Combined type rubber shock absorber

A technology of rubber shock absorber and rubber shock absorber, which is applied in the direction of spring/shock absorber, spring assembly composed of several springs, springs, etc., can solve the problem of limited bonding strength, loss of shock absorber function, T Eliminate the tearing of the type rubber vibration damping pad, etc., to achieve the effect of strong designability and enhanced reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

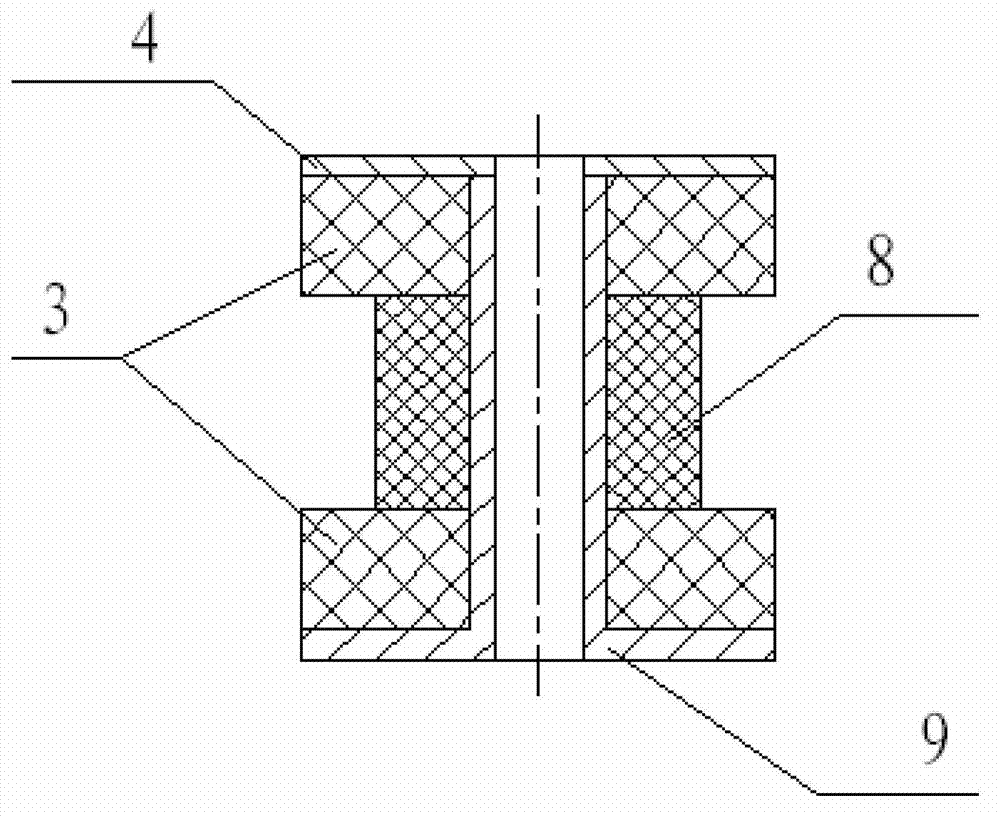

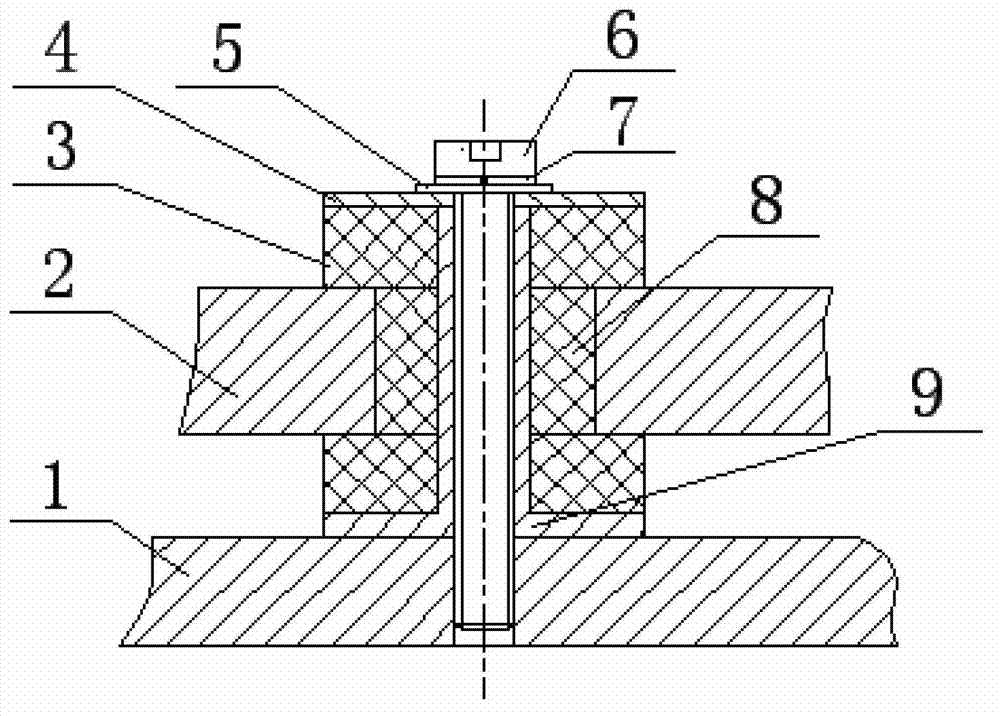

[0026] A combined rubber shock absorber, such as figure 1 As shown, it includes rubber damping pad 3, rubber damping column 8, metal limit bushing 9 and metal limit washer 4;

[0027] The cross section of the metal limit bushing 9 is an inverted "T" shape, the upper part is a hollow cylinder, and the lower part is a ring;

[0028] The top and the bottom of the metal limit bushing 9 are rubber damping pads 3, and the rubber damping pads 3 are set on the cylinder of the metal limit bushing 9;

[0029] The middle part of the metal limit bushing 9 is a rubber damping column 8, and the rubber damping column 8 is set on the cylinder of the metal limit bushing 9;

[0030] The rubber damping pad 3 is in contact with the rubber damping column 8;

[0031] The metal spacer 4 is screwed to the top end of the metal spacer bushing 9 .

