Patents

Literature

610results about How to "Flat shape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

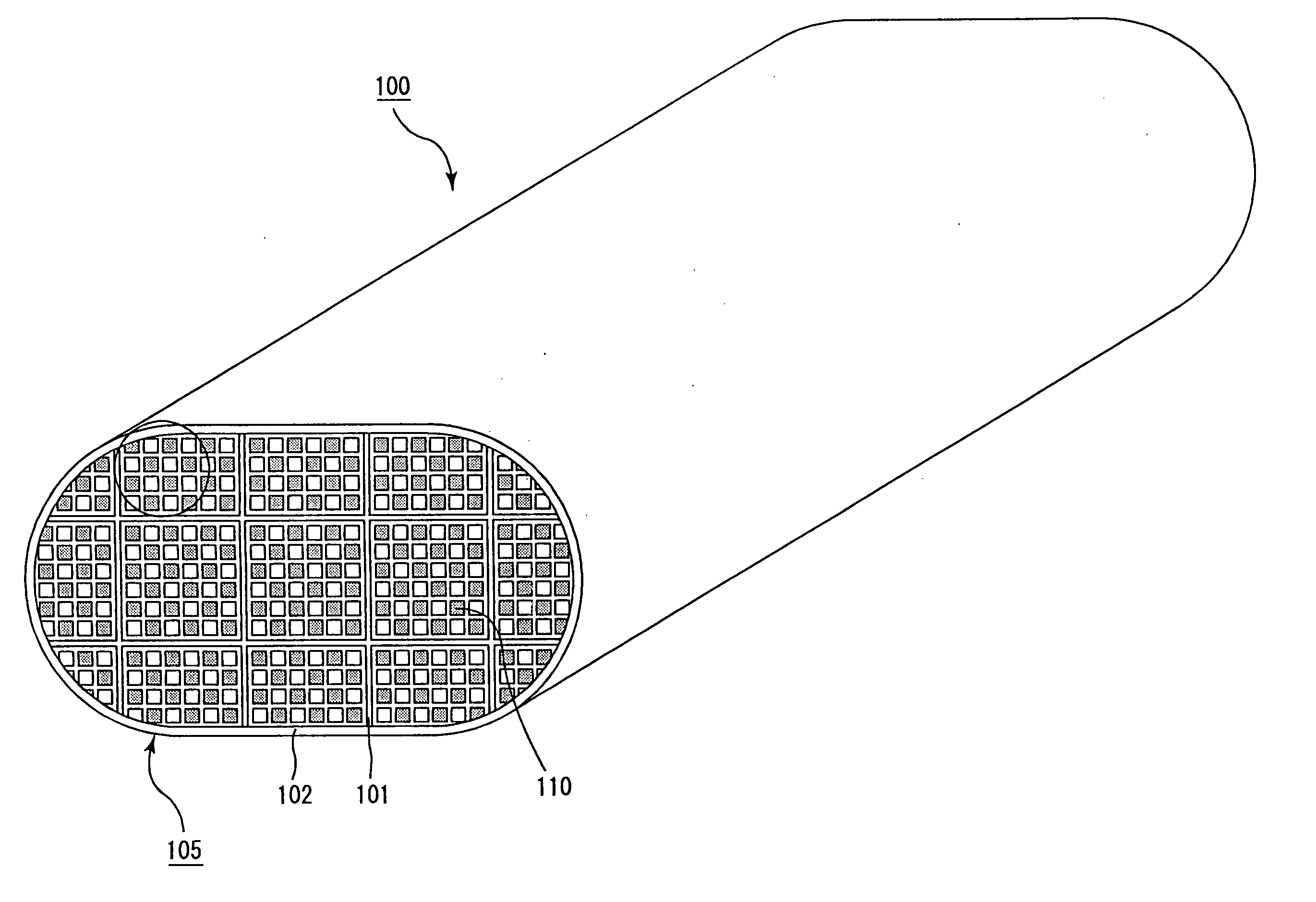

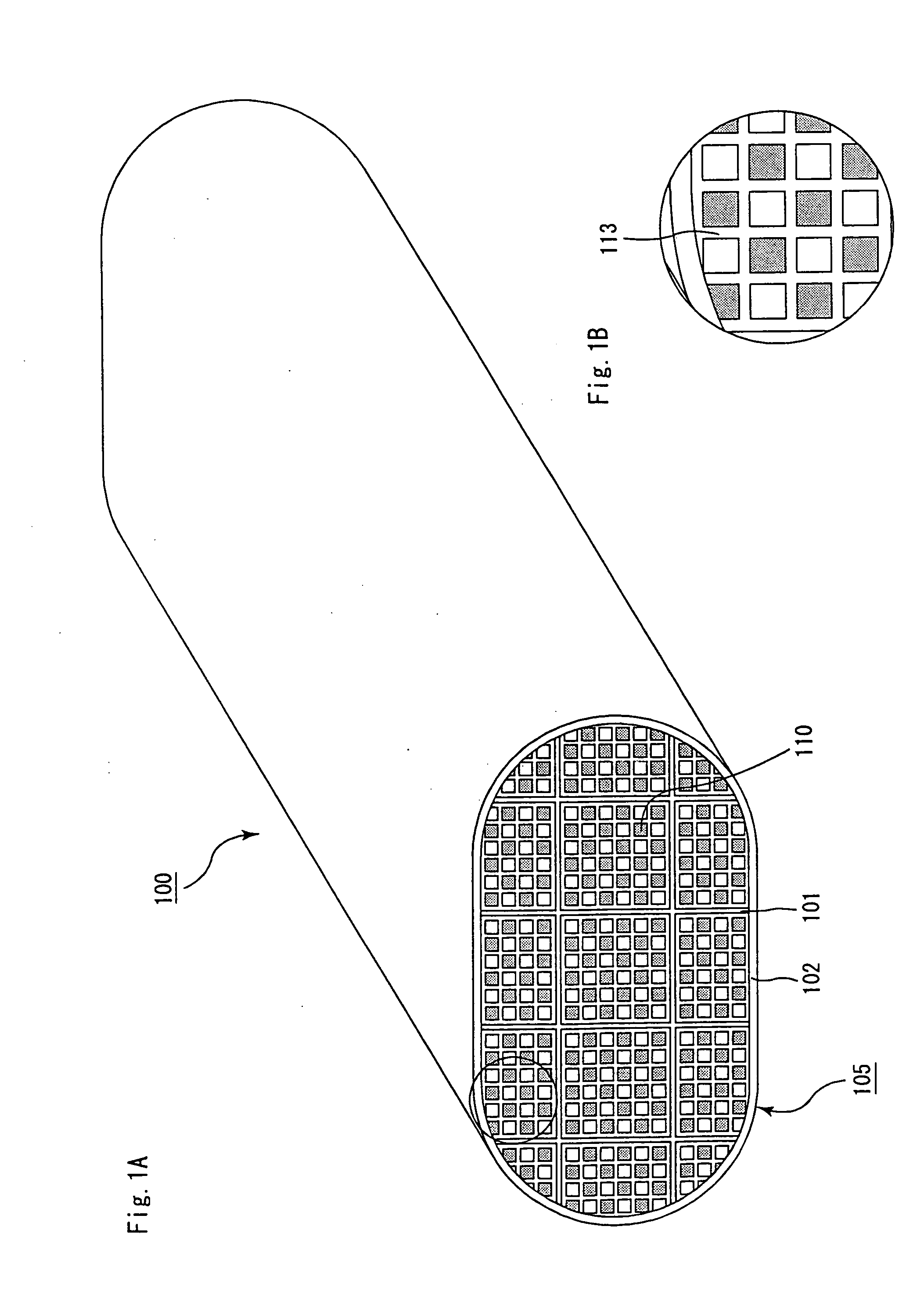

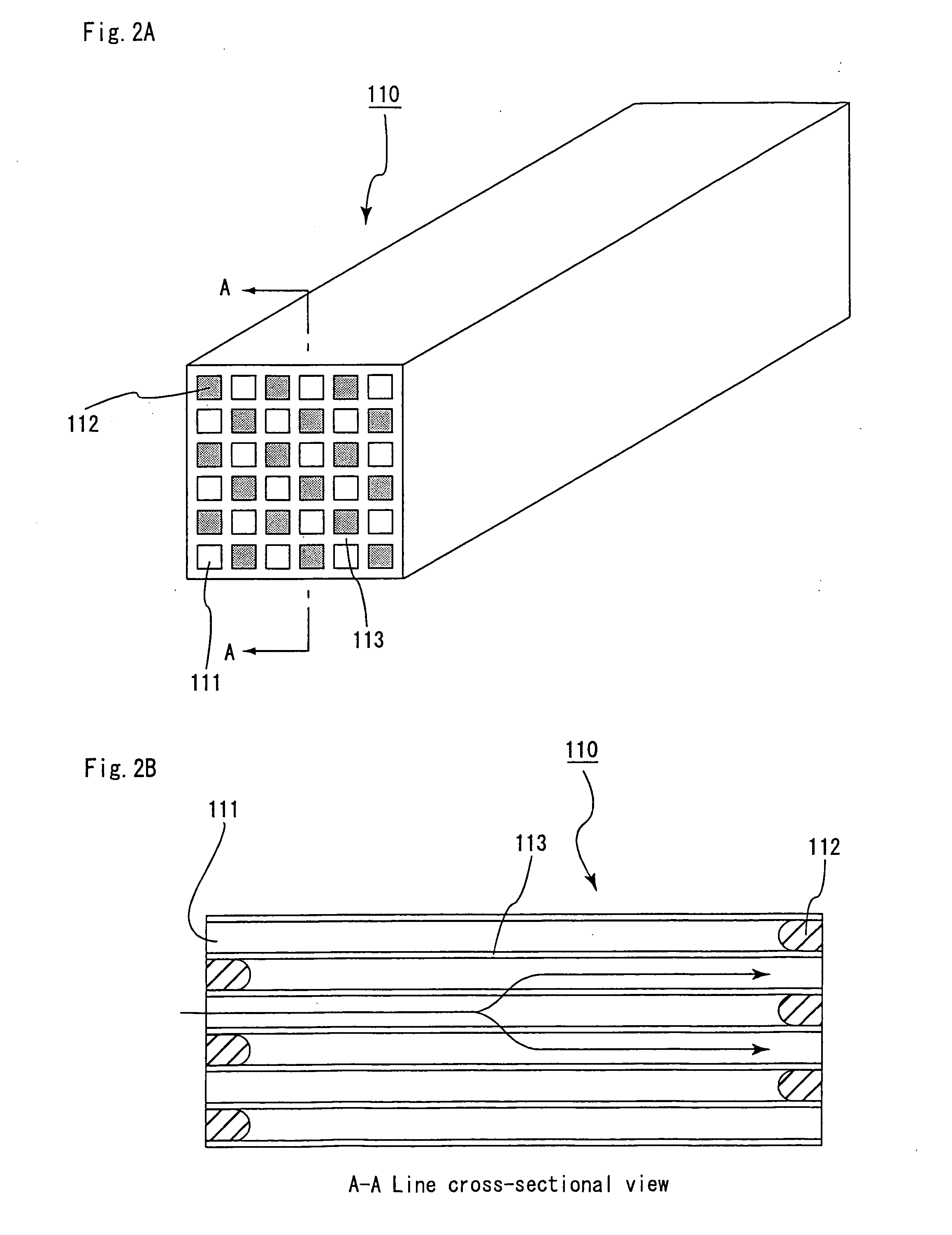

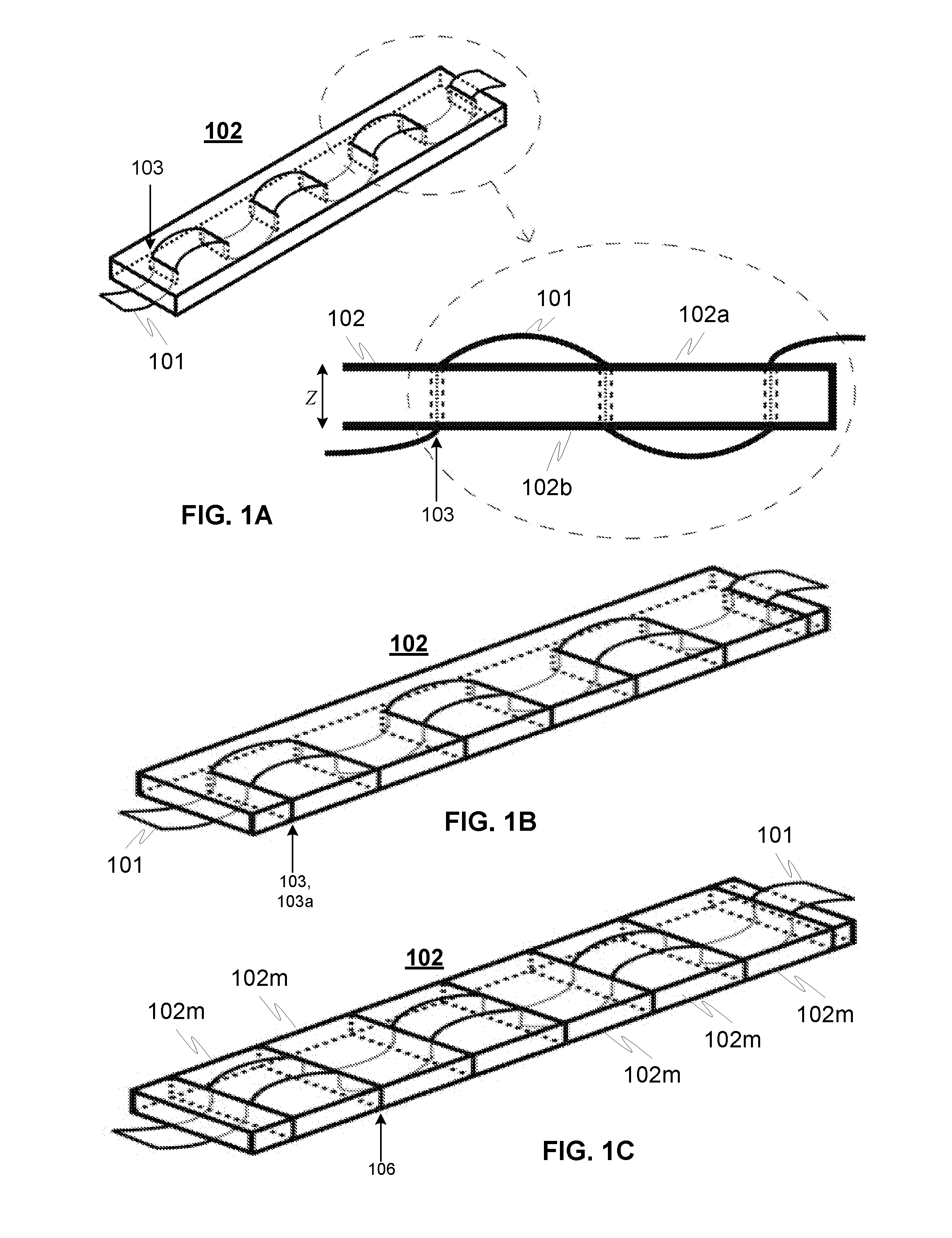

Honeycomb structural body and manufacturing method thereof

ActiveUS20050247038A1Great resistance to physical impactIncreased durabilityCatalyst carriersGas treatmentDiagonalHoneycomb structure

A honeycomb structural body comprising: a ceramic block having a flat shape in which a plurality of honeycomb units are bonded to each other through a sealing material layer, said honeycomb unit mainly comprises porous ceramic and includes a large number of through holes placed in parallel with one another in a longitudinal direction with a partition wall interposed therebetween; and a sealing material layer formed on a peripheral portion thereof, wherein the sealing material layer among the honeycomb units on a cross section perpendicular to the longitudinal direction has a pattern that is formed in a diagonal direction with respect to a major axis of a shape forming a contour of the cross section.

Owner:IBIDEN CO LTD

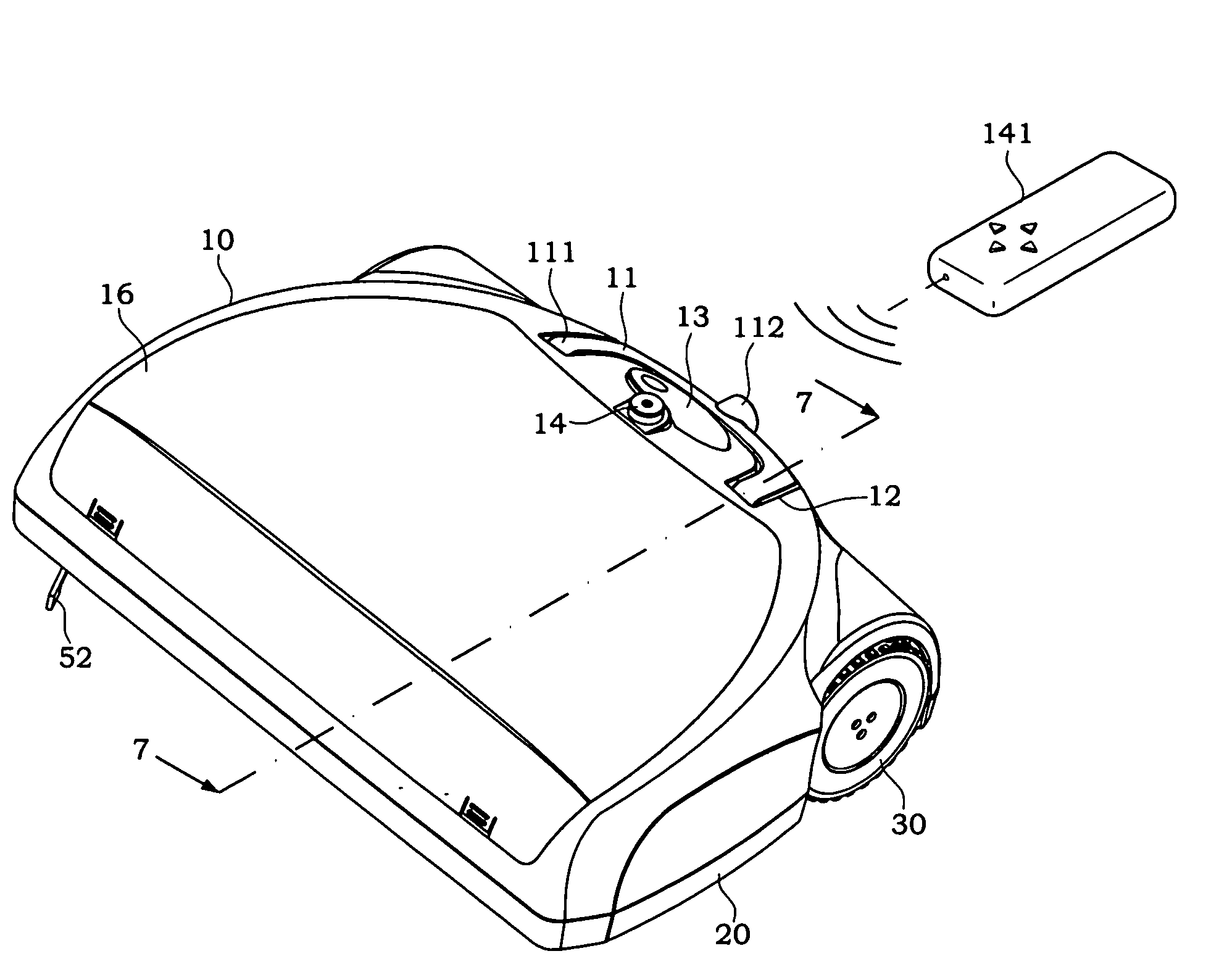

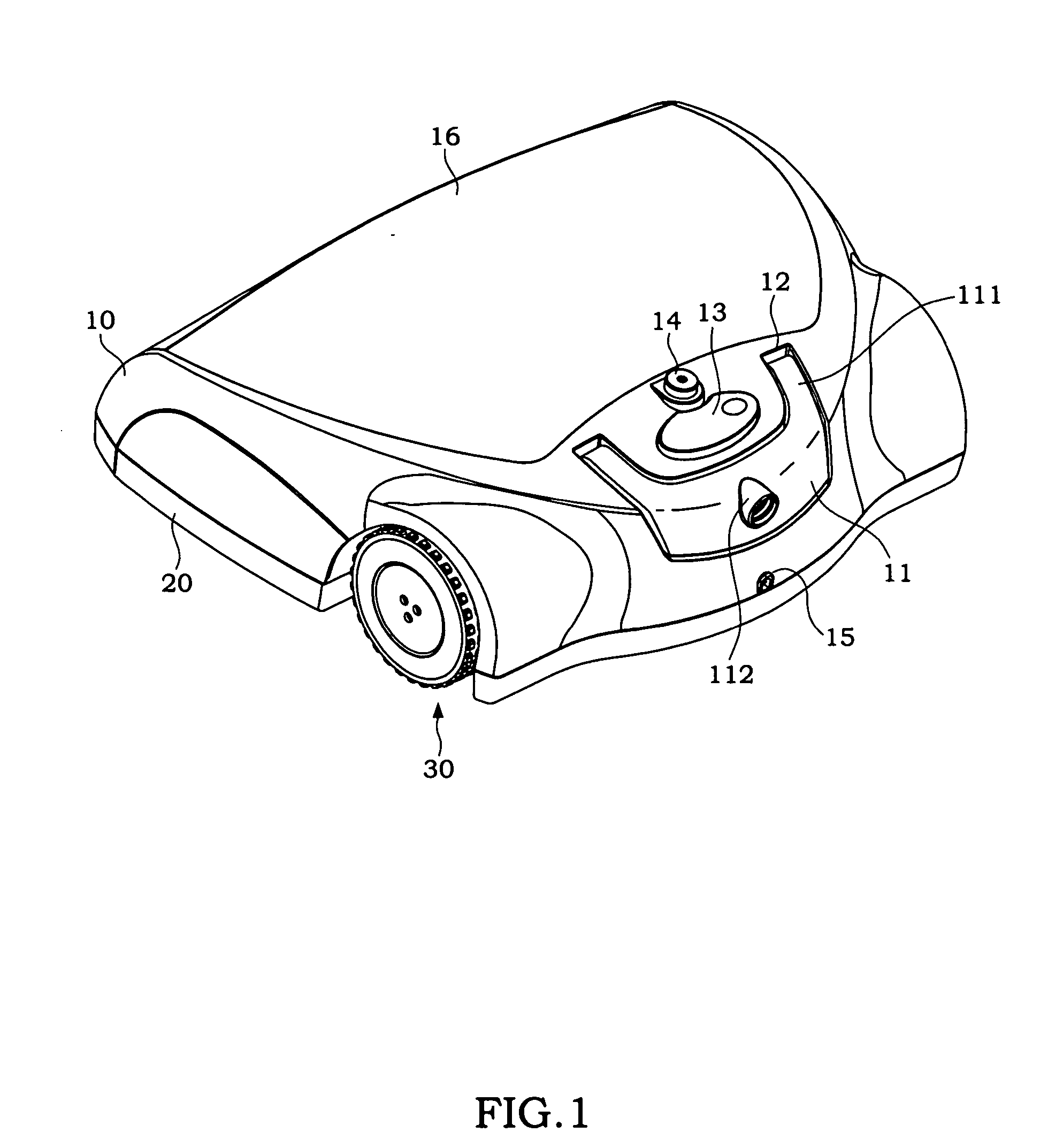

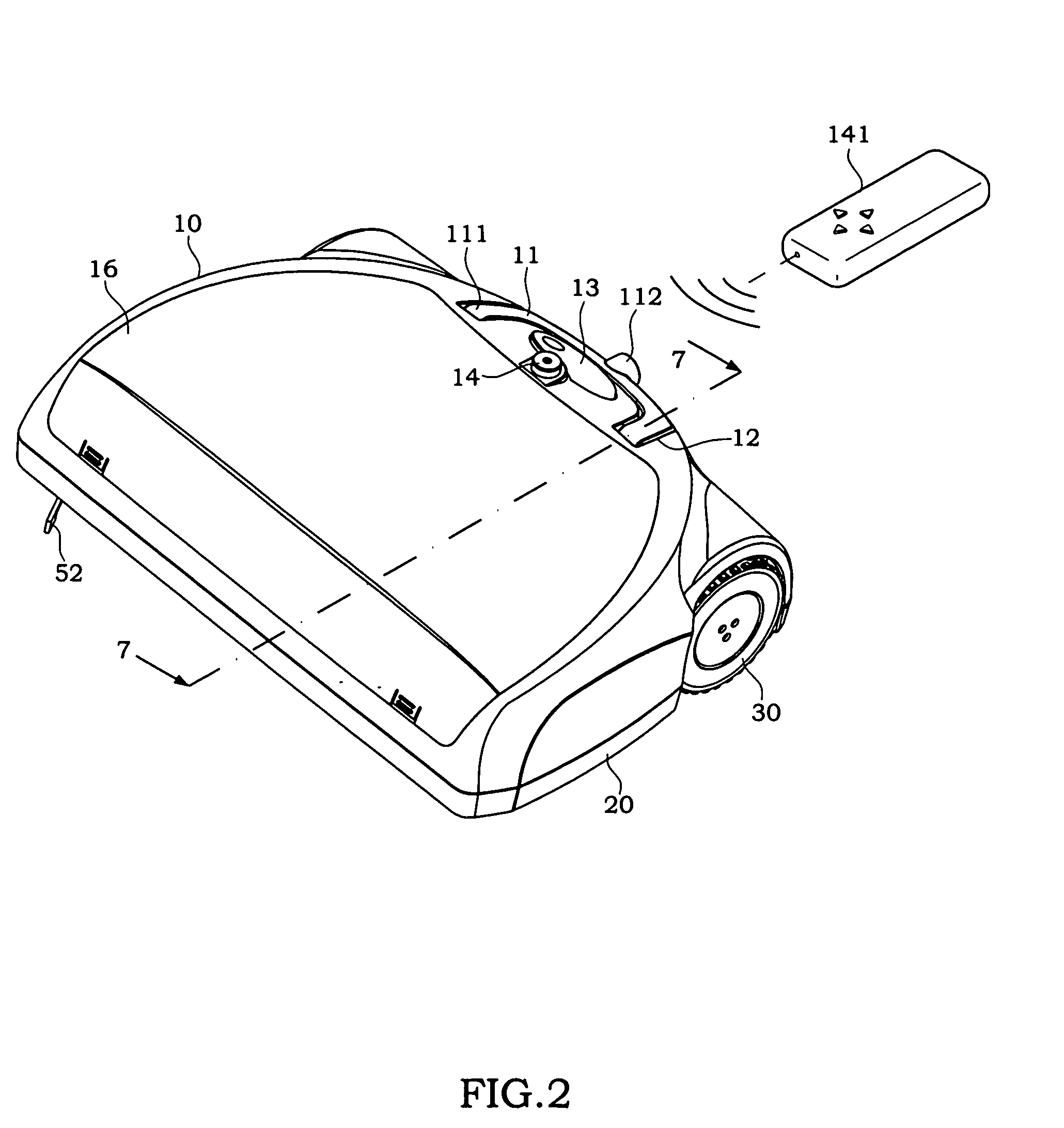

Remote control sweeper

InactiveUS20070006404A1Direction is limitedSmall sizeMechanical cleaningPressure cleaningWireless transmissionControl signal

A remote control sweeper includes a wireless remote control receiver installed at the sweeper; a remote control for transmitting a direction control signal to the remote control receiver via a wireless transmission to control the moving direction of the sweeper, such that the sweeper can be moved to automatically clean up the dirt and collect the dust on a floor.

