Method used for preparing hydrogen via embedded bacteria fermentation

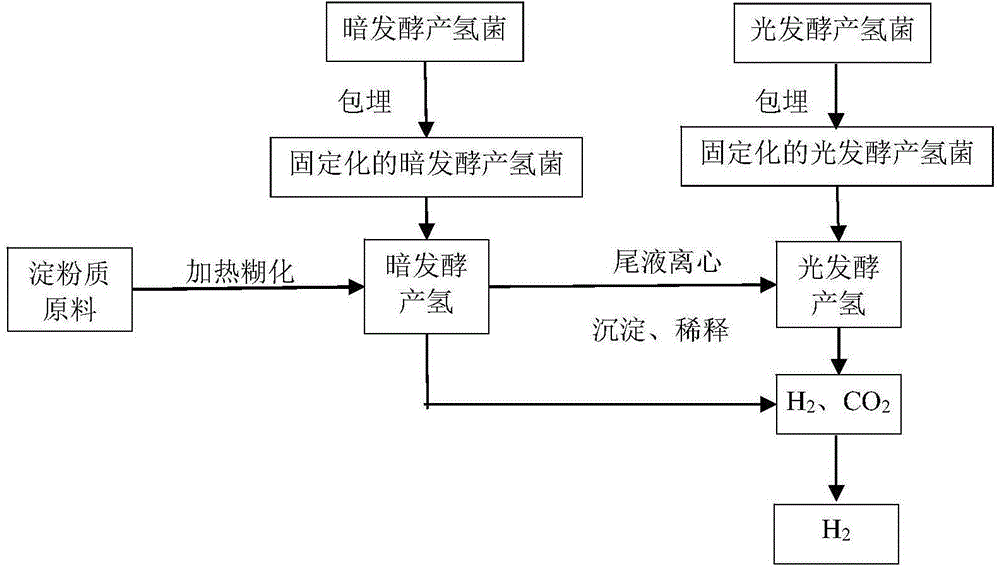

An embedding method and strain technology, applied in the field of biomass energy production, can solve the problem of affecting the mass transfer performance and light transmittance of embedded particles, affecting the substrate absorption efficiency, the hydrogen release rate, and the hydrogen production efficiency. It is impossible to achieve breakthroughs. It can improve the hydrogen production rate and substrate conversion rate, shorten the hydraulic retention time, good mass transfer performance and light transmittance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] For the preparation step (1) of the embedded strain of the present invention, those skilled in the art can appropriately select the type and concentration of the medium and cross-linking agent according to the description in this manual, and the hydrogen-producing strains produced by photofermentation and hydrogen production by dark fermentation strains. In one embodiment, the medium is an organic medium. Preferably, the organic medium is sodium alginate, polyacrylamide or a mixture of the two; the crosslinking agent is CaCl 2 . In one embodiment of the present invention, the dark fermentation hydrogen-producing strain is selected from the group consisting of Clostridium butyricum, Enterobacteraerogenes, Enterobacter cloacae, Clostridium thermocellum One or more of the group consisting of Clostridium barati and Bacillus thermophilus. In one embodiment of the present invention, the photofermentative hydrogen-producing bacteria are selected from Rhodospirillum, Rhodops...

Embodiment 1

[0083] Embodiment 1: Utilize the method for producing hydrogen by embedding strain fermentation

[0084](1) Preparation of embedded bacteria: Mix sodium alginate and deionized water at a mass volume ratio of 2:100 (g / ml, the same below) and heat to dissolve. When the solution is cooled to 30-40°C, follow the seaweed Sodium acid solution and bacteria solution are in a ratio of 1:2 (v / v) (the concentration of the bacteria is 2.0g / L), and the medium is evenly mixed with the dark fermentation hydrogen-producing bacteria solution and the light-fermented hydrogen-producing bacteria solution respectively. , and then injected with the aid of a syringe to a concentration of 1.5% CaCl 2 In the solution, immobilized dark-fermentation hydrogen-producing strains and immobilized light-fermentation hydrogen-producing strains are prepared. The dark-fermentation hydrogen-producing strain is Clostridium butyricum, and the light-fermentation hydrogen-producing strain is Rhodopseudomonas palustr...

Embodiment 2

[0090] Embodiment 2: Utilize the method for producing hydrogen by embedding strain fermentation

[0091] (1) Preparation of embedded bacteria: Mix polyacrylamide and deionized water at a mass volume ratio of 5:100 and heat to dissolve. When the solution is cooled to 30-40°C, the ratio of polyacrylamide to bacterial solution is 1: 3 (v / v) ratio (the strain concentration is 2.0g / L), the medium is uniformly mixed with the dark fermentation hydrogen-producing strain solution and the light-fermentation hydrogen-producing strain solution, and then injected with the aid of a syringe to a concentration of 3.0 % CaCl 2 In the solution, immobilized dark-fermentation hydrogen-producing strains and immobilized light-fermentation hydrogen-producing strains are prepared. The dark-fermentation hydrogen-producing strain is Enterobacter aerogenes, and the light-fermentation hydrogen-producing strain is Rhodobacter sphaericus.

[0092] (2) Heat gelatinization of starchy raw materials: put the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com