Patents

Literature

385results about How to "Strong design" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

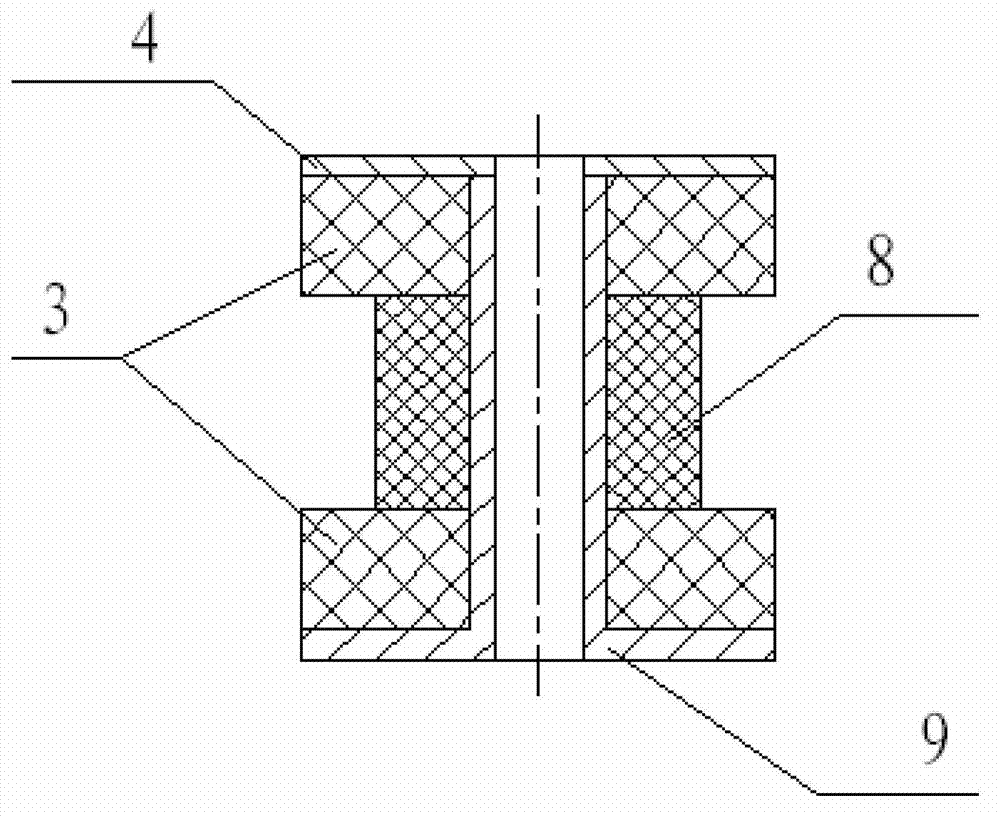

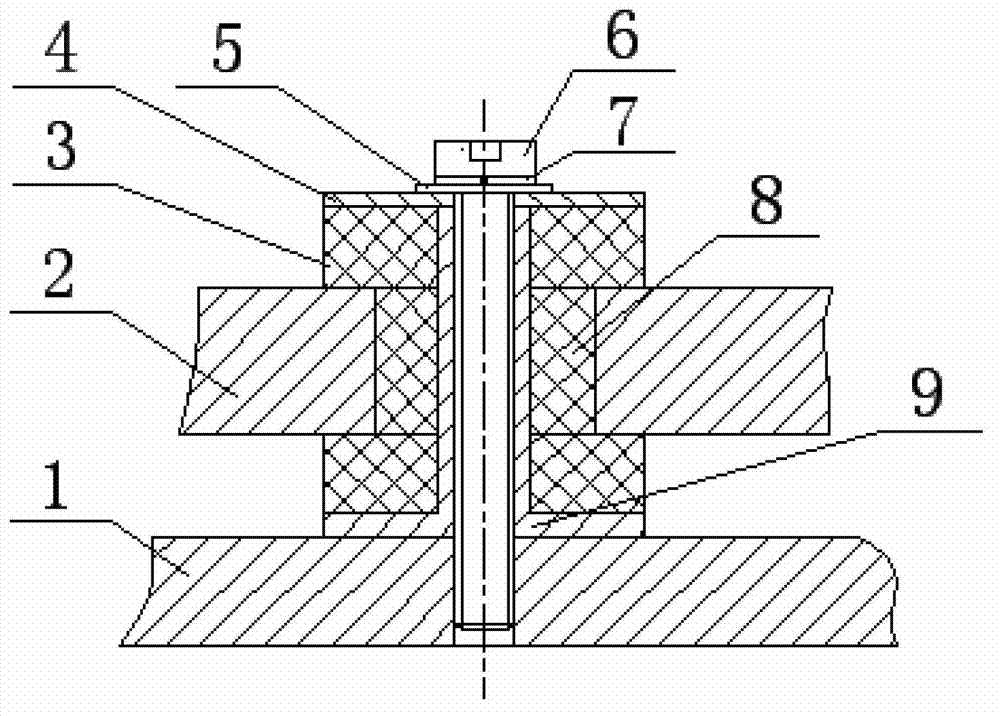

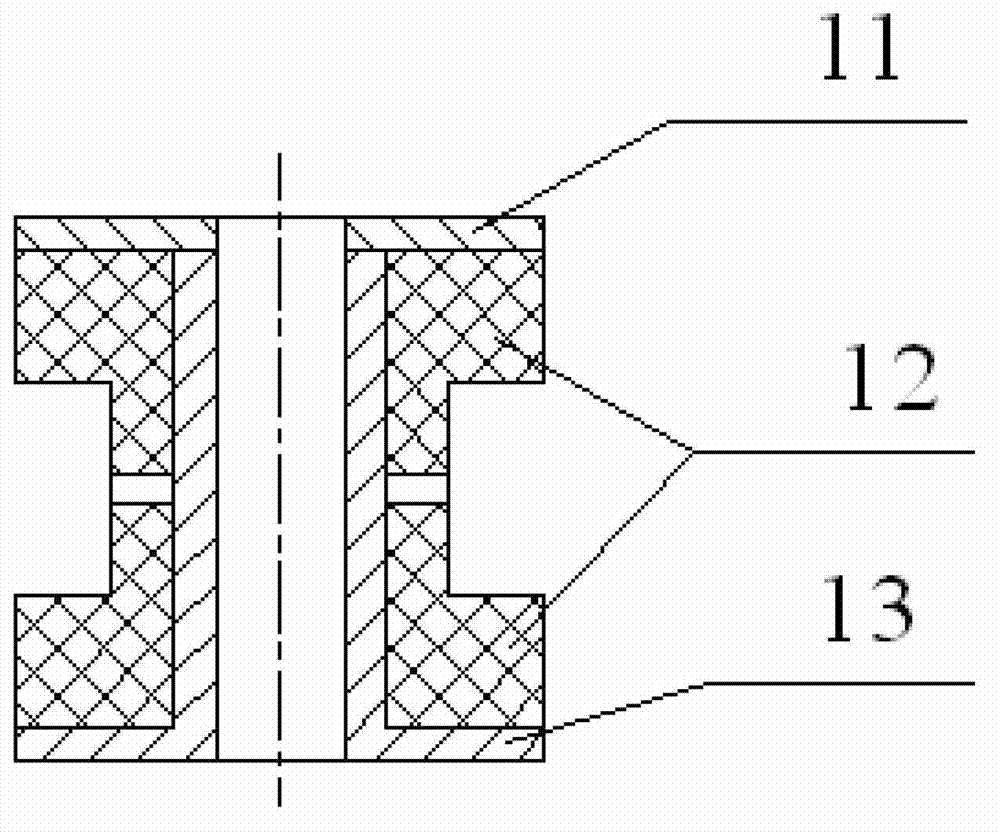

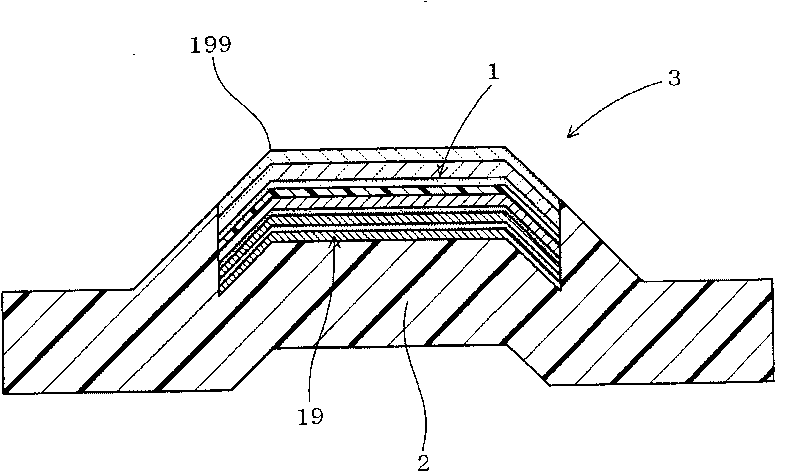

Combined type rubber shock absorber

ActiveCN103115100AImprove reliabilityStrong designabilityMultiple spring combinationsRubber materialEngineering

The invention relates to a combined type rubber shock absorber and belongs to the technical field of rubber vibration isolators. The combined type rubber shock absorber is mainly used for vibration and buffering processing of electronic equipment or instruments. The combined type rubber shock absorber comprises a rubber anti-vibration pad, a rubber anti-vibration column, a metal limiting lining and a metal limiting gasket. According to the combined type rubber shock absorber, vibration and impact energy is translated into heat energy and deformation energy of rubber materials through the deformation of rubber parts by means of a combined shock absorber structure, the rubber anti-vibration pad is capable of reducing dynamic energy of an instrument with vibration to be isolated in the axial direction, the rubber anti-vibration column is capable of reducing dynamic energy of the instrument with the vibration to be isolated in the radial direction, the metal limiting lining and the metal limiting gasket are used in a matching mode, dynamic displacement of the shock absorber is limited due to the fact that the shock absorber is installed on a base plate of the instrument through bolts, and then an installation function and a limiting function are achieved.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

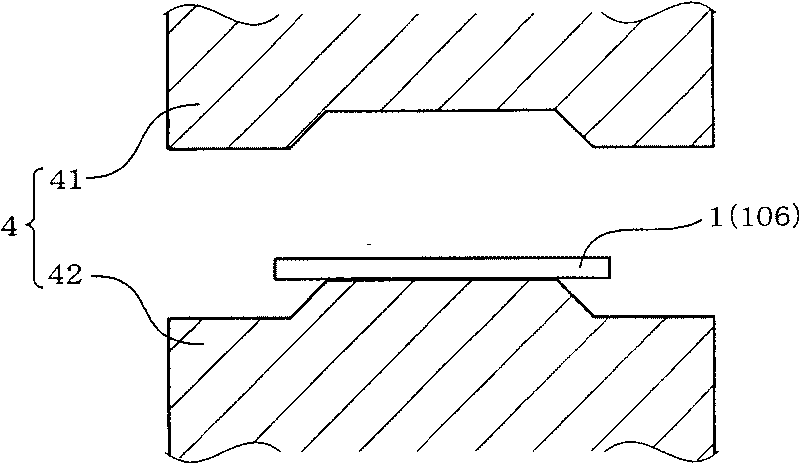

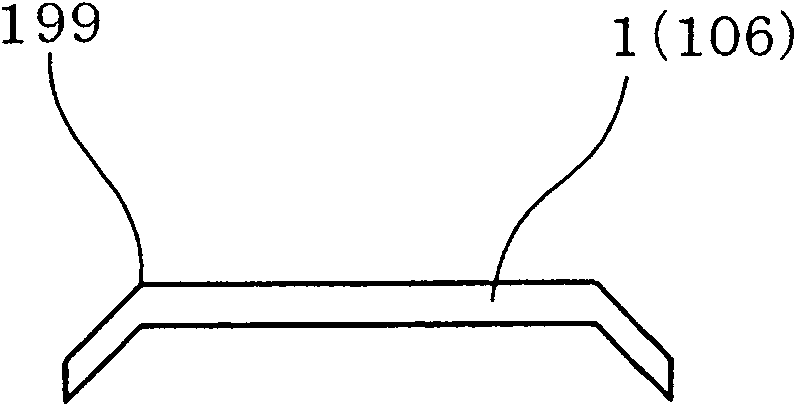

Resin-coated stainless steel foil, container and secondary battery

ActiveCN101331020AStrong adhesionImprove corrosion resistanceAlkaline accumulatorsChromatisationPolyolefinElectrical polarity

A resin-coated stainless steel foil that can maintain strong adherence to films even in an electrolyte solution and exhibit good corrosion resistance, excelling in processability, designability and stab resistance; and, making use of the same, a container and secondary battery. There is provided a resin-coated stainless steel foil characterized by having a chromate-treated layer of 2 to 200nm superimposed on at least one major surface of stainless steel foil and having, superimposed on the chromate-treated layer, at least a layer of polyolefin resin (A) containing a polar functional group. Further, there are provided, making use of the same, a container and secondary battery.

Owner:NIPPON STEEL CHEM &MATERIAL CO LTD

Percolator For Producing A Beverage From Powdered Material In A Container

InactiveUS20080236403A1Economical to useSuitable householdBeverage vesselsDomestic vesselsClassical mechanicsEngineering

A percolator, wherein a container, containing a measure of ground coffee, is inserted inside a fixed cup, which has a vertical first axis, is positioned with its concavity facing upwards, and has a lid which rotates, about a second axis crosswise to the first axis, to and from a closed position closing the cup; the lid having a pressurized-hot-water sprinkler which, when the lid is in the closed position, is moved, by a piston carried by the lid, onto the cup to define, with the cup, a percolating chamber for housing the wafer and a bolt device to lock the lid in the closed position.

Owner:SGL ITALA

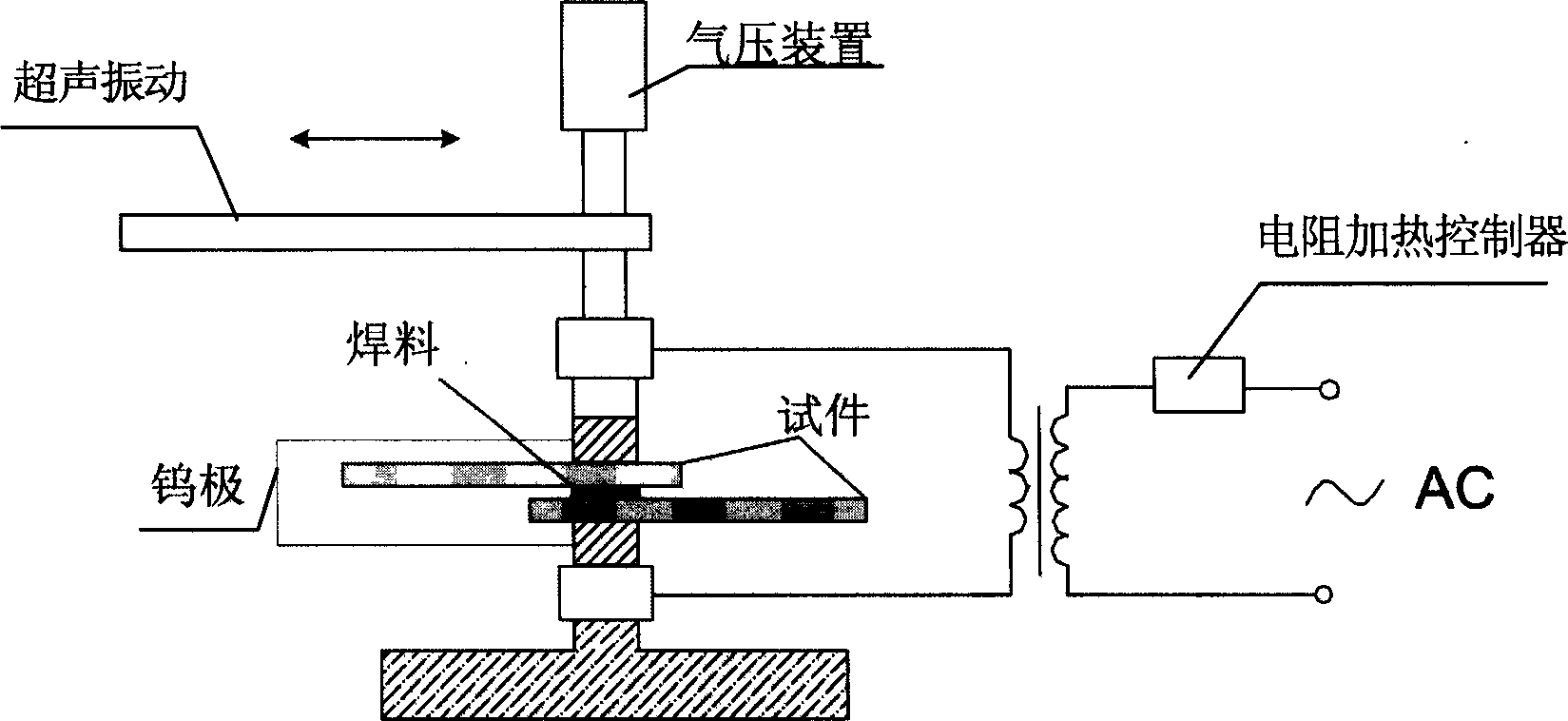

Aluminium base composite material ultra sonic electrical resistance welding method

InactiveCN1686659AEasy to operateStrong designWelding apparatusElectrical resistance and conductanceMegasonic cleaning

An ultrasonic-resistance welding method for the Al-based composition includes grinding the surfaces of Al-based compositions, ultrasonic cleaning, putting the flux between two surfaces to be welded, heating by electric resistance, decreasing the thickness of liquid film between two surfaces, ultrasonic vibrating, pressing and natural cooling.

Owner:HARBIN INST OF TECH

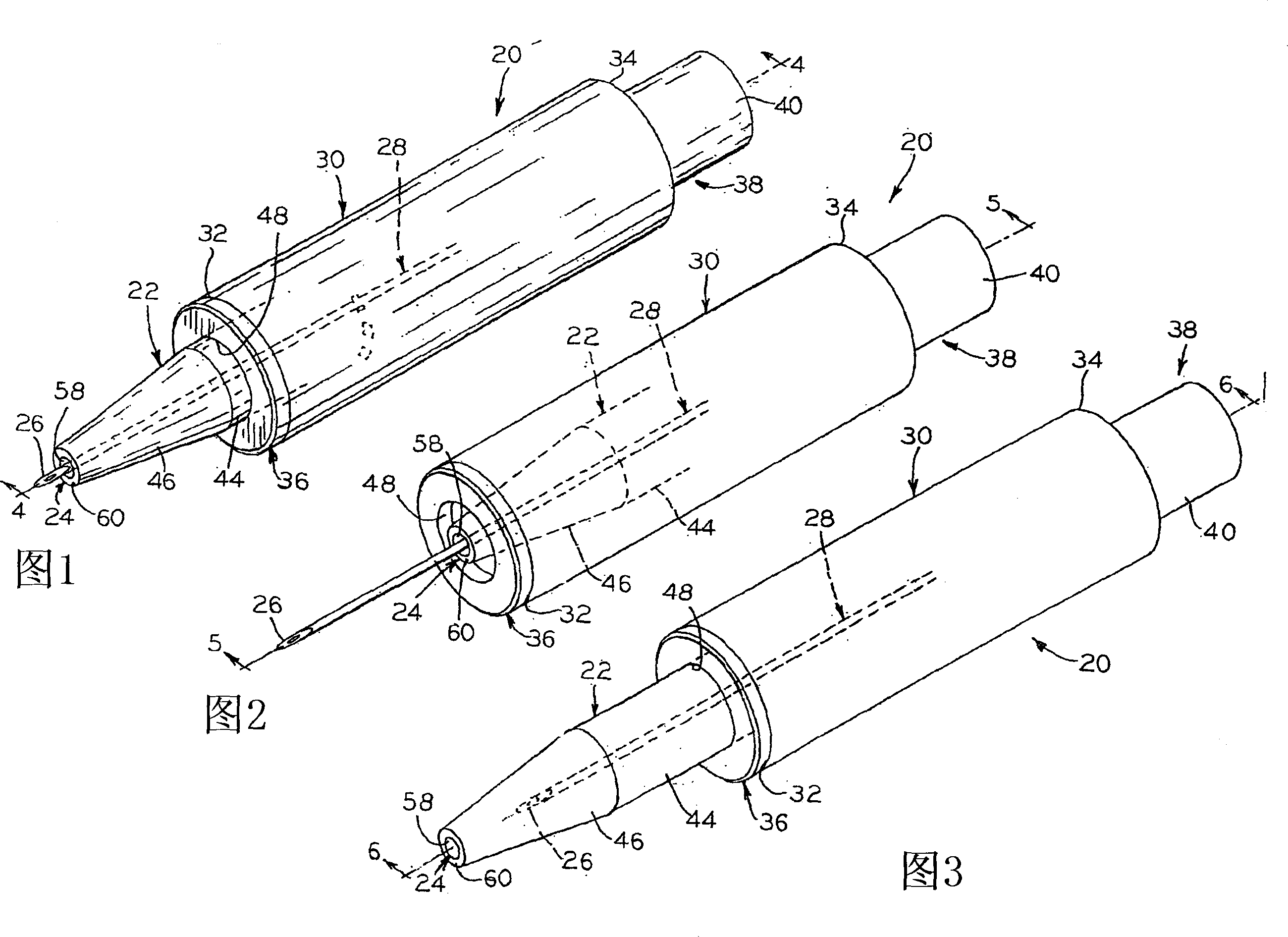

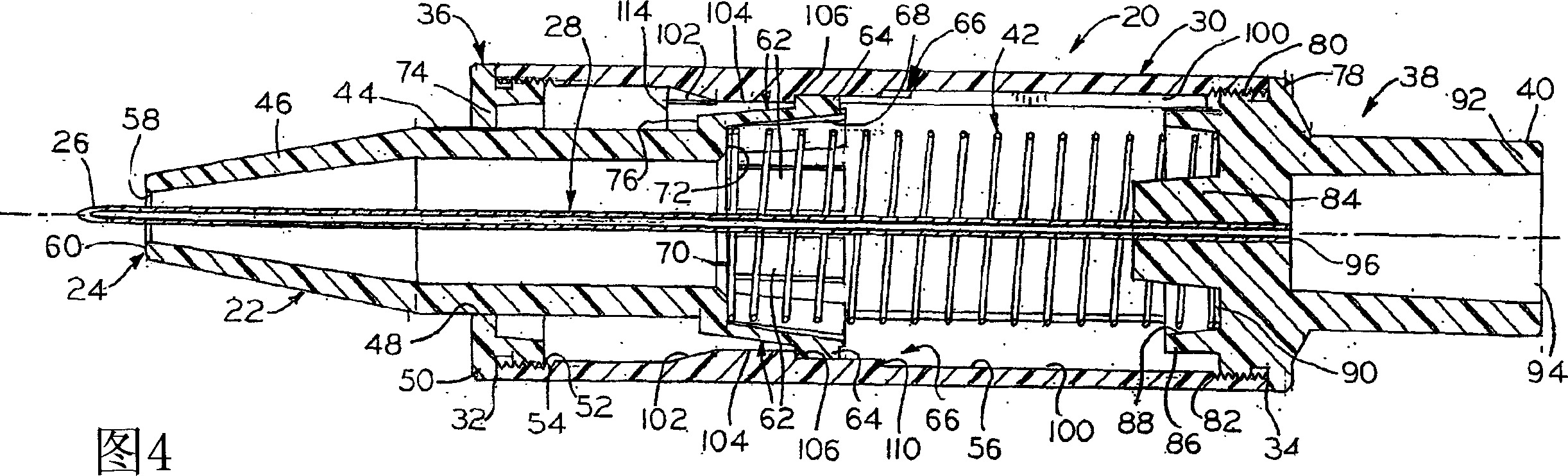

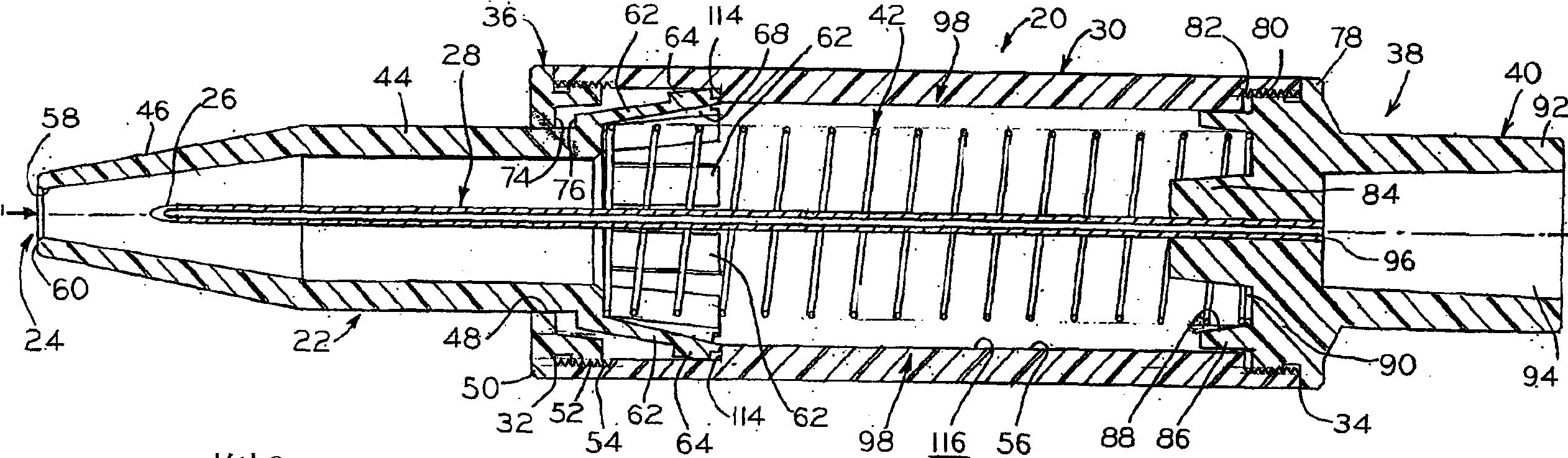

Safety needle

A safety needle (20) for use with a syringe including a casing (30) in which a needle (28) for injections or blood drawing is mounted. A sleeve (22) is slidably mounted in the casing (30). The sleeve (22) is biased by a spring (42) into a partially extended position, exposing only the sharp tip (26) of the needle. As the needle (28) is inserted into a patient, the sleeve (22) retracts into the casing. When the needle (28) is removed, the sleeve (22) returns to a fully extended position and by operation of a locking mechanism locks into place. The locking mechanism includes a plurality of fingers (62), at least one of which has a projection (64) formed thereon. The projection (64) travels along a track system (66) integrally formed in the inner wall (56) of the casing (30) to move from the initial sleeve position to the retracted position and then back to a locked position in which contact with the used needle (28) and reuse of the safety needle (20) is prevented.

