Patents

Literature

404 results about "Hydrogen yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

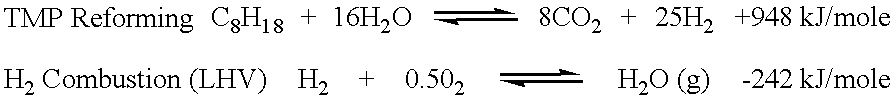

Method and system for supplying hydrogen for use in fuel cells

InactiveUS6348278B1Reduce hydrogen concentrationImprove concentrationElectricity cogenerationRegenerative fuel cellsHydrogenCombustor

The present invention provides a method and system for efficiently producing hydrogen that can be supplied to a fuel cell. The method and system of the present invention produces hydrogen in a reforming reactor using a hydrocarbon stream and water vapor stream as reactants. The hydrogen produced is purified in a hydrogen separating membrane to form a retentate stream and purified hydrogen stream. The purified hydrogen can then be fed to a fuel cell where electrical energy is produced and a fuel cell exhaust stream containing water vapor and oxygen depleted air is emitted. In one embodiment of the present invention, a means and method is provided for recycling a portion of the retentate stream to the reforming reactor for increased hydrogen yields. In another embodiment, a combustor is provided for combusting a second portion of the retentate stream to provide heat to the reforming reaction or other reactants. In a preferred embodiment, the combustion is carried out in the presence of at least a portion of the oxygen depleted air stream from the fuel cell. Thus, the system and method of the present invention advantageously uses products generated from the system to enhance the overall efficiency of the system.

Owner:MOBIL OIL CORP

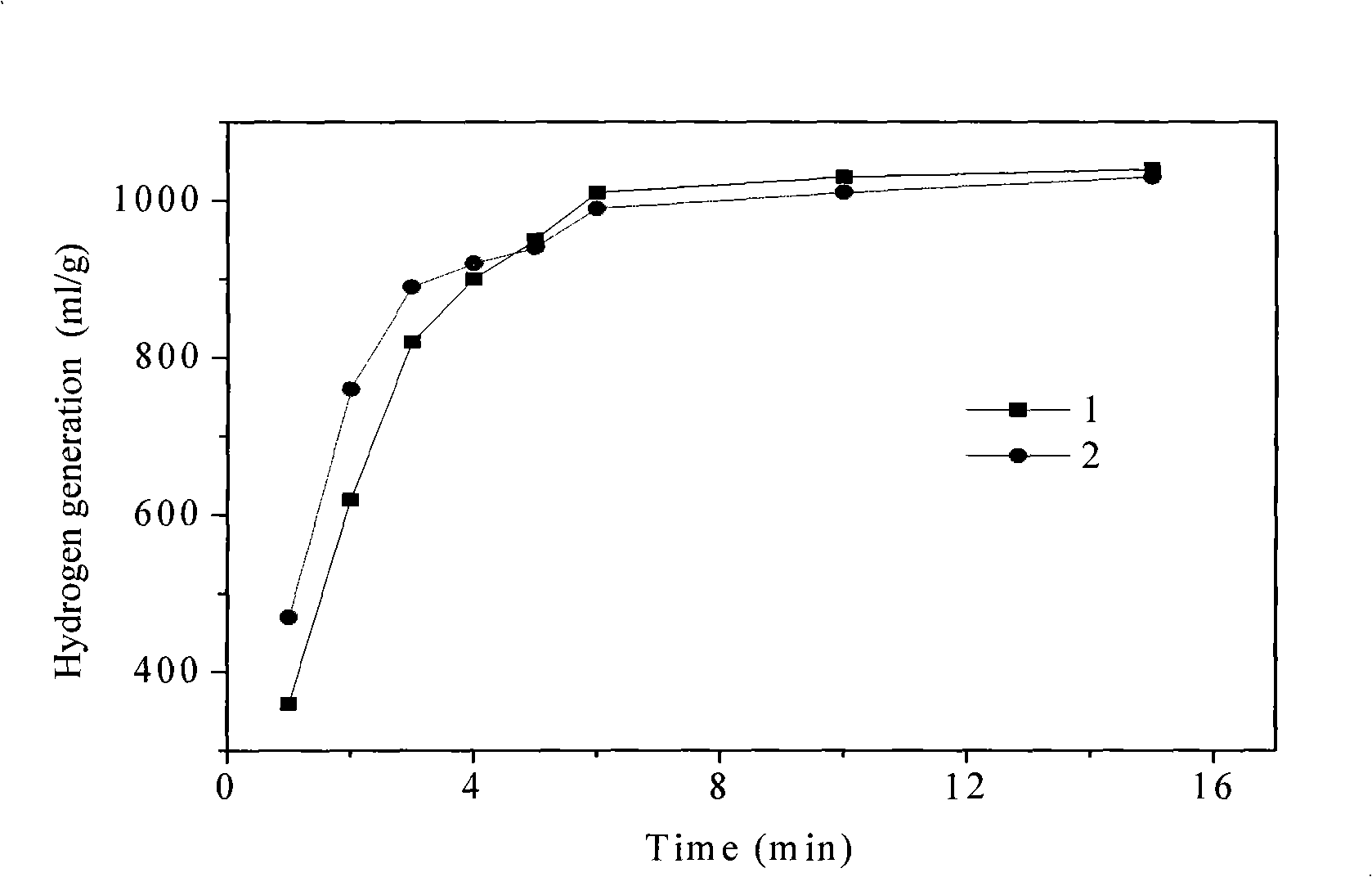

Aluminum alloy for preparing hydrogen by hydrolytic decomposition and preparation thereof

InactiveCN101289163ALower the hydrolysis reaction temperatureImprove electrochemical activityHydrogen productionDecompositionReaction rate

The invention relates to a hydrogen preparation method by hydrolyzing aluminum alloy, in particular to an aluminum alloy which can be hydrolyzed to make hydrogen and a preparation method thereof. The alloy consists of simple-substance metal aluminum, metal bismuth, metals with low melting point and water-soluble compound; according to weight percentage, the content of the metal bismuth is 8 to 50 percent, low melting point metal is 0 to 15 percent, water soluble compound is 1 to 40 percent and metal aluminum is 40 to 90 percent. The method of the invention reduces reaction temperature of aluminum hydrolysis, speeds up reaction rate of aluminum hydrolysis, enhances hydrogen yield rate, simplifies reaction devices as well as reduces hydrogen storage cost. The aluminum alloy prepared by the method of the invention is portable easily, is capable of preparing and providing hydrogen at any time and is applicable to providing humid hydrogen for fuel cells.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

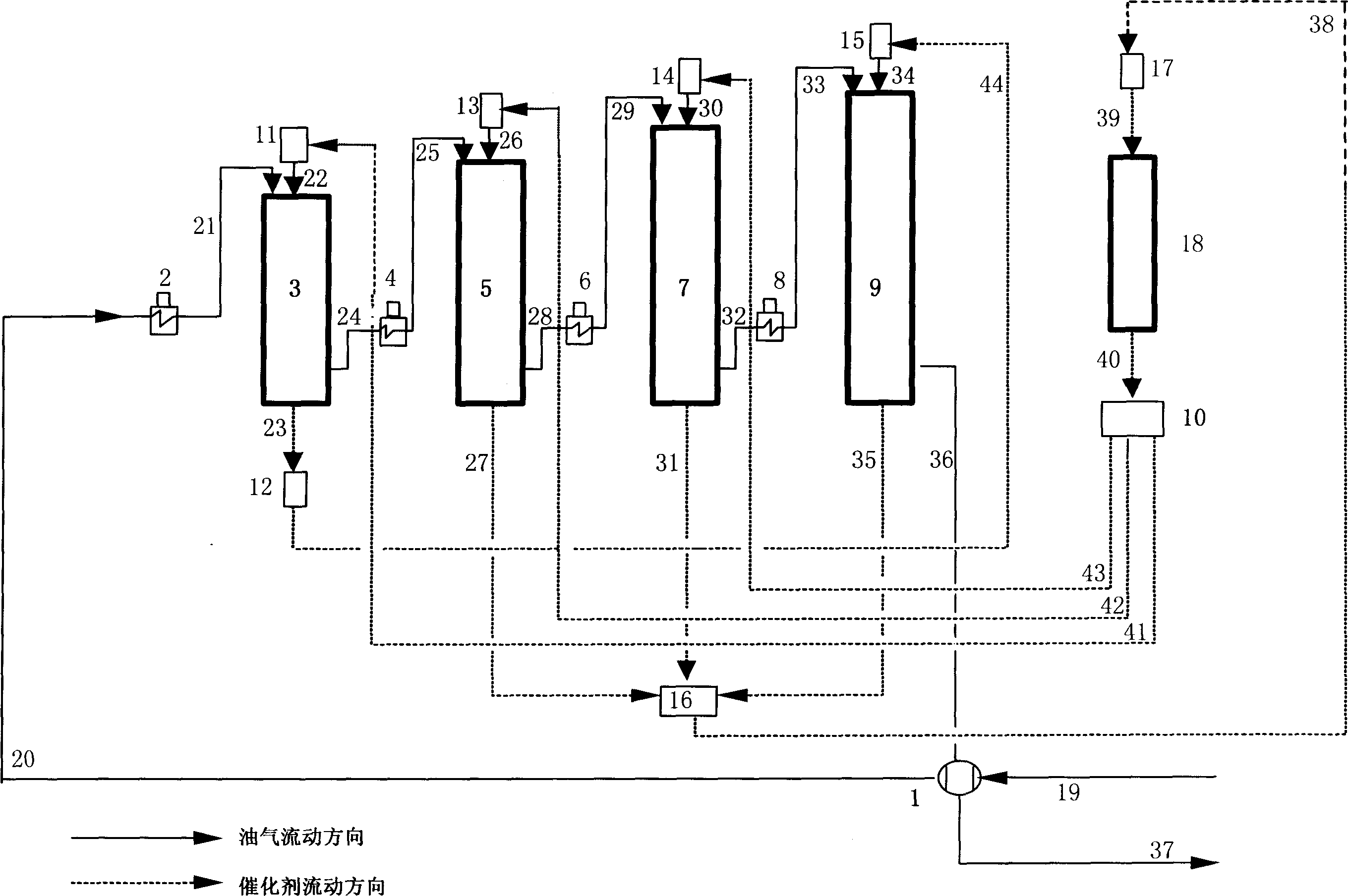

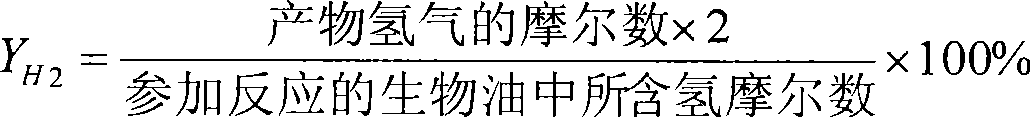

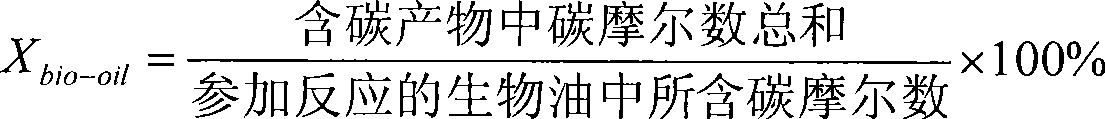

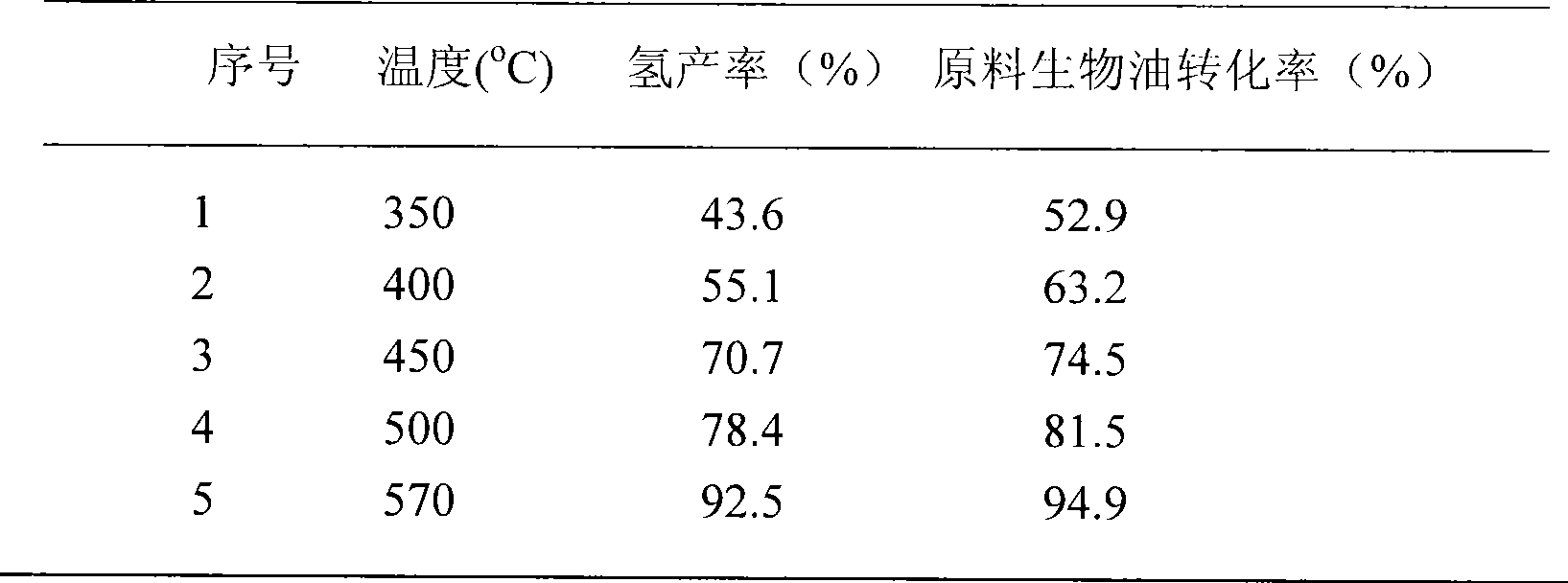

Biomass quick cracked oil water vapour catforming hydrogen production method

InactiveCN101318622AExtended service lifeSolve the phenomenon of carbon depositionHydrogenCatalytic reformingGas phase

The invention discloses a method by adopting biomass fast pyrolysis oil which carries out two sections of fixed bed reactors and water vapor catalytic reforming for producing hydrogen; the two sections of fixed bed reactors are connected in series, the natural dolomite which is relatively cheap and easily available is taken as catalyst in water vapor reforming reaction at the first section of fixed bed reactor, while the second fixed bed reactor adopts Ni / Mgo as catalyst to further improve the purity and yield of the target product gas. Comparatively high temperature and comparatively high S / C (more than 12) are extremely important for the effective transformation of the biomass pyrolysis oil in the first fixed bed reactor. However, for any temperature point, low mass space velocity can facilitate the increasing of the yield of any gas product and the total gas phase transformation ratio of the biomass oil is increased accordingly. The Ni / MgO catalyst is extremely effective in the purification stage, when S / CH4 is not less than 2 and the temperature is not lower than 800 DEG C, the transformation ratio of methane can reach 100 %. Low mass space velocity can facilitate effective transformation of methane; when mass space velocity is not higher than 3600h<-1>, the potential hydrogen yield can reach 81.1%.

Owner:EAST CHINA UNIV OF SCI & TECH

Hydrogen product method and apparatus

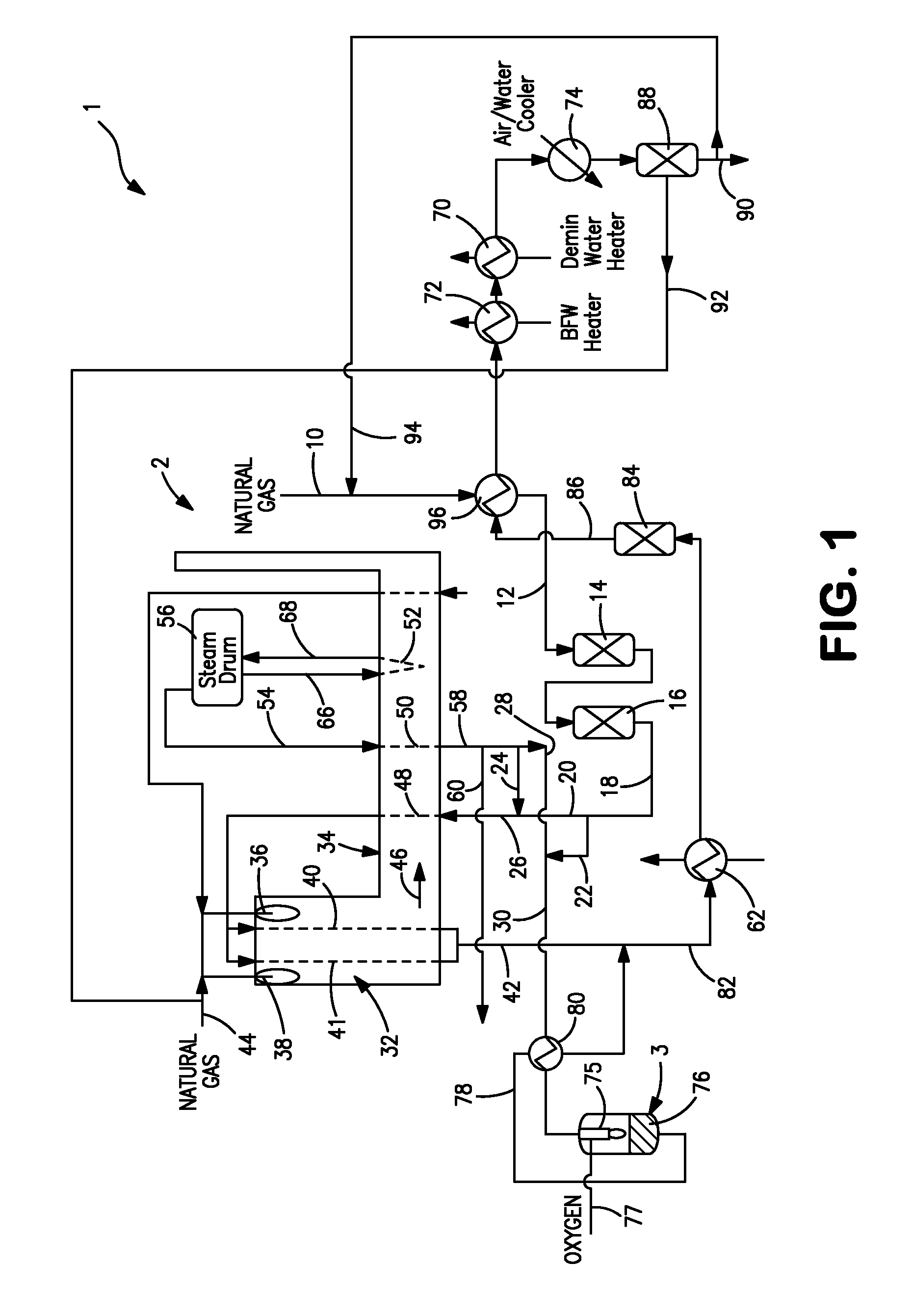

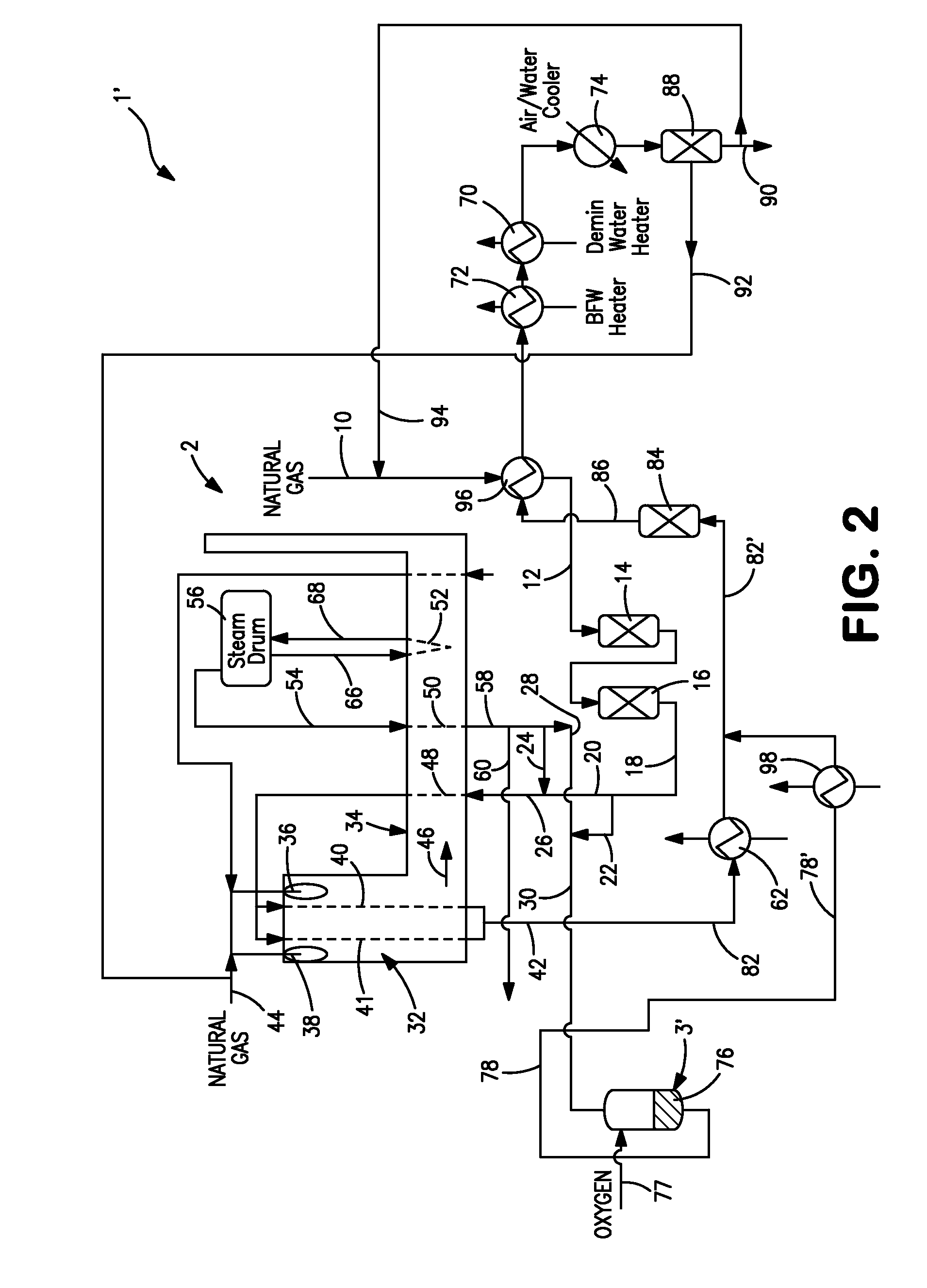

InactiveUS20110085967A1Reduce consumptionIncrease productionHydrogen separation using solid contactChemical industryMethane reformerHydrocarbon

A method and apparatus for producing a hydrogen containing product in which hydrocarbon containing feed gas streams are reacted in a steam methane reformer of an existing hydrogen plant and a catalytic reactor that reacts hydrocarbons, oxygen and steam. The catalytic reactor is a retrofit to the existing hydrogen plant to increase hydrogen production. The resulting synthesis gas streams are combined, cooled, subjected to water-gas shift and then introduced into a production apparatus that can be a pressure swing adsorption unit. The amount of synthesis gas contained in a shifted stream made available to the production apparatus is increased by virtue of the combination of the synthesis gas streams to increase production of the hydrogen containing product. The catalytic reactor is operated such that the synthesis gas stream produced by such reactor is similar to that produced by the steam methane reformer and at a temperature that will reduce oxygen consumption within the catalytic reactor.

