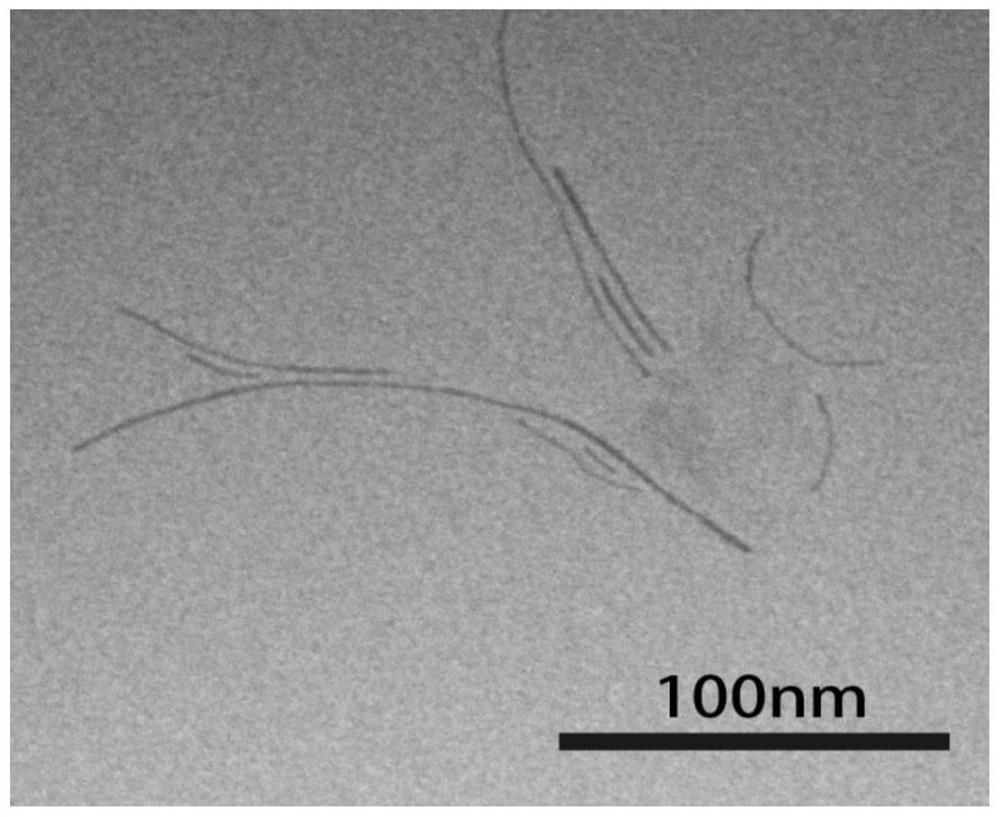

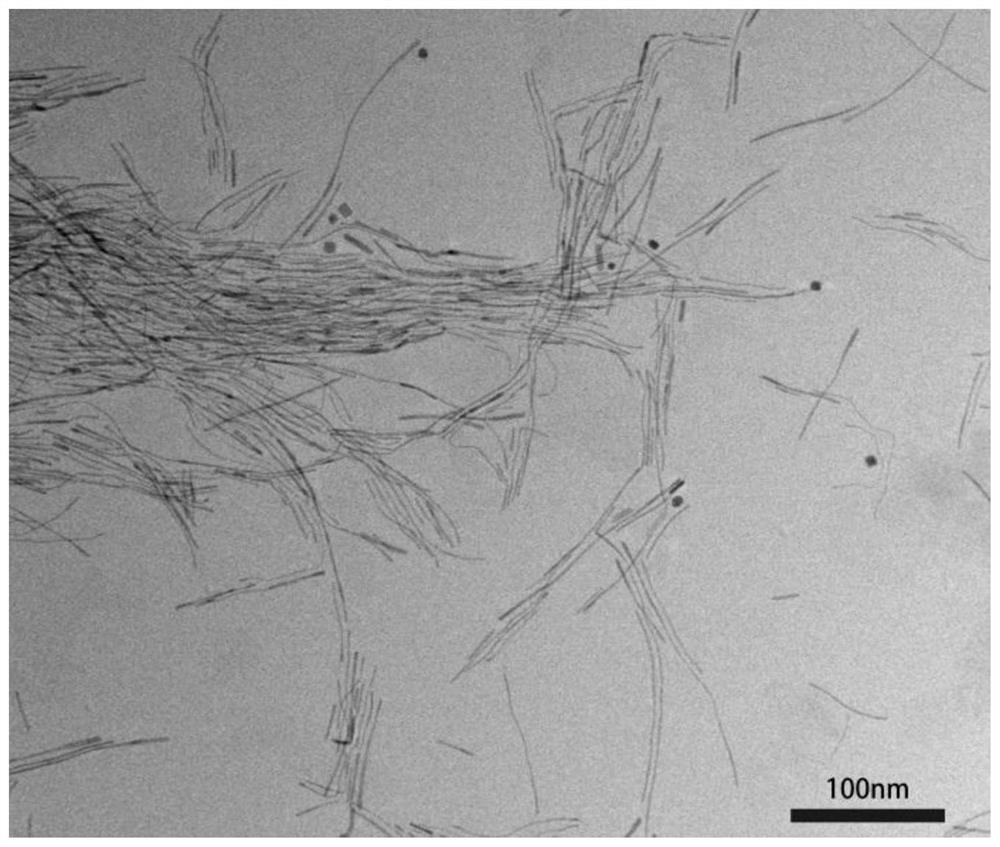

Preparation method and application of two-dimensional multi-element metallic nano material

InactiveCN109759081AGood size controlMorphological rulesMaterial nanotechnologyMetal/metal-oxides/metal-hydroxide catalystsPolyvinylpyrrolidoneMetal salts

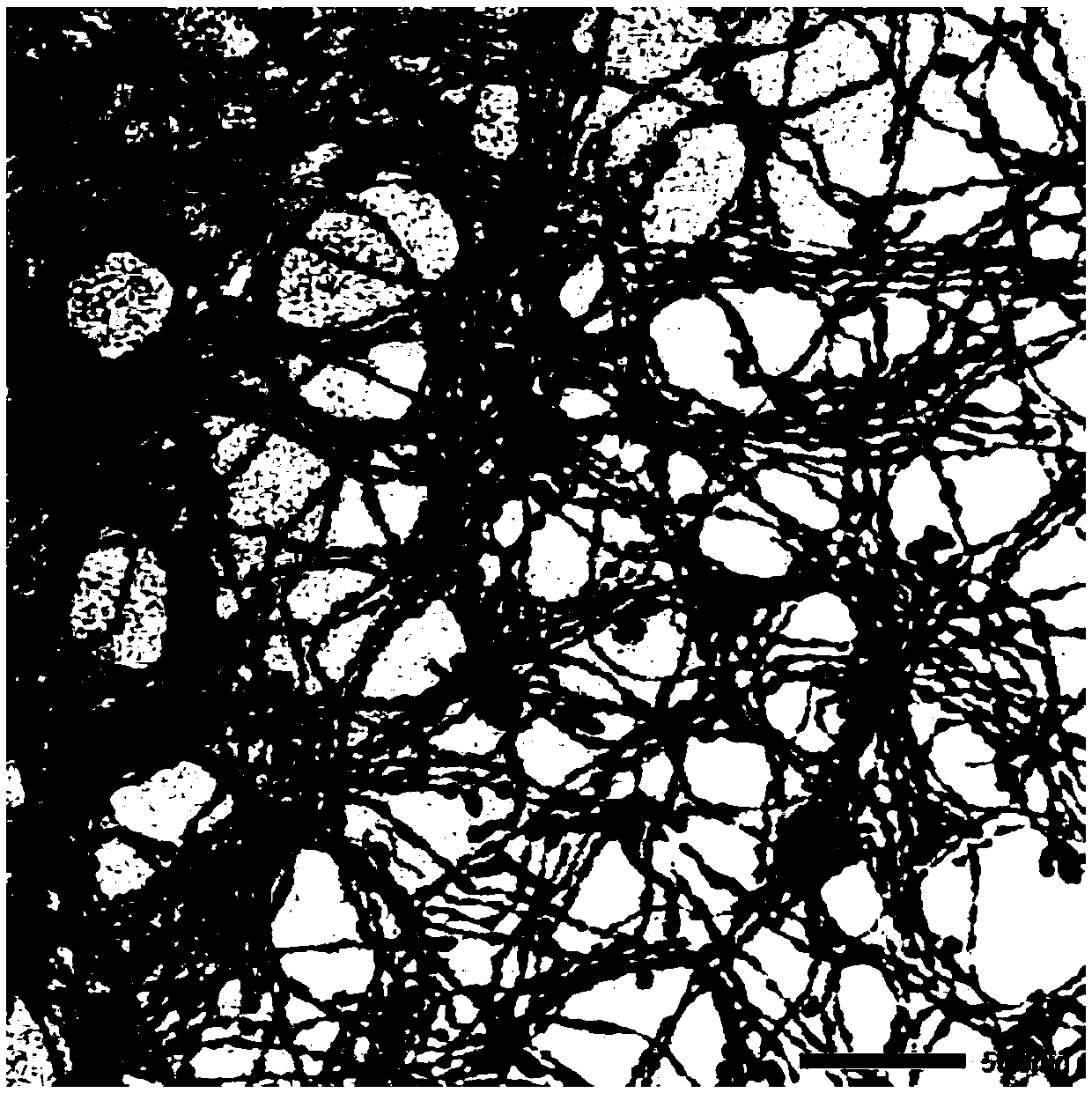

The invention discloses a preparation method and application of a two-dimensional multi-element metallic nano material. The preparation method comprises the steps that palladium acetylacetonate, bisplatinum, selectable soluble metal salt, a structure regulating agent, polyvinylpyrrolidone and N-N dimethyl formamide are mixed and stirred for 30-120 minutes at room temperature, then molybdenum hexacarbonyl is added to react with the mixture for 1-3 hours at the temperature of 60-80 DEG C, the temperature is increased to be 120-150 DEG C, reaction is conducted for 1-24 hours, the product is naturally cooled to be at room temperature, and then sufficiently washed with the mixture of ethyl alcohol and acetone, and the two-dimensional multi-element metallic nano material is obtained. The two-dimensional multi-element metallic nano material is synthesized through a one-step method, and the two-dimensional ultrathin multi-metal nano electrocatalyst with the size being controllable and the morphology being regular is prepared by regulating reaction kinetics to control different metal nucleation and growth speed and sequence.

Owner:HUAQIAO UNIVERSITY

Preparation method of polyisobutene amine serving as main agent of gasoline cleaning agent

ActiveCN104774282ANo corrosionLower requirementLiquid carbonaceous fuelsFuel additivesEnvironmental resistanceCombustion chamber

The invention relates to polyisobutene amine serving as a main agent of a gasoline cleaning agent, which is a surface active agent. According to the technical scheme, a preparation method of the gasoline cleaning dispersing agent comprises the following steps: preparing epoxidation polyisobutene with high yield by using molybdenum hexacarbonyl as a catalyst and tert-butyl hydroperoxide as an oxygen source; and catalyzing and aminating the epoxidation polyisobutene serving as a raw material to obtain the polyisobutene amine product, and preparing the gasoline cleaning dispersing agent by using the polyisobutene amine, carrying oil, a demulsifying agent, an antioxidant, a polymerization inhibitor, an antirust agent, a metal deactivator and the like in proportion. The whole technological process is green and environmentally-friendly; and the product has excellent performances. The polyisobutene amine serves as the main agent of the gasoline cleaning agent and can effectively clean up carbon deposit of oil nozzles and deposits of intake valves and combustion chambers.

