Patents

Literature

39results about How to "Limit contact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

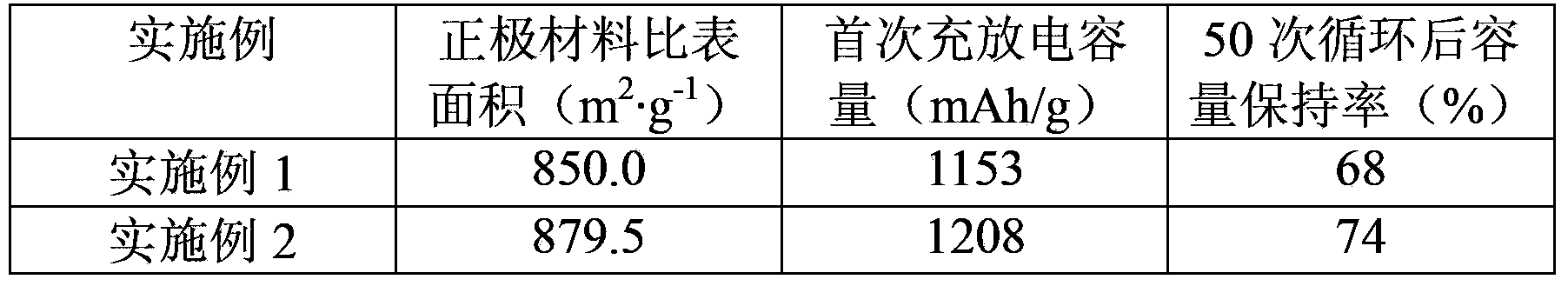

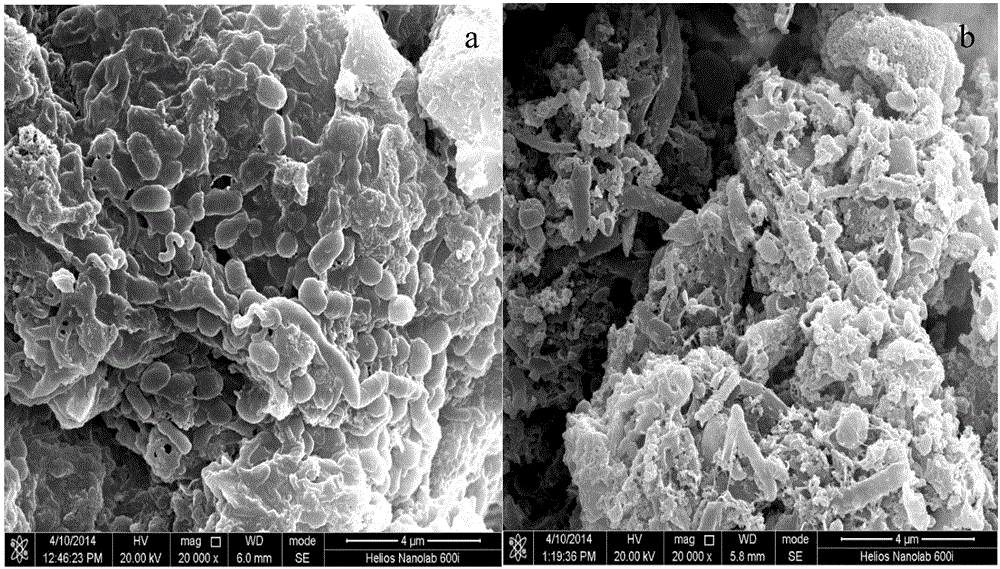

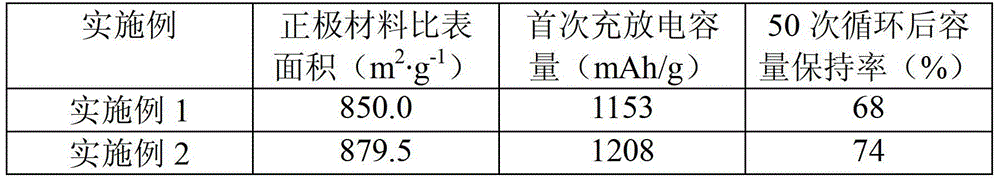

Positive electrode material for lithium sulfur battery, and lithium sulfur battery positive electrode

ActiveCN104143624ASimple processImprove controllabilityElectrode carriers/collectorsFilament/thread formingFiberLithium–sulfur battery

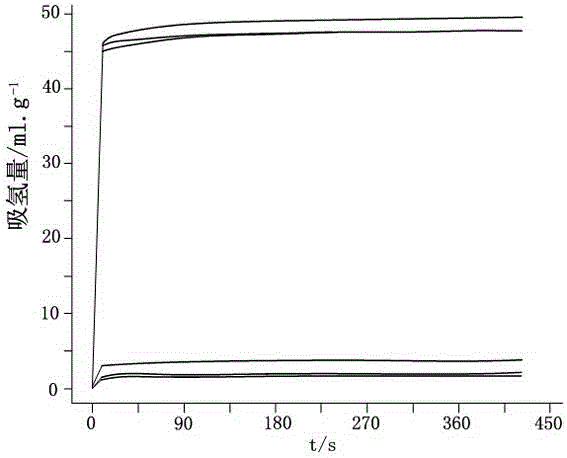

The invention relates to a positive electrode material for a lithium sulfur battery. The positive electrode material is a graphene doped porous hollow fiber, and the doping amount of graphene is 0.005-0.2% of the total mass of the positive electrode material; the porous hollow fiber is a porous hollow tubular structure, the external diameter of the tube is 80-1000nm, the internal diameter of the tube is 30-400nm, and the aperture of pores on the sidewall of the tube is 2-80nm; and graphene is embedded into the sidewall of the porous hollow fiber tube. A battery assembled by adopting a positive electrode made by using the positive electrode material has high discharge specific capacity and good cycle stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

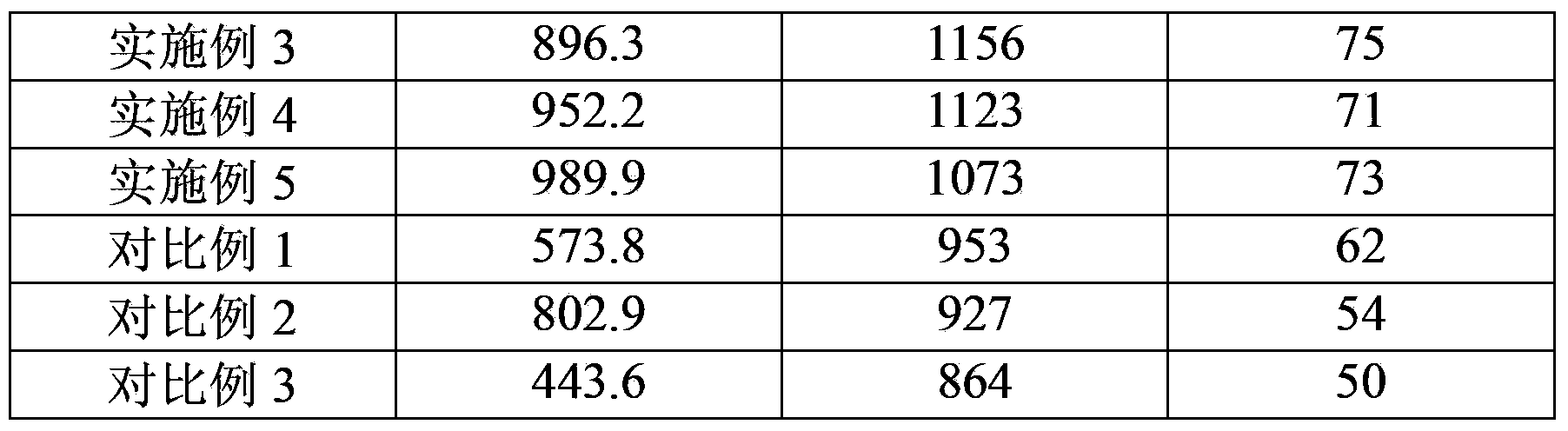

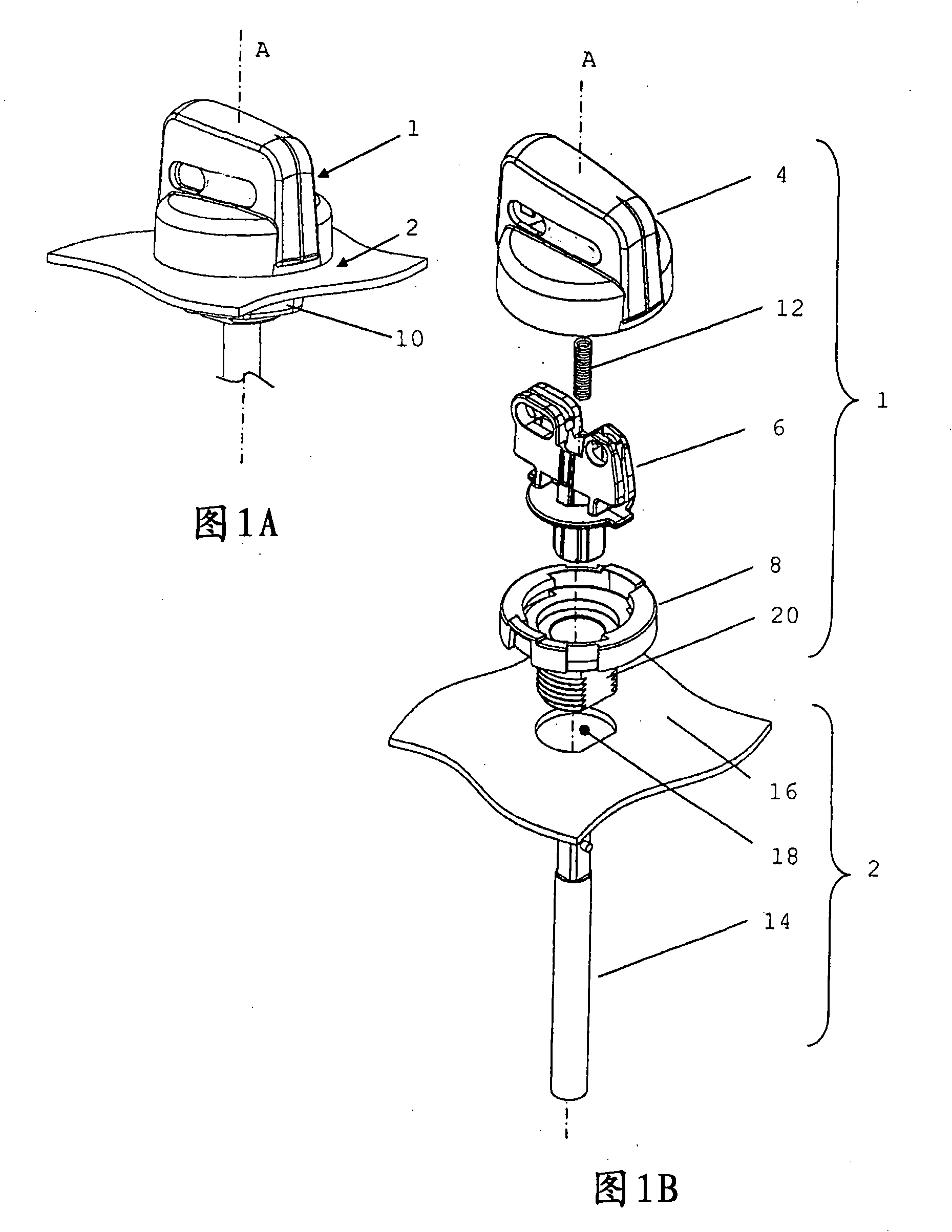

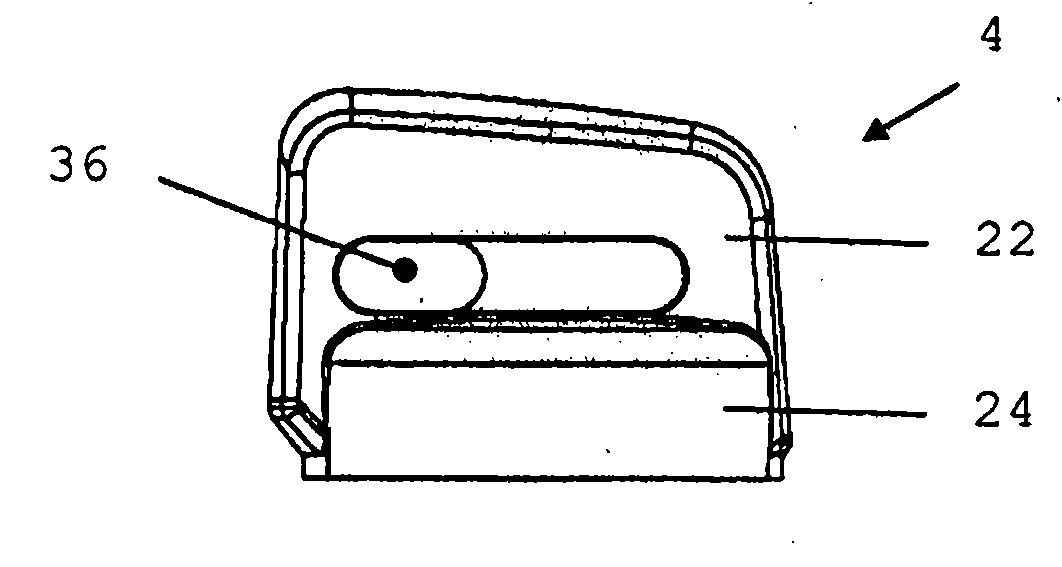

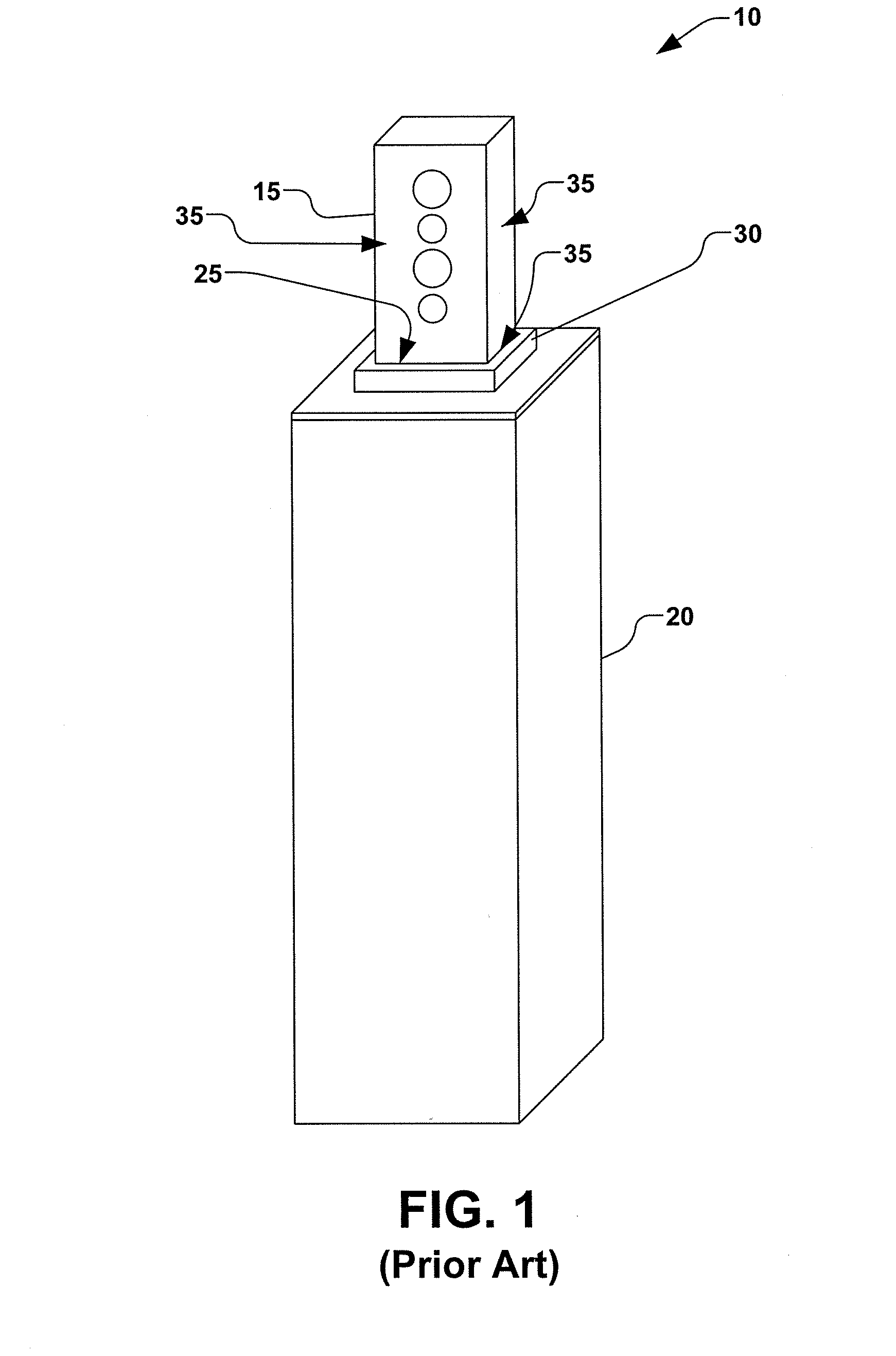

Safety rotary operator assembly

InactiveCN101901021APrevent first level securityPrevent rotationControlling membersMechanical apparatusRotational axis

A rotary operator assembly comprises a grip member, a spindle member, and an operator body member. The spindle member is attached to the operator body member, being rotatable with respect to the operator body member about an operative axis of rotation. The grip member is movably coupled to the spindle member and the operator body member and is translatable between a first translational position and a second translational position with respect to the operator body member. The grip member and the operator body member comprise cooperating means for blocking rotation of the grip member with respect to the operator body member about the operative axis of rotation in the first position and for allowing rotation of the grip member with respect to the operator body member about the operative axis of rotation in the second position from a first angular position to a second angular position. The grip member is configured to operably couple with the spindle member in at least the second translational position, and the grip member comprises at least one portion cooperating with at least one portion of the spindle member for preventing translation of the grip member between the first translational position and the second translational position in the first angular position.

