Patents

Literature

699results about How to "Improve curing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

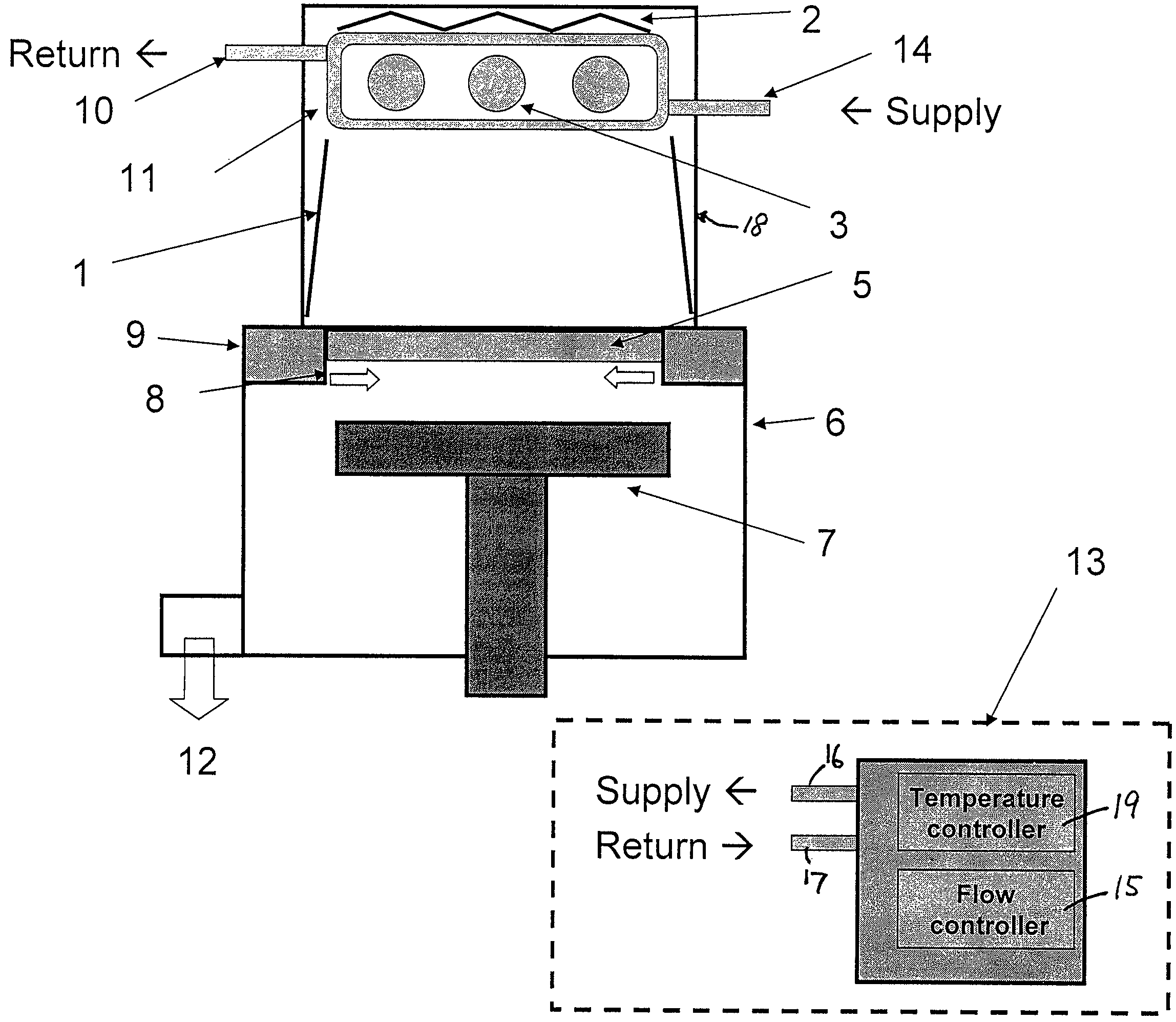

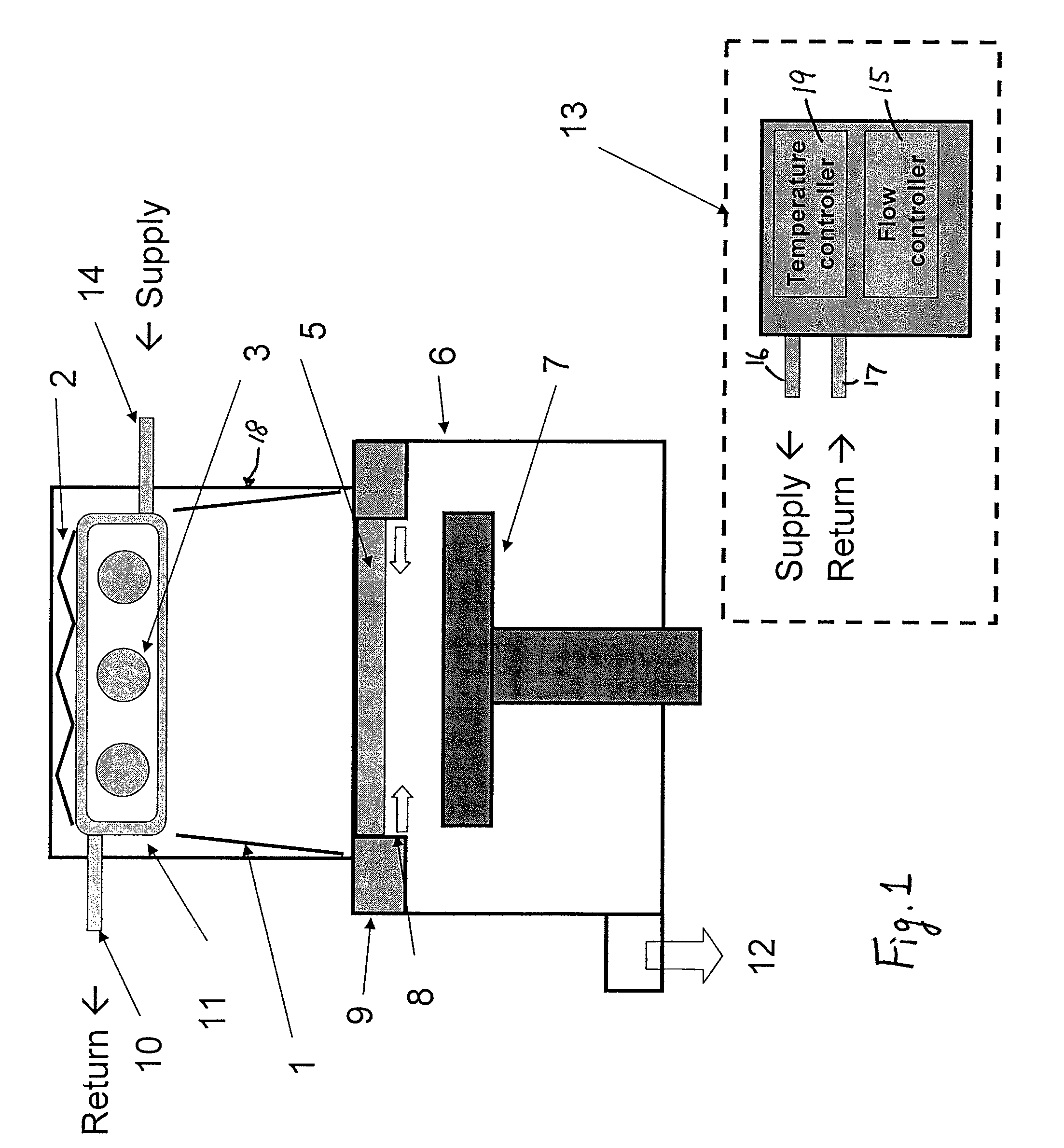

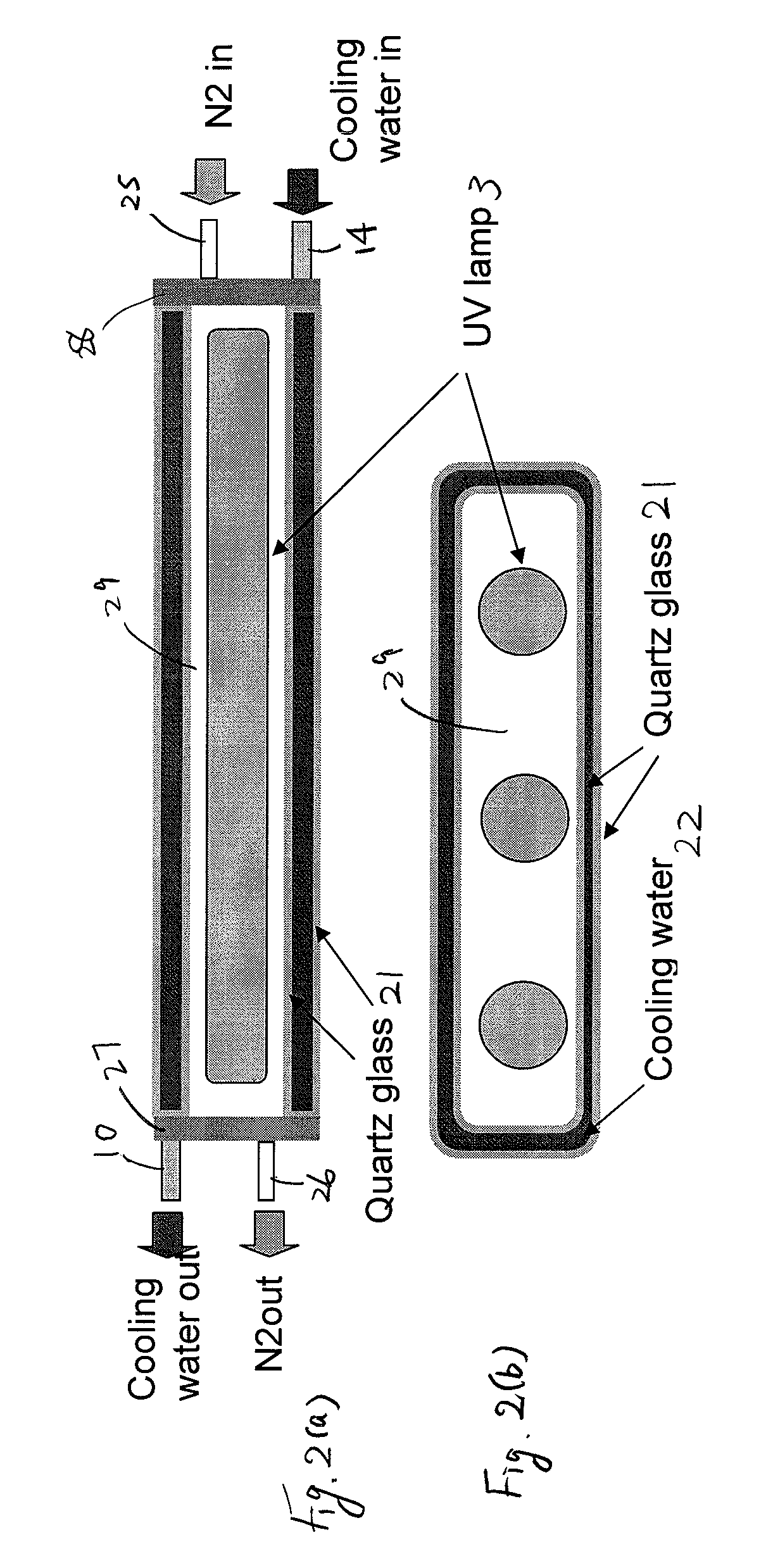

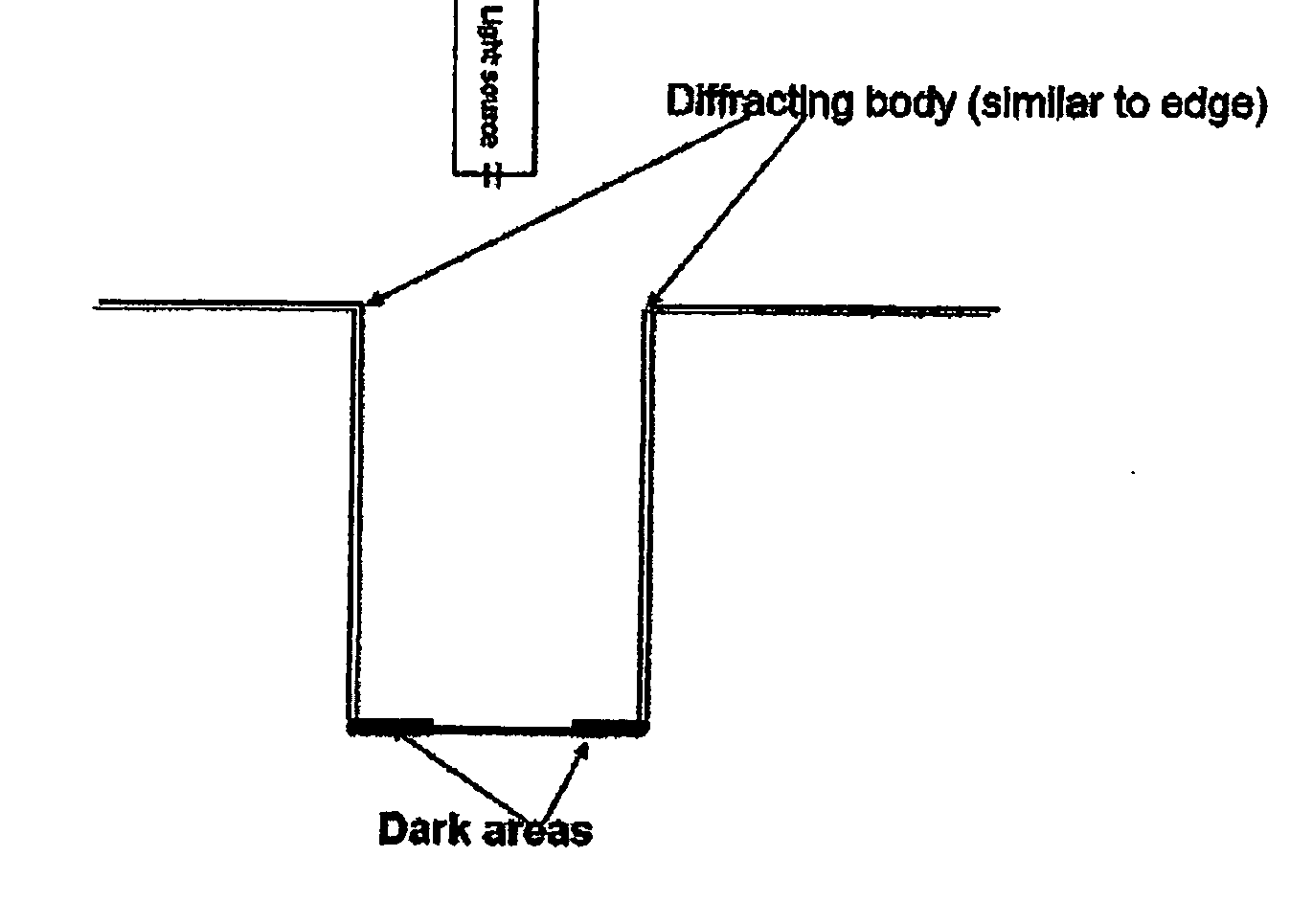

UV light irradiating apparatus with liquid filter

ActiveUS7763869B2High mechanical strengthHigh energyMirrorsOptical filtersLiquid layerLight irradiation

A UV light irradiating apparatus for irradiating a semiconductor substrate with UV light includes: a reactor in which a substrate-supporting table is provided; a UV light irradiation unit connected to the reactor for irradiating a semiconductor substrate placed on the substrate-supporting table with UV light through a light transmission window; and a liquid layer forming channel disposed between the light transmission window and at least one UV lamp for forming a liquid layer through which the UV light is transmitted. The liquid layer is formed by a liquid flowing through the liquid layer forming channel.

Owner:ASM JAPAN

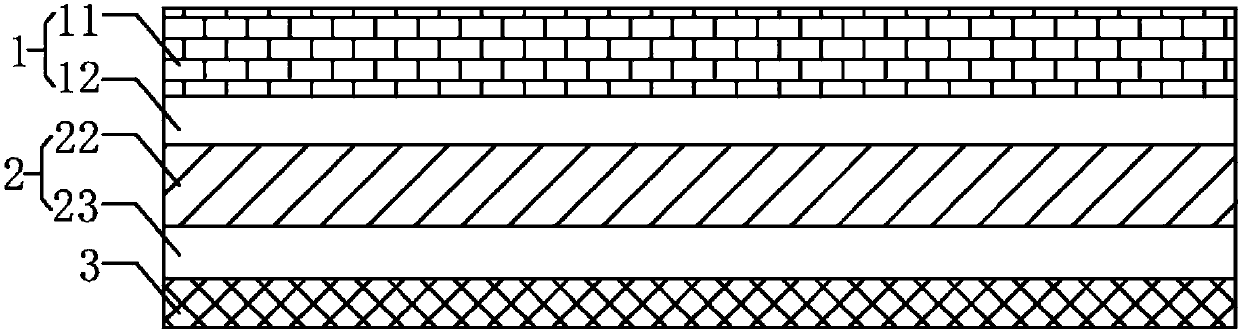

Solar battery back plate adopting ultraviolet (UV) curing weather-proof coating and manufacture method of solar battery back plate

ActiveCN102610680AGood insulation of the materialLow water vapor transmission rateCoatingsPhotovoltaic energy generationFilling materialsUV curing

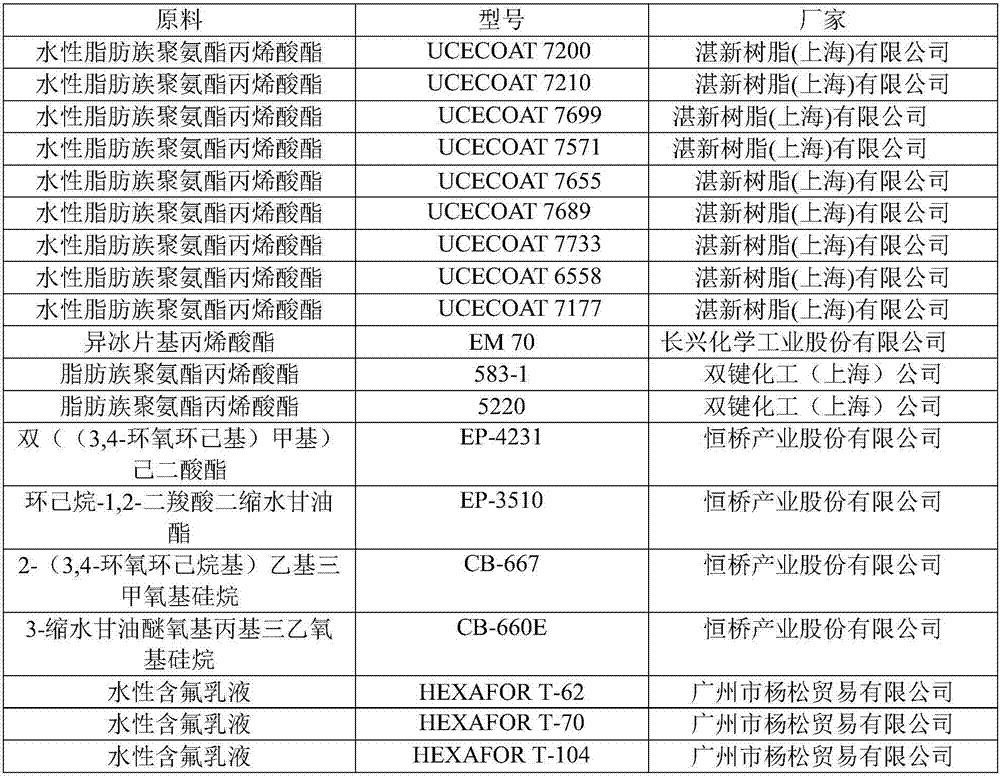

The invention discloses a solar battery back plate adopting an ultraviolet (UV) curing weather-proof coating and a manufacture method of the solar battery back plate. The solar battery back plate comprises a substrate, wherein at least one side of the substrate is coated with the UV curing weather-proof coating, the UV curing weather-proof coating is prepared from the following materials: 50 to 80 weight percent of weather-proof photosensitive resin, 10 to 20 weight percent of reactive diluent, 2 to 15 weight percent of initiating agent, 5 to 30 weight percent of filling material, 0.5 to 2 weight percent of dispersing agent, 0.5 to 2 weight percent of antioxidant, 0.5 to 2 weight percent of hydrolysis-resistant agent and 0.5 to 2 weight percent of anti-aging agent. The UV curing weather-proof coating is adopted and directly coated onto the substrate, the coating curing efficiency is high, the production efficiency of the solar battery back plate is improved, and meanwhile, the use of organic solvents causing serious pollution to the environment is avoided, so the organic solvent volatilization is avoided in the whole production process, and the solar battery back plate conforms to the green and environmental friendly standard.

