Biomass hydrogen production in water vapour atmosphere and series fluidized bed apparatus system thereof

A biomass and fluidized bed technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of complex purification process, high energy consumption, low hydrogen yield, etc., and achieve large hydrogen production and reaction speed. Fast and energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

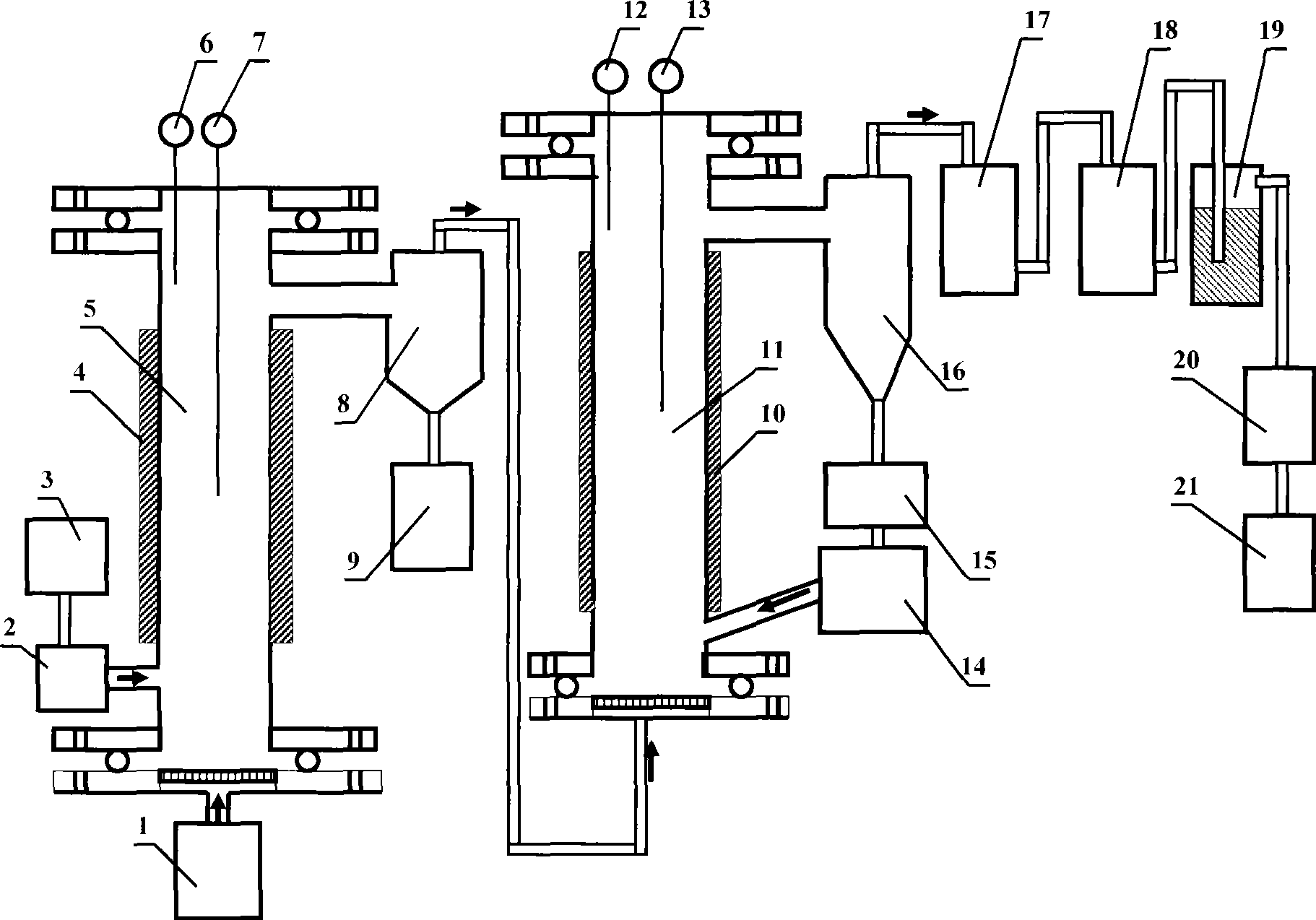

[0028] Biomass raw material is sawdust powder with a particle size of 1-2mm obtained after drying and sieving. The equipment used is such as figure 1 shown. Wherein, the height and inner diameter of the biomass cracking fluidized bed (5) are 1700 cm and 70 cm respectively, and the height and inner diameter of the organic steam reforming fluidized bed (11) are respectively 2000 cm and 10 cm.

[0029] In this embodiment, according to the above-mentioned determined fluidized bed size and related data, the selected biomass feed rate per unit time is 10kg / hr, and the water vapor feed rate per unit time is 8kg / hr, which meets the requirements of biomass and water vapor at the same time. The feed mass ratio per unit time is (0.8-1.5) / 1. In the biomass cracking fluidized bed, the biomass cracking reaction temperature is selected as 550°C. According to the ratio of the solid particle filling amount (kg) of the heat carrier to the biomass feed amount (kg) per unit time (hour), the rat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com