Patents

Literature

116results about How to "High hydrogen yield" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

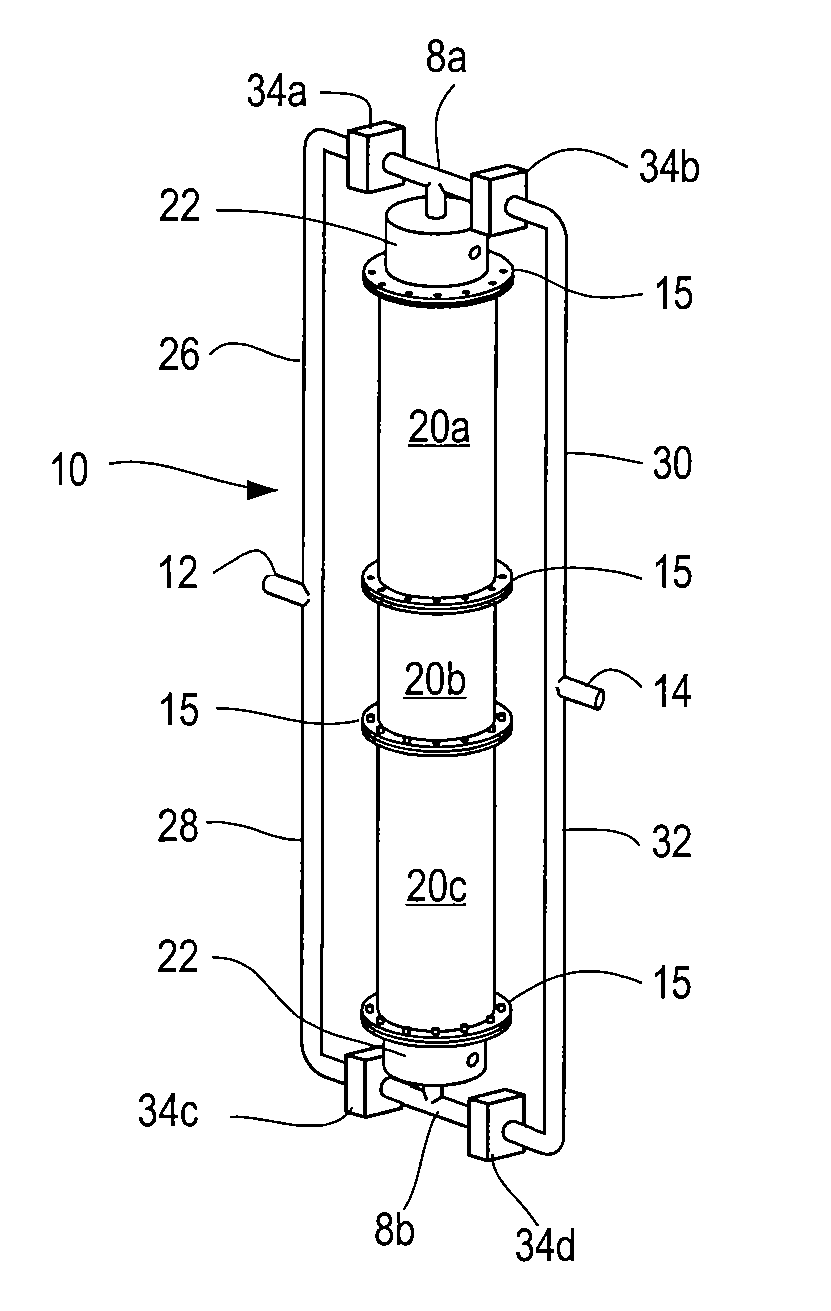

Reformation of hydrogen-containing fluids in a cyclic flow reactor

ActiveUS20090062591A1Efficient processingImprove efficiencyHydrocarbon purification/separationSulfur compoundsExternal energyPorous medium

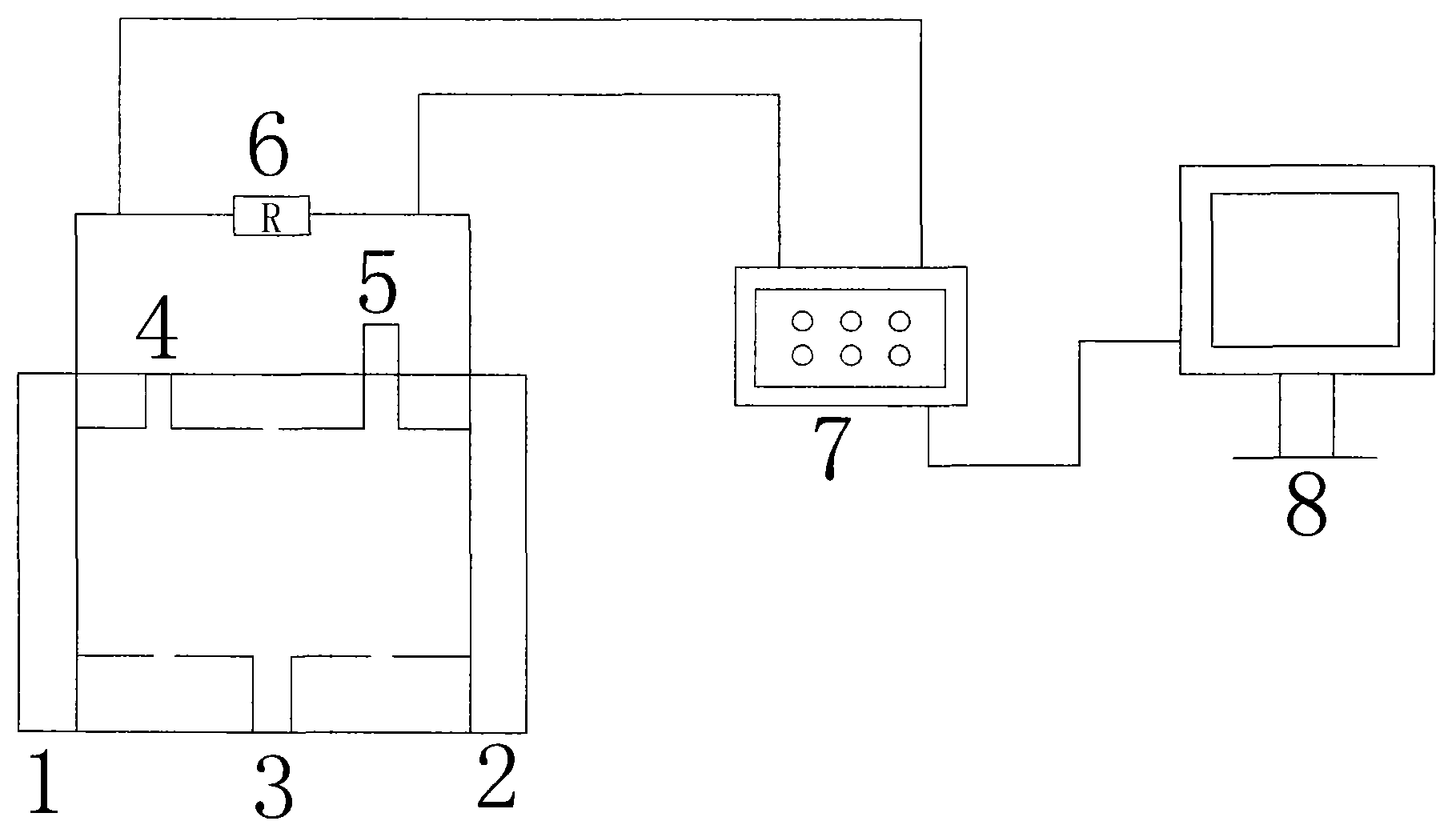

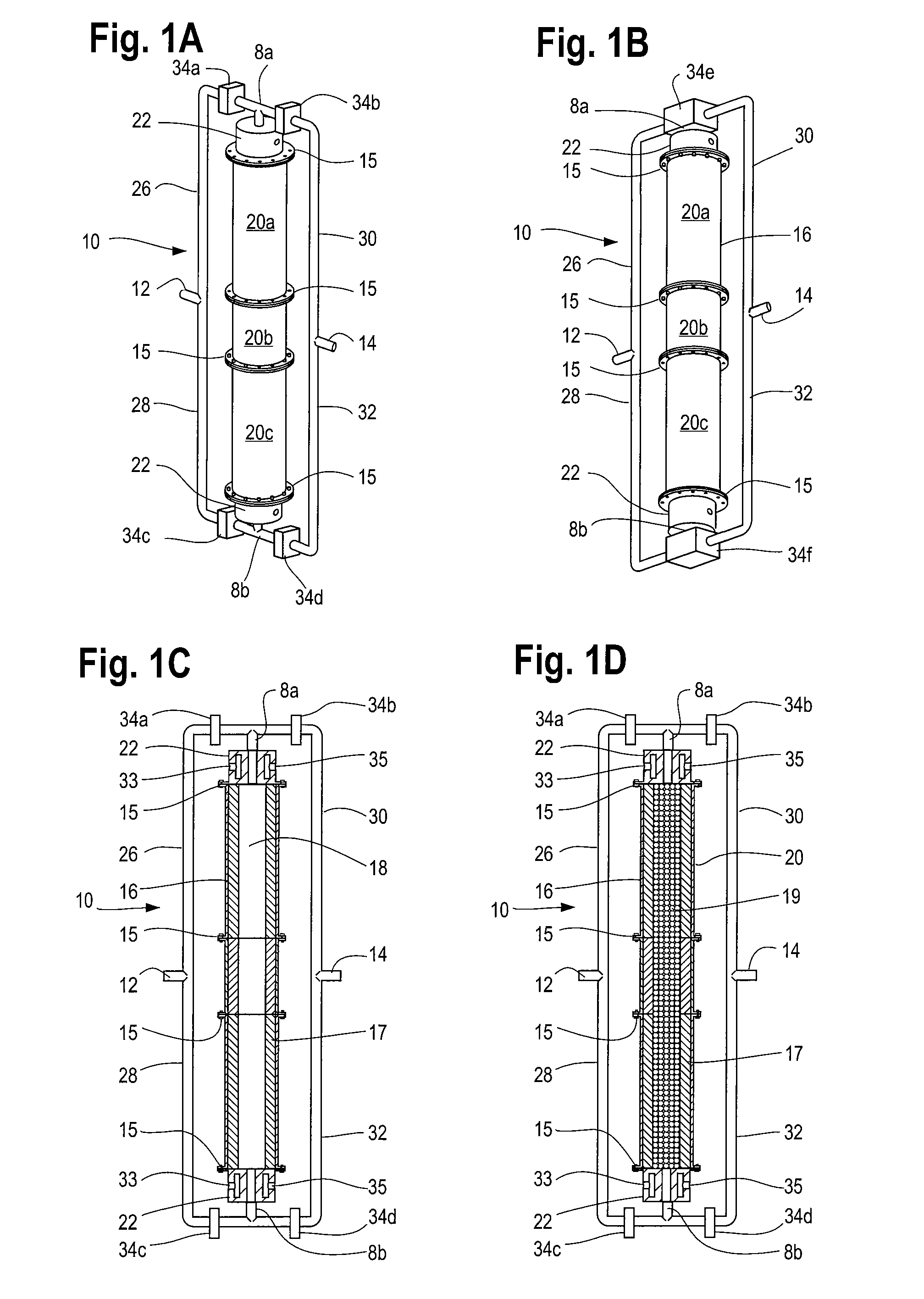

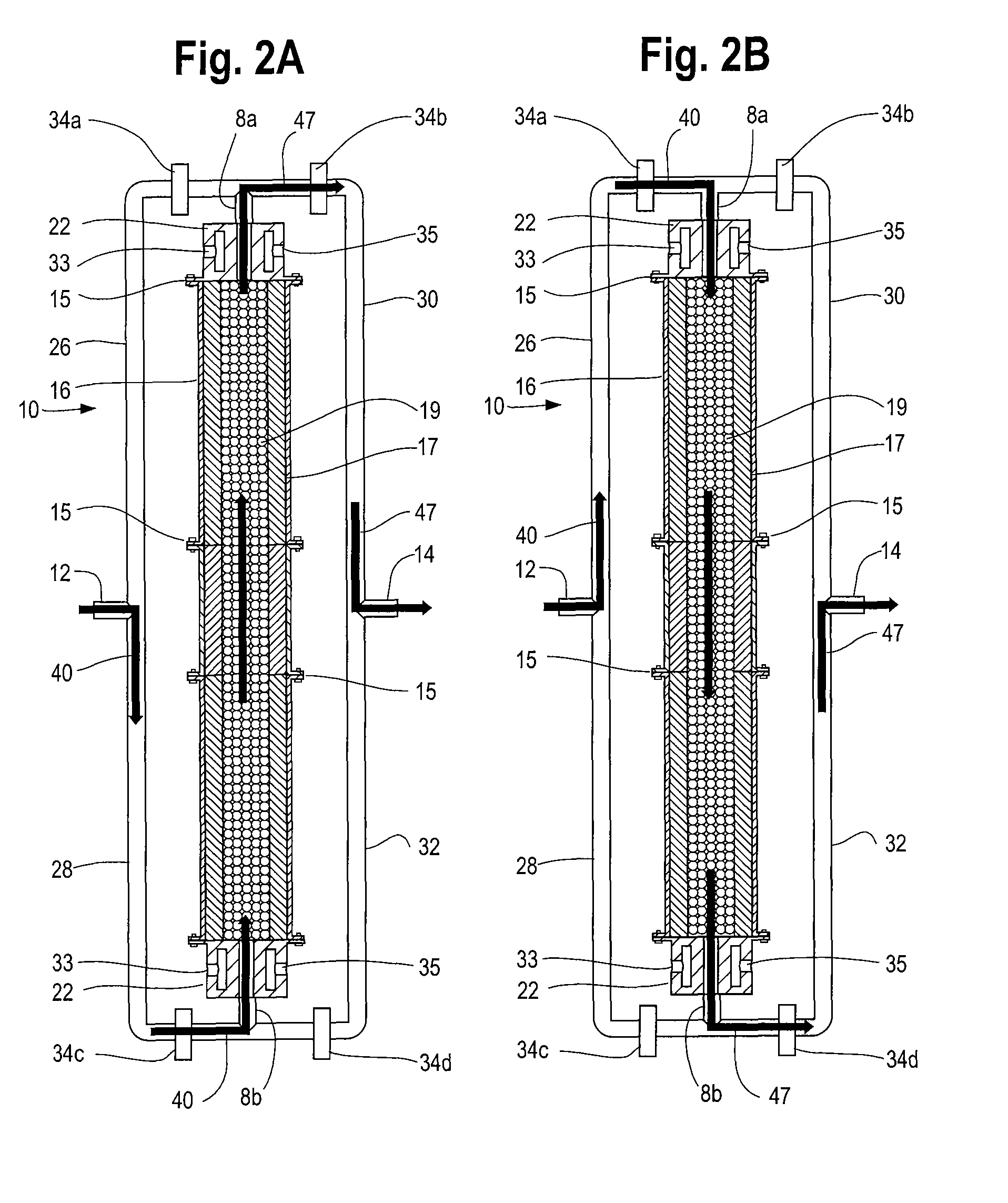

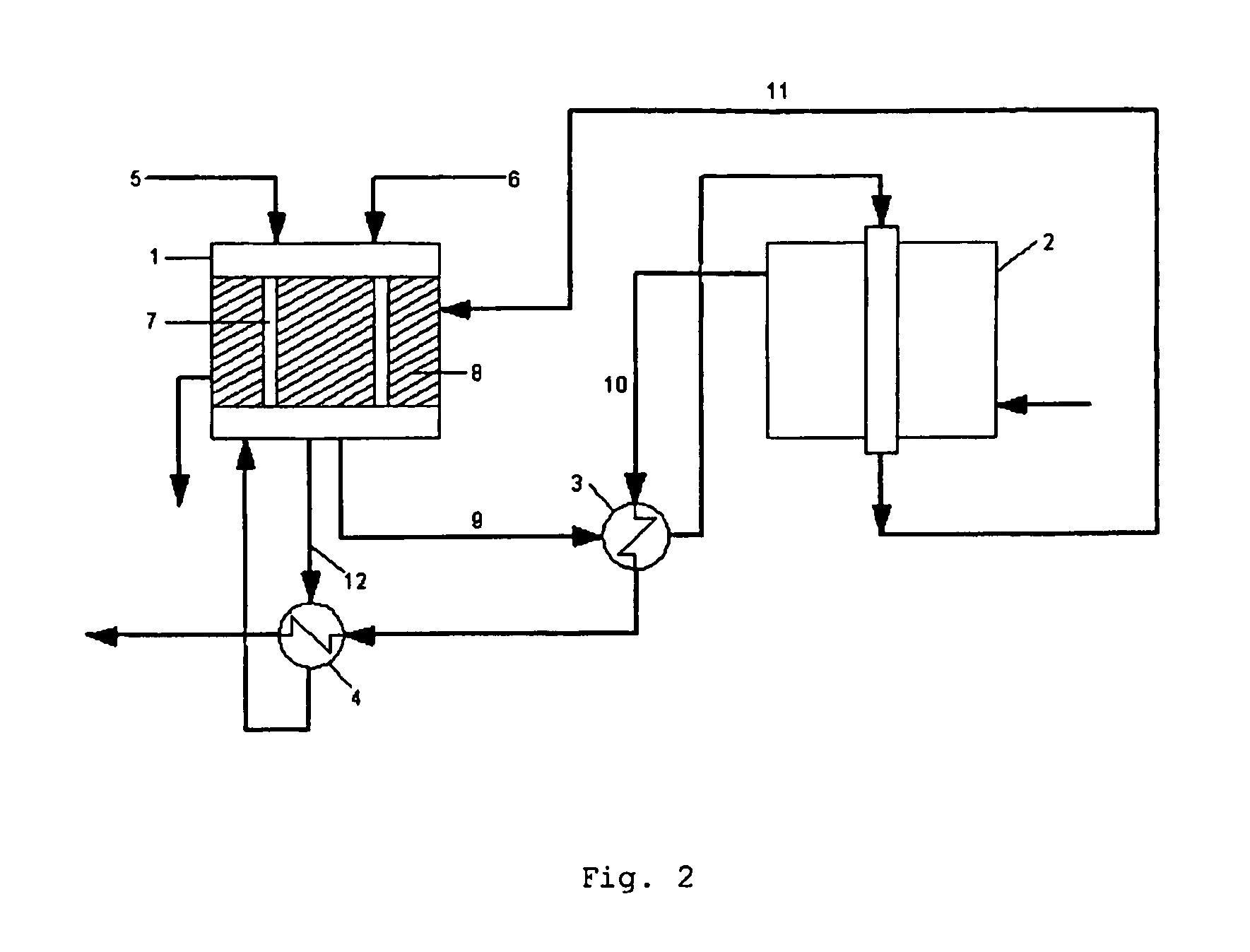

The invention discloses an apparatus and process for the reformation of hydrogen containing fluids to hydrogen and other constituents, more particularly, the reformation of hydrocarbons or mixtures of hydrocarbons in a cyclic flow inert porous media reactor for the production of hydrogen and other constituents. In an alternate embodiment, the apparatus and process can be used for the reformation of hydrogen sulfide to produce hydrogen and sulfur.The cyclic flow reactor comprises a reaction chamber filled with a porous media matrix containing an unconstrained reaction zone located in any portion of the reactor chamber. This reactor system employs valves to canalize the reactant mixture and product mixture during flow cycling channeling the reactant mixture through the porous media matrix, and reacting the reactant mixture. In another embodiment, the reactor system may further comprise at least one aperture along the axial length of the reactor casing to enable mounting of an external energy source and / or at least one heat exchanger to provide a source of heat transfer to the inlet pipe and outlet pipe as well as the reactant mixture and product mixtures.

Owner:INNOVATIVE ENERGY SOLUTION

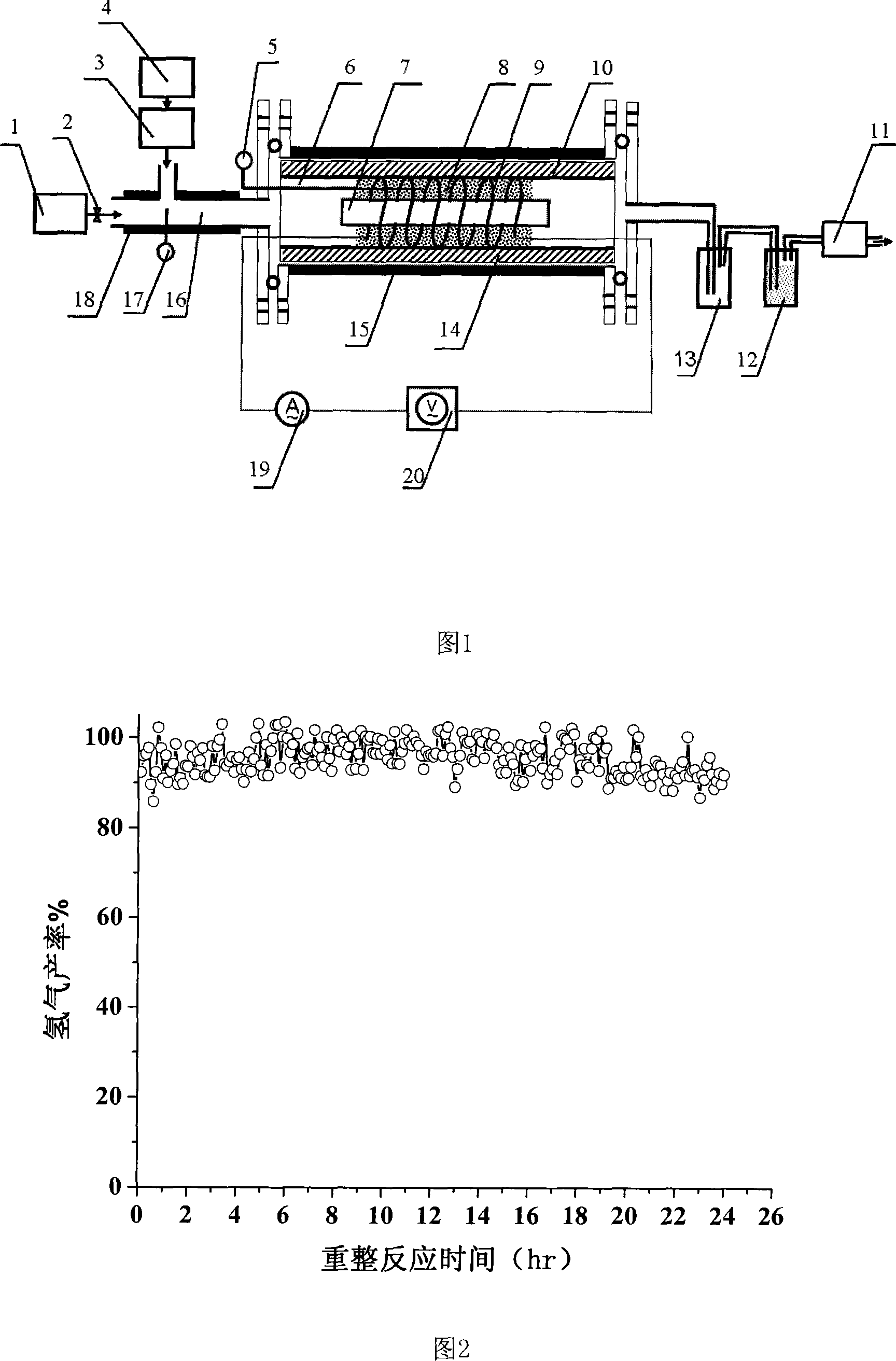

Device and method for preparing hydrogen by the electrocatalysis water vapour recapitalization biological oil

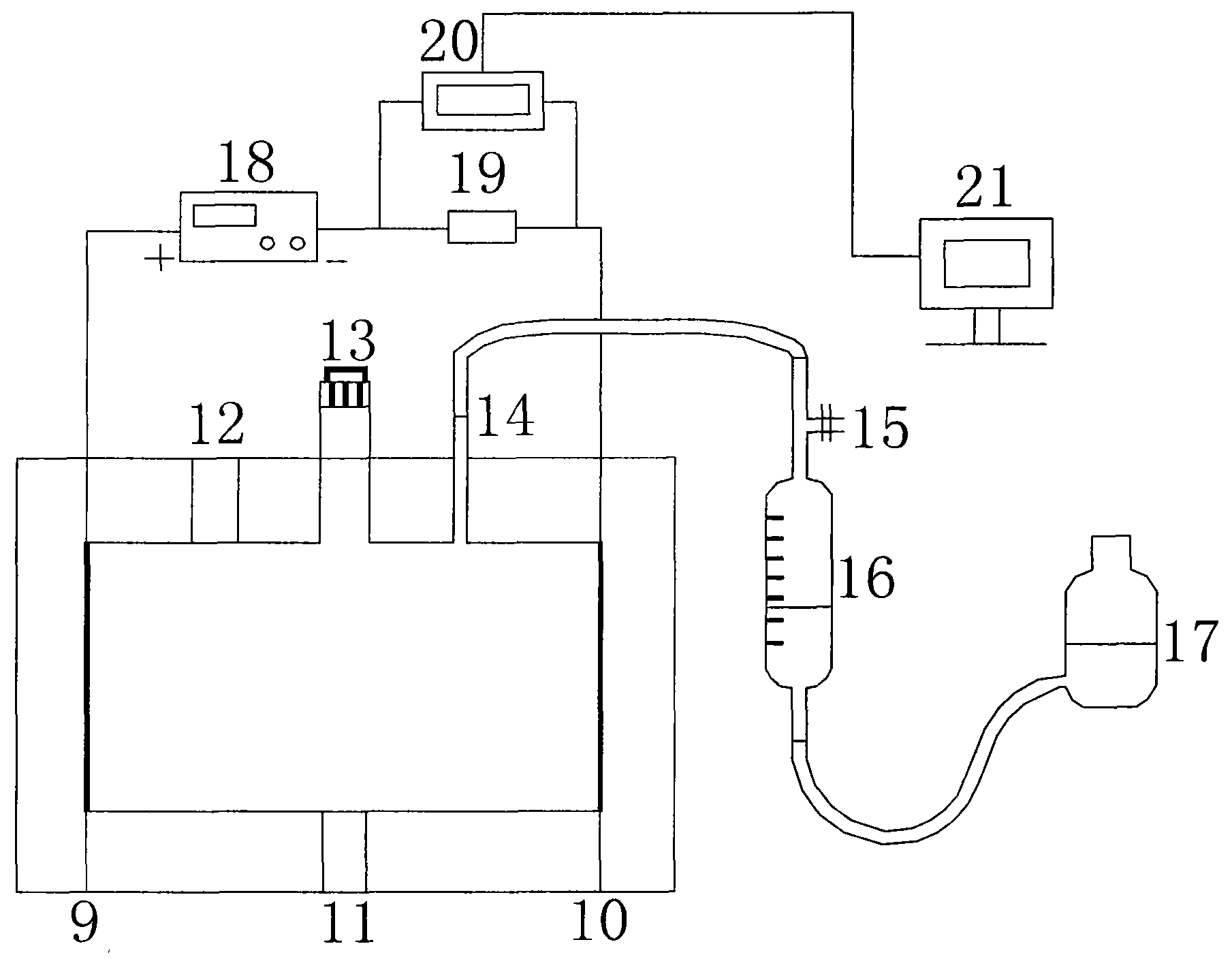

The invention relates to the technology of electrocatalytic reforming of organic compounds, in particular to a method and device for producing hydrogen from bio-oil by electrocatalytic steam reforming. The device includes a cylindrical reactor with a reforming catalyst and an external heating furnace, a bio-oil storage tank, a steam generator connected to an inlet pipeline with a preheating device, and a tail gas collection and purification system on the output pipeline. An electric furnace wire is arranged in the inner cavity of the device. When producing hydrogen, the external power supply of the electric furnace wire is first connected to heat the catalyst; then the mixed fluid of raw bio-oil and water vapor is passed into the inner cavity of the reactor, so that the bio-oil can be electrocatalyzed by water in a water vapor atmosphere and a medium temperature environment. Steam reforming reaction and water gas shift reaction convert carbon-hydrogen-oxygen-containing organic matter into hydrogen and carbon dioxide mixed gas. The invention utilizes heating electric furnace wire to provide hot electrons for the catalyst surface to dissociate and degrade various complex carbon-hydrogen-oxygen macromolecules in bio-oil, and obtain high hydrogen yield and bio-oil conversion under the condition of 450-550°C Rate.