Owner:EWAC HLDG

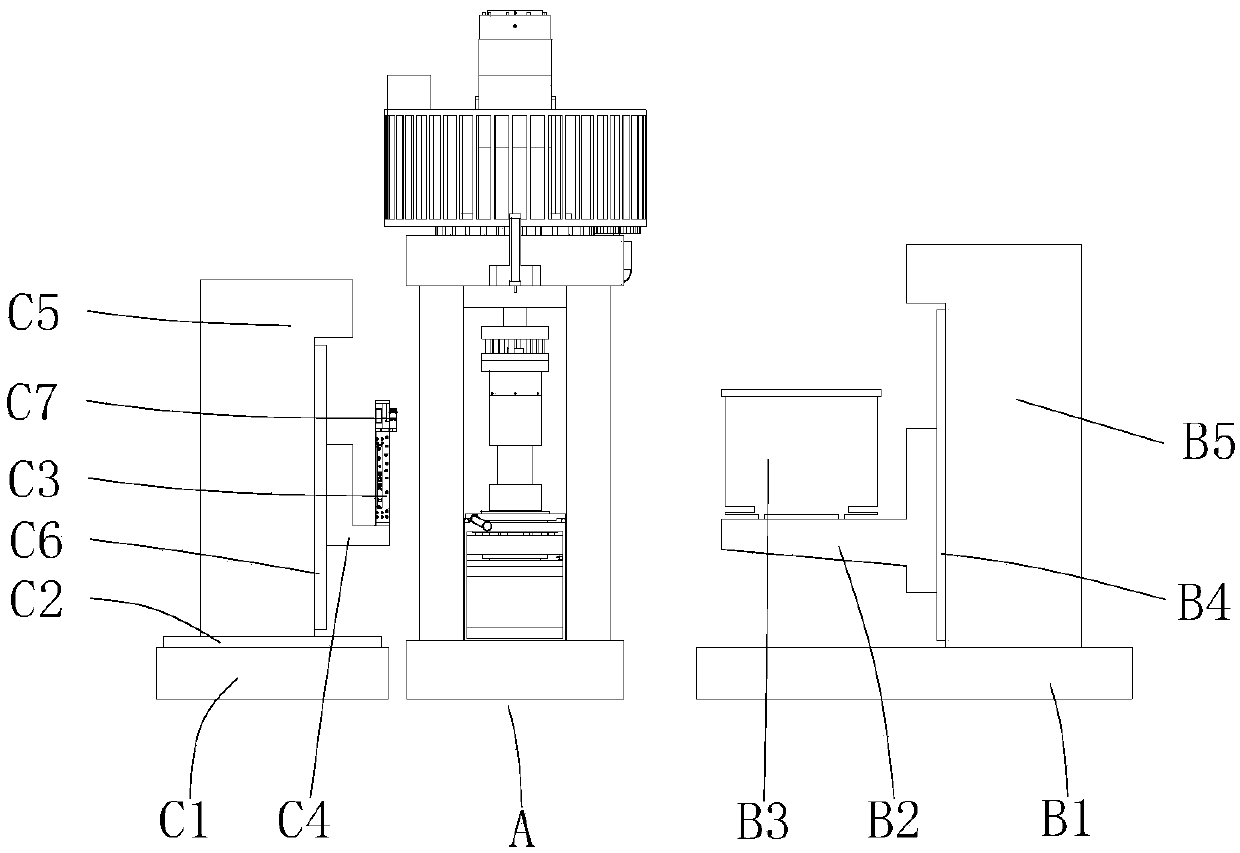

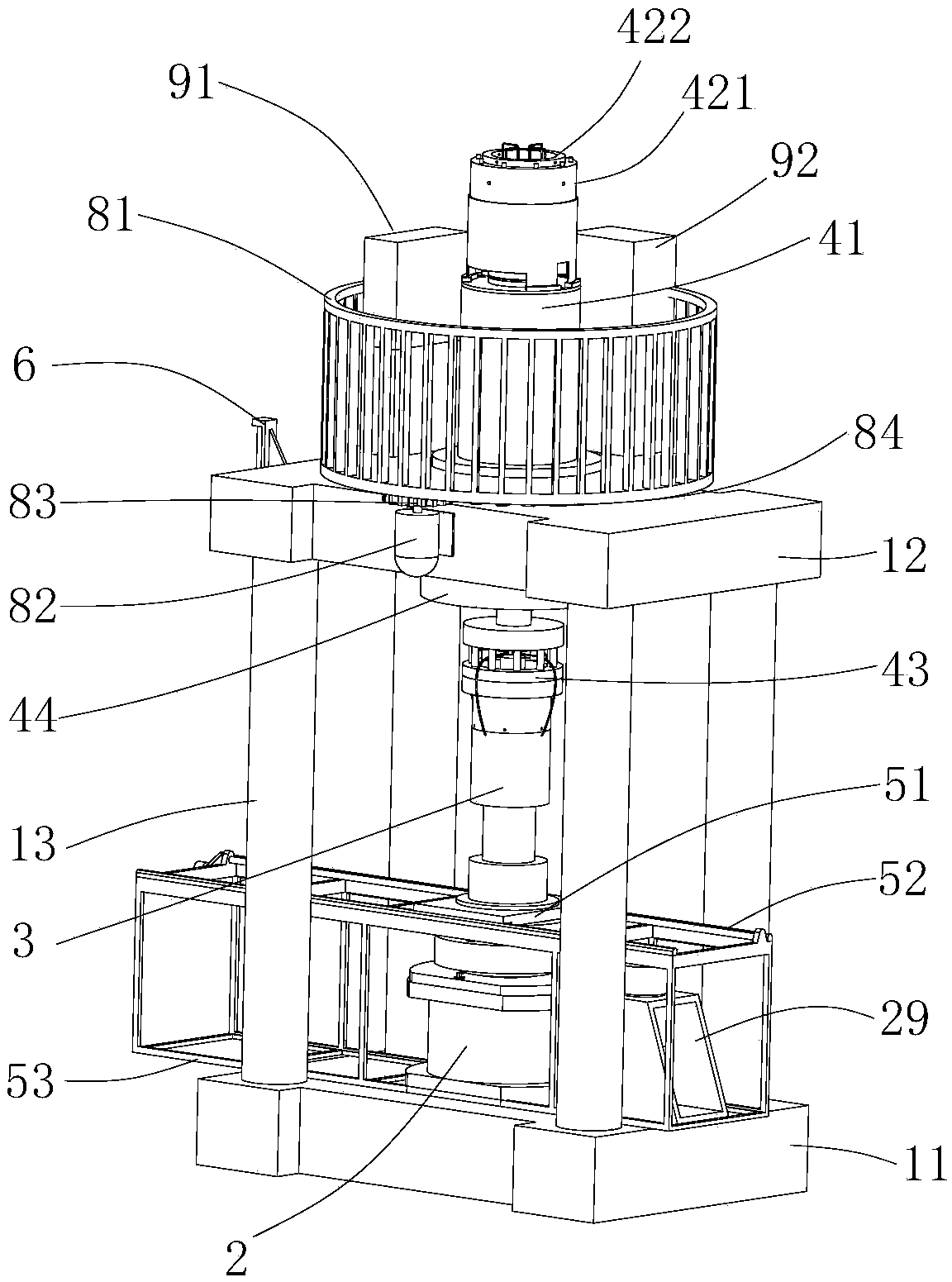

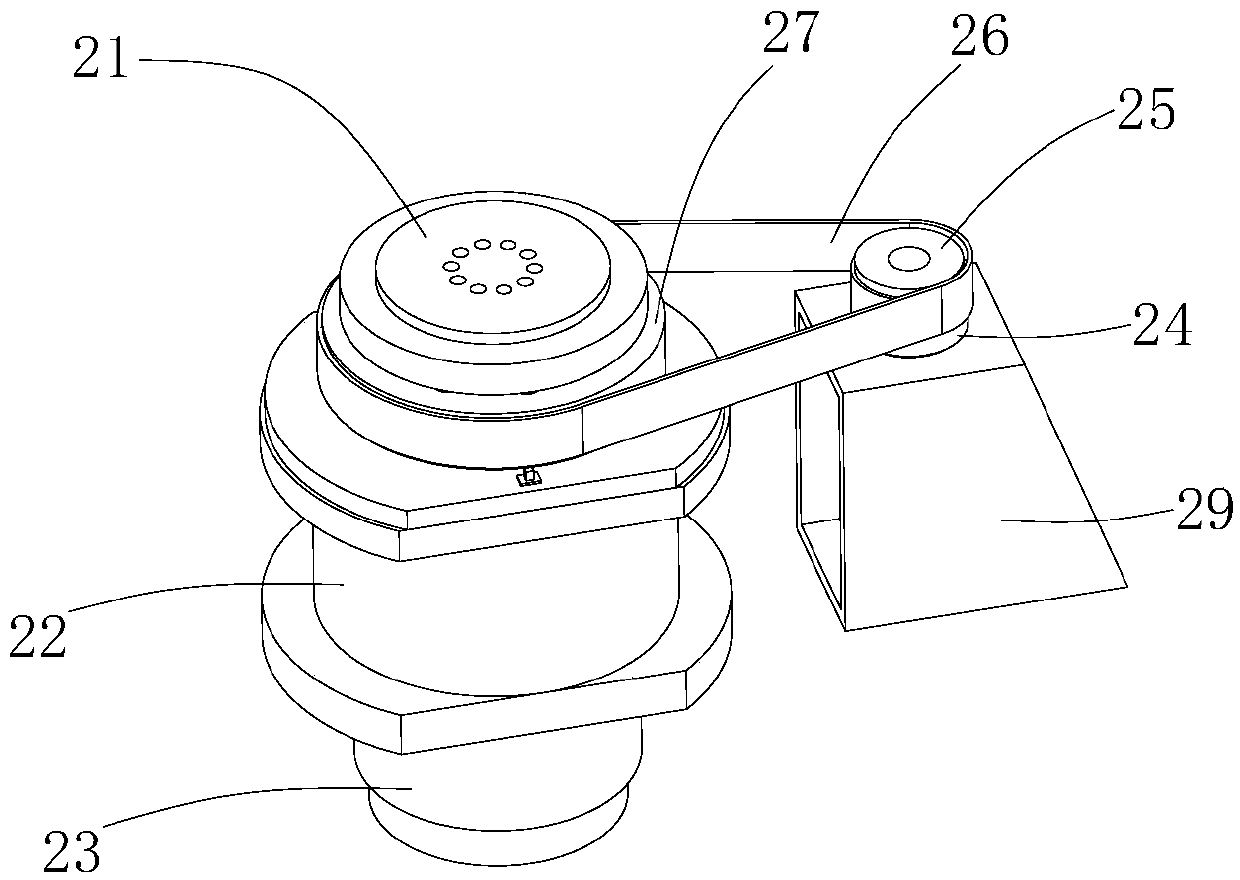

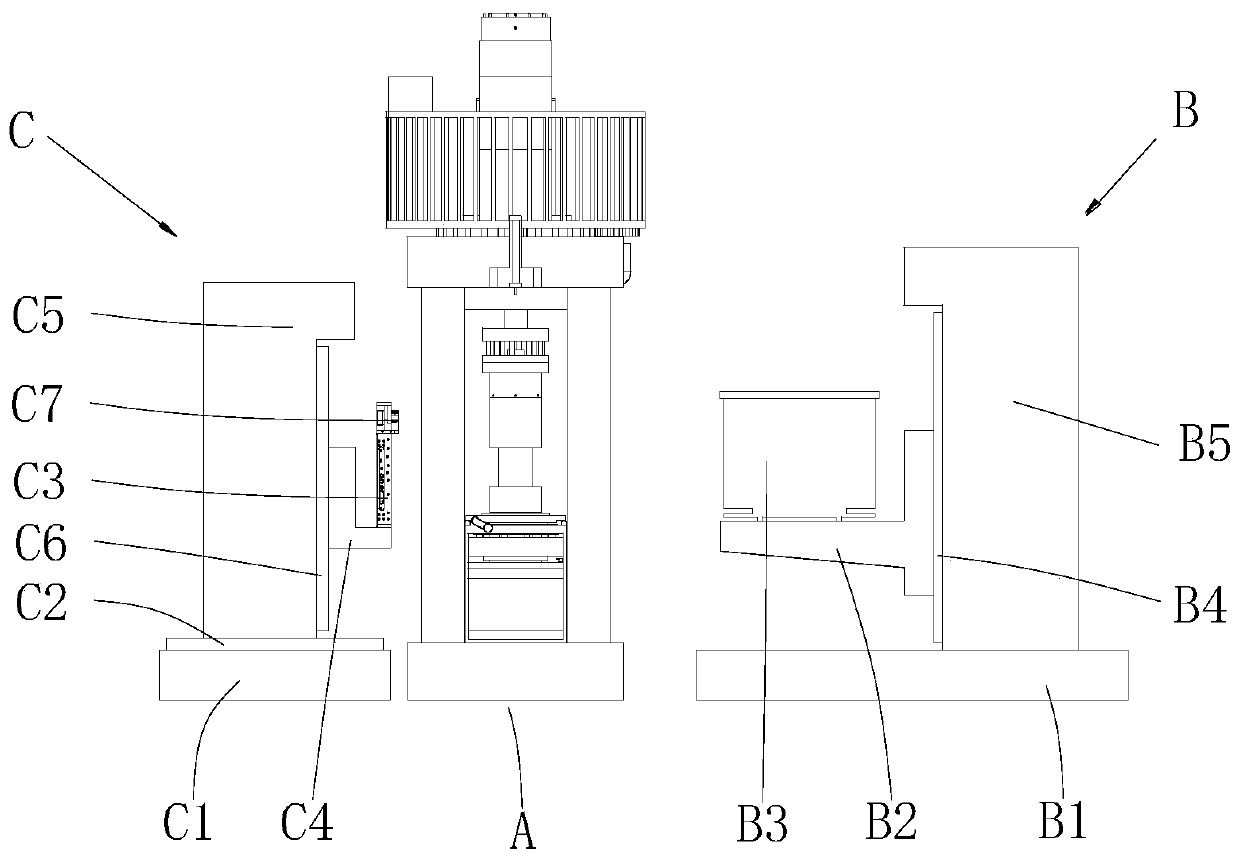

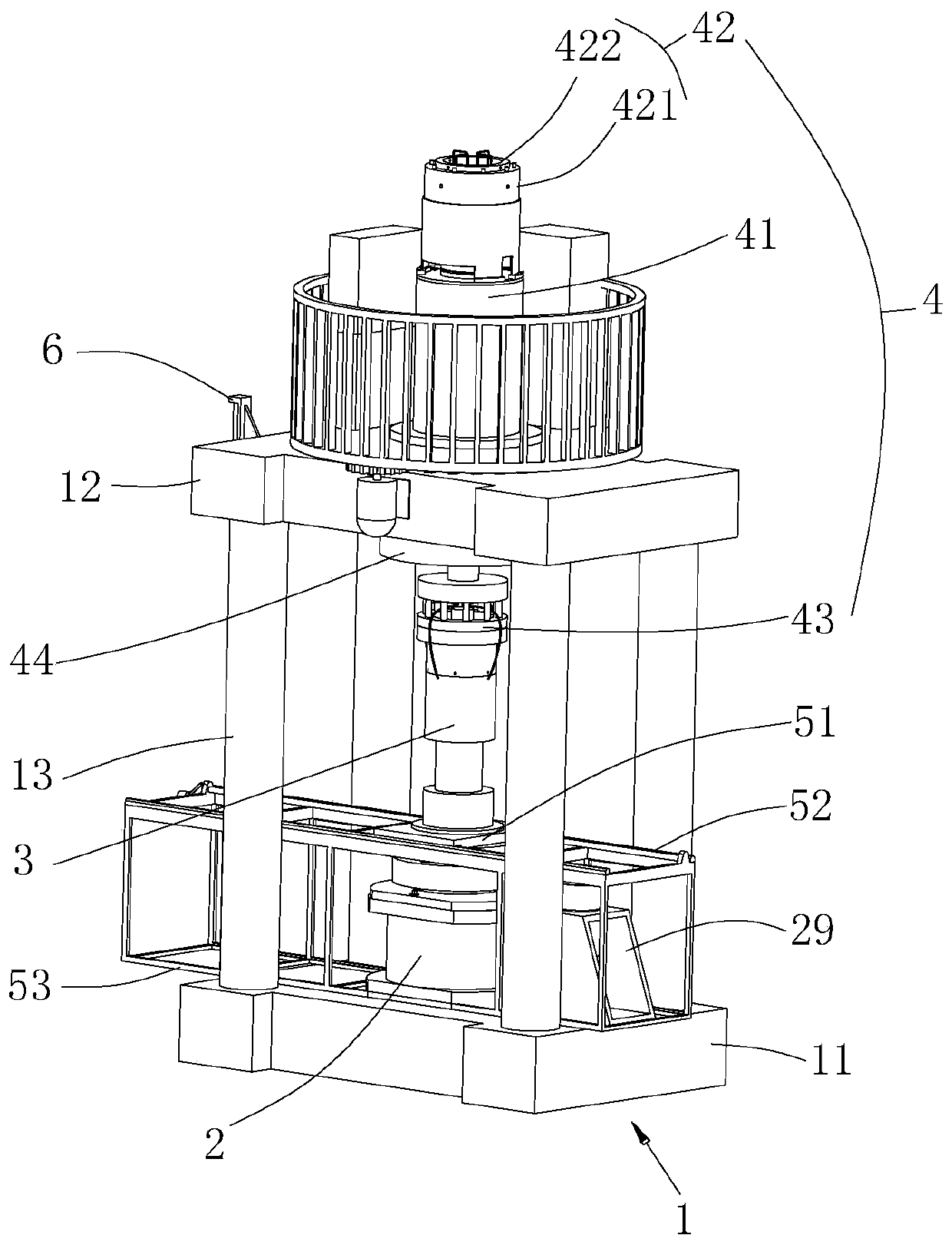

High-energy accelerator CT rock mechanics test system

ActiveCN109580365AReflect heterogeneityReflect continuityMaterial strength using tensile/compressive forcesMaterial analysis by transmitting radiationTest sampleHigh energy accelerator

The invention belongs to the technical field of mechanics test devices, and specifically relates to a high-energy accelerator CT rock mechanics test system. The high-energy accelerator CT rock mechanics test provided by the invention comprises a mechanics test machine, a high-energy accelerator CT ray source and a detector, the mechanics test machine is arranged between the high-energy acceleratorCT ray source and the detector, the mechanics test machine comprises a fixed component, a rotary apparatus and a pressure chamber, the rotary apparatus is arranged on the fixed component, the pressure chamber is connected with the rotary apparatus, and when a test is executed, the pressure chamber can rotate relative to the fixed component under driving of the rotary apparatus. The test machine is provided with the rotary apparatus, and when the test is executed, the pressure chamber is driven by the rotary apparatus to rotate, namely, a test sample can be scanned in a process in which a loadtest is executed for the test sample, consequently, CT imaging can completely reflect a structural state of the test sample when the test sample is loaded, and scientific researches are facilitated more.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

