Patents

Literature

336 results about "Sludge fermentation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for achieving partial short-cut nitrification-Anammox/denitrification of sewage by using sludge fermentation materials

ActiveCN108439595ARealize deep denitrificationAchieve reductionTreatment with aerobic and anaerobic processesAmmonia-oxidizing bacteriaNitrogen gas

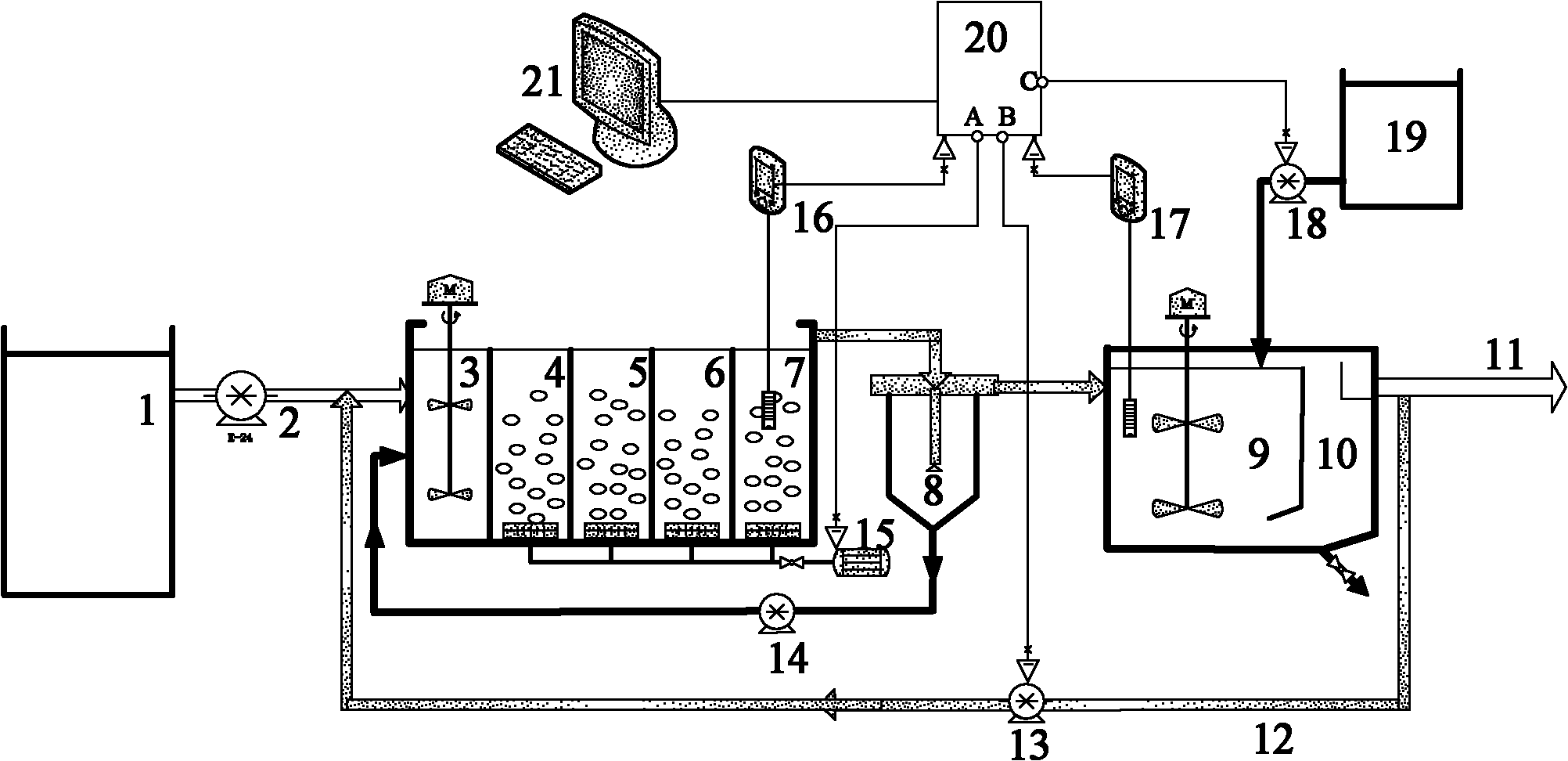

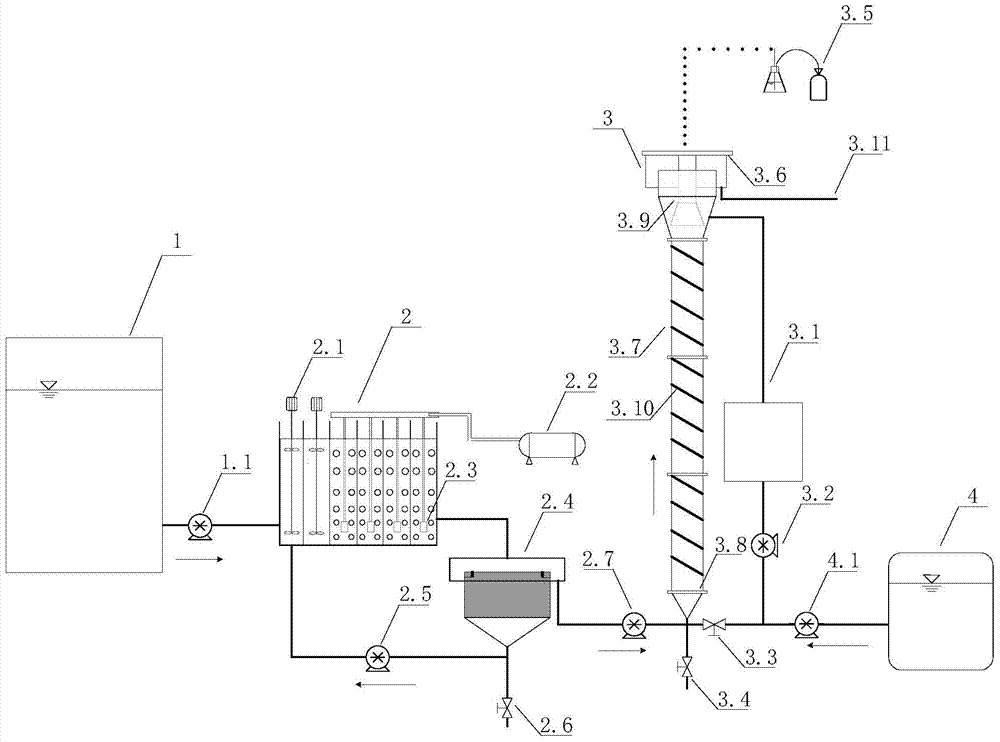

The invention provides a method for achieving partial short-cut nitrification-Anammox / denitrification of sewage by using sludge fermentation materials, and belongs to the field of treatment of sewagesludge. A device used by the method comprises a raw water tank, an SBR reactor, a sludge fermentation material storage tank and a residual sludge fermentation tank. The method comprises mixing residual sludge fermentation materials with domestic sewage for treating, and achieving the short-cut nitrification by using the sludge fermentation materials, wherein the inhibition of the sludge fermentation materials on nitrite oxidizing bacteria is far greater than the inhibition of the sludge fermentation materials on ammonia oxidizing bacteria. The method is specifically characterized in that in ananaerobic phase, polyphosphate accumulating bacteria are used for releasing phosphorus by using the sludge fermentation materials and carbon sources in raw water, and storing the inner carbon sources, in an aerobic phase, the partial short-cut nitrification is achieved through real-time control on DO and pH, in an anoxic phase, anaerobic ammonia oxidizing bacteria are used for converting ammonianitrogen and nitrite nitrogen into nitrogen and nitric nitrogen, and heterotrophic bacteria are used for reducing residual nitrite nitrogen and the generated nitric nitrogen into nitrogen by using theinner carbon sources. Through the method, the aeration intensity is reduced; meanwhile, the deep denitrification of the domestic sewage with a low C / N ratio and the reduction of exogenous sludge areachieved.

Owner:BEIJING UNIV OF TECH

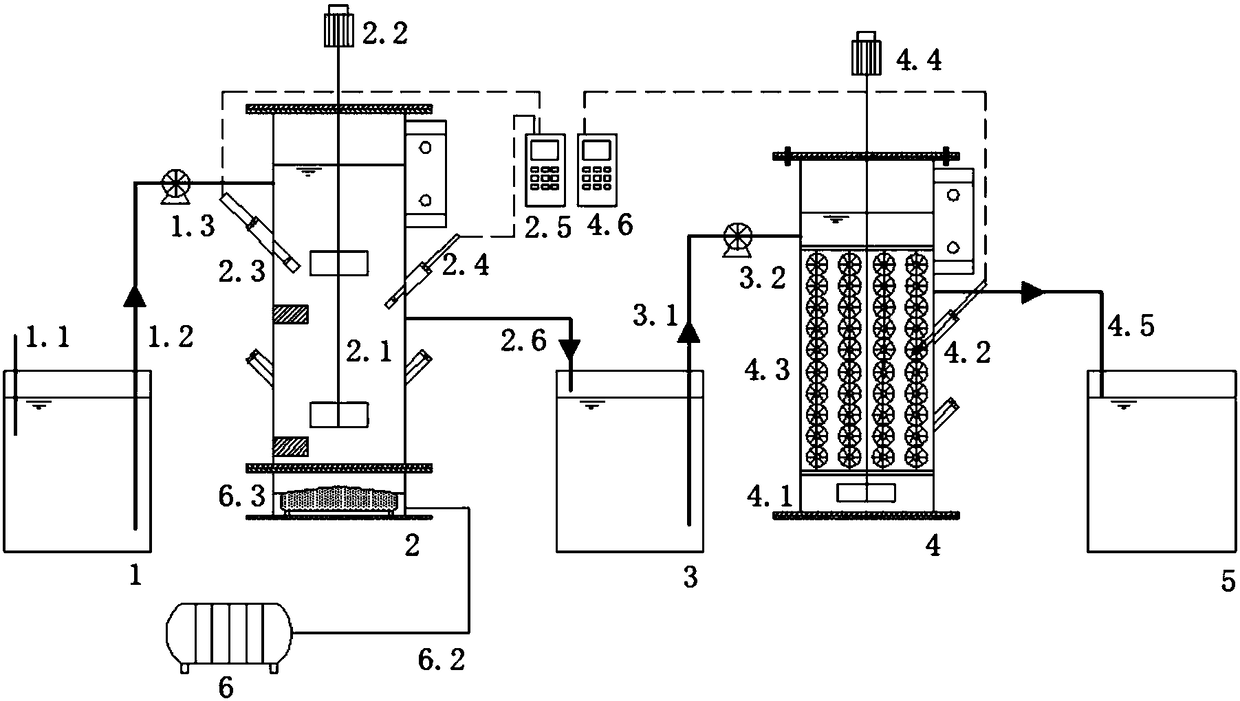

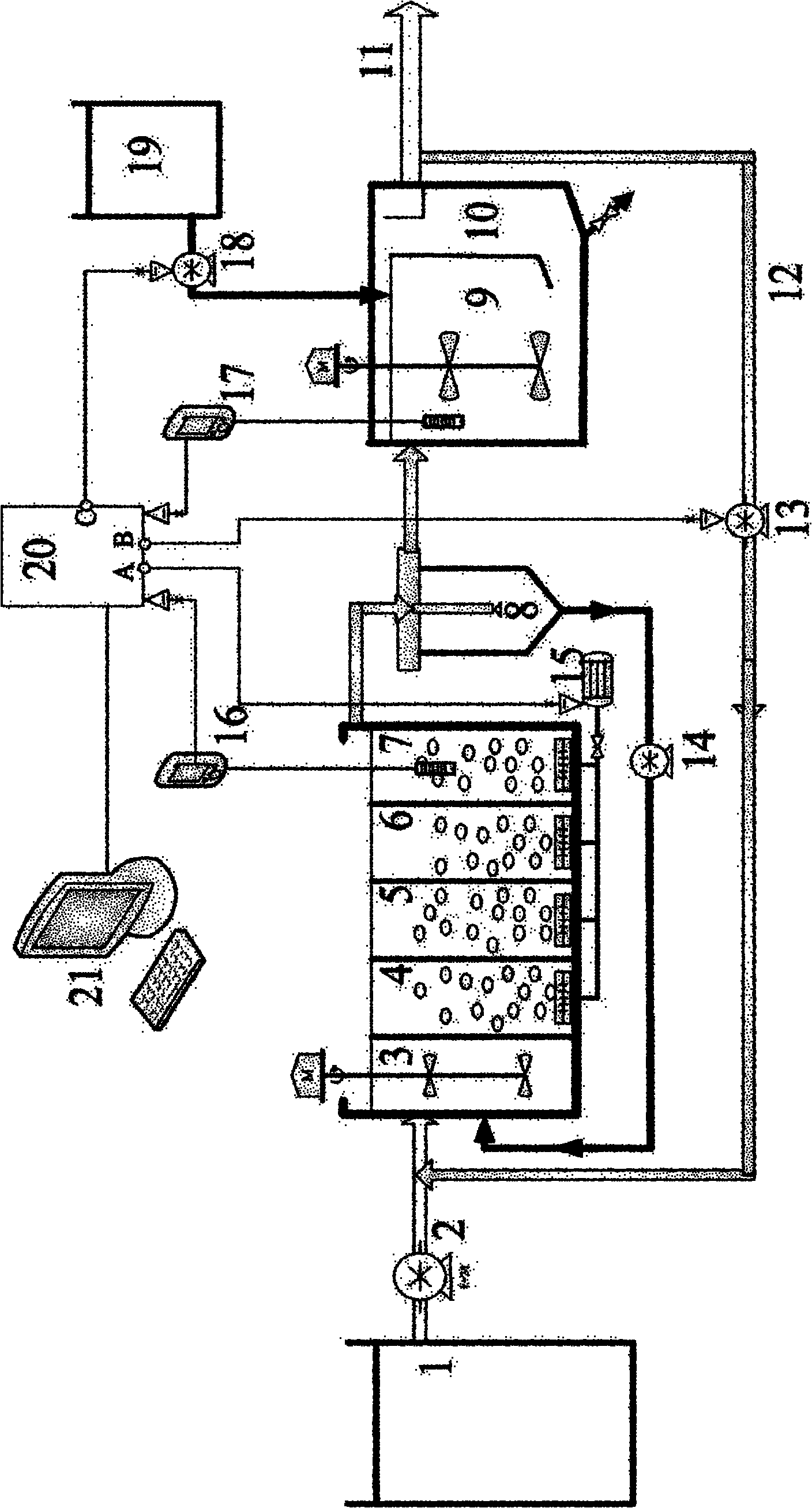

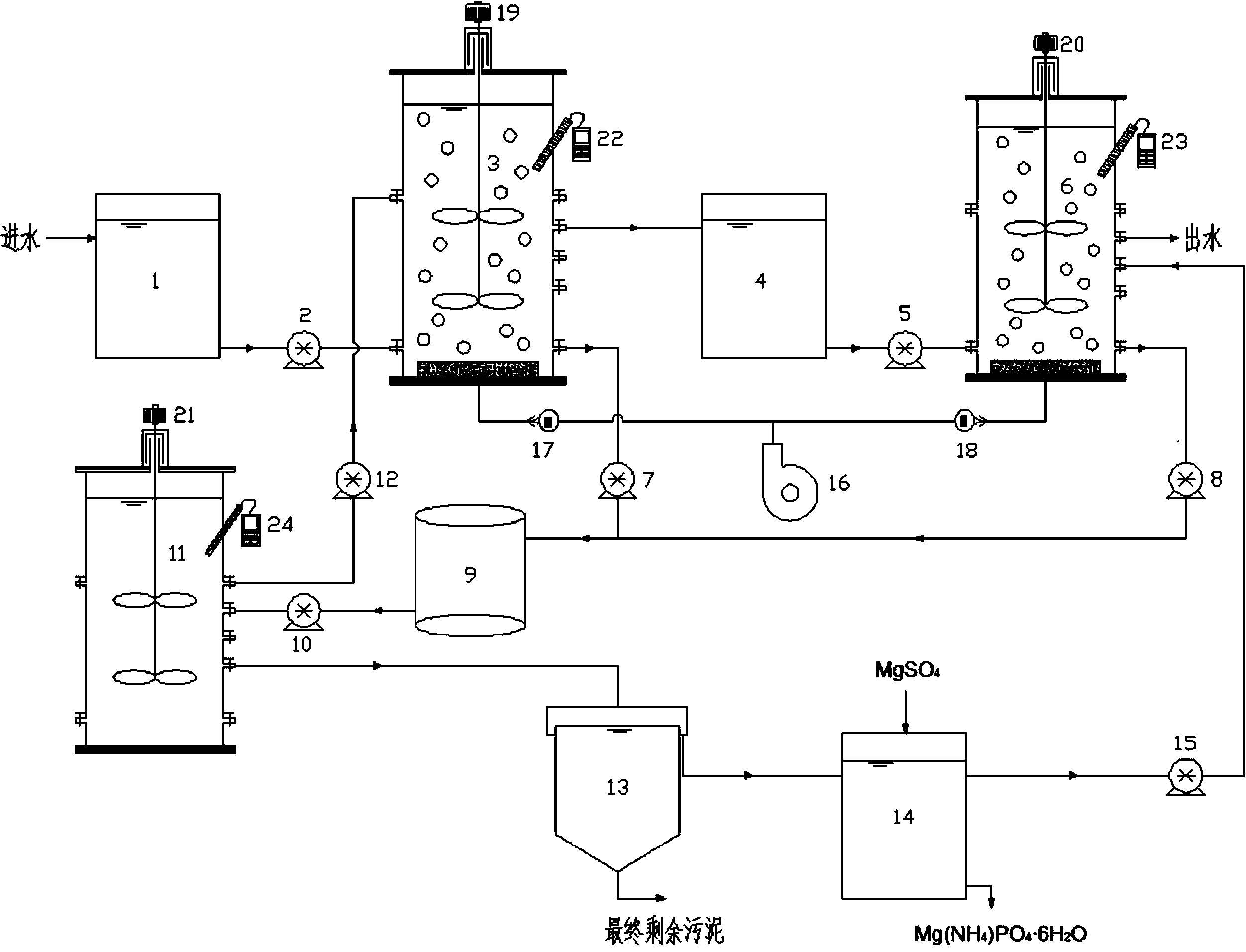

Technology for treating domestic sewage by realizing partial short-cut nitrification, sludge fermentation coupling denitrification and anaerobic ammonia oxidation in sequencing batch reactor

ActiveCN108585202AEasy to upgradeAchieve reductionTreatment with aerobic and anaerobic processesSustainable biological treatmentSequencing batch reactorNitration

The invention discloses a technology for treating domestic sewage by realizing partial short-cut nitrification, sludge fermentation coupling denitrification and anaerobic ammonia oxidation in a sequencing batch reactor, and belongs to the field of the sewage sludge biological treatment. The technology comprises an inlet water tank, a partial short-cut nitrification reactor (PN-SBR), an intermediate water tank, an anaerobic ammonia oxidation coupling sludge fermentation and denitrification reactor (ASFD-SBR), and an outlet water tank. The partial short-cut nitrification is performed in the partial short-cut nitrification reactor (PN-SBR), and a part of ammonia nitrogen in raw water is converted to nitrite nitrogen. The influent ammonia nitrogen and the nitrite nitrogen are converted to a nitrogen gas and a little of nitrate nitrogen by anaerobic ammonium oxidation bacteria in the anaerobic ammonia oxidation coupling sludge fermentation and denitrification reactor (ASFD-SBR), and the generated nitrate nitrogen is reduced to the nitrogen gas by a carbon source generated by sludge fermentation, wherein static bed filler is used for retaining the anaerobic ammonium oxidation bacteria, and denitrification and sludge fermentation processes are performed in floc sludge. The technology is capable of saving energy consumption, and simultaneously realizing the deep denitrification of theurban domestic sewage in a low carbon nitrogen ratio (C / N) and the recycling of the sludge.

