Patents

Literature

77results about How to "Good size controllability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

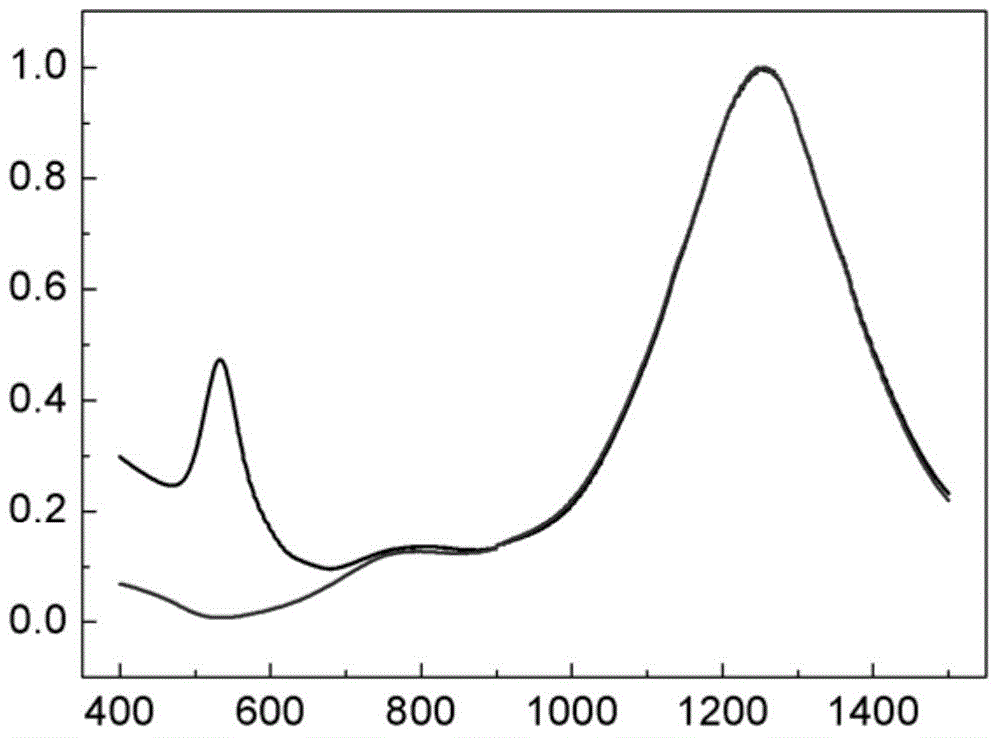

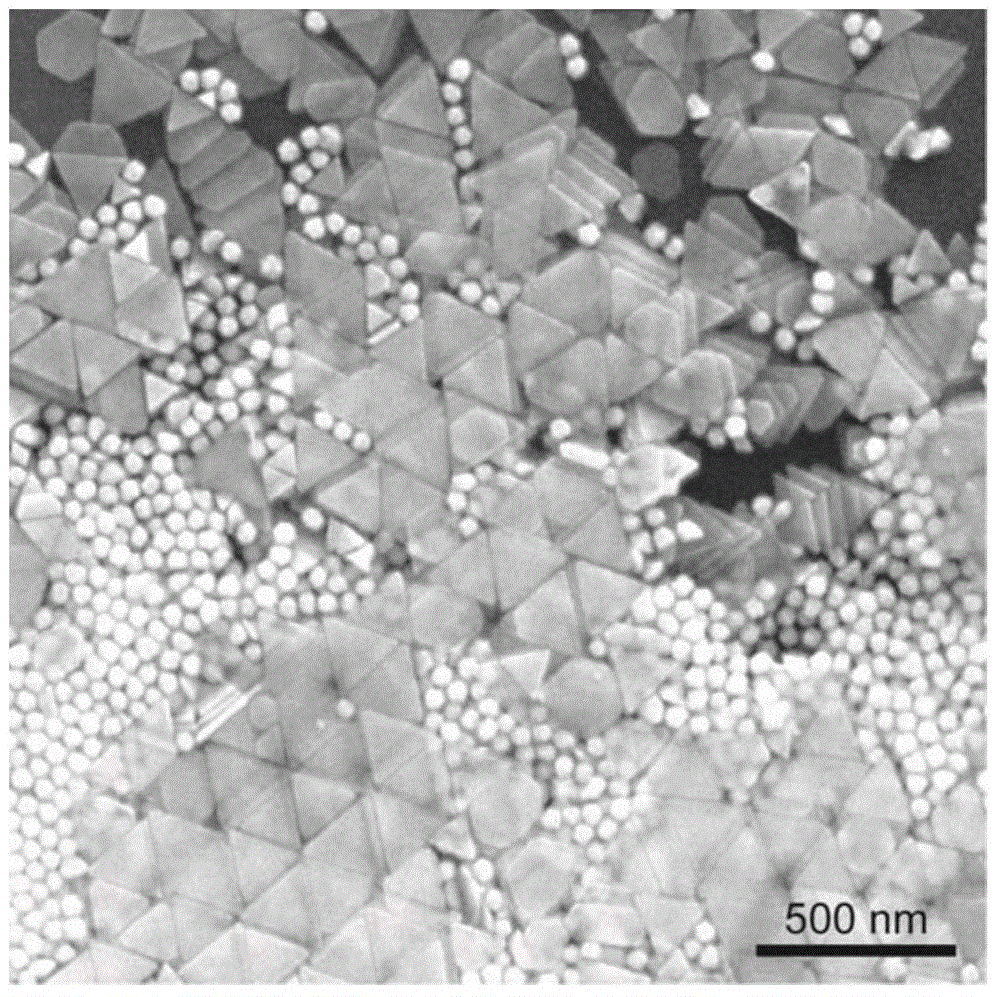

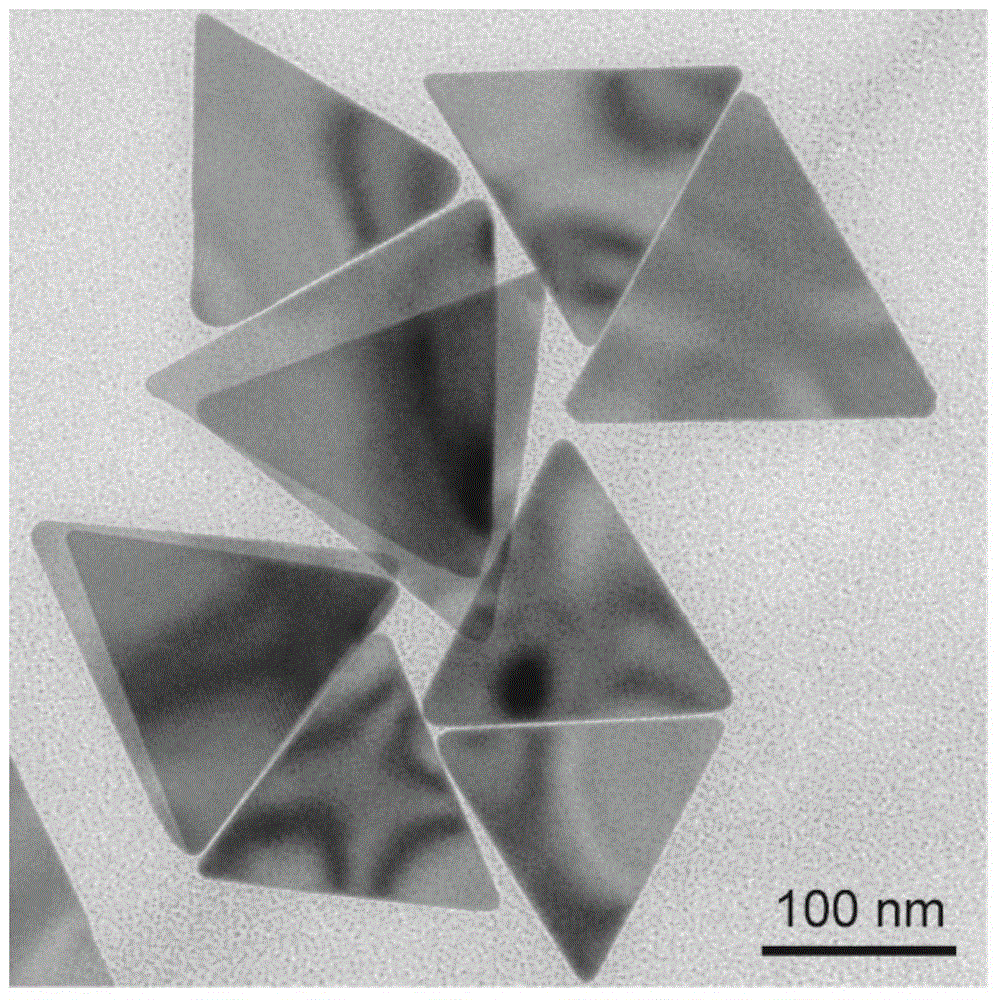

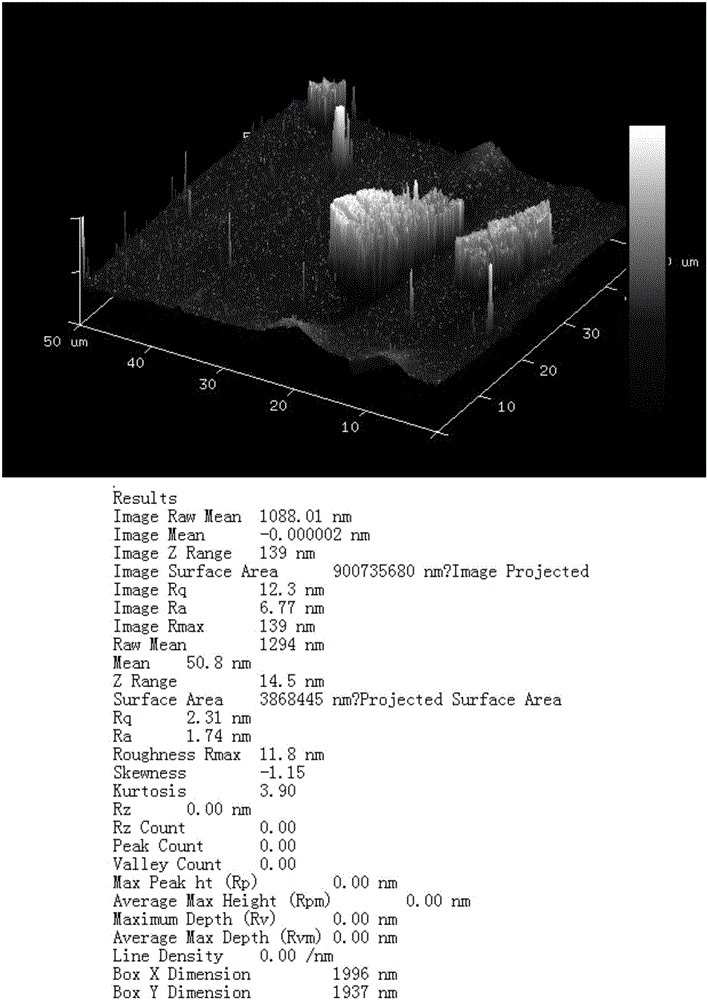

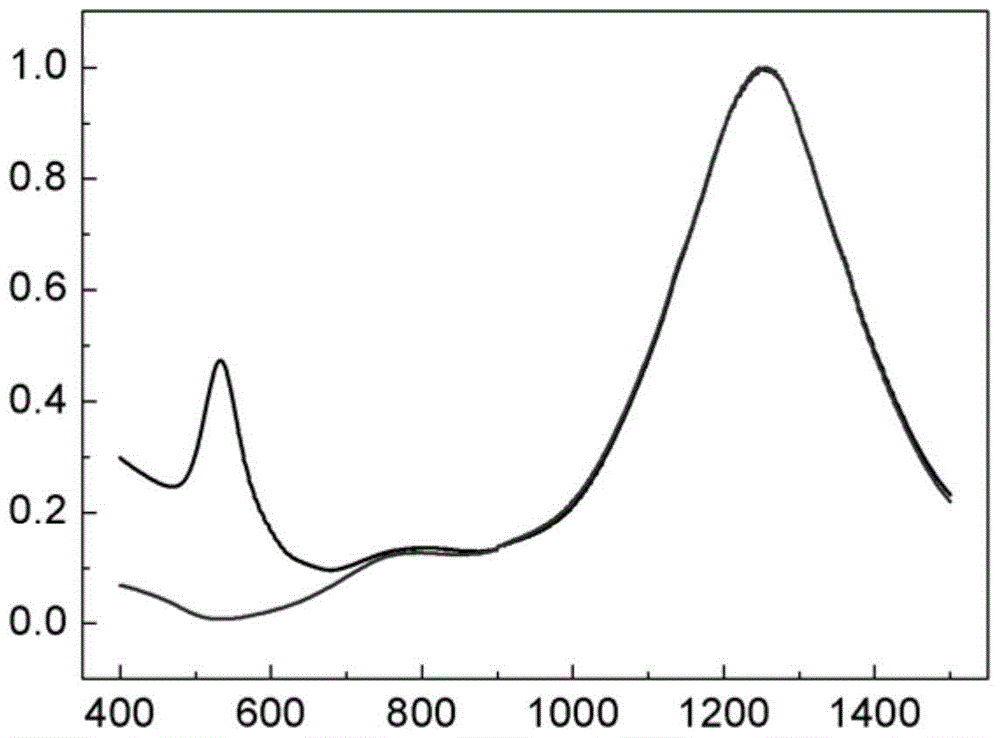

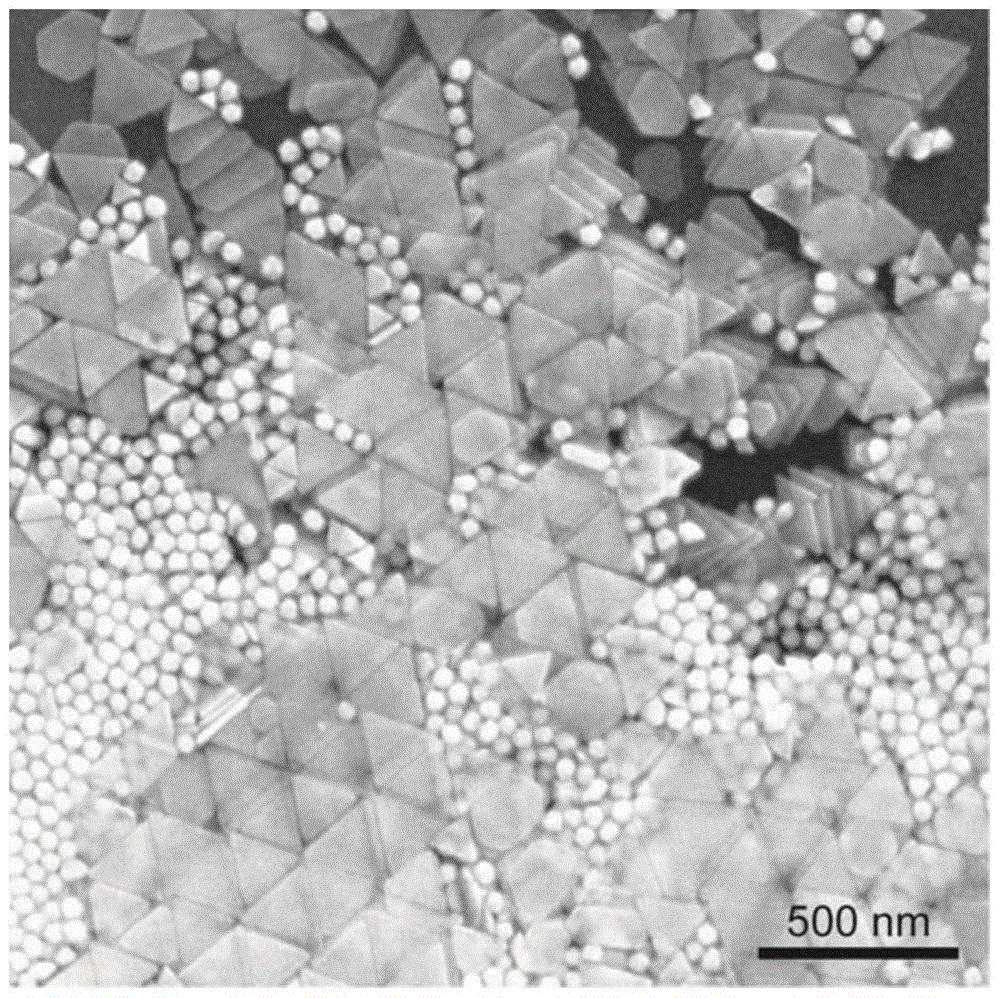

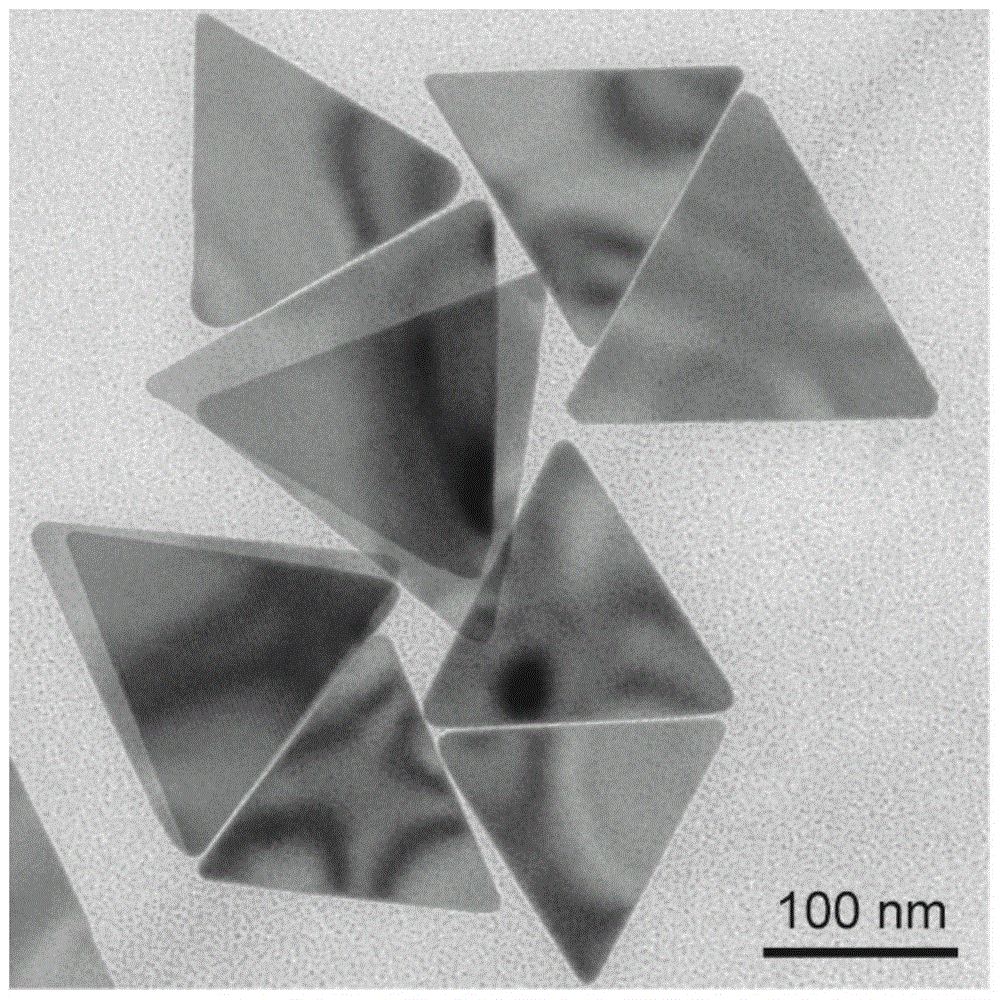

Gold nanoparticle triangular plate preparing method and method for preparing gold nanoparticle discs and gold nanoparticle hexagonal pieces on basis of gold nanoparticle triangular plate preparing method