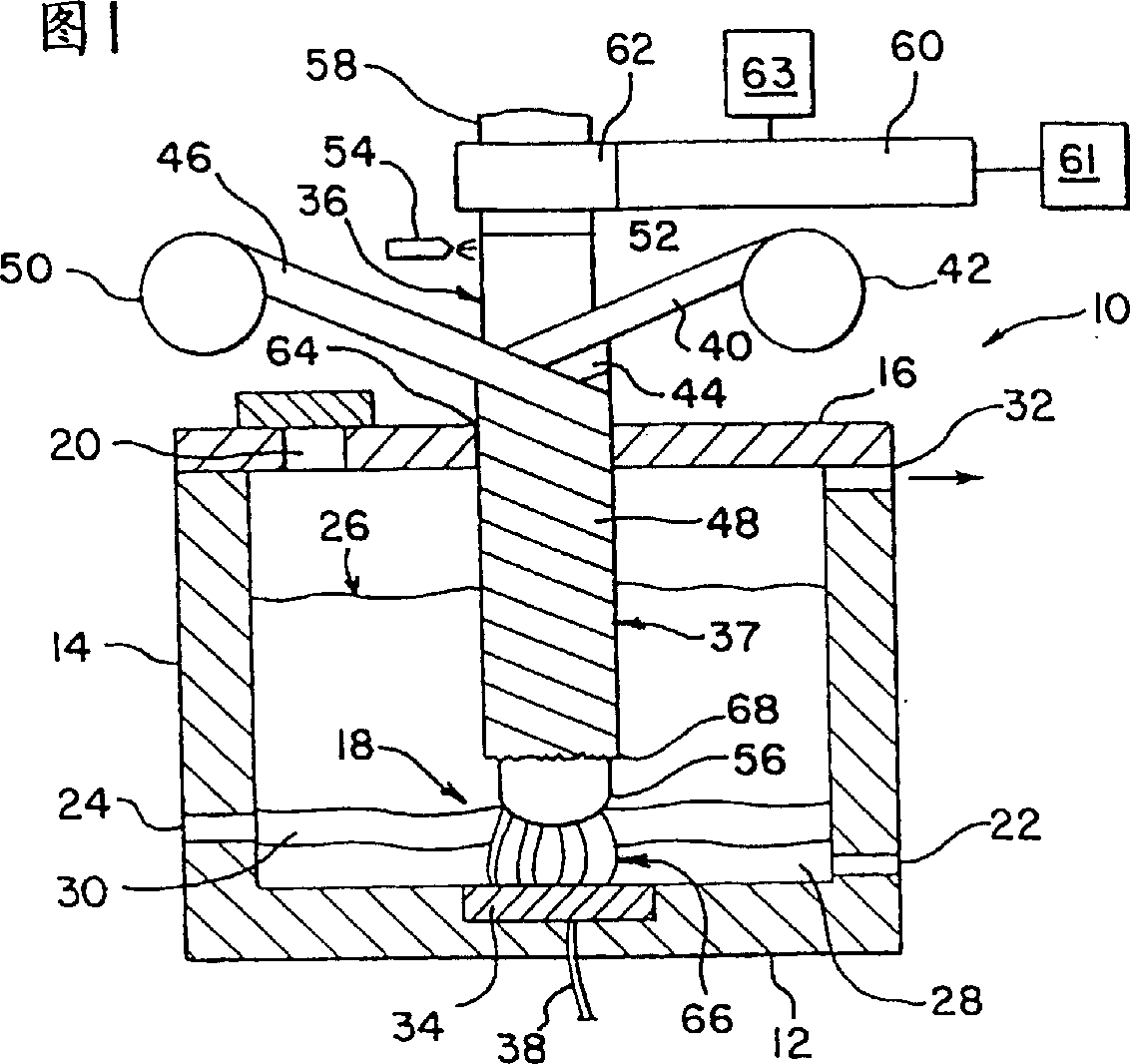

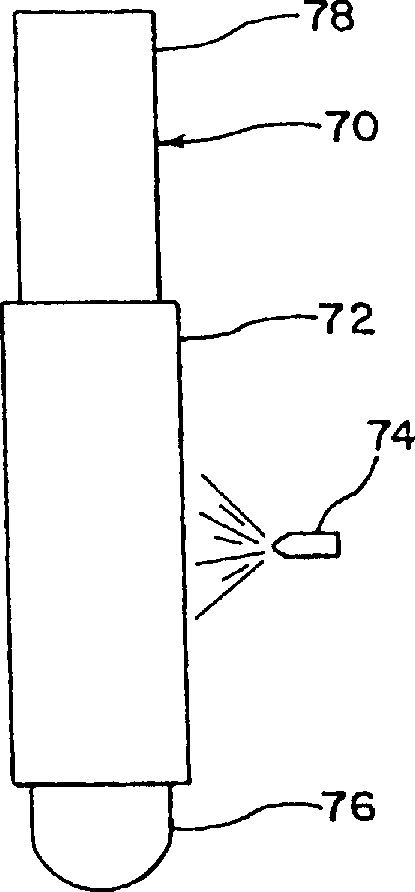

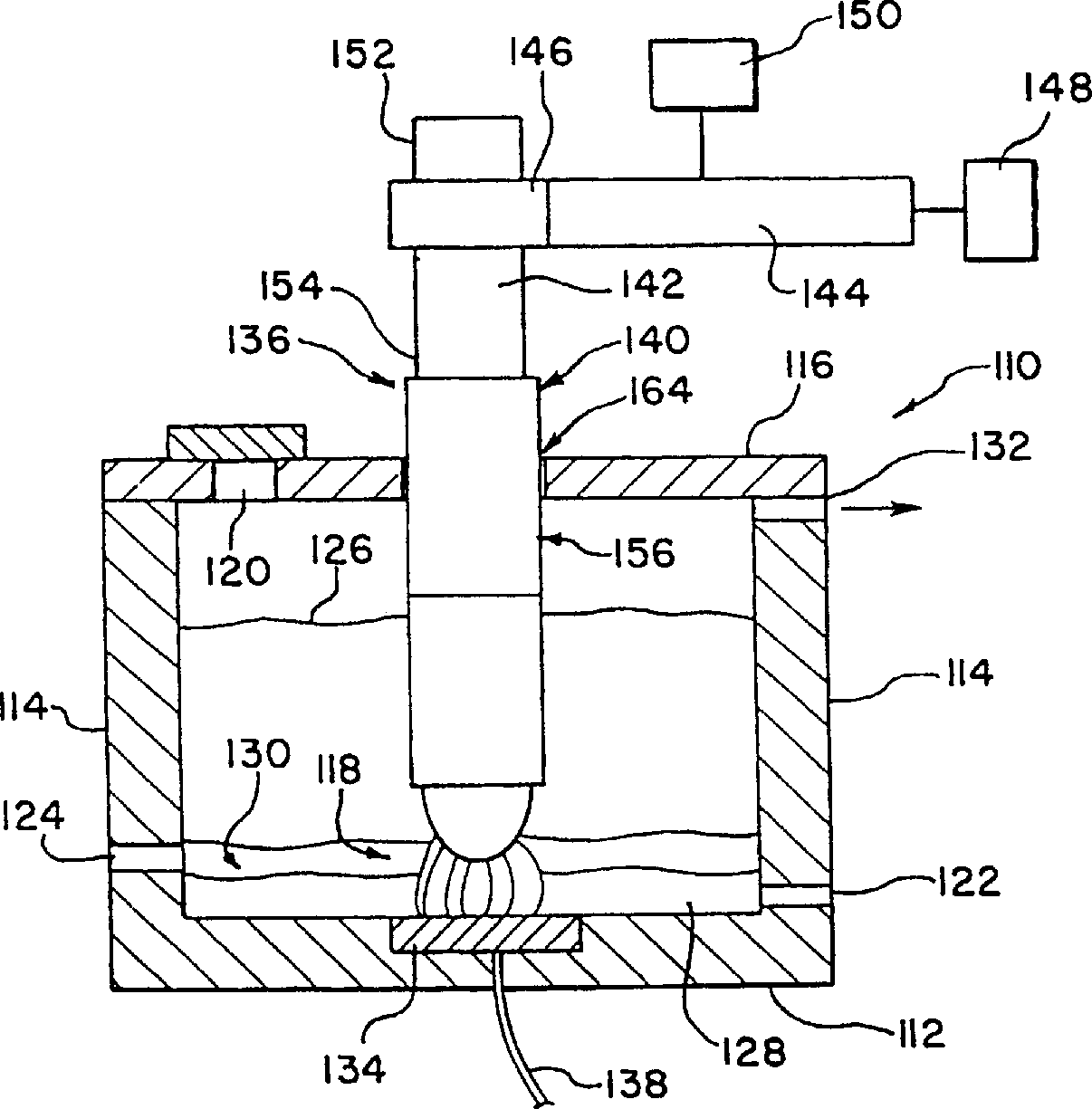

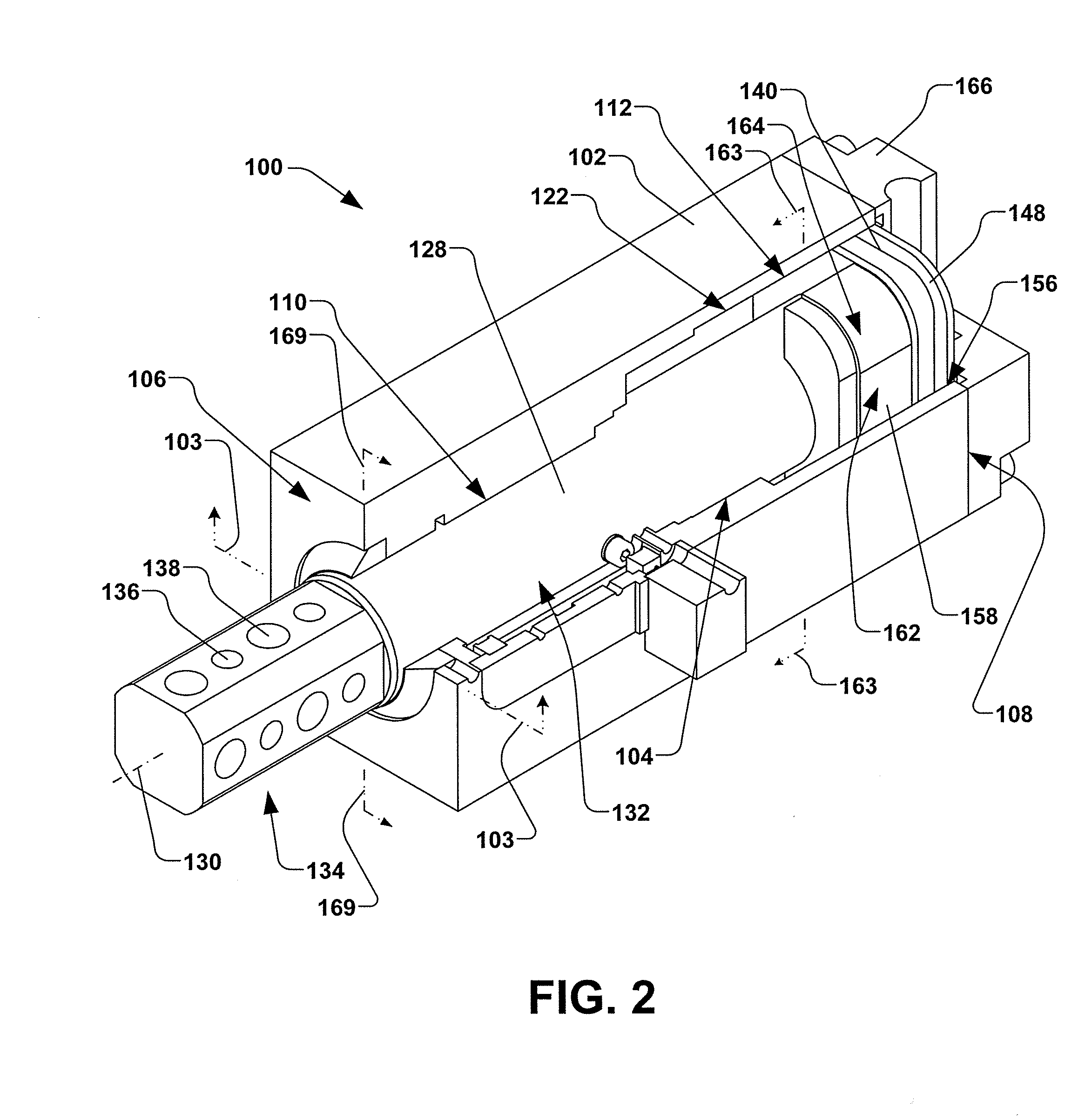

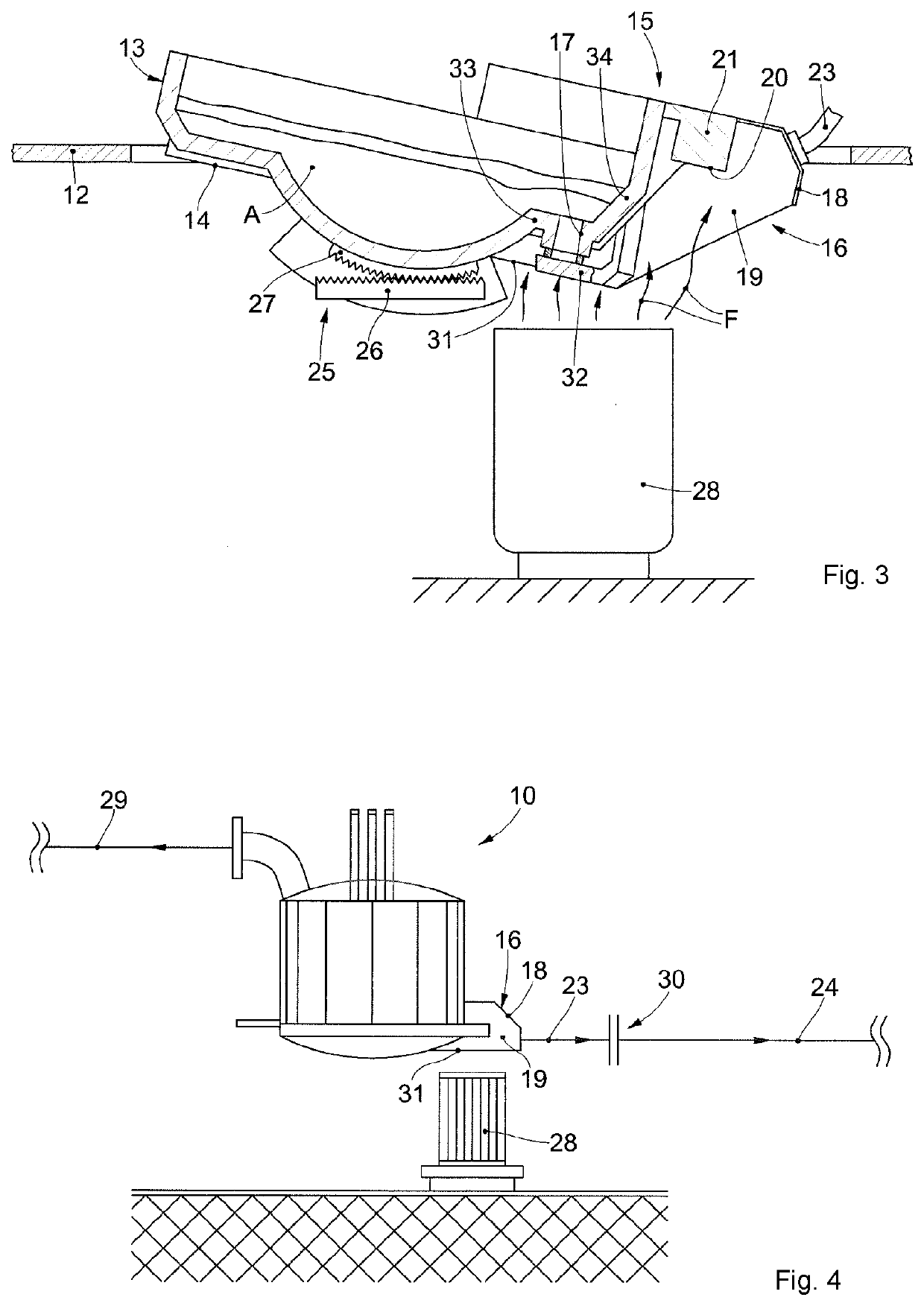

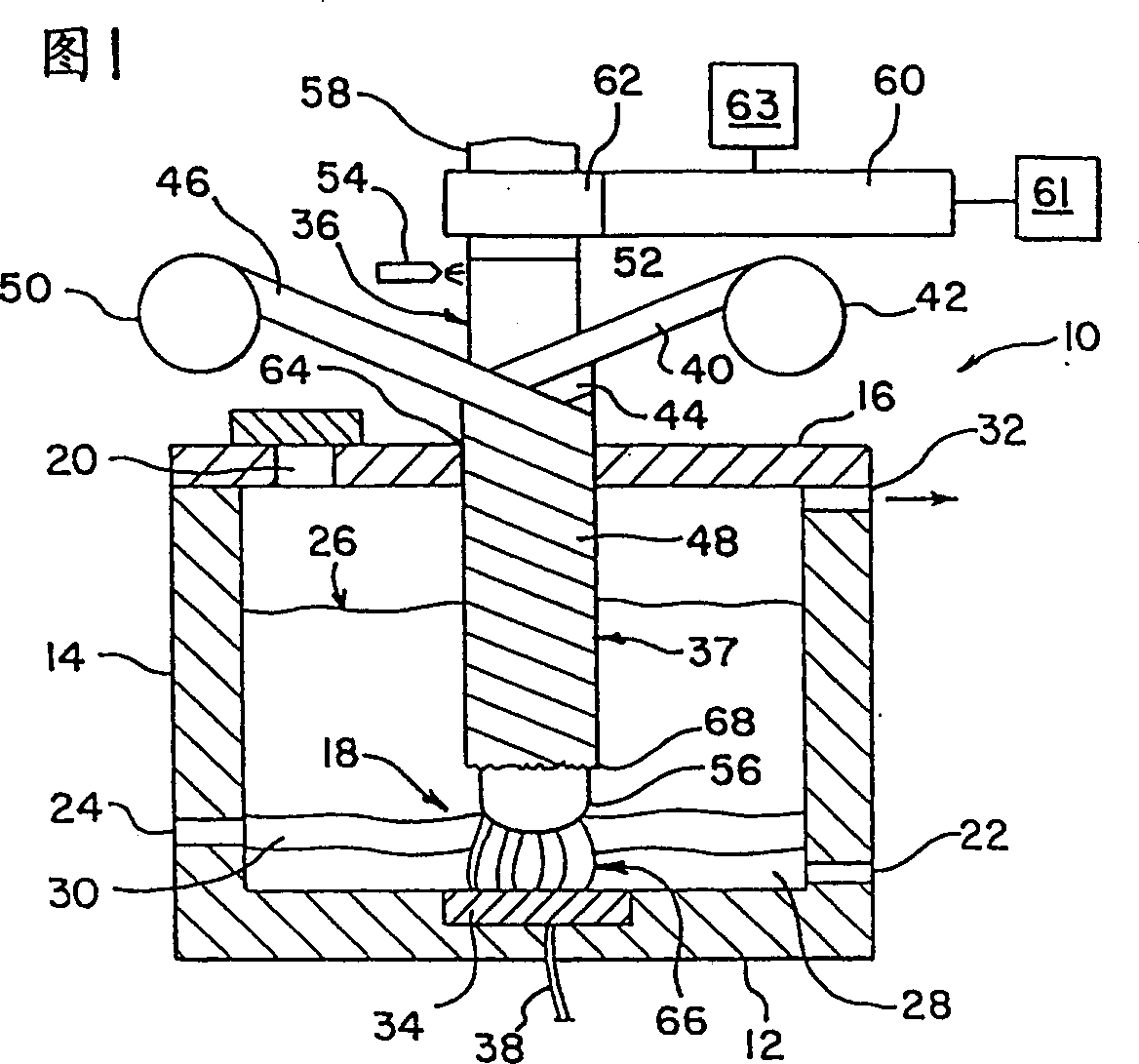

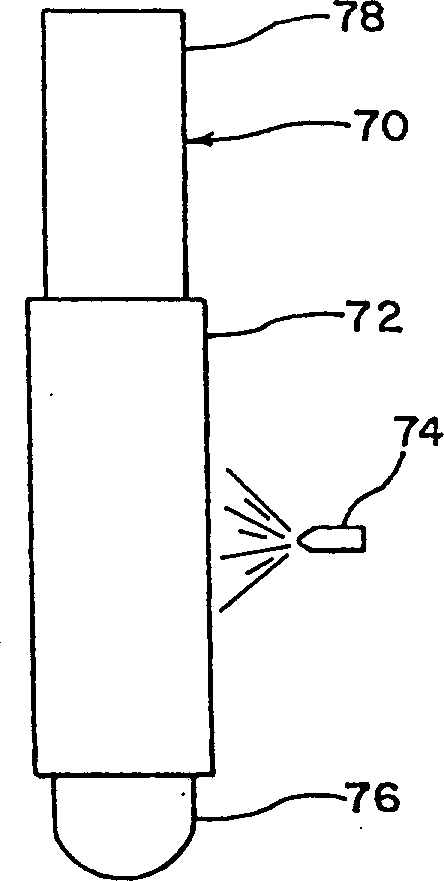

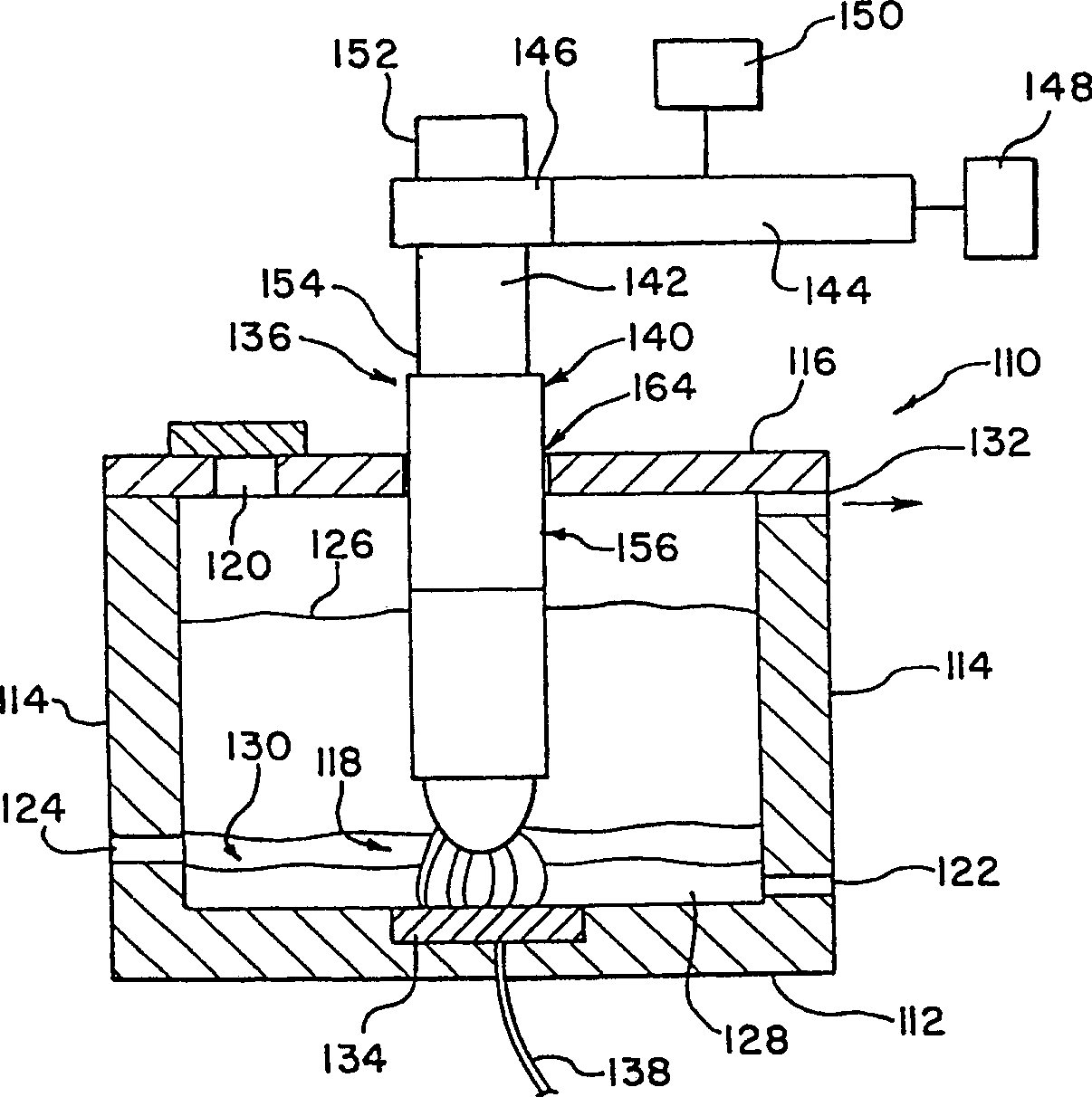

Electric furnace with insulated electrode and process for producing molten metals

InactiveCN1251618ADo not reduce voltageResistivity effectElectric discharge heatingOhmic-resistance electrodesSlagCast iron

An electric arc furnace (10) having a partially insulated electrode (37) produces molten metal (28) such as foundry iron from an iron source where little or no slag (30) is produced. The furnace (10) includes at least one insulated electrode (37) for immersing deep into the metal charge (26). An insulating coating can be a fibrous mat (48) wrapped around the electrode or a spray coating (72). In one embodiment, the electrode (156) has a coupling (172) at a first end (176) for coupling with an electrically conducting member (142) and a coupling (172) at the second end (178) for coupling with an adjacent electrode to form an electrode column. The coupling members (172) can be an internally threaded recess (166, 168) in the ends thereof. An externally threaded coupling member (172) can be threaded into the recesses (166, 168) of the electrodes (157) for coupling two or more electrodes (157) together.

Owner:ALABAMA POWER

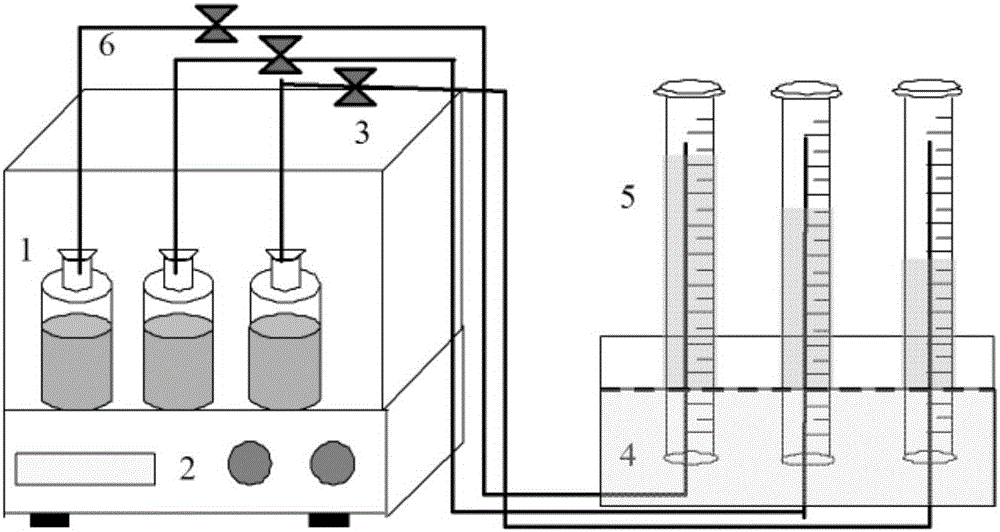

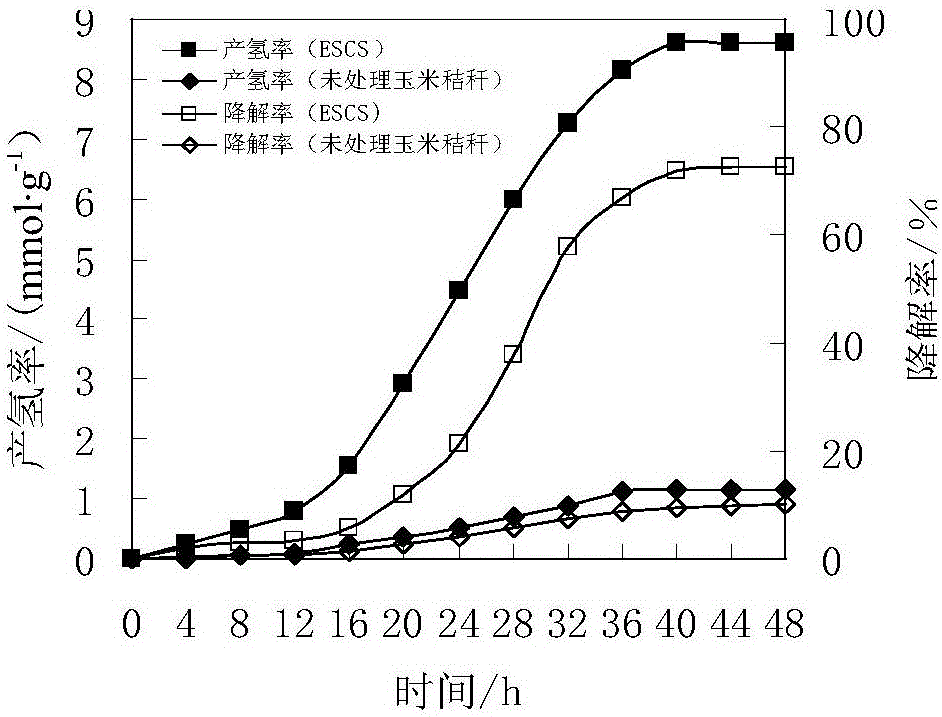

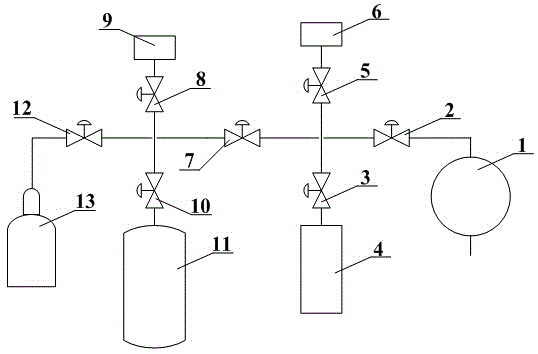

Combined pretreatment method for synergically degrading straw cellulose through compound florae and producing hydrogen through fermentation

InactiveCN106119289ARealize resourcesHigh hydrogen production rateFermentationCellulosePretreatment method

The invention relates to a combined pretreatment method for synergically degrading straw cellulose through compound florae and producing hydrogen through fermentation, belonging to the technical field of processing of solid waste. The combined pretreatment method for combining the compound florae with the combined pretreatment of sodium hydroxide and acidification steam explosion is utilized for carrying out efficient anaerobic fermentation biological hydrogen production for the first time. The method comprises the steps of firstly grinding straws into 30-60-mesh powder, carrying out sodium hydroxide pretreatment, finally carrying out acidification steam explosion pretreatment to obtain pretreated straw powder, adding the compound florae, culturing the mixture in an intermittent fermentation hydrogen production testing device, and carrying out the efficient anaerobic fermentation biological hydrogen production. According to the combined pretreatment method, by virtue of the combined pretreatment of sodium hydroxide and acidification steam explosion, the hydrogen production rate and the cellulose degradation rate of the straw fermentation hydrogen production are increased, and the recycling and the energy regeneration of lots of straws are realized.

Owner:LIAONING UNIVERSITY

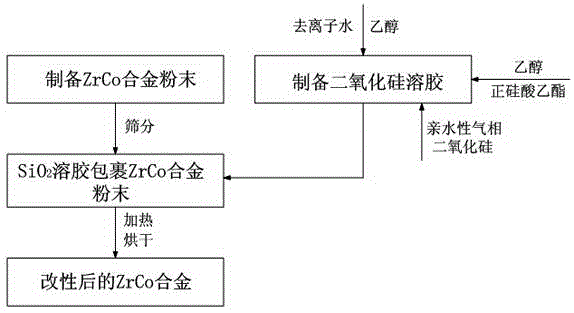

