Hydraulic hoisting monitor system and its use in hydraulic hoisting control

A technology of hydraulic lifting and monitoring system, applied in general control system, control/regulation system, program control in sequence/logic controller, etc. It can achieve the effects of good remote controllability and real-time performance, reasonable system configuration, and powerful design functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

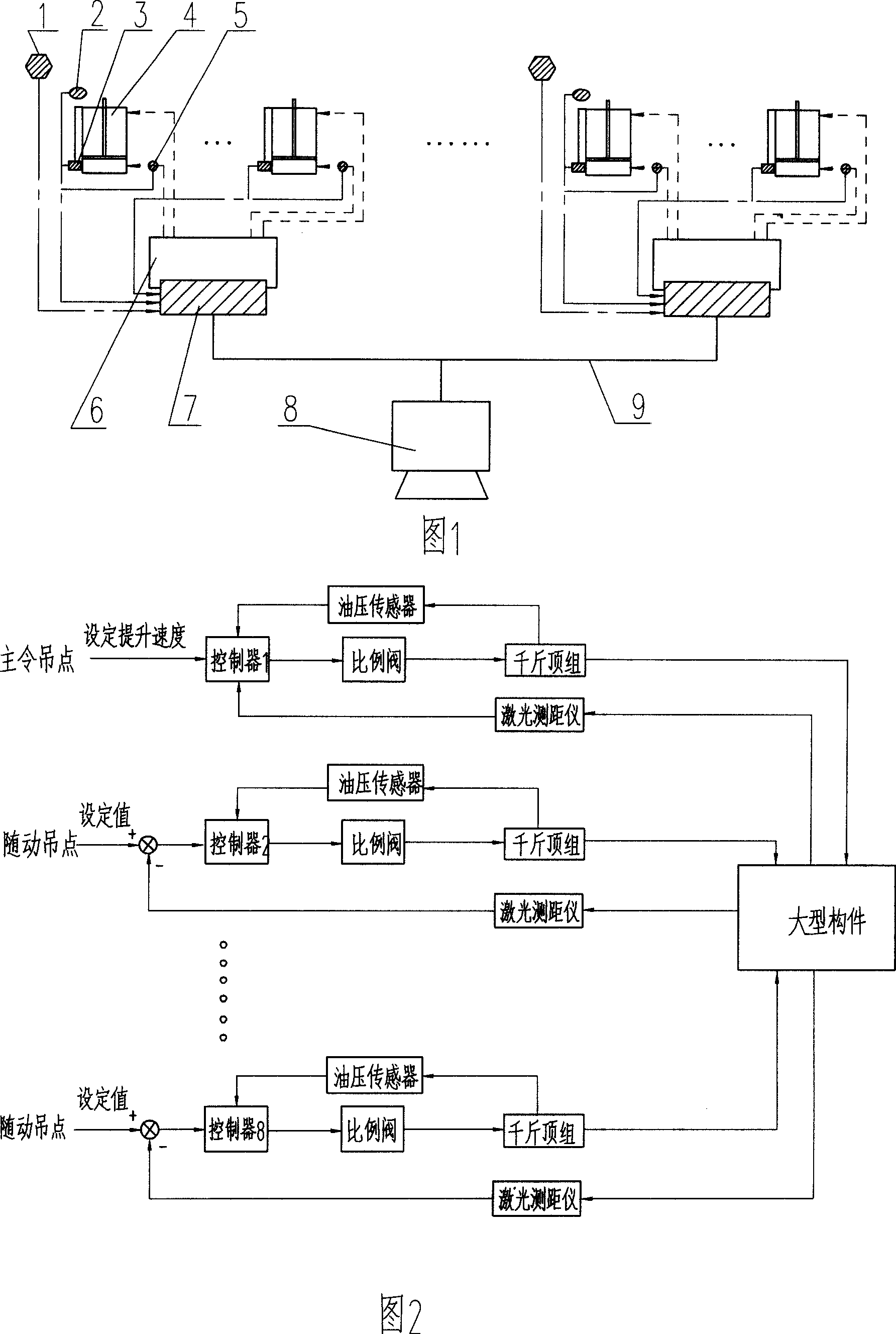

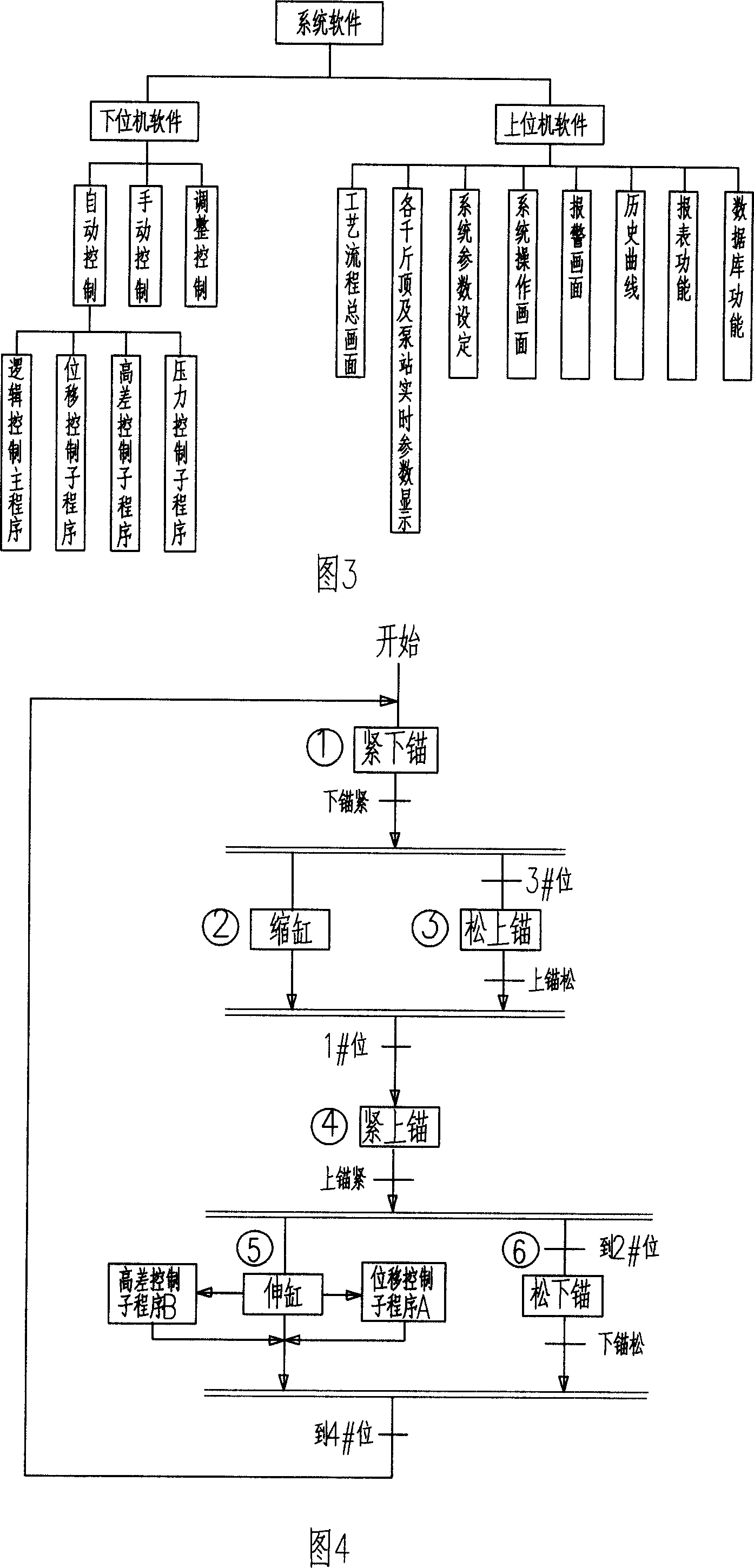

[0050] A hydraulic lifting monitoring system is composed of an upper computer, a lower computer and a data acquisition system. The upper computer 8 is a monitoring computer with monitoring software to realize system monitoring and data management, and the lower computer is written in 8 field controllers 7 composed of 8 programmable controllers with logic control main program and synchronous adjustment subroutine, 8 field controllers 7 are respectively installed on 4 hydraulic pump stations 6, and communicate with the monitoring computer through the real-time network Connected, each site controller 7 controls 4 hydraulic lifting jacks, and the data acquisition device includes a displacement sensor 3 installed on the main top of each jack 4 for detecting piston displacement, a pressure sensor 5 for detecting the pressure of the oil inlet, The proximity switch group 2 installed on the upper and lower anchorages to detect the tightness of the anchorage and the laser instrument 1 in...