Owner:GUTEN ELECTRONICS IND

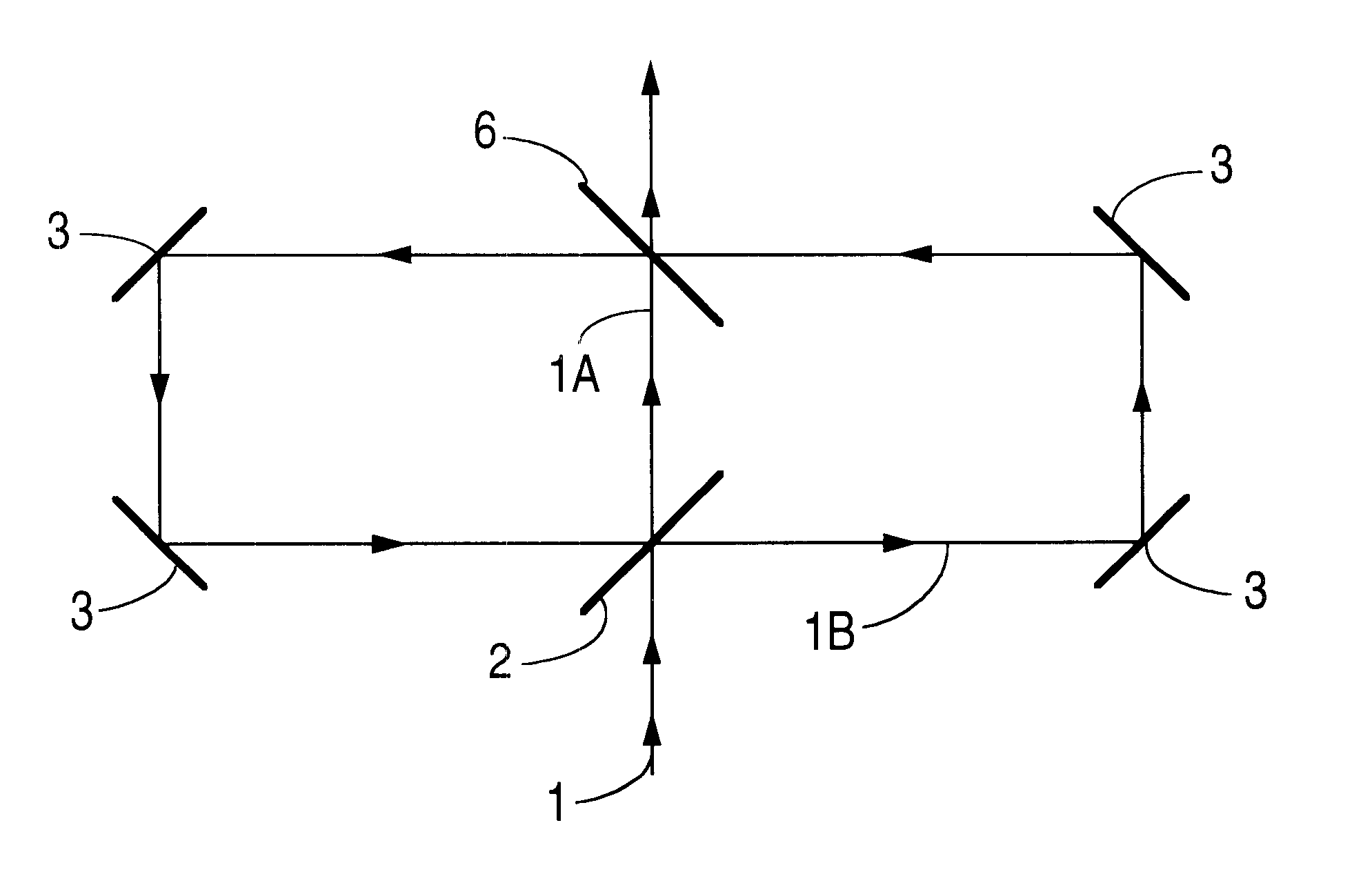

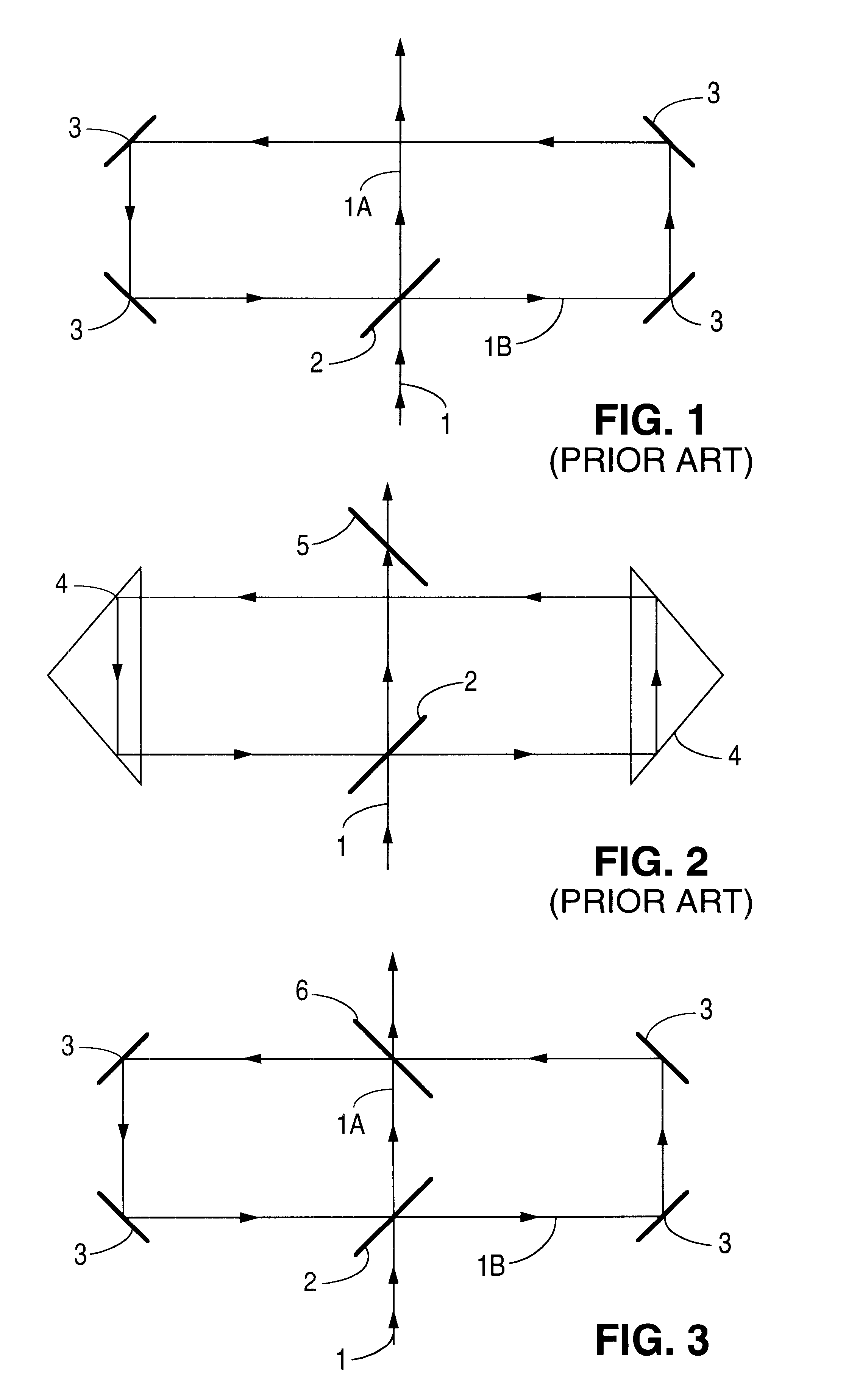

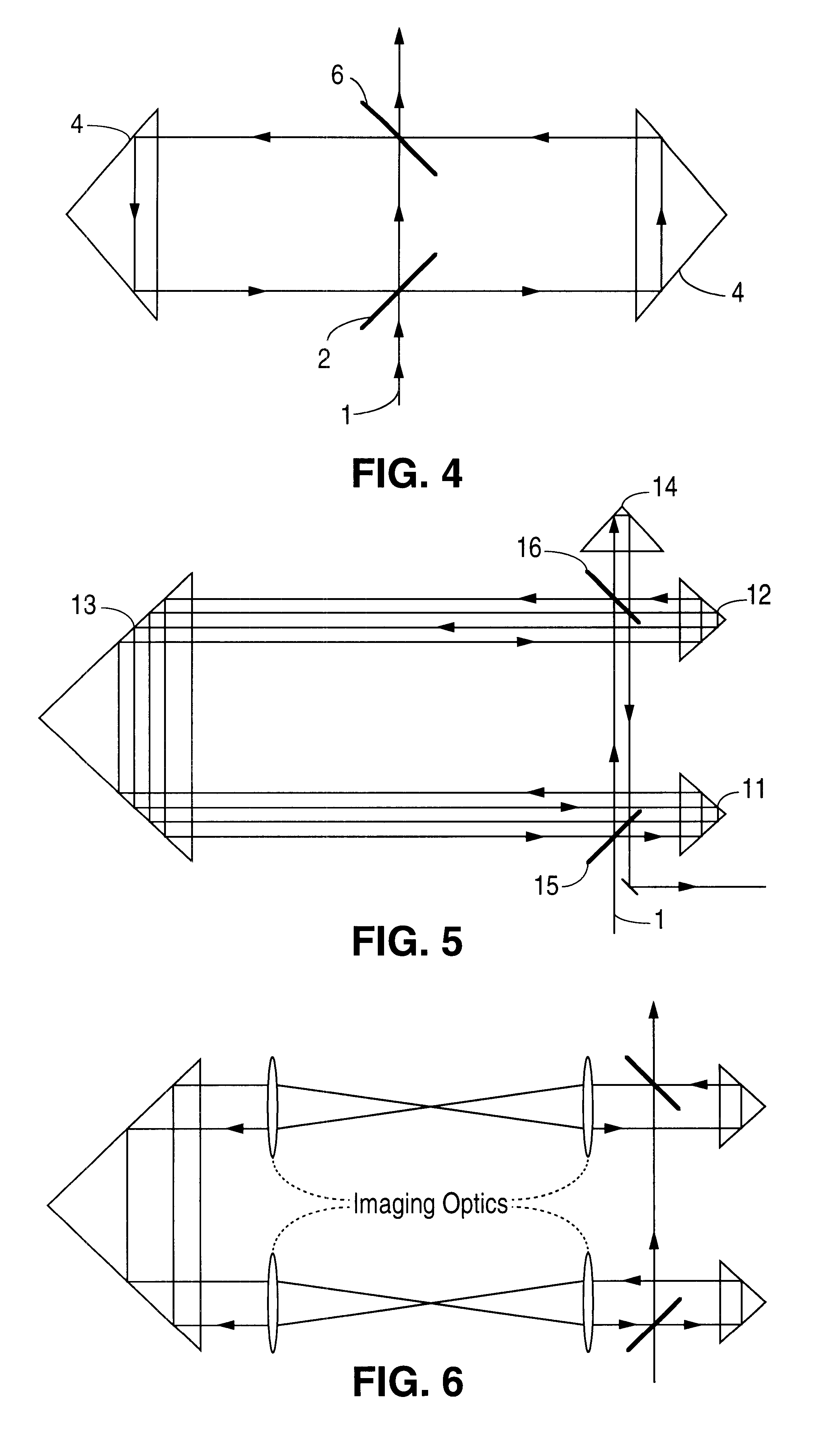

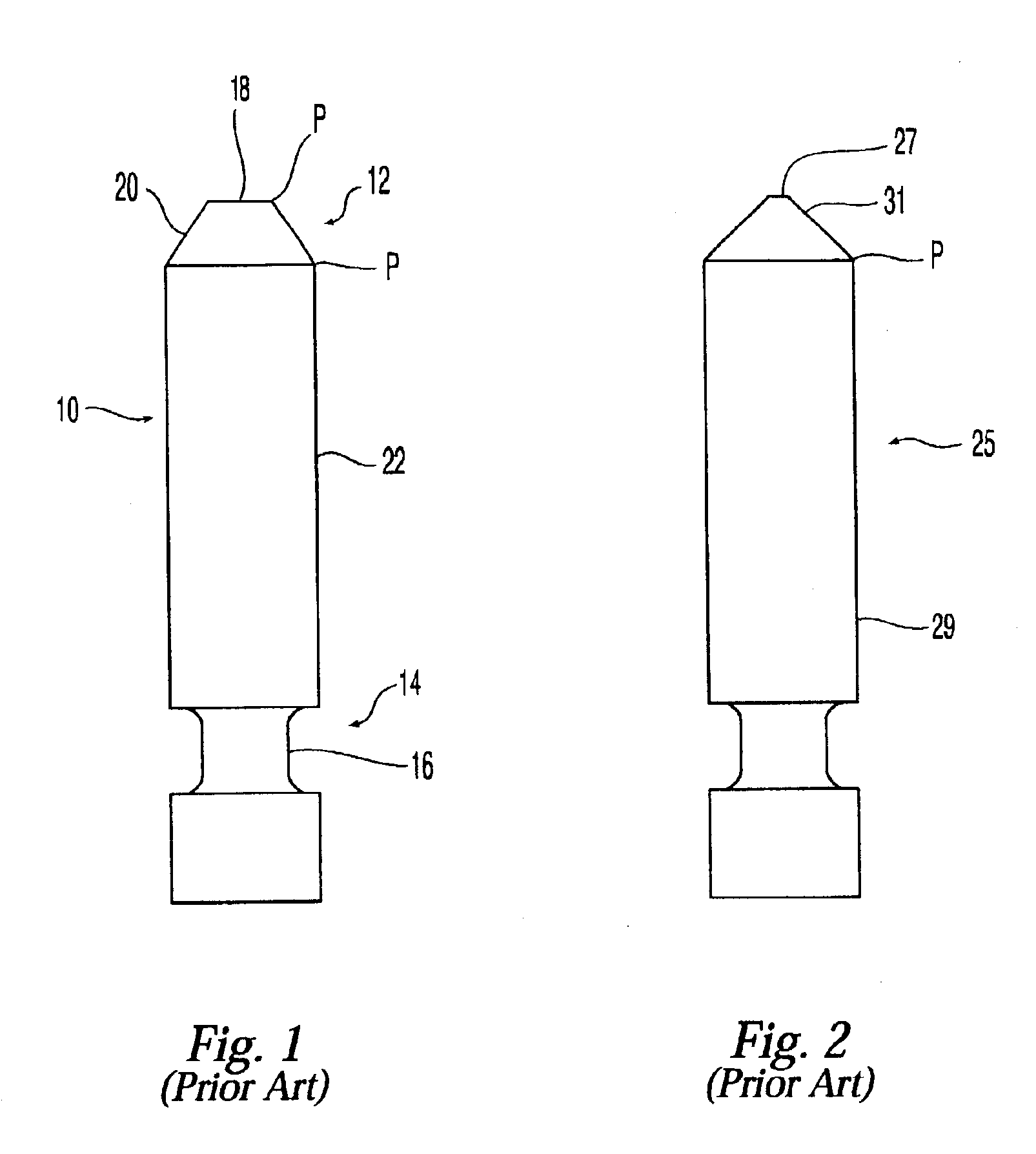

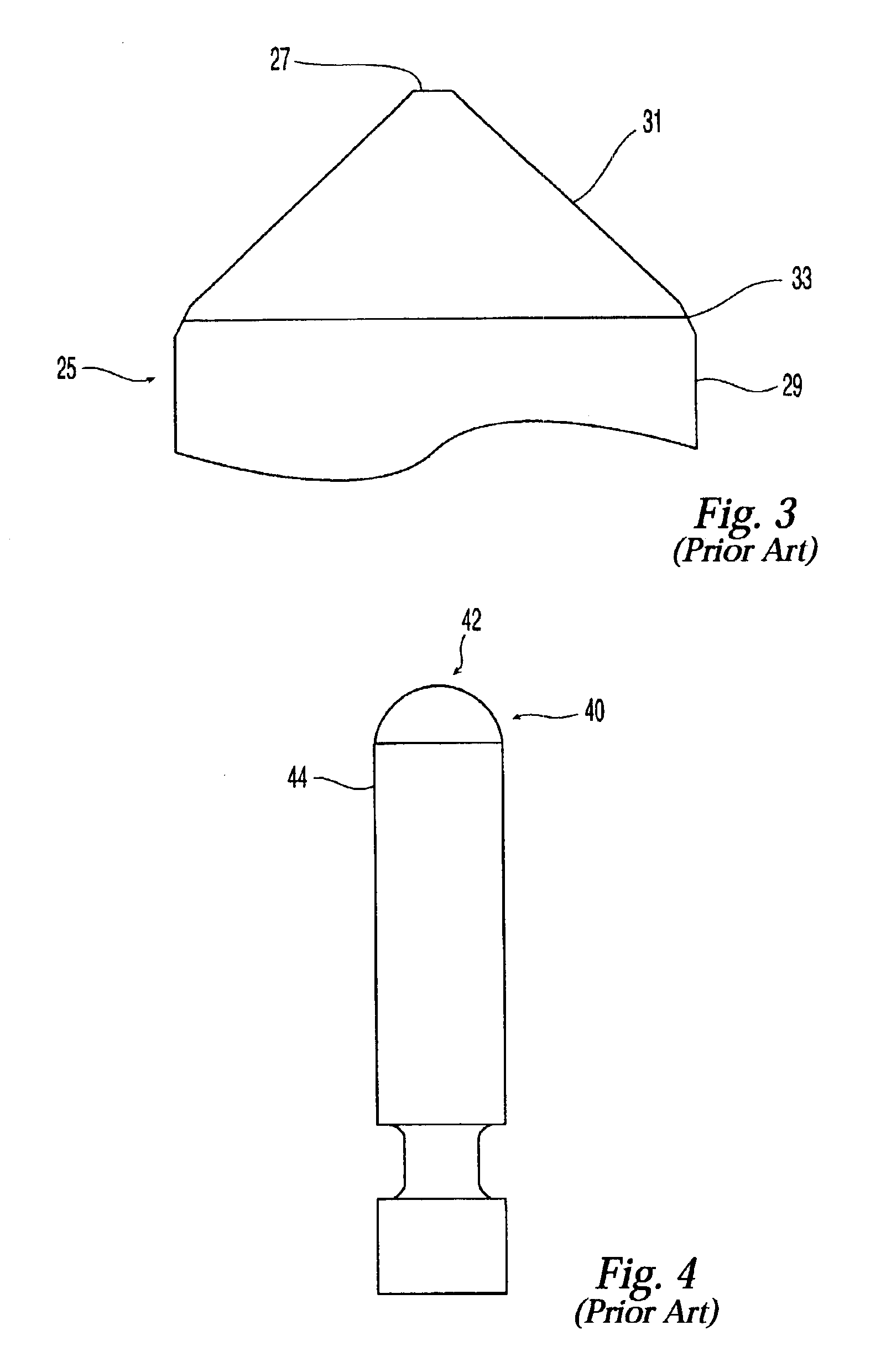

Optical pulse stretching and smoothing for ArF and F2 lithography excimer lasers

InactiveUS6389045B1Easy to stretchFlat shapeOptical resonator shape and constructionGenerators/motorsOptical reflectionLithographic artist

A method and apparatus are provided for temporally stretching and smoothing of the pulses of an output beam of excimer and lithography lasers. The method and apparatus are based upon providing an optical delay line or circuit having a plurality of optical reflectors and a plurality of beam recombiners or splitters so arranged as to divide the pulse into numerous portions which vary in their travel time through the circuit. As a result, the energy of the incident pulse is greatly stretched and smoothed.

Owner:COHERENT GMBH

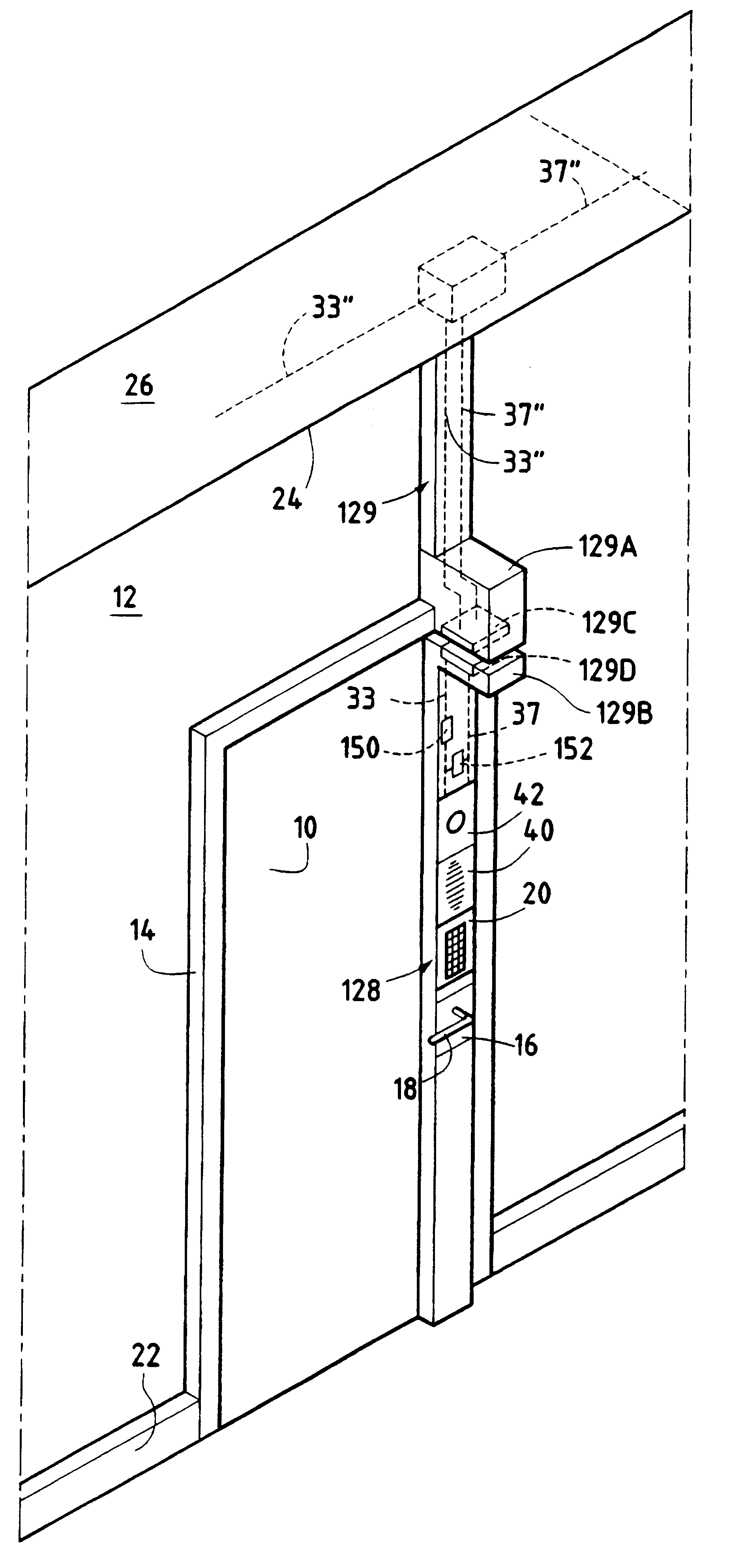

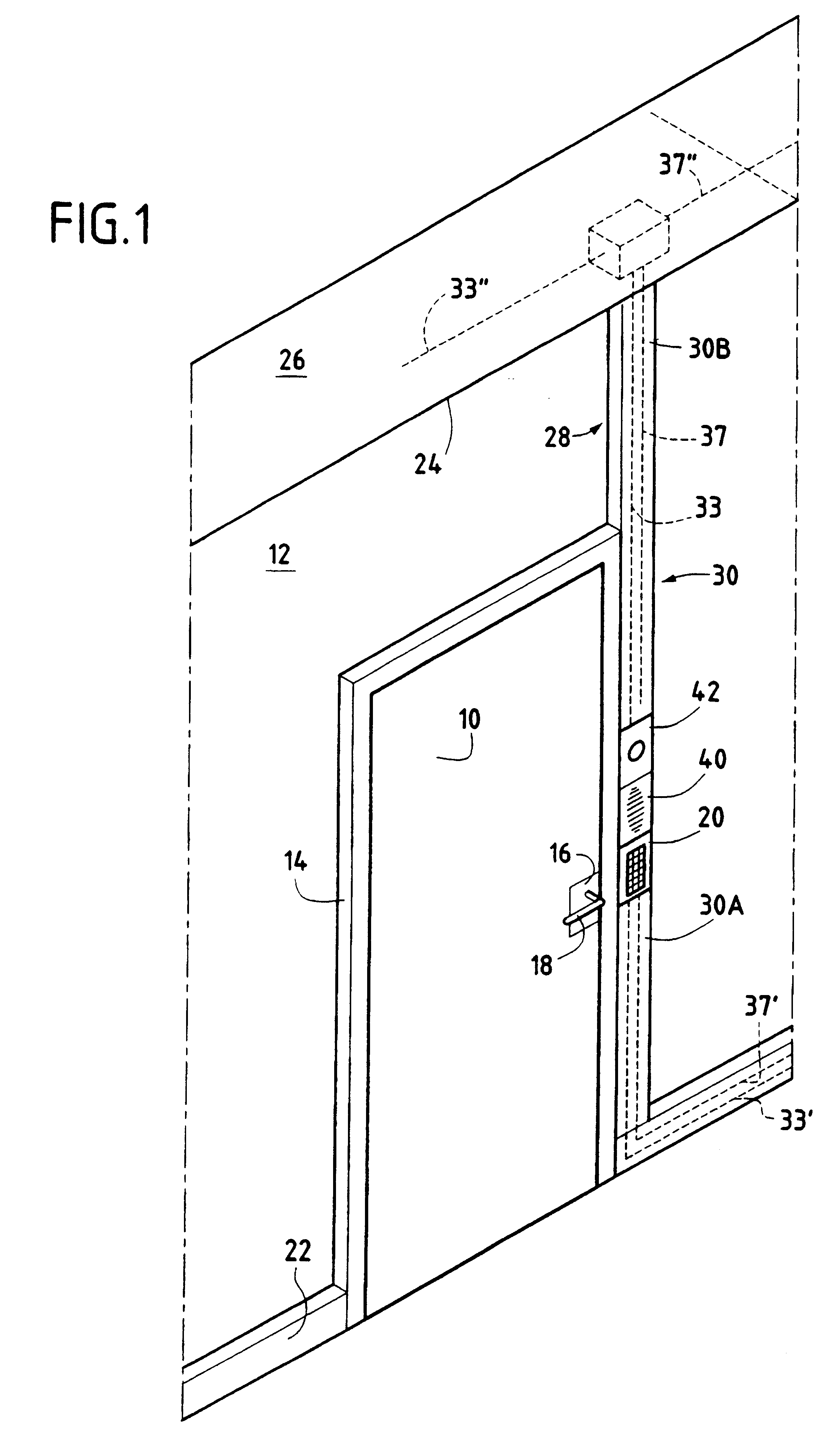

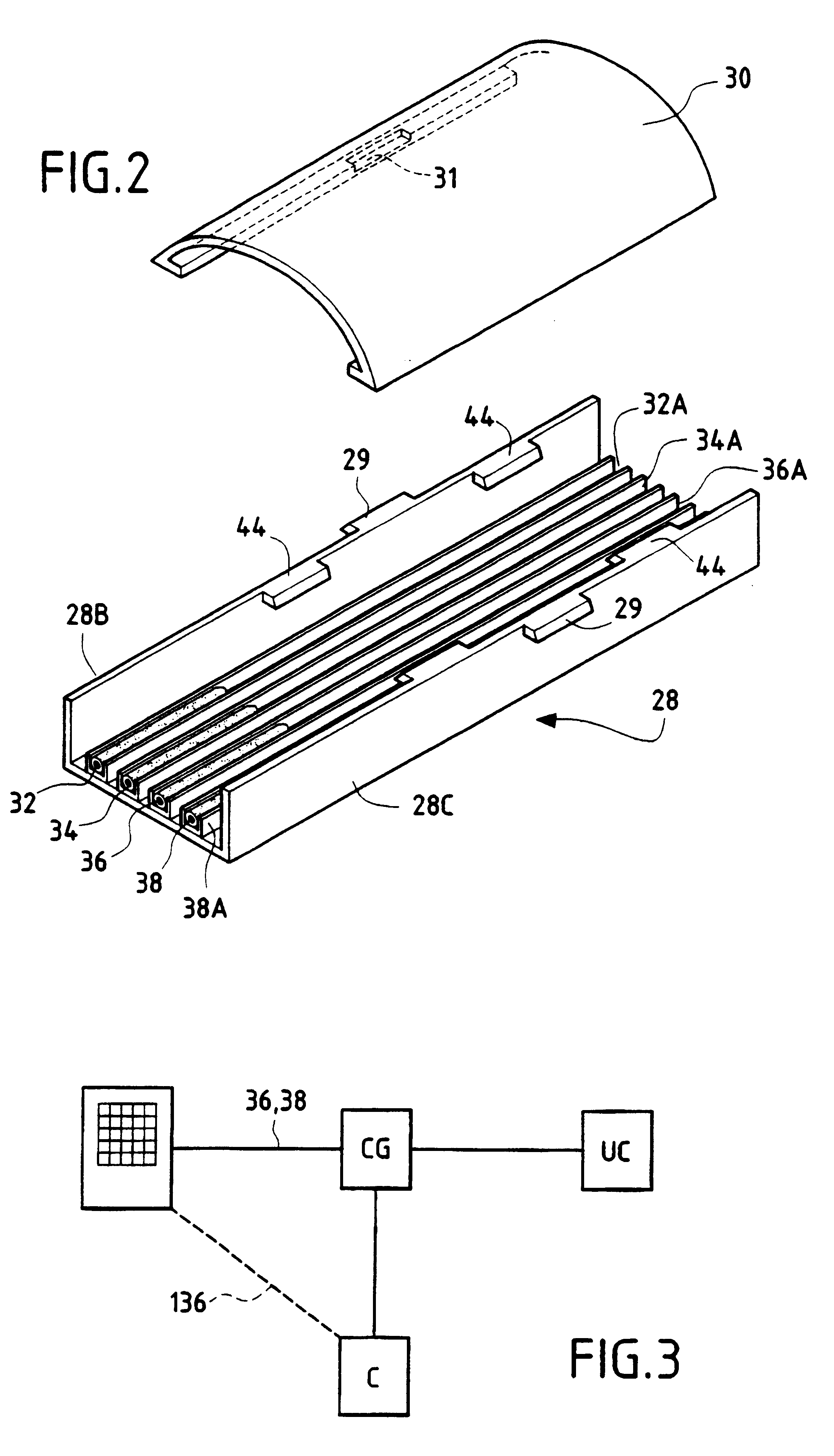

Apparatus for controlling the opening of a door

InactiveUS6347486B1Improve appearanceSimpler to put into placeNon-mechanical controlsWing fastenersData transmissionEngineering

Apparatus for controlling the opening of a door that is held in its closed position in a partition by door-blocking. The apparatus comprises a section bar support of length at least substantially equal to the height of the door, and fixed to the door or to the partition in a position such that it has a first end located at one of the top and bottom ends of the door or of the partition. The support is fitted with power supply and with data transmission comprising at least two conductors which extend substantially to said first end so as to be connected to conductors situated in the vicinity of the end of the door or the partition at which said first end is located. The support is fitted with quick-fixing and with quick-connection for receiving one or more modules, and in particular a detection module for detecting door-opening control information, said module being suitable for connection to data transmission to transmit a control signal for controlling the door-blocking, which control signal is established as a function of the information detected by the detection module. In addition, the apparatus includes cover-forming in the form of a section bar and designed to cover the zones of the support in which no module is present.

Owner:UNITECHN

Method for producing atmosphere heat drying and vacuum oil frying combined dewatered fruit and vegetable crisp chip

InactiveCN1554274AAvoid severe deformationKeep shapeFood preservationFood preparationFood materialEdible mushroom

The present invention belongs to the field of fruit and vegetable food producing technology. The production process of crisp fruit and vegetable chip includes the steps of: selecting fruit, vegetable material, edible mushroom and other food material; pre-treatment including washing, peeling, slicing, scalding to kill enzyme, etc; heating to dry at normal pressure; oil frying to dewater, centrifuging to eliminate oil, seasoning and packing. Owing to the combined dewatering process of normal pressure hot drying and vacuum frying, the present invention has low oil content in crisp fruit and vegetable chip, short frying time and well maintained food shape.