Owner:ZHEJIANG WAZAM NEW MATERIAL CO LTD

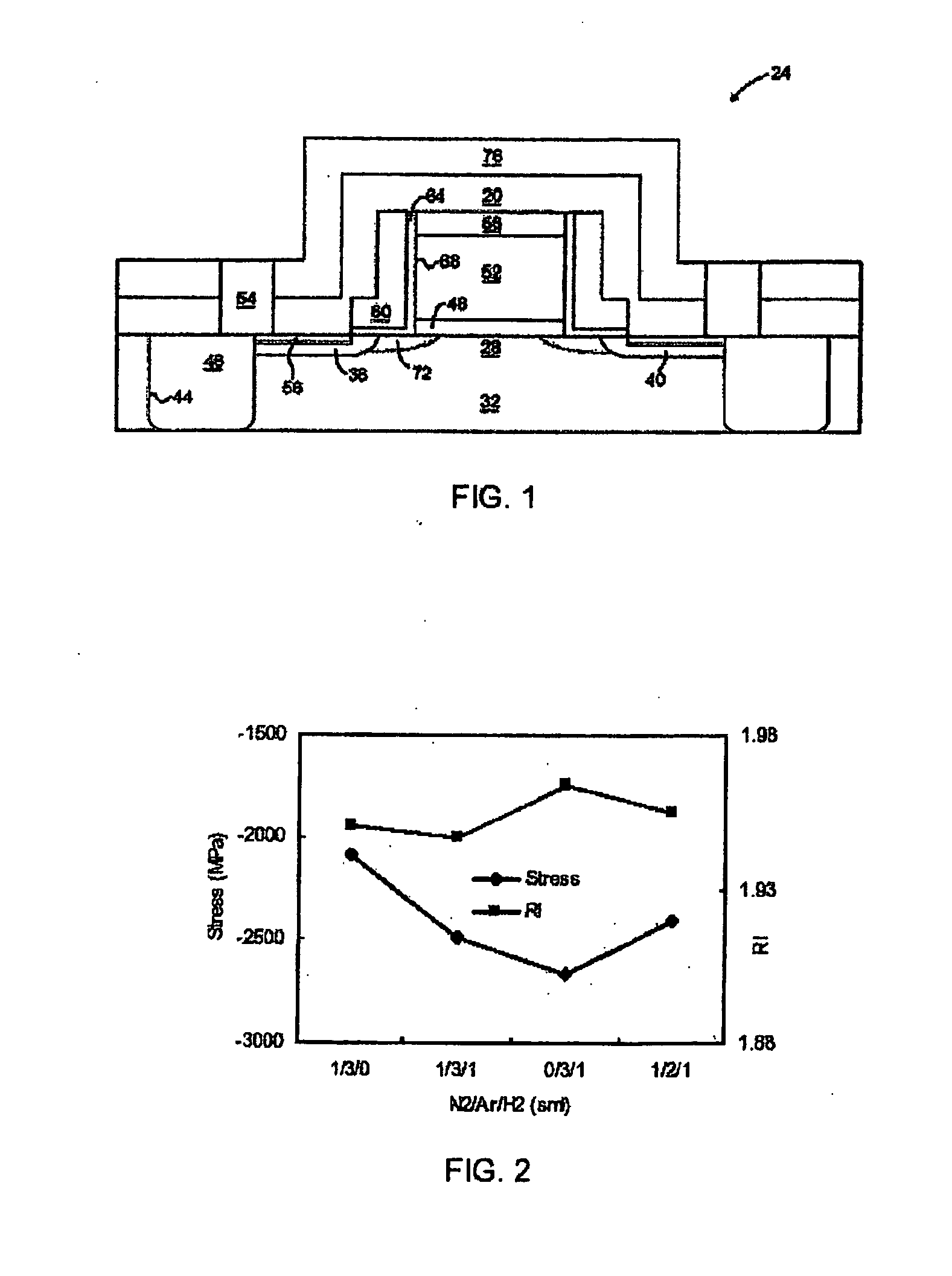

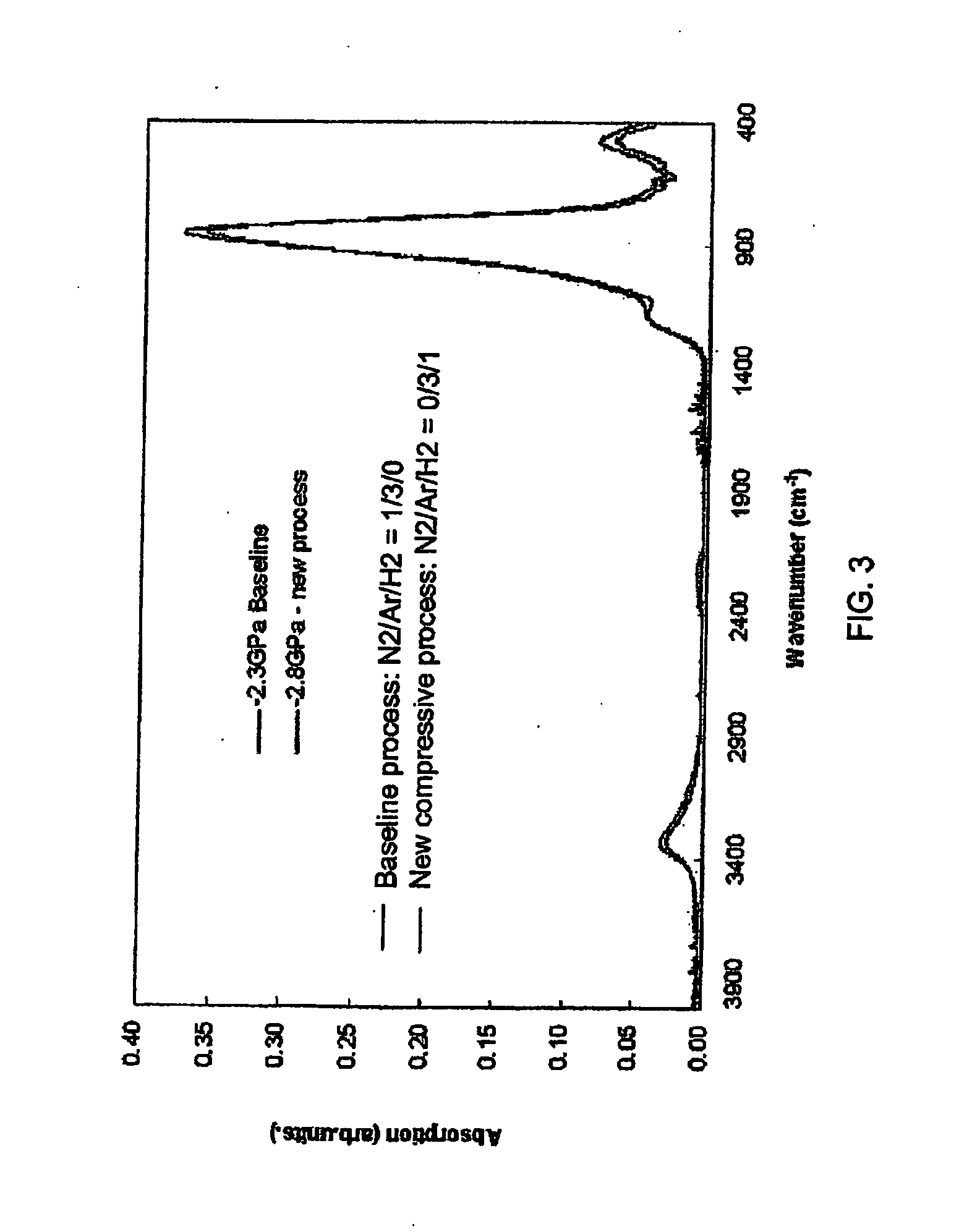

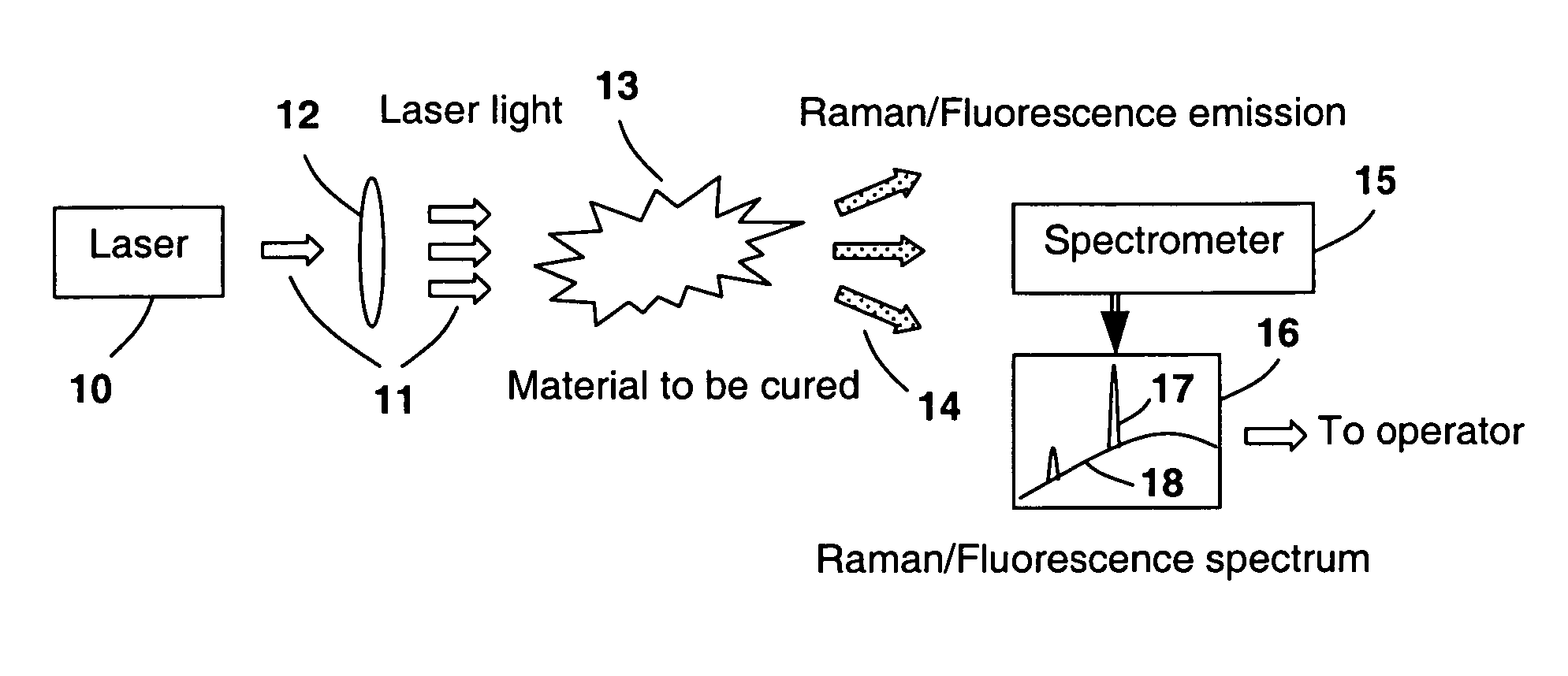

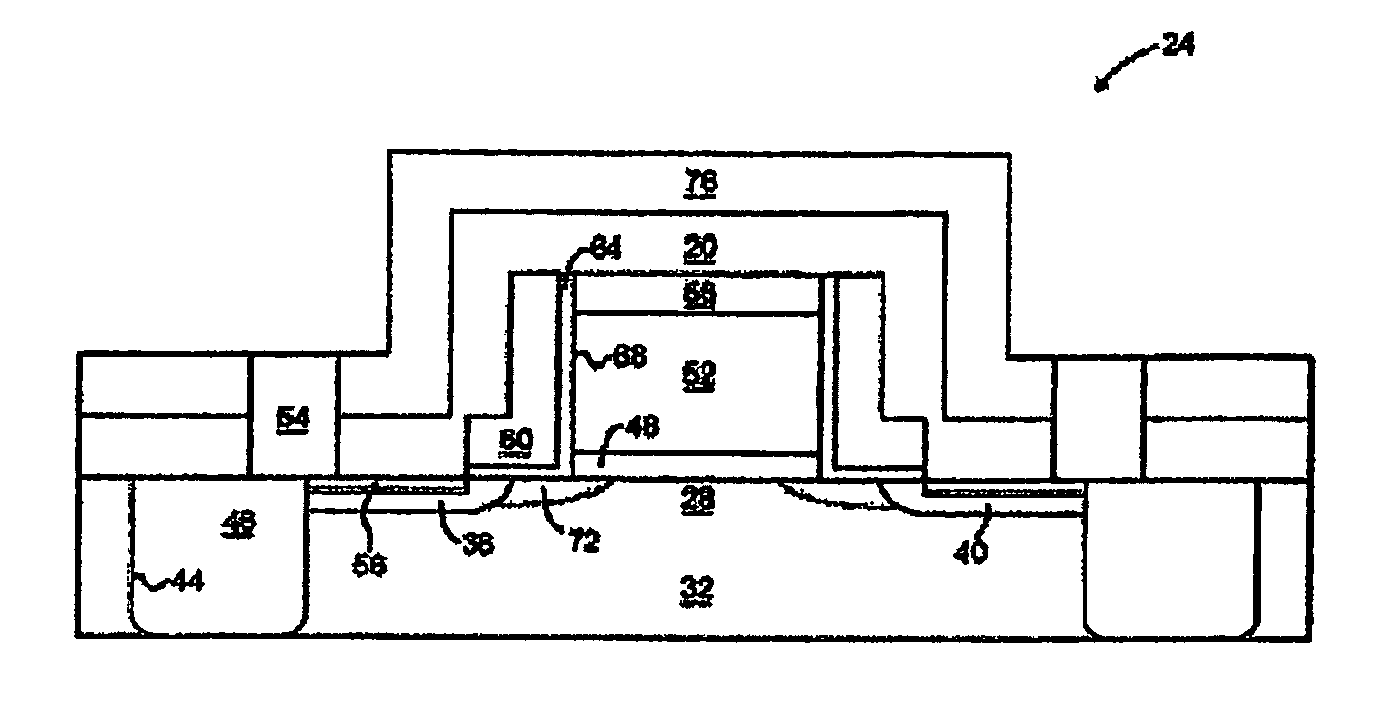

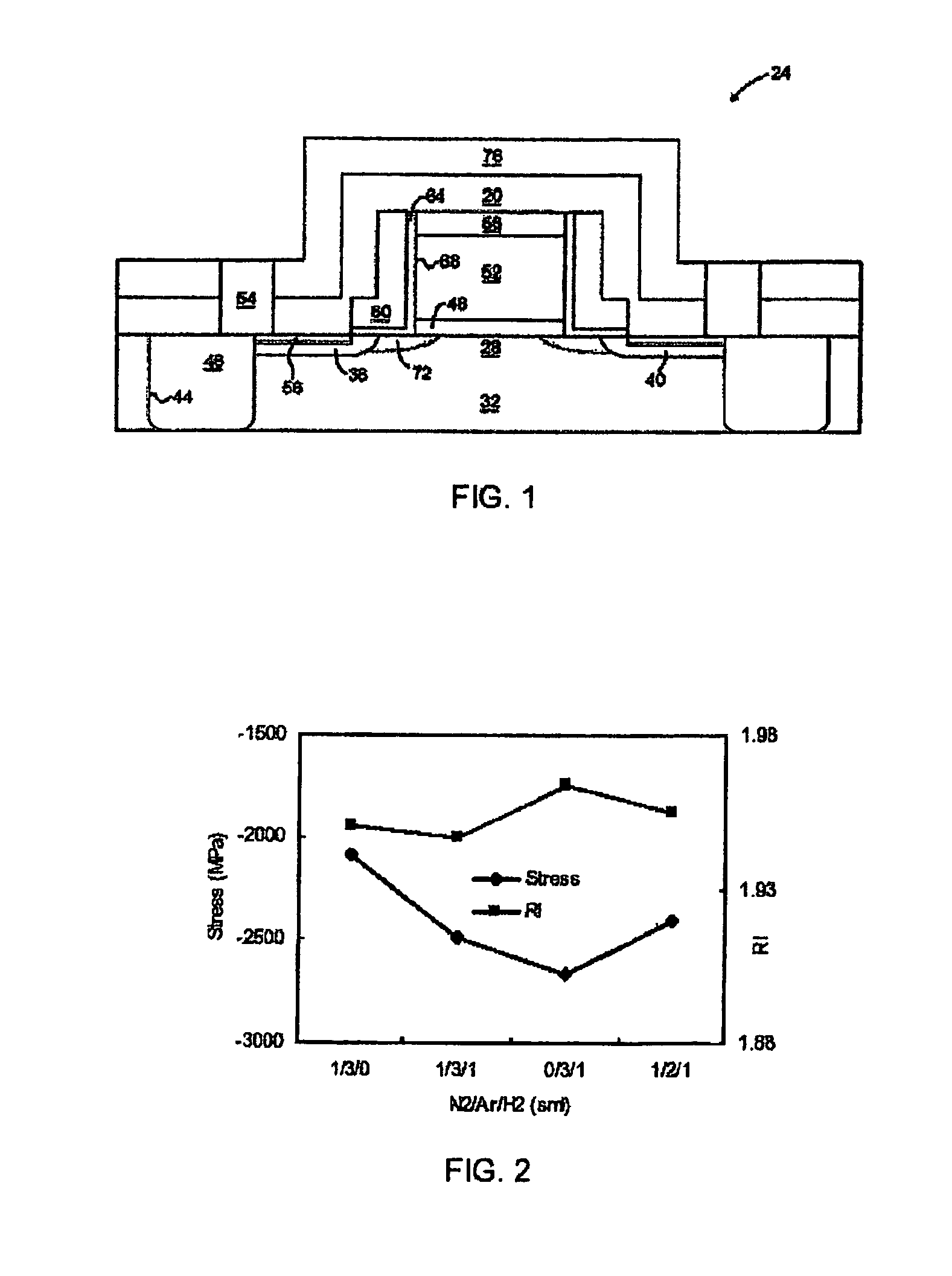

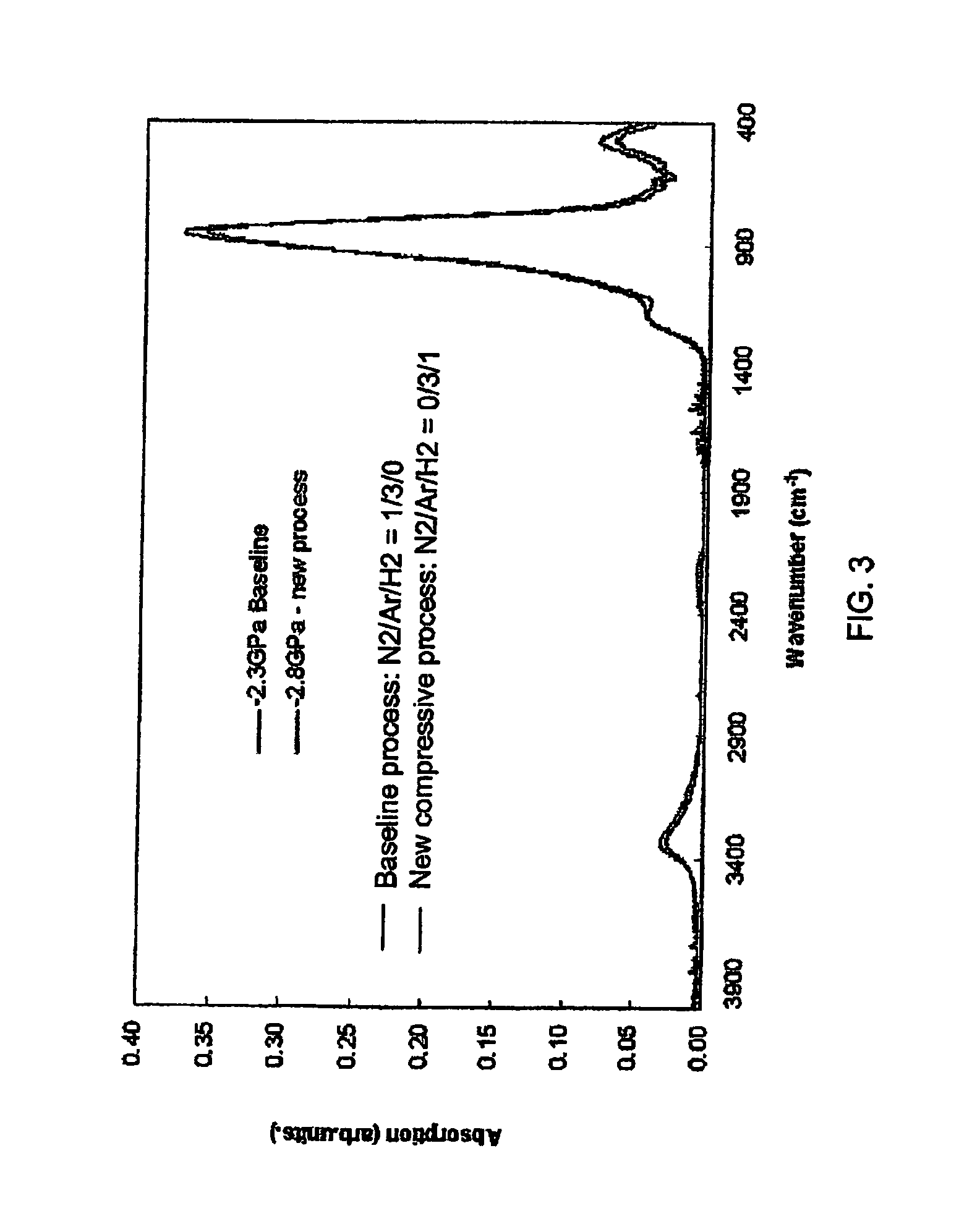

Integration process for fabricating stressed transistor structure

ActiveUS20060270217A1Enhance radiation curing efficiencyFilm stress is increasedSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDevice materialEngineering

A process flow integration scheme employs one or more techniques to control stress in a semiconductor device formed thereby. In accordance with one embodiment, cumulative stress contributed by RTP of a nitride spacer and polysilicon gate, and subsequent deposition of a high stress etch stop layer, enhance strain and improve device performance. Germanium may be deposited or implanted into the gate structure in order to facilitate stress control.