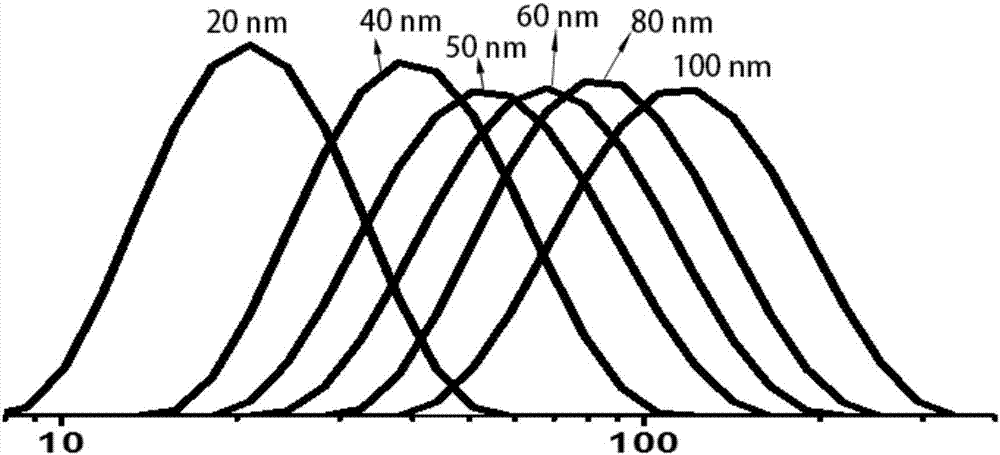

The invention provides a gold nanoparticle triangular plate preparing method and a method for preparing gold nanoparticle discs and gold nanoparticle hexagonal pieces on the basis of the gold nanoparticle triangular plate preparing method, relates to the technical field of gold nanoparticle preparing, and aims at providing the method which is easy and convenient to operate, high in repeatability and efficiency and is used for preparing gold nanoparticle triangular plates, gold nanoparticle discs and gold nanoparticle hexagonal pieces. The gold nanoparticle triangular plate preparing method includes the steps of preparing a gold nanoparticle seed solution through a sodium citrate aqueous solution, a tetrachloroauric acid aqueous solution and a sodium borohydride aqueous solution, preparing a gold nanoparticle triangular plate solution through the preapraed seed solution, a cetyl trimethyl ammonium bromide aqueous solution, a tetrachloroauric acid aqueous solution, a potassium iodide or sodium iodide aqueous solution, a sodium hydroxide aqueous solution and a ascorbic acid aqueous solution, and obtaining gold nanoparticle triangular plates after the liquid supermatant is abandoned. The method is easy and convenient to operate and high in repeatability and controllability, the prepared gold nanoparticle plates are unified in size, gold nanoparticle plates of different types and sizes can be synthesized, and the purity reaches 95% or higher.

Owner:NANOSEEDZ

Preparation method of perovskite crystal nanowire

The invention discloses a preparation method of a perovskite crystal nanowire. Firstly perovskite nano-particles are synthesized and dissolved in an organic solvent and evenly stirred, the solution isdropped on a substrate of 80-150 DEG C so that the solvent is enabled to be rapidly evaporated and the perovskite nano-particles are enabled to be evenly adhered on the substrate, then the substrateis arranged in an enclosed culture dish so that the perovskite nano-particles are enabled to be exposed in the saturated vapor pressure environment of good solvent for culturing 1-15 days under the temperature of 10-50 DEG C, and the perovskite crystals grow along the one-dimensional direction so as to obtain the nanowire material. The method comprises the process of rapid precipitation of the nanocrystals in solvent evaporation under high temperature and the process of self-assembling of the nanocrystals occurred in the culture dish under the saturated vapor pressure. The size of the perovskite nanowires changes along with the change of the culture time, the hydrophilic-hydrophobic property of the substrate material and the culture temperature.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

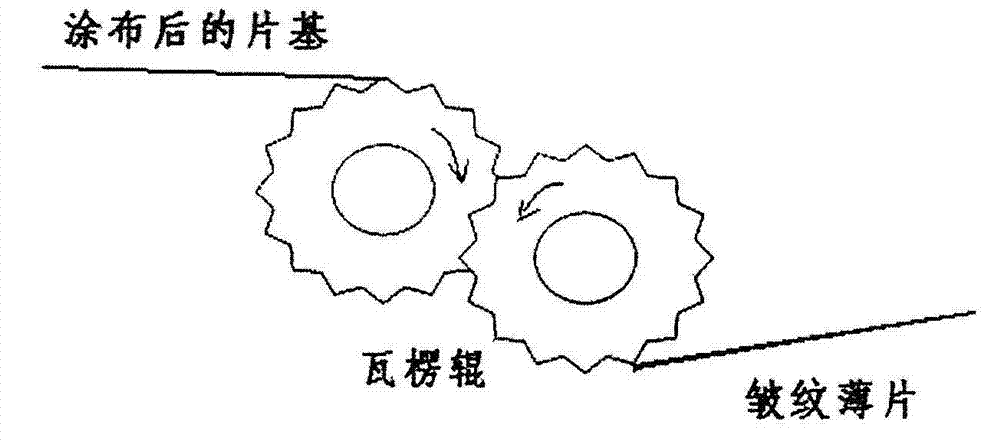

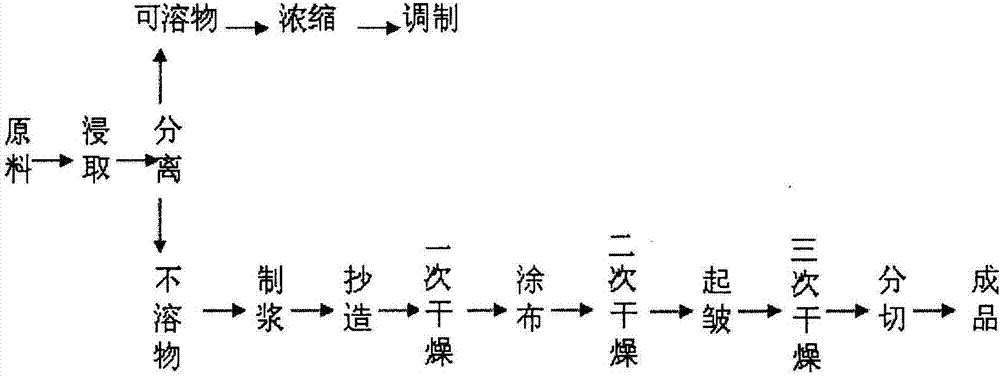

Manufacturing technique of tobacco remaking with fold paper-making method

InactiveCN103082396AEasy to fillGood size controllabilityTobacco preparationCombustionInsoluble fiber

The invention provides a manufacturing technique of tobacco remaking with a fold paper-making method. The manufacturing technique of tobacco remaking with the fold paper-making method comprises the following steps: raw materials of tobacco are soaked and extracted through extraction agent, insolubility fiber materials are separated from soluble substances, film base is made of insoluble substances through pulping, coating liquid is made of the soluble substances by concentration in a modulation mode, and the coating liquid is dip-coated or spray-coated on a slice film base, and enters a drying machine to dry. The manufacturing technique of tobacco remaking with the fold paper-making method is characterized in that slice film base after being dried is made to be diamond-shaped through a pair of corrugated rollers reversely rotating, and is made into a fold tobacco slice after being dried and cut. The manufacturing technique of tobacco remaking with the fold paper-making method is not limited by drying modes, is simple in manufacturing technique, and capable of being widely applied to the production of tobacco remaking with the fold paper-making method, and facilitates improving padding performance of remade tobacco, and reducing consumption of raw materials and production cost. According to measurement and calculation, compared with the prior ordinary tobacco remaking, the manufacturing technique of tobacco remaking with the fold paper-making method can save the consumption of the raw materials by 1.0% or so, improve combustion performance of cigarettes, reduce suction resistance and improve suction quality of the cigarettes.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

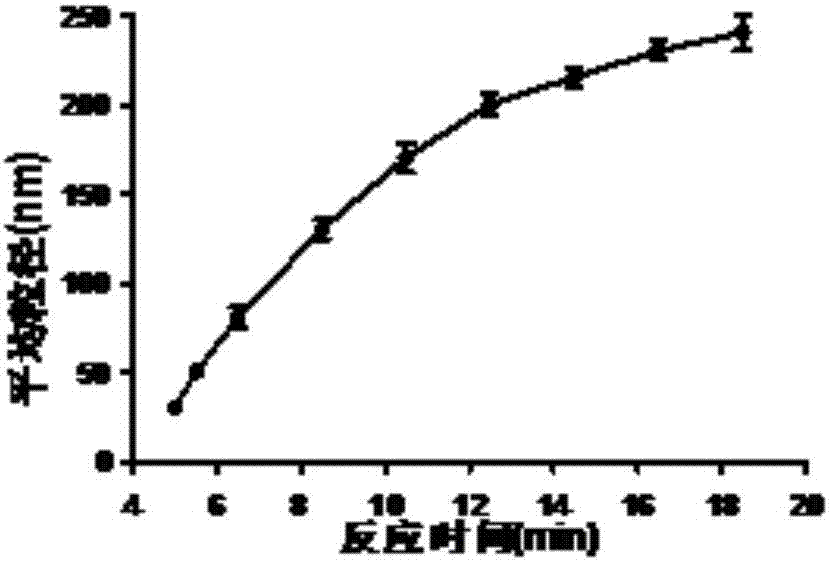

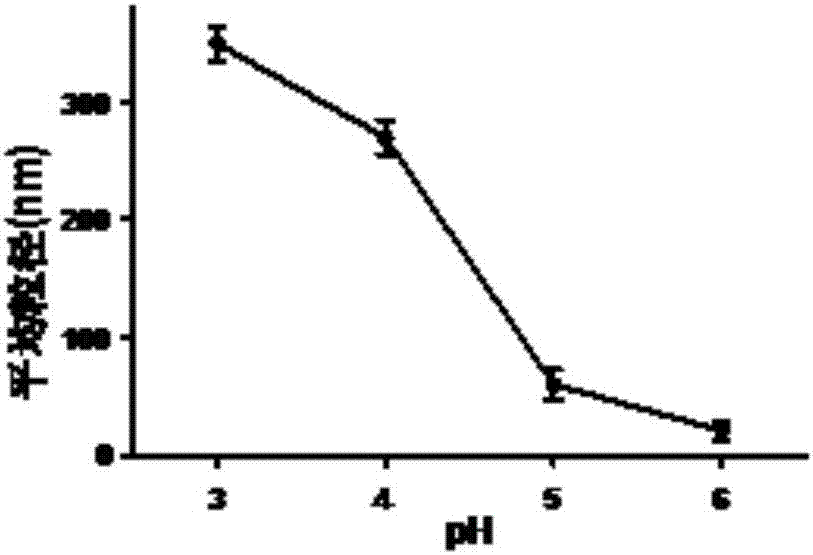

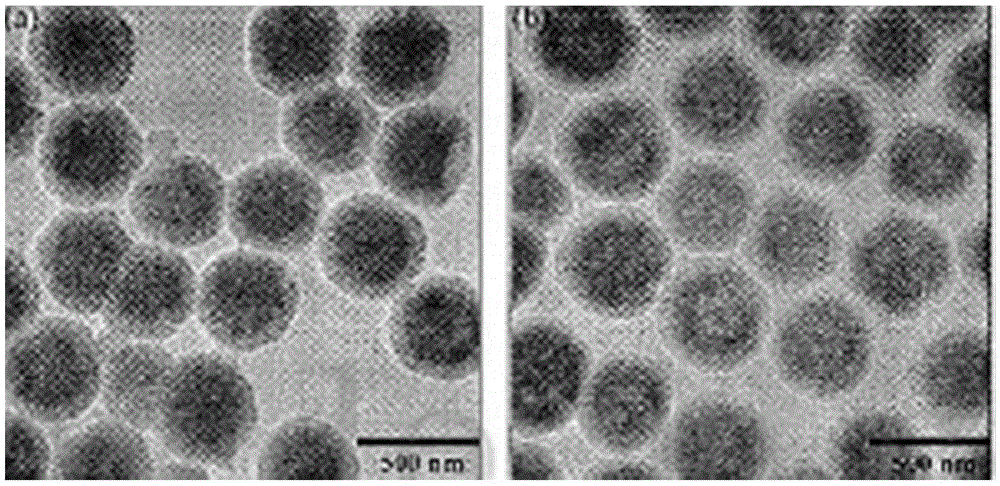

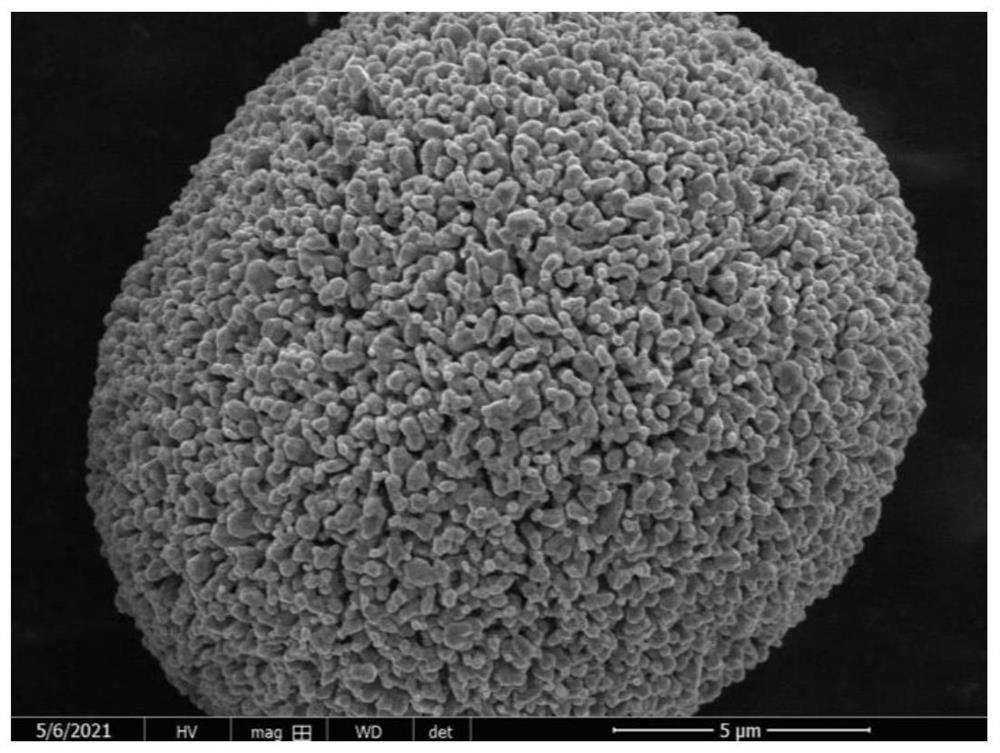

Protein self-assembled novel nanovaccine and preparation method thereof

ActiveCN107157933ASimple componentsQuality improvementSsRNA viruses negative-senseAntibacterial agentsCross-linkImmune effects

The invention relates to a protein self-assembled novel nanovaccine and a preparation method thereof. The protein self-assembled novel nanovaccine is prepared on the basis of antigen protein self-assembly; in the process of vaccine preparation, a molecular adjuvant is selectively introduced, the antigen content is higher than or equal to 85%, a high-efficiency immune effect can be triggered without needing assistance of an aluminum adjuvant, a Freund's adjuvant and the like, mercapto groups between protein molecules are exposed by virtue of physical regulation and control, and stable protein nanoparticles mainly based on disulfide bond crosslinking are formed through a mercapto / disulfide bond exchange reaction. The defects that the conventional nanovaccine needs to be introduced with an exogenous carrier or a cross-linking agent and the like are overcome, and the immune effect and the biosafety of the vaccine can be improved at the same time; the obtained vaccine granules are tidy in morphology, high in stability, flexible in regulation and control mode and good in repeatability, and can effectively stimulate dendritic cell maturation; the protein self-assembled novel nanovaccine has relatively strong generality and universality, is verified in a series of antigen proteins, and has a potential significant application value in the fields of novel vaccinating methods and biological pharmacy.

