Patents

Literature

275results about How to "Cause corrosion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for increasing combustion efficiency of combustion engine

InactiveCN101701558ATake advantage ofIncrease the itineraryInternal combustion piston enginesCombustion-air/fuel-air treatmentJet aeroplanePlasma technology

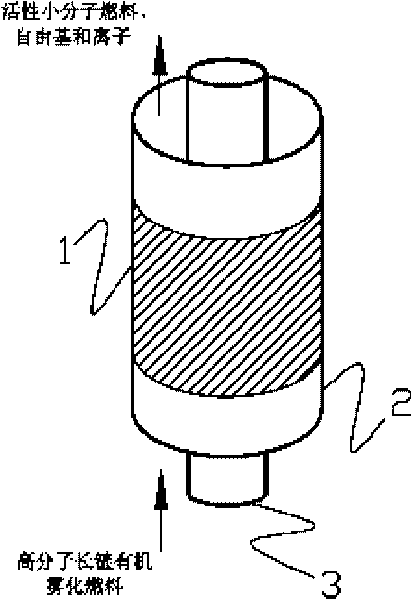

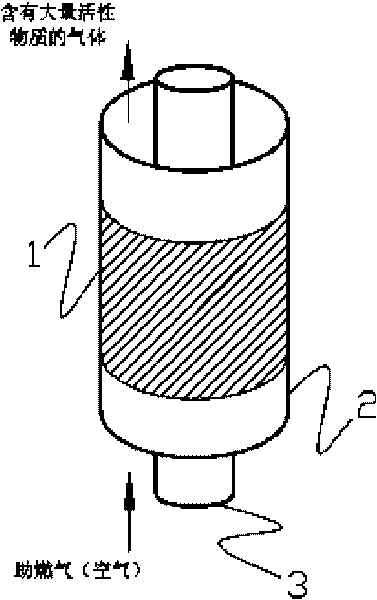

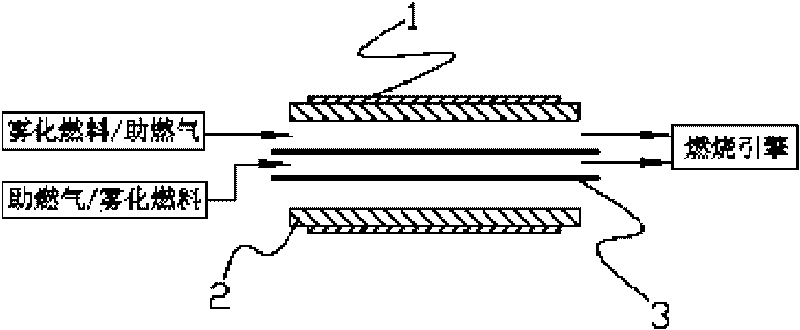

The invention provides a new method for increasing combustion efficiency of a combustion engine; based on non equilibrium plasma technology, a non equilibrium plasma generator with low power is designed and applied, has small volume, can be widely applied to such as fuel power equipment such as automobiles, airplanes and the like and really realizes the combustion efficiency increase of the fuel equipment and exhaust emission reduction. The non equilibrium plasma generator provided by the invention is applied for carrying out controllable dielectric barrier discharge so as to activate fuel or combustion-supporting fuel, thus fundamentally improving combustion situation of the fuel, causing the fuel to fully and effectively burn and simultaneously achieving the effect of energy saving and emission reduction.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

Acid-proof ink for protecting one glass solution (OGS) touch screens and preparation method thereof

The invention provides acid-proof ink for protecting one glass solution (OGS) touch screens and a preparation method thereof, relating to ink. The acid-proof ink comprises 1-8 parts of curing agent, 5-50 parts of resin, 10-80 parts of solvents, 1-5 parts of emulsifier and 5-30 parts of filler by mass. The preparation method comprises the following steps: mixing natural resin, synthetic resin and the solvents, adding the emulsifier and heating the materials until the natural resin and the synthetic resin are totally dissolved, thus obtaining a mixture; stirring the prepared mixture under normal temperature and discharging the material when the temperature is cooled to the room temperature, thus obtaining mixed emulsion; adding the curing agent to the prepared mixed emulsion, adding the filler after stirring the materials and grinding the mixture, thus obtaining the liquid acid-proof ink for protecting OGS touch screens. The acid-proof ink has the advantages and technical effects that the ink has smaller particles and denser film, so that the ink can not permeate even if being strengthened; the ink has high particle packing density and is 5-10mu m thinner than the printing thickness of common protective ink; the stability of viscosity of the ink in the printing process can be maintained and the ink does not become dry easily, has good printing effects and does not stick to screen printing plates.

Owner:XIAMEN HOWER MATERIAL

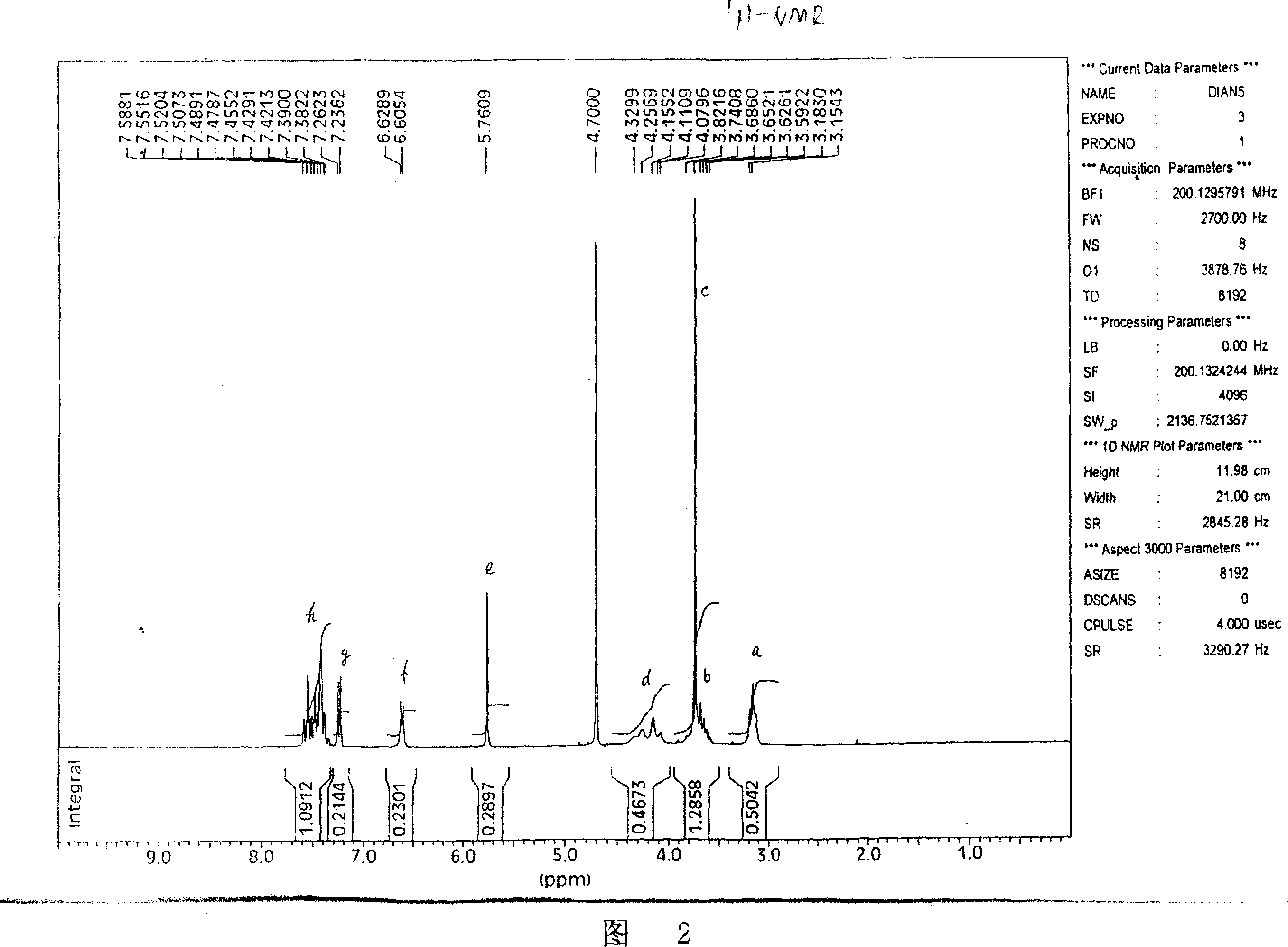

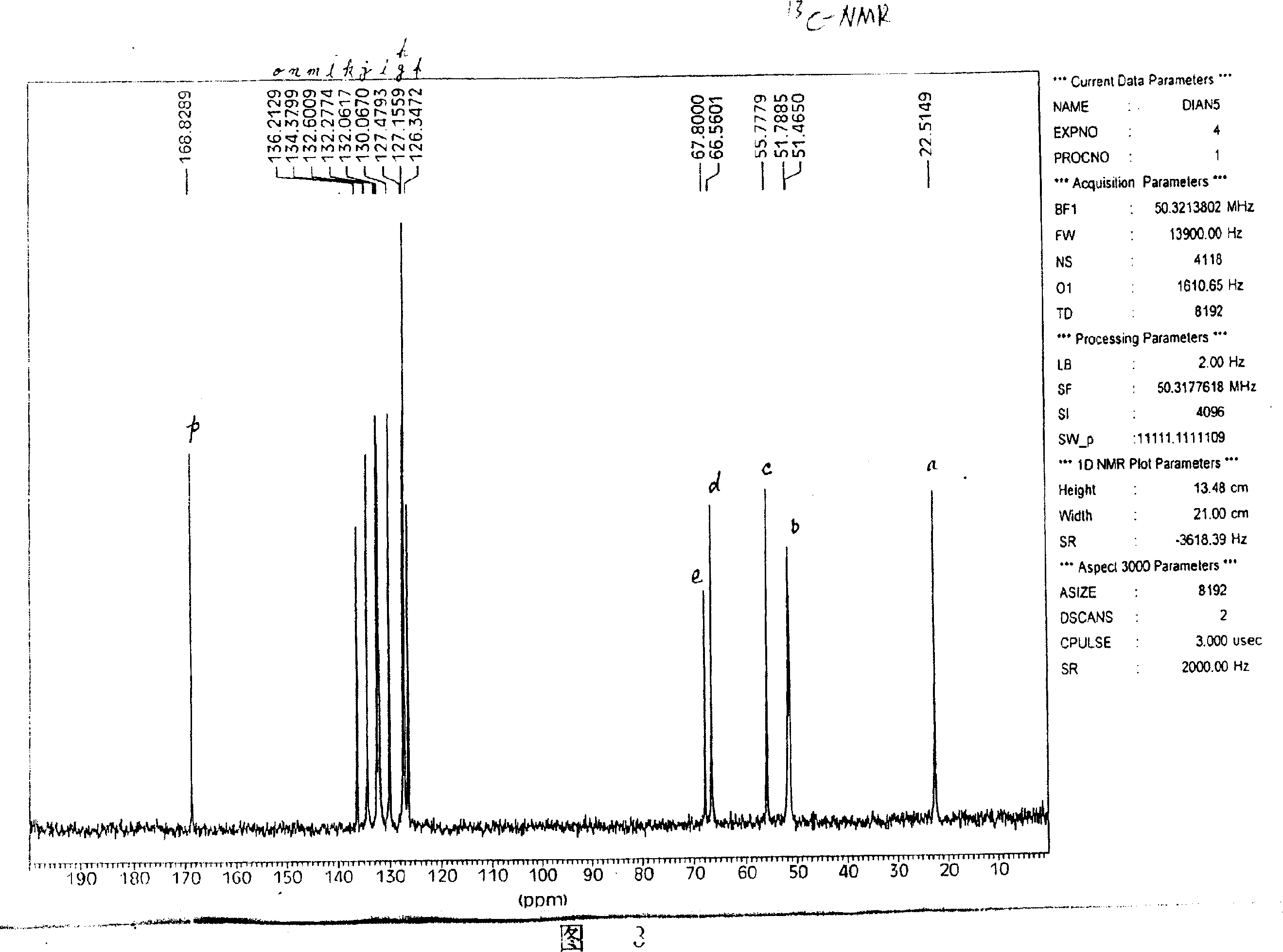

Preparation process of clopidogre and its salt

InactiveCN100999525AEasy to operate and save timeShort reaction cycleOrganic chemistryAnticoagulant effectClopidogrel

The present invention provides one kind of compound with anticoagulant effect, and is especially new preparation process of clopidogrel and its pharmaceutical salt. The preparation process includes the following four steps: 1. resolving recemized methyl o-chlorophenyl glycinate to obtain (+)-methyl o-chlorophenyl glycinate and (-)-methyl o-chlorophenyl glycinate; 2. recemizing (-)-methyl o-chlorophenyl glycinate to obtain recemized (-)-methyl o-chlorophenyl glycinate; 3. repeating the steps 1 and 2; and 4. preparing clopidogrel with (+)-methyl o-chlorophenyl glycinate obtained in the step 1 and preparing the obtained clopidogrel into corresponding salt. The process of the present invention has simple path, short circulating period, low cost, high product purity, less toxic side effect and corrosion to the production apparatus.