Owner:PRAXAIR TECH INC

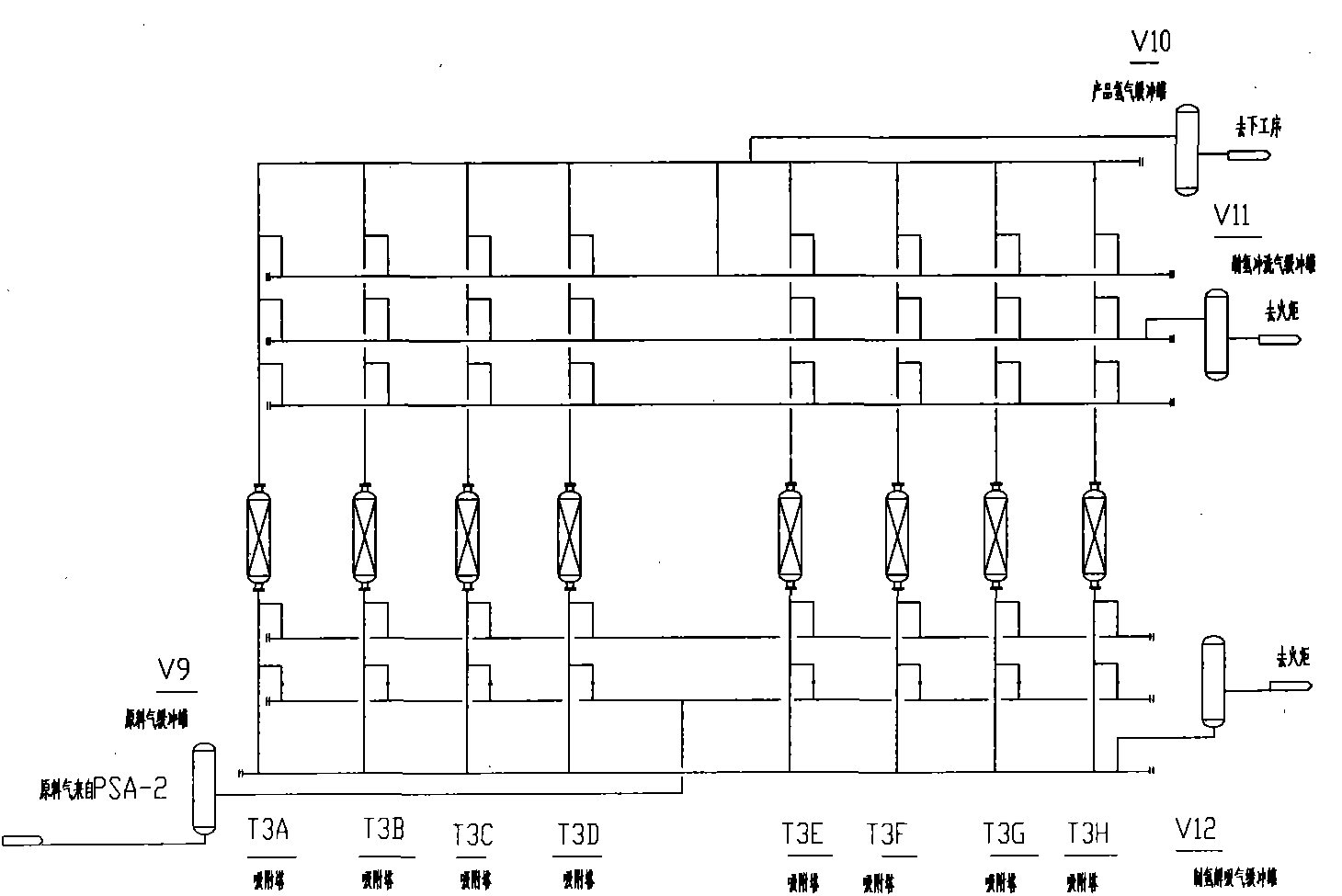

Method for separating and purifying hydrogen from water gas by pressure swing adsorption

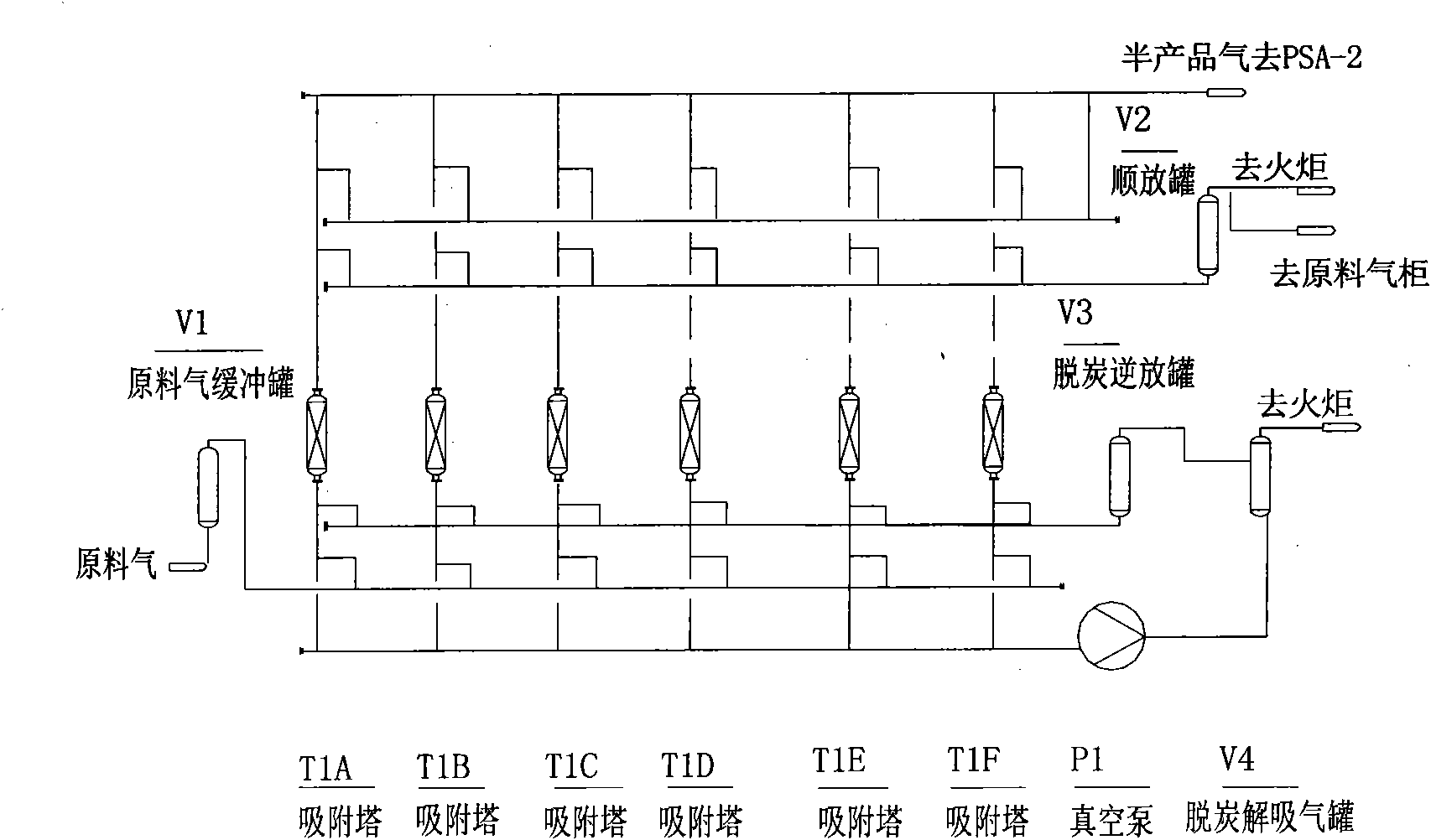

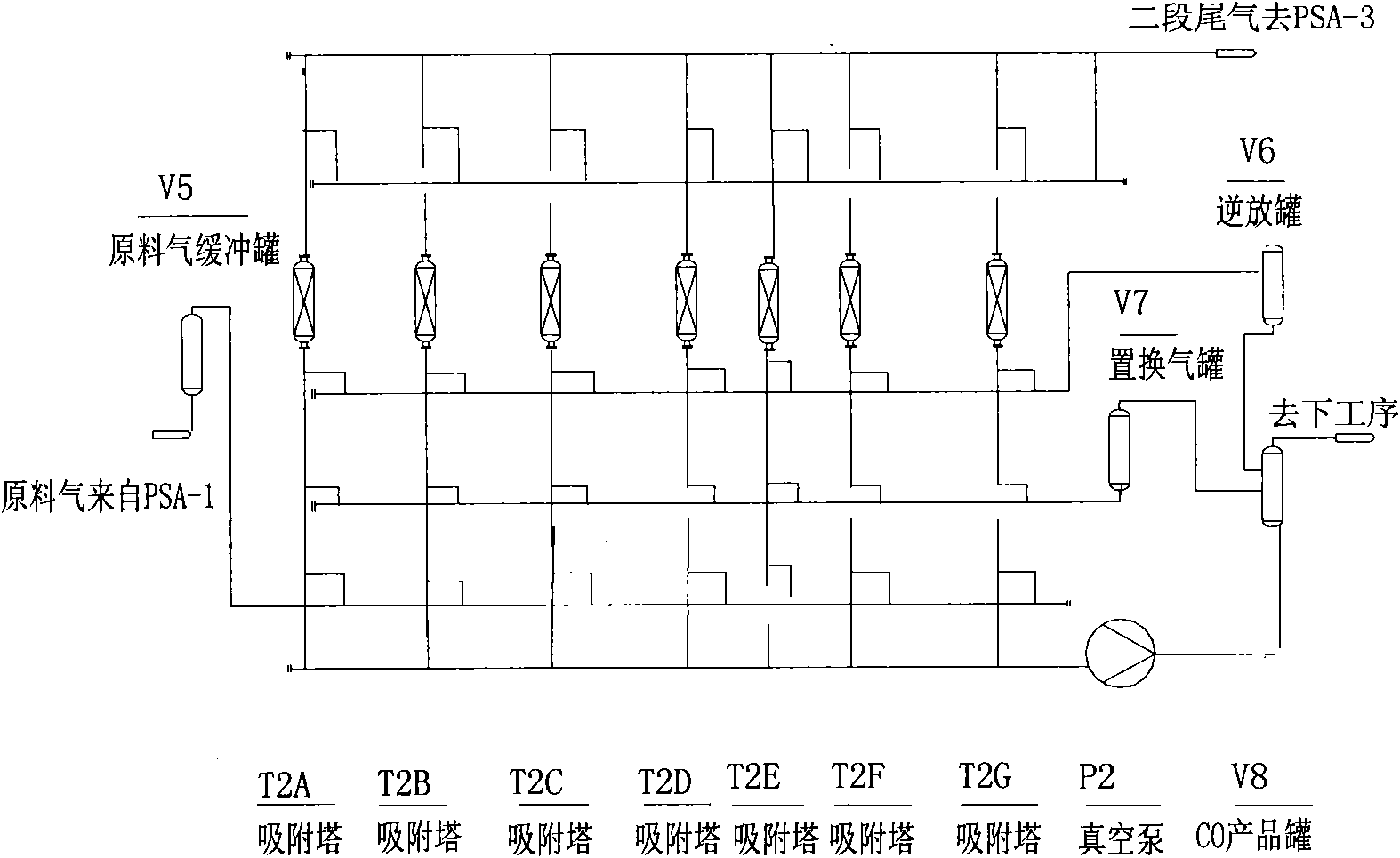

InactiveCN102078740AImprove hydrogen yieldReduce the loss of effective componentsProductsReagentsGas compressorProduct gas

The invention relates to a method for separating and purifying hydrogen from water gas by pressure swing adsorption. Raw material gas is sequentially subjected to a PSA-1 (Pressure Swing Adsorption) decarburization working procedure, a PSA-2 CO purification working procedure and a PSA-3 H2 purification working procedure. Six adsorption beds ABCDEF of a primary adsorption tower T1, seven adsorption beds ABCDEFG of a secondary adsorption tower T2 and eight adsorption beds ABCDEFGH of a tertiary adsorption tower T3 are mainly provided. Backward discharge gas in the PSA-3 H2 purification working procedure is used as the outward blowing gas for the PSA-1 decarburization working procedure, thereby increasing the hydrogen yield by about 3%; forward discharge gas recovered by the six beds of PSA-1 is circularly purified at the inlet of a raw material gas compressor, thereby reducing the loss of effective components in the decarburization working procedure; the content of methane in the process product gas generated by the seven beds of PSA-2 is decreased to 0; and the yield of the product CO is improved to be above 80%.

Owner:甘肃银光聚银化工有限公司 +1

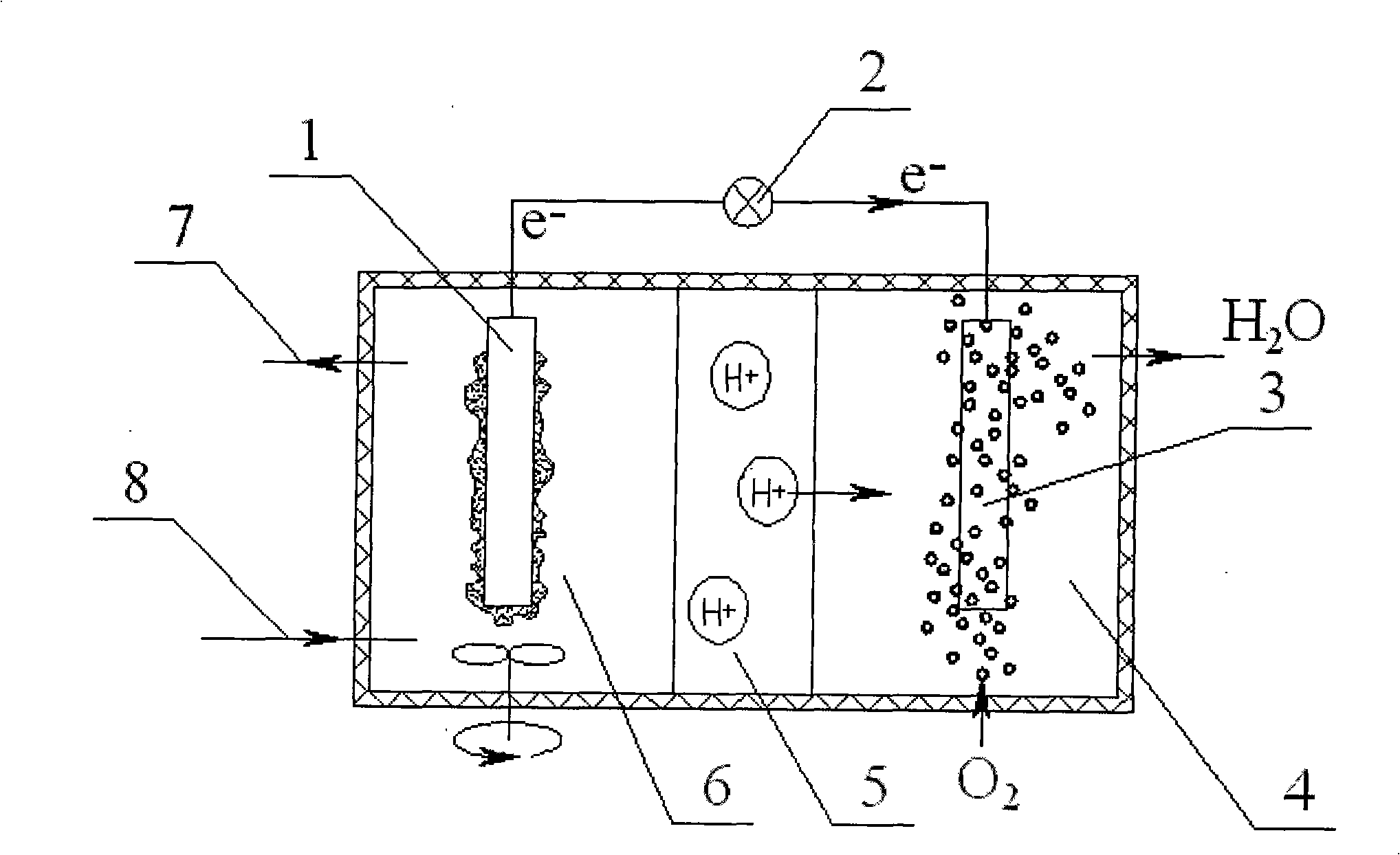

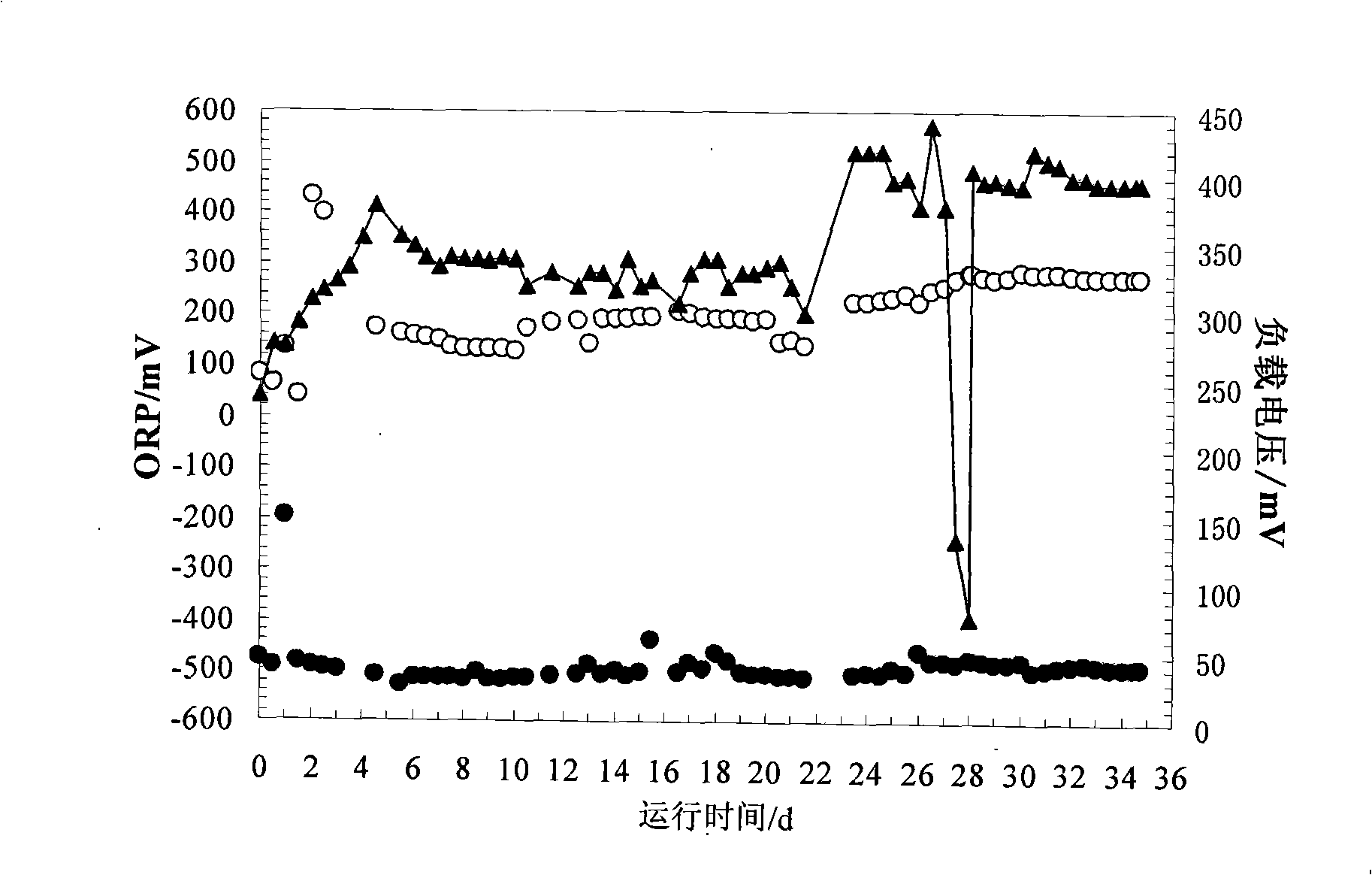

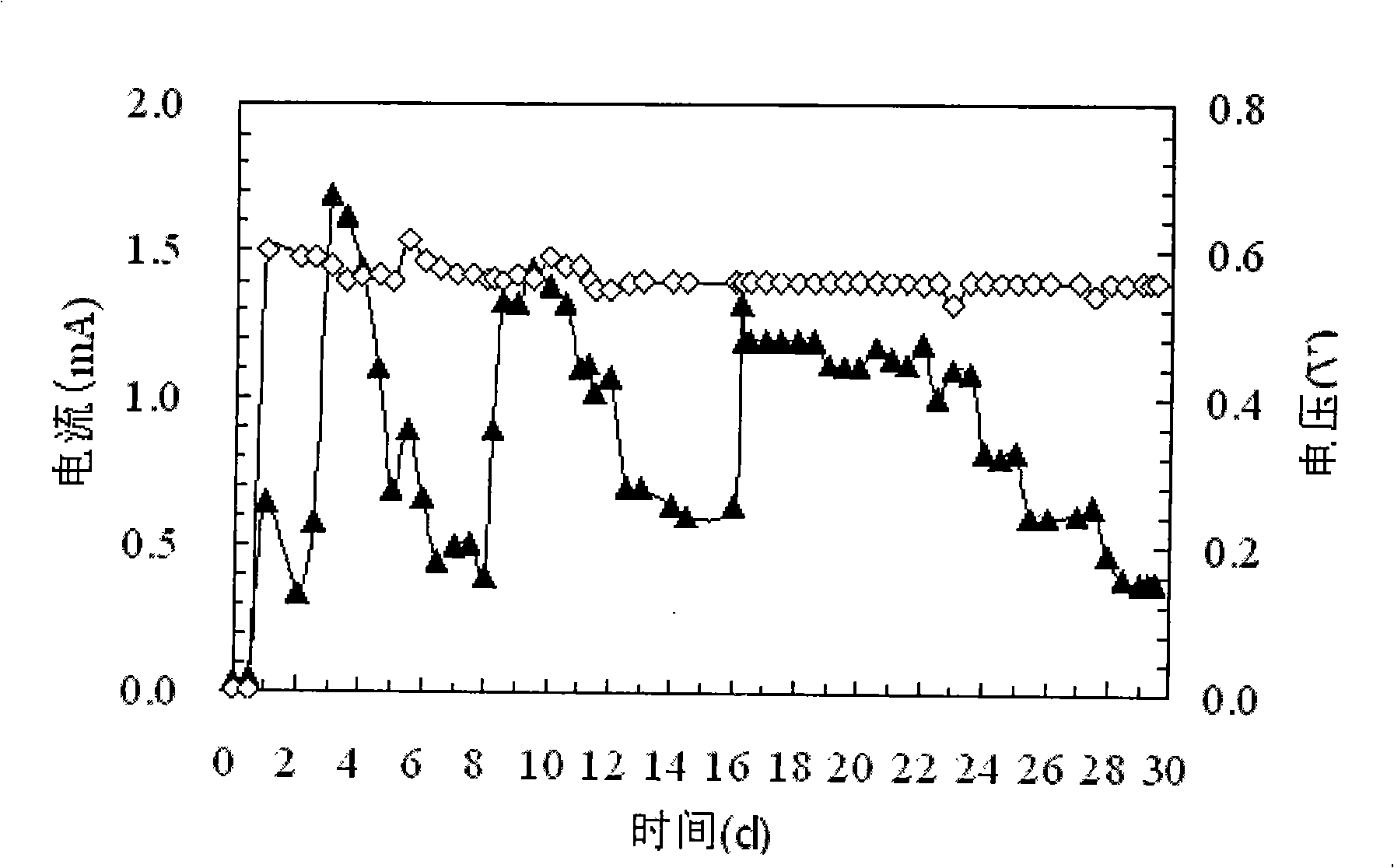

Method for preparing hydrogen with biology and with utilization of organic waste water step