Owner:TONGJI UNIV

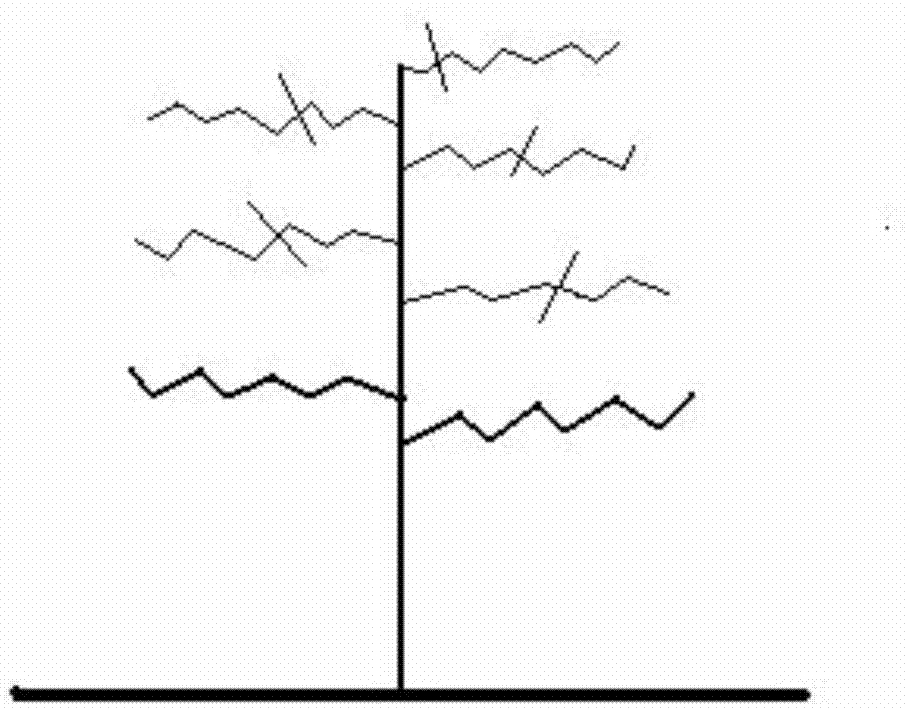

Simplified tree form reforming method suitable for high-density jujube orchard

InactiveCN103109715AGood size controllabilityEasy to shapeCultivating equipmentsEngineeringTree shaped

Disclosed is a simplified tree form reforming method suitable for a high-density jujube orchard. Since the grafting year of direct seeding and orchard building or the planting year, by about five-year continuous reforming, a jujube head form tree is formed with tree height of 2.5-3.5 meters, branch spreading of 1-1.5 meters, central trunk bending upwards, and 10-20 bending horizontally stretching fruiting branch groups directly inserted on the central trunk. The reforming method is suitable for wide-row dense-planting high-density jujube orchards (tree row space is 0.5-1.5m*3-4.5m), and simple in reforming. The reformed trees are slim and high, the branches are well-spaced without crossing, large row space can be guaranteed under high-density conditions, good ventilation and light permeability are achieved, high and stable yield and good quality are guaranteed, mechanical operation is facilitated, manpower for cutting is saved by more than 80%, and the problems that the high-density jujube orchard is prone to closing, complex to manage and the like are solved.

Owner:HEBEI AGRICULTURAL UNIV.

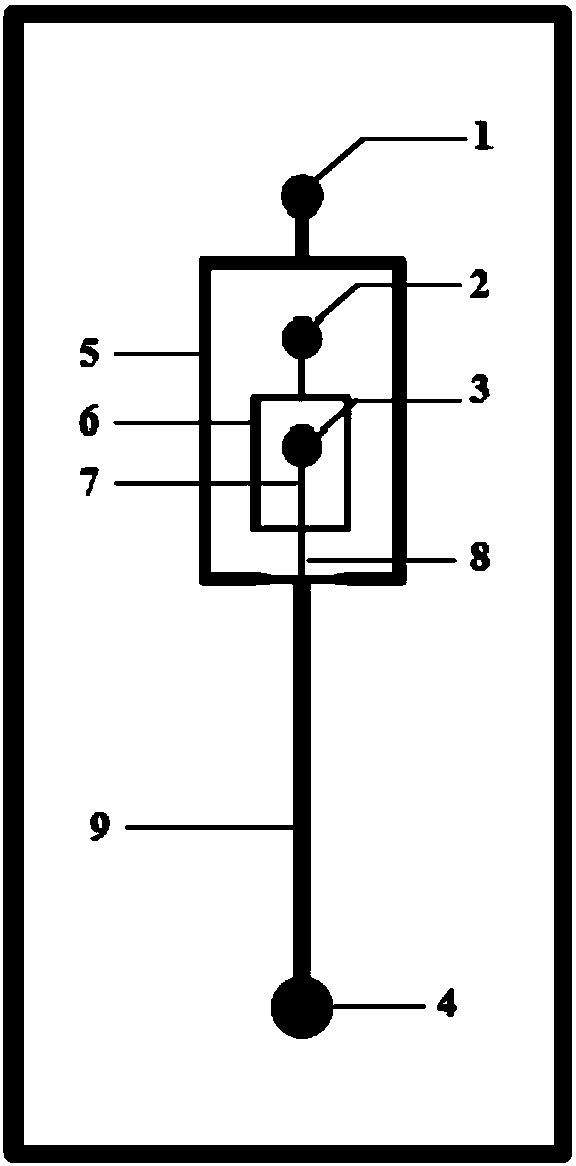

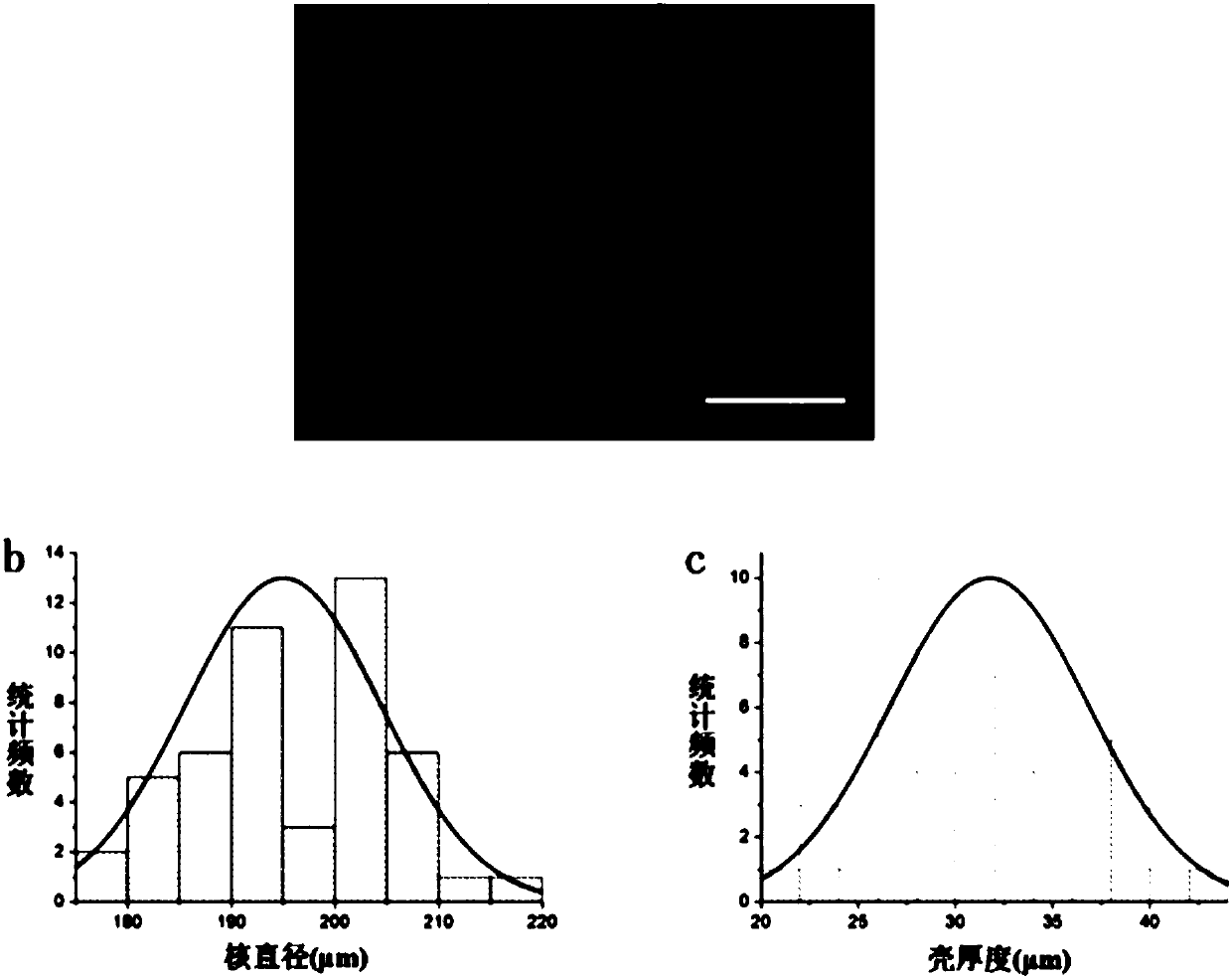

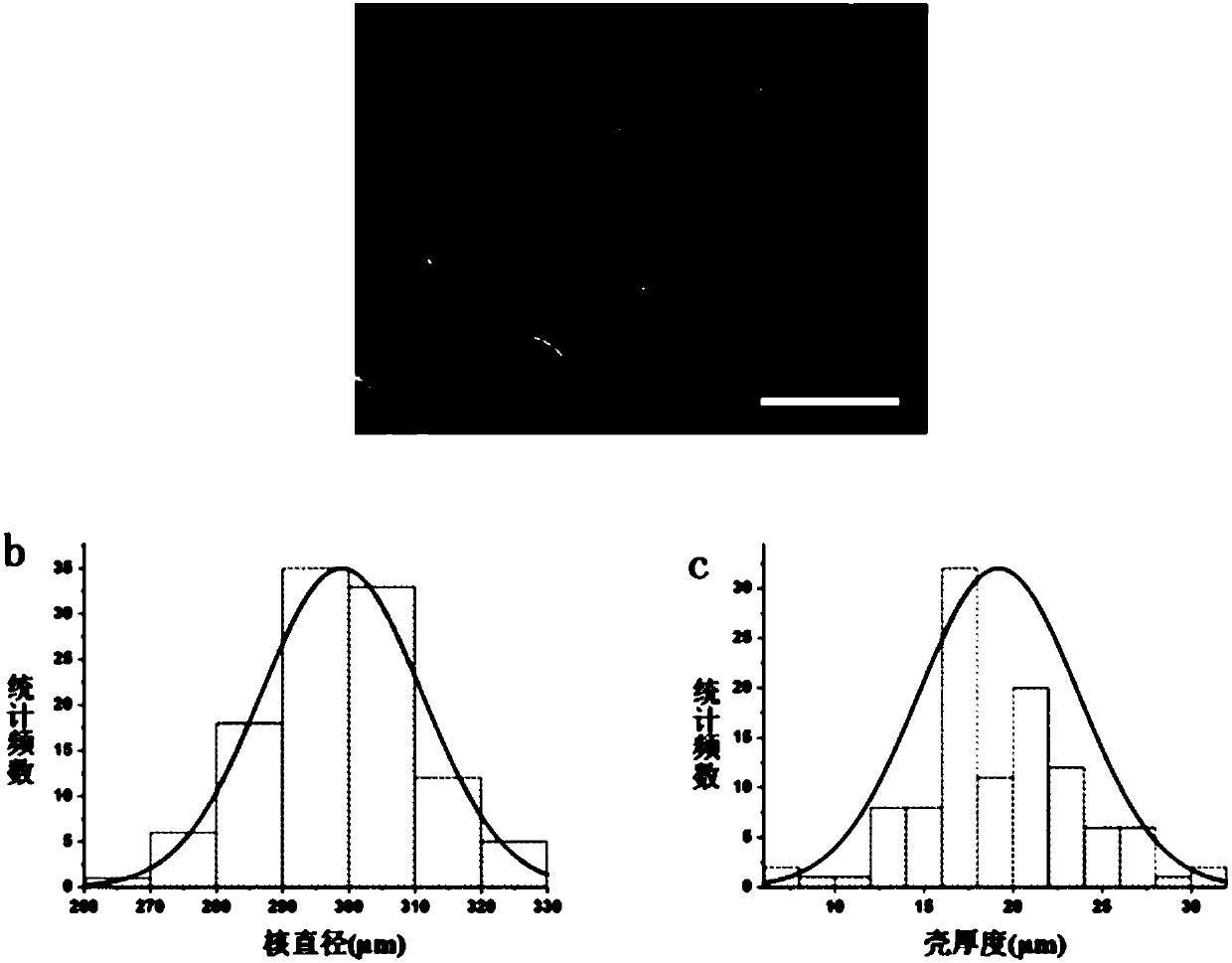

Preparation method of gelatin methacrylamide core-shell microsphere based on microfluidics technique

ActiveCN109806918AUniform sizeGood size controlLaboratory glasswaresMicroballoon preparationMicrosphereMain channel

The invention discloses a preparation method of a gelatin methacrylamide core-shell microsphere based on a microfluidics technique. A microfluidics chip mainly consists of a continuous phase inlet, ashell fluid inlet, a shell fluid inlet, a microsphere outlet, a continuous phase channel, a shell fluid channel, a shell fluid channel, a laminar flow channel and a main channel. The preparation method of the core-shell microsphere using the chip mainly comprises the following steps of synthesizing of a gelatin methacrylamide material, and preparation of the gelatin methacrylamide core-shell microsphere. The preparation method provided by the invention has the advantages that the laminar flow property and oil-water interface tension of the two-phase water solution are utilized, the core-shellliquid droplets are formed on the microfluidics chip in one step, the cured gelatin methacrylamide shell is formed by photo-chemical crosslinking, and the core is the water solution; the technique canbe applied to the biology application, such as construction of in-vivo microtissue models,angiogenesis, and transplanting of tissue blocks.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

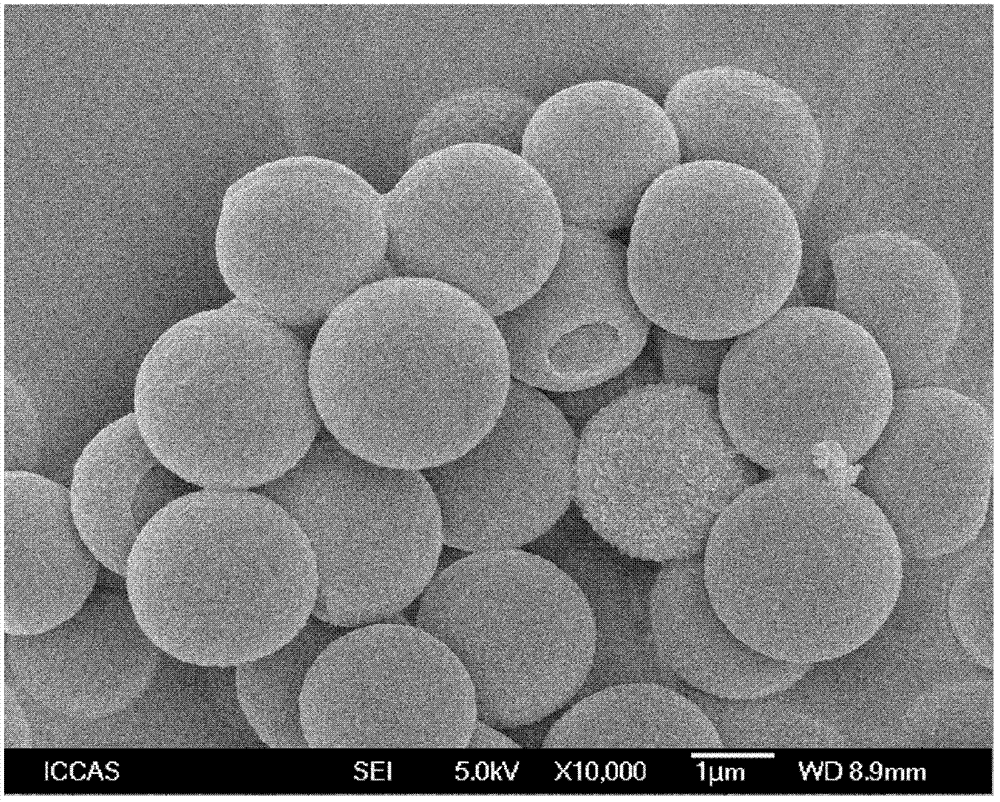

Phase-change microcapsules with solid-solid phase transition core material, and preparation method thereof

ActiveCN102952523AGood size controllabilityMonodisperseHeat-exchange elementsMicroballoon preparationAlkaneIn situ polymerization

