Parallel-flow catalytic reforming processing method for multiple movable bed reactors

A moving bed reactor, catalytic reforming technology, applied in the petroleum industry, naphtha treatment, etc., can solve the problems of intensified side reactions, accelerated catalyst deactivation speed, affecting liquid product yield and hydrogen yield, etc., to achieve The effect of increasing octane number, improving liquid product yield and hydrogen production rate, and improving utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

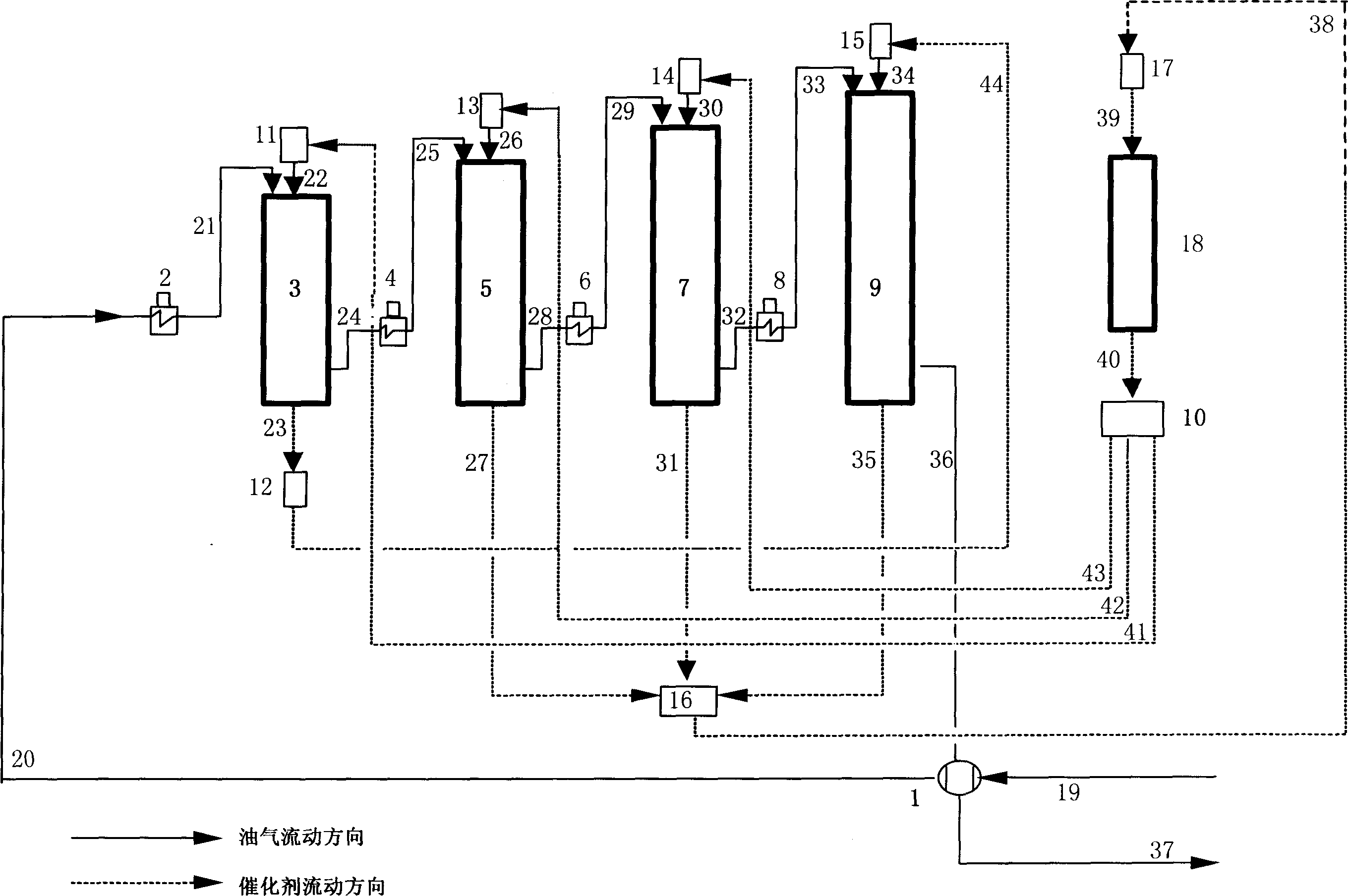

[0028] In this embodiment, according to the flow process of accompanying drawing, the flow direction of reaction material between reactors is successively: R 1 →R 2 →R 3 →R 4 , the regenerated catalyst is divided into three parallel paths: the flow direction of the first path is R 1 →R 4 , the second path flows to R 2 , the third way flows to R 3 , and the test results are listed in Table 1.

[0029] It can be seen from Table 1 that under the same severity, the C5+ liquid product yield of the co-current continuous reforming process is 1.3 percentage points higher than that of the co-current process and the counter-current process, and the hydrogen production rate is higher than that of the co-current process and the counter-current process. Craft was 0.1 percentage points and 0.04 percentage points higher, respectively.

[0030] Comparative example 1

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com