ActiveCN101270368AImprove Coulombic efficiencyHigh process energy conversion rateWater contaminantsFermentationActivated sludgePhosphate

The invention discloses a method of hydrogen production of biological cascade utilization on organic wastewater and relates to a method of producing hydrogen. The invention solves the existing problem of low conversion on biological hydrogen production with organic wastewater fermentation by using anaerobic activated sludge. The hydrogen production method of the invention is carried out as follows: firstly an anode chamber is in the anaerobic condition during startup procedure, anaerobic activated sludge is put into the anode chamber, the nutrient solution with pH value of 6.8 to 7.0 is introduced into the anode chamber, phosphate buffer is added into a cathode chamber, aeration is carried out in the cathode chamber in the previous 28 to 35 days of the startup procedure, startup is successful till the output voltage is continuously and steadily over 400 mV; secondly the organic wastewater is filled into the anode chamber from an inlet of the anode chamber and the organic wastewater is processed in the anode chamber, consequently hydrogen is obtained in the cathode chamber. The coulombic efficiency of the organic substrate conversion of the method reaches as high as over 80 percent, the electron transfer efficiency of transferring the cathode electron into hydrogen approaches to 100 percent, the purity of the hydrogen obtained in the cathode chamber in the entire process reaches 99.5 percent, the energy conversion efficiency of the entire process reaches over 80 percent, and the hydrogen yield calculated based on the input voltage is 288 percent.

Owner:HARBIN INST OF TECH

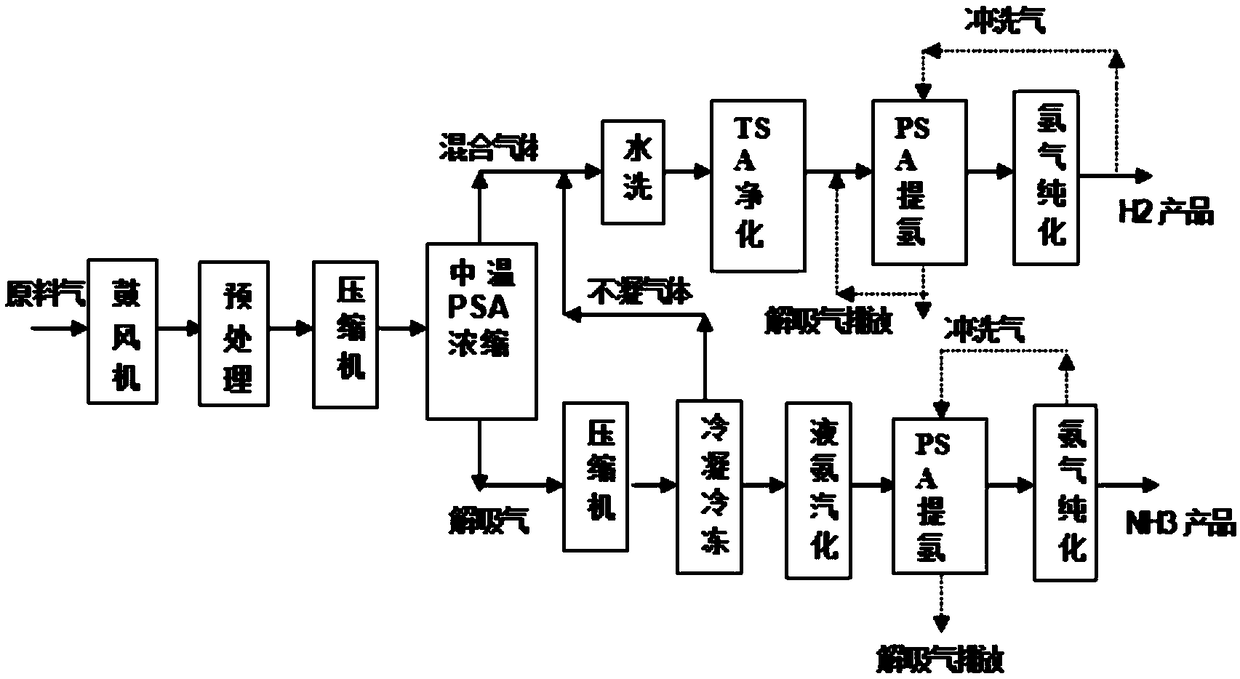

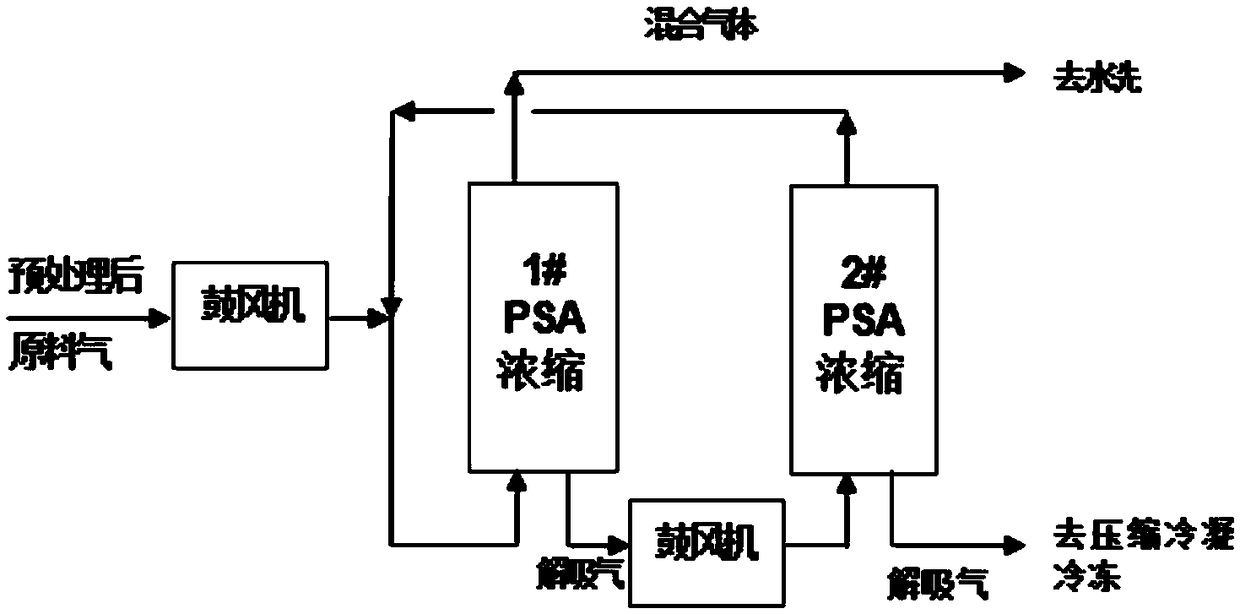

Method for recycling and reusing all components of LED-MOCVD (Light Emitting Diode-Metal Organic Chemical Vapor Deposition) preparation process tail gas through pressure swing adsorption in whole temperature process

ActiveCN108658042ARealize the recycling and reuse of all componentsEmission reductionHydrogen separation using solid contactDispersed particle separationDistillationLight-emitting diode

The invention discloses a method for recycling and reusing all components of an LED-MOCVD (Light Emitting Diode-Metal Organic Chemical Vapor Deposition) preparation process tail gas through pressure swing adsorption in a whole temperature process. The method comprises procedures of pretreatment, medium-temperature pressure swing adsorption concentration, variable-temperature adsorption purification, pressure swing adsorption (PSA) hydrogen refining, hydrogen purification, condensation, freezing or ammonia gas distillation, liquid ammonia gasification, pressure swing adsorption ammonia extraction and ammonia gas purification, and hydrogen or ammonia-containing waste gases of the LED-MOCVD preparation process are purified till standards of electron-scale hydrogen (of which the purity is greater than or equal to 99.99999%v / v) and an electron-scale ammonia gas (of which the purity is greater than or equal to 99.99999%v / v) used in the LED-MOCVD preparation process, then recycling and reuseof waste gases are achieved, the hydrogen yield is greater than or equal to 75-86%, and the ammonia gas yield is greater than or equal to 70-85%. By adopting the method, the technical difficulty thata normal-pressure or low-pressure waste gas in the LED-MOCVD preparation process cannot be recycled or reused in the LED-MOCVD preparation process can be solved, and blanks of green and circular economic development of the LED industry can be made up.

Owner:SICHUAN TECHAIRS

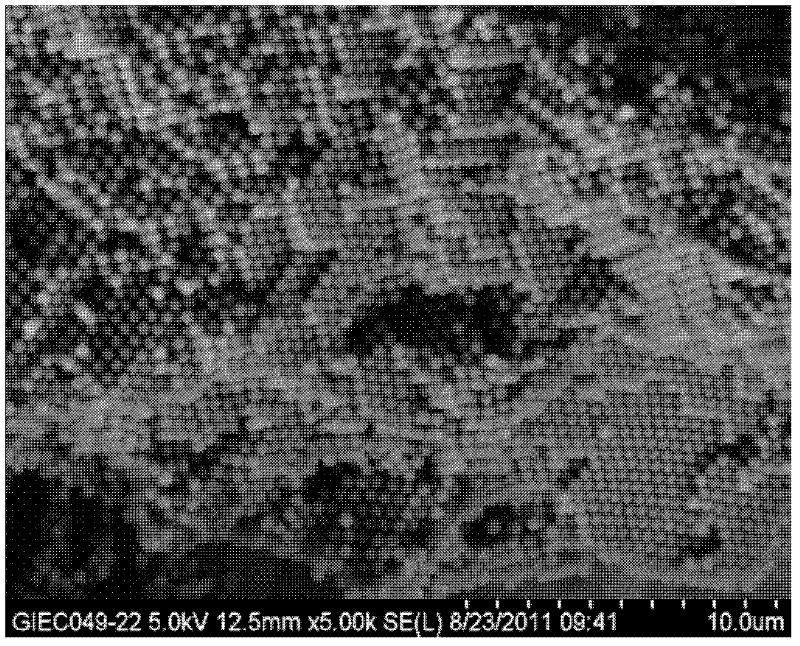

Nickel-based catalyst for hydrogen production by ethanol steam reforming and preparation method thereof

InactiveCN101444737AHigh mechanical strengthHigh catalytic activityHydrogenMetal/metal-oxides/metal-hydroxide catalystsSteam reformingNanowire

The invention discloses a nickel-based catalyst for hydrogen production by ethanol steam reforming and a preparation method thereof. The catalyst is made by taking nanoporous silicon dioxide aerogel as a catalyst carrier, a metal elementary substance nickel nanowire as an active component, and nano-particles of MgO or CaO or ZrO2 or TiO2 or CeO2 or compound nano-particles thereof as an adjuvant. The preparation method comprises the following steps: preparing a sol from silanolate, an alcohol solvent, nickel nitrate or magnesium nitrate or calcium nitrate or zirconium nitrate or cerous nitrate or complex nitrate thereof and an acidic catalyst at certain proportions; forming a wet gel complex, and then performing supercritical fluid drying. The catalyst has strong catalytic activity and selectivity for the hydrogen production by the ethanol steam reforming, has higher hydrogen yield and stronger CO2 selectivity at a lower temperature, and limits the selectivity of byproducts CH4 and CO at a lower level. Meanwhile, the preparation method has simple process, low cost and certain mechanical strength.

Owner:HUNAN SHANGYIFENG NEW MATERIAL TECH CO LTD

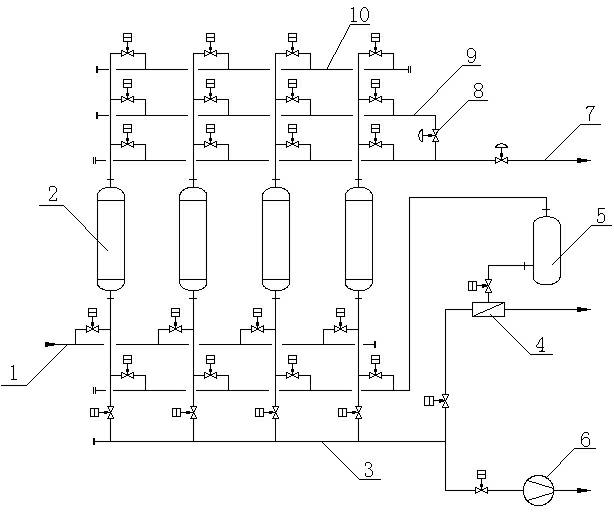

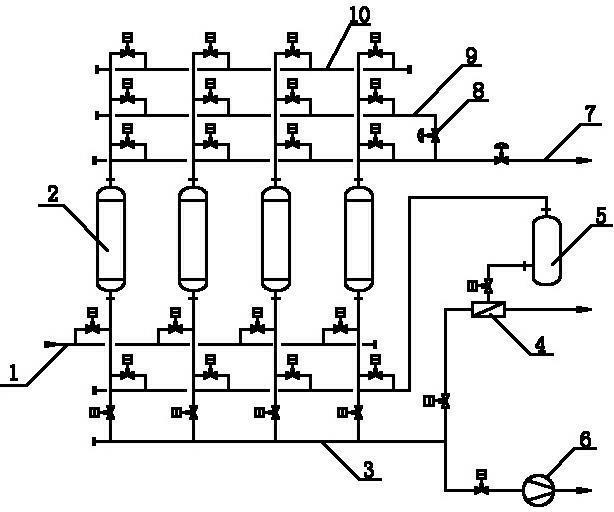

One-stage hydrogen separating and purifying method based on pressure swing adsorption membrane and device for realizing same

ActiveCN102674249ASmall scaleLarge amount of processingHydrogen separation using solid contactSorbentBuffer tank

The invention discloses a one-stage hydrogen separating and purifying method based on a pressure swing adsorption membrane and a device for realizing the same. The method comprises the following steps of: a, adsorption, wherein feed gas with hydrogen content of 75%, carbon dioxide content of 24.5%, carbon monoxide content of 0.5% and pressure of 1.2Mpa is fed into an adsorption tower, a hydrogen purification adsorbent filled in the adsorption tower adsorbs the carbon dioxide and the carbon monoxide in the feed gas, effective gas component hydrogen is output from the top of the adsorption tower, and the product hydrogen is sent to a user from the device through an outlet valve; and b, regeneration, wherein after the feed gas is adsorbed in the adsorption tower, equalized pressure drop and inverse discharge are performed on the adsorption tower, inversely discharged gas enters into a membrane separation unit, infiltration gas is stored in a buffer tank and then returned into the evacuated adsorption tower, and finally equalized pressure increasing and final charge are performed on the adsorption tower. By utilizing the process, the size of a pressure swing adsorption device can be reduced, the hydrogen yield is improved, and the cost is lowered.

