Patents

Literature

632results about "Self acting brakes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

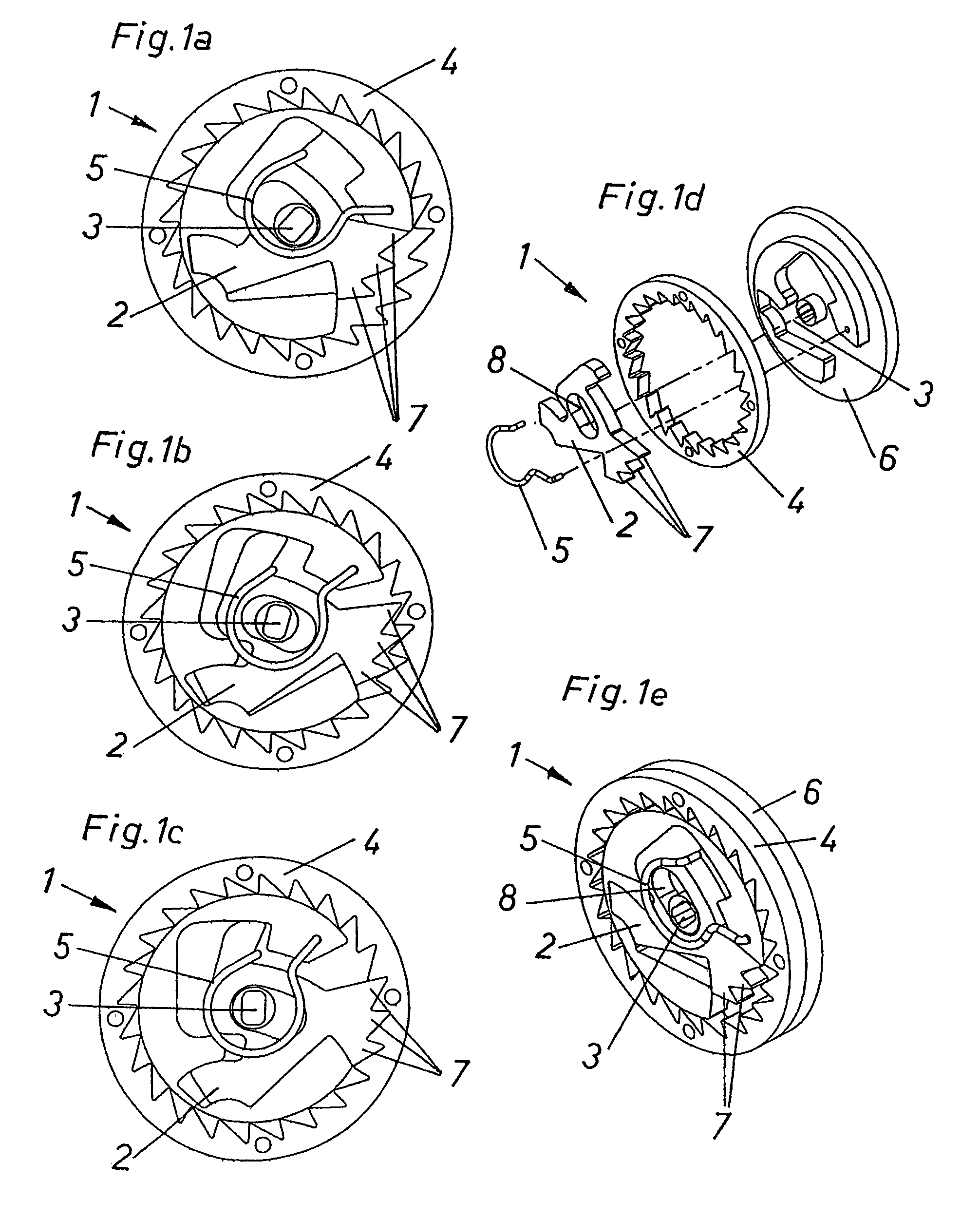

Braking mechanisms

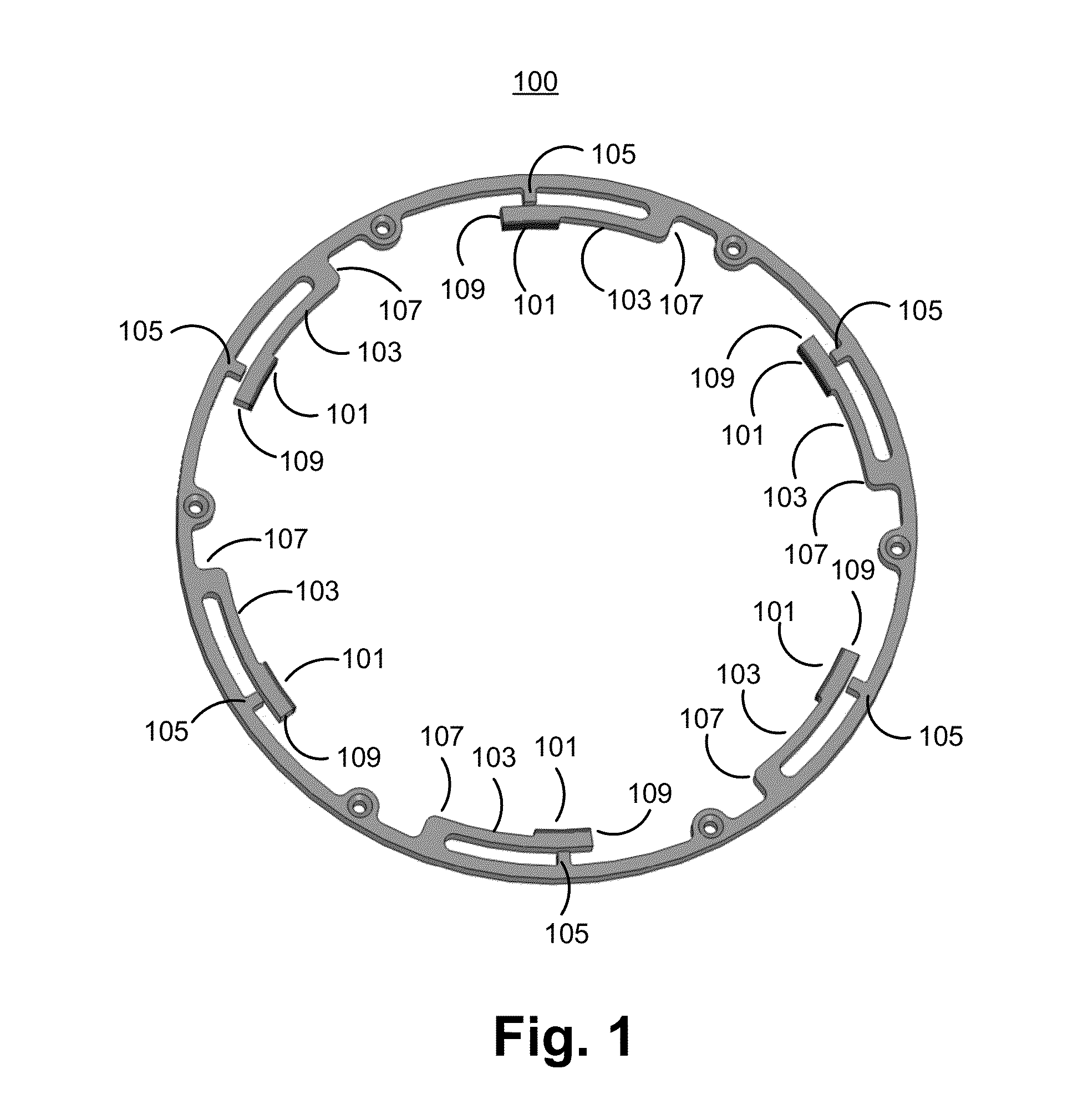

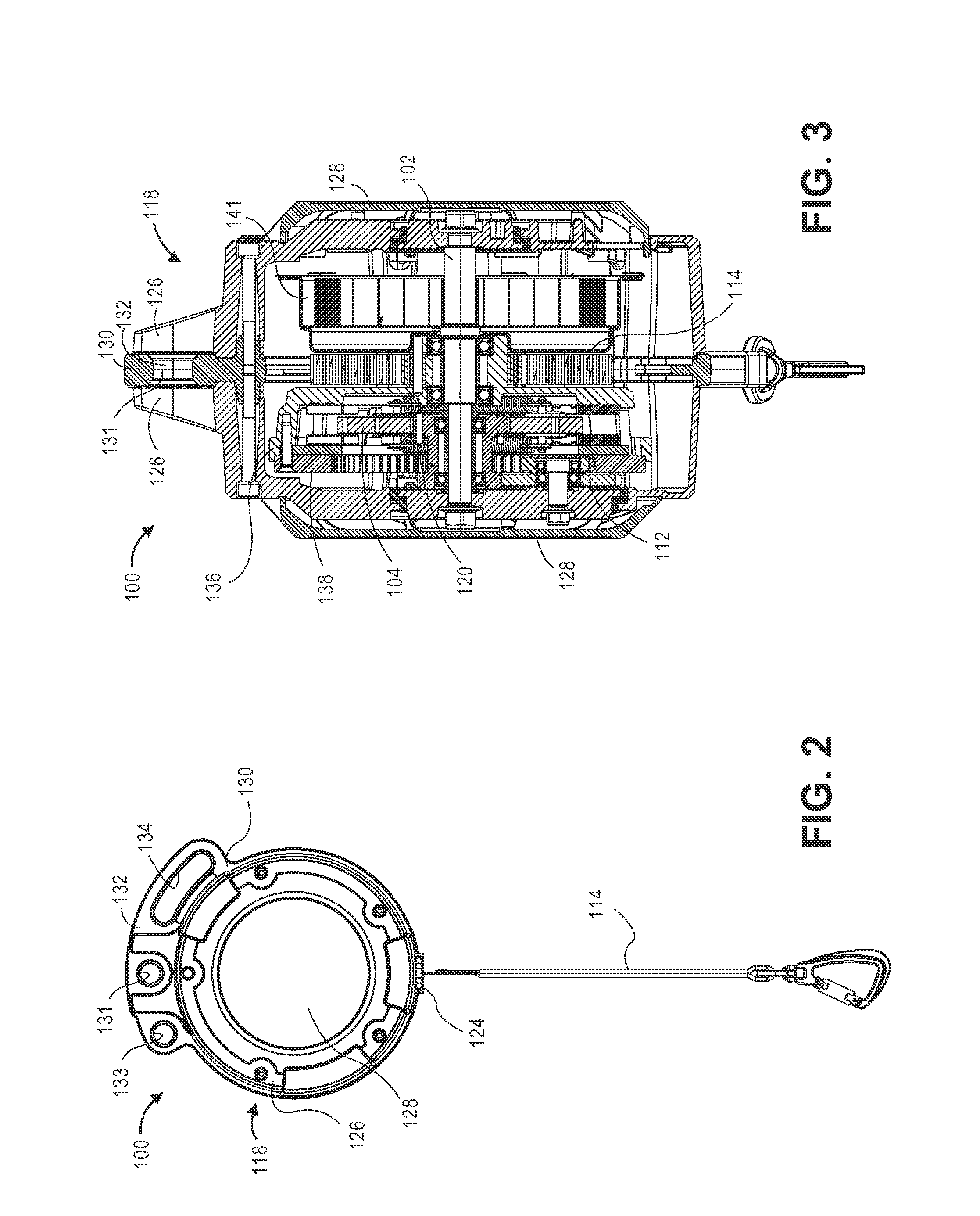

ActiveUS20120055740A1Improve braking effectEffective meanSafety beltsSelf acting brakesEngineeringEddy current

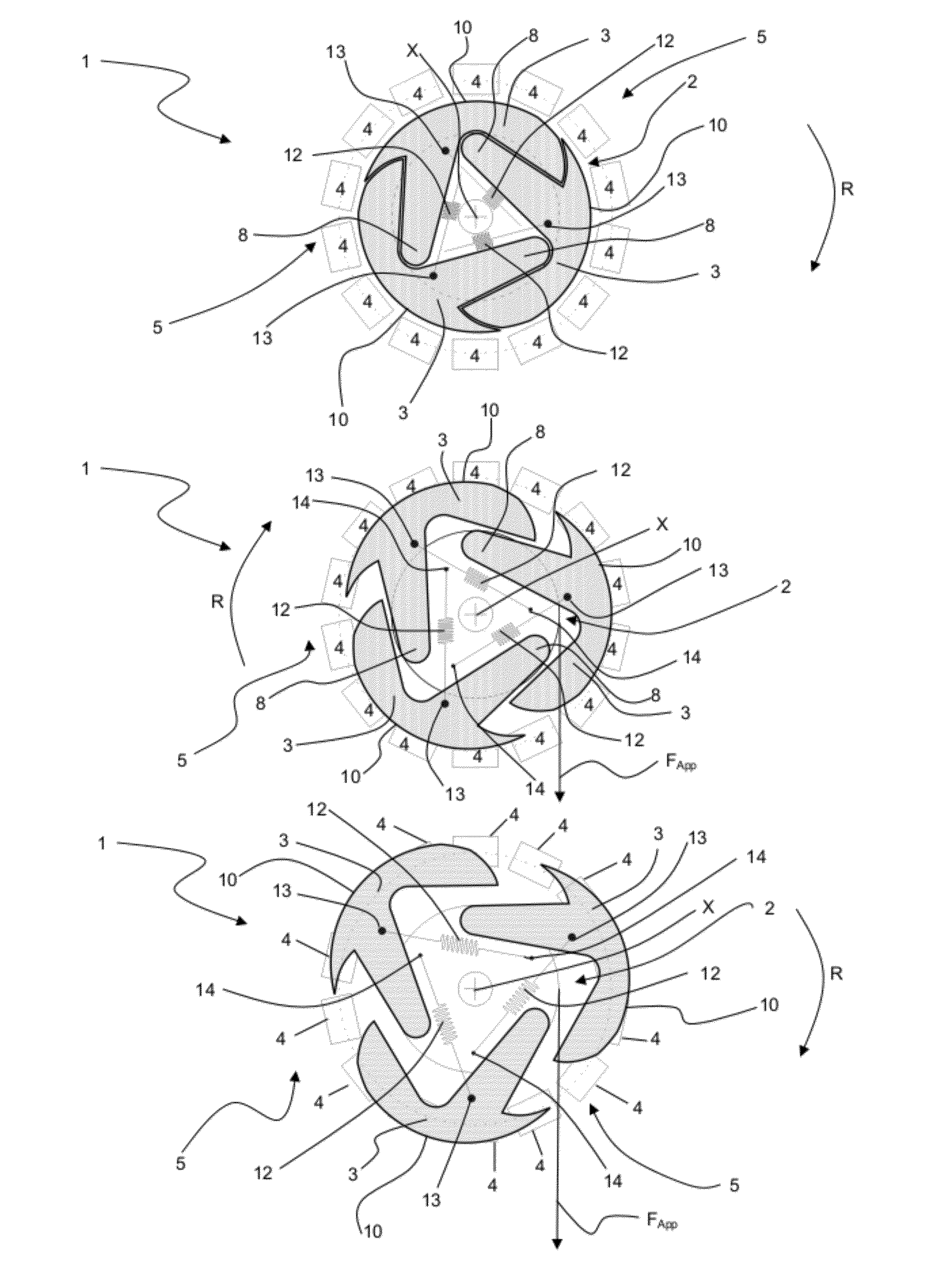

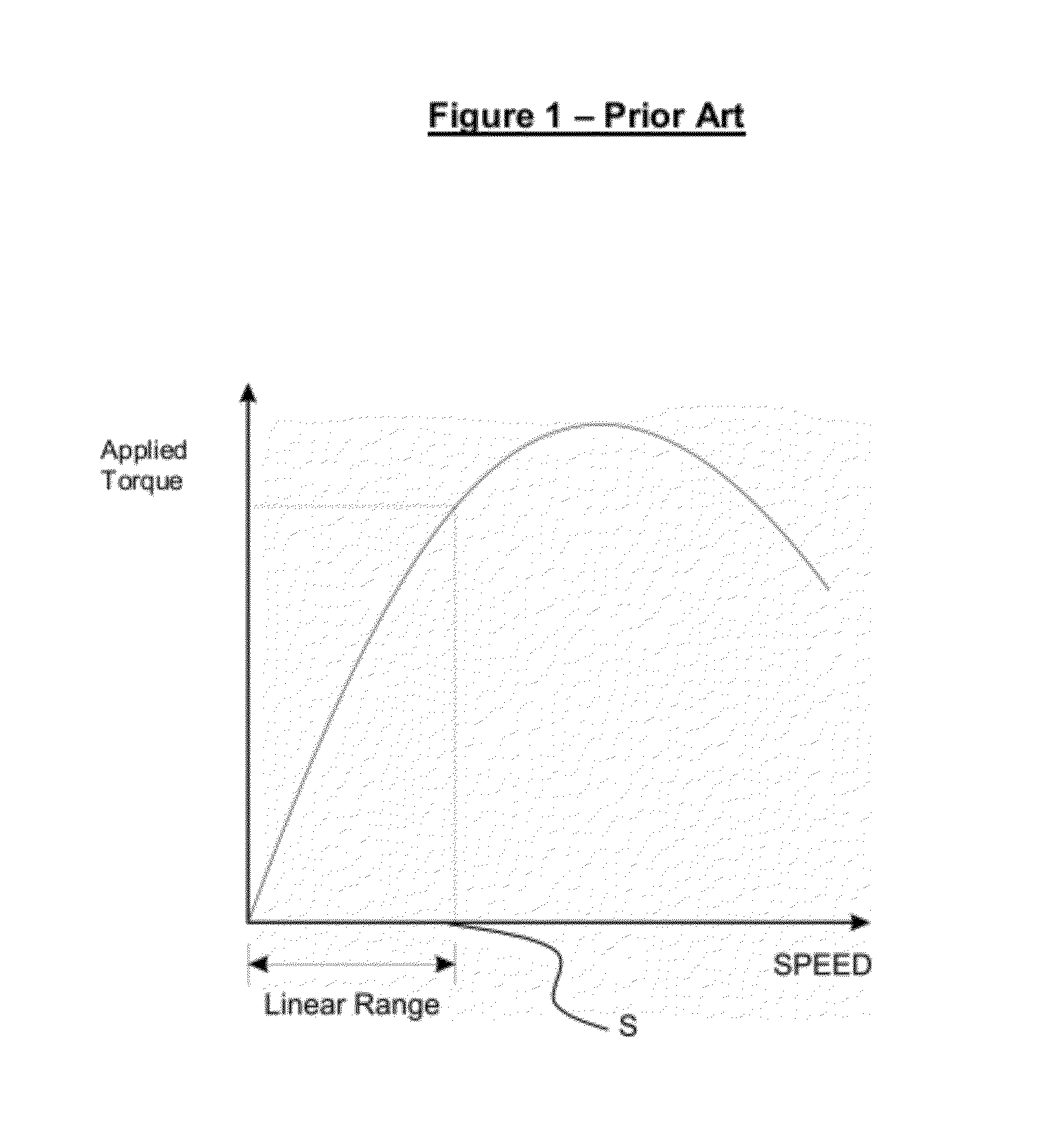

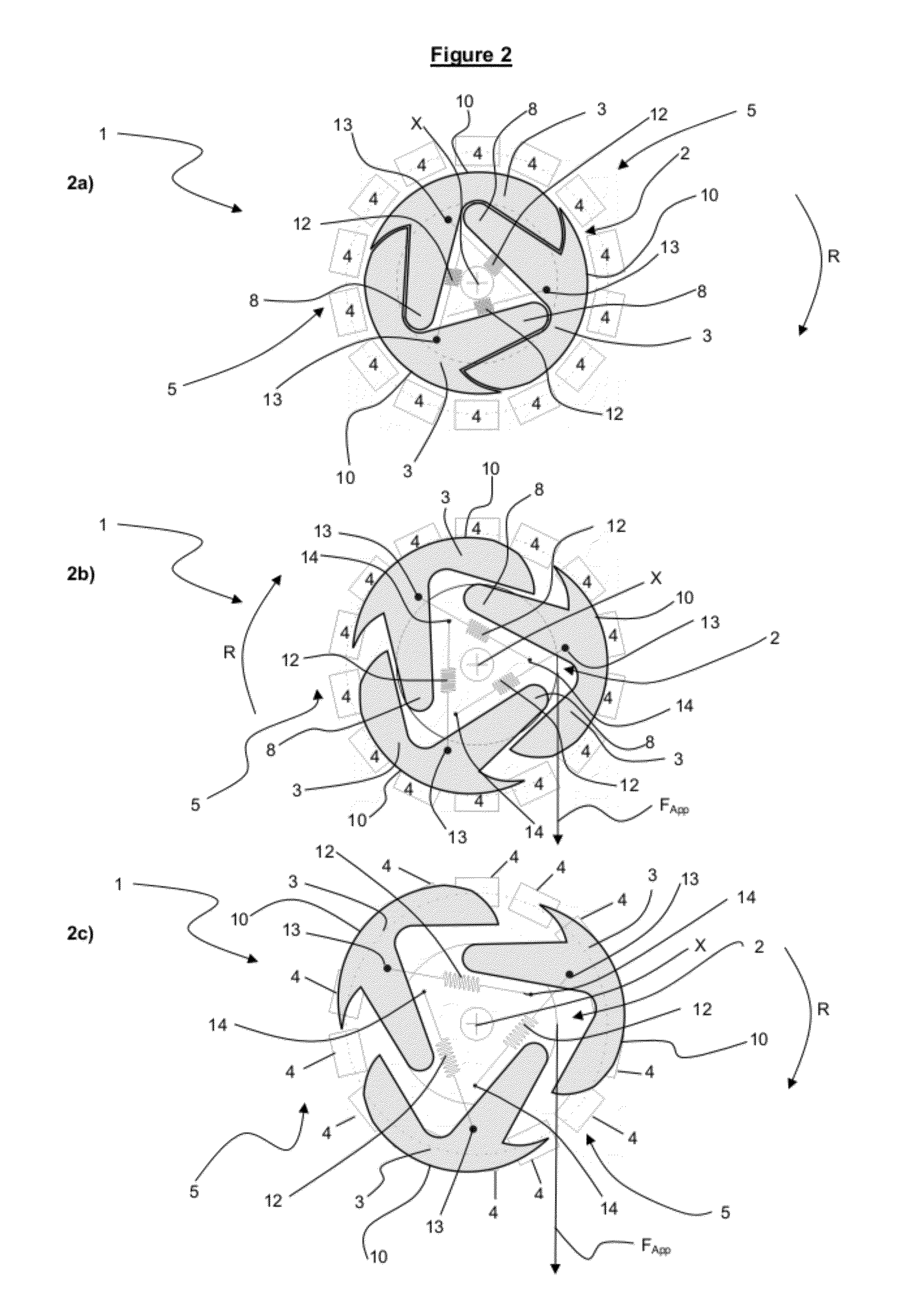

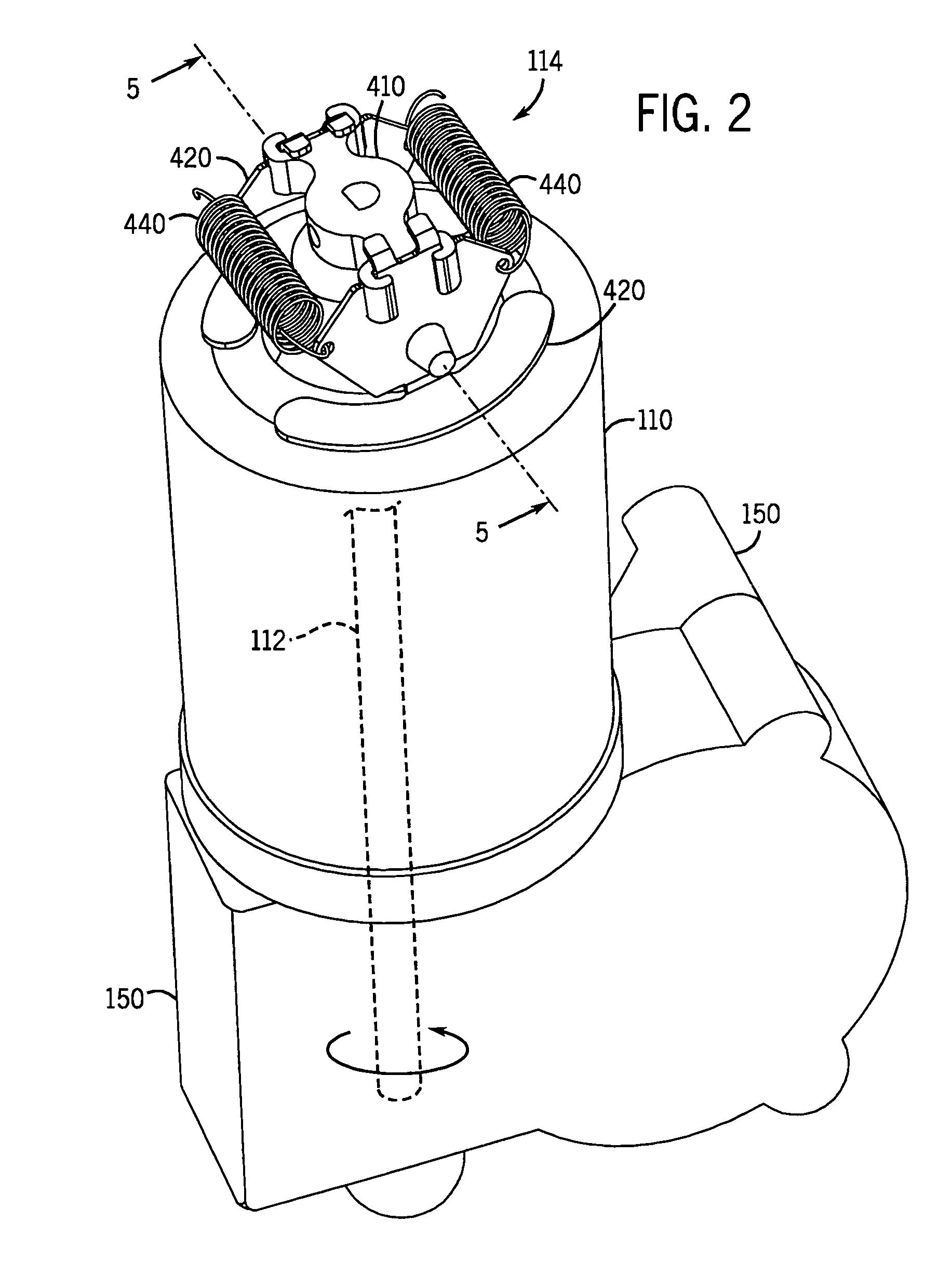

An eddy-current braking mechanism including a rotor, rotatable about a rotor axis; at least one electrically conductive member coupled to the rotor for rotation therewith; at least one magnet configured to apply a magnetic field extending at least partially orthogonal to the plane of rotation of the conductive member, and characterised in that upon rotation of the rotor, the conductive member is configured to move at least partially radially from the rotor axis into the applied magnetic field.

Owner:EDDY CURRENT PARTNERSHIP

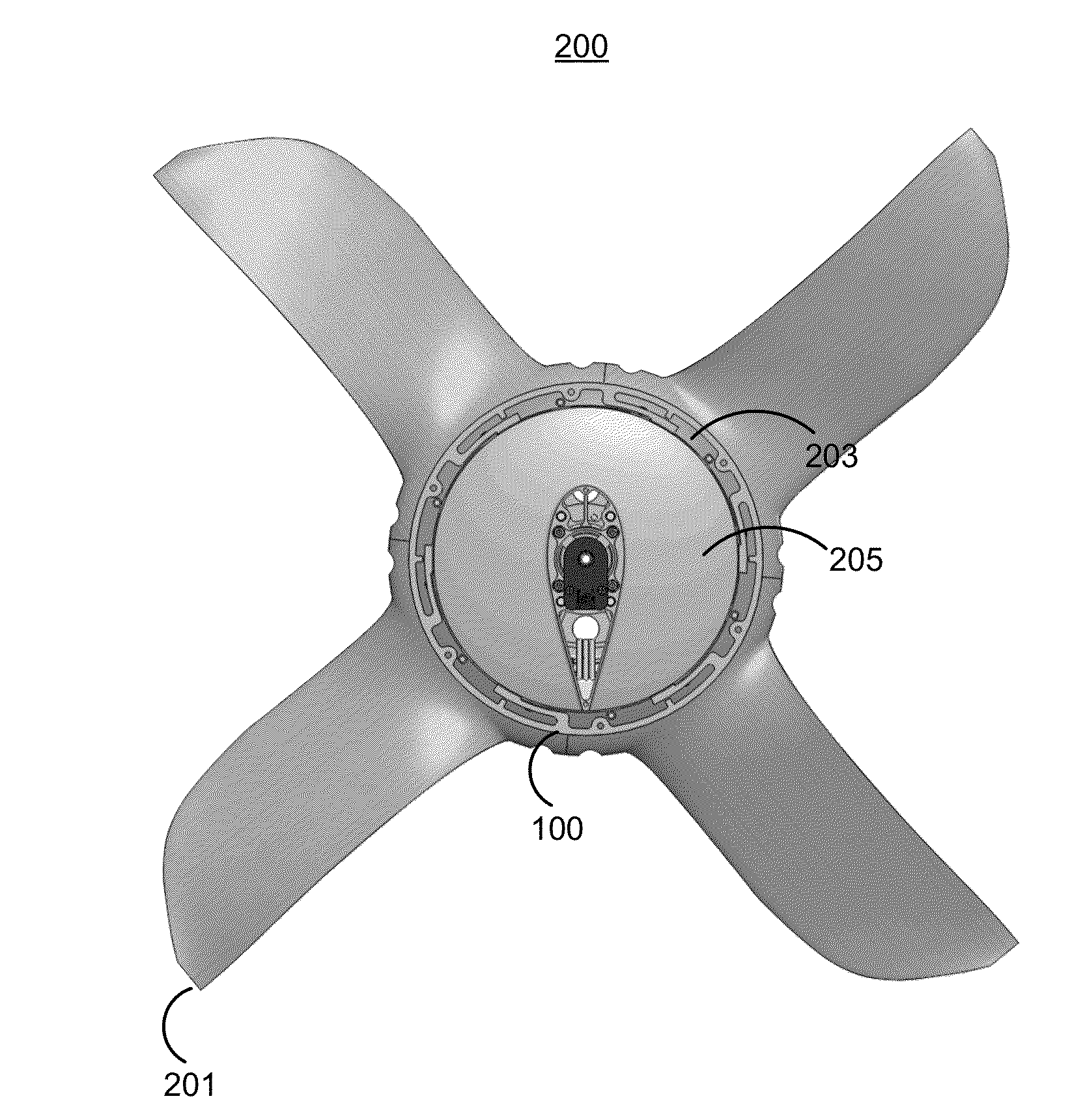

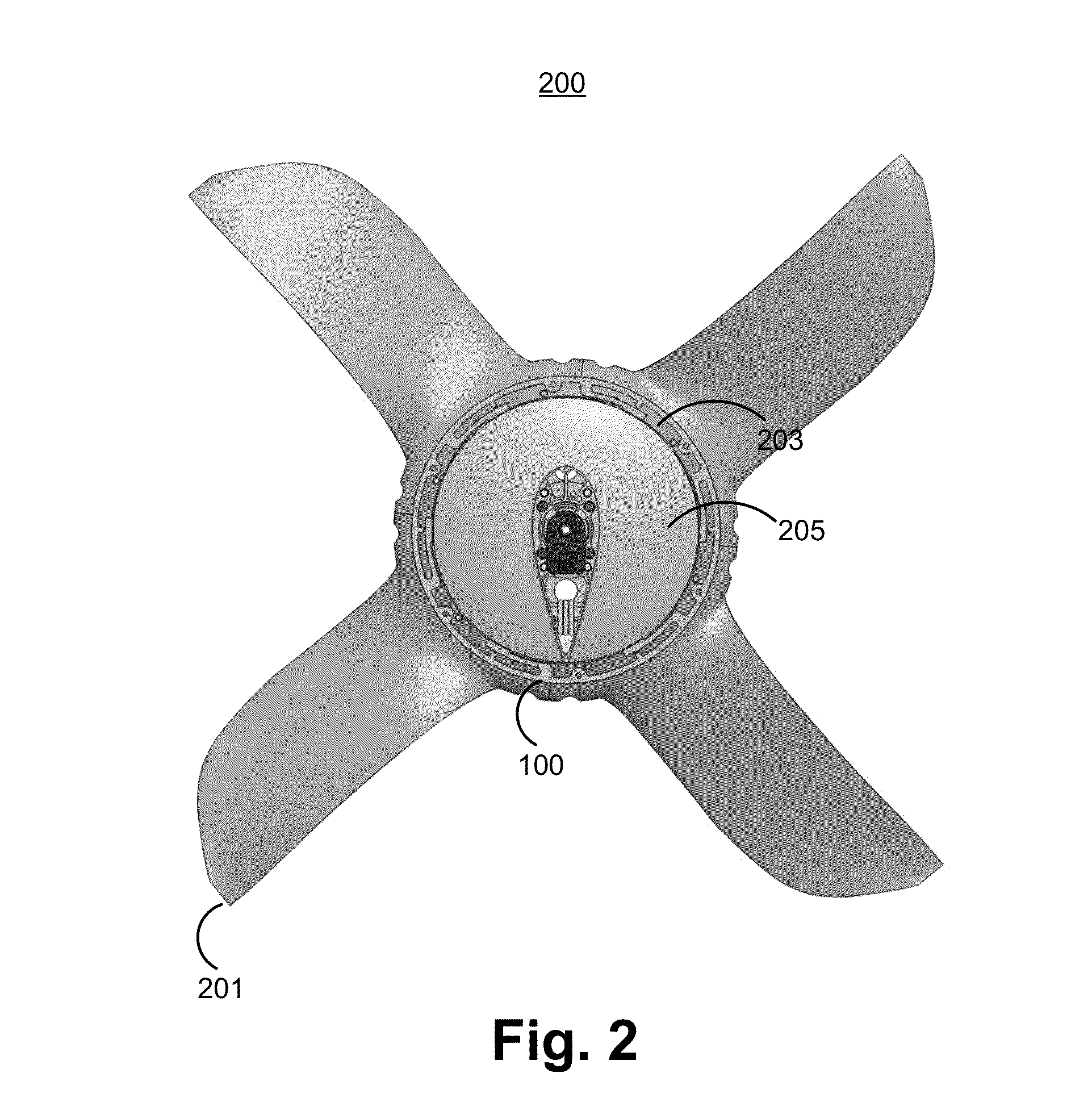

Centrifugal De-Clutch

ActiveUS20130118856A1Increase frictionPrevent rotationPropellersMechanical actuated clutchesEngineeringClutch