Owner:APPLIED MATERIALS INC

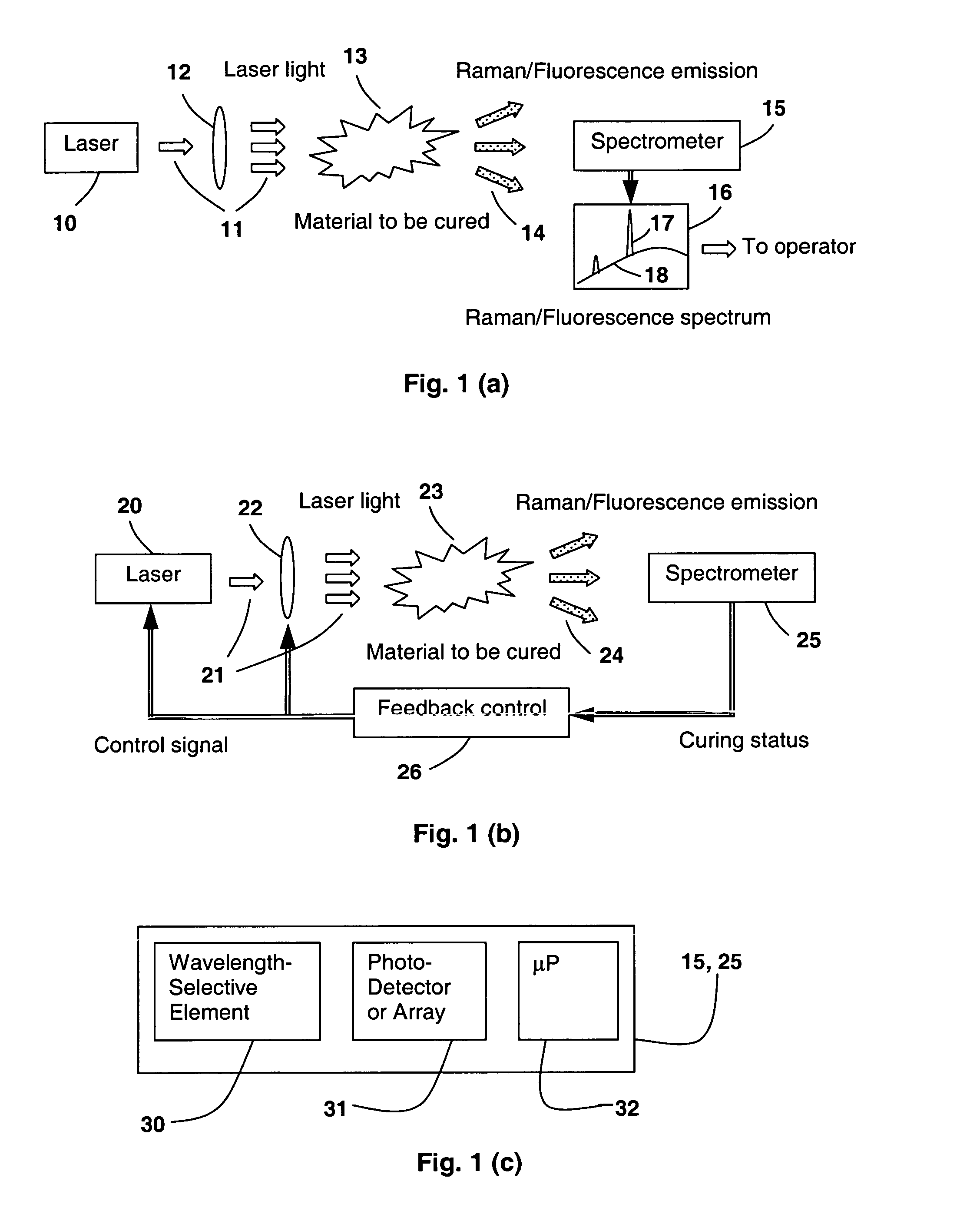

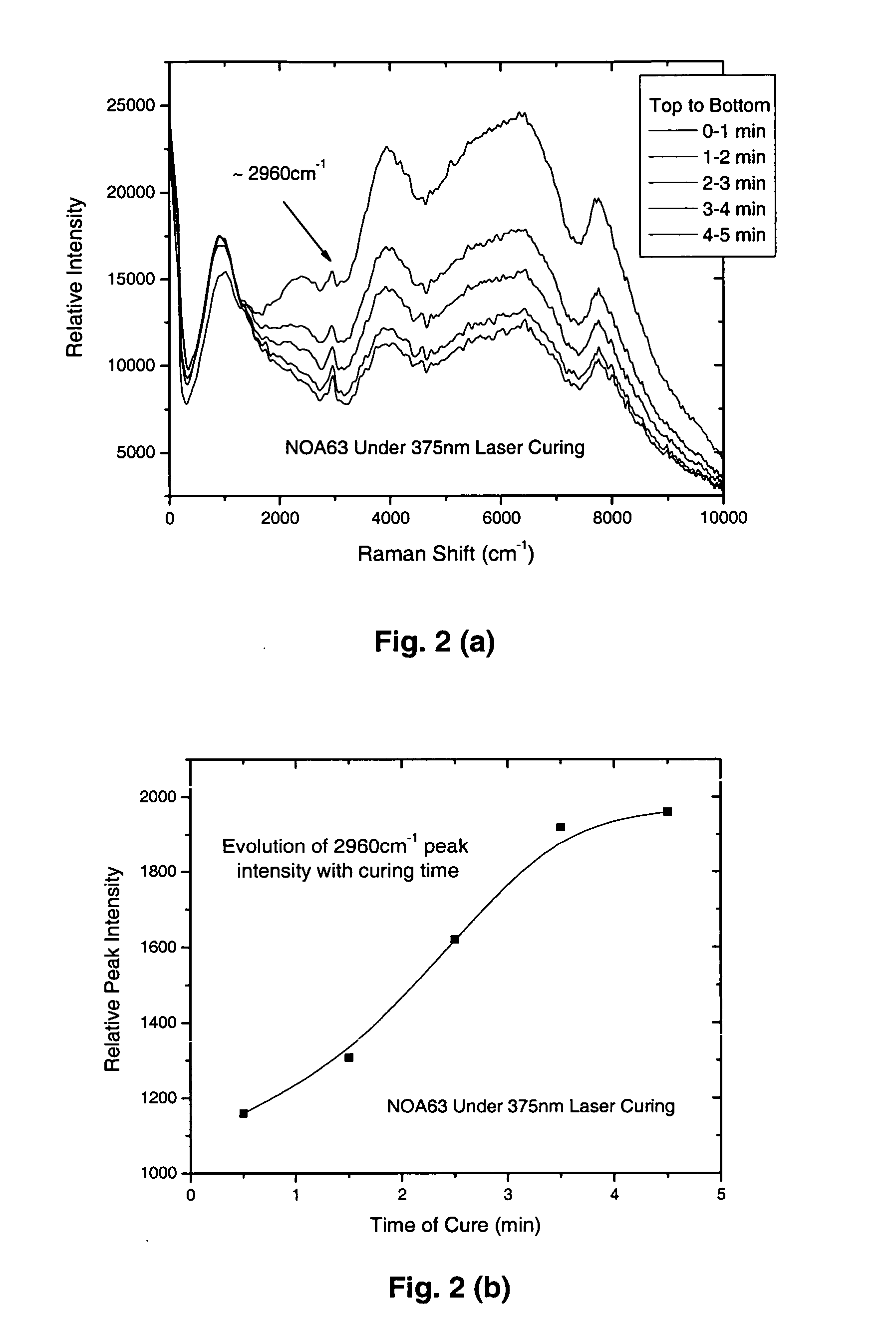

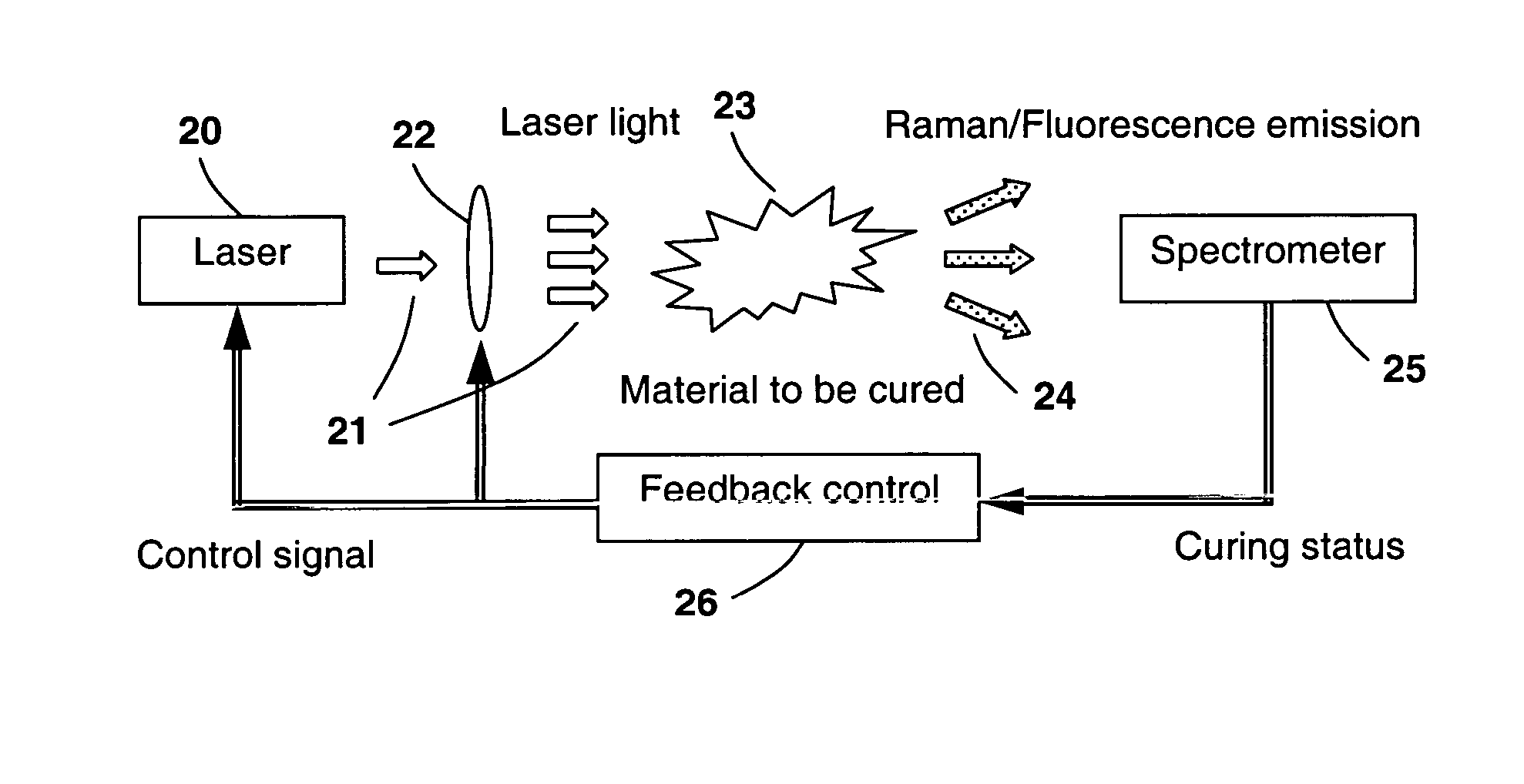

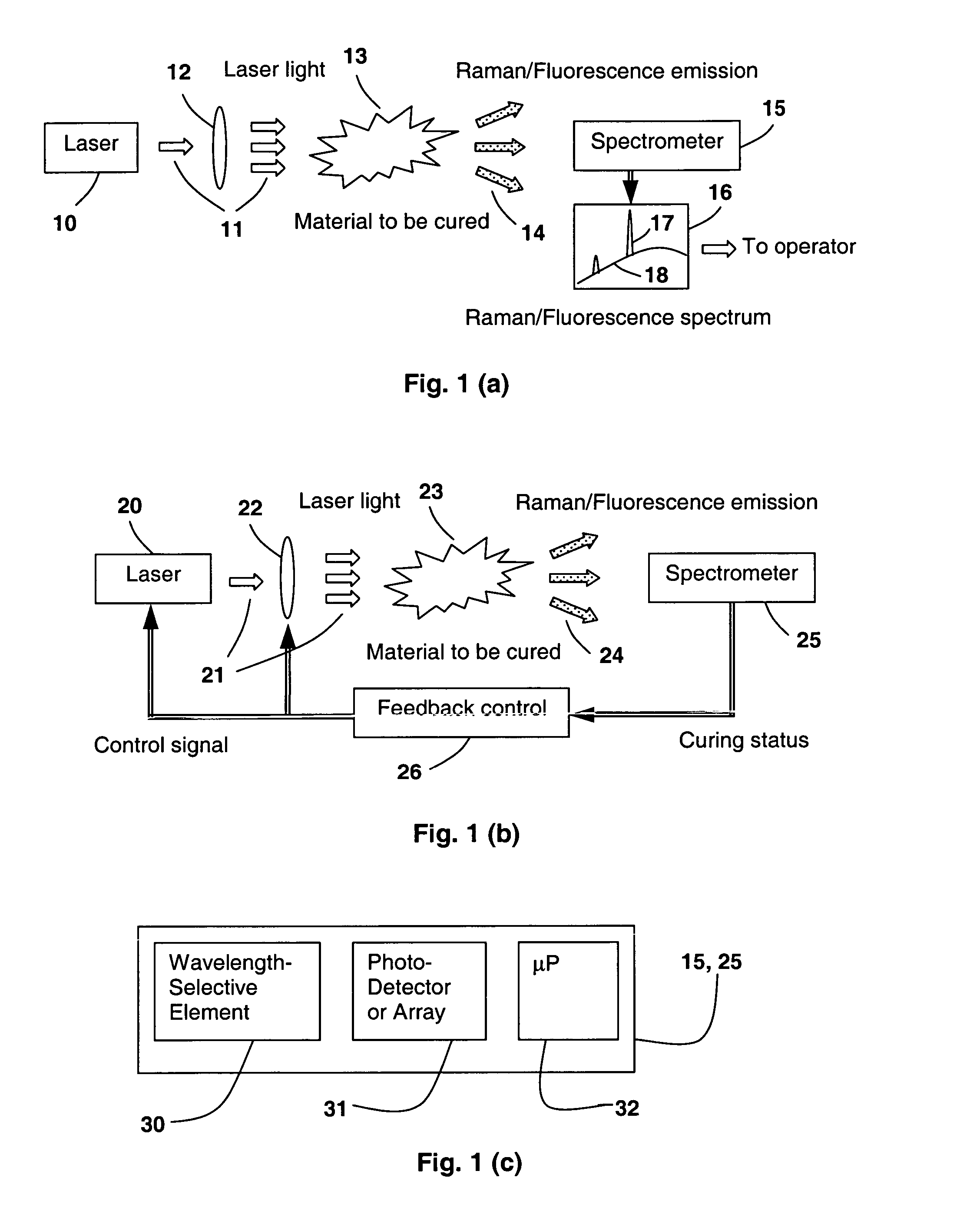

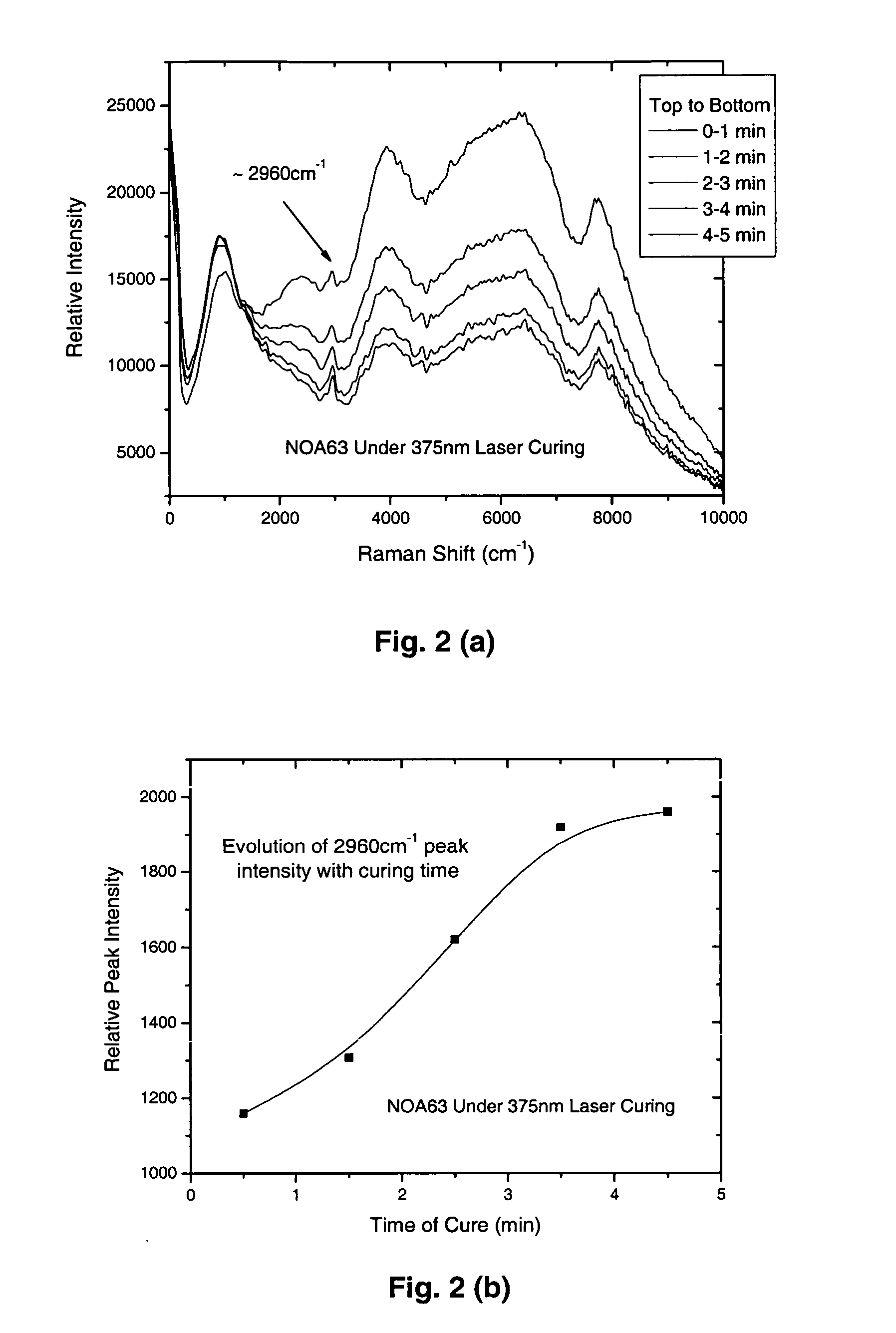

Laser curing apparatus with real-time monitoring and control

InactiveUS20060044555A1Improve curing effectAvoid over-curingRadiation pyrometrySpectrum investigationOptoelectronicsMonitoring and control

In a laser based curing apparatus, the acts both as the curing light and the excitation source for a Raman spectroscopic sensor. The spectroscopic sensor provides real-time, in situ, non-invasive curing status monitoring via Raman spectroscopy. The spectroscopic information can be further used to control the operation parameters of the laser to achieve the optimum cure result.