Owner:NMT GRP PLC

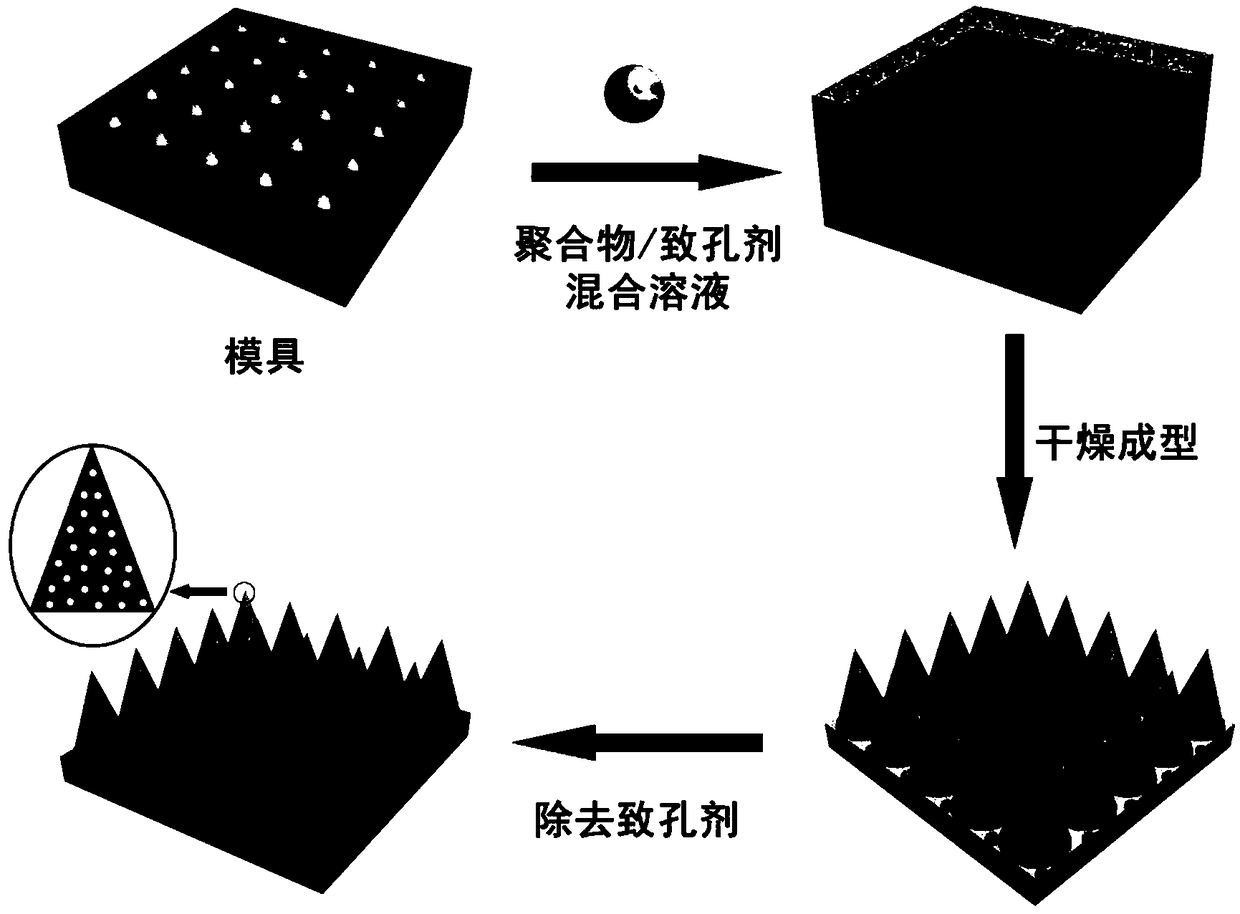

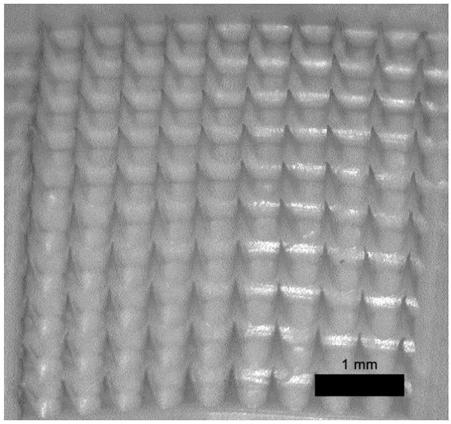

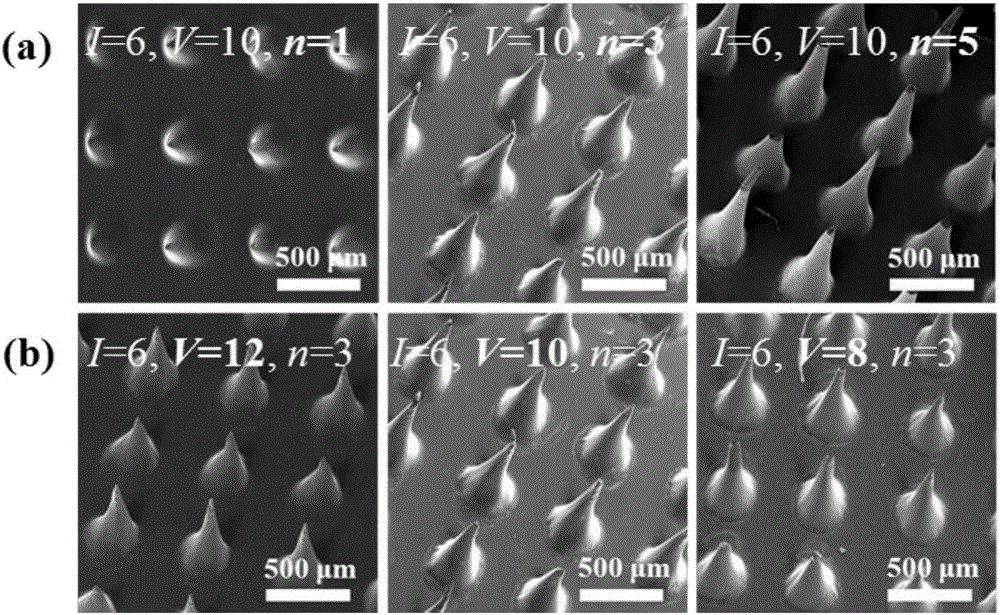

Method for preparing porous polymer micro needle by using template method and application thereof

InactiveCN109364366AOvercome the cumbersome preparation processOvercome the conditionsMicroneedlesPharmaceutical delivery mechanismTissue fluidHair growth

The invention discloses a method for preparing a porous polymer micro needle by using a template method and an application thereof. The method comprises the following steps of: (1) dissolving a polymer and a template agent in a solvent to prepare a polymer solution; (2) filling the polymer solution into a micro needle mould; (3) removing the solvent in the obtained micro needle mould to obtain a solid micro needle; (4) removing the template agent in the obtained solid micro needle to obtain the porous polymer micro needle. By improving the overall process flow design of the preparation method,the method can solve the technical problems of a complex preparation process, harsh conditions, a complicated process, high price, difficult control of the pore structure and size, difficult large-scale production and application and the like of the porous polymer micro needle, the obtained porous polymer micro needle can be used for tissue fluid extraction and transdermal administration, such asskin tissue fluid and blood extraction and transdermal administration of proteins, polypeptides and small molecular drugs in cosmetic, hair growth, immunity, treatment and other applications.

Owner:HUAZHONG UNIV OF SCI & TECH +1

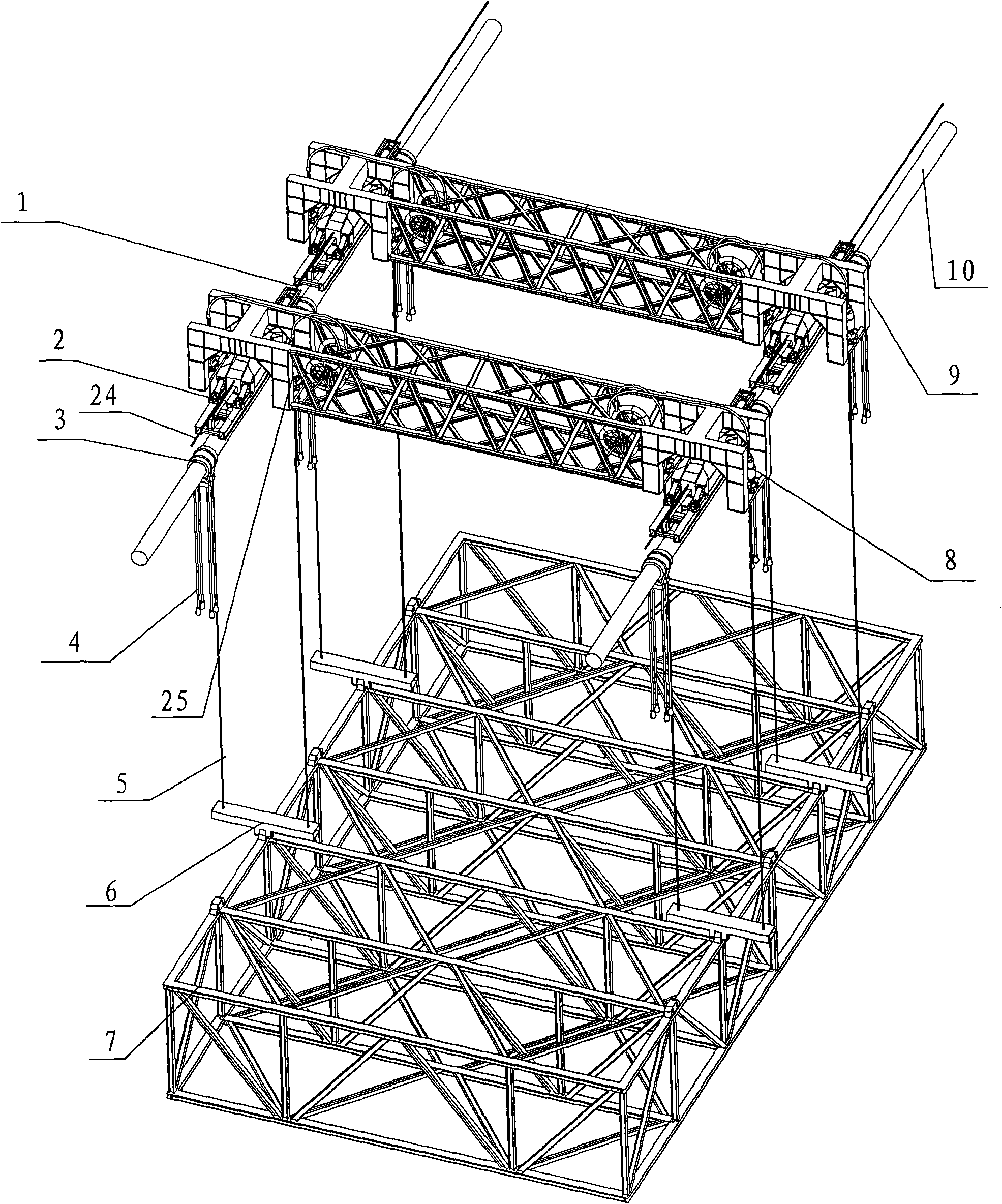

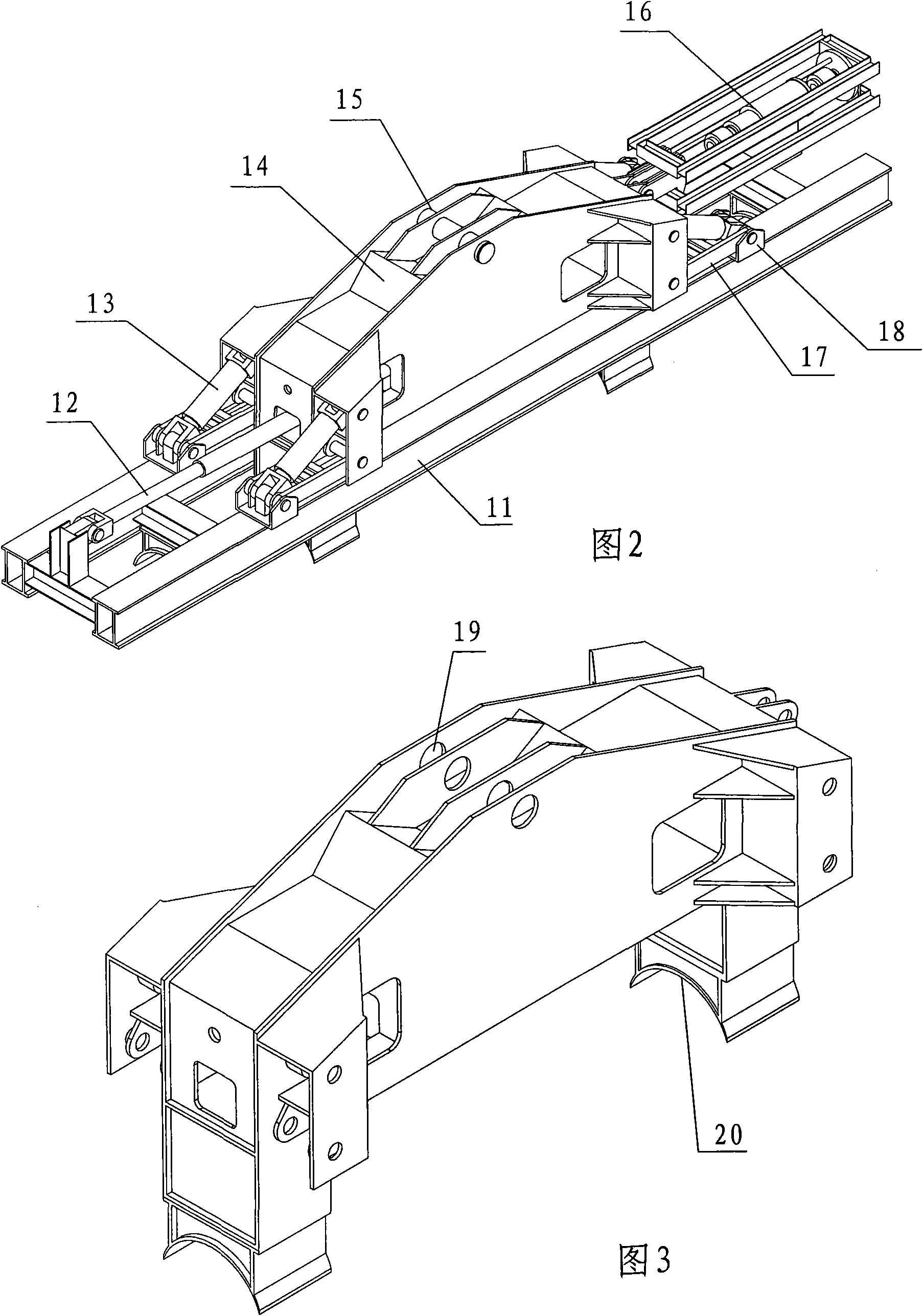

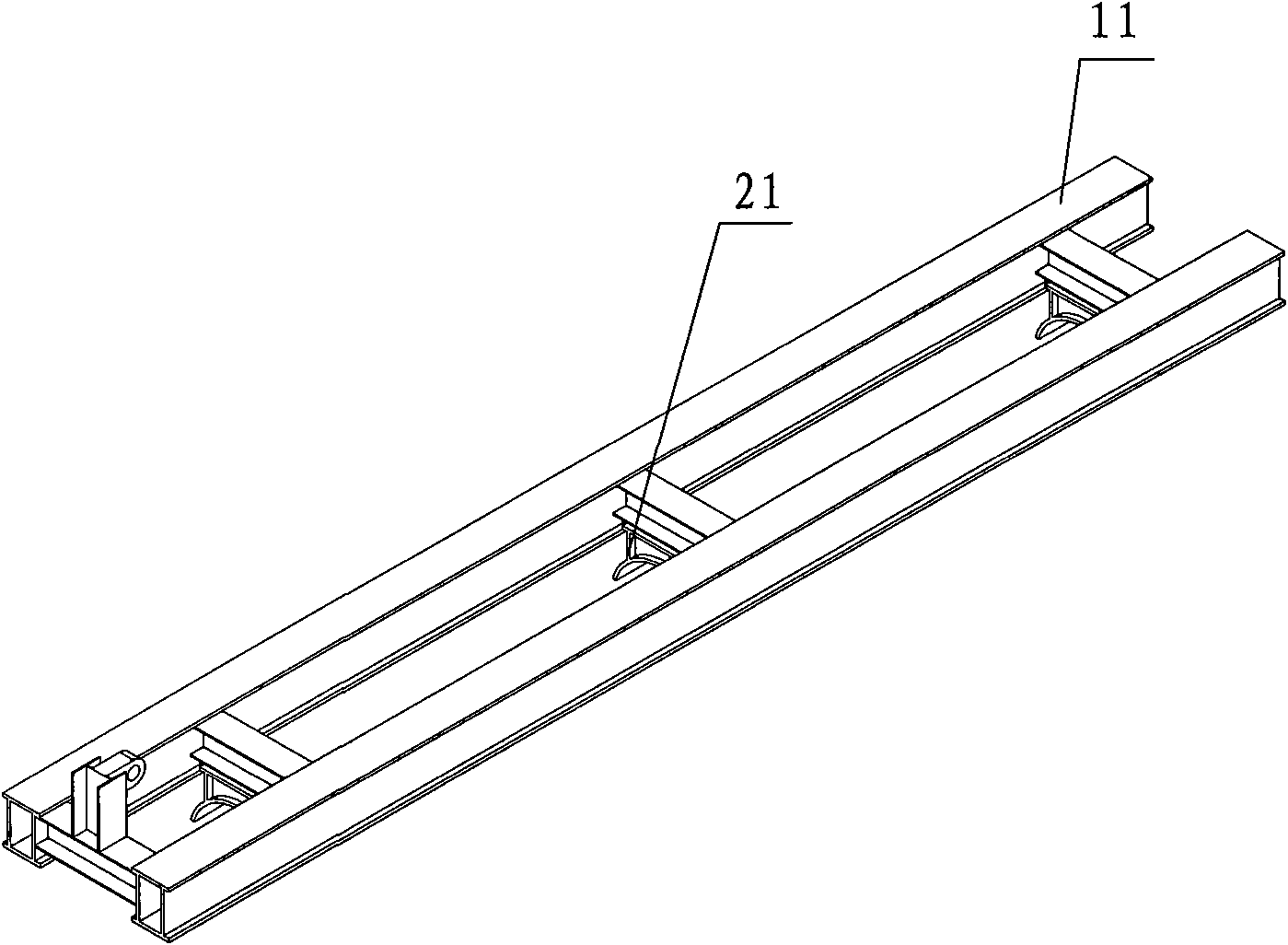

Dual-machine loading-and-walking type hydraulic numerical control deck erection gantry and control system and control method

ActiveCN101786577AImprove lifting performanceImprove work efficiencyCable carsSafety gearNumerical controlControl system

The invention provides a dual-machine loading-and-walking type hydraulic numerical control deck erection gantry, which comprises two sets of loading-and-walking type hydraulic numerical control deck erection gantries and a control system, wherein each set of the loading-and-walking type hydraulic numerical control deck erection gantries comprises the following four parts: a transverse truss girder, two sets of walking type loading-and-walking devices arranged at two ends of the transverse truss girder, a hydraulic lifting device and a carrying pole of a hanger; each set of the walking type loading-and-walking devices consists of a guideway, a walking mechanism steel framework, m traction jacks, 4n load conversion jacks, a supporting pull rod, a walking roller bracket and P guideway walking jacks; all the components are connected with one another by pin shafts; and the control system of the deck erection gantry is a distributed computer network control system which consists of a main control station, Y field controllers, Y pump stations, Y pump station starting boxes, a data acquisition system, and a plurality of data wires and communication wires. The deck erection gantry has the advantages of great lifting force and high work efficiency and stability; and when the deck erection gantry walks with load, the control system of the deck erection gantry can effectively and synchronously control every jack.

