Patents

Literature

1298 results about "Work roll" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

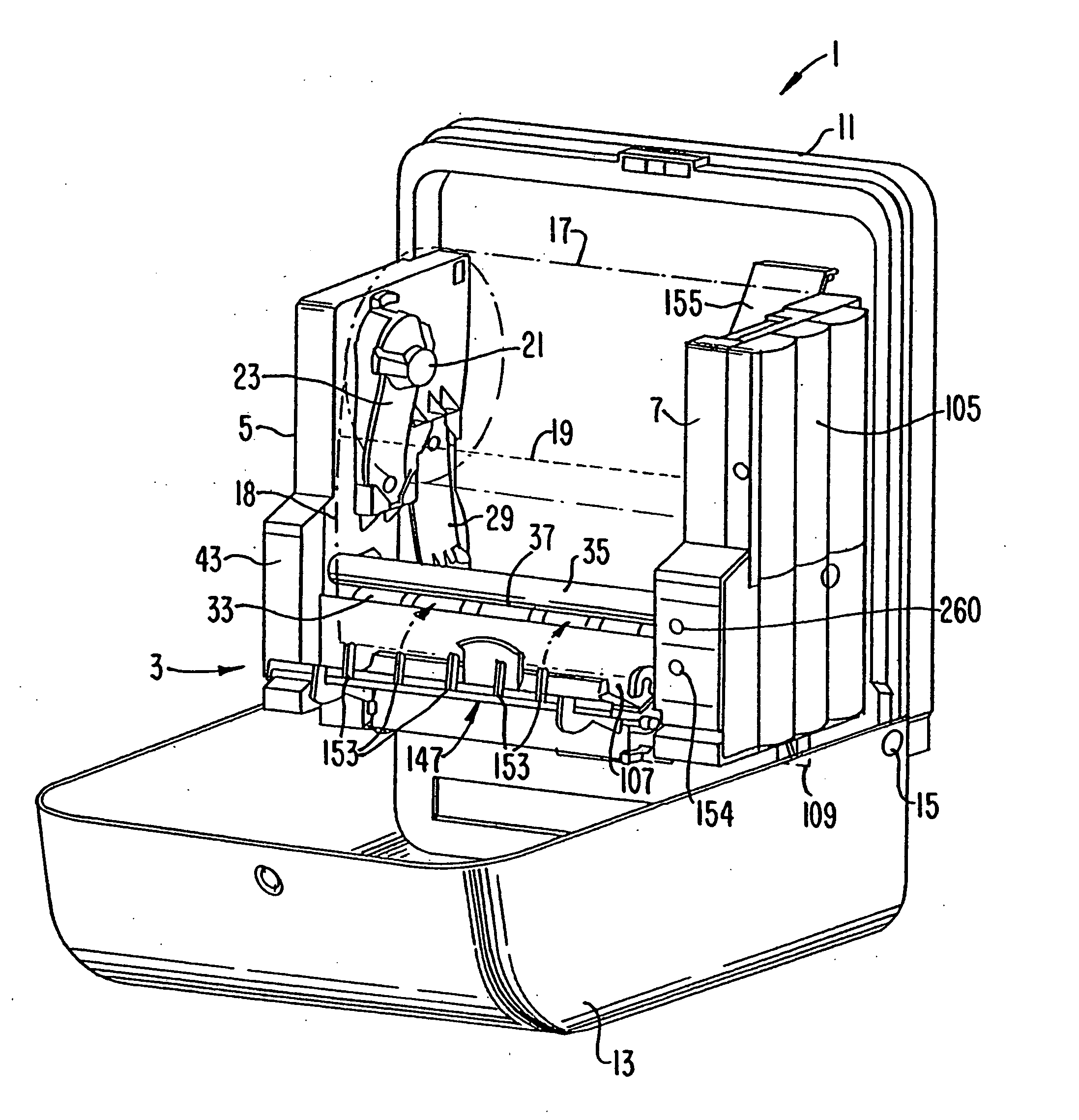

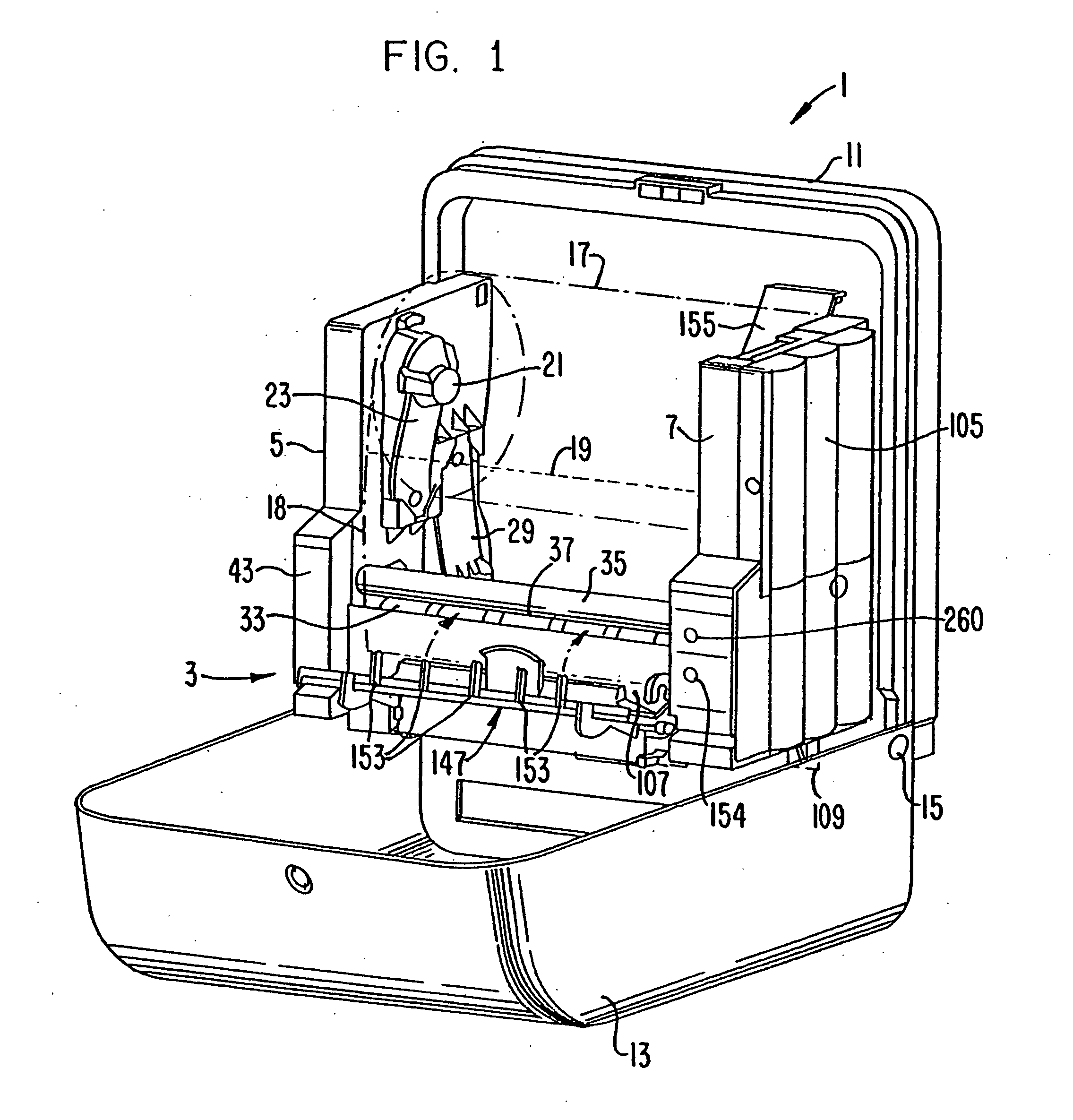

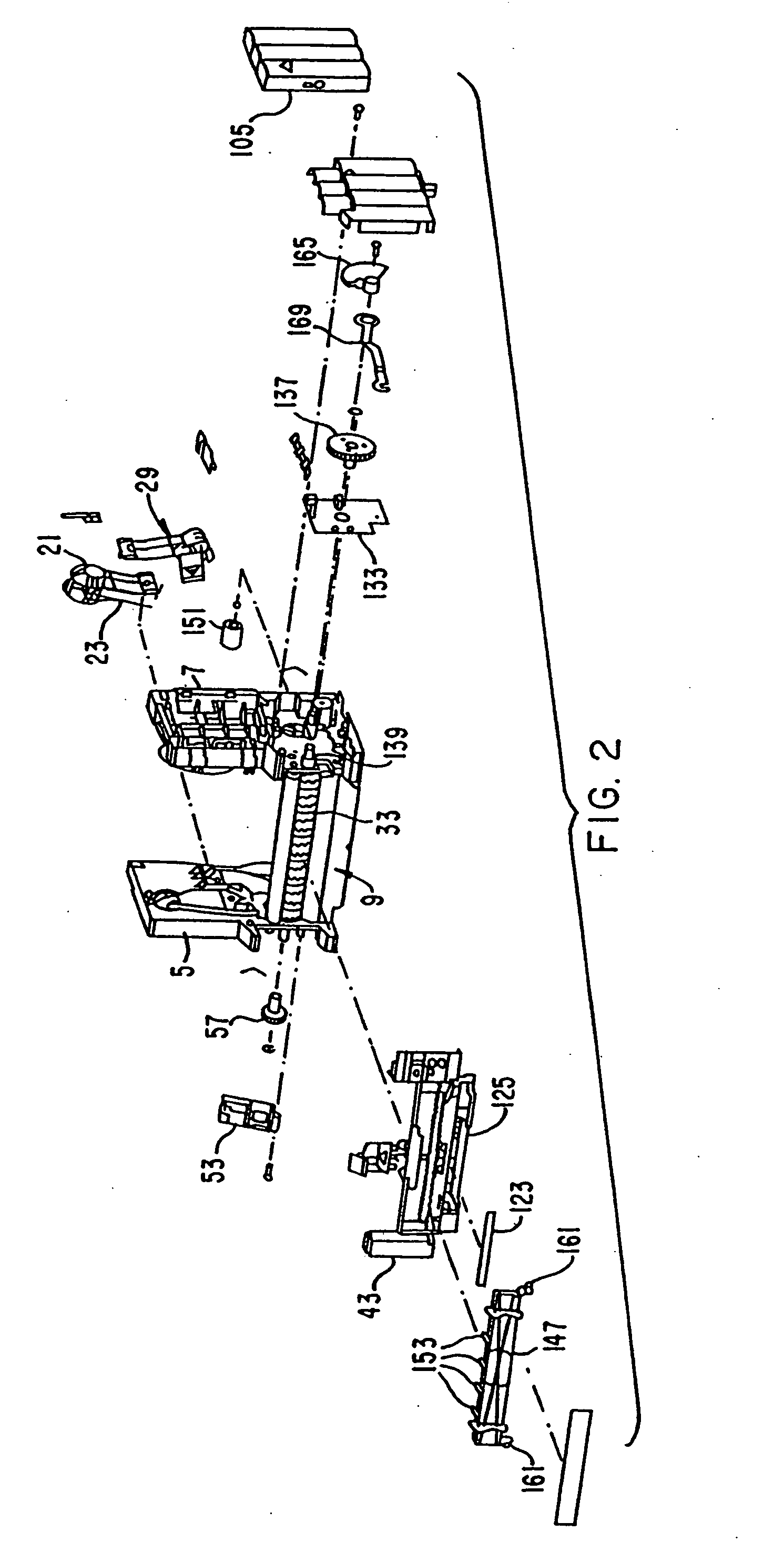

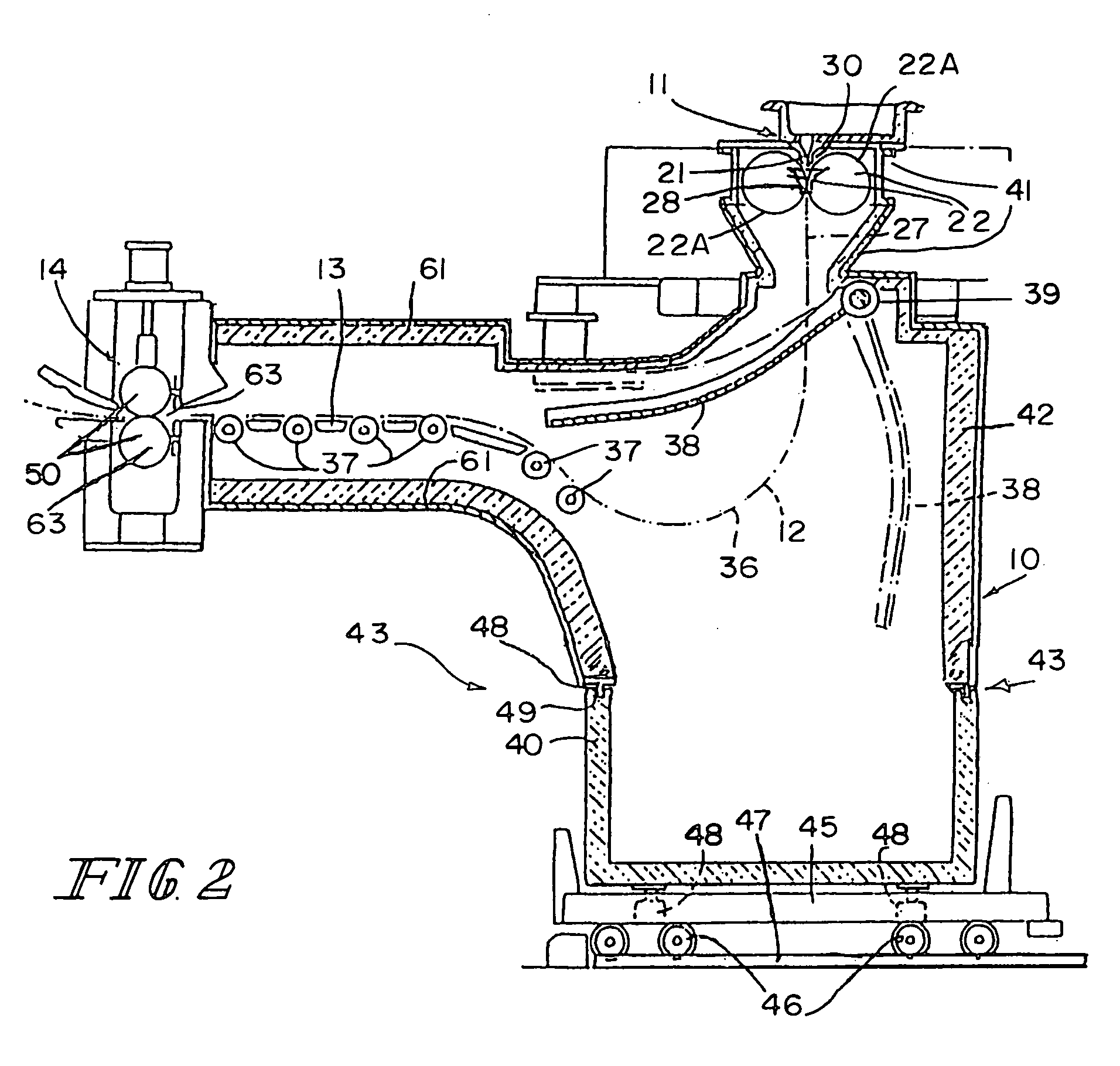

Apparatus and methods usable in connection with dispensing flexible sheet material from a roll

InactiveUS20050150992A1Improve convenienceImprove simplicityFilament handlingMetal-working apparatusTransfer mechanismCapacitance

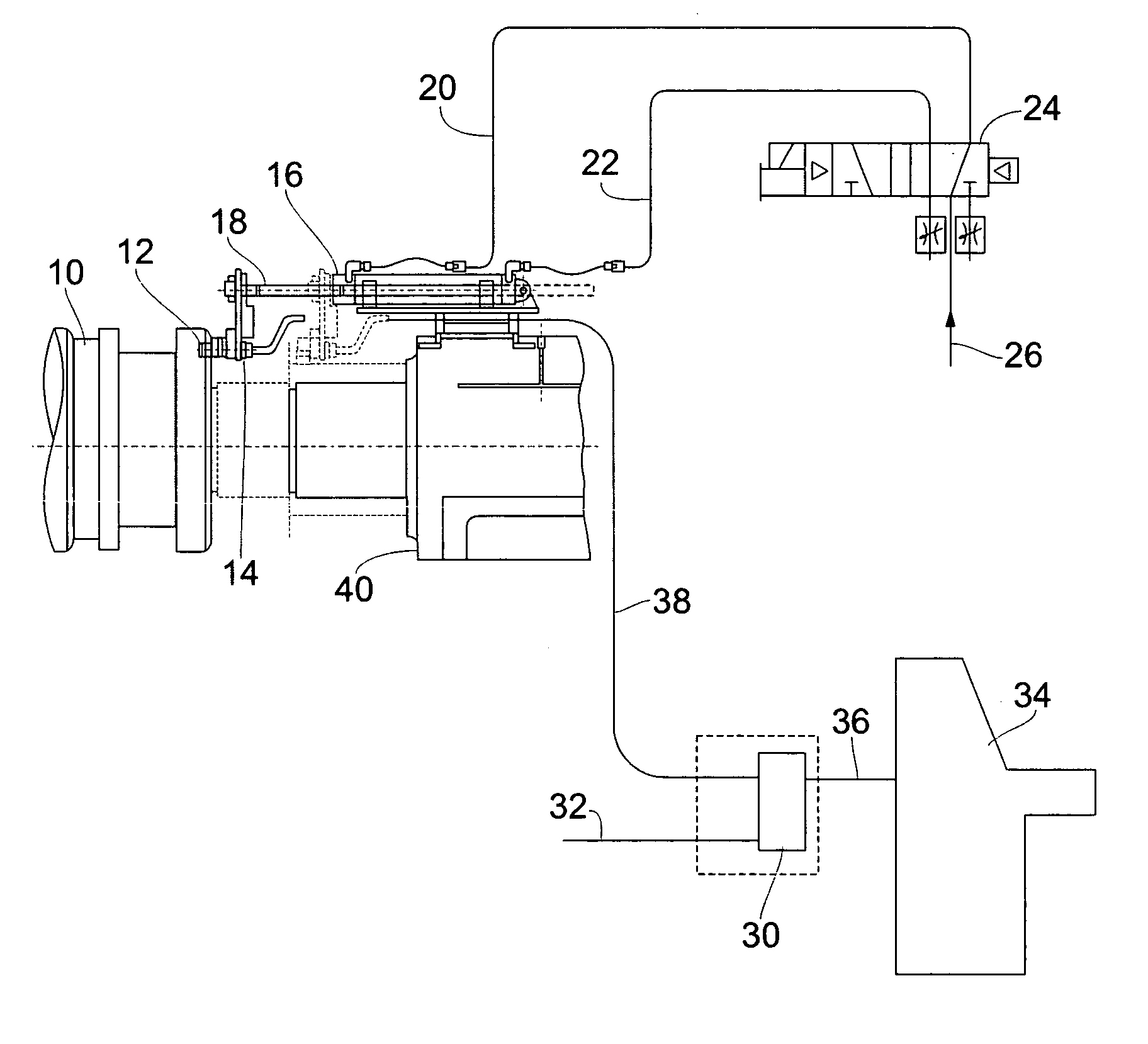

A powered dispenser for dispensing individual sheet segments from a continuous roll of sheet material provided with spaced tear lines comprises a powered feed mechanism, a releasable, powered drive mechanism, a powered transfer mechanism, a pair of web sensing sensors, a capacitive sensing system providing automatic sensitivity adjustment, and control circuitry. A dual power supply system provides a mechanical lock-out functionality, and the control system is protected from electrostatic build-up on the surface of the feed roller. The web sensor, and an antenna plate of the capacitive sensing system, are provided on respective printed circuit boards mounted in overlying relation. Utilizing signals received from the pair of web sensors and the capacitive sensing system, the control circuitry senses the presence of a user to activate the powered drive mechanism, and prevents further dispensing of the sheet material until a previously dispensed segment is separated from the roll. The web sensors detection of a leading edge of the sheet material initiates a predetermined interval of sheet material advancement providing a proper placement of successive tear lines. Various approaches may be utilized to accommodate inadvertent sheet “tabbing” scenarios. The web sensors, together with the control circuitry, are also used to detect the depletion, or absence, of a working roll of sheet material, whereupon the control circuitry controls the powered transfer mechanism to automatically transfer the web feed supply from a depleted working roll to a reserve roll. The powered transfer mechanism may include a motor driven transfer bar, or provide motor driven release of a spring biased transfer bar. Another arrangement allows for ready release of a roll core, and drop of the same into an open dispenser cover for removal.