Owner:SHENZHEN SALUBRIS PHARMA CO LTD +1

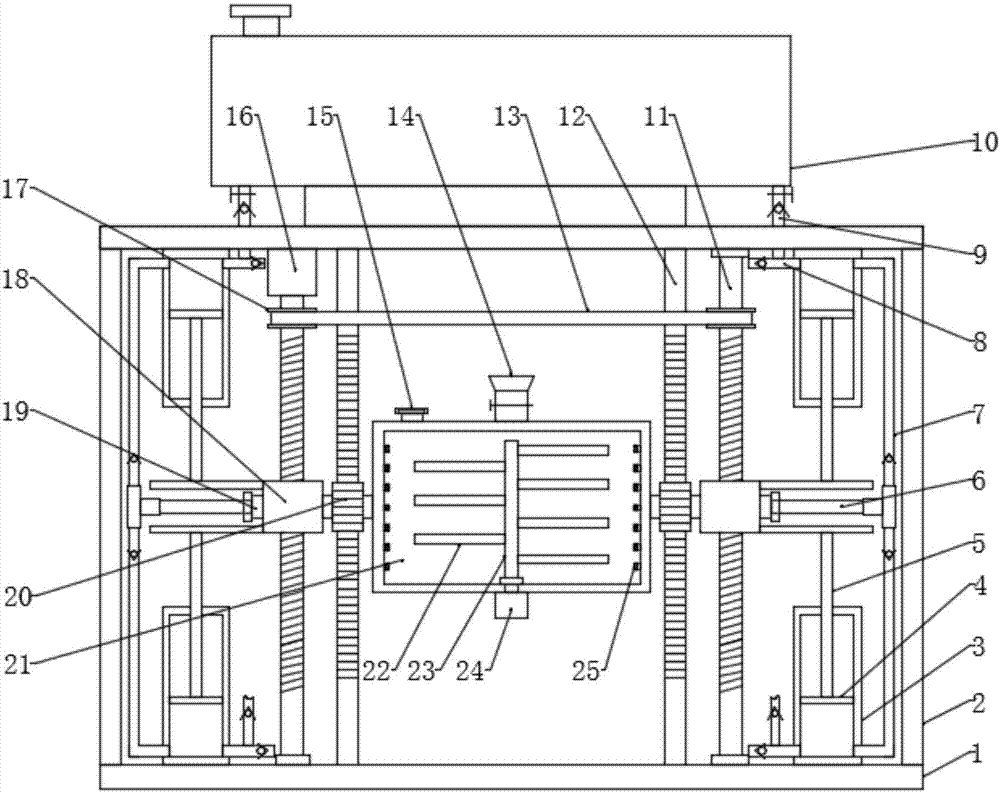

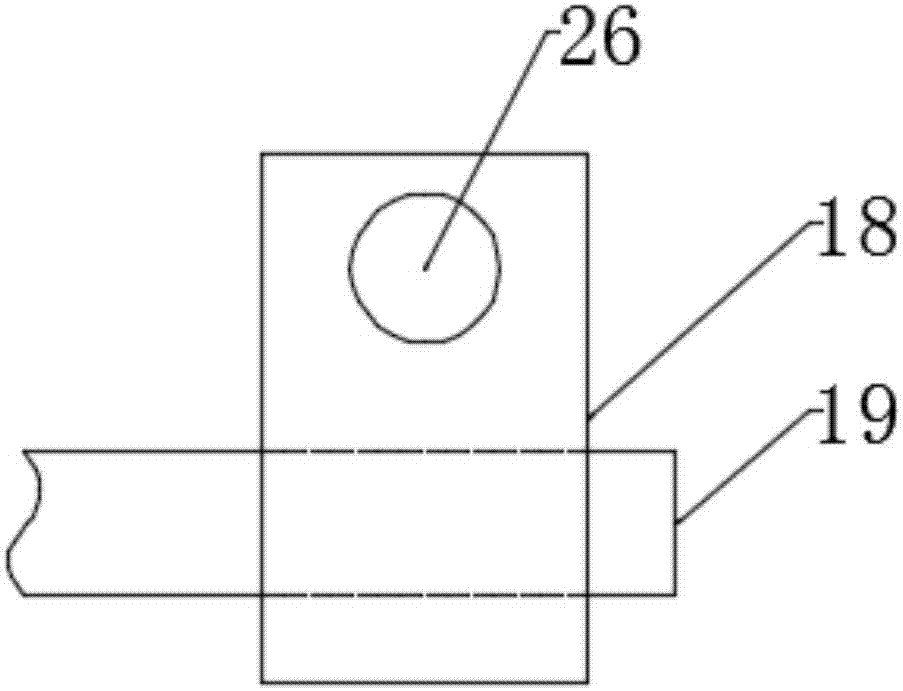

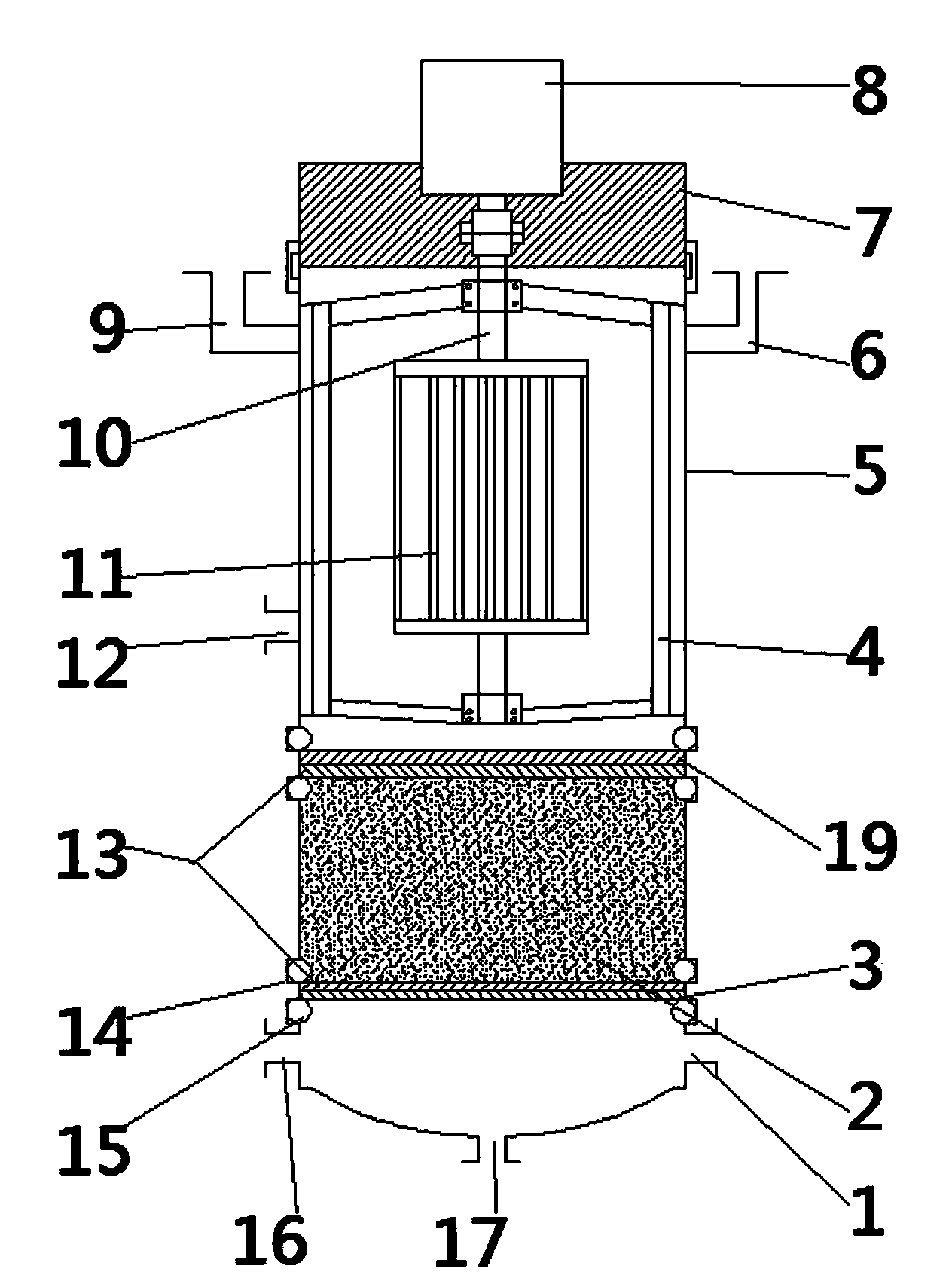

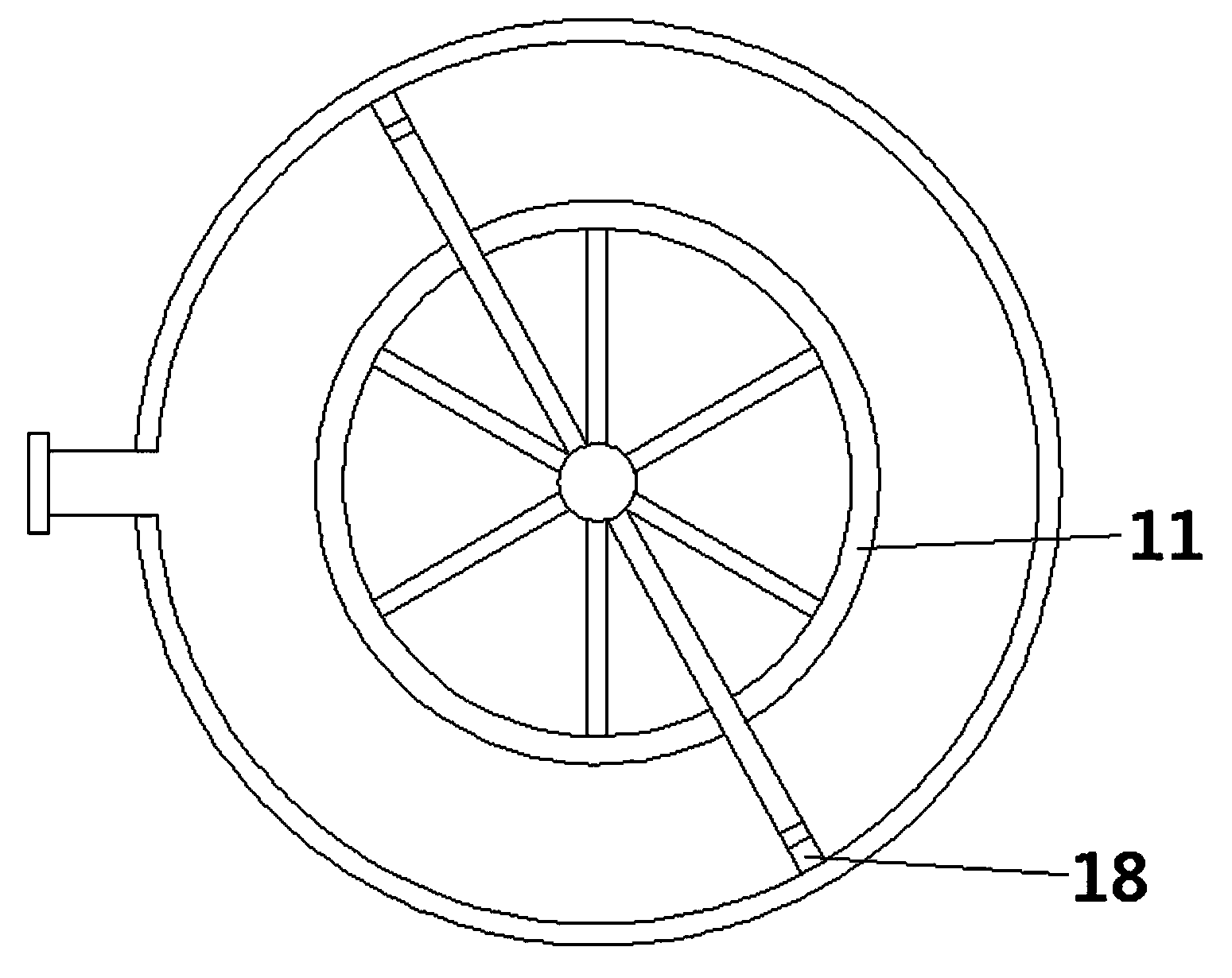

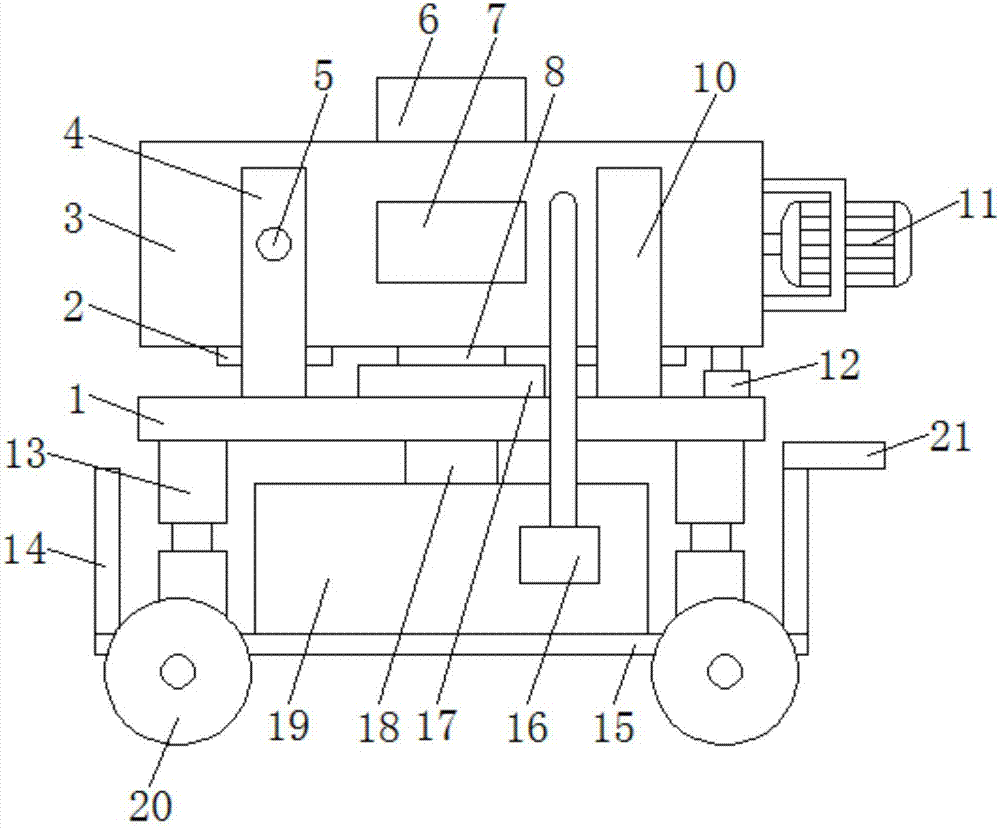

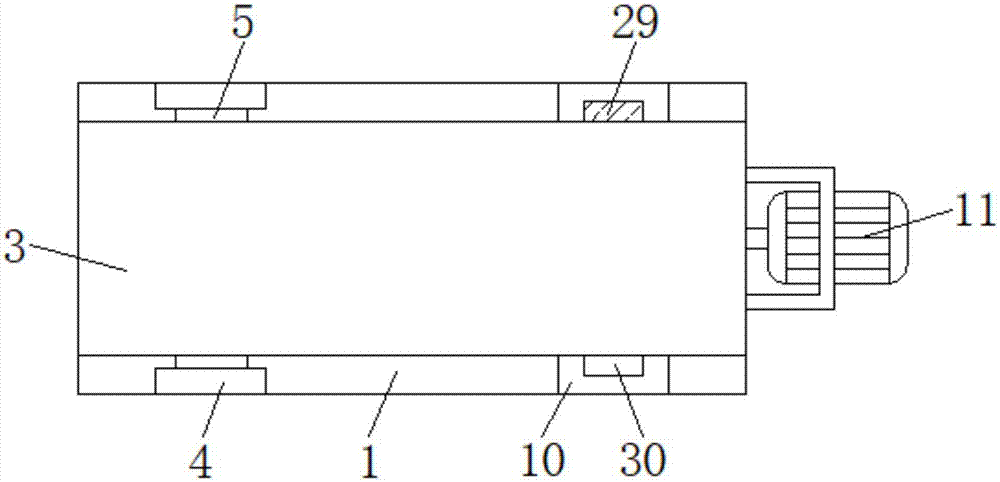

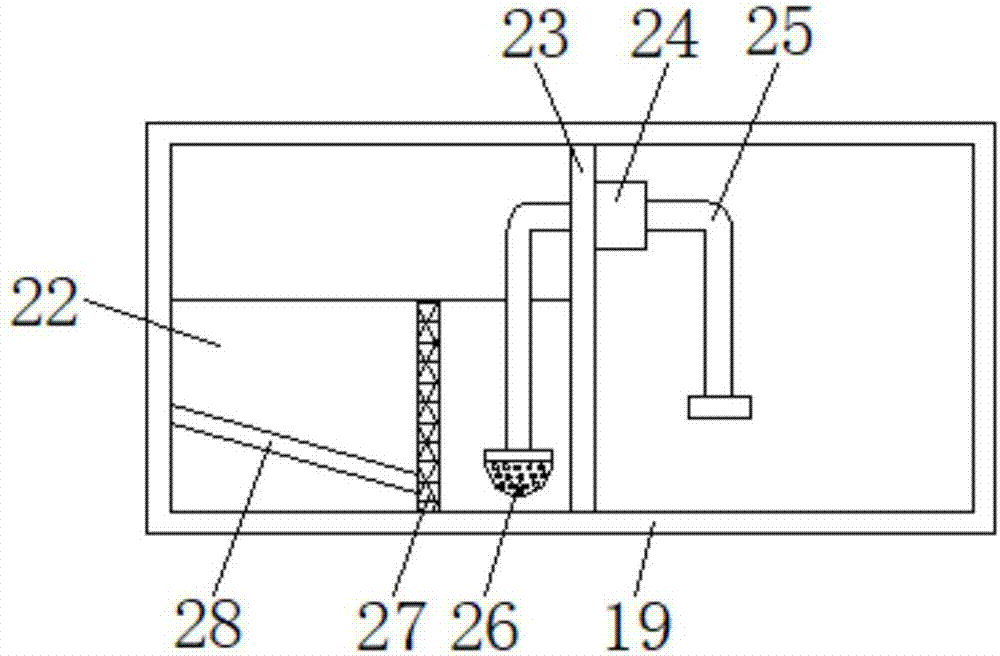

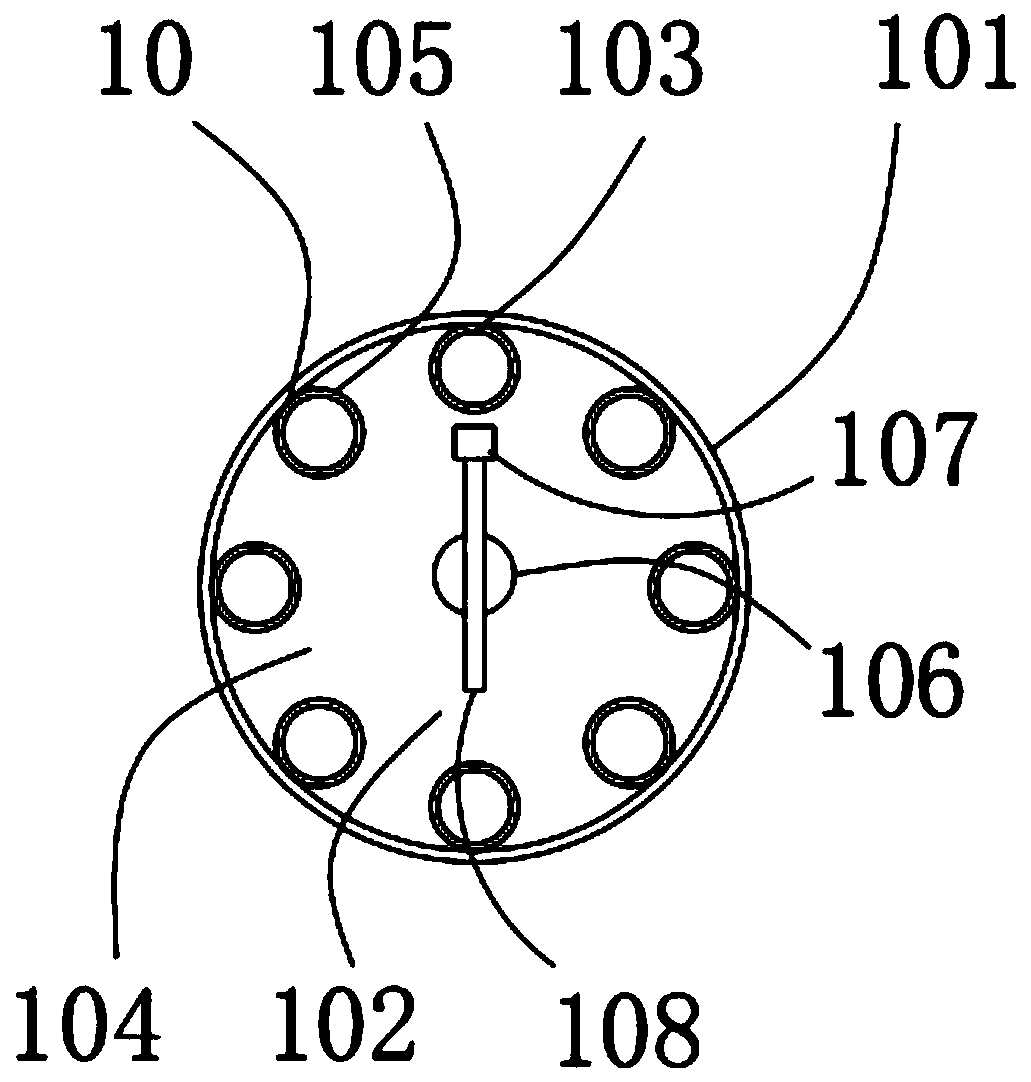

Chemical raw material stirring and drying device

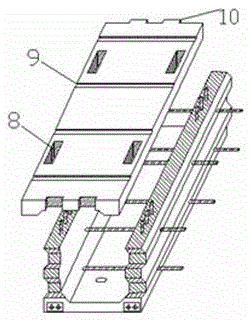

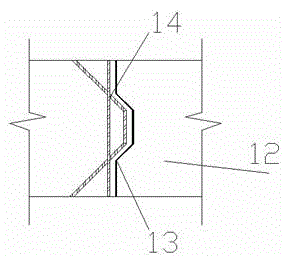

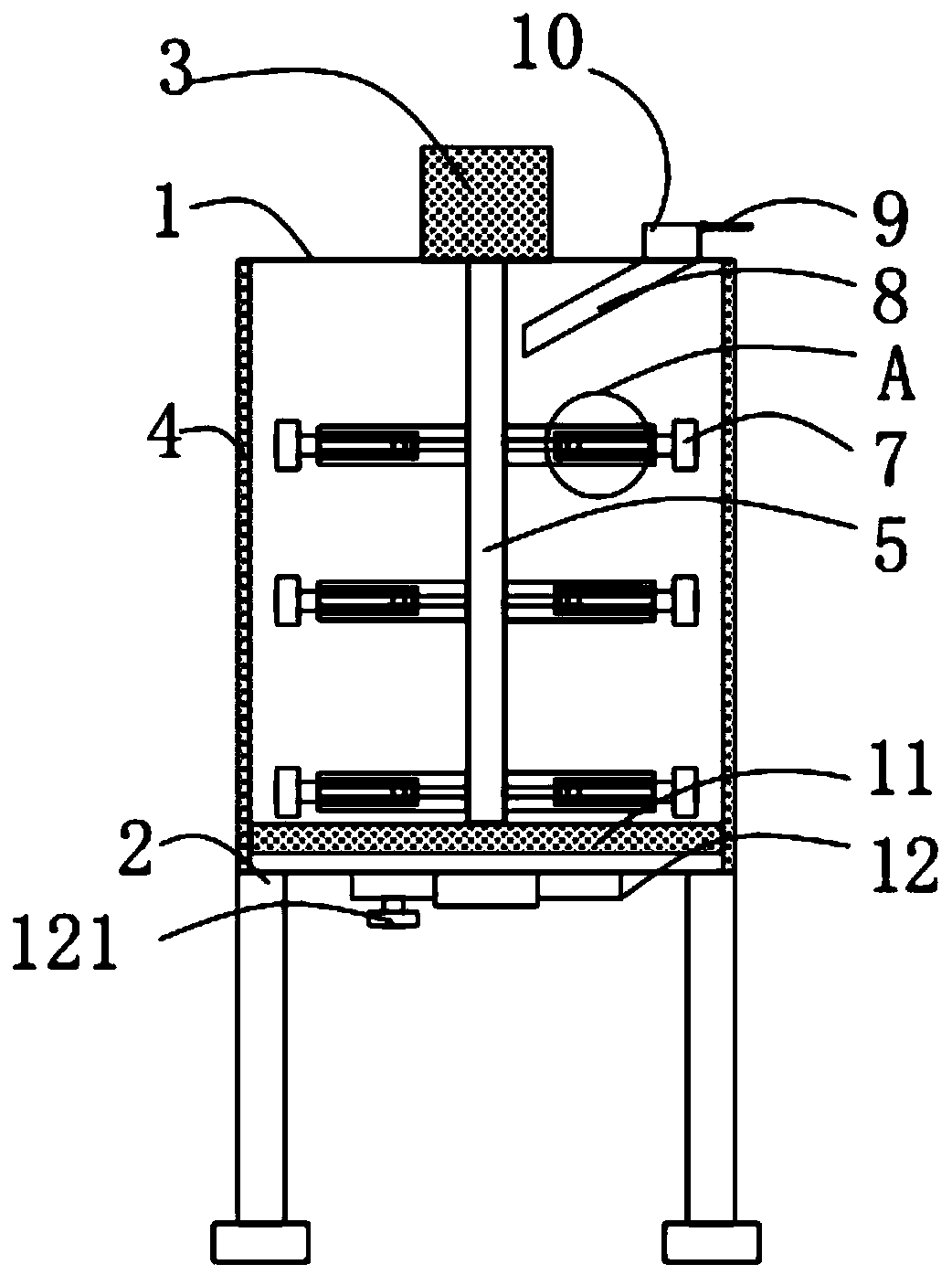

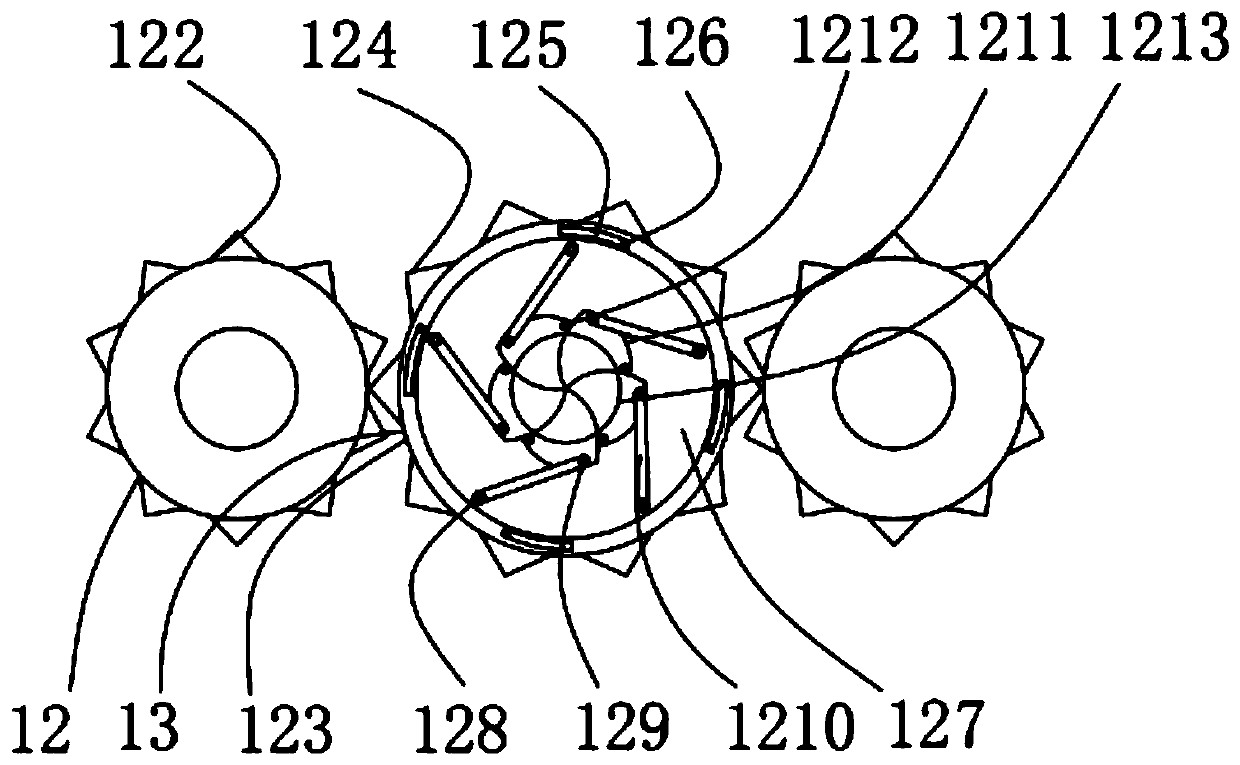

InactiveCN107983248AIncrease the stirring areaStir wellShaking/oscillating/vibrating mixersTransportation and packagingPistonSpray nozzle

The invention discloses a chemical raw material stirring and drying device. The chemical raw material stirring and drying device comprises a bottom plate, a stirring box, a first motor, a stirring shaft, a stirring rod, a hollow rotary shaft, a movable block, a thread rod, a second motor, a belt wheel, a belt, a gear, a rack, a T-shaped rod, a piston, a cylinder body, a first pipeline, a gas inletpipe, a second pipeline and a spraying nozzle. According to the chemical raw material stirring and drying device disclosed by the invention, the first motor, the second motor, the stirring shaft, thestirring rod, the belt wheel, the belt, the movable block, the thread rod, the hollow rotary shaft, the gear, the rack and the stirring rod are arranged in a staggered manner, so that a stirring region is enlarged; when the stirring box moves up and down, the stirring box rotates frontward and backward, so that chemical raw materials in the