Nickel-base catalyst used for autothermal reforming of ethanol for producing hydrogen and preparation method thereof

A nickel-based catalyst, autothermal reforming technology, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve problems such as catalyst deactivation, and achieve hydrogen High yield, improved low-temperature reactivity, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

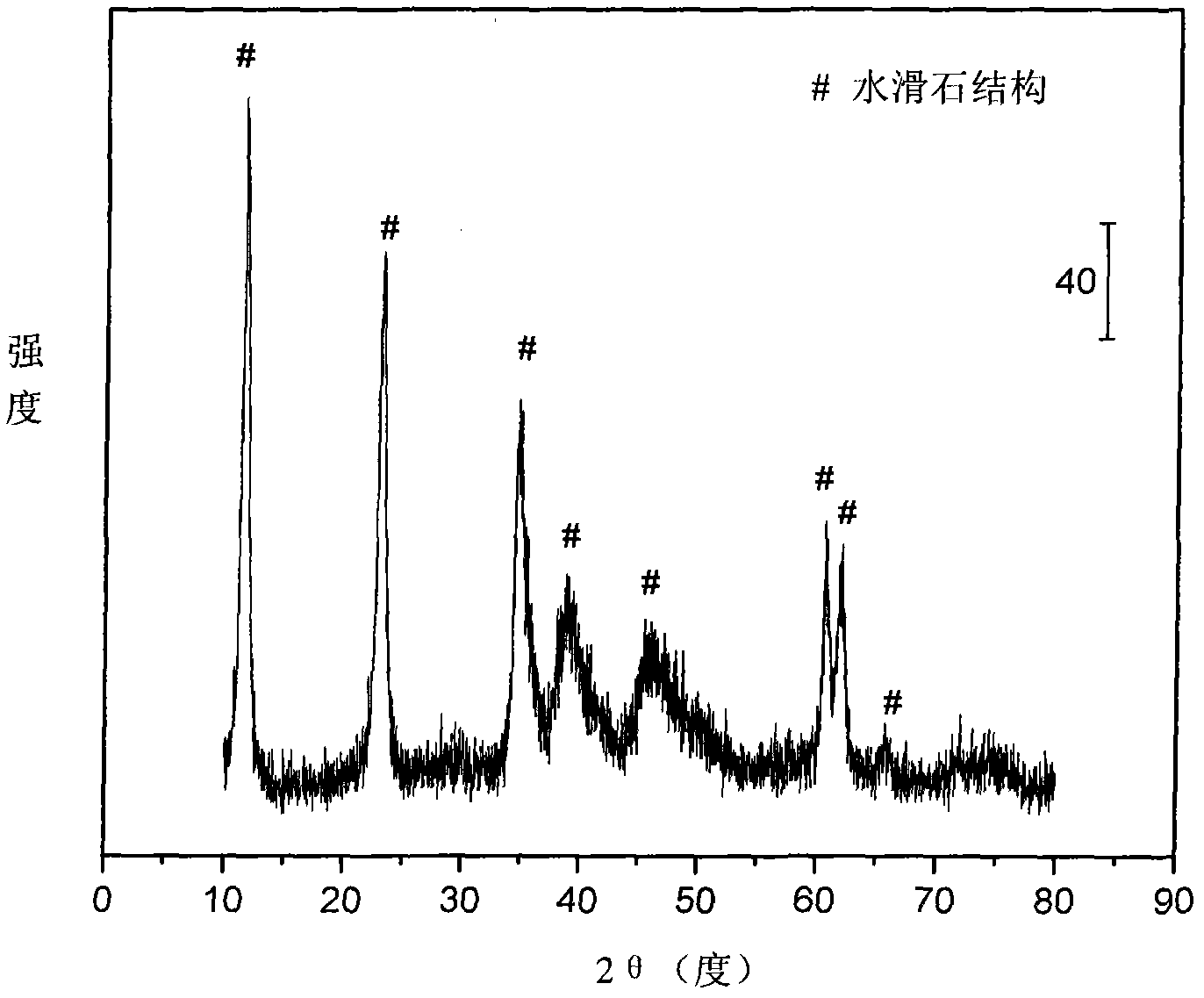

Embodiment 1

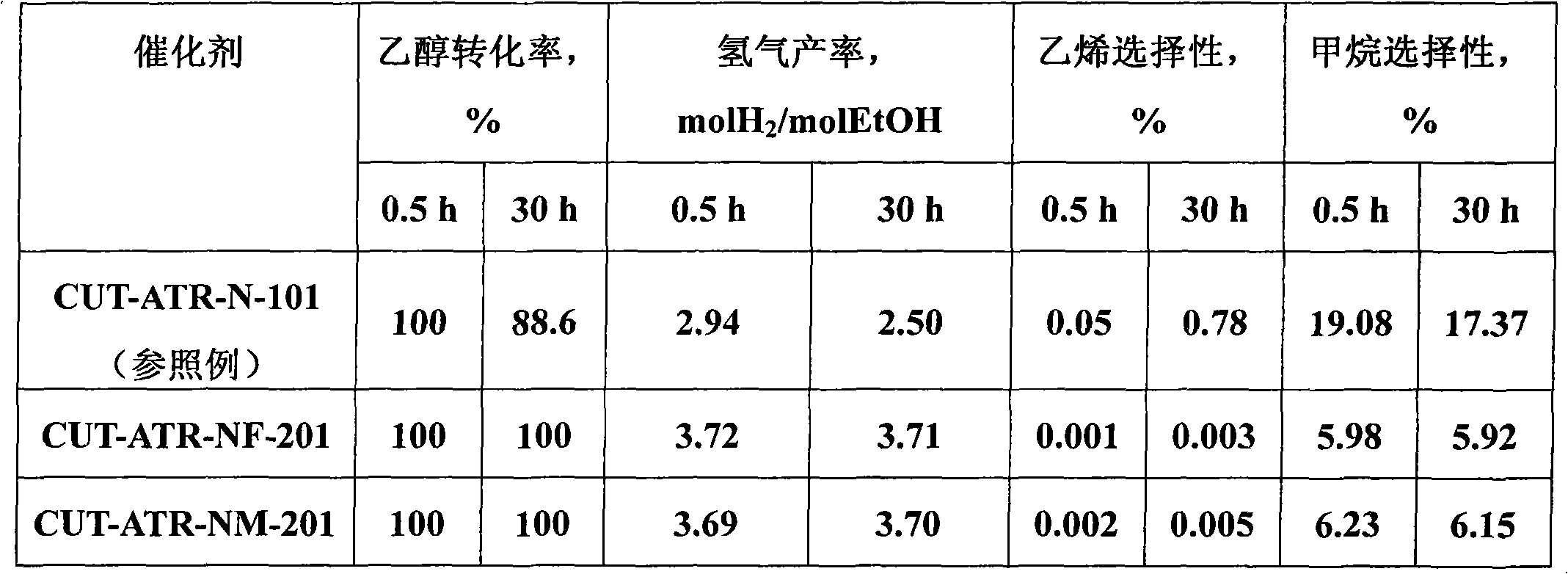

[0031] Weigh 4.410 grams of Ni (NO 3 ) 2 ·6H 2 O, 27.402 grams of Mg (NO 3 ) 2 ·6H 2 O, 7.564 grams of Al(NO 3 ) 3 9H 2 O and 8.146 g of Fe(NO 3 ) 3 9H 2 O, add 161ml of deionized water to make solution #1. Weigh 12.905 grams of NaOH and 2.137 grams of NaOH 2 CO 3 , was added to 343ml of deionized water to prepare solution #2. Subsequent steps were the same as those in Reference Example 1 to obtain catalyst CUT-ATR-NF-201. The weight composition of the catalyst is as follows: the content of nickel oxide is 13.2%, the content of magnesium oxide is 53.8%, the content of aluminum oxide is 12.8%, and the content of iron oxide is 21.2%.

[0032] The results of the catalyst in the ethanol autothermal reforming reaction are shown in Table 1. The reaction conditions are temperature 550°C, water / ethanol / oxygen molar ratio 3 / 1 / 0.5, normal pressure, and space velocity 11000h -1 , its ethanol conversion was stable at 100%, and its hydrogen yield was stable at about 3.7molH ...