Owner:METROHM SPECTRO INC

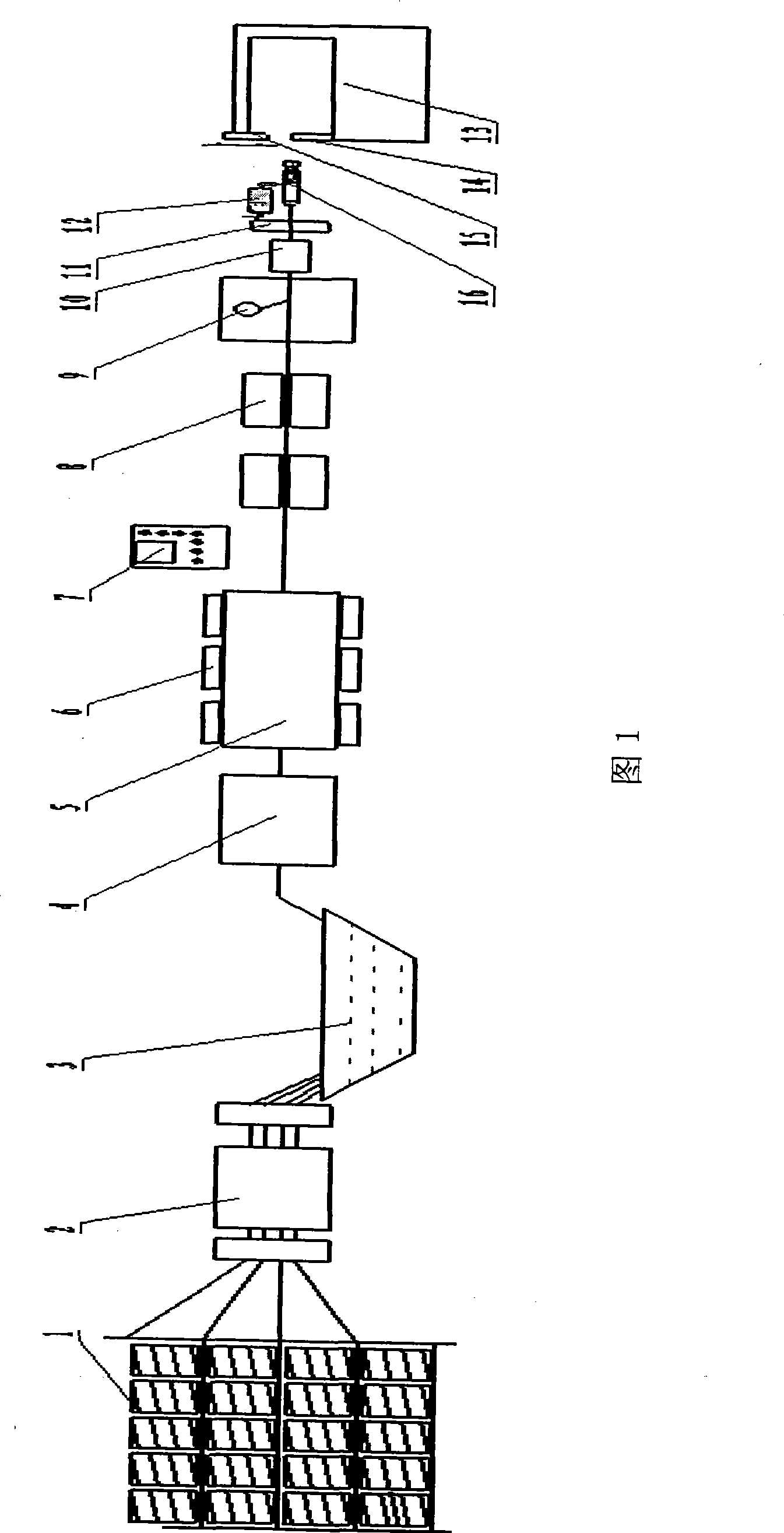

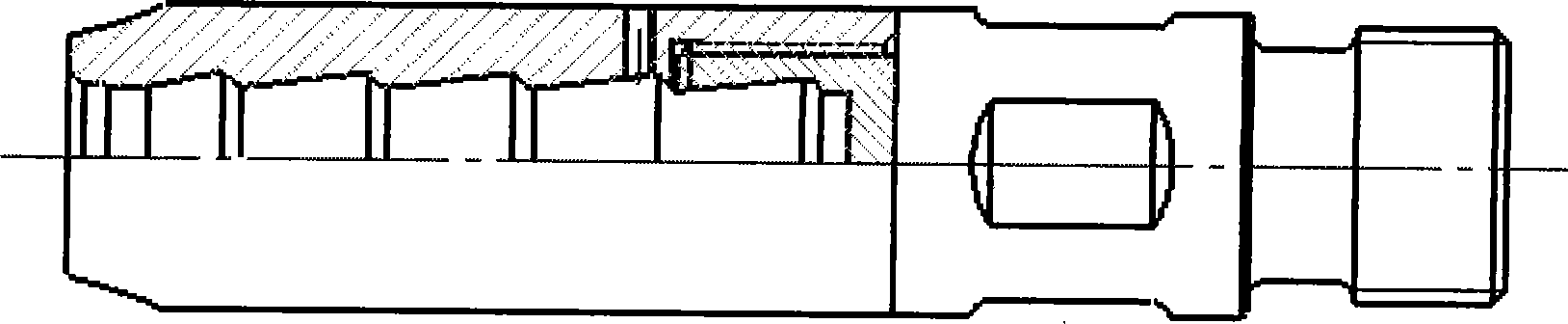

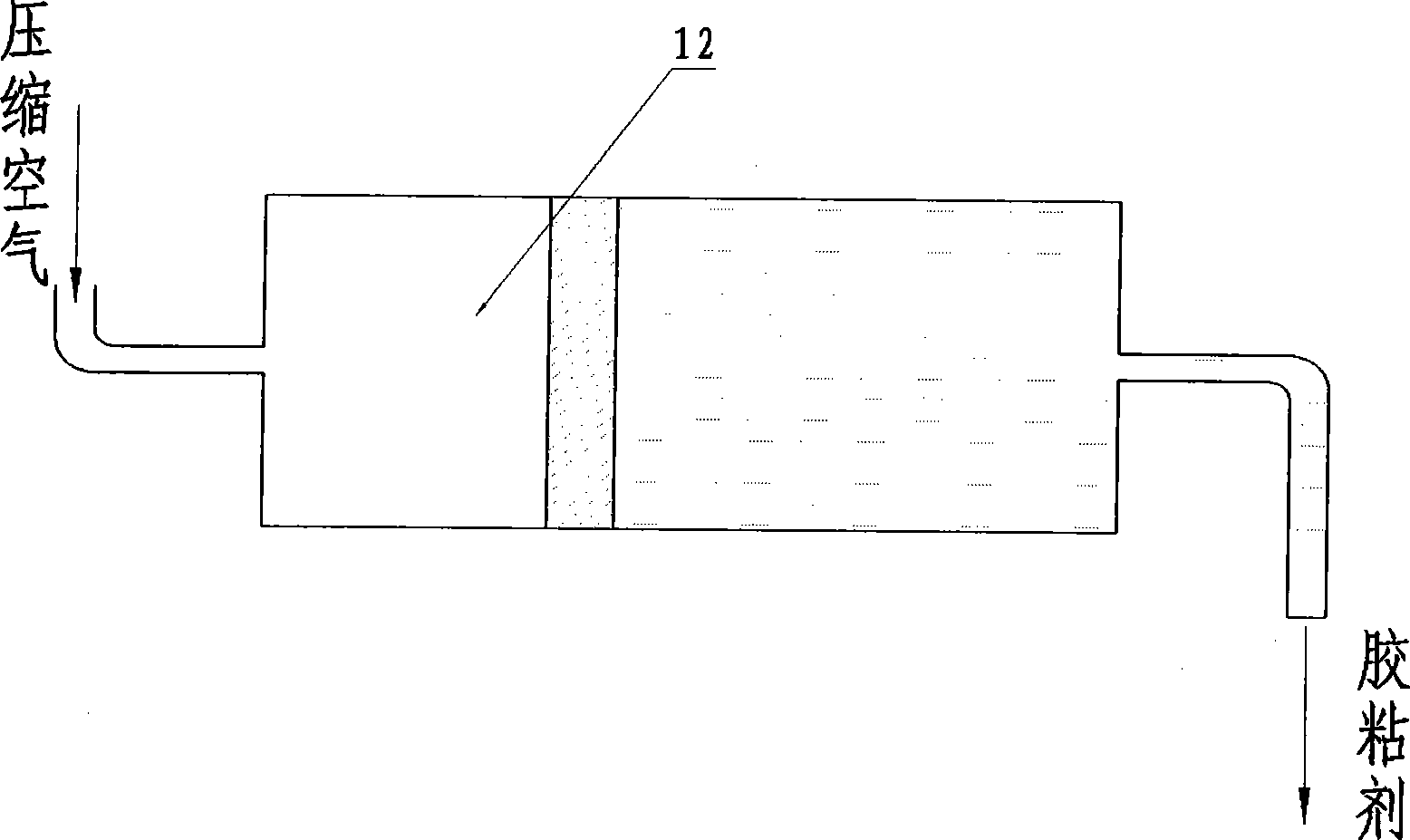

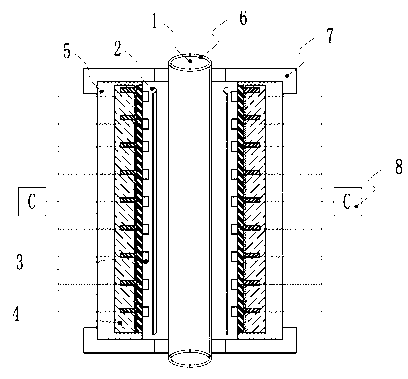

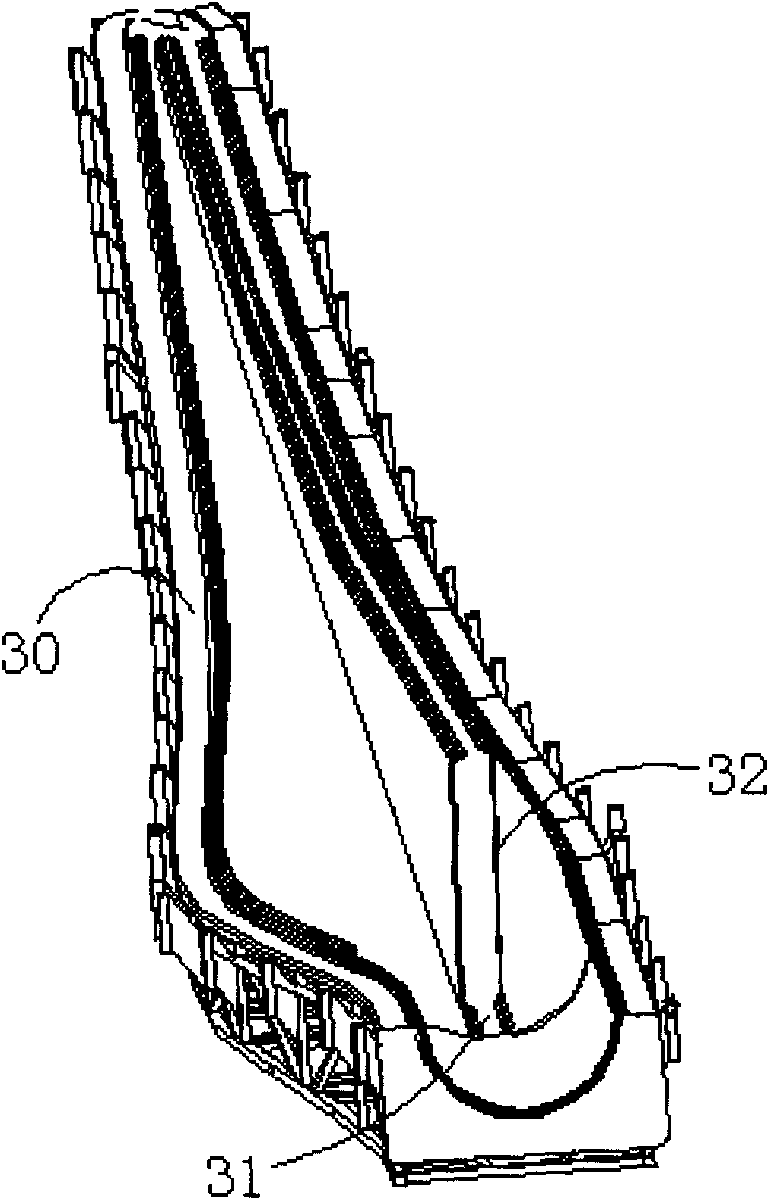

Preparation method and device of eccentric wear prevention pumping rod

InactiveCN101396874AExcellent performance of anti-eccentric wearPrevent slippageDrilling rodsDomestic articlesPre stressResin matrix

The invention relates to a method for preparing a composite material sucker rod which can prevent camber wear and a device thereof. Combining pultrusion and winding, fibre is immersed by resin matrix, and the composite material sucker rod is prepared by pultrusion, curing and shaping; the surface of the rod body is continuously wound with wearing fibre immersed by resin matrix glue after shaping; the rod body of the sucker rod, the surface of which is provided with a camber wear preventing layer of a spiral bar shape is obtained by curing; the rod body of the sucker rod is cut to be in fixed length, is connected with a metal joint by glue, and is treated in a joint curing furnace; the whole sucker rod is stretched by inherent stress. The surface of the rod body of the sucker rod is provided with the camber wear preventing layer of a spiral bar shape, thus having excellent camber wear preventing performance while ensuring a high intensity of the sucker body; the inverse cone structure of the metal joint and the pressure injection glue connection process ensure the joint part has the properties of high intensity and fatigue proof, the service life of which is consistent with the composite material rod body, and the reliability of the products is greatly improved.

Owner:BEIJING UNIV OF CHEM TECH

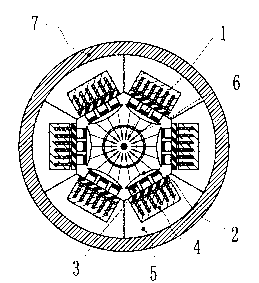

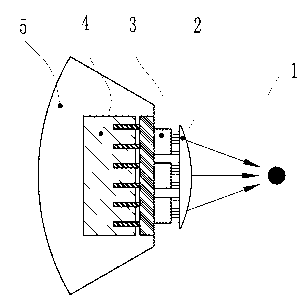

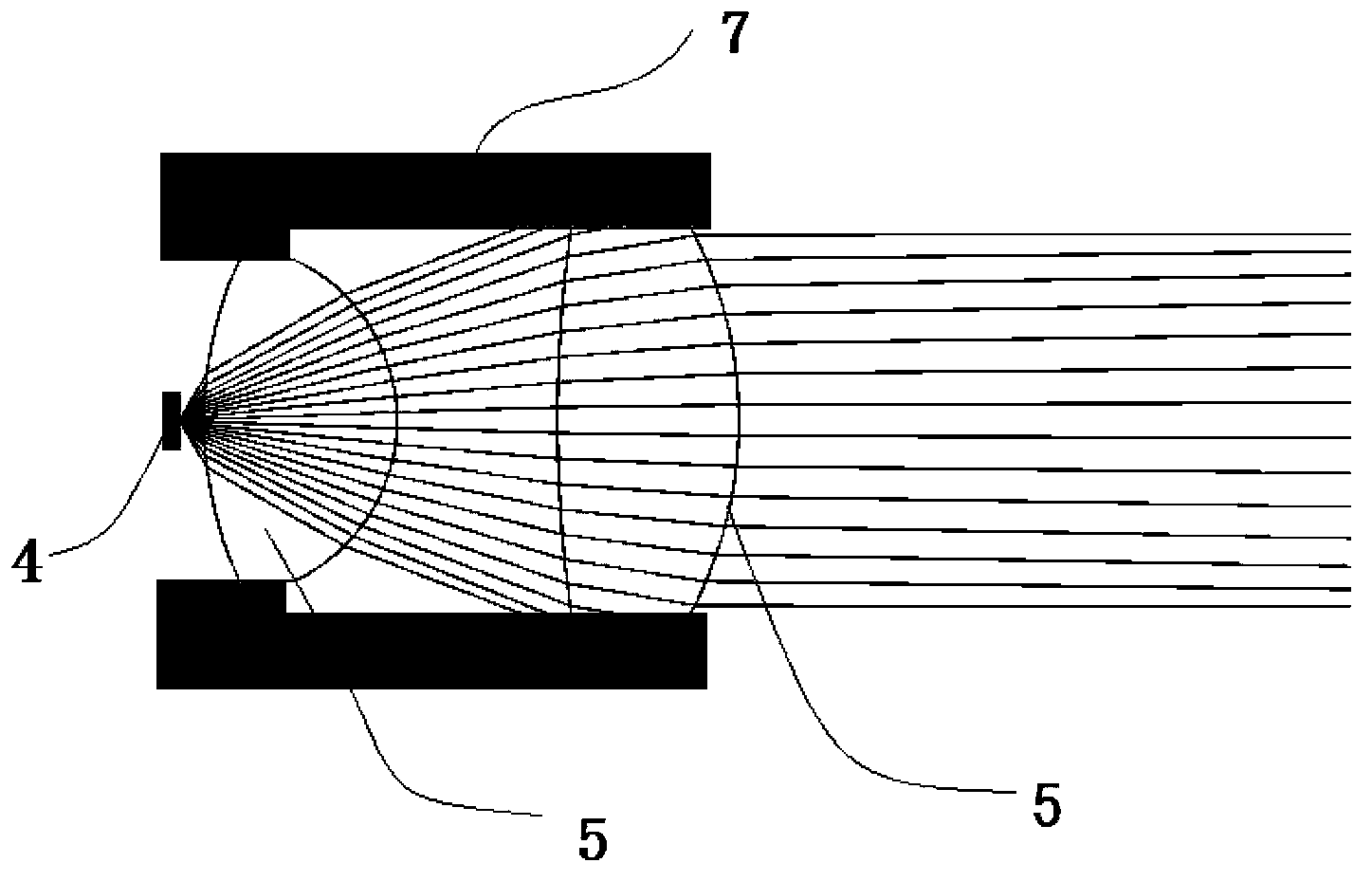

Ultraviolet curing equipment and method for optical fiber coating

ActiveCN103319100AImprove curing efficiencyExtended service lifeLight pillarUltraviolet light emitting diodes

The invention relates to ultraviolet curing equipment and method for an optical fiber coating. The equipment comprises a cylindrical mounting base, wherein an inner cavity of the cylindrical mounting base is provided with UVLED (Ultraviolet Light Emitting Diode) light source modules in a peripheral direction and an axial direction; a cylindrical focusing lens is arranged in front of light-emitting surfaces of the UVLED light source modules, so that ultraviolet rays emitted from the UVLED light source modules are focused on a same curing axis. The ultraviolet curing equipment disclosed by the invention is long in service life, small in heating amount and low in energy consumption; a layout space of light sources is large, so that the output of the UV light sources of a plurality of UVLED light source modules are focused on the curing axis to form a UV light column with high light intensity; an optical fiber absorbs UV and is cured when passing through the UV light column; the light strength of the light column is high and the light sources are from multiple directions, so that the equipment has higher curing efficiency and better curing uniformity, the curing time is shortened, the work efficiency of wiredrawing of the optical fiber is improved, and the curing quality of the coating is improved.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

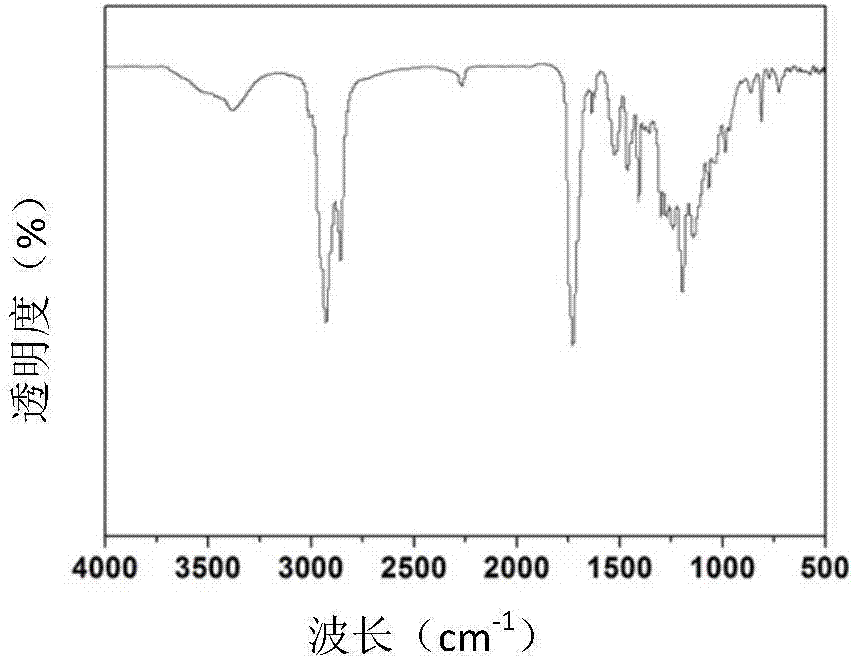

Polyfunctional castor oil-based photo-cured resin as well as preparation method and application thereof

InactiveCN106866929AFast cross-linking and curingImprove curing efficiencyAdditive manufacturing apparatusInksOptical radiationPolymer science

The invention relates to a polyfunctional castor oil-based photo-cured resin as well as a preparation method and application thereof. The preparation method comprises the following steps: with isocyanate and hydroxyl acrylate as raw materials, adding a polymerization inhibitor and a catalyst, introducing nitrogen for protection, and reacting for a certain period of time, so as to obtain an intermediate isocyanate semi-blocked prepolymer; adding castor oil into the prepared isocyanate semi-blocked prepolymer, so as to obtain castor oil-based urethane acrylate resin; and mixing the castor oil-based urethane acrylate resin with a photoinitiator and a diluent, and carrying out ultraviolet light radiation, so as to obtain UV castor oil-based resin with excellent performance. The photo-cured resin synthesized by virtue of the preparation method has relatively high molecular weight and viscosity, so that the interaction among resin molecules is enhanced, and the photo-crosslinking reaction efficiency of the resin is improved; the photo-cured resin contains more terminal double bonds, can be rapidly photo-cured and is suitable for being used as UV cured coatings, 3D printing materials and the like; and the prepared photo-cured resin has the beneficial effects that the water absorption rate and volume shrinkage rate of a cured film are substantially increased, meanwhile, the cost is low, the process is simple and controllable, and a product is relatively environment-friendly.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

