Casting forming process for large wind power planetary carrier

A technology of casting molding and planetary carrier, which is applied in the direction of casting molding equipment, casting mold components, manufacturing tools, etc., can solve the problems of isolated thermal joints of planetary carrier castings, easily lead to cracks, dispersion, etc., to facilitate modeling operations and improve surface quality , the effect of reducing size deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

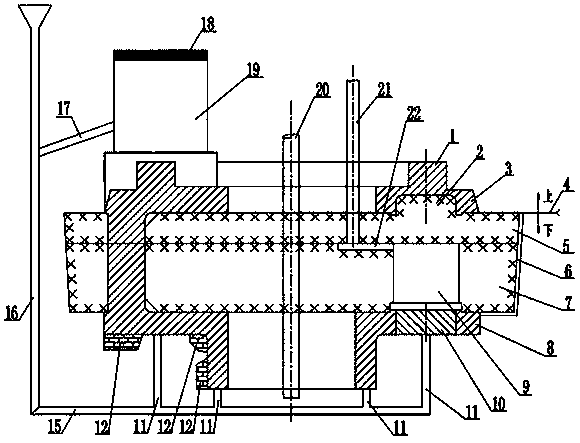

[0031] The technical solutions and beneficial effects of the present invention will be further described in detail below in conjunction with the accompanying drawings.

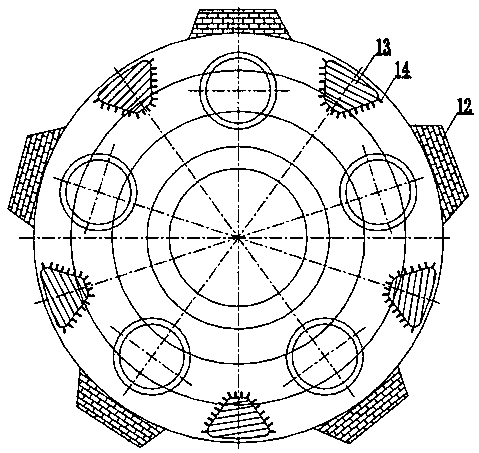

[0032] Such as figure 1 , figure 2In the large-scale wind power planetary carrier casting process shown, the planetary carrier casting 1 includes an upper annular plate 3 and a lower annular plate 8 vertically connected to five evenly distributed triangular columns 13, and the upper annular plate 3 is provided with 5 openings facing The lower conical planetary shaft blind hole 2, the middle area of the lower annular plate 8 is provided with 5 evenly distributed planetary shaft through holes 10, the planetary shaft through holes 10 do not need to be cast, and the parting surface of the planetary carrier casting 1 is set on the upper There are 4 intersections between the annular plate 3 and the triangular column 13; the first sand core 5 and the second sand core 7 are arranged between the upper annular plate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com