Owner:GPCP IP HLDG LLC

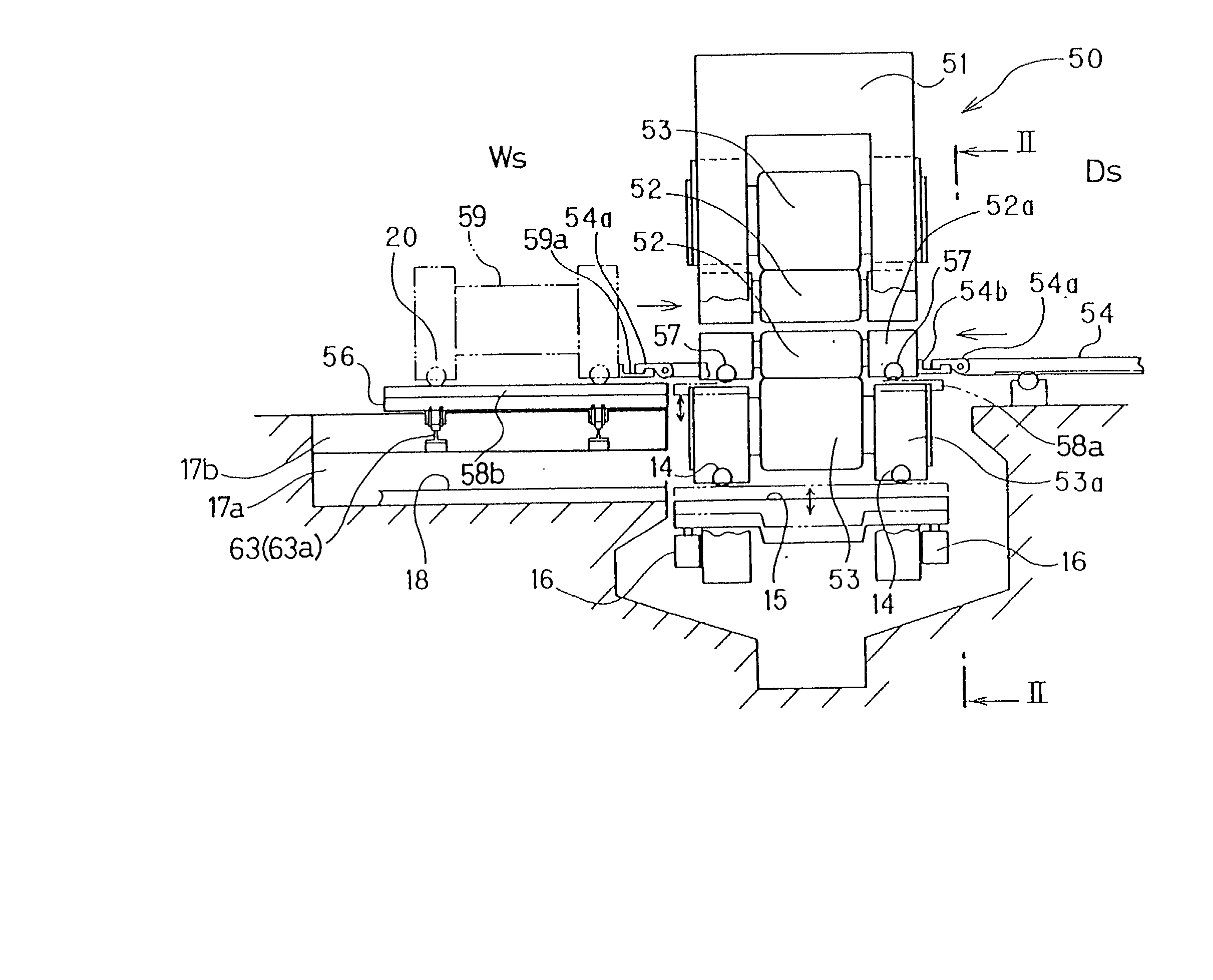

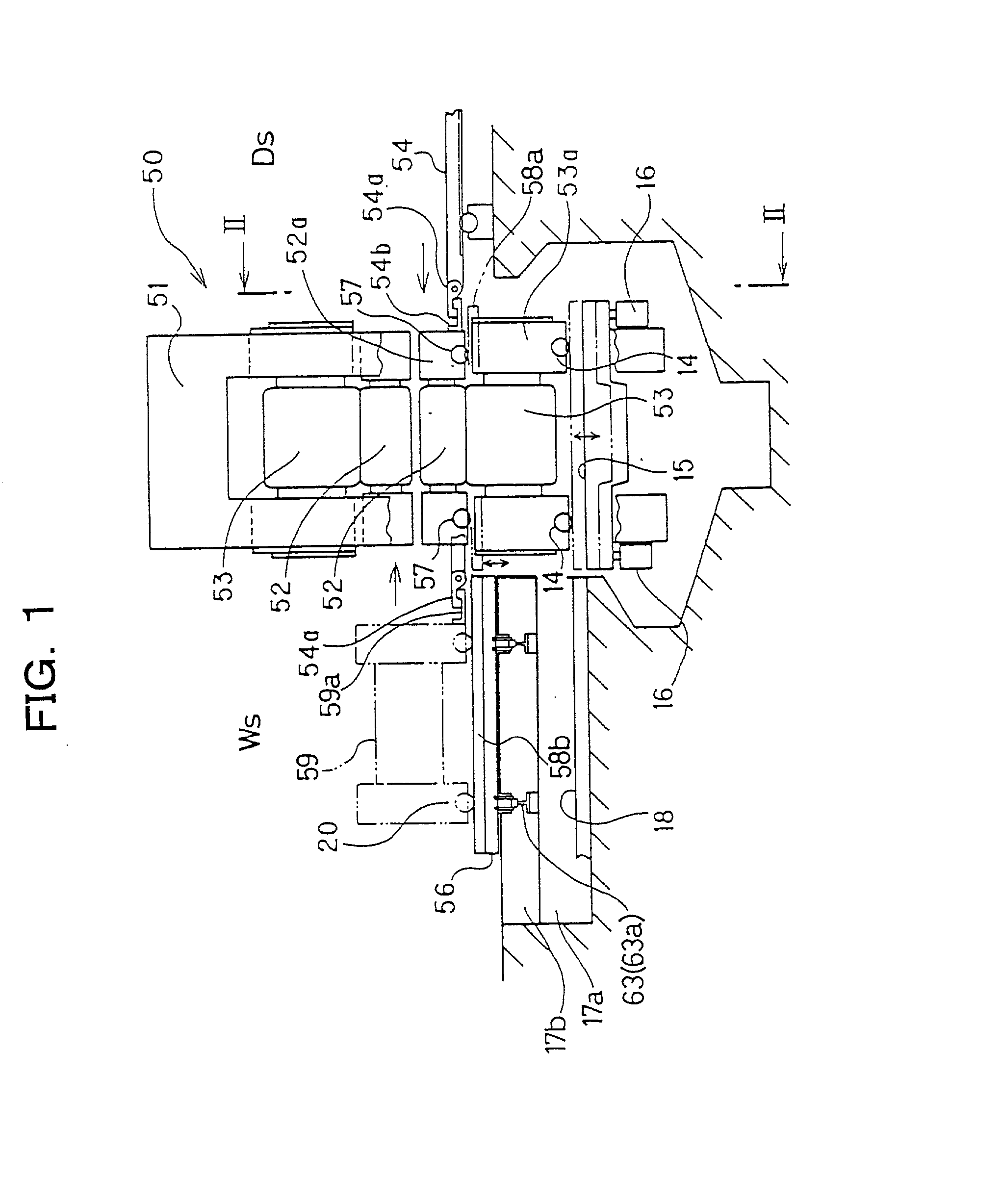

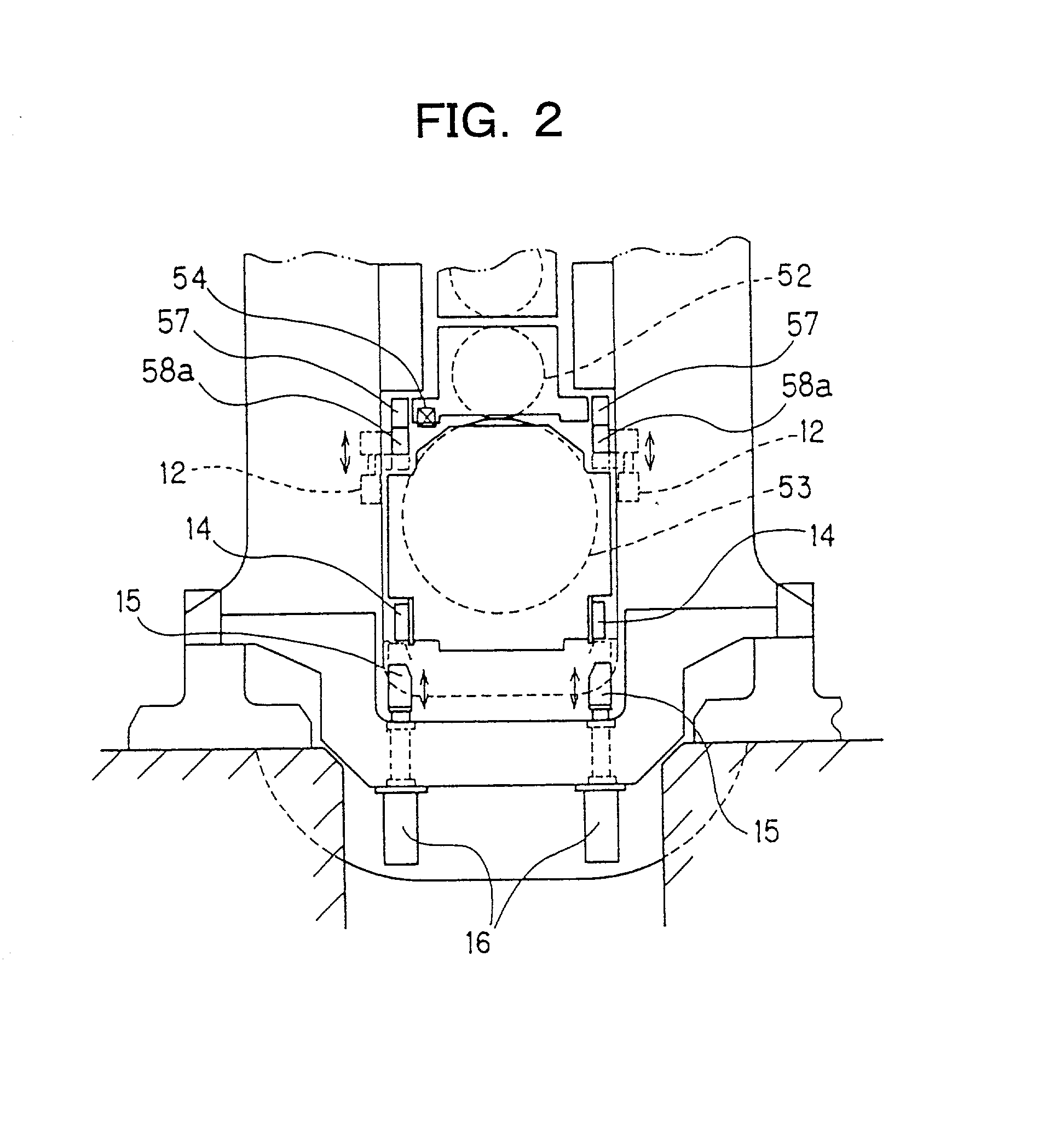

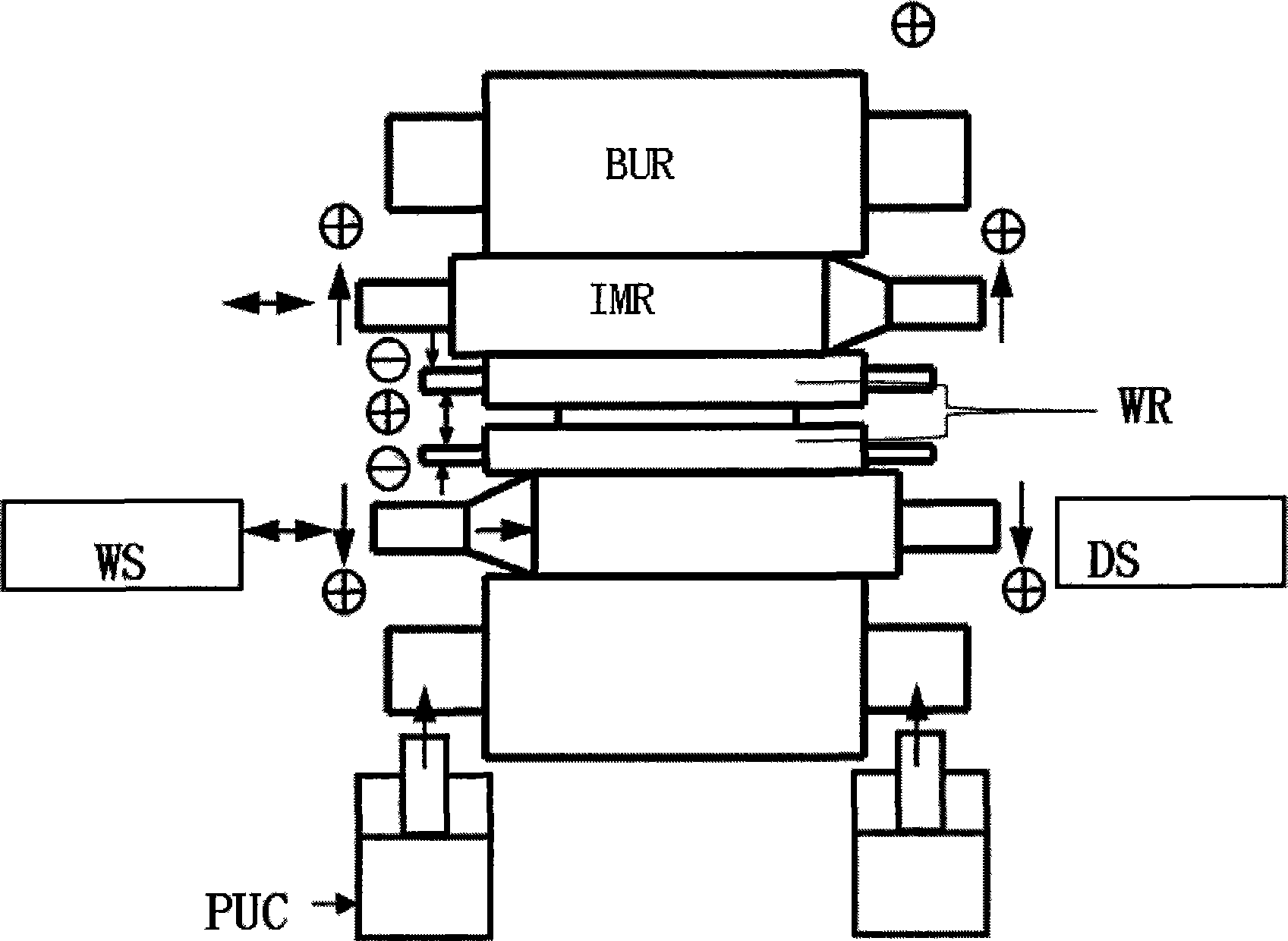

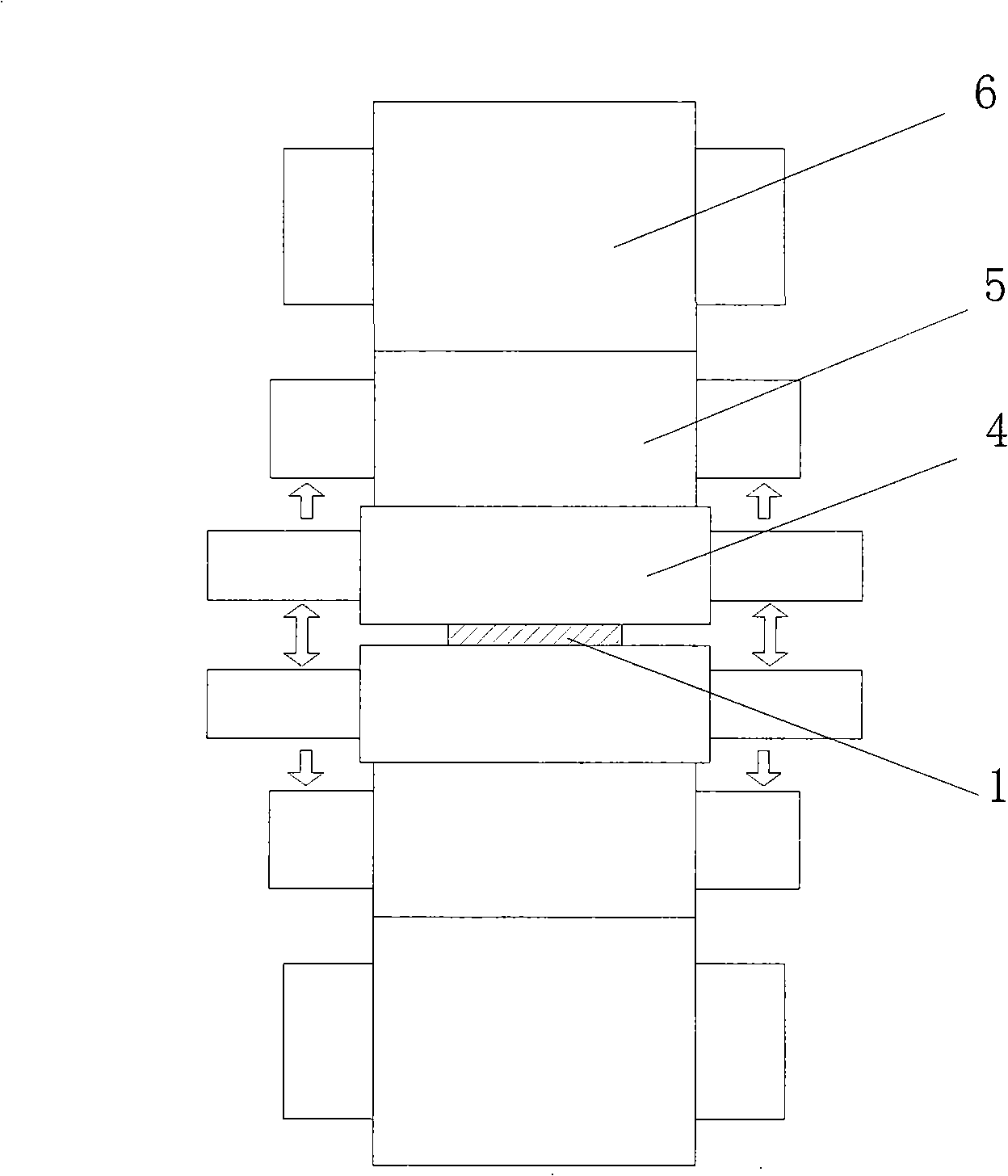

Roll changing apparatus and roll changing method for rolling mill

InactiveUS20020078728A1Low costReduce Fixture CostsMetal rolling stand detailsRollsWork rollEngineering

A roll changing apparatus for a four-high rolling mill comprises rails, provided in a rolling mill stand and on a work side of the rolling mill, for incoming and outgoing of a work roll assembly and a backup roll assembly, and a pusher, provided on a drive side or the work side of the rolling mill, for roll admission and withdrawal for both of work rolls and backup rolls. The roll changing apparatus can be modified into a side shift type roll changing apparatus with ease, at a low cost, and in a short time.

Owner:MITSUBISHI HEAVY IND LTD

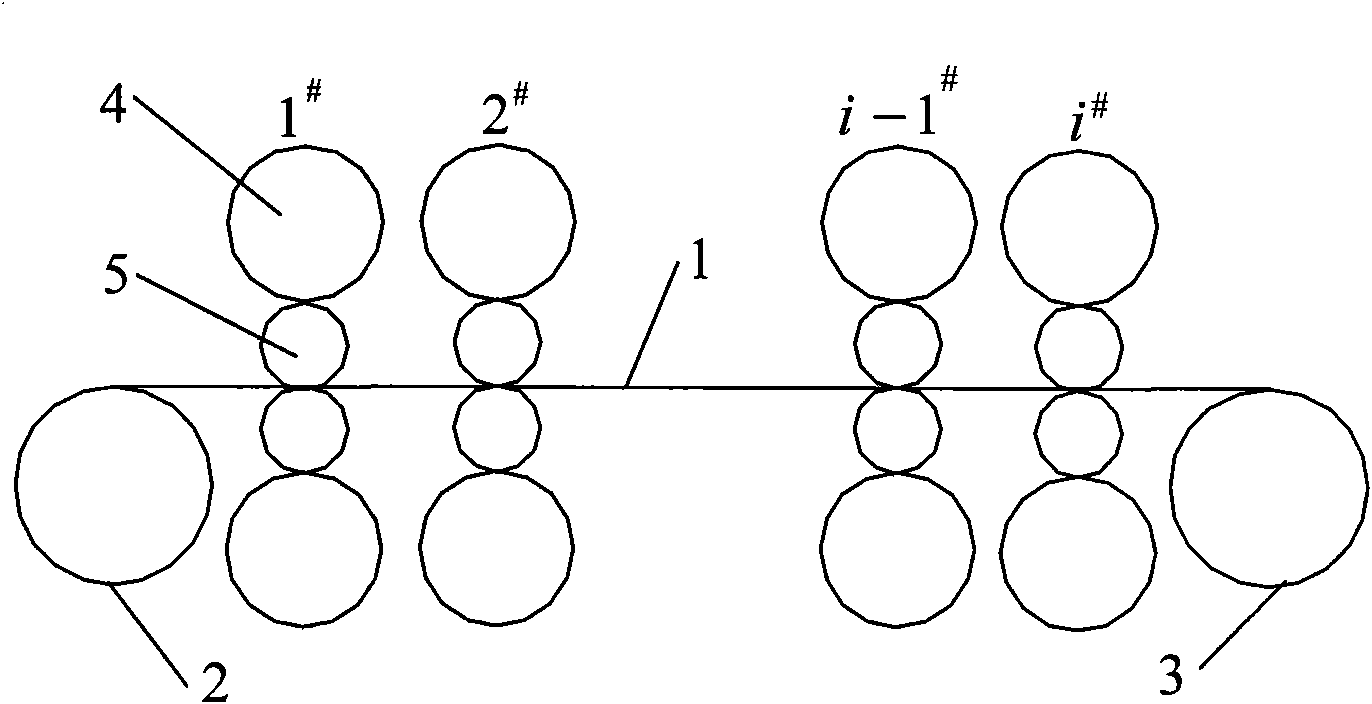

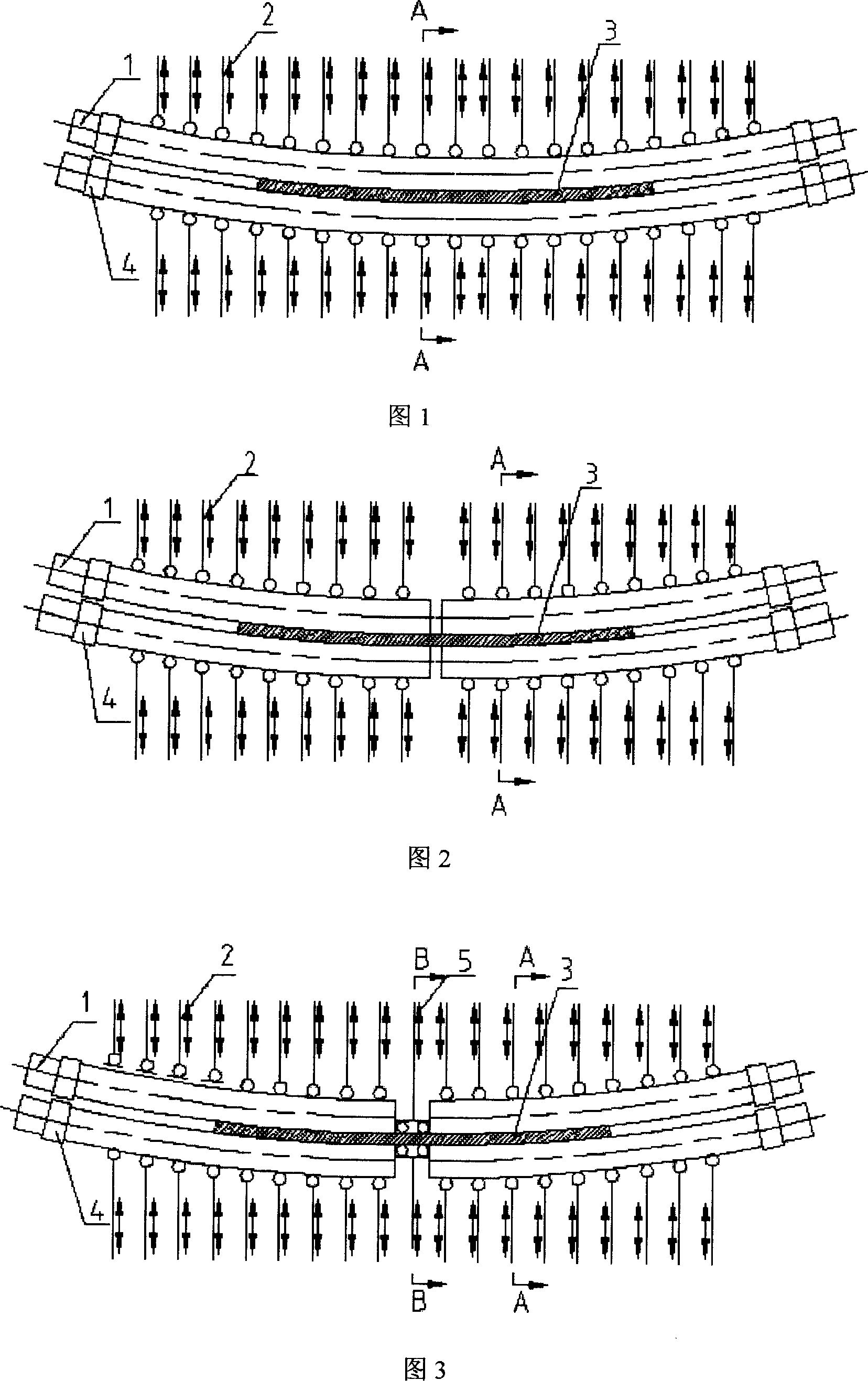

Control method of tandem cold rolling mill emulsion section cooling

The invention discloses a control method of tandem cold rolling mill emulsion section cooling, comprising the following steps: a. collecting the device parameter of a rolling mill and the key parameter of band steel to be rolled; b. collecting a technological lubrication institution parameter; c. giving emulsion section cooling flow distribution initial value and iteration precision; d. calculating corresponding work roll thermal crown; e. calculating the lateral distribution value of a slipping factor; f. comparing the slipping factor maximum value with a critical value; g. calculating the lateral distribution value of a slip injury index; h. comparing the maximum value of the slip injury index with the critical value; i. calculating the corresponding strip shape distribution value; j. calculating the function value of a strip shape objective function; and k. judging whether Powell condition is available, and obtaining the control curve of the optimal section cooling flow. The controlmethod of the invention combines device section condition with practical flow control precision to set the emulsion flow in sections, reduces problems of slipping, hot slip injury and the like causedby lubrication and ensures the strip shape and the surface quality index of chassis outlet strip steel rolled stock.

Owner:BAOSHAN IRON & STEEL CO LTD

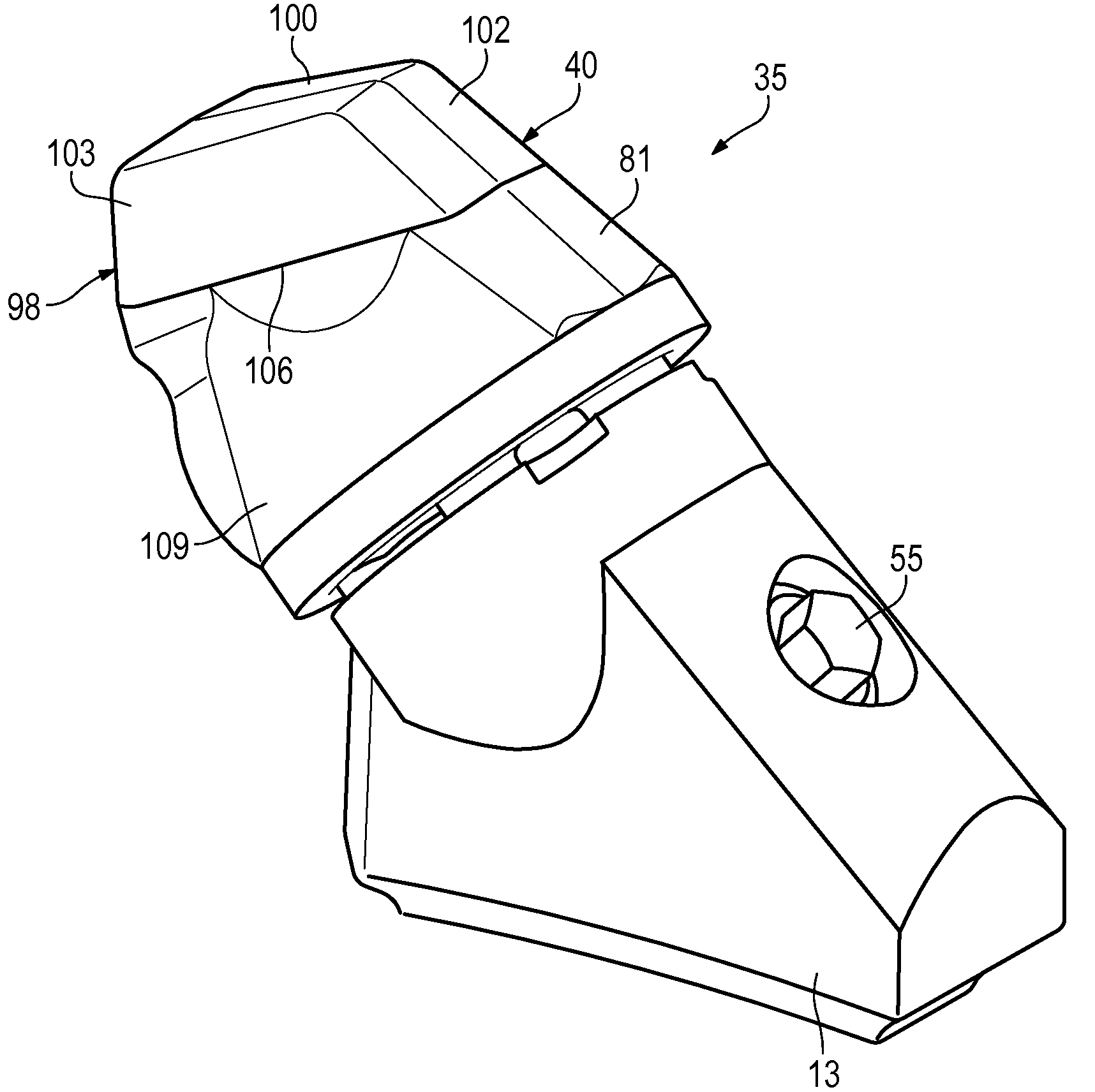

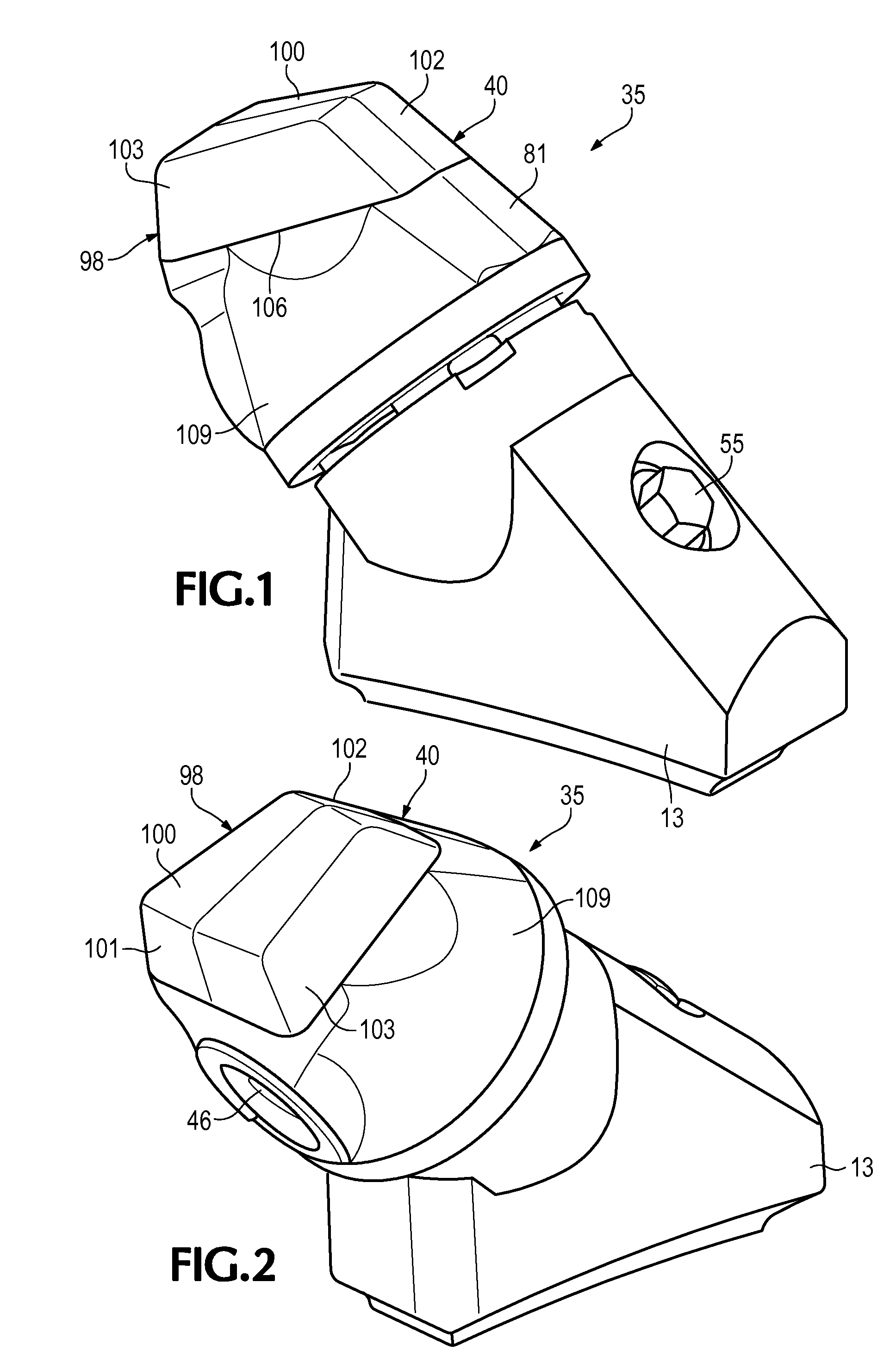

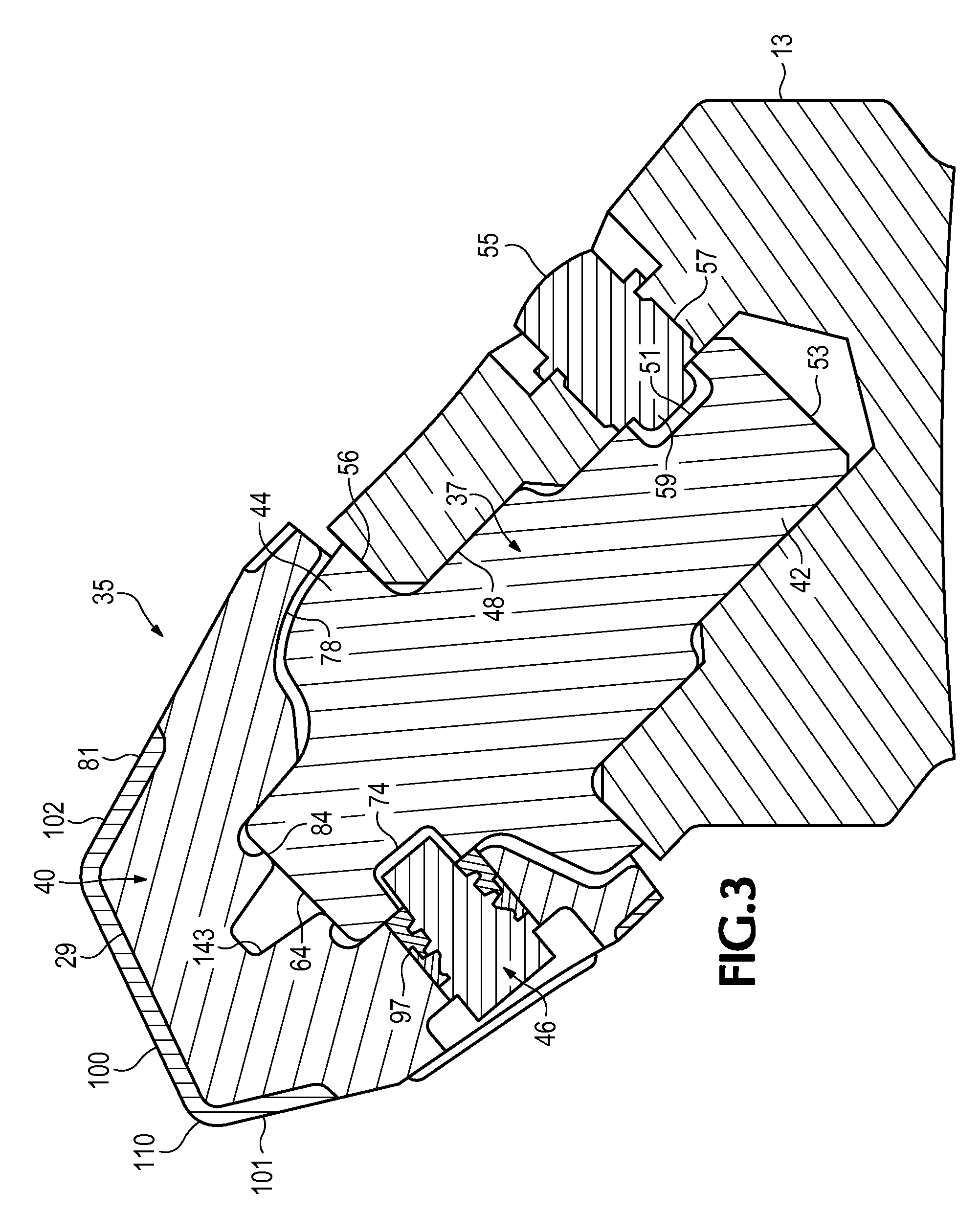

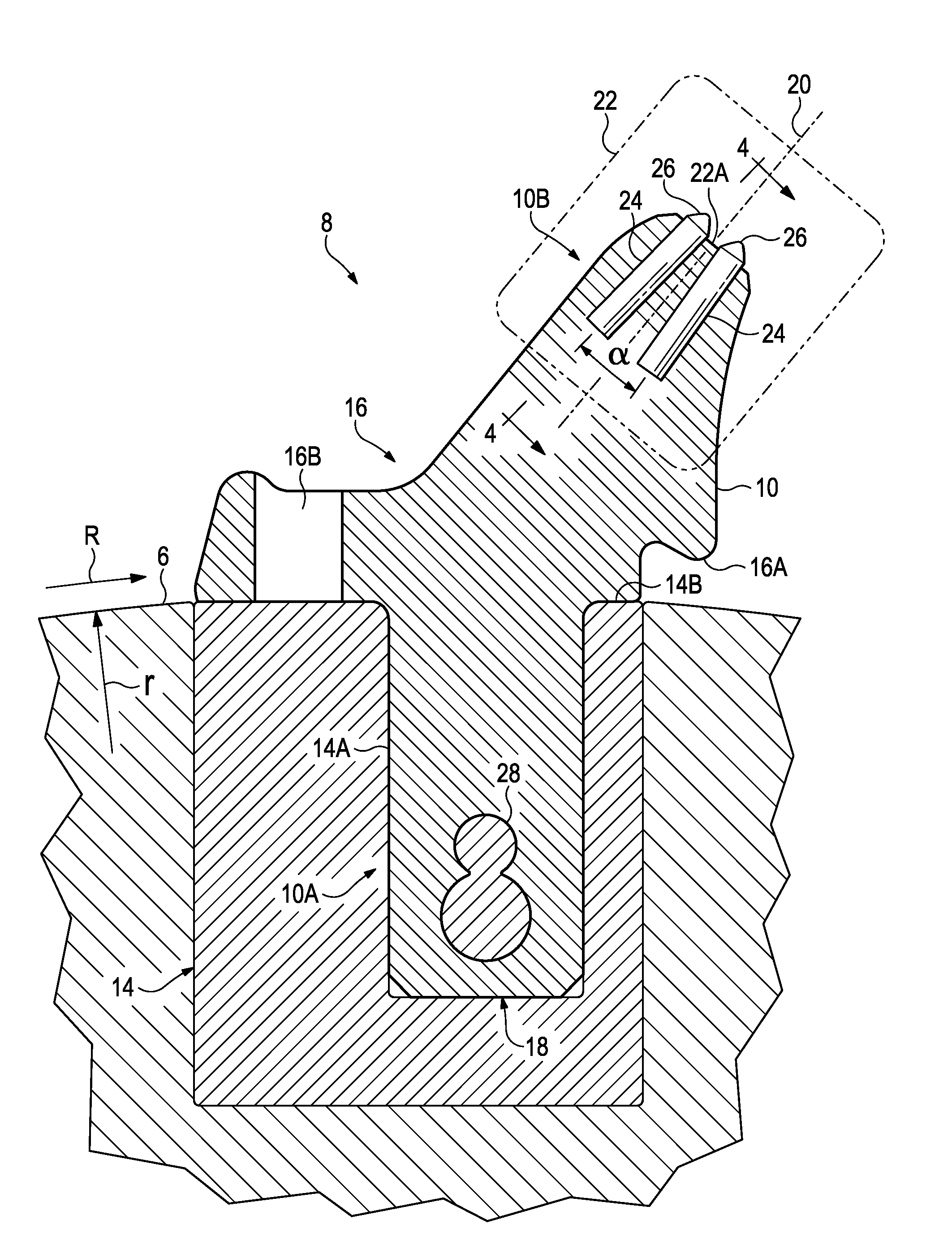

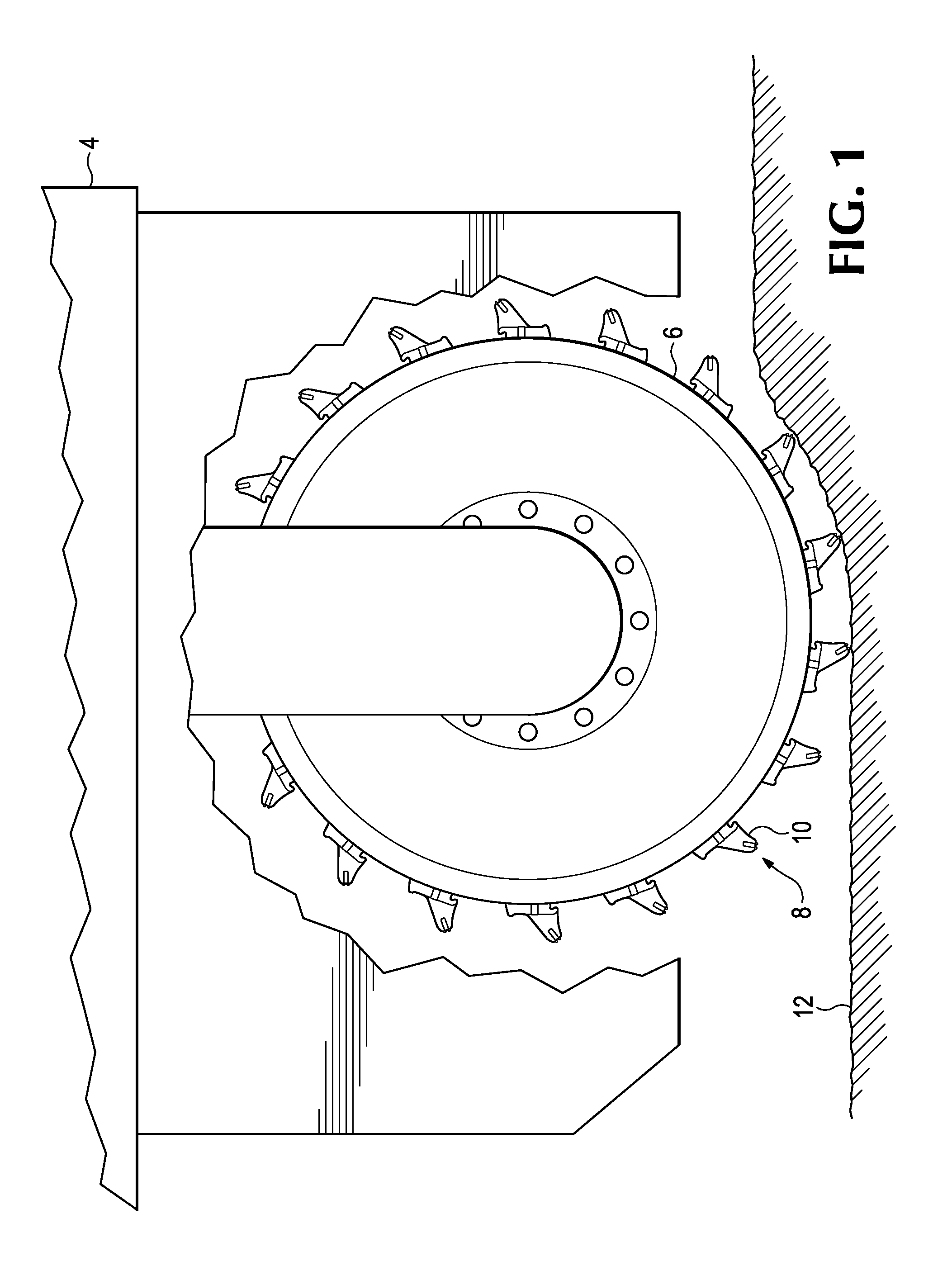

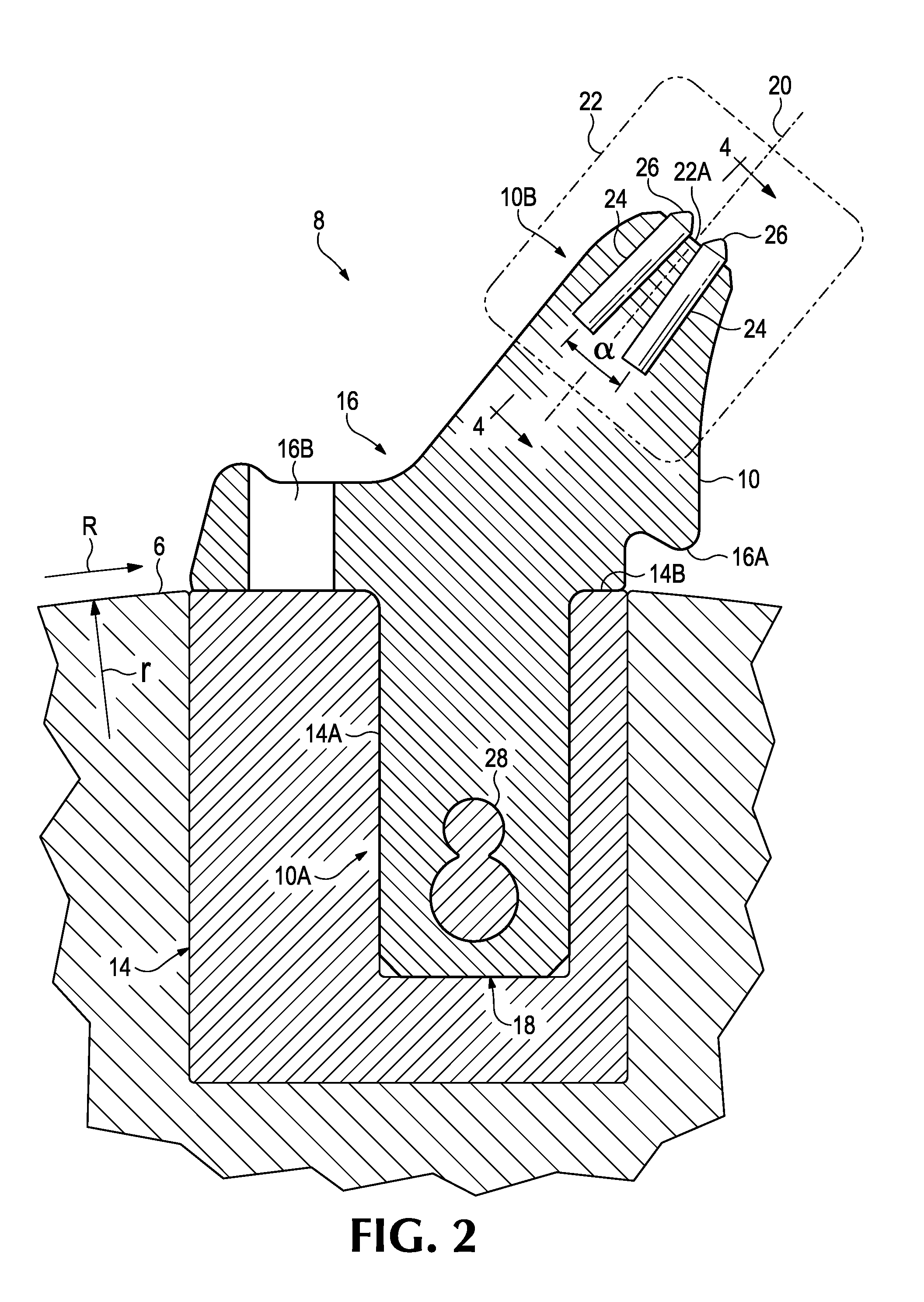

Tip for an earth working roll

ActiveUS20090174252A1Reduce wearReduced service lifeDisloding machinesUnderground miningWork rollCrusher

A tip for use on an earth working roll for mining, construction and public works machines such as crushers, surface miners, milling machines and the like includes a working end provided with side relief to reduce drag and wearing, require less power to drive the rolls, and lengthen the usable life of the tip. The working end can also have a generally flat front surface to improve the yield in a crushing or other similar operation. The tip includes a base and a wear cap releasably secured together by a retainer.