Owner:SICHUAN TECHAIRS

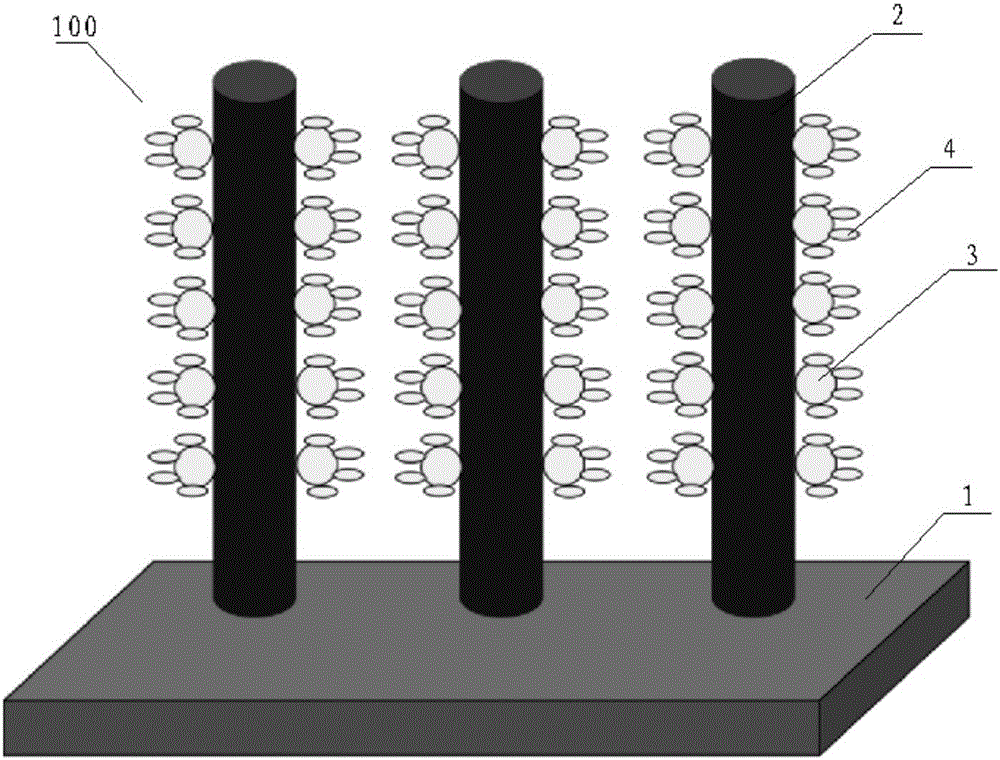

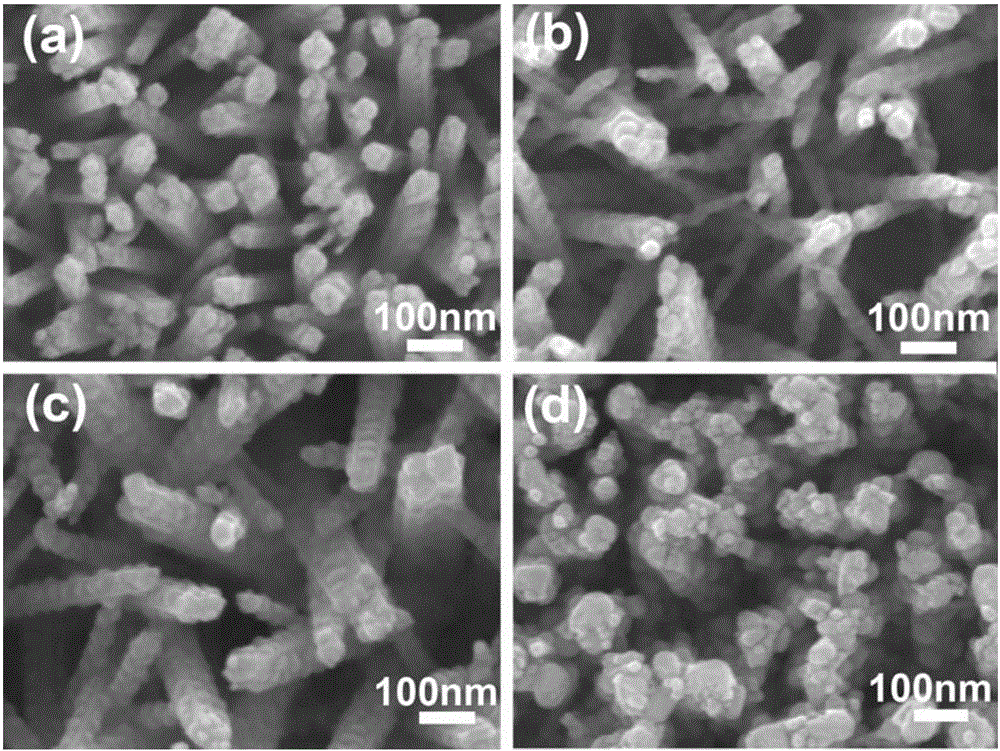

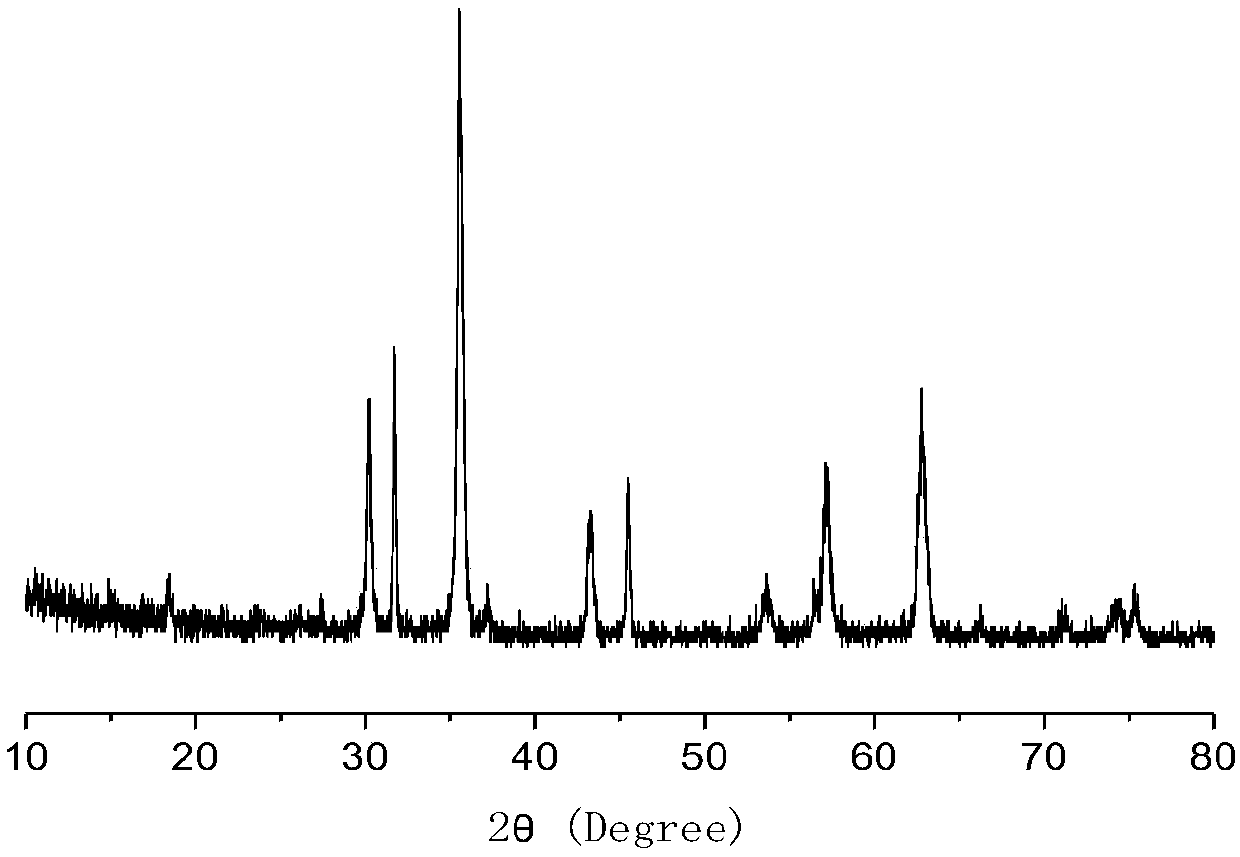

TiO2/BiVO4 photo-anode material and preparation method thereof

InactiveCN104988533AEfficient separationEfficient decompositionElectrodesNano structuringLattice defects

The invention discloses a TiO2 / BiVO4 photo-anode material which comprises a substrate, a TiO2 nano-rod array perpendicularly grown on the surface of the substrate, and a BiVO4 nano-particle layer deposited on the surface of the TiO2 nano-rod array. Through adoption of the TiO2 / BiVO4 photo-anode material, the water photoelectrolysis property is improved; compared with other water photoelectrolysis materials, the TiO2 / BiVO4 photo-anode material effectively overcomes the lattice defect of an interface layer, reduces the composition of photo-generated electrons and hole pairs, improves the own stability, expands the absorption spectrum range of visible light, promotes the effective separation of the photo-generated electrons and the hole pairs, realizes the synchronous reaction of hydrogen production and oxygen production, ensures that the ratio of the hydrogen yield to the oxygen yield is close to 2: 1, and is a relatively ideal water photoelectrolysis material. Moreover, the invention further discloses a preparation method of the TiO2 / BiVO4 photo-anode material. The preparation method has the characteristics that the nano-structure control is easy to realize technically, the prepared binary nano-rod array is excellent in crystallization property, and the interface quality is relatively high.

Owner:HUBEI UNIV

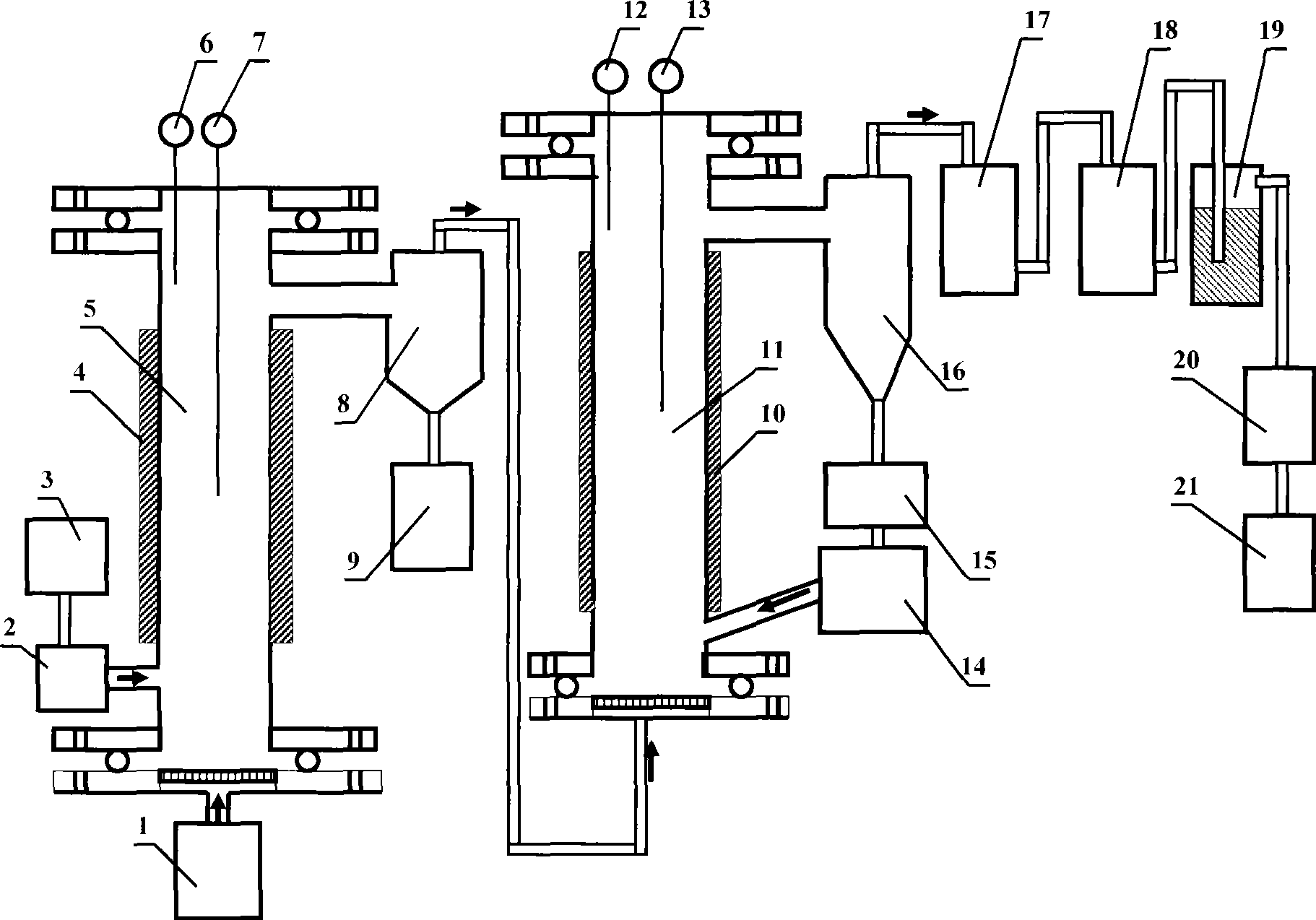

Biomass hydrogen production in water vapour atmosphere and series fluidized bed apparatus system thereof

InactiveCN101475143ALow reaction temperatureReduce energy consumptionHydrogenSteam reformingGas solid

The invention relates to a method for preparing hydrogen by biomass in water vapor atmosphere and a device system. The device comprises a biomass cracking fluid bed, an organic substance vapor reforming fluid bed, and an input pipeline and an output pipeline of the reforming fluid bed, wherein the bottom of the cracking fluid bed is communicated with a water vapor generator, a cracking tail gas delivery pipe is communicated with the input pipeline of the reforming fluid bed through a gas-solid separation device, the reforming fluid bed is also connected with a catalyst input pipeline, and a reforming tail gas output pipeline is connected with the gas-solid separation device and then connected with common series devices for condensation, purification, drying and hydrogen storage. When the hydrogen is prepared, the biomass is thermally cracked quickly at intermediate temperate to generate organic substance vapor, then the vapor is subjected to gas-solid separation and then flows into the reforming fluid bed to carry out water vapor reforming reaction to generate mixed gas of hydrogen, carbon dioxide and the like, and the mixed gas is purified to obtain pure hydrogen. The method uses the tandem fluid bed device system, and organically combines cracking of the biomass and hydrogen preparation of organic substance vapor reforming in the water vapor atmosphere, thereby simplifying the purification process, obtaining high hydrogen yield under the intermediate temperate condition, and improving energy efficiency greatly.