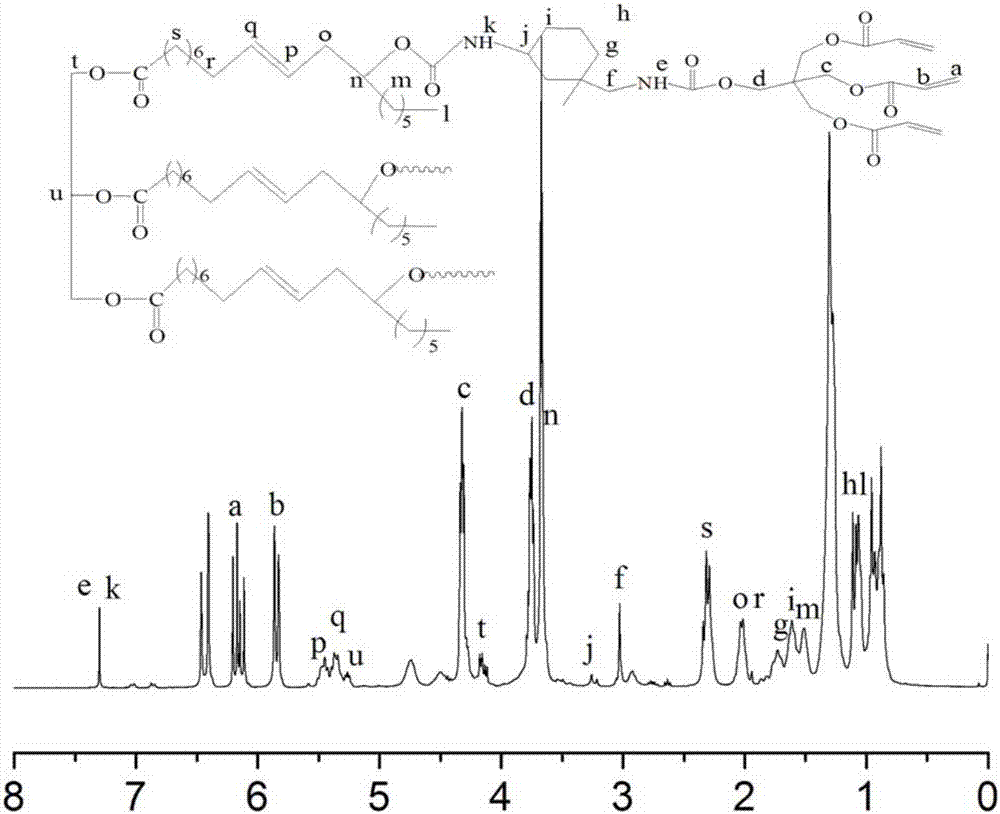

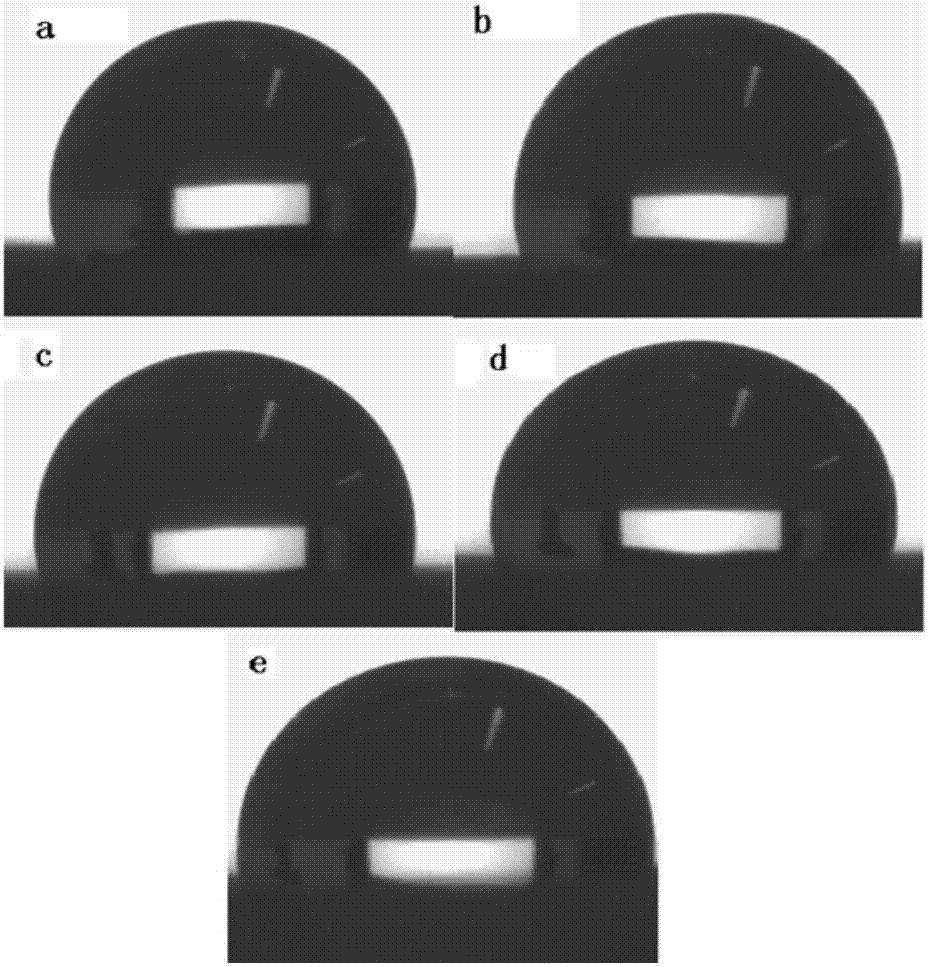

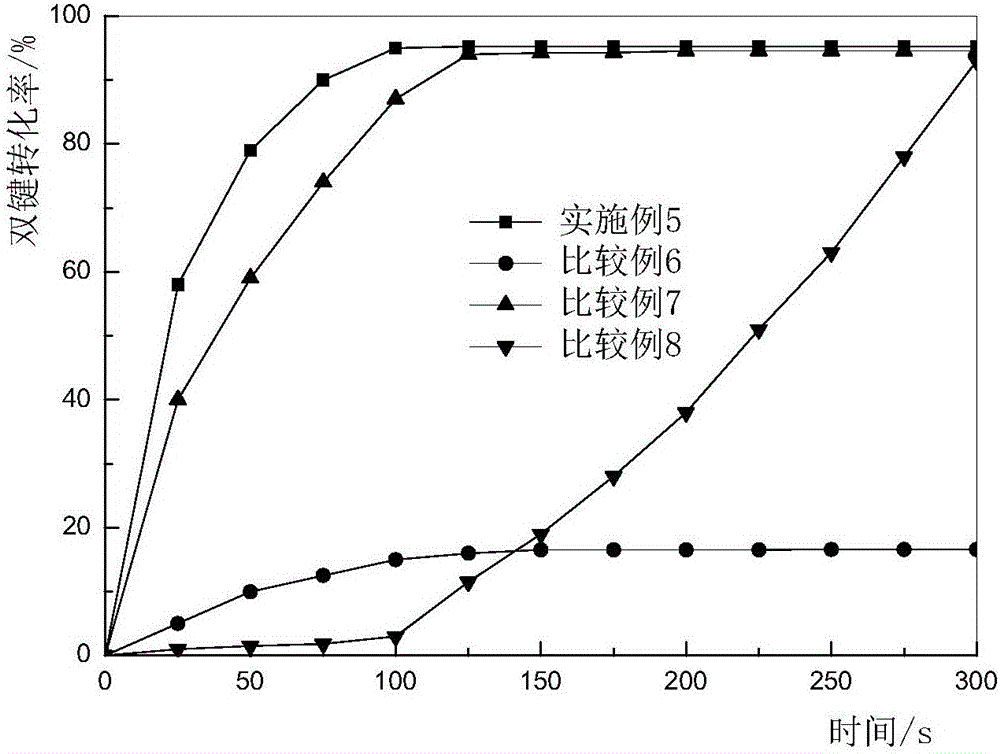

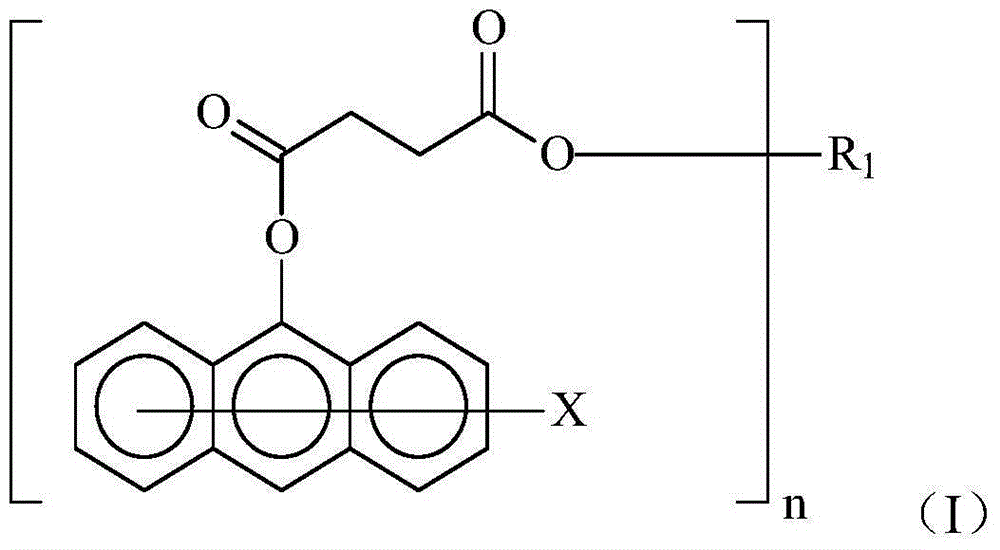

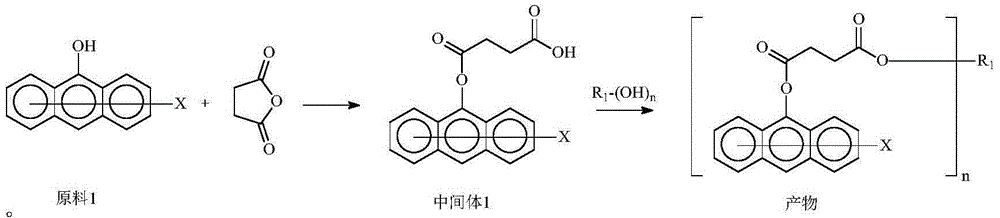

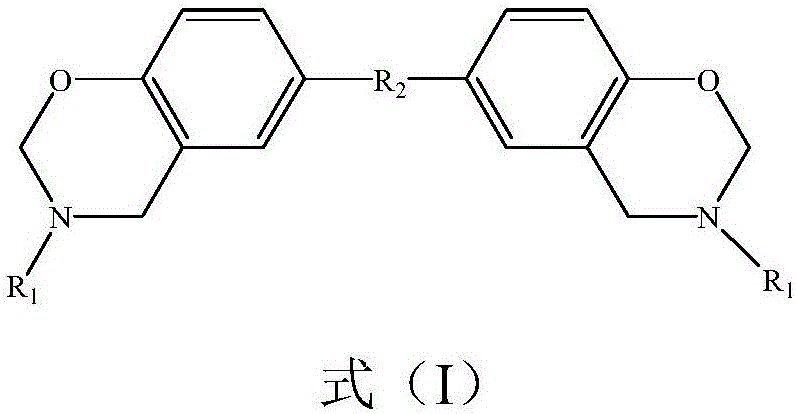

Anthracene-series sensitizer and application of same in UV-LED light-curing system

ActiveCN105001081AGood synergistic effectImprove curing efficiencyOrganic compound preparationCarboxylic acid esters preparationAnthraceneIrradiation

The invention discloses an anthracene-series sensitizer as shown in a formula (I). The sensitizer is perfectly compatible to a conventional photoinitiator, can substantially improve curing efficiency under the irradiation of a UV-LED light source when applied to a light-cured composition and has excellent application performance, thereby facilitating popularization and application of UV-LED light-curing technology.

Owner:CHANGZHOU TRONLY NEW ELECTRONICS MATERIALS +1

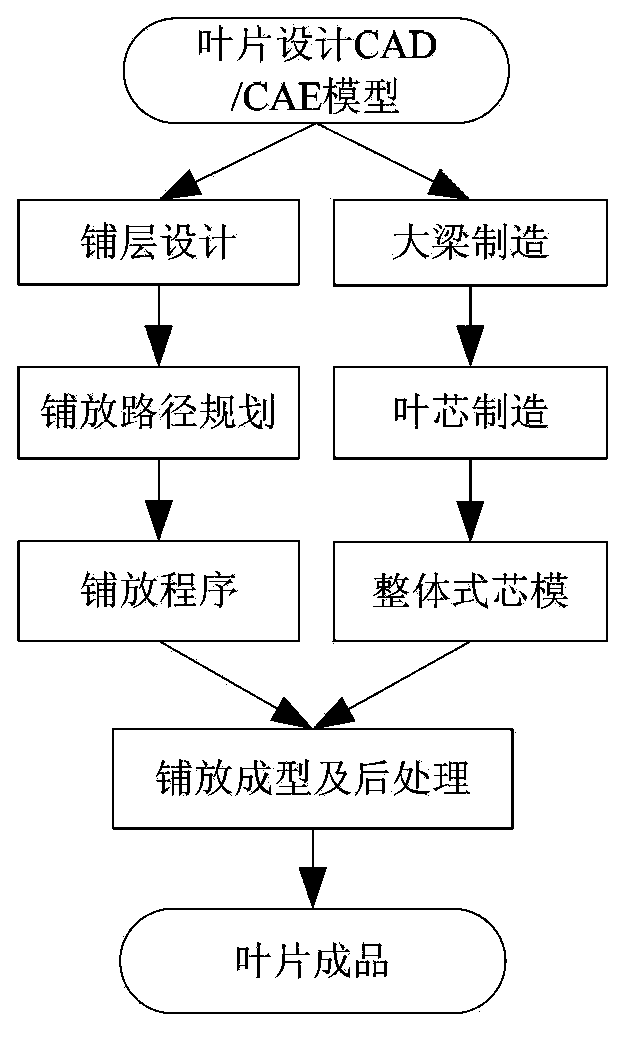

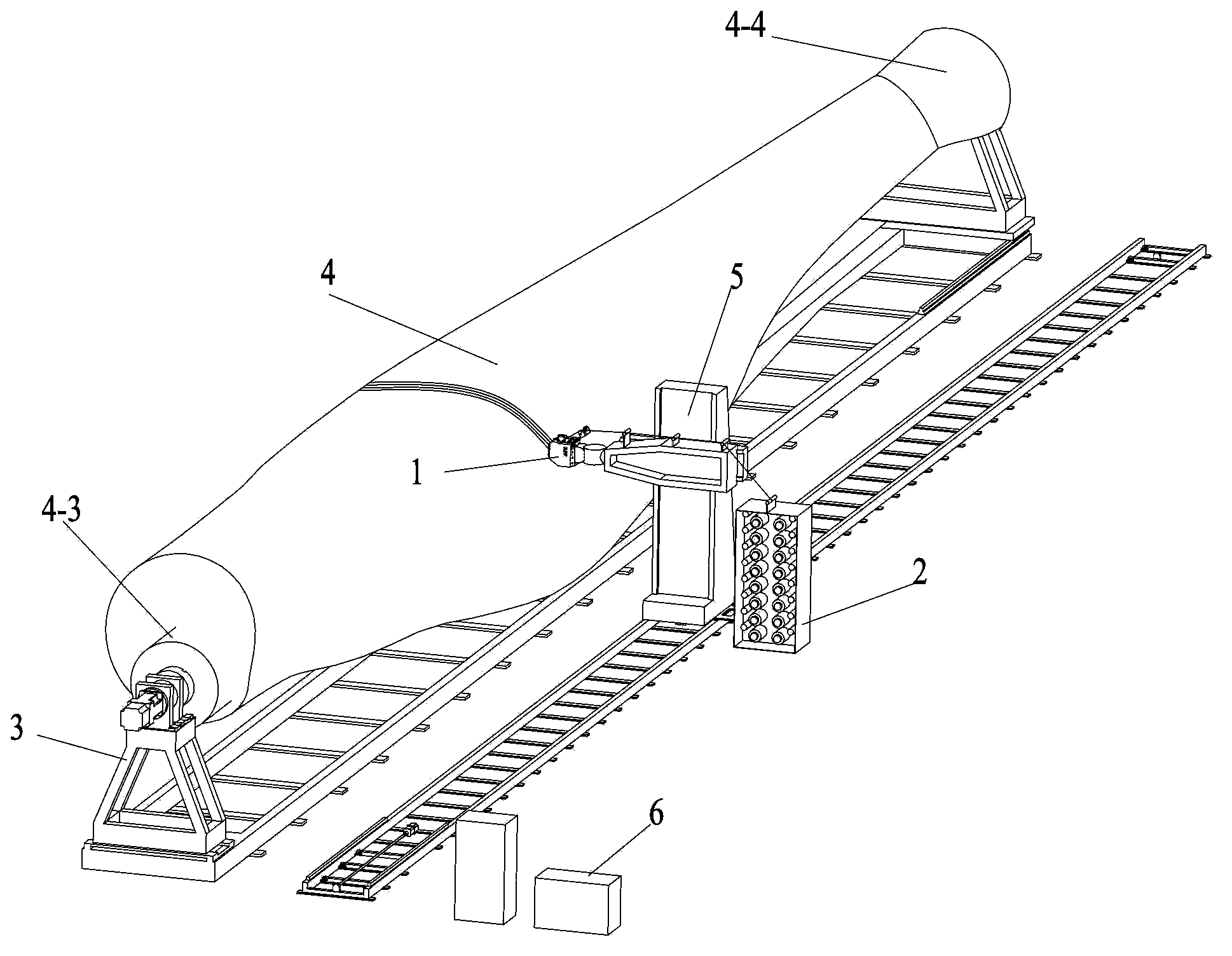

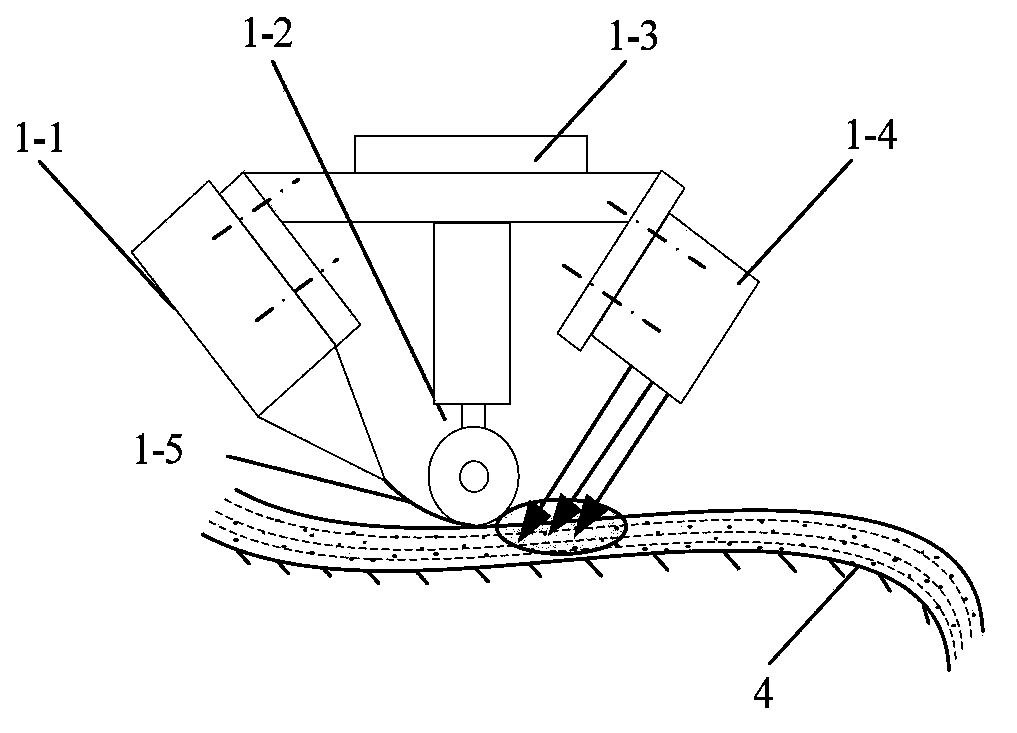

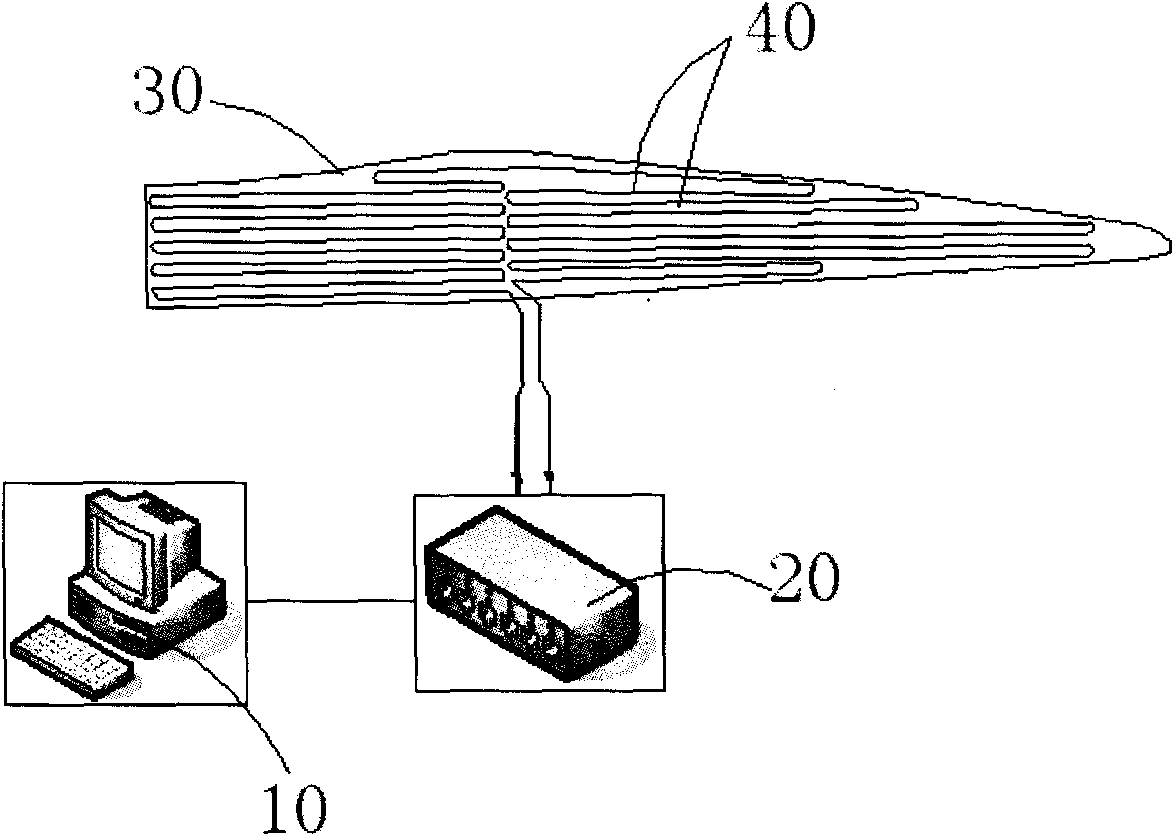

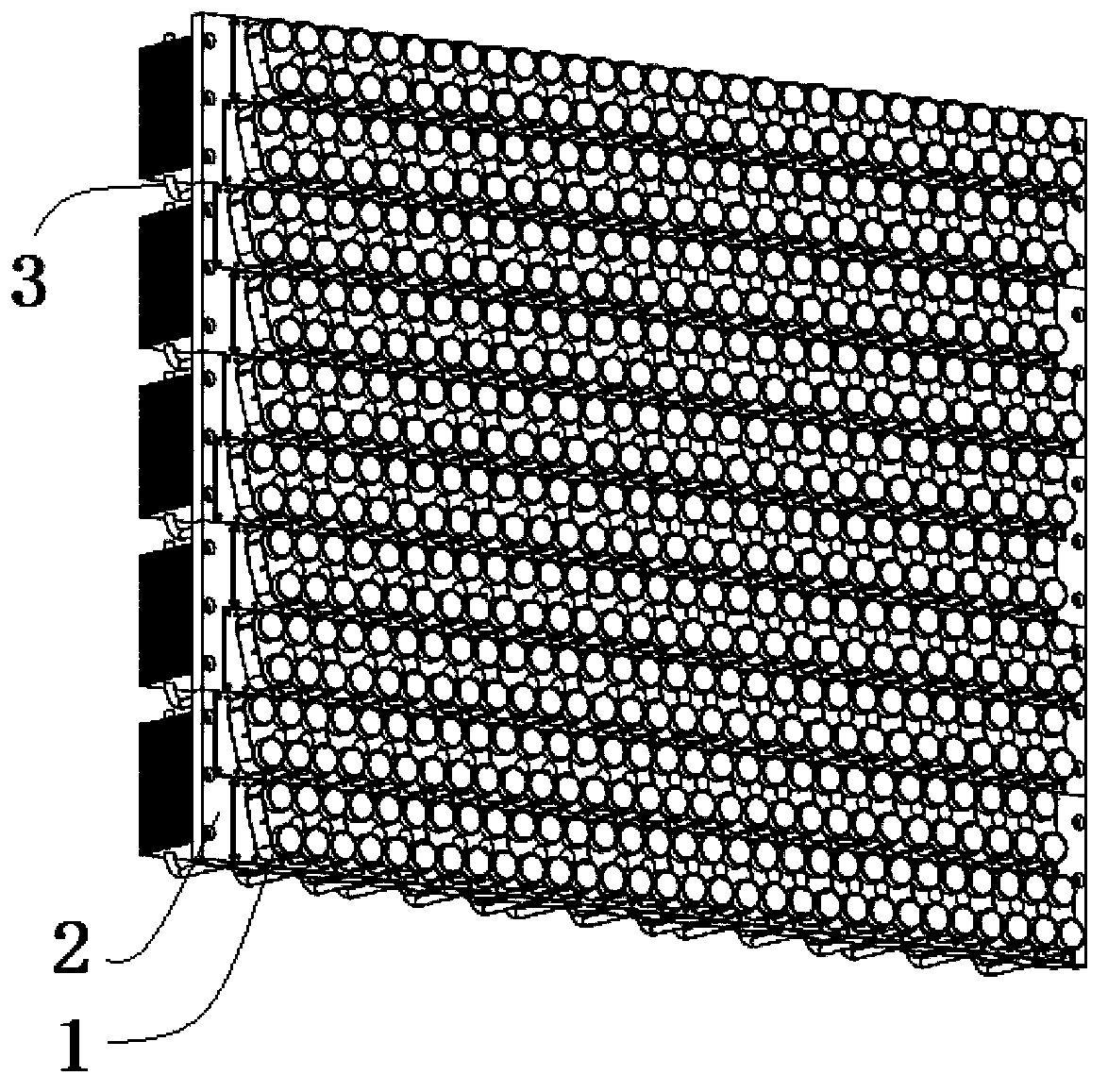

Integral wind-power blade ultraviolet light/electron beam in situ curing fiber laying forming device and integral wind-power blade ultraviolet light/electron beam in situ curing fiber laying forming method

