Curable resin composition for light guide, curable dry film for light guide

A curable resin, optical waveguide technology, applied in the direction of optical waveguide light guide, light guide, optics, etc., can solve the problems of dry film cracking and cracking, optical waveguide performance degradation, dry film storage stability and other problems such as insufficient performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

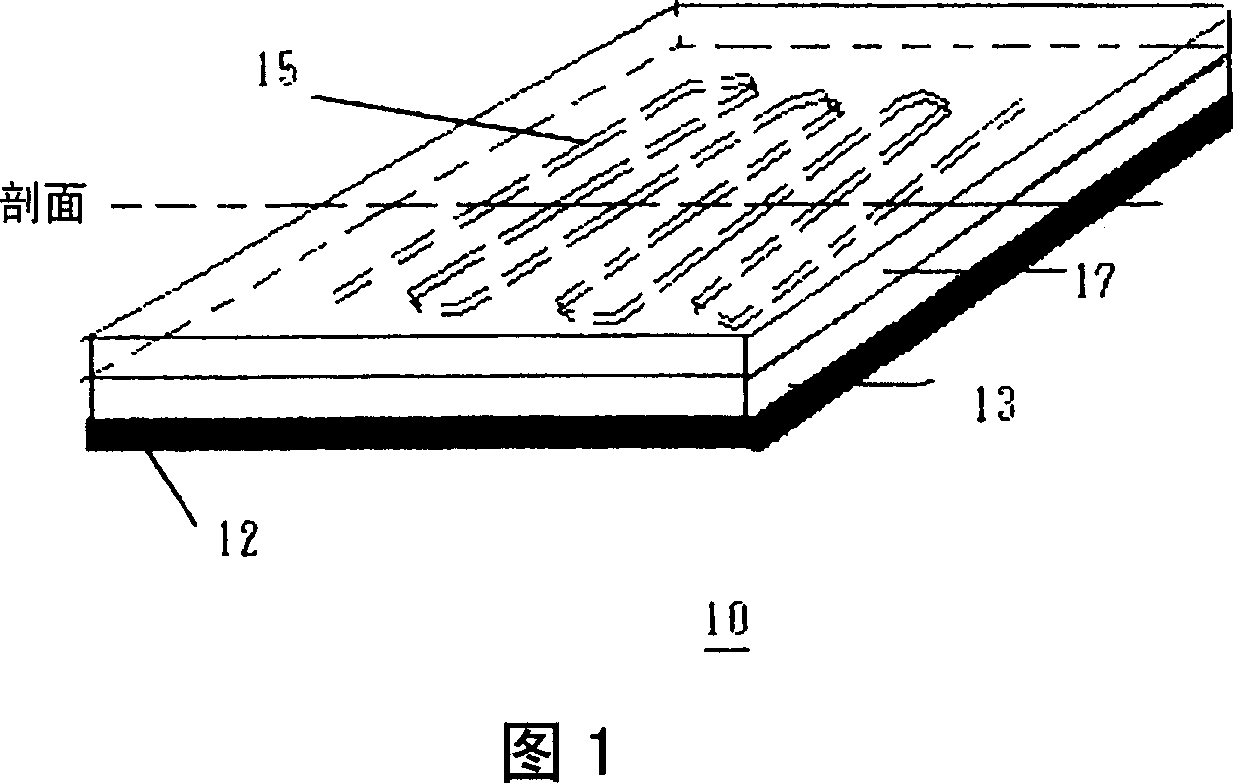

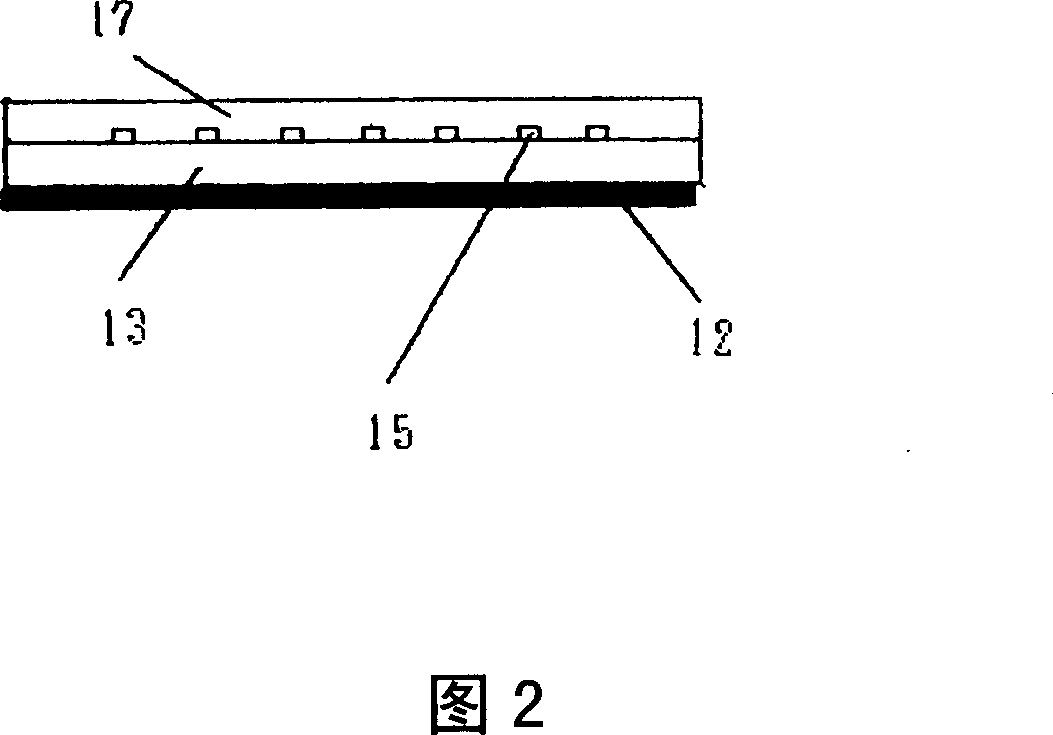

Embodiment 1

[0111] A solution containing the above-mentioned curable resin composition 1 for an optical waveguide was applied on a plastic substrate by spin coating, and dried at 80° C. for 30 minutes. Then, through a photomask having a line pattern with a width of 30 μm, irradiate with a wavelength of 365 nm and a luminous intensity of 10 mW / cm 2 UV light for 100 seconds to make it UV curable. Then, the substrate having the resin composition layer irradiated with ultraviolet rays was immersed in a developer composed of 1.8% tetramethylammonium hydroxide aqueous solution (TMAH aqueous solution) to dissolve the unexposed part of the resin composition, and then dried. . Thus, a core portion having a linear pattern with a width of 30 μm was formed. As a result, a thin core-shaped substance can be formed, and the contours of the concave portions among the convex portions of the core portion are clearly defined. In addition, such a substance having a well-defined concave portion does not ca...

Embodiment 2~4

[0113] A core portion was formed in the same manner as in Example 1, except that each solution containing the above-mentioned curable resin compositions 2 to 4 for optical waveguides was used. As a result, a thin core-shaped substance can be formed, and the contours of the concave portions among the convex portions of the core portion are clearly defined. In addition, such a substance having a well-defined concave portion does not cause the core portion to be deformed by the upper cladding layer or the transmission loss of the optical waveguide to be reduced due to the inclusion of air bubbles in the concave portion.