Owner:ESCO GRP LLC

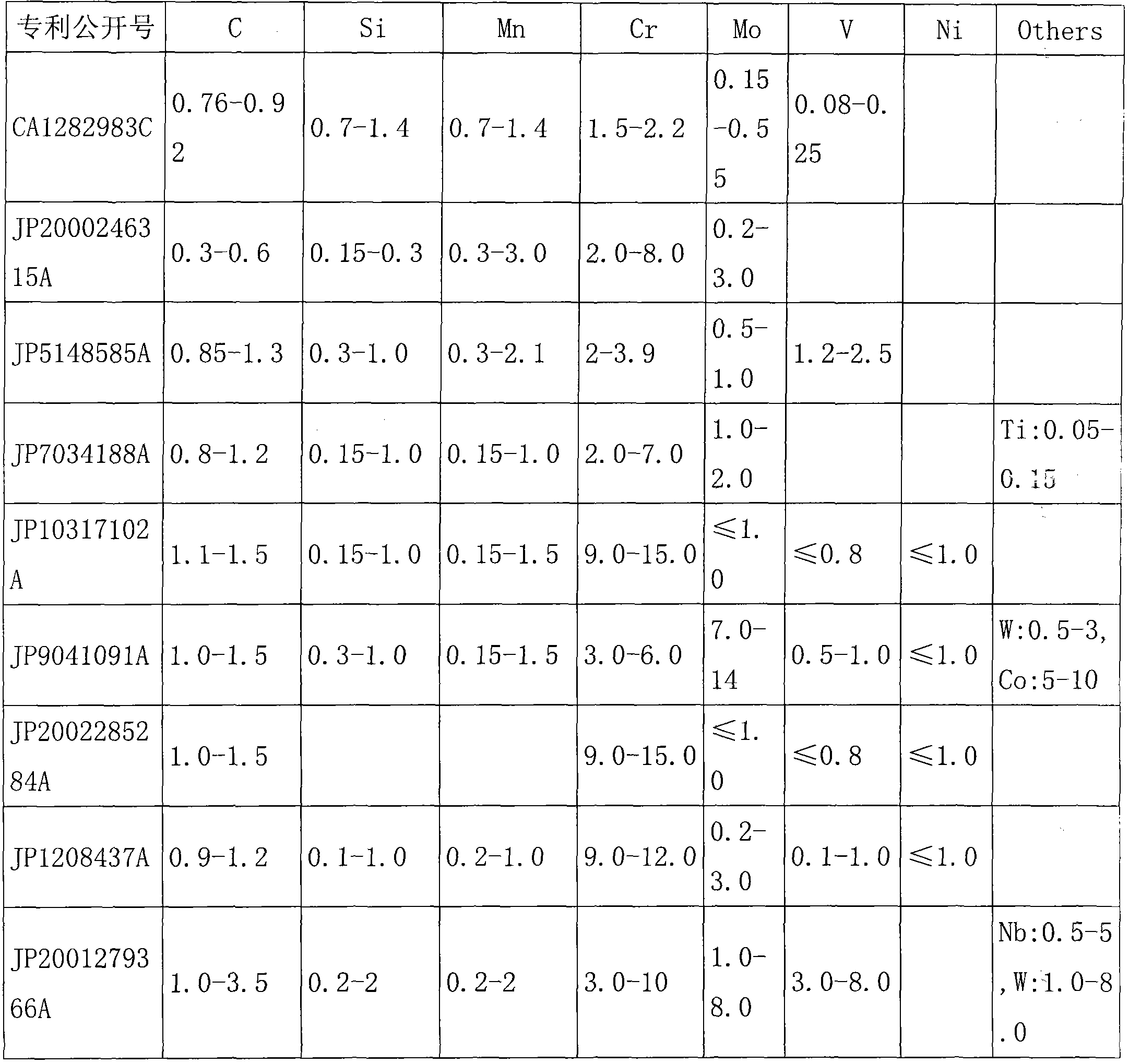

Cold work roll steel for high-strength steel rolling, cold work roll and its manufacturing method

The invention discloses cold work roll steel for high-strength steel rolling, a cold work roll and its manufacturing method. The material of cold work roll is composed of the following chemical components of: by weight, 0.6-0.8% of C; 0.6-1.5% of Si; 0.6-1.5% of Mn; 4.0-6.0% of Cr; 0.5-2.0% of Mo; 0.5-1.0% of V; P being less than or equal to 0.020%; S being less than or equal to 0.015%; and the balance being Fe and unavoidable impurities. The manufacturing process comprises steps of: electric furnace smelting; secondary refining; vacuum degasification; electric bar casting; electroslag refining; ingot casting; forging; preheat treatment; rough machining; quenching and tempering treatment; semi-finish machining; final heat treatment; finish machining; and finished product. According to thenovel cold work roll provided by the invention, the ratio of the alloy elements is optimized based on 5% of Cr. By the adoption of a short-time high-temperature solid solution quenched-tempered heat treatment technology, the roll strength and wear resistance of the cold work roll are improved, thus satisfying production requirements of high-strength cold rolled strips.

Owner:BAOSHAN IRON & STEEL CO LTD

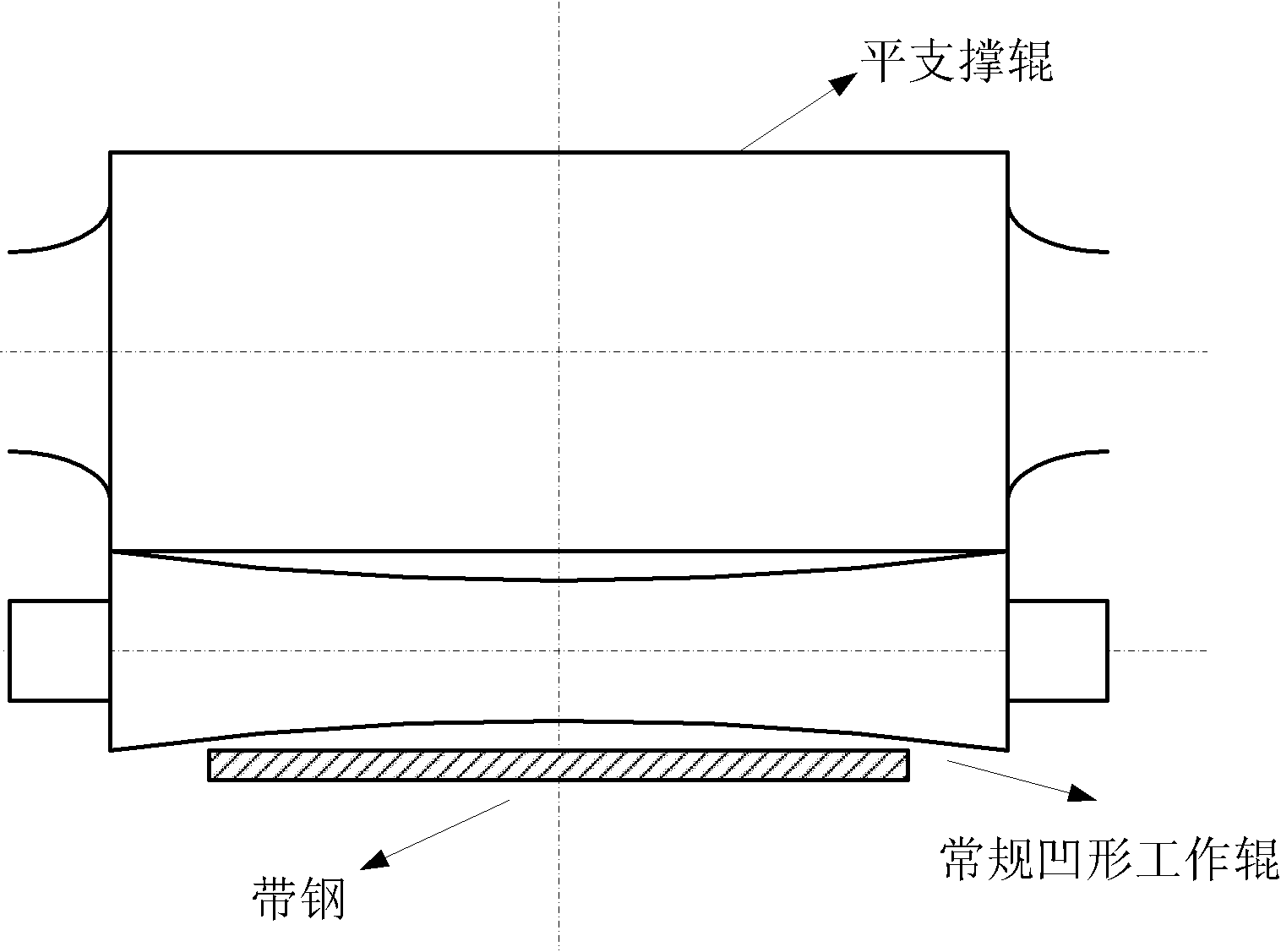

Work roll with steel rim drop-control and flat degree control

InactiveCN101254508AGood control effectTo achieve the purpose of edge landing controlRollsMetal rolling arrangementsWork rollStrip steel

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

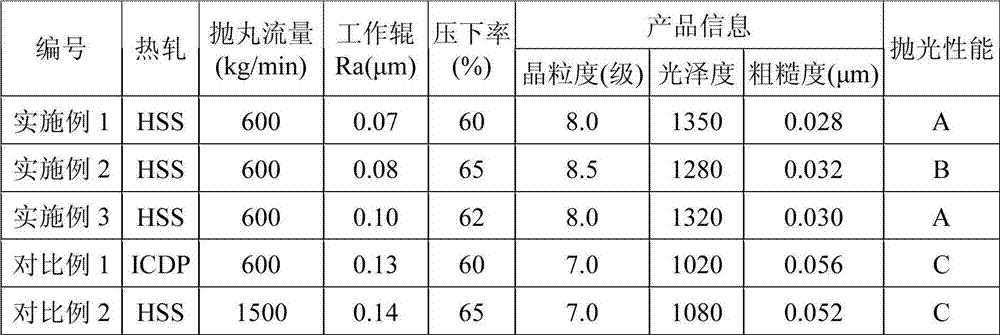

Manufacture method of austenitic stainless steel with good polishing performance

The invention provides a manufacture method of austenitic stainless steel with good polishing performance, comprising the following steps of: carrying out hot rolling, carrying out hot-rolling annealing, carrying out acid washing after hot-rolling annealing, carrying out cold rolling, carrying out cold-rolling annealing, carrying out acid washing after cold-rolling annealing, and refining. The manufacture method is characterized in that the hot rolling adopts a centrifugal composite high-speed steel roller, wherein the hot-rolling is carried out on a raw material blank due to the width change; the cold rolling is carried out by a cold-rolling machine, wherein the roughness of a work roll of the cold-rolling machine is less than 0.3mum; and the refining elongation rate is 0.3-3.0%. According to the manufacture method provided by the invention, the grinding performance and the surface polishing performance of the austenitic stainless steel can be improved, and the stainless steel manufactured by the manufacture method provided by the invention can be used for manufacturing a mirror surface decorative sheet with good polishing performance and the like.

Owner:ZHANGJIAGANG POHANG STAINLESS STEEL

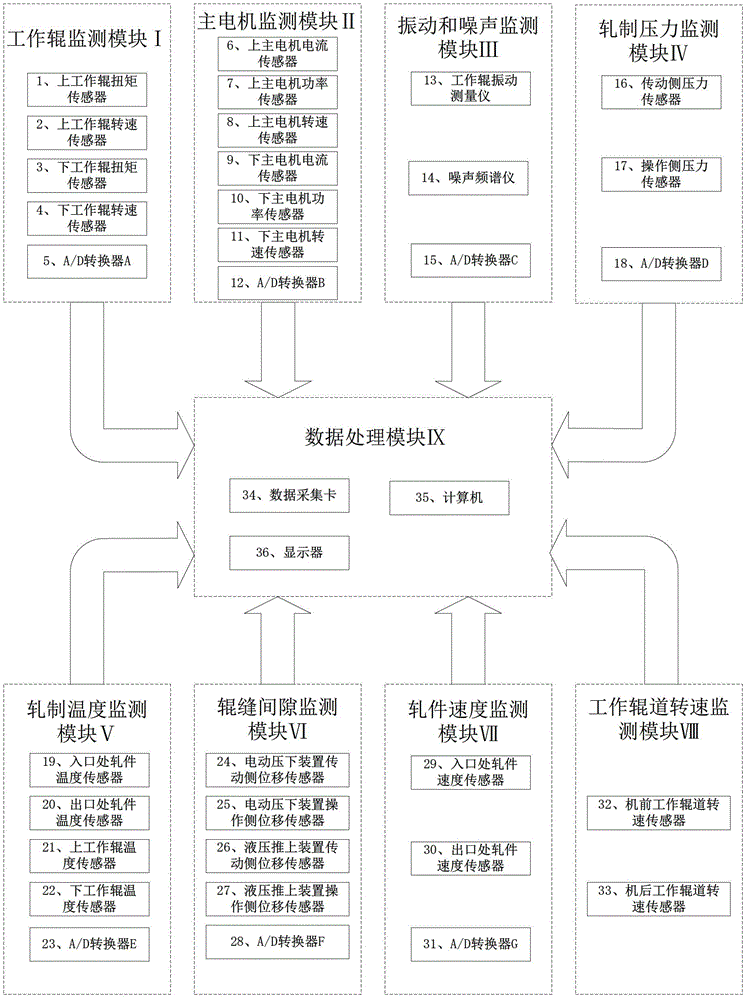

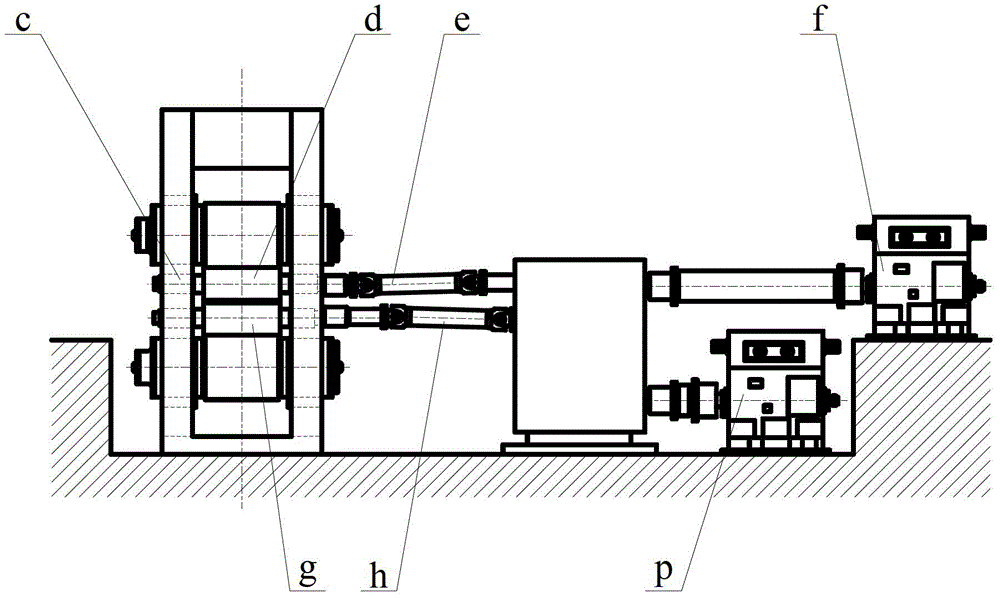

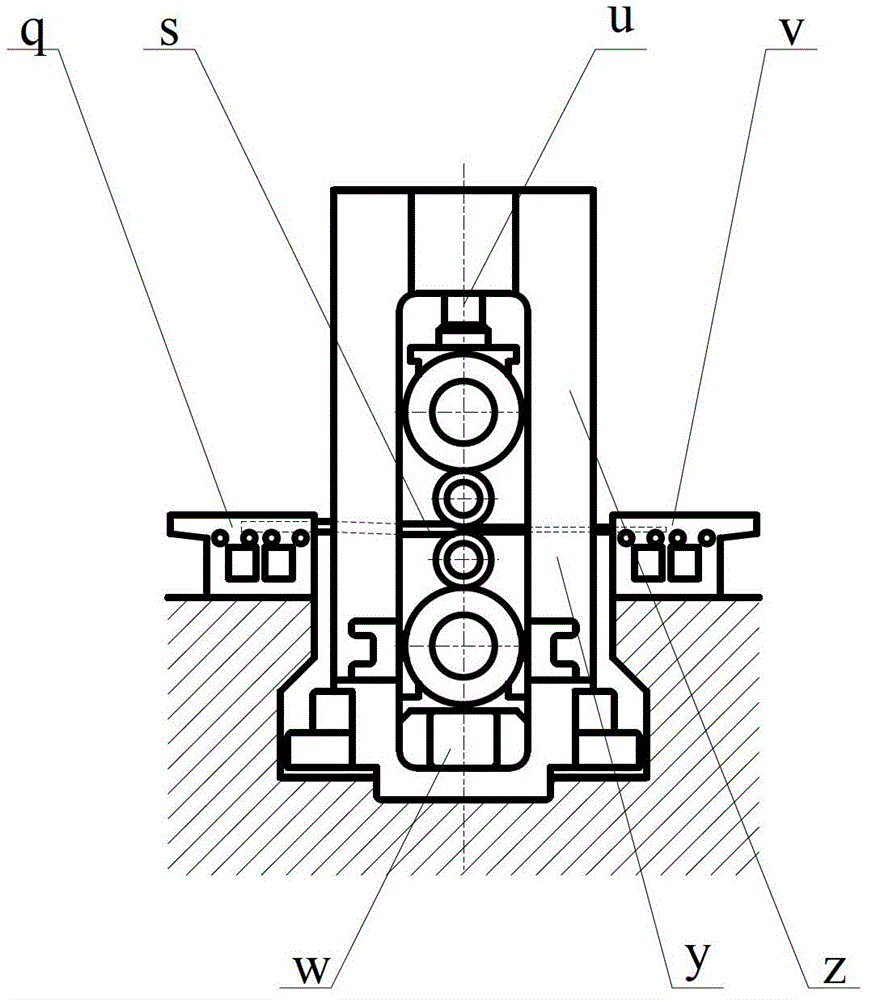

Magnesium alloy plate rolling parameter monitoring and fault diagnosing system and method

InactiveCN103331310AGuaranteed operational reliabilityHigh industrial applicabilityMeasuring devicesMetal rolling arrangementsNoise monitoringWork roll

The invention discloses a magnesium alloy plate rolling parameter monitoring and fault diagnosing system and method. The system is composed of a work roll monitoring module, a main motor monitoring module, a vibration and noise monitoring module, a rolling pressure monitoring module, a rolling temperature monitoring module, a roll gap interval monitoring module, a piece rolling speed monitoring module, a work roll way revolving speed monitoring module, a data processing module and a rolling mill, technological parameters such as rolling force and the rolling temperature and equipment parameters such as the motor current are monitored at the same time, the operating state of equipment is provided according to the parameters, and temperature prediction and fault diagnosis are conducted. Operating data of the equipment are recorded, a temperature monitoring model and a fault diagnosis model are completed, and an intelligent monitoring and diagnosing system with self-learning capacity is set up. A basis is provided for the design of the magnesium alloy rolling equipment, and the magnesium alloy plate rolling parameter monitoring and fault diagnosing system and method has guiding significance for the design of rolling equipment. The magnesium alloy plate rolling parameter monitoring and fault diagnosing system and method is strong in industrial applicability and has very good application prospects.

Owner:JILIN UNIV

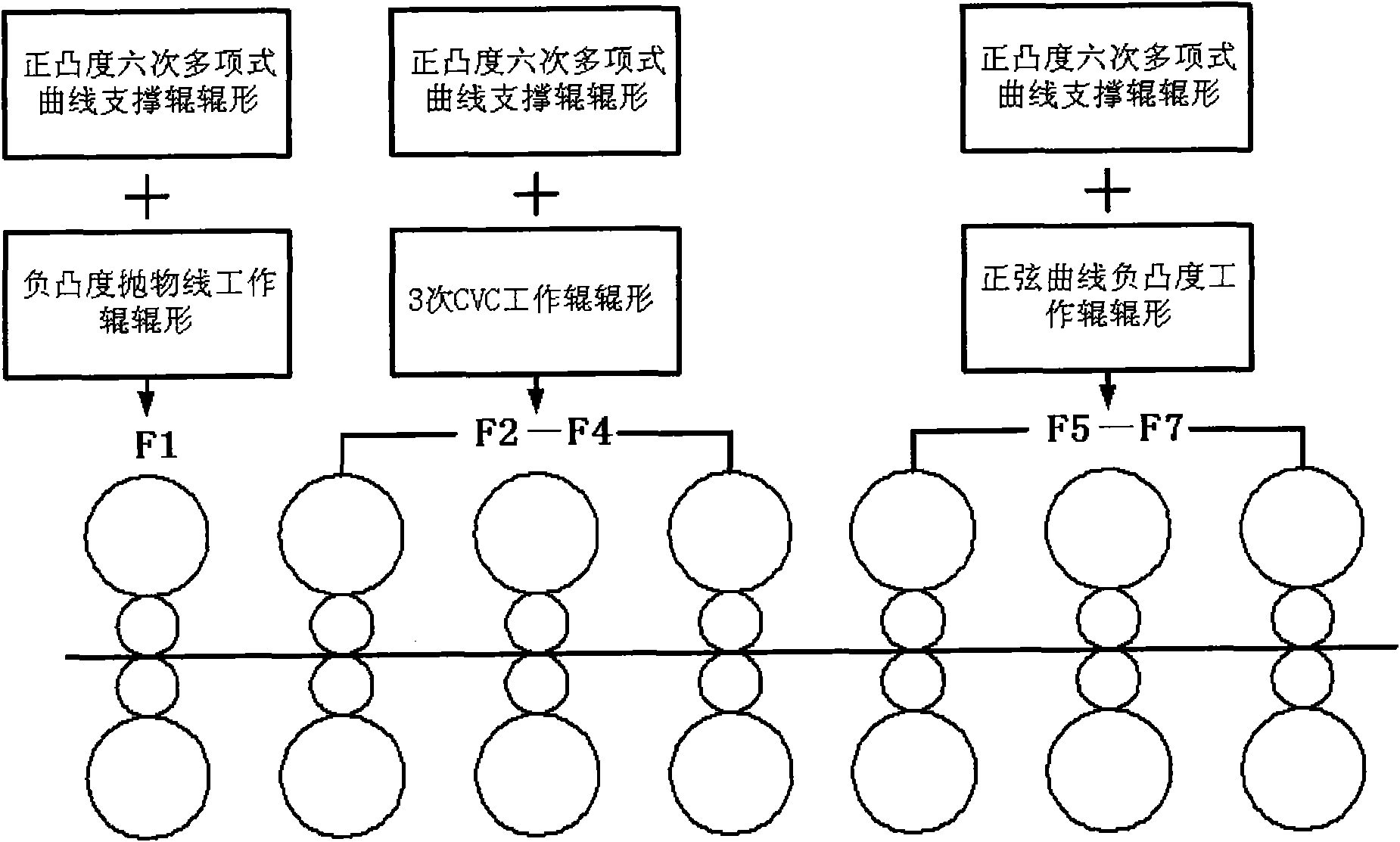

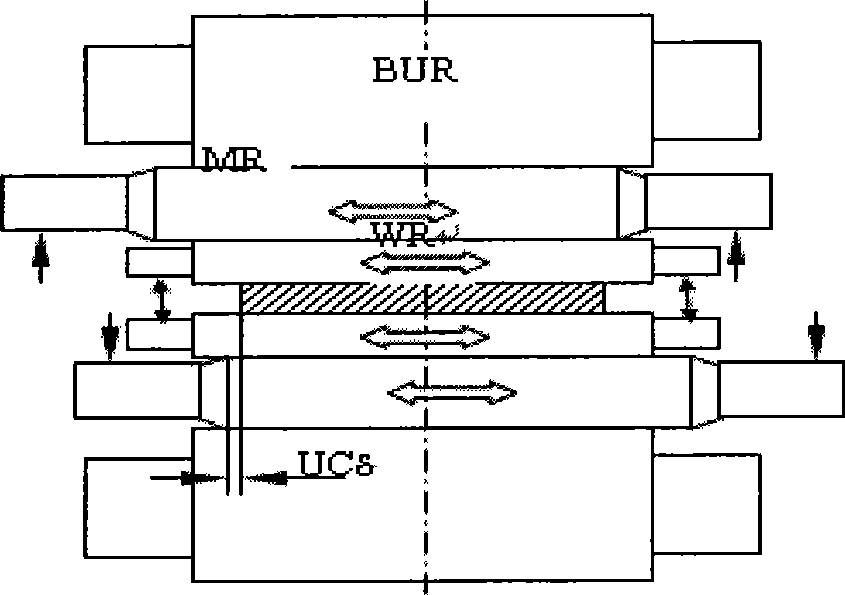

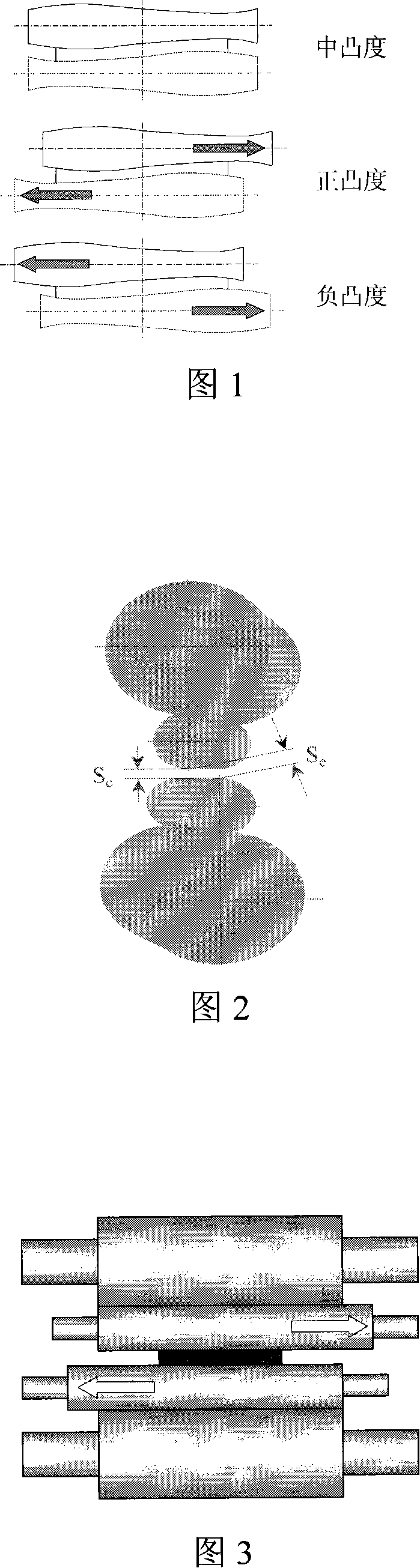

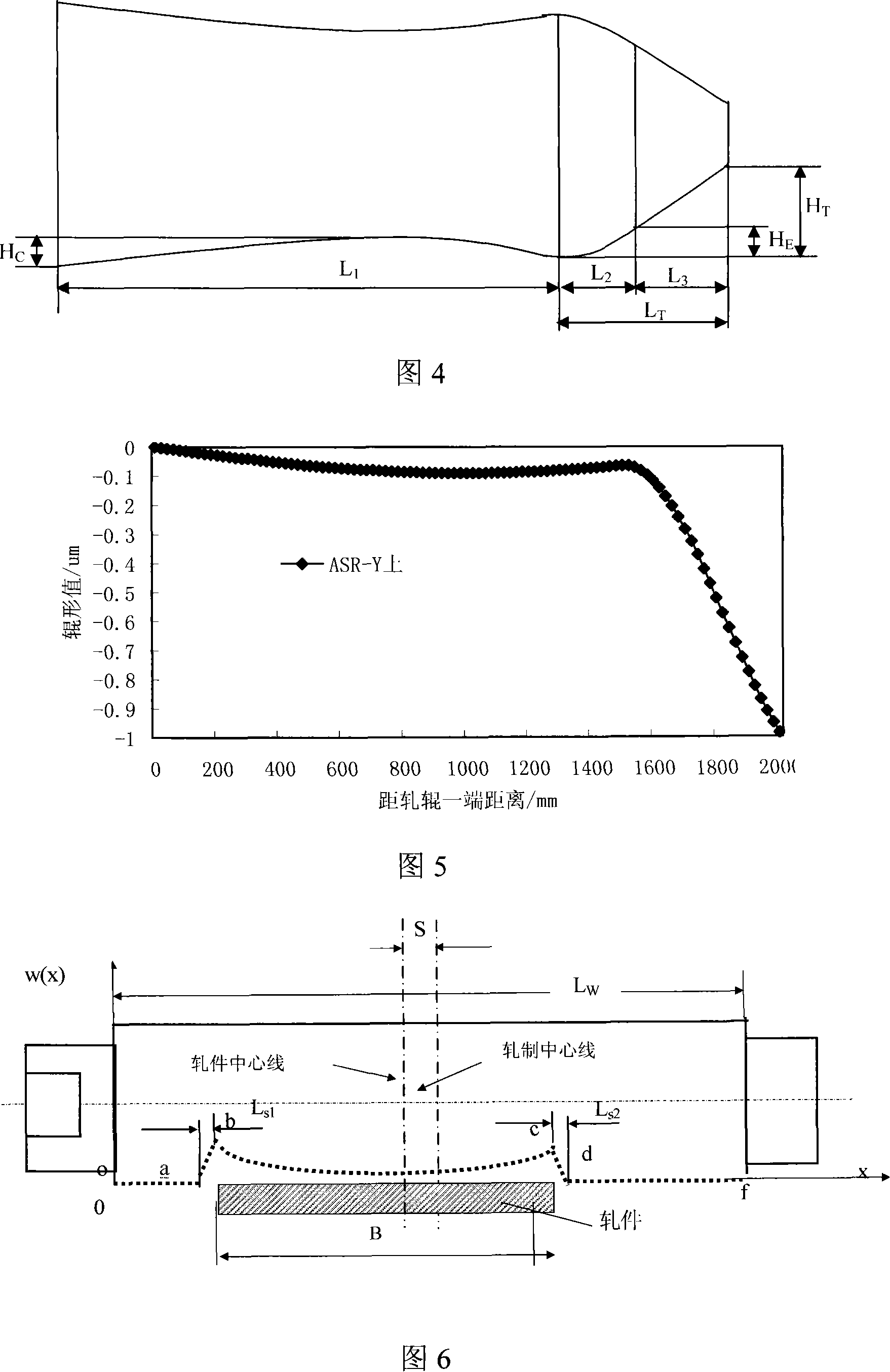

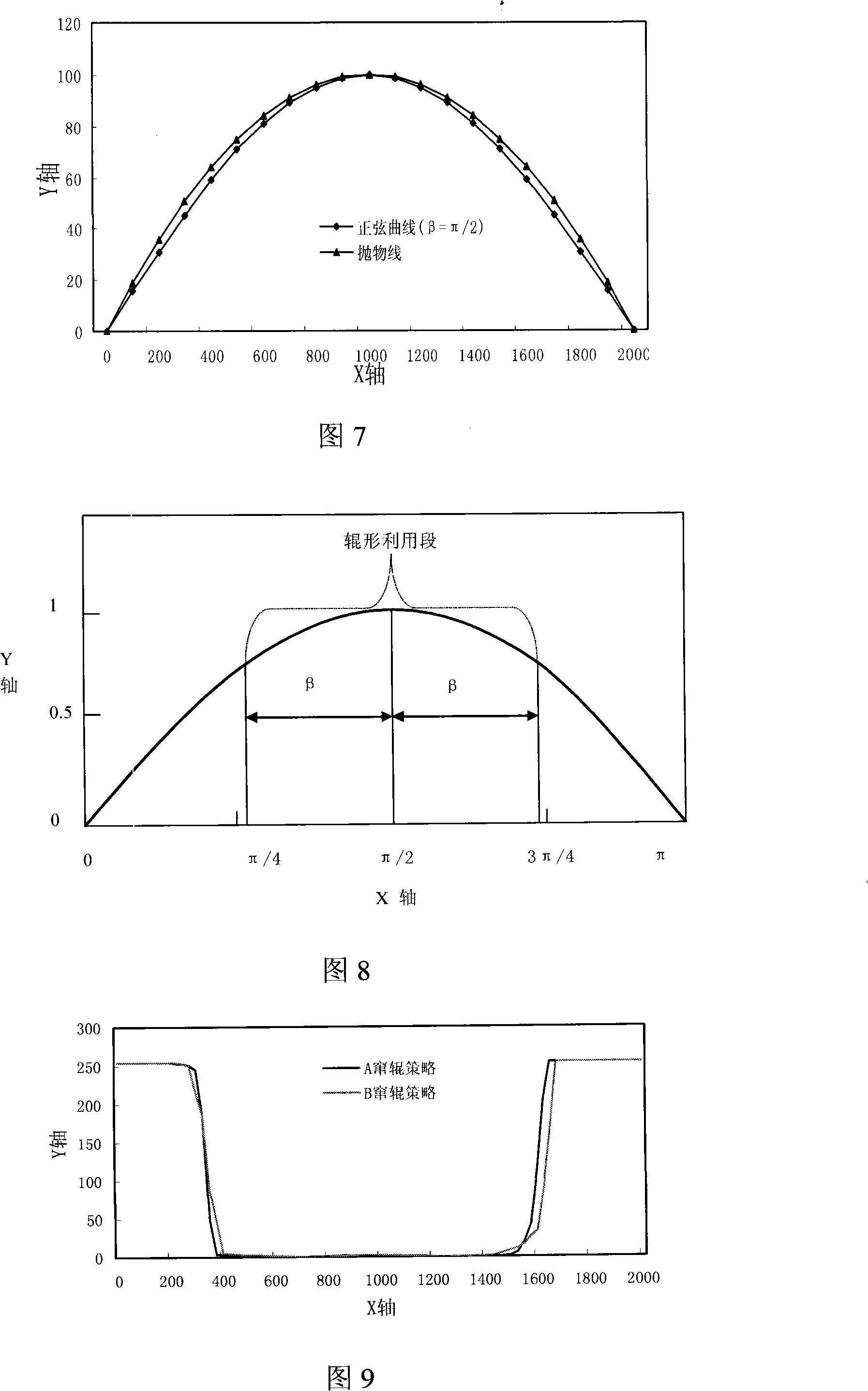

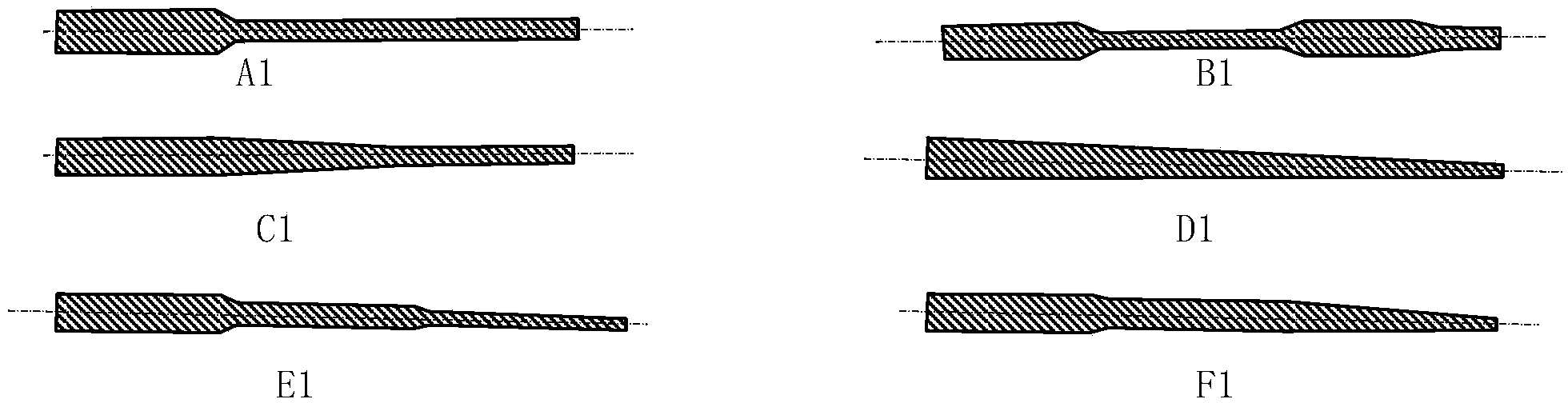

Complete roll forming configuring method for wide flat steel hot rolling finish mill set