Owner:WISK AERO LLC

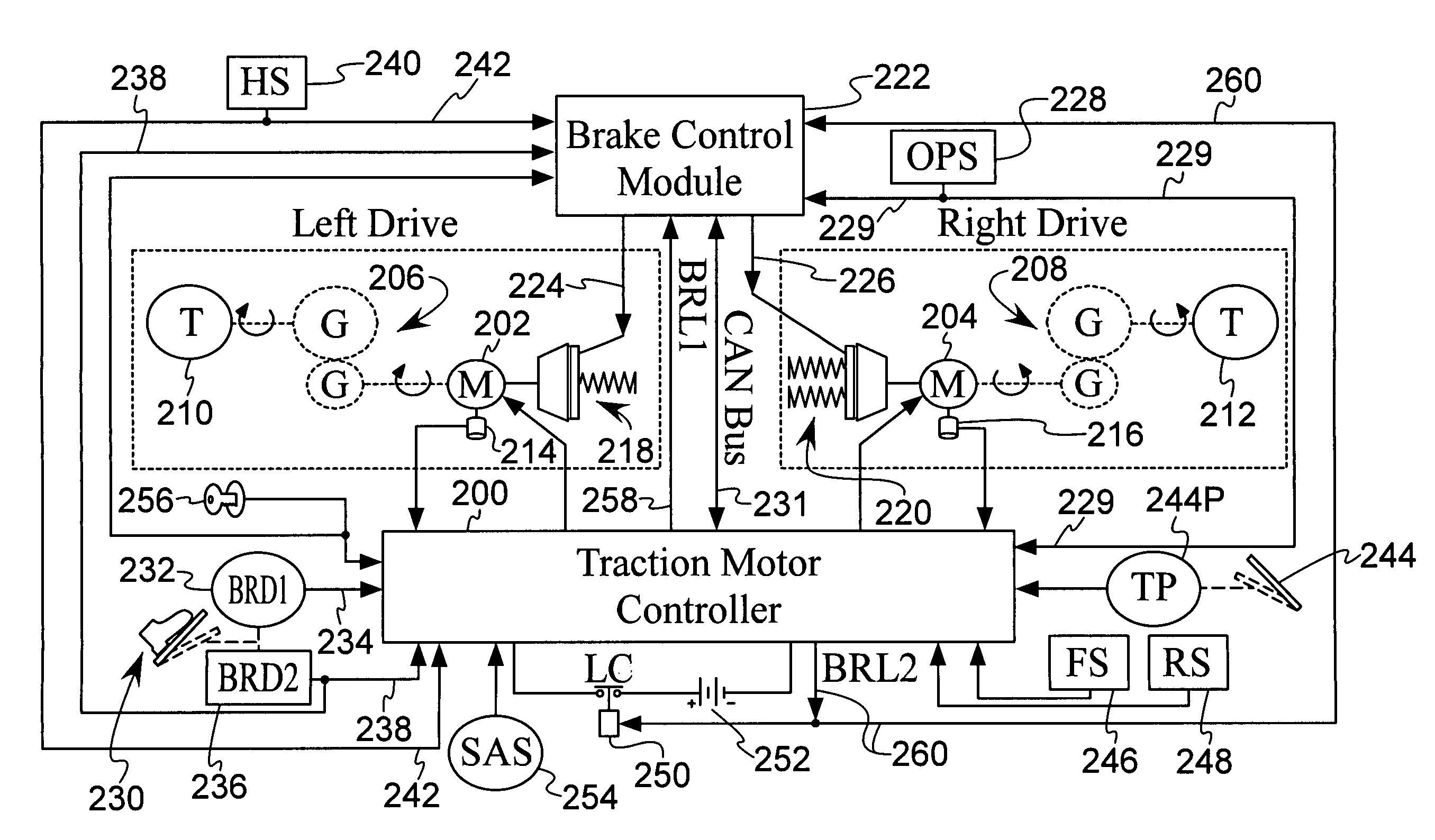

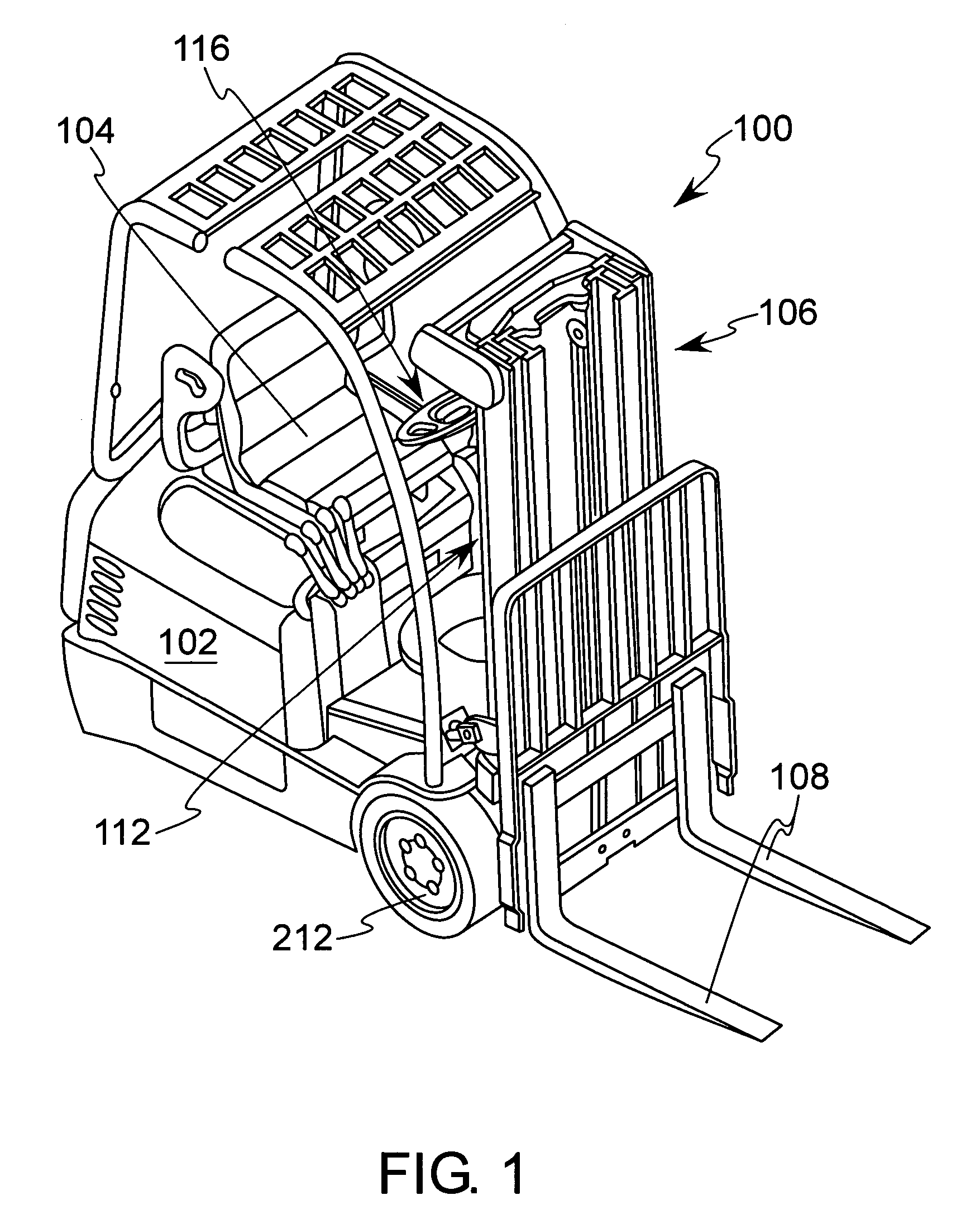

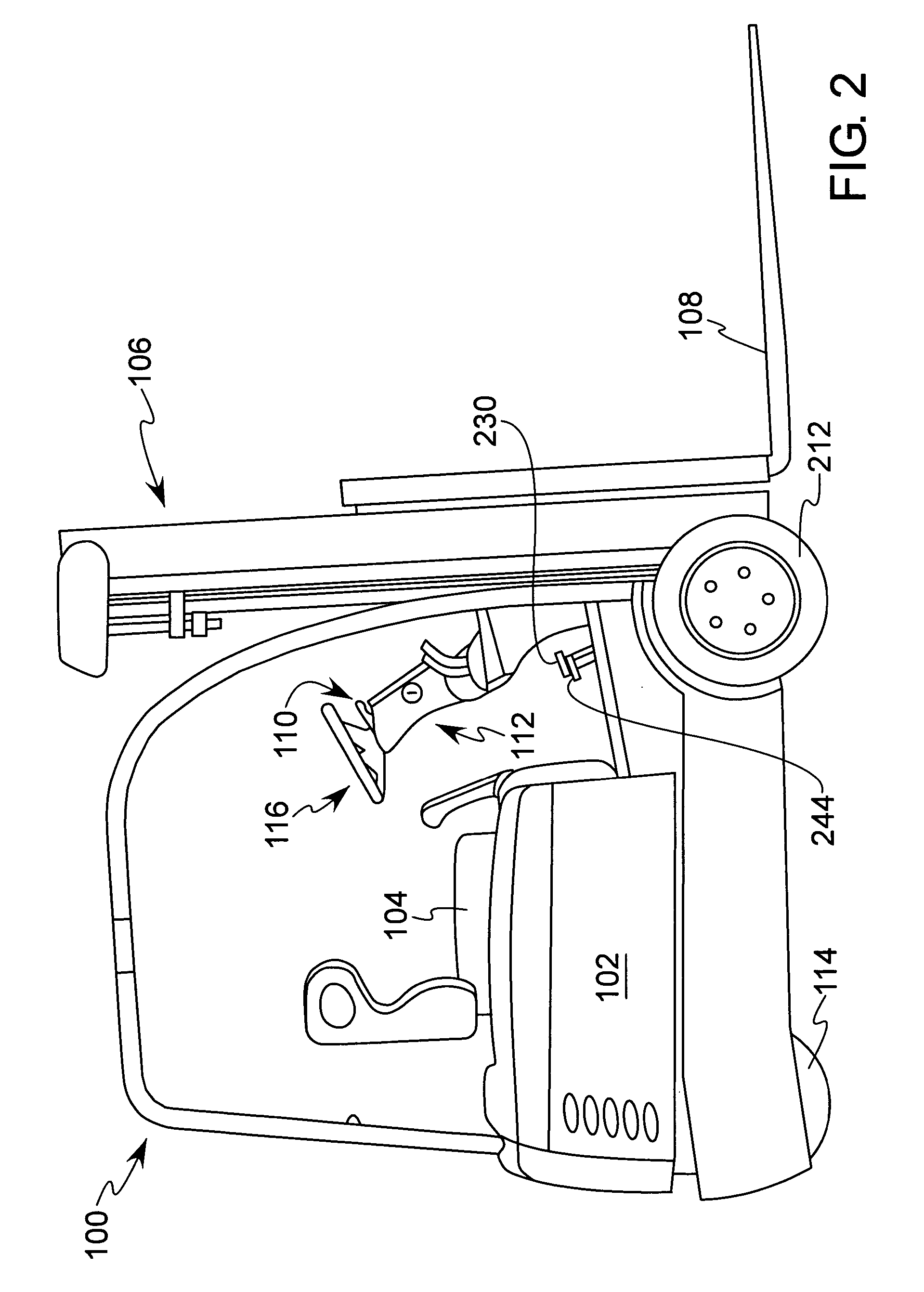

Braking system for a lift truck

Owner:CROWN EQUIP CORP

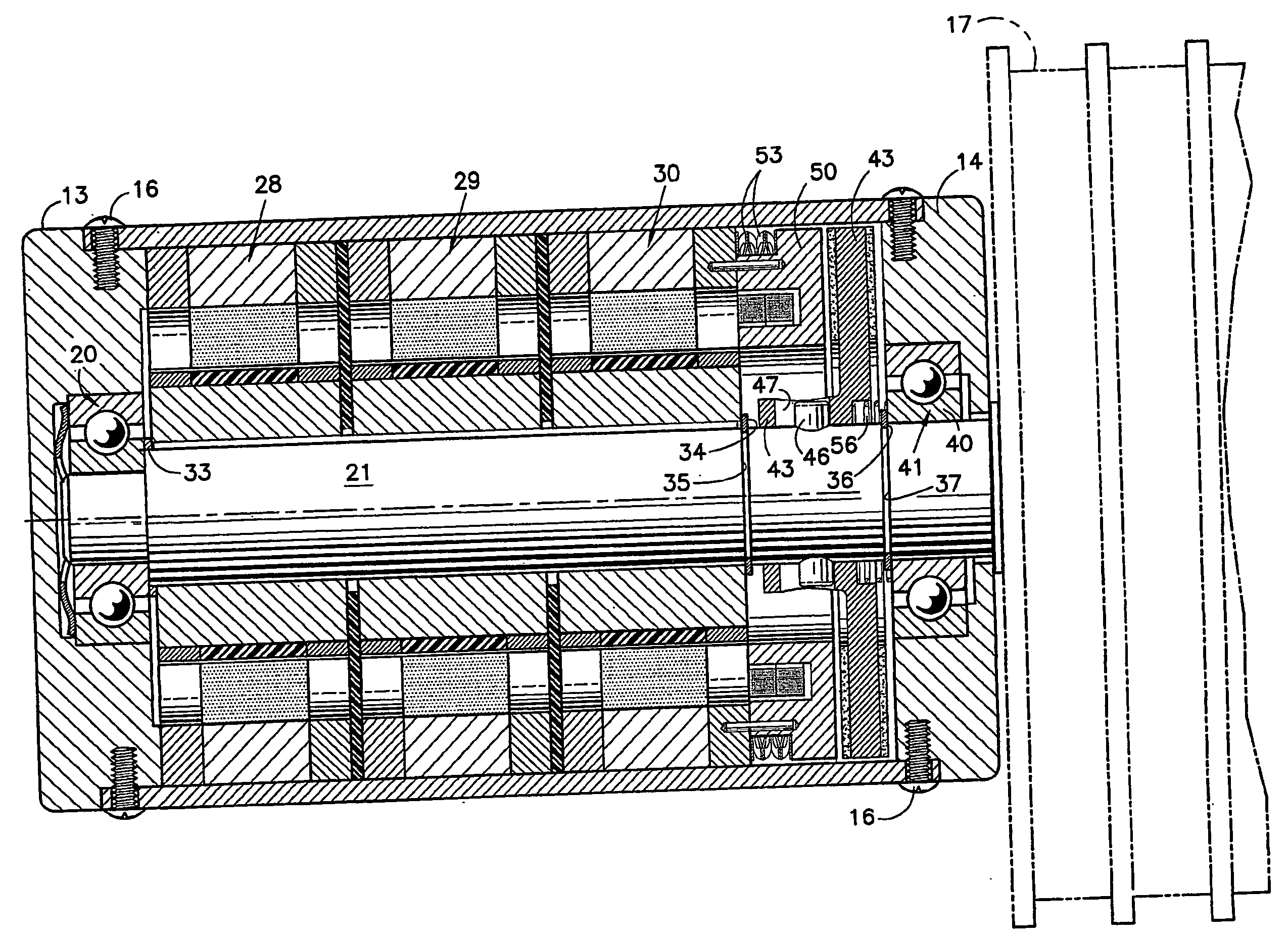

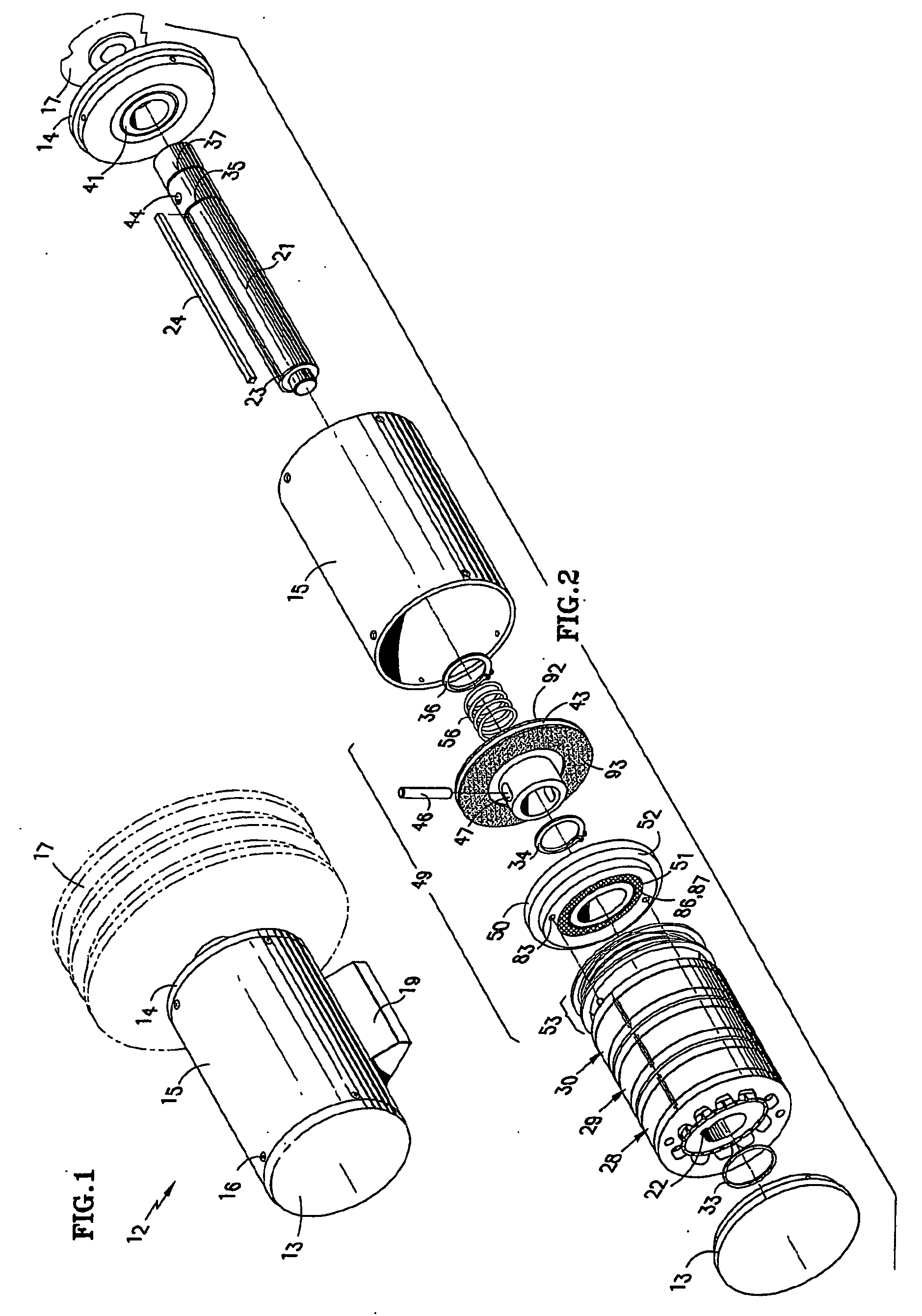

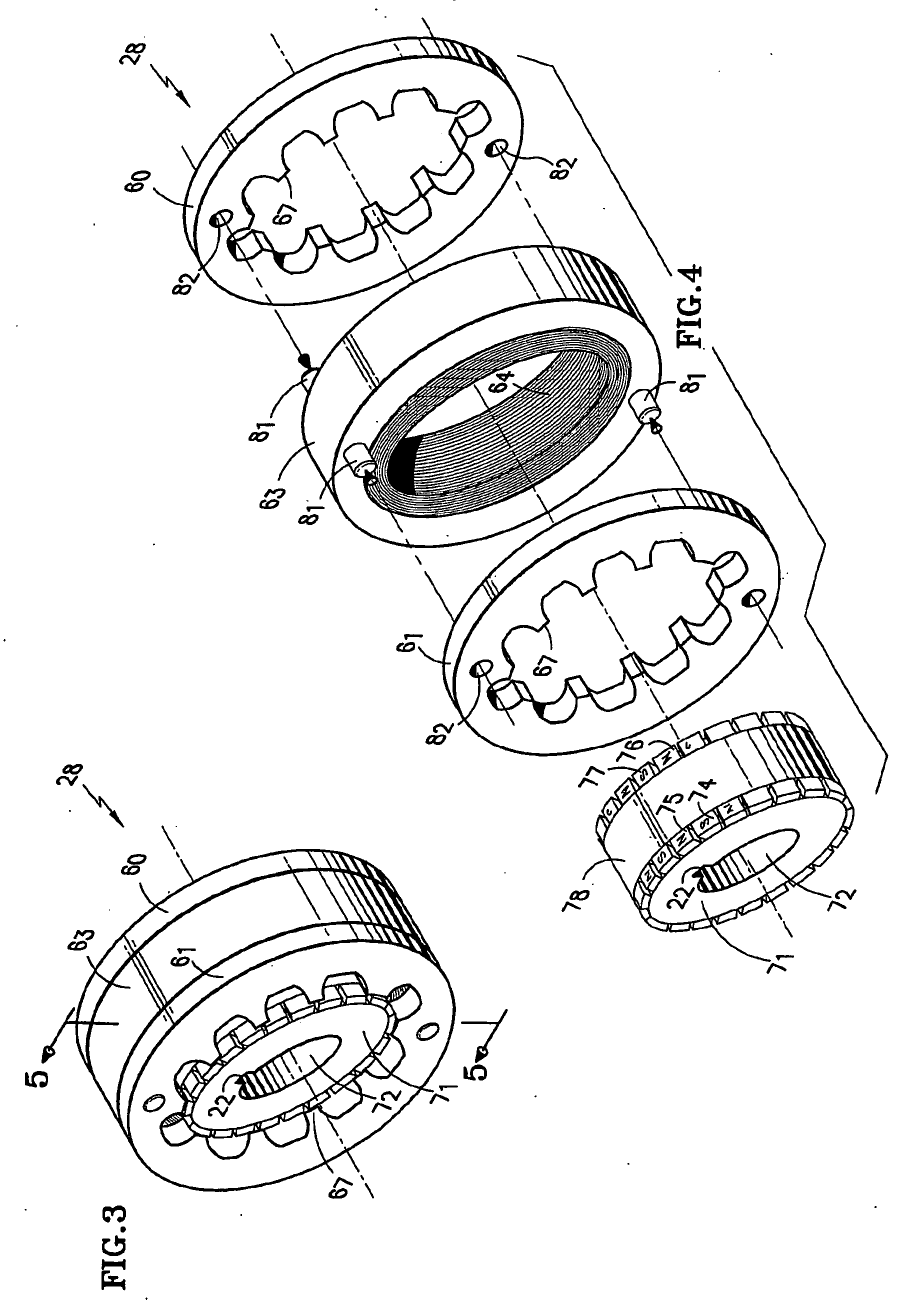

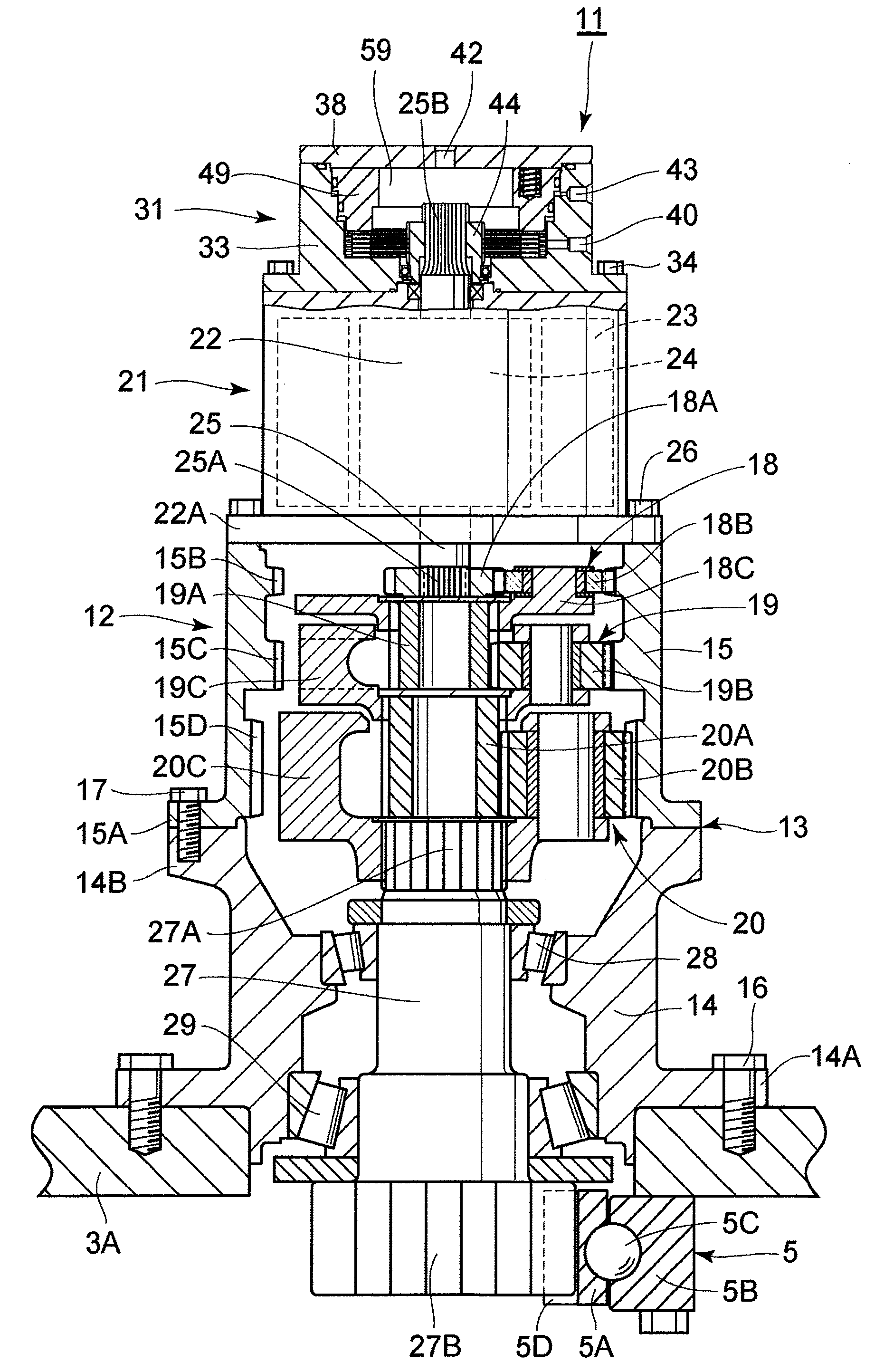

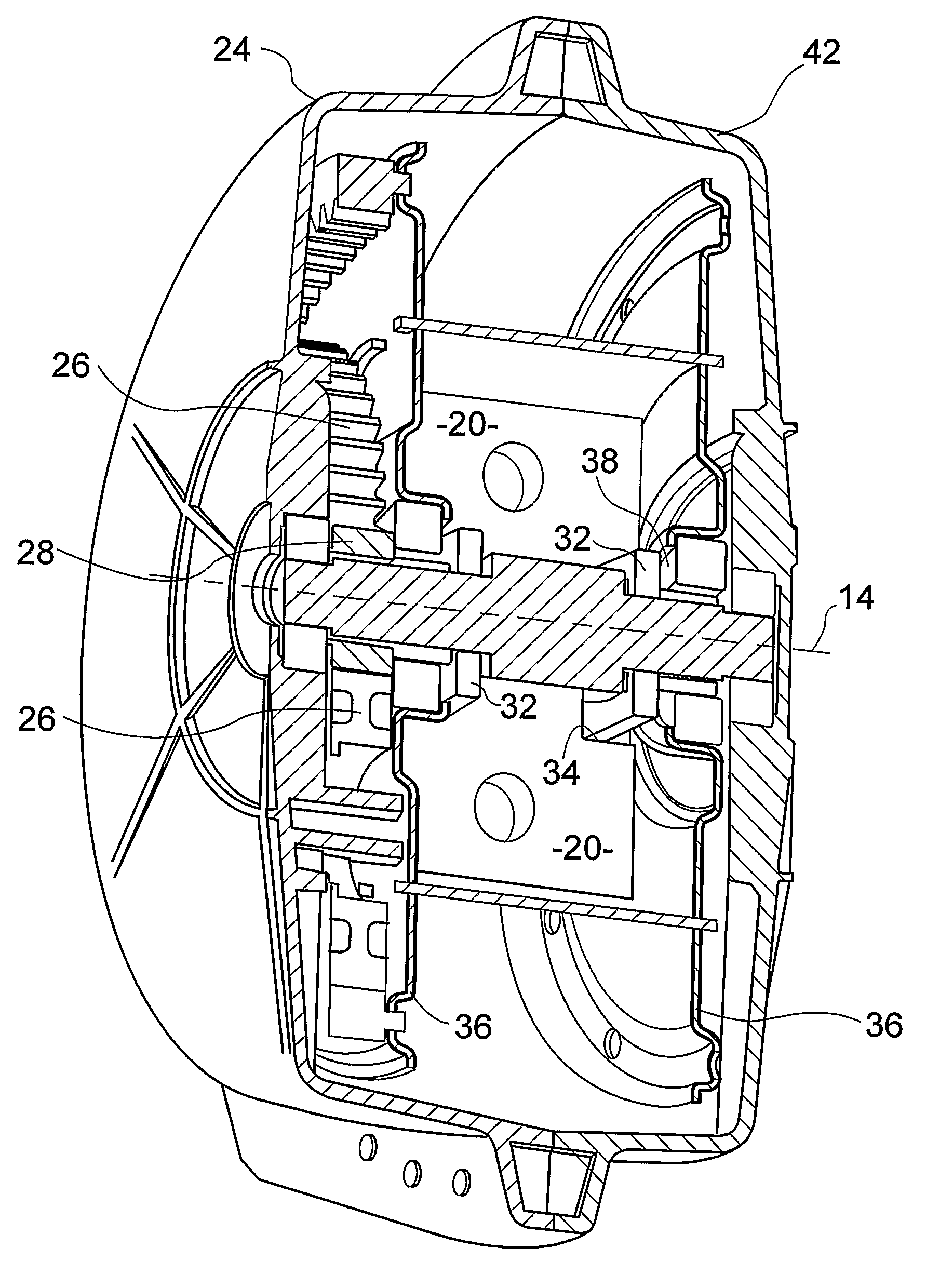

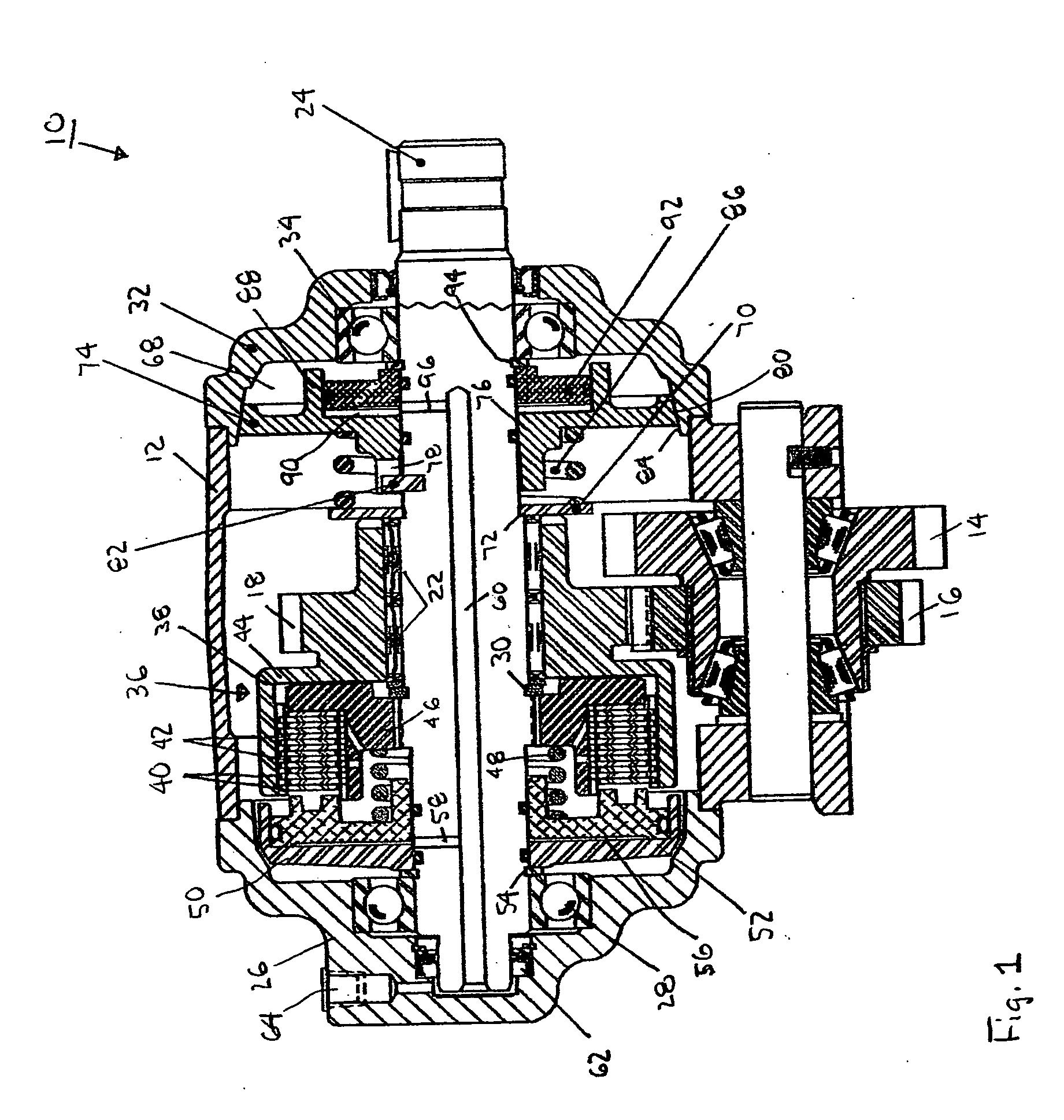

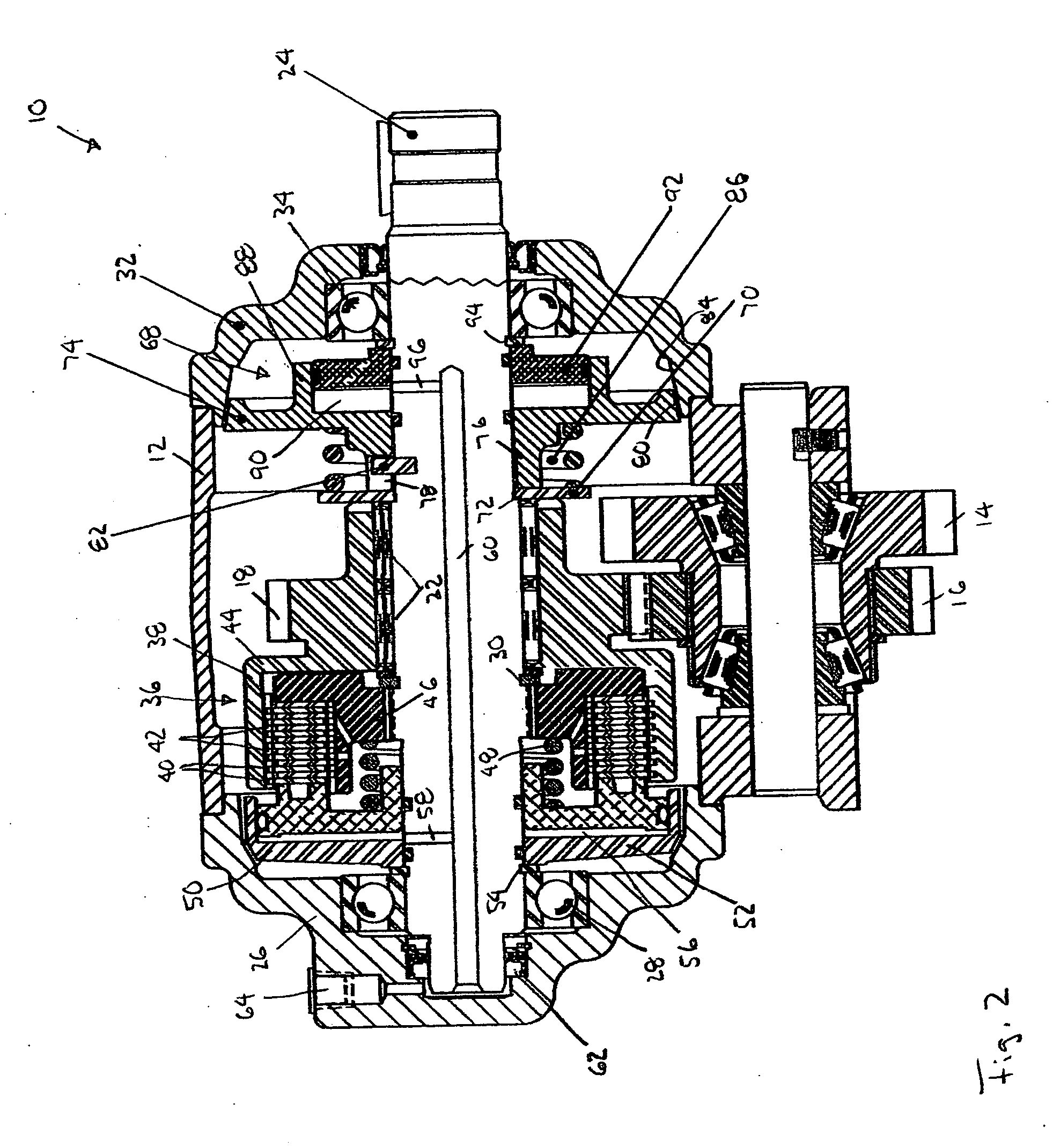

Modular transverse flux motor with integrated brake

InactiveUS20060192453A1Increased torque densityImprove efficiencySynchronous generatorsDynamo-electric brakes/clutchesTransverse fluxMotor end plates

An elevator machine (12) has a plurality of identical transverse flux rotor / stator modules (28-30) of a generally cylindrical configuration arranged contiguously on a common shaft (21) to provide torque to the shaft equal to the torque capability of the modules times the number of modules. A disc brake (49) is integrated with the motor; a two-sided brake disc (49) has friction pads (92, 93) on both sides, braking force being applied to motor end plate (14) and through the brake disc to a stator (60) of one phase (30) of the motor. A process (113) forms variously-sized motors from identically sized modular components, in various configurations (12, 100, 110).

Owner:OTIS ELEVATOR CO

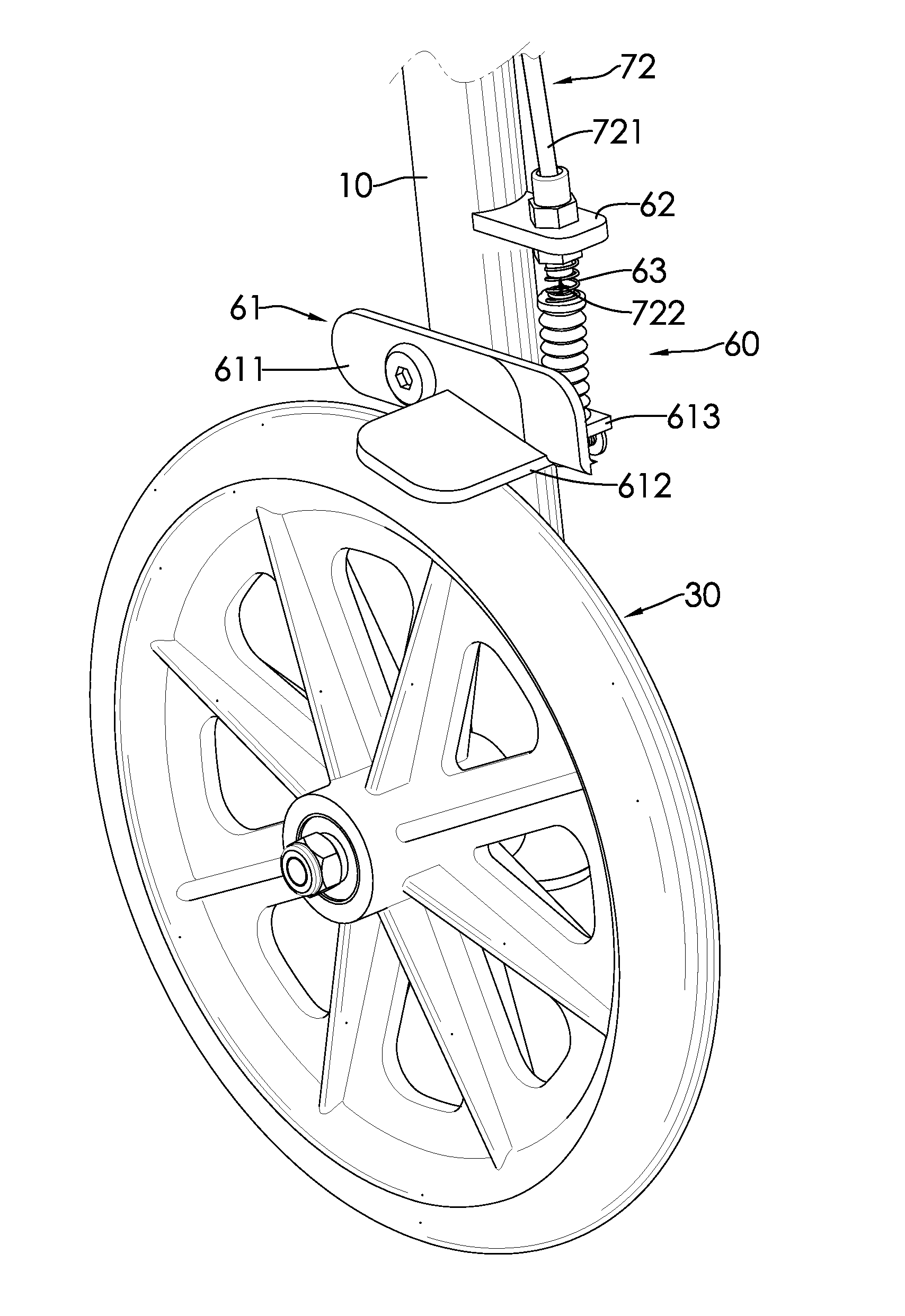

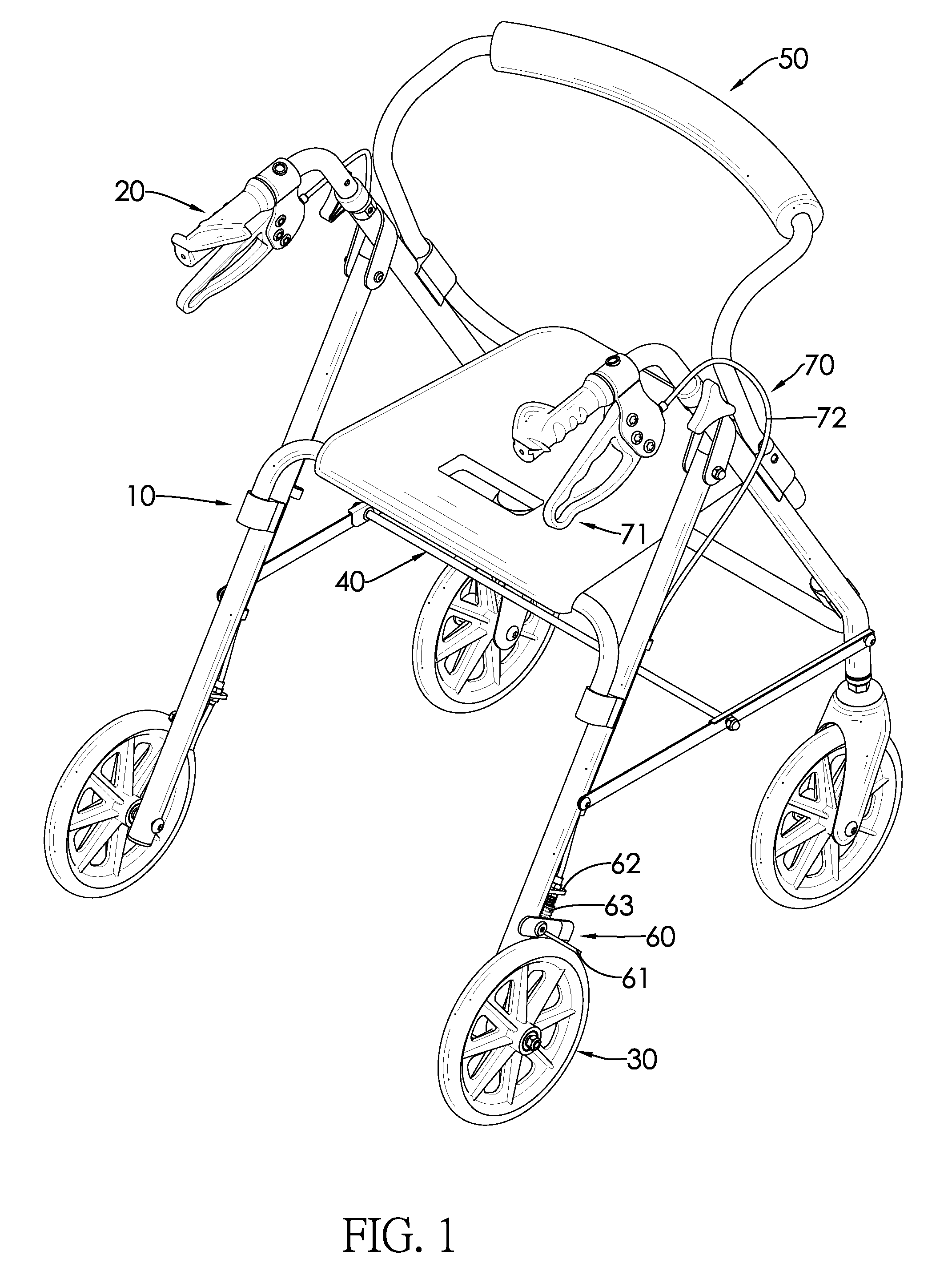

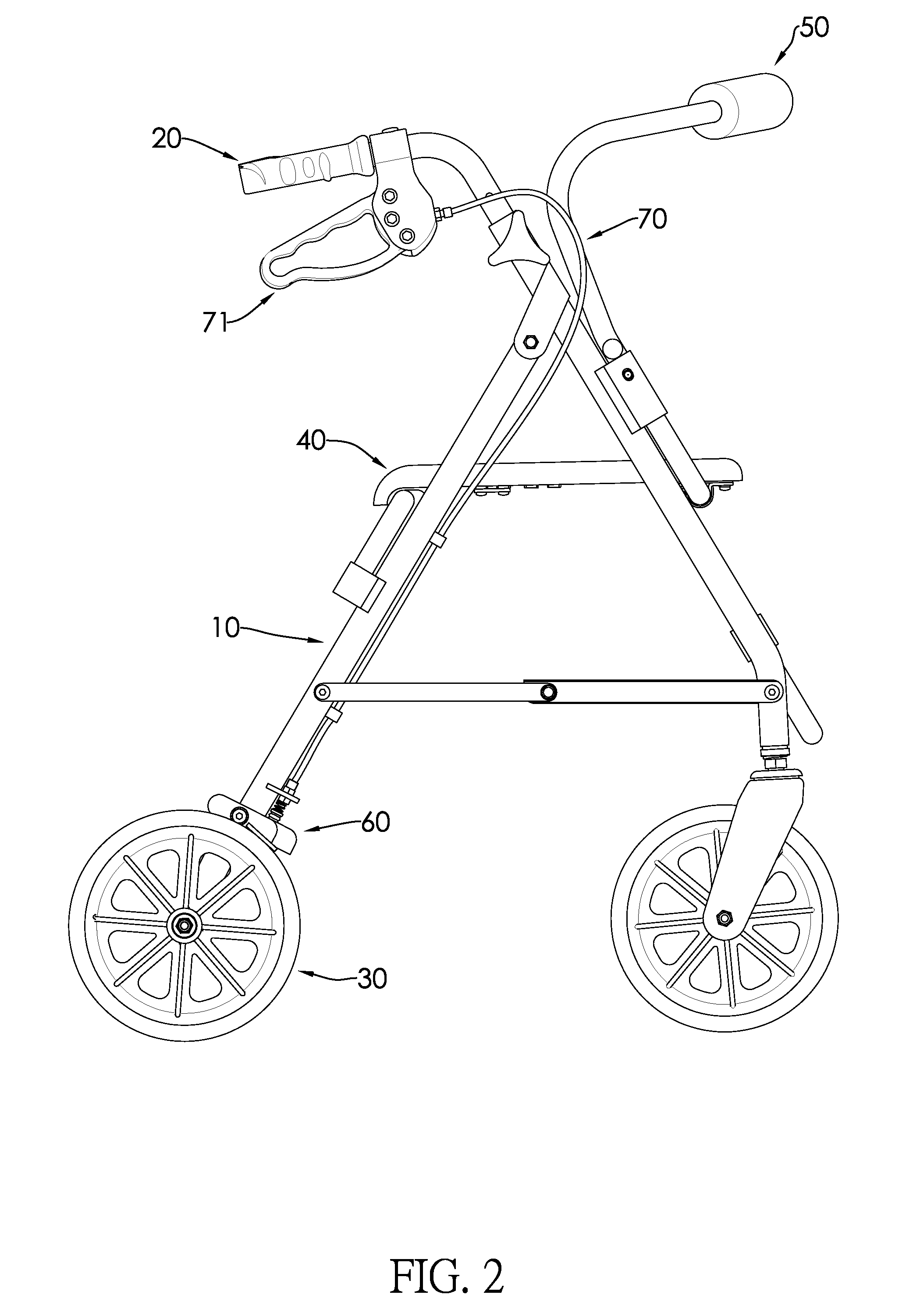

Braking system, rollator and transport chair with the same

ActiveUS8998223B2Prevent rotationCarriage/perambulator accessoriesBraking element arrangementsEngineeringBraking system

A braking system is mounted on a rollator or a transport chair and includes a braking part and an operating system. The braking part is mounted adjacent to a wheel of a rollator or a transport chair. When the operating system is unactuated, the braking part abuts a corresponding wheel to avoid a rotation of the corresponding wheel. When a user wants to walk and move the rollator or the transport chair, the user can press the operating system such that the braking part departs from the wheels and releases a brake. When the user wants to sit on the seat cushion and rest, the user can keep the braking system actuated without pressing the operating system, and accordingly the rollator or the transport chair would not be slidable when sat on, thereby avoiding danger. In addition, when the user walks on a slope, the user can release their hands from the rollator or the transport chair without making the rollator or the transport chair slide down the slope.

