Complete roll forming configuring method for wide flat steel hot rolling finish mill set

A technology of finishing rolling unit and configuration method, applied in the direction of roll, metal rolling, metal rolling, etc., can solve the problems of unreasonable roll shape configuration of work roll and backup roll, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Shougang Qiangang’s 1580mm hot-rolled wide-band steel production line was put into operation in November 2009. At the initial stage of production, the finishing rolling unit was a 7-stand four-high rolling mill. The work rolls and backup rolls had no roll shape, and all stand rolls used Flat roll shape, the main problems that lead to the control of plate shape are:

[0057] 1) The shape control accuracy is low;

[0058] 2) Thin gauge rolling stability is poor.

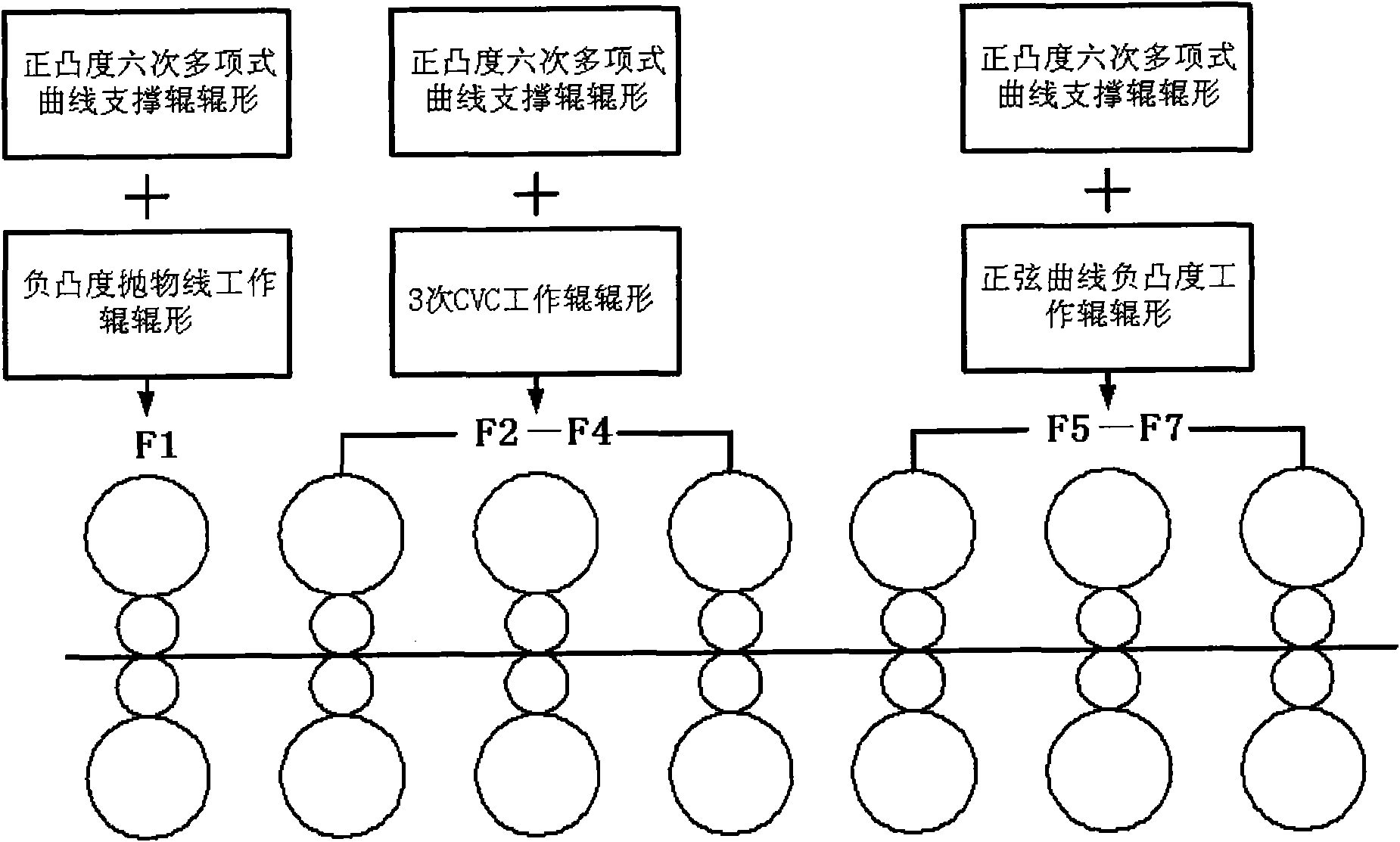

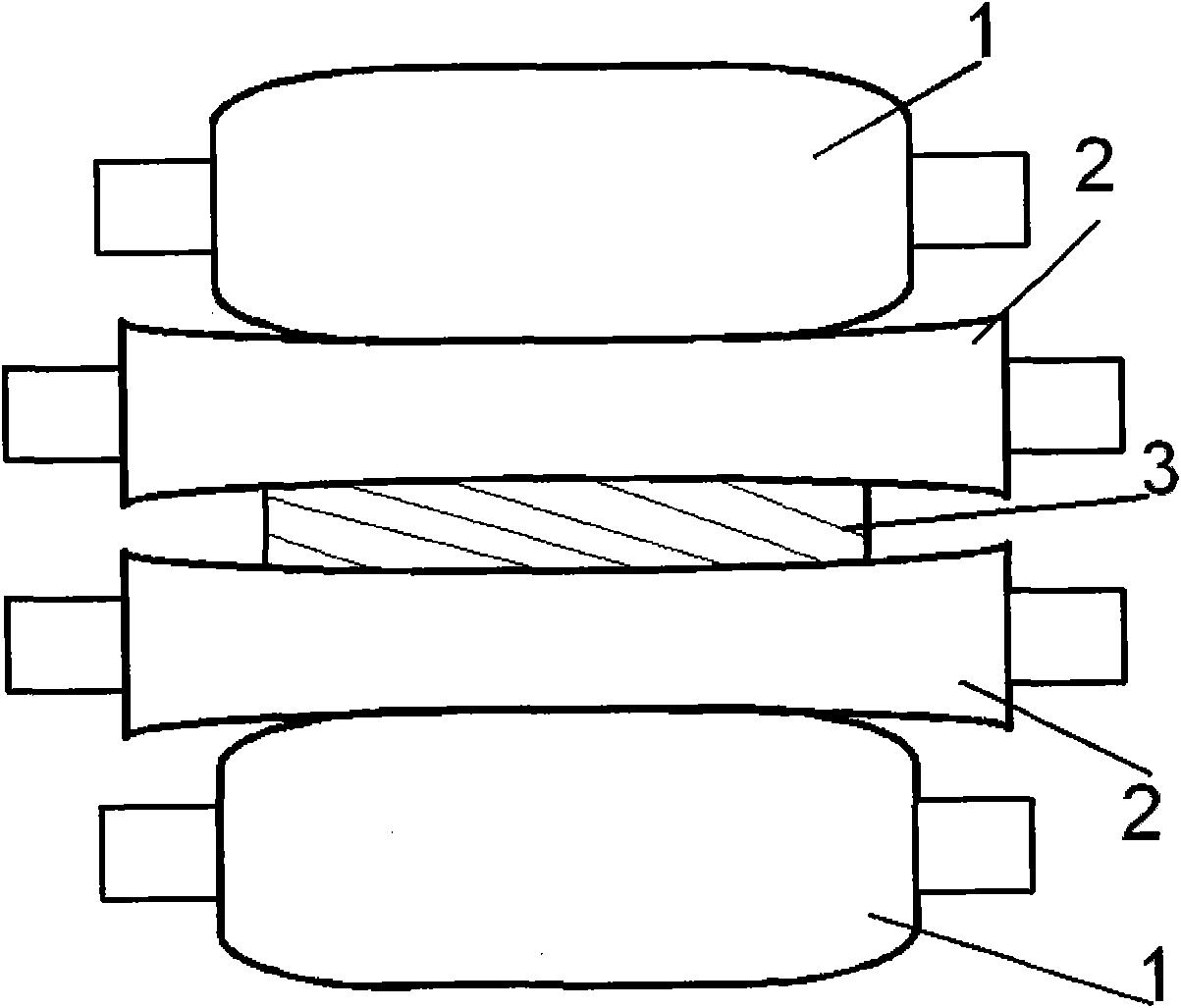

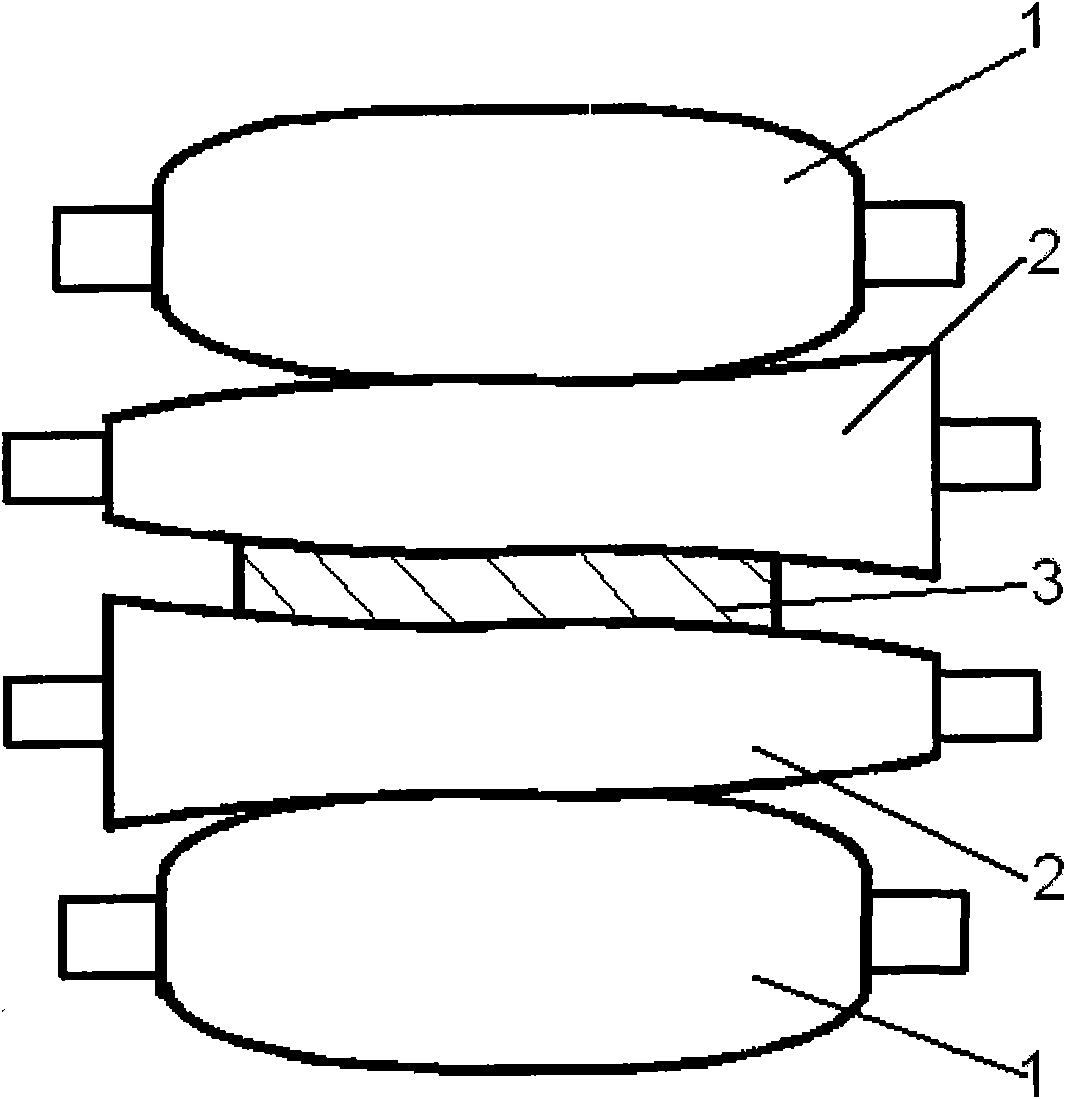

[0059] In order to improve the control accuracy of crown and flatness of hot-rolled strip steel and the stability and shape quality of thin-gauge strip steel rolling, it is necessary to design the work roll and backup roll shape of the finishing rolling unit. According to the characteristics of controlling the convexity of the upstream stand and the flatness of the downstream stand of the hot continuous rolling strip finishing mill, a new roll configuration method for the finishing mill is finally determined. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com