Owner:山东京博众诚清洁能源有限公司

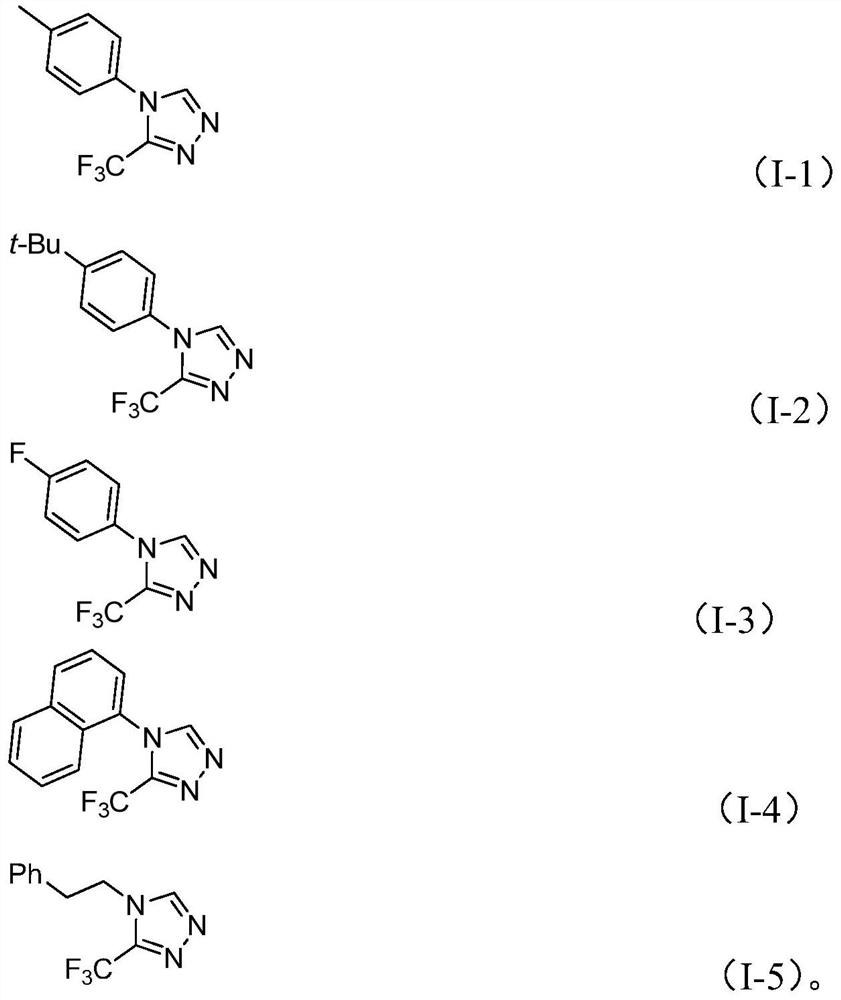

Preparation method of 3-trifluoromethyl substituted 1,2,4-triazole compound

InactiveCN113307778AStrong designabilityWide range of toleranceOrganic chemistryOrganosolvEthyl group

The invention discloses a preparation method of a 3-trifluoromethyl substituted 1,2,4-triazole compound. The preparation method comprises the following steps: adding molybdenum hexacarbonyl, cuprous acetate, triethylamine, a molecular sieve, trifluoroethylimidoacyl chloride and functionalized isonitrile (NIITP) into an organic solvent, conducting reacting at 70-90 DEG C for 18-30 hours, and after the reaction is completed, performing post-treatment to obtain the 3-trifluoromethyl substituted 1,2,4-triazole compound. The preparation method has the advantages of mild conditions, simple operation, cheap and easily available initial raw materials and high reaction efficiency, can be expanded to gram-level reaction, can synthesize trifluoromethyl-containing 1,2,4-triazole compounds substituted by different functional groups through substrate design, and is convenient to operate and widened in applicability.

