Patents

Literature

56results about How to "High hydrogen production rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Methanol catalytically reforming hydrogen producing apparatus utilizing afterheat of internal combustion engine and its control method

InactiveCN1887691AImprove conversion rateHigh hydrogen production rateHydrogenHydrogenExternal combustion engine

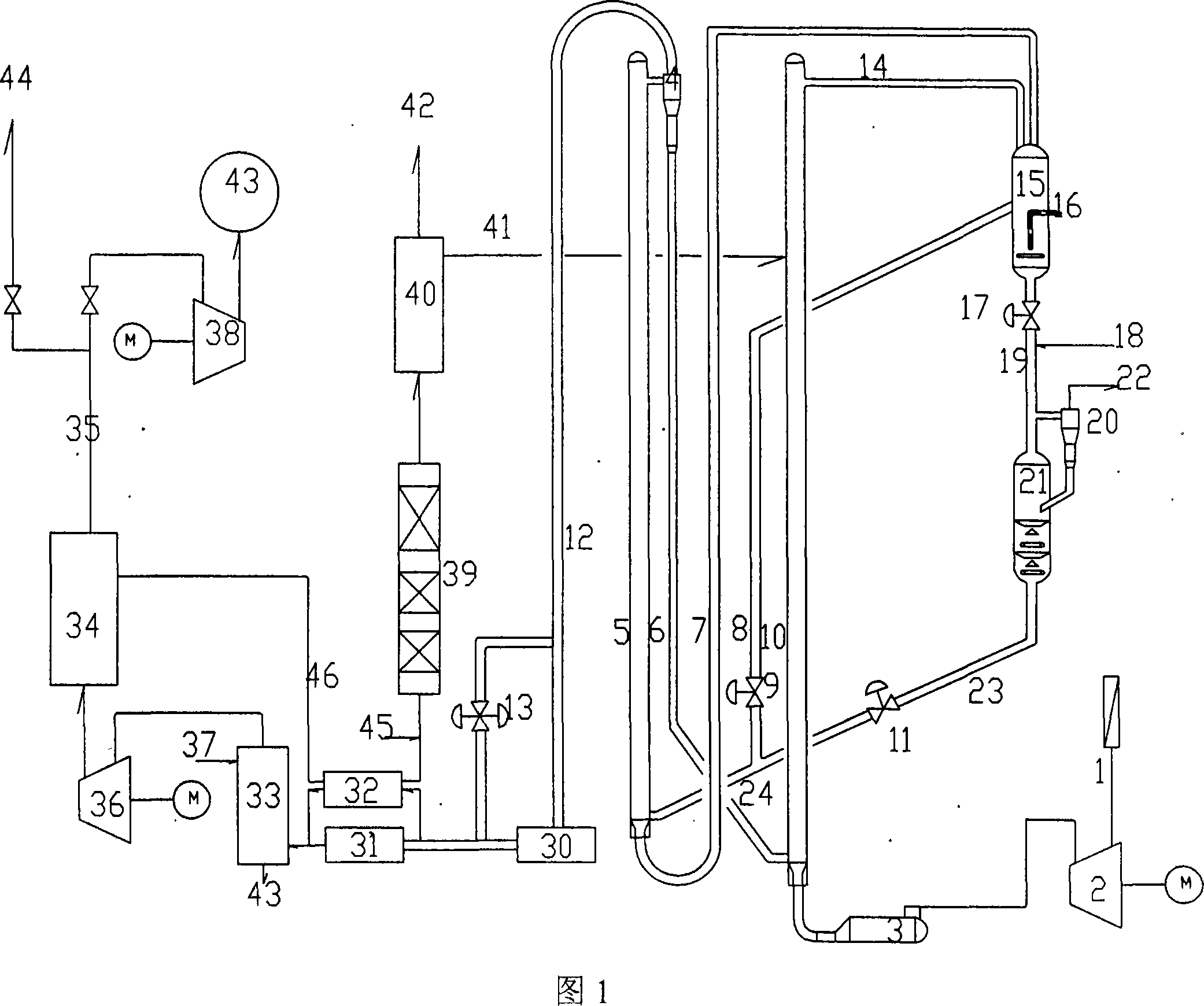

The present invention relates to internal combustion engine afterheat utilizing technology, and is especially methanol catalytically reforming hydrogen producing apparatus utilizing afterheat of internal combustion engine and its control method. The apparatus includes mainly methanol aqua gasifying cavities in the front part, middle part and back part of the reformer casing, catalytically reacting cavity and reformed gas product cavity. In the middle part inside the reformer casing, there are porous honeycomb ceramic with inside catalytically reacting cavity; and the inner wall of the catalytically reacting cavity has set honeycomb pores with reforming catalyst coated to the inner wall. One heat exchange pipe penetrates the porous honeycomb ceramic axially. The present invention has integrated heat exchange pipe and porous honeycomb ceramic, and possesses compact structure, high heat exchange efficiency, high hydrogen rate and other advantages.

Owner:BEIJING UNIV OF TECH

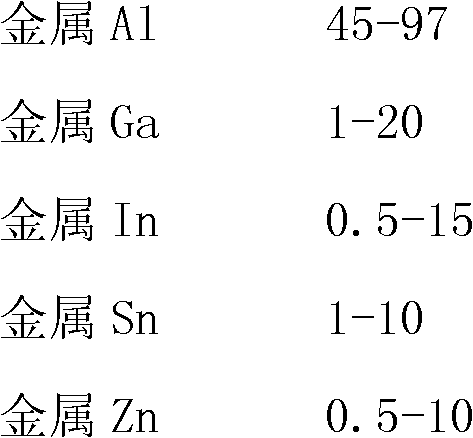

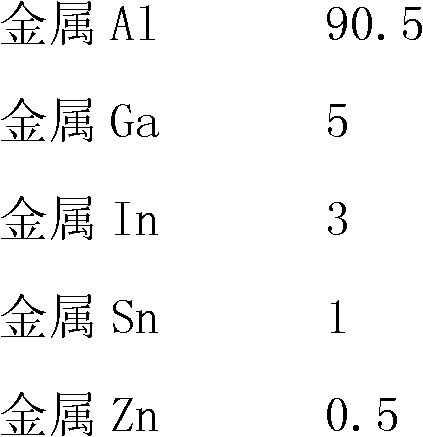

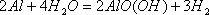

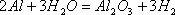

Al-Ga-In-Sn-Zn alloy as well as preparation method and application thereof

The invention relates to an Al-Ga-In-Sn-Zn alloy as well as a preparation method and an application thereof. The alloy is prepared from the following components by weight percent according to a mechanical alloying technique: 45-97wt% of metal Al, 1-20wt% of metal Ga, 0.5-15wt% of metal In, 1-10wt% of metal Sn and 0.5-10wt% of metal Zn. The alloy of the invention can directly react with water at the temperature of larger than or equal to zero DEG C so as to realize the effect of rapidly producing hydrogen; and hydrogen-producing rate reaches more than 90% of a theoretical value, and the reaction rate reaches 200ml / min.s, thereby meeting the dynamic powder requirement of hybrid electric vehicle travelling and greatly improving the utilization rate of gasoline.

Owner:HUBEI UNIV OF TECH

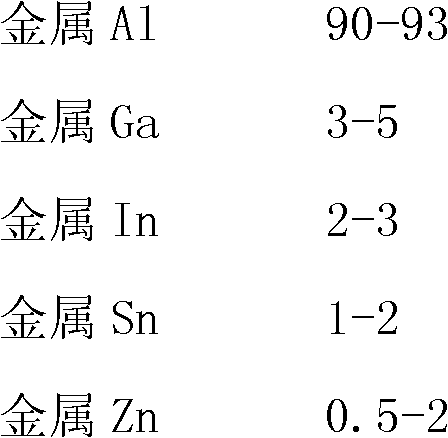

Active aluminum-rich alloy for preparing high purity hydrogen through hydrolysis and preparation method thereof

InactiveCN102560198AHigh hydrogen production rateEasy to prepareHydrogen productionVacuum induction furnaceLiquid alloy

The invention relates to an active aluminum-rich alloy for preparing high purity hydrogen through hydrolysis. The alloy is characterized in that the alloy which is composed of four elements of Al, Ga, In and Sn comprises the following two phases: an Al solid solution and GaIn3Sn. A preparation method of the alloy concretely comprises the following steps: 1, melting the alloy to form a molten alloy by adopting a vacuum induction furnace, wherein the vacuum degree of the vacuum induction furnace is 10<-2>-10<-3>Pa; and 2, stirring the molten alloy by adopting an electromagnetic stirring technology, casting the molten alloy to a water-cooled copper mold, and solidifying, wherein the cooling rate is 101-103DEG C / s. The alloy has the advantages of high hydrogen yield, no pollution, low cost, simple preparation method, convenient operation and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Perovskite material/organic polymer compound photocatalyst, preparation and application

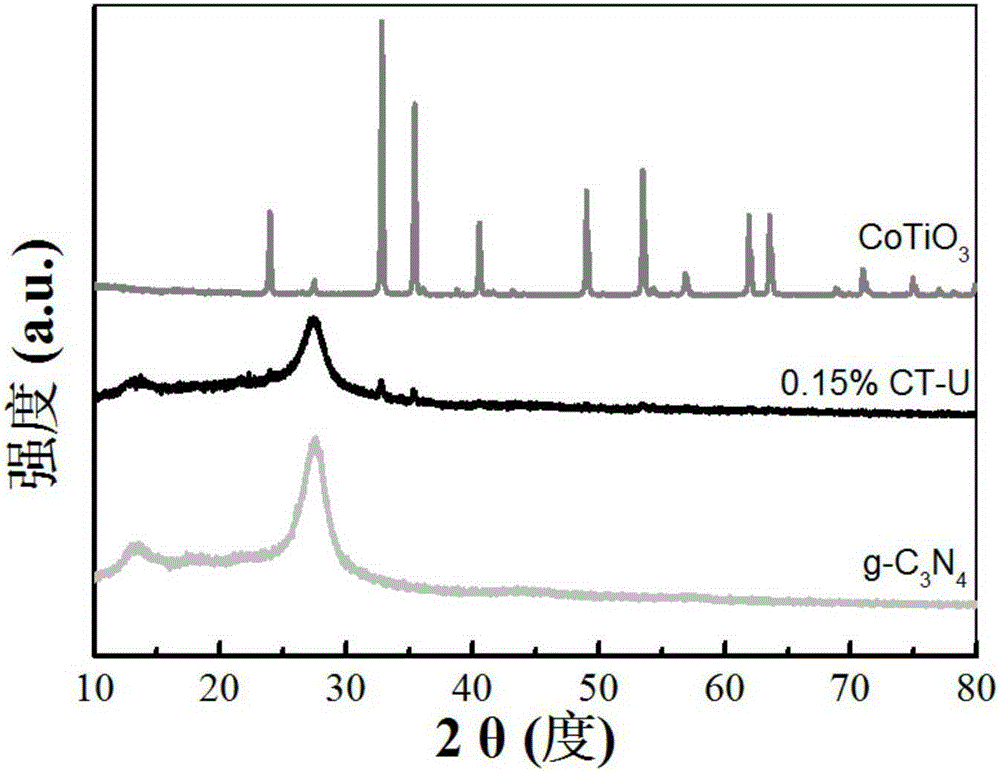

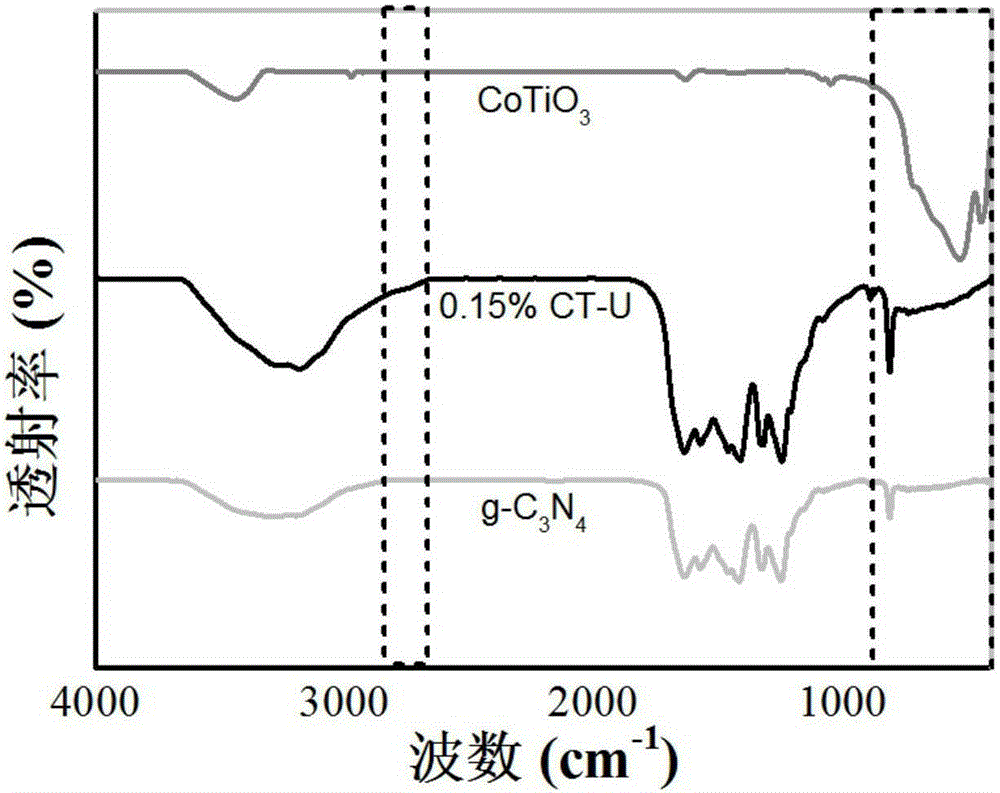

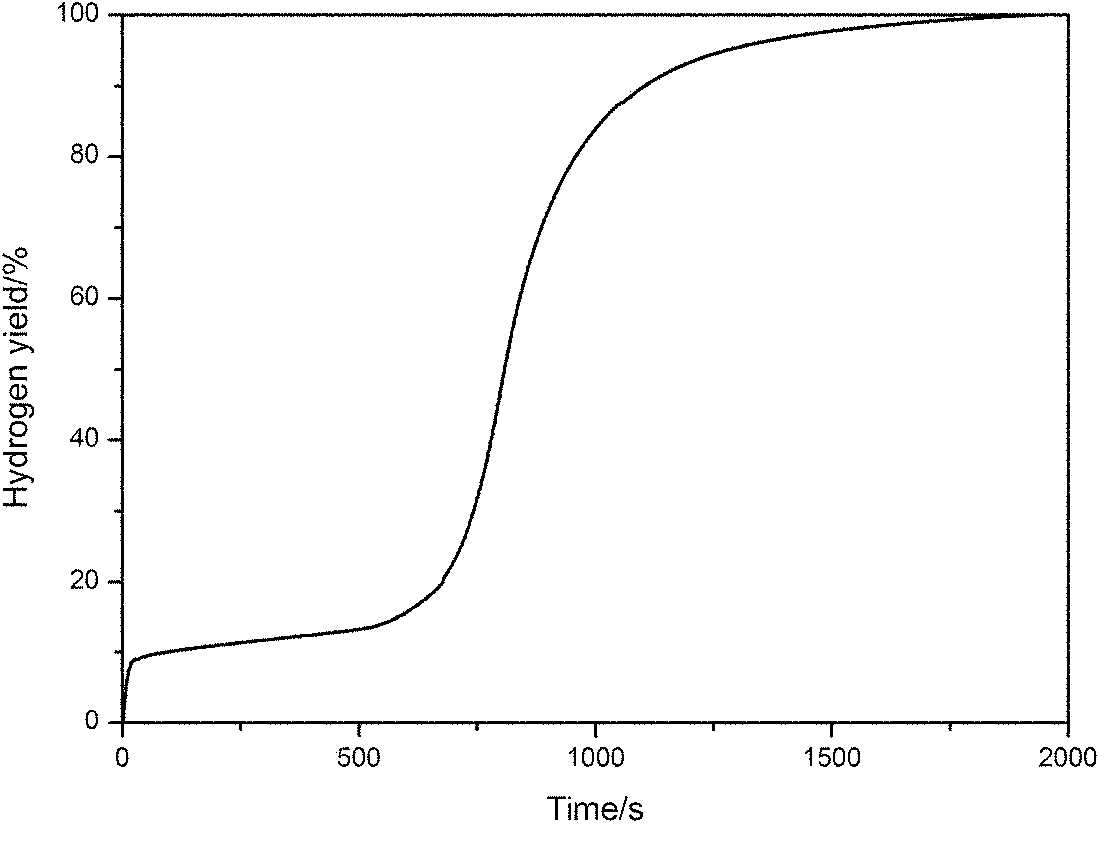

ActiveCN105170173AEasy to prepareEasy to operateOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen productionValence bandCarbon nitride

The invention discloses a perovskite material / organic polymer compound photocatalyst, preparation and application, and belongs to the field of perovskite material / organic polymer compound photocatalyst. Rolled-piece-shaped carbon nitride is successfully dispersed on the surface of cobalt titanate, through compounding of electrons on a cobalt titanate conduction band and holes in a carbon nitride valence band, holes in a cobalt titanate valence band and electrons on a carbon nitride conduction band are separated, and therefore the photocatalytic performance is greatly improved. The material is applied to the field of water photolysis hydrogen production, and the hydrogen production rate is substantially increased compared with pure carbon nitride.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing hydrogen by cracking water by using aluminum-based material

InactiveCN101948093AHigh hydrogen production rateWide variety of sourcesHydrogen productionHydrogenPhysical chemistry

The invention provides a method for preparing hydrogen by cracking water by using an aluminum-based material. The aluminum-based material is prepared from aluminum and oxide or carbonate with different mass percents serving as raw materials and an added salt serving as activating agent; and hydrogen is quickly produced by reacting the aluminum-based material with reaction medium. The hydrogen preparation rate and yield can be adjusted by varying the percent of each component in the aluminum-based material. The aluminum-based material can suppress production of an inertial aluminum oxide film on the surface, greatly improve the hydrogen production rate of alloy and reduce the hydrogen preparation cost.