Owner:UNIV OF SCI & TECH OF CHINA

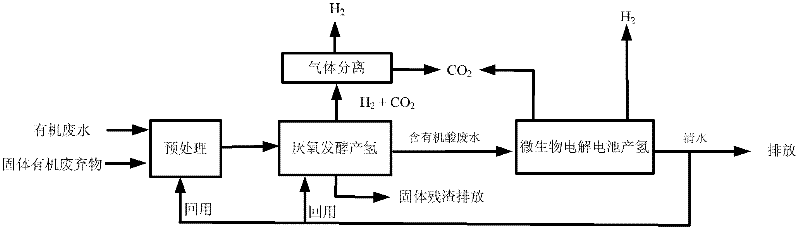

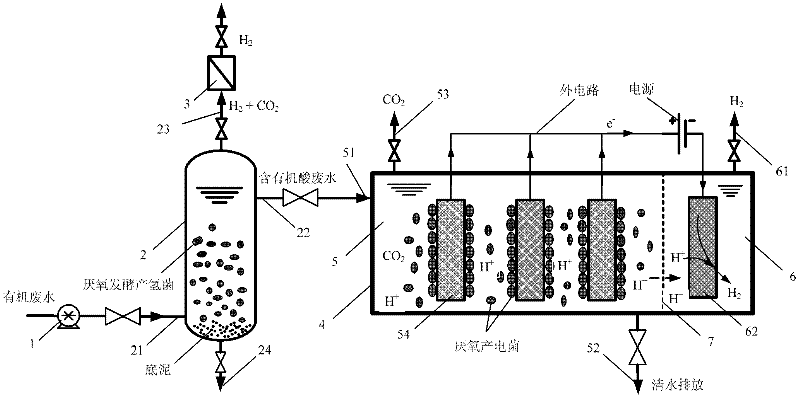

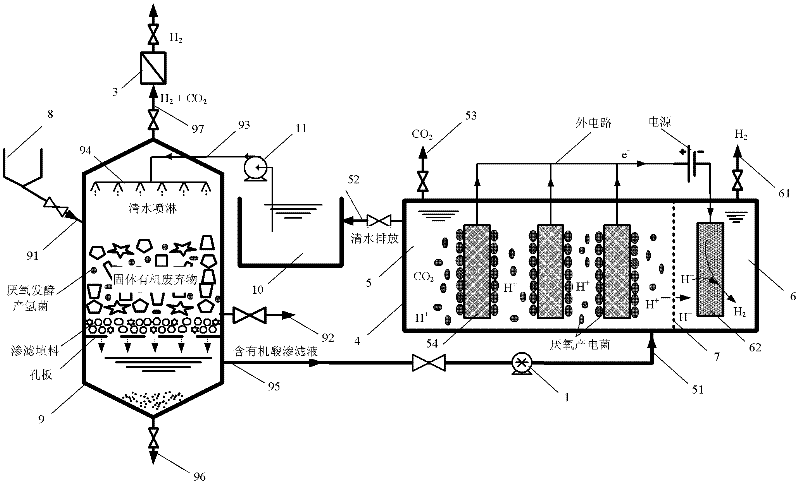

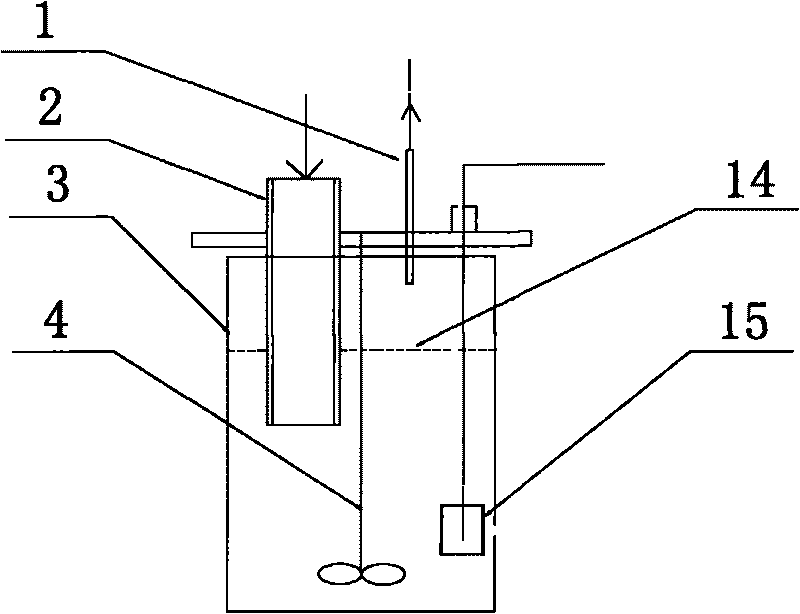

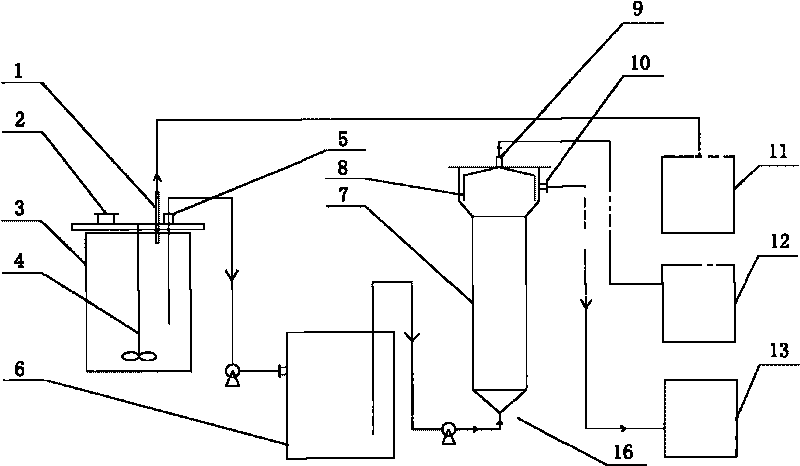

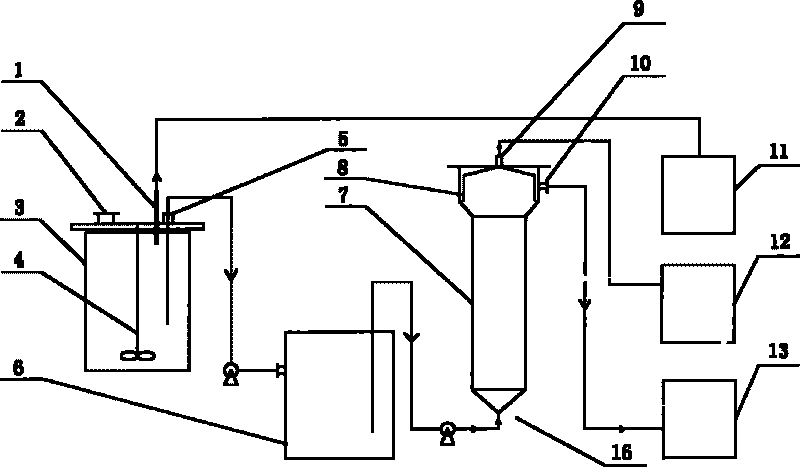

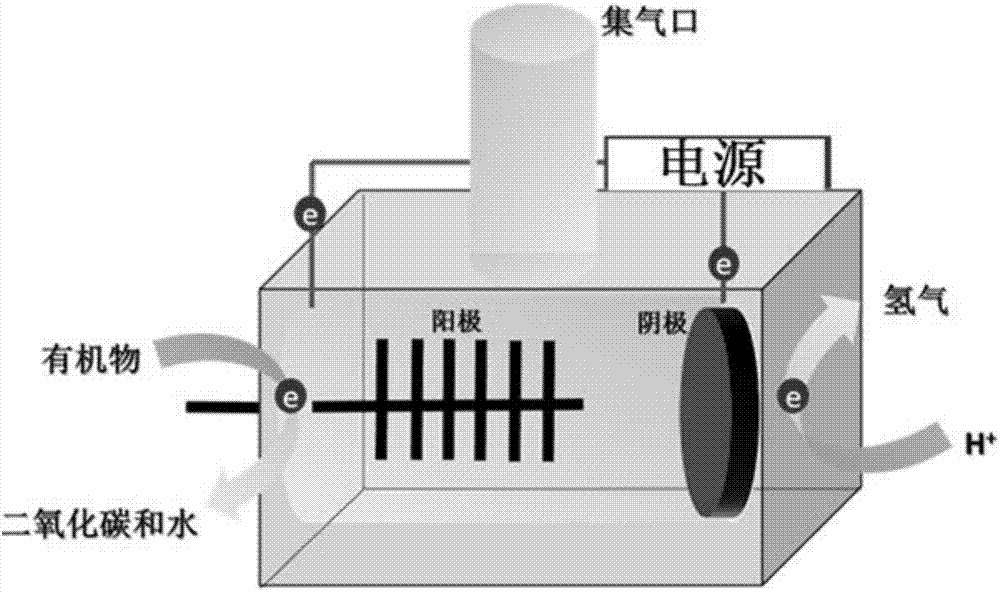

A method and device for two-step biological hydrogen production from organic waste

ActiveCN102286537AHigh hydrogen yieldExpand the scope of raw material utilizationBioreactor/fermenter combinationsGas production bioreactorsChemistryHydrogen yield

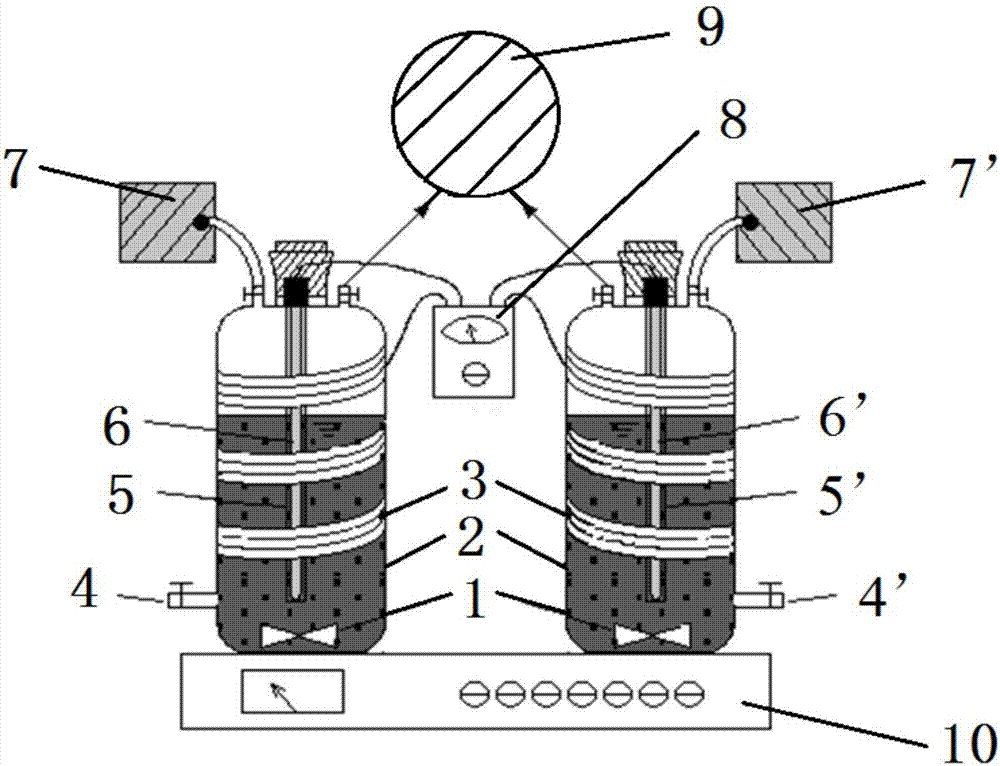

The invention provides a two-step biological hydrogen production method by using organic waste and a device thereof, and aims to enhance the hydrogen yield of organic waste and implement advanced treatment of organic waste. The method comprises the following steps: (1) strain preparation and raw material pretreatment; (2) hydrogen production by anaerobic fermentation; (3) hydrogen production in a microbial electrolysis cell; and (4) clear water recycling or discharge. The device provided by the invention comprises a feeding device, an anaerobic hydrogen production reactor and a microbial electrolysis cell which are sequentially connected, wherein a water outlet of the anaerobic hydrogen production reactor is communicated with a water inlet of an anode chamber of the microbial electrolysis cell. By combining the anaerobic fermentation hydrogen production and microbial electrolysis cell technique, the invention increases the hydrogen yield, widens the raw material utilization range, enhances the hydrogen yield of organic substances and the recovery rate of energy sources, and implements thorough recycling of organic substances and advanced treatment of organic waste. The method and device provided by the invention are suitable for treating various types of organic waste water and solid organic waste.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

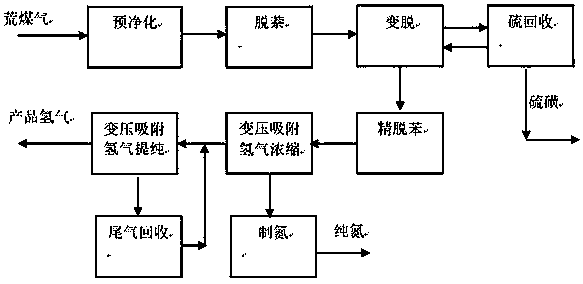

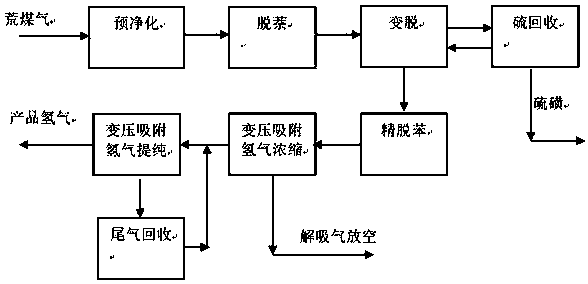

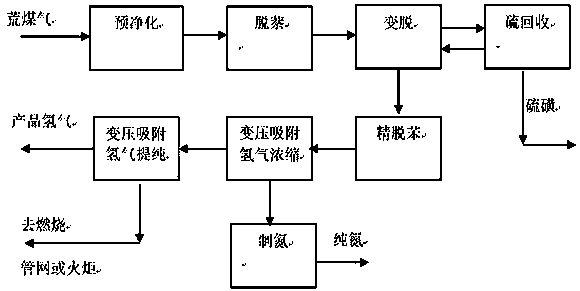

Low-energy-consumption high-yield method for preparing hydrogen from raw gas

InactiveCN107758615AReduce consumptionEmission reductionNitrogen purification/separationHydrogen separation using solid contactSulfurNitrogen

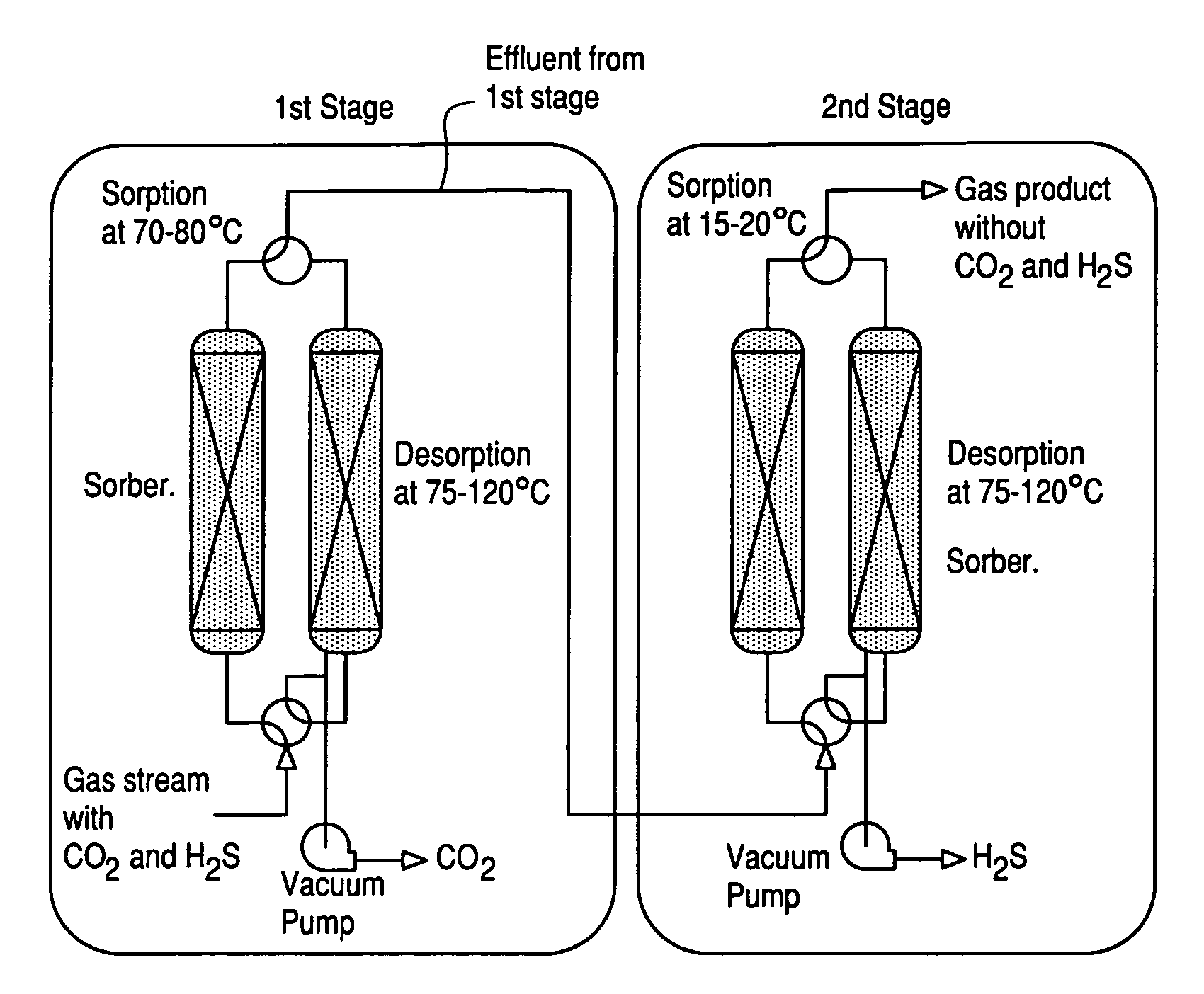

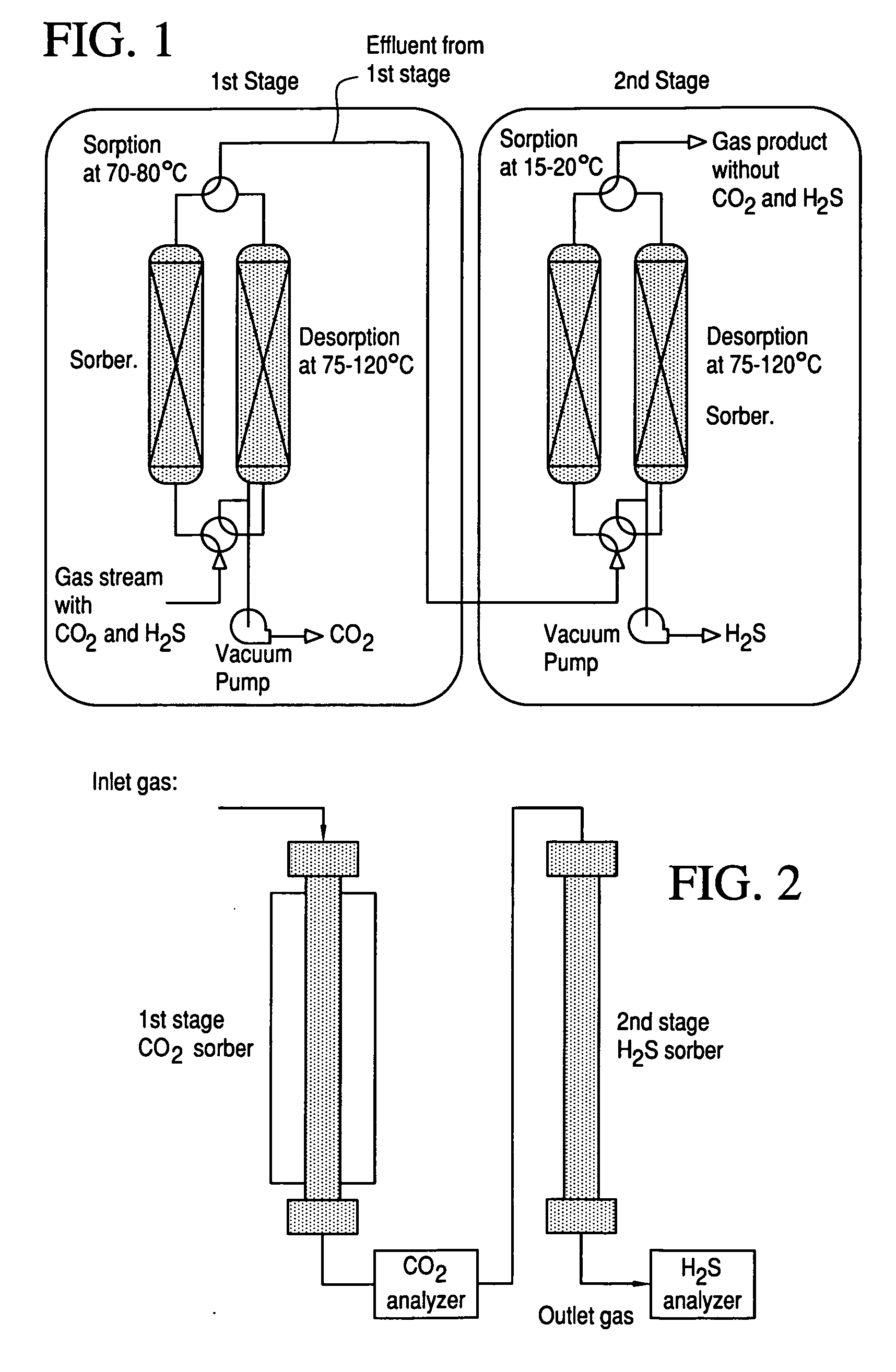

The invention discloses a low-energy-consumption high-yield method for preparing hydrogen from raw gas. The method comprises the following procedures: pre-cleaning; naphthalene removal; transformationand desulfurization; sulfur recovery; refined debenzolization; pressure swing adsorption for hydrogen production; recovery of tail gas; nitrogen production; etc. After pretreatment and naphthalene removal, raw gas is allowed to enter the procedure of transformation and desulfurization so as to obtain more hydrogen and increase the yield of hydrogen, and then desulfurization is carried out in a desulfurization tower; then pure hydrogen is prepared through the procedure of refined debenzolization and the procedure of pressure swing adsorption for hydrogen production; through the procedures of tail gas recovery and nitrogen production, effective hydrogen in desorbed gas is recovered, and hydrogen yield is further increased; and pure nitrogen with a purity of 99% or more is further prepared through a nitrogen production unit. The method provided by the invention substantially reduces the energy consumption of an apparatus for hydrogen production from raw gas, increases hydrogen yield, recovers almost all the effective hydrogen component in the desorbed gas, realizes recovery and graded utilization of each component in the raw gas while guaranteeing low energy consumption and high yield, and by-produces sulfur, pure nitrogen and the other products while preparing pure hydrogen.

Owner:SICHUAN TECHAIRS

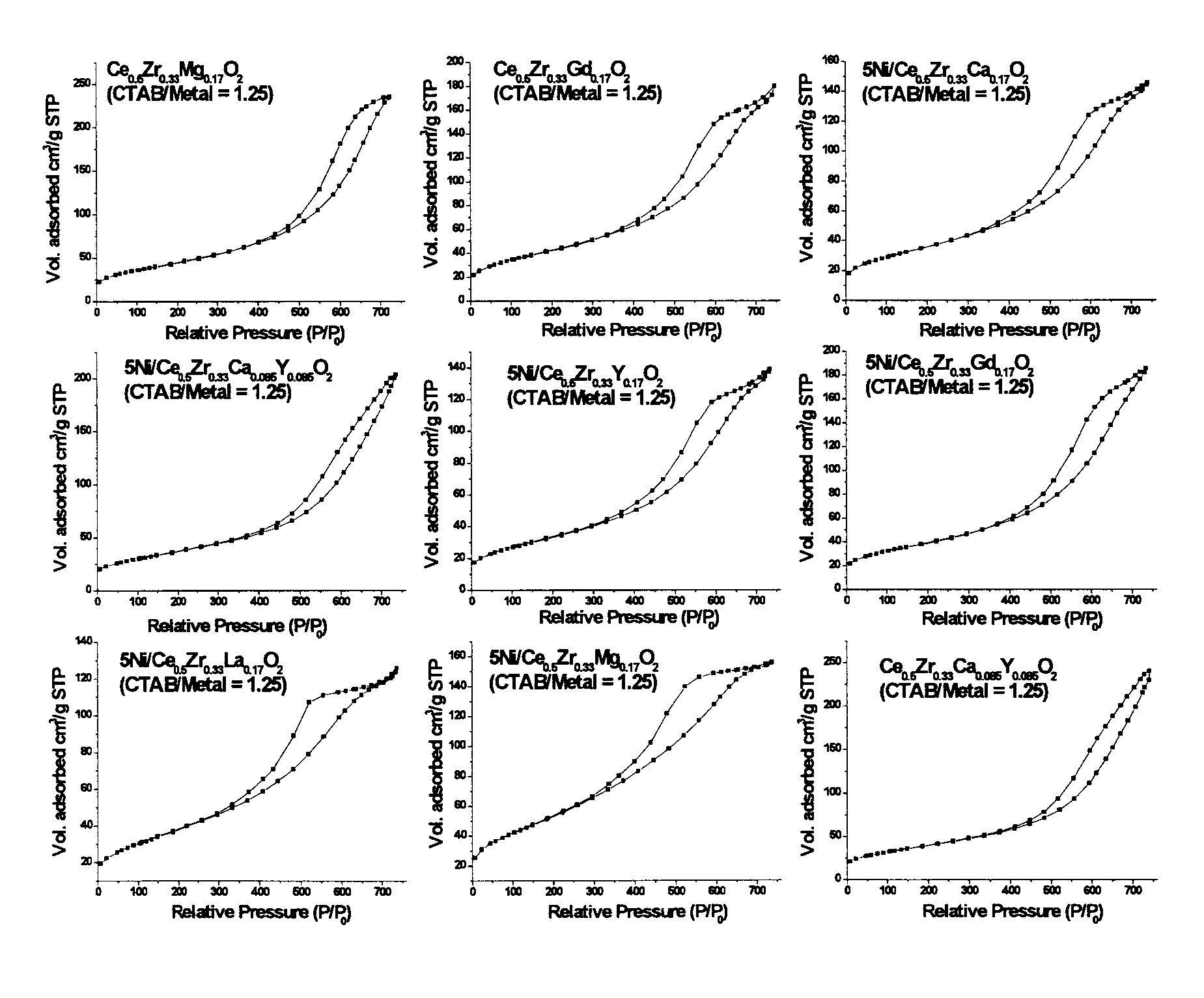

Catalysts for feedstock-flexible and process-flexible hydrogen production

InactiveUS20130058861A1Highly active andEasy to switchHeterogenous catalyst chemical elementsCatalyst activation/preparationSyngasPtru catalyst

A series of ternary oxide and quaternary oxide catalysts were prepared and evaluated for various reforming processes. Representative examples of these catalysts were found to be active and stable for all the processes tested verifying the “feedstock and process flexible” nature of these catalysts. Thus, feedstock- and process-flexible reforming catalysts for hydrogen and / or syngas production have been developed.