Owner:HANGZHOU VOCATIONAL & TECHN COLLEGE

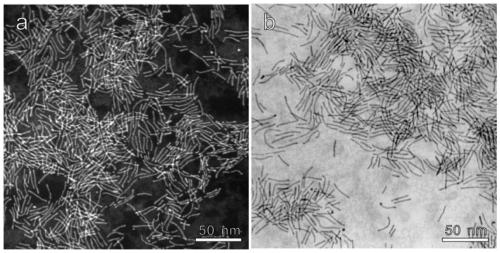

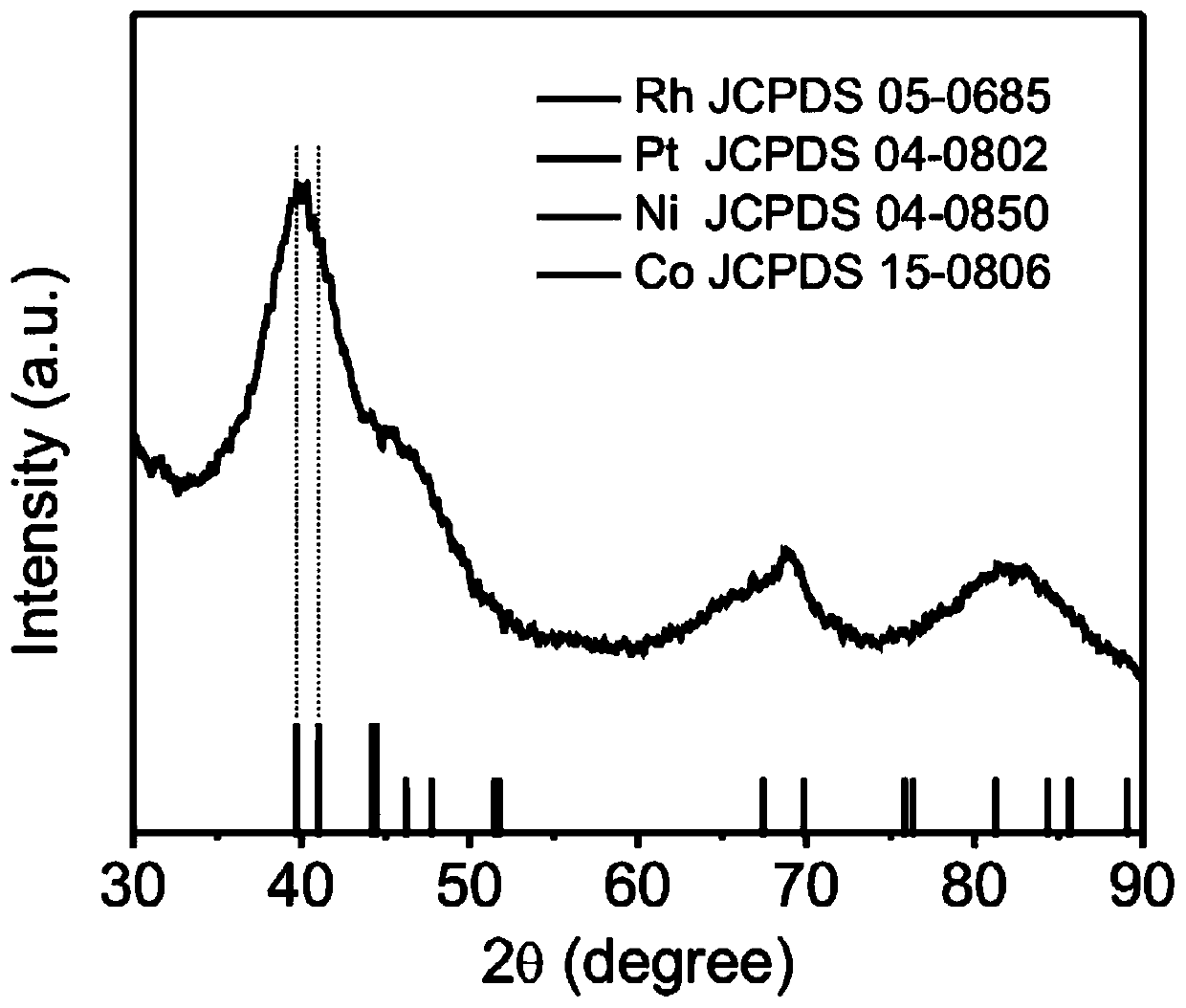

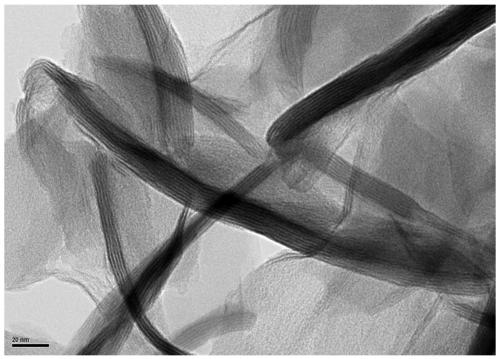

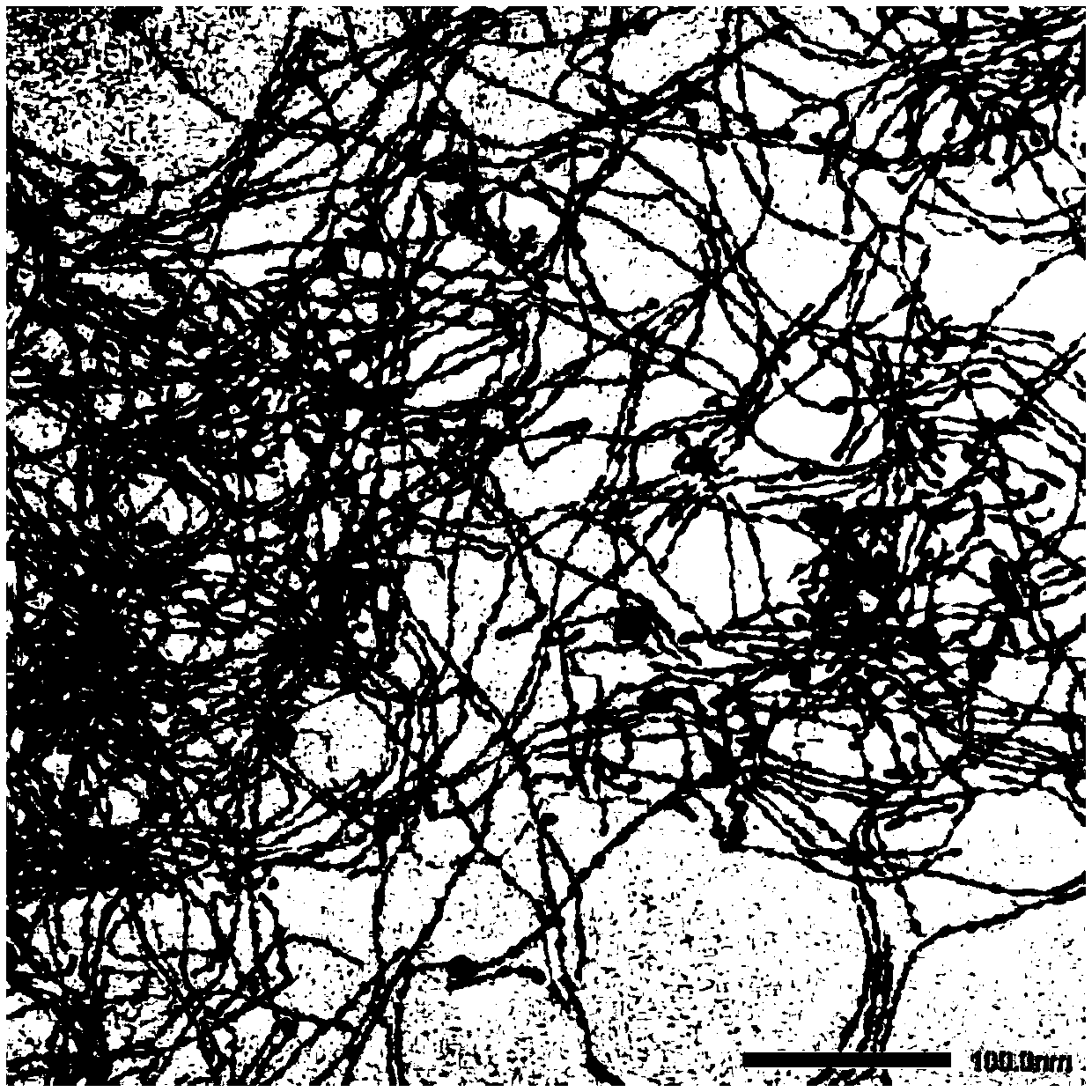

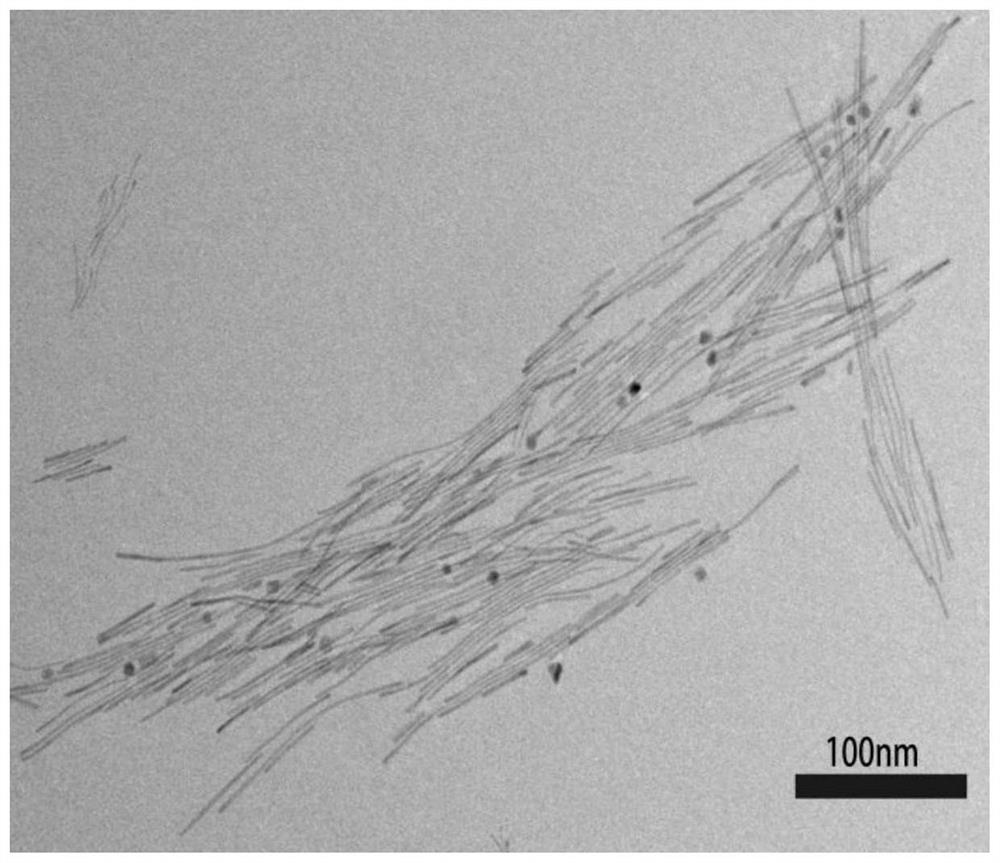

Multi-metal one-dimensional nano material, preparation method and catalyst

InactiveCN111068713AComponents are easy to controlUniform shapeElectrolytic organic productionMetal/metal-oxides/metal-hydroxide catalystsPtru catalystOleylamine

The invention discloses a multi-metal one-dimensional nano material, a preparation method and a catalyst, and the method comprises the following steps: adding soluble metal salt and hexadecyl trimethyl ammonium chloride into oleylamine, stirring for 5-30 minutes at room temperature, and carrying out ultrasonic treatment for 5-30 minutes; then adding molybdenum hexacarbonyl, reacting at 180 DEG C for 6-12 hours, finally naturally cooling to room temperature, washing with ethanol and n-hexane, and carrying out centrifugal treatment so as to obtain the multi-metal one-dimensional nano material, wherein the soluble metal salt comprises platinum acetylacetonate, and further comprises at least two of rhodium acetylacetonate, cobalt acetylacetonate and nickel acetylacetonate.

Owner:HUAQIAO UNIVERSITY

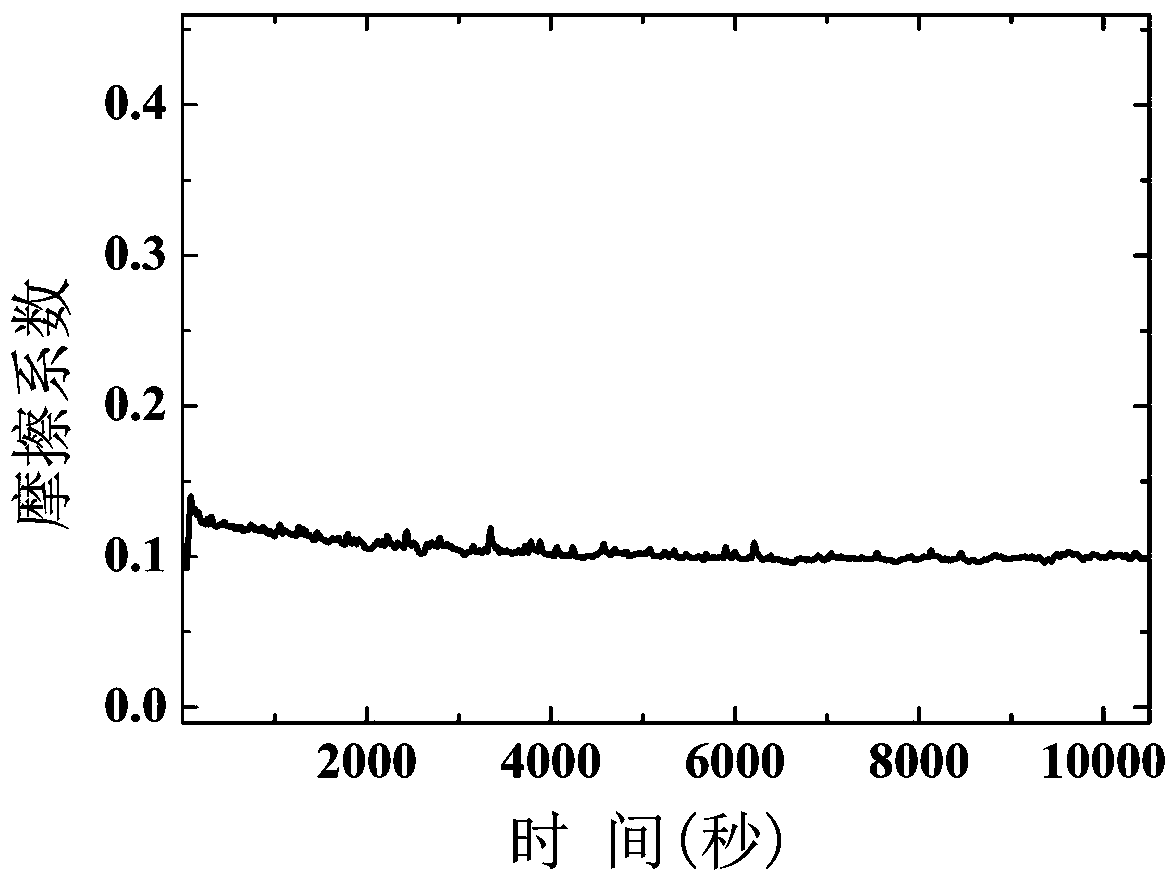

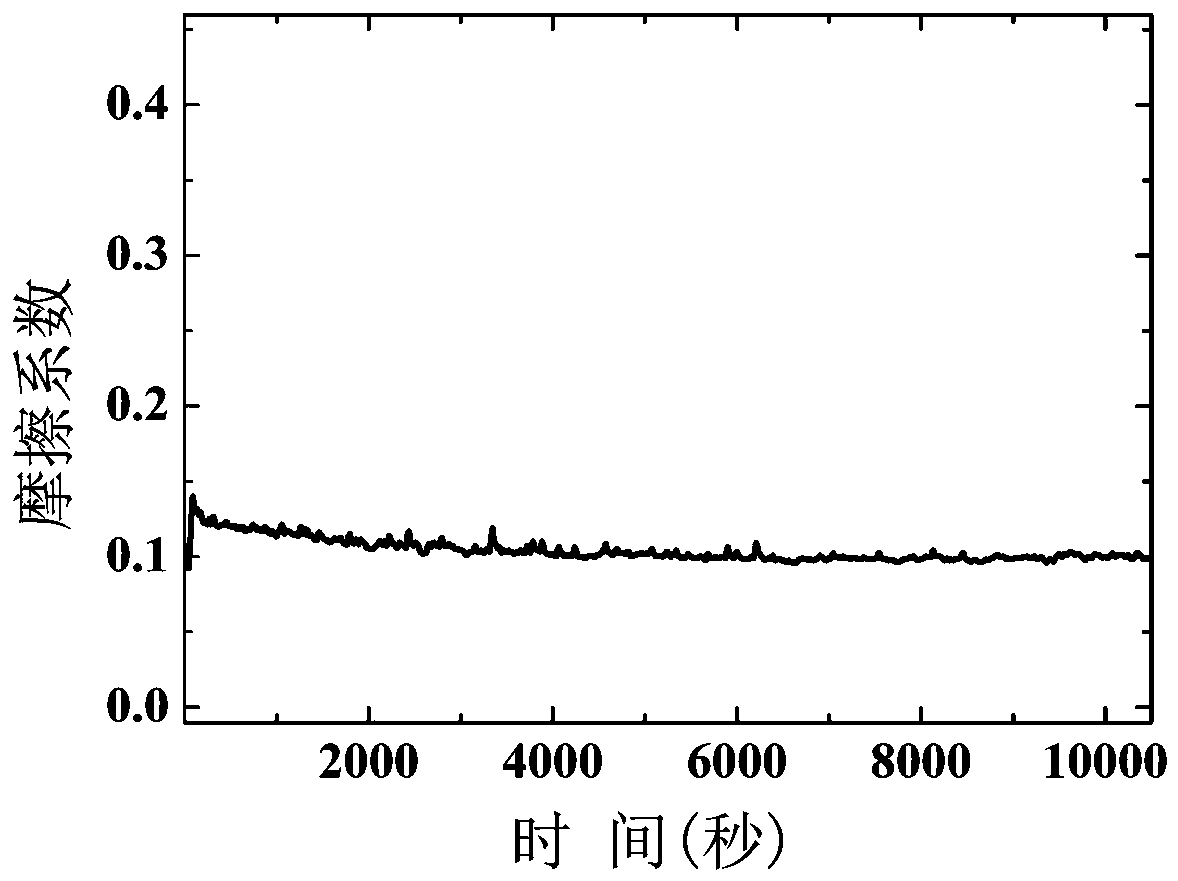

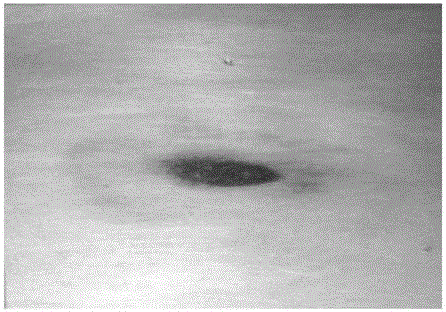

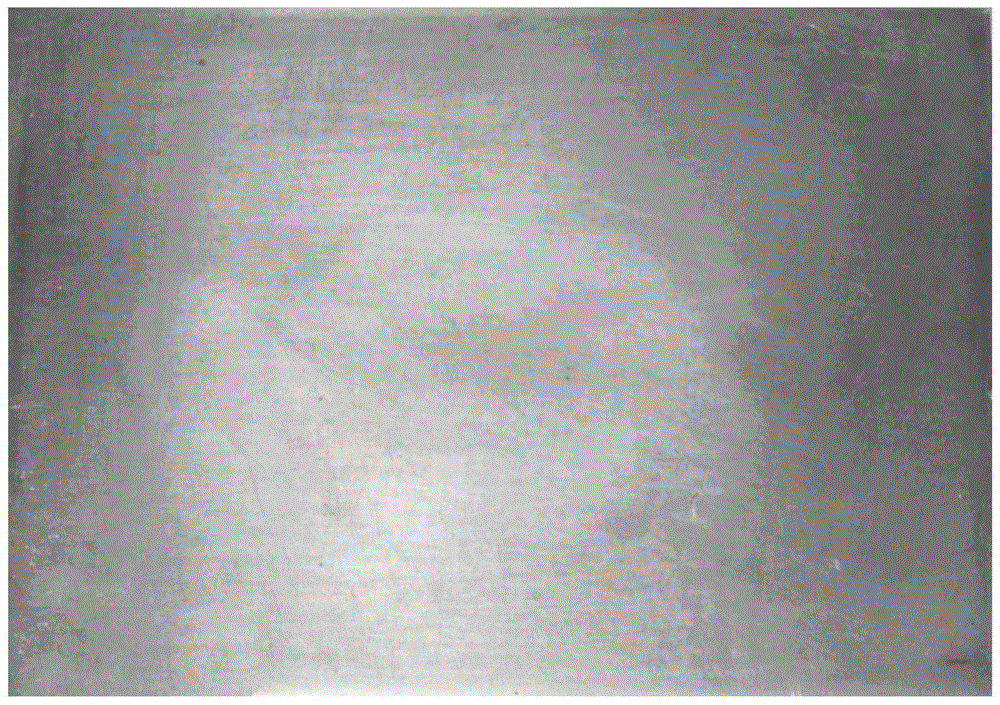

Method for one-step preparing of molybdenum disulfide film with ultra-lubricating function through atomic layer deposition and product and application of molybdenum disulfide film