Owner:UNIV OF SCI & TECH OF CHINA

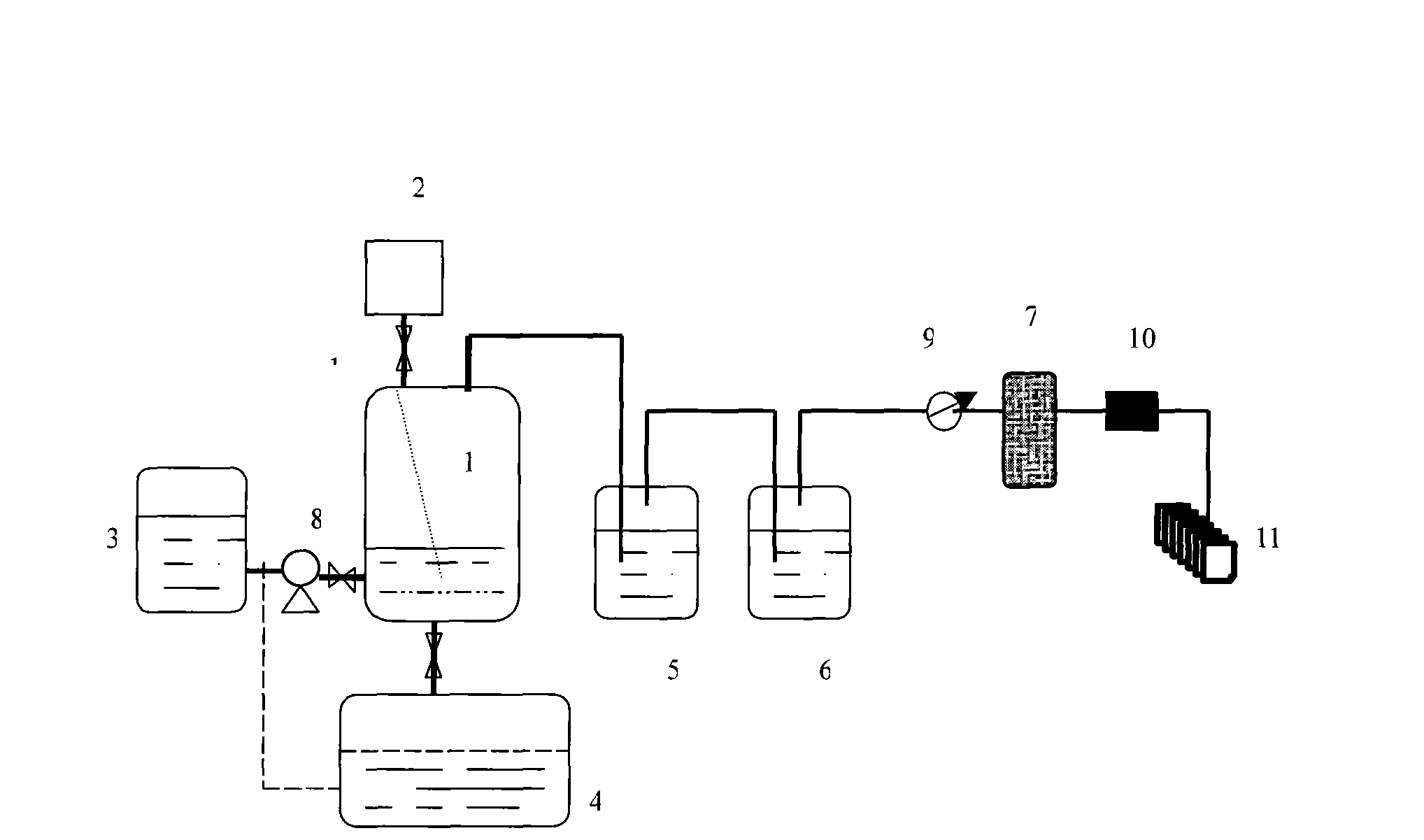

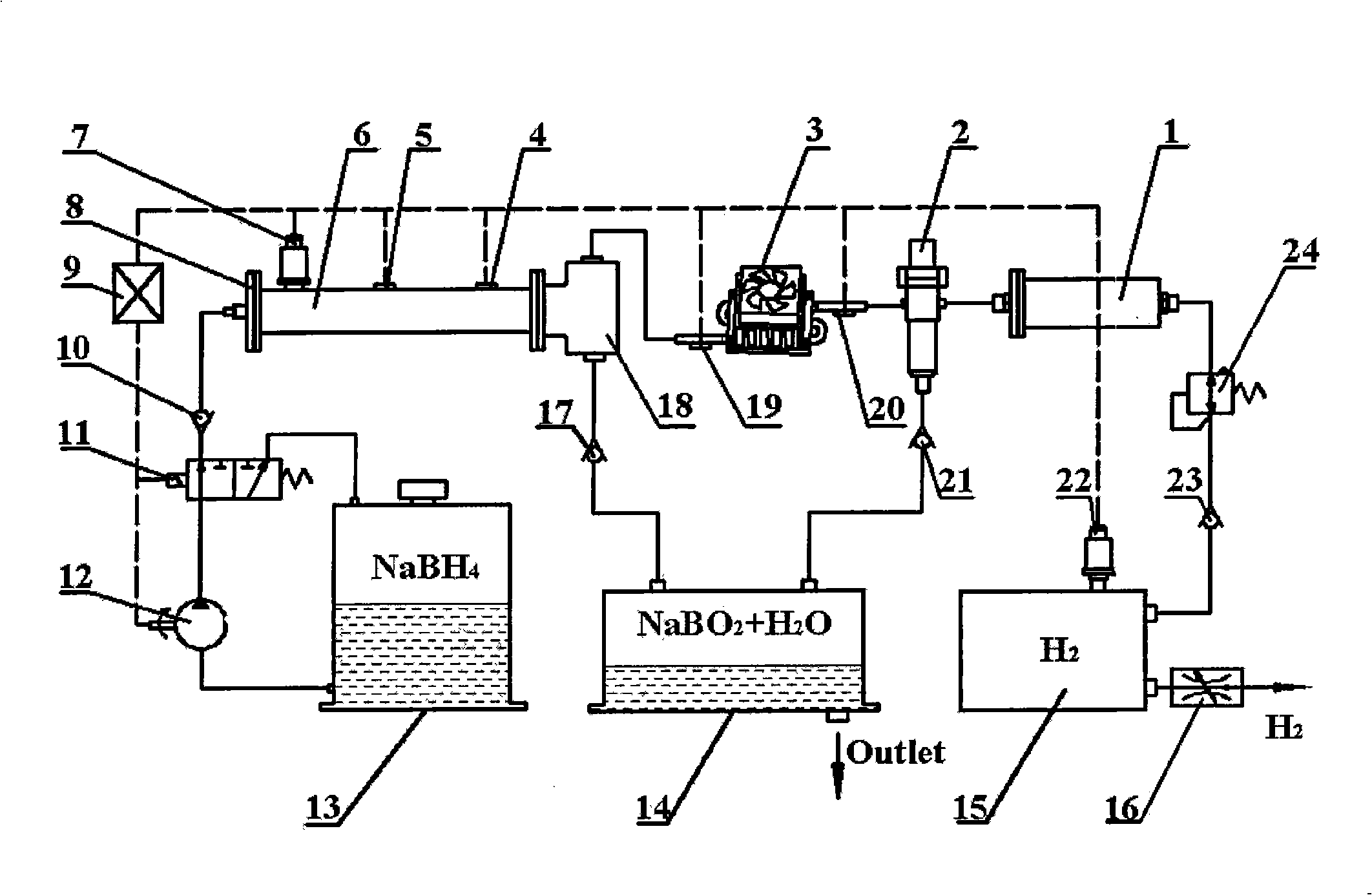

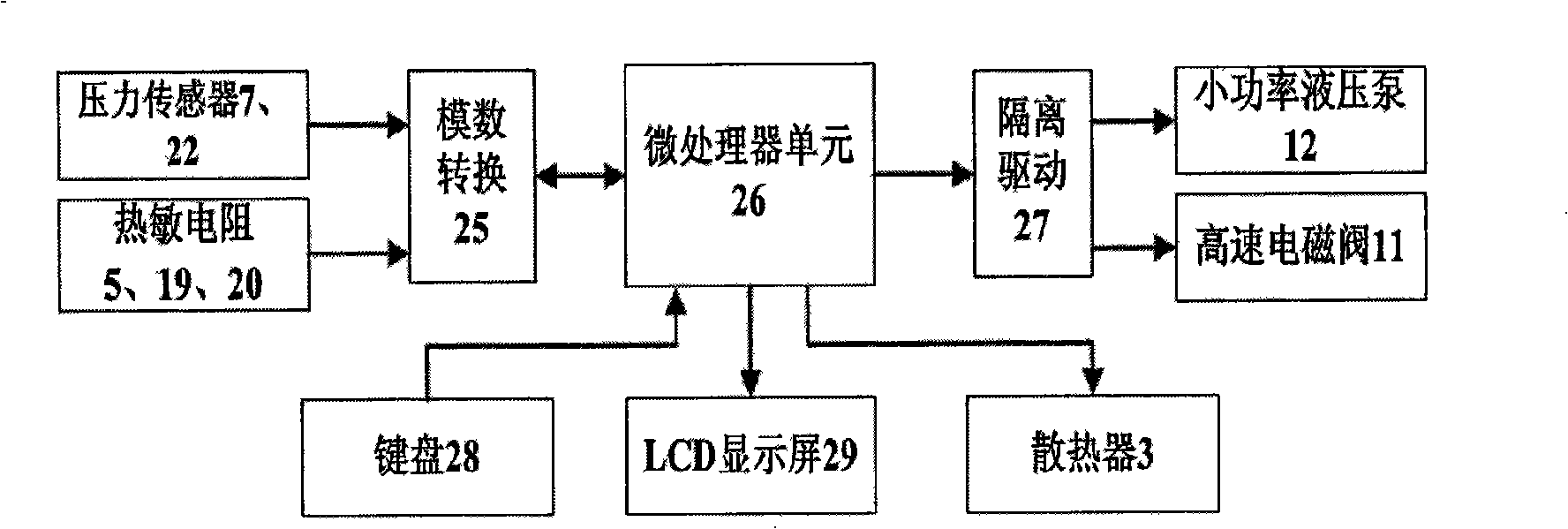

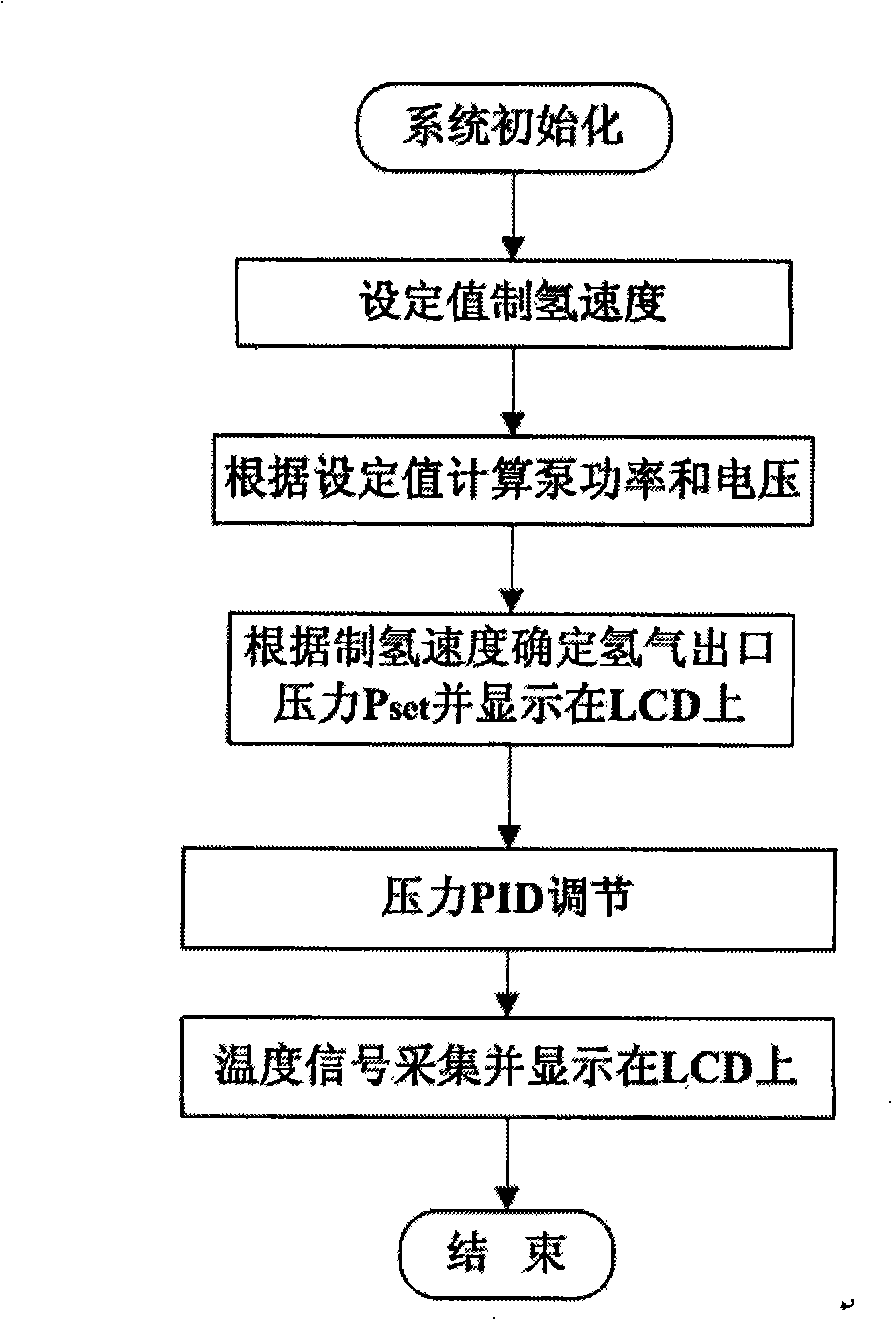

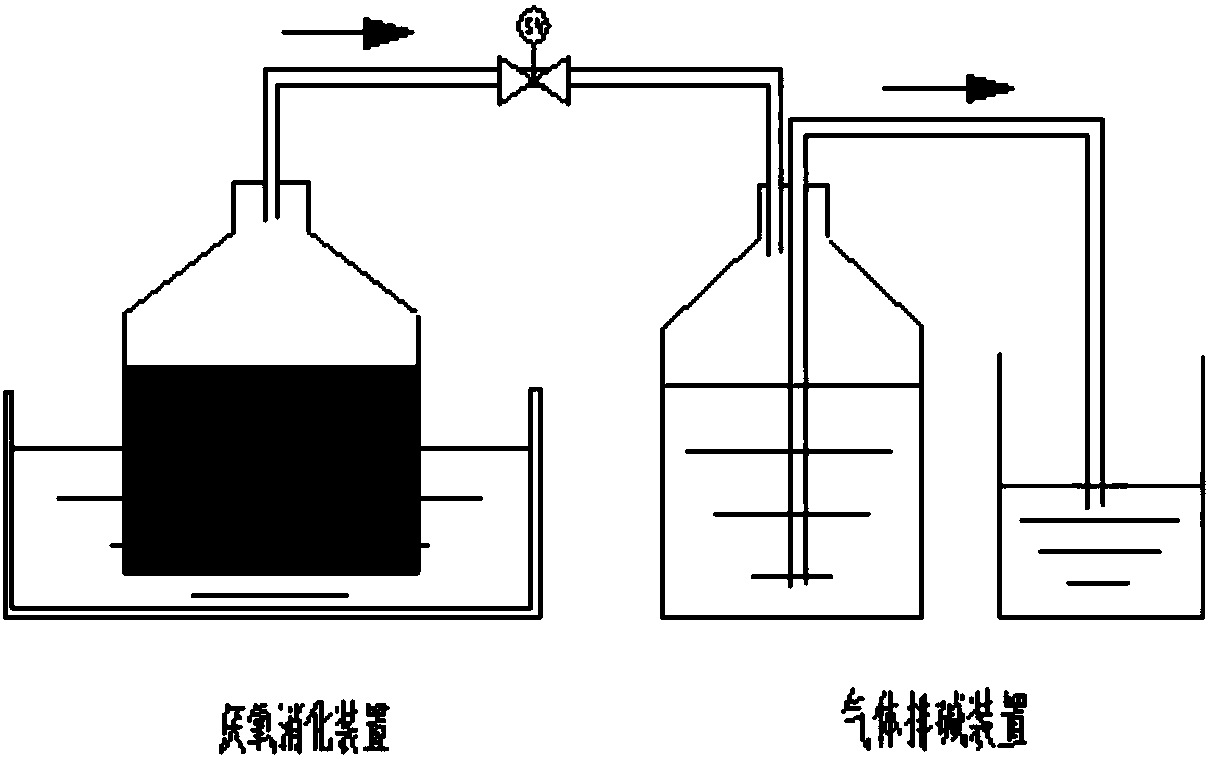

Sodium borohydride hydrogen making reaction device and method thereof

InactiveCN101353155AWill not cause poisoningHigh degree of automationHydrogen productionSolenoid valveHydraulic pump

The invention discloses a reaction device for making hydrogen with sodium borohydride and a method thereof. The device comprises a reaction device and a control device. A micro-processing unit of the control device is electrically connected with an analog-digital converting circuit, a keyboard, an LCD display screen, a radiator and an isolation drive circuit respectively; the analog-digital converting circuit is electrically connected with a hydrogen sensor, a pressure sensor and a thermistor respectively; the isolation drive circuit is electrically connected with a low-power hydraulic pump and a high-speed solenoid valve respectively; one pressure sensor, one thermistor and the hydrogen sensor are positioned on a reaction chamber. With regard to the method for making the hydrogen with the sodium borohydride, the low-power hydraulic pump is adopted to control the reaction speed and the hydrogen yield by automatically regulating the flow of the sodium borohydride solution which is added to the reaction chamber and according to reaction conditions. The device for making the hydrogen with the sodium borohydride has the advantages of high reaction efficiency in making the hydrogen, high automation degree, being easy to control the reaction speed, being safe and reliable in use, convenient and simple operation, and the like; and is especially suitable for supplying hydrogen source in a movable manner.

Owner:SOUTH CHINA UNIV OF TECH

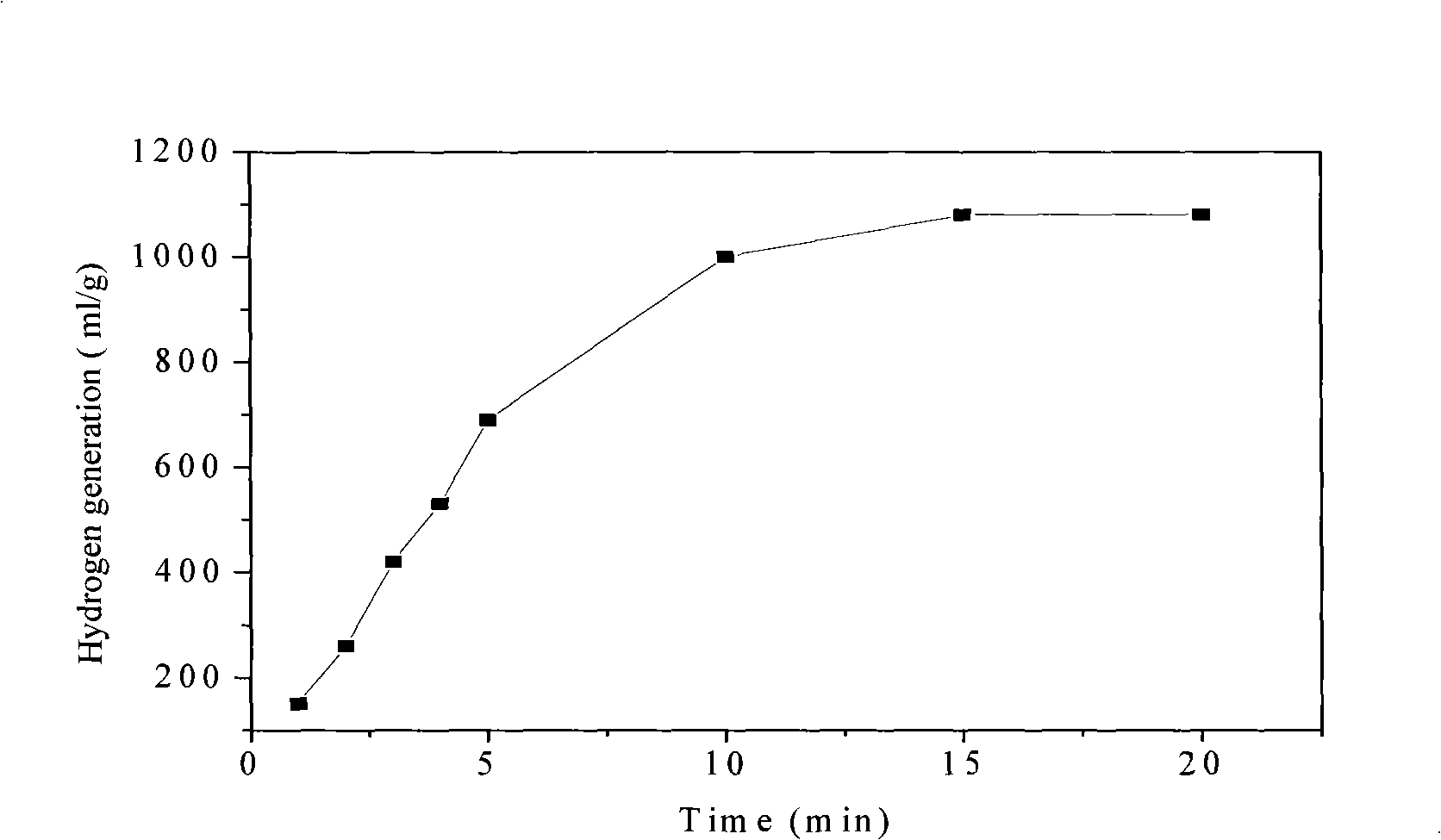

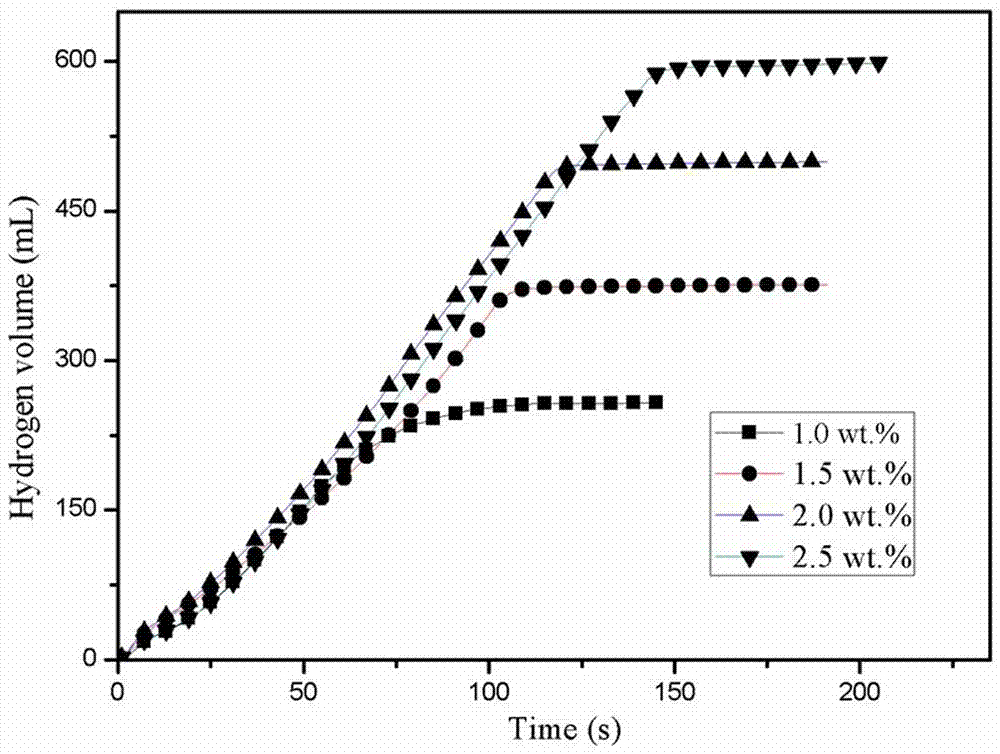

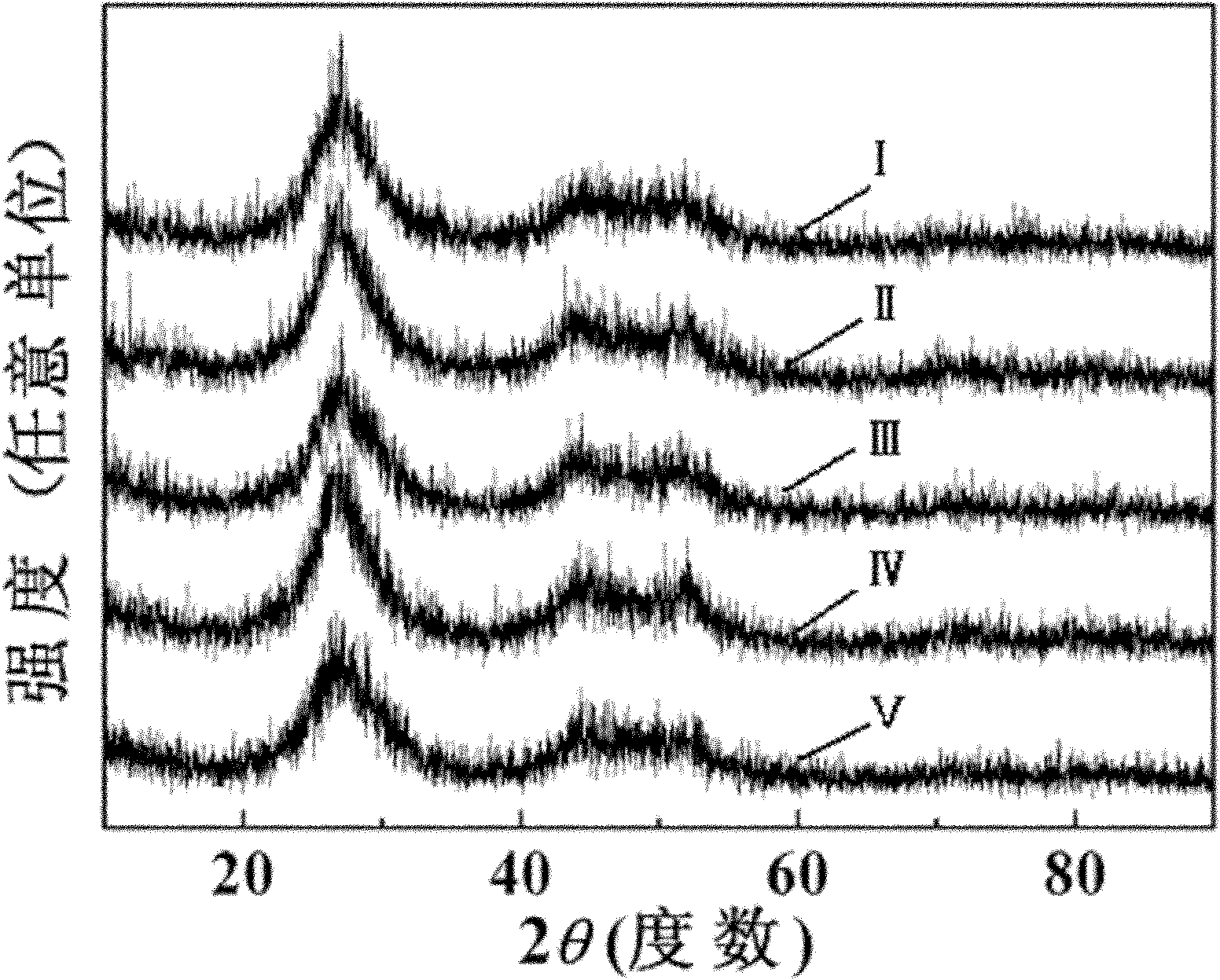

Active aluminum-rich alloy for preparing high purity hydrogen through hydrolysis and preparation method thereof

InactiveCN102560198AHigh hydrogen production rateEasy to prepareHydrogen productionVacuum induction furnaceLiquid alloy

The invention relates to an active aluminum-rich alloy for preparing high purity hydrogen through hydrolysis. The alloy is characterized in that the alloy which is composed of four elements of Al, Ga, In and Sn comprises the following two phases: an Al solid solution and GaIn3Sn. A preparation method of the alloy concretely comprises the following steps: 1, melting the alloy to form a molten alloy by adopting a vacuum induction furnace, wherein the vacuum degree of the vacuum induction furnace is 10<-2>-10<-3>Pa; and 2, stirring the molten alloy by adopting an electromagnetic stirring technology, casting the molten alloy to a water-cooled copper mold, and solidifying, wherein the cooling rate is 101-103DEG C / s. The alloy has the advantages of high hydrogen yield, no pollution, low cost, simple preparation method, convenient operation and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

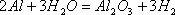

Method for treating easily-degradable organic waste in two-phase hydrogen-production methane-production coupling reaction

InactiveCN102796765AIncreased degradability and anaerobic digestion potentialIncrease productionWaste based fuelFermentationChemistryHydrogen+Methane

The invention discloses a method for treating easily-degradable organic waste in a two-phase hydrogen-production methane-production coupling reaction, and belongs to the field of efficient resource utilization of organic solid wastes. In the existing two-phase technology, the end product is only methane, and hydrogen is directly discharged; and the partial hydrogen-methane coproducing technology is difficult to apply because the yield of hydrogen is low. According to the invention, the easily-degradable organic waste is stirred and then added into an acidifying reactor; solid and liquid phases in reaction products directly enter into a rear end to produce a methane phase; a gas phase is subjected to pressure swing adsorption to decarburize; and a product gas the main component of which is H2 is introduced into the methane phase to react with CO2 which is produced by methanation reaction to generate CH4. By using the method, on one hand, the yield of CH4 is improved, and on the other hand, the purity of CH4 in the product gas is improved. The method disclosed by the invention has the advantages of high treatment efficiency, high gas producing rate, short period, no discharged waste water and the like, and can be used for continuously and stably producing the gas.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