Owner:INST OF CHEM CHINESE ACAD OF SCI

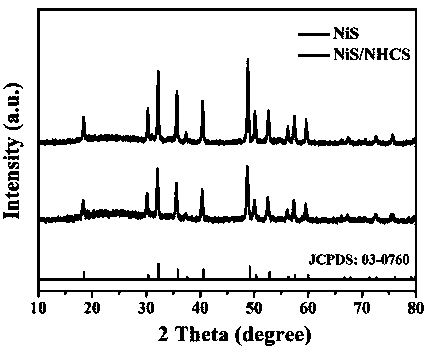

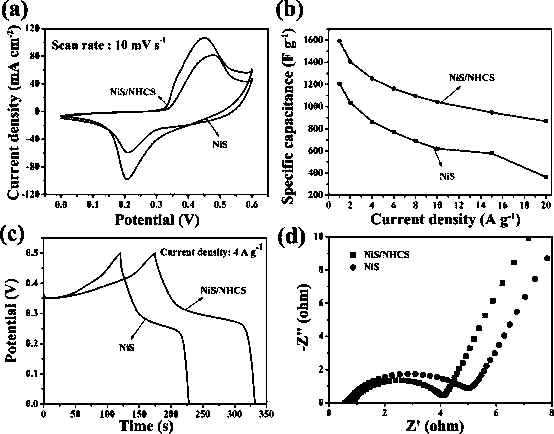

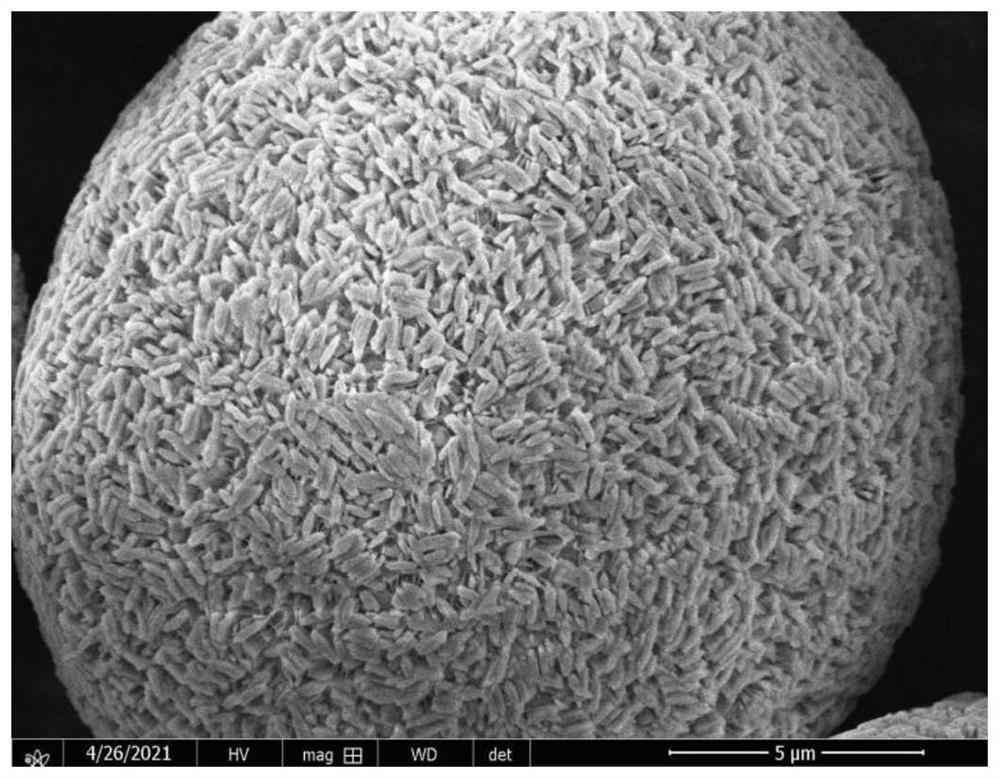

Hollow biological carbon sphere-based nickel sulfide nanorod supercapacitor and preparation method

ActiveCN110060873ASuppress volume effectImprove stability and specific capacityHybrid capacitor electrodesHybrid/EDL manufactureMuffle furnaceIon

The invention discloses a preparation method of a nickel sulfide nanorod loaded hollow biological carbon shell supercapacitor; specifically, biological yeast is added into a mixed solution of glutaraldehyde and deionized water to be subjected to hydrothermal reaction for 12h at 180 DEG C, and a brown red sample is collected by centrifugal drying. The collected sample is then added into a muffle furnace to be heated to 300 DEG C at the heating rate of 1 DEG C / min and the temperature is kept for 1h; the collected black sample is placed into a tubular furnace to be heated to 800 DEG C at the heating rate of 2 DEG C / min and the temperature is kept for 3h to obtain a hollow nitrogen-doped biological carbon shell. The hollow nitrogen-doped biological carbon shell is added to a mixed solution ofnickel nitrate, thiourea and sodium phosphite to carry out ultrasonic wave and stirring treatment; then hydrothermal reaction is performed at 180 DEG C for 6 hours, and then centrifugal drying is carried out to obtain a NiS / NHCS composite sample. The preparation method disclosed by the invention is characterized in that green and environment-friendly cheap biological yeast is used in the preparation process; the hollow nitrogen-doped biological carbon shell is coated with nickel sulfide so as to better improve the specific capacity, the rate performance and the stability of the nickel sulfide.In the long-time oxidation reaction process, the damage of the loaded nickel sulfide nanorod to the hollow nitrogen-doped biological carbon shell is reduced, the specific surface area is enlarged, the conductivity of the composite material is increased, and the prepared composite material has high rate performance.

Owner:QILU UNIV OF TECH

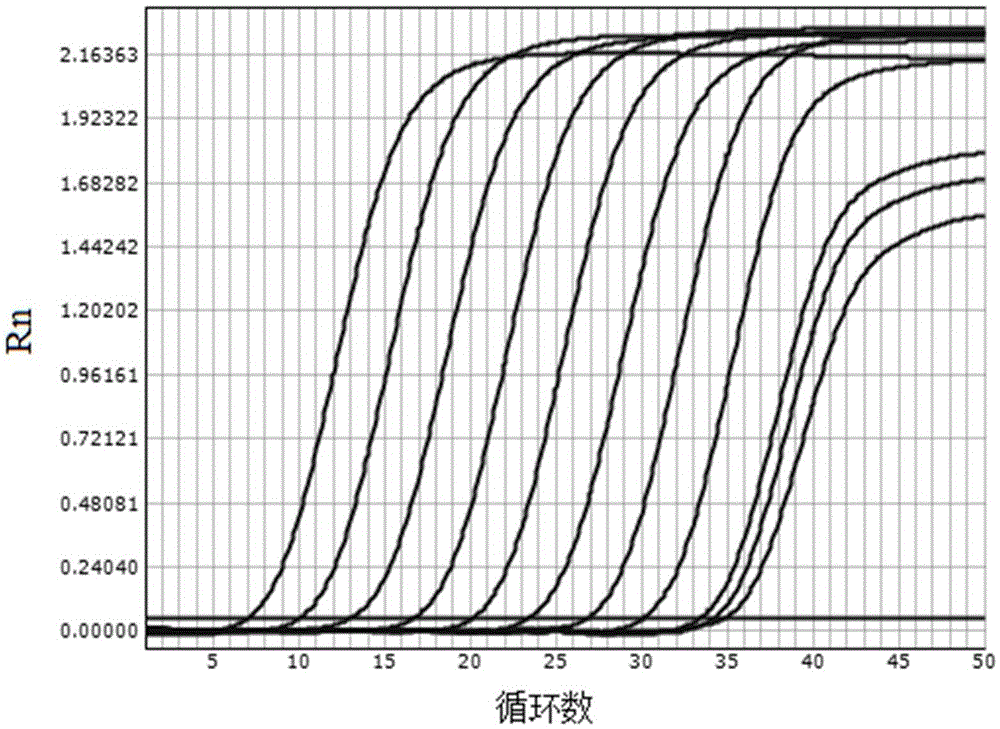

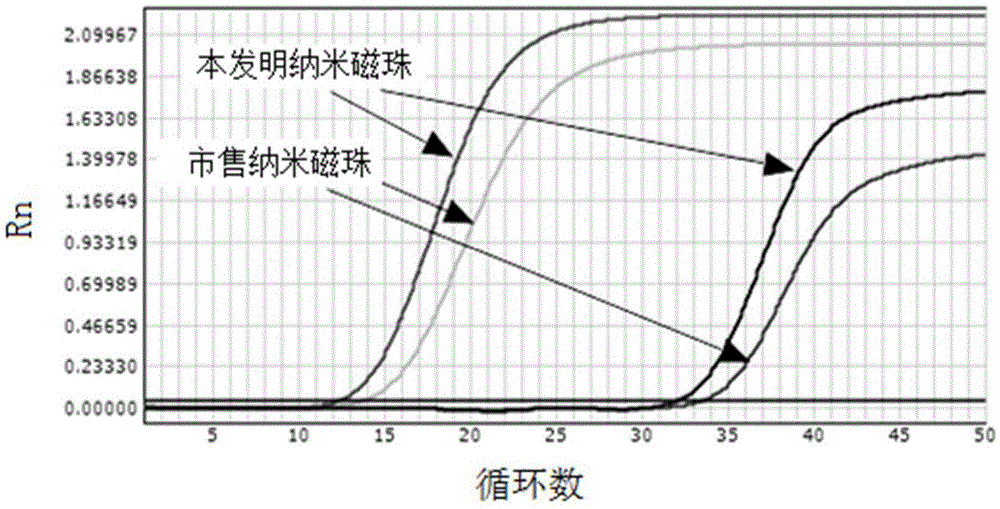

Nano magnetic bead for nucleic acid purification

InactiveCN105561914AEfficient purificationReduce workloadOrganic/organic-metallic materials magnetismAlkali metal oxides/hydroxidesMagnetic beadMicrosphere

The invention provides a nano magnetic bead for nucleic acid purification. A preparation method of the nano magnetic bead includes the processes of preparation and surface modification of nano microspheres. The biologically-magnetic microspheres of certain sizes are obtained through an aqueous phase reaction, groups capable of adsorbing nucleic acid are introduced to the surfaces of the biologically-magnetic microspheres, through the character that silicon dioxide is electrified to adsorb nucleic acid, multiple complex samples can be efficiently purified, and therefore automation of nucleic acid purification is achieved and the workload of working staff is greatly reduced. The nano magnetic bead has the advantages that dispersibility is good, cost is low, particle uniformity is good, and the size of the magnetic bead is high in controllability, the nano magnetic bead can be effectively used for diagnostic reagent earlier purification and clinical nucleic acid detection, and has wide application prospects and social and economic benefits in the field of sequencing and the fields of biologically-magnetic microsphere targeted therapy and biological medicine development.

Owner:BEIJING NAGENE DIAGNOSTIC REAGENT CO LTD

Ultra-thin diamond saw blade made of rare-earth modified tungsten-base binding agent and manufacturing method of ultra-thin diamond saw blade

ActiveCN104148642ASolve temperature problemsSolve defects that are difficult to practical applicationRare-earth elementManganese

The invention discloses an ultra-thin diamond saw blade made of a rare-earth modified tungsten-base binding agent and a manufacturing method of the ultra-thin diamond saw blade. The method includes: fully mixing diamond powder and the rare-earth modified tungsten-base binding agent; subjecting the mixture to cold press molding, and then performing vacuum hot-pressing sintering at the temperature of 900-960 DEG C under the force of 90-200KN for 25-35 minutes; then performing hot isostatic pressing sintering at the temperature of 840-900 DEG C under the pressure of 80-120 Mpa for 5-10 minutes to obtain a crude product of the ultra-thin diamond saw blade; finishing the crude product of the ultra-thin diamond saw blade to obtain a finished product of the ultra-thin diamond saw blade. The rare-earth modified tungsten-base binding agent comprises 40-75 parts of tungsten, 2-6 parts of nickel, 2-5 parts of ferrum, 8-30 parts of stannum, 7-20 parts of copper, 0.4-1 part of manganese and 0.1-1 part of rare earth elements. Holding force of diamond particles can be enhanced remarkably, abrasion resistance of the ultra-thin diamond saw blade is improved, and accordingly processability is improved while service life of the ultra-thin diamond saw blade is prolonged.

Owner:南安华大石材产业技术研究院

Diamond circular saw blade with rare earth modified tungsten-based binding agent and manufacturing method thereof

ActiveCN104128605ASolve temperature problemsSolve defects that are difficult to practical applicationTurbinesOther manufacturing equipments/toolsRare-earth elementManganese

The invention discloses a diamond circular saw blade with a rare earth modified tungsten-based binding agent and a manufacturing method of the diamond circular saw blade with the rare earth modified tungsten-based binding agent. Diamond powder and the rare earth modified tungsten-based binding agent are fully mixed, wherein the rare earth modified tungsten-based binding agent comprises 40-75 parts of tungsten, 2-6 parts of nickel, 2-5 parts of iron, 8-30 parts of tin, 7-20 parts of copper, 0.4-1 part of manganese and 0.1-1 part of rare earth elements; after a mixture is formed in a cold pressing mode, vacuum hot-pressing sintering is carried out for 25-35 minutes under 900-960 DEG C and 140-200 KN; then hot isostatic pressing sintering is carried out for 5-10 minutes under 840-900 DEG C and 80-120 MPa, and diamond circular saw blade segments are obtained; the diamond circular saw blade segments are installed and connected to a circular saw blade base body, and then the diamond circular saw blade is obtained. The hold force of diamond particles can be improved significantly, abrasion resistance of the diamond circular saw blade is increased, and therefore the machining performance of the diamond circular saw blade is improved, and the service life of the diamond circular saw blade is prolonged.

Owner:HUAQIAO UNIVERSITY

Diamond grinding wheel adopting rare-earth modified tungsten-based bond and manufacturing method thereof

ActiveCN104175237AImprove gripHigh hardnessAbrasion apparatusGrinding devicesDiamond grindingRare-earth element

The invention discloses a diamond grinding wheel adopting a rare-earth modified tungsten-based bond and a manufacturing method thereof. The manufacturing method comprises the steps as follows: diamond powder and the rare-earth modified tungsten-based bond are mixed sufficiently, wherein the rare-earth modified tungsten-based bond comprises 40-75 parts of tungsten, 2-6 parts of nickel, 2-5 parts of iron, 8-30 parts of tin, 7-20 parts of copper, 0.4-1 part of manganese and 0.1-1 part of rare earth elements; the mixture is subjected to vacuum hot pressing sintering for 25-35 min under the conditions of 900-960 DEG C and 140-200 KN after cold press molding and then subjected to hot isostatic pressing sintering for 5-10 min under the conditions of 840-900 DEG C and 80-120 MPa to obtain a diamond grinding wheel tire body; and the diamond grinding wheel tire body is assembled to a grinding wheel substrate to obtain the diamond grinding wheel. The diamond grinding wheel and the manufacturing method have the advantages that the holding force of diamond particles can be increased remarkably, and the wear resistance of the diamond grinding wheel can be improved, so that the machinability of the diamond grinding wheel is improved, and the service life of the diamond grinding wheel is prolonged.

Owner:南安华大石材产业技术研究院

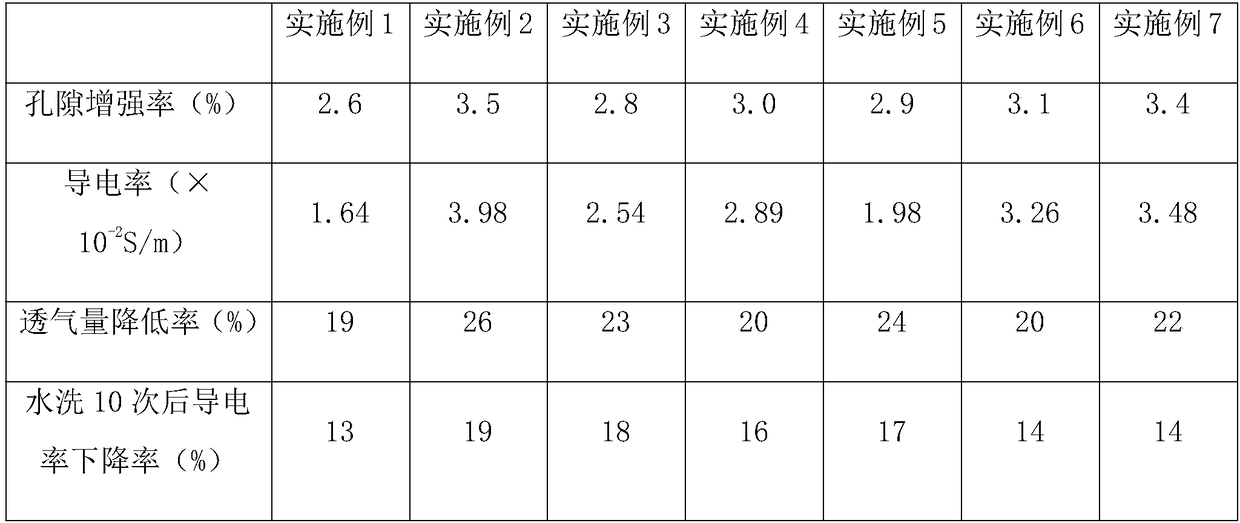

Preparation method for graphene sponge reinforced nanofiber membrane

InactiveCN108486862AHigh porosityPorous connectivity is goodSynthetic fibresVegetal fibresUltrasonic dispersionVacuum drying

The invention provides a preparation method for a graphene sponge reinforced nanofiber membrane. The preparation method comprises the following concrete steps: adding a titanium-containing microemulsion into a graphene oxide solution, carrying out uniform mixing under stirring at a high speed so as to obtain a precursor solution, subjecting the precursor solution to rapid freezing and vacuum drying treatment in a low-temperature environment, , then introducing hydrogen for reduction at a high temperature so as to obtain a graphene-based porous sponge; and crushing and grinding the graphene-based porous sponge to a micron size, dispersing the micron-sized graphene-based porous sponge in deionized water, carrying out ultrasonic dispersion so as to obtain an electrophoresis solution, immersing a nanofiber membrane in the electrophoresis solution, inserting positive and negative electrodes into two sides of the nanofiber membrane, carrying out an electrophoresis reaction, and then taking the nanofiber membrane out for drying so as to obtain the graphene sponge reinforced nanofiber membrane. According to the graphene sponge reinforced nanofiber membrane prepared in the invention, the micron-sized graphene sponge is allowed to uniformly infiltrate and adhere to the surface of the nanofiber membrane in virtue of electrophoresis technology, so the functionality of the nanofiber membrane is improved; and the graphene sponge reinforced nanofiber membrane is specially applicable as a composite reinforcement or a carrier.