Owner:BEIJING UNIV OF TECH

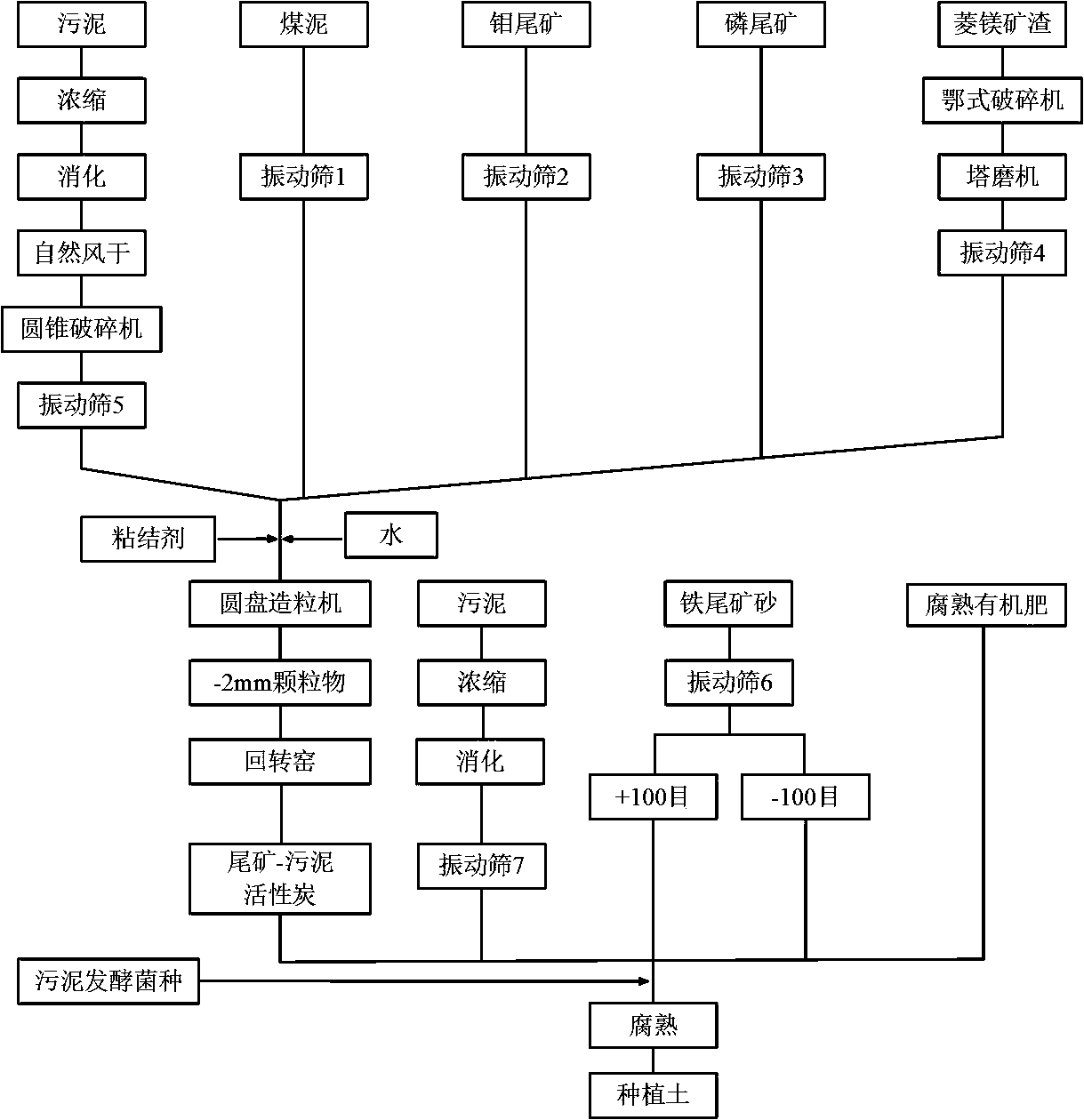

Planting soil and preparation method thereof

ActiveCN107821090ASolve the occupation of land resourcesSolve the pollution of the environmentBio-organic fraction processingMagnesium fertilisersLand resourcesMass ratio

Owner:DALIAN DEETOP ENVIRONMENTAL TECH CO LTD

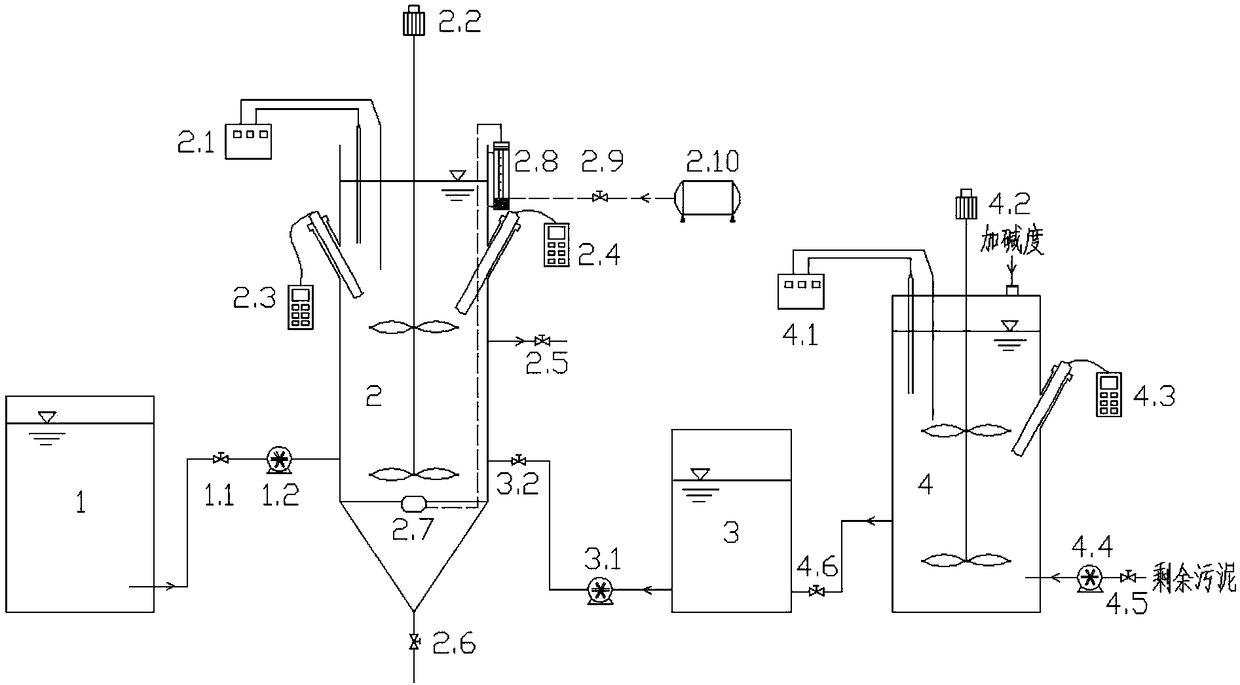

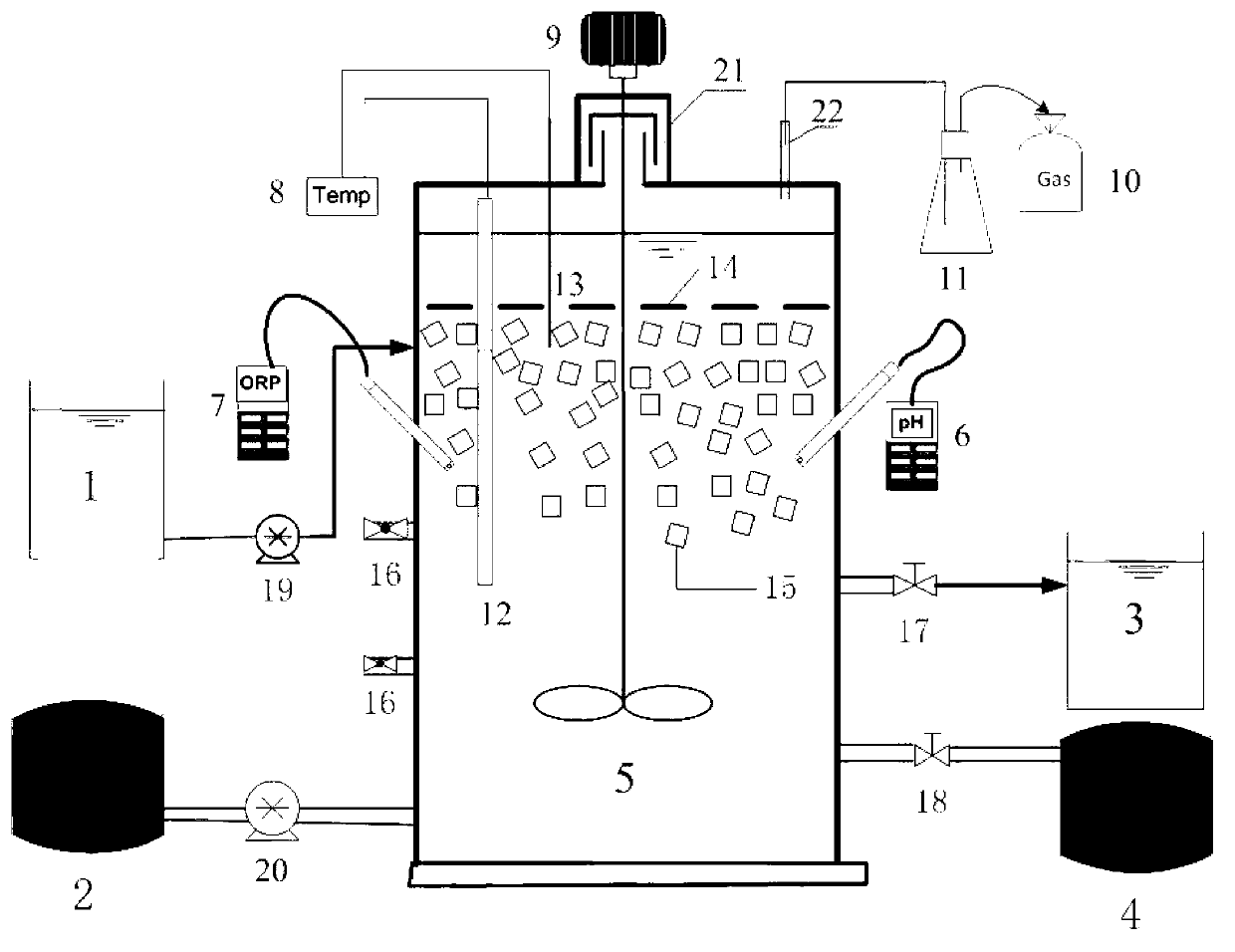

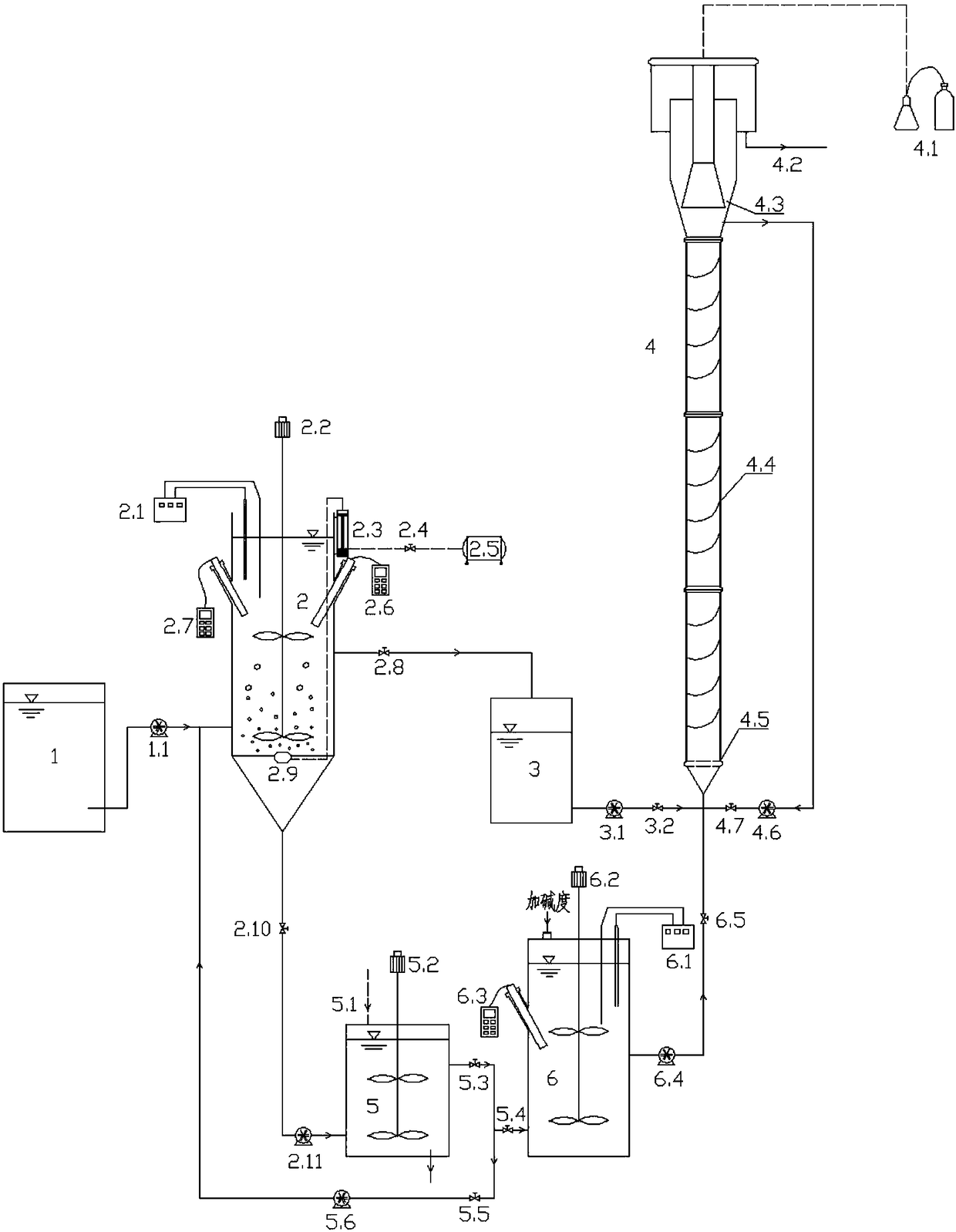

Device and method for synchronously treating high-ammonia-nitrogen wastewater through sludge fermentation

ActiveCN103663879ASave dosingSave on processing costsMultistage water/sewage treatmentSequencing batch reactorNitrogen removal

The invention provides a device and a method for synchronously treating high-ammonia-nitrogen wastewater through sludge fermentation. A raw water pool in a system is connected with an SBR (Sequencing Batch Reactor); the SBR is connected with a sludge fermentation coupled denitrification synchronous autotrophic nitrogen removal reactor through a middle water tank and a sludge storage pool. The method comprises the following steps: high-ammonia-nitrogen wastewater firstly enters the SBR through the raw water pool for partial nitrification, the SBR drains water into the middle water tank, and then the water and residual sludge together enter the sludge fermentation coupled denitrification synchronous autotrophic nitrogen removal reactor for synchronous residual sludge fermentation, anaerobic ammonia oxidation and nitrogen removal by denitrification. The device and the method which are disclosed by the invention are suitable for advanced high-ammonia-nitrogen wastewater treatment, so that low-carbon-consumption sewage denitrification is realized, and the yield of the residual sludge in the system can be reduced.

Owner:BEIJING UNIV OF TECH

Sewage sludge compost and preparation method of sewage sludge compost

InactiveCN102603375ALow costDehydration fastBio-organic fraction processingOrganic fertiliser preparationOrganic fertilizerSludge dewatering

The invention discloses sewage sludge compost. The compositions of the sewage sludge compost comprises the following components in proportion by weight: 2-6 parts of sewage sludge, 0.5-1.5 parts of plant ash, 0.1-0.3 part of straw powder, 0.5-1.5 parts of mushroom residue, 0.5-1.5 parts of chicken manure, and 0.5-1.5 parts of leavening agent. In the above way, the invention provides the sewage sludge compost and a preparation method of the sewage sludge compost, the sewage sludge is transformed into high-quality organic fertilizer for greening, reduce the cost, so that the environmental pollution is reduced, the cost of processing sewage sludge by dehydrating is reduced, and the fermentation treatment of the sewage sludge is accelerated; and the sewage sludge compost has the characteristics of obvious efficiency and low cost.