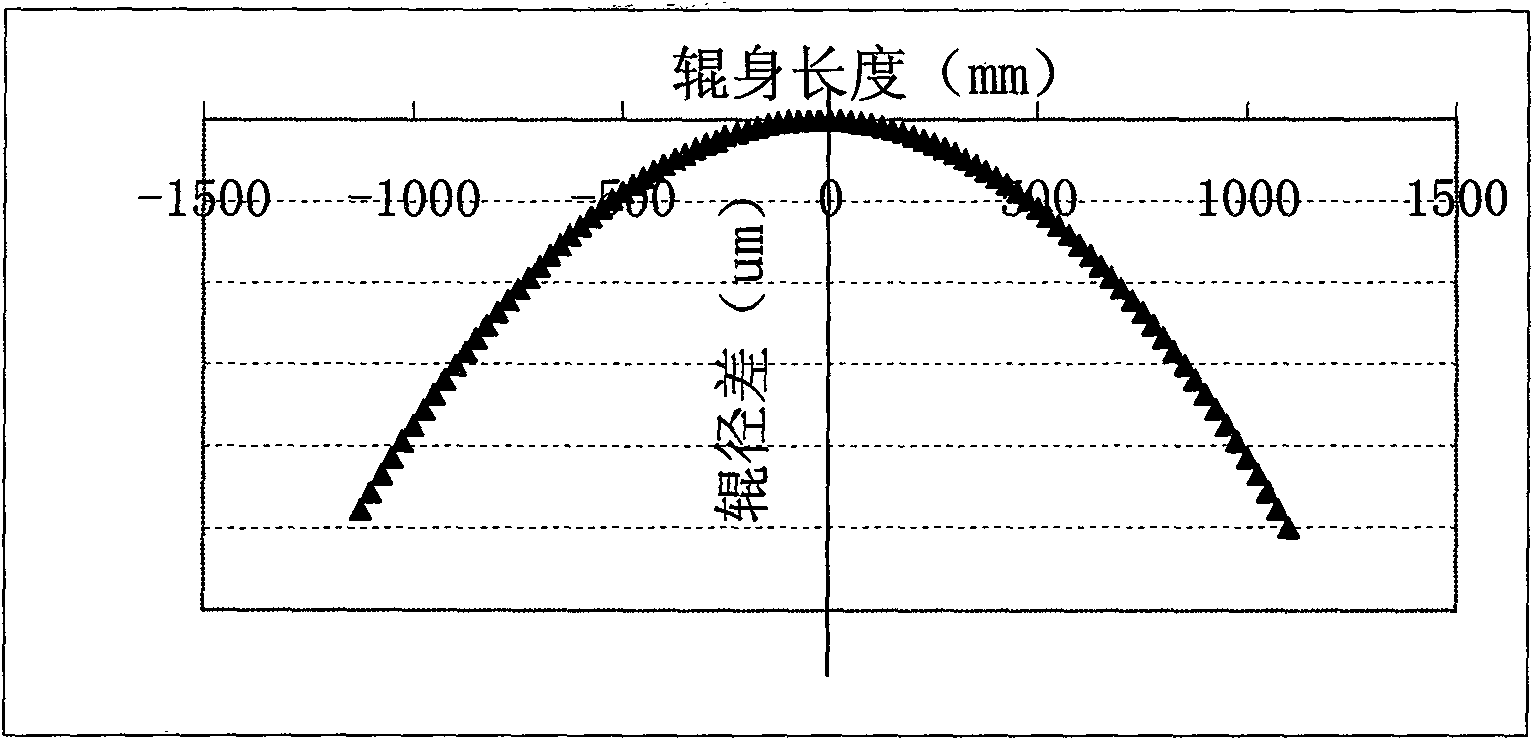

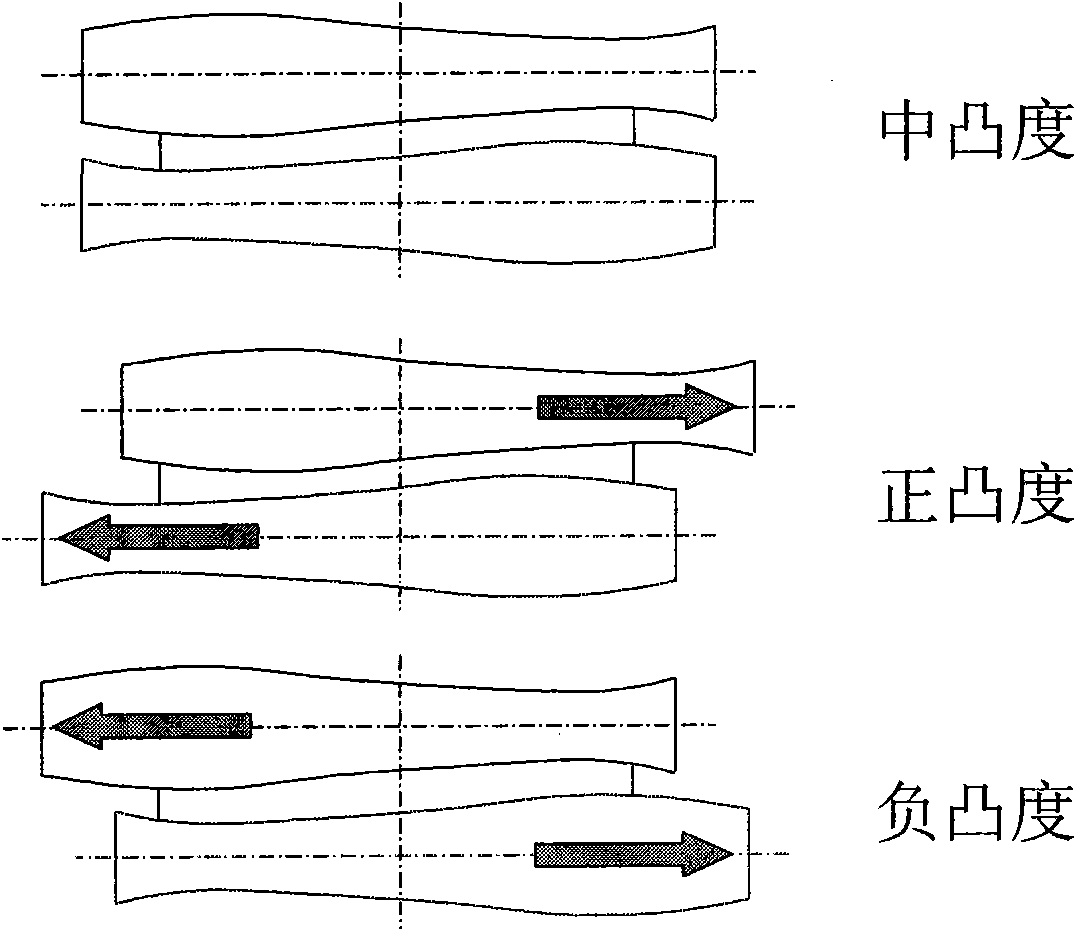

ActiveCN101890429AReasonable configurationHigh precisionRollsMetal rolling arrangementsWork rollRoll forming

The invention relates to a complete roll forming configuring method for a wide flat steel hot rolling finish mill set. According to the characteristics that an upstream machine frame controls the convexity and a downstream machine frame controls the flatness in the seven-machine frame and four-roll hot rolling wide flat steel finish mill, a finish rolling inlet machine frame F1 adopts negative convexity working roll forming, a machine frame F2, a machine frame F3 and a machine frame F4 adopt cubic CVC working roll forming, and a machine frame F5, a machine frame F6, and a machine frame F7 adopt negative convexity working roll forming of sine curves and are matched with periodic roll shifting of the working roll with long stroke. The supporting rolls of all the machine frames of the finish mill set adopt positive convexity roll forming of sextic polynomes. The method improves the transverse rigidity of the machine frames of the finish mill, improves regulation and control efficiency of roll bending force of the working roll, and reduces flexibility deformation of the roll. The roll forming configuring method for the finish mill set improves stability of the wide flat steel rolling, reduces the deflection amount of the wide flat steel, prolongs the planned length for rolling and greatly improves profile shape control precision of the wide flat steel.

Owner:SHOUGANG CORPORATION

Cold rolling working roll with anti-rollar mark and high-wearing resistance and manufacturing method thereof

The invention discloses a cold rolling working roll with roller impression resistance and high wearing resistance and a manufacturing method thereof. The materials of the cold rolling working roll comprises the following chemical compositions in terms of weight percentage: 0.85 percent to 1.10 percent of C, 0.6 percent to 1.0 percent of Si, 0.20t percent to 0.8 percent of Mn, 5.5 percent to 7.5percent of Cr, 0.30 percent to 0.8 percent of Mo, 0.1 percent to 0.3 percent of V, no more than 0.4 percent of Ni, no more than 0.020 percent of P, no more than 0.015 percent of S and the balance of Fe and inevitable impurities. The manufacturing method comprises the following steps: 1. the cold rolling roll billet is manufactured by adopting the conventional production technique according to the chemical compositions and the content thereof; 2. rough turning and tempering are carried out on the roll billet; 3. quenching heat treatment is carried out at the temperature of 950 DEG C to 1010 DEG C; 4. cold treatment is carried out at the temperature of minus 80 DEG C to minus 50 DEG C for 2 hours to 3 hours; and 5. tempering is carried out at the temperature of 120 DEG C to 145 DEG C for 60 hours to 150 hours. The cold rolling working roll has rolling marks resistance and high wearing resistance.

Owner:BAOSTEEL ROLL SCI & TECH

Working roll technique for controlling edge drop of cold-rolled steel

InactiveCN101367092AImproved shape controlPrevent peelingRollsProfile control deviceElectrical steelContact pressure

The invention relates to a working roll technology for controlling the edge drop of cold rolled steel. With the special high-order curve working roll forming technology, the technology solves the disadvantages that a rolling machine with a working roll which can not axially move has weak capacity of controlling the edge drop when electric steel is rolled. The technology can control the edge drop of the electric steel below 10 mu m, simultaneously improve the control performance of the plate shape of the rolling machine, increase the transverse rigidity for bearing roll gap, improve the state of contact pressure between rolls and prevent the roll from shelling off caused by local pressure peak. The technology is suitable for the cold rolling machine with the working roll which can not axially move, in particular for the rolling machine which infrequently changes the rolling width and the rolling specification.

Owner:UNIV OF SCI & TECH BEIJING

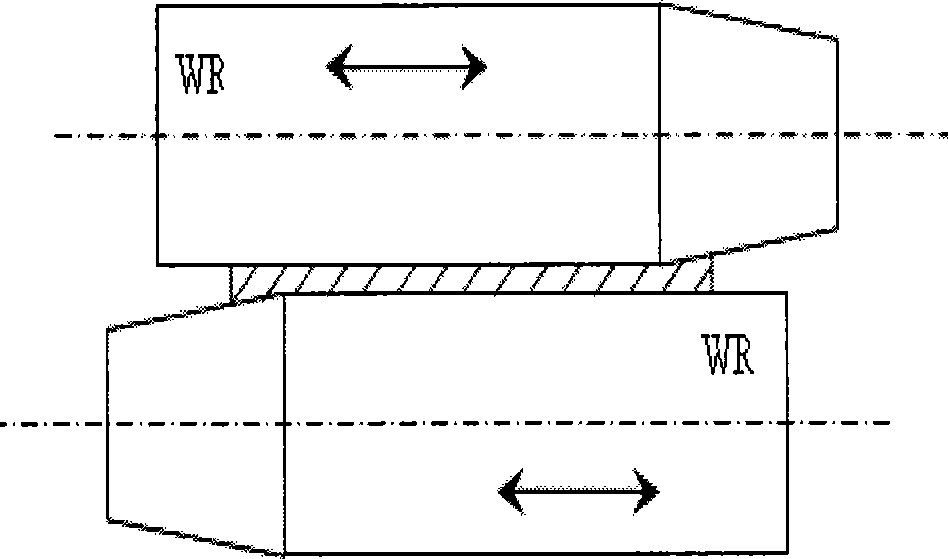

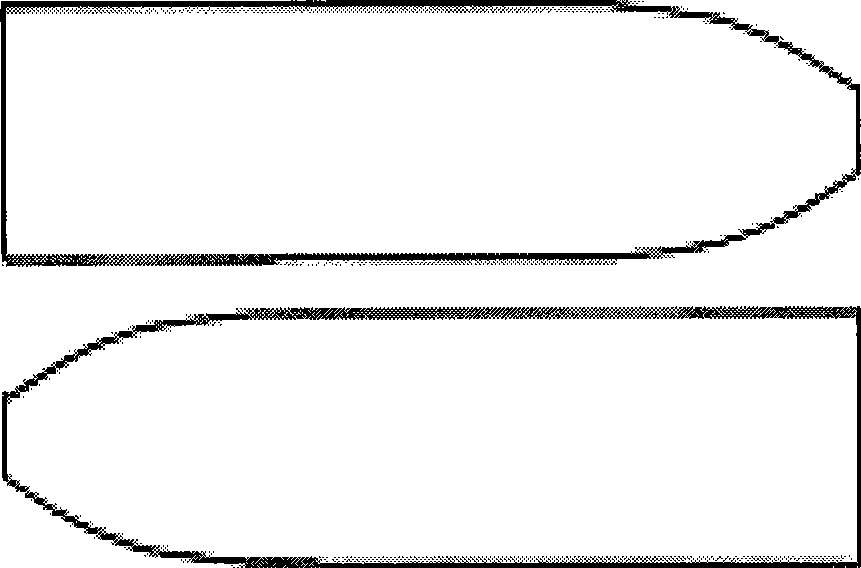

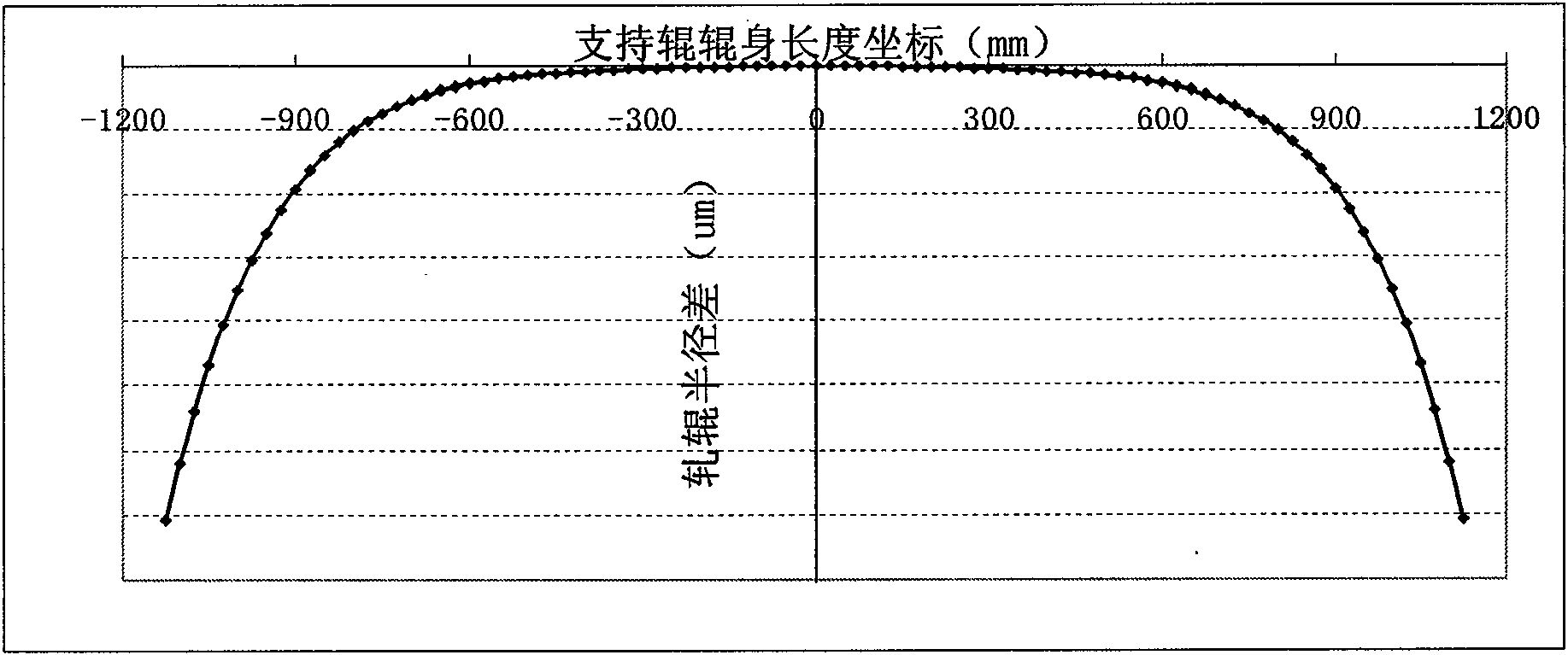

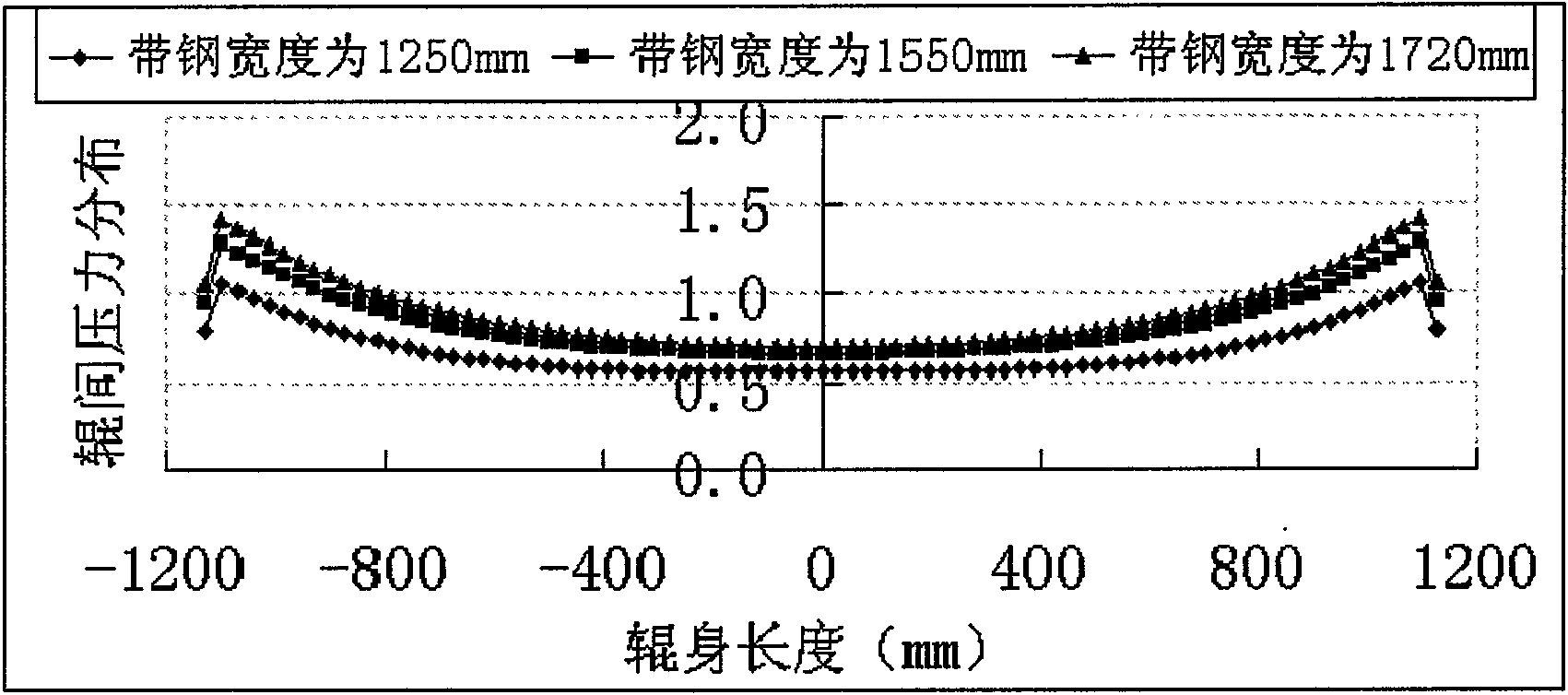

Method for configuring shape of supporting roll of four-high mill and shape of working roll thereof

ActiveCN101554635ASolve peelingSolve the large amount of wear and tearCounter-pressure devicesRollsProduction lineStress concentration

The invention relates to a method for configuring the shape of a supporting roll of a four-high mill and the shape of a working roll thereof, belonging to the technical field of steel rolling. According to three types of width specifications of band steel which are most rolled by hot-rolling band steel production line, sixth-power polynomial supporting roll shape technology and second-power working roll shape curve are used for configuration so as to lead the contact length of the supporting roll and the working roll and the width of the rolled band steel to be fit. The method has the advantages of eliminating hazardous contact areas in which the parts of the two ends of the supporting roll with the flat roll shape and the working roll expand out of the edge of the band steel to generate large deflection and deformation, solving the problems that the stress concentration of the edges of the supporting roll and the working roll in a hot continuous mill for wide band steel causes stripping and the mill roll with the flat roll shape has large wearing capacity and is not even, reducing the consumption of the mill rill, saving energy, reducing consumption and reducing cost for rolling steel; and by the technical configuration of R2 working roll shape and the supporting roll shape, the invention solves the plate-shape problems that the middle blank generates negative convexity and the wedge shape is large, and improves the control precision of the shape of hot-rolled band steel.

Owner:SHOUGANG CORPORATION

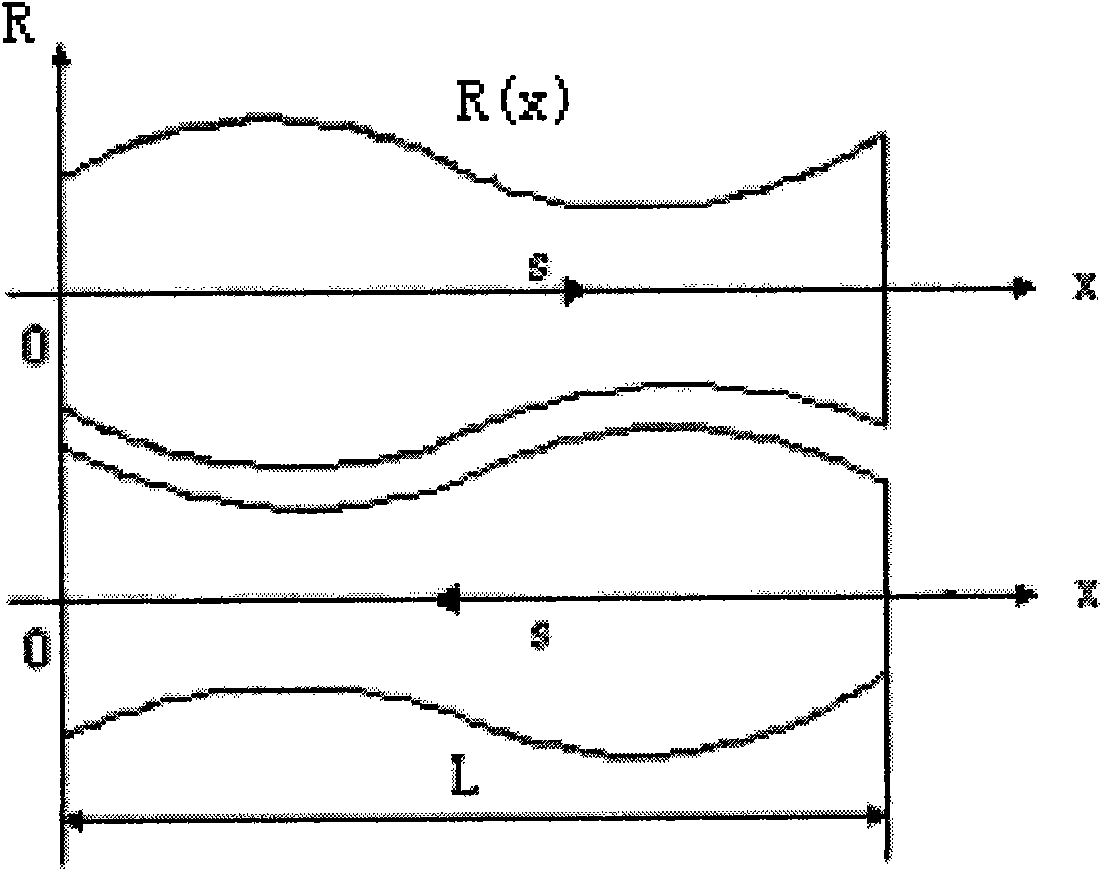

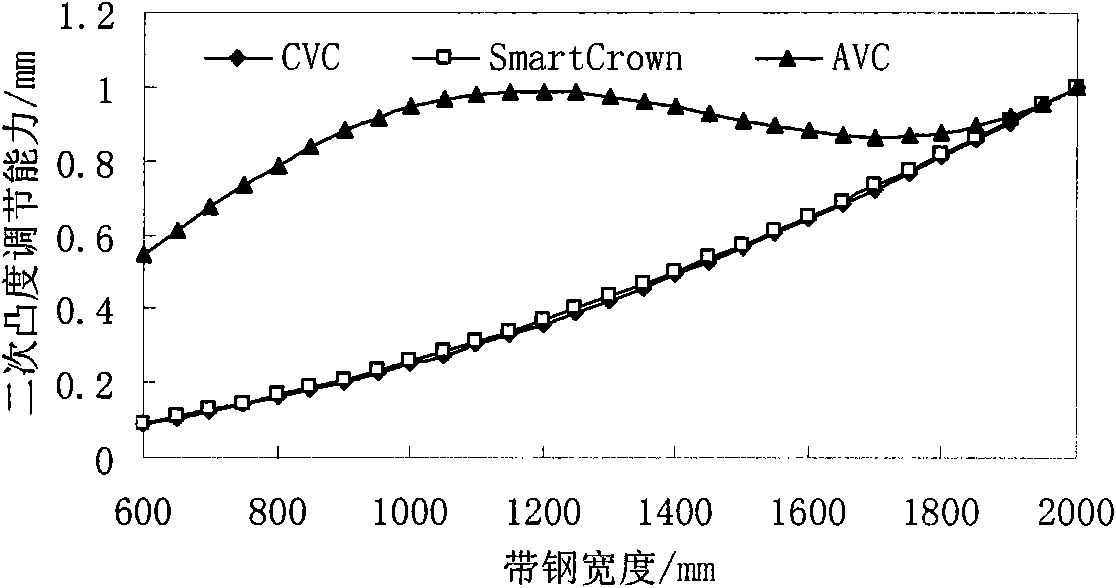

Variable convexity working roll for rolling plates, sheets and strips

InactiveCN101569894AImproved shape controlStrong quadratic convexity control abilityRollsProfile control deviceWork rollWave shape

The invention provides a variable convexity working roll for rolling plates, sheets and strips, and a roll shape curve thereof adopts a composite function. The special roll shape curve form of the working roll can balance the secondary convexity control capability of wide and narrow strip steel at the same time of ensuring the secondary convexity regulation capability of no-load roll gap and the shift amount of a rolling roll to show an approximate linear relationship. Compared with the continuous variable convexity roll shape technology, the variable convexity working roll improves the control capability to the narrow strip steel under the situation of also having stronger convexity control capability to the strip steel with wide specification; in addition, the variable convexity working roll further has the control function to high-order wave shape, thereby enhancing the whole plate shape control capability of a rolling machine and meeting the technical requirements on high-precision rolling of plates, sheets and strips.

Owner:UNIV OF SCI & TECH BEIJING

Control method for cold rolling mill for improving surface quality of strip steel

ActiveCN101543841AEasy to shapeImprove roll shapeNumerical controlProfile control deviceWork rollEngineering

The invention discloses a control method for a cold rolling mill for improving the surface quality of strip steel, which comprises the following steps: independently controlling a previous stander X-1 of a last stander X or controlling the last stander X and the previous stander X-1 at the same time; and before a shape of the strip steel changes, predicting changes of the roll force to carry out precompensation on a bending roll so as to reduce the generation of a serious dual-side long edge, optimize the shape of export strip steel of a rolling mill, improve a shape of a working roll, and eliminate compression roller marks of an outer ring of a steel coil on a coiling machine. In addition, the method does not produce influence on stable rolling of the rolling mill.