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

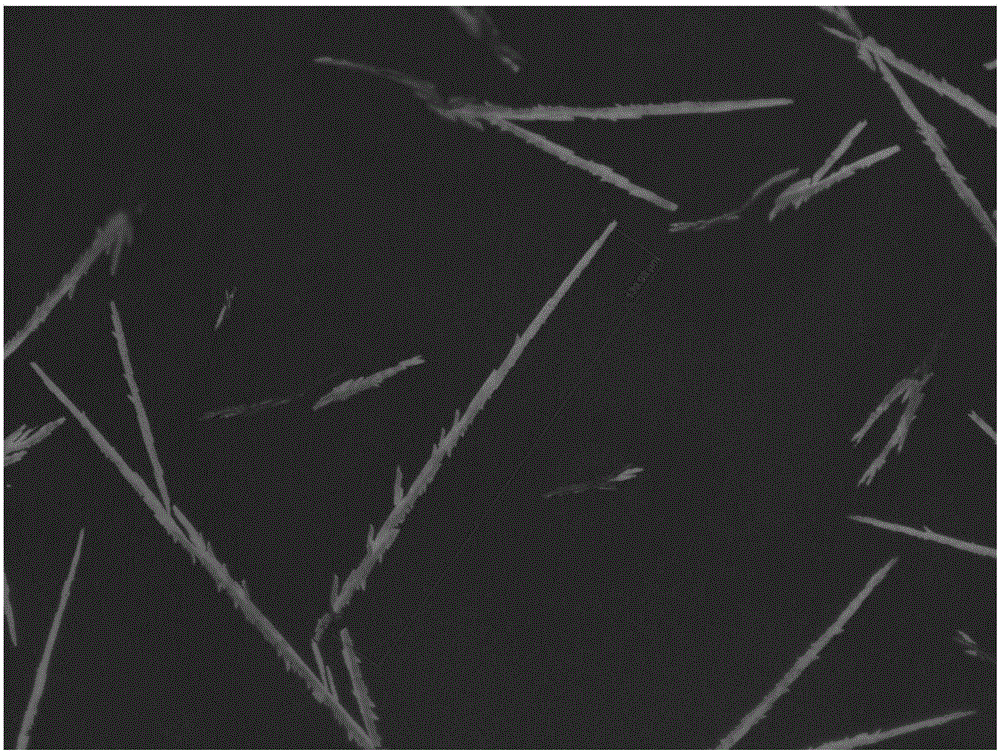

A kind of preparation method of tungsten disulfide nanotube

ActiveCN108046327BGood size controllabilityHigh crystallinityNanotechnologyTungsten compoundsTungsten hexacarbonylCrucible

The invention discloses a tungsten disulfide nanotube preparation method. The method includes process steps: 1) laying hexacarbonyl tungsten at the bottom of a ceramic crucible, positioning a porous anodic aluminum oxide template with an opening downward above hexacarbonyl tungsten, sealing the crucible, putting into a tubular furnace, performing low-temperature sublimation deposition and high-temperature pyrolysis under gas shielding, and cooling; 2) after the vacuum tubular furnace is cooled to the room temperature, positioning the template with the opening downward into the ceramic cruciblefilled with sulfur powder, sealing the crucible, and heating to enable direction reaction of elemental sulfur with metal tungsten; 3) using dilute acid solution to remove the porous anodic aluminum oxide template, using carbon disulfide to remove excessive sulfur, performing suction filtration and drying to obtain a finished product. The tungsten disulfide nanotube preparation method is simple instep and free of environmental pollution and complicated equipment, a prepared tungsten disulfide nanotube powder material is high in size controllability and crystallinity, morphological uniformityof nanotube walls is realized, and accordingly comprehensive performances of tungsten disulfide nanotube powder material products are remarkably improved. In addition, the tungsten disulfide nanotubepreparation method is extensive in applicability and beneficial to large-scale industrial production.

Owner:FOSHAN UNIVERSITY

Method for preparing tungsten ditelluride nanotubes

ActiveCN107934928AGood size controllabilityHigh crystallinityNanotechnologyMetal selenides/telluridesSingle substanceFiltration

The invention discloses a method for preparing tungsten ditelluride nanotubes. The method comprises the following steps: 1) laying tungsten hexacarbonyl to the bottom of a ceramic crucible, laying a porous anodic aluminum oxide mold plate with an opening facing downwards on the tungsten hexacarbonyl, sealing the ceramic crucible, putting into a tubular furnace, performing low-temperature sublimation deposition in the presence of a gas, and continuously performing heating pyrolysis; 2) cooling the vacuum tubular furnace to the room temperature, putting the mold plate with the opening facing downwards into a ceramic crucible with tellurium powder, sealing the ceramic crucible, heating in the presence of the gas, and enabling a single substance, namely tellurium, to react with a metal, namelytungsten, directly; 3) removing the excessive aluminum oxide mold plate and excessive tellurium by using a diluted acid solution, performing suction filtration treatment, and drying, thereby obtaining a finished product. The method disclosed by the invention is simple in step, free of environment pollution and free of complex equipment, a tungsten ditelluride nanotube powder material prepared byusing the method is good in size controllability, good in crystallinity and uniform in nanotube wall and morphology, and thus the comprehensive properties of a finished product of the tungsten ditelluride nanotube powder material are greatly improved. The method is wide in applicability and beneficial to large-scale industrial production.

Owner:FOSHAN UNIVERSITY

Tungsten disulfide nanotube preparation method

ActiveCN108046327AGood size controllabilityHigh crystallinityNanotechnologyTungsten compoundsFiltrationCrystallinity

The invention discloses a tungsten disulfide nanotube preparation method. The method includes process steps: 1) laying hexacarbonyl tungsten at the bottom of a ceramic crucible, positioning a porous anodic aluminum oxide template with an opening downward above hexacarbonyl tungsten, sealing the crucible, putting into a tubular furnace, performing low-temperature sublimation deposition and high-temperature pyrolysis under gas shielding, and cooling; 2) after the vacuum tubular furnace is cooled to the room temperature, positioning the template with the opening downward into the ceramic cruciblefilled with sulfur powder, sealing the crucible, and heating to enable direction reaction of elemental sulfur with metal tungsten; 3) using dilute acid solution to remove the porous anodic aluminum oxide template, using carbon disulfide to remove excessive sulfur, performing suction filtration and drying to obtain a finished product. The tungsten disulfide nanotube preparation method is simple instep and free of environmental pollution and complicated equipment, a prepared tungsten disulfide nanotube powder material is high in size controllability and crystallinity, morphological uniformityof nanotube walls is realized, and accordingly comprehensive performances of tungsten disulfide nanotube powder material products are remarkably improved. In addition, the tungsten disulfide nanotubepreparation method is extensive in applicability and beneficial to large-scale industrial production.

Owner:FOSHAN UNIVERSITY

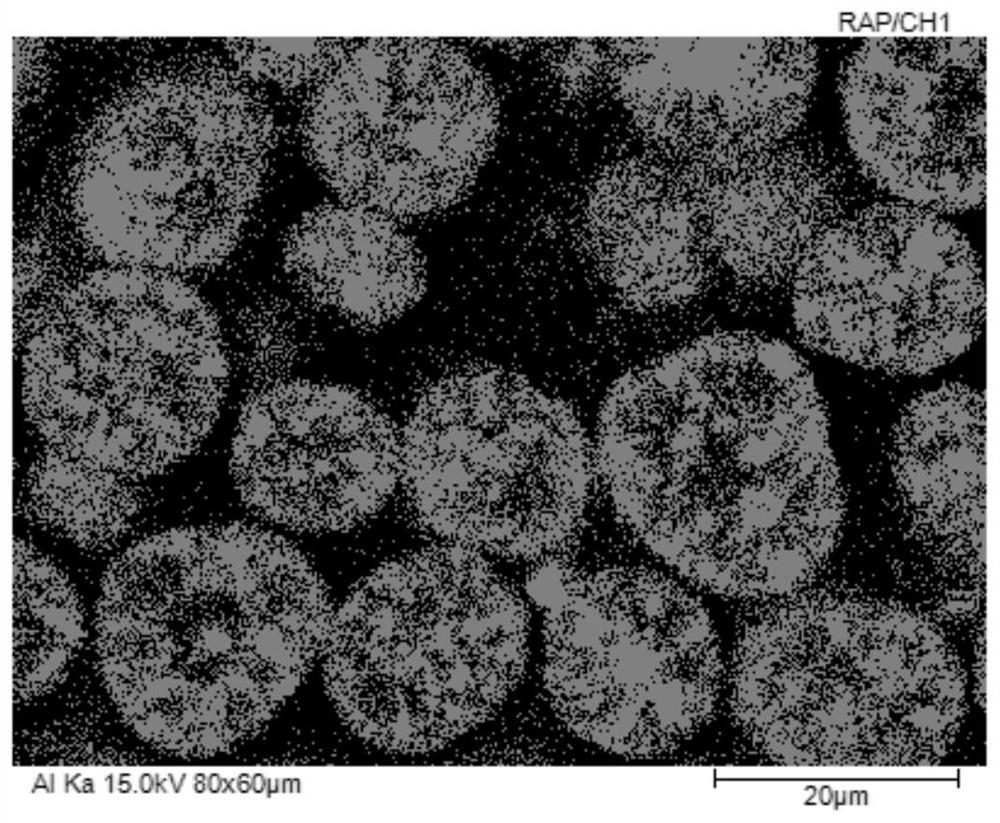

Preparation method of aluminum-doped cobaltosic oxide particles

PendingCN114368792AImprove uniformityReduce sedimentation rateCobalt oxides/hydroxidesPeristaltic pumpAluminum Ion

The invention discloses a preparation method of aluminum-doped cobaltosic oxide particles, which comprises the following steps: firstly, respectively preparing a cobalt salt solution, an ammonium bicarbonate solution and a sodium metaaluminate solution with certain concentrations; then adding the solution into a reaction kettle in which a certain amount of base solution is reserved in advance through a peristaltic pump in a parallel flow manner, reacting, and controlling the reaction temperature to be 35-60 DEG C and the pH value of a reaction system to be 7-7.6; and finally, the obtained product is calcined, the calcination temperature is 200-900 DEG C, the calcination time is 4-15 h, and finally the aluminum-doped cobaltosic oxide particles are obtained. In the method disclosed by the invention, Al enters the reaction kettle in the form of anion AlO2 <->, so that the precipitation rate of aluminum ions in the reaction kettle is slowed down, the uniformity of Al doped in cobaltosic oxide is improved, and the aluminum salt adopts an independent feeding mode, so that the content of aluminum element in cobalt carbonate is better regulated and controlled, the reaction is easier to control, and the reaction yield is improved. Large-particle aluminum-doped uniform cobaltosic oxide can be prepared, and the particle size can reach 14-17 microns.

Owner:JINGMEN GEM NEW MATERIAL

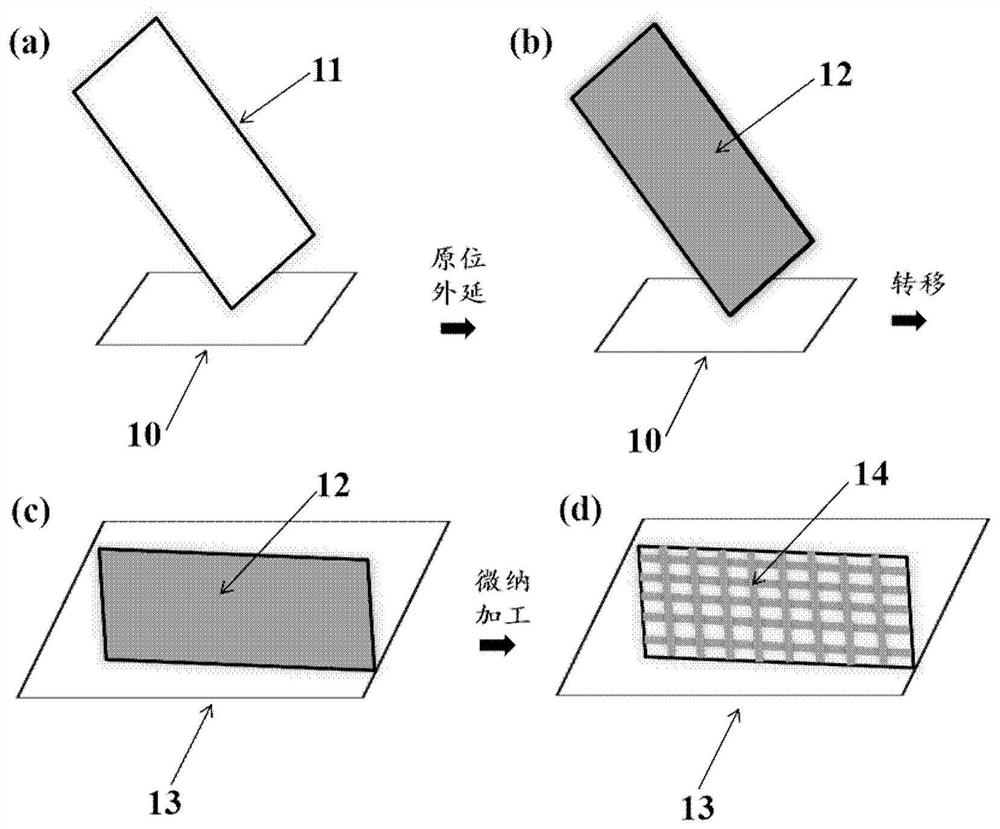

Preparation method of semiconductor/superconductor heterojunction nanowire network

ActiveCN111704105AImprove crystal qualityGood size controllabilitySpecific nanostructure formationNanoinformaticsSemiconductorMaterials science

The invention provides a preparation method of a semiconductor / superconductor heterojunction nanowire network. The preparation method comprises the following steps: preparing a vertical semiconductornanosheet on a first substrate; performing in-situ epitaxy of a superconductor on the semiconductor nanosheet to obtain a semiconductor nanosheet with the superconductor epitaxy; transferring the semiconductor nanosheet on which the superconductor is extended to a second substrate; processing an in-situ epitaxial superconductor on a semiconductor nanosheet into a nanowire network by utilizing micro-nano processing to obtain a semiconductor / superconductor heterojunction nanowire network.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

Graphene-CBS composite pre-dispersed rubber master batch and preparation method for same

The invention discloses a graphene-CBS composite pre-dispersed rubber master batch which includes, by weight, 35-45% of graphene, 20-40% of N-cyclohexyl-2-benzothiazolesulfenamide, 3-8% of bis-[gamma-(triethoxylsilicon)propyl]-tetrasulfide, 7-15% of ethylene propylene diene monomer, 3-5% of EVA resin, 1-3% of triethanolamine, 1-4% of a wetting agent and 8-13% of a softening agent. The rubber master batch contains two active components graphene and CBS, and can solve the problems of dispersibility of graphene and CBS and dust pollution in rubber products. When being used for producing vulcanized rubber in subsequent steps, the rubber master batch can promote vulcanization of rubber and improve mechanical performance and aging resistance of rubber, and especially can increase yield and production efficiency of a vulcanized rubber extruded product. The preparation method of the rubber master batch has excellent operability. The graphene-CBS composite pre-dispersed rubber master batch has low Mooney viscosity and maintains the original activities of the graphene and CBS, so that the graphene and CBS are uniformly dispersed in the rubber master batch.

Owner:NINGBO ACTMIX POLYMER

Preparation method of molybdenum disulfide nanotubes

ActiveCN108059189AGood size controllabilityHigh crystallinityNanotechnologyMolybdenum sulfidesFiltrationControllability

The invention discloses a preparation method of molybdenum disulfide nanotubes. The preparation method comprises the following technological steps: 1) paving molybdenum hexacarbonyl on the bottom of aceramic crucible; then putting a porous anodic aluminum oxide template above the molybdenum hexacarbonyl in a manner of placing an opening of the porous anodic aluminum oxide template downward; aftersealing the crucible, putting the crucible into a tubular furnace; under gas protection, sublimating and depositing at low temperature and pyrolyzing at high temperature; then cooling; 2) after cooling the vacuum tubular furnace to room temperature, putting the template into the ceramic crucible filled with sulfur powder in the manner of placing the opening of the template downward; after sealingthe crucible, raising the temperature under the gas protection, so as to enable monomer sulfur and metal molybdenum to directly react; 3) removing the porous aluminum oxide template by adopting a diluted acid solution and removing surplus sulfur by utilizing carbon disulfide; then carrying out suction filtration treatment and drying to obtain a finished product. The method disclosed by the invention has simple steps and no environment pollution and does not need complicated equipment; a prepared molybdenum disulfide nanotube powder material has strong size controllability and good crystallization performance; the nanotubes have a shape and uniform tube wall, so that the comprehensive performance of a molybdenum disulfide nanotube powder material finished product is greatly improved. The molybdenum disulfide nanotubes disclosed by the invention have wide applicability and large-scale industrial production is facilitated.

Owner:FOSHAN UNIVERSITY

Method for preparing molybdenum ditelluride nanotubes

ActiveCN107934927AGood size controllabilityHigh crystallinityNanotechnologyMetal selenides/telluridesSingle substanceMolybdenum telluride

The invention discloses a method for preparing molybdenum ditelluride nanotubes. The method comprises the following steps: 1) laying molybdenum hexacarbonyl to the bottom of a ceramic crucible, layinga porous anodic aluminum oxide mold plate with an opening facing downwards on the molybdenum hexacarbonyl, sealing the ceramic crucible, putting into a tubular furnace, performing low-temperature sublimation deposition in the presence of a gas, and continuously performing heating pyrolysis; 2) cooling the vacuum tubular furnace to the room temperature, putting the mold plate with the opening facing downwards into a ceramic crucible with tellurium powder, sealing the ceramic crucible, heating in the presence of the gas, and enabling a single substance, namely tellurium, to react with a metal,namely molybdenum, directly; 3) removing the excessive aluminum oxide mold plate and excessive tellurium by using a diluted acid solution, performing suction filtration treatment, and drying, therebyobtaining a finished product. The method disclosed by the invention is simple in step, free of environment pollution and free of complex equipment, a molybdenum ditelluride nanotube powder material prepared by using the method is good in size controllability, good in crystallinity and uniform in nanotube wall and morphology, and thus the comprehensive properties of a finished product of the molybdenum ditelluride nanotube powder material are greatly improved. The method is wide in applicability and beneficial to large-scale industrial production.