Owner:JIANGNAN UNIV +1

Method for producing instant pleurotus eryngii chips

The invention relates to a method for producing instant pleurotus eryngii chips, and belongs to the technical field of the deep processing of agricultural products. The main pleurotus eryngii chip production process comprises: performing pretreatment such as conventional selection, washing, precise segmenting, blanching, enzyme killing, cooling and the like on pleurotus eryngii, and performing ultrasonic auxiliary dipping, hot-air drying, vacuum frying and dewatering, centrifugal deoiling, seasoning and packaging. In the method, due to the adoption of a new process of combining the ultrasonic auxiliary dipping, the hot-air drying, the vacuum frying and dewatering, the dipping efficiency is improved, the moisture content of pleurotus eryngii pieces is reduced due to hot-air predrying, and the vacuum frying time is shortened greatly; and products of the pleurotus eryngii chips have the characteristics of high puffing rate, low oil content, excellent sensory quality and the like. In the method, the pleurotus eryngii is not processed by conventional freezing, so the production period of the finished products is shortened greatly, the production cost is saved, and a feasible new path is provided for the deep processing of the pleurotus eryngii.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

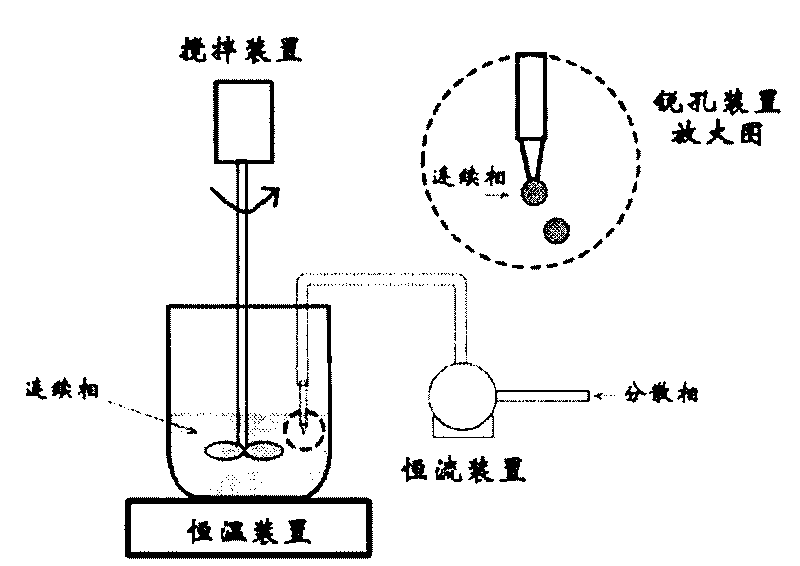

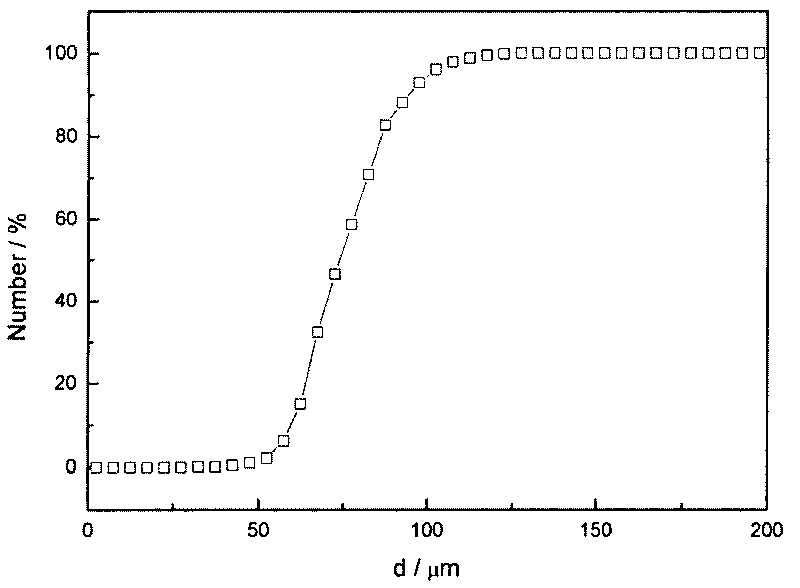

Method for preparing polymer micro balls with uniform grain diameter and controllable size

InactiveCN101690879AFlat shapeGood sphericityMicroballoon preparationMicrocapsule preparationPolymer scienceMicrometer

The invention discloses a method for preparing polymer micro balls with uniform grain diameter and controllable size, which comprises the following steps: a disperse phase (organic solution of polymers) is introduced into a continuous phase (water solution containing surfactant) through an orifice device; under the scouring action of the continuous phase, the disperse phase forms tiny liquid drops with uniform grain diameter; and after being solidified in the continuous phase without a solvent, the liquid drops form the polymer micro balls with uniform grain diameter. The invention is characterized in that the grain diameter of the polymer micro balls can be changed by adjusting the operation parameters to prepare the polymer micro balls with uniform grain diameter; and the average grain diameter of the polymer micro balls with uniform grain diameter can be adjusted within the range of 10-1000 micrometers, and the dispersion coefficient is smaller than 20%. The prepared polymer micro balls have the advantages of uniform grain diameter, low dispersion coefficient, smooth surface and no adhesion; and the method has the advantages of strong adjustability, simple equipment and stable operation.

Owner:ZHEJIANG UNIV

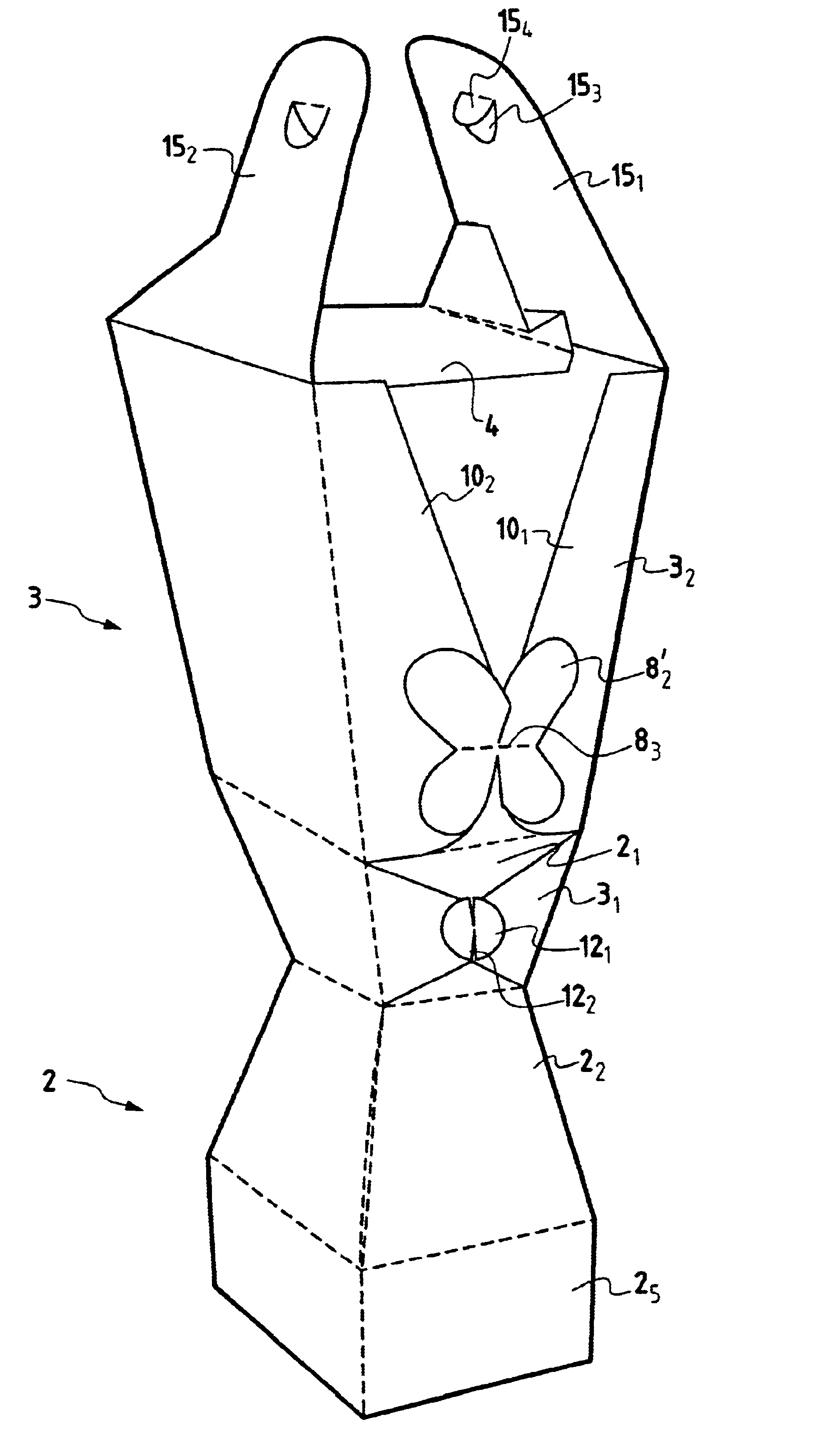

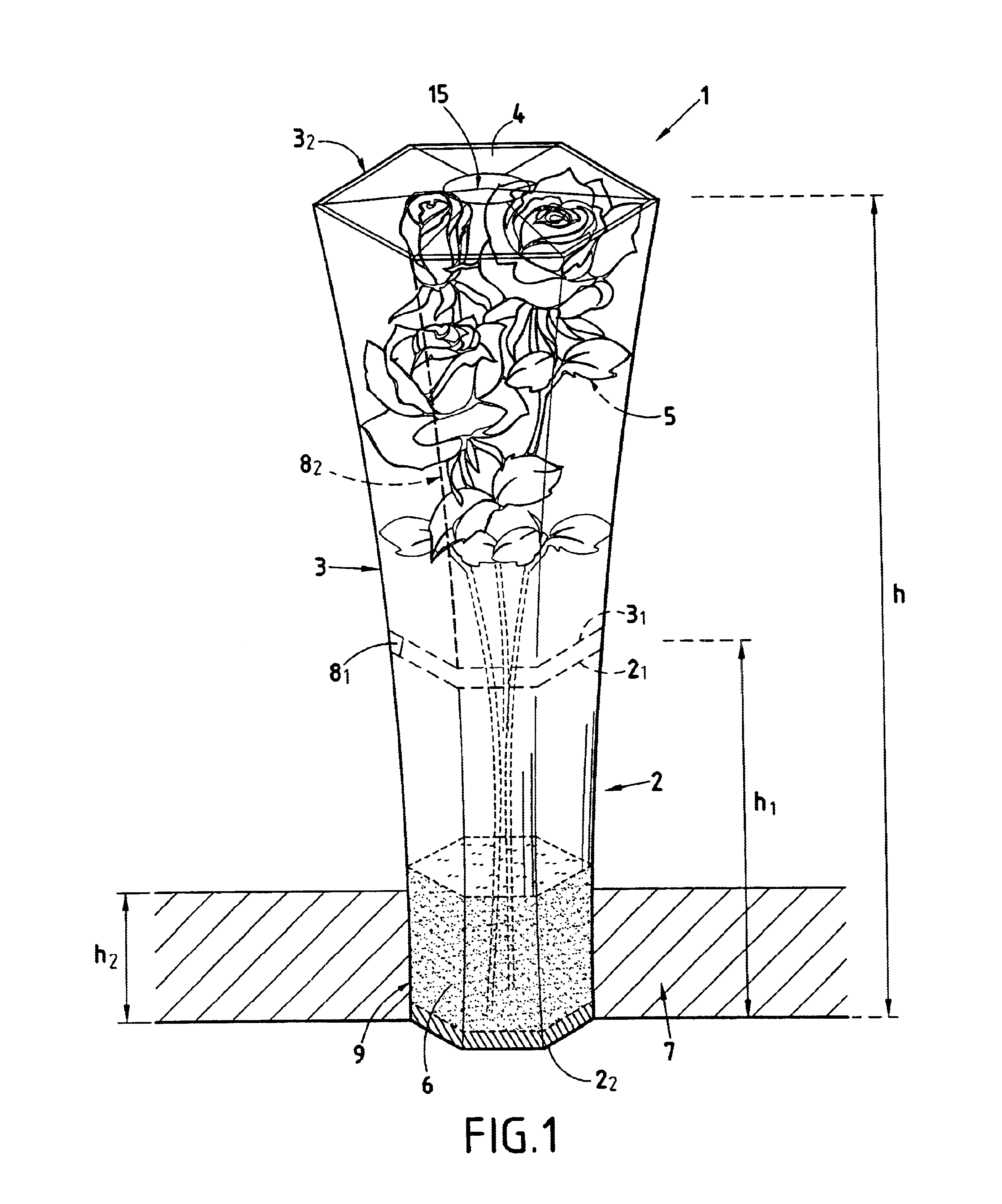

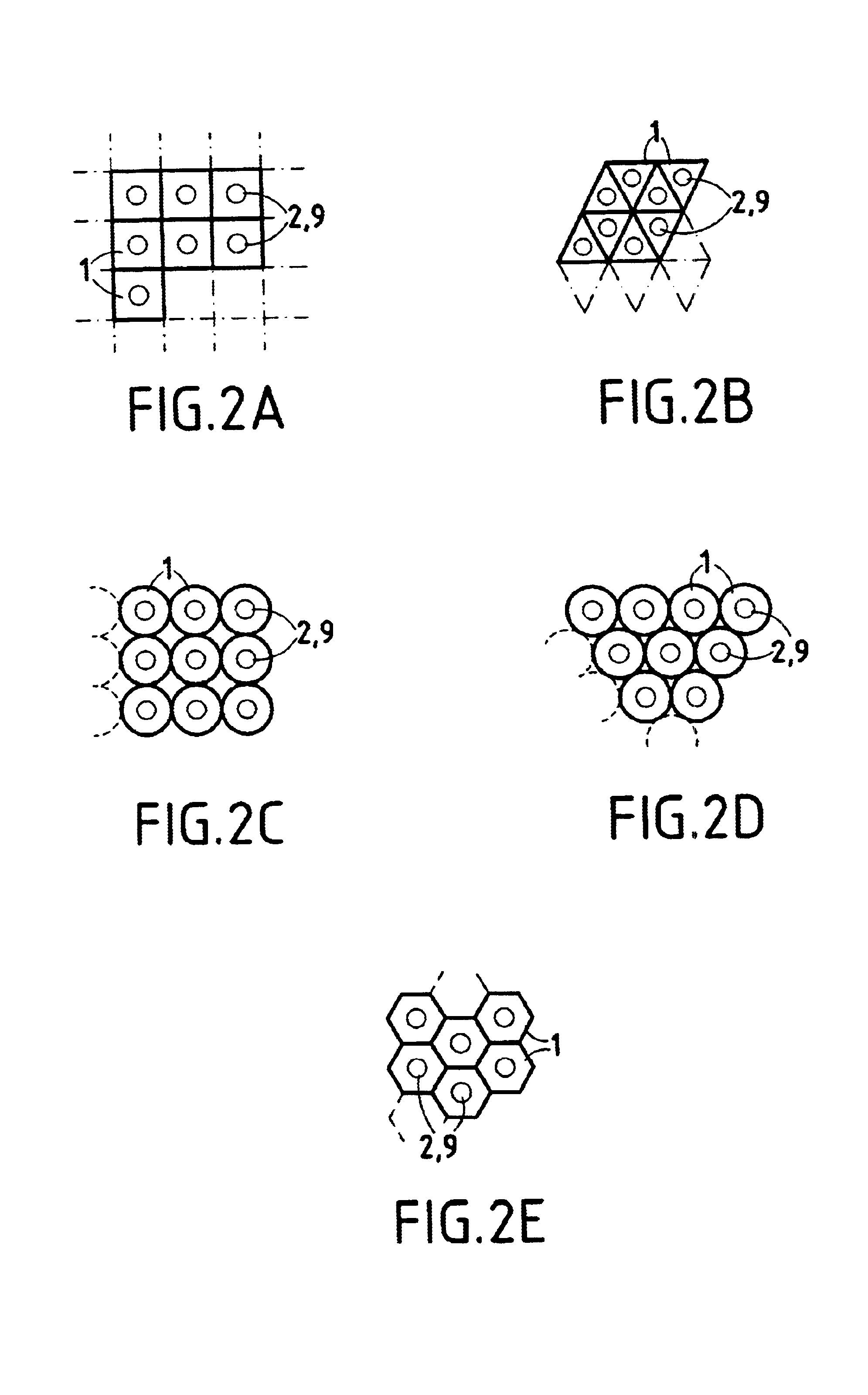

Package for transporting and displaying bunches of fresh cut flowers

InactiveUS6672002B1Increase spaceFlat shapeLiving organism packagingFloral handlingBiological bodyCut flowers

The technical field of the invention is that of making receptacles, packages, or parcels for living organisms or materials that are sensitive to changes in atmospheric conditions or surroundings, such as cut flowers. The lower portion (31) of a funnel-shaped shell overlies and matches the shape of a top portion (21) of a vase (2) which has the same funnel shape as the lower portion of the shell.

Owner:GUMPPER MARIE

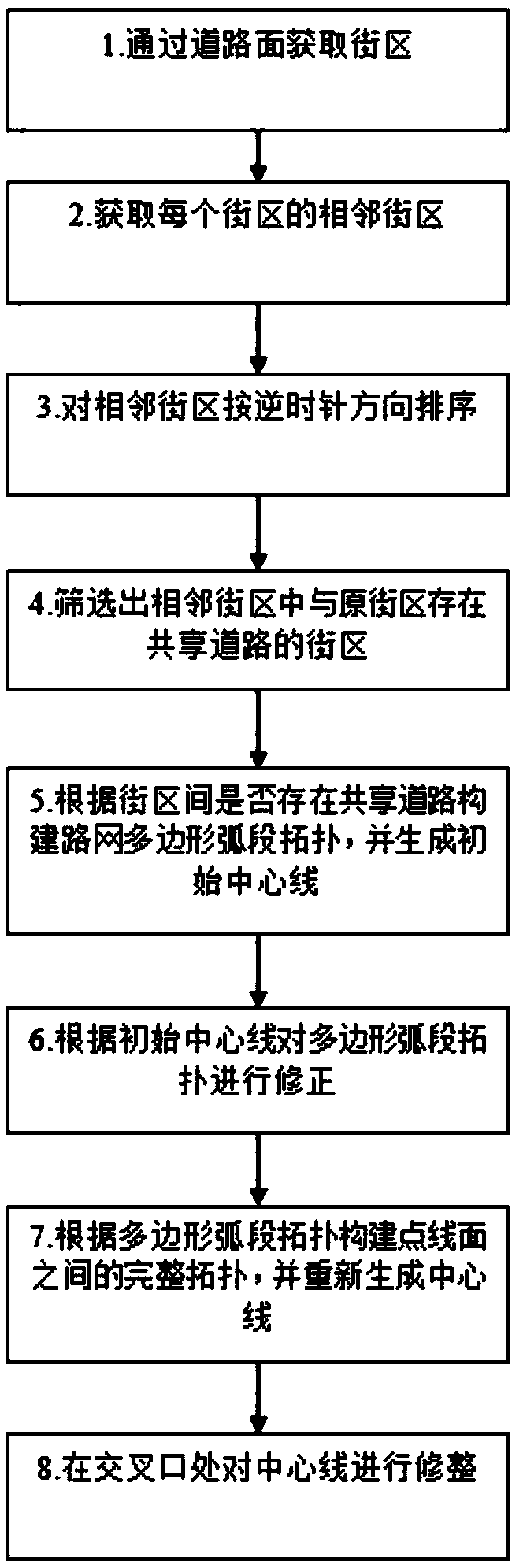

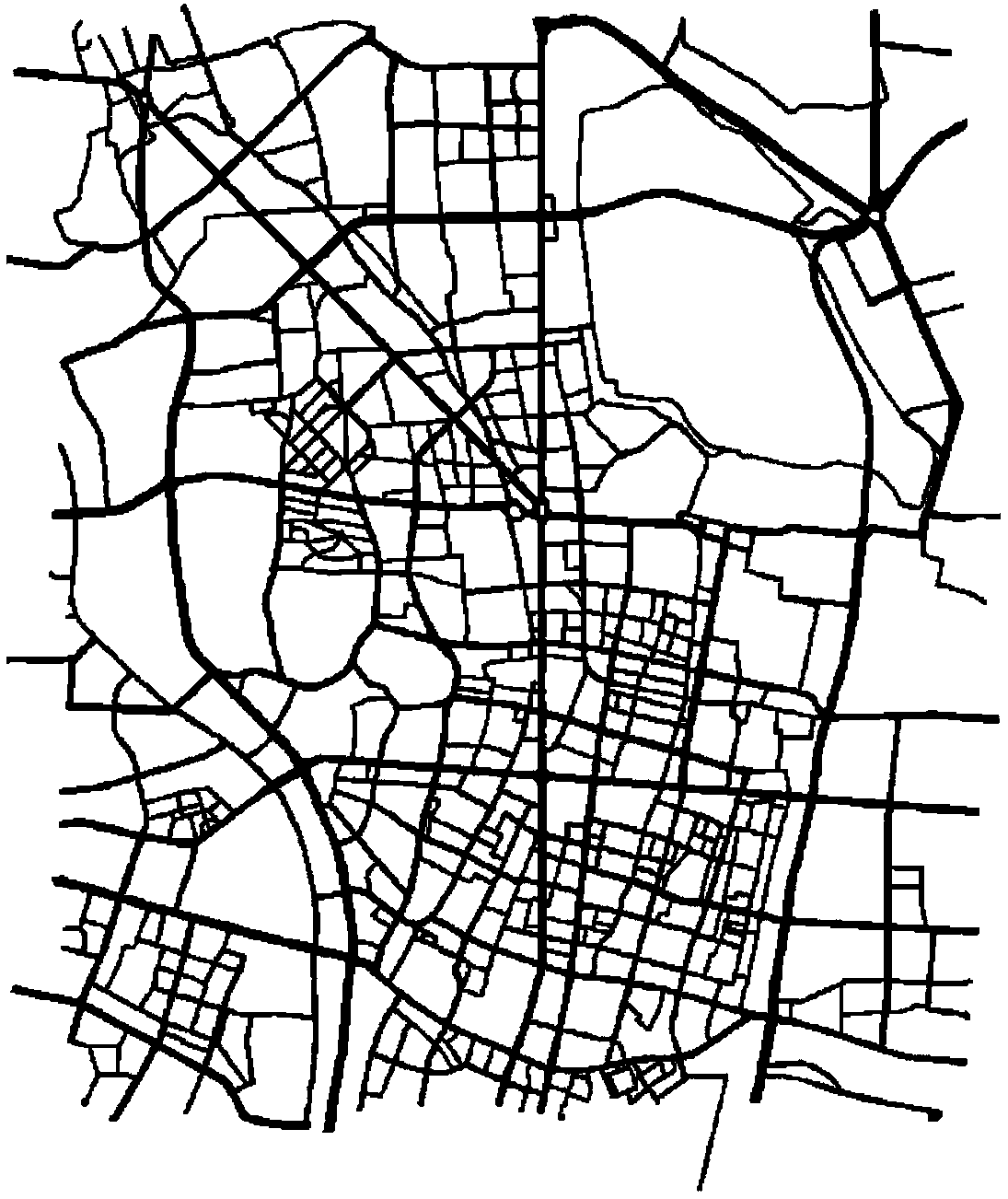

Street center line extraction method

Owner:SOUTHEAST UNIV

High-strength mobile phone medium plate aluminum alloy strip and preparing method thereof

InactiveCN107475583AHigh strengthImprove surface qualityMetal rolling arrangementsIngotHigh intensity

The invention discloses a high-strength aluminum alloy strip for mobile phone mid-plate and a manufacturing method thereof. The components are calculated by mass fraction: Si 0.05-0.10%, Fe 0.05-0.20%, Cu 0.01-0.10%, Mn 0.12-0.22 %, Mg 5.5‑6.0%, Cr 0.01‑0.10%, Zn 0.01‑0.02%, Ti 0.01‑0.03%, and the balance is Al and unavoidable impurities. The production method is to use aluminum ingots, aluminum intermediate alloy ingots, magnesium ingots, and manganese agents as raw materials to obtain aluminum alloy strips for mobile phone mid-plates through melting, casting, soaking, hot rolling, cold rolling, annealing, cleaning and straightening. The aluminum alloy strip for the middle plate of the mobile phone obtained according to the manufacturing method of the present invention has good surface quality, smooth plate shape, high strength, good formability, and high thermal conductivity; the aluminum alloy strip for the middle plate of the mobile phone produced by the present invention Alloy strip, the yield strength reaches 280~330MPa, the tensile strength reaches 370‑400MPa, and the elongation is ≥10%.