Embodiment 2

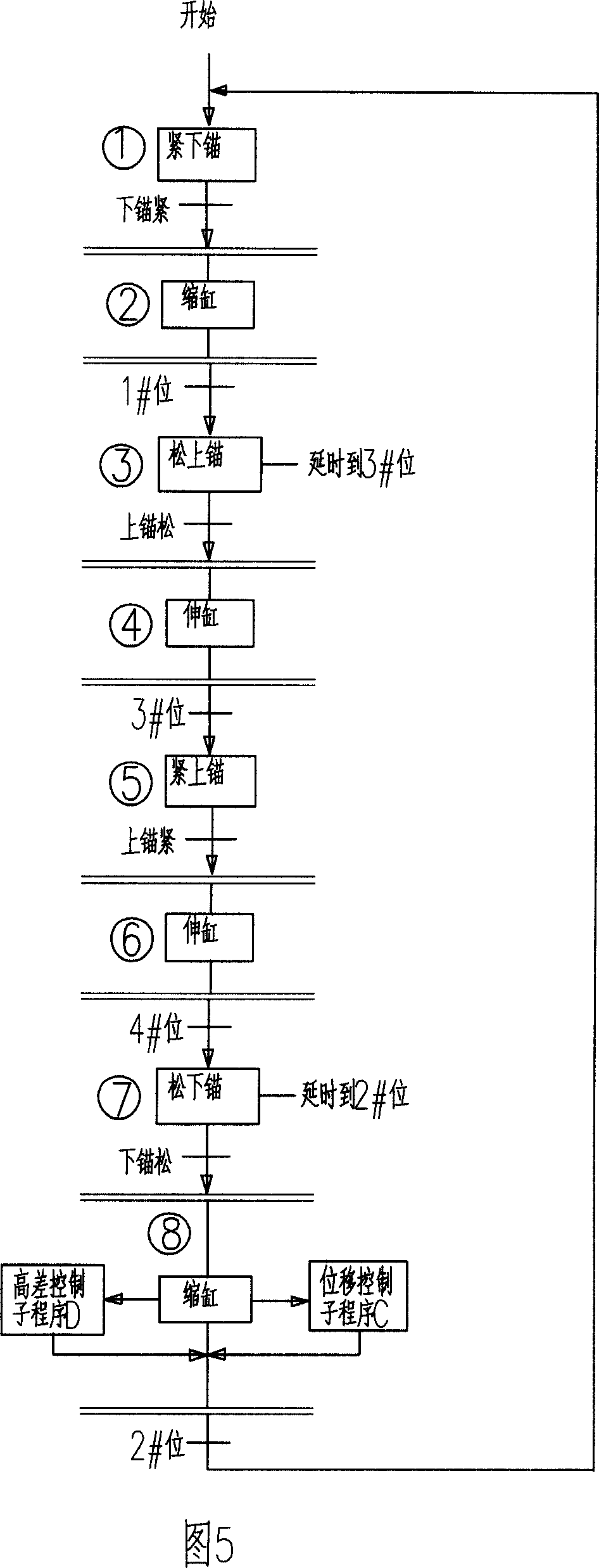

[0055] The application of the above-mentioned hydraulic lift monitoring system to hydraulic lift control—that is, the method of using the above-mentioned hydraulic lift monitoring system for hydraulic lift control.

[0056] The method that the lifting monitoring system is used for hydraulic lifting control is a system control method, and the system control includes a remote control mode and a local control mode:

[0057] The remote control mode is the highest level of the system. All operations are completed on the host computer—monitoring computer. At this time, the operations of all on-site controllers are invalid. Manual and automatic control to complete effective controls such as lifting, lowering, anchor tightening, and anchor loosening; the maximum pressure of each platform can be set to ensure the safety of the system, and the extension cylinder of the jack can also be changed by changing the opening size of the proportional valve , Shrink cylinder speed.

[0058] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com