Owner:FOSHAN UNIVERSITY

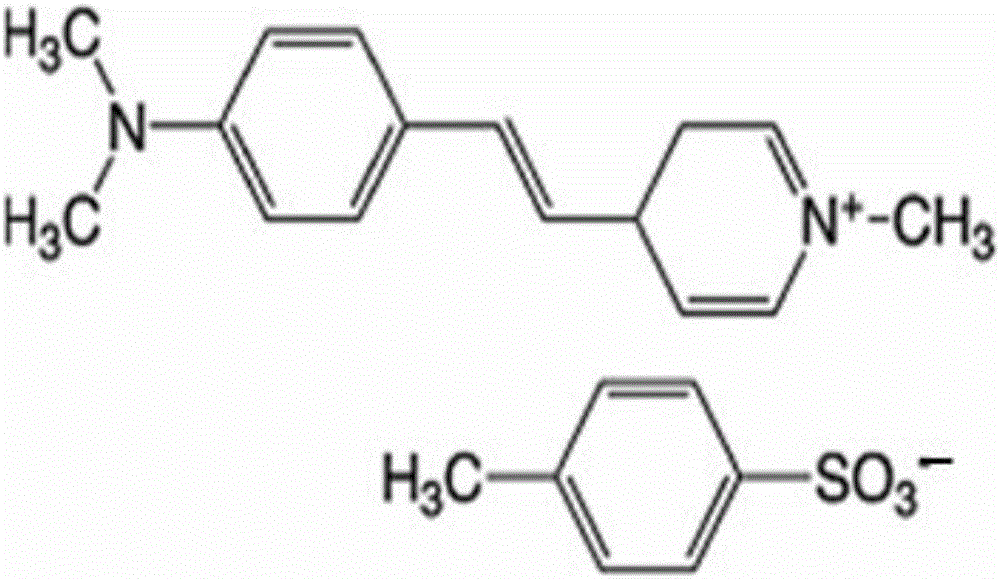

Method for preparing mesoscopic scale line-shaped organic crystal

InactiveCN105970298AGood size controllabilityReduce defectsPolycrystalline material growthFrom normal temperature solutionsOrganic crystalSelf-assembly

The invention discloses a method for preparing mesoscopic scale line-shaped organic crystal. The method comprises the steps of dissolving an organic crystal raw material and a modifier into a first organic solvent, and evenly stirring; after that, dripping the mixed solution onto a substrate with temperature of 50-150 DEG C for evaporating, wherein the evaporation time is controlled to be within 5 minutes; then, putting the substrate into a culture dish, culturing for 5-20 hours, and enabling organic crystal to grow along the single direction to obtain the mesoscopic scale line-shaped organic crystal. According to the method, there is not enough time for polymerization due to high crystal precipitation speed, and a self-assembly process of the solution is influenced by the hydrophilia degree of the material of the heated substrate, so that the mesoscopic scale line-shaped organic crystal appears; furthermore, the size and direction of the mesoscopic scale line-shaped organic crystal change along with the change of a mass ratio of the modifier to the organic crystal, the temperature of the heated substrate and the hydrophilia of the substrate.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Preparation method of gold nanotriangular sheet and method for preparing gold nanodisc and gold nanohexagonal sheet based on the method

ActiveCN104625086BAdvantages of preparation methodUniform sizeMaterial nanotechnologySodium iodidePotassium iodine

The invention provides a gold nanoparticle triangular plate preparing method and a method for preparing gold nanoparticle discs and gold nanoparticle hexagonal pieces on the basis of the gold nanoparticle triangular plate preparing method, relates to the technical field of gold nanoparticle preparing, and aims at providing the method which is easy and convenient to operate, high in repeatability and efficiency and is used for preparing gold nanoparticle triangular plates, gold nanoparticle discs and gold nanoparticle hexagonal pieces. The gold nanoparticle triangular plate preparing method includes the steps of preparing a gold nanoparticle seed solution through a sodium citrate aqueous solution, a tetrachloroauric acid aqueous solution and a sodium borohydride aqueous solution, preparing a gold nanoparticle triangular plate solution through the preapraed seed solution, a cetyl trimethyl ammonium bromide aqueous solution, a tetrachloroauric acid aqueous solution, a potassium iodide or sodium iodide aqueous solution, a sodium hydroxide aqueous solution and a ascorbic acid aqueous solution, and obtaining gold nanoparticle triangular plates after the liquid supermatant is abandoned. The method is easy and convenient to operate and high in repeatability and controllability, the prepared gold nanoparticle plates are unified in size, gold nanoparticle plates of different types and sizes can be synthesized, and the purity reaches 95% or higher.

Owner:NANOSEEDZ

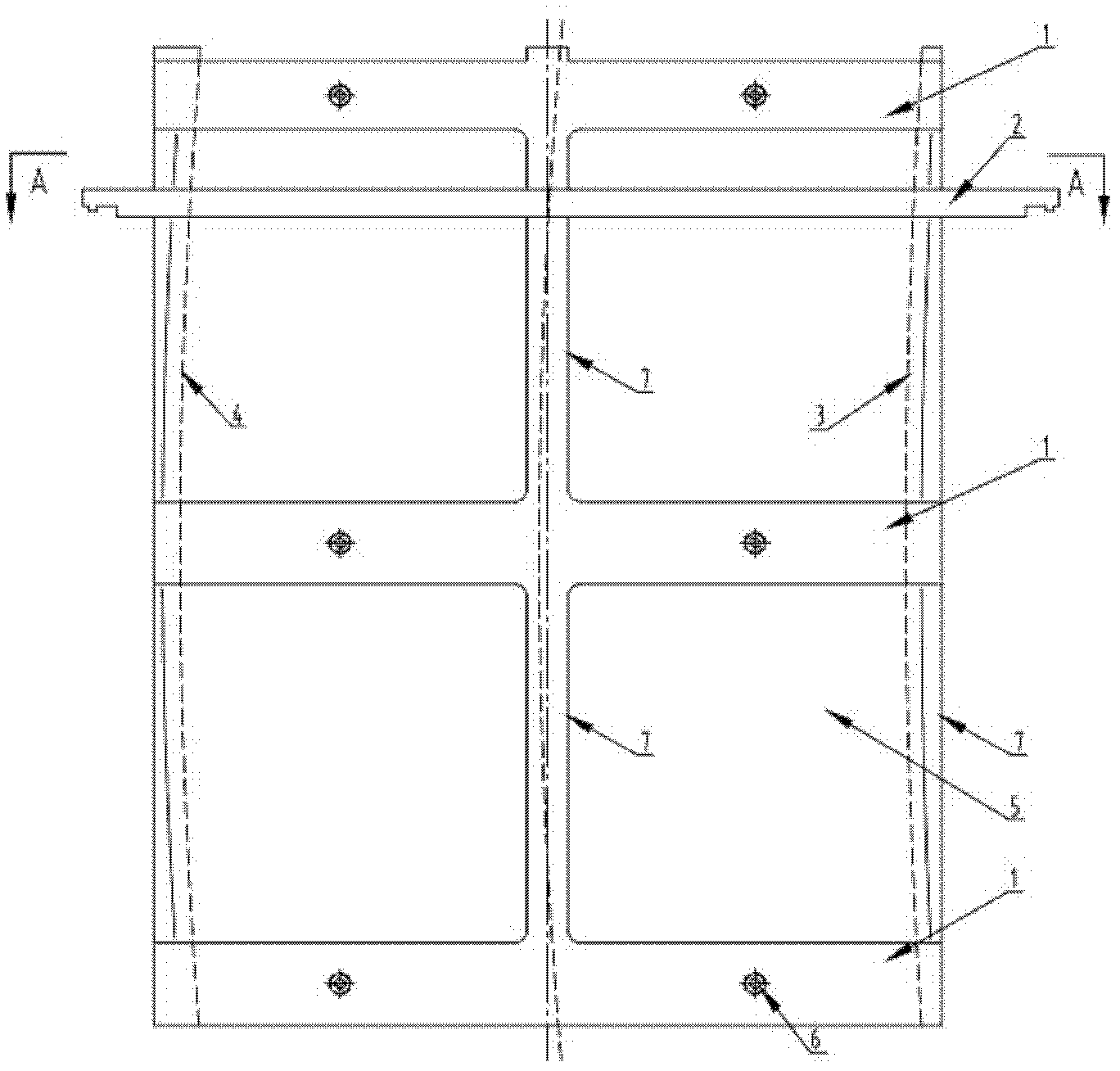

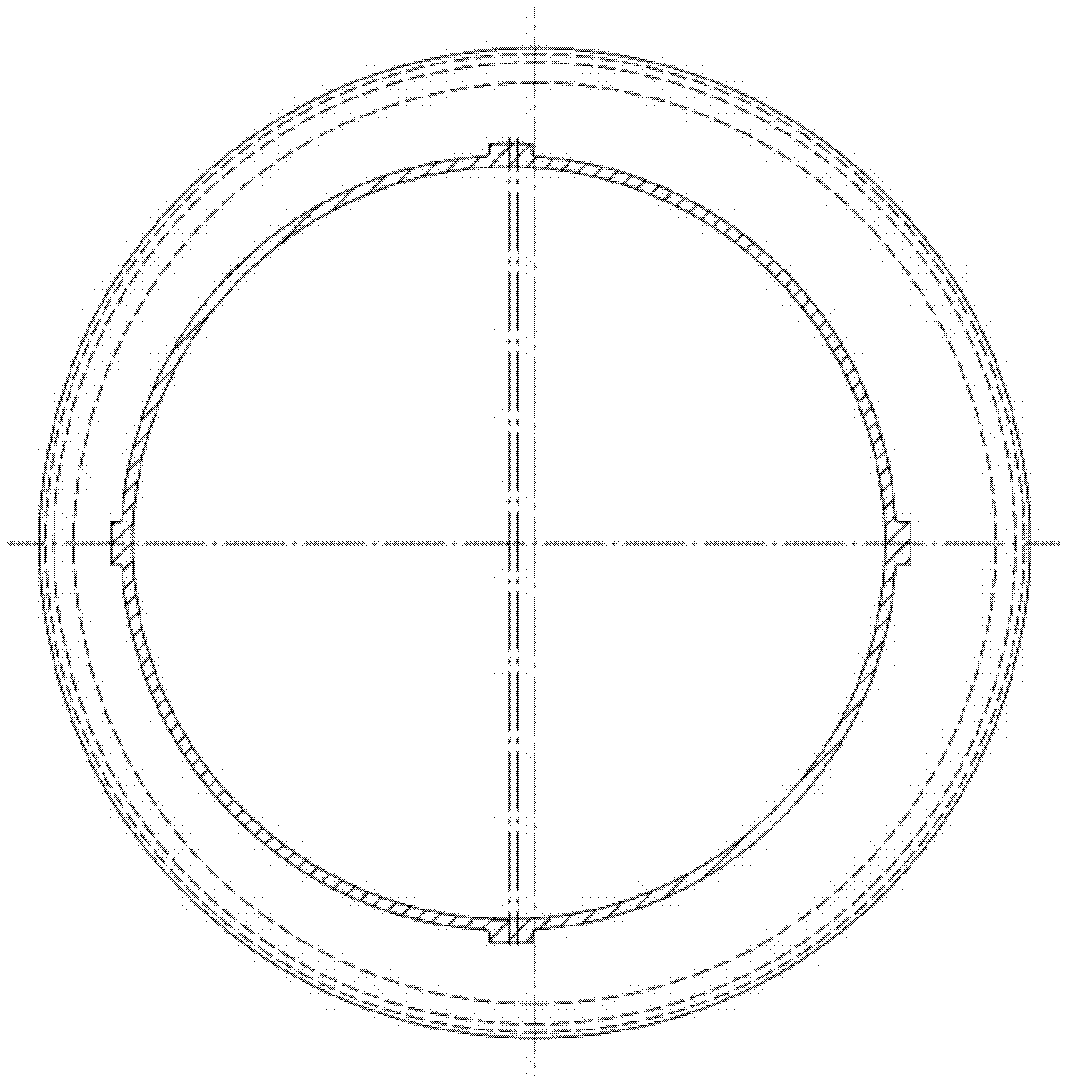

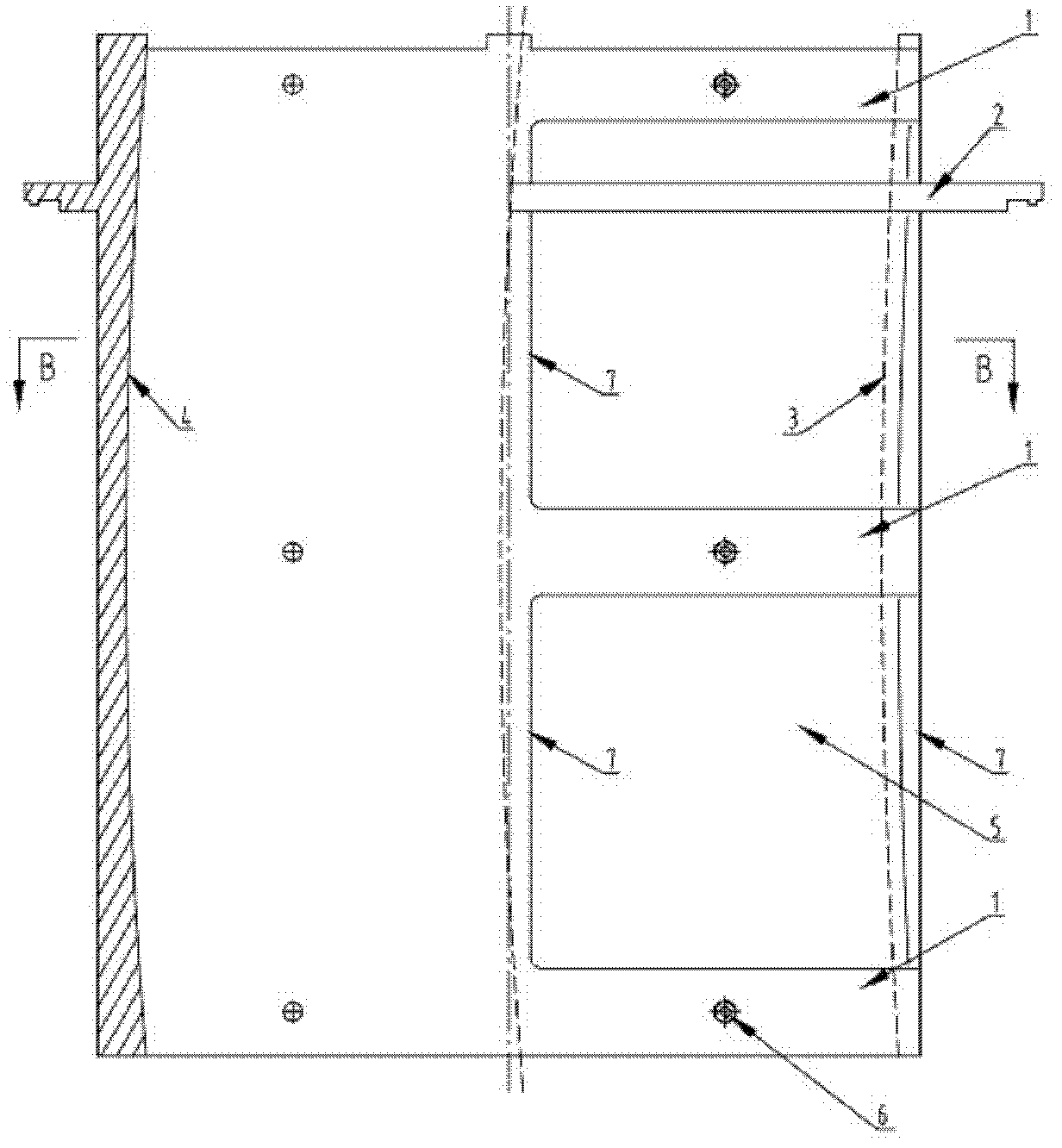

Big round bloom water jacket casted with high precision

InactiveCN102218508AImprove rigidityGuaranteed machining accuracyFoundry mouldsFoundry coresGreat circleWater jacket

The invention relates to a big round bloom water jacket casted with high precision, which overcomes the defects existed in the present water jacket formed by a welding process, and creatively provides the big round bloom water jacket casted with high precision. A resin casting molding technology is used for preciously casting stainless steel raw material to the molding big round bloom water jacket by one step, the finished products have the advantages that the steel performance is strong, and precision of the size is easy to guarantee. The invention is characterized in that a resin casting stainless steel molding technology is used, stainless steel water jacket, positioning flange, annular and vertical flange reinforcement on the external cylindrical of the water jacket are directly casted to an integral body through a high precision casting method.