Owner:UNIVERSITY OF REGINA

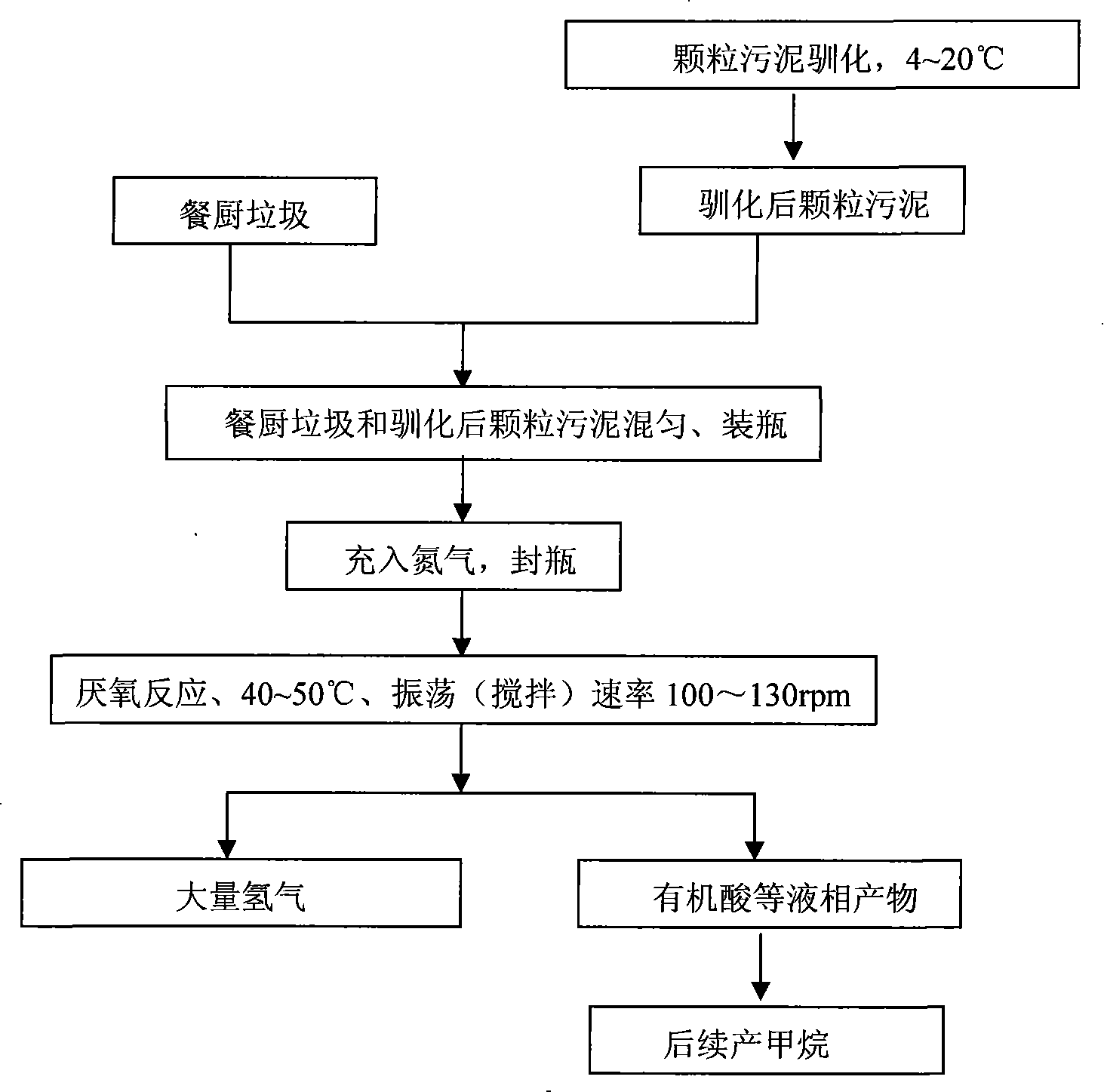

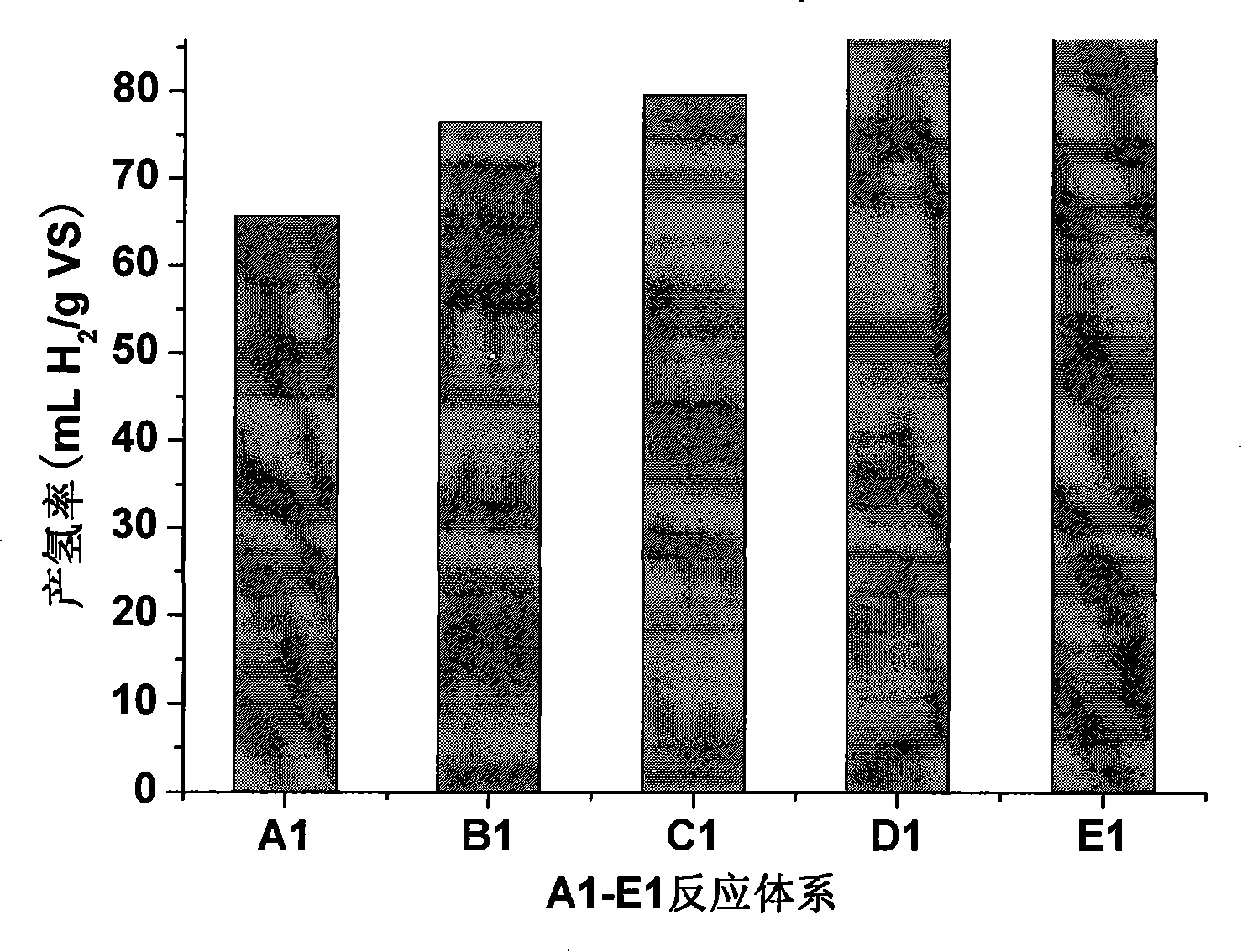

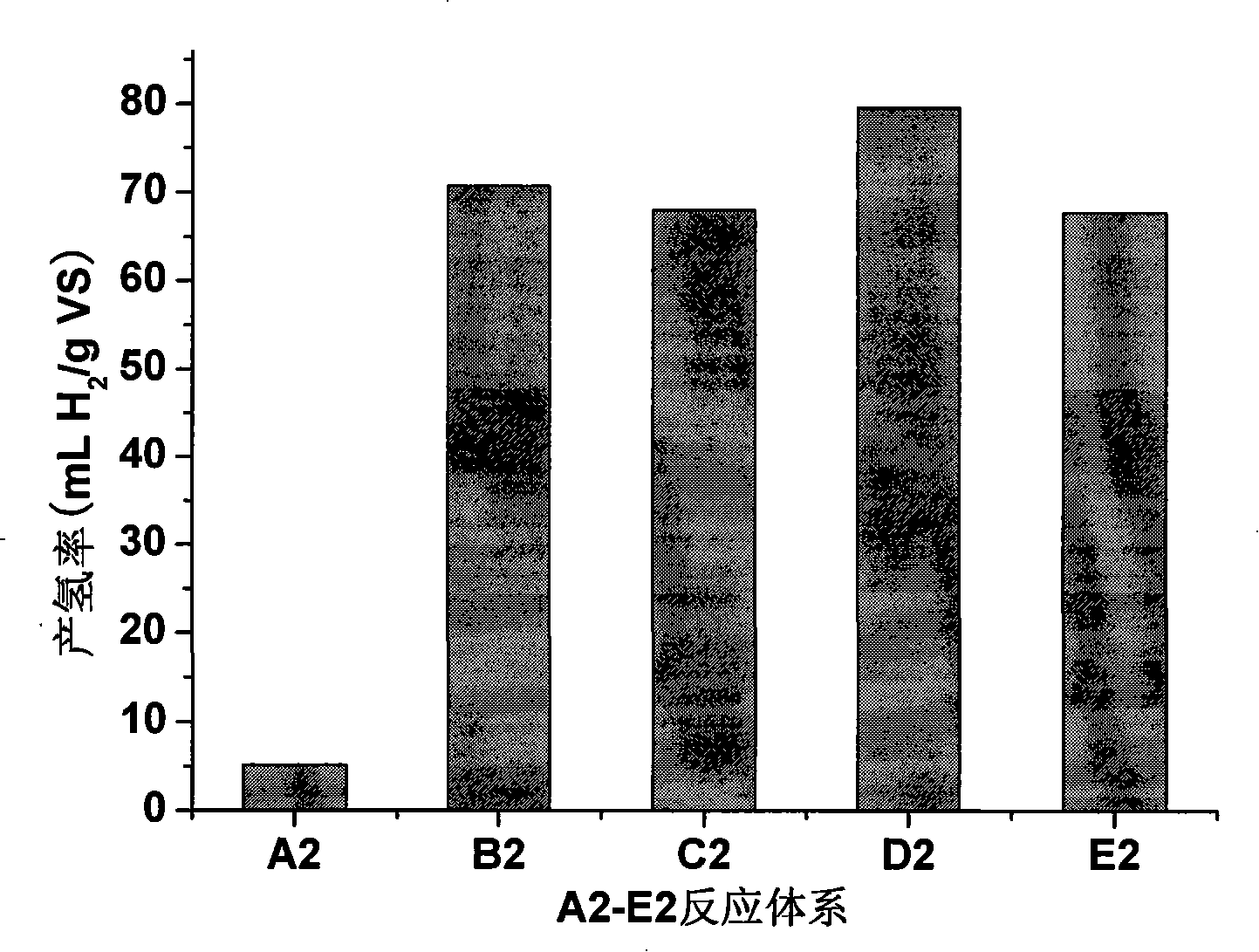

Method for improving hydrogen gas yield of kitchen waste anaerobic digestion

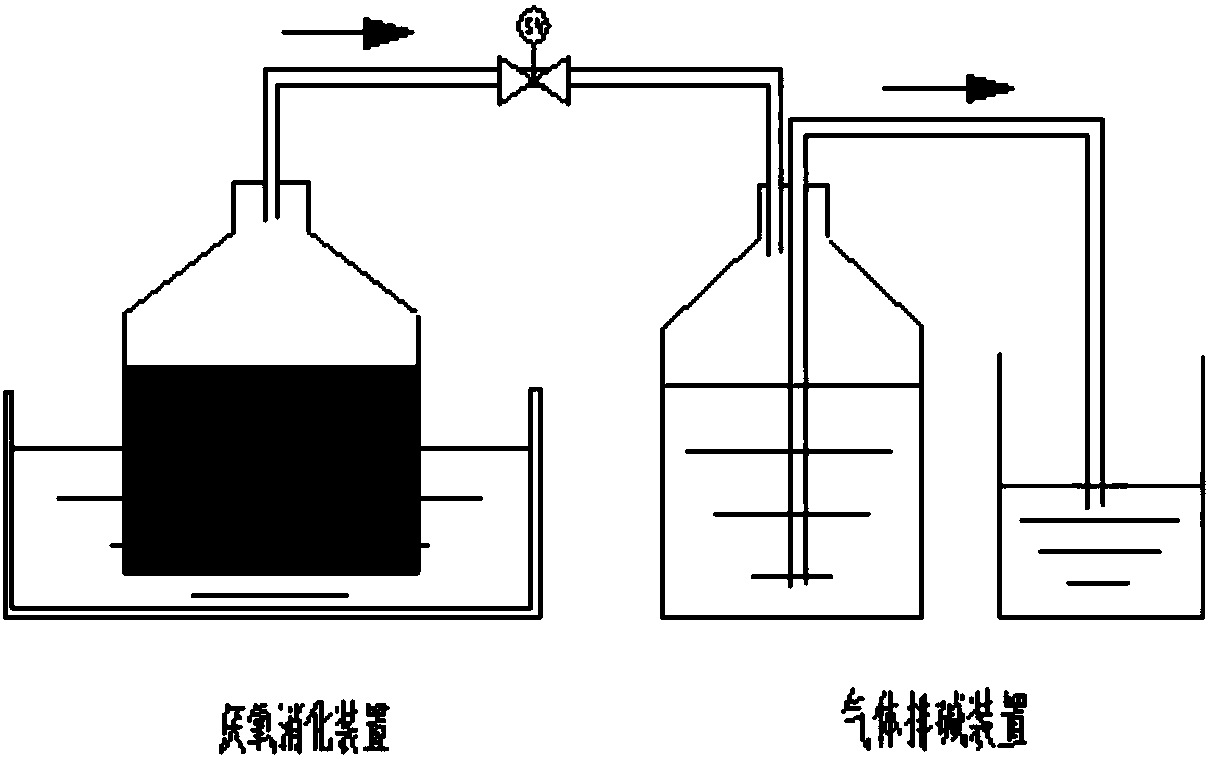

InactiveCN101250554AInhibitory activityHigh hydrogen yieldWaste based fuelFermentationDry weightNitrogen gas

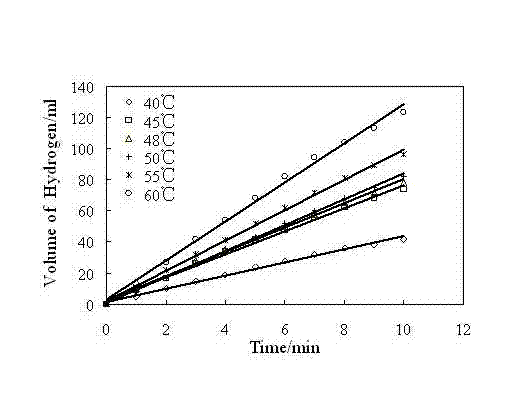

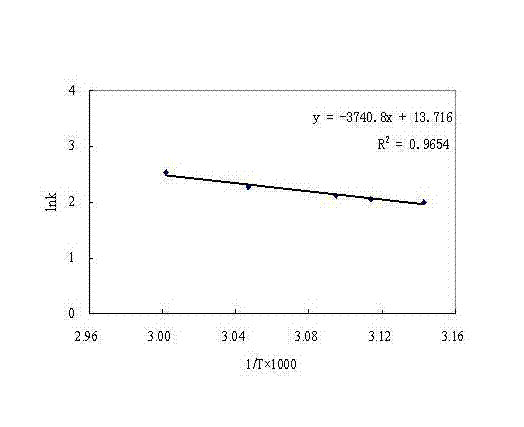

The invention relates to a method for increasing the hydrogen output through anaerobically digesting restaurant garbage and relates to a method for producing the hydrogen output through anaerobically digesting the restaurant garbage, which comprises following steps: firstly, weighing according to granular sludge: the restaurant garbage=1:0.2-0.4 part dry weight, adding the granular sludge and the restaurant garbage into a bottle, filling nitrogen or argon, sealing, statically culturing under the temperature of 4-20DEG C, finishing domestication when the pH value is lowered to 4.5-5.5, preserving, then, weighing according to the restaurant garbage: the granular sludge which is domesticated well=1 part dry weight:0.59-0.294part dry weight, then, arranging the restaurant garbage and the granular sludge into a container, evenly mixing, filling the nitrogen or the argon, then, sealing, concussing and stirring under the temperature of 40-50DEG C and the speed of 100-130r / min, starting anaerobic digestion, wherein the hydrogen yield is 65.63mL / g VS-94.04mL / g VS, fermenting firedamp with residual material after the hydrogen stops producing, and transforming the residual material into the firedamp. The method of the invention has the characteristics of low energy consumption, low cost and high heat value net output rate, and the hydrogen yield can reach 93mL / g restaurant garbage (dry weight) through using the method of the invention, which is increased by 20-30% compared with existing hydrogen yield.

Owner:TONGJI UNIV

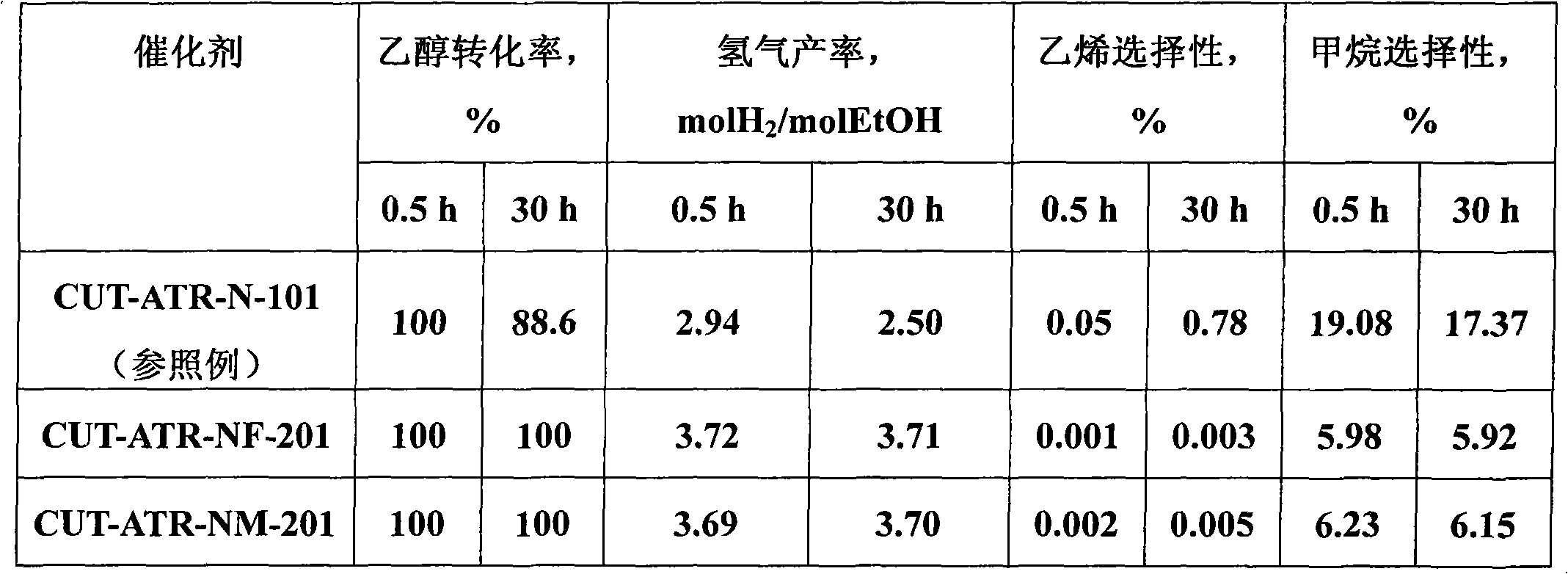

Nickel-base catalyst used for autothermal reforming of ethanol for producing hydrogen and preparation method thereof

InactiveCN101972656AEasy to introduceLarge specific surface areaHydrogenMetal/metal-oxides/metal-hydroxide catalystsManganeseCarbon deposit

The invention relates to a nickel-based catalyst used for the autothermal reforming of ethanol for producing hydrogen and a preparation method thereof. Aiming at the problems of structural change, oxidation and sintering of active ingredients and deactivation of the conventional catalyst during the autothermal reforming of the ethanol, the invention provides a novel catalyst with a stable structure, sintering resistance, carbon deposit resistance, oxidation resistance and high activity. The chemical formula of the catalyst is NiaMgbAlcXdO4.5+ / -delta, wherein X is an auxiliary agent Fe or Mn, a is 0.25 to 0.40, b is 2.6 to 2.75, c is 0.1 to 0.8 and d is 0.2 to 0.9. A brucite-based (Mg(OH)2.mH2O) hydrotalcite structure is taken as a precursor, so that the active ingredient nickel and the auxiliary agent heteroion component are introduced into a laminated structure and a position between laminated structures; meanwhile, the auxiliary agent iron or magnesium is introduced, so the reducibility and stability of the active ingredients of the catalyst are improved, and the yield of the hydrogen is obviously improved and remains stable.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

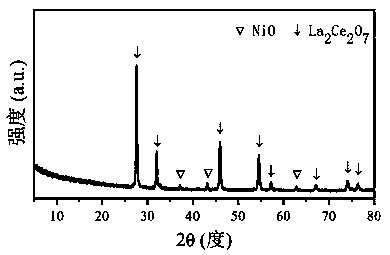

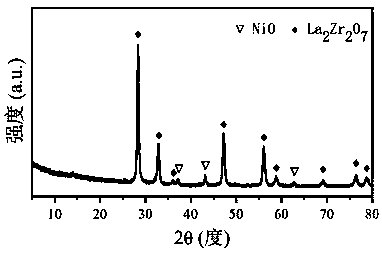

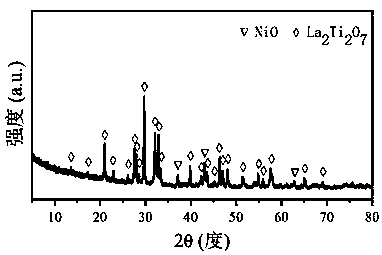

Ni/La2X2O7 catalyst for hydrogen production by autothermal reforming of acetic acid

ActiveCN111111674AGood choiceHigh catalytic activityHydrogenHeterogenous catalyst chemical elementsAcetic acidPtru catalyst

The invention relates to a Ni / La2X2O7 catalyst for hydrogen production by autothermal reforming of acetic acid. , Aiming at the problem of inactivation of an existing catalyst in the acetic acid autothermal reforming process, the invention provides the novel catalyst which is stable in structure and high in activity. A catalyst precursor is prepared by adopting a sol-gel method, and roasted by adopting an impregnation method to obtain the Ni / La2X2O7 (X is Ce, Zr or Ti) catalyst. According to the catalyst, the stability of active components is improved, the yield of hydrogen is increased, and generation of byproducts such as methane and acetone is effectively inhibited.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

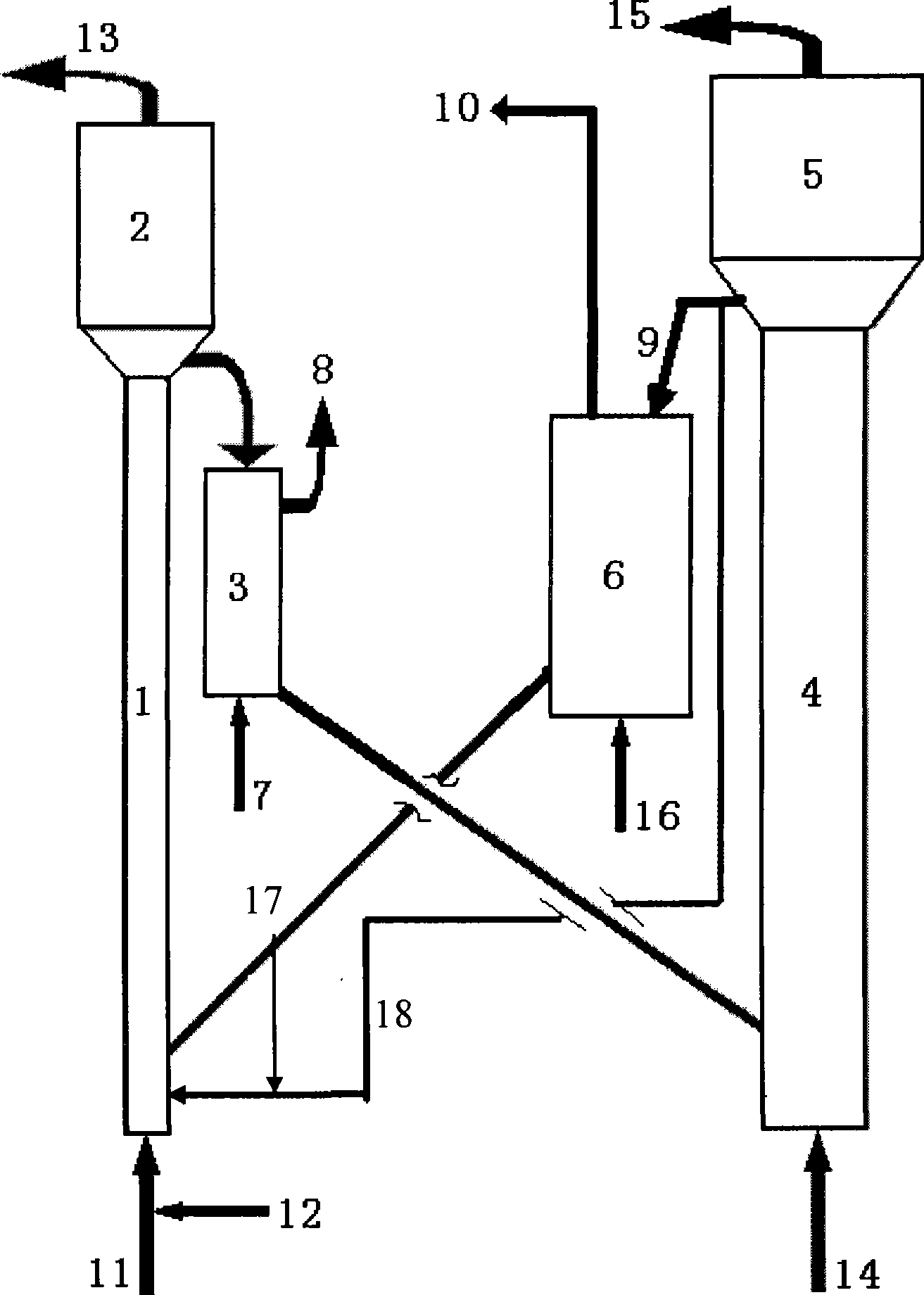

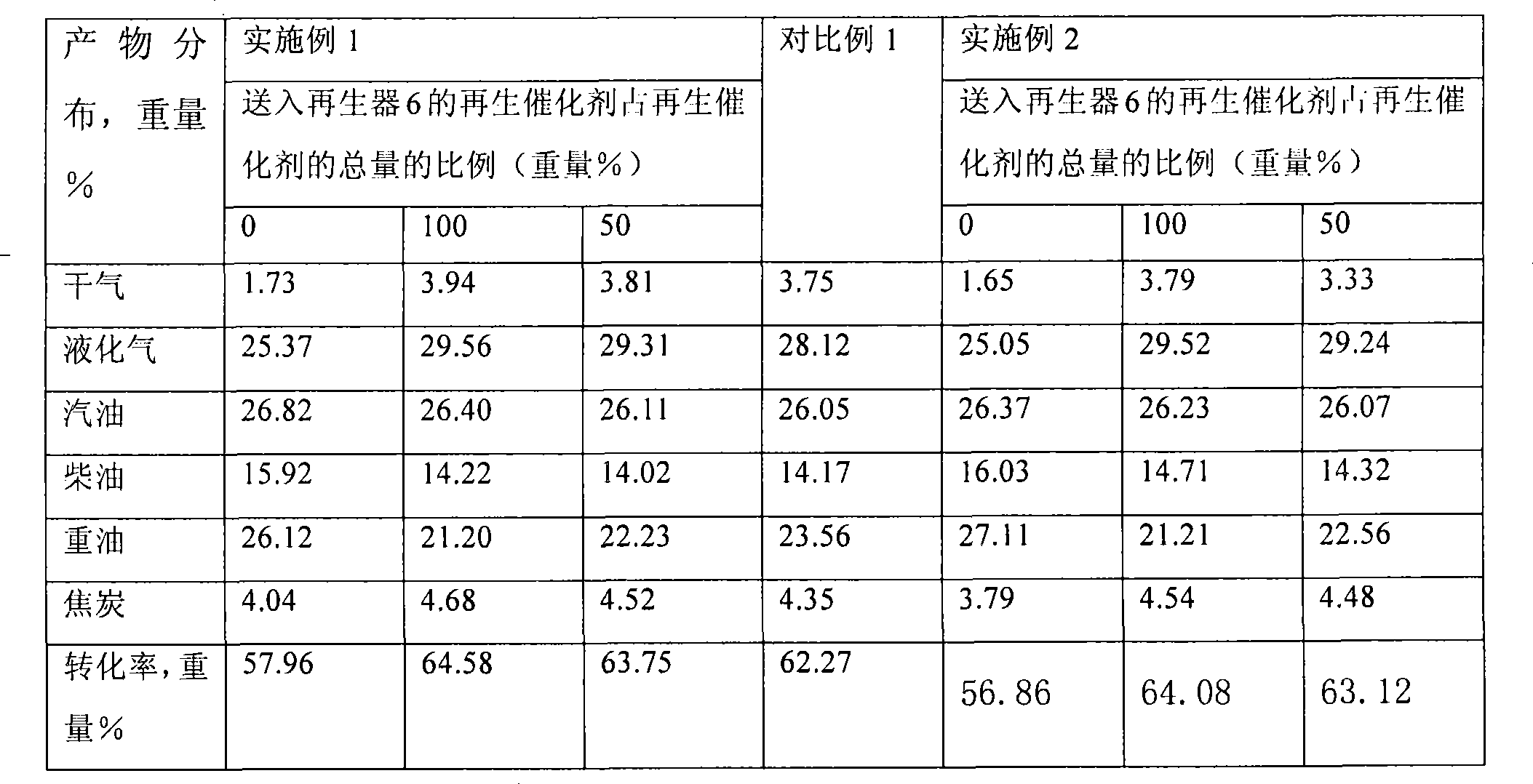

Hydrocarbon oil conversion method

ActiveCN101457152AIncrease productionImprove product distributionHydrogenCatalytic crackingForming gasHydrogen

The present invention discloses a hydrocarbon oil convert method, wherein the method includes the following procedures: under cracking condition, contact hydrocarbon oil with energizing agent in a reactor to obtain reaction product and spent catalyst; separate the reaction product and spent catalyst, and contact the spent catalyst with water vapor and oxygen-containing gas inside a gasifying stove to obtain forming gas and semi-regenerated catalyst; separate the forming gas with the semi-regenerated catalyst, and transmit at least part of the semi-regenerated catalyst into the reactor for periodic duty, wherein reaction temperature inside the gasifying stove is from 500 DEG C to lower than 800 DEG C. The hydrocarbon oil convert method provided in the invention makes spent catalyst contactwith water vapor and oxygen-containing gas in the temperature from 500 DEG C to lower than 800 DEG C, and that can increase production quantity of carbon monooxide and hydrogen; carbon monooxide can be converted to hydrogen in the following course of working to obtain higher hydrogen rate of production; the energizing agent that regenerated in the temperature from 500 DEG C can improve hydrogen rate of production and improve product distribution of hydrocarbon oil reaction product.