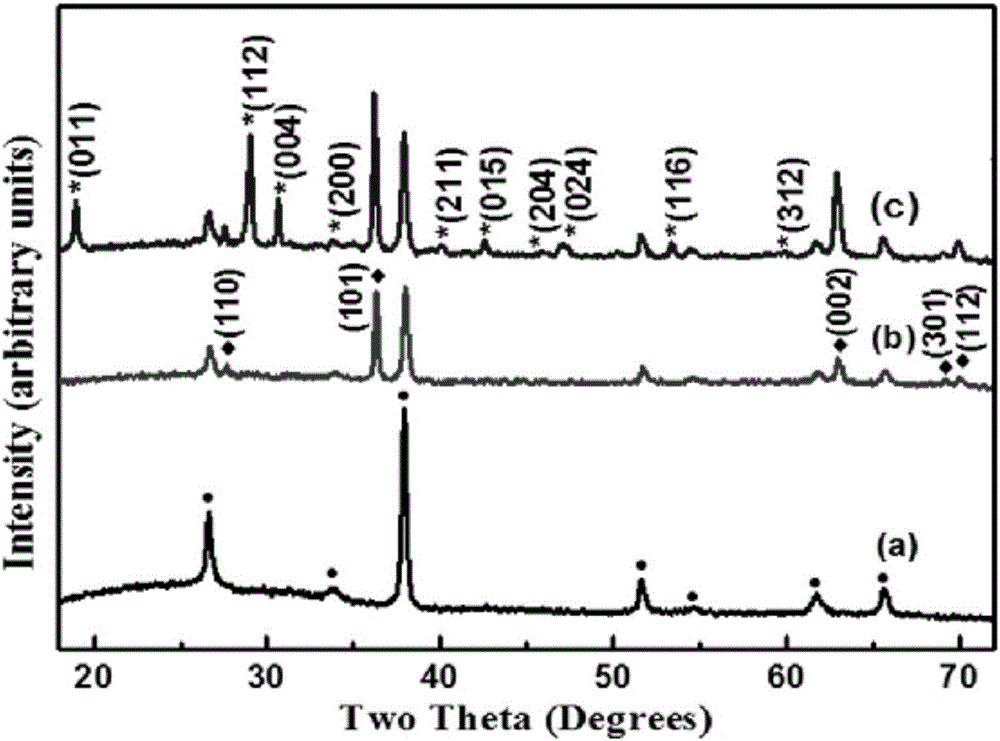

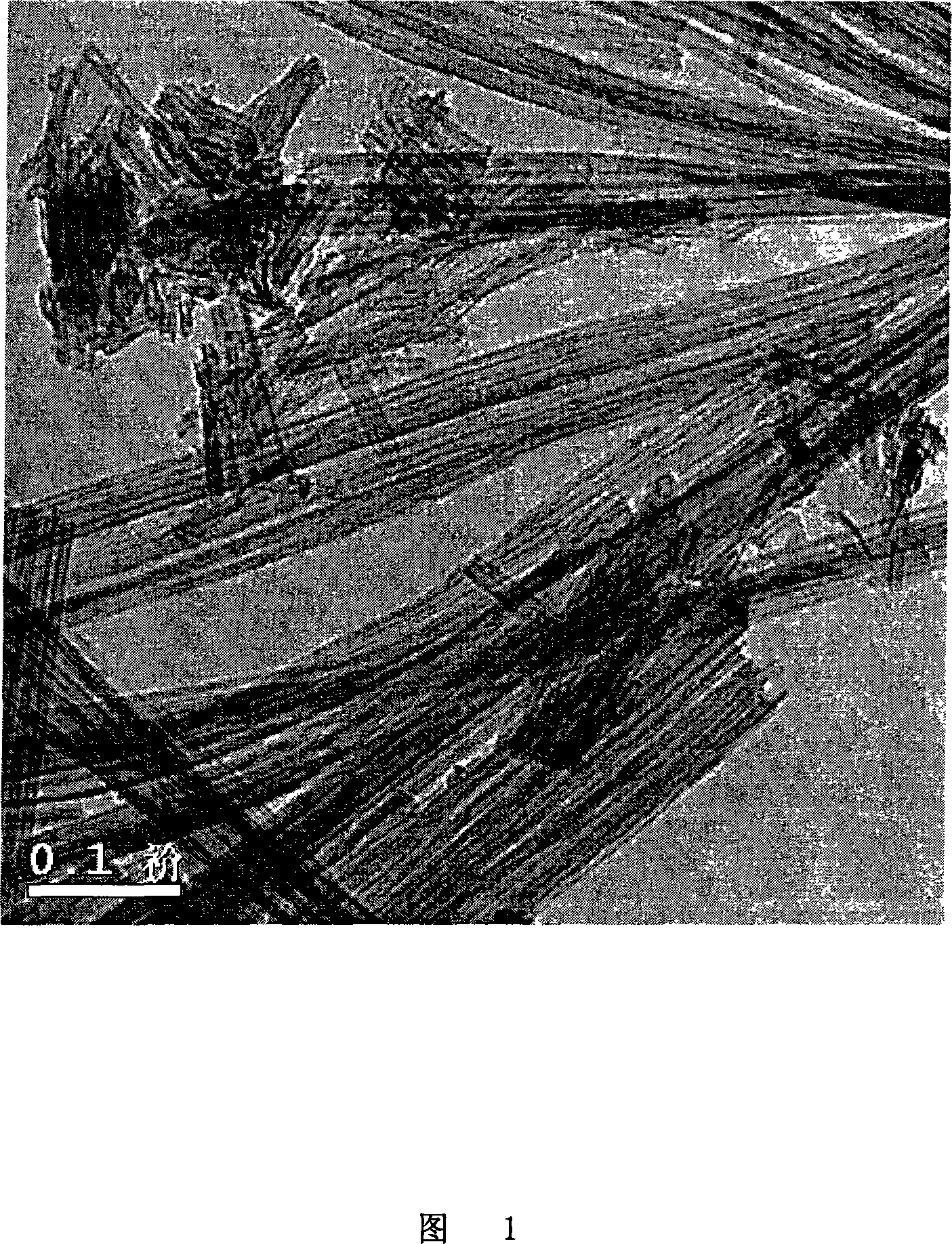

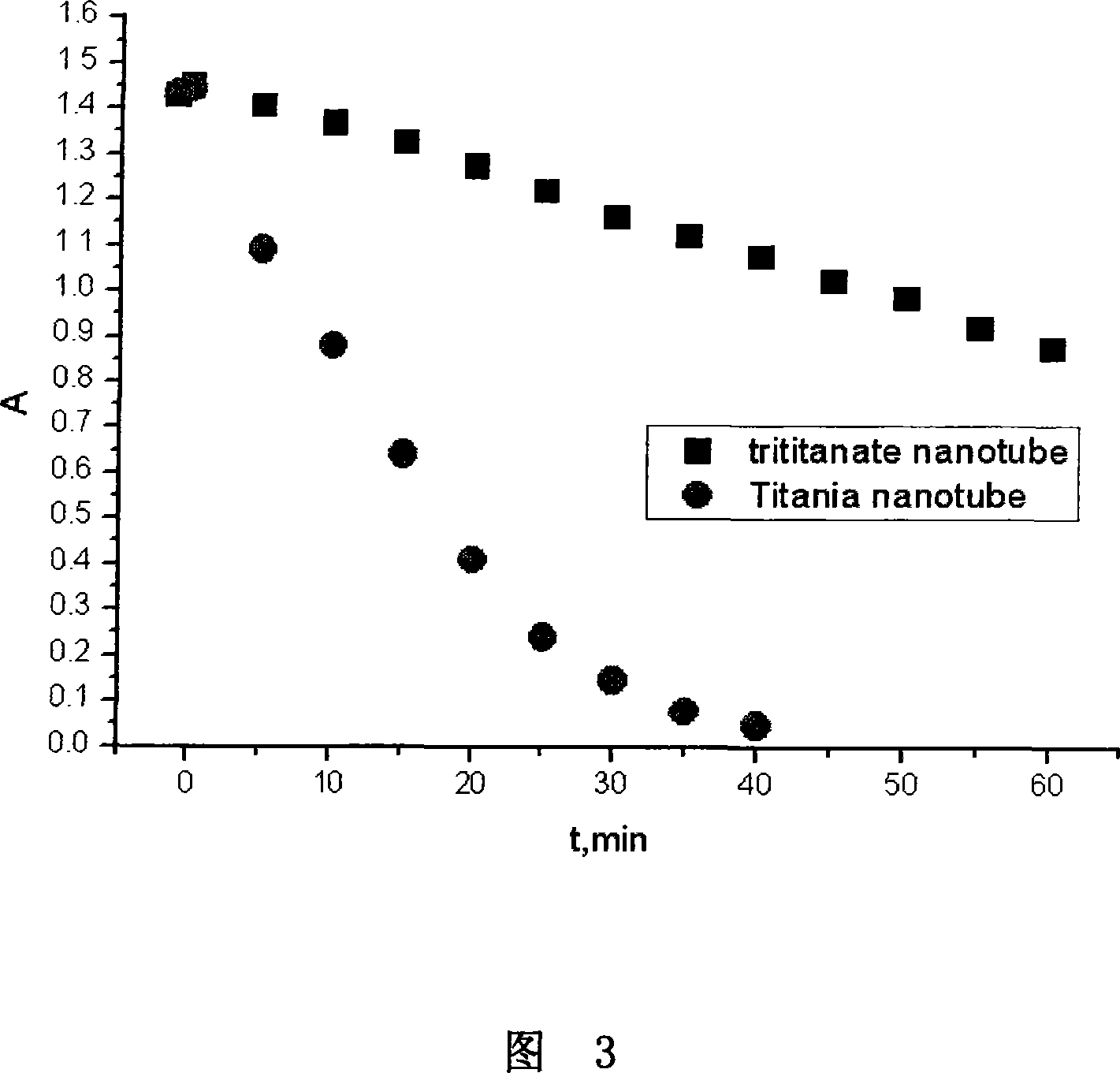

Method for preparing titanium dioxide nano-tube

InactiveCN101182033AImprove photocatalytic activityGood light transmissionNanostructure manufacturePhysical/chemical process catalystsTio2 nanotubeSodium titanate

The invention discloses a preparation method of TiO2 nanotubes, which comprises the following steps: an appropriate amount of sodium titanate nanotubes obtained by a hydrothermal synthesis method is dispensed to be fully dipped in mixed solution of ammonium fluorotitanate and boric acid with the filtered molar concentration ratio of 1:1-1:5 for deposition with the deposition time of 10-120mins; the mixed solution is reacted to obtain the sodium titanate nanotubes with TiO2 films formed which are then dried in an oven and next treated with heat treatment in a muffle furnace and cooled naturally so as to obtain the anatase type TiO2 nanotubes. The TiO2 nanotubes prepared by the method has anatase crystal form and relatively high catalytic activity, so the hydrogen yield of photocatalysis hydrogen production can be increased and the photoelectric transformation efficiency of dye-sensitized solar cells can be improved.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI +1

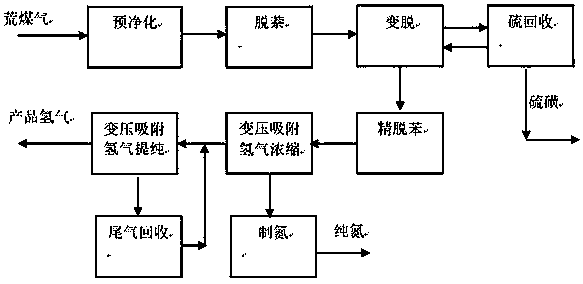

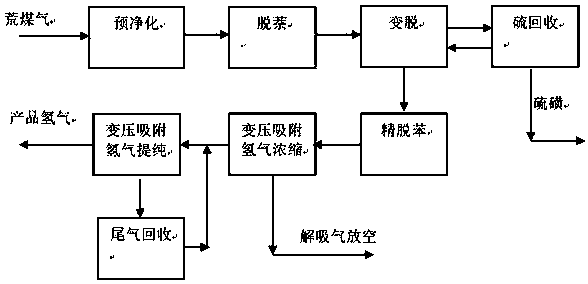

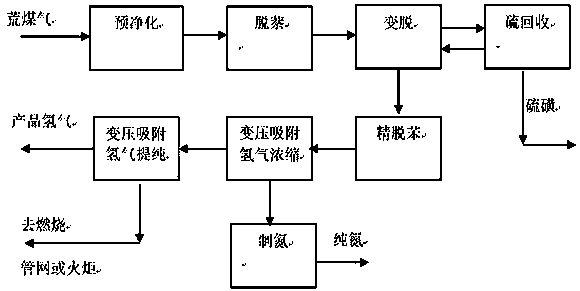

Low-energy-consumption high-yield method for preparing hydrogen from raw gas

InactiveCN107758615AReduce consumptionEmission reductionNitrogen purification/separationHydrogen separation using solid contactSulfurNitrogen

The invention discloses a low-energy-consumption high-yield method for preparing hydrogen from raw gas. The method comprises the following procedures: pre-cleaning; naphthalene removal; transformationand desulfurization; sulfur recovery; refined debenzolization; pressure swing adsorption for hydrogen production; recovery of tail gas; nitrogen production; etc. After pretreatment and naphthalene removal, raw gas is allowed to enter the procedure of transformation and desulfurization so as to obtain more hydrogen and increase the yield of hydrogen, and then desulfurization is carried out in a desulfurization tower; then pure hydrogen is prepared through the procedure of refined debenzolization and the procedure of pressure swing adsorption for hydrogen production; through the procedures of tail gas recovery and nitrogen production, effective hydrogen in desorbed gas is recovered, and hydrogen yield is further increased; and pure nitrogen with a purity of 99% or more is further prepared through a nitrogen production unit. The method provided by the invention substantially reduces the energy consumption of an apparatus for hydrogen production from raw gas, increases hydrogen yield, recovers almost all the effective hydrogen component in the desorbed gas, realizes recovery and graded utilization of each component in the raw gas while guaranteeing low energy consumption and high yield, and by-produces sulfur, pure nitrogen and the other products while preparing pure hydrogen.

Owner:SICHUAN TECHAIRS

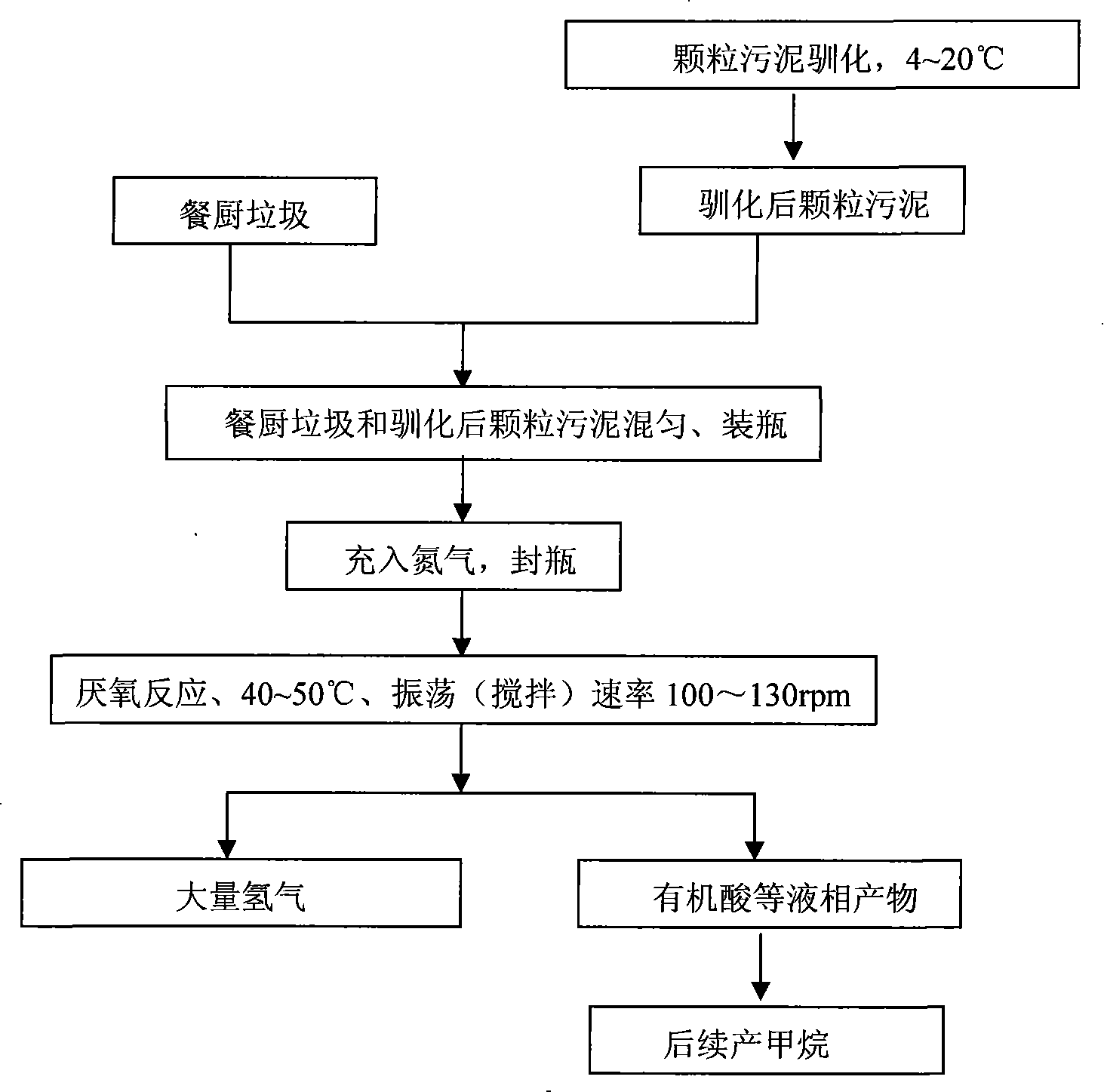

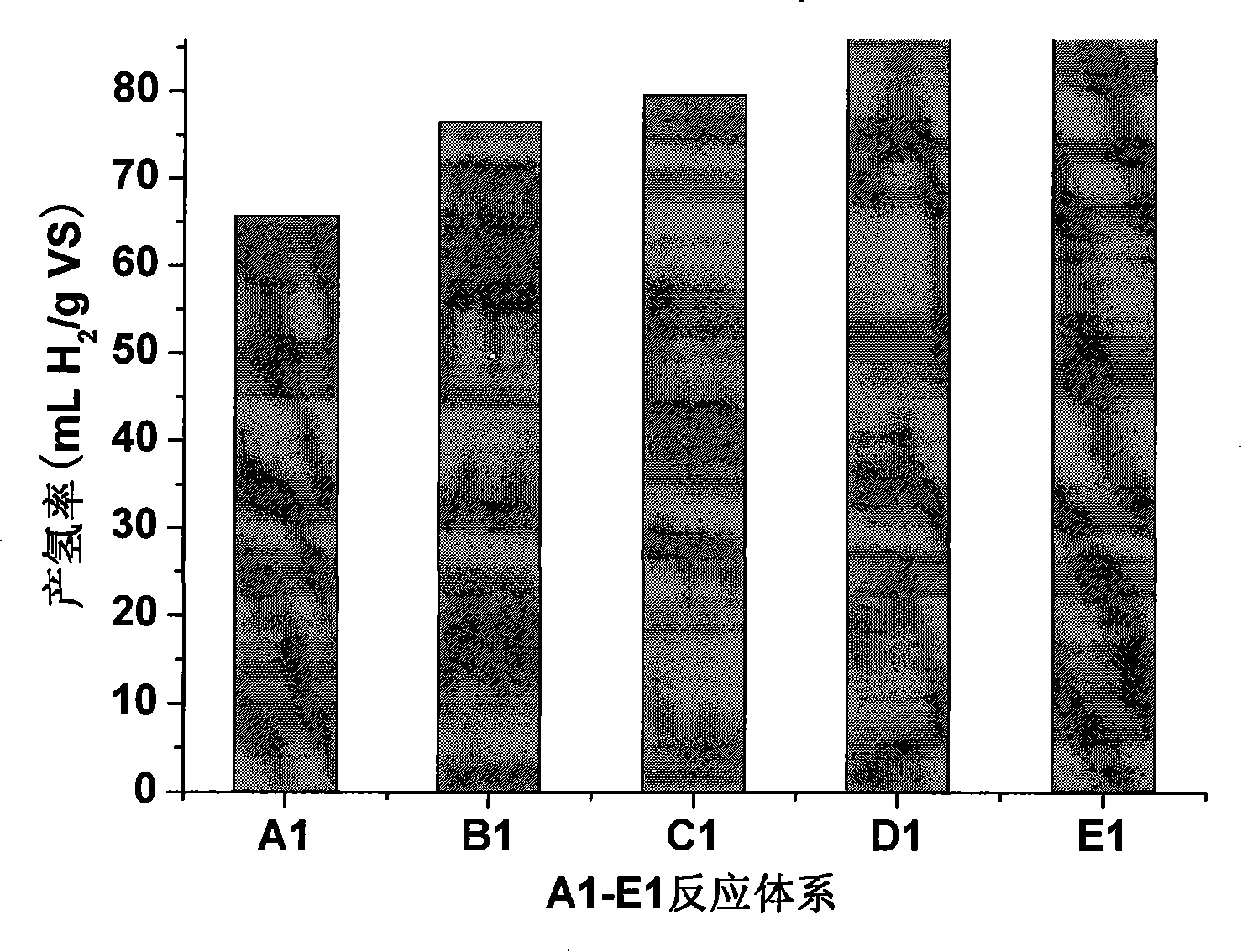

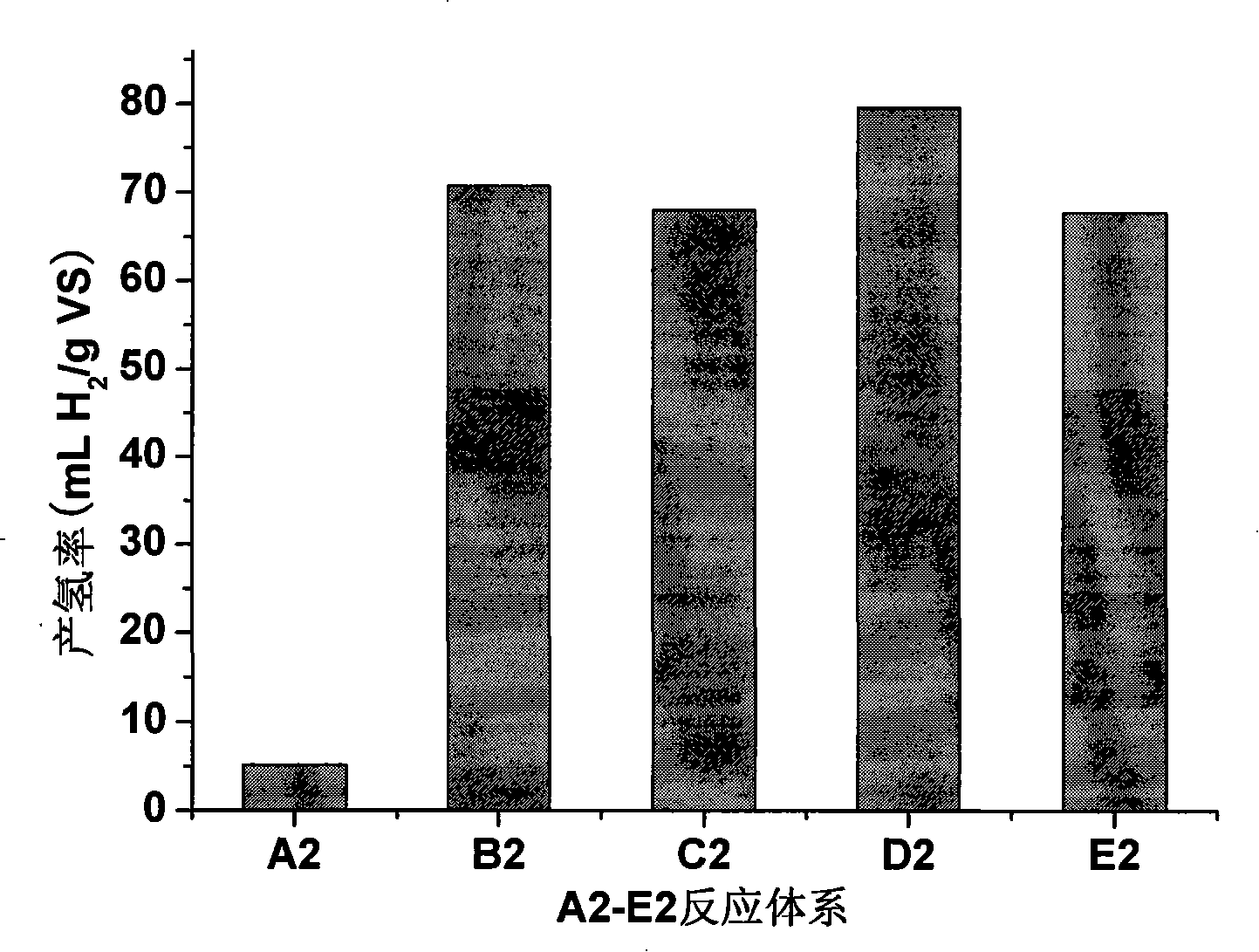

Method for improving hydrogen gas yield of kitchen waste anaerobic digestion

InactiveCN101250554AInhibitory activityHigh hydrogen yieldWaste based fuelFermentationDry weightNitrogen gas

The invention relates to a method for increasing the hydrogen output through anaerobically digesting restaurant garbage and relates to a method for producing the hydrogen output through anaerobically digesting the restaurant garbage, which comprises following steps: firstly, weighing according to granular sludge: the restaurant garbage=1:0.2-0.4 part dry weight, adding the granular sludge and the restaurant garbage into a bottle, filling nitrogen or argon, sealing, statically culturing under the temperature of 4-20DEG C, finishing domestication when the pH value is lowered to 4.5-5.5, preserving, then, weighing according to the restaurant garbage: the granular sludge which is domesticated well=1 part dry weight:0.59-0.294part dry weight, then, arranging the restaurant garbage and the granular sludge into a container, evenly mixing, filling the nitrogen or the argon, then, sealing, concussing and stirring under the temperature of 40-50DEG C and the speed of 100-130r / min, starting anaerobic digestion, wherein the hydrogen yield is 65.63mL / g VS-94.04mL / g VS, fermenting firedamp with residual material after the hydrogen stops producing, and transforming the residual material into the firedamp. The method of the invention has the characteristics of low energy consumption, low cost and high heat value net output rate, and the hydrogen yield can reach 93mL / g restaurant garbage (dry weight) through using the method of the invention, which is increased by 20-30% compared with existing hydrogen yield.