Owner:MCC EASTECH

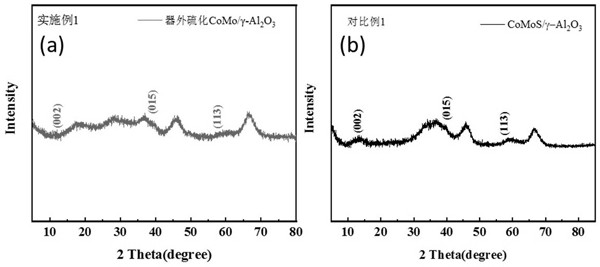

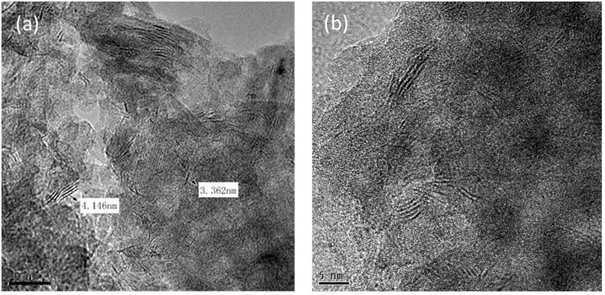

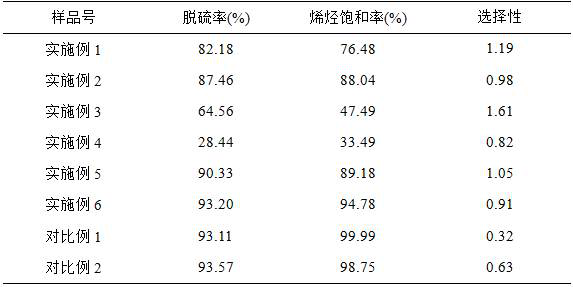

Catalytically cracked gasoline hydrodesulfurization catalyst and preparation method thereof

ActiveCN112371141AReduce forceGood particle size controllabilityPhysical/chemical process catalystsRefining to eliminate hetero atomsPtru catalystRotary evaporator

The invention relates to a catalytically cracked gasoline hydrodesulfurization catalyst and a preparation method thereof. The preparation process of the Co3O4-MoS2 / gamma-Al2O3 catalyst comprises the three steps: making Co impregnated onto an aluminum oxide carrier through an isopyknic method, and carrying out drying and roasting to obtian a Co3O4 / gamma-Al2O3 precursor; dissolving a sulfur-containing compound and molybdenum-containing metal salt into ammonia water, and carrying out refluxing to prepare an ammonium tetrathiomolybdate crystal; and putting the ammonium tetrathiomolybdate crystal,a reducing agent and the Co3O4 / gamma-Al2O3 precursor into a rotary evaporator, and preparing the Co3O4-MoS2 / gamma-Al2O3 catalyst by virtue of a rotary evaporation method. According to the Co3O4-MoS2 / gamma-Al2O3 catalyst prepared by the preparation method disclosed by the invention, the active phase is changed into Co3O4 from conventional Co9S8, and when being used in a selective hydrodesulfurization reaction of catalytically cracked gasoline, the Co3O4-MoS2 / gamma-Al2O3 catalyst shows higher desulfurization selectivity.

Owner:FUZHOU UNIV

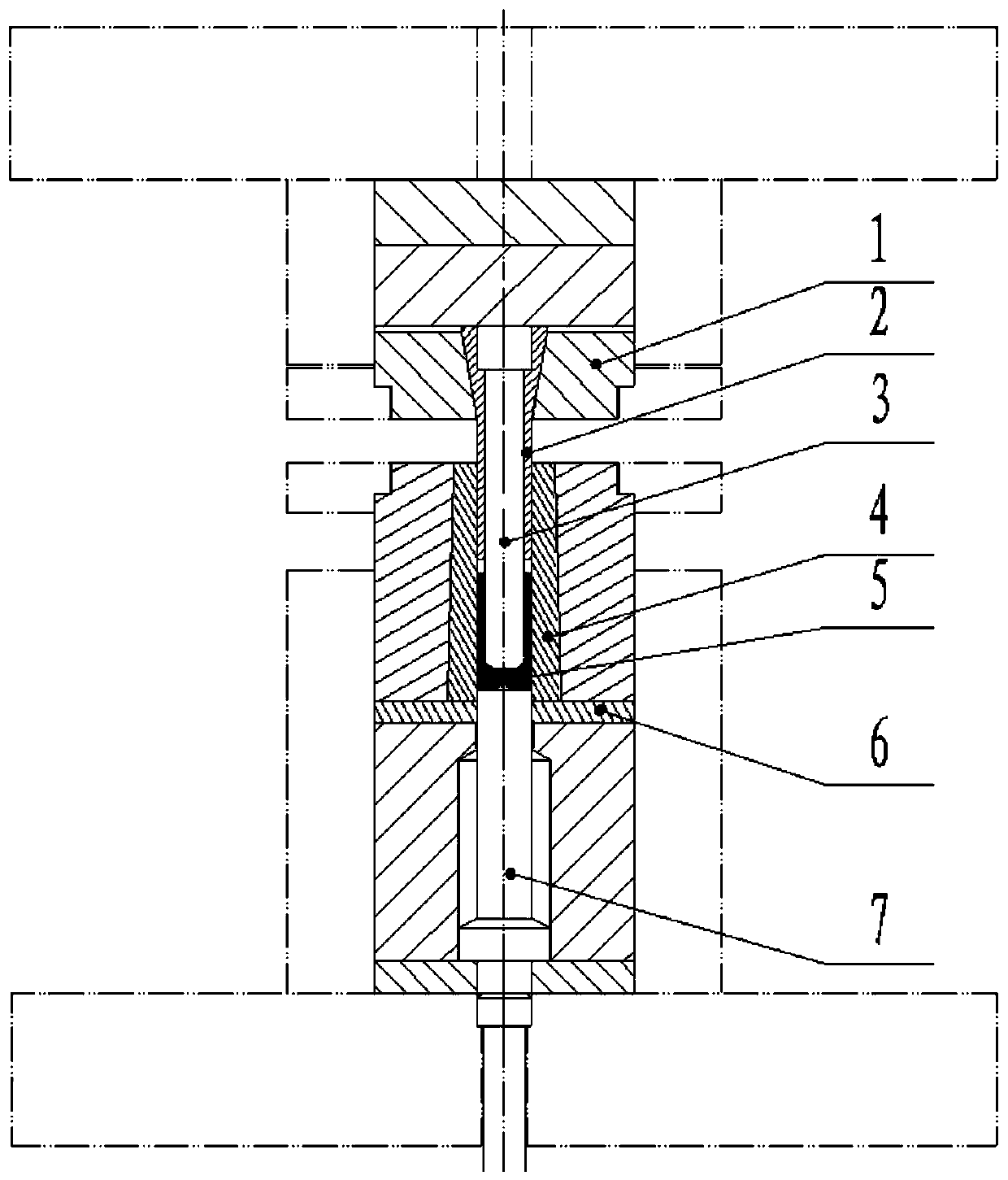

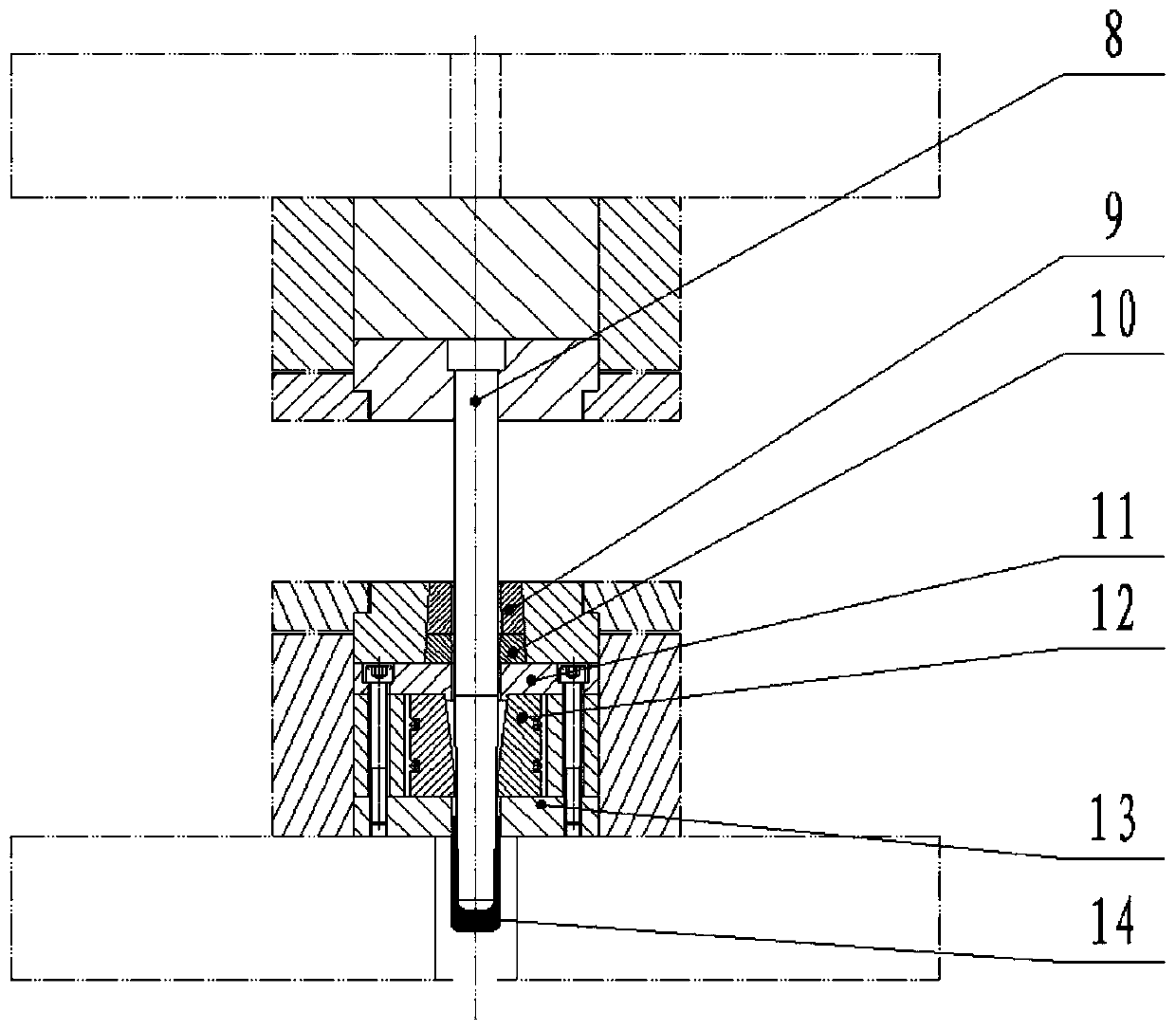

Preparing method of superhigh-strength aluminum alloy cylinder

ActiveCN110153653AHigh cylinder dimensional accuracySolve the problem of plastic deformation and easy crackingNeck partsUltimate tensile strength

The invention provides a preparing method of a superhigh-strength aluminum alloy cylinder, and belongs to the technical field of precise plastic forming. The method comprises the steps of mold preparing, blank turning, annealing, and appearance machining and is characterized in that after annealing and before appearance machining, jar extrusion, multi-pass thinning drawing, and closing in are carried out in sequence, and after appearance machining, heat treatment is carried out. A large-draw-ratio variable wall thickness thin-wall closing-in cylinder is adopted, the problems that superhigh-strength aluminum alloy is poor in moulding, tensile deformation appears, cracking is prone to appearing, in the cylinder manufacturing process, concave pits easily appear in the closing-in position andthe conical neck part, the surface is rough and has grains, and is even cracked, the thickness and the size is not controllable, and the production stability is poor are solved, and the product yieldand the yield of the method are both above 98%.

Owner:NO 59 RES INST OF CHINA ORDNANCE IND

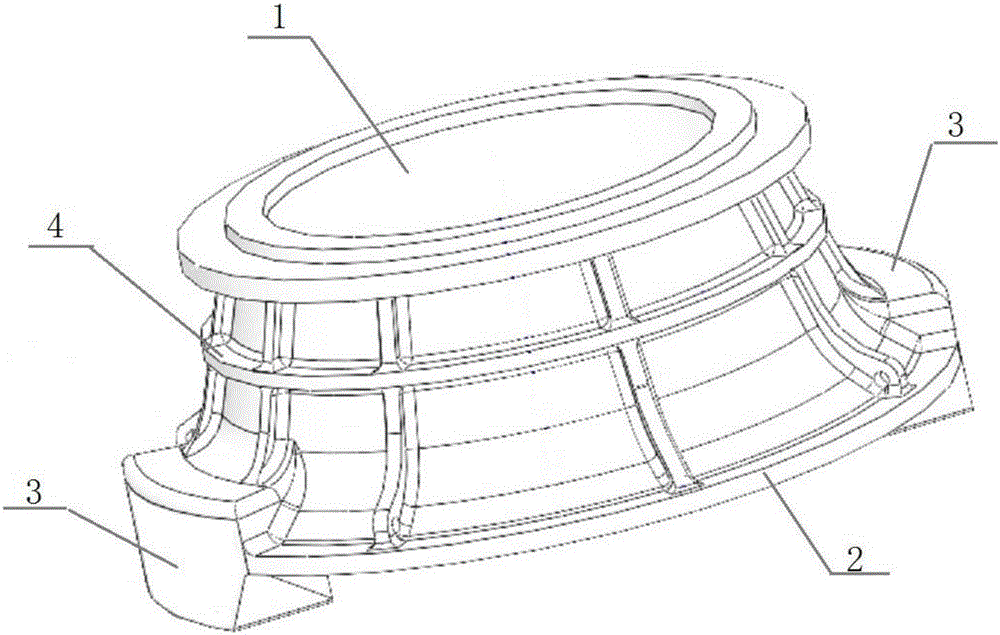

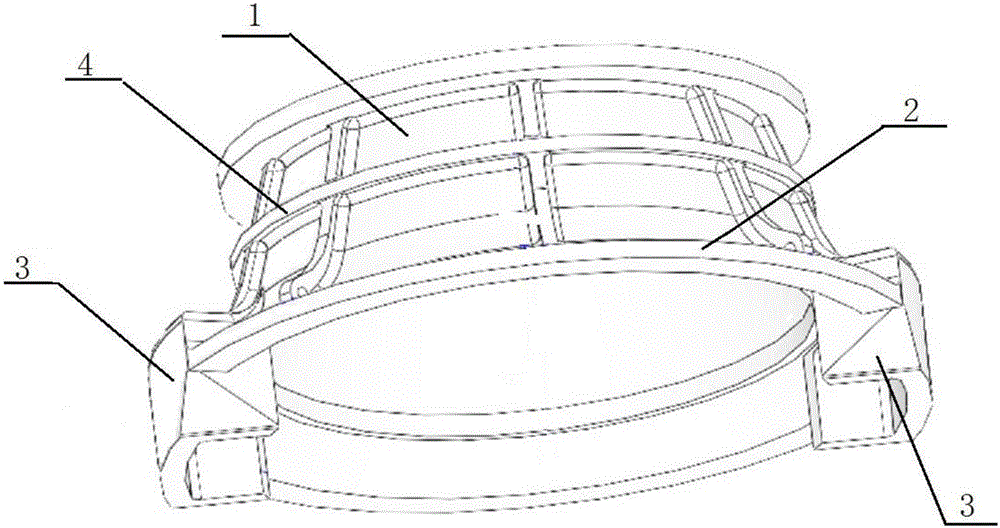

Casting molding process for shell on mine crusher

InactiveCN106734890AAccurate shapeGood size controllabilityFoundry mouldsFoundry coresGlass fiberMolten steel

The invention relates to a casting molding process for a shell on a mine crusher. The casting molding process for the shell on the mine crusher comprises the steps that firstly, a hollow actual sample is manufactured; secondly, rib plates and circular beads outside a casting are all made into movable blocks; thirdly, a solid core print is arranged on the lower portion of the hollow actual sample; fourthly, glassfiber reinforced plastics adhere to the inner surface and the outer surface of the hollow actual sample; fifthly, the movable blocks are fixed; sixthly, box molding of the hollow actual sample is performed, and sample plate core assembly molding is adopted for a bottom flange of the casting and a boss; and seventhly, box closing and molten steel casting are performed. In the casting molding process for the shell on the mine crusher, a molding method of the hollow actual sample is adopted for a body structure of the shell on the mine crusher, the casting and molding difficulty is substantially reduced, molding of the casting is made more accurately, box closing is more convenient, the sand mold size controllability is good, the inner and outer surface quality of the casting is effectively guaranteed, the manufacturing period is greatly shortened, and the later-period machining amount is reduced.