stirring box are continuously overturned; furthermore, the stirring and mixing efficiency is improved; the T-shaped rod, the piston, the cylinder body, the water tank and the spraying nozzle are arranged so that continuous gas-spraying drying is realized and the drying efficiency is improved; the inner part of the stirring box also can be washed so that a phenomenon that the chemical raw materials are used for a long period so that the stirring box iscorroded and the service life of the stirring box is influenced is avoided.

Owner:长沙德科投资管理咨询有限公司

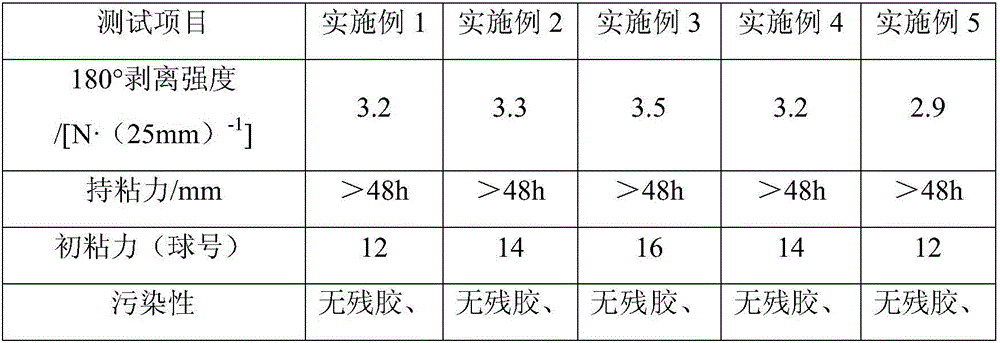

UV-curable composition and adhesive film comprising same, adhesive tape, and adhesive member

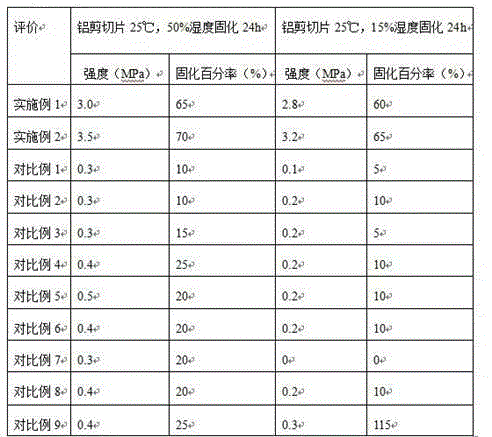

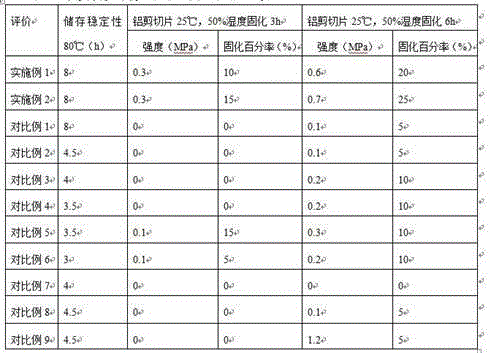

ActiveCN110643286ACause corrosionStrength reachedMonocarboxylic acid ester polymer adhesivesNon-macromolecular adhesive additivesEpoxyPolymer science

The invention relates to a UV-curable composition, and an adhesive film comprising the same, an adhesive tape, and an adhesive member. The UV-curable composition is a photo-base catalyzed UV curable composition. The UV-curable composition comprises: (1) an acrylic polymer and / or an ethylene-vinyl acetate copolymer; (2) a curable component containing a polyfunctional thiol and a polyfunctional epoxy resin; and (3) a photo-alkali generating agent. The composition disclosed by the invention can be coated into an adhesive tape or an adhesive film, and the adhesive tape or the adhesive film has initial viscosity when UV curing is not carried out, and can reach the strength of a semi-structural adhesive or a structural adhesive after UV curing.