Owner:FLYING EAGLE TECH

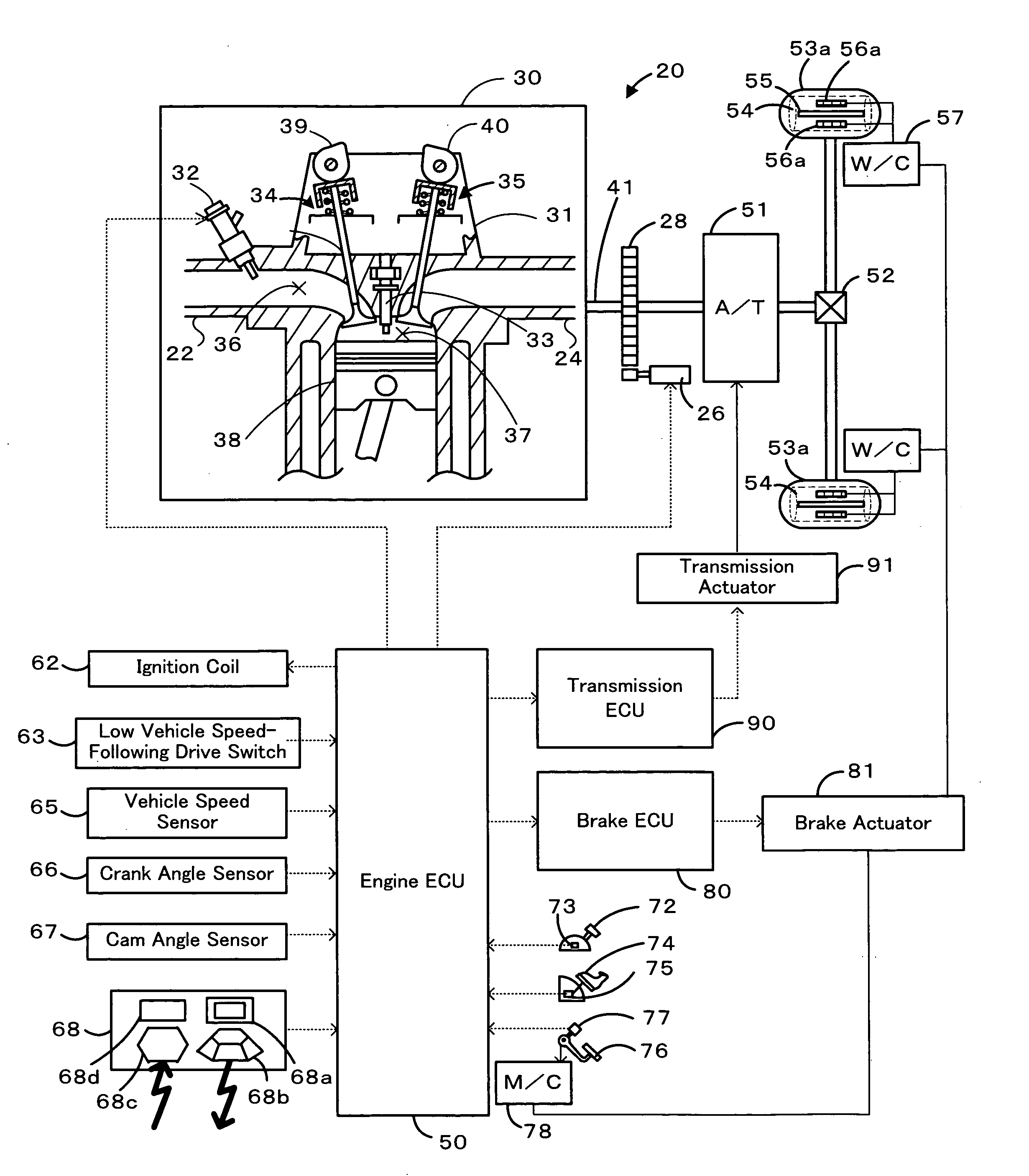

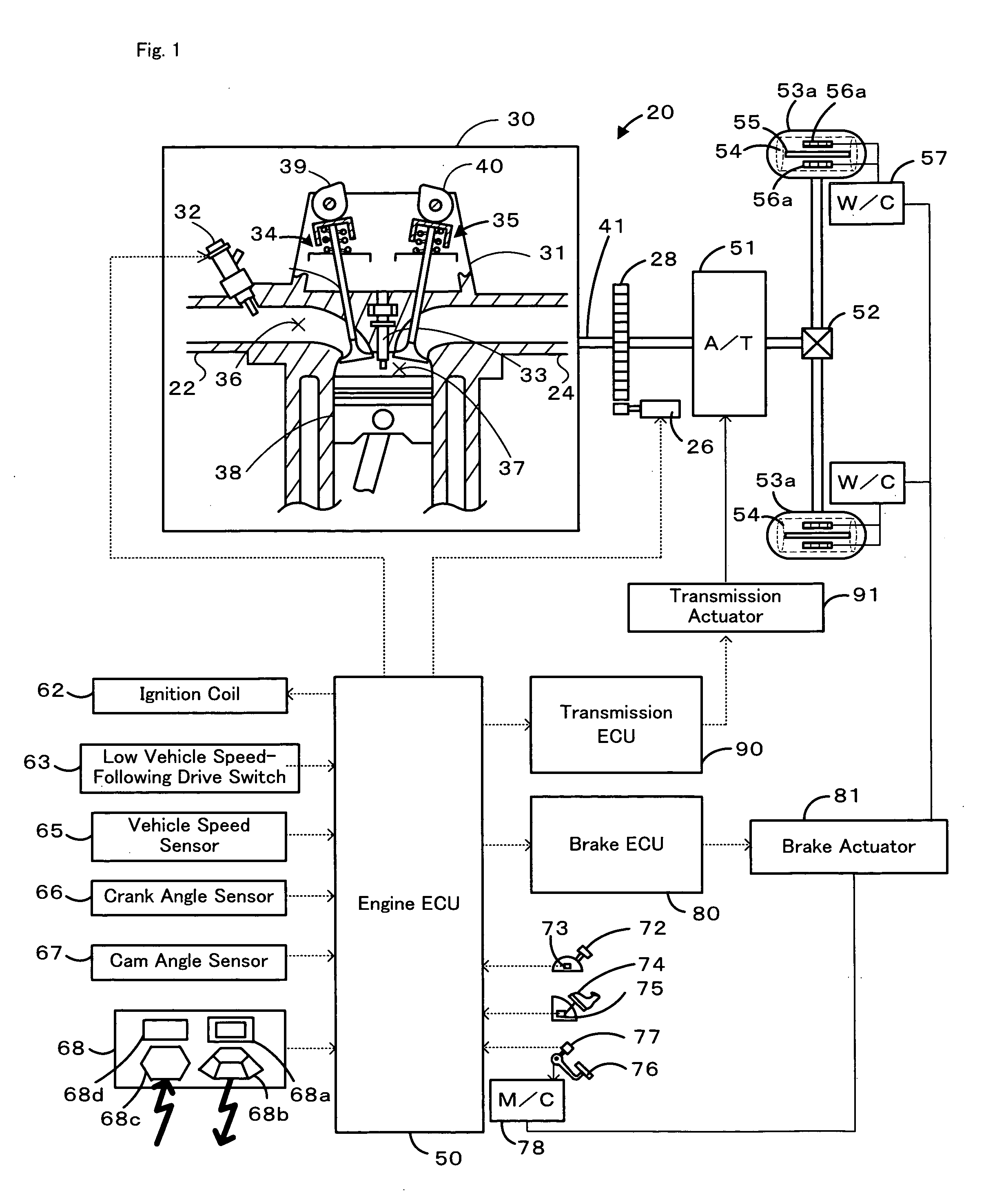

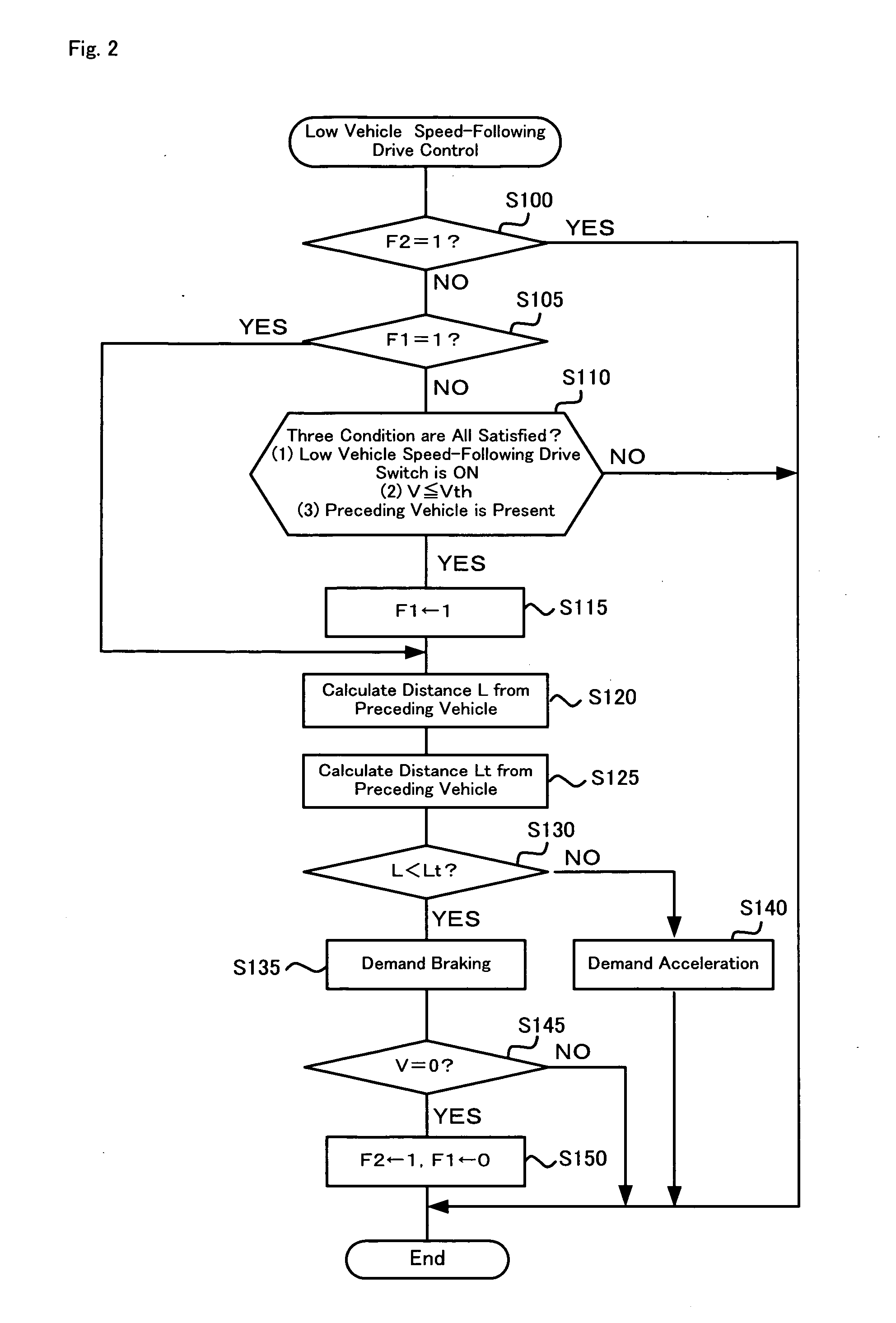

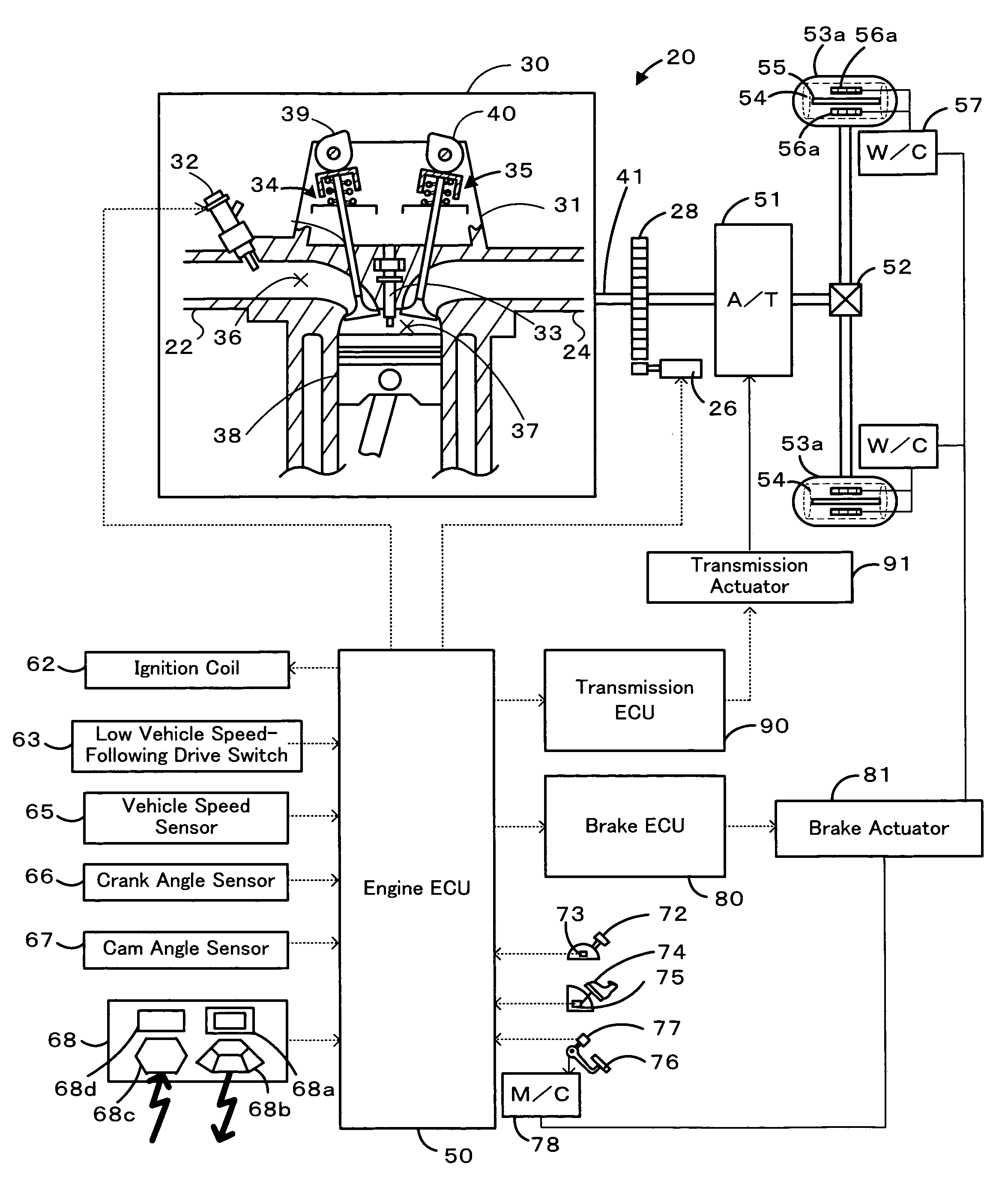

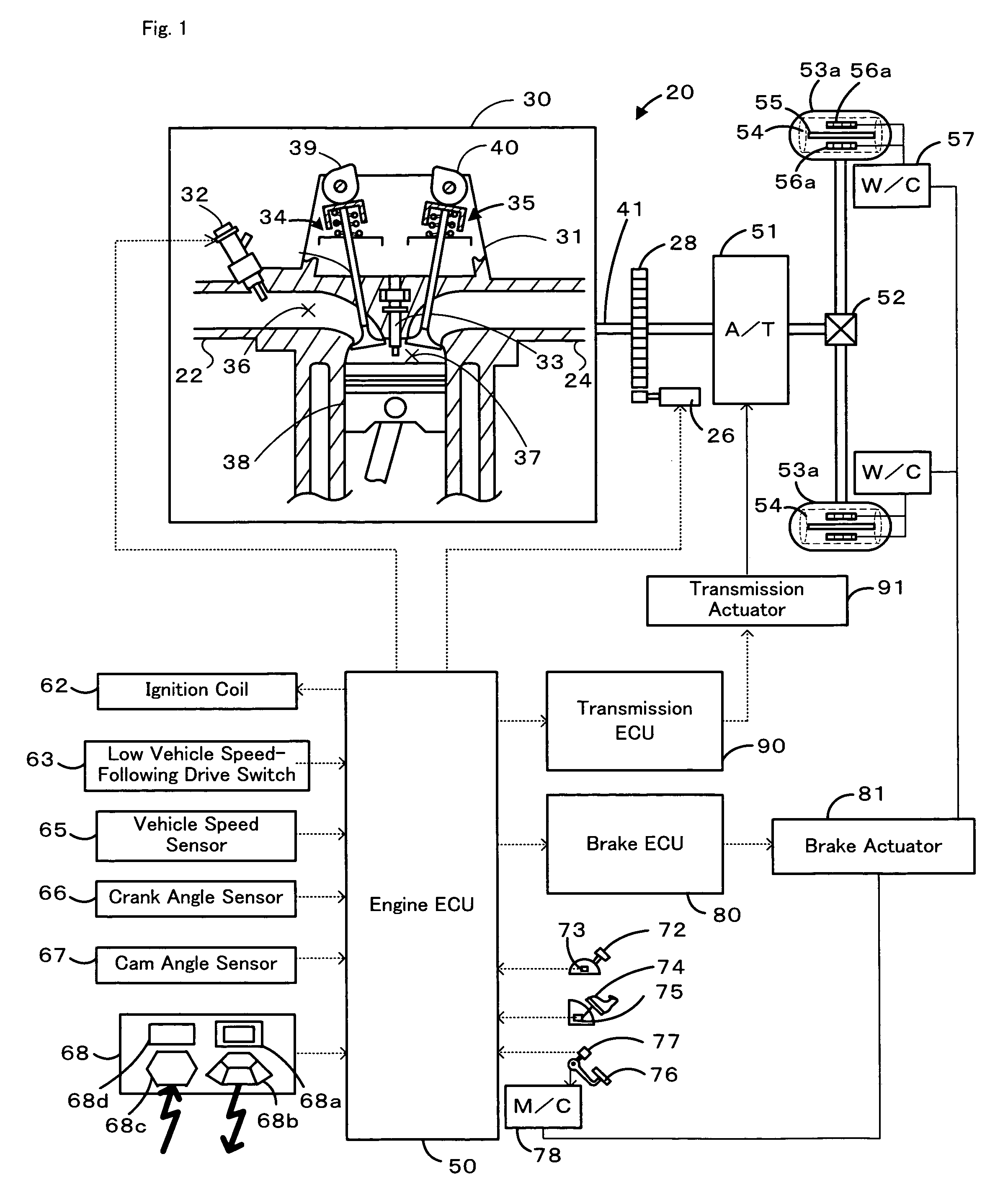

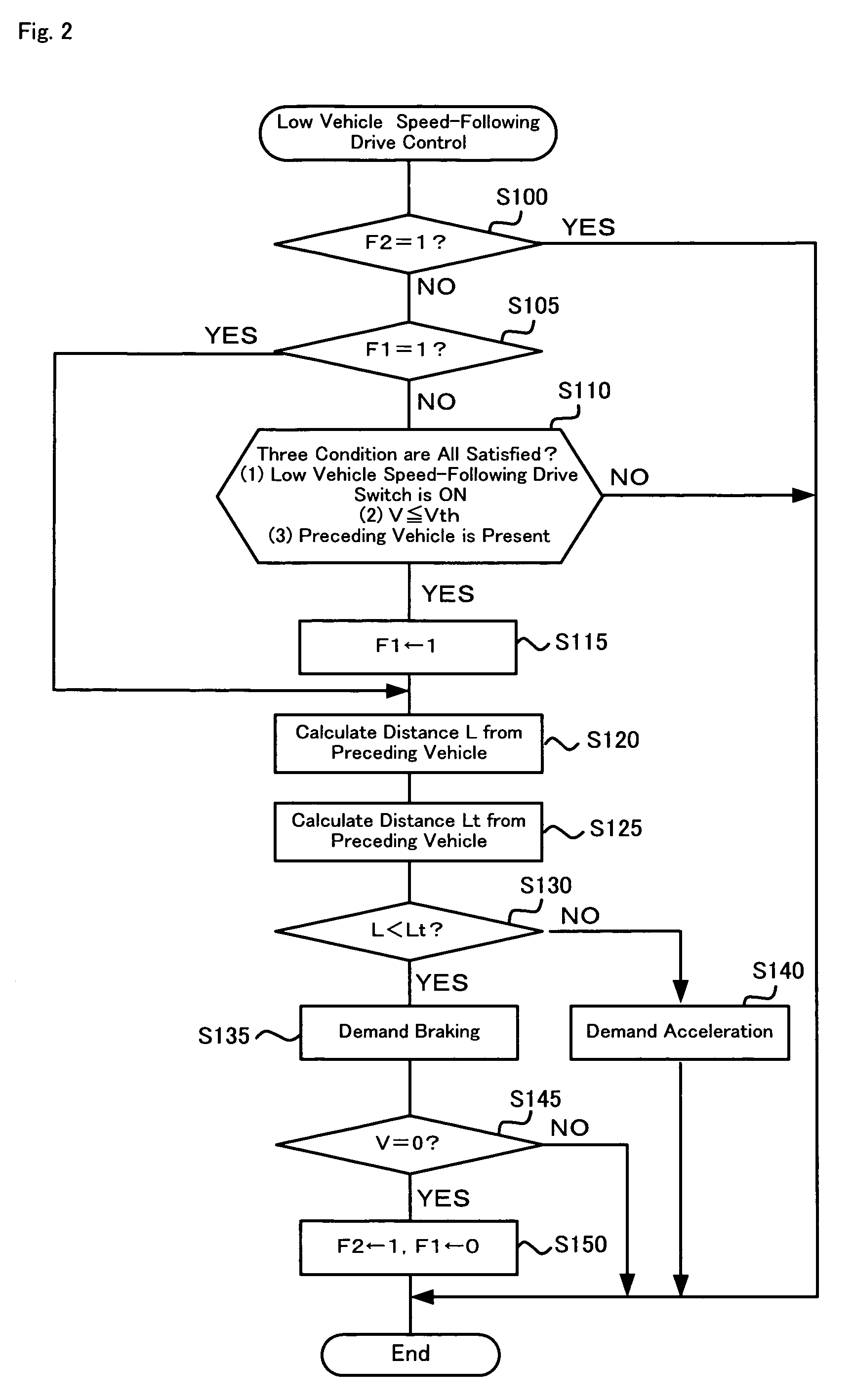

Engine automatic stop restart control apparatus, vehicle equipped with engine automatic stop restart control apparatus, and engine automatic stop restart method

ActiveUS20060142121A1Increase fuel consumptionDrawback can be obviatedAnalogue computers for vehiclesVehicle fittingsMobile vehicleIdle speed

In a vehicle having idle stop functions and low vehicle speed-following drive functions, when a vehicle automatic stop flag F2 is identified as 1 at step S220, determines whether all engine stop conditions except depression of brake pedal are satisfied in step S240. When it is determined all the engine stop conditions except depression of the brake pedal are satisfied, ignition and fuel injection in each cylinder of engine are stopped to automatically stop the engine in step S260. In this arrangement, the driver's depression of brake is excluded from the engine stop conditions. Therefore, even when the motor vehicle automatically stops without the driver's depression of brake, the engine is automatically stopped.

Owner:TOYOTA JIDOSHA KK

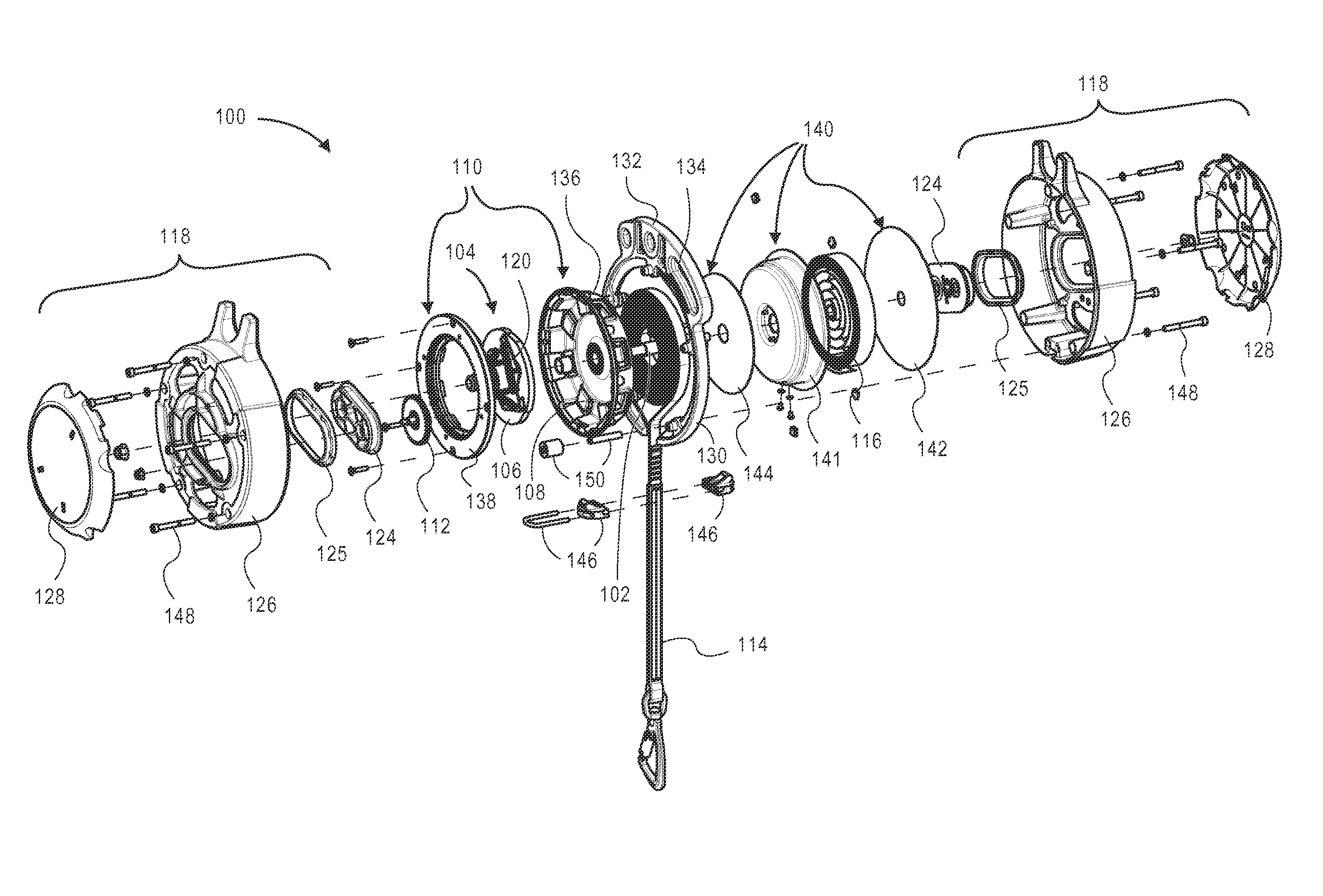

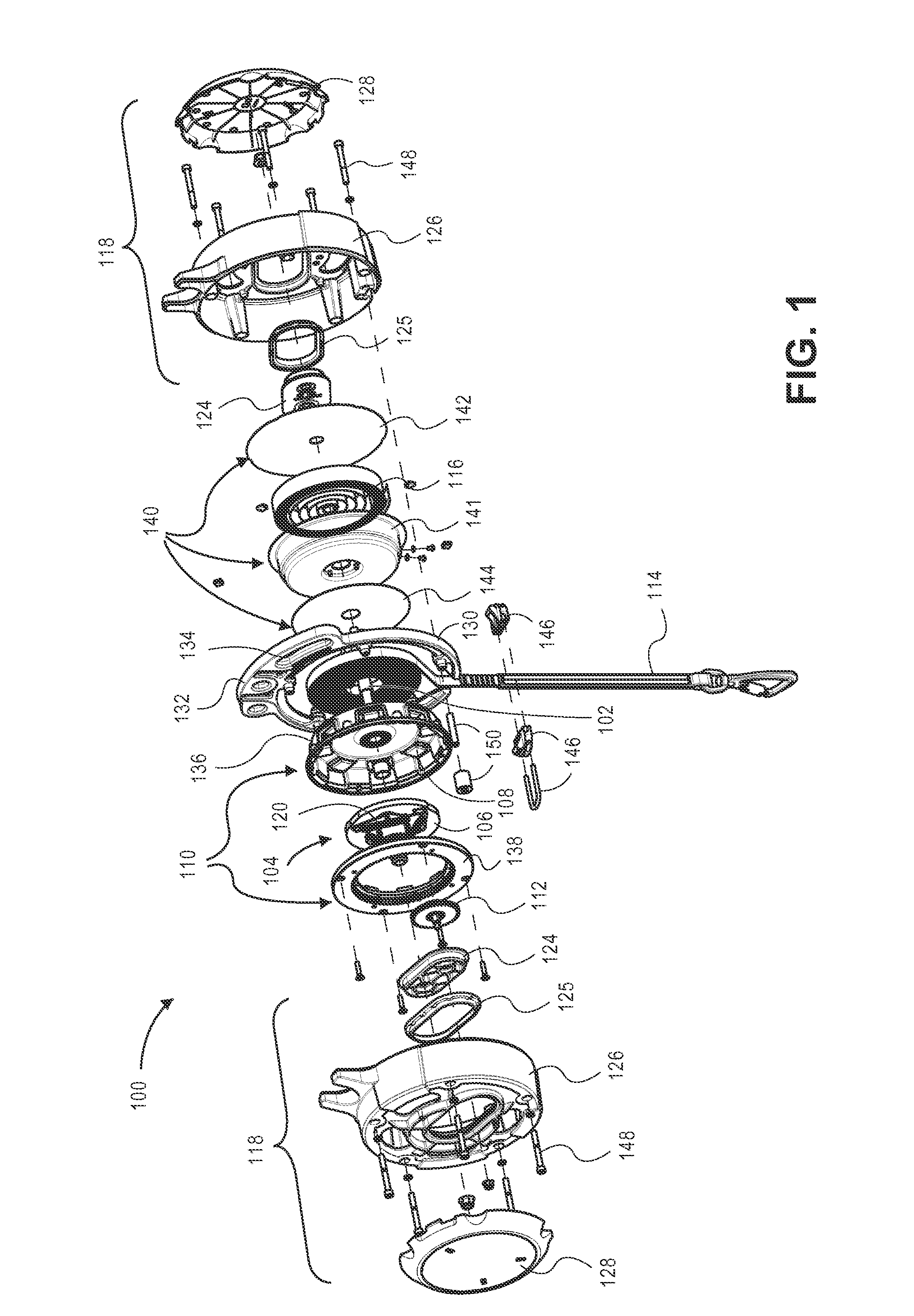

Line dispensing device with eddy current breaking for use with climbing and evacuation