Owner:CENT SOUTH UNIV

Method for preparing hydrogen and nitrogen by catalytic cracking regenerative fume

InactiveCN101143289ASimple processLow main air consumptionHydrogenProductsHydrogenGlobal wind patterns

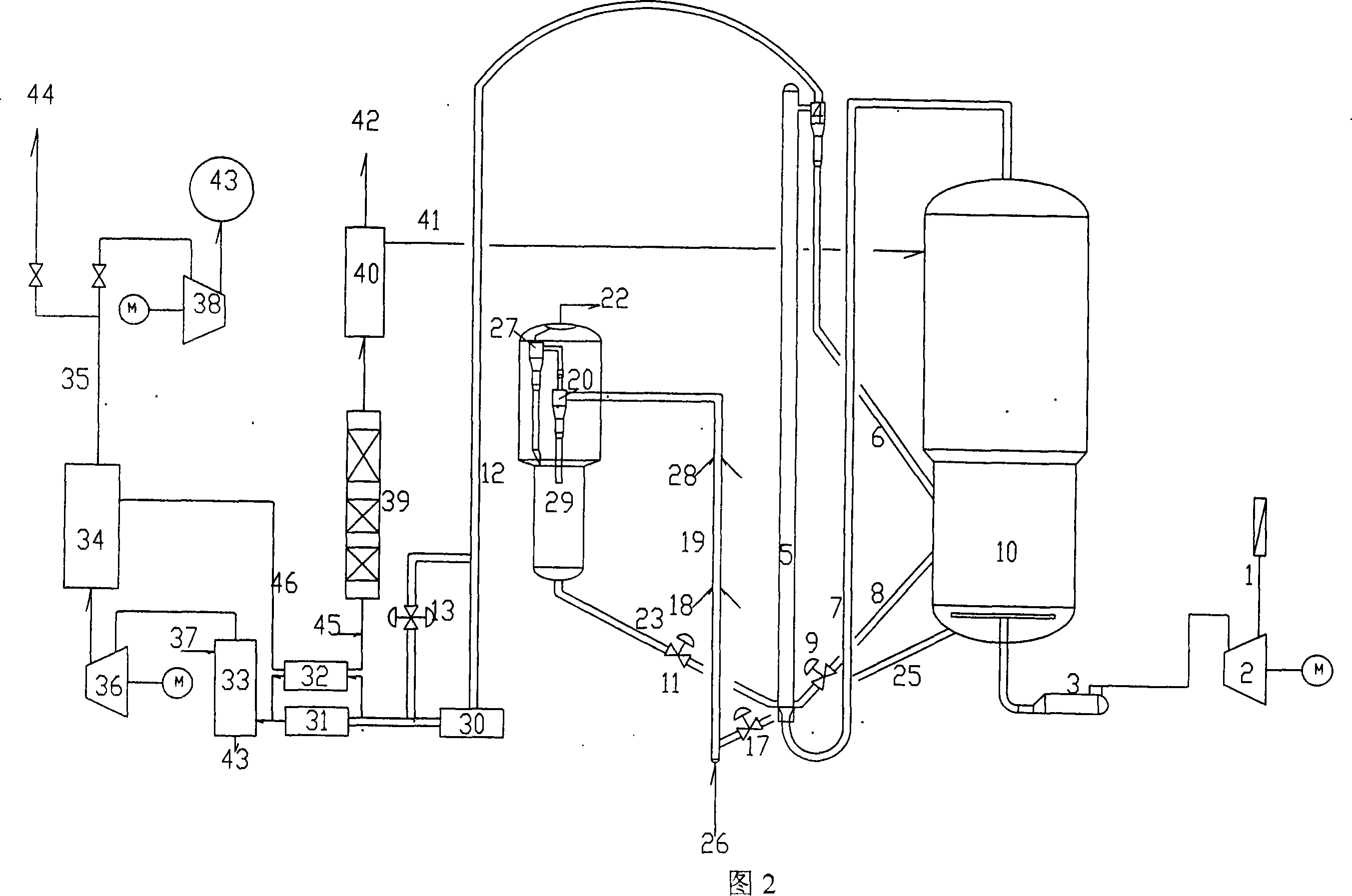

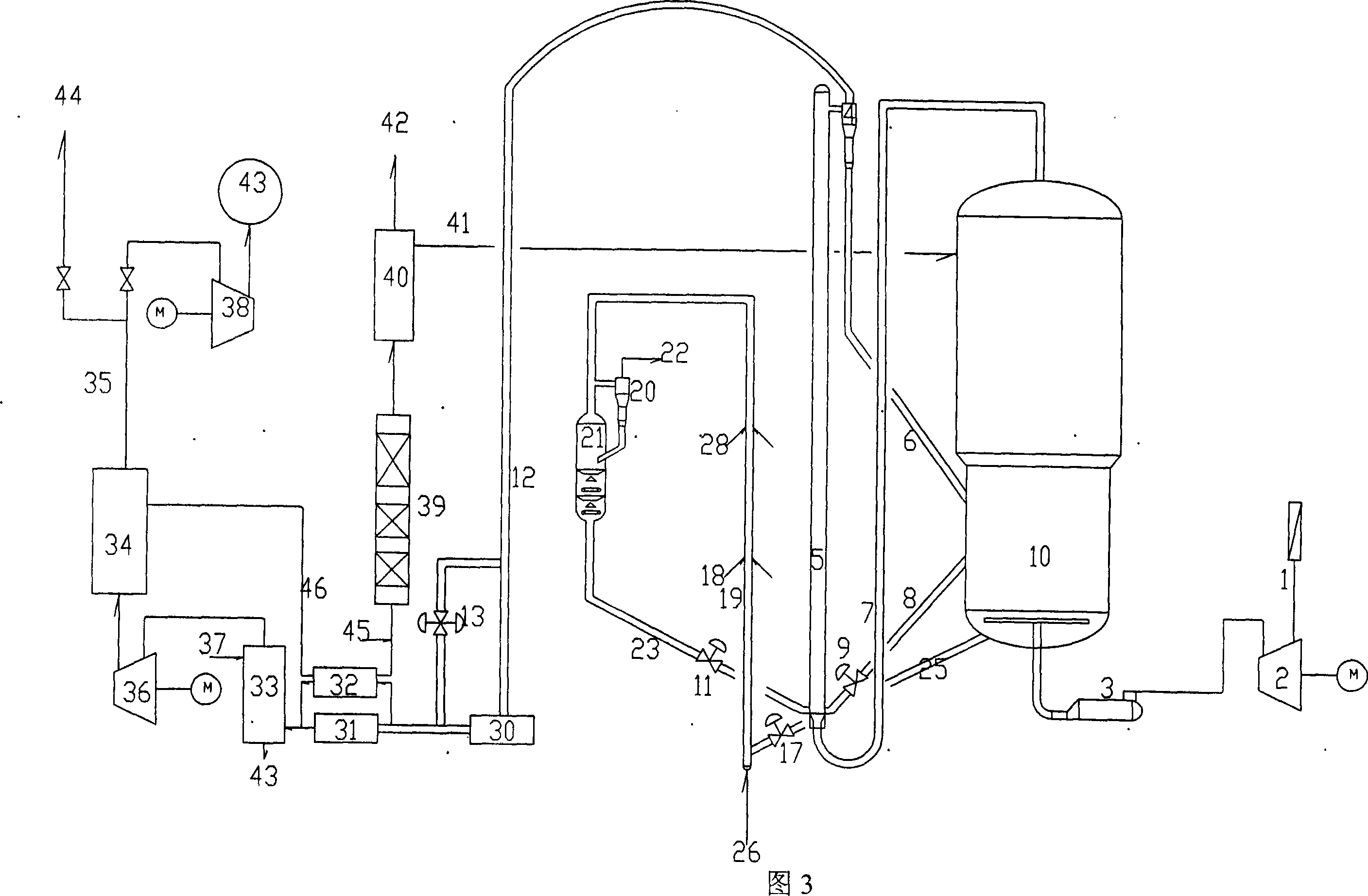

The invention relates to a method of producing hydrogen and nitrogen by catalytic cracking regenerator gas. The invention has main content that: the high temperature oxygen-contained gas of a second regenerator enters to the bottom of a first regenerator, and is contacted, heated and burnt with a mixing catalyst composed of a carbon deposition catalyst in a self stripper and a regenerant in the second regenerator. The regenerating gas on the upper part of the first regenerator is separated from a half-regenerant by a cyclone separator. The generating gas enters into a pressure energy recovery system, and then enters into the subsequent hydrogen and nitrogen producing process. The half-regenerant enters into the second regenerator through a dipleg, and then is contacted and burnt with full burnt prevailing wind. The stripped carbon deposition catalyst backs into the first regenerator, and then a circulating is formed, in order to effectively use CO and CO2 in the regenerating gas and CO2 produced in the subsequent CO intermediate temperature changing process, and to improve the ratio of the carbon deposition on the first regenerator catalyst transferring into CO, and furthermore to improve the unit carbon deposition hydrogen yield rate of the catalyst.

Owner:高玉玲

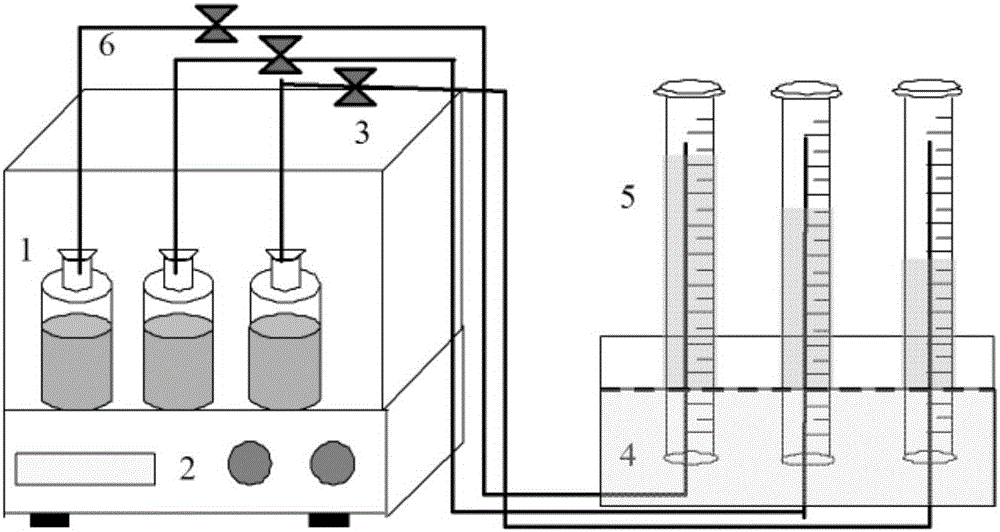

A method of increasing an anaerobic biological hydrogen production yield from organic waste water or waste

InactiveCN105543282ANo additional energy consumptionImprove hydrogen production efficiencyFermentationStress based microorganism growth stimulationSludgeBiological organism

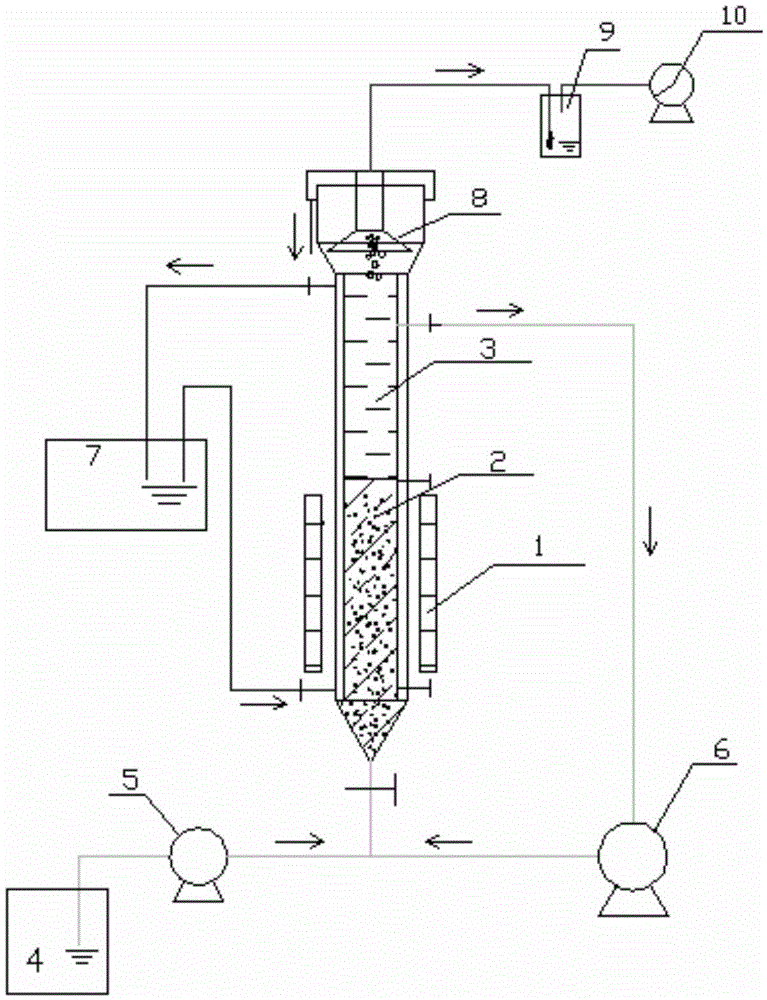

A method of increasing an anaerobic biological hydrogen production yield from organic waste water or waste is disclosed. According to the method, a magnetic field with certain intensity is evenly disposed on the outer wall of a traditional anaerobic hydrogen-producing reactor by means of permanent magnets or electrified coils, or a proper amount of a magnetic carrier material is added into the hydrogen-producing reactor and adopted as a carrier to which hydrogen-producing bacteria are attached, and temperature and a primary pH value of the organic waste water or the waste fed into the hydrogen-producing reactor are controlled, thus enhancing natural selection of anaerobic mixed flora, promoting culture and enrichment of anaerobic bacteria and improving biological activity and settling performance of the hydrogen-producing bacteria, and therefore objectives of efficiently enriching the hydrogen-producing bacteria and efficiently producing hydrogen from the organic waste water or the waste are achieved under a condition that inoculated sludge and the organic waste water are free of pretreatment.