Owner:CHINALCO RUIMIN

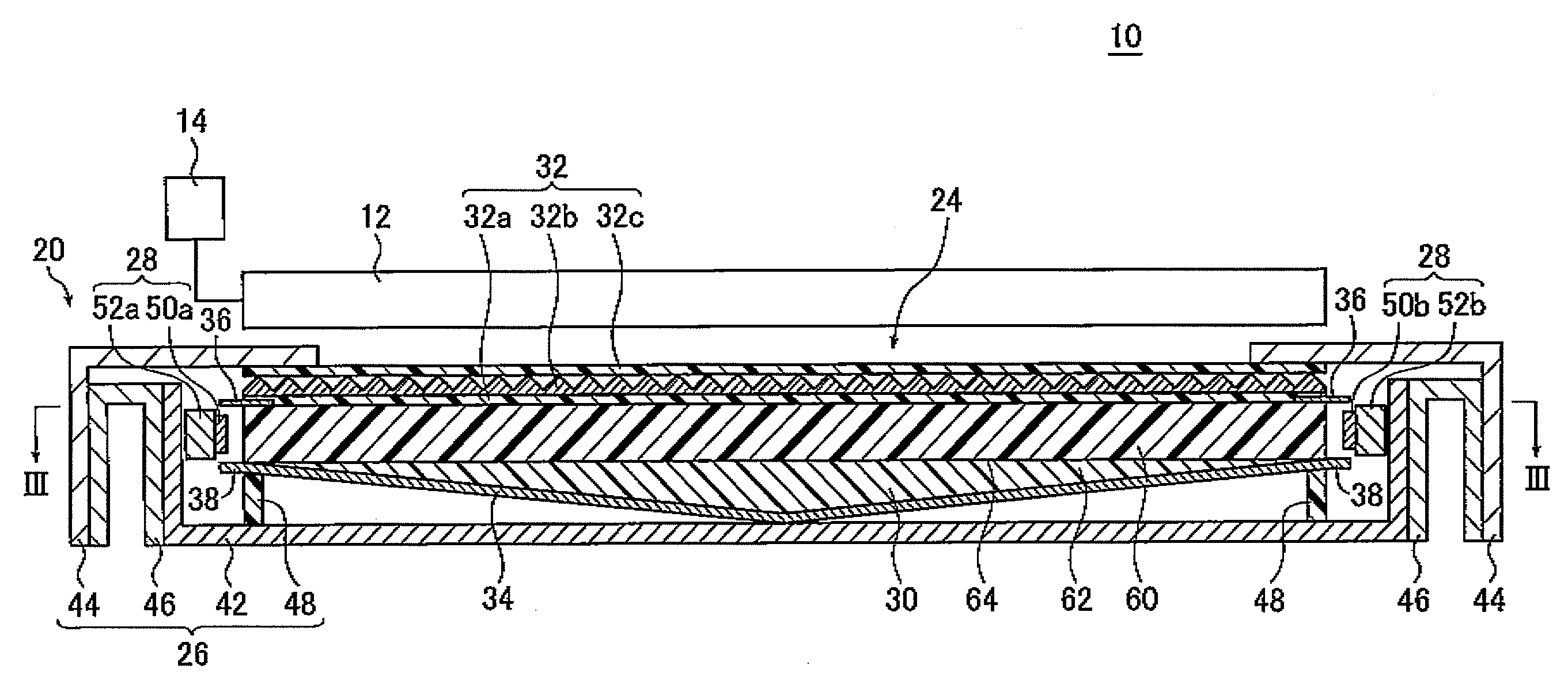

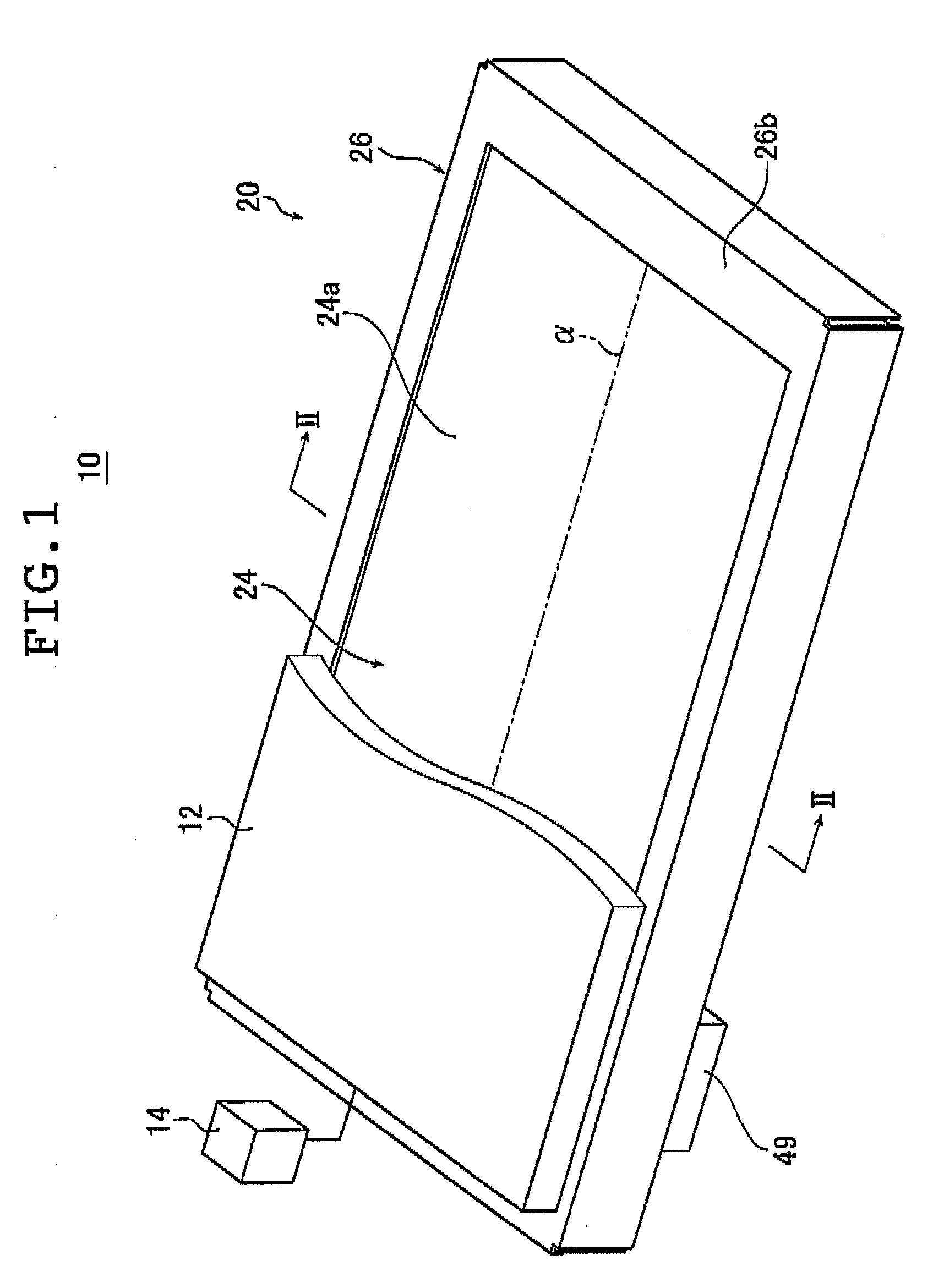

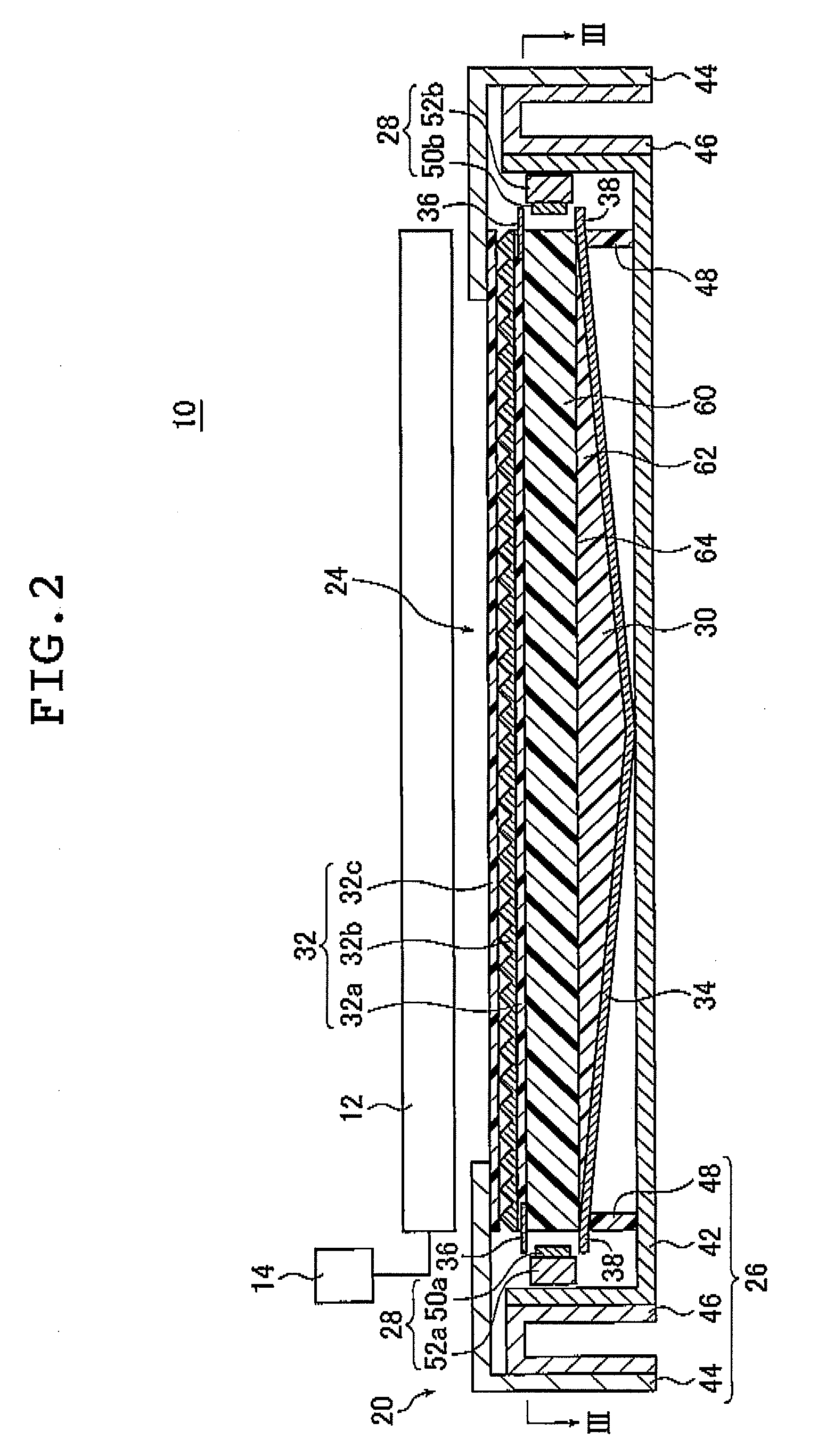

Light guide plate

InactiveUS20090103327A1Increasing the thicknessIncreasing weight and costMechanical apparatusLight guides for lighting systemsExit planeLight guide

The light guide plate includes a rectangular light exit plane, a light entrance plane containing one side of the light exit plane, and a rear plane located on the side opposite from the light exit plane and scattering particles for scattering light propagating inside the light guide plate dispersed therein. The light guide plate has two layers, a first layer located on the side closer to the light exit plane and having a first particle density of the scattering particles, and a second layer located on the side opposite from the light exit plane and having a second particle density that is greater than the first particle density of the first layer. Npo and Npr satisfy Npo<Npr, where Npo is the first particle density and Npr is the second particle density.

Owner:FUJIFILM CORP

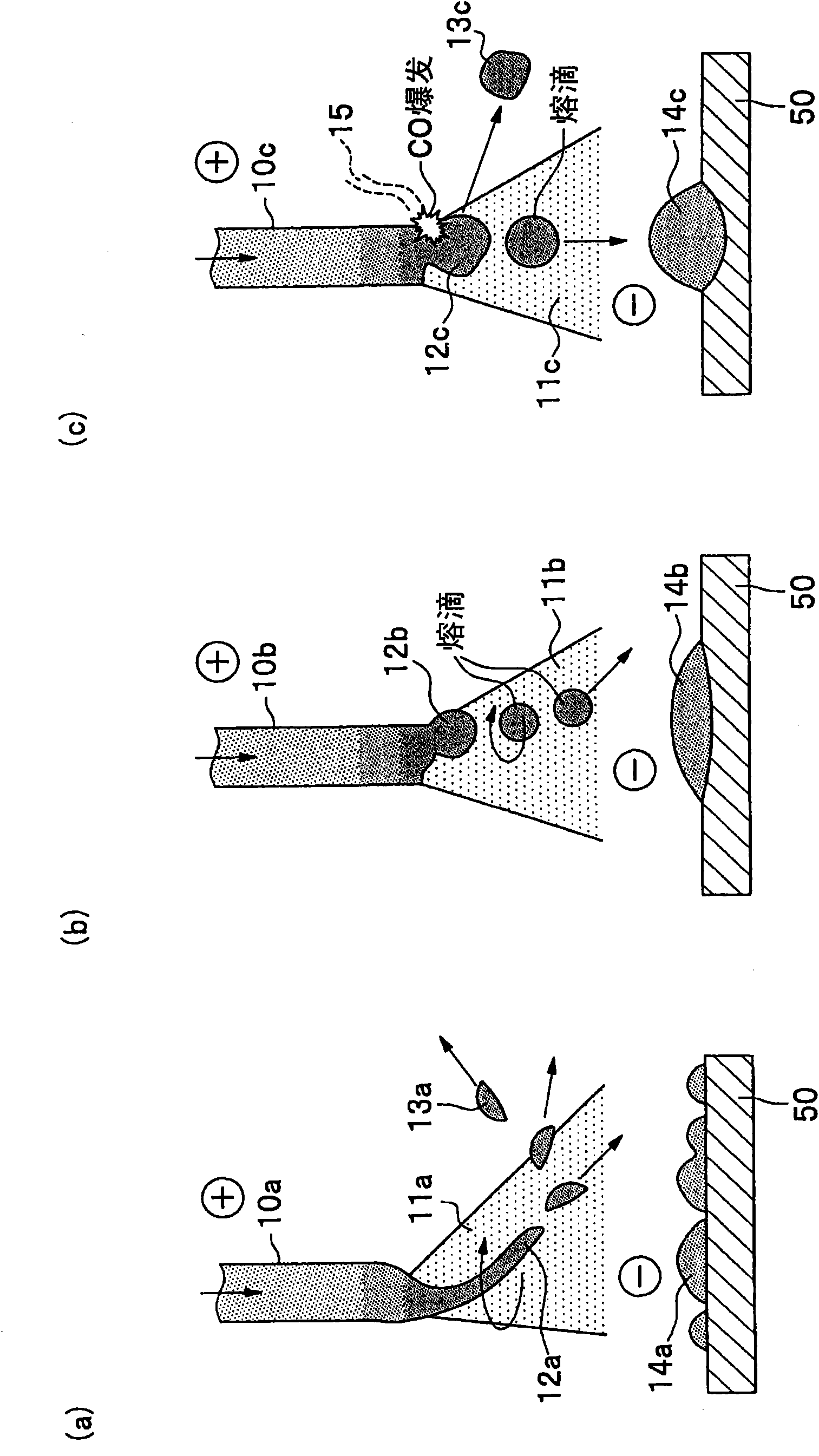

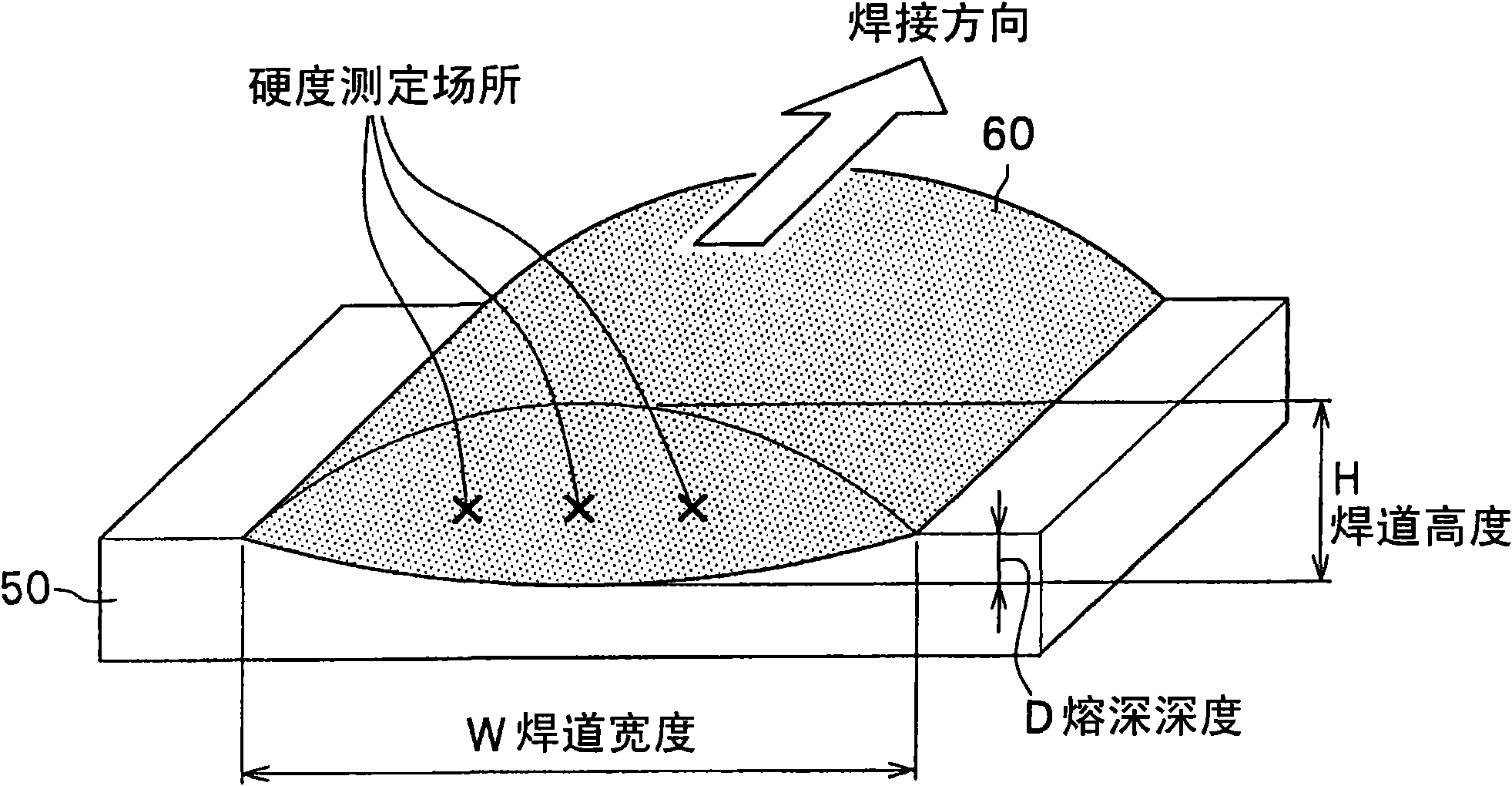

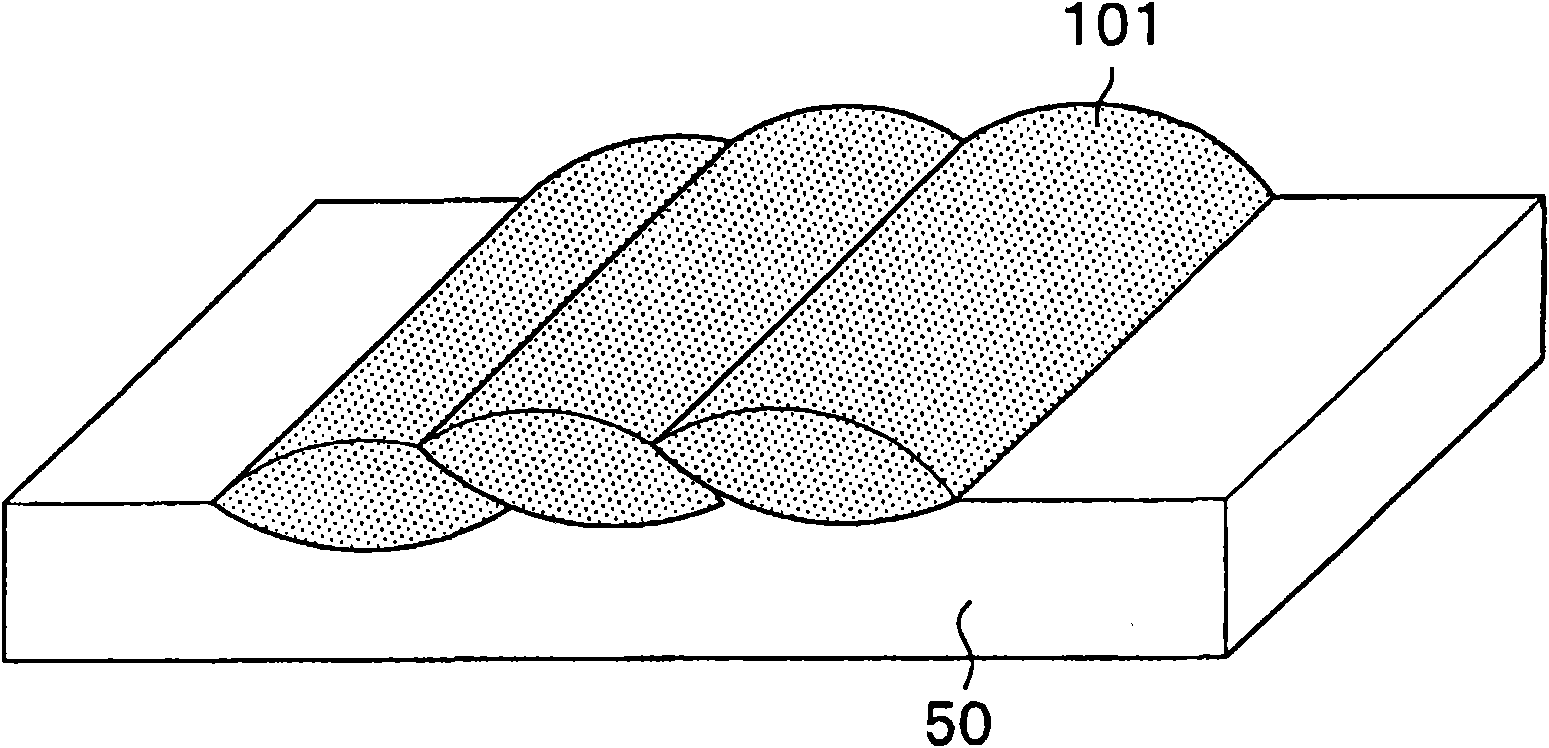

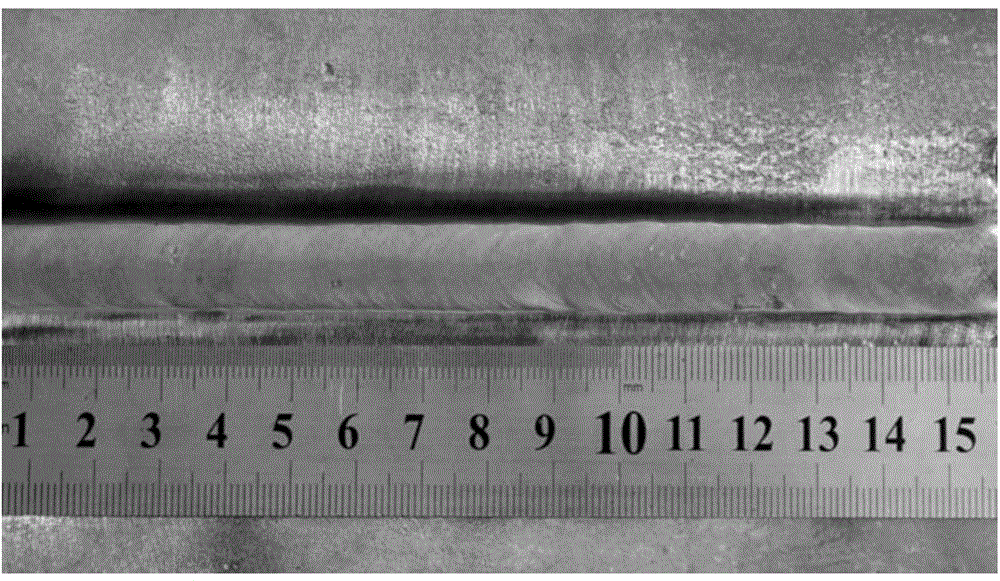

Hardfacing MIG-arc welding wire and hardfacing MIG-arc welding process

InactiveCN102059476AFlat shapeFull hardnessArc welding apparatusWelding/cutting media/materialsShielding gasCarbon Dioxide / Helium

A wire is adopted to hardfacing MIG-arc welding using a pure argon gas as a shielding gas. The wire is a flux-cored wire prepared through drawing a steel hoop or steel pipe as a sheath in which a flux is filled. The flux contains, based on the total mass of the wire, C: 0.12 to 5.00 percent by mass, Si: 0.50 to 3.00 percent by mass, Mn: 0.30 to 20.00 percent by mass, P: 0.050 percent by mass or less, S: 0.050 percent by mass or less, and at least one of TiO2, ZrO2, and Al2O3 (TiO2+ZrO2+Al2O3) in a total content of 0.10 to 1.20 percent by mass and has a total content of silicon and manganese (Si+Mn) of 1.20 percent by mass or more. The wire has a ratio of the total mass of the flux to the mass of the wire of 5 to 30 percent by mass.

Owner:KOBE STEEL LTD

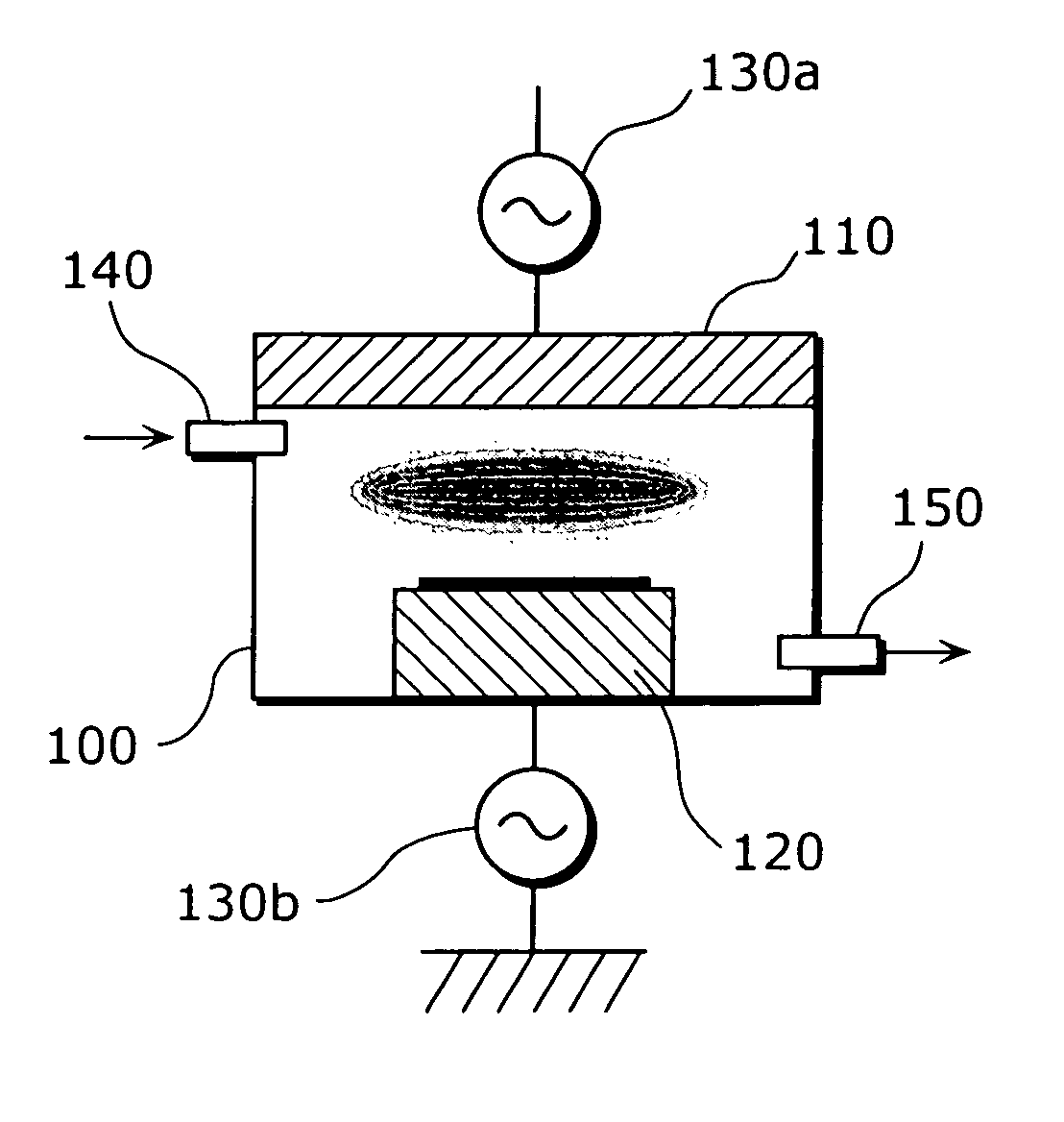

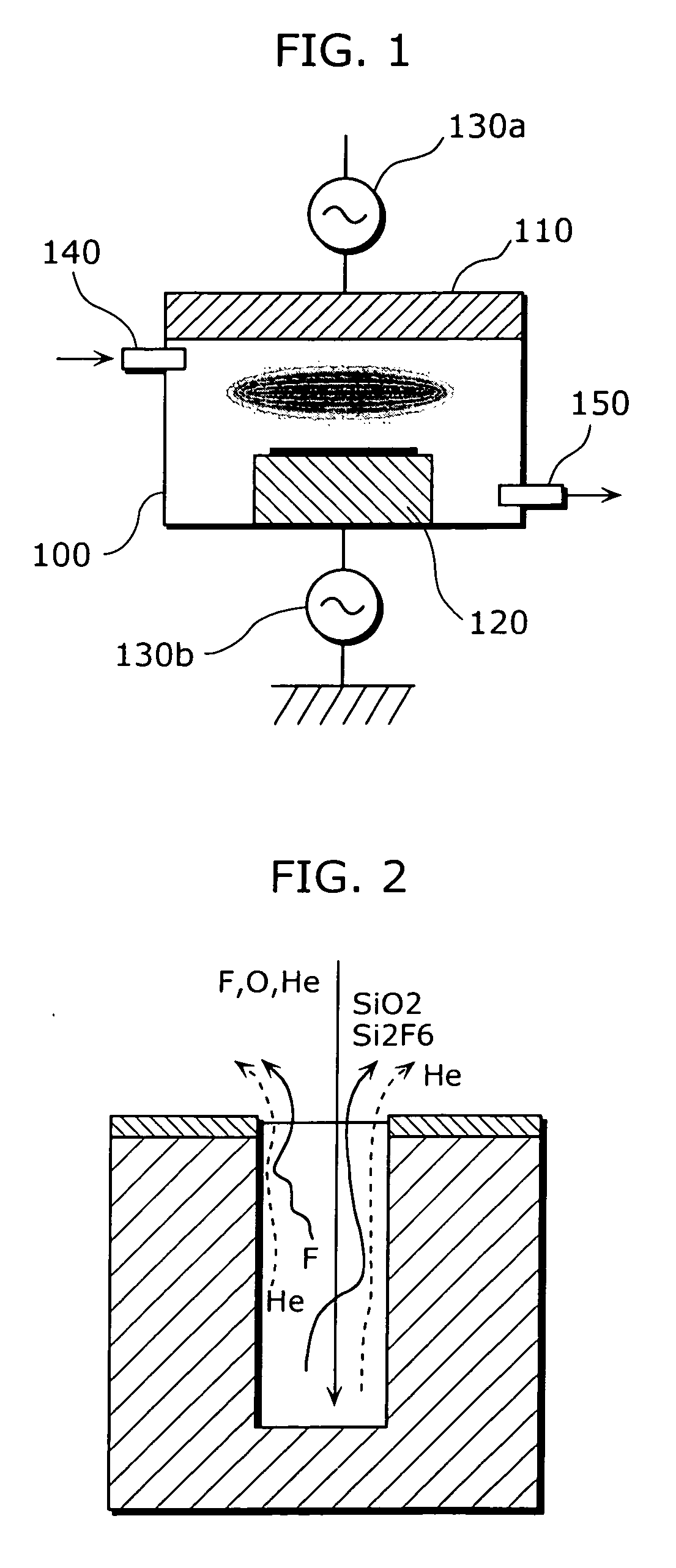

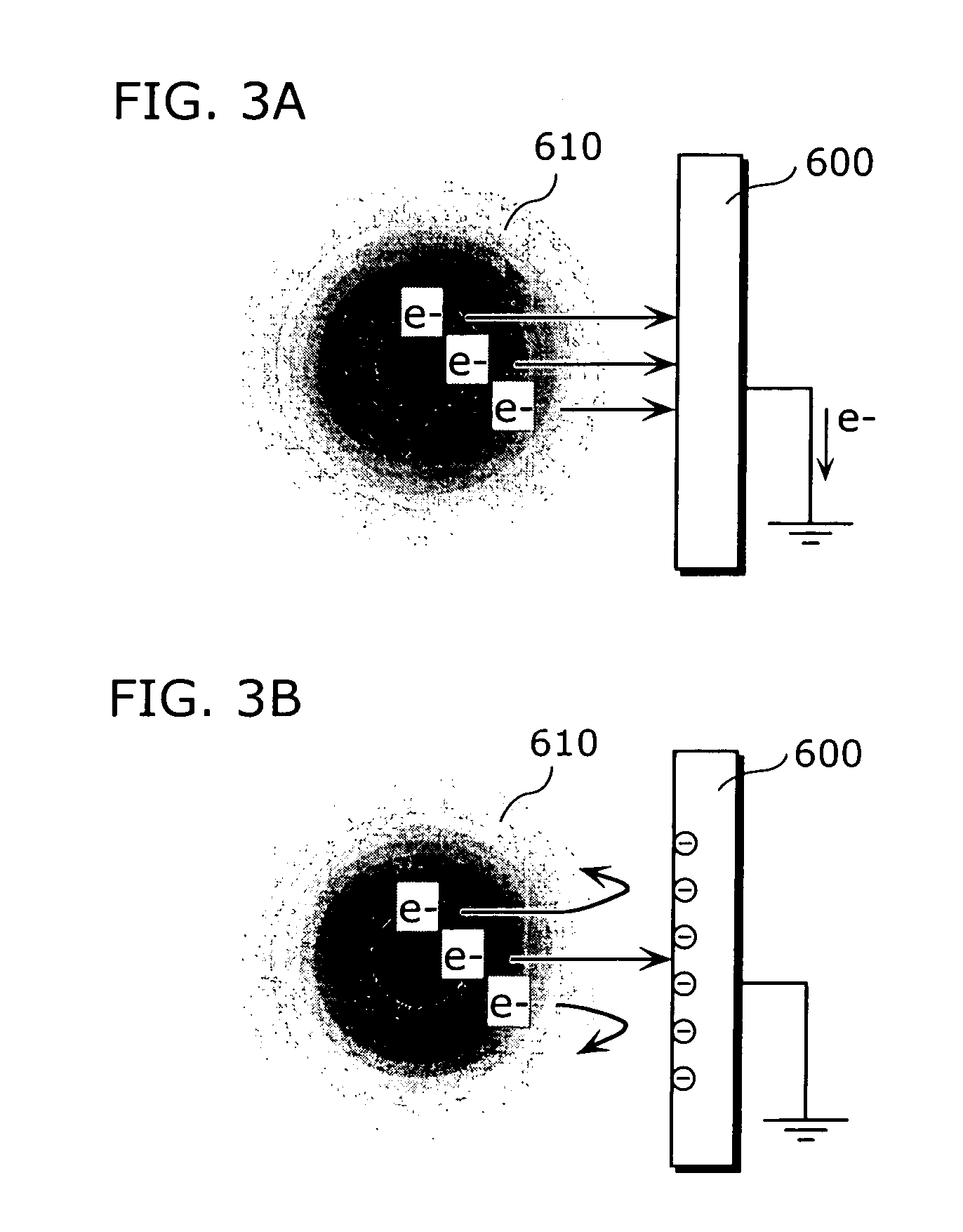

Plasma etching method

InactiveUS20070131652A1High dimensional accuracyHigh aspect ratioElectric discharge tubesDecorative surface effectsElectricityHigh frequency power

An object of the present invention is to provide a plasma etching method by which both of a requirement for a trench shape and a requirement for a aspect ratio can be satisfied, and a trench having a side wall of a smooth shape can be formed. According to the present invention, a silicon substrate is placed on a lower electrode (120), etching gas is supplied through a gas introducing port (140) and exhausted from an exhaust port (150), high frequency powers (130a, 130b) supply high-frequency electricity to an upper electrode (110) and a lower electrode (120), respectively, in order to energize the etching gas into plasma state, using an ICP method, and then activated species are generated to make etching of the silicon substrate be progressed. As the etching gas, mixed gas, which includes mainly SF6 gas added with O2 gas and He gas, is used.