Owner:TONGJI UNIV

Aluminum-rare earth micro nano composite hydrogen manufacturing material

InactiveCN101798061ANo pollution in the processStable in natureHydrogen productionTectorial membraneMicro nano

The invention belongs to a rare earth micro nano composite hydrogen manufacturing material, in particular to an aluminum-rare earth micro nano composite hydrogen manufacturing material. The existing material for manufacturing hydrogen by hydrolysis has the defects that after reacting with water, the surface of Al is formed with a compact oxide film, the hydrogen manufacturing reaction is not complete, the reaction rate is slow, the synthesizing process is complicated and the production cost is high. The aluminum-rare earth micro nano composite hydrogen manufacturing material of the invention is prepared from aluminum and rare-earth metal. The preparation method of the hydrogen manufacturing material has the following steps: adding aluminum powder, metal powder and salt into a stainless steel ball milling pot; adding absolute ethyl alcohol, adding the rare-earth metal powder under the protection of argon gas to seal the opening of the pot; placing the stainless steel pot on a planetary ball mill for ball milling for 1-2 hours, wherein the ratio of grinding media to material is 1:10-100, and the rotate speed is 300-600 revolutions per minute; and preparing the aluminum-rare earth micro nano composite hydrogen manufacturing material. The invention has the advantages that the preparation process is simple, no environmental pollution exists in the process of preparation; the hydrogen manufacturing material has small grain diameter, large specific surface area and high chemical activity; the hydrogen yield is high; and the raw materials has rich resources, low price and easy obtainment.

Owner:SHANGHAI NORMAL UNIVERSITY

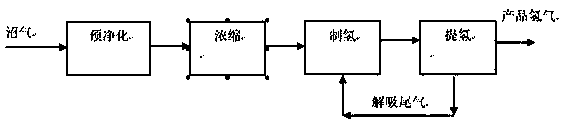

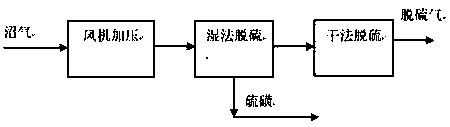

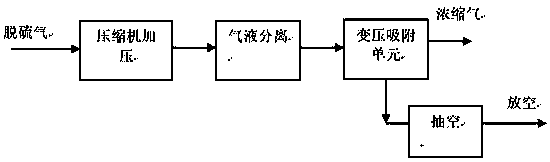

Method for producing hydrogen from biogas biomass

Owner:SICHUAN TECHAIRS

Application of three-dimensional ordered macro-porous perovskite type oxide in preparing hydrogen through carbonic fuel chemical chain

InactiveCN102515096AStable structureIncrease contact areaHydrogenBulk chemical productionWater vaporDecomposition

The invention provides an application of a three-dimensional ordered macro-porous perovskite type oxide which is used as an oxygen carrier for preparing hydrogen through a carbonic fuel chemical chain. The three-dimensional ordered macro-porous perovskite type oxide has the characteristics of the perovskite type oxide and has a three-dimensional ordered macro-porous structure of an inverse opal structure. The three-dimensional ordered macro-porous perovskite type oxide is used as an oxygen carrier for preparing the hydrogen through the carbonic fuel chemical chain and has a general formula of ABO3, wherein A is rare-earth metal and B is transition metal. The three-dimensional ordered macro-porous structured perovskite structure has stable properties and longer service life; pore channels and specific surface area are bigger; during a contact process of the oxygen carrier and a carbonic fuel, much more lattice oxygen for participating in reaction can be supplied; the contact of the oxygen carrier and the carbonic fuel can be boosted; the specific surface area of the oxygen carrier can be increased by abundant pore channels; catalytic conversion between small particles and gas molecules is boosted; the three-dimensional ordered macro-porous perovskite type oxide has higher reaction activity in chemical chain combustion and steam pyrolytic decomposition; and compared with the conventional metal oxygen carrier, the three-dimensional ordered macro-porous perovskite type oxide has higher reaction activity and hydrogen yield.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

Cobalt-based MOFs material, and preparation method and application thereof

InactiveCN107573233AExperiment operation is simpleRegular structureOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen productionNitrateAlcohol

The invention discloses a cobalt-based MOFs material. The cobalt-based MOFs material is formed by cobalt-nitrate hexahydrate which is reacted with terephthalic acid through a hydrothermal method, andthen is washed and dried through N, N-dimethyl formamide and an absolute ethyl alcohol solvent. A preparation method comprises the following steps: firstly, adding cobalt-nitrate hexahydrate in absolute ethyl alcohol, and performing magnetic stirring, so as to obtain a clear cobalt nitrate solution, adding terephthalic acid in N, N-dimethyl formamide, and performing magnetic stirring, so as to obtain clear a terephthalic acid solution, and performing mixed ultrasonic treatment on the two solutions; secondly, loading the solution subjected to mixed ultrasonic treatment into a reaction kettle, and arranging the reaction kettle into an oven, ensuring that the solution is reacted under a certain condition, and filtering, washing and drying a reaction product in certain condition after the reaction, so as to obtain the cobalt-based MOFs material. When the material is applied to the catalysis of hydrolysis of sodium borohydride, the hydrolysis speed reaches 1700 to 2400 mL min-1g-1, and thecatalytic performance keeps 47 to 50 percent of the original hydrogen yield after circulation. The material has excellent catalytic performance, and has a wide application prospect in the field of thepreparation of new energy resources.

Owner:GUILIN UNIV OF ELECTRONIC TECH

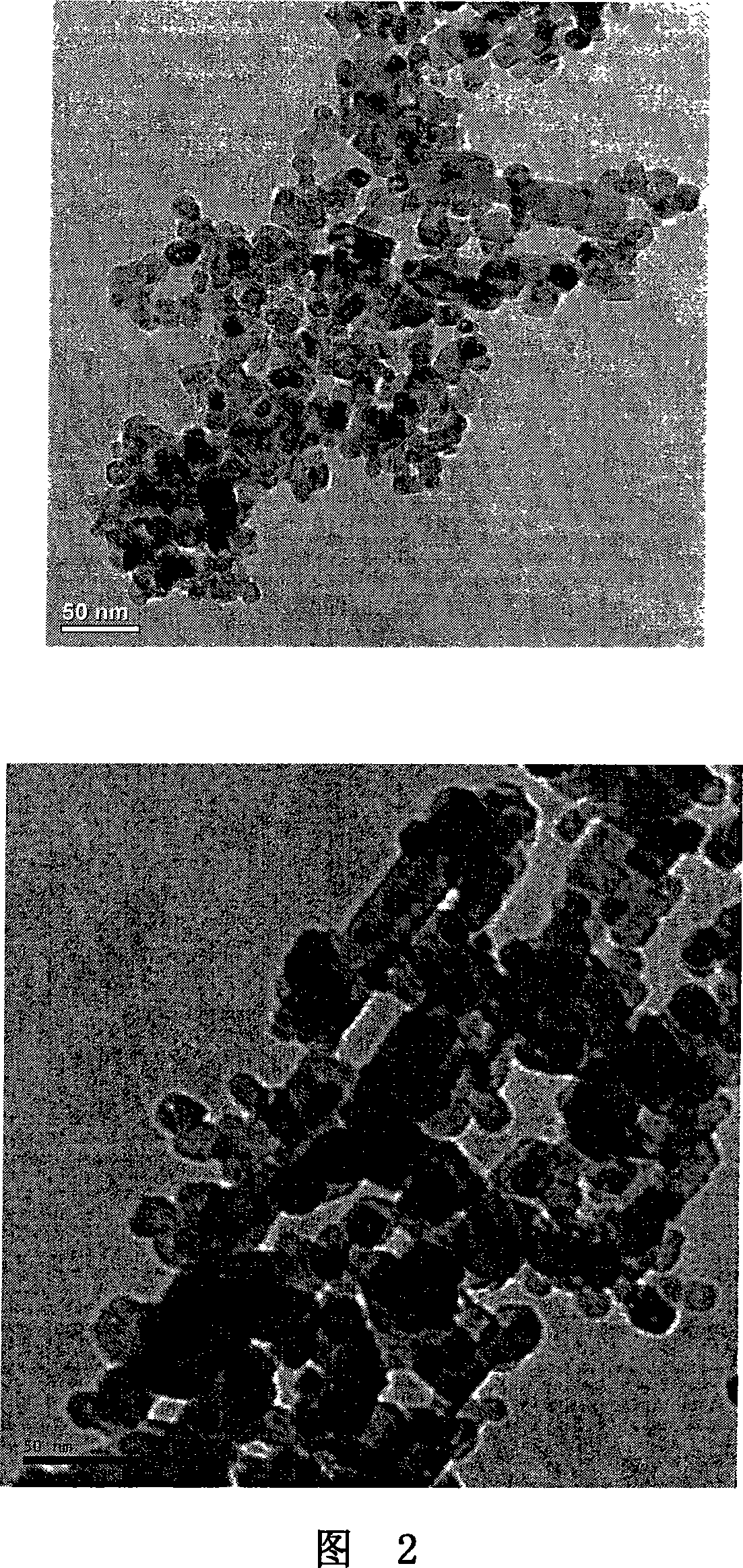

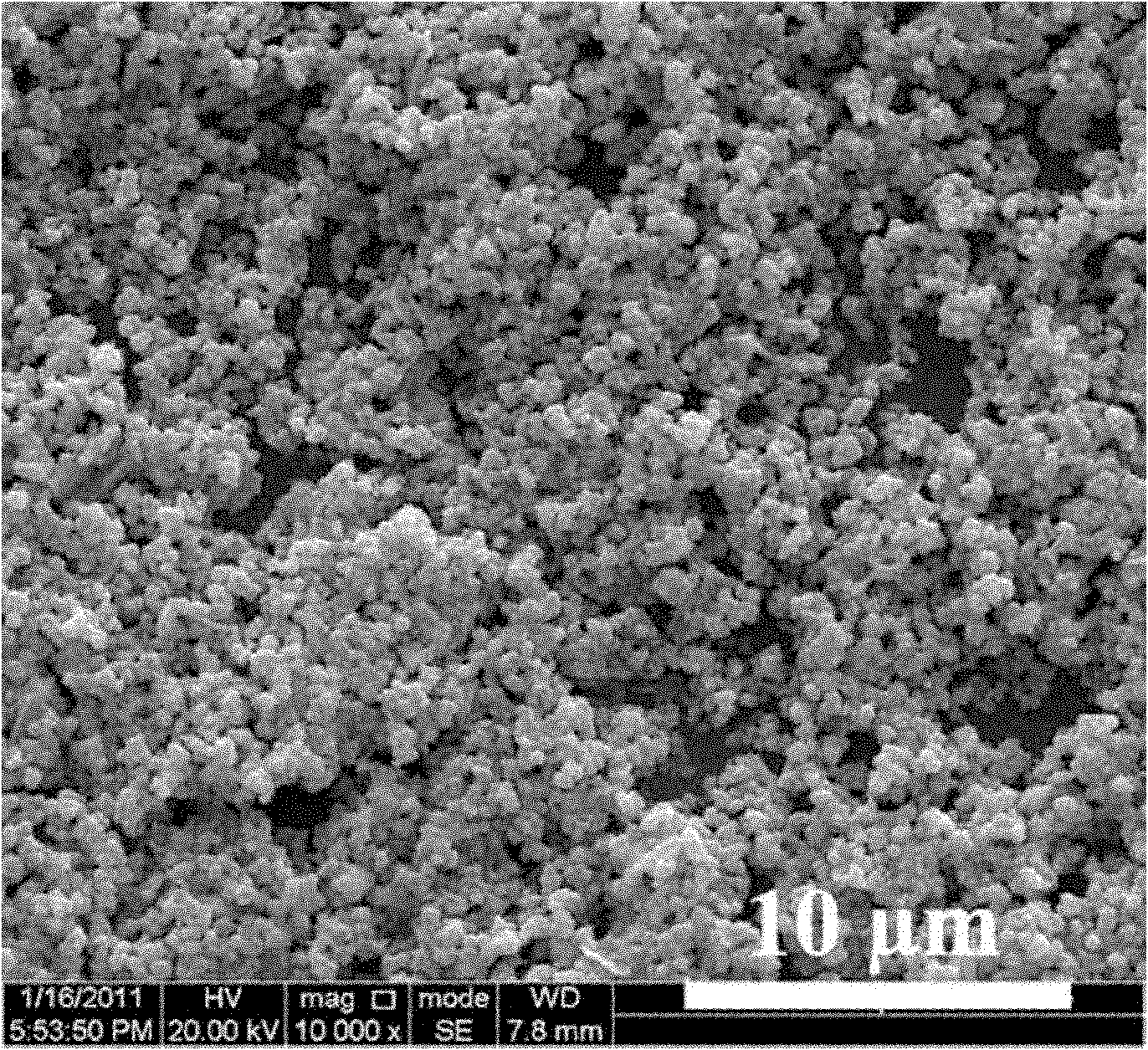

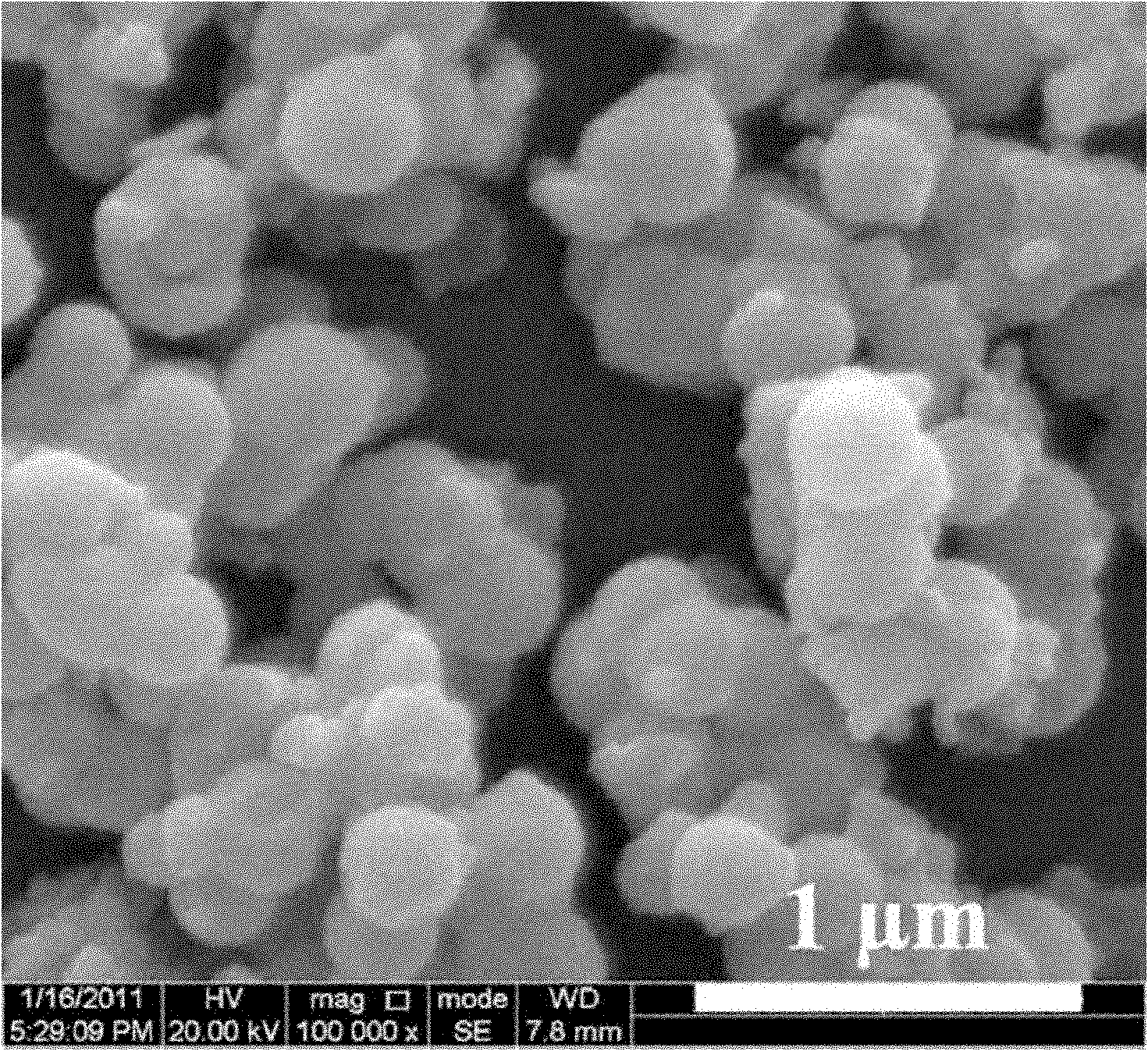

CdS/MoO3 composite photocatalyst and preparation method thereof

InactiveCN102068996AHigh catalytic activityUniform particlesPhysical/chemical process catalystsRoom temperatureNanocrystal

The invention discloses a CdS / MoO3 composite photocatalyst and a preparation method thereof, which relate to a catalyst material and a preparation method thereof. The catalyst solves the problems that the conventional hydrogen production by utilizing the light to decompose H2O is low in catalyst activity and hydrogen yield under visible light and cannot degrade organic pollutants. The CdS / MoO3 composite photocatalyst is prepared from Cd(Ac)2.2H2O, (NH4)6Mo7O24.4H2O and thioacetamide. The preparation method comprises the steps of: adding the Cd(Ac)2.2H2O, the (NH4)6Mo7O24.4H2O and the thioacetamide into solution of acetone or ethanol, sealing the obtained solution, then placing the obtained solution into an ultrasonic reactor to react, then cooling a product to room temperature, and then washing and drying to obtain the CdS / MoO3 composite photocatalyst. The composite photocatalyst is of nanosphere shapes, the particle size of the nanospheres is between 300 and 350nm, the composite photocatalyst is obtained by the self-assembling of each small particle with the particle size of between 5 and 20nm, and additionally, CdS nanocrystals are uniformly embedded in the nanospheres; and the catalyst is high in catalytic activity, and the hydrogen production rate can reach 2 to 5.25mmol / h.

Owner:HARBIN INST OF TECH

Parallel-flow catalytic reforming processing method for multiple movable bed reactors

The parallel flow catalyst reforming process with multiple movable bed reactors includes: making material oil flow from the first movable bed reactor to the last one successively for the material oil to contact with the reforming catalyst in different reactors, separating the reformed oil in subsequent separator, regenerating catalyst out of the second movable bed reactor through the last one, separating the regenerated catalyst into several parts, and feeding the first part to the first reactor and the last reactor successively while feeding the other parts to the second reactor through the last reactor but one separately. The said process has raised liquid product yield and hydrogen yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

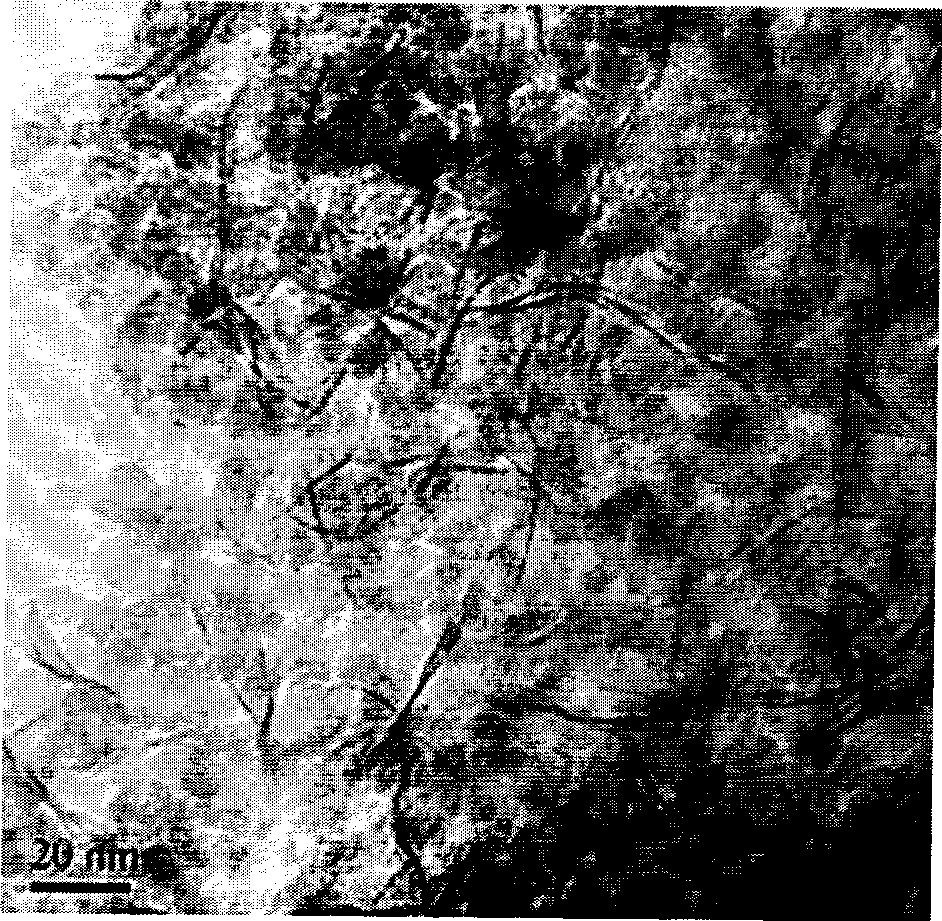

Carbon nano tube supported nickel catalyst as well as preparation method and application thereof

InactiveCN101530801ALarge specific surface areaIncrease the areaHydrogenMetal/metal-oxides/metal-hydroxide catalystsNickel catalystCarbon nanotube

The invention discloses a carbon nano tube supported nickel catalyst as well as a preparation method and application thereof. The carbon nano tube supported nickel catalyst consists of 10-35% mass percentage content of nickel and 65-90% mass percentage content of carbon nano tube. The catalyst of the invention vastly reduces the energy consumption during bio-oil hydrogen production, and improves the bio-oil conversion rate, hydrogen yield and the catalyst service life by the synergy of the active constituent, being favorable for realizing biomass fast pyrolysis bio-oil preparing technology and reforming bio-oil hydrogen production technology integration.