Owner:EDDY CURRENT PARTNERSHIP

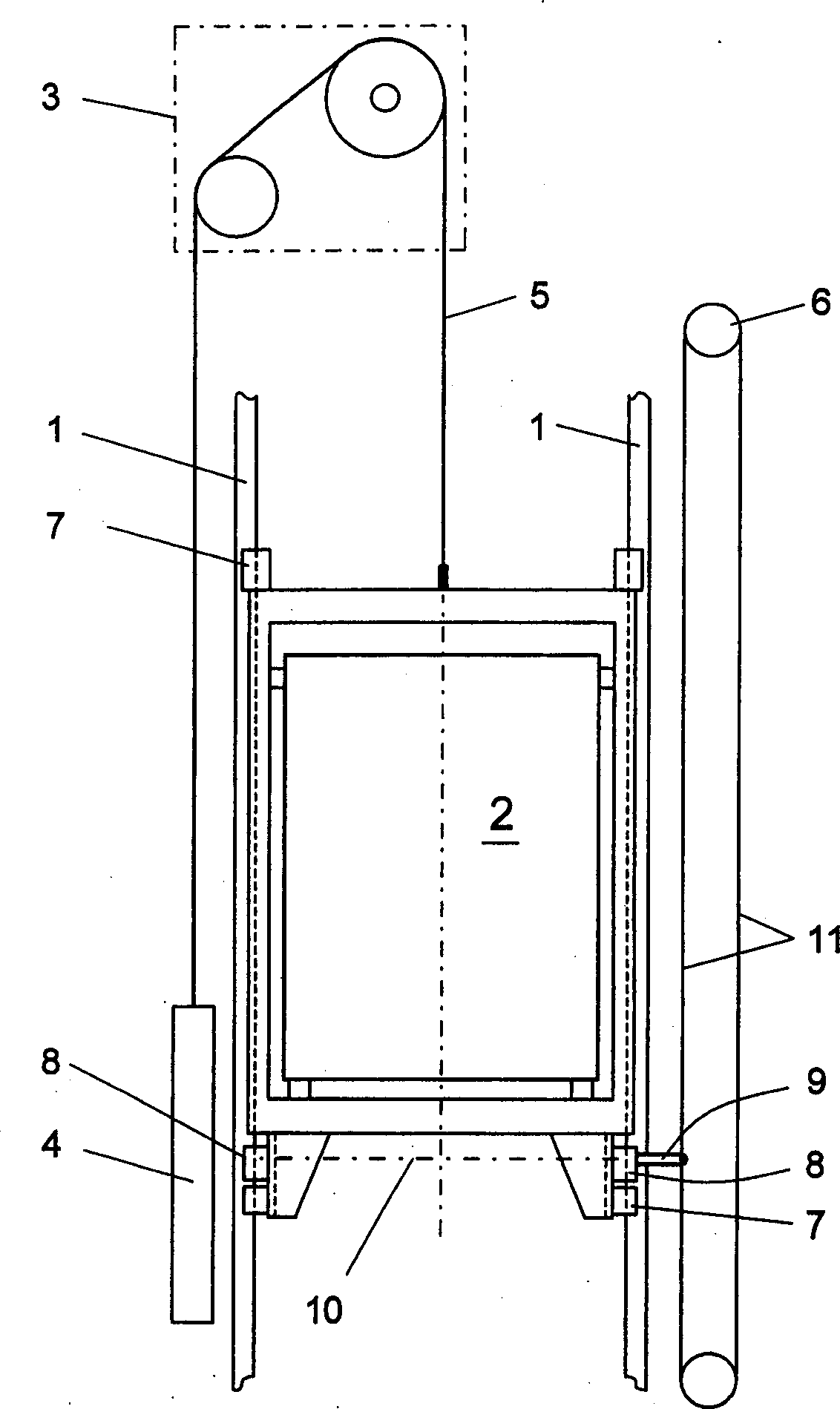

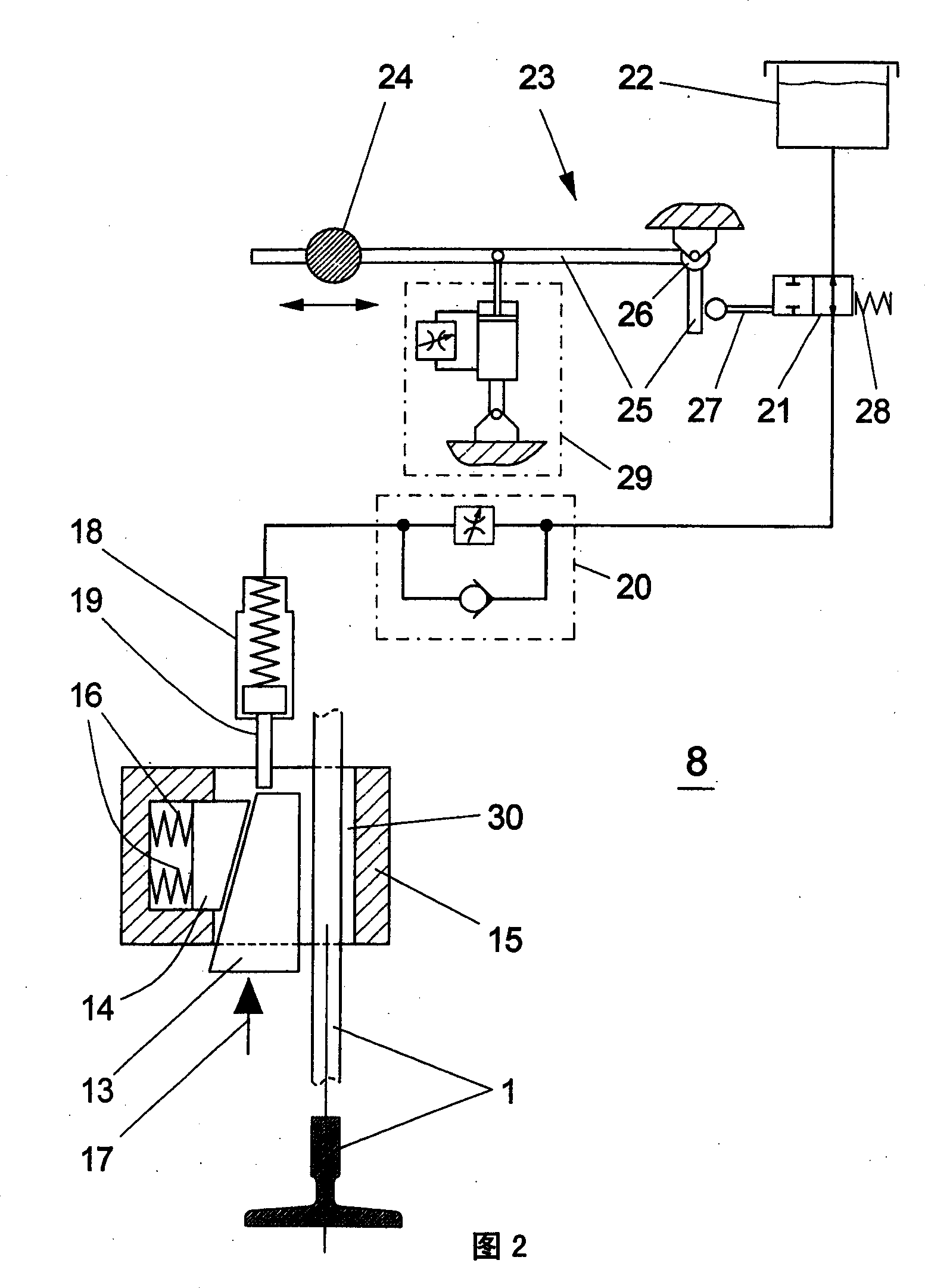

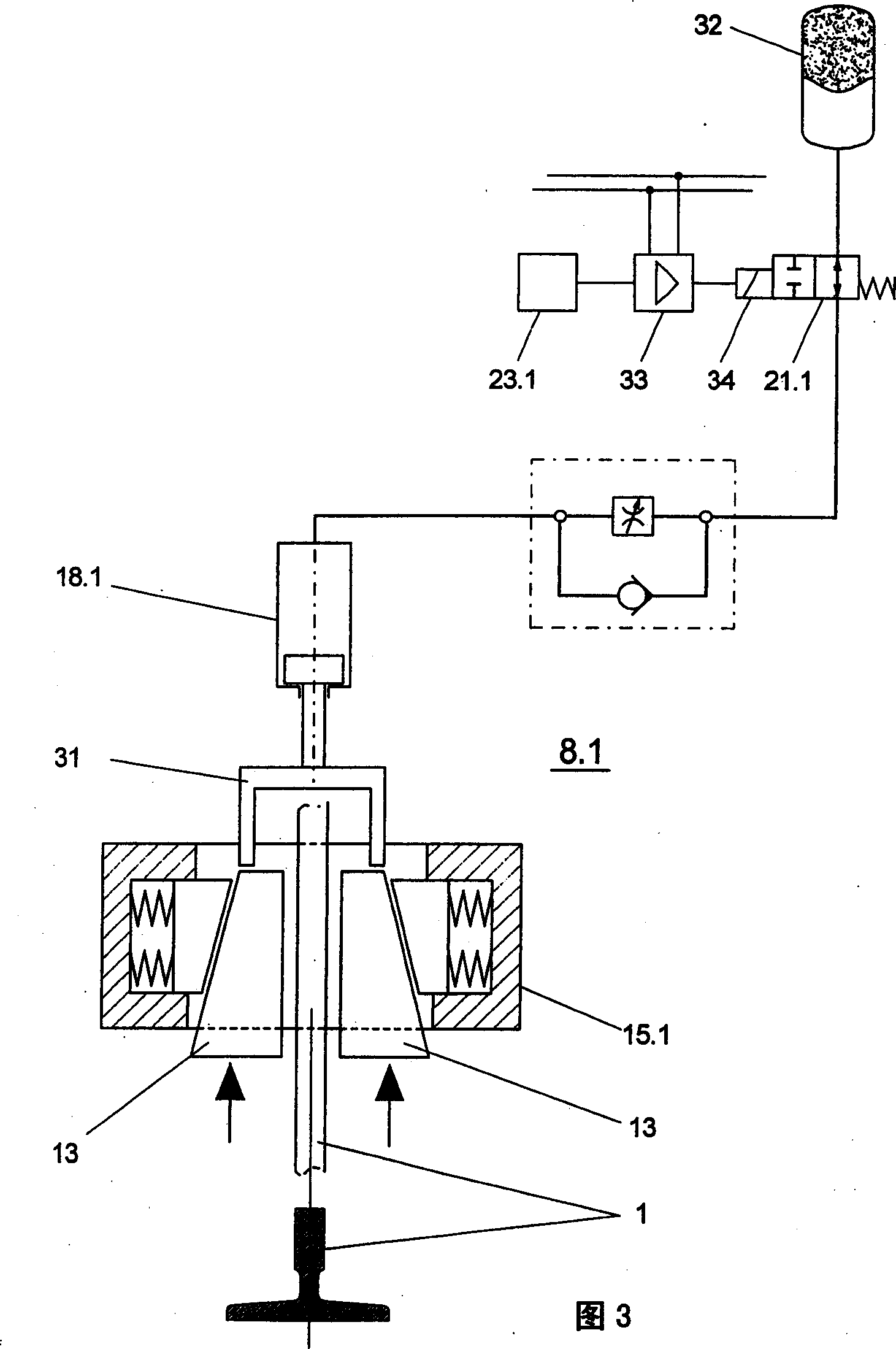

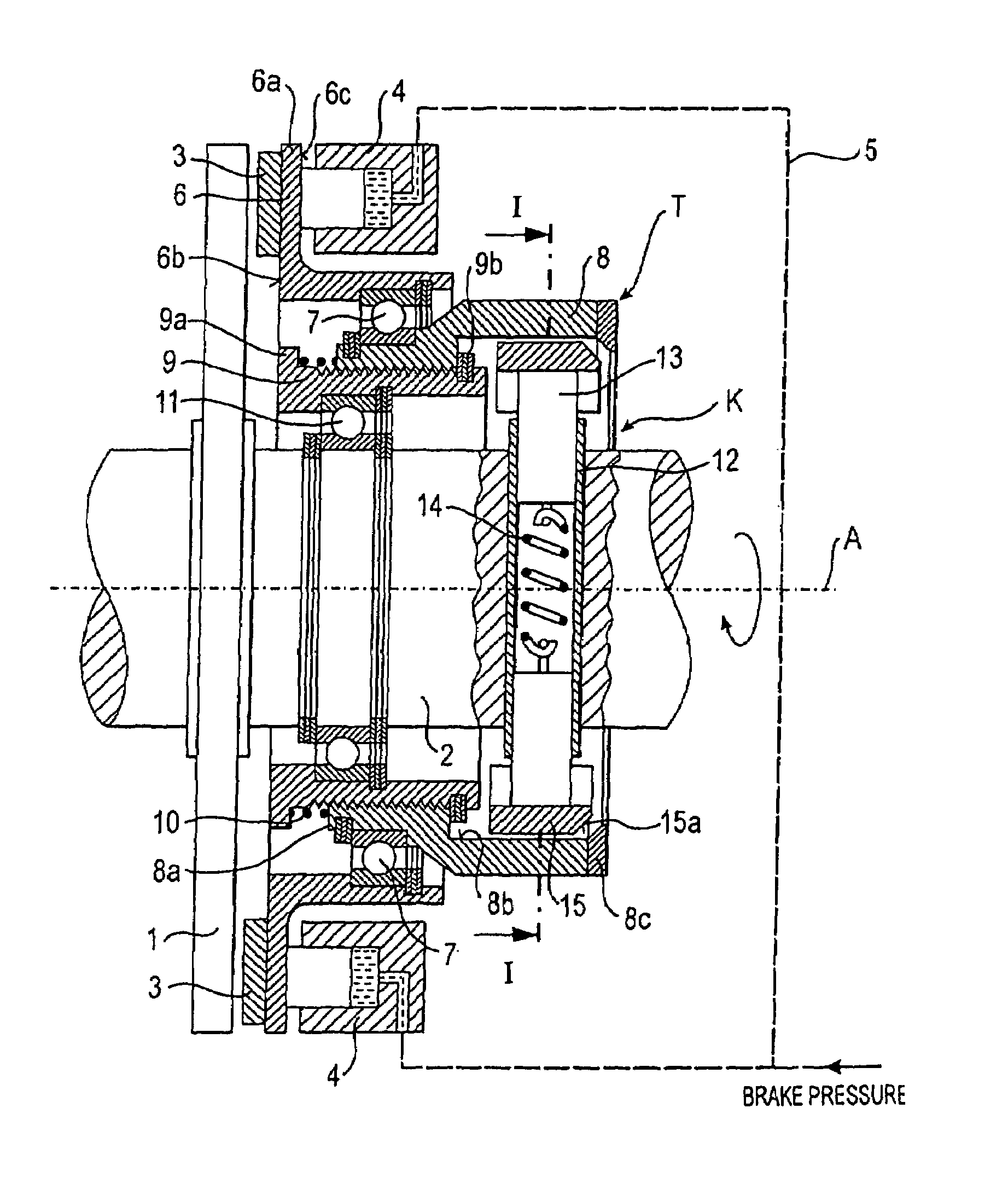

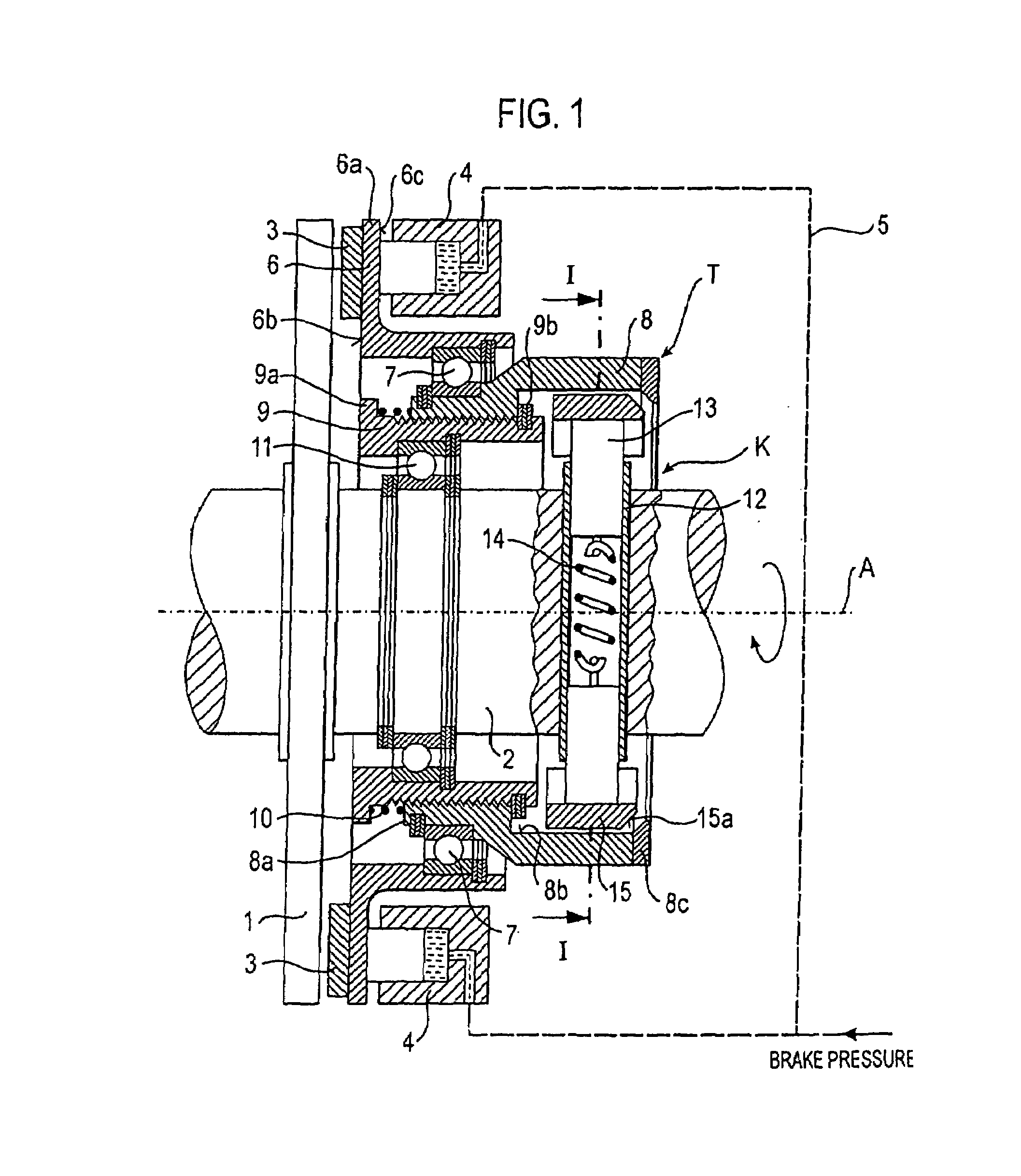

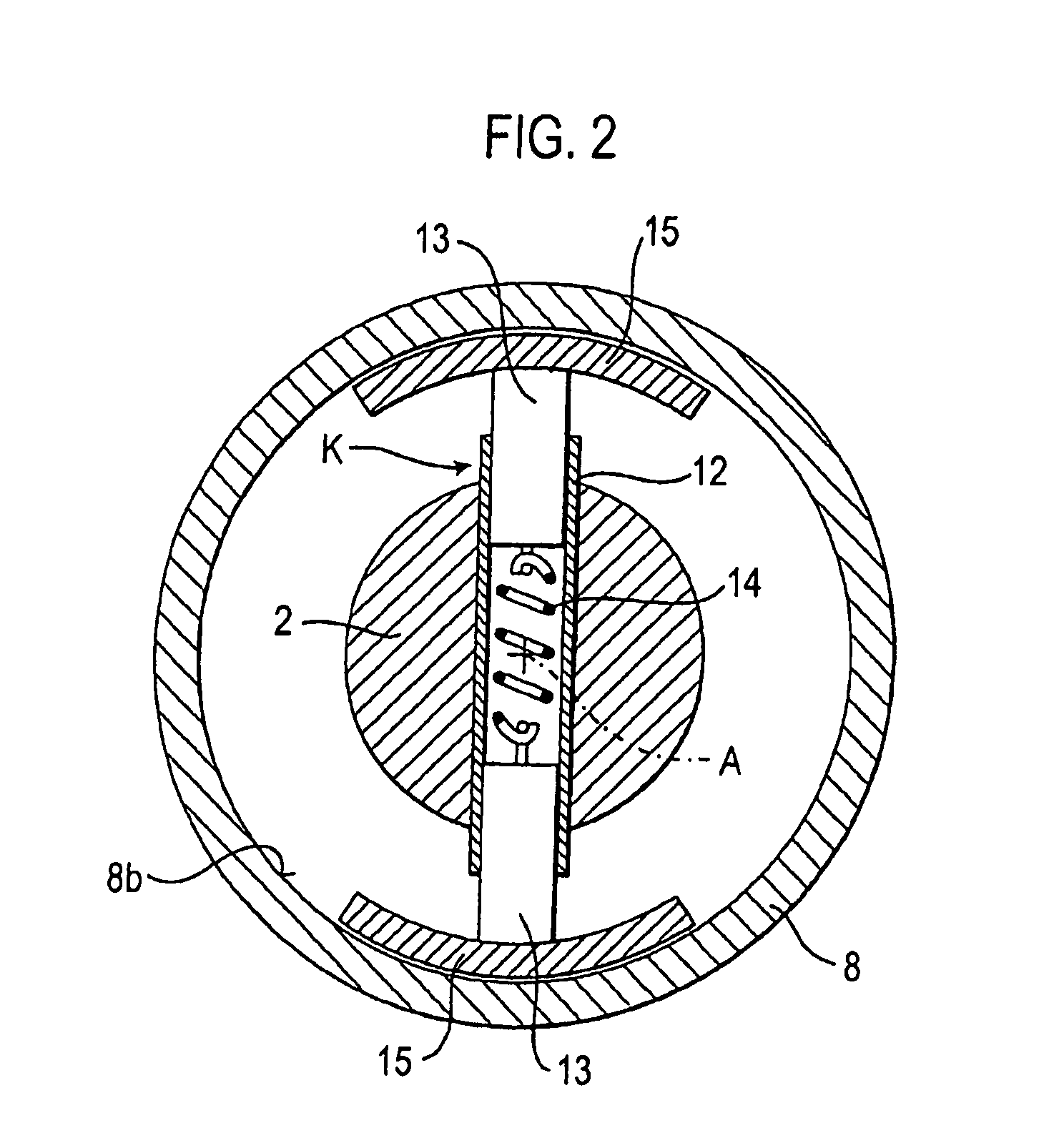

Safety brake iwth relative delayed brake force

InactiveCN1357488AGuaranteed reliabilityEasy to understandSelf acting brakesElevatorsEngineeringMechanical engineering

A safety brake for a load receiving means of a lift, in which at least one brake wedge (13) penetrates into a tapering gap between a resiliently supported pressure body (14) and a guide rail (1) of the load receiving means (2) and thereby generates a braki ng force, is equipped with a device (18) which limits the stroke of the brake wedge and thus the braking force in dependence on the retardation occurring at the load receivi ng means.

Owner:INVENTIO AG

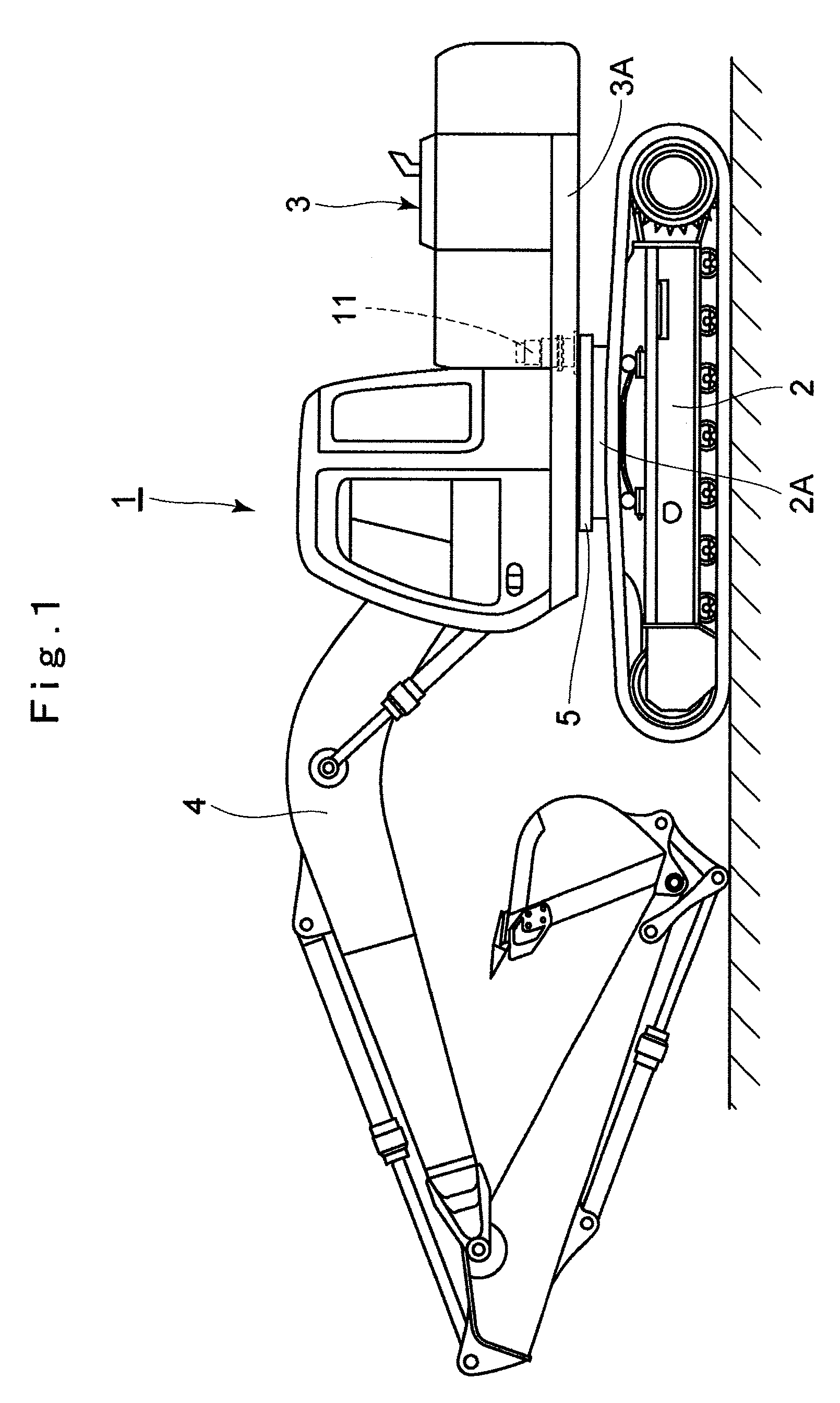

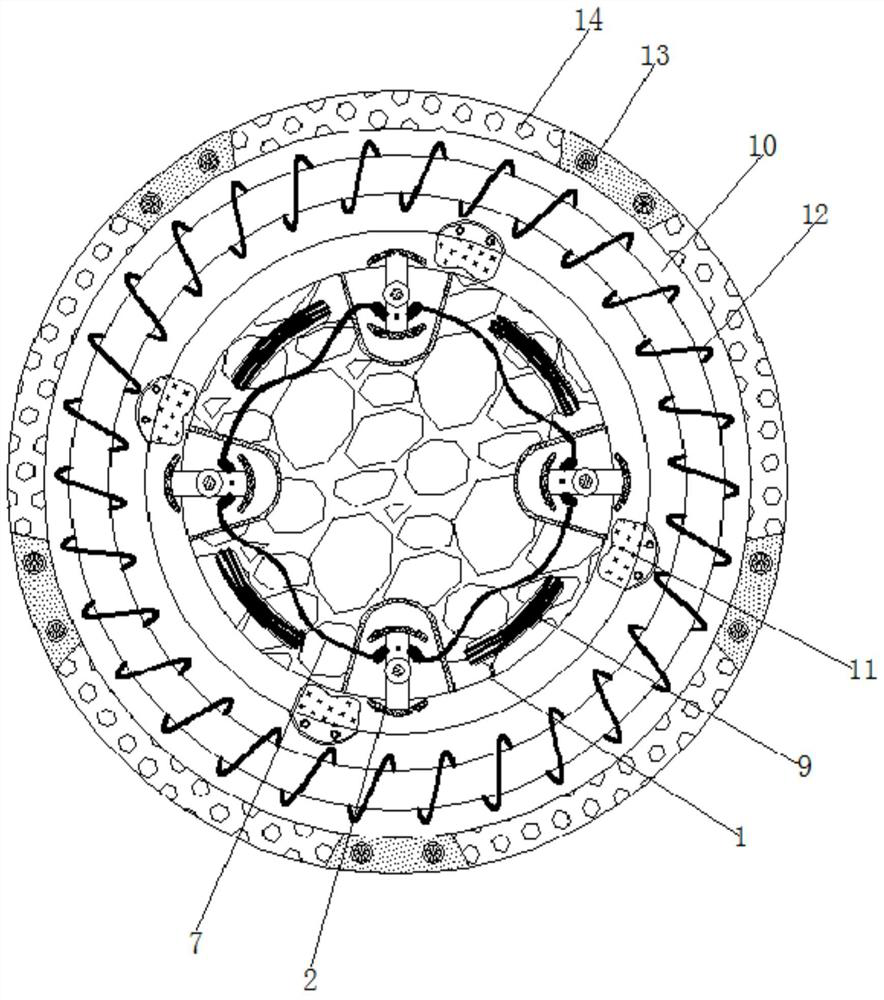

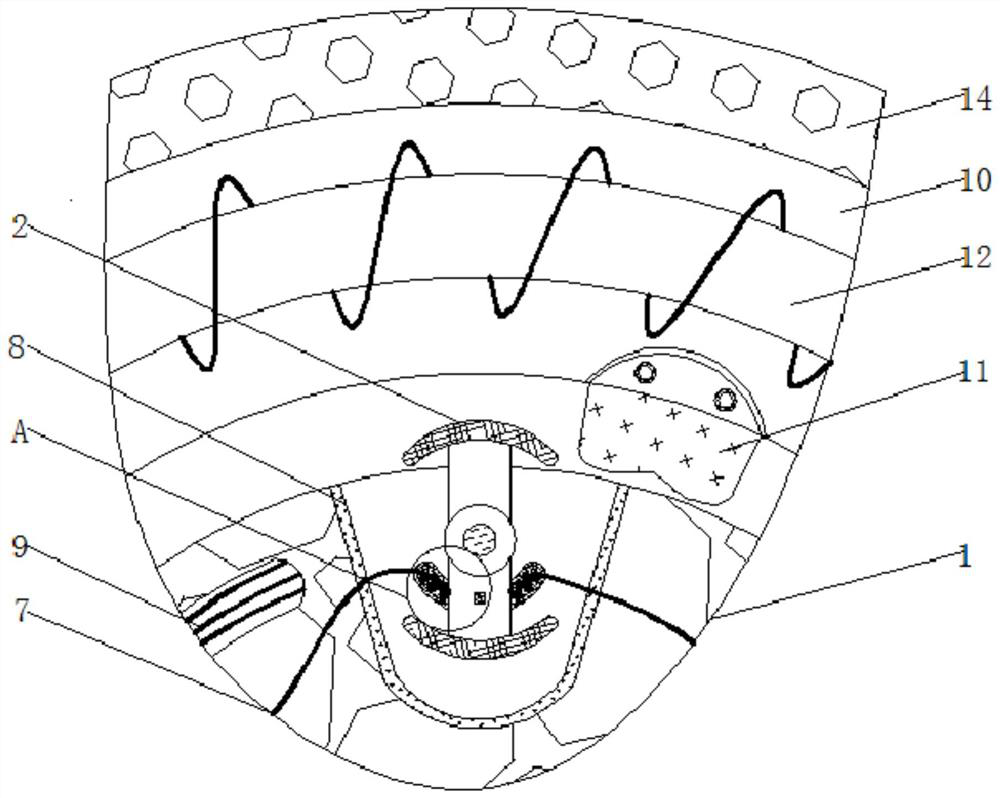

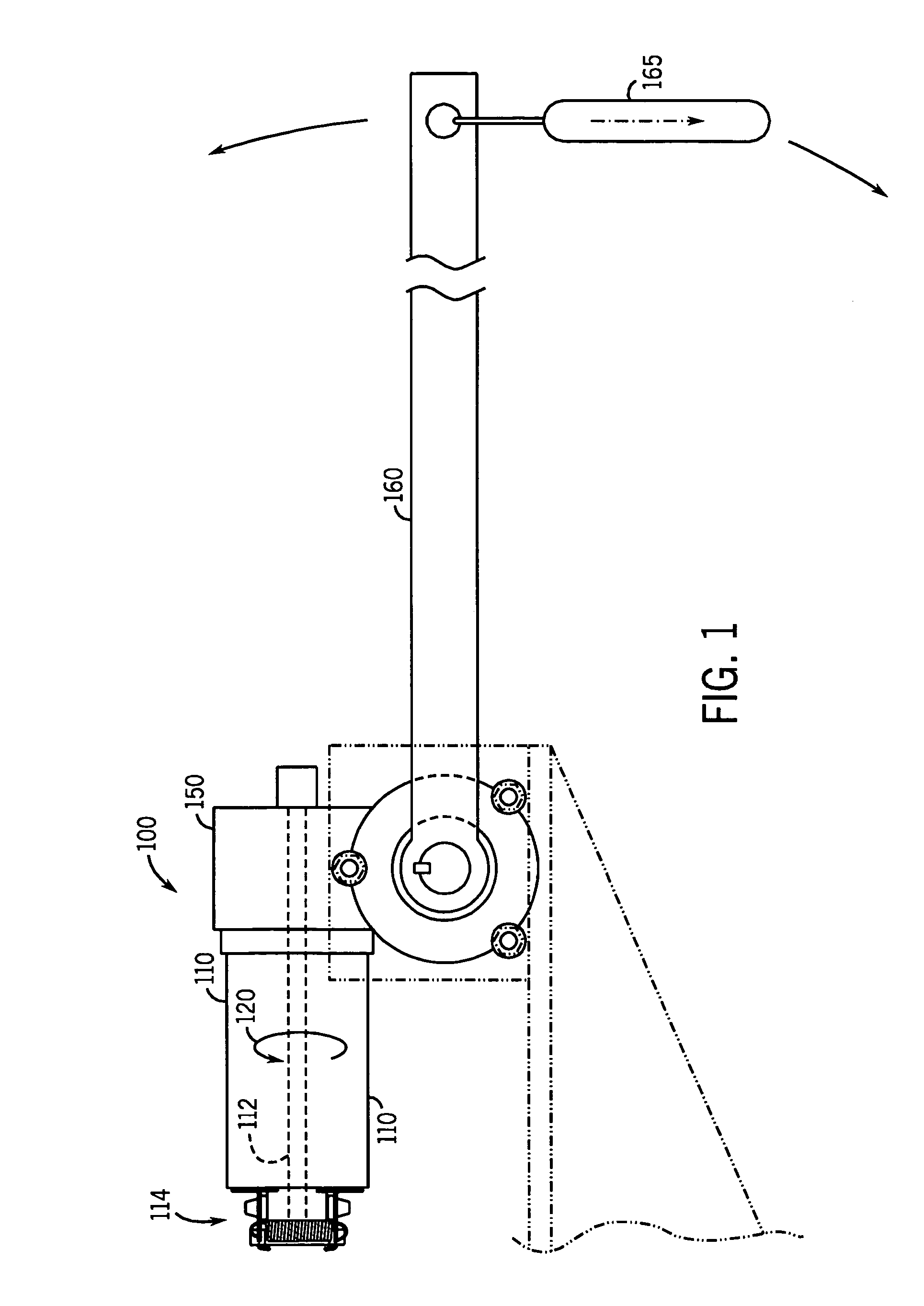

Vehicle speed control device and vehicle equipped with vehicle speed control device

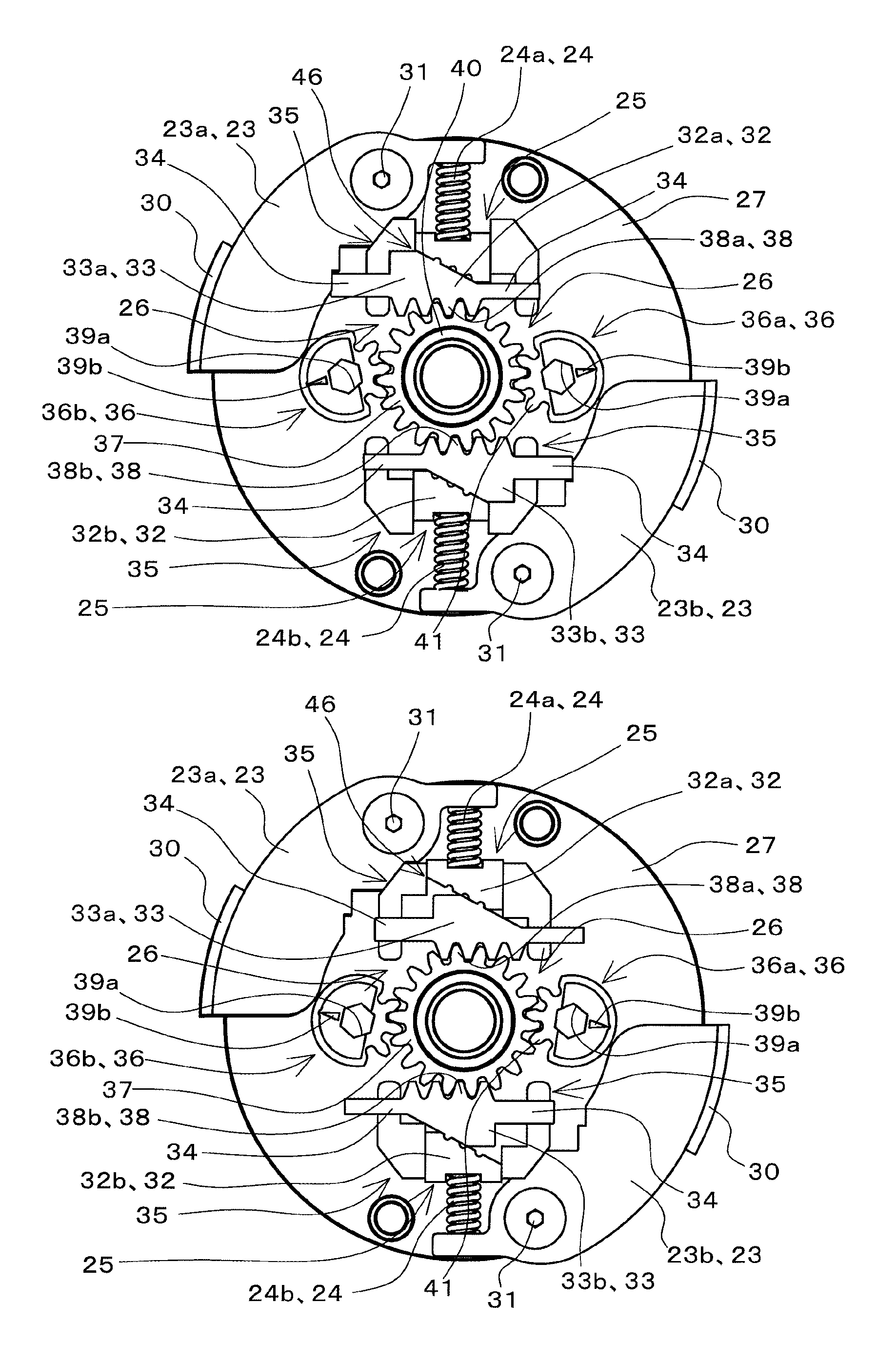

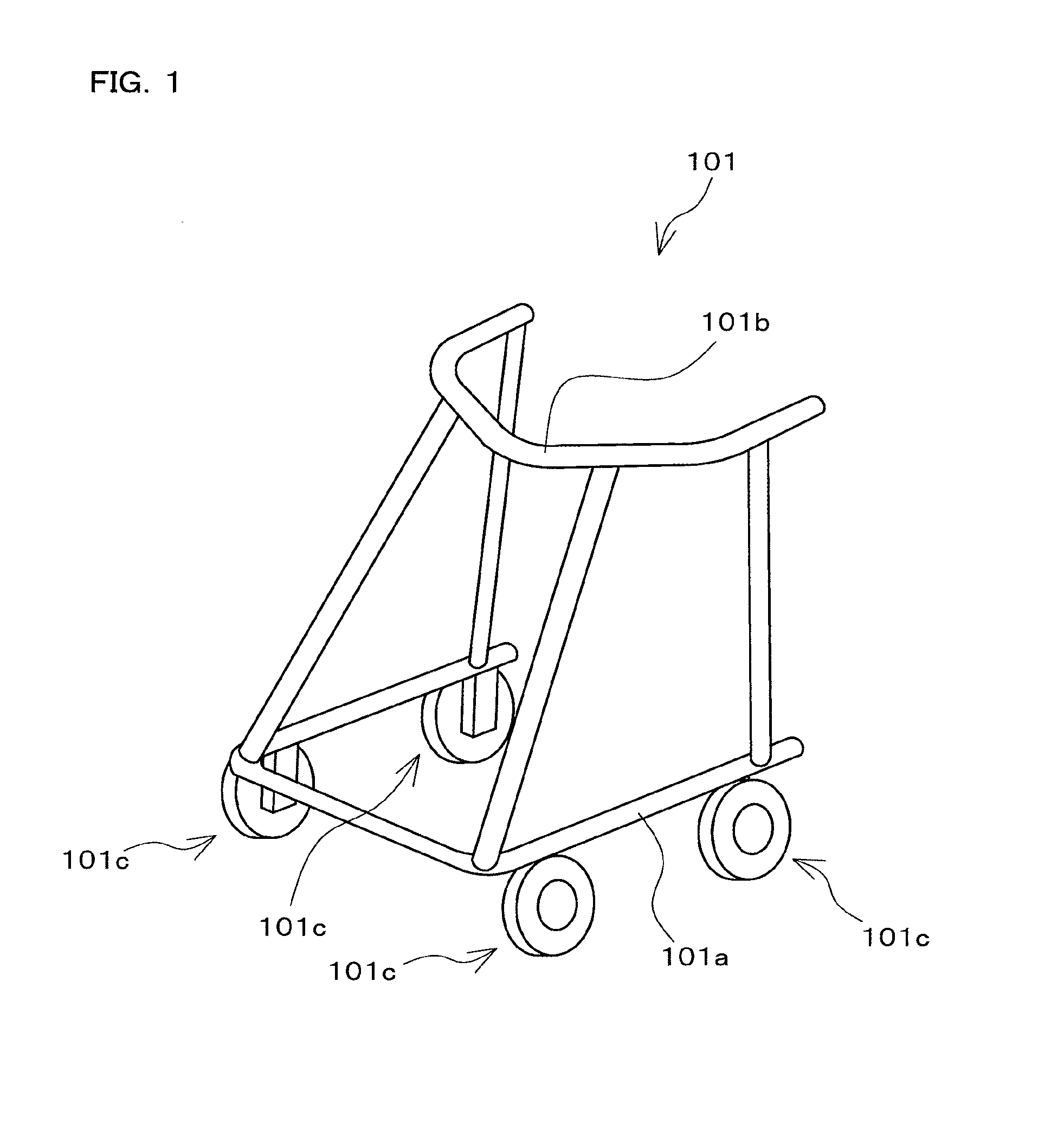

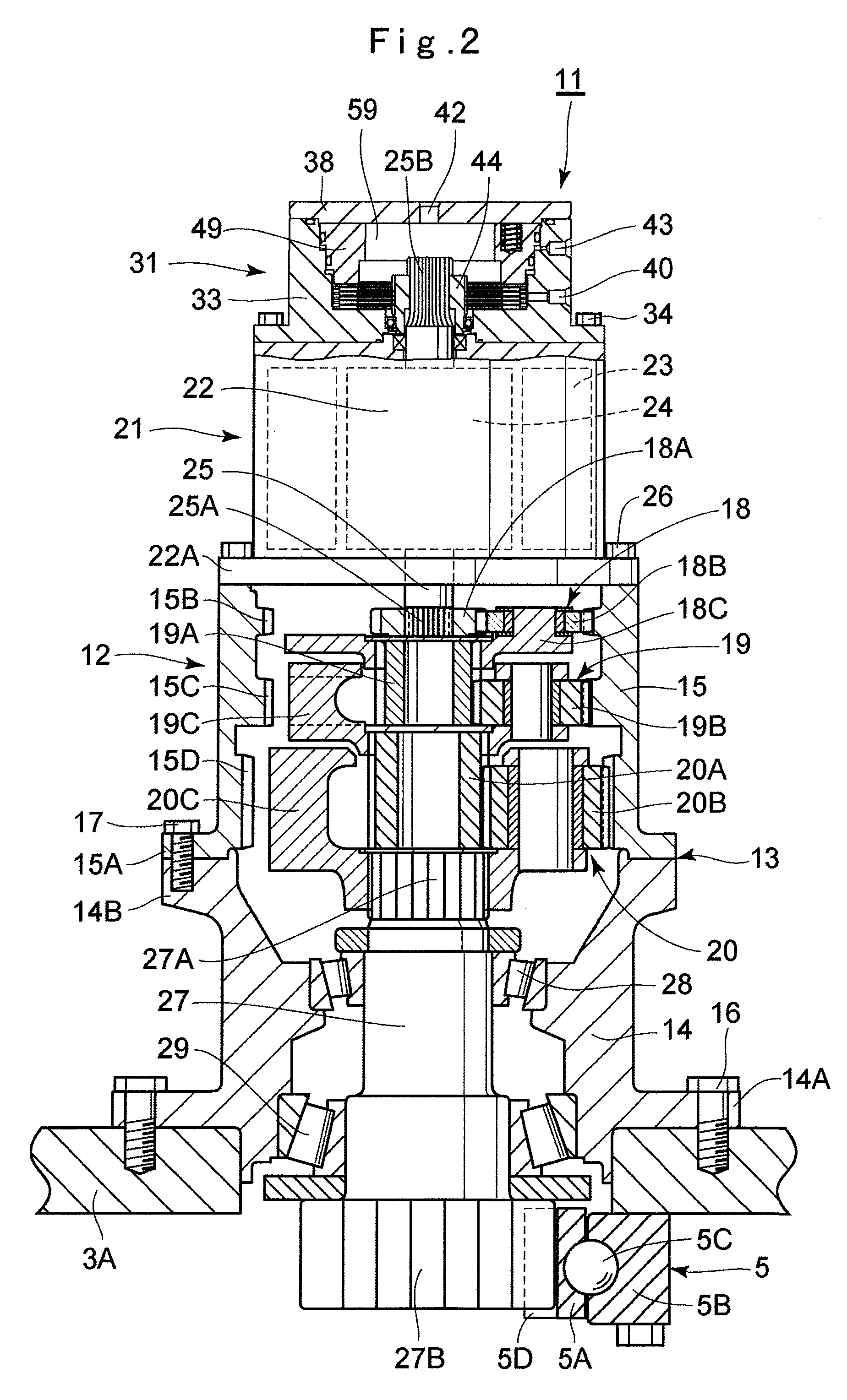

ActiveUS20140224597A1Easy to changeBraking element arrangementsSelf acting brakesEngineeringBrake shoe

Provided is a vehicle speed control device with respect to which the speed at which a centrifugal brake operates can be easily changed from the outside without disassembling the device. A brake drum 11 is fixed to a vehicle body 101a. A brake shoe 23 rotates around a rotary shaft 20 of the wheel 101c, and reduces the rotation speed of the wheel 101c as a result of coming into contact with an inner circumferential side face of the brake drum 11. A spring 24 prevents contact between the brake drum 11 and the brake shoe 23 when the rotation speed of the wheel 101c is lower than or equal to a predetermined speed, and permits contact between the brake drum 11 and the brake shoe 23 when the rotation speed of the wheel 101c exceeds the predetermined speed. A position change mechanism 25 is installed within the brake drum 11, and changes the position of an end of the spring 24 on one end side. A transmission mechanism 26 transmits a force that is input by an external operation to the position change mechanism 25 and drives the position change mechanism.