Owner:XIANGTAN UNIV

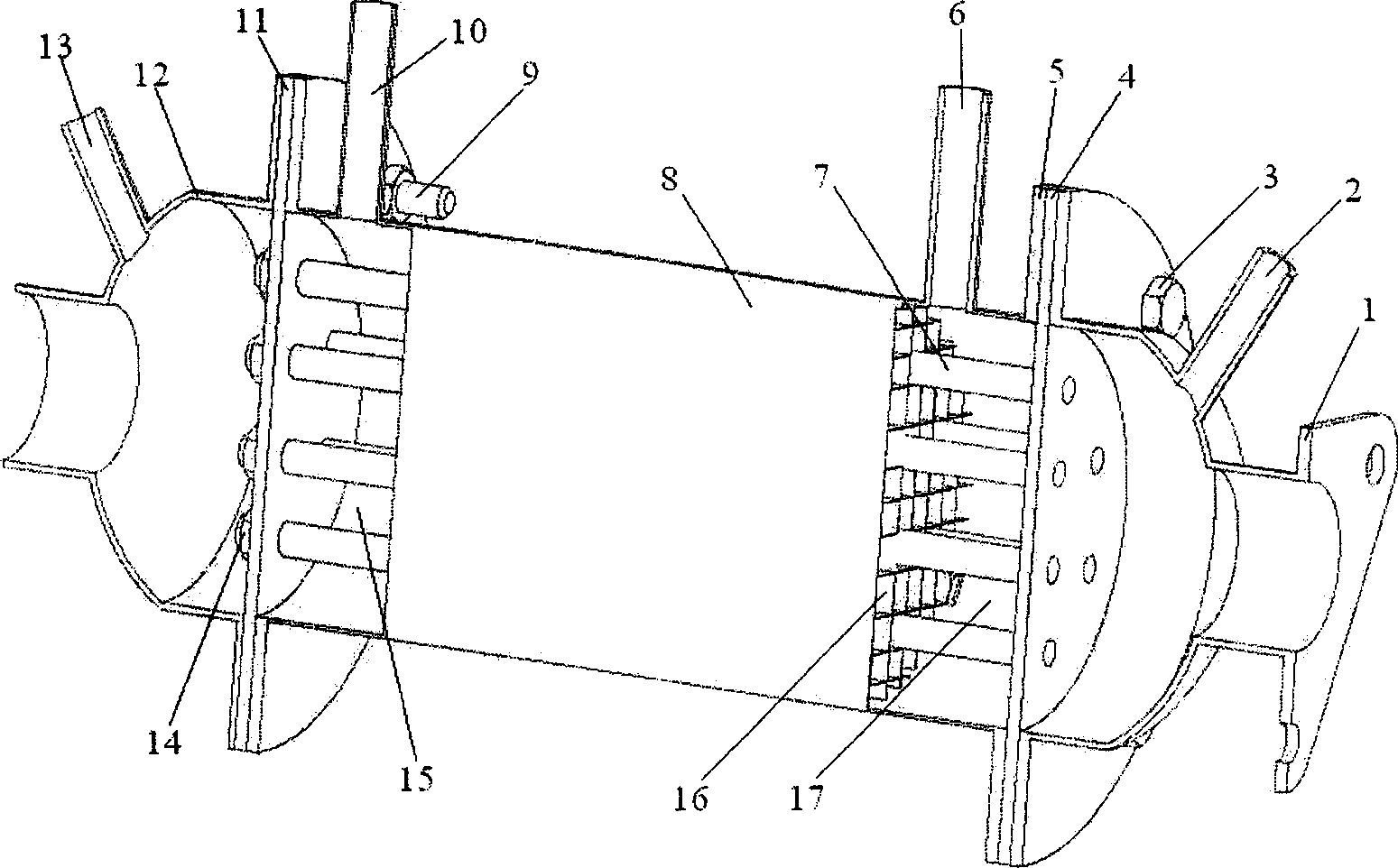

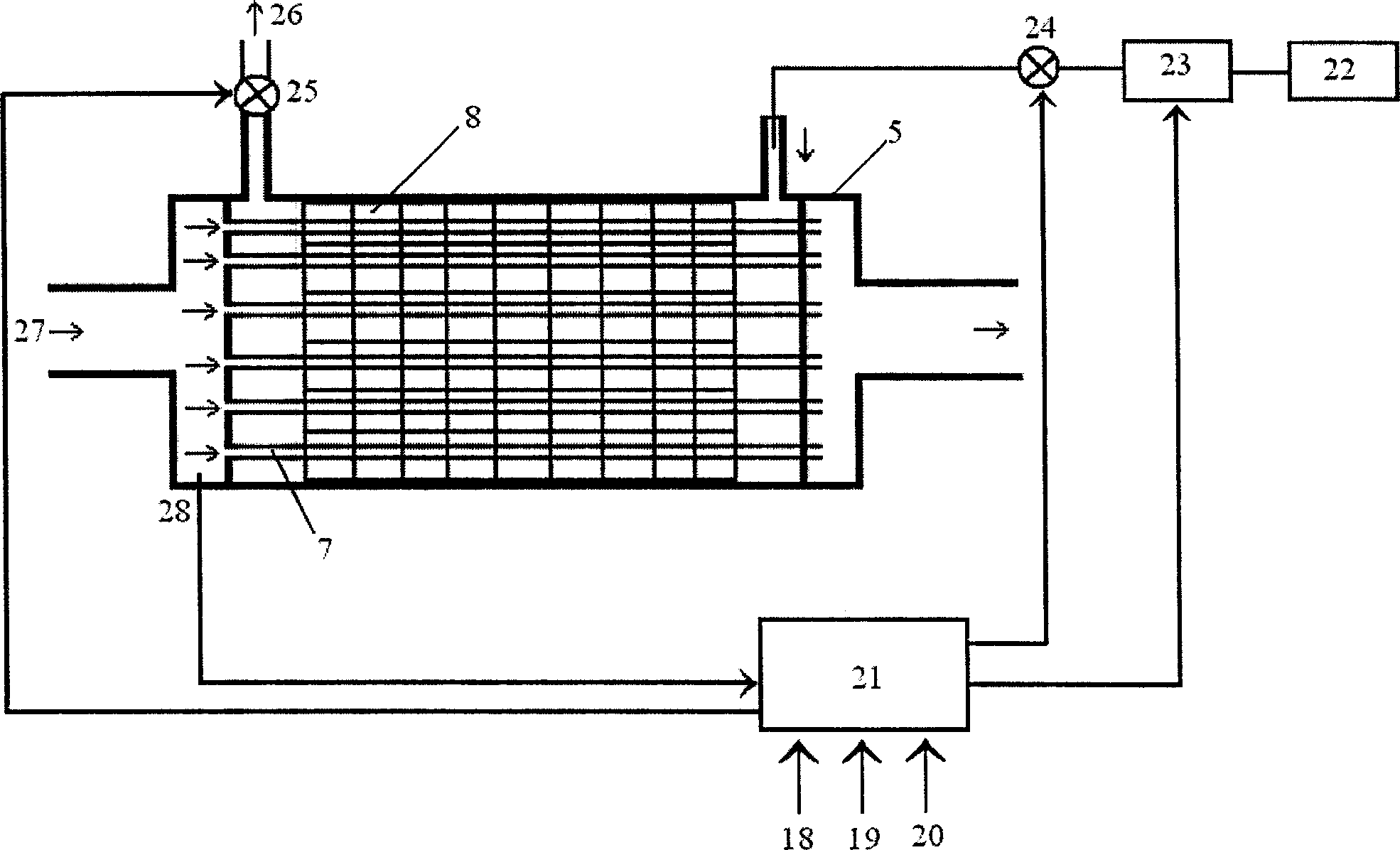

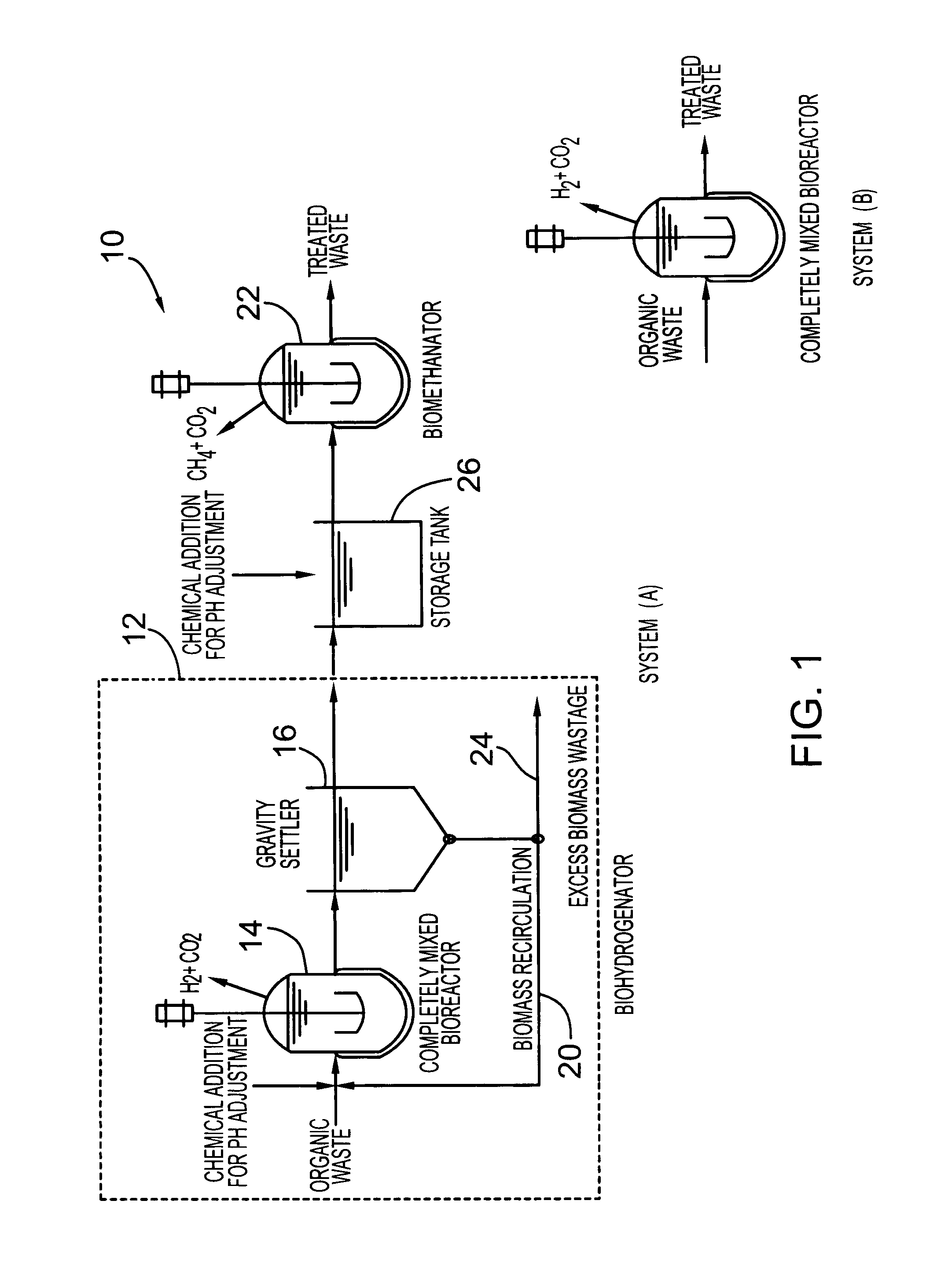

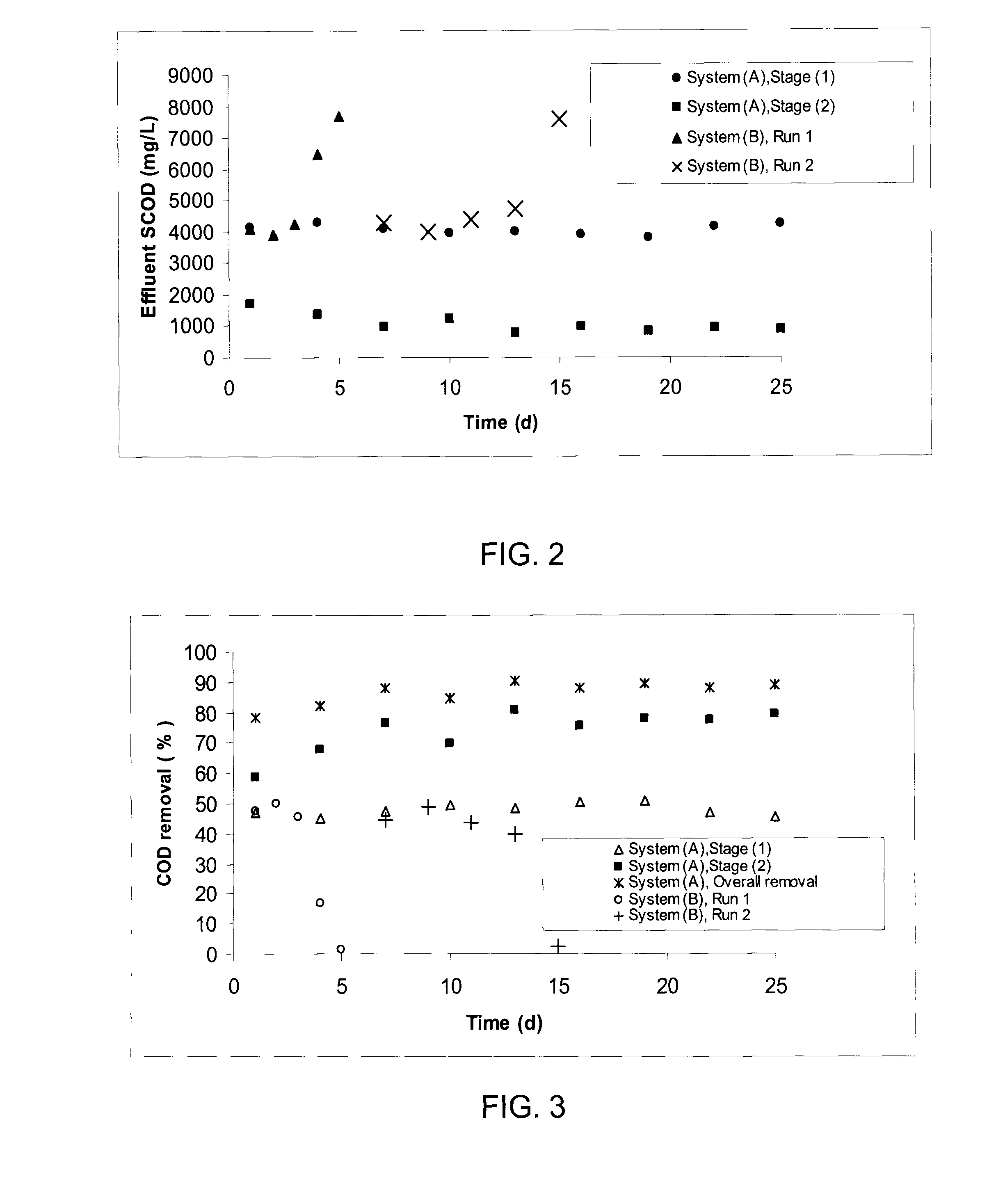

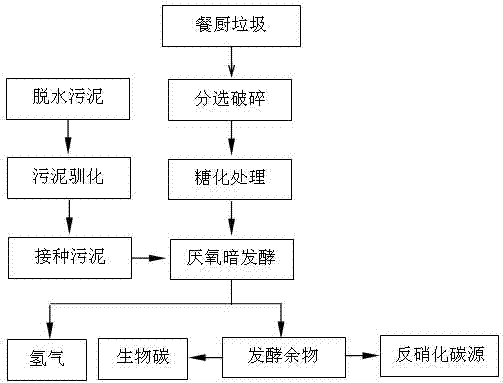

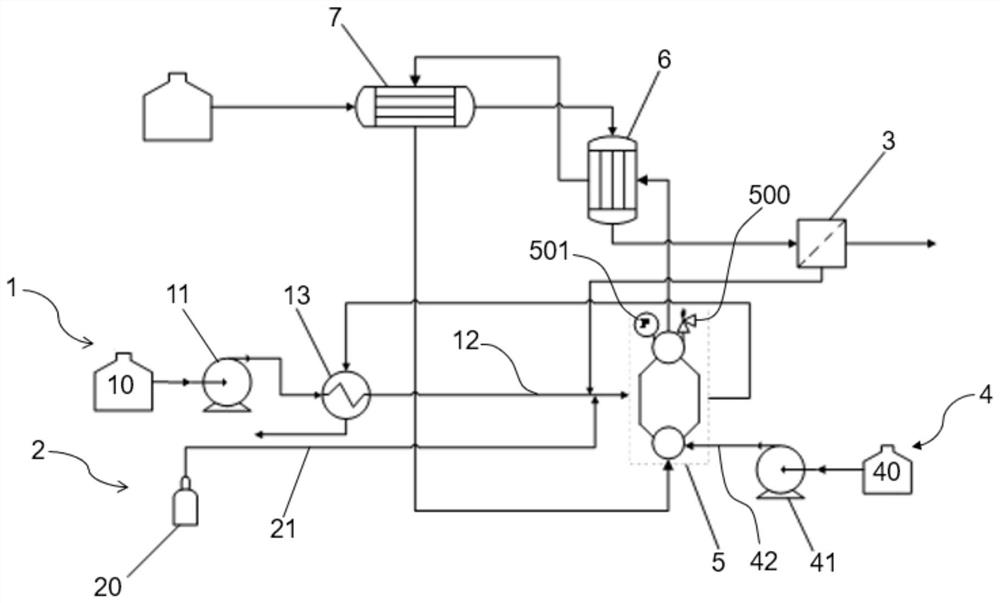

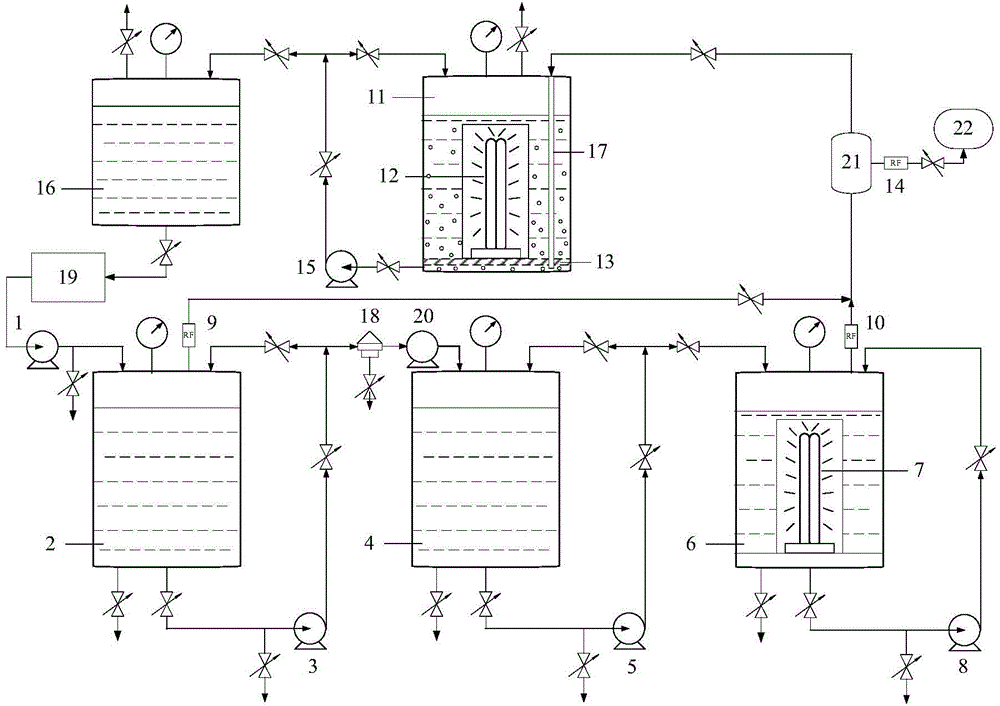

Integrated system for hydrogen and methane production from industial organic wastes and biomass

ActiveUS20120009643A1High hydrogen production rateHigh hydrogen yieldBioreactor/fermenter combinationsBiological substance pretreatmentsBiomassChemistry

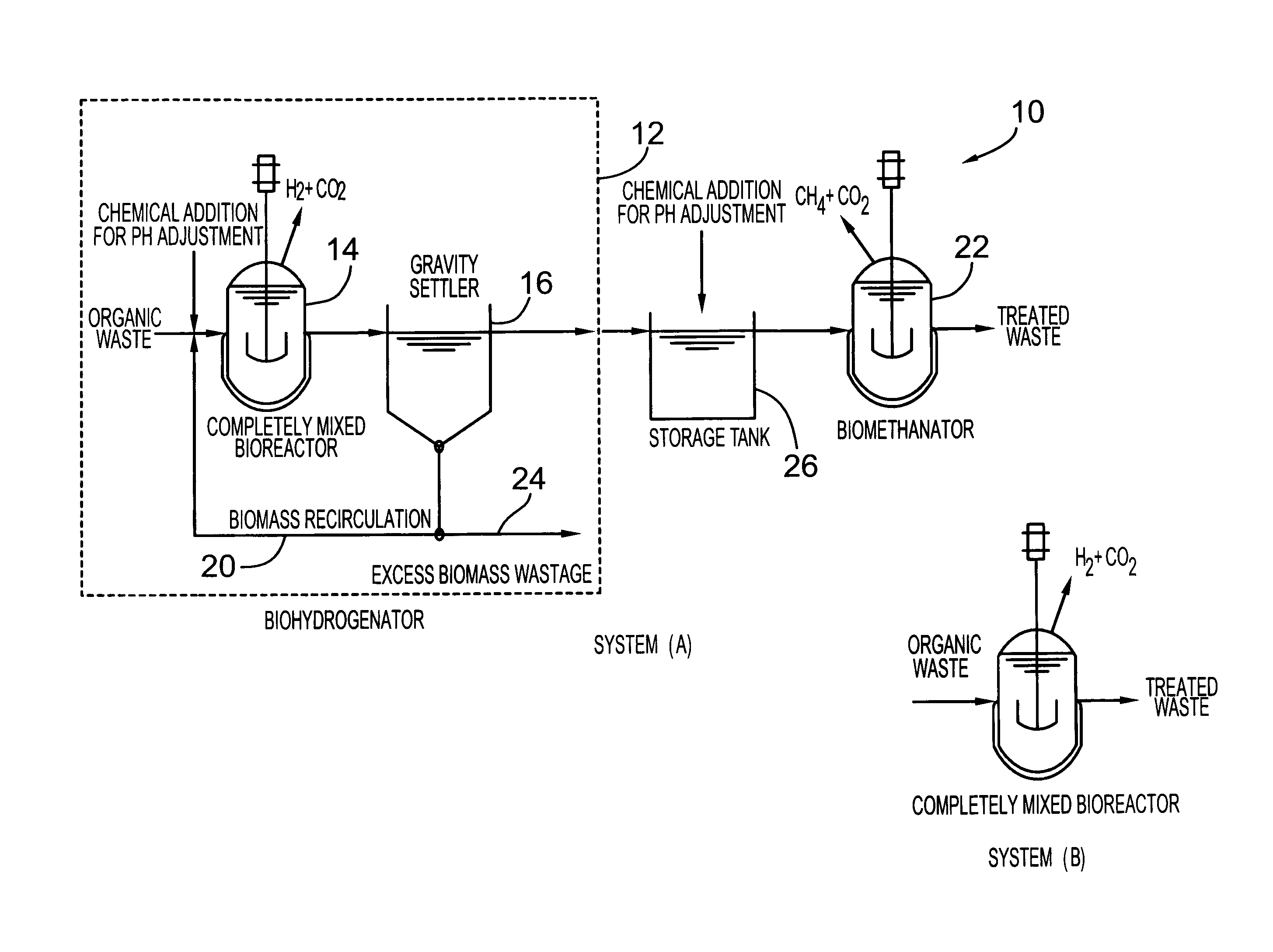

The present invention provides a system that has been devised to overcome the two most important limitations for sustained biological hydrogen production, namely contamination of the microbial hydrogen-producing cultures with methane-producing cultures necessitating frequent re-start-up and / or other methanogenic bacteria inactivation techniques, and the low bacterial yield of hydrogen-producers culminating in microbial washout from the system and failure. The system includes a continuously stirred bioreactor (CSTR) for biological hydrogen production, followed by a gravity settler positioned downstream of the CSTR, which combination forms a biohydrogenator. The biomass concentration in the hydrogen reactor is kept at the desired range through biomass recirculation from the bottom of the gravity settler and / or biomass wastage from the gravity settler's underflow. The gravity setter effluent is loaded with volatile fatty acids, as a result of microbiological breakdown of the influent waste constituents by hydrogen-producing bacteria, and is an excellent substrate for methane-forming bacteria in the downstream biomethanator.