Owner:PANASONIC CORP

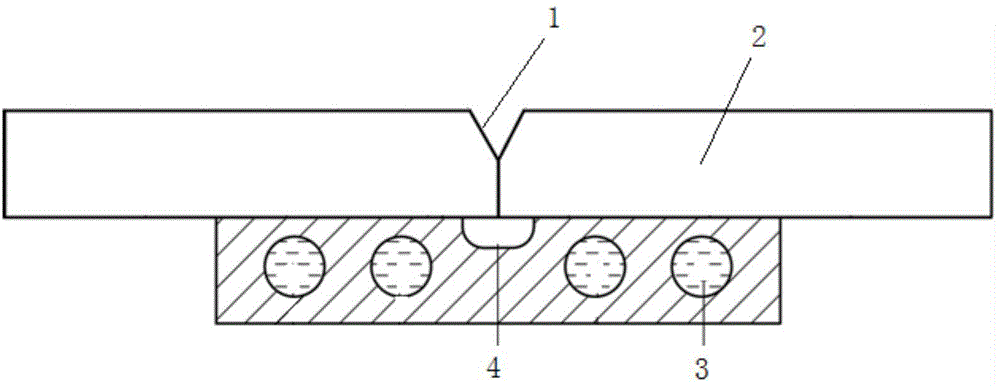

Method for combined welding of austenitic stainless steel moderate thickness plate

InactiveCN104858557ALittle thermal impactNo crackWelding/soldering/cutting articlesWelding apparatusButt weldingButt joint

The invention relates to a method for combined welding of an austenitic stainless steel moderate thickness plate. The method comprises the steps of opening a V-shaped groove at the position of the to-be-welded butt joint surface of austenitic stainless steel; polishing and cleaning the surface of a to-be-welded workpiece and the position of the V-shaped groove; performing gapless tight fixed assembly of the workpiece, performing spot welding fixation on a run-on plate, an arc blowout plate and a test plate; pre-leading in protective gas prior to butt welding, guaranteeing that sufficient protective atmosphere is formed on the surface of the stainless steel groove and the bottoms of the weld joints; adopting pulsed plasma arc welding to perform bottoming welding; adopting low carbon welding wires to perform cosmetic welding of pulse wire filling argon tungsten-arc welding, performing the bottoming welding of the pulsed plasma arc welding and cosmetic welding of the pulse wire filling argon tungsten-arc welding simultaneously, and cooling the workpiece while performing the welding. The PC-PAW bottoming welding is adopted, the micropore effect is utilized to achieve one-side welding and double-sided free forming of the moderate thickness plate, the backs of the weld joints are smoothly formed and are free of cracks and edge snapping defects, the process is stable and easy to achieve, and the quality is reliable.

Owner:SHANDONG UNIV

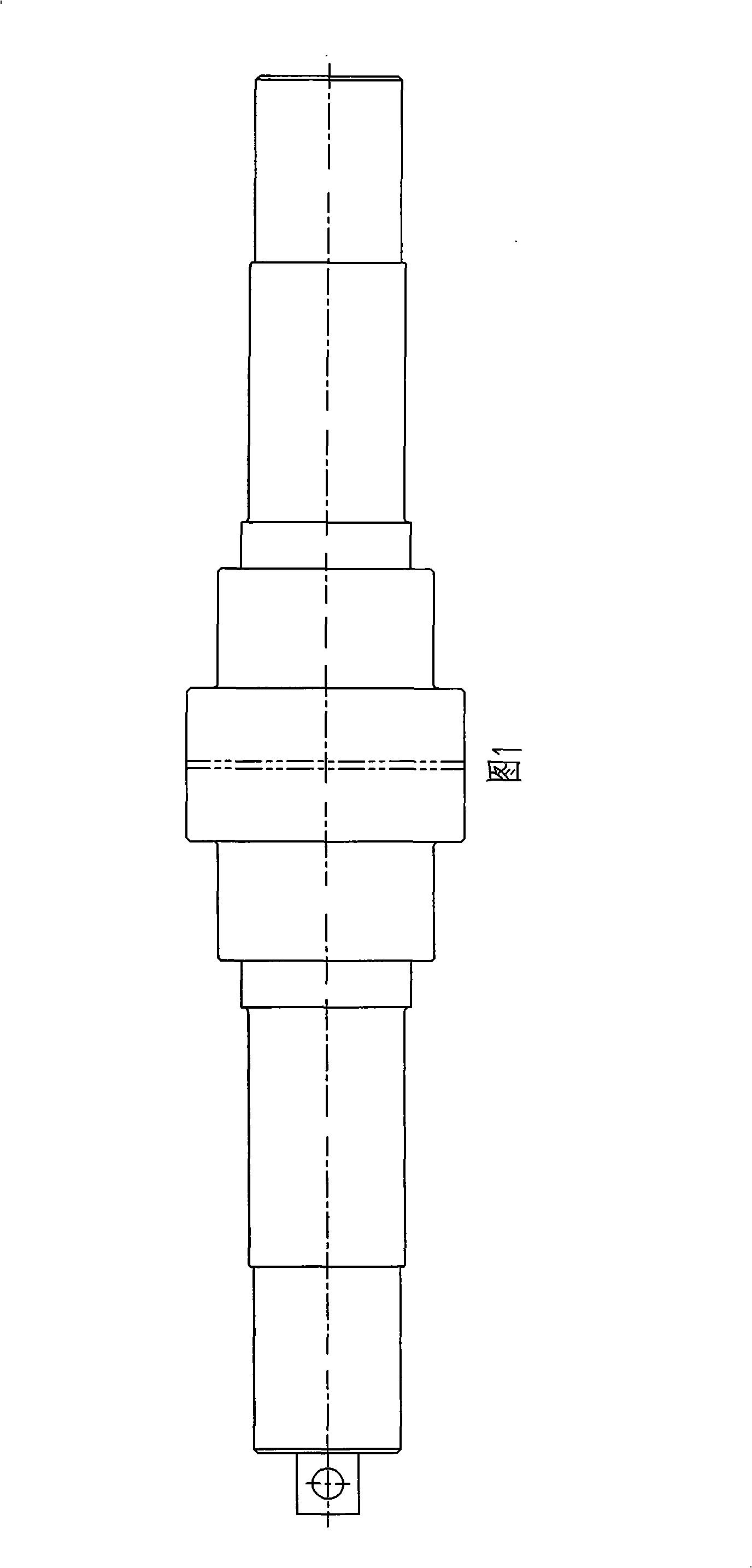

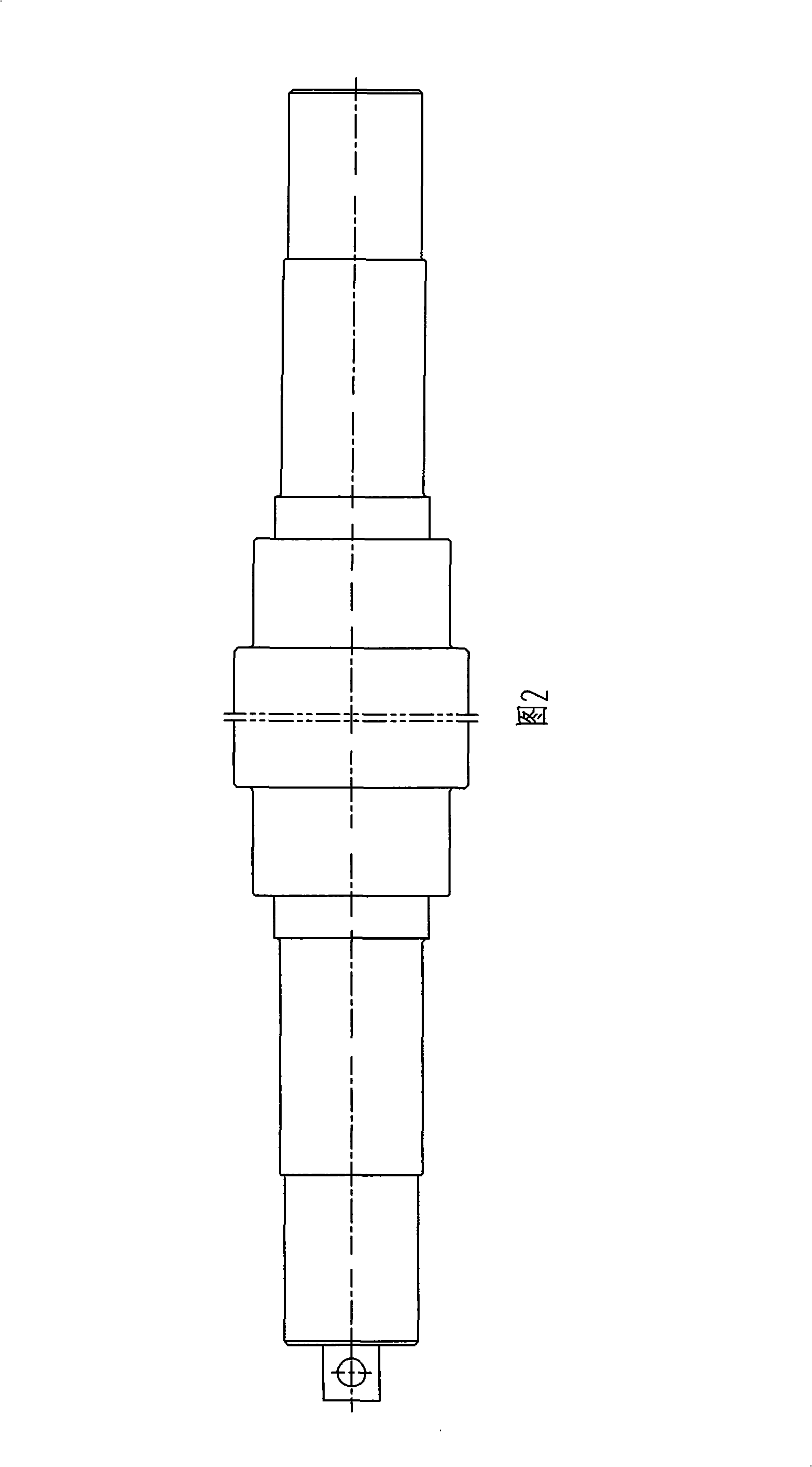

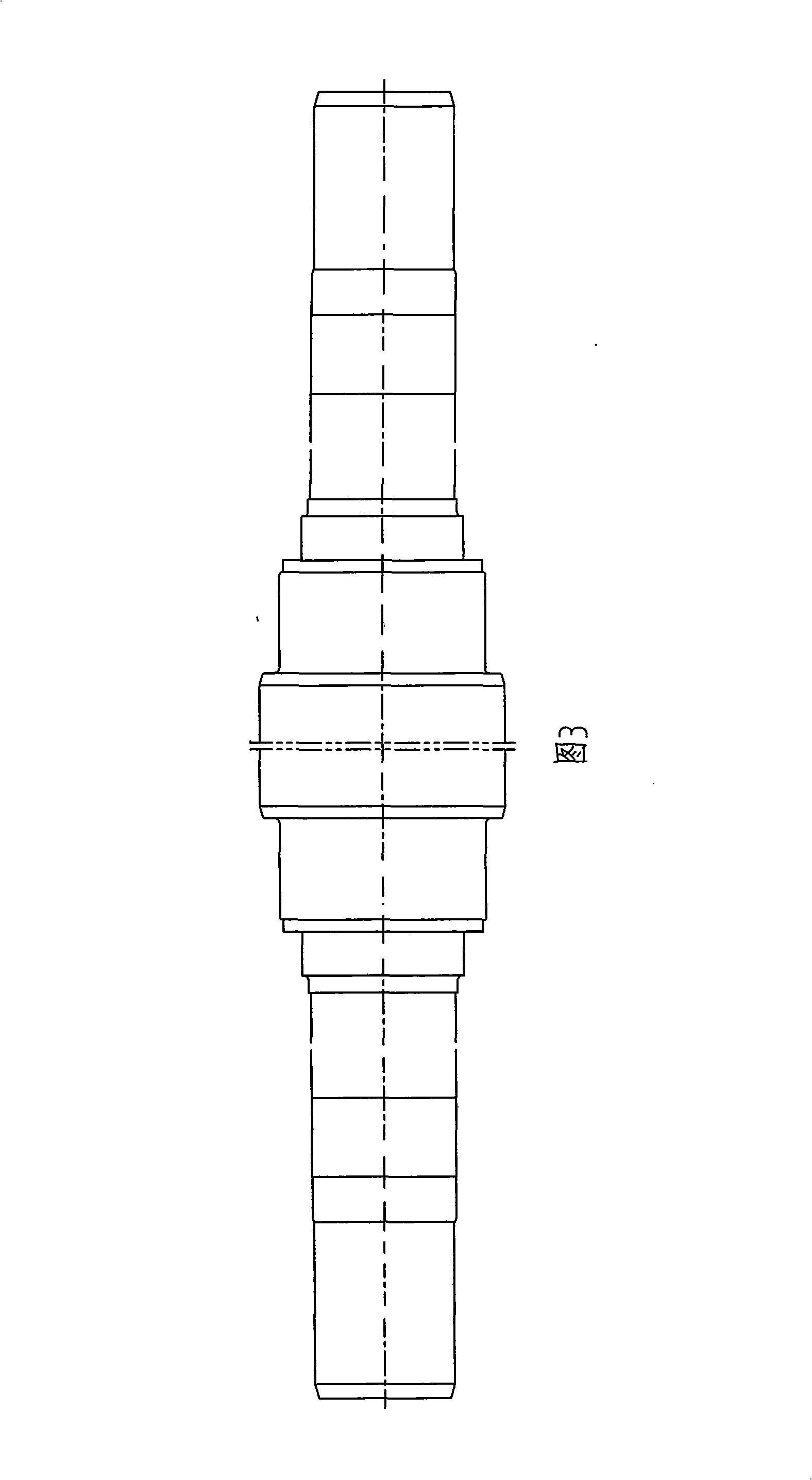

Cold roller production process

The invention relates to the cold roller technical field, in particular to a cold roller production process which is characterized in that: blank which is made of high chrome alloy material in forging way is annealed and then is polished into a finished product by steps of rough turning processing, thermal refining, semi-finish turning processing, falling duplex frequency treatment, finish turning processing, etc. The high chrome alloy material and specific falling duplex frequency treatment quenching technology are adopted for manufacturing cold rollers. The effective hardening depth of the manufactured cold rollers reaches to unilateral 20mm above, the hardness uniformity of the roller body is not larger than two Shore units, and the hardness value is larger than Shore 98 degrees. The cold rollers can be used for rolling pure aluminum and billet aluminum with the rolling amplitude of 2200mm and the thickness of under 0.5mm. The rolled aluminum plate has the characteristics of high surface finish degree, uniform thickness and smooth plate profile.

Owner:CHANGZHOU ECCO ROLLER

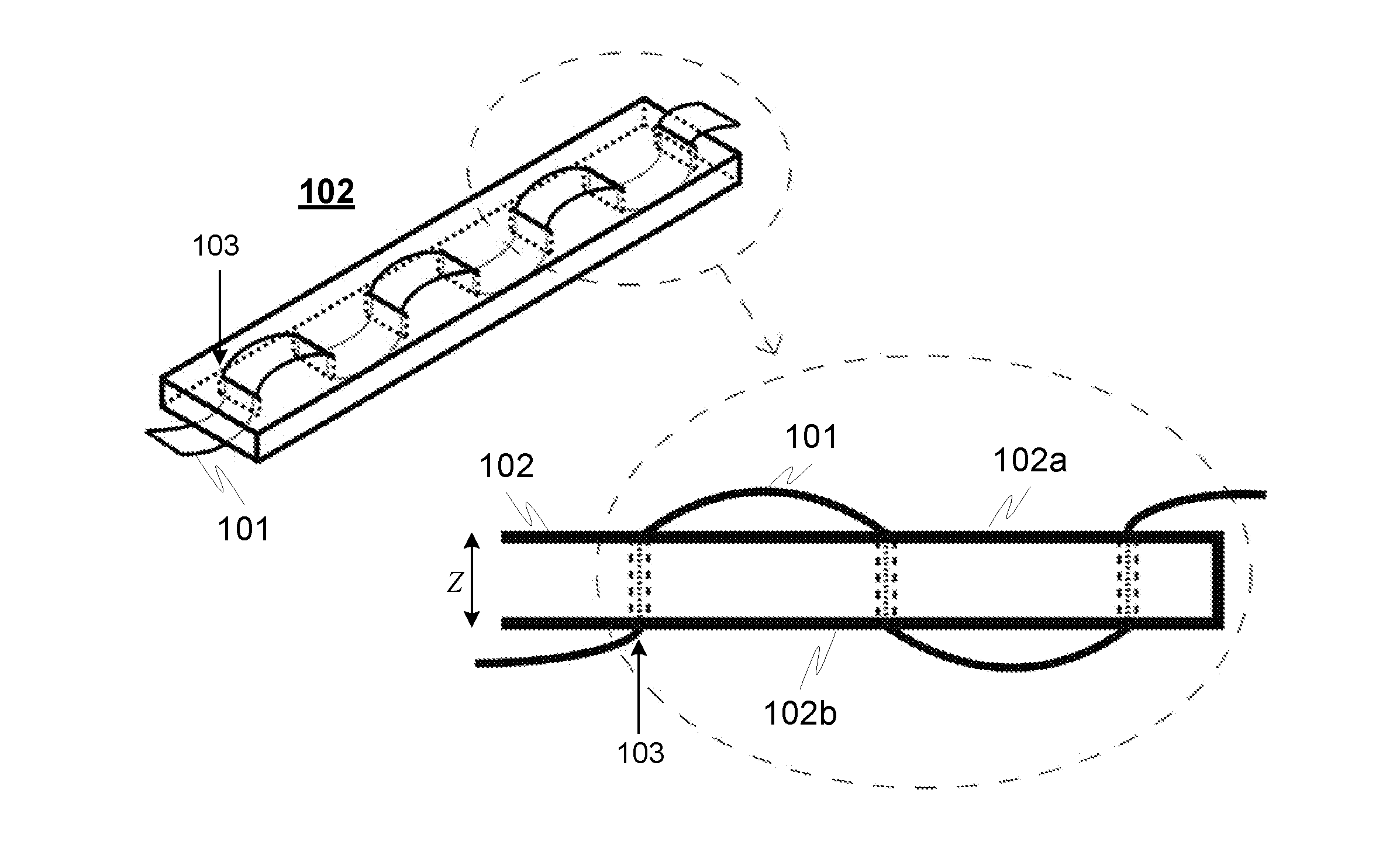

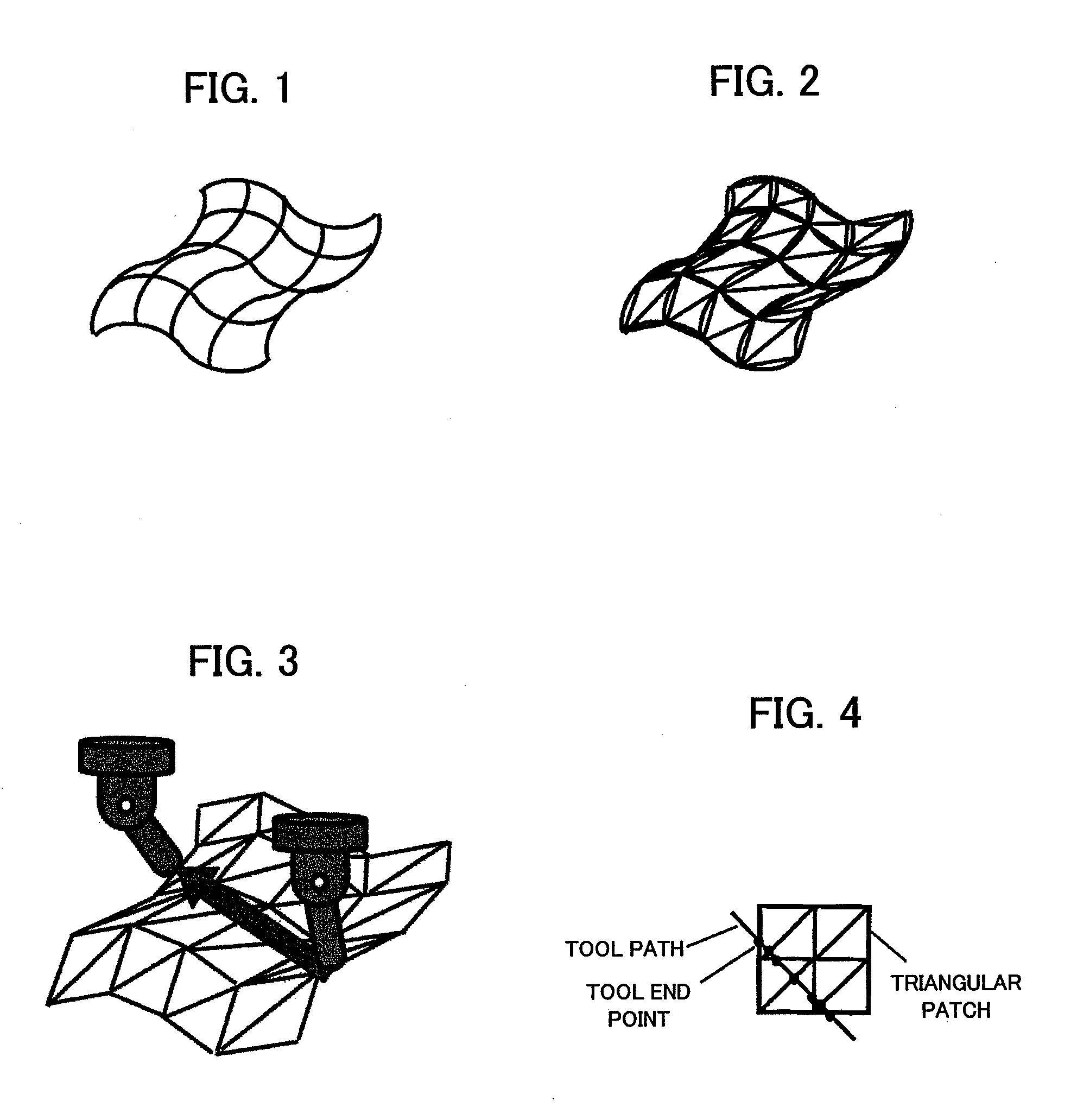

Stretchable device for transmitting signal

InactiveUS20150289364A1Manufacturing processMinimizing conductionCircuit bendability/stretchabilityPrinted circuit aspectsEngineeringVIT signals

A stretchable device for transmitting signal between end points, such as a sensor and electronic unit, includes a conductive element, which is coupled with a supporting structure by introducing the conductive element successively through the thickness of the supporting structure to the first and second side of the supporting structure, thereby providing a corrugated structure for the conductive element, which is configured to be straighten out at least partially during stretching the device in its longitudinal direction. The conductive element is coupled with the supporting structure between first and second outer layers thereby providing the stretchable device.