Owner:ANSTEEL CAST STEEL CO LTD

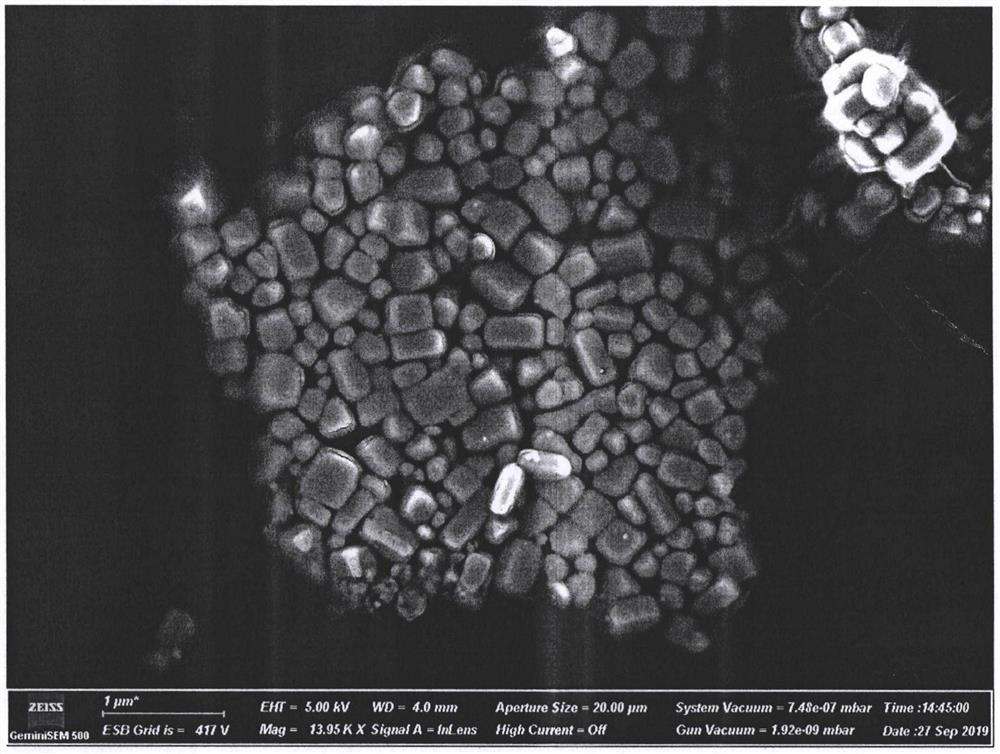

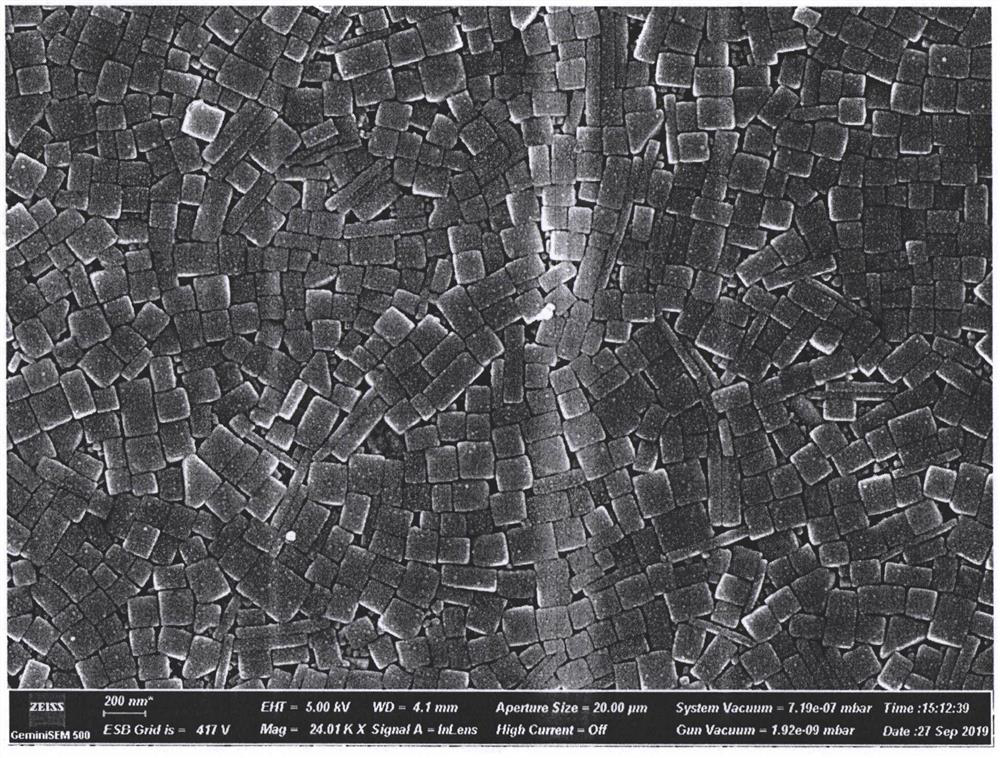

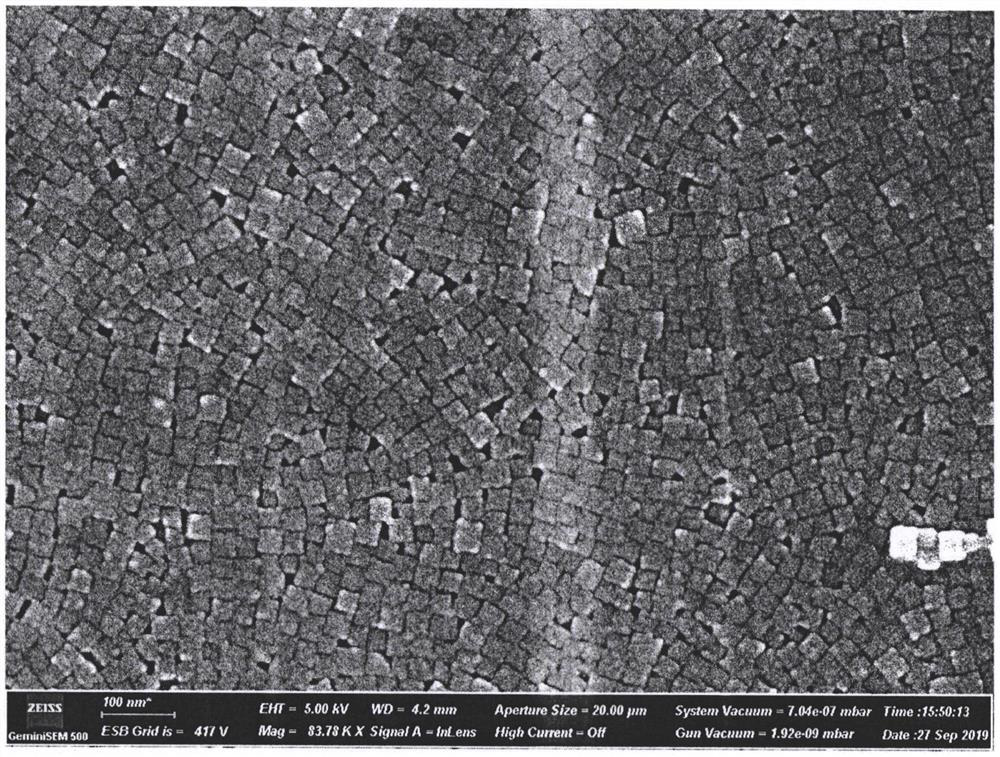

Preparation method of silver/silver chloride composite nanocube

PendingCN112221520ALow reaction temperatureSmall sizeMaterial nanotechnologyPhysical/chemical process catalystsSulfonateFreeze-drying

The invention relates to a preparation method of a silver / silver chloride composite nanocube. The silver / silver chloride composite nanocube comprises the following components: a sodium chloride solution with a concentration of 0.1-5 wt%, a silver nitrate solution with a concentration of 0.5-10 wt% and a lignosulfonate solution with a concentration of 0.5-10 wt%. The preparation method comprises the following steps: 1) weighing 1 mL to 100 mL of the lignosulfonate solution and 0.1 mL to 50 mL of the sodium chloride solution, stirring and mixing the solutions in a beaker, and carrying out heating to 30-80 DEG C; 2) measuring 0.2 mL to 100 mL of the silver nitrate solution, rapidly injecting the silver nitrate solution into the mixed solution, and continuing stirring for 1 h to 12 h at a temperature of 30 DEG C to 80 DEG C to form a silver / silver chloride composite nanocube colloidal solution; and 3) washing the prepared silver / silver chloride composite nanocube colloidal solution with deionized water, carrying out centrifugal separation at 10000 rpm for 20 min, removing supernatant liquid, and carrying out freeze drying to obtain silver / silver chloride composite nanocube particles.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

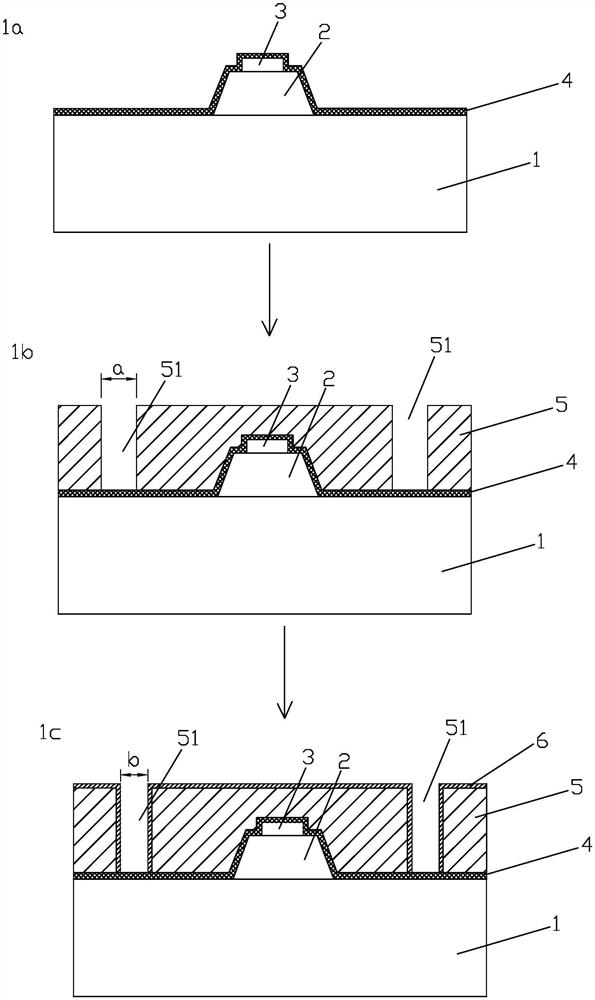

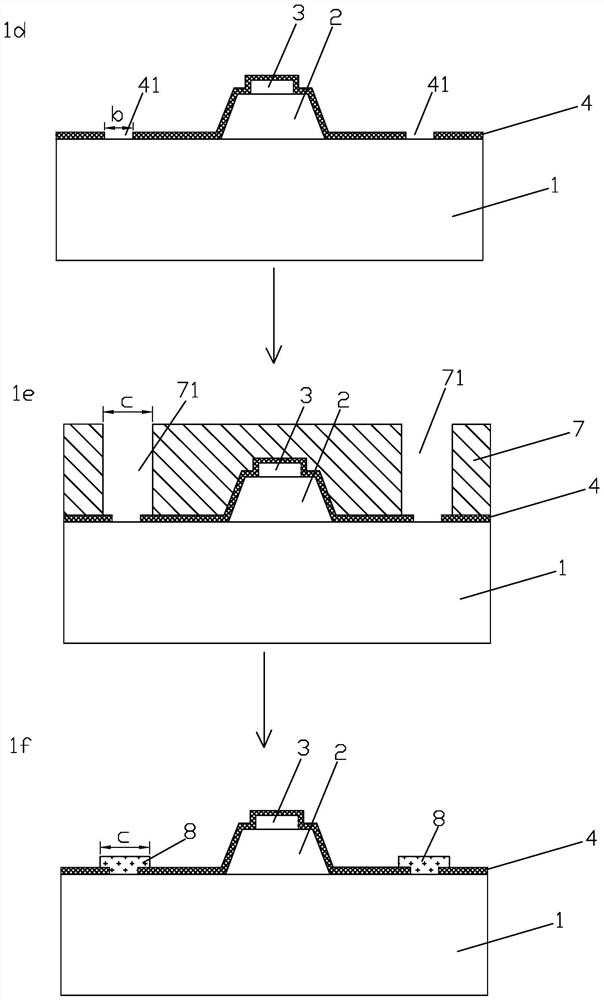

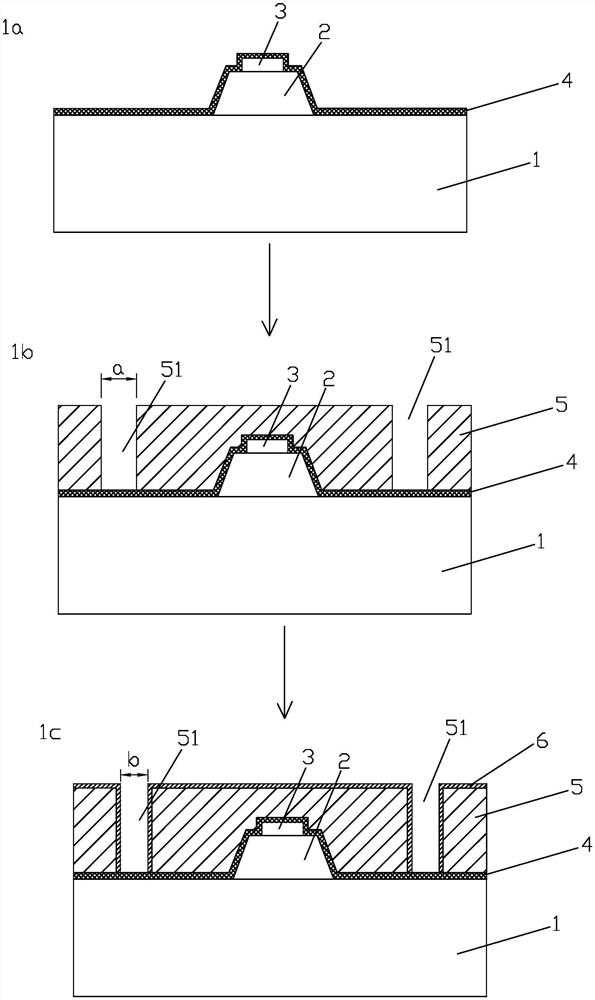

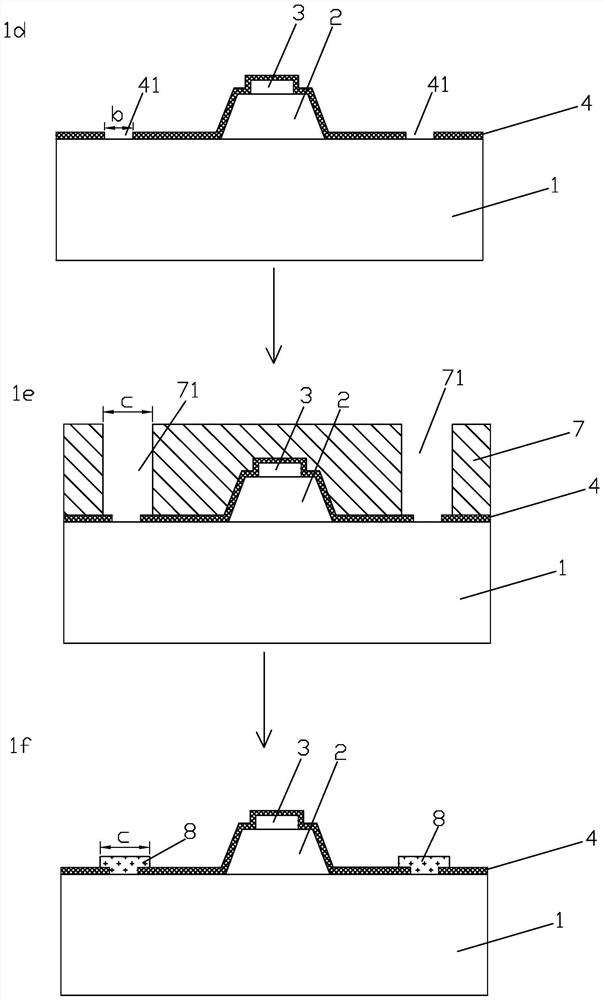

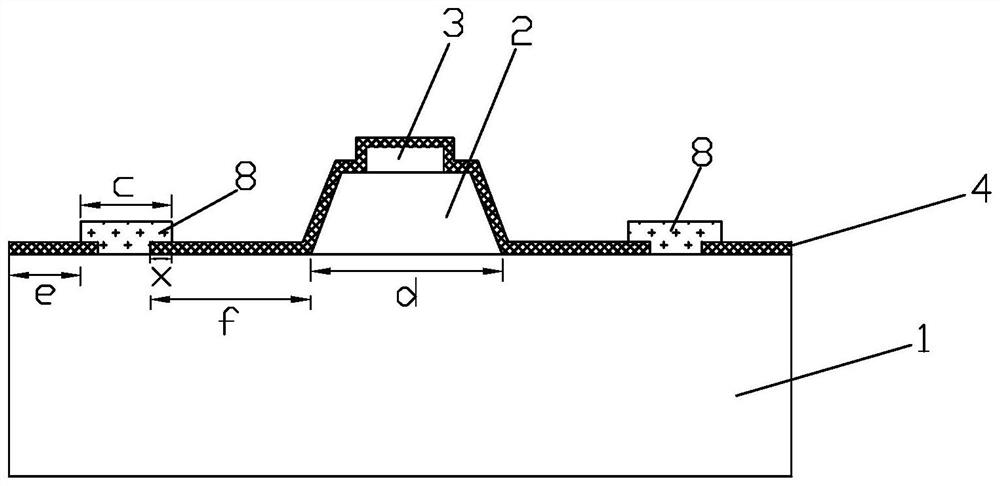

Structure for reducing b-c junction capacitance of heterojunction bipolar transistor and manufacturing method thereof

ActiveCN113078063AReduce junction areaLower junction capacitanceSemiconductor/solid-state device manufacturingSemiconductor devicesCapacitanceEngineering

The invention discloses a structure for reducing the b-c junction capacitance of a heterojunction bipolar transistor and a manufacturing method thereof, and the method comprises the steps: firstly coating a chip structure with a first light resistor, exposing and developing the first light resistor to form a first window, then coating a second light resistor, and forming a second window; after the line width of the first window is reduced through a miniature and backflow process, etching the passivation layer in the first window to form a first opening, after the photoresist is removed, coating the passivation layer with a third photoresist, performing exposure and development to form a second window located on the first opening, wherein the line width of the second window is larger than that of the first opening; and depositing metal in the second window and the first opening to form base metal, and removing light resistance. The base metal structure with the bottom line width smaller than the top line width is formed, the b-c junction area is reduced under the condition that the base resistance is not increased, the effect of reducing the b-c junction capacitance is achieved, and therefore the highest oscillation frequency is improved.

Owner:XIAMEN SANAN INTEGRATED CIRCUIT

A structure and production method of reducing heterogeneous knot dual-crystal tube B-C knotted capacitance

ActiveCN113078063BReduce junction areaLower junction capacitanceSemiconductor/solid-state device manufacturingSemiconductor devicesCapacitanceEngineering

Owner:XIAMEN SANAN INTEGRATED CIRCUIT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com