Owner:3M INNOVATIVE PROPERTIES CO

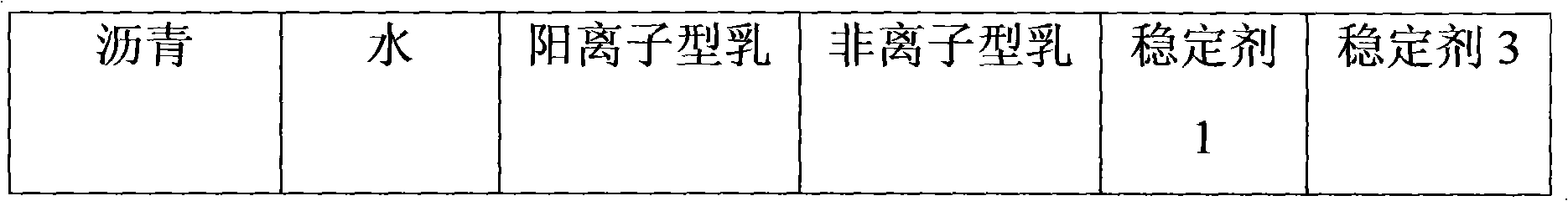

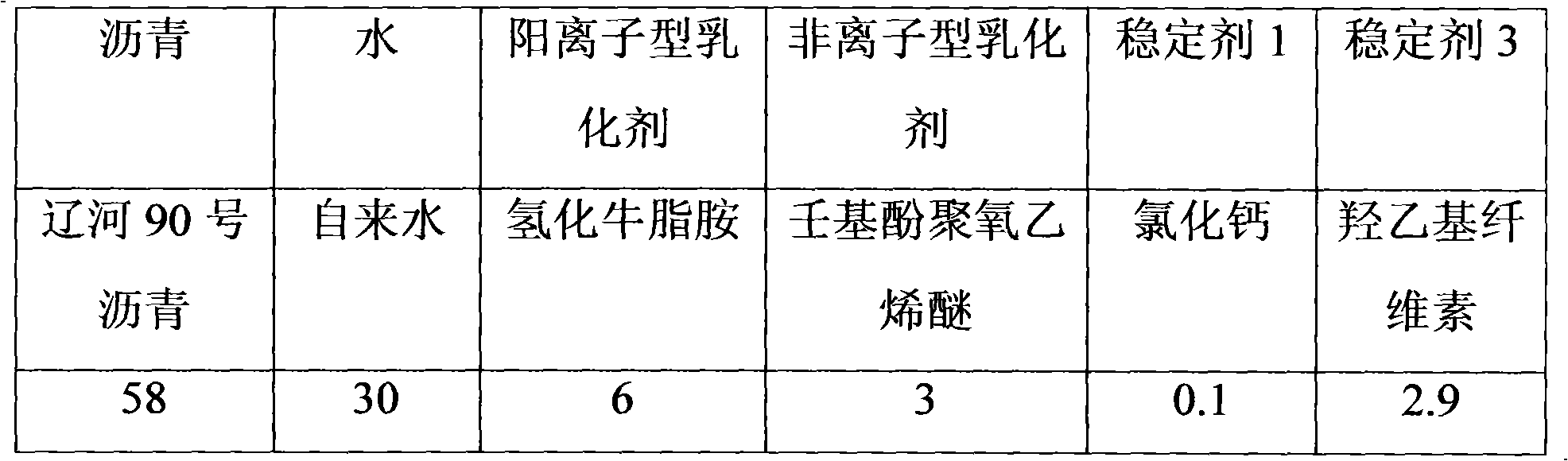

Emulsified asphalt for slab ballastless track

InactiveCN102030998AImprove early strengthGood storage stabilityBuilding insulationsAir contentRebar

The invention provides emulsified asphalt for a slab ballastless track, which comprises the following materials in percentage by weight: 55-65% of asphalt, 3-10% of cationic emulsifier, 3-10% of nonionic emulsifier, 1-5% of stabilizer and the balance water. The emulsified asphalt can effectively avoid the separation of cement-asphalt (CA) mortar and enable the working time of CA mortar to be up to one hour. The CA mortar prepared from the emulsified asphalt has high early strength, and the air content, the fluidity, the early strength, the material separation degree and other indices of the CA mortar are easy to control. The emulsified asphalt has favorable storage stability, and can be stored for at least six months at 0-40 temperature without stratification and separation, thereby facilitating transportation and storage. Besides, the emulsified asphalt can not corrode steel devices and steel bars in concrete.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

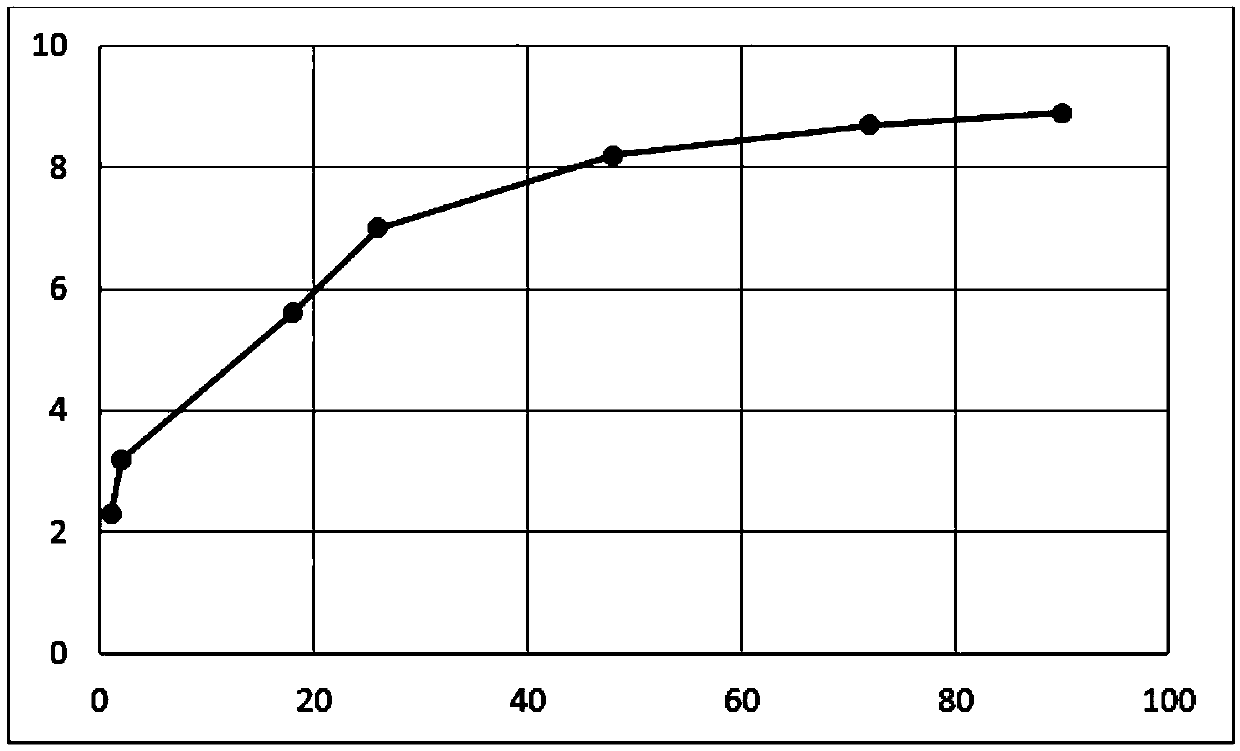

Emulsification asphalt used for high speed railway or light rail plate type slag-free orbit CA mortar

InactiveCN101054470AGood storage stabilityInhibition of segregationBuilding insulationsActive agentBitumen emulsion

The invention requires to protect an emulsified asphalt specially used for high-speed railway or light rail plate ballastless track CA sand pulp. The composition is as follows by weight: asphalt 38-55%, cationic surface active agent 3-20%, non-ion surface active agent 5-20%, assistant agents 2.0-8.0%, residual water. The emulsified asphalt can effectively avoid CA sand pulp isolation and give a proper working period of the sand pulp, more than 1 hour and leave an adequate time for practical construction. The CA sand pulp produced by such emulsified asphalt has a high early strength of 1.5-2.0MPa which is easy to control the air content, fluidity, early strength, material separation degree of the CA sand pulp. The emulsified asphalt has a good storage stability which can be stored for at least 6 months at 0-40 DEG C without layered isolation, and is easy to transport and store and will not erode the steel equipments and reinforcing steel bar in the concrete.

Owner:CHONGQING NORMAL UNIVERSITY +1

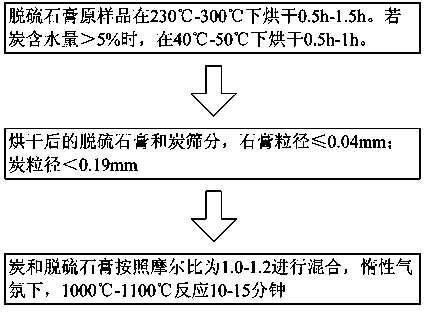

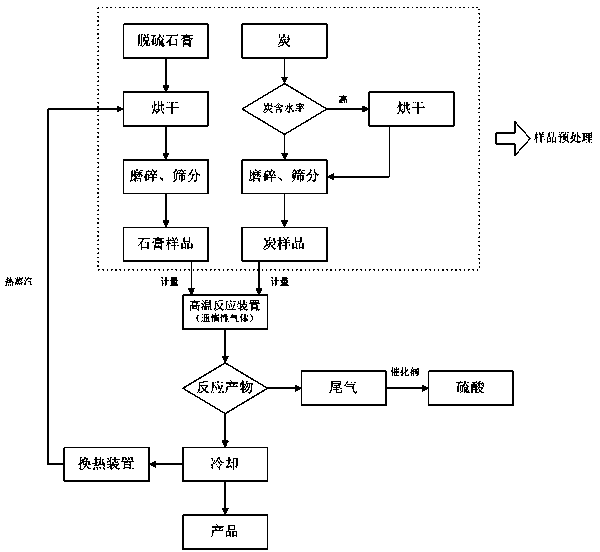

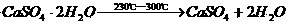

Production technology for preparing calcium oxide and sulfur dioxide through utilizing desulfurized gypsum

ActiveCN103482584AAvoid secondary pollutionReduce miningSulfur compoundsCalcium/strontium/barium oxides/hydroxidesNitrogen gasAtmospheric pollution

The invention discloses a production technology for preparing calcium oxide and sulfur dioxide through utilizing desulfurized gypsum. The technology comprises the following steps: drying desulfurized gypsum at 230-300DEG C for 0.5-1.5h, wherein drying pretreatment is carried out at 40-50DEG C for 0.5-1h if the water content of carbon is above 5%; screening the desulfurized gypsum and the carbon for controlling the gypsum particle size below 40mum and the carbon particle size below 187.5mum; and mixing the screened carbon and the screened desulfurized gypsum according to a carbon-to-calcium sulfate mole ratio of 1:1-1.2:1 to obtain a mixed sample, putting the mixed sample in a high temperature reaction device, and reacting at 1000-1100DEG C under the protection of nitrogen or an inert gas under a gas flow velocity of 4-10m / s for 10-15min. The technology has the advantages of high reaction efficiency, fast reaction speed, less carbon consumption, high finally-obtained product quality, and no atmospheric pollution.

Owner:NANJING UNIV OF SCI & TECH

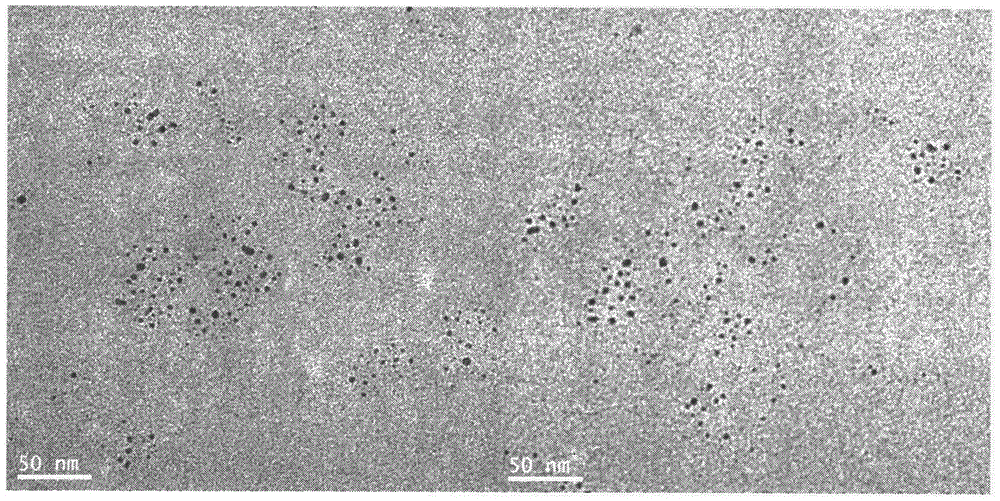

Preparation method of nanometer titanium dioxide composite nanometer silver sol

InactiveCN104824020ARemoval of harmful substances and improvement of bactericidal performanceSimple preparation processBiocideDispersed particle separationSal ammoniacAmmonium hydroxide

The invention provides a preparation method of nanometer titanium dioxide composite nanometer silver sol. The preparation method comprises the following steps of 1, dissolving titanyl sulfate or titanium sulfate in water, carrying out stirring, adjusting pH by ammonium hydroxide and carrying out stirring, 2, adding citric acid as a stabilizing agent into titanium hydroxide, carrying out stirring, adding hydrogen peroxide as an oxidizing agent into the mixed solution, carrying out full stirring and standing the mixture for 10h or more, 3, carrying out stirring heating reflux on the reaction solution in an oil bath at a temperature of 90-120 DEG C for 2-6h, 4, dissolving a protective agent and a reducer into the nanometer titanium dioxide sol to obtain a reduction solution, 5, dissolving a silver-containing oxidizing agent in water to obtain an oxidation solution, 6, putting the reduction solution into a reactor with a stirring reflux device at a temperature of 100-160 DEG C, and dropwisely adding the silver-containing oxidizing agent into the reduction solution, and 7, after dropwise addition, carrying out heating reflux stirring for 1-6h to obtain the nanometer titanium dioxide composite nanometer silver sol.

Owner:上海上星家居用品有限公司

Hair sewage treatment tank with self-cleaning function

InactiveCN103861379APrevent winding and cloggingSimple structureFiltration circuitsSewageEngineering

The invention relates to a hair sewage treatment tank with a self-cleaning function. The hair sewage treatment tank comprises a backflushing water inlet, an active carbon filter layer, a fine filter screen, a cleaning rack, a tank body, a water inlet, a seal cover, a motor, an exhaust hole, a shaft, a hair collecting cage, a hair water outlet, a filter plate, a groove, reinforcing ribs, a water outlet, a breast hole, sponge and a piece of non-woven fabric, wherein the tank body is divided into a hair collecting area, a sewage filtering area and a depositing area from top to bottom. The hair sewage treatment tank is simple in structure, is used for preventing intertwining and blockage of hairs, and is extremely convenient to mount, maintain and clean; even if the replacement is required in the event of a failure, only a filter device needs to be replaced or an individual component is replaced after the filter device is taken out, so that the cost and labor force are greatly saved.