InactiveCN103358564AImprove curing efficiencyEfficient automated manufacturingBonding strengthMachine tool

The invention discloses an integral wind-power blade ultraviolet light / electron beam in situ curing fiber laying forming device and an integral wind-power blade ultraviolet light / electron beam in situ curing fiber laying forming method, which can be applied to the automatic manufacturing field of large-scale composite material wind-power blades. Aiming at the problems that a perfusion and mold-splitting type wind-power blade manufacturing process has low degree of automation, high labor intensity and unstable quality, a two-piece type wind-power blade has low bonding strength, integral strength and stiffness, blade laying cannot be optimally designed, and a large-scale wind-power blade is difficultly manufactured and the like, the invention adopts the ultraviolet light in situ curing fiber laying manufacturing method and the ultraviolet light in situ curing fiber laying manufacturing device. According to the method, an ultraviolet light / electron beam in situ curing process is utilized for completing the forming and curing processes of the large-scale wind-power blade one time, the large-scale wind-power blade is integrally formed, and the curing efficiency and the overall performance of the blade are improved. Meanwhile, a large-scale wind-power blade fiber laying manufacturing system is combined and comprises an ultraviolet light / electron beam in situ curing fiber laying head, a presoaking belt conveying system, a core mold supporting device, an integral wind-power blade core mold, a horizontal or vertical multi-freedom machine tool system and a laying control system so as to realize the automatic manufacturing of the integral large-scale wind-power blade.

Owner:XI AN JIAOTONG UNIV

Spherical activated carbon and preparation method thereof

InactiveCN104030287AAchieve mass productionReduce the difficulty of ball forming processCarbon compoundsAir atmosphereActivated carbon

The invention discloses spherical activated carbon, and belongs to the field of production of activated adsorption materials. A preparation method includes the steps that pitch, thermosetting resin, aromatic hydrocarbon molecules and oxidation accelerators are evenly ground and mixed and then balled through a spraying method or a centrifugal method, and spherical pitch with the diameter ranging from 0.1 mm to 1.5 mm is obtained and screened; secondly, in an air atmosphere or a mixed atmosphere of air and oxidation promotion gas, cured spherules are obtained through thermal treatment; thirdly, porous cured spherules are obtained through extraction of composite steeping liquor; fourthly, the cured spherules are steeped into a thermosetting resin solution, the solution is filtered out, and the spherules are dried; fifthly, rapid thermal treatment is conducted on the spherules in the air atmosphere or the mixed atmosphere of air and oxidation promotion gas, and then spherules are obtained; sixthly, carbonization activation is conducted on the non-melting pitch spherules in the active atmosphere, and then the spherical activated carbon is prepared. The spherical activated carbon has the advantages that the specific surface area ranges from 800 m<2> / g to 1700 m<2> / g, the strength of the spherical activated carbon is larger than 95%, the strength is high, the process is simple, production efficiency is high, and cost is low.

Owner:SICHUAN CHUANGYUE CARBON MATERIAL

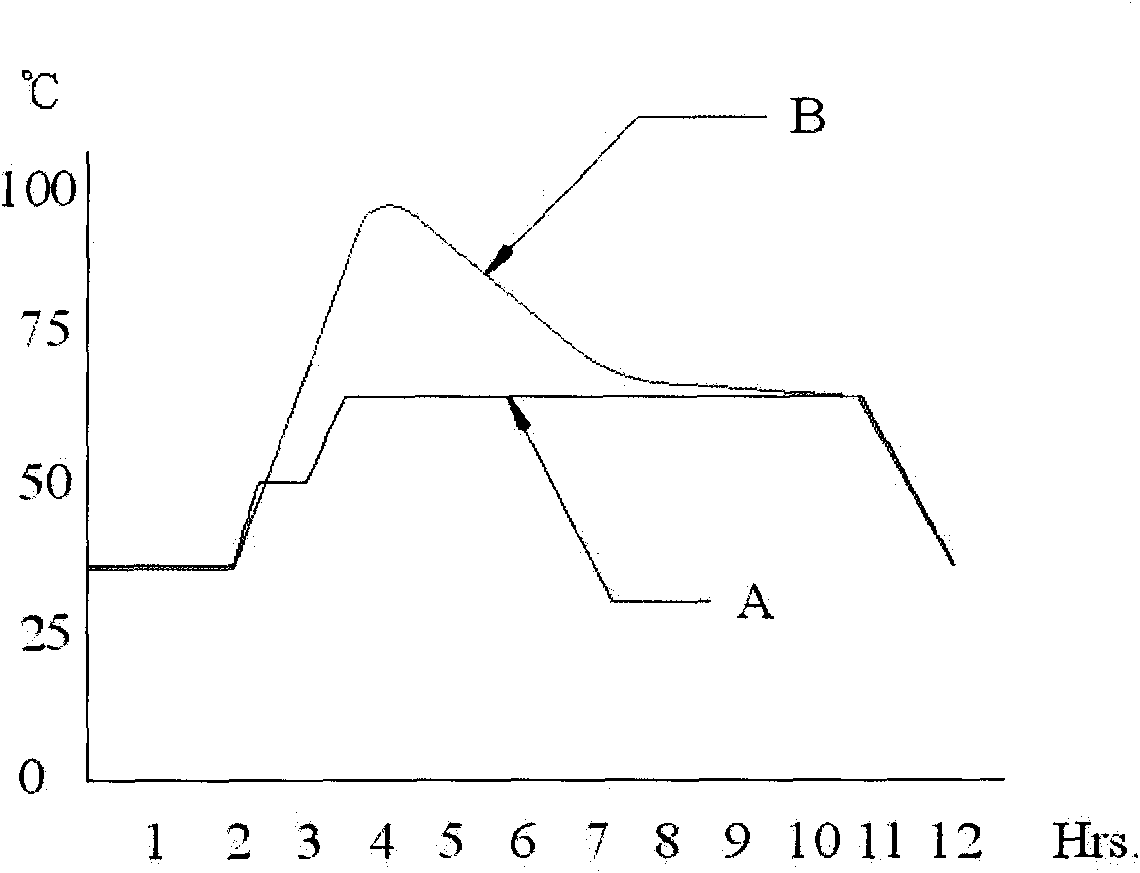

Intelligent segmental temperature control system of wind power blade die

The invention relates to an intelligent segmental temperature control system of a wind power blade die, which is provided based on the technical theory that segmental temperature control is bound to be carried out based on the differences on the formed region thickness of a designed blade structure and the energy-saving purpose can be achieved by lowering the dependence on external heating in a curing manufacturing procedure by utilizing the reaction exothermic character of a matrix material. To achieve the purpose, the invention adopts the technical measures of the construction of a die segmental temperature control pipeline, which ensures that each temperature segment can be heated or cooled independently based on requirements on thermal energy in the curing manufacturing procedure; the establishment of an intelligent temperature control system, wherein temperature and hardness data of the die and a blade shell can be captured to judge whether heating setting, exothermic peak initiating temperature and the states of completion degree, gel curing degree and the like are completed or conform to design values; and antecedent technical measures, wherein energy consumption is saved by utilizing the reaction heat of materials per se to heat and reaction and temperature control are combined to match the design of a temperature curve, which are helpful for obtaining the blades with uniform curing and excellent quality and can improve the production efficiency as a characteristic.

Owner:上海力仓实业有限公司

Ultraviolet cured paint for electric product surface coating

InactiveCN101358048AImprove wear resistanceHigh efficiency and speed of curingCoatingsSolventFunctional monomer

The invention relates to a UV-curable coating used in surface coating for electronic products, which is prepared by the components with the following weight percentage: 10 to 30wt percent of dual-functional polyurethane acrylate, 5 to 40wt percent of multi-functional nuclear hybrid acrylate monomer, 5 to 30wt percent of ethoxylated or propoxylated multi-functional acrylate monomer, 0 to 15wt percent of single-functional monomer, 1 to 6wt percent of photoinitiator, 0 to 5wt percent of modified nano material, 0.1 to 2wt percent of flatting agent, and 10 to 50wt percent of solvent. The UV-curable coating of the invention is widely applicable to the surface coating of electronic products, such as mobile phones, MP3, MP4 and digital cameras, etc, and has the advantages of high wear resistance, high transparency, strong adhesion, high gloss, etc.

Owner:SOUTH CHINA UNIV OF TECH

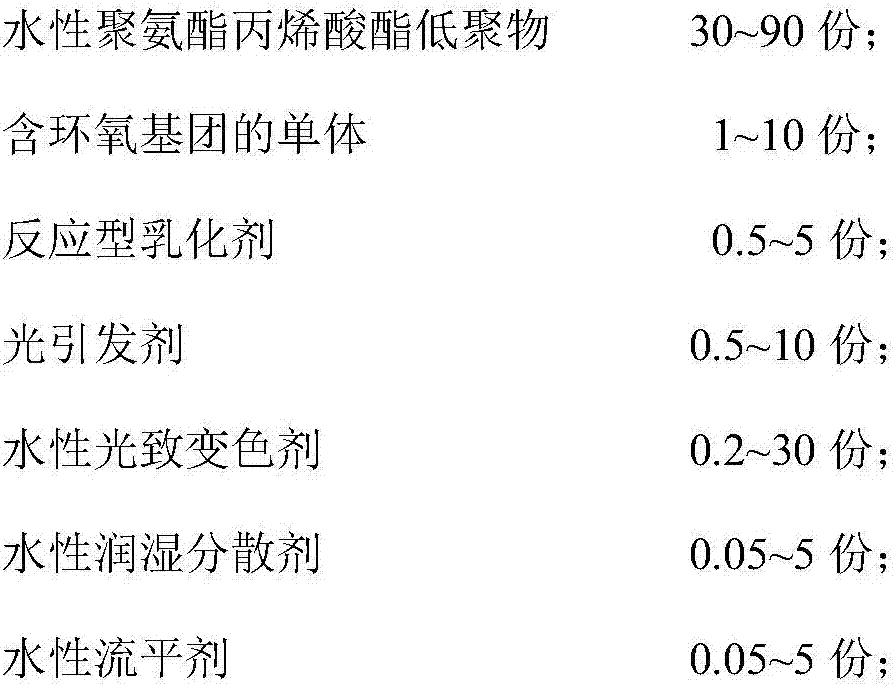

Waterborne photochromic coating as well as nail polish and decorative material

ActiveCN107325603ASolve the problem of slow curing speed and low efficiencyFully curedCosmetic preparationsAntifouling/underwater paintsOligomerSolvent

The invention discloses a waterborne photochromic coating as well as nail polish and a decorative material. The waterborne photochromic coating is prepared from the following components in parts by weight: 30 to 90 parts of a waterborne polyurethane acrylate oligomer, 1 to 10 parts of an epoxy group-containing monomer, 0.5 to 5 parts of a reactive emulsifier, 0.5 to 10 parts of a photoinitiator, 0.2 to 30 parts of a waterborne photochromic agent, 0.5 to 5 parts of a waterborne wetting dispersant, 0.05 to 5 parts of a waterborne flatting agent and 1 to 20 parts of deionized water. The waterborne photochromic coating disclosed by the invention has the advantages that the problems of low curing speed and low efficiency of a heat curable photochromic coating, and the problem that a large amount of solvents or volatile monomers are used in a UV (ultraviolet) photochromic coating are solved; the waterborne photochromic coating is suitable for coating various plastic substrates or nail, and has relatively-high industrial production benefits and a good application prospect.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Preparation of solidification type dead burning structure glue in low-temperature and humidity surroundings

InactiveCN101314706ALow viscosityEasy curingNon-macromolecular adhesive additivesEpoxy resin adhesivesCompressive strengthUltimate tensile strength

A method for preparing steel-bonding structural adhesive curable in low-temperature and humid environment comprises the following steps: preparing a component A; preparing a component B; and mixing the component A with the component B at a weight ratio of 1:(0.3 to 0.5) to obtain the steel-bonding structural adhesive curable in low-temperature and wet environment. The steel-bonding structural adhesive can fully meet the requirement for steel-bonding construction in the environment with a temperature of subzero 10 to 0 DEG C and a relative humidity larger than 65 percent. A test shows that, 168 hours after the curing, the compressive strength of the adhesive is equal to or larger than 65 MPa, steel-steel tensile shear strength is equal to or larger than 15 MPa, steel-steel adhesion tensile strength is equal to or larger than 33 MPa, and the normal tensile bonding strength with concrete is equal to or larger than 2.5 MPa.

Owner:镇江市天益工程科技有限公司

Laser curing apparatus with real-time monitoring and control

InactiveUS7245371B2Reduce sensitivityReduce monitoring costsRadiation pyrometrySpectrum investigationOptoelectronicsMonitoring and control

In a laser based curing apparatus, the acts both as the curing light and the excitation source for a Raman spectroscopic sensor. The spectroscopic sensor provides real-time, in situ, non-invasive curing status monitoring via Raman spectroscopy. The spectroscopic information can be further used to control the operation parameters of the laser to achieve the optimum cure result.

Owner:METROHM SPECTRO INC

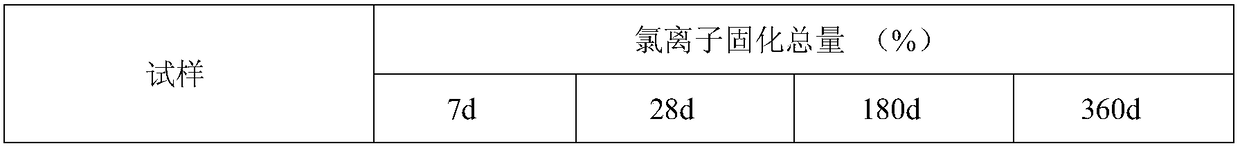

Concrete additive capable of solidifying chlorions efficiently for long time as well as application

ActiveCN108129051AEnhance physical adsorption capacity and stabilityLow transfer rateSodium BentoniteSilicon

The invention discloses a concrete additive capable of solidifying chlorions efficiently for a long time as well as a preparation method. A silicon aluminum phase component is added in the concrete additive capable of solidifying chlorions efficiently for a long time and accounts for 20 to 46.75 percent of the total mass of the concrete additive capable of solidifying chlorions efficiently for a long time; the silicon aluminum phase component is bentonite and / or kaolin which is calcined at 400 to 800 DEG C, the particle diameter is 80-um square hole sieve residue less than or equal to 10 percent and the mass percentage of Al2O3 is more than or equal to 35 percent; furthermore, the silicon aluminum phase component can generate Friedel salt (calcium chloraluminate hydrate) with the purity being more than 90 percent under the concrete alkaline environment. According to the concrete additive, the chlorions in the concrete can be solidified efficiently and stabilized for a long time, and the transmission speed of the chlorions in the concrete is effectively reduced. In conclusion, the technology has the technical advantages of low mixing amount (1 to 5 percent by mass of substituted gelmaterial), high chlorion solidification efficiency and long-term stable solidification effect.

Owner:JIANGSU SOBUTE NEW MATERIALS

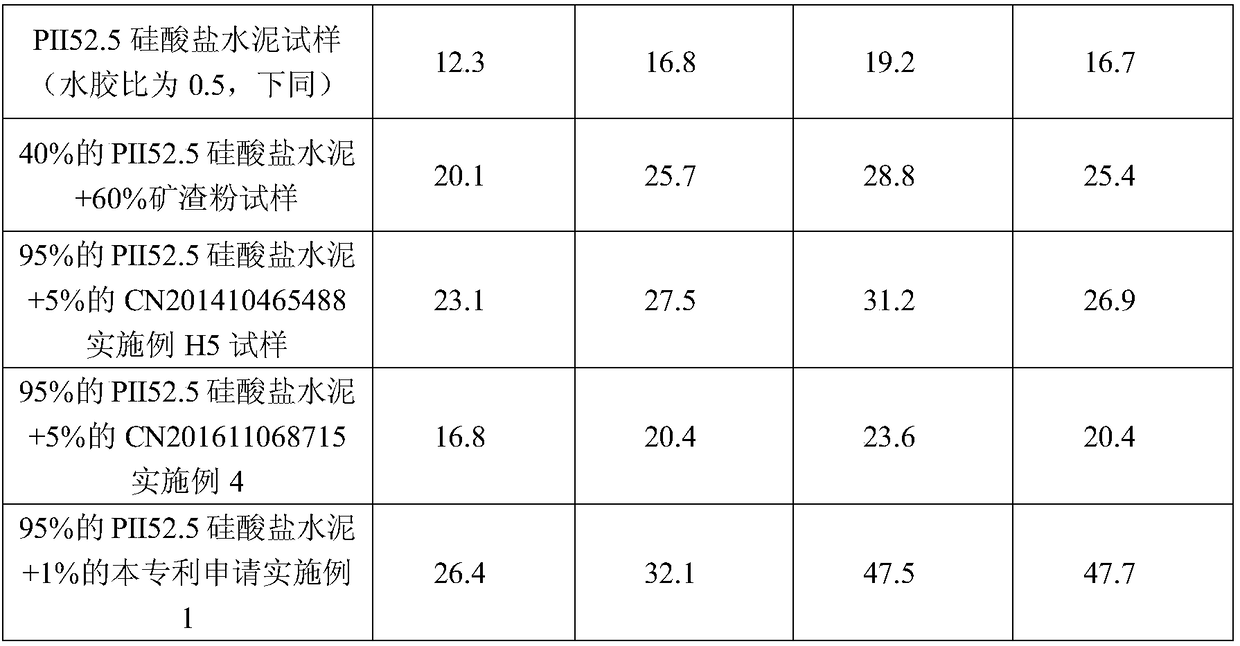

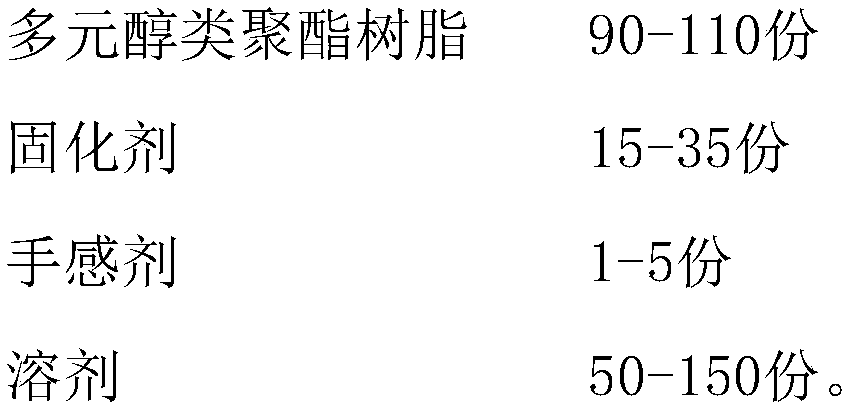

Flexible all-coating soft film and preparation method thereof

ActiveCN107936860AEvenlyGood flexibilityPolyureas/polyurethane adhesivesPressure sensitive film/foil adhesivesTectorial membraneEngineering

The invention relates to the technical field of protective films, and particularly relates to a flexible all-coating soft film and a preparation method thereof. The flexible all-coating soft film comprises a film protecting layer, a using layer and a stripping layer which are sequentially adhered from top to bottom; the protecting film layer comprises a base material layer and a film protecting glue layer which are sequentially adhered from top to bottom; the using layer comprises a self-repairing layer, a flexible soft film layer and a using glue layer which are sequentially adhered from topto bottom; the lower surface of the film protecting glue layer is adhered to the upper surface of the self-repairing layer; and the lower surface of the using layer is adhered to the upper surface ofthe stripping layer. The flexible all-coating soft film provided by the invention has smooth hand feeling and large stripping force, a curved screen can be all coated, relatively good resilience and self-repairing effect can be achieved, scratch marks can be repaired automatically, and the service life of the flexible all-coating soft film is prolonged. The preparation method provided by the invention is simple, the operation control is convenient, conventional production processes are simplified, the production efficiency is high, the production cost is low, the prepared product is high in yield and stable in quality, and the preparation method is suitable for large-scale industrial production.