Owner:LIUZHOU OVM MASCH CO LTD

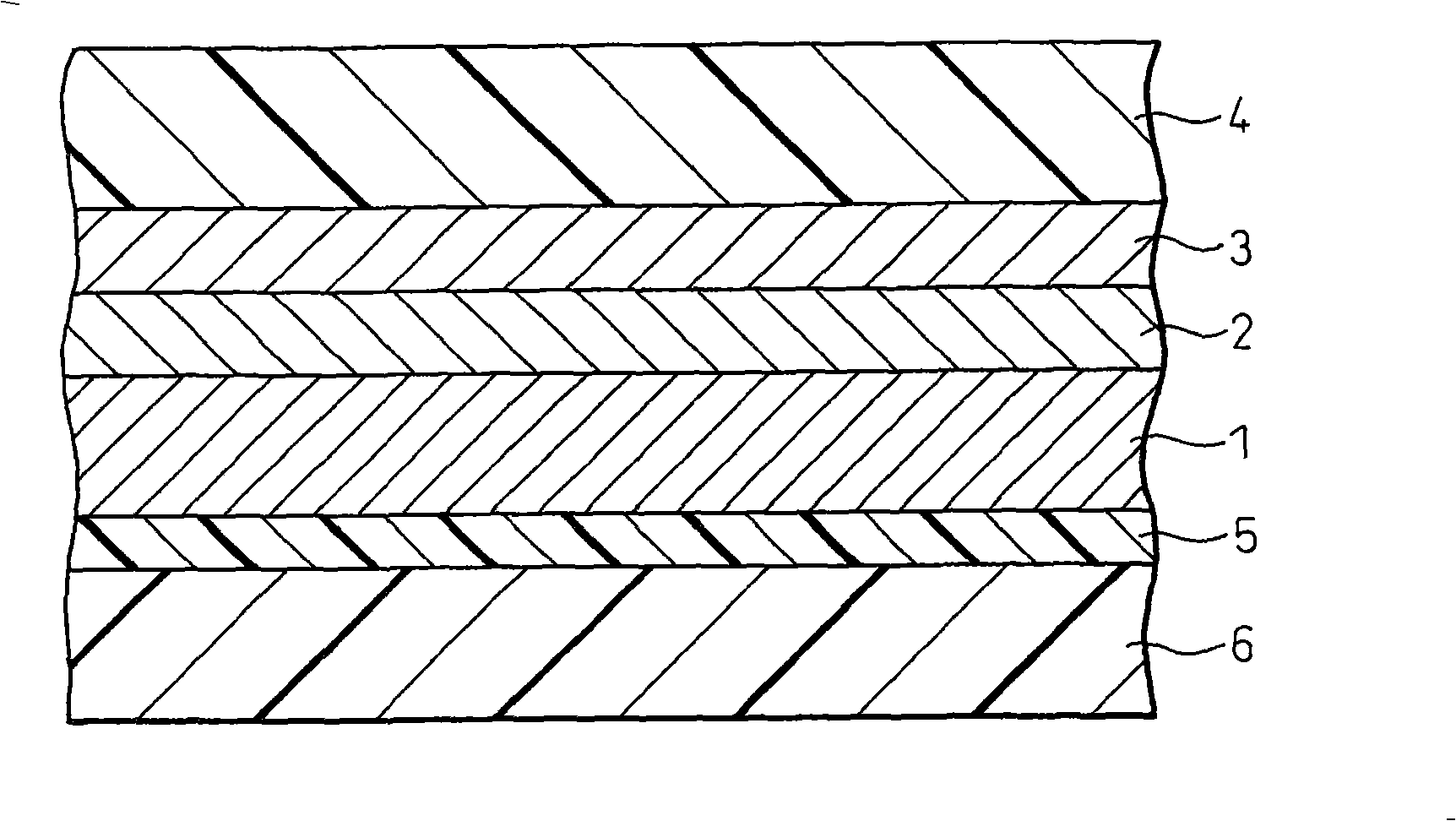

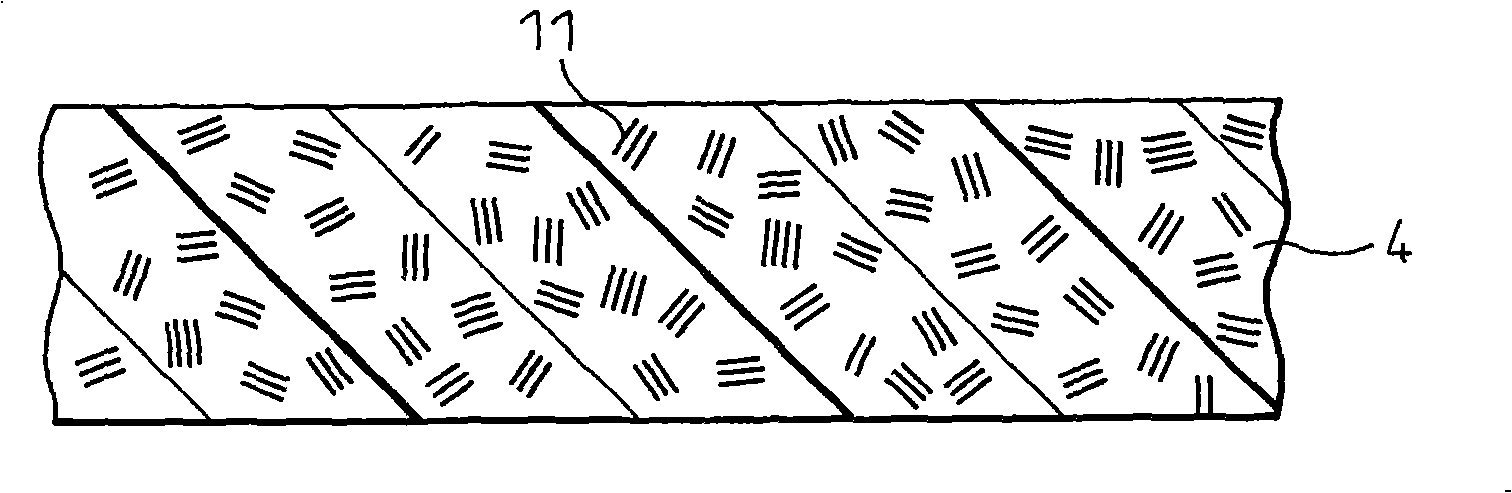

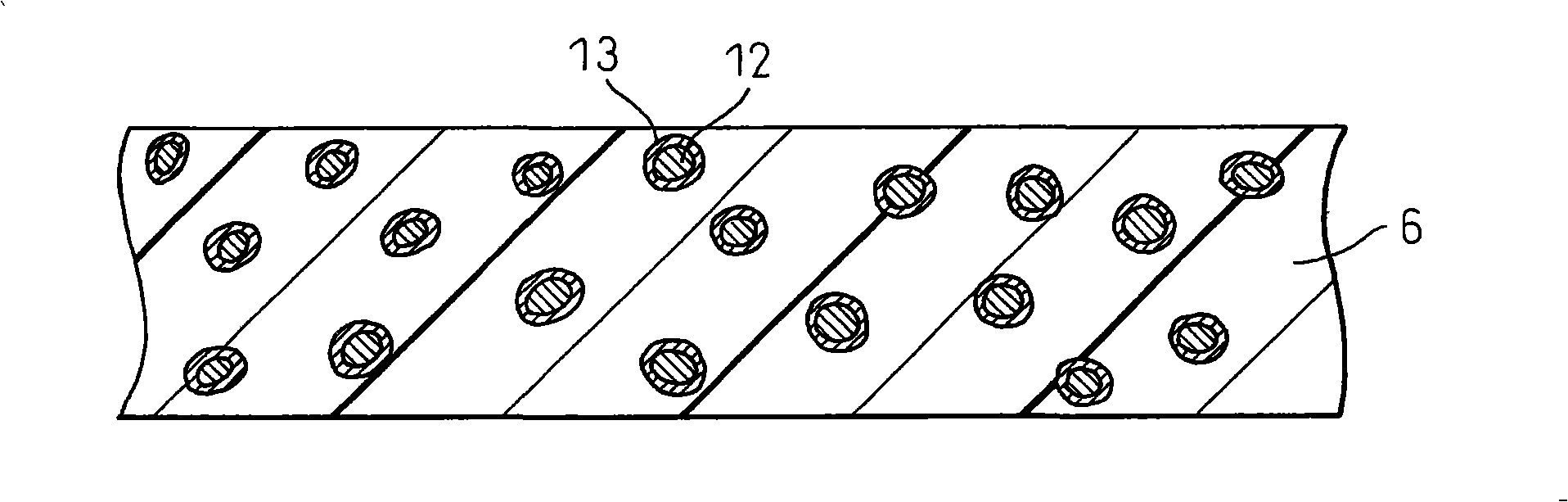

Three-dimensional braided composite material mechanical arm and manufacturing method thereof

ActiveCN105602200AImprove performanceImprove rigidityLamination ancillary operationsSynthetic resin layered productsHigh intensityConductor Coil

The invention discloses a three-dimensional braided composite material mechanical arm and a manufacturing method thereof. The mechanical arm sequentially comprises a body rigid structure layer, an anti-impact layer and a surface machining assembly layer from inside to outside. The body rigid structure layer comprises a three-dimensional braided structure and a resin layer, wherein the three-dimensional braided structure is manufactured from high-modulus fibers, and the resin layer is solidified on the three-dimensional braided structure in a dipping mode. The anti-impact layer comprises a three-dimensional braided structure and a resin layer, wherein the three-dimensional braided structure is manufactured from hybrid fibers composed of high-modulus fibers and organic fibers, and the resin layer is solidified on the three-dimensional braided structure in a dipping mode. The surface machining assembly layer comprises a two-dimensional winding layer fabric structure and a resin layer, wherein the two-dimensional winding layer fabric structure is manufactured from high-strength fibers, and the resin layer is solidified on the two-dimensional winding layer fabric structure in a dipping mode. The mechanical arm has the advantages of being high in strength, high in rigidity, low in weight, not prone to deformation and high in designability, machinability and assembling ability, the weight of components is reduced, the power of a motor is reduced, energy consumption is reduced, and stability and quality of products are guaranteed.

Owner:SHANDONG ZHONGHENG CARBON FIBER TECH DEV CO LTD

Novel electromagnetic shielding composite material and preparation method thereof

ActiveCN108394148AStrong designLamination ancillary operationsMagnetic/electric field screeningFiberElectromagnetic shielding

The invention provides a novel electromagnetic shielding composite material. The composite material comprises a metal layer, thermosetting resin and a carbon fiber woven fabric, wherein the metal layer is one or composite structure of two selected from a metal foam layer and a metal mesh layer; a viscosity range of the thermosetting resin is 0.1-0.5 Pa.s, the thermosetting resin is uniformly mixedwith a nano conductive filler to form a resin mixed solution, and the nano conductive filler accounts for 1-10% by weight of the resin mixed solution; and the outer surface of the metal layer is provided with the carbon fiber woven fabric through the resin mixed solution, and the metal layer and the carbon fiber woven fabric are fully wetted and infiltrated in the resin mixed solution. The novelelectromagnetic shielding composite material provided by the invention has the advantages of a light weight, high bonding strength, stronger corrosion resistance, a wide application range, good shielding stability and a wide shielding wave band range.

Owner:SHANDONG LUTAI HLDG GRP CO LTD +1

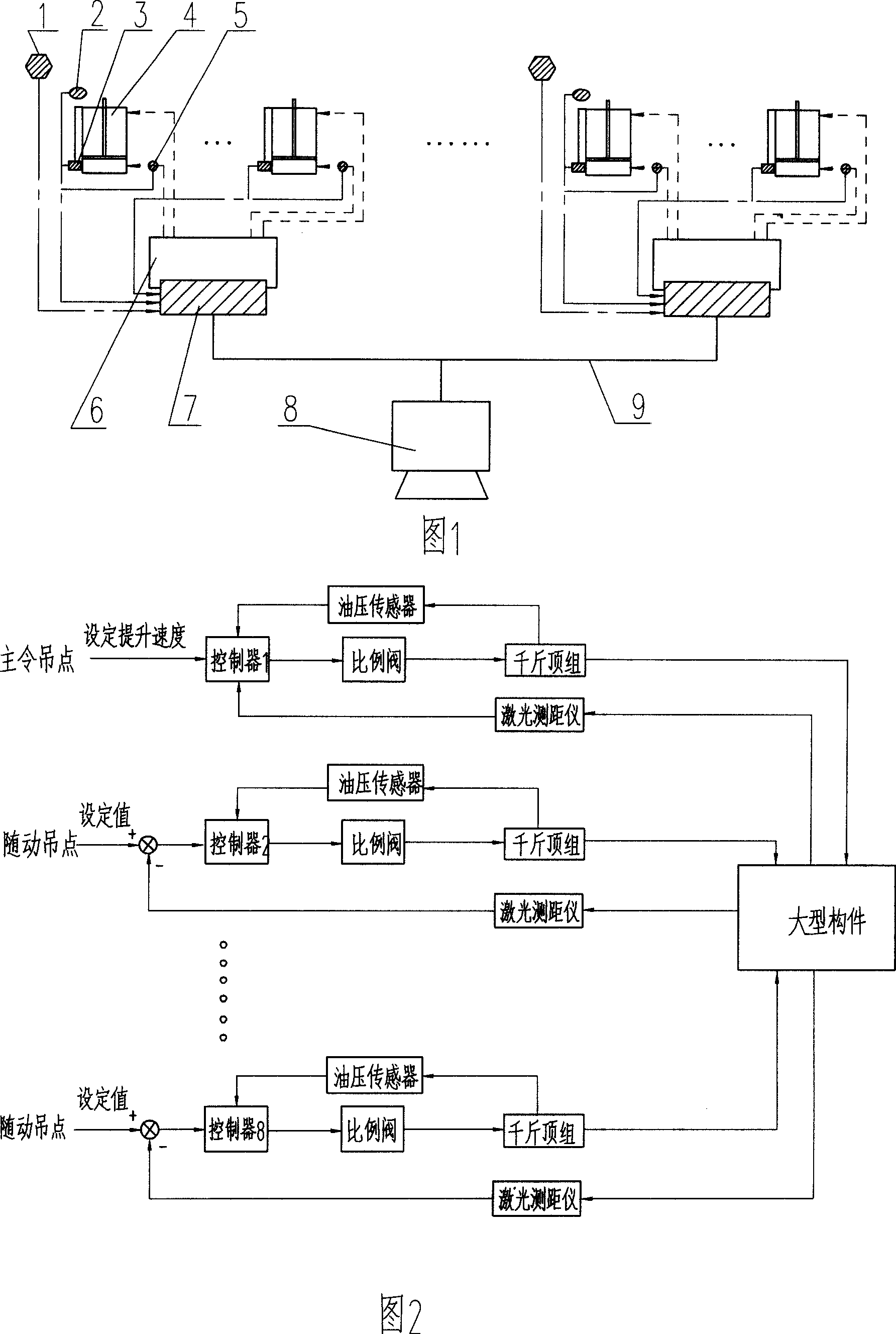

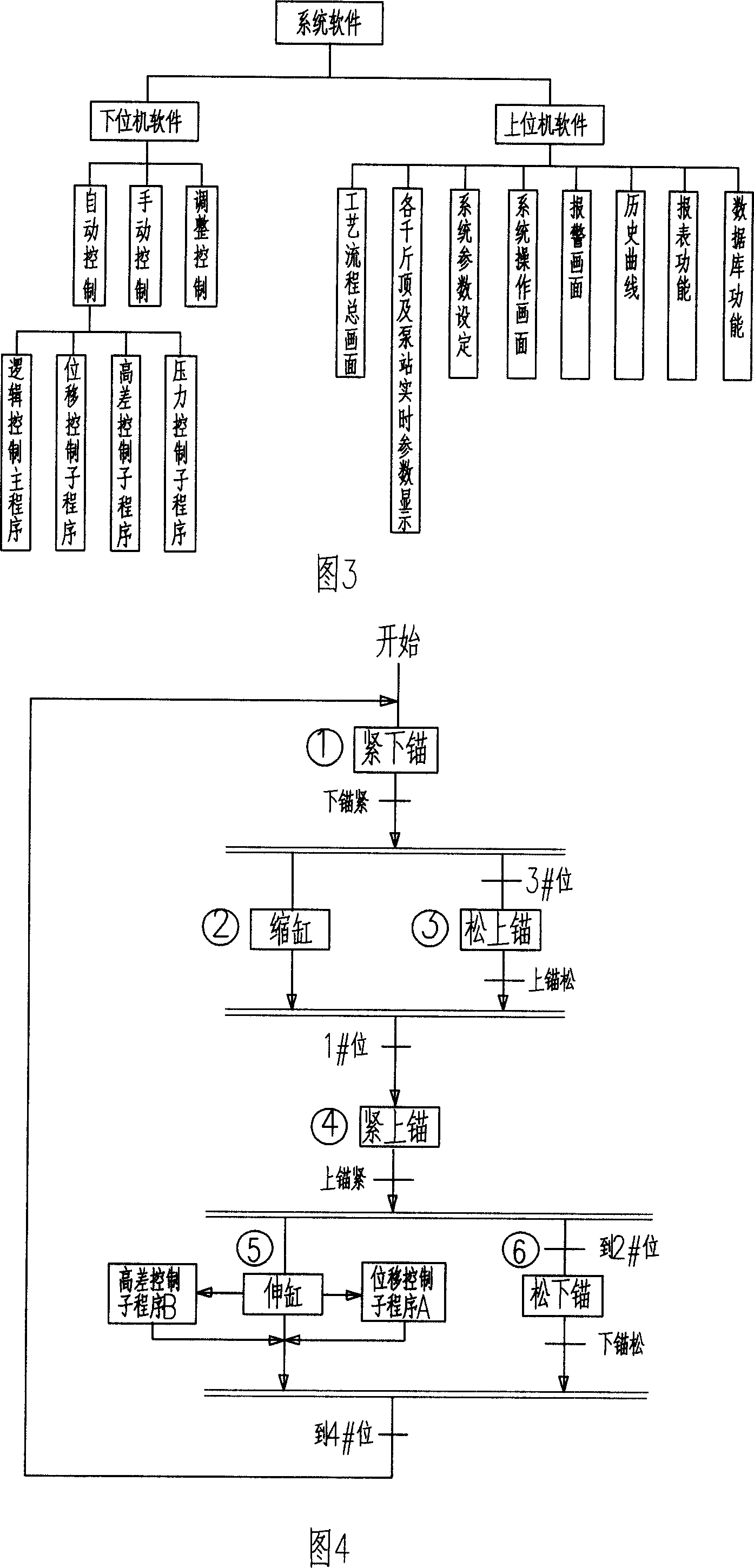

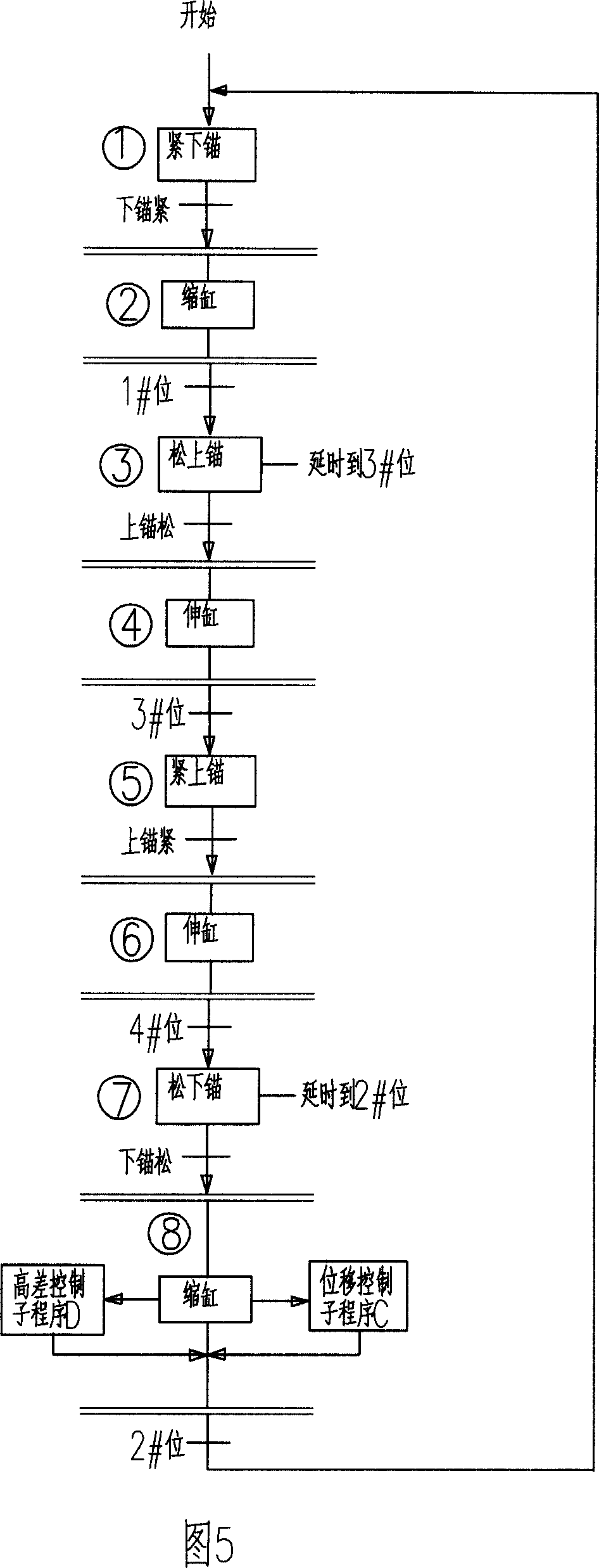

Hydraulic hoisting monitor system and its use in hydraulic hoisting control

ActiveCN1987700AReasonable configurationStrong fault toleranceSafety devices for lifting equipmentsComputer controlData acquisitionEngineering

The monitored control (MC) system is composed of up device, low device and data acquisition system. The up device is a MC computer with monitored control software in use for monitored controlling system and data management. The low device includes n pieces of site controller composed of n pieces of programmable controller with logic control main program and synchronous adjustment sub program being written into. Being installed on y pieces of hydraulic power unit, the n pieces of site controller through real time network is connected to MC computer. The method includes remote control mode, and local control mode. No mater how large the system is, direct selecting mode for jacks is adopted in the system. Features are: simple system circuit, intuitive operations, and accurate measurement. Configuration software is in use for monitoring system and querying historical data. The invention is in use for lifting control of large-scale component.

