Quickly cured anaerobic plane sealant and initiator composition and preparation method

A flat sealing and rapid curing technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc., can solve the problems of decreased storage stability, difficulty in fast and effective curing, etc., to ensure stability, promote anaerobic adhesive curing, Fast and good curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

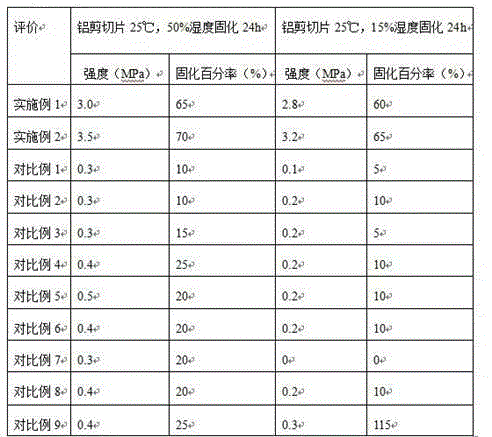

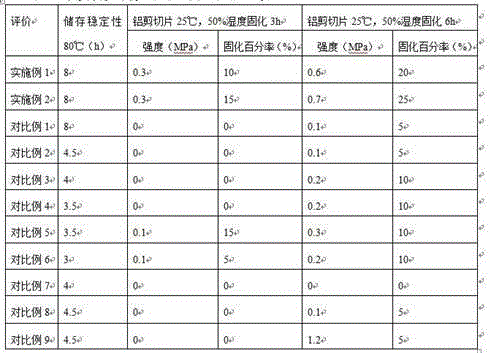

Examples

Embodiment 1

[0041]Mix 80 parts (parts by mass, the same below) of polyurethane methacrylate oligomer with a viscosity of 4000~20000 mPa·s at 25°C, 10 parts of hydroxyethyl methacrylate, 5 parts of methacrylic acid, 15 parts of methyl Isobornyl acrylate is put into the reactor, and at a speed of 250 rpm, 0.001 part of stabilizer naphthoquinone, 0.001 part of metal chelating agent EDTA sodium salt, 2 parts of o-benzoylsulfonimide, 0.8 part of N- Acetyl phenylhydrazine, stirred for 2 hours until completely dissolved. Then add 1 part of deionized water, 1 part of dimethyl sulfoxide, and 3 parts of cumene hydroperoxide, and stir for 10 to 20 minutes until uniform. Then add 8 parts of polyethylene powder and 2.5 parts of fumed silica, stir at 800 rpm for 20~40 minutes until uniform, and then vacuum at -0.08~-0.10MPa at 15 rpm After 10-20 minutes, the material can be discharged after the inspection performance is qualified, and it is packed in a low-density polyethylene tube.

Embodiment 2

[0043] Mix 70 parts (parts by mass, the same below) of polyurethane methacrylate oligomer with a viscosity of 25,000~30,000 mPa·s at 25°C, 7 parts of hydroxyethyl methacrylate, 4 parts of methacrylic acid, 11 parts of methyl Isobornyl acrylate and 5 parts of 2-phenoxyethyl acrylate are put into the reactor, and at a speed of 250 rpm, 0.001 part of stabilizer naphthoquinone, 0.001 part of metal chelating agent EDTA sodium salt, 1.5 parts of o-phthalic acid Formylsulfonimide, 0.5 parts of N-acetylphenylhydrazine, stirred for 2 hours until completely dissolved. Then add 1 part of deionized water, 1 part of dimethyl sulfoxide, and 0.5 parts of 3 parts of cumene hydroperoxide, and stir for 10 to 20 minutes until uniform. Then add 8 parts of polytetrafluoroethylene powder and 2 parts of gas phase white carbon black, stir at 800 rpm for 20~40 minutes until uniform, and then at 15 rpm at a vacuum of -0.08~-0.10MPa Vacuumize for 10-20 minutes, after the inspection performance is quali...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com