Owner:贵州天下家政有限公司

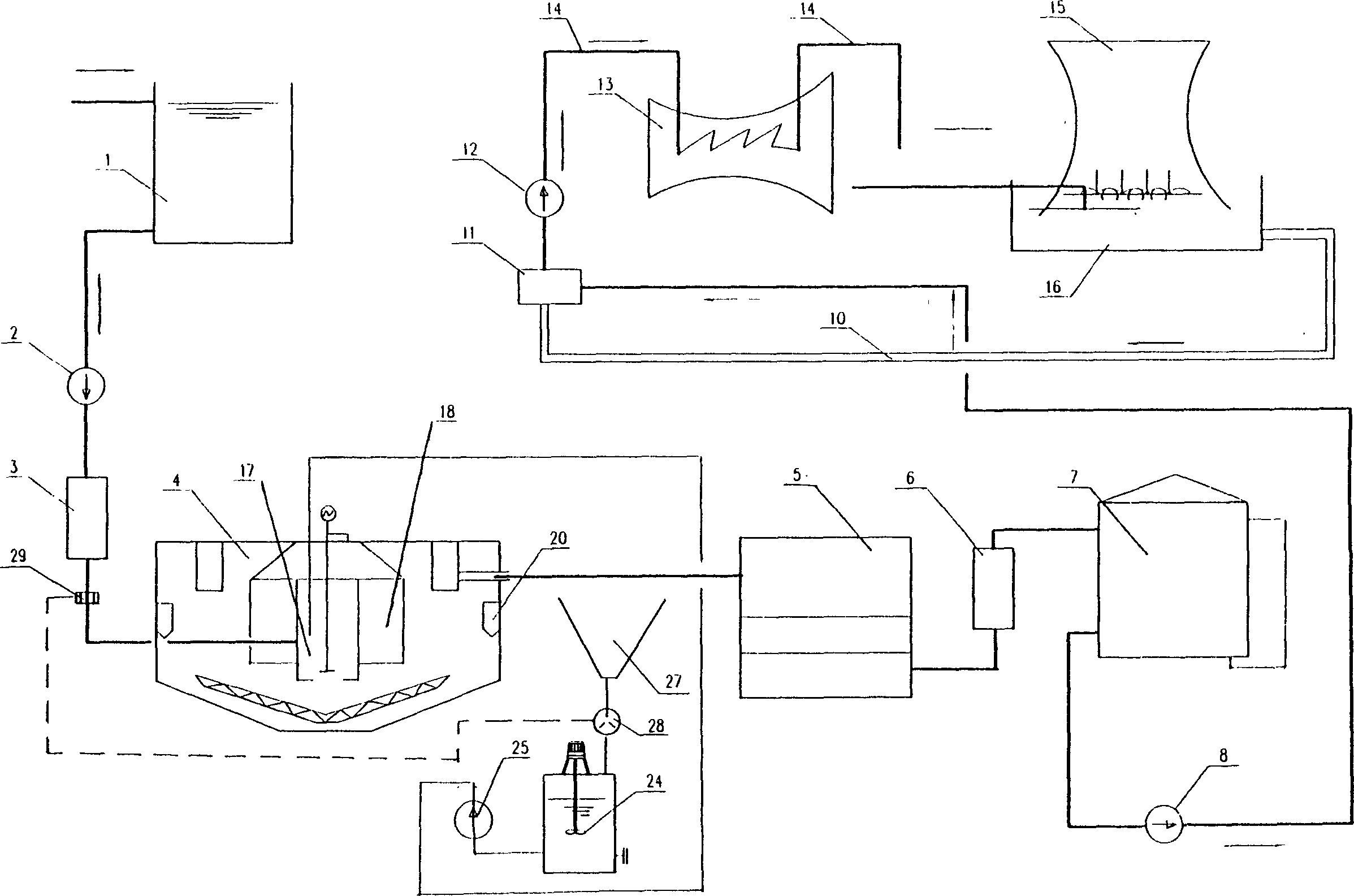

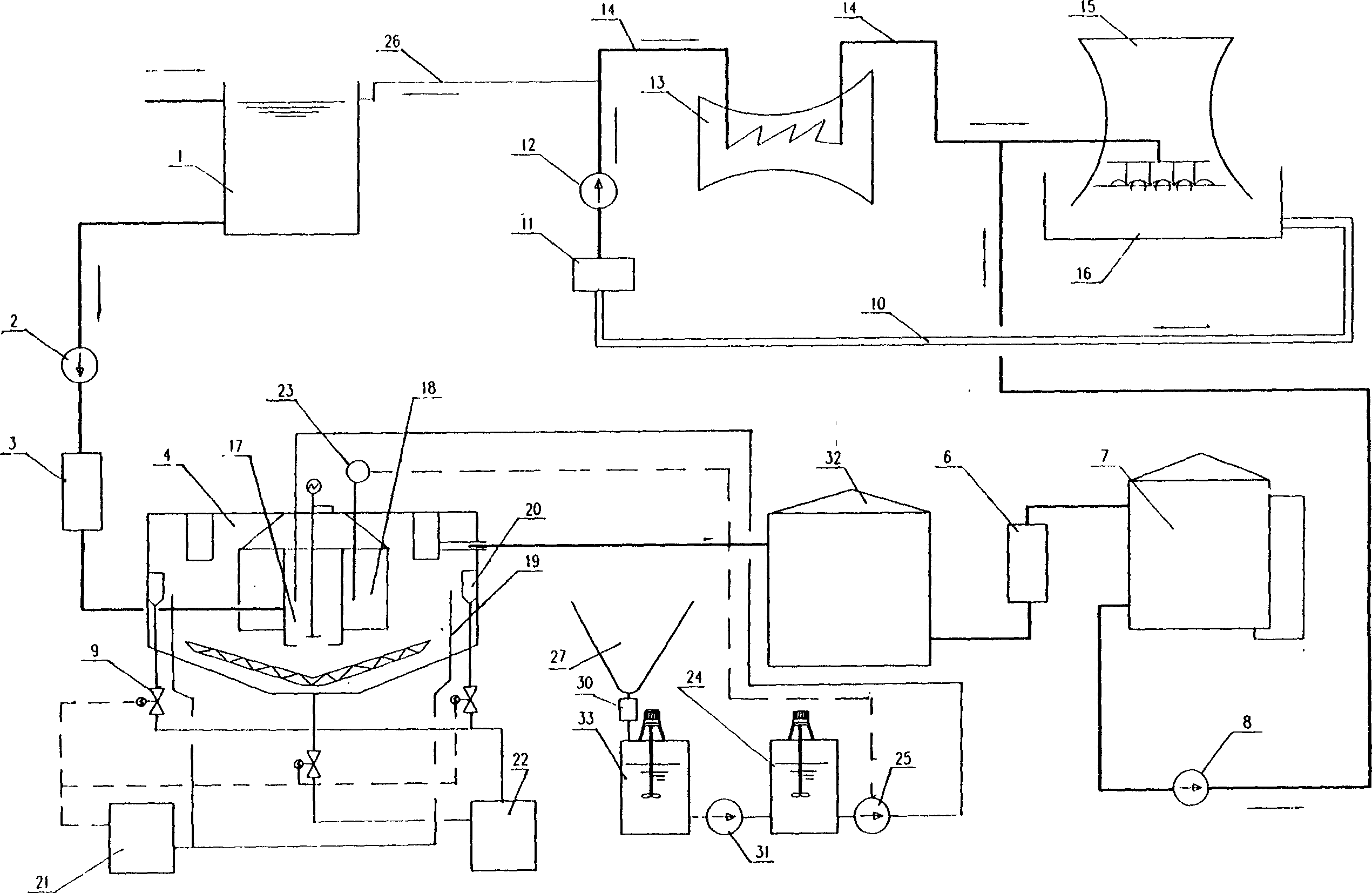

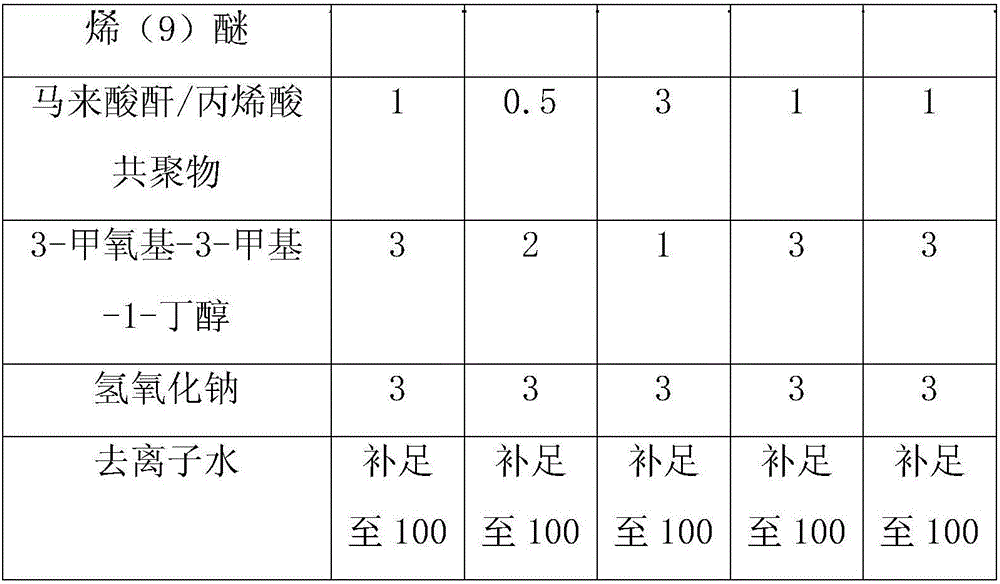

Advanced treatment method for urban middle water as industrial recirculated cooling water

InactiveCN1524807AHigh degree of automationPrecise adjustment and controlMultistage water/sewage treatmentWater flowReclaimed water

The invention discloses a deep processing method of urban recycled water by using it as industrial cycling cooling water comprising the steps of, the urban recycled water being collected and entering the recycled water pool, then entering pressure type mixer, entering into clarification tank, liming by wet method for softening, condensation, settlement and automatic de-sludging, the output water flowing into the circular double chamber filter, then entering clean water tank through pressure type mixer, the clean water being pumped to the cycling water pump discharge pressure tube after the compensator to be used for re-circulated cooling water system.

Owner:胡笳

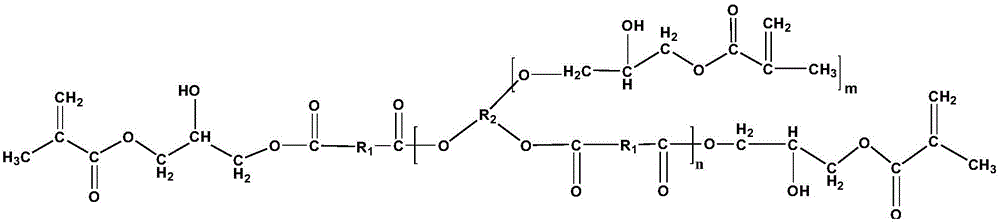

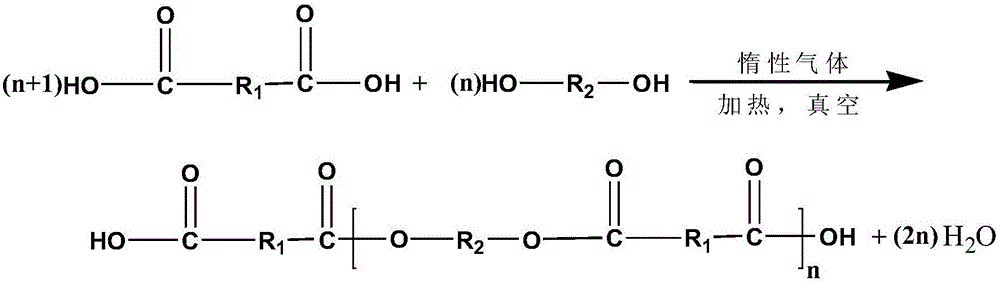

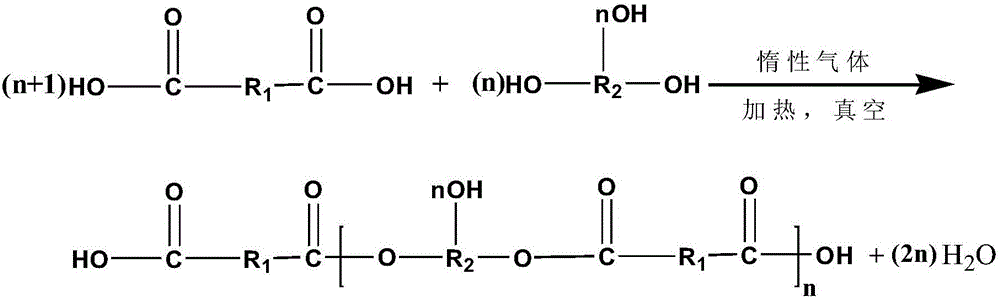

Preparation method of novel ultraviolet light curing powder coating resin

ActiveCN105669962ANo pollutionReduce generationPowdery paintsAdhesivesGlycidyl methacrylateUltraviolet lights

The invention discloses a preparation method of novel ultraviolet light curing powder coating resin. Polyhydric alcohol and / or dihydric alcohol and binary acid react according to the mole ratio of (0.8-1.2):1 to obtain saturated polyester, and saturated polyester and glycidyl methacrylate (GMA) react according to the mole ratio of 1:(2-5) to prepare ultraviolet light curing resin. The powder resin has excellent performance of rapid curing speed, low contraction percentage, high flexibility, corrosion resistance, impact resistance and the like, and is an environment-friendly, energy-saving, economical and efficient resin product.