Owner:CLOTHING PLUS MBU

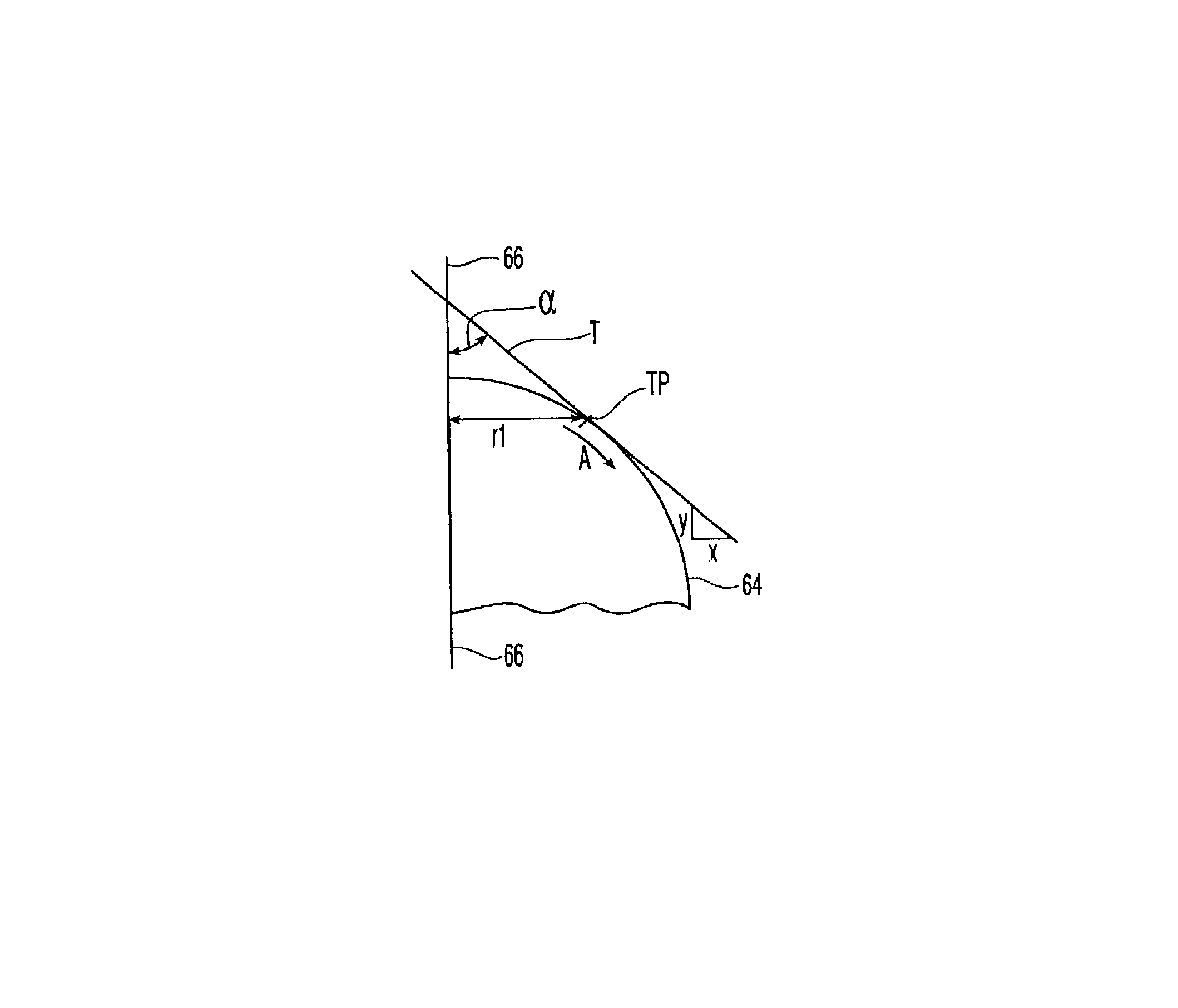

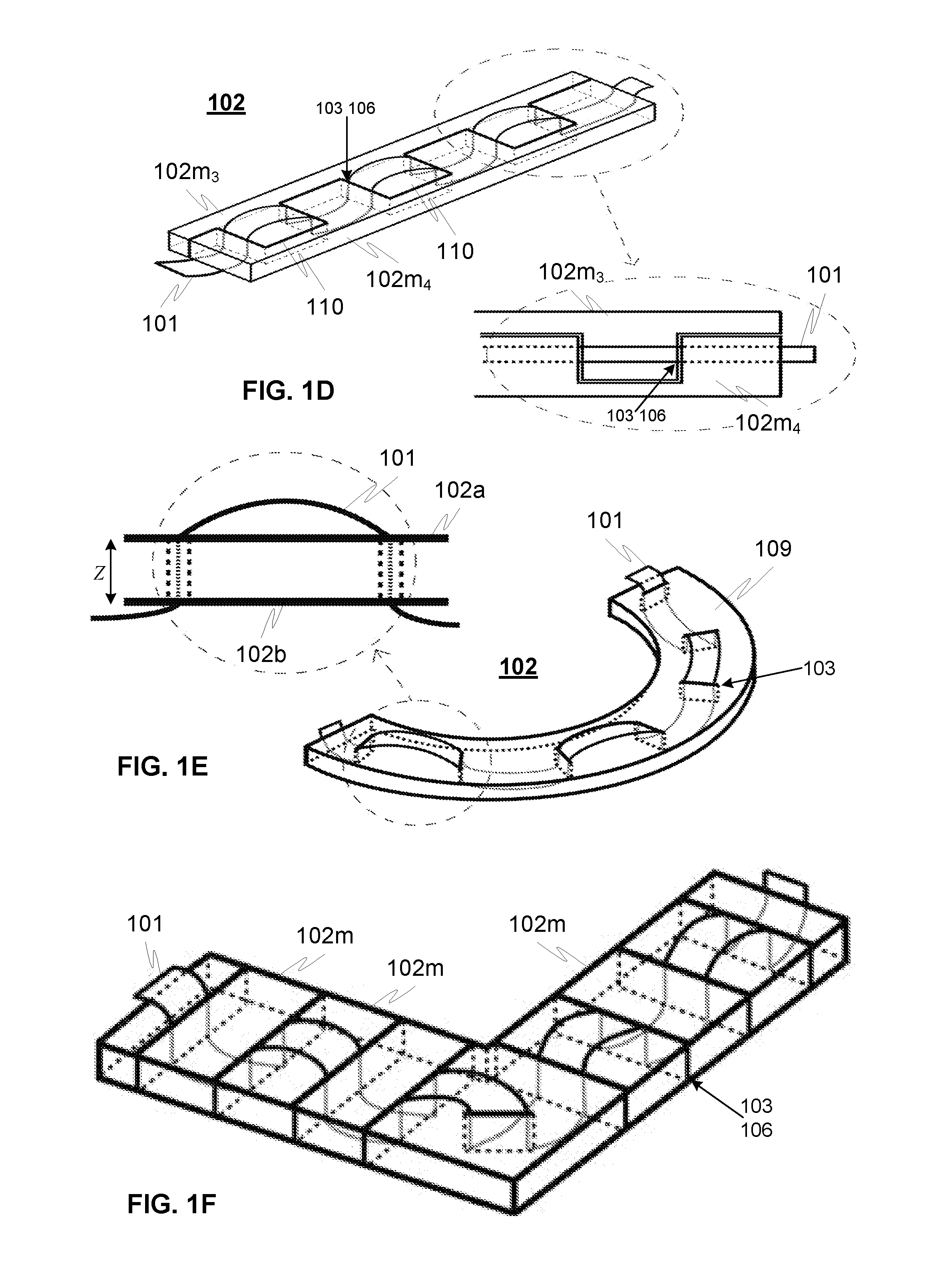

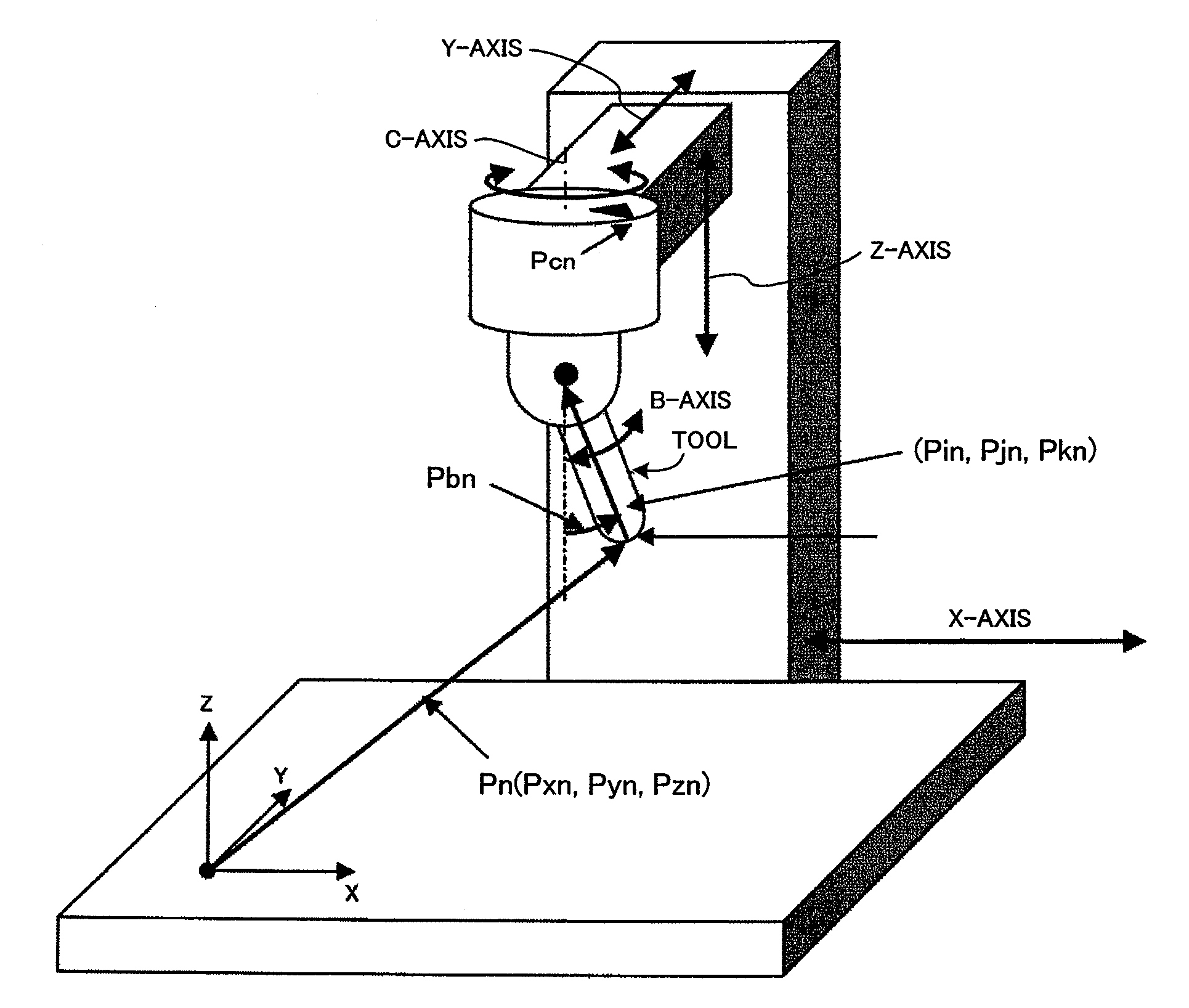

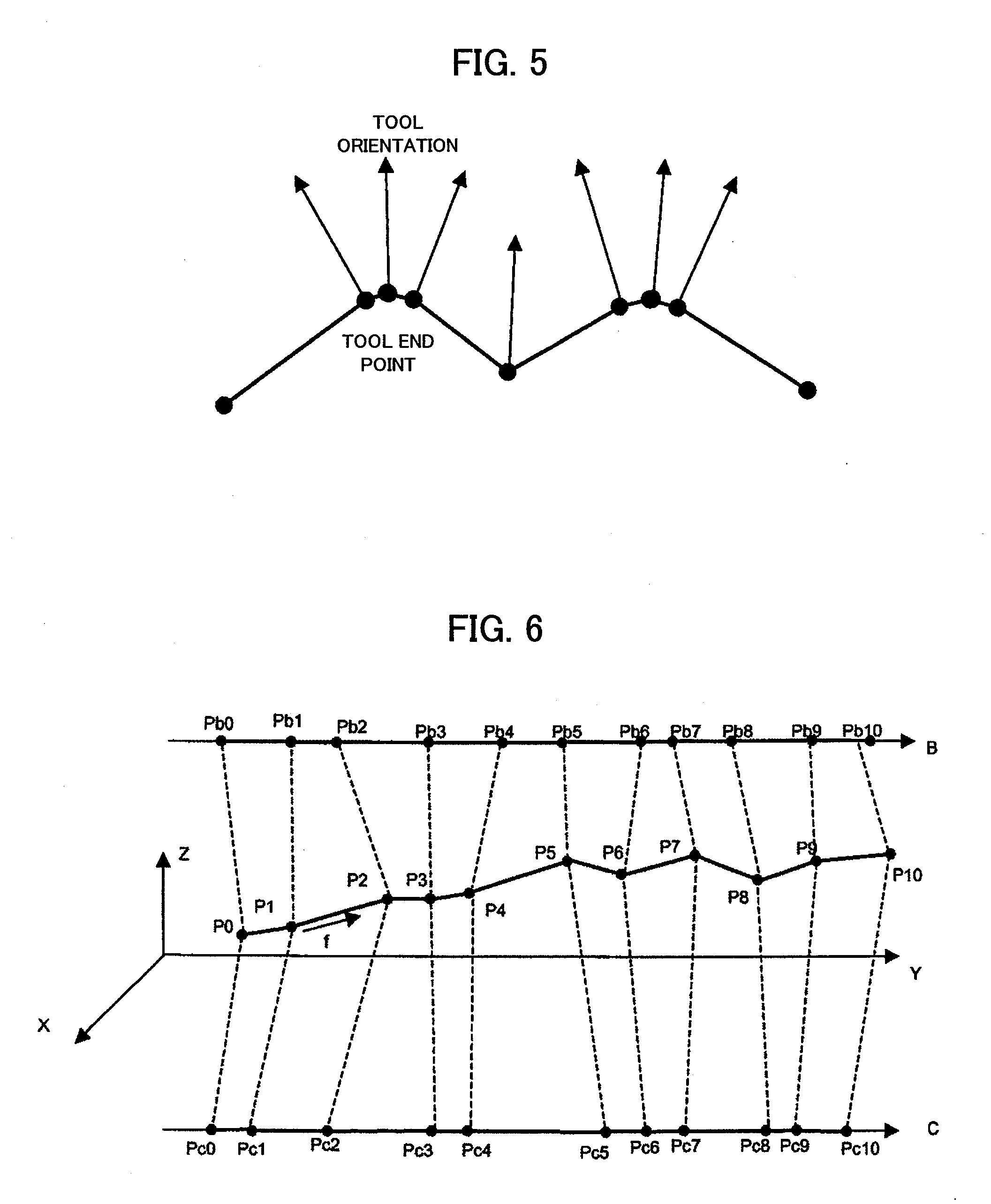

Numerical controller for controlling five-axis machining apparatus

ActiveUS20090157218A1Reduce processing timeFlat shapeComputer controlSimulator controlMachined surfaceEngineering

A numerical controller for controlling a five-axis machining apparatus, in which a tool orientation command is corrected to thereby attain a smooth machined surface and a shortened machining time. The numerical controller includes command reading means that successively reads a tool orientation command, tool orientation command correcting means that corrects the tool orientation command so that a ratio between each rotary axis motion amount and a linear axis motion amount is constant in each block, interpolation means that determines respective axis positions at every interpolation period based on the tool orientation command corrected by the tool orientation command correcting means, a motion path command, and a relative motion velocity command such that a tool end point moves along a commanded motion path at a commanded relative motion velocity, and means that drives respective axis motors such that respective axis positions determined by the interpolation means are reached.

Owner:FANUC LTD

A kind of processing method of jujube chips

The invention discloses a processing method of red jujube chips. After cleaning the red dates, remove the pits, slice them, and freeze them, then take out the frozen jujube slices and dry them under vacuum at 50-600Pa and 30-50°C for 1-2 hours. 3h, and finally sterilized under microwave and vacuum packed. The present invention adopts the combination method of freezing and vacuum drying to prepare red jujube chips, and while retaining the original flavor, color, nutrition and crispy taste of fruits and vegetables to the greatest extent, it also retains the original appearance and shape of jujube chips, making the product smooth , bright color, and has moisture absorption resistance, short production cycle, low energy consumption.

Owner:SHAANXI UNIV OF SCI & TECH

Production method for ready-to-eat instant nutritive edible fungus soup

The invention discloses a production method for ready-to-eat instant nutritive edible fungus soup, which belongs to the technical field of deep processing of agricultural products. The production method mainly comprises the steps of selecting, cleaning, precise cutting, mixed boiling, spreading, pre-freezing and microwave vacuum freeze drying on screened raw materials such as edible fungi, thus obtaining the product which is subjected to nitrogen-filled packaging after being taken out of storage. The raw materials of the edible fungus soup is dewatered by a microwave vacuum freeze drying technology according to a modern food nutrition principle, so that the original color, aroma, taste and nutrients of the product are kept to the hilt, and compared with those of a conventional process, the drying efficiency is remarkably improved, the production cycle is shortened, the production cost is effectively reduced, and the special sterilizing effect of microwaves further guarantees the product quality at the same time. The edible fungus soup produced by the method is flat in shape, bright in color and luster, rich in nutrition, good in water regaining effect and long in storage time, and a feasible new way is provided for deep processing and utilization of the edible fungi.

Owner:NANJING UNIV OF FINANCE & ECONOMICS +1

Manufacture method of cold-rolled electrolytic tin substrate

ActiveCN102794301AStable productionReduce manufacturing costWork treatment devicesFurnace typesHydrogenPush pull

The invention discloses a manufacture method of a cold-rolled electrolytic tin substrate. The manufacture method comprises the steps of: (1) processing the produced molten iron by converter smelting, vacuum treatment, continuous casting and hot rolling after desulfuration to obtain a cold-rolled material; (2) pickling by a shallow-trench turbulent push-pull hydrochloric acid pickling set; (3) carrying out cold rolling for the first time by using a six-roller HC reversing mill, and rolling to a semi-product with a thickness of 0.5 to 0.6 mm after passing through 4 to 7 rolling passes; (4) cleaning by an electrolytic degreasing set; (5) carrying out annealing for the first time in a full-hydrogen shine-cover annealing furnace; (6) carrying out cold rolling for the second time by using the six-roller HC reversing mill; (7) carrying out annealing for the second time in the full-hydrogen shine-cover annealing furnace; (8) leveling by using a four-roller leveling machine, wherein the rolling force is controlled between 3000 to 4500kN; and (9) trimming by a re-reeling set, oiling, packaging and storing in a warehouse. The manufacture method disclosed by the invention has the advantages of stable production and low production cost, and can meet the requirement for high-quality electrolytic thin substrate in the food package industry.

Owner:山东泰山轧钢有限公司

Baked snack

InactiveUS20070098865A1Improve textureAdd flavorLeguminous plant bakery productsBaking mixturesHigh volume manufacturingGluten

A baked snack having a hollow stick shape obtained by baking a dough including an non-gelatinized flour and a gelatinized flour, wherein the dough does not substantially include active gluten. According to the present invention, a baked snack having a hollow stick shape that can be reliably shaped, easily melts in the mouth and is well-moistened with no powdery and dry texture is provided. In the baked snack of the present invention, a large amount of taste providing material can be blended in order to improve the taste thereof. The novel baked snack having the hollow stick shape suitable for the mass production and processing and having an even shape with reduced blistering can be provided without demanding any special device and complicated process.

Owner:EZAKI GLICO CO LTD

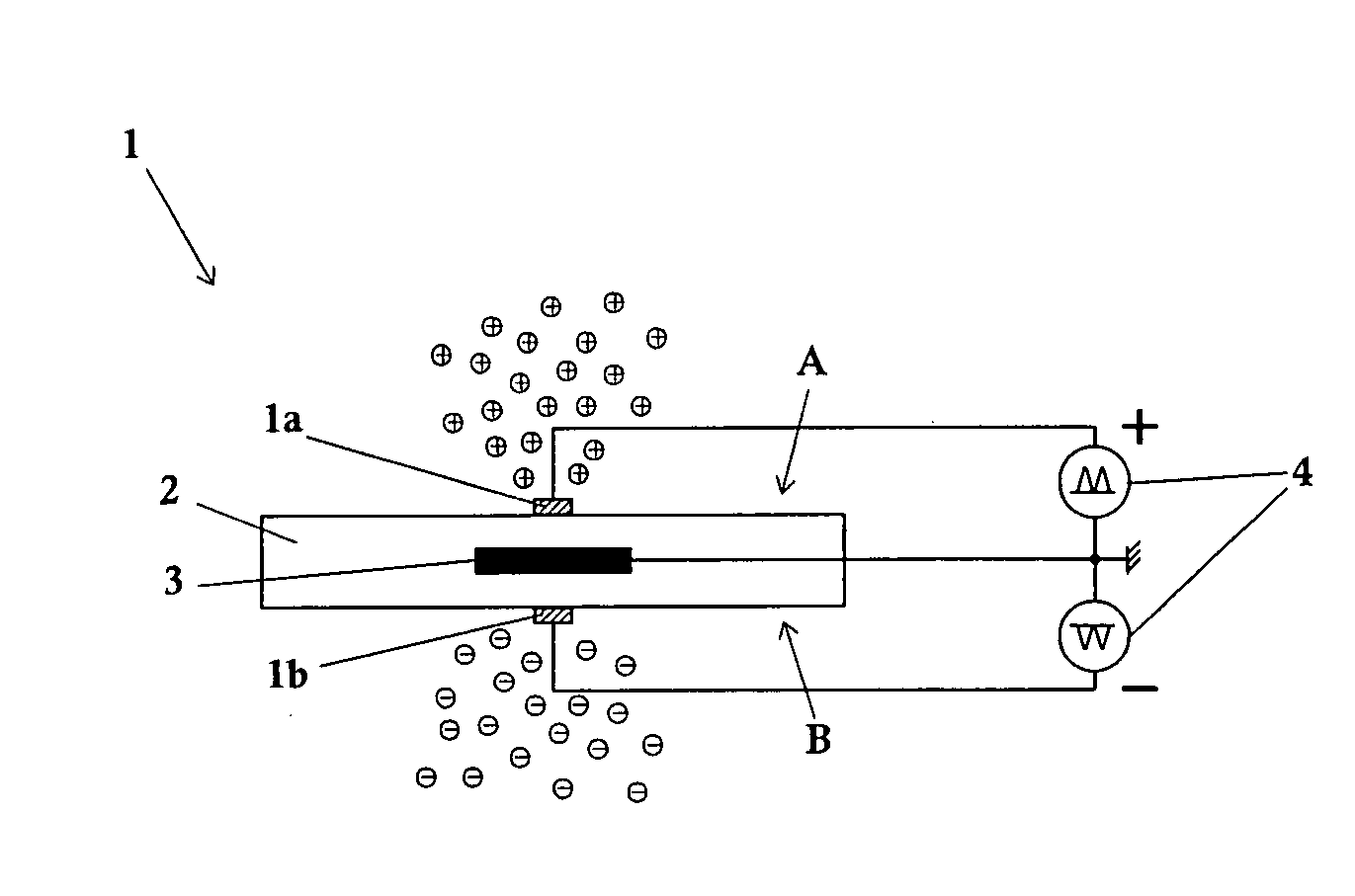

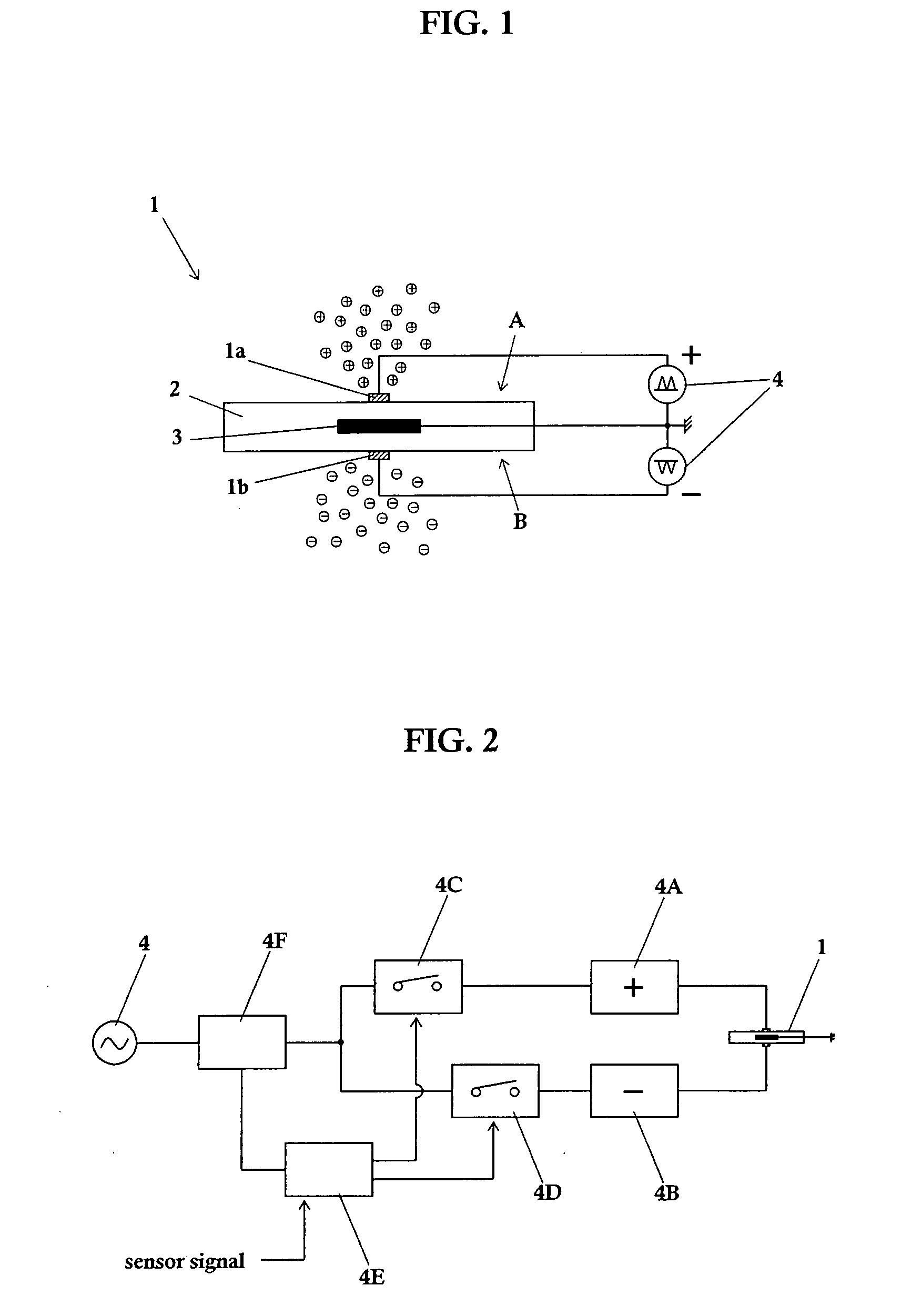

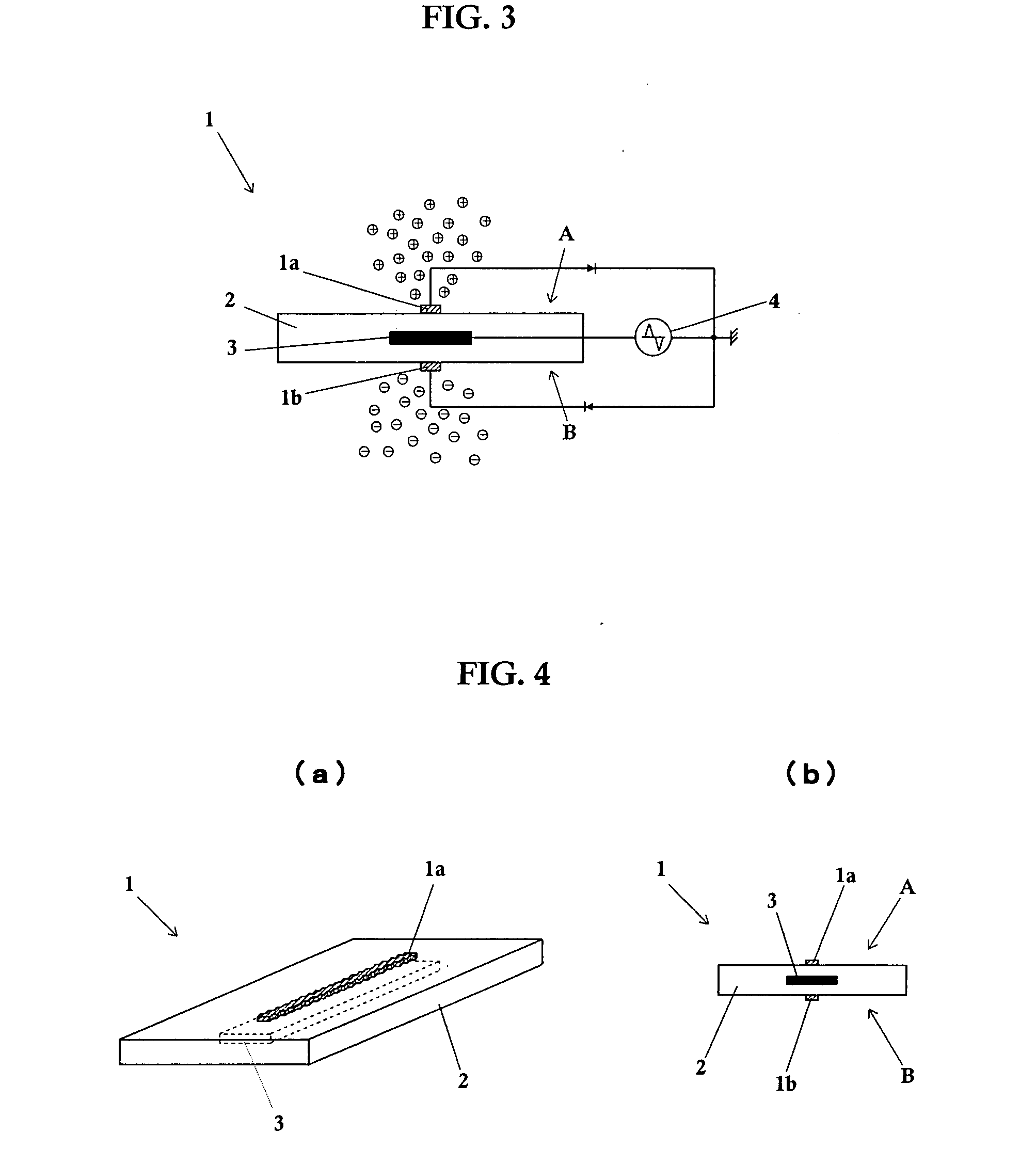

Ion Generating Element, Ion Generator and Neutralizer

InactiveUS20090207548A1Stable ion generationSolve the low generation efficiencyCorona dischargeElectrostatic chargesIonElectricity

An ion generating element capable of cost reduction and space saving while exhibiting a high generation efficiency of positive ions and negative ions and stabilized generation capacity with less variation, and an ion generator and a neutralizer employing it. The ion generating element comprises a dielectric body having at least two faces, at least two discharge electrodes arranged on the at least two faces of the dielectric body, and an induction electrode arranged in the dielectric body and subjected to the action of the at least two discharge electrodes and is characterized in that positive ions and negative ions are generated on the body, and ions are generated from the at least two faces of the dielectric body through discharge generated because of the potential difference between the discharge electrode of the ion generating element and the induction electrode when a drive voltage is applied between them.