Owner:LIUZHOU OVM MASCH CO LTD

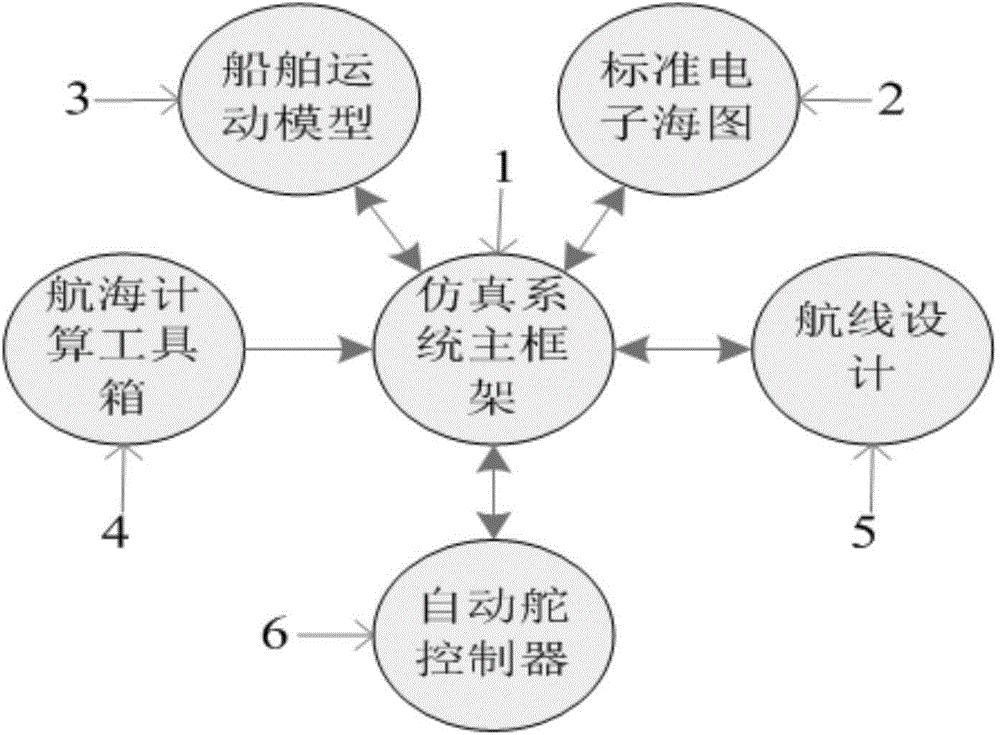

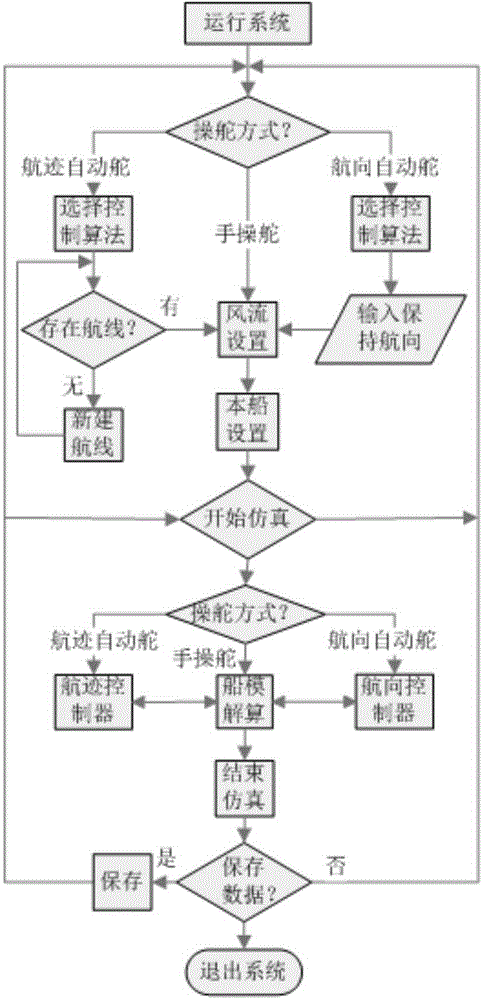

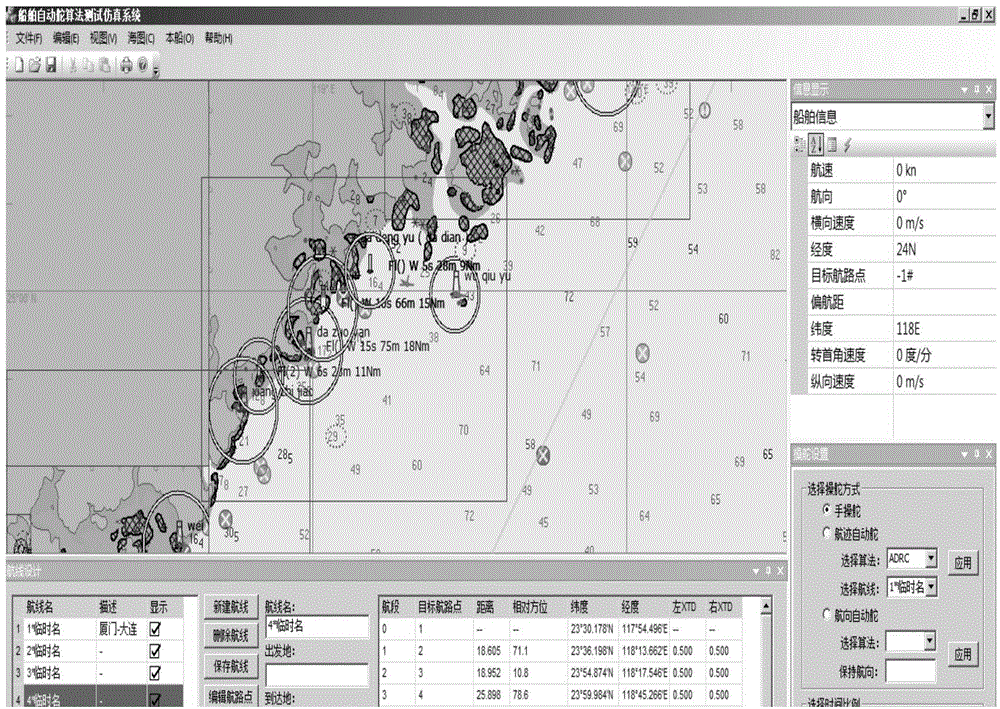

Ship autopilot algorithm testing simulation system

InactiveCN104483845ASimple and beautiful interfaceQuick and intuitive call upSimulator controlPosition/course control in two dimensionsData displayInternational standard

The invention discloses a ship autopilot algorithm testing simulation system, which comprises a main framework, a standard electronic chart module, a ship moving mathematical model module, a navigation calculation toolkit module, a route design module and an autopilot controller module. The standard electronic chart module is built in the ship autopilot algorithm testing simulation system, the standard electronic chart module is based on an international standard electronic chart and can load global electronic chart data at an S57 format, in addition, the global chart can be browsed in a stepless zooming way at any proportional scale, various data display modes and color display schemes are realized, and the whole interface is simple, compact and attractive. The ship autopilot algorithm testing simulation system has the advantages that different wind flow conditions can be set, so that a ship can realize the simulated navigation under the vivid maritime interference condition. A user can test a ship autopilot for a long time in a large range in any sea area in the global range without time and place limitation, so that the problems of great risk, long debugging period and high cost in real ship testing of the ship autopilot are solved.

Owner:DALIAN MARITIME UNIVERSITY

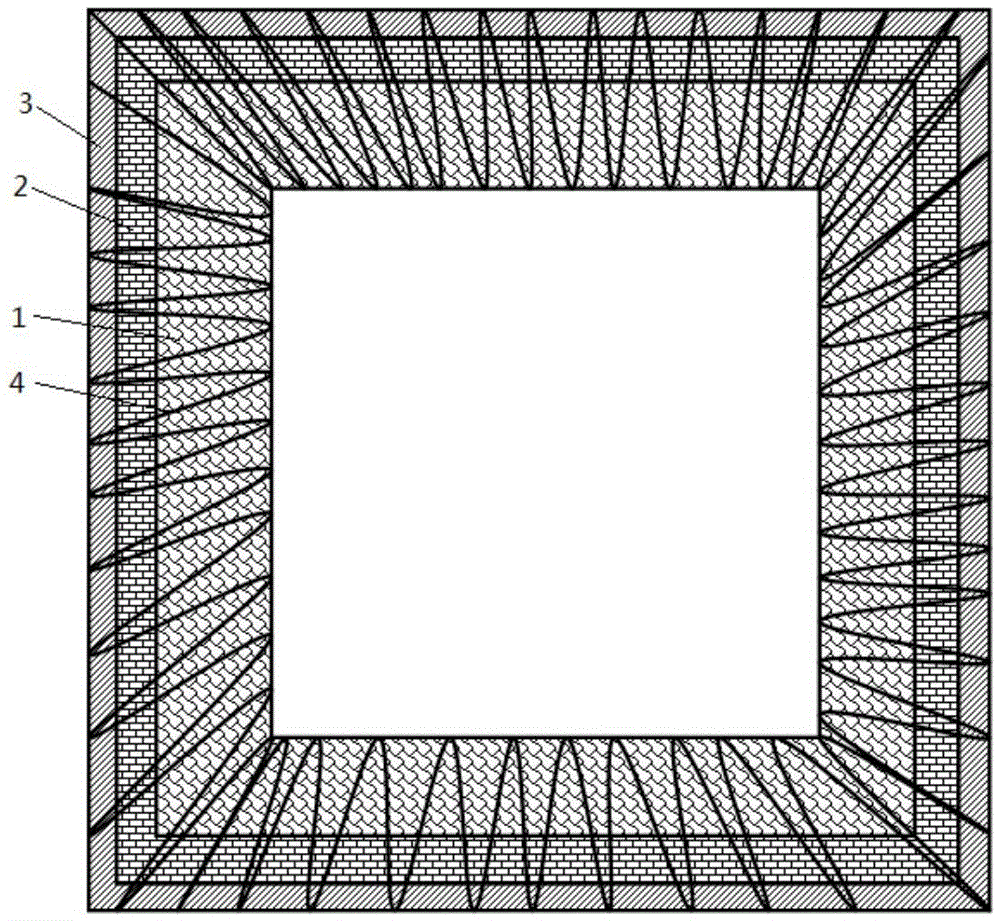

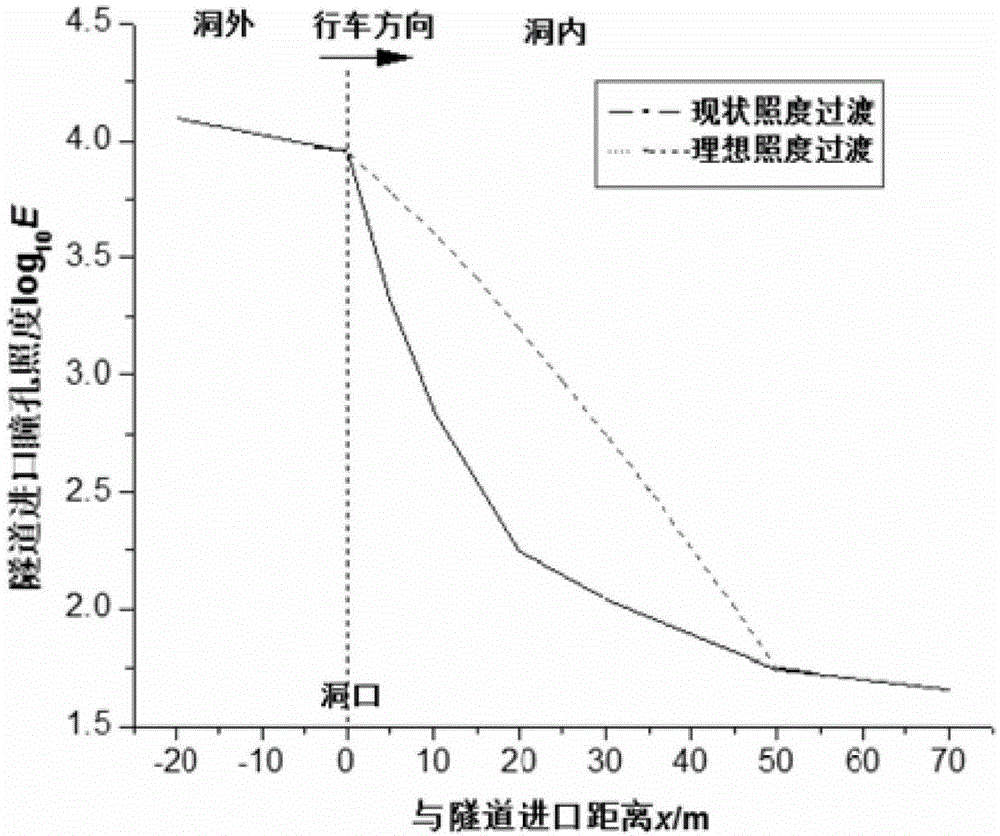

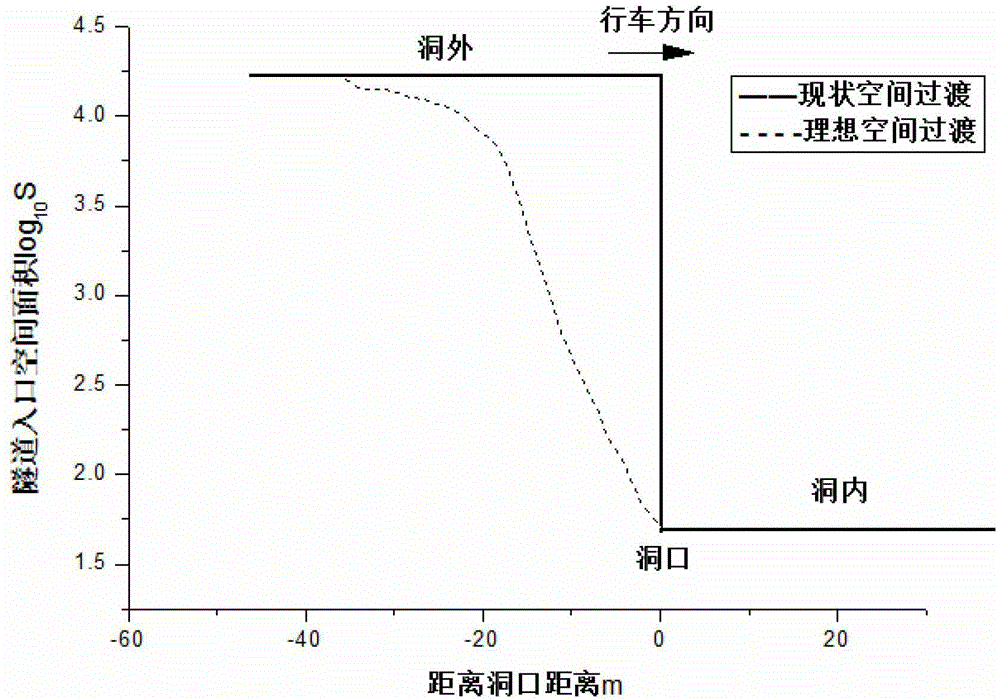

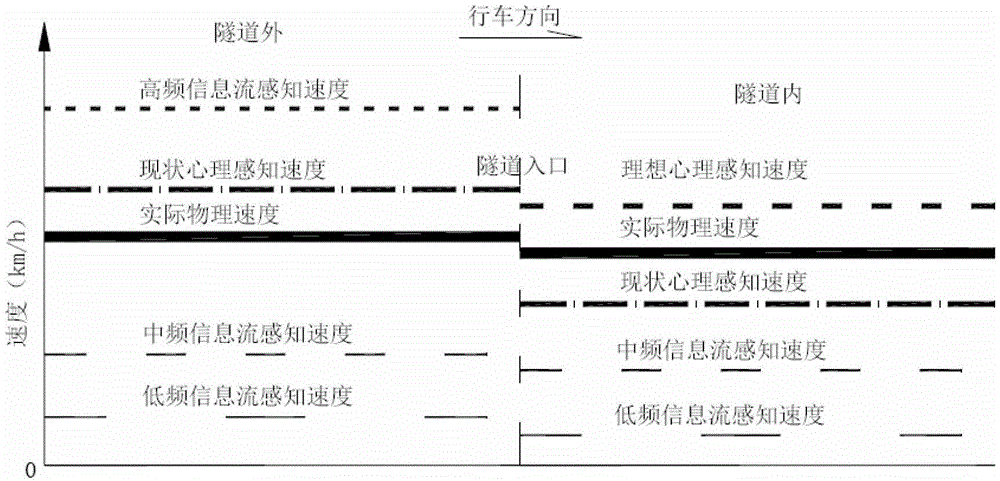

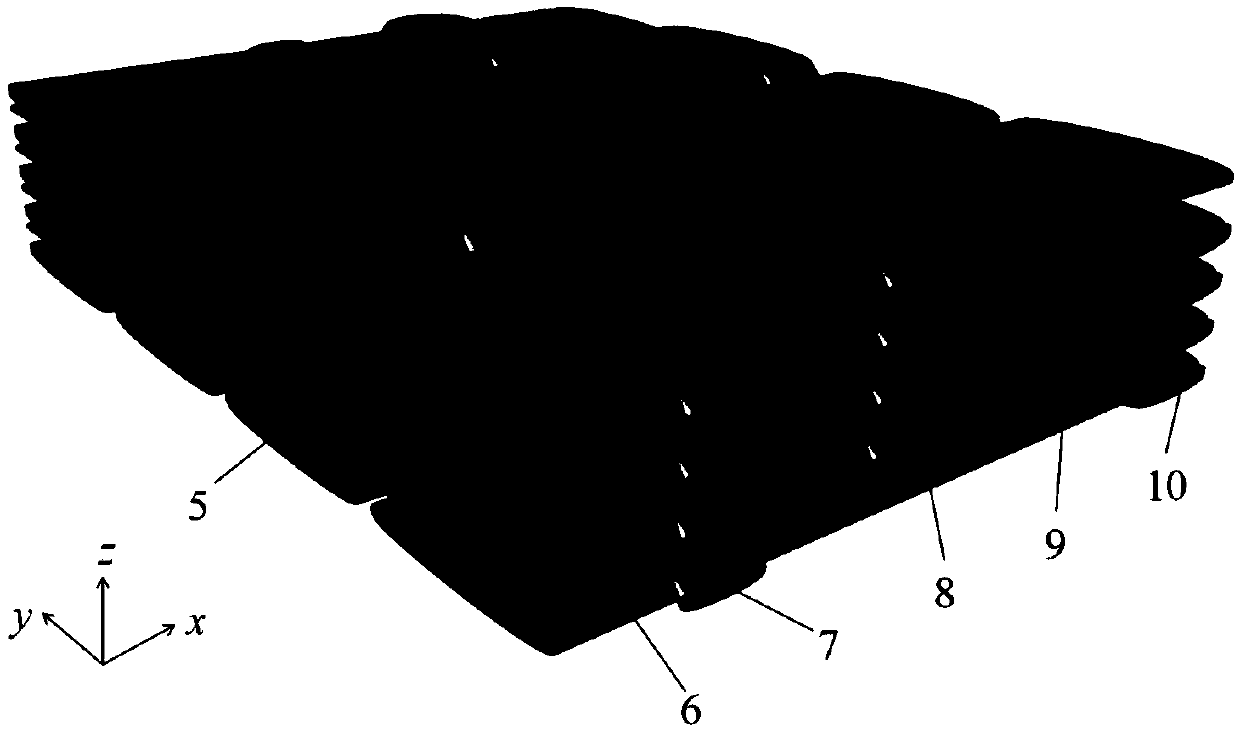

Method for designing shading transition facility for road tunnel entrance

The invention relates to a method for designing a shading transition facility for a road tunnel entrance. The facility mainly comprises transparent toughened glass plates (2), a plurality of arched steel-structure upright columns (3), cicada-wing-shaped nontransparent shading films (5) and a shading transition retroreflection system, wherein the arched steel-structure upright columns (3) are gradually heightened outwardly from tunnel cave entrance end walls (1), and horn-shaped openings are formed by the arched steel-structure upright columns (3) and the transparent toughened glass plates (2) on the upright columns; the cicada-wing-shaped nontransparent shading films are arranged on inner layers of the transparent toughened glass plates, and contour line planes and side face projections of the shading films are Boltzmann curves, and the two sides of each arched steel structure are triangularly hollowed; the retroreflection system comprises medium-frequency steel-structure upright column contour marks (7), medium-frequency guardrail contour marks (8), high-frequency guardrail facade marks (9), high-frequency pavement marking lines (10) and high-frequency pavement protrusion marks (11). The shading transition facility has the advantages that the intense transition of space, luminance and reference of the tunnel entrance can be improved, and the black-hole effect on the tunnel entrance is relieved.

Owner:WUHAN UNIV OF TECH

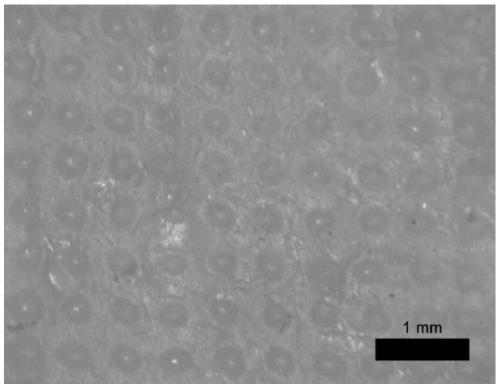

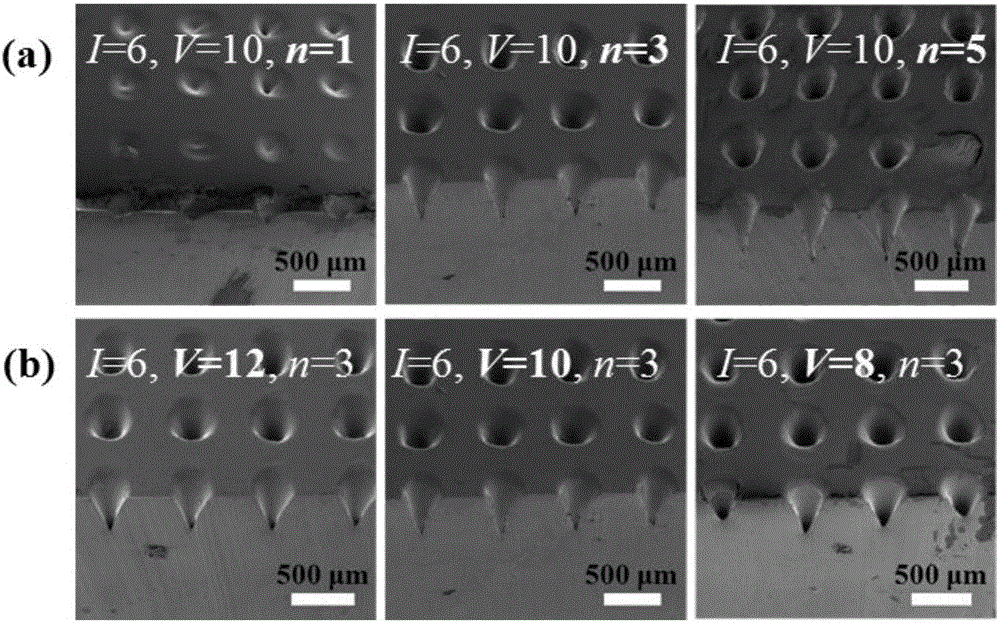

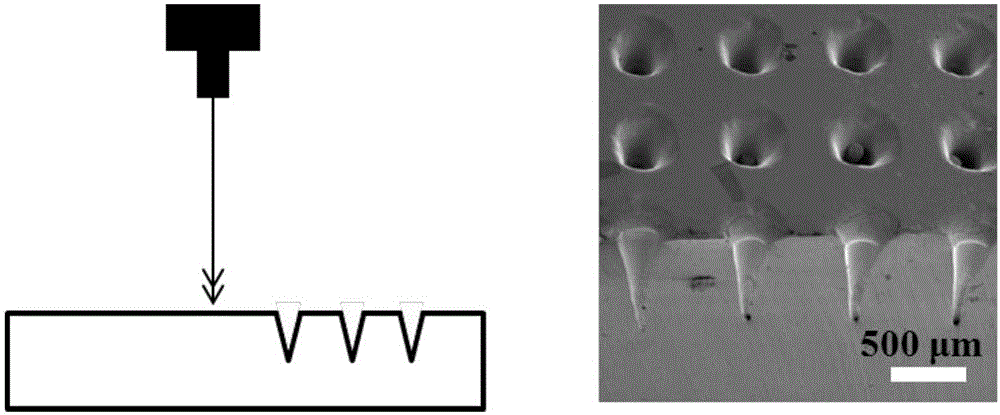

Method for producing micro-needle array templates based on laser etching technology as well as products and application thereof

InactiveCN106511257AImprove skin permeabilityImprove the effect of transdermal treatmentSurgeryPharmaceutical delivery mechanismOptoelectronicsTemplate based

The invention discloses a method for producing micro-needle array templates based on a laser etching technology as well as products and application thereof. The method comprises the following steps: (1) curing and cooling PDMS and a curing agent to obtain a PDMS substrate; (2) designing a laser etching mask plate pattern and enabling the pattern to be a concentric circle array; and (3) placing the PDMS substrate in an engraving area of a laser engraving machine and setting condition parameters of laser processing technology, subsequently carrying out laser treatment on the PDMS substrate with reference to the laser etching mask plate pattern so as to obtain the PDMS substrate etched by laser, wherein the PDMS substrate is the micro-needle array template. According to the method, the key laser etching process conditions are improved, so that the problems that the micro-needle array templates are complex in production process, high in cost and poor in structural design, and large-scale production and application of the micro-needle array templates are difficult can be effectively solved.