Owner:WUXI HIT SAINT OPTOELECTRONICS MATERIAL TECH CO LTD

Electrochemical polishing method of nickel-tungsten alloy base-band for coated conductor

The invention discloses an electrochemical polishing method of a nickel-tungsten alloy base-band for a coated conductor. The method comprises the following steps: preparing an electrochemical polishing solution by utilizing sulphuric acid, water and propanetriol according to a certain volume ratio; taking an Ni-5at.%W base-band as an anode, taking stainless steel as a cathode, submerging the anodeand the cathode in the electrochemical polishing solution, switching on a power supply, and polishing under the voltage of 5 to 8 V and the current density of 1 to 1.3A*cm<2>, wherein the temperatureof the polishing solution is kept between 0 DEG C and the room temperature, time is controlled between 30 to 60 s, and polishing polar distance is controlled between 30 to 40 mm; and repeatedly washing and drying the base-band by alcohol and deionized water. The invention has the advantages of stable component of the polishing solution, stable polishing effect and low cost. The method can effectively reduce the roughness of the surface of the base-band on the basis of maintaining the original texture sharpness of the base-band, and is applicable to the scale polishing treatment of the Ni-5at.% base-band.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

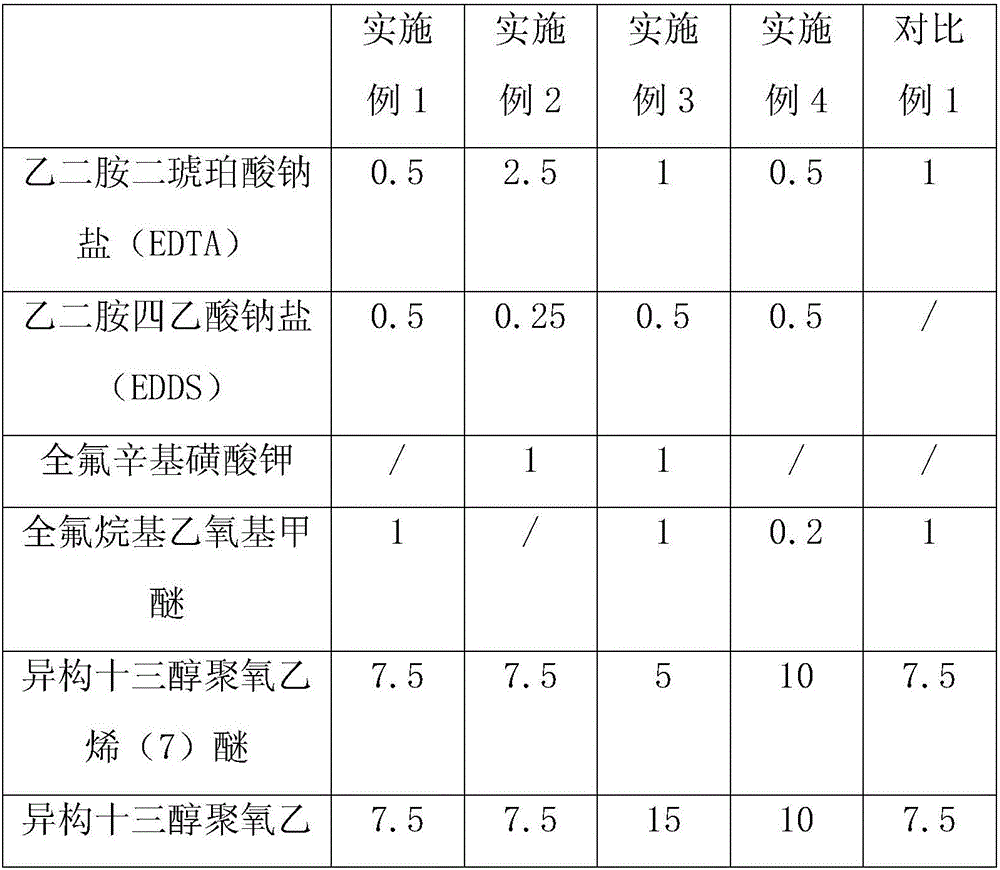

Silicon wafer cleaning agent

InactiveCN106675811AGood degreasing and degreasing effectCause corrosionOrganic detergent compounding agentsDetergent mixture composition preparationCleansing AgentsFatty alcohol

The invention belongs to the technical field of monocrystalline silicon wafer appliance, and particularly relates to a silicon wafer cleaning agent. The invention discloses the silicon wafer cleaning agent characterized by comprising the following components by weight: 0.5-2% of a metal chelating agent, 0.2-2% of a fluorocarbon surfactant, 5-20% of fatty alcohol polyoxyethylene ether, 0.5-3% of polymer additives, 0.5-2% of a co-solvent, 1-5% of an alkaline agent and the balance of water. The beneficial effects of the invention are that the compound metal chelating agent of EDTA and EDDS can effectively chelate and remove metal ions on the surface of a silicon wafer in the process of cleaning the silicon wafer, especially Cu, Fe, Zn and other ions having relatively great influence on the photoelectric conversion efficiency of the silicon wafer at a later stage; the cleaning agent has no irritating smell, has good oil stain removing effect on the silicon wafer, and does not cause serious corrosion to the silicon wafer.

Owner:DEQING LIJING ENERGY TECH CO LTD

Water source heat pump units capable of automatically backwashing sewage water

InactiveCN101275791ATake advantage ofExpand the range of water sourcesHeat pumpsCompression machines with reversible cycleWater source heat pumpFour-way valve

A water source heat pump unit automatically back washing sewage relates to the air conditioner technology field. The invention comprises a compressing evaporating and condensing unit composed of a compressor, a condenser, an expander, an evaporator and a four-way valve. The structure is characterized in that a water supply line of the evaporator is provided orderly with a filter one, a water pump, a three-way valve and a filter two connected in series with a sewage source. A water return pipe line of the evaporator is provided orderly with a motorized valve two connected in series with a drain water pond. A pressure difference sensor is connected in parallel between an inlet and an outlet of the evaporator. A motorized valve one is connected in parallel between the connection of the filter and the three-way valve and the outlet of the motorized valve. Another outlet of the three-way valve is connected with the outlet end of the motorized valve. The evaporator is provided with a blow off pipe on a top end wherein a motorized valve three is arranged. Compared with prior art, the invention is capable of directly exchanging heat between the industrial sewage or the reclamation of sewage and the refrigerant heat interchanger, which reduces temperature difference of heat transfer, improves the efficiency of the unit and reduces the cost of the device.

Owner:TONGFANG ARTIFICIAL ENVIRONMENT

Highly anti-bending and wearing-resistant lightweight concrete

The invention discloses highly anti-bending and wearing-resistant lightweight concrete, which comprises the following raw material constituents in parts by weight: 200-250 parts of cement, 100-150 parts of coal ash, 150-200 parts of river sand, 100-180 parts of manganese residue, 150-200 parts of ceramsite, 20-50 parts of silicon carbide, 15-35 parts of plant fiber, 200-250 parts of water, 0.3-1.5 parts of dipropyl ethylene glycol monobutyl ether, 3-6 parts of silicon resin polyether emulsion, 0.3-1.8 parts of sodium chloride, 2-5 parts of triethanolamine, 0.3-1 part of sodium sulfate, 1-3 parts of epoxy resin, 1-3.5 parts of waste polyurethane, 1-2.3 parts of sodium stearate, 5-16 parts of nano calcium oxide, 0.3-0.9 part of coagulant, 2-5 parts of melamine water reducer and 5-18 parts of foaming agent. The highly anti-bending and wearing-resistant lightweight concrete provided by the invention has high anti-bending strength, good wear resistance, light weight and excellent water resistance.

Owner:无为县严桥双龙建材厂

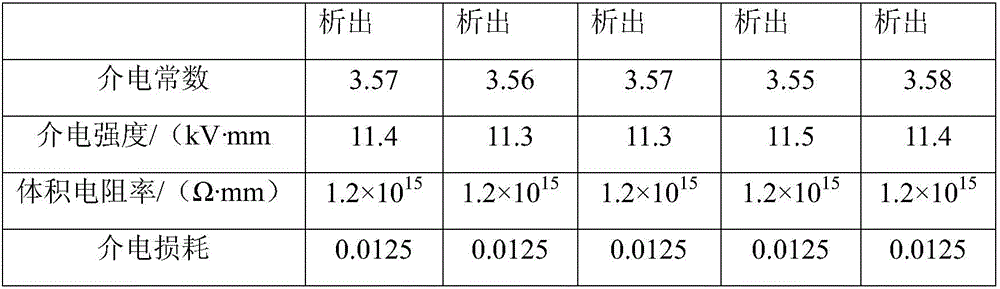

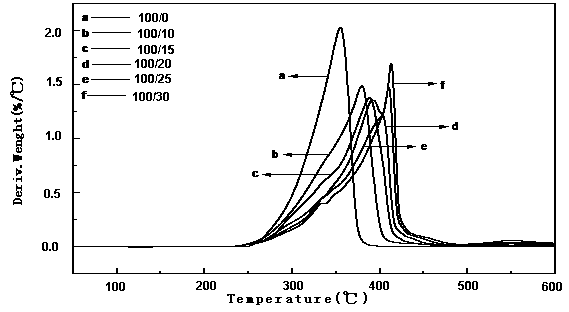

Butyl rubber based pressure-sensitive protective tape and preparation method thereof

InactiveCN106554728AImprove mechanical propertiesGood electrical propertiesNon-macromolecular adhesive additivesMacromolecular adhesive additivesPlasticizerElectrical performance

The invention relates to a butyl rubber based pressure-sensitive protective tape and a preparation method thereof. The protective tape is obtained by coating a substrate layer with a pressure-sensitive adhesive. Specifically, the pressure-sensitive adhesive comprises the following components by mass: 30-55 parts of matrix resin, 15-40 parts of tackifying resin, 10-20 parts of a plasticizer, and 5-15 parts of inorganic filler. The protective tape provided by the invention has the advantages of excellent mechanical properties and electrical performance, simple preparation method and low cost, is suitable for industrial production and has good application prospect.

Owner:宁波朝辉新材料有限公司

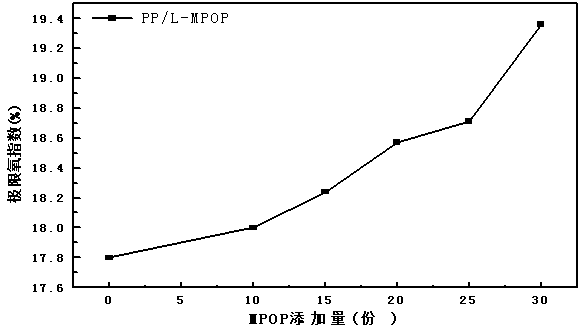

Preparation method of MPOP

InactiveCN105504292AHigh degree of polymerizationLow water solubilityOrganic chemistryFiltrationReaction temperature

The invention provides a preparation method of MPOP. The method comprises steps as follows: (1) preparation of an intermediate: urea phosphate is dissolved in water, the concentration of urea phosphate is controlled to range from 10% to 50%, a certain amount of melamine is added to react with urea phosphate, the molar ratio of urea phosphate to melamine is 1:(0.8-1.25), the reaction temperature is controlled within 25-100 DEG C, the reaction time is 0.5-2.5 h, filtration, washing and vacuum drying are performed, and the intermediate is obtained; (2) preparation of MPOP: the intermediate prepared in Step A is calcined at the temperature of 200-400 DEG C for 1-5 h, cooling, grinding and sieving are performed, and a flame retardant, namely, MPOP is obtained. The technology is simple, industrialization is easy to realize, the operation condition is mild, water is taken as a reaction medium, and the method is clean and pollution-free.

Owner:WENGFU (GRP) CO LTD +2

Concrete mixing device for building construction

ActiveCN107351244AAvoid material depositsWell mixedHollow article cleaningCement mixing apparatusArchitectural engineeringBlock match

The invention discloses a concrete mixing device for building construction. The concrete mixing device comprises a supporting plate. Two first fixed plates and two second fixed plates are fixedly mounted on the two sides of the upper surface of the supporting plate correspondingly. A stirring bucket is arranged on the upper side of the supporting plate. The left end of the stirring bucket is hinged to the first fixed plates through a rolling shaft arranged on the outer surface of the stirring bucket. An arc groove is formed in the inner wall of each second fixed plate. An arc block matched with the arc grooves is welded to the right side of the outer surface of the stirring bucket. A feeding hopper is fixedly mounted at the top of the stirring bucket. A motor is fixedly mounted at the right end of the stirring bucket. According to the concrete mixing device, a stirring shaft, stirring rods and scraping plates are arranged in the mixing device, materials at the bottom of the stirring bucket can be scraped at the joints of the scraping plates and the inner walls of the stirring bucket, and therefore material deposition can be avoided, and concrete can be mixed more uniformly; and the concrete can be prevented from being bonded to the inner wall of the stirring bucket, the stirring bucket can be prevented from being corroded, and waste can be reduced.

Owner:江苏正苏基础工程有限公司

Quickly cured anaerobic plane sealant and initiator composition and preparation method

InactiveCN104356997ANo loss of stabilityFacilitated releaseNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMethacrylatePolymer science

The invention relates to an anaerobic plane sealant which has an effect of increasing the curing speed on an aluminum and aluminum alloy material, and a preparation method of the anaerobic plane sealant. The invention mainly provides a novel approach of promoting the curing speed of the anaerobic plane sealant on aluminum and aluminum alloy without influencing the storage stability. The method comprises the step of adding a proper amount of water and dimethyl sulfoxide into an anaerobic curing sealant containing polyurethane-methacrylate prepolymer, free radical polymerizable monomer, organic peroxide, an accelerant and a stabilizer. The preparation method provided by the invention is simple and convenient, and the anaerobic plane sealant has excellent storage stability, and can still be used for quickly well adhering aluminum and aluminum alloy at a low-humidity environment.

Owner:TONSAN ADHESIVES INC

Automatic tire patching agent

ActiveCN103031109AEnhanced bonding propertiesReduce condensation shrinkageOther chemical processesChemistryComposite material

The invention provides an automatic tire patching agent, which comprises an air pressure agent, an air pressure inhibiting agent, gels, rubber particles, fibers, solvents, additives and nanometer carbon powder. After the automatic tire patching agent provided by the invention is added with the nanometer carbon powder, the bonding characteristic is enhanced, the condensing shrinkage rate of the tire patching agent is reduced, and meanwhile, the friction resistance performance of tires is improved.

Owner:常熟市知识产权运营中心有限公司

Positive photo-resist stripping solution for semiconductor bump processing

InactiveCN106154772AImprove stabilityExtended service lifePhotosensitive material processingResistOrganic solvent

The invention relates to a positive photo-resist stripping solution for semiconductor bump processing. The positive photo-resist stripping solution comprises the following components in percentage by weight: 35%-60% of water-soluble organic solvent, 10%-50% of organic amines, 0.05%-0.1% of metal protective agent, 0.05%-0.1% of surfactant, 0.01%-0.04% of surface active coagent and the balance of purified water. According to the positive photo-resist stripping solution, the system stability is improved, the service life is long, the surface tension is low, the removal effect for a photo-resist in a tiny gap is good; and while the photo-resist is effectively removed, a semiconductor bump substrate metal layer is not corroded.

Owner:JIANGYIN RUNMA ELECTRONICS MATERIAL

Heavy cracking-fluid formula

An emphasized fracturing liquid formula consists of water 500 proportion, emphasizing agent 180-483 proportion, gelatinizer hydroxypropyl guar gum 2-3 proportion, pH value adjuster sodium carbonate 0.8-1 proportion, pH value adjuster sodium hydrate 0.15-0.27 proportion, auxiliary 3.0-3.3 proportion, and emphasized fracturing liquid density is between 1.25-1.5g / cm3. It can be used to increase liquid column pressure in well and decrease construction pressure on well opening and finish oil-well fracture of deep well, super-deep well, abnormal high-pressure well and realize storage-layer transformation.