Method for enhancing performance of ZrCo alloy to resist CO, CO2 and air poison and anti-pulverization performance of alloy

The invention discloses a method for enhancing the performance of ZrCo alloy to resist CO, CO2 and air poison and the anti-pulverization performance of the alloy, which comprises the steps of S1: preparing ZrCo alloy powder; S2: sieving the ZrCo alloy powder; S3: mixing ethyl alcohol with deionized water, and stirring to obtain a mixed solution; S4: adding concentrated hydrochloric acid to adjust the pH value and obtain a first mixture; S5: mixing tetraethoxysilane with ethyl alcohol to obtain a second mixture; S6: mixing the first mixture with the second mixture to obtain a third mixture; S7: standing, and heating the third mixture to volatilize the ethyl alcohol; S8: adding hydrophilic gaseous phase silicon dioxide to the third mixture so as to obtain a silicon dioxide sol; S9: adding the ZrCo alloy powder to the silicon dioxide sol so as to obtain paste; S10: heating and drying the paste. According to the method disclosed by the invention, the problem that the ZrCo alloy is poor in anti-pulverization capability and poor in anti-poison capability is solved, the use stability of the ZrCo alloy is enhanced, and the service life of the ZrCo alloy is prolonged.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Preparation method for rolled magnesium-aluminum laminated plate prefabricated blank

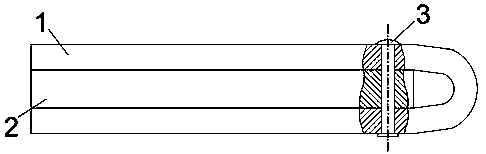

InactiveCN111420990AIncreased co-morphing capabilitiesLimit contactWork heating devicesWork cleaning devicesHeating furnaceComposite plate

The invention discloses a preparation method for a rolled magnesium-aluminum laminated plate preformed blank, and belongs to the technical field of metal composite plate preparation. The preparation method is characterized by comprising the following implementation steps that S1, a magnesium plate is placed into a heating furnace, and subjected to heat preservation for 0.5 h at the temperature of300 DEG C and annealing treatment; S2, an aluminum plate is placed into the heating furnace, and subjected to heat preservation for 1 h at the temperature of 350 DEG C and annealing treatment; S3, thesuperposed surface of the above magnesium plate and the above aluminum plate is ground and washed in the rolling width direction; S4, the aluminum plate is folded in half and bent, the magnesium plate is placed into the bent aluminum plate, and the bent end is fixed with an aluminum rivet to form a "sandwich" structure; and S5, the above "sandwich" structure combined blank is placed into the heating furnace, subjected to heat preservation for 10 min-30 min within the temperature range of 350 DEG C-400 DEG C, and then immediately placed into a press machine to be pressurized at a constant speed, or fed into a rolling mill to be rolled. The preparation method has the advantages that the temperature is carried out, and pressurizing is carried out, so that a tightly-attached pre-composite surface is formed between the magnesium-aluminum plates, the high-temperature oxidation of a to-be-composited interface in the hot rolling process is limited, and the cooperative deformation capacity ofbimetal is improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