Owner:GREENFIELD SPECIALTY ALCOHOLS

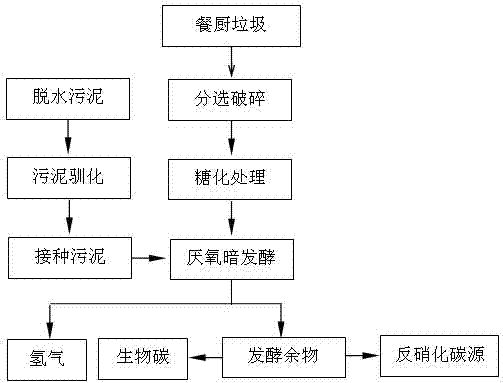

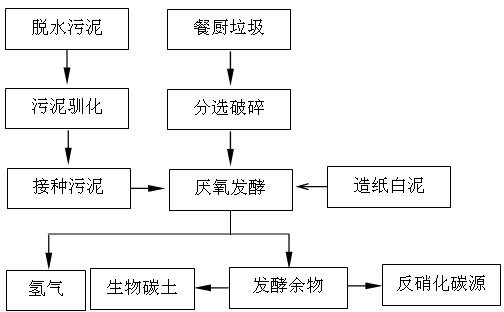

Method for producing hydrogen through kitchen waste enzymolysis and reinforced dark fermentation

InactiveCN102363794AKeep aliveGood hydrogen production capacityFermentationAmylaseFermentative hydrogen production

The invention discloses a method for producing hydrogen through kitchen waste enzymolysis and reinforced dark fermentation. The method comprises steps that: impurities are removed from dehydrated sludge discharged from a sewage factory; the sludge is settled for 10 to 20 days under anoxic stress, and is sealed and processed through heat treatment; glucose and peptone are added to the sludge, and the sludge is cultivated and acclimatized under a temperature of 50 to 53 DEG C, such that inoculated sludge is obtained; alpha-amylase and glucoamylase are added to kitchen waste for carrying out saccharification; the saccharified kitchen waste and the inoculated sludge are added into a fermentation bottle, and anaerobic fermentation is carried out under a temperature of 50 to 53 DEG C, such thathydrogen is produced; when the gas production is almost stopped, the reaction is stopped. According to the invention, alpha-amylase and glucoamylase are used for carrying out pre-treatment upon kitchen waste for a short time, such that a fermentation substrate micromolecular glycan which is rich and easy to utilize is provided for hydrogenogens. Therefore, fermentation time is shortened, and hydrogen yield is improved. The method provided by the invention has advantages of simple technology, fast starting, and low cost.

Owner:QILU UNIV OF TECH

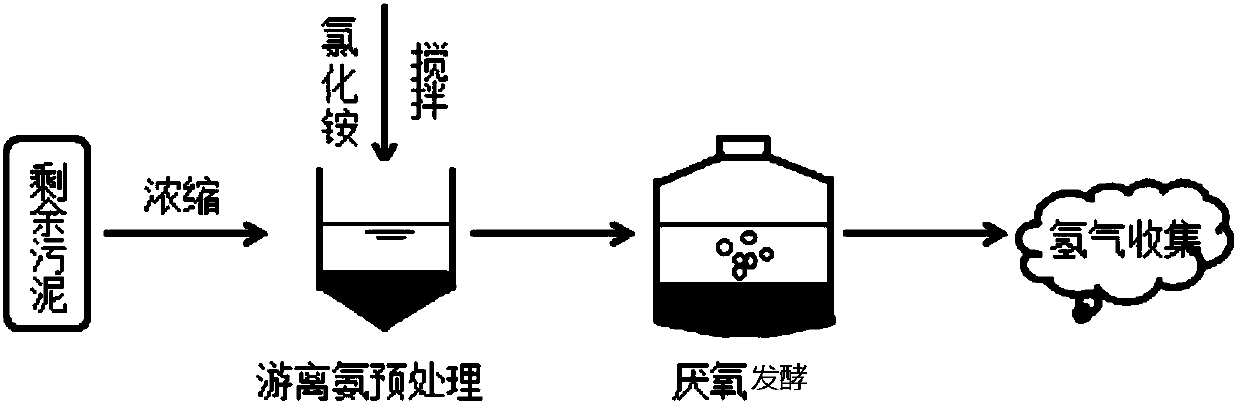

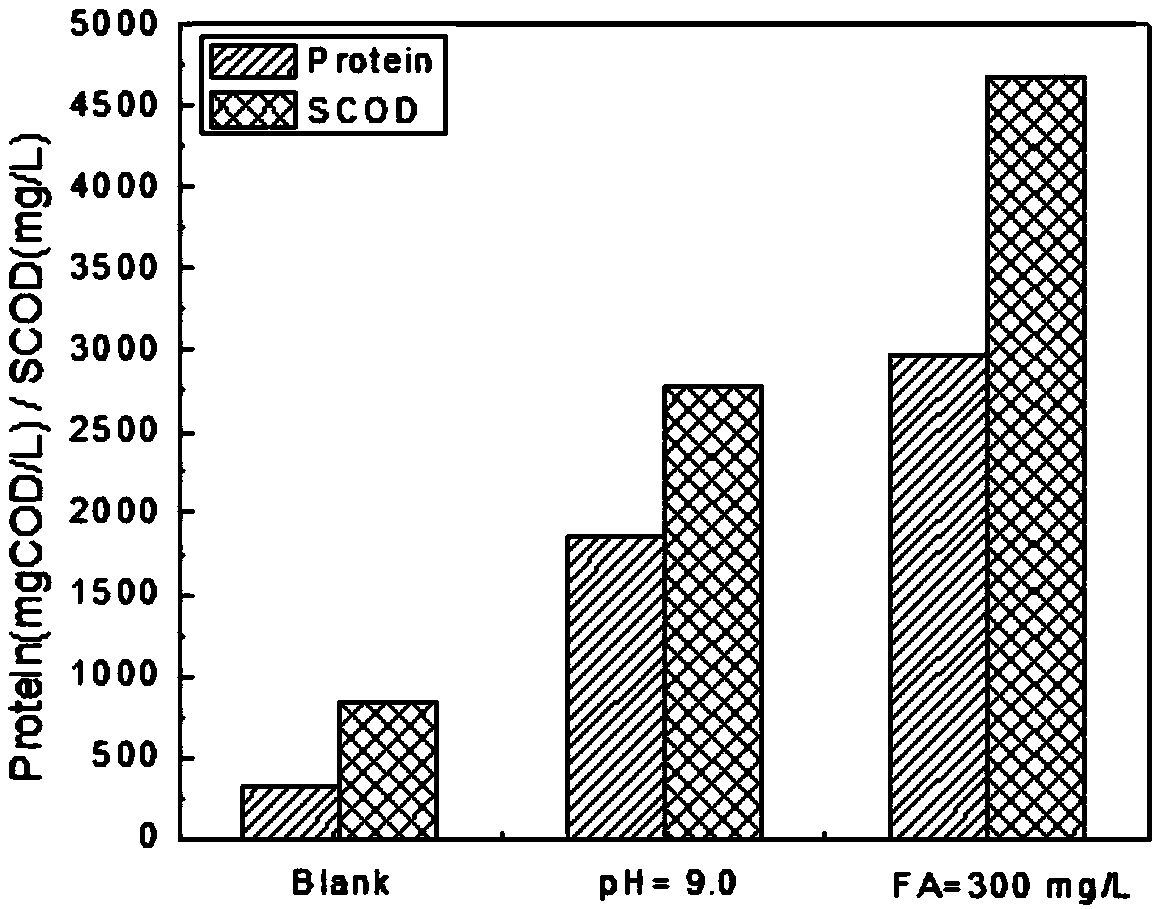

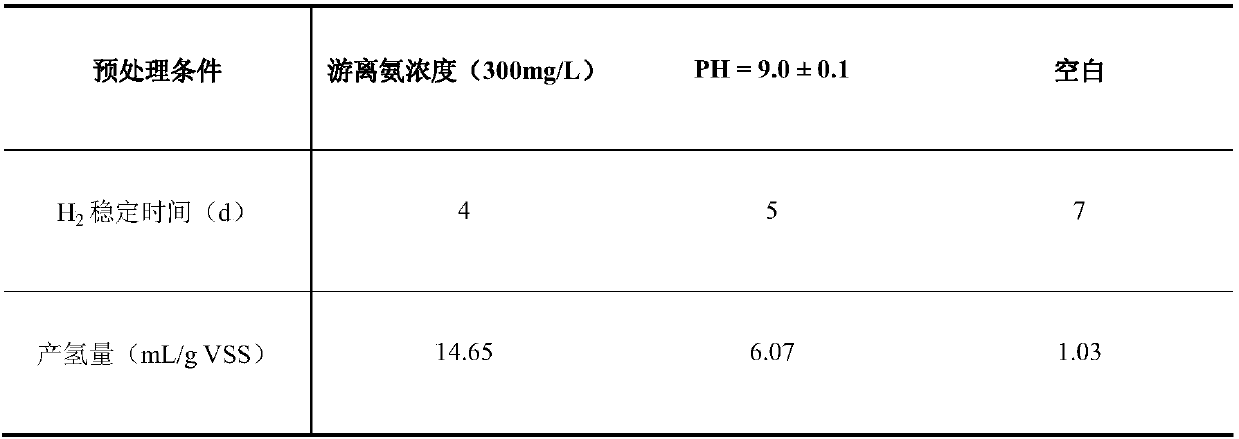

Pre-treatment method used for increasing residual activated sludge anaerobic fermentation hydrogen production efficiency

ActiveCN109554399ASpeed up the hydrolysis processRealize resourcesSpecific water treatment objectivesFermentationActivated sludgePretreatment method

The invention discloses a pre-treatment method used for increasing residual activated sludge anaerobic fermentation hydrogen production efficiency. The pre-treatment method comprises following specific steps: municipal sewage plant secondary sedimentation tank sludge is taken as a fermentation base material, ammonium chloride is added into the fermentation base material, fermentation system pH value is adjusted, at a constant temperature, a certain free ammonia (FA) concentration is achieved for 12h of pre-treatment, and anaerobic fermentation is carried out for hydrogen production. The free ammonia based pre-treatment is capable of promoting dissolving out of organic matters in sludge, fully inhibiting the activity of hydrogen-consuming microorganisms such as acetogenic bacteria and methanogens of the same type, and increasing hydrogen production efficiency greatly. The free ammonia pretreatment hydrogen production rate is as high as 14.65ml H2 / g VSS, and is 14.22 times of that of a blank group, and is 2.41 times of that of an alkalescence pretreatment group (pH is 9.0+ / -0.1). The pre-treatment method is simple in operation and high in hydrogen production efficiency; adding of additional special bacterial strains as hydrogenogens is not necessary; cost is low; sludge quantitative reduction, resource recycling, and stabilization can be realized at the same time; and important environmental protection ecological meaning is achieved.

Owner:HUNAN UNIV

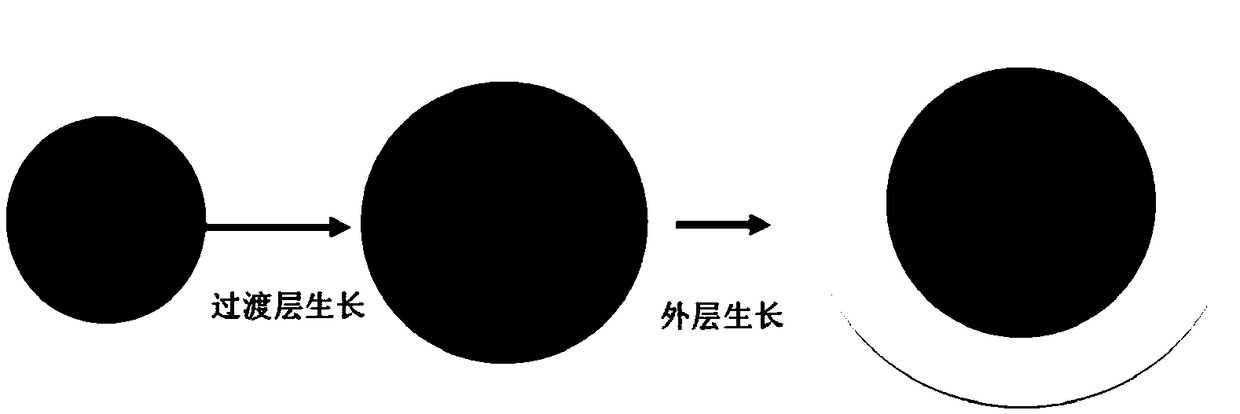

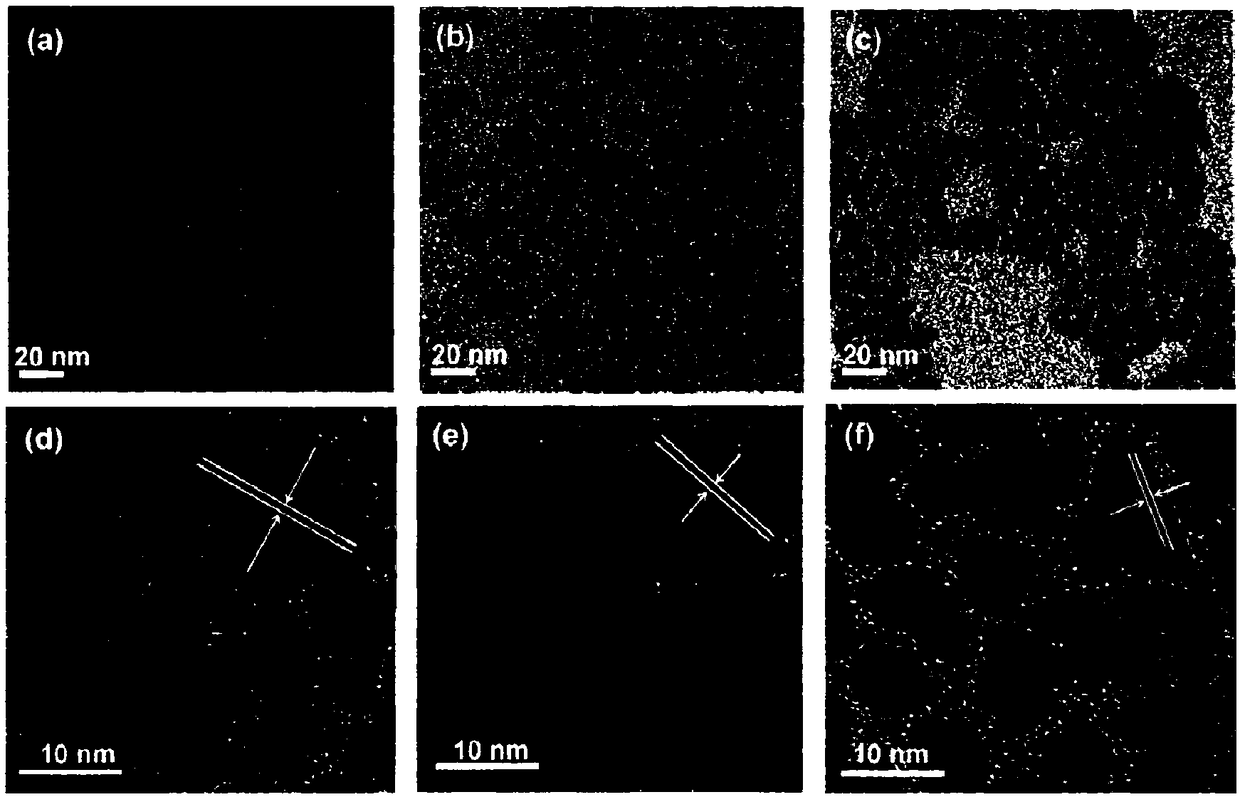

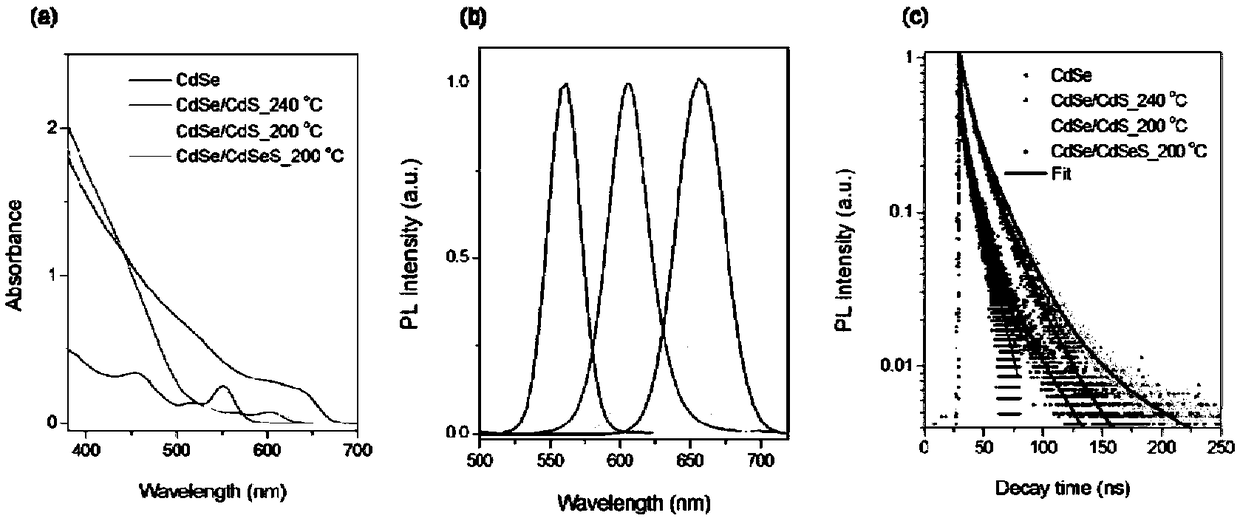

Core-shell structure quantum dot with transition layer, fabrication method and application of core-shell structure quantum dot, photoanode, solar photo-electro-chemical device and application of solar photo-electro-chemical device

InactiveCN108806989AImprove stabilityQuick responseLight-sensitive devicesEnergy inputElectron holeQuantum dot

The invention belongs to the technical field of a semiconductor nanometer material and application thereof, and relates to a core-shell structure quantum dot with a transition layer, a fabrication method and application of the core-shell structure quantum dot, a photoanode, a solar photo-electro-chemical device and application of the solar photo-electro-chemical device. The structure of the core-shell structure quantum dot with the transition layer comprises a core layer, the transition layer and a shell layer, wherein the transition layer is yCdSe<x>S<1-x>, the shell layer is CdS, x is more than 0 but less than 1, and y is more than 1. By changing the material structure of the quantum dot and adjusting the energy band structure of the quantum dot, the response of the quantum dot on sunlight is promoted, moreover, the separation of electron hole pairs is facilitated, and the photoelectronic generation efficiency is improved.