Owner:NALI OPTICAL MATERIAL DONGGUAN

Integration process for fabricating stressed transistor structure

ActiveUS7566655B2Defects are reducedIncrease compressive stressSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringHigh stress

A process flow integration scheme employs one or more techniques to control stress in a semiconductor device formed thereby. In accordance with one embodiment, cumulative stress contributed by RTP of a nitride spacer and polysilicon gate, and subsequent deposition of a high stress etch stop layer, enhance strain and improve device performance. Germanium may be deposited or implanted into the gate structure in order to facilitate stress control.

Owner:APPLIED MATERIALS INC

Silt hardening agent and preparation method and application method thereof

The invention relates to a silt hardening agent. The silt hardening agent is characterized by comprising, by weight, 1%-5% of sodium polyacrylate, 2%-8% of biomass activated carbon, 2%-7% of sodium lignin sulfonate, 1%-5% of polyrotaxane, 4%-25% of reduced graphene oxide, 15%-50% of cement, 5%-25% of quicklime and 10%-35% of coal ash. The hardening agent is non-toxic and harmless and can be used on a large scale; synergistic effect among the raw materials is achieved, moisture content of silt can be effectively reduced, and strength of the silt is improved to meet requirements of earthwork reclamation; heavy metals and organic substances in the silt can be effectively sealed, and risk of secondary exposure of pollutants is avoided.

Owner:宁波国科微藻科技有限公司 +2

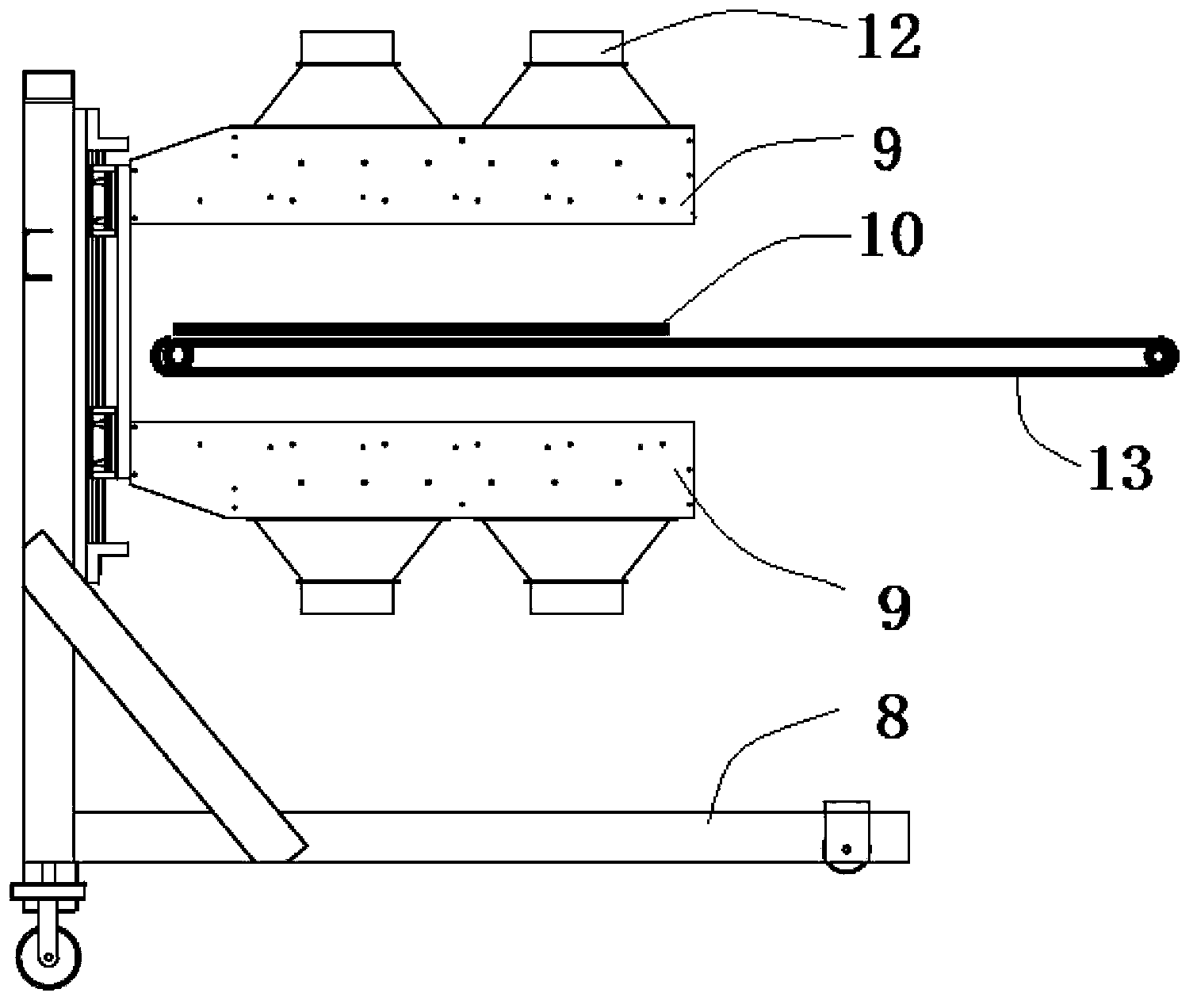

Parallel light curing equipment with staggered area array light sources and curing method thereof

InactiveCN103406246AImprove curing effectRealize dislocation movementPretreated surfacesCoatingsLight beamOptoelectronics

The invention discloses a piece of parallel light curing equipment with staggered area array light sources. The parallel light curing equipment comprises a conveying device, an area array light source curing device, a cooling device, a light source control device and a working table, wherein the cooling device is connected with the area array light source curing device, the light source control device is connected with the area array light source curing device, and the area array light source curing device is installed on the working table. The working table comprises a trolley. The trolley is movably arranged inside the working table. A longitudinal guiding rail and a guiding rail driving mechanism are arranged at the upper portion of the trolley. The area array light source curing device is arranged on the guiding rail of the trolley. The conveying device fixes a workpiece to be cured in a vacuumized mode and conveys the workpiece to be cured to the portion over the area array light source curing device or the portion under the area array light source curing device. The invention further discloses a curing method by utilizing the curing equipment. According to the parallel light curing equipment with the staggered area array light sources and the curing method, due to the fact that the staggered movements of the area array light sources and the workpiece are controlled, the evenness of curing is improved, and due to the fact that a condensing lens converts UV light beams into parallel light, the curing efficiency and precision are improved.

Owner:广东科视光学技术股份有限公司

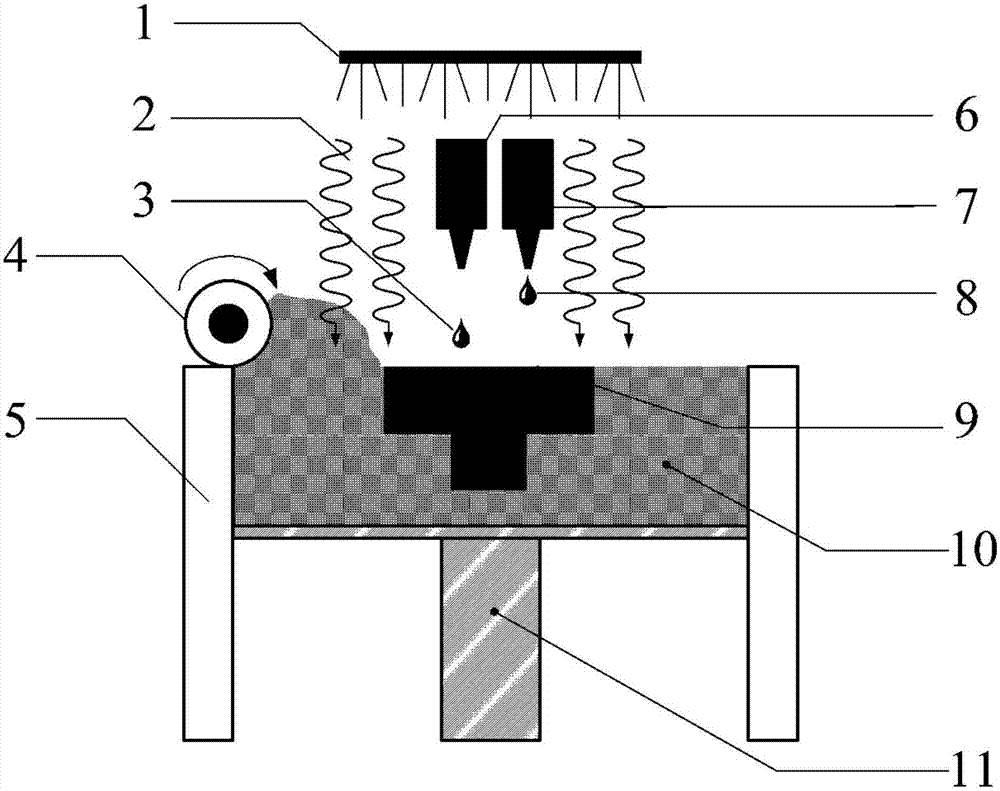

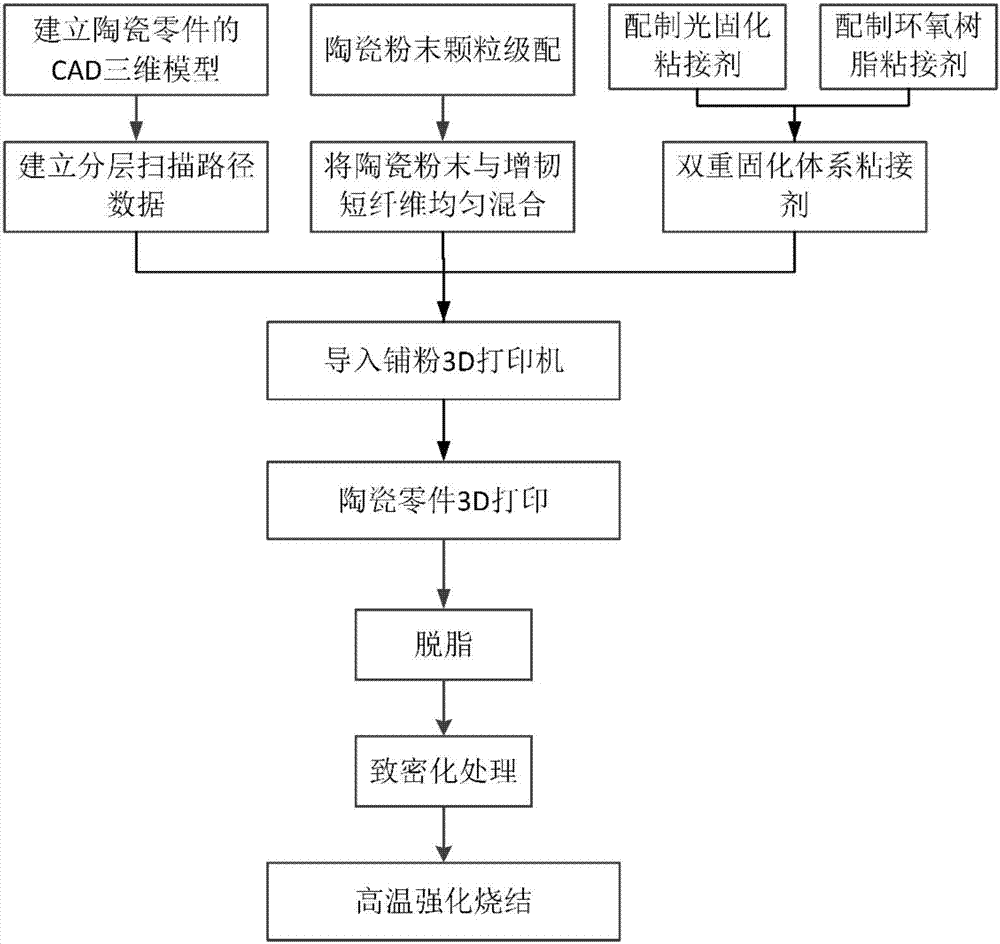

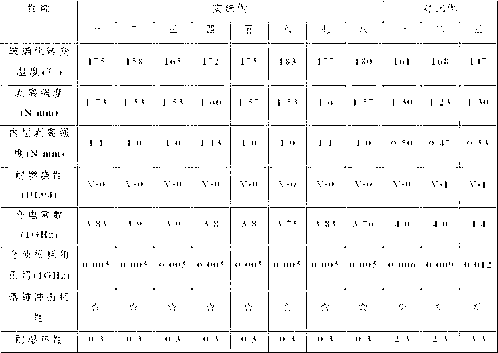

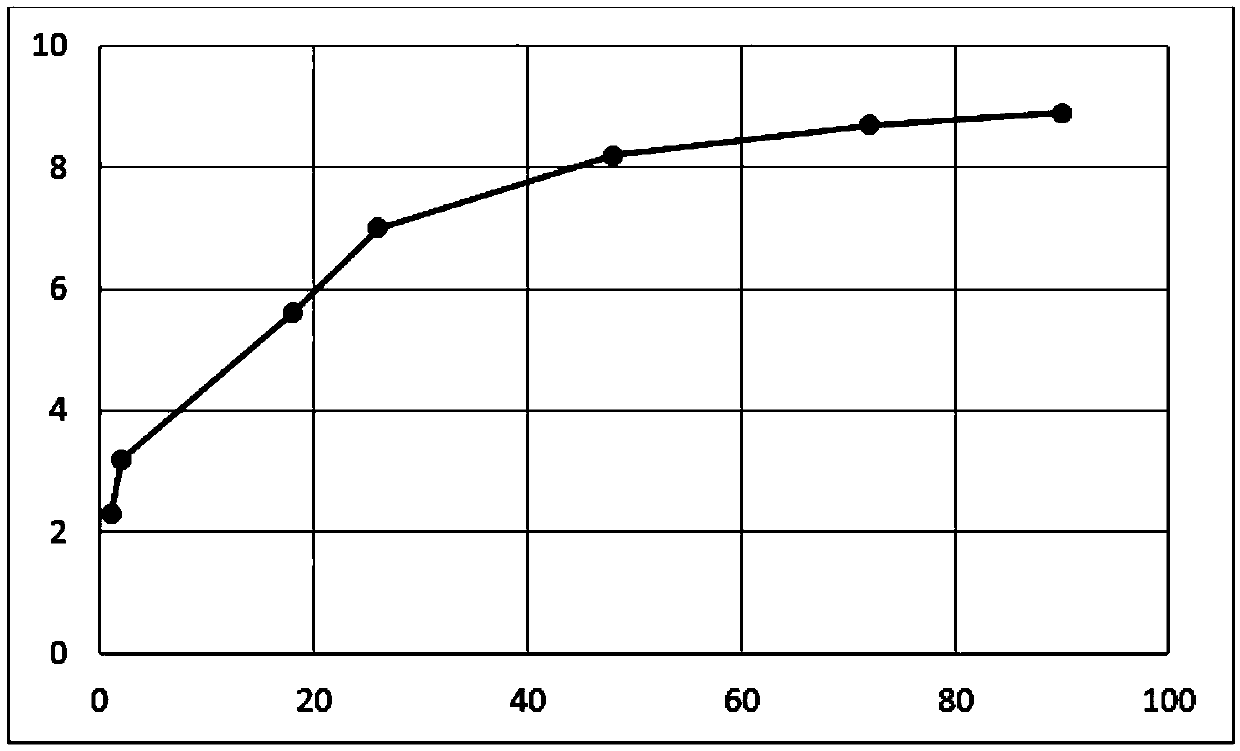

Ceramic part 3D (three dimensional) printing method based on adhesives of dual curing systems

InactiveCN107098715AWon't clogImprove curing efficiencyAdditive manufacturing apparatusSolubilityDual cure

The invention discloses a ceramic part 3D (three dimensional) printing method based on a photocuring adhesive. In a first curing system, a photosensitive resin-based adhesive solidifies quickly under the irradiation of ultraviolet light, bonds powder so as to take shape and has high curing efficiency; only when the photosensitive resin-based adhesive encounters the ultraviolet light, the photosensitive resin-based adhesive solidifies; and as the photosensitive resin-based adhesive is not likely to encounter the ultraviolet light in a spray nozzle, the photosensitive resin-based adhesive is not likely to solidify and block the printing spray nozzle. In a second curing system, an epoxy resin-based adhesive can also solidify quickly by adding polymercaptan serving as a solidification triggering agent; and as the epoxy resin and the polymercaptan triggering agent are in different spray nozzles and do not contact with each other, the epoxy resin-based adhesive is not likely to solidify and block the spray nozzle. As the adhesives of the dual curing systems are resin-based adhesives and no water is added all the time in the preparation process, the adhesives of the dual curing systems can be used for bonding water-solubility ceramic powder; and the green bodies of ceramic parts formed by the dual curing systems have very high strength and forming accuracy.

Owner:XI AN JIAOTONG UNIV

High-frequency resin composition as well as semi-cured sheet and laminated board manufactured by high-frequency resin composition

ActiveCN103232705AReduce the temperatureReduce heatSynthetic resin layered productsMetal layered productsDielectric lossBottle

The invention discloses a high-frequency resin composition. The high-frequency resin composition comprises the following components in parts by weight: (a), 15-80 parts of anhydride-modified benzoxazine resin prepolymer, (b),10-60 parts of halogen-free epoxy resins, (c), 5-40 parts of fire retardant, (d), 0.001-2 parts of accelerant and (e), 0-70 parts of inorganic fillers, wherein the number-average molecular weight of the anhydride-modified benzoxazine resin prepolymer is 400-20000. The preparation method of the anhydride-modified benzoxazine resin prepolymer comprises the following steps of: getting and placing benzoxazine and anhydride compounds in a reaction bottle, heating up to 60 DEG C to 200 DEG C, adding a catalyst which is 0%-2% of the total weight of the reactants, and reacting for 10minutes-150minutes to obtain uniform and transparent anhydride-modified benzoxazine resin prepolymer. According to the high-frequency resin composition as well as a semi-cured sheet and a laminated board manufactured by the high-frequency resin composition, the anhydride-modified benzoxazine resin prepolymer is used for lowering concentration of hydroxyl groups generated by the epoxy resin curing process by the anhydride, so that the content of benzene ring is relatively improved, and the dielectric constant and the dielectric loss of the product are greatly lowered.

Owner:SHENGYI TECH SUZHOU

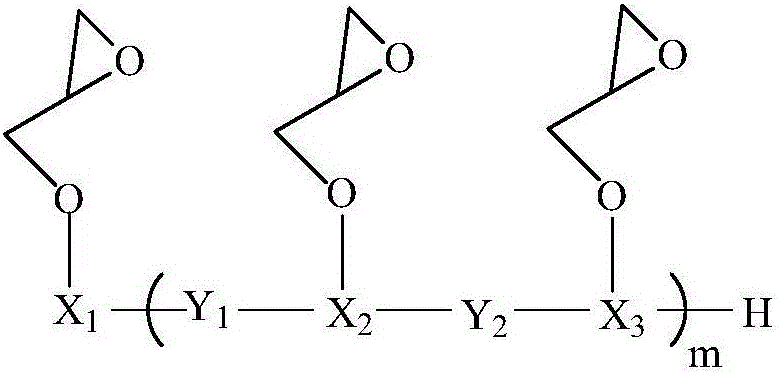

UV-curable composition and adhesive film comprising same, adhesive tape, and adhesive member

ActiveCN110643286ACause corrosionStrength reachedMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesEpoxyPolymer science

The invention relates to a UV-curable composition, and an adhesive film comprising the same, an adhesive tape, and an adhesive member. The UV-curable composition is a photo-base catalyzed UV curable composition. The UV-curable composition comprises: (1) an acrylic polymer and / or an ethylene-vinyl acetate copolymer; (2) a curable component containing a polyfunctional thiol and a polyfunctional epoxy resin; and (3) a photo-alkali generating agent. The composition disclosed by the invention can be coated into an adhesive tape or an adhesive film, and the adhesive tape or the adhesive film has initial viscosity when UV curing is not carried out, and can reach the strength of a semi-structural adhesive or a structural adhesive after UV curing.

Owner:3M INNOVATIVE PROPERTIES CO

Silicon carbide ceramic paste for photocuring and preparation method thereof

InactiveCN110451985AImprove curing depthReduce clumpingAdditive manufacturing apparatusCeramic sinteringDispersity

The invention discloses silicon carbide ceramic paste for photocuring and a preparation method thereof. The paste is prepared by mixing SiC mixed powder, a dispersing agent, a monomer, a compatilizerand a photoinitiator, wherein the surface of the SiC mixed powder is coated with a SiO2 layer, so that the refractive index difference between the final paste and light-cured resin is reduced, and then printing efficiency is further improved. SiO2 can improve the solid phase content of the whole slurry, so that the sintering density of sintered ceramic and the mechanical property of finally formedceramic can be improved during subsequent ceramic sintering. Through addition of the dispersing agent into the slurry, the agglomeration phenomenon of the slurry can be reduced, the dispersity is improved, and the solid phase content of the whole slurry can be increased. Verification finds that the solid phase content in the paste can finally reach 40%-60%.