Owner:HUAZHONG UNIV OF SCI & TECH +1

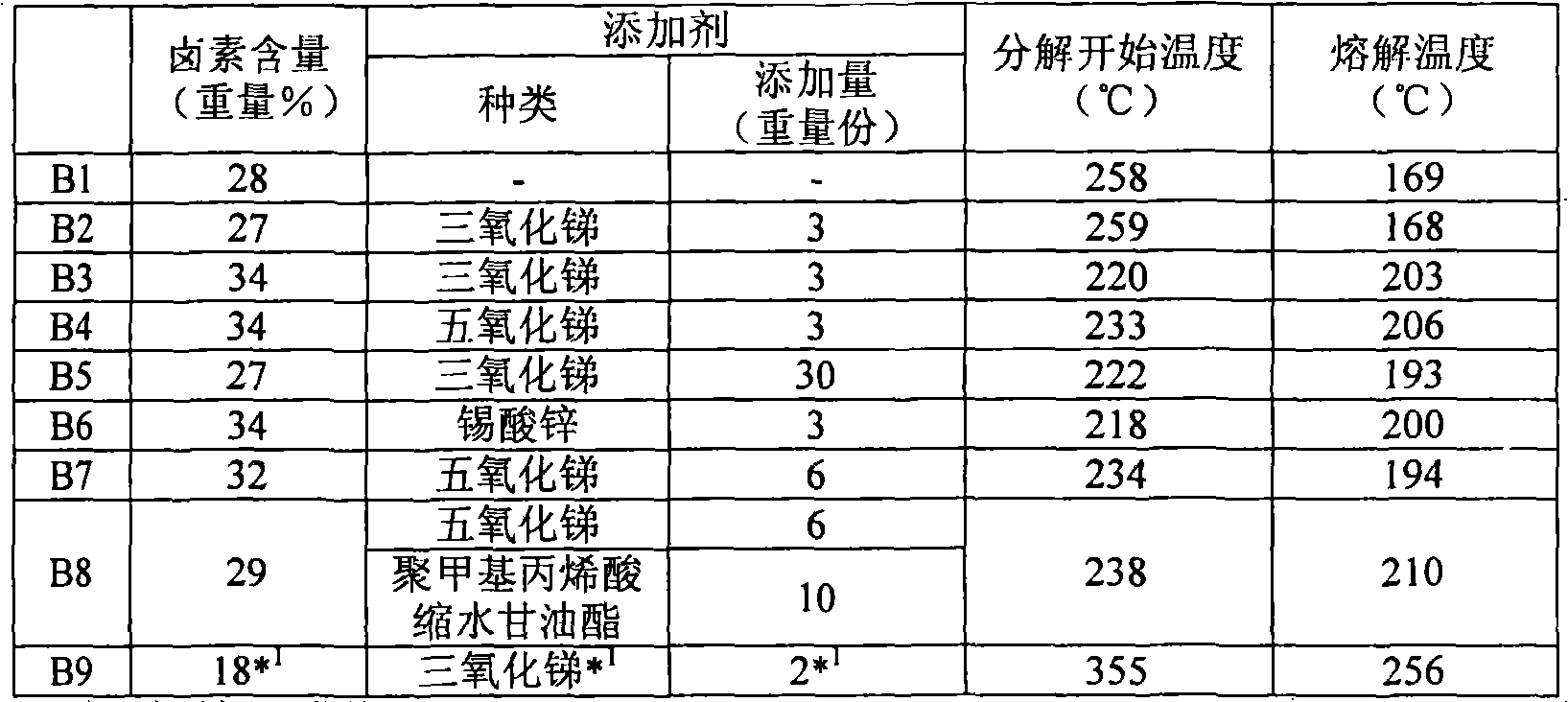

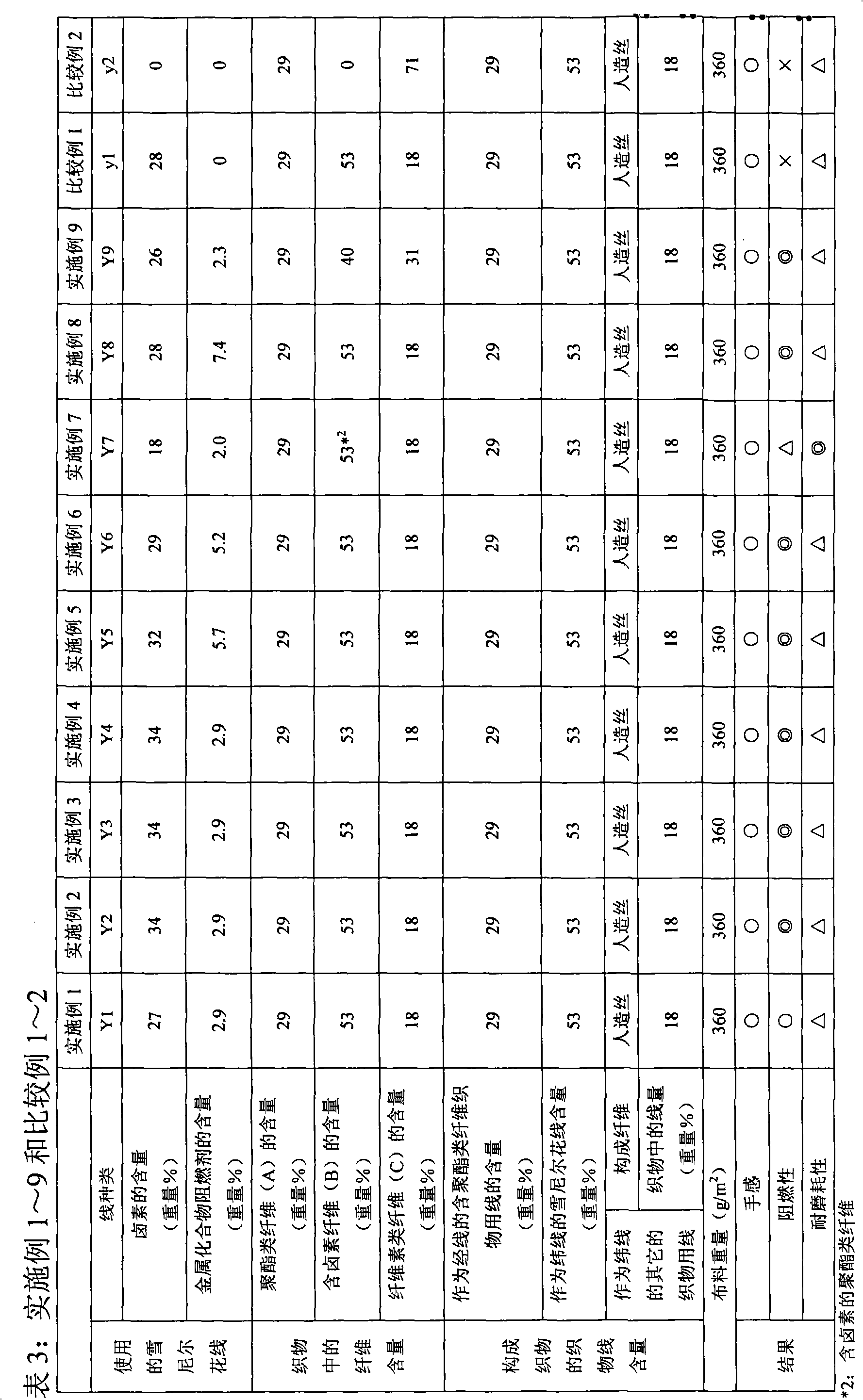

Flame-retardant fiber composite and fabric produced therefrom.

ActiveCN1806071AImprove featuresImprove flame retardant performanceWoven fabricsNon-woven fabricsFiberCellulose

A flame-retardant fiber composite which comprises: 20 to 85 wt.% fibers (A) comprising 100 parts by weight of a polymer containing at least 17 wt.% halogen atoms and 0.5 to 50 parts by weight of an antimony compound; 5 to 80 wt.% heat-resistant fibers (B); 0 to 40 wt.% cellulosic fibers (C); and 0 to 40 wt.% flammable fibers (D). When used in applications such as indoor furniture or beddings, the composite further improves the flame retardancy of materials and enables the materials to be used in fields where higher flame retardancy is required.

Owner:KANEKA CORP

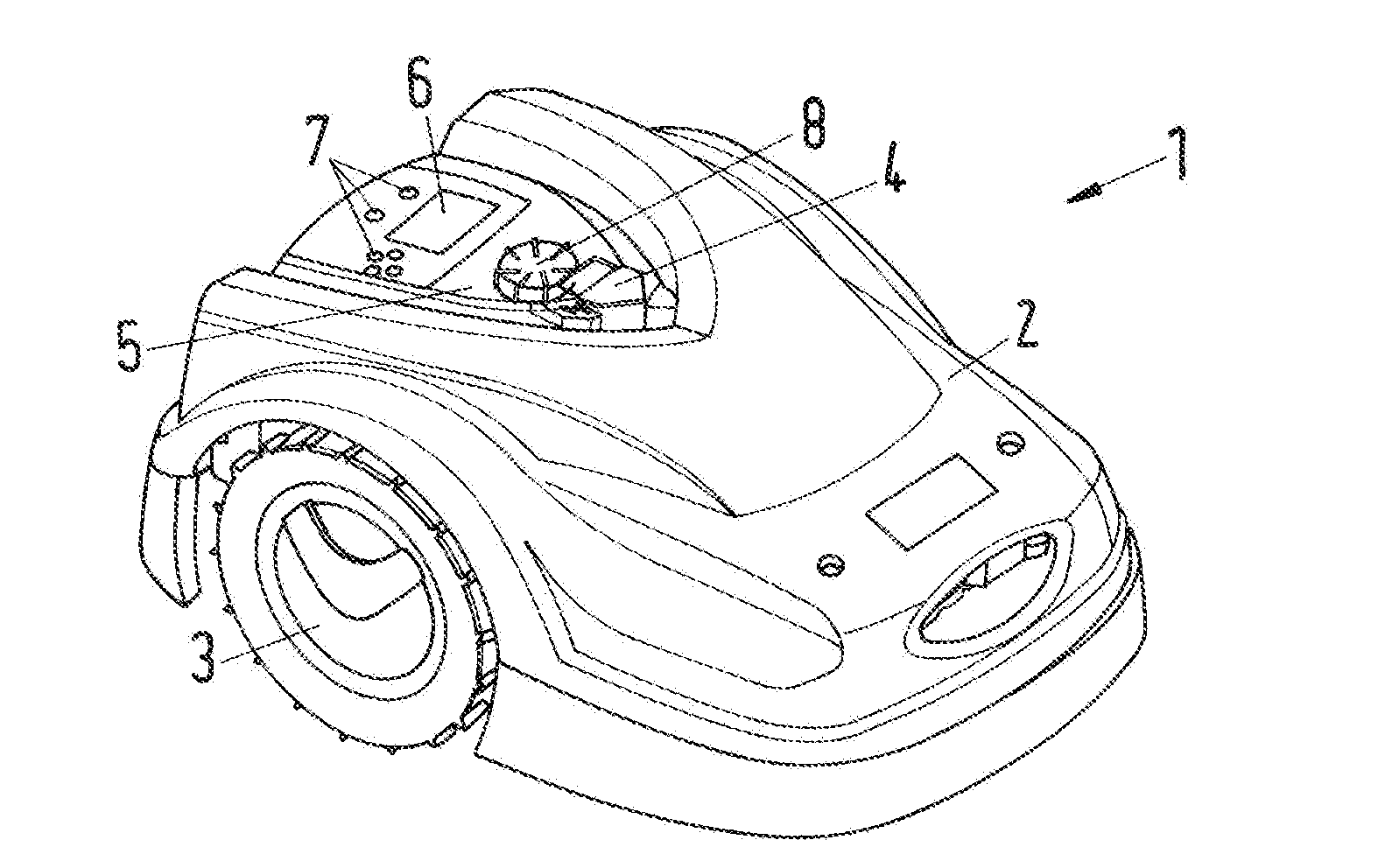

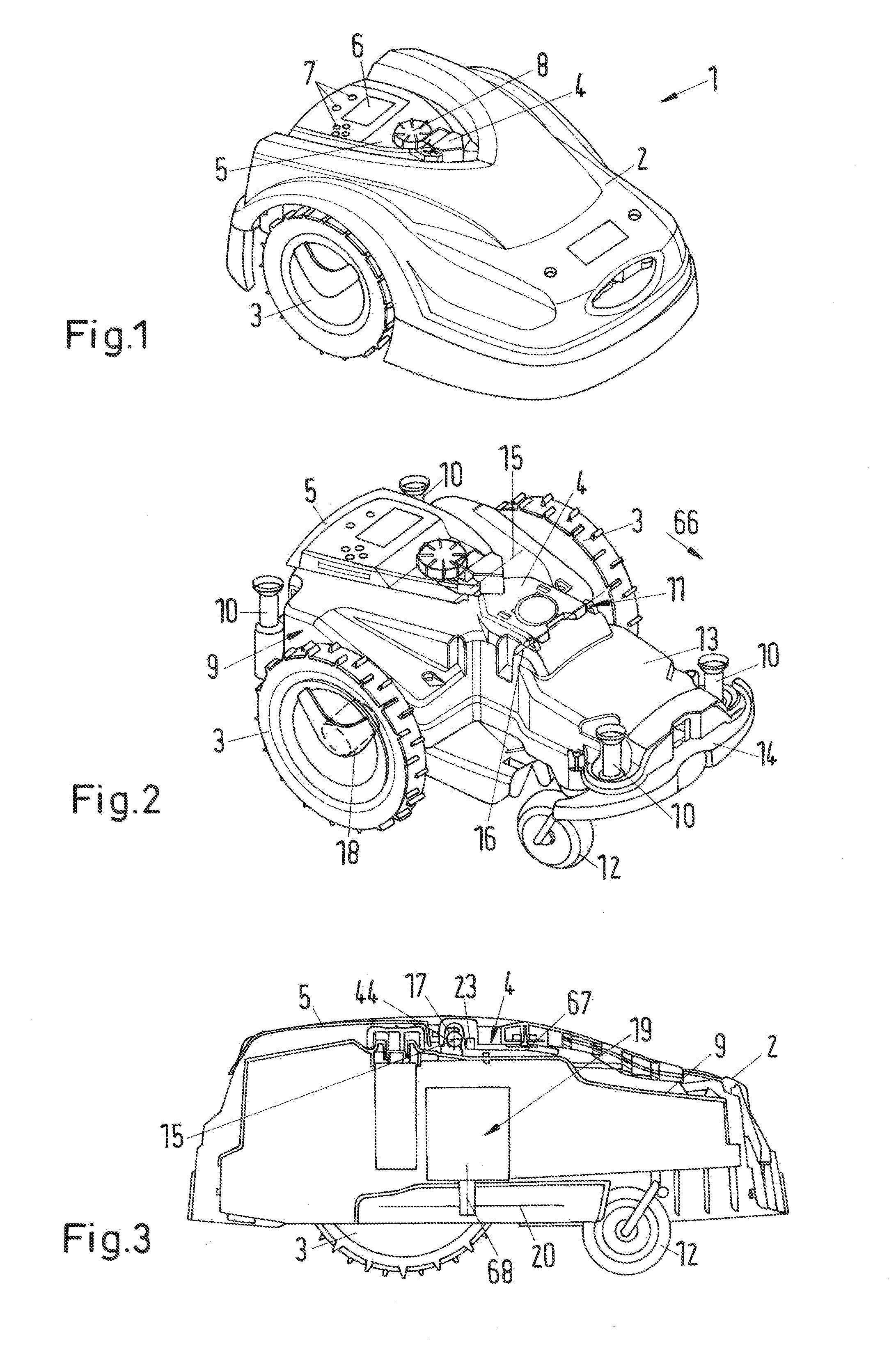

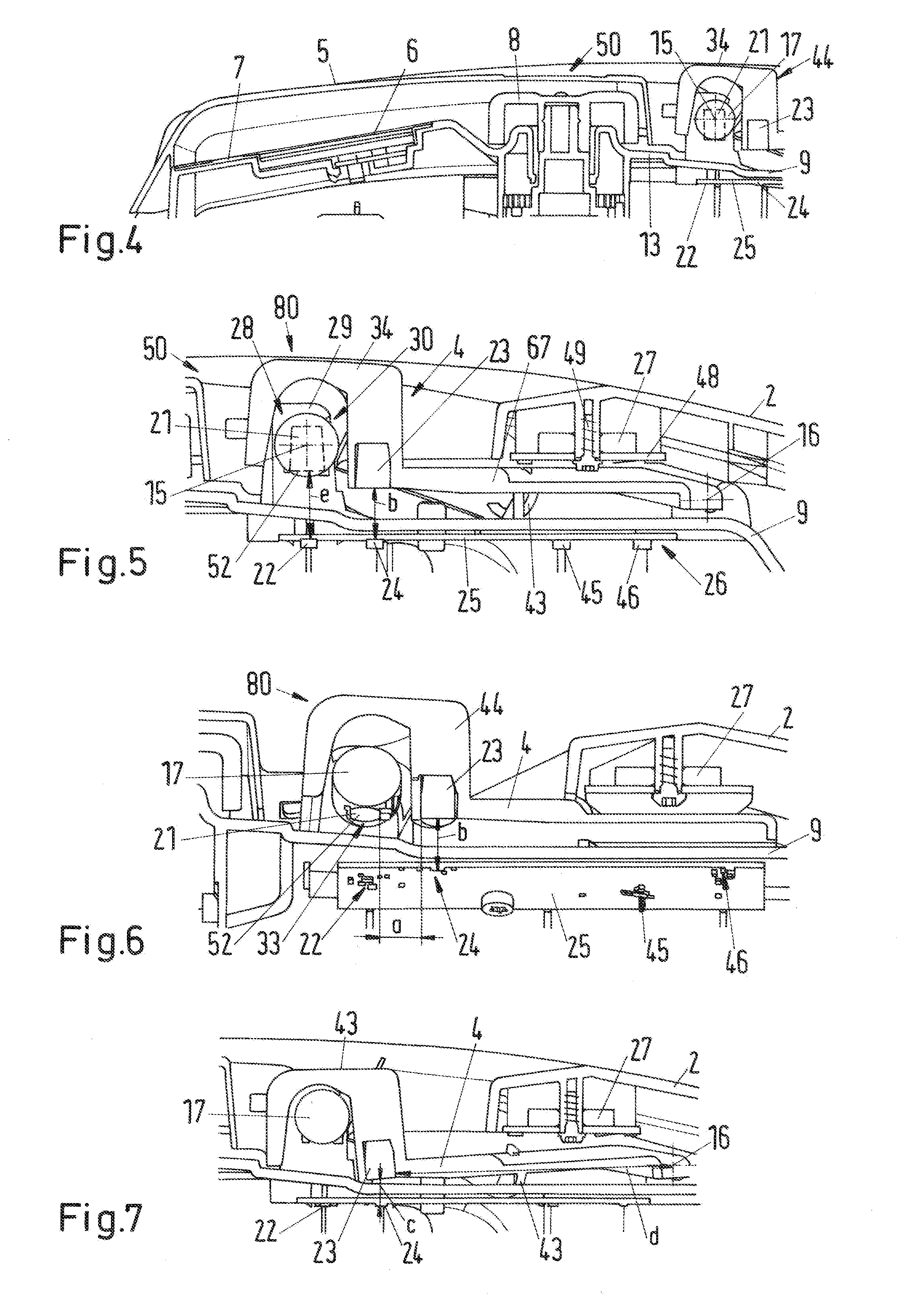

Self-Propelled Working Device

ActiveUS20160081526A1Avoid liftingSimple configurationCarpet cleanersMowersEngineeringMechanical engineering

Owner:ANDREAS STIHL AG & CO KG

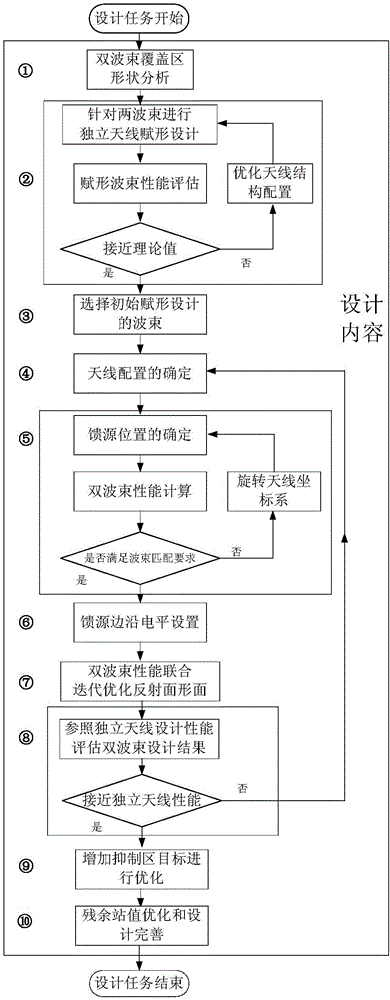

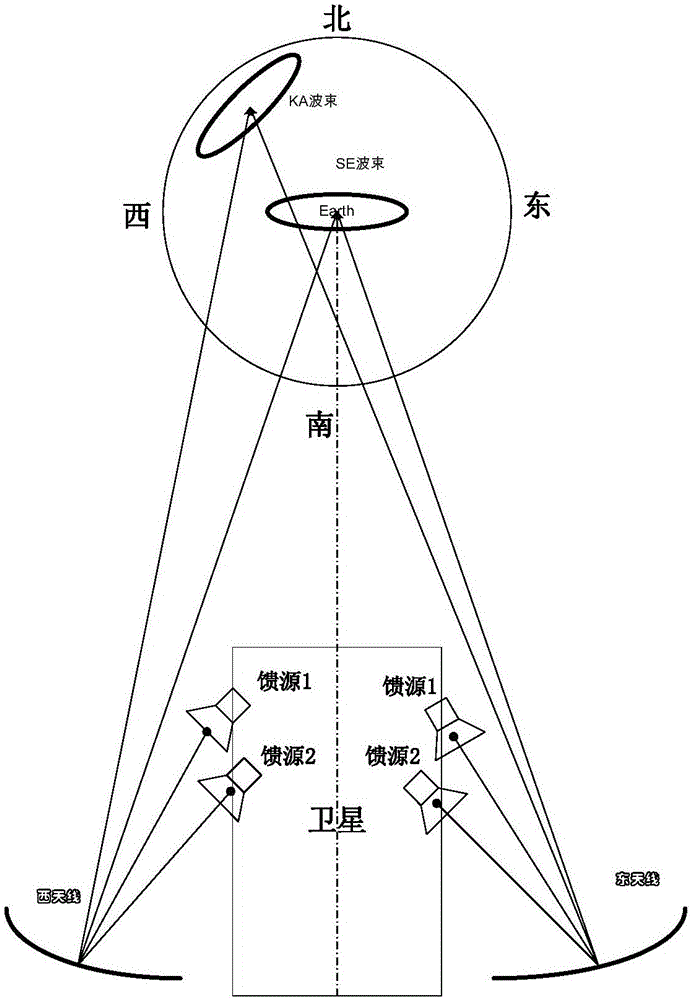

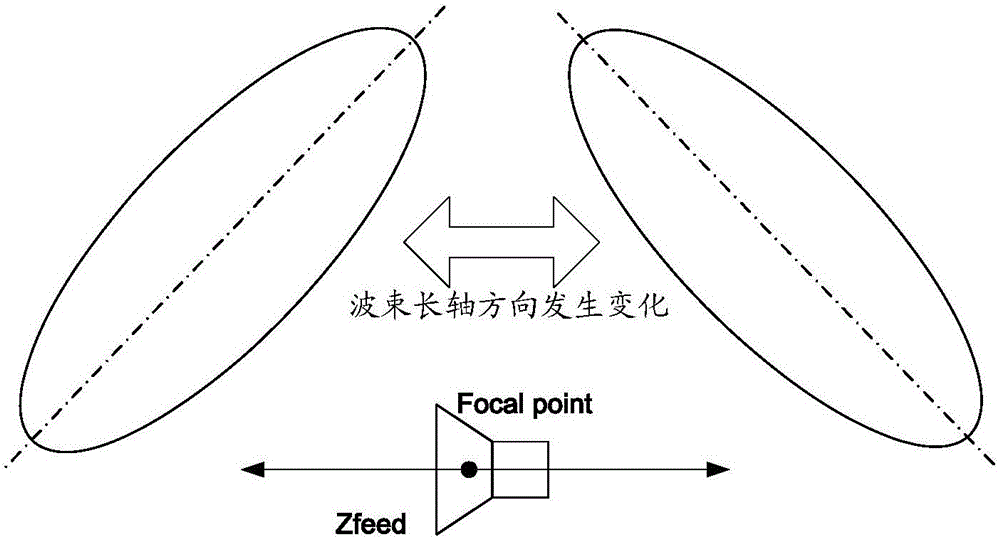

Reflecting surface antenna double-beam forming design method

ActiveCN106450788AConducive to compact designGood compatibilityAntennas earthing switches associationDesign methodsPlane wave

The invention provides a reflecting surface antenna double-beam forming design method. Through creatively introducing a double-beam covering area shape characteristic analyzing step in a designing process, a targeted initial beam acquiring manner and a corresponding antenna structure configuration strategy are made. Based on searching of a reflection plane scattered field focusing point under planar wave excitation according to a conjugate field matching theory, a rotation rule in long axis direction of a longitudinal movement beam of feed sources at two sides of a focusing point is utilized, and wave beam covering matching design is performed. Through feed source position adjustment, axial torsion of the whole reflection surface antenna system is performed, thereby improving beam covering matching property of double beams and performance of a restraining area, and furthermore improving gain of a double-beam coverage area after optimization. According to the reflecting surface antenna double-beam forming design method, according to a wave beam shape characteristic relationship, antenna layout and the like, and design principles such as a wave beam shape is adjusted according to the feed source position. A design order, a parameter selecting principle and technical details in double-beam design are described, and gain improvement of the double-beam coverage area is realized.