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

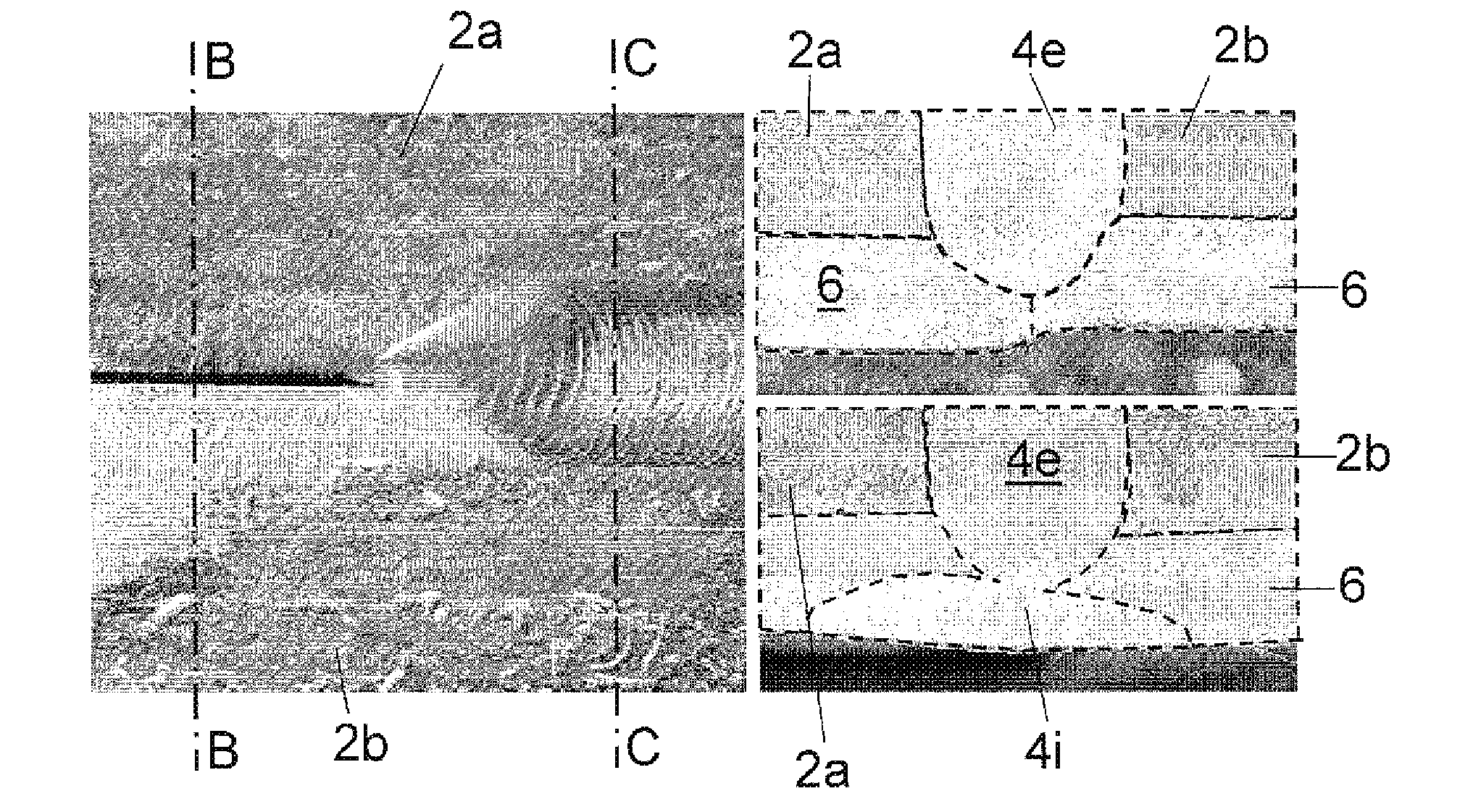

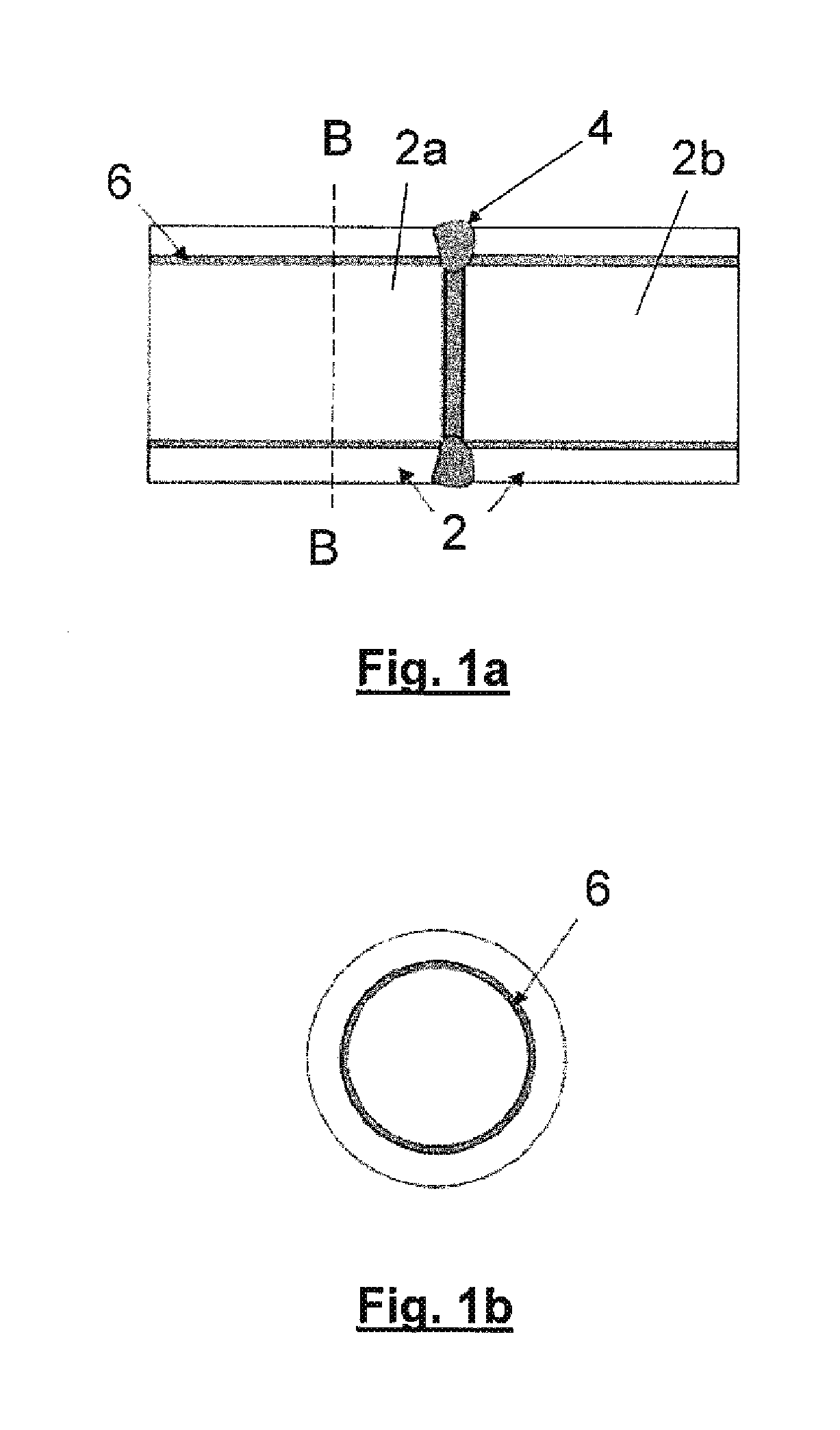

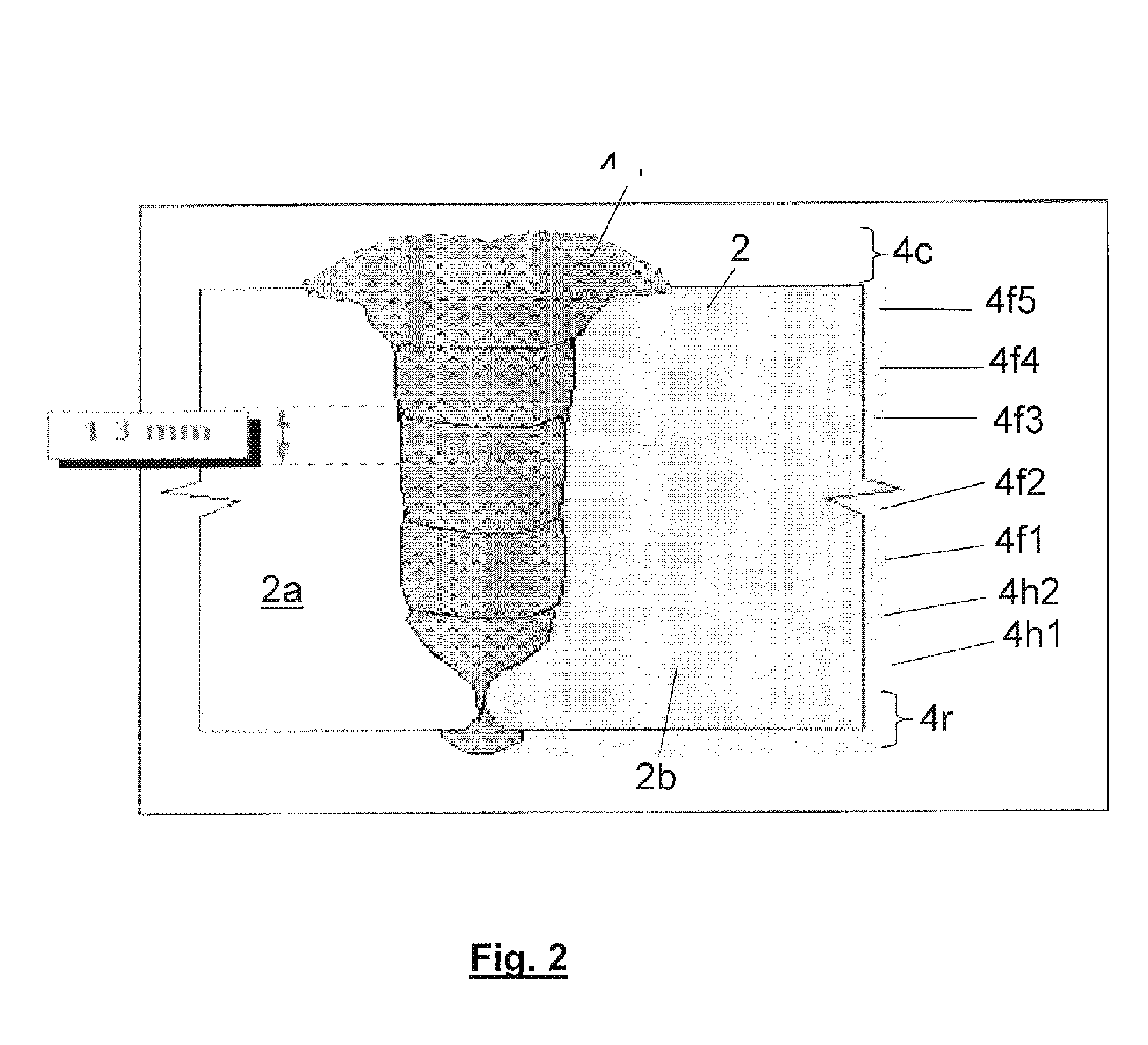

Method of and a welding station for laying a pipeline, with pipe section welded together by internal and external welding

ActiveUS20120298628A1Reduce chanceImprove welding qualityWelding/cutting auxillary devicesArc welding apparatusCorrosion resistant alloyEngineering

A method of laying a pipeline is described in which both internal and external weld passes are performed in order to weld together the pipe sections. The method includes arranging a pipe section adjacent to the end of a pipeline thereby defining a circumferential joint to be welded, performing an external weld pass, with for example GMAW—MIG torches, on the root of the joint to be welded during which weld material is deposited in the root of the joint to be welded, thereby forming a root weld, and then performing an internal weld pass, with for example a GTAW—TIG torch, on the root weld during which the root weld is melted and re-shaped. The method has particular application in relation to pipes clad with corrosion resistant alloy.

Owner:SAIPEM SPA

Preparation method for plate for aluminium alloy carriage

The invention provides a preparation method for a plate for an aluminium alloy carriage. The preparation method comprises the following contents that: (1) the plate for the aluminium alloy carriage comprises the following components: 0.05 to 0.4 weight percent of Si, 0.15 to 0.45 weight percent of Fe, 0.03 to 0.15 weight percent of Cu, 0.3 to 0.6 weight percent of Mn, 4.6 to 5.8 weight percent of Mg, 0.03 to 0.15 weight percent of Cr, 0.01 to 0.03 weight percent of Ti, and the balance of Al and unavoidable impurities; (2) a manufacturing method comprises the following steps: taking aluminium ingots, aluminium intermediate alloy ingots, magnesium ingots, a manganese agent, a copper agent and a chromium agent as raw materials; performing low liquid level casting after smelting, preserving heat, degassing, and double-stage deep bed filtering are performed; and performing the processes of sawing and surface milling, heating, hot rolling, cold rolling, cleaning, annealing, stretching and straightening, and transversely shearing to obtain the plate for the aluminium alloy carriage. The obtained plate for the aluminium alloy carriage has high strength, a flat and neat plate shape, and good corrosion resistance, good bending machining performance and welding performance.

Owner:CHINALCO RUIMIN

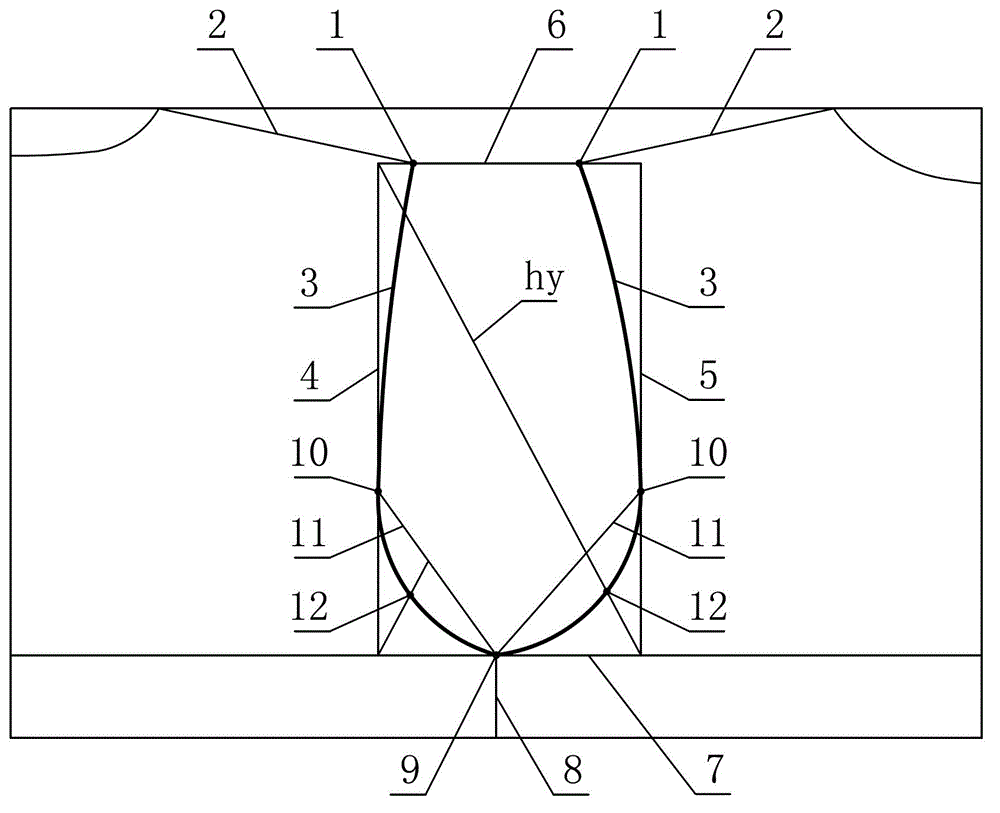

Original number tailoring method for clothing armhole

The invention relates to an original number tailoring method for a clothing armhole, which comprises the steps that original clothing numbers, namely the armhole perimeter, the chest width, the back width, the shoulder width, the chest circumference and the clothing length are determined according to anthropometric data; the armhole is designed into a notched ellipse; a diagonal line of an external rectangle of the notched ellipse is a perimeter mark hy; and the ratio of the perimeter mark hy to the armhole perimeter is y; an hy operational method is created; a base line of the external rectangle of the notched ellipse and an armhole circumflexion identification line are determined according to the original clothing numbers, such as the armhole perimeter, the chest width, the back width, the shoulder width and the chest circumference; then, relevant points are determined; and an armhole perimeter line is drawn. The armhole tailoring method is quick in tailoring and high in the precision of the armhole tailoring line, meets the fast-paced requirements of the clothing market on clothing transformation, is applicable to the tailoring of high-grade clothing, and is simple, convenient and practical.

Owner:NANJING JIHUA NO 3503 GARMENT

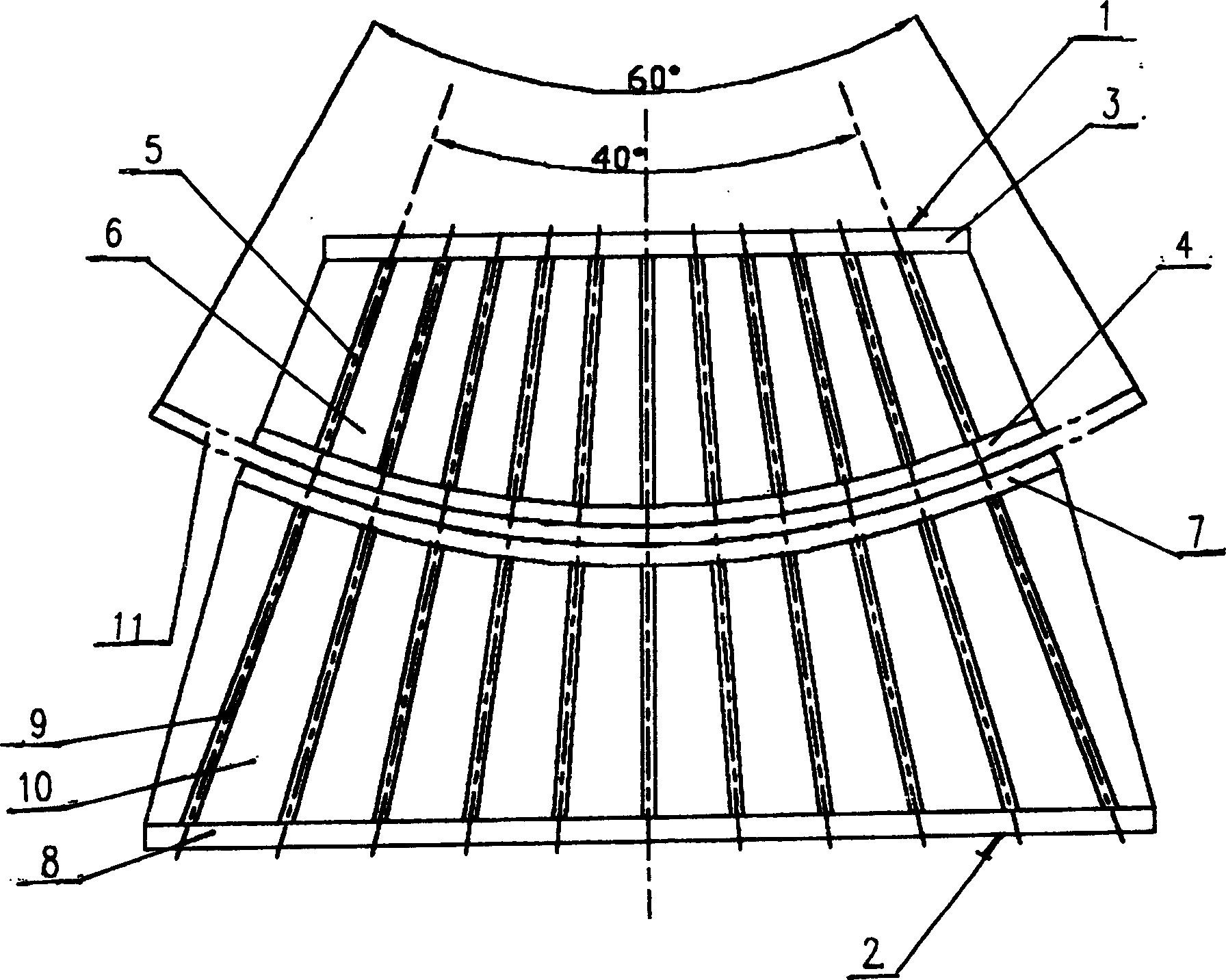

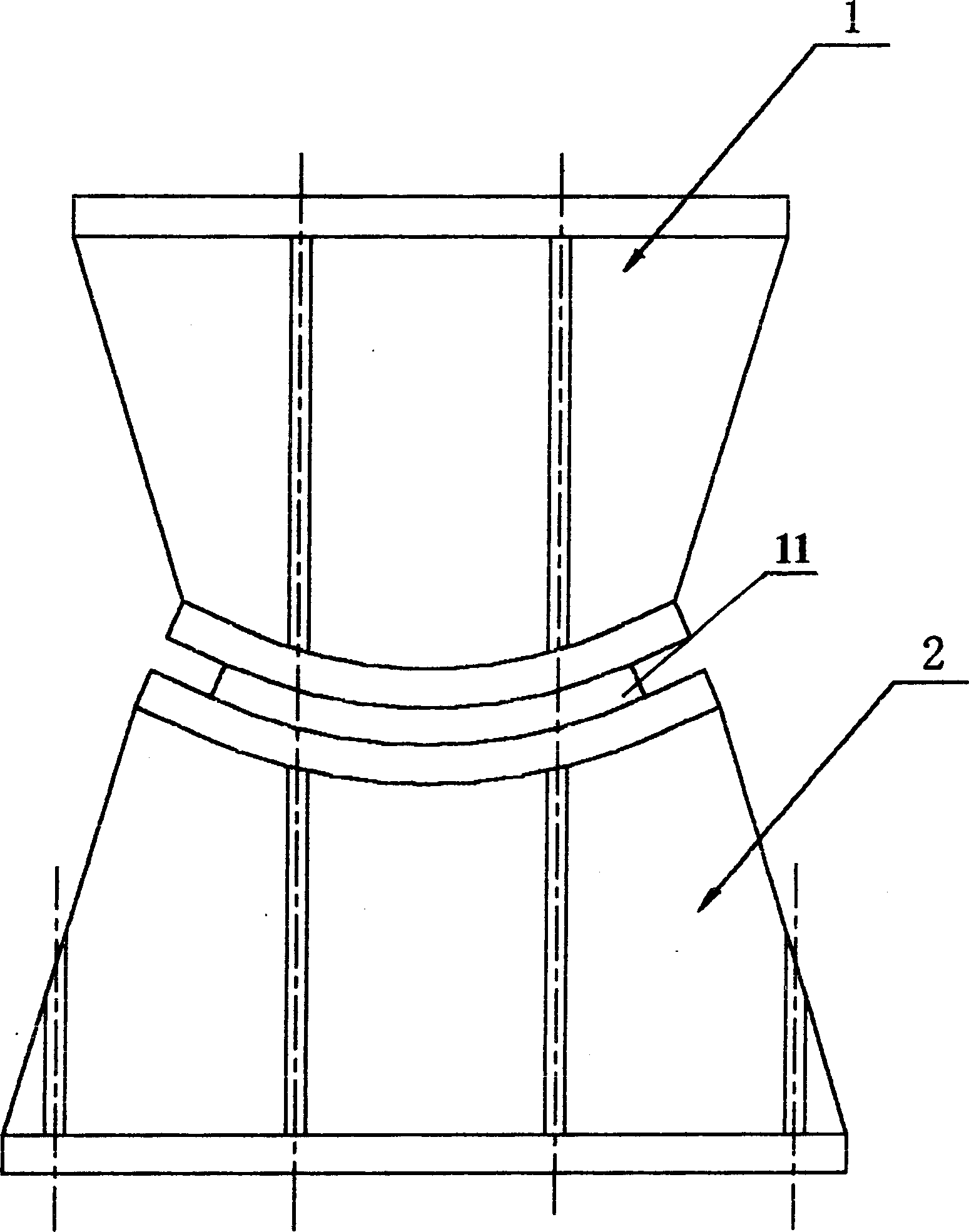

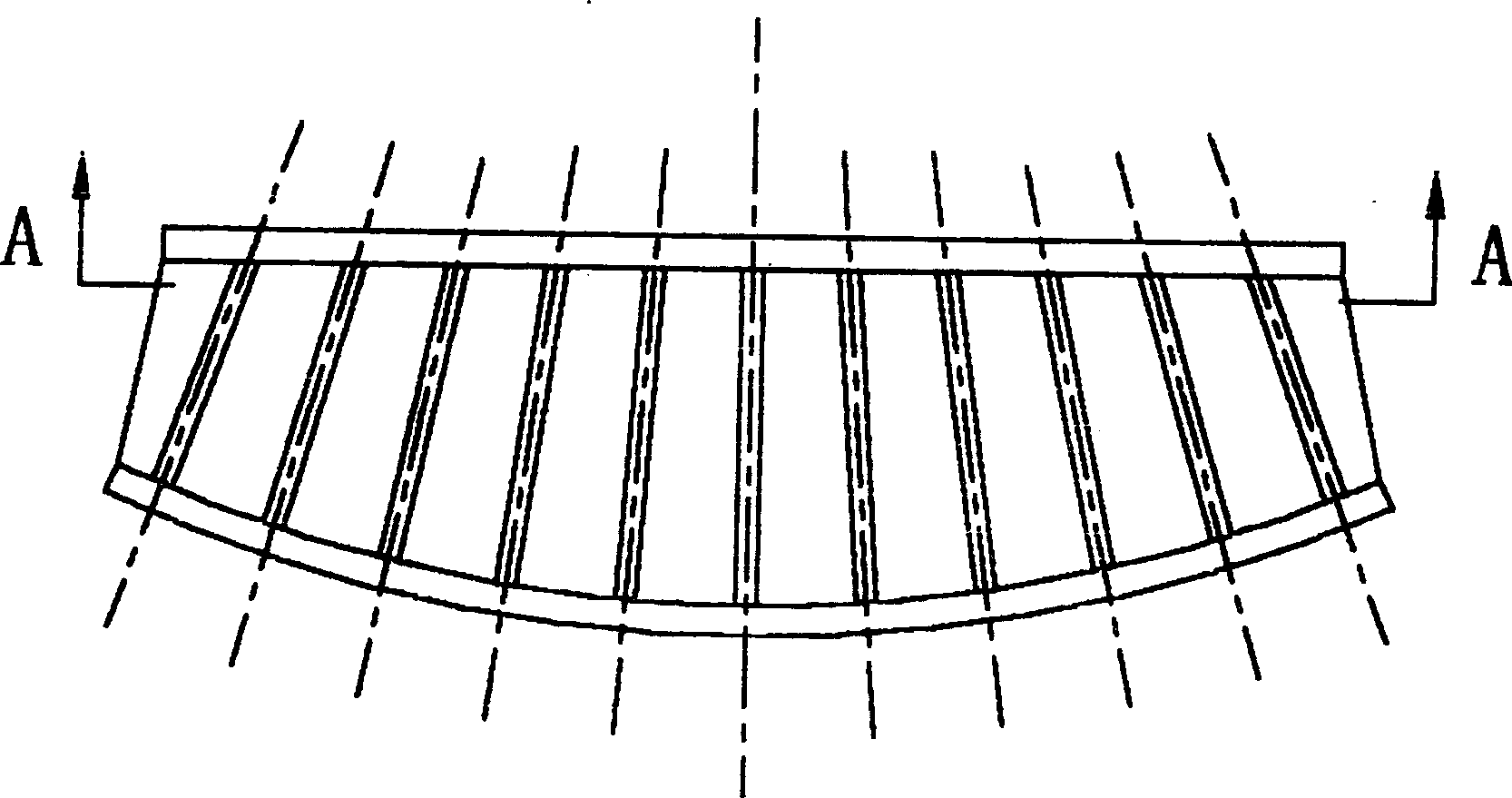

Double curvature plate cold press forming method and equipment thereof

The present invention relates to double curvature plate cold pressing formation method and apparatus. The formation process includes the following steps: determining the rebound elasticity of cold pressed steel plate, determining the curvature radius and size of upper and lower working plates, setting plate material, cutting, pressing, etc. The formation apparatus includes upper pressing mold, lower pressing mold, reinforcing ribbed plates welded onto the top plate, upper working plate, lower working plate and bottom plate, and oil press. The present invention makes it possible to produce high quality double curvature plate with smooth surface.

Owner:中国船舶集团渤海造船有限公司

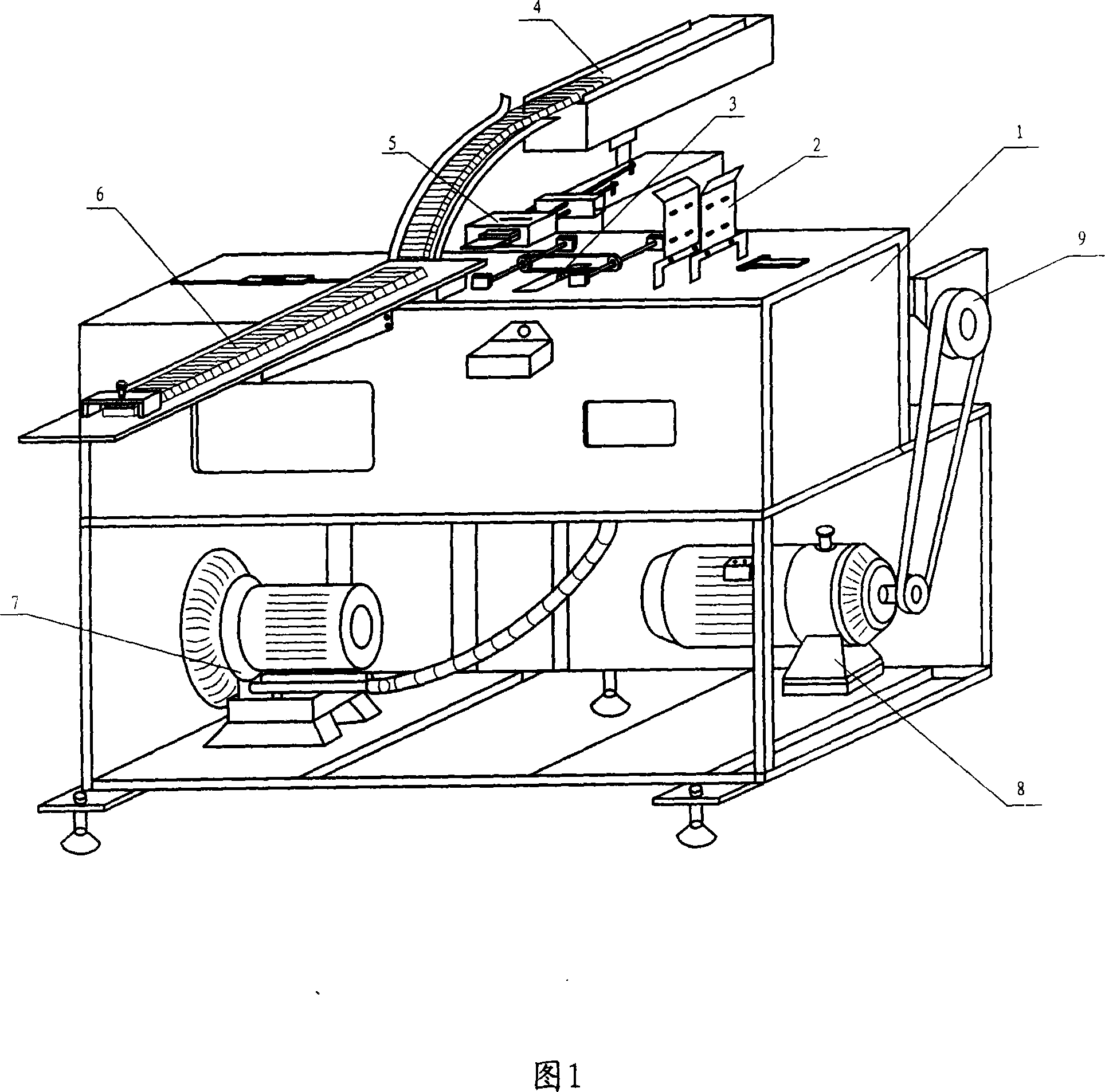

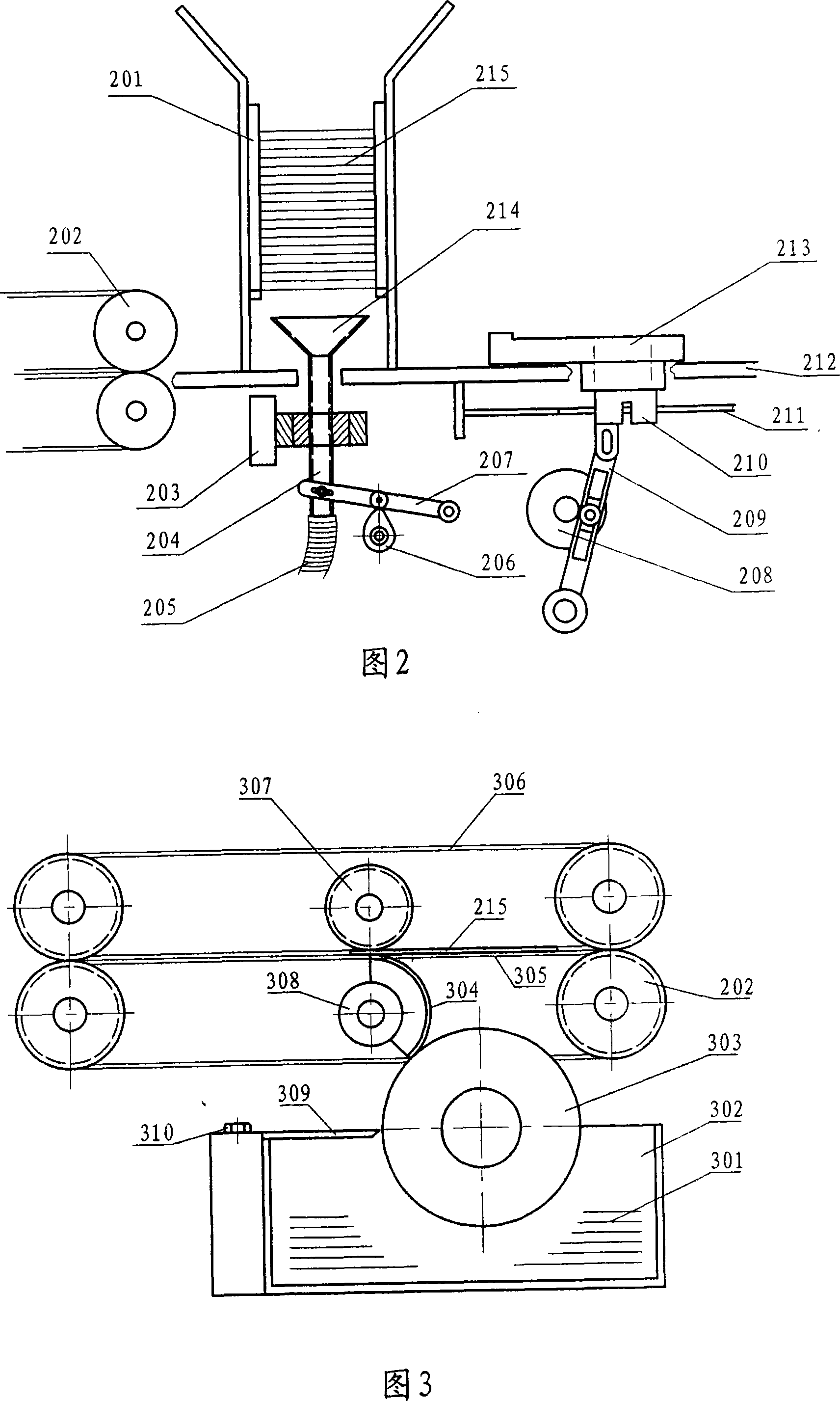

Erasing rubber trade mark paper bundle pasting machine

InactiveCN101117162AReduce laborFlat shapeLabelling flat rigid surfacesLabelling machinesTrademarkPulp and paper industry

An eraser label paper wrapping and gluing machine is used to wrap and glue label paper on eraser, comprising a machine body provided with a paper feeding mechanism, a glue pasting mechanism, an eraser feeding mechanism, a paper folding mechanism, a finished product output mechanism, a fan, a motor and a driving device seperately, wherein the air suction port of the fan faces the paper feeding mechanism; the motor is connected with the paper feeding mechanism, the glue pasting mechanism, the eraser feeding mechanism, the paper folding mechanism and the finished product output mechanism respectively through the driving device. The working procedure of the invention is that: label paper is conveyed to the glue pasting mechanism for glue spreading by the paper feeding mechanism; eraser and label paper after glue spreading by the glue pasting mechanism is conveyed to the paper folding mechanism for wrapping and gluing in opposite direction and then are output by the finished product output mechanism. The invention realizes fully automatic wrapping and gluing of eraser label paper by machinery and obtains leveled-off wrapping and gluing shape, firm gluing and aesthetic appearance; meanwhile, the work efficiency of the invention is 15 times of that of manual wrapping and gluing, thereby greatly increasing labor efficiency so as to help enterprises cut down recruitment to lower cost.