Owner:NABLESCO CORP +1

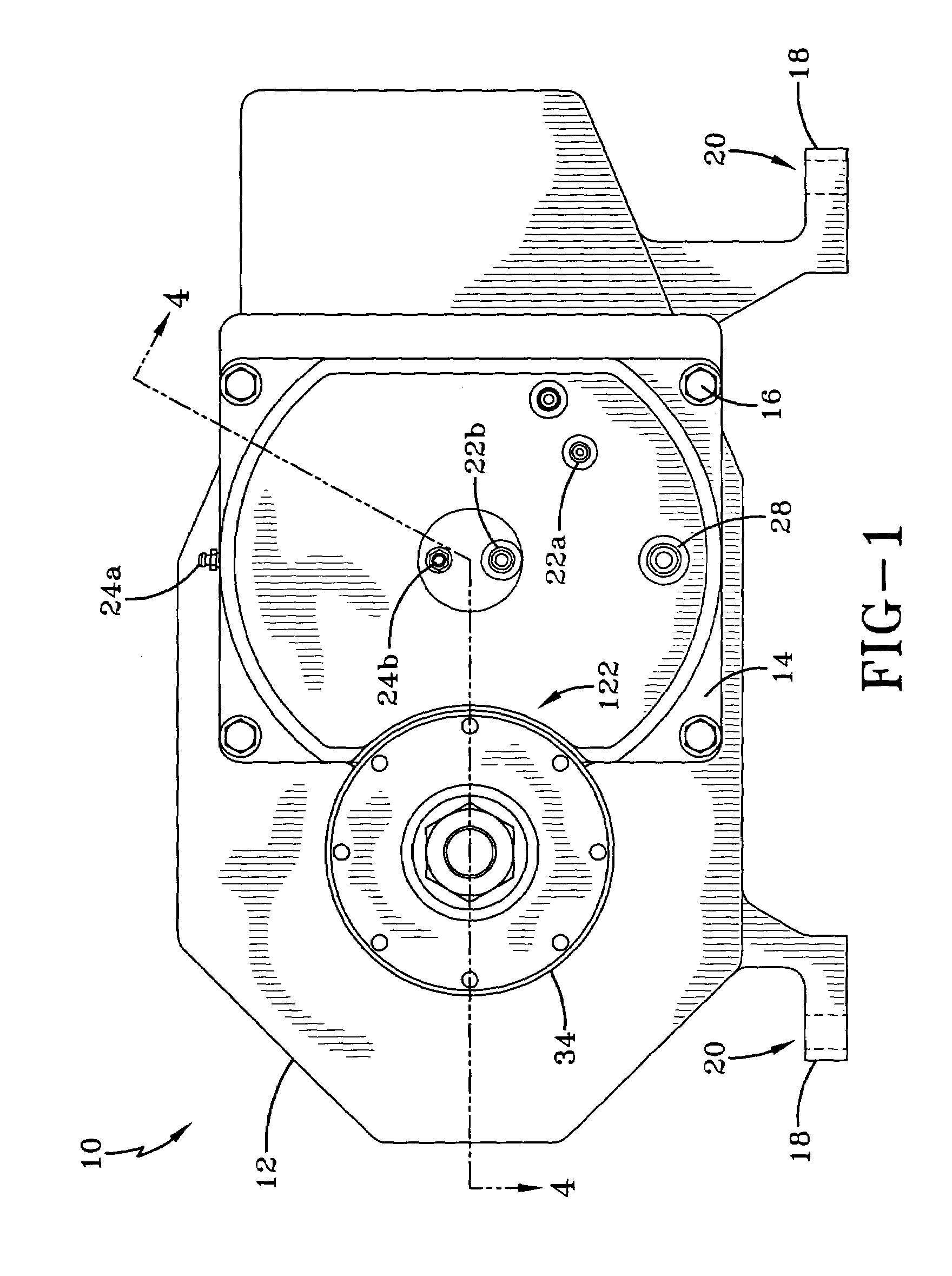

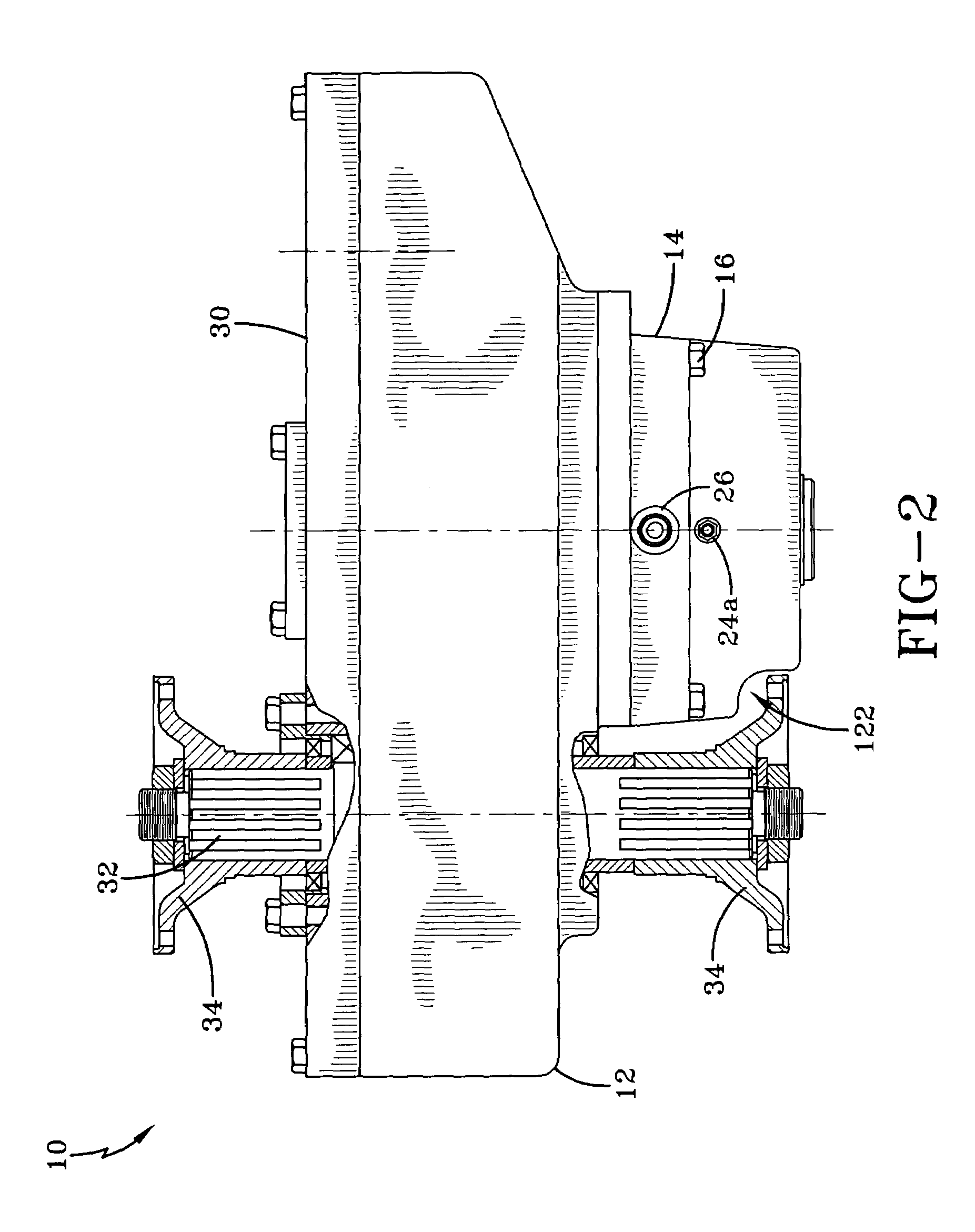

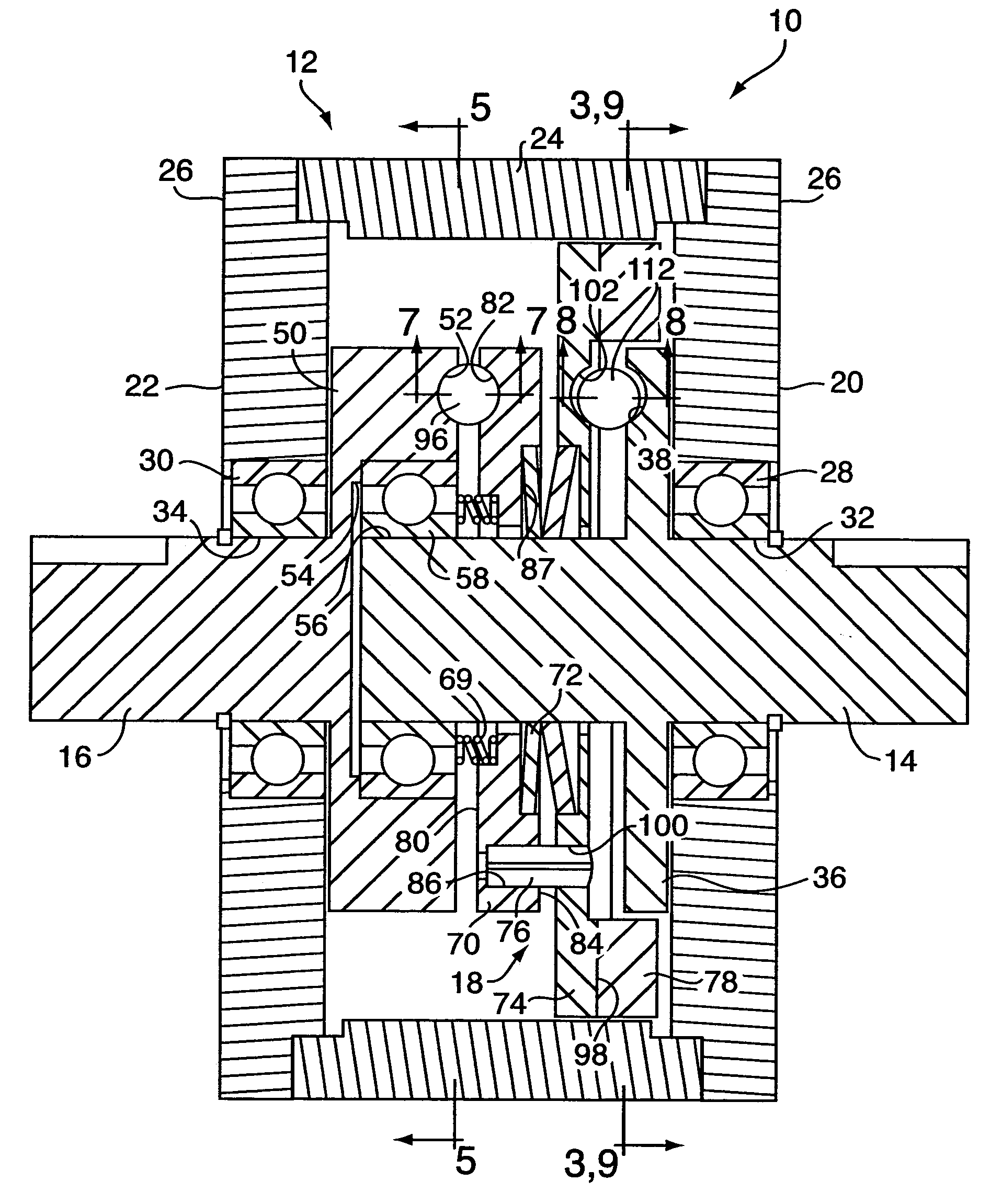

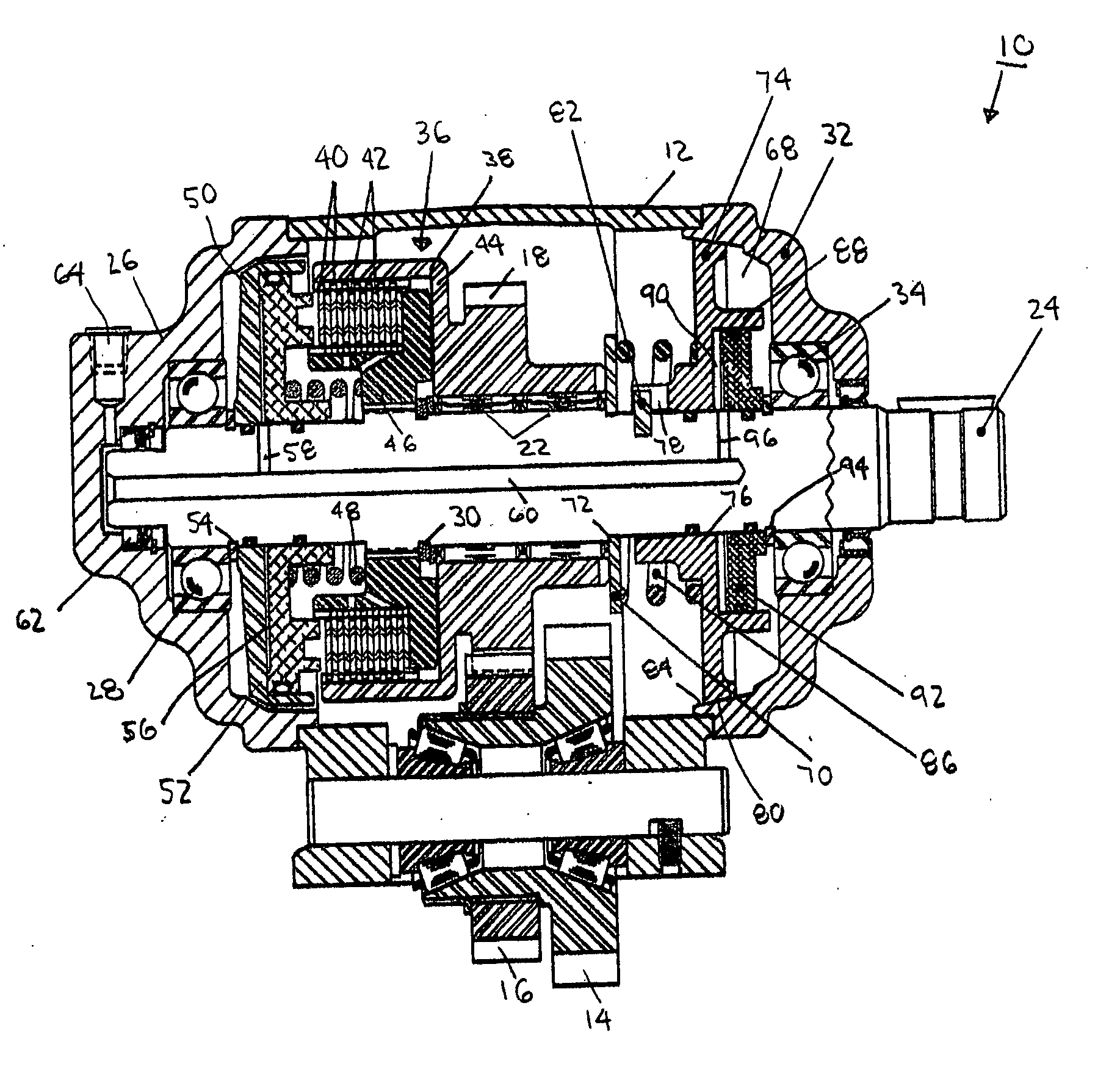

Gearbox brake for mining machinery

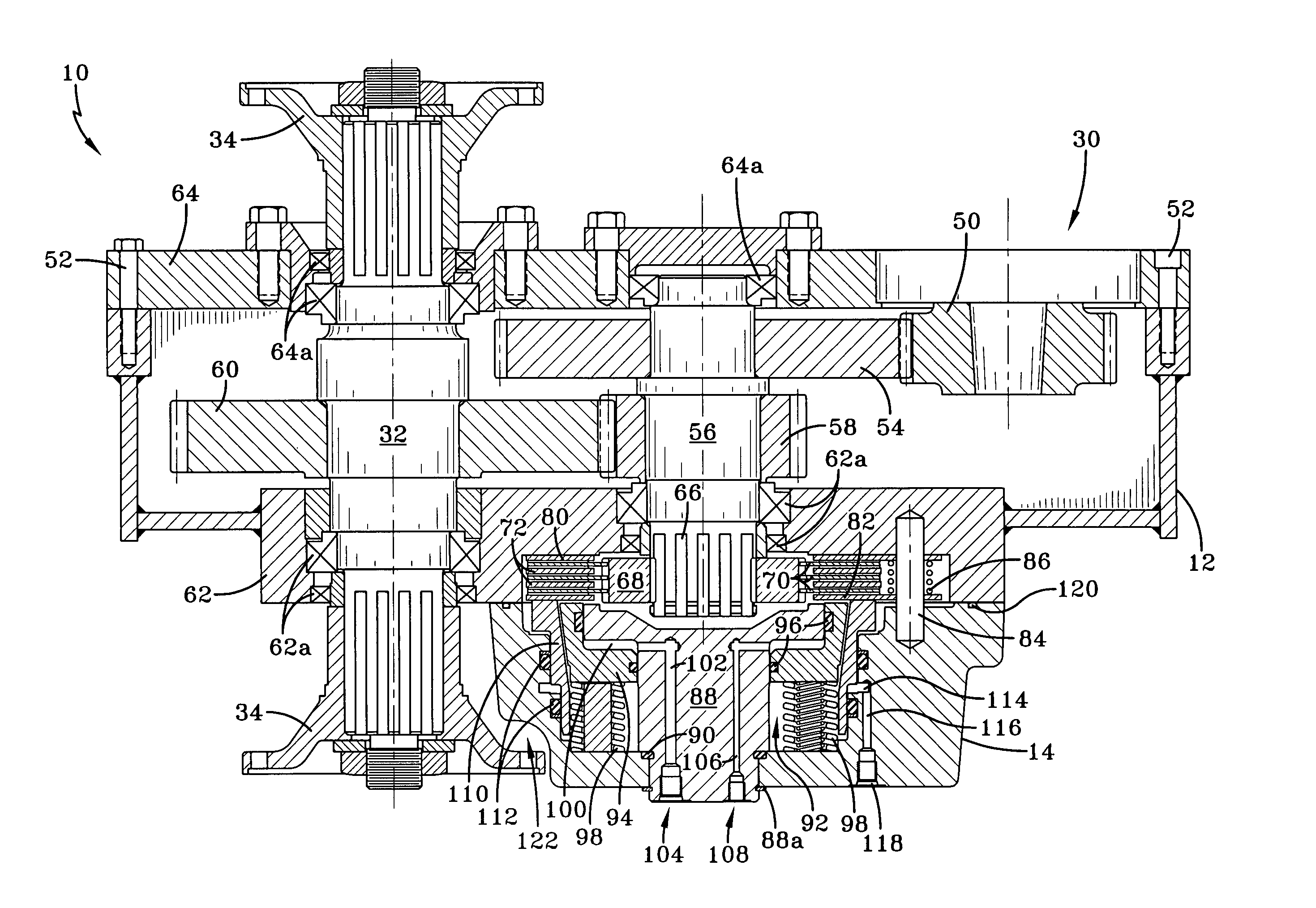

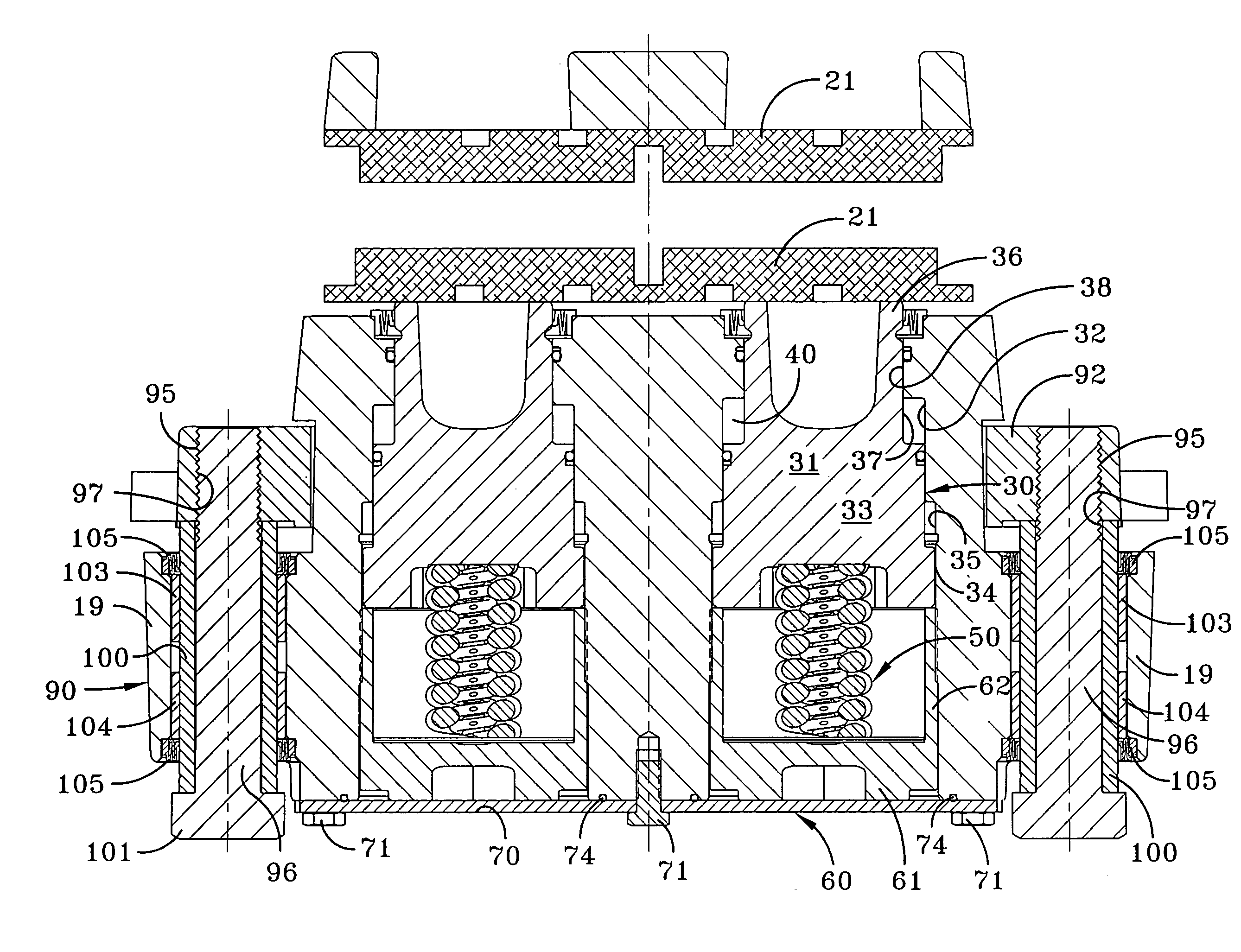

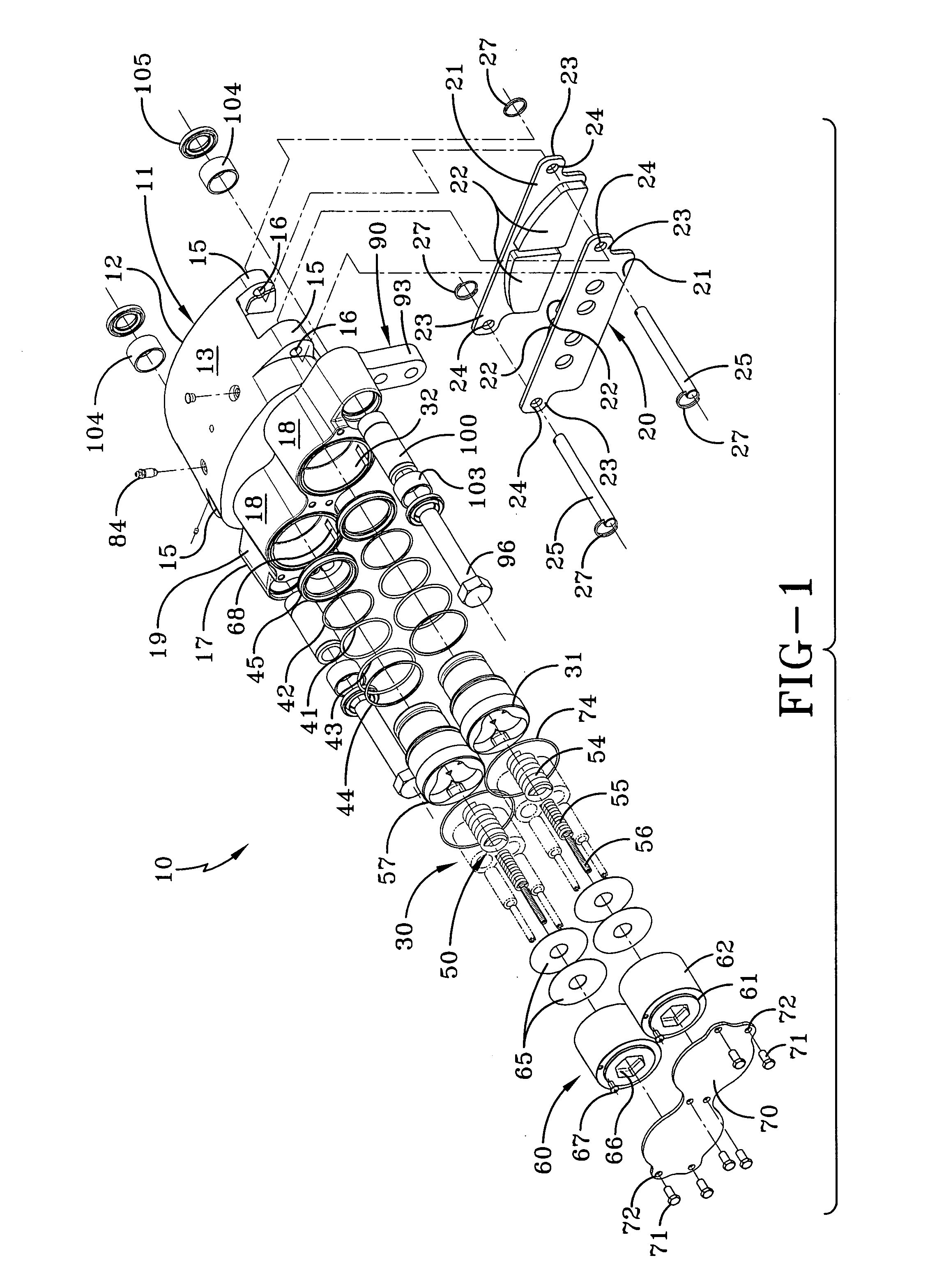

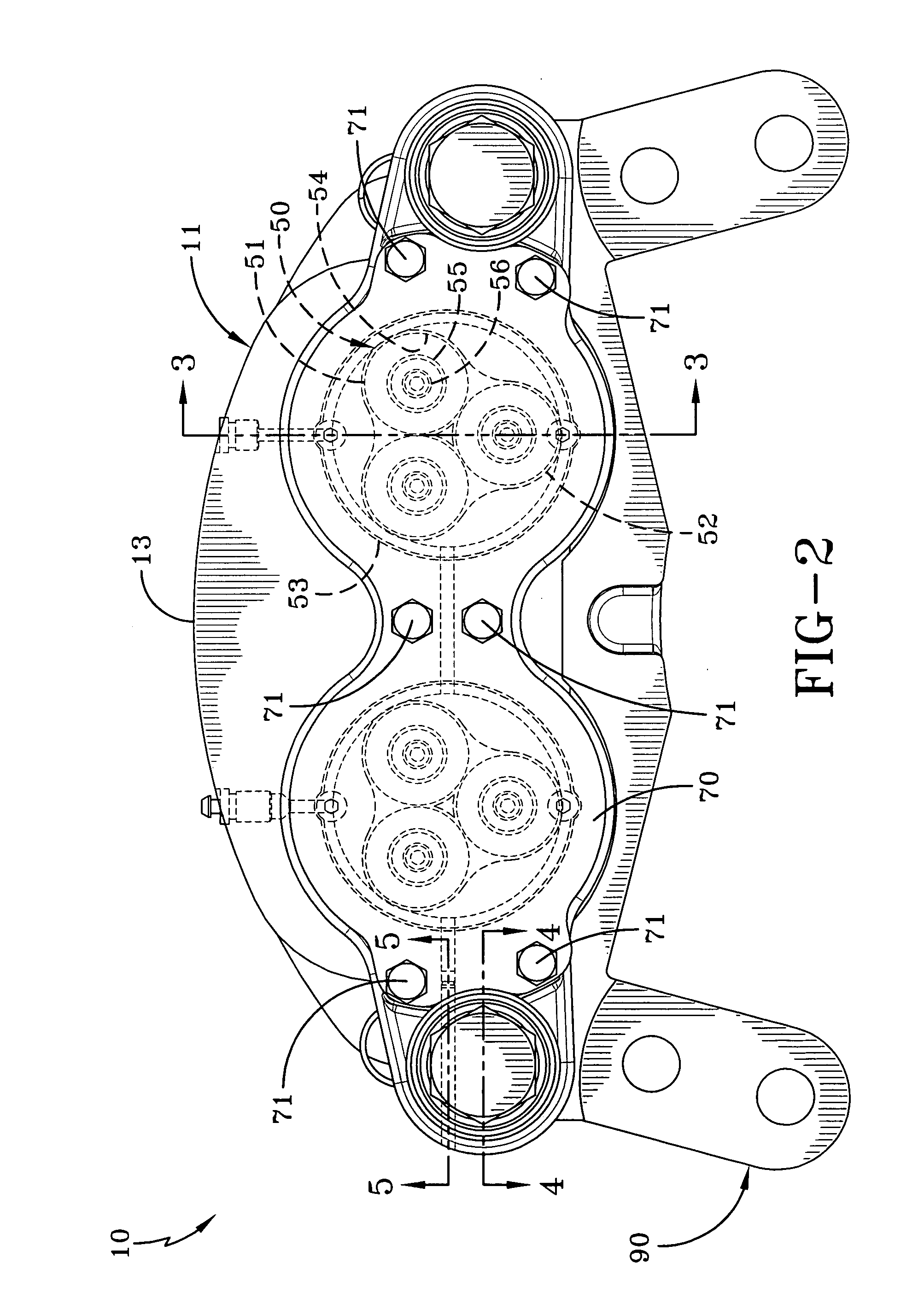

InactiveUS7493992B2Increasing envelopeEasy maintenanceSelf acting brakesMechanically actuated brakesTransmission brakeEngineering

A gearbox having an integral wet brake assembly is provided to replace the prior gearbox assembly of an underground mining machine. The brake housing is configured and contoured to be nestingly received upon the gearbox housing and without intrusion upon the output drive flanges. The brake housing includes concentric parking and service brake pistons adapted to engage and disengage a brake disc stack provided within a cavity machined into an end plate of the gear box assembly. An intermediate shaft of the gearbox is provided with a hub to engage the rotary discs of the brake disc stack. The parking brake is normally engaged by a spring and released by hydraulic pressure, while the service brake is normally released by a spring and engaged by hydraulic pressure.

Owner:PT TECH INC

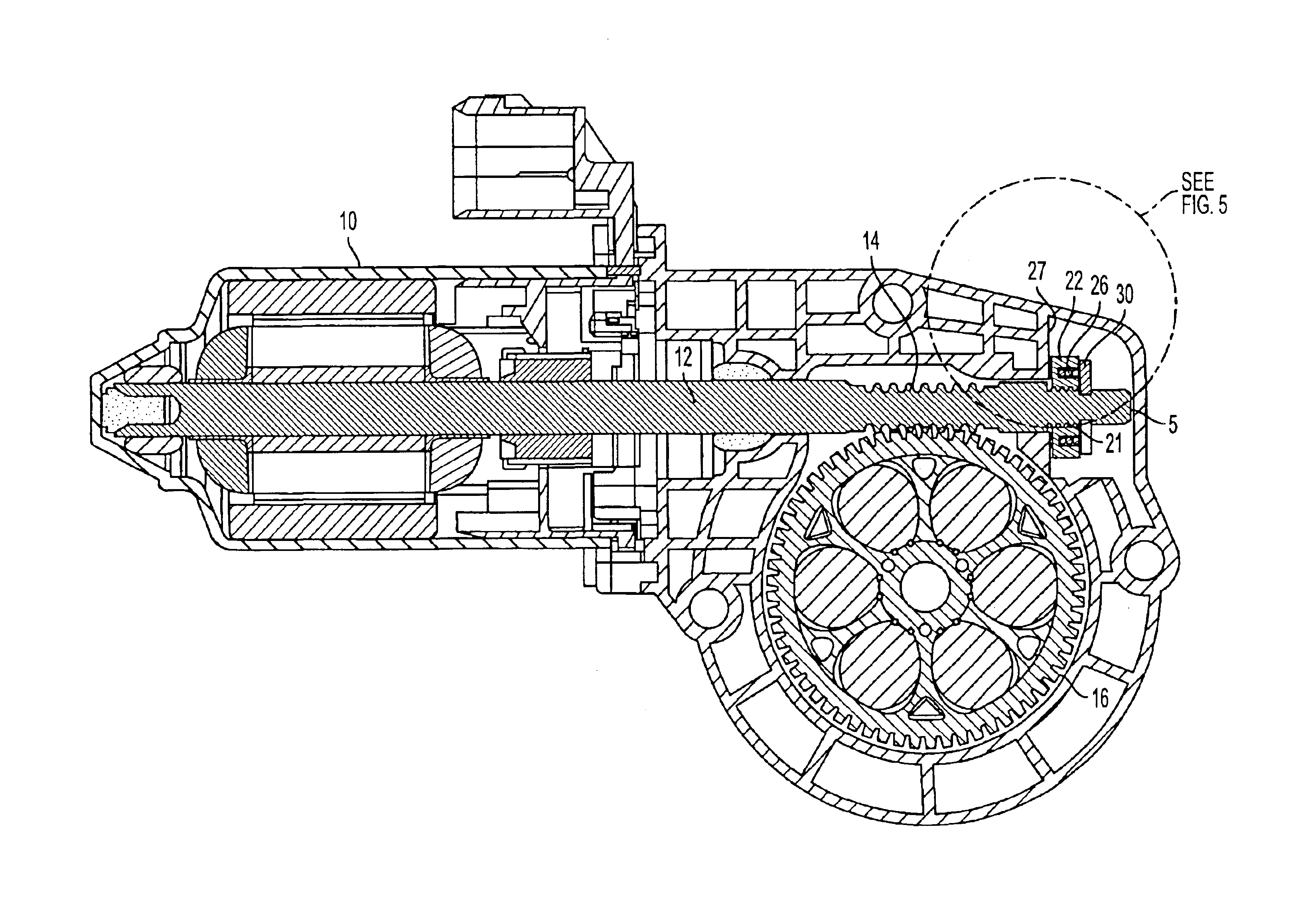

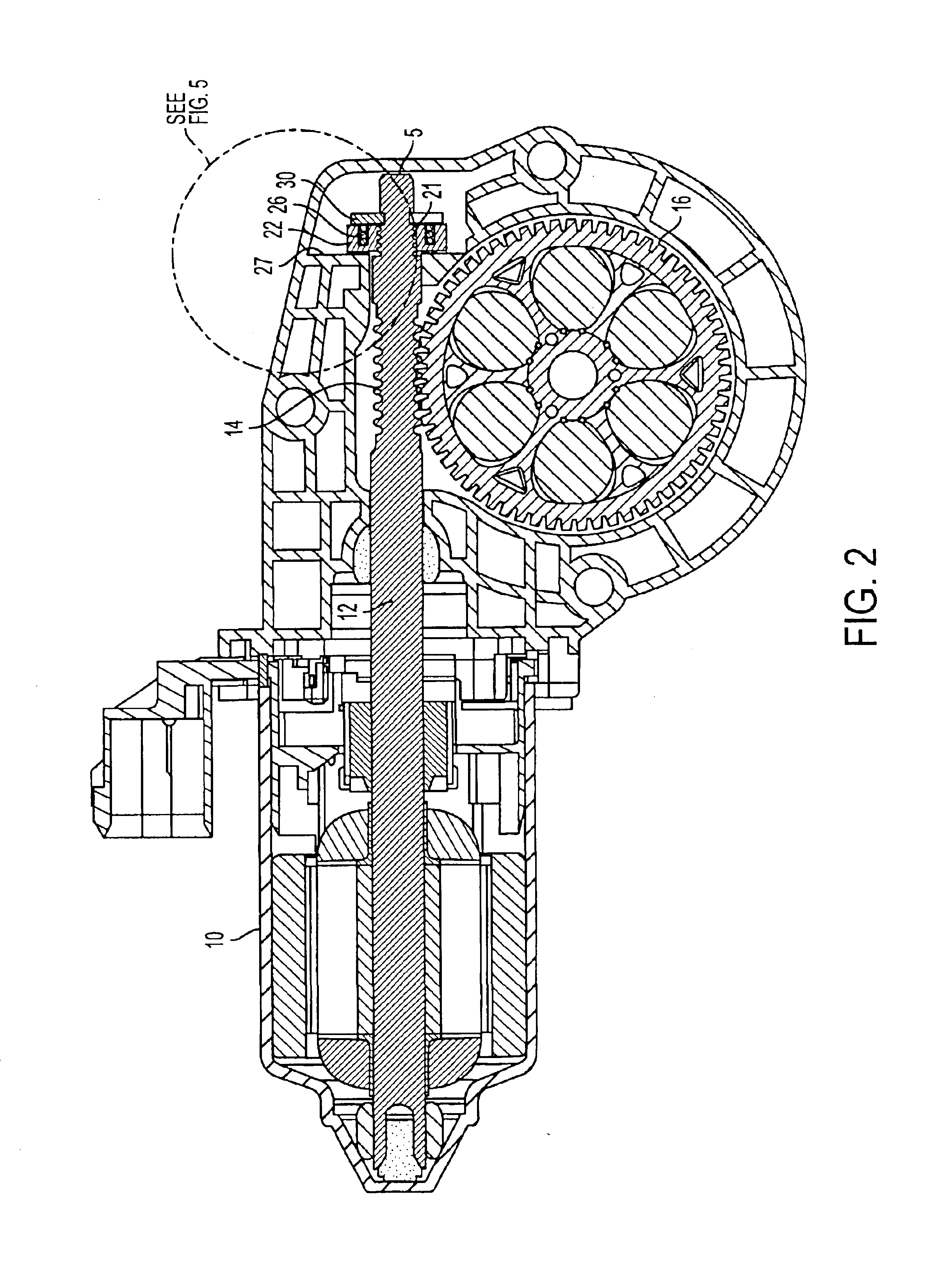

Inertia clutch mechanism in motors to prevent backdrive

A clutch mechanism 20 is provided for a motor 10. The motor has a shaft 12, a worm 14 associated with the shaft, a gear 16 engaged by the worm, and a friction surface 27. The clutch mechanism 20 includes a pressure plate 22 mounted for movement with respect to the shaft toward and away from the friction surface 27. A spring 26 is constructed and arranged to bias the pressure plate towards the friction surface. A stop 30 is constructed and arranged to limit movement of the pressure plate in a direction away from the friction surface. Whereby, under a back drive condition of the motor when the motor is not energized and the gear is moved by an externally applied torque causing an axial force to be exerted on the worm inducing an axial and an angular movement to the shaft, the pressure plate is constructed and arranged to move towards and engage the friction surface thereby impeding rotation of the shaft.

Owner:RPX CORP +1

Engine automatic stop restart control apparatus, vehicle equipped with engine automatic stop restart control apparatus, and engine automatic stop restart method

ActiveUS7354379B2Drawback can be obviatedIncrease fuel consumptionAnalogue computers for vehiclesVehicle fittingsMobile vehicleIdle speed

In a vehicle having idle stop functions and low vehicle speed-following drive functions, when a vehicle automatic stop flag F2 is identified as 1 at step S220, determines whether all engine stop conditions except depression of brake pedal are satisfied in step S240. When it is determined all the engine stop conditions except depression of the brake pedal are satisfied, ignition and fuel injection in each cylinder of engine are stopped to automatically stop the engine in step S260. In this arrangement, the driver's depression of brake is excluded from the engine stop conditions. Therefore, even when the motor vehicle automatically stops without the driver's depression of brake, the engine is automatically stopped.

Owner:TOYOTA JIDOSHA KK

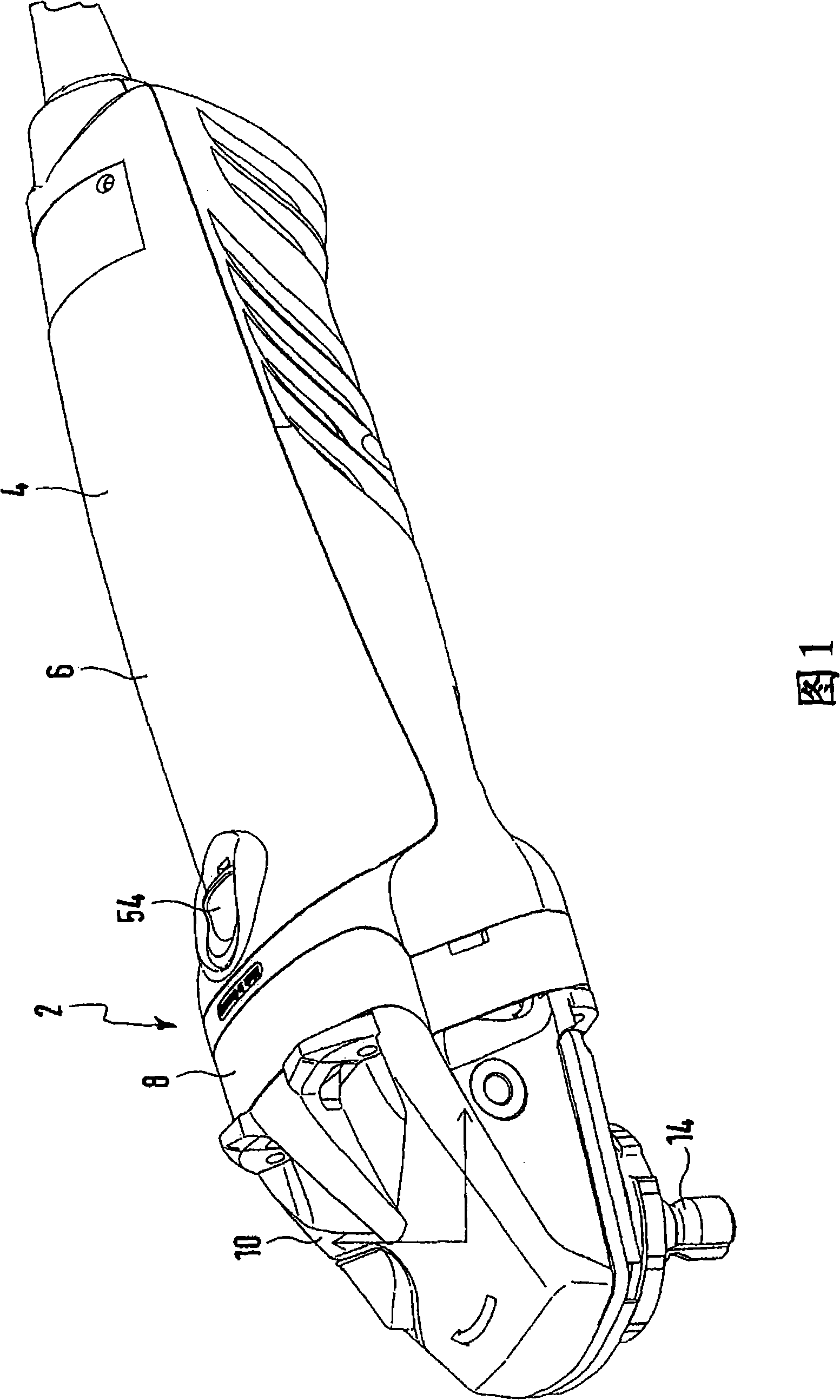

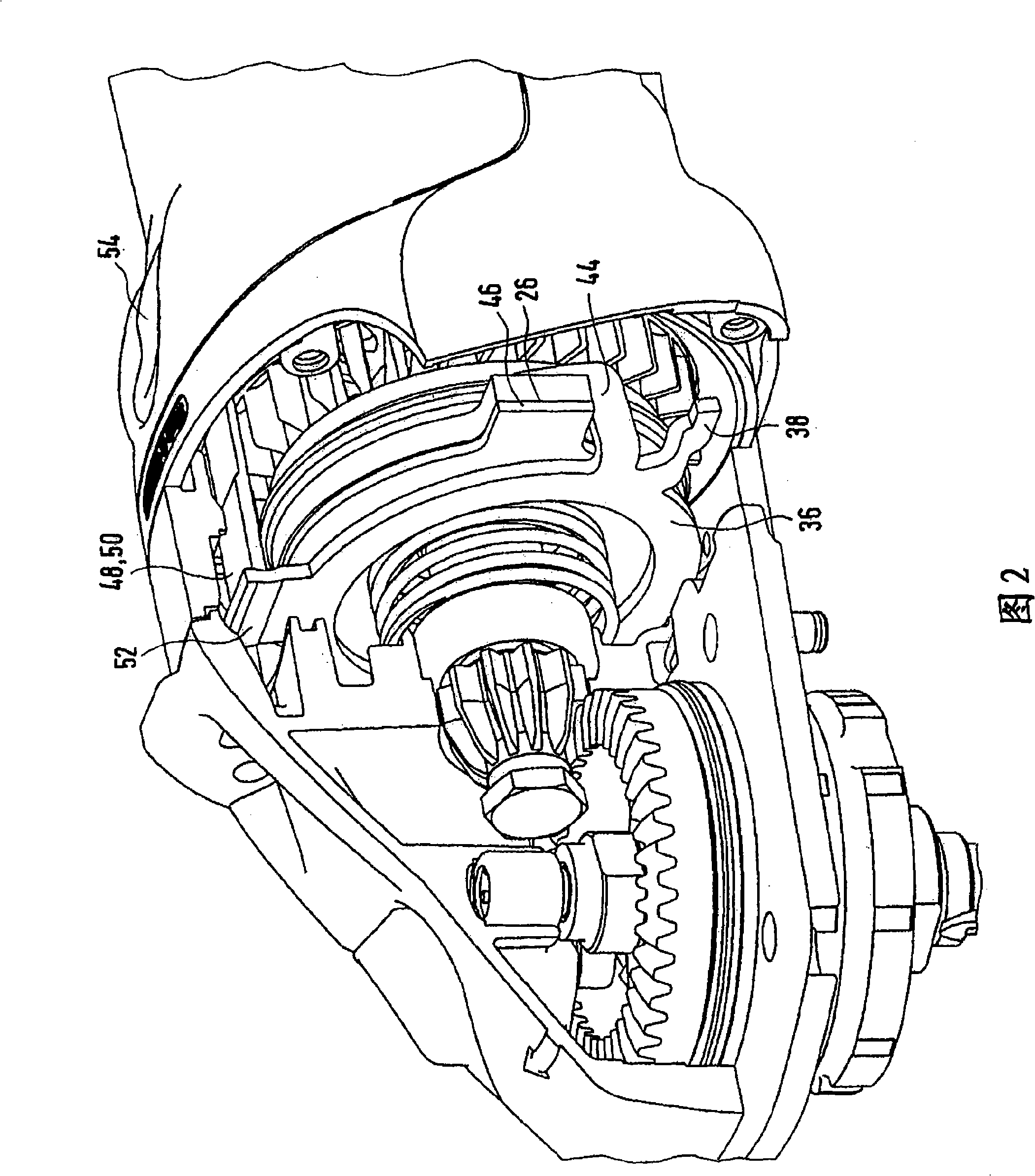

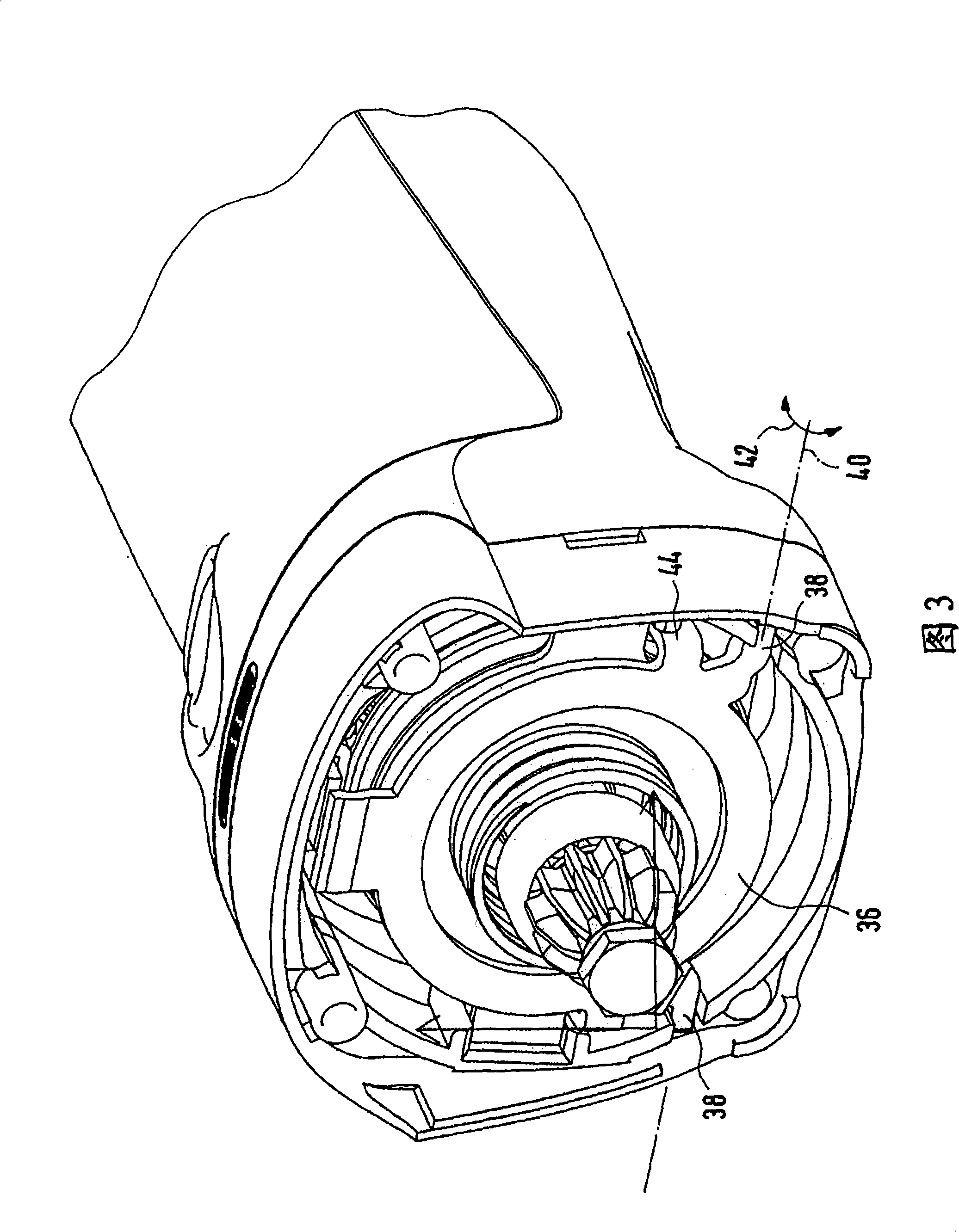

Portable electric tool with braking device

ActiveCN101254588AStable floating installationEasy to installSelf acting brakesPortable grinding machinesEngineeringAngle grinder

The electrical hand tool unit, particularly angle grinder or cut-off grinder, has a drive housing (10), a motor housing part (6) and handle part. A counter-brake disc (26) is moved in release direction from a laminar actuating mechanism (36) extending in a level parallel to the level of the counter-brake disc against the spring pre-tensioning and the laminar actuating mechanism is tilted relative to the earlier level around a certain level.

