CdS/MoO3 composite photocatalyst and preparation method thereof

A catalyst and composite light technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of inability to degrade organic pollutants, low activity, low hydrogen production rate, etc., and achieve uniform particle size. , the effect of high catalytic activity and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

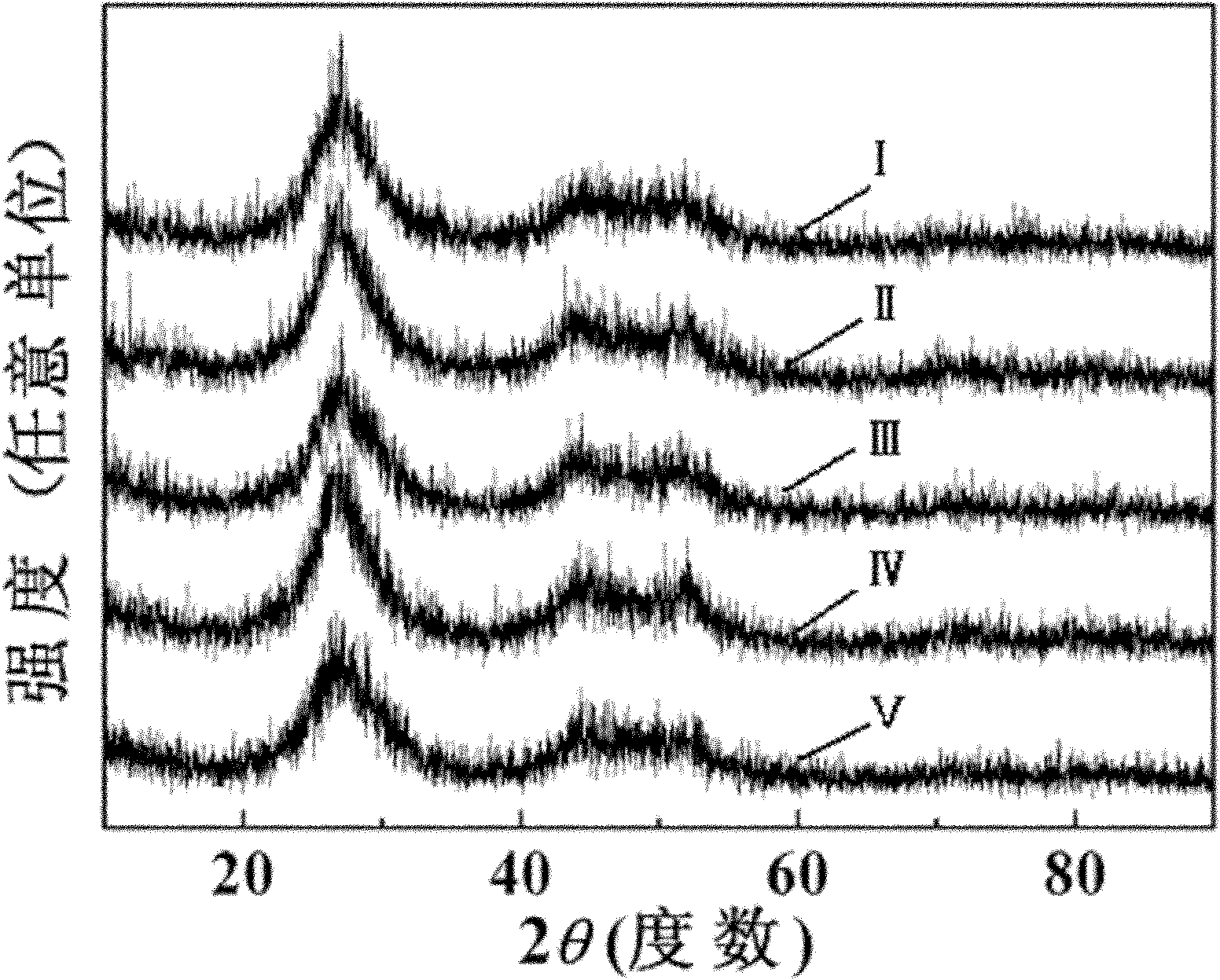

[0012] Specific implementation mode 1: CdS / MoO in this implementation mode 3 Composite photocatalyst composed of Cd(Ac) 2 2H 2 O, (NH 4 ) 6 Mo 7 o 24 4H 2 Made from O and thioacetamide; where (NH 4 ) 6 Mo 7 o 24 4H 2 O and Cd(Ac) 2 2H 2 The molar ratio of O is 0.1:1~3, Cd(Ac) 2 2H 2 The molar ratio of O to thioacetamide is 1:1.03-8.24.

