Cold roller production process

A production process and technology of cold rolling rolls, applied in the field of cold rolling rolls, can solve the problems of poor quality of aluminum plates, poor hardness uniformity, short service cycle, etc., and achieve the effects of uniform thickness, flat shape and high surface finish.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] to produce Taking the work roll of the widest domestic cold rolling mill as an example, the process of producing cold rolling rolls is explained in detail.

[0016] The high chromium alloy material used can be 9Cr3MoV or 9Cr4MoV or 9Cr5MoV, and these materials can meet the performance requirements of cold rolling roll manufacturing.

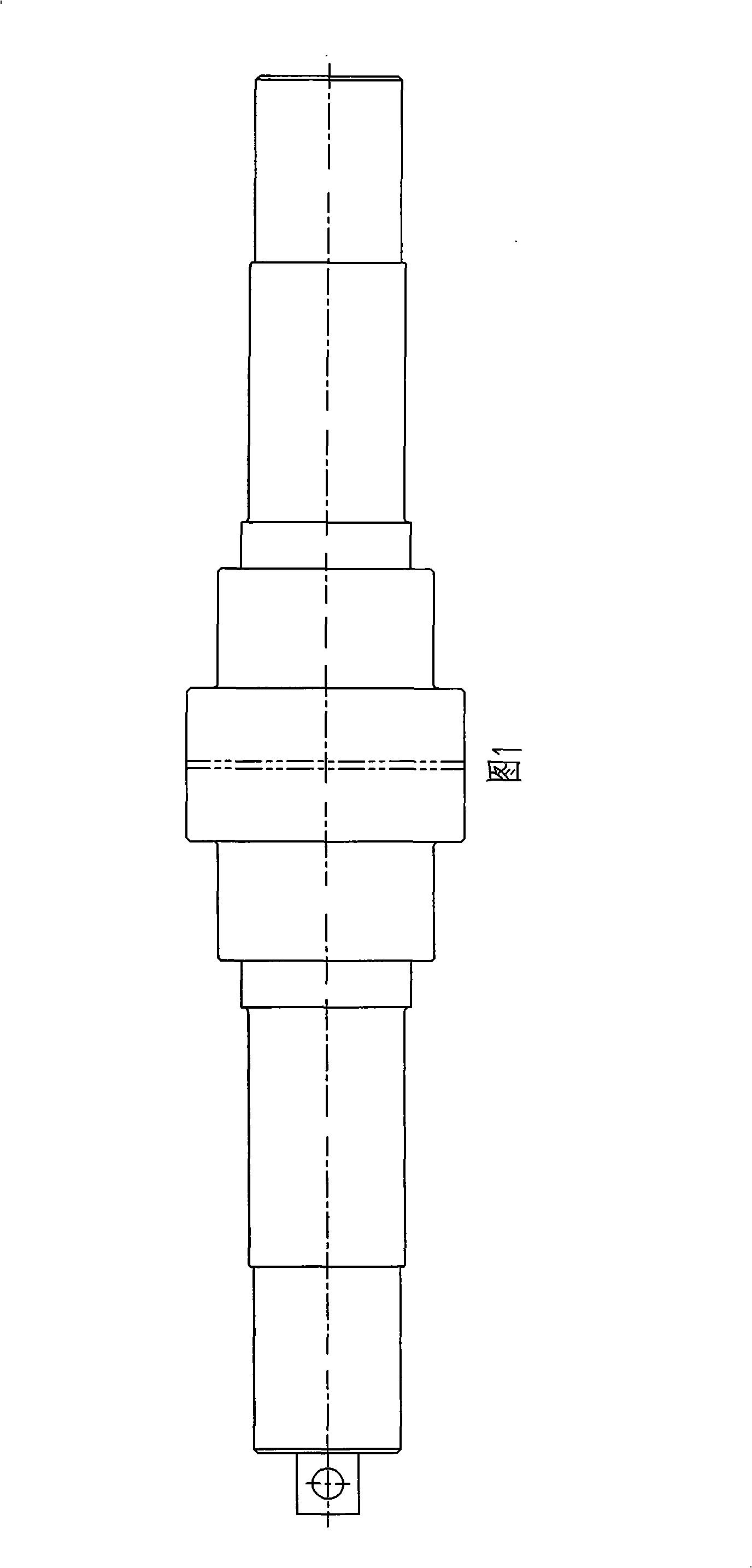

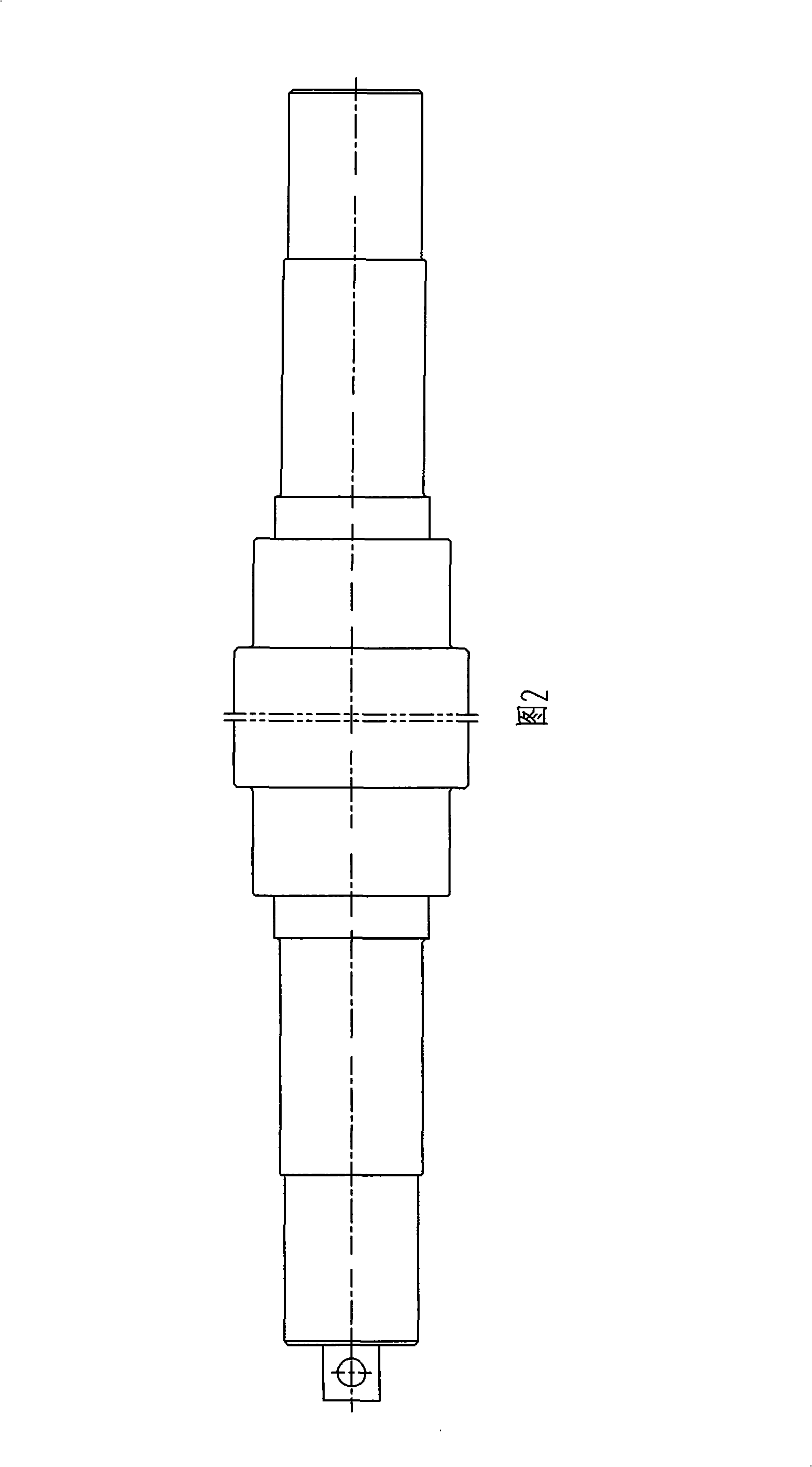

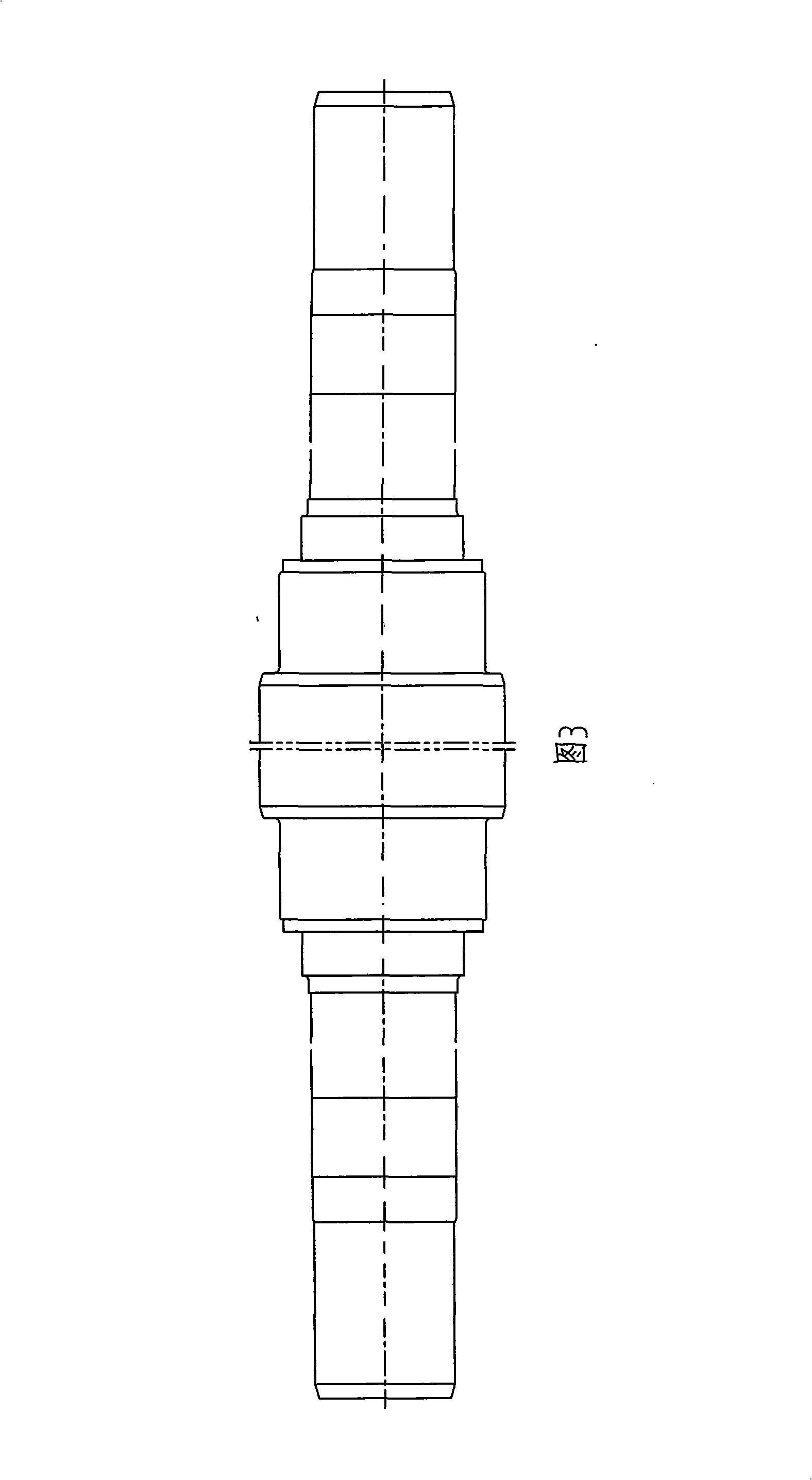

[0017] The specific process steps of the cold rolling roll are as follows: a. The blank made of 9Cr3MoV high-chromium alloy material is forged and annealed, and then the blank is inspected, and then transferred to gold processing after passing the test; b. Milling the two ends of the blank; c. Marking the center of both ends Hole line, drill center hole A20 at both ends; d. Top center hole, rough turning processing, at this time, the diameter of the roll body reaches Φ512 0 -1 ,See figure 1 ; e. Make a hoisting hole Φ60mm at the left end, and mark the roll number at the end of the hoisting hole, and then conduct ultrasonic flaw detecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com