ActiveCN107740069ASuper lubricatingReduce coefficient of frictionChemical vapor deposition coatingVulcanizationPlasma technology

The invention relates to a method for one-step preparing of a MoS2 film with an ultra-lubricating function through atomic layer deposition and a product and application of the MoS2 film. A Si substrate is cleaned in the following manner that after the Si substrate is wiped by ethyl alcohol and acetone, the Si substrate is subjected to ultrasonic oscillating for 5-10 min sequentially in acetone anddeionized water, then, the Si substrate is repeatedly washed through deionized water and is blown dry through a nitrogen gun, the Si substrate is placed in an atomic layer deposition system reactionchamber, a Mo(CO)6(molybdenum hexacarbonyl) solid source and SH(CH2)2SH(dithioglycol) liquid source are adopted, and atomic layer deposition is adopted for one-step preparing of the MoS2 film with theexcellent lubrication effect. The additional high-temperature vulcanization process is not needed in the related preparing method, the integral preparing process is effectively simplified, the MoS2 film with the extremely low friction coefficient is obtained under the condition that the plasma technology and other auxiliary technologies are not used, large-scale batched production is easy to achieve, and important application potentials are achieved.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

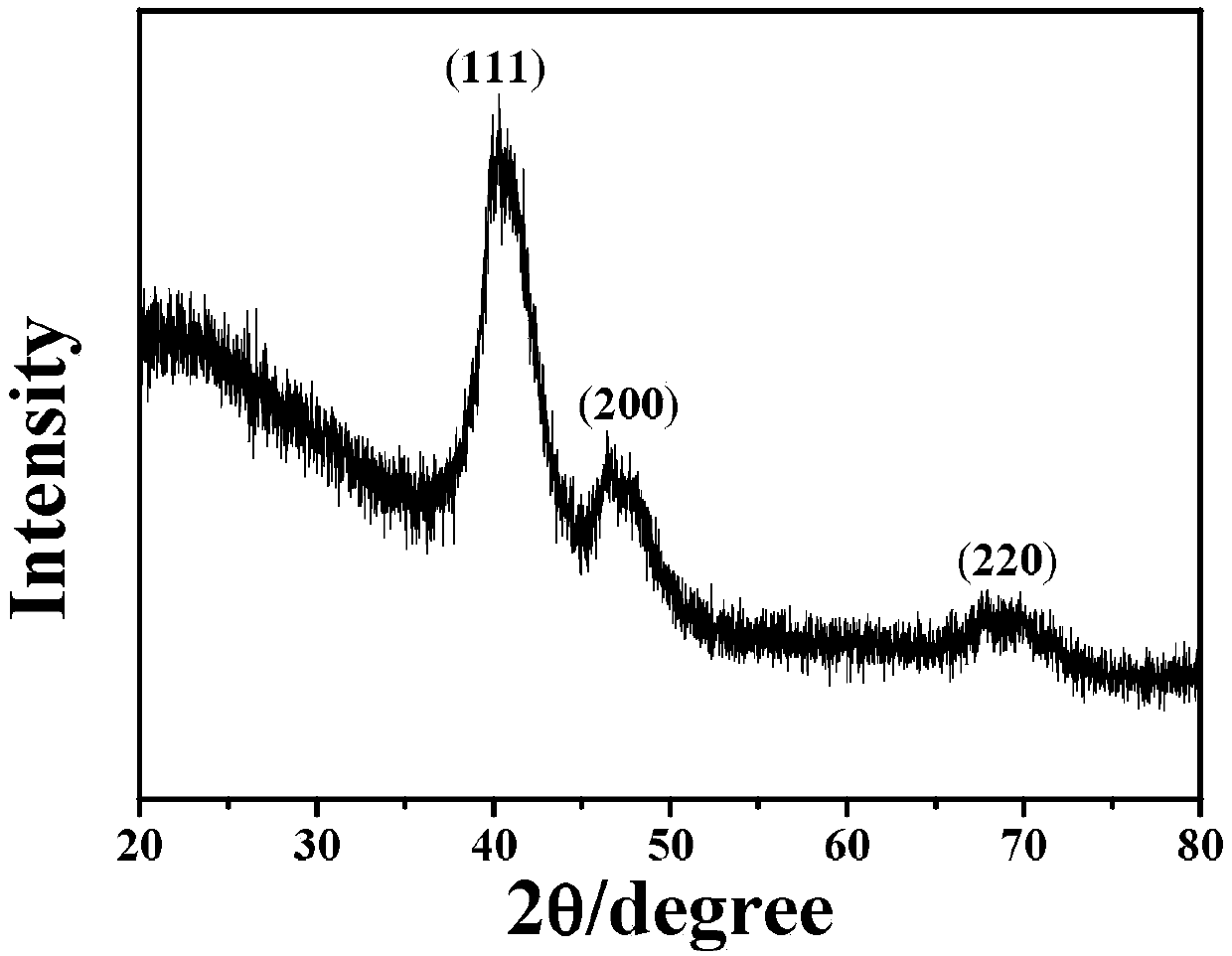

Platinum-rhodium-yttrium nanowire and preparation method and application thereof

ActiveCN110635142ALarge specific surface areaReduce defectsMaterial nanotechnologyCell electrodesNanowireCO poisoning

The invention relates to the technical field of electrocatalytic materials, in particular to a platinum-rhodium-yttrium nanowire and a preparation method and application thereof. Cetylammonium chloride is used as a surfactant and a structure directing agent, Hexacarbonyl molybdenum is mixed with a platinum source, a rhodium source and yttrium acetylacetonate as a structure limiting agent and participates in the preparation process of the platinum-rhodium-yttrium nanowire, and a nanowire with a face-centered cubit structure with disordered atoms is obtained through combination of the hydrothermal reaction. The platinum-rhodium-yttrium nanowire prepared by the method has larger specific surface area, a large number of active sites and fast electron transmission efficiency so that the platinum-rhodium-yttrium nanowire has higher catalytic performance. Meanwhile, the platinum-rhodium-yttrium nanowire reduces the content of metal platinum and enhances the ability to resist CO poisoning in comparison with the metal platinum catalyst, and thus the ability of electrochemical catalytic methanol oxidation can be improved.

Owner:YANSHAN UNIV

Method for preparing molybdenum trioxide nanotube

ActiveCN108147460ANo pollution in the processStrong diameter controllabilityMaterial nanotechnologyMolybdenum oxides/hydroxidesFiltrationCrucible

The invention discloses a method for preparing a molybdenum trioxide nanotube. The method comprises the following process steps: 1) using hexacarbonyl molybdenum as a raw material, and porous anodizedalumina as a template, placing the opening of the template downward above a raw material, sealing a crucible and then placing in a muffle furnace for heating, performing low temperature sublimation,depositing the hexacarbonyl molybdenum, and continuously increasing the temperature, so that the hexacarbonyl molybdenum deposited in the porous anodized alumina template is thermally decomposed to form a metal molybdenum deposit; 2) continuously increasing the temperature so that the metal molybdenum deposit in step 1) is oxidized; 3) removing the porous alumina template with a dilute acid solution, followed by suction filtration and drying, to obtain the finished product. The method disclosed by the invention has simple steps, no environmental pollution, and no need for complicated equipment, and the prepared molybdenum trioxide nanotube material has strong diameter controllability, good crystallinity, and uniform nanotube wall morphology, thereby greatly improving the comprehensive performance of the finished molybdenum trioxide nanotube material product. The method disclosed by the invention has wide applicability and is favorable for large-scale industrial production.

Owner:FOSHAN UNIVERSITY

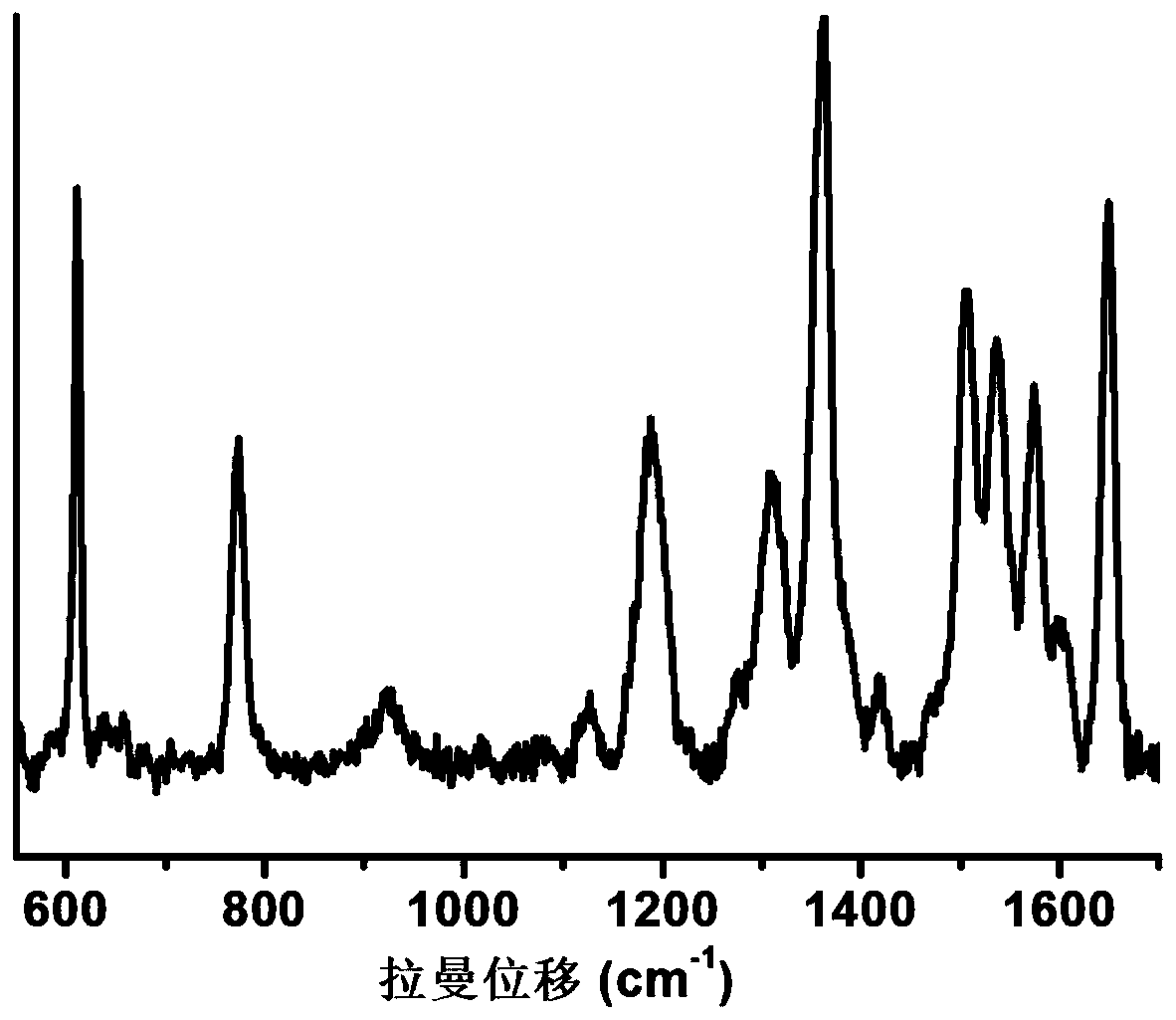

Synthesis method of ultrathin MoO2 nanosheet with SERS (Surface Enhanced Raman Scattering) effect and application of synthesis method

InactiveCN110156083ALow priceGood repeatabilityMaterial nanotechnologyRaman scatteringSynthesis methodsSolvent

The invention discloses a synthesis method of an ultrathin MoO2 nanosheet with an SERS (Surface Enhanced Raman Scattering) effect and application of the synthesis method. The synthesis method comprises the following step: by taking molybdenum hexacarbonyl as a raw material, and tertiary butanol as a solvent and a structure template, carrying out synthesis under a medium temperature condition. Thesynthesis method which is disclosed by the invention and has solvothermal is simple and reliable, low in price, good in repeatability and easy to popularize. The ultrathin MoO2 nanosheet synthesized by using the synthesis method disclosed by the invention can be directly used as a Raman detection substrate and is capable of intensifying a Raman signal for 106 times.