Owner:NAT INST CORP OF ADDITIVE MFG XIAN

Method for carrying out pressure grouting soil fixation by combining microorganisms with enzyme inhibitor

InactiveCN108049409AImprove uniformityOvercome the problem of easy cloggingBuilding constructionsOrganic fertilisersMicroorganismUltimate tensile strength

The invention discloses a method for carrying out pressure grouting soil fixation by combining microorganisms with an enzyme inhibitor. The method comprises the steps that (1), a mixed single-liquid with the volume being 1-1.2 times of the pore volume of a to-be-fixed soil body area is injected into a grouting floral pipe by utilizing a grouting pump, wherein the mixed single-liquid comprises a microbial liquid, a culture solution, the inhibitor and a consolidating fluid; (2), the mixed single-liquid in the step (1) is injected into the to-be-fixed soil body area by utilizing a pressure pump,and the mixed single-liquid is left to stand for 10-15 hours after being completely injected; (3), deionized water is injected into the grouting floral pipe by utilizing an agent injecting pump; (4),the deionized water is injected into the soil body by utilizing the pressure pump; and (5), the operation from the step (1) to the step (4) is repeatedly carried out, and grouting is stopped until thestrength of the to-be-fixed soil body reaches the requirement or the mixed single-liquid cannot be injected into the to-be-fixed soil body. According to the method for carrying out pressure groutingsoil fixation by combining the microorganisms with the enzyme inhibitor, the biological activity of the microorganisms is not influenced, and meanwhile, the mixed single-liquid can be injected into the soil body around the grouting floral pipe quickly and efficiently to the greatest extent.

Owner:HOHAI UNIV

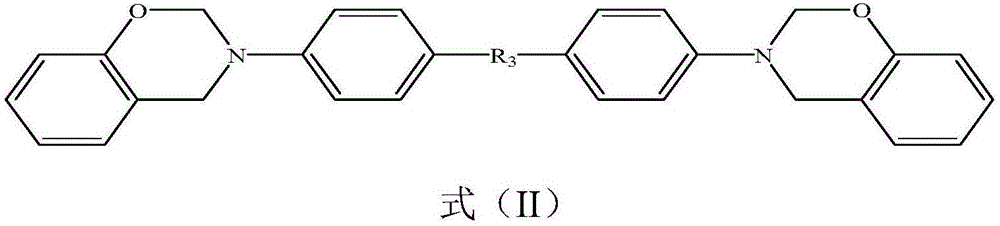

Preparation method of benzoxazine-containing resin composition, and prepreg and plywood produced from resin composition

ActiveCN106700548APromote polymerizationReduce usageSynthetic resin layered productsPrinted circuit aspectsEpoxyHeat resistance

The invention relates to a preparation method of a benzoxazine-containing resin composition, and a prepreg and a plywood produced from the resin composition. The preparation method of the benzoxazine-containing resin composition is characterized in that an acidic filler is added to the benzoxazine-containing resin composition. The addition of the acidic filler to the resin composition greatly promotes the polymerization reaction of benzoxazine and epoxy resin, and reduces the solidifying temperature needed by polymerization of the benzoxazine and epoxy resin; and the plywood made of the composition containing the acidic filler has high anti-stripping stability, high glass transition temperature, low water absorption rate, high heat resistance, high bending strength and good technologic processability, and realizes low heat expansion coefficient.

Owner:GUANGDONG SHENGYI SCI TECH

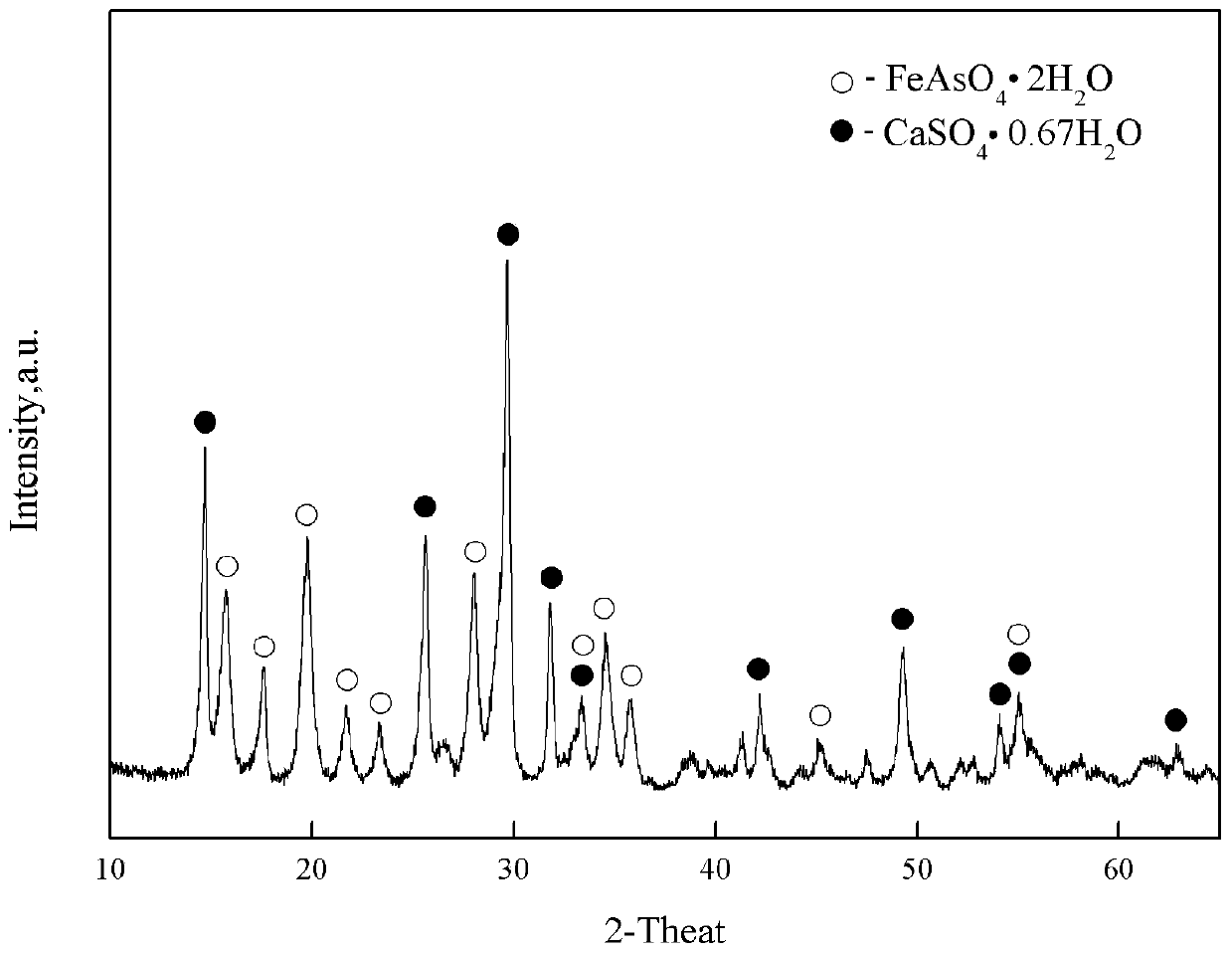

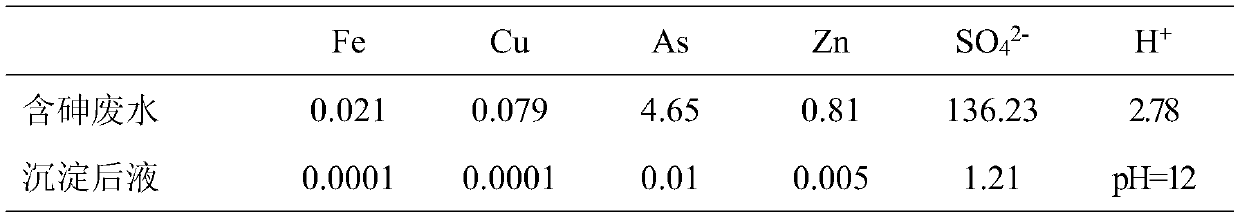

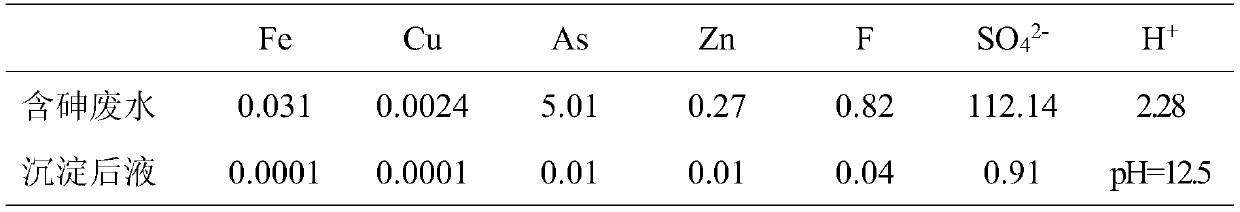

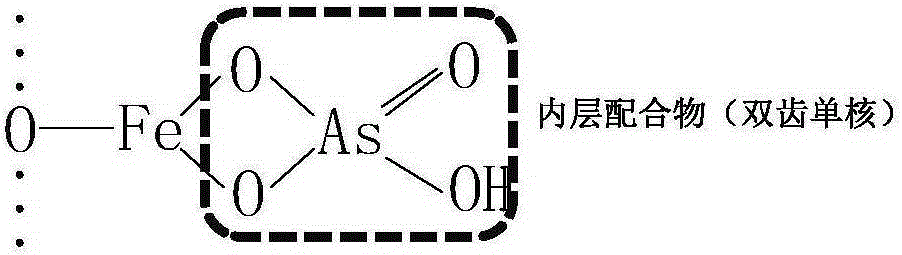

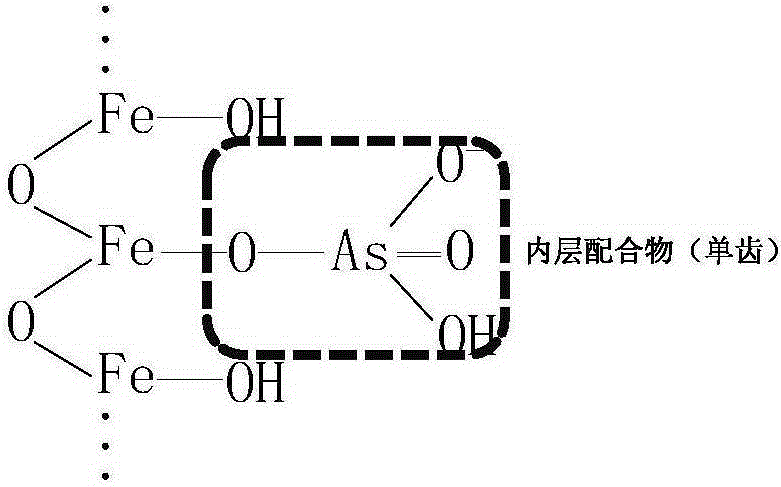

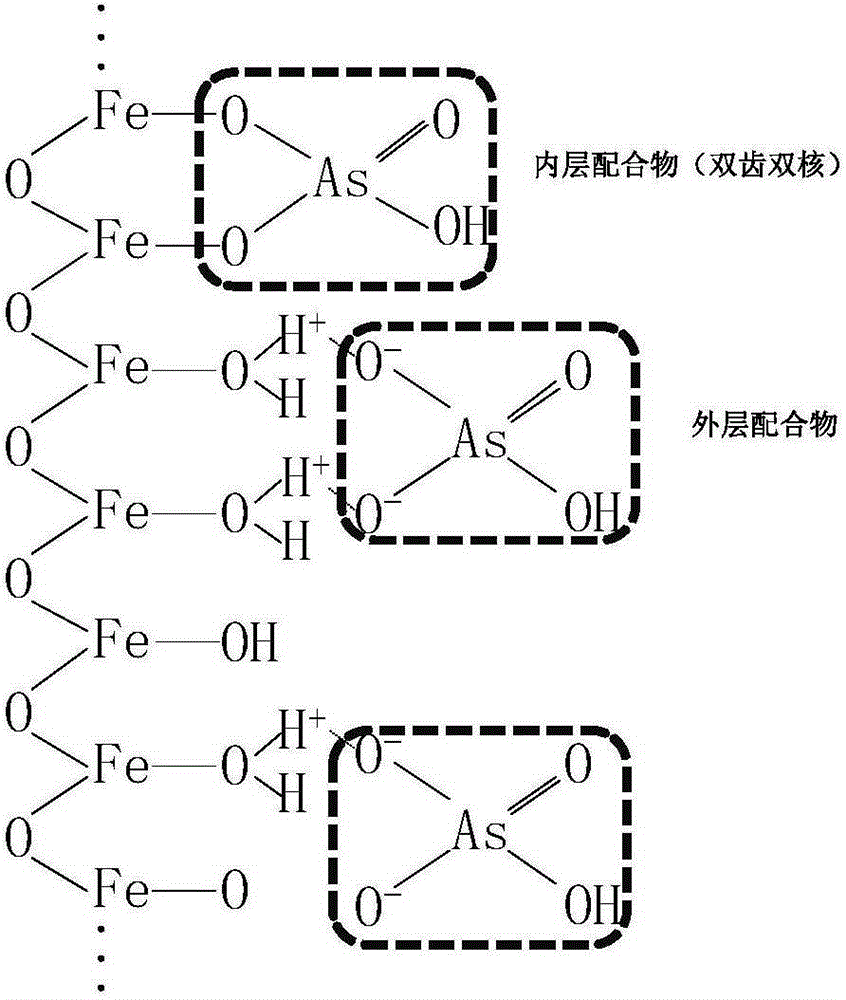

Method for treating arsenic-containing wastewater and solidifying arsenic

ActiveCN111170510AHigh removal rateReduce the temperatureWater contaminantsTreatment involving filtrationIron sulfateArsenous acid

The invention discloses a method for treating arsenic-containing wastewater and solidifying arsenic. The method comprises the following steps: separating and enriching arsenic in the arsenic-containing wastewater in the form of calcium arsenate or / and calcium arsenite precipitate; and oxidizing the obtained arsenic enriched product in a ferric sulfate or ferrous sulfate solution, and carrying outnormal-pressure reaction or pressurized hydrothermal reaction or normal-pressure hydrothermal reaction, so that arsenic in the arsenic enriched product is solidified in the form of scorodite crystals.The obtained scorodite crystals are complete in grain development, uniform in grain distribution and stable in structure under acidic conditions. The method has the advantages of high operation efficiency, good arsenic fixation effect, convenience in operation, low arsenic solidification treatment cost and the like, and is suitable for industrial application of harmless treatment of arsenic-containing wastewater.

Owner:宁波弗镁瑞环保科技有限公司 +2

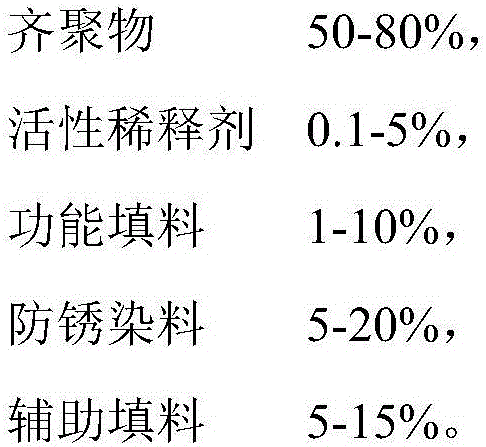

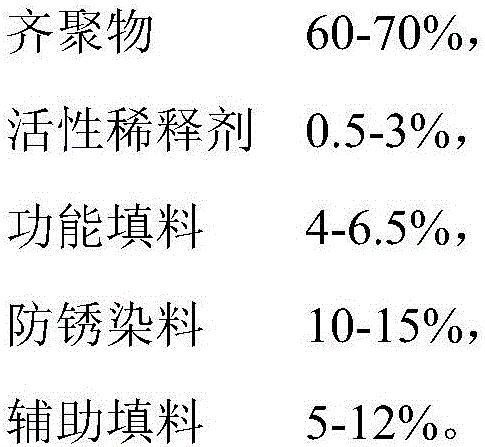

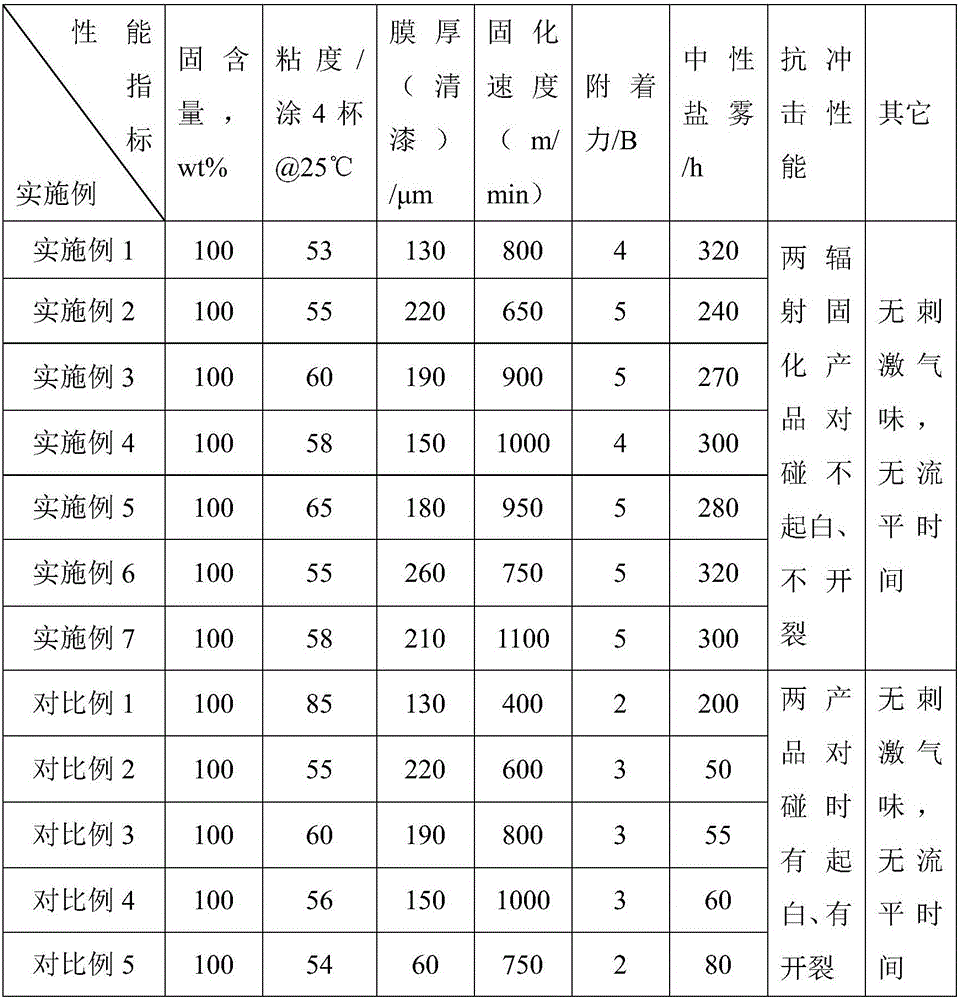

Electron beam radiation curing coating for metal heavy anti-corrosion

ActiveCN106433258AImprove curing efficiencyReduce energy consumptionAnti-corrosive paintsBeam energyOligomer

The invention discloses an electron beam radiation curing coating for metal heavy anti-corrosion. The coating is prepared from, by mass, 50%-80% of oligomer, 0.1-0.5% of reactive diluent, 1-10% of functional filler, 5-20% of antirust dyestuff and 5-15% of auxiliary filler, and the total mass percentage of the components is 100%. The curing coating for metal heavy anti-corrosion is cured by electron beam radiation, has the advantages of high efficiency and energy conservation, environment friendship and convenient operation, cured depth of the coating is high, thickness is big, and the adhesive force between the coating and the substrate is strong. A conductive carbon material is doped in the curable coating, thus the problem of metal heavy anti-corrosion is solved while electron beam energy absorption is avoided, and it is guaranteed that cured efficiency is not affected. The electron beam radiation curing coating for metal heavy anti-corrosion has excellent wear-resistance and corrosion-resistance, can be applied to the field of metal heavy anti-corrosion anti-corrosion, and is particularly applicable to the field of maritime work heavy anti-corrosion.

Owner:NANJING INST OF TECH +1

Steel slag-desulfurized gypsum based soil solidification agent applicable to arsenic contaminated soil

InactiveCN106467745AReduce the amount of blendingSmall increase ratioContaminated soil reclamationOrganic fertilisersSlagGypsum

The invention discloses a steel slag-desulfurized gypsum based soil solidification agent applicable to arsenic contaminated soil. The soil solidification agent contains the ingredients in percentage by weight: 40% to 45% of steel slag, 15% to 25% of desulfurized gypsum, 22% to 30% of slag, 7% to 10% of cement clinker and 3% of excitant. According to the soil solidification agent disclosed by the invention, arsenic is solidified and stabilized mainly by means of chemical wrapping and in-phase replaced solidifying, and the age of a solidifying reaction can be shortened and the mixed amount of the solidification agent and solidified volume increase ratio in engineering applications can be lowered while a solidifying effect is guaranteed, so that the solidifying efficiency is increased greatly.

Owner:WUHAN UNIV

High-temperature-resistant toughened light-cured resin composition and preparation method thereof

ActiveCN107513247AImprove the shortcomings of slow printing speed and low curing efficiencyImprove curing efficiencyAdditive manufacturing apparatusEpoxyAcrylic resin

Owner:HANGZHOU LEYI NEW MATERIAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com