Owner:UNIV OF SCI & TECH OF CHINA

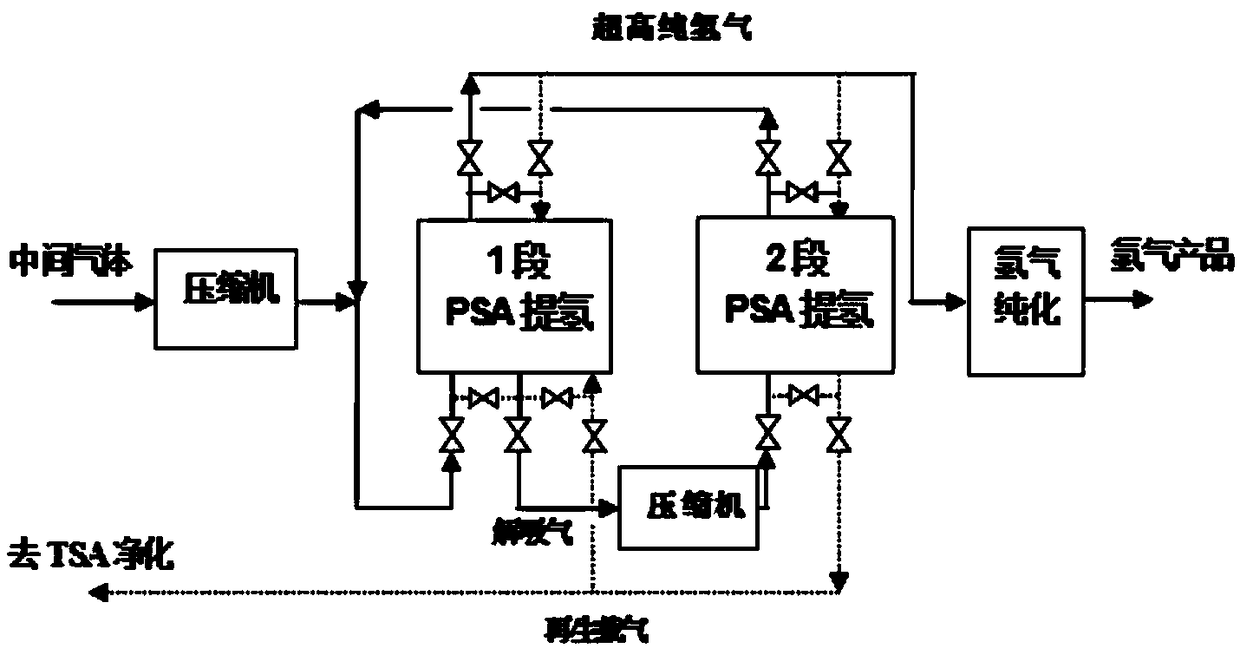

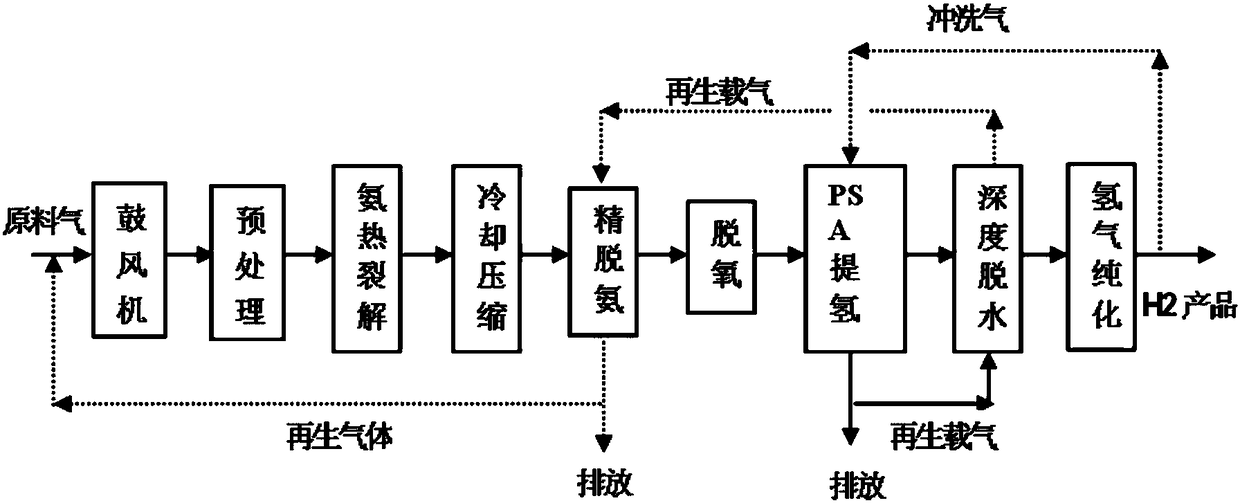

Method for FTrPSA (full temperature range-pressure swing adsorption) hydrogen production recycling of high-concentration ammonia-containing tail gas from LED-MOCVD (light emitting diode-metal oxide chemical vapor deposition) processing

ActiveCN108609583AAchieve reuseEmission reductionHydrogen separation using solid contactDispersed particle separationHigh concentrationChemical vapor deposition

The invention discloses a method for FTrPSA (full temperature range-pressure swing adsorption) hydrogen production recycling of high-concentration ammonia-containing tail gas from LED-MOCVD (light emitting diode-metal oxide chemical vapor deposition) processing. By the process of pretreatment, ammonia thermal cracking, fine deamination, pressure swing adsorption based hydrogen extraction and hydrogen purification, high-concentration ammonia-containing waste gas from the LED-MOCVD processing is subjected to thermal cracking and purification to meet the electronic grade hydrogen standard required by the LED-MOCVD processing, the waste gas is recycled, and the hydrogen yield is higher than or equal to 80%-90%. The technical problem that recycled normal-pressure or low-pressure high-concentration ammonia-containing waste gas from the LED-MOCVD processing cannot return to the LED-MOCVD processing to be used is solved, and the blank in green and circular economy development of the LED industry is filled up.

Owner:SICHUAN TECHAIRS

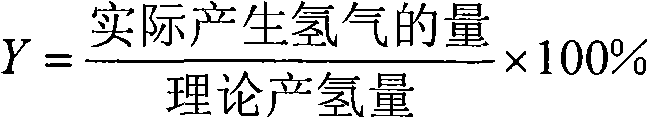

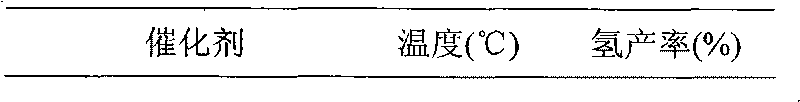

Integral catalyst applied to biological oil reforming hydrogen production, preparation and application thereof

InactiveCN101757919AHeating evenlyReduce mass transfer resistanceHydrogenCatalyst activation/preparationSteam reformingMass transfer resistance

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

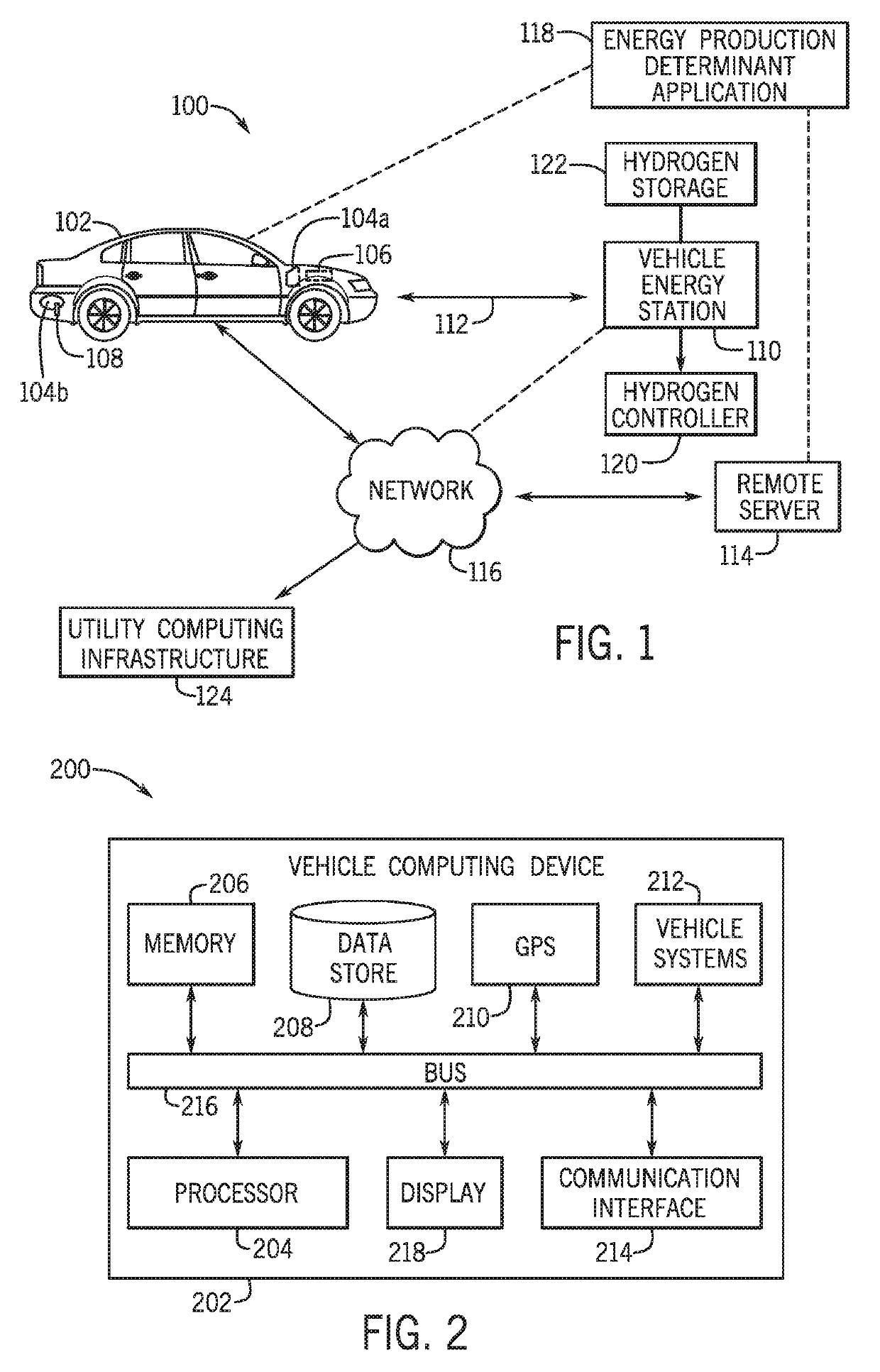

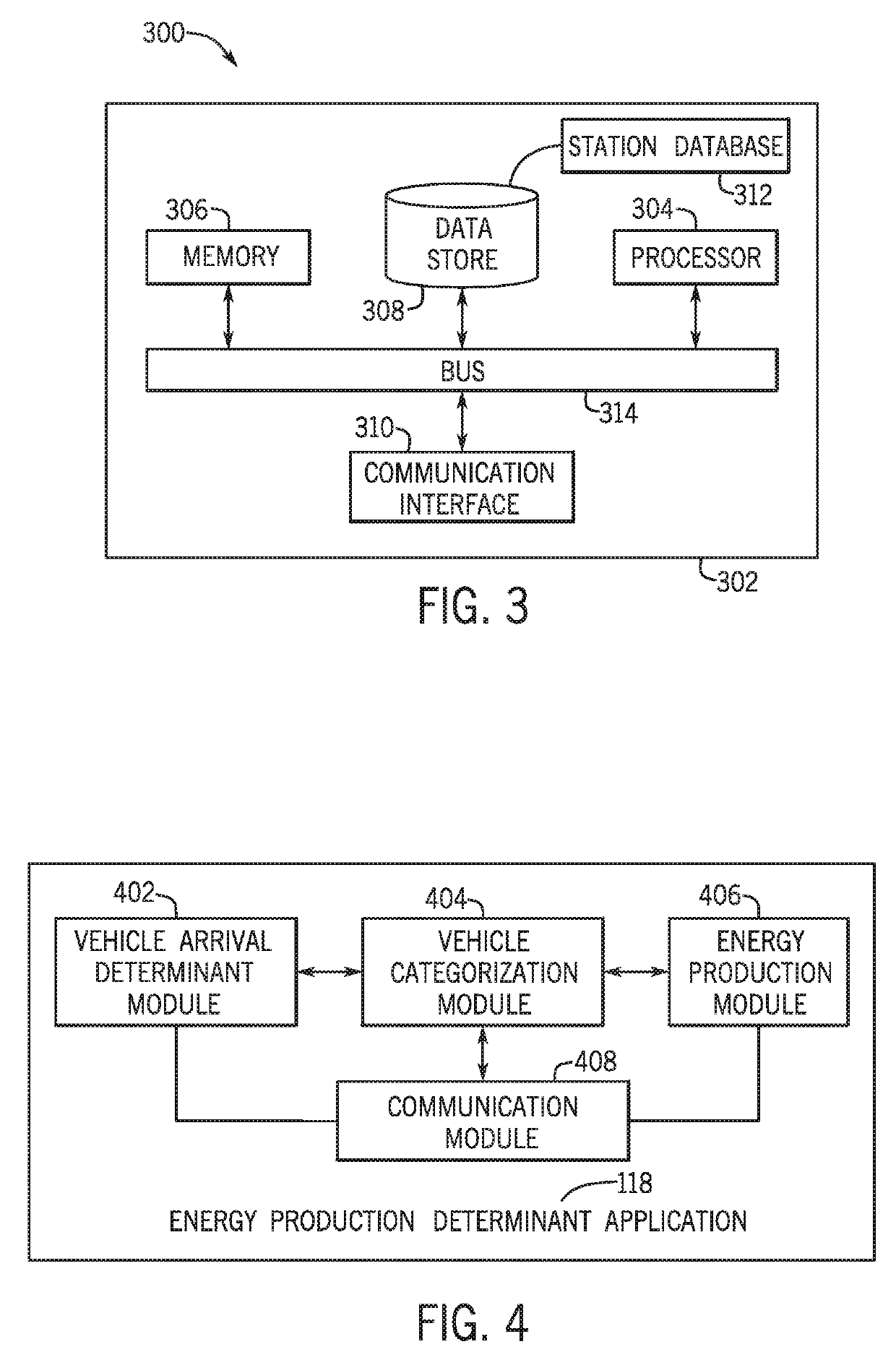

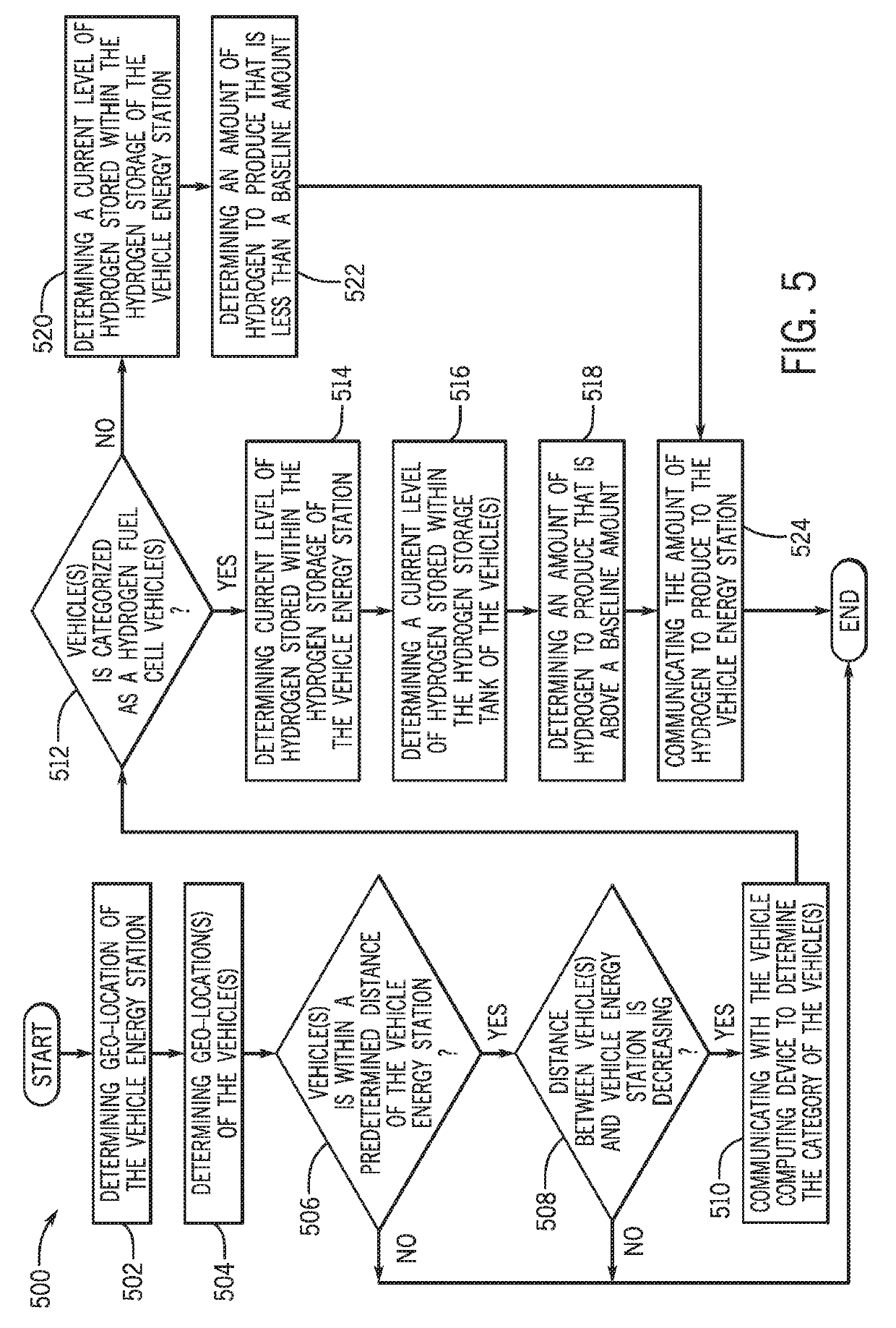

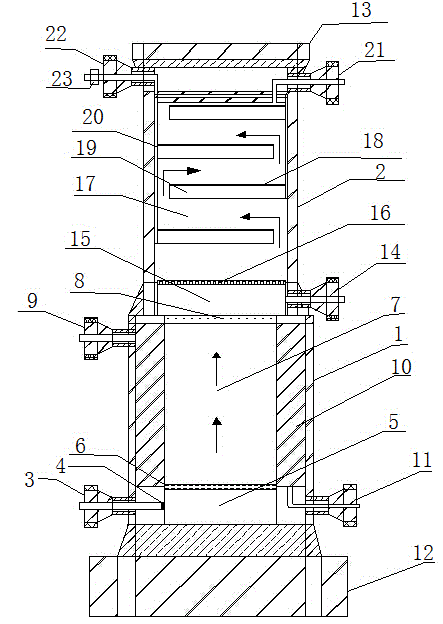

System and method for determining hydrogen production to provide energy to at least one vehicle

ActiveUS20190255952A1Internal combustion piston enginesGas handling applicationsHydrogen productionAutomotive engineering

A system and method for determining hydrogen production to provide energy to at least one vehicle that include determining that at least one vehicle is arriving towards a vehicle energy station. The system and method also include determining if the vehicle energy station includes a sufficient amount of hydrogen to refuel the at least one vehicle arriving towards the vehicle energy station. The system and method further include controlling production of hydrogen by the vehicle energy station if it is determined that the vehicle energy station includes an insufficient amount of hydrogen to refuel the at least one vehicle arriving towards the vehicle energy station.

Owner:HONDA MOTOR CO LTD

Device and method for catalytic hydrogen preparation from methane and carbon dioxide

The invention discloses a device and a method for catalytic hydrogen preparation from methane and carbon dioxide, and belongs to the technical field of chemical industry. The method mainly comprises the following two steps: (1) reforming methane and carbon dioxide in a synthetic gas generation section to generate a synthetic gas; and (2) performing reaction on water vapor and the synthetic gas in the step (1) in a section for water gas conversion and hydrogen separation, and separating hydrogen by virtue of a hydrogen membrane separation component. Raw materials of the method disclosed by the invention are wide in source and low in price, which is of great significance for energy conservation and emission reduction; moreover, the preparation process is simple, the equipment investment is low, the membrane separation performance is good, and the hydrogen yield is high; and the device and the method are suitable for fields of petroleum, chemical industry and fuel batteries.

Owner:TAIYUAN UNIV OF TECH

Nano-iron-loaded biochar, preparation method of nano-iron-loaded biochar, and application of nano-iron-loaded biochar in dark fermentation hydrogen production process

InactiveCN107858379AEasy reunionAchieve releaseFerric oxidesCarbon preparation/purificationDark fermentationBiochar

The invention relates to nano-iron-loaded biochar, a preparation method of the nano-iron-loaded biochar, and an application of the nano-iron-loaded biochar in a dark fermentation hydrogen production process. Ferrite and soluble starch are taken as raw materials which are subjected to reaction under proper conditions and are dried and charred to obtain the nano-iron-loaded biochar, wherein the maincomponent of the nano-iron-loaded biochar is Fe2O3 / C, and the particle diameter range of the nano-iron-loaded biochar is 2-150nm. The biochar is of an amorphous structure, and Fe2O3 is of a mesoporous structure. By adding the iron-loaded biochar to an anaerobic fermentation system, a synergistic strengthening effect of iron and biochar in the dark fermentation hydrogen production process is realized, so that the hydrogen yield and the process stability are improved. Fe2O3 can not only release iron ions to enhance the activity of fermentative hydrogen producing bacterium hydrogenase but also increase the transfer rate of electrons; and furthermore, the biochar in nano-particles can enrich microorganisms, improve the concentration of hydrogen producing bacteria, buffer acid accumulation andrelieve ammonia inhibition.

Owner:QILU UNIV OF TECH

Method for preparing hydrogen from cellulose

The invention relates to a method for preparing hydrogen from cellulose. In the method, a reaction is performed under the hydrothermal conditions of a lower temperature of between 180 and 320 DEG C and lower pressure of between 1 and 20MPa, wherein the process mainly comprises cellulose hydrolysis and hydrothermal reforming of a hydrolysis product; the cellulose hydrolysis is catalyzed by H+ produced through reversible ionization of extra water soluble Bronsted acid, water soluble Lewis acid, solid acid or water; a metal catalyst consists of an active ingredient and a carrier; the active ingredient of the metal catalyst is one or more of Pt, Pd, Ni, Co, Ir, Ru and Rh and accounts for 2 to 10 weight percent of the total amount of the catalyst; and the catalyst is prepared by a chemical reducing method or an immersion method. The method has the advantages of simple equipment, single reactor, no need of special equipment, relatively mild reaction conditions and high product hydrogen yield (20.3mmol / g cellulose) and selectivity and is easy to operate.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com