Terminal fisheye contour forming process

A fisheye and terminal technology is applied in the field of fisheye shape forming process of backplane communication terminals, which can solve the problems of easy generation of burrs, large angular size error, and unsmooth fisheye shape, and achieves good electrical connection performance and small size deviation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

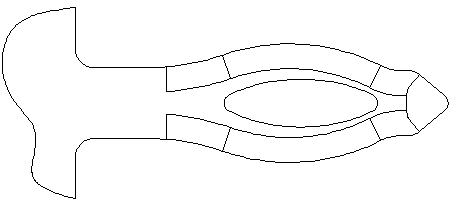

[0040] like figure 2As shown, take a piece of phosphor bronze substrate (for the sake of illustration, the thickness of the phosphor bronze substrate we choose is 0.2mm), pre-cut the first knife on the substrate 1, pre-cut half of the fish-eye shape, and then continue to pre-cut Make a second cut to pre-cut the other half of the fish-eye shape to get a complete fish-eye shape.

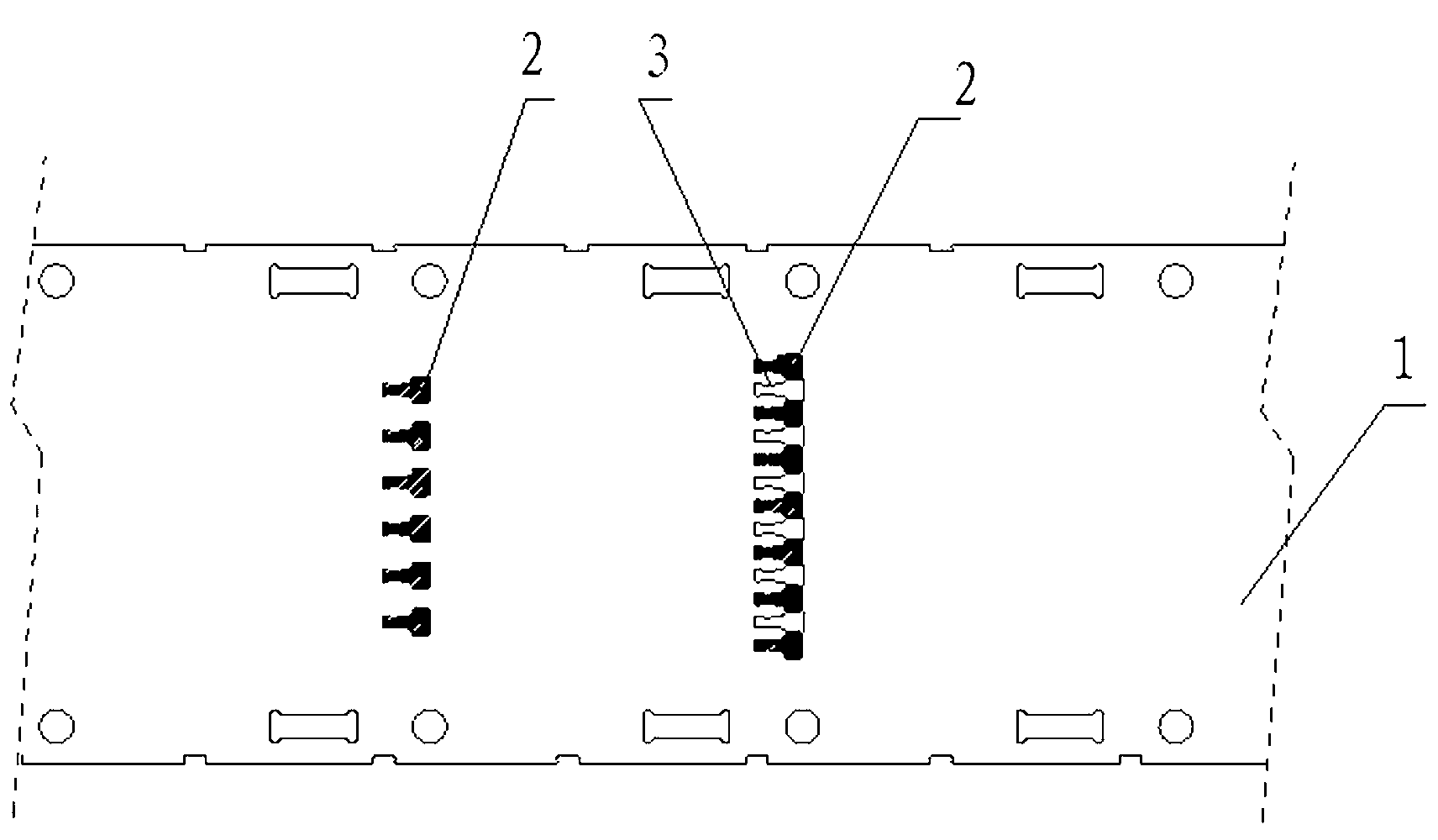

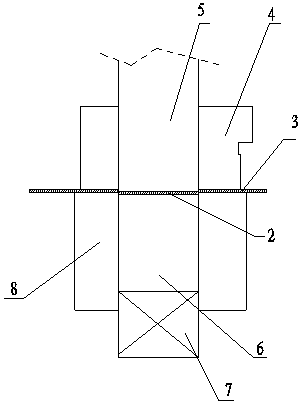

[0041] like image 3 As shown, the substrate 1 that has been pre-cut out of the fisheye shape of the terminal is sent to the piercing station for piercing. The piercing station includes a punch 5, a knife edge 8, an insert 4 and a stripping pin 6. The insert 4 is used for the positioning of the punch 5, the punch 5 is set above the knife edge 8, a groove is provided in the middle of the knife edge 8, the stripping pin 6 is installed in the groove, and the stripping pin 6 is installed below There is a spring 7, and the punch 5 and the knife edge 8 are used to puncture the pre-cut terminal fisheye sha...

Embodiment 2

[0045] This embodiment is basically the same as Embodiment 1, except that the substrate 1 is a nickel-copper alloy substrate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com