Owner:江苏田娘农业科技有限公司

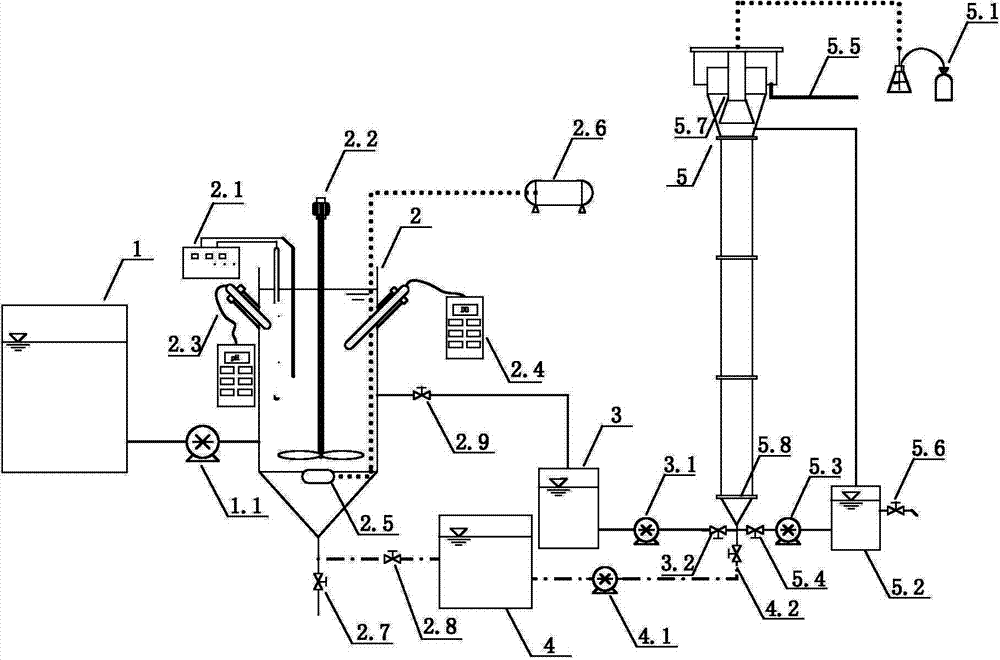

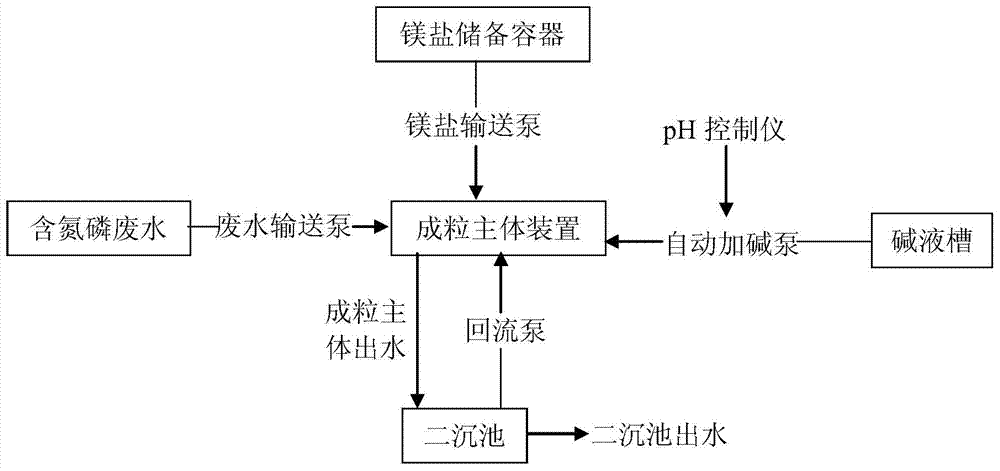

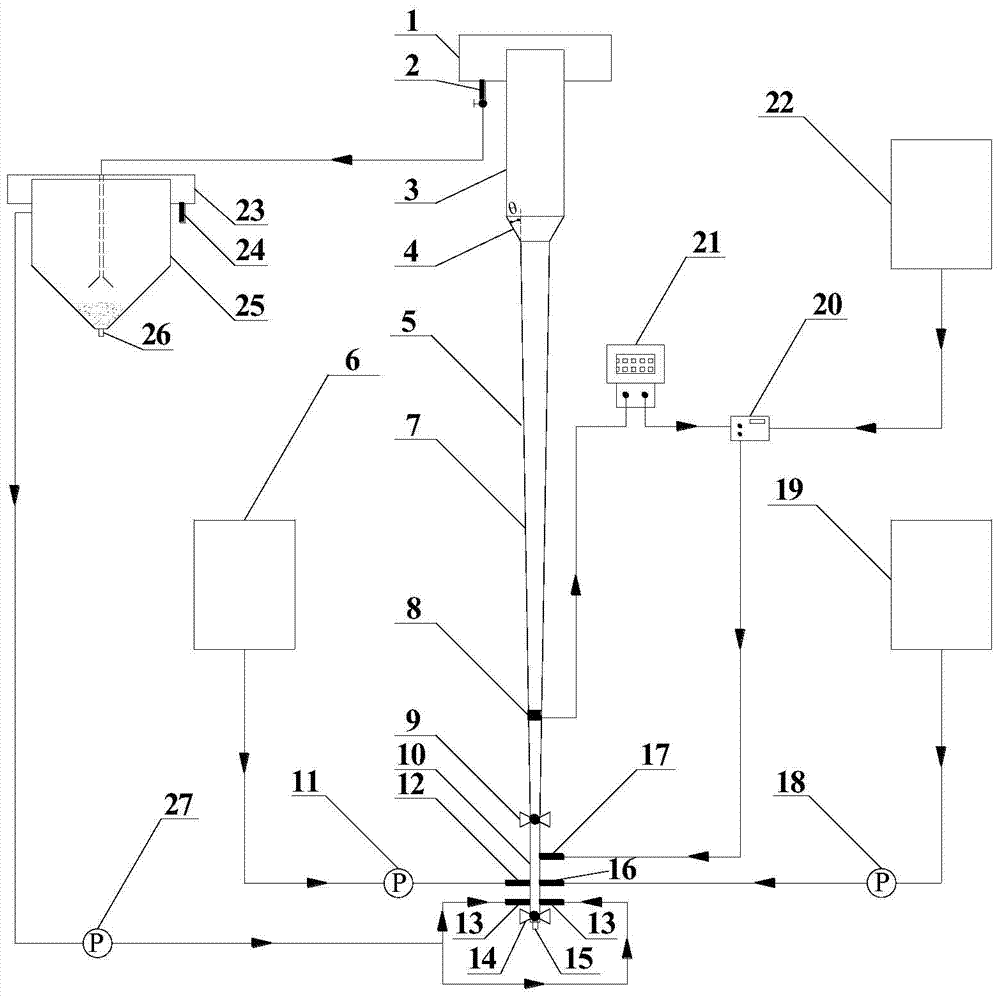

Device and process for preparing struvite crystals from nitrogen and phosphorus in sewage

InactiveCN102963970AIncreased turbulence intensityCompact structureWater/sewage treatment by flocculation/precipitationPhosphorus compoundsStruvite CrystalsSmall footprint

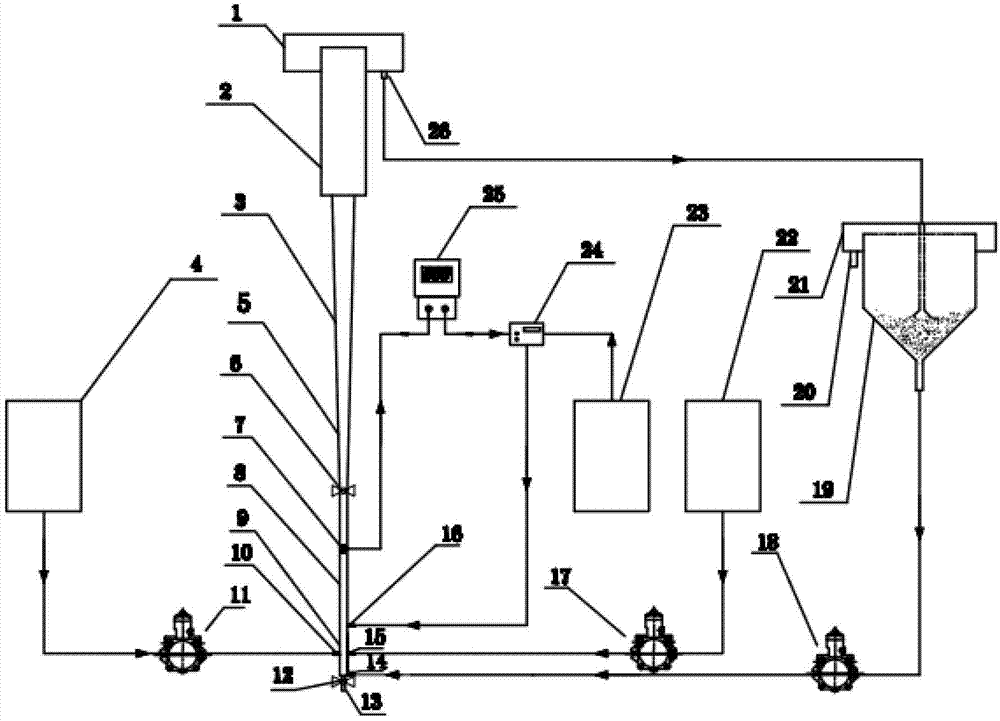

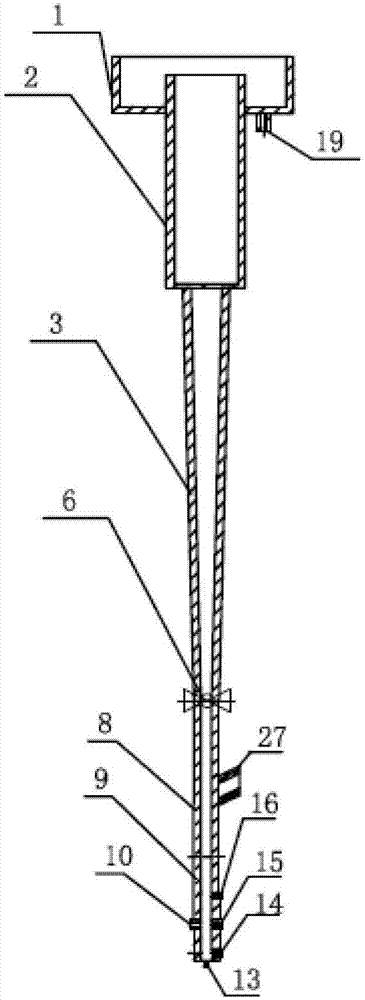

The invention relates to a device and a process for preparing struvite crystals from nitrogen and phosphorus in sewage. The device comprises a reactor (5), a pH (potential of Hydrogen) controller (25), a pH regulating pump (24), an alkali liquor tank (23), a nitrogen and phosphorus containing waste water tank (22) and a secondary sedimentation tank (19), wherein the reactor (5) is composed of a reactor feed pipe (9), a reactor crystal collecting pipe (8), a reactor growth tube (3) and a reactor sediment tube (2) from bottom to top. The process comprises the steps of pumping nitrogen and phosphorus containing wastewater into the reactor (5) and pumping a magnesium chloride solution into the reactor (5) to ensure that the molar ratio of NH3-N to PO43-P to Mg <2+> in the reactor (5) is (1:1:1)-(1:1:1.3); controlling the reflux ratio between 14 and 28 and the pH equal to 6.4-9.2; and forming the struvite crystals in the reactor (5) by using the nitrogen, phosphorus and magnesium containing solution. The device disclosed by the invention has the advantages of simple structure and small floor space, is simple and easy to operate and difficult to scale, can be widely applied to preparation of the struvite crystals from the nitrogen and phosphorus containing wastewater such as coking wastewater, pig manure wastewater or sludge fermentation liquor, and is capable of realizing the resource recycling of nitrogen and phosphorus.

Owner:TONGJI UNIV

Method for treating high-content ammonia and nitrogen for shortcut nitrification to discharge effluent by coupling simultaneous denitrification of sludge fermentation with autotrophic nitrogen removal

ActiveCN103058374ALow costImprove dehydration effectTreatment with aerobic and anaerobic processesBiological sludge treatmentDenitrifying bacteriaTotal nitrogen

The invention discloses a method for treating high-content ammonia and nitrogen for shortcut nitrification to discharge effluent by coupling simultaneous denitrification of sludge fermentation with autotrophic nitrogen removal, belonging to the technical field of biochemical process sewage treatment. The high-efficiency removal of total nitrogen in wastewater and the reduction of sludge are realized in the same space by combined action of hydrolysis acidifying bacteria, denitrifying bacteria and anaerobic ammonium oxidation bacteria. The method is characterized in that part of NO2--N in effluent is reduced by short-chain fatty acid generated by hydrolytic acidification of residual sludge under the action of the denitrifying bacteria; and the other part of NO2--N and ammonia nitrogen released in the hydrolytic acidification process are removed by an anaerobic ammonia oxidation reaction, thereby greatly reducing the concentration of total nitrogen in the effluent and finishing the reduction of the residual sludge simultaneously. The technology is suitable for advanced treatment of high-content ammonia and nitrogen for shortcut nitrification to discharge the effluent.

Owner:TIANJIN HUANCHUANG TECH DEV CO LTD

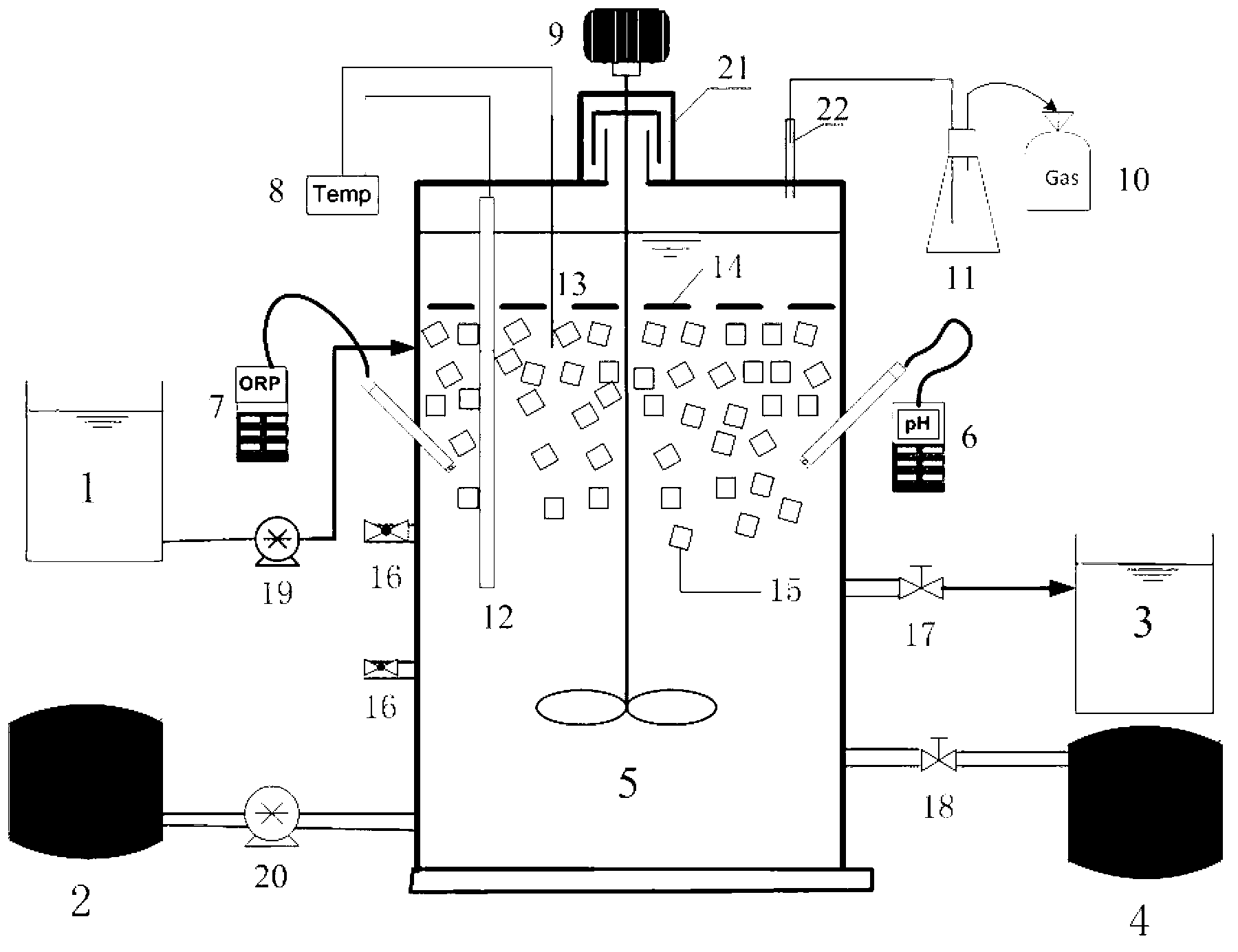

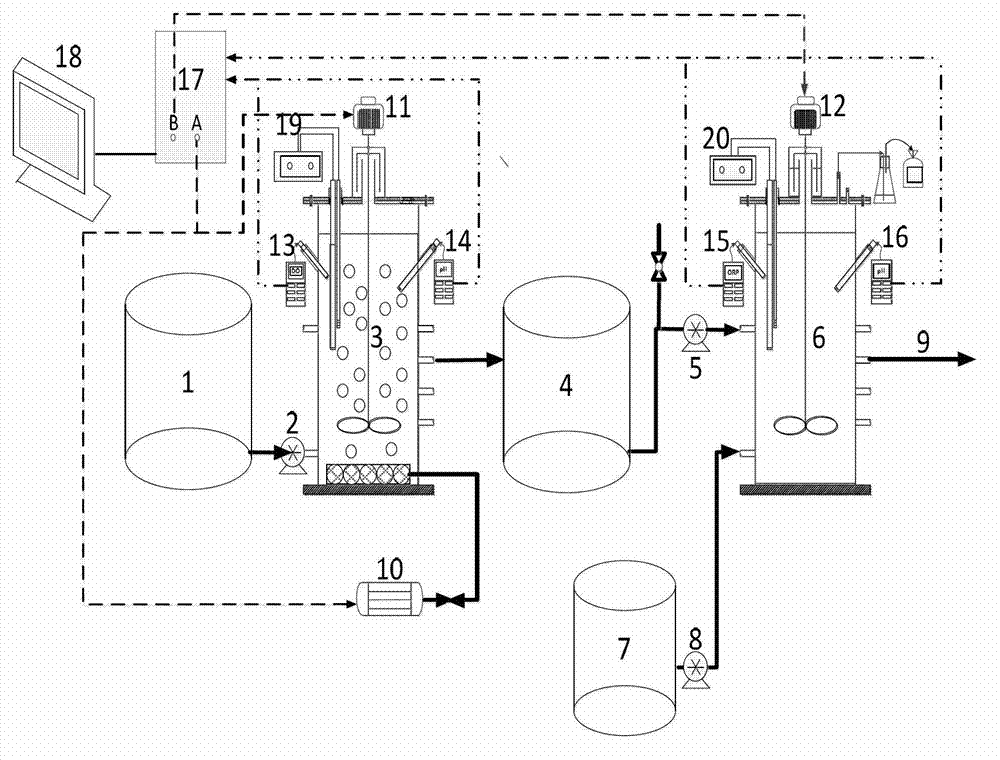

Control method and method for treating sludge digestion liquid through sludge-fermentation-coupled denitrification

ActiveCN102101745AAvoid incomplete oxidationImprove utilization efficiencyMultistage water/sewage treatmentDigestionDose Frequency

The invention discloses a control method and a control method for treating sludge digestion liquid through sludge-fermentation-coupled denitrification, and belongs to the technical fields of high-ammonia-nitrogenous wastewater treatment and primary sludge biochemical treatment. The device is provided with a raw water tank, a sludge-fermentation-coupled denitrification reactor, a sedimentation tank and a sludge storage tank; and through oxide resume power (ORP) / pH sensors arranged in an aerobic reaction area and a fermentation-coupled denitrification reaction area, the aeration amount supply, the effluent backflow ratio and the dosing frequency and quality of primary sludge are optimally controlled. The invention is suitable for optimally controlling the treatment of the sludge digestion liquid by dosing the primary sludge serving as a denitrification carbon source, and can save carbon sources and improve denitrification efficiency. In addition, the control strategy has the advantages of simple operation and obvious effect.