Owner:CHINESE ACAD OF INSPECTION & QUARANTINE

Preparation method of molybdenum disulfide nanotubes

ActiveCN108059189AGood size controllabilityHigh crystallinityNanotechnologyMolybdenum sulfidesFiltrationControllability

The invention discloses a preparation method of molybdenum disulfide nanotubes. The preparation method comprises the following technological steps: 1) paving molybdenum hexacarbonyl on the bottom of aceramic crucible; then putting a porous anodic aluminum oxide template above the molybdenum hexacarbonyl in a manner of placing an opening of the porous anodic aluminum oxide template downward; aftersealing the crucible, putting the crucible into a tubular furnace; under gas protection, sublimating and depositing at low temperature and pyrolyzing at high temperature; then cooling; 2) after cooling the vacuum tubular furnace to room temperature, putting the template into the ceramic crucible filled with sulfur powder in the manner of placing the opening of the template downward; after sealingthe crucible, raising the temperature under the gas protection, so as to enable monomer sulfur and metal molybdenum to directly react; 3) removing the porous aluminum oxide template by adopting a diluted acid solution and removing surplus sulfur by utilizing carbon disulfide; then carrying out suction filtration treatment and drying to obtain a finished product. The method disclosed by the invention has simple steps and no environment pollution and does not need complicated equipment; a prepared molybdenum disulfide nanotube powder material has strong size controllability and good crystallization performance; the nanotubes have a shape and uniform tube wall, so that the comprehensive performance of a molybdenum disulfide nanotube powder material finished product is greatly improved. The molybdenum disulfide nanotubes disclosed by the invention have wide applicability and large-scale industrial production is facilitated.

Owner:FOSHAN UNIVERSITY

Molybdenum ditelluride electrochemical energy storage material, preparation method and application thereof

InactiveCN106395765BAchieve synthesisMeets requirementsMetal selenides/telluridesBinary selenium/tellurium compoundsMolybdenum tellurideNew energy

The invention provides a molybdenum ditelluride electrochemical energy storage material, the material is metastable molybdenum ditelluride, and its expression is 1T'-MoTe 2 , the morphology is a nanoflower structure or a nanosphere structure assembled by ultrathin nanosheets. The invention also provides a preparation method and application of the material, using oleylamine as the reducing agent, molybdenum hexacarbonyl or molybdenum pentachloride as the precursor of molybdenum, injecting the tellurium-trioctylphosphine precursor at a certain temperature, and controlling the reaction temperature and reaction time, thereby preparing a metastable hexagonal phase molybdenum ditelluride nanoflower structure or nano spherical structure with uniform size and regular shape. This type of material exhibits excellent supercapacitor energy storage performance and is suitable for the field of new energy development.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for preparing molybdenum ditelluride nanotubes

ActiveCN107934927AGood size controllabilityHigh crystallinityNanotechnologyMetal selenides/telluridesSingle substanceMolybdenum telluride

The invention discloses a method for preparing molybdenum ditelluride nanotubes. The method comprises the following steps: 1) laying molybdenum hexacarbonyl to the bottom of a ceramic crucible, layinga porous anodic aluminum oxide mold plate with an opening facing downwards on the molybdenum hexacarbonyl, sealing the ceramic crucible, putting into a tubular furnace, performing low-temperature sublimation deposition in the presence of a gas, and continuously performing heating pyrolysis; 2) cooling the vacuum tubular furnace to the room temperature, putting the mold plate with the opening facing downwards into a ceramic crucible with tellurium powder, sealing the ceramic crucible, heating in the presence of the gas, and enabling a single substance, namely tellurium, to react with a metal,namely molybdenum, directly; 3) removing the excessive aluminum oxide mold plate and excessive tellurium by using a diluted acid solution, performing suction filtration treatment, and drying, therebyobtaining a finished product. The method disclosed by the invention is simple in step, free of environment pollution and free of complex equipment, a molybdenum ditelluride nanotube powder material prepared by using the method is good in size controllability, good in crystallinity and uniform in nanotube wall and morphology, and thus the comprehensive properties of a finished product of the molybdenum ditelluride nanotube powder material are greatly improved. The method is wide in applicability and beneficial to large-scale industrial production.

Owner:FOSHAN UNIVERSITY

Method for growing single-layer telluride doping structure through impulse type injection of reactants

InactiveCN110863189APrecise and controllable growth conditionsEasy to operateChemical vapor deposition coatingMolybdenum tellurideReaction temperature

The invention discloses a method for growing a single-layer telluride doping structure through impulse type injection of reactants. According to the method, a plurality of transition metal organics and diethyl tellurium or molybdenum hexacarbonyl and a plurality of chalcogens are injected simultaneously to control the carrier gas flow to control the amount of telluride doping, the reaction temperature and the reaction time are controlled to control the area and the number of layers of telluride growth, and thus high-quality molybdenum ditelluride with the doping structure is obtained. The method has the advantages that growth conditions are precise and controllable, operation is easy and convenient, and the stable molybdenum ditelluride with the single-layer doping structure can be prepared. The prepared molybdenum ditelluride with the single-layer doping structure has broad application prospects in the fields of nano-electronical appliances, lubricating materials, photocatalysis and the like.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

Method for preparing molybdenum diselenide nanotubes

ActiveCN107934926AGood size controllabilityHigh crystallinityNanotechnologyMetal selenides/telluridesSingle substanceFiltration

The invention discloses a method for preparing molybdenum diselenide nanotubes. The method comprises the following steps: 1) laying molybdenum hexacarbonyl to the bottom of a ceramic crucible, layinga porous anodic aluminum oxide mold plate with an opening facing downwards on the molybdenum hexacarbonyl, sealing the ceramic crucible, putting into a tubular furnace, performing low-temperature sublimation deposition in the presence of a gas, and continuously performing heating pyrolysis; 2) cooling the vacuum tubular furnace to the room temperature, putting the mold plate with the opening facing downwards into a ceramic crucible with selenium powder, sealing the ceramic crucible, heating in the presence of the gas, and enabling a single substance, namely selenium, to react with a metal, namely molybdenum, directly; 3) removing the excessive aluminum oxide mold plate and excessive selenium by using a diluted acid solution, performing suction filtration treatment, and drying, thereby obtaining a finished product. The method disclosed by the invention is simple in step, free of environment pollution and free of complex equipment, a molybdenum diselenide nanotube powder material prepared by using the method is good in size controllability, good in crystallinity and uniform in nanotube wall and morphology, and thus the comprehensive properties of a finished product of the molybdenumdiselenide nanotube powder material are greatly improved. The method is wide in applicability and beneficial to large-scale industrial production.

Owner:FOSHAN UNIVERSITY

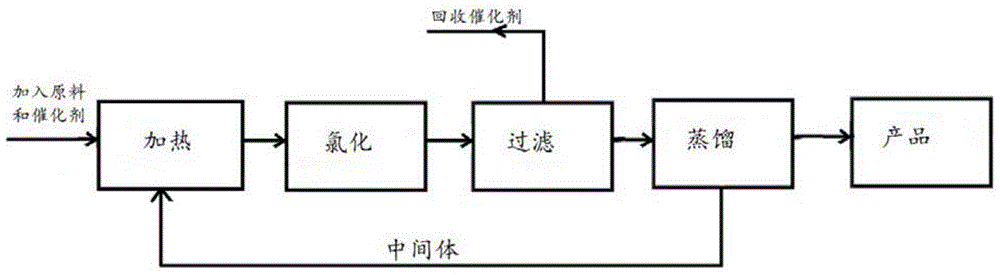

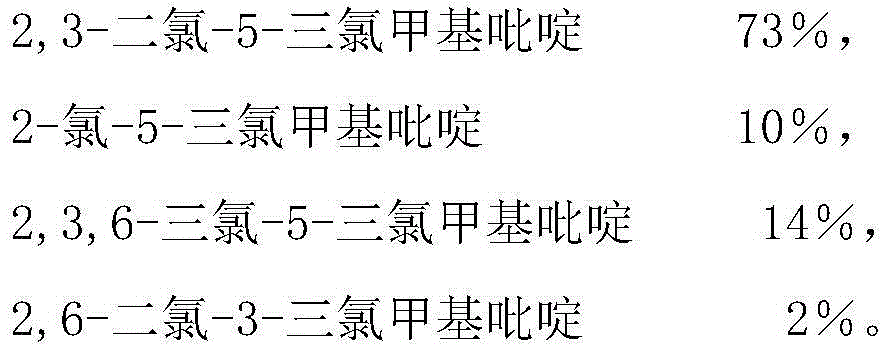

Method for synthesizing 2,3-dichloro-5-trichloromethyl pyridine

The invention discloses a method for synthesizing 2,3-dichloro-5-trichloromethyl pyridine. The method comprises the following steps: heating 2-chloro-5-chloromethylpyridine as a raw material to reaction temperature of 70-280 DEG C, at 1-10 atmospheric pressure, in the presence of a catalyst, carrying out chlorination reaction on 2-chloro-5-chloromethylpyridine and chlorine and filtering to obtain 2,3-dichloro-5-trichloromethyl pyridine, wherein the catalyst is one or a combination of more selected from ferric chloride, ruthenium trichloride, cobalt dichloride and hexacarbonyl molybdenum. The method has the advantages of cheap raw material and higher purity and yield, and is simple in operation and convenient for after-treatment, and the large-scale industrial production can be performed.

Owner:YANGZHOU UNIV

One-step atomic layer deposition method for preparing molybdenum disulfide film with superlubricating effect and its products and applications

ActiveCN107740069BSuper lubricatingReduce coefficient of frictionChemical vapor deposition coatingVulcanizationPlasma technology

The invention relates to a method for one-step preparing of a MoS2 film with an ultra-lubricating function through atomic layer deposition and a product and application of the MoS2 film. A Si substrate is cleaned in the following manner that after the Si substrate is wiped by ethyl alcohol and acetone, the Si substrate is subjected to ultrasonic oscillating for 5-10 min sequentially in acetone anddeionized water, then, the Si substrate is repeatedly washed through deionized water and is blown dry through a nitrogen gun, the Si substrate is placed in an atomic layer deposition system reactionchamber, a Mo(CO)6(molybdenum hexacarbonyl) solid source and SH(CH2)2SH(dithioglycol) liquid source are adopted, and atomic layer deposition is adopted for one-step preparing of the MoS2 film with theexcellent lubrication effect. The additional high-temperature vulcanization process is not needed in the related preparing method, the integral preparing process is effectively simplified, the MoS2 film with the extremely low friction coefficient is obtained under the condition that the plasma technology and other auxiliary technologies are not used, large-scale batched production is easy to achieve, and important application potentials are achieved.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

A kind of preparation method of polyisobutylene amine used as main agent of gasoline detergent

ActiveCN104774282BNo corrosionLower requirementLiquid carbonaceous fuelsFuel additivesCombustion chamberAntioxidant

The invention relates to polyisobutene amine serving as a main agent of a gasoline cleaning agent, which is a surface active agent. According to the technical scheme, a preparation method of the gasoline cleaning dispersing agent comprises the following steps: preparing epoxidation polyisobutene with high yield by using molybdenum hexacarbonyl as a catalyst and tert-butyl hydroperoxide as an oxygen source; and catalyzing and aminating the epoxidation polyisobutene serving as a raw material to obtain the polyisobutene amine product, and preparing the gasoline cleaning dispersing agent by using the polyisobutene amine, carrying oil, a demulsifying agent, an antioxidant, a polymerization inhibitor, an antirust agent, a metal deactivator and the like in proportion. The whole technological process is green and environmentally-friendly; and the product has excellent performances. The polyisobutene amine serves as the main agent of the gasoline cleaning agent and can effectively clean up carbon deposit of oil nozzles and deposits of intake valves and combustion chambers.