Owner:宝钢日铁汽车板有限公司

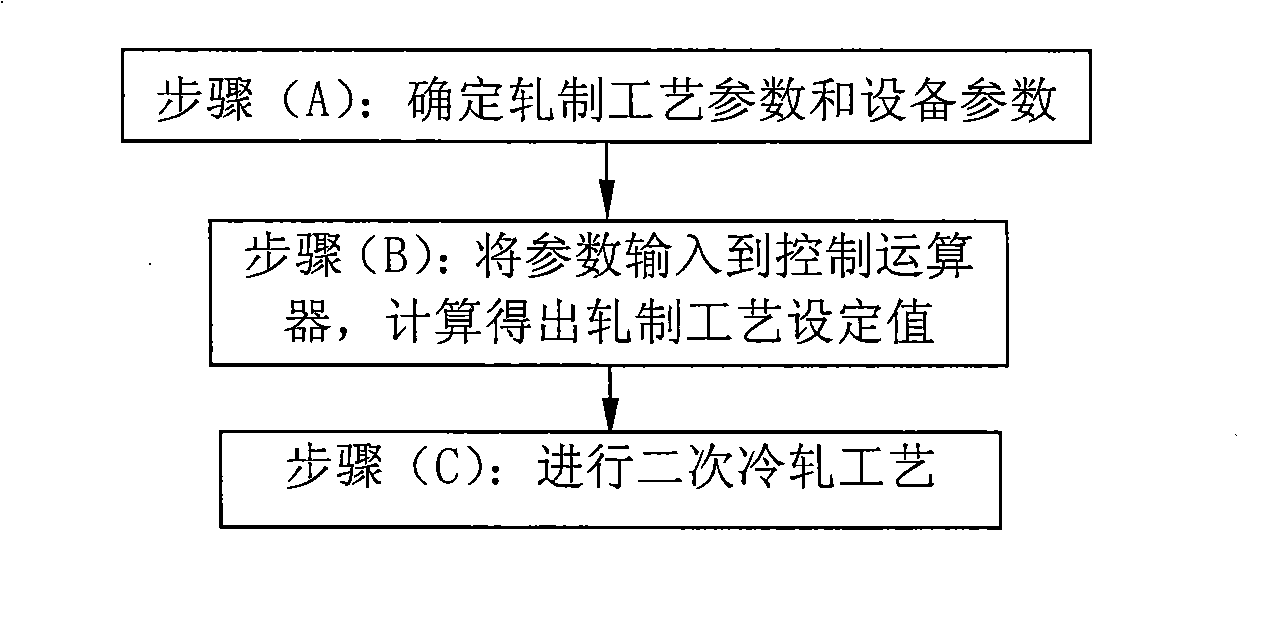

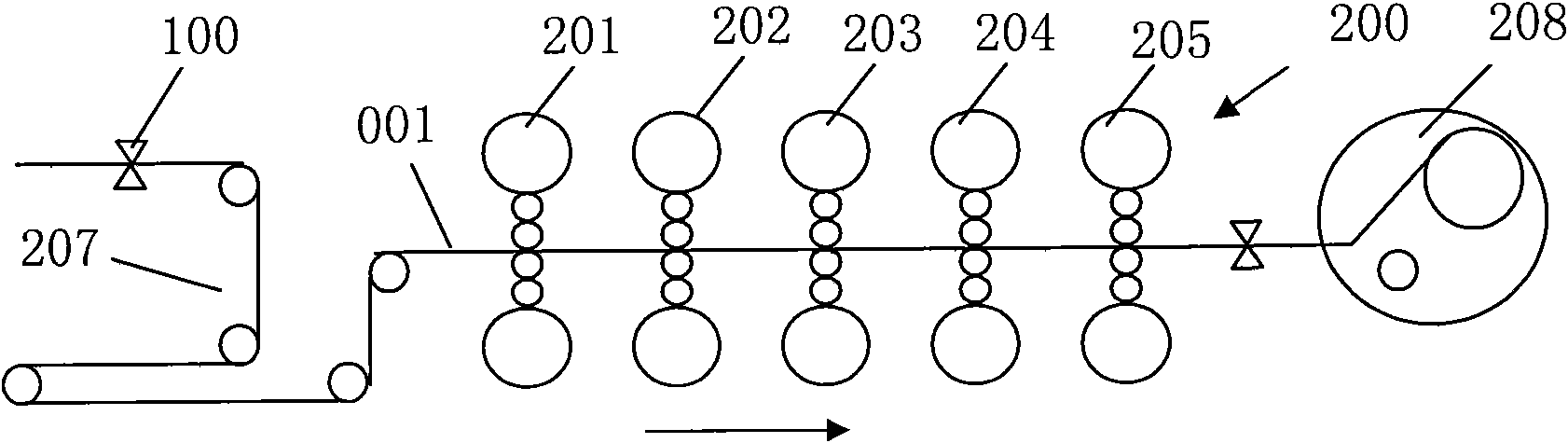

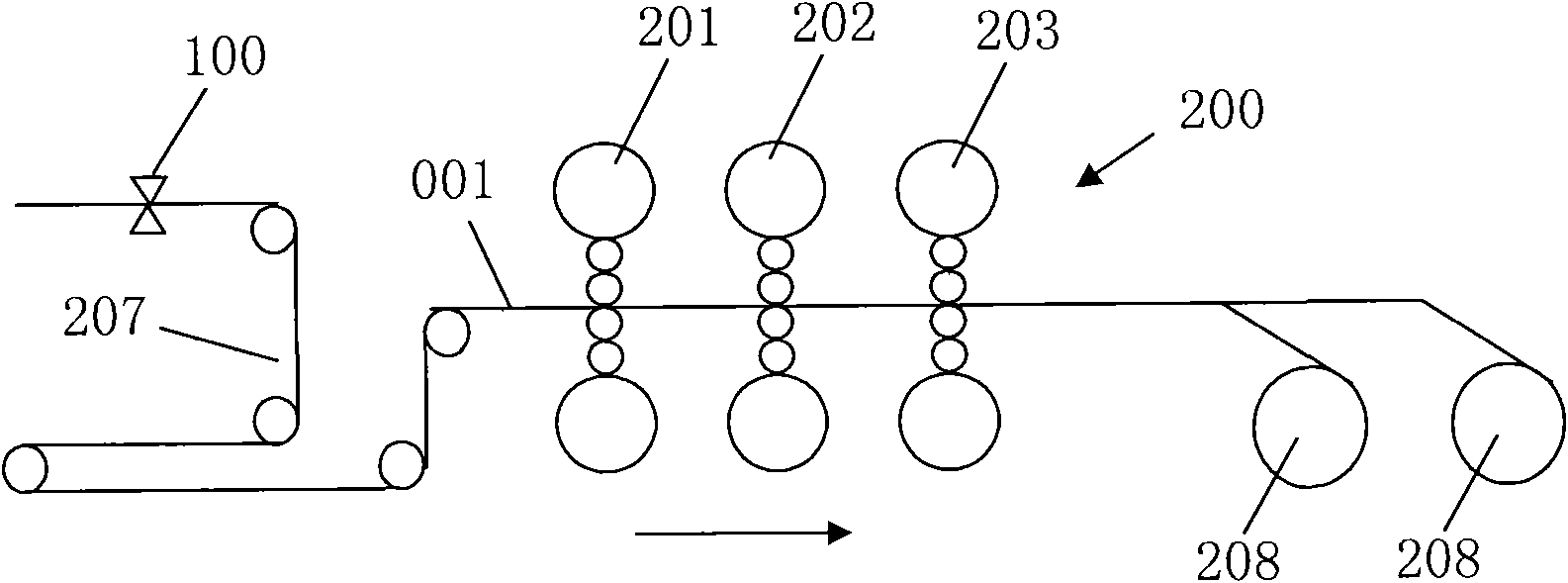

Method for leveling strip produced by secondary cold rolling unit

ActiveCN101513647AEasy to shapeQuality improvementTension/compression control deviceProfile control deviceHorizontal distributionWork roll

The invention provides a method for leveling a strip produced by a secondary cold rolling unit, which controls the surface roughness of the strip by reasonably setting the partition coefficients of the roughness and elongation of the working rolls of first and second machine frames and controls the shapes of finished strips other possible surface defects by reasonably setting a bending-roller force, a roll shifting rate and the tension of the front, middle and rear sections of the machine frames to achieve uniform front tension of finished strips and uniform horizontal distribution of a rolling force, thereby establishing effectively improved technology for leveling high-brightness micro plates produced by a secondary cold rolling unit. The principle of the method is clear, a secondary cold rolling process is carried out smoothly according to obtained rolling process set values, the quality of the shape and surface of leveled strips is high, the calculation is quick, and the method issuitable for online use.

Owner:BAOSHAN IRON & STEEL CO LTD

Pick For Earthworking Machine

A pick to be used on an earth working roll for mining, construction and public works machines such as crushers, surface miners, milling machines and the like. The pick includes a working end with holes that extend into the pick and inserts are received into the holes. The inserts during operation impact and fracture a consolidated material to separate the material. Impacting the material generates heat in the pick at the working end of the pick which must be dissipated and attenuated to limit thermal fatigue in the inserts that occurs at high temperatures. The inserts in the working end are configured to dissipate the generated thermal energy from the inserts to the body of the pick.

Owner:ESCO HYDRA UK

Working roll consideration to strip steel convexity, edge drop control and abrasion control and using method

InactiveCN101214501AImproved convexity controlImproved edge controlRollsProfile control deviceWork rollEngineering

Owner:WUHAN IRON & STEEL (GROUP) CORP +1

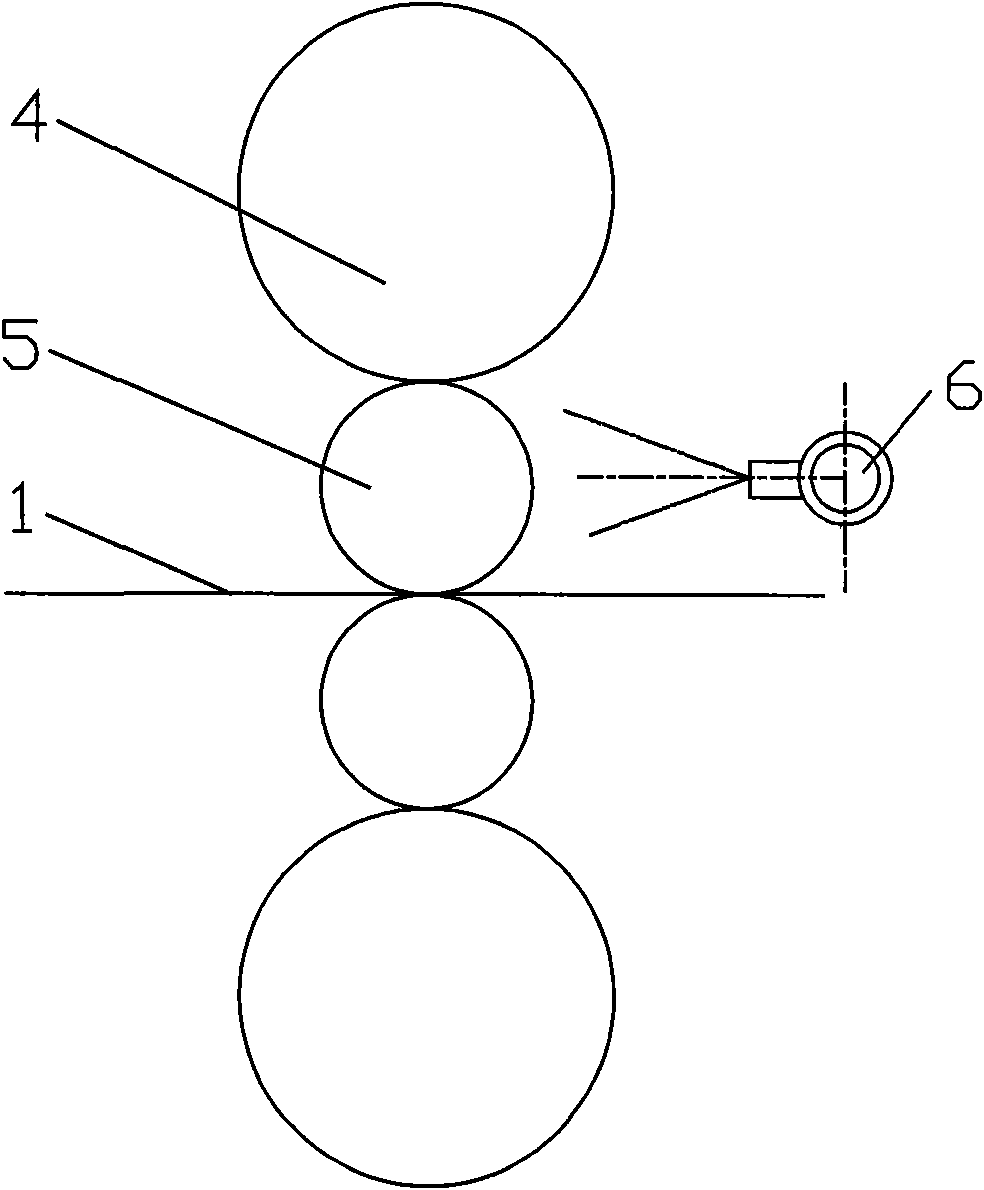

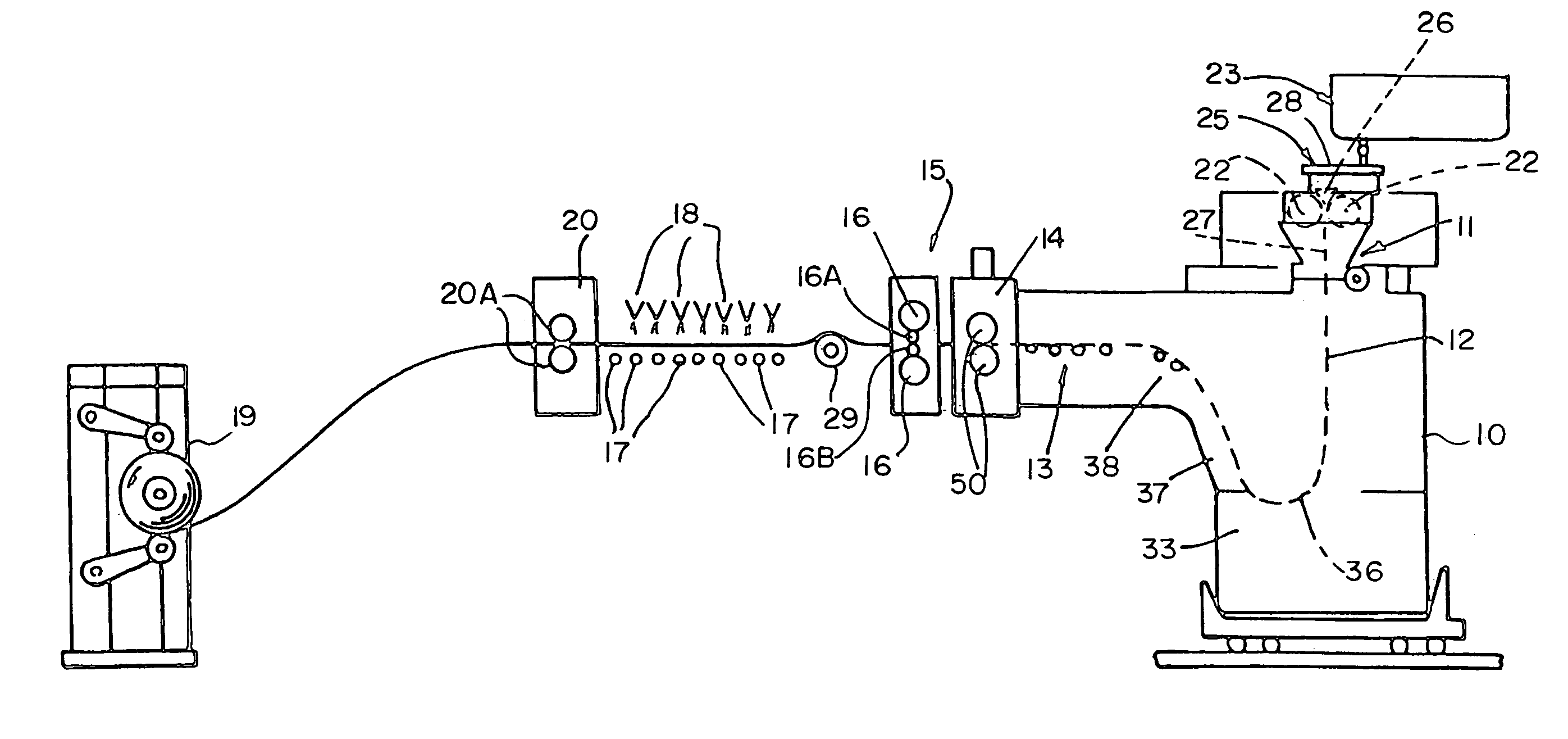

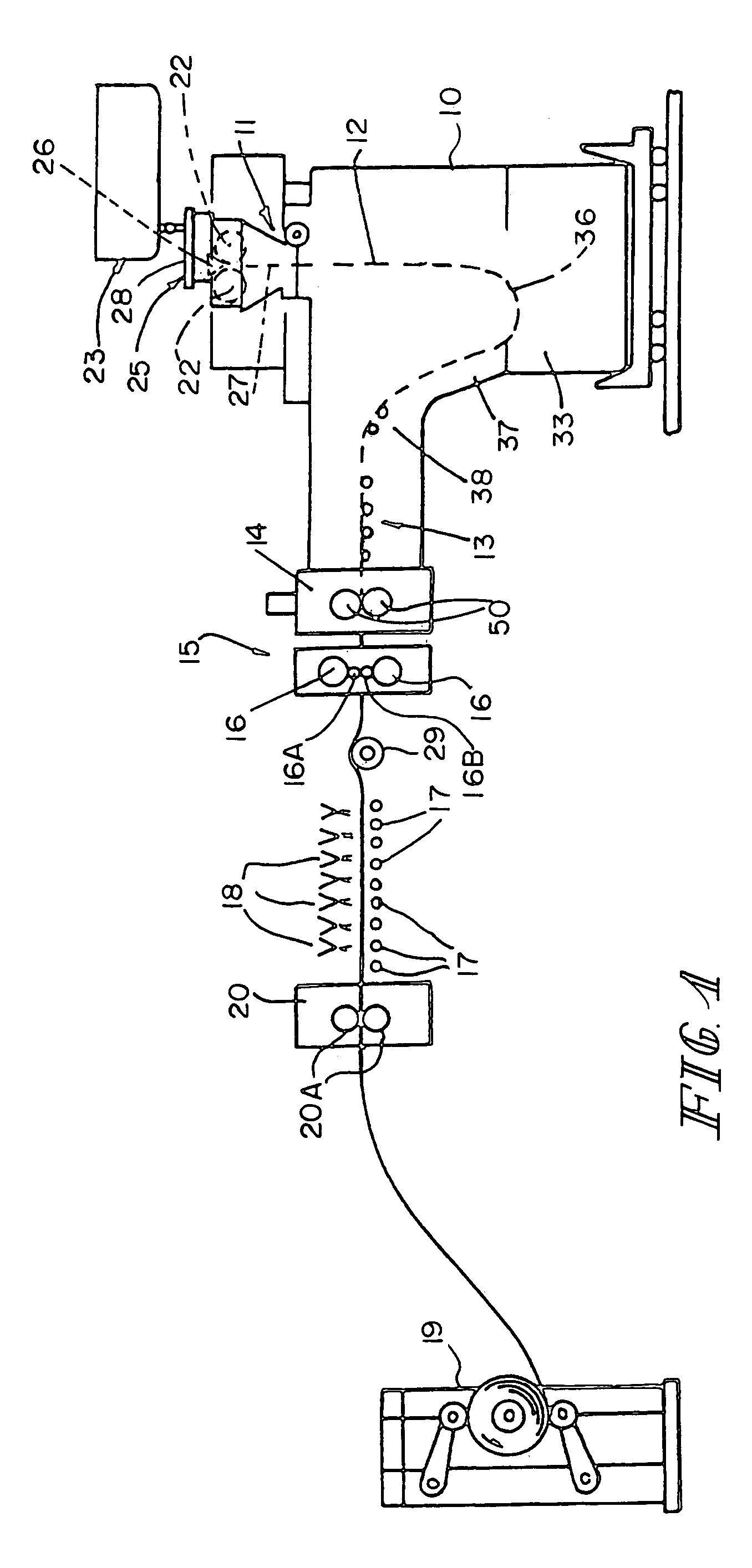

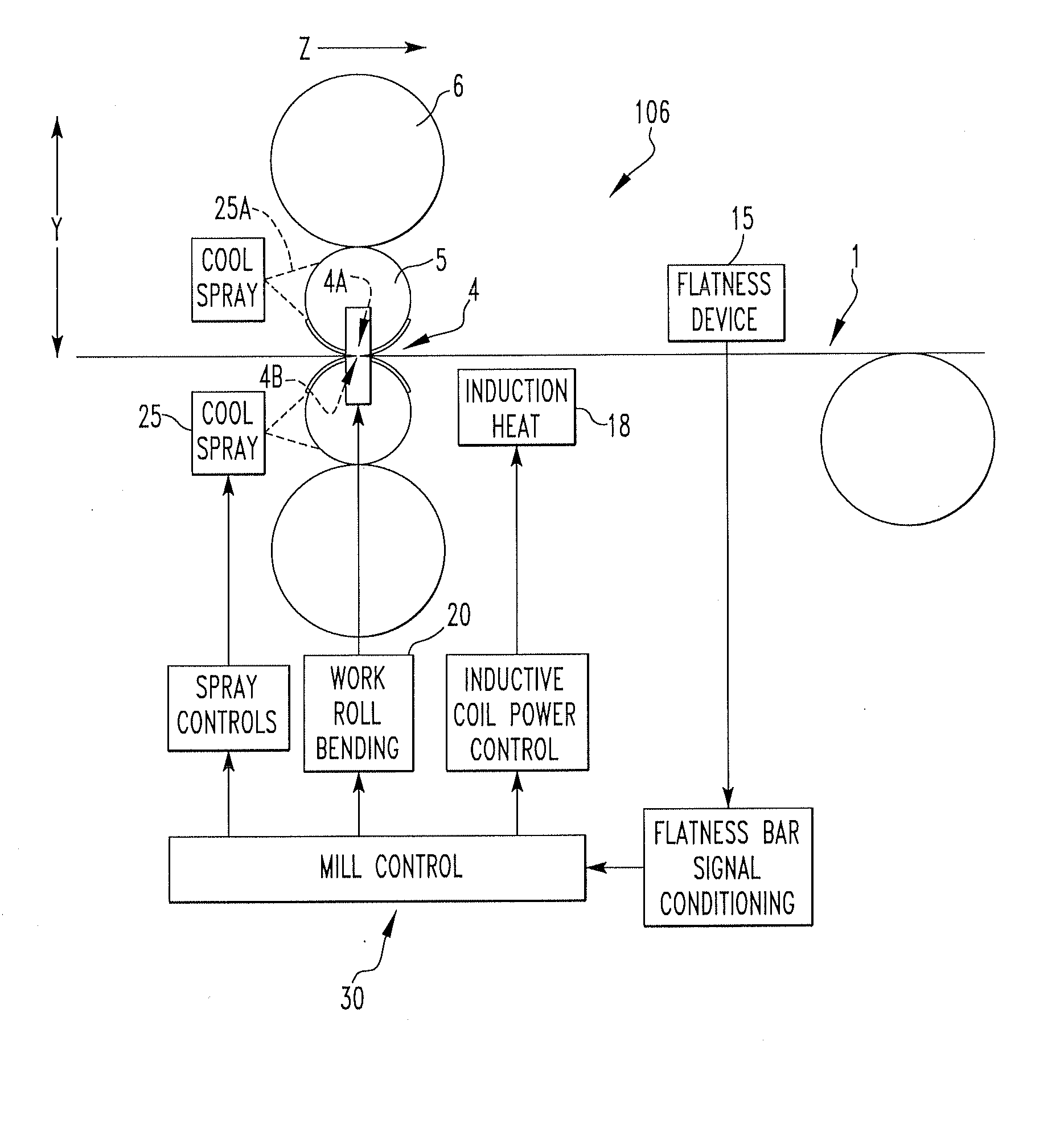

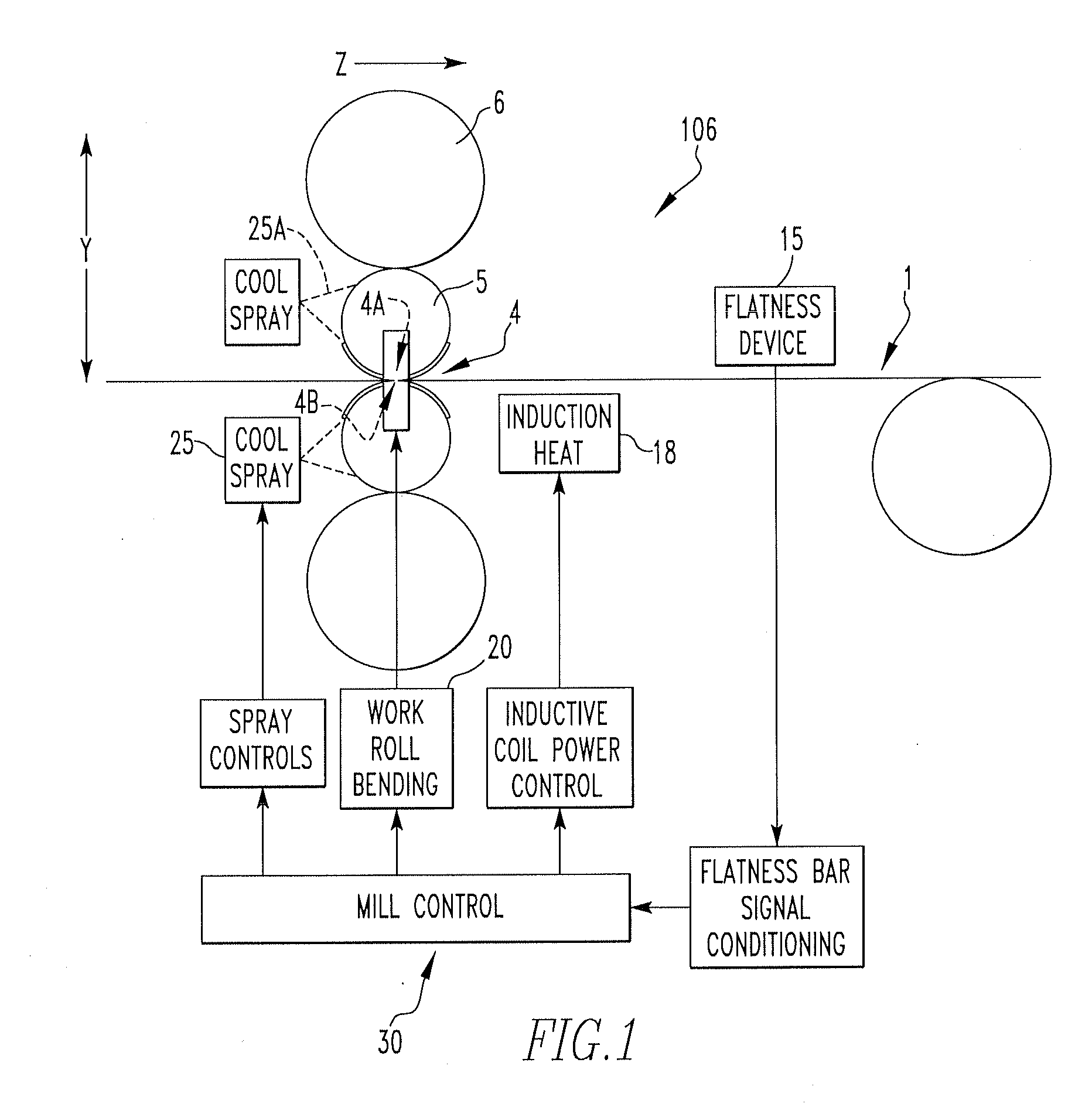

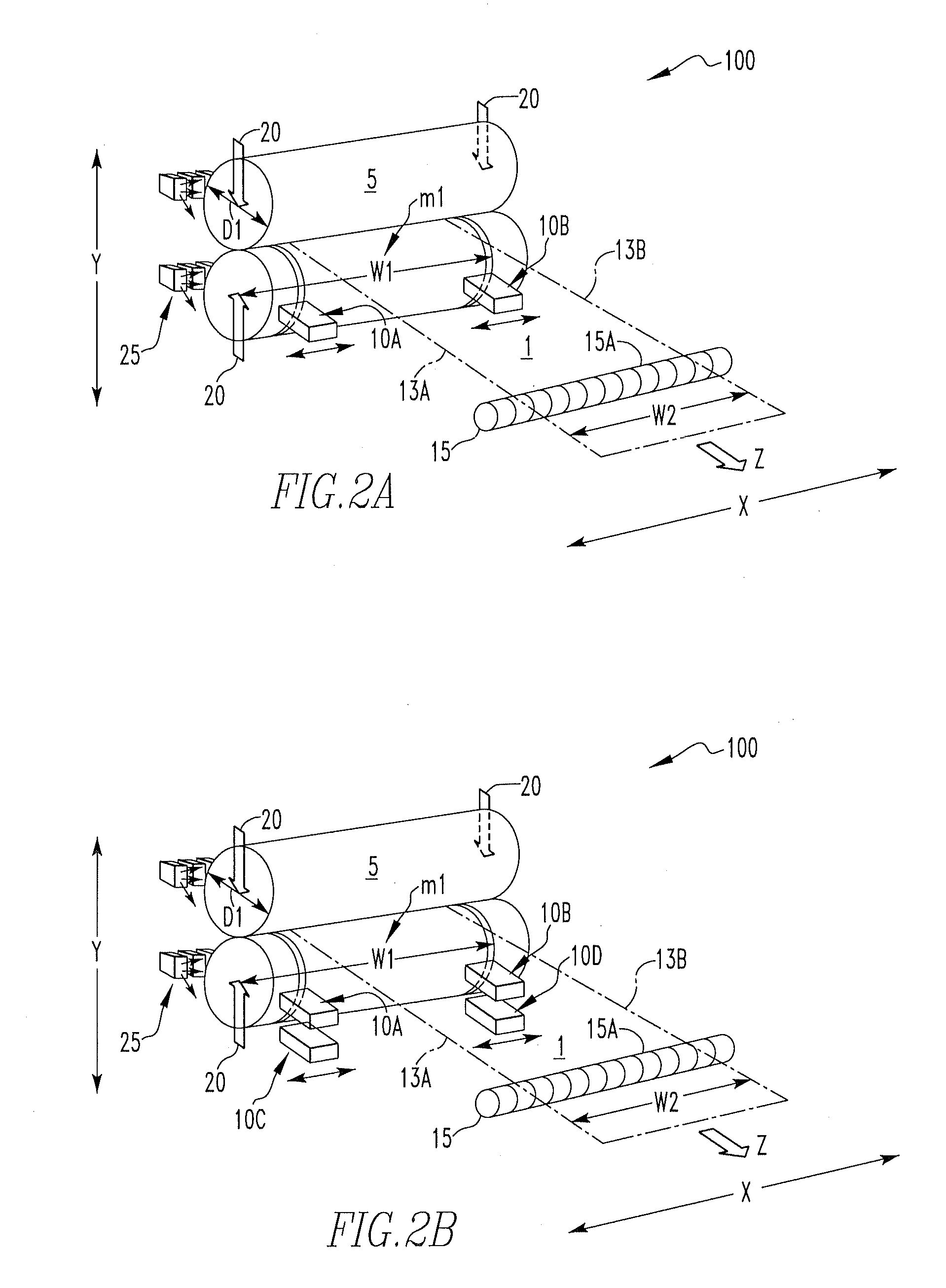

Application of induction heating to control sheet flatness in cold rolling mills

A system for rolling metal sheet having a substantially uniform flatness including a rolling mill including a pair of work rollers for reducing the thickness of a metal sheet, an induction heating apparatus in close proximity to at least one roller, bending jacks corresponding to each of the rollers, and a cooling spray system in proximity to rollers; a flatness measuring device positioned to measure a differential in flatness of the metal sheet; and an mill control interface connected between the flatness measuring device and the rolling mill's actuators, in which the mill control interface is configured to actuate the induction heating apparatus, the bending jacks and the cooling spray system to substantially eliminate flatness differentials is the metal sheet's flatness. The induction coil heating apparatus is configured to eliminate high tension on the strip edges caused by the temperature gradients in the work rolls at the edges of the metal strip.