Owner:彭永臻

Method for enhancing nitrogen and phosphorus removal of urban sewage by sludge fermentation

ActiveCN103086511AReduce phosphorus contentGood removal effectTreatment with aerobic and anaerobic processesNitrogen removalSequencing batch reactor

The invention discloses a method for enhancing nitrogen and phosphorus removal of urban sewage by sludge fermentation, relates to the coupling control technology of sludge fermentation enhanced nitrogen and phosphorus removal technology and sludge fermentation technology, and belongs to the fields of urban sewage treatment and sludge biochemical treatment. The method employs a sequencing batch reactor to couple the sludge fermentation effect and the urban sewage nitrogen and phosphorus removal effect into a same system, so that easily degradable carbon source generated by sewage fermentation can be consumed timely by phosphorus-accumulating bacterium and denitrifying bacterium, the nitrogen removal effect of the urban sewage with a low C / N ratio is enhanced, the problem of lowered fermentation reacting rate caused by accumulation of products in the fermentation process is avoided, and the initial stabilization of primary sludge is achieved at the same time. The method for enhancing nitrogen and phosphorus removal of urban sewage by sludge fermentation is applicable to the enhanced nitrogen and phosphorus removal of the urban sewage with low C / N ratio and C / P ratio and the initial decrement and stabilization of the sludge. The method for enhancing nitrogen and phosphorus removal of urban sewage by sludge fermentation is saving in carbon source and improved in nitrogen removal efficiency, and has the advantages of simple equipment, flexible operation, high nitrogen removal efficiency and the like.

Owner:北控水务(中国)投资有限公司

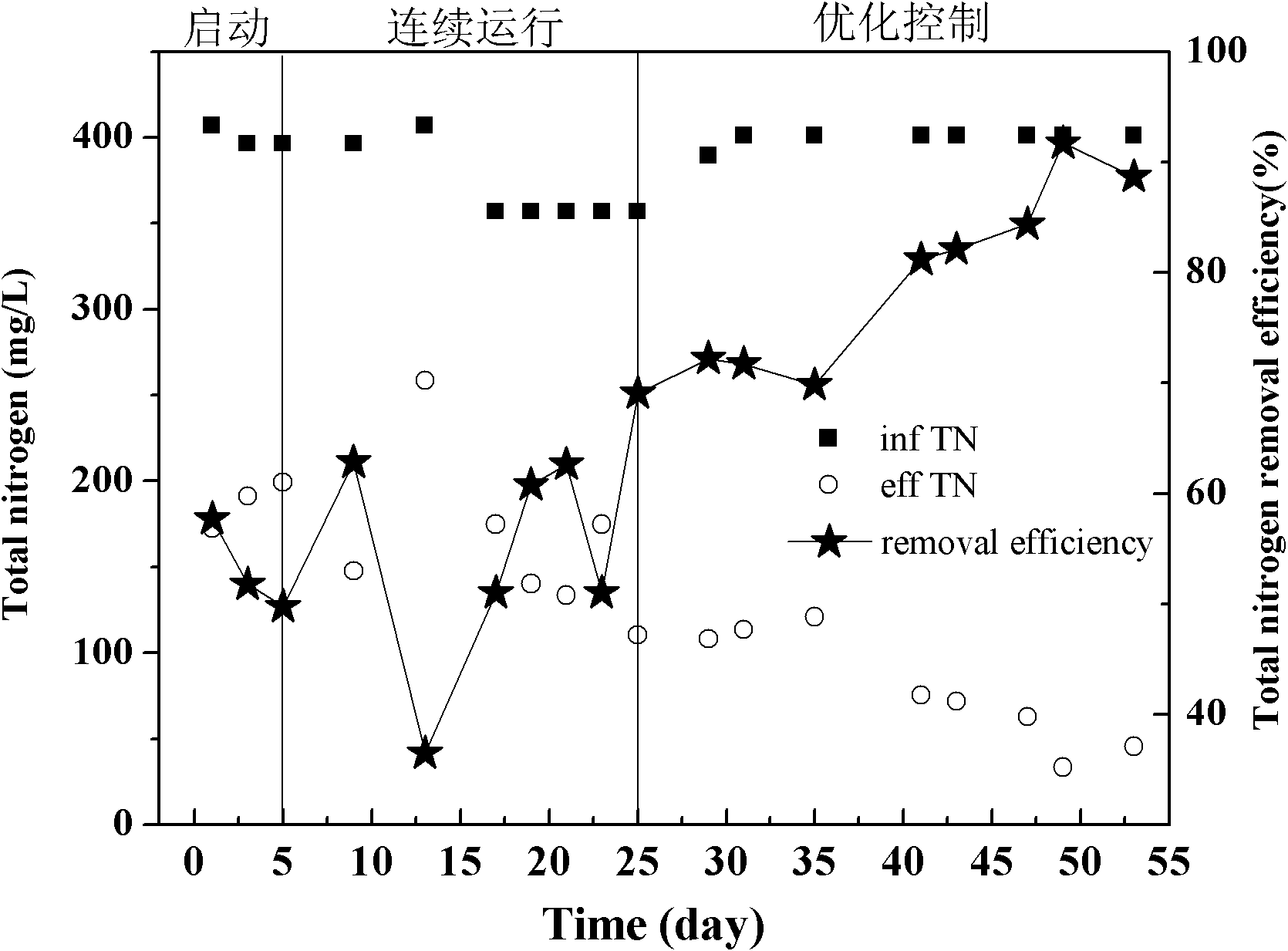

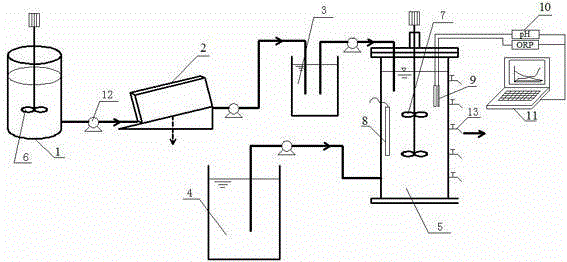

Device and method for realization of partially denitrified synchronous autotrophic nitrogen removal by sludge fermentation coupled denitrification

InactiveCN103601289AAchieve reductionImplement resourcesWater contaminantsTreatment with anaerobic digestion processesTotal nitrogenWater processing

The invention discloses a device and a method for realization of partially denitrified synchronous autotrophic nitrogen removal by sludge fermentation coupled denitrification, and belongs to the technical field of water treatment; the device comprises a sludge hydrolysis acidification reactor, a sludge dewatering machine, a fermentation liquid reserve tank, a raw water tank and a partially denitrified synchronous autotrophic nitrogen removal reactor; the denitrification method is as follows: putting sludge into the sludge hydrolysis acidification reactor for anaerobic hydrolysis acidification, then sending a sludge water mixed liquid into the sludge dewatering machine, sending a dewatered fermentation liquid into the fermentation liquid reserve tank, pumping nitrate wastewater in the raw water tank into the partially denitrified synchronous anaerobic ammonia oxidation reactor, meanwhile pumping the fermentation liquid into the reactor for a denitrified synchronous anaerobic ammonia oxidation reaction, when a pH curve displayed in a control system is no longer risen and an ORP (oxidation-reduction potential) curve is no longer dropt, discharging a supernatant with a volume of 1 / 2-2 / 3 of the effective volume of the reactor. The device and the method save the processing cost, and are simple in operation, the system effluent TN (total nitrogen) is less than 5mg / L, and deep nitrogen removal efficiency can be achieved.

Owner:NORTHEAST NORMAL UNIVERSITY

Composite conditioner for preparing sludge compost and application thereof

InactiveCN101913920APromote degradationShorten the fermentation cycleBio-organic fraction processingClimate change adaptationCelluloseSludge compost

The invention discloses a composite conditioner for preparing a sludge compost and application thereof. The composite conditioner for preparing the sludge compost is combined by an agricultural waste fermentation product and non-metallic ore powder in a volume ratio of 1-10:5-1, wherein the agricultural waste fermentation product is prepared by performing direct pile fermentation on one or a mixture of more of sawdust, barks, rice hulls, straw and bagasse or adding zymophyte for aerobic fermentation; and the non-metallic ore powder is one or more of pearlite, vermiculite, zeolite, medical stone and sepiolite with the grain size of smaller than 0.5cm. The composite conditioner can quickly degrade cellulose, shorten the sludge fermentation period to 7-15 days, improve the C / N ratio of the sludge and reduce the diffused odor, also can adjust the pH value of mixed materials, is more favorable for the growth of microorganisms, and can improve fertilizer efficiency and improve the soil.

Owner:娄底市裕德科技有限公司

Method for processing urban sewage nitrifying liquid by sludge fermentation and denitrification coupled with anaerobic ammonia oxidation

ActiveCN103121752ALow costInhibition releaseTreatment with anaerobic digestion processesTotal nitrogenBiochemical Process

The invention discloses a method for processing urban sewage nitrifying liquid by sludge fermentation and denitrification coupled with anaerobic ammonia oxidation, and belongs to the technical field of sewage treatment by a biochemical process. Efficient removal of total nitrogen wastewater in the same space is achieved by combined action of hydrolytic acidate bacteria, denitrifying bacteria and anaerobic ammonium oxidation bacteria. The method concretely comprises the steps of restoring NO3-N into NO2-N and N2 by short-chain fatty acid produced by primarily participated sludge in a hydrolysis acidification process in a single reactor; and removing NO2-N accumulated in the denitrification process and ammonia nitrogen released in the hydrolysis acidification process by anaerobic ammonia oxidation reaction. Thus, the total nitrogen concentration of the outlet water is greatly reduced; and minimization of the primarily participated sludge is finished at the same time. Thus, the technology is suitable for deep treatment of nitrifying water of urban sewage.

Owner:SDIC XINKAI WATER ENVIRONMENT INVESTMENT CO LTD

Device and method for strengthening sludge fermentation by FNA and realizing short-distance nitrogen and phosphorus removal of wastewater

ActiveCN108217950AComplex structureStrong impact resistanceWater contaminantsTreatment with aerobic and anaerobic processesAmmonia-oxidizing bacteriaOxygen

The invention discloses a device and a method for strengthening sludge fermentation by FNA and realizing short-distance nitrogen and phosphorus removal of wastewater, and belongs to the field of wastewater and sludge treatment. The device comprises a raw water tank, an SBR reactor, an intermediate water tank, a UASB reactor, a sludge treatment reactor, and a sludge fermentation tank. According tothe method, FNA is used for inhibiting nitrite oxidizing bacteria to achieve short-cut nitrification and taken as sludge fermentation pretreatment step to promote the combination of hydrolysis and acidification, a part of sludge discharged by a short-range nitrification reactor is returned after being treated by FNA, and the other part of the sludge enters into the sludge fermentation tank. The SBR reactor firstly performs anoxic denitrification to remove excessive nitrite in the upper cycle, then anaerobic phosphorus release, aerobic phosphorus absorption and partial short-range nitrification, effluent enters UASB together with sludge fermentation broth, a part of ammonia nitrogen and nitrite are subjected to autotrophic nitrogen removal through anaerobic ammonia oxidizing bacteria, and residual nitrite and produced nitrate nitrogen are removed by denitrification of organic matters in the sludge fermentation broth. According to the invention, FNA is used for promoting the developmentof an internal carbon sources and realizing nitrogen and phosphorus removal of municipal wastewater, and the amount of the sludge is reduced, and the energy consumption of wastewater treatment is reduced.

Owner:BEIJING UNIV OF TECH

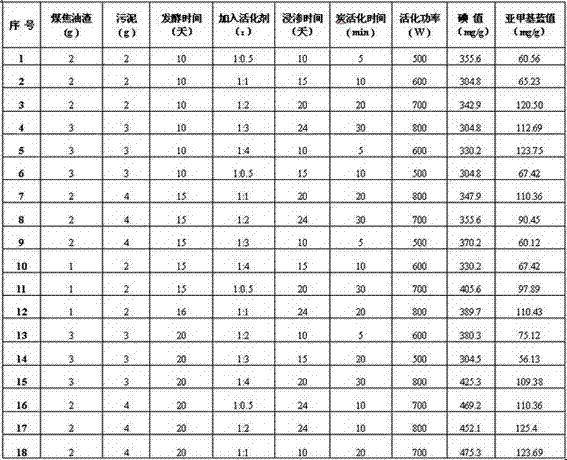

Method for producing activated carbon by thermally activating coal tar dreg/ sludge fermentation body by using microwaves

ActiveCN102381705ALower activation energyReduce manufacturing costActivated carbonIndustrial effluent

The invention discloses a method for producing activated carbon by thermally activating a coal tar dreg / sludge mixed fermentation body by using microwaves. The method comprises the steps of: firstly crushing and grinding coal tar dreg into more than 200 meshes, then, mixing the ground coal tar dreg with sludge, and performing aerobic fermentation for 10-20 days; then, adding zinc chloride servingas an activator into the mixed fermentation body, and infiltrating for 12-24h at 70-80 DEG C, wherein the added zinc chloride is 0.5-4 times more than the mixed fermentation body in mass; and finally, carbonizing and activating for 30-120min in a microwave carbonization furnace under a N2 protection condition to obtain coal tar dreg / sludge mixed activated carbon, washing with water till a neutralcondition is achieved, and drying to obtain a product disclosed by the invention. The method disclosed by the invention has the advantages of simplicity and convenience for operation, easiness for control, low cost, high product synthesis rate and favorable product performance, and can be widely applied to industrial wastewater treatment, refractory wastewater treatment, sound insulation, noise reduction, deodorization, oil absorption, lipid suction and other industries.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Ecological method for restoring polycyclic aromatic hydrocarbon polluted farmland soil

InactiveCN101797581AGuaranteed incomeImprove fertilityContaminated soil reclamationPolycyclic aromatic hydrocarbonGrowth plant

The invention provides an ecological method for restoring polycyclic aromatic hydrocarbon polluted farmland soil, which comprises the following steps: selecting plants such as corns, soybean, castor-oil plants and alfalfa with the restoring function of the polycyclic aromatic hydrocarbon polluted soil for seeding according to a plant conventional mode, wherein the plant growth period is one growth season and is between 100 and 150 days; 2, applying efficient biological microbial agents to farmland at 5 to 10 days before the plant seeding with the application amount between 40 to 50 kg / mu, and carrying out ploughed fallow on the farmland in 24 hours after the application; 3, applying sludge fermentation fertilizer into the farmland at 2 to 3 days before the plant seeding with the application amount of 100 to 200 kg / mu, and carrying out ploughed fallow and ridge preparation on the land in 24 hours after the application; and 4, installing a water discharge pump used for water discharge in a rain reason in the restoring field every 4 to 5 ridges of the land, and carrying out ploughed fallow for 2 to 3 times in each month of the three months before the plant growth. The invention has the characteristics of low cost, strong operability, no secondary pollution and high restoring efficiency.

Owner:SHENYANG UNIV

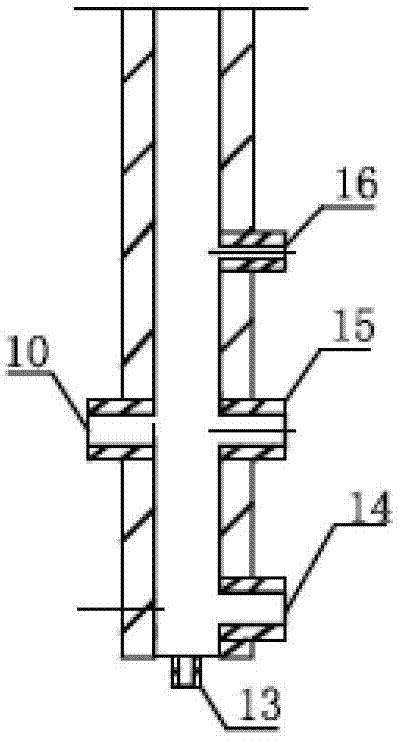

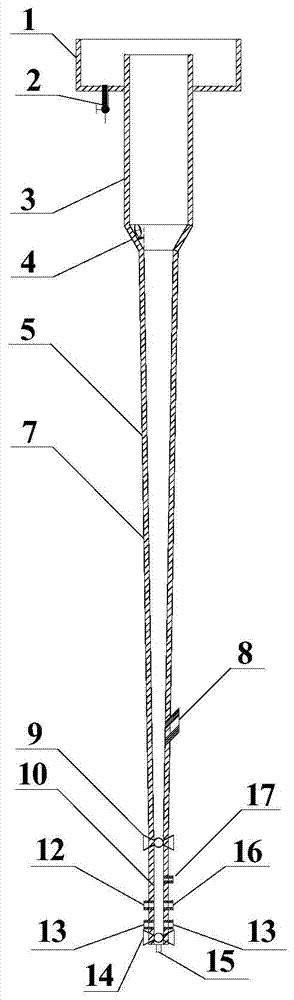

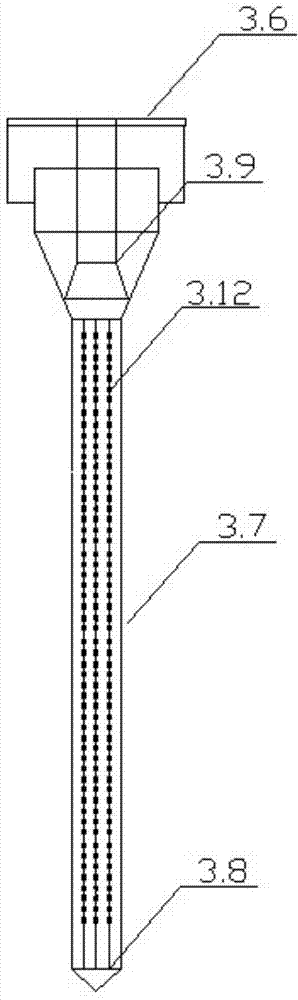

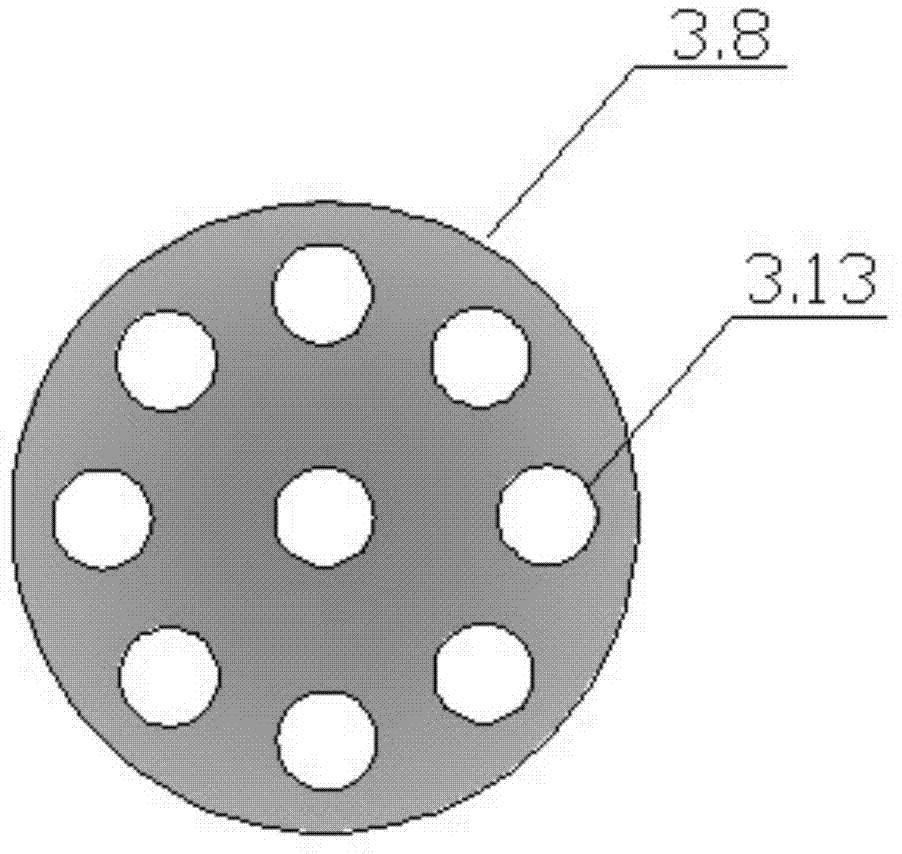

Method for recycling high concentration ammonia nitrogen and making ammonia nitrogen into large granule high purity struvite