Owner:CHINA PETROLEUM & CHEM CORP +1

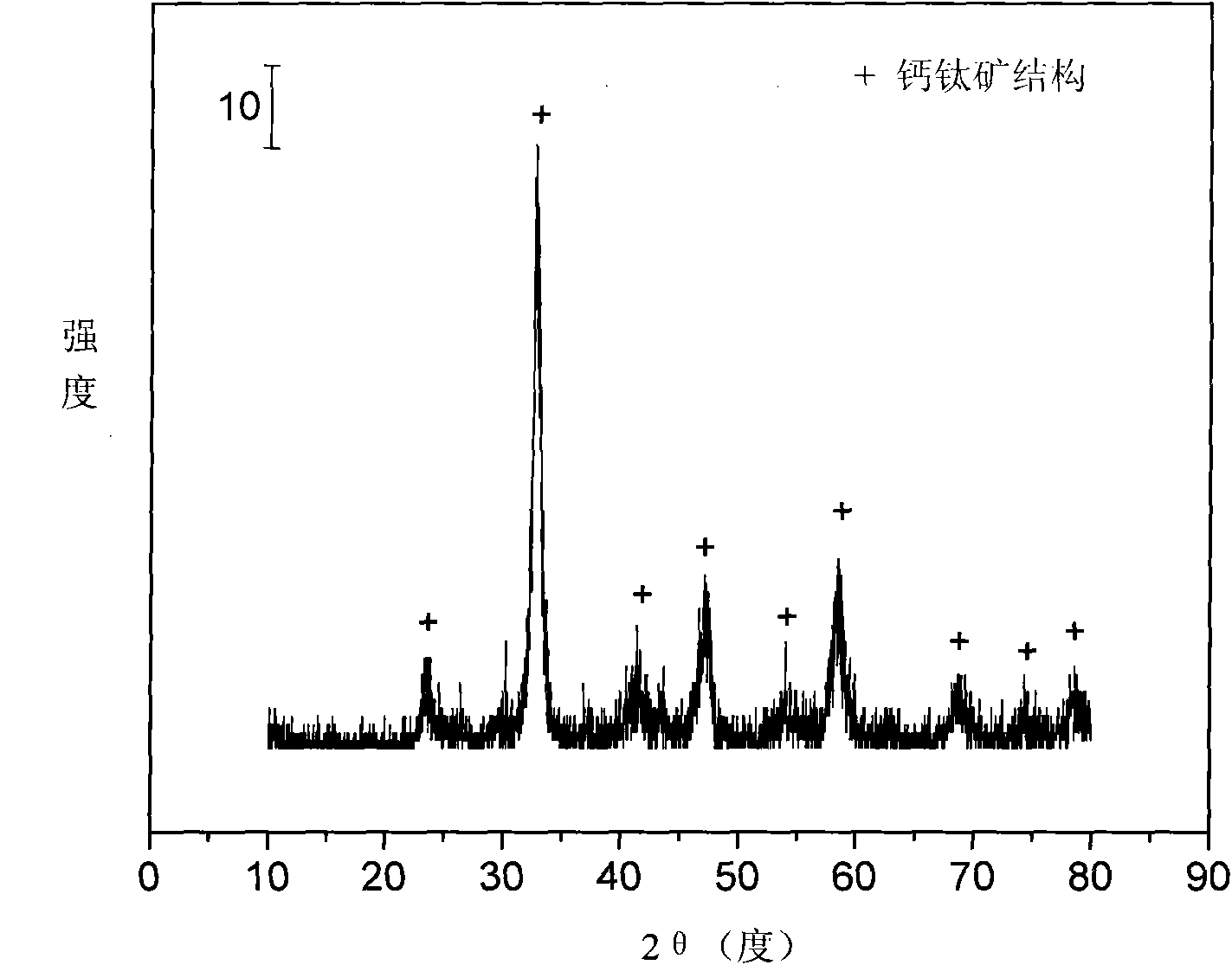

Perovskite catalyst used for autothermal reforming of ethanol for producing hydrogen and preparation method thereof

InactiveCN101972659AChange the adsorption and desorption propertiesEnhanced autothermal reforming activityHydrogenMetal/metal-oxides/metal-hydroxide catalystsManganeseOxygen

The invention relates to a perovskite catalyst used for the autothermal reforming of ethanol for producing hydrogen and a preparation method thereof. Aiming at the problems of structural change, oxidation and sintering of active ingredients and deactivation of the conventional catalyst during the autothermal reforming of the ethanol, the invention provides a novel catalyst with sintering resistance, carbon deposit resistance, oxidation resistance and high activity. The chemical formula of the catalyst is LaaSrbNicXdO3, wherein X is one of Fe, Mn and Cr, a is 0.7 to 1.0, b is 0 to 0.3, c is 0.7 to 0.95 and d is 0.05 to 0.3. The nickel-based catalyst with an ABO3 perovskite structure is prepared by a glycine complexation method, lanthanum is partially substituted by strontium at a position A and nickel is partially substituted by an auxiliary agent at a position B, so oxygen defects and lattice structure defects on the surface of the perovskite catalyst are increased; meanwhile, the auxiliary agent, namely iron, magnesium or chromium is introduced, so the acidity of the catalyst is inhibited, the reducibility and stability of the active ingredients of the catalyst are improved, and the yield of the hydrogen is obviously improved and remains stable.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Method for producing hydrogen and/or methane through fermentation of fiber wastes and device thereof

InactiveCN101760481ASolve pollutionWidely used valueBioreactor/fermenter combinationsBio-organic fraction processingFiberLiquid storage tank

The invention provides a method for producing hydrogen and / or methane through fermentation of fiber wastes and a device thereof. The method comprises the following steps: smashing a straw into a certain grain diameter, placing into a hydrogen production reactor, adding a given amount of water and nutrient solution and then mixing with thermophile bacteria seed liquid together for fermentation to prepare the hydrogen; pumping hydrogen fermentation liquid into a liquid storage tank, continuously pumping into the hydrogen production reactor for fermentation to prepare the methane after pH is adjusted. Because of adopting fiber wastes, raw materials used by the invention have rich resource and low cost, effectively solve the resource problem of biological hydrogen production and overcome the problem that the fiber raw materials of the traditional straw are hard to effectively produce the hydrogen when being not subjected to pretreatment; and the semi-continuous hydrogen production is achieved through the fiber waste dynamic immobilization technology. The invention is easier to popularize and apply by adopting a coupled continuous methane production system and has the advantages of simple and highly-efficient method, energy conservation, low cost and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

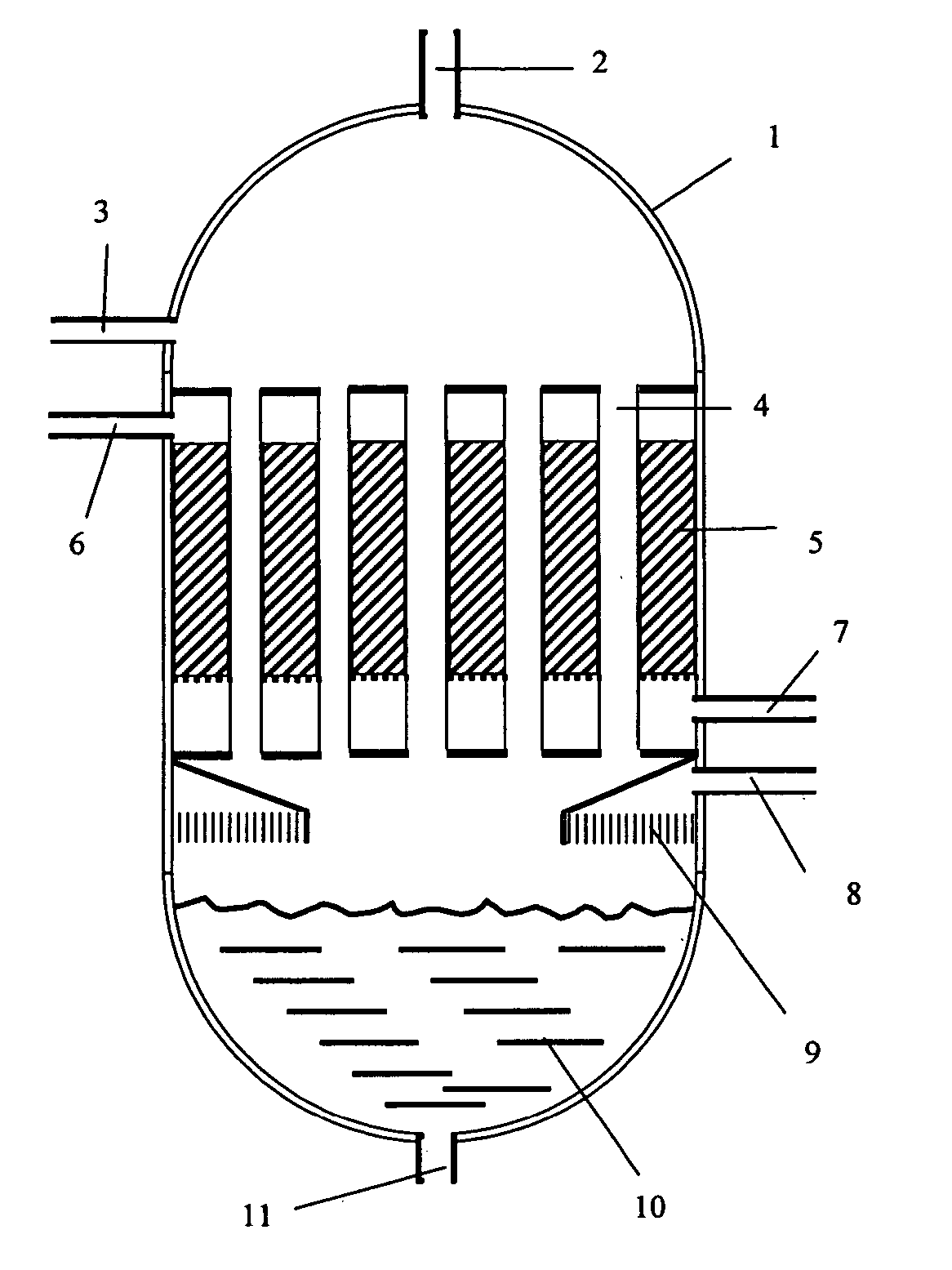

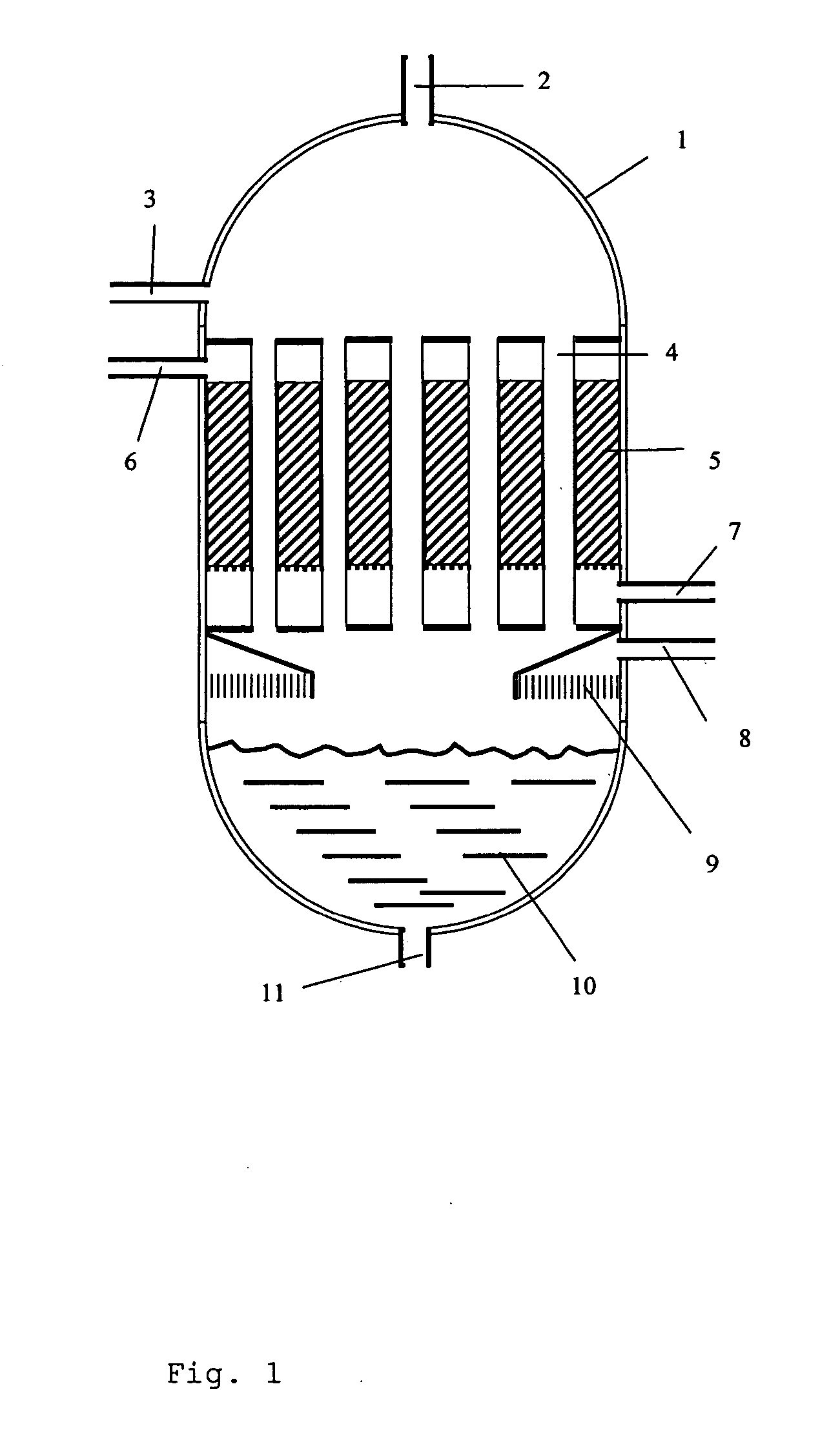

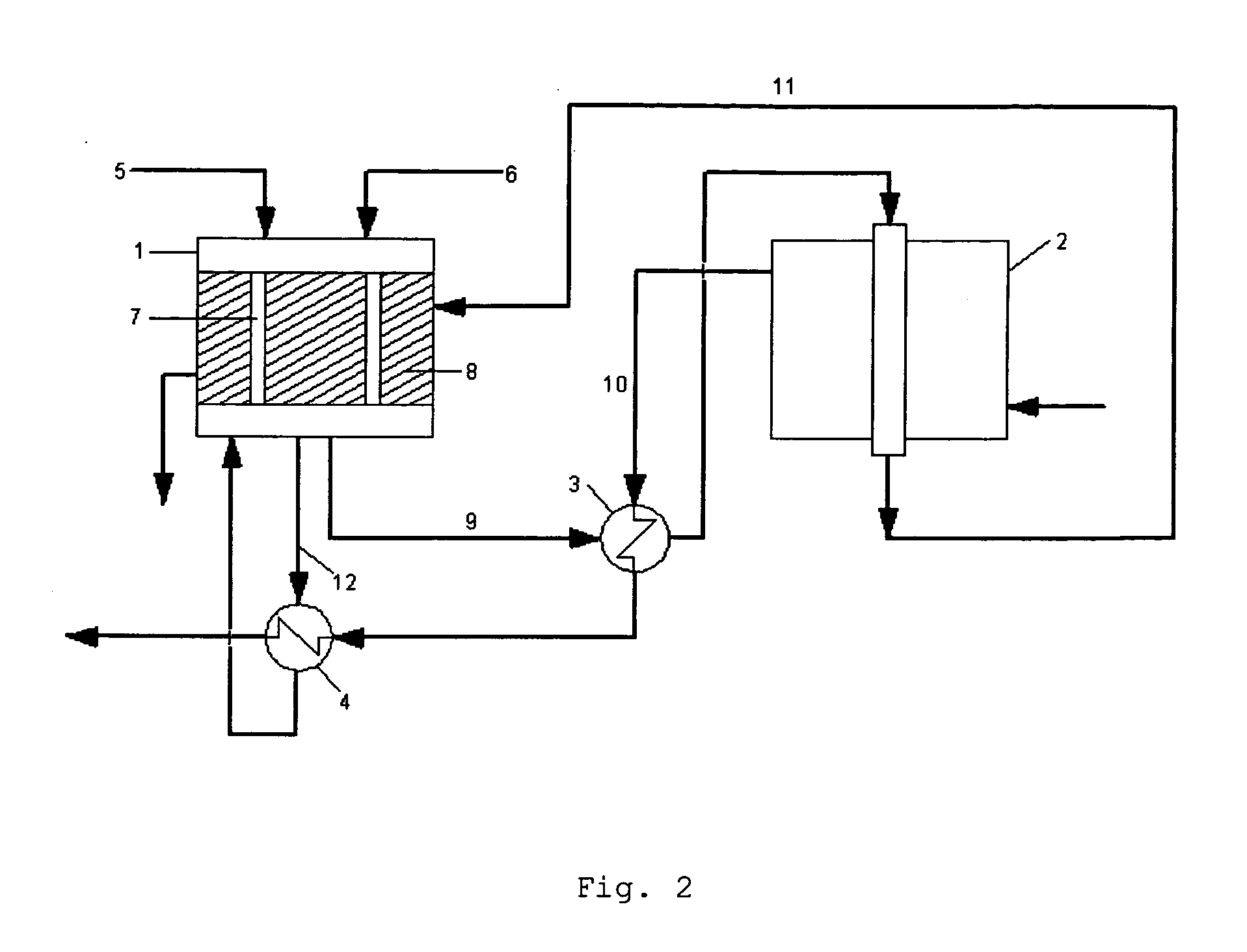

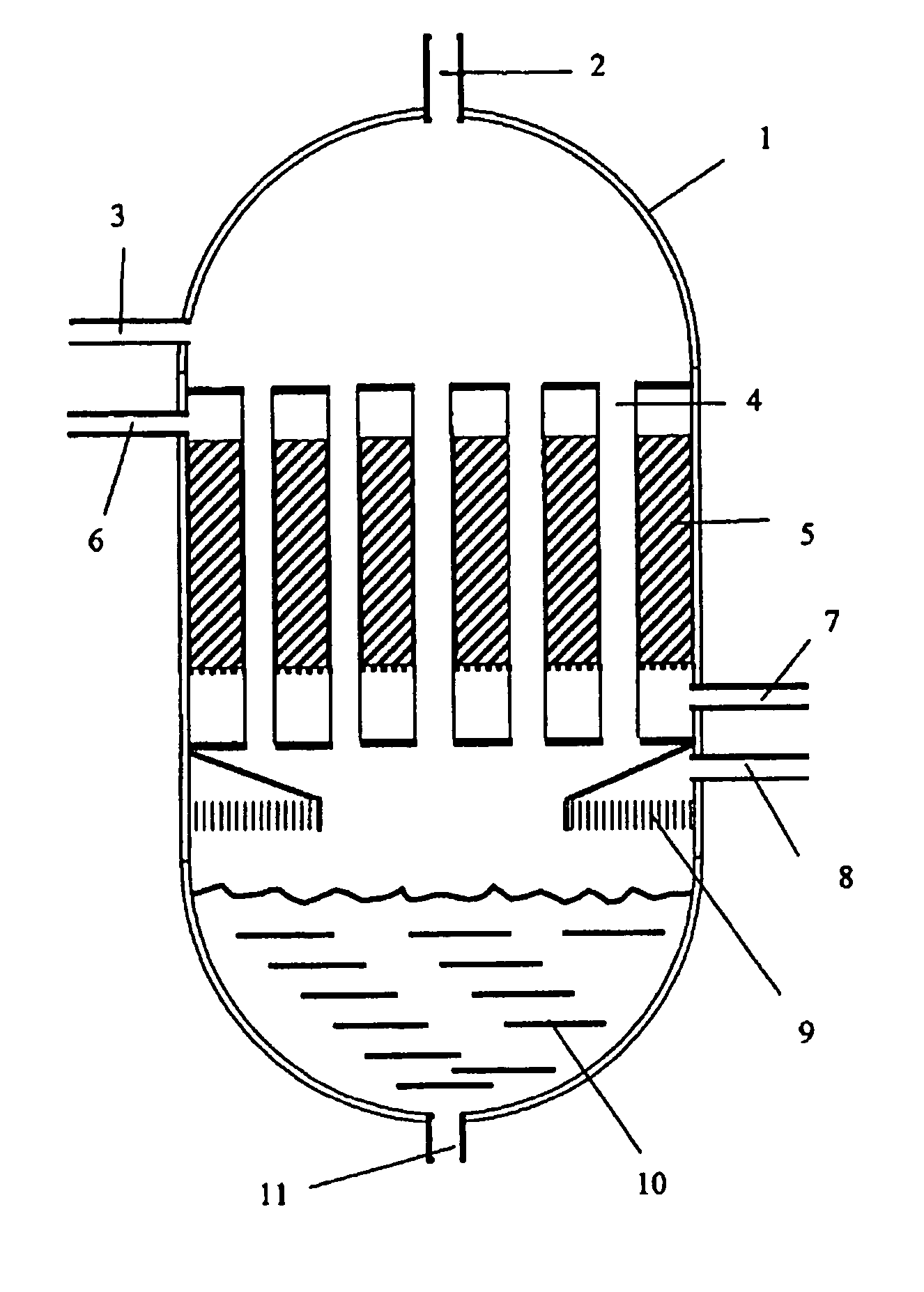

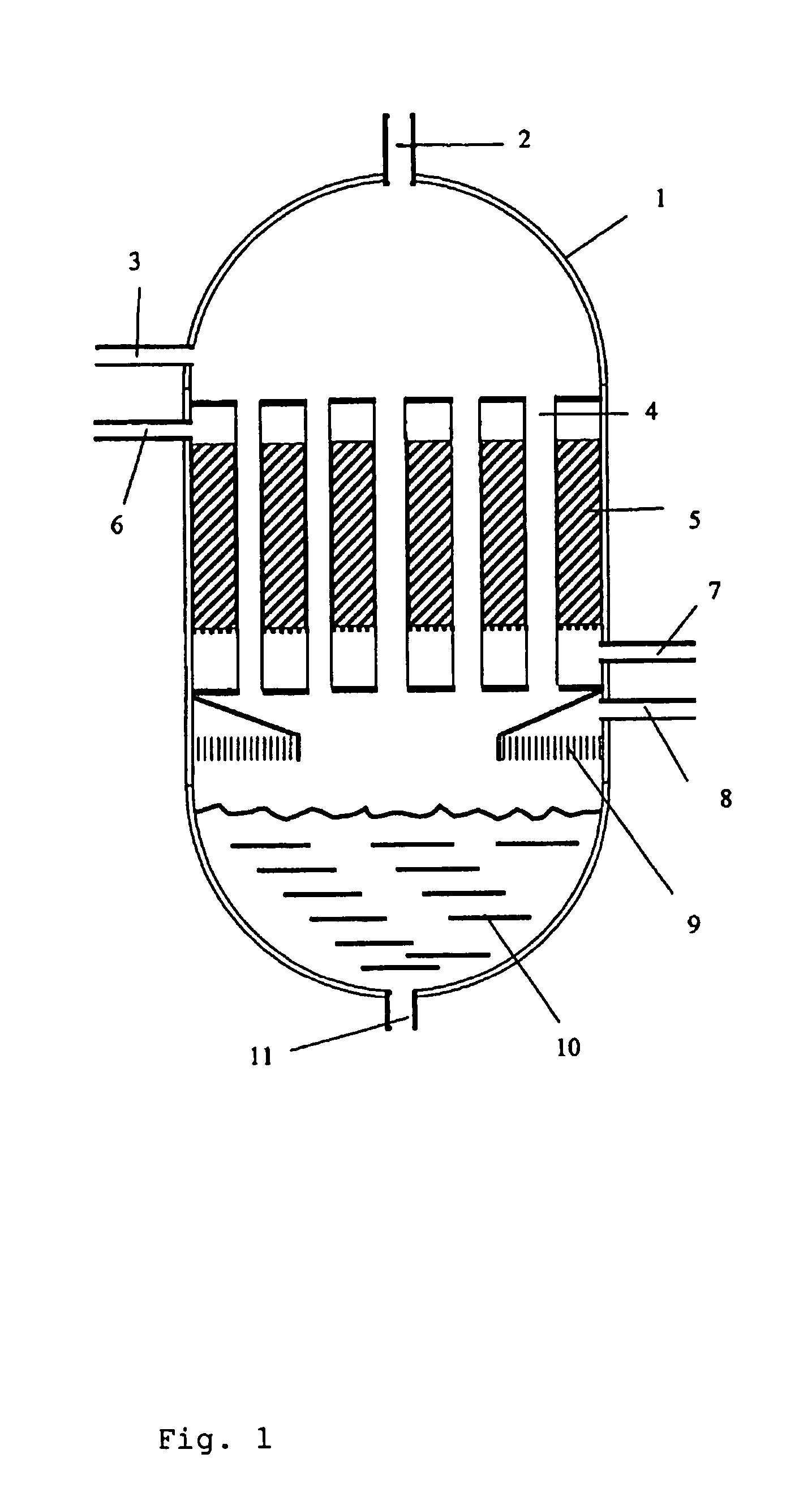

Process for cooling an exothermic reaction zone and reactor unit

InactiveUS20050188619A1Reduce the temperatureHigh hydrogen yieldSemi-permeable membranesHydrogen separation using solid contactWater flowFixed bed

Process for cooling an exothermic reaction zone by introducing a stream of water and a hydrocarbon-containing stream into a plurality of humidifying tubes extending through a catalytic exothermic reaction zone of a catalytic fixed bed with solid catalyst, introducing a process stream into the reaction zone for one or more catalytic exothermic reactions, passing the stream of water in a falling film along the inner circumference of the humidifying tubes, humidifying the hydrocarbon-containing stream with water in the humidifying tubes in indirect heat exchange with the exothermic reaction zone, withdrawing cooled reaction product of the exothermic reaction from the reaction zone, withdrawing the heated humidified, hydrocarbon-containing stream from the humidifying tubes, and transferring the heated humidified, hydrocarbon-containing process stream for further processing.