[0032] The rubber damping pad 3 is made of damping material ZN-35, and its size is: inner diameter 10mm, outer diameter 24mm, height 6mm;

[0033] The ...

Embodiment 2

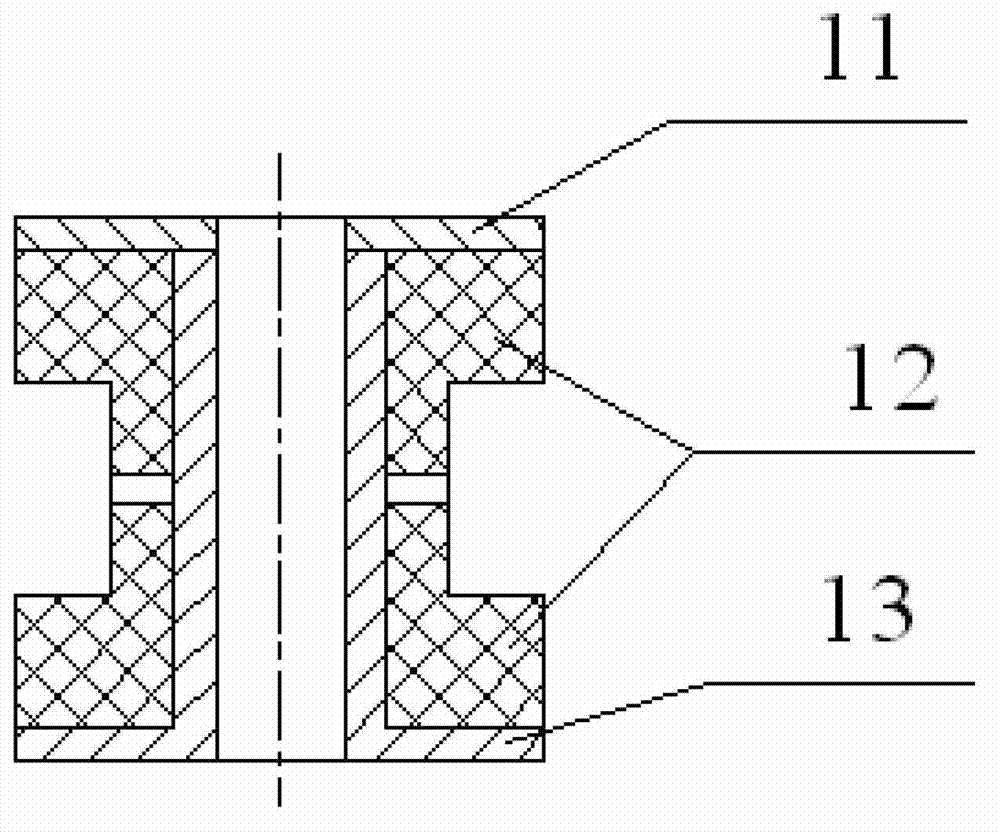

[0045] A combined rubber shock absorber, comprising a rubber shock absorber 3, a rubber shock absorber column 8, a metal spacer bushing 9 and a metal spacer 4;

[0046] The cross section of the metal limit bushing 9 is an inverted "T" shape, the upper part is a hollow cylinder, and the lower part is a ring;

[0047] The top and the bottom of the metal limit bushing 9 are rubber damping pads 3, and the rubber damping pads 3 are set on the cylinder of the metal limit bushing 9;

[0048] The middle part of the metal limit bushing 9 is a rubber damping column 8, and the rubber damping column 8 is set on the cylinder of the metal limit bushing 9;

[0049] The rubber damping pad 3 is in contact with the rubber damping column 8;

[0050] The metal spacer 4 is screwed to the top end of the metal spacer bushing 9 .

[0051] The rubber damping pad 3h and the rubber damping column 8 are made of damping material 35, and the size is: inner diameter 11mm, outer diameter 29mm, height 13mm; ...

Embodiment 3

[0062] A combined rubber shock absorber, comprising a rubber shock absorber 3, a rubber shock absorber column 8, a metal spacer bushing 9 and a metal spacer 4;

[0063] The cross section of the metal limit bushing 9 is an inverted "T" shape, the upper part is a hollow cylinder, and the lower part is a ring;

[0064] The top and the bottom of the metal limit bushing 9 are rubber damping pads 3, and the rubber damping pads 3 are set on the cylinder of the metal limit bushing 9;

[0065] The middle part of the metal limit bushing 9 is a rubber damping column 8, and the rubber damping column 8 is set on the cylinder of the metal limit bushing 9;

[0066] The rubber damping pad 3 is in contact with the rubber damping column 8;

[0067] The metal spacer 4 is screwed to the top end of the metal spacer bushing 9 .

[0068] The rubber damping pad 3h and the rubber damping column 8 are made of damping material ZN-37, and the dimensions are: inner diameter 7mm, outer diameter 17mm, hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com