Owner:山东京博众诚清洁能源有限公司

A kind of ultrafine copper-platinum alloy nanowire and preparation method thereof

InactiveCN107335802BHigh purityGood crystal formMaterial nanotechnologyTransportation and packagingNanowirePetrochemical

Owner:HARBIN INST OF TECH

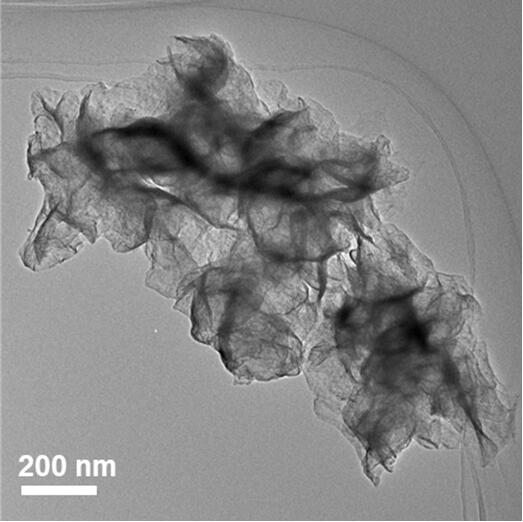

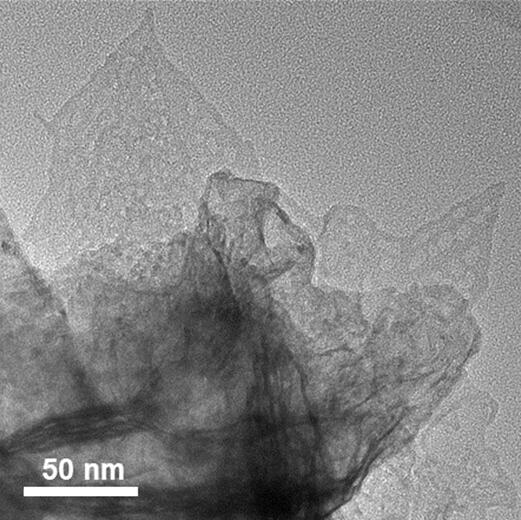

Preparation method of two-dimensional Pd nano sieve rich in catalytic activity boundary

ActiveCN113560593AComplete restorationLarge specific surface areaCell electrodesNanotechnologyPtru catalystMixed materials

The invention relates to the technical field of two-dimensional precious metal nano materials, and discloses a preparation method of a two-dimensional Pd nano sieve rich in catalytic activity boundary. The preparation method specifically comprises the steps of adding palladium acetylacetonate, molybdenum hexacarbonyl, hexadecyl trimethyl ammonium bromide and ascorbic acid into a mixed solution of ethanol and water, uniformly stirring and reacting the mixed materials, and separating, cleaning and drying the obtained solid-liquid mixture to obtain the Pd nano sieve. The nano sieve can be used for a fuel cell and an efficient electrocatalyst in an electrochemical oxygen reduction process. The ultrathin porous nanostructure has a large specific surface area and excellent charge transfer capability. A large number of low-index crystal faces and steps beneficial to oxygen reduction catalysis are exposed on the edges of holes, the number of unsaturated active sites is greatly increased, and the electrocatalytic activity is effectively improved. The method is high in yield, easy to operate, low in energy consumption and beneficial to further scientific research, popularization and application of the two-dimensional precious metal nano material.

Owner:TAIYUAN UNIV OF TECH

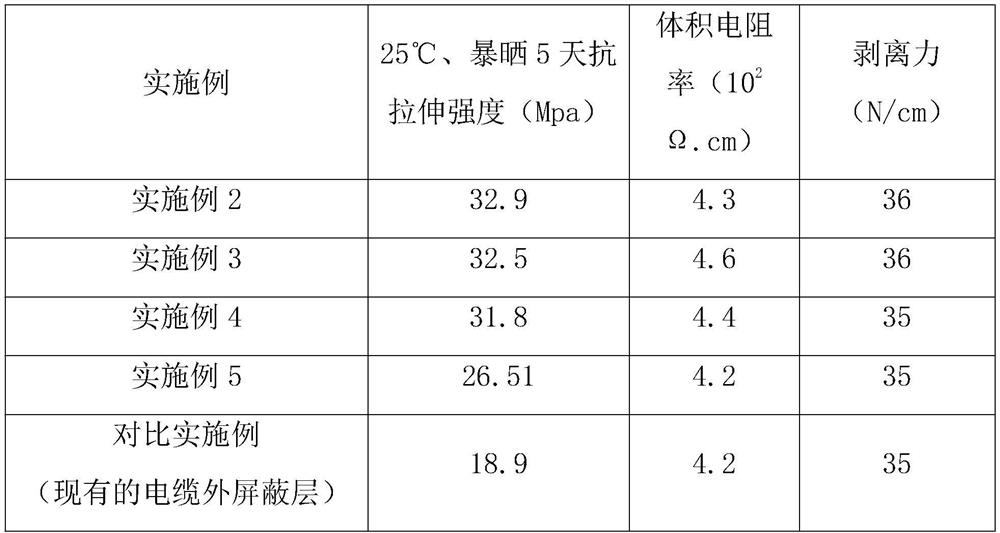

Three-layer co-extrusion outer shielding peelable material for rubber sleeve cable and preparation method of three-layer co-extrusion outer shielding peelable material

PendingCN114672108AAvoid breakingIncrease gravitySynthetic resin layered productsNon-conductive material with dispersed conductive materialAntioxidantPolyvinyl chloride

The invention relates to the technical field of cable manufacturing materials, and discloses a rubber sleeve cable three-layer co-extrusion outer shielding peelable material and a preparation method thereof.The preparation method comprises the steps that aromatic hydrocarbon free radical modified conductive carbon black is dispersed in an ethanol solution, trichloroacetyl isocyanate is added, ultrasonic oscillation reaction is carried out, molybdenum hexacarbonyl is added, and ultrasonic oscillation reaction is carried out; adding a vinyl chloride monomer, introducing current, stirring at a low speed, heating, and irradiating with gamma rays to obtain a second reaction solution; heating and melting polyvinyl chloride, adding the second reaction liquid and graphite powder into the molten polyvinyl chloride in a stirring state, and stirring at a high speed to obtain a third reaction liquid; adding a stripping agent, a reinforcing agent, an anti-aging agent, a plasticizer and a dispersing agent, stirring, adding an antioxidant, and mixing in an open mill to obtain a mixed material; and aging the mixed material after mixing for 12-24 hours to obtain the external shielding peelable material after aging. The rubber sleeve cable has better oxidation resistance and tensile property, and the service life of the rubber sleeve cable is prolonged.

Owner:浙江元通线缆制造有限公司

A kind of preparation method of molybdenum trioxide nanotube

ActiveCN108147460BNo pollution in the processStrong diameter controllabilityMaterial nanotechnologyMolybdenum oxides/hydroxidesFiltrationCrucible

The invention discloses a method for preparing a molybdenum trioxide nanotube. The method comprises the following process steps: 1) using hexacarbonyl molybdenum as a raw material, and porous anodizedalumina as a template, placing the opening of the template downward above a raw material, sealing a crucible and then placing in a muffle furnace for heating, performing low temperature sublimation,depositing the hexacarbonyl molybdenum, and continuously increasing the temperature, so that the hexacarbonyl molybdenum deposited in the porous anodized alumina template is thermally decomposed to form a metal molybdenum deposit; 2) continuously increasing the temperature so that the metal molybdenum deposit in step 1) is oxidized; 3) removing the porous alumina template with a dilute acid solution, followed by suction filtration and drying, to obtain the finished product. The method disclosed by the invention has simple steps, no environmental pollution, and no need for complicated equipment, and the prepared molybdenum trioxide nanotube material has strong diameter controllability, good crystallinity, and uniform nanotube wall morphology, thereby greatly improving the comprehensive performance of the finished molybdenum trioxide nanotube material product. The method disclosed by the invention has wide applicability and is favorable for large-scale industrial production.