Owner:麦太保有限公司

One-way bidirectional clutch

According to the present invention, a one-way, bi-directional clutch, includes an outer casing, an input shaft, an output shaft and a brake assembly. The input shaft includes a release cam portion and the output shaft includes a locking cam portion. The brake assembly includes a release cam portion that is complementary to the release cam portion of the input shaft, a locking cam portion that is complementary to the locking cam portion of the output shaft, a biasing element and at least one brake pad. The complementary release cam portion of the input shaft and brake assembly are operable to move the brake assembly to a release position when the sufficient torque is applied to the input shaft. The complementary locking cam portions of the output shaft and the brake assembly are operable to move the one or more brake pads to the brake position when the sufficient torque applied to the output shaft.

Owner:CARLYLE JOHNSON MACHINE COMPANY LLC THE

Wet brake device

ActiveUS20130248303A1Improve cooling effectReduce speedFluid actuated brakesBraking element arrangementsPistonLubricant

A plurality of rotating side brake disks and a plurality of non-rotating side brake disks are arranged outside in the radial direction from a motor shaft in a brake case while alternately overlapping with each other. A frictional material is provided on the non-rotating side brake disk, and an oil groove is provided in a frictional engaging surface of this frictional material. It is configured such that, when a braking force is applied by a brake piston to the motor shaft, lubricant oil flowing into the brake case from a lubricant oil inlet port flows from the outer diameter side to the inner diameter side between the rotating side brake disk and the non-rotating side brake disk only through the oil groove. As a result, the lubricant oil having flowed into the brake case efficiently cools the frictional engaging surface.

Owner:NIHON KENKI CO LTD

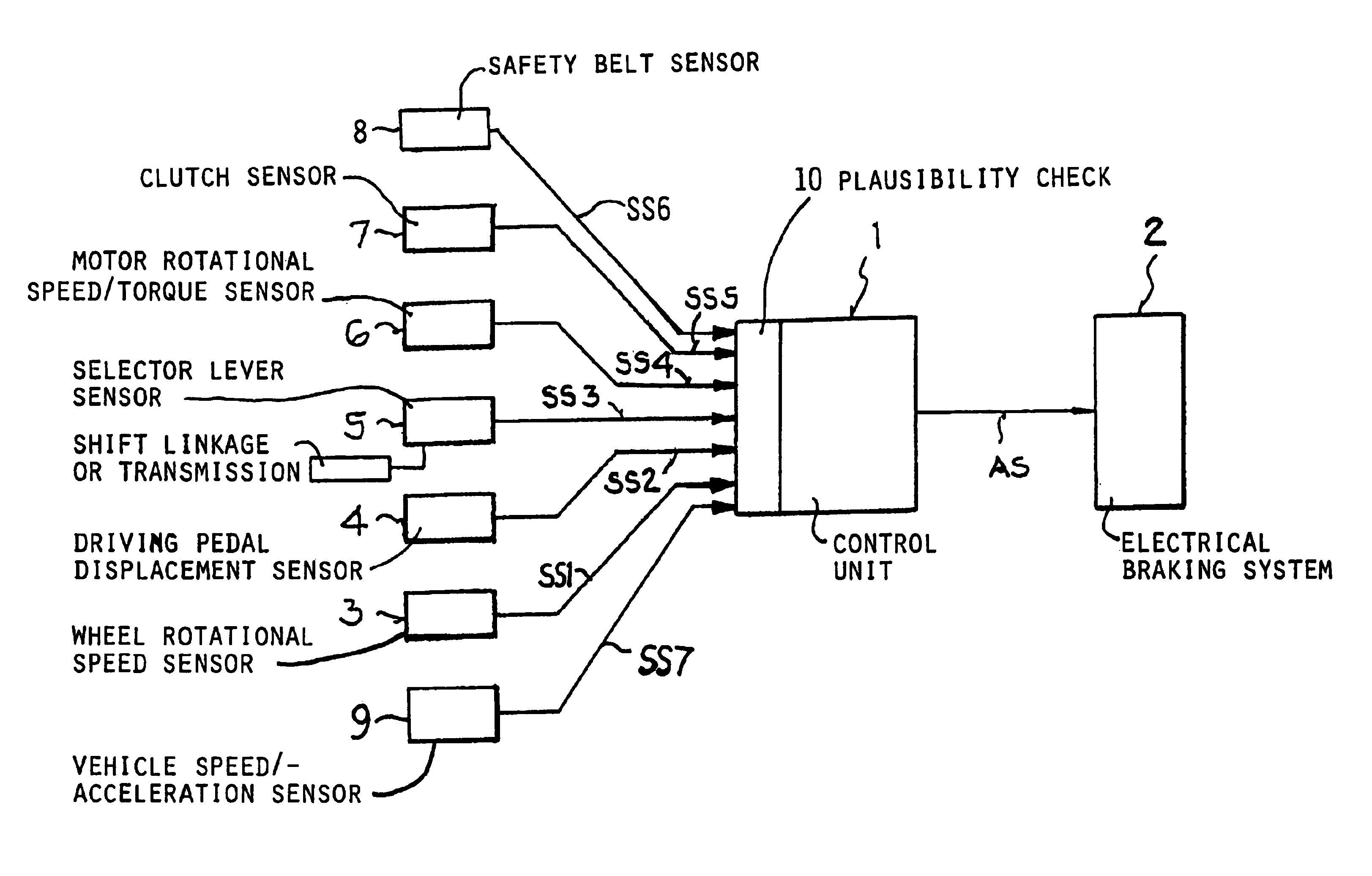

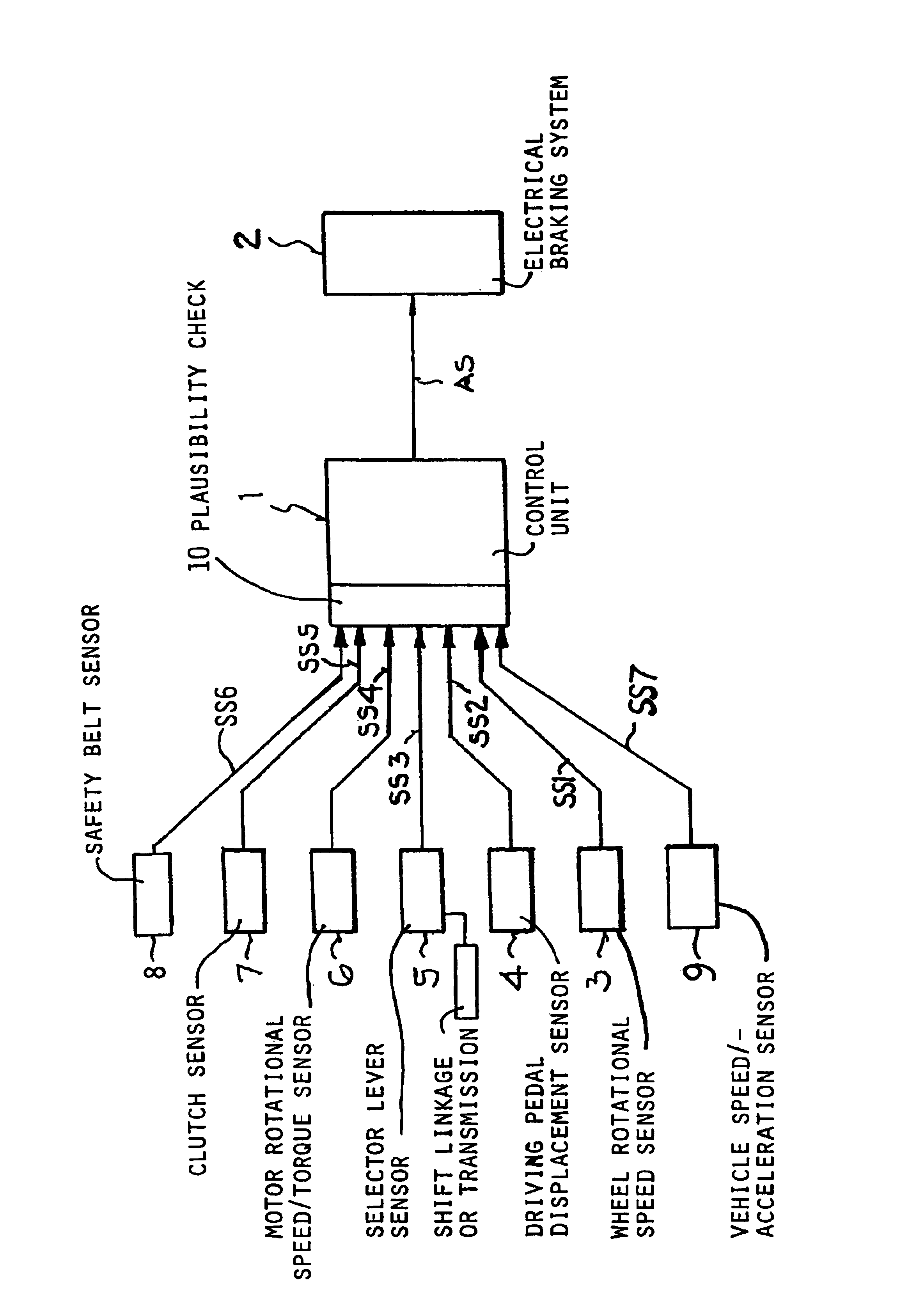

Method for operating a motor-driven vehicle

InactiveUS6951528B2Improve reliabilityImprove securitySelf acting brakesFoot actuated initiationsElectricityMobile vehicle

To avoid damaging the electrical braking system of a motor vehicle due to driving with an applied parking brake, the parking brake is automatically released, if the speed of the motor vehicle exceeds a prescribed minimum value, and the drive unit of the motor vehicle is driven in a specific operating state, and at least one operating element (e.g. gas pedal, gear shift lever, clutch pedal, safety belt, etc.) of the motor vehicle has been actuated by the driver of the motor vehicle. Sensor signals of sensors that sense the state of the above parameters are subjected to a plausibility check.

Owner:CONTI TEMIC MICROELECTRONIC GMBH

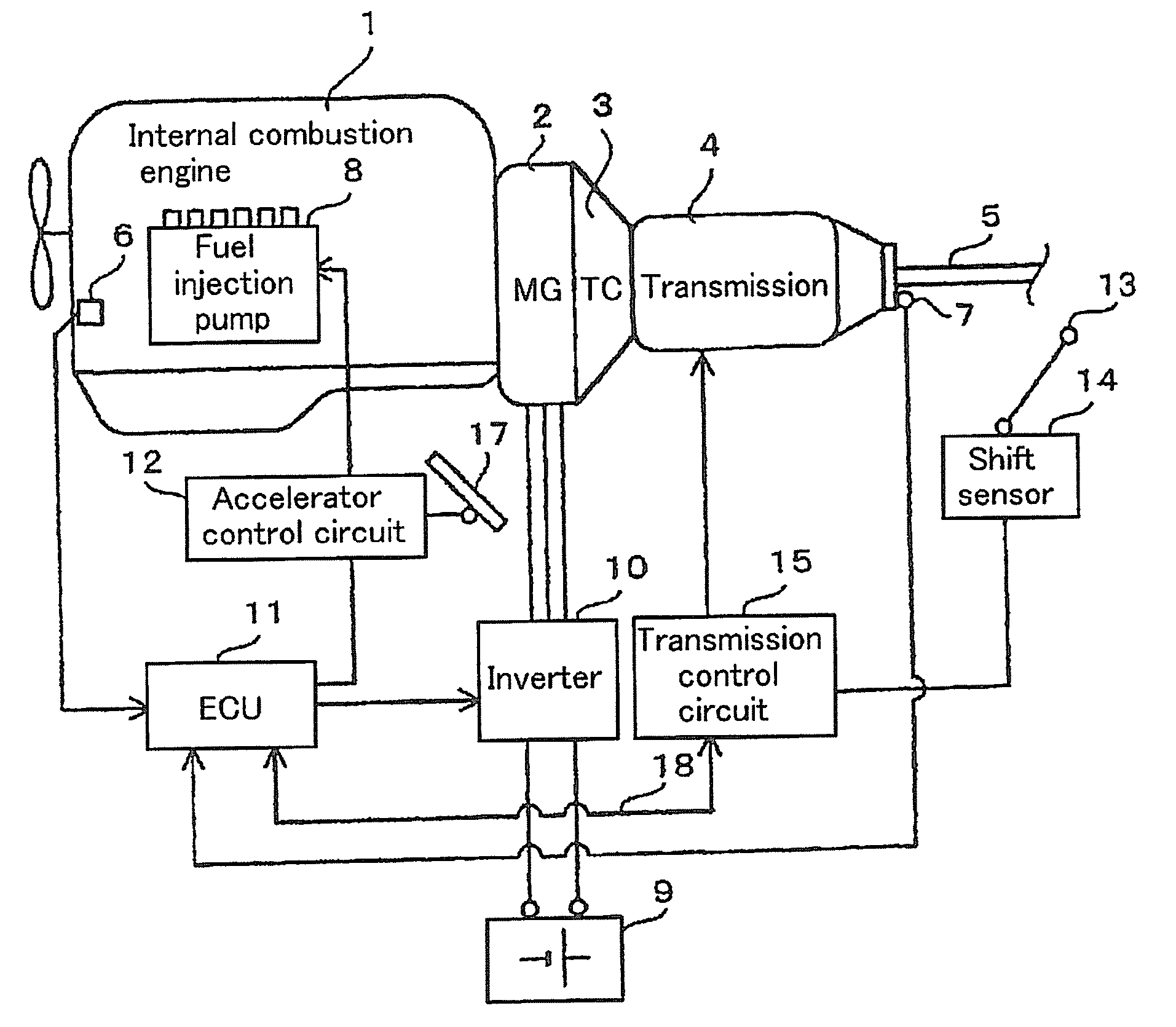

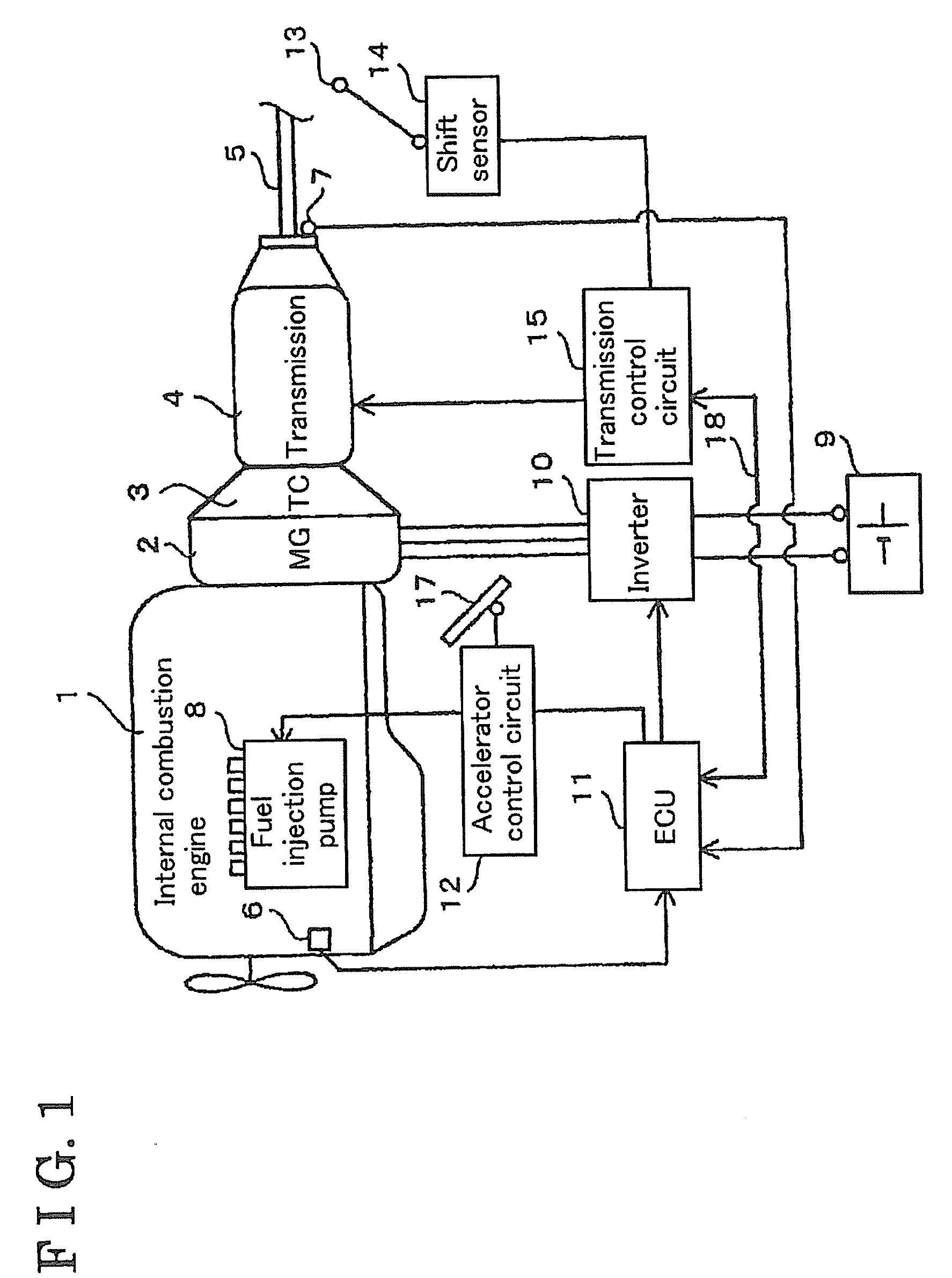

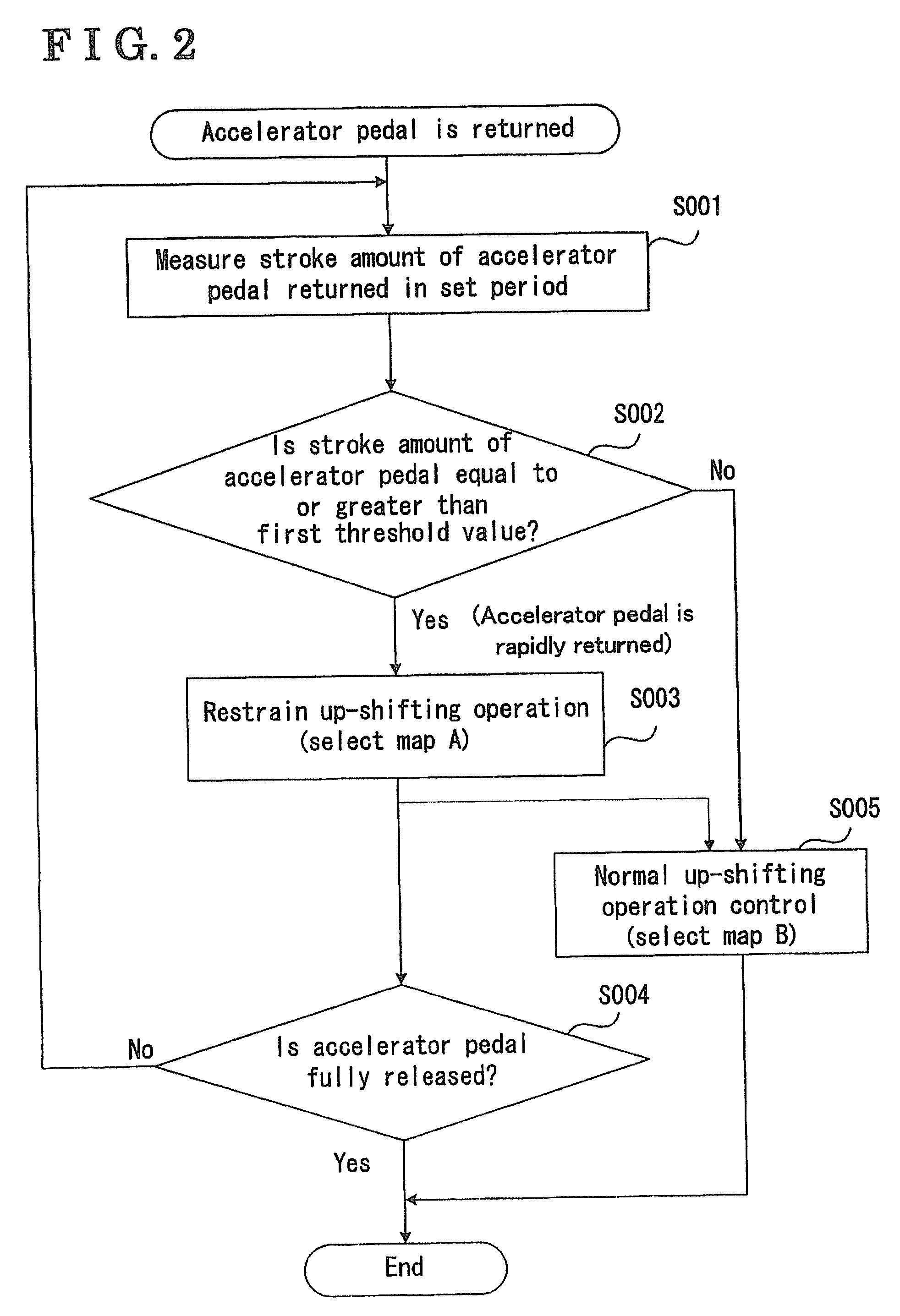

Control apparatus for transmission

A control apparatus of a transmission for a vehicle, which includes an electric generator provided between an engine and the transmission and regenerating electricity when torque is transmitted from a drive shaft of the vehicle via the transmission in a braking condition, includes a releasing speed measuring unit, an up-shifting operation allowing unit and an up-shifting operation restraining unit. The releasing speed measuring unit measures a releasing speed of an accelerator pedal. The up-shifting operation allowing unit is applied to allow an up-shifting operation under the accelerator pedal being released when a releasing speed of the accelerator pedal is lower than a first threshold value. The up-shifting operation restraining unit is applied to restrain the up-shifting operation under the accelerator pedal being released when the releasing speed of the accelerator pedal is equal to or lower than the first threshold value.

Owner:AISIN SEIKI KK +1

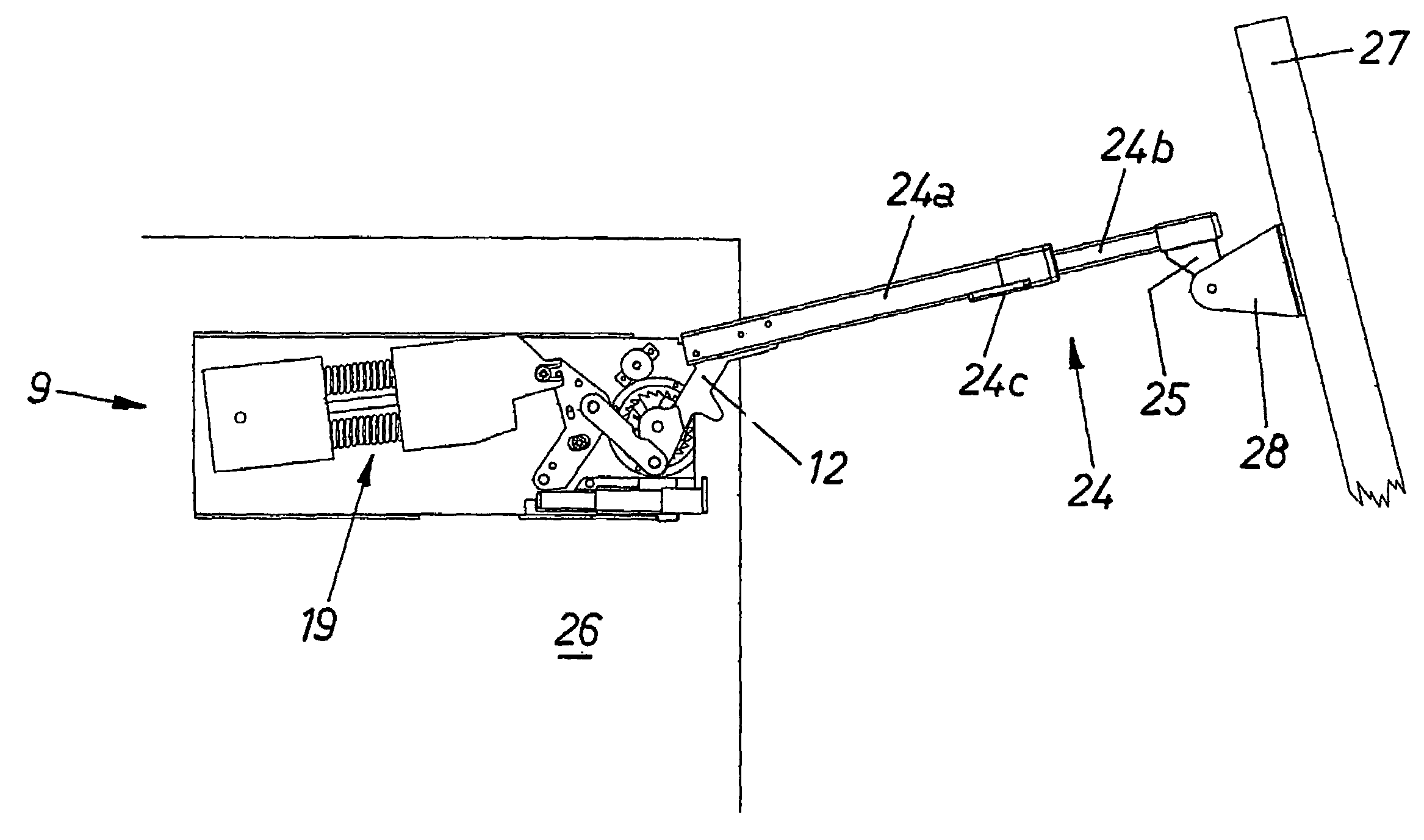

Actuating device with at least one actuating arm

ActiveUS7562757B2Reduce swing speedSwing speed of the actuating arm can thereby beSelf acting brakesBuilding braking devicesEngineeringMechanical engineering

The invention relates to an actuating device for moving a flap of a piece of furniture, including at least one actuating arm for moving the flap, a base member on which the actuating arm is pivotally arranged, and a spring device able to act upon the actuating arm. An assembly securing device for the vacant actuating arm, which has not yet been fitted with a flap, includes a braking device which limits the opening speed of the vacant actuating arm.

Owner:JULIUS BLUM GMBH

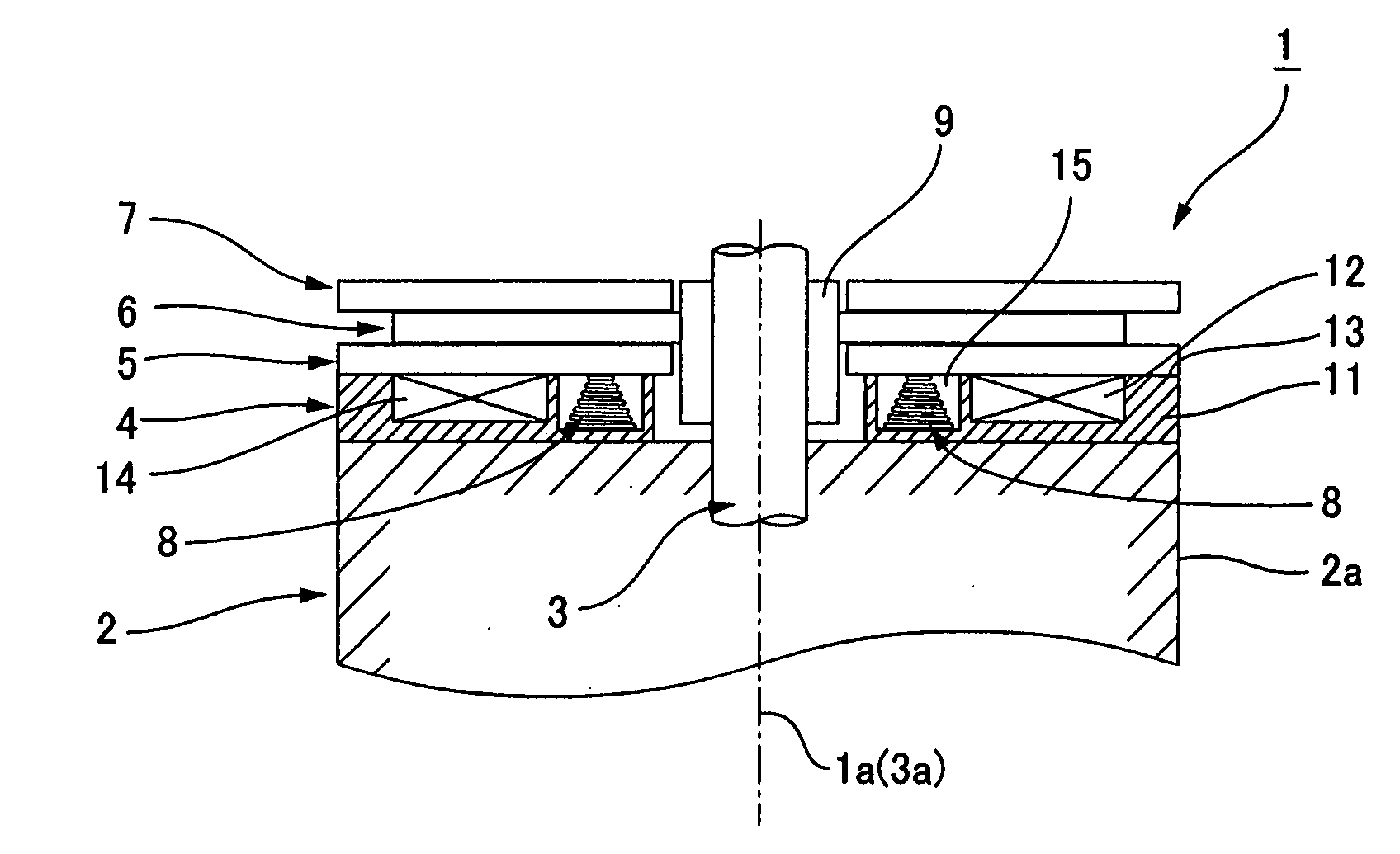

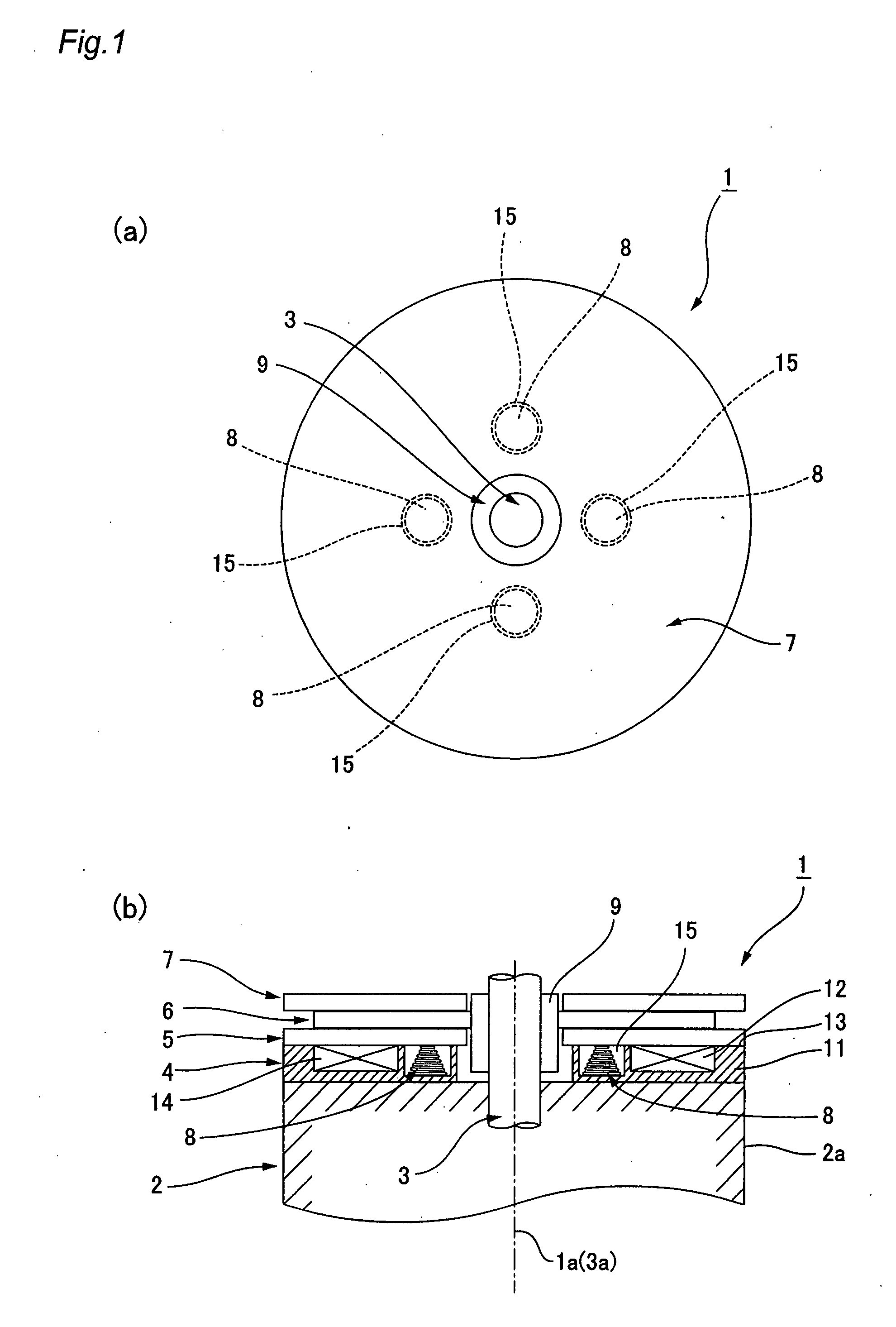

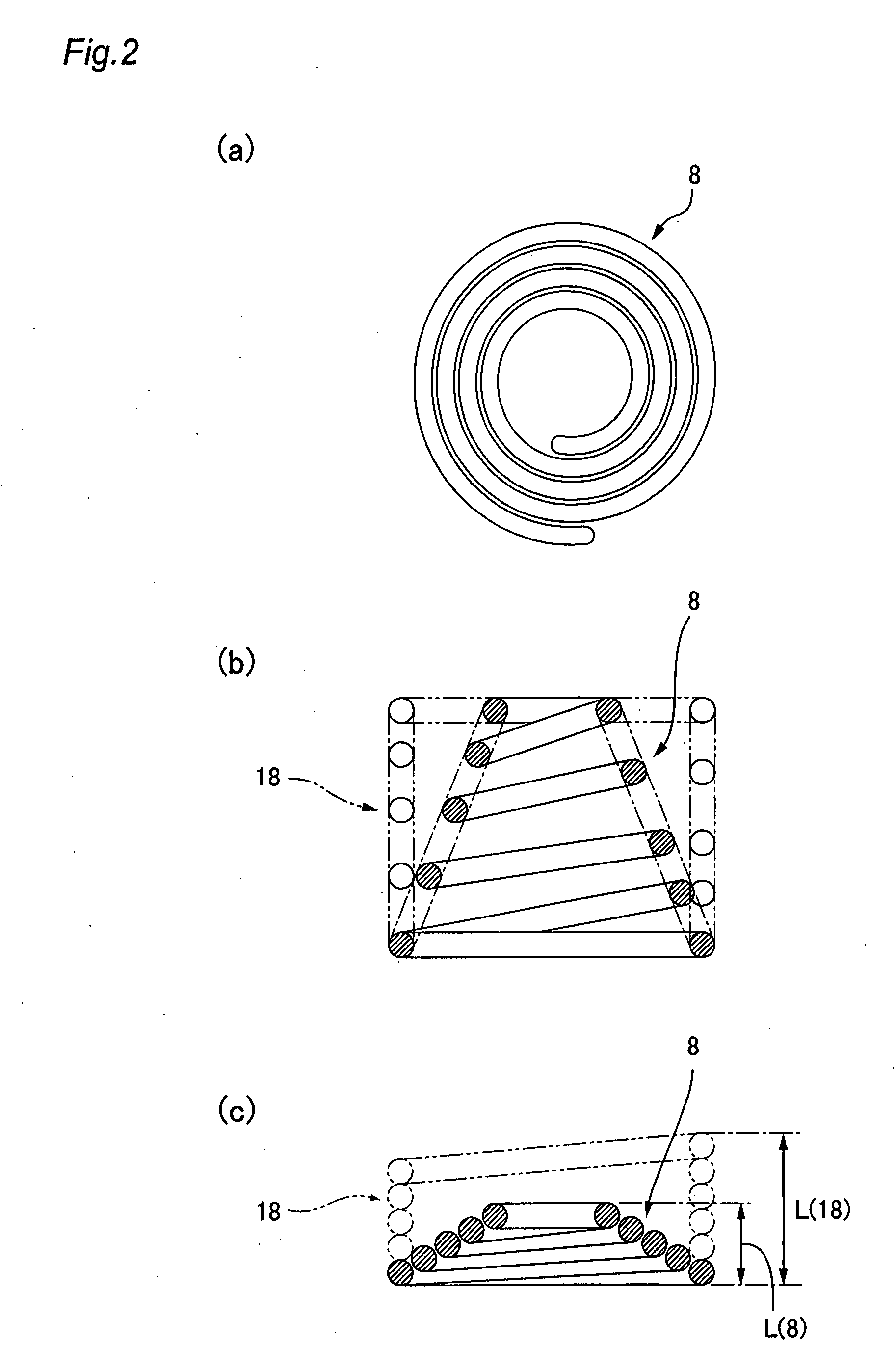

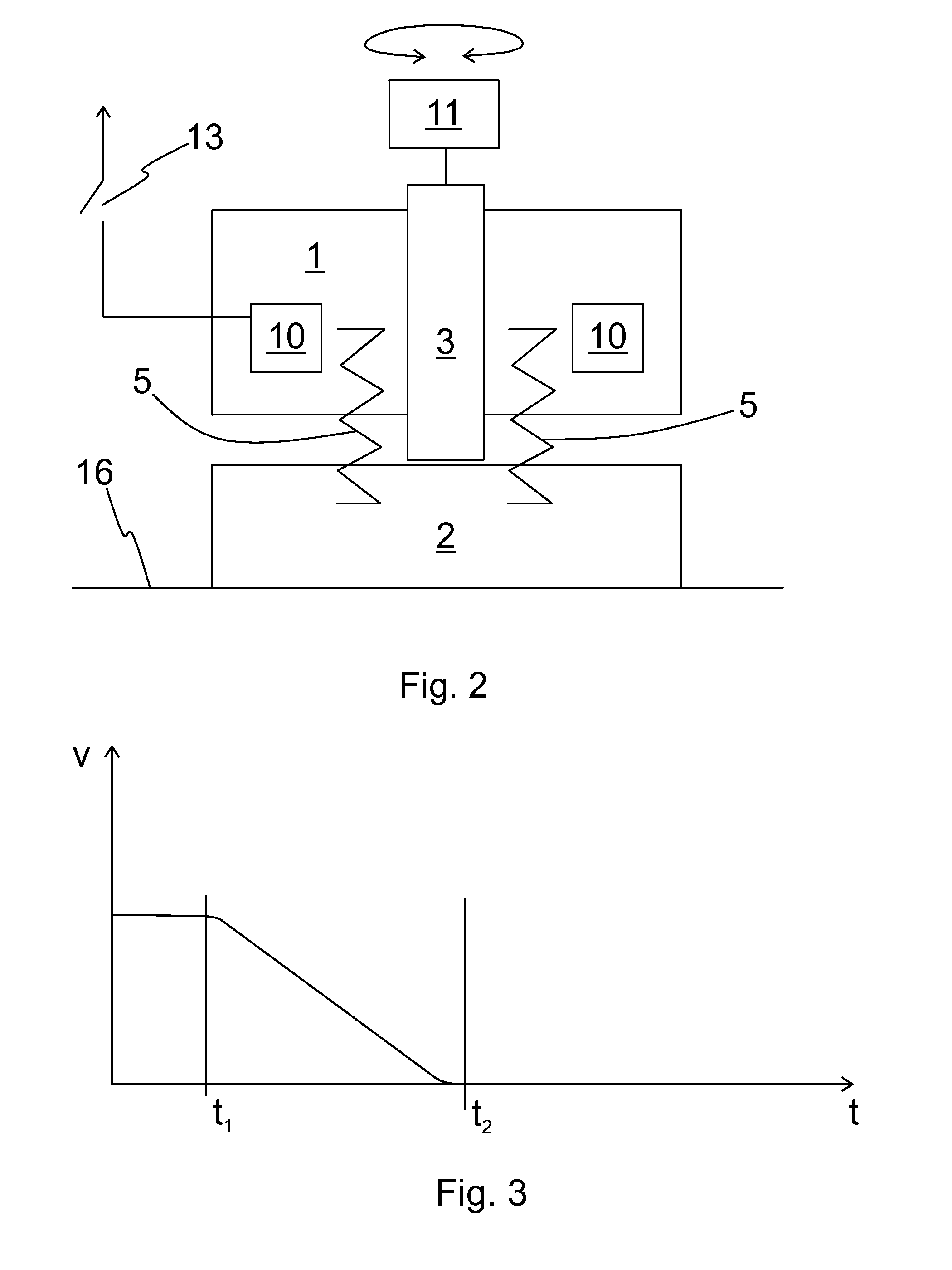

Electromagnetic Brake Device

InactiveUS20080156594A1Compression lengthMade thinnerAxially engaging brakesSelf acting brakesCoil springEngineering

A deenergization operation type electromagnetic brake device (1), comprising a plurality of conical springs (8) for pressing an armature disk (5) against a fixed disk (7) through a friction disk (6) held therebetween. The conical springs (8) are inserted into the spring insertion recessed parts (15) of the yoke (11) of an electromagnet (4), and held between the bottom faces of the recessed parts and the armature disk (5) in a compressed state. Since the conical springs (8) are shorter than cylindrically coiled springs in a compressed state, the spring insertion recessed parts (15) can be made shallower and the thickness of the yoke (11) determined by the recessed parts can be reduced. As a result, the electromagnetic brake device (1) can be advantageously formed flat.