ActiveCN103935974AAvoid lostAvoid breakingWater/sewage treatmentPhosphorus compoundsHigh concentrationChemistry

The invention relates to a method for recycling high concentration ammonia nitrogen and making ammonia nitrogen into large granule high purity struvite. At first, a granulating main body is changed to a three-section tapered fluidized bed reactor. The reactor is composed of a feeding tube, a granulating tube, and a sediment tube; the connection part between the sediment tube and the granulating tube is in a truncated cone shape, the inclined angel theta of the generatrix of the connection part is 25 degree to 45 degree; the ratio of the external diameter of the big end of the granulating tube to the external diameter of the small end of the granulating tube is equal to 3:1; the ratio of the length of the granulating tube to the external diameter of the small end of the granulating tube is equal to 50:1; a pH probe is arranged in the granulating tube, the bottom of the granulating tube and the top of the feeding tube are both provided with a granulating tube valve; the bottom of the feeding pipe which is provided with five material inlets is provided with a discharging valve; and the length ratio of the sediment tube to the granulating tube to the feeding tube is equal to 2:5:1. High concentration nitrogen-phosphor wastewater with a NH4<+>-N concentration of 1000 to 1600 mg / L and a magnesium chloride solution are simultaneously pumped into the granulating main body, at the same time the mole ratio of NH4<+>-N: PO4<3>-P:Mg<2+> is controlled at 1.5:1:1.1-1.5:1:1.3, the pH value is controlled at 6 to 7, the reflux ratio is controlled at 12 to 30, the diameter of the formed struvite particle is in a range of 3 to 8 mm, the purity of the struvite particle can reach 97.5% or more, and the hardness of the struvite particle is (20.3 + / - 1) kg / mm2. The method can used to prepare struvite from high concentration ammonia nitrogen industrial and poultry culture wastewater, garbage leachate, or sludge fermentation broth.

Owner:TONGJI UNIV

Sludge fermentation dehydration drying method

ActiveCN101007695ALow calorific valueSpeed up fermentationSludge treatment by de-watering/drying/thickeningClimate change adaptationCaloric valuesFilter press

The invention discloses a ferment dewater drying method of sludge, which comprises the following steps: inputting sludge with moisture percentage at 90-97% into tempering groove; adding Fe3+ with 0.5-1.5% and Ca2+ or chemical materials to stir and mix 8-16min; tempering evenly; injecting modified sludge into plate filter press; keeping 30-70min at 1.5Mpa-2.5Mpa; descending moisture percentage of sludge to about 55-65%; introducing sludge of being pressed to sludge fermentation tank through band carrier; blowing air through the bottom with volume of blast at 4500-5000m3 / h; accelerating speed of fermentation to dry water from sludge. The invention can drop caloric value of sludge.

Owner:SWISON CREATIVE ENVIRONMENTAL SOLUTIONS CO LTD

Method for accelerating anaerobic fermentation of residual sludge by utilizing zero-valent iron technology

ActiveCN103288319APromote reductionHigh yieldWaste based fuelBiological sludge treatmentTemperature controlAnaerobic microorganisms

A method for accelerating anaerobic fermentation of residual sludge by utilizing a zero-valent iron technology comprises the following steps: mixing a high solid sludge with a solid ratio of less than 10% and iron scraps, putting the mixture into an anaerobic fermentation reactor, and inoculating with anaerobic microorganisms; undergoing the anaerobic fermentation in the reactor with stirring, and collecting methane generated during the fermentation process; having requirements of the stirring speed, the pH value in the reactor, the temperature control during the stirring process; after finishing fermentation, discharging the sludge, wherein the residual iron scraps remaining in the anaerobic fermentation reactor are used for next batch of the sludge fermentation. With the method for accelerating the anaerobic fermentation of the residual sludge by utilizing the zero-valent iron technology, the following technical effects are achieved: reduction of the high solid sludge is promoted after the anaerobic fermentation, and at the same time, the methane generation amount during the fermentation process is improved. The method has low investment cost, simple technical operation, and strong processing ability, and can be applied to upgrade reconstruction of new built sludge anaerobic fermentation equipment or existing equipment.

Owner:DALIAN UNIV OF TECH

A kind of method for processing sludge fermentation to produce bio-organic fertilizer

InactiveCN102260104ANitrogen fixation, phosphorus and potassiumStrong for fatteningBio-organic fraction processingClimate change adaptationProcess equipmentBiochemical engineering

The invention discloses a method for producing a high-efficiency biological organic fertilizer by quickly fermenting sludge. The method comprises the following steps of: preparing a culture medium; fermenting; crushing; balling; drying; cooling and the like. The method has the advantages of wide raw material sources, simple process equipment, low cost, convenience in operation, and short fermentation time; and the fermented sludge can be used for producing the organic fertilizer, so that the technical problems of secondary environmental pollution and the waste of massive organic fertilizer sources in the prior art are solved.

