High-strength mobile phone medium plate aluminum alloy strip and preparing method thereof

A technology of aluminum alloy strip and manufacturing method, which is applied in metal rolling and other directions, can solve the problems of dredging to the outside, and achieve the effects of good forming performance, flat shape, and increased elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

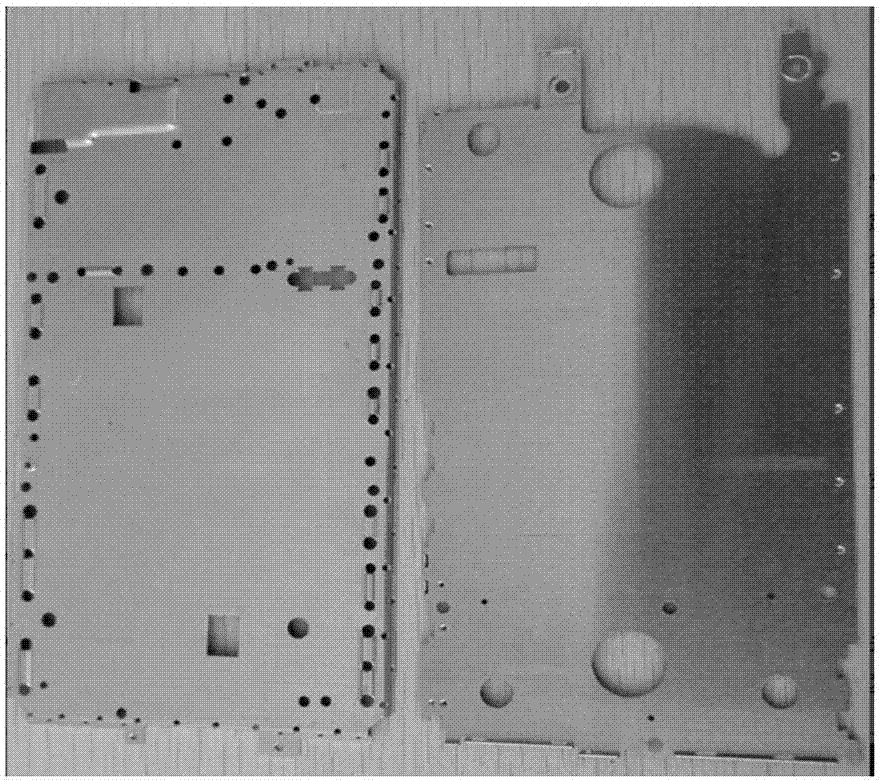

Image

Examples

Embodiment 1

[0034] The composition and mass fraction percentage of a high-strength aluminum alloy strip for mobile phone plates are: Fe 0.18%, Si 0.05%, Cu 0.02%, Mn 0.22%, Mg 5.76%, Cr 0.03%, Zn 0.01%, Ti 0.01%, others: 0.05%, the rest is Al, and the sum of the content ratios of each component is 100%.

[0035] The manufacturing method of the aluminum alloy strip for the high-strength mobile phone middle plate is as follows:

[0036] 1) The raw materials of pure aluminum ingots, aluminum intermediate alloy ingots, magnesium ingots, and manganese agent prepared according to the above weight ratio are added to the melting furnace, and melted, refined, and slag-removed at a temperature of 720°C to obtain molten aluminum, and then At a temperature of 730°C, add Al-5Ti-0.2B grain refiner to the molten aluminum and use argon gas with a purity ≥ 99.999% for refining, then use a low-level semi-continuous casting method to place the refined aluminum solution for 0.5 Cast into the aluminum alloy ...

Embodiment 2

[0047] The composition and mass fraction of a high-strength aluminum alloy strip for mobile phone panels are: Fe 0.15%, Si 0.08%, Cu 0.10%, Mn 0.20%, Mg 5.8%, Cr 0.10%, Zn 0.02%, Ti 0.015%, others: 0.05%, the rest is Al, and the sum of the content ratios of each component is 100%.

[0048] The manufacturing method of the aluminum alloy strip for the high-strength mobile phone middle plate is as follows:

[0049] 1) The raw materials such as pure aluminum ingots, aluminum intermediate alloy ingots, magnesium ingots, and manganese agent prepared according to the above weight ratio are added to the melting furnace, melted, refined, and slag-removed at a temperature of 750°C to obtain molten aluminum, and then At a temperature of 690°C, add Al-5Ti-0.2B grain refiner to the molten aluminum and use argon gas with a purity ≥99.999% for refining, then use a low-level semi-continuous casting method to put the refined aluminum solution still After 1 hour, it is cast into an aluminum al...

Embodiment 3

[0060] The composition and mass fraction of a high-strength aluminum alloy strip for mobile phones are: Fe 0.20%, Si 0.10%, Cu 0.05%, Mn 0.12%, Mg 6.0%, Cr 0.00%, Zn 0.015%, Ti 0.02%, others: 0.05%, the rest is Al, and the sum of the content ratios of each component is 100%.

[0061] The manufacturing method of the aluminum alloy strip for the high-strength mobile phone middle plate is as follows:

[0062] 1) The pure aluminum ingots, aluminum intermediate alloy ingots, magnesium ingots, and manganese agent prepared according to the above weight ratio are added to the melting furnace, and melted, refined, and slag-removed at a temperature of 735°C to obtain molten aluminum, and then At a temperature of 710°C, add Al-5Ti-0.2B grain refiner to the molten aluminum and use argon gas with a purity ≥ 99.999% for refining, then use a low-level semi-continuous casting method to put the refined aluminum solution still After 1 hour, it is cast into an aluminum alloy flat ingot with spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com