Owner:FOSHAN UNIVERSITY

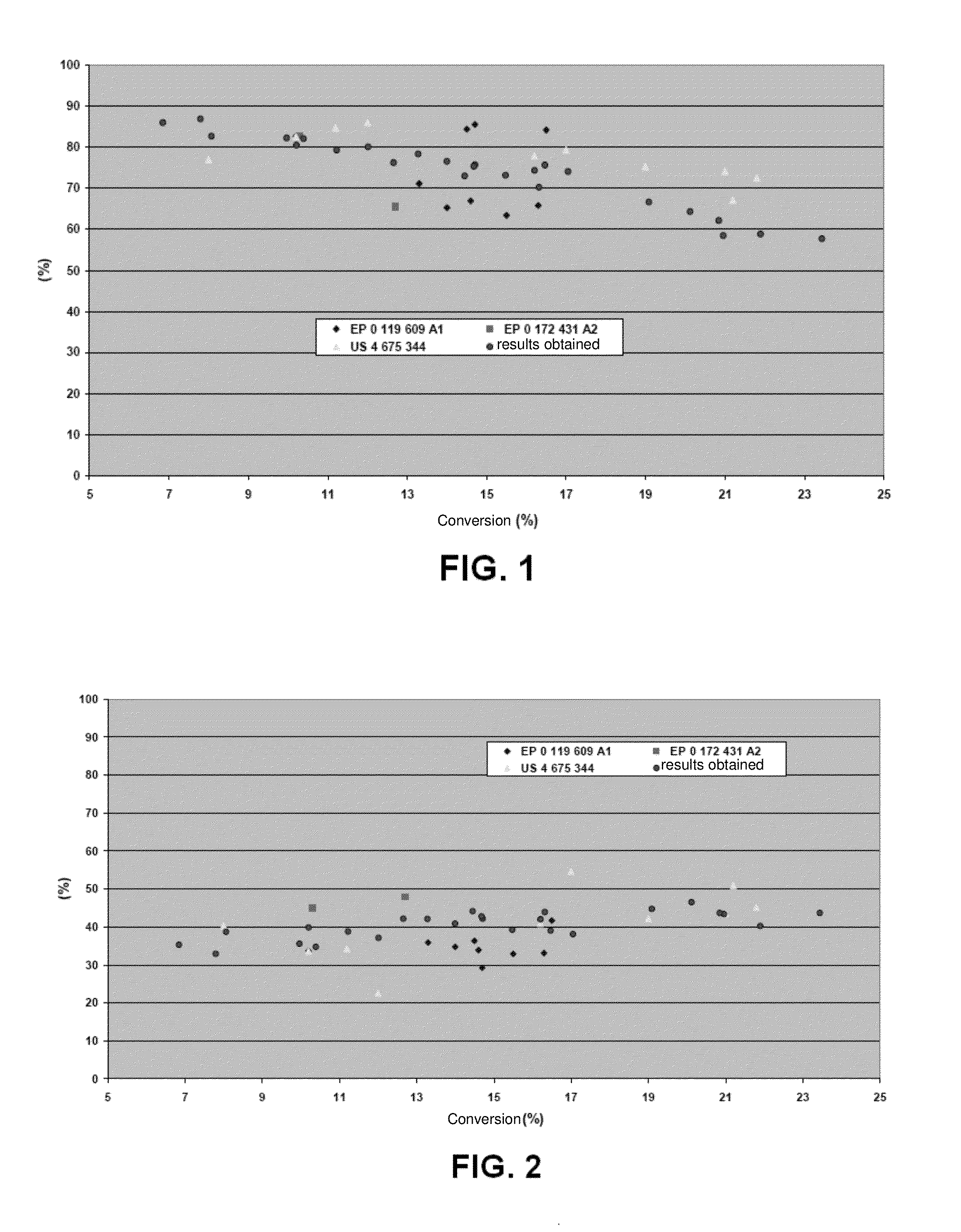

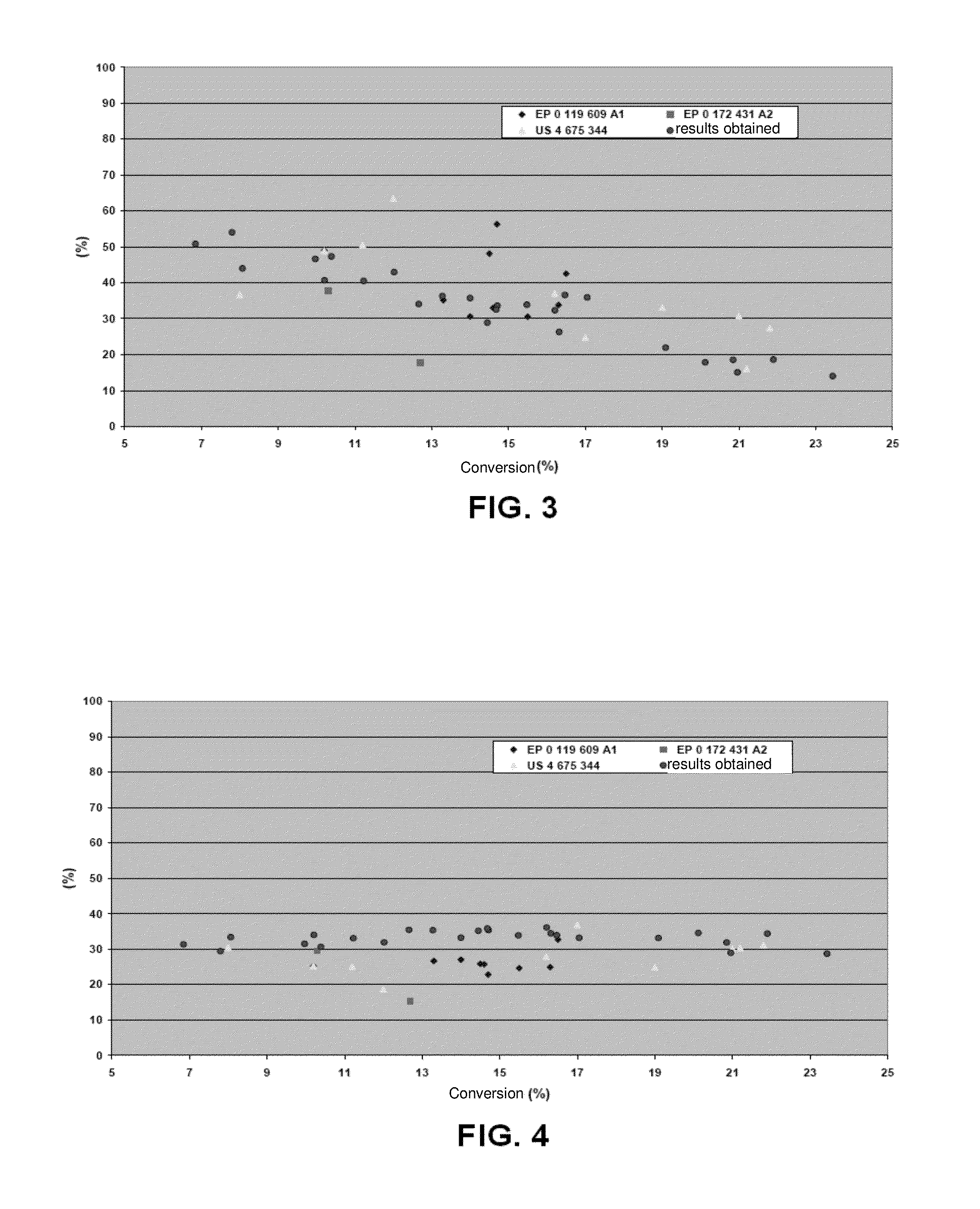

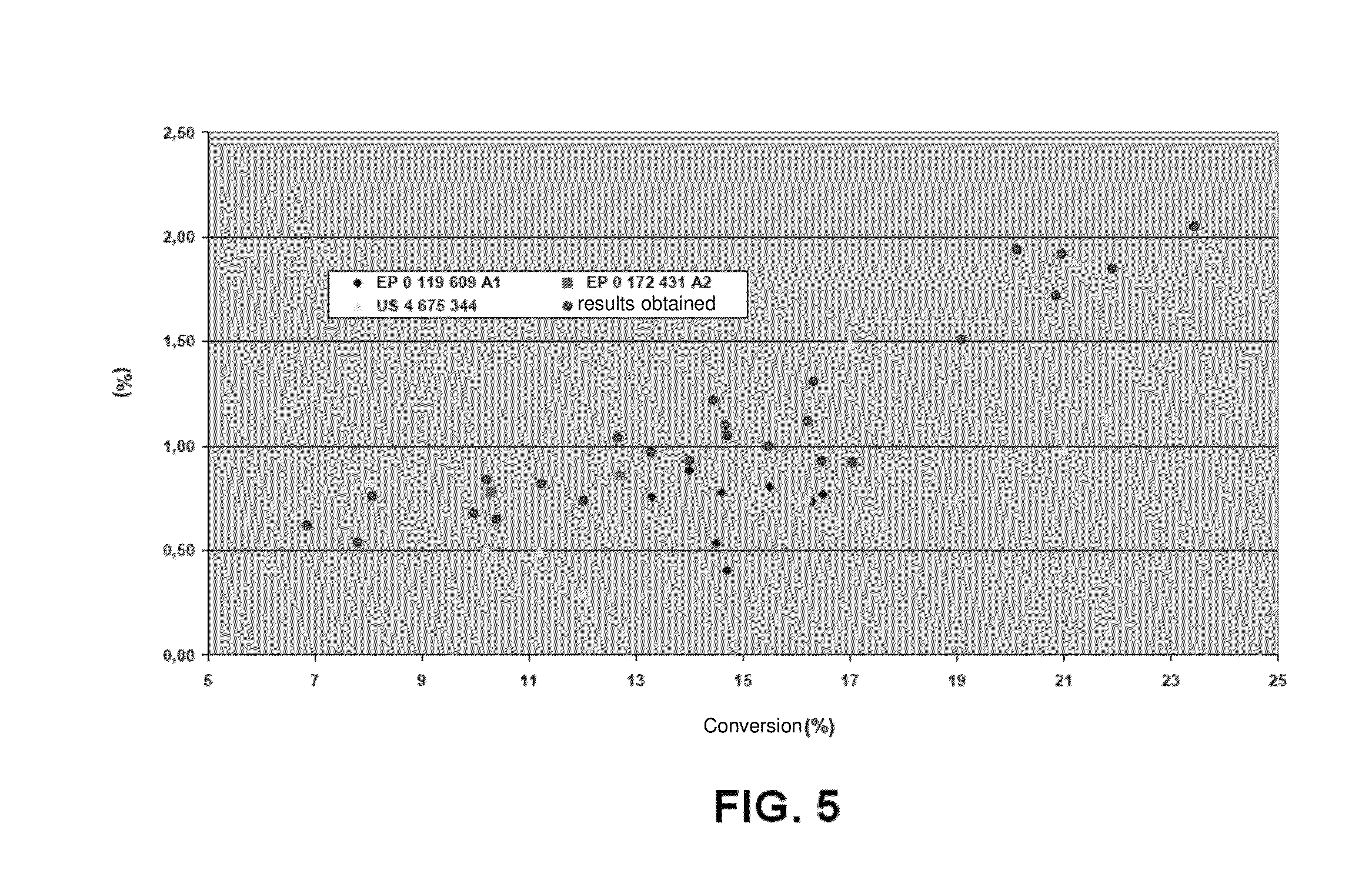

Method for preparing catalysts for producing alcohols from synthesis gas

InactiveUS20150018198A1Good choiceRaise the ratioOrganic compound preparationHydroxy compound preparationAlcoholSulfur

The present invention relates to a method of preparing catalysts based on molybdenum sulphide, with an alkaline promoter incorporated, said catalysts being employed in the production of alcohols, especially ethanol, from synthesis gas. The method involves reaction of molybdenum hexacarbonyl (Mo(CO)6) with sulphur, so as to generate molybdenum sulphide, in which an alkaline promoter is then incorporated, so as to obtain a solid catalyst for application in processes of production of alcohols from synthesis gas, selective for ethanol.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

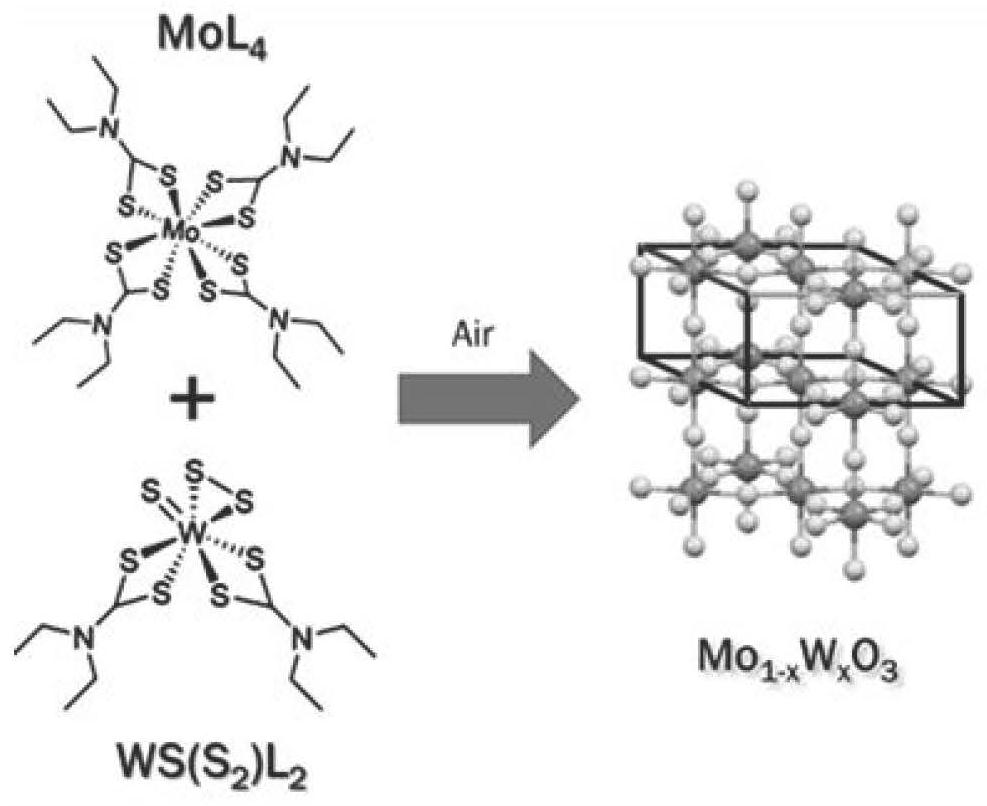

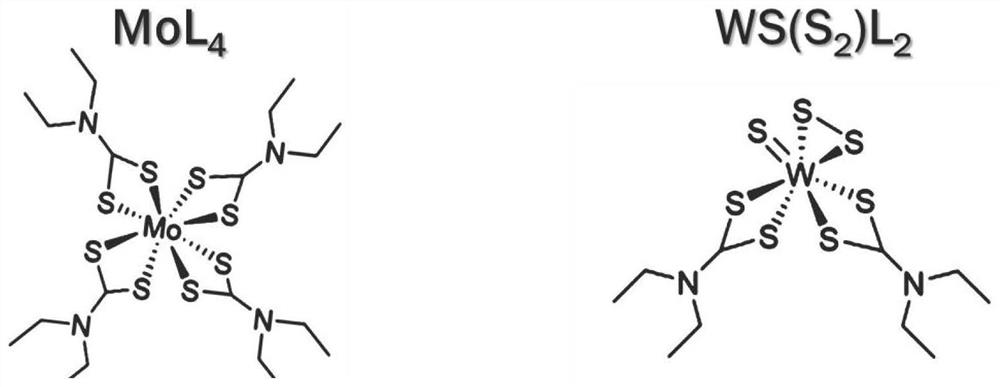

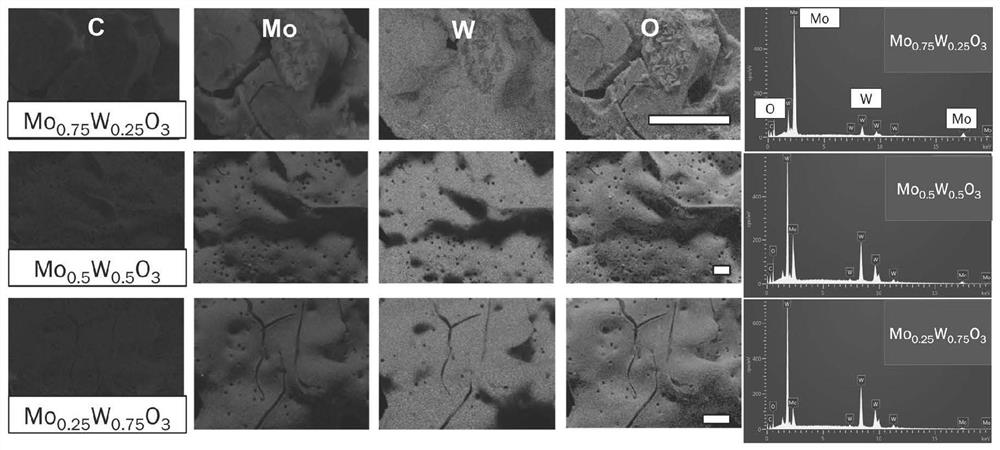

High-concentration molybdenum-doped tungsten trioxide photocatalytic nano material and preparation method and application thereof

PendingCN111617758AAchieve preparationReduce electron-hole recombination rateWater/sewage treatment by irradiationWater treatment compoundsHigh concentrationPhotocatalytic reaction

The invention relates to the technical field of preparation of photocatalytic nano materials, and discloses a high-concentration molybdenum-doped tungsten trioxide photocatalytic nano material and a preparation method and application thereof. The method comprises the following steps: (1) reacting molybdenum hexacarbonyl with tetraethylthiuram disulfide to obtain a molybdenum precursor MoL4; (2) carrying out a reaction on ammonium tetrathiotungstate and sodium diethyldithiocarbamate to obtain a tungsten precursor WS (S2) L2; (3) mixing the molybdenum precursor and the tungsten precursor, then heating for pyrolytic reaction, and cooling to obtain a nano-doped powder material; and (4) optionally, carrying out ultrasonic treatment and centrifugation on the nano-doped powder material to obtaina high-concentration molybdenum-doped tungsten trioxide nano solution or suspension. According to the high-concentration molybdenum-doped tungsten trioxide photocatalytic nano material prepared by themethod, the absorption width of the nano material to a solar spectrum in a photocatalytic reaction can be increased so that the utilization rate of the photocatalytic reaction to sunlight is increased.