Owner:YANTAI UNIV

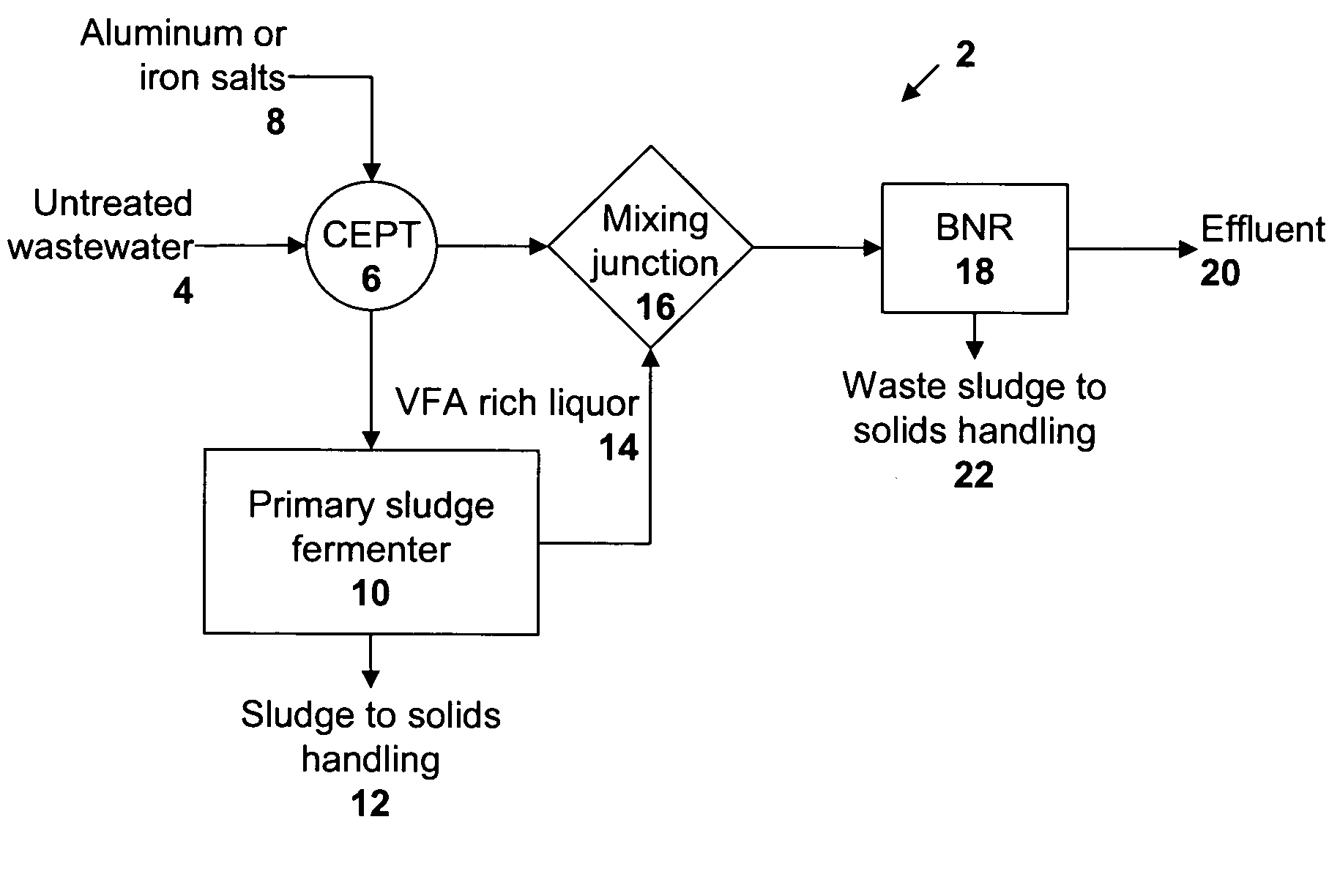

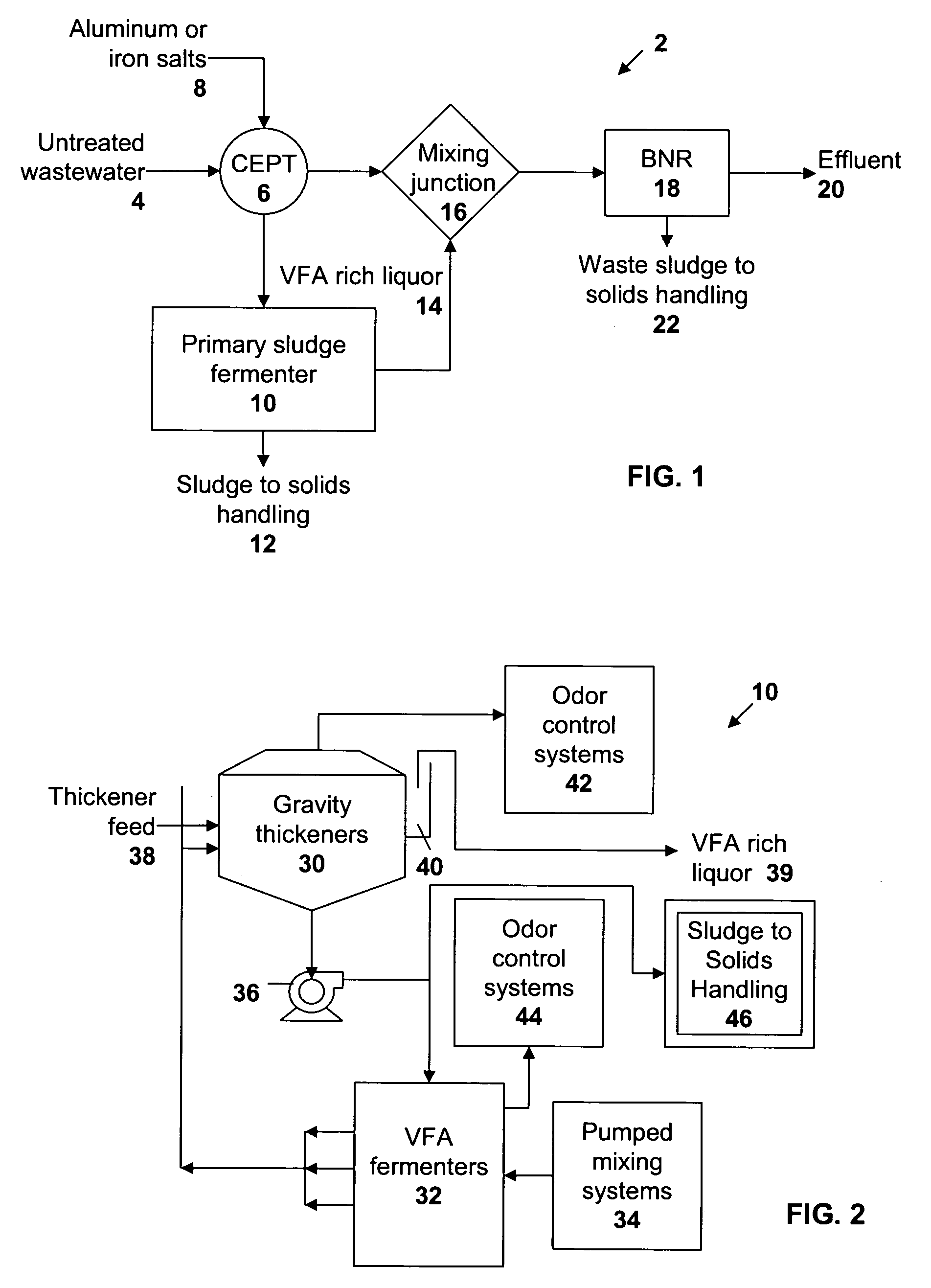

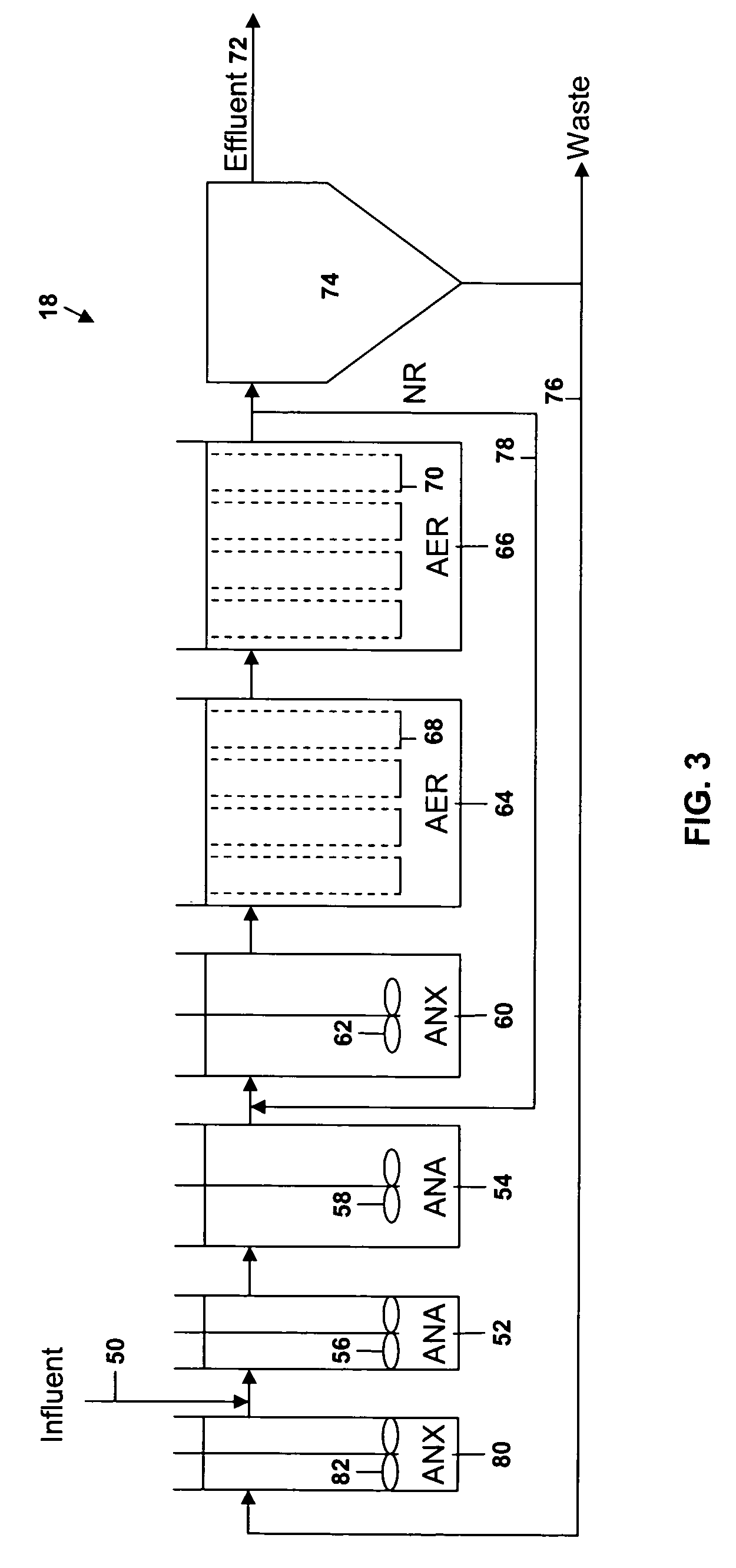

Chemically enhanced primary sludge fermentation method

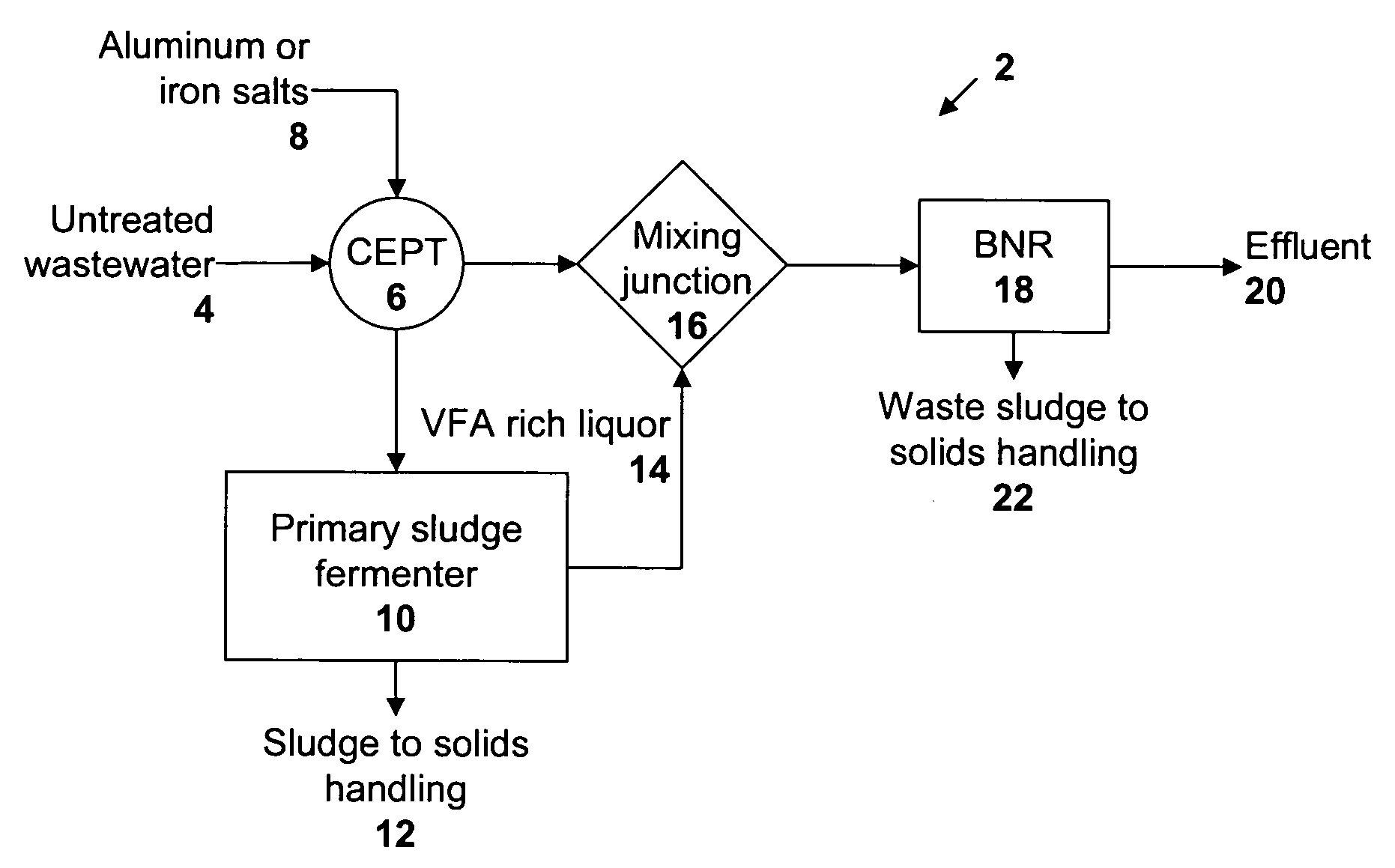

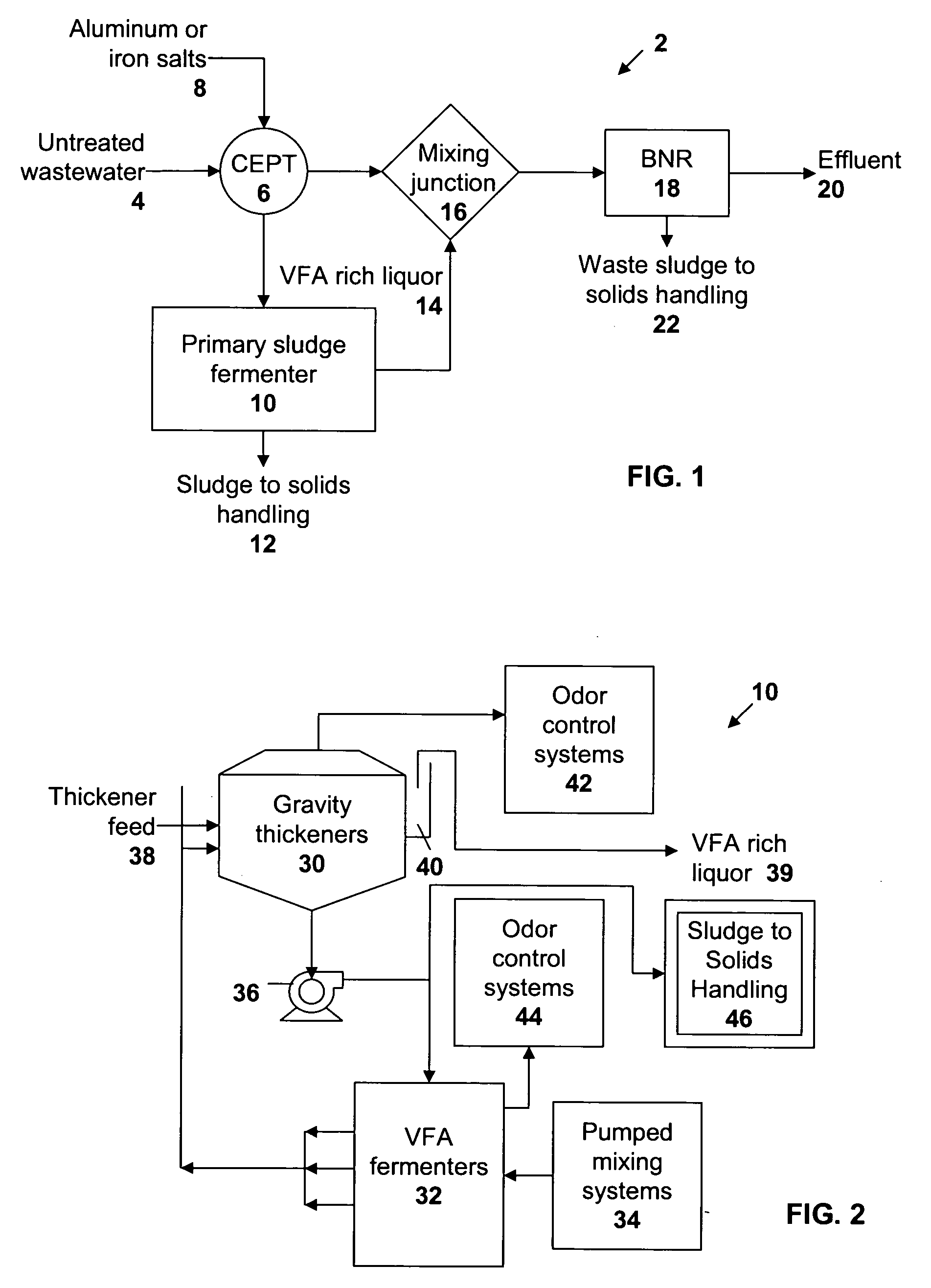

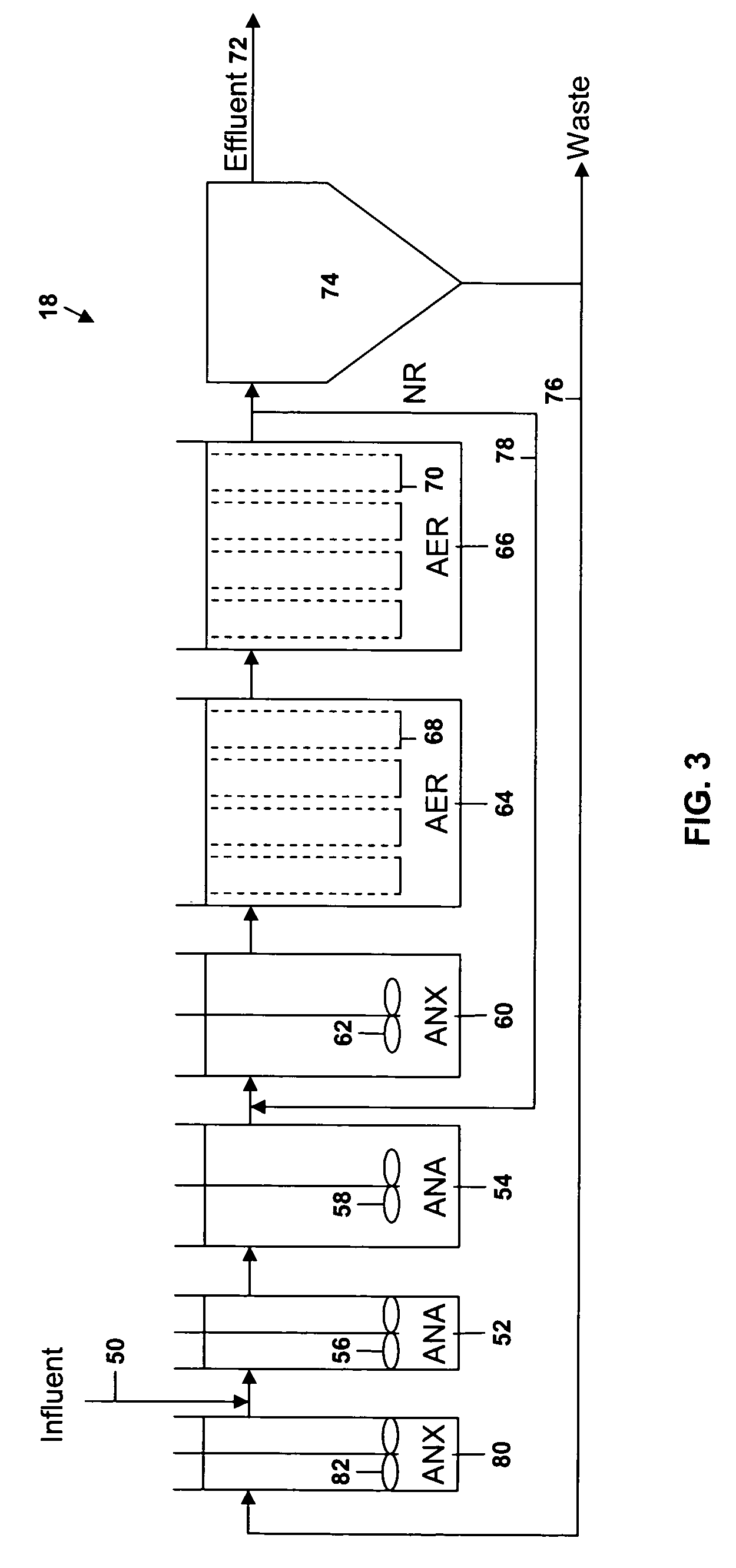

ActiveUS6982036B2Easy to separateImprove the level ofSludge processingSeparation devicesChemical treatmentIron salts

A method of treating wastewater to increase effluent volatile fatty acid content consisting of providing wastewater to a primary treatment vessel and adding a select quantity of a chemical, typically an aluminum or iron salt, to the wastewater, enhancing the separation of organic matter. Separated organic matter is then removed from the chemically treated wastewater forming a primary sludge and a primary effluent. A portion of the primary sludge is fermented to form a volatile fatty acid rich liquor. The volatile fatty acid rich liquor may then be used with the primary effluent, directed to a bioreactor, thereby forming a volatile fatty acid enriched bioreactor feed. The volatile fatty acid enriched influent may be further treated through known biological phosphorous and nitrogen removal methods.

Owner:CH2M HILL

Process for preparing fresh scent strong-flavor Chinese spirit

InactiveCN103666927AHas a strong fragrance styleOvercoming technical difficulties in anaerobic cultureAlcoholic beverage preparationAcetic acidYeast

The invention discloses a process for preparing fresh scent strong-flavor Chinese spirit. The process comprises distiller's yeast preparation, bacterial sludge preparation, construction of bacterial sludge pits and fermenting and distilling, wherein the step of bacterial sludge preparation comprises material pretreatment, culture of methane bacteria liquid and pit sludge fermentation and culture. Sludge pits in which methane bacteria serve as a primary flora and caproic acid bacteria serve as a secondary flora are constructed by adopting common conditions such as tile crocks and pits in common liquor factories, and conditions are created for producing fresh scent strong-flavor Chinese spirits. According to the process, the technical problem of factory-like methane bacteria anaerobic culture is overcome, and preparation of the sludge pits in which methane bacteria serve as the primary flora and caproic acid bacteria serve as the secondary flora is realized. The liquor is brewed by utilizing the prepared sludge pits and process thereof, and a fresh scent strong-flavor Chinese spirit with a primary component of ethyl acetate, a secondary component of ethyl caproate and an auxiliary material of 2,3-butanedione is formed. Partial characteristics of traditional daqu liquor and Xiaoqu wine processes are combined, and a process of the fresh scent strong-flavor Chinese spirit is formed.

Owner:DAZHOU CHUANHU FOOD

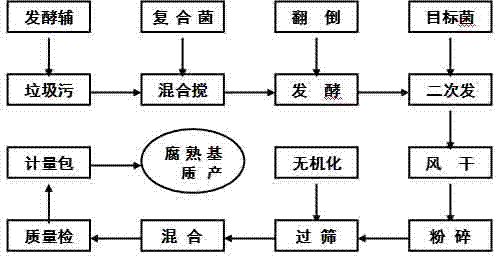

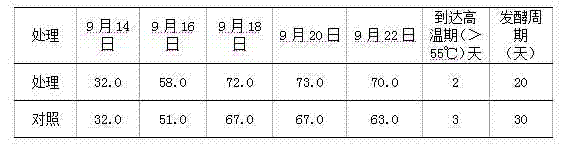

Domestic garbage and sludge decomposing bacterium agent and application thereof and prepared decomposing matrix

ActiveCN103966149AImprove qualityPromote repairPlant growth regulatorsBio-organic fraction processingTrichoderma longibrachiatumAspergillus niger

The invention discloses a rural domestic garbage and sludge decomposing bacterium agent and a using method as well as a decomposing matrix prepared by using the bacterium agent and a specific process through fermentation. The bacterium agent is compounded by 0.5-2 parts of bacillus subtilis, 0.5-2 parts of streptomyces microflavus, 0.5-2 parts of trichoderma longibrachiatum, 0.5-2 parts of aspergillus nige and 0.5-2 parts of bacillus mucilaginosus in parts by weight; the effective viable count of the bacterium agent is 5*10<8> / g; the bacterium agent can be used for decomposing garbage and sludge, deodorizing, resisting fusarium wilt of cucumber and increasing the yield when being applied to crops; the fermentation period of the treated garbage and sludge is 20 days when the bacterium agent is inoculated and 30 days when the bacterium agent is not used. The decomposing matrix is prepared by adding 1 kilogram of bacterium agent into every 5 square mixture through the specific process and fermentation; the mixture is formed by mixing 40-60% of domestic garbage, 20-40% of sludge and 5-15% of corn straws in percentage by weight; when the matrix is applied in cucumber cultivation, the yield is increased by 11% per mu, the income is increased by 859 yuan, and 200mL of pesticide is saved.

Owner:天津市农业科学院

Chemically enhanced primary sludge fermentation method

ActiveUS20050016920A1Increase effluent volatile fatty acid contentEasy to separateSludge processingSeparation devicesChemical treatmentIron salts

A method of treating wastewater to increase effluent volatile fatty acid content consisting of providing wastewater to a primary treatment vessel and adding a select quantity of a chemical, typically an aluminum or iron salt, to the wastewater, enhancing the separation of organic matter. Separated organic matter is then removed from the chemically treated wastewater forming a primary sludge and a primary effluent. A portion of the primary sludge is fermented to form a volatile fatty acid rich liquor. The volatile fatty acid rich liquor may then be used with the primary effluent, directed to a bioreactor, thereby forming a volatile fatty acid enriched bioreactor feed. The volatile fatty acid enriched influent may be further treated through known biological phosphorous and nitrogen removal methods.

Owner:CH2M HILL

Method for producing acid through promoting anaerobic fermentation of residual sludge by virtue of rhamnolipid biosurfactant

InactiveCN102796764APromote degradationImprove the environmentMicroorganism based processesFermentationRhamnolipidChemical Surfactants

The invention discloses a method for producing acid through promoting anaerobic fermentation of residual sludge by virtue of a rhamnolipid biosurfactant, and the method is used for solving the problems that in the existing method for producing acid through promoting the anaerobic fermentation of the residual sludge by virtue of a chemical surfactant, the chemical surfactant is toxic, can not be biodegraded and can cause the secondary pollution of the residual sludge, and the acidifying effects of the chemical surfactants sodium dodecyl sulfate and sodium dodecyl benzene sulfonate on the residual sludge are weak. The method comprises the following steps of: 1, preparing a sludge sample; 2, adding rhamnolipid; and 3, carrying out anaerobic fermentation. According to the invention, the rhamnolipid biosurfactant is good in biodegradability and environmental friendliness, can be used for gradually eliminating the toxicity and secondary pollution of the residual sludge and has the great promotion effect of acid production by the fermentation of the residual sludge. The method disclosed by the invention is used for promoting acid production by the anaerobic fermentation of the residual sludge.