Owner:NINGBO WENBAI MACHINERY MFG

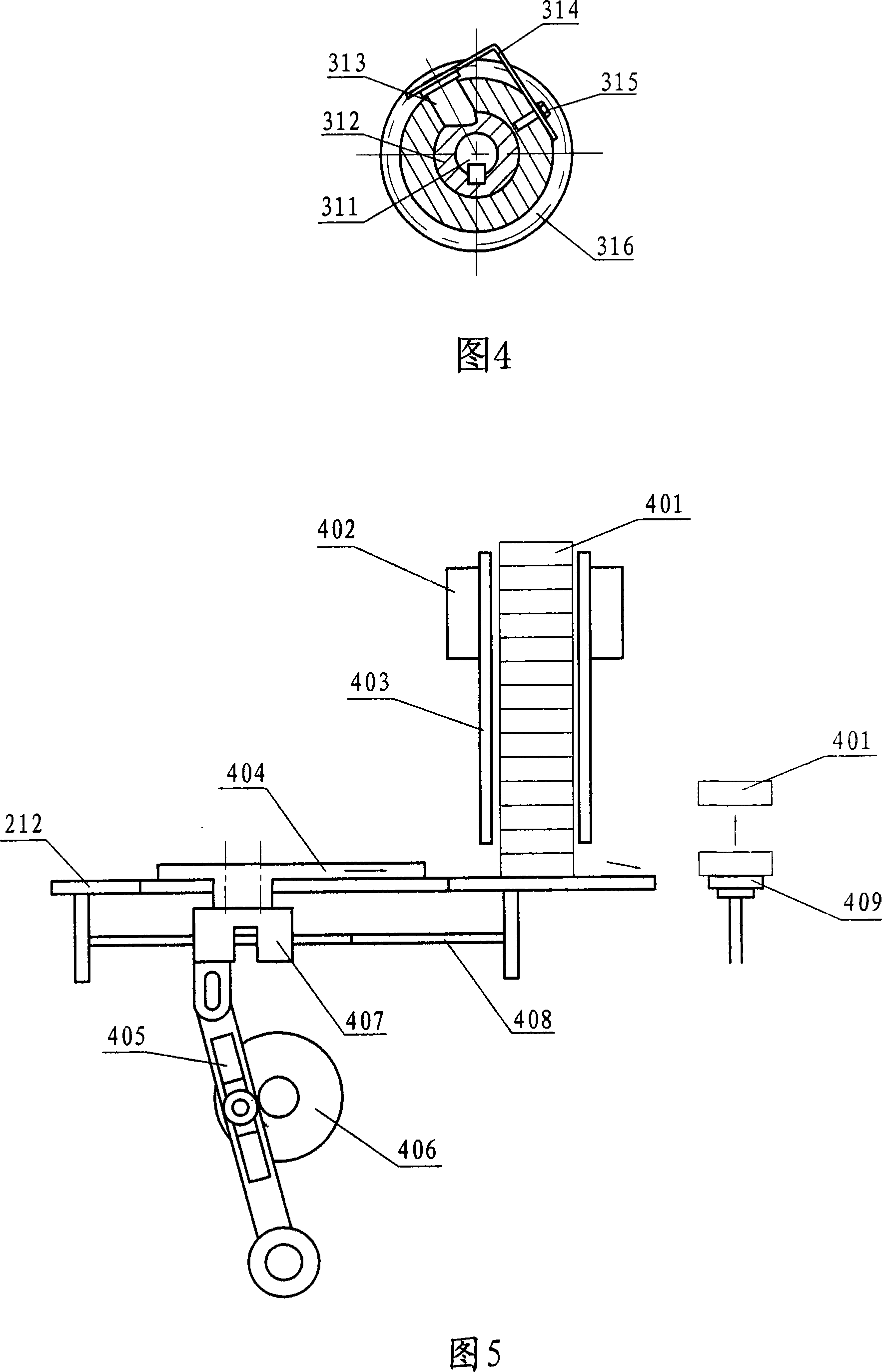

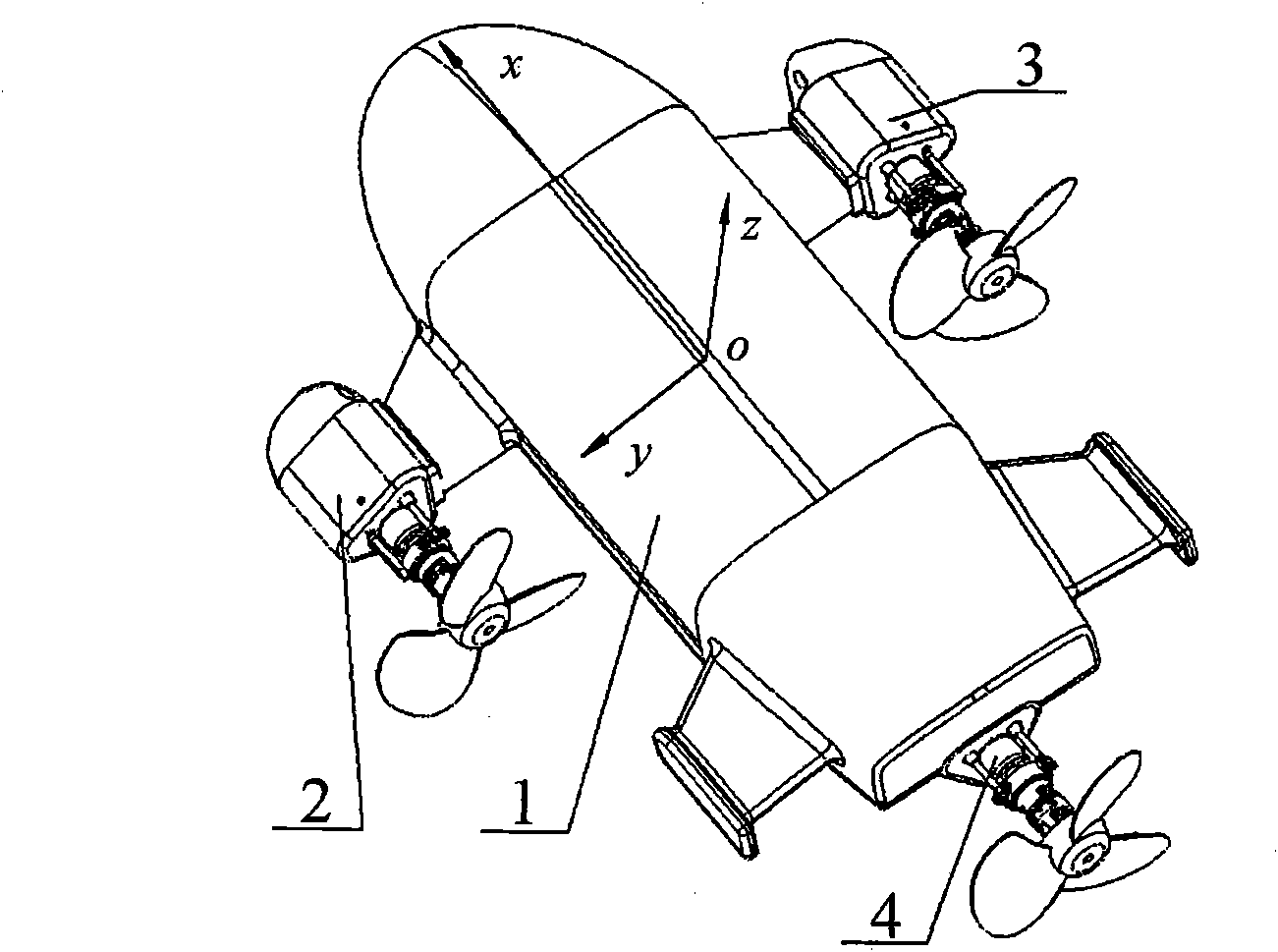

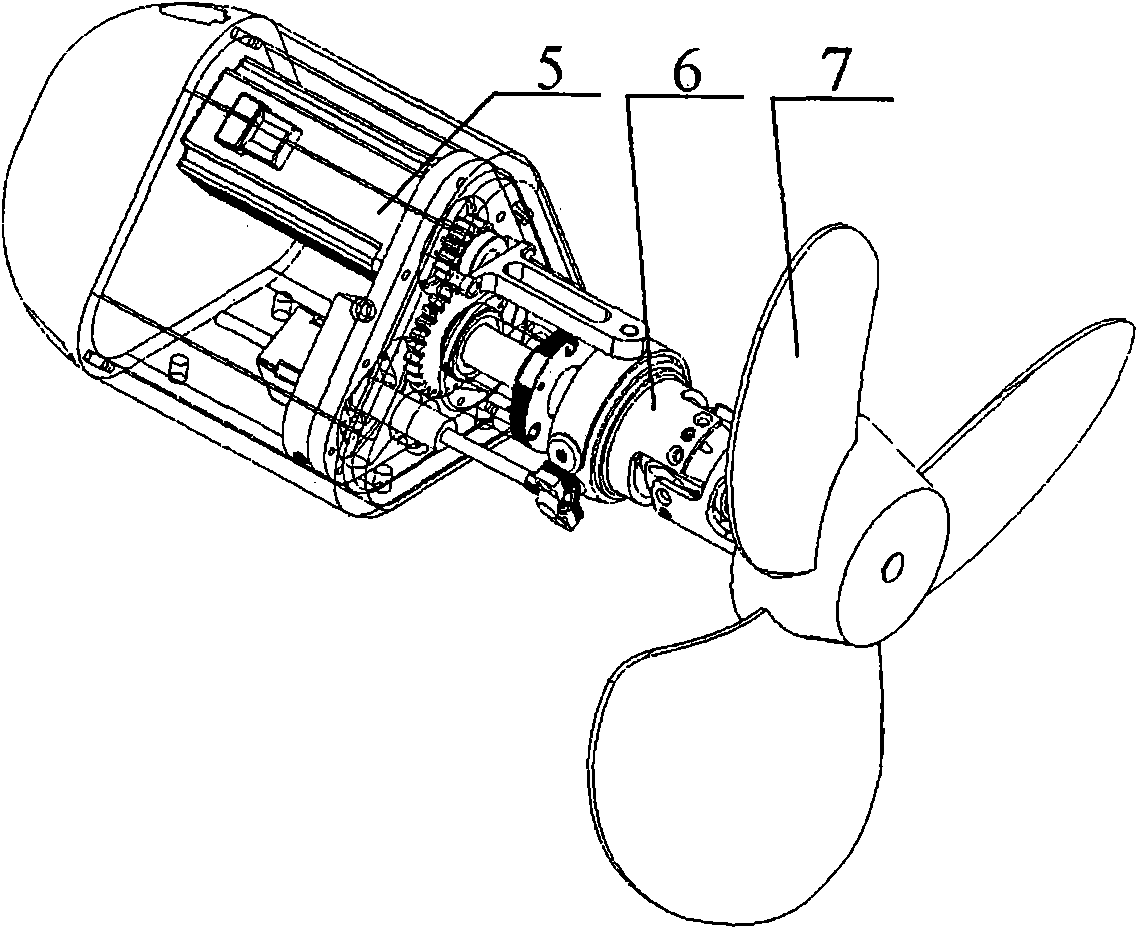

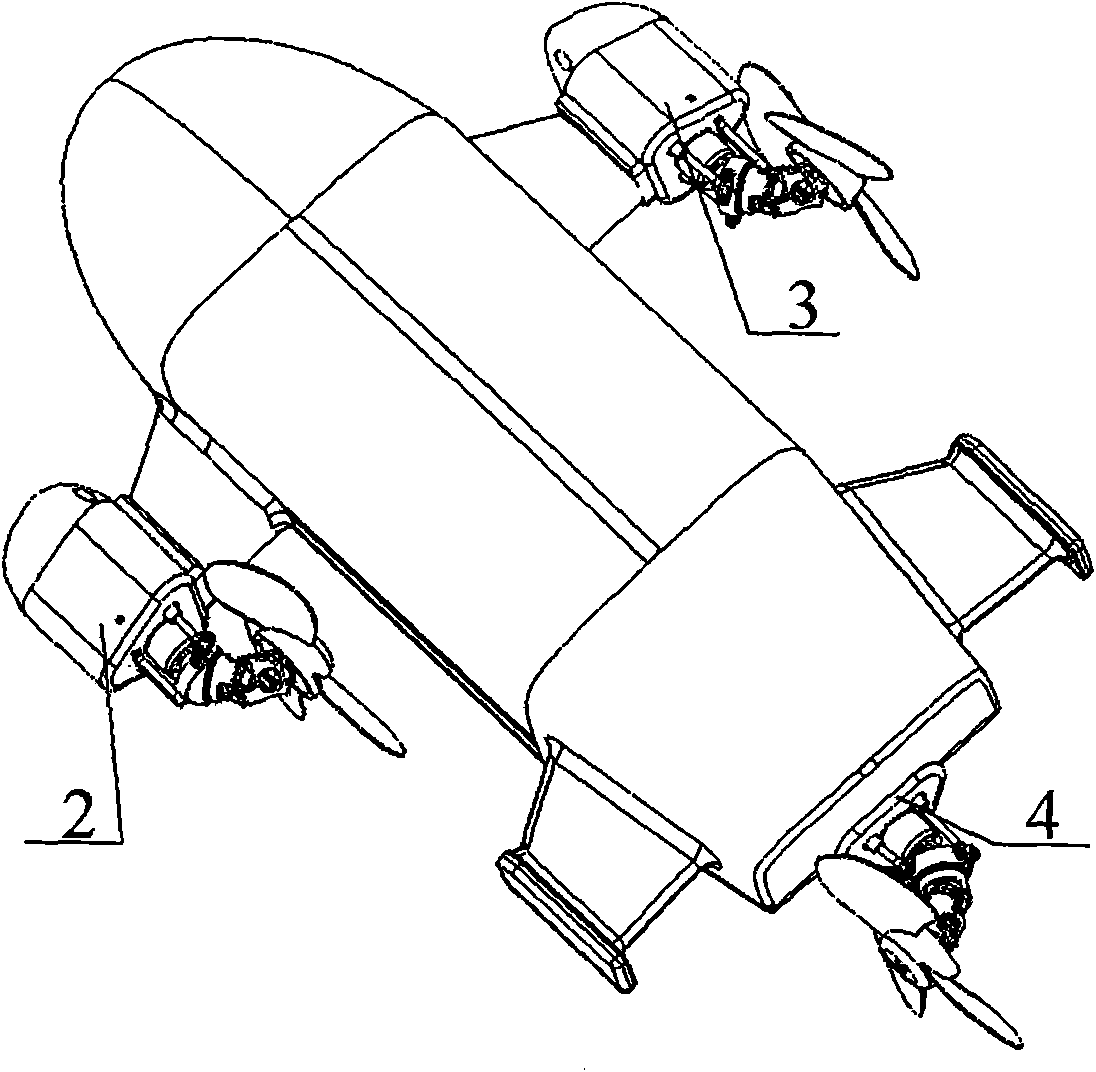

Active vector thrusting method of three screw propellers

InactiveCN101596931ASimplify the propulsion systemImprove portabilityUnderwater vesselsUnderwater equipmentUnderwaterPropeller

The invention provides an active vector thrusting method of three screw propellers, comprising the following steps: (1) mounting three sets of screw propeller active vector thrusters on an underwater aircraft carrier (1), wherein the first and second screw propeller active vector thrusters (2,3) are transversely symmetrically arranged at the two wings of the underwater aircraft carrier (1); the third screw propeller active vector thruster (4) is arranged at the tail of the underwater aircraft carrier (1); and (2) realizing the forward moving, backward moving, turning, floating upward, submerging, yawing, pitching, underwater suspending, lateral translating and controllable rolling of the underwater aircraft by operating the three sets of screw propeller active vector thrusters. The invention greatly simplifies the thrusting system of the underwater aircraft, has strong portability, practicality, simple structure, smooth outline and low cost.

Owner:NAT UNIV OF DEFENSE TECH

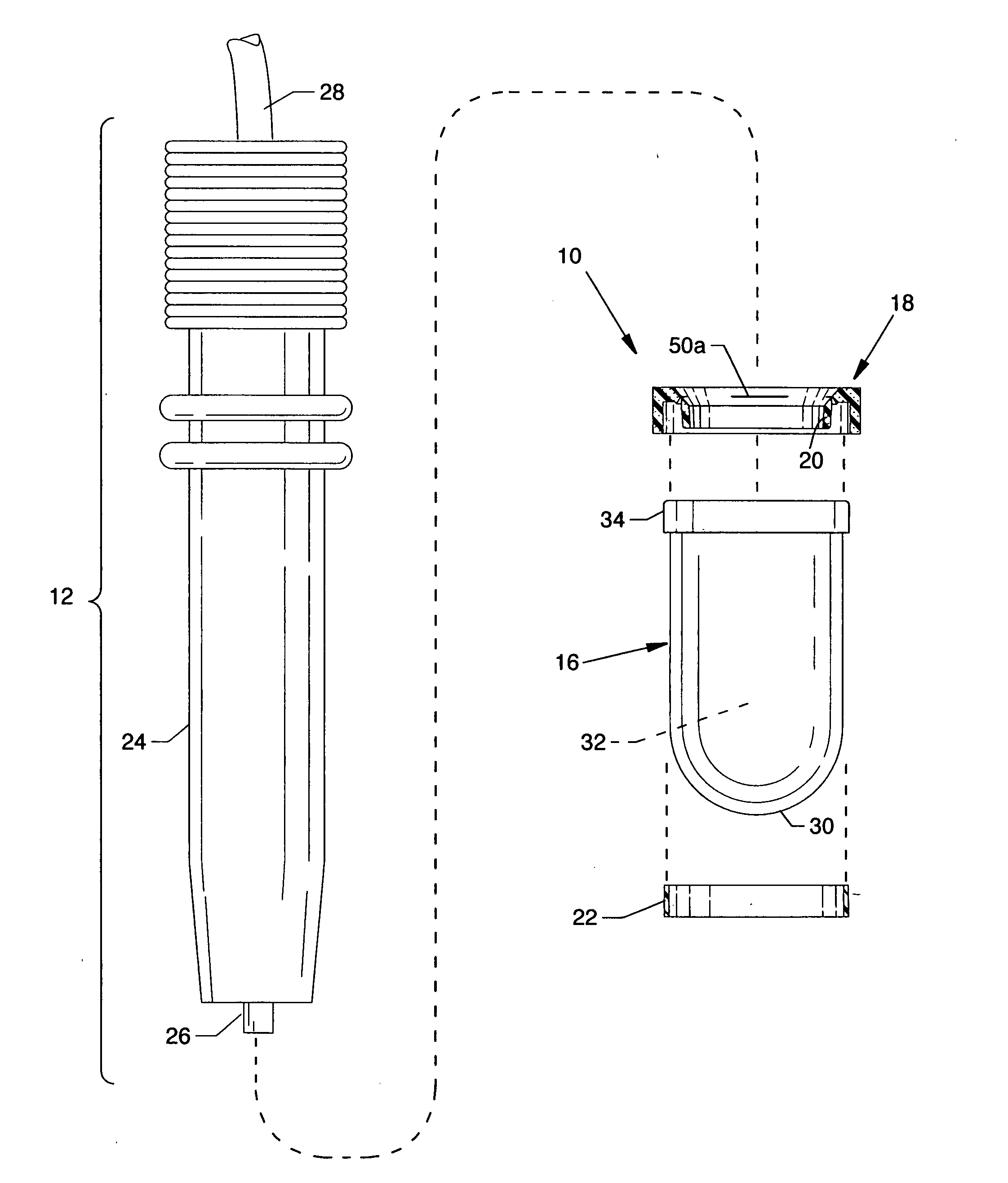

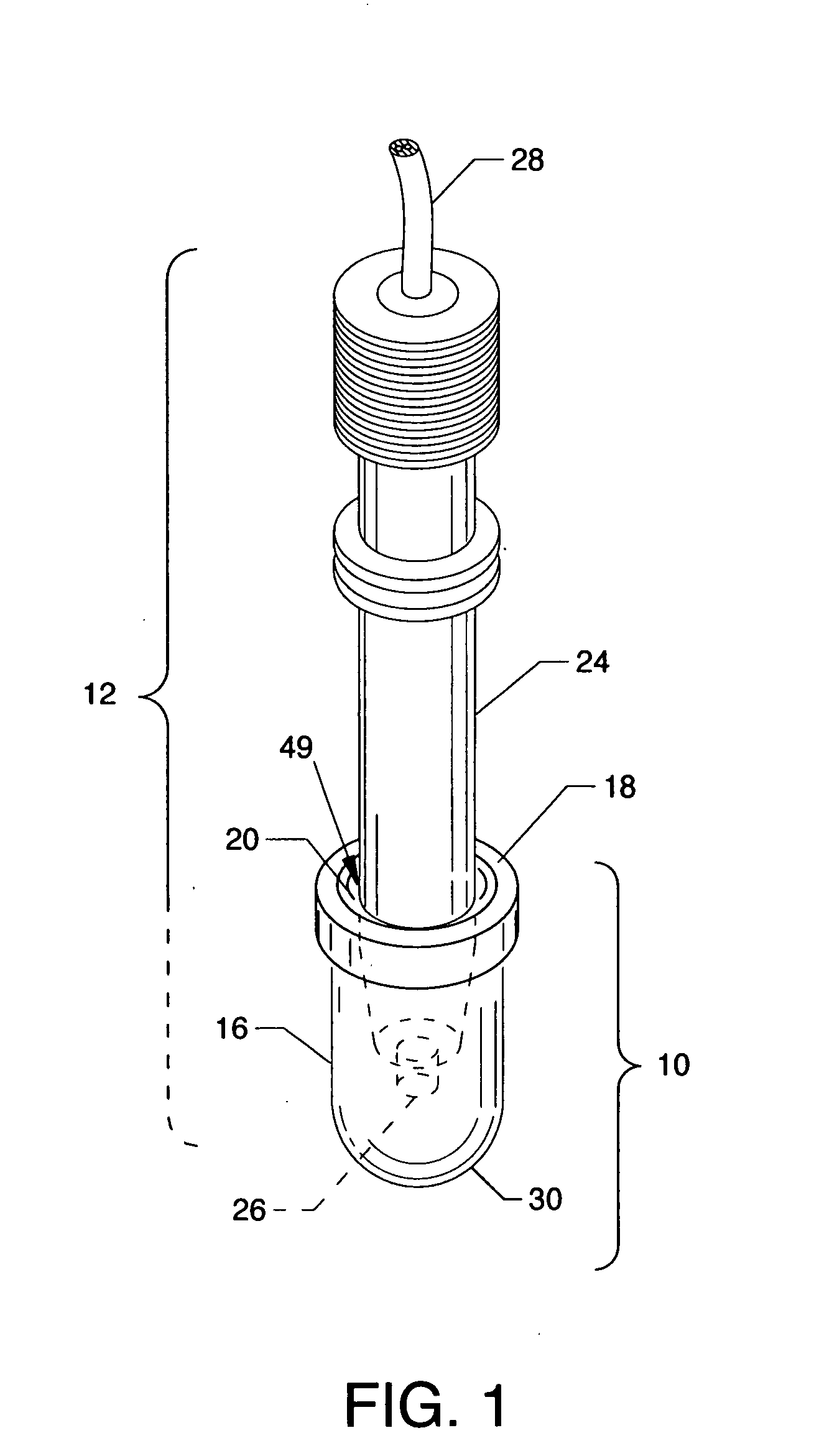

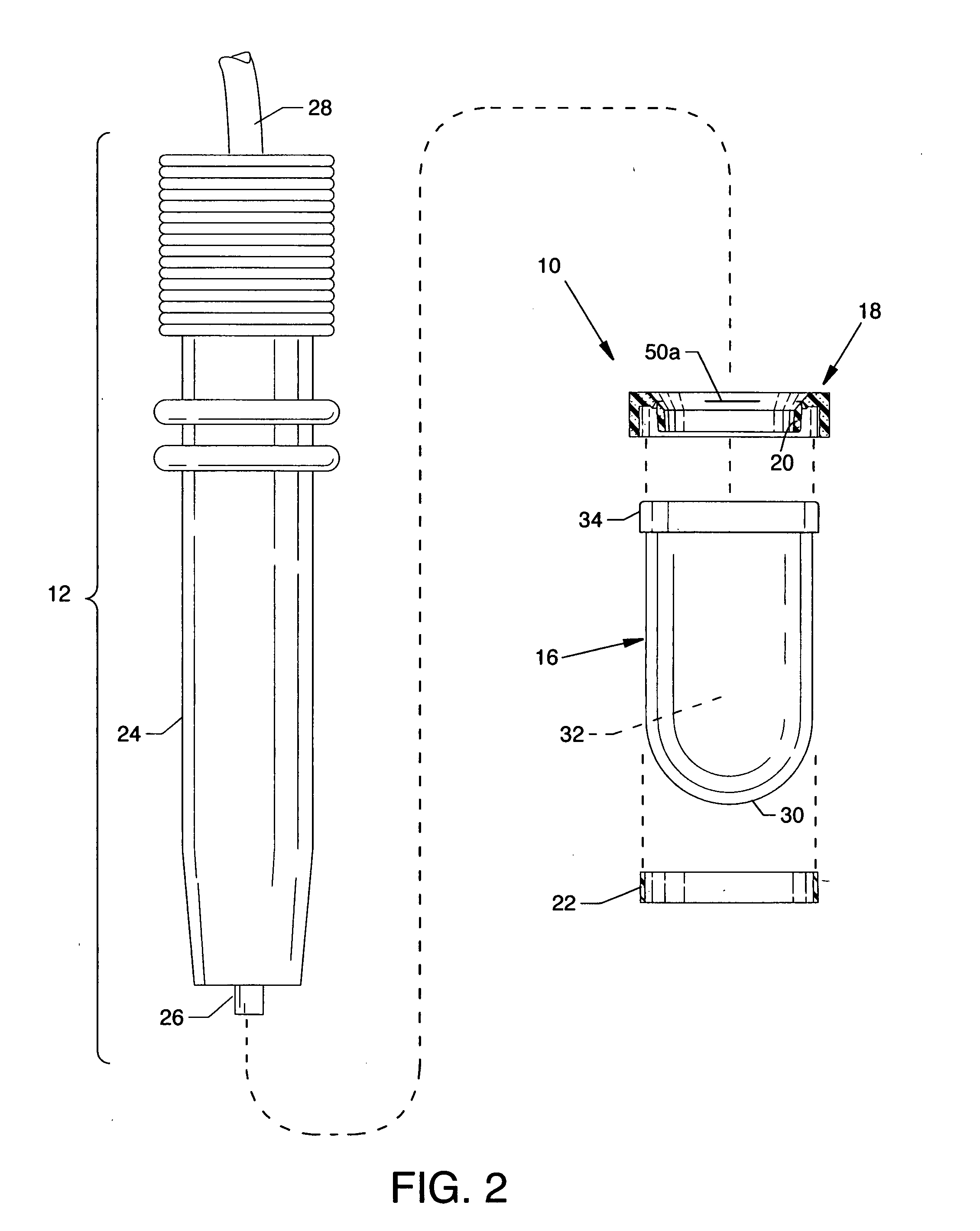

Immersion bag system for use with an ultrasound probe

ActiveUS20080161693A1Reduce the possibilityAvoid structureMaterial analysis using sonic/ultrasonic/infrasonic wavesInfrasonic diagnosticsEngineeringVertical axis

An immersion bag system for use with an ultrasound probe to overcome near field artifact includes a flexible thin wall thickness immersion bag with an attached flexible collar having an integral internal seal. The immersion bag contains a gel or other ultrasound transmission medium and is sealingly and removably attached by a mutually formed probe / seal valve to the tip end of an ultrasound probe. The immersion bag is able to conform to a cornea, as well as to other surfaces, whether flat or irregular, thereby enabling an ultrasound probe to be used easily on such surfaces. An ultrasound probe in use with the immersion bag system is maintained at a distance above the contact surface of the immersion bag and is positionable about the vertical axis while the immersion bag maintains stationary conformal contact with the structure against which it is in contact.

Owner:ESI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com