Owner:HALDOR TOPSOE AS

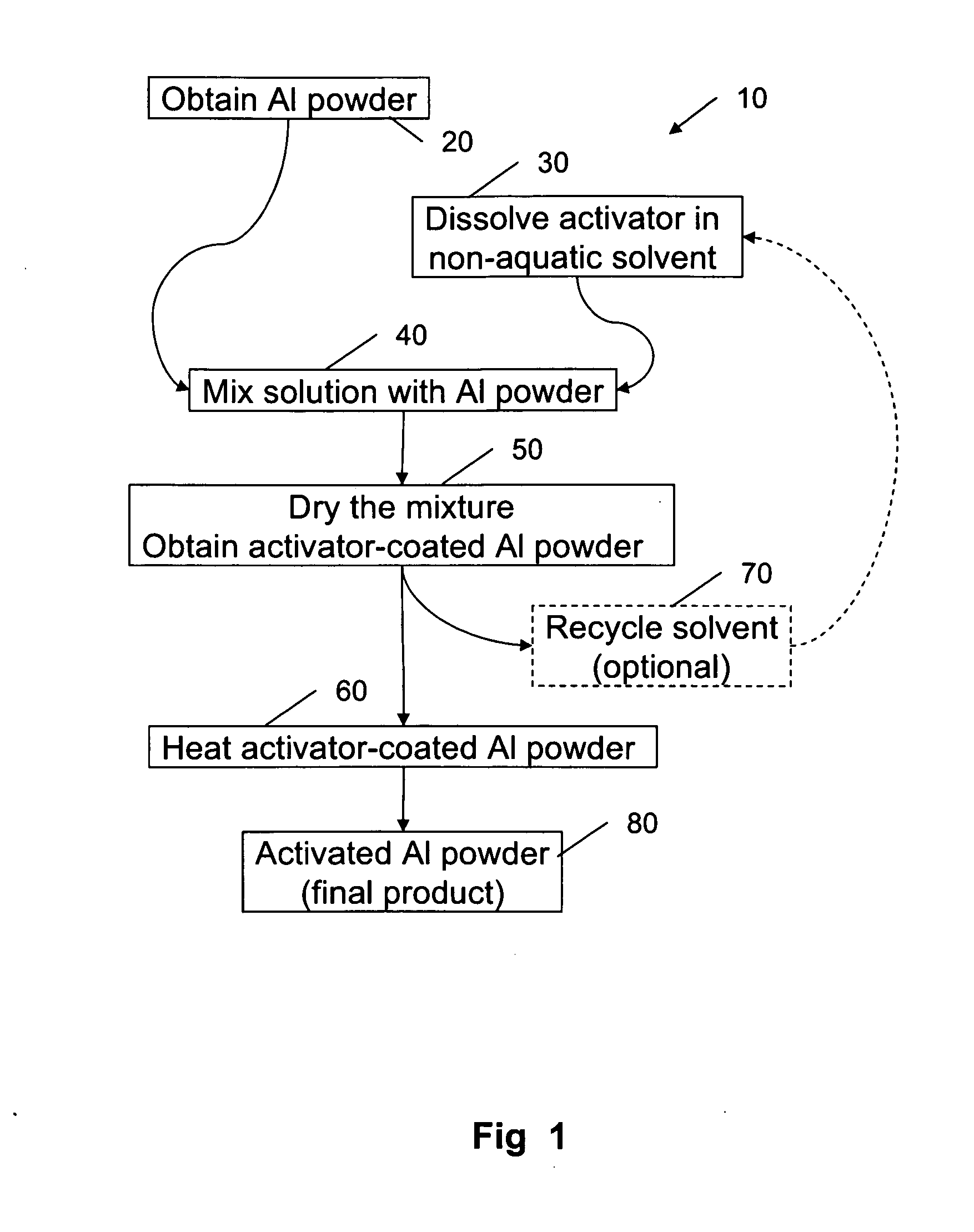

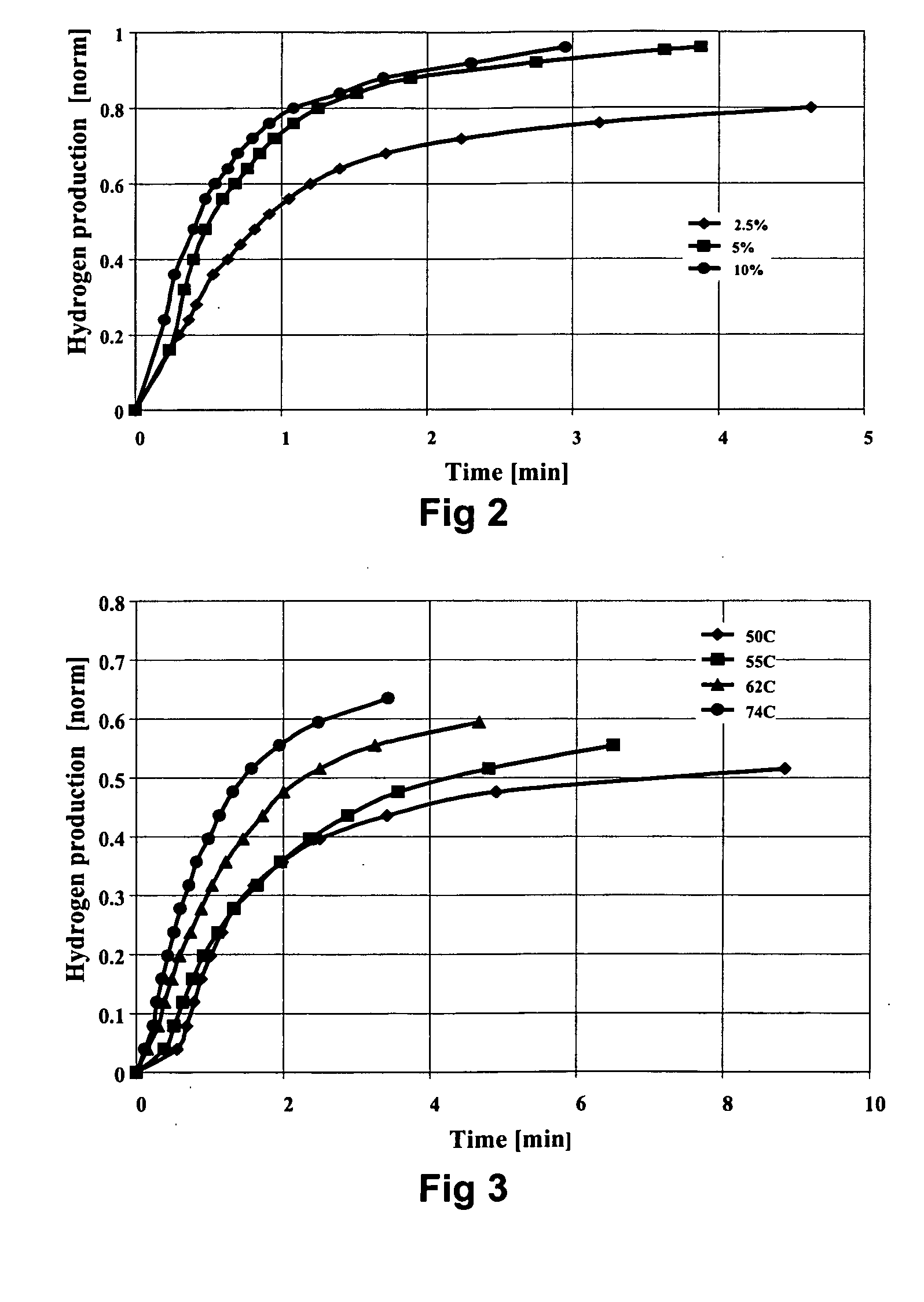

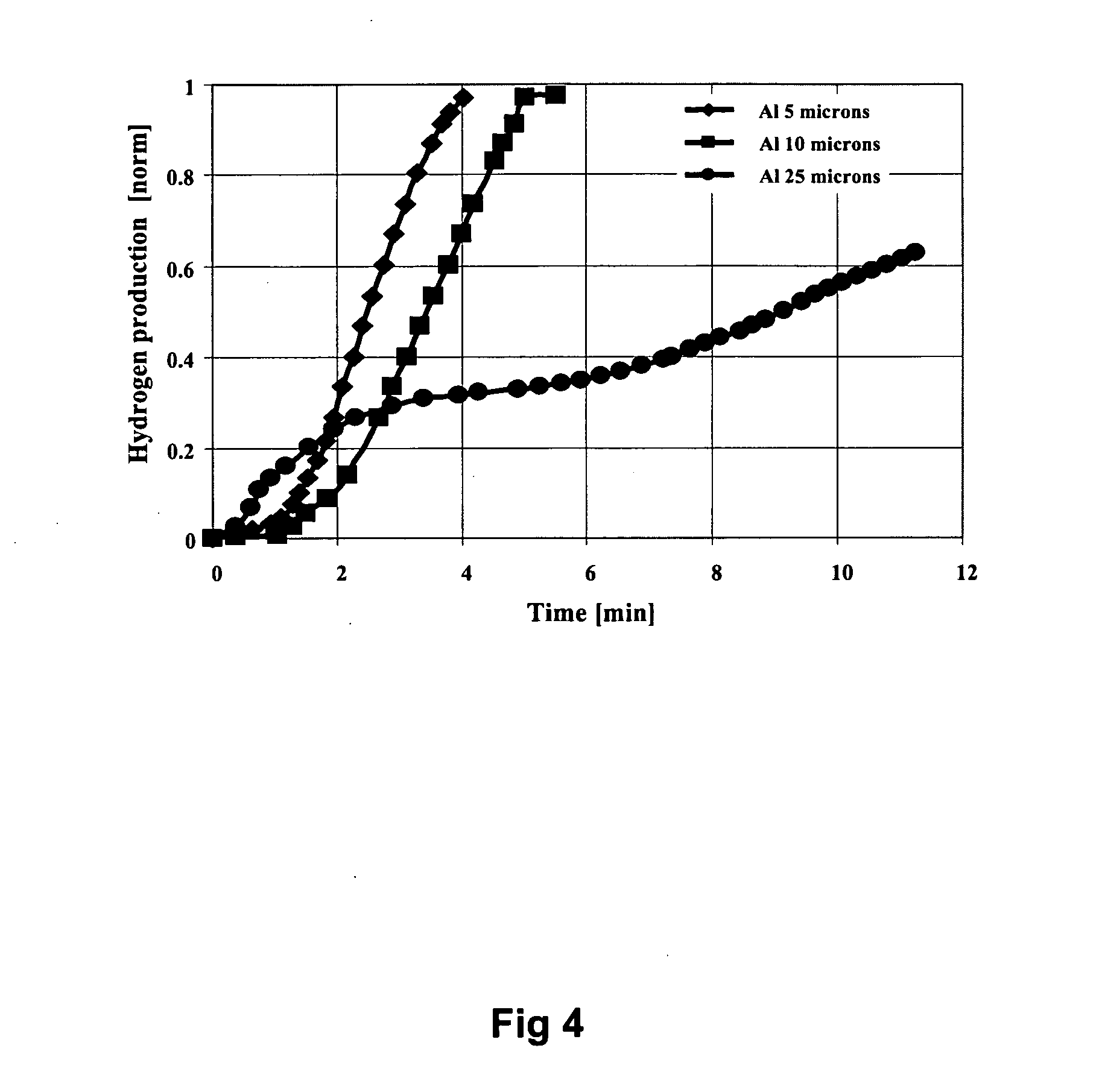

Compositions and methods for hydrogen generation

ActiveUS20100173225A1Low costHigh purityTurbine/propulsion fuel supply systemsOther chemical processesAlkaline earth metalMetal particle

The present invention relates to compositions and methods for producing hydrogen from water involving reacting metal particles with water in the presence of an effective amount of activator. In particular the invention pertains to compositions and methods for producing hydrogen upon reaction of metal particles selected from the group consisting of aluminum (Al), magnesium (Mg), boron (B), silicon (Si), iron (Fe), and zinc (Zn) with water, in the presence of an effective amount of an activator catalyst, wherein the activator is selected from the group consisting of: alkali metals, earth alkali metals, hydrides of alkali metals, hydrides of earth alkali metals, hydroxides of alkali metals, and hydroxides of earth alkali metals.

Owner:TECHNION RES & DEV FOUND LTD

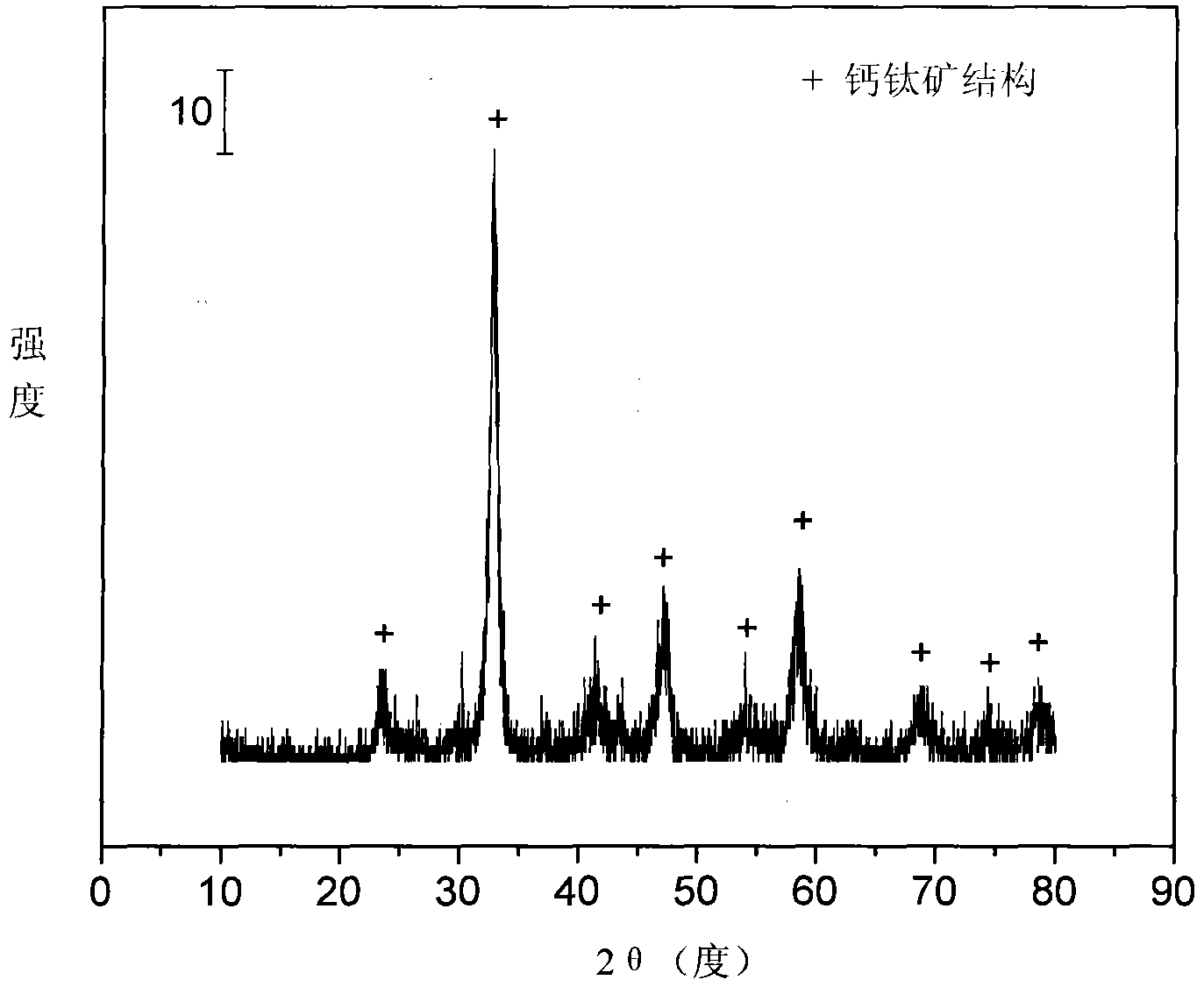

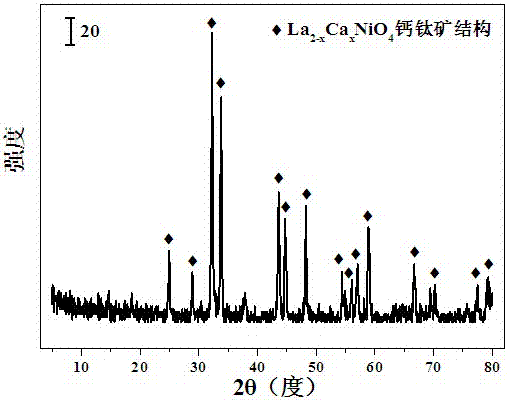

Layered perovskite catalyst for hydrogen generation from acetic acid autothermal reforming and preparation method

ActiveCN107042111AImprove stabilityAdd Surface Defect BitsHydrogenHeterogenous catalyst chemical elementsLanthanumHYDROSOL

The invention relates to a layered perovskite catalyst for hydrogen generation from acetic acid autothermal reforming and a preparation method. A novel catalyst which is sintering resistant, carbon deposition resistant, antioxidant and high in activity is provided for the problem of catalyst deactivation due to sintering, oxidation and carbon deposition of an existing catalyst in the acetic acid autothermal reforming process. A nickel-based catalyst with an A2BO4 layered perovskite structure is prepared by employing a sol-gel method; and the chemical component is La<2-x>Ca<x>NiO<4>, wherein x is equal to 0-1.5. An oxygen defect and a lattice structure defect of the surface of the perovskite catalyst are increased through replacing lanthanum with a calcium part, and the reducibility, the heat stability and the oxidation resistance of the active component nickel are improved, so that the activity and the stability of the catalyst are improved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

Nano-iron-loaded biochar, preparation method of nano-iron-loaded biochar, and application of nano-iron-loaded biochar in dark fermentation hydrogen production process

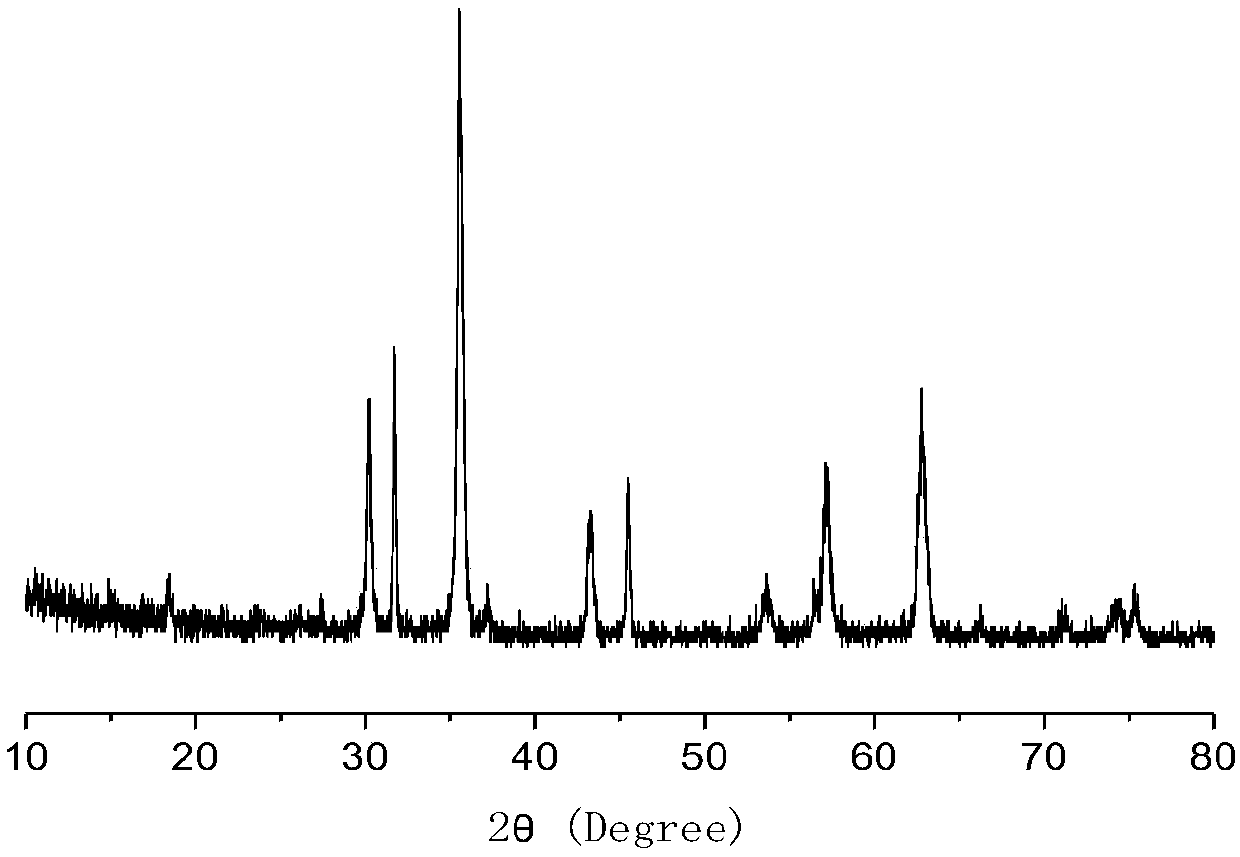

InactiveCN107858379AEasy reunionAchieve releaseFerric oxidesCarbon preparation/purificationDark fermentationBiochar

The invention relates to nano-iron-loaded biochar, a preparation method of the nano-iron-loaded biochar, and an application of the nano-iron-loaded biochar in a dark fermentation hydrogen production process. Ferrite and soluble starch are taken as raw materials which are subjected to reaction under proper conditions and are dried and charred to obtain the nano-iron-loaded biochar, wherein the maincomponent of the nano-iron-loaded biochar is Fe2O3 / C, and the particle diameter range of the nano-iron-loaded biochar is 2-150nm. The biochar is of an amorphous structure, and Fe2O3 is of a mesoporous structure. By adding the iron-loaded biochar to an anaerobic fermentation system, a synergistic strengthening effect of iron and biochar in the dark fermentation hydrogen production process is realized, so that the hydrogen yield and the process stability are improved. Fe2O3 can not only release iron ions to enhance the activity of fermentative hydrogen producing bacterium hydrogenase but also increase the transfer rate of electrons; and furthermore, the biochar in nano-particles can enrich microorganisms, improve the concentration of hydrogen producing bacteria, buffer acid accumulation andrelieve ammonia inhibition.

Owner:QILU UNIV OF TECH

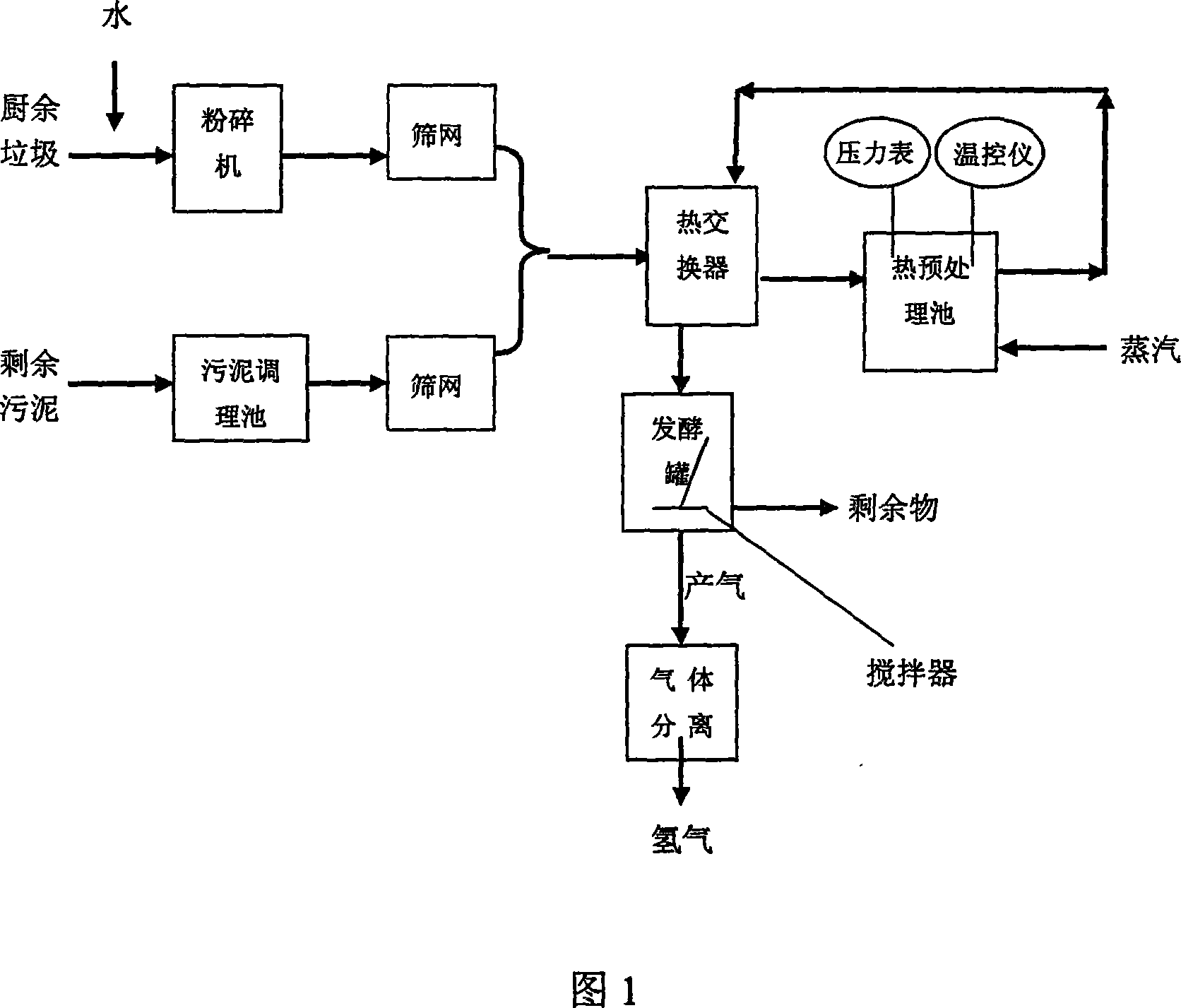

Kitchen residual garbage normal temperature anaerobic fermentation method

InactiveCN101063152AIncrease temperatureImprove thermal efficiencyFermentationSocial benefitsHydrogen

The invention discloses a method to proceed normal temperature anaerobic fermentation with kitchen garbage, which comprises the following steps: mixing the kitchen garbage and water with a finite proportion; grinding to proper grain size with food breaker; sieving; sieving the surplus sludge; mixing with the grinding garbage with a finite proportion; proceeding heat treatment; getting mixture; using as joint ferment base material; placing in closed fermenter; proceeding anaerobic fermentation at room temperature; generating hydrogen; proceeding simple pretreatment; using as fuel or generating raw material. This invention possesses better economic benefit, social benefit and environmental benefit.

Owner:DONGGUAN KECHUANG FUTURE ENERGY SOURCE TECHDEV

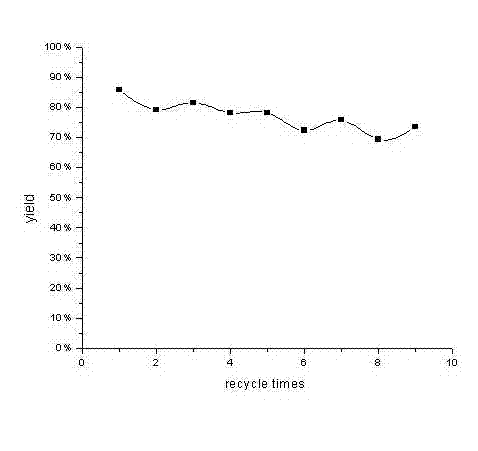

Polymer supported Pd-Ni-B nano-catalyst, preparation method and application thereof

InactiveCN102847555AEasy to separateHigh reactivityOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen productionNano catalystPtru catalyst

The invention discloses a polymer supported Pd-Ni-B nano-catalyst, a preparation method and application thereof, belonging to the field of polymer supported nano-catalyst. The catalyst is characterized by preparing by mixing polyvinylpyrrolidone (PVP), palladium chloride and nickel sulfate, reacting to form PVP-Pd-Ni metal complex, and reducing the PVP-Pd-Ni metal complex to obtain solution a; mixing acrylamide, acrylamide cross-linking agent, water and initiator to obtain solution b; and mixing solutions a and b, and reacting to obtain the polymer supported Pd-Ni-B nano-catalyst. The inventive catalyst has obvious effect in catalyzing hydrolysis of sodium borohydride in hydrogen preparation, and still has good catalytic effect after multiple times of usage.