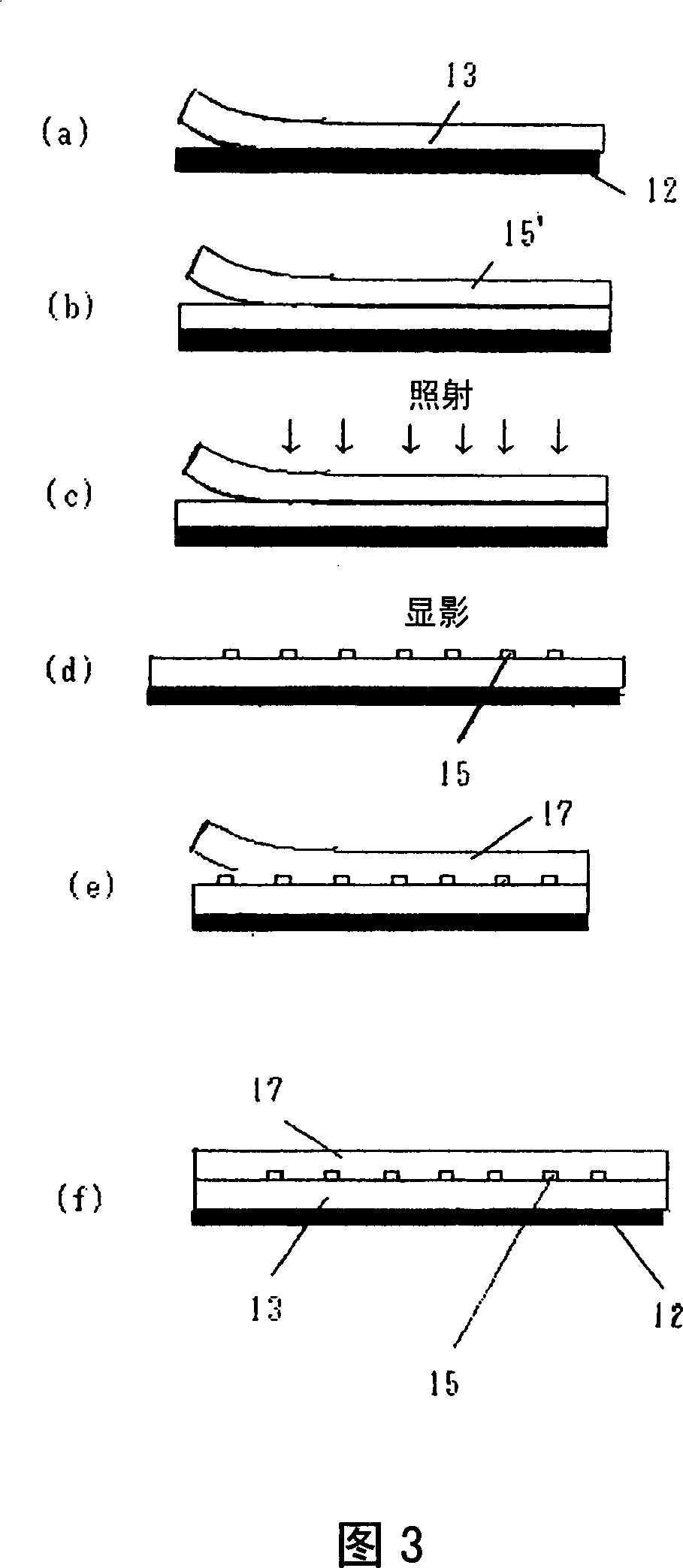

Embodiment 5

[0115] The above-mentioned curable dry film 1D for optical waveguide was transferred to the surface of the plastic substrate by the normal-pressure hot roll bonding method (temperature: 100° C.), and the polyethylene terephthalate film was peeled off. Then, through a photomask having a line pattern with a width of 30 μm, irradiate with a wavelength of 365 nm and a luminous intensity of 10 mW / cm 2 UV light for 100 seconds to make it UV curable. Then, this was immersed in a developing solution composed of a 1.8% TMAH aqueous solution to dissolve the unexposed portion of the dry film, and then dried. Thus, a core portion having a linear pattern with a width of 30 μm was formed. As a result, a thin core-shaped substance can be formed, and the contours of the concave portions among the convex portions of the core portion are clearly defined. In addition, such a substance having a well-defined concave portion does not reduce the transmission loss of the optical waveguide due to de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com