Owner:HARBIN INST OF TECH

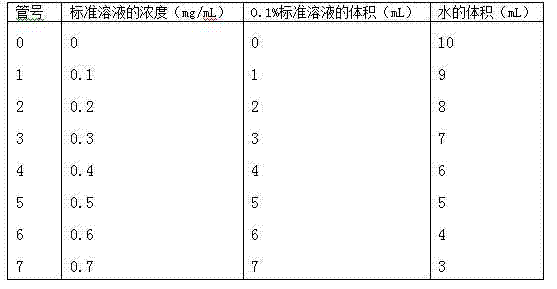

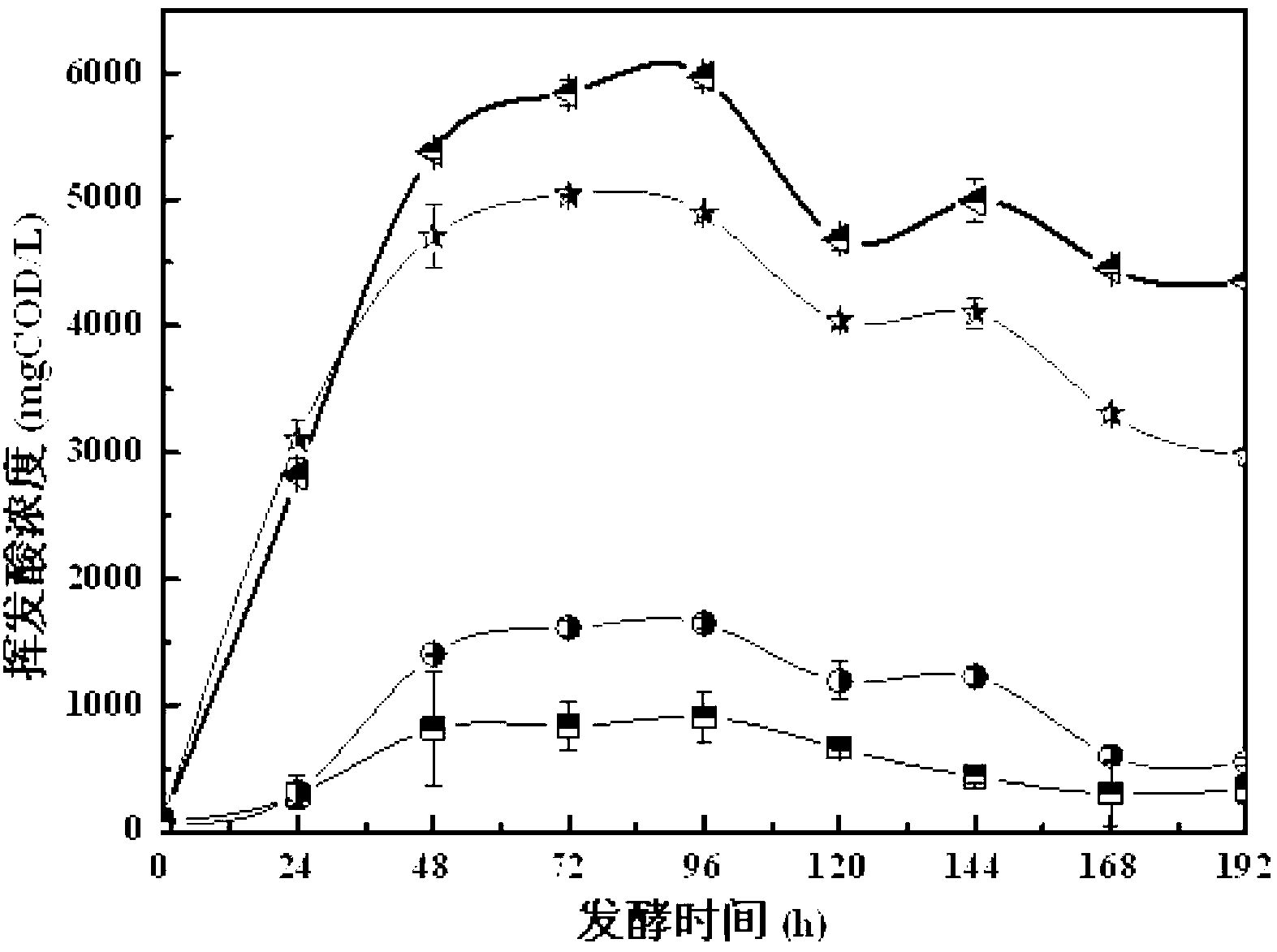

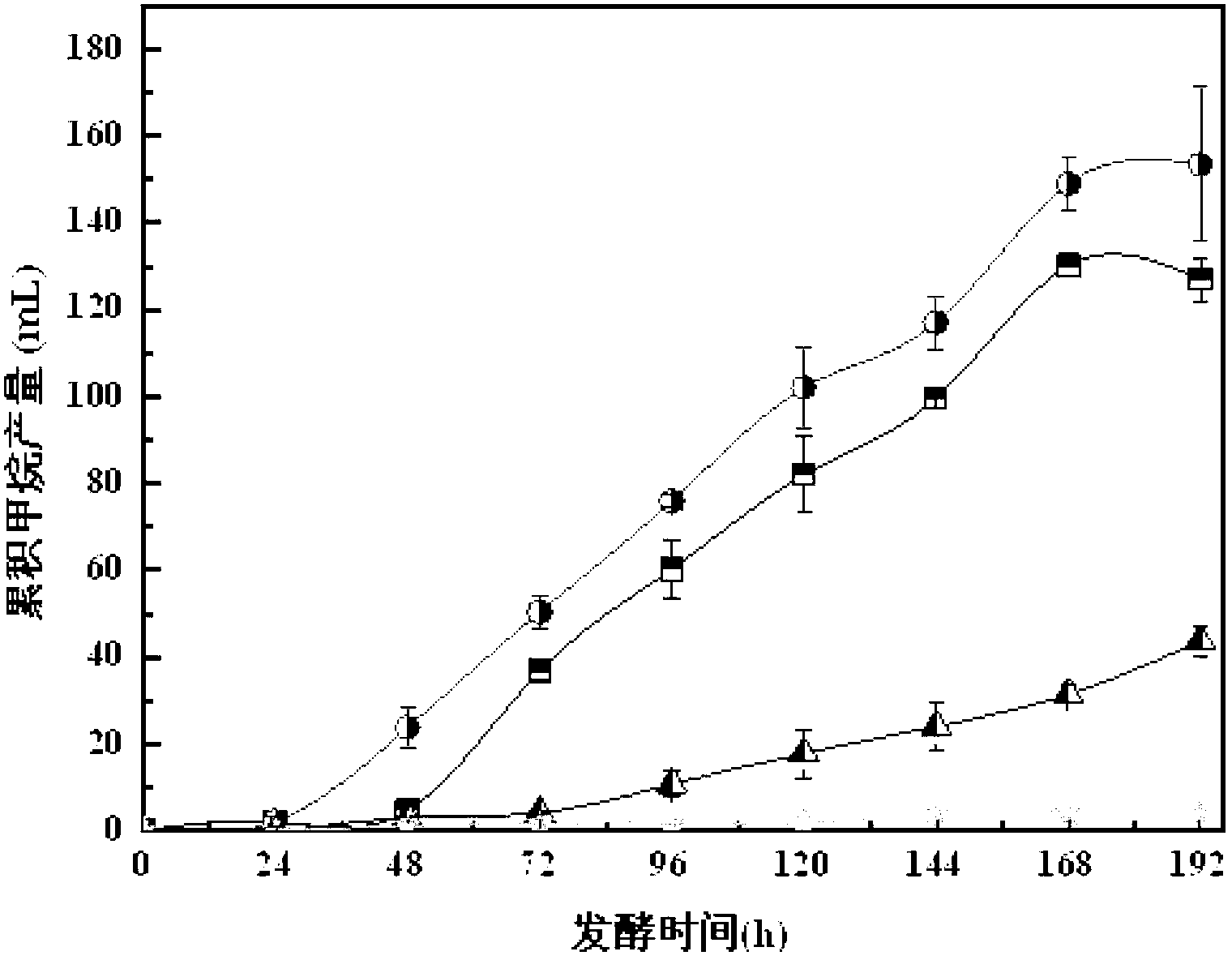

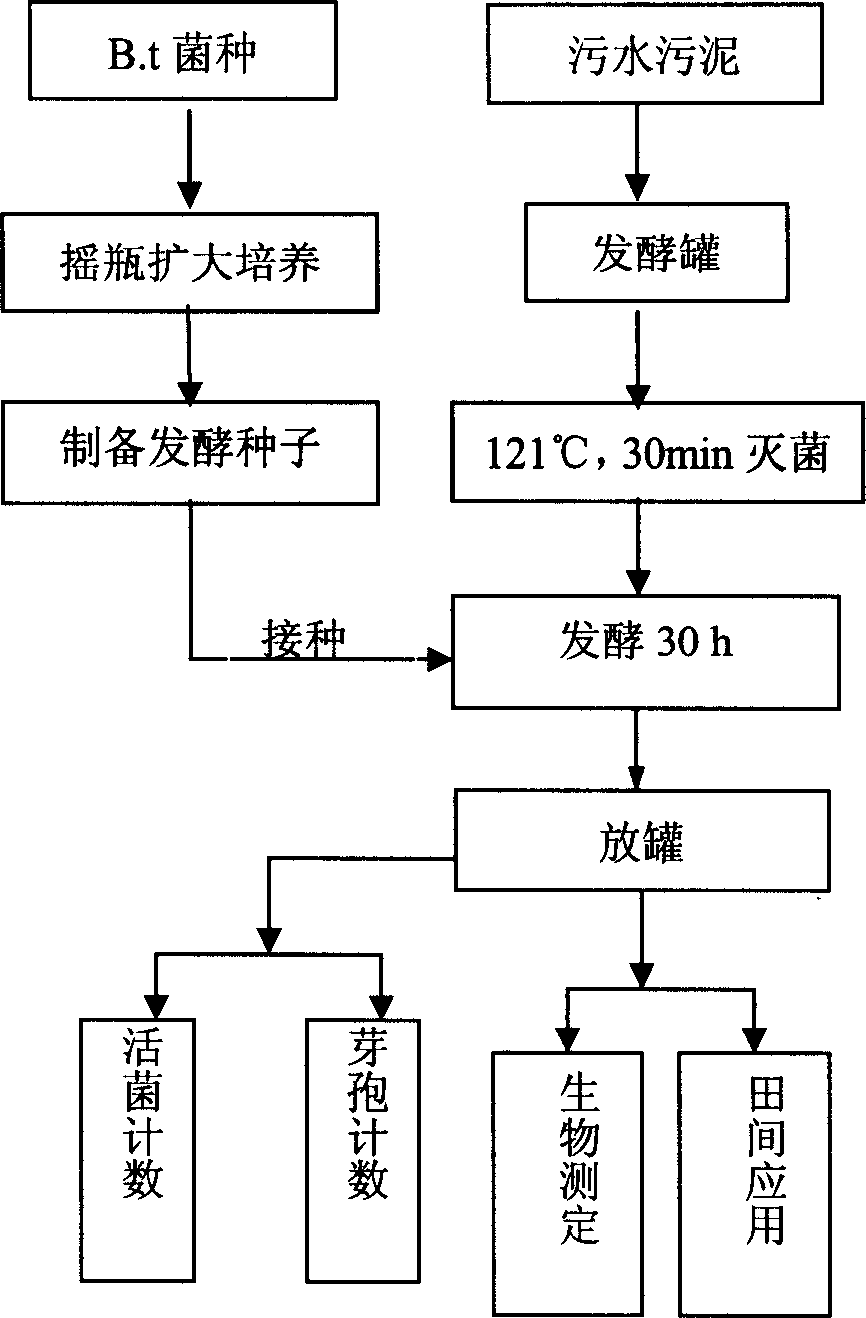

Sewage and sludge fermentation process of producing biopesticide bacillus thuringiensis

The present invention relates to technology of utilizing waste in producing high efficiency biopesticide, sewage sludge with solid content of 1.5-5 % is used as the material for fermentation producing Bacillus thuringiensis (B.t). Sludge is filled into fermenting tank, pH regulated to 7.2, sterilized at 121 deg.c for 20 min and inoculated with B.t seed in 1-4 wt%. After aerobic fermentation at 28 deg.c and 200 rpm stirring for 30 hr, the fermented matter with cell number up to 10E9 and spore accounting for over 90 % is discharged. Sludge with rich organic carbon, nitrogen and inorganic salt is excellent medium for B.t to grow, and compared with culturing in soybean powder culture medium, the sewage sludge fermentation process has 10 hr shorter production period, higher biotoxicity of crystal cell mixture and 3 times lower cost.

Owner:NANJING AGRICULTURAL UNIVERSITY

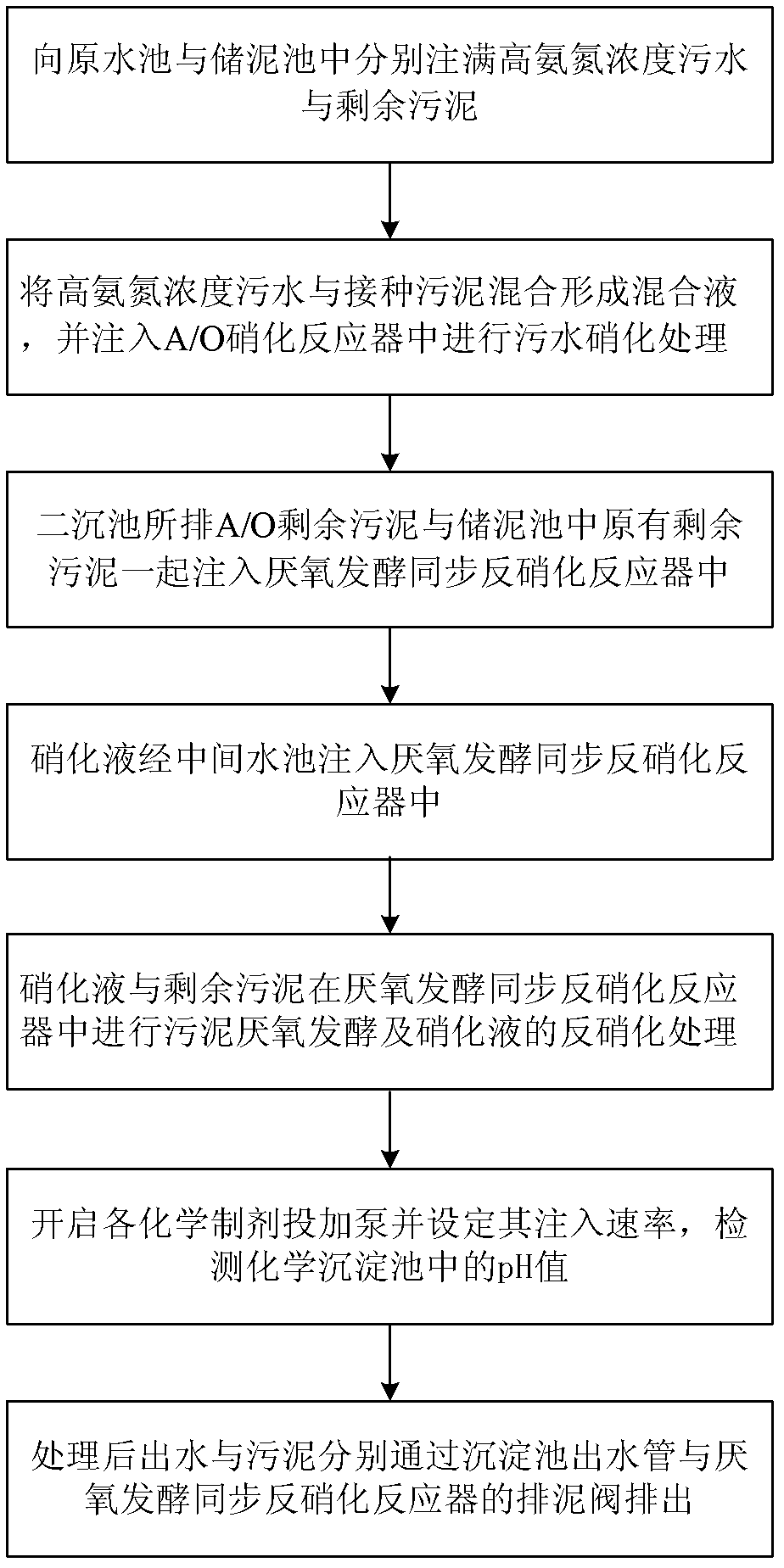

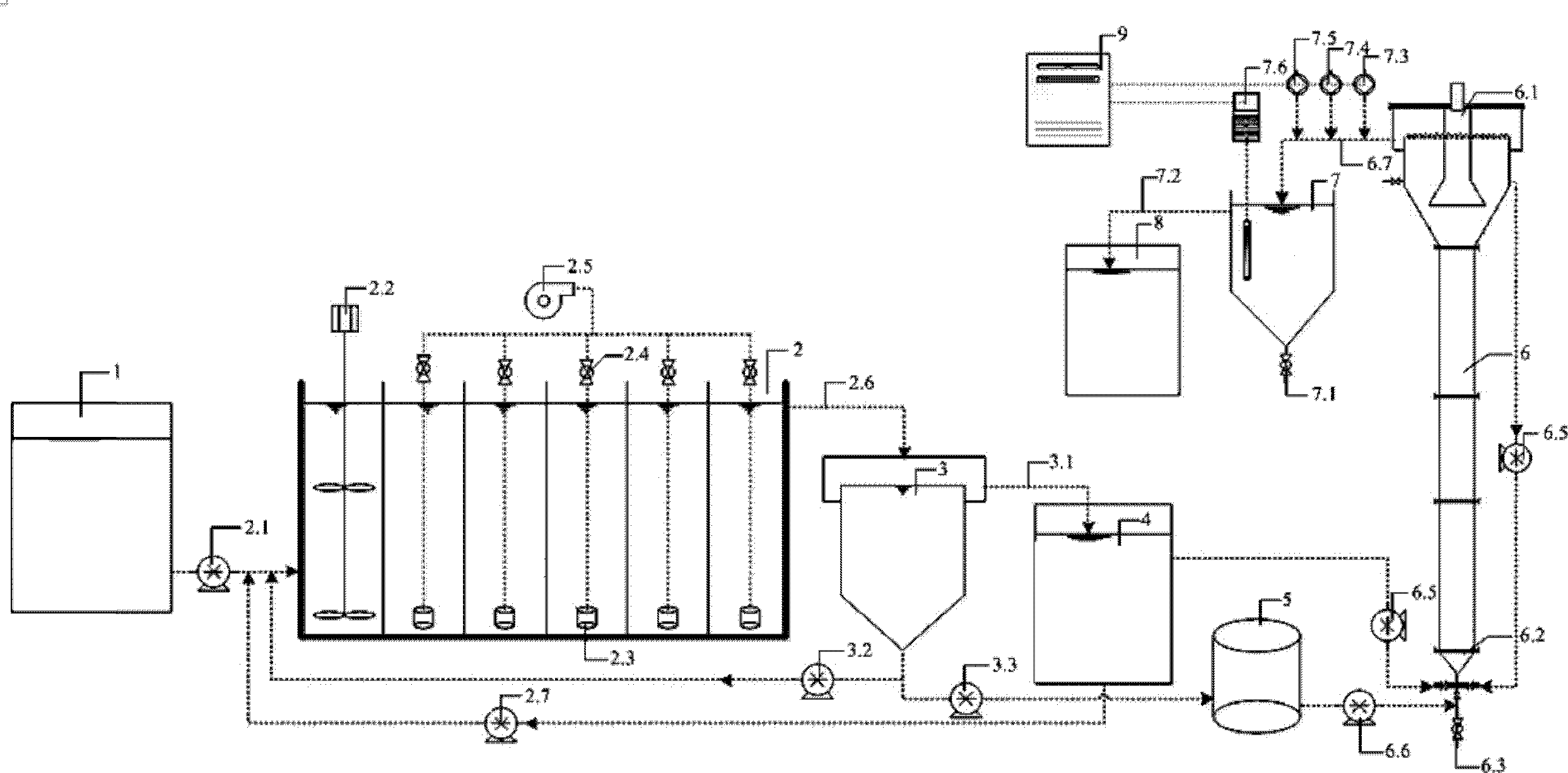

Device and method for strengthening sludge digestion and synchronously denitrifying and dephosphorizing

ActiveCN103693813AImprove denitrification effectGood removal effectMultistage water/sewage treatmentHigh concentrationCoupling

The invention relates to a device and a method for strengthening sludge digestion and synchronously denitrifying and dephosphorizing, and belongs to the technical field of low-carbon-nitrogen-ratio (C / N) and high-concentration ammonia nitrogen wastewater biological denitrification. The device is provided with a raw water tank, an A-O (anaerobic-oxic) reactor, a sedimentation tank, a sludge fermentation, coupling and denitrification synchronization autotrophic denitrification (SFDANR) reactor and a sludge storage tank, wherein the raw water tank is connected with the A-O reactor by a raw water inlet pump; a water outlet of the sedimentation tank is connected with the SFDANR reactor by a water outlet pump; and the SFDANR reactor is provided with a self-circulation pipeline. The method comprises the following steps of starting the A-O reactor, starting the SFDANR reactor, and allowing the A-O reactor and the SFDANR reactor to run in series. The device and the method are suitable for deep denitrification and dephosphorization of high ammonia nitrogen domestic sewage and a sludge digestion solution; a technology is advanced; a sludge yield is reduced effectively; and energy saving and consumption reduction advantages are obvious.