Owner:HARMONIC DRIVE SYST IND CO LTD

Speed loss braking device for electric wheelchair transmission shaft

InactiveCN111692248AEasy to useGuaranteed speedSelf acting brakesWheelchairs/patient conveyanceControl theoryElectric wheelchairs

The invention relates to the technical field of aged-providing equipment and discloses a speed loss braking device for an electric wheelchair transmission shaft. The speed loss braking device for theelectric wheelchair transmission shaft comprises a rotary shaft. Moving blocks are movably connected outside the rotary shaft. Connecting plates are fixedly connected outside the moving blocks. Shellsare movably connected inside the rotary shaft. Springs are movably connected inside the shells. Electrorheological fluids are movably connected inside the shells. Electric wires are movably connectedinside the shells. Anticollision pads are movably connected inside the rotary shaft. Conductors are movably connected outside the rotary shaft. According to the speed loss braking device for the electric wheelchair transmission shaft, through interaction among the rotary shaft, the moving blocks, the connecting plates, the shells, the springs, the electrorheological fluids, the electric wires andthe anticollision pads, when the wheelchair travels normally and the rotating speed of the rotary shaft is normal, normal use of the wheelchair is not influenced; in this way, it can be avoided thatnormal use of the wheelchair is influenced because of speed limit, and the influence of a maximum-degree braking structure on the rotary shaft can be avoided; and in this manner, the device is more applicable to use under actual conditions.

Owner:浙江火萌互娱信息技术有限公司

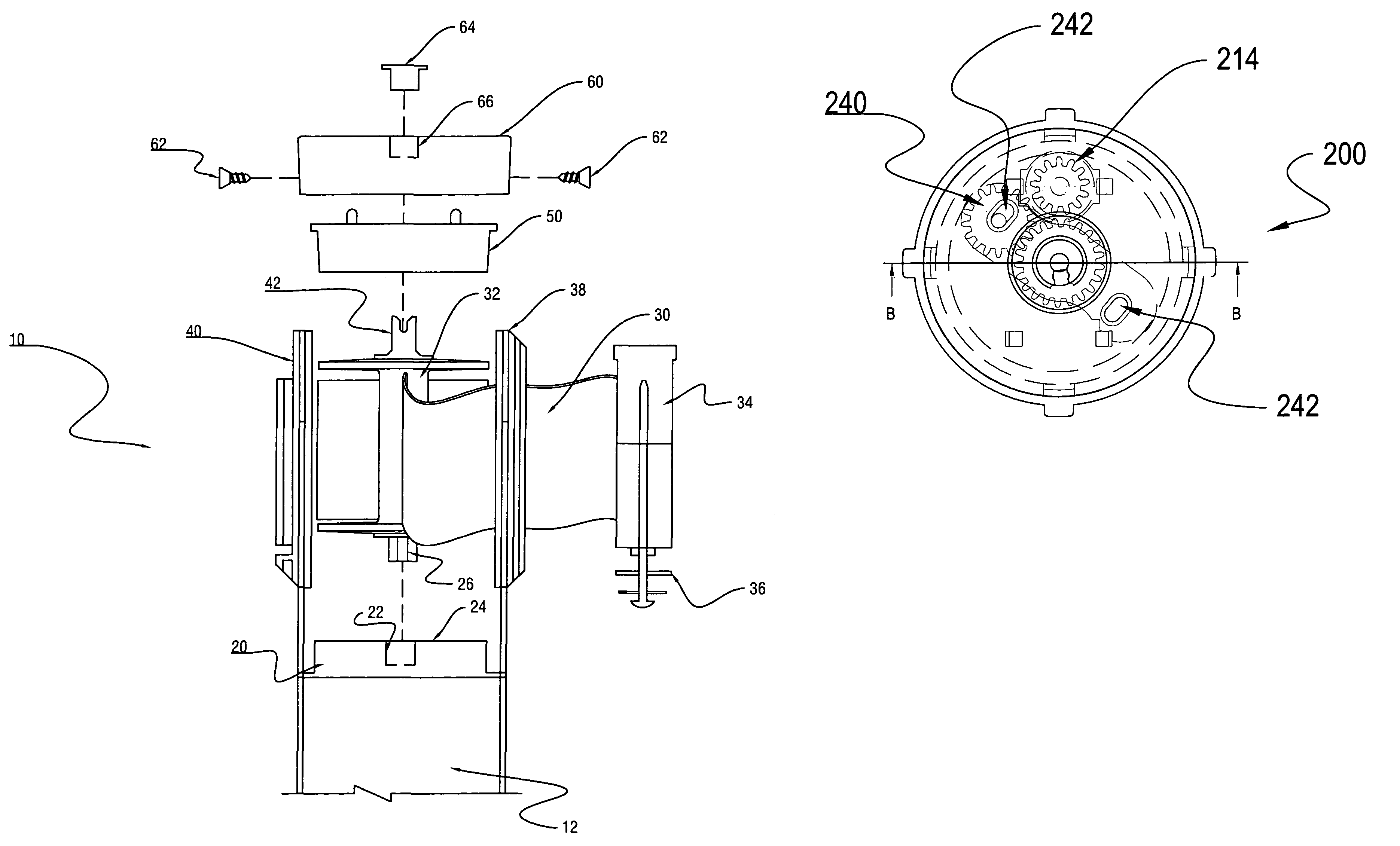

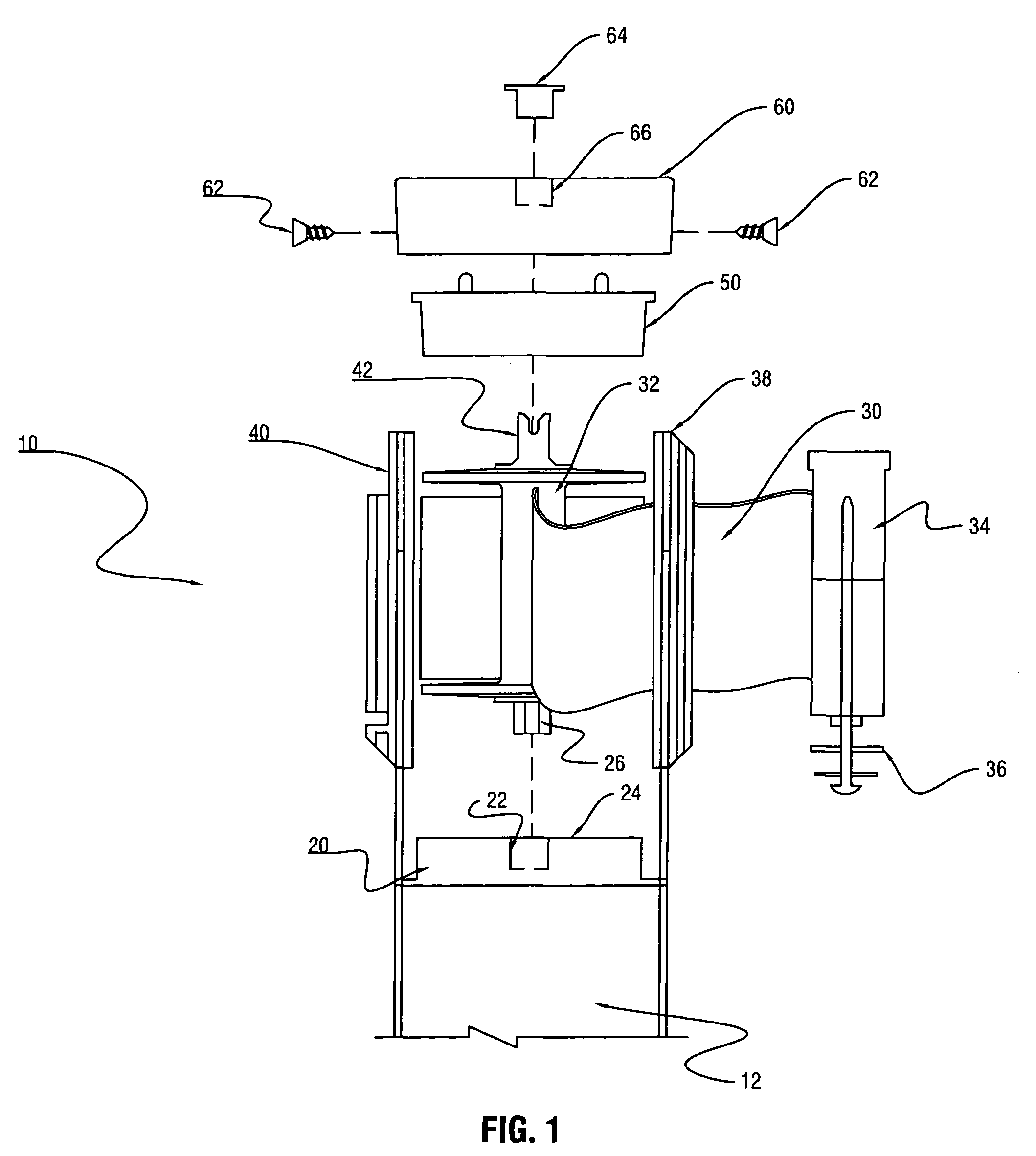

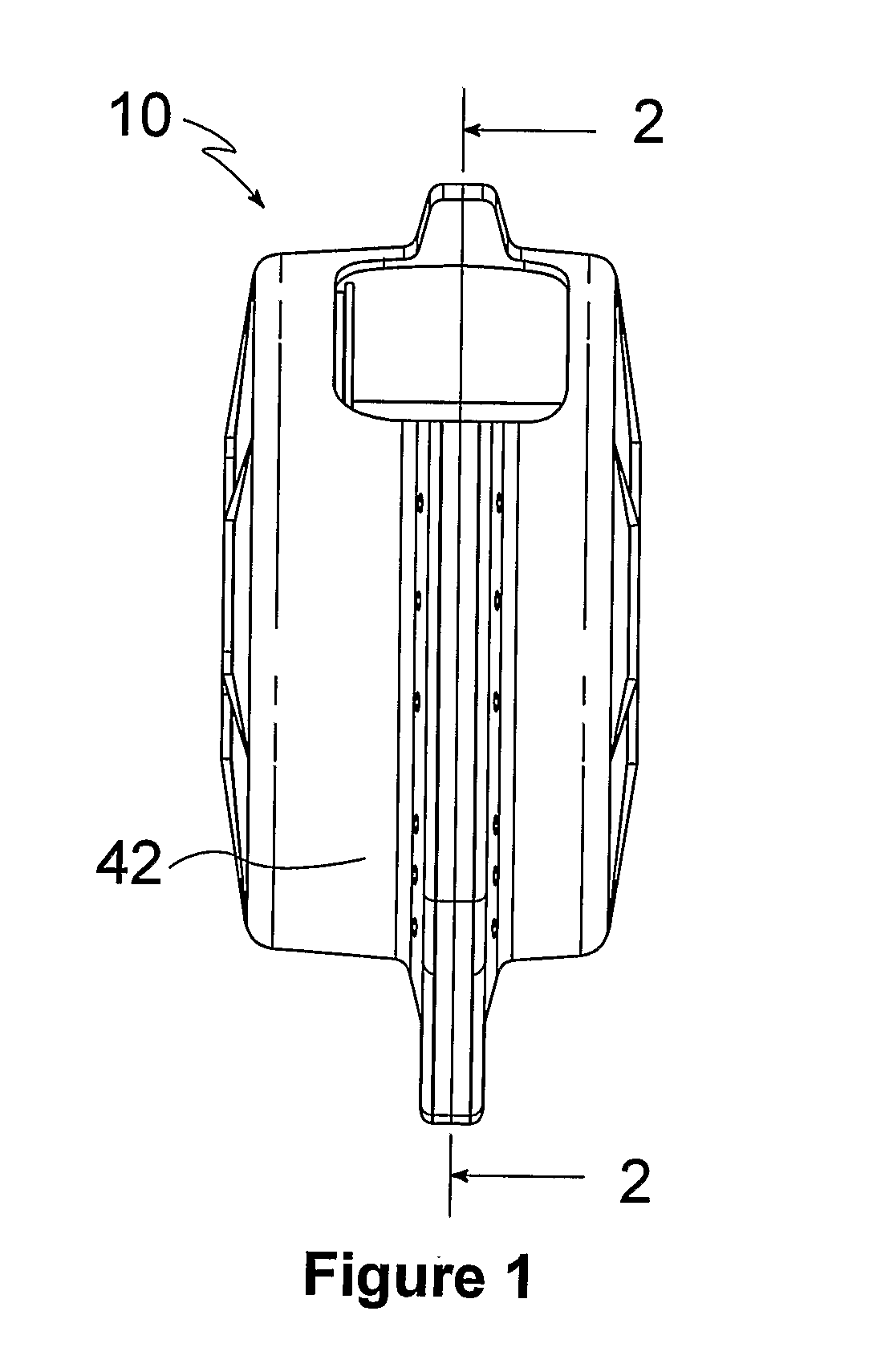

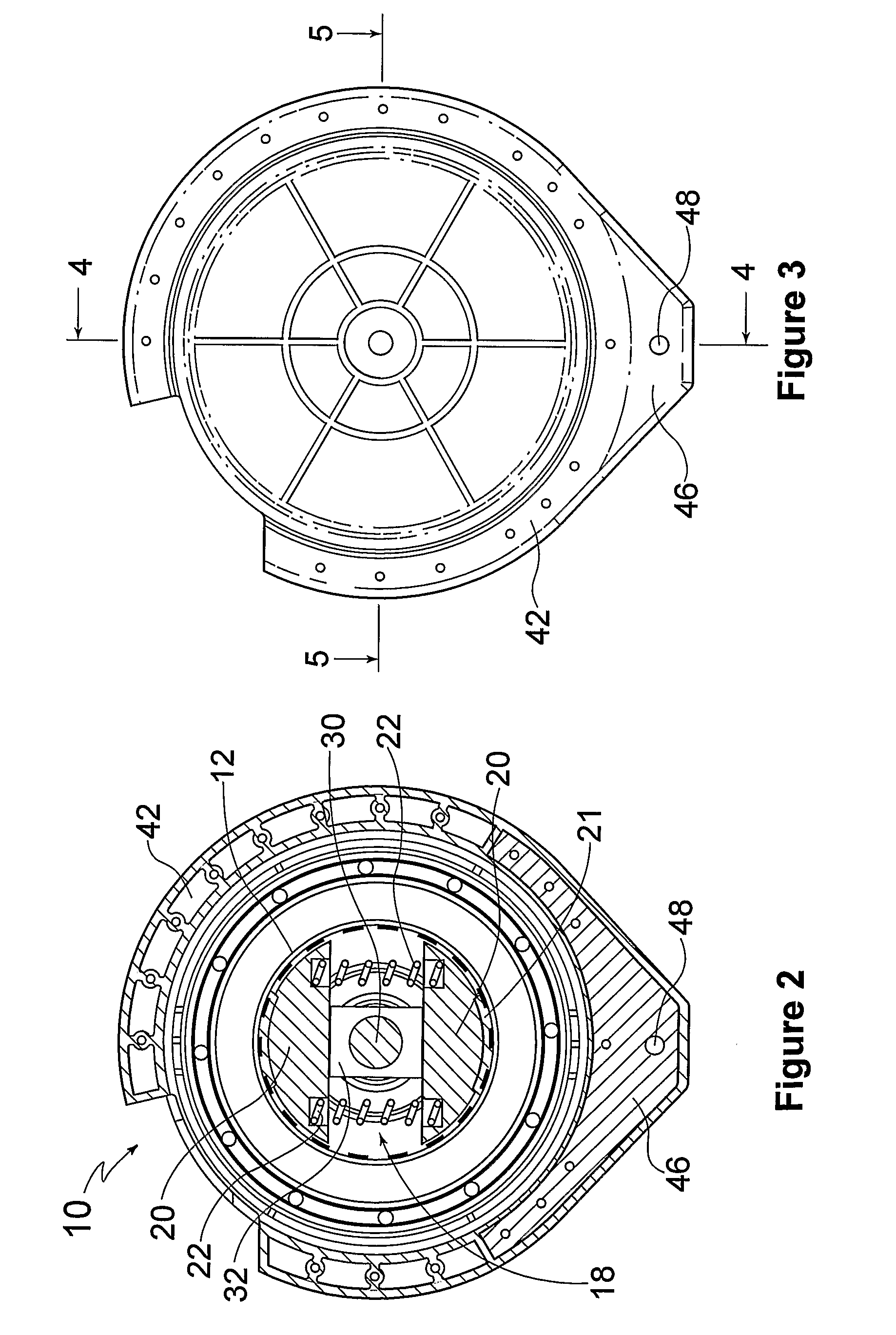

Retracta Belt Brake System

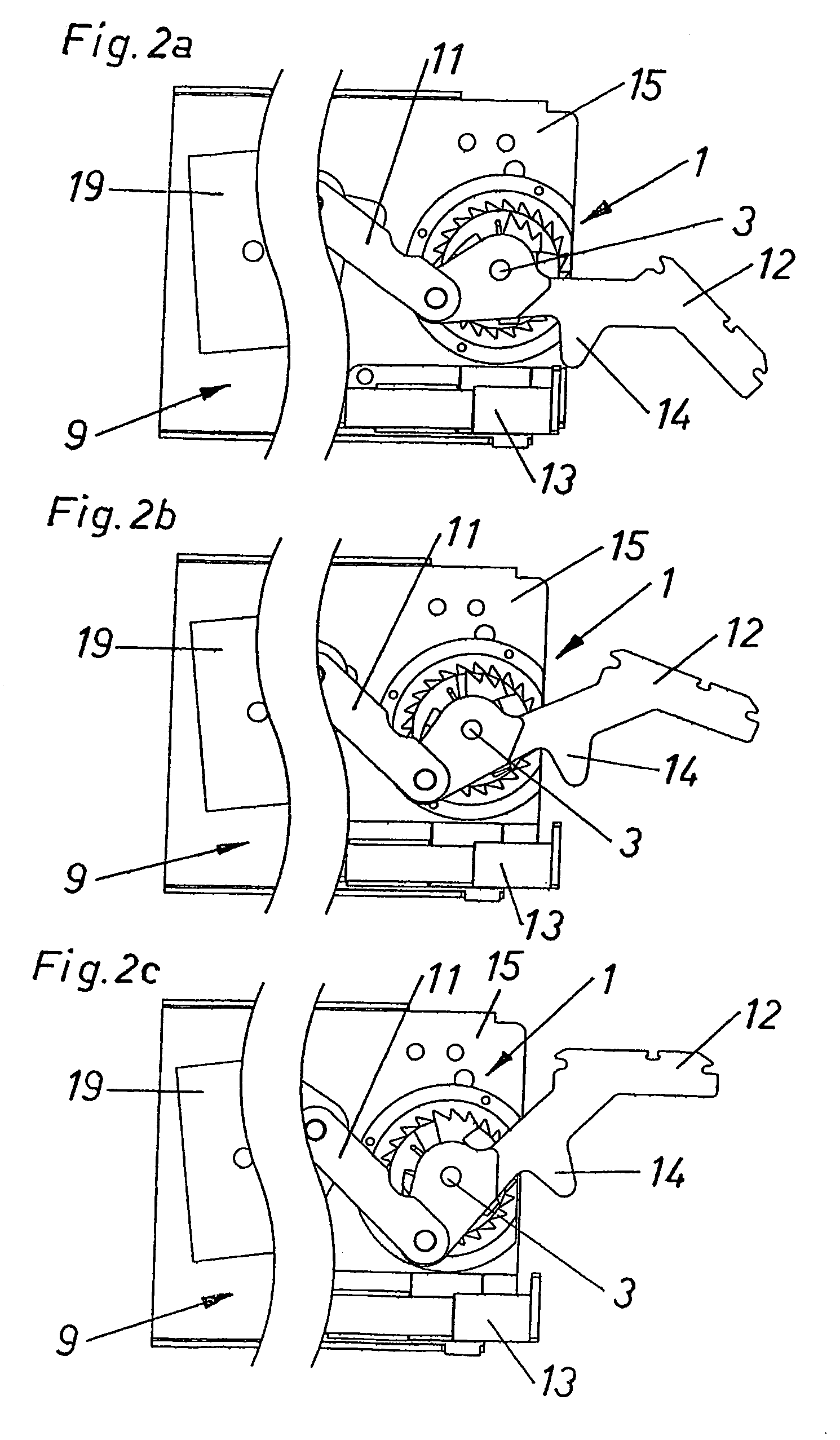

InactiveUS20110120823A1Dampen rate of rotationSuppressed rotationLiquid resistance brakesSelf acting brakesGear driveGear wheel

A pedestrian traffic control stanchion including a post having an upper end and a lower end; a belt cassette assembly mounted on an upper end of the post; a spring case assembly positioned adjacent to and operatively connected to the belt cassette assembly to provide tension on a belt as the belt is extracted from the belt cassette assembly; a brake case assembly positioned adjacent to the belt cassette assembly and operatively connected to the belt cassette assembly to dampen the rate of rotation of the belt cassette assembly as the belt is retracted into the belt cassette assembly under the tension force exerted by the spring case assembly; the brake case assembly including a housing, a drive gear positioned within the housing, said drive gear being configured to be connected to the belt cassette assembly, a floating gear positioned within the housing in a position to engage the drive gear, the floating gear having an axial shaft extending therefrom, wherein the axial shaft of the floating gear is positioned within a slot formed in the housing, the slot having a first end and a second end; and a gear driven damper assembly positioned within the housing and configured to engage the floating gear when the axial shaft of the floating gear is positioned in one of the first end or the second end.

Owner:VISIONTRON CORP

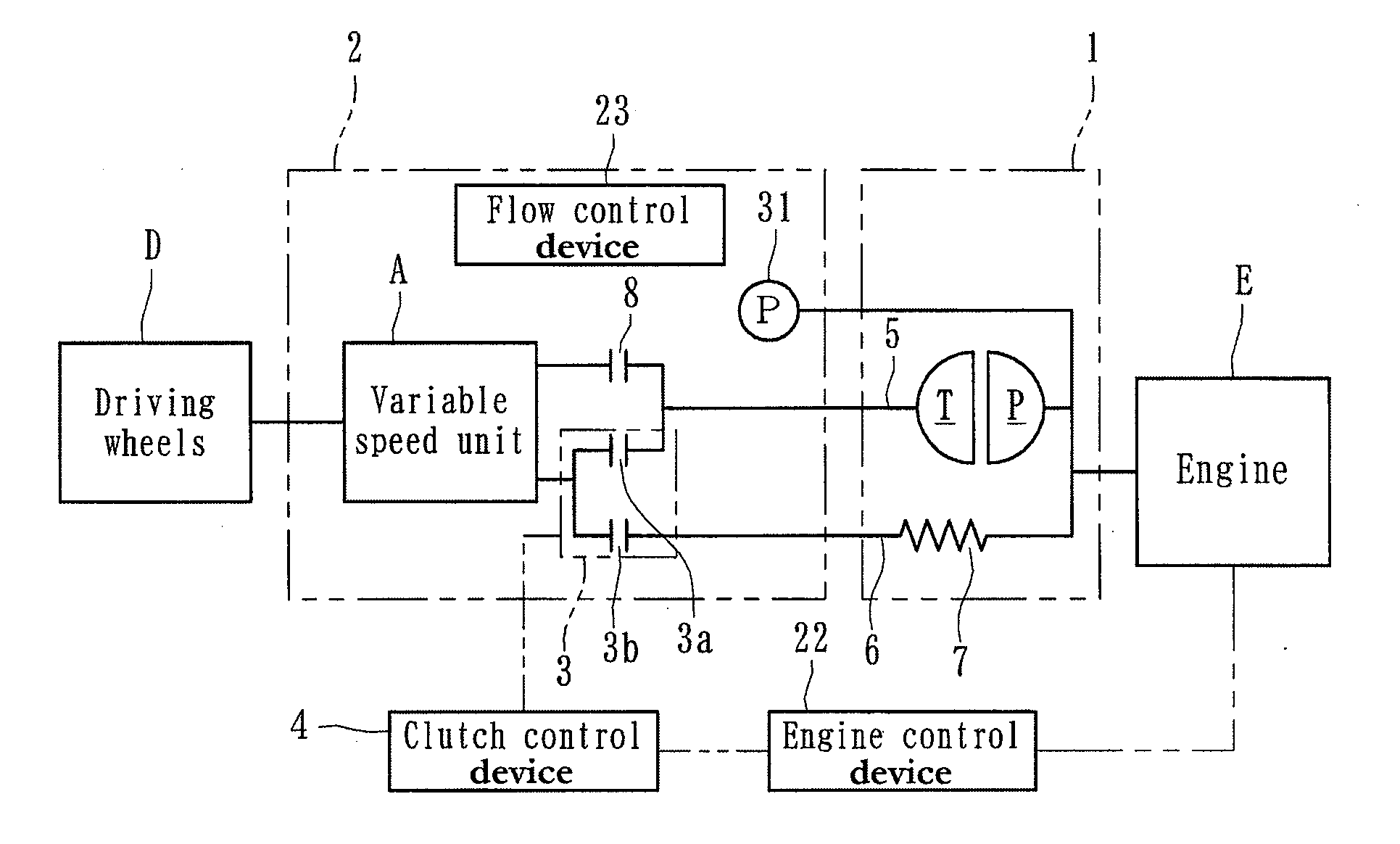

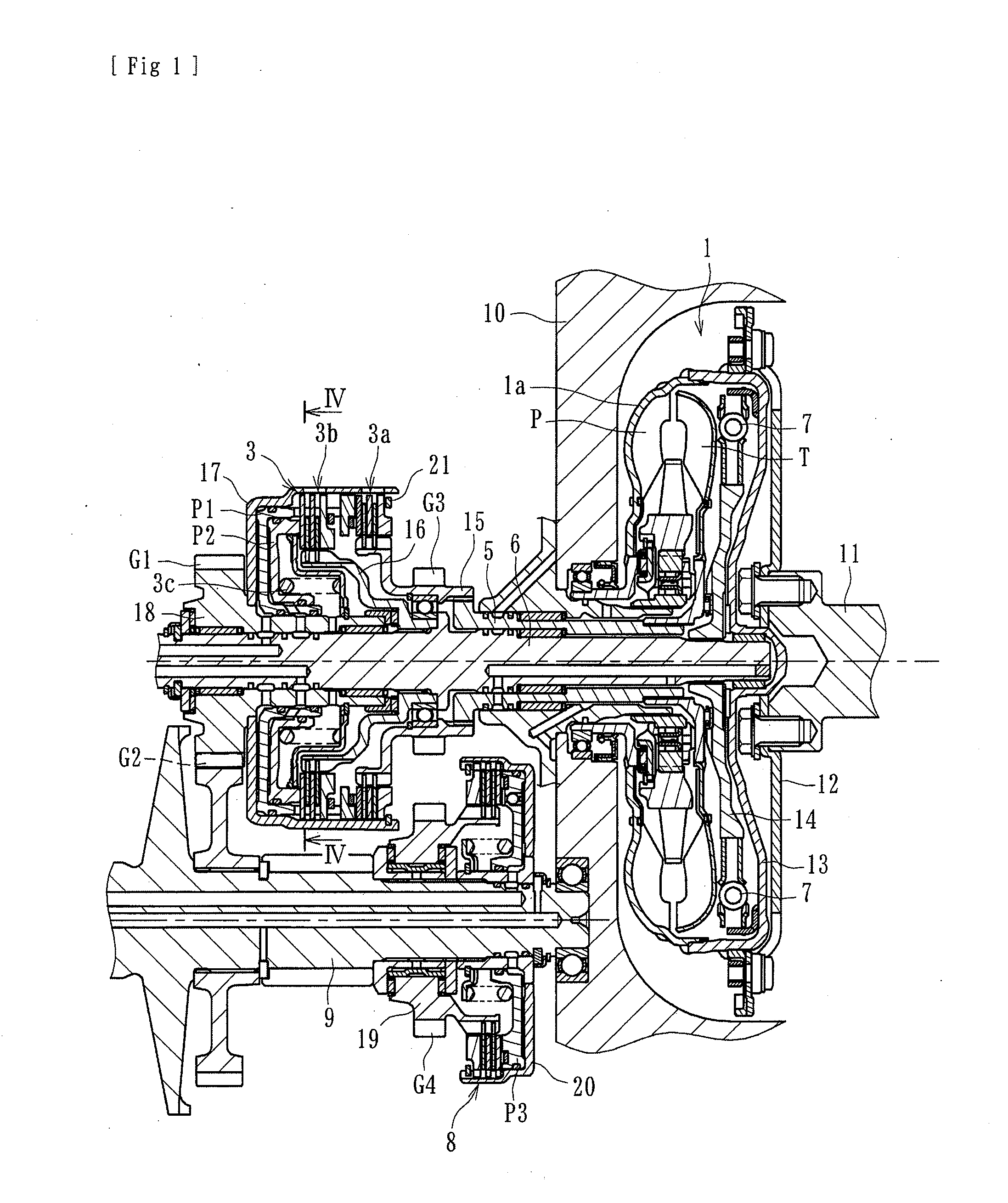

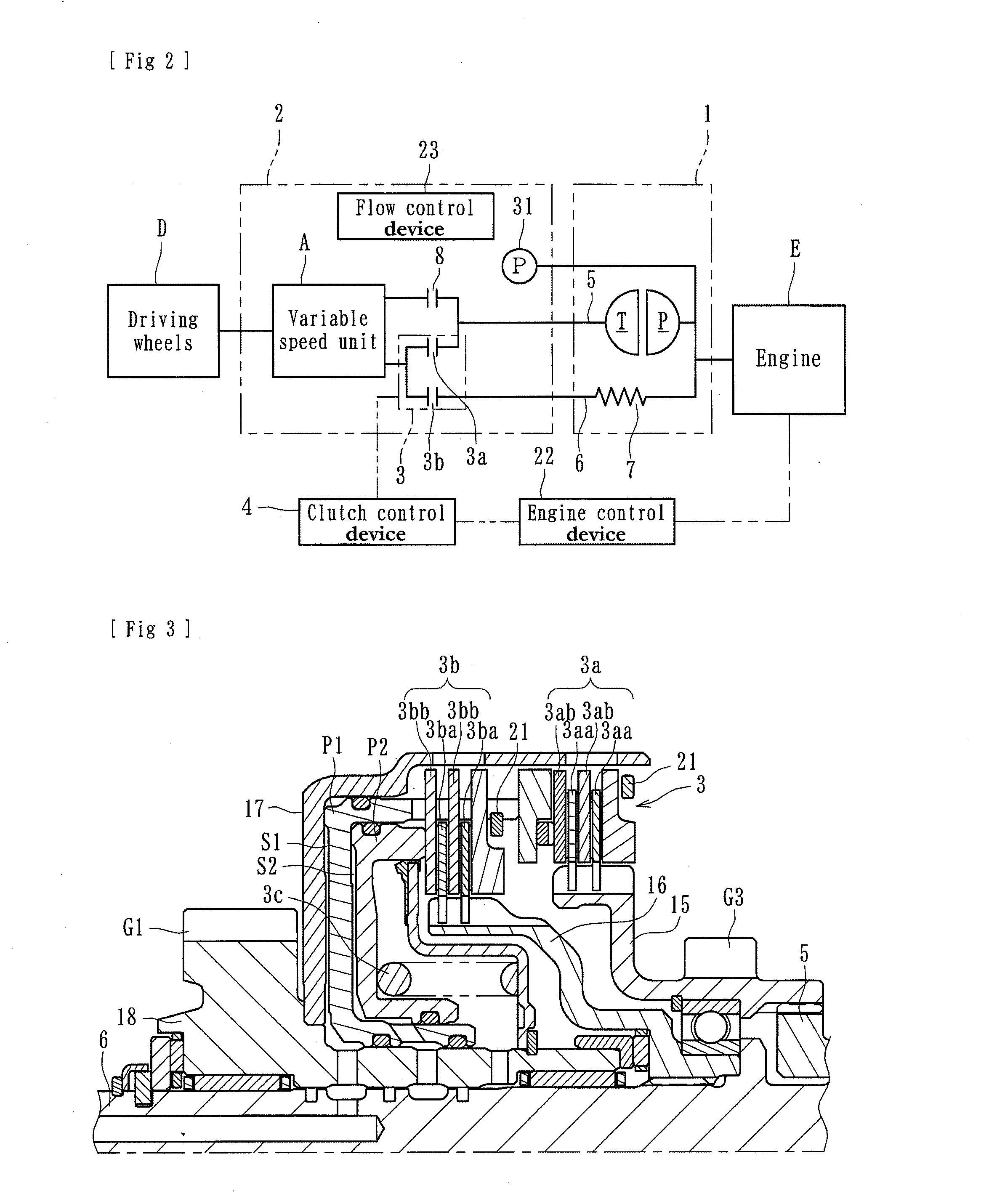

Power transmitting apparatuses

ActiveUS20120065022A1Increase fuel consumptionImprove fuel economyElectrical controlInternal combustion piston enginesManufacturing cost reductionElectric power transmission

A power transmitting apparatus for a vehicle mounted with a torque converter and an idle-stop mechanism can be configured to improve fuel economy without cancelling a fuel-cut-ff during vehicle speed reduction and to reduce the manufacturing cost by eliminating an electrically-driven oil pump. A power transmitting apparatus can comprise a torque converter, a clutch mechanism, an oil pump, a continuously variable transmission, a clutch control device, an engine control device, and a flow control device. The flow control device can be configured to limit or prevent the supply of oil to the torque converter by the oil pump and to prioritize the supply of oil to the clutch mechanism and the continuously variable transmission when the vehicle speed is reduced below a predetermined value with fuel being cut off by the engine control device during vehicle speed reduction.