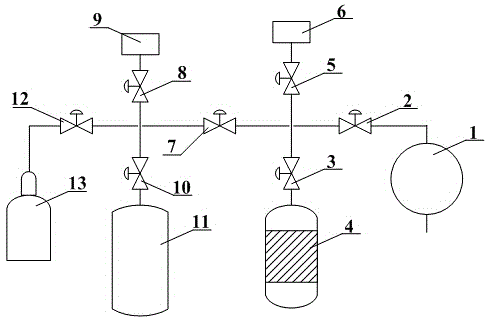

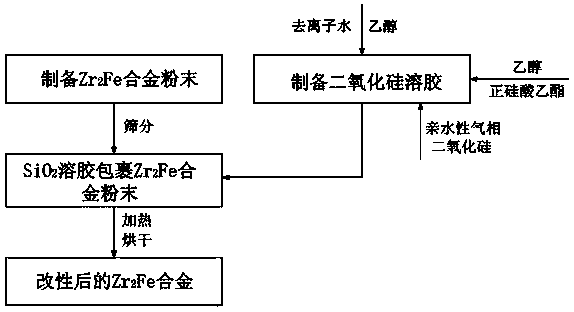

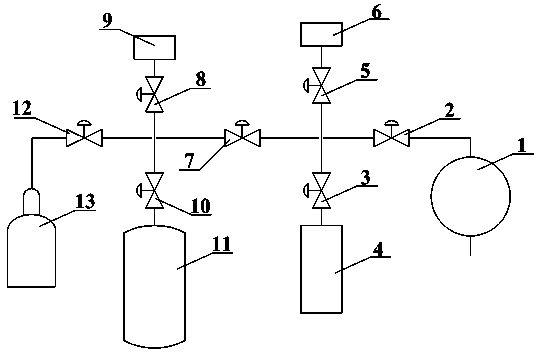

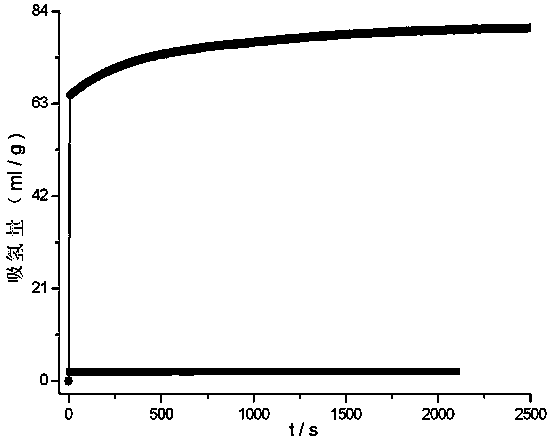

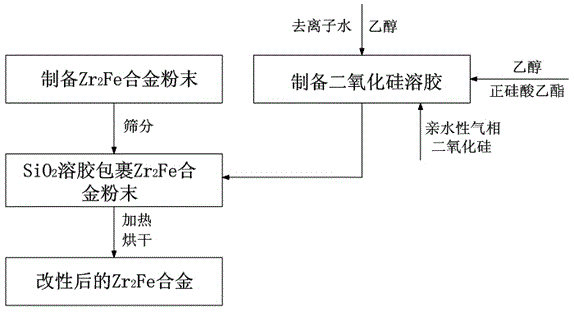

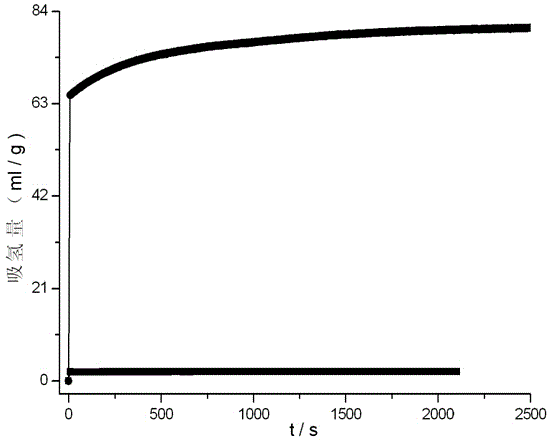

Method for enhancing air poison resistance of Zr2Fe alloy

The invention discloses a method for enhancing air poison resistance of Zr2Fe alloy. The method for enhancing the air poison resistance of the Zr2Fe alloy includes steps: S1, simultaneously loading Zr2Fe alloy particles and stainless steel balls into a stainless steel vacuum ball milling tank, and connecting the stainless steel vacuum ball milling tank with a hydrogen storage performance test system; S2, pumping gas out of the stainless steel vacuum ball milling tank, and inflating the stainless steel vacuum ball milling tank with argon gas; S3, performing ball milling on the Zr2Fe alloy particles; S4, inflating the stainless steel vacuum ball milling tank with the argon gas, and passivating the Zr2Fe alloy particles; S5, placing the stainless steel vacuum ball milling tank into a glove box, controlling air inflow of air, and exposing Zr2Fe alloy powder to air; S6, sieving the Zr2Fe alloy powder; S7, preparing silicon dioxide sol; S8, adding the Zr2Fe alloy powder into the silicon dioxide sol and stirring the Zr2Fe alloy powder so as to form cream; S9, heating and drying the cream. The method for enhancing the air poison resistance of the Zr2Fe alloy solves the problem that the Zr2Fe alloy is poor in air poison resisting ability, strengthens use stability of the Zr2Fe alloy, and prolongs use life of the Zr2Fe alloy.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

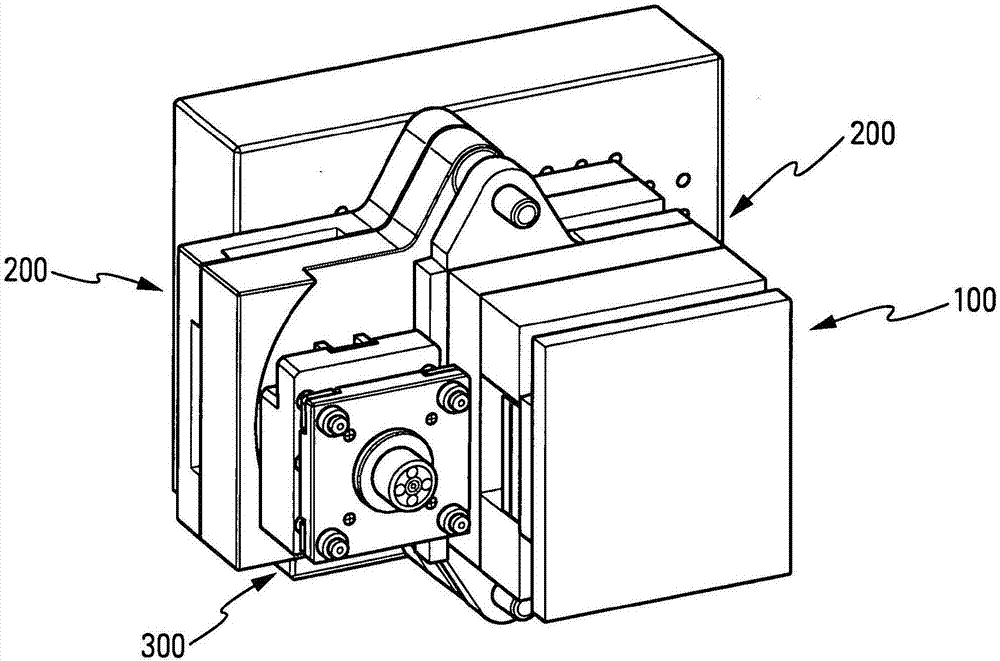

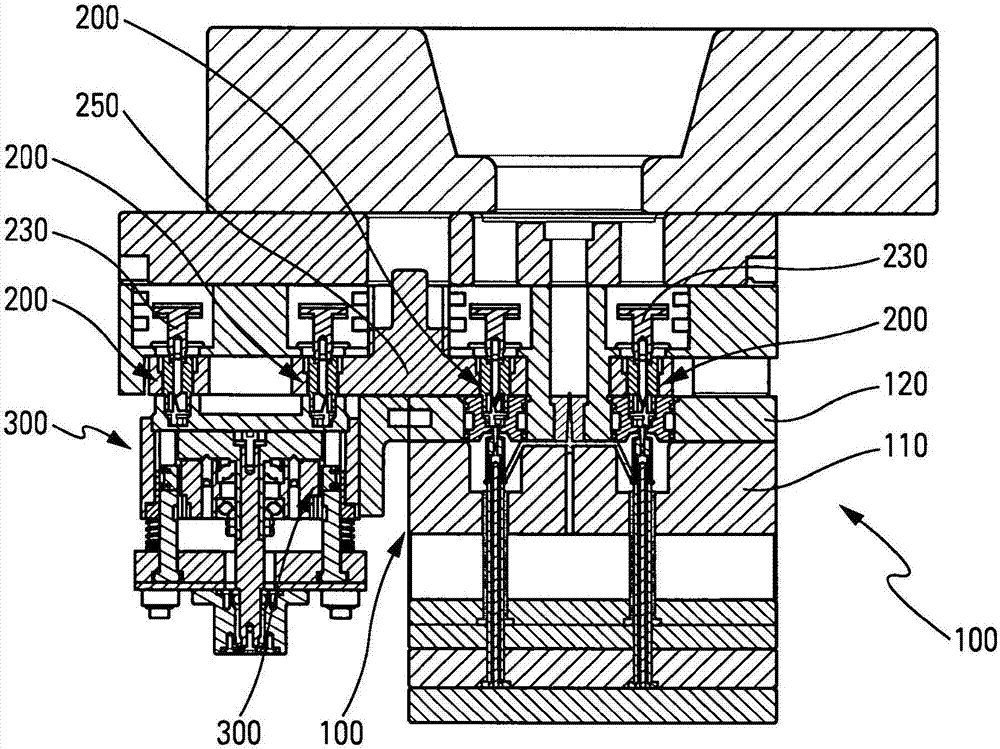

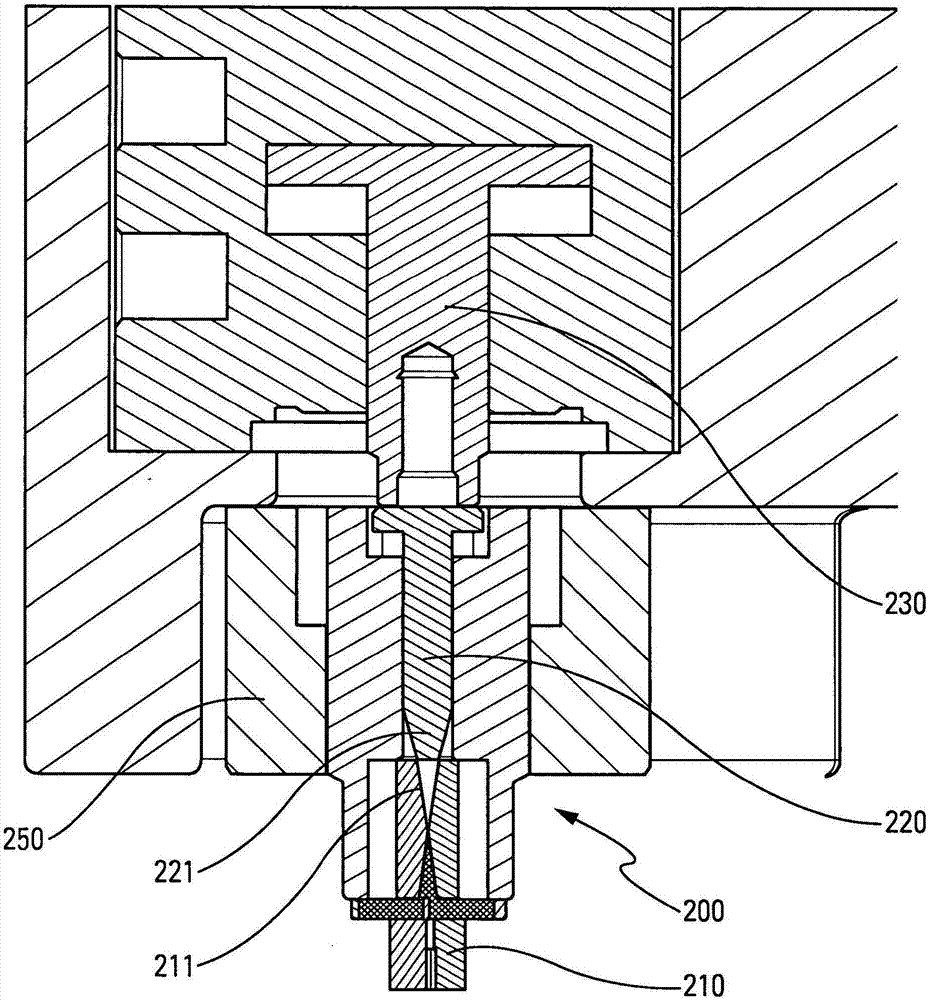

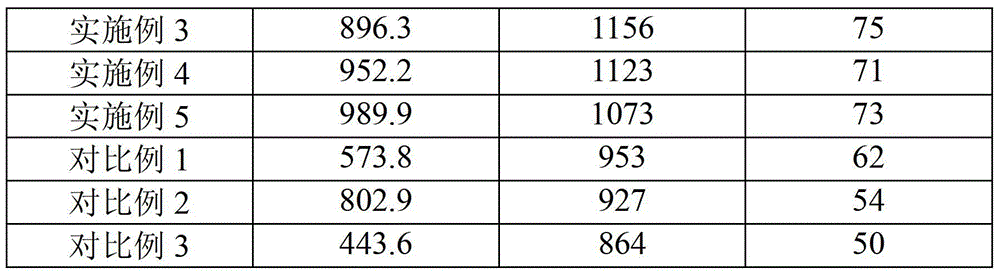

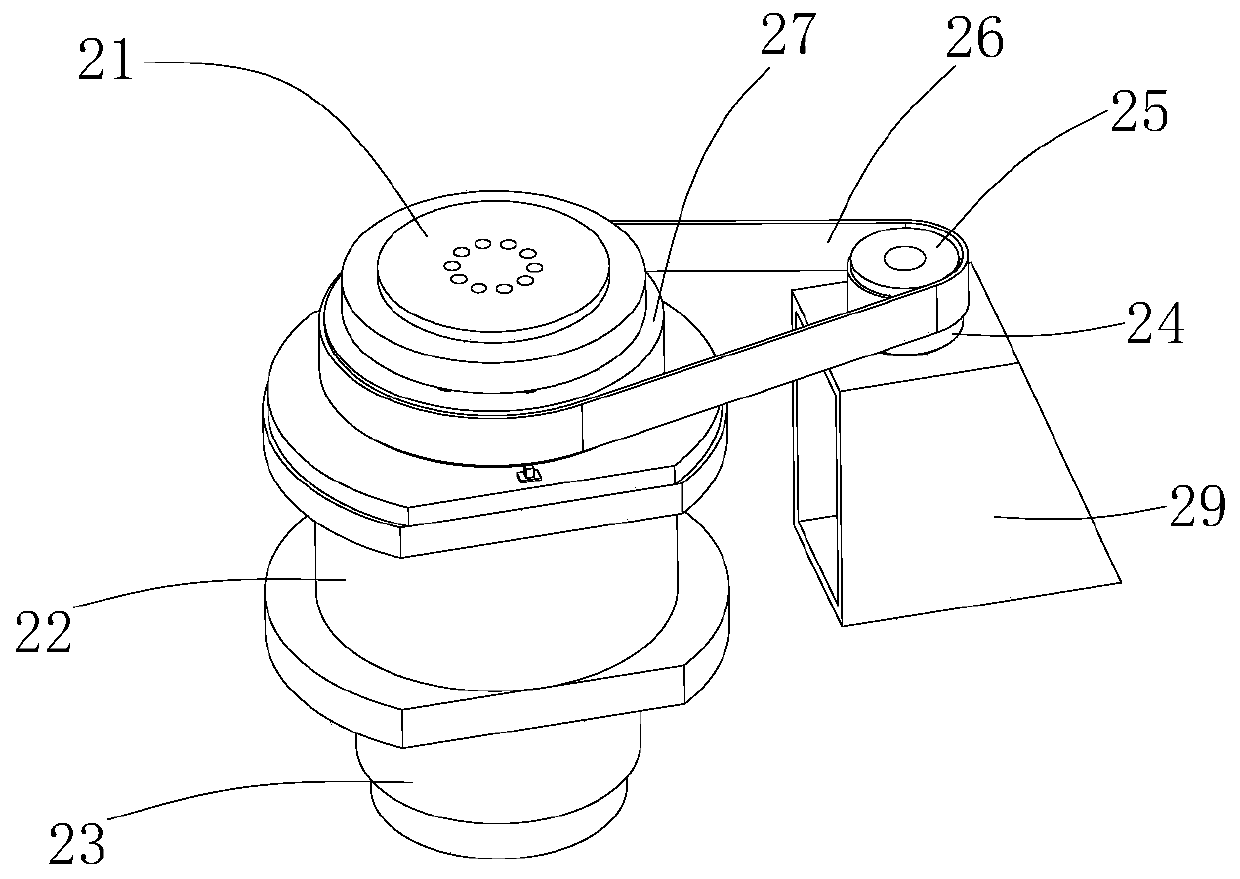

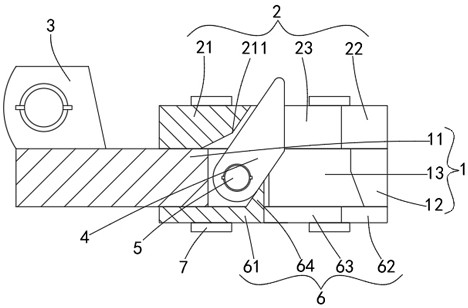

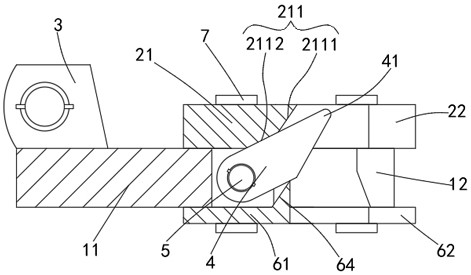

Moulding assembly and method for producing a syringe body

ActiveCN107206648APrecise positioningAvoid the risk of damaging the piercing tipDomestic articlesCoatingsEngineeringBiomedical engineering

A moulding assembly for producing at least one syringe body (10), each syringe body (10) being provided with a cannula (20), each syringe body (10) comprising a cylindrical portion (11) and a hub portion (12) to which said cannula (20) is attached, the moulding assembly comprising: at least one mould unit (100), each mould unit (100) comprising a first mould portion (110), a second mould portion (120) that can be moved axially relative to said first mould portion (110) between an open position and a closed position, wherein said first and second mould portions (110, 120) together define a mould cavity (130), and a core (140) located in said mould cavity (130) in order to define the shape of said syringe body (10); and at least one clamping unit (200) for a cannula (20), each clamping unit (200) comprising a clamp (210) that can be moved between an open position, in which a cannula (20) can be loaded into a proximal axial end of said clamp (210), and a closed position, in which said cannula (20) is held in said clamp (210), said clamping unit (200) being movable axially relative to said mould unit (100) in order to arrange a cannula (20) in said mould cavity (130), the movement of said clamp (210) between the open and closed positions of same being independent of the axial movement of said first and second mould portions (110, 120) between the open and closed positions of said mould unit (100).