Owner:XIAN INSTITUE OF SPACE RADIO TECH

Method for preparing polyolefin-based complex fiber through modified nano-particles

ActiveCN103436976AHigh grafting rateAvoid steric hindranceMonocomponent polyolefin artificial filamentArtifical filament manufactureFiberPolymer science

The invention relates to a method for preparing polyolefin-based complex fiber through modified nano-particles. The method comprises the following steps of: implementing hydroxylation to nano-particles, enabling the nano-particles to react with a prepared reagent with a function of initiating living radical polymerization of a monomer, implementing photo-initiated living radical polymerization grafting to the monomer on the surfaces of the nano-particles to form nano-particles covered by multiple layers of organic casings, and mixing the nano-particles with polyolefin to obtain the polyolefin-based complex fiber. The method, in comparison with the prior art, is convenient and simple to operate, and simultaneously, the method can be used for effectively controlling grafting generations of the monomer; the method is high in grafting rate, and molecular chains grated to the surfaces of the nano-particles are narrow in molecular weight distribution, so that compatibility of the nano-particles with the polyolefin as well as dispersion of the nano-particles in the polyolefin are greatly improved; the polyolefin-based complex fiber which is enhanced in mechanical property can be prepared with a low additive amount.

Owner:SHANGHAI RES INST OF CHEM IND

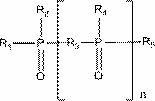

Liquid halogen-free phosphorus-nitrogen collaboration flame retardant and preparation method thereof

InactiveCN102532599AEasy to makeLow costInorganic compound additionWood impregnation detailsEndcappingPolymer science

The invention discloses a synthesizing method of a liquid halogen-free P-N collaboration flame retardant. A phosphorous long-chain intermediate is prepared through a condensation reaction between diamine (glycol and urea) and phosphorus source materials, then alcohol (amine and urea) are utilized to carry out end sealing, and accordingly a series of liquid halogen-free P-N collaboration flame retardants with good flame-retardant performance are synthesized. The flame retardant prepared by the method not only is low in price, low in using quantity and good in flame-retardant effect and has small influence on mechanical performance of a material, but also avoids being precipitated when being added into the material. The flame retardant can be widely applied to materials including plastics, foam materials, wood, paper and the like, has remarkable social benefits and industrial application value, and is suitable for large-scale popularization and application.

Owner:QINGHAI NORMAL UNIV +1

Decorative sheet and decorative molded article

InactiveCN101712223AGood flexibilityImprove resistance to damageSynthetic resin layered productsPaper/cardboard layered productsPolyurethane adhesivePolyethylene terephthalate

Owner:TOYODA GOSEI CO LTD

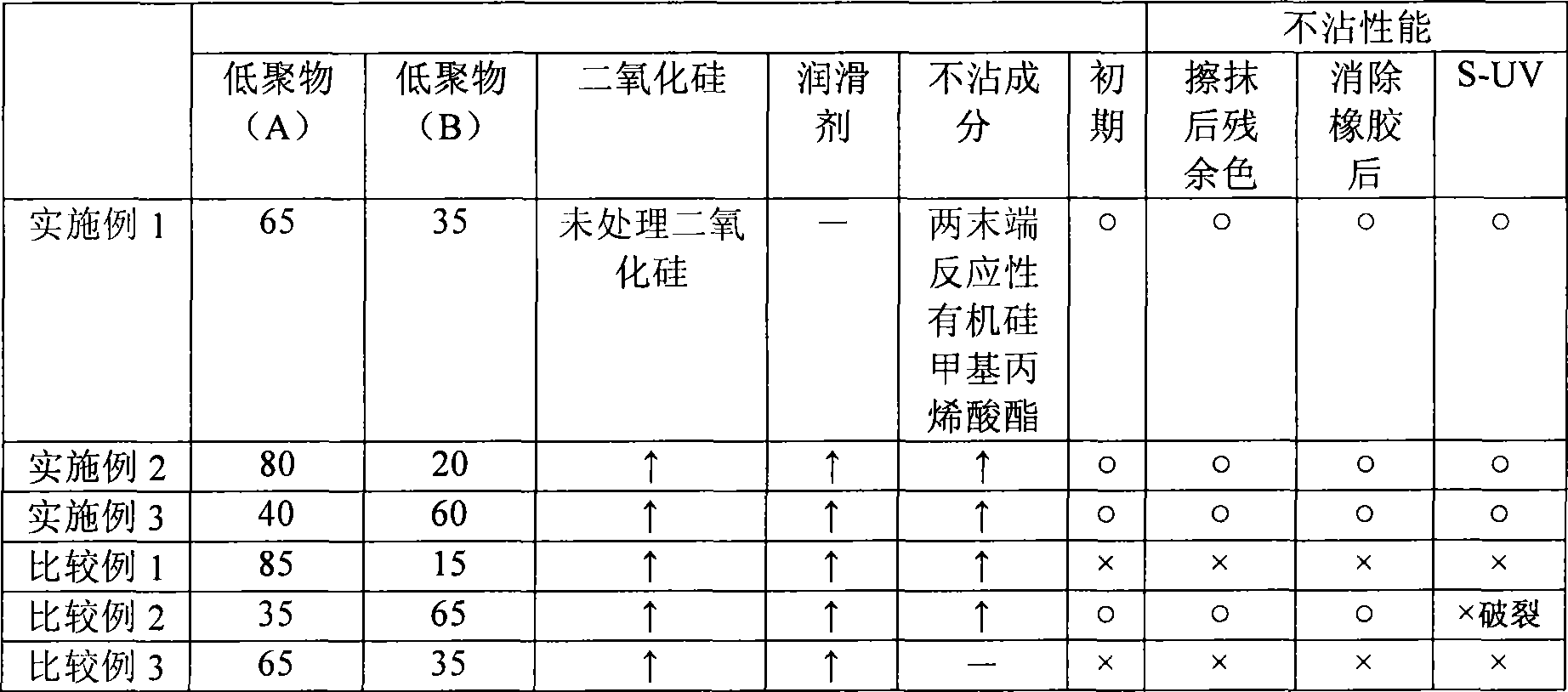

Solvent-free urethane composition

ActiveCN1894299AReduce loadHigh hardnessPolyureas/polyurethane adhesivesPolyurea/polyurethane coatingsPolyolSolvent free

A solvent-free composition is prepared, which is a composition comprising a polyol component (A) and a polyisocyanate component (B), wherein the polyol component (A) is composed of a low-molecular-weight polyol (A1) with a molecular weight of 350 or less. The viscosity of the aforementioned low-molecular polyol (A1) may be 500 mPa·s or less at 25°C. The aforementioned low-molecular polyol (A1) may be, for example, C2-6 alkylene glycol or the like. In addition, the polyol component (A) may be composed of a low-molecular polyol (A1) and a polymer polyol (A2) as a diluent. The aforementioned polyisocyanate component (B) may be a modified product or a derivative of polyisocyanate (for example, a multimer of diisocyanate, etc.). The aforementioned solvent-free composition may further contain an epoxy group-containing compound (aliphatic diol glycidyl ether, aliphatic polyhydric alcohol glycidyl ether having a hydroxyl group, etc.) (C) that may have a hydroxyl group. Such a solvent-free composition has a small load on the environment, has excellent coating film properties, and has high application efficiency.

Owner:日本硅石株式会社

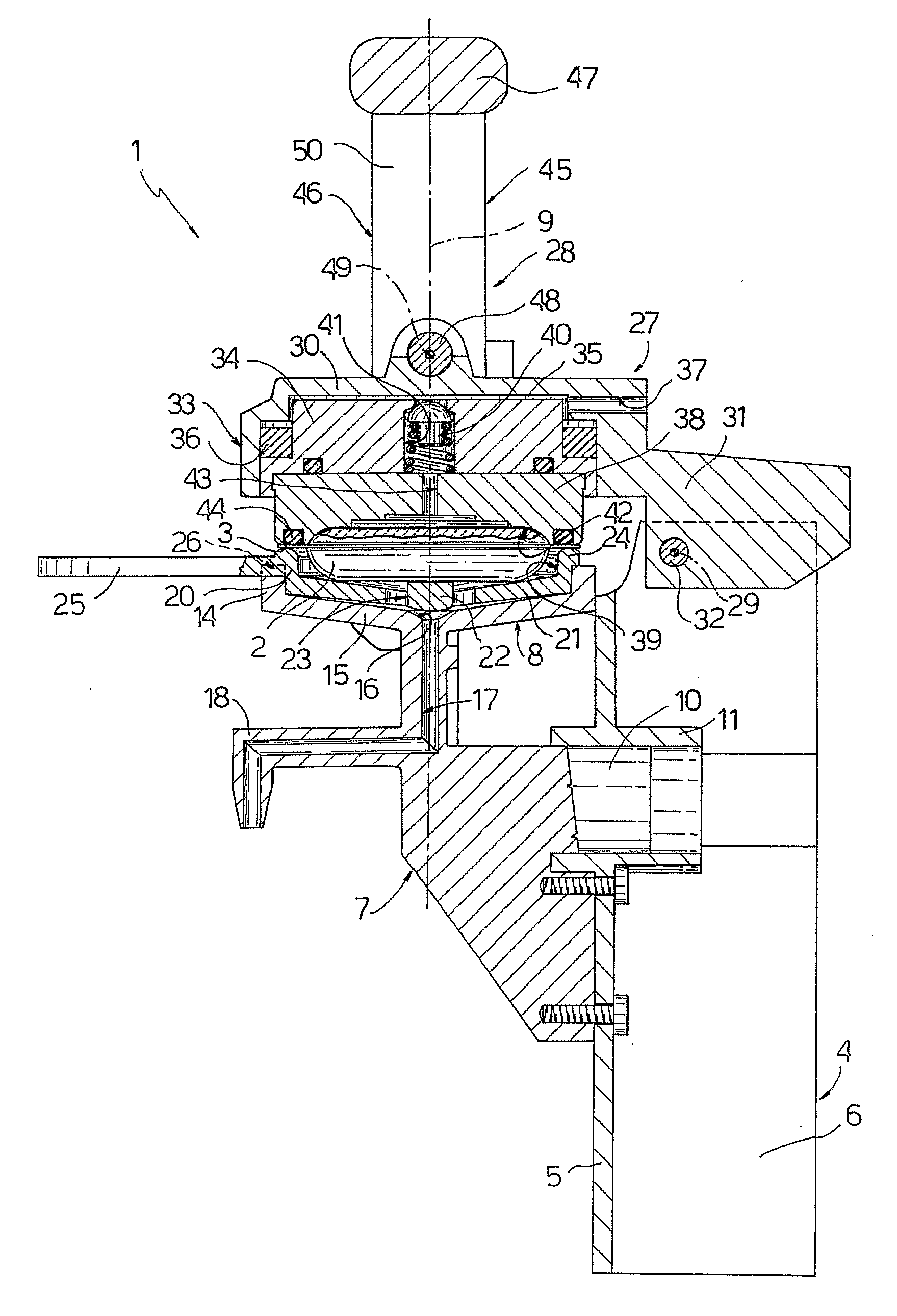

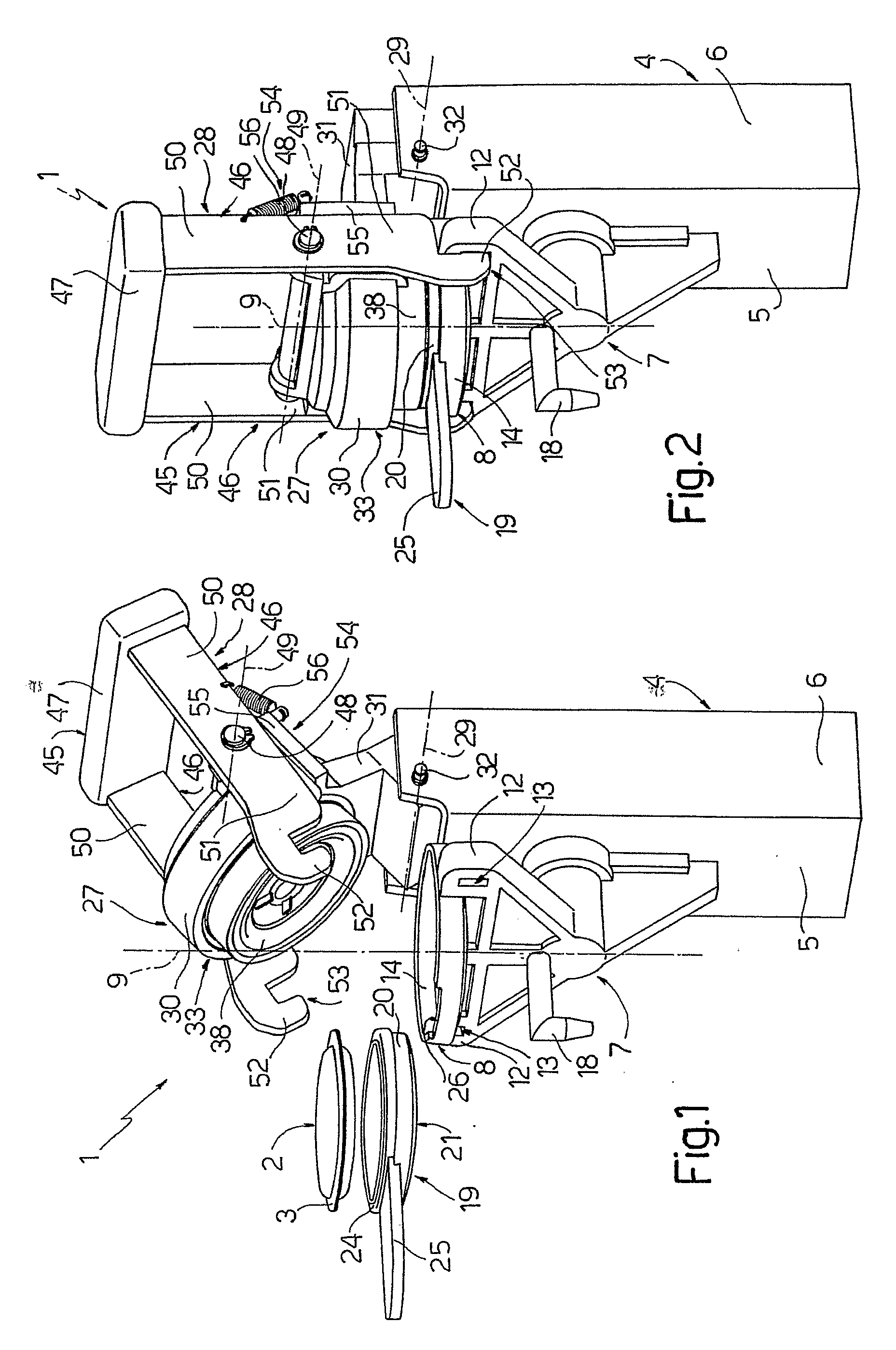

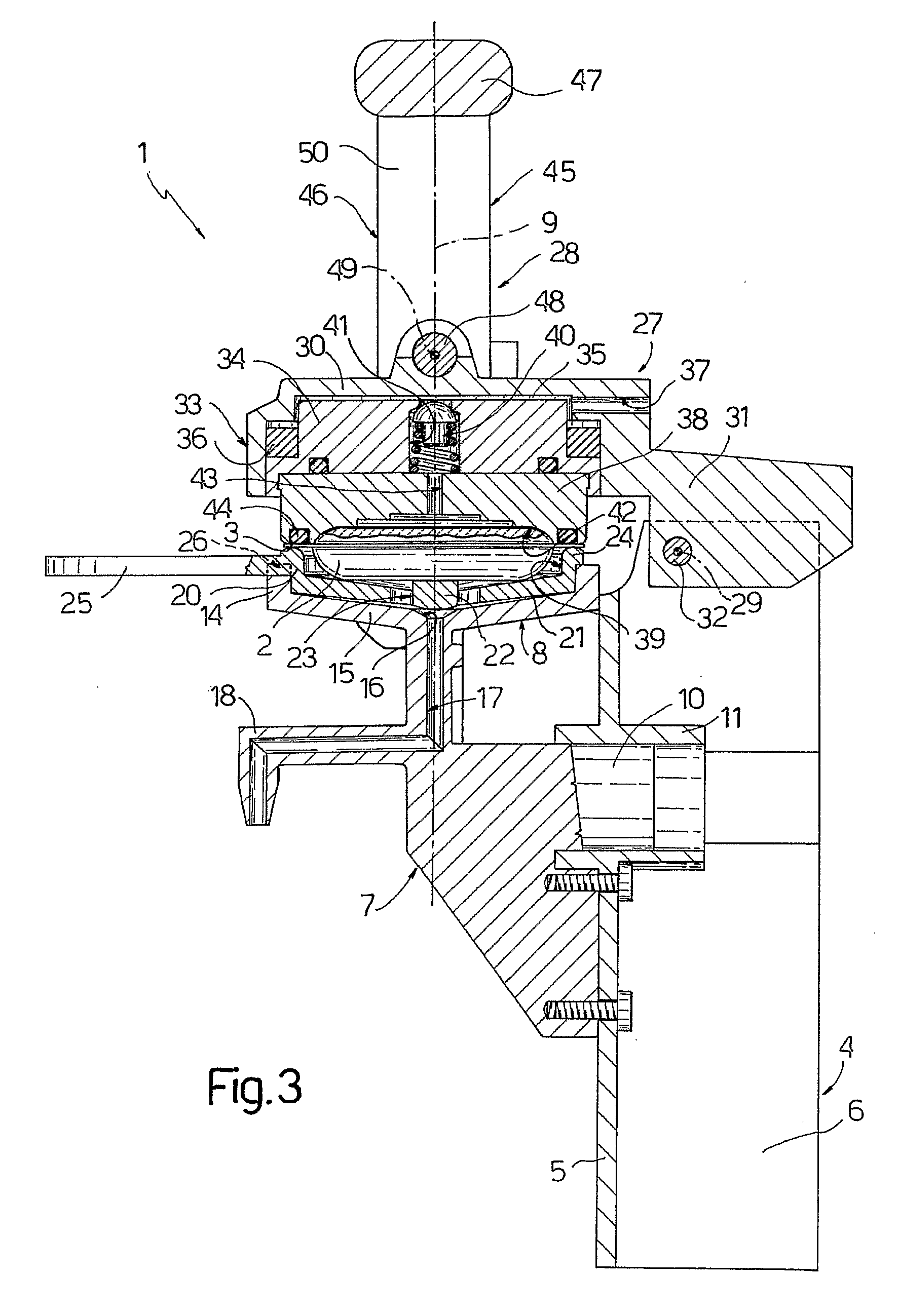

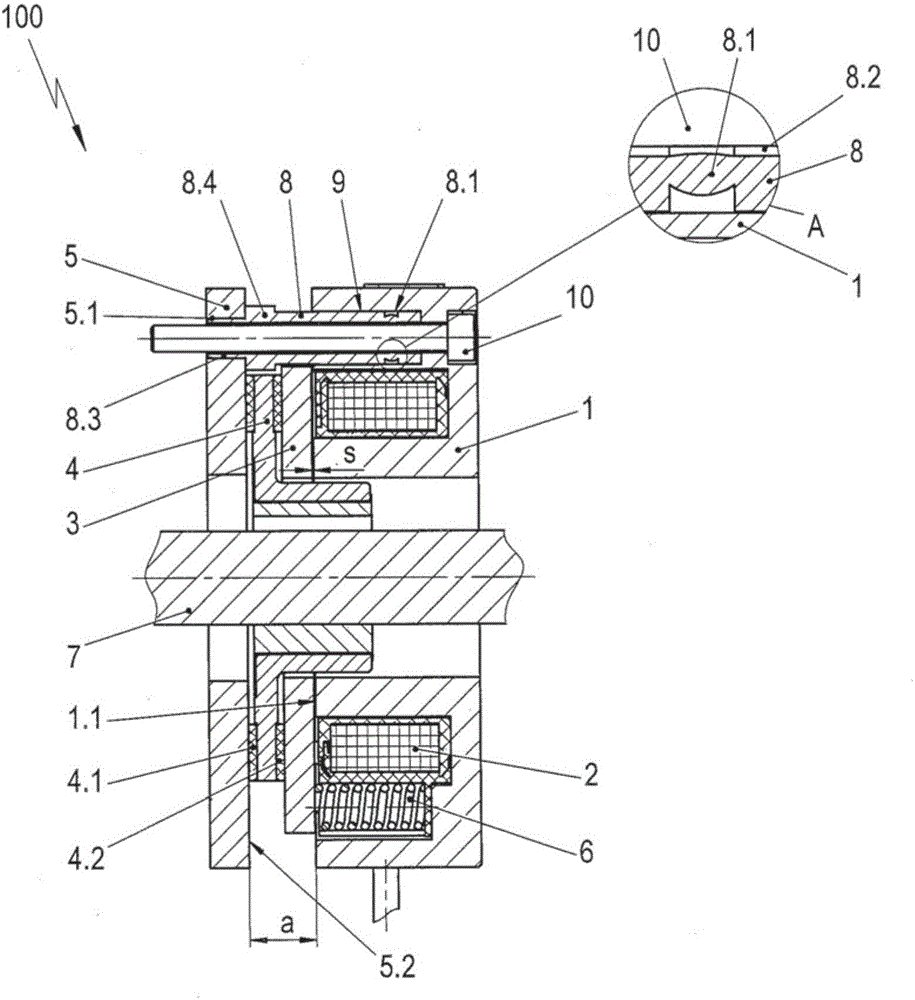

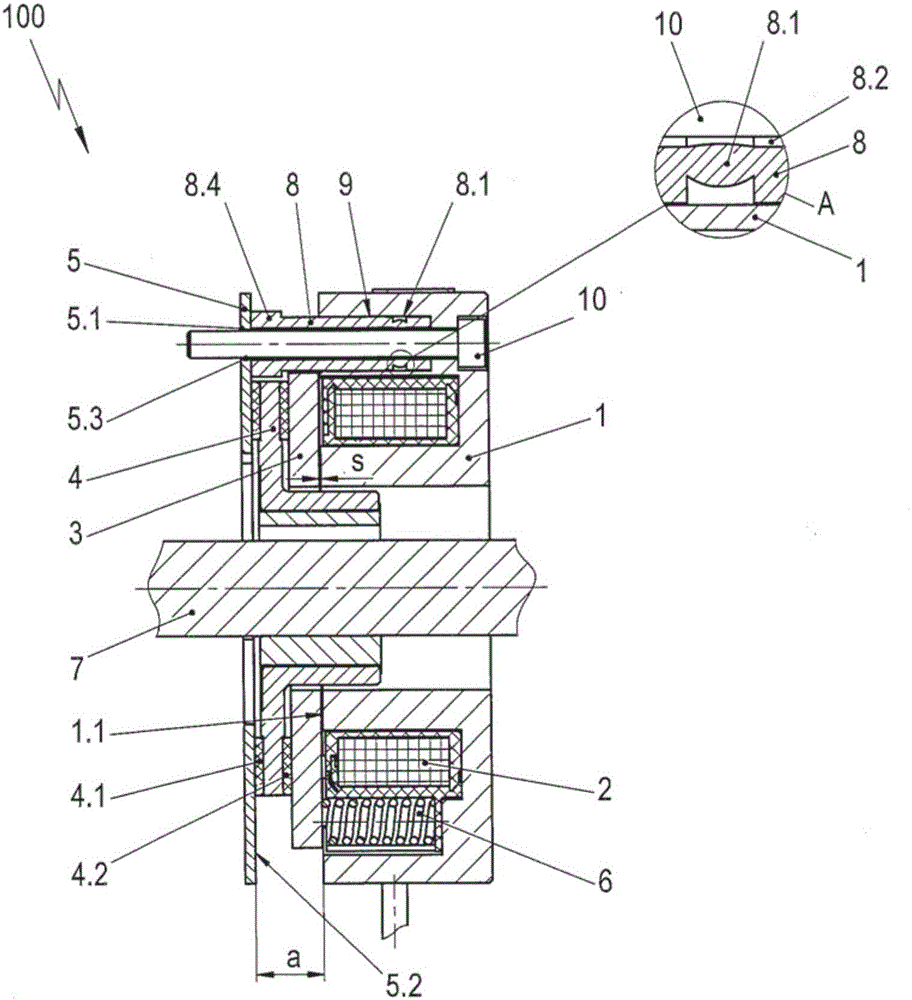

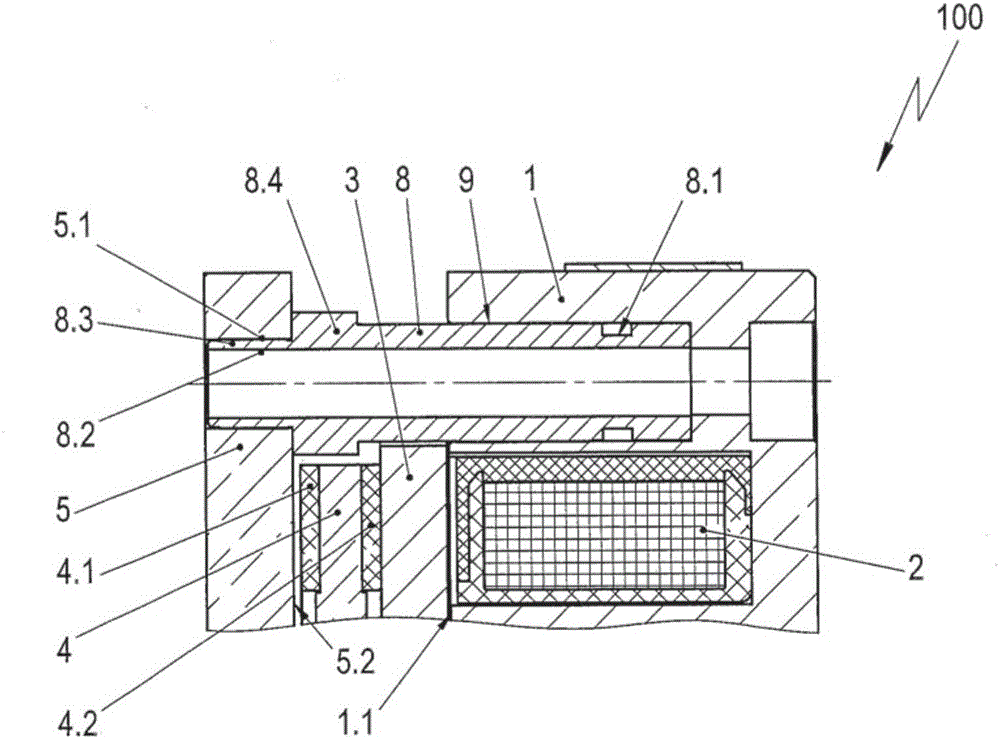

Electromagnetically actuatable spring pressure brake and method for the production thereof