Owner:FCC KK

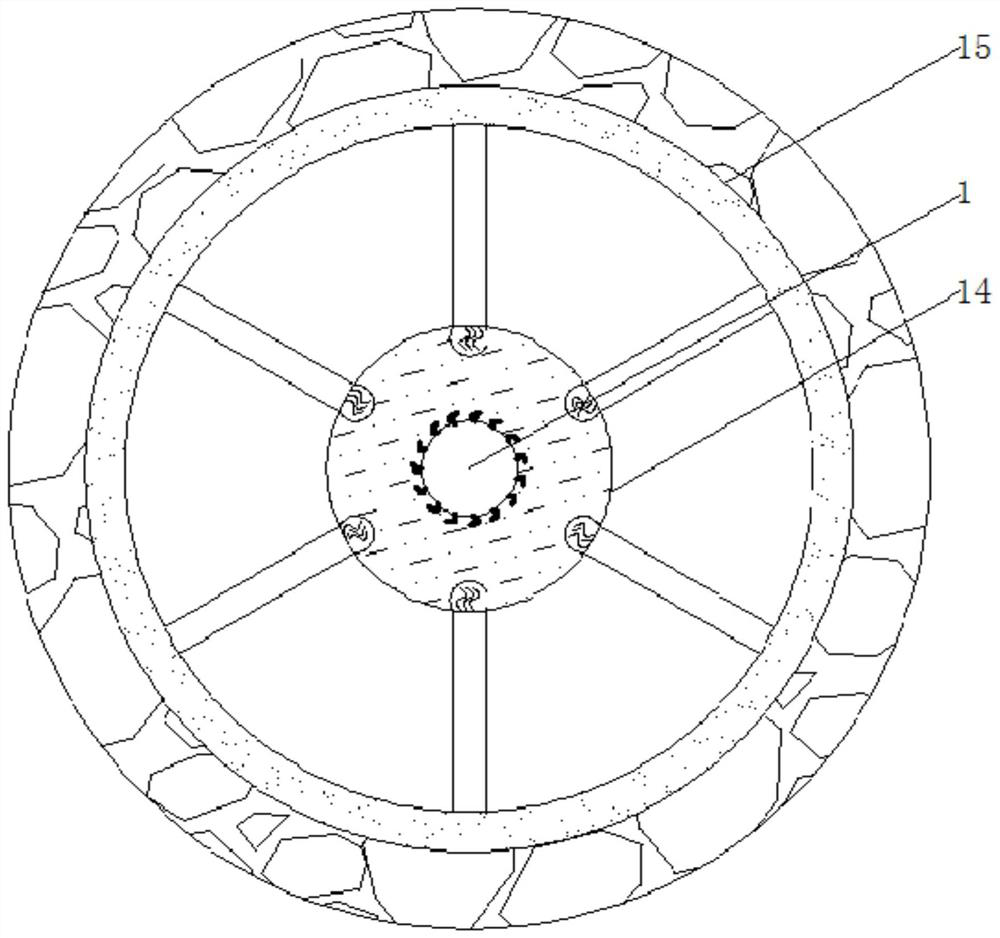

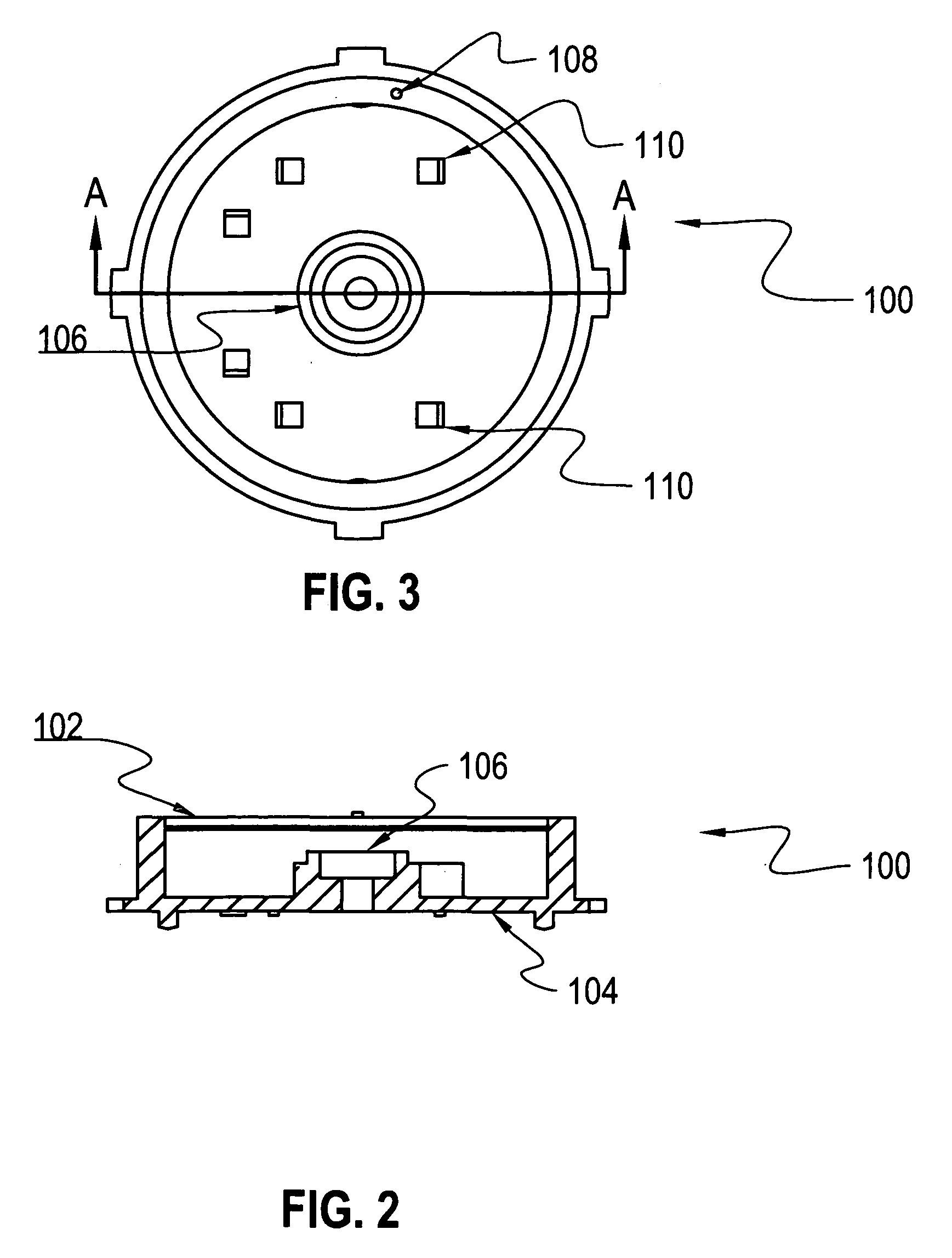

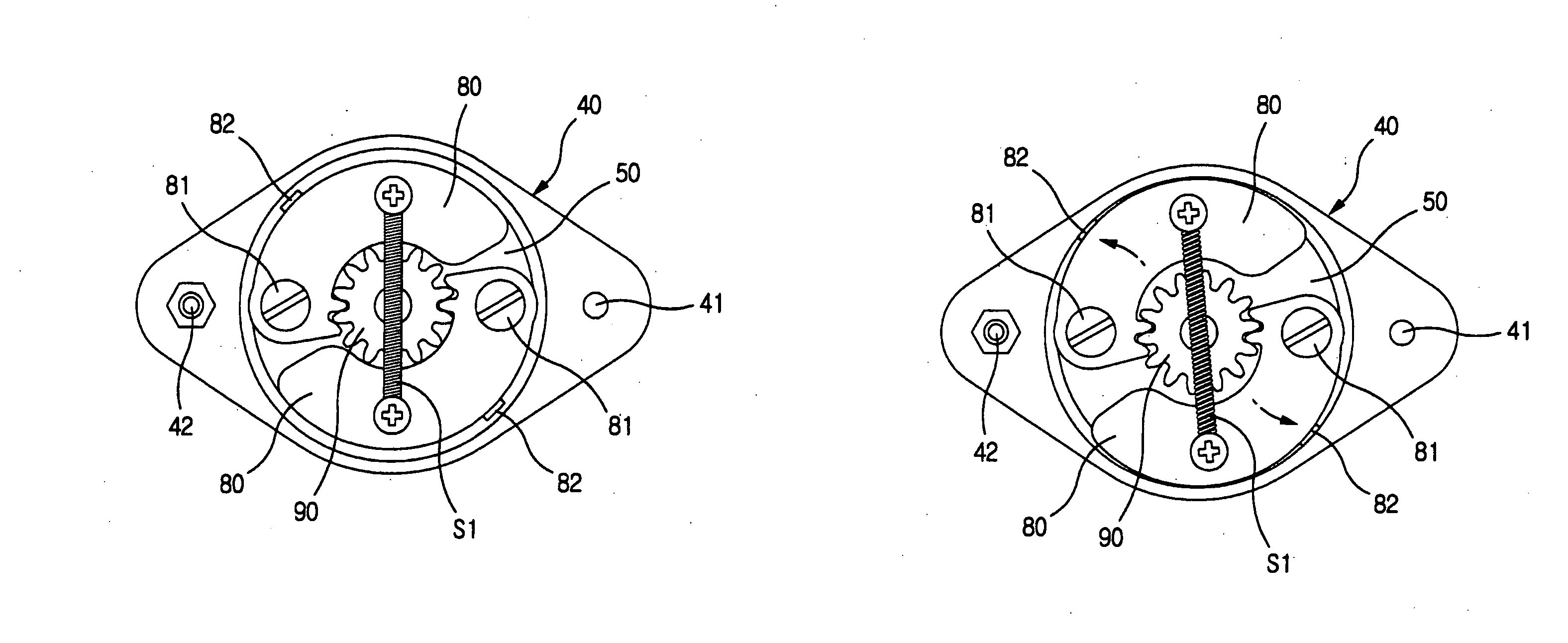

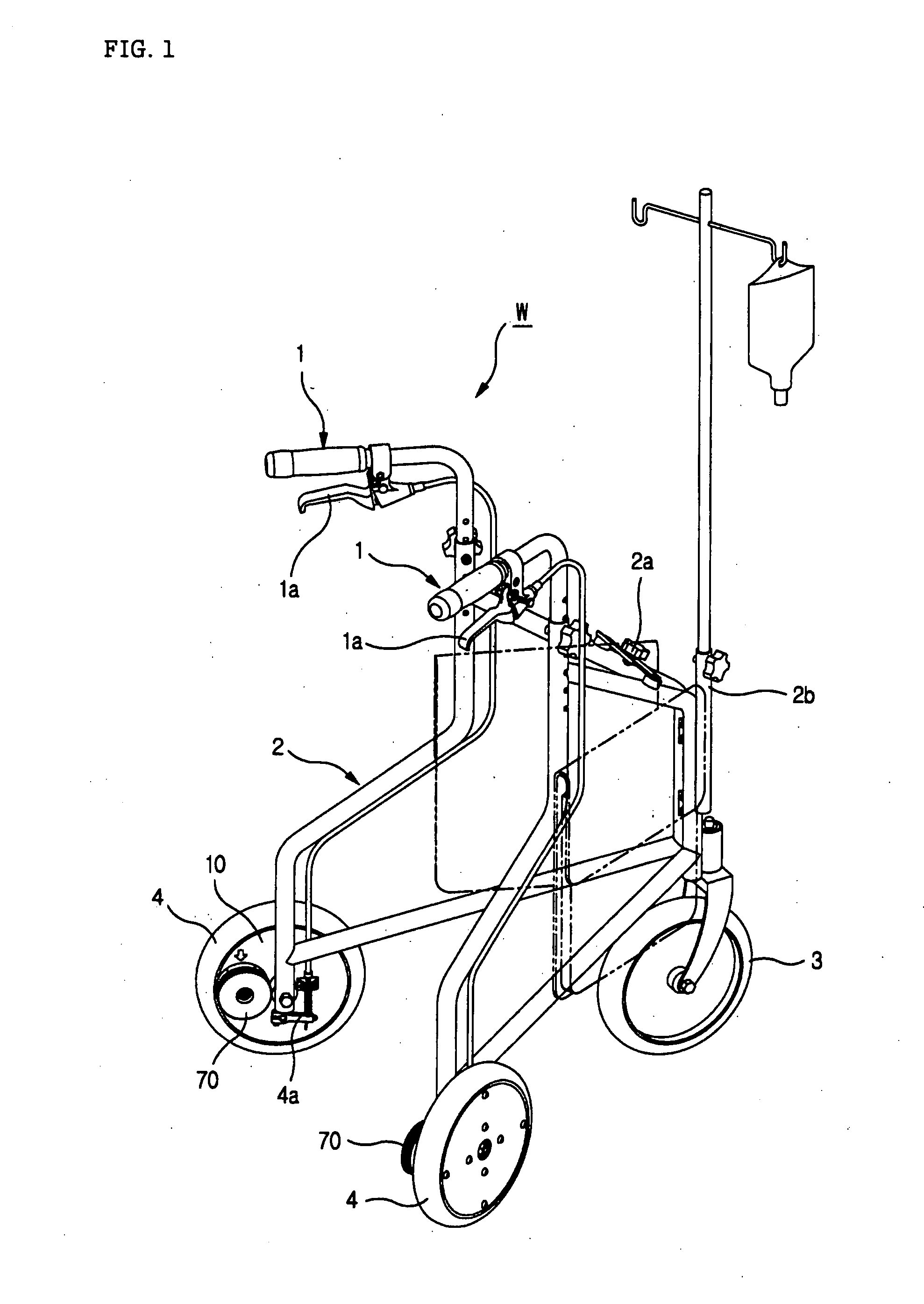

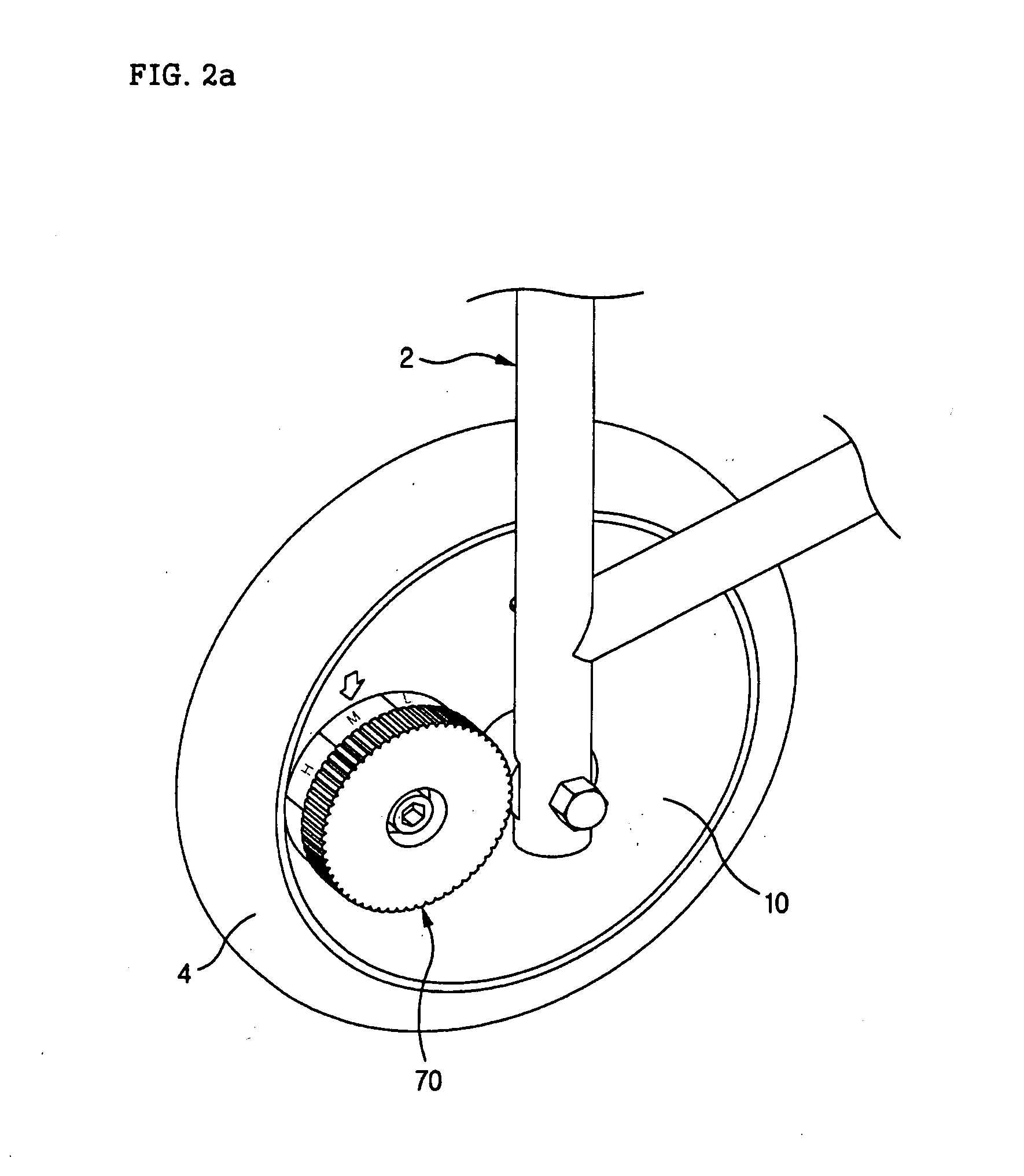

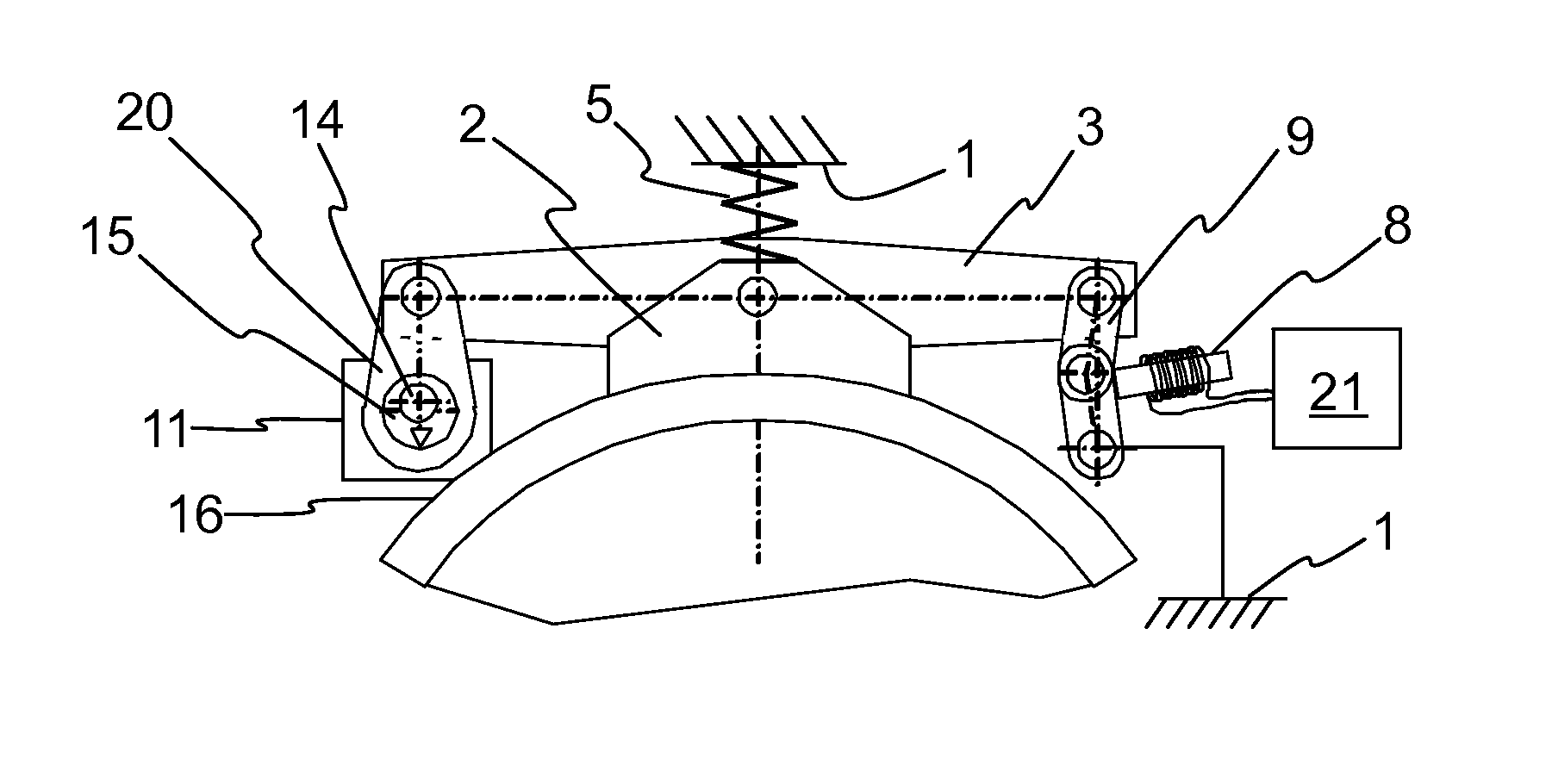

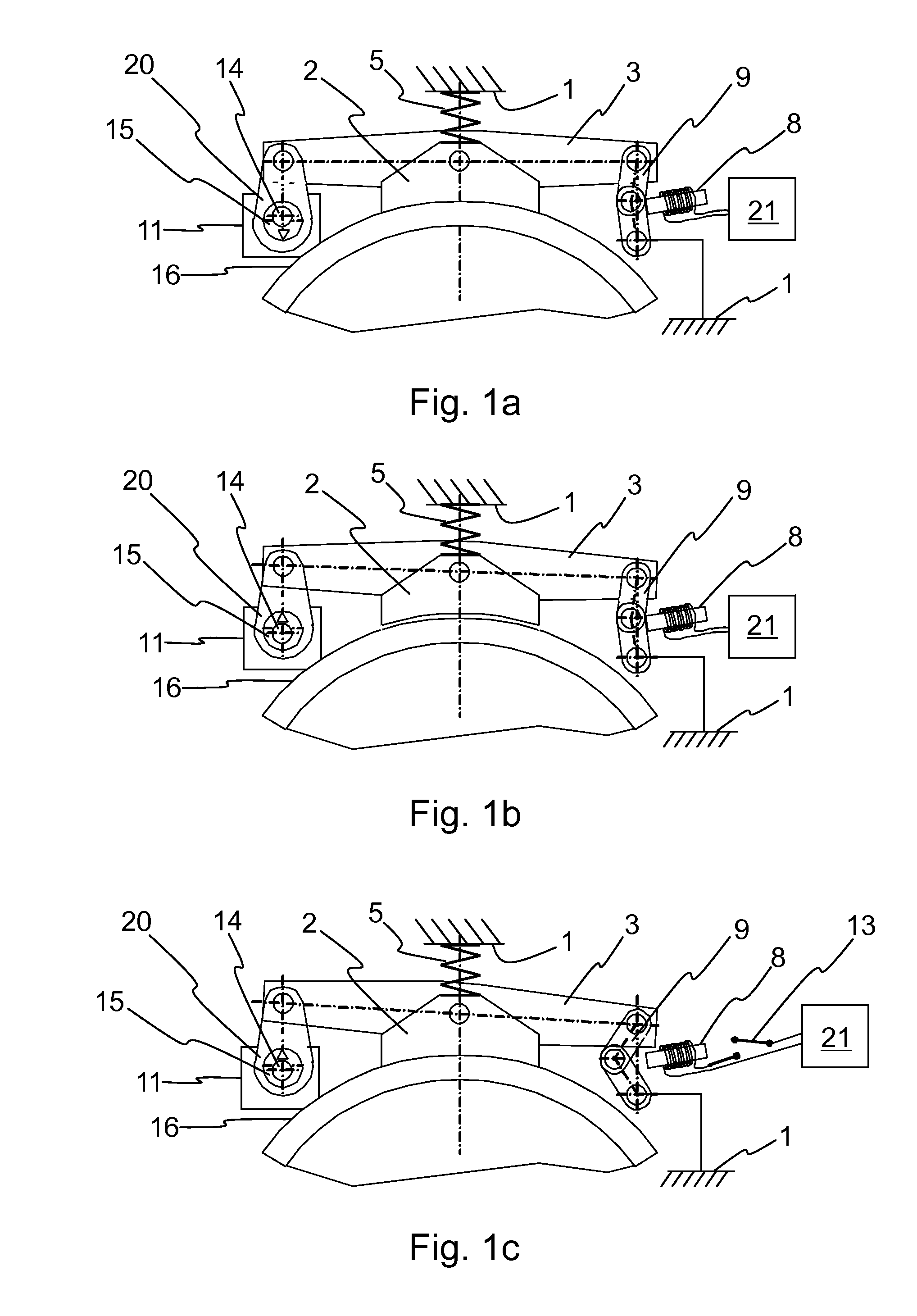

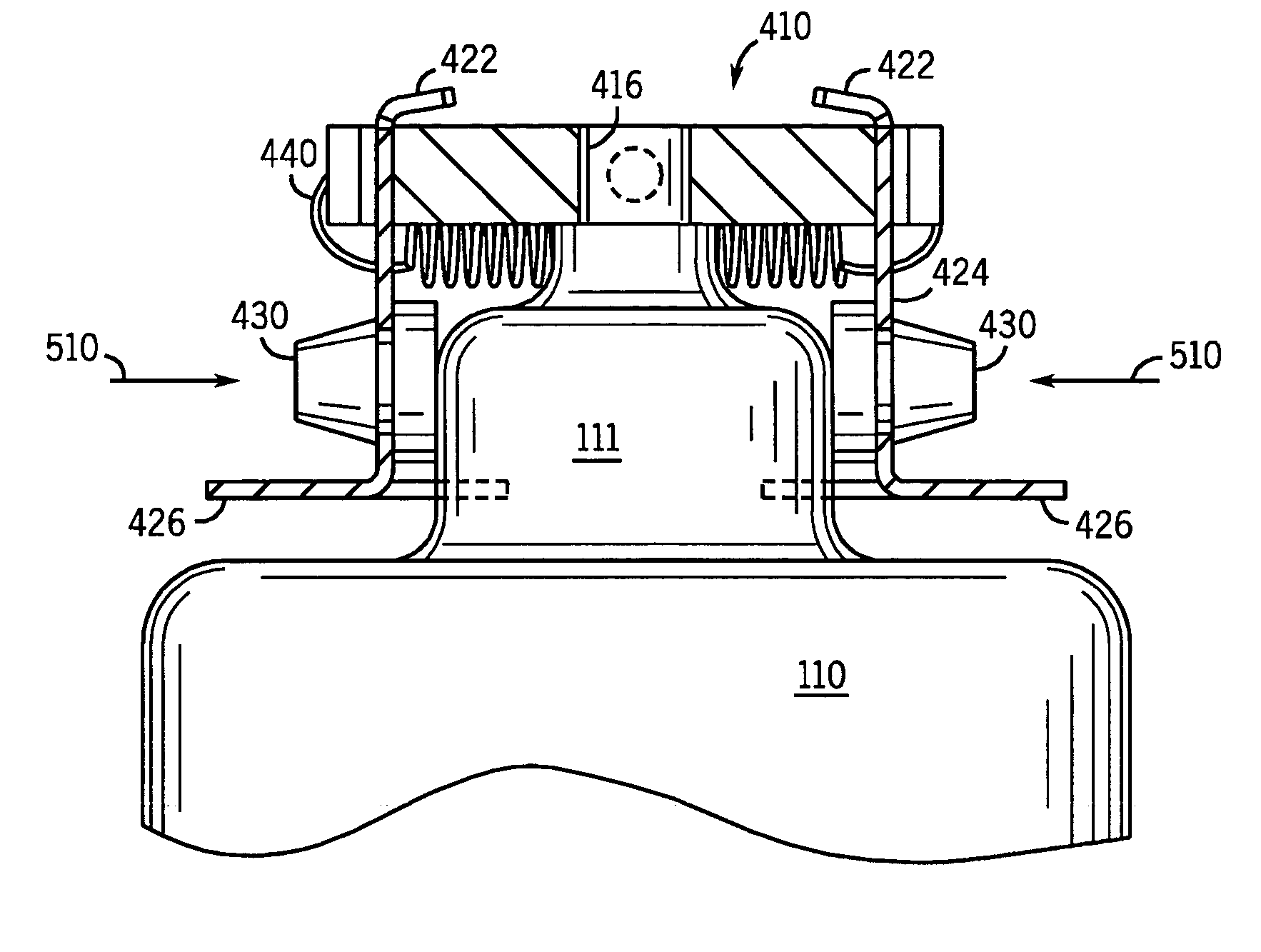

Apparatus for automatic brake of walking support machine

InactiveUS20080142315A1Prevent speedingImprove the problemSelf acting brakesWalking aidsLow speedEngineering

The present invention relates to an apparatus for automatic brake of walking support machine which is safe on downward slopes by preventing over speed due to the acceleration of gravity and protect user on upward slopes.The present invention is devised for walking support machines consist of steering handles (1), main body (2), and a front wheel (3) and 3 rear wheels (4), and is characterized by being comprised of; fixed disks (10) which are installed at the bottom of said main body (2) and support rear wheels (4) to enable rotation; high speed gears (20) and low speed gears (30) which are installed in said rear wheels (4) concentrically; brake drums (40) which are installed on the outside of said fixed disks (10); 1st gears (50) installed on the center shaft of said brake drums (40); 2nd gears (60) which are installed on one side of said brake drums (40) with unidirectional clutches (C) to prevent backward running and assembled with said 1st gear; adjusting knobs (70) which are installed inside of said fixed disks (10), rotatable, and assembles 1st gears (50) and 2nd gears (60) selectively with high speed gears (20) and low speed gears (30); and two pairs of brake disks (80) installed inside said brake drums (40) to receive spring (S1) tension and rotate in connection with said 1st gears (50); in said two rear wheels.

Owner:WOOSUNG TECH

Caliper brake system

ActiveUS20090026024A1Increase braking powerPrevent leakageFluid actuated brakesBraking action transmissionEngineeringCalipers

A caliper brake system includes a housing, a bore within the housing, and a piston slidably positioned within the bore. The brake system also includes a spring assembly, a fluid chamber defined by the bore and the piston, and a hydraulic fluid supply network. The spring assembly provides a biasing force to maintain the piston in an actuated position engaging a stator which engages the rotor of a vehicle. The hydraulic fluid supply network provides pressurized fluid to the fluid chamber to selectively overcome the biasing force of the spring assembly and move the piston to an unactuated position to release the rotor. Thus, the caliper brake is spring actuated and hydraulically released.

Owner:LAMBERT BRAKE

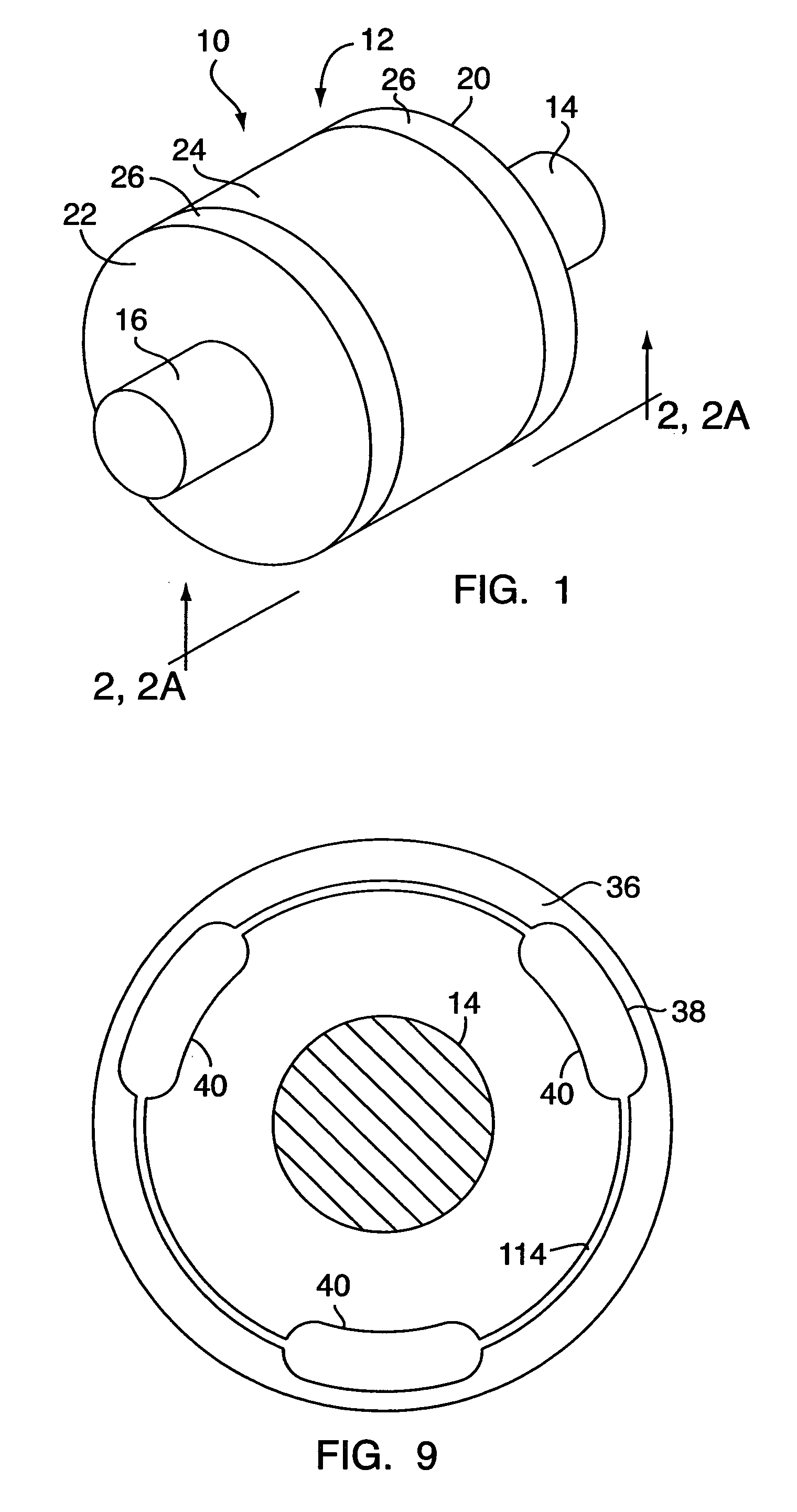

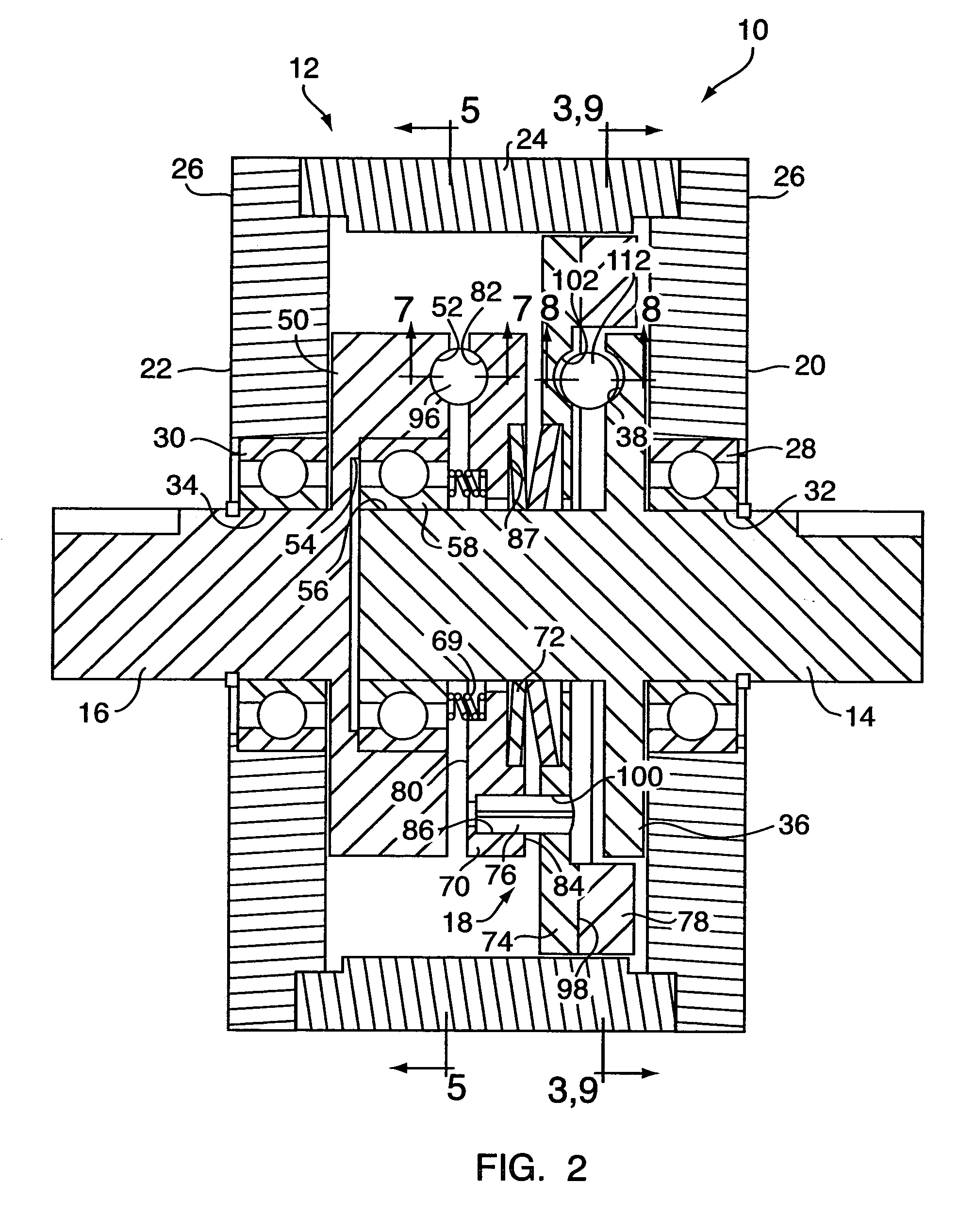

Descent device

There is disclosed herein a descent device (10) comprising a hollow spool (12) rotatable about a rotational axis (14) and a lifeline, in the form of a braided steel cable (not shown), wound about the spool (12). A centrifugal brake mechanism (18) including a brake assembly, comprising a pair of brake shoes (20) and associated brake pads (21), is engageable with the spool (12) to apply a braking force to the spool (12) as the spool (12) rotates. Biasing members, in the form of a compression springs (22), extend between the brake shoes (20) for biasing the brake shoes (20) and pads (21) into engagement with the spool (12).

Owner:LIFELINE DESCENT SYST

Brake

ActiveUS20150129365A1Avoid noiseAvoid disturbing noiseBraking element arrangementsNoise/vibration controlSpring forceEngineering

The invention relates to a brake and to a method for controlling the brake. The brake comprises a base part, a braking piece movably supported on the base part, which braking piece is configured to be moved between a braking position and a releasing position, a spring, with the spring force of which the braking piece can be dropped into a braking position, a support member for limiting the initial position of the drop-out movement of the braking piece and also a controllable actuator, which is mechanically connected to the aforementioned support member and configured to displace the initial position of the drop-out movement of the braking piece with respect to the braking position.

Owner:KONE CORP

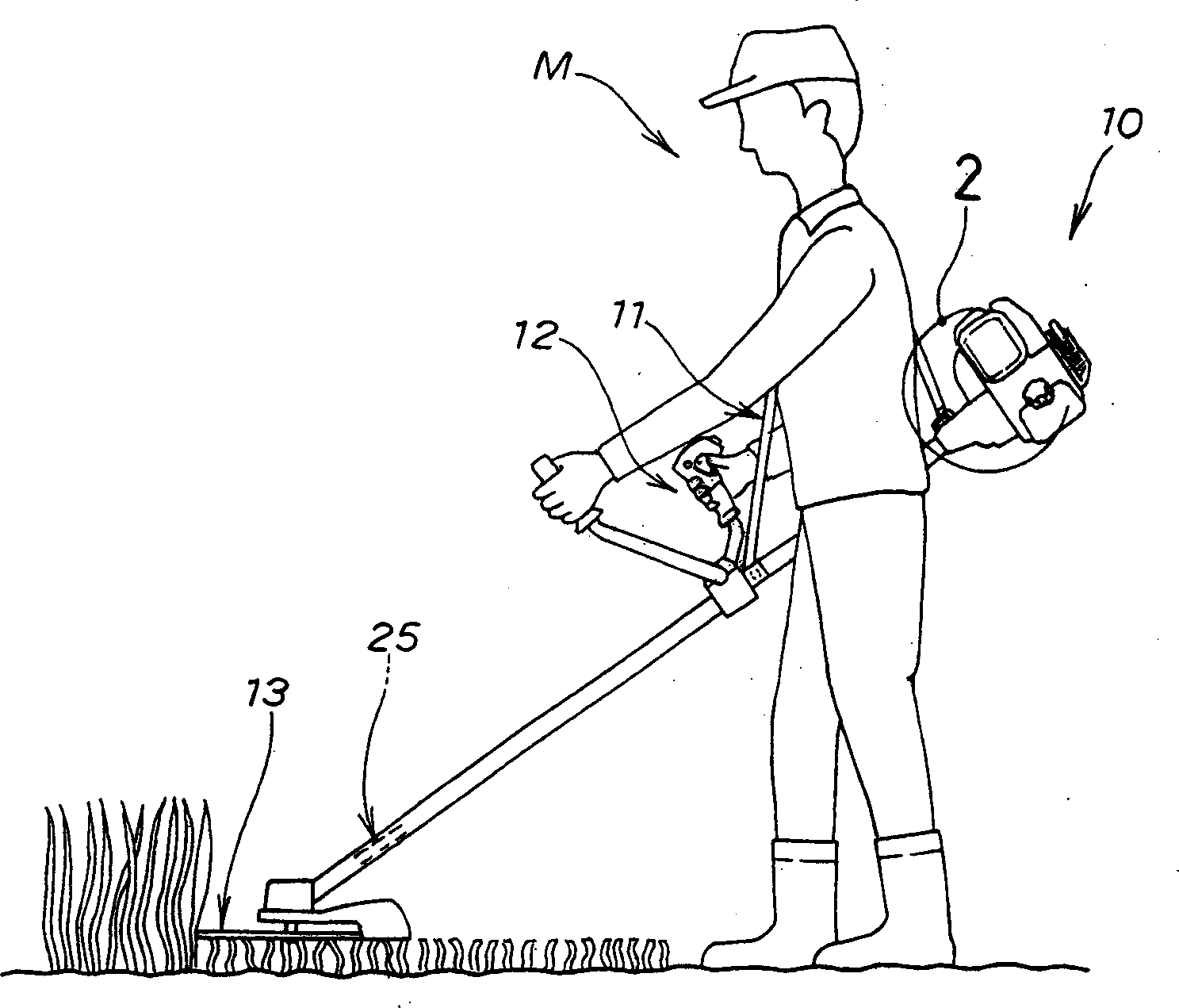

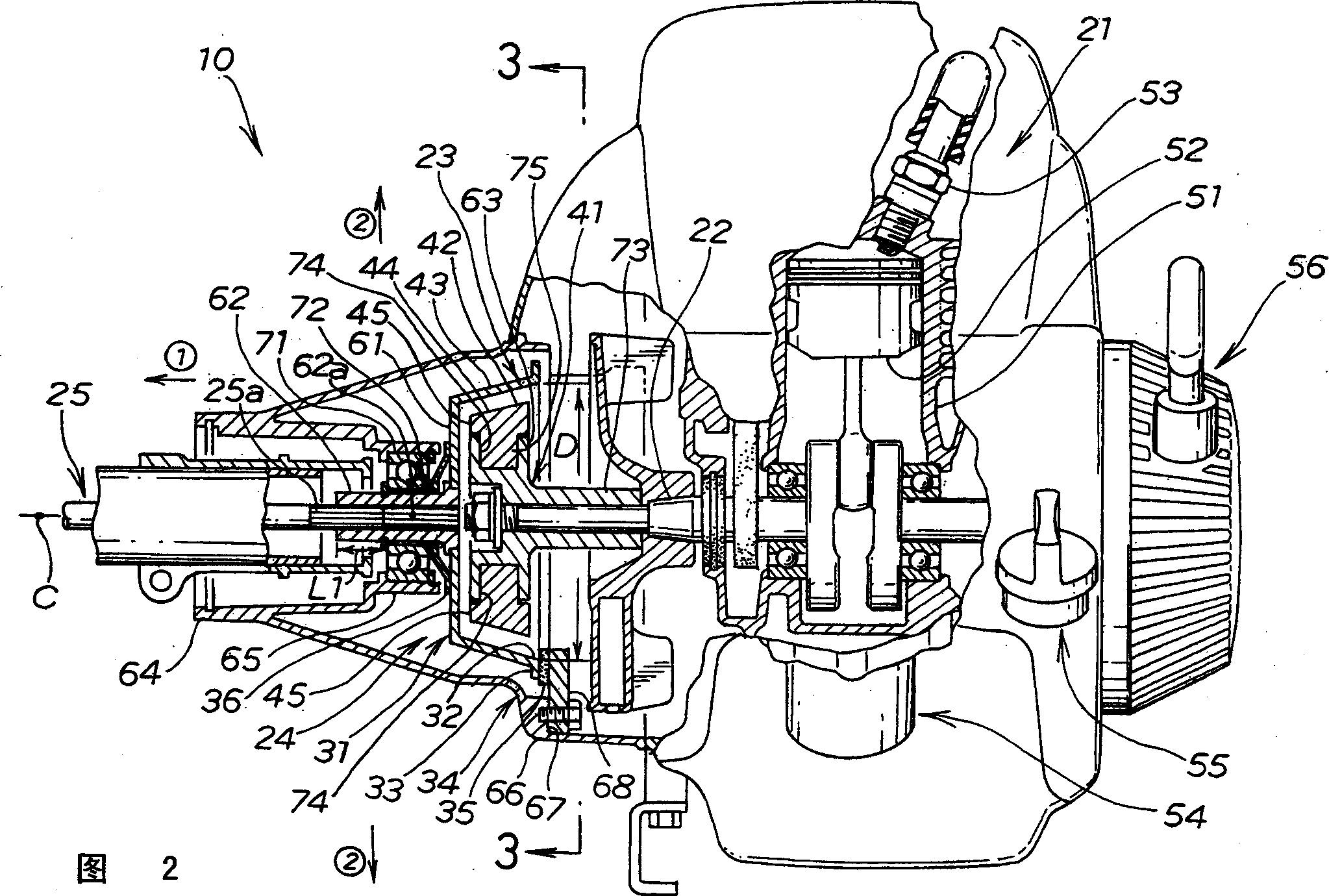

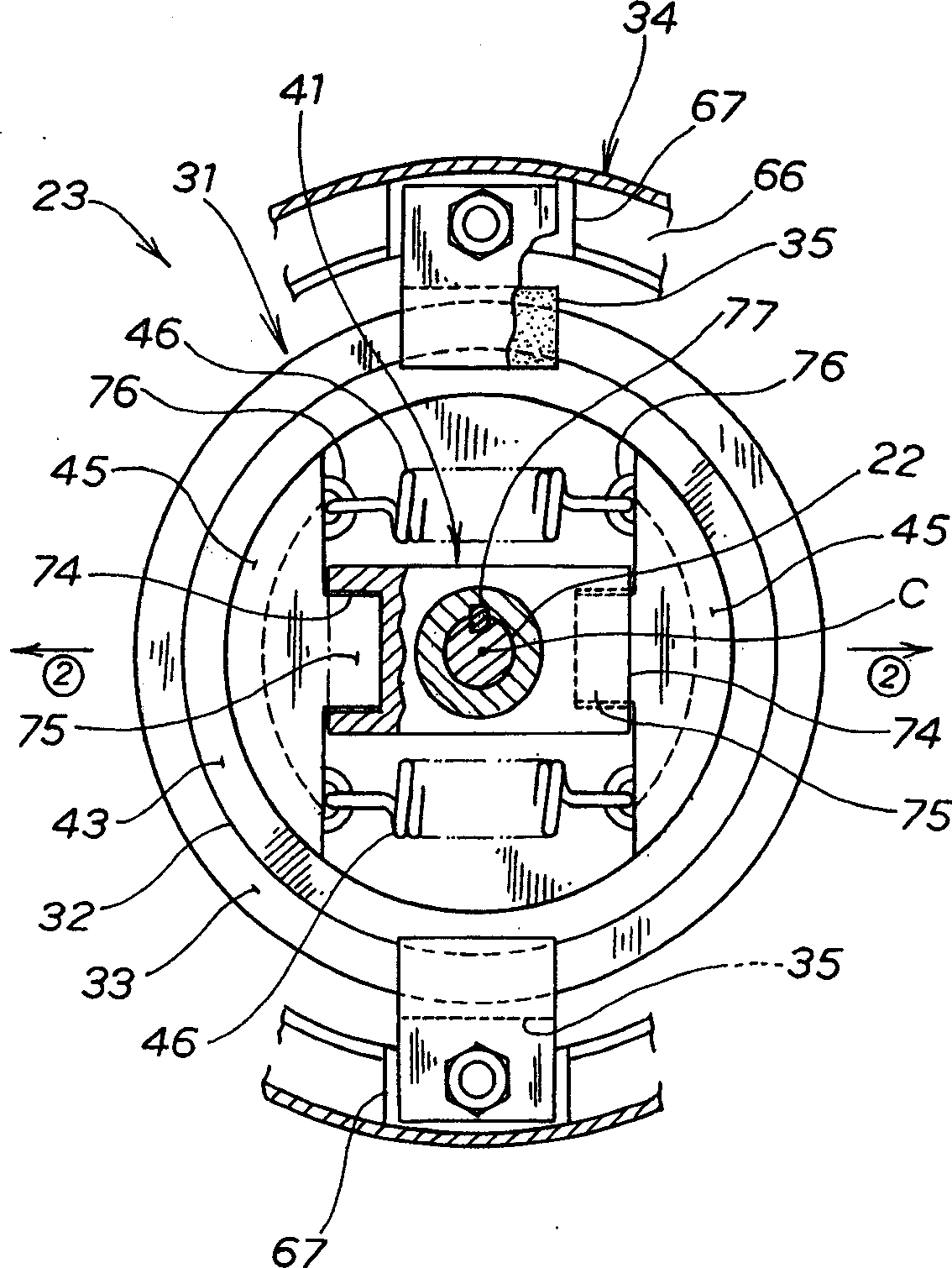

Cutting equipment for brush

When the rotation speed of the driving source (21) has been lower than a predetermined value, the clutch moving element (45; 85) is disengaged from the clutch drum (31; 81) under the action of the clutch elastic element (46), thus making the clutch drum (31; 81) elastically slides back to a predetermined braking position under the action of the braking elastic element (36), where the brake shoe (33; 83) presses against the brake pad (35) to apply Braking action. When the rotational speed of the source device (21) has increased beyond a predetermined value, the clutch moving element (45; 85) slides radially outwards under centrifugal force in such a way that the clutch moving element (45; 85) Overcoming the bias of the brake elastic element (36), applying pressure to the clutch drum (31; 81) and making the clutch drum (31; 81) axially slide to the non-braking position, so that the brake shoe (33; 83 ) is disengaged from the brake pad (35) to release the braking effect.

Owner:HONDA MOTOR CO LTD

Rotor brake as well as rotor and rotary-wing aircraft with such a rotor brake

InactiveUS7168533B2Avoid disadvantagesEffective preventionSelf acting brakesEfficient propulsion technologiesEngineeringCentrifugal force

Owner:AIRBUS HELICOPTERS DEUT GMBH

Automatic drag brake for a power take-off unit output shaft

ActiveUS20050258012A1Spin easilyMaximizes braking surfaceAgricultural machinesSelf acting brakesEngineeringTruck

Improvement in a drag brake assembly for a power take-off unit, for use on trucks and the like, including a first reaction member axially located on an output shaft thereon; a brake disc rotatably affixed to and axially movable on the output shaft; a second reaction member forming an inner surface portion of one of the bearing caps; and a spring member interposed between the first reaction member and the brake disc, for normally biasing the brake disc into an engaged position wherein the brake disc engages the second reaction member inner surface portion, with the brake disc including a first frusto-conical outer surface portion and the second reaction member inner surface being provided with a complementary second frusto-conical surface, with the engagement therebetween keeping the output shaft from rotating.

Owner:PARKER INTANGIBLES LLC

Brake

A motor brake can be coupled to the rotatable motor drive shaft. The brake includes a shaft-mountable support that rotates uniformly with the drive shaft. One or more brake shoes, which can include flyweights or the like, are hingedly mounted to the support and include brake pads. A centripetal force is applied to the brake shoes using one or more springs or other biasing means that bias the brake pads against a braking surface when rotation of the shaft is below a minimum rotational velocity. The brake pads disengage from the braking surface when shaft rotation exceeds the minimum rotational velocity. The centrifugal force induced and applied to the brake shoes and brake pads by rotation of the motor drive shaft overcomes the biasing force to disengage the brake pads from the braking surface, which may be the housing of a motor to which the brake is affixed.

Owner:AUTOADAPT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com