Owner:SHAOXING UNIVERSITY

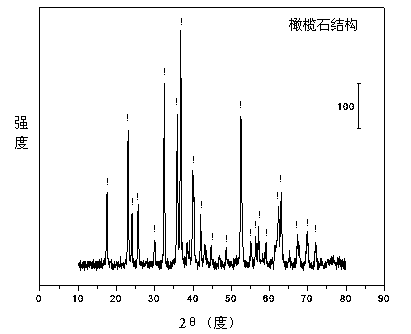

Olivine nickel-based catalyst for preparing hydrogen through autothermal reforming of acetic acid

InactiveCN103657654AIncrease lattice defectsEnhanced autothermal reforming activityHydrogenMetal/metal-oxides/metal-hydroxide catalystsNickel catalystAcetic acid

The invention relates to an olivine nickel-based catalyst for preparing hydrogen through autothermal reforming of acetic acid. Aiming to solve the problems of low hydrogen yield and oxidation / sintering inactivation of active constituents of the conventional supported nickel-based catalyst in an autothermal reforming process of acetic acid, the invention provides a novel catalyst with the effects of large specific surface area, stable structure, sintering resistance, oxidation resistance and stable activity. The catalyst provided by the invention has a chemical component of MgaFebNicSiO4, wherein a is 1.0-1.7, b is 0-0.7 and c is 0.3-0.5. The nickeliferous catalyst taking an olivine structure as a main body is prepared by a hydro-thermal synthesis method; the catalyst has rich hole structures so that the specific surface area and the dispersity of active constituents of the catalyst are effectively improved; meanwhile, the active constituents, such as nickel and iron, and additives substitute for bivalent magnesium to enter an olivine skeletal structure to effectively refrain the phenomenon of oxidation / sintering inactivation of the catalyst, so that the stability and the hydrogen yield of the catalyst in the autothermal reforming process of acetic acid are improved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

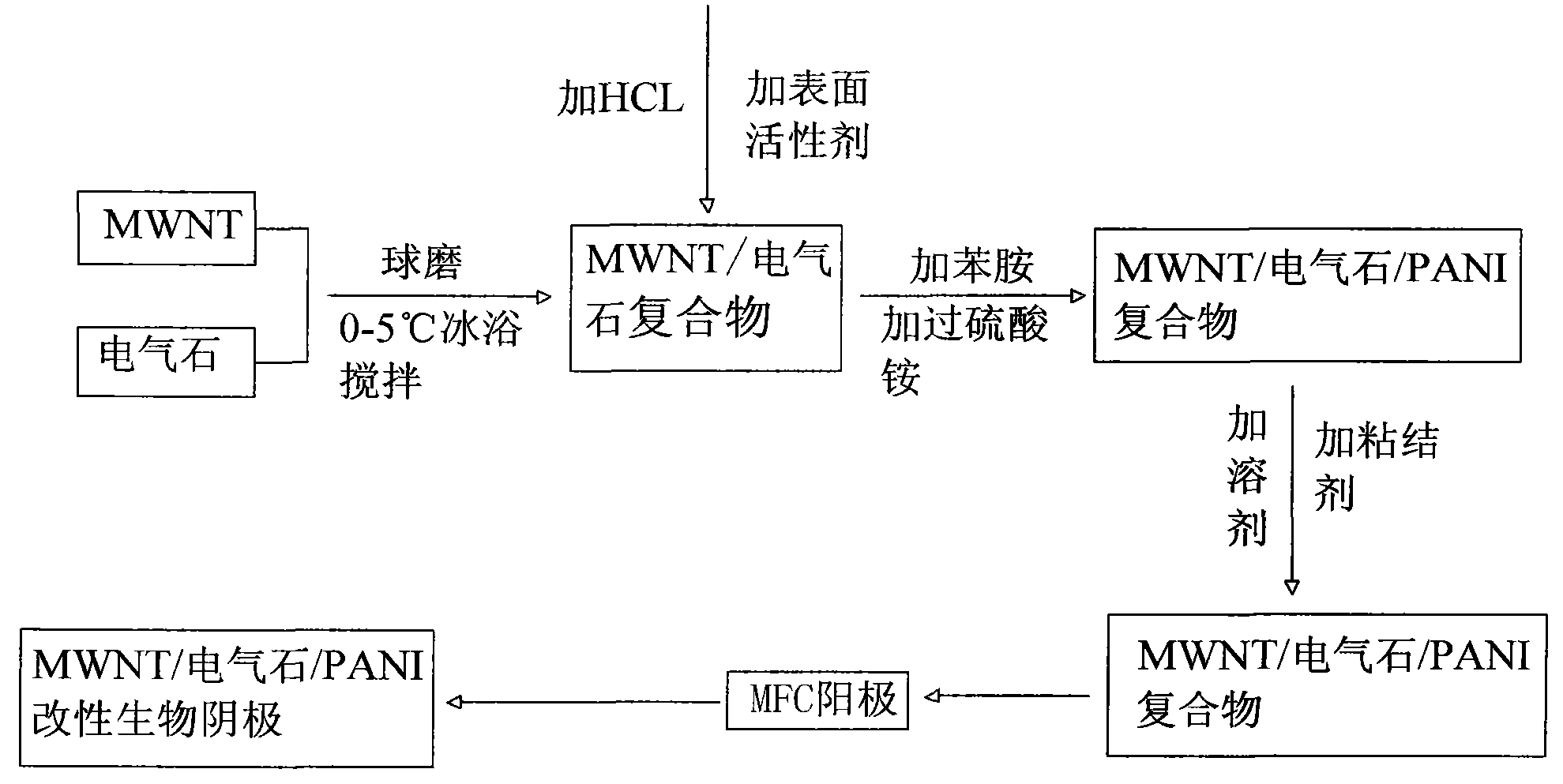

Microbial electrolysis cell (MEC) modified biological cathode preparation method and application thereof

The invention discloses a microbial electrolysis cell (MEC) modified biological cathode preparation method and application thereof. The invention uses an MWNT (multi-walled nanotube) / tourmaline / PANI (polyaniline) composite electrode as a substrate to prepare the MEC modified biological cathode. The preparation method comprises the following steps: mixing MWNT and tourmaline powder by ball milling, adding a solvent, aniline and ammonium persulfate, stirring to react under ice bath conditions, washing, and drying to obtain an MWNT / tourmaline / PANI composite; mixing the composite with a binding agent and acetone to obtain an MWNT / tourmaline / PANI composite electrode, naturally drying in air to obtain an MFC anode, carrying out biofilm domestication by a conventional method, transferring to an MEC cathode, and finally constructing the MWNT / tourmaline / PANI modified biological cathode. The modified biological cathode prepared by the method disclosed by the invention has the functions of stimulating biological catalytic activity and chemically enhancing the biological catalytic hydrogen production, has the advantages of high conductivity and low cost, and provides technical support for implementing large-scale application of MEC synchronous wastewater treatment and hydrogen production.

Owner:NANJING UNIV OF TECH

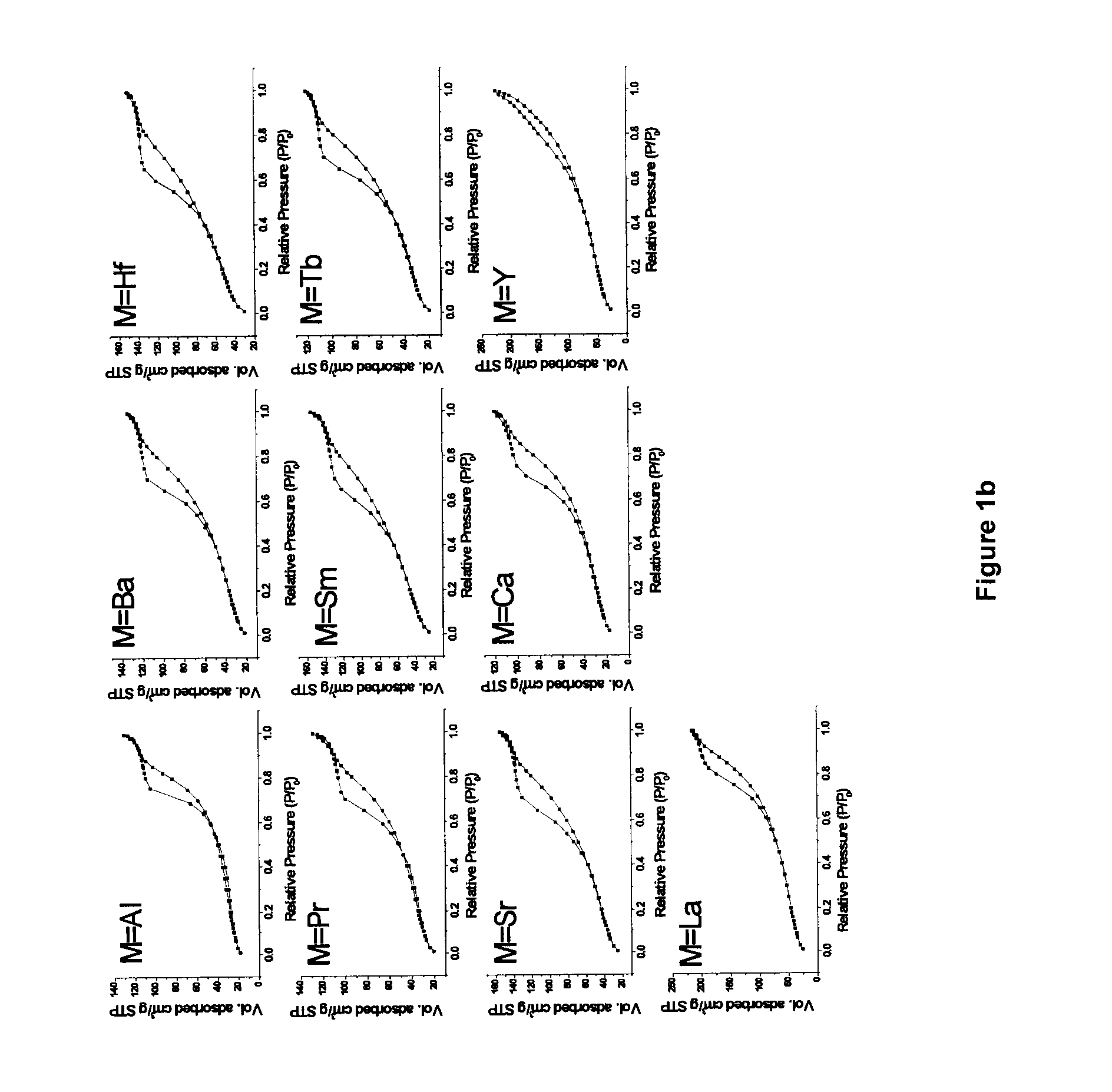

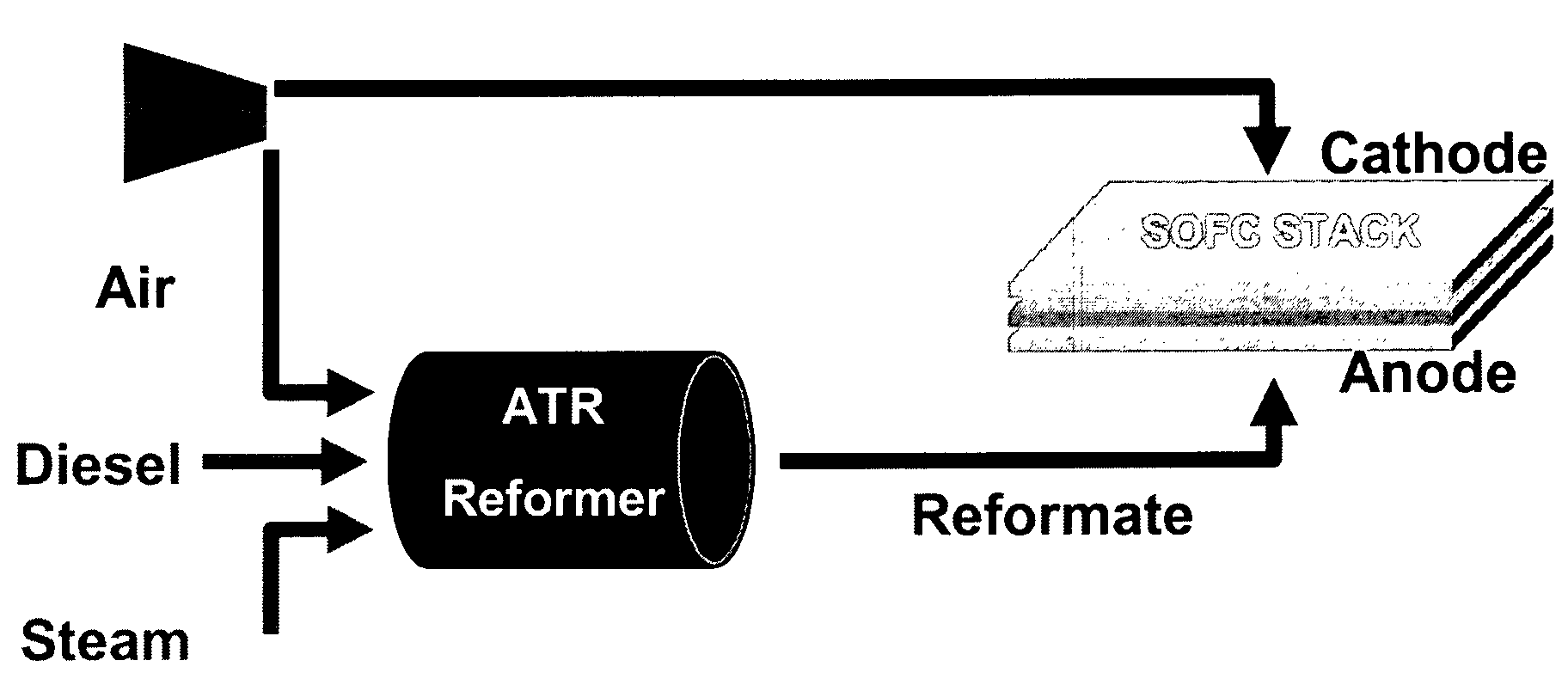

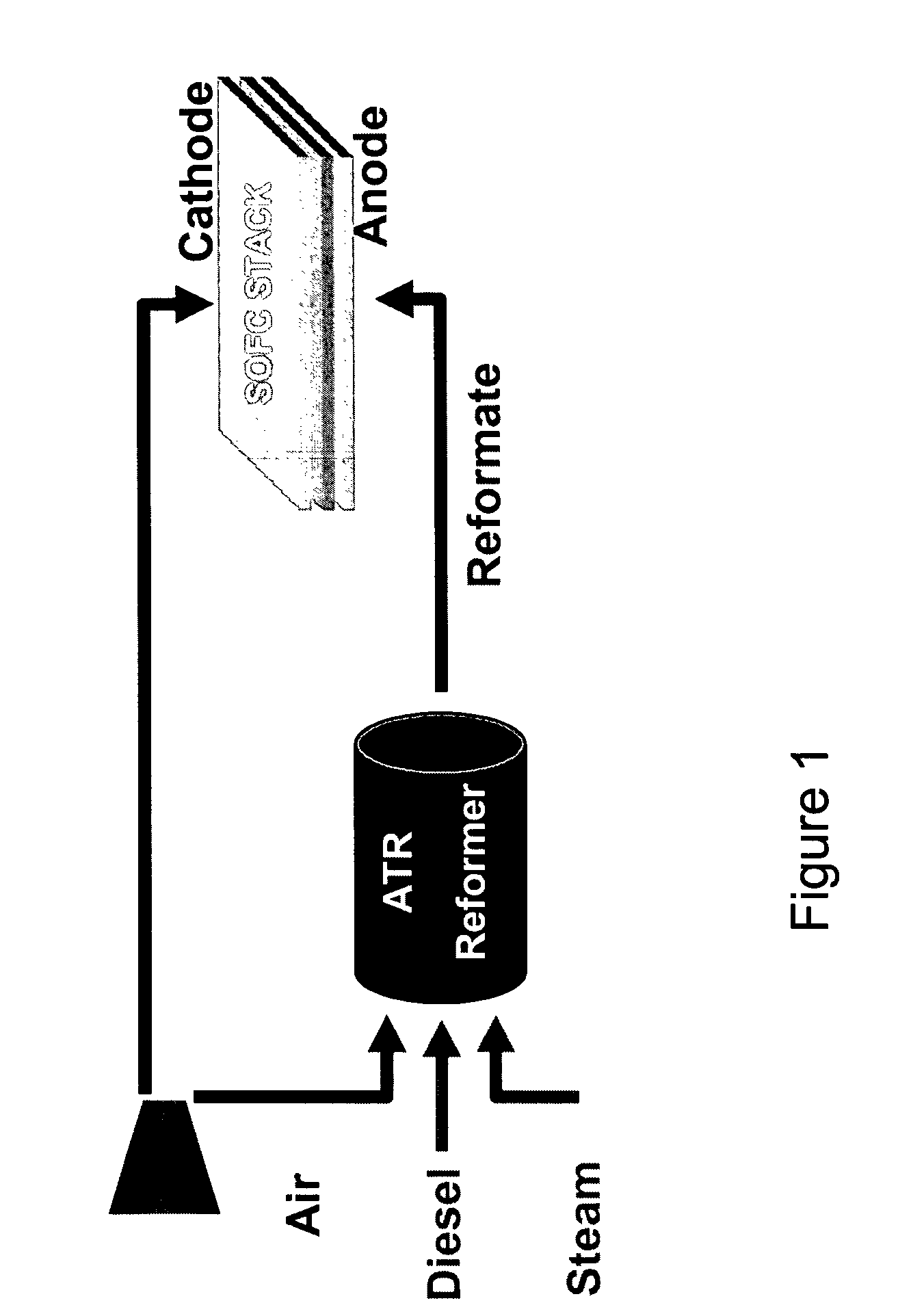

Sulfur-tolerant and carbon-resistant catalysts

ActiveUS20080265212A1High catalytic activityMinimizing sulfur poisoningHydrogenHydrocarbon from carbon oxidesSteam reformingChemical synthesis

The invention relates to novel bimetallic and trimetallic catalysts, their manufacture and use in both steam reforming and oxidative steam reforming of liquid fuels such as jet fuels, diesel fuels and gasoline to produce synthesis gas and / or hydrogen for fuel cell applications. The invention further relates to manufacture of synthesis gas and / or hydrogen gas for chemicals synthesis and fuel processing. The catalysts have high sulfur tolerance and carbon resistance when used in steam reforming and / or oxidative steam reforming of heavy hydrocarbon fuels.

Owner:PENN STATE RES FOUND

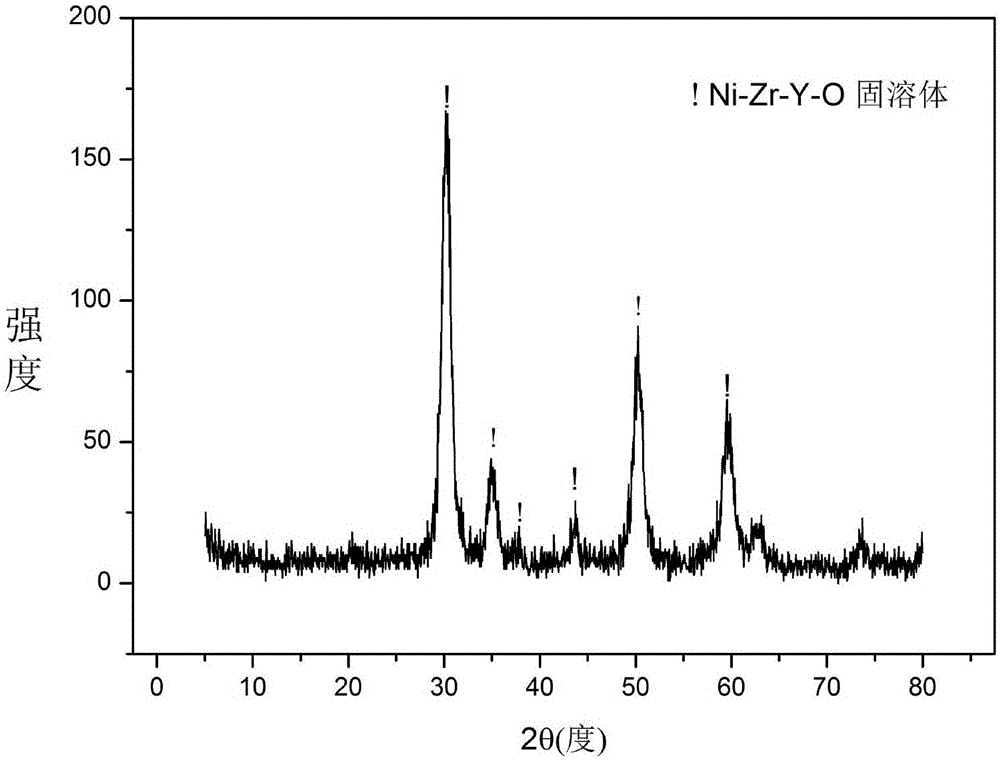

Solid solution catalyst for acetic acid self-heating hydrogen production by reforming and preparation method

ActiveCN106391036AGood dispersionImprove thermal stabilityHydrogenHeterogenous catalyst chemical elementsPolyethylene oxideEvaporation

The invention relates to a solid solution catalyst for acetic acid self-heating hydrogen production by reforming. Aiming at the problem that in an acetic acid self-heating reforming reaction of an existing catalyst, by means of oxidizing, sintering, carbon depositing and other factors of the active components of the catalyst, the catalyst is inactivated, the novel catalyst is stable in structure, resistant to sintering, resistant to carbon depositing and oxidization and stable in activity, and the composition by weight of the catalyst is (NiO)a(YO1.5)b(ZrO2)c, wherein a ranges from 0.07 to 0.20, b ranges from 0.02 to 0.35, and c ranges from 0.58 to 0.91. According to the catalyst, zirconium oxide is adopted as a carrier, an aid yttrium oxide is introduced, a polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer is adopted as a template, a mesoporous structure is formed through evaporation self-assembly, and the nickel-based catalyst with the stable ZrxY1-xOy solid solution as the main structure is obtained. The hydrogen productivity, stability and carbon depositing resisting capacity of the acetic acid self-heating reforming process are effectively improved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

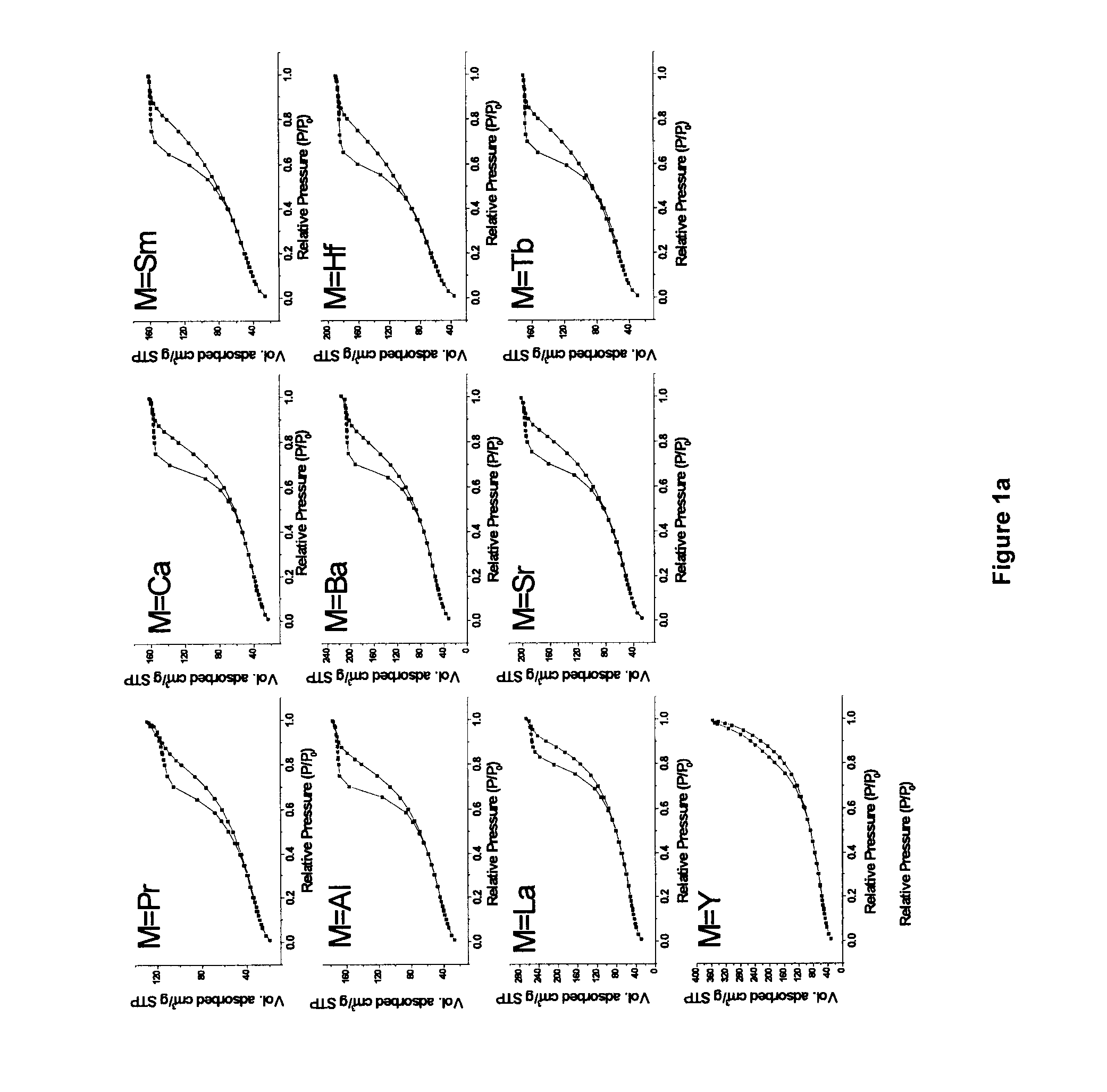

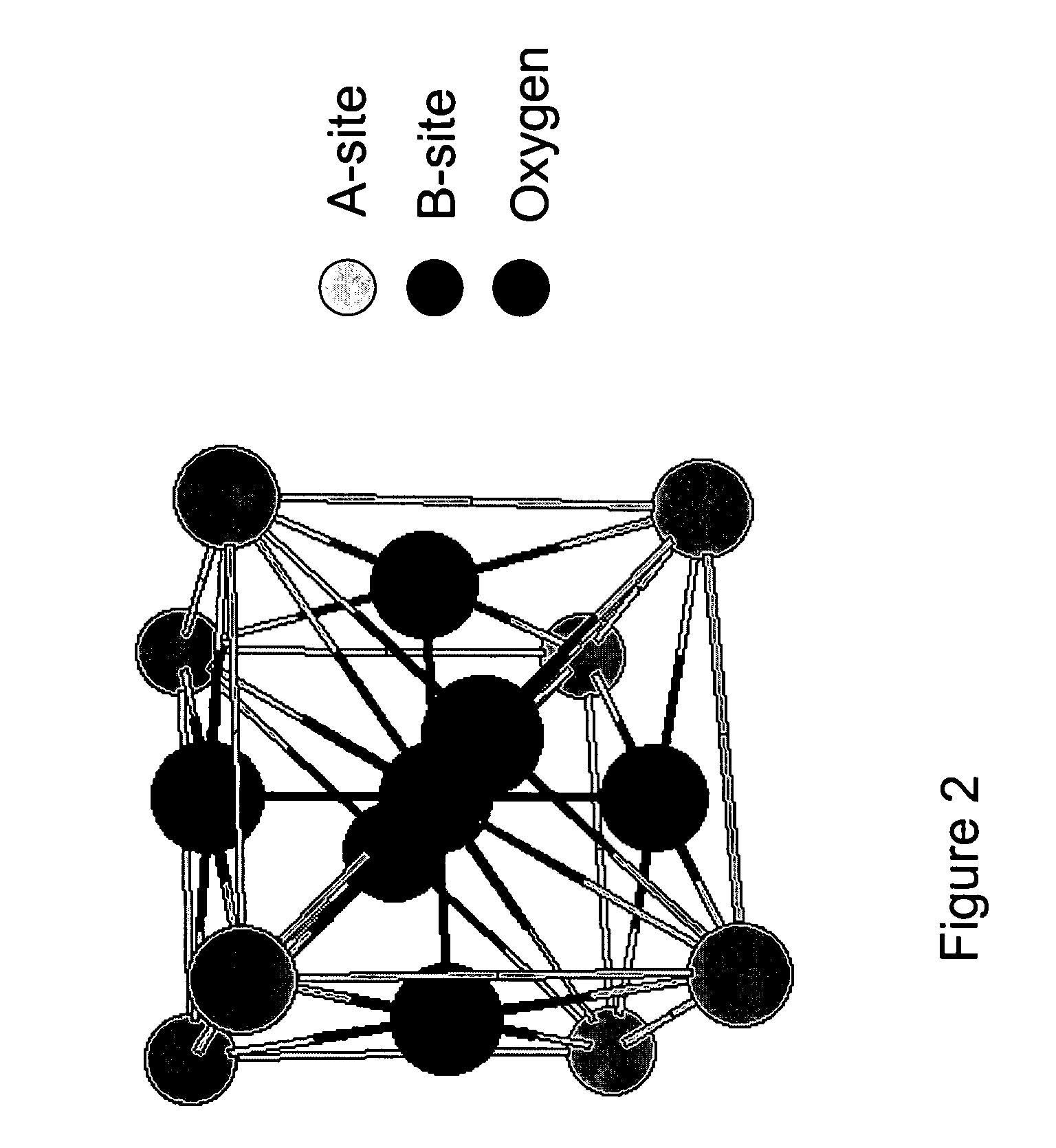

Autothermal reforming catalyst having perovskite structure

InactiveUS7507690B2High yieldLow reformingHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementEngineering

The invention addressed two critical issues in fuel processing for fuel cell application, i.e. catalyst cost and operating stability. The existing state-of-the-art fuel reforming catalyst uses Rh and platinum supported over refractory oxide which add significant cost to the fuel cell system. Supported metals agglomerate under elevated temperature during reforming and decrease the catalyst activity. The catalyst is a perovskite oxide or a Ruddlesden-Popper type oxide containing rare-earth elements, catalytically active firs row transition metal elements, and stabilizing elements, such that the catalyst is a single phase in high temperature oxidizing conditions and maintains a primarily perovskite or Ruddlesden-Popper structure under high temperature reducing conditions. The catalyst can also contain alkaline earth dopants, which enhance the catalytic activity of the catalyst, but do not compromise the stability of the perovskite structure.

