Preparing method of superhigh-strength aluminum alloy cylinder

An ultra-high-strength, aluminum alloy technology, which is applied in the field of preparation of ultra-high-strength aluminum alloy cylinders, can solve problems such as rough texture, uncontrollable size, and low production pass rate, and achieve high cylinder dimensional accuracy and production stability Good, good size controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A method for preparing an ultra-high-strength aluminum alloy closed cylinder, comprising the following steps:

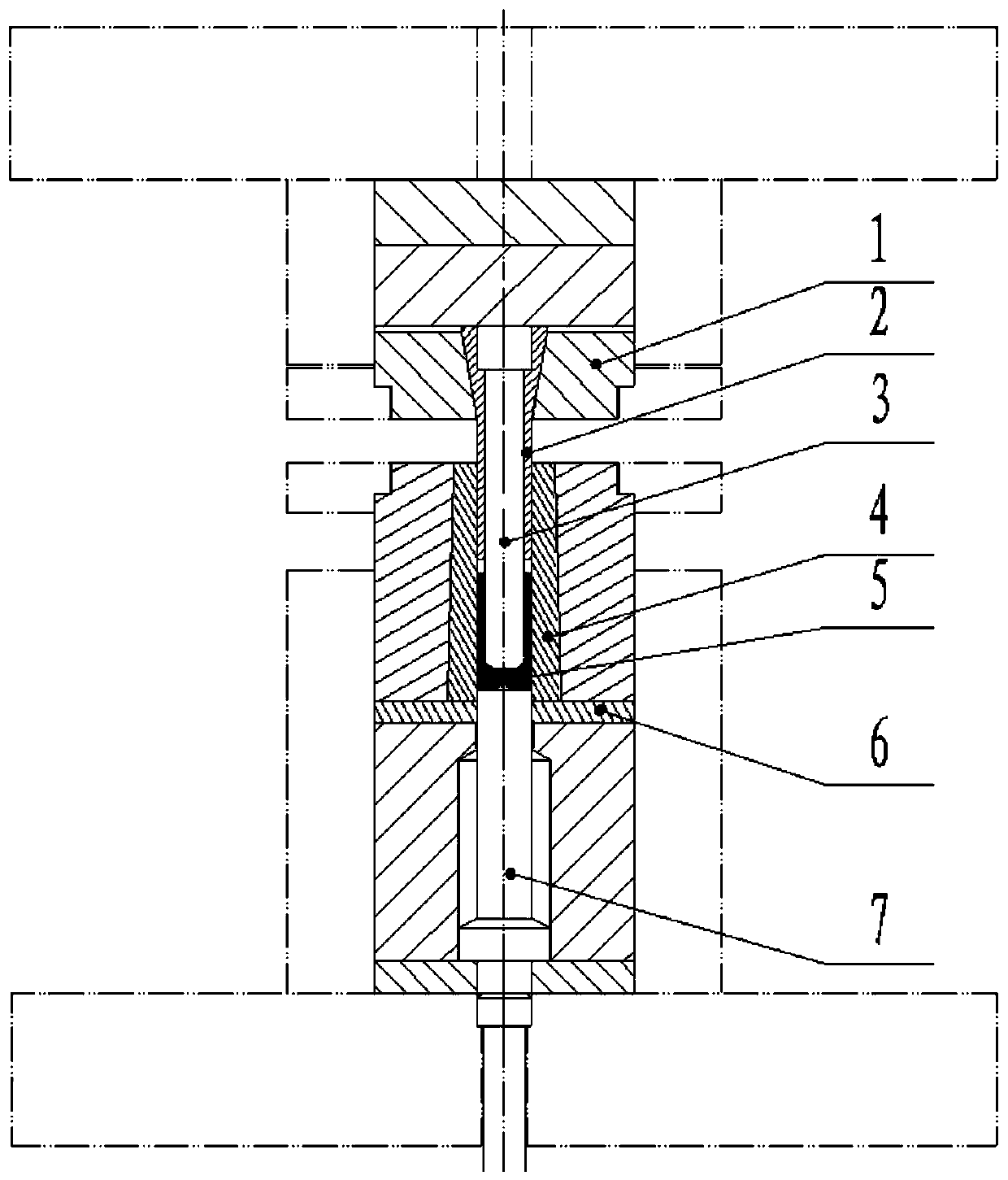

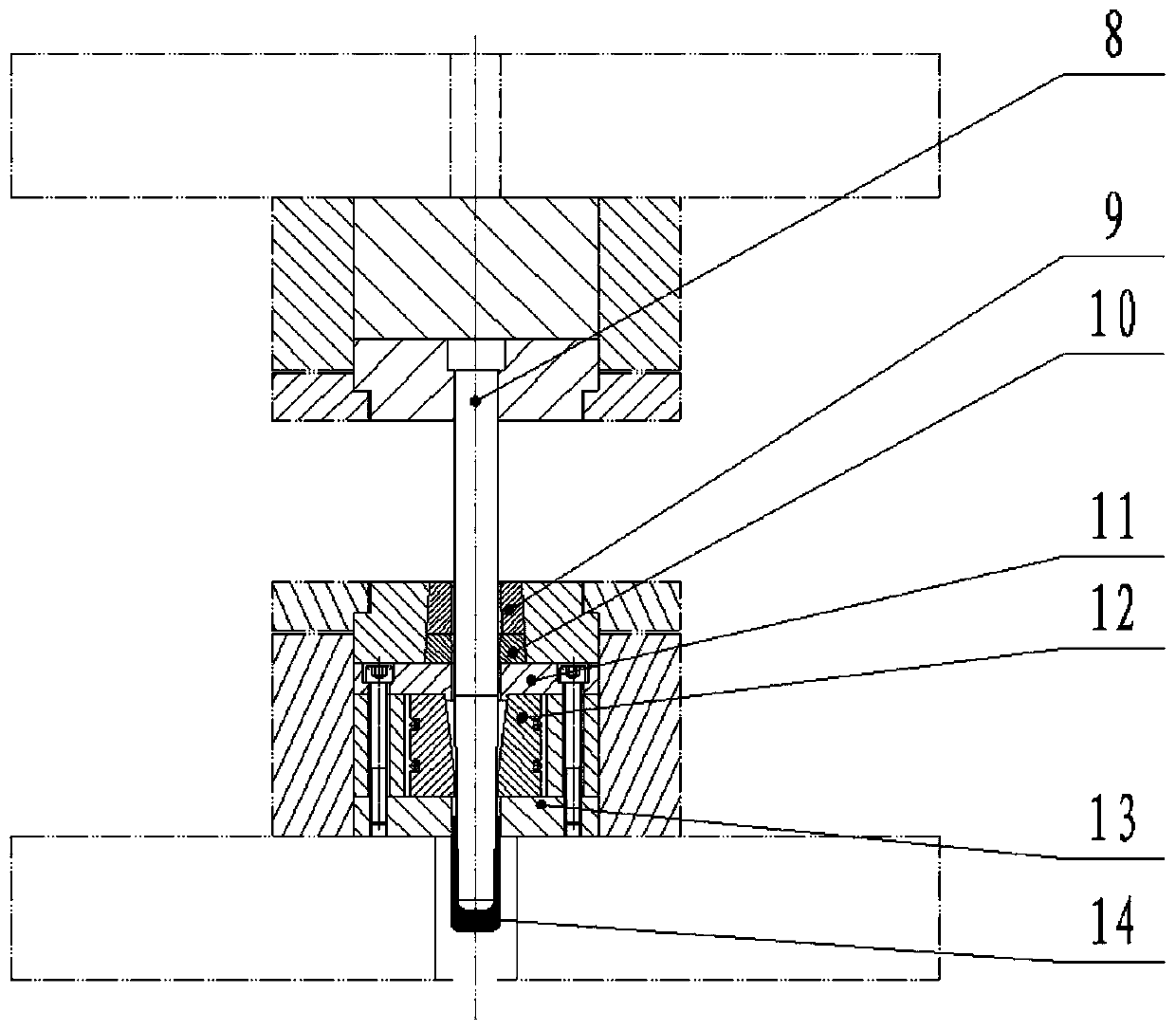

[0051] 1. According to the shape and size requirements of the designed large length-to-diameter ratio variable wall thickness and thin-walled ultra-high-strength aluminum alloy closing cylinder, design extrusion, thinning and stretching and closing dies. The extrusion die is mainly composed of a fixed plate, a punch insert, a punch, a die, a guide pad and a ejector rod; a thinning stretch die is mainly composed of a punch, a stretch guide cylinder, a stretch die, and an upper pad. Plate, scraper, and lower backing plate; closing die is mainly composed of punch, closing die, closing ejector rod, and guiding backing plate. The positive tolerance of the punch in the mold is 0.1mm, and the negative tolerance is 0; the positive tolerance of the die is 0, and the negative tolerance is 0.1mm.

[0052] 2. The punch, die and ejector rod in the extrusion, thinning and ...

Embodiment 2

[0062] A method for preparing a large and ultra-high-strength aluminum alloy closed cylinder, comprising the following steps:

[0063] 1. According to the shape and size requirements of the designed large length-to-diameter ratio variable wall thickness and thin-walled ultra-high-strength aluminum alloy closing cylinder, design extrusion, thinning and stretching and closing dies. The extrusion die is mainly composed of a fixed plate, a punch insert, a punch, a die, a guide pad and a ejector rod; a thinning stretch die is mainly composed of a punch, a stretch guide cylinder, a stretch die, and an upper pad. Plate, scraper, and lower backing plate; closing die is mainly composed of punch, closing die, closing ejector rod, and guiding backing plate. The positive tolerance of the punch in the mold is 0.1mm, and the negative tolerance is 0; the positive tolerance of the die is 0, and the negative tolerance is 0.1mm.

[0064] 2. The punch, die and ejector rod in the extrusion, thin...

Embodiment 3

[0074] A method for preparing a large and ultra-high-strength aluminum alloy closed cylinder, comprising the following steps:

[0075] 1. According to the shape and size requirements of the designed large length-to-diameter ratio variable wall thickness and thin-walled ultra-high-strength aluminum alloy closing cylinder, design extrusion, thinning and stretching and closing dies. The extrusion die is mainly composed of a fixed plate, a punch insert, a punch, a die, a guide pad and a ejector rod; a thinning stretch die is mainly composed of a punch, a stretch guide cylinder, a stretch die, and an upper pad. Plate, scraper, and lower backing plate; closing die is mainly composed of punch, closing die, closing ejector rod, and guiding backing plate. The positive tolerance of the punch in the mold is 0.1mm, and the negative tolerance is 0; the positive tolerance of the die is 0, and the negative tolerance is 0.1mm.

[0076]2. The punch, die and ejector rod in the extruding, thinn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com