Owner:BEIJING UNIV OF TECH

Device and method for enhancing reduction of denitrified coupling sludge in urban sewage by using intra-sludge carbon sources by two stages of sequencing batch reactors (SBR)

ActiveCN103910431AEasy to purifyPromote enrichmentTreatment with aerobic and anaerobic processesSequencing batch reactorCoupling

The invention discloses a device and method for enhancing the reduction of denitrified coupling sludge in urban sewage by using intra-sludge carbon sources by two stages of sequencing batch reactors (SBR), belonging to the field of low C / N ratio(mole ratio) urban sewage treatment and excess sludge biochemical treatment. The device disclosed by the invention mainly comprises a SBR1, a SBR2 and a sequencing batch excess sludge fermentation reactor (SBRF). According to the invention, an excess sludge fermentation mixture is taken as a carbon source of SBR1 denitrification, so that biological denitrification is enhanced, and excess sludge is further reduced; deep denitrification is realized by taking excess sludge fermented liquid as a carbon source of SBR2 denitrification, so that discharged water can reach the level-A standard. According to the invention, an anaerobic biological treatment technology and an aerobic biological treatment technology are coupled so as to achieve the purposes of optimally controlling low C / N ratio (mole ratio) urban sewage treatment, saving carbon sources, improving the utilization rate of carbon sources, and reducing the yield of excess sludge. In addition, the device and method disclosed by the invention have the advantages of simple equipment, flexible operation, and the like.

Owner:BEIJING UNIV OF TECH

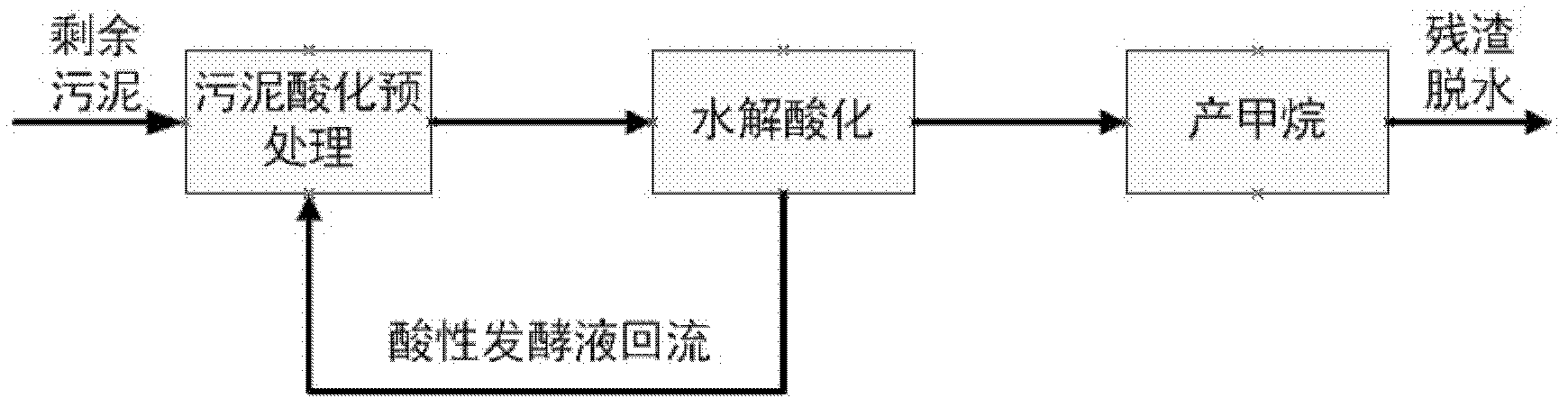

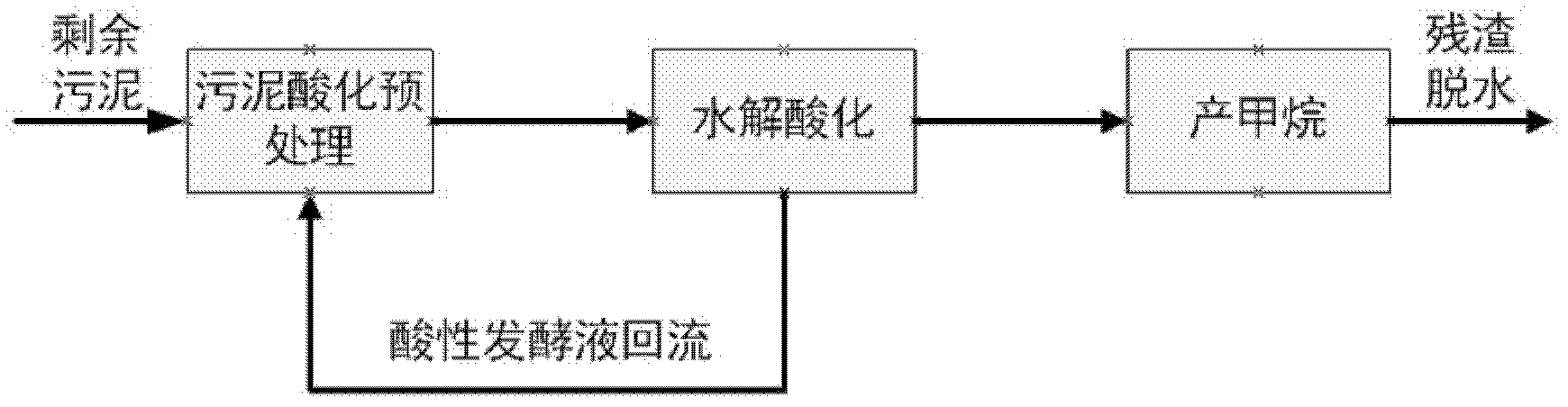

Method for treating sludge through refluxing of acidified fermentation liquor and application of method

InactiveCN102531311AIncrease productionReduce pretreatment costsWaste based fuelBiological sludge treatmentMethane productionPre treatment

The invention discloses a method for treating sludge through the refluxing of acidified fermentation liquor and application of the method. The method comprises the following steps of: performing hydrolytic acidification on the sludge, refluxing the acidified fermentation liquor of the sludge, performing acidification pretreatment on the sludge, and performing hydrolytic acidification fermentation on the pretreated sludge and producing methane by using a product. The sludge is subjected to acidification pretreatment by using the fermentation liquor of the sludge, so that the time required by anaerobic digestion is shortened, the gas yield is improved, and the operating cost is reduced.

Owner:TIANJIN UNIV

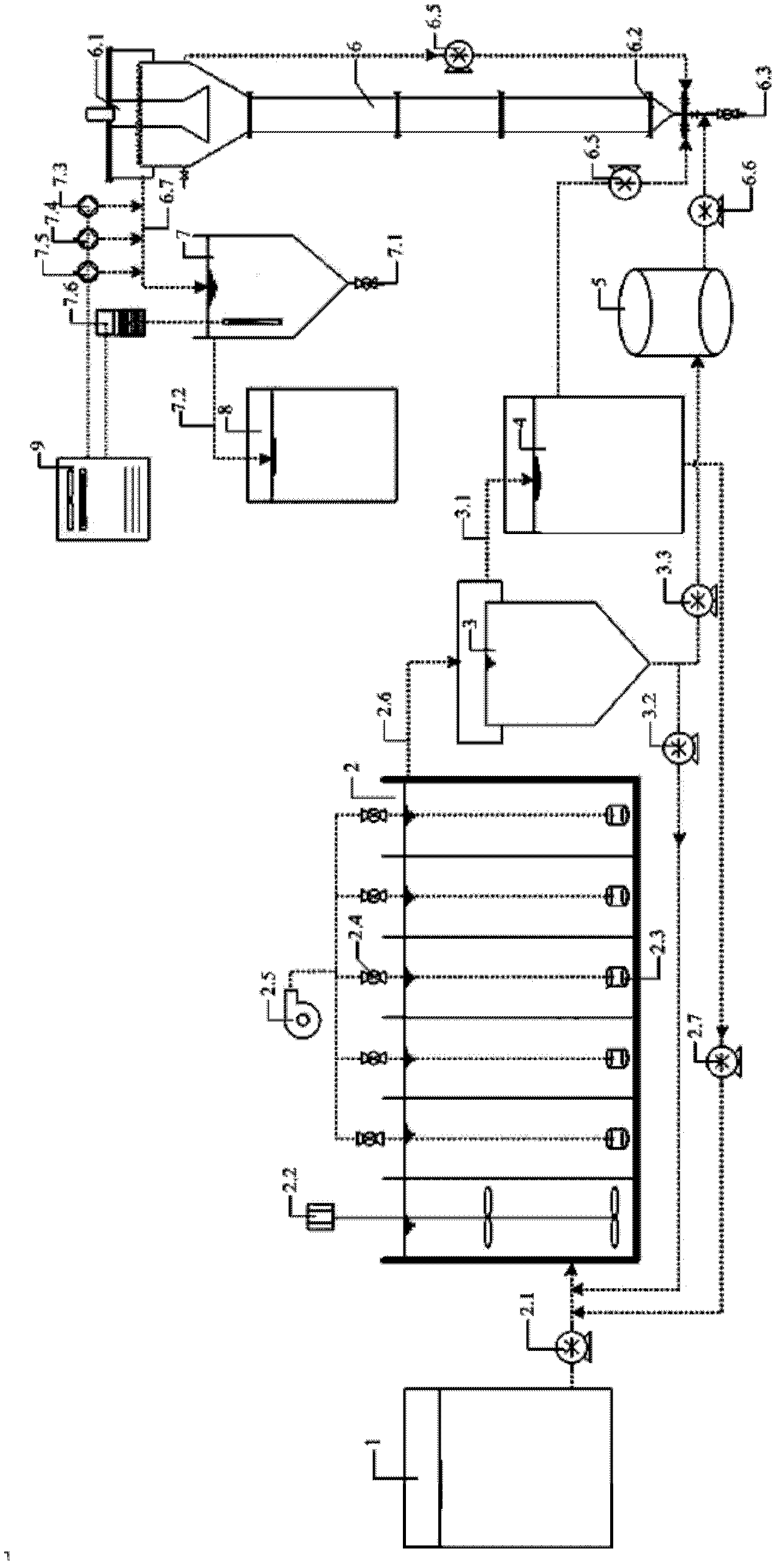

Enhanced sewage denitrification and dephosphorization system exploiting and utilizing carbon source in sludge in situ and enhanced sewage denitrification and dephosphorization method exploiting and utilizing carbon source in sludge in situ

InactiveCN102557360AReduce processing costsAchieve deep removalMultistage water/sewage treatmentBiological sludge treatmentChemical treatmentOxygen

The invention provides an enhanced sewage denitrification and dephosphorization system exploiting and utilizing the carbon source in sludge in situ and an enhanced sewage denitrification and dephosphorization method exploiting and utilizing the carbon source in sludge in situ. The treatment system comprises a raw water tank, an A / O nitrification reactor, a secondary sedimentation tank, an intermediate water tank, a sludge storage tank, an anaerobic fermentation-synchronized denitrification reactor, a chemical precipitation tank, a controller and a drain tank. The method applying the treatment system is as follows: high-ammonia nitrogen concentration sewage and residual sludge are respectively filled up in the raw water tank and the sludge storage tank, the sewage is first nitrified in the A / O nitrification reactor, the sewage and the residual sludge then enter the anaerobic fermentation-synchronized denitrification reactor together, residual sludge fermentation product is utilized as carbon source to carry out denitrification, and finally, the sewage and the sludge enter the chemical precipitation tank assorted with the on-line controller in order to precipitate and remove ammonia nitrogen and phosphorus, and are then discharged. The invention organically integrates the anaerobic biological treatment technology, the aerobic treatment technology and the chemical treatment technology in order to realize the low-carbon consumption treatment of high-pollution sewage and the reduction of residual sludge and recycle resource matters in sewage.

Owner:BEIJING UNIV OF TECH

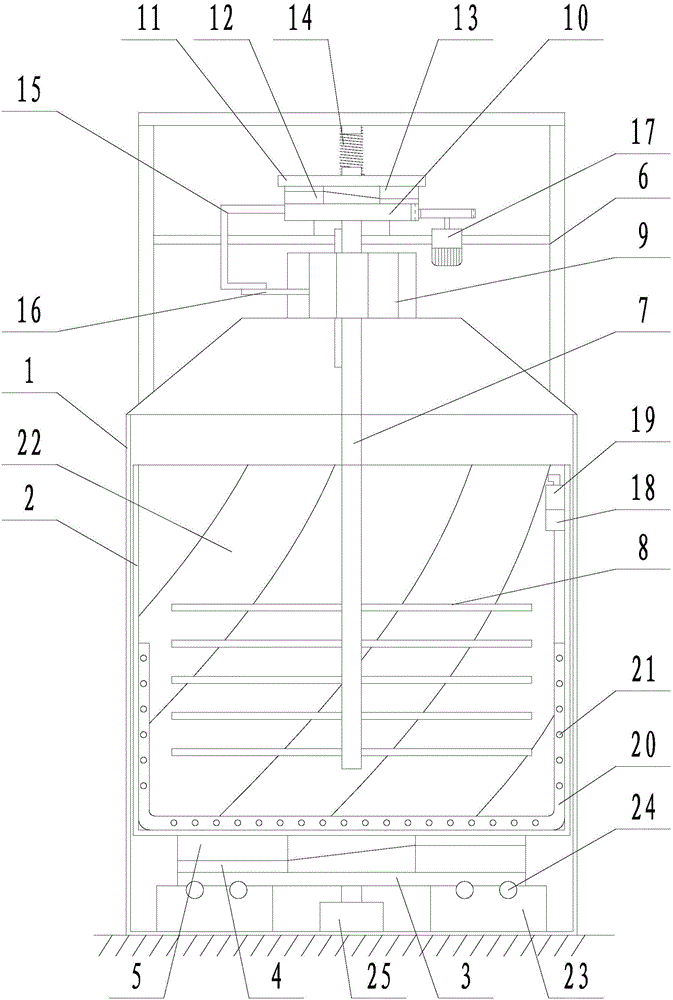

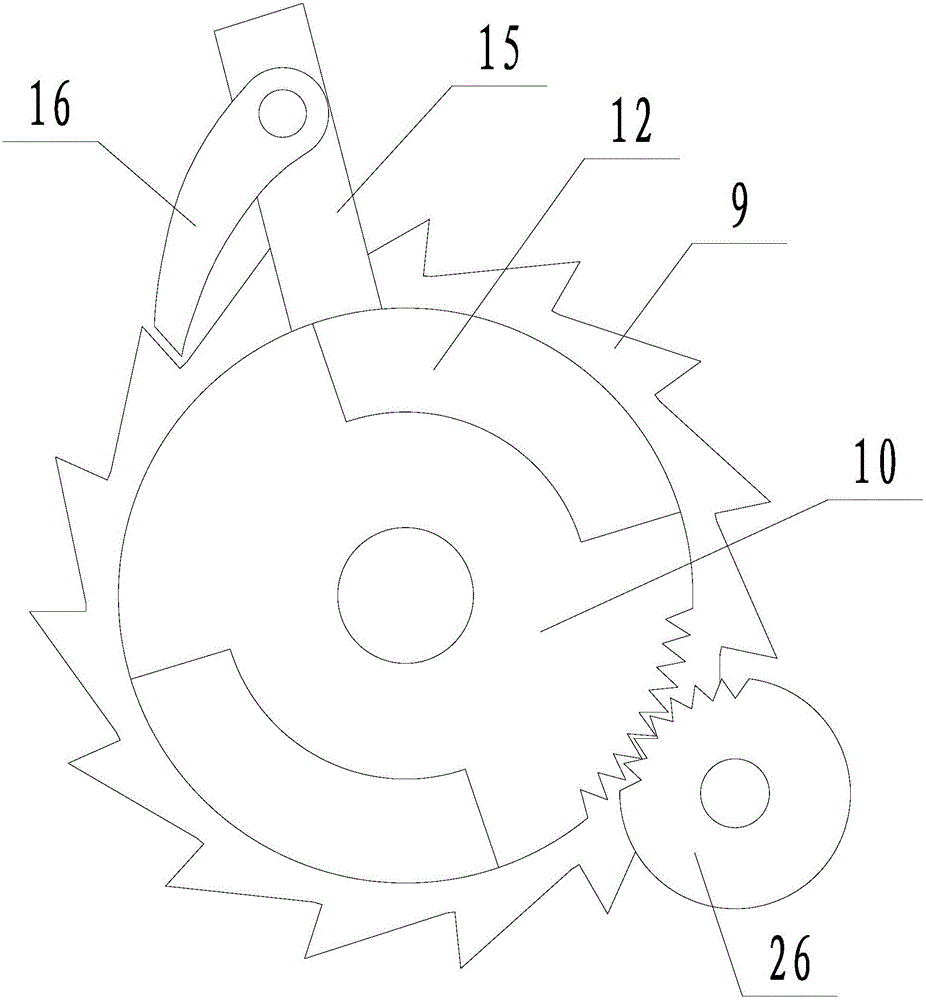

Novel anaerobic fermentation equipment and method for sludge

InactiveCN105859083AStir wellImprove the mixing effectWaste based fuelBiological sludge treatmentPulp and paper industryWedge shape

The invention discloses novel anaerobic fermentation equipment and method for sludge. The equipment and the method are used for solving the problems of the existing anaerobic fermentation equipment for the sludge during sludge fermentation that the stirring is nonuniform, the stirring effect is poor, the sludge fermentation rate is low, the work efficiency is low, and biogases generated from the sludge fermentation cannot be exhausted from the sludge promptly. According to the equipment and the method, a stirring shaft moves downwards while carrying out stirring, so that the sludge stirring effect is greatly improved, and the stirring of the sludge is more uniform. The stirring shaft carries out rotary stirring intermittently, so that the reduction of stirring resistance is facilitated, and the phenomenon of jamming is prevented. Wedge-shaped convex ribs on a rotating table and butting convex ribs on the external bottom surface of a fermentation drum are in butted fit so as to regularly dither the fermentation drum while carrying out stirring on the sludge, thus, on one hand, the stirred sludge can be prevented from overflowing from the fermentation drum, on the other hand, the sludge is vibrated, and the timely discharge of the gases from the sludge is facilitated.

Owner:ZHEJIANG OCEAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com