Owner:曾妮婷

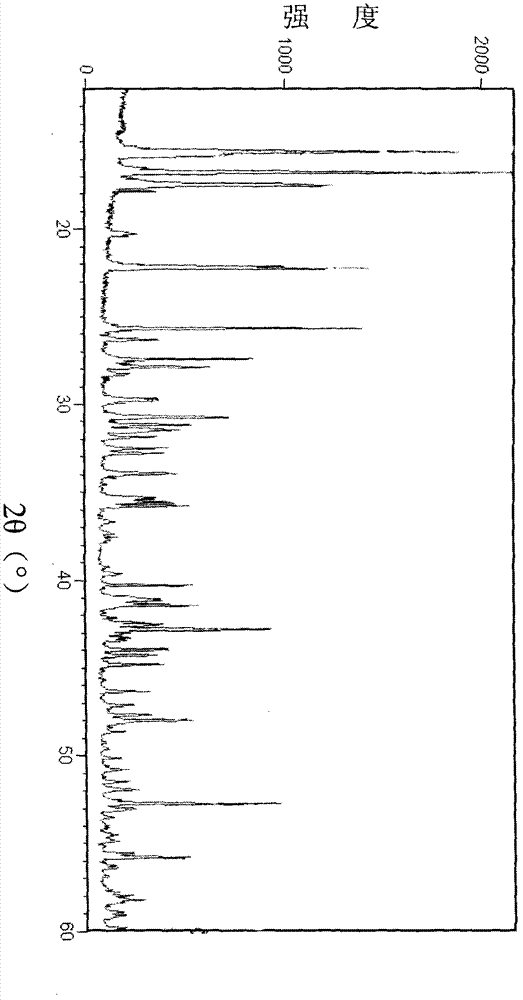

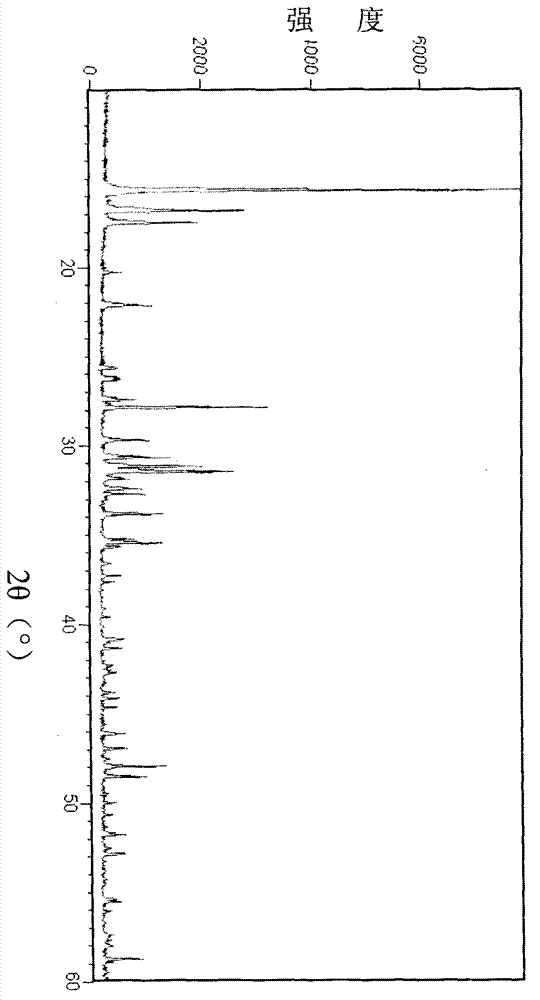

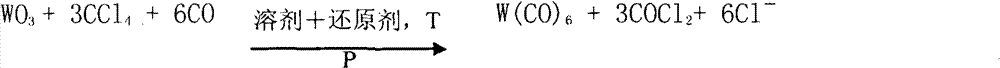

Method for directly synthesizing metal (tungsten or molybdenum) carbonyl complex from tungsten oxide or molybdenum oxide

InactiveCN102173447BLower requirementOvercome deliquescenceMolybdeum compoundsTungsten compoundsReducing agentPowder metallurgy

The invention relates to a method for directly synthesizing a metal (tungsten or molybdenum) carbonyl complex from tungsten oxide or molybdenum oxide, belonging to the technical field of powder metallurgy. The method comprises the following steps: putting tungsten or molybdenum oxide, carbon tetrachloride, a nonpolar organic solvent and an independently packaged reducer into a sealed reaction kettle provided with a stirrer; replacing air in the reaction system by repeatedly charging carbon monoxide into the reaction kettle and discharging the carbon monoxide from the reaction kettle, heating the reaction kettle to 200-250 DEG C, and keeping the temperature for 4-8 hours; after the reaction system is cooled to 30-50 DEG C, introducing carbon monoxide to 5-20 MPa, keeping the pressure, starting the stirrer of the reaction kettle, breaking the container packaging the reducer, wherein the stirring is carried out at the rotation speed of 100-200 rpm for 1-12 hours; and after the reaction finishes and the solution is cooled to room temperature, taking out the reaction solution, distilling and heating for sublimation to obtain the clear crystal of tungsten hexacarbonyl or molybdenum hexacarbonyl. The invention has the advantages of simple technique, high safety in production, low cost and high synthesis efficiency, and has wide application prospects in the market.

Owner:BEIJING CISRI GAONA TECH

A kind of preparation method of molybdenum disulfide nanotube

ActiveCN108059189BGood size controllabilityHigh crystallinityNanotechnologyMolybdenum sulfidesFiltrationCrucible

The invention discloses a preparation method of molybdenum disulfide nanotubes. The preparation method comprises the following technological steps: 1) paving molybdenum hexacarbonyl on the bottom of aceramic crucible; then putting a porous anodic aluminum oxide template above the molybdenum hexacarbonyl in a manner of placing an opening of the porous anodic aluminum oxide template downward; aftersealing the crucible, putting the crucible into a tubular furnace; under gas protection, sublimating and depositing at low temperature and pyrolyzing at high temperature; then cooling; 2) after cooling the vacuum tubular furnace to room temperature, putting the template into the ceramic crucible filled with sulfur powder in the manner of placing the opening of the template downward; after sealingthe crucible, raising the temperature under the gas protection, so as to enable monomer sulfur and metal molybdenum to directly react; 3) removing the porous aluminum oxide template by adopting a diluted acid solution and removing surplus sulfur by utilizing carbon disulfide; then carrying out suction filtration treatment and drying to obtain a finished product. The method disclosed by the invention has simple steps and no environment pollution and does not need complicated equipment; a prepared molybdenum disulfide nanotube powder material has strong size controllability and good crystallization performance; the nanotubes have a shape and uniform tube wall, so that the comprehensive performance of a molybdenum disulfide nanotube powder material finished product is greatly improved. The molybdenum disulfide nanotubes disclosed by the invention have wide applicability and large-scale industrial production is facilitated.

Owner:FOSHAN UNIVERSITY

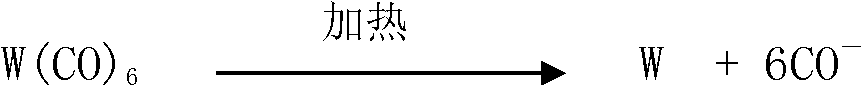

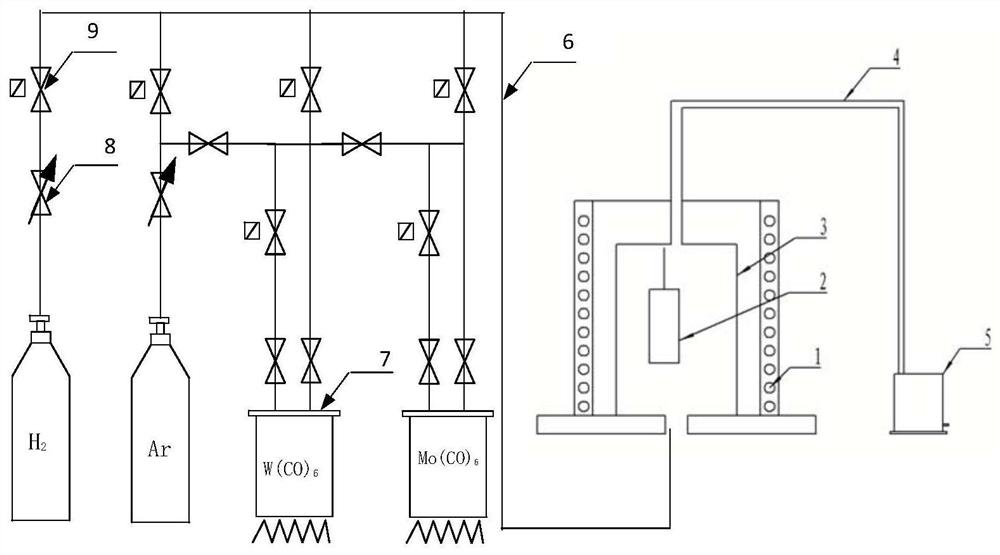

Tungsten alloy coating preparation equipment and method

ActiveCN109182996BThe preparation process temperature is lowImprove high temperature resistanceChemical vapor deposition coatingSurface engineeringAlloy coating

The invention provides tungsten alloy coating preparation equipment and method and relates to the technical field of surface engineering, in particular to tungsten alloy coating preparation equipmentcomprising a reactor arranged in a heating furnace. The reactor communicates with a tail gas treatment device through an exhaust pipeline and communicates with hydrogen, argon, tungsten hexacarbonyl and molybdenum hexacarbonyl through gas delivery pipelines correspondingly, and the argon and the tungsten hexacarbonyl communicate with the molybdenum hexacarbonyl. The invention further provides thetungsten alloy coating preparation method comprising the steps that an atmospheric pressure chemical vapor deposition method is adopted for preparing a metal tungsten alloy coating, precursors used for deposition are the tungsten hexacarbonyl and the molybdenum hexacarbonyl, decomposition reaction is conducted under low temperature to prepare a tungsten coating, and the reaction equation is W(CO)6->W+6CO, Mo(CO)6->Mo+6CO. the technical scheme is adopted, resistance to high temperature gas oxidation scouring and resistance to corrosive medium erosion of a C / C composite, graphite, steel, titanium and other materials can be improved, and service time is prolonged.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

A kind of platinum rhodium yttrium nanowire and its preparation method and application

ActiveCN110635142BLarge specific surface areaReduce defectsMaterial nanotechnologyCell electrodesNanowirePtru catalyst

The invention relates to the technical field of electrocatalytic materials, in particular to a platinum-rhodium-yttrium nanowire and a preparation method and application thereof. The present invention uses cetyl ammonium chloride as a surfactant and a structure-directing agent, and molybdenum hexacarbonyl as a structure-limiting agent is mixed with a platinum source, a rhodium source and yttrium acetylacetonate, and participates in the preparation process of platinum-rhodium-yttrium nanowires , and combined with hydrothermal reaction, nanowires with a face-centered cubic structure of atoms in disordered arrangement are obtained. The platinum rhodium yttrium nanowires prepared by the method have a large specific surface area, a large number of active sites and fast electron transport Efficiency, so that it has a higher catalytic performance, and at the same time, the platinum-rhodium-yttrium nanowires reduce the content of metal platinum compared with metal platinum catalysts, and enhance the ability to resist CO poisoning, thereby improving the ability of electrochemically catalyzing methanol oxidation.

Owner:YANSHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com