Isothermal forging die and forging technology thereof of magnesium alloy die forge piece of step type structure

A technology of isothermal forging and magnesium alloy, which is applied in the field of warm forging die and forging process of warm forging die, can solve the problems of magnesium alloy heating temperature and holding time, difficult plastic deformation processing, increased plastic properties, etc. The effect of uniform equiaxed fine grain structure and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

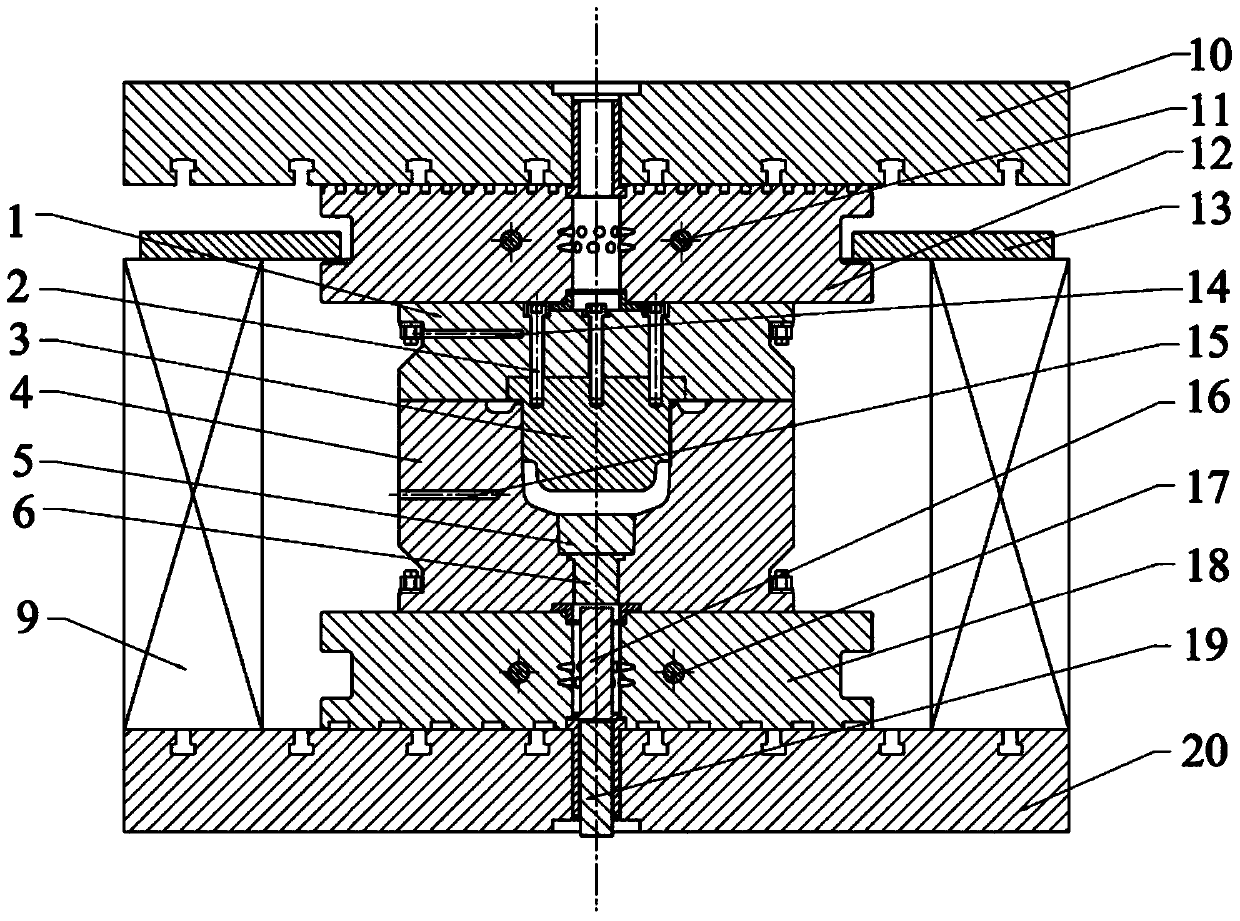

[0025] see figure 1 , the upper mold base 1 is fixed on the upper heating pad 12, the upper heating pad 12 is fixed on the upper water cooling plate 10, and the upper water cooling plate 10 is connected with the press; the lower mold 4 is fixed on the lower heating pad 18, and the lower heating pad The plate 18 is fixed on the lower water-cooled plate 20, and the lower water-cooled plate 20 is connected to the mobile workbench of the press. The two sides in the width direction of the upper mold 3 and the lower mold 4 are closed by plane bonding to form a closed cavity. Direction without flash. The heating system consists of an upper heating tube 11, an upper heating pad 12, a lower heating tube 17, a lower heating pad 18, an annular mold heating furnace 9, a thermocouple, and a temperature controller. When heating, the mold heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com