Owner:ARCONIC INC

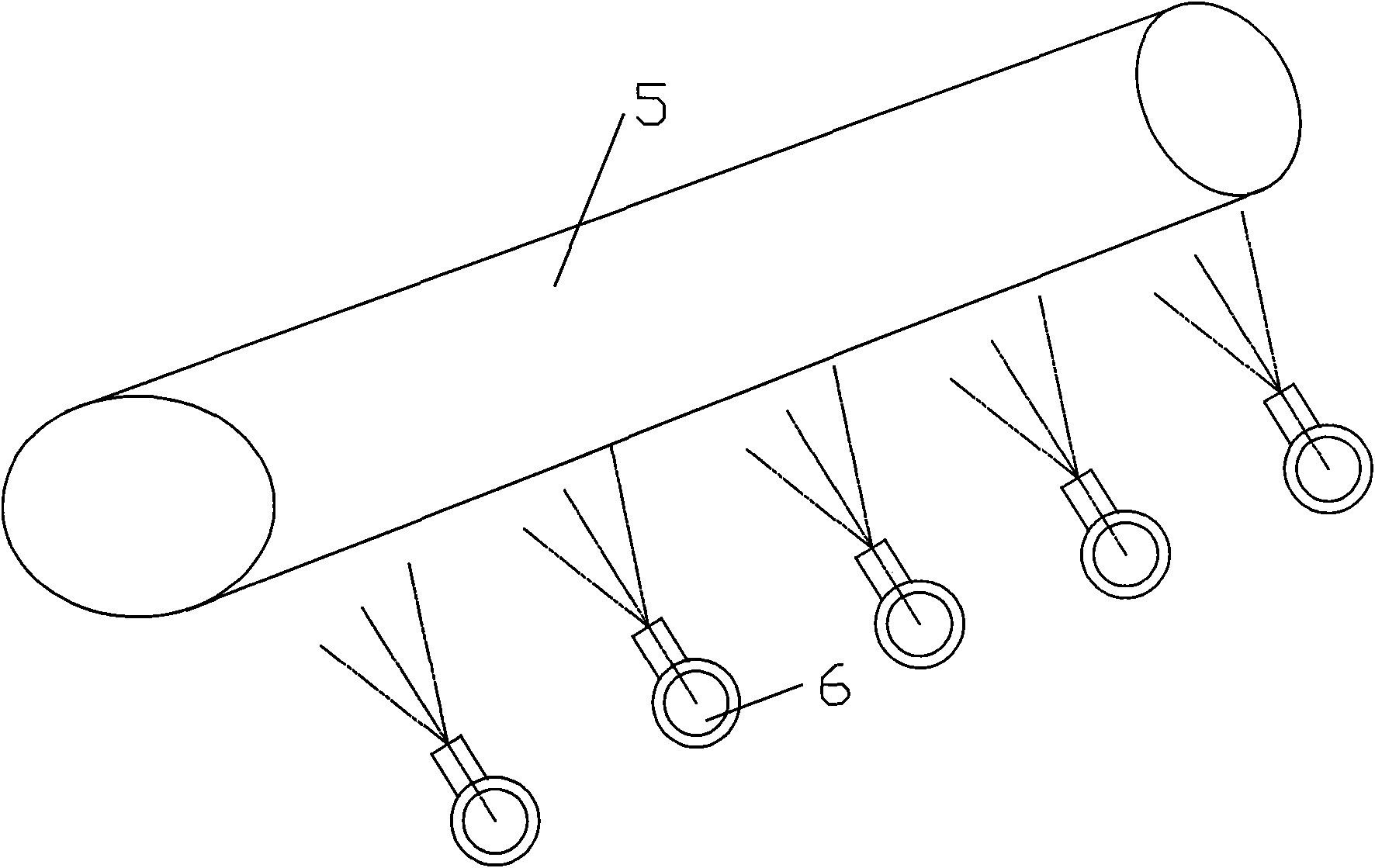

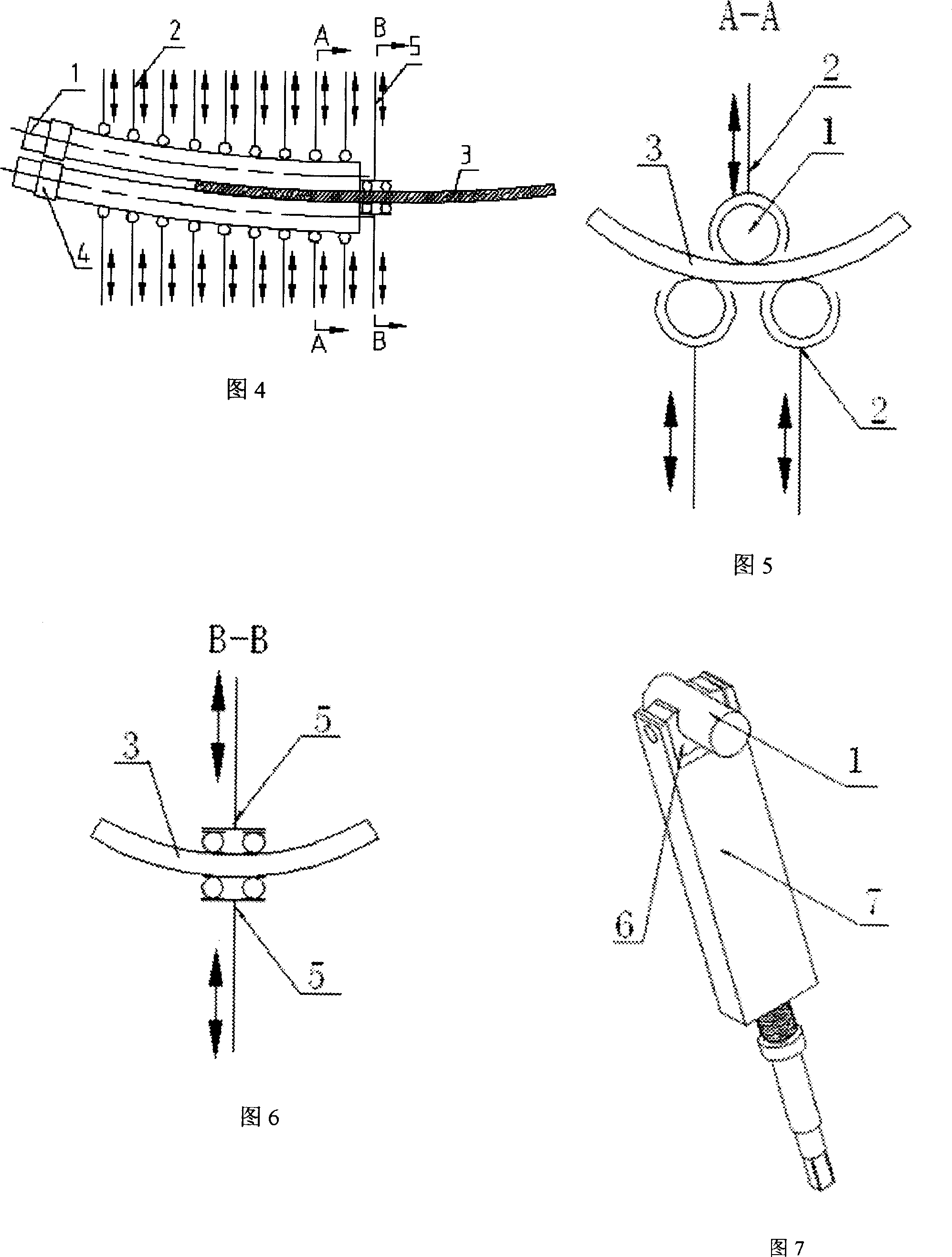

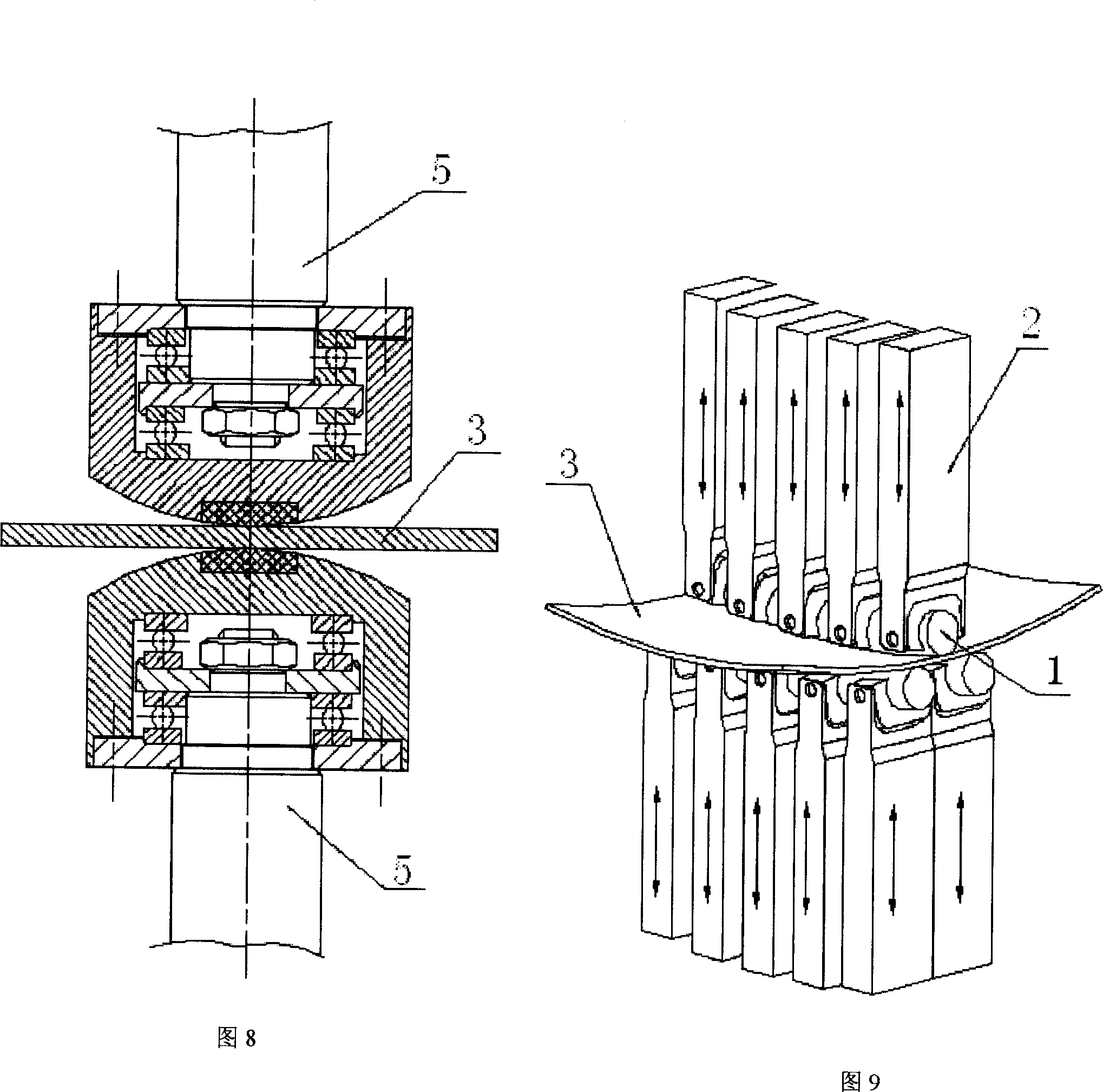

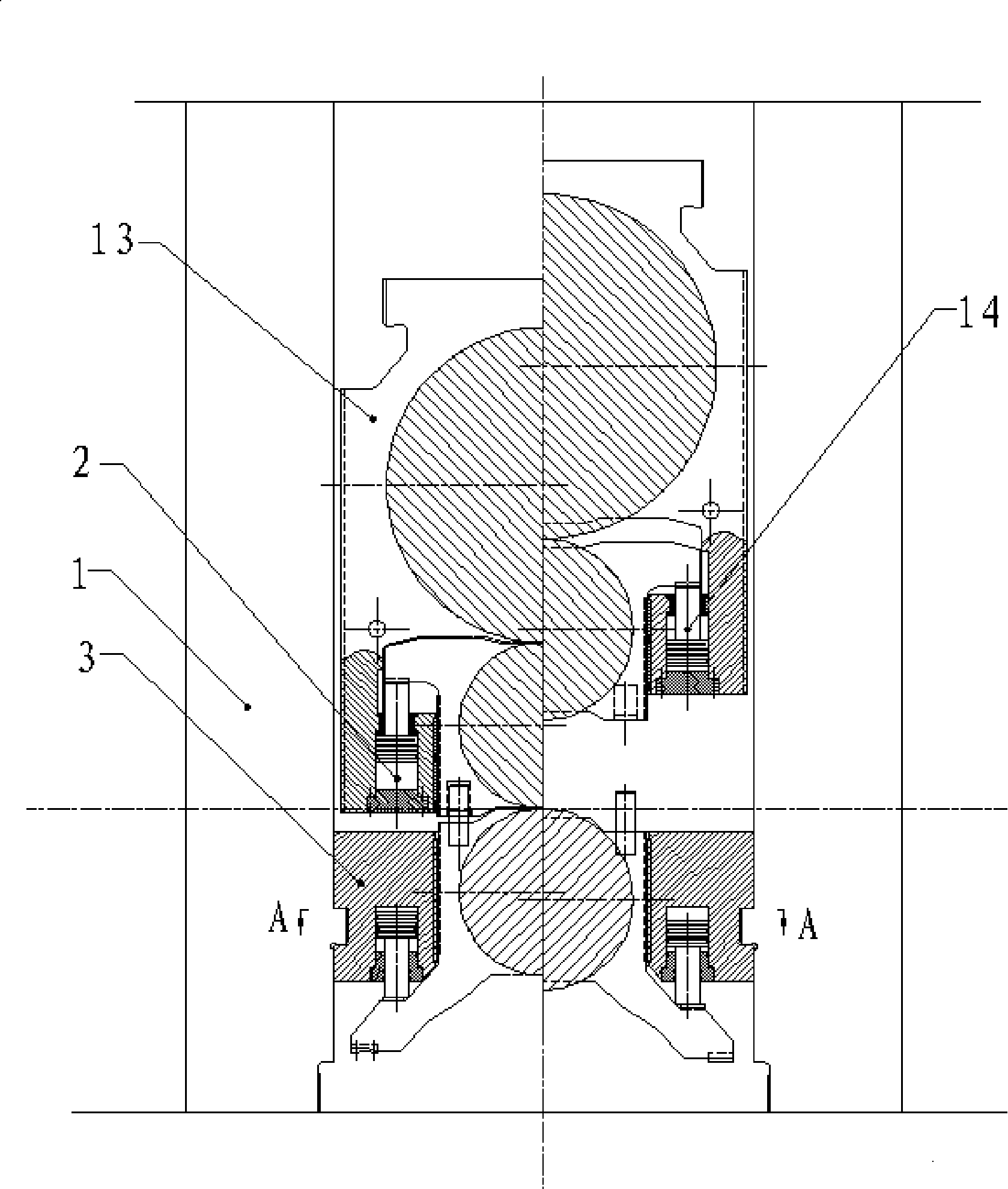

Three-dimensional curve flexible shaping device using bend flexible roller

The present invention relates to a equipment for flexible formation, in particular, it relates to a three-dimensional curved surface forming equipment capable of using flexible roll. Said equipment consists of working roll, machine frame, working roll regulation mechanism and workpiece holding and rotating mechanism. Said equipment has at least two working rolls, at least one of them can be bent and can be regulated. Besides, said invention also provides the working principle of said three-dimensional curved surface flexible forming equipment and its concrete operation method.

Owner:JILIN UNIV

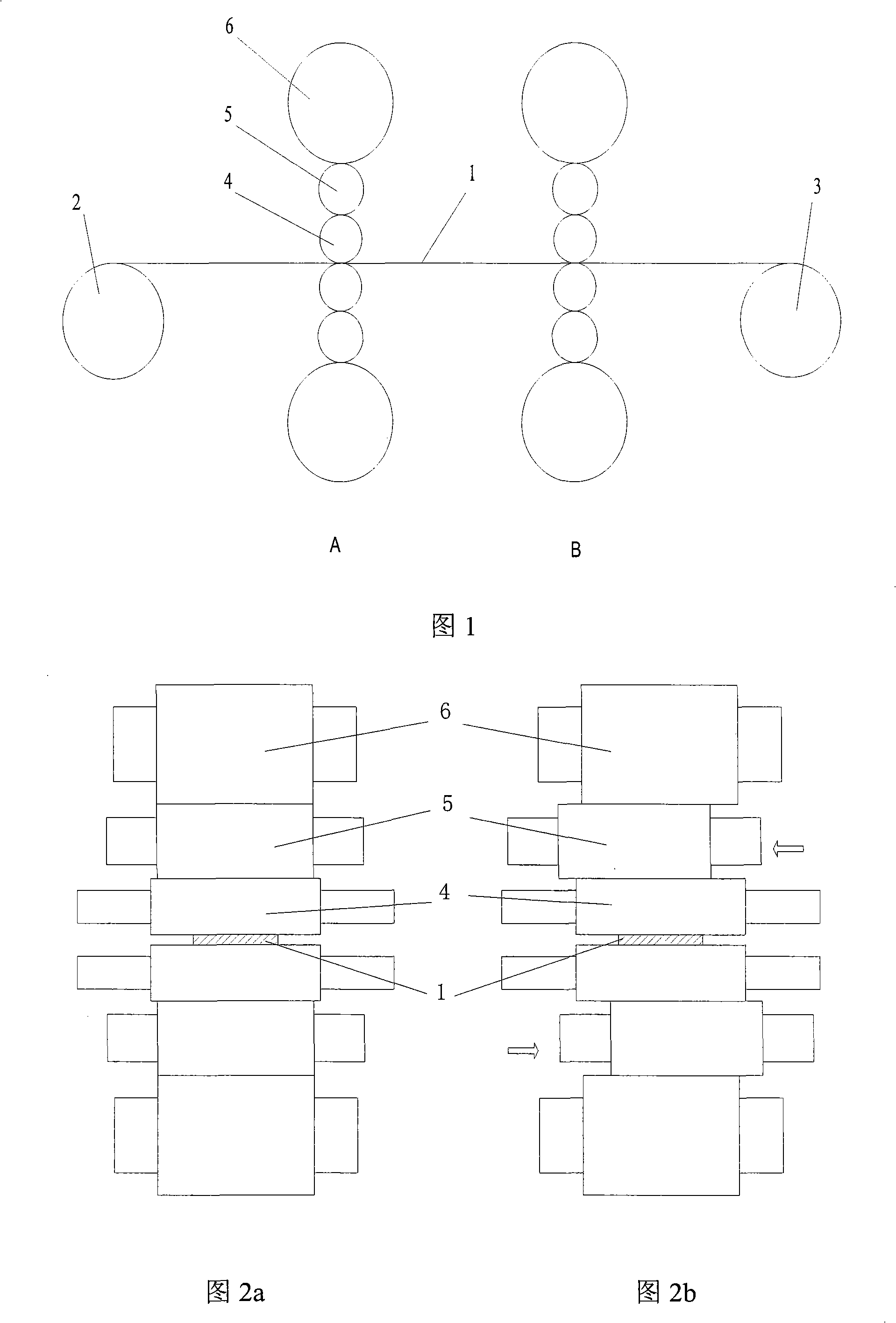

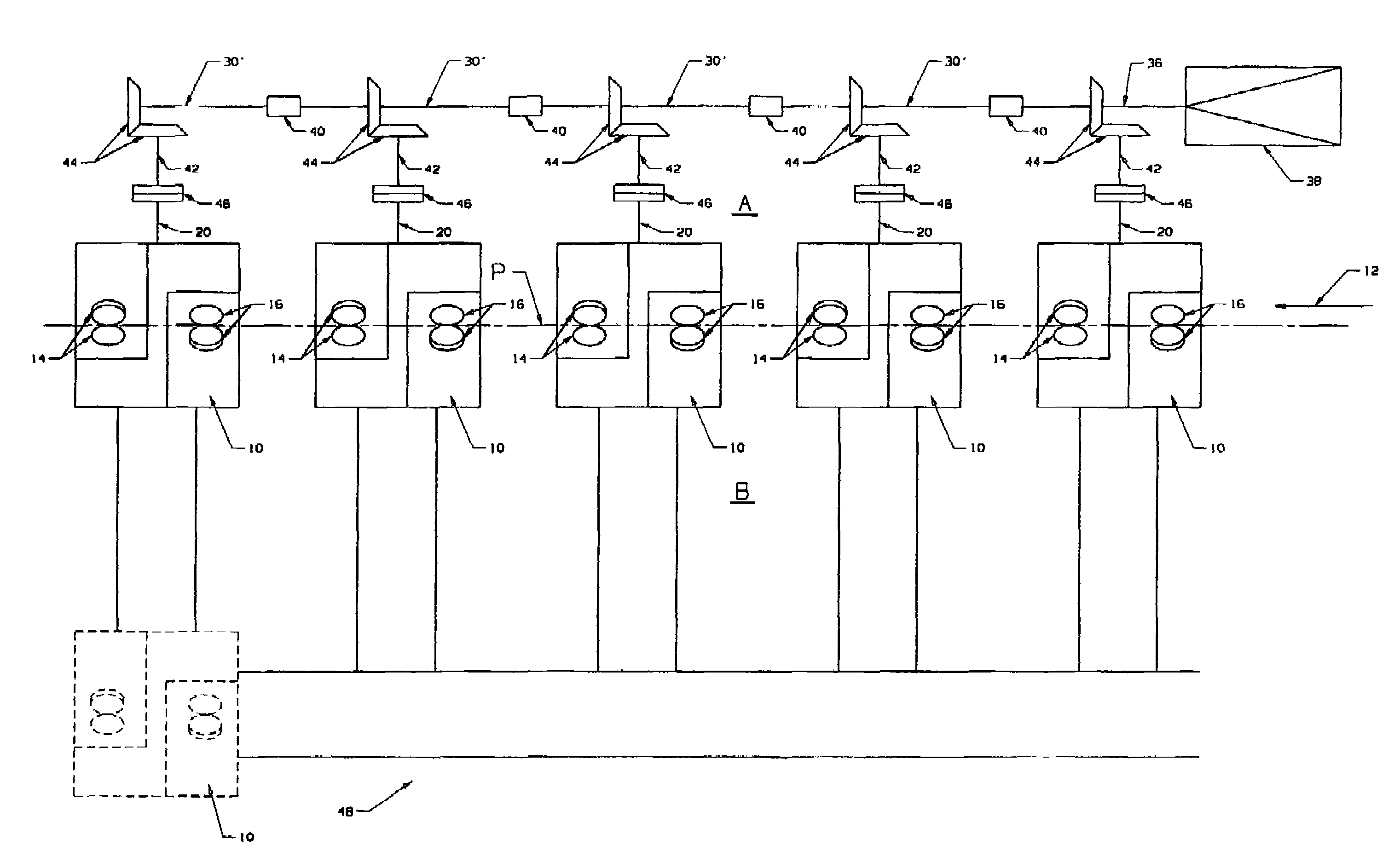

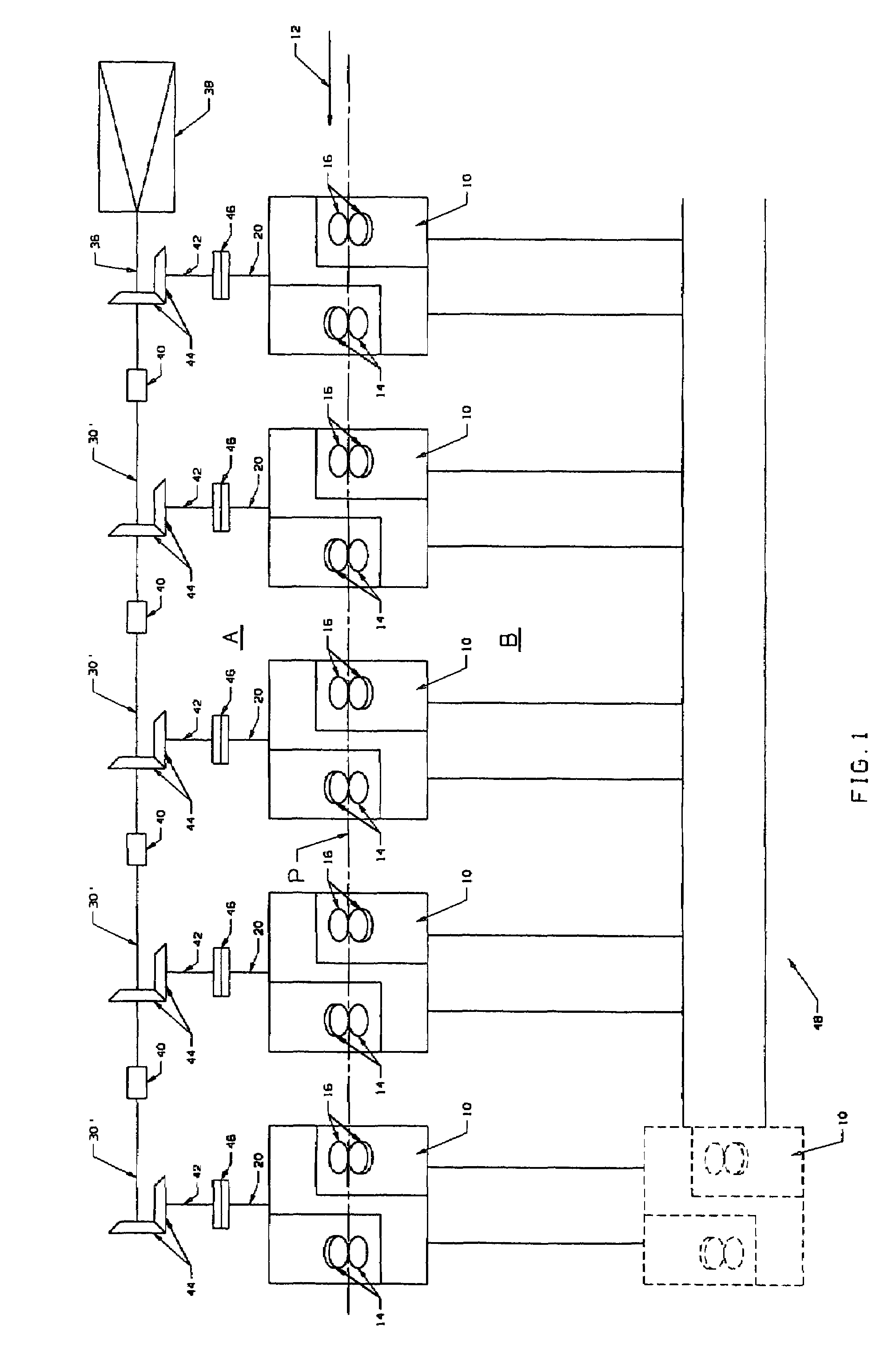

Modular rolling mill

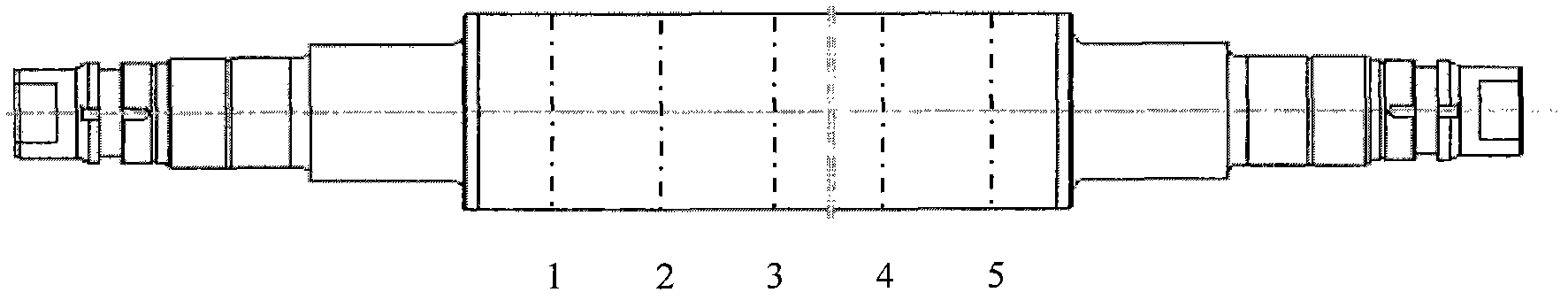

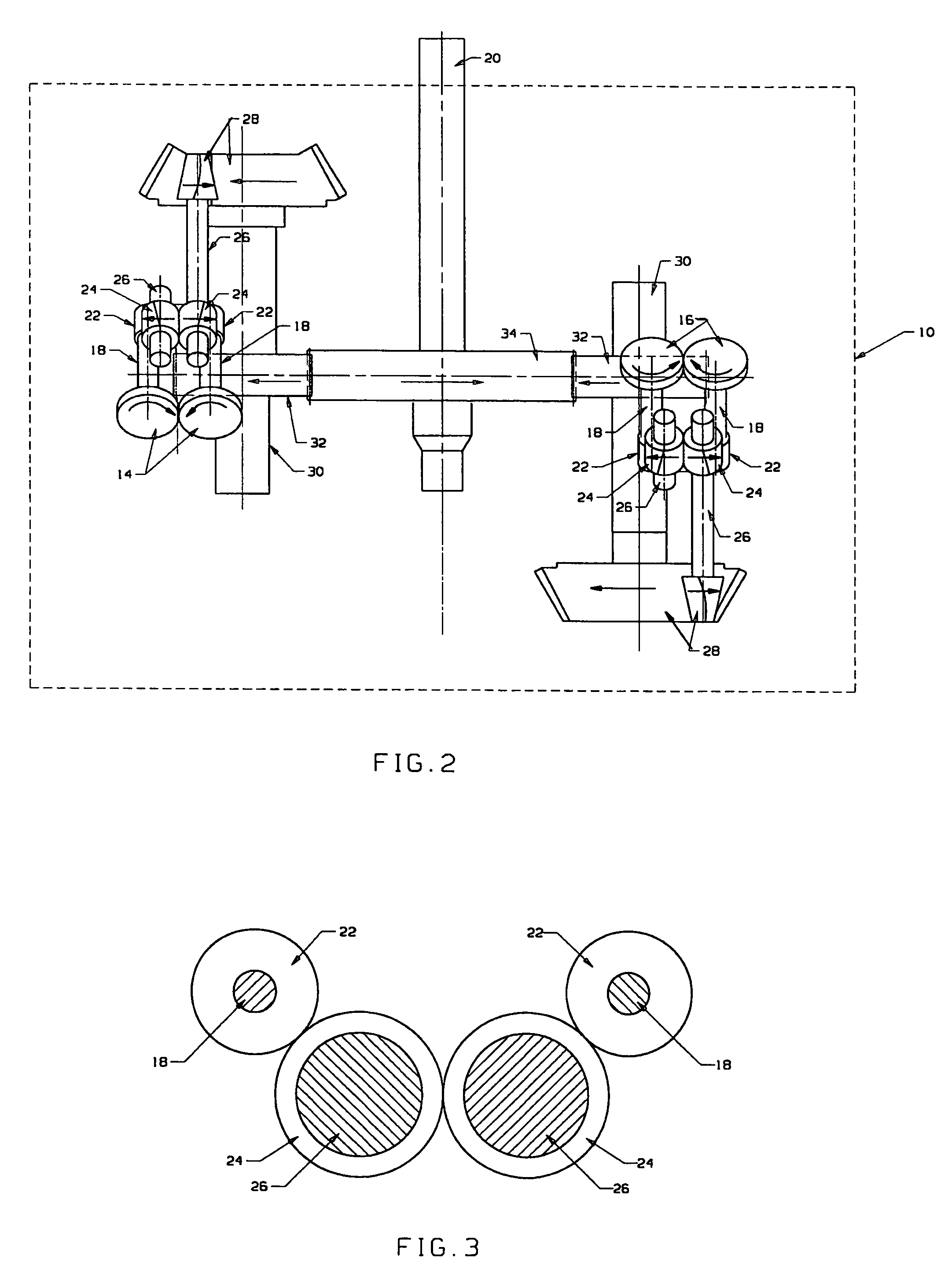

InactiveUS7191629B1Metal rolling stand detailsGuiding/positioning/aligning arrangementsLine shaftWork roll

A modular rolling mill comprises a plurality of separate rolling units arranged along a mill pass line. Each rolling unit includes at least two pairs of work rolls defining oval and round roll passes and carried on roll shafts that are staggered 90° with respect to each other. The rolling units contain intermediate drive trains configured to connect the roll shafts to parallel input shafts projecting to a first side of the pass line from the respective rolling units. A single driven line shaft is parallel to and on the first side of the pass line. Output shafts are mechanically coupled to the line shaft by bevel gear sets. The output shafts project laterally from the line shaft towards the pass line and are connected by separable couplings to the input shafts of the rolling units.

Owner:PRIMETALS TECH USA

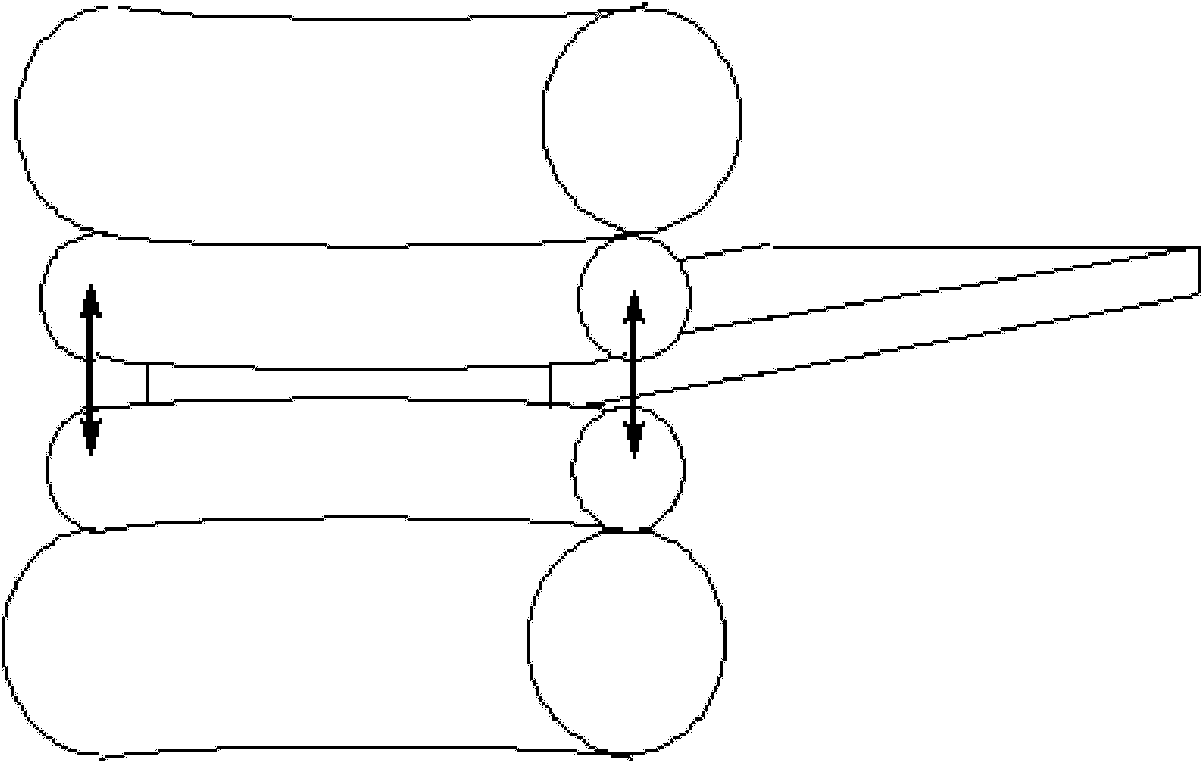

Forecasting method of rolling pressure and roll gap pressure of DC rolling mill

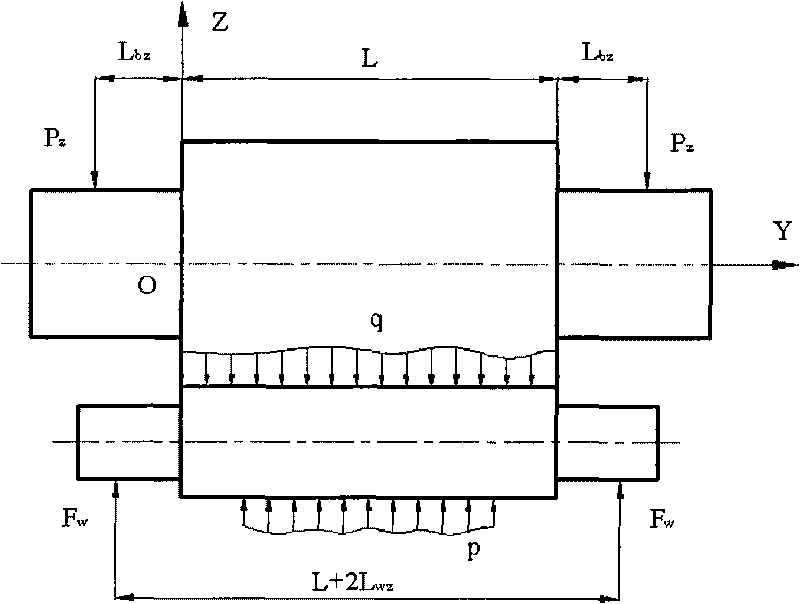

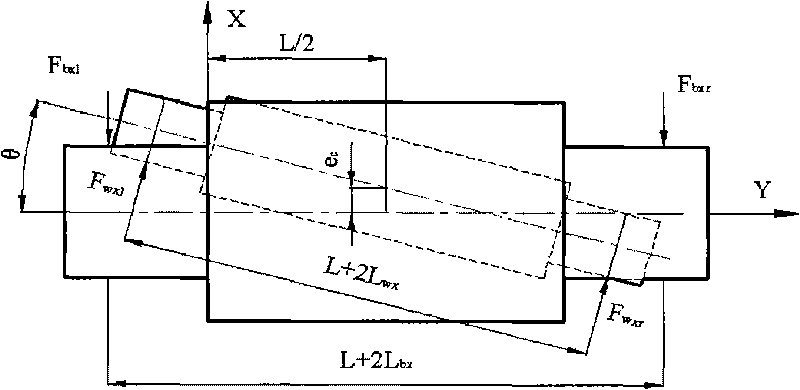

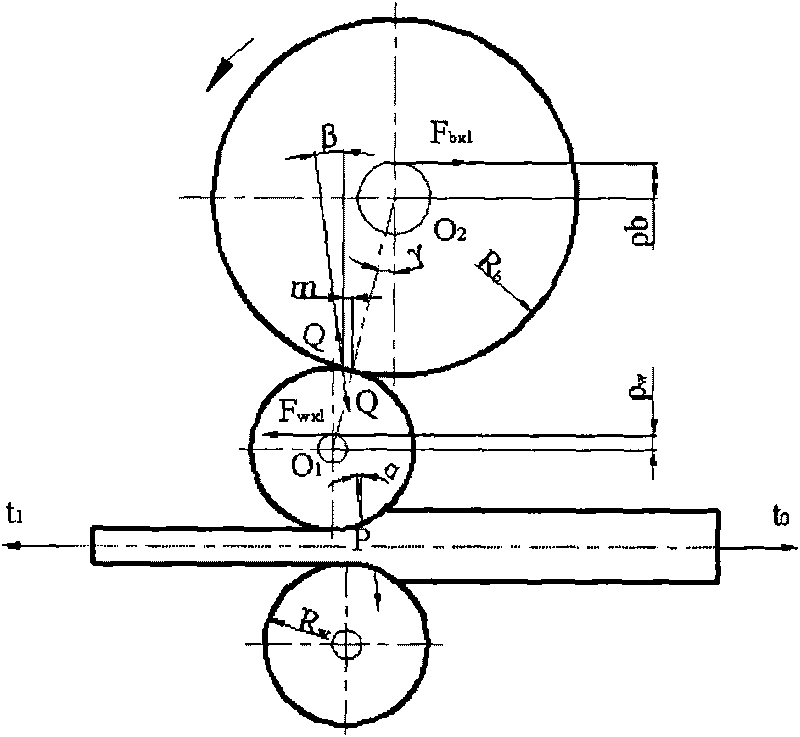

InactiveCN101716604AImprove accuracyHigh control precisionTension/compression control deviceMetal rolling arrangementsRolling resistanceWork roll

The invention discloses a forecasting method of rolling pressure and roll gap pressure of a DC rolling mill, which comprises the following steps of: (a) collecting equipment parameters and process parameters of a real DC rolling mill; (b) discretizing a roll system and a roll member; (c) assuming an initial roll gap shape; (d) setting the rolling pressure; (e) setting the roll gap pressure; (f) computing the roll gap shape h1 (y) and judging whether the roll gap shape is restrained or not, if not, going to the step d; and (g) checking the force balance condition (torque) of a working roll. The invention reasonably sets the rolling pressure and the roll gap pressure of the DC rolling mill by fully considering the influences of factors of rolling friction and the like according to the offset and alternately rolling the DC rolling mill, and forecasts the rolling pressure and the roll gap pressure of the DC rolling mill by coupling a metal model and a roll system deformation model. The forecasting method with higher precision is beneficial to not only improving the accuracy of the computation of the roll system deformation model, but also increasing the control accuracy of the thickness and the shape of the DC rolling mill, thereby improving the quality of products.