Owner:PETROCHINA CO LTD

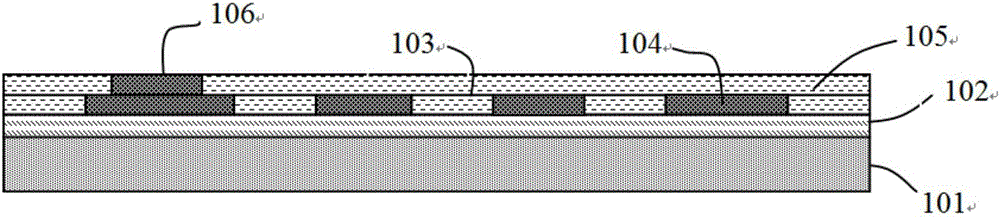

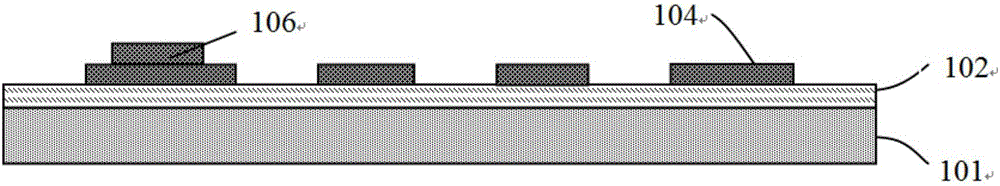

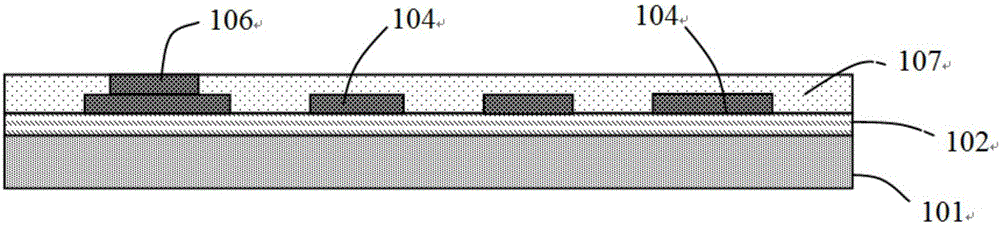

Printed circuit board and fully-additive manufacturing method therefor

ActiveCN105934084ACause corrosionMeet the requirements of impedance characteristicsPrinted circuit aspectsElectrical connection printed elementsState of artDielectric plate

The invention discloses a printed circuit board. The printed circuit board mainly comprises multiple first structures and second structures which are overlapped in a lamination manner, wherein the first structures and the second structures are arranged at intervals; the first structures and the second structures are formed in a hot-pressing manner; the first structures mainly consist of circuit carriers; conductive convex blocks and circuit layers are embedded in the circuit carriers; the conductive convex blocks are electroplated on the circuit layers; the second structures mainly consist of insulating dielectric plates; conductive blocks are embedded in the insulating dielectric plates; and the circuit layers on the adjacent two first structures are connected through the conductive blocks. Compared with the prior art, the printed circuit board provide by the invention enables fine circuits to satisfy special impendence characteristic requirement; meanwhile, the prepared circuit is high in conductivity and low in cost; the first structures and the second structures are overlapped in a crossed manner in sequence, so that the printed circuit at any layer can be formed by one-time lamination; and therefore, the printed circuit board is high in production efficiency and capable of reducing the production time and the production cost.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA +1

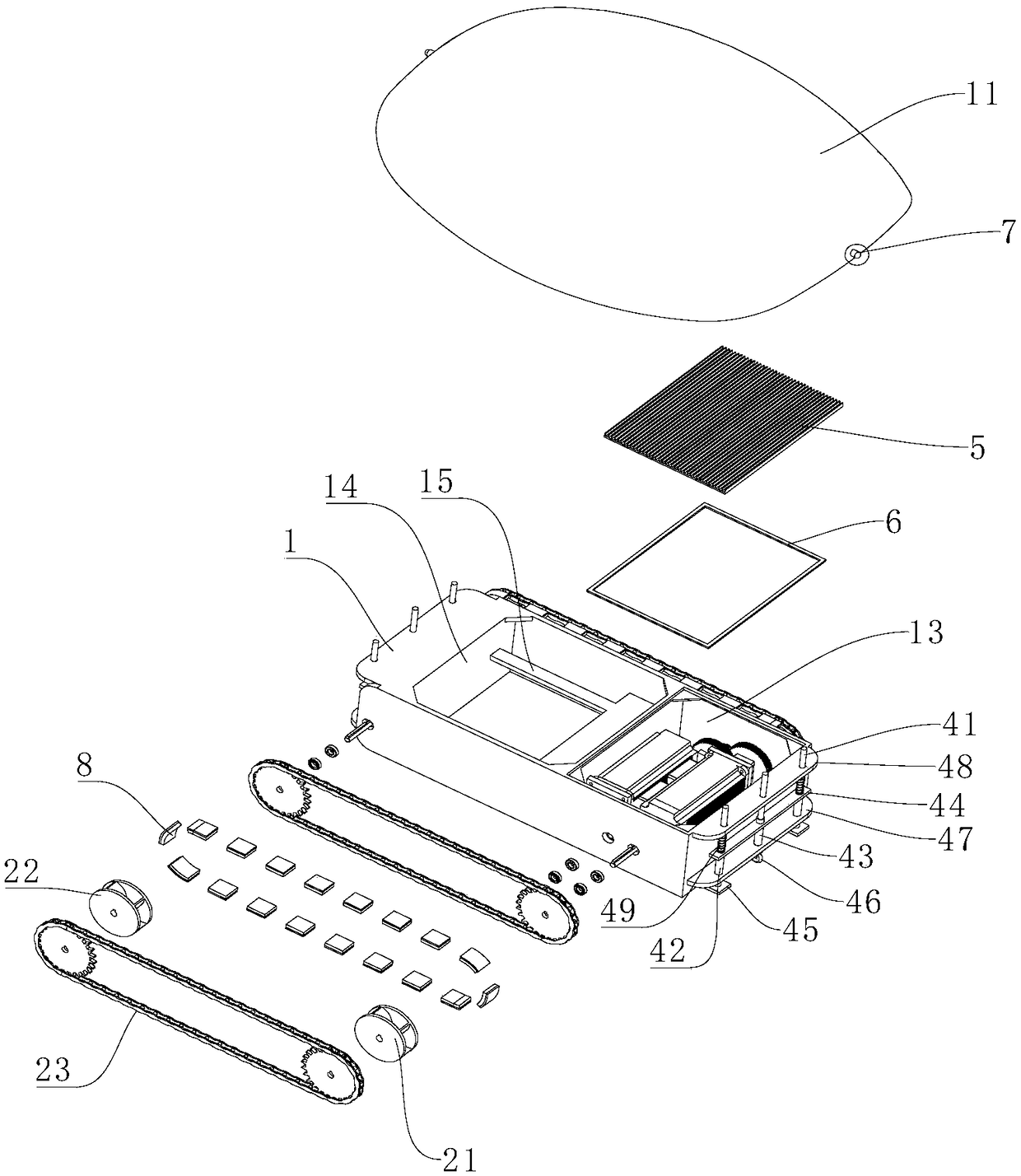

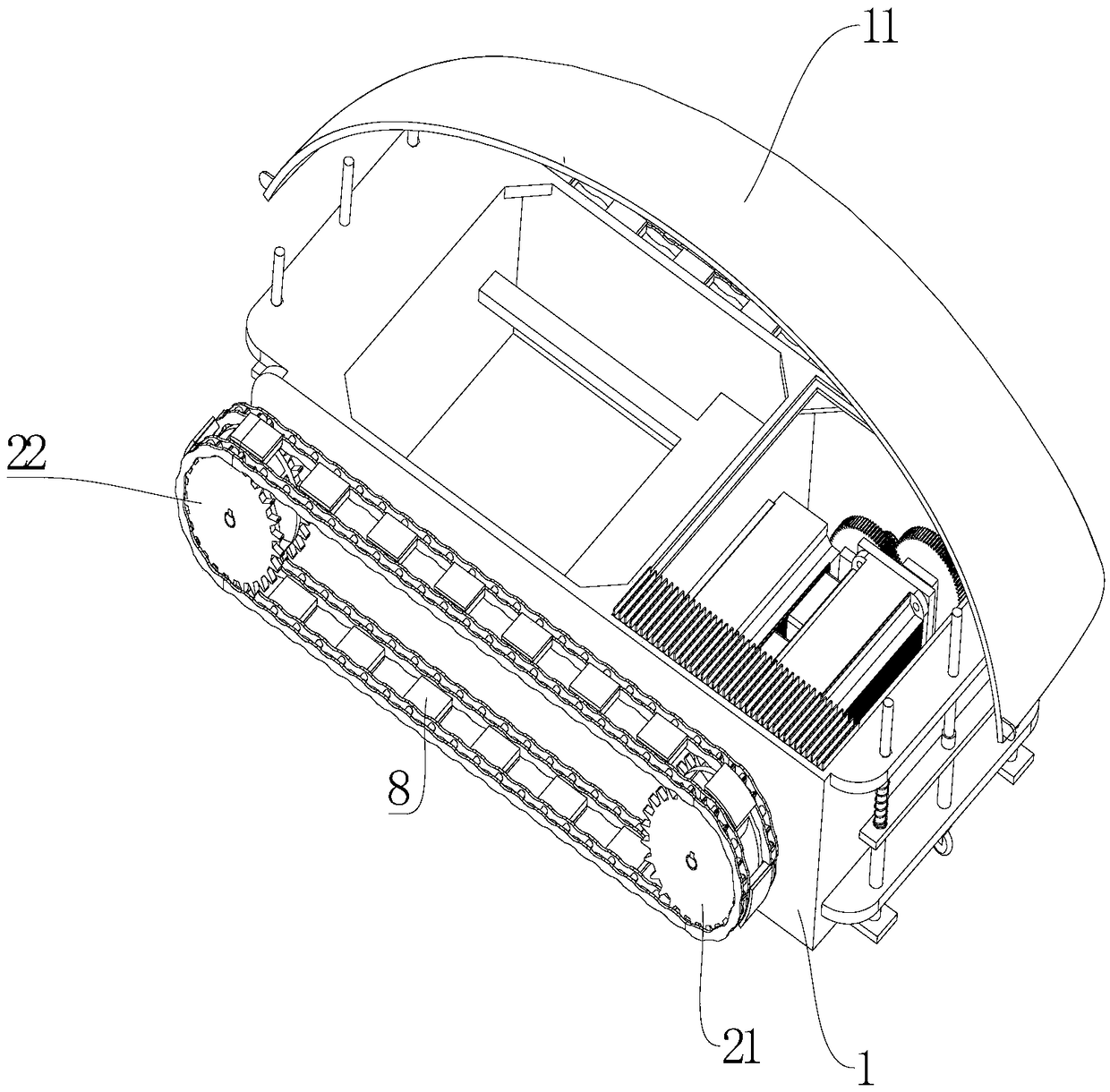

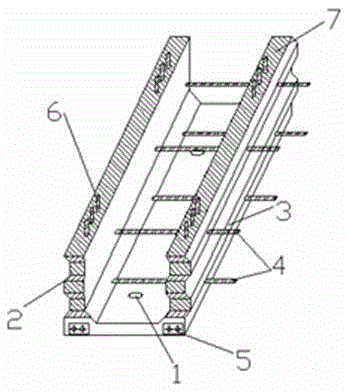

Flexible magnetic adsorption underwater wall climbing robot

The invention discloses a flexible magnetic absorption underwater wall climbing robot, Including a duplex stainless steel body, a Flexible-magnetically-attractive crawler travel device and a magneticforce compensation device, magnetic compensation devices are arrange at that front and rear of the airframe respectively, A magnetic force compensation device comprise a lifting bracket, Universal wheels and magnets, A lifting bracket comprises a lifting plate, Left lifting lever, the middle lifting lever and the right lifting lever, Left lifting lever, the middle part of the middle lifting lever and the right lifting lever penetrate the lifting plate and are fixedly connected with the lifting plate, Left lifting lever, the intermediate lifting lever and the right lifting lever are slidablyinstalled on the machine body, A left lifting lever and a right lifting lever are sleeved with springs, The upper ends of the springs are against the body, the lower ends of the springs are against the lifting plate, the bottom of the left lifting rod and the right lifting rod are both provided with attractive magnetic blocks, and the bottom of the middle lifting rod is provided with a universal wheel, which can solve the technical problem of cleaning the ship surface adhesives under water when the ship is sailing on the water surface.

Owner:深圳聚纵科技有限公司

Assembling type sectional precast concrete hollow plate girder structure and manufacturing method thereof

The invention discloses an assembling type sectional precast concrete hollow plate girder structure and a manufacturing method thereof. The assembling type sectional precast concrete hollow plate girder structure comprises top plates and U girders, which are connected to formed a plate girder structure, wherein the top plates and the U girders are made through casting concrete and are respectively formed by splicing a plurality of sections in the longitudinal direction; shear keys are arranged on the outer surfaces and the longitudinal cross sections of webs of the U girders and on the longitudinal cross section of the top plates in a matching and precast manner; the plate girder structure is provided with longitudinal pre-stressed tendons and horizontal pre-stressed tendons, and epoxy resins are applied to interfaces of spliced seams. Compared with a conventional plate girder structure, the plate girder structure disclosed by the invention has the advantages that hinged joint damage is avoided, the bridge completeness of the hollow plate girders is improved, longitudinal cracks generated in bottom plates are avoided, transportation and hoisting are facilitated, the coming off of inner molds of the hollow plate girders are facilitated through U-shaped section, the strength of seams is improved, the cast-in-situ construction quantity is small, mechanized effect is facilitated, influence on environment and ground traffic is small, construction cost is reduced, and the construction period is shortened.

Owner:HOHAI UNIV

Chemical reaction vessel

ActiveCN110538622AStir fullyStirring effect is goodHollow article cleaningChemical/physical/physico-chemical stationary reactorsChemical industryChemical reaction

The invention relates to a chemical reaction vessel and relates to the technical field of chemical industry production. The chemical reaction vessel comprises a vessel body, wherein the bottom end ofthe vessel body is connected with a bottom bracing, a driving motor is mounted at the top end of the vessel body, a heating pipe is connected with the inner side of the internal wall of the vessel body, a stirring shaft is mounted inside the vessel body, and a stirring mechanism is connected with the external wall of the stirring shaft. The chemical reaction vessel has the beneficial effects thatstirring vanes can rotate along with that the driving motor drives the stirring shaft to rotate under the action of the stirring mechanism, thus, chemical liquid can enter inner grooves inside the stirring vanes, spaces inside the inner grooves are occupied by the chemical liquid, floating plates with buoyancy can move outwards from the inner grooves in internal sliding grooves of the stirring vanes along with connected sliding blocks during the rotation of the stirring vanes, and thus, the floating plates are abutted against the internal wall of the vessel body; and by such an arrangement, the stirring vanes can comprehensively stir the chemical liquid in the vessel body, and the stirring reaction of the chemical liquid is good in effect.

Owner:江门市新会天御硅制品有限公司

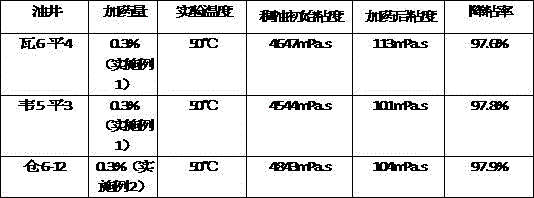

Heavy oil viscosity reducer and preparation method thereof

The invention relates to a heavy oil viscosity reducer and a preparation method thereof. According to the method, monomers in certain quantities are weighed in a charging ratio, fatty acid methyl ester is placed in a sealable reaction container firstly, heated to 50 DEG C plus / minus 5 DEG C and subjected to vacuum pumping, then N2 is used for replacing residual air, a mixture is stirred and heated to 130-140 DEG C, a catalyst is added under the pressure of 0.2-0.4 mpa, ethylene oxide is added dropwise, then propylene oxide is added dropwise, the mixture reacts for 6-8 h, a product is cooled to the room temperature, dodecyl dimethyl betaine, methanol and water are added and mixed uniformly, and the finished viscosity reducer product is obtained. The heavy oil viscosity reducer has the characteristics of small dosage, good viscosity reducing effect and high usability for heavy oil.