ActiveCN105899835AAccurate settingLow costSelf acting brakesBrake actuating mechanismsBrake torqueSpring force

The invention relates to an electromagnetically actuatable spring pressure brake (100), comprising: a magnet housing (1) having a coil (2); an armature (3), which is arranged coaxial to the coil (2) and in such a way that the armature can be moved axially with respect to a shaft (7) to be braked; a friction element (5), which is spaced in a rotationally fixed manner with respect to the magnet housing (1) by means of at least one bolt-shaped connecting element (8) and which has a friction surface (5.1); a friction disk (4), which is arranged between the armature (3) and the friction element (5) and which is arranged in a rotationally fixed manner on the shaft (7) to be braked; and at least one compression spring (6), which applies pressure to the armature (3) and the spring force of which causes a braking torque on the shaft (7) to be braked in the currentless state of the coil (2) by the pressing of the friction disk (4) against the armature (3) and against the friction surface (5.1) of the friction element (5). According to the invention, for the adjustment of the distance (a) between the friction element (5) and the magnet housing (1), the at least one bolt-shaped connecting element (8) is designed having a compression zone (8.1) that can be compressed in an axial direction of the connecting element. According to alternative solutions, the compression zone can also be arranged in the region of a blind hole (9) accommodating the at least one connecting element (8) or in an accommodating opening (5.1) of a brake element (5) designed as a brake plate. The invention further relates to a method for producing the spring pressure brake (100) according to the invention.

Owner:KENDRION VILLINGEN GMBH

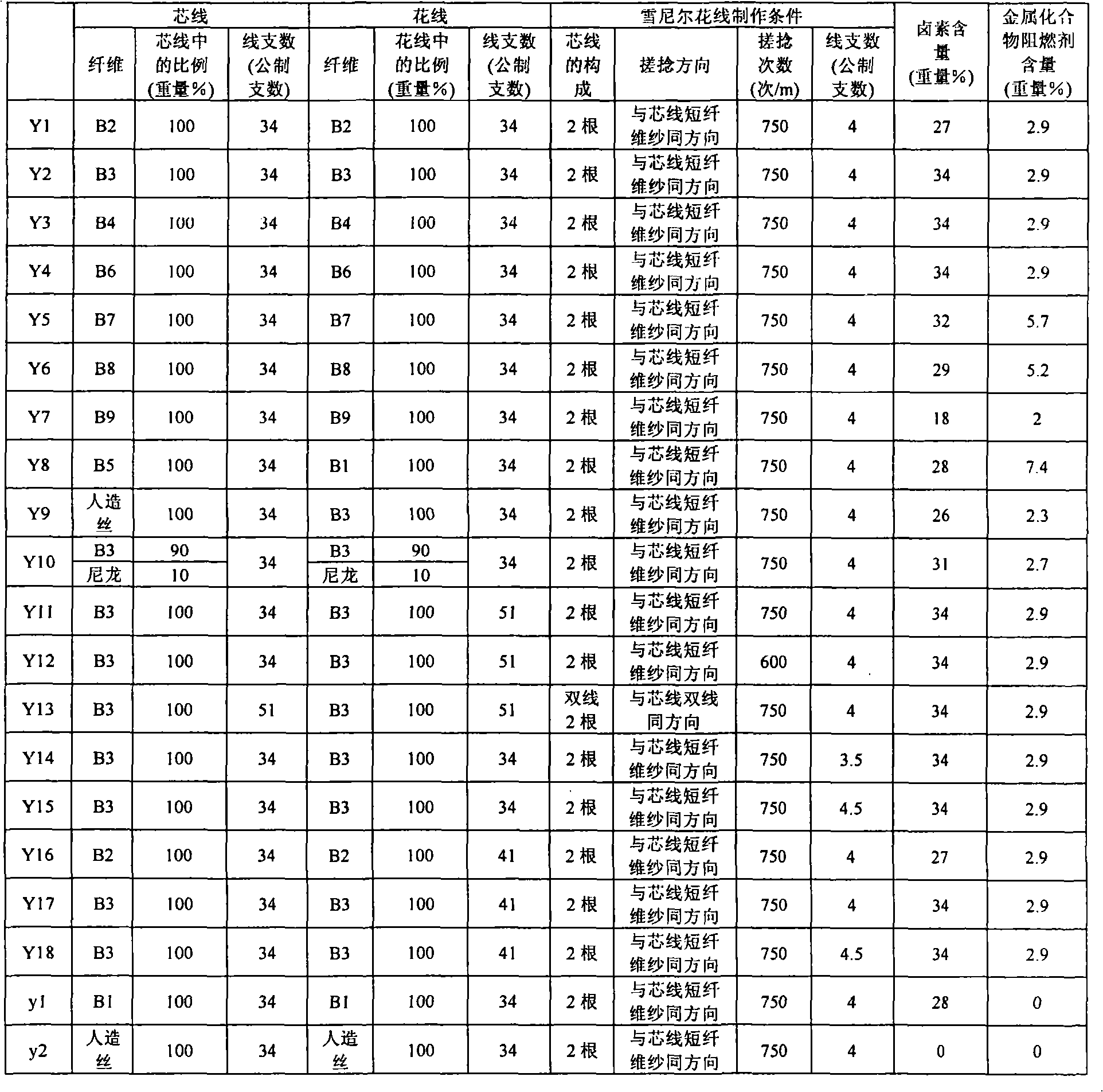

Flameproof union fabric for chair upholstery

A union fabric comprising 6 to 60% by weight of a polyester fiber (A), 35 to 85% by weight of a halogen-containing fiber (B), and 5 to 55% by weight of a cellulose fiber (C) in which fabric the warp comprises weaving yarn containing the polyester fiber and the weft comprises flameproof chenille yarn and other weaving yarn, with the chenille yarn containing 10 to 70% by weight of halogen and 1 to 35% by weight of a flame retardant consisting of a metal compound, and in which fabric the content of the warp-constituting weaving yarn containing the polyester fiber is 20 to 40% by weight and those of the weft-constituting flameproof chenille yarn and the weft-constituting other weaving yarn are 35 to 70% by weight and 10 to 45% by weight respectively. This union fabric is excellent in design, texture, comfortableness in use, and abrasion resistance and exhibits high flameproofness, in spite of its being one produced at a low cost.

Owner:KANEKA CORP

Decorative sheet

InactiveCN101519018APrevent seepageImprove pollutionSynthetic resin layered productsSpecial ornamental structuresAntistatic agentOligomer

Owner:DAI NIPPON PRINTING CO LTD

Quick bonding repair method of ultraviolet-curing composite material

InactiveCN104371488AImprove curing efficiencyHigh tensile strengthNon-macromolecular adhesive additivesEpoxy resin adhesivesUltraviolet lightsTransmittance

The invention provides a quick bonding repair method of an ultraviolet-curing composite material. An ultraviolet-curing resin composition with quick self-propagating curing characteristic, which is used as a base material, is mixed with a fiber reinforcing material to obtain a composite material repair patch. The method comprises the following steps: 1) carrying out surface treatment on a damage region in need of bonding repair; 2) laying a composite material layer on the treated damaged region surface, wherein the thickness and direction of the composite material layer are determined according to the actual demands for repair; and 3) irradiating the composite material layer by an ultraviolet light source to form the composite material repair patch, thereby completing the bonding repair on the damage structure. The composite material repair patch has high designability, can be cured only by single irradiation in the preparation process, and has the advantages of high curing efficiency, favorable tensile strength, high repair efficiency and the like; the curing is not influenced by the number of the fiber layers and the light transmittance of the enhanced phase of the resin-base composite material; and thus, the method is especially suitable for emergency repair operation.

Owner:青岛煊龙机电科技有限公司

Black-plated steel sheet

ActiveCN104245997AStrong designImprove retentionHot-dipping/immersion processesSolid state diffusion coatingBrightness perceptionBlack oxide

A black-plated steel sheet has a Zn-plating layer containing molten Al and Mg, containing Al in the amount of 1.0-22.0 mass%, containing Mg in the amount of 1.3-10.0 mass%, and having a Zn black oxide distributed in a lamella pattern in the plating layer. The Zn black oxide is a Zn oxide derived from a Zn2Mg phase. The brightness of the surface of the Zn-plating layer containing the molten Al and Mg has an L* value of 60 or less.

Owner:NISSHIN STEEL CO LTD

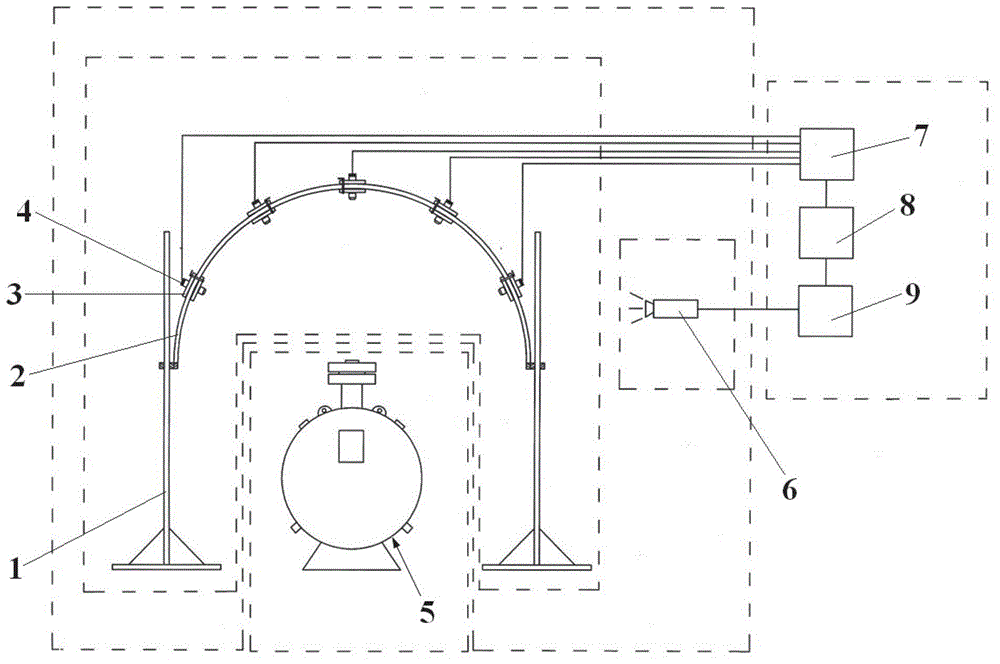

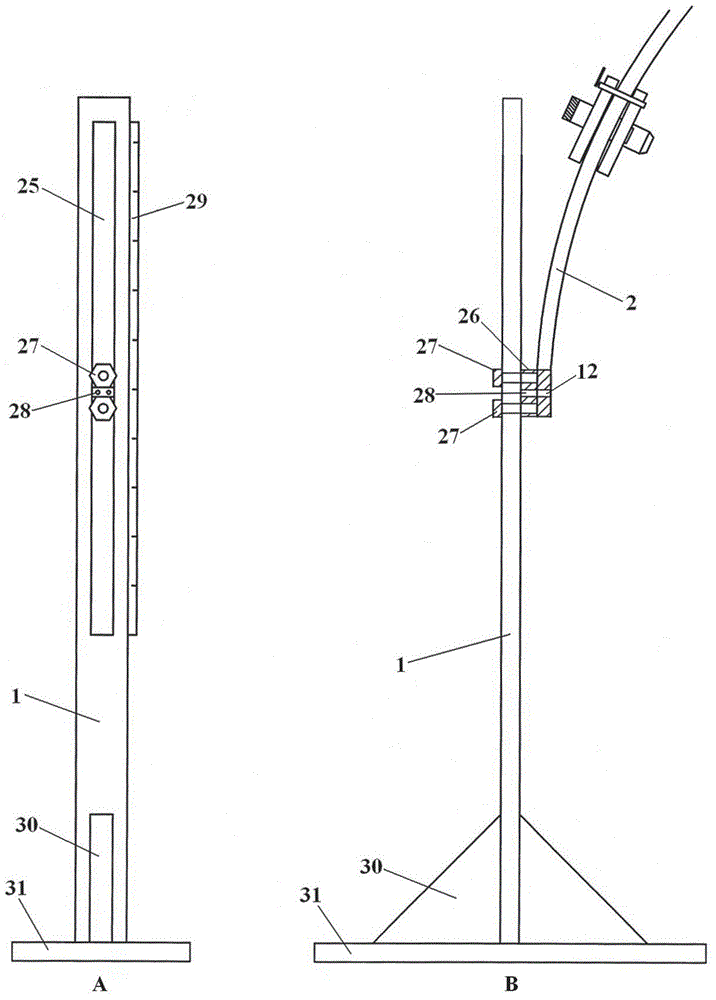

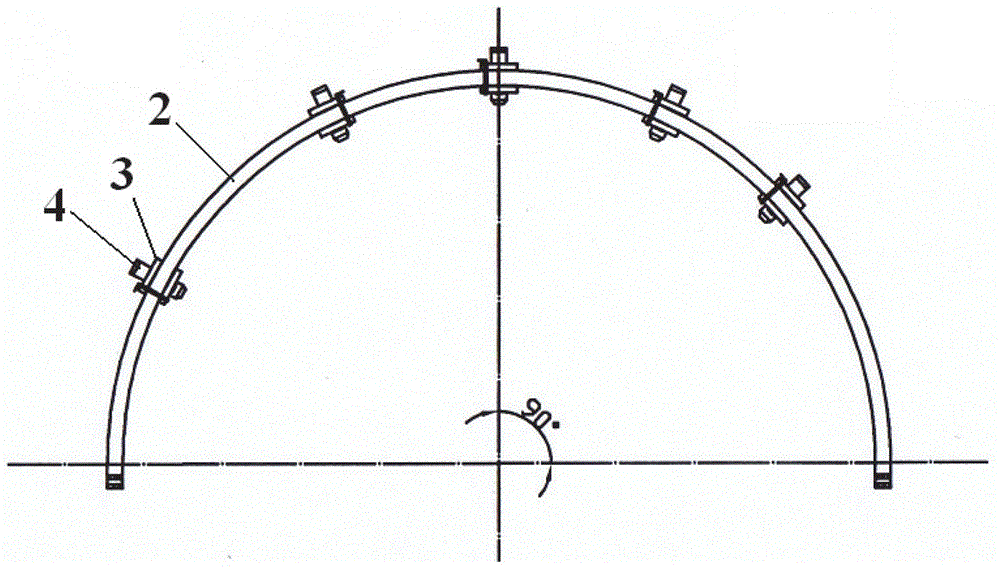

Combustible gas explosion venting harm effect testing device and analytical method

ActiveCN102879428AStrong designComprehensive measurementMaterial exposibilityShock waveCombustible gas

The invention relates to a combustible gas explosion venting harm effect testing device and an analytical method. The device comprises a harm effect parameter collecting device, an explosion device and a data collecting device. Disadvantages of shortages of existing combustible gas explosion venting harm effect research devices and methods are overcome, the combustible gas explosion venting harm effect testing device is reasonable in design, convenient to operate and capable of measuring corresponding parameters of pressure at any position of an external space of a pressure container and jet flames after explosion venting of combustible gas comprehensively and accurately, and also the harm effect analytical method is built. The device and the method can be widely used in dangerousness analyses such as shock waves and jet flames of petrochemical industry production devices after explosion venting of the combustible gas under an actual working condition, and have remarkable effects on anti-explosion safety design, personnel protection and the like.