Owner:YANSHAN UNIV

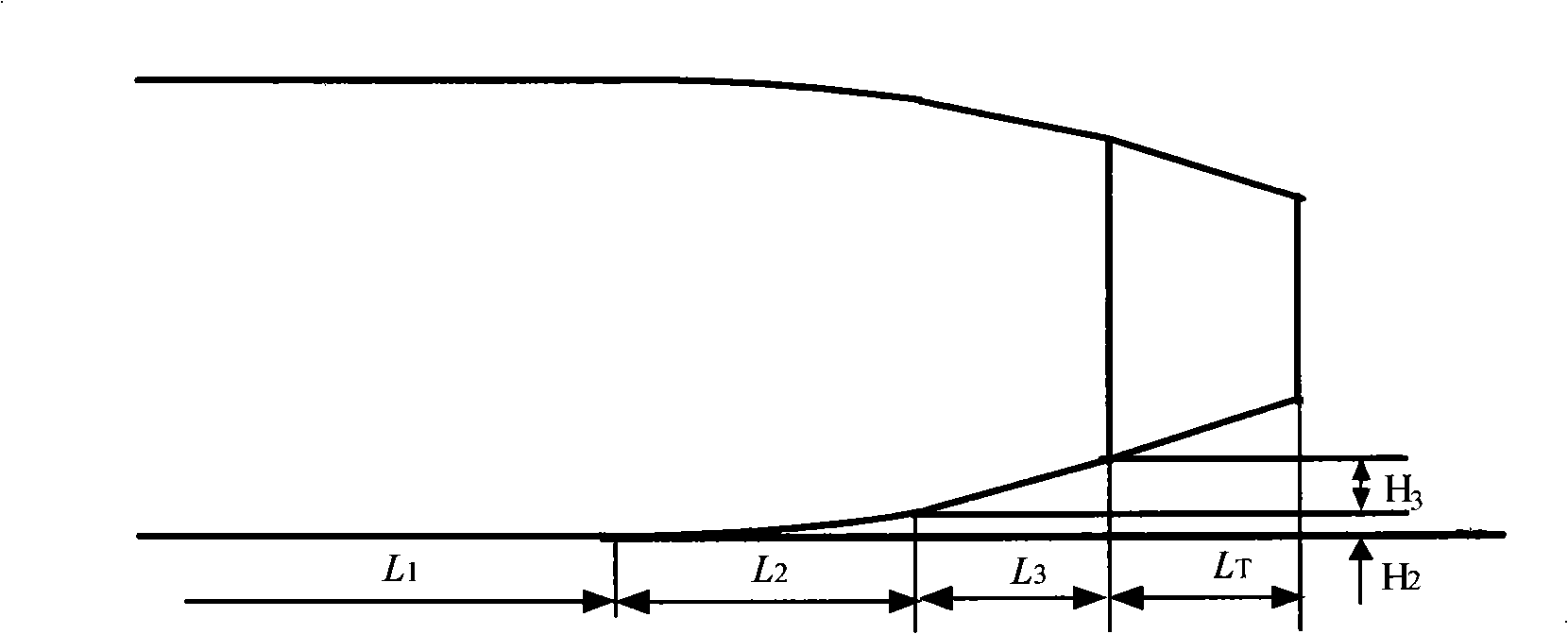

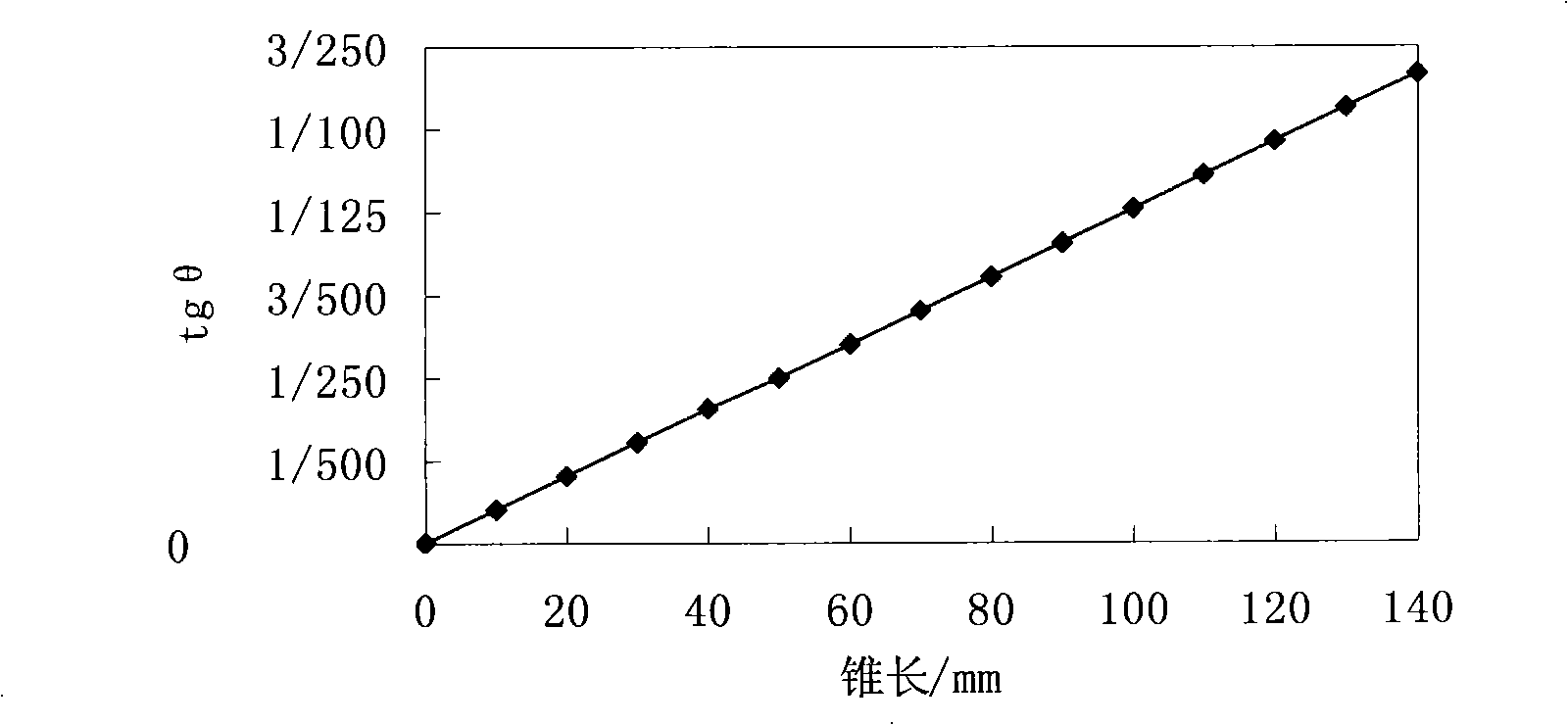

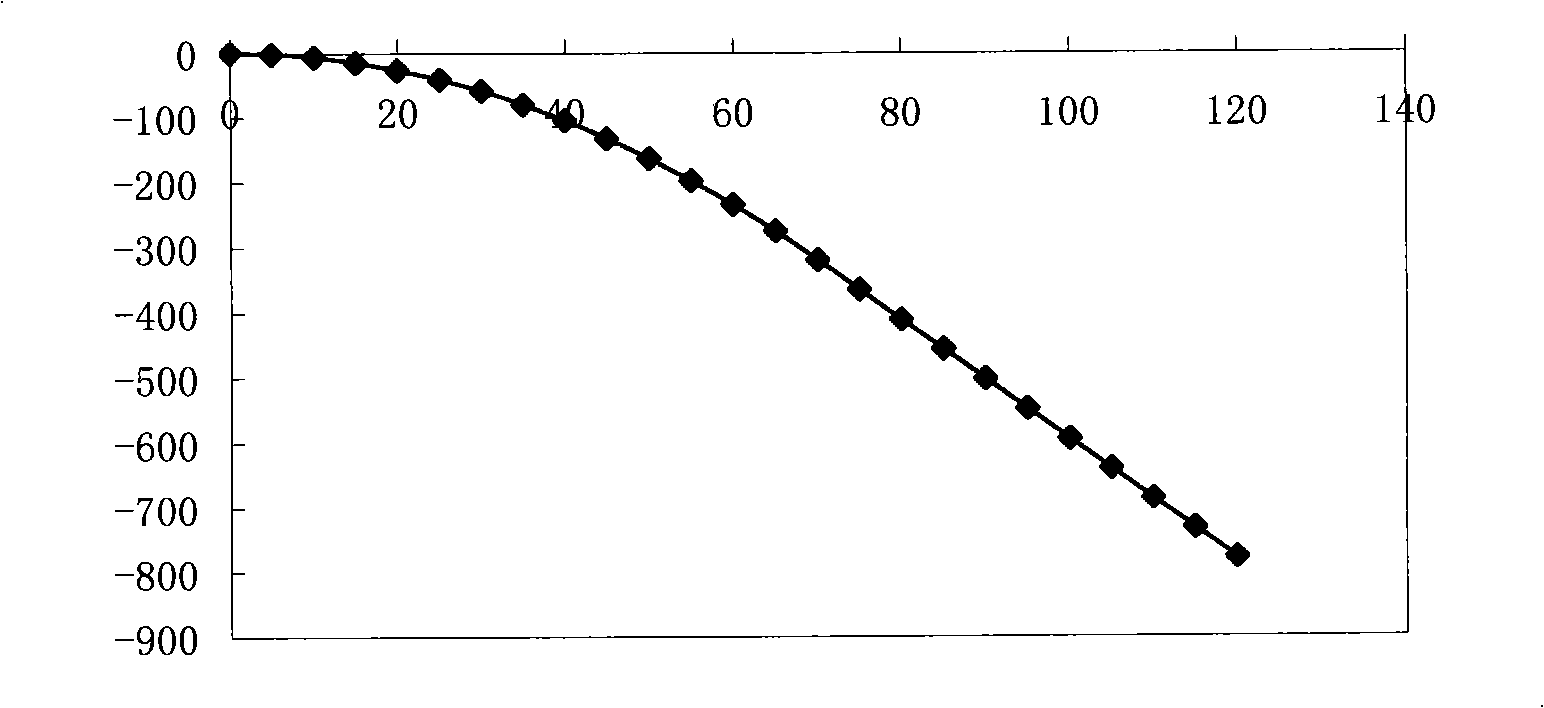

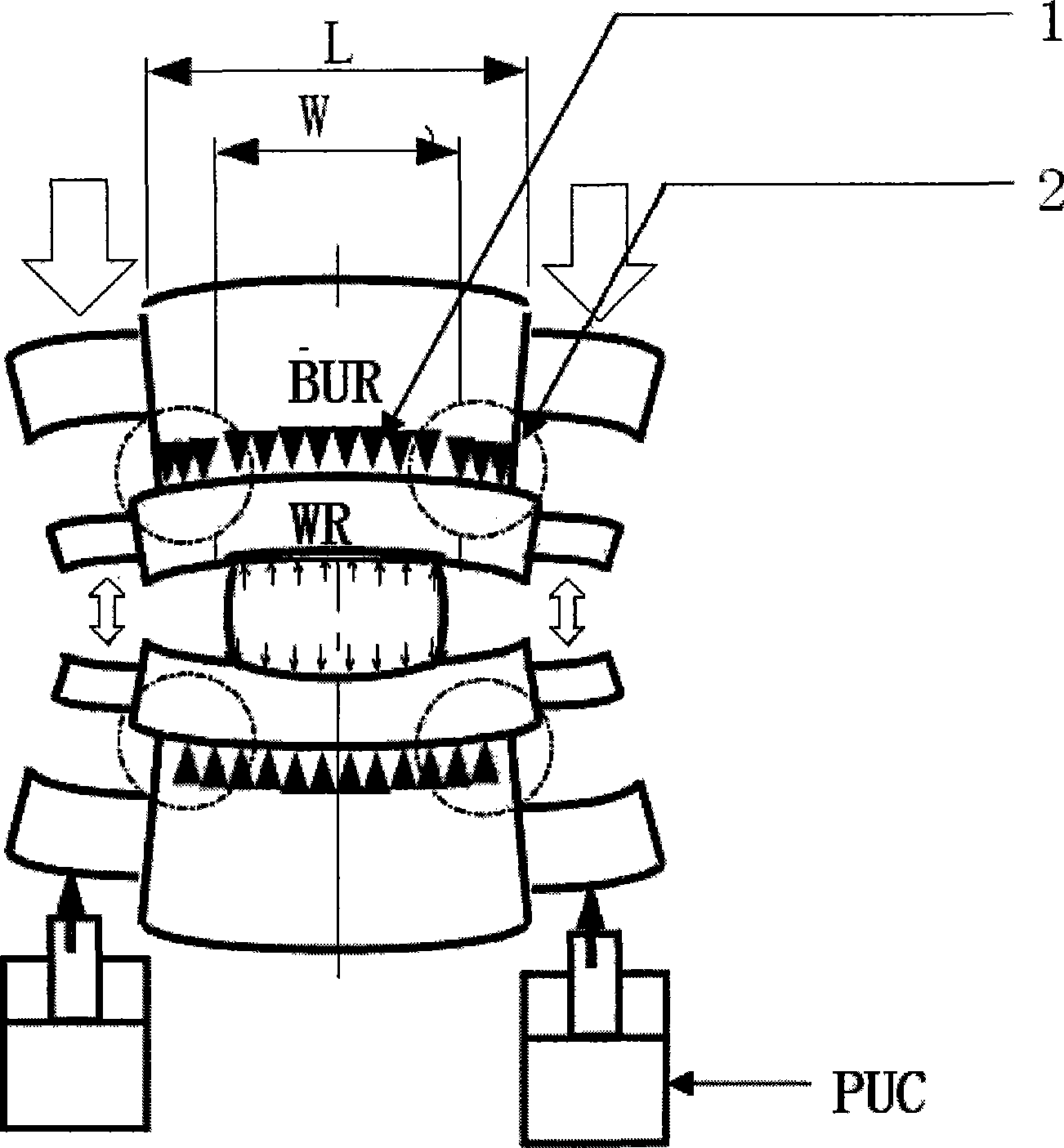

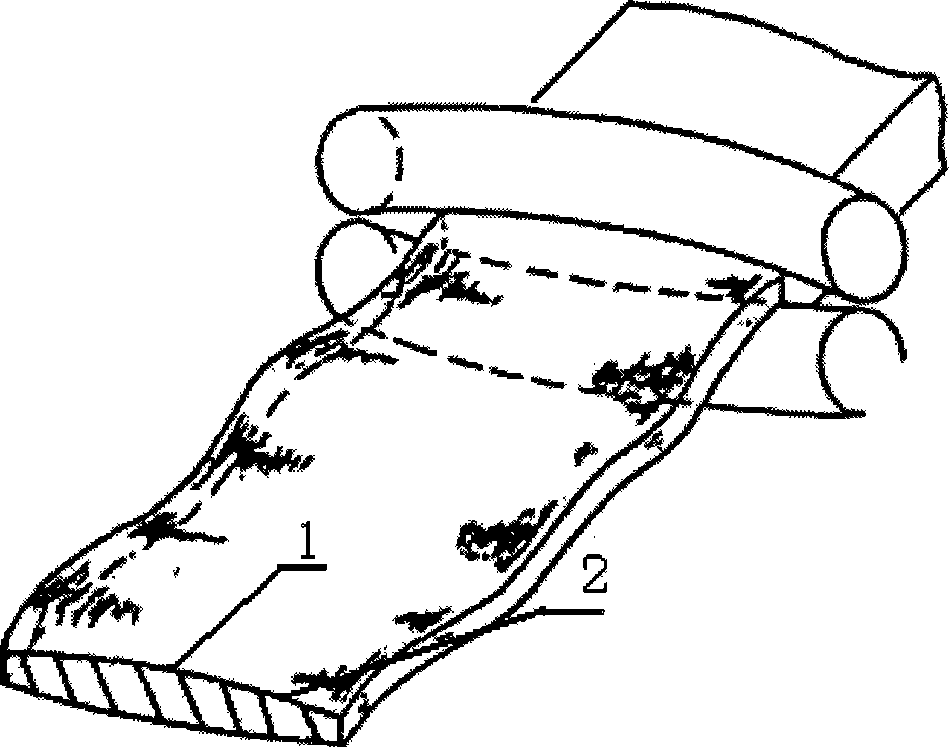

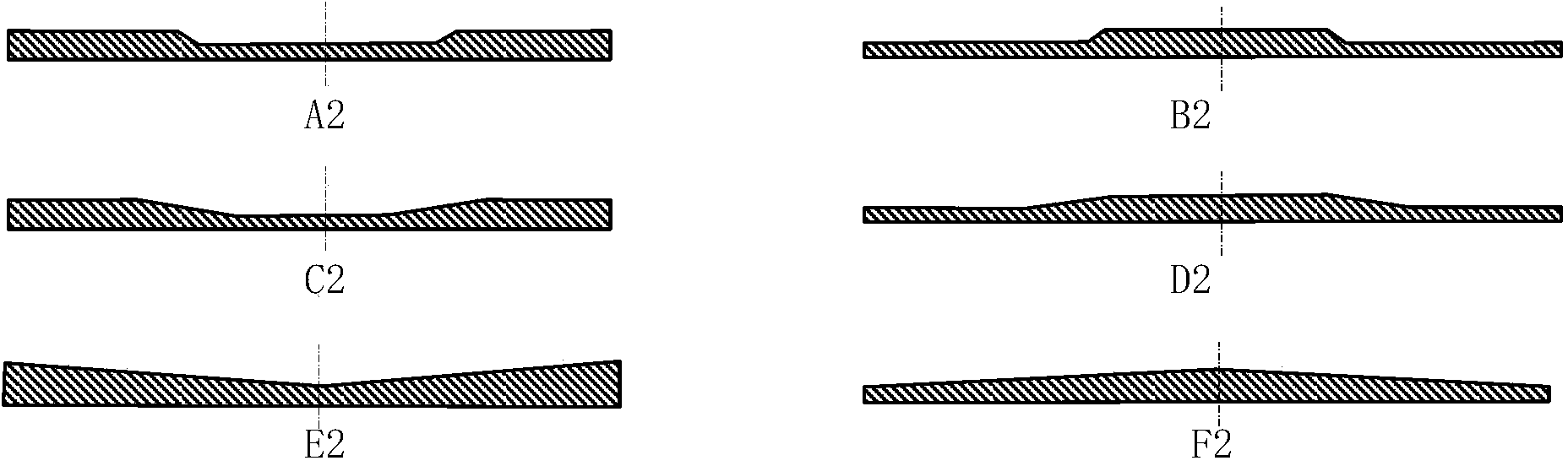

Crosswise thickness-variable strip and preparation method thereof

ActiveCN103822081ASave materialReduce structural weightSheets/panelsMetal rolling arrangementsWork rollMetallic materials

The invention relates to a crosswise thickness-variable strip and a preparation method thereof. The crosswise thickness-variable strip is composed of at least two equal thickness areas and at least one transition area, at least one equal thickness area and at least one wedge-shaped area, one or more than two wedge-shaped areas, or more than two curved thickness-variable areas. The preparation method comprises the following steps: (1) performing transition rolling, wherein at least one bulge and at least one groove are arranged on both of the two working rolls of a rolling machine or at least one bulge and at least one groove are respectively arranged on the two working rolls of the rolling machine; 2) performing forming rolling. According to the preparation method provided by the invention, the purposes of saving metal materials and reducing structure weight are achieved. According to the method for producing the crosswise thickness-variable strip by utilizing a rolling method, the defects of low production efficiency, higher production cost, and the like, of the production of the crosswise thickness-variable strip according to a welding method are avoided.

Owner:NORTHEASTERN UNIV

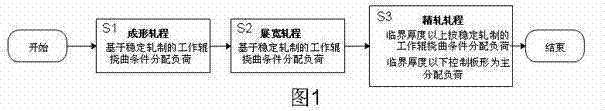

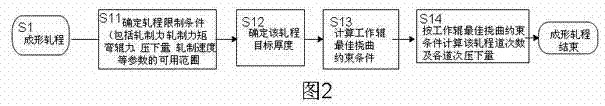

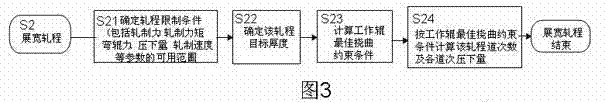

Method for overcoming camber defect in hot rolling process of steel plate

ActiveCN102451838AOvercome Process Control DifficultiesIncrease productivityRoll mill control devicesMetal rolling arrangementsWork rollSheet steel

The invention discloses a method for overcoming a camber defect in the hot rolling process of a steel plate, which relates to a method for processing a rolled piece and is used for solving the problems that the defect is not controlled basically and the equipment is required to be optimized in the prior art. In the method, rolling schedules are designed respectively in a forming rolling process, a widening rolling process and a fine rolling process specific to different characteristics of three phases of the hot rolling process of the steel plate on the basis of a stably-rolled working roll flexure condition, the stably-rolled working roll flexure is taken as a constraint condition, the centering of a working roll flexure reinforcing rolled piece is enhanced, and the problem of deviation of the rolling central line of the rolled piece is reduced and even eliminated, so that the aim of overcoming the camber defect is fulfilled, the plate shape of a product is considered simultaneously, and a hot-rolled steel plate of which the size and shape meet practical requirements are finally obtained. Due to the adoption of the method, the conventional mode of adjusting working roll inclination or optimizing the equipment structure based on defect detection is changed, the camber defect is controlled radically, and equipment refitting is not required.

Owner:BAOSHAN IRON & STEEL CO LTD

Flux-cored wire and method for welding cold-rolled back-up roll by same

InactiveCN101722384AImprove wear resistanceImprove toughnessArc welding apparatusFurnace typesWork rollManganese

The invention discloses a flux-cored wire and a method for welding a cold-rolled back-up roll by the same, and relates to the welding technology. By using a steel strip as a sheath, the flux-cored wire comprises the following components in percentage by mass: 0.15 to 0.50 percent of carbon, 0.10 to 1.00 percent of silicon, 0.30 to 2.00 percent of manganese, 3.50 to 7.00 percent of chromium, 0.50 to 2.50 percent of molybdenum, 1.00 to 3.50 percent of tungsten, 0.20 to 1.00 percent of vanadium, 0.20 to 3.00 percent of nickel, 0 to 0.03 percent of sulfur, 0 to 0.03 percent of phosphorus, and the balance of iron. The flux-cored wire needs to maintain the surfacing interpass temperature of the cold-rolled back-up roll between 300 and 350 DEG C during constant temperature surfacing work. The flux-cored wire well solves the problem that the intensity of a surfacing material is not matched with the toughness after surfacing of the cold-rolled work roll, so that the hot-rolled back-up roll has high intensity and excellent toughness. Therefore, the service life of the cold-rolled back-up roll is improved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +1

