Synthesis method of ultrathin MoO2 nanosheet with SERS (Surface Enhanced Raman Scattering) effect and application of synthesis method

A synthesis method and nanosheet technology, applied in the field of detection, can solve the problems of weak Raman signal, application limitation, low sensitivity, etc., and achieve the effects of strong repeatability, easy promotion and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Ultrathin flexible MoO 2 The synthesis steps of nanosheets are as follows:

[0028] Mix 50 mL of water with 20 mL of tert-butanol, add 0.264 g of molybdenum hexacarbonyl, and stir on a magnetic stirrer for 2 hours.

[0029] Transfer the resulting solution into a Teflon-lined high-pressure reactor, place it in an oven and heat it up to 220°C, keep it warm for 10 hours, then cool it down to room temperature naturally, pour out the supernatant in the reactor, and precipitate through 10000r / m Centrifuge for min, wash with water and ethanol three times.

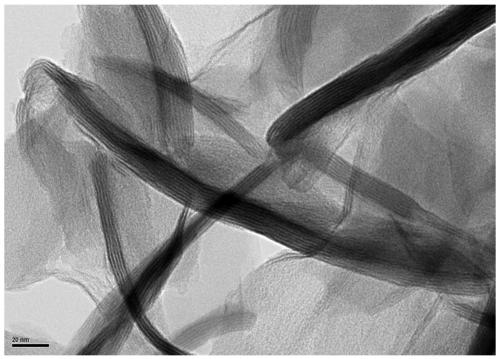

[0030] The obtained product was characterized by XRD, SEM, TEM and EDS, etc., and was determined to be MoO with a sheet-like structure. 2 nanomaterials. see figure 1 ( figure 1 The scale in the lower left corner is 20nm), and the resulting ultrathin flexible MoO 2 Transmission electron micrograph of the nanosheets, whose cross-sectional lattice fringes show a thickness of only 5-10 atomic layers.

Embodiment 2

[0032] Mix 50 mL of water with 25 mL of tert-butanol, add 0.364 g of molybdenum hexacarbonyl, and stir on a magnetic stirrer for 2 hours.

[0033] Transfer the obtained solution into a Teflon-lined high-pressure reactor, place it in an oven and heat it up to 180°C, keep it warm for 16 hours, then cool it down to room temperature naturally, pour out the supernatant in the reactor, and precipitate through 10000r / m Centrifuge for min, wash with water and ethanol three times.

[0034] The obtained product was characterized by XRD, SEM, TEM and EDS, etc., and was determined to be MoO with a sheet-like structure. 2 nanomaterials.

Embodiment 3

[0036] There is the synthetic method of the ultrathin MoO2 nanosheet of SERS effect, comprises the steps:

[0037] 1) First mix tert-butanol with water, stir on a magnetic stirrer for 2 hours to obtain a mixed solution, then add molybdenum hexacarbonyl to the mixed solution, and stir evenly; the mass ratio of tert-butanol to water is 3: 5. The mass ratio of molybdenum hexacarbonyl to the mixed liquid is 1:160.

[0038] 2) The mixture obtained in step 1) was placed in a Teflon-lined autoclave, heated to 240° C. in an oven, maintained for 18 hours, and then naturally cooled to room temperature.

[0039] The obtained product was characterized by XRD, SEM, TEM and EDS, etc., and was determined to be MoO with a sheet-like structure. 2 nanomaterials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com