Owner:NANJING UNIV OF TECH

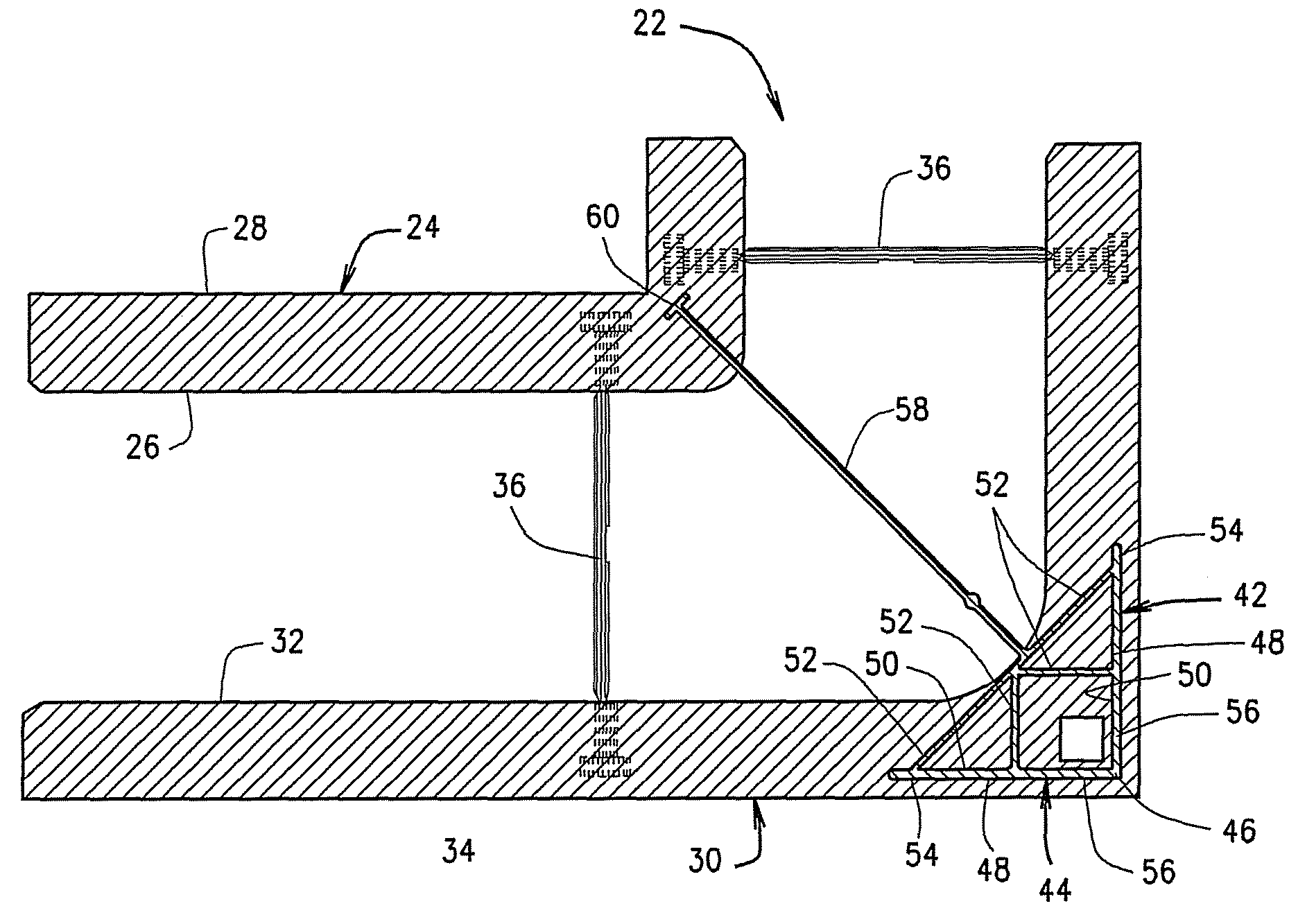

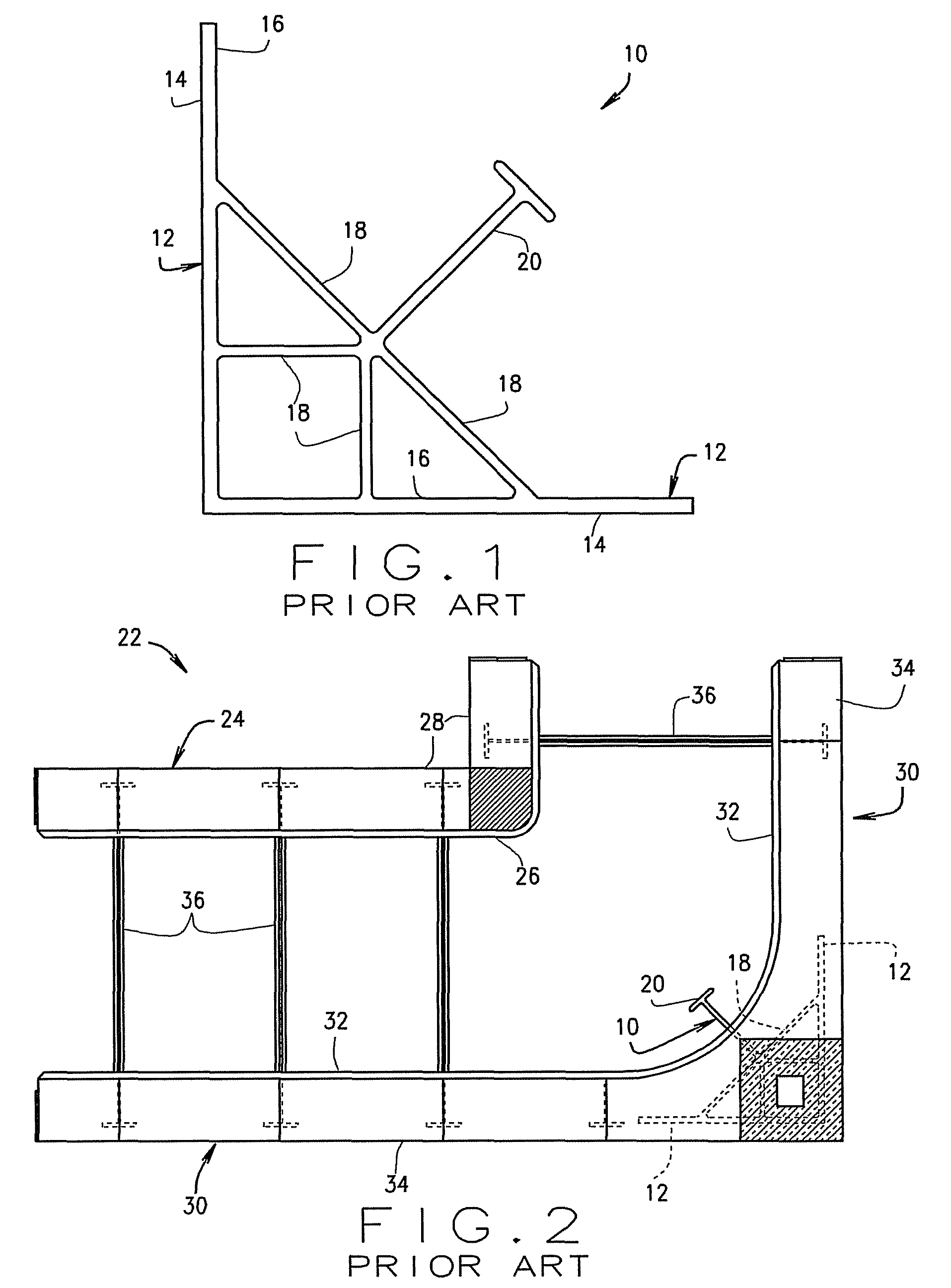

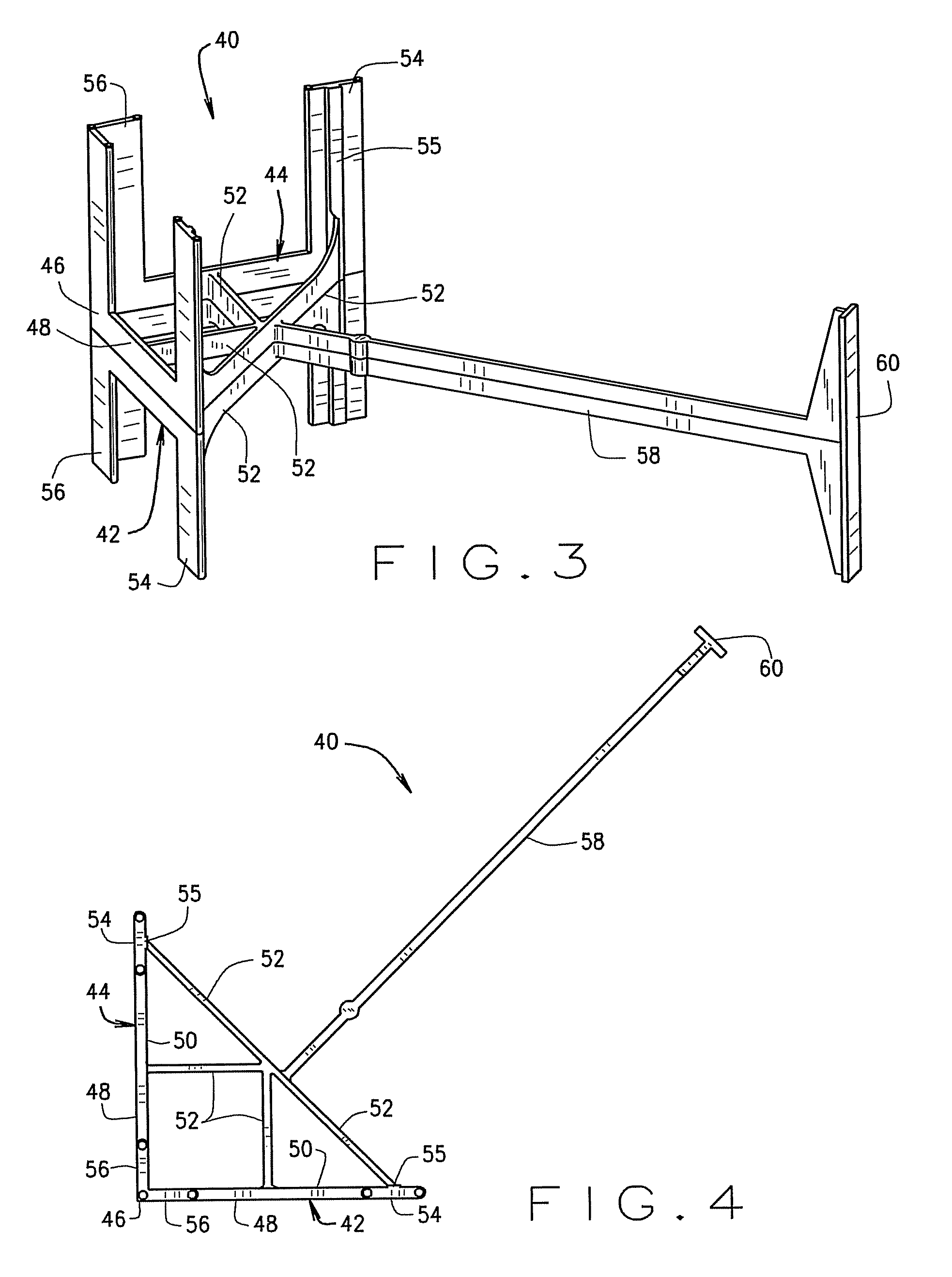

Corner tie bracket for use with insulated concrete form systems

Owner:AIRLITE PLASTICS

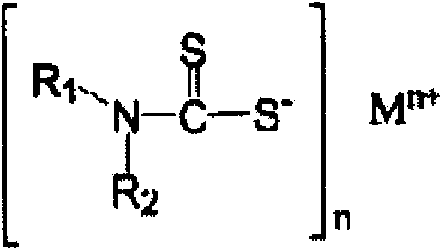

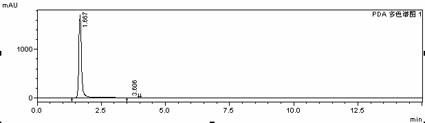

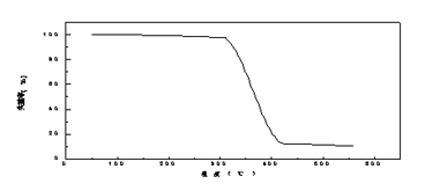

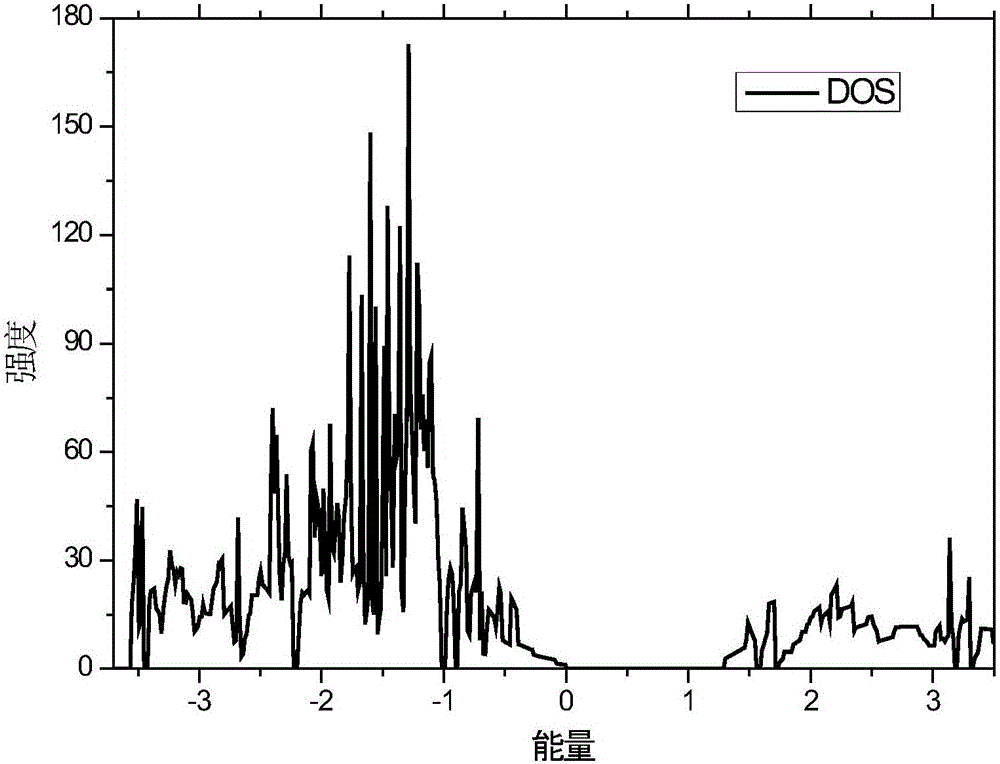

Method for designing organic metal surface battery material

InactiveCN106021732AReduce R&D cycle and costStrong designDesign optimisation/simulationSpecial data processing applicationsCell materialElectronic states

The invention discloses a method for designing an organic metal surface battery material. Material Studio modeling software is used for establishing a model of an organic metal solar battery surface material, Vasp software is used for calculating the electronic structure property and the optical property of the surface material, and drawing tool origin software is used and combined with output files DOSCAR, EIGENVAL and OUTCAR to make graphs including the density of electronic states, the energy band structure, the absorption spectrum and the like of the surface material, clear the internal photoelectric conversion mechanism of the surface material and analyze and determine the characteristics of the optical property of the surface material so as to design the high-efficiency organic metal solar battery surface material. Through the method that the internal photoelectric conversion mechanism and the optical property of the organic metal solar battery surface material are calculated to design the high-efficiency solar energy battery surface material, a theoretical method is provided for the production design of the battery, and development periods and cost are effectively shortened and reduced.

Owner:SOUTHEAST UNIV

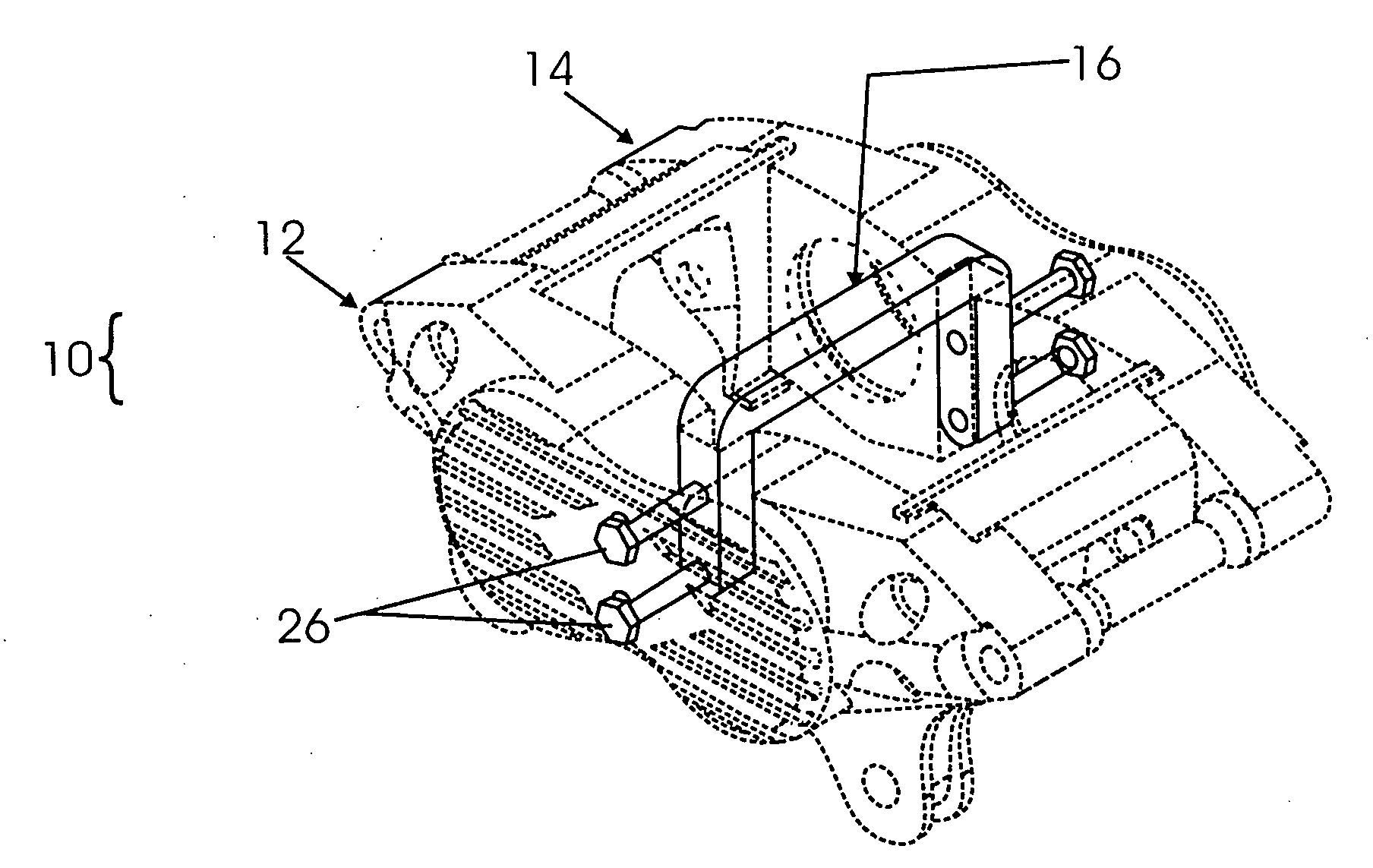

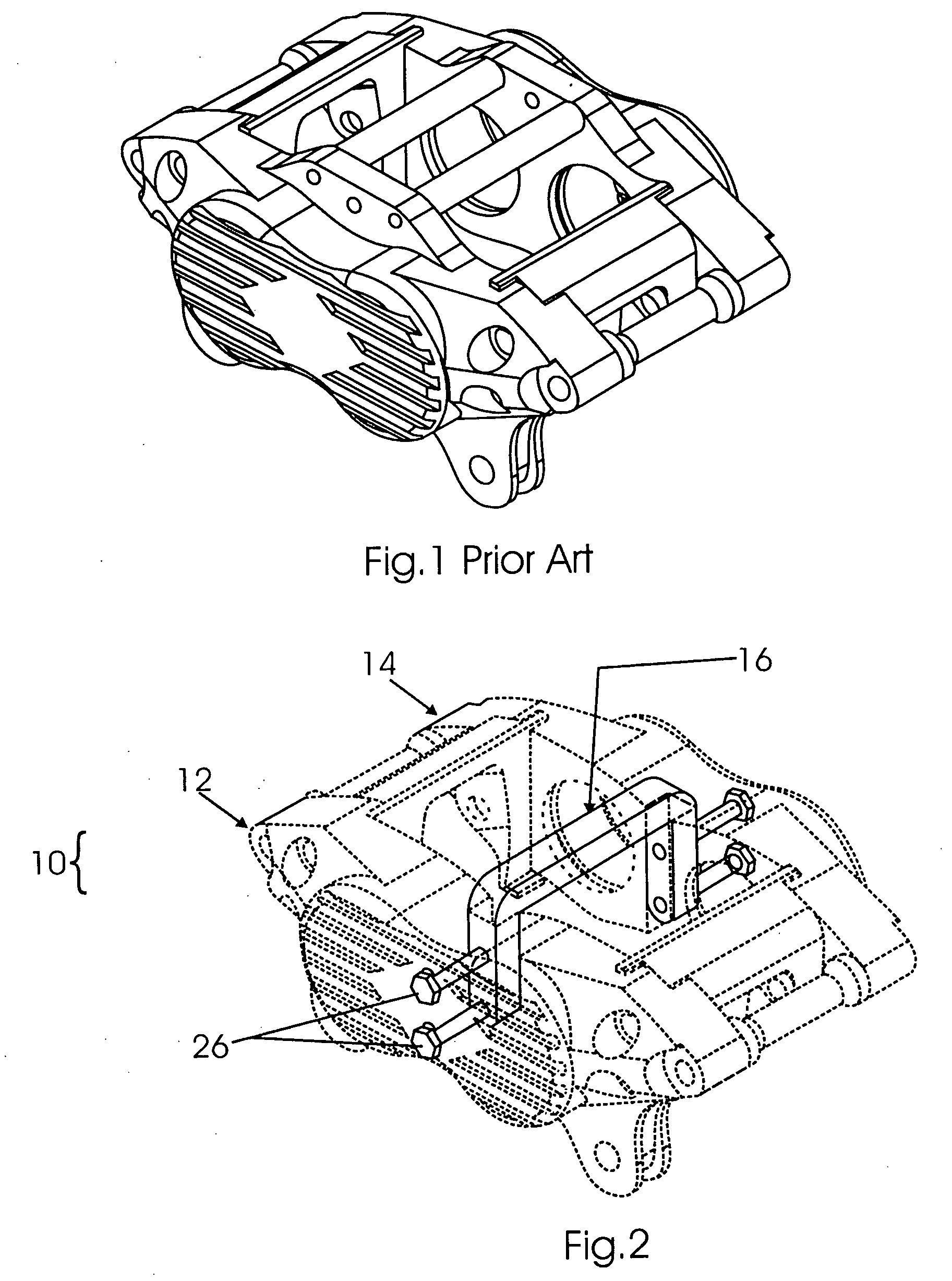

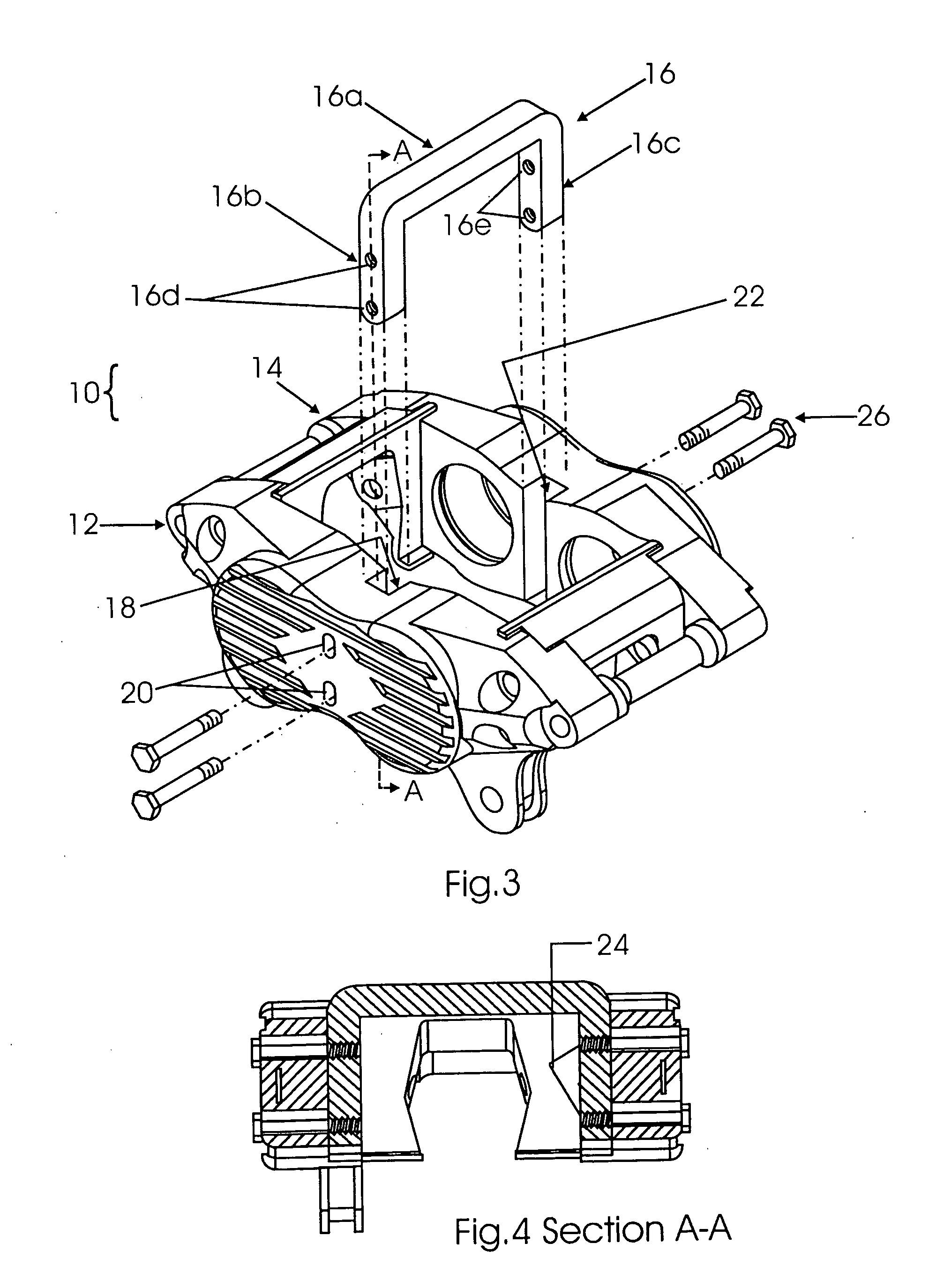

Disk brake caliper having re-enforcing bridge

A brake apparatus includes a caliper with two housing members secured together by a C-section bridge. The housing members straddle a rotor, so as to be able to urge one or more pistons disposed therein to apply brake pads against the rotor, thereby effectuating a braking force on the rotor. The C-section bridge provides support for the members and reduces the clamshell effect generated by application of the breaking force.

Owner:GILLILAND WARREN

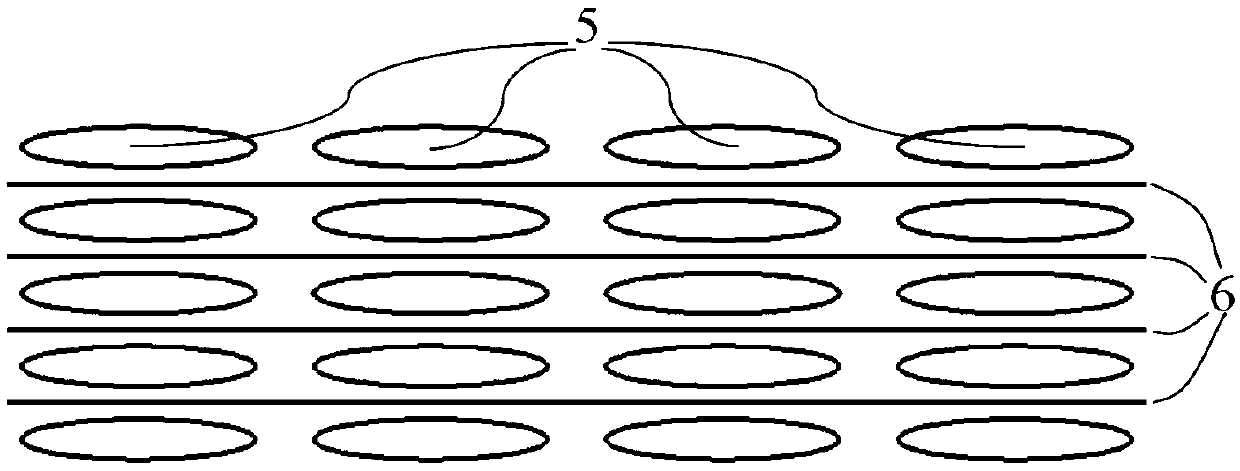

Preset weak area 2.5D woven composite fragile cover and preparation method thereof

The invention discloses a preset weak area 2.5D woven composite fragile cover, and belongs to the technical field of missile firing and protection. The preset weak area 2.5D woven composite fragile cover a throwing body and a framework wrapping the periphery of the throwing body. The combined position of the framework and the throwing body is divided into a weft separation area and a warp separation area. The invention further discloses a preparation method of the preset weak area 2.5D woven composite fragile cover. A 2.5D woven part reinforced epoxy resin composite serves as the material of the preset weak area 2.5D woven composite fragile cover; and according to the defect presetting manner in the weft separation area, the quantity of weft yarn keeps unchanged, and the density of warp yarn is reduced; and according to the defect presetting manner in the warp separation area, the quantity of warp yarn keeps unchanged, and the density of weft yarn is reduced. The fragile cover is light, the separation areas are novel in structure, a cover body is formed integrally and does not need to be cut, the strength of the fragile cover can be adjusted according to different pressure parameter requirements by adjusting the density of the yarn of the separation areas of the fragile cover, the fragile cover can bear pressure within a specific range and can be smoothly separated and thrown out under the action of missile gas flow, and the fragile cover is of a novel structure.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com