Owner:APTAR FRANCE SAS

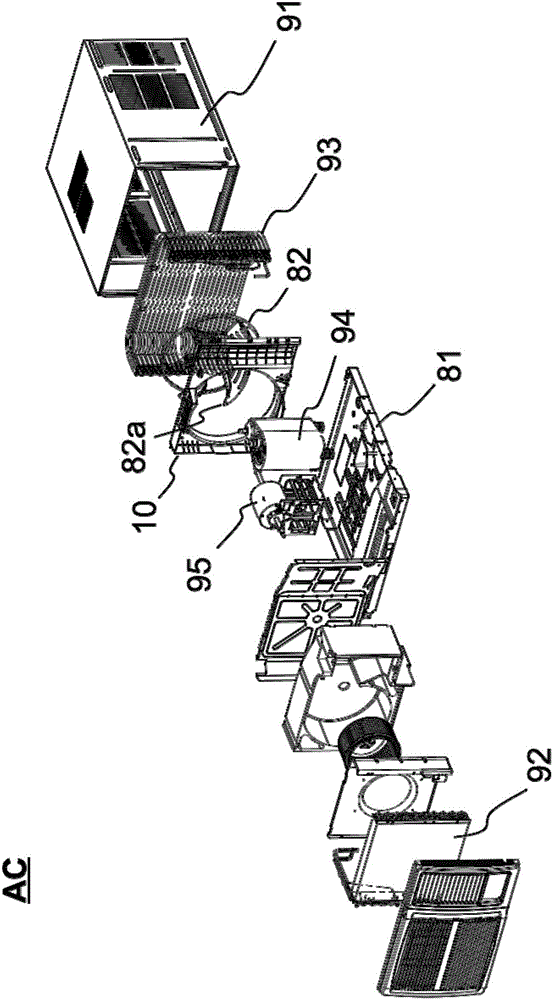

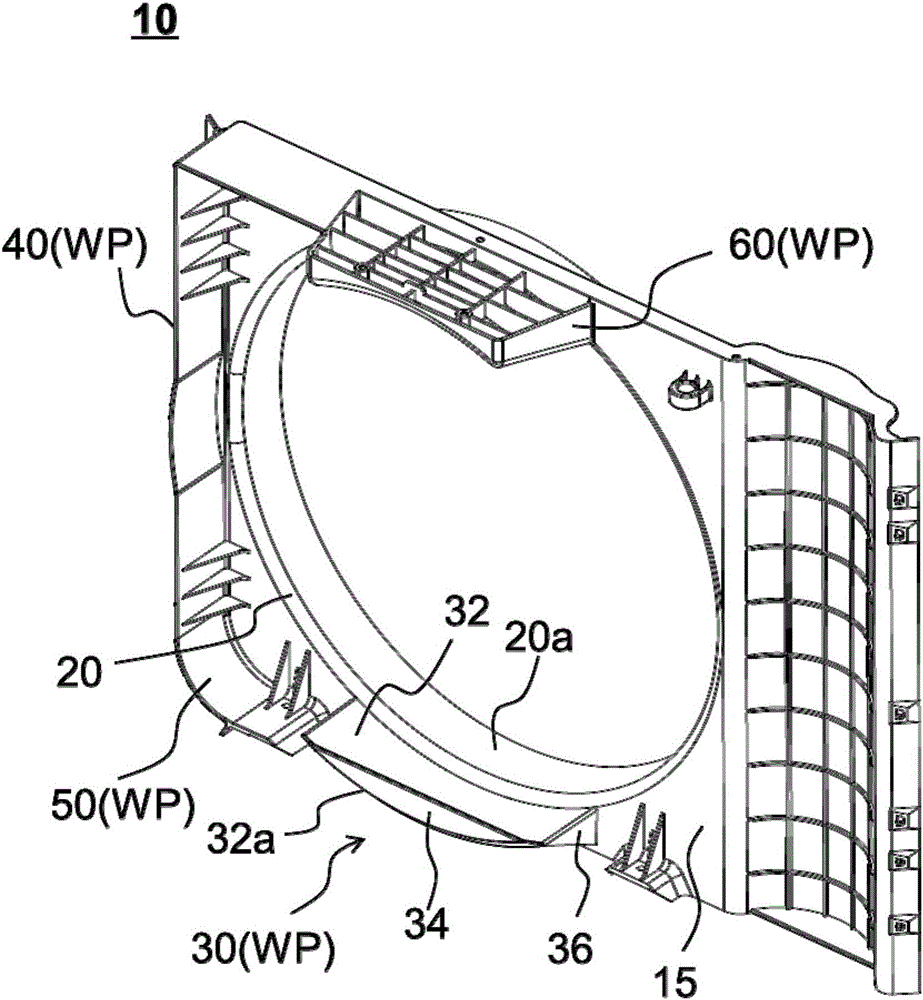

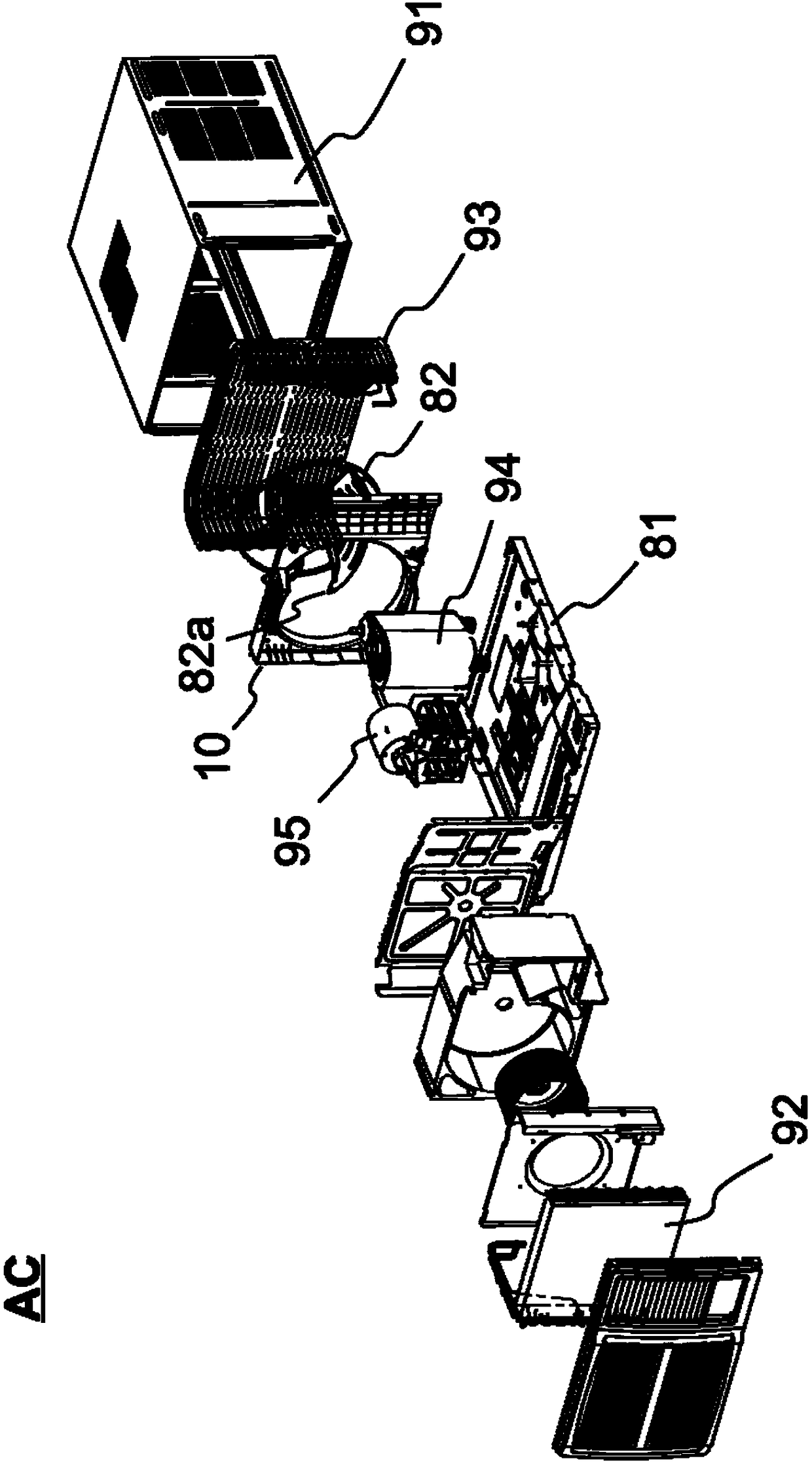

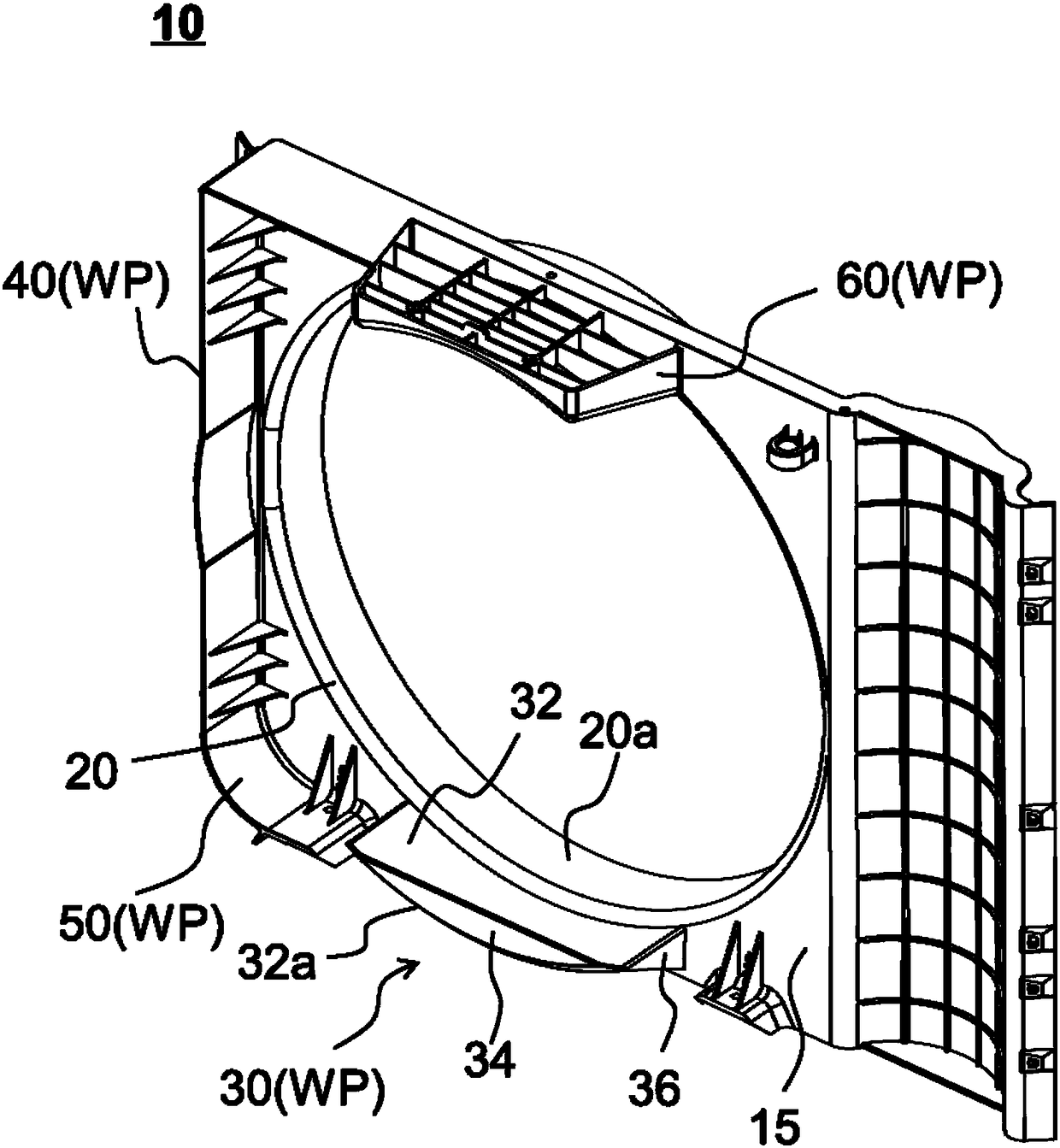

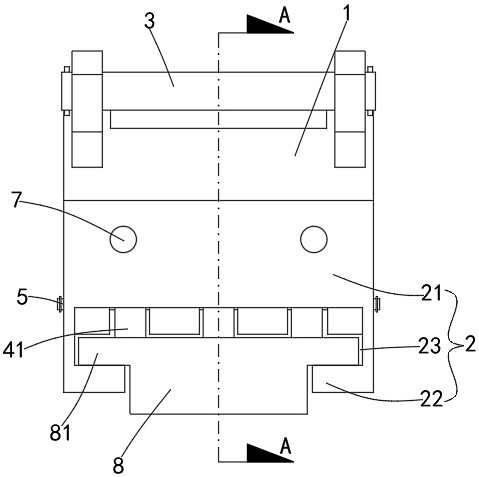

Partition plate used for window air conditioner, and window air conditioner

ActiveCN106338135AReduce flying waterSolve or alleviate the problem of flying waterLighting and heating apparatusSpace heating and ventilation detailsEngineeringFan blade

The invention relates to a partition plate used for a window air conditioner, and the window air conditioner. The partition plate (10) used for the window air conditioner (AC) is provided according to one aspect of the invention. The window air conditioner (AC) comprises a bottom plate (81) and a fan (82). A flow guide ring (20) is arranged on the partition plate (10). Fan blades of the fan (82) correspond to the flow guide ring (20). The partition plate (10) is provided with a water flying preventing structure (WP) suitable for limiting accumulated water on the bottom plate (81) from splashing towards the outside of the window air conditioner (AC). According to the other aspect of the invention, the window air conditioner (AC) comprising the partition plate (10) is provided. According to the partition plate used for the window air conditioner, and the window air conditioner, the problem that water splashes when the window air conditioner operates under a humidity-state working condition can be solved or relieved.