Owner:扬州润达油田化学剂有限公司

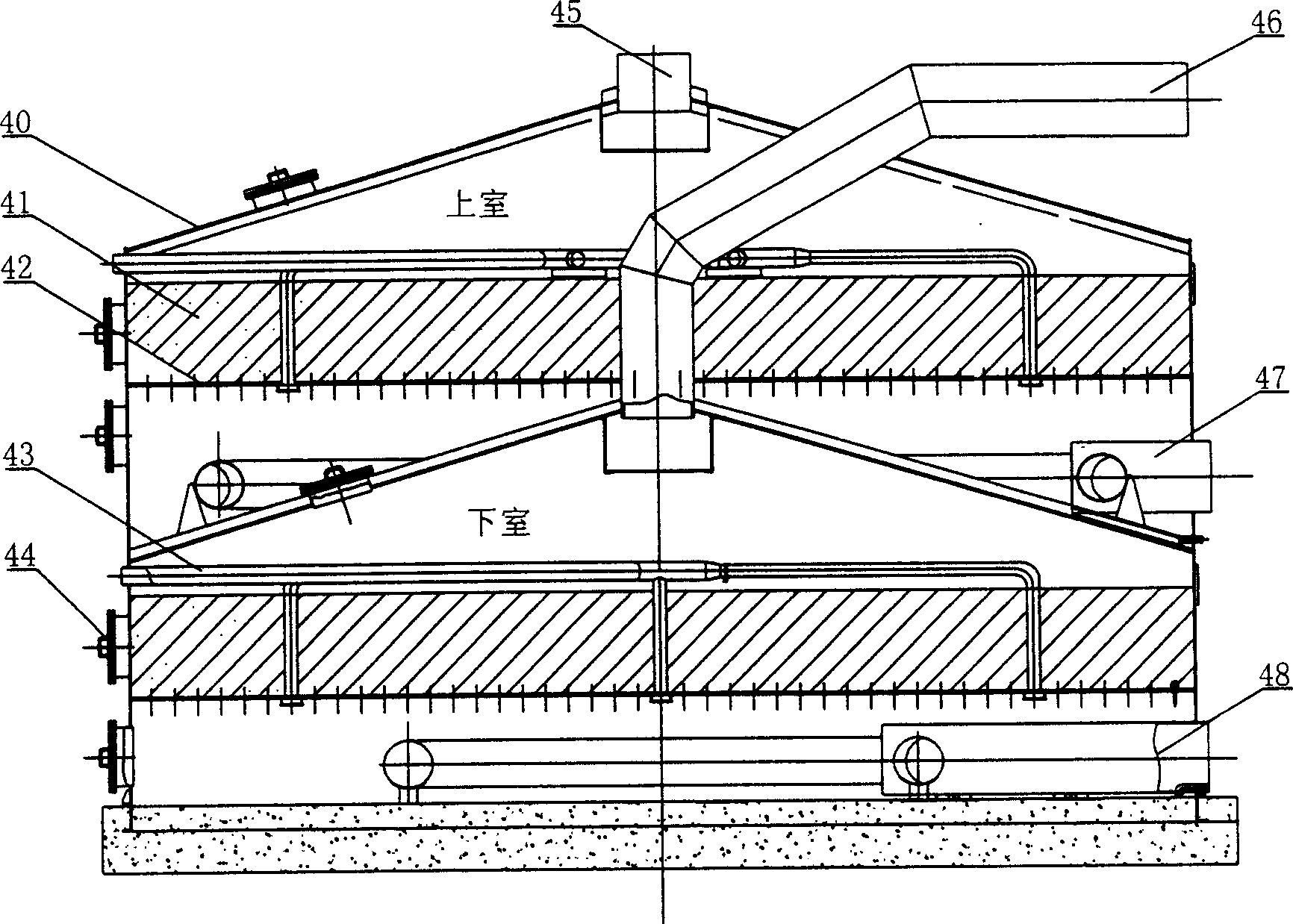

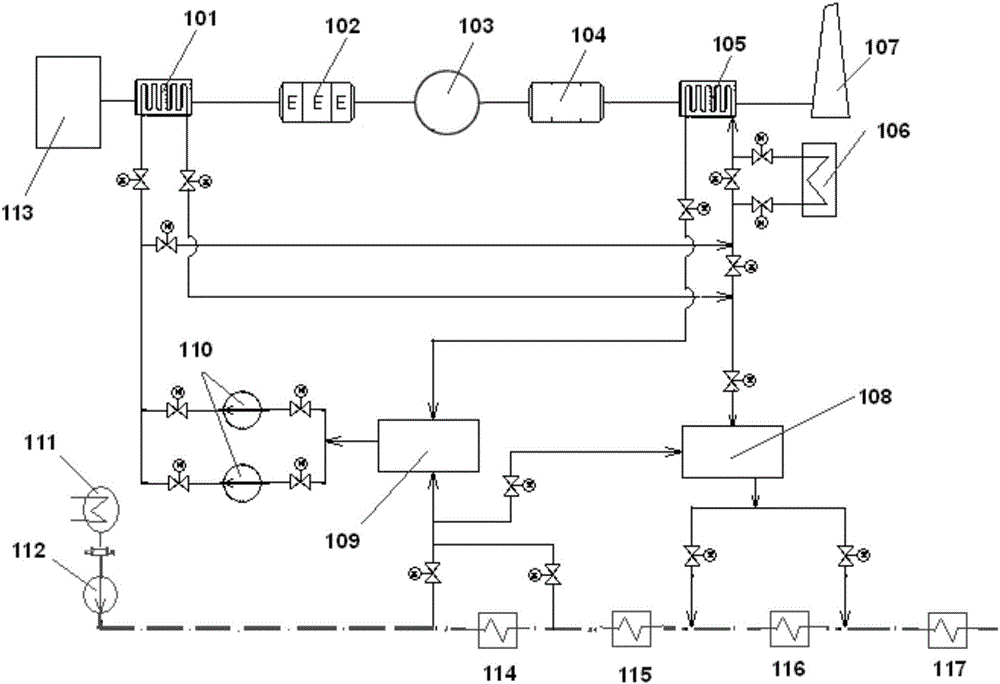

Open lower temperature waste heat utilization system of ultra-clean emission coal-fired unit

PendingCN106765265AAvoid condensationAvoid Low Temperature CorrosionFeed water supplyCombustion technology mitigationGas heaterGas cooler

The invention discloses an open lower temperature waste heat utilization system of ultra-clean emission coal-fired unit, and relates to a steady controllable open MGGH system. A water outlet of a gas cooler is communicated with a gas-gas heater and a water inlet of waste heat recovery hot water mixer through pipeline systems with valves respectively, and the water inlet pipeline of the gas-gas heater is also provided with an auxiliary steam heater; the water outlet of the gas-gas heater is communicated with the water inlet of the gas cooler through a circulating water and make-up water mixer, a variable frequency booster pump and the pipeline systems with the valves; the water inlet of the circulating water and make-up water mixer is also communicated with a condensation water pipeline, and the water outlet of the waste heat recovery hot water mixer is communicated with a low-temperature heating system pipeline through at least two pipelines with the valves. In the invention, the problems that the inlet gas temperature of an electrostatic precipitator and chimney inlet gas temperature are difficult to control, the low-temperature heating adjustment of the unit is difficult to control and the disturbance is severe due to poor heat exchange effect of a plate heat exchanger in the existing MGGH technology are solved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

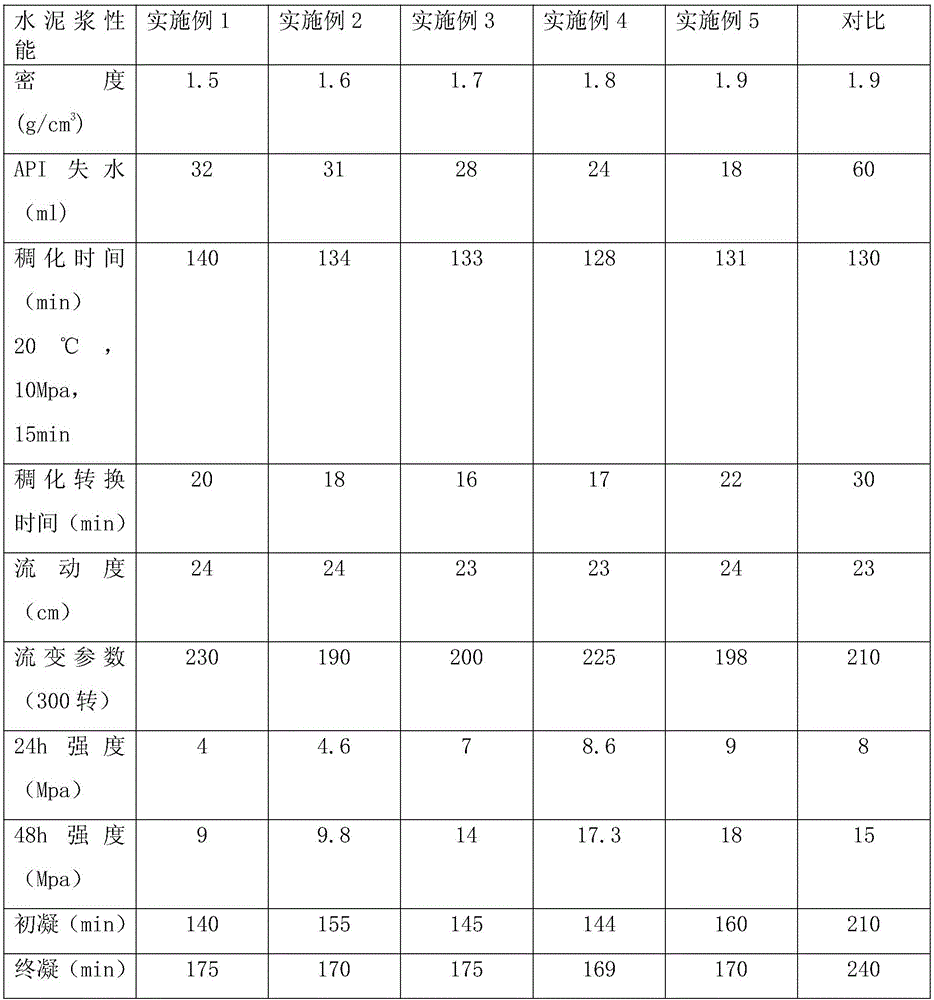

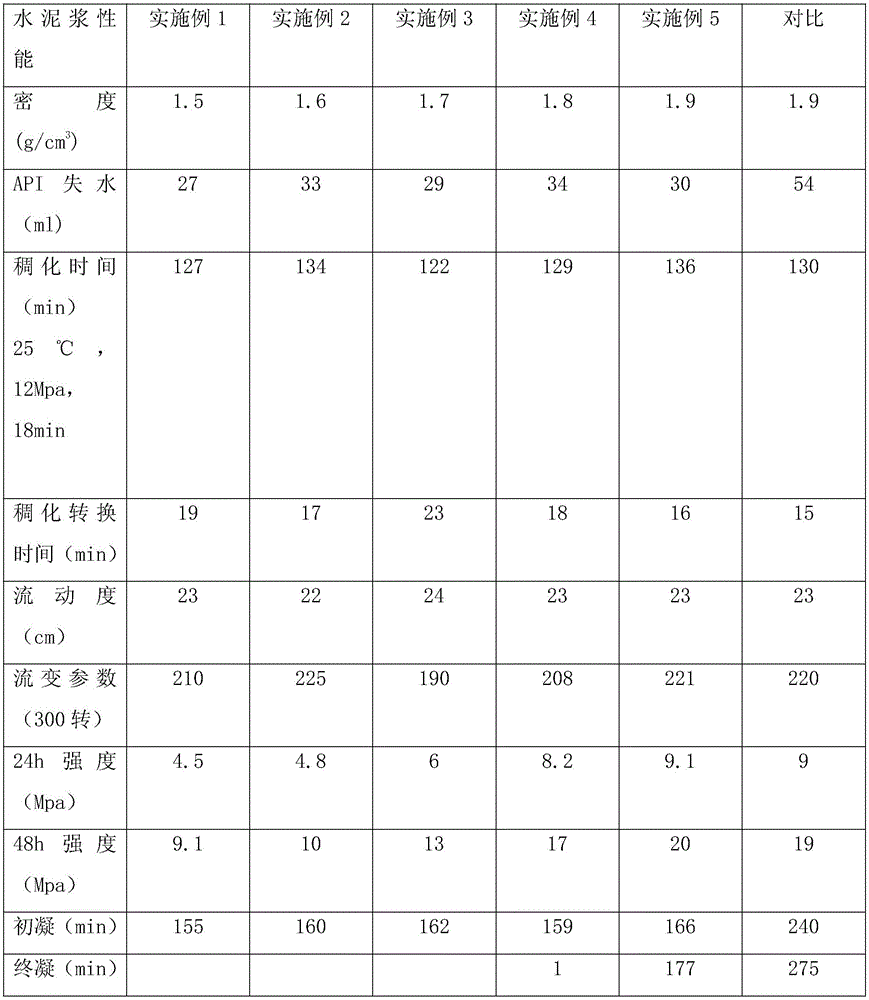

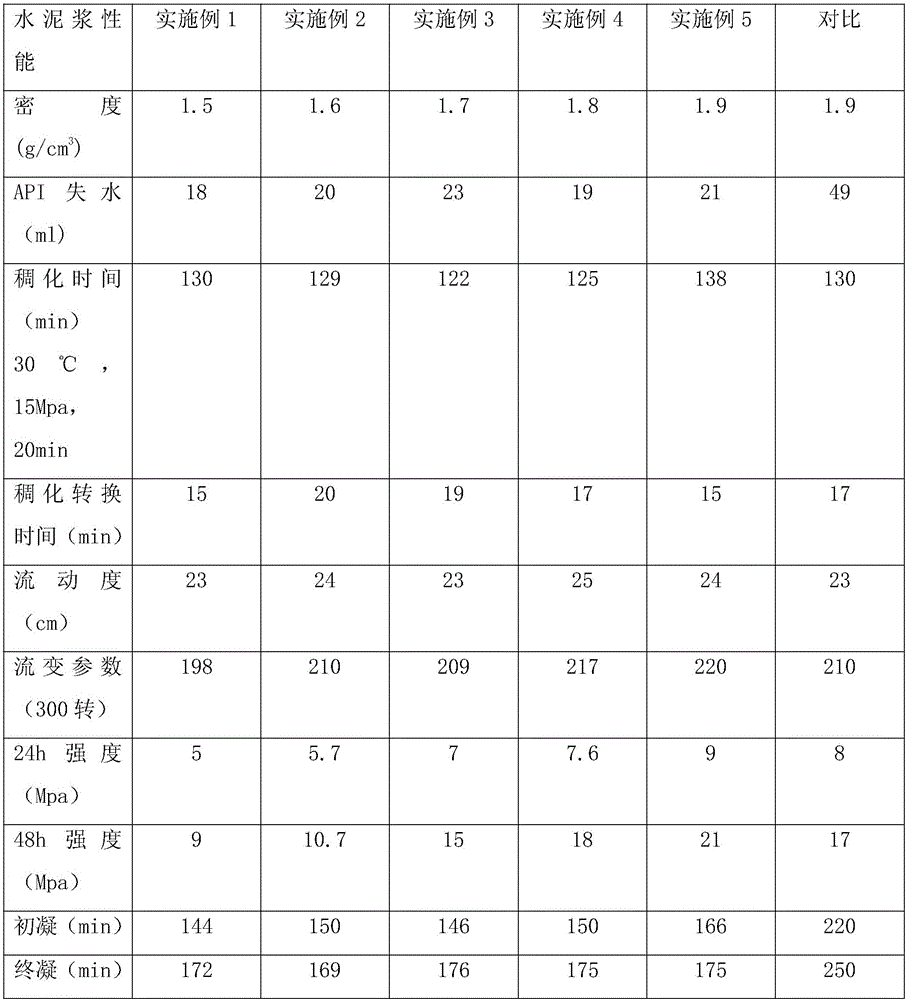

Low-temperature early-strength salt-resistant well cement slurry system

The invention discloses a low-temperature early-strength salt-resistant well cement slurry system comprising 100 parts of class-G oil well cement, 0.8-1 part of low-temperature salt-resistant fluid loss agent, 2-3 parts of compound early strength agent, 0-13.5 parts of hollow glass micro-beads, 0.2-0.5 part of dispersant, 3-4 parts of micro-silicon and 41-81 parts of salt water. The low-temperature early-strength salt-resistant well cement slurry system can realize well cementing in the density range from 1.50g / cm<3> to 1.90g / cm<3>, is good in low temperature resistance, strong in salt resistance, safe and convenient for on-site construction, good in well cementing quality, and provides a reliable and safe guarantee for well drilling and oil production.

Owner:四川凯尔油气田技术服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com