Owner:QINGDAO UNIV

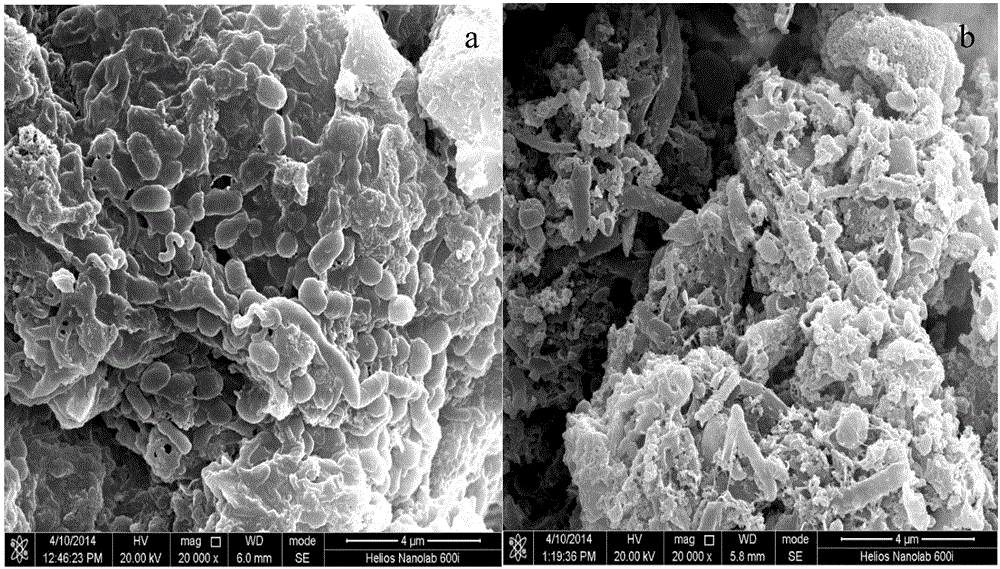

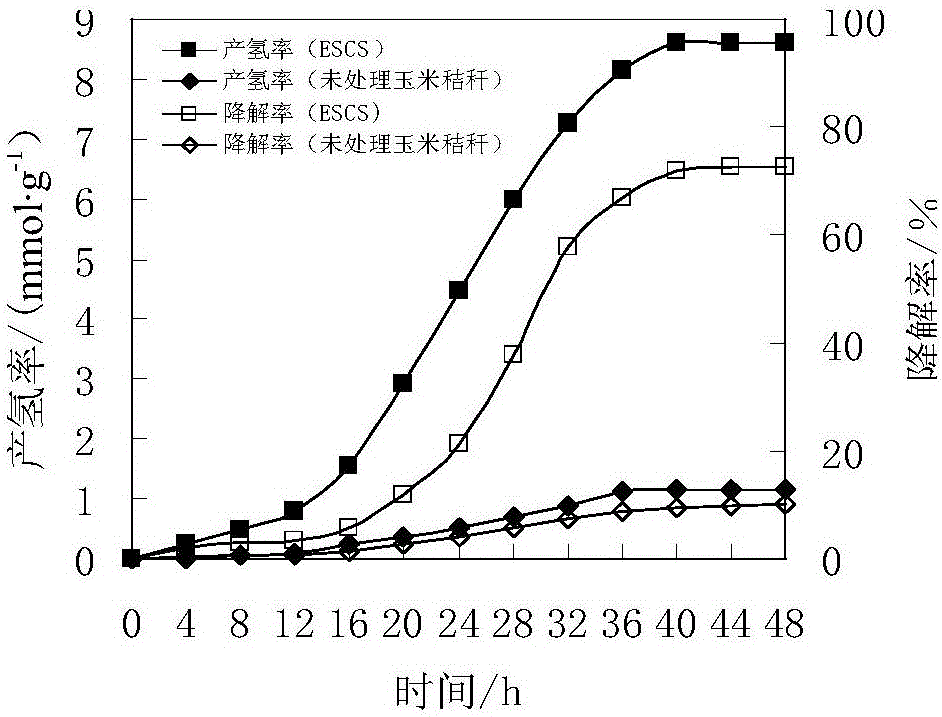

Combined pretreatment method for synergically degrading straw cellulose through compound florae and producing hydrogen through fermentation

InactiveCN106119289ARealize resourcesHigh hydrogen production rateFermentationCellulosePretreatment method

The invention relates to a combined pretreatment method for synergically degrading straw cellulose through compound florae and producing hydrogen through fermentation, belonging to the technical field of processing of solid waste. The combined pretreatment method for combining the compound florae with the combined pretreatment of sodium hydroxide and acidification steam explosion is utilized for carrying out efficient anaerobic fermentation biological hydrogen production for the first time. The method comprises the steps of firstly grinding straws into 30-60-mesh powder, carrying out sodium hydroxide pretreatment, finally carrying out acidification steam explosion pretreatment to obtain pretreated straw powder, adding the compound florae, culturing the mixture in an intermittent fermentation hydrogen production testing device, and carrying out the efficient anaerobic fermentation biological hydrogen production. According to the combined pretreatment method, by virtue of the combined pretreatment of sodium hydroxide and acidification steam explosion, the hydrogen production rate and the cellulose degradation rate of the straw fermentation hydrogen production are increased, and the recycling and the energy regeneration of lots of straws are realized.

Owner:LIAONING UNIVERSITY

Application of papermaking white clay in biological fermentative hydrogen production

The present invention discloses an application of papermaking white clay in biological fermentative hydrogen production, which is characterized in that: the papermaking white clay is used as pH buffering agent and an inorganic nutrient of hydrogenogens; and the papermaking white clay is mixed with kitchen garbage and dewatered sludge of a sewage plant for performing biological fermentative hydrogen production. The application of papermaking white clay in biological fermentative hydrogen production has the advantages of simple operation and low cost. The papermaking white clay is adopted for performing reinforcement treatment for a kitchen garbage fermentation hydrogen production system. Not only is pollution of the papermaking white clay reduced, but also stability and gas production rateof the fermentation process are greatly improved. The activity of the hydrogenogen is improved. The hydrogen production rate can reach up to 112.39mL / gVS.

Owner:QILU UNIV OF TECH

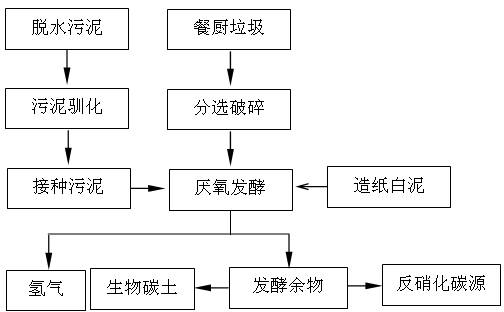

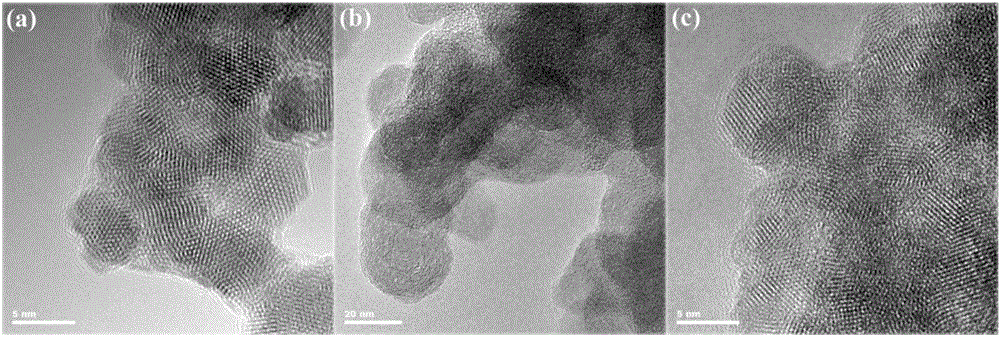

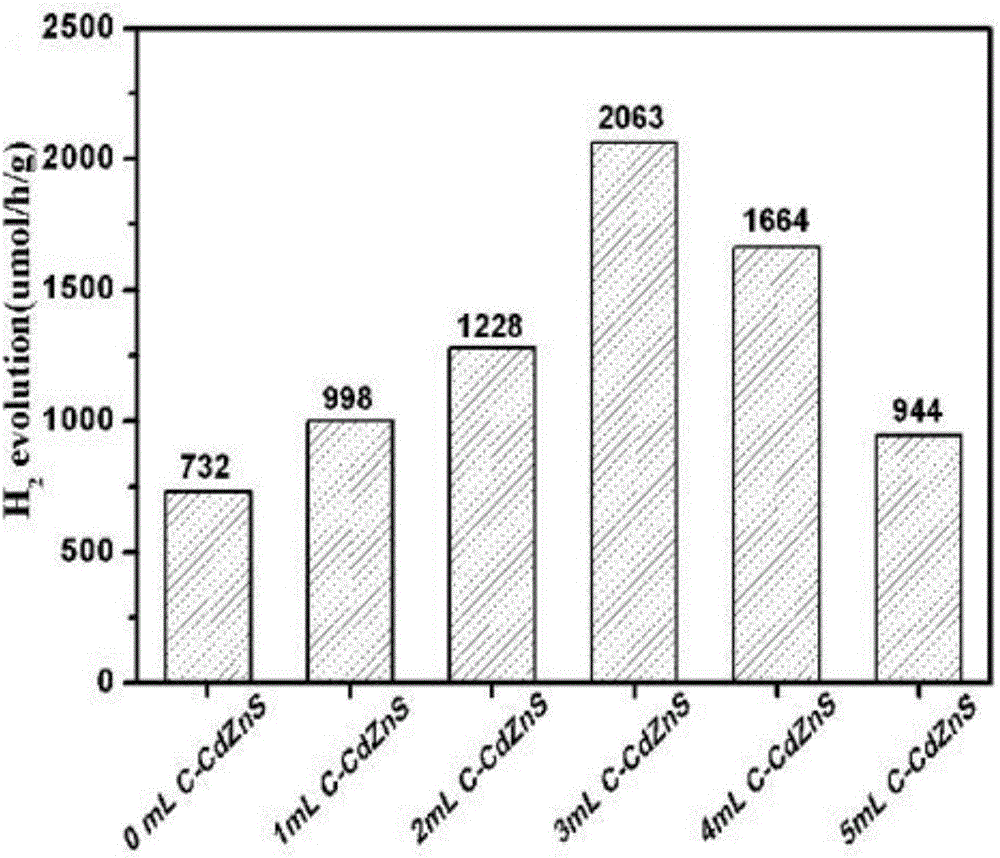

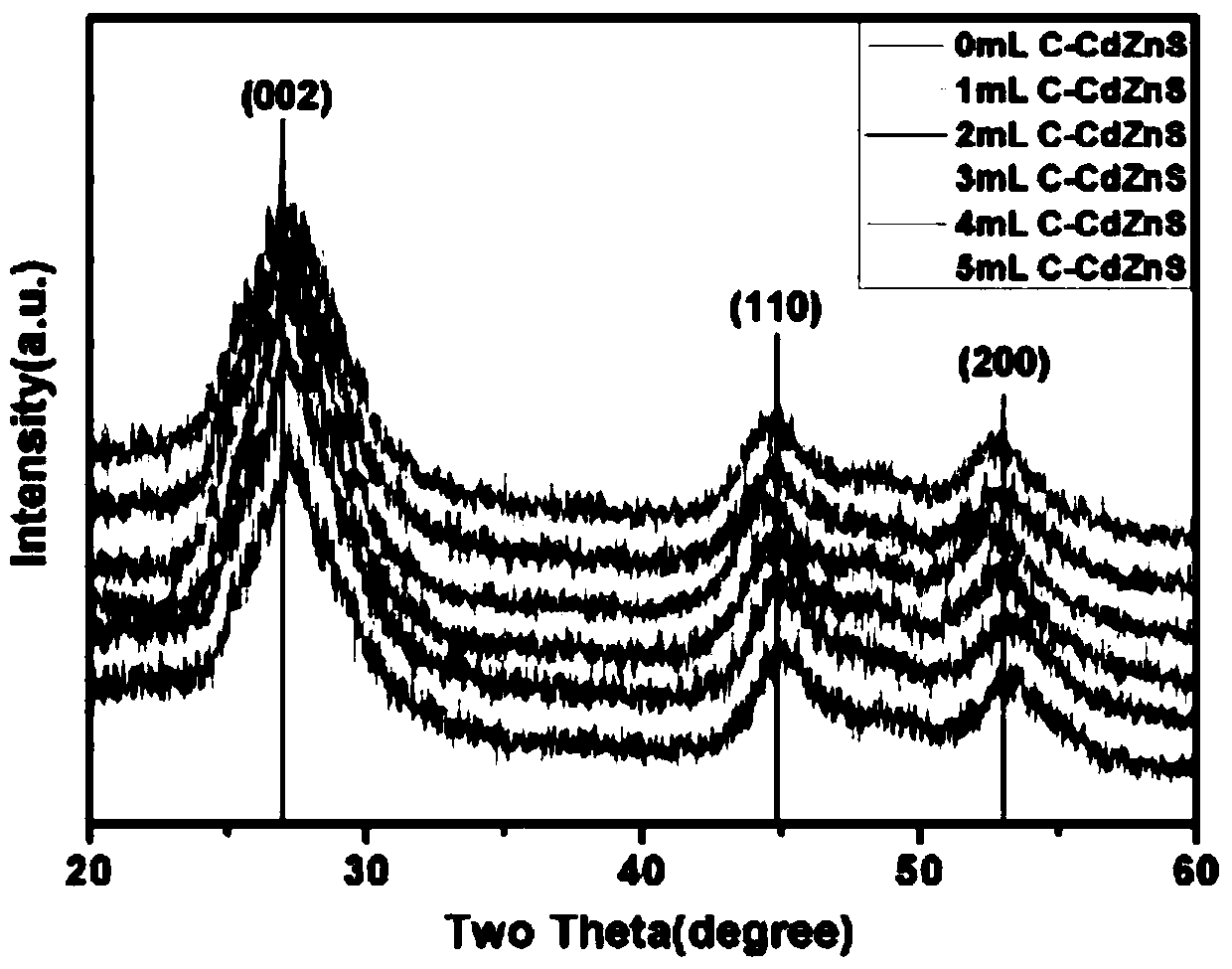

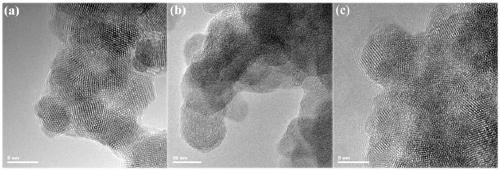

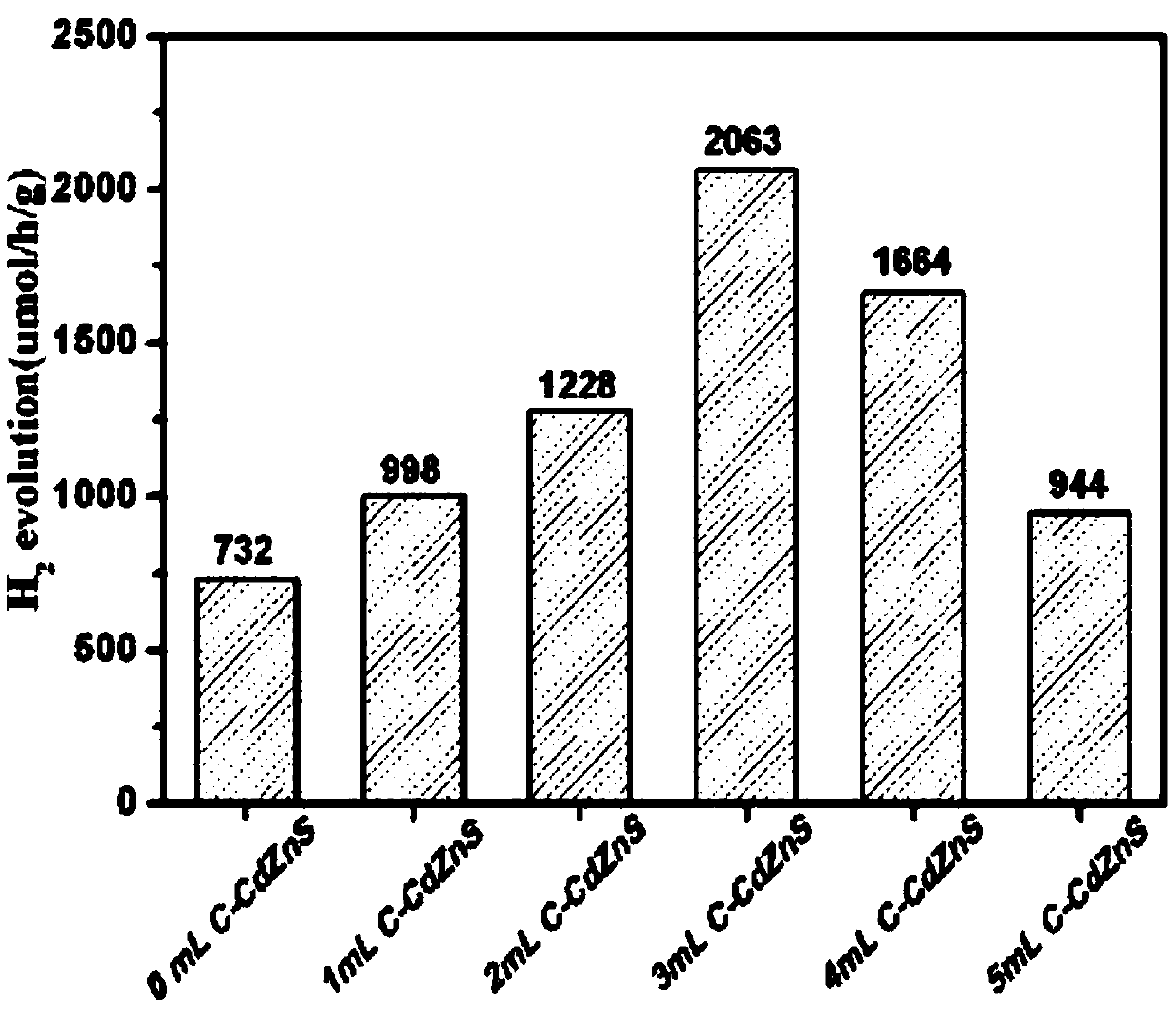

Nano-material for compounding CdZnS quantum dots and carbon dots, preparation method of nano-material and application

ActiveCN106622289AReduce usageSimple processMaterial nanotechnologyPhysical/chemical process catalystsNanoparticleQuantum dot

The invention provides a nano-material for compounding CdZnS quantum dots and carbon dots, a preparation method of the nano-material and an application. The nano-material comprises nano-particles, a plurality of CdZnS quantum dots are uniformly dispersed and loaded on the carbon dots to form the nano-particles, the diameter of each CdZnS quantum dot is 4-8 nanometers, sulfide precursors and dispersion liquid with the carbon dots are uniformly mixed, and the nano-material is prepared by a solvothermal method. A preparation process is simple and easy to operate and control, the obtained nano-material is stable in nature and low in cost and can serve as a photocatalyst, the CdZnS quantum dots in the nano-particles are uniformly loaded on the carbon dots, aggregation of the CdZnS quantum dots is reduced, stability of the hydrogen production process of substances can be improved, and hydrogen production efficiency is improved.