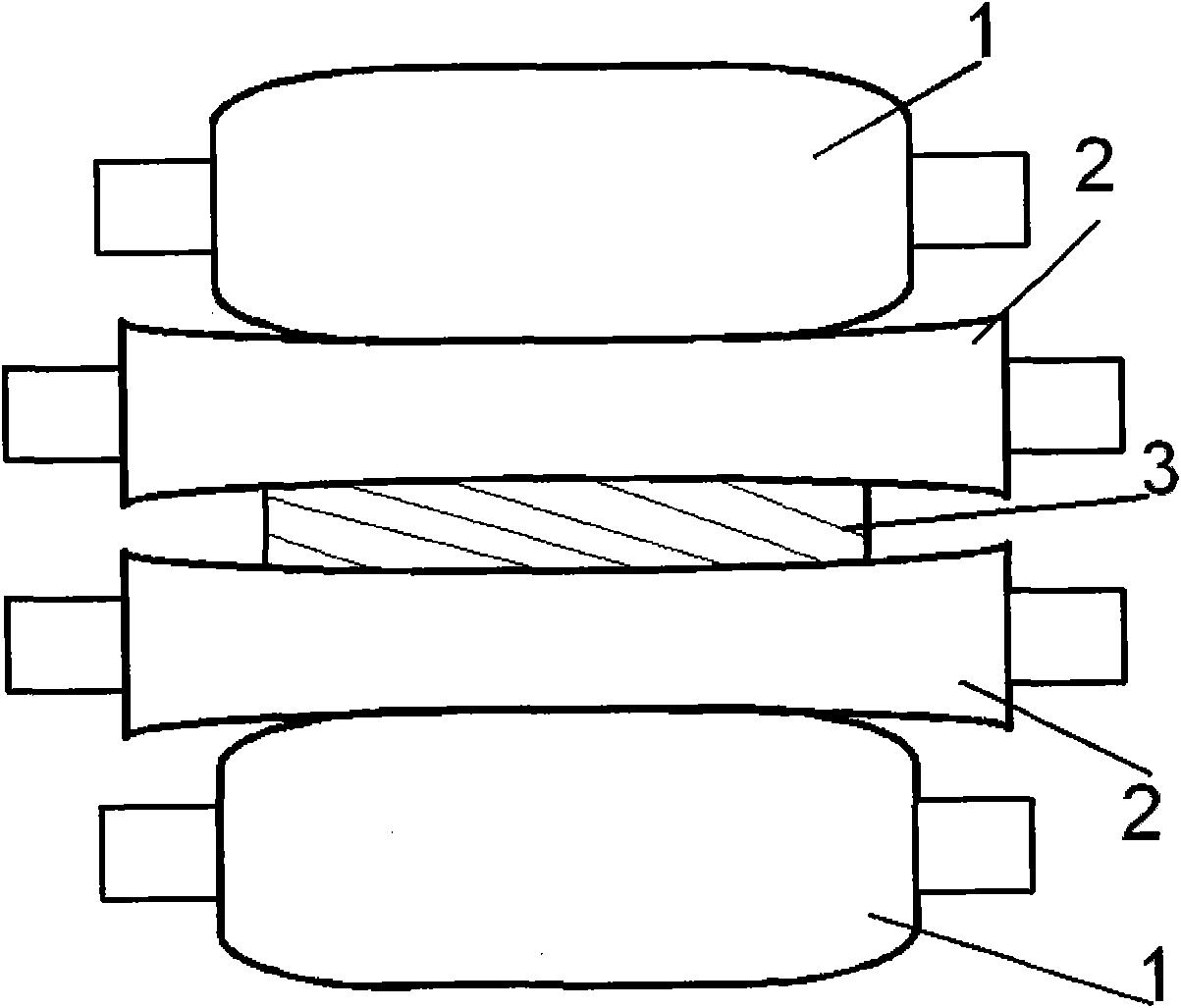

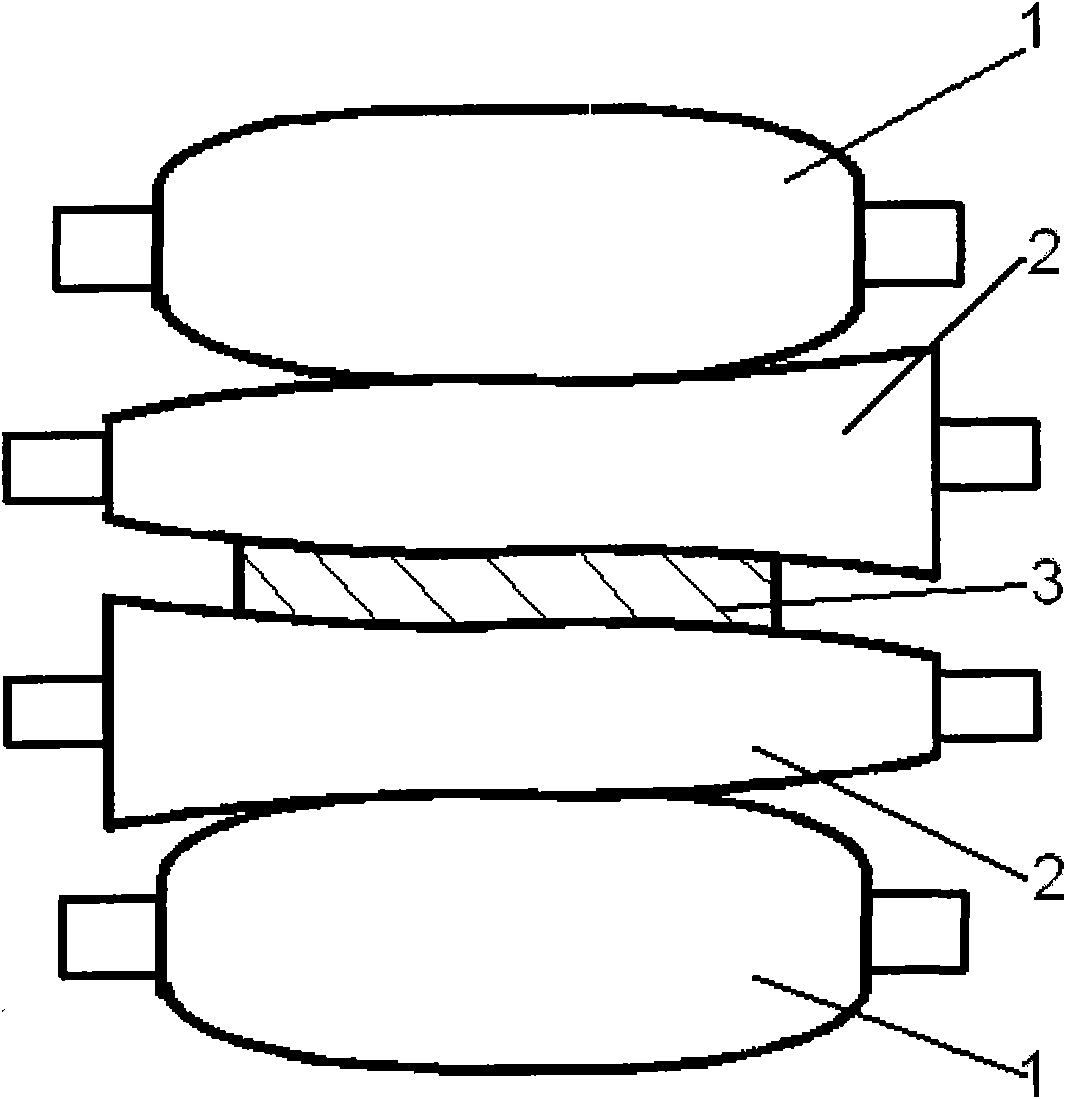

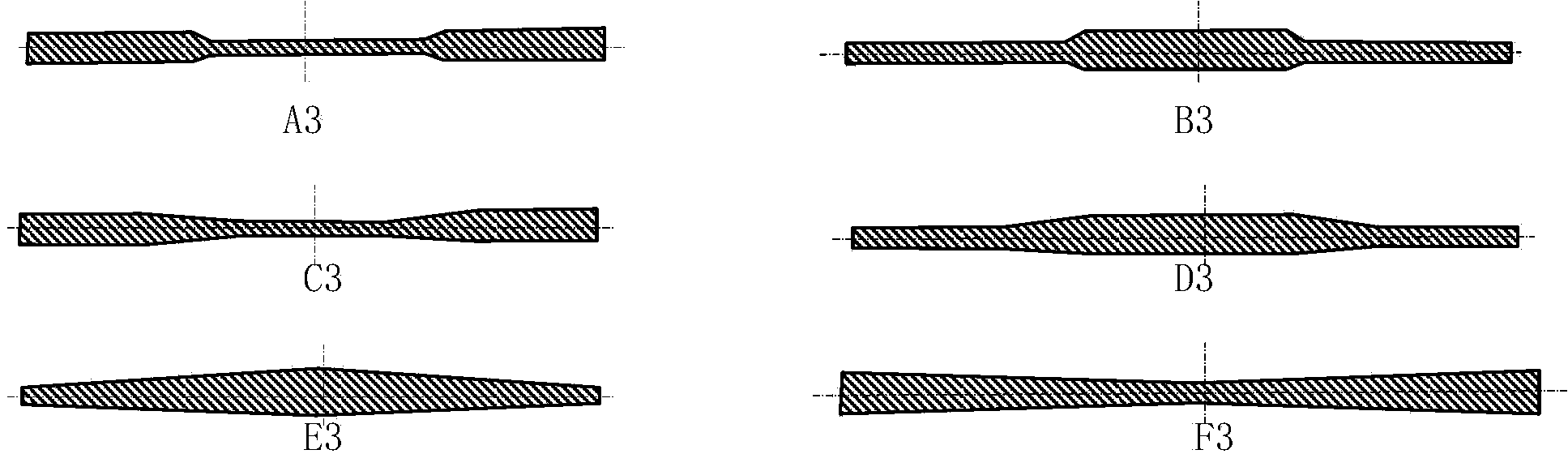

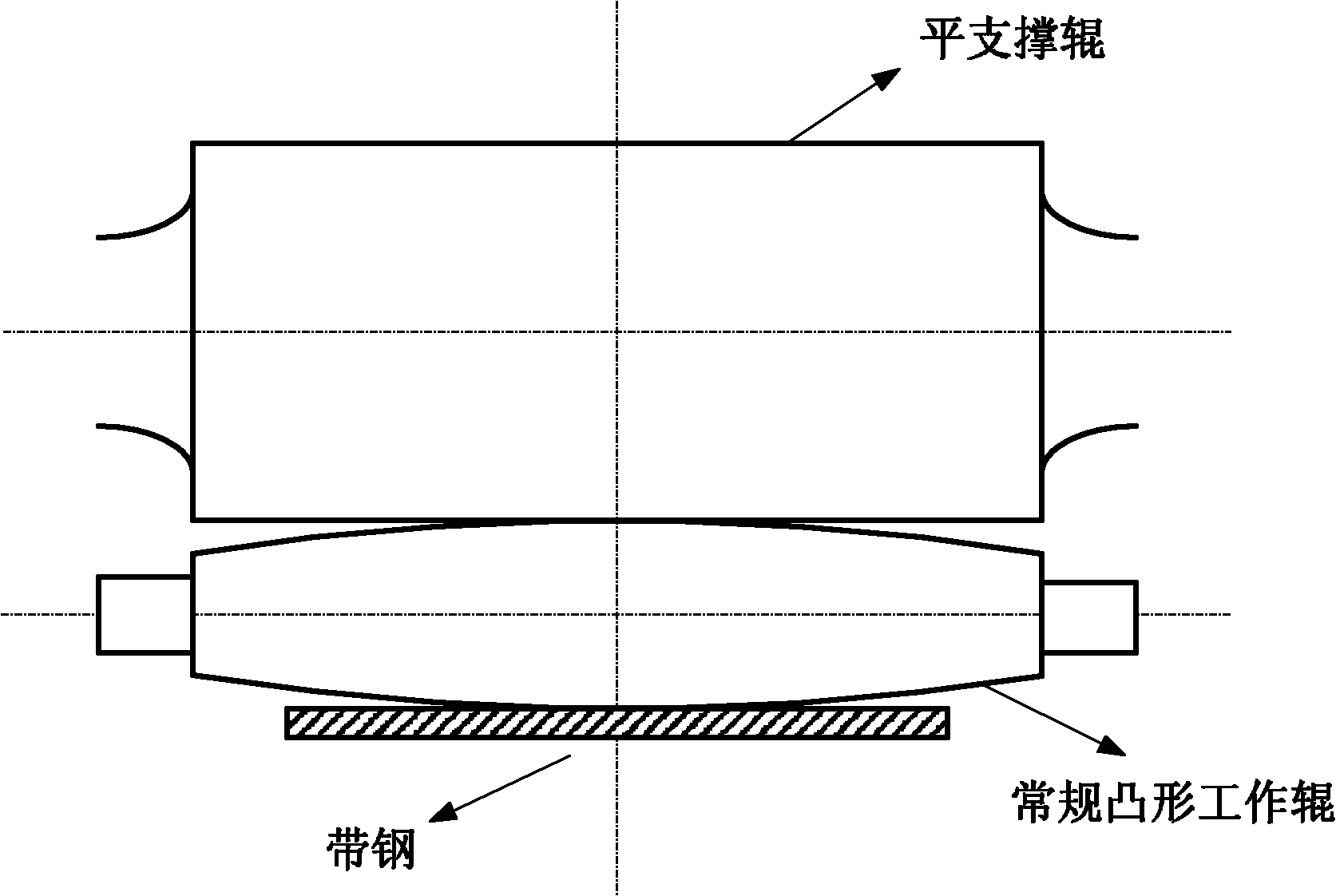

Configuration method of medium and heavy plate roll system with consideration of both rolling stability and cross-section shape

InactiveCN102009067ASuppression of rolling instabilityImprove controlCounter-pressure devicesRollsWork rollEngineering

The invention relates to a configuration method of a medium and heavy plate roll system with consideration of both rolling stability and cross-section shape, in particular to a fit way between a working roll and a supporting roll in different periods of service life of medium and heavy plate supporting roll. By comprehensively considering the impacts of a roll gap on the rolling stability and influencing factors of cross-section shape control, the invention provides the following scheme: the six-time polynomial curve supporting roll with big roll diameter at the middle and small roll diameter at two ends is adopted on a medium and heavy plate mill, and the six-time polynomial curve working roll with the small roll diameter at the middle and the big roll diameter at two ends is adopted for matching with the supporting roll; and the six-time polynomial curve working roll with the big roll diameter at the middle and the small roll diameter at two ends is adopted for matching with the supporting roll after abrasion during the later stage of the service life of the supporting roll. The configuration method of the roll system can solve the contradiction between the stability of medium and heavy plate rolling and the control of the cross-section shape, and the field application can obtain significant effects.

Owner:UNIV OF SCI & TECH BEIJING

Method for controlling strip-steel edge drop of tandem mills

ActiveCN101648215AAdvantages of strip edge control methodAdvantages of the control methodRoll mill control devicesMetal rolling arrangementsWork rollStrip steel

The invention provides a method for controlling strip-steel edge drop of tandem mills. The method comprises that: a, an edge drop instrument is arranged in front of a tandem mill; b, when strip steelpasses through the edge drop instrument, a PLC controller determines a sampling length according to the position of the edge drop instrument in the length of a whole roll of strip steel, and the edgedrop instrument acquires data of strip-steel edge drop on two side parts of the sampling length, calculates a preset value of leap position of a leap work roll of the tandem mill within the sampling length, and stores the value, thus the PLC controller finishes determining the sampling length, calculating and storing the preset value of the leap position of the leap work roll of the tandem mill within the sampling length, and then finishes determining next sampling length, calculating and storing the preset value of the leap position within the next sampling length in sequence; and c, when each sampling length passes through the leap work roll of the tandem mill, the PLC controller controls the leap work roll to leap on the strip steel within the sampling length according to the preset value of the leap position within the sampling length. The method has the advantage of realizing high-precision control of strip-steel edge drop.

Owner:BAOSHAN IRON & STEEL CO LTD

Automatic roll data acquisition system

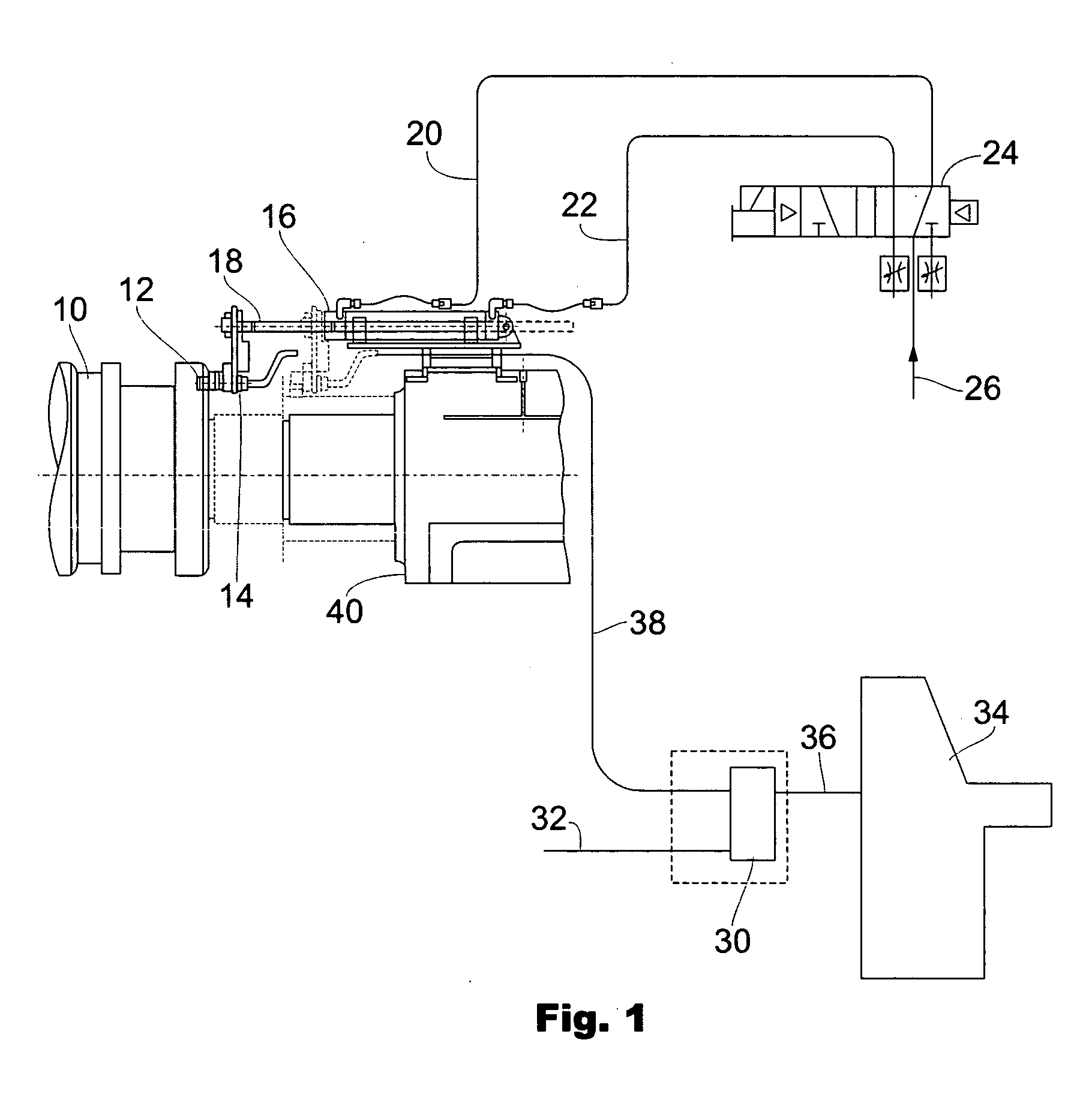

InactiveUS20050197044A1Protect from harmSafer environmentRolling equipment maintainenceAutomatic grinding controlWork rollMachine control

The present invention discloses a method, system and apparatus for use in a roll grinding machine. Data is read from an RFID tag automatically by providing an RF read / write sensor on a movable cylinder rod. The RF sensor is held away from the work roll area while the work roll is loaded or removed. When the work roll is placed in the position for grinding, a signal to rotate the roll is sent to the grinding machine, and also operates to advance the cylinder rod. An RFID tag embedded in the work roll and containing identification and other data related to the work roll, is read by a read / write sensor, and the data is then transferred from the sensor to a serial control interface, which converts the data and transmits the information to the grinding machine control desk and the computer control management data base. The work roll identification information is transmitted automatically to the grinding machine, eliminating errors in transposing information manually and avoiding potential injury to personnel from having to scan the RFID tag using handheld RF read / write modules.

Owner:USX CORP

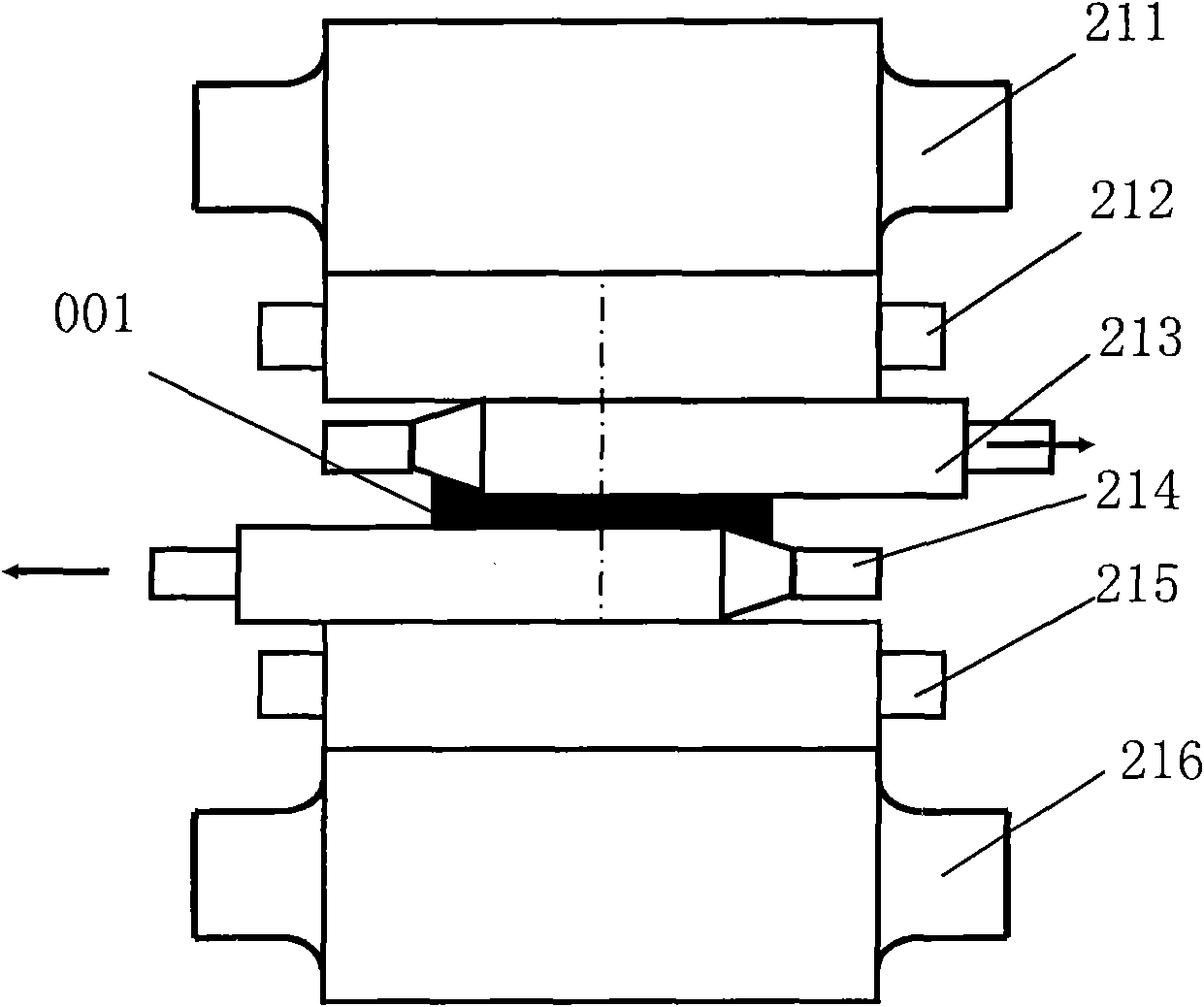

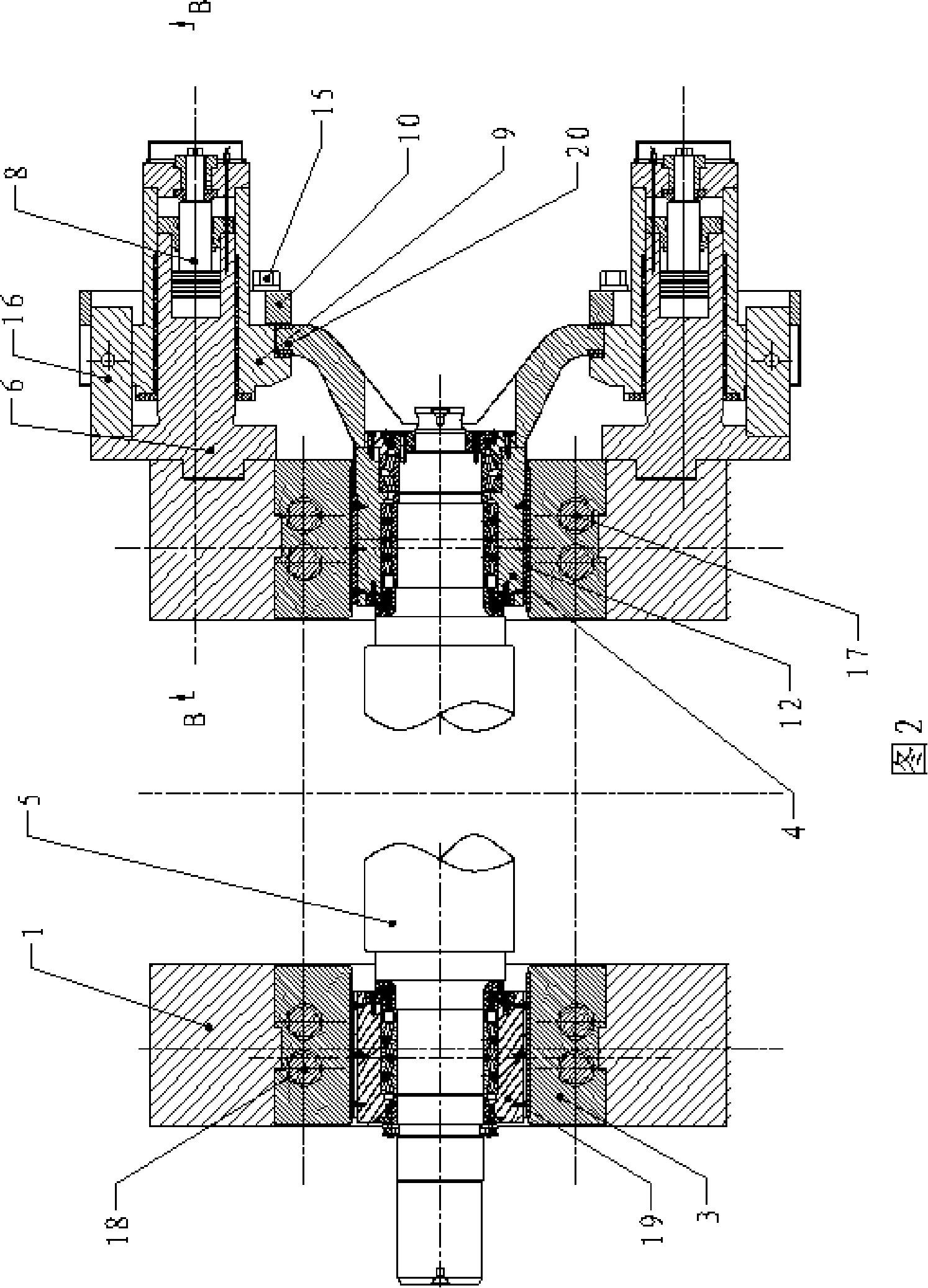

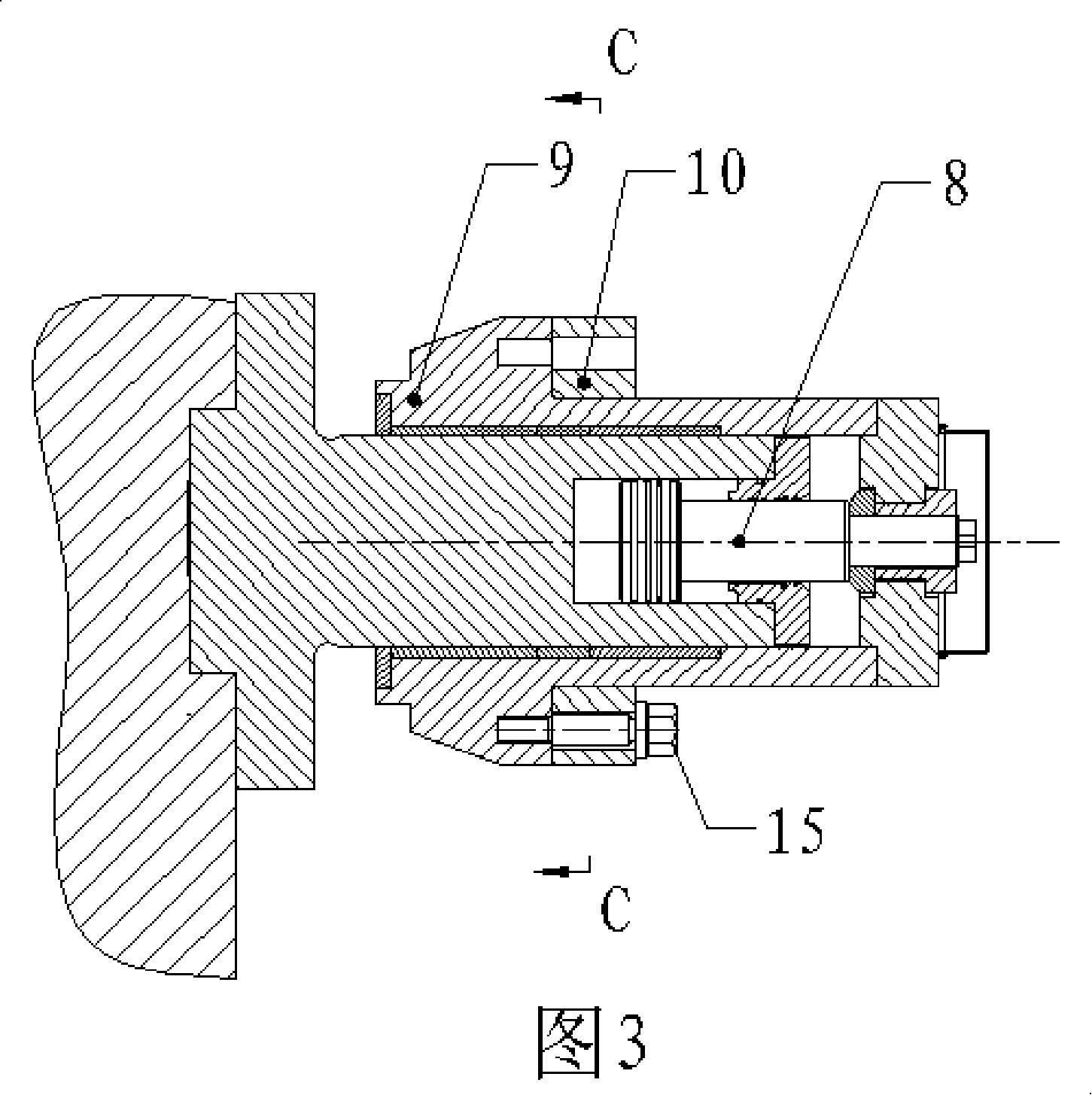

Roller mill roll bending and shifting device

ActiveCN101185942AAvoid unbalanced loadExtended service lifeMetal rolling stand detailsProfile control deviceHydraulic cylinderWork roll

The invention discloses a rolling mill bending roll and shift roll device, which has the advantage that a working roll bearing has no offset load moment when the roll is shifting. The rolling mill bending roll and shift roll device comprises upper bending roll hydraulic cylinders, lower bending roll hydraulic cylinders and bearing bases respectively arranged on the fore side and the backside, a shift roll hydraulic cylinder, a shift roll cylinder of the fore side, a frame work and a working roll arranged up and down; the working roll arranged up and down is installed on the bearing base of the fore side and the backside, the bearing base on the fore side and the backside is axially and movably arranged opposite to the frame work, the upper bending roll hydraulic cylinder and the lower bending roll hydraulic cylinder on the fore side is radially acted on the bearing base of the fore side, and the upper bending roll hydraulic cylinder and the lower bending roll hydraulic cylinder of the backside is radially acted on the bearing base of the backside, the shift roll hydraulic cylinder is distributed along the axes of the working roll and acted on he bearing base of the fore side, the upper bending roll hydraulic cylinders and the lower bending roll hydraulic cylinders of the fore side and the backside are fixedly arranged opposite to the frame work, and at least two of the upper bending roll hydraulic cylinders and the lower bending roll hydraulic cylinders are respectively arranged. The device can effectively avoid the offset load of the working roll bearing base, thus prolonging the service life.

Owner:CHINA ERZHONG GRP DEYANG HEAVY IND

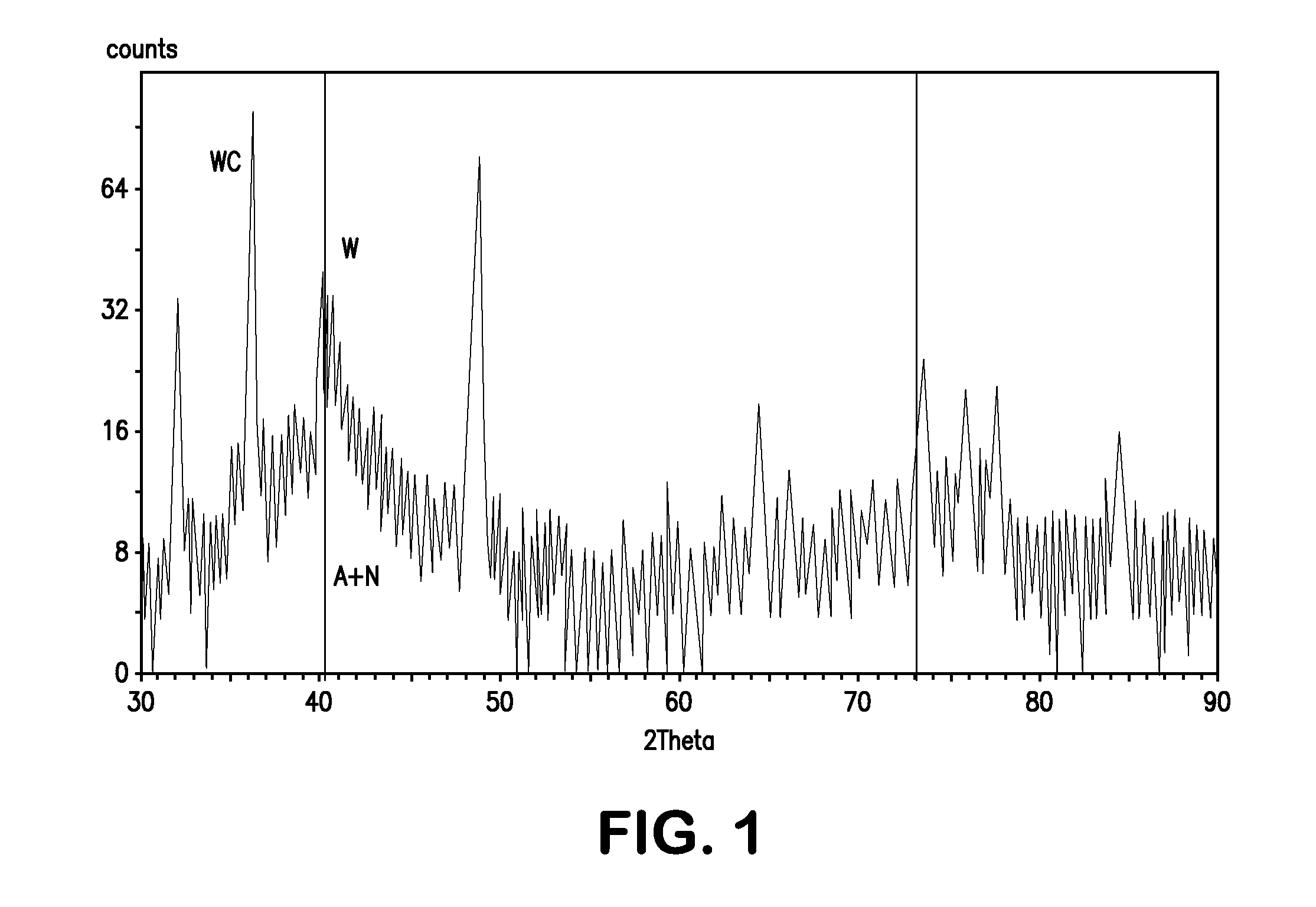

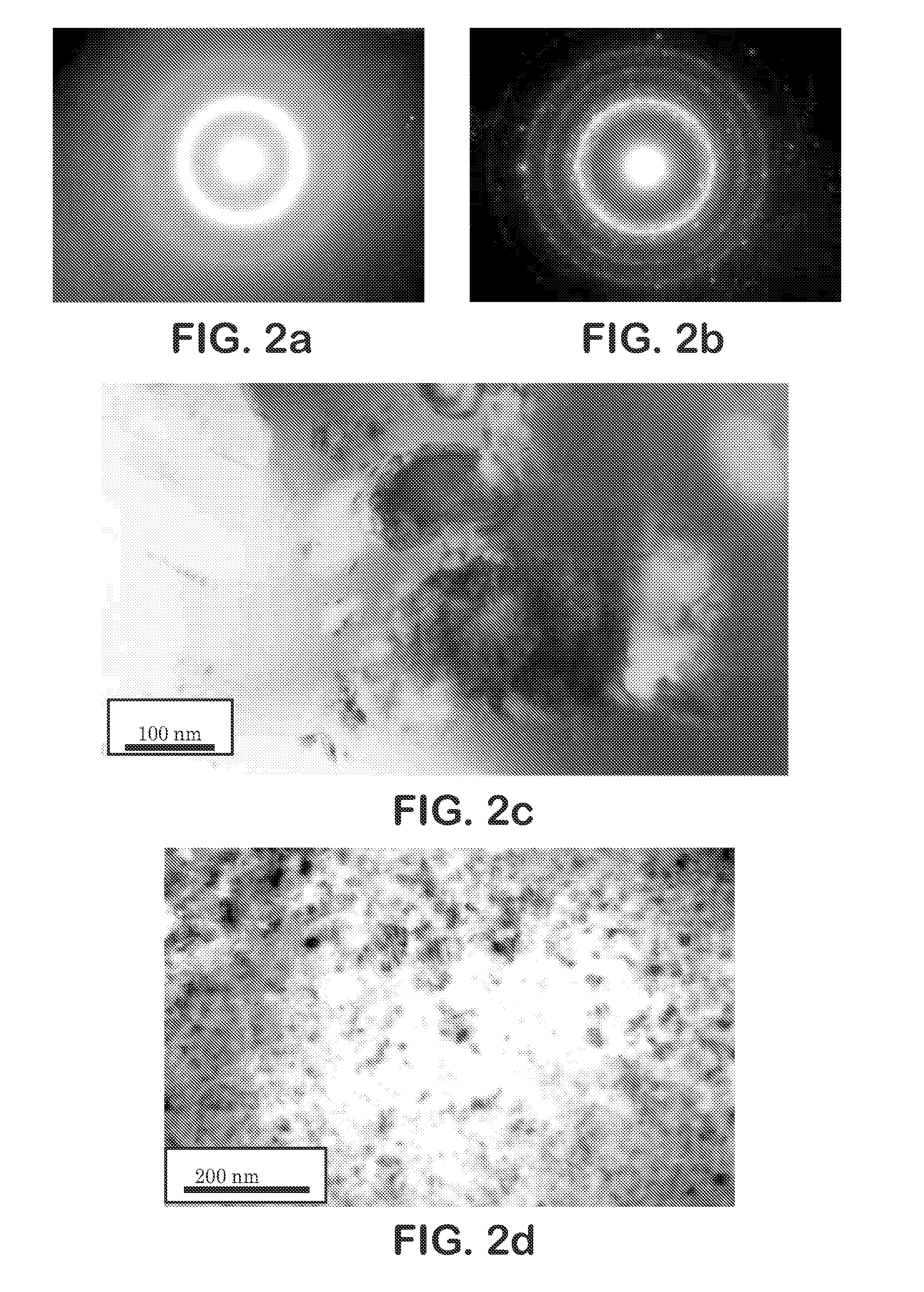

Amorphous-nanocrystalline-microcrystalline coatings and methods of production thereof

InactiveUS20120171469A1Improve corrosion resistanceImprove wear resistanceMaterial nanotechnologyLiquid surface applicatorsWork rollThermal spraying

This invention relates to thermally sprayed coatings having an amorphous-nanocrystalline-microcrystalline composition structure, said thermally sprayed coating comprising from about 1 to about 95 volume percent of an amorphous phase, from about 1 to about 80 volume percent of a nanocrystalline phase, and from about 1 to about 90 volume percent of a microcrystalline phase, and wherein said amorphous phase, nanocrystalline phase and microcrystalline phase comprise about 100 volume percent of said thermally sprayed coating. This invention also relates to methods for producing the coatings, thermal spray processes for producing the coatings, and articles coated with the coatings. The thermally sprayed coatings of this invention provide enhanced wear and corrosion resistance for articles used in severe environments (e.g., landing gears, airframes, ball valves, gate valves (gates and seats), pot rolls, and work rolls for paper processing).

Owner:PRAXAIR ST TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com