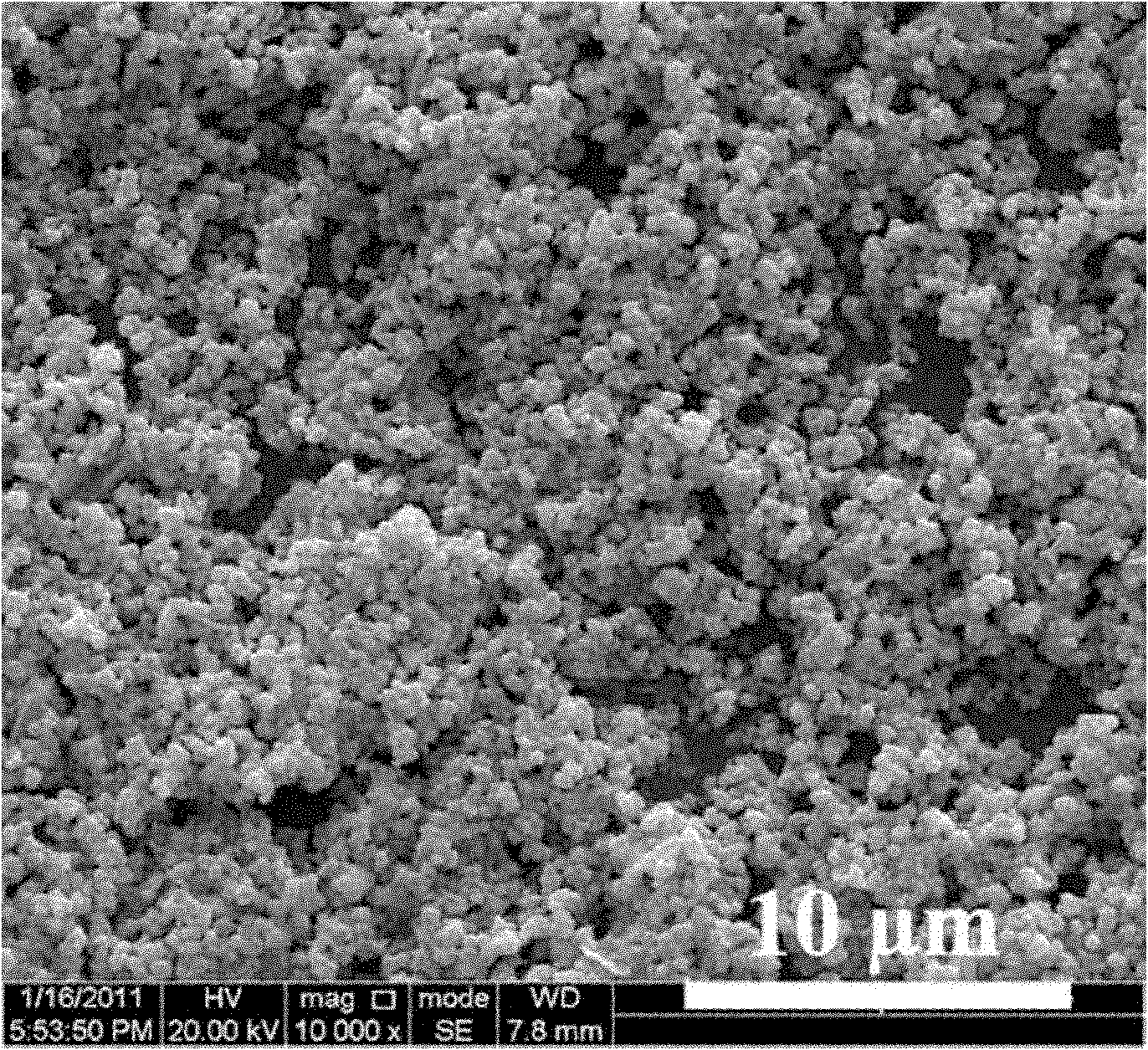

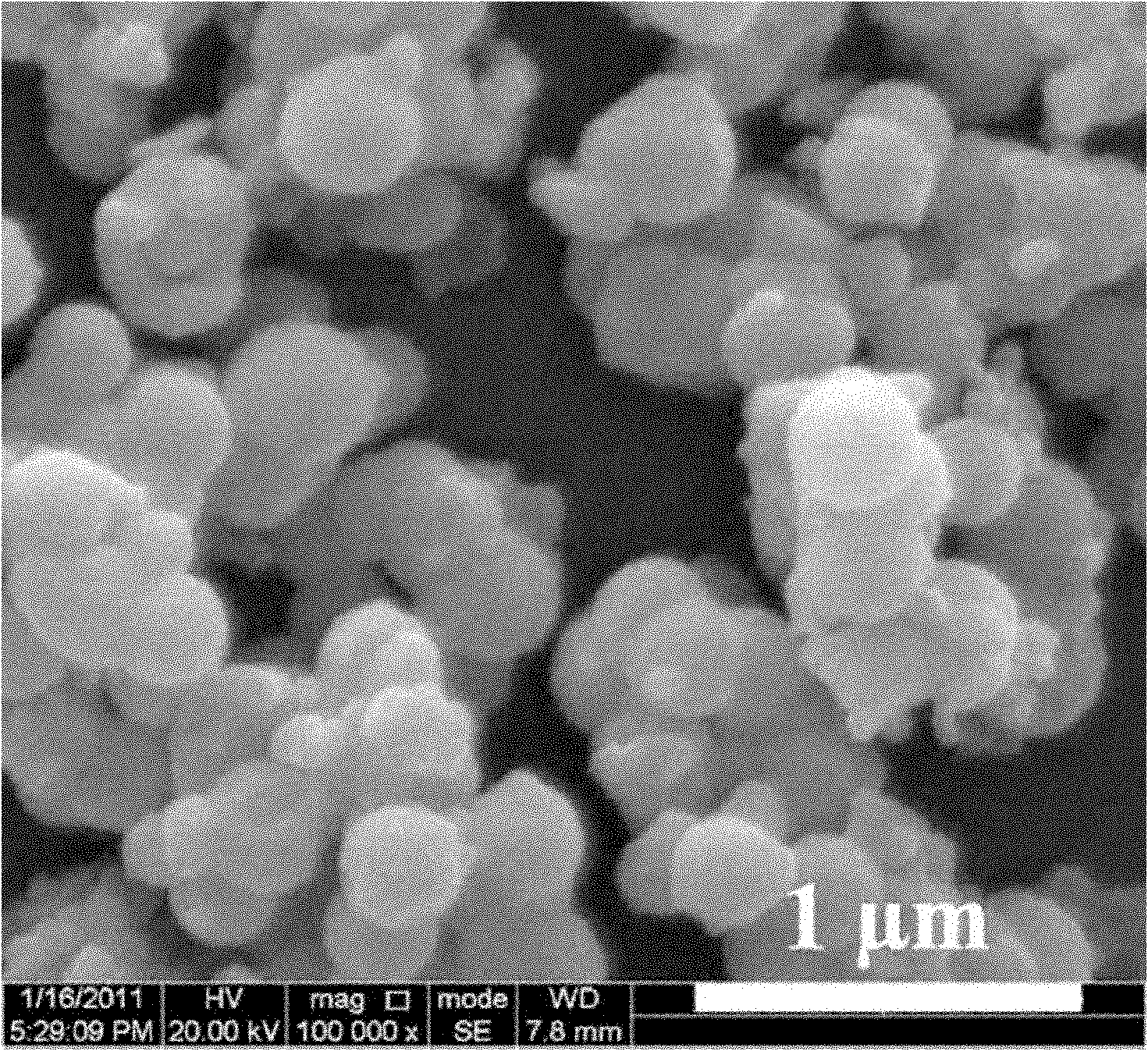

[0013] The composite photocatalyst obtained in this embodiment is nano-spherical, the nano-sphere particle size is 300nm-350nm, and is self-assembled by small particles each particle size is 5-20nm, and the nano-spheres are evenly embedded with CdS nanocrystals.

specific Embodiment approach 2

[0014] Specific embodiment two: the difference between this embodiment and specific embodiment one is (NH 4 ) 6 Mo 7 o 24 4H 2 O and Cd(Ac) 2 2H 2 The molar ratio of O is 0.1:2, Cd(Ac) 2 2H 2 The molar ratio of O to thioacetamide is 1:5. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: CdS / MoO in this implementation mode 3 The preparation method of composite photocatalyst is as follows: one, weigh Cd(Ac) 2 2H 2 O, (NH 4 ) 6 Mo 7 o 24 4H 2 O and thioacetamide are then added to 5mL-20mL of acetone or ethanol solution to form a mixture, in which (NH 4 ) 6 Mo 7 o 24 4H 2 O and Cd(Ac) 2 2H 2 The molar ratio of O is 0.1:1~3, Cd(Ac) 2 2H 2 The molar ratio of O to thioacetamide is 1:1.03~8.24; 2. Seal the mixture obtained in step 1 and put it into an ultrasonic reactor, and react at 40°C~80°C for 0.5h~8h; 3. Put the mixture in step 1 The product obtained by the second reaction is cooled to room temperature, washed with absolute ethanol for 2 to 5 times, and then dried in an oven at 50°C for 0.5h to 5h to obtain a composite photocatalyst.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com