Owner:UCHICAGO ARGONNE LLC

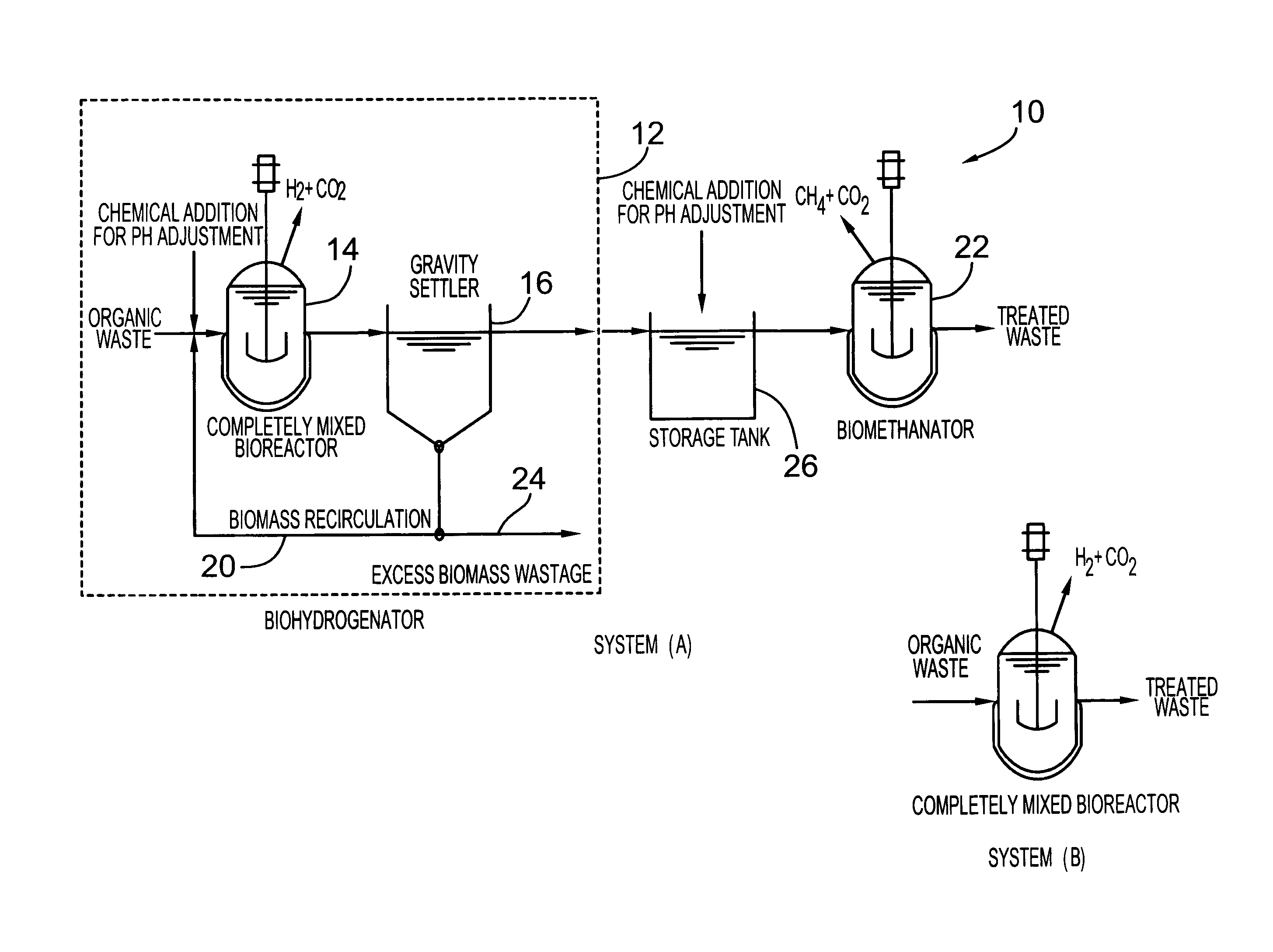

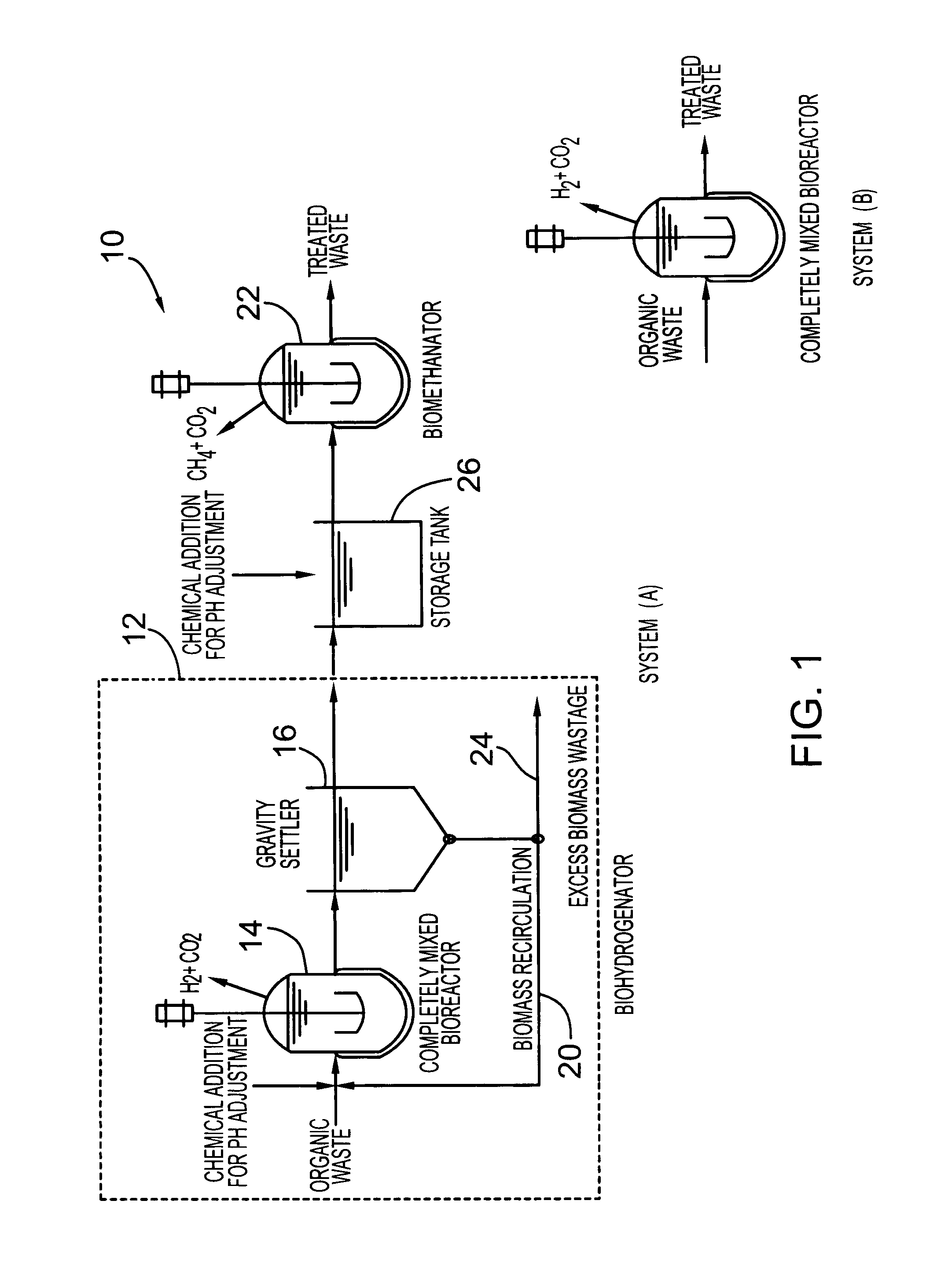

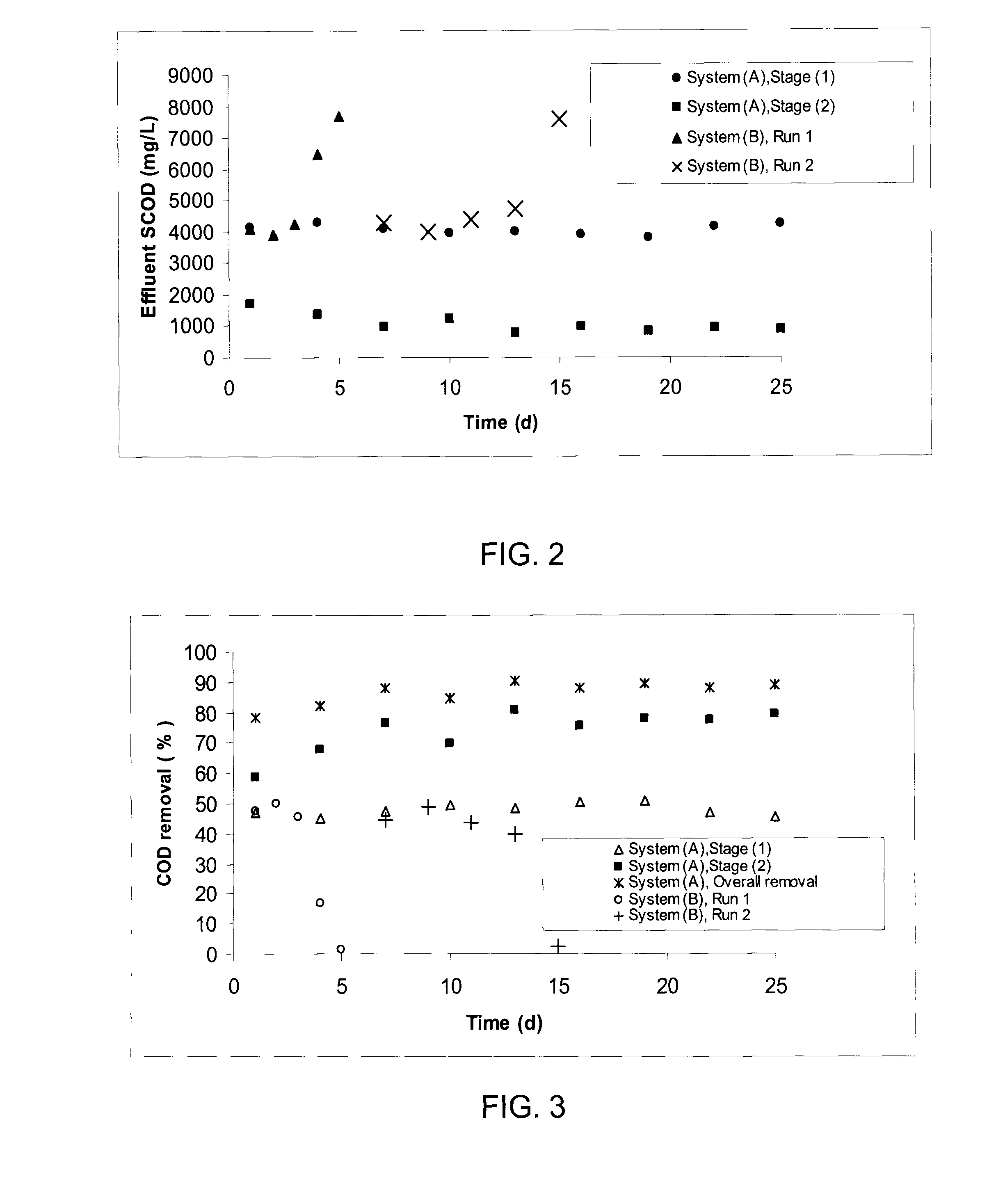

Integrated system for hydrogen and methane production from industial organic wastes and biomass

ActiveUS20120009643A1High hydrogen production rateHigh hydrogen yieldBioreactor/fermenter combinationsBiological substance pretreatmentsBiomassChemistry

The present invention provides a system that has been devised to overcome the two most important limitations for sustained biological hydrogen production, namely contamination of the microbial hydrogen-producing cultures with methane-producing cultures necessitating frequent re-start-up and / or other methanogenic bacteria inactivation techniques, and the low bacterial yield of hydrogen-producers culminating in microbial washout from the system and failure. The system includes a continuously stirred bioreactor (CSTR) for biological hydrogen production, followed by a gravity settler positioned downstream of the CSTR, which combination forms a biohydrogenator. The biomass concentration in the hydrogen reactor is kept at the desired range through biomass recirculation from the bottom of the gravity settler and / or biomass wastage from the gravity settler's underflow. The gravity setter effluent is loaded with volatile fatty acids, as a result of microbiological breakdown of the influent waste constituents by hydrogen-producing bacteria, and is an excellent substrate for methane-forming bacteria in the downstream biomethanator.

Owner:GREENFIELD SPECIALTY ALCOHOLS

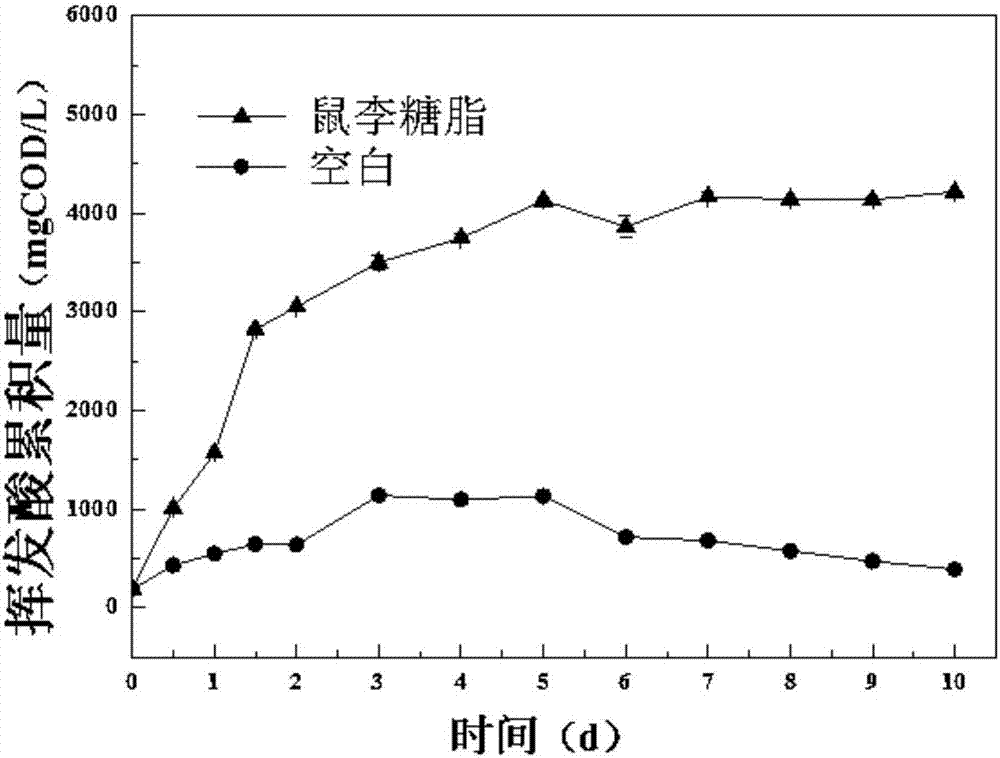

Method for coupling rhamnolipid strengthened sludge pre-treatment and microorganism electrolysis to produce hydrogen

InactiveCN106977065APromote sludge hydrolysis fermentationShorten the fermentation cycleWater treatment compoundsSludge treatment with immiscible liquidsChemistryNitrogen gas

The invention discloses a method for coupling rhamnolipid strengthened sludge pre-treatment and microorganism electrolysis to produce hydrogen. The method comprises the following steps: (1) adjusting the concentration of residual sludge of a secondary sedimentation tank to be 10g / L to 20g / L for later use; adding 0.04g / g VSS to 0.10g / g VSS of rhamnolipid and refrigerating for later use; (2) carrying out nitrogen aeration on the sludge which is pre-treated by the rhamnolipid to remove oxygen; fermenting the sludge at constant temperature of 30 DEG C to 37 DEG C; after fermenting, taking out the sludge and carrying out solid-liquid separation; taking supernatant as a fermentation solution for later use; (3) inoculating and starting a single-pole-compartment MEC reactor by utilizing the sludge subjected to the solid-liquid separation in step (2); additionally applying voltage of 0.6V to 1.2V and externally connecting a 10ohm resistor, wherein a distance between electrodes is 0.5cm to 2.0cm; after successfully starting the reactor, replacing a culture solution with the fermentation solution in step (2) and starting a rapid hydrogen production process. Compared with traditional sludge fermentation and hydrogen production, the method has the characteristics of short fermentation period and high hydrogen yield of unit sludge.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

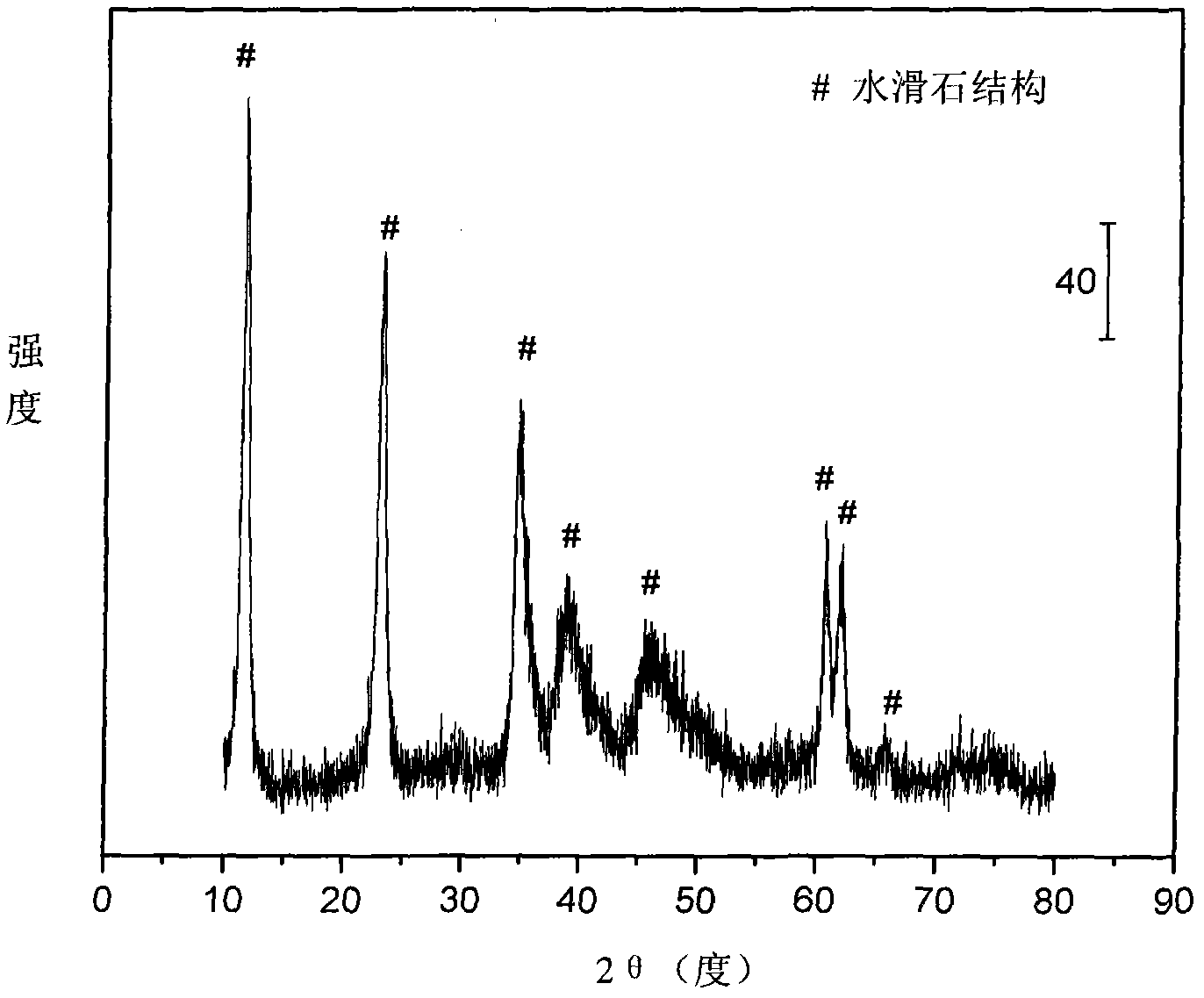

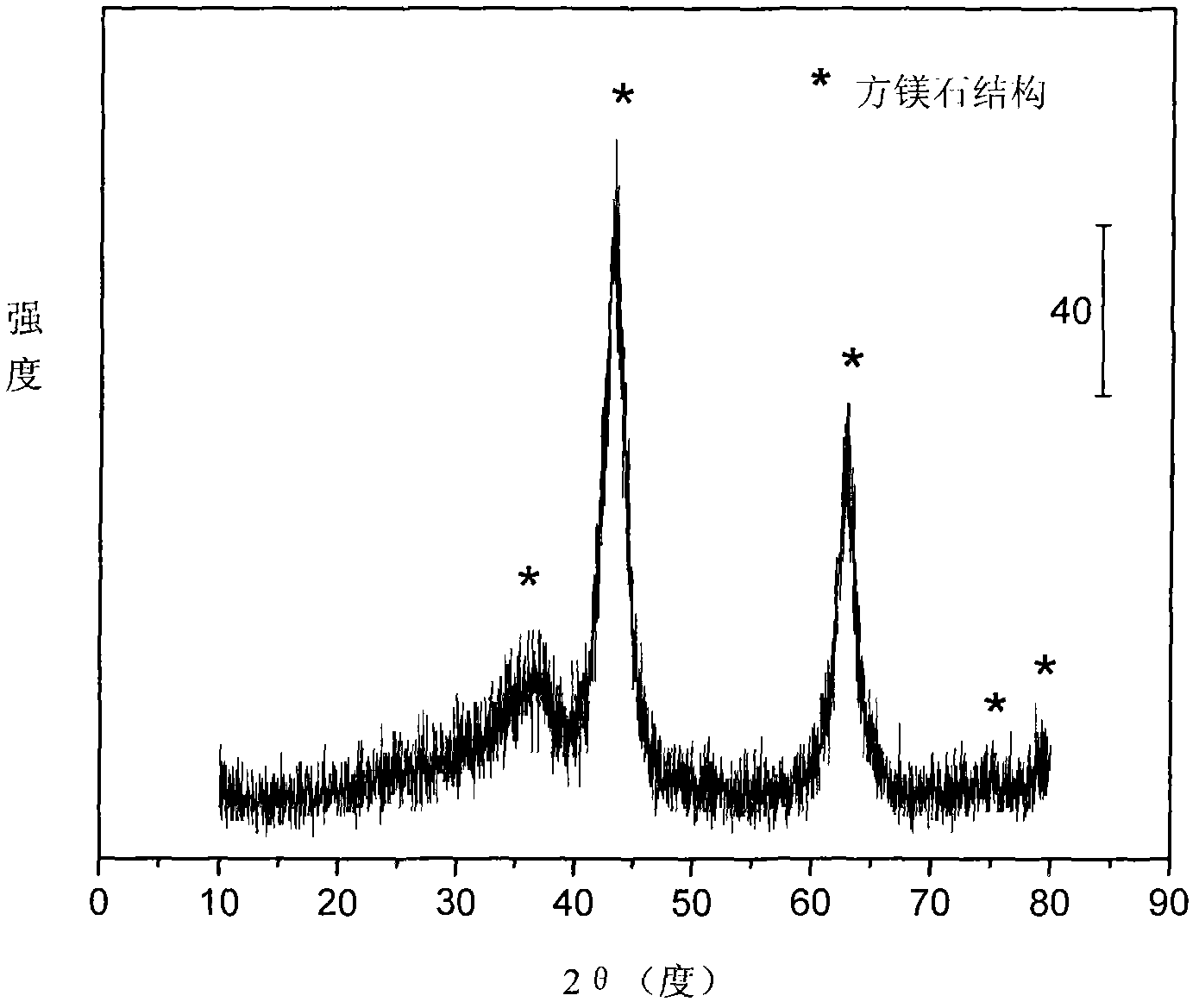

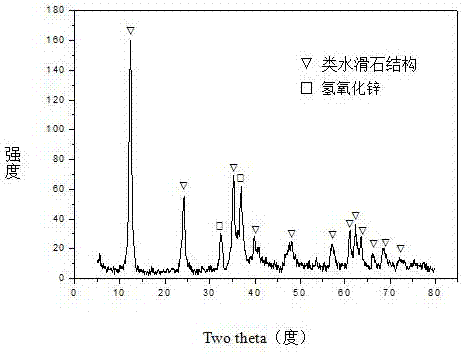

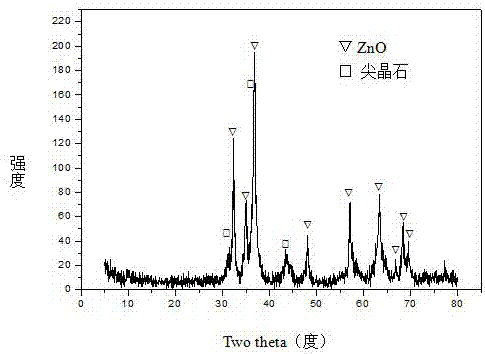

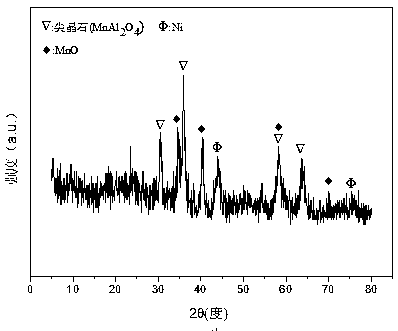

Hydrotalcite-like type iron-promoted nickel-based catalyst for hydrogen preparation through autothermal reforming of acetic acid and preparation method

ActiveCN107282050AStable performanceEnhanced interactionHydrogenCatalyst activation/preparationAluminiumHydrotalcite

The invention relates to a hydrotalcite-like type iron-promoted nickel-based catalyst for hydrogen preparation through autothermal reforming of acetic acid and a preparation method and provides a high-activity novel catalyst resisting oxidation, sintering and carbon deposition to solve the problem that existing catalysts are inactivated due to the structure change as well as oxidation and sintering of active components of the catalysts in the autothermal reforming process of acetic acid. The chemical component of the catalyst is (ZnO)a(NiO)b(AlO1.5)c(FeO1.5)d, wherein a ranges from 0.75 to 3.25, b ranges from 0.25 to 0.75, c ranges from 0 to 1.0 and d ranges from 0 to 1.0. The Zn-Al type carbonate hydrotalcite-like structure is prepared with a co-precipitation method to serve as a precursor, and an active component nickel and an auxiliary iron are introduced and enter the position of the hydrotalcite-like structure through isomorphous substitution of zinc for nickel and isomorphous substitution of aluminum for iron; a compound oxide obtained through sintering effectively inhibits possible migration, accumulation, oxidation and sintering of the active component nickel under the high-temperature reaction condition, and the activity and the stability of the catalyst are improved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

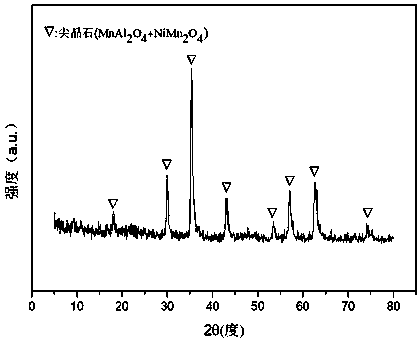

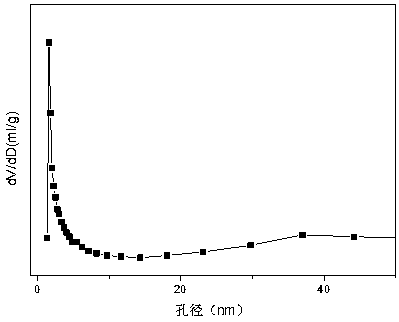

Nickel-manganese-aluminum composite oxide catalyst for producing hydrogen by autothermal reforming of acetic acid

ActiveCN109225249AHigh specific surface areaGood dispersionHydrogenHeterogenous catalyst chemical elementsManganeseOxidation resistant

The invention relates to a nickel-manganese-aluminum composite oxide catalyst for producing hydrogen by autothermal reforming of acetic acid. For the problem of oxidization and sintering of an activecomponent of the catalyst in the process of autothermal reforming of acetic acid and catalyst deactivation, the invention provides a new anti-carbon, oxidation-resistant and high-activity catalyst with a stable structure. The catalyst has a molar composition of (NiO)a(MnO)b(AlO<1.5>)c, wherein a is 0.12-0.15, b is 0.32-0.78 and c is 0.10-0.50. The catalyst is prepared by using a co-precipitation method, nickel is used as the active component, and an auxiliary agent of manganese and a carrier of aluminum oxide are simultaneously introduced, the substances are roasted to form the stable composite oxide catalyst containing a NiMn2O4 and MnAl2O4 spinel structure. The oxidation resistance and the dispersibility of the active component are improved, and meanwhile the hydrogen yield and the sintering resistance and anti-carbon capability in the process of autothermal reforming of acetic acid are improved.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