Owner:HUBEI UNIV

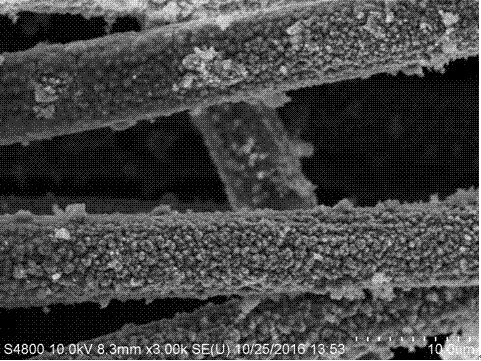

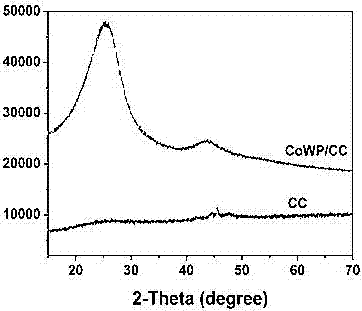

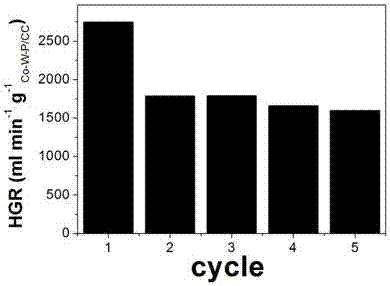

Carbon fiber supported CoWP catalyst and preparation method

PendingCN107159282AHigh hydrogen production rateCompact distributionCell electrodesCatalyst activation/preparationChemistryTungsten

The invention discloses a carbon fiber supported CoWP catalyst and a preparation method, and belongs to the field of hydrogen energy and fuel cells. The catalyst comprises a carbon fiber fabric and surface cobalt, tungsten and phosphorus. Three elements are supported on the surface of a carbon fiber by an electrodeposition method. The carbon fiber is pretreated and cleaned, and then cobalt, tungsten and phosphorus are supported on the surface of the carbon fiber by a two-step electrodeposition method. The catalyst has catalytic performances such as low cost, high hydrogen production rate and stable performance.

Owner:XUZHOU NORMAL UNIVERSITY

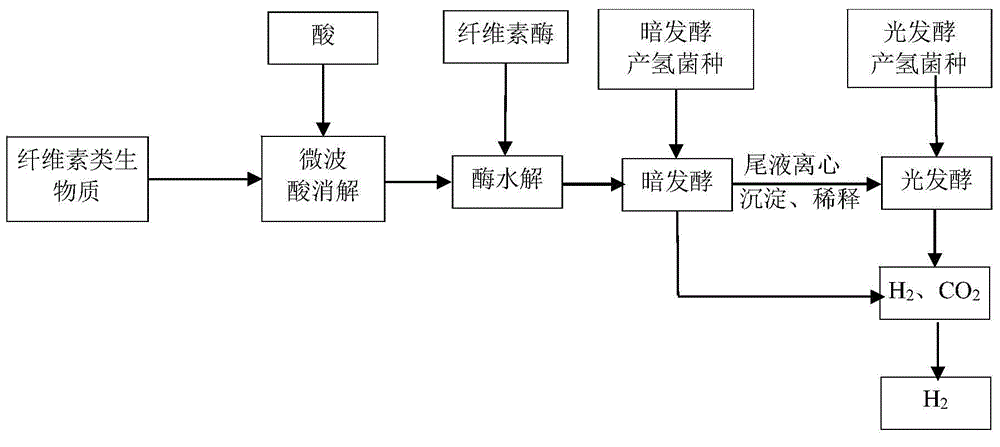

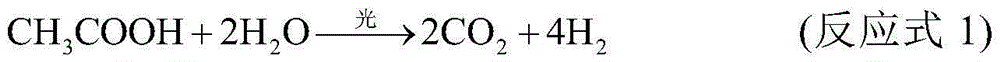

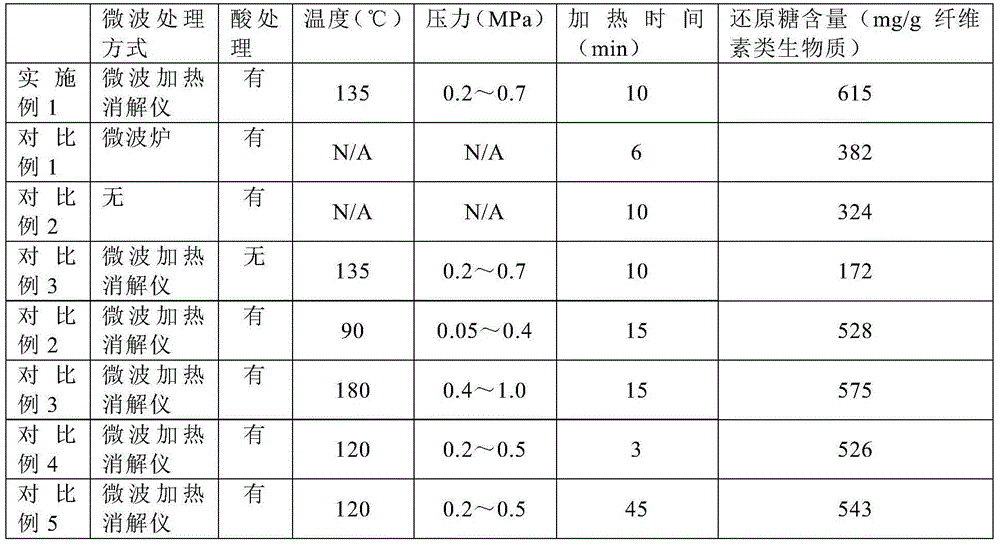

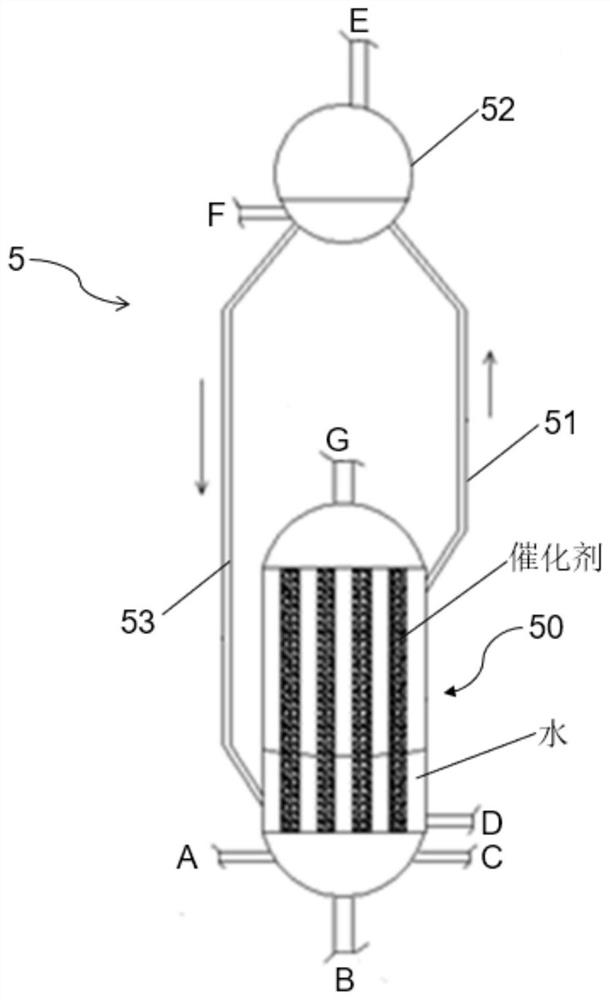

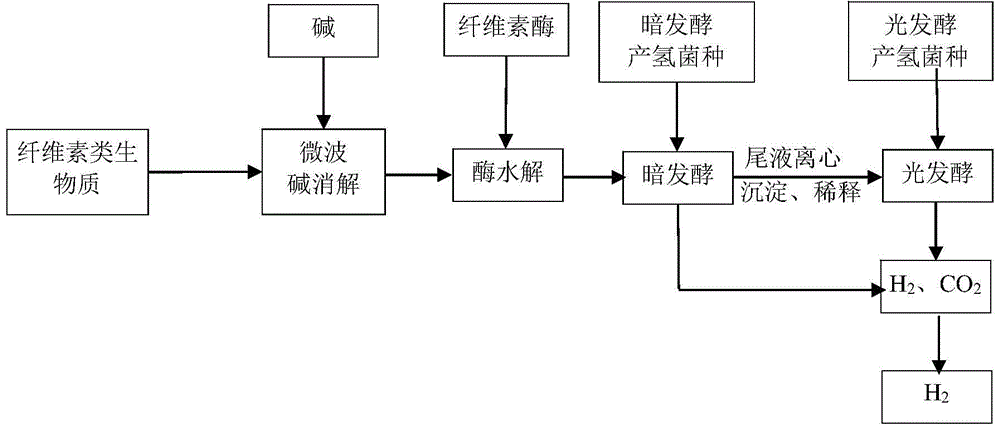

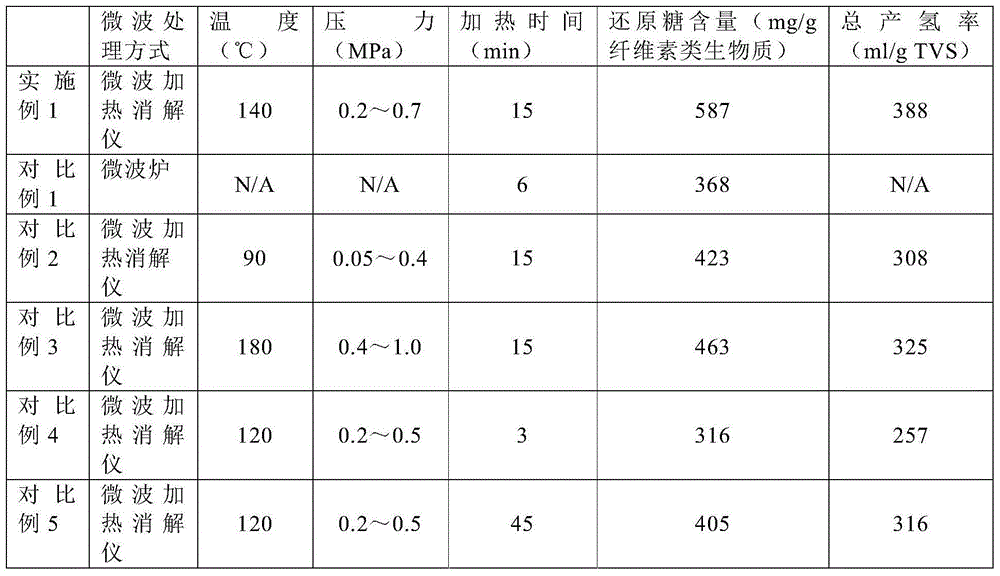

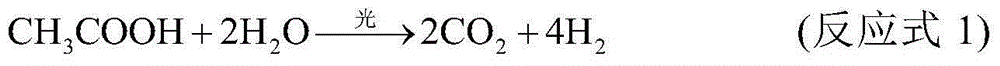

Method used for producing hydrogen by taking cellulose as raw material

InactiveCN105713926AReduce crystallinityImprove degradation efficiencyMicroorganism based processesFermentationCelluloseMicrowave

The invention provides a method used for producing hydrogen by taking cellulose as a raw material. The method comprises following steps: 1, microwave acid digestion; 2, enzyme hydrolysis; 3, dark fermentation hydrogen production; 4, photo fermentation hydrogen production; and 5, purification. The method is high in hydrogen yield, hydrogen production efficiency, substrate utilization ratio, and energy conversion efficiency.

Owner:COFCO GROUP +1

Heat supply system and method for hydrogen production by methanol reforming

PendingCN111762757ASave installation and operation and maintenance costsCompact structureHydrogenHydrogen/synthetic gas productionProcess engineeringHydrogen production

The invention discloses a heat supply system for hydrogen production by methanol reforming. The system comprises: a water vapor generation device for heating liquid water and separating out saturatedsteam; a methanol feeding device, wherein the methanol feeding device comprises a methanol tank and a methanol feeding pipeline which are connected in sequence, and an outlet of the methanol feeding pipeline is connected with a methanol inlet in the water vapor generation device; an oxygen inlet device, wherein the oxygen inlet device comprises an oxygen tank and an oxygen inlet pipeline, and an outlet of the oxygen inlet pipeline is connected with an air inlet in the water vapor generation device; a water inlet device, wherein the water inlet device comprises a water tank and a water inlet pipe with a water pump, and the water inlet pipe is connected with a fresh water inlet in the water vapor generation device; and a reforming reactor connected with a water vapor outlet in the water vapor generation device and circularly connected to the water vapor generation device through an evaporator. The invention further provides a heat supply method for hydrogen production by methanol reforming. The heat supply system and the heat supply method are uniform and constant in heat supply, and the reforming hydrogen production reaction efficiency can be improved.

Owner:SHANGHAI MICROPOWERS

Method used for producing hydrogen by taking cellulose as raw material

InactiveCN105713925AReduce crystallinityImprove degradation efficiencyMicroorganism based processesFermentationCelluloseMicrowave

The invention provides a method used for producing hydrogen by taking cellulose as a raw material. The method comprises following steps: 1, microwave alkali digestion; 2, enzyme hydrolysis; 3, dark fermentation hydrogen production; 4, photo fermentation hydrogen production; and 5, purification. The method is high in hydrogen yield, hydrogen production efficiency, substrate utilization ratio, and energy conversion efficiency.

Owner:COFCO GROUP +1

Separation method of butyric acid oxidized hydrogen-producing acetogenic dominant microorganisms

InactiveCN101724595AHigh removal rateButyric acid concentration decreasedBacteriaMicroorganism based processesHigh concentrationActivated sludge

The invention discloses a separation method of butyric acid oxidized hydrogen-producing acetogenic dominant microorganisms, relating to a separation method of hydrogen-producing acetogenic bacteria and solving the problems that the traditional separation method is difficult to separate and the hydrogen-producing rate of the cultured hydrogen-producing acetogenic bacteria is low. The separation method comprises the following steps of: firstly, preliminarily domesticating anaerobic activated sludge; secondly, preparing a bacterial suspension A; thirdly, enriching a back bacterial suspension; fourthly, enriching and culturing the enriched back bacterial suspension again; fifthly, preparing compound microorganisms of butyric acid oxidized hydrogen-producing acetogenic bacteria and methanogen; sixthly, preparing the butyric acid oxidized hydrogen-producing acetogenic microorganisms; seventhly, transferring the butyric acid oxidized hydrogen-producing acetogenic microorganisms to a butyric acid culture medium for vibration velocity culture; and eighthly, repeating the step seven for 3-6 times and then separating. The method has easy separation and simple operation, and the hydrogen-producing rate of the separated dominant microorganisms is about 7-10 times of that of the hydrogen-producing bacteria. The advantageous bacterium group not only can degrade the butyric acid with higher concentration, but also can effectively improve the treating efficiency of organic wastewater with high concentration.

Owner:HARBIN INST OF TECH

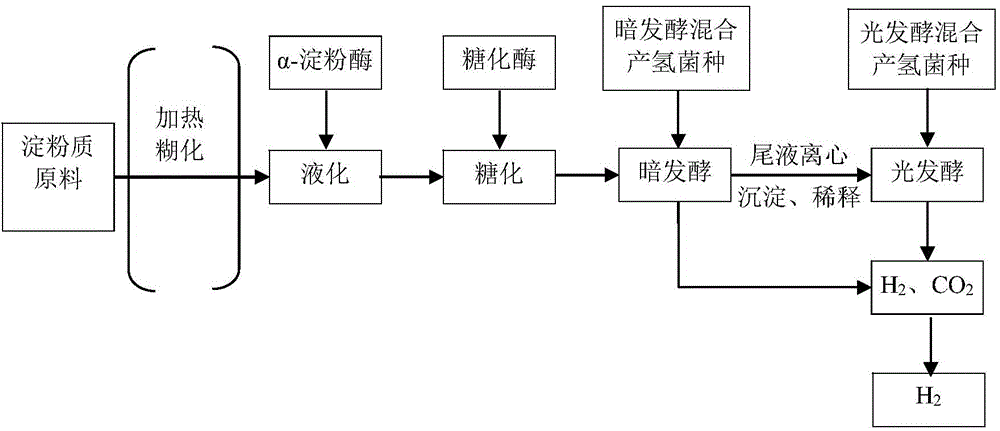

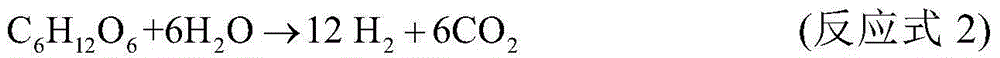

Method for fermenting starchy raw material with mixed strain to produce hydrogen

InactiveCN105713948AImprove absorption efficiencyImprove utilization efficiencyMicroorganism based processesFermentationEnergy conversion efficiencyFermentation

The invention provides a method for two-step fermentation of a starchy raw material with a mixed strain to produce hydrogen. The method comprises the steps of: (1) liquefaction; (2) saccharification; (3) dark fermentation to produce hydrogen; (4) photo-fermentative hydrogen production; and (5) purification. The method provided by the invention has excellent hydrogen production rate, hydrogen production velocity, substrate utilization rate and energy conversion efficiency.

Owner:COFCO GROUP +1

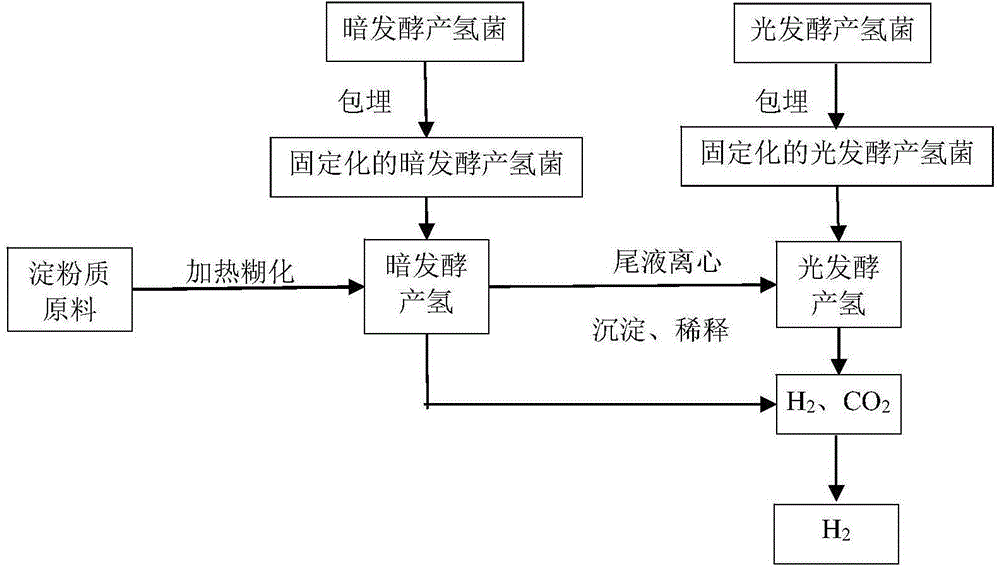

Method used for preparing hydrogen via embedded bacteria fermentation

InactiveCN105713927AIncrease the concentration of hydrogen-producing bacteriaIncrease concentrationMicroorganism based processesOn/in organic carrierEnergy conversion efficiencyDark fermentation

The invention provides a method used for preparing hydrogen via fermentation of starchy raw materials by embedded bacteria. The method comprises following steps: 1, preparation of the embedded bacteria; 2, heating gelatinization of the starchy raw materials, 3, dark fermentation and hydrogen production, 4, photo fermentation and hydrogen production; and 5, purification. The method is high in hydrogen yield, hydrogen production rate, substrate utilization ratio, and energy conversion efficiency.