Owner:GREE ELECTRIC APPLIANCES INC

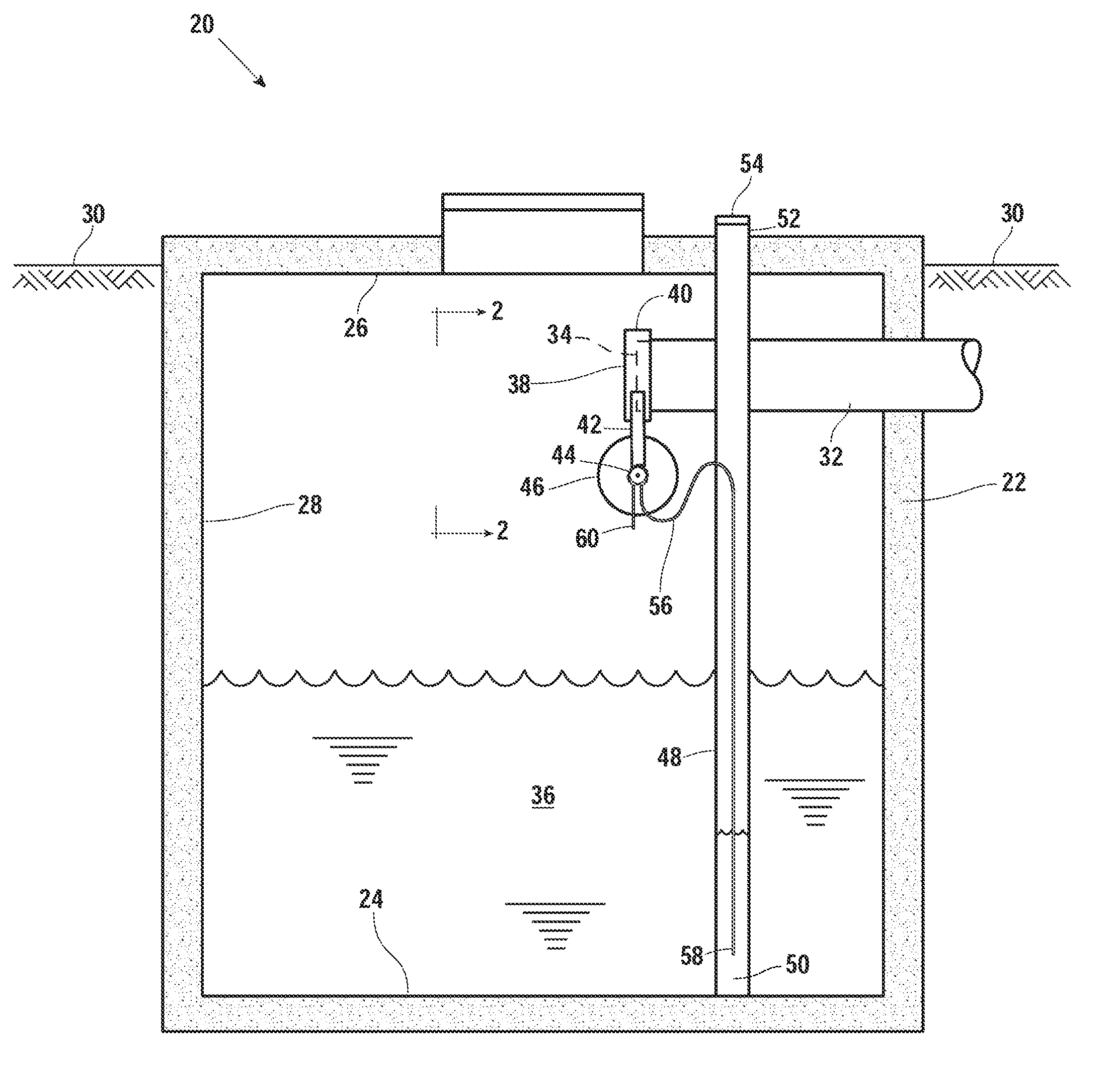

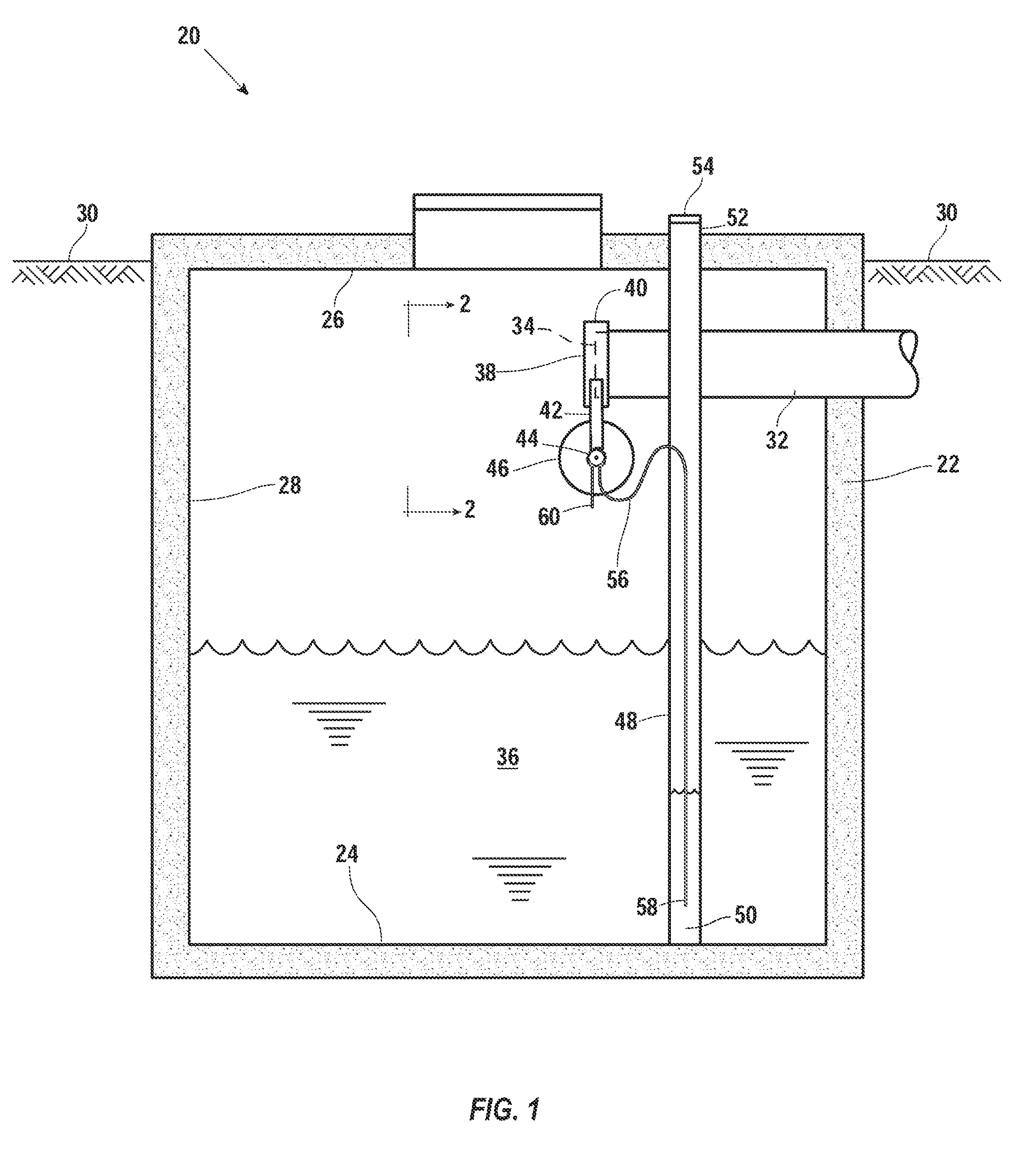

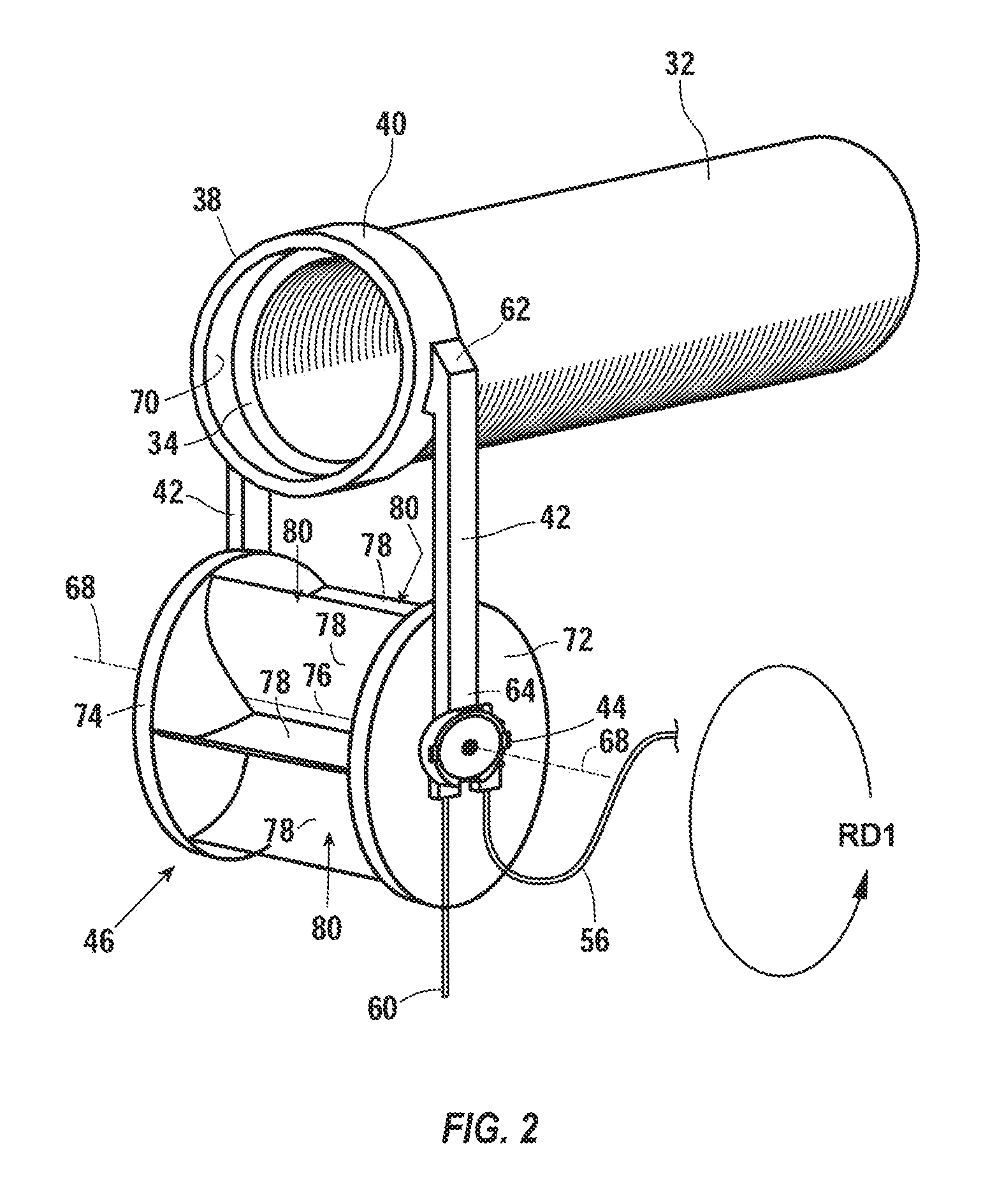

Chemical Delivery System for Water or Effluent Treatment

ActiveUS20160251242A1Limit contactLong contact timeSpecific water treatment objectivesWater/sewage treatment by substance additionDisinfectantCompound (substance)

A system for delivering disinfectant or other chemicals to effluent or water within a containment vessel, such as a wastewater storage tank. The invention includes a mounting bracket or housing; a rotor rotationally connected to the mounting bracket; a shaft connecting the rotor to the mounting bracket; a pump connected to the shaft, the pump having a casing and a rotor assembly; a container; and an tube having a first end within the container and a second end outside the container, a portion of the tube positioned within the pump and in contact with the rotor assembly.

Owner:BRADEN MICHAEL R

Preparation method and application of rare earth yttrium-doped alumina nano-material

ActiveCN105056876AInhibit sinteringUniform pore sizeOther chemical processesWater/sewage treatment by sorptionYttriumSOLUTION/DROPS

The invention provides a preparation method and application of a rare earth yttrium-doped alumina nano-material. The preparation method comprises the following steps: 1, preparing an aluminium sulfate solution; 2, preparing a sodium metaaluminate solution; 3, dripping the sodium metaaluminate solution into the aluminium sulfate solution to obtain a suspension; 4, ageing the suspension to obtain a white sediment; 5, washing the white sediment; 6, adding the washed white sediment and cetyl trimethyl ammonium bromide into water to obtain a mixed solution; 7, adding rare-earth yttrium nitrate into the mixed solution to obtain a rare-earth mixed solution; 8, performing static crystallization on the rare-earth mixed solution, and then drying to obtain a precursor of a rare earth yttrium-doped alumina nano-material; 9, calcining to obtain the rare earth yttrium-doped alumina nano-material which is used for adsorbing arsenic in water. The prepared rare earth yttrium-doped alumina nano-material has the properties of being uniform in doping and crystal aperture, can be used for adsorbing arsenic in water and has a favorable application prospect.

Owner:朱新洁

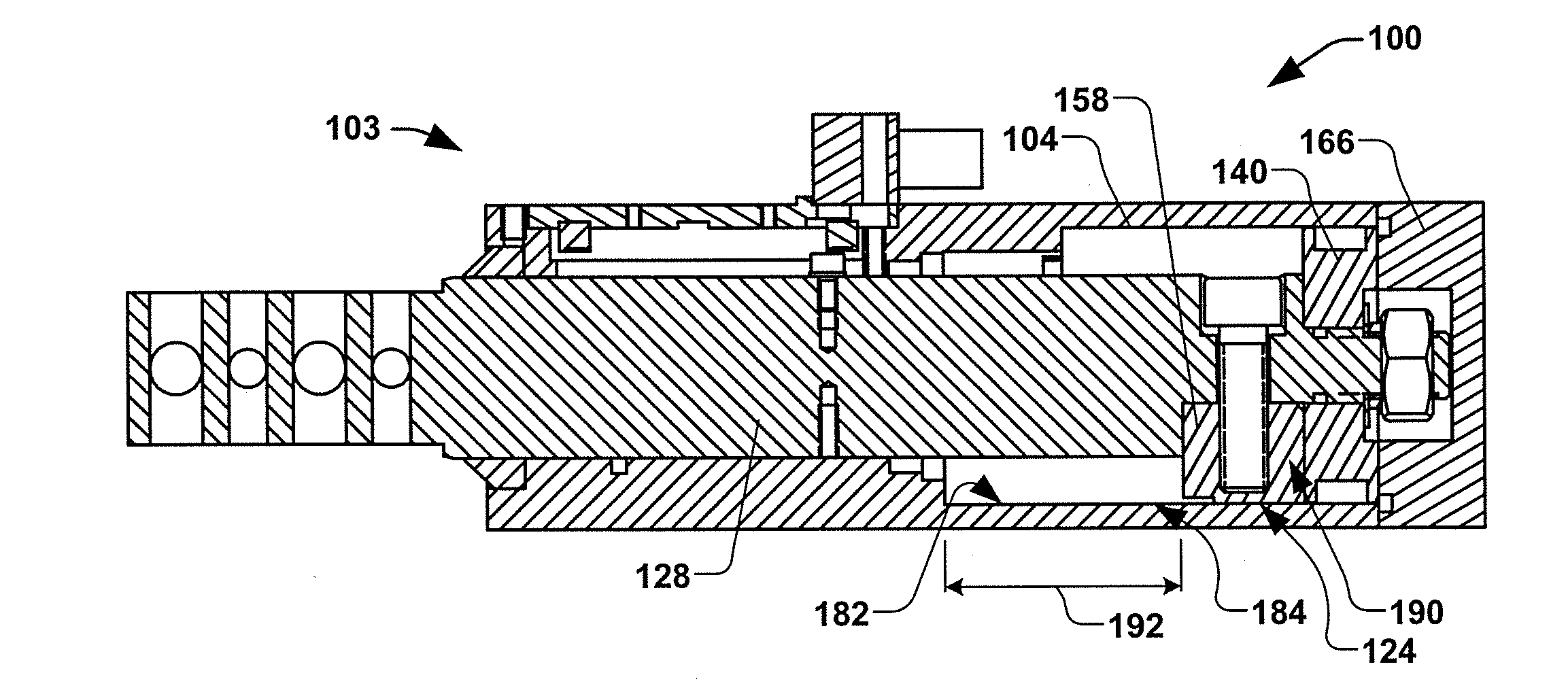

Compact Linear Actuator with Anti-Rotation Device

ActiveUS20130269516A1Limit contactPrevent from rotatePlungersFluid-pressure actuatorsBearing surfacePiston

A linear actuator is provided having a housing with a bore having at least first and second portions extending therethrough. The second portion has a polygonal geometry with substantially rounded corners having at least one planar bearing surface. A shaft is in sliding engagement with the first portion of the bore, and a piston member is operatively coupled to the shaft. The piston member has a mating geometry to the second portion of the bore, wherein the piston member is in sliding engagement with the second portion of the bore. An anti-rotation member is coupled to the piston member or shaft and has a generally D-shaped geometry with a planar anti-rotation bearing surface. Contact between the anti-rotation member and the housing is limited to a sliding engagement between the anti-rotation bearing surface and one of the at least one bearing surfaces based on an orientation of the anti-rotation member.

Owner:ZAYTRAN

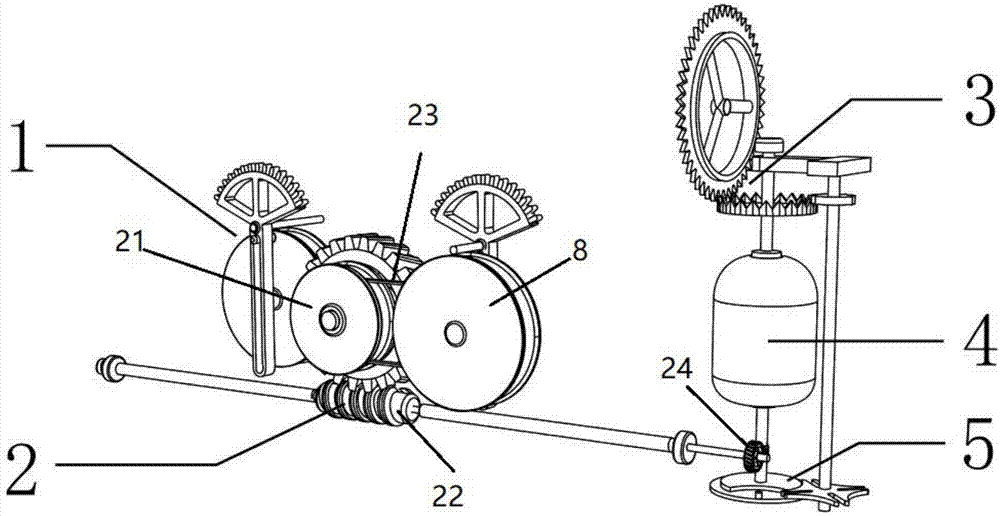

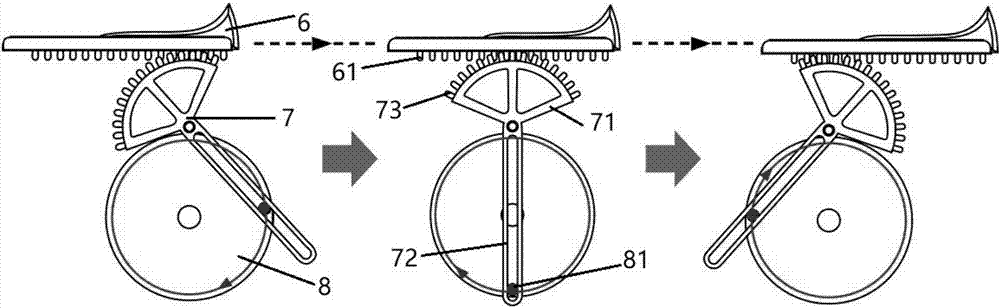

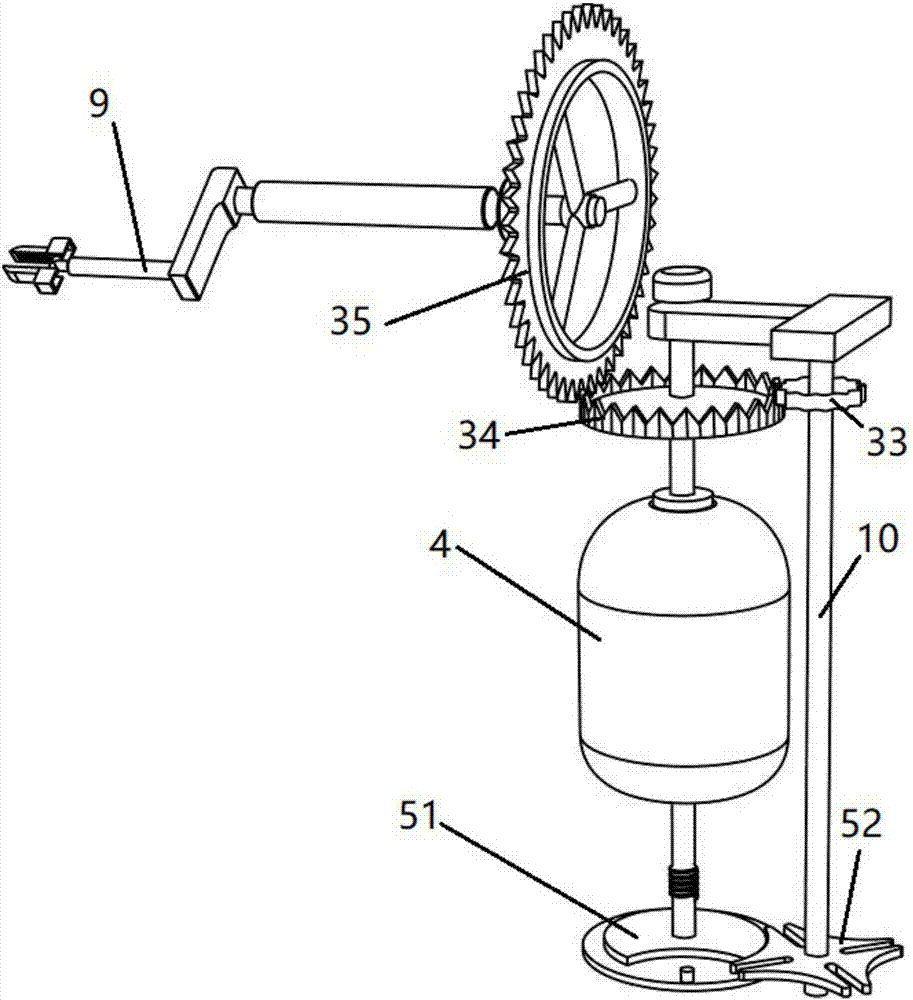

Equipment applicable to bamboo furniture processing

PendingCN107351215AReduce manual errors and scrapImprove yield rateWood splittingCane mechanical workingScrapEngineering

The embodiment of the invention discloses equipment applicable to bamboo furniture processing. A driving mechanism drives a chopper on a linear reciprocating motion mechanism to conduct linear motion, and also drives a groove wheel mechanism at the same time to further drive a clamping mechanism to make a bamboo cylinder rotate for a certain angle after the chopper conducts reciprocating motion every time, and the chopper can repeatedly process the bamboo cylinder on the clamping device to obtain a plate surface of the finished product bamboo furniture. The equipment applicable to bamboo furniture processing can accurately process the bamboo cylinder, and reduce manual errors and scraps, the yield is increased, the contact of the human hand and a cutter is limited, and the safety is improved.

