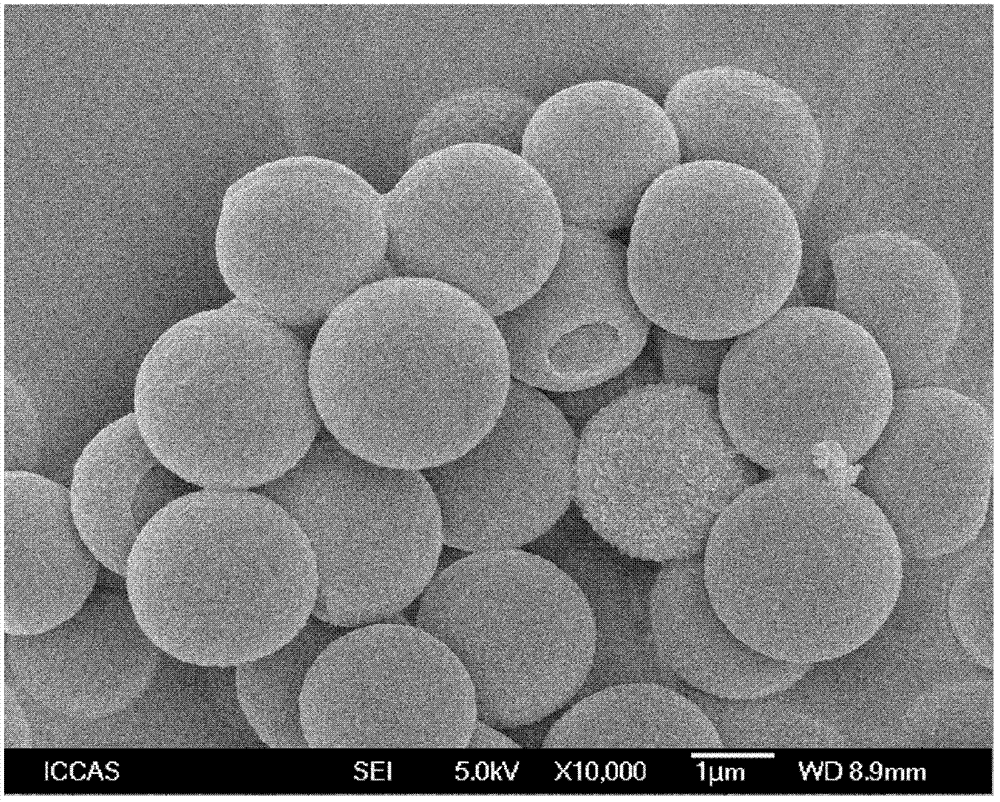

Phase-change microcapsules with solid-solid phase transition core material, and preparation method thereof

A technology of phase-change microcapsules and phase-change core materials, which is applied in the direction of microcapsule preparation, microsphere preparation, chemical instruments and methods, etc., to achieve the effects of controllable size, easy-to-obtain raw materials, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Preparation of monomer solution: take 1 g of octadecyl acrylate, and raise the temperature above its melting point, add AIBN accounting for 0.2 wt% of the total amount of stearyl acrylate and AIBN and stir to make the octadecyl acrylate The ester is fully dissolved to obtain a solution of octadecyl acrylate monomer;

[0024] 2) Preparation of phase-change core material emulsion: add 0.25g Triton-100 (Triton-X100) and 50ml deionized water into a 150ml three-neck flask; emulsify the above at a stirring speed of 200rpm-400rpm The temperature of the emulsifier aqueous solution is gradually raised from room temperature to 70° C.; all the solution of stearyl acrylate monomer obtained in step 1) is added to the emulsifier aqueous solution, and stirred evenly to obtain a phase-change core material emulsion;

[0025] 3) Synthesis of melamine resin wall material prepolymer solution: 0.3g melamine, 3ml mass concentration of 37% formaldehyde and 5ml deionized water are mixed to ...

Embodiment 2

[0028] 1) Preparation of the monomer solution: take 3.6g lauryl acrylate, and raise the temperature above its melting point, add AIBN accounting for 0.5wt% of the total amount of the lauryl acrylate and AIBN and stir to make the acrylic acid ten The diester is fully dissolved to obtain a solution of lauryl acrylate monomer;

[0029] 2) Preparation of phase change core material emulsion: add 0.25g Triton-100 (Triton-X100) and 50ml deionized water into a 150ml three-necked flask; The temperature of the aqueous solution is gradually raised from room temperature to 70° C.; all the lauryl acrylate monomer solution obtained in step 1) is added to the emulsifier aqueous solution, and stirred evenly to obtain a phase-change core material emulsion;

[0030] 3) Synthesis of melamine resin wall material prepolymer solution: 0.3 g of melamine, 3 ml of formaldehyde with a mass concentration of 37% and 5 ml of deionized water are mixed to obtain a mixed solution, and the pH value of the mix...

Embodiment 3

[0033] 1) Preparation of monomer solution: take 0.1g cetyl acrylate, and raise the temperature above its melting point, add AIBN accounting for 0.2wt% of the total amount of cetyl acrylate and AIBN and stir to make the cetyl acrylate The hexaester is fully dissolved to obtain a solution of hexadecyl acrylate monomer;

[0034] 2) Preparation of phase-change core material emulsion: 0.25g Tween 60 and 50ml deionized water were added to a 150ml three-necked flask; while the stirring speed was 800rpm-1000rpm, the temperature of the above-mentioned emulsifier aqueous solution was gradually changed from room temperature to The temperature is raised to 70° C.; all the cetyl acrylate monomer solution obtained in step 1) is added to the emulsifier aqueous solution, and stirred evenly to obtain a phase change core material emulsion;

[0035] 3) Synthesis of melamine resin wall material prepolymer solution: 0.3g melamine, 3ml mass concentration of 37% formaldehyde and 5ml deionized water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com