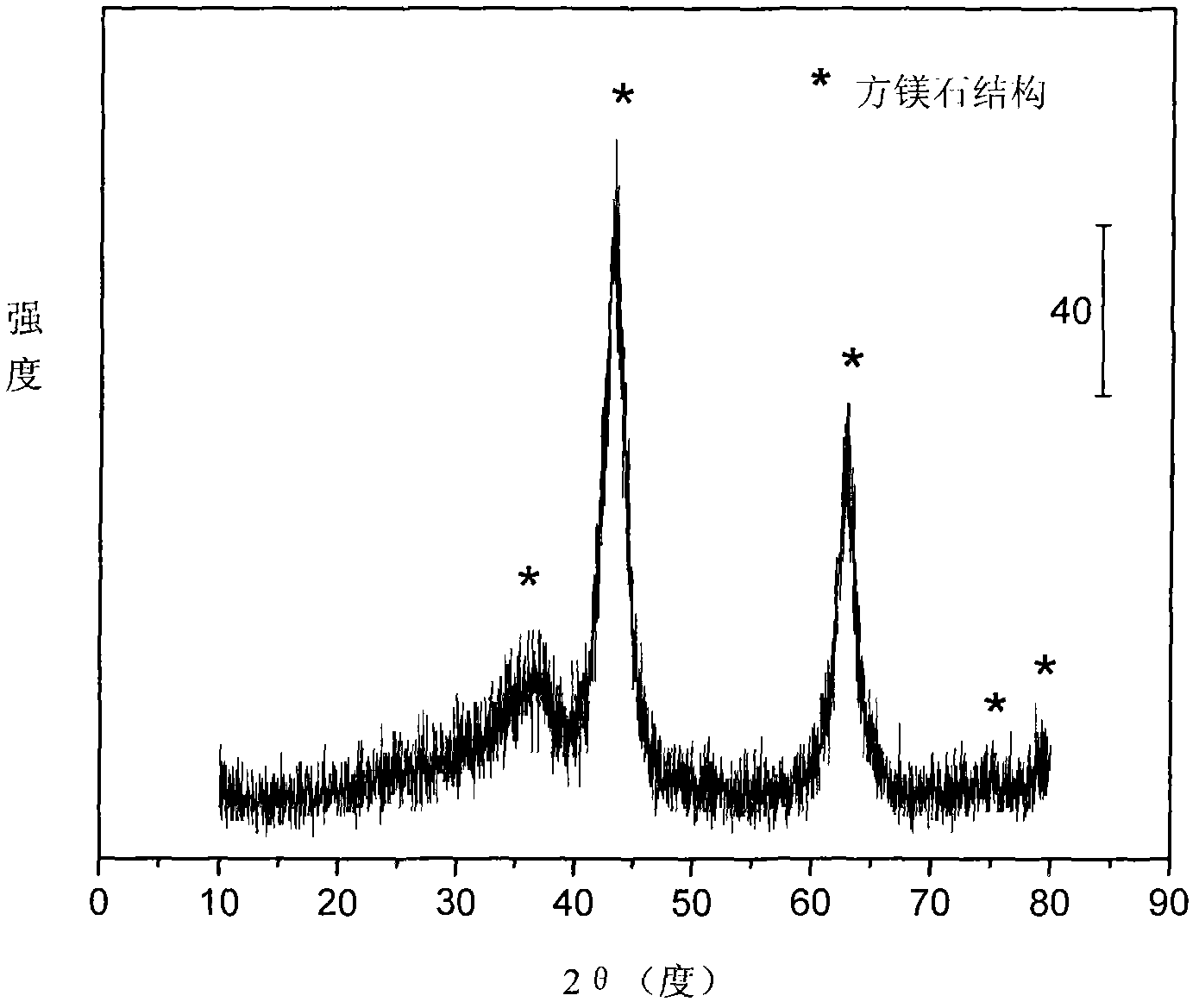

Embodiment 2

[0034] Weigh 4.227 grams of Ni (NO 3 ) 2 ·6H 2 O, 28.223 grams of Mg(NO 3 ) 2 ·6H 2 O and 10.907 g of Al(NO 3 ) 3 9H 2 O, measure the weight ratio of 4.460ml and be 50% Mn (NO 3 ) 2 Solution, add 166ml of deionized water to make solution #1. Weigh 13.292 grams of NaOH and 2.201 grams of NaOH 2 CO 3 , was added to 353ml of deionized water to prepare solution #2. Subsequent steps were the same as in Reference Example 1 to obtain catalyst CUT-ATR-NM-201. The weight composition of the catalyst is as follows: the content of nickel oxide is 13.4%, the content of magnesium oxide is 54.9%, the content of aluminum oxide is 18.3%, and the content of manganese dioxide is 13.4%.

[0035] The results of the catalyst in the ethanol autothermal reforming reaction are shown in Table 1. The reaction conditions are temperature 550°C, water / ethanol / oxygen molar ratio 3 / 1 / 0.5, normal pressure, and space velocity 11000h -1 , the ethanol conversion rate was 100%, and the hydrogen prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com