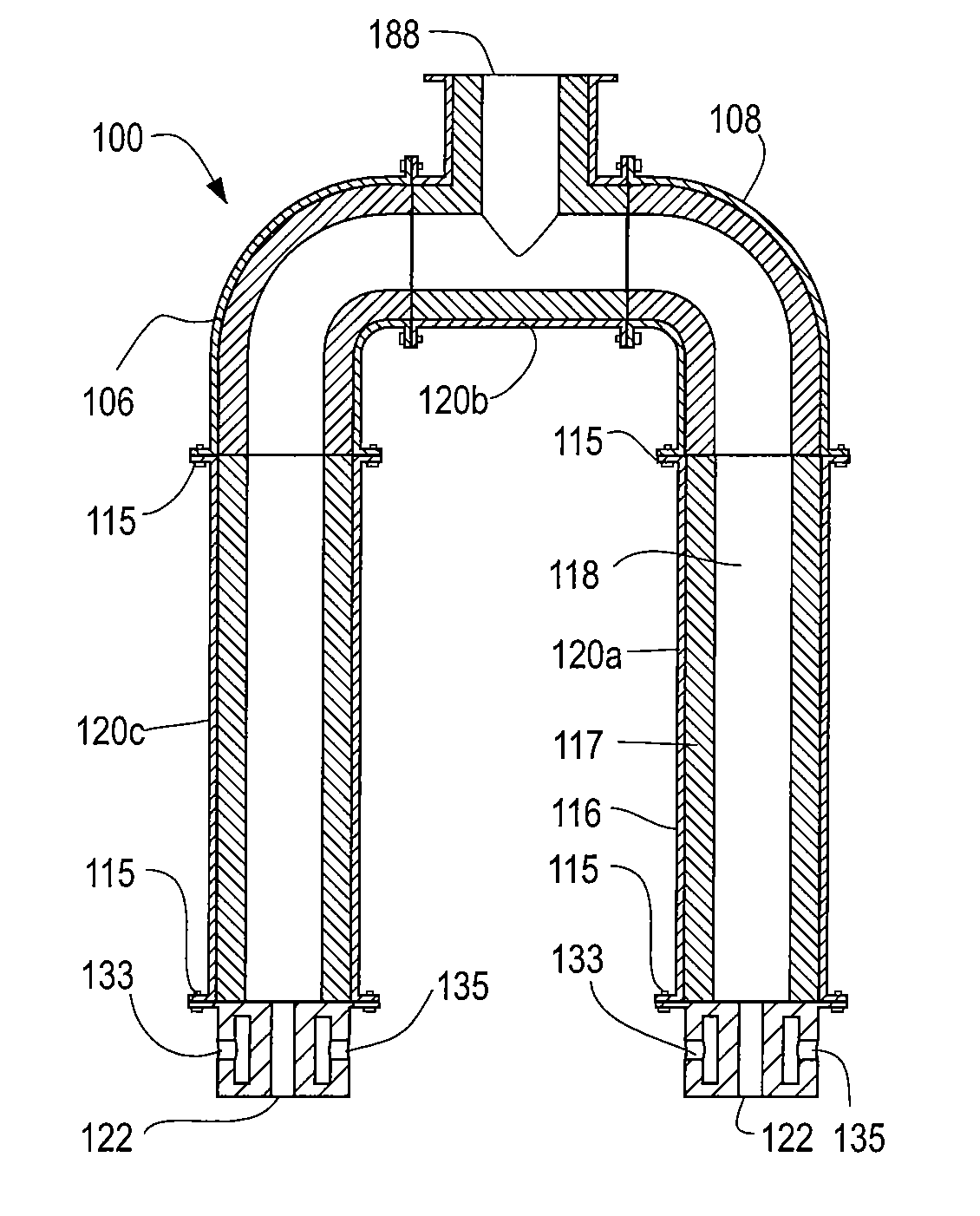

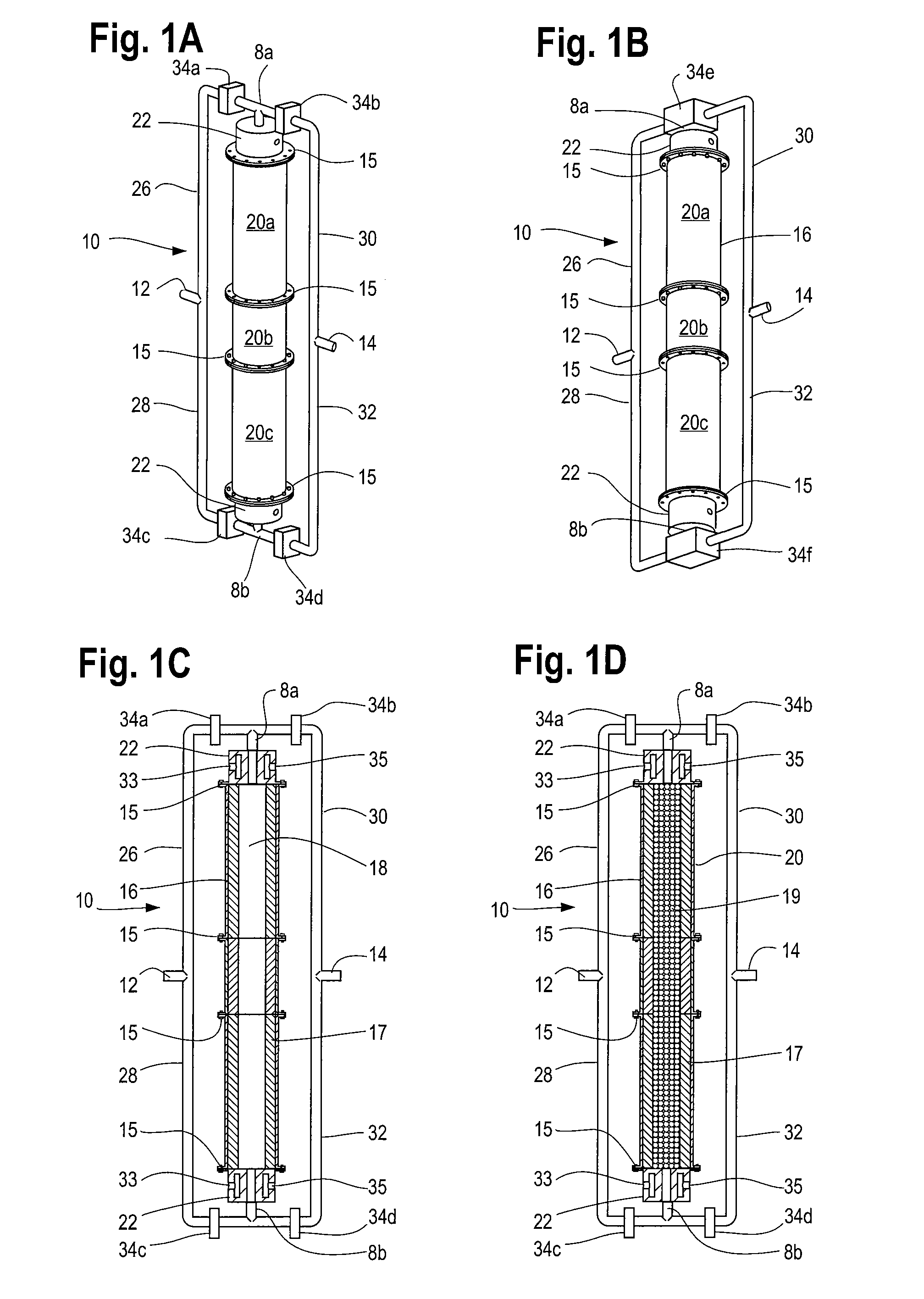

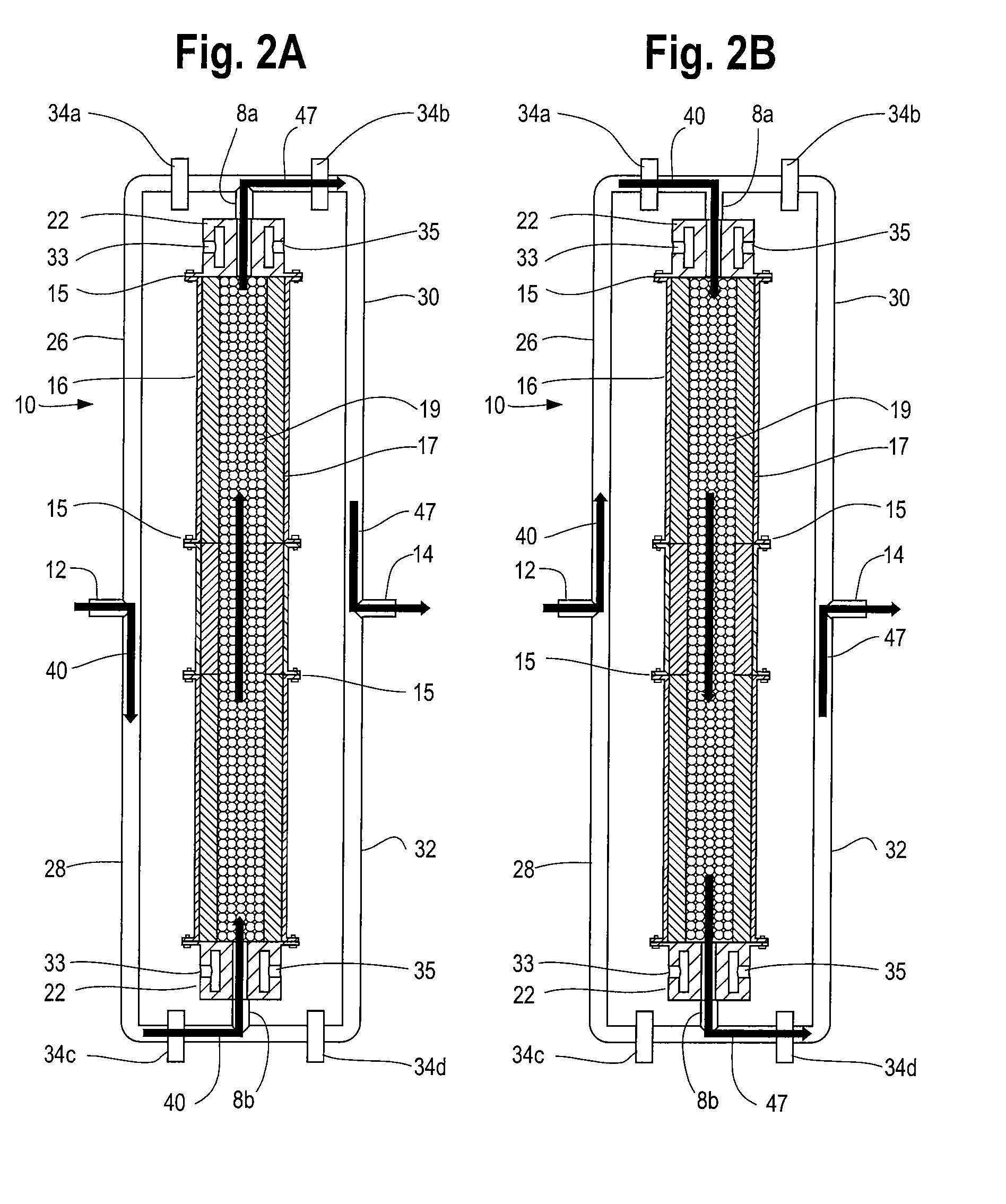

Reformation of hydrogen-containing fluids in a cyclic flow reactor

ActiveUS8323363B2Improve energy efficiencyHigh hydrogen yieldSulfur compoundsHydrocarbon purification/separationExternal energyPorous medium

The invention discloses an apparatus and process for the reformation of hydrogen containing fluids to hydrogen and other constituents, more particularly, the reformation of hydrocarbons or mixtures of hydrocarbons in a cyclic flow inert porous media reactor for the production of hydrogen and other constituents. In an alternate embodiment, the apparatus and process can be used for the reformation of hydrogen sulfide to produce hydrogen and sulfur.The cyclic flow reactor comprises a reaction chamber filled with a porous media matrix containing an unconstrained reaction zone located in any portion of the reactor chamber. This reactor system employs valves to canalize the reactant mixture and product mixture during flow cycling channeling the reactant mixture through the porous media matrix, and reacting the reactant mixture. In another embodiment, the reactor system may further comprise at least one aperture along the axial length of the reactor casing to enable mounting of an external energy source and / or at least one heat exchanger to provide a source of heat transfer to the inlet pipe and outlet pipe as well as the reactant mixture and product mixtures.

Owner:INNOVATIVE ENERGY SOLUTION

Process for cooling an exothermic reaction zone and reactor unit

InactiveUS7481859B2Reduce the temperatureHigh hydrogen yieldSemi-permeable membranesHydrogen separation using solid contactWater flowFixed bed

Process for cooling an exothermic reaction zone byintroducing a stream of water and a hydrocarbon-containing stream into a plurality of humidifying tubes extending through a catalytic exothermic reaction zone of a catalytic fixed bed with solid catalyst,introducing a process stream into the reaction zone for one or more catalytic exothermic reactions,passing the stream of water in a falling film along the inner circumference of the humidifying tubes,humidifying the hydrocarbon-containing stream with water in the humidifying tubes in indirect heat exchange with the exothermic reaction zone,withdrawing cooled reaction product of the exothermic reaction from the reaction zone,withdrawing the heated humidified, hydrocarbon-containing stream from the humidifying tubes, andtransferring the heated humidified, hydrocarbon-containing process stream for further processing.

Owner:HALDOR TOPSOE AS

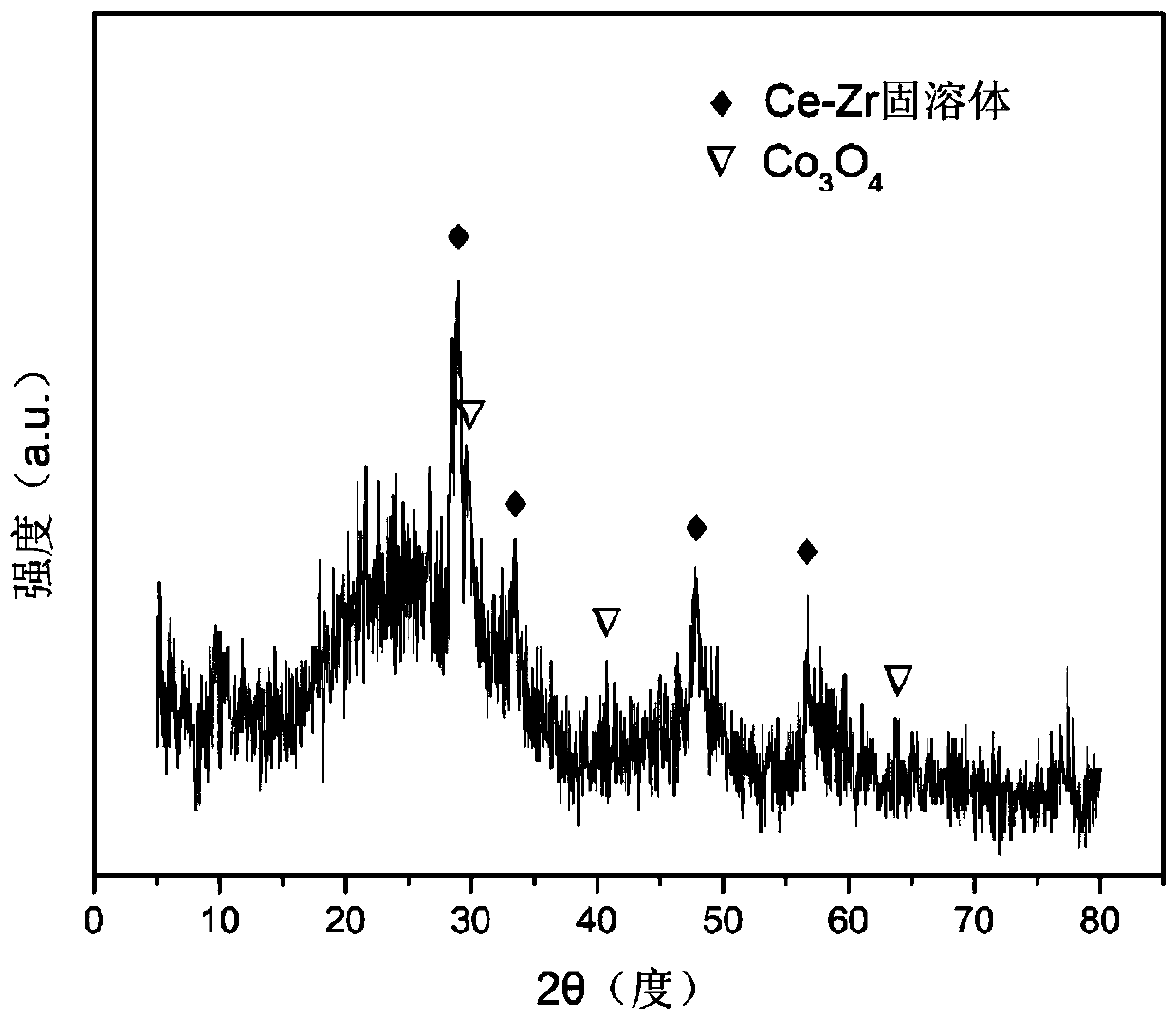

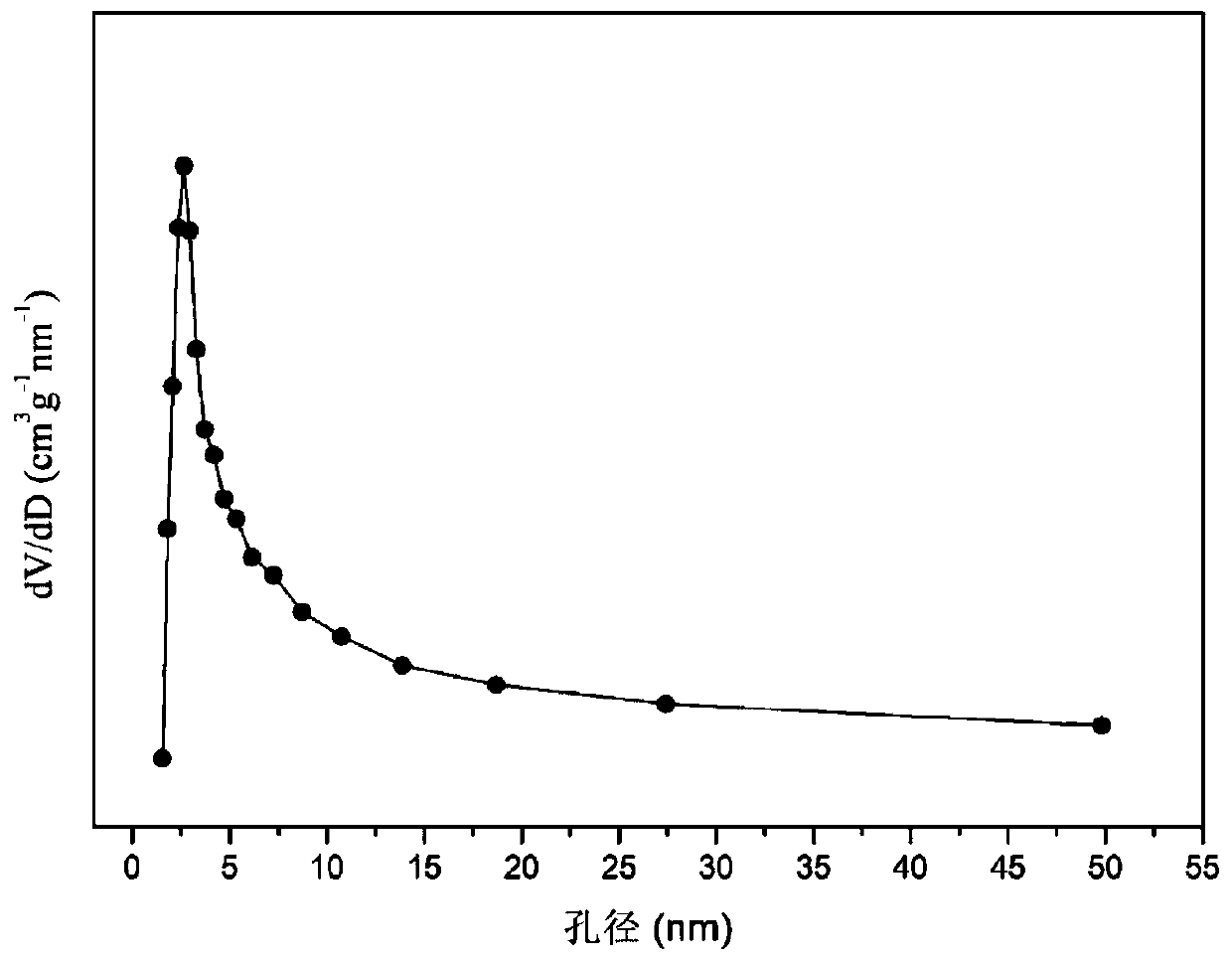

Oxygen storage solid solution loaded cobalt-based catalyst for hydrogen production by autothermal reforming of acetic acid

InactiveCN109718790AGood choiceHigh catalytic activityHydrogenMetal/metal-oxides/metal-hydroxide catalystsCarbon depositCobalt

The invention relates to an oxygen storage solid solution loaded cobalt-based catalyst for hydrogen production by autothermal reforming of acetic acid. Directed at the problems of oxidation, sinteringand carbon deposit of existing catalysts in the autothermal reforming process of acetic acid, the invention provides a new catalyst characterized by stable structure, sintering resistance, carbon deposition resistance, oxidation resistance and high activity. The molar composition of the catalyst is: (CoO4 / 3)a(CeO 2)b(ZrO2)c, wherein a is 0.68-1.46, b is 1.00-3.00, and c is 1.00-3.00. The invention adopts coprecipitation method to prepare a catalyst precursor, and then roasting is carried out to obtain the oxygen storage solid solution loaded cobalt-based catalyst containing Co3O4 and Ce-Zr-Ox. The catalyst provided by the invention effectively improves the yield of hydrogen and the stability of active components, and effectively inhibits the formation of methane, acetone and other by-products.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

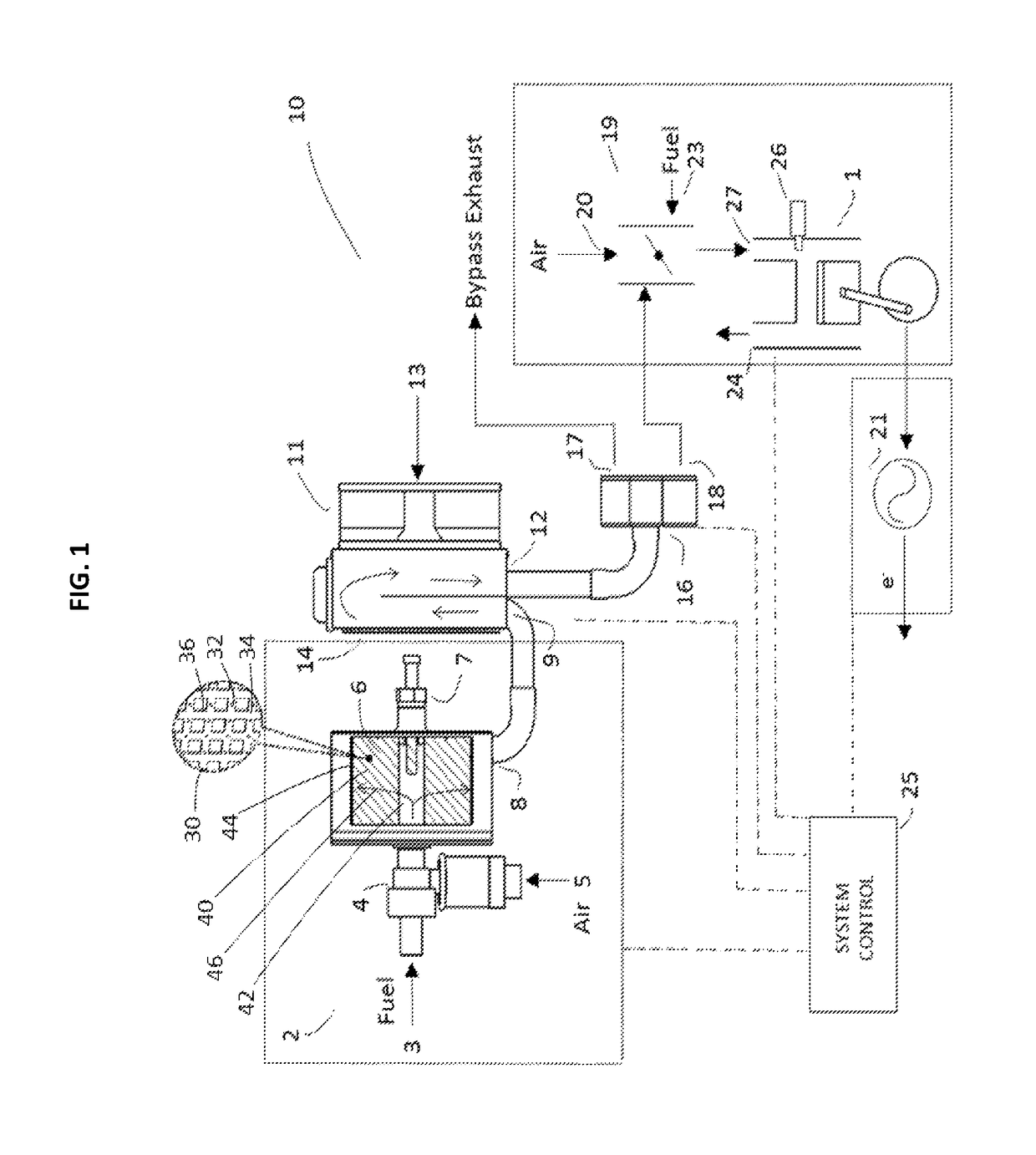

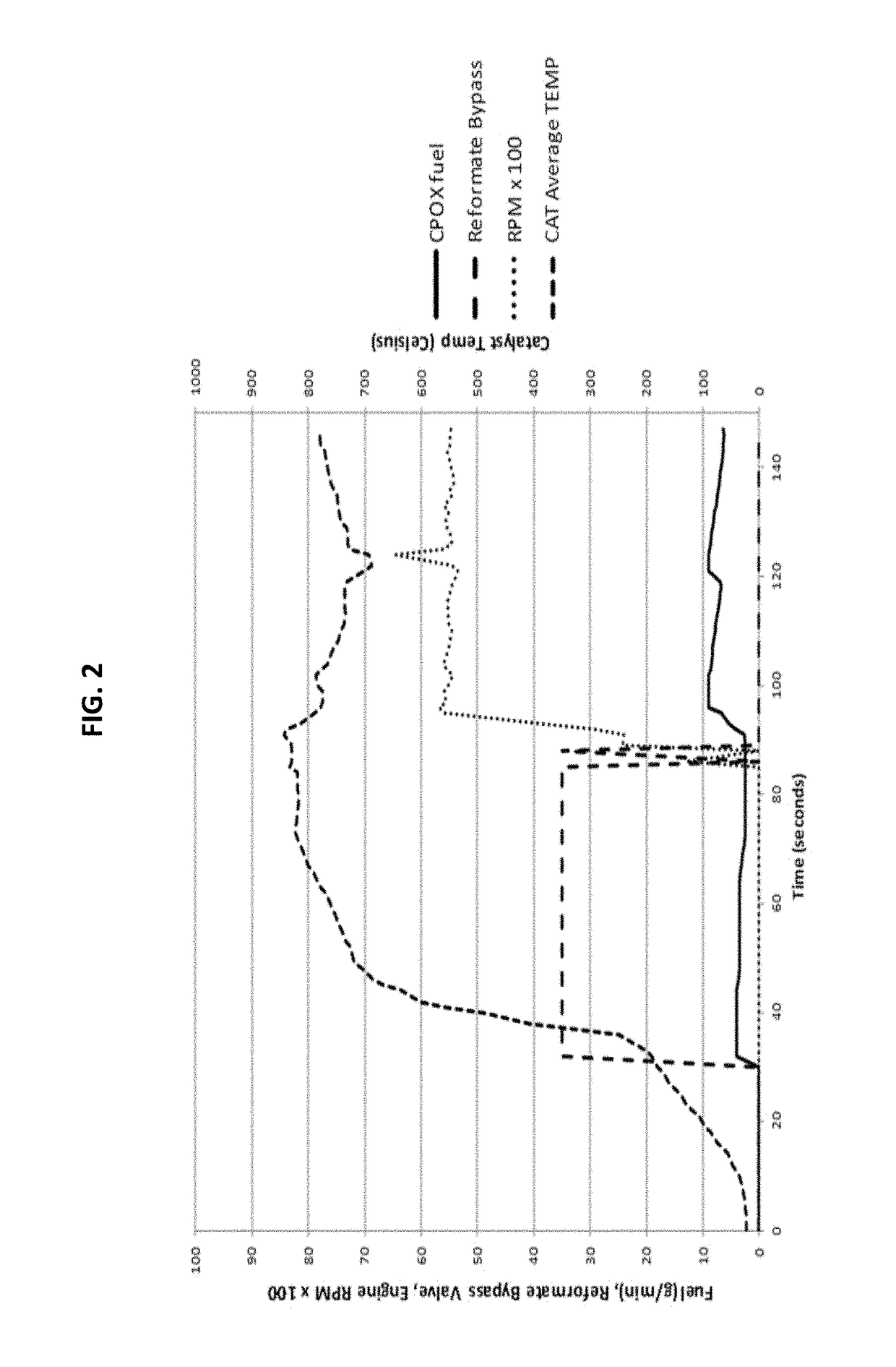

Spark-ignited internal combustion engine modified for multi-fuel operation

ActiveUS10060344B1Reduce productionEmission reductionElectrical controlInternal combustion piston enginesExternal combustion engineGasoline

A spark-ignited (SI) internal combustion (IC) engine designed to operate on high octane fuels, such as gasoline, is reconfigured to operate on low octane fuels including logistically preferred distillate fuels, such as diesel or JP-8. Design modifications involve coupling a fuel reformer module to the internal combustion engine. Auxiliary components include a system control module, a heat exchange module, a bypass valve to facilitate start-up, and / or a throttle body to control a reformate-oxidizer mixture fed to the engine. Small portable generators having 0.3-3.0 kWe power output are disclosed based upon the modified SI-IC engine design.

Owner:PRECISION COMBUSTION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com