Owner:COFCO GROUP +1

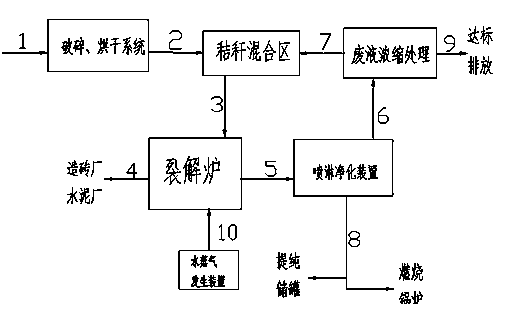

Method for promoting cracking of household garbage by using water vapor

InactiveCN103627441AHigh hydrogen production rateControl the cracking temperatureWaste processingSolid waste disposalWater vaporCombustible gas

The invention provides a method for promoting cracking of household garbage by using water vapor, which belongs to the fields of renewable energy sources and environmental protection. The method comprises the following steps: (1) crushing and drying household garbage, then mixing the treated household garbage with straw, and delivering an obtained mixture into a cracking furnace for cracking; (2) spraying water vapor into the cracking furnace in the process of cracking; and (3) allowing a gas-liquid mixture produced in the process of cracking to pass through a spraying purification apparatus. With the method, combustible gas with a high calorific value can be prepared, material cracking temperature in the cracking furnace is effectively controlled, and energy loss is reduced.

Owner:黄广禧

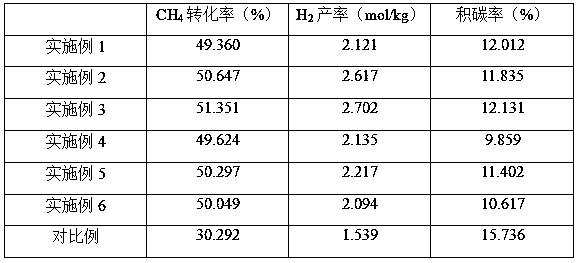

La-Cu-Mn series oxygen storage-oxygen release material as well as preparation method and application thereof

ActiveCN109607477AImprove activity stabilityImprove thermal stabilityHydrogenHeterogenous catalyst chemical elementsThermal stabilityCarbon deposition

The invention discloses a La-Cu-Mn series oxygen storage-oxygen release material as well as a preparation method and application thereof, and belongs to the technical field of materials. The La-Cu-Mnseries oxygen storage-oxygen release material has a chemical general formula of LaxCu1-xMnO3-delta, wherein values of x and delta satisfy the relationships of 0.1 <= x <= 0.95, and 0 <= delta <= 3; and the La-Cu-Mn series oxygen storage-oxygen release material is prepared by adopting a sol-gel method. The La-Cu-Mn series oxygen storage-oxygen release material provided by the invention has high reactivity and thermal stability in a chemical chain reforming hydrogen production reaction, has a higher hydrogen production rate, better carbon deposition resistance and a high CH4 conversion rate.

Owner:KUNMING UNIV OF SCI & TECH

A nanomaterial composited with cdzns quantum dots and carbon dots and its preparation method and application

ActiveCN106622289BThe synthesis method is simpleReduce reunionMaterial nanotechnologyPhysical/chemical process catalystsNanoparticleQuantum dot

The invention provides a nanomaterial composed of CdZnS quantum dots and carbon dots and its preparation method and application. The nanomaterial is a nanoparticle composed of several CdZnS quantum dots with a diameter of 4-8 nanometers evenly dispersed and loaded on the carbon dots. , the sulfide precursor is uniformly mixed with a dispersion containing carbon dots, and is produced by a solvothermal method. The preparation process is simple and easy to control. The resulting nanomaterial has stable properties and low cost, and can be used as a photocatalyst. CdZnS quantum dots in nanoparticles Evenly loading on the carbon dots not only reduces the agglomeration of CdZnS quantum dots, but also improves the stability of the material's hydrogen production process and improves the hydrogen production efficiency.

Owner:HUBEI UNIV

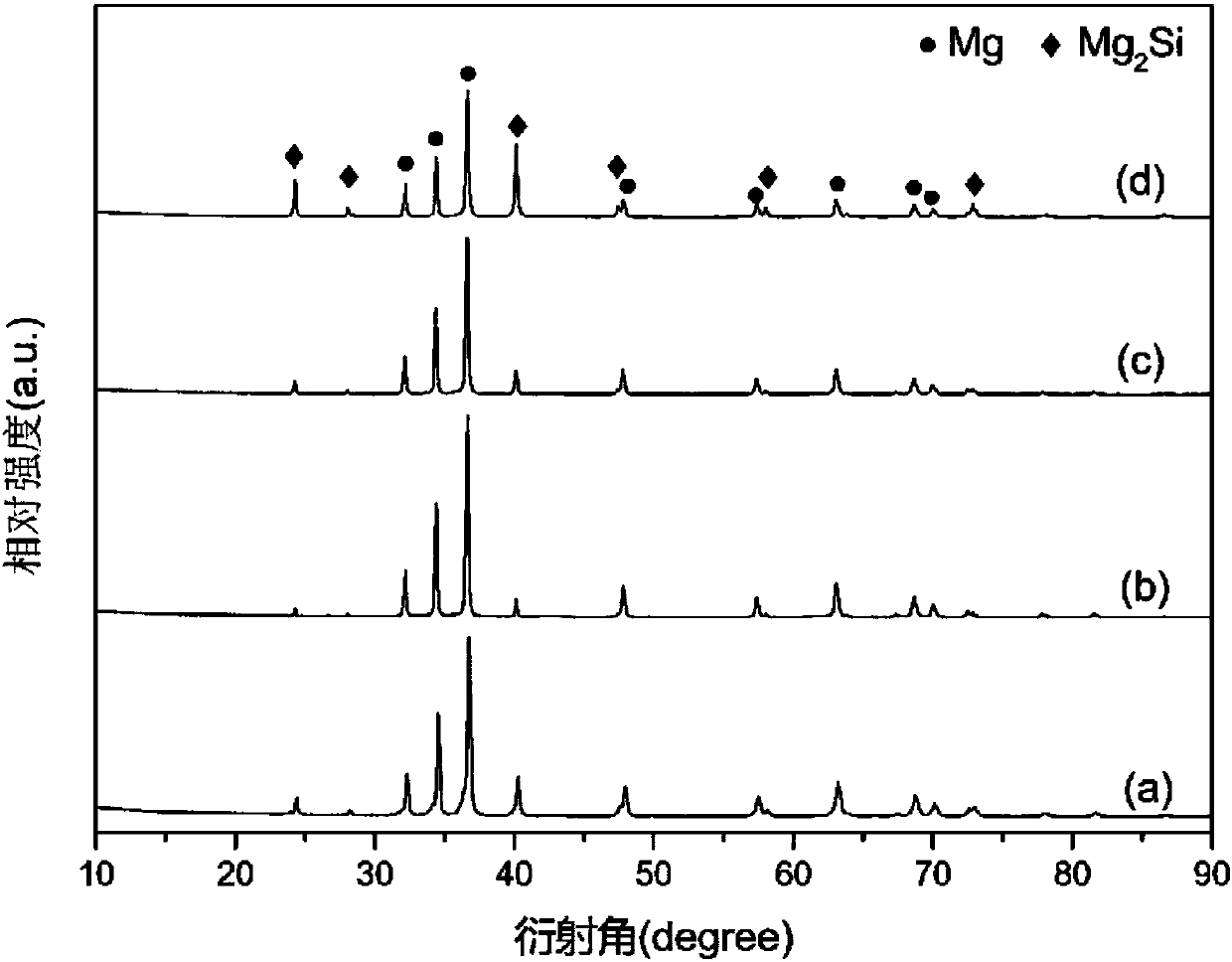

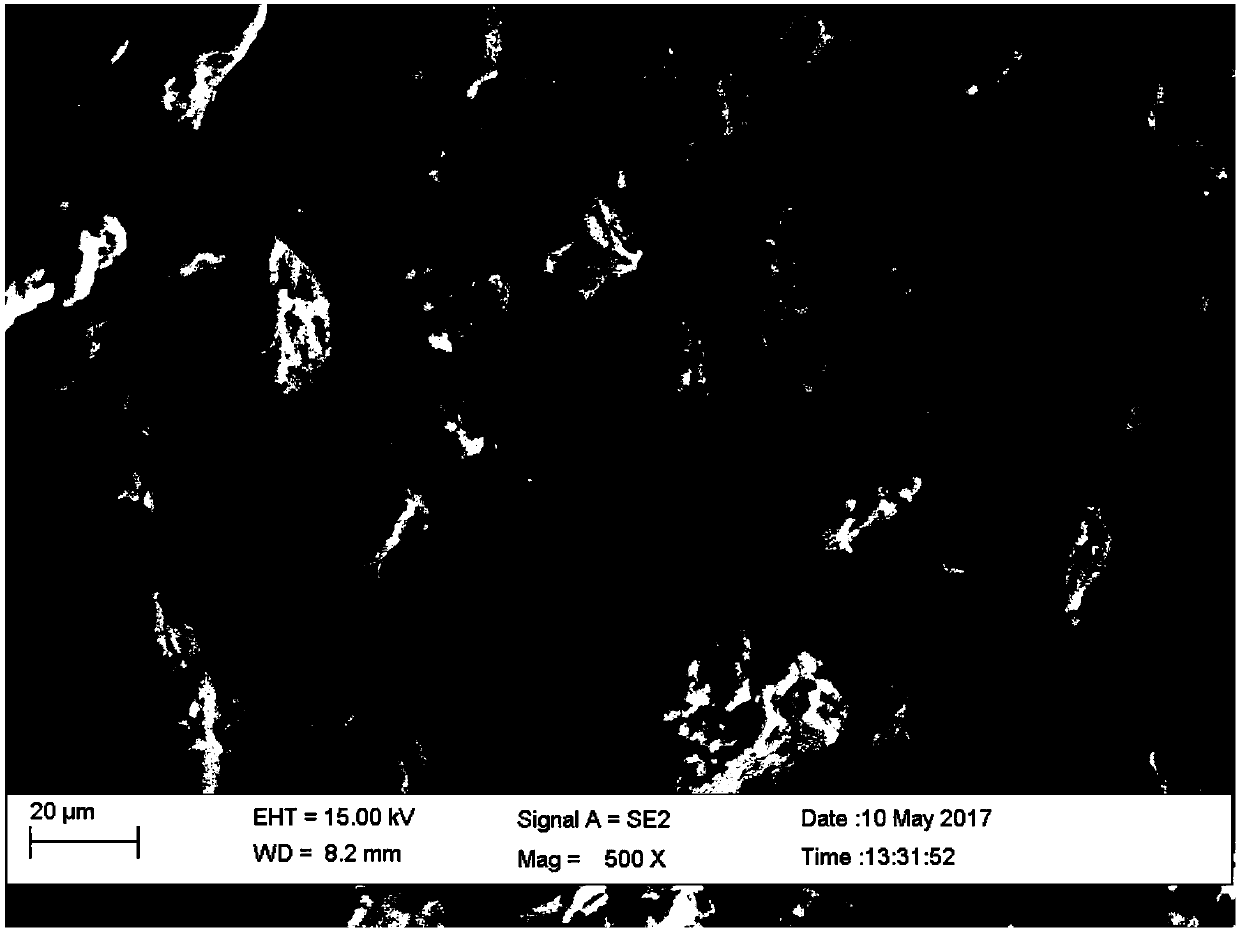

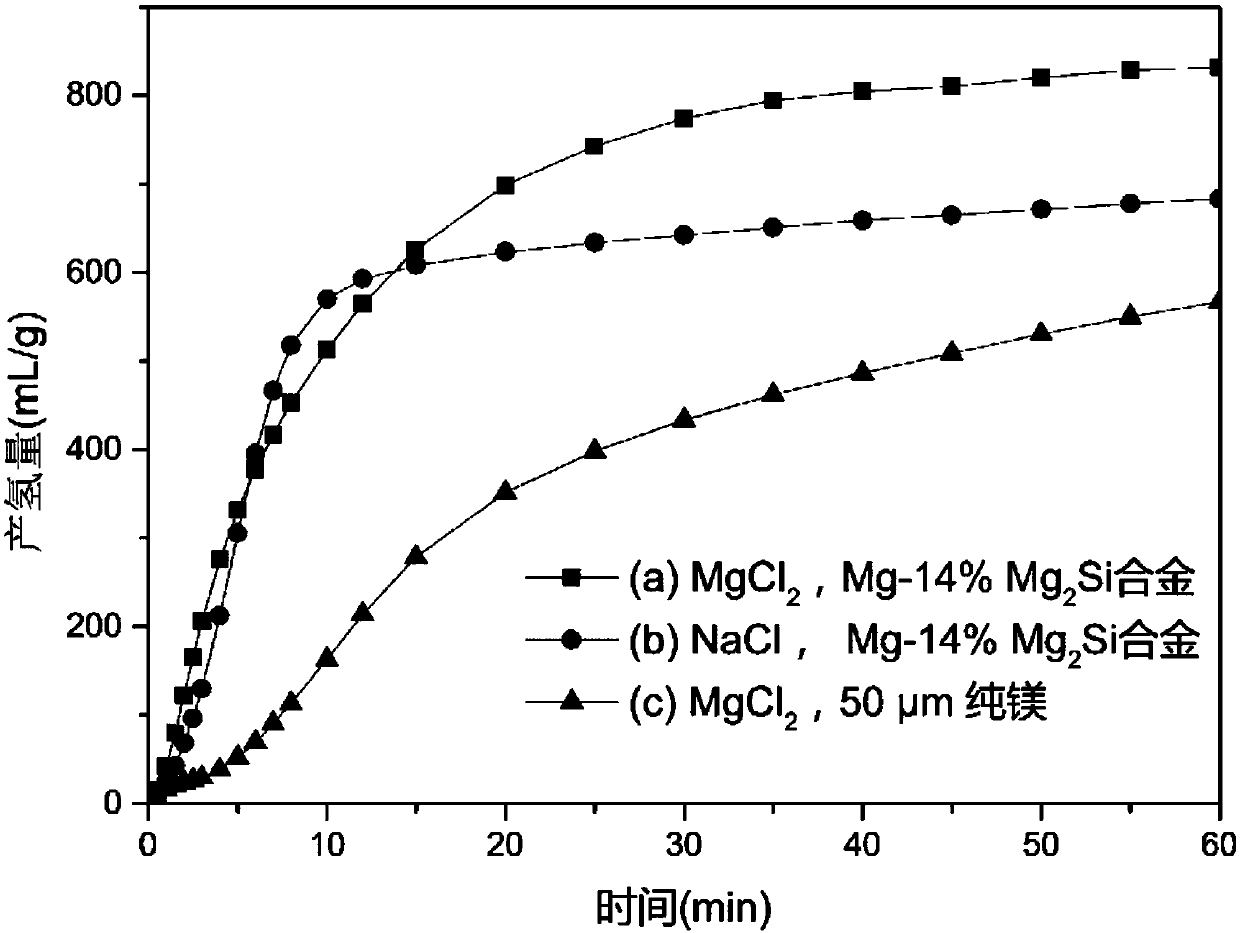

Mg-Mg2Si composite hydrolytic hydrogen production material, preparation method thereof, and method using material to realize hydrolytic hydrogen production

The invention discloses a Mg-Mg2Si composite hydrolytic hydrogen production material, a preparation method thereof, and a method using the material to realize hydrolytic hydrogen production. Mg2Si accounts for 5-30% of the total mass of a composite material in the Mg-Mg2Si composite hydrolytic hydrogen production material. The Mg-Mg2Si composite hydrolytic hydrogen production material has the advantages of low density, high cost performance, and high unit hydrogen yield. The preparation method of the Mg-Mg2Si composite hydrolytic hydrogen production material is characterized in that the magnesium-silicon alloy composite material containing the above mass percentage of the Mg2Si or a Mg powder and Mg2Si powder mixture is placed in a ball mill and undergoes ball-milling to obtain the Mg-Mg2Si composite hydrolytic hydrogen production material. The method using the composite hydrolytic hydrogen production material to realize hydrolytic hydrogen production is characterized in that the Mg-Mg2Si composite hydrolytic hydrogen production material and an aqueous salt solution are mixed, and undergo a hydrolysis reaction. The hydrogen production method has the advantages of high efficiency, simplicity, no complex devices or processes during the production, high hydrogen production efficiency, and facilitation of industrialization and marketization.