Owner:GUANGDONG UNIV OF TECH

A kind of cathode material for lithium-sulfur battery and lithium-sulfur battery cathode

ActiveCN104143624BSimple processImprove controllabilityElectrode carriers/collectorsFilament/thread formingFiberLithium–sulfur battery

The invention relates to a positive electrode material for a lithium sulfur battery. The positive electrode material is a graphene doped porous hollow fiber, and the doping amount of graphene is 0.005-0.2% of the total mass of the positive electrode material; the porous hollow fiber is a porous hollow tubular structure, the external diameter of the tube is 80-1000nm, the internal diameter of the tube is 30-400nm, and the aperture of pores on the sidewall of the tube is 2-80nm; and graphene is embedded into the sidewall of the porous hollow fiber tube. A battery assembled by adopting a positive electrode made by using the positive electrode material has high discharge specific capacity and good cycle stability.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Melting apparatus for the production of steel

ActiveUS20200164433A1Limit contactAvoids useCasting apparatusDirt cleaningManufacturing engineeringIron production

Owner:DANIELI & C OFF MEC SPA

Ca and Ru-containing lead alloy for lead bath for austenitic heat treatment

InactiveCN108588479AReduce volatilityReduce hazards to people and the environmentHeat treatment bathsLead alloyNew materials

The invention discloses a Ca and Ru-containing lead alloy for a lead bath for austenitic heat treatment and processing process thereof. The Ca and Ru-containing lead alloy is prepared from the components in percentage by weight of 1.5-2.4 wt% of Ca, 0.2-0.8 wt% of Ru, 0.5-1.0 wt% of In, 3.0-5.0 wt% of Cu, 1.0-2.0 wt% of Sr, 0.4-0.8 wt% of Hf and the rest of Pb. The development of the lead alloy for austenitic heat treatment can promote China to develop new high-quality materials independently and occupy the international market of new high-quality materials.

Owner:GUANGZHOU YUZHI TECH CO LTD

High energy accelerator CT rock mechanics test system

ActiveCN109580365BFully reflect the state of the structureFacilitate scientific researchMaterial strength using tensile/compressive forcesMaterial analysis by transmitting radiationHigh energy acceleratorTest sample

The invention belongs to the technical field of mechanics test devices, and specifically relates to a high-energy accelerator CT rock mechanics test system. The high-energy accelerator CT rock mechanics test provided by the invention comprises a mechanics test machine, a high-energy accelerator CT ray source and a detector, the mechanics test machine is arranged between the high-energy acceleratorCT ray source and the detector, the mechanics test machine comprises a fixed component, a rotary apparatus and a pressure chamber, the rotary apparatus is arranged on the fixed component, the pressure chamber is connected with the rotary apparatus, and when a test is executed, the pressure chamber can rotate relative to the fixed component under driving of the rotary apparatus. The test machine is provided with the rotary apparatus, and when the test is executed, the pressure chamber is driven by the rotary apparatus to rotate, namely, a test sample can be scanned in a process in which a loadtest is executed for the test sample, consequently, CT imaging can completely reflect a structural state of the test sample when the test sample is loaded, and scientific researches are facilitated more.

Owner:INST OF GEOLOGY & GEOPHYSICS CHINESE ACAD OF SCI

Anti-corrosion Ru-containing zinc alloy for high-carbon steel hot-dip galvanizing

InactiveCN108411233ANo reduction in mechanical propertiesImprove mechanical propertiesHot-dipping/immersion processesZinc alloysNew materials

The invention discloses an anti-corrosion Ru-containing zinc alloy for high-carbon steel hot-dip galvanizing, and a processing technology thereof. The alloy is prepared from the components in percentage by weight: 0.8 to 1.4 percent of Ba, 0.2 to 0.6 percent of Sc, 1.0 to 1.8 percent of Ru, 1.5 to 2.0 percent of Pd, 0.4 to 0.8 percent of Mo, 0.2 to 0.5 percent of In, and the balance zinc. The anti-corrosion Ru-containing zinc alloy for high-carbon steel hot-dip galvanizing, and the processing technology thereof provided by the invention are conducive to developing the high-quality zinc alloy for hot-dip galvanizing, and have a promoting effect on improving Chinese independent research and development high-quality new materials and occupying an international high-quality new material market.

Owner:GUANGZHOU YUZHI TECH CO LTD

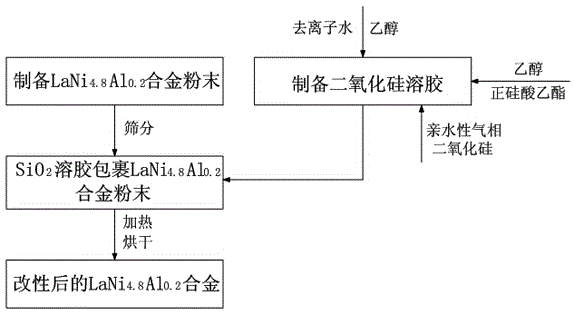

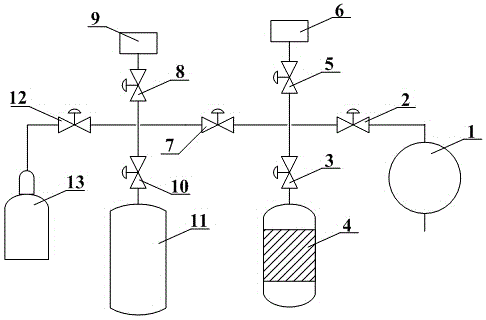

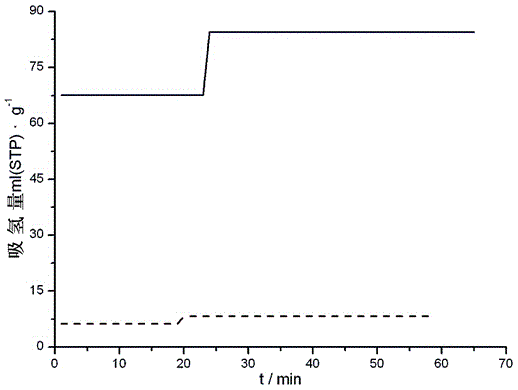

Method for enhancing lani4.8al0.2 alloy's resistance to CO, CO2, air poisoning and pulverization

The invention discloses a method for enhancing the performance of LaNi4.8Al0.2 alloy to resist CO, CO2 and air poison and the anti-pulverization performance of the alloy, which comprises the steps of S1: preparing LaNi4.8Al0.2 alloy powder; S2: sieving the LaNi4.8Al0.2 alloy powder; S3: mixing ethyl alcohol with deionized water to obtain a mixed solution; S4: adding concentrated hydrochloric acid to adjust the pH value and obtain a first mixture; S5: mixing tetraethoxysilane with ethyl alcohol to obtain a second mixture; S6: mixing the first mixture with the second mixture to obtain a third mixture; S7: standing, and heating the third mixture to volatilize the ethyl alcohol; S8: adding hydrophilic gaseous phase silicon dioxide to the third mixture so as to obtain a silicon dioxide sol; S9: adding the LaNi4.8Al0.2 alloy powder to the silicon dioxide sol so as to obtain paste; S10: heating and drying the paste. According to the method disclosed by the invention, the problem that the LaNi4.8Al0.2 alloy is poor in anti-pulverization performance and poor in anti-poison capability is solved, the use stability of the LaNi4.8Al0.2 alloy is enhanced, and the service life of the LaNi4.8Al0.2 alloy is prolonged.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Re and Ge-containing bismuth bath alloy for thermal treatment of high work efficiency leadfree troostite

InactiveCN108441676APrevent flash evaporationPrevent oxidationFurnace typesQuenching agentsHardnessAlloy

The invention discloses a Re and Ge-containing bismuth bath alloy for thermal treatment of high work efficiency leadfree troostite and a processing technology thereof. The Re and Ge-containing bismuthbath alloy is prepared from the following components in percentage by weight: 1.0-1.5wt.% of Ba, 0.5-1.4wt.% of Re, 2.0-2.5wt.% of Ge, 0.2-0.4wt.% of Sc, 0.4-0.5wt.% of Pr, 1.5-2.0wt.% of Ni and thebalance of bismuth. The bismuth alloy replaces a lead bath alloy for thermal treatment, so that contact of a steel wire and air is limited to prevent decarbonization. Compared with common heating methods, the hardness of the surface of the steel wire is improved, the probability of crack formation and expansion is reduced, and the fatigue performance of the steel wire is improved.

Owner:GUANGZHOU YUZHI TECH CO LTD

Partitions for window air conditioners and window air conditioners

ActiveCN106338135BSolve or alleviate the problem of flying waterLimit contactLighting and heating apparatusSpace heating and ventilation detailsEngineeringFan blade

The invention relates to a partition plate used for a window air conditioner, and the window air conditioner. The partition plate (10) used for the window air conditioner (AC) is provided according to one aspect of the invention. The window air conditioner (AC) comprises a bottom plate (81) and a fan (82). A flow guide ring (20) is arranged on the partition plate (10). Fan blades of the fan (82) correspond to the flow guide ring (20). The partition plate (10) is provided with a water flying preventing structure (WP) suitable for limiting accumulated water on the bottom plate (81) from splashing towards the outside of the window air conditioner (AC). According to the other aspect of the invention, the window air conditioner (AC) comprising the partition plate (10) is provided. According to the partition plate used for the window air conditioner, and the window air conditioner, the problem that water splashes when the window air conditioner operates under a humidity-state working condition can be solved or relieved.

Owner:GREE ELECTRIC APPLIANCES INC

Lead alloy for high-temperature heat treatment and with anti-oxidation and evaporation-resistance characteristics

The invention discloses lead alloy for high-temperature heat treatment and with anti-oxidation and evaporation-resistance characteristics and a processing technique thereof. The lead alloy is preparedfrom, by weight, 1.0-2.0 wt.% of Ca, 0.5-1.2 wt.% of Os, 0.8-1.5 wt.% of Sb, 2.0-4.0 wt.% of Y, 1.2-1.8 wt.% of Ba, 0.2-0.4 wt.% of Eu and the balance Pb. The lead alloy for austenitizing heat treatment has a promoting effect on improving the independent research and development of novel high-quality materials in China and occupying the international market of novel high-quality materials.

Owner:GUANGZHOU YUZHI TECH CO LTD

A method to enhance the anti-air poisoning performance of zr2fe alloy

The invention discloses a method for enhancing air poison resistance of Zr2Fe alloy. The method for enhancing the air poison resistance of the Zr2Fe alloy includes steps: S1, simultaneously loading Zr2Fe alloy particles and stainless steel balls into a stainless steel vacuum ball milling tank, and connecting the stainless steel vacuum ball milling tank with a hydrogen storage performance test system; S2, pumping gas out of the stainless steel vacuum ball milling tank, and inflating the stainless steel vacuum ball milling tank with argon gas; S3, performing ball milling on the Zr2Fe alloy particles; S4, inflating the stainless steel vacuum ball milling tank with the argon gas, and passivating the Zr2Fe alloy particles; S5, placing the stainless steel vacuum ball milling tank into a glove box, controlling air inflow of air, and exposing Zr2Fe alloy powder to air; S6, sieving the Zr2Fe alloy powder; S7, preparing silicon dioxide sol; S8, adding the Zr2Fe alloy powder into the silicon dioxide sol and stirring the Zr2Fe alloy powder so as to form cream; S9, heating and drying the cream. The method for enhancing the air poison resistance of the Zr2Fe alloy solves the problem that the Zr2Fe alloy is poor in air poison resisting ability, strengthens use stability of the Zr2Fe alloy, and prolongs use life of the Zr2Fe alloy.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Sn-Mn-containing bismuth bath alloy for heat treatment and with excellent heat transfer performance

InactiveCN108642322APrevent oxidationPrevent volatilizationFurnace typesQuenching agentsAlloyBismuth

The invention discloses a Sn-Mn-containing bismuth bath alloy for heat treatment and with excellent heat transfer performance and a processing technology of the Sn-Mn-containing bismuth bath alloy. The Sn-Mn-containing bismuth bath alloy comprises, by weight percentage, 1.0-1.8 wt.% of Ba, 4.0-6.0 wt.% of Sn, 0.5-1.0 wt.% of Mn, 0.2-0.5 wt.% of Sc, 0.2-0.3 wt.% of Sm, 1.0-2.0 wt.% of Ni and the balance bismuth. The bismuth bath alloy is used to replace a lead bath alloy for heat treatment, so that the contact between a steel wire and air is limited, and decarburization is prevented; and compared with a common heating method, the hardness of the steel wire surface is improved, the possibility of crack formation and spreading is reduced, and the fatigue performance of the steel wire is improved.

Owner:GUANGZHOU YUZHI TECH CO LTD

Preparation method and application of a rare earth yttrium-doped alumina nanomaterial

ActiveCN105056876BLimit contactPrevent sinteringOther chemical processesWater/sewage treatment by sorptionSodium aluminateYttrium

The invention provides a preparation method and application of a rare earth yttrium-doped alumina nano-material, comprising: step 1, preparing an aluminum sulfate solution; step 2, preparing a sodium metaaluminate solution; step 3, adding the sodium metaaluminate solution dropwise into the aluminum sulfate solution to obtain a suspension; step 4, aging the suspension to obtain a white precipitate; step 5, washing the white precipitate; step 6, washing the white precipitate and hexadecyl triethyl Ammonium bromide is added to water to obtain a mixed solution; step 7, adding rare earth yttrium nitrate to the mixed solution to obtain a rare earth mixed solution; step 8, performing static crystallization on the rare earth mixed solution, and then drying to obtain rare earth yttrium-doped alumina Precursor of nanomaterials; step 9, calcining to obtain rare earth yttrium-doped alumina nanomaterials, and using it to adsorb arsenic in water. The nanometer material prepared by the invention has the properties of uniform doping and uniform crystal pore size, can be used to adsorb arsenic in water, and has good application prospects.

Owner:朱新洁

Energy-saving type zinc alloy containing Re for white spot and black spot free steel wire hot-dip galvanizing

InactiveCN108396180ALow melting pointPrevent oxidationHot-dipping/immersion processesBlack spotZinc alloys

The invention discloses energy-saving type zinc alloy containing Re for white spot and black spot free steel wire hot-dip galvanizing and a machining process for the zinc alloy. The alloy comprises the ingredients of, in percentage by weight, 0.4-0.6% of Ba, 0.3-0.8% of Se, 0.4-0.6% of Re, 1.2-1.5% of Ge, 0.4-0.6% of Mo, 0.5-0.8% of Bi and the balance zinc. By means of the energy-saving type zincalloy containing Re for white spot and black spot free steel wire hot-dip galvanizing and the machining process for the zinc alloy, development of the high-quality zinc alloy for hot-dip galvanizing is facilitated, the zeta-free phase galvanizing layer can be obtained, and white spots and black spots of the plating layer can be inhibited.

Owner:GUANGZHOU YUZHI TECH CO LTD

Electric fornace with insulated electrode and process for producing molten metals

InactiveCN1073629CDo not reduce voltageResistivity effectElectric discharge heatingOhmic-resistance electrodesFiberElectric arc furnace

An electric arc furnace (10) having a partially insulated electrode (37) produces molten metal (28) such as foundry iron from an iron source where little or no slag (30) is produced. The furnace (10) includes at least one insulated electrode (37) for immersing deep into the metal charge (26). An insulating coating can be a fibrous mat (48) wrapped around the electrode or a spray coating (72). In one embodiment, the electrode (156) has a coupling (172) at a first end (176) for coupling with an electrically conducting member (142) and a coupling (172) at the second end (178) for coupling with an adjacent electrode to form an electrode column. The coupling members (172) can be an internally threaded recess (166, 168) in the ends thereof. An externally threaded coupling member (172) can be threaded into the recesses (166, 168) of the electrodes (157) for coupling two or more electrodes (157) together.

Owner:ALABAMA POWER

Lead-free In-containing and Ta-containing bismuth bath alloy for troostite heat treatment

InactiveCN108531772APrevent oxidationPrevent volatilizationFurnace typesQuenching agentsAlloyBismuth

The invention discloses a lead-free In-containing and Ta-containing bismuth bath alloy for troostite heat treatment and a processing technology thereof. The lead-free In-containing and Ta-containing bismuth bath alloy comprises, by weight, 1.0-1.5% of Ba, 0.2-0.4% of In, 0.6-1.2% of Ta, 0.4-0.6% of Sc, 0.2-0.3% of Sm, 1.0-2.0% of Co, and the balance bismuth. The bismuth bath alloy is used for replacing a lead bath alloy for heat treatment, the contact between steel wires and the air is limited, and decarburization is prevented. Compared with an ordinary heating method, the hardness of the steel wire surface is improved, the possibility of crack formation and expansion is reduced, and the fatigue property of the steel wires is improved.

Owner:GUANGZHOU YUZHI TECH CO LTD

A t-shaped guide rail fall arrester

ActiveCN112727049BPrevent fallingRealize active triggeringScaffold accessoriesBuilding support scaffoldsControl theoryFriction force

The present invention proposes a T-shaped guide rail fall arrester, which includes a main body, a first movable body, a hinge mechanism and a locking part. There is a cavity on the side. The first movable body includes a first movable part and a first trigger part. The first movable part is slidably connected to the upper surface of the first fixed part and can move horizontally in the direction of the second fixed part. The locking part is located in the cavity. In the groove, the locking part has a movable end, and the movable end can rotate clockwise or counterclockwise around the horizontal line between the abutment surface and the end surface of the guide rail facing the wall; when the guide rail falls freely, through the friction force and the downward impact force It will cause the trigger part to move away from the wall, drive the movable end to screw into the first space and approach the second fixed part, and press the movable end, so that the flange plate of the guide rail is fixedly clamped between the movable end and the second fixed part. Between the two fixed parts, the purpose of preventing the guide rail from falling is realized.

Owner:GUANGZHOU DAMON SECURITY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com