Owner:SOUTH CHINA UNIV OF TECH

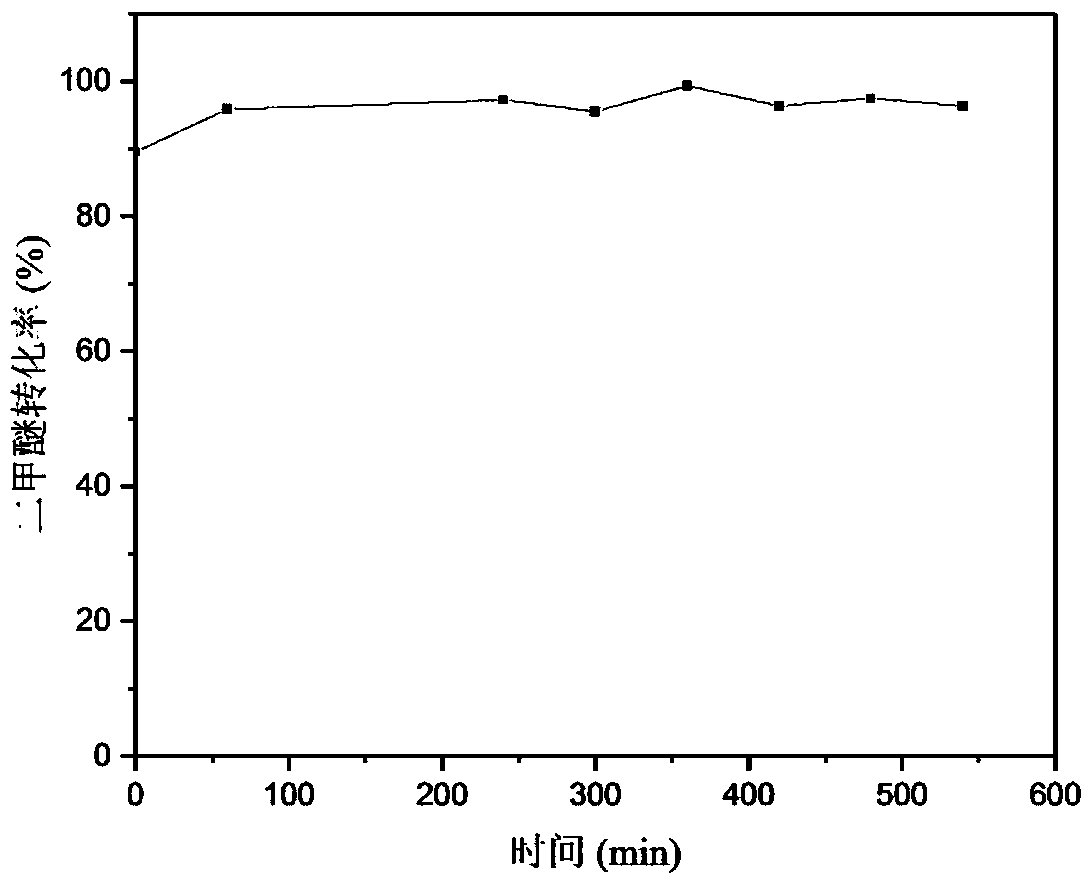

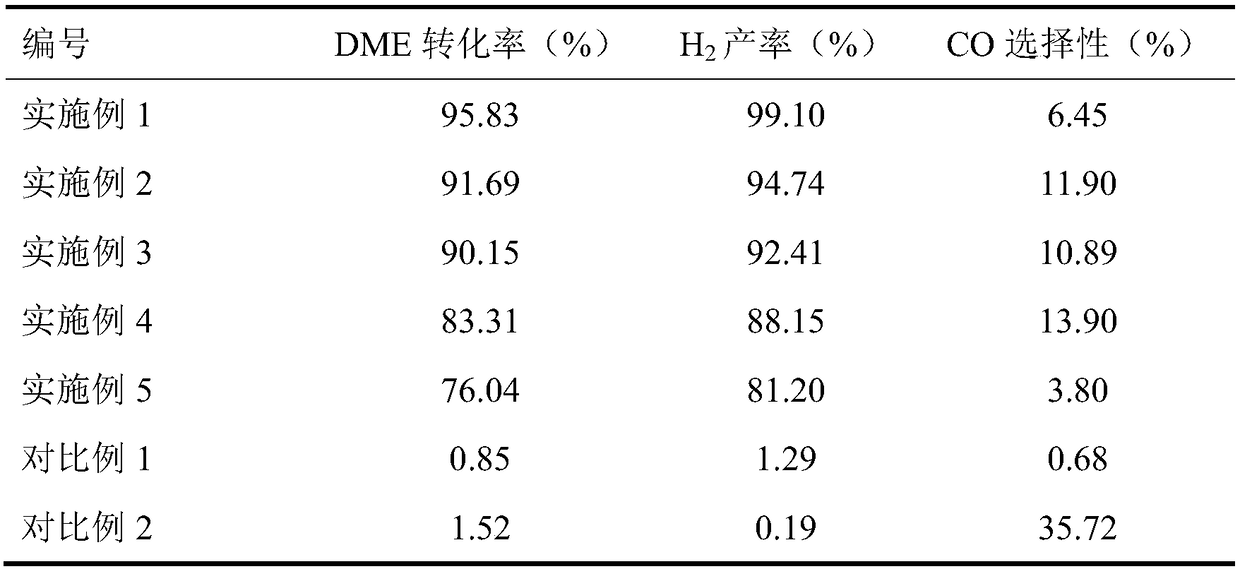

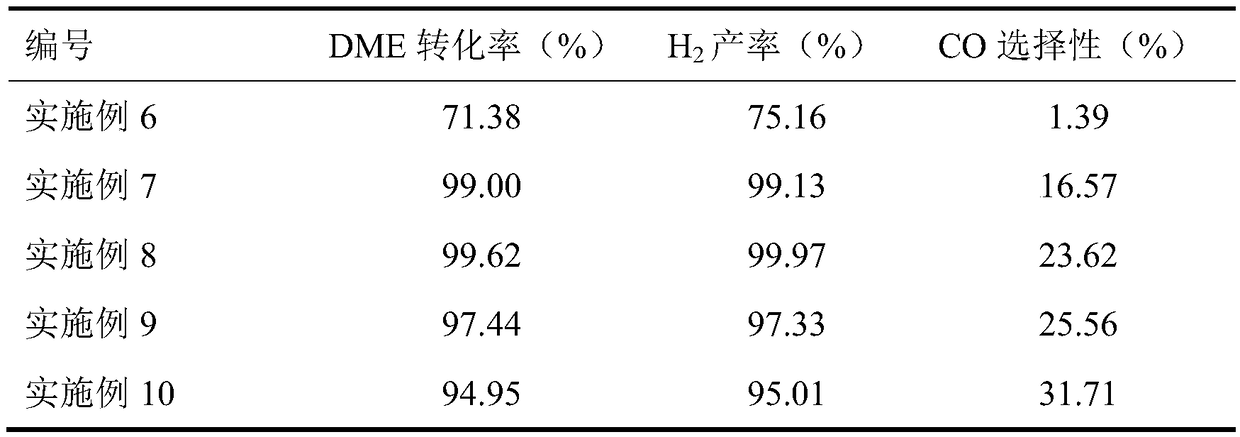

Dimethyl ether water vapor reforming catalyst, and hydrogen production method thereof

ActiveCN108927133AOvercome the defect of high reforming temperatureHigh hydrogen production rateHydrogenHeterogenous catalyst chemical elementsWater vaporReaction temperature

The invention discloses a dimethyl ether water vapor reforming catalyst, and a hydrogen production method thereof. According to the dimethyl ether water vapor reforming catalyst, gamma-Al2O3 is takenas a dimethyl ether hydrolysis active ingredient, and ZnO-ZrO2 solid solution is taken as a methanol reforming active ingredient so as to obtain a double-function catalyst (ZnO-ZrO2 / gamma-Al2O3). In the ZnO-ZrO2 / gamma-Al2O3 catalyst, the mass ratio of ZnO-ZrO2 solid solution to gamma-Al2O3 is 0.5 to 5. The hydrogen production method comprises following steps: the ZnO-ZrO2 / gamma-Al2O3 catalyst is introduced into a fixed bed reactor, N2 is taken as a diluent gas, water vapor is mixed with dimethyl ether, reforming reaction is carried out in a reaction temperature zone after contact with the catalyst so as to obtain hydrogen gas. The largest activity of the catalyst is achieved at 380 DEG C, and the largest activity is 95.83%. The catalyst is high in activity, and hydrogen yield, low in CO selectivity, and excellent in stability; and the reforming reaction temperature of the catalyst is lower than that of a conventional zinc-based catalyst.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method and application of porous two-dimensional carbon nitride@graphene@carbon nitride sandwich structure photocatalytic material

ActiveCN110773220AThe preparation process is simple and reliableImproved photocatalytic hydrogen production activityPhysical/chemical process catalystsGrapheneCarbon nitrideCarbon graphite

The invention discloses a preparation method and application of a porous two-dimensional carbon nitride@graphene@carbon nitride sandwich structure photocatalytic material. The preparation method comprises the steps that firstly, GO nanosheets are synthesized by adopting an improved Hummer method, then melamine is used as a nitrogen source, a simple local in-situ thermal oxygen erosion strategy isadopted, and the porous two-dimensional carbon nitride@ graphene@carbon nitride sandwich structure photocatalytic material can be prepared. According to the preparation method and application of the porous two-dimensional carbon nitride@graphene@carbon nitride sandwich structure photocatalytic material, only a low-cost and environmentally friendly solvent and a controlled heating process need to be used, and toxic reagents and cumbersome post-treatment processes are not needed to be used; and compared with pure CN, an optimized GOCN composite material shows significantly improved photocatalytic hydrogen production activity, and the hydrogen production rate can reach up to 12.48 mmolg<-1>h<-1>, and is 32.0 times higher than CN under the same conditions.

Owner:XIANGTAN UNIV

Process for the separation of hydrogenogen of pentose and hexose at high temperature

InactiveCN101402924AIncrease profitExpand the scope of useBacteriaMicroorganism based processesGlucose polymersD-Glucose

The invention discloses an isolating method of high-temperature hydrogen bacteria of pentaglucose and hexose, relating to an isolating method of high-temperature hydrogen bacteria. The isolating method solves the problems in the existing isolating method of hydrogen bacteria that separation is only carried out under the condition of comparatively low temperate and the isolated hydrogen bacteria is only applied to the fermentation and the hydrogen production of hexose (mainly glucose). The isolating method includes the step: 1. bacteria suspension A is prepared; 2. the bacteria suspension after enrichment is prepared; 3. the bacteria suspension after enrichment is diluted in multiple proportions and then a tube is rolled, and the suspension is cultured till the occurrence of bacterial colony in the tube; 4. bacteria suspension B is prepared; 5. the bacteria suspension B is diluted in multiple proportions and then a tube is rolled, the suspension B is cultured till the occurrence of bacterial colony in the tube and then single bacterial colony is picked for culture again; and 6. the step 3 to step 5 are repeated for five times and then the isolation can be carried out. The isolating method of high-temperature hydrogen bacteria of pentaglucose and hexose can realize isolation at high temperature and the isolated hydrogen bacteria are not only applied to the fermentation and the hydrogen production of hexose but also to the fermentation and the hydrogen production of pentaglucose.

Owner:HARBIN INST OF TECH

Low-carbon zero-emission circulating hydrogen preparing device

InactiveCN105624026AEmission reductionHigh hydrogen production rateBioreactor/fermenter combinationsBiological substance pretreatmentsEnvironmental resistanceHydrogen

The invention provides a low-carbon zero-emission circulating hydrogen preparing device adopting microalgae biomass as fermentation substrate. The device comprises pretreatment equipment, a dark fermentation reactor, solid-liquid separation equipment, a photo fermentation reactor, gas separation equipment and a microalgae growing reactor. According to the device, liquid and gas pollution discharge can be obviously reduced, cyclic utilization and zero emission of carbonic materials can be realized, hydrogen used as clean energy can be prepared, and the hydrogen preparing device is efficient, clean, and environmentally friendly.

Owner:COFCO GROUP +1

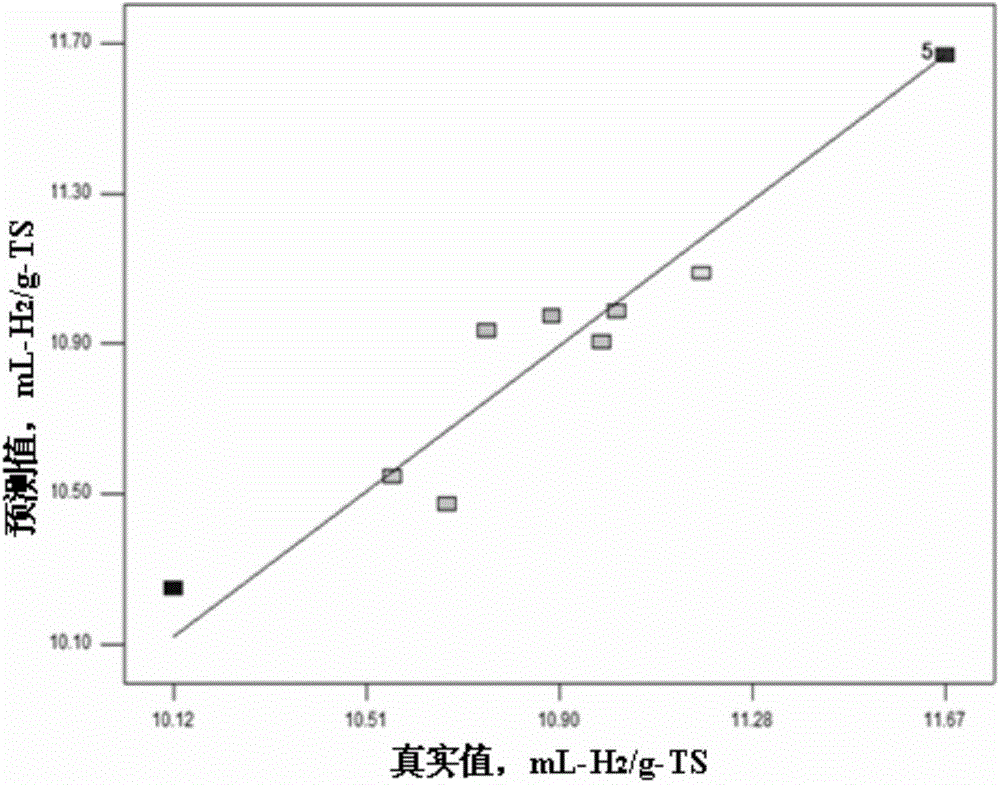

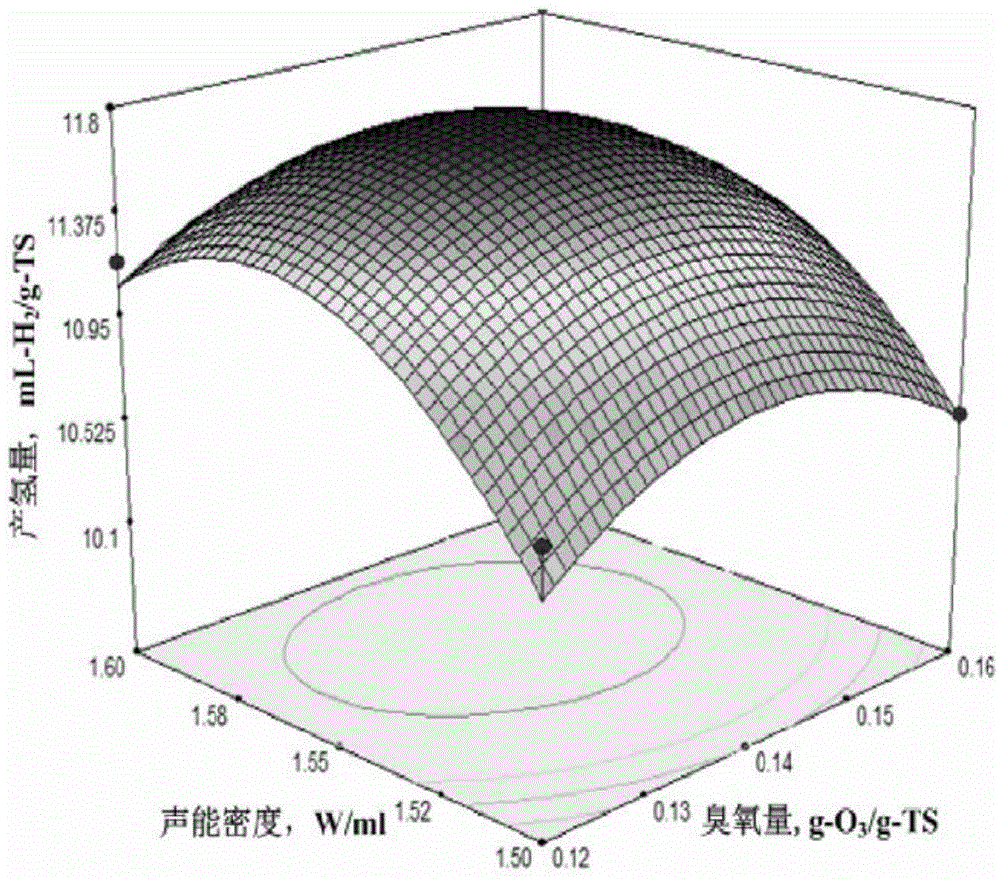

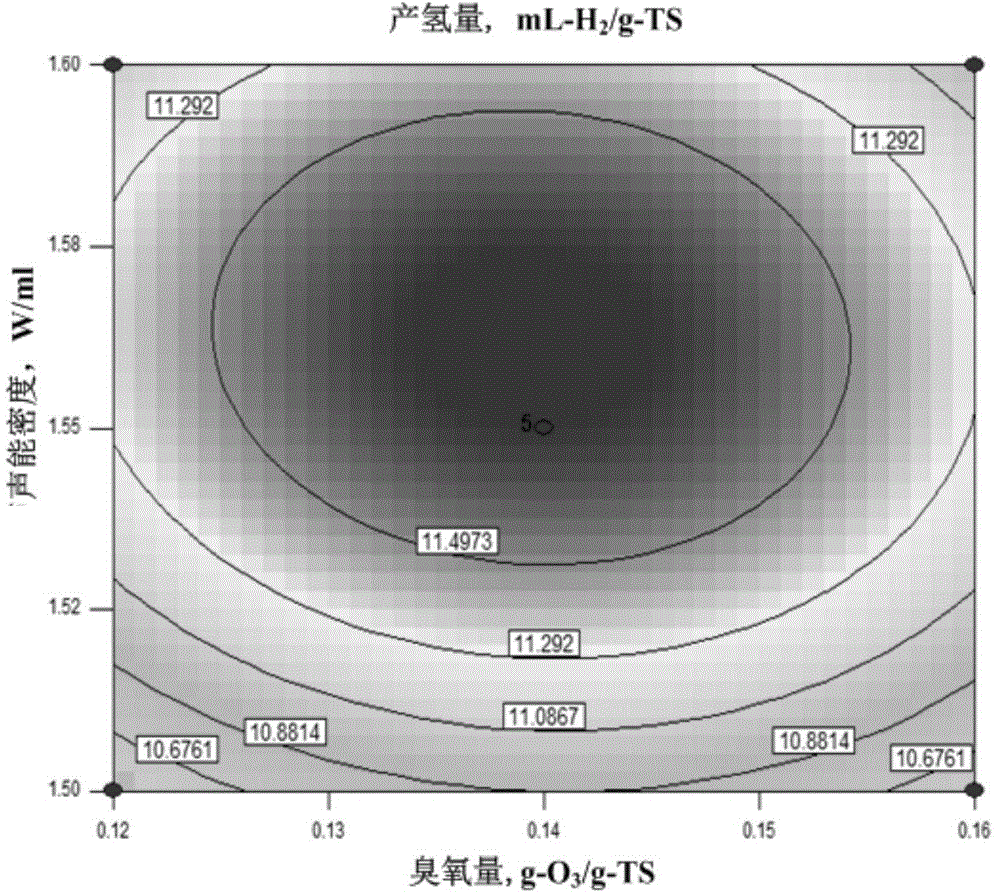

Method for producing hydrogen by using excess sludge

The invention provides a method for producing hydrogen by using excess sludge. The method comprises the following steps: a) subjecting the excess sludge to low-frequency ultrasonic treatment so as to obtain hydrogen-producing seed sludge; b) subjecting the excess sludge to hydrolysis so as to obtain a fermentation substrate; and c) mixing the seed sludge with the fermentation substrate and carrying out fermentation; wherein the sequence of the step a) and the step b) is not limited. Compared with the prior art, the method provided by the invention has the following advantages: a hydrogen production rate is high, and cost for production of hydrogen from excess sludge is substantially reduced since special bacteria is not additionally added as hydrogenogen. Experiment results show that the hydrogen production rate of the method reaches 13.03 mL-H2 / g-TS.

Owner:UNIVERSTAR SCI & TECH SHENZHEN +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com